Process and apparatus for preparing porous metal by combined physical gas-phase deposition techinque

A physical vapor deposition, porous metal technology, applied in metal material coating process, electrical components, ion implantation plating, etc., to avoid heat accumulation, simplify the production process, and improve the effect of sponge aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

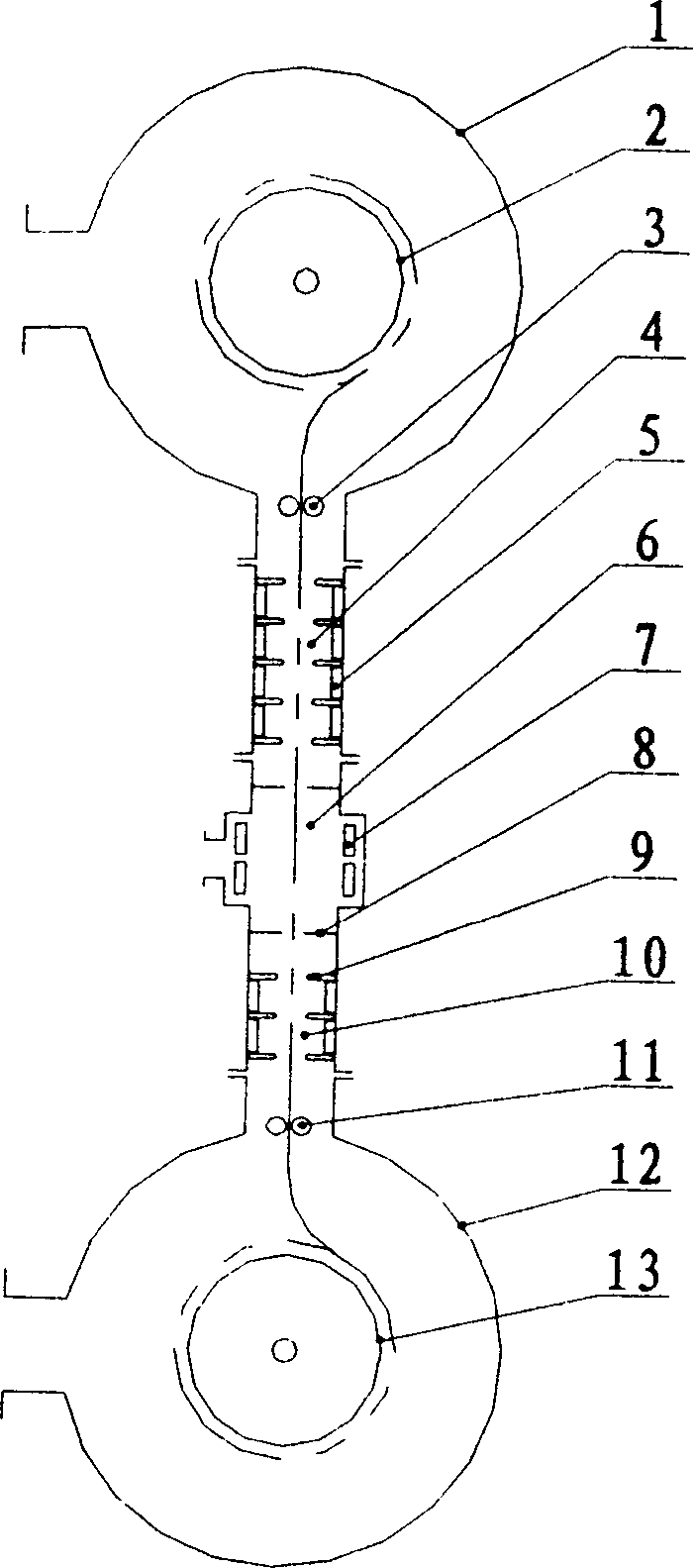

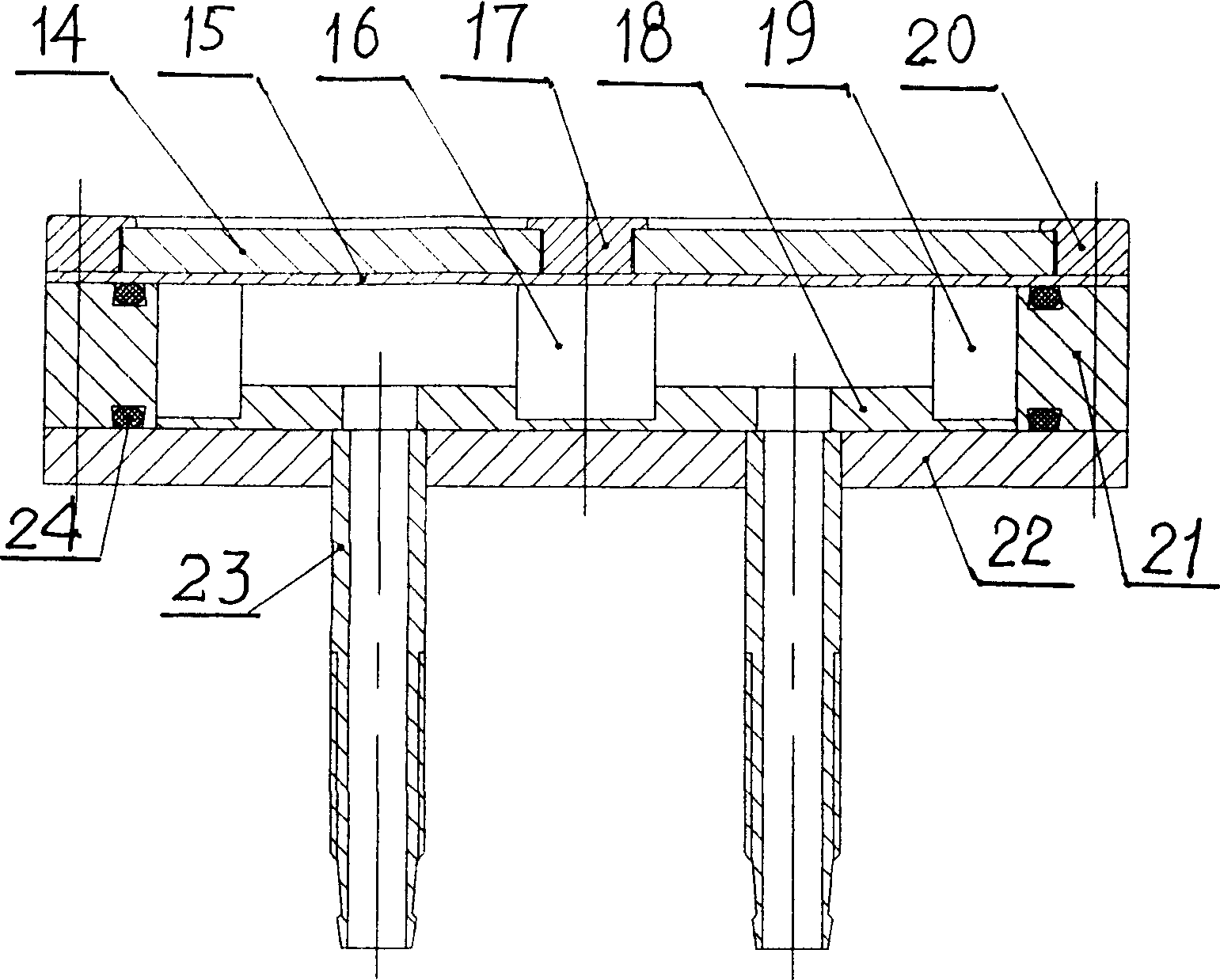

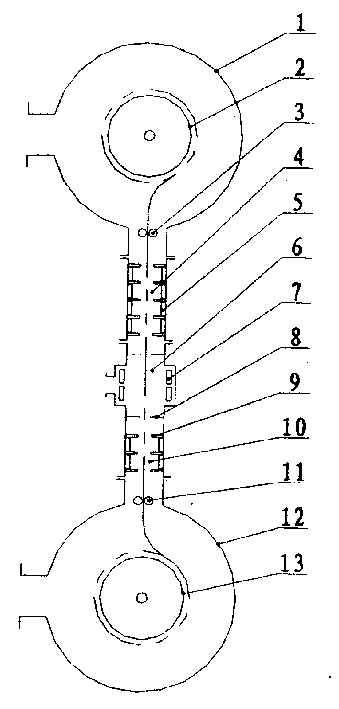

[0040] see figure 1 , 1-rewinding (unwinding) volume chamber, 2-receiving (unwinding) volume roller, 3-measuring roller, 4-magnetic control coating chamber,

[0041] 5-Magnetic control target, 6-Arc evaporation chamber 7-Arc evaporation target, 8-Separator, 9-Cooling water jacket, 10-Pretreatment chamber, 11-Guide roller, 12-Unwinding (rewinding) volume chamber, 13- Put (close) roll roller.

[0042] The present invention combines evaporation plating, sputtering plating, and ion plating with one of the above-mentioned methods, such as the combination of arc evaporation plating and magnetron sputtering plating, and the combination of arc ion plating and magnetron sputtering plating to form a specific preparation. Methods and equipment. This type of PVD technology is called PVD combined technology because it is different from the single form of PVD technology commonly used. The present invention particularly relates to the technology of arc evaporation plating and magnetron sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com