Non-punch-through deep trench IGBT with field stop structure and manufacturing method thereof

A non-punch-through, manufacturing method technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of not using high-voltage technology, poor high-voltage withstand performance, and high-frequency application limitations, and achieve easy implementation. , The effect of high short-circuit tolerance and small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

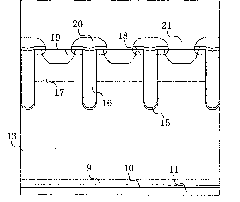

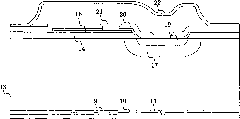

[0030] refer to Figure 1 ~ Figure 3 , a non-punch-through deep trench IGBT with a field stop structure, comprising an NMOS field effect transistor and a PNP bipolar transistor driven by the NMOS field effect transistor; or including a PMOS field effect transistor and a PMOS field effect transistor driven by the PMOS field effect transistor An NPN bipolar transistor driven by a tube, an NMOS field effect transistor or a PMOS field effect transistor includes an emitter electrode, a gate electrode and a silicon substrate body region, and a PNP bipolar transistor or an NPN transistor includes an emitter electrode, a silicon substrate body region and a collector electrode , which is characterized in that: on one side of the silicon substrate body region 12 (close to the gate electrode 3 and the emitter electrode 4), a cell region 1 with a high withstand voltage d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com