Radiation-resistant additive and synthesis thereof, and method for preparing radiation-resistant silicone rubber material

A technology of radiation resistance and additives, which is applied in the field of preparation of radiation-resistant silicone rubber materials to achieve the effect of improving radiation resistance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

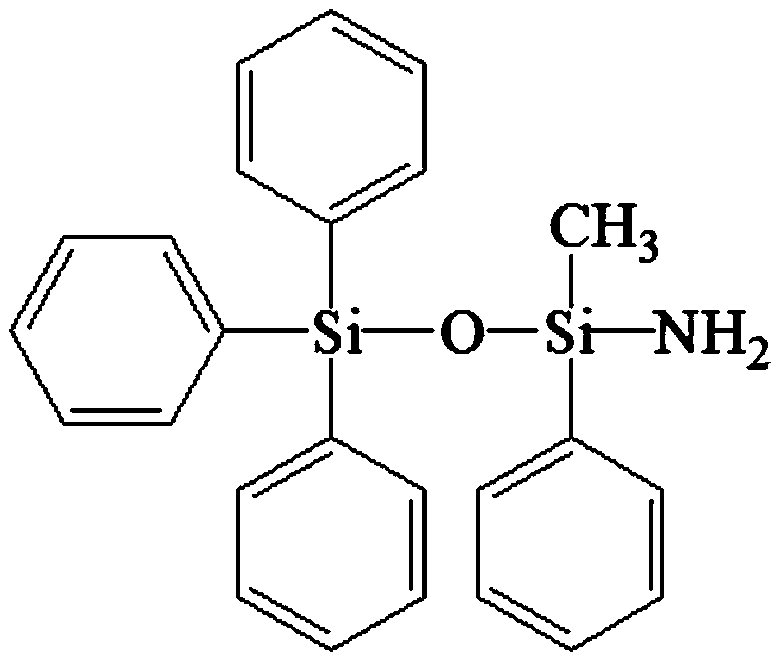

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment technical scheme of the present invention is described in further detail:

[0029] The steps of the preparation method of the silazane damping agent containing triphenylsiloxane structure are:

[0030] (1) Preparation for synthesis

[0031] Molecular sieves are dried in a box-type resistance furnace at 400°C for 3.0 hours, put into a desiccator to cool, then put dry molecular sieves into a container containing toluene, and place them for more than 2 days before use; the glass instruments and stirring After the rod is cleaned, put it into the oven, set the temperature of the oven at 120°C, bake for 2 hours, and wait for use after cooling. The glass instrument includes a four-necked reaction bottle, an air guide tube, a reflux condenser, and a constant pressure dripping device.

[0032] (2) intermediate synthesis reaction

[0033] Install a stirring device at the middle port of the four-necked reaction bottle, install an air guide pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com