Comprehensive plugging method for karst leakage

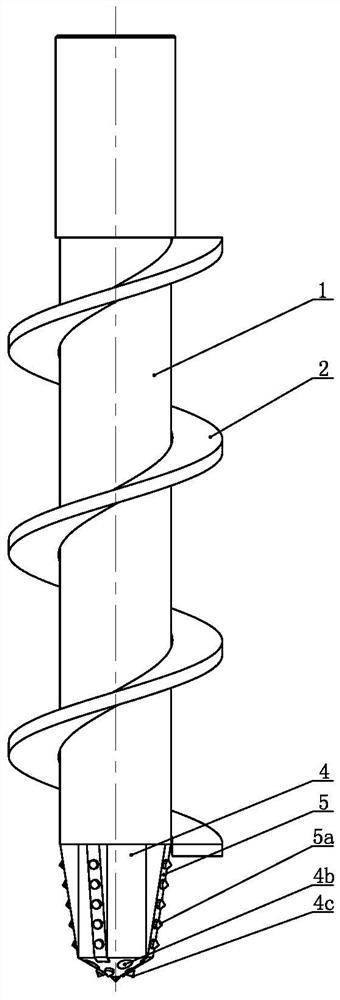

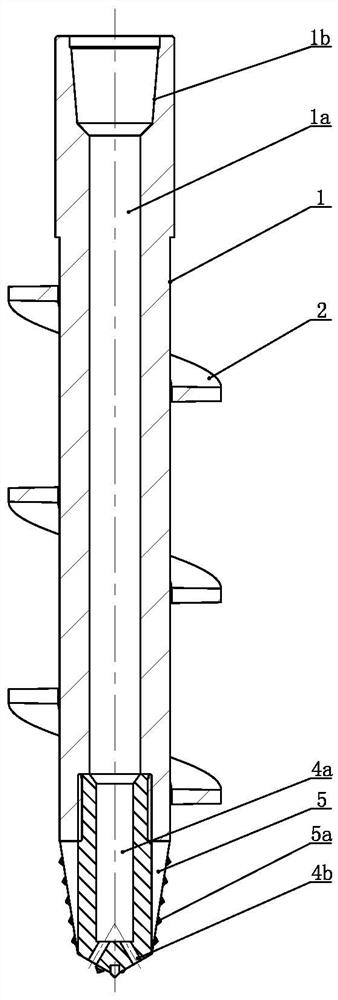

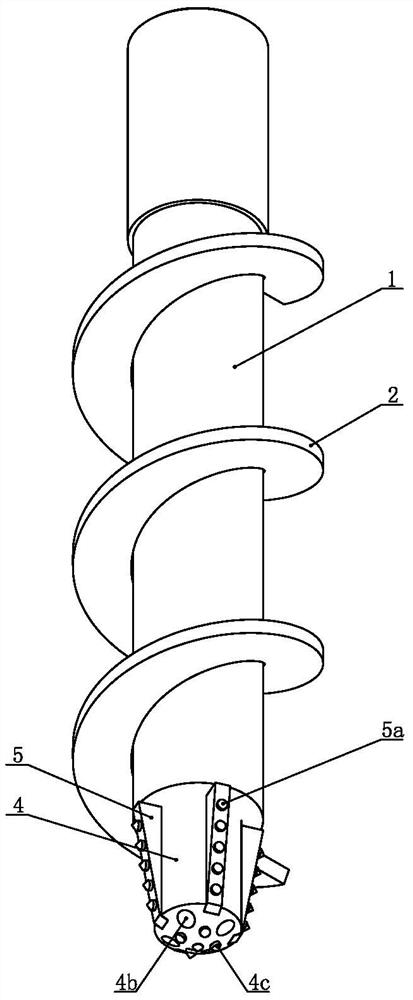

A plugging method and karst cave-type technology, applied in the field of oil drilling, can solve the problems of plugging materials being taken away, long processing time, easily damaged drill bits and male cones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is directed to the comprehensive plugging method for karst-cavity leakage, which comprises the following steps in turn: (1) When a loss of return occurs when drilling into a karst cave, the drilling is stopped first, and the position and size of the karst cave are determined and then immediately tripped; when drilling, the drilling tool The venting section is the location of the karst cave, and the venting distance is regarded as the size of the karst cave; grouting is performed while tripping to ensure the downhole pressure is balanced and the well wall is stable; liquid level.

[0035] (2) Prepare large, medium and small tetrahedron structure materials and mix them evenly; the edge length specifications of large, medium and small tetrahedrons are 30mm, 20mm and 10mm respectively, and the volume mixing ratio of large, medium and small tetrahedrons is Large:Medium:Small = 1:8:27.

[0036] (3) Calculate the single injection volume of the hybrid arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com