Low-temperature circulation dryer for crop seeds

A cycle drying and drying machine technology, applied in the direction of dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of residual seeds, large temperature gradient, uneven drying, etc., to reduce thermal stress and moisture deviation stress, Effect of suppressing stress cracks and ensuring drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

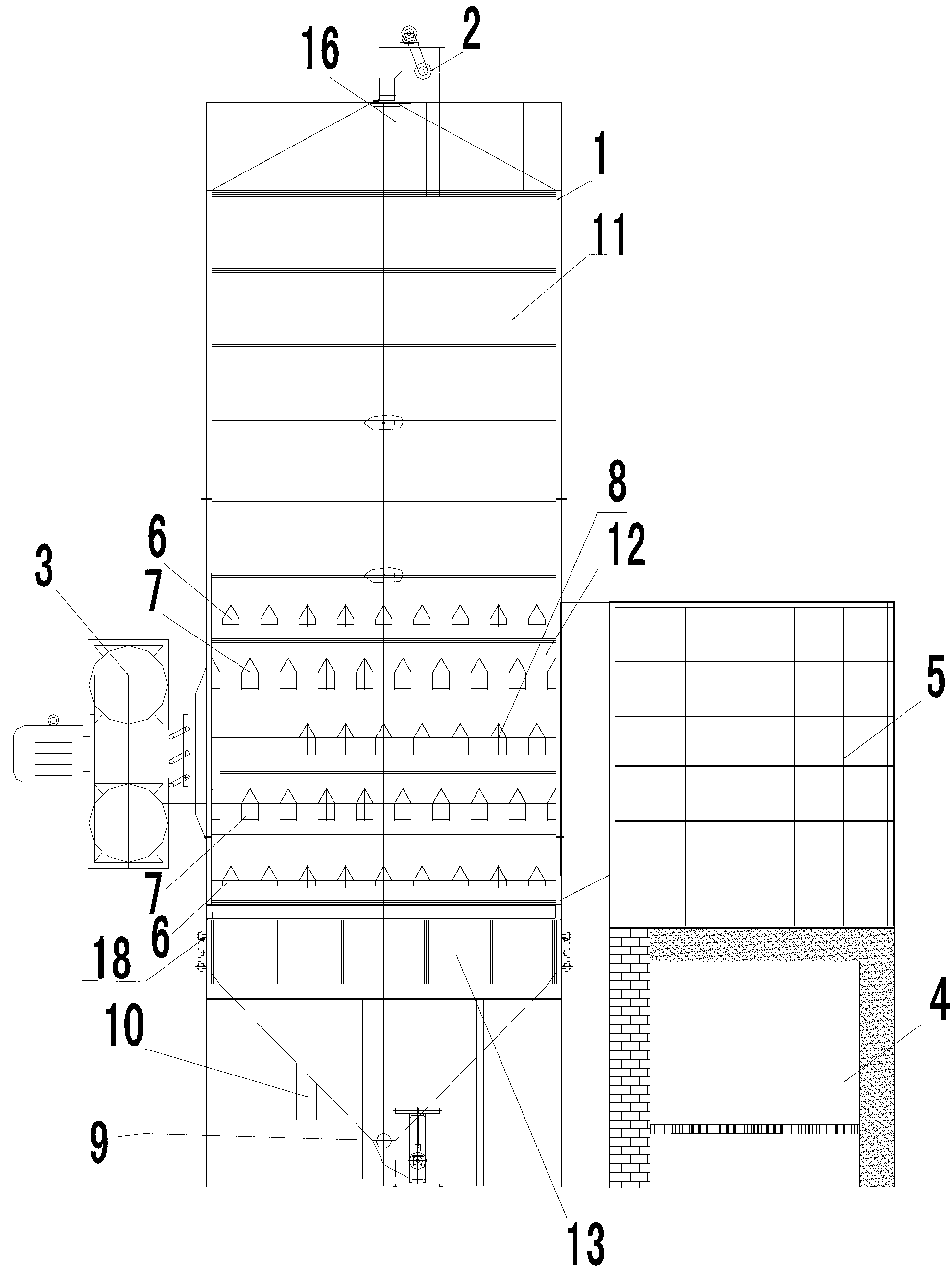

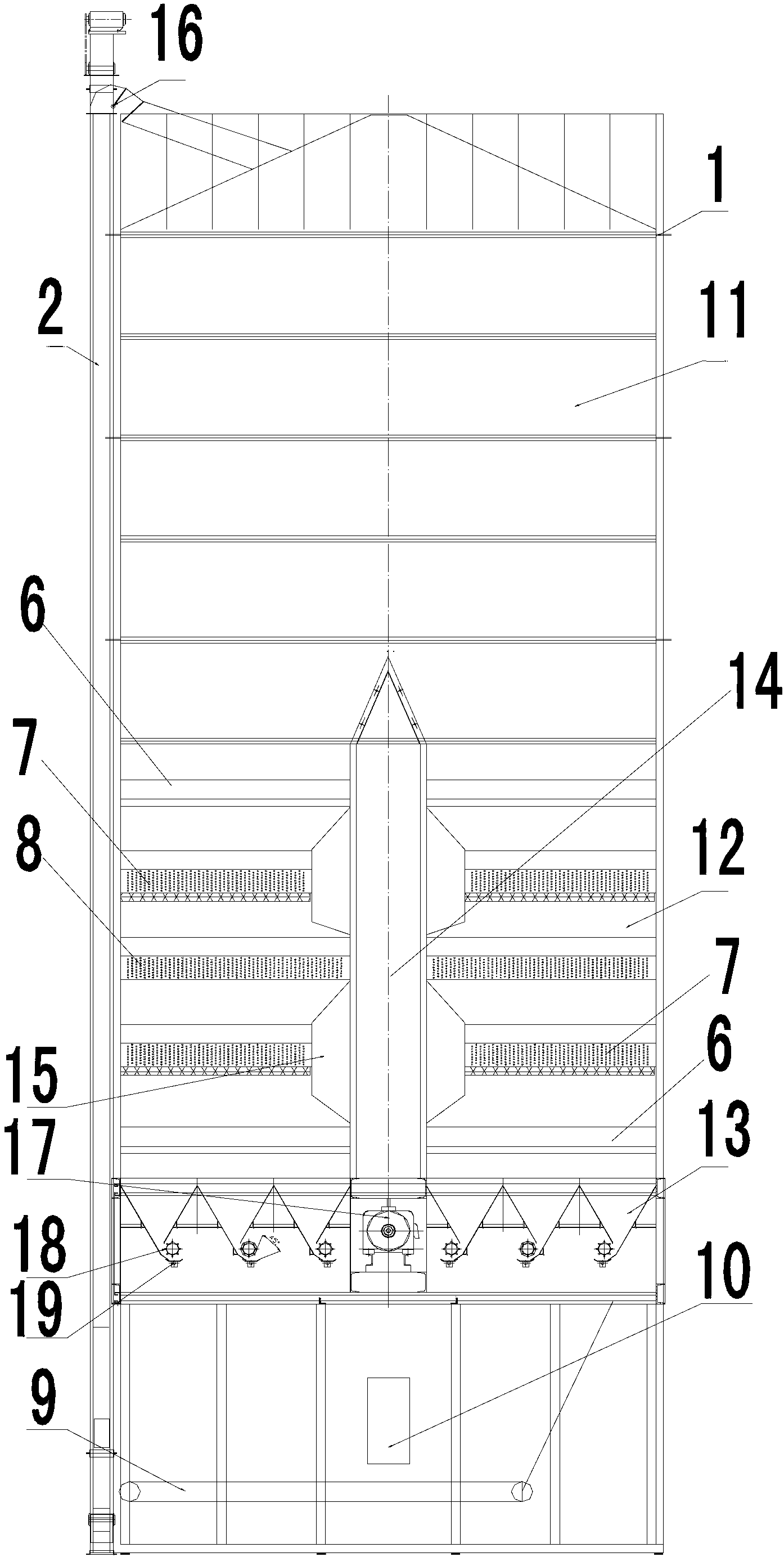

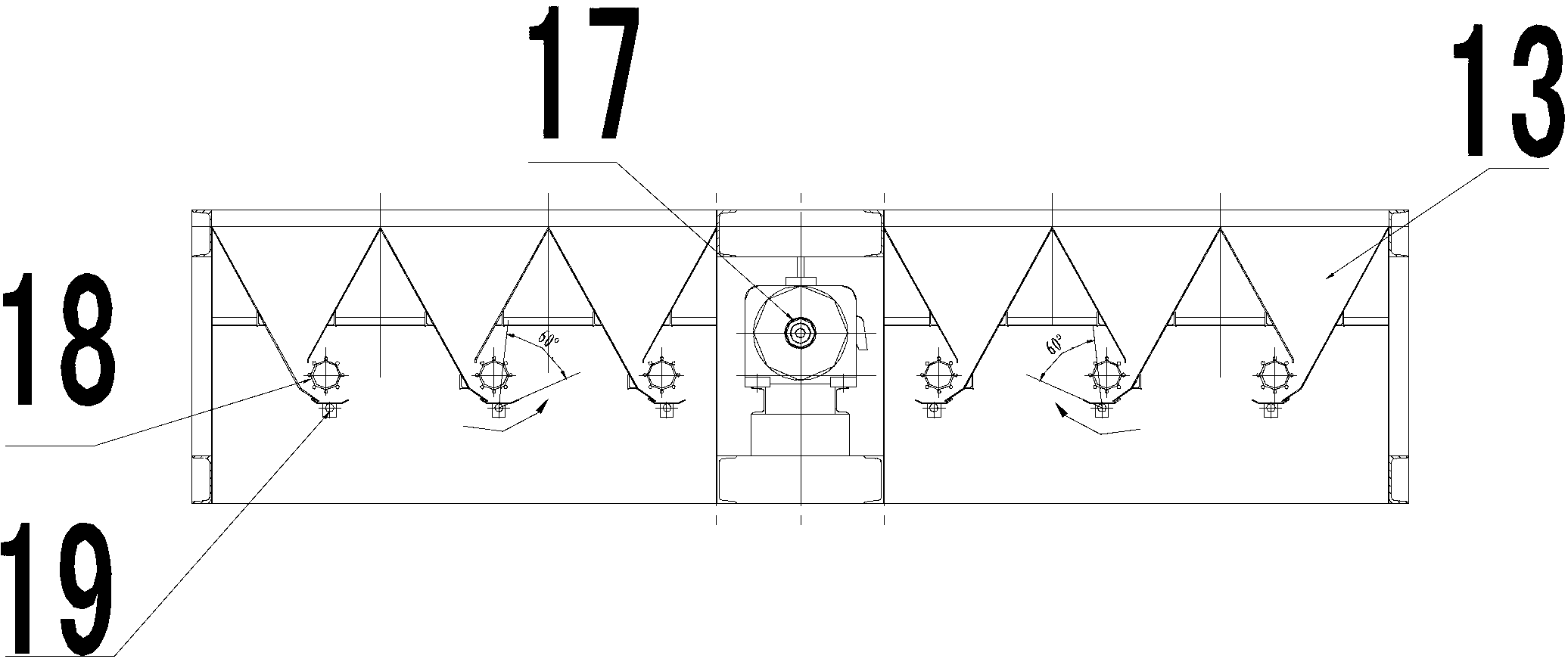

[0036] like Figure 1~11 As shown, a low-temperature circulation dryer for crop seeds includes a hoist 2, a secondary valve 16, and a dryer body 1 arranged in sequence according to the flow direction of grain transportation. 11. The drying section 12 and the grain discharge section 13, after being detected by the grain moisture and drying temperature online detector 10, fall into the lower conveyor 9 and then sent back to the hoist 2. The grain moisture and drying temperature in this embodiment are on-line. The detector 10 is commercially available. The hoist 2 is installed on the side of the dryer body 1, the induced draft fan 3 is installed on the front of the dryer body 1, the air inlet of the induced draft fan 3 is directly connected with the exhaust duct 15, and the hot blast stove 4 and the heat exchanger 5 are designed in the dryer. The back side of machine body 1. The air inlet of the air inlet channel 14 is directly connected with the air outlet of the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com