Preparation method of dried shitake mushroom and product thereof

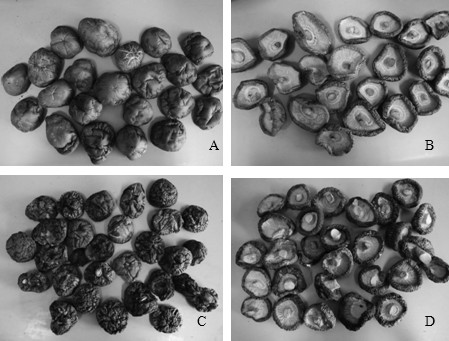

A technology for dried shiitake mushrooms and shiitake mushrooms, which is applied in the directions of food preparation, food preservation, food science, etc., can solve the problems of easy browning and poor color and luster of dried shiitake mushrooms, and achieves the effects of plump appearance, simple method and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of dried shiitake mushrooms comprises the following steps:

[0020] a. Pick fresh shiitake mushrooms, cut off the stipe, and then lay it flat and place it at 4°C for 18 hours to remove the moisture on the surface of the shiitake mushrooms to obtain pretreated shiitake mushrooms;

[0021] b. The surface of the pretreated shiitake mushrooms obtained in step a is evenly sprayed with 7.5mL shiitake mushroom color protection liquid per kilogram of shiitake mushrooms to obtain color protection shiitake mushrooms; wherein the shiitake mushroom color protection liquid consists of 6 parts of calcium chloride, 0.15 parts of citric acid, tea Composed of 0.2 parts of polyphenols, 0.1 parts of L-cysteine and 1000 parts of water, the mushroom color protection solution was heated to 55°C before spraying;

[0022] c. Put the color-protecting shiitake mushrooms obtained in step b into a constant temperature blast drying oven (DHG-9140A electric heating consta...

Embodiment 2

[0025] The preparation method of dried shiitake mushrooms comprises the following steps:

[0026] a. Pick fresh shiitake mushrooms, cut off the stipe, and then lay it flat at 4°C for 24 hours to remove the moisture on the surface of the shiitake mushrooms to obtain pre-treated shiitake mushrooms;

[0027] b. The surface of the pretreated shiitake mushrooms obtained in step a is evenly sprayed with 10mL shiitake mushroom color-protecting liquid per kilogram of shiitake mushrooms to obtain color-protecting shiitake mushrooms, wherein the shiitake mushroom color-protecting liquid consists of 4 parts of calcium chloride, 0.12 parts of citric acid, and more Composed of 0.15 parts of phenol, 0.08 parts of L-cysteine and 1000 parts of water, the mushroom color protection solution was heated to 50°C before spraying;

[0028] c. Put the color-protecting shiitake mushrooms obtained in step b into a constant-temperature blast drying oven (DHG-9140A electric heating constant-temperat...

Embodiment 3

[0031] The preparation method of dried shiitake mushrooms comprises the following steps:

[0032] a. Pick fresh shiitake mushrooms, cut off the stipe, and then lay it flat at 4°C for 24 hours to remove the moisture on the surface of the shiitake mushrooms to obtain pre-treated shiitake mushrooms;

[0033] b. The surface of the pretreated shiitake mushrooms obtained in step a is evenly sprayed with 5mL shiitake mushroom color protection liquid per kilogram of shiitake mushrooms to obtain color protection shiitake mushrooms; wherein the shiitake mushroom color protection liquid consists of 8 parts of calcium chloride, 0.18 parts of citric acid, tea poly Composed of 0.25 parts of phenol, 0.12 parts of L-cysteine and 1000 parts of water, the mushroom color protection solution was heated to 60°C before spraying;

[0034] c. Put the color-protecting shiitake mushrooms obtained in step b into a constant-temperature blast drying oven (DHG-9140A electric heating constant-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com