Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2392results about How to "Reduce production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

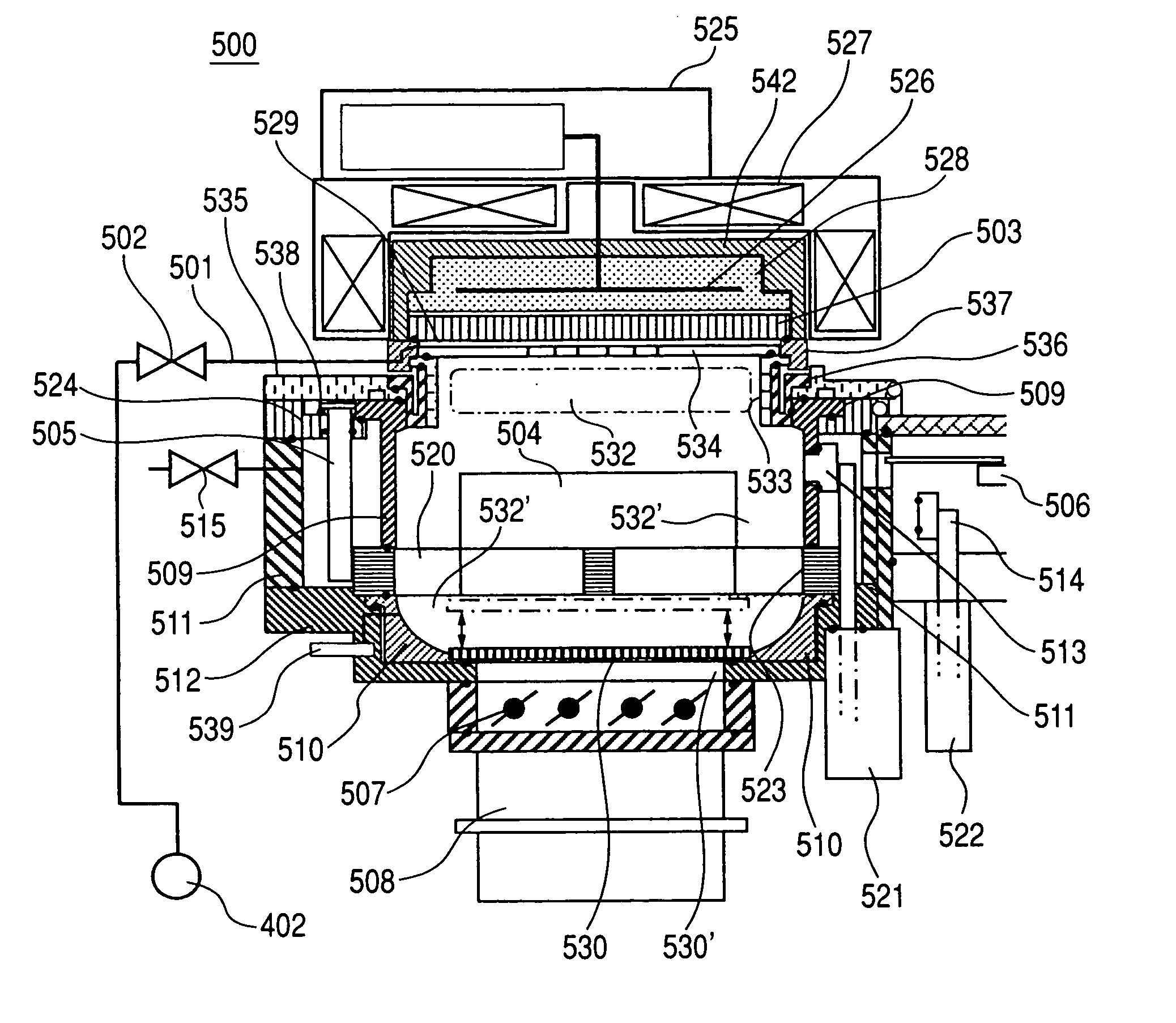

Vacuum processing apparatus

ActiveUS20050193948A1Reduced installation areaEasily perform operationPressurized chemical processSemiconductor/solid-state device manufacturingElectricityEngineering

The present invention provides a vacuum processing apparatus which is small-sized and requires a small installation area. The vacuum processing apparatus includes a vacuum container which has a processing chamber inside thereof, wherein the pressure inside the processing chamber is reduced and plasma used for processing a sample is formed inside the processing chamber, a bed portion which is arranged below the vacuum container and stores a device for supplying electricity and electric signals used for processing inside the vacuum container, and a transport chamber which is connected with the vacuum container and includes a transport device for transporting the sample inside thereof. The vacuum processing apparatus further includes a connector portion which is mounted on the bed portion in a state that the connector portion faces a lower portion of the transport chamber, wherein the bed portion is configured to be detachably mounted on the vacuum processing apparatus in a state that the bed portion performs the connection and the disconnection at the connector portion.

Owner:HITACHI HIGH-TECH CORP

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

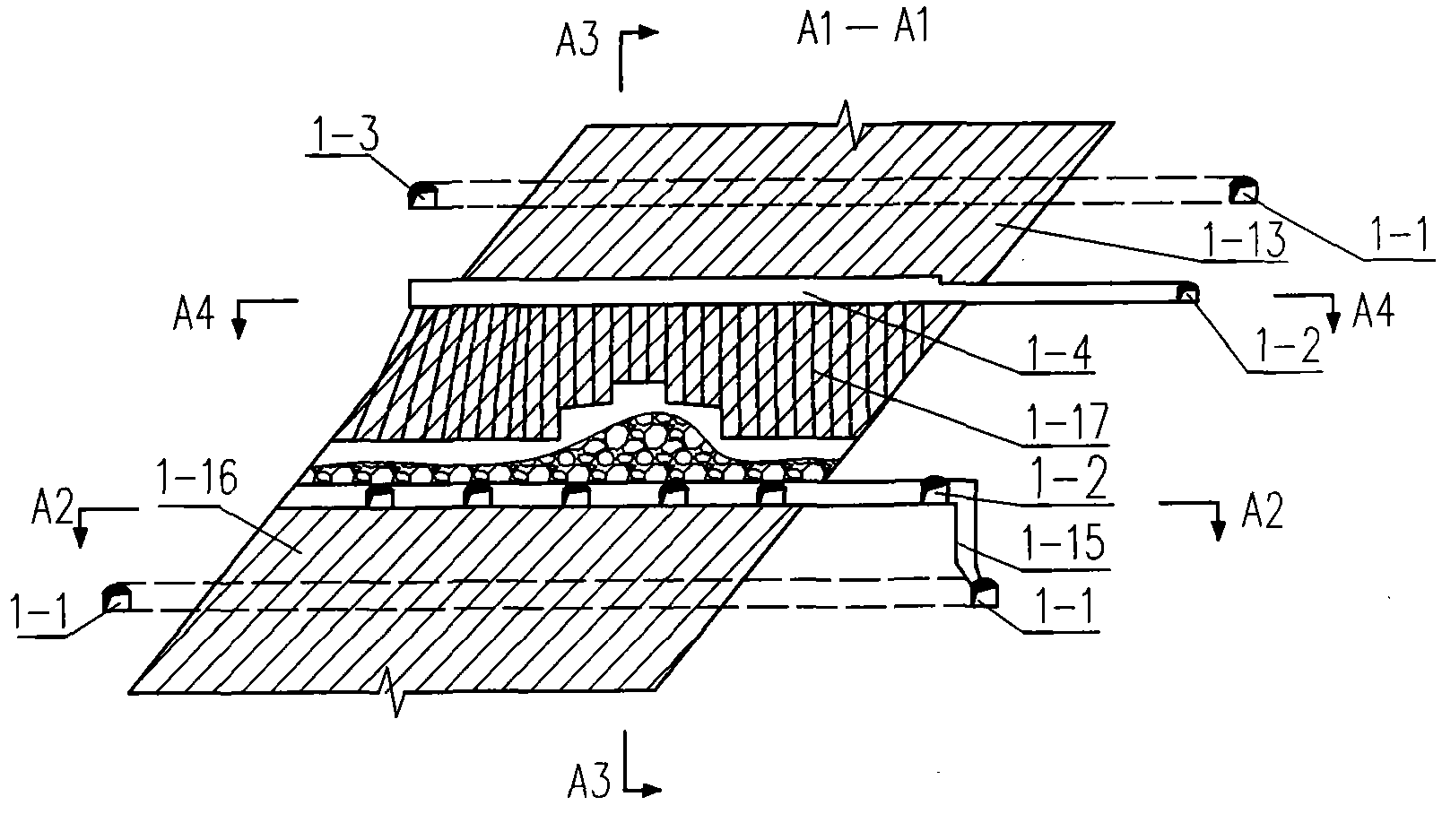

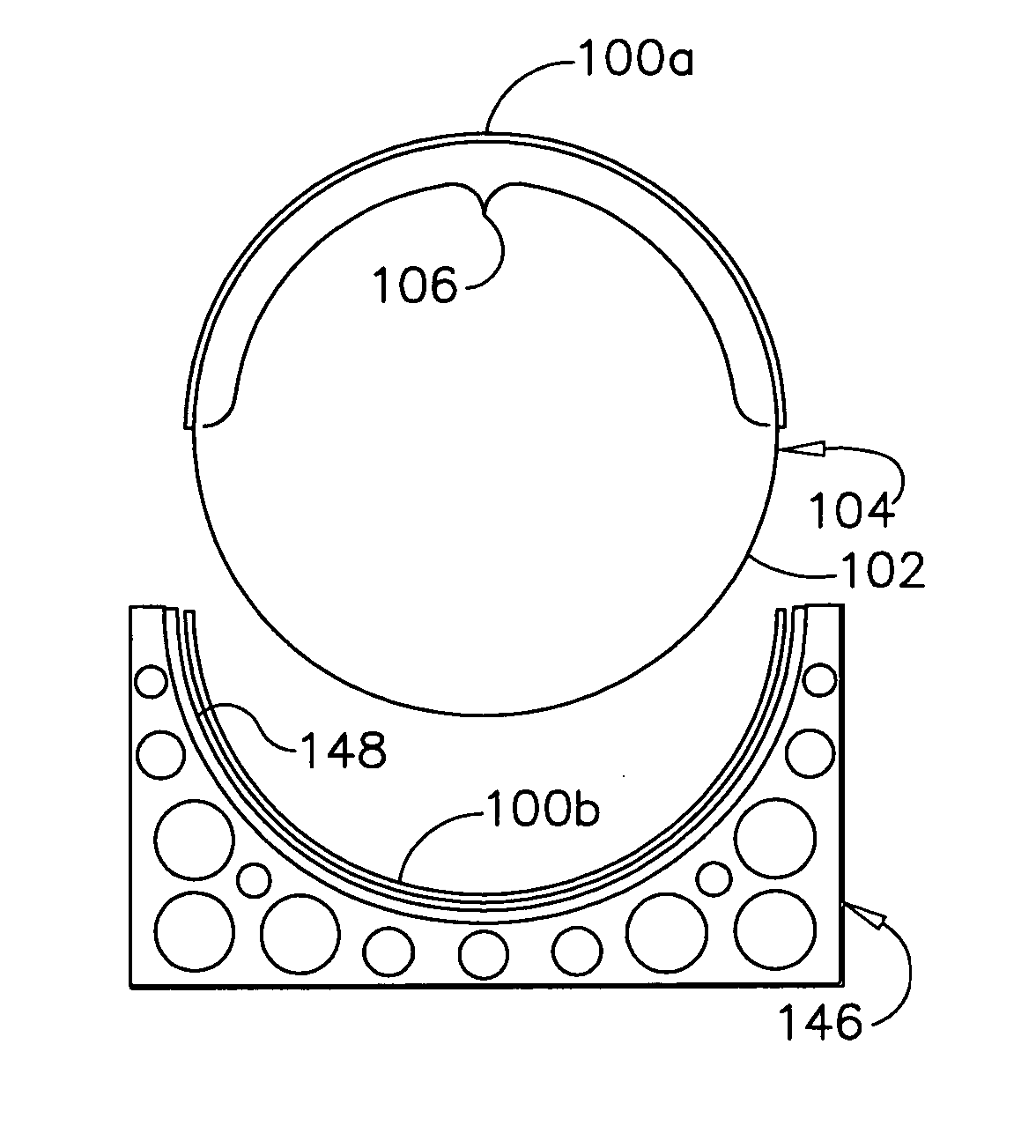

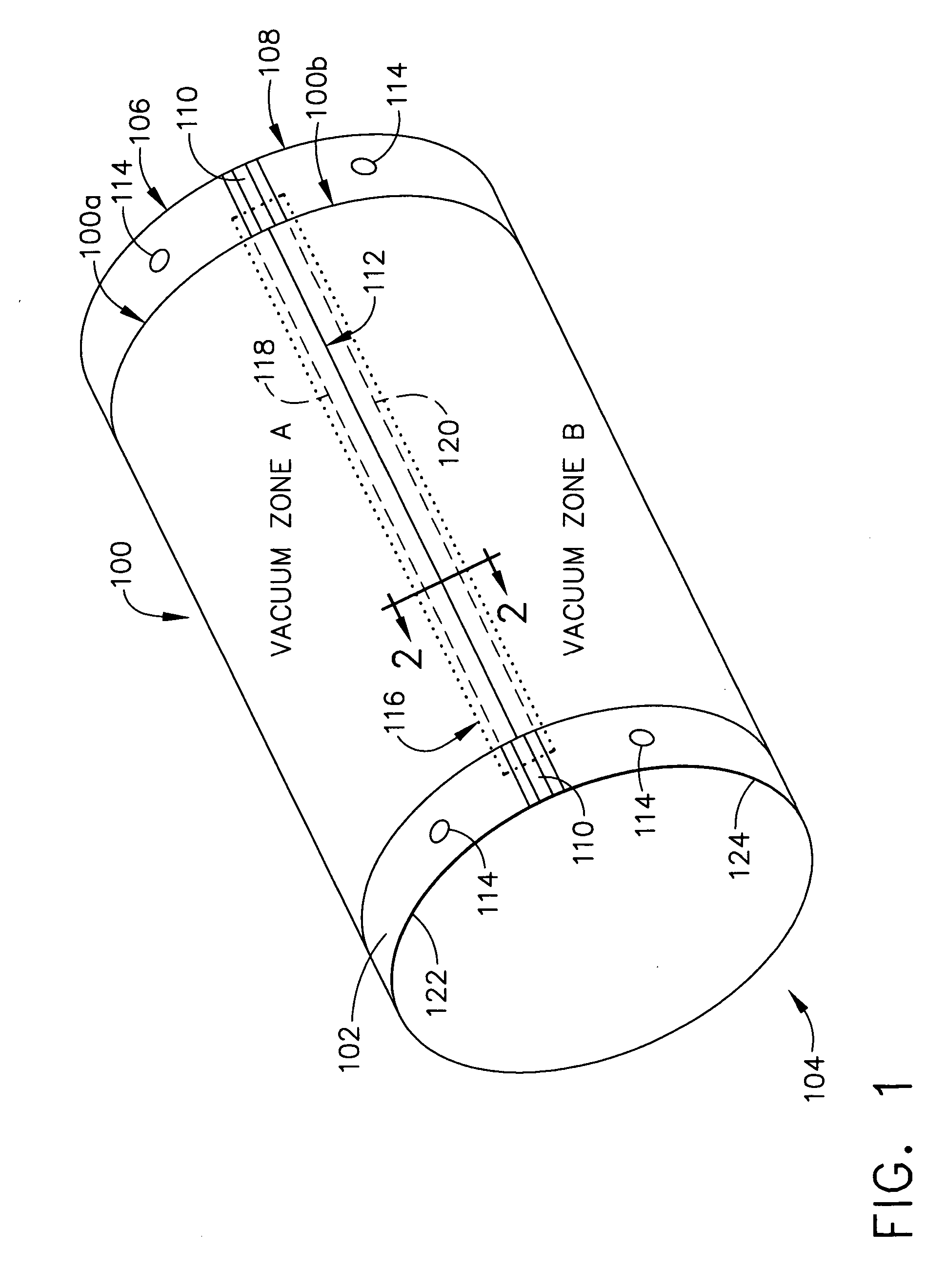

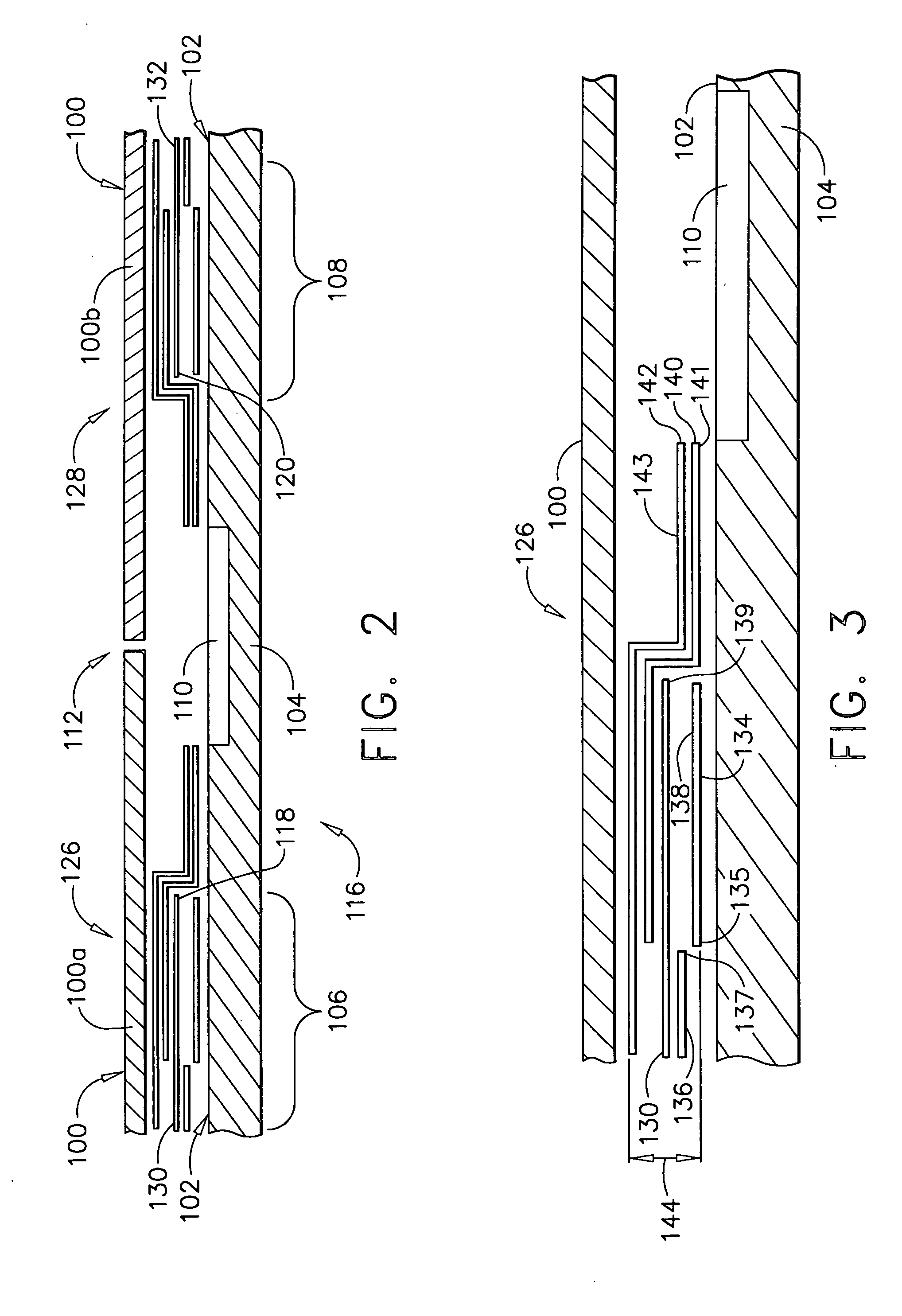

Method of transferring large uncured composite laminates

InactiveUS20050102814A1Desired aero-smoothnessLow capital equipment investmentLaminationEfficient propulsion technologiesComposite laminatesEngineering

A method of transferring an uncured composite laminate skin from a lay-up surface of a male mandrel tool to a female cure tool includes defining multiple vacuum zones on the lay-up surface, each zone corresponding to one of a multiple of portions into which the skin is to be separated. For example, to separate the skin into two portions, a low profile seal of a first membrane to the lay-up surface is formed at a first vacuum zone and a second low profile seal for a second membrane is formed at a second vacuum zone. The method further includes laying up a composite laminate skin over all the vacuum zones; separating the composite laminate skin into portions, for example, a first portion over the first vacuum zone and a second portion over the second vacuum zone; and releasing the portions individually into cure tools having an outside mold line surface.

Owner:THE BOEING CO

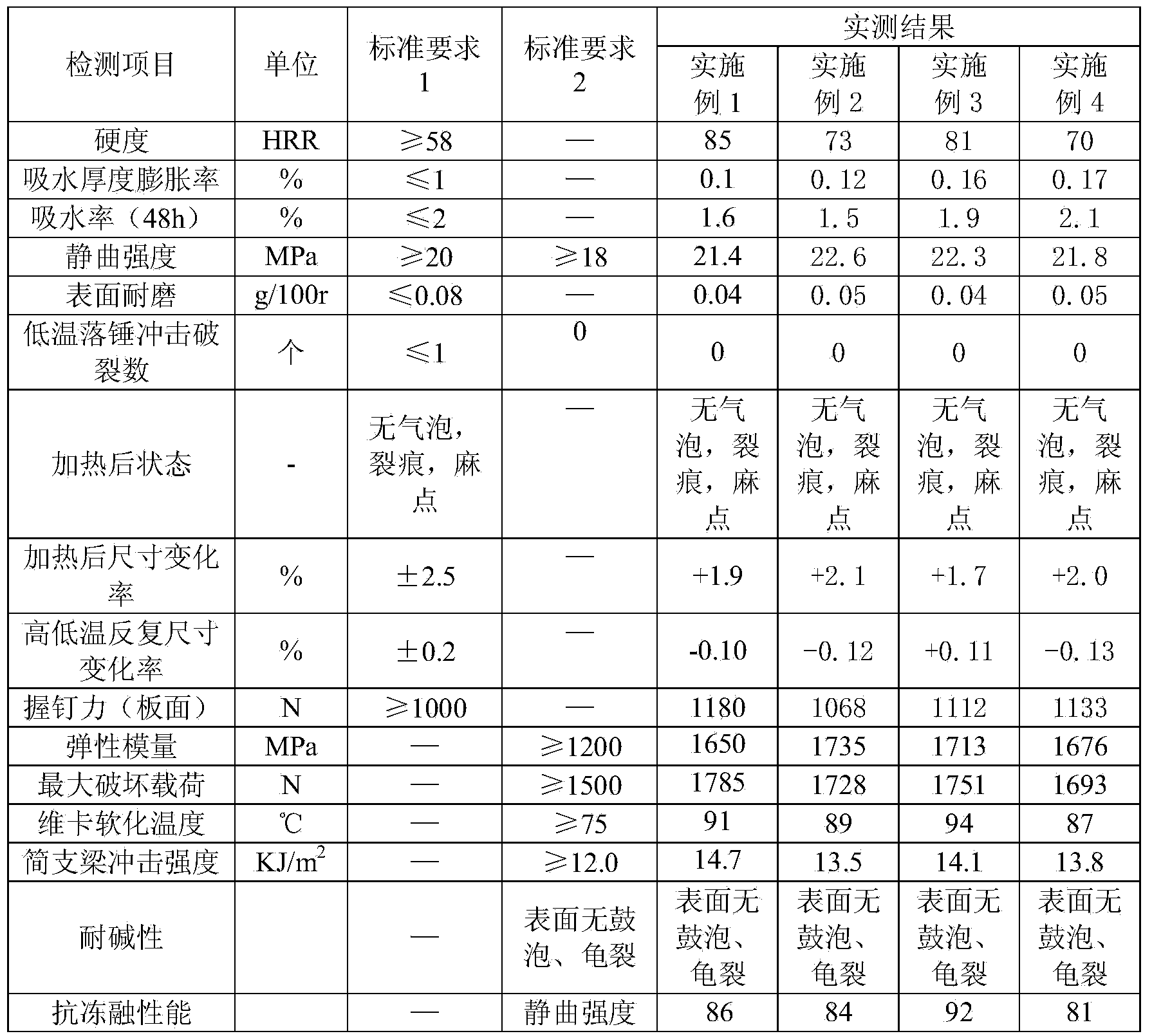

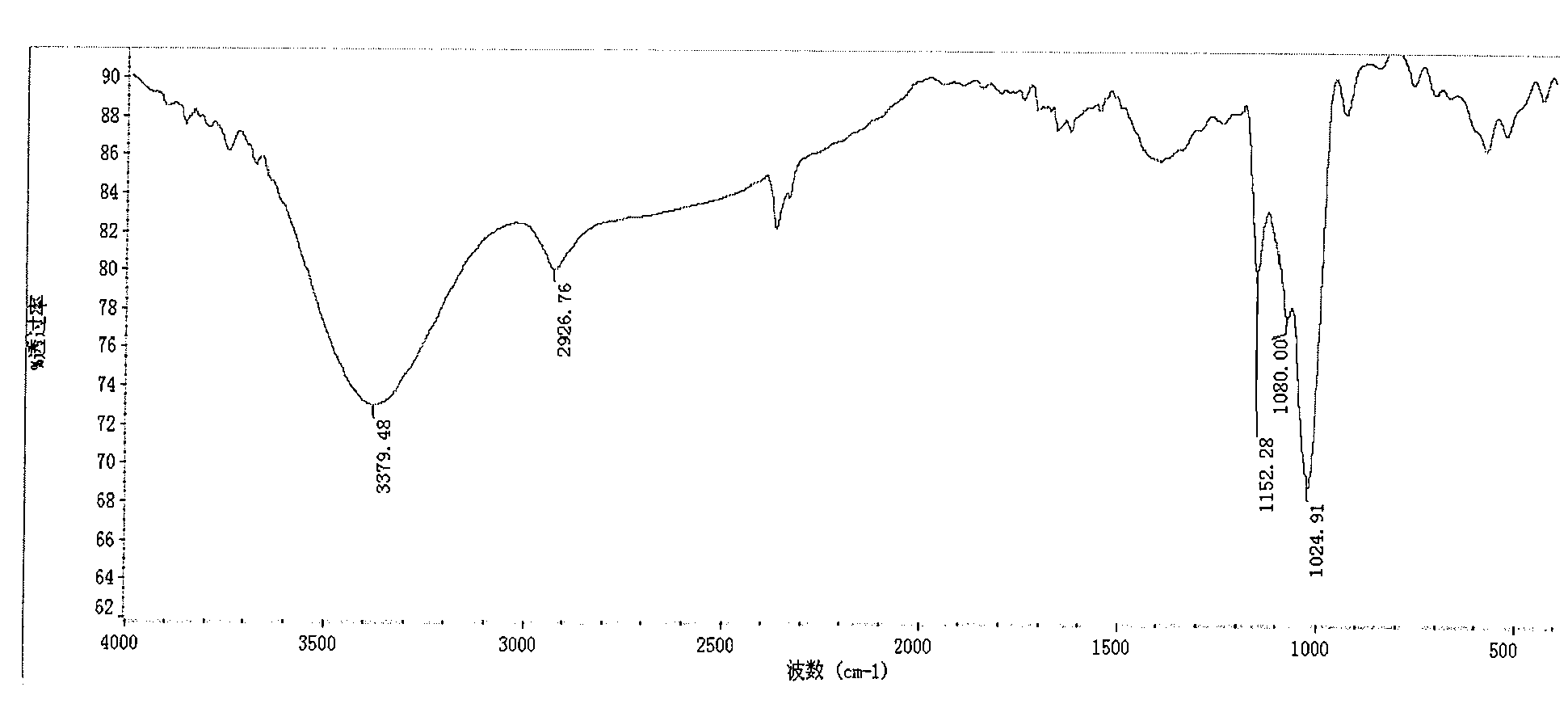

Environment-friendly single-layer microcellular foam PVC (polyvinyl chloride) wood-plastic composite board and preparation method thereof

The invention discloses an environment-friendly single-layer microcellular foamPVC (polyvinyl chloride) wood-plastic composite board and a preparation method thereof. According to an adopted raw material formula,the board comprises the components in percentage by mass as follows: 20%-60% of a PVC reclaimed material, 15%-45% of PVC resin, 5.6%-10% of wood fiber powder, 5%-8.9% of filler, 4%-4.4% of a foaming conditioning agent, 1%-1.5% of a compound stabilizer, 0.7%-0.9% of a foaming agent, 2%-2.5% of a reinforcing agent, 2.2%-2.4% of an impact modifier, 0.3%-0.45% of a lubricating agent, 0.1%-0.15% of a coupling agent and 3%-5% of a functional additive, and the functional additive is an anti-aging agent, a fire retardant or a coloring agent. The composite board has the processability similar to that of wood, can substitute for a wood board and also has thecharacteristics of fireproof property, moistureproof property, smooth and attractive appearance and the like, and the wood does not have the characteristics; according to the preparation method of the composite board, waste PVC can be used for performing cycle production, waste materials can be changed into things of value, waste of wood resources can be reduced, and the pollution caused by plastic products to the environment can also be avoided.

Owner:JIANGSU RUNJU ENVIRONMENTAL TECH CO LTD +1

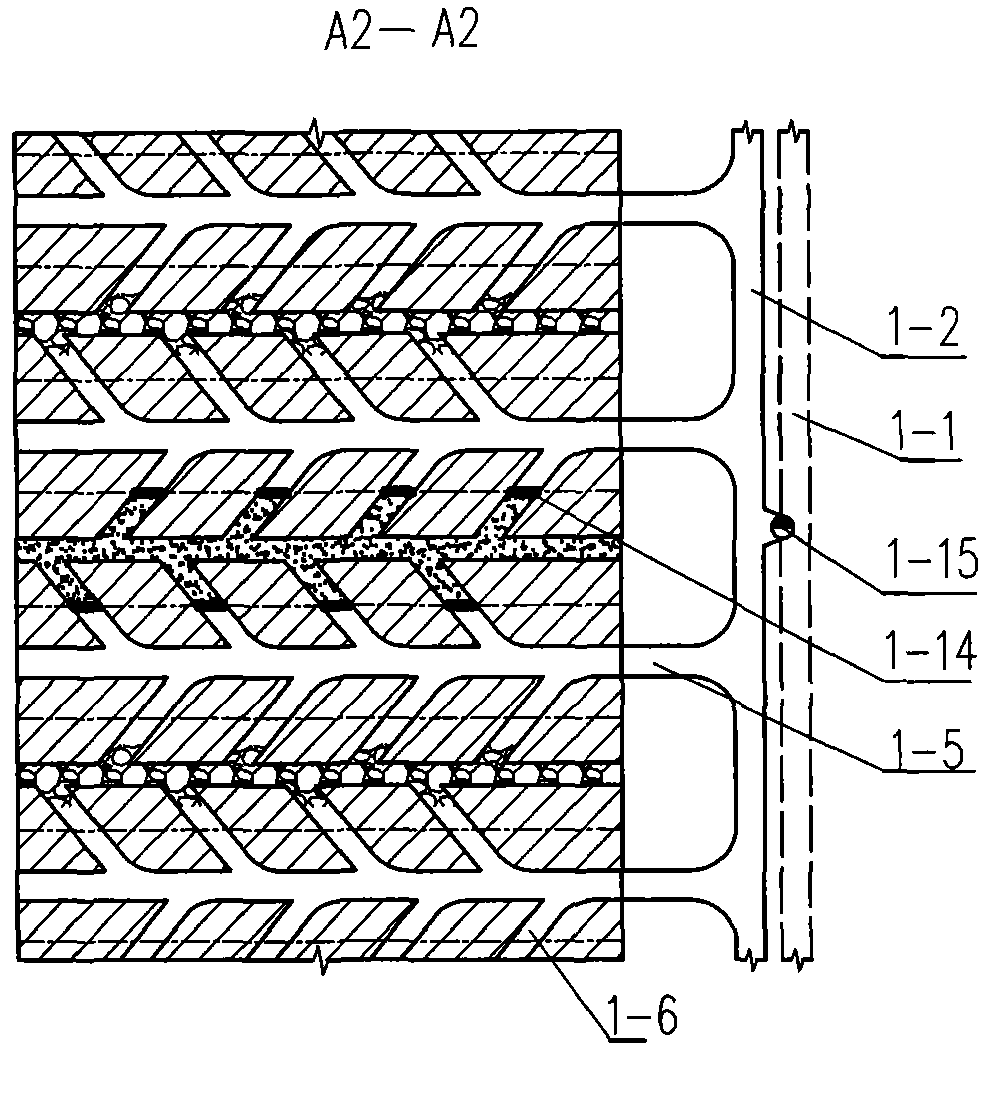

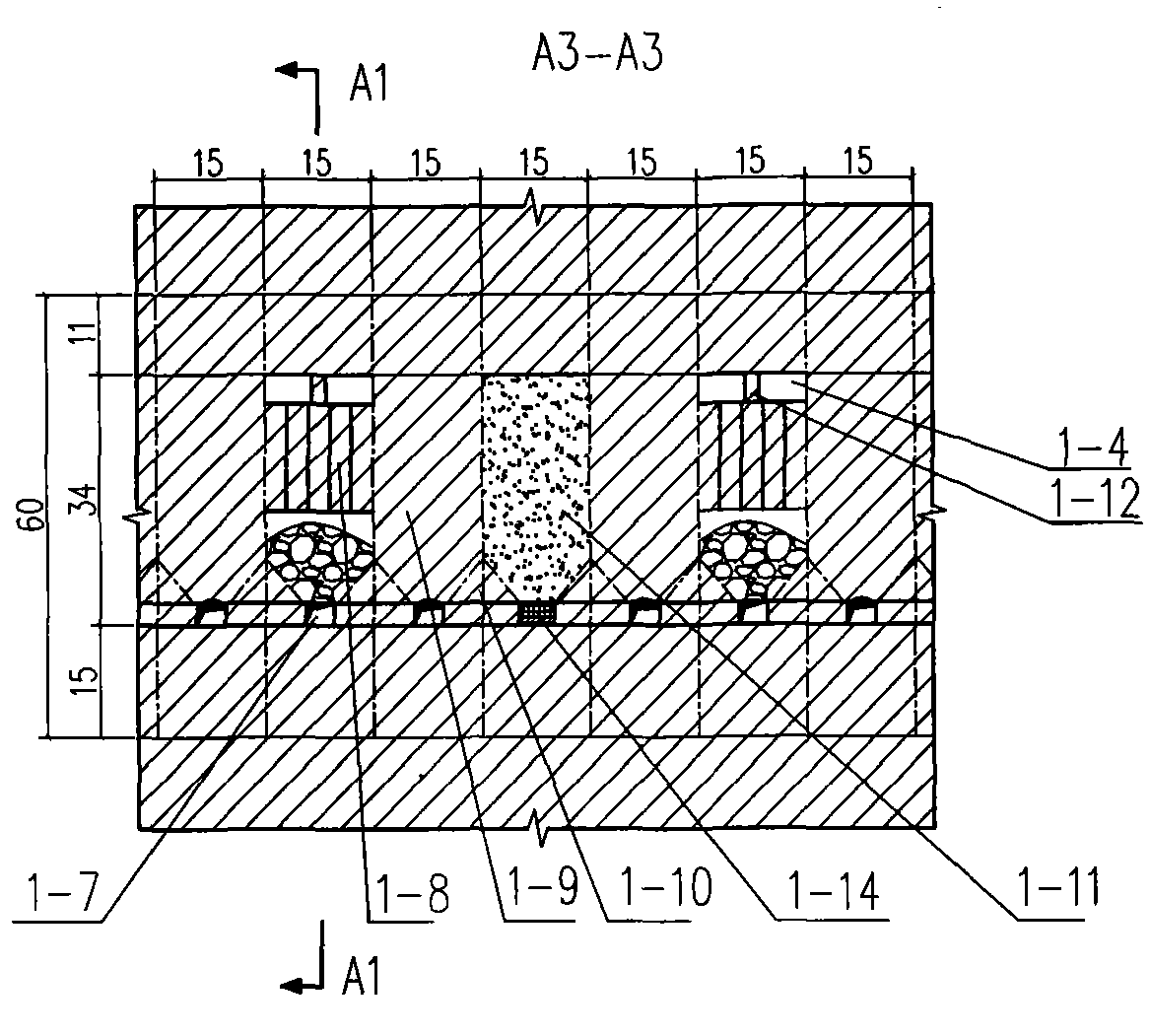

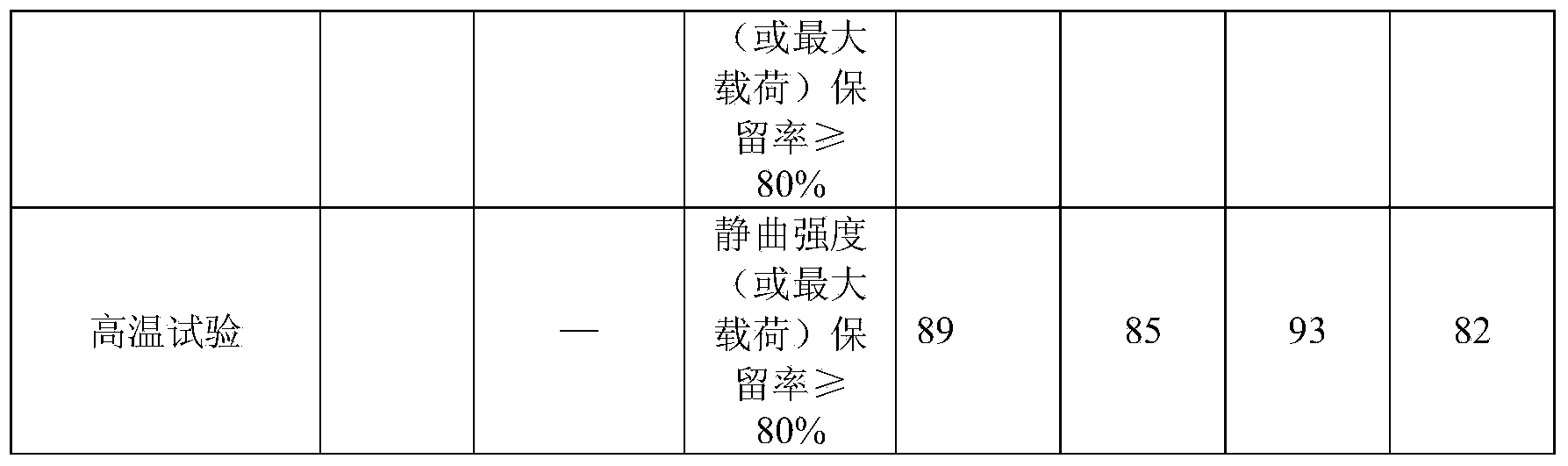

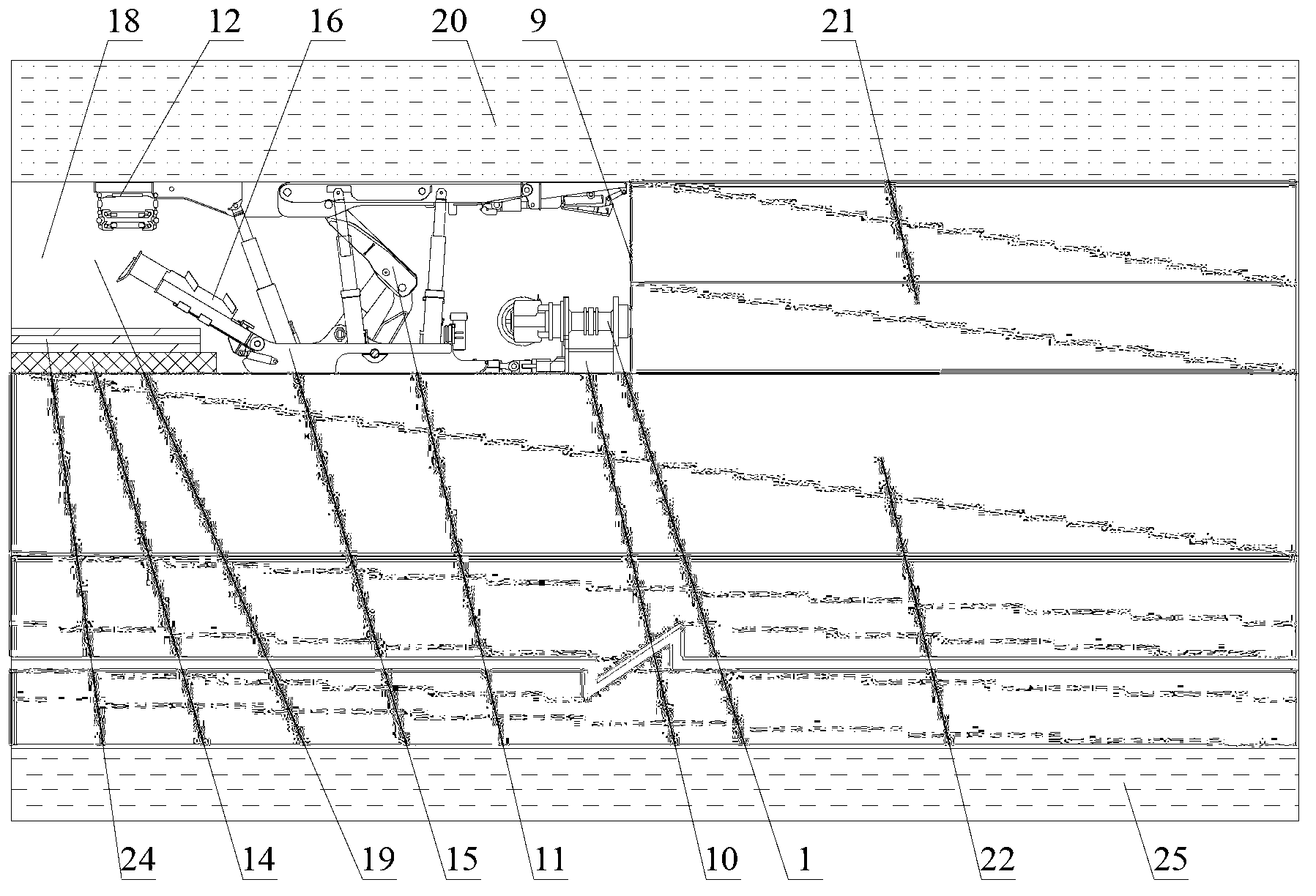

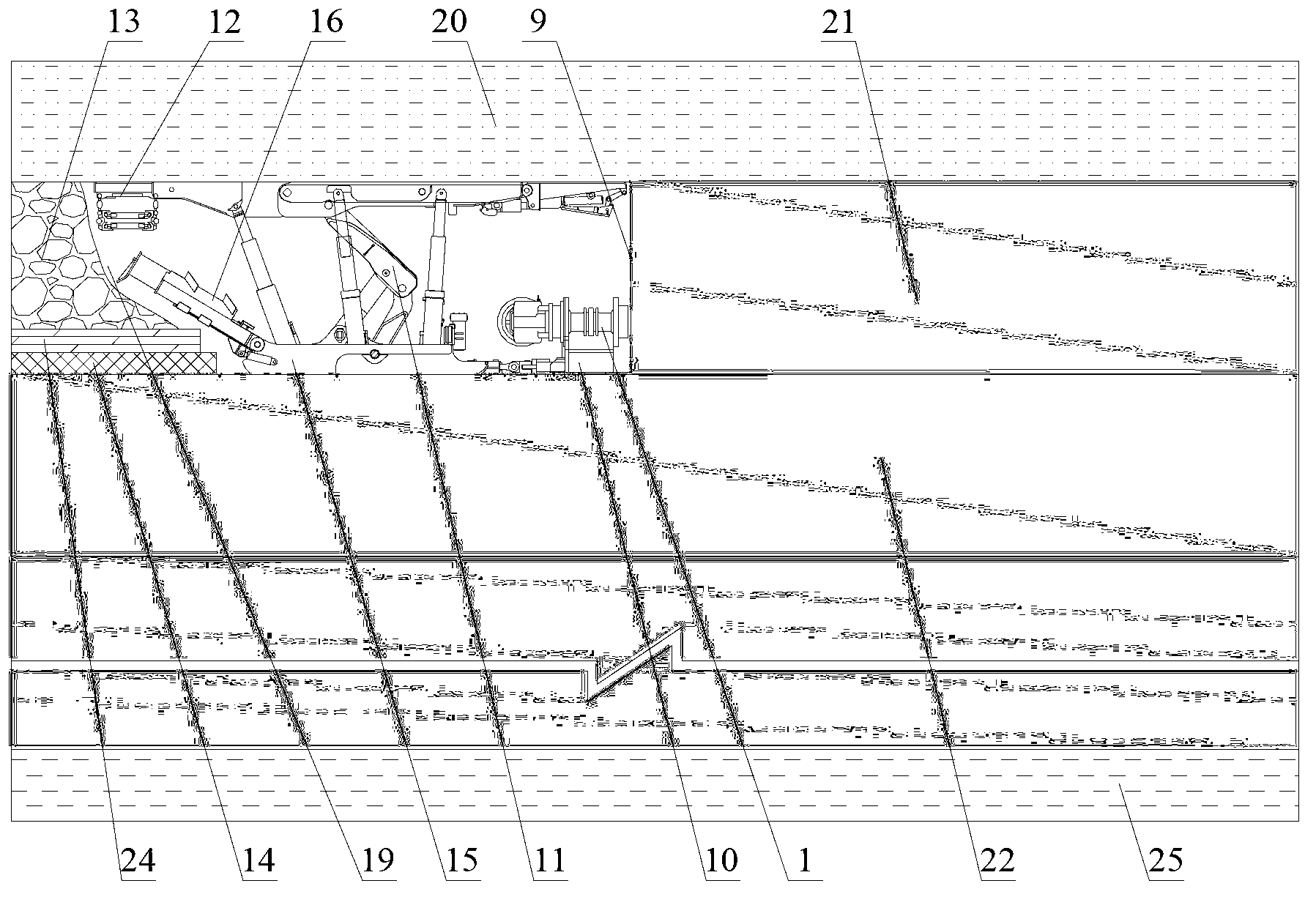

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

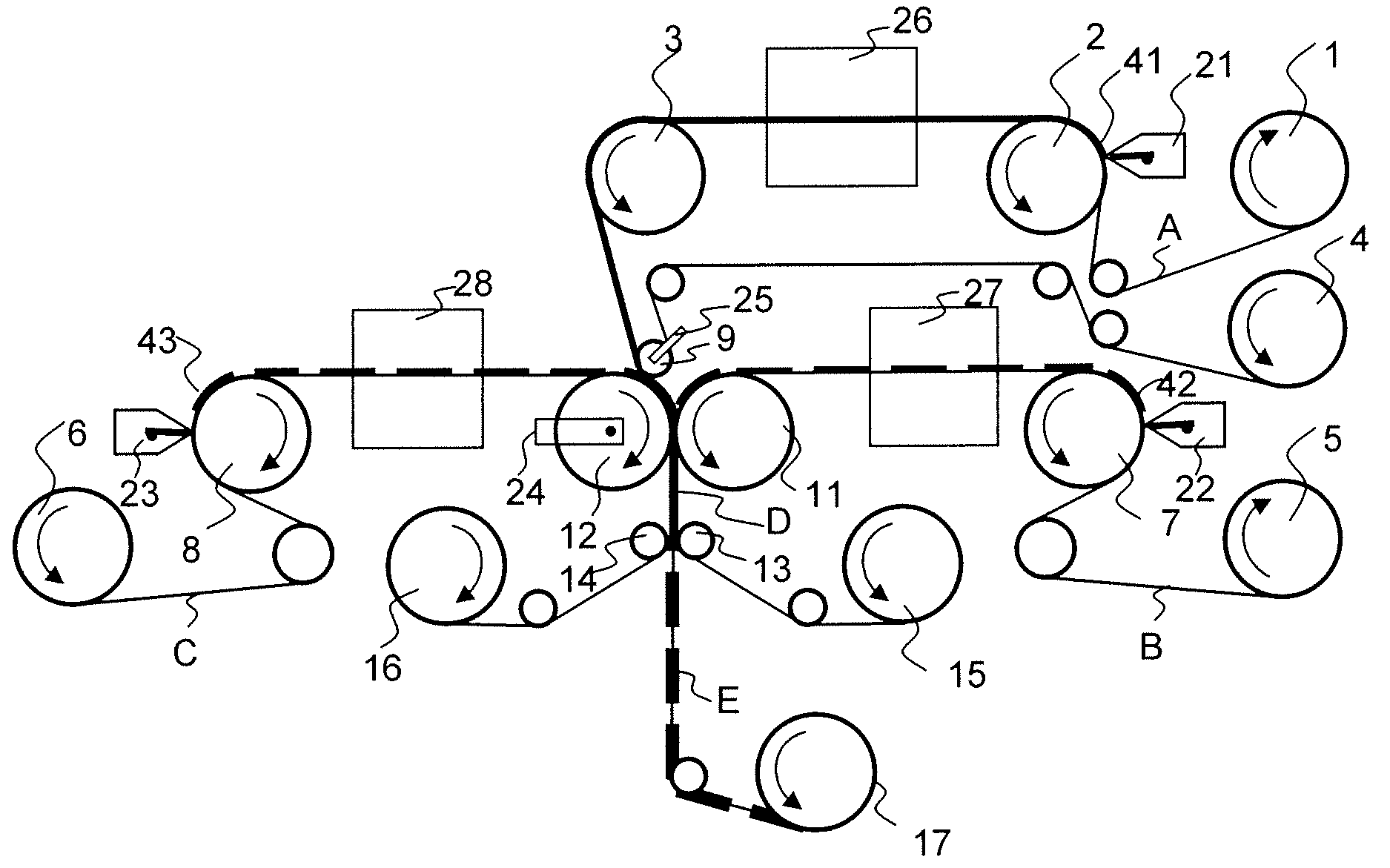

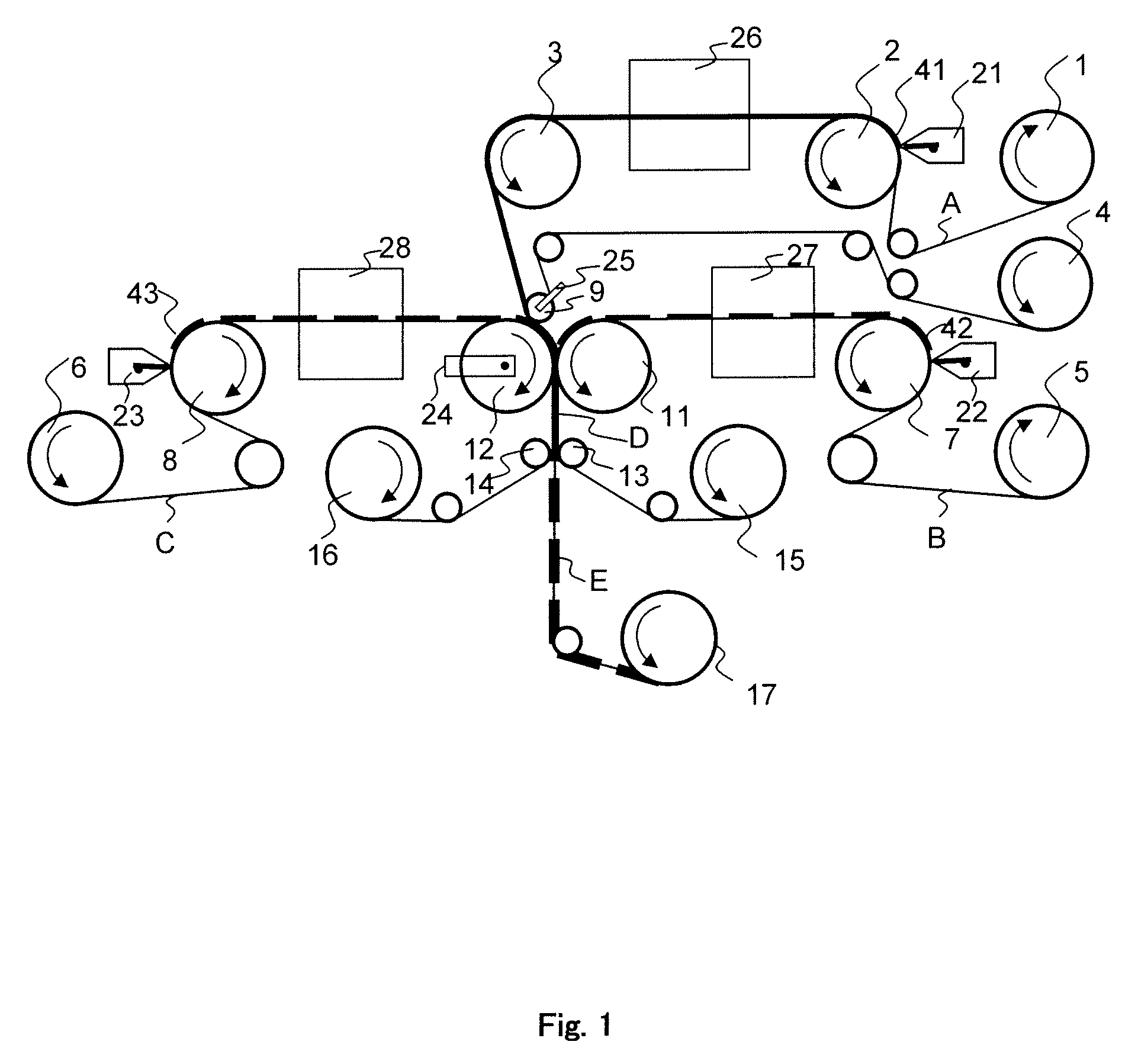

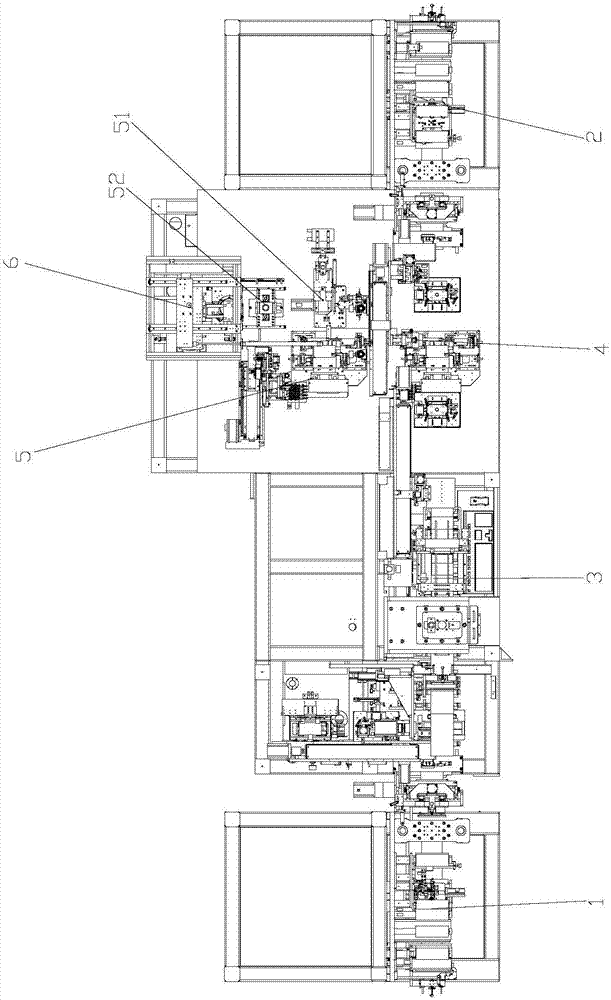

Manufacturing Equipment and Manufacturing Method of Membrane Electrode Assembly

InactiveUS20100051181A1Improve the level ofReduce production efficiencyElectrode manufacturing processesLamination ancillary operationsFuel cellsBiochemical engineering

The present invention provides a manufacturing method and manufacturing equipment which makes it possible to manufacture a fuel cell MEA (membrane electrode assembly) continuously and stably with a high level of precision. The present invention provides a manufacturing method of a fuel cell MEA which includes transferring three carrier films in belt shapes, coating an electrolyte membrane in predetermined regions on one of the carrier films, coating electrode catalyst layers intermittently in predetermined regions on the other two carrier films, drying the electrolyte and the electrode catalyst layers on the carrier films, laminating the electrolyte membrane onto an electrode catalyst layer on one of the carrier films with a pressure and peeling off and removing the carrier film of the electrolyte membrane, laminating the other electrode catalyst layer onto the electrolyte membrane laminated on the electrode catalyst layer with heat and a pressure, and peeling off the carrier films from the resultant laminated product of the electrolyte membrane and the electrode catalyst layers.

Owner:TOPPAN PRINTING CO LTD

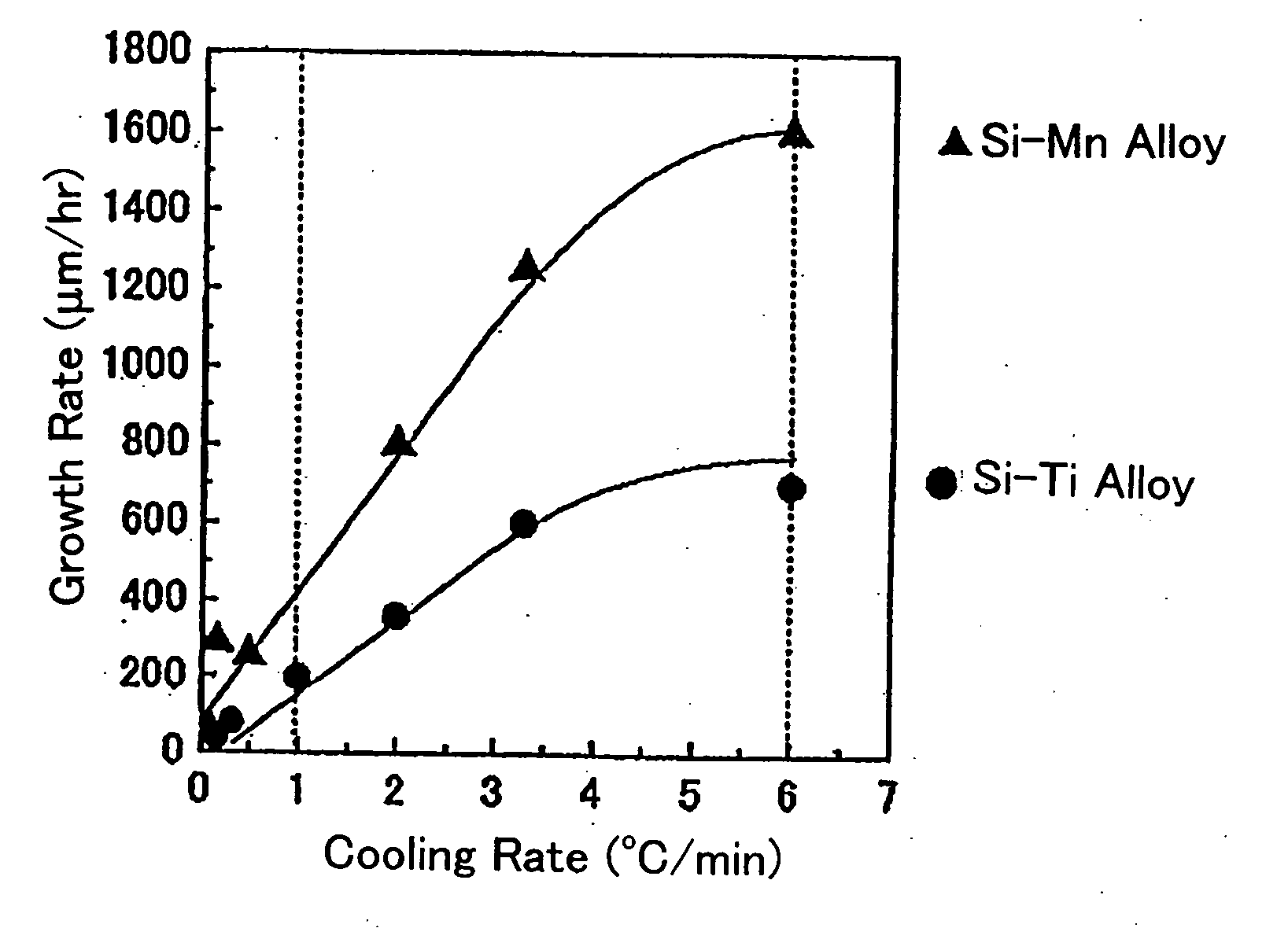

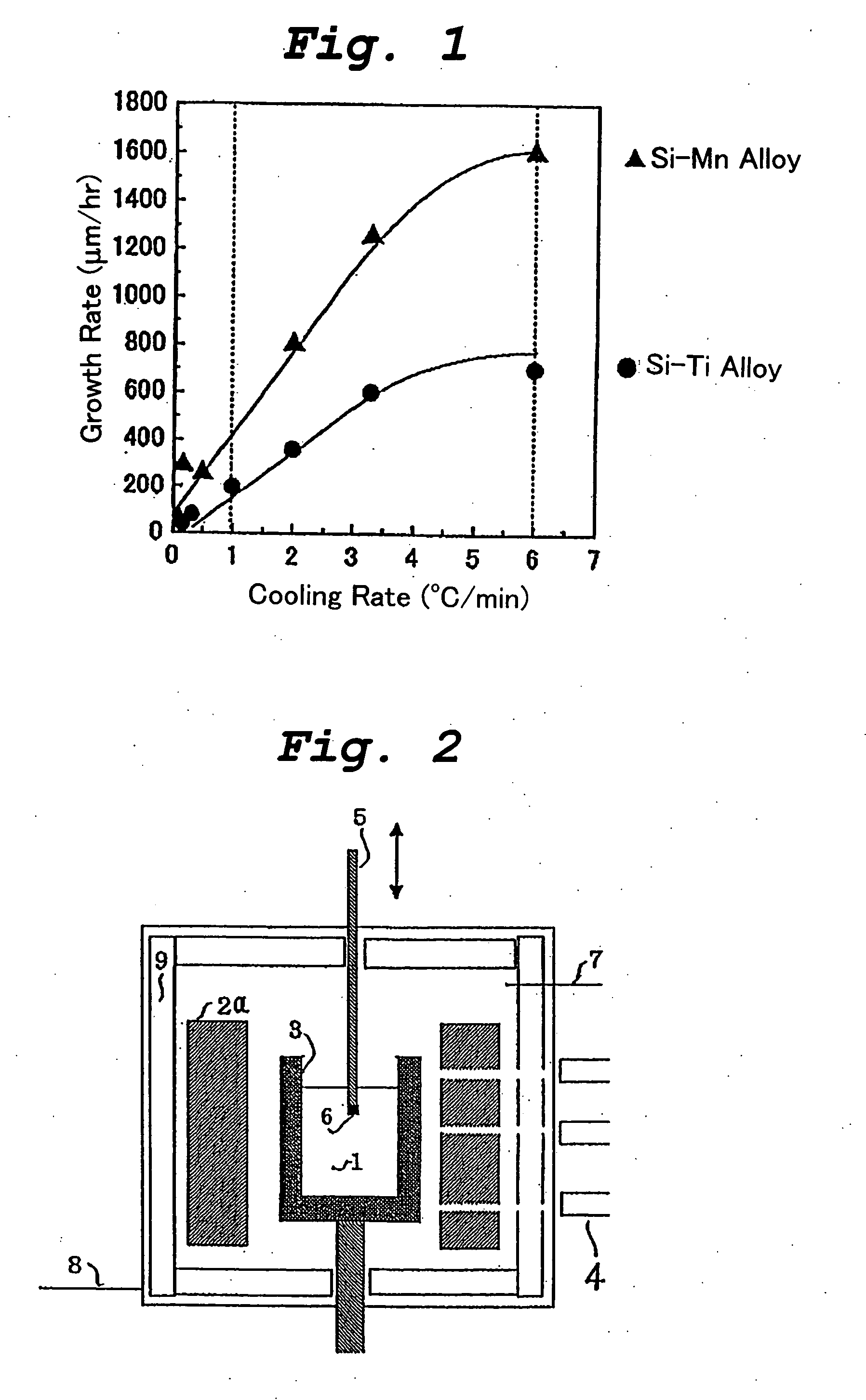

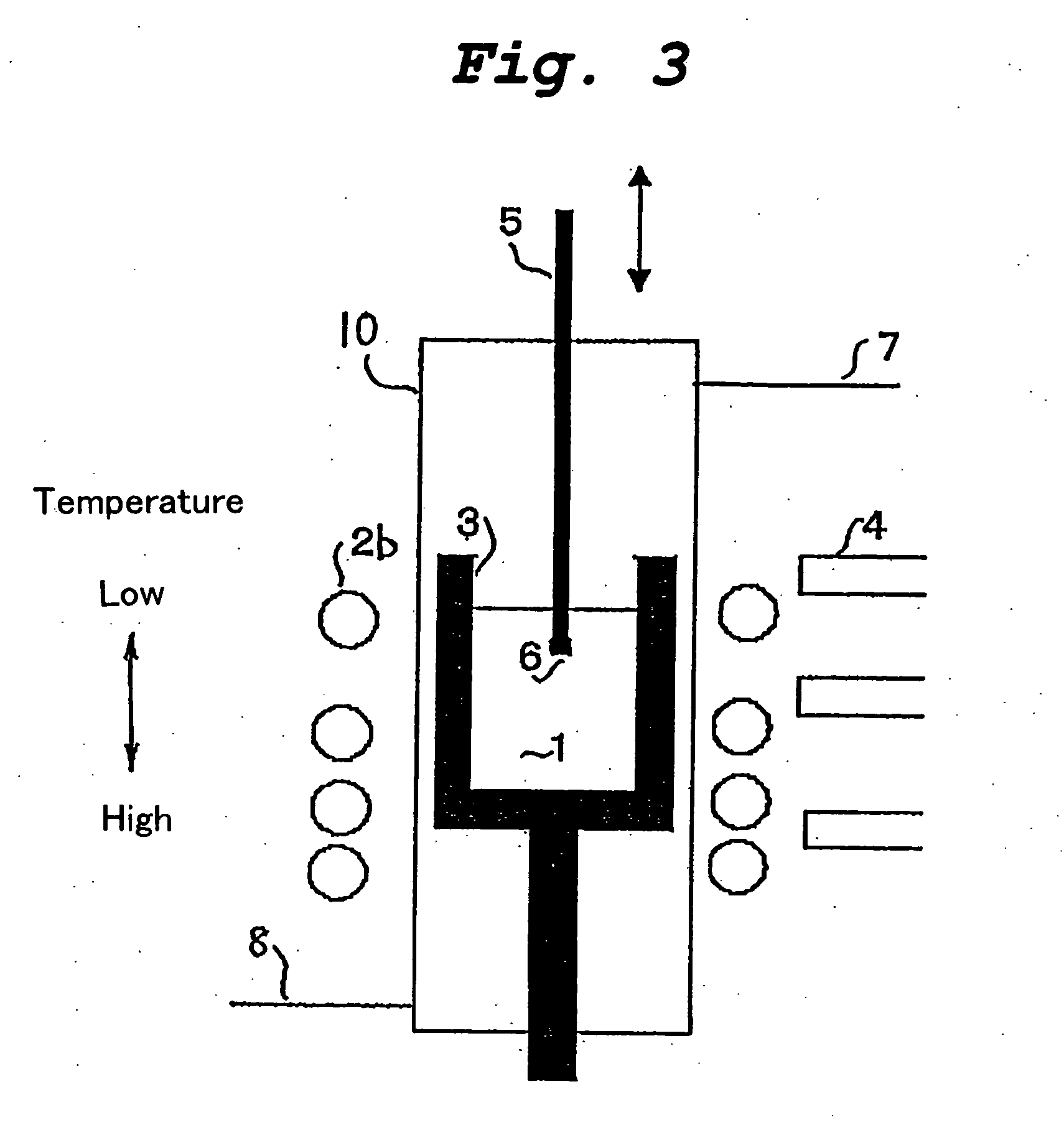

Silicon carbide single crystal and a method for its production

InactiveUS20050183657A1Easy to handleStable productionFrom gel statePolycrystalline material growthAlloyDissolution

A bulk silicon carbide single crystal of good crystalline quality which includes a minimized number of structural defects and is free from micropipe defects can be produced by crystal growth in a melt of an alloy comprising Si, C, and M (wherein M is either Mn or Ti) and having an atomic ratio between Si and M in which the value of x, when express as Si1-xMx, is 0.1≦×≦0.7 in the case where M is Mn or 0.1≦×≦0.25 in the case where M is Ti at a temperature of the melt which is below 2000° C. The C component is preferably supplied into the melt by dissolution of a graphite crucible which contains the melt such that the melt is free from undissolved C. One method of crystal growth is performed by cooling the melt after a seed substrate is immersed in the melt.

Owner:NIPPON STEEL CORP

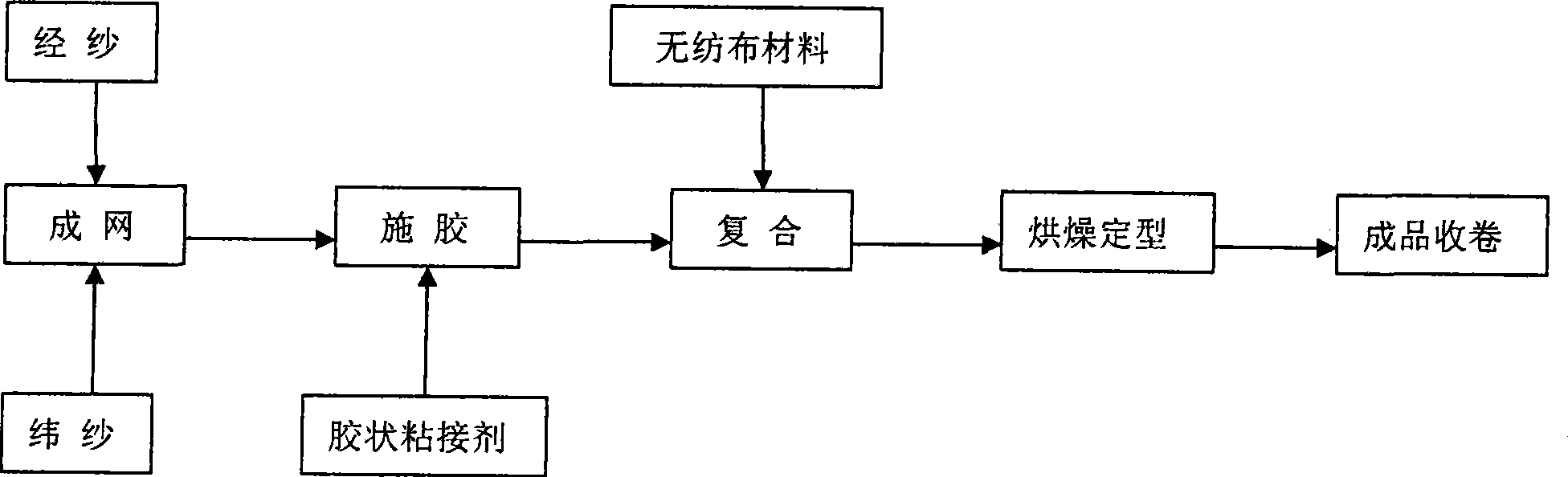

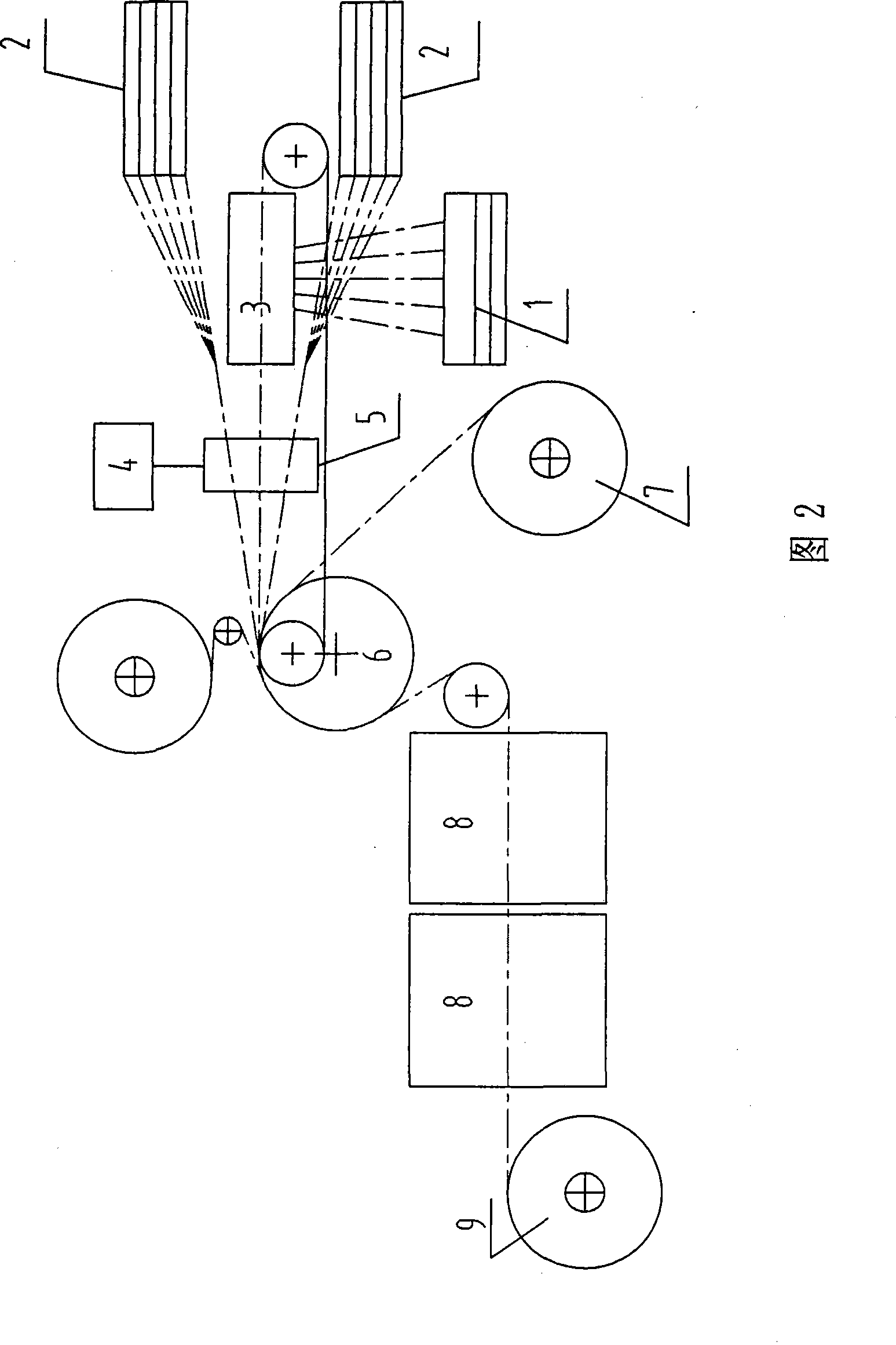

Method for producing nonwoven gridding reinforced composite nonwoven fabrics

ActiveCN101392433AReduce production efficiencyLeading technology levelNon-woven fabricsProduction lineEngineering

The invention discloses a method for producing nonwoven griddling reinforced compound non-woven fabrics. The method is characterized in that the invention adopts a new technical proposal that a continuous fiber, a non-woven fabric material and gelatineous adhesive agent are taken as raw materials, by adopting a mode of continuous filament multi-head weft-covering, the grid is formed and the glue is applied on the production line, then the grid is compounded with the nonwoven fabrics and the obtained product is then dried and finalized, thus producing a new strengthening nonwoven grid reinforced compound nonwoven fabrics. The technology provided by the invention totally changes the traditional weaving concept and compounding technology, changes the structural characteristics of mechanics of the materials, thus drastically improves the overall property and the production efficiency of the product and greatly reduces the material cost of the relevant strengthening fabrics.

Owner:CHANGZHOU NEWLAND COMPOSITE MATERIAL

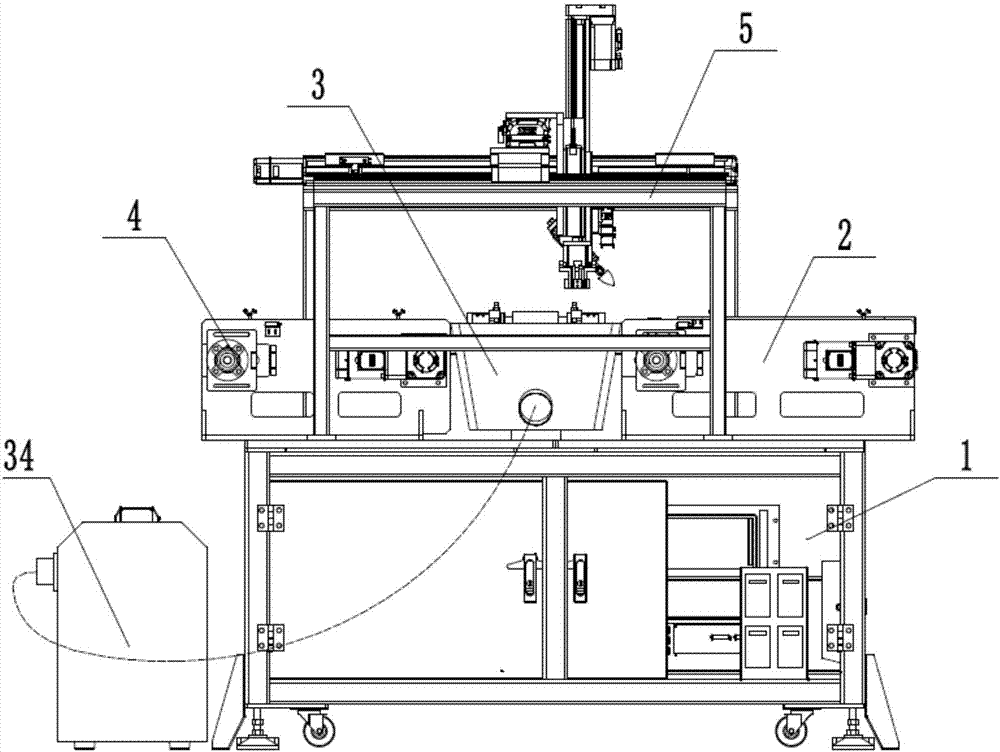

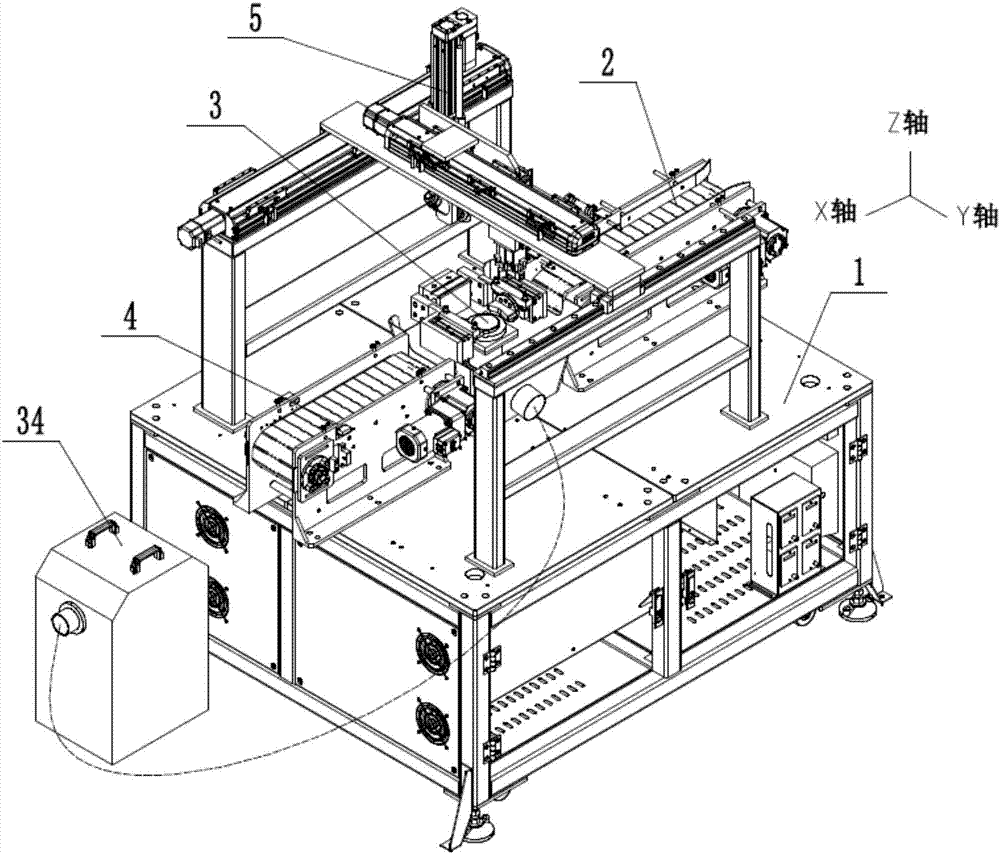

Automobile hub double-face full-automatic polishing production line

InactiveCN108000273AAccurate capturePrecise positioningEdge grinding machinesGrinding carriagesProduction lineManipulator

The invention discloses an automobile hub double-face full-automatic polishing production line which comprises a rack and a polishing mechanism. The rack is sequentially provided with a feeding mechanism, a hub polishing rotary table and a discharging mechanism, the polishing mechanism is located above the polishing mechanism, and the characteristics are that the feeding mechanism comprises a first chain plate conveyor, two guide plates and a stopping air cylinder; the hub polishing rotary table comprises a grinding collecting box, a hub polishing jacking table and an overturning tool; the overturning tool comprises a vertical plate, a wide type gas claw, two clamping connecting plates, two rotary air cylinders and two clamping blocks; the polishing mechanism comprises a support, an X-axisguide rail, an X-axis sliding base, a Y-axis sliding base, an X-axis electric cylinder, a Y-axis electric cylinder, a Z-axis electric cylinder, a Z-axis stretchable cylinder, an electric polishing head and a carrying mechanical arm; and the discharging mechanism at least comprises a second chain plate conveyor. The automobile hub double-face full-automatic polishing production line is used for automobile hub full-automatic polishing production, the front and back faces of a hub can be switched at will, and the reliability and the stability can be improved.

Owner:李茂菊

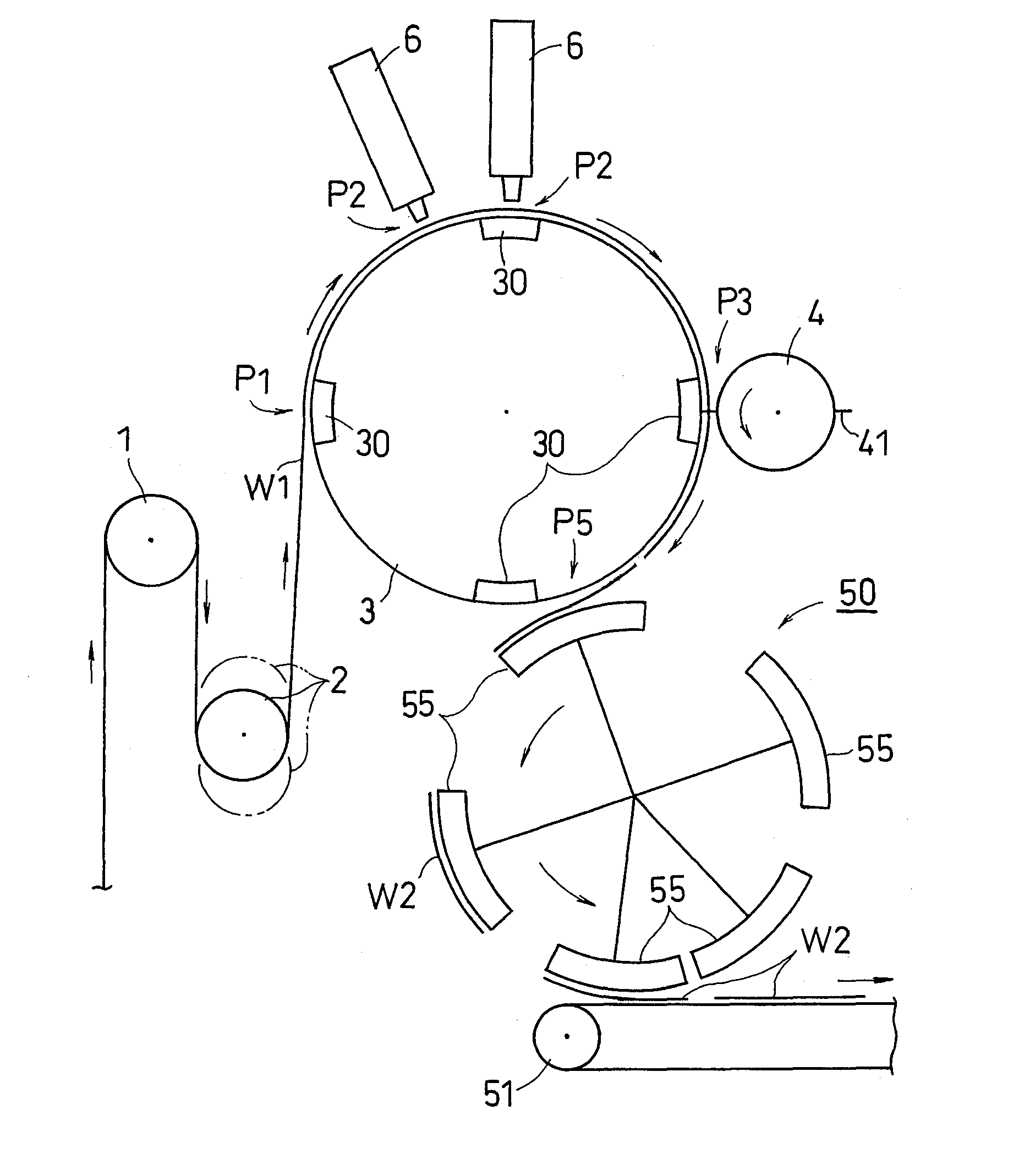

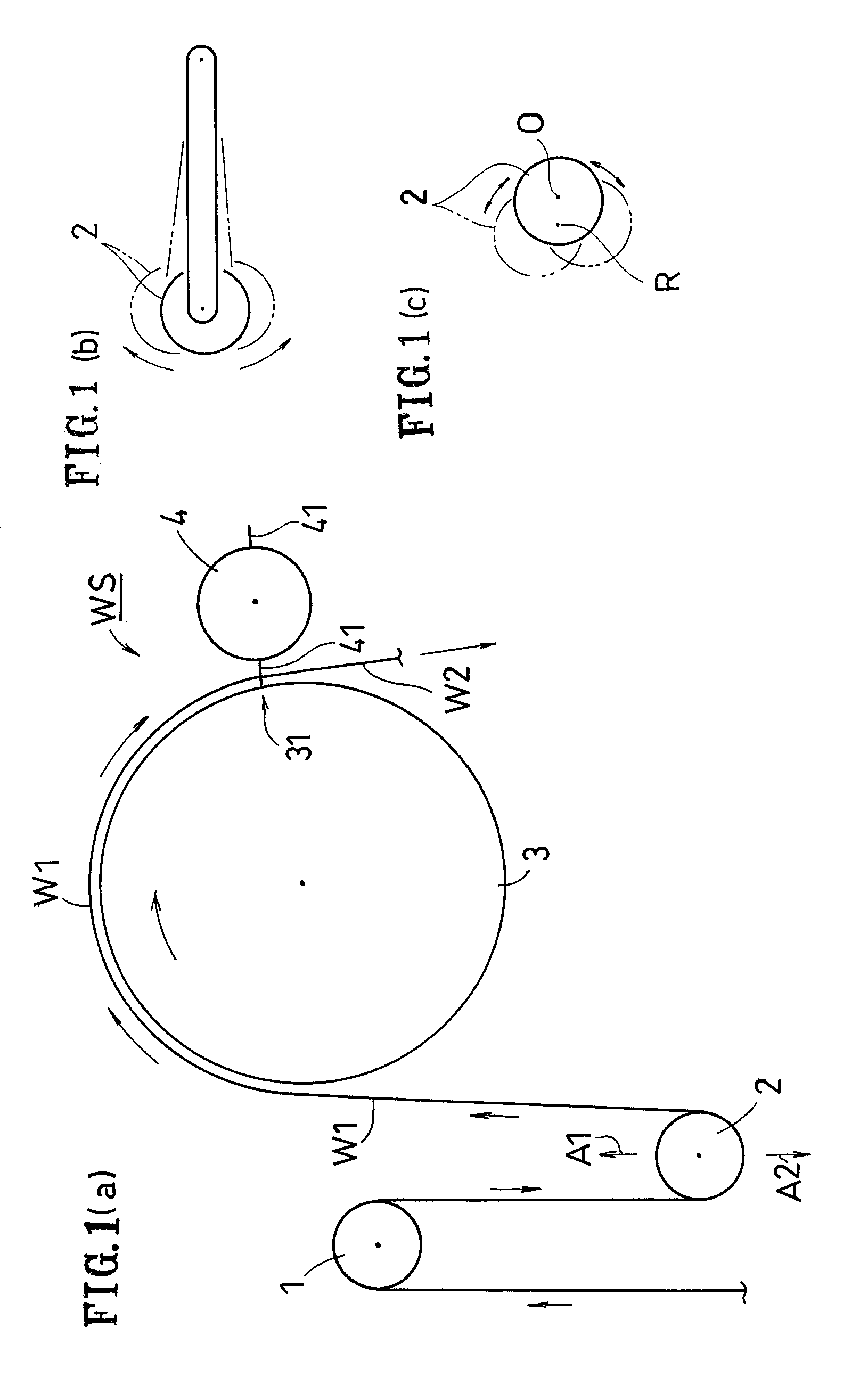

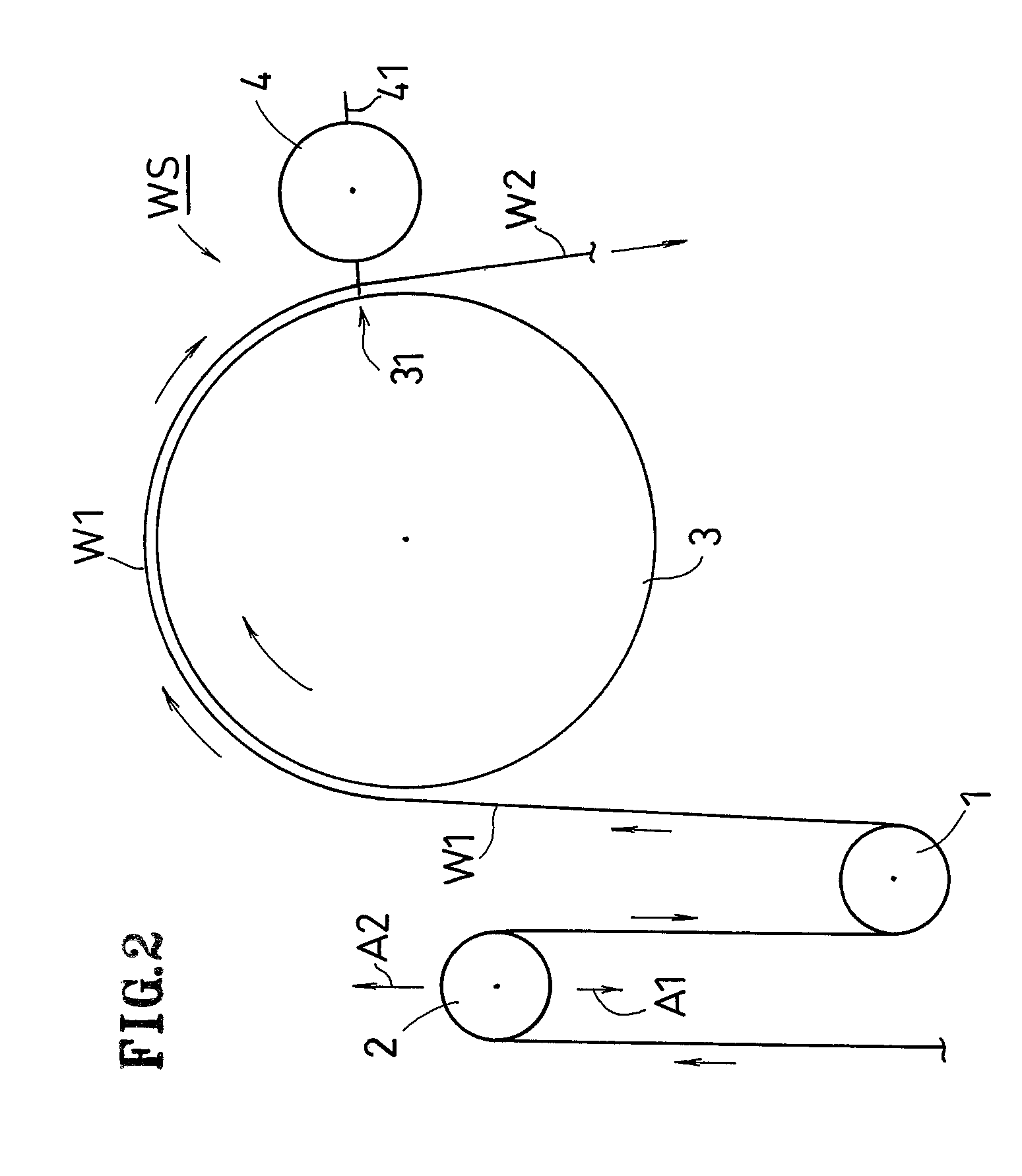

Velocity-changing apparatus for web

InactiveUS8062459B2More processedReduce production efficiencyLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:ZUIKO CORP

Novel 6063 aluminum alloy material and its production technology

The invention discloses a novel 6063 aluminum alloy material. Rare earth elements are added into the original 6063 aluminum alloy. The novel 6063 aluminum alloy material comprises, based on the weight percentage,0.36%- 0.4% of Si, 0.48% - 0.52% of Mg, 0 -0.35% of Fe, 0 -0.1% of Cu, 0 - 0.05% of Mn, 0 - 0.05% of Cr, 0 - 0.05% of Zn, 0 - 0.05% of Ti, 0.18%-0.22% rare earth elements, 0-0.1% of the remaining impurities and the balance of Al. According to the invention, the content of Mg and Si is controlled within a narrow range. At the same time, cerium-based mixed rare earth elements and alloying element boron are added, which keeps alloy material high strength and high electrical and thermal conductivity; improves machining property and plastic extrusion; and improves production efficiency.

Owner:CHENGDU SUNSHINE ALUMINUM

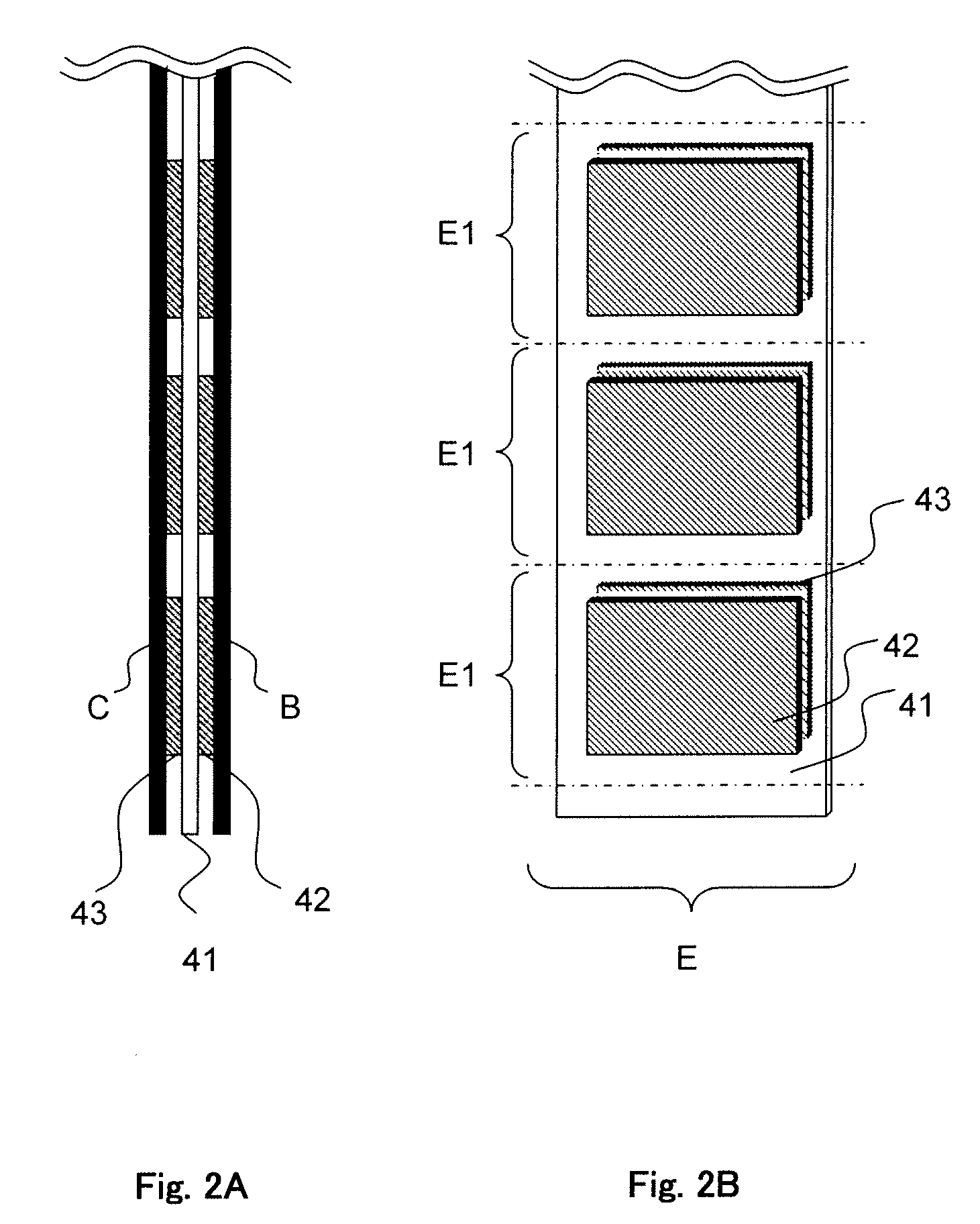

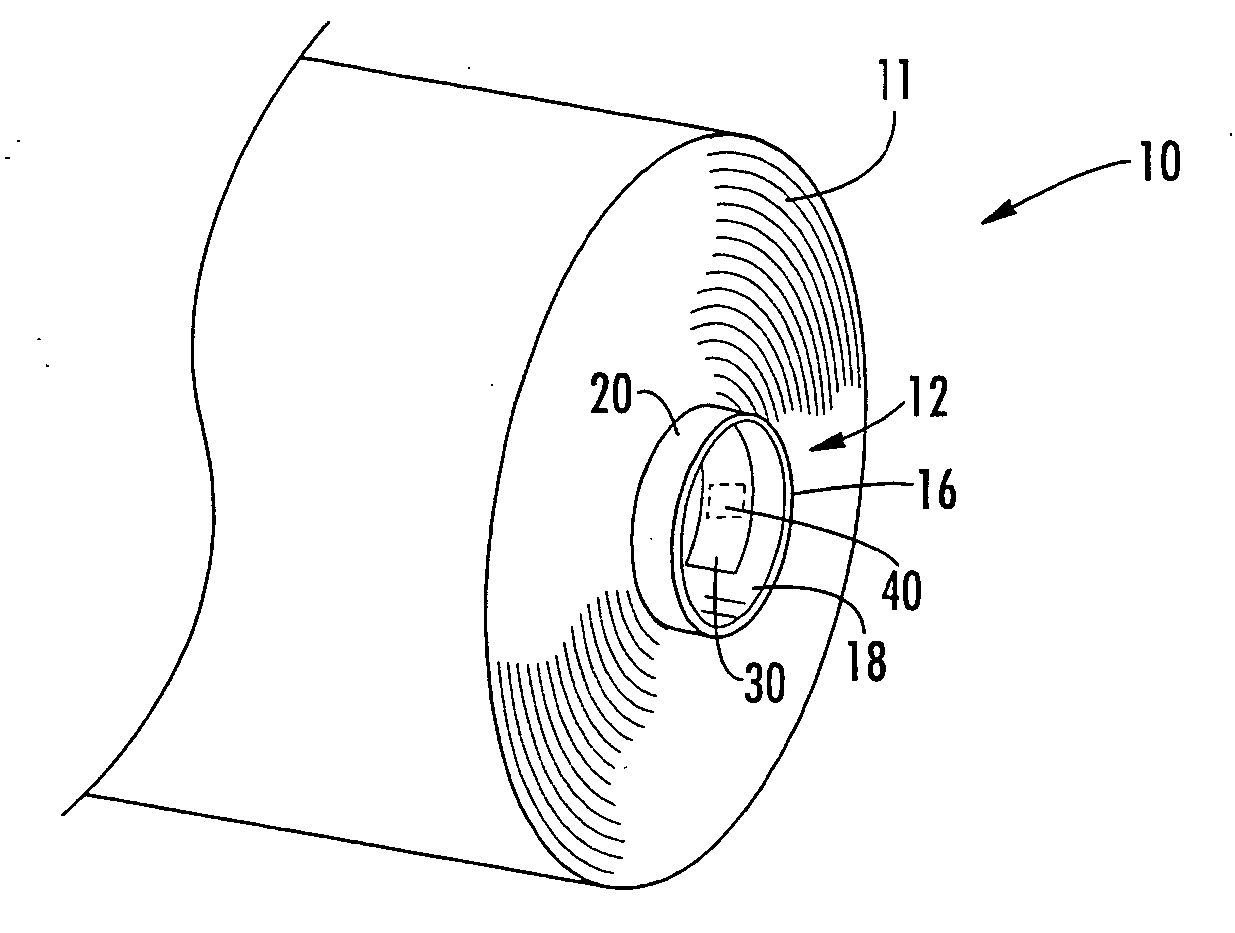

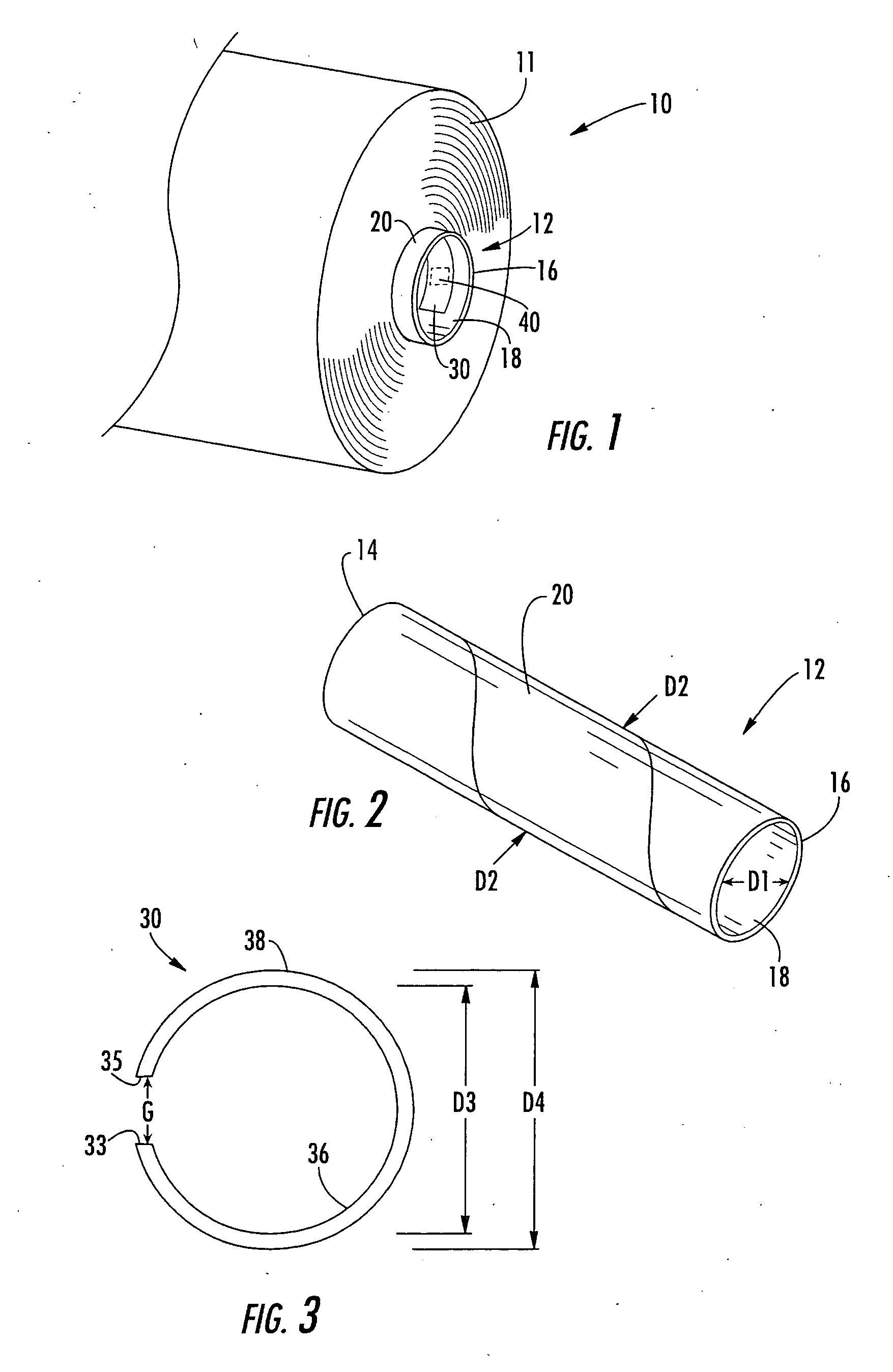

Removable identification device for multilayer tubular structures

InactiveUS20050237199A1Protection from damageLess riskContainer decorationsLevel indicationsIdentification deviceEngineering

A multilayer tubular structure for products with an identification device is disclosed. In one embodiment, a resiliently flexible band is biased with respect to the tubular structure, and the identification device, such as a radio frequency identification device, is interposed therebetween.

Owner:SONOCO DEV INC

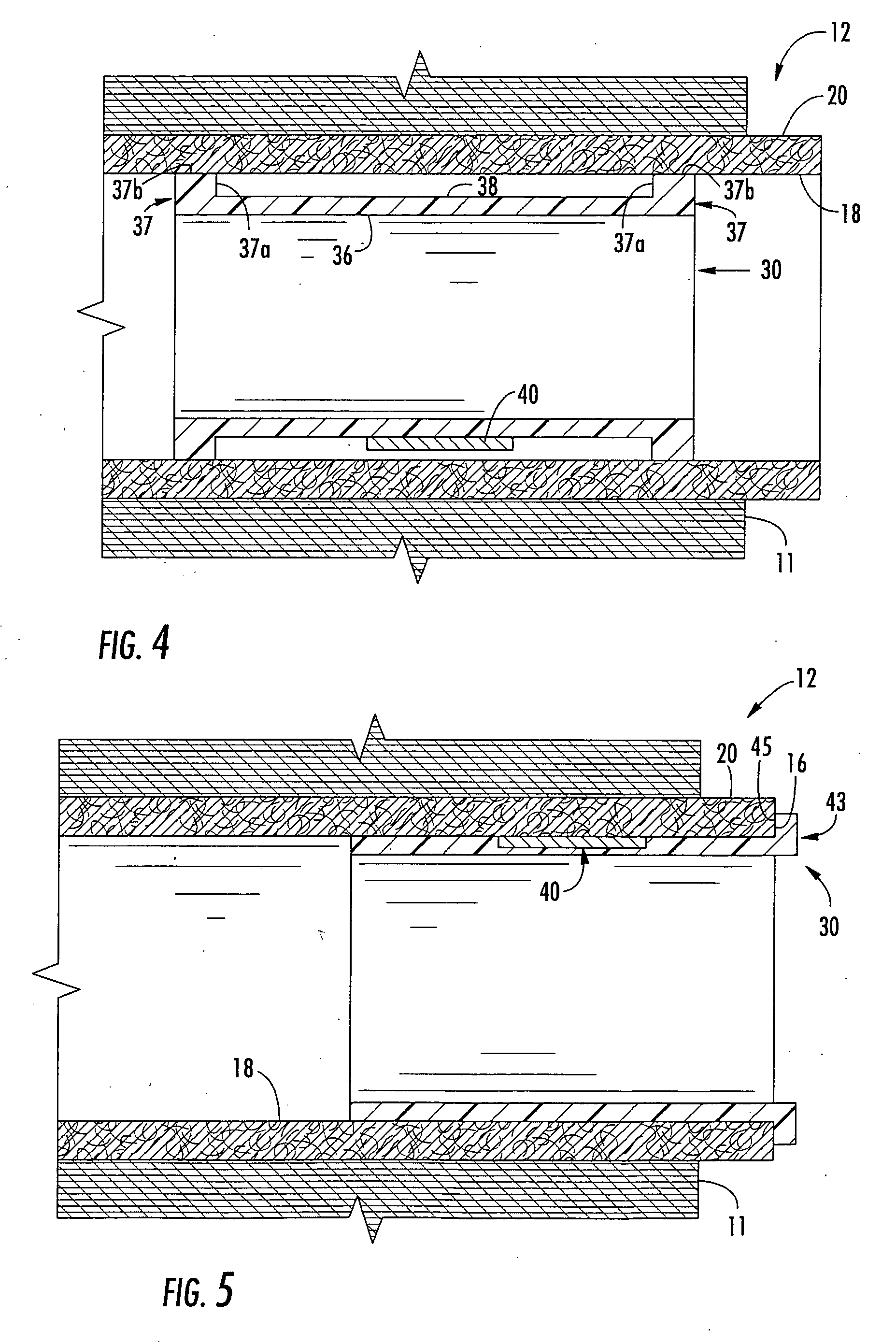

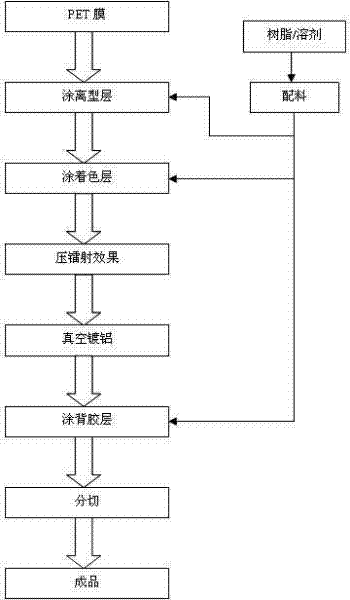

Cold-hot film process

ActiveCN102442098AReduce pollutionFast stamping speedDuplicating/marking methodsPolyethylene terephthalateLaser

The invention mainly discloses a cold-hot film process which comprises the following steps of: firstly, cutting a needed PET (polyethylene terephthalate) film, and coating a releasing layer on the PET film; secondly, coating a coloring layer on the releasing layer, stamping a laser layer effect on the coloring layer, performing vacuum-plating of aluminum above the laser layer, and coating a back glue; and finally, cutting the prepared finished product. The process disclosed by the invention has the advantages of high thermo-printing speed, high accuracy, and short production cycle; and the final product can embody a gradual changing effect and has strong stereovision.

Owner:绍兴虎彩激光材料科技有限公司

Strengthened glass substrate manufacturing method and strengthened glass substrate

InactiveUS20150044473A1Reduce thicknessLow costGlass forming apparatusGlass/slag layered productsMolten saltIon exchange

A method of manufacturing a tempered glass substrate includes: melting glass raw materials blended so as to have a glass composition including, in terms of mass %, 40 to 71% of SiO2, 3 to 23% of Al2O3, 0 to 3.5% of Li2O, 7 to 20% of Na2O, and 0 to 15% of K2O; forming the resultant molten glass into a sheet shape; and performing ion exchange treatment in a KNO3 molten salt, the KNO3 molten salt having a controlled concentration of Na ions, to form a compressive stress layer in a surface of the glass.

Owner:NIPPON ELECTRIC GLASS CO LTD

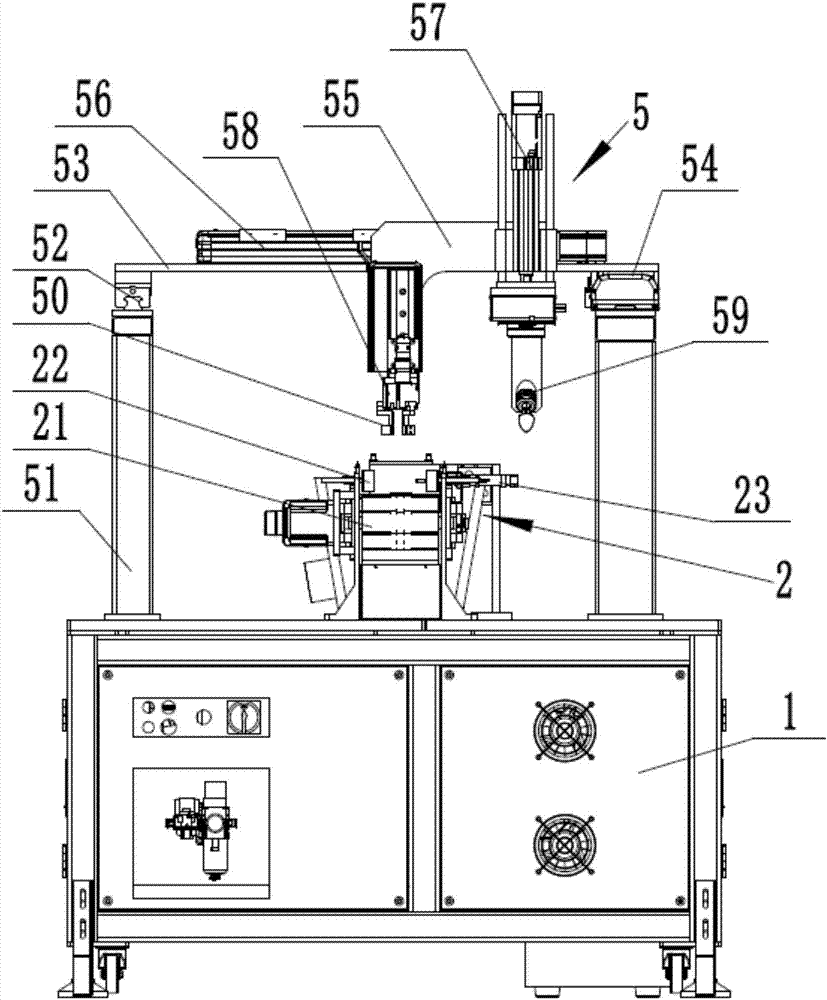

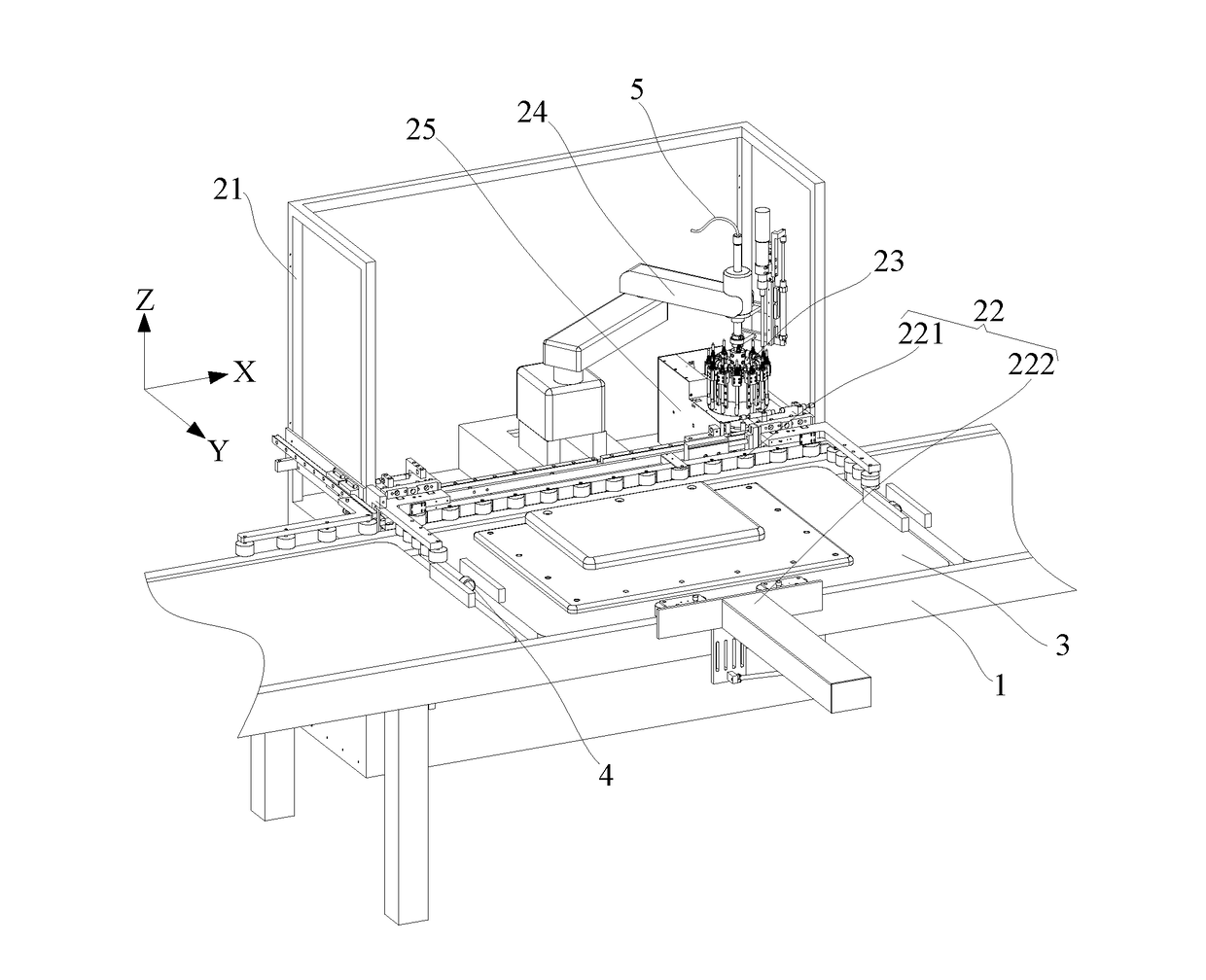

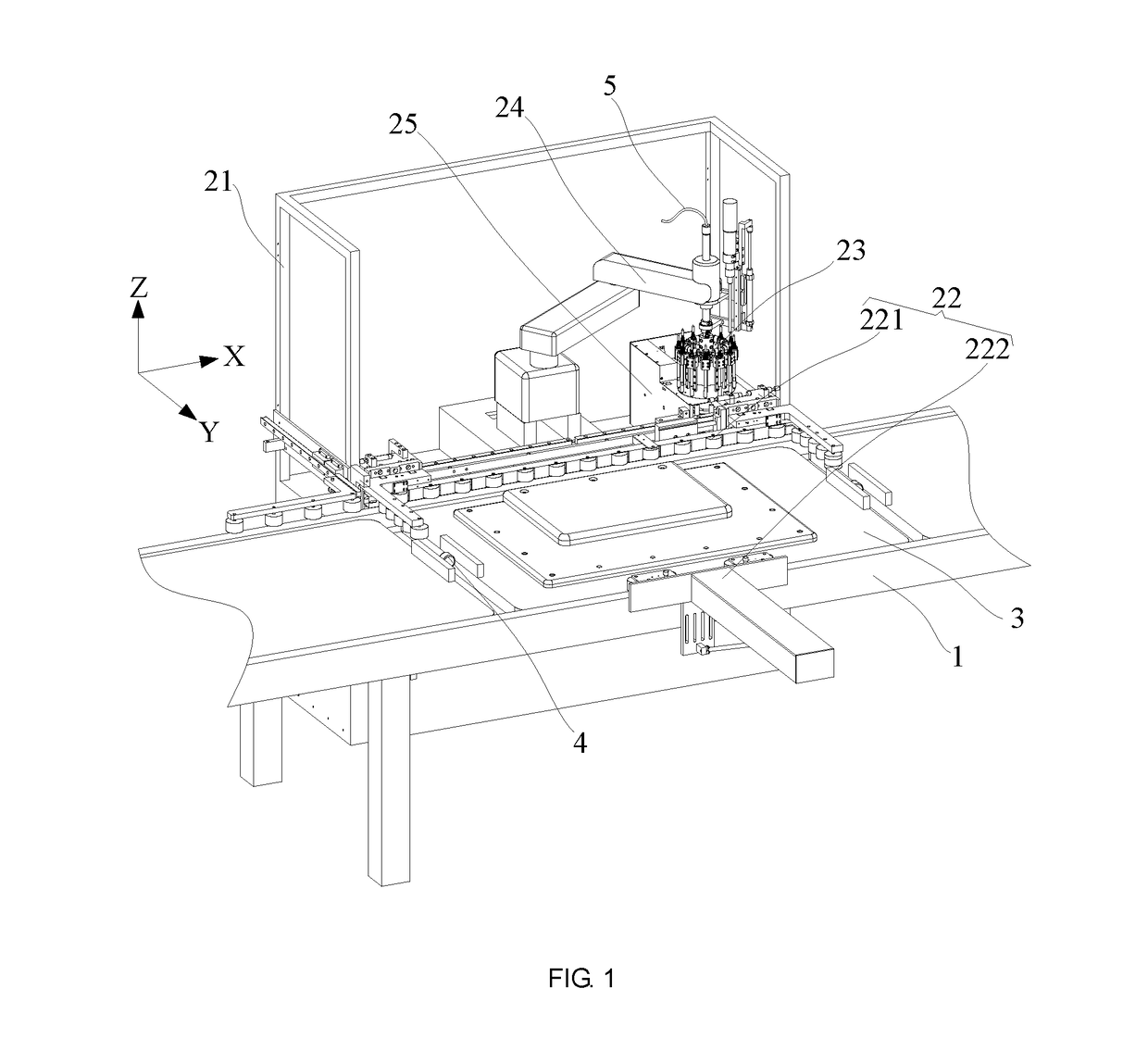

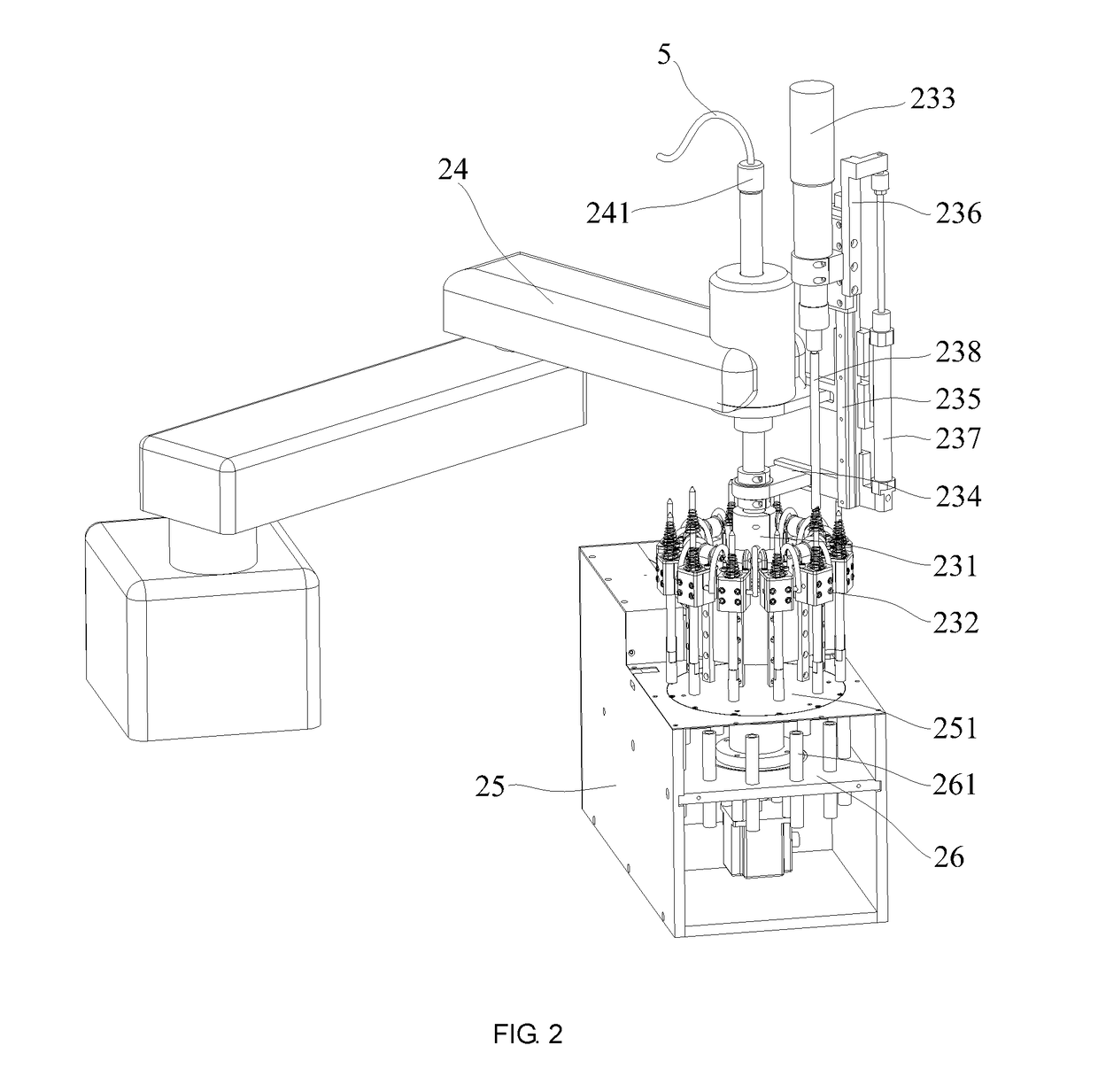

Device for automatically mounting screw and automatically mounting system

ActiveUS20170157724A1Low production costEfficient productionMetal working apparatusEngineeringMechanical engineering

The invention discloses a device for automatically assembling screw and an automatically assembling system, the device includes a frame, a locating member, a taking member, a driving member and a screw feeding member: the locating member is for locating a product to special position; the taking member includes a rotating plate, at least three sucking elements fixed below the rotating member and located at a same circumference, and an electric screwdriver connected with the driving member and located upon the circumference; the driving member drives the rotating plate rotating, the electric screwdriver is movably located on the driving member; the screw feeding member includes a feeding plate including feeding positions, each feeding position corresponds to one sucking element; the (driving member drives the sucking element acquiring the screw, and drives the sucking element moving the acquired screw to a position for the electric screwdriver assembling the screw to the product.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

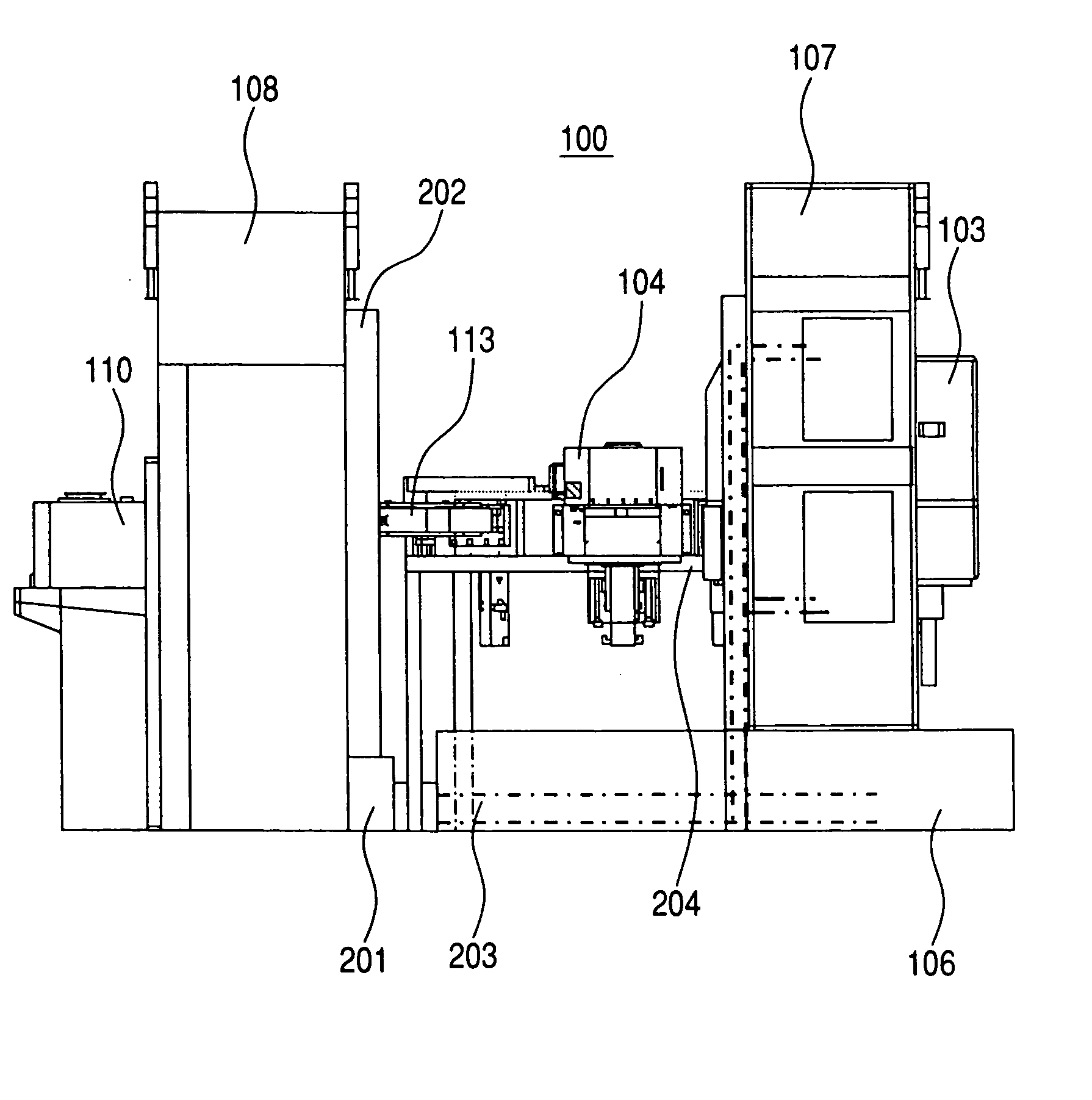

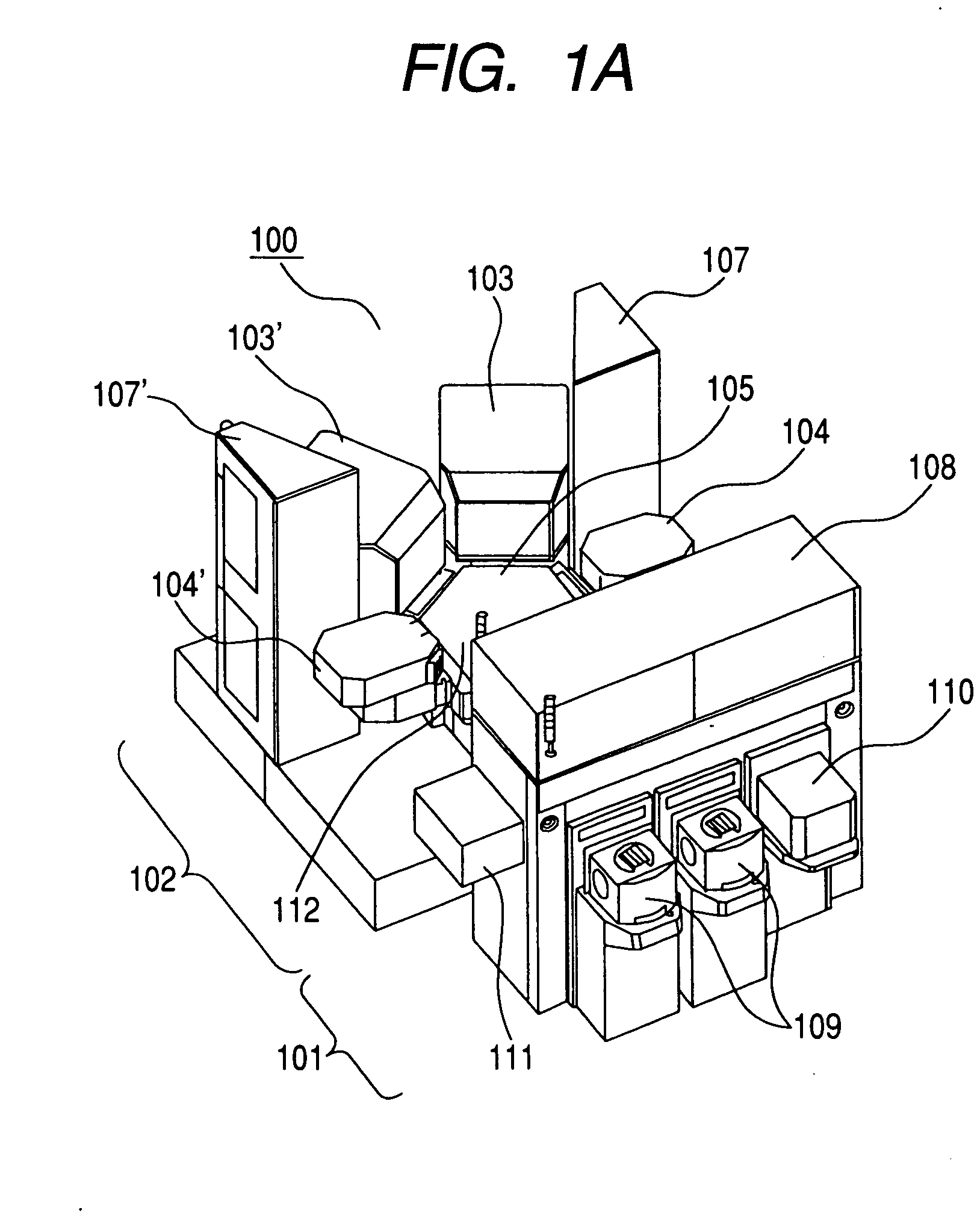

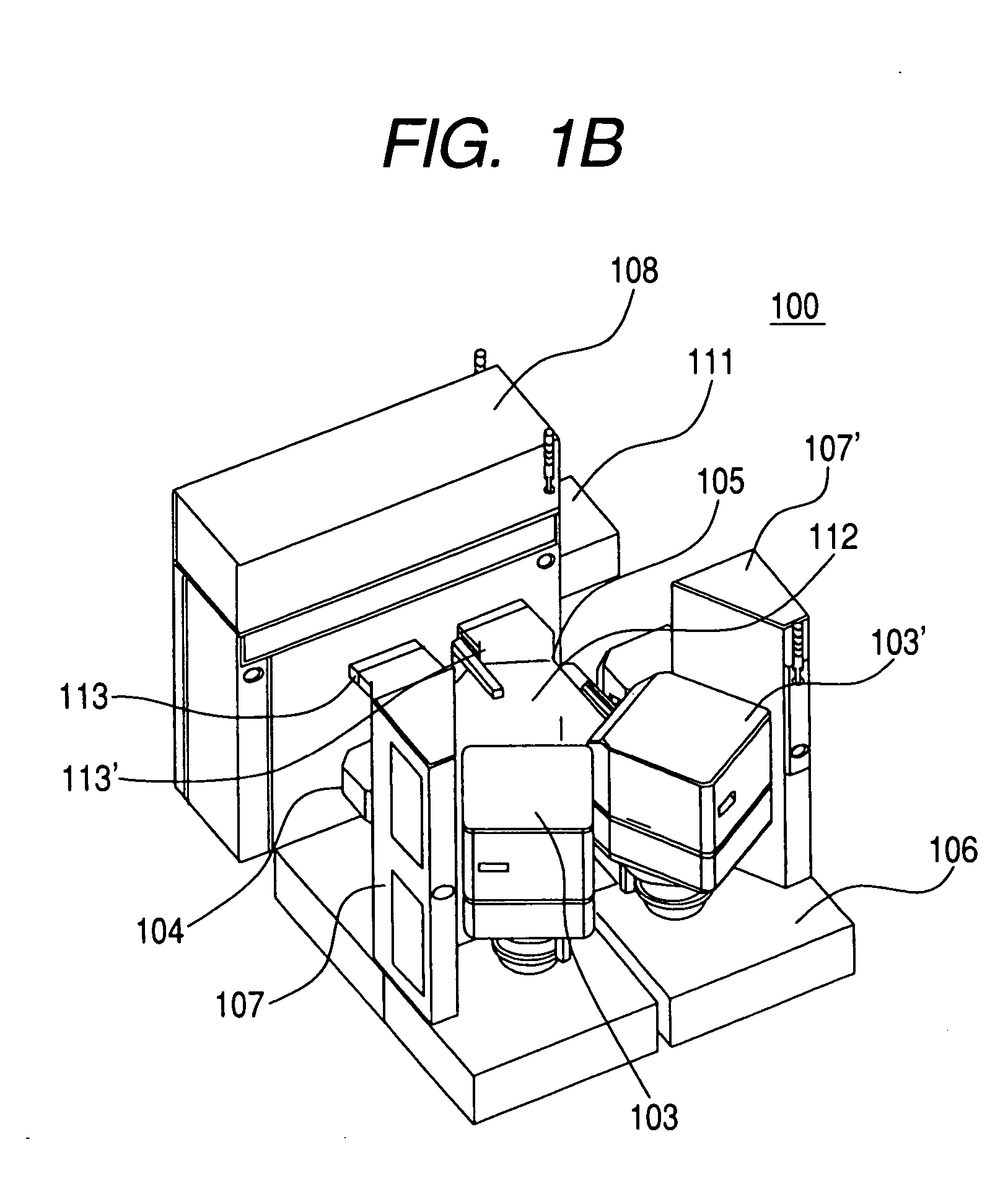

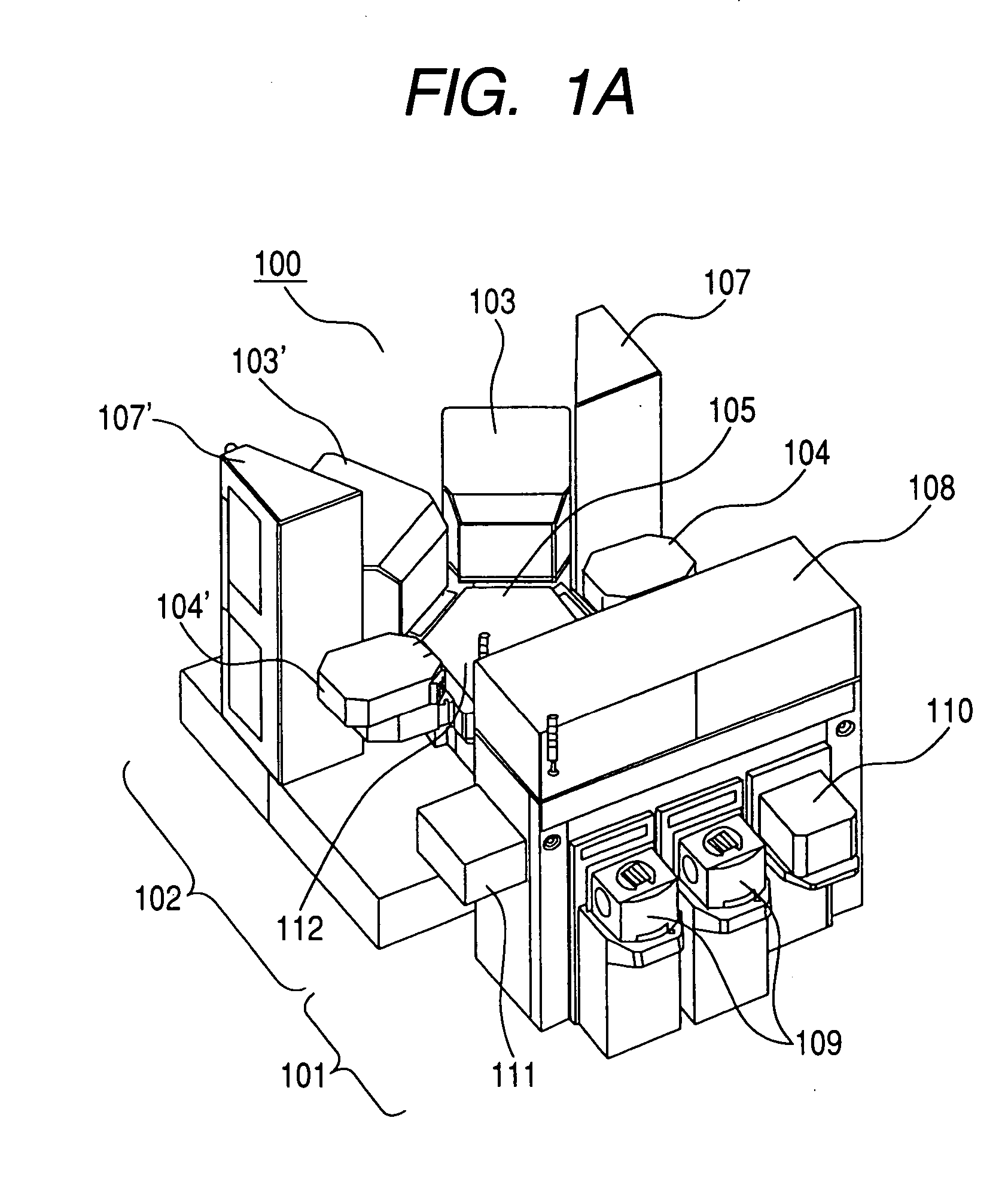

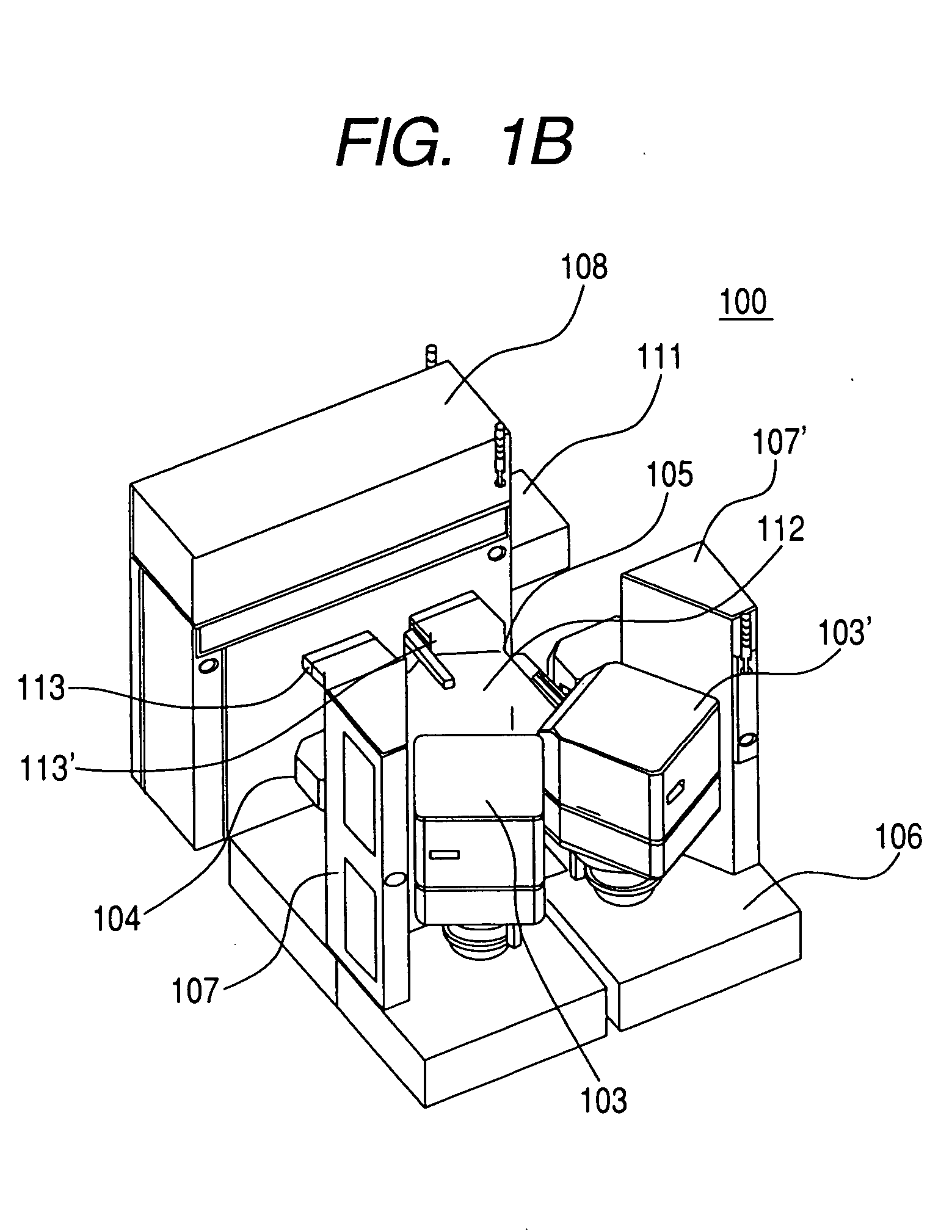

Plasma processing apparatus

ActiveUS20050193953A1Reduced installation areaEasily perform operationElectric discharge tubesSemiconductor/solid-state device manufacturingMechanical engineeringElectric signal

The present invention provides a vacuum processing apparatus which is small-sized and requires a small installation area. The vacuum processing apparatus includes a vacuum container which has a processing chamber inside thereof, wherein the pressure inside the processing chamber is reduced and plasma used for processing a sample is formed inside the processing chamber, a bed portion which is arranged below the vacuum container and stores a device for supplying electricity and electric signals used for processing inside the vacuum container, and a transport chamber which is connected with the vacuum container and includes a transport device for transporting the sample inside thereof. The vacuum processing apparatus further includes a connector portion which is mounted on the bed portion in a state that the connector portion faces a lower portion of the transport chamber, wherein the bed portion is configured to be detachably mounted on the vacuum processing apparatus in a state that the bed portion performs the connection and the disconnection at the connector portion.

Owner:HITACHI HIGH-TECH CORP

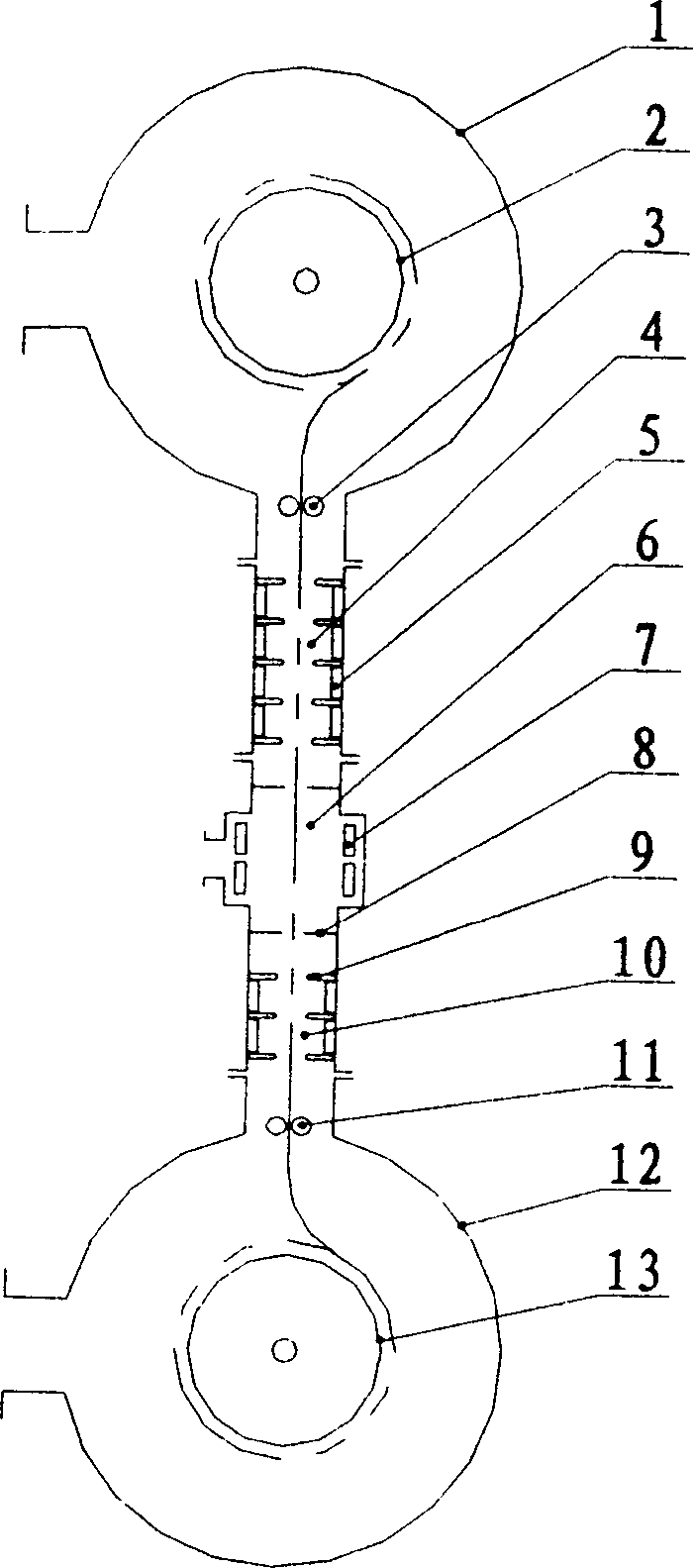

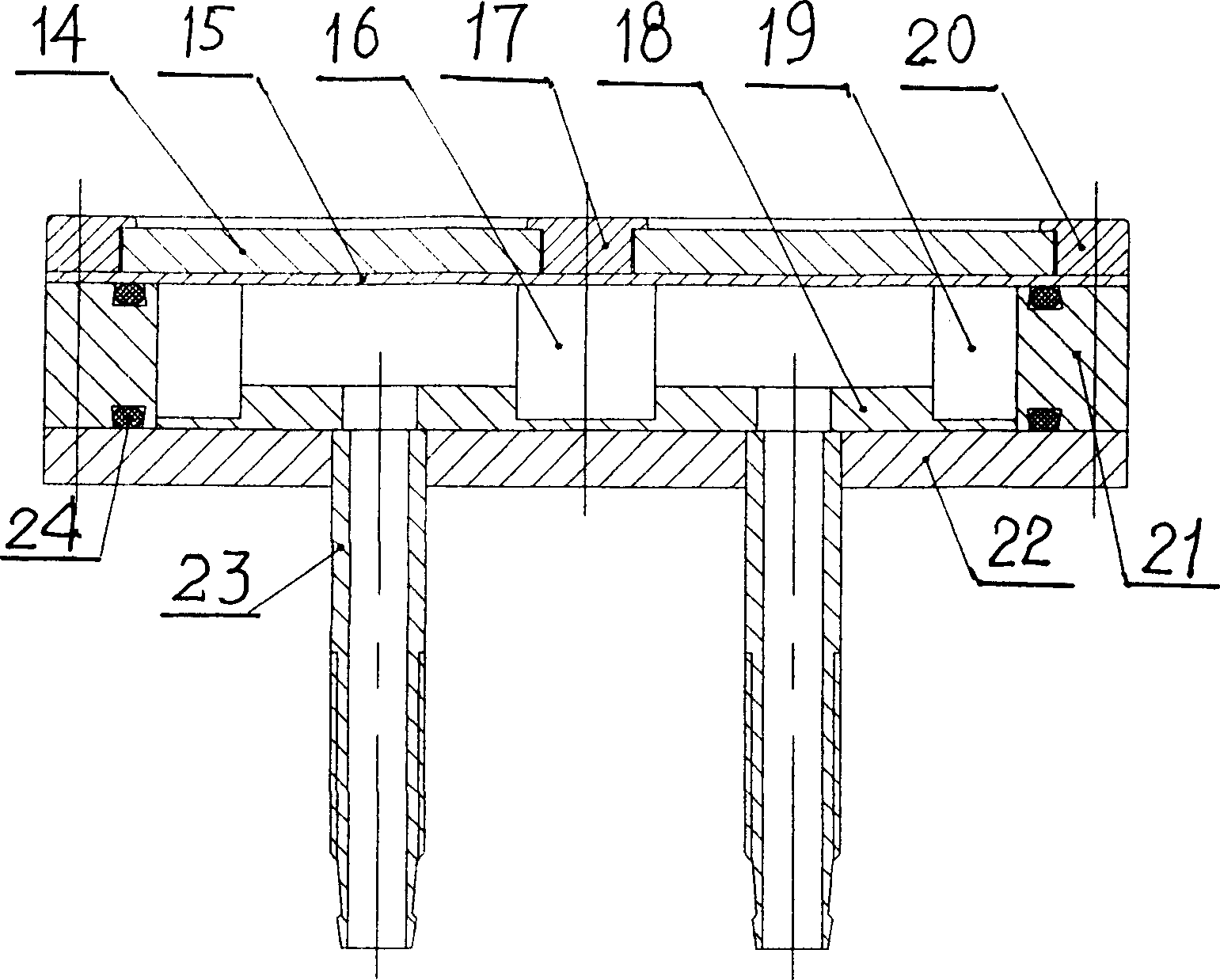

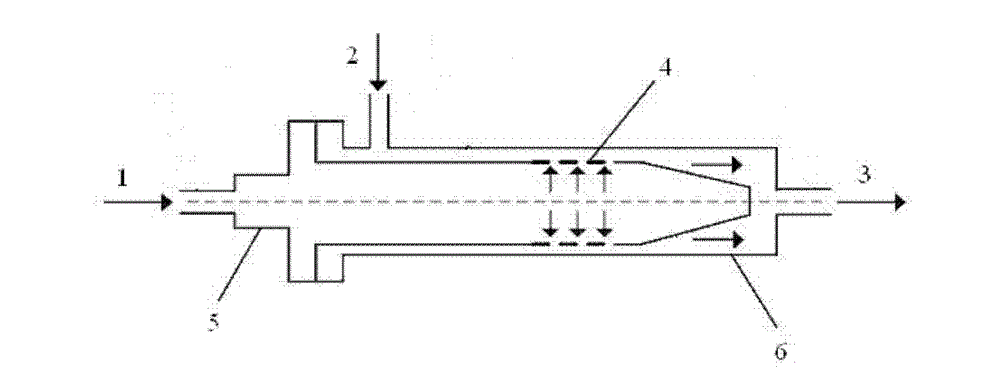

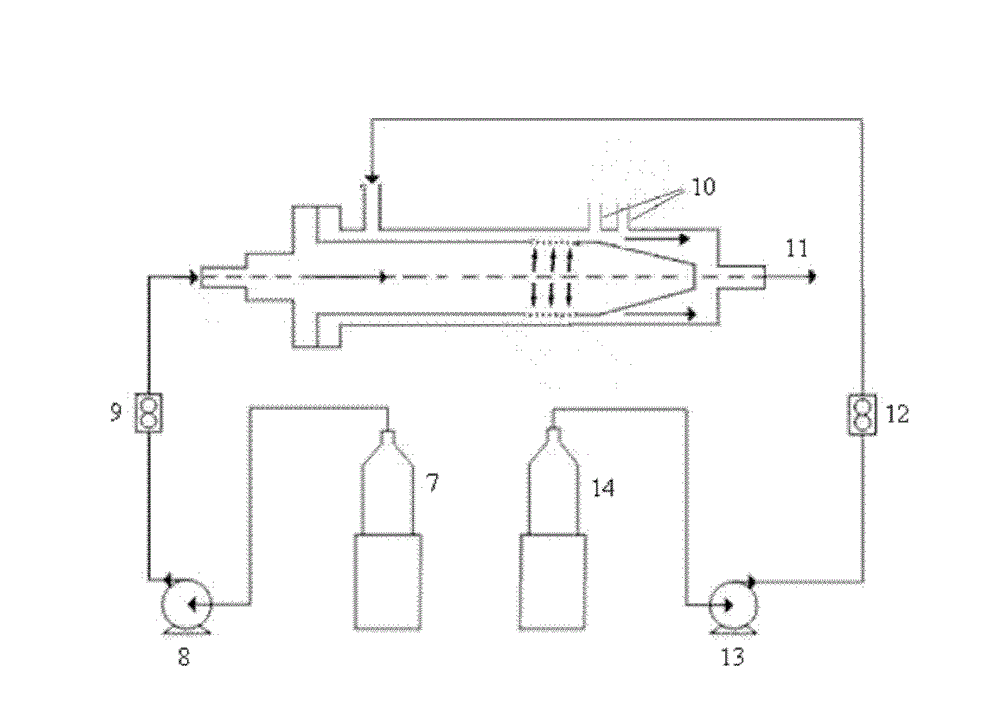

Process and apparatus for preparing porous metal by combined physical gas-phase deposition techinque

InactiveCN1397654AStrong noveltyCreativeElectrode carriers/collectorsVacuum evaporation coatingGas phaseWater jacket

A technology and apparatus for preparing porous metal by combined physical gas-phase deposition features that two of evaporating, sputtering and ion plating are combined in a coil-type vacuum coatingmachine. The said coil-type vacuum coating machine is composed of coiling-uncoiling reel and chamber, measuring roller, magnetically controlled plating chamber and its target, are evaporating chamberand its target, partition, cooling water jacket, etc.

Owner:HUNAN CORUN NEW ENERGY CO LTD

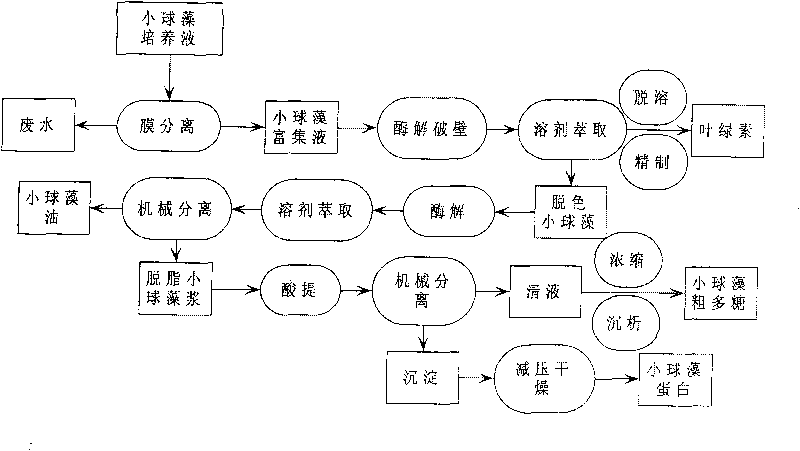

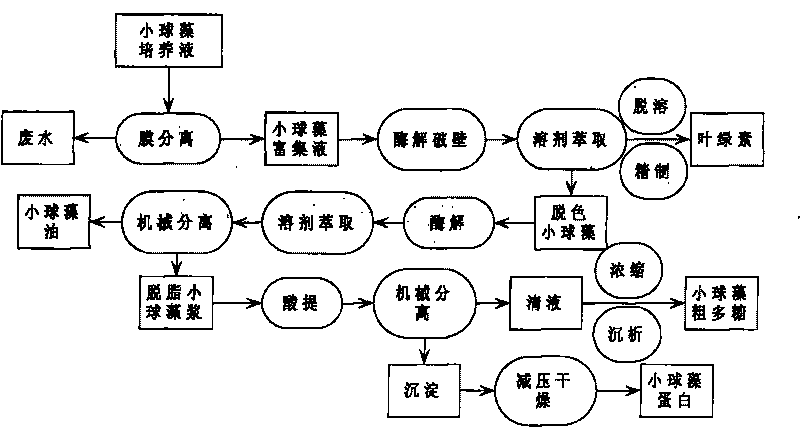

Method for continuously extracting functional components of chlorella vulgaris

InactiveCN101736045AEasy to keep activeReliable operationPeptide preparation methodsNatural dyesSolventChemistry

The invention relates to a method for continuously extracting functional components of chlorella vulgaris, which comprises the steps of enriching the chlorella vulgaris through the membrane separation technology, obtaining concentrated slurry of the chlorella vulgaris, adding a proper enzyme in a liquid phase system for wall-breaking, and using a solvent for extracting chlorophyll from chlorella vulgaris solution after wall-breaking, thereby being capable of obtaining a functional pigment product and reducing the color value of follow-up products; and firstly carrying out enzymatic hydrolysis on a water phase of the chlorella vulgaris after decoloring, then using the solvent for extracting functional grease, extracting active polysaccharides from the obtained degreased chlorella vulgaris by using the acid method, and then drying the other parts for obtaining crude proteins of the chlorella vulgaris. The main products comprise the chlorophyll, the active polysaccharides of the chlorella vulgaris, the functional grease of the chlorella vulgaris, the proteins of the chlorella vulgaris and the like, and the method optimizes the process on the basis of ensuring the activity of the functional components of the chlorella vulgaris, thereby obtaining high yield and reducing production cost.

Owner:BOHAI UNIV

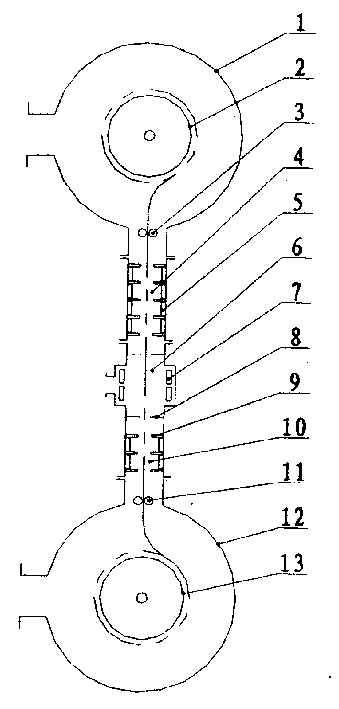

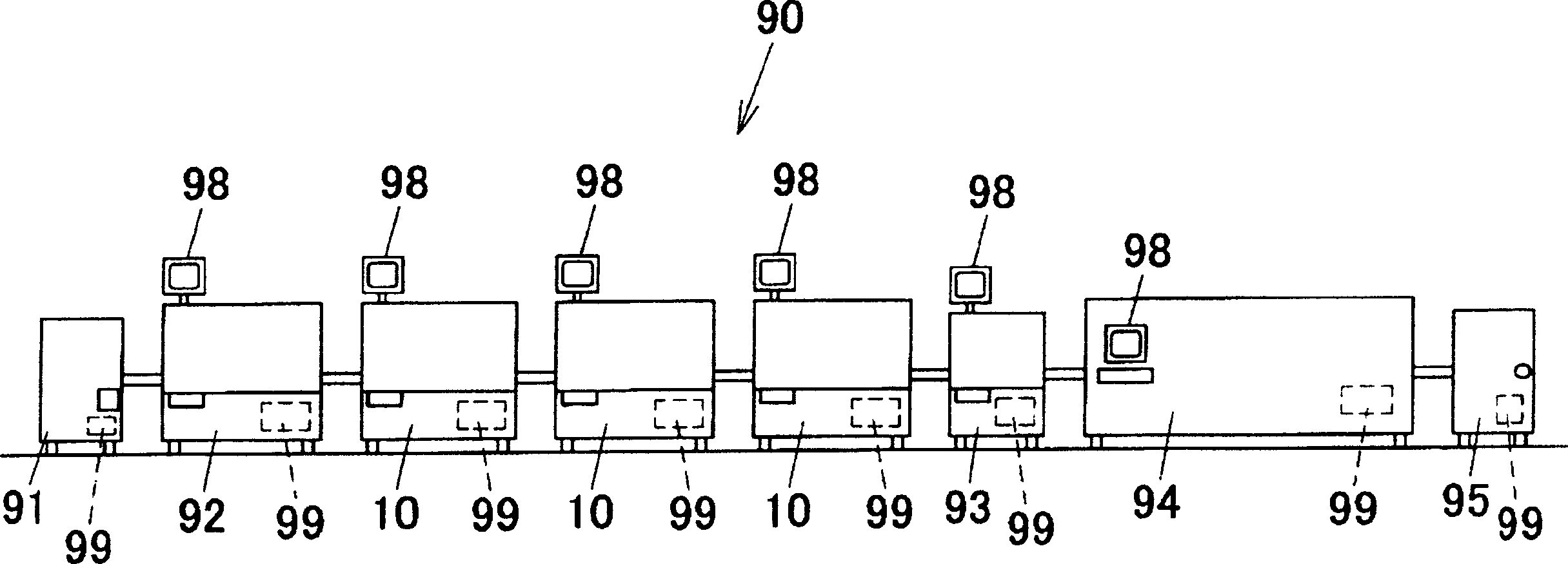

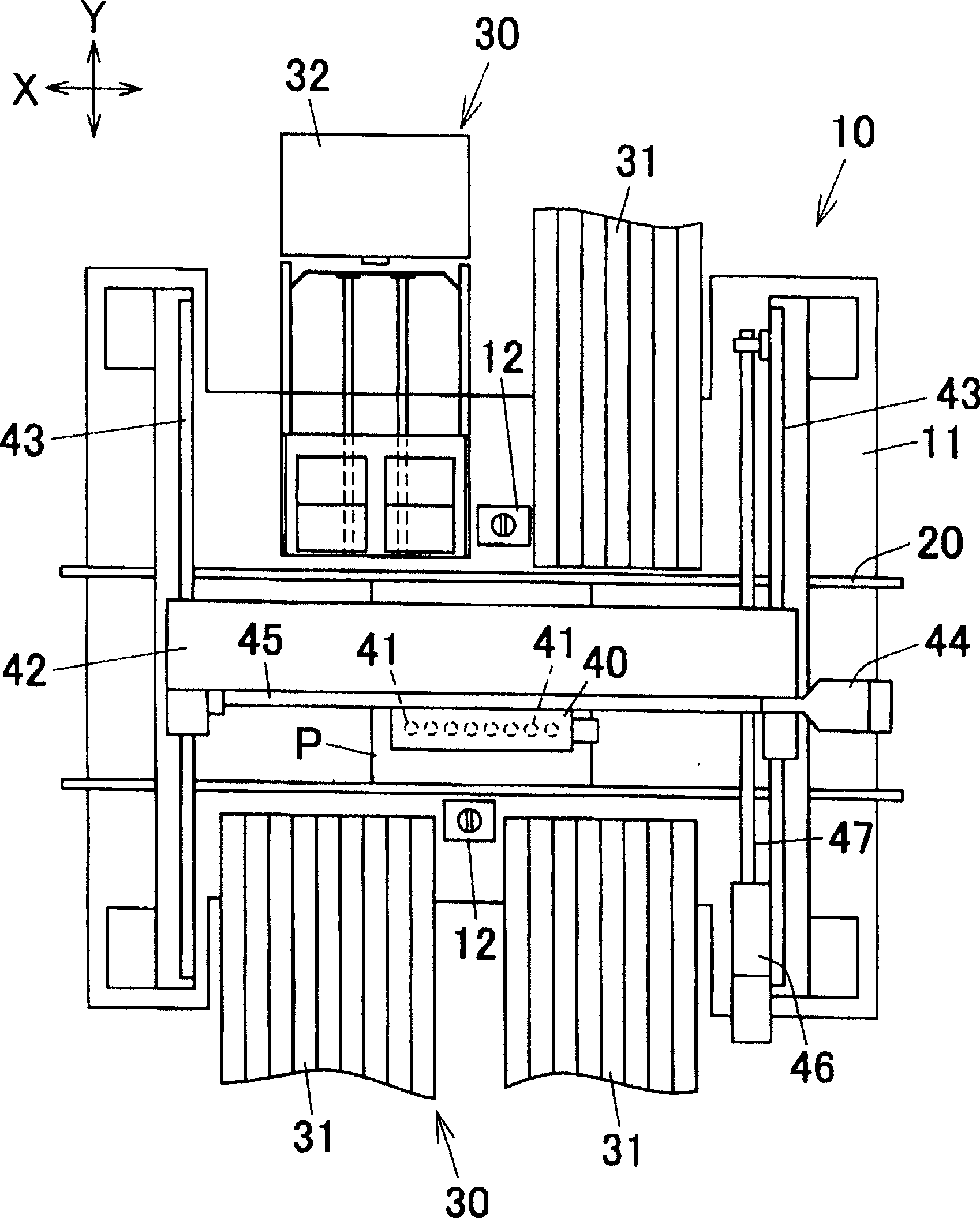

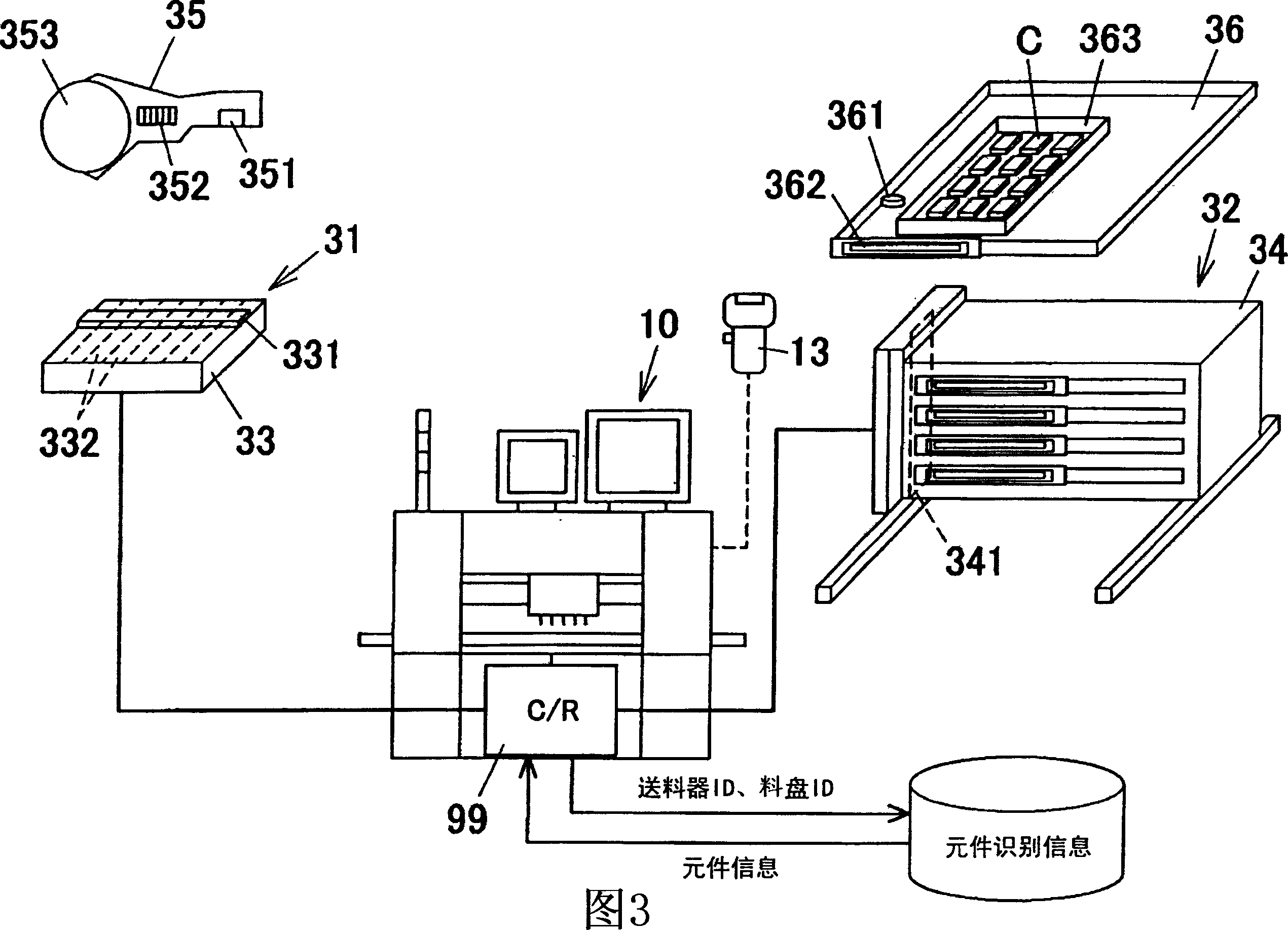

Installation work management method, installation machine and preparation support method, installation assembly line

ActiveCN1878460AFlexible configuration changesEfficient productionPrinted circuit assemblingElectrical componentsAssembly lineEngineering

The present invention provides one kind of installation task managing method, installing machine, preparing and backup method and installation flow line. Among the installing machines, the current configurations of the element suppliers for different pieces of equipment and the configurations of the element suppliers the production programs of different installing machine are transferred mutually. Furthermore, the installation job designated to some installing machine may be transferred to some other one with the element suppliers for executing the installation job. In this way, corresponding to the current configurations of the element suppliers, the installing jobs for the base plate as the production object may be designated to different installing machines, and the preparing jobs on element suppliers, etc of the operator may be decreased.

Owner:YAMAHA MOTOR CO LTD

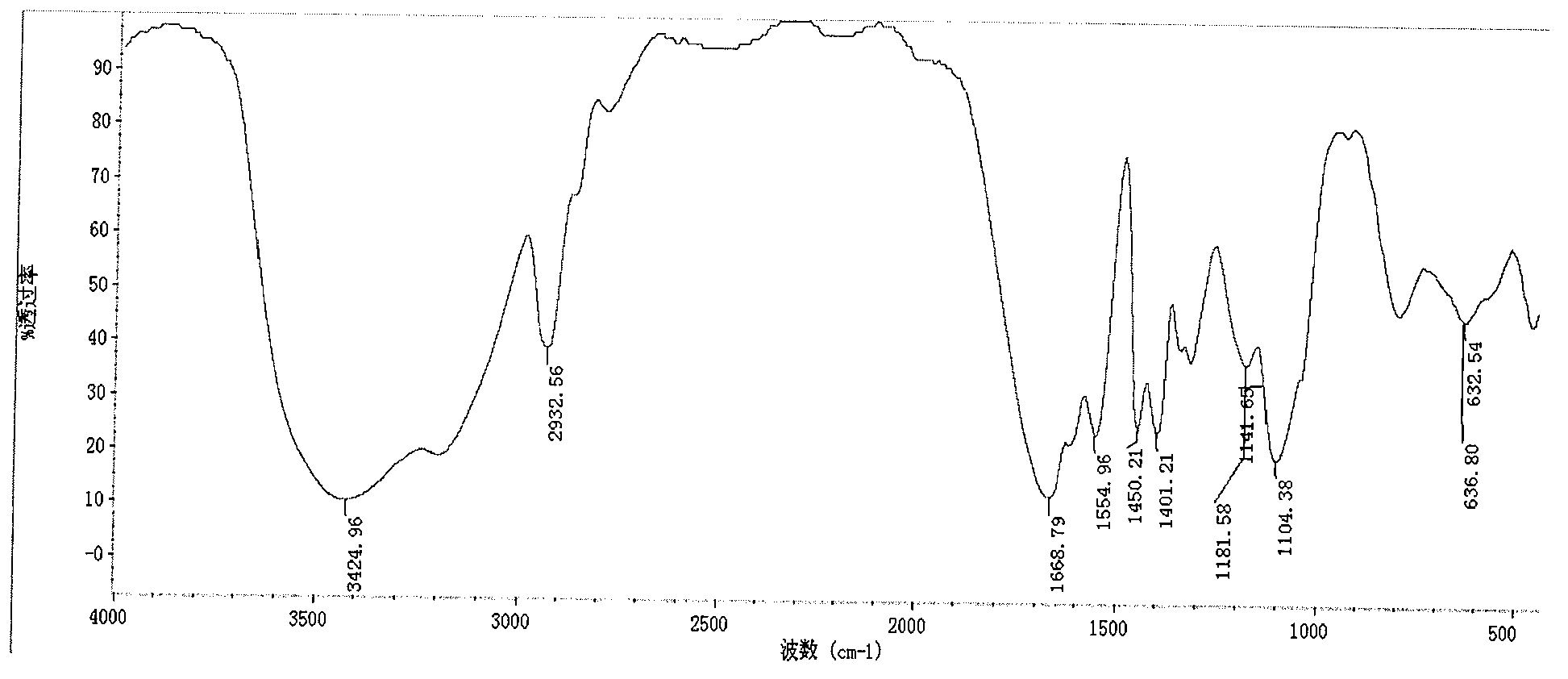

Preparation method of polyacrylamide emulsion

ActiveCN103232573AHigh molecular chain densityHigh densityNon-fibrous pulp additionPaper/cardboardHydrocarbon solventsPapermaking

The invention discloses a preparation method of a polyacrylamide emulsion. The preparation method comprises the following steps of adding acrylamide, one or more anion monomers, a grafting matrix, an aqueous stabilizer, a molecular weight conditioning agent and an initiator into water, adjusting a pH value to obtain a water phase, adding an emulsifier into a hydrocarbon solvent to obtain an oil phase, dropwisely adding the water phase into the oil phase, carrying out one-step emulsification or multistep emulsification to obtain an emulsion, carrying out displacement deoxygenation on the emulsion by inert gas, and adding the initiator into the emulsion for polymerization initiation to obtain a branched anion polyacrylamide water-in-oil anti-phase emulsion after polymerization is finished. The polyacrylamide emulsion obtained by the preparation method is used for the modern papermaking industry, avoids inorganic filler re-falling after retention, improves inorganic filler actual retention effects, avoids falling-off of dust and lint of a screen cloth, guarantees uniform and stable retention of an inorganic filler in a page, and properly reduces a bentonite use amount.

Owner:JIANGSU FEYMER TECH

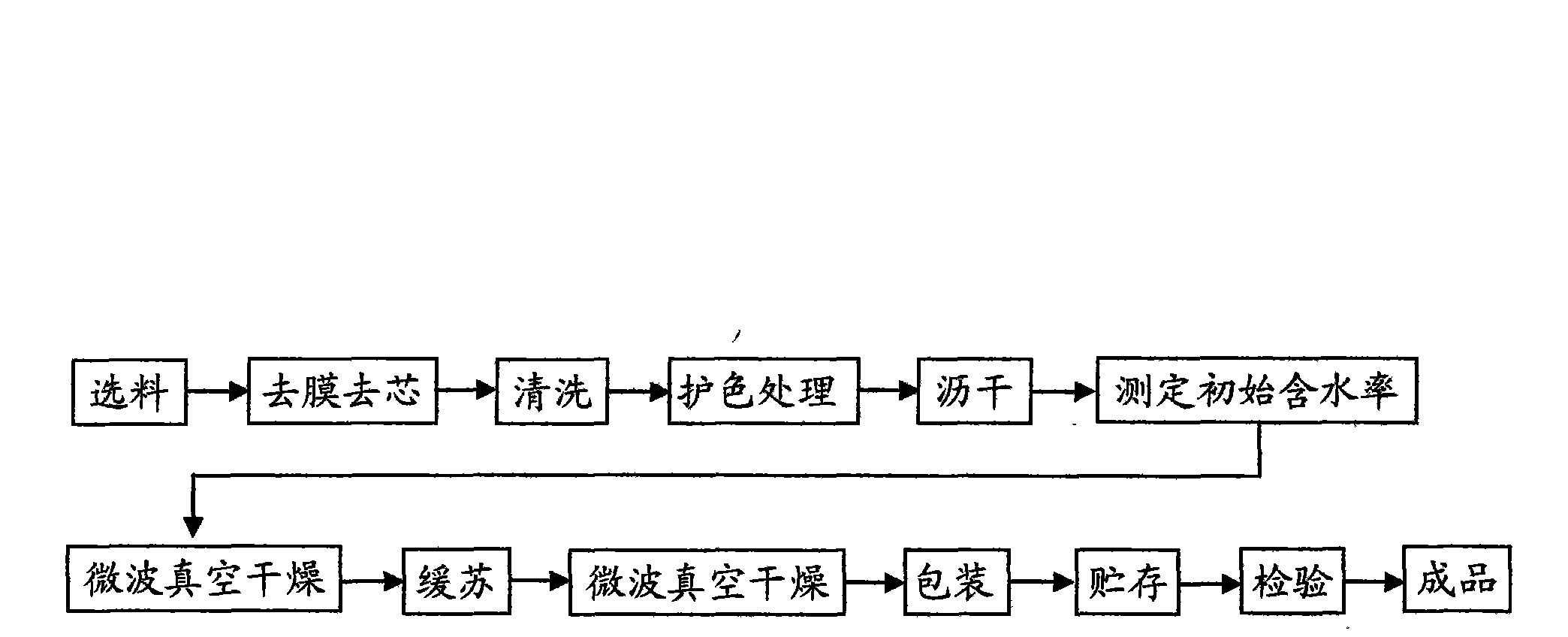

Microwave vacuum drying process for lotus seed

The invention provides a microwave vacuum drying process for lotus seeds, comprising the following steps of: selecting materials, removing films and cores, protecting color, dewatering, vacuum drying by microwave, packaging and storing, thus preparing the dry lotus seed product. The process aims at improving the quality research of the dry lotus seed and reducing the energy consumption, dries the fresh lotus seeds by microwave vacuum drying technology, improves the quality of the lotus seeds, and prolongs the shelf life of the product; the application of the high combination drying technology inaugurates another dry preparation way for drying preparation of fresh lotus seeds; the process is easy for instant control and the production is environment-protective; and the real continuous automatic clean production can be realized.

Owner:FUJIAN AGRI & FORESTRY UNIV

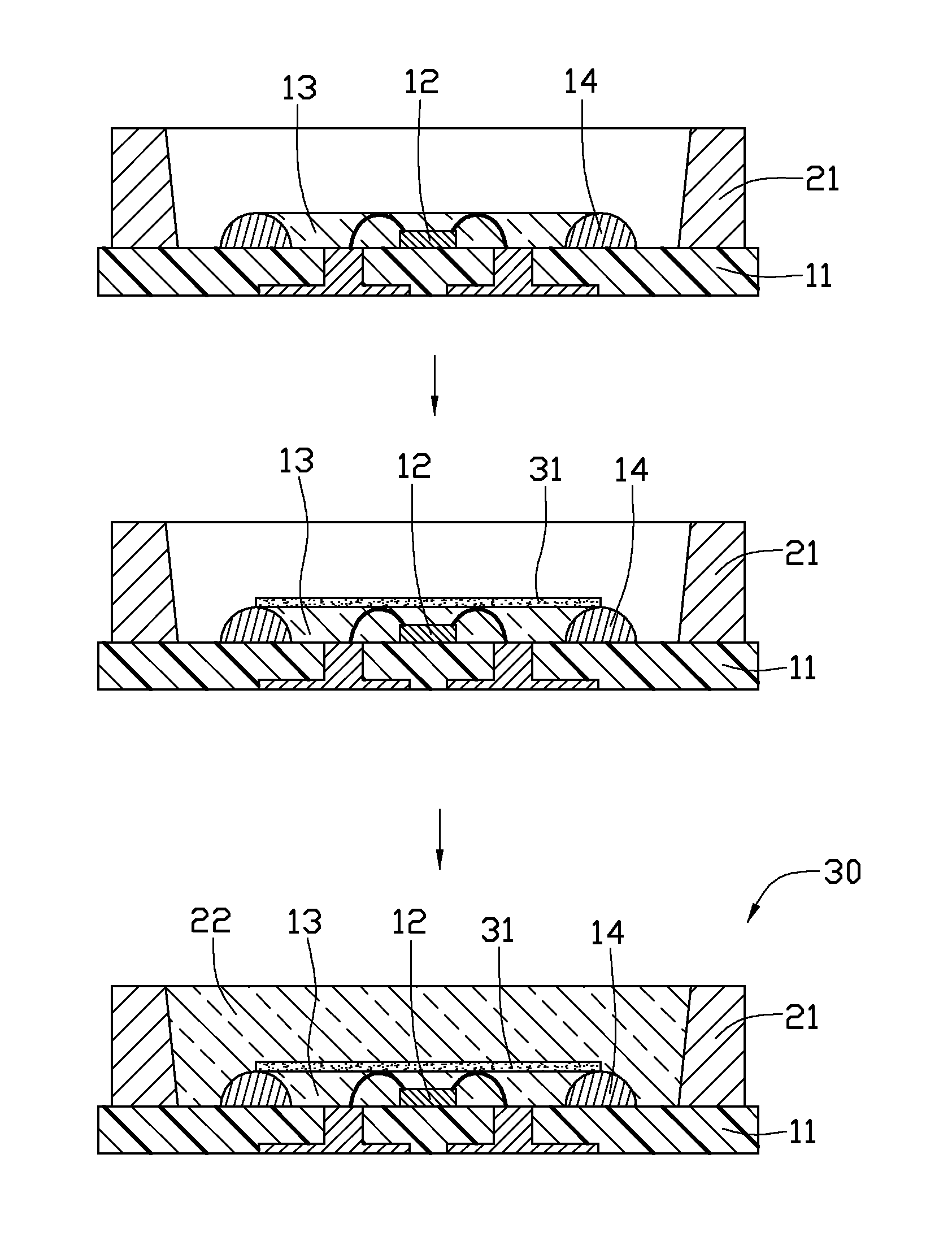

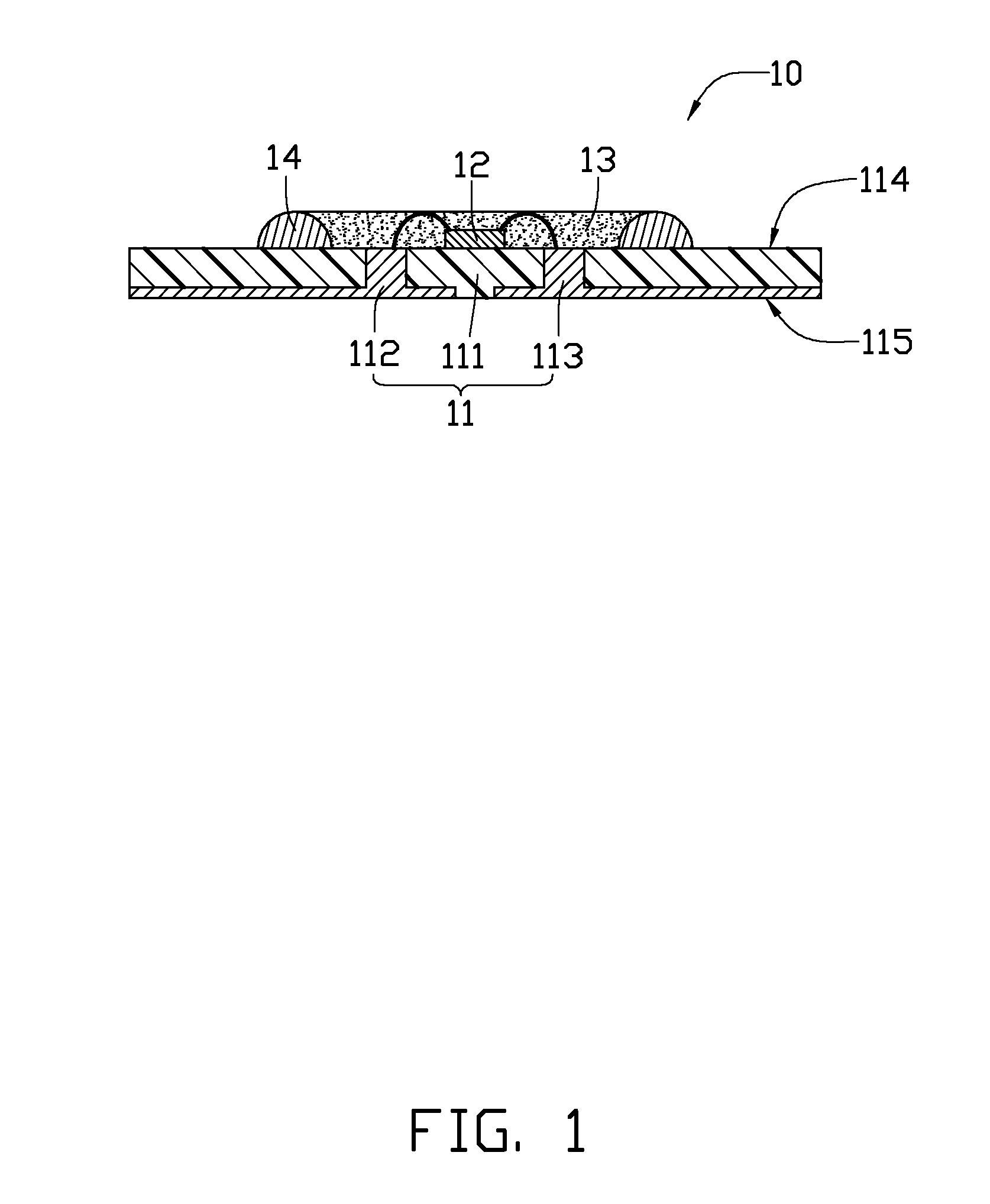

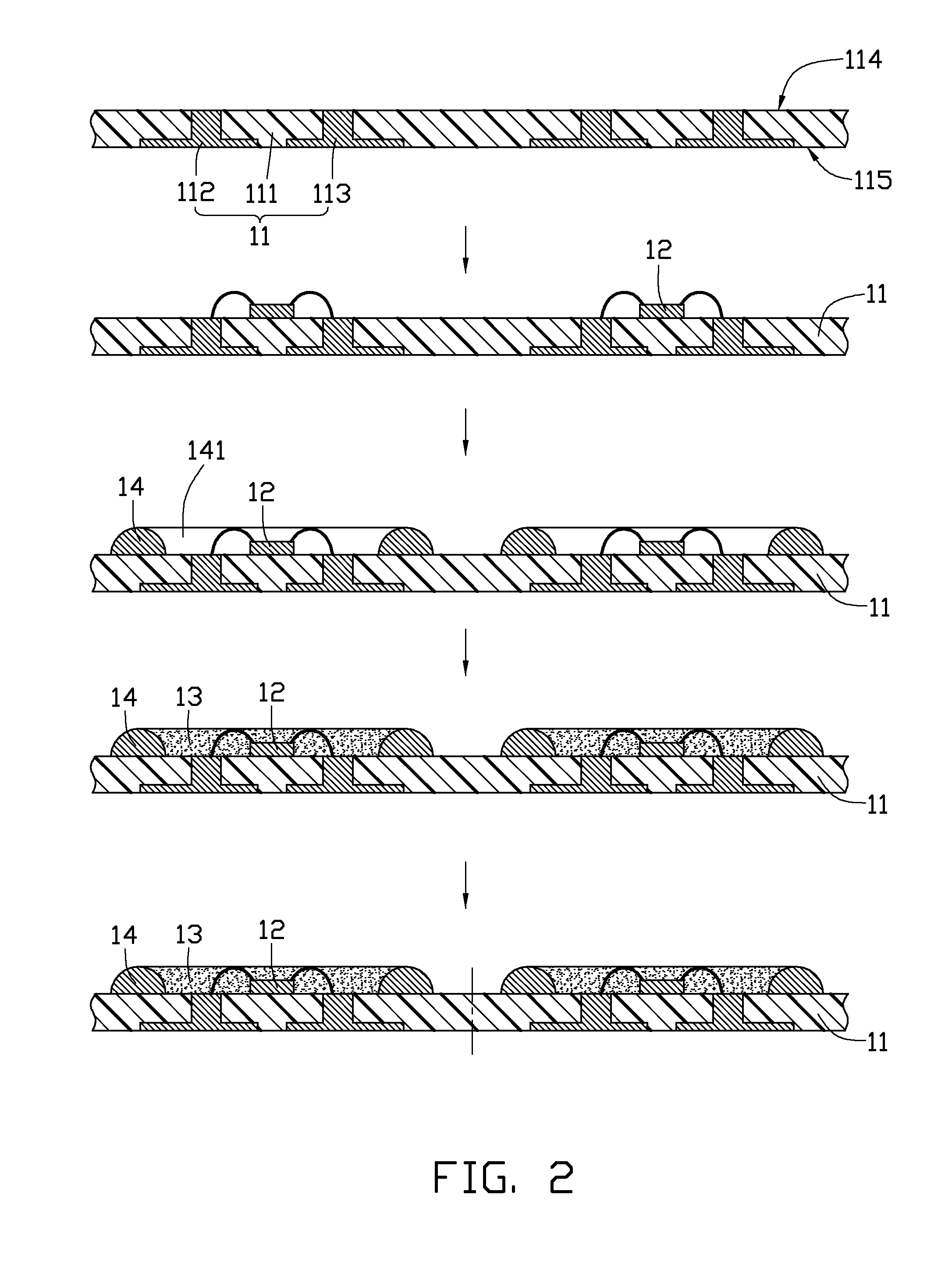

LED package and method for manufacturing the same

InactiveUS20120025243A1Reduce production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineering

An LED package includes a substrate, an LED chip, a bounding dam, and a first encapsulation. The substrate includes a first surface and a second surface opposite to the first surface. The LED chip is mounted on the first surface of the substrate. The bounding dam is formed on the first surface of the substrate and surrounds the LED chip. The bounding dam and the substrate cooperatively define a receiving space. The bounding dam is made of thermoset resin. The first encapsulation is formed in the receiving space and encloses the LED chip.

Owner:ADVANCED OPTOELECTRONICS TECH

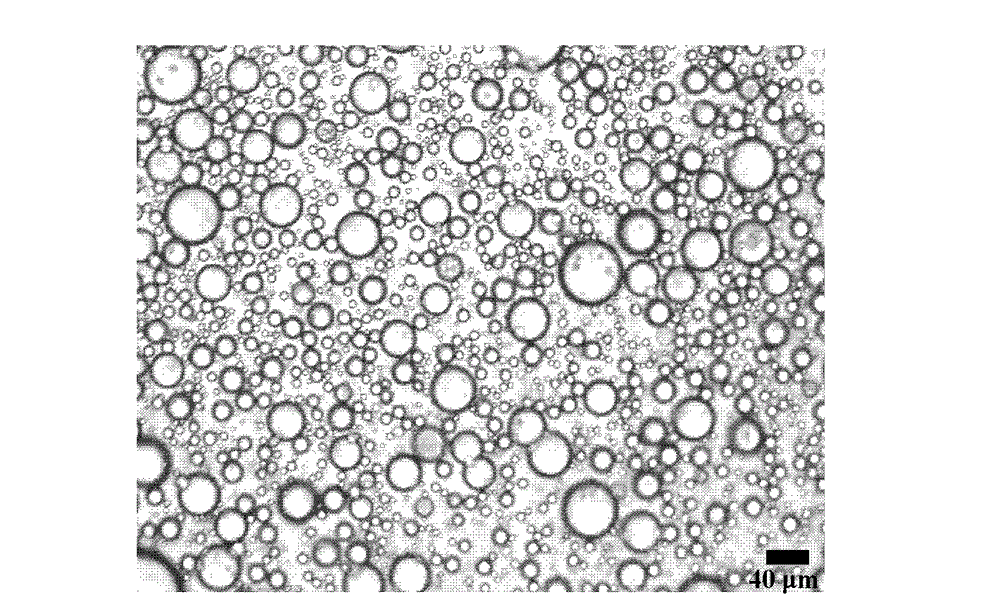

Method for preparing monodisperse emulsion

InactiveCN102794119AUniform particle sizeQuality improvementFlow mixersMixing methodsContact formationEmulsion droplet

The invention discloses a method for preparing monodisperse emulsion and belongs to the technical field of emulsion. The monodisperse emulsion is prepared by using a tube-in-tube annular channel reactor; a continuous phase is introduced into an outer tube of the tube-in-tube annular channel reactor, a disperse phase is introduced into an inner tube of the tube-in-tube annular channel reactor, and the continuous phase and the disperse phase fully contact on micropore parts to form the emulsion; and according to the method, equipment is simple, cost is low, flux is high, and continuous operation can be realized, so that the preparation cycle can be greatly shortened, and production efficiency is improved. The emulsion prepared by the method is high in quality, stable in performance, and high dispersibility; and emulsion droplets are uniform in particle size.

Owner:BEIJING UNIV OF CHEM TECH

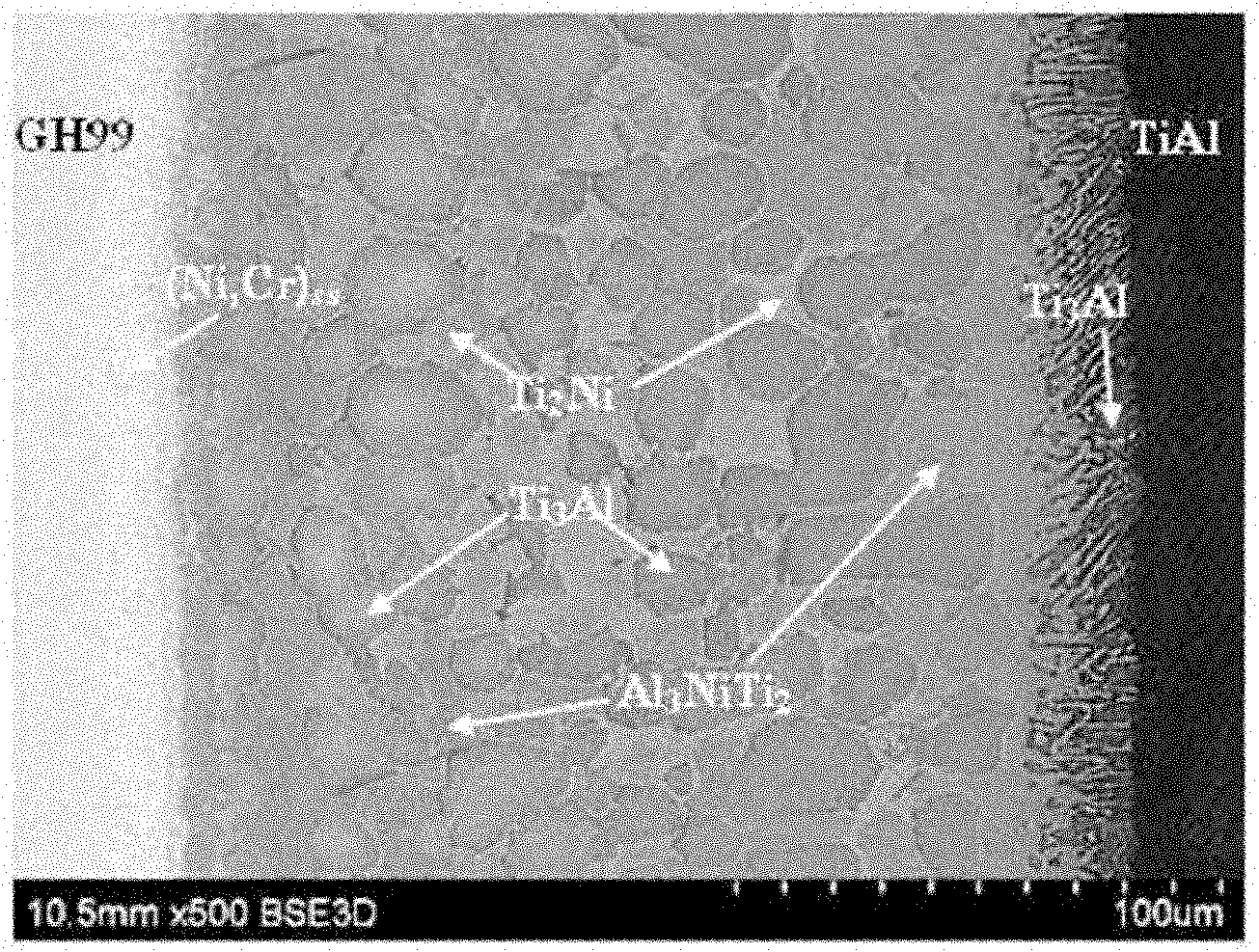

Contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy

ActiveCN101972877AAchieving a soldered connectionSimple processSoldering apparatusContact reactionsSuperalloy

The invention discloses a contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy, relating to a welding method for the TiAl based alloy and the Ni based high-temperature alloy and solving the problems of the traditional diffusion connection method for the TiAl based alloy and the Ni based high-temperature alloy that the process is complicated, the cost is high, the connection thermal cycle period is long, the efficiency is low, the requirement on the to-be-welded surface of a weldment is high, a silver brazing joint is not resistant to high temperature, and the brittle phase of high-temperature brazing is easy to aggregate and grow. The method comprises the steps of: treating the to-be- surface of a Ti foil, the TiAl based alloy and the Ni based high-temperature alloy, placing the Ti foil between the TiAl based alloy and the Ni based high-temperature alloy to form a weldment to be welded, and welding the weldment to be welded in a vacuum brazing furnace. The joint obtained in the invention has high shear strength up to 240-300MPa, and the shear strength is 180-210MPa at the high temperature of 800 DEG C, and the joint can be used as a hot end part for aerospace under high-temperature environment.

Owner:HARBIN INST OF TECH

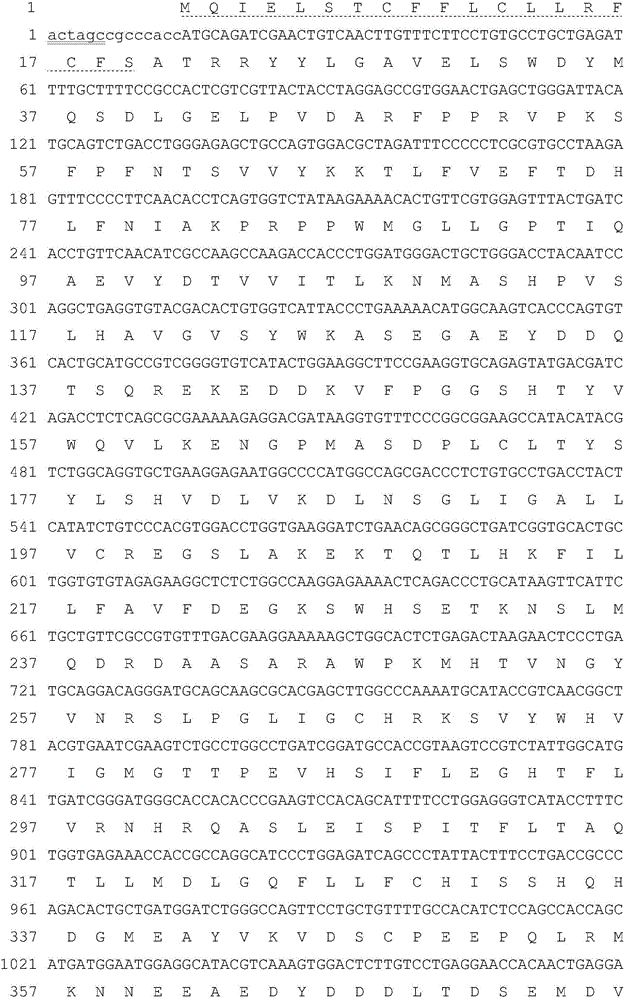

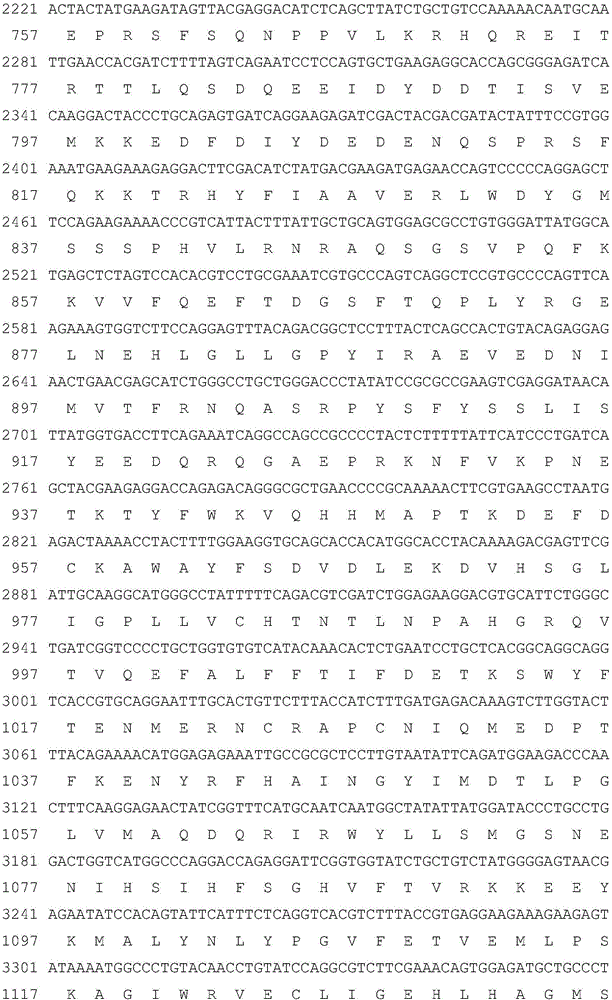

Hyperglycosylatedhuman coagulation factor VIII fusion protein and preparation method and application thereof

ActiveCN106279437AIncrease productionExtended half-life of activity in vivoFactor VIIPeptide/protein ingredientsHuman Chorionic Gonadotropin Beta SubunitHalf-life

The invention discloses a hyperglycosylated human coagulation factor VIII (FVIII) fusion protein and a preparation method and application thereof. The fusion protein successively contains human FVIII, a soft peptide connector, at least one human chorionic gonadotropin betasubunitcarboxyl terminal peptide rigid unit and prolonged half-life period portion (preferably ahumanIgG Fc variant) from an end N to an end C. The fusion protein has biological activity similar to that of recombinant FVIII and prolonged in-vivo activity half-life period, thereby improving the pharmacokinetics and drug efficacy.

Owner:AMPSOURCE BIOPHARMA (SHANGHAI) INC +3

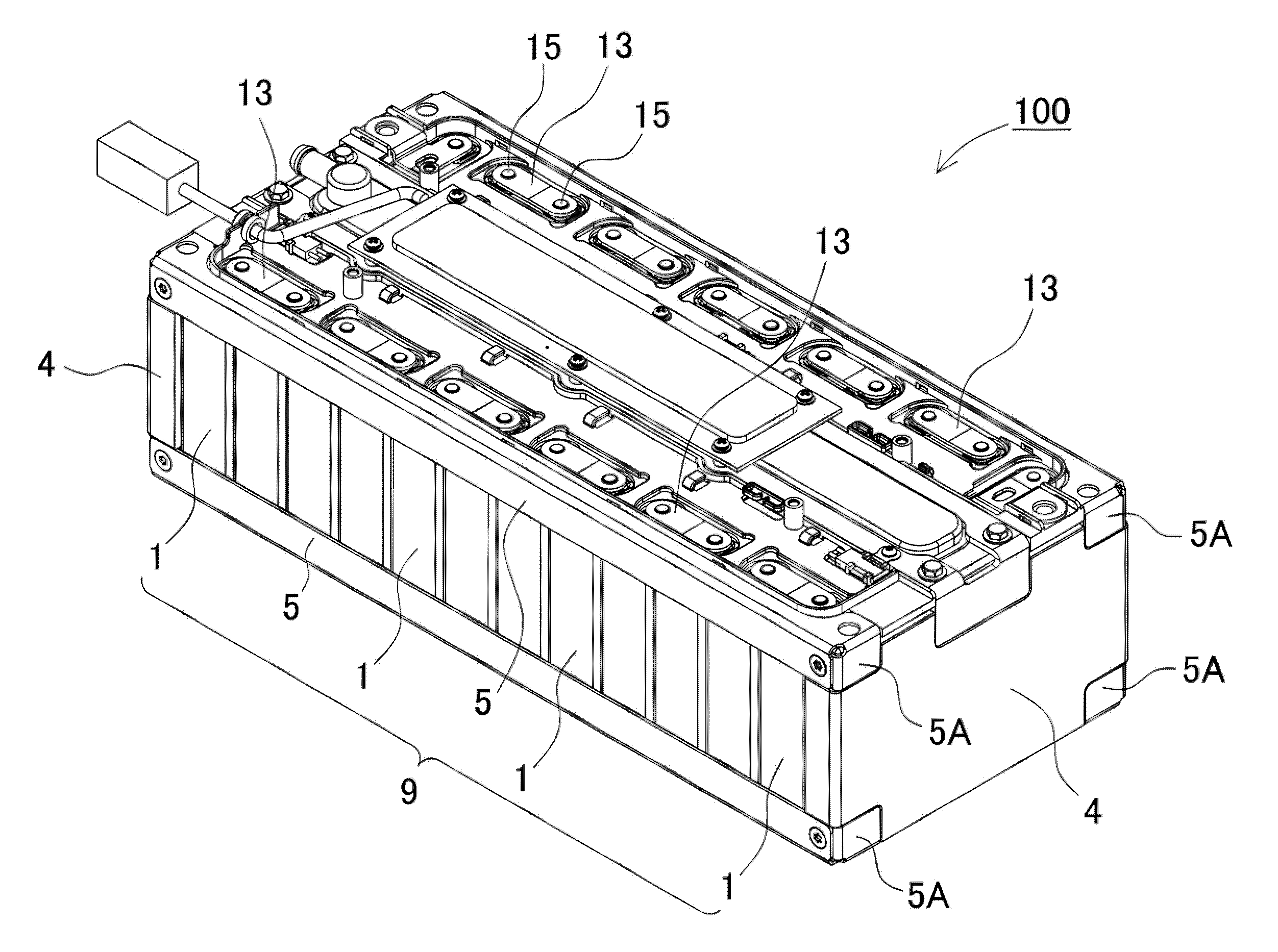

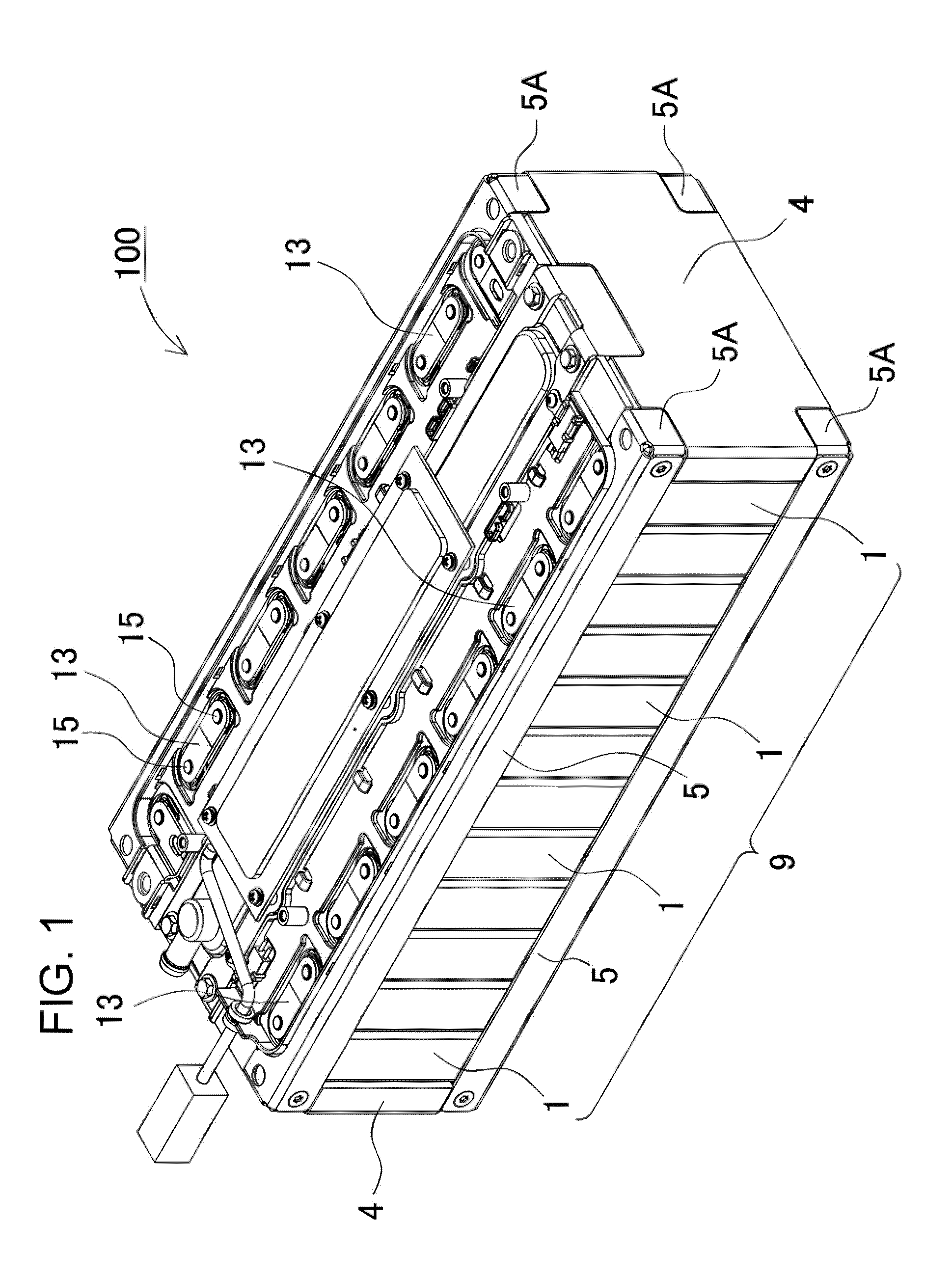

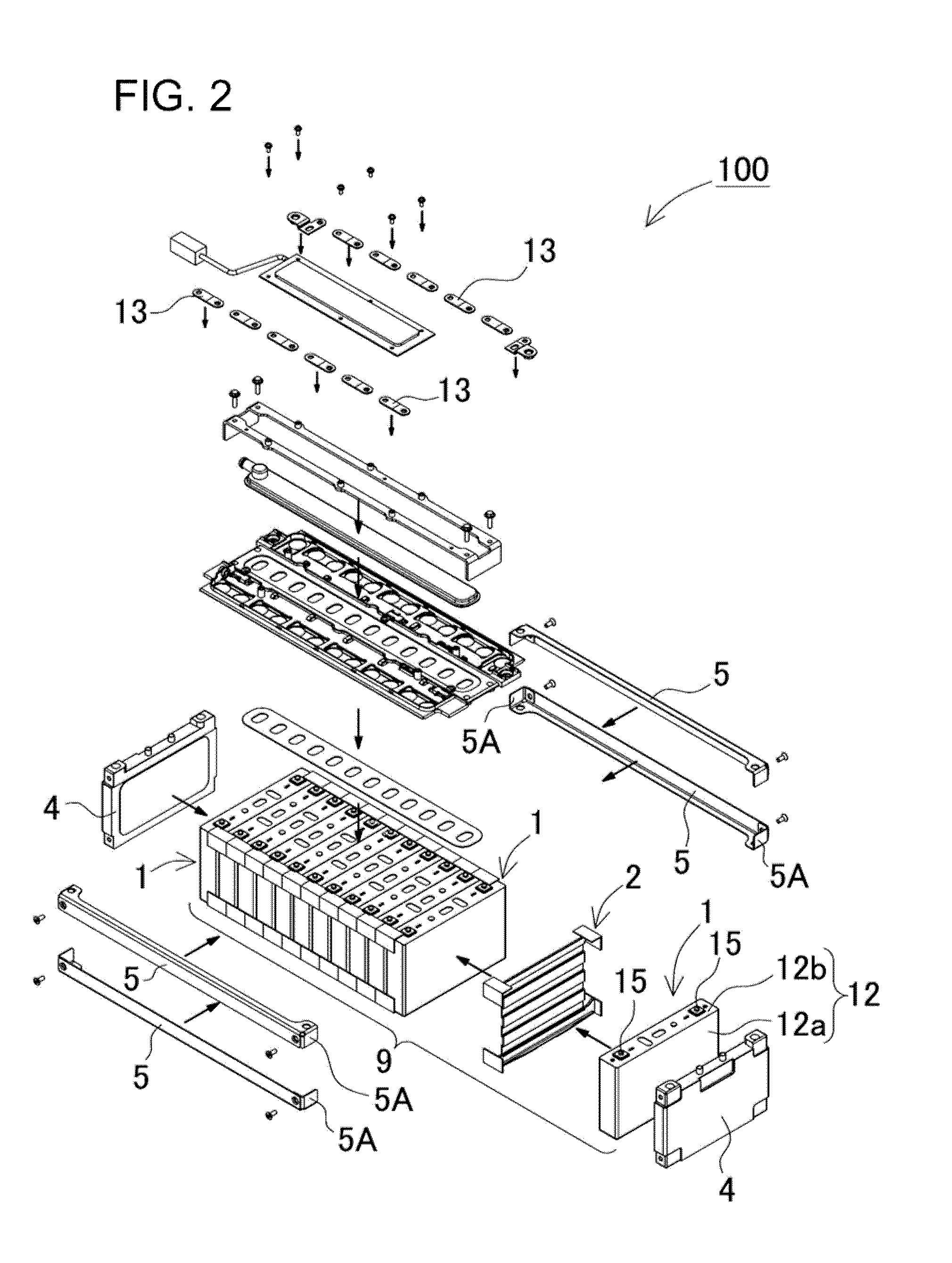

Method for producing battery pack

InactiveUS20150135522A1Long cycle timeReduce production efficiencyFinal product manufacturePrimary cellsBiomedical engineeringElectrolyte

A method for manufacturing a battery pack comprises a compressing step of stacking a plurality of flat secondary batteries, compressing and fixing in a pressed state of the flat secondary batteries constituting the battery staked member by applying a predetermined pressure in the stacking direction. Further, in the pressed shaping step, a pressing pressure of pressing the spiral electrode assembly is set, such that it is possible to insert the pressed electrode assembly into the outer can, and such that it is possible that the electrode assembly is swollen until the electrode assembly presses against the inner surface of the outer can when the electrode assemblies are swollen by the electrolyte injected into the outer can in the electrolyte injection step, and in the compressing step, the swollen electrode assemblies are pressed through the outer cans by pressing the outer cans of the flat secondary batteries.

Owner:SANYO ELECTRIC CO LTD

Method for producing oxygen-free copper rod from secondary copper

ActiveCN103114208ALow costReduce physical workloadProcess efficiency improvementMetal rolling arrangementsNatural gasMetal impurities

The invention discloses a method for producing an oxygen-free copper rod from secondary copper, which comprises the following steps of: (A) feeding the secondary copper into a furnace, and heating for melting; (B) refining to remove metal impurities; (C) reducing with natural gas to obtain pure copper; (D) adding rare earth and a complex deoxidizer and then outputting copper; and (E) casting, and performing continuous casting and rolling to obtain an oxygen-free copper rod. Compared with a traditional up-draw process, the method disclosed by the invention can adopt the easily available secondary copper as a raw material for production and can process a great quantity of secondary copper once, and overcomes the shortcomings of high production cost and low production efficiency of the up-draw process adopting secondary copper as raw material; natural gas reduction replaces poling, thereby being more environment-friendly and ensuring lower cost; and moreover, the labor capacity is small, and the defect of bad working condition in poling is overcome.

Owner:绵阳铜鑫铜业有限公司

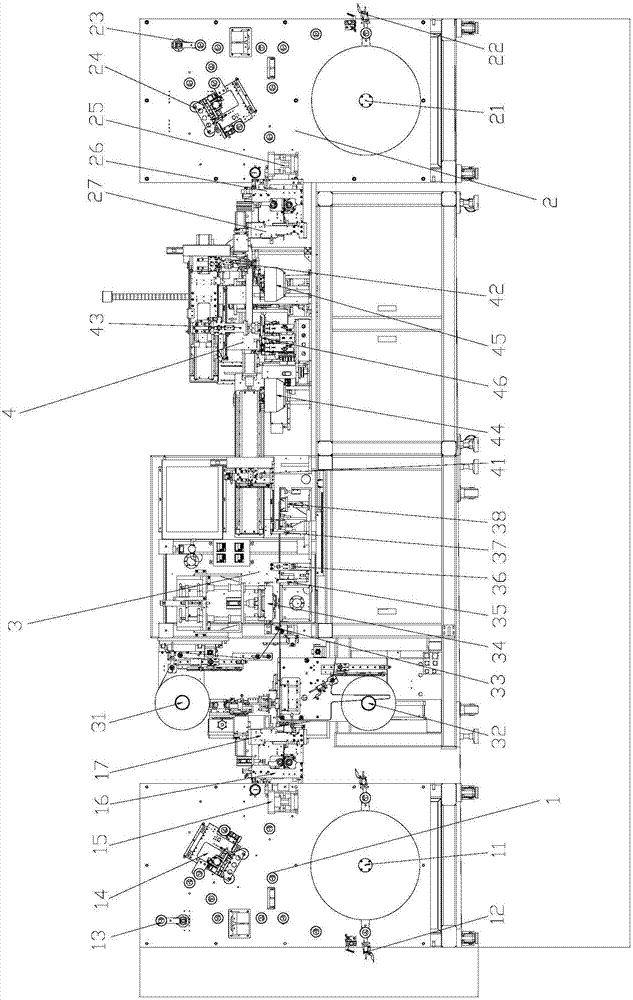

Die cutting, bag making and laminating integrated equipment for battery pole pieces

PendingCN107482171AHigh degree of automationImprove work efficiencyElectrode manufacturing processesState of artPole piece

The invention discloses die cutting, bag making and laminating integrated equipment for battery pole pieces. The equipment is characterized by comprising a positive pole piece die cutting mechanism, a negative pole piece die cutting mechanism, a composite bag making mechanism and a laminating mechanism, wherein the positive pole piece die cutting mechanism comprises a positive pole unwinding device, a positive pole correction sensor, a positive pole tension adjusting assembly, a positive pole correction assembly, a positive pole tab cutting die device, a positive pole pull belt drive device and a positive pole cutter assembly; the negative pole piece die cutting mechanism comprises a negative pole unwinding device, a negative pole correction sensor, a negative pole tension adjusting assembly, a negative pole correction assembly, a negative pole tab cutting die device, a negative pole pull belt drive device and a negative pole cutter assembly. The die cutting, bag making and laminating integrated equipment for the battery pole pieces has the advantages of simple structure, small occupied area, high automation degree, high production efficiency, low labor cost and the like which are absent in the prior art.

Owner:SHENZHEN GREENSUN TECH CO LTD

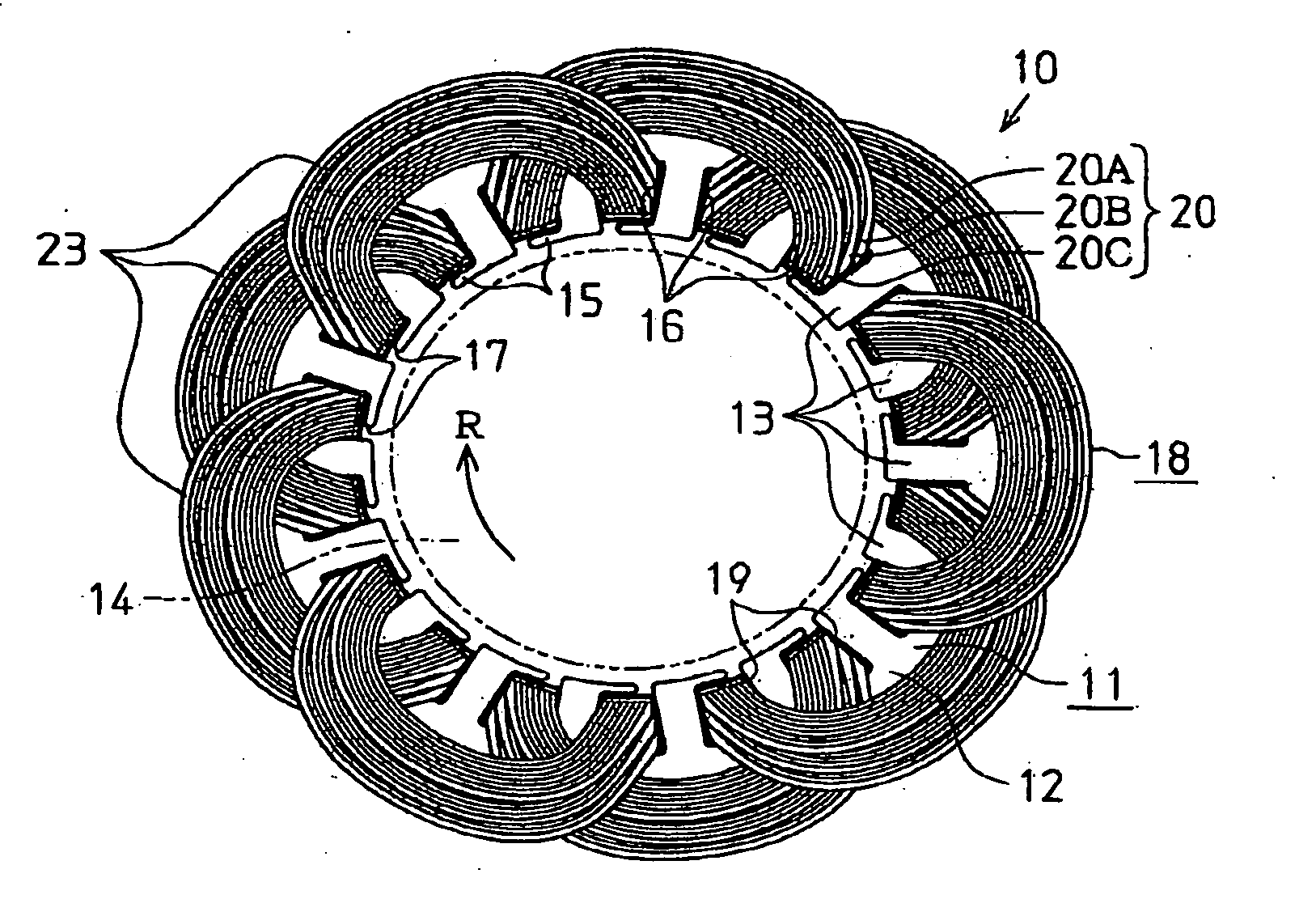

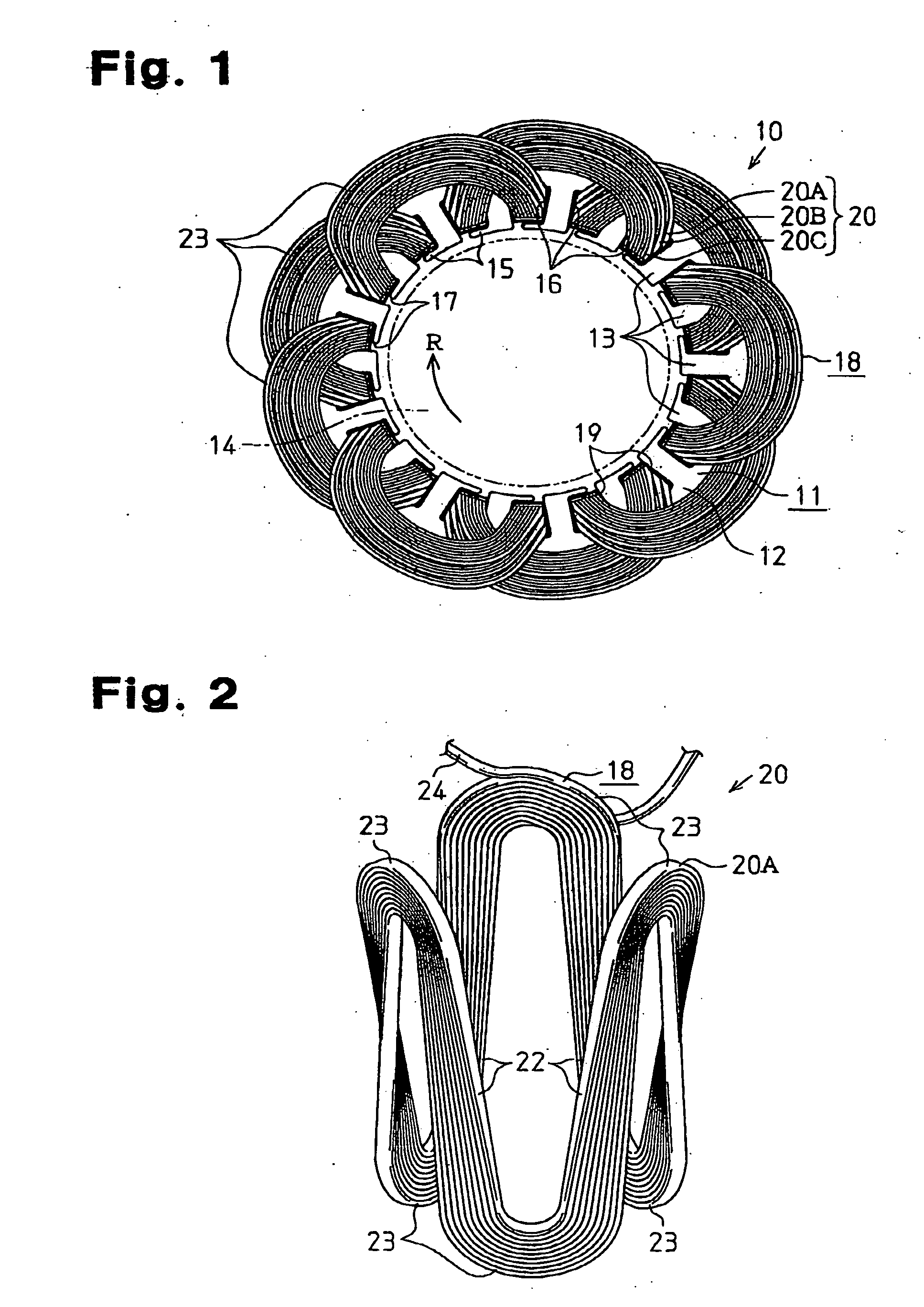

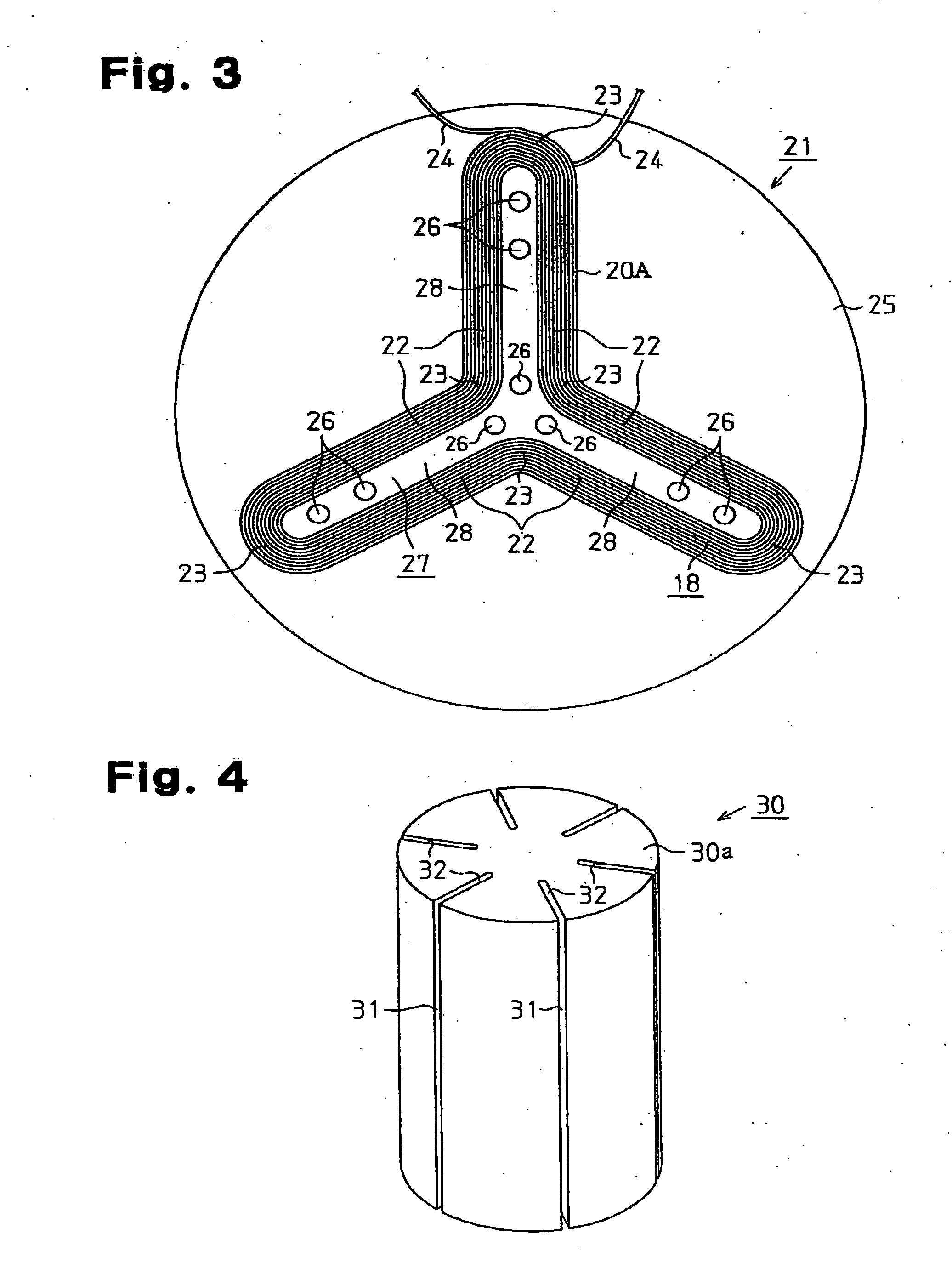

Rotary electric machine and method for mounting coil on core for rotary electric machine

InactiveUS20050218746A1Improve output characteristicImprove output characteristicsSynchronous generatorsLine/current collector detailsEngineeringSingle row

A method for mounting a coil onto a stator for a rotary electric machine. The method includes forming a coil piece by winding wire having a flat cross section into a single row lamination state including wire layers that are aligned along a line that is perpendicular to flat surfaces of the wire. The coil piece is formed so that a first portion to be inserted in the slot and a second portion that is not inserted in the slot appear alternately along the coil piece. The method also includes displacing the wire layers at the first portion from one another to change the single row lamination state to a connectively laminated stat e in which the wire layers at the portion to be inserted in the slot each adjacent pair of the wire layers partially overlap with respect to a direction perpendicular to the flat surfaces of the wire. The method further includes inserting the wires of the first portion into the slot, by passing each of the wire layers through the opening of the slot successively from the wire layer at the top of the lamination and displacing each of the wire layers at the first portion from each other.

Owner:TOYOTA IND CORP

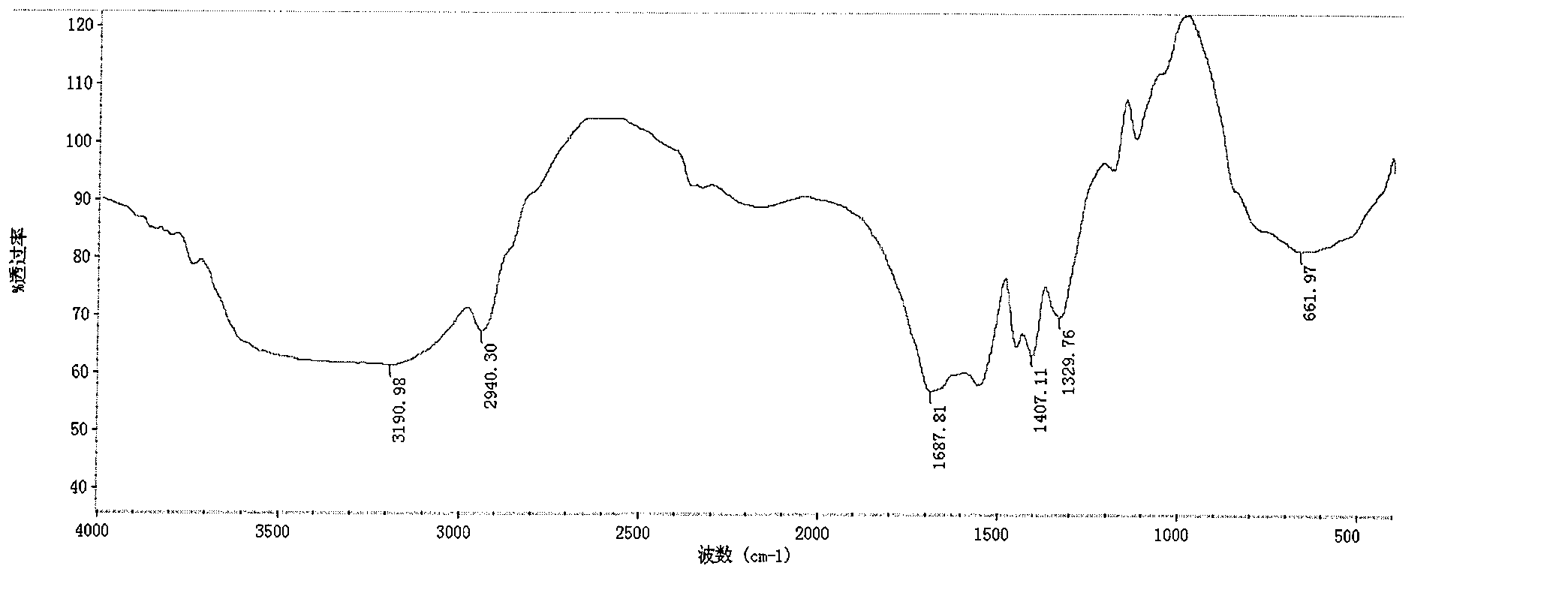

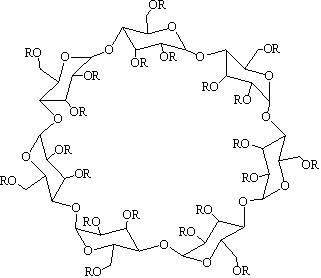

Method for preparing hydroxypropyl-beta-cyclodextrin

ActiveCN102040675AWill not cause decompositionLow impurity contentMacromolecular non-active ingredientsNanofiltrationPharmaceutic Adjuvant

The invention discloses a method for preparing hydroxypropyl-beta-cyclodextrin, which comprises the steps of etherification, neutralization, decoloring, nanofiltration, resin purification, and spray drying. The method of the invention is small in pollution, and the yield in weight is more than 80 percent; meanwhile, the product prepared by using the method of the invention is narrow in substituted ratio range and low in impurity content, and can be used as a pharmaceutic adjuvant.

Owner:石药集团中诺药业(石家庄)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com