Preparation method of fruit/vegetable yoghourt pulp

A fruit and vegetable acid and milk slurry technology, applied in the field of food processing, can solve problems such as insufficient effect, high energy consumption, complicated operation process, etc., and achieve the effect of maintaining color and luster and comprehensive nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

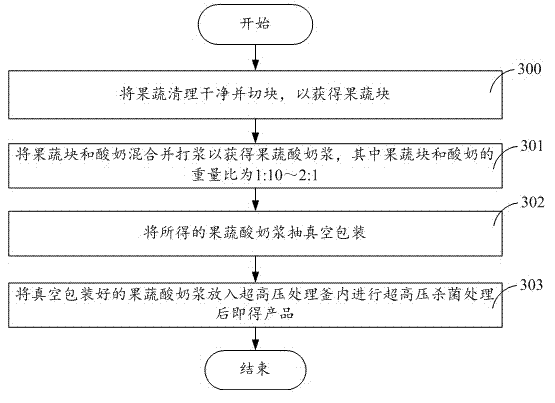

[0016] Please see figure 1 , which is a flow chart of a method for preparing fruit and vegetable yogurt slurry in a preferred embodiment, the preparation method of the fruit and vegetable yogurt slurry includes the following steps:

[0017] Step S300, cleaning and cutting the fruits and vegetables into pieces to obtain fruit and vegetable pieces. Among them, fruits and vegetables include fruits and vegetables, and different fruits and vegetables can be selected according to different eating needs, for example, only select high-quality fruits as raw materials for cutting, or only select high-quality vegetables as raw materials for cutting, or choose fruits and vegetables at the same time Cut into pieces as raw materials, fruits and vegetables can be washed by soaking in water, spraying with water mist, etc. Fruits and vegetables can be selected arbitrarily according to needs, such as bananas, apples, carrots, yams, watermelons and pears.

[0018] Step S301 , mixing and beating...

Embodiment 1

[0022] Embodiment 1, the preparation of banana yoghurt slurry.

[0023] (1) Peel the bananas, cut them into small pieces, weigh them, put the banana pieces into the beater, and then add yogurt at a weight ratio of 1:2 for beating.

[0024] (2) Put the obtained banana yogurt slurry in a flexible packaging bag, vacuum seal the bag, the vacuum degree is 0.09 MPa, and the vacuuming time is 50 seconds, so as to fully discharge the air in the banana yogurt slurry. Wherein, the flexible packaging bag can be a composite nylon bag.

[0025] (3) Put the vacuum-packed banana yogurt slurry into the ultra-high pressure treatment kettle, add water as the pressure transmission medium, then close the ultra-high pressure treatment kettle, and carry out ultra-high pressure treatment, the treatment pressure is 250 MPa, and the treatment time is 60 min.

[0026] (4) Open the ultra-high pressure treatment kettle, take out the banana yoghurt pulp, and obtain a product that has the natural color o...

Embodiment 2

[0027] Embodiment 2, the preparation of yam yoghurt slurry.

[0028] (1) Peel the yam, clean it, cut it into slices, put the yam slices into a beater after weighing, and then add yogurt at a weight ratio of 1:10, and add a small amount of sugar according to taste requirements for beating.

[0029] (2) The obtained yam yoghurt slurry is packed in a flexible packaging bag, vacuumized and sealed, the vacuum degree is 0.075 MPa, and the vacuuming time is 60 seconds, so that the air in the yam yoghurt slurry is fully discharged.

[0030] (3) Put the vacuum-packed yam yogurt slurry into the ultra-high pressure treatment kettle, add water as the pressure transmission medium, then close the ultra-high pressure treatment kettle, and carry out ultra-high pressure treatment. The treatment pressure is 600 MPa, and the treatment time is 6 minutes.

[0031](4) Open the ultra-high pressure treatment kettle, take out the yam yogurt slurry, and obtain a product that has the natural color of ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com