Aqueous acrylic acid-modified alkyd resin and preparation method thereof

A technology of water-based acrylic and alkyd resins, which is applied in coatings and other directions, can solve the problems of poor storage stability, water resistance and aging resistance of acrylic modified alkyd resins, and achieve excellent gloss and color retention Excellent film performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

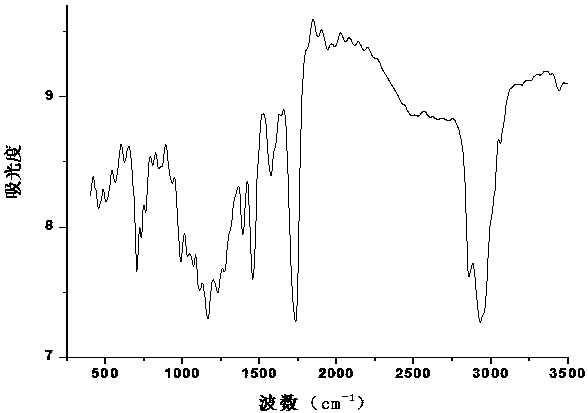

Image

Examples

Embodiment 1

[0052] 1. Waterborne acrylic modified alkyd resin products

[0053] Prepare 30g of linoleic acid, 6g of benzoic acid, 11g of trimethylolpropane, 2g of pentaerythritol, 2g of maleic anhydride, 9g of isophthalic acid, 20g of ethylene glycol monobutyl ether, and 17g of butanol into a basic alkyd resin ; In this basic alkyd resin 46g, add styrene 9g, methyl methacrylate 11g, butyl acrylate 10g, acrylic acid 7g, vinyltriethoxysilane 1.2g, benzoyl peroxide 0.9g, tert-butyl Hydrogen peroxide 0.09g, ethylene glycol monobutyl ether 1.5g, dimethylethanolamine 7g and sodium metasilicate 1g were used to prepare water-based acrylic modified alkyd resin.

[0054] Two, the preparation method of waterborne acrylic acid modified alkyd resin:

[0055] Step A, preparation of basic alkyd resin:

[0056] The basic alkyd resin is prepared from the following quality raw materials: linoleic acid 30g, benzoic acid 6g, trimethylolpropane 11g, pentaerythritol 2g, maleic anhydride 2g, isophthalic acid ...

Embodiment 2

[0072] 1. Waterborne acrylic modified alkyd resin products

[0073] Prepare 35g of linolenic acid, 5g of benzoic acid, 12g of trimethylolpropane, 4g of pentaerythritol, 1.5g of maleic anhydride, 8g of isophthalic acid, 18g of ethylene glycol monobutyl ether, and 19g of butanol into basic alkyd Resin; In this basic alkyd resin 50g, add styrene 8g, methyl methacrylate 9g, butyl acrylate 11g, acrylic acid 8g, vinyltriisopropoxysilane 1.5g, benzoyl peroxide 1.1g, 0.11 g of tert-butyl hydroperoxide, 1.7 g of ethylene glycol monobutyl ether, 10 g of dimethylethanolamine, and 5 g of sodium metasilicate were prepared to obtain a water-based acrylic modified alkyd resin.

[0074] Two, the preparation method of waterborne acrylic acid modified alkyd resin:

[0075] Step A, preparation of basic alkyd resin:

[0076] The base alkyd resin is prepared from raw materials of the following qualities: linolenic acid 35g, benzoic acid 5g, trimethylolpropane 12g, pentaerythritol 4g, maleic anhy...

Embodiment 3

[0091] 1. Waterborne acrylic modified alkyd resin products

[0092] 33g of soy oil, 4g of benzoic acid, 10g of trimethylolpropane, 3g of pentaerythritol, 1g of maleic anhydride, 10g of isophthalic acid, 17g of ethylene glycol monobutyl ether, and 20g of butanol were prepared into a basic alkyd resin; 11 g of styrene, 7 g of methyl methacrylate, 8 g of butyl acrylate, 10 g of acrylic acid, 1.0 g of vinyltrimethoxysilane, 0.7 g of benzoyl peroxide, and 0.7 g of tert-butyl peroxide were added to 48 g of the basic alkyd resin. 0.1 g of hydrogen oxide, 1.9 g of ethylene glycol monobutyl ether, 8.5 g of dimethylethanolamine, and 1.5 g of sodium metasilicate were used to prepare a water-based acrylic modified alkyd resin.

[0093] Two, the preparation method of waterborne acrylic acid modified alkyd resin:

[0094] Step A, preparation of basic alkyd resin:

[0095] The basic alkyd resin is prepared from the following quality raw materials: 33g soy oil, 4g benzoic acid, 10g trimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com