Patents

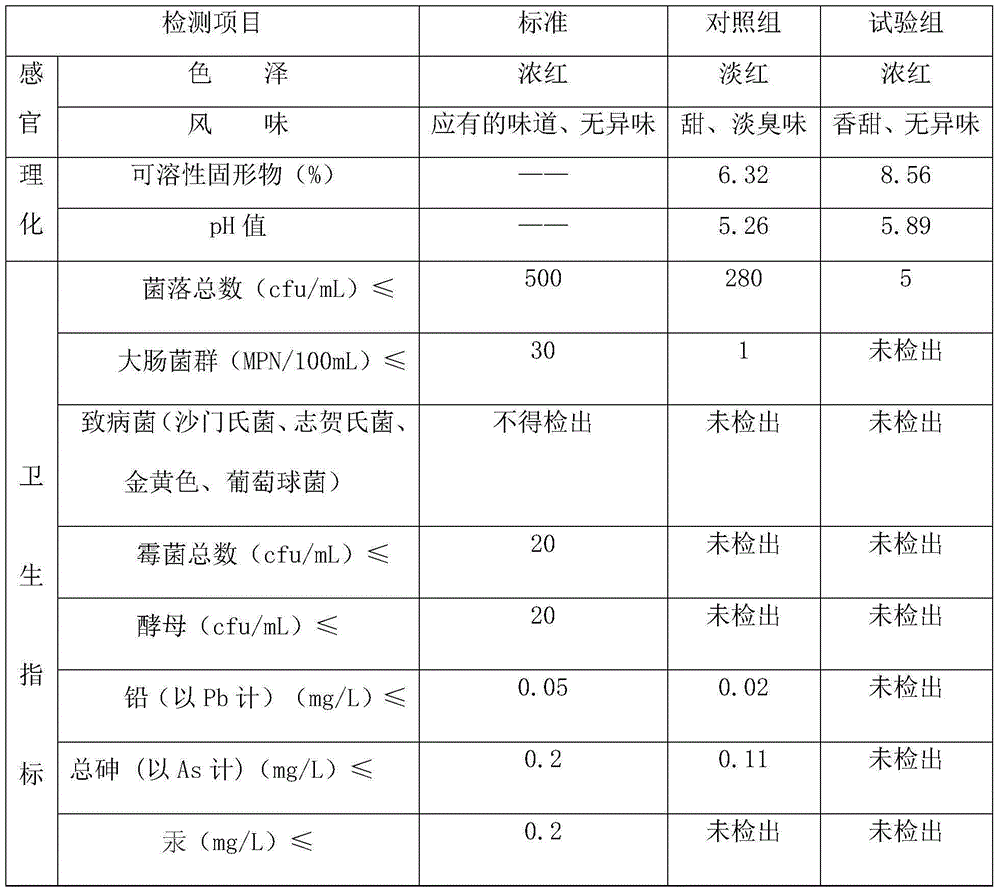

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

545 results about "Browning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Browning is the process of food turning brown due to the chemical reactions that take place within. The process of browning is the chemical reactions that take place in food chemistry and represents an interesting research topic regarding health, nutrition, and food technology. Though there are many different ways food chemically changes over time, browning in particular falls into 2 main categories: enzymatic versus non-enzymatic browning processes.

Heat-stable concentrated milk product

ActiveUS20070172548A1Extended shelf lifeIncrease in sizeMilk preparationMilk preservationBiotechnologyBrowning

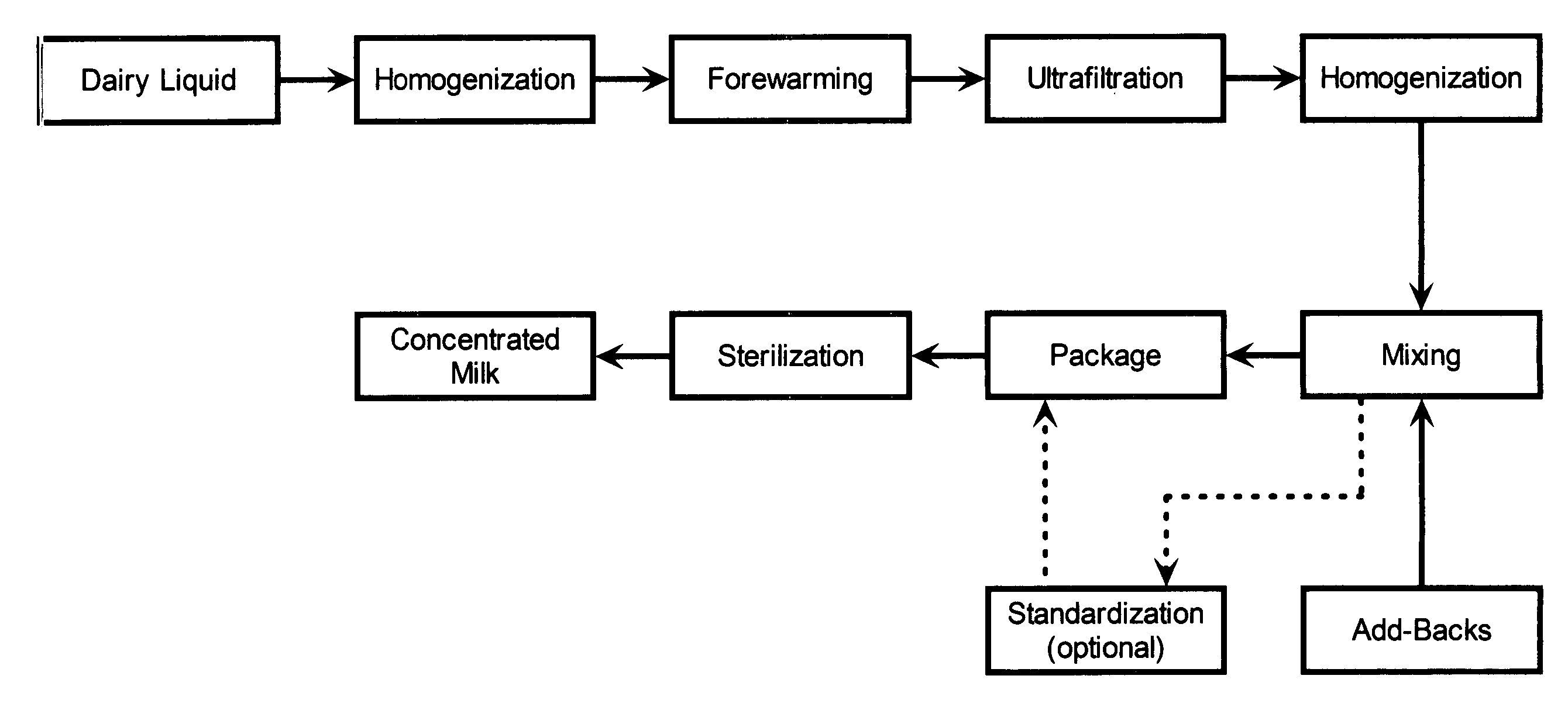

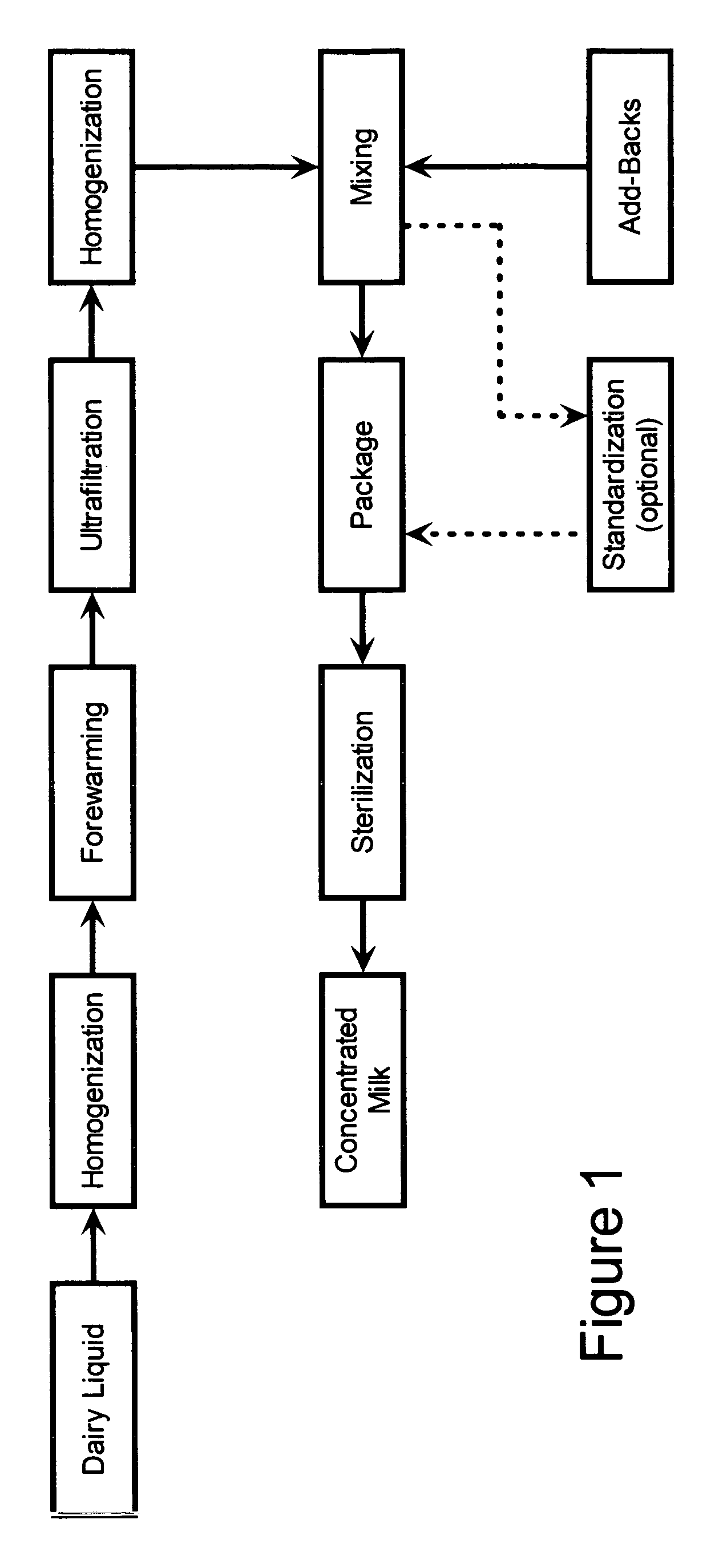

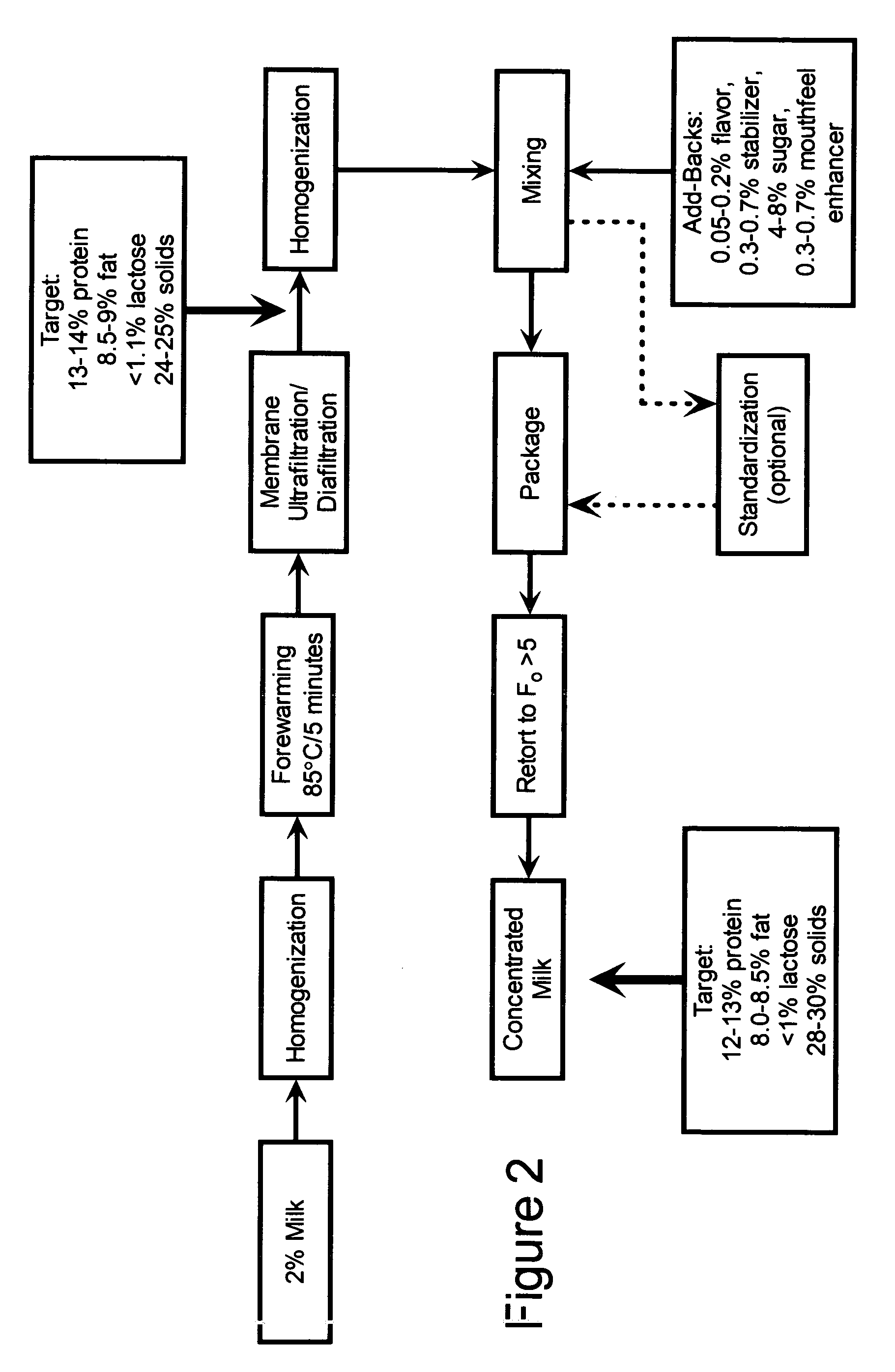

The invention provides a stable concentrated dairy liquid, such as concentrated milk, with improved flavor, color, and mouthfeel, and a method of production thereof. The method utilizes specific thermal treatments to produce the stable concentrated dairy liquid to which a stabilizer and mouthfeel enhancer are added. The resulting products have a sterilization value Fo of at least 5 that is also resistant to gelling and browning during high temperature sterilization and is also resistant to gelling and browning during storage for greater than six months. The method balances such thermal treatments with addition of stabilizer and enhancer to achieve the desired flavor / mouthfeel and sterilization and to achieve reduced level of soluble protein in the concentrated milk prior to concentration to resist gelation and minimize browning. Moreover, such processing may be utilized in a milk that is concentrated to a factor of 2.7 fold or higher and contains at least 8.5 percent protein.

Owner:KONINK DOUWE EGBERTS BV

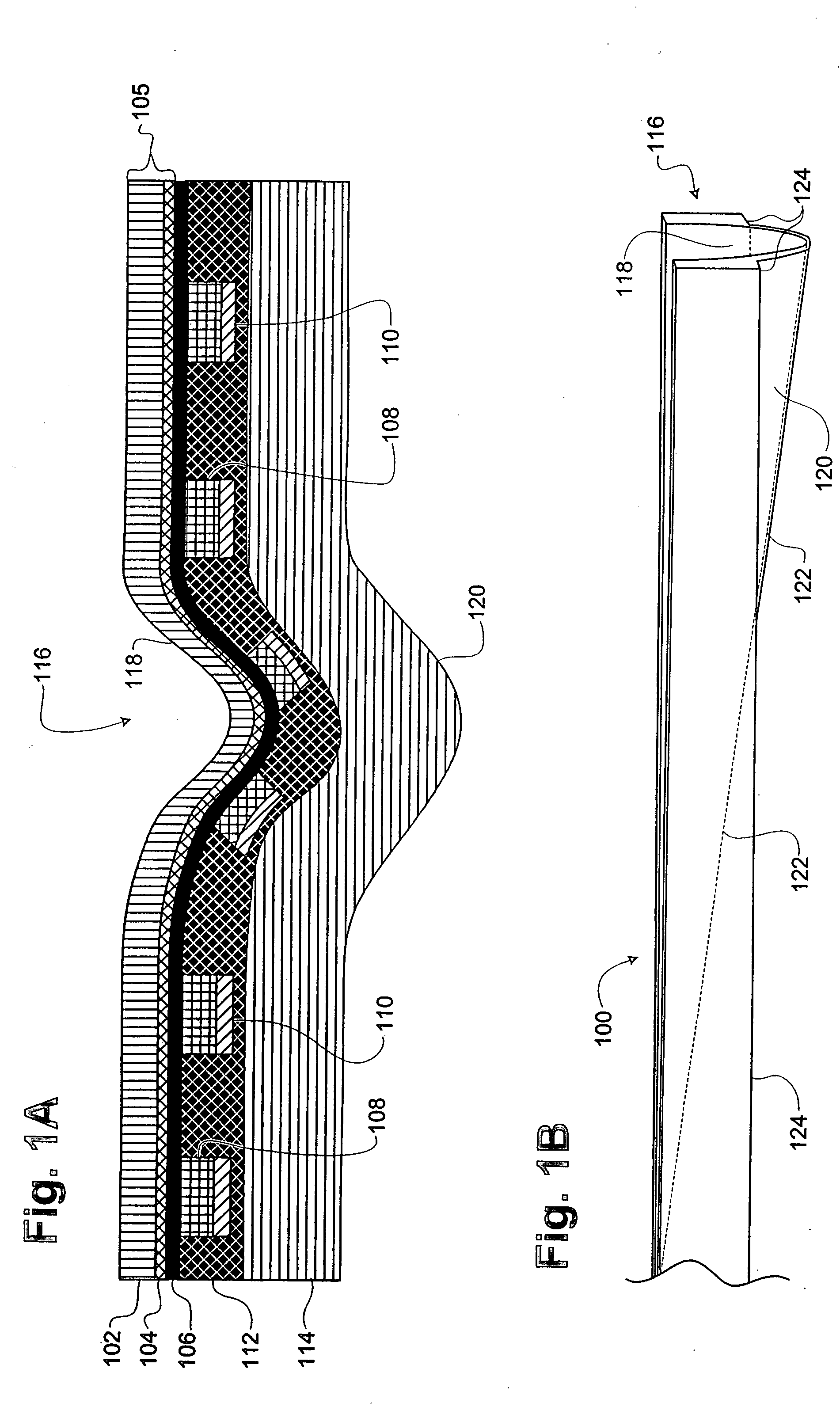

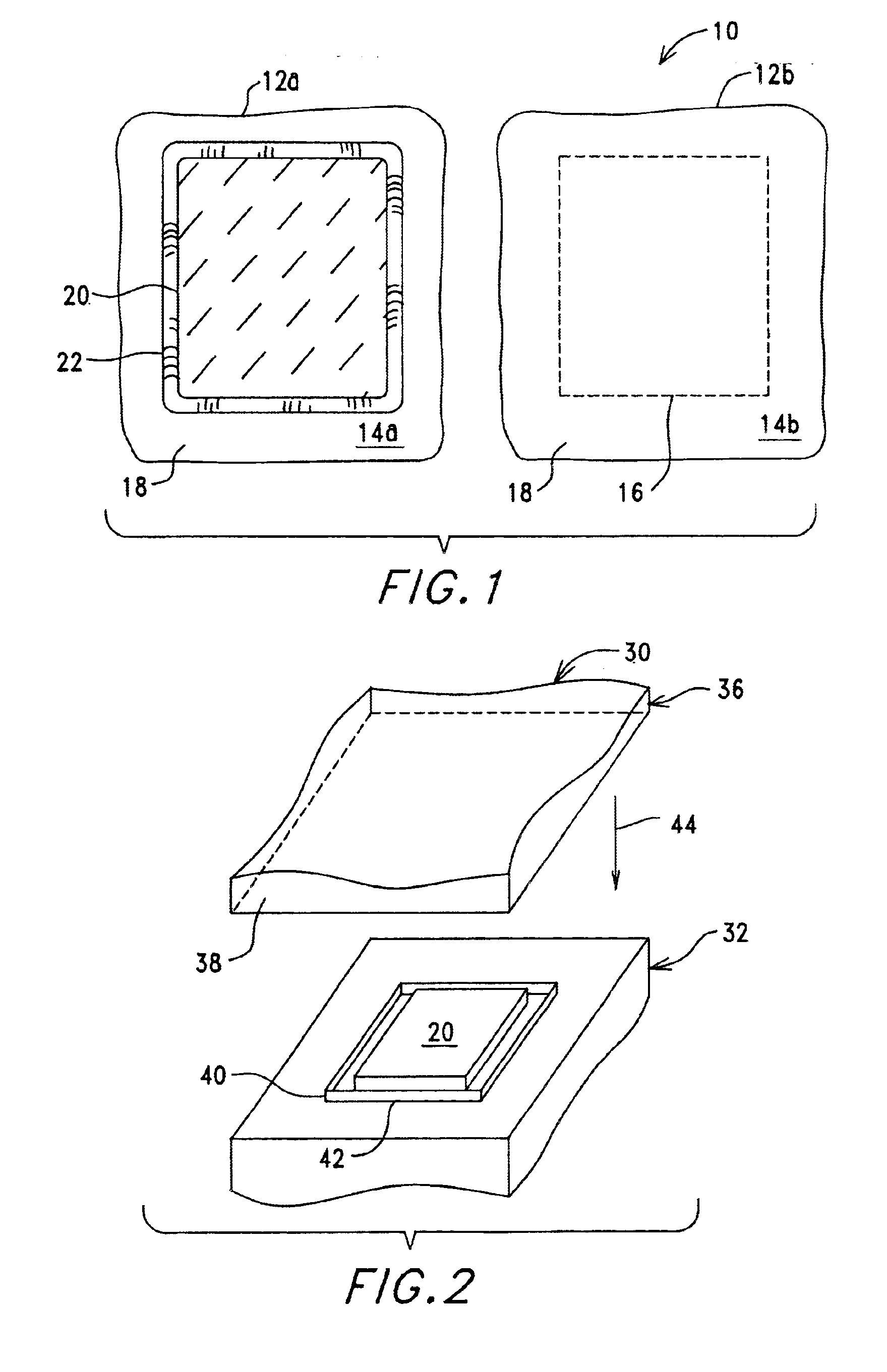

Microwave packaging with indentation patterns

InactiveUS20060011620A1Improve cooking resultsGood cooking effectMilk preparationReady-for-oven doughsCooking & bakingEngineering

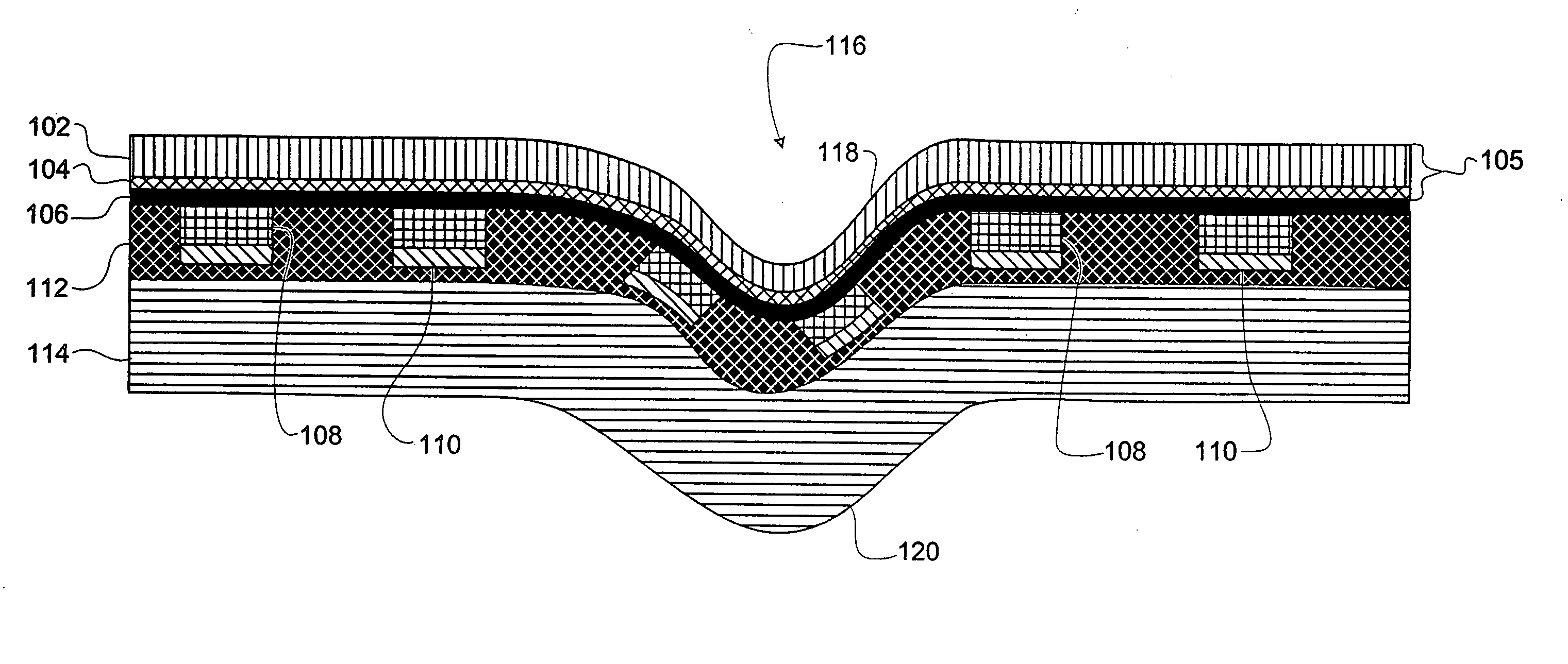

Indentation patterns in microwave packaging materials can enhance the baking and browning effects of the microwave packaging materials on food. The indentation patterns can provide venting to either channel moisture from one area of the food product to another, trap moisture in a certain area to prevent it from escaping, or channel the moisture completely away from the food product. The indentation patterns can cause the microwave packaging material underneath a food product to be slightly elevated above the cooking platform in the base of a microwave. The indentation patterns can lessen the heat sinking effect of the cooking platform by providing an air gap for insulation. Elevating the base of the microwave packaging material further allows more incident microwave radiation to propagate underneath the microwave packaging material to be absorbed by the food product or by microwave interactive materials in the microwave packaging material that augment the heating process.

Owner:GRAPHIC PACKAGING INT

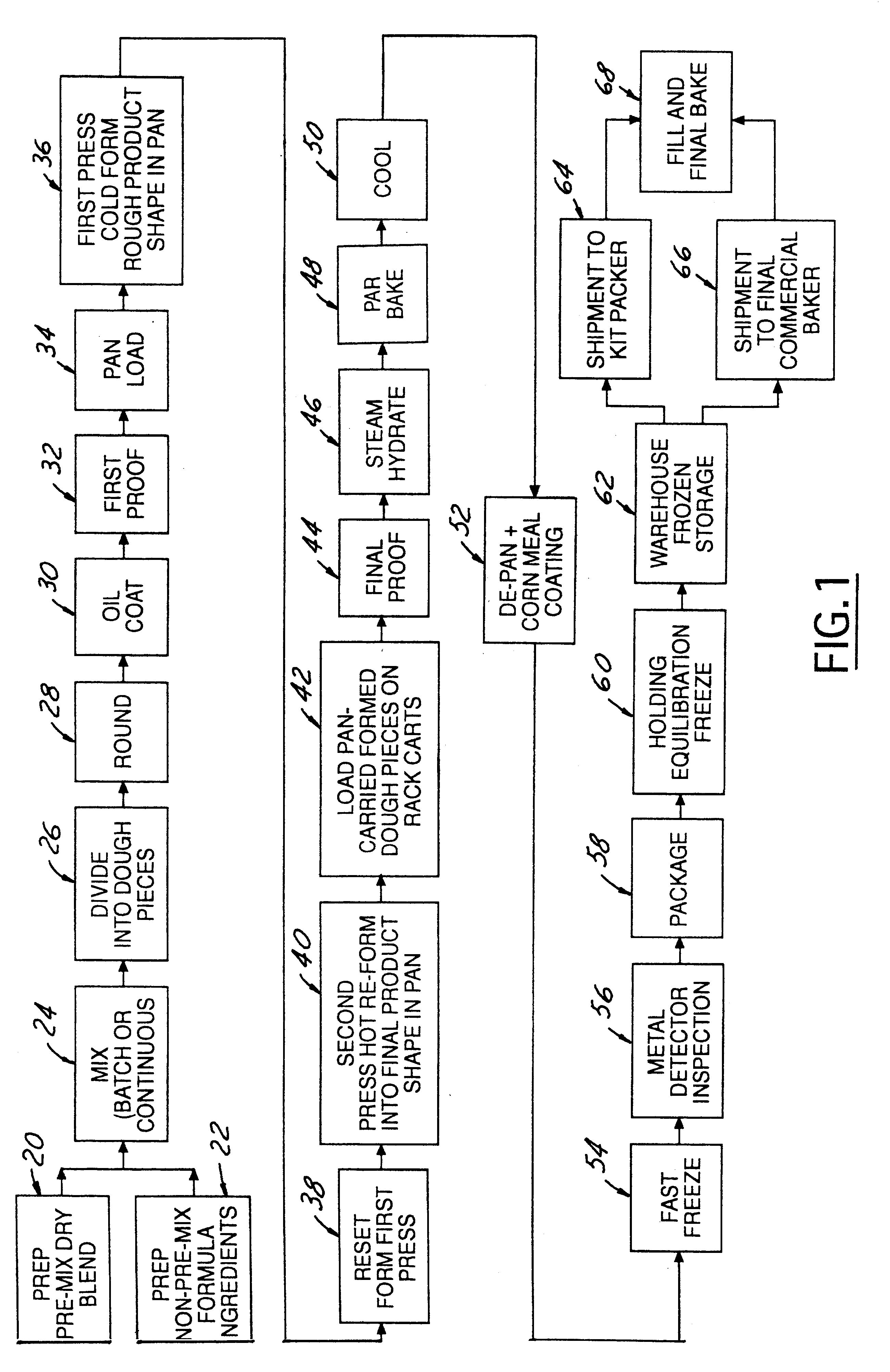

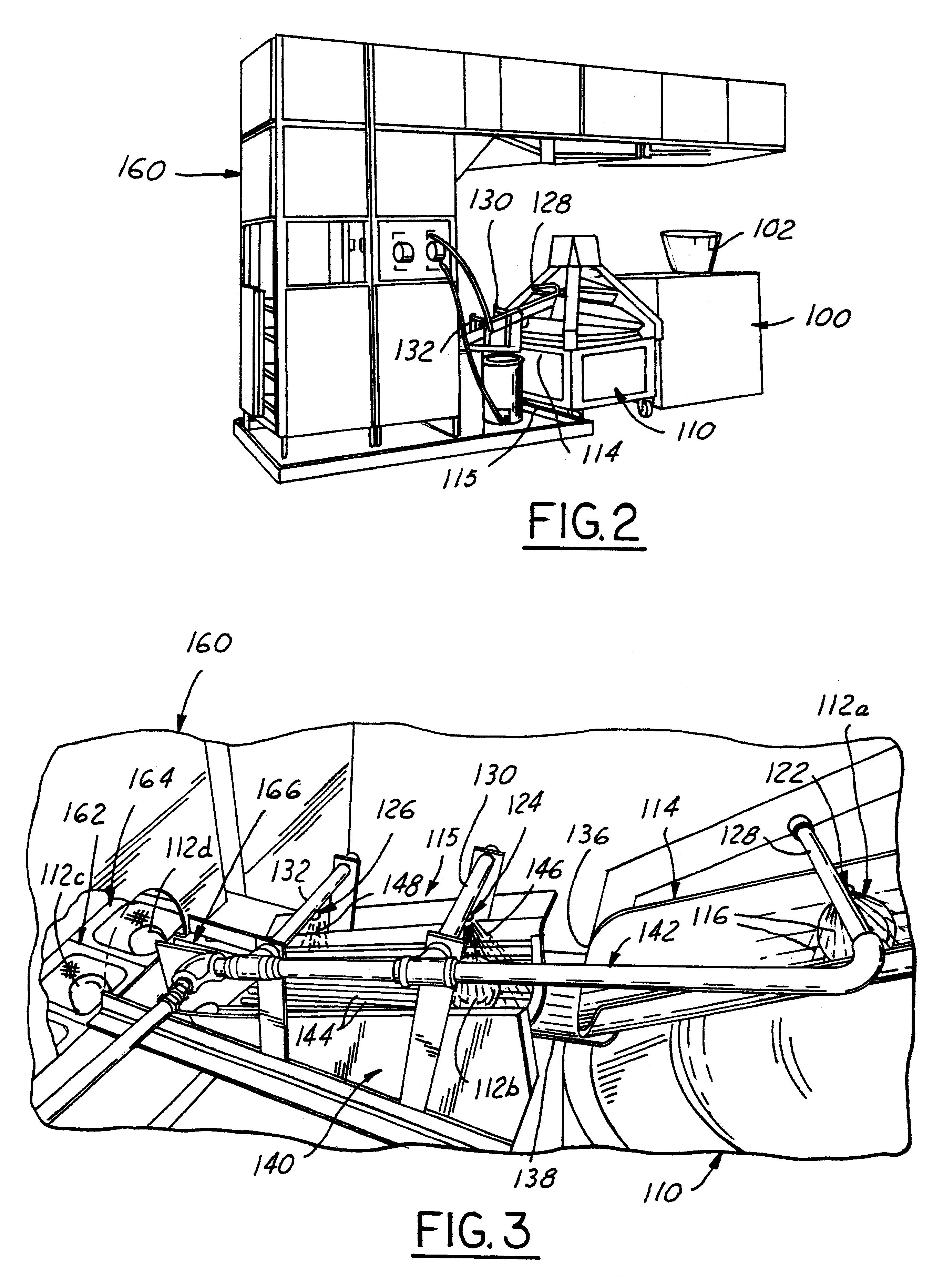

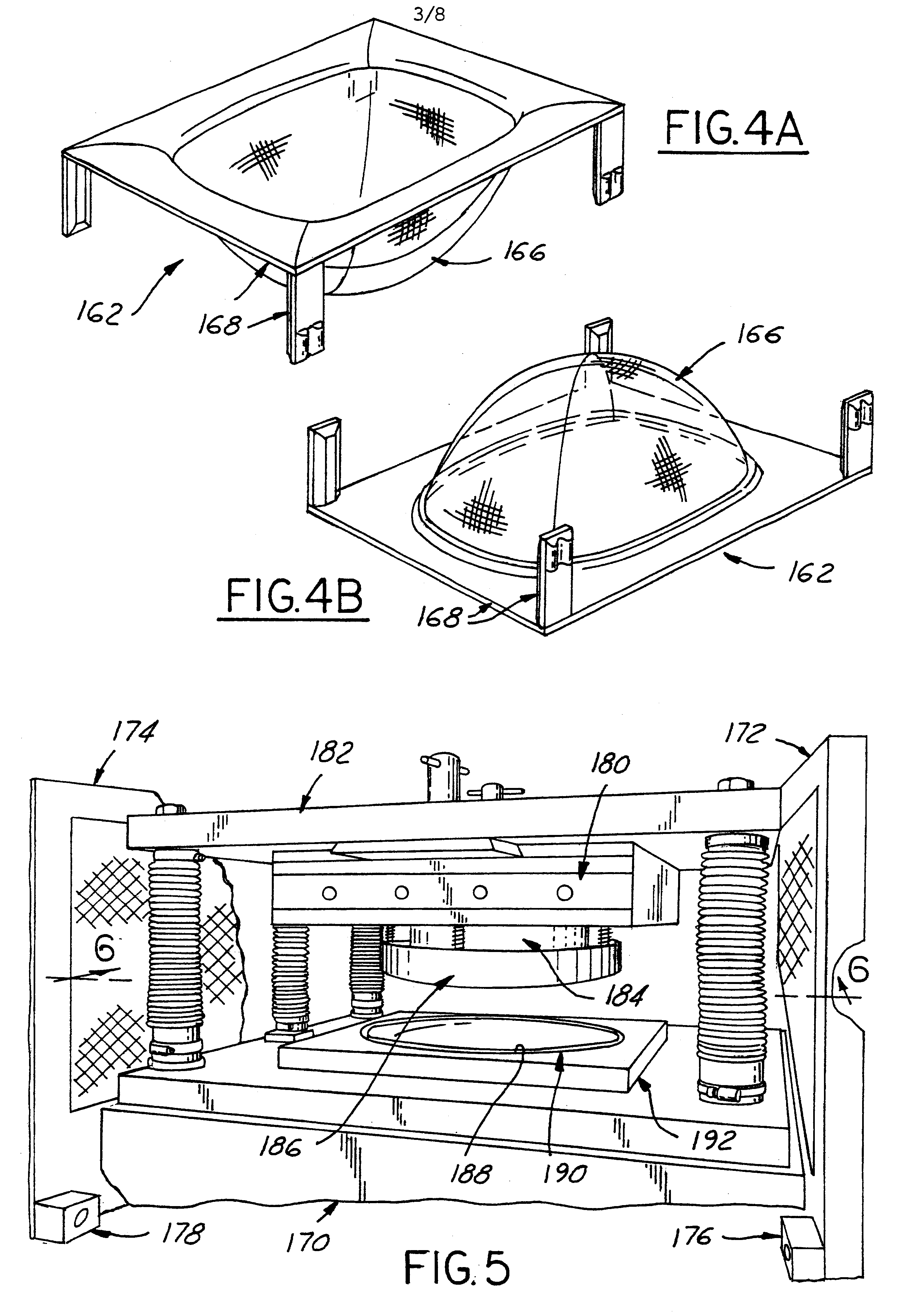

Pizza crust and process and apparatus for making same

InactiveUS6365210B1Increase moistureImprove the finishMilk preservationDough treatmentMoisture absorptionSugar

A method of preparing parbaked food products, such as pizza crust shells, apparatus and dough formulation used therein, and the product produced by the process. The process comprises the steps of providing a dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed. The prepared dough piece is then steam hydrated under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition is adjusted selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough.

Owner:M & M HLDG

Production process of solidified brown yogurt, and product of process

ActiveCN103141572AEnhances gel strength and water holding capacityThick and smoothMilk preparationFlavorChemistry

The invention relates to a production process of solidified brown yogurt and a product of the process, which belong to the technical field of liquid milk processing. The production process comprises the following steps of: uniformly mixing 87.5%-90.5% of raw milk, 7.5%-8.5% of edible sugar, 1.5%-2.5% of whey protein and 0.5%-1.5% of milk protein concentrate in percentage by weight, and performing homogenization, sterilization for browning, cooling, inoculation, bottling, fermentation and cold storage on the mixture to obtain the yogurt. The process can be used for producing the solidified brown yogurt having the characteristics that the curd is firm, no whey is separated out, the color is brown, the mouthfeel is thick and smooth, and the yogurt has a pleasant Maillard flavor. By virtue of the process, under the condition that no additive needs to be used, the jelly strength and the water retention property of the yogurt can be improved, so that the solidified brown yogurt is thick and smooth in mouthfeel and has the pleasant Maillard flavor; and in logistic and sale links, the mechanical disruption resistance of the yogurt is high, and no whey is separated out in the shelf life of the yogurt.

Owner:HANGZHOU NEW HOPE BIMODAL DAIRY CO LTD

Process for the co-manufacture of ingredients for use in foods and beverages using potatoes as starting material

InactiveUS20010041199A1Reduce the amount requiredPrevent enzymatic browningBeer fermentationAlcoholic beverage preparationBiotechnologyFruit juice

Disclosed is a process for the co-manufacture of ingredients having food and beverage applications, using potatoes as starting material. The process comprises six steps. The first step is a cutting and dipping of washed raw potatoes in an anti-oxidant solution. The second step is an extraction of undiluted juice free of starch and fibers from a purée made from the anti-oxidant-dipped raw potatoes. The third step is a concentration and enzymatic treatment of the juice. The fourth step is a heating of the juice to specific temperatures to cause precipitation of proteins and separation of precipitated protein therefrom. The fifth step is a thermal browning of the clear juice. The sixth step is an adjustment of the final pH of the juices of the fourth and fifth steps and a blending of these juices in ratios appropriate for intended use. These six steps yield products which may be used as the main flavor principle in malt-free beer, as a coffee substitute and as a flavor enhancer in savory mixes. They also yield dietary fibers, a concentrated edible protein and non-gelatinized granular starch, thereby increasing revenues derived from potato processing while minimizing liquid waste stream.

Owner:SENSICULTURE FY BIOTECH

Low-alcohol ice wine and brewing process thereof

The invention discloses low-alcohol ice wine. The brewing process comprises the following steps of: harvesting grapes, sorting, squeezing, diluting, fermenting, clarifying, resisting oxidation, freezing, degerming, filtering and filling. The invention adopts a temperature-controlled oak barrel fermentation process, converts part of glucose into gluconic acid at the initial period of fermentation by adding GOX, and lowers the generation quantity of ethanol, thereby lowering the alcoholic strength of the wine. After wine liquor is clarified, SO2 and EDTA are adopted to carry out synergic anti-oxidation processing, which reduces the use quantity of the SO2 greatly, lowers the influence of sulfite on the quality of the wine and also lowers the browning degree of the wine liquor effectively. The invention has the advantages that the color and the taste of the wine are enhanced, the wine has full-bodied wine fragrance and oak fragrance and more conforms to the healthy drinking requirements of modern people, and the alcoholic strength is also lowered.

Owner:山东中科生物创新产业园管理有限公司

Processing method of soybean milk raw material and preparation technology of soybean milk

Owner:JOYOUNG CO LTD

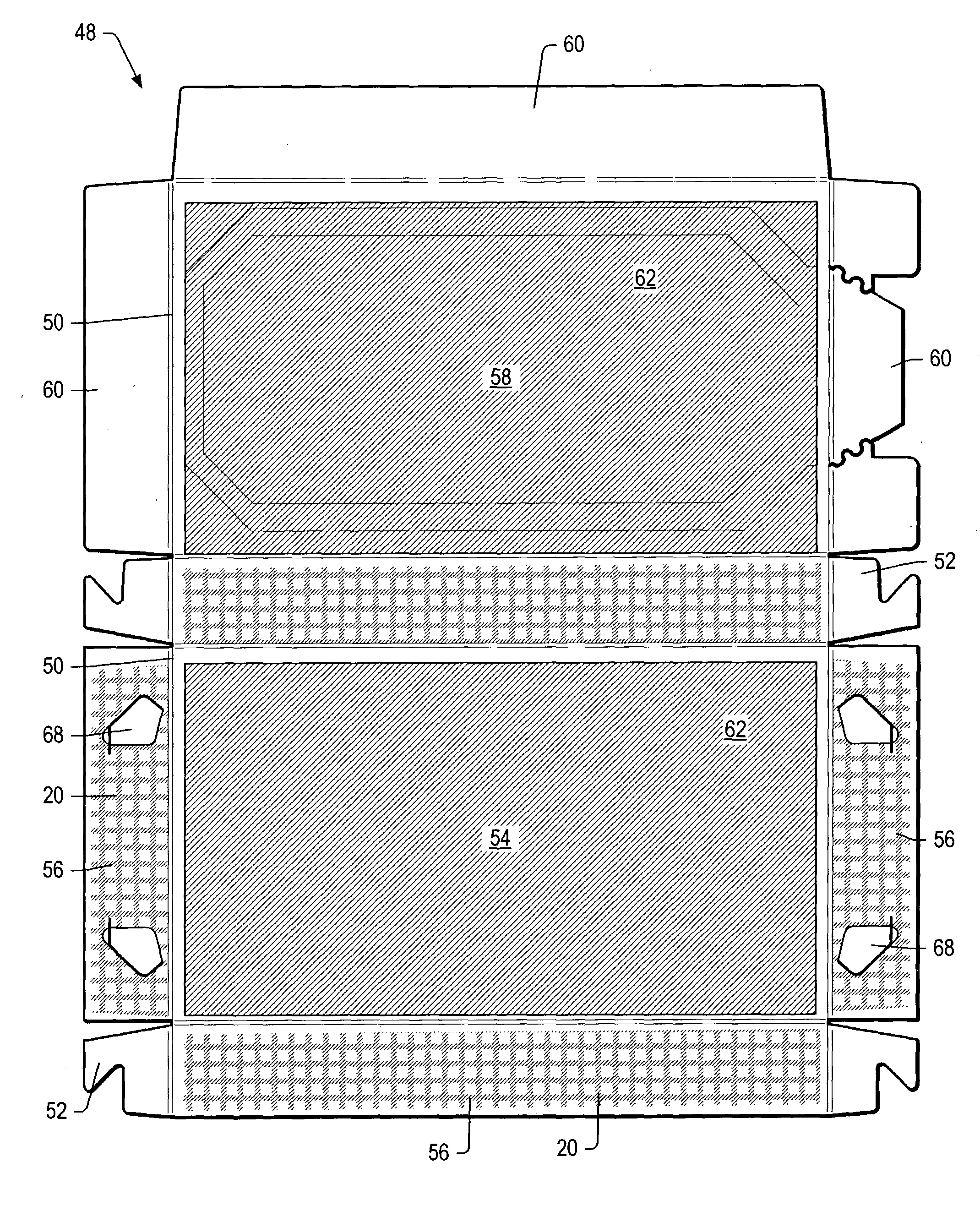

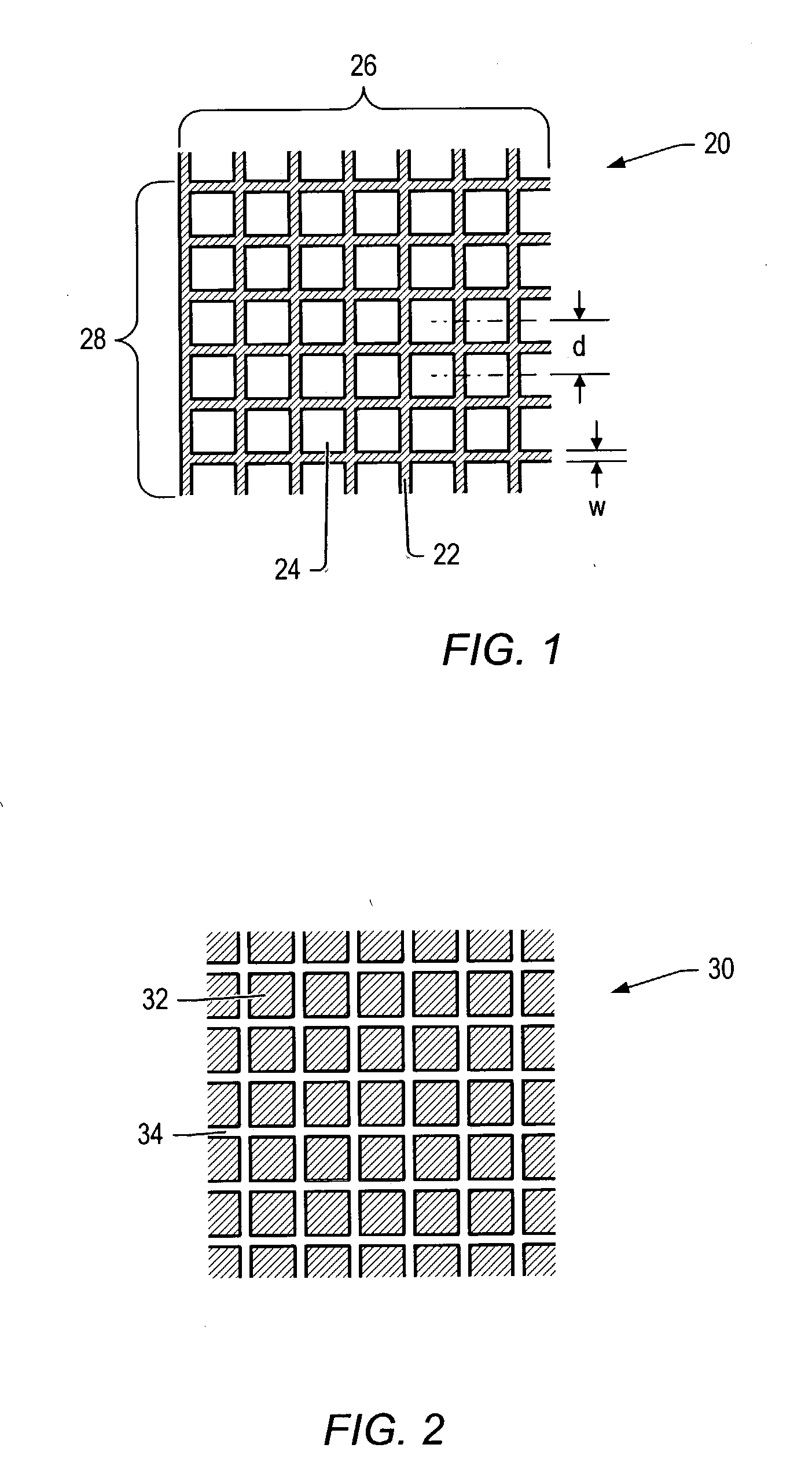

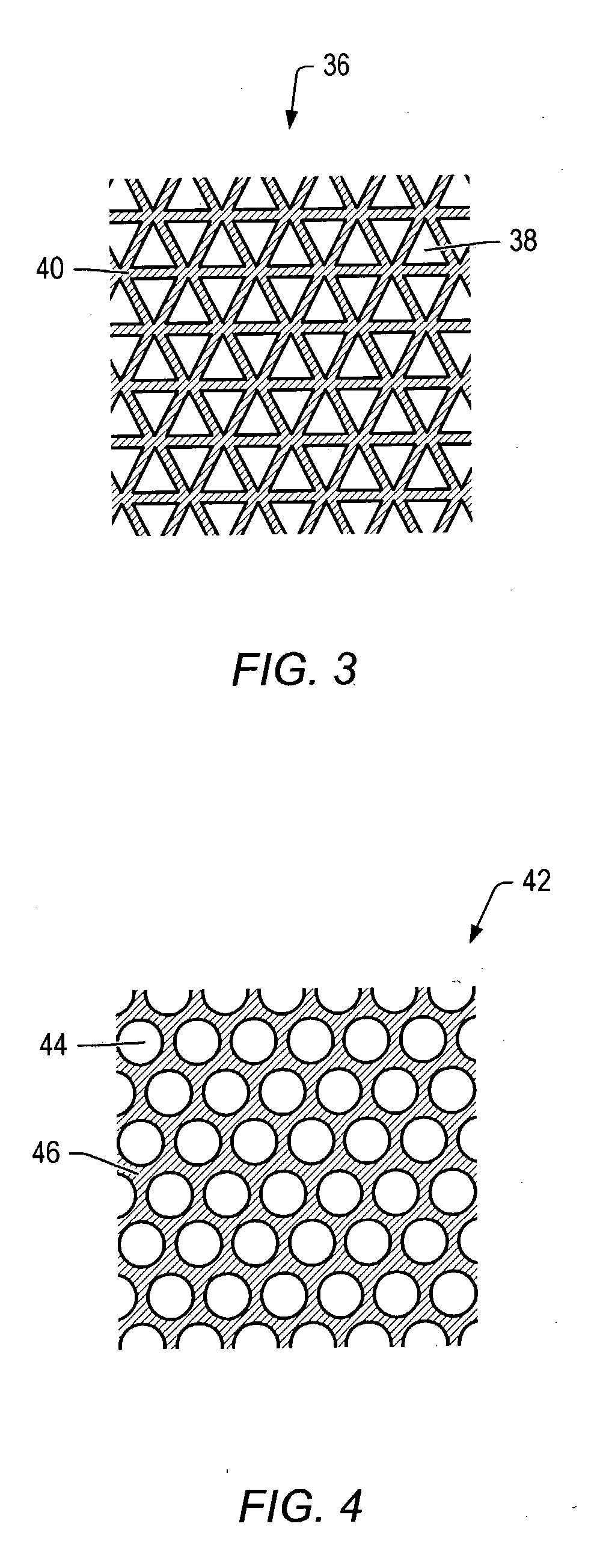

Package for microwave cooking

A microwavable package may include one or more microwave-absorbing regions, microwave-shielding regions, and / or embossed regions designed to enhance microwave cooking of food products including raw meat, poultry, and fish as well as breaded, battered, and dough containing items. Microwave-absorbing regions (i.e., solid susceptors) may promote thermal cooking, browning, and / or crisping of food products. Microwave-shielding regions (i.e., patterned susceptors) may promote uniform cooking and inhibit overcooking of food products. A patterned susceptor may be a conductive grid or a grid of conductive or non-conductive shapes (e.g., squares, triangles, circles). In an embodiment, solid susceptors and patterned susceptors may be formed from a common thin metal film on a common polymer barrier layer and laminated to a common structural backing layer. An embossed region of a microwavable package may promote crisping of a food product by allowing air to circulate between the food product and an interior surface of the microwavable package.

Owner:MICRO CHEF

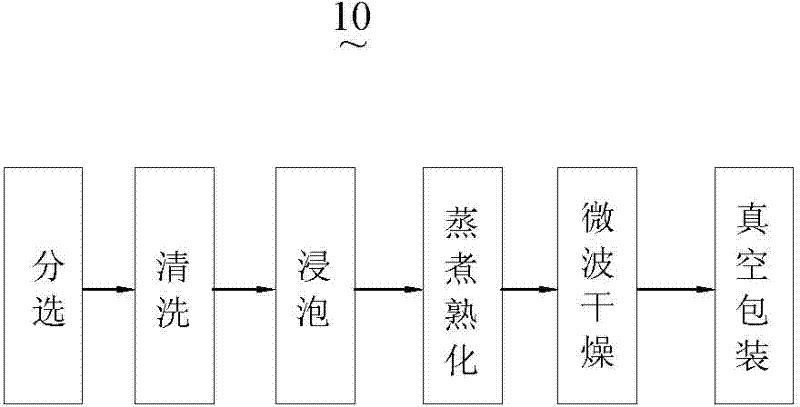

Dried persimmon processing method

The invention discloses a dried persimmon processing method. The processing is executed by combining microwave sterilization and baking in a baking room of a heat pump. The method comprises the specific steps of: selecting persimmon fruits, sterilizing the persimmon fruits, baking the persimmon fruits, softening the persimmon fruits, removing bitterness, stacking and covering, shaping, packaging and scattering flour. In the method, the microwave sterilization is used, microorganisms on the surfaces of the persimmon fruits can be quickly killed, so that the persimmon fruits can be prevented from going bad during the processing; furthermore, polyphenol oxidase (PPO) in the persimmon fruits can be killed; the brown stain of the persimmon fruits can be prevented; during the processing of dried persimmon, most working procedures can be executed in the baking room; the continuity is high; the pollution of the dried persimmon is avoided; the dried persimmon production efficiency is improved; the production cost is reduced; the dried persimmon processing method is easy to operate and low in investment; the quality of the dried persimmon is controllable; and the dried persimmon processing method is suitable for large-scale industrial production.

Owner:桂林普兰德生物科技有限公司 +1

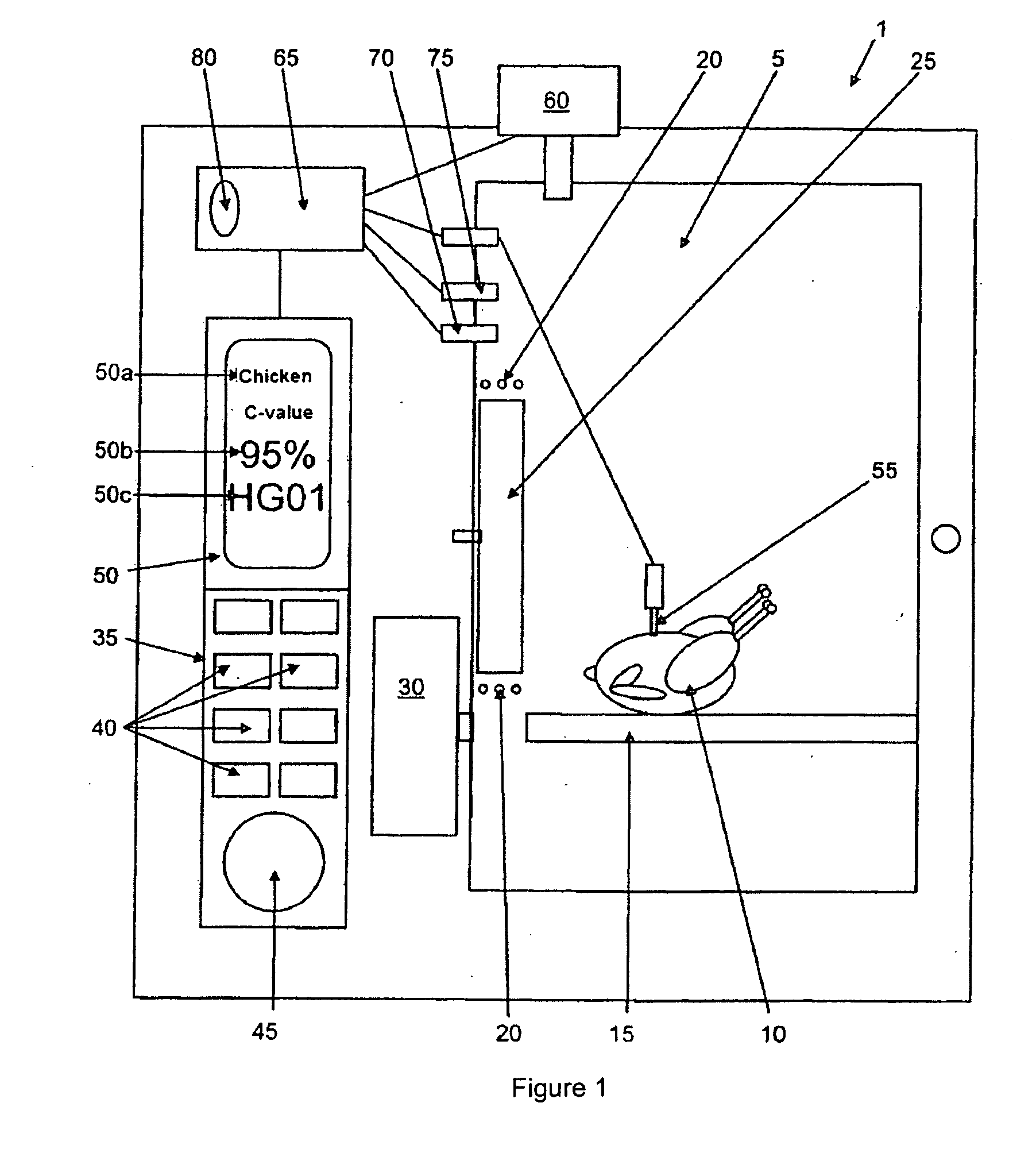

Method and cooking appliance for cooking according to the c-value

ActiveUS20090061070A1Overcome disadvantagesSuitable for processingDomestic stoves or rangesLighting and heating apparatusProcess engineeringCore temperature

A method for the cooking of a cooking product in a cooking appliance with a cooking chamber that comprises at least one heating device, a computer device, a memory device and at least one sensor device, is carried out, in dependence on a degree of cooking of a cooking product and / or of a cooking duration, in particular determined by the core temperature, the browning, the pH value and / or the cooking value, from values measured by the sensor device with consideration of the at least occasionally deposited values in the memory device via the computer device, wherein at least two steps separated from one another in time, comprising a pre-cooking step, which is interrupted when a determined intermediate value of the degree of cooking and / or of the duration of cooking, in particular a determined remaining time for reaching the cooking duration is reached, and a finishing cooking step, in particular a finishing step that is recalled at a later time point in order to end the cooking of the cooking product with consideration of the intermediate value.

Owner:RATIONAL AG

Farinaceous surface product that is toaster reheatable and method

A protective coating or film is applied to at least a portion of the outermost surfaces of the outermost layers of a farinaceous product including a high solid fat index lipid or hard butter to form an outer high solid fat index layer. Reheating the product in a toasting environment from a refrigerated or frozen state causes the high solid fat index layer to transfer heat into the interior of the food product by continuously melting and resolidifying in a controlled way to limit toasting while absorbing into the surface of the product at a rate limited by the high solid fat index. The film serves as a protective barrier which limits toasting (i.e., browning) in the toasting environment by conducting heat into the interior of the product and to prevent moisture escape from the product during refrigerated or frozen storage and during the reheating process.

Owner:SMTM GROUP

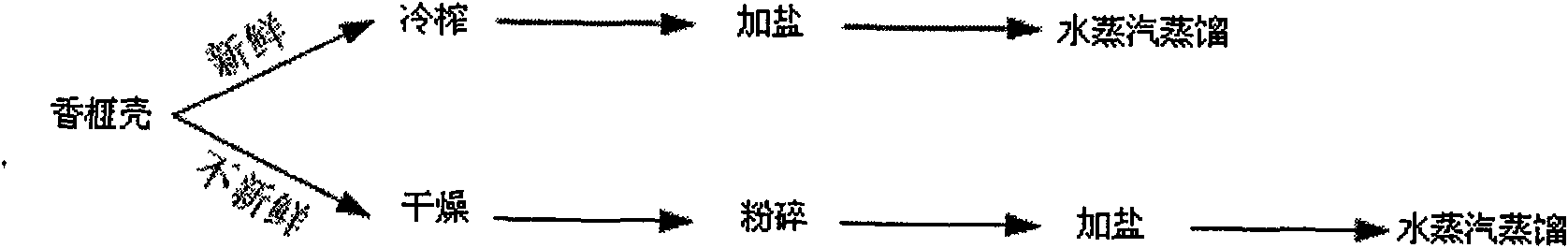

Extraction method of Chinese torreya shell essential oil

InactiveCN101550378ASimple and efficient extractionSolve the use problemEssential-oils/perfumesWater vaporSteam distillation

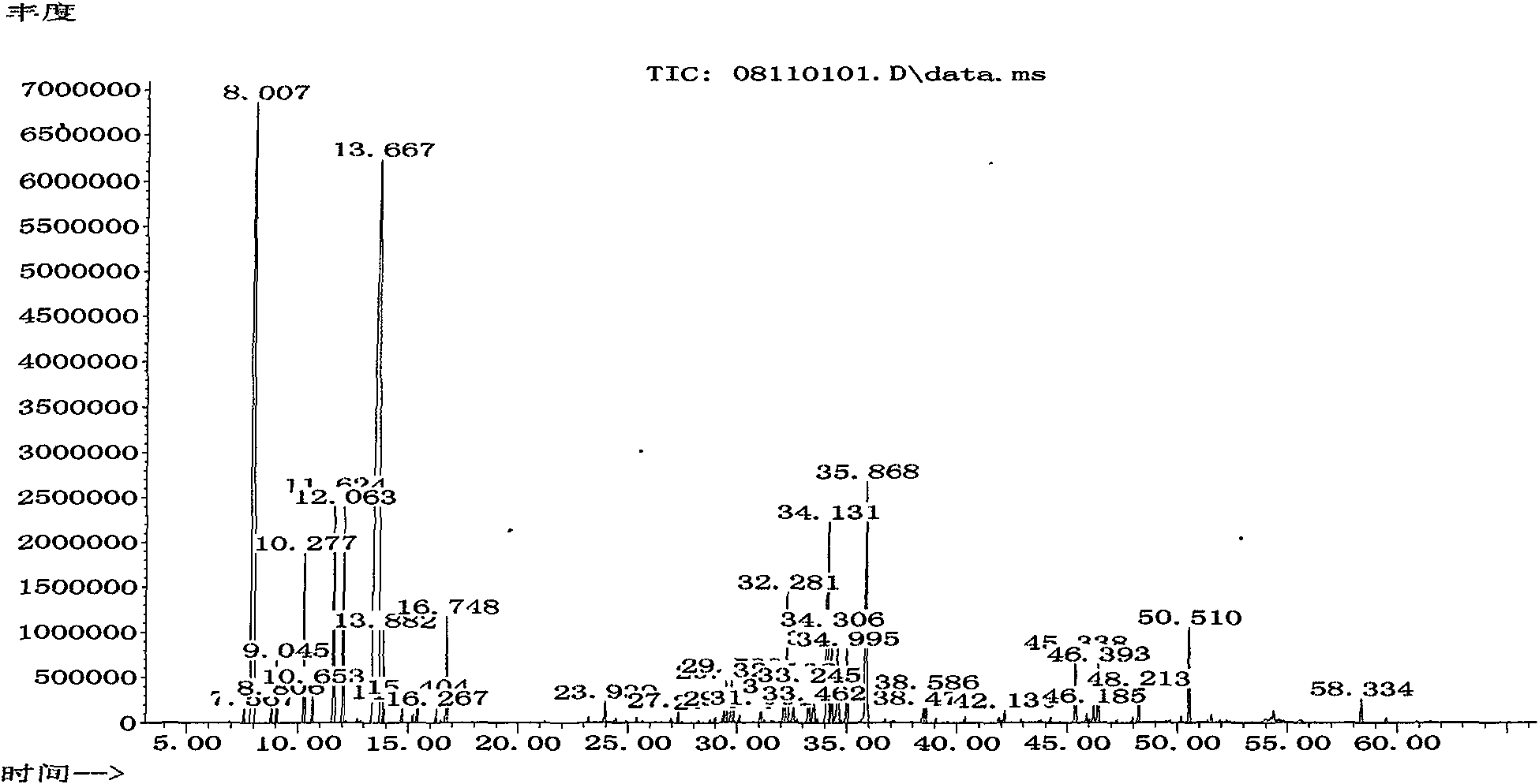

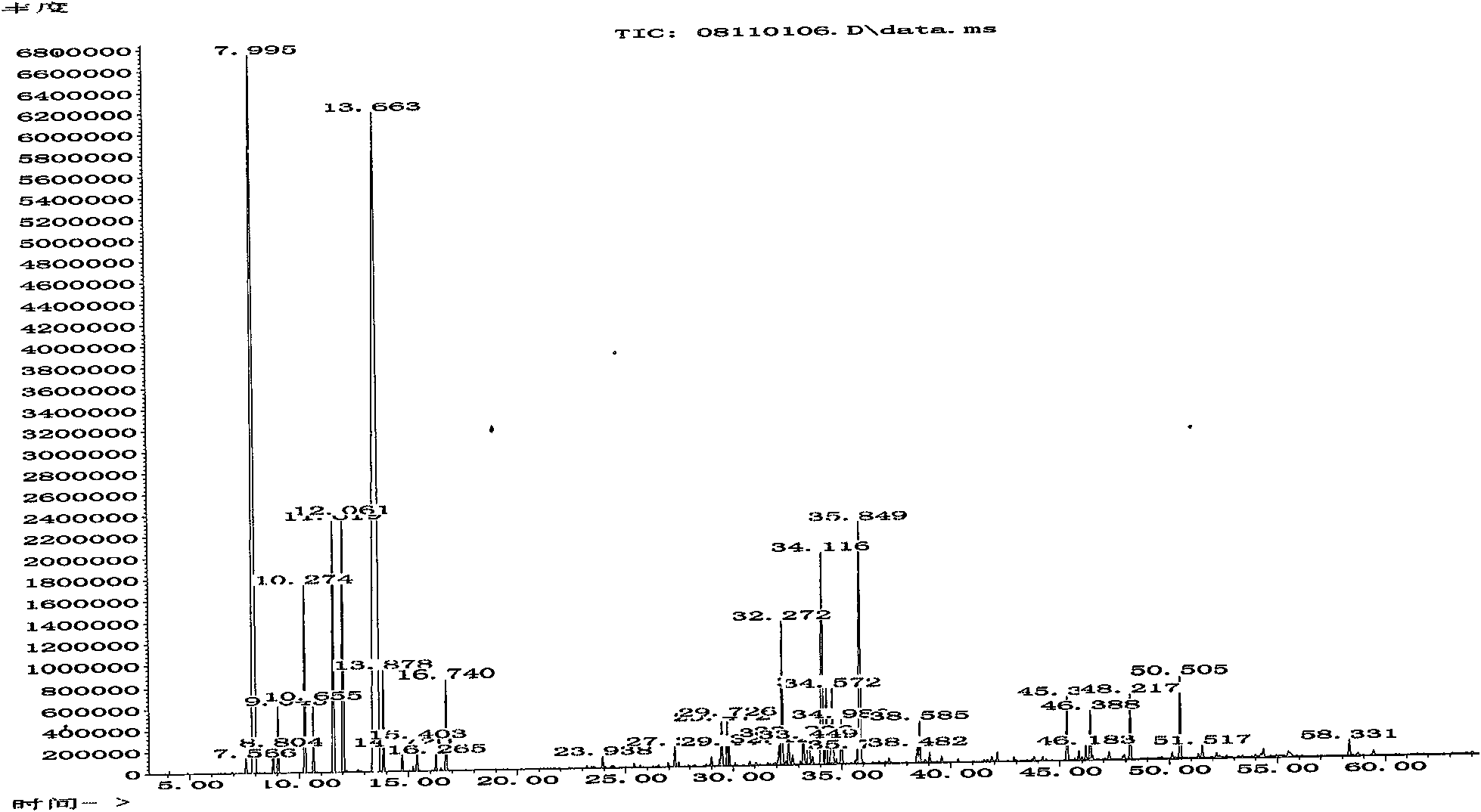

The invention relates to an extraction method of essential oil and selects two technological extraction ways depending on the difference of freshness of the Chinese torreya shell raw material. As regard to fresh Chinese torreya shells, namely the Chinese torreya shells stored for no more than 1 day under normal temperature and pressure, and a method of first cold pressing and then steam distillation can be adopted; as regard to stale Chinese torreya shells, namely the Chinese torreya shells stored for more than 1 day under normal temperature and pressure and serious browning occurs, a method of first drying, then grinding and finally steam distillation can be adopted. The oil yields of the Chinese torreya shell essential oils obtained by the two extraction methods are respectively 0.3-0.5 percent (v / w, wet basic weight) and 1-1.25 percent (v / w, dry basic weight). By GC-MS analysis and electronic nose comparison, the flavour and constituents of the two essential oils are quite similar. By adopting different extraction processes according to the difference of freshness of the raw materials, the invention finally utilizes the steam distillation technology to extract the Chinese torreya shell essential oil and the method is characterized by safety, convenience, high efficiency, low cost, etc.

Owner:SHANGHAI INST OF TECH

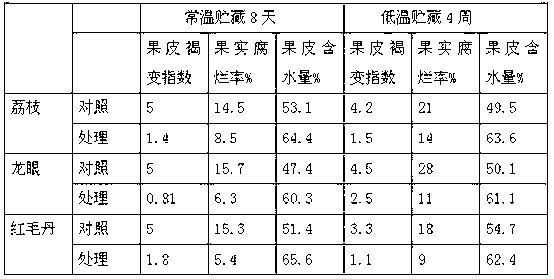

Preservation technology of litchi, longan or rambutan

InactiveCN103283812AKeep aliveMaintain disease resistanceFruit and vegetables preservationBiotechnologyBrowning

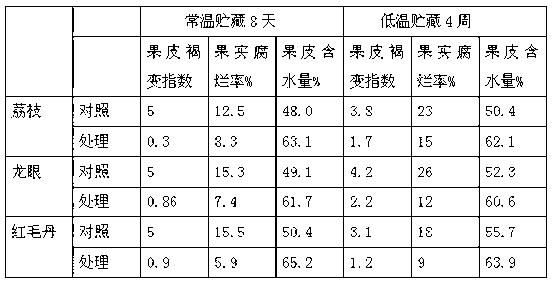

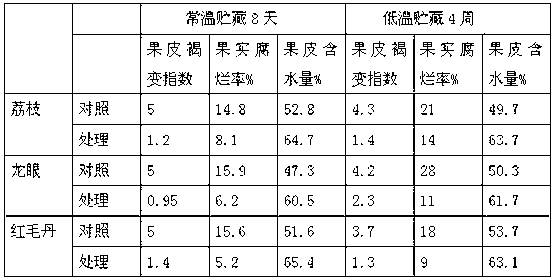

The invention relates to the technical field of fruit preservation, and specifically provides a preservation technology for litchi, longan or rambutan in sapindaceae. The litchi, longan and rambutan are hardest preserved fruits, the fast browning of the peel is the most important problem influencing the preservation and sale; the water loss of the peel is the key factor causing the browning of the litchi, longan and rambutan; since the peel of the fruit in sapindaceae is loosen in structure and the water loss of the peel cannot be supplemented from the pulp, the water is fast lost and the peel is fast brown. The method provided by the invention comprises the following steps of: performing selecting and preservative and fresh-keeping on the mature fresh litchi, longan or rambutan with carpopodium or spur by routine, adopting a water-absorbing material or directly providing a water source at the carpopodium or spur so that the fruit is capable of actively absorbing water to maintain the high water content of the peel and the inherent color of the fruit, the peel browning is delayed, and the fruit rotting rate is reduced.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing okra tea biscuits

InactiveCN103431018AFit for consumptionWide variety of sourcesDough treatmentBakery productsBiotechnologyVegetable oil

The invention provides a method for preparing okra tea biscuits. The method comprises the following steps: mixing 5-10 parts by weight of okra juice, 2-3 parts by weight of tea powder, 25-40 parts by weight of corn flour, 100-120 parts by weight of low gluten powder, 10-15 parts by weight of xylose and 10-15 parts by weight of vegetable oil, adding water to the mixture, kneading the mixture into dough, and then carrying out forming treatment; and baking the formed dough, and cooling to obtain the okra tea biscuits. The method for preparing okra tea biscuits has the advantages that okra and green tea resources which have relatively high nutrition and healthcare functions can be fully developed and utilized, the produced biscuits can be effectively prevented from oxidizing and browning, the storage life of the food is prolonged, the adopted green tea is a pure natural green preservative, the using amount of synthesized preservatives is reduced, and the method is in line with the healthy eating idea of wide consumers.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Method for processing wild small trash fish

The invention relates to a method for processing wild small trash fish, which belongs to the technical field of aquatic food processing. The invention has the following steps of: preparing wild small trash fish used as raw materials; cleaning the small trash fish, removing entrails and pickling, pre-dehydrating fish bodies by microwave vacuum drying till moisture content is 15%-18%, and then carrying out vacuum microwave frying to obtain crisp dry fish with moisture content of 6%-7%. The invention adopts two-stage combination treatment technology of microwave vacuum drying and microwave vacuum frying, and solves the difficult problems of crispness and easy breaking in the processing of small trash fish. The processed dried fish has the advantages of low browning level, small puffing, high crispness, low oil content of products, short production period and low energy consumption.

Owner:JIANGNAN UNIV +1

Litch dry-wine and brewing method

This inventionm discloses a method for brewing dry-type lichee wine including taking lichees as the raw material, squeezing them, fermenting with barm at low temperature, hydrolyzing them with bio-enzymes, metabolic controlling fermentation and clarifying and filtering them to get the raw wine, which is processed for stability including: adding metal ionic complexant to coordinate metallic ions in the spirit to suppress browning of non-biologies, adding silica gel at low temperature to adsorb cold turbid proteins in the spirit and adding bio-antioxidation enzyme resisting against oxidation browning of the lichee wine.

Owner:广东荔枝庄园酒业有限公司

Fermented soymilk beverage and preparation method thereof

ActiveCN104719490AHigh extraction rateUniform systemMilk substitutesFood scienceBiotechnologyGellan gum

The invention provides a fermented soymilk beverage. In terms of a total weight of 100 weight parts, the fermented soymilk beverage comprises the following raw materials: 3-10 parts by weight of soybean, 0.5-15 parts by weight of white granulated sugar, 3.0-9.0 parts by weight of reducing sugar, 0.21-0.65 parts by weight of a thickening agent and 0-0.20 parts by weight of an acidity regulator. The fermented soymilk beverage is prepared by soybean slurry grinding, batching, browning and fermentation. The thickening agent includes pectin, arabic gum and gellan gum, and is added after fermentation. The invention also provides a preparation method of the fermented soymilk beverage. The fermented soymilk beverage product system provided by the invention is uniform, and almost has no floating, precipitation or stratification phenomenon when it is placed at room temperature.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

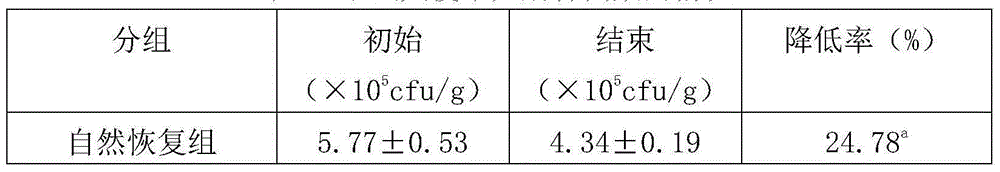

Probiotic foodstuff and preparation method thereof

The invention discloses a probiotic foodstuff and a preparation method thereof. In the fermentation process of yoghourt, a functional starter, germinated brown rice, Chinese herbal medicine extract with anti-heat-and-cold irritability and a stabilizing agent capable of effectively enhancing stability are added; temperature-varying yoghurt fermentation enables propagation of lactic acid bacteria to be maximized and anti-heat-and-cold stress capability of lactic acid bacteria to be improved; non-thermal processing technology is employed for pretreatment of yoghurt and fruit and vegetable pulp so as to prevent infection with infectious microbes in preparation process, improve juice yield of the fruit and vegetable pulp, increase the content of soluble cellulose in the fruit and vegetable pulp and prevent browning of the fruit and vegetable pulp; and a scientifically compounded cryoprotectant with good anti-refrigeration effect is added during mixing of the fruit and vegetable pulp and the yoghurt. Eventually, the prepared probiotic foodstuff has fine mouthfeel, uniform texture, stable state, natural quality, a great number of live bacteria, strong functionality and long shelf life, wherein the content of the live bacteria is 1.75 * 10<11> to 2.55 * 10<11> CFU / g, and the shelf life is 30 to 36 months at normal temperature.

Owner:邵素英

Instant tea paste and processing technology thereof

The invention relates to instant tea paste and a processing technology thereof. The technology comprises the following steps: performing light-degree freezing and microwave treatment, mixing with circulating water, ultrasonic extracting, concentrating in low temperature and vacuum, freeze-drying and shaping in vacuum and the like. Through light-degree freezing, more effective ingredients can be extracted and flavor substances and pigment of tea can be reserved. Through microwave treatment, tea cells are broken, which is beneficial to improving extraction efficiency; and the heat generated by microwave treatment is absorbed by ice crystal, thus having no high-temperature reaction on tea and less loss on the flavor substances and the pigments of tea. Mixing with low-temperature circulating water is combined with ultrasonic extracting to realize low-temperature extraction with short extraction time, high extraction yield and high extraction efficiency of effective components in tea up to over 80%, less damage to the original color, flavor and nutrient substances, and better taste. The instant tea paste especially overcomes the defects of easy browning of color of the traditional tea paste.

Owner:上海美泰投资管理有限公司

Beverage of Chinese chestnut, and preparation method

InactiveCN1957772AYellowish colorImprove stabilityFood preparationMilk substitutesNutritive valuesFiltration

A chestnut beverage with high nutritive value is prepared from chestnut, sweetening agent, souring agent, stabilizer, and oligose through choosing chestnut, removing shell and film, grinding, protecting color, filtering, liquefying, boiling, saccharifying, mixing, homogneizing, filling it in containers, and sterilizing.

Owner:SHENYANG AGRI UNIV

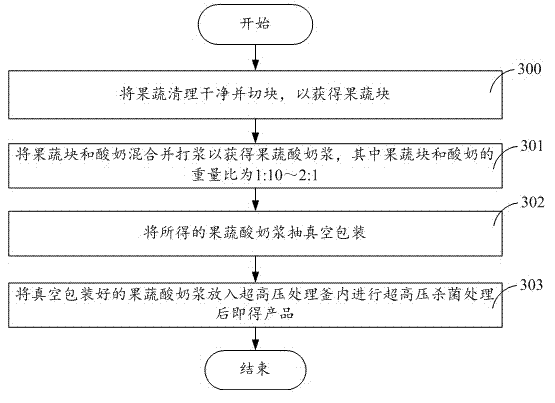

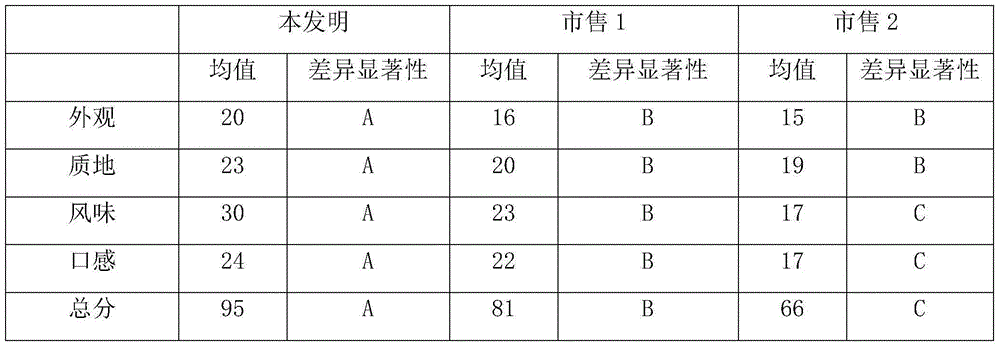

Preparation method of fruit/vegetable yoghourt pulp

The invention discloses a preparation method of fruit / vegetable yoghourt pulp. The preparation method comprises the following steps: cleaning and slicing fruits / vegetables to obtain fruit / vegetable slices; mixing the fruit / vegetable slices with yoghourt, and performing pulping to obtain the fruit / vegetable yoghourt pulp, wherein the weight ratio of the fruit / vegetable slices to the yoghourt is 1:(10-2):1; performing vacuum packaging on the obtained fruit / vegetable yoghourt pulp; putting the vacuum-packaged fruit / vegetable yoghourt pulp into an ultra-high-pressure treatment kettle, and performing sterilization treatment under ultra-high pressure to obtain a fruit / vegetable yoghourt pulp product. According to the preparation method of the fruit / vegetable yoghourt pulp, browning during and after pulping of the fruits / vegetables is suppressed by using various browning-suppressing chemical components in the yoghourt; meanwhile, through the nutrition mixing of the yoghourt and the fruits / vegetables, the fruit / vegetable pulp is comprehensive in nutrition. Compared with a heat sterilization technology, an ultra-high-pressure sterilization technology for the fruit / vegetable yoghourt pulp has the advantage that the original color, nutrition and rheological characteristics of the fruit / vegetable yoghourt pulp product can be well maintained.

Owner:NINGXIA UNIVERSITY

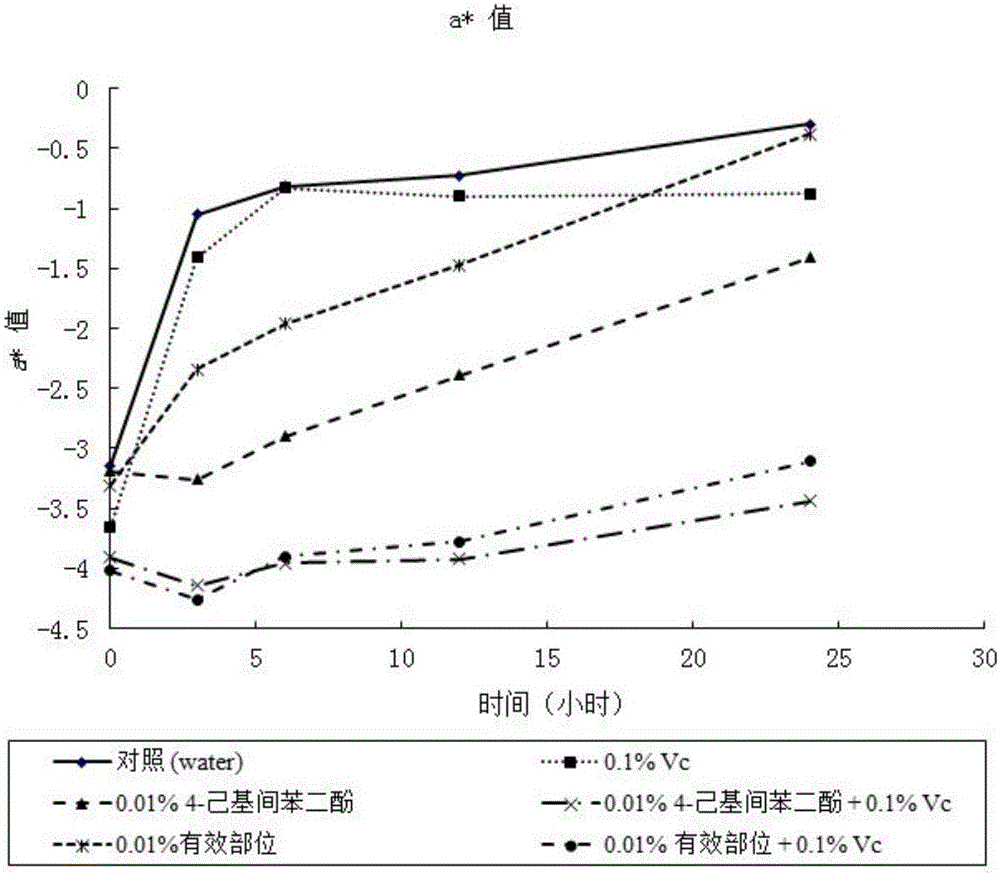

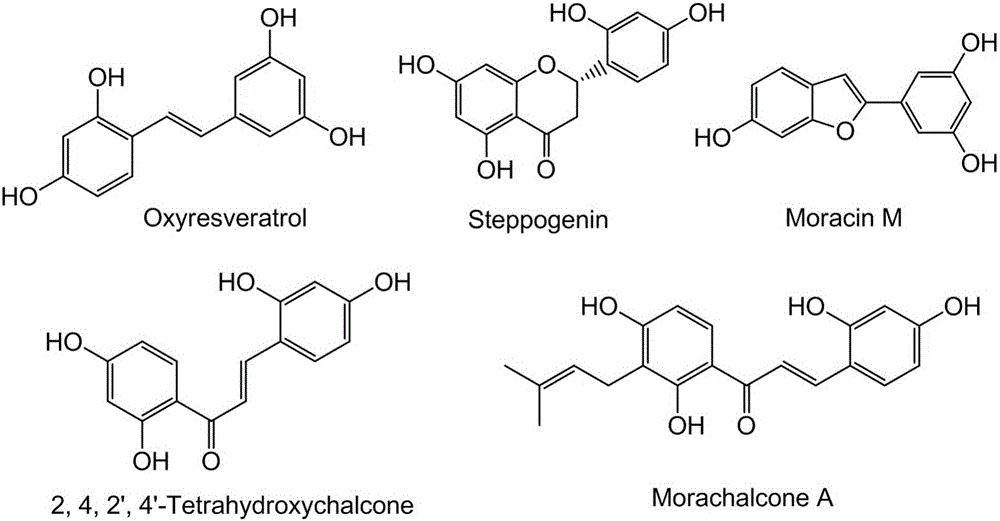

Preparation method and application of mulberry twig effective part with tyrosinase inhibiting effect

ActiveCN106008172AHigh activityImprove quality controlCosmetic preparationsHydroxy compound active ingredientsDiseaseMelanoma

The invention discloses a preparation method and an application of a mulberry twig effective part with a tyrosinase inhibiting effect and belongs to the technical field of medicine and food. The mulberry twig effective part with the tyrosinase inhibiting effect contains five polyphenol compounds which are extracted from mulberry twigs and have tyrosinase inhibiting activity, and the five polyphenol compounds include oxyresveratrol, Steppogenin, Moracin M, 2,4,2',4'-tetrahydroxychalcone and mole Morachalone A. The mulberry twig effective part with the tyrosinase inhibiting effect can be effectively applied to inhibition for enzymatic browning of fruits and vegetables and skin whitening of cosmetics, used for preventing and treating human pigmentation diseases and melanoma caused by excessive melanin, and applied to various preparations of drugs for treating diseases requiring inhibition of tyrosinase activity.

Owner:广州箴美科技有限公司

Brown fermented milk and production method thereof

The invention provides brown fermented milk, which comprises the following raw materials that: 3 to 5 percent of white sugar, 0.2 to 6 percent of glucose and 84 to 90 percent of skim milk, wherein the temperature is increased to 95 to 98 DEG C to be maintained for 1.5 to 2.5 hours during a sterilization step and a fermentation step in the preparation process. The invention also provides a production method of the brown fermented milk. Due to the raw material ingredients and production process, the fermented milk has reaction during the sterilization and the fermentation. The fermented milk is brown, produces brown coloring matters to prevent the automatic oxidation of grease so as to have resistance to oxidation, and is beneficial to the health of the human body.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Freeze-dried tablets and preparation method thereof

The invention discloses freeze-dried tablets and a preparation method thereof. According to preparation method of the freeze-dried tablets, a functional leavening agent, functional germinated brown rice, Chinese herbal medicine extracts with ambient temperature stress resistance, and a stabilizer capable of effectively improving stability are added in the yoghurt fermentation process; through the adoption of a variable-temperature yoghurt fermentation technology, the propagation of lactic acid bacteria is maximized, and the ambient temperature stress resistance of lactic acid bacteria is improved; yoghurt and fruit puree are pre-processed by adopting a non-thermal processing technology, so that the sundry bacteria contamination is prevented during the process, the juice yield of fruit juice is increased, the content of soluble cellulose of the fruit puree is increased, and the browning of the fruit puree is prevented; in addition, a freezing protecting agent scientifically compounded and having better anti-freezing effect is added during the mixing of the yoghurt and fruit puree; finally, the freeze-dried tablets which are delicate in mouth feel, uniform in texture, stable in state, great in quantity of live bacteria, good in functionality and long in shelf life. The content of live bacteria in the freeze-dried tablets is 1.55*10<11>-2.52*10<11> CFU / g, and the shelf life is 30-36 months at the normal temperature.

Owner:邵素英

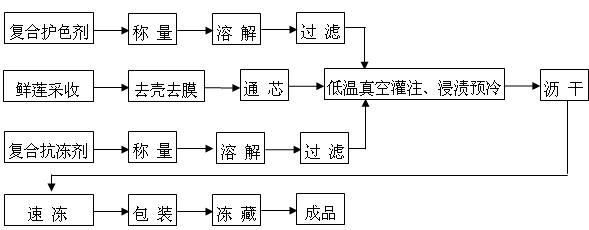

Quick-frozen daylily making method

InactiveCN102599233AMaintain structural propertiesMaintain nutrientsFruits/vegetable preservation by freezing/coolingBrowningProcess engineering

The invention belongs to the technical field of vegetable freezing and freshness preservation, and specifically relates to a quick-frozen daylily making method. The quick-frozen daylily making method comprises the steps of raw material screening, cleaning, scalding, color protecting, water draining, packaging, precooling, quick-freezing and freezing storage. According to the invention, a liquid immersion type quick-frozen technology is applied to the freshness preservation of daylily for the first time, therefore, the structure characteristics and nutritional components of daylily are kept maximumly; and through combining the scalding and the color protecting with the liquid immersion type quick-frozen technology, the problem that the previous daylily after being defrosted is easy to brown is solved; and in addition, equipment adopted in the invention is easy to control, and the method is low in energy consumption and suitable for the mass production of frozen daylily, therefore, the method creates a new way for the development of the daylily industry.

Owner:GUANGDONG KEQI SUPER QUICK FREEZING TECH

A method for preventing brown stain in process of fruit and vegetable pulping by use of liquid nitrogen hypothermia and deoxygenation

InactiveCN1864537AProtect natural colorImprove quality and tasteFood preservationDeoxygenationEnzyme

The present invention discloses liquid nitrogen low temperature fruit and vegetable pulping process without browning and belongs to the field of food processing technology. The technological scheme includes the following steps: sorting fruit or vegetable, washing, microwave deactivation of enzyme, peeling, pre-cooling, crushing, pulping while spraying liquid nitrogen, blending, homogenizing, sterilizing to obtain fruit or vegetable paste product or semi-product, and abacterial packing or further processing. Spraying liquid nitrogen for low temperature no-oxygen pulping can reduce browning of fruit and vegetable, especially tropical and subtropical fruit and vegetable, obviously, and raise quality and taste of fruit and vegetable products.

Owner:杨公明

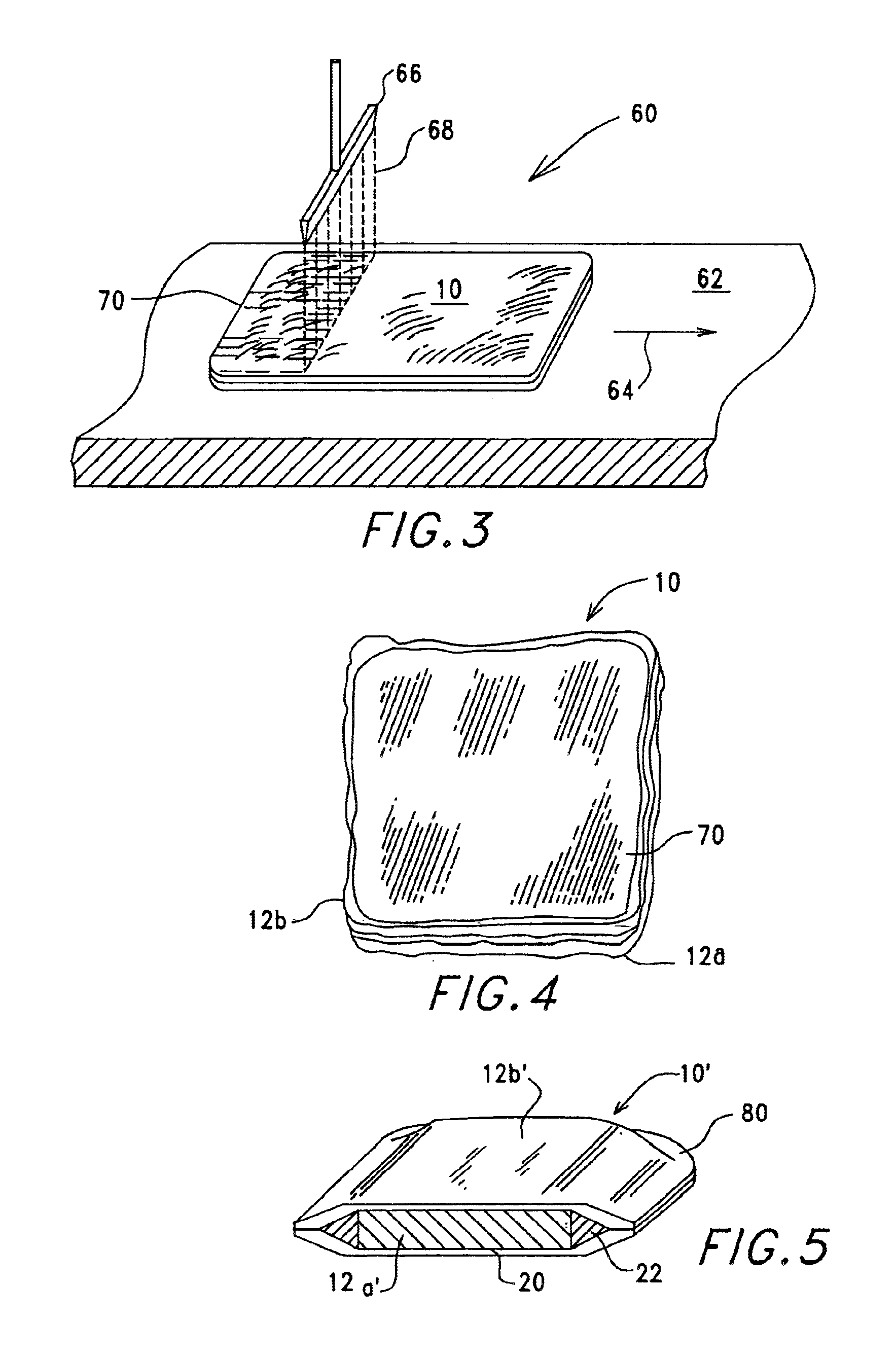

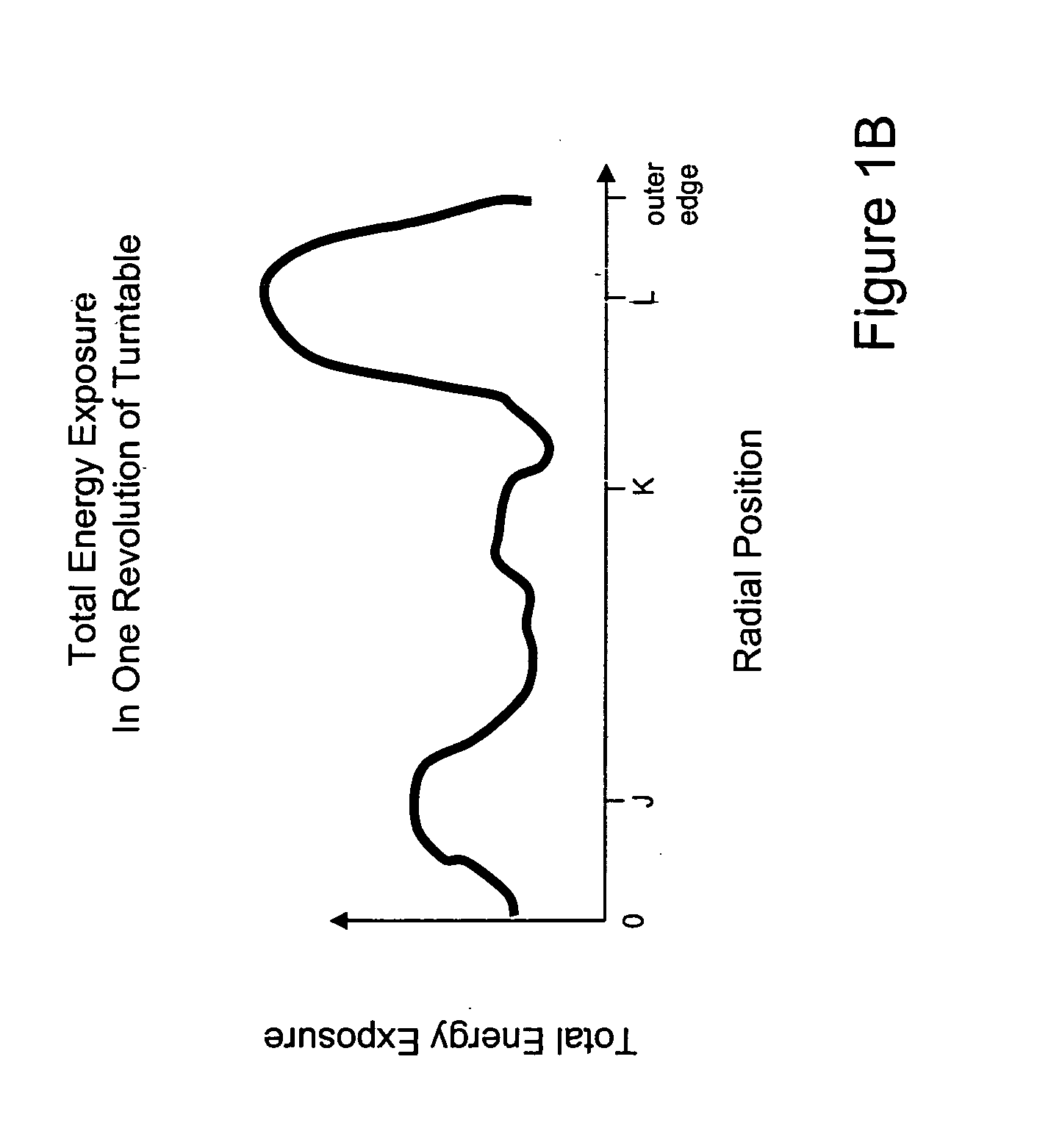

Susceptor assembly and field director assembly for use in a microwave oven

InactiveUS20070187399A1Additional componentUniform effectMicrowave heatingPackagingUltrasound attenuationSusceptor

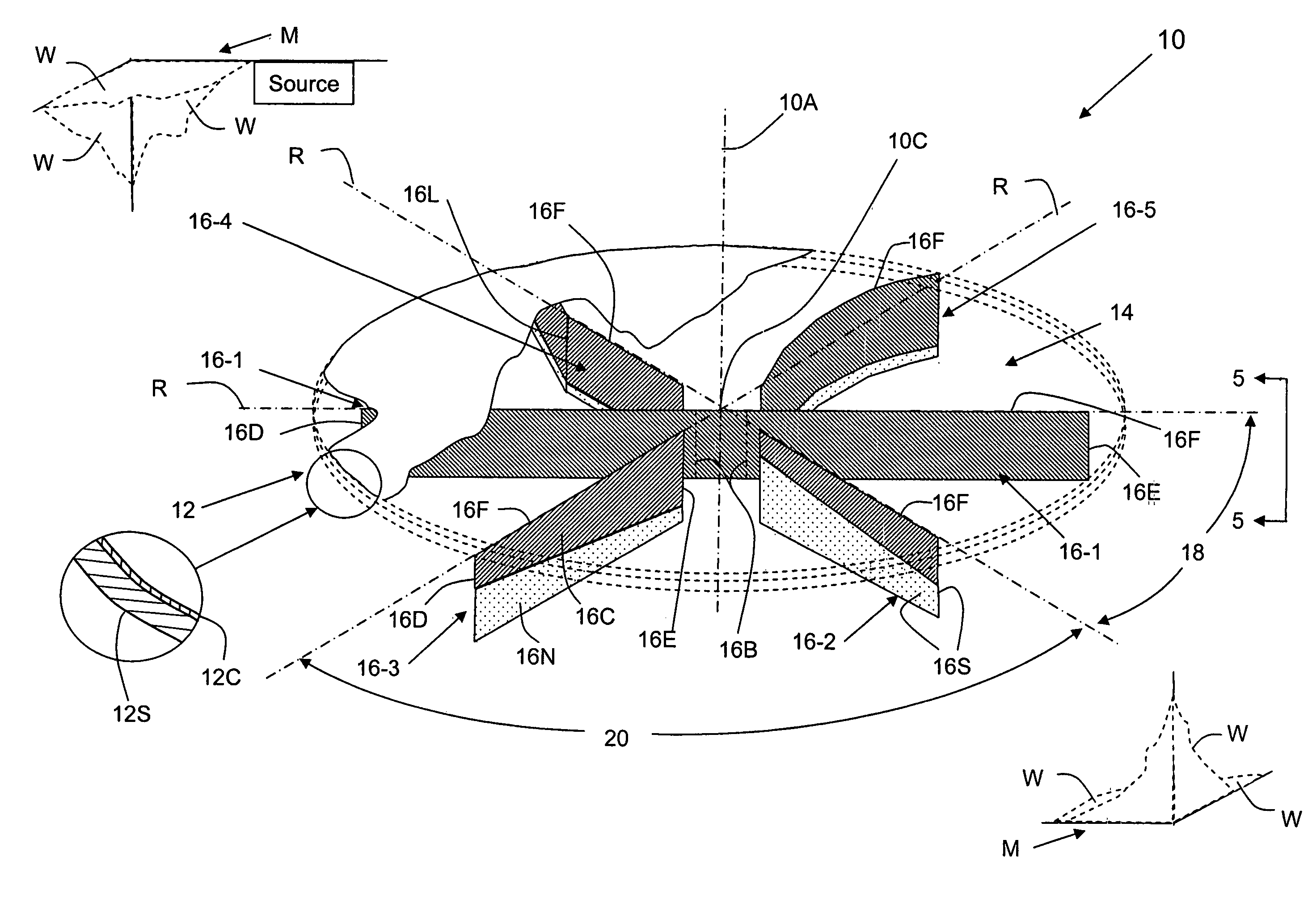

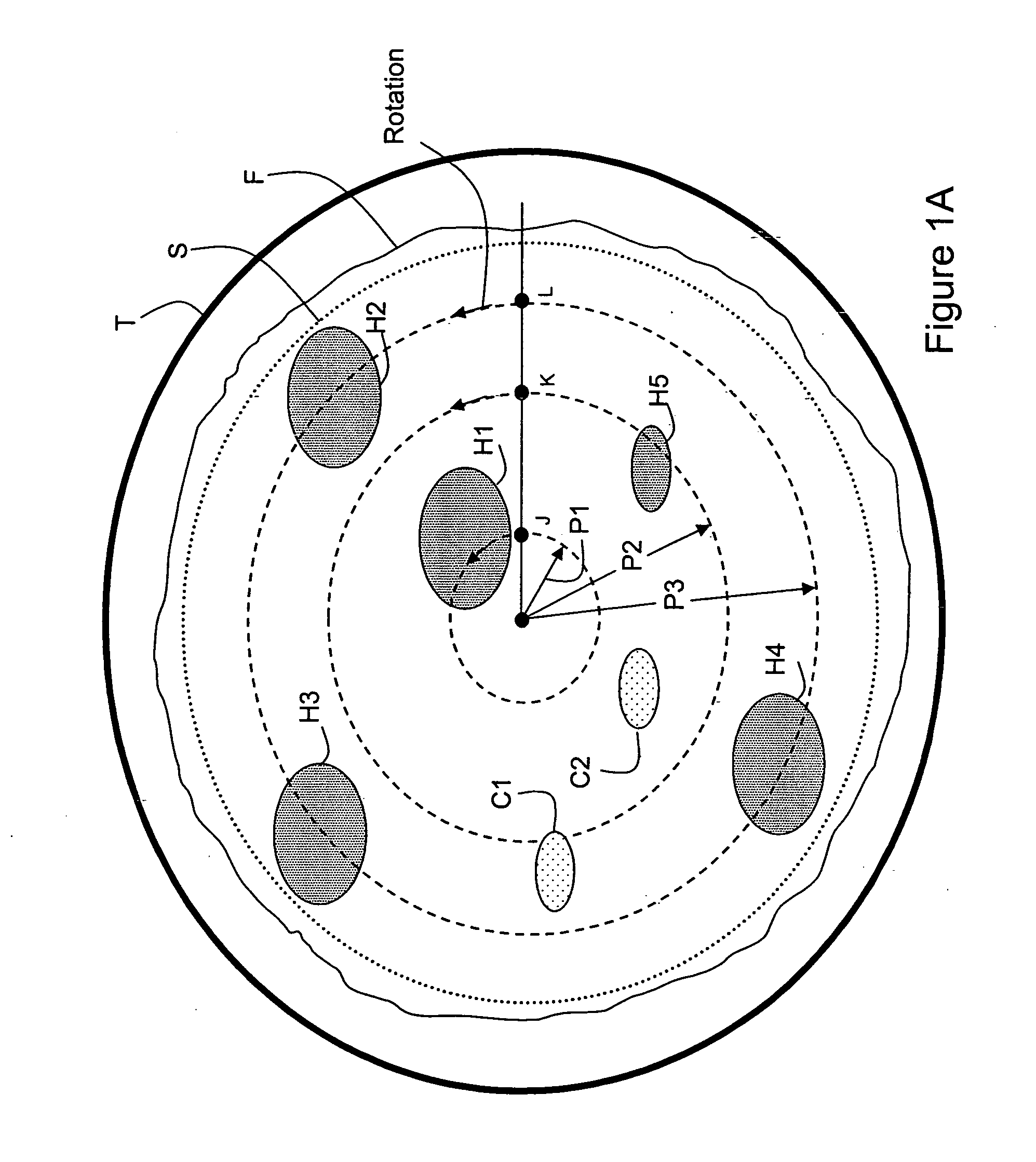

A susceptor assembly comprises a generally planar susceptor having an electric field director structure mechanically connected thereto. The field director structure includes at least one, but more preferably, a plurality of two or more vanes mechanically connected to the susceptor. Each vane has a surface at least a portion of which is electrically conductive. The vane(s) are most preferably disposed substantially orthogonal to the planar susceptor. The connection may be either a fixed or a flexible articulating connection. In use, such as in the presence of a standing electromagnetic wave generated within a microwave oven, only an attenuated electric field component of the electromagnetic wave exists in a plane tangent to the surface of the vane in the vicinity of the conductive portion of the vane. Attenuation of the electric field component of the electromagnetic wave in the plane tangent to the surface of the vane resulting in enhancement of the component of the electric field substantially orthogonal to the conductive surface. Rotation of the susceptor assembly within the oven, or variation of the standing electromagnetic wave generated within the oven (as by a mode stirrer) results in a substantially uniform warming, cooking and browning effect on a food product placed on the planar susceptor.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of dried shitake mushroom and product thereof

InactiveCN102630931AGood colorFull appearanceFood preservationFood preparationBrowningPhenolic content in tea

The invention discloses a preparation method of dried shitake mushroom. The preparation method comprises the following steps: fresh shitake mushrooms are picked, the mushroom stems are cut off, the moisture in the surface of the shitake mushrooms is removed, and pretreated shitake mushrooms are obtained; color fixing solution is uniformly sprayed on the surfaces of the pretreated shitake mushrooms, so color-fixed shitake mushrooms are obtained; the color fixing solution for the shitake mushrooms is the water solution containing calcium chloride, citric acid, tea polyphenol and L-cysteine; and then the color-fixed shitake mushrooms are dried, so that dried shitake mushrooms are obtained. By adopting the method disclosed by the invention to prepare dried shitake mushrooms, the browning of the shitake mushrooms is effectively prevented, and the prepared shitake mushrooms are good in luster, so that the preparation method is applicable to the processing of the dried shitake mushrooms.

Owner:SOUTHWEST UNIV

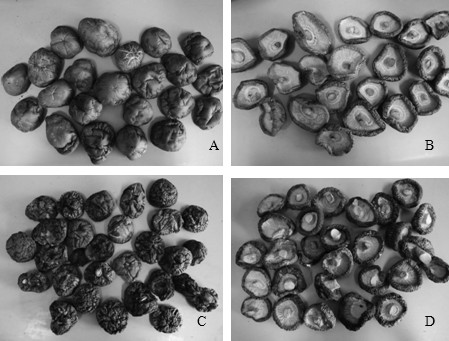

Method for processing quick-frozen fresh lotus

ActiveCN101965860AReduce damage and softenReduce the temperature difference between inside and outsideFruit and vegetables preservationBiotechnologyBrowning

The invention provides quick-frozen fresh lotus processing technology. In the technology, a quick-frozen fresh lotus finished product is obtained by the harvesting of fresh lotus, shelling, stripping, core hollowing, low-temperature vacuum filling, impregnation for pre-cooling, draining, quick-freezing, packaging and cold storage. Due to the adoption of the low-temperature vacuum filling technology to combine pre-cooling, color conservation and anti-freezing processes, the technology inhibits the activity of PPO and POD, prevents the browning of the quick-frozen fresh lotus in the processing and storage, reduces the damage and softening of tissue cells, endows the product with crisp texture and faint scent, improves the ion concentration and osmotic pressure of the cells of the fresh lotus, effectively rises the vitrification transition temperature, promotes the exhaust of air from tissues, reduces the swelling pressure of ice crystals, prevents low-temperature breakage, shortens the processing time, is easy to control, high in operability, less in energy consumption and suitable for the large-scale production of the quick-frozen fresh lotus, and develops a new way for the deep processing of the lotus industry. The product completely keeps the original taste and smell of the fresh lotus, has the faint scent and is convenient to take.

Owner:福建闽江源绿田实业投资发展有限公司

Complex sprouting protein nutrition powder and preparation method thereof

InactiveCN104286729AHigh nutritional valueImprove bioavailabilityFood ingredient functionsFood preparationBiotechnologyBrowning

The invention relates to complex sprouting protein nutrition powder and a preparation method thereof, and belongs to the field of food processing. The complex sprouting protein nutrition powder is prepared through the following steps: firstly, soybean sprouts and peanut sprouts are steamed for 30-50 minutes at 95-100 DEG C, and then subjected to forced air drying at 60 DEG C; secondly, the dried sprouts are smashed into soybean sprout coarse powder and peanut sprout coarse powder with particle sizes of 80-120 meshes at 20-25 DEG C; thirdly, the soybean sprout coarse powder and peanut sprout coarse powder are mixed and smashed into fine powder with the particle sizes of 400 meshes above. According to the complex sprouting protein nutrition powder and the preparation method thereof, the soybean sprouts and peanut sprouts are prepared into powder products for the first time; the bioavailability and the working depth of the soybeans and the peanuts are improved; the utilization rate of the edible parts is improved to 95% above; through the adoption of a steaming method for curing, the brown stain of the soybean sprouts and the peanut sprouts as well as the loss of the effective components in the sprouts are prevented effectively; the protein nutrition powder provided by the invention has the unique fragrance and flavor of the soybeans and the peanuts, and is fresh and pleasing in color and luster, fine and smooth in mouthfeel, low in grease content, and long in storage period.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com