Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1851 results about "Kilogram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The kilogram (also kilogramme) is the base unit of mass in the metric system, formally the International System of Units (SI), having the unit symbol kg. It is a widely used measure in science, engineering, and commerce worldwide, and is often called a kilo. The kilogram is, within 30 ppm, the mass of one litre of water.

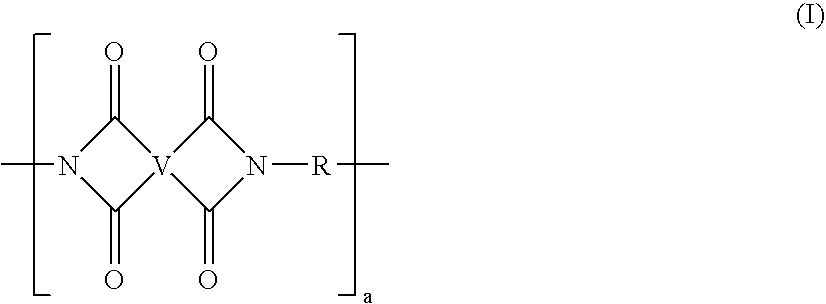

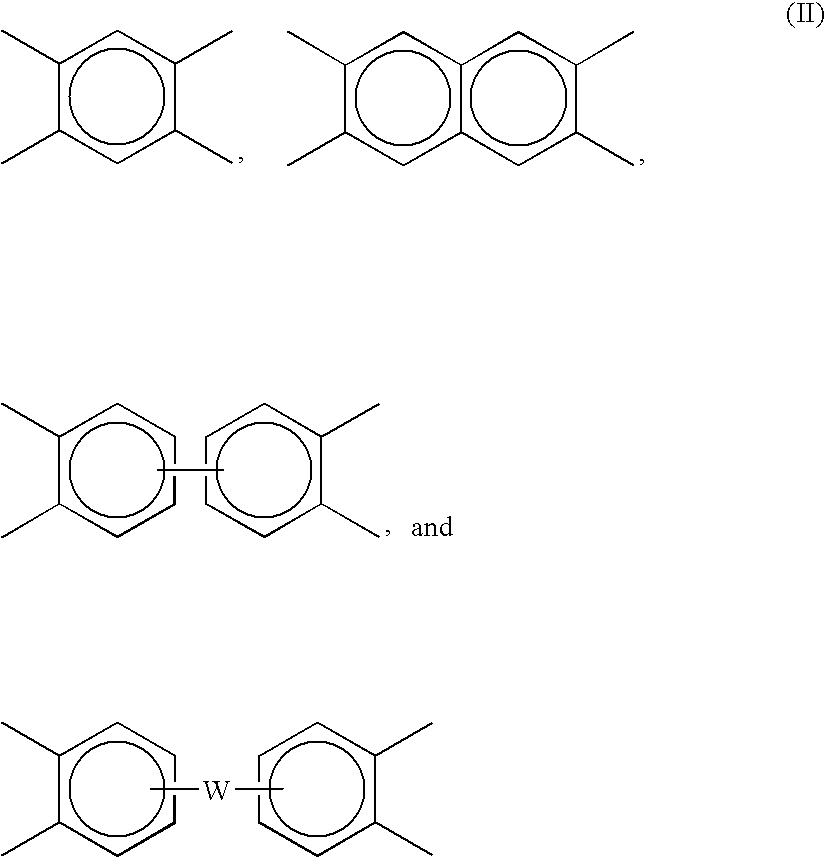

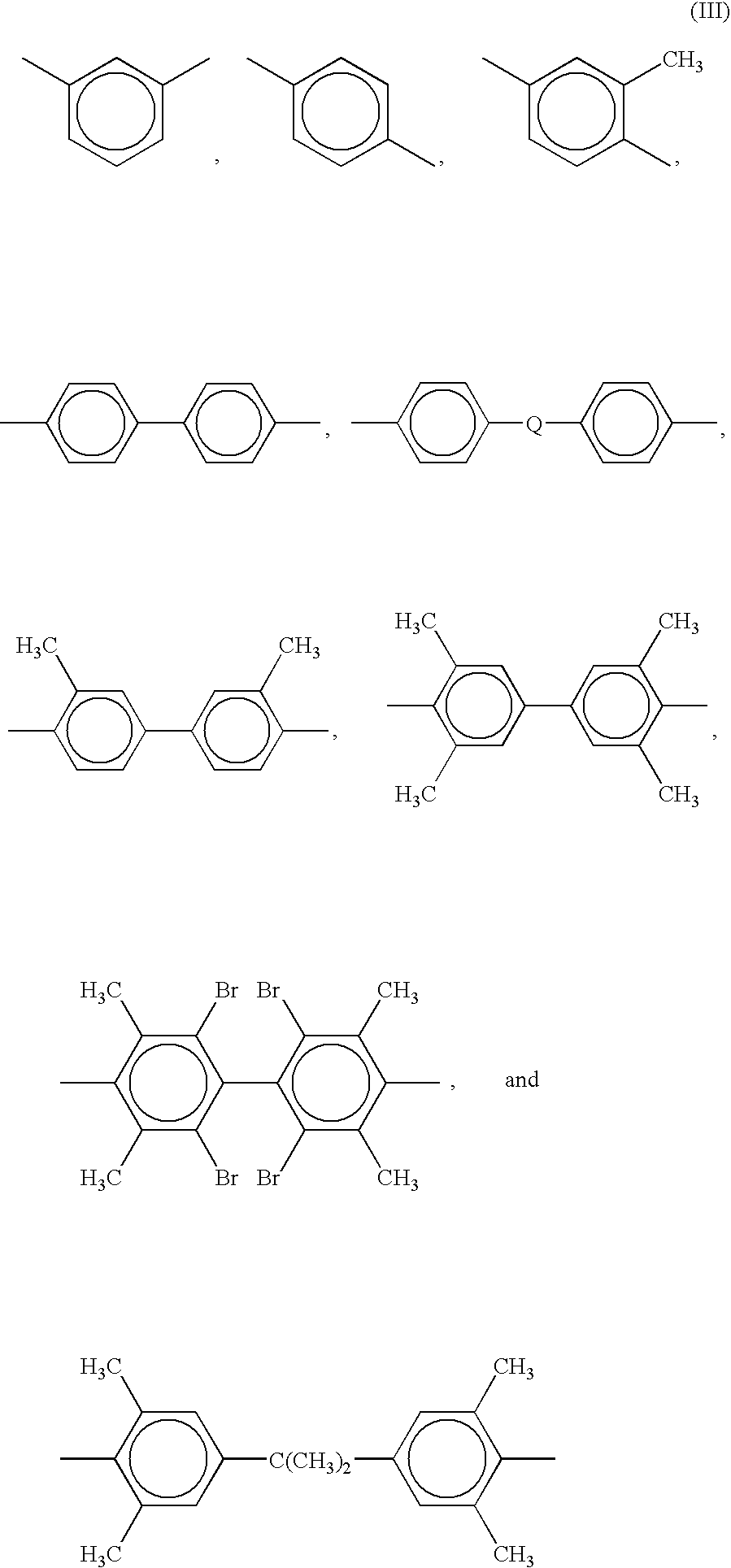

Polyimide sulfones, method and articles made therefrom

InactiveUS7041773B2Synthetic resin layered productsCeramic shaping apparatusVitrificationPolymer science

Polyimide sulfone resins are provided with a glass transition temperature of from 200–350° C., residual volatile species concentration of less than 500 ppm and a total reactive end group concentration of less than about 120 milliequivalents / kilogram resin. The resins have high heat capability and good melt stability. Methods to prepare the said resins and articles made from the resins are also provided.

Owner:SHPP GLOBAL TECH BV

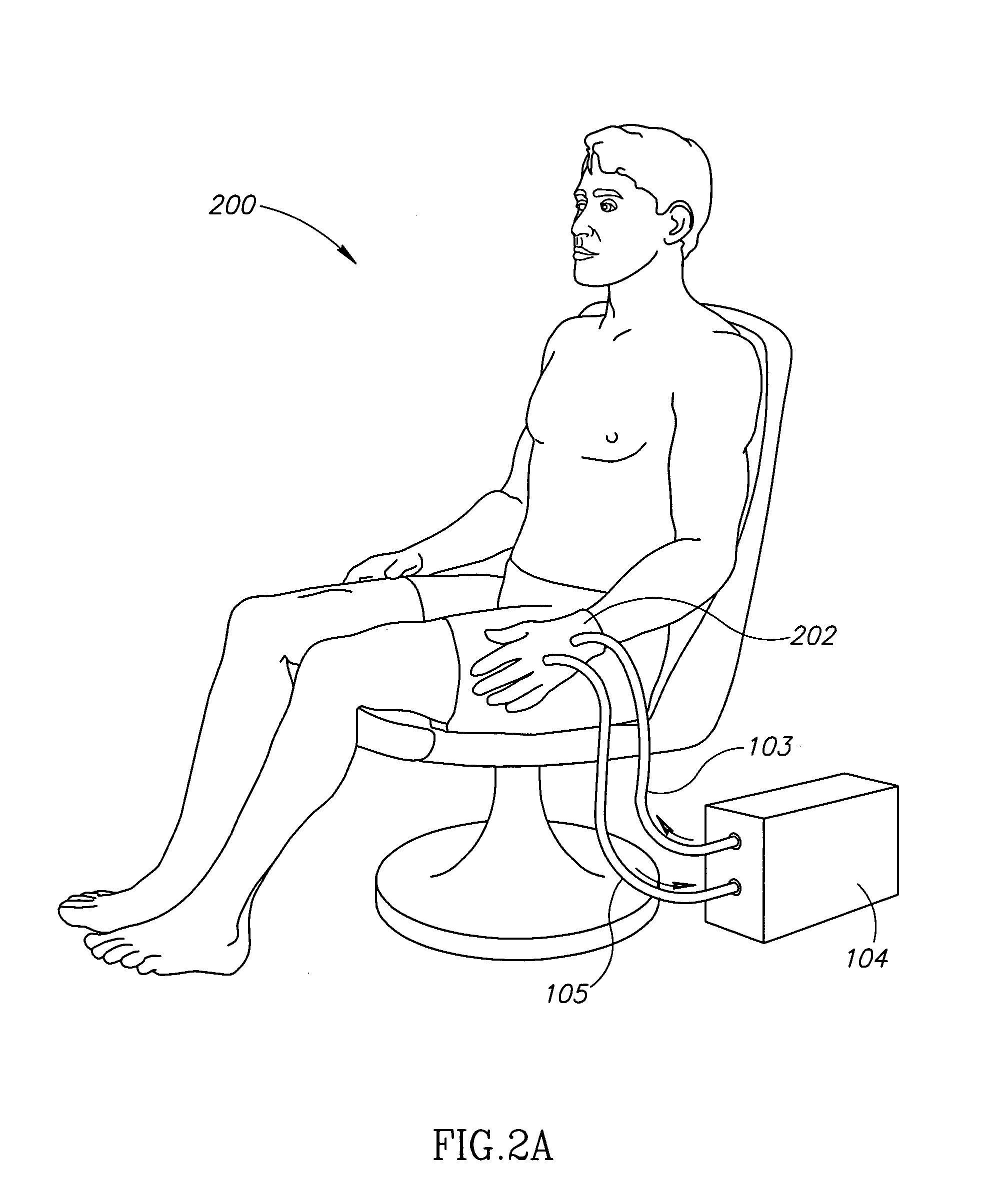

Metabolic Sink

InactiveUS20090312676A1To promote metabolismAvoids and reduces painElectrotherapyChiropractic devicesLost WeightChemistry

A method for increasing metabolism of a subject's body in order to lose weight, comprising:a) contacting a part of the body with a cooling element to remove heat from the body; andb) repeating or continuing (a) so as to remove enough heat in total to lose at least 1 kilogram of body weight.

Owner:TYLERTON INT INC

Flame retardant polycarbonate polyester composition

InactiveUS20020128357A1Improve performanceImprove impact performancePlastic/resin/waxes insulatorsDyeing processPass ratePolyester resin

A transparent / translucent flame redardant composition comprises a uniform blend of a miscible resin blend of a polycarbonate resin and a cycloaliphatic polyester resin wherein the composition has at least a 80% pass rate in 10 test specimen in the Norme Francaise NF-P-92-505 flammability test of L'Association Francaise de Normalisation using test specimens with weight between about 1.0 to about 6.0 kilograms per square meter.

Owner:GENERAL ELECTRIC CO

Chinese medicine label for eliminating ache and preparation thereof

InactiveCN101244252AGood curative effectLittle side effectsHeavy metal active ingredientsAnthropod material medical ingredientsClematisMyrrh

The invention relates to a Chinese herbal medicine paste for relieving pain, comprising a plurality of medicine materials of angelica, cassia twig, rhizoma chuanxiong, olibanum, myrrh, sylvestris, pubescent angelica, milettia reticulate, pheretima, siegesbeckiae, balsamine, japan yam rhizome, futokadsura stem, orientavine, a millet liquor flavored with the root bark, nuxvomica, Chinese polyphaga, homalomena rhizome, Chinese clematis radix clematidis with fixed weight proportions. The preparation method comprises the following steps: immerse the Chinese herbal medicine materials with fixed weight proportions into sesame oil; 1 kilogram medicine consumes 0.5kg sesame oil; after sever days of immersion, heat mixture for boiling and deslag the mixture; place the residual material on cloth to form a plaster. When in use, slightly heat the plaster and adhere the plaster to the affected part; and each plaster can be used for four days. The Chinese herbal medicine paste has the advantages of effective pain relief and elimination, simple application, rapid and persistent therapeutic effect and low side effect.

Owner:张金星

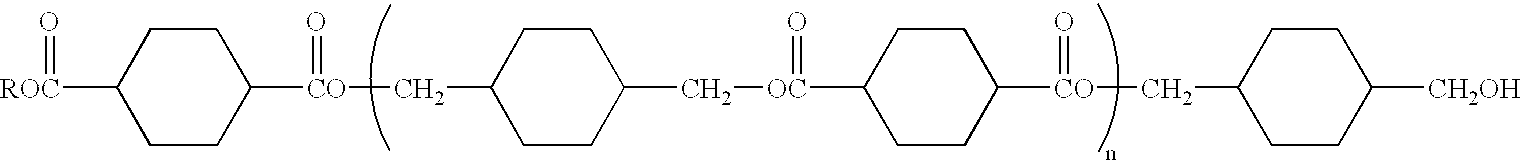

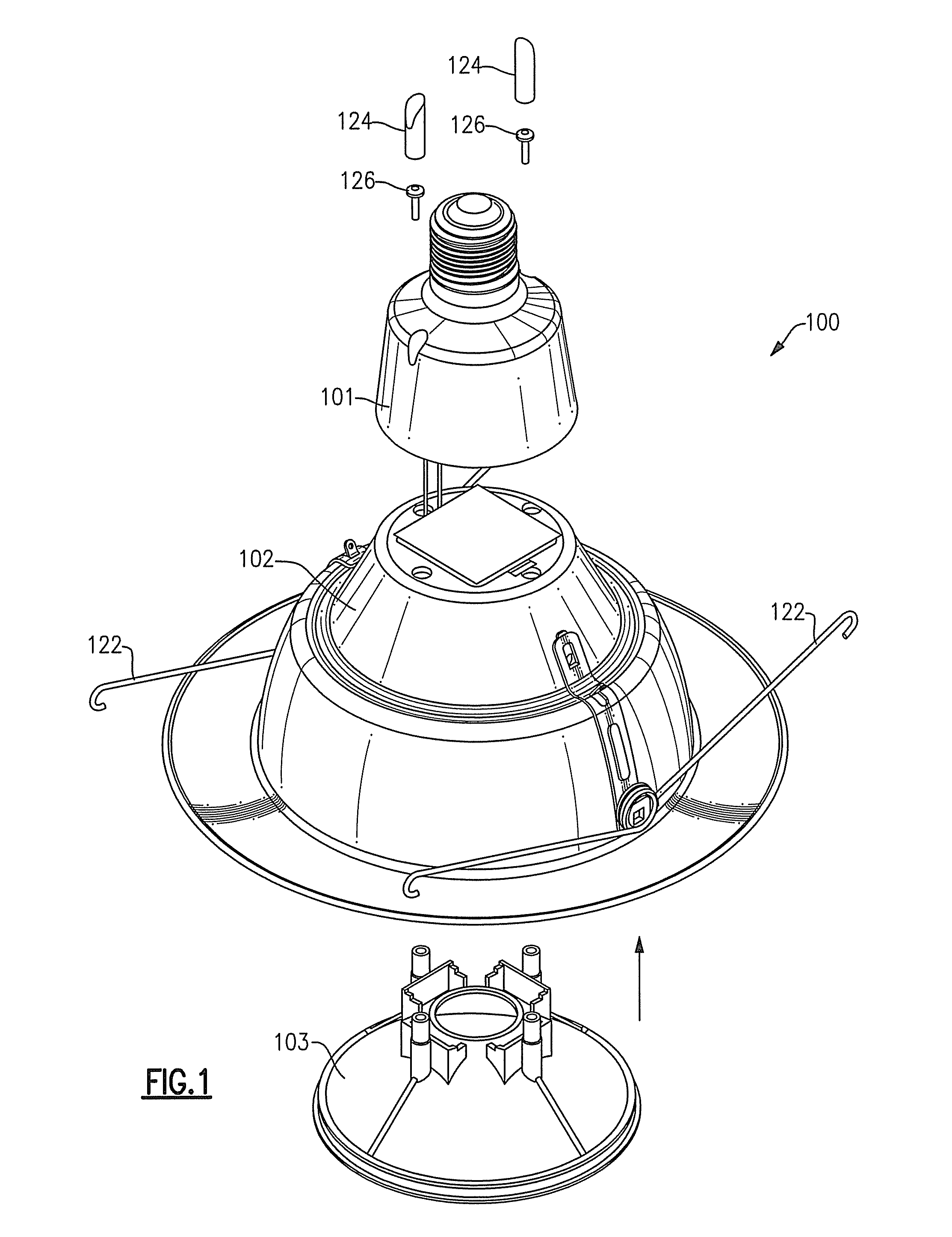

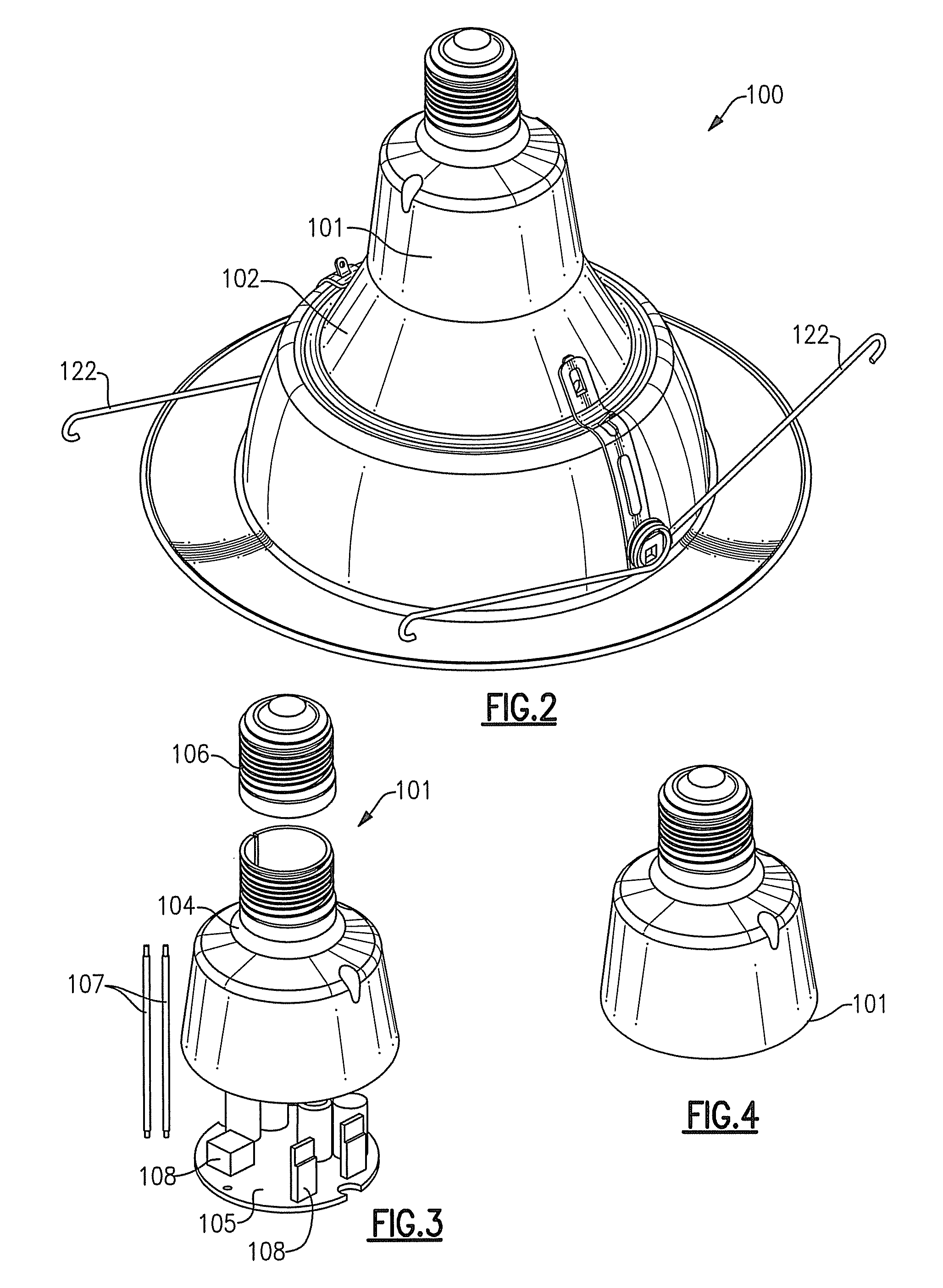

Lighting devices comprising solid state light emitters

ActiveUS8777449B2Improve efficiencyQuality improvementCoupling device connectionsPlanar light sourcesElectricityLight equipment

A lighting device comprising a trim element, an electrical connector and at least one solid state light emitter, the lighting device weighing less than one kilogram. If current of about 12 watts (or in some cases about 15 watts, or in some cases not more than about 15 watts) is supplied to the electrical connector, the at least one solid state light emitter will illuminate so that the lighting device will emit white light of at least 500 lumens. Also, a lighting device that weighs less than one kilogram and can generate white light of at least 500 lumens using a current of not more than about 15 watts. Also, a lighting device for mounting in a recessed housing, comprising a unitary structure trim element that conducts heat away from at least one solid state light emitter and dissipates at least some of the heat outside of the recessed housing.

Owner:IDEAL IND LIGHTING LLC

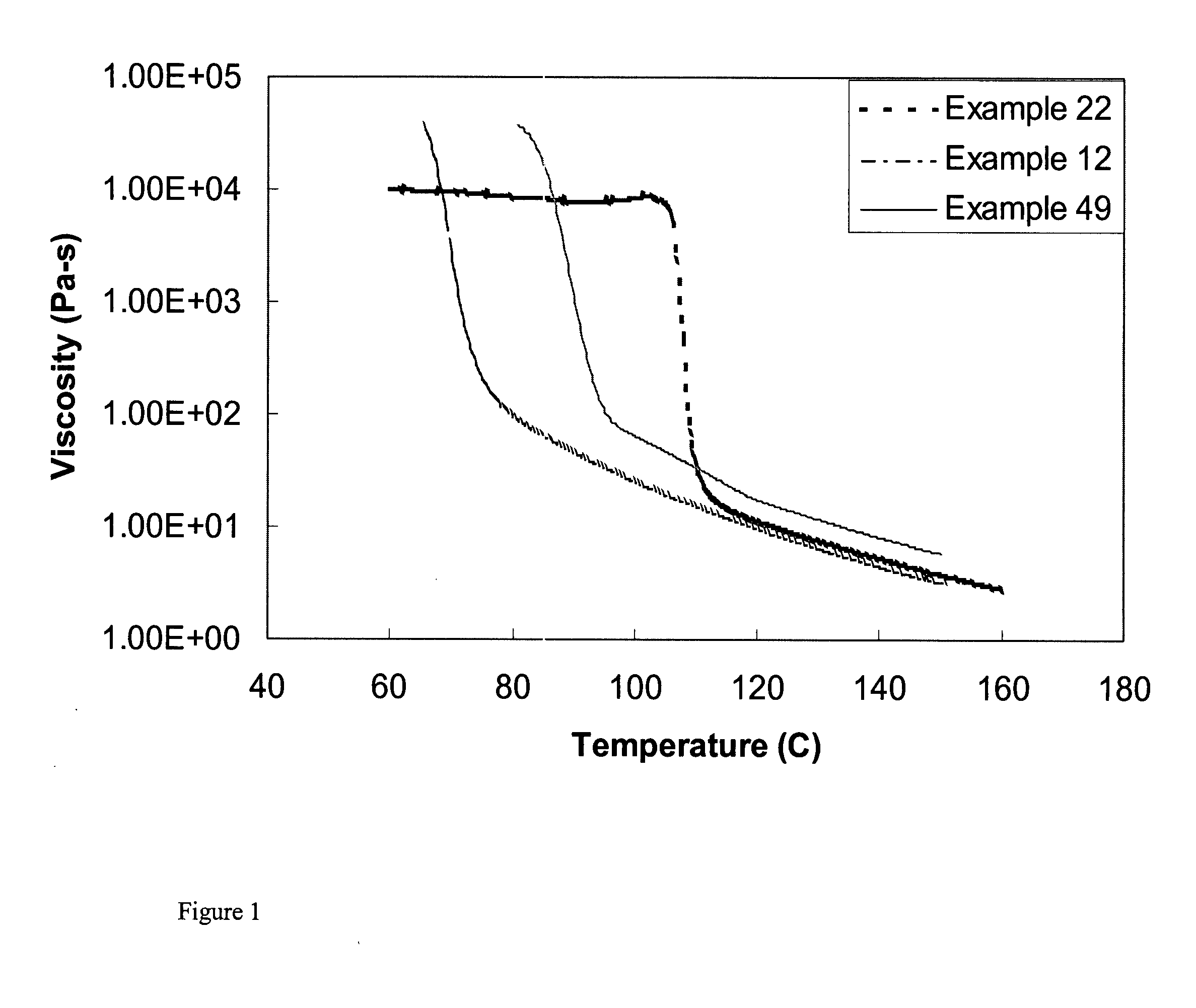

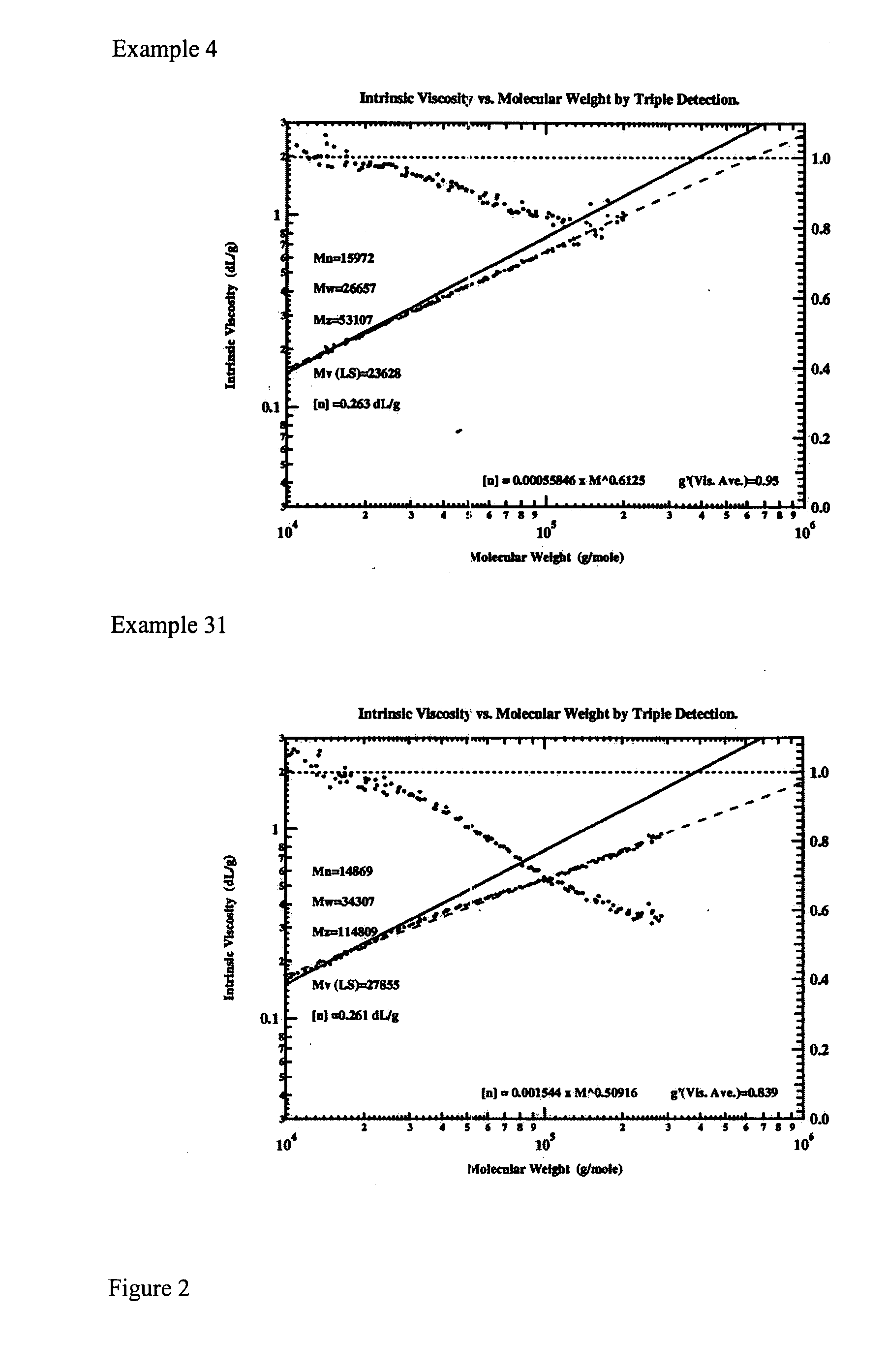

Multiple catalyst system for olefin polymerization and polymers produced therefrom

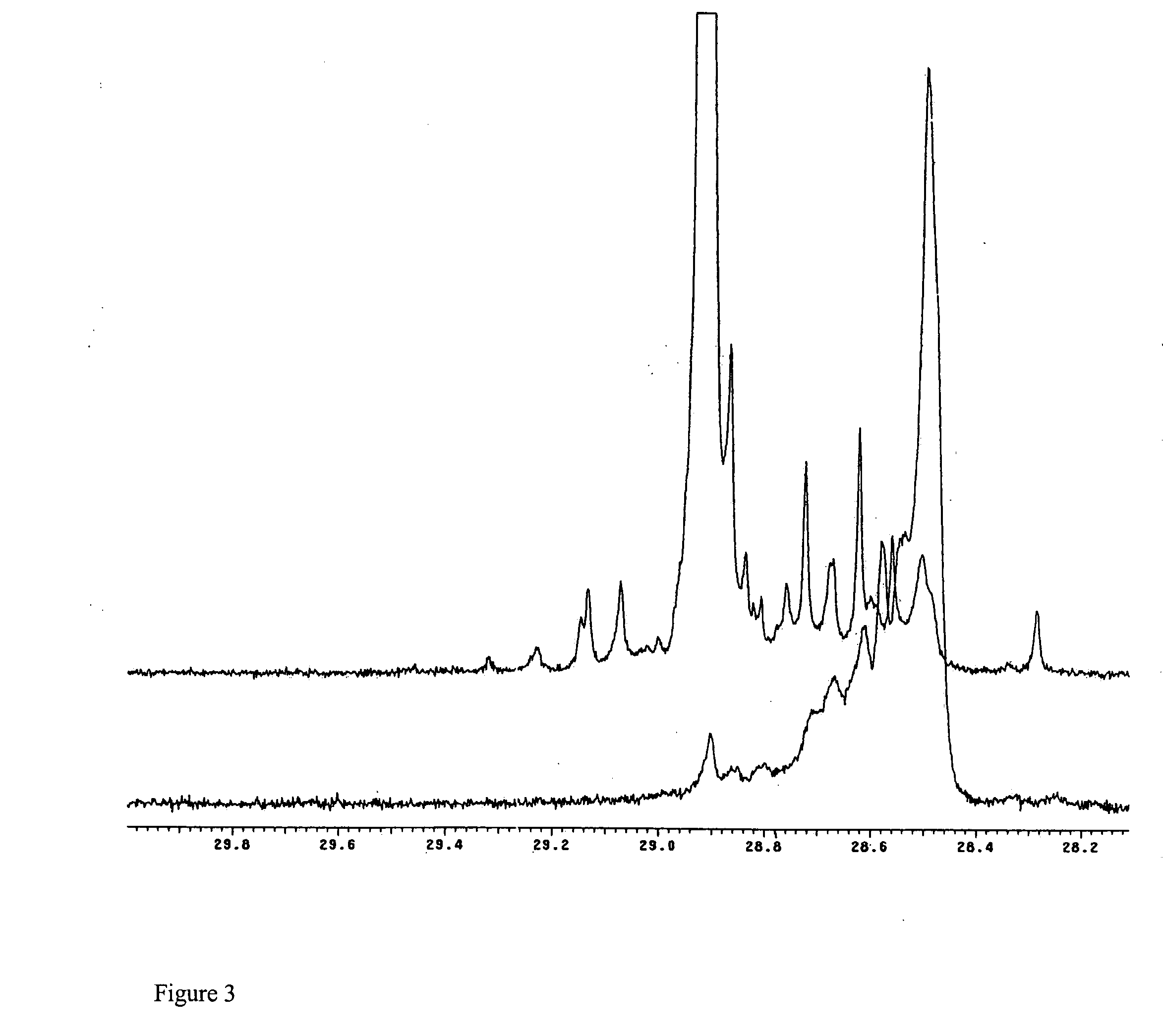

This invention relates to a polymer comprising one or more C3 to C40 olefins, optionally one or more diolefins, and less than 15 mole % of ethylene, where the polymer has: a) a Dot T-Peel of 1 Newton or more; and b) a branching index (g′) of 0.95 or less measured at the Mz of the polymer; c) an Mw of 100,000 or less. This invention also relates a polymer comprising one or more C3 to C40 olefins where the polymer has: a) a Dot T-Peel of 1 Newton or more on Kraft paper; b) a branching index (g′) of 0.95 or less measured at the Mz of the polymer; c) a Mw of 10,000 to 100,000; and d) a heat of fusion of 1 to 70 J / g. This invention also relates a polymer comprising one or more C3 to C40 olefins where the polymer has: a) a Dot T-Peel of 1 Newton or more on Kraft paper; b) a branching index (g′) of 0.98 or less measured at the Mz of the polymer; c) a Mw of 10,000 to 60,000; d) a heat of fusion of 1 to 50 J / g. This invention also relates to a homopolypropylene or a copolymer of propylene and up to 5 mole % ethylene having: a) an isotactic run length of 1 to 30 (isotactic run length “IRL” is defined to be the percent of mmmm pentad divided by 0.5× percent of mmmr pentad) as determined by Carbon 13 NMR, preferably 3 to 25, more preferably 4 to 20, b) a percent of r dyad of greater than 20%, preferably from 20 to 70% as determined by Carbon 13 NMR, and c) a heat of fusion of 70 J / g or less, preferably 60 J / g or less, more preferably between 1 and 55 J / g, more preferably between 4 and 50 J / g. This invention further relates to a process to produce an olefin polymer comprising: 1) selecting a first catalyst component capable of producing a polymer having an Mw of 100,000 or less and a crystallinity of 5% or less at selected polymerization conditions; 2) selecting a second catalyst component capable of producing polymer having an Mw of 100,000 or less and a crystallinity of 20% or more at the selected polymerization conditions; 3) contacting the catalyst components in the presence of one or more activators with one or more C3 to C40 olefins, at the selected polymerization conditions in a reaction zone; 4) obtaining the polymer. This invention further relates to a continuous process to produce a branched olefin polymer comprising: 1) selecting a first catalyst component capable of producing a polymer having an Mw of 100,000 or less and a crystallinity of 5% or less under selected polymerization conditions; 2) selecting a second catalyst component capable of producing polymer having an Mw of 100,000 or less and a crystallinity of 20% or more at the selected polymerization conditions; 3) contacting the catalyst components in the presence of one or more activators with one or more C3 to C40 olefins, and, optionally one or more diolefins; 4) at a temperature of greater than 100° C.; 5) at a residence time of 120 minutes or less; 6) wherein the ratio of the first catalyst to the second catalyst is from 1:1 to 50:1; 7) wherein the activity of the catalyst components is at least 100 kilograms of polymer per gram of the catalyst components; and wherein at least 20% of the olefins are converted to polymer.

Owner:EXXONMOBIL CHEM PAT INC

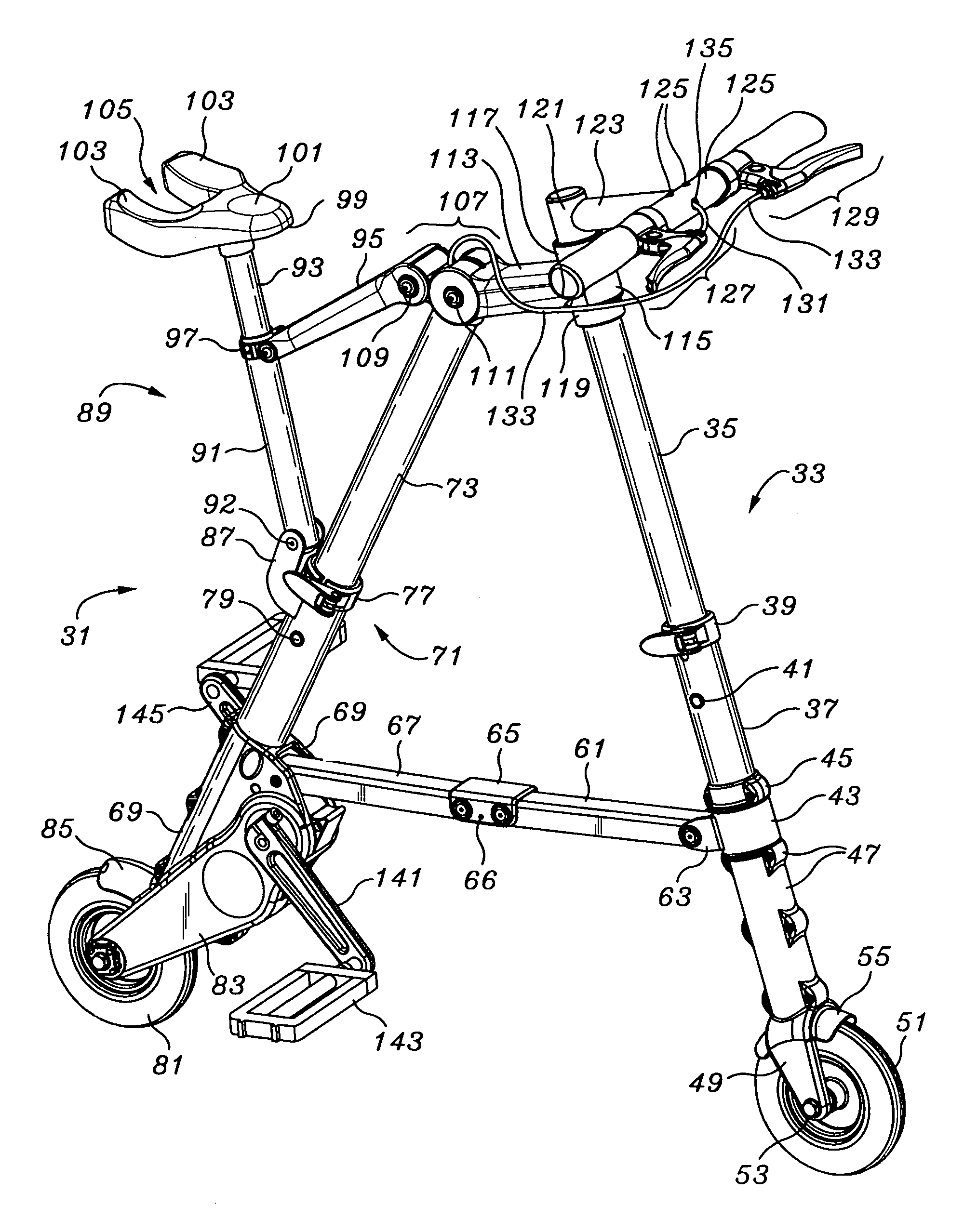

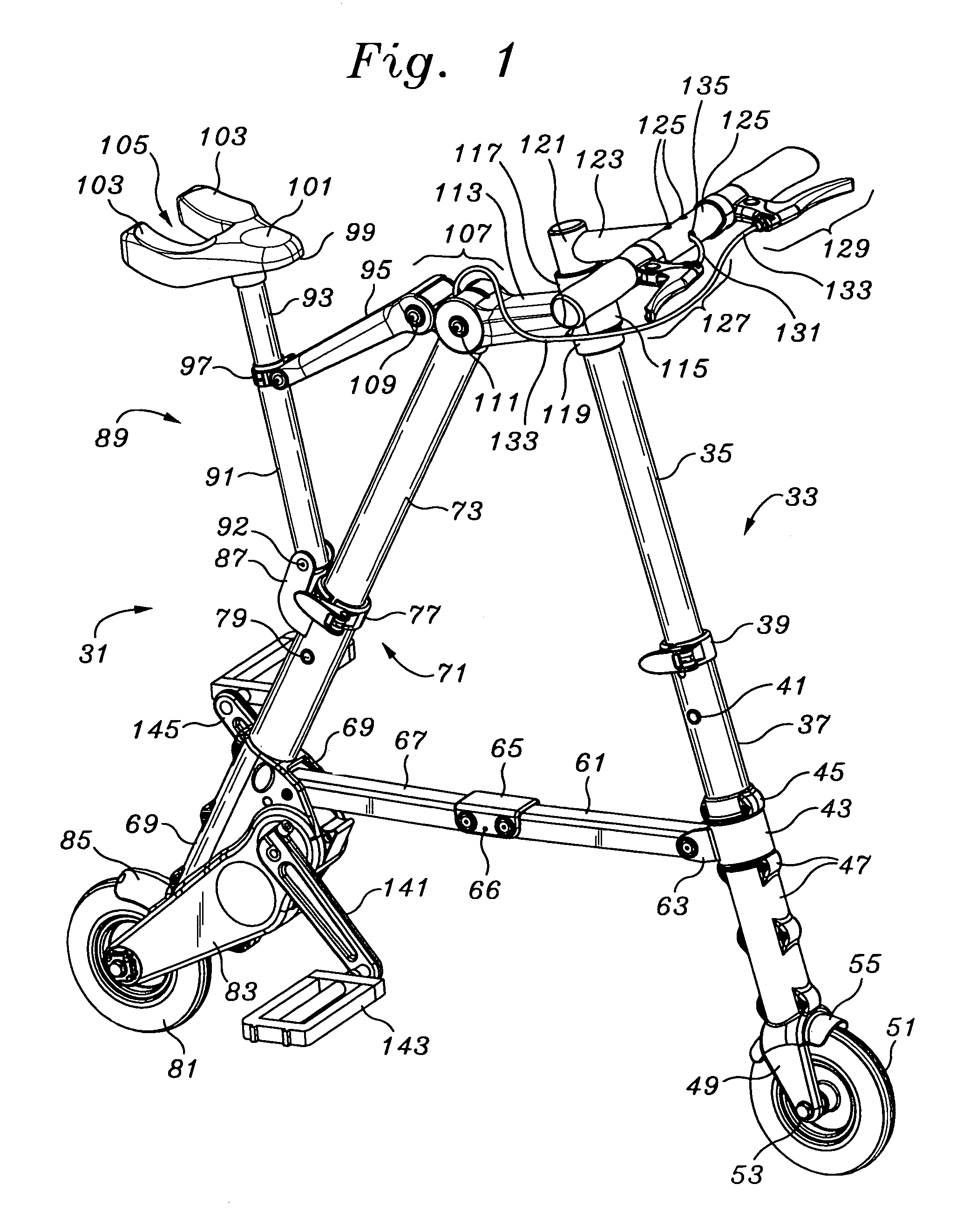

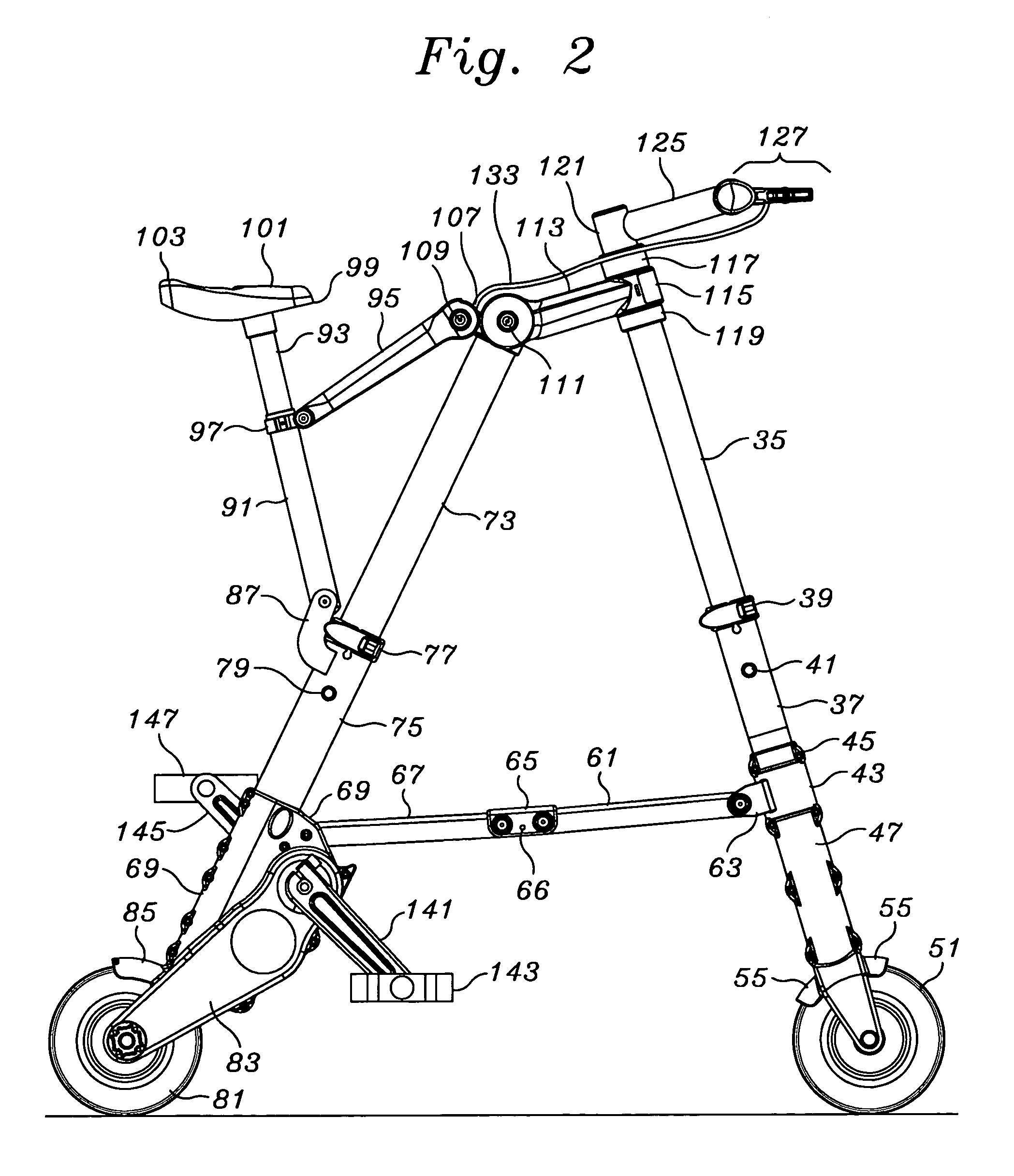

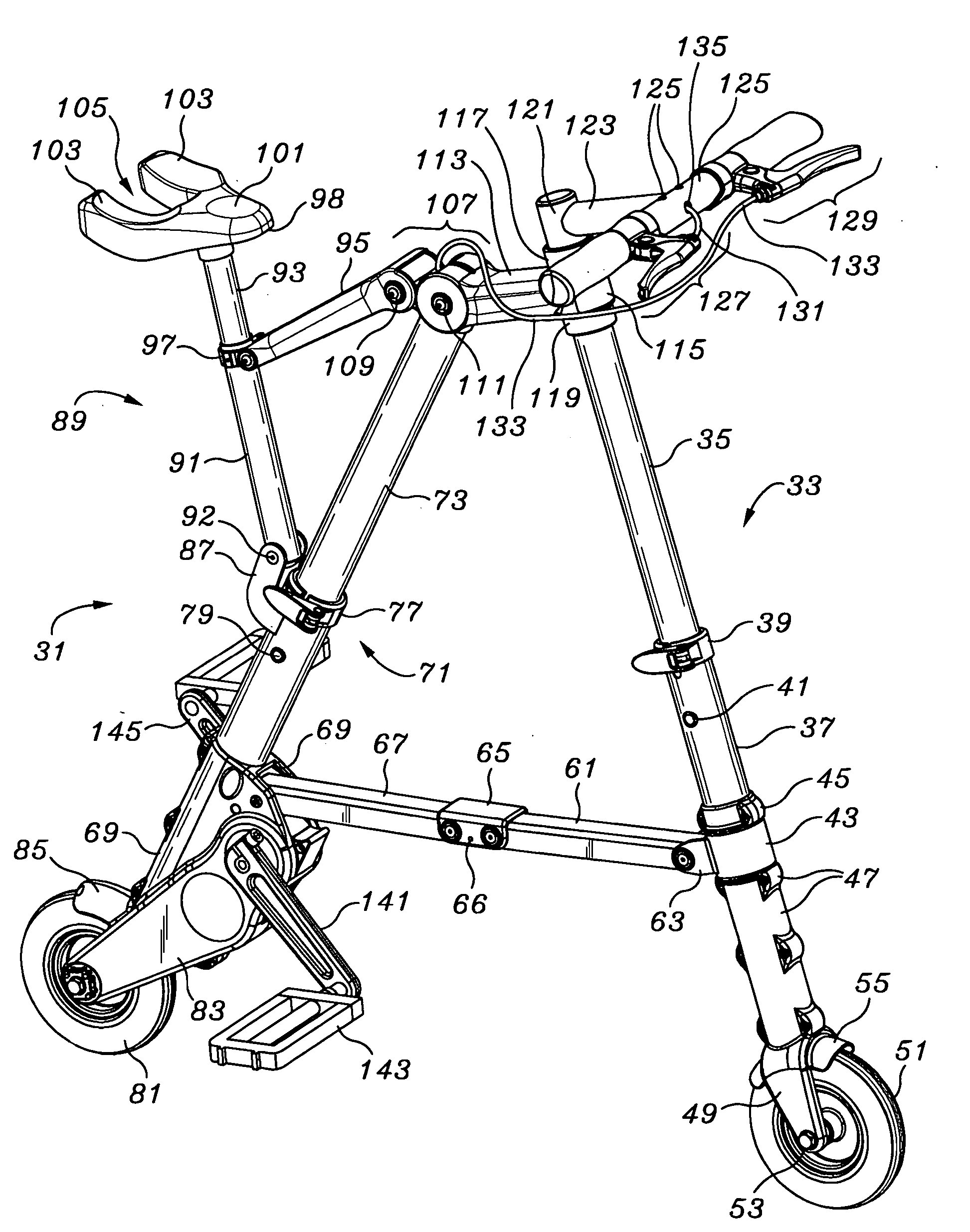

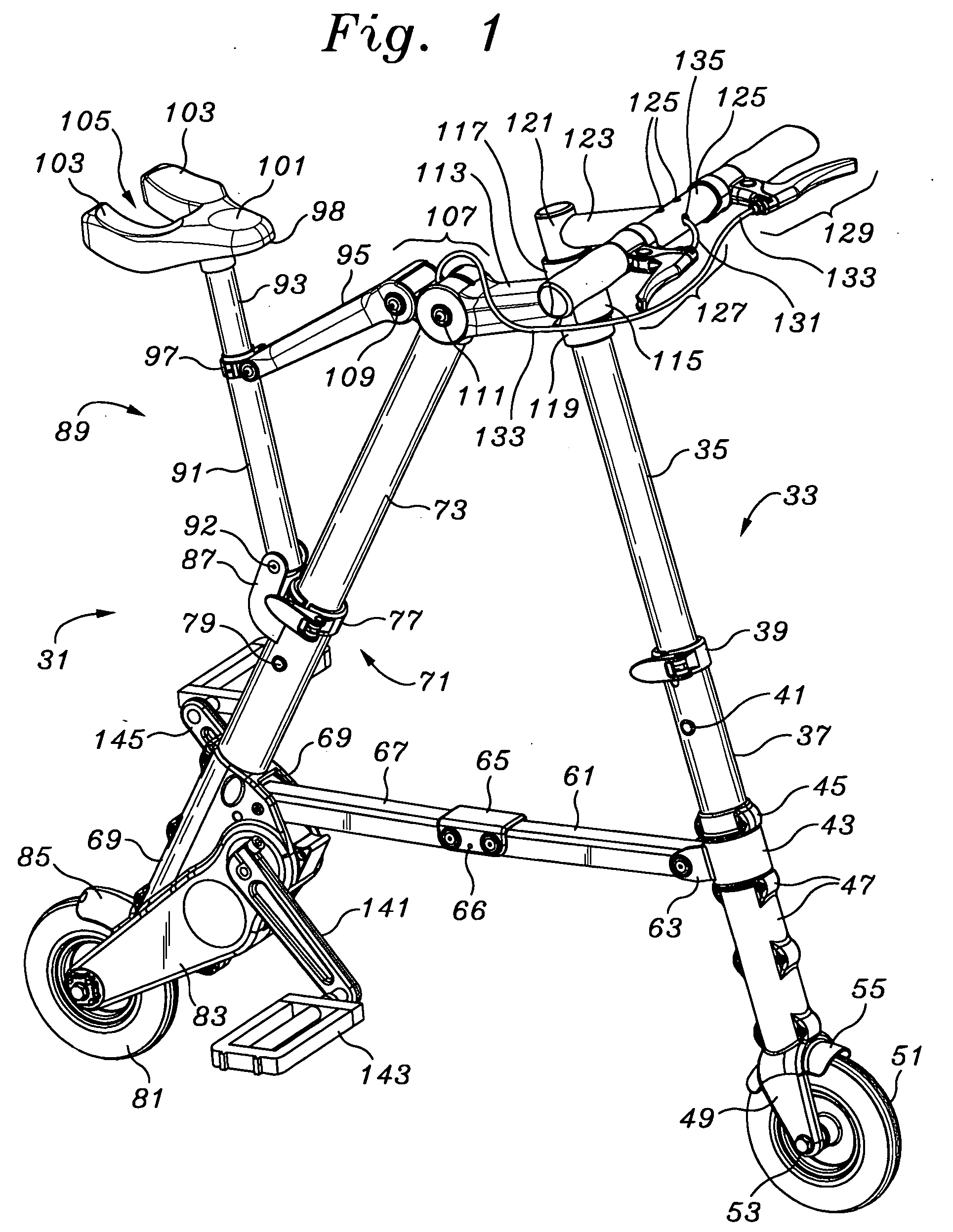

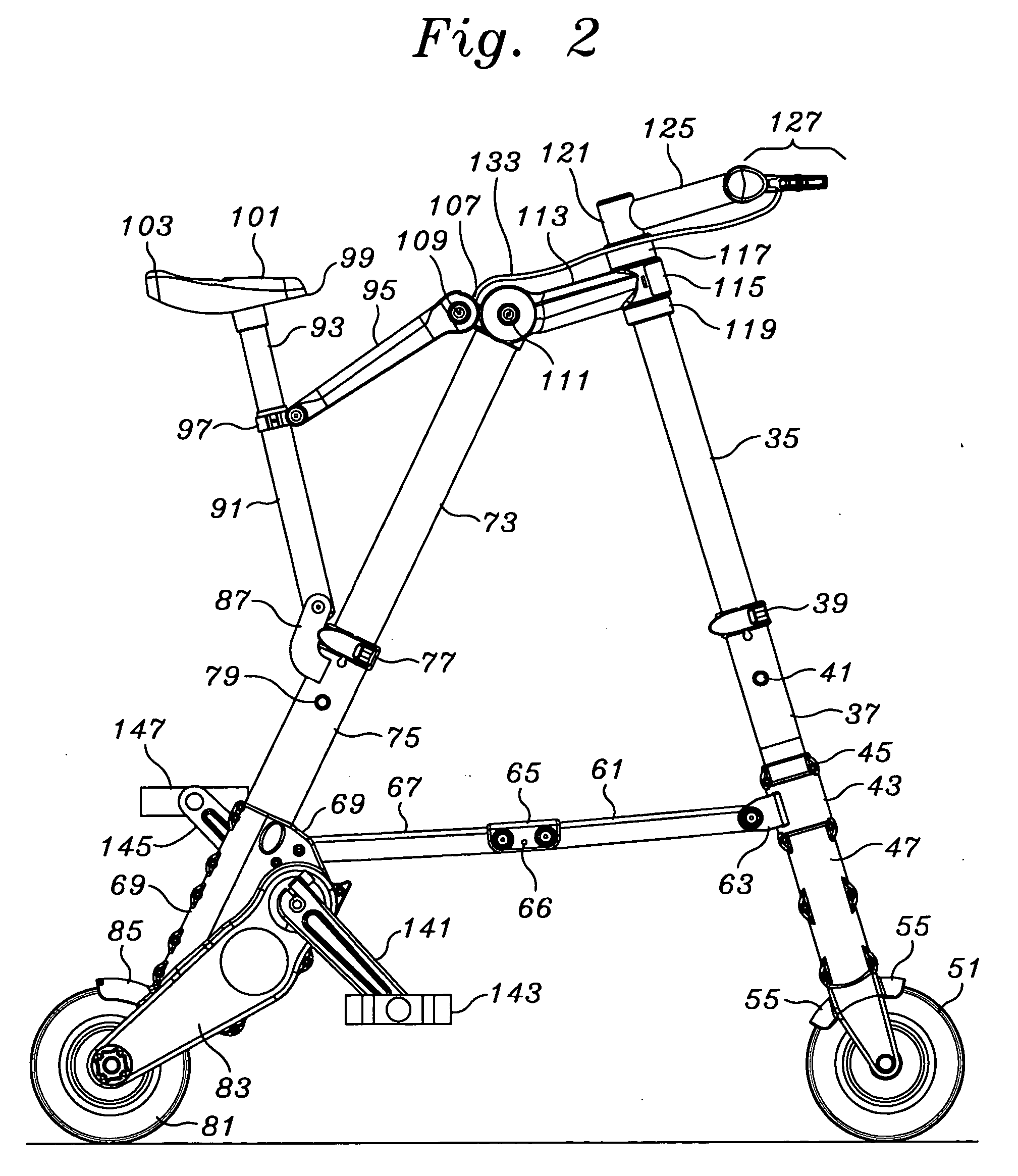

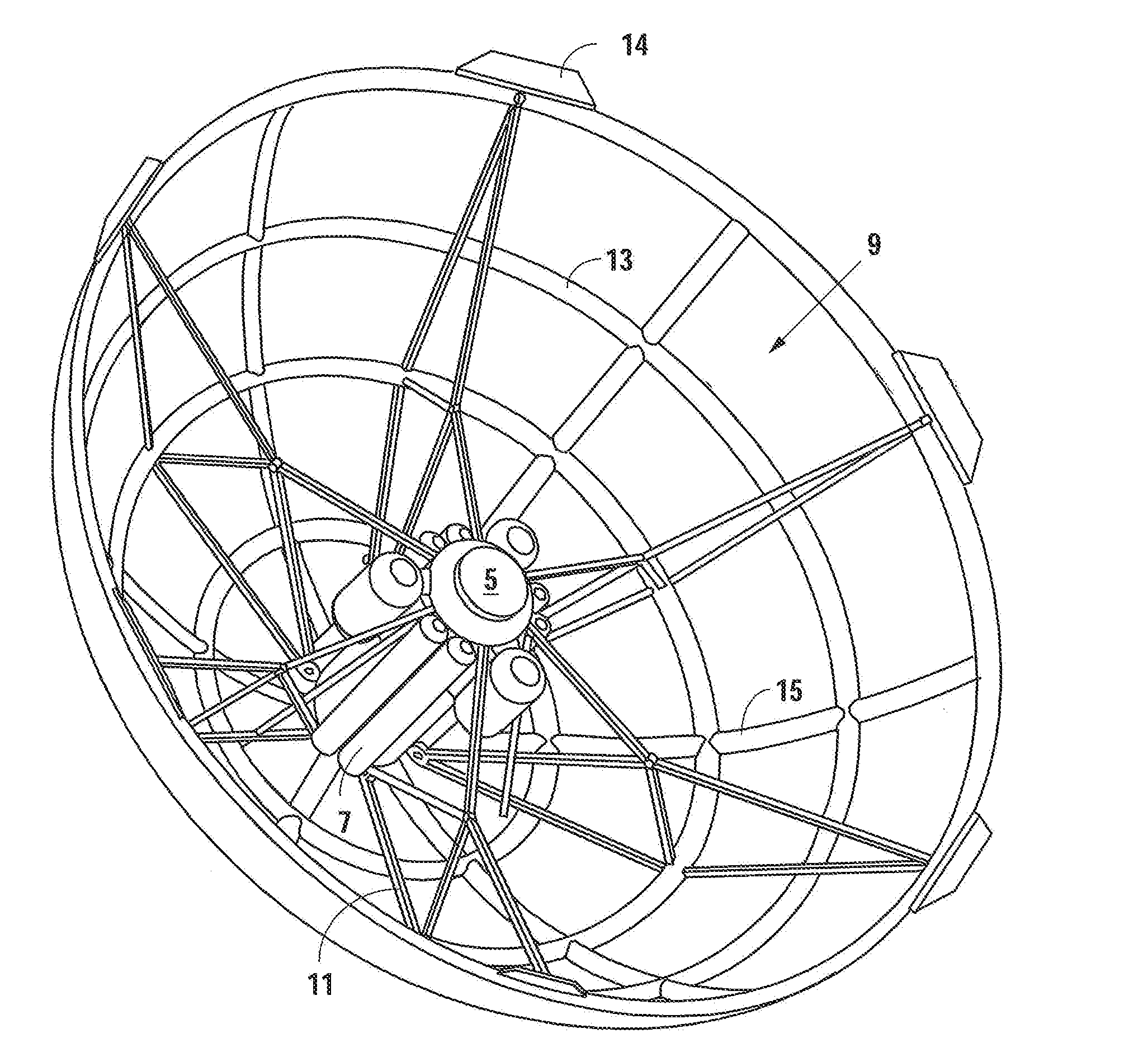

Portable folding bicycle

InactiveUS6986522B2Eliminate riskReadily be taken awayPassenger cyclesWheel based transmissionDeployment timeEngineering

Owner:SINCLAIR REFINING

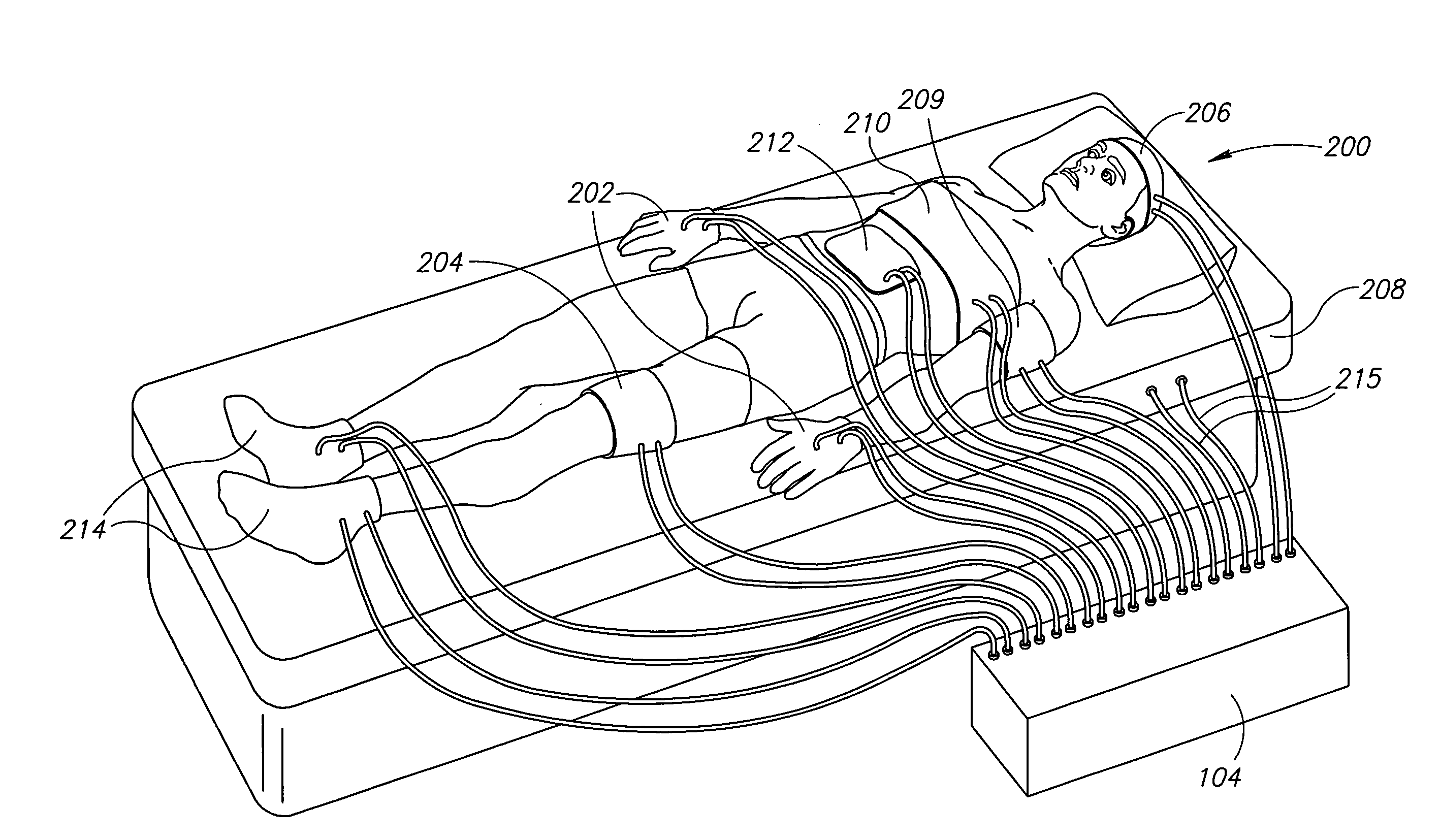

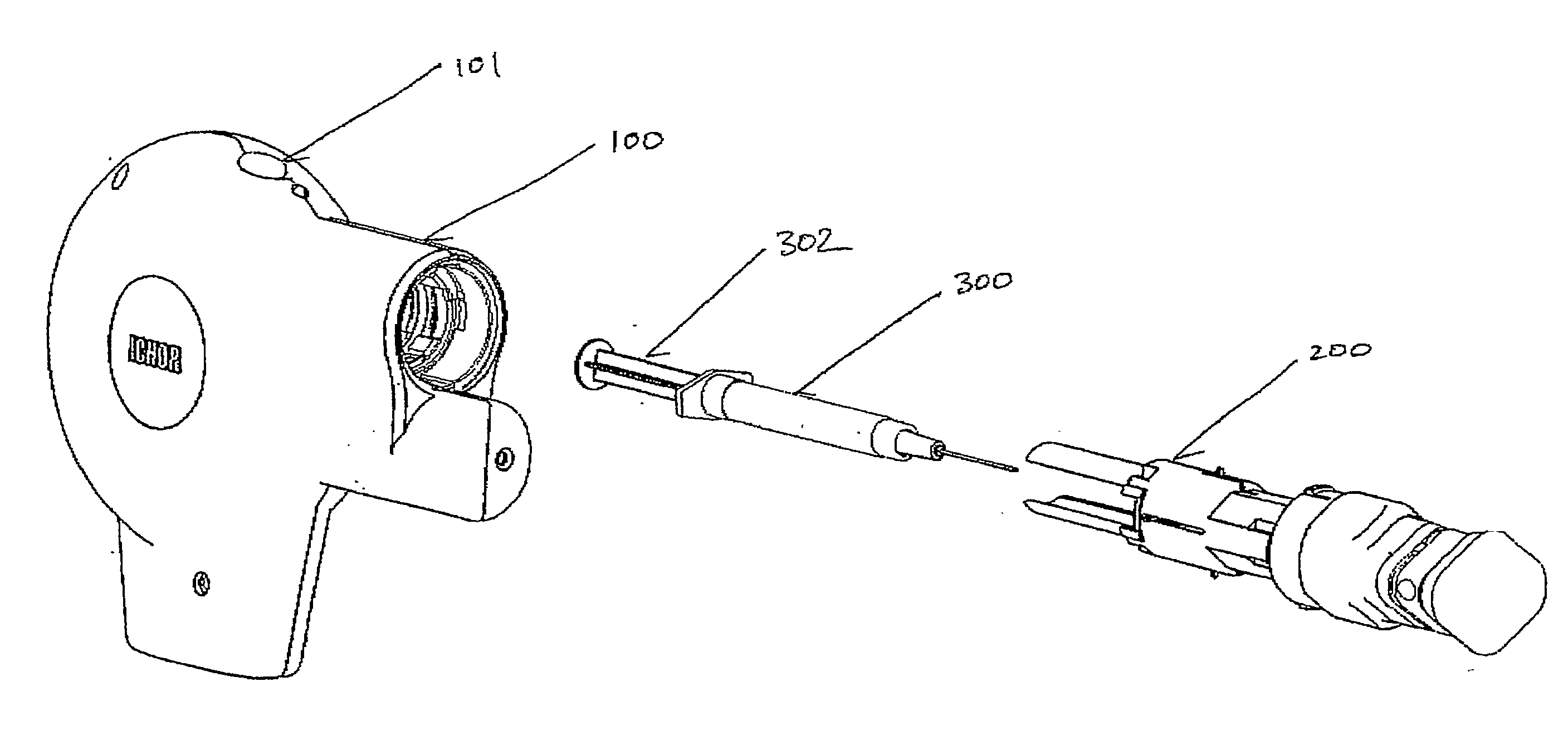

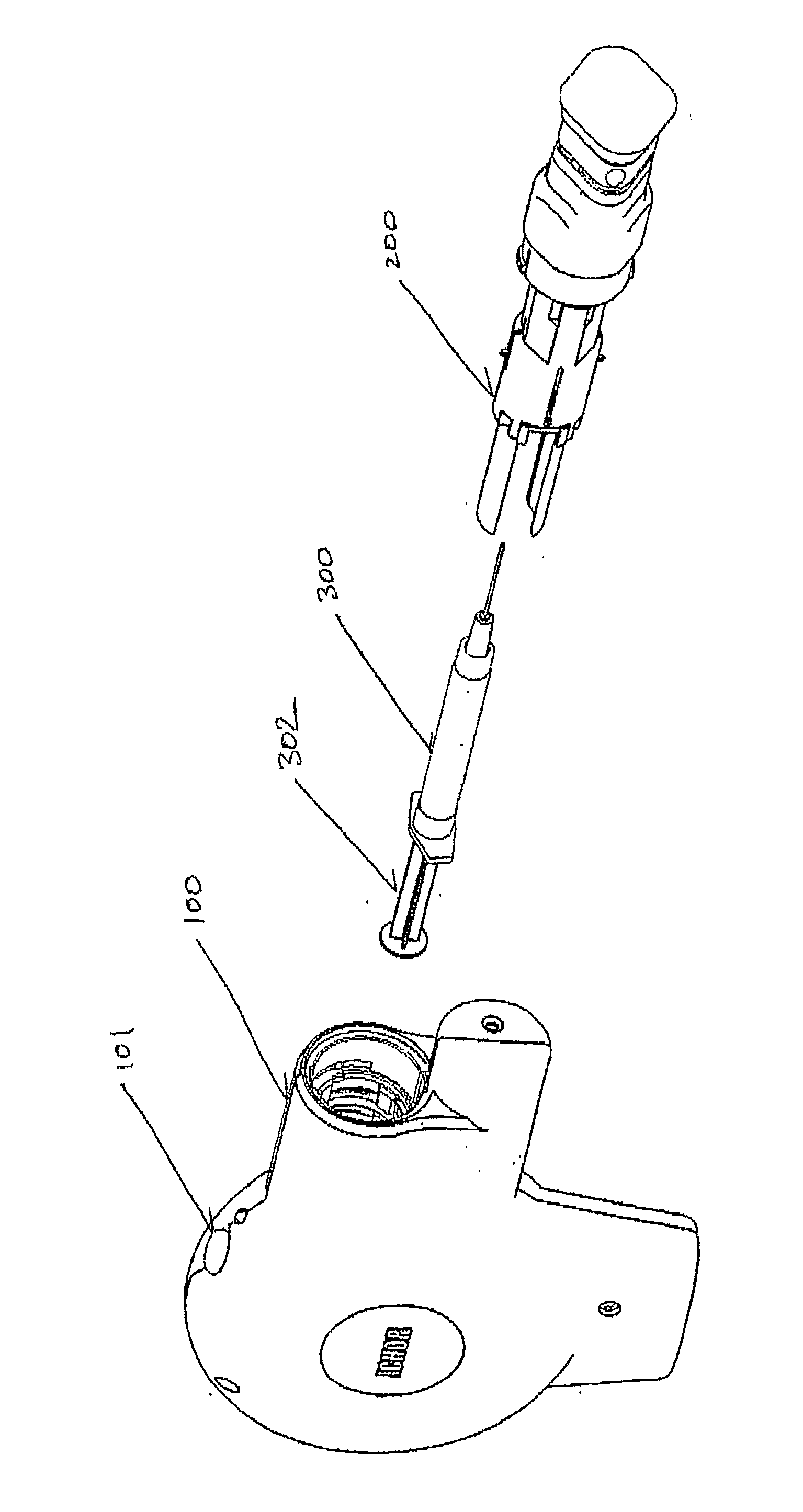

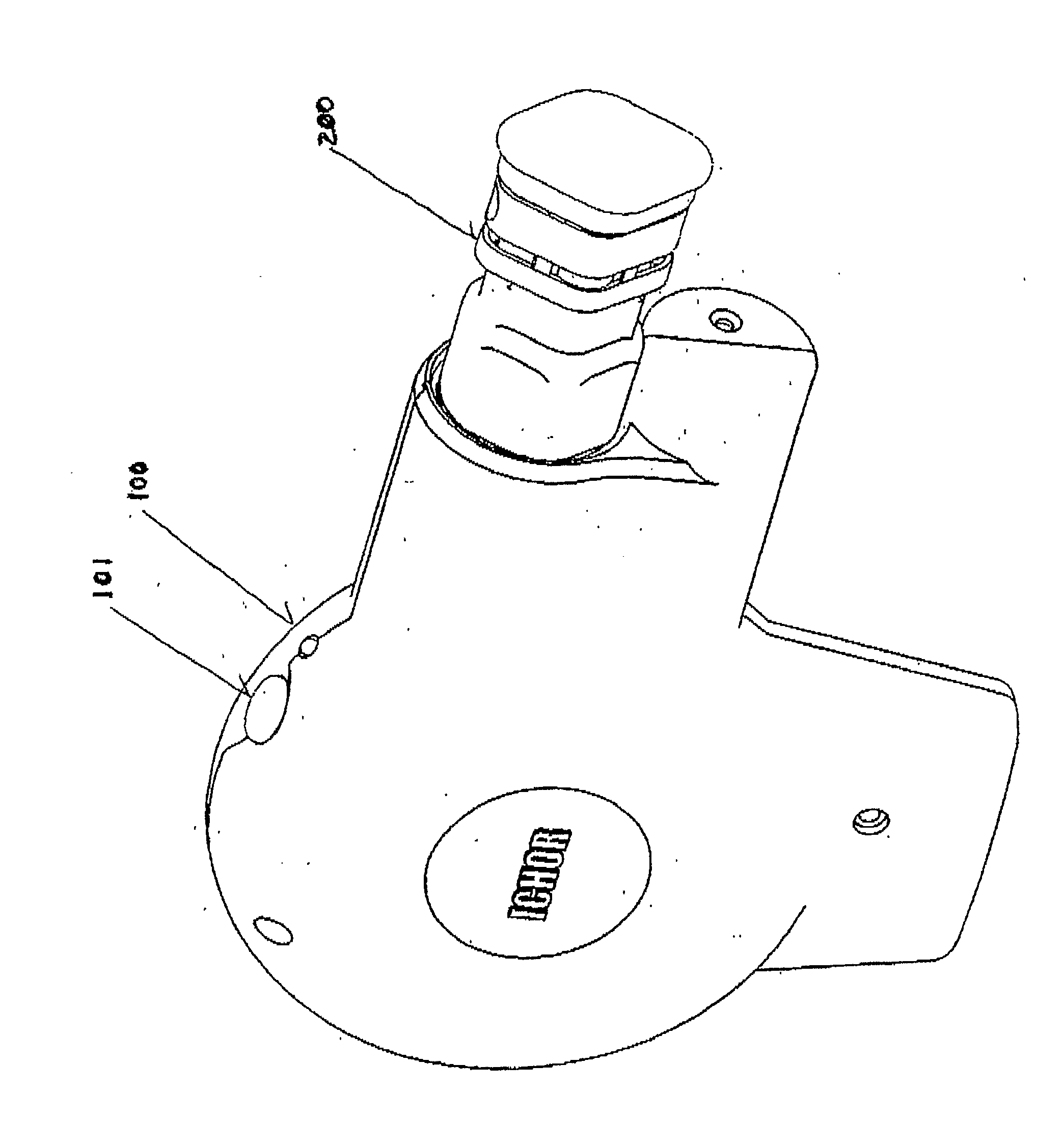

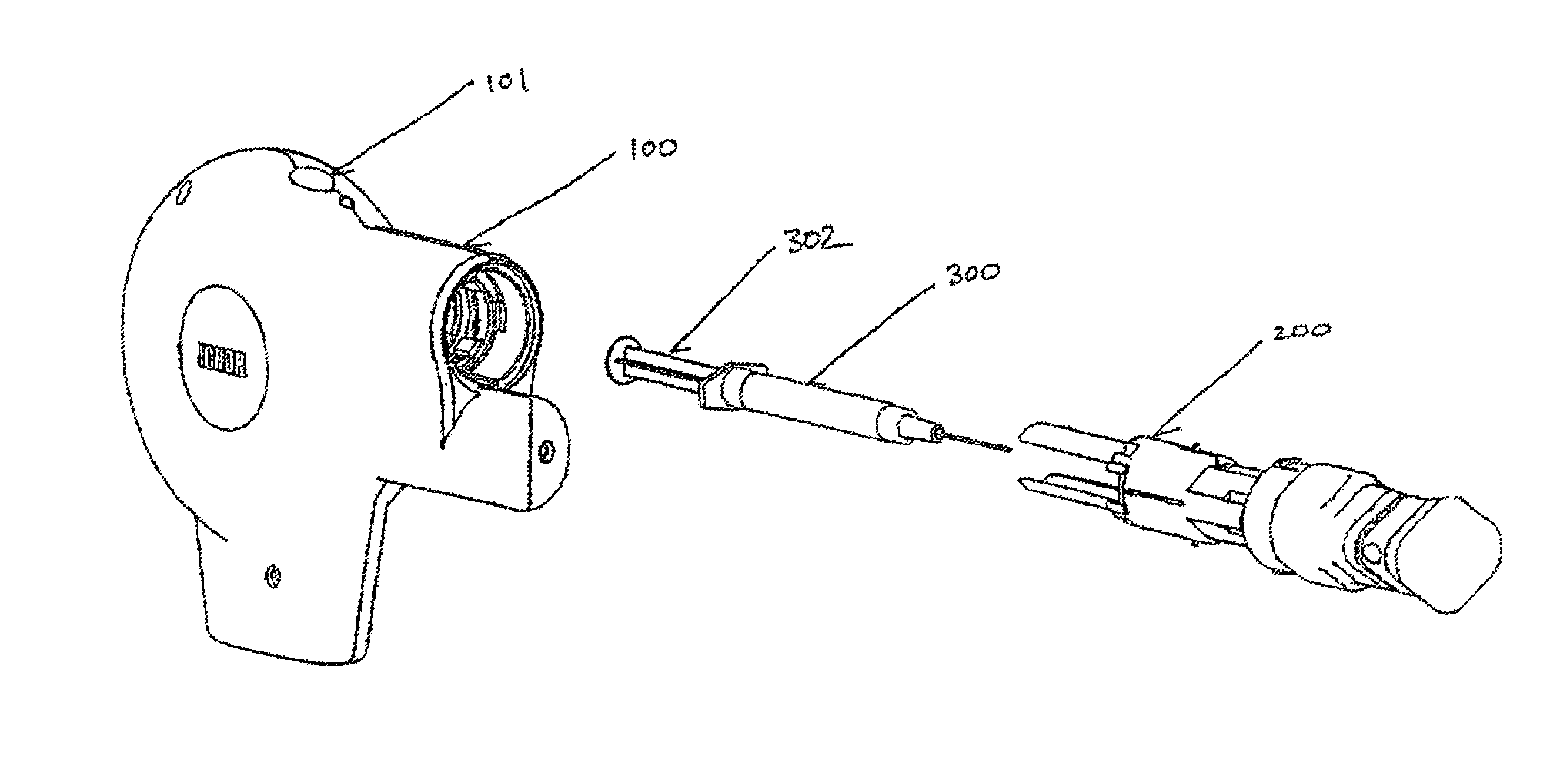

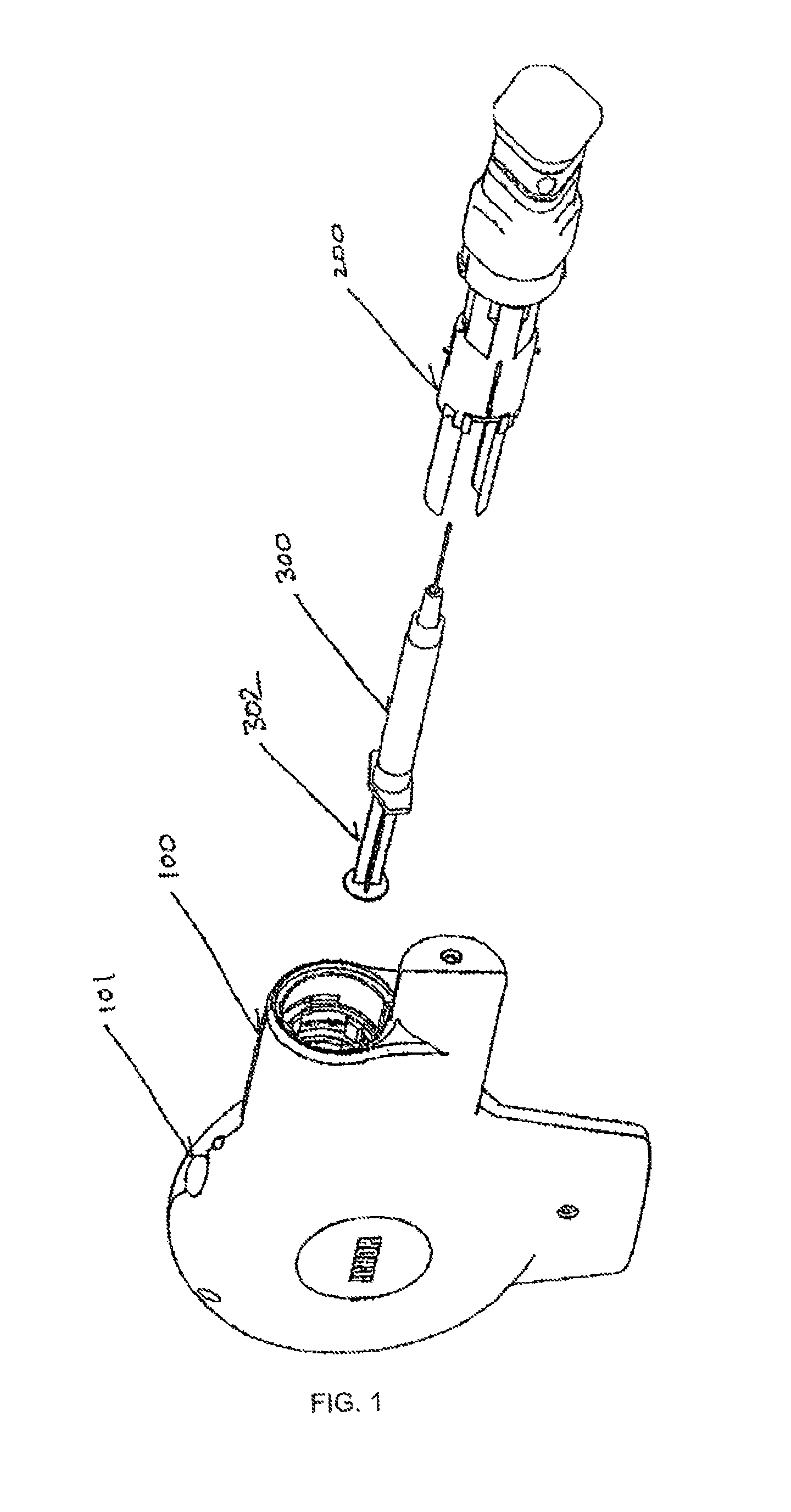

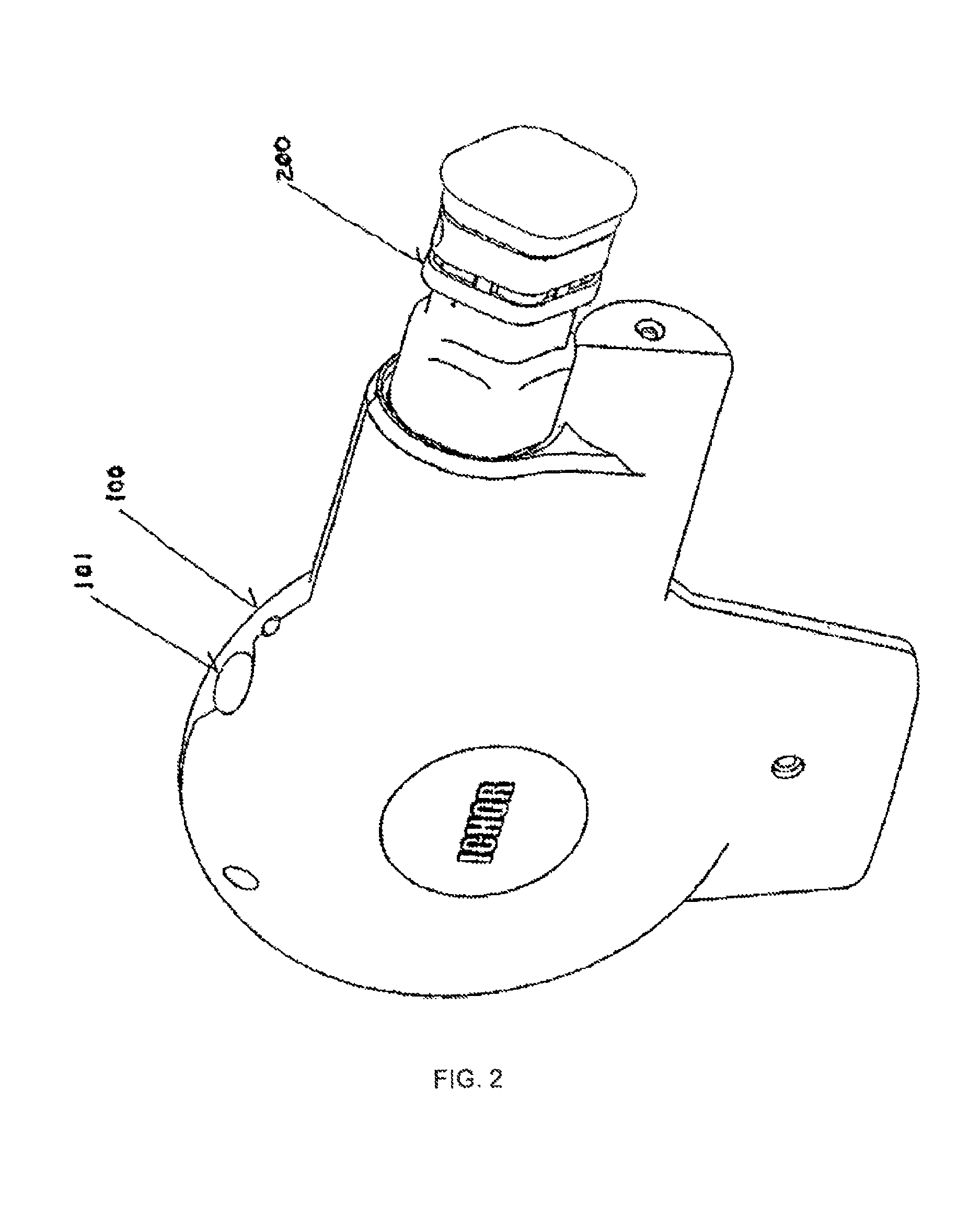

Apparatus for electrically mediated delivery of therapeutic agents

ActiveUS20120078161A1Easy to adaptFunction increaseSkin piercing electrodesElectricitySquare Millimeter

Apparatus for the delivery of an electrical field which facilitates the intracellular delivery of a therapeutic agent to a predetermined site within the tissue of a patient. The apparatus will comprise a plurality of penetrating electrodes arranged in a predetermined spatial relationship, each electrode with a cross sectional area contributing to the total cross sectional area of all electrodes, and structural means incorporating an inanimate source of energy operatively connected to the plurality of electrodes for deploying the electrodes, wherein the source of energy is sufficient to impart a force of at least 1000 pounds per square inch (0.7 kilogram per square millimeter) of total cross sectional area of all electrodes at the initiation of the deployment of the electrodes. The apparatus will also comprise means for generating an electrical field which facilitates the intracellular delivery of a therapeutic agent, which means is operatively connected to said electrodes at least in their deployed state.

Owner:ICHOR MEDICAL SYST

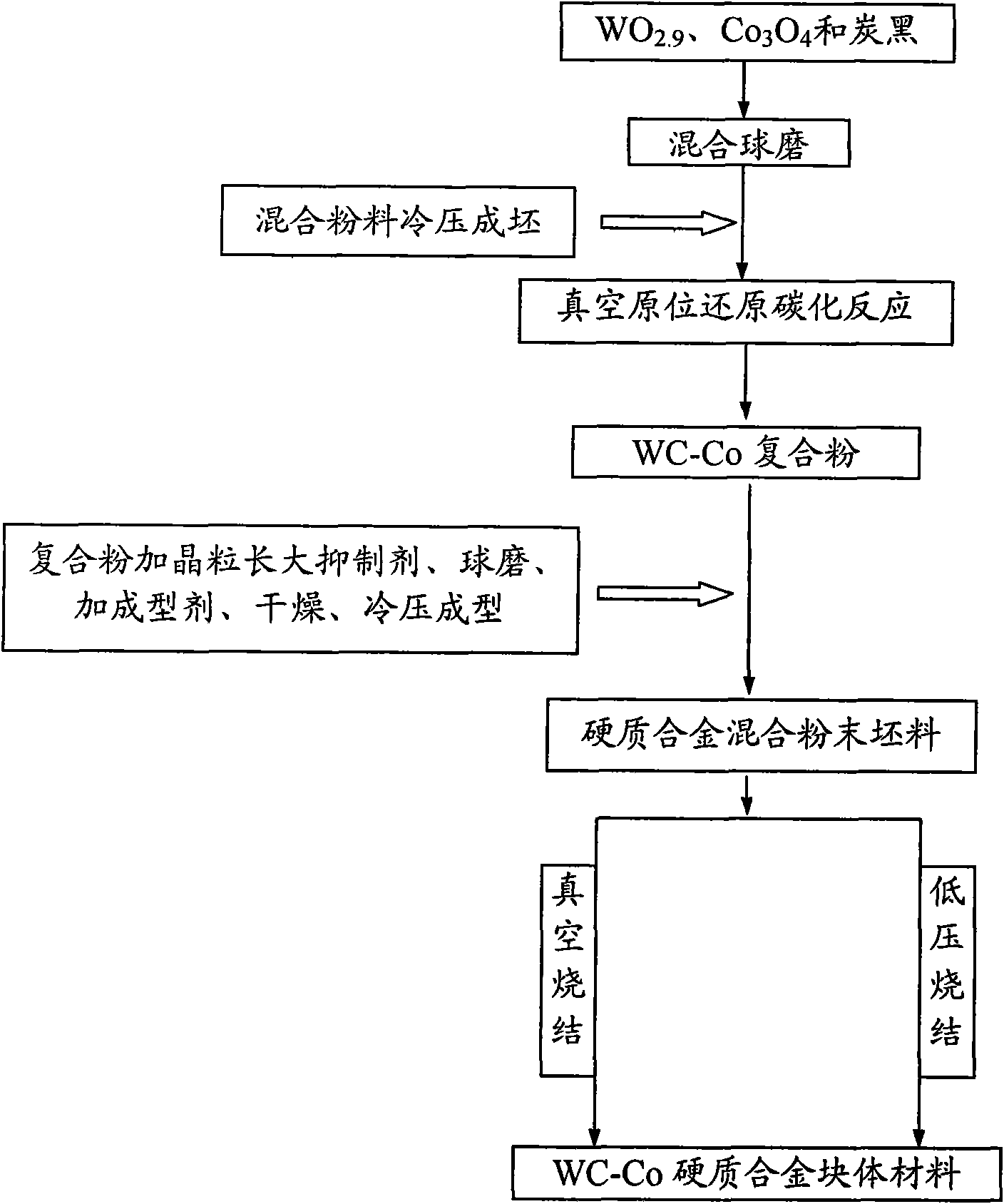

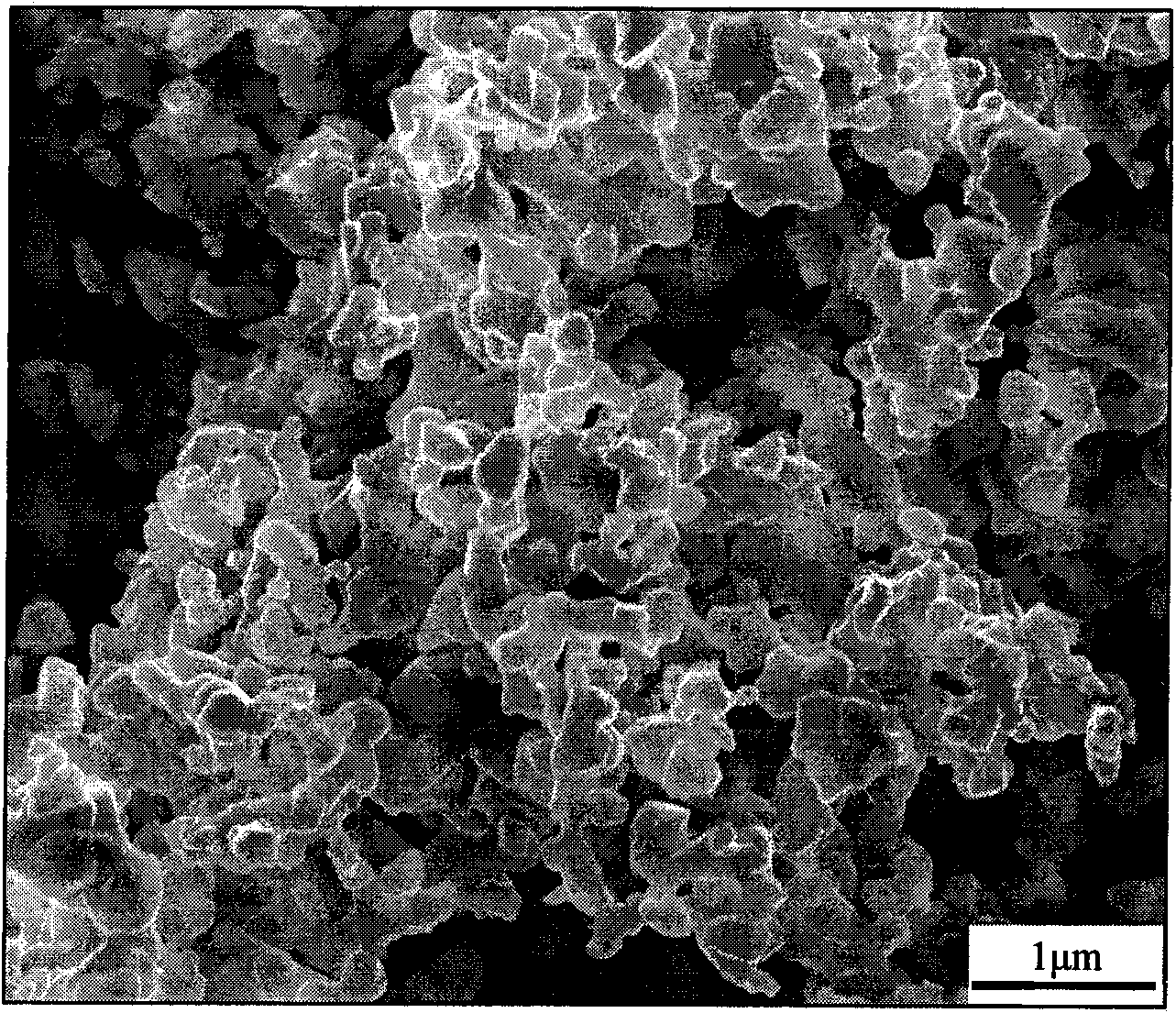

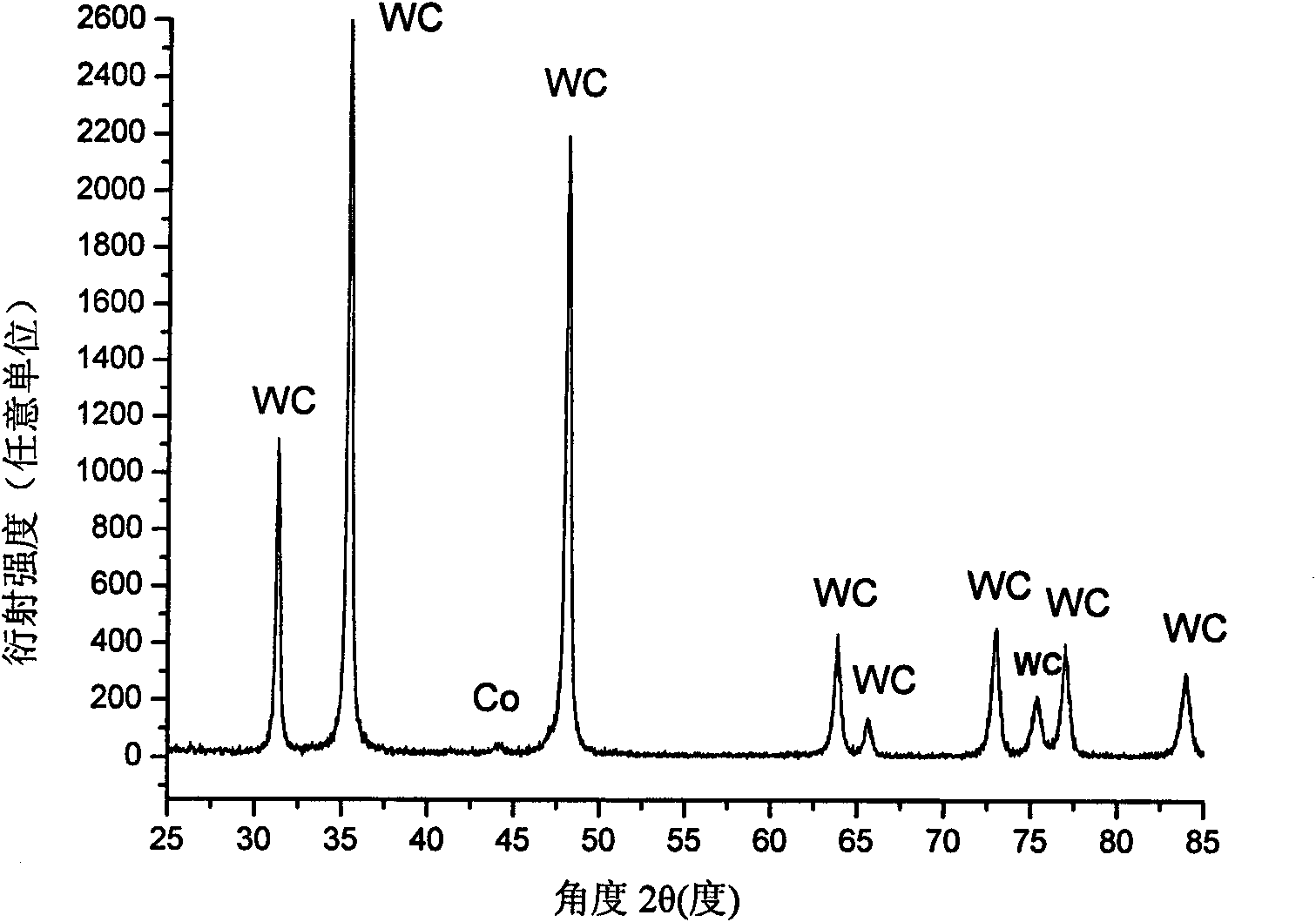

Industrialized preparation method of WC-Co hard alloy with low cost and high performance

ActiveCN101624673ASolve the problem that it is difficult to mix evenlyReduce energy consumptionPolyethylene glycolPrice ratio

The invention relates to an industrialized preparation method of a WC-Co hard alloy with low cost and high performance, which belongs to the technical field of hard alloys and powder metallurgy. The method comprises the following steps: taking WO2.9, Co3O4 and carbon soot as raw materials, and computing the usage ratio of the three materials according to the requirement of the Co content in a final hard alloy block material; adding 0-1.0 percent by weight of grain growth inhibitor into the prepared WC-Co composite powder, and adding polyethylene glycol as a forming agent into a ball milling tank 4-8 hours before ball milling is finished, wherein 30-80ml of polyethylene glycol is added into the powder material per kilogram; acquiring WC-Co mixed powder with a nanocrystal structure after ball milling, and putting the mixed powder into a mould for press forming after vacuum drying; and sintering the mixed powder stock after press forming in a mode of vacuum sintering or low-pressure sintering. The industrialized preparation method markedly shortens a production period, the provided integrated preparation course markedly reduces the production cost while ensuring the high performance of the hard alloy and has a high performance-price ratio, and the preparation method is suitable for industrialized scale production.

Owner:北硬科技香河有限公司

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

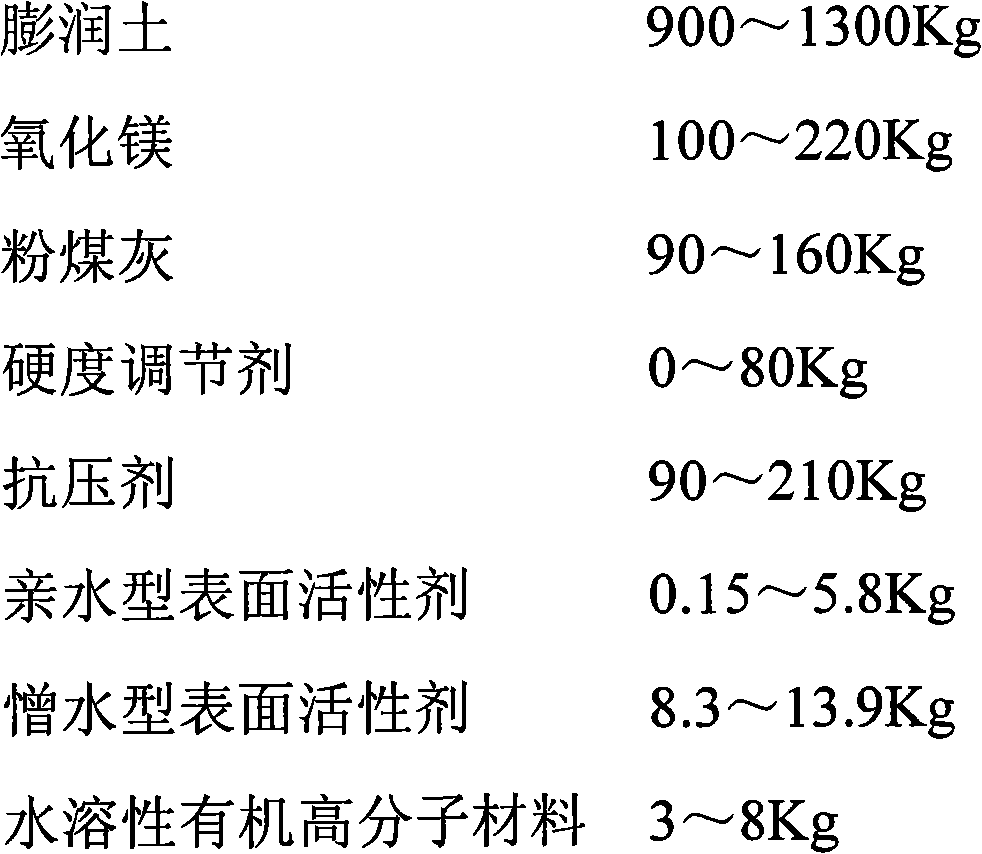

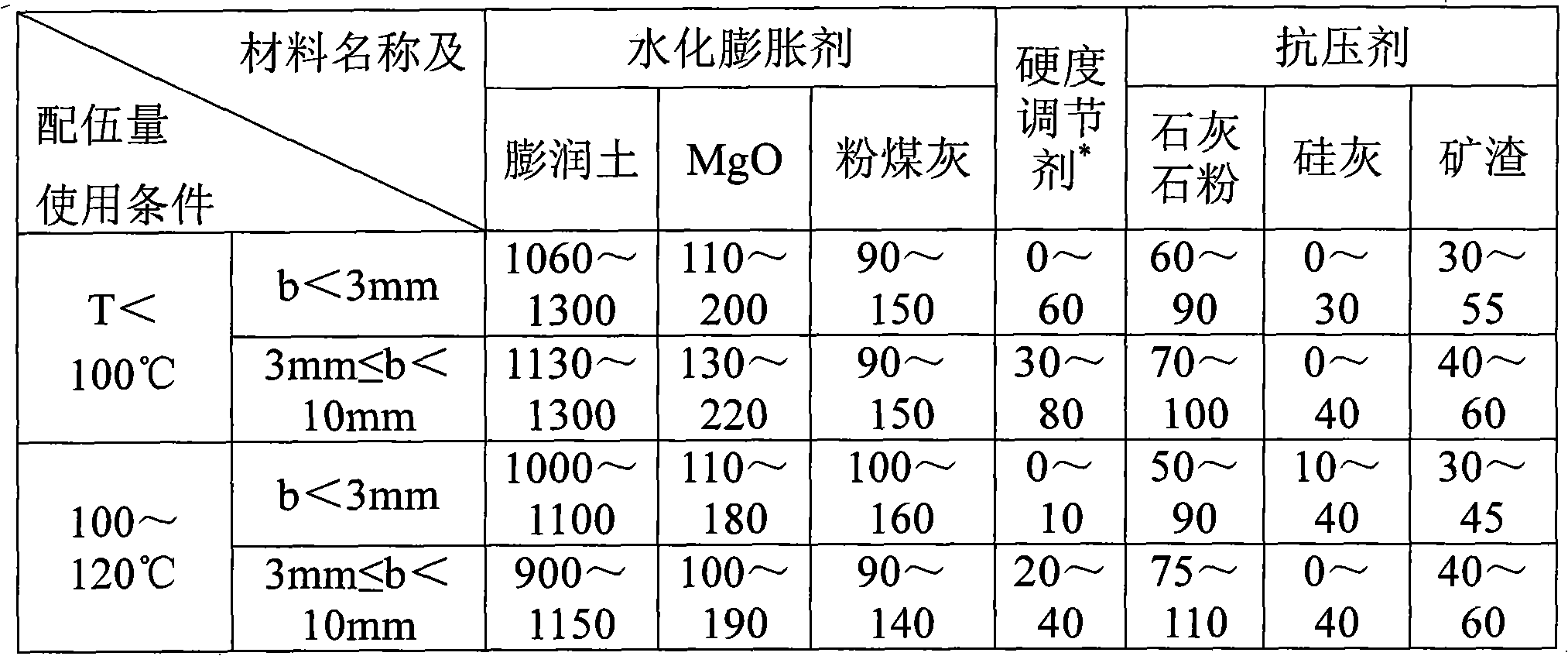

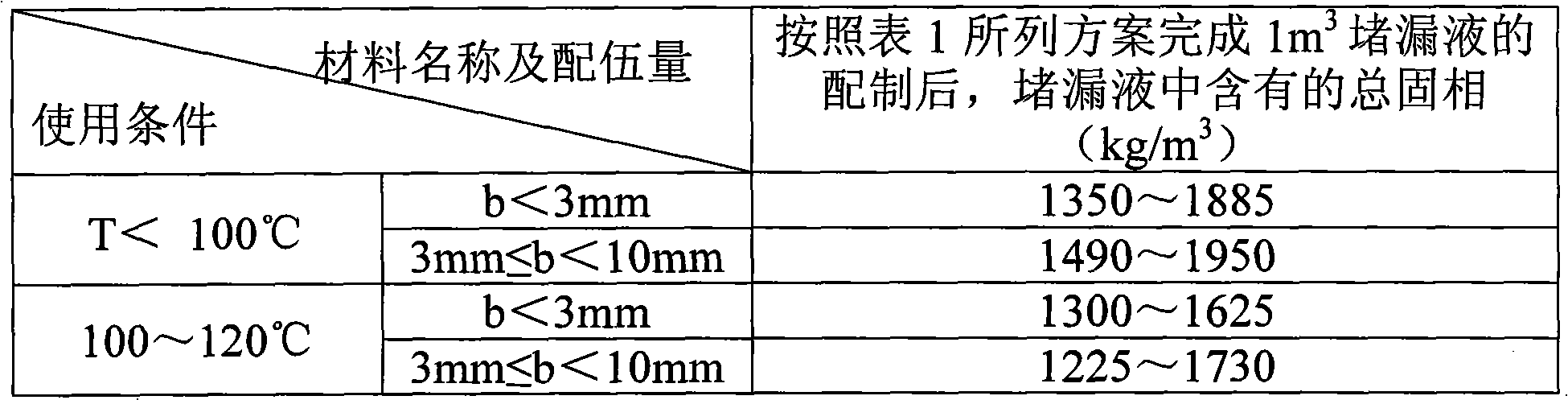

Plugging bearing material for petroleum drilling, and preparation method and application thereof

ActiveCN102061151ASuitable for lipophilic and hydrophilic propertiesGuaranteed preparationDrilling compositionSealing/packingHigh fracturePetroleum

The invention provides a plugging bearing material for petroleum drilling, and a preparation method and application thereof. The plugging bearing material comprises the following components: 900 to 1,200 kilograms of bentonite, 100 to 220 kilograms of magnesium oxide, 90 to 160 kilograms of fly ash, 0 to 80 kilograms of hardness regulator, 90 to 210 kilograms of compression resisting agent, 0.15 to 5.8 kilograms of hydrophilic surfactant, 8.3 to 13.0 kilograms of hydrophobic surfactant and 3 to 8 kilograms of water-soluble organic high polymer material. A plugging material formed by the plugging bearing material has high fracture plugging capability, and a plugging belt formed by the plugging bearing material plays a certain stable role in fracturing rocks. The plugging bearing material, and the preparation method and the application thereof are suitable for processing formation leakage of various forms.

Owner:CHINA PETROLEUM & CHEM CORP +1

Apparatus for electrically mediated delivery of therapeutic agents

ActiveUS9364664B2Function increaseShorten the lengthSkin piercing electrodesElectricitySquare Millimeter

Owner:ICHOR MEDICAL SYST

Feed for improving sow oestrum and increasing farrowing amount

ActiveCN101120731AImprove fertilityImprove conception rateFood processingAnimal feeding stuffAnimal sciencePhosphate

The present invention discloses a feed for promoting sows aphrodisiac and more farrowing, which belongs to the technical field of pig feed. The feed comprises the components as the weight of 600 to 700 shares of corn, 220 to 280 shares of soybean meal, 20 to 50 shares of corn gluten meal, 20 to 50 shares of fish meal, 10 to 30 shares of soybean oil, 5 to 15 shares of dicalcium phosphate, 10 to 20 shares of rock powder, 3 to 5 shares of salt, 2 to 4 shares of lysine, 0.2 to 0.5 shares of methionine, 0.2 to 0.5 shares of threonine, 2 to 4 shares of minerals vitamin and 5 to 15shares of additives. The sows can definitely have more than four kilograms daily meal after weaning with the feed and feeding about six days, the main function of the present invention is to early estrus, and more litter. Using the feed can make sow early estrus and more litter, and strengthen the needs of nutrition for sows breeding, supplement the iron and zinc trace elements, and enhance the ability of the breeding sows.

Owner:沂水和美华福泰华饲料有限公司

Method for increasing yield of plums

The invention relates to a method for planting plums. The method is suitable for the popularization and development of plum planting areas in south of Sichuan areas. The detailed technical scheme is provided emphatically from aspects of planting, tree pruning, soil and fertilizer management, the prevention and control of plant diseases and insect pests and the like by the integrated management and cultivation of seedlings of plum trees and adult trees. The method has the advantages that 1, field planting is performed according to the standard, namely 40 to 45 plants are subjected to field planting in soil per mu by a method for purifying the plums and a method for increasing the yield, and the planting number is neither more nor less; 2, yield and efficiency are high, namely the yield of a single plant of 7-age trees reached 40 to 60 kilograms in 2011; 3, benefits can be achieved for multiple times by performing field planting once, and the tree age is 30 to 35 years; and 4, cold resistance is improved. By the technology, in a chasmogamous period, the cold resistance and a fruit-bearing rate can be ensured under the condition of low-temperature overcast and rainy weather, so the plums which are stably yielded are obtained.

Owner:GAO COUNTY SIHEYUAN AGRI TECH

A method for cultivating high-quality Pleurotus eryngii with waste mushroom residue

The invention discloses a method for culturing high-quality pleurotus geesteranus by using waste pleurotus eryngii residue. The method is characterized in that: when raw materials are prepared and treated, the culture material composition for production, namely the formula composition of raw materials, comprises the following raw materials in part by weight: 400 to 700 parts of waste pleurotus eryngii residue, 200 to 300 parts of sawdust, 300 to 500 parts of corn straw, 100 to 200 parts of cotton seed hull, 200 to 350 parts of bran, 10 to 20 parts of gypsum, 15 to 15 parts of lime, and 10 to 1 5 parts of white sugar. A proper amount of sodium selenite serving as a clearing auxiliary agent is added into each 100 kilograms of dry culture material. By the method, the waste is utilized, the cost of the raw materials is lowered, the resource waste is reduced, environmental pollution is lightened, the sources of the raw materials are easily solved, the process is simple, labor and effort are saved in management, and stable yield and high yield are achieved; and by adding a little amount of sodium selenite (Na2SeO3) serving as the clearing auxiliary agent, the cadmium content of the pleurotus geesteranus finished product is reduced, and the production and the export scale are enlarged.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Building silt soil non-sintered ceramic aggregate and preparation method thereof

ActiveCN102617107ASimple technical processEasy accessSolid waste managementSolid componentEnvironmental resistance

The invention discloses a building silt soil non-sintered ceramic aggregate, which is characterized by comprising solid components and water, wherein every kilogram of solid components comprise the following components in percentage by weight: 60-80 percent of building silt soil, 2-5 percent of cement, 2-5 percent of quick lime, 2-5 percent of desulfurized gypsum, 2-7 percent of perlite, 2-8 percent of fly ash and 5-10 percent of water glass; and the amount of the water accounts for 45-60 percent of the total mass of the solid components. The invention also discloses a preparation method of the ceramic aggregate. The ceramic aggregate and the preparation method thereof have the characteristics of simple pretreatment of building silt soil, simple preparation process and capabilities of eliminating industrial wastes such as fly ash and desulfurized gypsum without large-sized calcining equipment and expanding the utilization approach of the solid waste material; and by adopting a non-sintering process, the ceramic aggregate and the preparation method thereof have the advantages of environmental protection effects such as energy conservation and low carbon compared with a roasting process.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Process for producing acetic acid

ActiveUS7476761B2Decrease in reaction rate can be inhibitedIncrease hydrogen partial pressurePreparation from carboxylic acid saltsOrganic compound preparationCarbon numberReaction rate

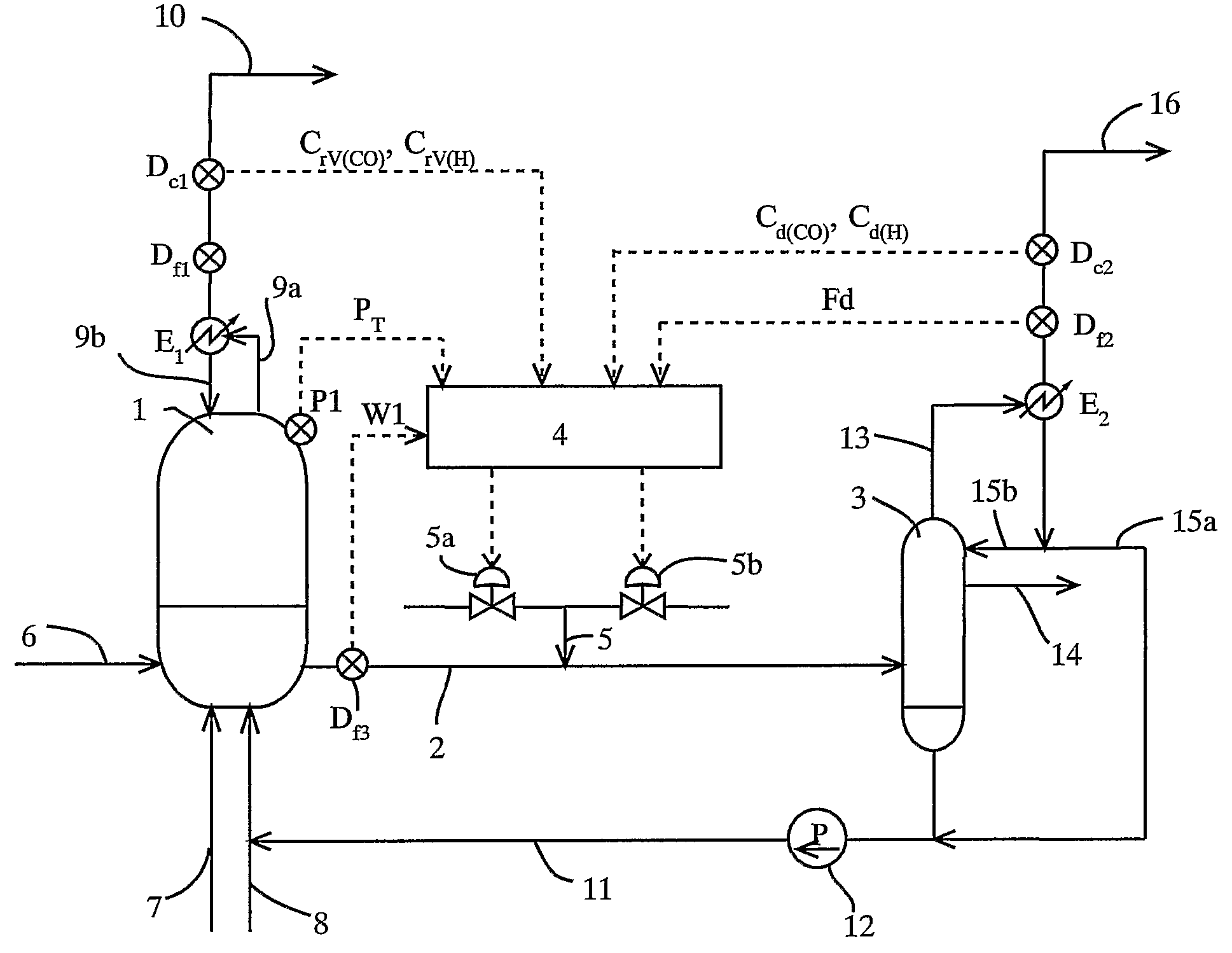

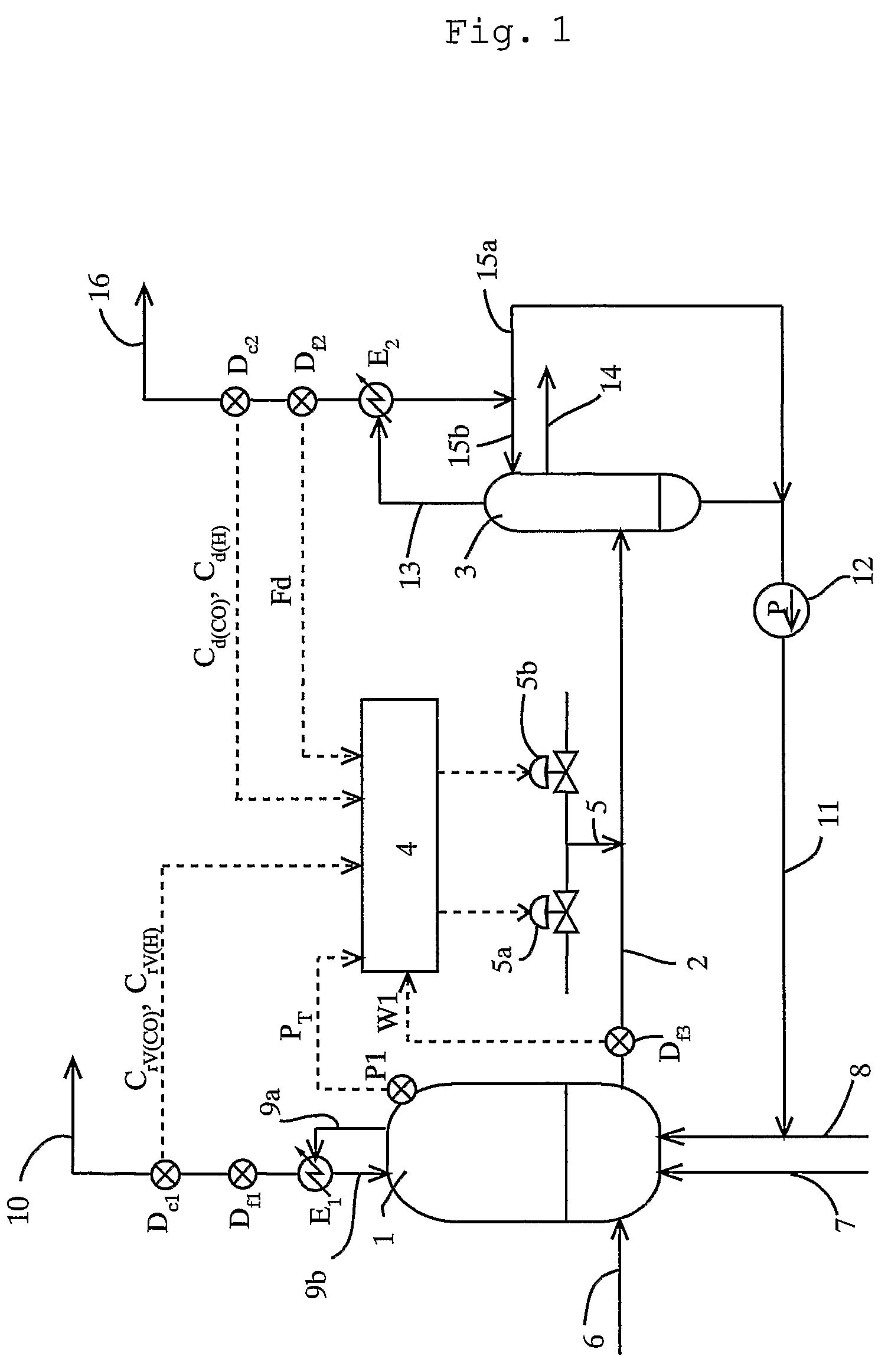

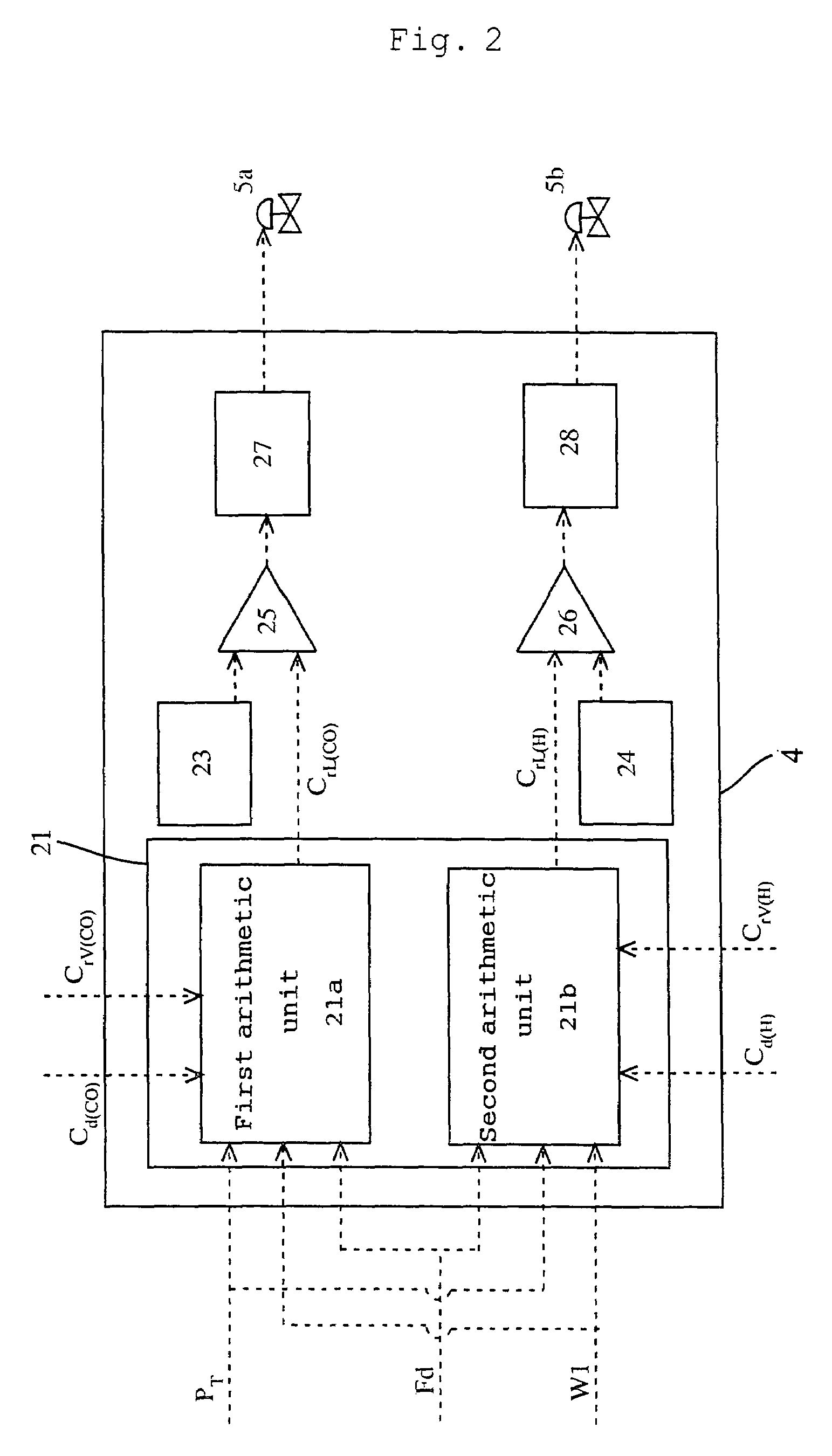

A process for producing a carboxylic acid comprises allowing an alcohol having a carbon number of “n” to continuously react with carbon monoxide in the presence of a carbonylation catalyst system, and a limited amount of water, continuously withdrawing the reaction mixture from the reaction system 1, introducing the withdrawn reaction mixture into a distillation step (distillation columns 3a and 3b), and separating a higher-boiling component and a lower-boiling component containing a carboxylic acid having a carbon number of “n+1”, respectively. In the process, the amount of carbon monoxide and / or hydrogen contained in a liquid phase of the reaction system is adjusted to at least one of the following conditions (i) and (ii): (i) the amount of carbon monoxide relative to 1 kilogram of the liquid phase by weight is at least 2 mmol per 1 MPa of carbon monoxide partial pressure of the reaction system, and (ii) the amount of hydrogen relative to 1 kilogram of the liquid phase by weight is at least 50 mmol per 1 MPa of hydrogen partial pressure of the reaction system. Such a process inhibits deactivation of a metal catalyst and deterioration in a reaction rate, and decreases formation of by-products in producing a carboxylic acid under a low water content.

Owner:DAICEL CHEM IND LTD

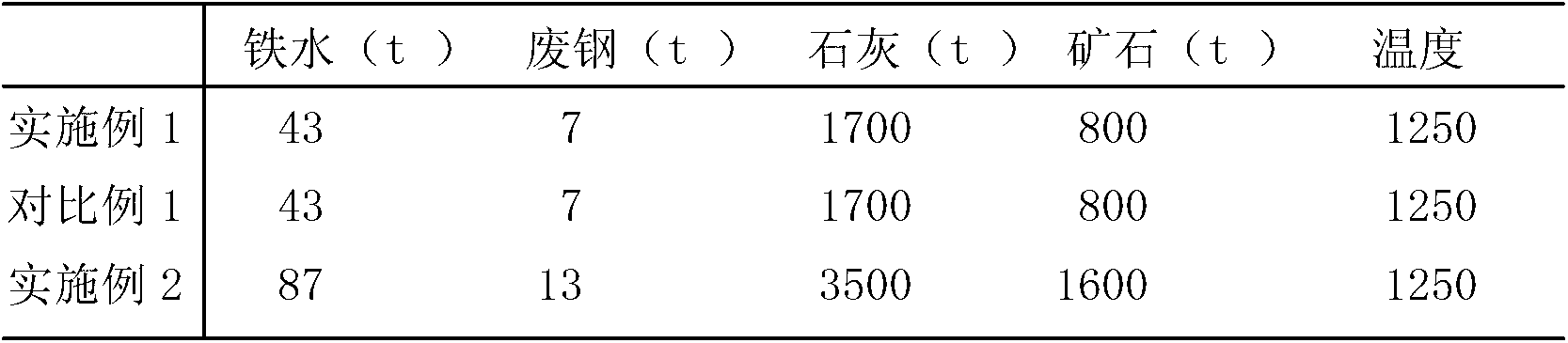

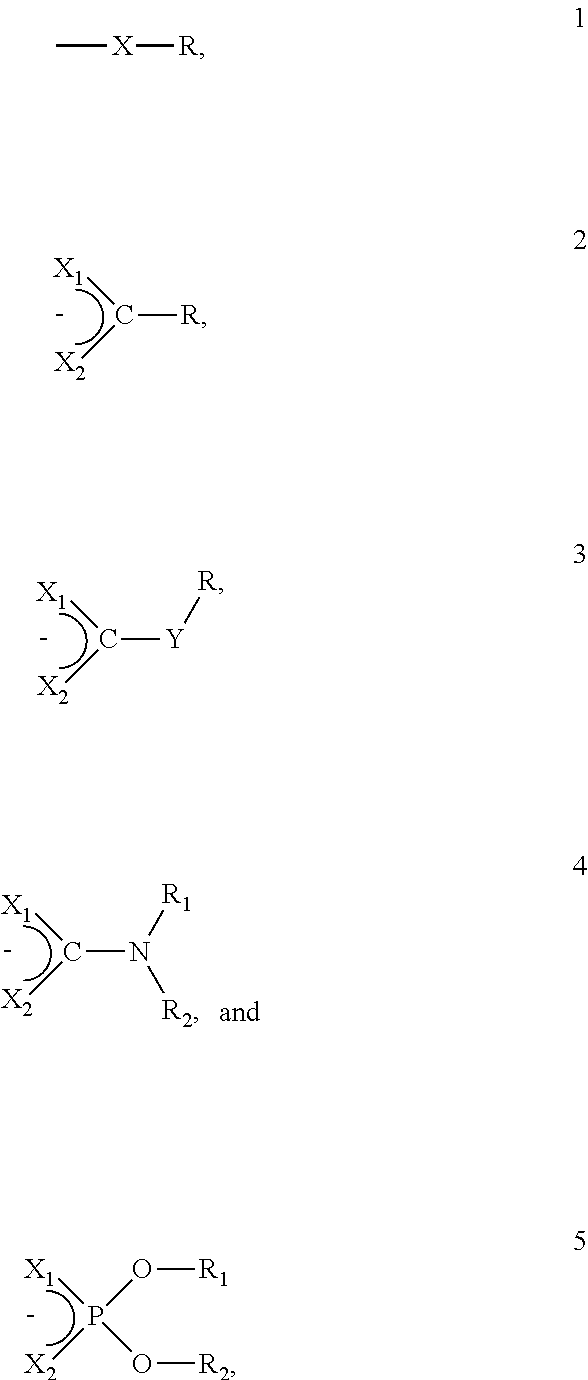

Smelting method for improving phosphorus removal rate of converter

ActiveCN103060508ALower oxygen pressureFoamy splash preventionManufacturing convertersSmelting processOxygen pressure

The invention discloses a smelting method for improving the phosphorus removal rate of a converter. The method comprises the following steps of: at the later stage when steel splashing slag is emptied in the converter, adding 500 to 800 kilograms of lime, slightly stirring, pre-heating, adding waste steel, and blending molten iron; adding a bath of slag forming material such as lime, lightly burnt magnesium blocks, ores and the like when blowing to 45 to 60 seconds, lifting an oxygen lance by 200 millimeters when blowing for 4.5 minutes, continuously adding 4 to 5 batches of ores, and uniformly controlling the heating speed of a molten pool to increase the FeO content of slag; when blowing to 7 minutes, properly lowering the lance for 50 to 100 millimeters, meanwhile, reducing the oxygen pressure to 0.80MPa, and continuously adding 2 to 3 batches of rest lime; and keeping the position of the final point pressure lance at 1,000 millimeters for 1 minute. By adopting the method, full-process slag smelting can be realized, the slag is not re-dried, a good phosphorus removal effect is obtained, the phosphorus removal rate is improved by 10 percent compared with the conventional smelting process, and the requirement for smelting the molten iron with a high content of phosphorus can be met.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

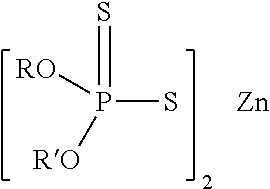

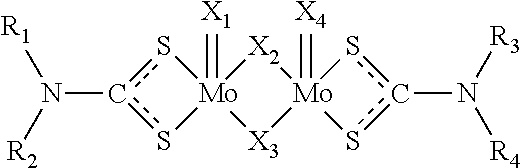

Lubricating Oil Composition

InactiveUS20110245120A1Trend downLow-temperature fluidity enhancedLiquid carbonaceous fuelsAdditivesChemical compositionAlkaline earth metal

A lubricating oil composition having a phosphorus content of up to 0.12 wt %, a sulfated ash content of up to 1.2 wt % comprising (a) a major amount of an oil of lubricating viscosity; (b) an alkali metal or alkaline earth metal alkyl salicylate lubricating oil detergent providing from 7-15 mmol salicylate soap per kilogram of lubricating oil composition; (c) one or more dispersants providing the lubricating oil composition with from at least 0.12 wt % to 0.20 wt % atomic nitrogen, based on the weight of the lubricating oil composition, and (d) a dispersant-viscosity modifier.

Owner:BERSTREETCAR RICHARD D +2

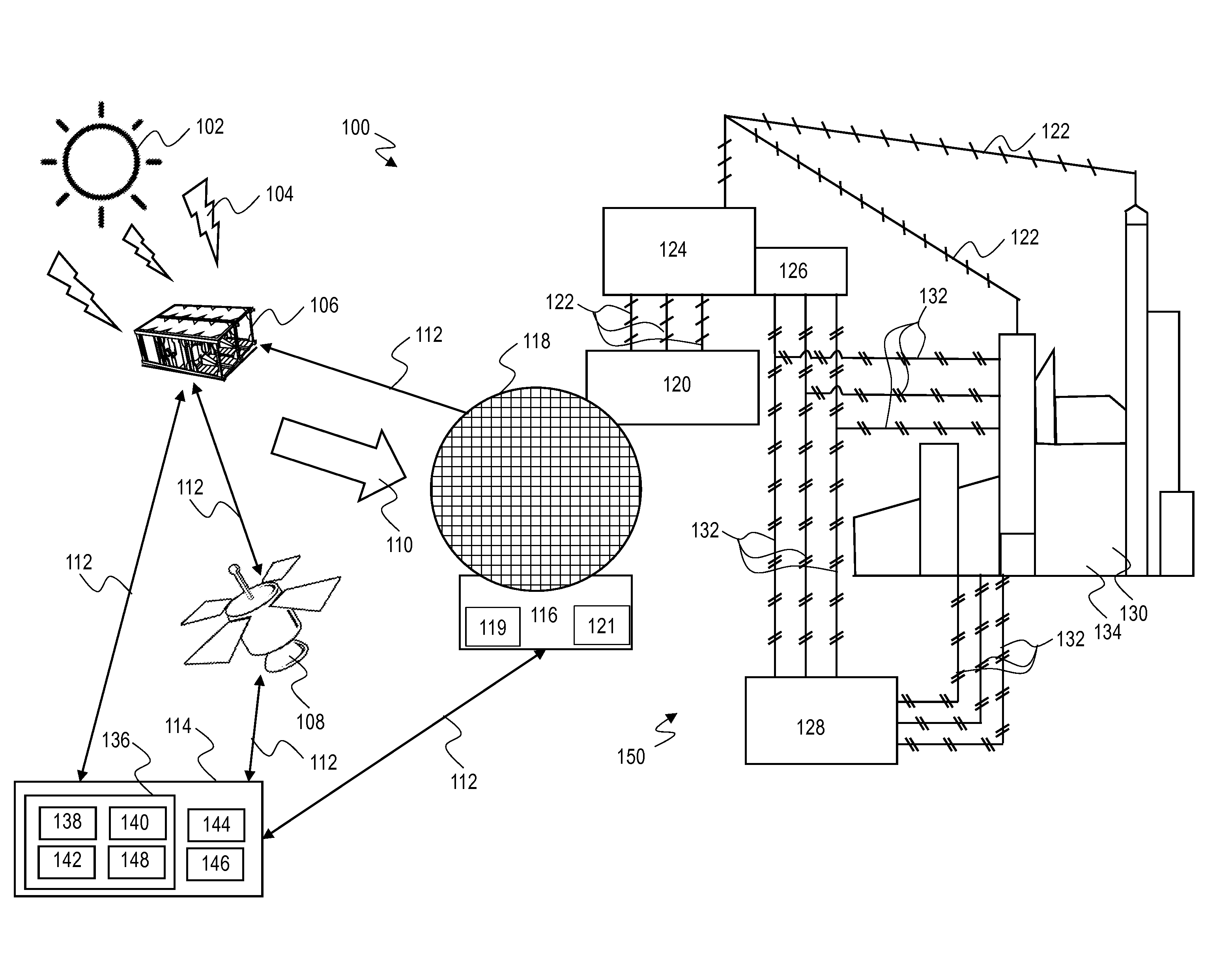

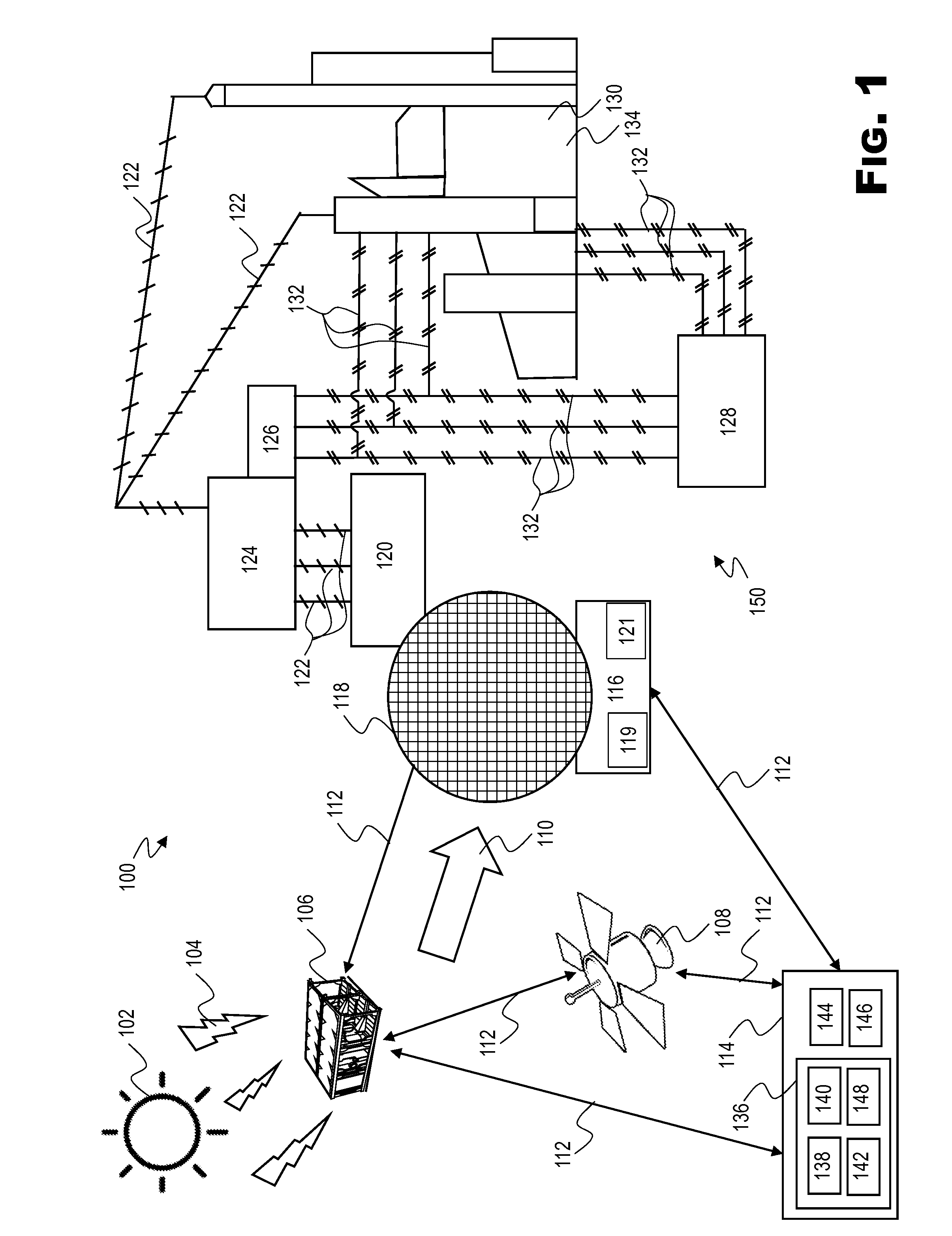

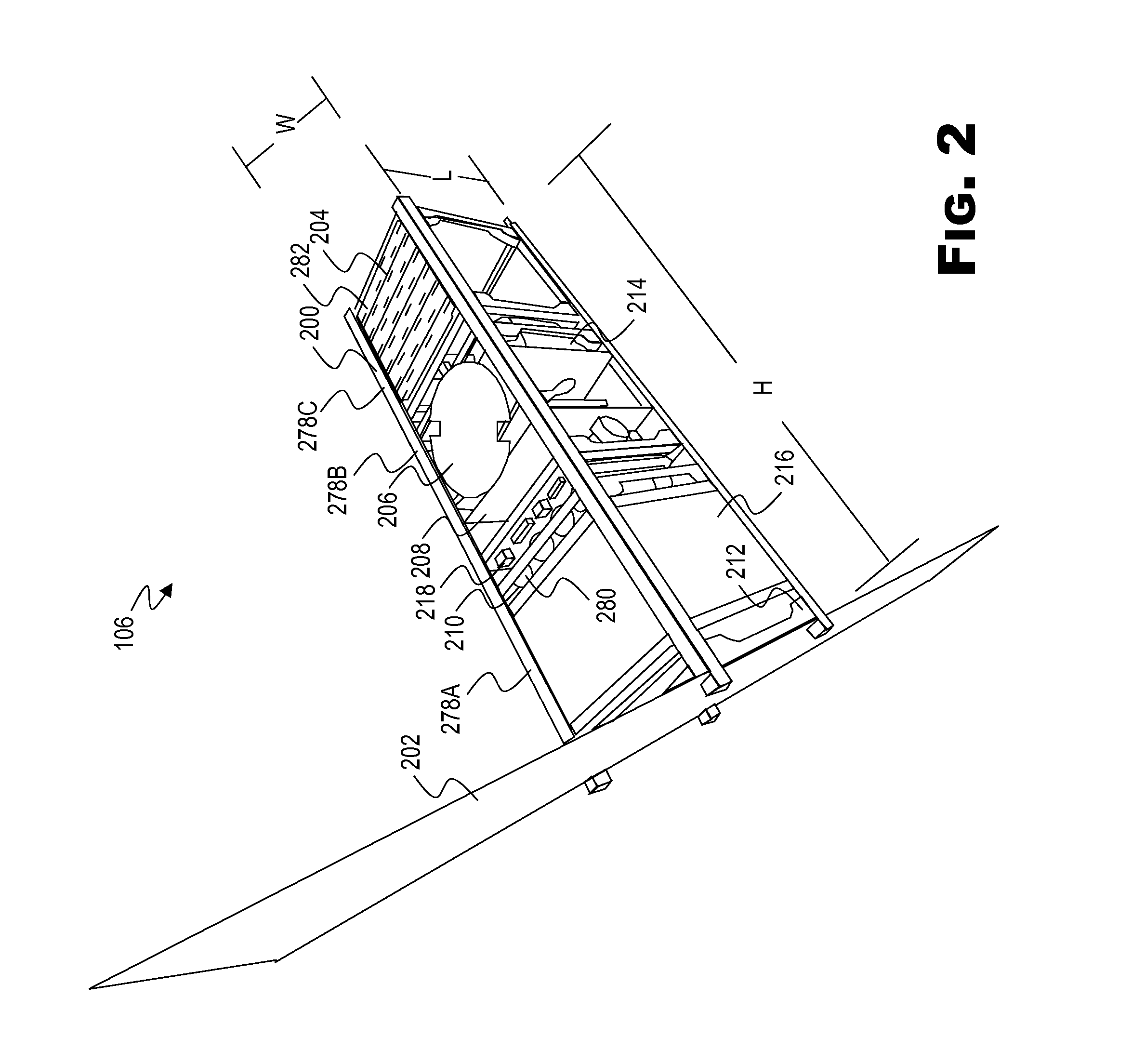

Solar Energy Conversion and Transmission System and Method

InactiveUS20160065006A1Dc network circuit arrangementsElectromagnetic wave systemElectricityMicrowave

A modular satellite for converting solar energy to microwave energy and transmitting the microwave energy to the earth to be converted into electricity includes solar panels configured to convert solar energy into direct current; a magnetron operatively connected to the solar panels to receive the direct current and configured to convert the direct current into microwave energy; a planar wave guide antenna operatively connected to the magnetron to receive the microwave energy and direct the microwave energy to a station on earth; and a coupling system for coupling with another satellite to form an array in response to at least one of locking, unlocking, and navigational commands. The satellite has a mass equal to or less than four kilograms, and a volume equal to or less than three liters.

Owner:WOODS JAMES JOSHUA

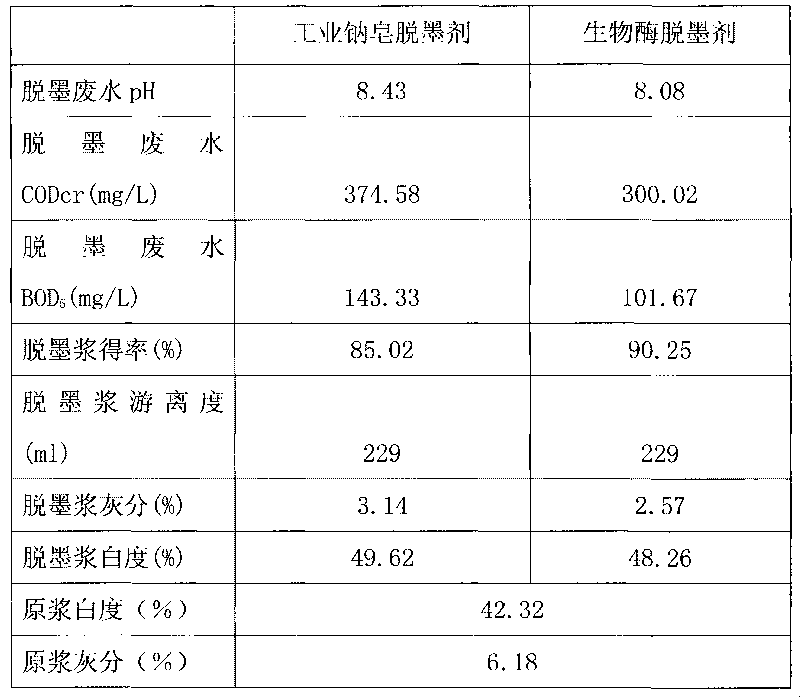

Process for de-inking waste newspaper by biologic enzyme

InactiveCN101718050AReduce usageImprove water filtration performancePaper recyclingWaste paper working-upHigh concentrationPrinting ink

The invention provides a process for de-inking waste newspaper by a biologic enzyme, which relates to the process of the pulping of waste paper. The process is characterized by comprising the following technological procedures of: (1) preparing a de-inking agent: adding one or several of alkali lipase, amylase and xylanase into cellulase to prepare a composite enzyme and then adding 0.05-0.15 kilogram of surfactant into the composite enzyme with the weight to form the de-inking agent, wherein the composite enzyme comprises the following components in proportion: 2000-10000U of cellulase, 10000-100000U of alkali lipase, 1000-5000U of xylanase and 8000-15000U of amylase; (2) pulping by using a high-concentration pulper: adding 40-60 DEG C water into the high-concentration pulper, counting by 100 kilograms of absolutely dry paper, putting 10-150 grams of de-inking agent and 0.2-0.4 kilogram of sodium metassilicate nonahydrate into waste newspaper and journal paper and stopping after starting the pulper for 10-30 minutes; and (3) carrying out the procedures of floatation and printing ink separation to obtain the de-inked pulp. The invention has the advantages that sodium hydroxide and hydrogen peroxide are not used, and the production cost and the wastewater pollution are lowered.

Owner:FUJIAN JIAFENG BIOCHEM

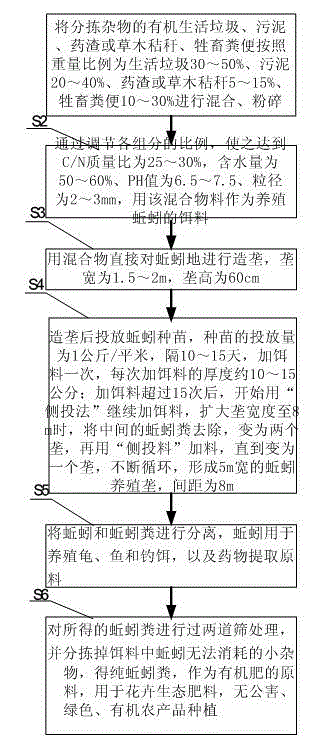

Organic solid waste bio-treatment technology based on earthworm breeding

InactiveCN104082251ALarge amount of processingAchieve biological purificationFood processingClimate change adaptationLivestock manureFeces

The invention discloses an organic solid waste bio-treatment technology based on earthworm breeding. The organic solid waste bio-treatment technology based on earthworm breeding comprises the following steps that household garbage, sludge, medicine residuals or vegetation straws, animal excrement, fruit and vegetable leaves and the like, rich in organics, of sorted impurities are mixed and fermented according to a weight proportion; the mixture serves as the bait for breeding earthworms; ridges are built on a earthworm field through the mixture; young earthworms are put into the field after ridge building, and the input quantity of the young earthworms is 1 kilogram per square meter, bait is added every 11-16 days, the thickness of bait added each time is about as high as 10-15 cm, the earthworms are collected when the ridges are heightened to 60 cm, then bait continues to be added through a lateral input method, the earthworms are collected every two times of bait adding, and the work is repeated. The organic solid waste bio-treatment technology based on earthworm breeding saves energy, protects the environment, carries out treatment through a pure biological method, is high in processing efficiency and large in processing amount, develops a new treatment method for domestic garbage, and achieves perfect combination of social benefits, ecological benefits and economic benefits.

Owner:西安市沣东新城康运种养殖专业合作社

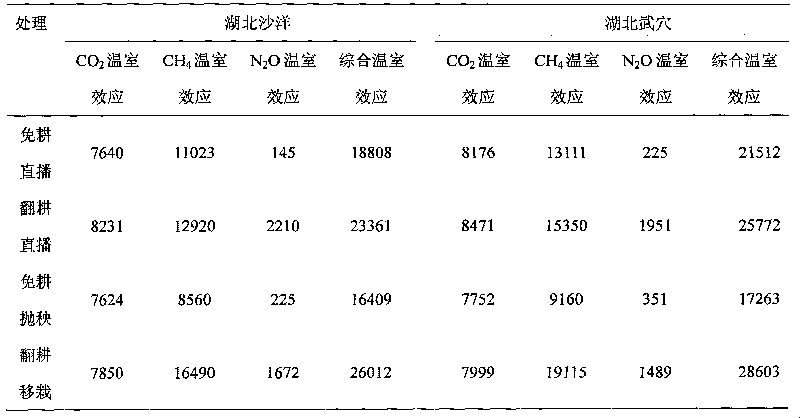

No-tillage seedling-throwing overall aerobic cultivation method for oil crop-medium rice fixed compartment ditch

The invention belongs to the field of rice cultivation, and particularly relates to a cultivation method suitable for no-tillage rice in a fixed compartment of an oil crop-medium rice field. The cultivation method comprises the following steps that: (1) rice seeds are coated by using dry-raised nurse, thick mud and dry fine soil serving as coating agents, wherein the components comprise 7.9 to 12.5 percent of dry-raised nurse, 25 to 26.3 percent of rice seeds, 12.5 to 13.2 percent of thick mud with 37 percent of water content and 50 to 52.6 percent of dry fine soil with 3 percent of water content in percentage by mass; the rice field is finished as required and the soil moisture is kept; and keeping the seedling age at 15 to 18 days; (2) the compartment width of the oil crop field is 1.2 meters, the width of the ditch is 0.3 meter, and the depth of the ditch is 0.25 meter; the rape seedlings are applied to the field; a ternary compound fertilizer of which pure nutrients comprise 15 percent of N, 15 percent of P2O5 and 15 percent of K2O is applied, and 30 kilograms of pure nitrogen is applied in each mu; 5.80 kilograms of zinc is applied in each mu; and 4.8 kilograms of boron fertilizer is applied in each mu, and the ditch is kept full of water; (3) rice seedlings with 50 to 100 grams of soil in each seedling in 15 to 18 days are directionally thrown according to a row space of 20 centimeters; and (4) the ditch is kept with water and the compartment surface has no water after throwing the seedlings till the heading stage, and dry and wet alternated cultivation is adopted from the grain filling stage to the maturation stage. Compared with the conventional method, the yield is averagely increased by 8.7 percent.

Owner:HUAZHONG AGRI UNIV

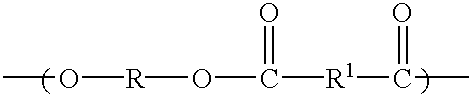

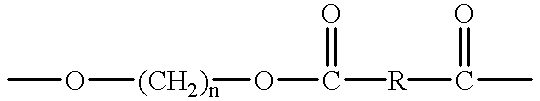

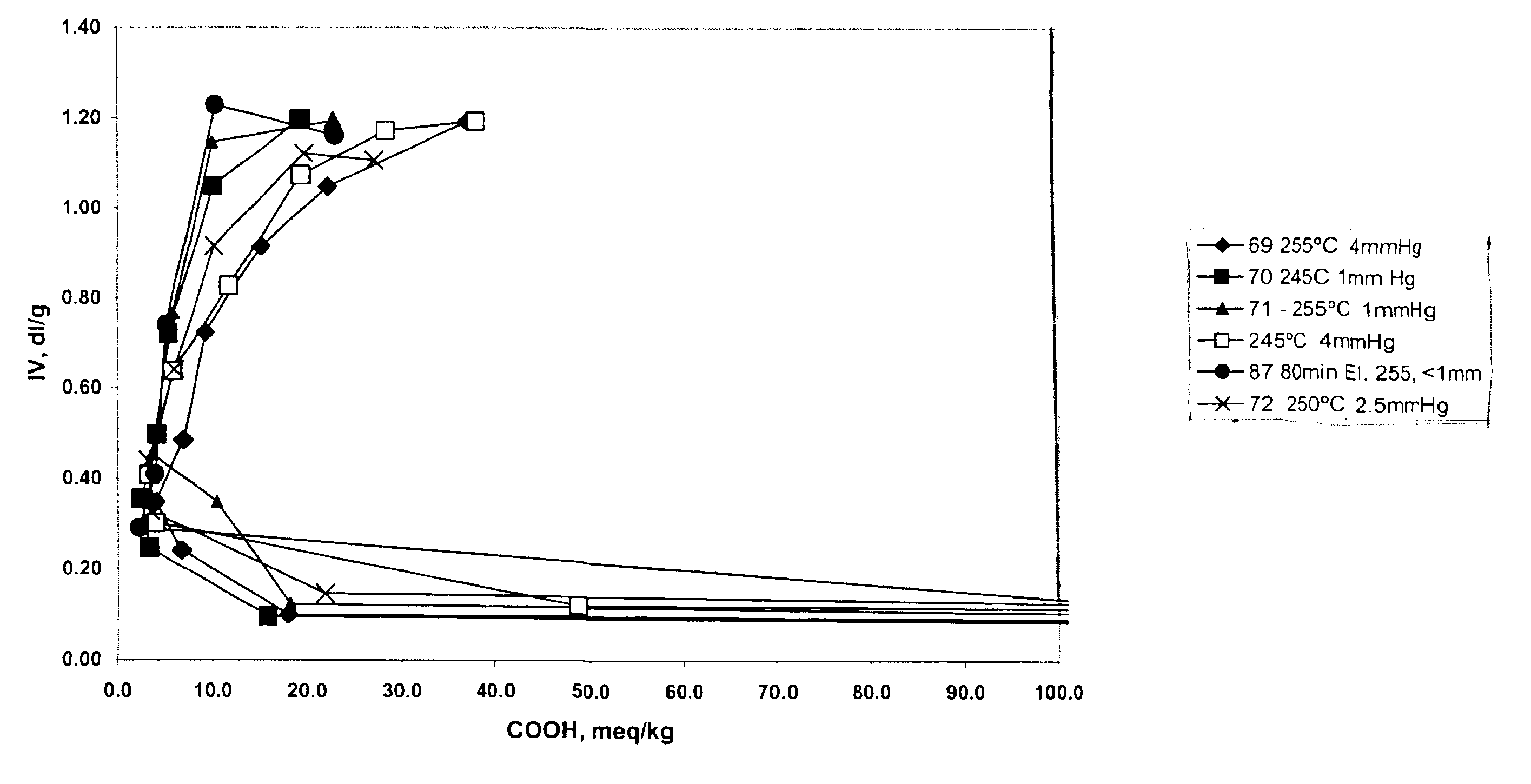

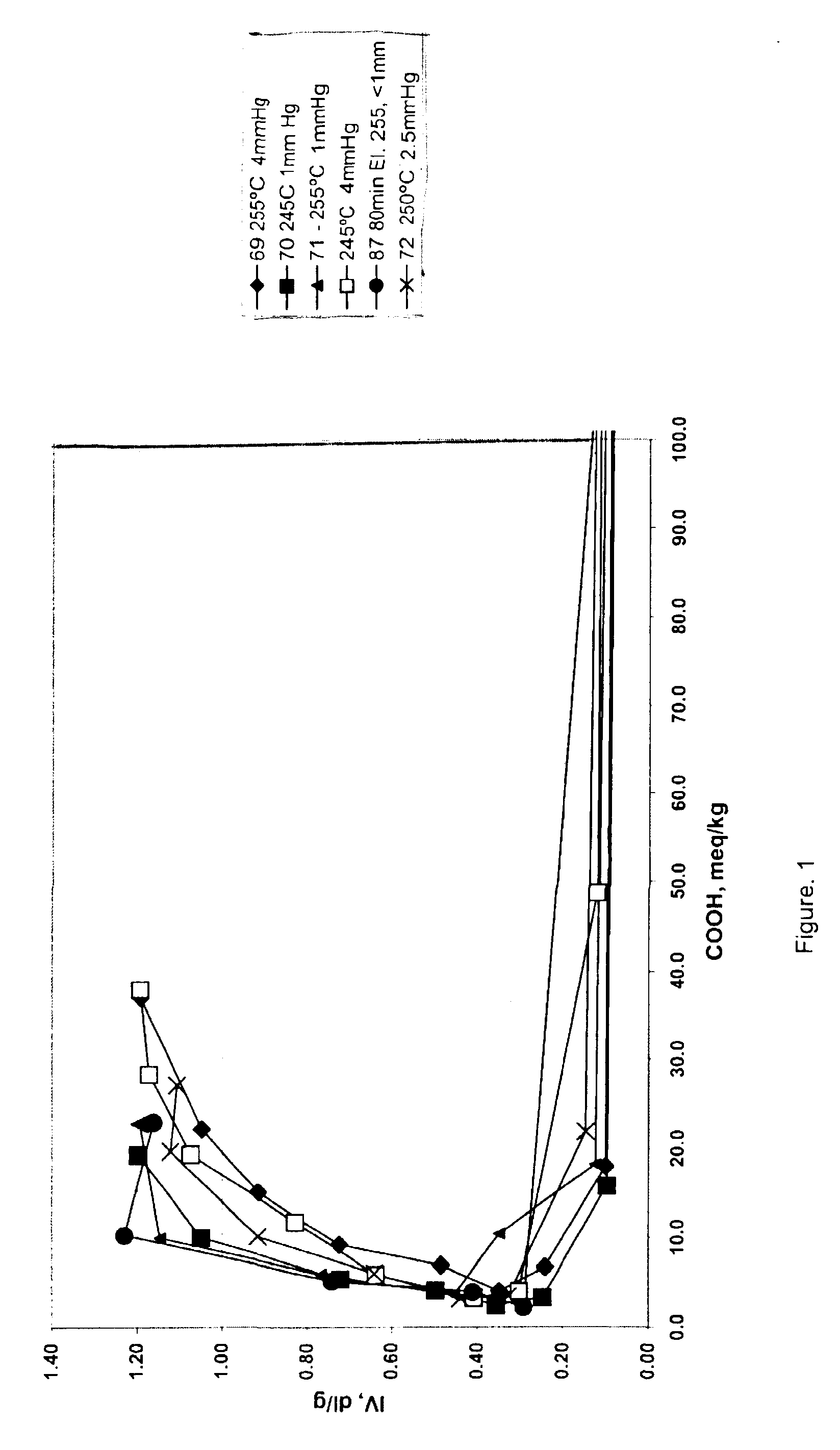

Crystalline polyester resins and processes for their preparation

An improved process for the preparation of high molecular weight, linear polyester resins comprises reacting an aromatic dicarboxylic acid with an excess of an alkane diol under conditions effective to reach the clearing point of the reaction; pre-condensing the cleared reaction mixture under conditions effective to produce oligomers having an intrinsic viscosity measured in 60 / 40 phenol / 1,1,2,2-tetrachloroethane at 25° C. of less than about 0.70 deciliters / gram and a carboxylic acid end group level of less than or equal to about 100 milliequivalents per kilogram; and polycondensing the oligomer under conditions effective to produce a linear polyester resin having an intrinsic viscosity less than or equal to about 2.0 dl / g as measured in 60 / 40 phenol / 1,1,2,2-tetrachloroethane by weight at 25° C. and a carboxylic acid end group level of about 10 to about 40 milliequivalents per kilogram.

Owner:SABIC GLOBAL TECH BV

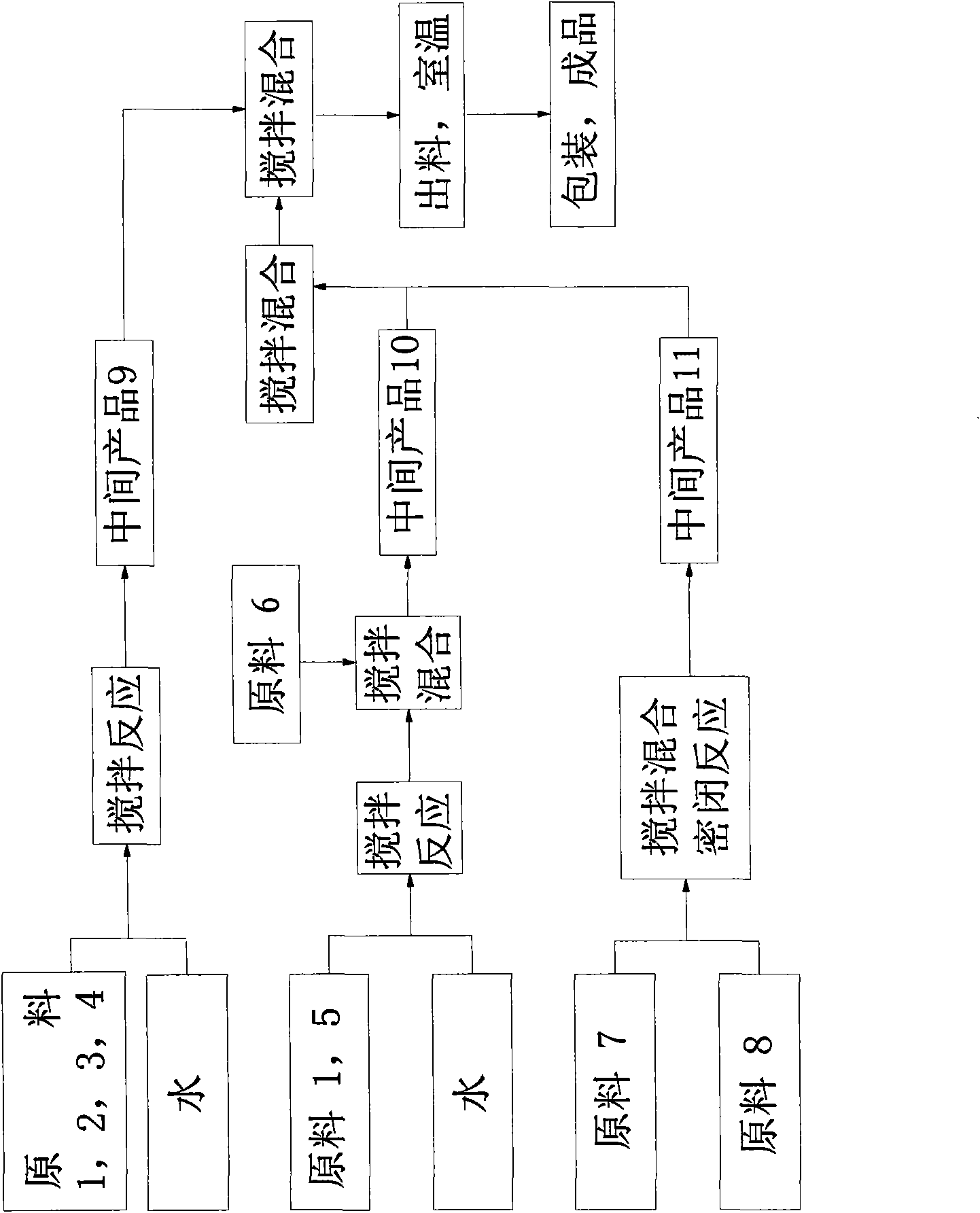

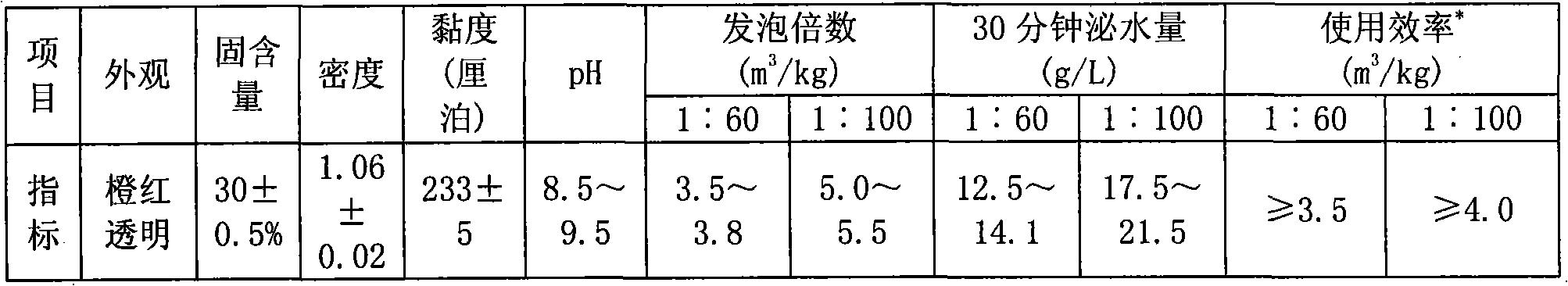

LC-01 type foam concrete foamer

The invention discloses an LC-01 type foam concrete foamer which belongs to a high-efficiency concrete air entraining agent. The invention adopts foaming time of the LC-01 type foam concrete foamer prepared form a double (multi) hydrophilic group surface active agent and a stabilizing agent; if the surface active agent and the stabilizing agent are diluted by the ratio of 1 to 100, 5.0 to 5.6m3 / kgis achieved; cement and powdery coal ash slurry are touched; the deforming rate is less than 12%; and four-stage foam concrete of more than 4m3 / kg can be produced; the cement is touched and defoamingis hardly operated; the four-stage foam concrete (containing 40% of powdery coal ash) which is larger than or equal to 3.5 to 3.8m3 / kg can be produced; and the compressive strength of the four-stagefoam concrete is from 1.2 to 1.5MPa. The invention better solves the contradiction between the foaming time of the foam concrete foamer and the stability when the foam comes into contact with the concrete slurry and enhances the production quantity and the compressive strength of the foam concrete for the foamer of each kilogram severalfold.

Owner:LUOYANG NORMAL UNIV +1

Portable folding bicycle

InactiveUS20050263979A1Readily be taken awayReduced consciousnessPassenger cyclesWheel based transmissionDeployment timeEngineering

A folding bicycle presents a number of advantages over both conventional and other foldable bicycles. The folded size of 12×25×6 inches (305×635×153 millimeters) compares favorably to other folding bicycles, and its 11 lb (eleven pound, or 5 kilogram mass) weight is significantly superior to even the closest lightweight model at eighteen pounds, and about half of the average portable bike weight of twenty-two pounds. The folded volume of the bike at 1800 square inches is slightly over one cubic foot. The portable bicycle has a folding stowage time of about 10 seconds, and a deployment time of about 6 seconds. A folding pedal and handle bar design contributes significantly to a folded lateral profile.

Owner:SINCLAIR REFINING

System for Emergency Crew Return and Down-Mass from Orbit

ActiveUS20160264266A1High level of operation safetyEconomy of scaleCosmonautic thermal protectionArtificial satellites3d shapesHuman use

A system for emergency crew return and down-mass orbit comprising a stowable, self-contained, deployable maneuvering reentry vehicle for automated, on-demand reentry to ground for cargo of 1-10 kilograms or up to single or multiple human use for evacuation of orbital facilities. The system includes a deployable “aeroshell” that is contiguous (a single geometric object—surface or hollow shape—that can morph in 3D shape), modular (a collection of modular components externally acting as a contiguous shape, but morphed in 3D via actuators contained in each modular member to create a general asymmetric geometry), or discontiguous (a collection of independently controlled surfaces or bodies that morph to form desirable asymmetric drag configurations). The system contains traditional spacecraft guidance, navigation and control, propulsion, and attitude control elements, in addition to communications, power, and actuator energetics systems for controlling the vehicle aeroshell shape during reentry, thus, minimizing the landing footprint of the vehicle.

Owner:STONE WILLIAM C

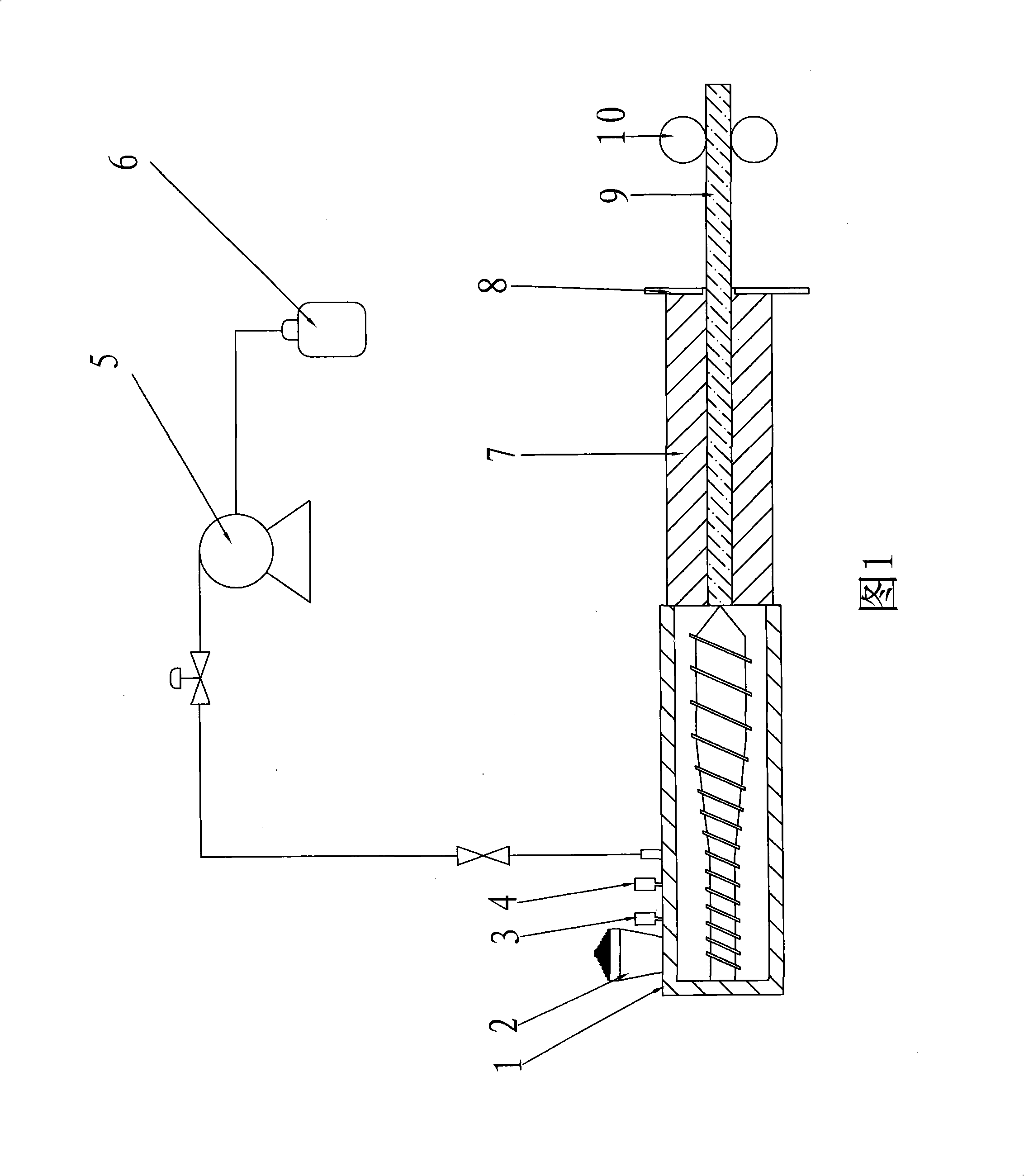

Pearl cotton plates with high compressive strength and high thickness and preparation thereof

The invention belongs to the packaging material technical field and discloses a pearl wool plank and a method for making the same. The pearl wool plant is made of 100 kilograms of low-density polyethylene, 15 to 20 kilograms of foaming agent, 0.5 to 1 kilogram of foaming nucleating agent and 1 to 2 kilograms of antishrinking agent which are foamed once. The method for making the pearl wool plank comprises the following steps that: low density polyethylene and foaming nucleating agent are added continuously at the screw tail part of a screw extruding press and are melted down at a temperature of between 150 and 180 DEG C; meanwhile, the antishrinking agent and the foaming agent are added inside the screw extruding press according to the dosage, the foaming agent is added near the middle part of a screw, the antishrinking agent is added between the positions of the low density polyethylene and the foaming agent; the melting low density polyethylene mixed with the foaming agent, the foaming nucleating agent and the antishrinking agent sprayed by the extruding press is extruded inside a flat plate die to form, the resin pressure at the front end of the screw is between 10 and 100MPa, the flat plate die is adopted. The plank is cooled and cut as well as packed. The pearl wool plank has a thickness more than 20 millimeters and a pressive strength higher than 1.0MPa, can be used for the high-class packaging material, has few manufacture processes, needs one step to form and has low process cost.

Owner:SHENZHEN BAODONGSHENG PLASTIC PACKING PRODS

Quality polymer foam from fluorinated alkene blowing agents

Alkenyl aromatic polymer foam comprising a polymer matrix containing one or more polymer and defining a plurality of cells having an average cell size wherein: (a) the alkenyl aromatic polymer foam has: —(i) an average cell size that is in a range of 0.02 and 5 millimeters; —(ii) a density of 64 kilograms per cubic meter or less; —(iii) an open cell content less than 30 percent; and—(iv) a cell size variation of 30% or less; and wherein the foam further comprises one or more fluorinated alkene blowing agent at a concentration of 0.03 moles or more and 0.3 moles or less per 100 grams of polymer foam.

Owner:DOW GLOBAL TECH LLC

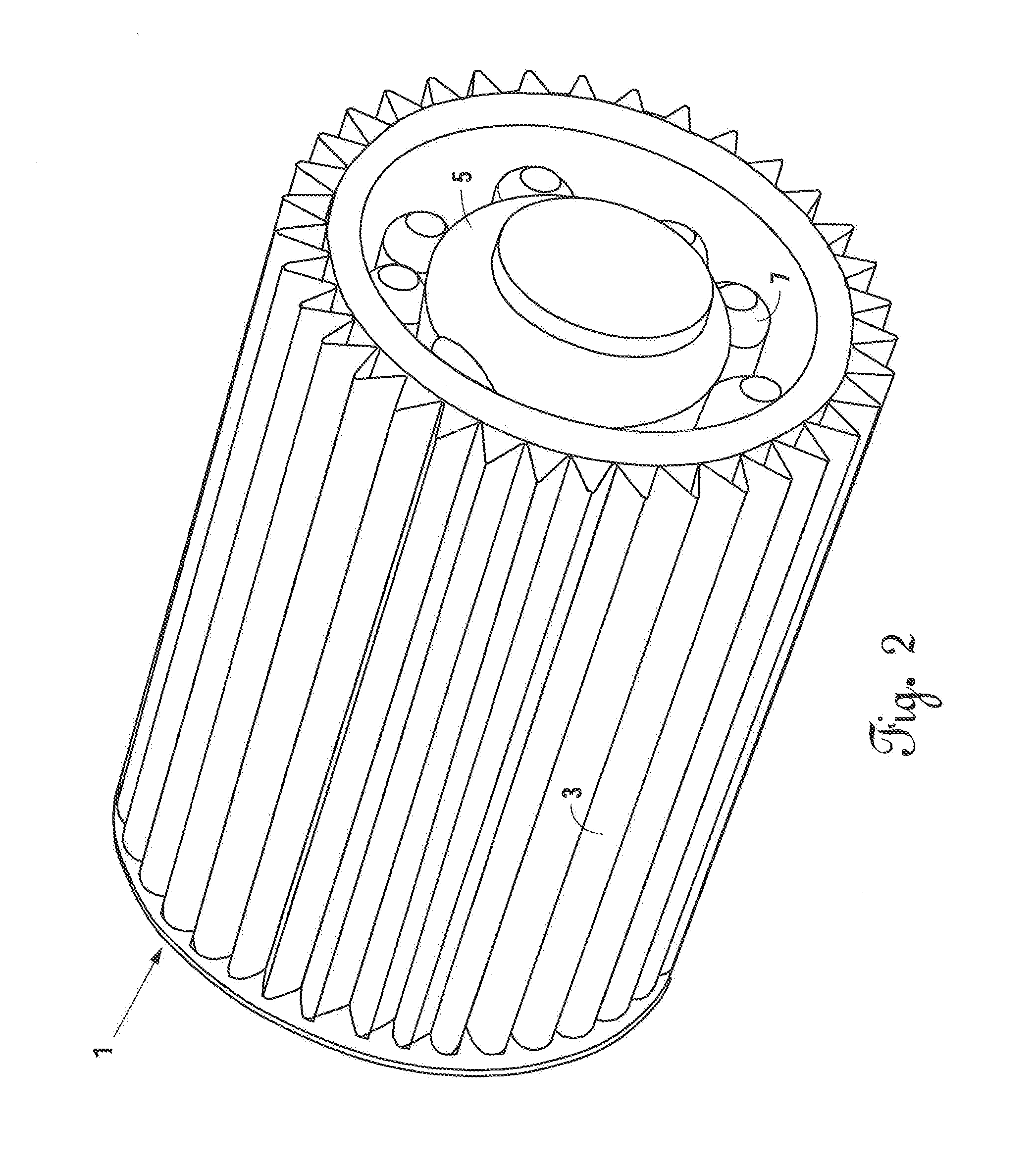

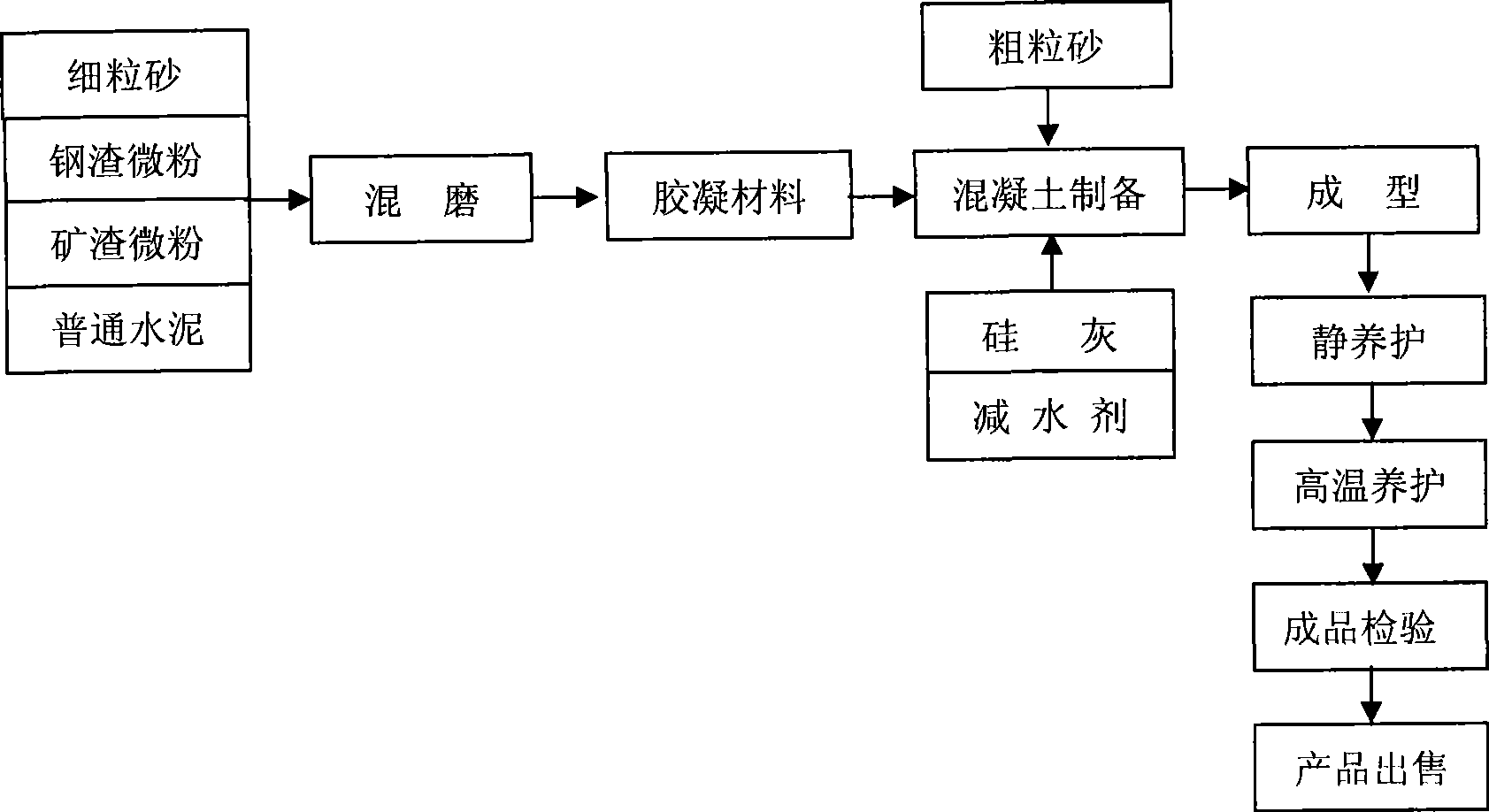

Artificial reef preparation with metallurgy slag as principal raw material

ActiveCN101475348AReduce manufacturing costImprove the living environmentSolid waste managementPisciculture and aquariaSlagSquare meter

The invention relates to a method for preparing an artificial fishing rock by using metallurgy residues as main materials, which belongs to the technical field of metallurgy residues treatment. The method is characterized by comprising the following steps: firstly, sieving and grading sea sand or river sand; secondly, mixing and grinding 0 to 20 percent of the obtained sand with the particle diameter of less than 5 millimeters with 10 to 80 percent of steel slag, 0 to 80 percent of mine refuse and 10 to 70 percent of cement clinker until the specific surface area is more than 350 square meters per kilogram; thirdly, mixing 20 to 70 percent of the mixture with 20 to 50 percent of the sieved coarse sand with the particle diameter of more than 5 millimeters and 0 to 40 percent of stones; and fourthly, obtaining the concrete artificial fishing rock with high and strong performance after high temperature maintenance. The artificial fishing rock has the advantages that the artificial fishing rock with high and strong performance is prepared by using the metallurgy residues as the main materials to remarkably reduce the preparation cost of the fishing rock, and the living environment for the aquatic lives around the fishing rock is fundamentally improved because the pH value of the concrete pore solution of the prepared fishing rock is close to that of sea water.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com