Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Does not affect physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid silicon rubber composition and preparation method thereof

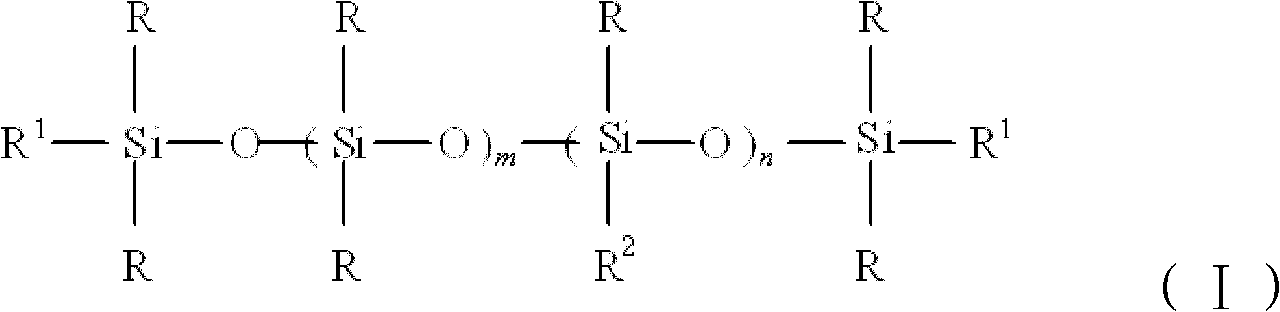

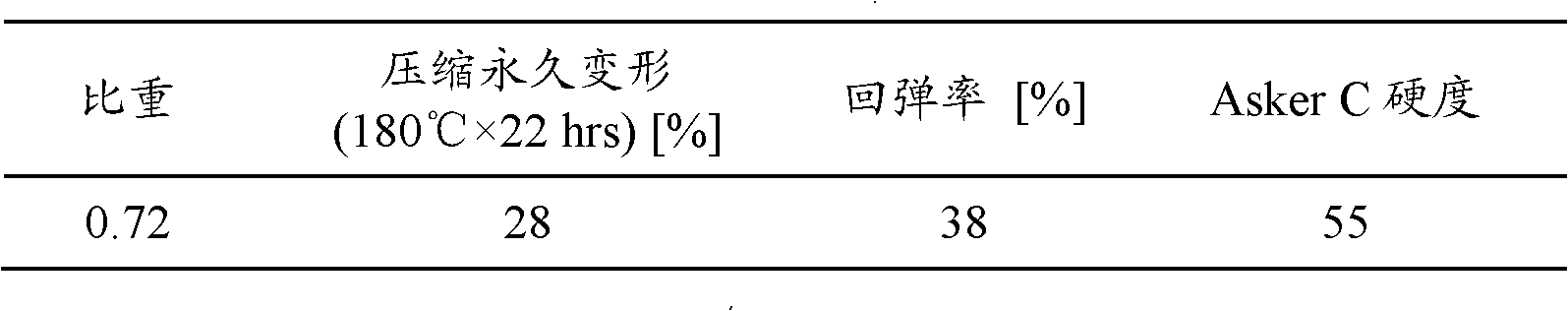

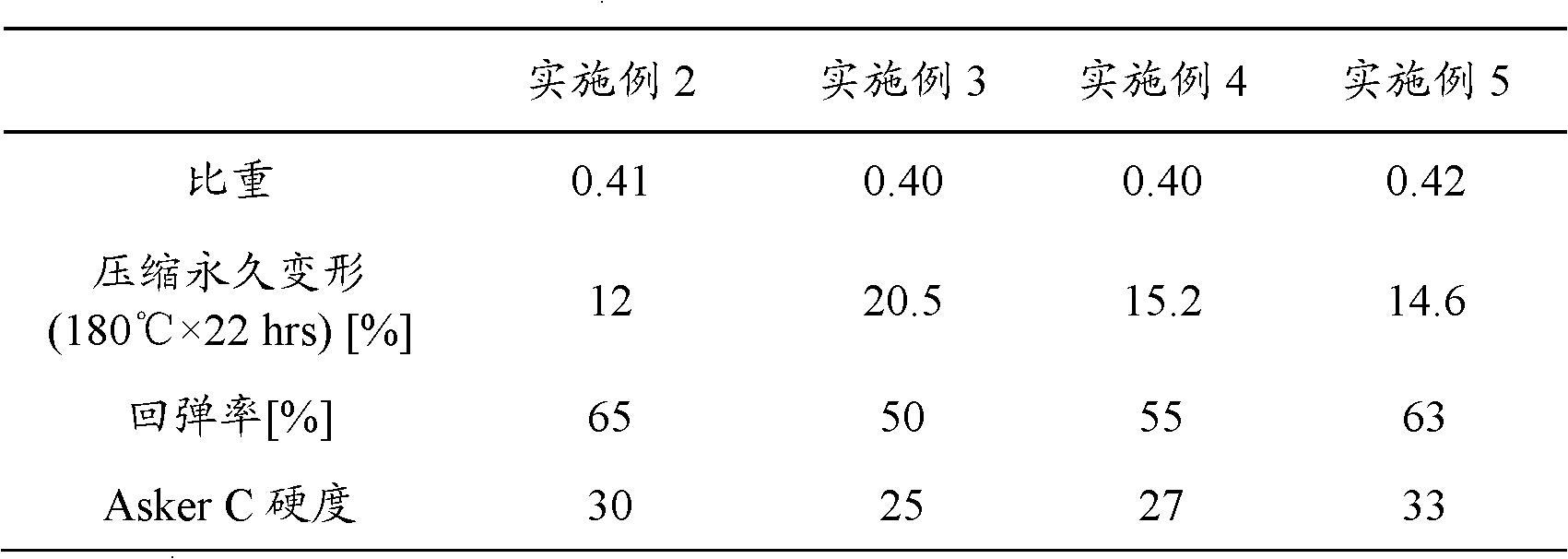

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

Novel pearly wood single plate coloring agent

InactiveCN101306546AImprove product added valueEvenly distributedReactive dyesWood treatment detailsAgent CombinationSingle plate

The invention discloses four novel preparative and operational versions of a staining agent of pearly single wood plate, and belongs to the wood modification field. The staining agent consists of a dye, a dyeing levelness and accelerating agent, a fixing agent and a penetrating agent. The wood imitation single plate can be levelly dyed at the temperature of 75 DEG C for 60 minutes to achieve the pearly effect. The agent combination has the advantages of reasonable design of preparation, good technical performance, uniform color, good pearly effect, small energy consumption, low cost, etc.

Owner:郭明辉 +1

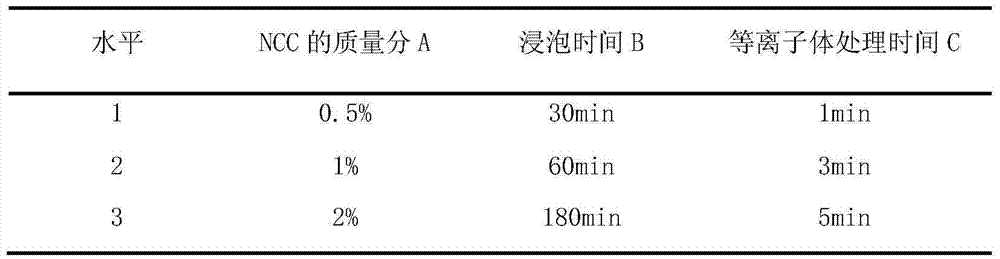

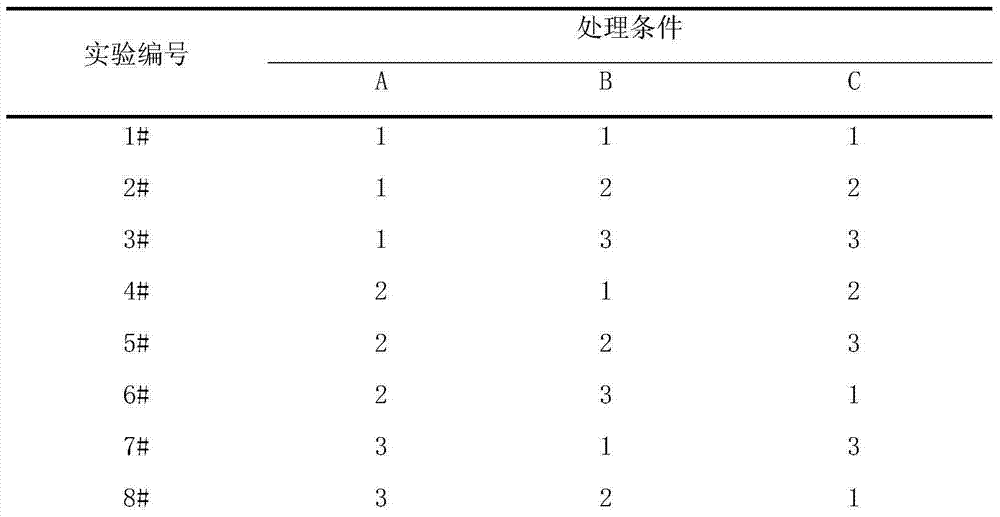

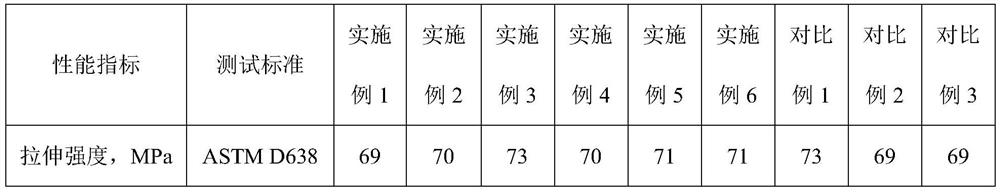

Method for improving felting resistance and pilling resistance of animal fibers or fabric thereof

The invention discloses a method for improving felting resistance and pilling resistance of animal fibers or a fabric thereof. The method specifically comprises the following steps: performing plasma treatment on the animal fibers or the fabric thereof; and further treating the animal fibers or the fabric thereof by using cellulose. The method adopts the combination of normal pressure air plasma treatment and nano cellulose finishing to regulate and control the surface friction mechanical properties of the animal fibers such as wool, cashmere, rabbit hairs and other animal fibers with scale layers covering the surfaces, thereby improving the felting resistance and the pilling resistance of the animal fibers, and improving the hand feeling comfort of the products of the animal fibers.

Owner:JIAXING UNIV

Formaldehyde elimination agent and preparation method thereof

InactiveCN101037576AImprove elimination effectReduce production efficiencyNon-macromolecular adhesive additivesDispersed particle separationStable stateFiber

The invention discloses a formaldehyde eliminating agent and preparing method thereof. Weight proportioning of raw material for the formaldehyde eliminating agent is: 100-300 quotient of formaldehyde, 150-700 quotient of urea, 50-500 quotient of water, 10-80 quotient of accelerant, 0.1-5 quotient of stabilizer, and 1-20 quotient of catalyst. The preparing method includes steps: adding each component into reaction kettle in turn, stirring the mixture at temperature of 20-50 DEG C until equally mixed and whole dissolved, adjusting pH between 7.5-9.0, and stirring until stable. Advantages of the formaldehyde eliminating agent are: preparing cost is low, formaldehyde eliminating effect is evident and permanent when the formaldehyde eliminating agent is used with urea-formaldehyde resin glue or melamine modified urea-formaldehyde resin glue for synthetic plate of incompetent formaldehyde releasing amount and E2 level synthetic plate, making formaldehyde releasing amount of incompetent and E2 level middle / high density fiber board reach to E2 and E1 level separately and observably reducing preparing cost of the middle / high density fiber board without reducing mechanics capability of the synthetic plate.

Owner:EVERFIRST WISEFUND TECH BEIJING

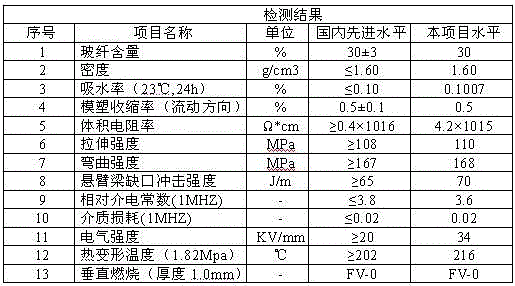

PBT (polybutylene terephthalate) enhanced flame-retardant laser printing material and preparation method thereof

ActiveCN104448735AGuaranteed mechanical propertiesMeet high temperature resistancePolytetramethylene terephthalateGlass fiber

The invention relates to a PBT (polybutylene terephthalate) enhanced flame-retardant laser printing material. The PBT enhanced flame-retardant laser printing material comprises the following raw materials: PBT resin, PBT laser powder, a flame retardant, an antioxidant, a flow aid, a demolding agent, 5%-8% of a toughening agent and glass fibers. The PBT enhanced flame-retardant laser printing material is prepared by the steps of feeding dried PBT into a double-screw extruder from the first section of a cylinder body, mixing the flame retardant, the PBT laser powder, the antioxidant, the flow aid, the demolding agent and the toughening agent by virtue of a high-speed mixer, adding the mixture into the double-screw extruder from the fourth section of the cylinder body by virtue of a proportioning feeding machine, simultaneously adding the glass fibers, and after blending materials by virtue of the double-screw extruder, carrying out extruding, cooling, particle dicing and measurement packing. The PBT enhanced flame-retardant laser printing material can resist high temperature and can be used for printing white fonts on a black substrate by virtue of laser, and the fonts are clear.

Owner:JIANGYIN JIHUA NEW MATERIAL

Mud tire sidewall rubber composition and preparation method thereof

The present invention belongs to the technical field of the special performance tire, and in particular relates to a mud tire sidewall rubber composition and a preparation method thereof. The composition consists of 20-30 parts of a natural rubber, 40-60 parts of styrene-butadiene rubber, 20-30 parts of butadiene rubber, 30-50 parts of a nano-sheet filler, 5-10 parts of white carbon black, 2-3 parts of zinc oxide, 4-10 parts of stearic acid, 4-5 parts of an antioxidant 4020, 2-4 parts of aromatic oil, 1.5-2.5 parts of sulfur, 0.5-1.2 parts of an accelerator NS, 10 -16 parts of tackifier resin. The technical scheme can significantly improve ozone aging resistance and flex cracking performance of rubber, and does not affect the original physical and mechanical properties of the rubber.

Owner:CONTINENTAL TIRES (CHINA) CO LTD

Mosquito-dispelling polyamide 6 fiber and preparation method thereof

InactiveCN102618959ASmall particle sizeLarge specific surface areaMelt spinning methodsArtifical filament manufactureFiberPolyamide

The invention provides a mosquito-dispelling polyamide 6 fiber and a preparation method thereof. The preparation method comprises the following steps of: after adsorbing mosquito-dispelling ester to attapulgite, adding an additive and polyamide 6 resin; extruding in a double-screw extruder and granulating to prepare mosquito-dispelling polyamide 6 master batch, wherein the mosquito-dispelling polyamide master batch comprises the following materials in percentage by weight: 60-70 percent of fiber-scale polyamide 6 resin, 15-30 percent of attapulgite, 0.1-1 percent of antioxidant, 0.1-1 percent of light stabilizer 78300 and 5-15 percent of mosquito-dispelling ester, wherein the antioxidant is a composition of MD 697 and one of a hindered phenolic antioxidant, a phosphite ester antioxidant and thiodipropionate antioxidant; and performing blended spinning on polyamide 6 slices and the mosquito-dispelling polyamide 6 master batch according to the weight ratio of80-90:10-20 to prepare the mosquito-dispelling polyamide 6 fiber. The mosquito-dispelling polyamide 6 fiber has the advantages of lasting mosquito-dispelling effect, simple process, low cost, wide application and the like.

Owner:HANGZHOU XINFU TEXTILE

Mould-proof aerated building block and making method thereof

InactiveCN105272349AWide variety of sourcesSimple processSolid waste managementCeramicwareThermal ageingSlag

The invention discloses a mould-proof aerated building block and a making method thereof. The mould-proof aerated building block is made from, by weight, 17-29 parts of silicon micro-powder, 22-36 parts of fluorite slag, 9-16 parts of crab shell powder, 12-18 parts of sulfur slag, 5-10 parts of nanometer silver supported zirconium phosphate, 4-7 parts of polyacrylamide, 5-10 parts of traditional Chinese medicinal residue ash, 13-21 parts of slag micro-powder, 14-22 parts of porous ceramsite, 15-25 parts of white cement, 11-17 parts of calcined loess, 10-15 parts of quicklime, 1-2 parts of hydrogen peroxide and a proper amount of water. The crab shell powder, the sulfur slag, the nanometer silver supported zirconium phosphate, polyacrylamide, the traditional Chinese medicinal residue ash and other raw materials added in the invention can obviously improve the mould proofing performance of the aerated building block and have no influences on the physical-mechanical performances of the aerated building block. The aerated building block made in the invention has excellent mould proofing performance, has a bacteriostasis rate reaching 99.5% or above, and also has excellent impact, thermal ageing and corrosion resistance.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

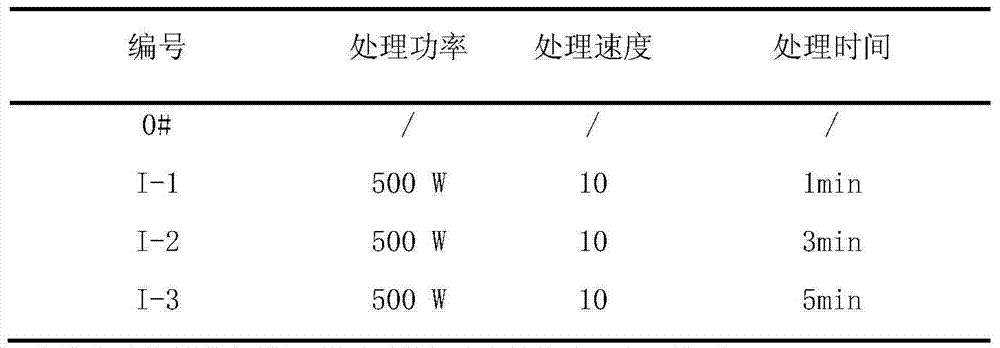

Method for improving adhesive property by processing chemigum through low temperature plasma using argon gas as medium

InactiveCN104987517ADoes not affect physical and mechanical propertiesHigh bonding strengthPhysical chemistryLow temperature plasma

The invention discloses a method for improving an adhesive property by processing chemigum through a low temperature plasma using argon gas as a medium. The method comprises the steps of: (1) processing the chemigum by using the low temperature plasma in the argon gas medium of which the degree of vacuum is 30-40 pascals; (2) enabling the processing power to be 70-110 watts and the time to be 3-10 minutes; and (3) within 5 hours after processing, using a chemnitz Locke glue adhesion agent (CH205) for adhering the chemigum and polytetrafluoroethylene, and performing vulcanization for 30 minutes at 140-150 DEGC. According to the method disclosed by the invention, the adhesion strength between the chemigum and the polytetrafluoroethylene is improved to at least 500 newtons per metre from 0; the processing method does not generate an influence on the physical mechanical performance of the chemigum.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for modifying polyvinyl alcohol fiber for high-ductility cement-based composite material

The invention provides a method for modifying polyvinyl alcohol fiber for a high-ductility cement-based composite material. The surface of the polyvinyl alcohol fiber contains a large amount of hydroxyl groups, the hydroxyl groups on the surface of the polyvinyl alcohol fiber react with a cement matrix to form a relatively strong chemical bonding force, and the strong chemical bonding force causesfiber breakage in the pull-out process, so that the ductility is affected. The method comprises the following steps: with the polyvinyl alcohol fiber as a raw material, firstly coating the surface ofthe polyvinyl alcohol fiber with a layer of epoxy resin, and then coating the surface of epoxy resin coating with a layer of fumed silica powder. Due to surface hydrophobicity of the modified polyvinyl alcohol fiber, the interfacial strength between the polyvinyl alcohol fiber and the cement matrix can be effectively weakened and the chemical bonding force can be reduced, so that the polyvinyl alcohol fiber is pulled out of the cement matrix in the stretching process, without breakage; the hydrophobicity and the wear-resistant slip property of a product are more stable, and the coating is more wear-resistant and the original physical and mechanical properties of the PVA fiber are not affected.

Owner:SOUTHEAST UNIV

Snowfield tire sidewall rubber material composition and preparation method

InactiveCN105482174AImprove ozone resistanceExcellent performanceSpecial tyresCarbon blackPolymer chemistry

The invention belongs to the technical field of tires with special properties, and particularly relates to a snowfield tire sidewall rubber material composition and a preparation method. The snowfield tire sidewall rubber material composition is prepared from 20-30 parts of styrene-butadiene rubber, 40-60 parts of natural rubber, 20-30 parts of butadiene rubber, 30-50 parts of nanoscale sheet filler, 5-10 parts of white carbon black, 2-3 parts of zinc oxide, 4-10 parts of stearic acid, 4-5 parts of anti-ageing agent 4020, 2-4 parts of aromatic oil, 1.5-2.5 parts of sulfur, 0.5-1.2 parts of accelerant NS and 10-16 parts of tackifying resin. By means of the technical scheme, the ozone aging resistance and the flex crack resistance of rubber materials can be greatly improved without influencing the existing physical and mechanical properties of the rubber materials.

Owner:SHANDONG YONGTAI CHEM GROUP

Hydrogenated pentablock styrene thermoplastic elastomer and preparation method thereof

InactiveCN109836547AImprove liquidityImprove permanent deformationThermoplastic elastomerMechanical property

The invention discloses a hydrogenated pentablock styrene thermoplastic elastomer and a preparation method thereof. The hydrogenated pentablock styrene thermoplastic elastomer is prepared by hydrogenation of a styrene-b-butadiene-b-styrene-b-butadiene-b-styrene pentablock copolymer. The preparation method includes: conducting segmented polymerization by anionic polymerization process to obtain a styrene-b-butadiene-b-styrene-b-butadiene-b-styrene pentablock copolymer sol, and then performing hydrogenation. The hydrogenated pentablock styrene thermoplastic elastomer provided by the invention has high fluidity and small permanent deformation, and at the same time has good mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rubber sheet isolating agent

The invention provides a rubber sheet isolating agent. The rubber sheet isolating agent is prepared from the following raw materials in parts by weight: 30-50 parts of bentonite, 10-30 parts of silicafume, 10-30 parts of light calcium carbonate, 5-10 parts of zinc oxide, 3-5 parts of fumed silicon oxide, 13-30 parts of fatty acid derivative, 4-6 parts of a surfactant, 0.6-1 part of an organic silicone solid defoamer and 0.2-0.3 part of drier. According to the rubber sheet isolating agent, the isolation effect is outstanding, the stack sticking phenomenon of rubber materials is well controlled, and rubber sheets still has excellent isolation effect for being stacked more than one month; the rubber sheet isolating agent can be widely used in the isolation of different types of rubber sheets, so that the rubber sheets do not bond with one another, and various properties of rubber can be maintained; and the manufacturing process is simple, use amount is low, the isolation ability is high,and the rubber sheet isolating agent is especially suitable for isolation of high-viscosity rubber sheets such as bromobutyl rubber.

Owner:建平天正矿业有限公司

Coating method of modified coating for improving coating weight

InactiveCN104480714ABalanced water resistance and moisture permeabilityDoes not affect physical and mechanical propertiesFibre typesCalciumState of art

The invention discloses a coating method of a modified coating for improving coating weight. The coating method comprises the following steps: preparing a fibroin solution with the solid content of 36.2g.L<-1> by taking silk fiber as a material and adopting a ternary system containing calcium chloride, ethanol and water to dissolve fibroin; mixing the fibroin solution with a formaldehyde-free crosslinking agent at first, then adding a waterborne coating adhesive, adding a polyurethane thickener, stirring for dispersion, coating a polyester fabric, controlling the coating amount, baking at 150 DEG C for 2 minutes, and detecting the moisture permeability, water resistance and physical and mechanical properties of a coated fabric, wherein 10g of the waterborne coating adhesive is added, the used amount of the fibroin solution is 3% of the mass of the waterborne coating adhesive, and the used amount of the formaldehyde-free crosslinking agent is 3% of the mass of the waterborne coating adhesive. Compared with the prior art, by adopting the coating method disclosed by the invention, the water resistance and moisture permeability of the coated fabric are balanced, and the physical and mechanical properties of the coated fabric are not influenced.

Owner:GUANGXI UNIV

Modification method of polyvinyl alcohol fiber for strain-hardening cement-based composite material

The invention discloses a modification method of polyvinyl alcohol fiber for a strain-hardening cement-based composite material. According to the method, the surface of the polyvinyl alcohol fiber asa raw material is coated with a layer of interface epoxy resin, and the surface of an epoxy resin coating is coated with a layer of nano graphite powder. By means of the method, the interfacial properties of the polyvinyl alcohol fiber and a cement matrix can be well regulated, the stability of the coating can be guaranteed, and no damage can be caused to the fiber.

Owner:SOUTHEAST UNIV

PBT enhanced flame retardant laser printing material and preparation method thereof

ActiveCN104448735BGuaranteed mechanical propertiesMeet high temperature resistancePolytetramethylene terephthalateGlass fiber

The invention relates to a PBT (polybutylene terephthalate) enhanced flame-retardant laser printing material. The PBT enhanced flame-retardant laser printing material comprises the following raw materials: PBT resin, PBT laser powder, a flame retardant, an antioxidant, a flow aid, a demolding agent, 5%-8% of a toughening agent and glass fibers. The PBT enhanced flame-retardant laser printing material is prepared by the steps of feeding dried PBT into a double-screw extruder from the first section of a cylinder body, mixing the flame retardant, the PBT laser powder, the antioxidant, the flow aid, the demolding agent and the toughening agent by virtue of a high-speed mixer, adding the mixture into the double-screw extruder from the fourth section of the cylinder body by virtue of a proportioning feeding machine, simultaneously adding the glass fibers, and after blending materials by virtue of the double-screw extruder, carrying out extruding, cooling, particle dicing and measurement packing. The PBT enhanced flame-retardant laser printing material can resist high temperature and can be used for printing white fonts on a black substrate by virtue of laser, and the fonts are clear.

Owner:JIANGYIN JIHUA NEW MATERIAL

Method for improving moisture penetrability and water repellency of coated fabric

InactiveCN104389170ARetain water resistanceGood moisture permeabilityFibre typesCross-linkWater based

The invention discloses a method for improving the moisture penetrability and the water repellency of a coated fabric. The method comprises the following steps: using silk fiber as a material, dissolving silk fibroin in a calcium chloride-ethanol-water ternary system according to the molar ratio of 1:2:8 to prepare a silk fibroin solution of which the solid content is 36.2 g.L<-1>; using 10 g of a water-based coating adhesive, the silk fibroin solution which is 3 percent by mass of the water-based coating adhesive and a formaldehyde-free cross-linking agent which is 0-7 percent by mass of the water-based coating adhesive, mixing the silk fibroin solution and the formaldehyde-free cross-linking agent first, then adding the water-based coating adhesive, adding a polyurethane thickener, stirring and dispersing the mixture, coating a polyester fabric subjected to water repellent finish, and detecting the moisture penetrability, the water repellency and the physical and mechanical properties of the coated fabric. The method provided by the invention is simple and easy; the obtained modified coating adhesive greatly improves the moisture penetrability of the coated fabric while maintaining the water repellency of the coated fabric, and doesn't influence the physical and mechanical properties of the coated fabric.

Owner:GUANGXI UNIV

Method for preparing floride-free super-hydrophobic cotton fabric

InactiveCN101397754BMeet the requirementsWide variety of sourcesVegetal fibresSilicon dioxideMechanical property

The invention provides a preparation method of fluoride-free super-hydrophobic cotton fabrics, pertaining to the technical field of water repellent finishing of cotton fabrics. The preparation method is characterized in that the concrete steps comprise: 3ml to 6ml of ammonia water with a mass concentration of 25wt percent to 28wt percent is added into 50ml to 100ml of ethanol and stirred. 5ml to 6ml of N-tetraethyl silicate is added in a dropwise manner and aged for 30min to 80min to obtain silica sol; the cotton fabric is immersed in the silica sol, dipped and rolled, and then dried at 60 DEG C to 100 DEG C for 1min to 5min; and the cotton fabric is immersed in alkane siloxane hydrolyzate, dried at room temperature and roasted for 30min to 120min in an oven which is preheated to 120 DEG C to 160 DEG C. The preparation method is environmentally-friendly, convenient and effective and meets the requirements of ecotypic textiles; the preparation method has wide sources of raw materials and the contact angle of the prepared cotton fabrics and water dripping exceeds 150 degrees and the prepared cotton fabrics have super-hydrophobic performance and does not influence the physical and mechanical properties of the cotton fabrics.

Owner:DONGHUA UNIV

Non-mechanical scabbling process for treating continuous end of prestressed concrete beam slab by using super retarder

InactiveCN111791349AEffect on mechanical propertiesDoes not cause post-processing difficultiesCeramic shaping apparatusPrestressed concrete beamConcrete beams

The invention discloses a non-mechanical scabbling process for treating a continuous end of a prestressed concrete beam slab by using a super retarder, and relates to the field of concrete construction methods. The method specifically comprises the following steps that S1, a beam plate continuous end mold is cleaned; S2, a retarder is brushed; and S3, after beam body concrete pouring is completed,the mold is removed, and scabbling is completed. The problem that in the common manual scabbling process, the quality of the concrete continuous end scabbling quality is difficult to control due to the difference of workers is solved; and the problems that in the common manual scabbling process, time and labor are wasted, noise and dust pollution is large, the difference of the scabbling qualityof the concrete continuous end is large due to different proficiency degrees and responsibilities of workers, and quality control is difficult are solved.

Owner:云南交投公路建设第四工程有限公司

A kind of anti-ultraviolet halogen-free flame-retardant nylon composition for fasteners and its preparation method

ActiveCN108795037BGuaranteed flame retardant performanceDoes not affect physical and mechanical propertiesPolymer scienceLight irradiation

The invention discloses an anti-ultraviolet halogen-free flame-retardant nylon composition used for fasteners, and a preparation method thereof. The anti-ultraviolet halogen-free flame-retardant nyloncomposition used for fasteners comprises following raw materials: 60 to 75 parts of PA66 resin, 15 to 30 parts of PA6 resin, 9 to 15 parts of a halogen-free fire retardant, 0.3 to 0.5 part of an ultraviolet ray absorber A, 0.1 to 0.3 part of an ultraviolet ray absorber B, 0.1 to 0.5 part of a free radical quenching agent, 0.3 to 0.5 part of a composite anti-oxidant, and 0.3 to 0.5 part of a lubricant. According to the preparation method, PA66 and PA6 are subjected to drying for 3 to 6h at 90 to 110 DEG C, and weighed raw materials are mixed to be uniform in a stirring machine; the mixed raw materials are introduced into a feeding bucket of a double screw extruder for extrusion, cooling, and granulation. The anti-ultraviolet halogen-free flame-retardant nylon composition possesses long lasting ultraviolet ray resistance, the chromatism value after 1000h of aging under xenon lamp irradiation is smaller than 5.0, and the chromatism value after 180d of aging under natural light irradiation is smaller than 5.0, so that the anti-ultraviolet halogen-free flame-retardant nylon composition is especially suitable to be used for fasteners with anti-ultraviolet requirements.

Owner:GUANGDONG JUSHI CHEM CO LTD

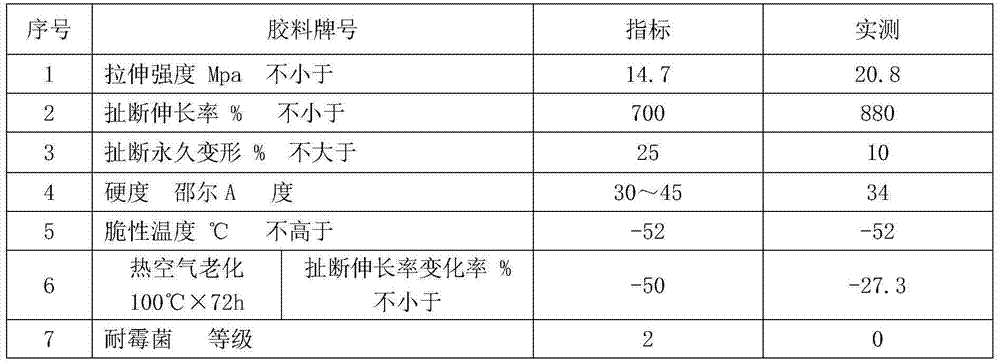

Method for improving fungus-proof performance of rubber material

InactiveCN104774351AImprove anti-mold performanceDoes not affect physical and mechanical propertiesRubber materialManufacturing technology

The invention belongs to the aeronautical material manufacturing technique and relates to a method for improving the fungus-proof performance of a rubber material. The method for improving the fungus-proof performance of the rubber material comprises the steps that 1, master refining of raw rubber is conducted, wherein filler and additives are added into the raw rubber, then master refining is conducted for 35-45 minutes, and the additives include a plasticizer and an anti-aging agent; 2, filtering is conducted, wherein fine filtration is conducted on the refined raw rubber with two layers of screens with meshes ranging from 80 to 100; 3, mixing is conducted, wherein mixing is conducted for 20-25 minutes at the temperature ranging from 40 DEG C to 55 DEG C after a mildew preventive and a vulcanizing agent are added to the filtered raw rubber according to the different types of the rubber, and the roller interval for mixing ranges from 2 mm to 2.5 mm, and the mildew preventive is the mildew preventive O or the mildew preventive BCM. By the adoption of the method, the fungus-proof performance of the rubber material can be improved remarkably, and meanwhile the physical and mechanical performance of the rubber material is not affected.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

A Modification Method of Polyvinyl Alcohol Fiber for Strain Hardening Cementitious Composite

Owner:SOUTHEAST UNIV

A kind of method for preparing surface silver-plated composite material

ActiveCN109487250BImprove the plating effectImprove conductivityLiquid/solution decomposition chemical coatingPyrrolidinonesGlycol synthesis

Owner:BEIJING UNIV OF CHEM TECH

A kind of treatment method and treatment solution for preparing fluorine-free superhydrophobic cotton fabric

The invention provides a treatment method and treatment liquid for preparing a fluoride-free super-hydrophobic cotton fabric. The treatment liquid comprises the following components: 1-8ml of ammonia water of which the mass percent concentration is 25-28%, 80-140ml of ethanol, 5-6ml of tetraethyl orthosilicate, 2-4ml of hexadecyl trimethoxy siloxane, 0.5-3ml of alkane siloxane and 0-4ml of 3-glycidol ether oxy-propyl trimethoxysilane. According to the treatment method, a large amount of modified silicon dioxide nano-particles with water repellency are modified on the surface of the fabric by dipping the fabric in the treatment liquid of modified silicon dioxide sol, so that the contact angle between the prepared fabric and a water drop is more than 150 degrees, the fabric has super-hydrophobic performance, and the physical and mechanical properties of the fabric are not affected. The treatment method and treatment liquid for preparing the fluoride-free super-hydrophobic cotton fabric are environment-friendly in process, simple, convenient, effective and in accordance with ecological textiles, and can meet requirements for industrial mass production.

Owner:MYPOLYMER JIAXING

A kind of rubber film release agent

The invention provides a rubber film release agent, comprising the following raw materials in parts by weight: 30-50 parts of bentonite; 10-30 parts of silica fume; 10-30 parts of light calcium carbonate; 5-10 parts of zinc oxide; 3-5 parts of silicon oxide; 13-30 parts of fatty acid derivatives; 4-6 parts of surfactants; 0.6-1 parts of organic silicon solid defoamer; 0.2-0.3 parts of drier. The rubber film isolating agent of the present invention has outstanding isolating effect, the sticking phenomenon of rubber materials has been well controlled, and the film still has excellent isolating effect after being stacked for more than one month. It can be widely used in the isolation of different types of rubber films, so that they do not bond with each other and can keep various properties of the rubber unchanged. The invention has the advantages of simple manufacturing process, low dosage and strong isolation ability, and is especially suitable for the isolation of high-viscosity sheets such as brominated butyl rubber.

Owner:建平天正矿业有限公司

Liquid silicon rubber composition and preparation method thereof

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Nylon flame retardant composite material and preparation method thereof

ActiveCN113493607BMeet the requirements of high processing temperatureDoes not affect physical and mechanical propertiesPolymer scienceAnoxomer

The invention discloses a nylon flame-retardant composite material and a preparation method thereof, belonging to the technical field of polymer composite materials. It includes the following raw material components in mass percentage: 59-94.5% of nylon 10T resin; 5-40% of polyphosphonate flame retardant; 0.5-1% of antioxidant; among them, polyphosphonate flame retardant It has the following structural formula: and in the above structural formula, n is a positive integer of 21-50. The high-temperature nylon flame-retardant composite material designed and obtained by the invention has high mechanical strength, good dimensional stability and good flame-retardant effect.

Owner:HONGHU YITAI TECH CO LTD

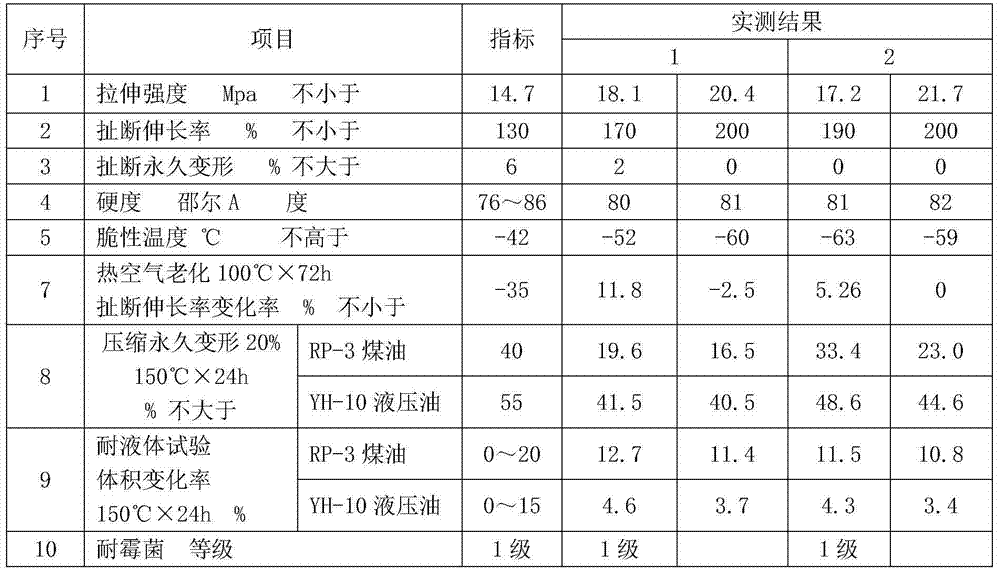

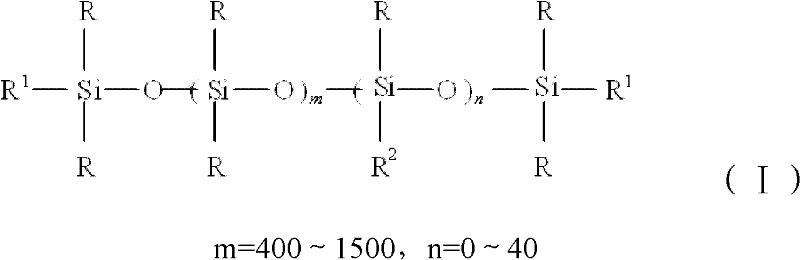

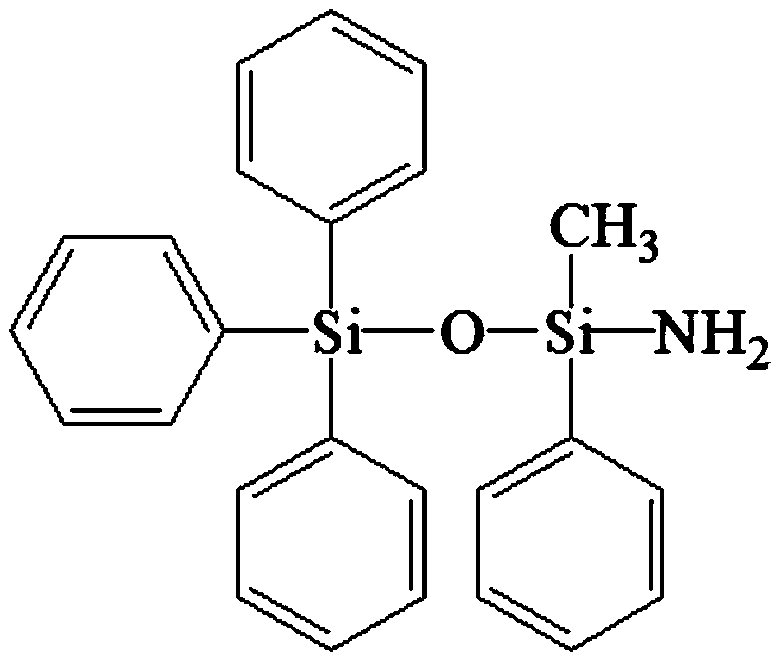

Radiation-resistant additive and synthesis thereof, and method for preparing radiation-resistant silicone rubber material

ActiveCN110128461AImprove radiation resistanceGood compatibilityGroup 4/14 element organic compoundsChemical industryPolymer science

The invention provides a radiation-resistant additive and synthesis thereof, and a method for preparing a radiation-resistant silicone rubber material, wherein the structure formula of the radiation-resistant additive is as follows, and mixing vulcanizing is performed by using the radiation-resistant additive as a radiation-resistant additive, using phenyl silicone rubber as a base rubber and adding a reinforcement agent, a structure control agent and a vulcanizing agent to prepare the radiation-resistant silicone rubber material. According to the present invention, the prepared radiation-resistant silicone rubber material has good radiation resistance, can be used for producing various kinds of rubber products such as electric wires, cable sheaths, rubber gaskets, sealing parts, member sheets and the like in various irradiation occasions, and can be widely used in aerospace, nuclear industry, electronic communications, chemical industry, medicine, marine and other fields requiring high-energy radiation.

Owner:BAIMTEC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com