Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2541results about "Seed preservation by drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

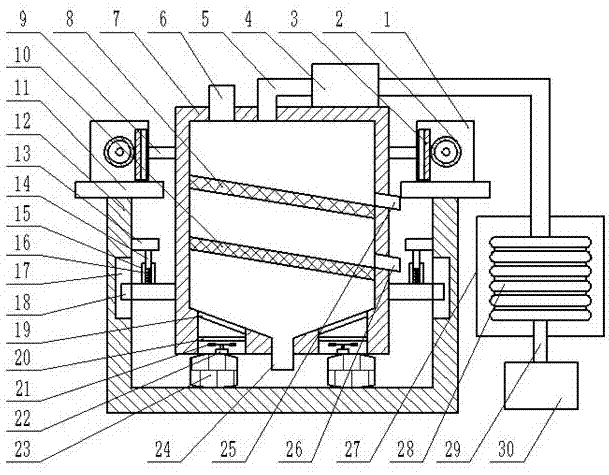

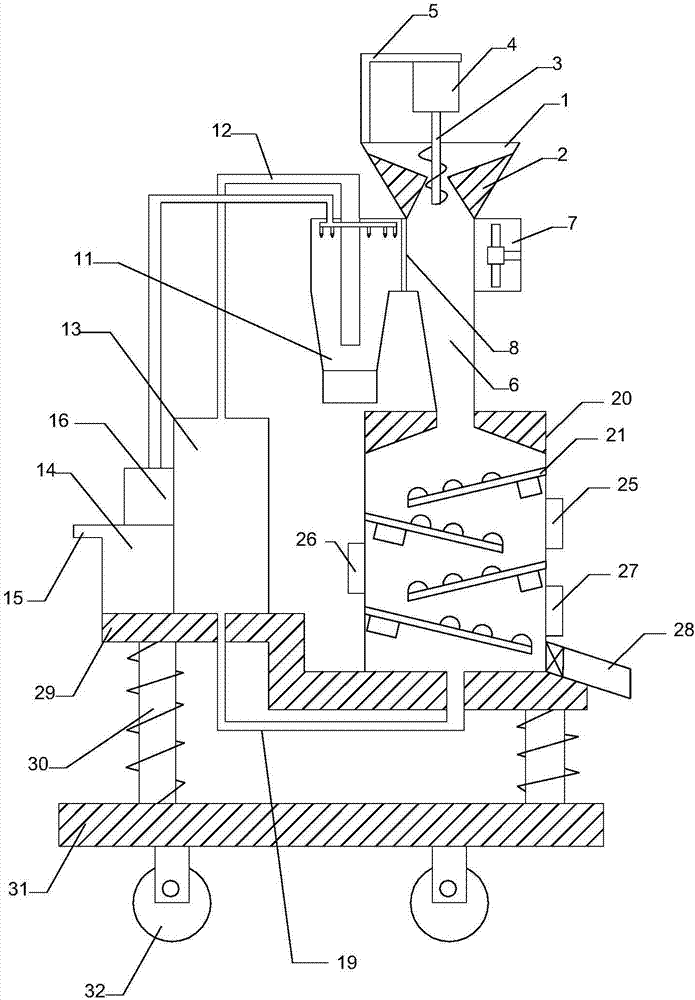

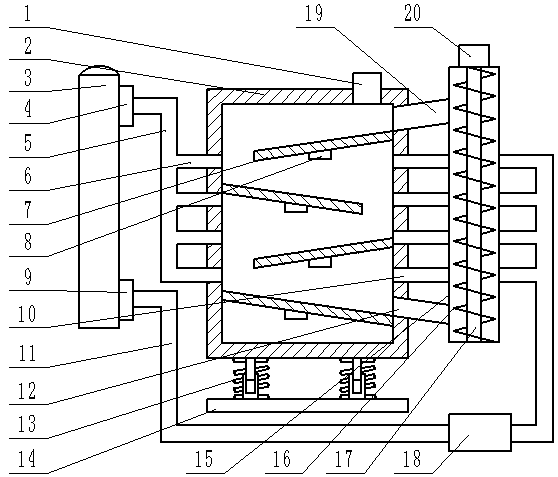

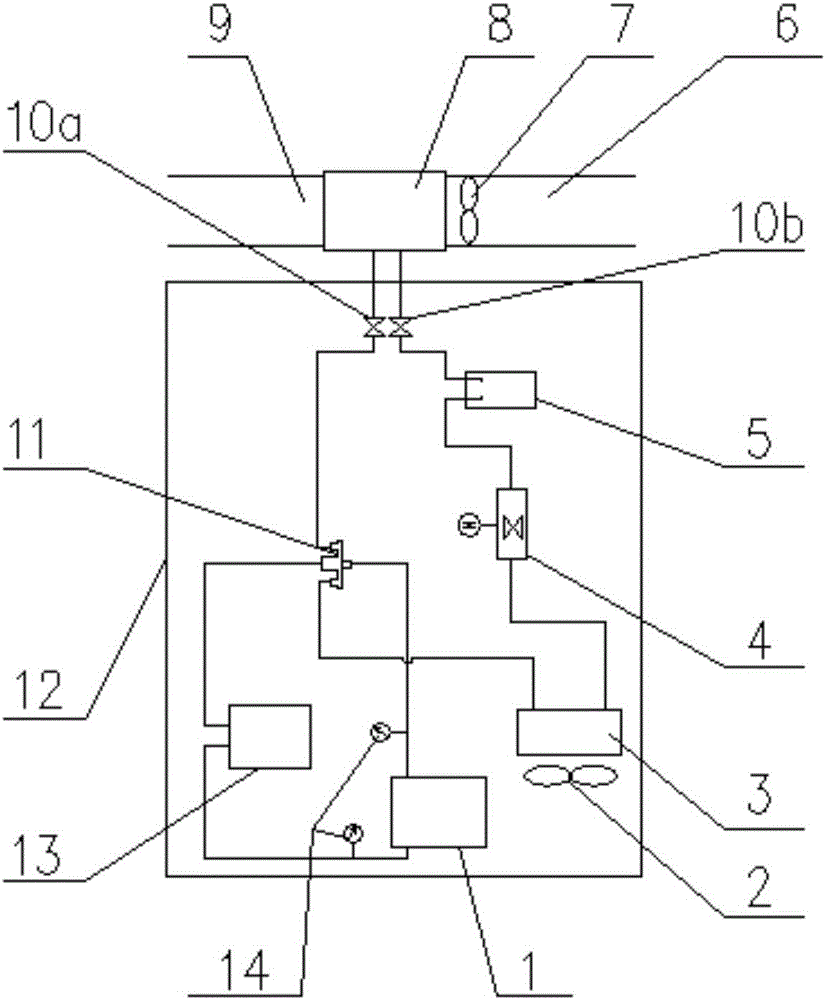

Rapeseed drying and impurity removal device

ActiveCN108662871ASpeed up dryingStir wellGas current separationDrying gas arrangementsHeat conductingRapeseed

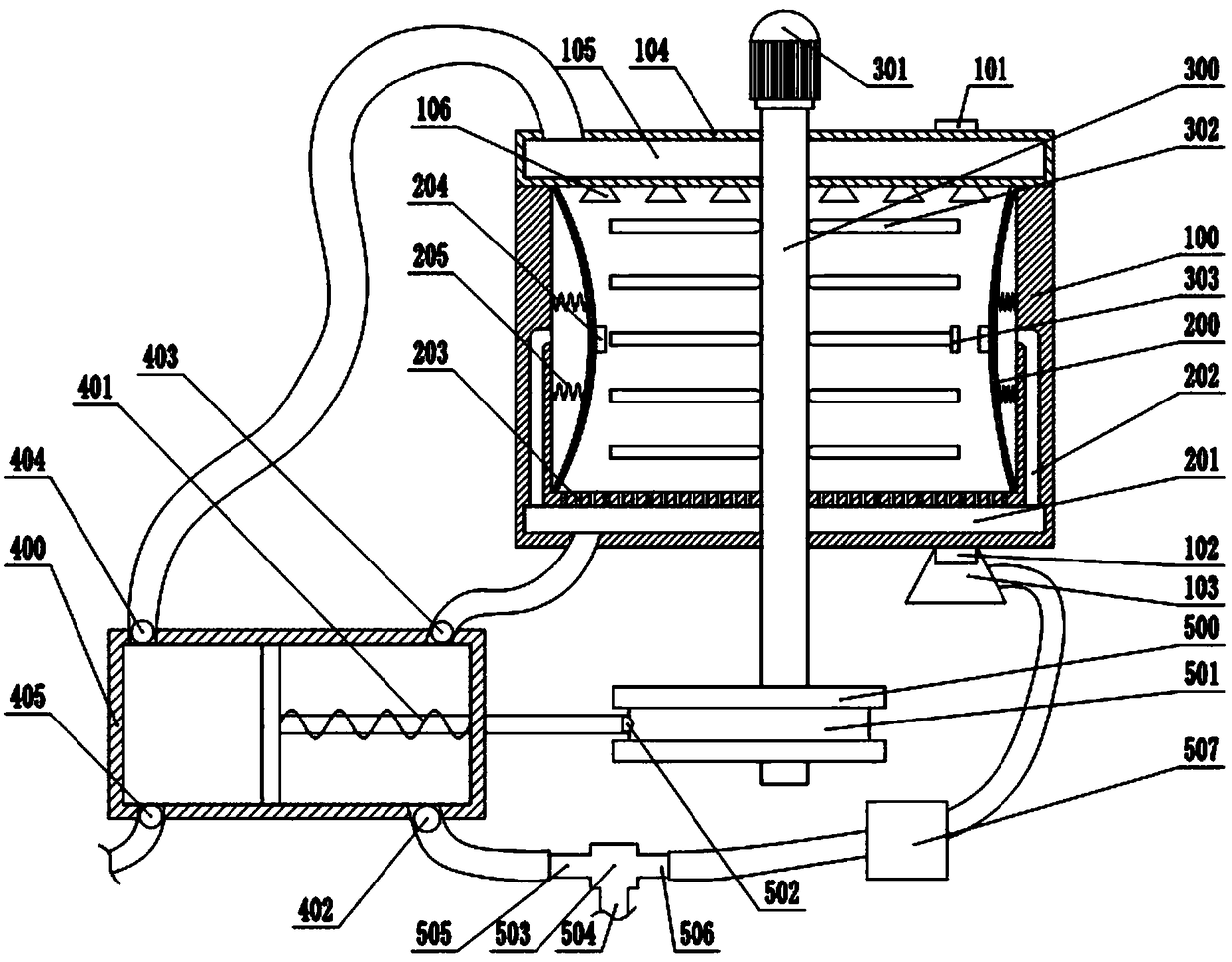

The invention relates to the technical field of drying equipment, and particularly discloses a rapeseed drying and impurity removal device. The rapeseed drying and impurity removal device comprises adrying barrel. A dust collecting cavity is formed in the top wall of the drying barrel, and dust absorbing covers are arranged on the top of the drying barrel. A vertical shaft is arranged in the drying barrel in a penetrating mode, and a plurality of stirring rods are arranged on the vertical shaft. Air bags are uniformly distributed on the inner wall of the drying barrel, a drying cavity is formed in the bottom wall of the drying barrel, and heat conducting pipes are arranged on the side wall of the drying barrel. Air outlet holes are uniformly distributed in the bottom of the drying barrel.Magnetic locating blocks are arranged on the air bags, and magnetic blocks are arranged at the ends of the stirring rods. An air cylinder is further arranged at the bottom of the drying barrel, an air inlet one-way valve and an air outlet one-way valve are arranged on the side wall of the air cylinder, and a feeding one-way valve and a discharging one-way valve are arranged on the side wall of the air cylinder. The air inlet one-way valve communicates with a heat supply device through a pipeline, the air outlet one-way valve communicates with the drying cavity through a pipeline, and the feeding one-way valve communicates with the dust collecting cavity through a pipeline. By the adoption of the rapeseed drying and impurity removal device, the problem that due to the fact that water vaporgenerated by rapeseeds in the drying process can condense again after touching the barrel wall of the drying barrel, drying of the rapeseeds cannot be sufficient is solved.

Owner:贵州务川八爷农场有限公司

Method of controlling ouput time and output priority of caption information and apparatus thereof

InactiveUS20060170819A1Drying solid materials with heatPicture reproducers using cathode ray tubesUser inputData storing

An apparatus and a method of arbitrarily adjusting the output time of caption information included in a received multimedia transport stream for broadcasting, by user input. The method includes: receiving an input of a time value for adjusting the output time of caption information, from a user through a user interface; by demultiplexing the multimedia transport stream, dividing the transport stream into video, audio, and data packets, decoding each packet, and storing the decoded packets in buffers corresponding to a type of each packet; resetting the output time of the caption information by adding the input time value to or subtracting the input time value from the output time included in the video or audio packet; and according to the output time of the reset caption information, blending the data stored in the buffer with the video information and presenting the blended information on the screen.

Owner:SAMSUNG ELECTRONICS CO LTD

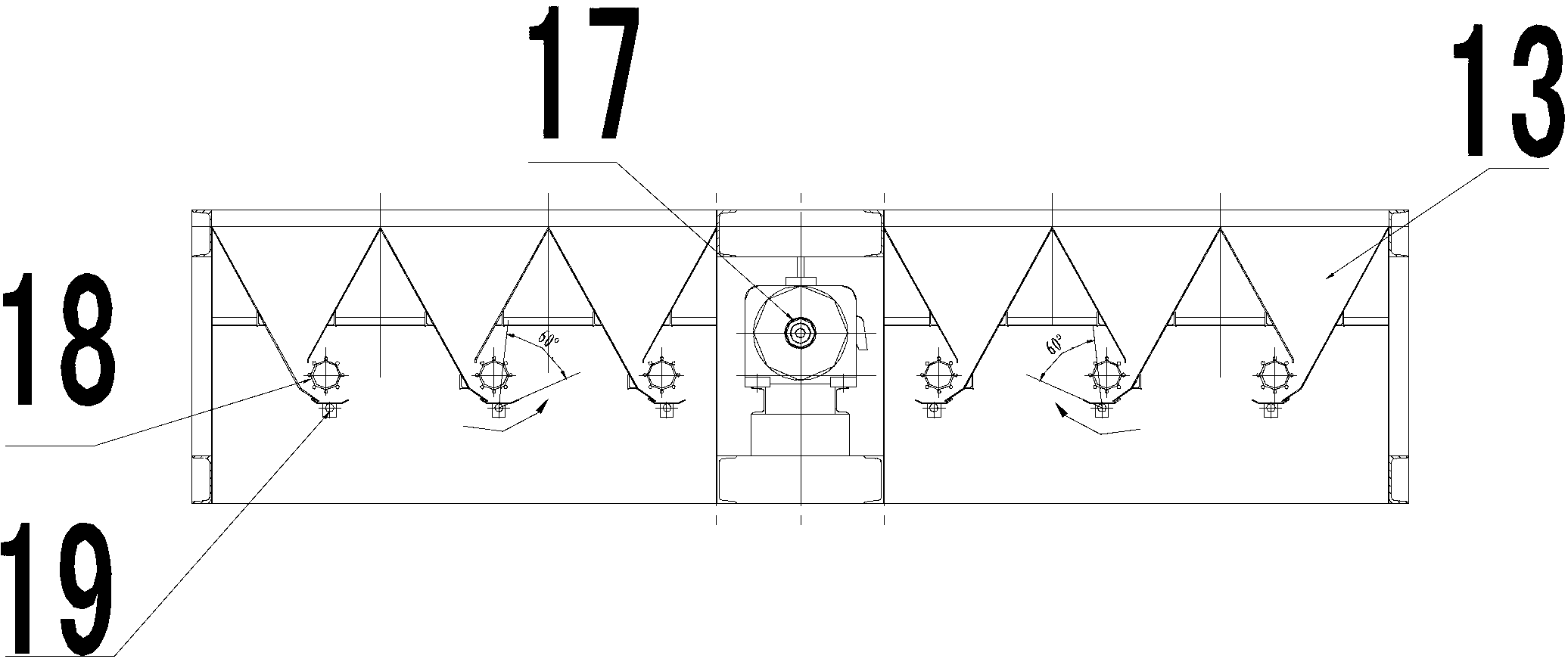

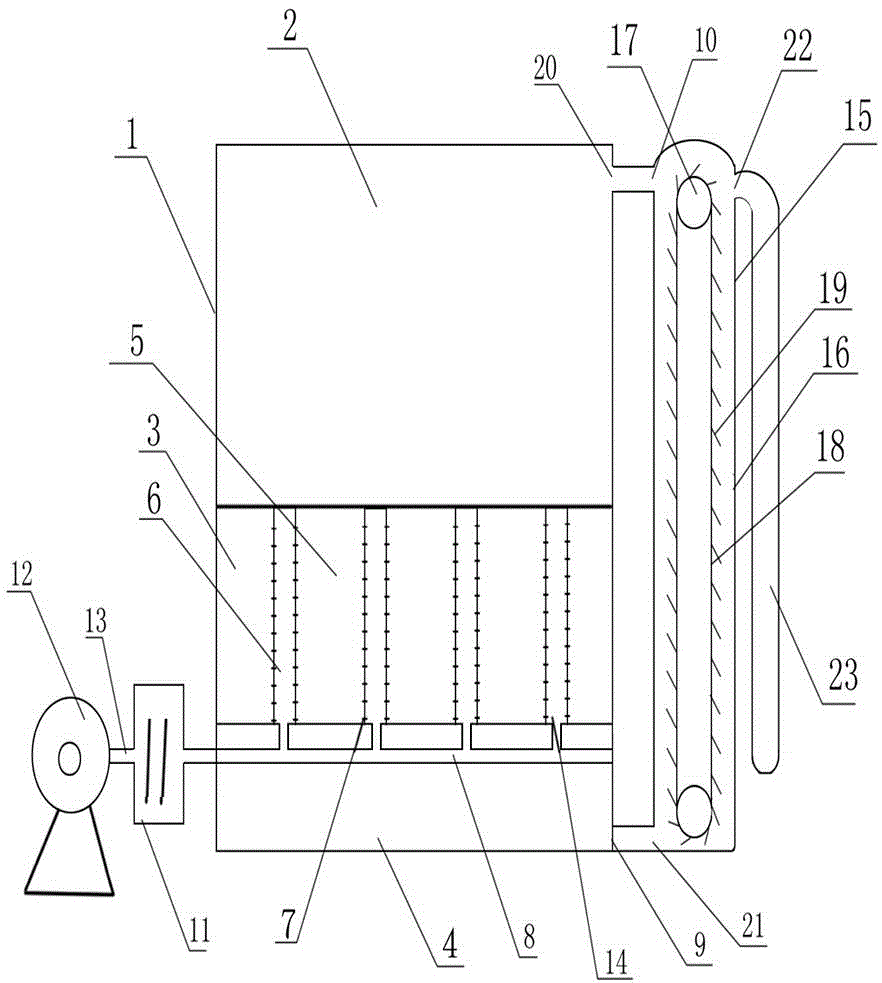

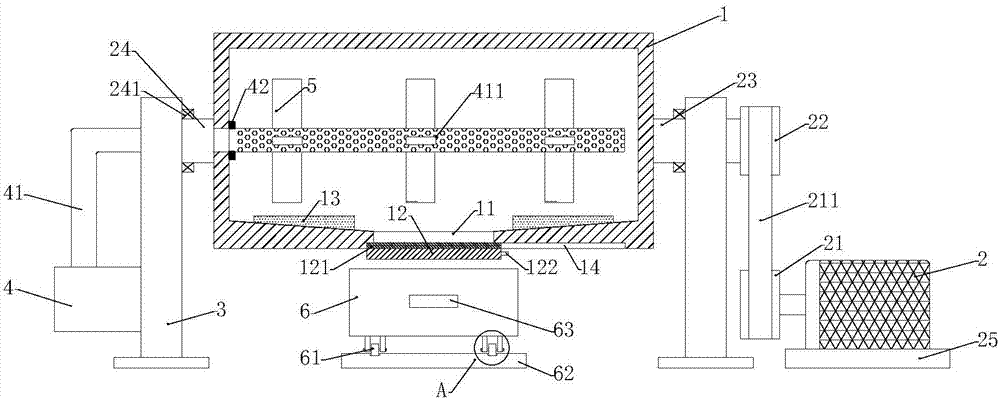

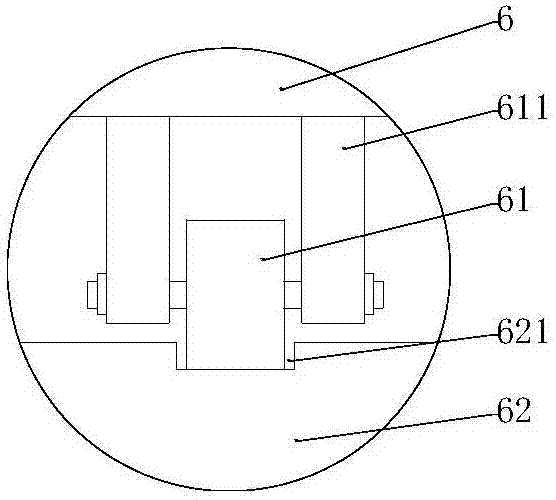

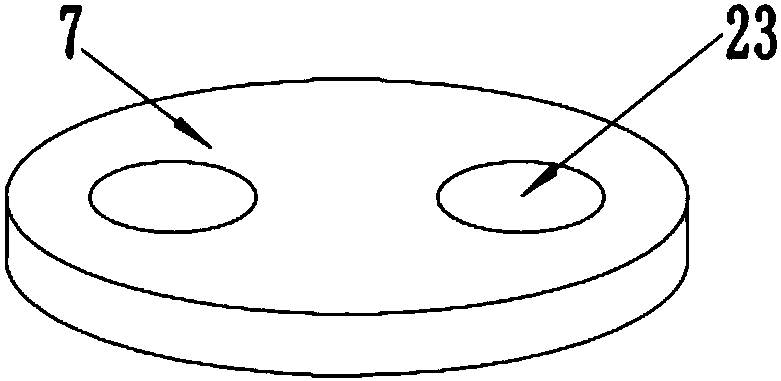

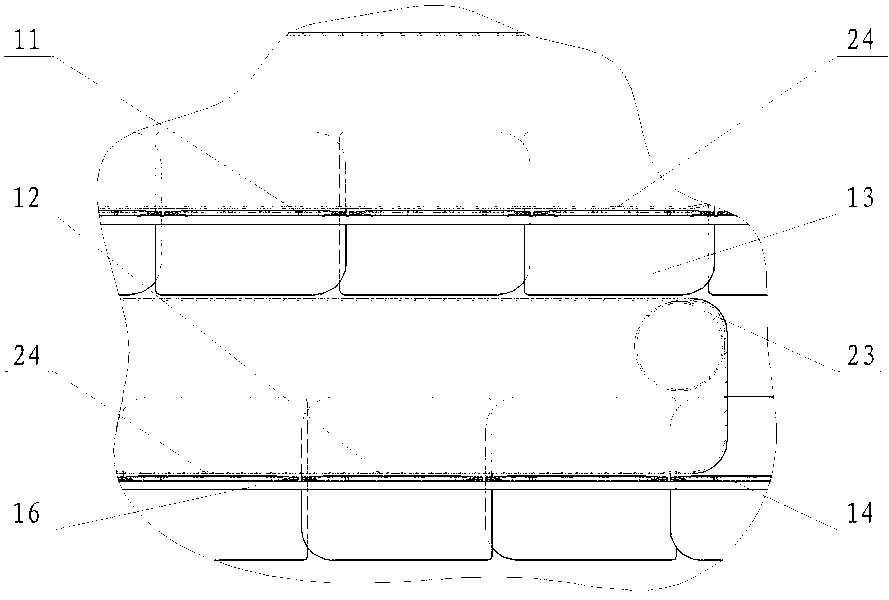

Stirring-type drying device for cereal

InactiveCN107484823AEfficient dryingImprove uniformityDrying gas arrangementsSeed preservation by dryingPulp and paper industryInjection air

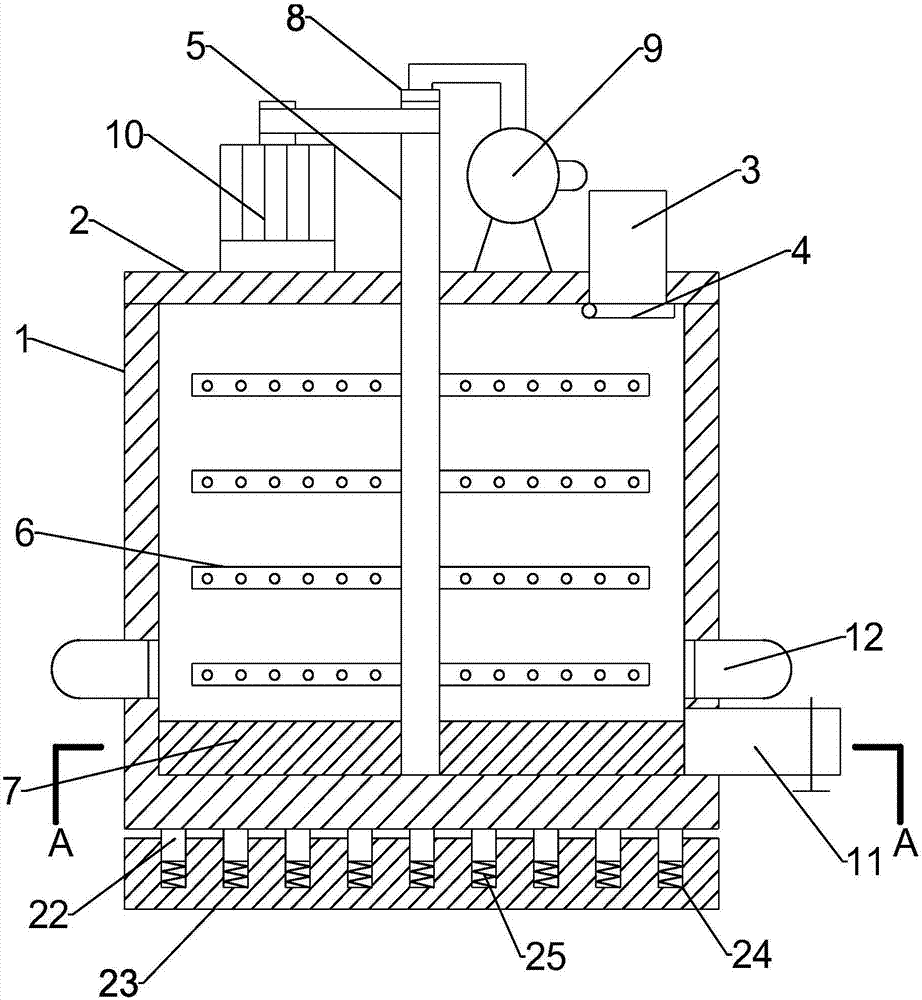

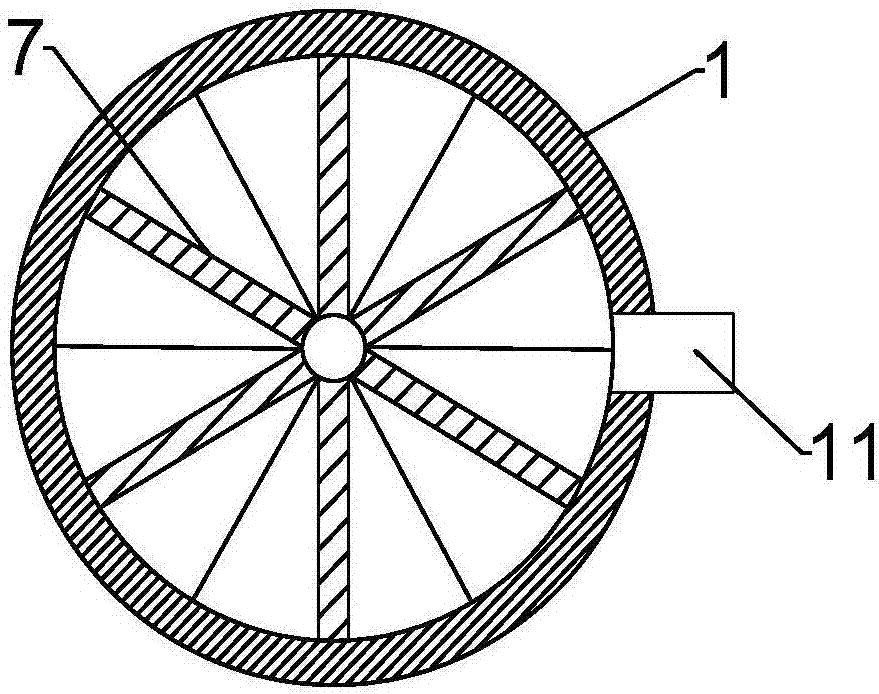

The invention discloses a stirring type drying device for grain, which comprises a casing, an upper cover is provided on the upper end of the casing, and a feeding pipe, a rotating baffle, an agitating shaft, an air pump and a motor are arranged on the upper cover; There are stirring fan rods, stirring fan blades, and rotating bearings; the right wall of the housing is provided with a discharge pipe and a circulating air outlet pipe, the left wall of the housing is provided with a circulating air intake pipe, and the rear side of the housing is provided with an air pump. There are one-way air intake pipe, one-way air outlet pipe, piston block, electric push rod, heating pipe and inclined block on the top, and the bottom of the shell is provided with a support rod and a support base plate. The invention uses a hollow stirring shaft and a stirring fan rod to inject air to stir and dry the grain, cooperate with a heatable air extraction cylinder, circulate air extraction and air injection and heat the air at the same time, can promote the movement of the grain in the shell and remove water vapor, and improve drying efficiency.

Owner:石岩

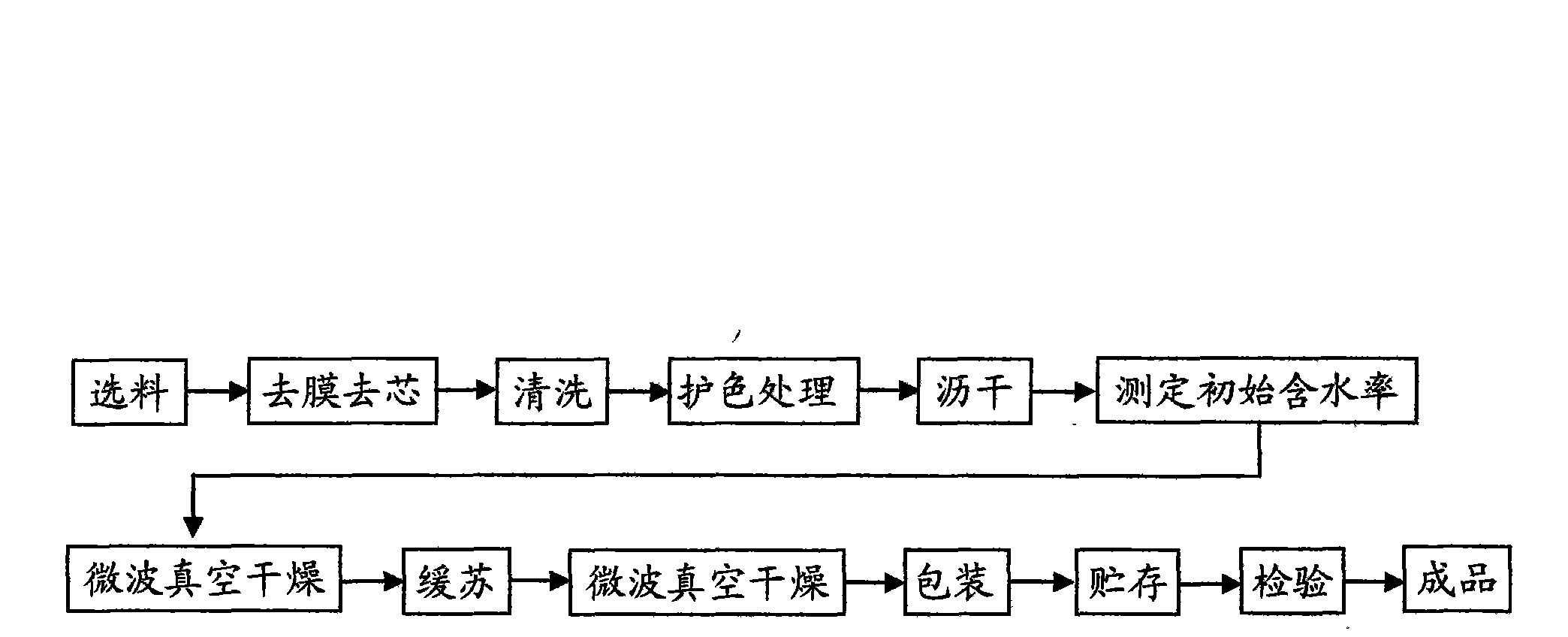

Microwave vacuum drying process for lotus seed

The invention provides a microwave vacuum drying process for lotus seeds, comprising the following steps of: selecting materials, removing films and cores, protecting color, dewatering, vacuum drying by microwave, packaging and storing, thus preparing the dry lotus seed product. The process aims at improving the quality research of the dry lotus seed and reducing the energy consumption, dries the fresh lotus seeds by microwave vacuum drying technology, improves the quality of the lotus seeds, and prolongs the shelf life of the product; the application of the high combination drying technology inaugurates another dry preparation way for drying preparation of fresh lotus seeds; the process is easy for instant control and the production is environment-protective; and the real continuous automatic clean production can be realized.

Owner:FUJIAN AGRI & FORESTRY UNIV

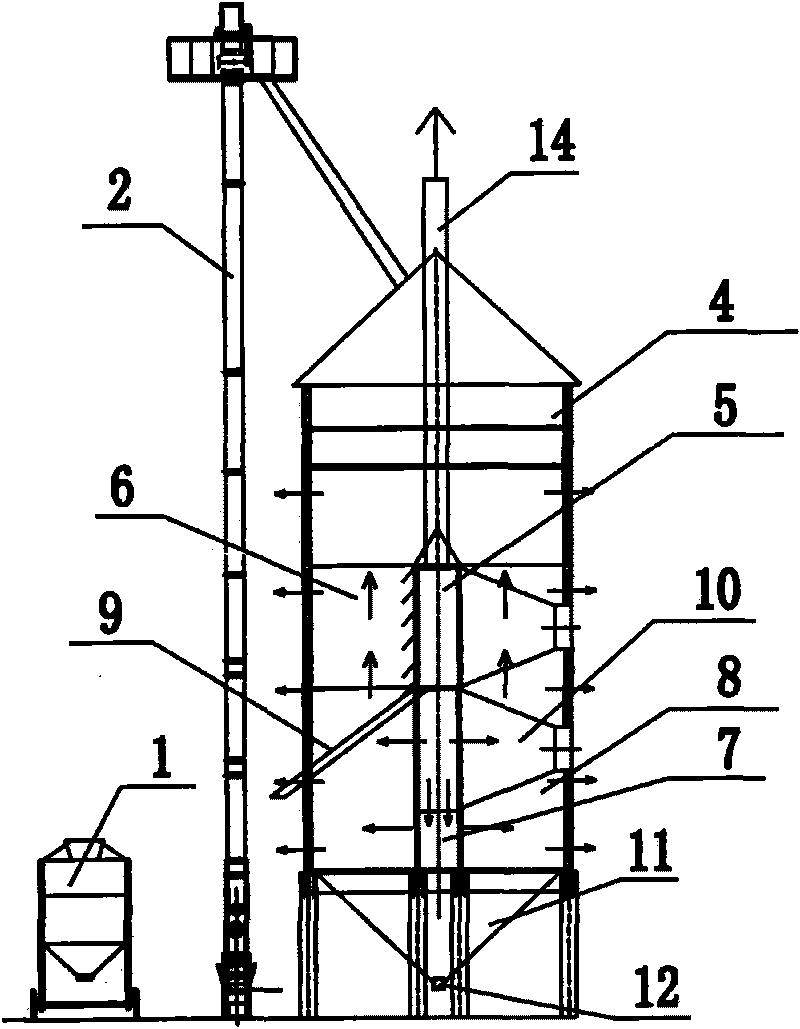

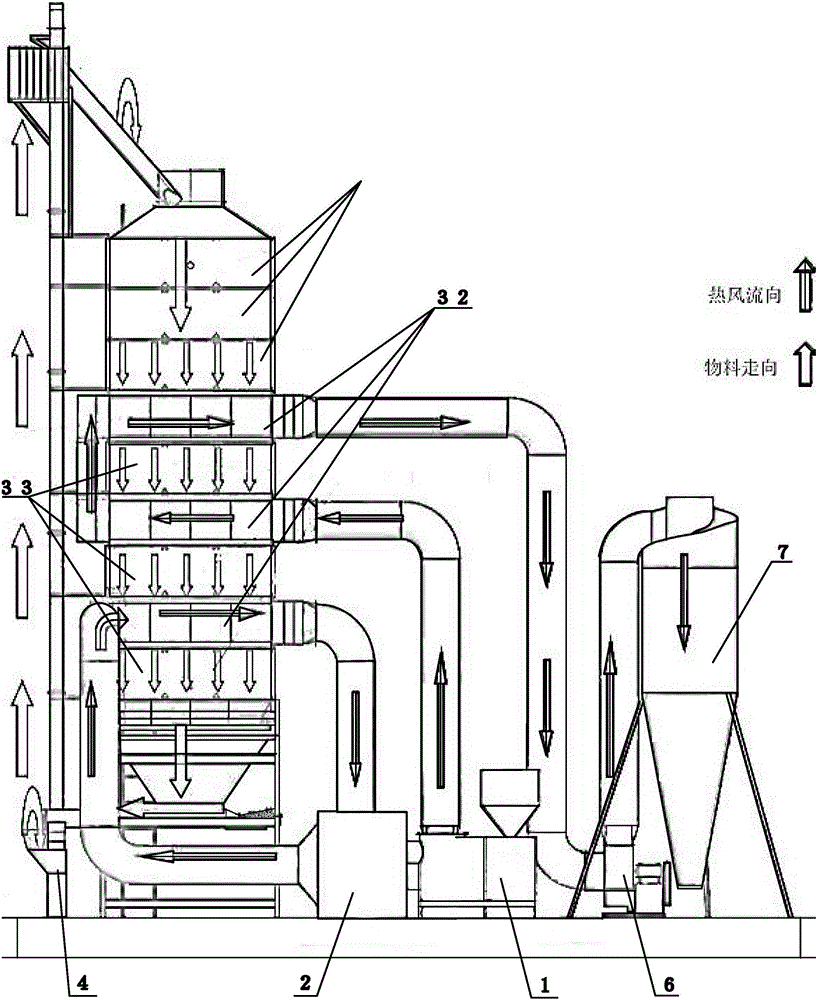

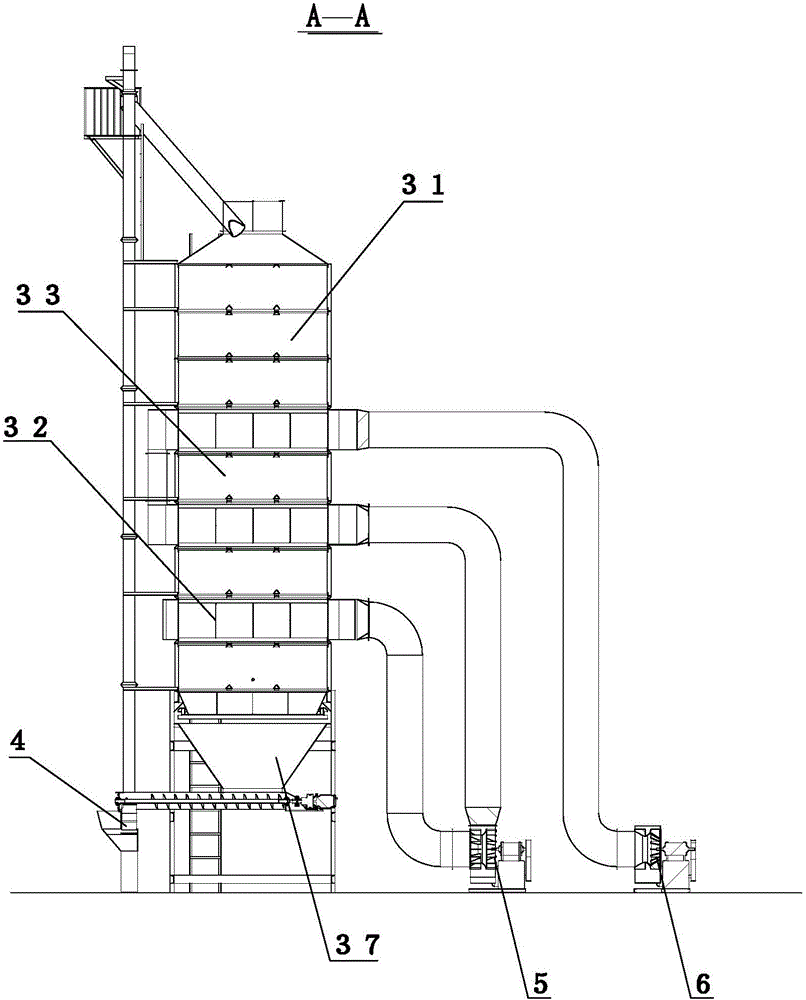

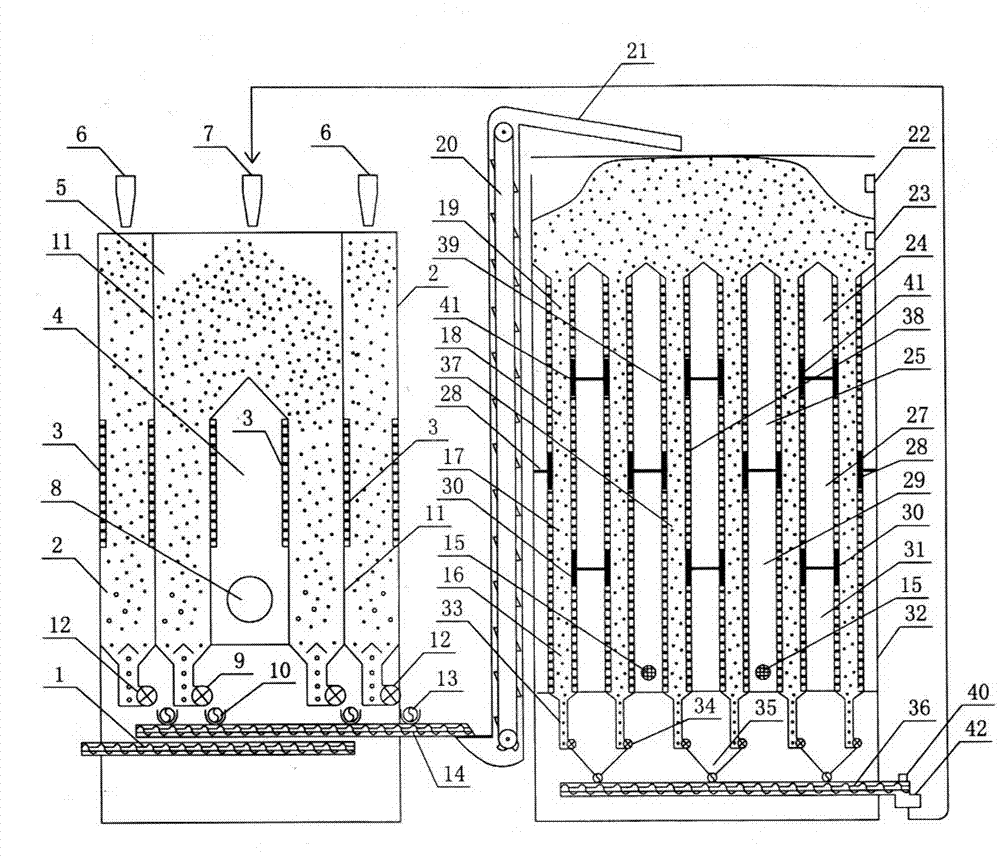

Centralized drying system of high-humidity grain and drying method thereof

InactiveCN101731327AImprove drying efficiencyReduce consumptionFood processingClimate change adaptationLiquid wasteEngineering

The invention relates to a centralized drying system of high-humidity grain and a drying method thereof. According to the grain deliver direction, the centralized drying system comprises a preliminary cleaning machine, a wet grain hoister, a wet grain dryer, a conveyor, a middle hoister, a main drying tower, a dry grain conveyor, a dry grain hoister and a dry grain storage silo which are successively connected, wherein the main drying tower successively comprises a high-temperature drying section, a low-temperature drying section and a cooling section; the system also comprises a hot-blast stove, a heat exchanger, a dust remover and a smoke draught fan which are successively connected, wherein the smoke draught fan is connected with the wet grain drier; the heat exchanger is connected to the main high-temperature drying section by an air heater, and the air heater is connected to the low-temperature drying section by a thermosistor; the heat exchanger is connected with the wet grain drier by a wind stopping device and an air cooler; and ambient air is communicated with the air cooler by the cooling section. The drying system can fully utilize natural air and recycle the waste heatand waste gas of the drying system to efficiently dry in an energy saving mode and reduce drying waste gas, waste liquid and dust emission; the drying system has favourable drying effect and is especially suitable for drying a great quantity of high-wet grain in a centralized mode.

Owner:SOUTH CHINA AGRI UNIV

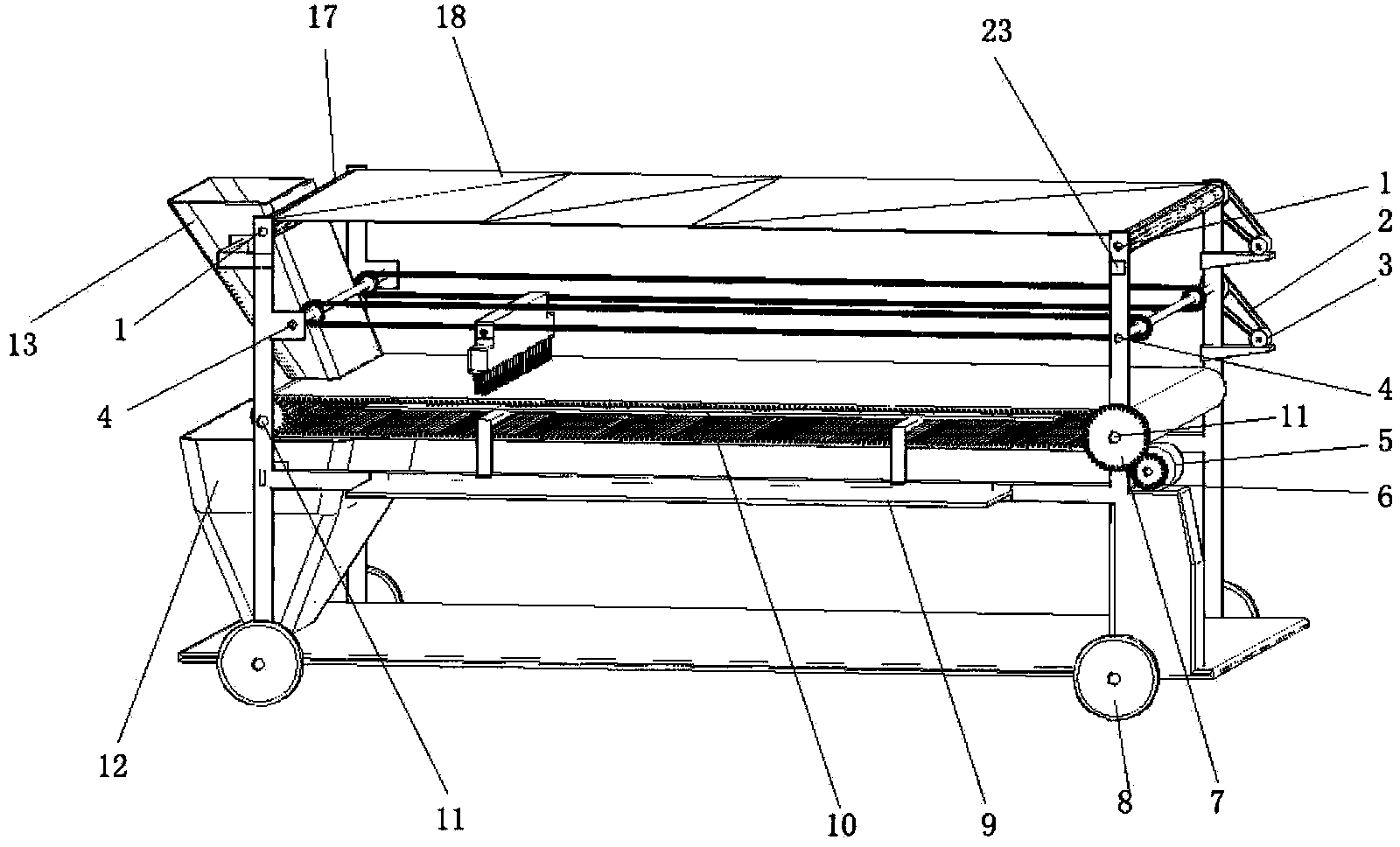

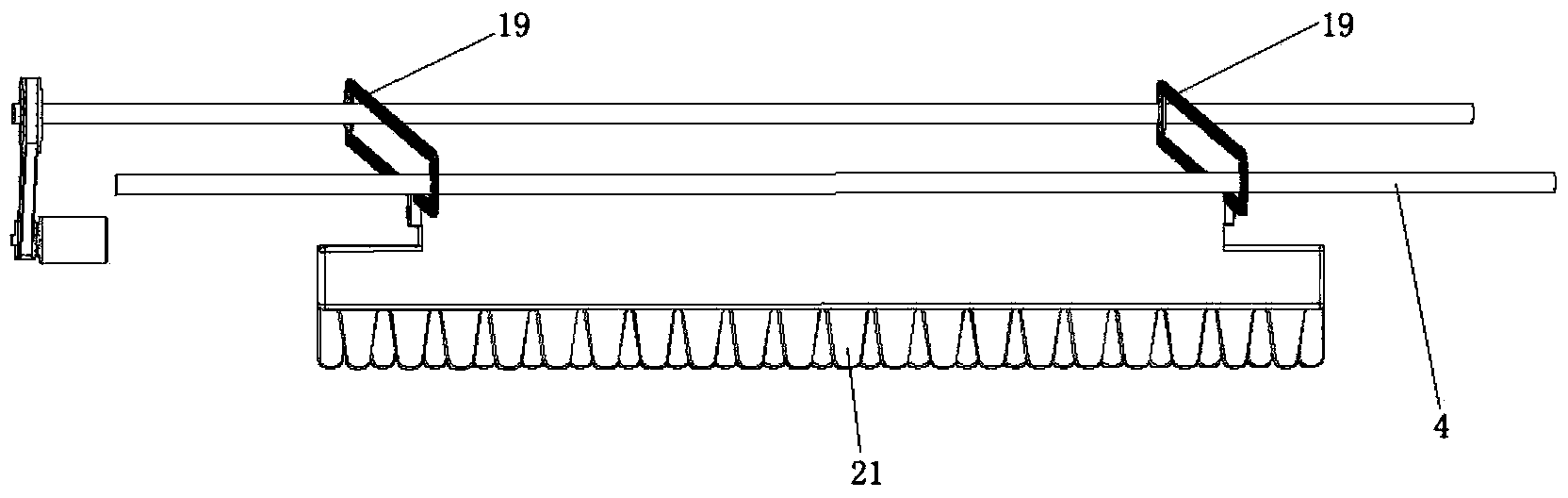

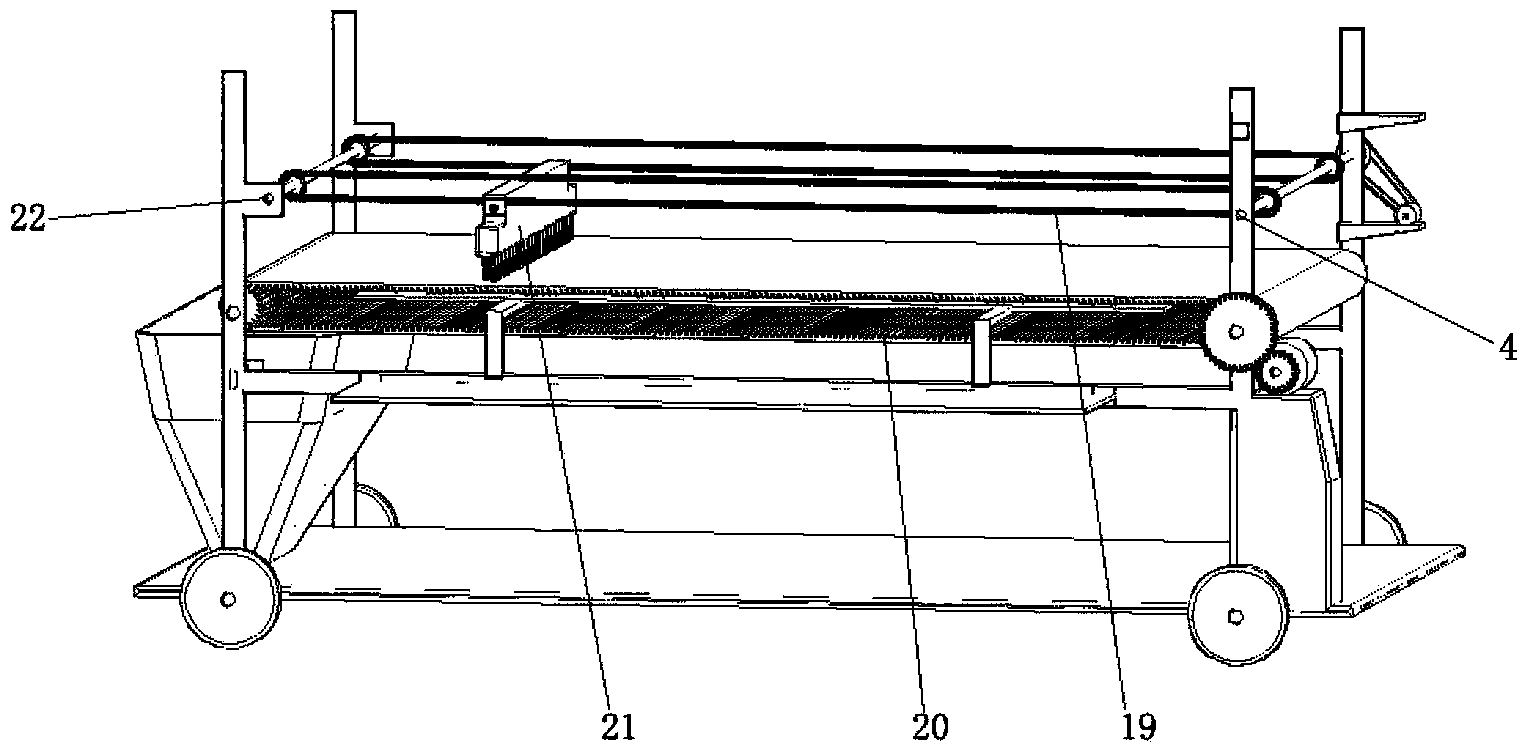

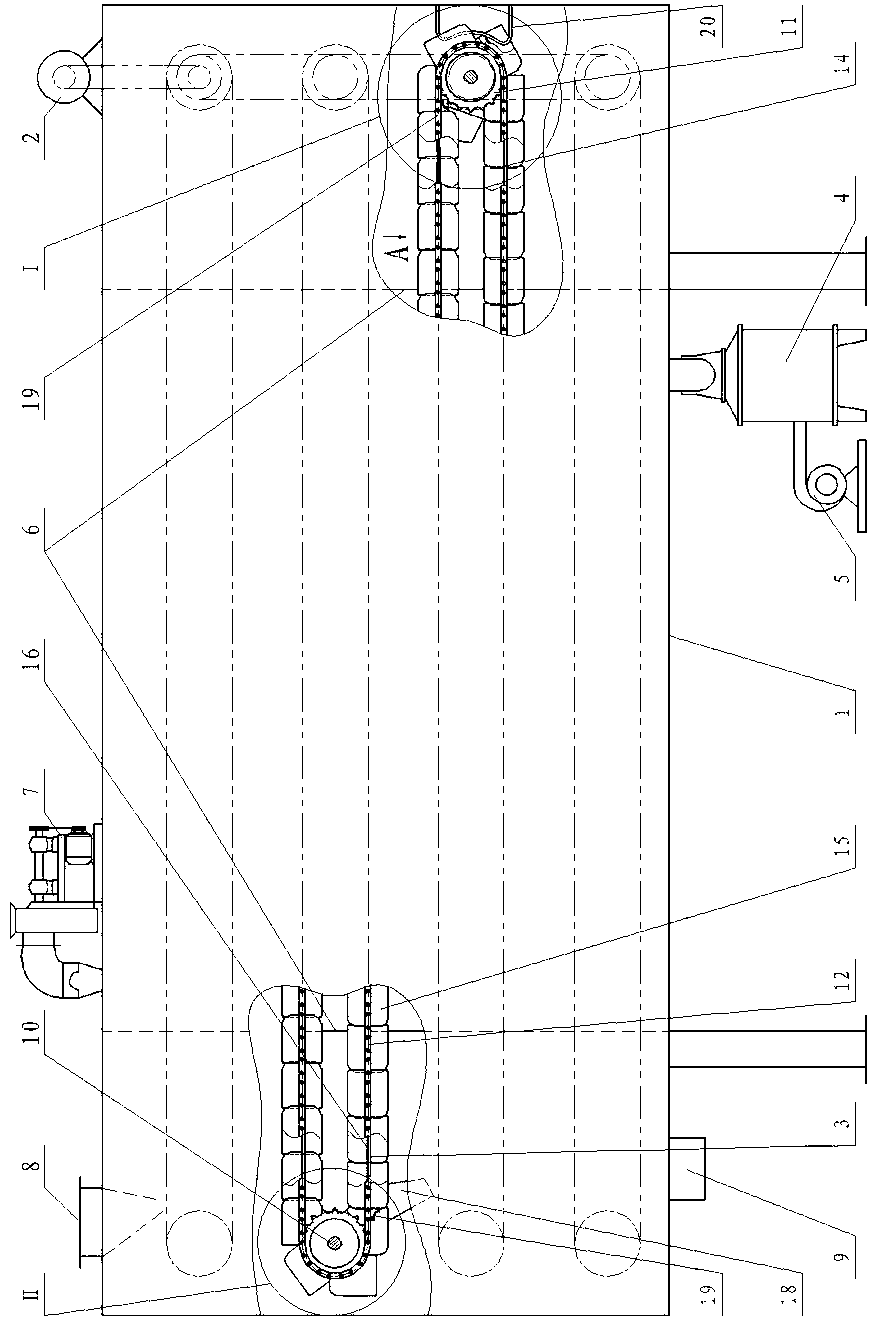

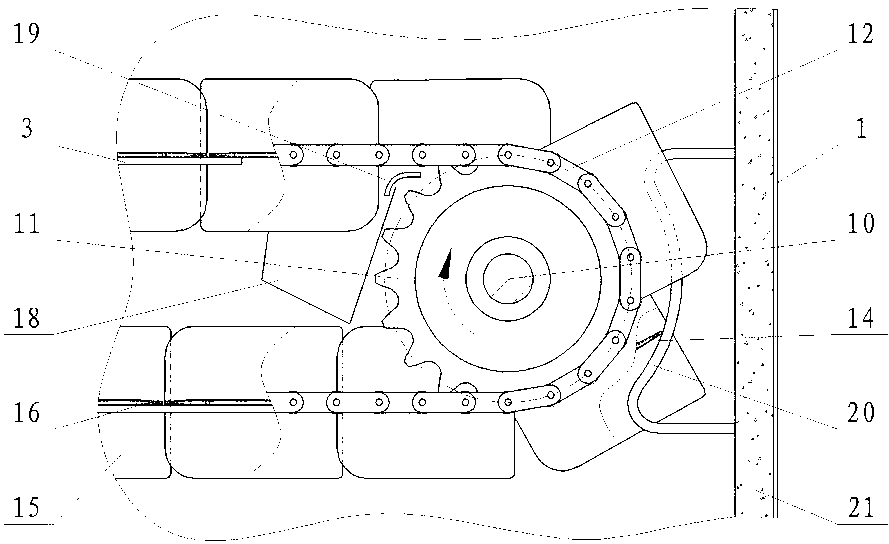

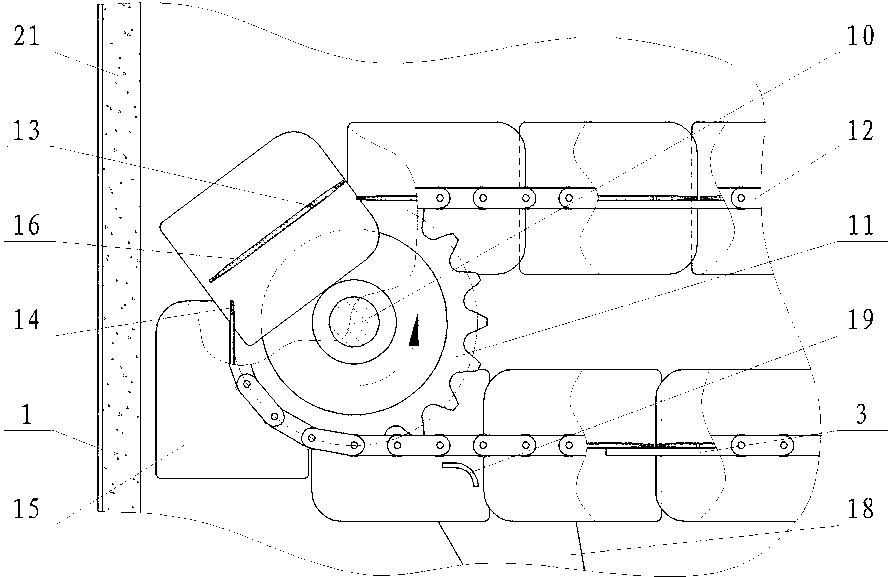

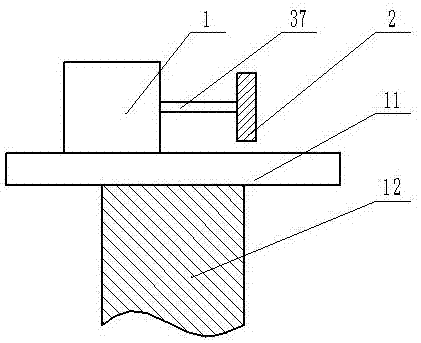

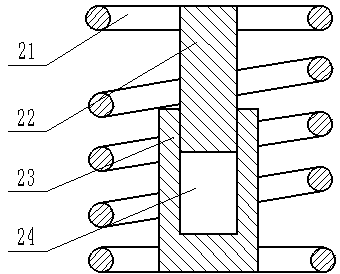

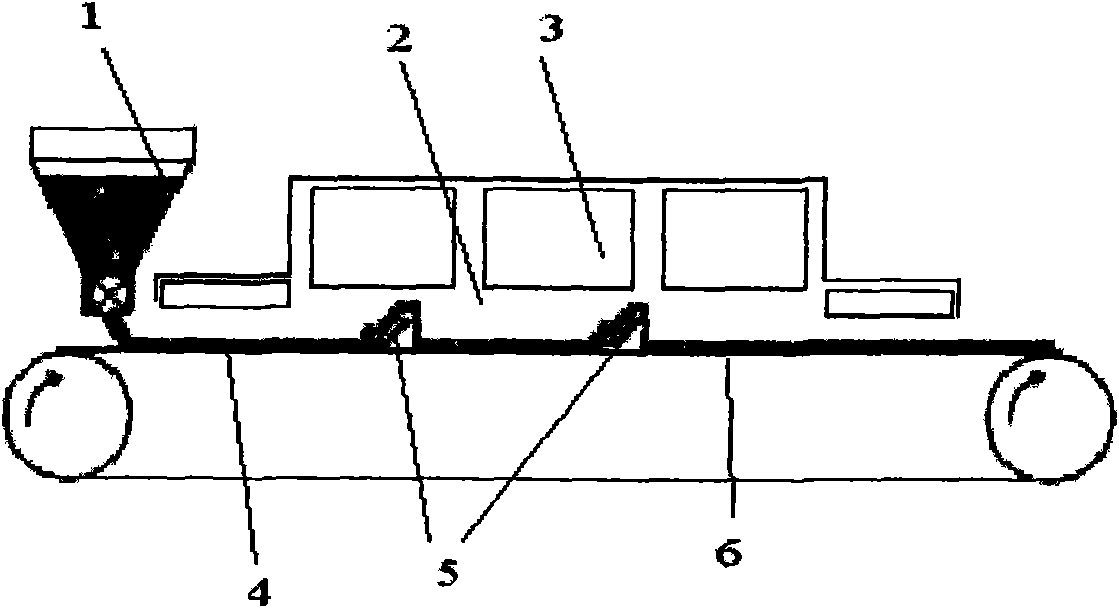

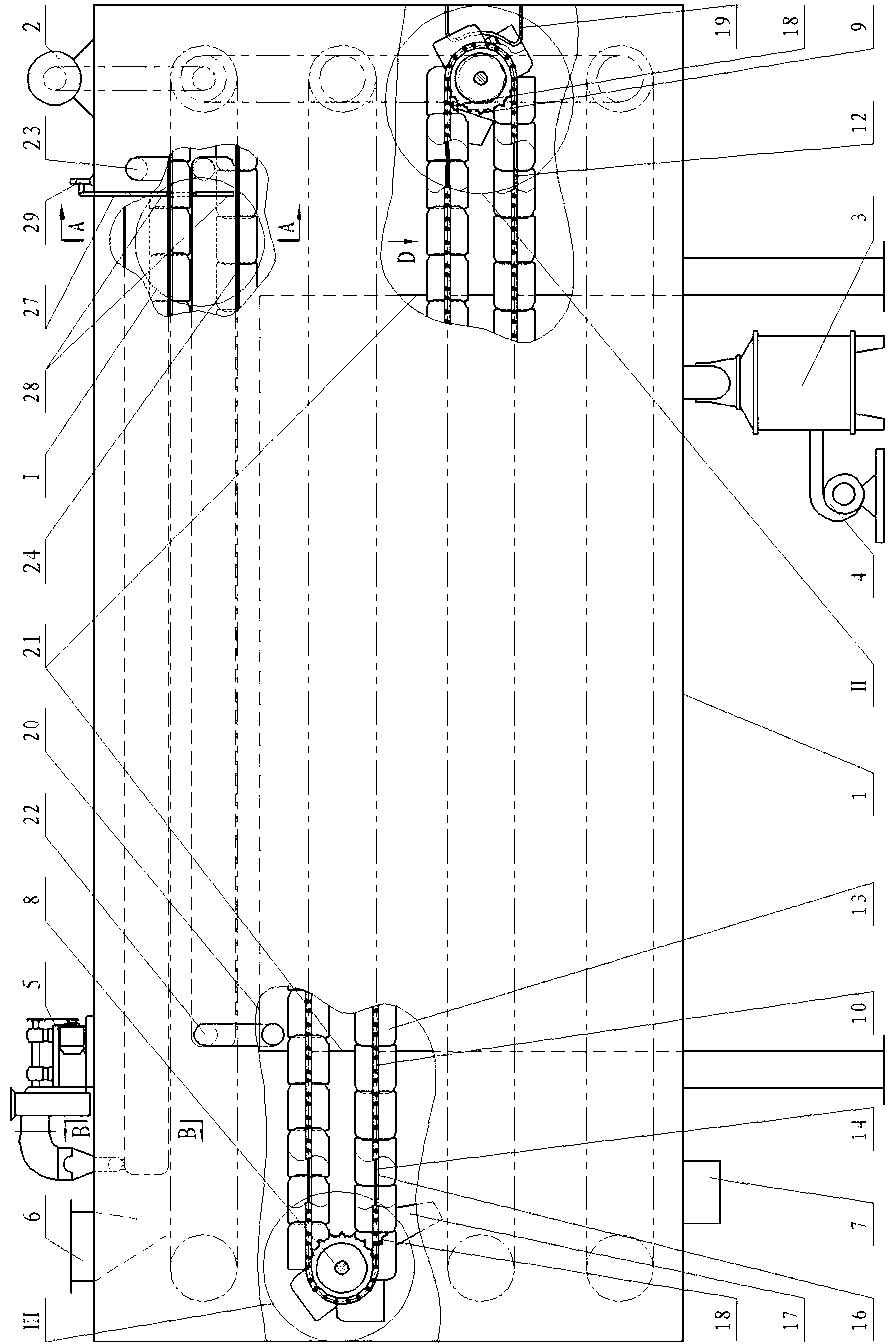

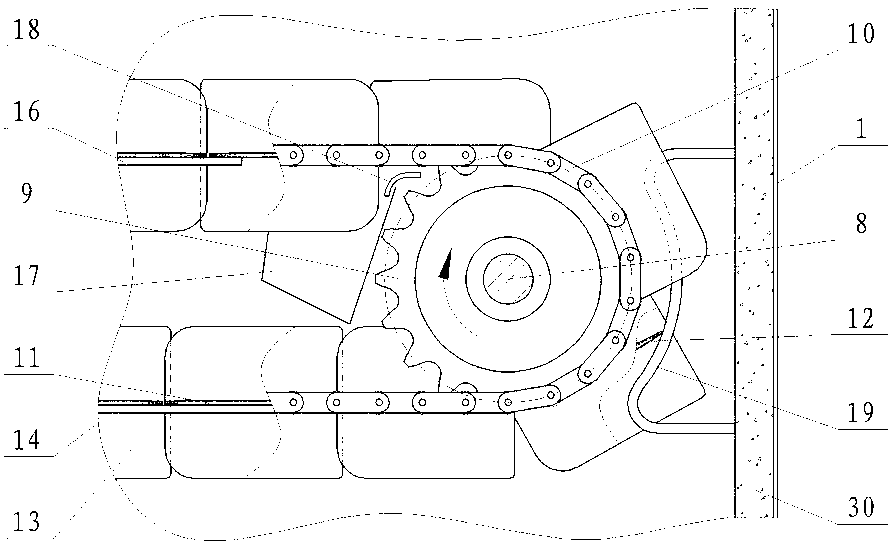

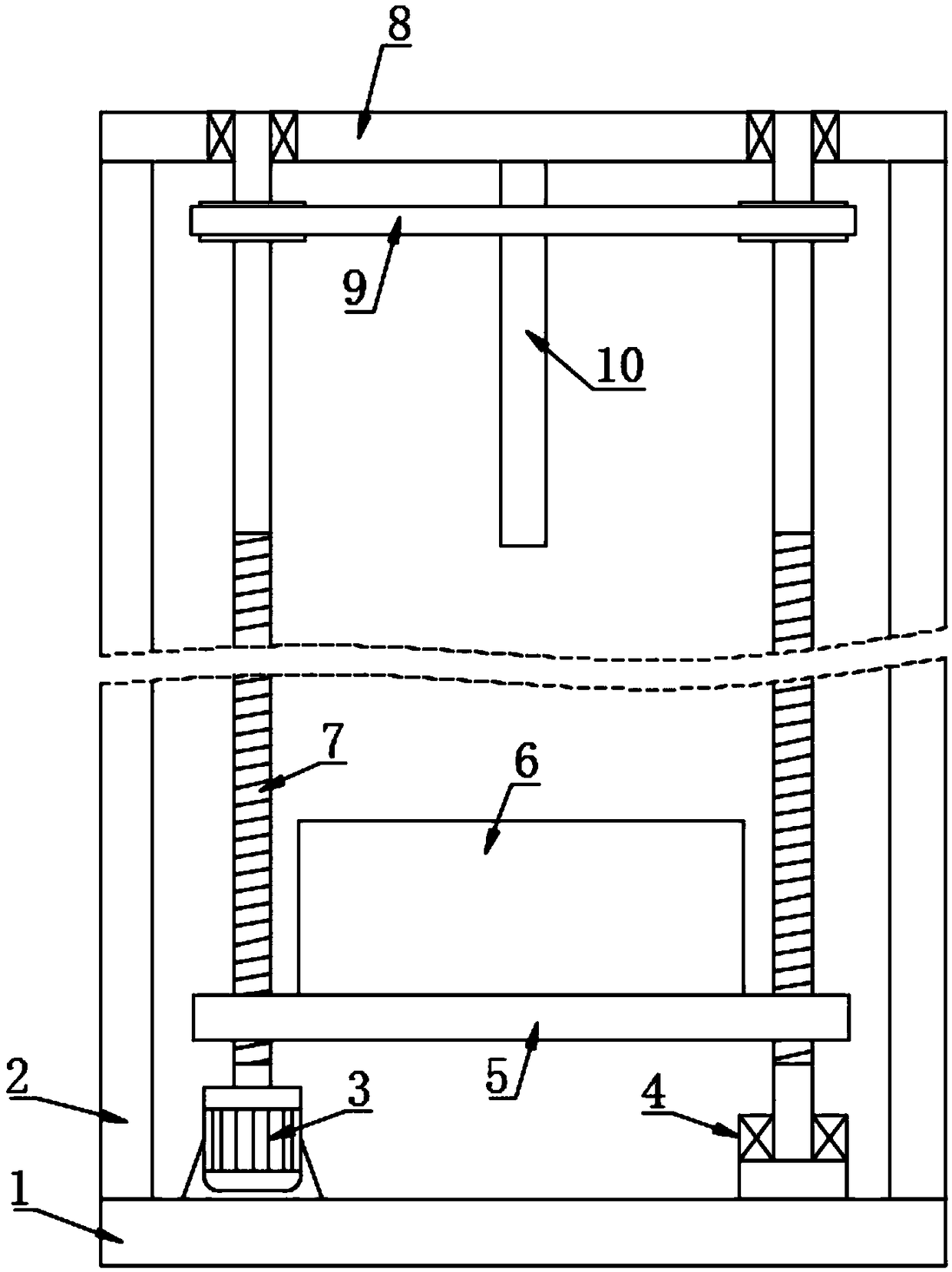

Household grain tedder

InactiveCN103478245ASimple structureEasy to installFood processingClimate change adaptationEngineeringConveyor belt

The invention relates to a household grain tedder which comprises a support frame (24), wherein a grain turning device and a transmission device are arranged on the support frame (24); the transmission device comprises a conveyor belt (20) and two first screw rods (11) which are symmetrically arranged on the support frame (24); the conveyor belt (20) is arranged on the two first screw rods (11) in a sleeved manner, and a first driving motor (5) is arranged on one of the two screw rods; the grain turning device comprises a grain turning chain (19), and two second screw rods (4) which are symmetrically arranged on the support frame (24); a second driving motor (3) is arranged on one of the second screw rods; the grain turning chain (19) is arranged on the two second screw rods (4) in a sleeved manner, and a grain turning rake (21) is arranged on the lower layer chain of the grain turning chain (19). The invention provides the household grain tedder which has a simple structure, is convenient to mount and is energy-saving and environment-friendly, thereby achieving the effects of strong strain capacity, reduced labor intensity and improved work efficiency.

Owner:SICHUAN AGRI UNIV

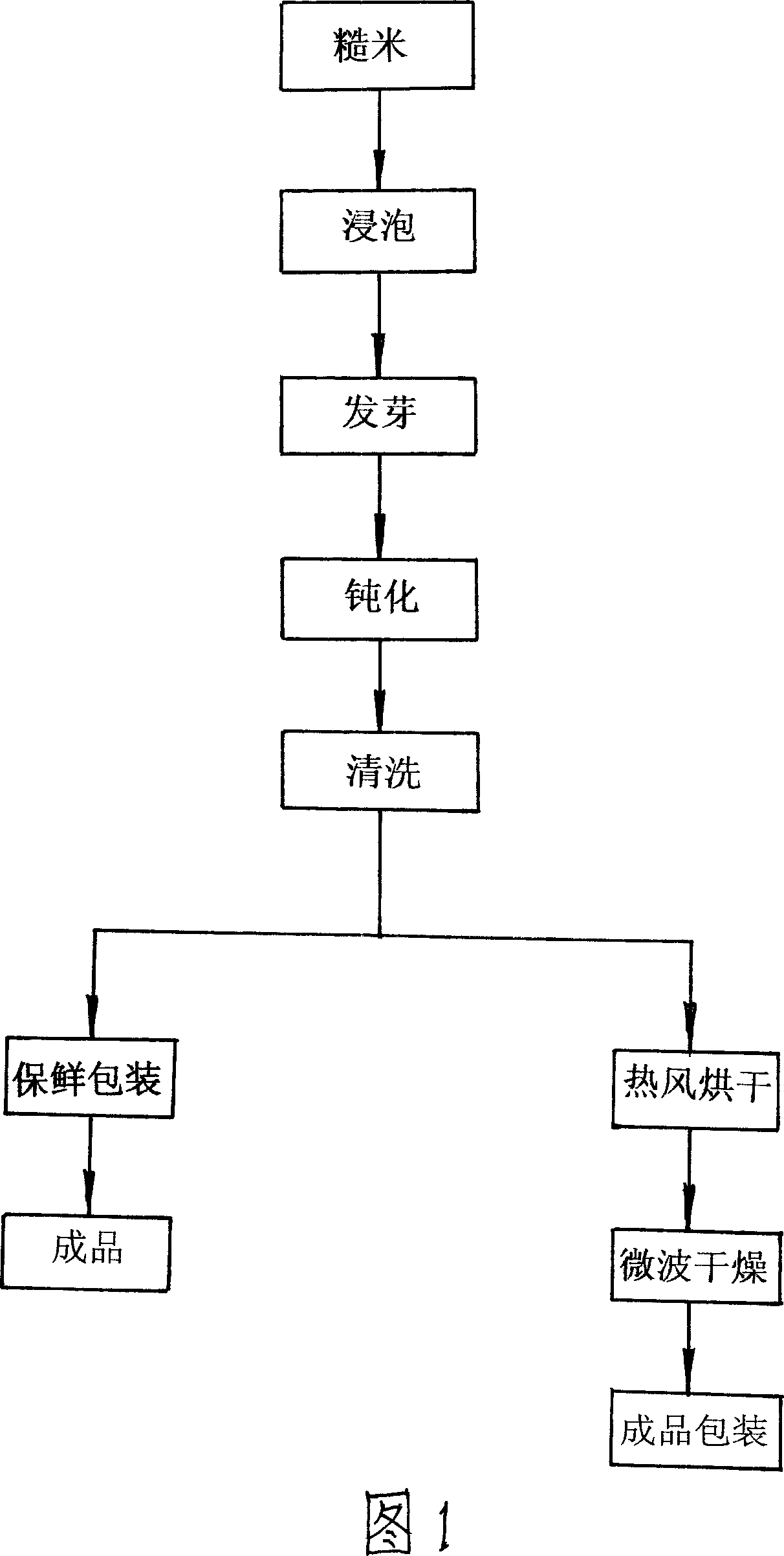

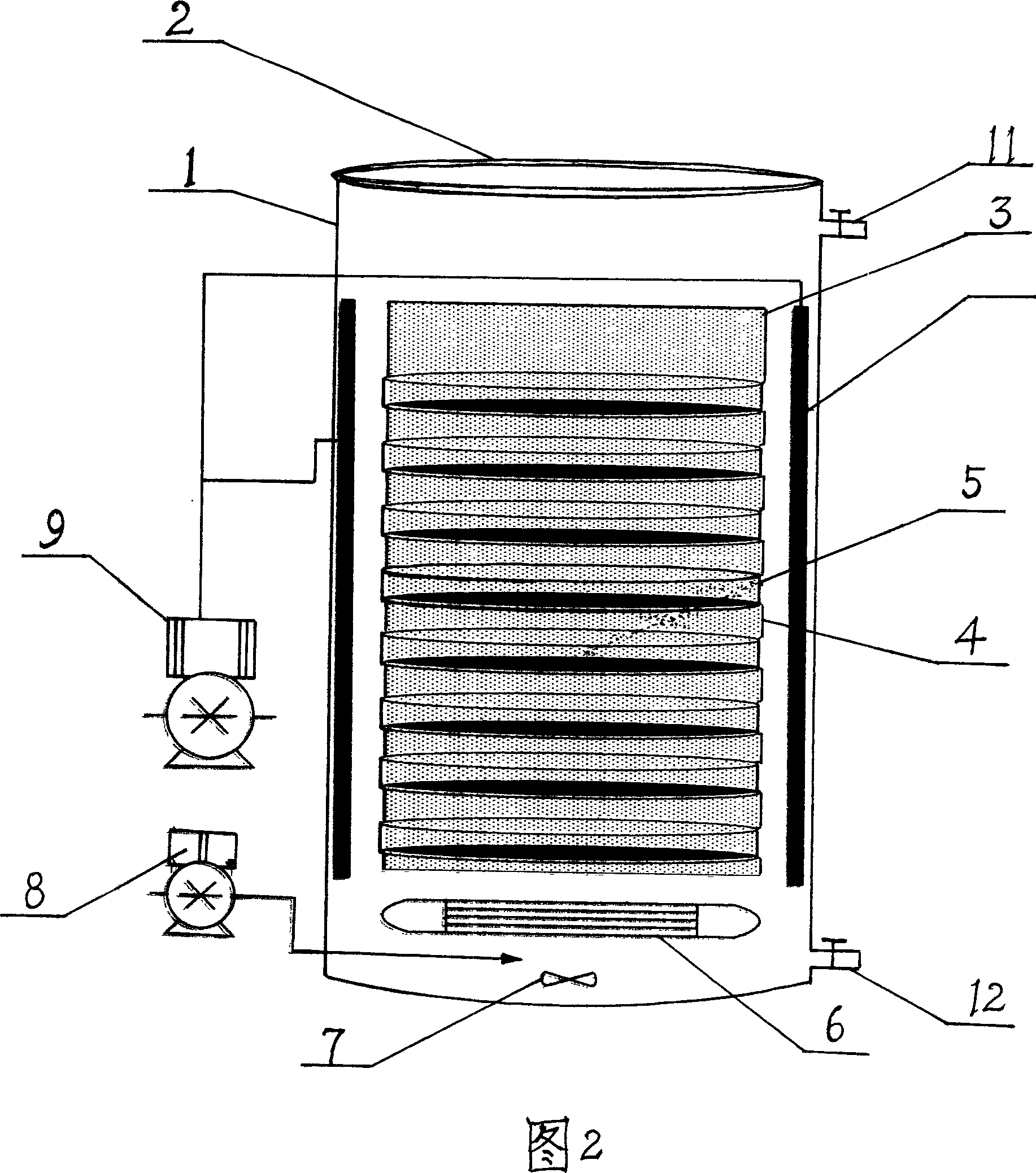

Method and equipment for producing sprouting half-polished rice

ActiveCN100998389AImprove whole bud rateHigh whole germination rateSeed preservation by heatingSeed preservation by dryingMicrowaveThin layer

A method for preparing the germinated embryo rice from non-glutinous rice includes such steps as spreading said rice to become thin layer, immersing in water, germinating, passivating in the water at 70-100 deg.C, washing, and antistaling packing or drying including hot air baking and microwave drying. Its apparatus is composed of container with openable cover or door, and rice spreading unit.

Owner:杨春华

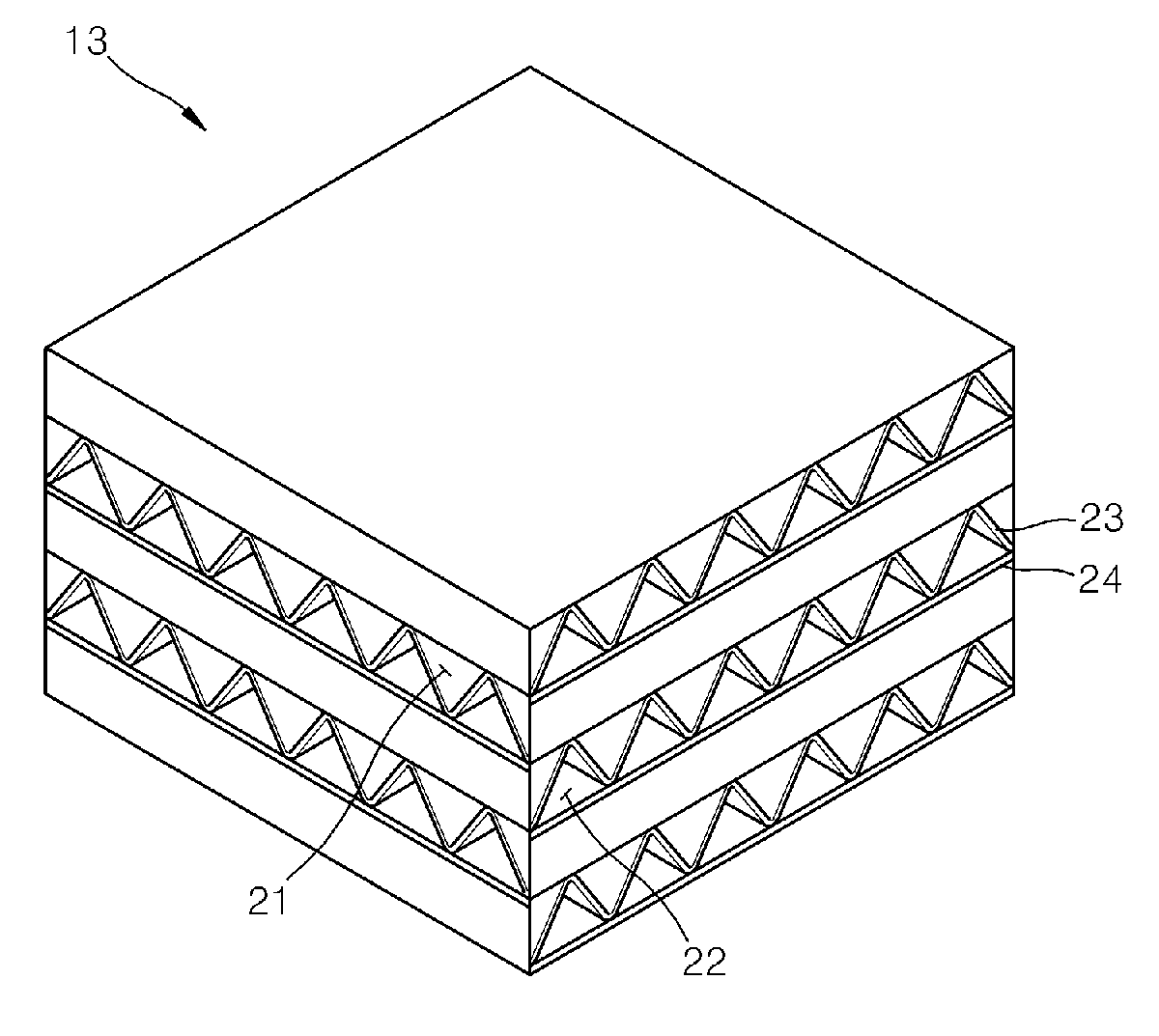

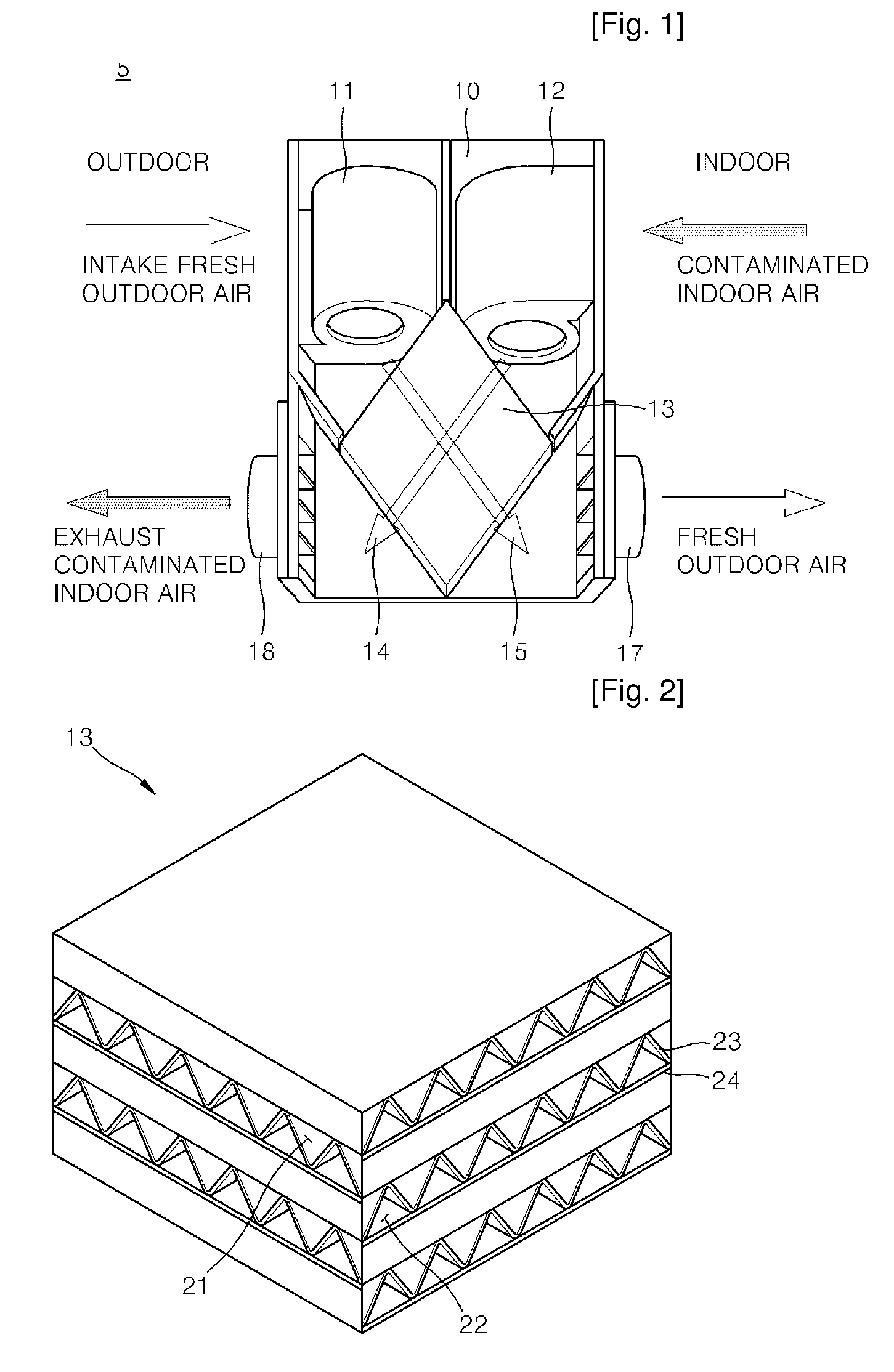

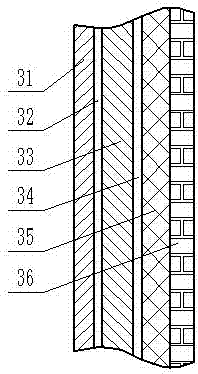

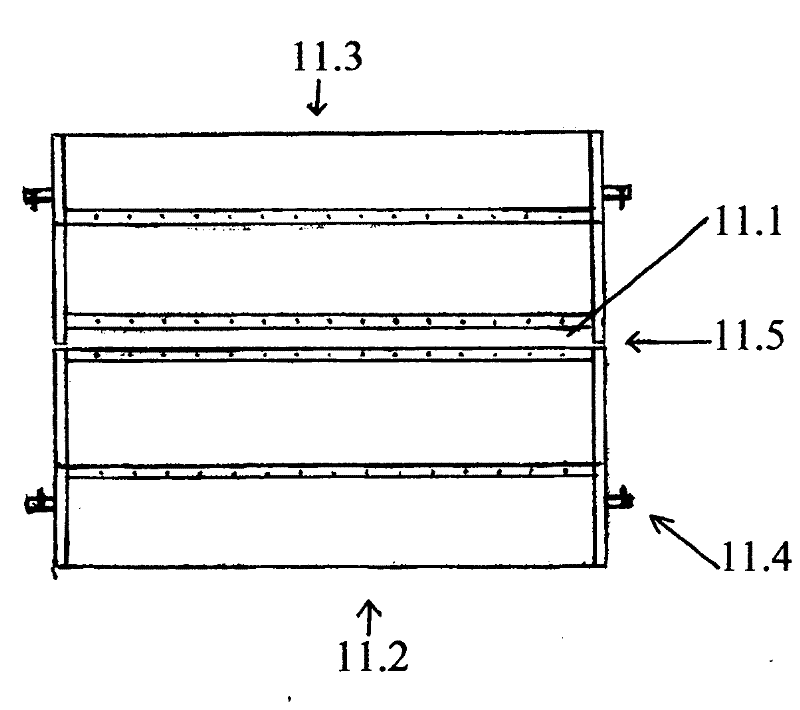

Heat conduction unit with improved laminar

InactiveUS20100032145A1Increase heatImproving moisture exchange performanceEnergy recovery in ventilation and heatingHeat recovery systemsMetal fiberCarbon nanotube

A heat conduction unit having an improved laminar is provided. The heat conduction unit of the present invention includes a pair of exhaust and intake layers crossing each other for exchanging heat between exhaust and intake airflows; and a laminar interposed between the exhaust and intake layers and having a having a fiber synthetic fabric layer with a high water absorbancy and heat conductivity. The fiber synthetic fabric layer is made by densely weaving a microfiber in the form of a fabric, the fabric being weaved by adding micro metal fiber, by adding microfiber plated with metal, or by adding at least ones of micro copper molecules, aluminum molecules, carbon black molecules, carbon nano tube molecules, titanium dioxide (TiO2) molecules, and nano-silver molecules, to a raw material resin of the microfiber.

Owner:LEE CHAN BONG

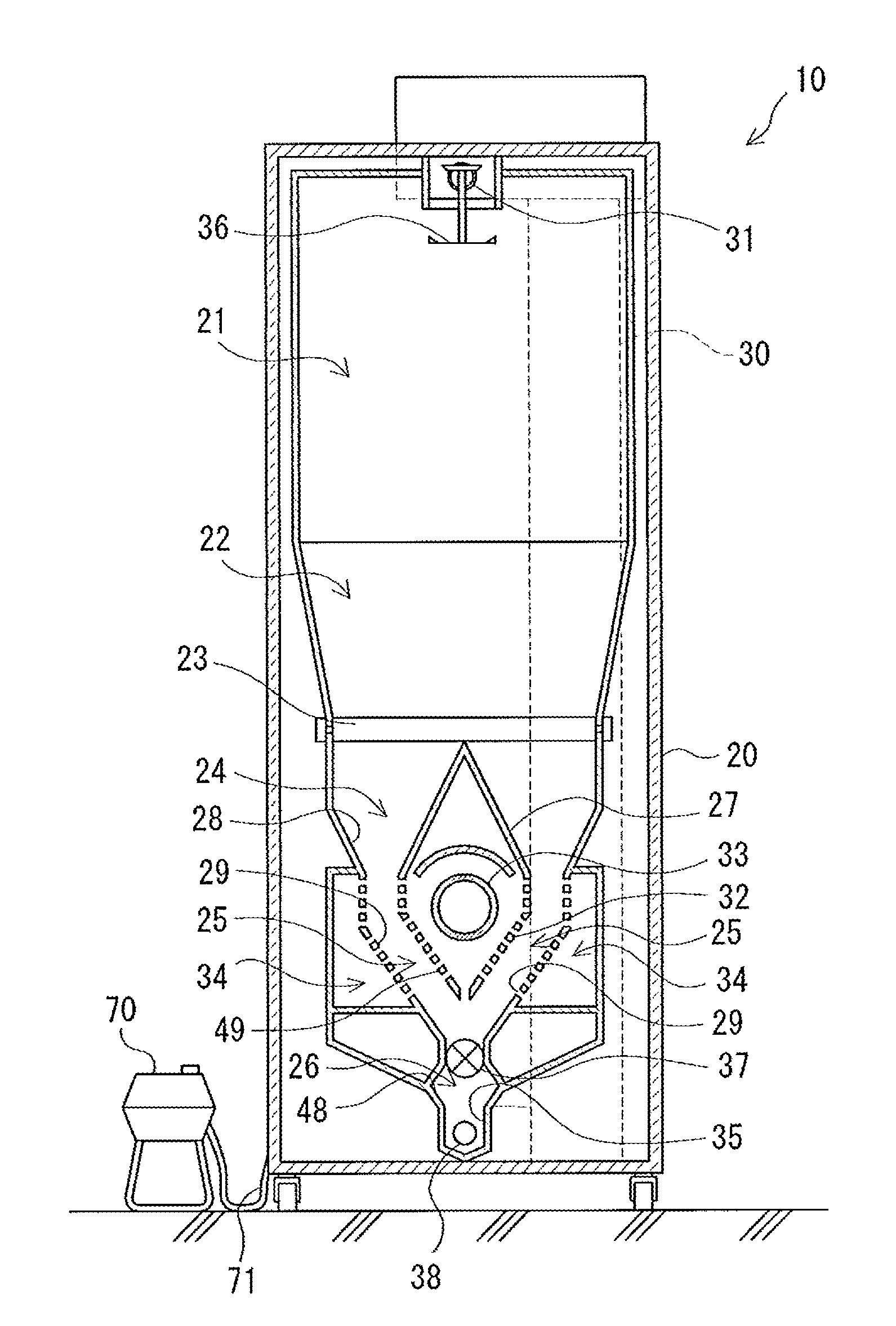

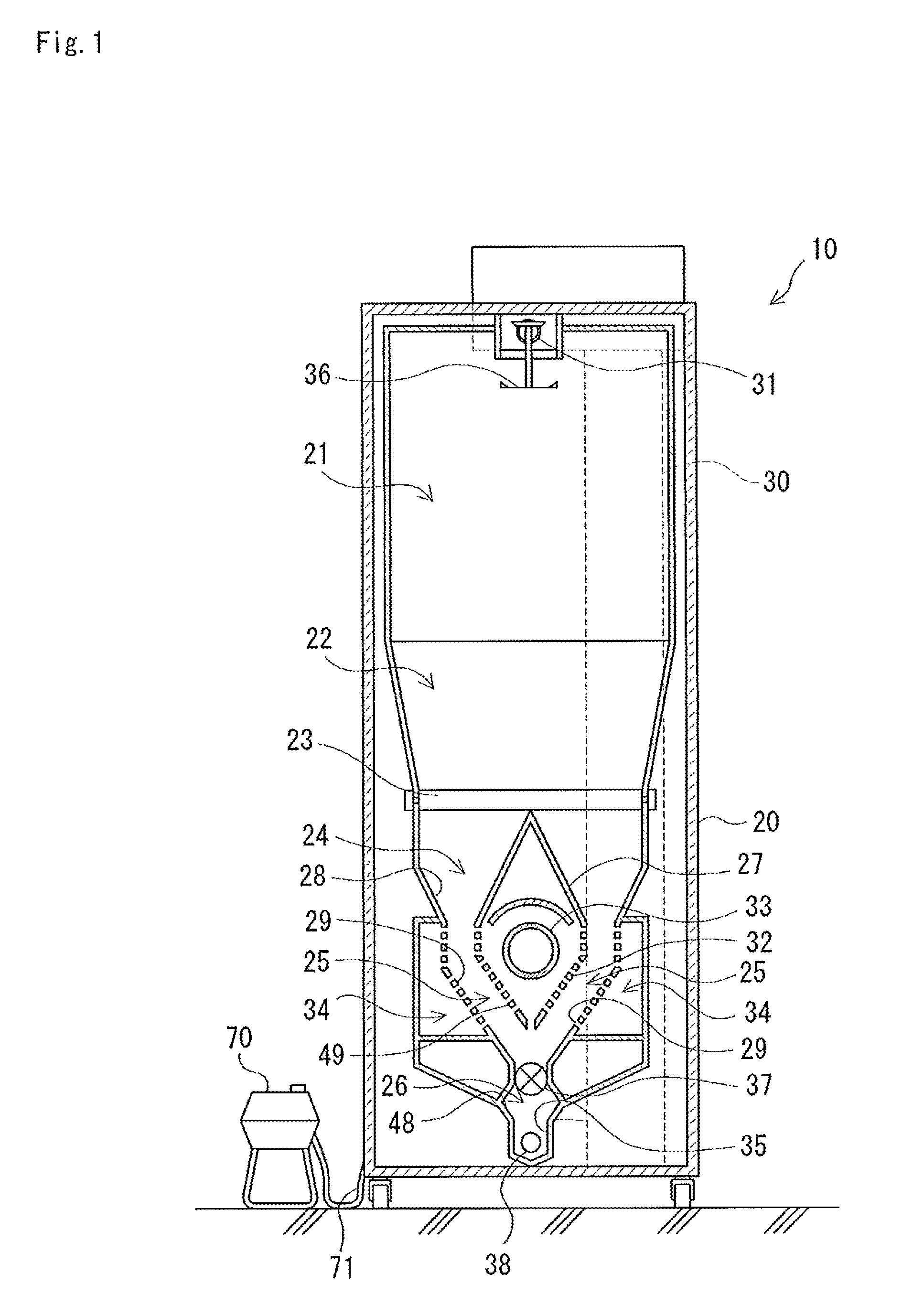

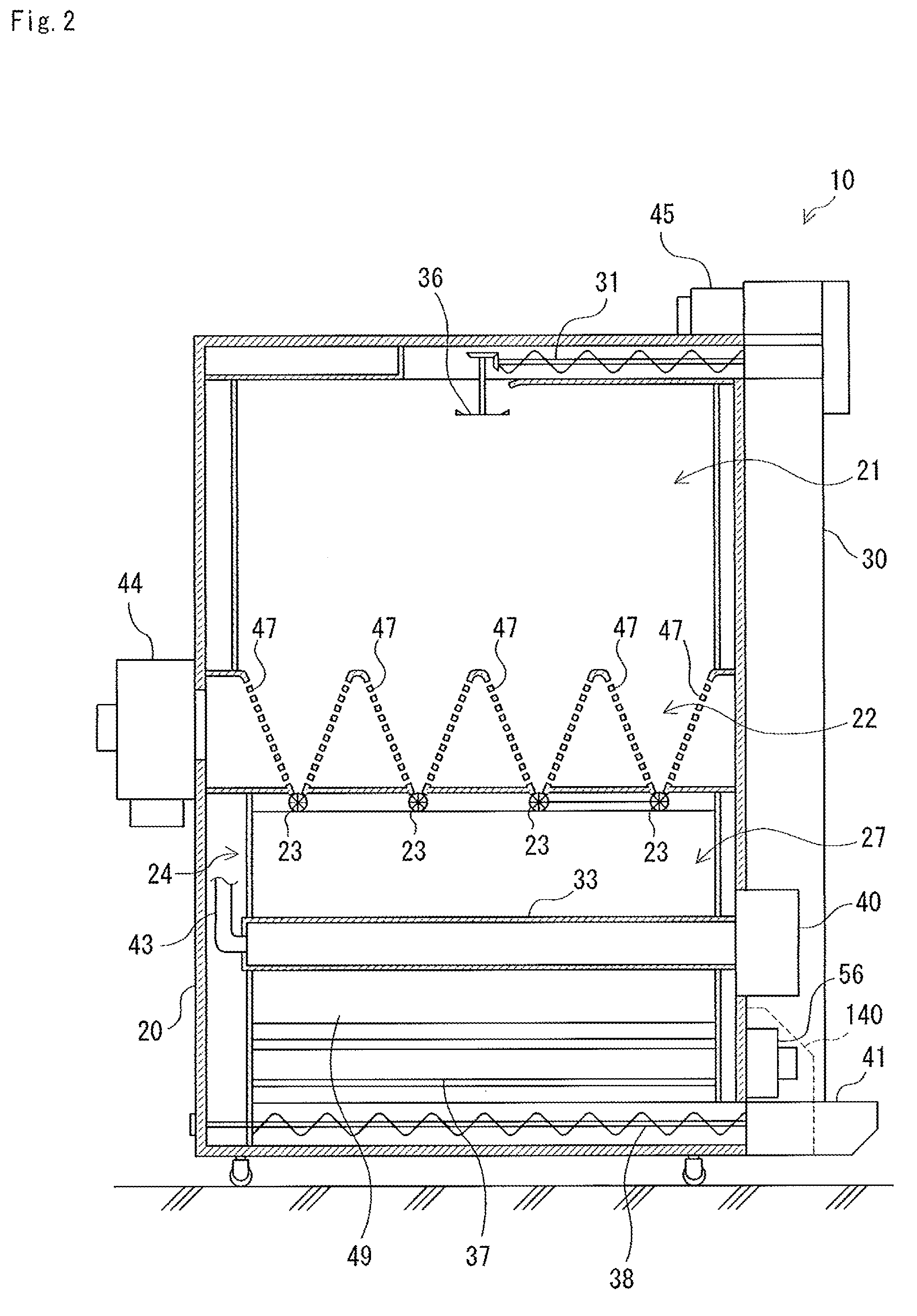

Nutrition-enriched gain manufacturing apparatus and gain drying facility including the same

InactiveUS20120066924A1Enrich a content of gamma aminobutyric acid in grain easily and efficientlyMilk preservationDrying solid materials with heatCombustorRotary valve

A nutrition-enriched grain manufacturing apparatus includes a heating processing portion including a far infrared ray radiator which emits far infrared rays to a flow-down path along which grain flows down, an upper rotary valve device and a lower rotary valve device which adjust a flow rate of the grain, an accumulation portion which accumulates the grain, a lower screw conveyer and a bucket conveyer which transport the grain which has flown down from the heating processing portion to the discharge portion to the accumulation portion, a moisture meter which measures a moisture content of the grain, a grain temperature sensor which measures a grain temperature, a main controller which controls output from a burner and operations of the upper rotary valve device and the lower rotary valve device such that the grain temperature is a predetermined grain temperature.

Owner:ANDO TOSHIHARU +1

Continuous corncob dryer

InactiveCN103070233AMeet delivery needsSolve the problem of high breakage rateSeed preservation by dryingSprocketEngineering

The invention provides a continuous corncob dryer, which is characterized in that an inner part of a tank body is divided into three parts by clapboards vertically; an air heater with a blower is arranged on a bottom part of the tank body in the middle; a draught fan and a feed inlet are arranged on a top part; a discharge hole is arranged on a bottom part; a plurality of conveyer devices driven by transmission devices to operate are arranged in the tank body; two conveyer chain wheels are arranged on a shaft of each conveyer device; a conveyer chain is hung on the conveyer chain wheels on the same ends of the shafts; inner ends of chain pins of the conveyer chains are correspondingly provided with pin shafts toward inner sides at intervals of the same section number in an extended way; two molding panels with a plurality of ventilation holes are bent, concave surfaces of the molding panels are in fit connection, and baffle plates are fixedly arranged on two ends of the molding panels, so that molding chain plates are formed; the type I molding chain plate and the type II molding chain plate with different lengths are alternately hung on the pin shafts extending out of the two conveyer chains of the same conveyer device; each molding chain plate is arrayed and supported on a guide rail to form a slot type material channel; and a material guiding slot is arranged under a tail end of the channel. The continuous corncob dryer has a large range of reducing moisture, good drying uniformity, and reliability in operation.

Owner:SHANDONG UNIV OF TECH

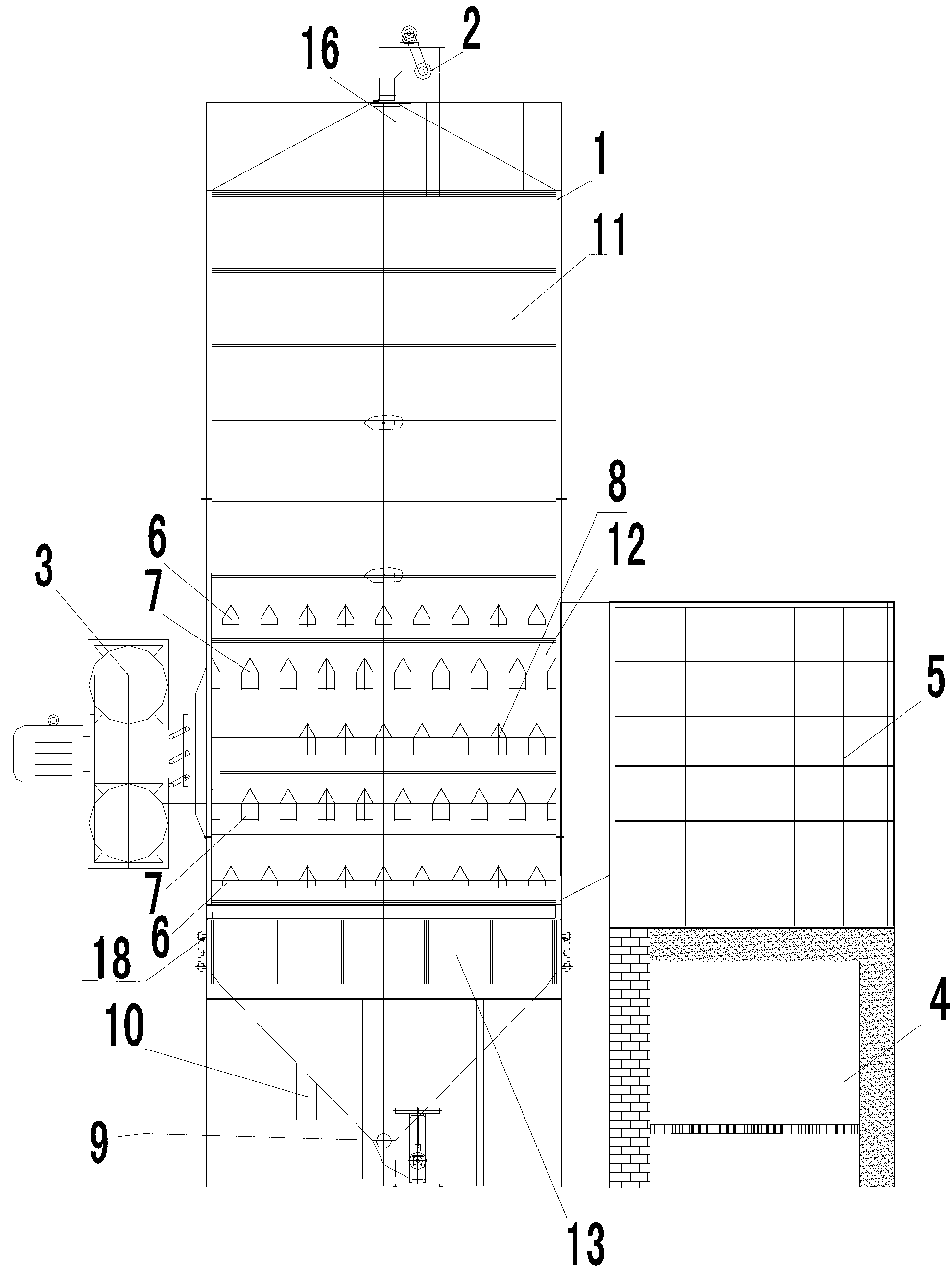

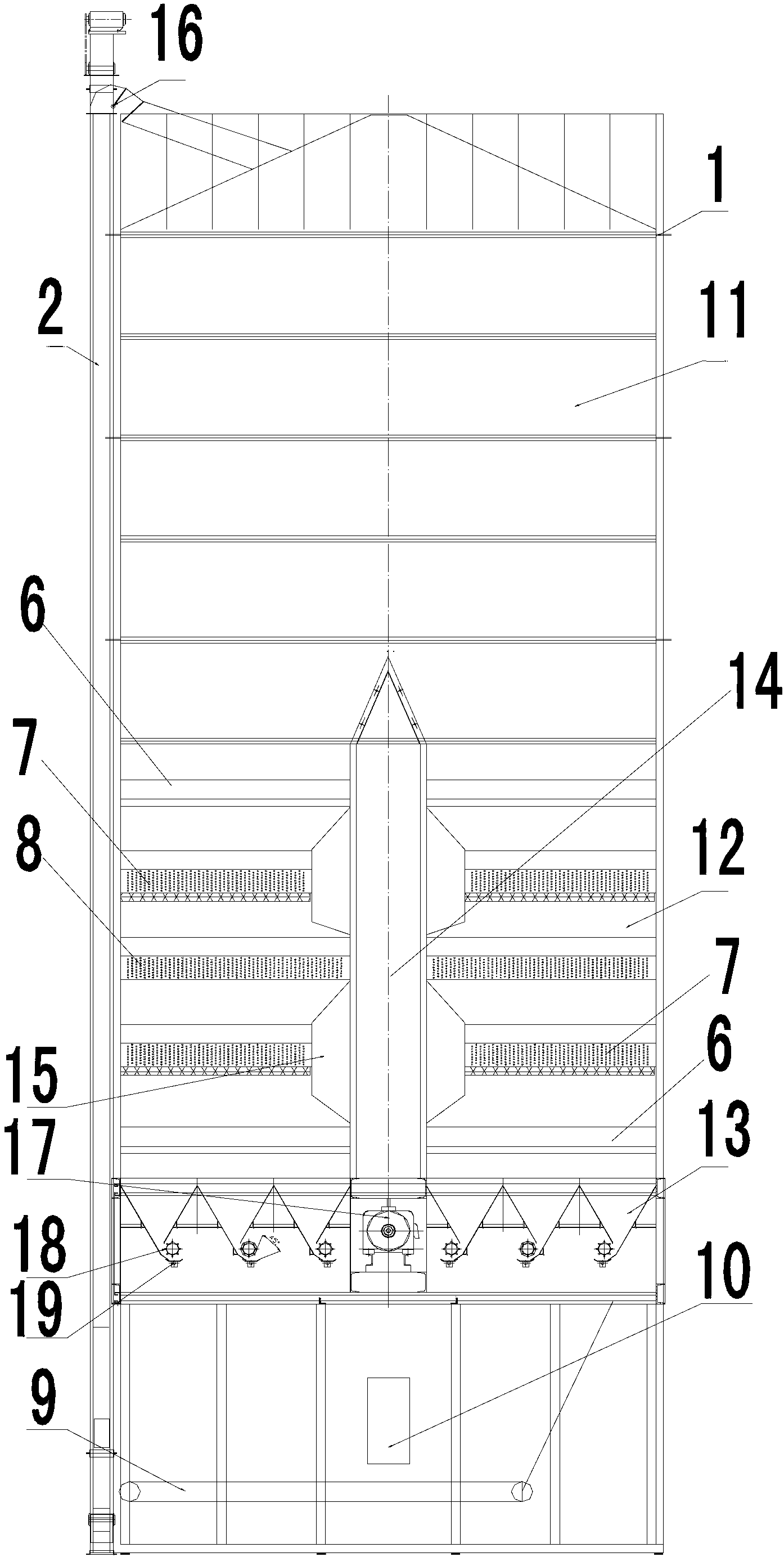

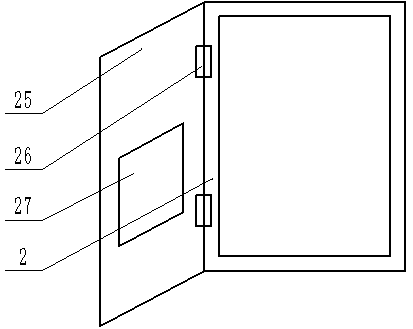

High-efficiency energy-saving grain drying machine and drying method

InactiveCN103749670AReduce drying costsHigh degree of intelligenceFood processingClimate change adaptationProcess engineeringMoisture sensor

The invention discloses a high-efficiency energy-saving grain drying machine and a drying method. The drying machine adopts a brand-new heat source design provided by an air energy heat pump. The high-efficiency energy-saving grain drying machine comprises an air energy dehumidifying pump, a main room body, an auxiliary room body, a heat exchanger, a fan, an intelligent controller, electromagnetic valves, a temperature-humidity sensor, a stacking bed, a dehumidifying mechanism and a cabin door; the intelligent controller is used for transmitting a multi-point average humidity-temperature signal inside a room obtained by the temperature-humidity sensor, and each electromagnetic valve is electrically connected with the intelligent controller so as to realize the intelligent operation of the drying machine. The high-efficiency energy-saving grain drying machine and the drying method are used for drying the grain, so that the characteristics of high efficiency, energy conservation, intelligentization in operation and good grain quality can be realized.

Owner:LONGYAN CHENGDE AGRI MACHINERY

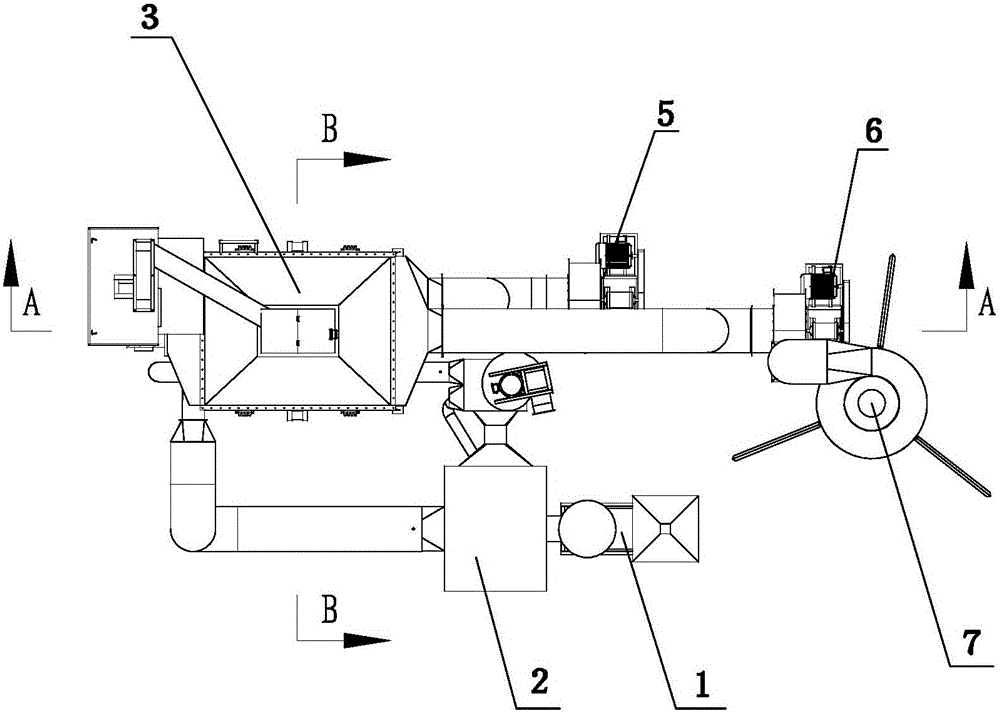

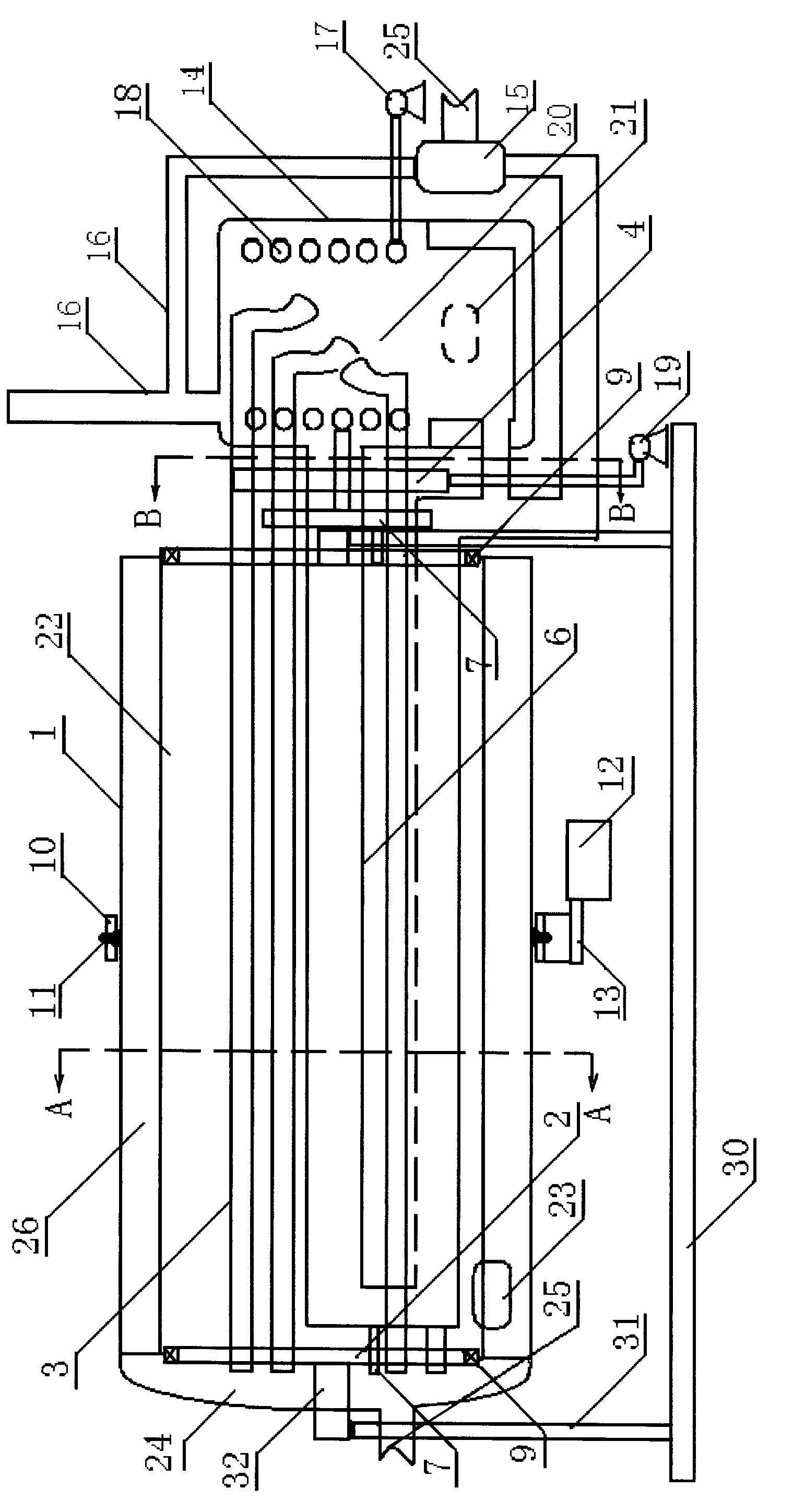

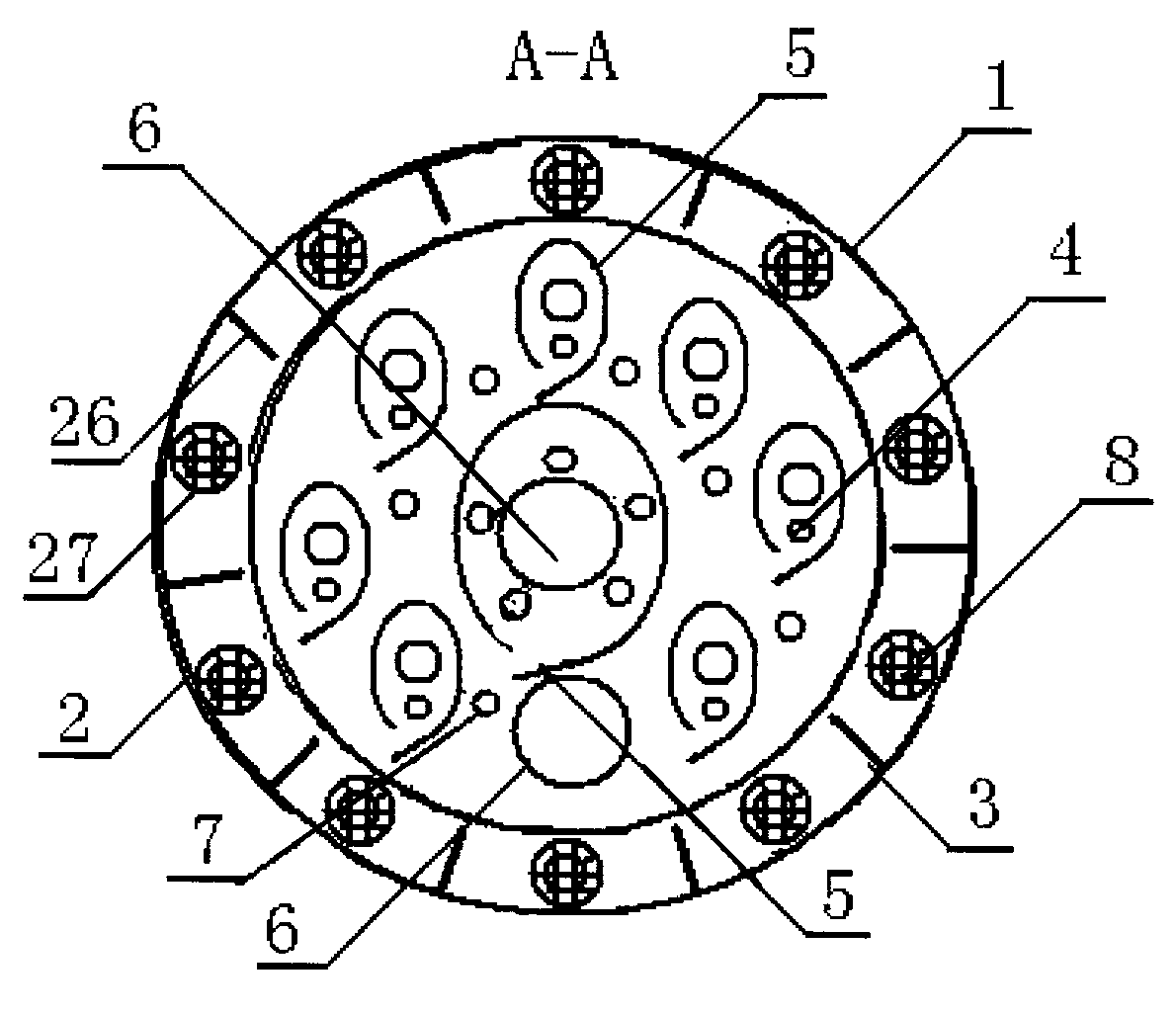

Low-temperature circulation dryer for crop seeds

InactiveCN103070232ARealize cycleImprove uniformityDrying gas arrangementsSeed preservation by dryingHigh energyEngineering

The invention discloses a low-temperature circulation dryer for crop seeds, which comprises a dryer body, a hoister, a draught fan, a hot-blast furnace, a heat exchanger, small air inflow angle boxes, air exhaust angle boxes, air inflow angle boxes, a grain discharge device, a delivery machine under the dryer and a grain-moisture and drying-temperature on-line detector. The low-temperature circulation dryer solves the problems of uneven material drying, higher energy consumption, a low annual utilization rate and the like in the prior art effectively, and has the characteristics of simple structure, simplicity in operation, high applicability, high-quality, efficient, safe and energy-saving low-temperature quick drying and the like.

Owner:SOUTH CHINA AGRI UNIV

Self-vibrating grain drying and sieving equipment

InactiveCN107339878AImprove the vibration effectPrevent fallingSievingScreeningEngineeringVacuum pump

The invention discloses self-vibrating grain drying and sieving equipment. The equipment comprises a shell, a support and a condensation chamber; the support is arranged outside the shell, sliding blocks are fixedly connected to the middle of the outside of the shell, sliding grooves are formed in both sides of the support, and the sliding blocks are connected with the sliding grooves in a sliding mode; connecting plates are arranged at the upper ends of the sliding grooves, the connecting plates are fixedly connected with the support, and floating devices are arranged between the connecting plates and the sliding blocks; a first sieving net and a second sieving net are fixedly connected to the inner side wall of the shell from top to bottom in sequence, a dehumidification pipe is arranged at the upper end of the shell, a vacuum pump is connected to the middle of the dehumidification pipe, one end of the dehumidification pipe is communicated with the interior of the shell, and the other end of the dehumidification pipe is connected with a condensation pipe in the condensation chamber. According to the self-vibrating grain drying and sieving equipment, the structure is simple, the design is reasonable, sieving of grain is completed through self-vibrating of the shell, and the sieving quality and efficiency are improved; meanwhile, drying equipment is added, the functionality of the device is enhanced, and rapid dehumidification can be conducted, so that the drying efficiency is improved.

Owner:俞纪洪

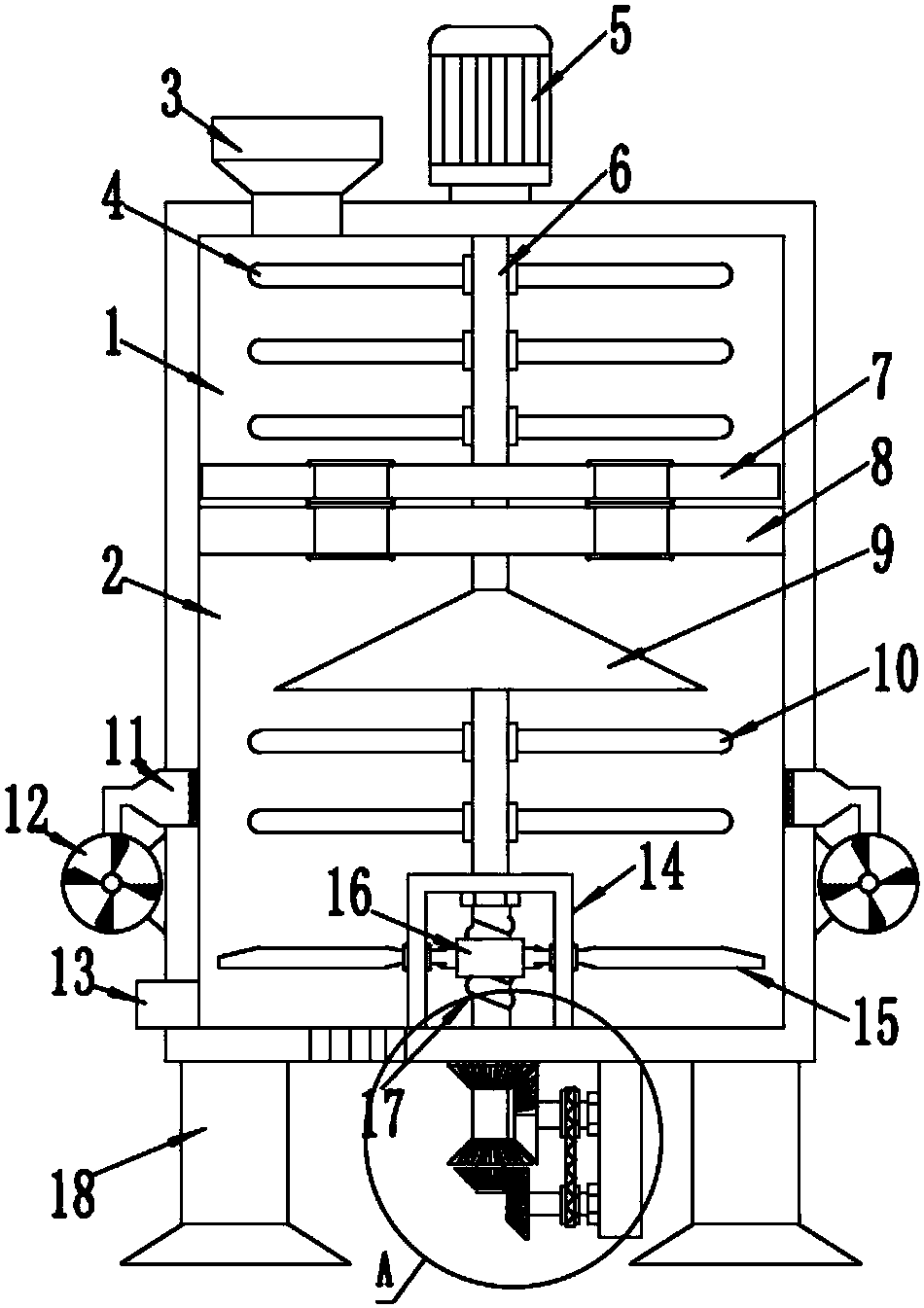

Grain dryer

The invention relates to a grain dryer. An inner cavity of a drying tower of the grain dryer comprises a feeding bin and a multi-stage drying bin and tempering bin alternate arrangement structure from top to bottom, a discharging bin is arranged below a tempering bin on the lowermost layer, hollow partitioning plates are arranged inside drying bins, cavities of the hollow partitioning plates are ventilated, grain passes through the gap between every two adjacent hollow partitioning plates, through holes are formed in the faces of the hollow partitioning plates, air channels comprise hot air channels and secondary hot air channels, hot air is transmitted layer by layer between the drying bins from bottom to top through hot air conveying pipelines, and in the drying bin on each layer, the hot air passes through the through holes in the corresponding hollow partitioning plates from the corresponding hot air channels to permeate into material channels and then permeates into the corresponding secondary hot air channels to enter the drying bin on the upper layer. The grain is dried inside the drying tower in a clockwise or anticlockwise mode, heat exchange is performed between the high-temperature hot air and the grain high in water content and low in temperature, the temperature of the grain is increased rapidly to evaporate water inside, the grain enters the tempering bins to be tempered for a period of time after being dried, the water inside the grain permeates outwards, next-time drying is performed, and evaporation of the water inside the grain is completed in a gradient mode.

Owner:山东宇龙机械有限公司

Hot air circulation grain drying device

InactiveCN107156291AImprove qualityReduce churnDrying gas arrangementsSeed preservation by dryingEngineeringHeat losses

The invention discloses a hot gas circulation grain drying equipment, which comprises a dehumidifier and a drying box; a dust removal channel is arranged above the drying box, and a winnowing device is arranged on the right side of the dust removal channel; the dust removal channel is connected with a cyclone dust collector A drying box is connected under the dust removal channel; a drying plate is arranged in the drying box; a first hot air blower, a second hot air blower and a third hot air blower are arranged between the drying plates. The present invention realizes the full utilization of the hot air and separate drying of the grains with different drying degrees by providing a circulating hot air drying device and hot air blowers with different powers, reducing heat loss and saving energy; the present invention is provided with staggered distribution The drying plate improves the drying efficiency and the drying effect; the invention is equipped with a high-school dust removal device to remove dust and shriveled grains in the grain, improves the quality of the grain, and saves storage space.

Owner:惠安益源信息技术咨询有限公司

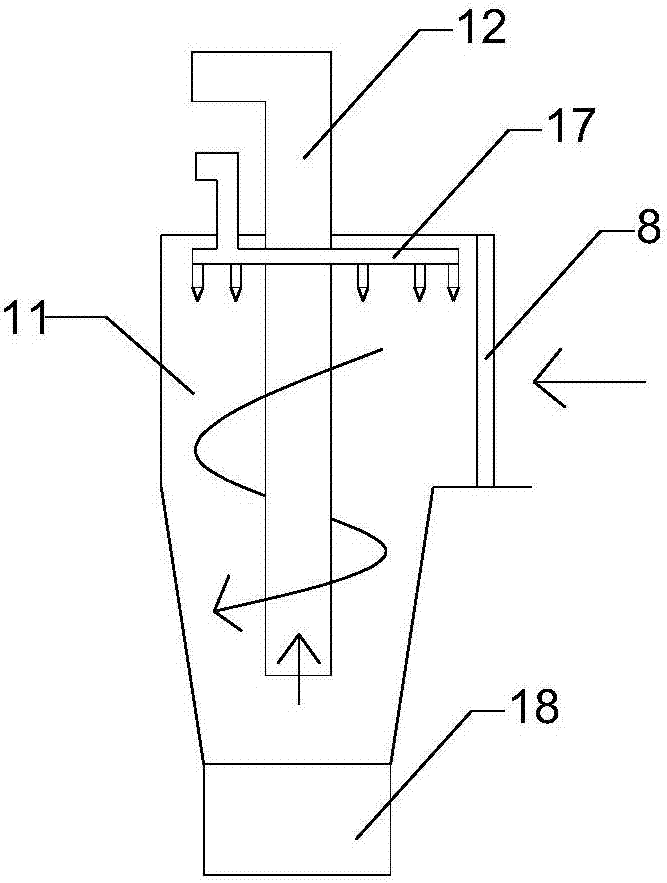

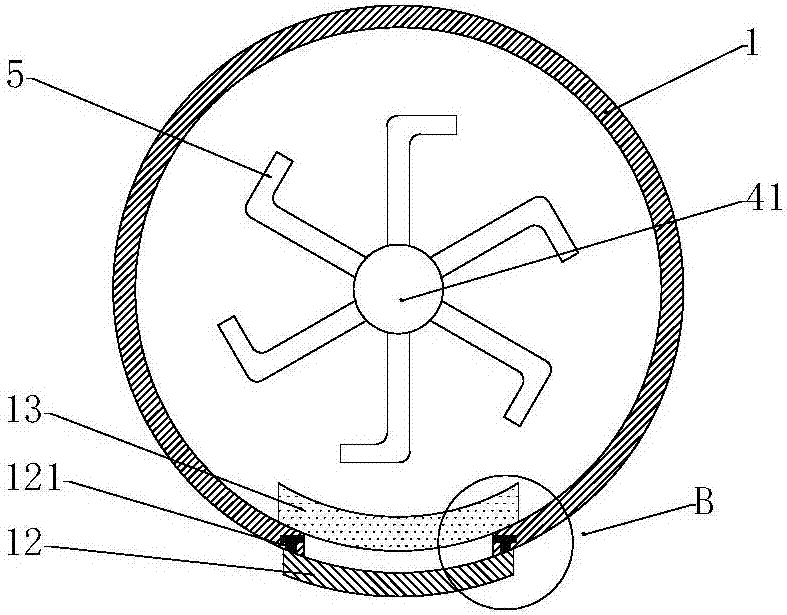

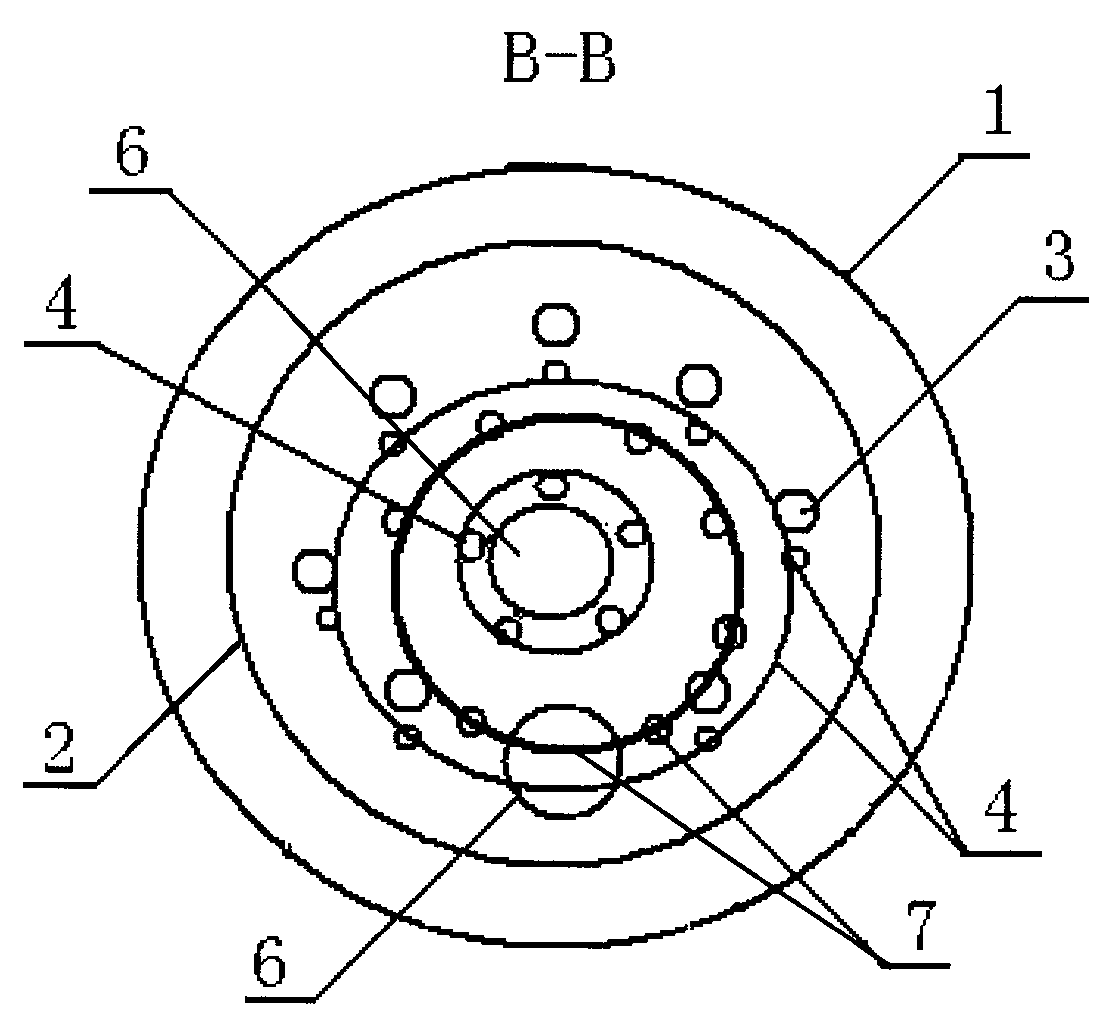

Cereal circular drying equipment

InactiveCN107687757AAvoid accumulationImprove drying qualityDrying gas arrangementsSeed preservation by dryingEngineeringHot blast

The invention discloses cereal circular drying equipment. The cereal circular drying equipment comprises a box body, a hot-blast stove and a lifting drum. A plurality of guide plates are arranged in the box body; the box body communicates to the lifting drum through a discharge pipe and a feeding pipe; a bottom plate is arranged below the box body; a plurality of damping devices are arranged between the bottom plate and the bottom surface of the box body; a plurality of air inlet branch pipes are uniformly arranged on the outer side wall of the left end of the box body; the air inlet branch pipes are connected to the air outlet of the hot blast stove through a main air inlet pipe; a plurality of air outlet branch pipes are uniformly arranged on the outer side wall of the right side of thebox body and are connected to the air inlet of the hot blast stove through a main air outlet pipe; the main air outlet pipe is connected to a dedusting and dehumidifying device; and the dedusting anddehumidifying device comprises a barrel. The cereal circular drying equipment disclosed by the invention is simple in structure and reasonable in design, can utilize human energy to the maximum extentby means of circulating air, and is very high in drying efficiency on cereals, and furthermore, the drying quality of cereals is very good and the dehydrating rate is very high.

Owner:俞纪洪

Unhulled rice drying device

InactiveCN104132524ADry evenlySimple structureDrying gas arrangementsSeed preservation by dryingEngineeringRice grain

Owner:孙现军

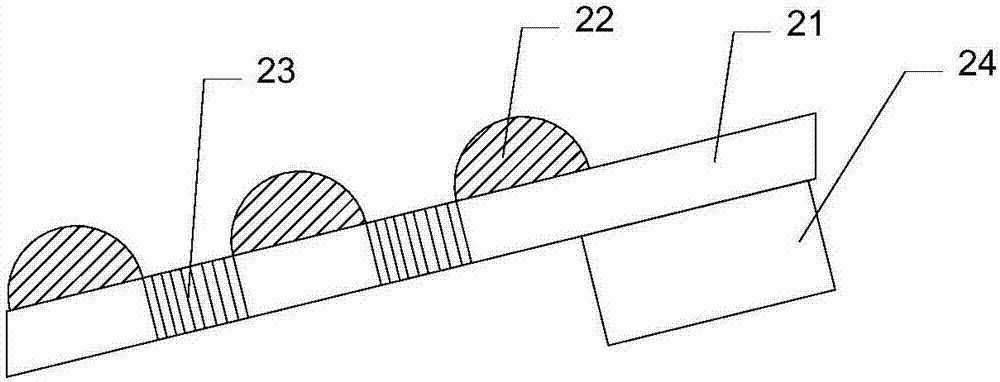

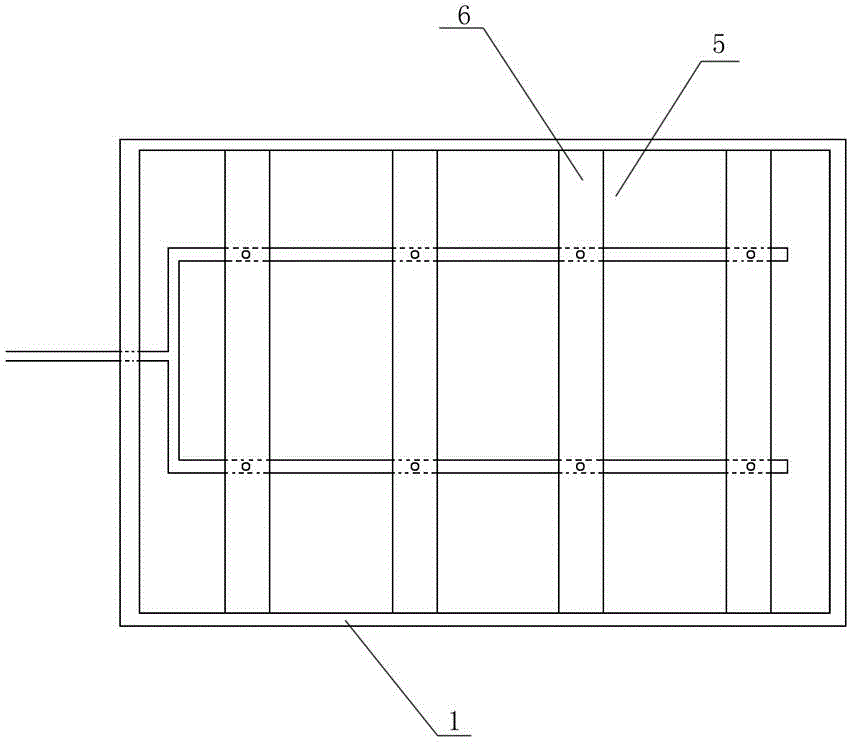

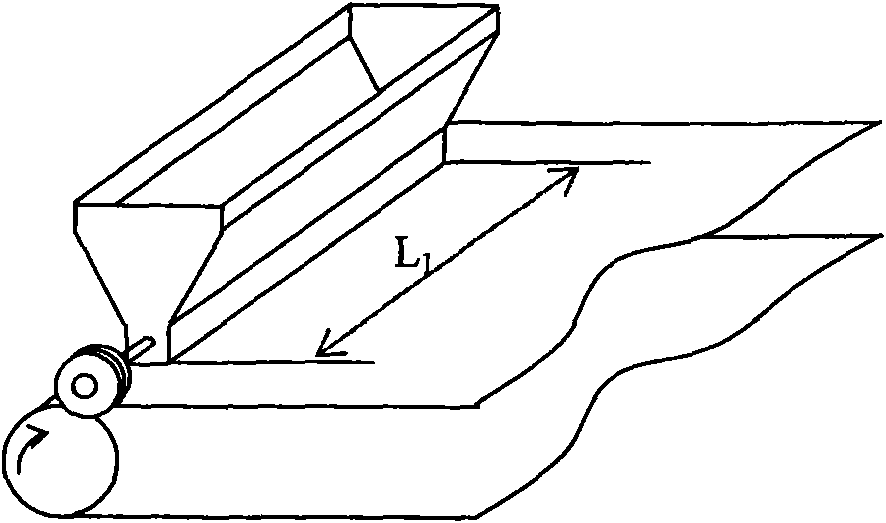

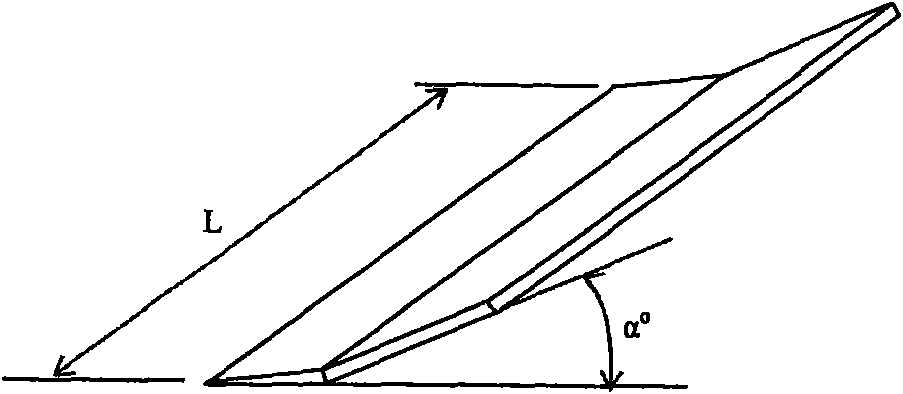

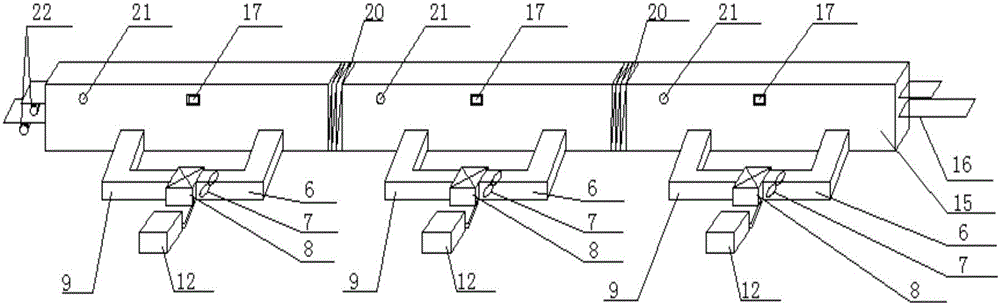

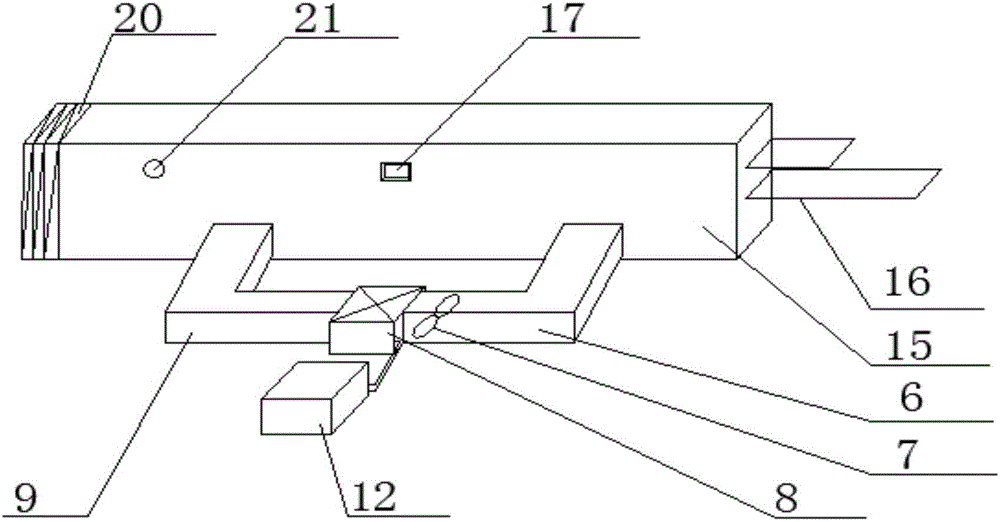

Continuous synchronous microwave enzyme inactivation and drying device and method for grain germ

InactiveCN101658205ALarge amount of processingReduce energy consumptionSeed preservation by heatingSeed preservation by dryingWheat germMicrowave

The invention provides a continuous synchronous microwave enzyme inactivation and drying device and method for grain germ, relating to the agricultural product drying field. The device comprises a microwave tunnel (2), a microwave generator (3) and a conveyer belt (6) and also comprises a feeder (1) and a germ overturning device (5); wherein the microwave generator (3) is arranged at the top of the microwave tunnel (2), the feeder (1) is arranged at the initial end of the conveyer belt (6), and the revolution of the feeder is adjustable; the conveyer belt (6) is connected with the feeder (1) and the microwave tunnel (2) to convey materials through the microwave tunnel (2), and conveying speed is adjustable; and the germ overturning device (5) is arranged on the conveyer belt (6). The watercontent of the grain germ through microwave enzyme inactivation and drying of the invention can be reduced to 1.9-4.4%; microwave treatment is carried out on different grain germs, the grain germs can be preserved for 6-8 months at normal temperature in winter and for 3-5 months at normal temperature in summer, quality requirement of follow-up processing can still be met, and the invention is widely applicable to enzyme inactivation and drying of grain germs such as wheat germ, corn germ, rice germ (rice bran) and the like.

Owner:JIANGSU UNIV

Efficient grain drying device capable of achieving feeding easily

InactiveCN106979674AFully contactedGuaranteed drying effectDrying gas arrangementsSeed preservation by dryingAgricultural engineeringStacker

The invention discloses a high-efficiency and easy-to-cut grain drying device, which includes a drying cylinder, a motor, symmetrically arranged support columns, a hot air blower and a material receiving frame; the drying cylinder is arranged between two support columns; The center position of the bottom of the drying cylinder is provided with a discharge opening, and a cover plate is arranged on the discharge opening, and the bottom of the drying cylinder is located on both sides of the discharge opening, and counterweights are fixed symmetrically; the hot air blower is installed on the left side On the supporting column, the hot air blower is connected to the hot air pipe, and the hot air pipe runs through the connecting shaft from the axis of the connecting shaft and goes deep into the right side of the drying cylinder. The hot air pipe is densely provided with air outlets; the hot air pipe is deeply dried A plurality of turning plates are fixed on the periphery of the tube body of the cylinder; a material receiving frame is arranged at the position directly facing the discharge opening under the drying cylinder. The grain drying device of the present invention has good drying effect and is convenient for unloading.

Owner:合肥智慧殿机械设计有限公司

Method for processing germinating rice

InactiveCN101278716AShorten germination timeReduce pollutionSeed preservation by heatingSeed preservation by dryingNutrientBiology

The invention discloses a processing method for germinating rice, which comprises the steps of selecting the raw material of fresh unpolished rice, cleaning, ultrasonic pregermination, soaking, germinating, drying by combining hot air with microwave, cooling, packing, etc. Compared with the prior art, the invention increases the processing step of the ultrasonic pregermination, which shortens the germinating time of the unpolished rice by 5 to 10 hours; the drying method of combining the hot air with the microwave is adopted, which shortens the drying time by 1.5 to 3 hours; the processing method has the advantages of improving the production efficiency, reducing the loss of nutriment, utilizing the sterilization function of the microwave effectively, reducing the microorganism pollution, controlling the quality of a product well and improving the safety of the product.

Owner:SOUTH CHINA AGRI UNIV

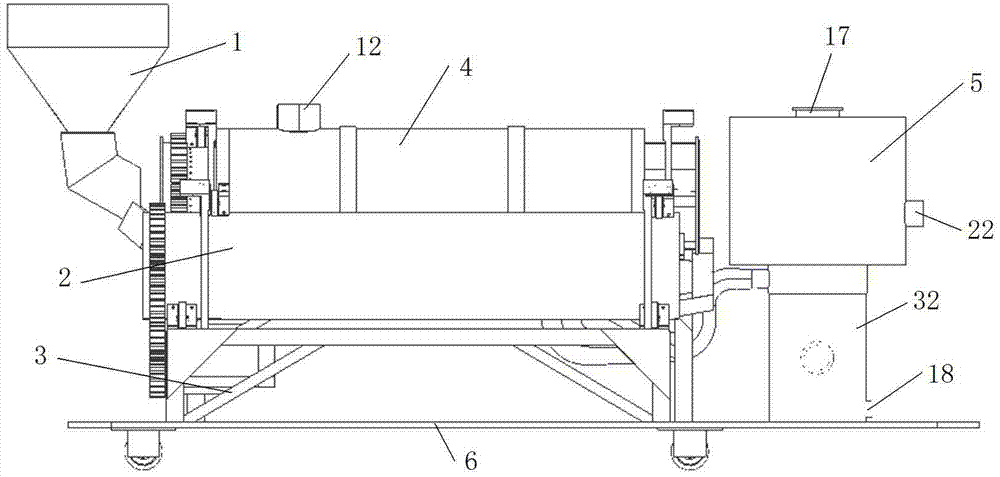

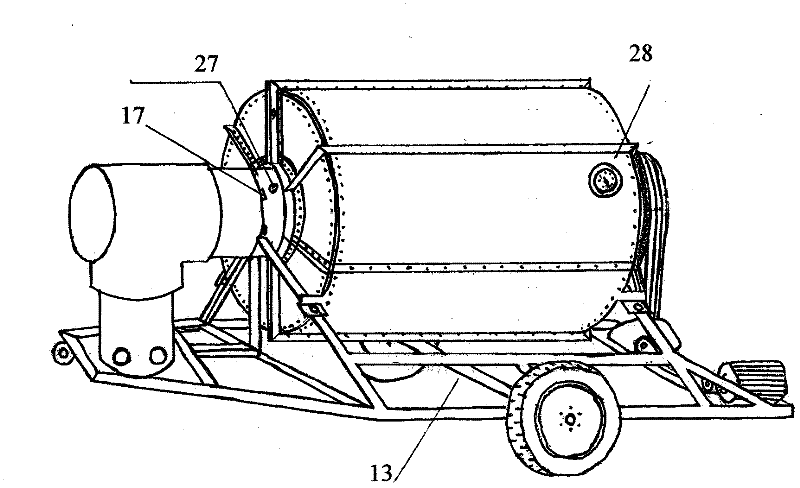

Small grain dryer

InactiveCN104719461AShorten the lengthReduce volumeDrying gas arrangementsSeed preservation by dryingCombustionAgricultural engineering

The invention discloses a small grain dryer comprising a feed hopper. The feed hopper is connected to the inlet of a drying rolling drum; the outlet of the drying rolling drum is connected to the inlet of a cooling rolling drum, the outlet of the cooling rolling drum is connected to a discharge hopper, and the air inlet of the drying rolling drum is connected to a hot air outlet of a straw combustion furnace; the drying rolling drum comprises an outer heat insulation drum, the outer heat insulation drum is provided with an inner rolling drum inside, asymmetric copy boards are distributed on the wall of the inner rolling drum circumferentially, the inner rolling drum is provided with hot air flowing holes, and the inner rolling drum and the outer heat insulation drum are sealed through a sealing sleeve; the outer heat insulation drum is fixed, and the inner rolling drum is capable of rotating; the inner rolling drum is provided with a temperature sensor, a humidity sensor and a microprocessor inside, the temperature sensor and the humidity sensor transmit the acquired data to the microprocessor, and the microprocessor transmits the data to an upper computer; the drying rolling drum, the cooling rolling drum and the straw combustion furnace are arranged on a trailer. By the aid of the small grain dryer, the problems of rural straw combustion and grain drying can be solved.

Owner:WUHAN UNIV OF TECH

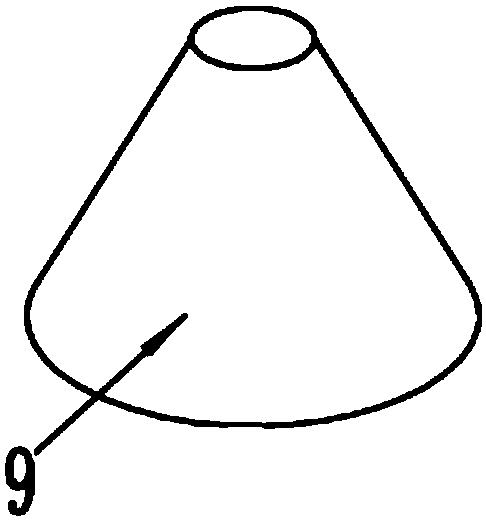

Grain drying device with intermittent feeding function

InactiveCN108444254APrevent drying effectRealize the function of intermittent feedingDrying gas arrangementsSeed preservation by dryingAgricultural engineeringThreaded rod

The invention discloses a grain drying device with intermittent feeding function. The device comprises a stirring chamber, a drying chamber, a motor, a tapered throwing plate and a transmission chamber, wherein the stirring chamber is arranged at the upper end of the drying chamber and is separated through a separating plate; a feeding bucket is arranged at the upper end of the stirring chamber, and the motor is arranged at the right side of the feeding bucket; the output end of the motor is fixedly connected to a rotating shaft; the rotating shaft passes through the stirring chamber and the drying chamber and is fixedly connected to a bevel gear C; the transmission chamber in which a threaded rod is arranged is formed in the middle of the bottom part of the drying chamber; a threaded sleeve is in thread connection with the threaded rod at the inner side of the transmission chamber; shifting plates are symmetrically hinged with two sides of the threaded sleeve. The device is novel in design; the arranged threaded rod can positively and negatively rotate to drive the shifting plates swing up and down in a reciprocating manner through the threaded sleeve; grain at the bottom part ofthe drying chamber can be raised again by the shifting plates, so that the contact area between the grain and hot air is further increased, and as a result, the grain drying effect is improved.

Owner:台州来智科技有限公司

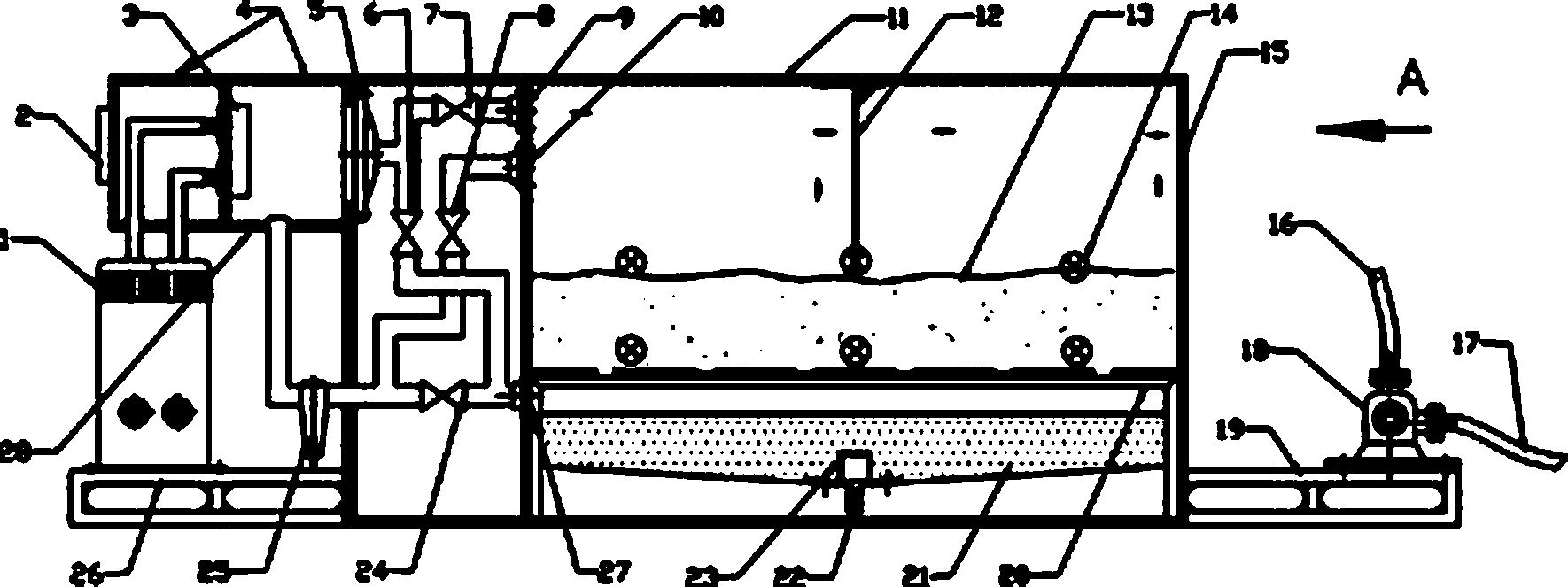

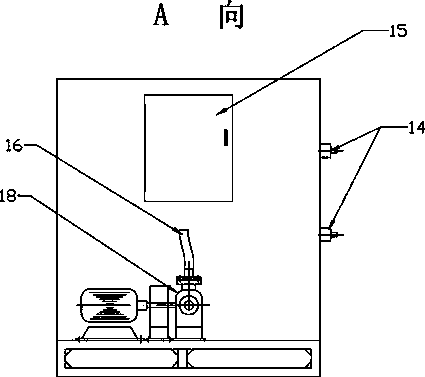

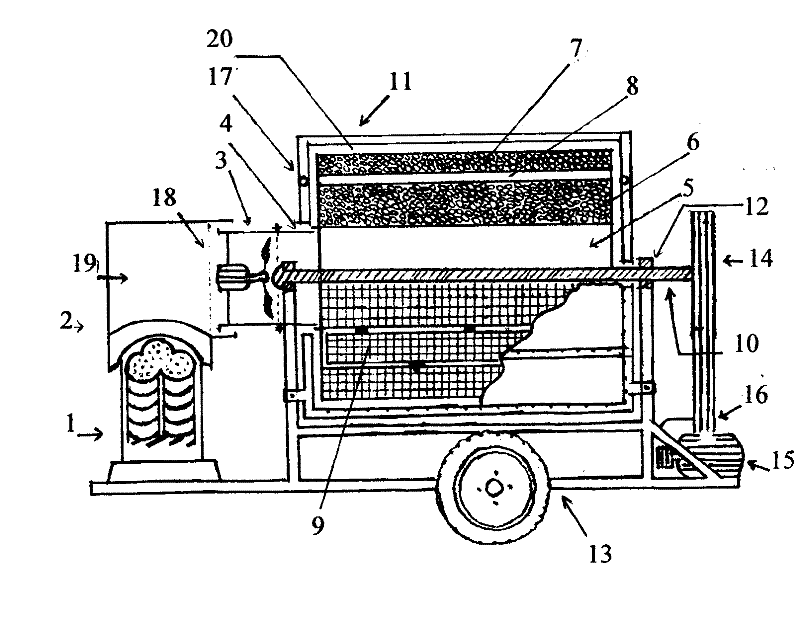

Movable multi-use drying machine

InactiveCN102538414ADry fastConsistent dryDrying gas arrangementsSeed preservation by dryingWalnut NutReducer

The invention relates to a drying device, in particular to a movable multi-use drying machine for dried fruits such as a walnut, a pepper, a Chinese chestnut and the like and a variety of traditional Chinese medicines as well as grains. The movable drying machine comprises a heating part, a main body part and a transmission part, wherein the heating part comprises a coal ball stove, a hot air cover and an axial-flow fan; the main body part comprises an inner drying box, an outer drying box and an insulation cover; and the transmission part comprises a main shaft, a bearing, a chassis frame, a big belt wheel, a motor and a speed reducer. According to the movable multi-use drying machine provided by the invention, dried matters can be rotated by 360 degrees in the drying boxes. In addition, the movable multi-use drying machine has the effects of realizing multiple functions and saving labor intensity.

Owner:尹雄虎

Quality-guaranteeing and energy-saving drying machine for grains

The invention discloses a quality-guaranteeing and energy-saving drying machine for grains. The drying machine comprises two wet grain preheating bins, a hot grain cooling bin and a drying bin, wherein the two wet grain preheating bins are arranged on the left side and the right side of the hot grain cooling bin respectively and are spaced from the hot grain cooling bin through baffles; a ventilating net plate is arranged between the baffles; a cold air chamber is formed in the middle of the hot grain cooling bin; a cold air inlet is formed in the bottom end of the cold air chamber; wet grain outlets are formed in the bottom sides of the wet grain preheating bins; a dry grain outlet is formed in the bottom side of the hot grain cooling bin; a hot grain shifting wheel is arranged on the right side of the dry grain outlet; a dry grain helical collector is arranged on the bottom side of the dry grain shifting wheel; a dry grain helical conveyer is arranged on the bottom side of the dry grain helical collector; the drying bin is arranged on the right sides of the wet grain preheating bins; 2-30 groups of grain distribution channels are formed in the middle of the drying bin; ventilating net plates are arranged on the left and right sides of each grain distribution channel; a hopper type lifting machine is arranged on the left side of the drying bin. The drying machine is reasonable in structure, unique in design and good in using effect.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH

Waste heat recovering ear-corn drying machine

InactiveCN103070234AOptimized drying programKeep dryFood processingClimate change adaptationChinese charactersEngineering

The invention provides a waste heat recovering ear-corn drying machine, which is characterized in that the chamber of the drying machine is divided into an upper area and a lower area by a partition I; the lower area is divided into three parts by partitions II; the bottom of the middle chamber is provided with an air heater with a blower; a plurality of heat exchange boxes are arranged in the upper area and are communicated with one another by annular air pipes; the heat exchange boxes on the lower part are communicated with the middle of the lower area of the chamber; the heat exchange boxes on the upper part are connected with an induced draft fan mounted at the top of the chamber; a water pump at the top of the chamber is connected with a straight pipe inserted in each heat exchange box by a water pipe which is shaped like a Chinese character 'YUE'; a plurality of conveying devices running under the driving of a driving device are arranged in the chamber; molding link plates of I and II types are hung on a pin shaft extending out of the inner side of a conveying chain at intervals and are arrayed and supported on a guide rail to form a trough material channel; a guide chute is arranged below the tail end of the channel; and a feed inlet and a discharge port are formed at the top and the bottom of the chamber respectively. The waste heat recovering ear-corn drying machine is large in moisture reducing range, good in preheating effect and reliable in working.

Owner:SHANDONG UNIV OF TECH

Split-range drying method for paddy

InactiveCN101878813AIncrease productionFast precipitationSeed preservation by dryingSocial benefitsEconomic benefits

The invention discloses a split-range drying method for paddy. The method has the technical points: performing preliminary cleaning and hot air drying on harvested high-moisture paddy, tempering, redrying and retempering the paddy, and keeping the ratio of the drying time to the tampering time within the range from 1 to 6 until the moisture content is reduced to 18.5 to 18 percent; conveying the paddy into a paddy temporary storage warehouse for slow cooling, ventilation and temporary storage; performing the hot air drying on the paddy of the temporary storage warehouse with a dryer after the paddy harvest season, retempering, drying and retempering the paddy, keeping the ratio of the drying time to the tampering time within the range from 1 to 8 until the moisture of the paddy is reduced to be below 14.5 percent; and conveying the paddy to a warehouse for storage. The method has the advantages of improving the moisture reducing rate and the utilization efficiency of the paddy dryer, reducing the loss after the paddy production caused by high moisture during the concentrated paddy harvest season, ensuring the safety for dry storage of the foodstuffs and having obvious economic benefit and social benefit on the premise of ensuring the drying quality of the paddy.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Belt-type temperature-variable type grain heat pump drying device

InactiveCN106568317AFull heat and moisture exchangeImprove storage efficiencyHeat recovery systemsFood processingNatural ventilationEngineering

The invention provides a belt-type temperature-variable type grain heat pump drying device which comprises at least three drying modules which are connected in sequence. Each drying module comprises a heat pump system, an air flue system connected with the heat pump system and a drying channel connected with an air supply opening and an air return opening of the air flue system. By means of the belt-type temperature-variable type grain heat pump drying device, the phenomenon of grain crack can be effectively prevented, quality of dried grains is improved, and the yield of the dried grains is raised; cooling is conducted directly after the grains are dried, and the defects that natural ventilation cooling time is long, and the grains absorb environmental moisture are overcome; time is saved, work efficiency is improved, the grains are dried in a layered manner in the drying channel, space can be effectively utilized, quality of the grains is improved, and the yield of the grains is raised.

Owner:浙江豪瓦特节能科技有限公司

Self-feeding type energy-saving grain drying device

InactiveCN108800832AEvenly heatedImprove drying effectFood processingDrying gas arrangementsSpiral bladePulp and paper industry

The invention discloses a self-feeding type energy-saving grain drying device comprising a base. A drying barrel is fixed to the top of the base through a support, a rotating tube is arranged in the center in the drying barrel, and the upper end and the lower end of the rotating tube are rotationally connected with the top wall and the bottom wall of the drying barrel correspondingly. A second speed reducing motor is fixedly arranged at the center of the top of the drying barrel, a motor shaft at the bottom end of the second speed reducing motor is fixedly connected with the top end of the rotating tube, and spiral blades are fixedly mounted at the tube section, located above a screen plate, of the rotating tube. A plurality of one-way air outlet holes are uniformly formed in the tube section, between the spiral blades, of the rotating tube. A hot air blower is fixedly arranged at the right part of the side wall of the drying barrel, the air inlet end and the air outlet end of the hotair blower are connected with hot air tubes correspondingly, and the air outlet end of each hot air tube is connected into the rotating tube. The hot air blower is used for introducing hot air into the rotating tube, the hot air is discharged from the one-way air outlet holes to dry grains, and the heat is uniformly distributed; and the spiral blades are driven by the rotating tube to rotate to drive the grains to roll, so that the grains are heated more uniformly when dried, and the drying effect is good.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

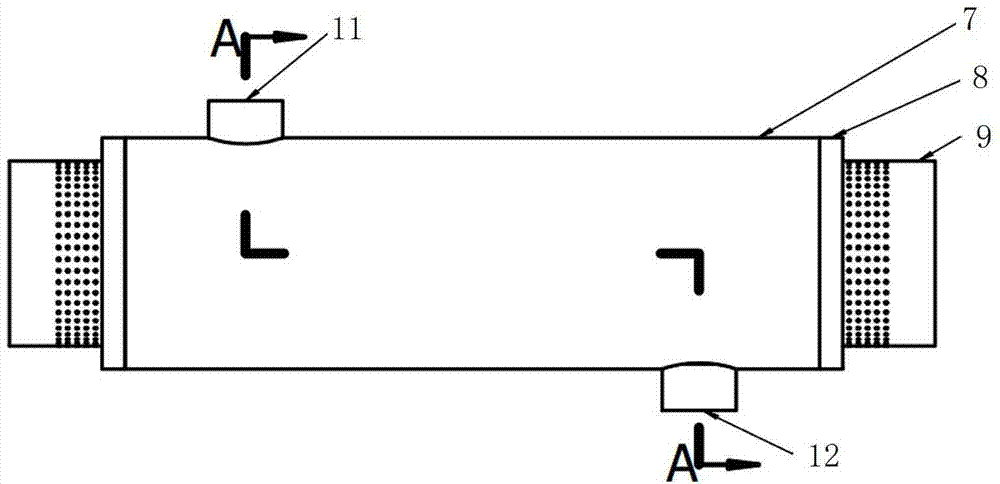

Horizontal convection integral grain drying machine

The invention discloses a horizontal convection integral grain drying machine, relating to a grain drying machine. By using the horizontal convection integral grain drying machine, the problems of high cost, low efficiency, low temperature, low warming speed, large energy consumption and pollutant discharge are solved. The stator reels of the grain drying machine are symmetrically arranged on two ends of a drying cylinder; a superconductive tube is arranged in the drying cylinder; the right end of the superconductive tube is arranged in the combustion chamber of a heat supply furnace by the stator reels; an air tube is arranged below the superconductive tube; the air tube and the superconductive tube are arranged in a hot-proof cyclone cover below which a hot wind port is arranged; and a dust catcher is arranged between a flue and a discharge flue. The horizontal convection integral grain drying machine has the advantages of compact design, small volume, simple structure, low cost, high efficiency and low cost, and is convenient in installation, is energy-saving, environment-friendly, wherein the grain drying machine can save energy by 30-40% and save electricity by 20-30% if compared with the existing drying equipment under the same condition, and improve efficiency by 15-20% if compared with the existing drying equipment, and the cost of the grain drying machine is 60-70% of that of the existing equipment.

Owner:HARBIN ZHONGSHENGLONG HEATING EQUIP TECH DEV

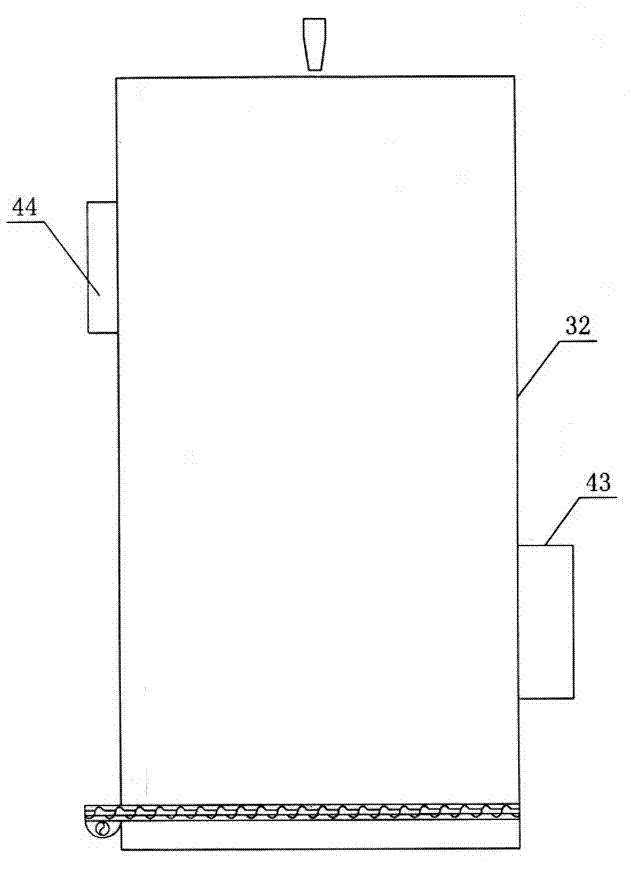

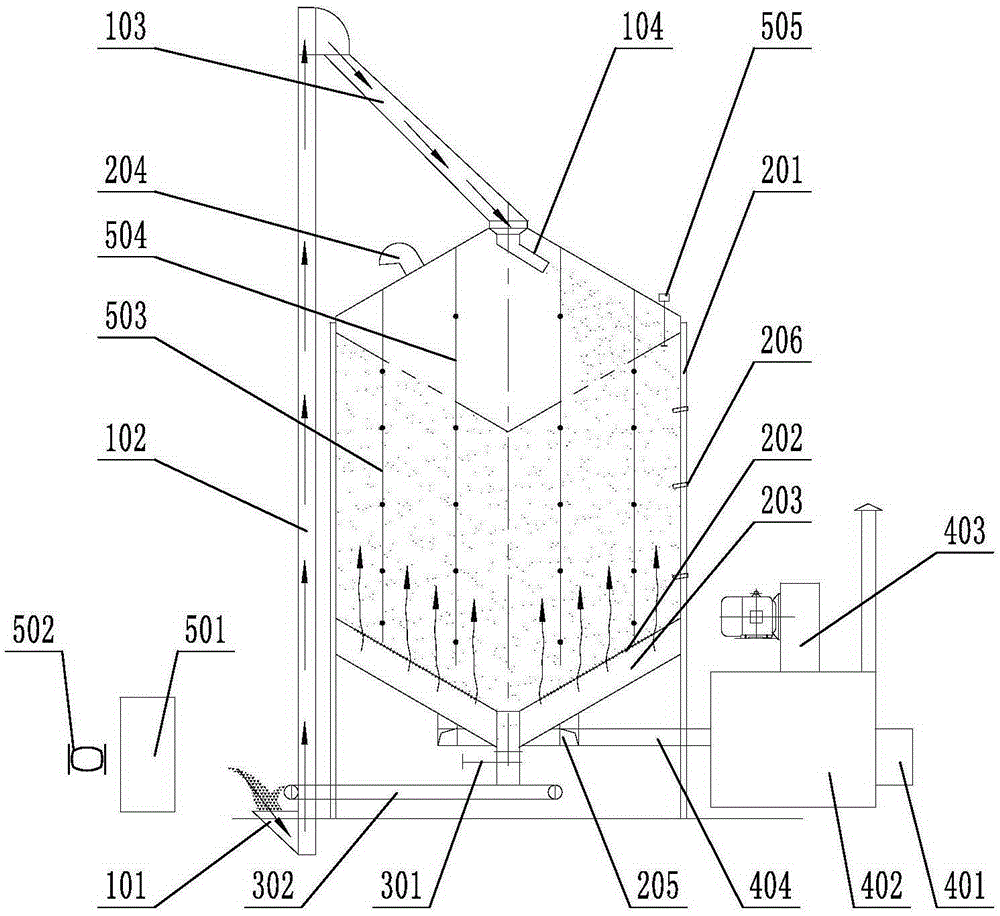

Grain intelligent baking storing integrated device

InactiveCN105341148AHigh degree of automationRealize automatic feedingAgriculture tools and machinesSeed preservation by dryingAgricultural engineeringIntelligent control

The invention relates to a grain intelligent baking storing integrated device with intelligent drying and storing functions, and belongs to the field of agricultural machinery grain drying and storing. The grain intelligent baking storing integrated device comprises a feeding unit, a storage unit, a discharging unit, an aeration-drying unit, and an intelligent control unit; the storage unit comprises a silo cell; the feed inlet of the silo cell is connected with the feeding unit; the feed outlet of the silo cell is connected with the discharging unit; the bottom of the silo cell is provided with an air passage; a wind chamber is arranged below the bottom of the silo cell; the wind chamber is communicated with the inner part of the silo cell via the air passage; the wind chamber is communicated with the aeration-drying unit via a wind passage; and the upper part of the silo cell is provided with an air exhausting device. According to the grain intelligent baking storing integrated device, grain drying and storing function are combined; automatic degree is high; the grain intelligent baking storing integrated device is safe and reliable to use; cost is reduced; grain drying and storing are not influenced by air factors; and the grain intelligent baking storing integrated device is suitable for small and medium-sized farmers, and big grain production households.

Owner:SHANDONG QUANGUAN MASCH TECH CO LTD

Popular searches

Drying machines with non-progressive movements Drying solid materials Picture reproducers with optical-mechanical scanning Picture reproducers using projection devices Analogue secracy/subscription systems Picture reproducers using solid-state color display Television signal transmission by single/parallel channels Color motion picture films scanning Selective content distribution Signal generator with optical-mechanical scanning

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com