Microwave vacuum drying process for lotus seed

A technology of microwave vacuum drying and lotus seeds, which is applied in the direction of drying and preserving seeds, can solve the problems of reduced edible quality and sensory quality, high water content of fresh lotus seeds, and poor color of dried lotus seeds, and achieves reduced activity and easy real-time control , The effect of shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

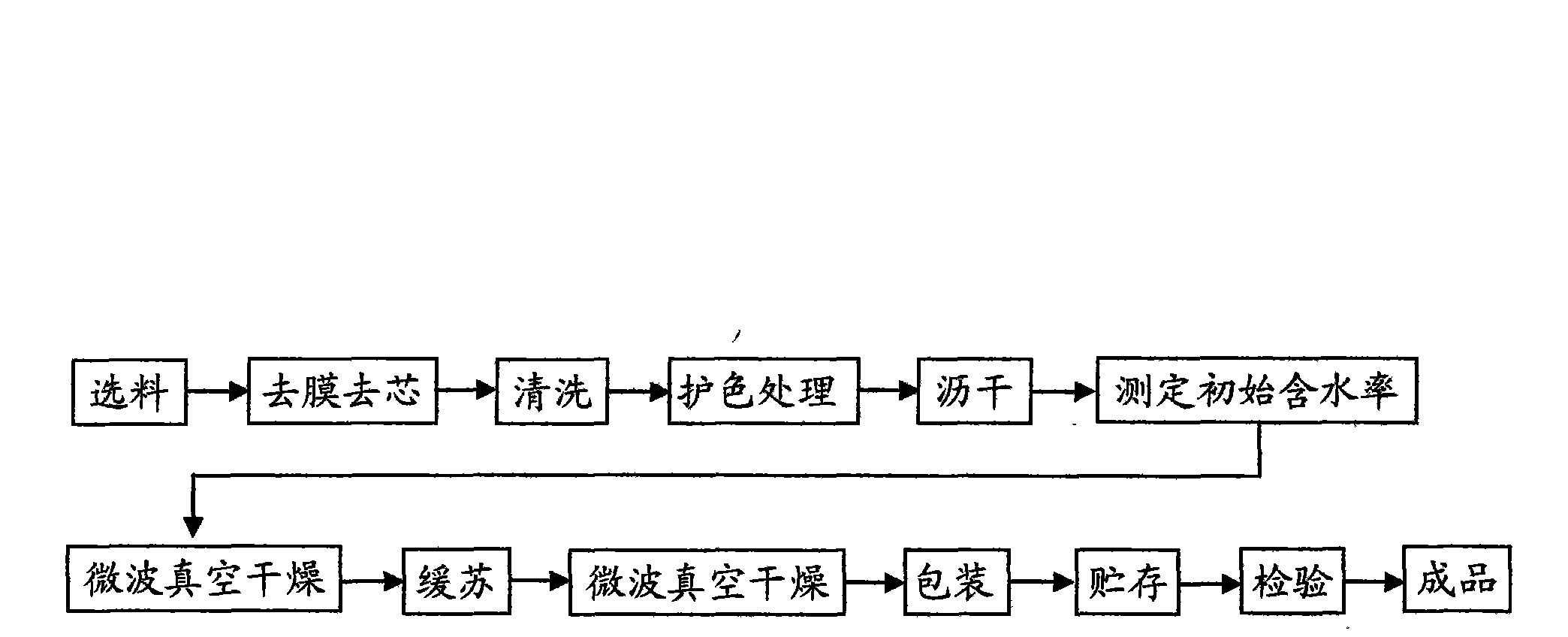

Image

Examples

Embodiment 1

[0031] (1) Material selection: select fresh lotus seeds with no pests and diseases and full grains as raw materials;

[0032] (2) Remove the membrane and remove the core: the fresh lotus seeds that are picked are removed through the membrane-removing and core-removing process;

[0033] (3) Cleaning: Put the fresh lotus seeds through the core into flowing purified water for cleaning to remove impurities such as membranes;

[0034] (4) Color protection treatment: soak the fresh lotus seeds after the core treatment in the color protection solution for color protection treatment; the color protection treatment refers to soaking the fresh lotus seeds after the core treatment in the color protection solution for 20 minutes , inhibit the polyphenol oxidase (PPO) in fresh lotus, prevent the browning of fresh lotus; Described color protection solution is prepared by the following method: disodium edetate 0.02%, vitamin C 0.1%, all the other are purification water;

[0035] (5) Drain:...

Embodiment 2

[0041] (1) Material selection: select fresh lotus seeds with no pests and diseases and full grains as raw materials;

[0042] (2) Remove the membrane and remove the core: the fresh lotus seeds that are picked are removed through the membrane-removing and core-removing process;

[0043] (3) Cleaning: Put the fresh lotus seeds through the core into flowing purified water for cleaning to remove impurities such as membranes;

[0044] (4) Color protection treatment: soak the fresh lotus seeds after the core treatment in the color protection solution for color protection treatment; the color protection treatment refers to soaking the fresh lotus seeds after the core treatment in the color protection solution for 30 minutes , inhibiting the polyphenol oxidase PPO in fresh lotus, preventing the browning of fresh lotus; the color protection solution is prepared by the following method: 0.2% disodium edetate, 0.3% vitamin C, and the rest is purified water;

[0045] (5) Drain: fish out ...

Embodiment 3

[0051] (1) Material selection: select fresh lotus seeds with no pests and diseases and full grains as raw materials;

[0052] (2) Remove the membrane and remove the core: the fresh lotus seeds that are picked are removed through the membrane-removing and core-removing process;

[0053] (3) Cleaning: Put the fresh lotus seeds through the core into flowing purified water for cleaning to remove impurities such as membranes;

[0054] (4) Color protection treatment: soak the fresh lotus seeds after the core treatment in the color protection solution for color protection treatment; the color protection treatment refers to soaking the fresh lotus seeds after the core treatment in the color protection solution for 25 minutes , inhibit the polyphenol oxidase (PPO) in fresh lotus, prevent the browning of fresh lotus; Described color protection solution is prepared by the following method: disodium edetate 0.1%, vitamin C 0.2%, all the other are purified water;

[0055] (5) Drain: fish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com