Pearl cotton plates with high compressive strength and high thickness and preparation thereof

A technology of compressive strength and manufacturing method, which is applied in the field of high compressive strength and high thickness pearl cotton sheet and its manufacturing field, can solve the problems of high processing cost, long processing procedure, failure to meet packaging requirements, etc., and achieves low processing cost, The effect of fewer manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

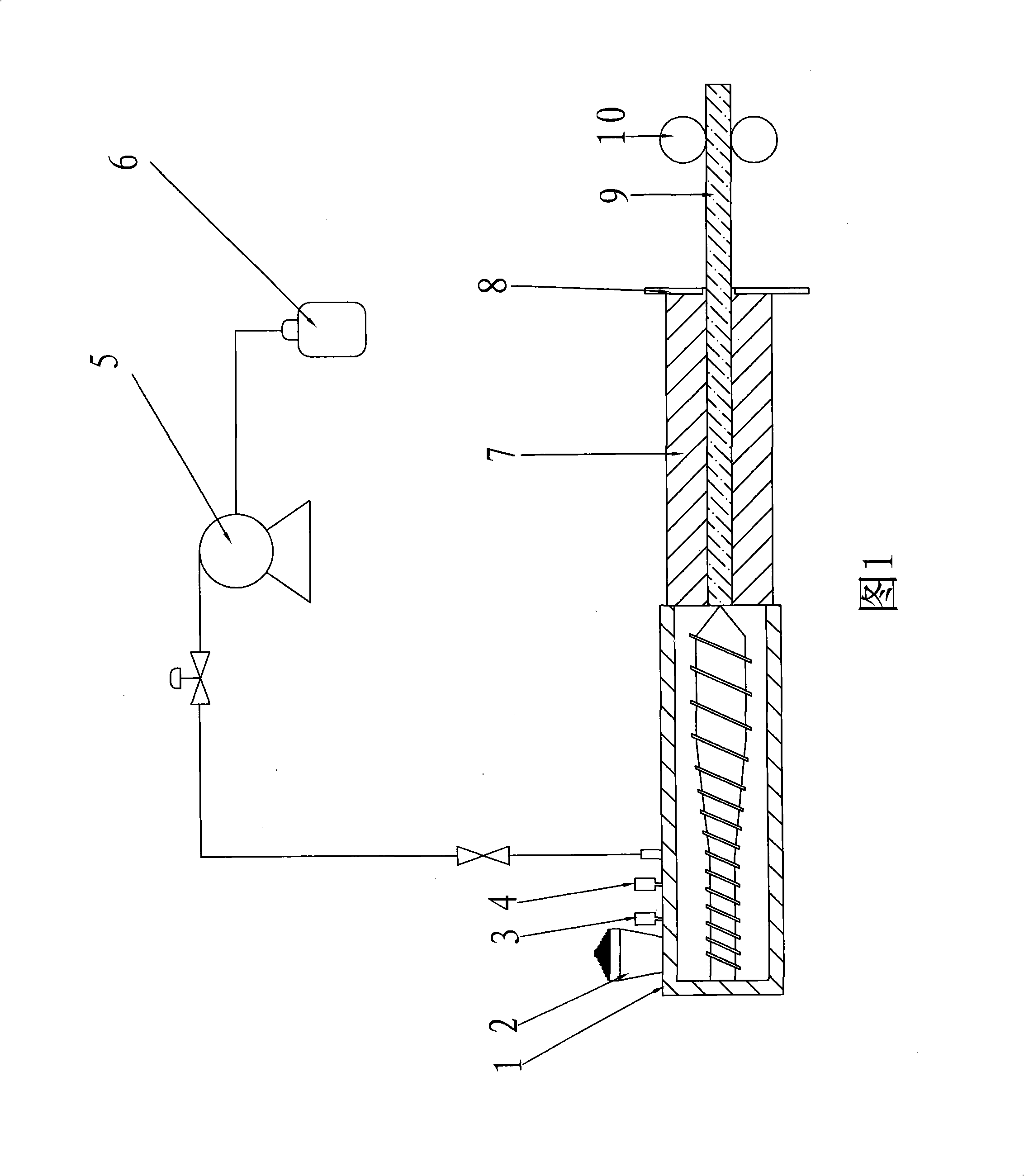

[0030] Referring to Fig. 1, a single-screw extruder 1 with a screw diameter of 200 mm and L / D=32 is used. The exit of the mold 7 is a rectangle with a length of 1,000 mm and a width of 300 mm, and the length of the mold is 2,000. A cooling device 8 is provided at the end of the mold, and ice water at 0°C is passed into it for cooling. Add 100 kilograms of low-density polyethylene (18D of Daqing Petrochemical Branch) into hopper 2, 0.8 kilograms of talcum powder into foaming nucleator hopper 3, and 1.5 kilograms of monoglyceride into anti-shrinking agent hopper 4. Ester, connect the blowing agent bottle 6. Start the extruder 1 and the heating device, heat the sleeve temperature to 170°C, and set the screw speed to 30 rpm. Open the hopper and feed continuously at the speed of 30 minutes, and pass in 18 kg of butane. At this time, the resin pressure at the tip of the screw was 20 MPa, and the residence time from passing the tip of the screw to the die outlet was 48 seconds. The prepa...

Embodiment 2

[0032] Basically similar to Example 1, 100 kg of low-density polyethylene, 20 kg of butane, 0.5 kg of talc and 1 kg of monoglyceride were used. The heating temperature is 180°C. Use a flat mold with a thickness of 30 cm. The test indexes of the prepared pearl cotton board are shown in Table 1.

Embodiment 3

[0034] Basically similar to Example 1, 100 kg of low-density polyethylene, 15 kg of butane, 1 kg of talc and 2 kg of monoglycerides were used. The heating temperature is 150°C. Use a flat mold with a thickness of 30 cm. The test indexes of the prepared pearl cotton board are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com