Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

345 results about "Screw speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In general, ball screws with small balls have somewhat lower speed limits than screws with larger balls. For Steinmeyer ball screws, speeds can range from 4,500 rpm for 3-mm balls) to about 1,050 rpm for 125-mm balls. (For a breakdown of speeds, see the table here.

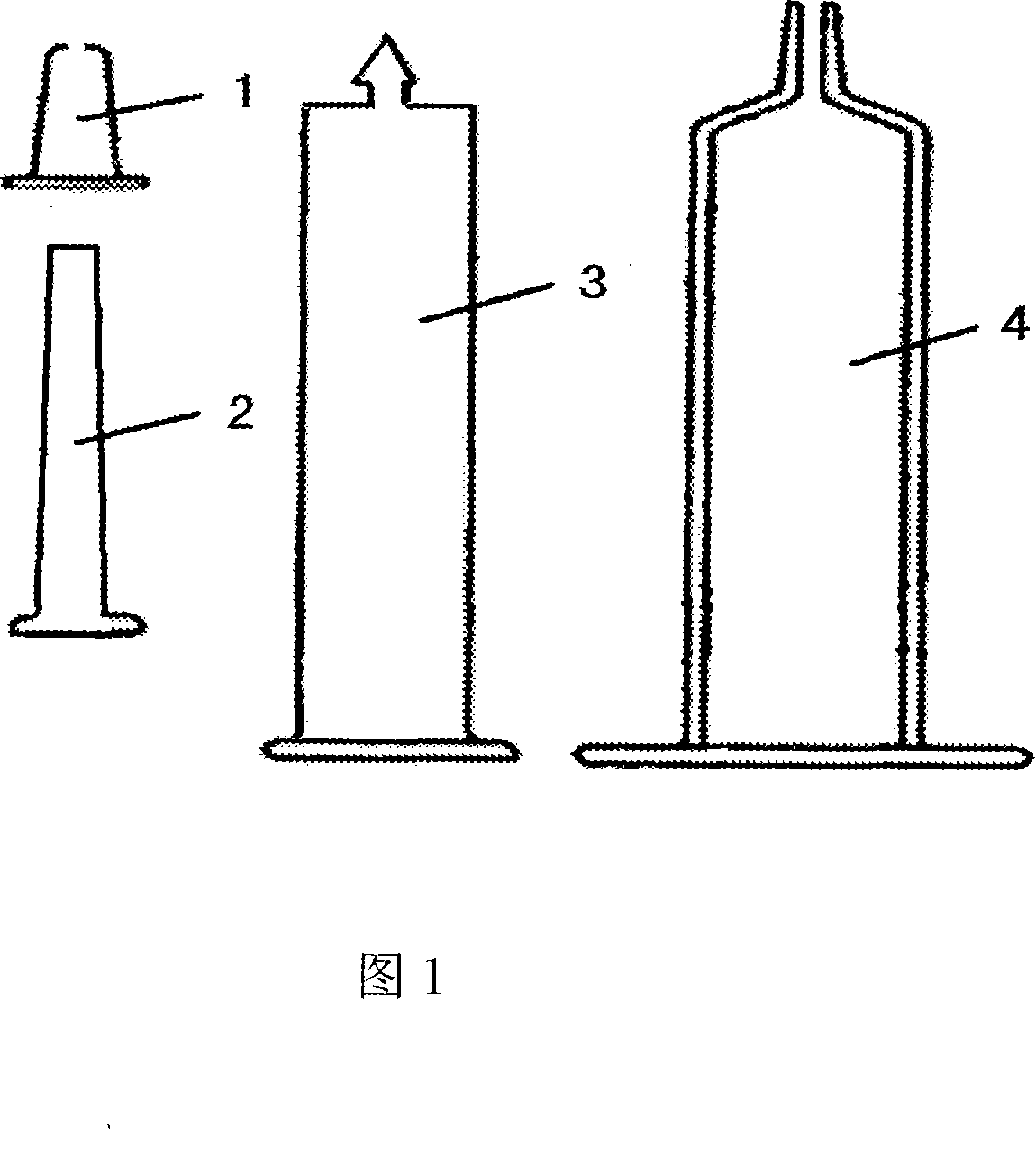

Degradation type disposable syringe and method of producing the same

ActiveCN101152588AThe preparation process is detailed and reasonableFast degradationInfusion syringesInfusion needlesPolyolefinInjection moulding

The invention relates to a degradation disposable syringe and a method of preparing the syringe. The syringe includes an outer cover, a core pin, a needle seat and a needle cap, which can be degraded in the natural environment. The basic material for degradation is prepared with degradable polymer main material, plasticizer, stabilizer, stabilizing additive and filling compound, etc. The detailed injection molding process for all parts of the syringe is: the injection temperature for a feeding opening is 20 to 60 DEG C; the injection temperature for a compression section is 100 to 200 DEG C; the injection temperature for a measurement section is 130 to 240 DEG C; the injection temperature for a spray nozzle is 130 to 220 DEG C; the mold temperature is 20 to 50 DEG C; the injection pressure is 40 to 200MPa; the injection time is 8 to 90 seconds; the pressure holding time is 0 to 5 seconds; the screw speed is 20 to 180 r / m; all performances of the degradation syringe totally meet the national standard (GB15810-2001). After being abandoned, the syringe does not pollute the environment, prevents illegal recycling, and can totally replace the disposable polyolefin syringes.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Low melting polyester polymers

ActiveUS20060046004A1Less energyShorten melting timeEnvelopes/bags making machineryLayered productsCarboxylic acidBottle

A bulk of polyester polymer particles comprising polyester polymer comprising greater than 75% virgin polyester polymer, the particles having: A) an It.V. of at least 0.72 dl / g, and B) 10 ppm or less of residual acetaldehyde; and C) at least two melting peaks, wherein one of said at least two melting peaks is a low peak melting point within a range of 140° C. to 220° C. and having a melting endotherm area of at least the absolute value of 1 J / g. The particles may also have a degree of crystallinity within a range of 20% and a maximum degree of crystallinity Tcmax defined by the equation: Tcmax=50%−CA−OH where CA is the total mole % of all carboxylic acid residues other than terephthalic acid residues, based on 100 mole % of carboxylic acid residues, and OH is the total mole % of all hydroxyl functional compound residues other than ethylene glycol residues, based on 100 mole % of hydroxyl functional compounds residues. The preforms and bottles made from these particles can be obtained by melt processing these particles at either lower overall power, faster screw speeds, lower residence time, or lower overall cycle time to thereby reduce the level of residual acetaldehyde generated in the melt.

Owner:ALPEK POLYESTER SA DE CV

Fiberglass reinforced fire retardant engineering plastics and preparation method

The invention discloses glass fiber reinforced flame retardant engineering plastic and a preparation method thereof. Besides glass fiber, 30-70 parts of polycaprolactam, 8-30 parts of acrylonitrile-butadiene-styrol copolymer, 3-6 parts of compatilizer, 12-16 parts of flame retardant, 0.3-0.5 parts of antioxidant and 0.3-0.8 parts of lubricant are put in a high-mixing machine to blend for 2-5 minutes, then the blending material is put in a double screw extruder; meanwhile, 18-35 parts of glass fiber are put in the rear half section of the double screw extruder to mix together to be granulated and molded; wherein, the processing temperature is 180-245 DEG C and the screw speed is 240-560 revolutions per minute. The prepared glass fiber reinforced flame retardant engineering plastic is characterized by high size stability, large mechanical strength, excellent heat resistance, etc. The combustibility can reach UL94 V-0(1.6mm) level, thus expanding the application in electronics.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

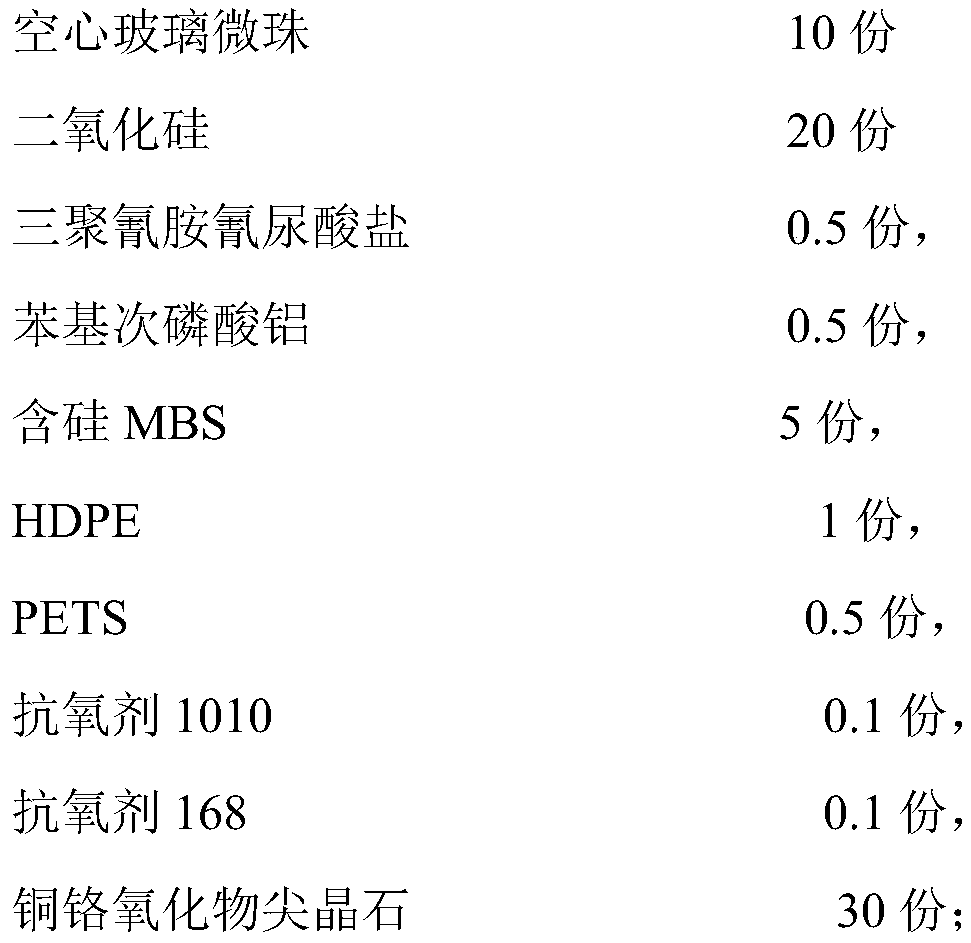

Low-dielectric laser direct structuring composite material suitable for 5G communication and preparation method thereof

ActiveCN110655792ALow dielectric constantHigh heat distortion temperatureChemical platingFire retardant

The invention relates to a low-dielectric laser direct structuring composite material suitable for 5G communication. The composite material is composed of the following components in parts by weight:52 to 86 parts of base resin, 0 to 30 parts of glass fibers, 10 to 30 parts of a filling agent, 1 to 9 parts of a flame retardant, 4 to 15 parts of a toughening agent, 0.1 to 1 part of a lubricating agent, 0.2 to 1 part of an antioxidant and 10 to 30 parts of a laser sensitive additive. A preparation method of the composite material comprises the steps that a twin-screw extruder is used for processing, the melt extrusion temperature is 250-380 DEG C, and the screw rotating speed is 150-300 rpm / min. The composite material has low dielectric property, so that improvement of the transmission speed of 5G communication millimeter wave signals is facilitated, the signal delay is reduced, and the signal loss is reduced; the composite material has the LDS processing capacity, can be rapidly prepared in a small size and a large number, can be subjected to batch laser etching and chemical plating to form a metal connecting circuit, and is an optimal solution of a 5G plastic antenna oscillator material.

Owner:中广核高新核材科技(苏州)有限公司

Processing method of fresh-cut potato rice-flour

ActiveCN106063545AReduce moisture contentOvercoming high moisture contentFood scienceTemperature controlSolanum tuberosum

The invention discloses a processing method of fresh-cut potato rice-flour. The method mainly contains the following steps: Step 1, soaking rice to obtain soaked rice; dicing fresh potatoes, and carrying out centrifugal dehydration until water content is 65-75% to obtain fresh-cut potato granules; Step 2, extrusion forming: mixing the soaked rice and the fresh-cut potato granules according to the mass ratio of 1-3:1, and carrying out extrusion forming to obtain primarily-processed rice flour, wherein technological conditions of the extrusion forming are as follows: bore diameter of a rice-noodle producing board is set as 1.5-2.0 mm; feed speed is 54-70 r / min; twin-screw speed is 130-170 r / min; and middle area temperature of an extrusion cylinder is 95-110 DEG C; Step 3, curing, letting the primarily-processed rice flour stand at the temperature of 18-20 DEG C at the relative humidity of 75-85% for 13-18h so as to obtain cured rice flour; and Step 4, drying: drying the cured rice flour by a gradient temperature-control and humidity-control oven drying method so as to obtain the rice flour.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

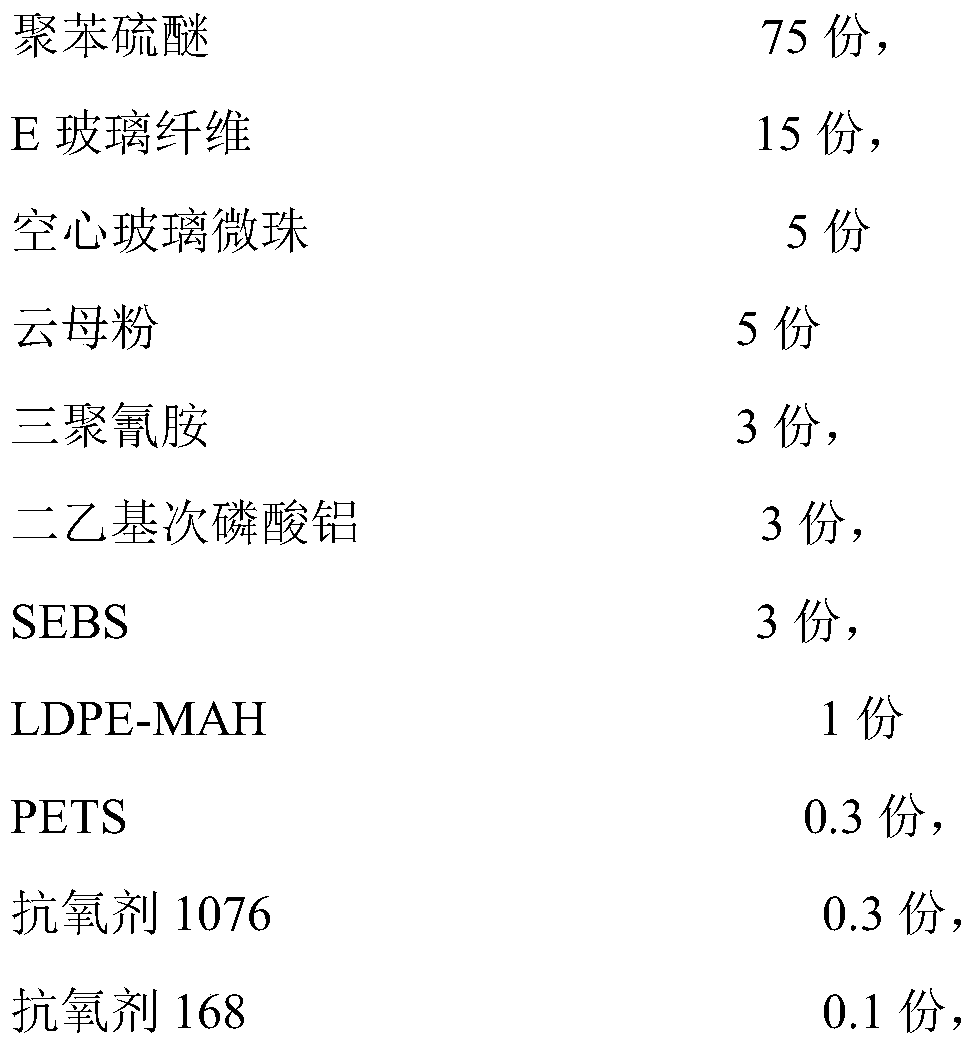

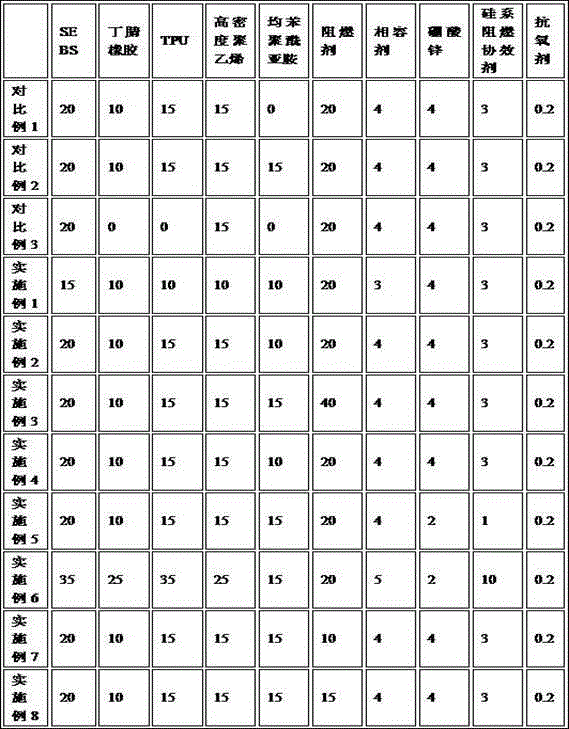

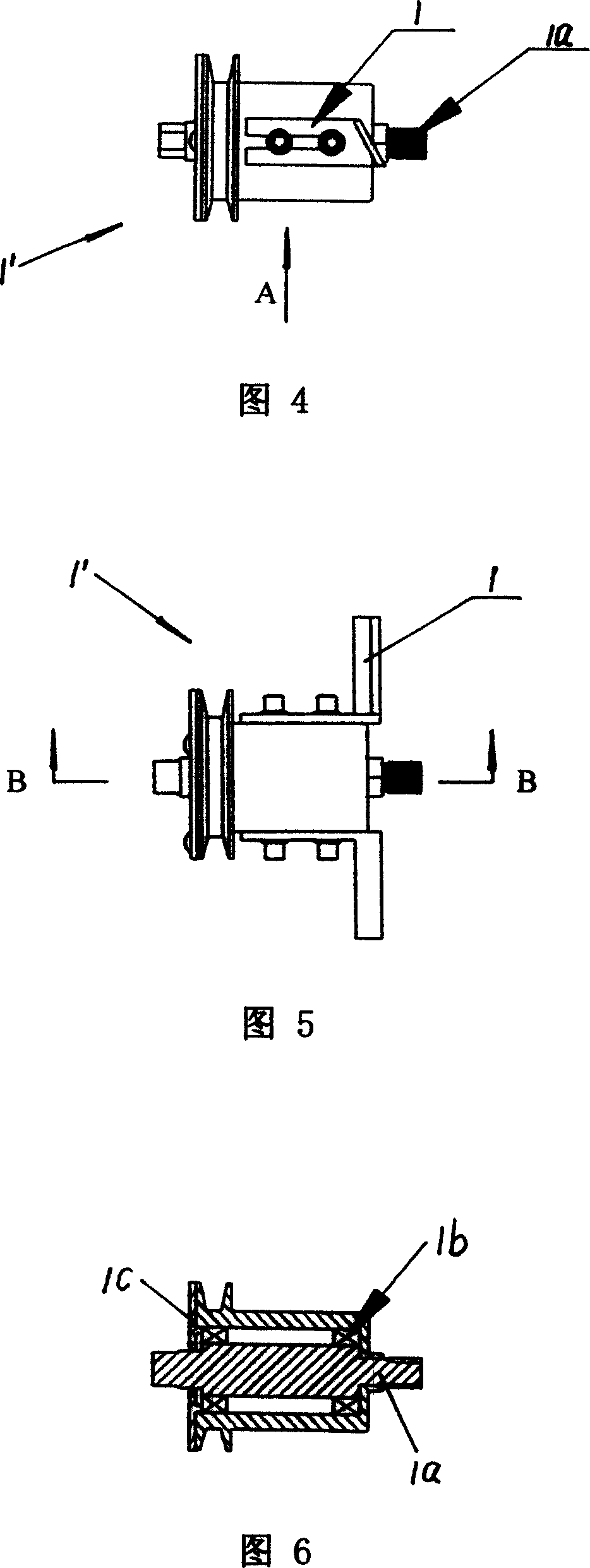

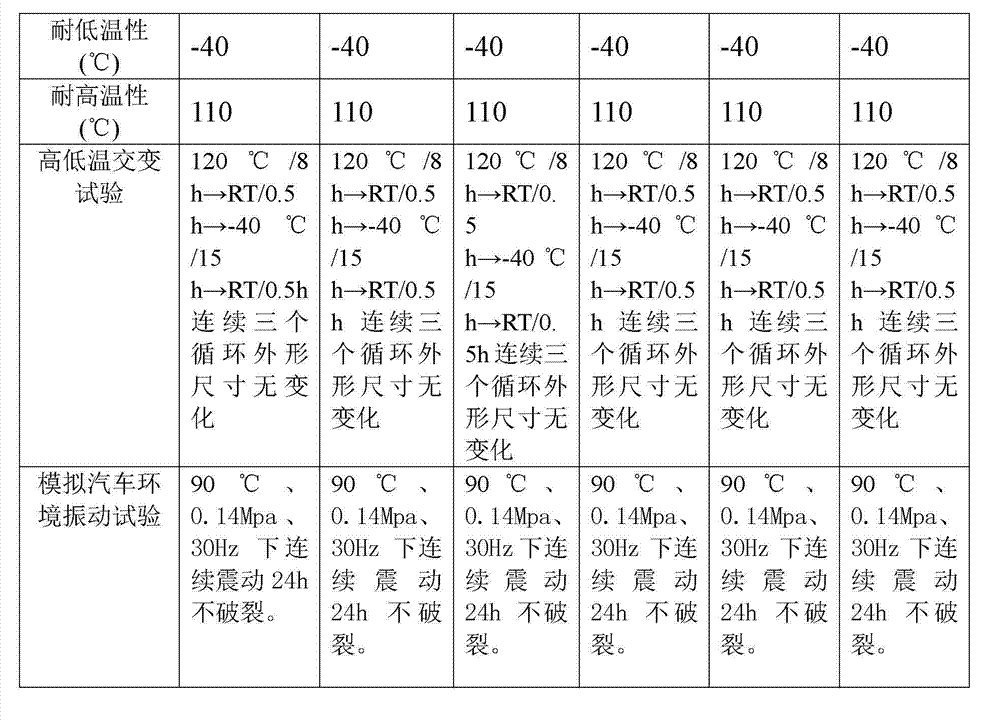

Elastomer cable material for oil-resistant cold-resistant high-temperature-resistant electric automobile charge piles and preparation method thereof

ActiveCN105038088AFulfil requirementsSoft for movementPlastic/resin/waxes insulatorsPolyolefinEngineering

The invention relates to an elastomer cable material for oil-resistant cold-resistant high-temperature-resistant electric automobile charge piles and a preparation method thereof. The elastomer cable material is characterized by mainly comprising the following raw materials in parts by weight: 15-35 parts of styrene elastomer, 10-35 parts of thermoplastic polyurethane elastomer, 10-25 parts of nitrile-butadiene rubber, 10-30 parts of reinforcer, 3-5 parts of compatilizer, 10-25 parts of polyolefin compound, 10-40 parts of flame retardant, 1-10 parts of flame-retardant synergist and 2-5 parts of smoke inhibitor. The preparation method comprises the following steps: 1. weighing the materials according to parts by weight; 2. adding the materials into a high-speed mixer, stirring for 8-10 minutes, and stopping stirring; 3. adding the obtained mixed material into a double screw extruder, and carrying out melt kneading and extrusion, wherein the extrusion temperature is 190-240 DEG C, and the screw speed is 200-500 rpm; and cooling the melt output substance with water, granulating, and packaging. The elastomer cable material has the advantages of excellent oil resistance, excellent cold resistance, excellent high temperature resistance, low smoke, no halogen and environment friendliness.

Owner:中广核三角洲(江苏)塑化有限公司 +1

High impact polyphenylene sulfide alloy material and method of producing the same

InactiveCN101130633AImprove impact resistanceGood physical and mechanical propertiesHigh intensityMass ratio

The invention discloses a high impact polyphenylene sulfide alloy material and preparing method, which comprises the following steps: allocating with mass ratio as 30-55% polyphenylene sulfide, 5-20% polycaproamide, 30-50% glass fiber, 2-8% inclusive agent, 0. 2-0. 5% anti-oxidant and 0. 1-2% other auxiliary agent; mixing; adding into twin-screw extruder; controlling the temperature at 250-280 deg. c; controlling the rotary speed of the bolt at 400-500rpm; pelleting; getting the product. This invention possesses high impact strength, high modulus and high-intensity, which can modify the defects of the material.

Owner:SHENZHEN KEJU NEW MATERIAL

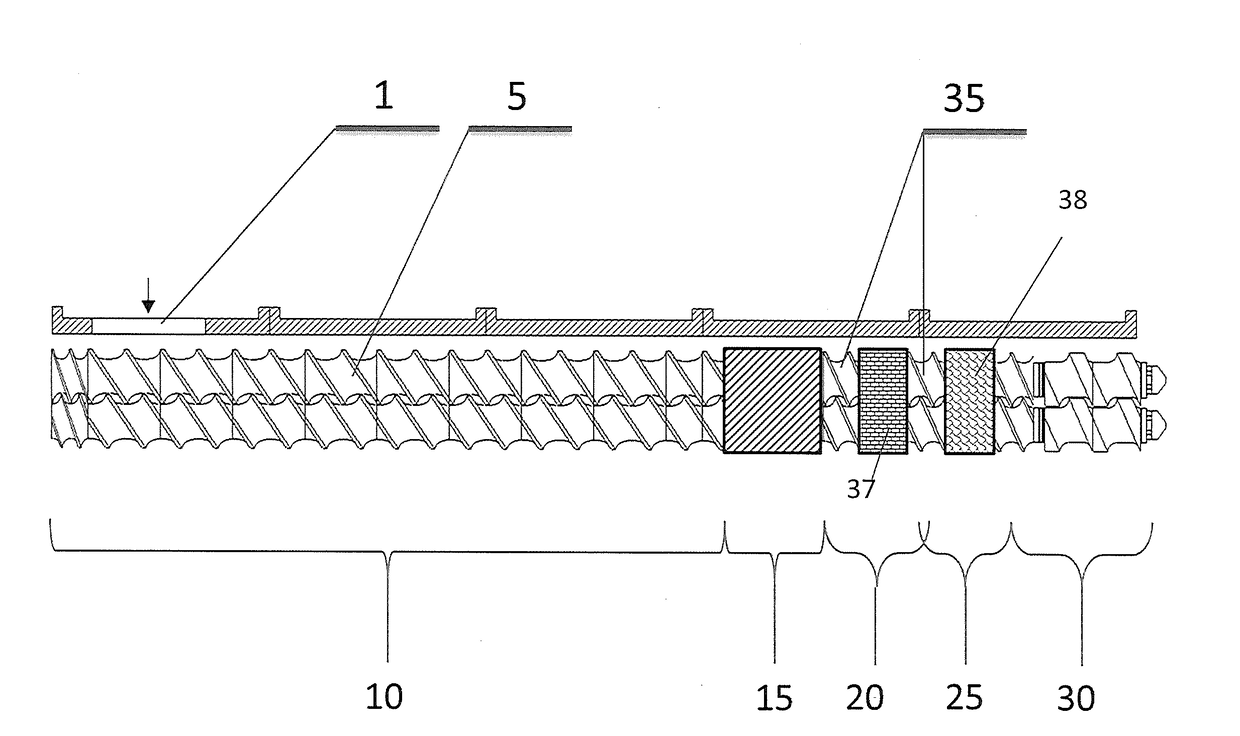

Method of separating a polymer from a solvent

InactiveUS20070225479A1Simple and yet elegant solutionChemical/physical/physico-chemical stationary reactorsPolymer scienceSolvent

The present invention provides a method of separating a polymer from a solvent comprising introducing a superheated polymer-solvent mixture into an extruder, and isolating a polymer product, said extruder being equipped with at least one vent operated at subatmospheric pressure and at least one vent operated at about atmospheric pressure, said extruder having a screw diameter D, said extruder being operated at a feed rate FR and at a screw speed RPM such that a devolatilization performance ratio (DPR) given by Equation (I)DPR=FR / RPM Equation (I)is selected from a predetermined set of devolatilization performance ratios which correlate with a target characteristic of the polymer product.

Owner:SABIC INNOVATIVE PLASTICS IP BV

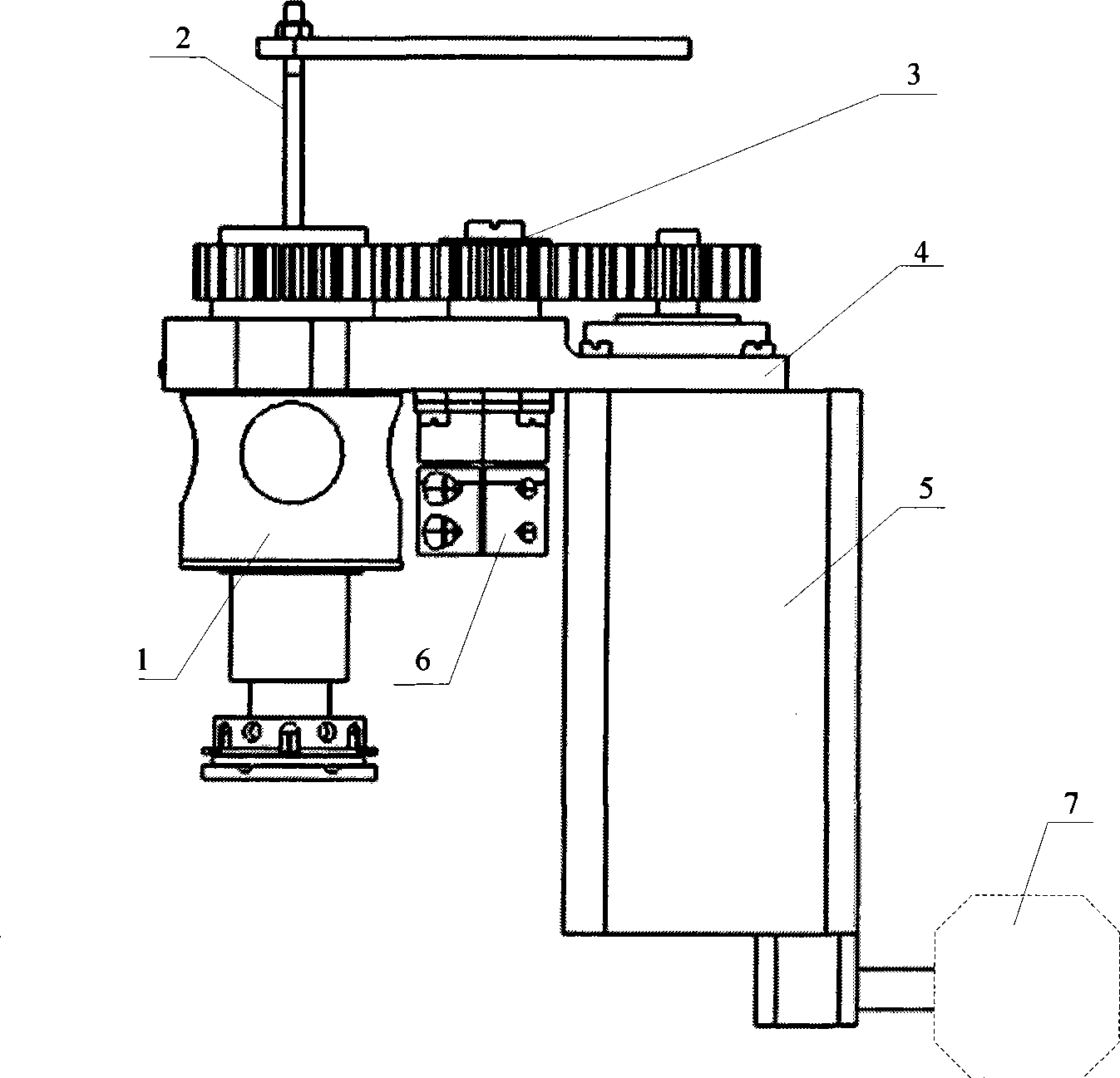

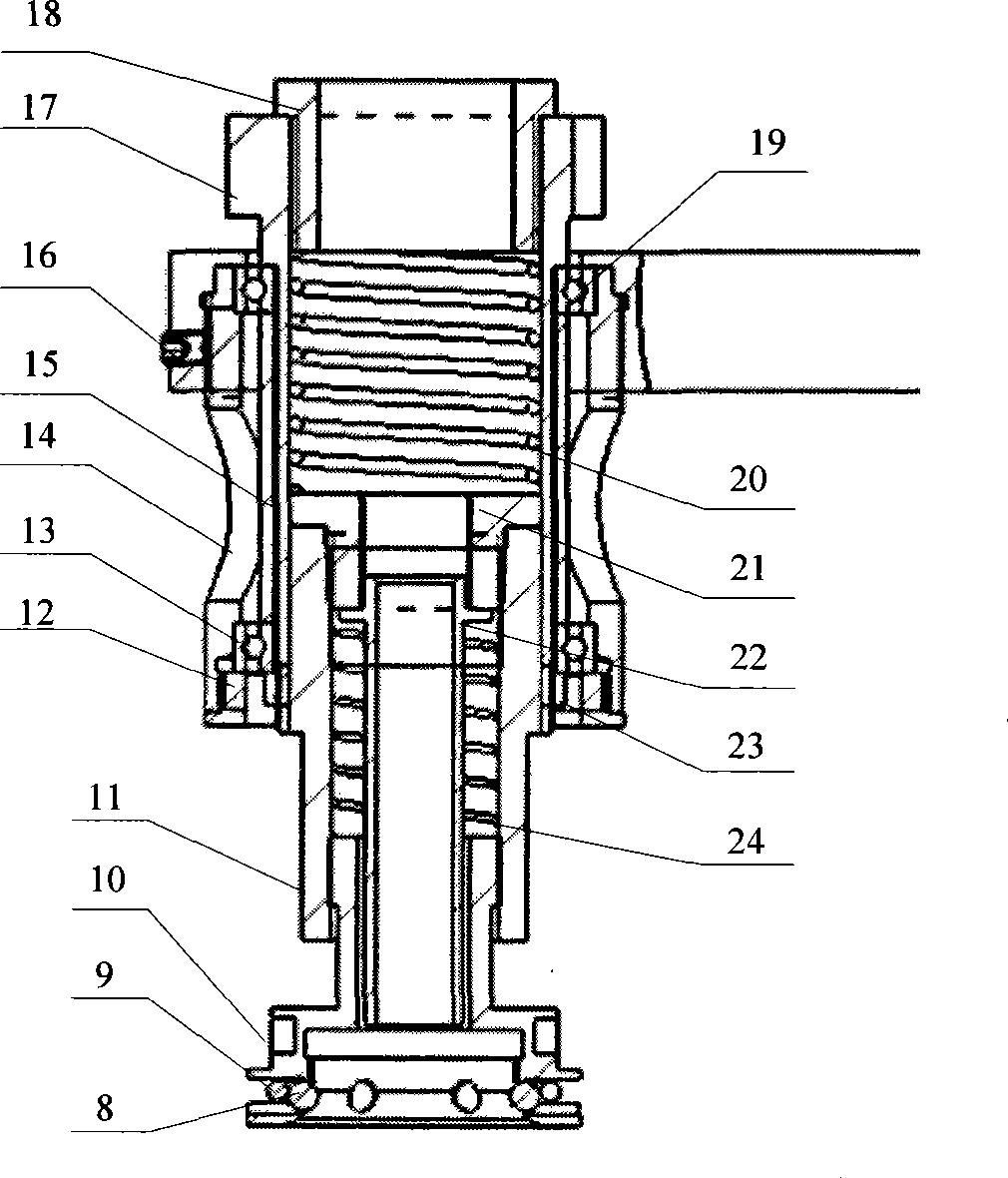

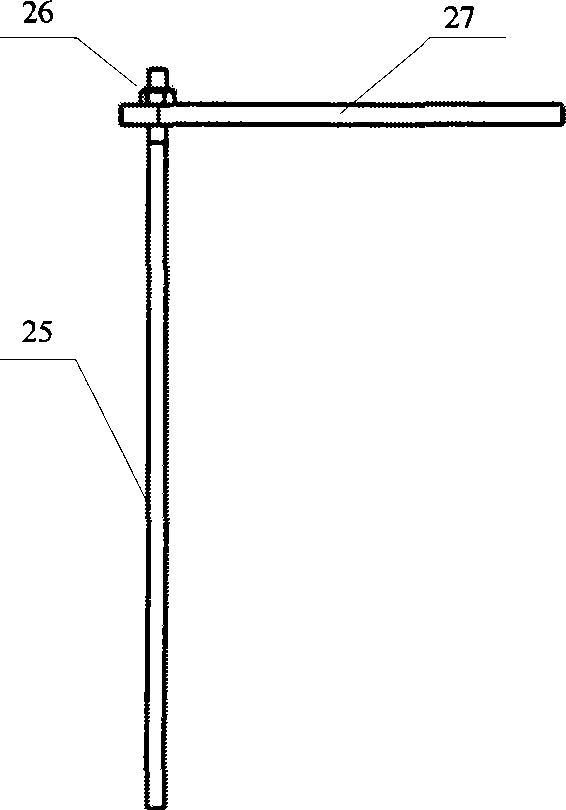

Servo bottle cap screwing mechanism

InactiveCN101386399APrevent crushingEffective screwingThreaded caps applicationPulp and paper industryServomotor

The invention relates to a servo bottle cap screwing mechanism in the technical field of packaging machinery, which comprises a cap screwing head, a waste cap withdrawing mechanism, an idler wheel mechanism, base blocks, a servomotor, a connecting support and a motor control system, wherein, the cap screwing head, the idler wheel mechanism, the servomotor and the connecting support are arranged on the base blocks, the motor control system controls the servomotor to rotate at certain rotating speed and torque, and the generated dynamic power is transferred to the cap screwing head by the idler wheel mechanism, so as to cause the cap screwing head to rotate along with the servomotor; the connecting support is connected with a lifting guide rod to drive the base blocks to raise and fall periodically, and the height of the waste cap withdrawing mechanism is unchanged, and the waste cap withdrawing mechanism is arranged at a cap screwing machine. Under the germfree condition, the entire bottle cap screwing mechanism is lubrication free, has no leakage, is convenient for frequent rinsing and disinfection; the cap screwing torque is controlled by computer, the cap screwing mechanism is driven by servomotor and has large adjustable range; and besides, the working torque, the cap screwing speed, and the like, of the single cap screwing mechanism can be displayed, and the cap screwing mechanism can automatically discharge waste or abnormal caps.

Owner:SHANGHAI JIAO TONG UNIV

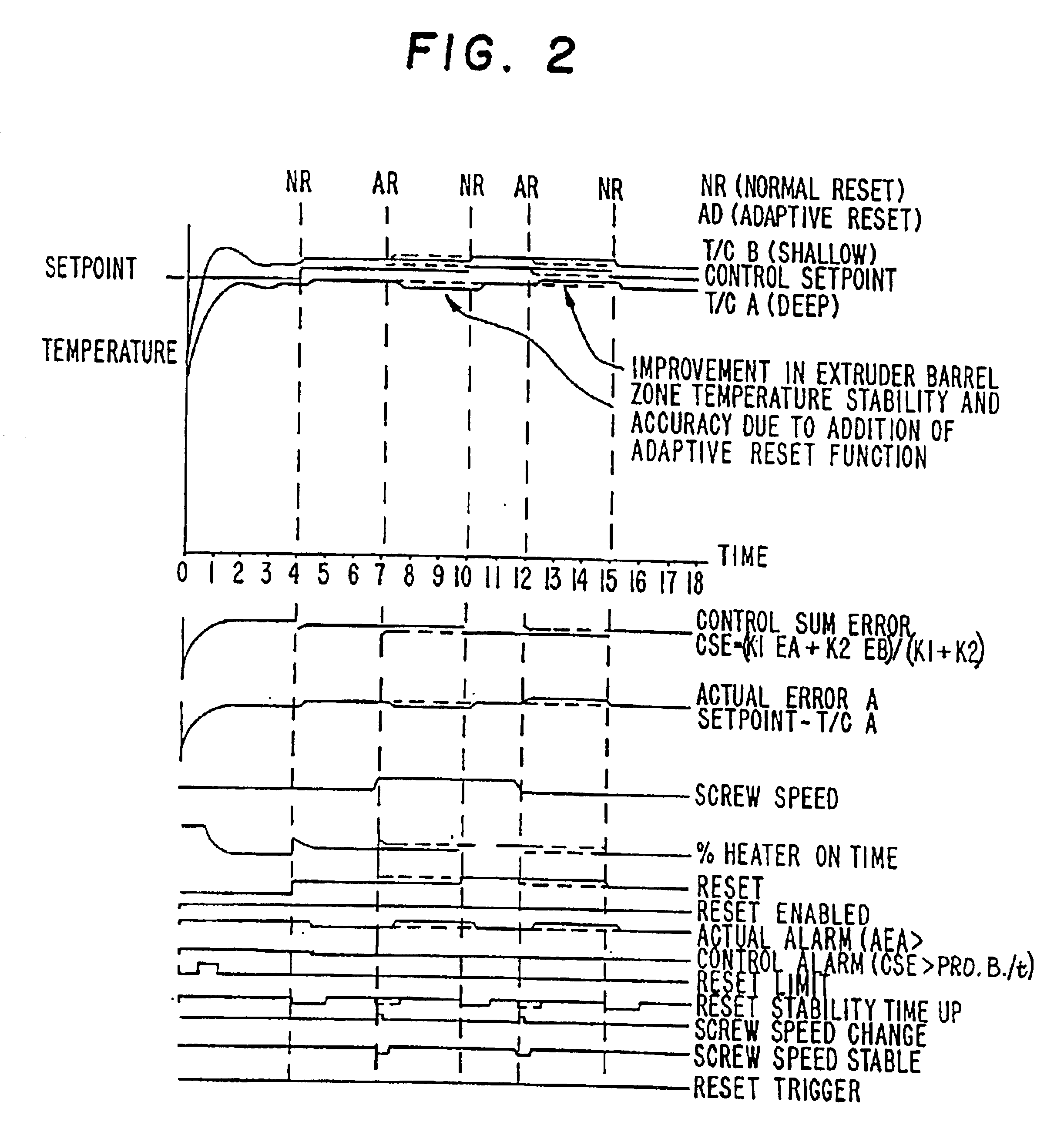

Method for operating extruder temperature controller with stable temperature reset

The invention is a method for operating an extruder temperature controller. The method can include sensing an actual screw speed for an extruder screw in an extruder barrel. The extruder barrel has at least one heat exchange means. The method can then involve indexing and storing a plurality of screw speeds. Each of the stored screw speeds corresponds to a temperature reset value. Comparing the actual screw speed with each of the stored screw speeds can then be performed. Selecting one of the stored screw speeds can then occur. The selected screw speed is a member of the plurality of stored screw speeds having a value most arithmetically equivalent to the actual screw speed. The step of selecting retrieves the temperature reset value corresponding to the selected, stored screw speed. Generating a control output driver signal to the heat exchange means can occur. The control output driver signal is responsive to the retrieved temperature reset value. The invention includes delaying a control alarm for a predetermined time when generating a control output driver signal to the heat exchange means is at or near maximum capacity.

Owner:DAVIS STANDARD

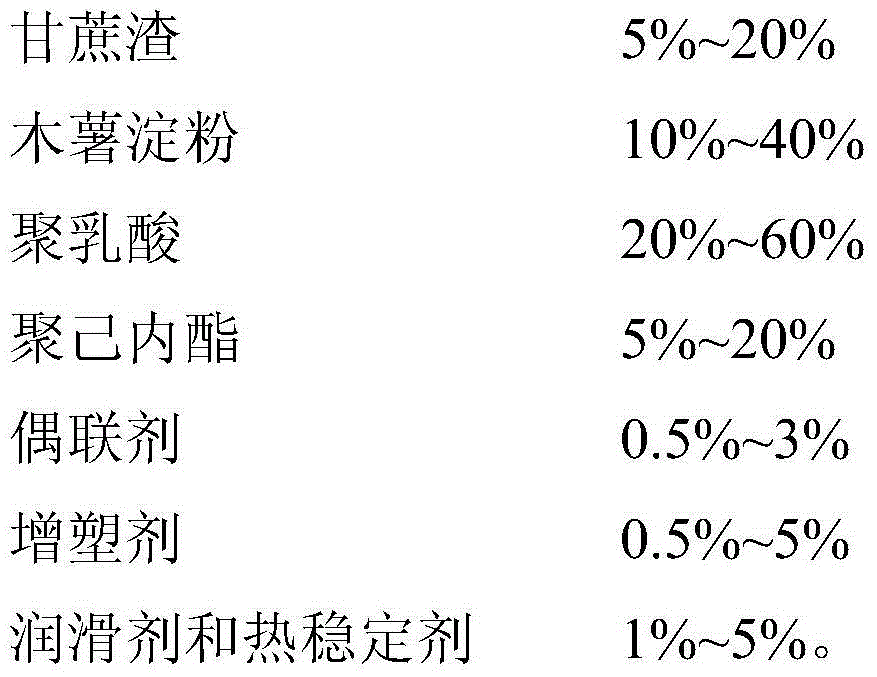

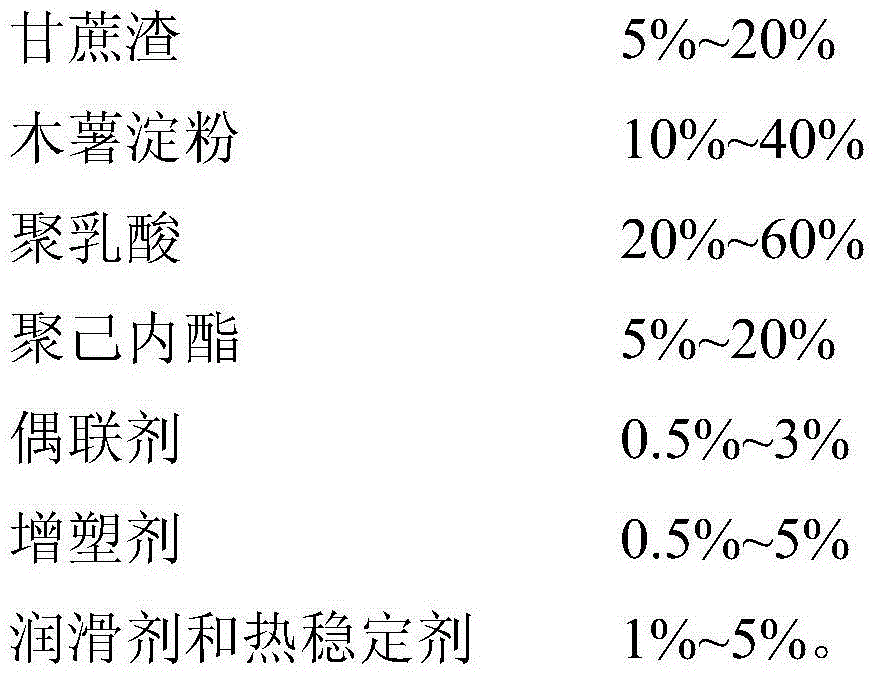

Bagasse/cassava starch polylactic acid biodegradable material, and preparation method and application thereof

The invention belongs to the technical field of biodegradable materials, and discloses a bagasse / cassava starch polylactic acid biodegradable material and a preparation method thereof. The bagasse / cassava starch polylactic acid biodegradable material comprises the following components in percentage by mass: 5-20% of bagasse, 10-40% of cassava starch, 20-60% of polylactic acid, 5-20% of polycaprolactone, 0.5-3% of coupling agent, 0.5-5% of plasticizer, and 1-5% of lubricant and heat stabilizer. The preparation method comprises the following steps: uniformly mixing the components, adding into a double screw extruder, and carrying out extrusion granulation at the extrusion temperature of 80-140 DEG C at the screw speed of 40-100 r / min to obtain the bagasse / cassava starch polylactic acid biodegradable material. The material has favorable biodegradability and mechanical properties, and can be used for preparing daily plastic products.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

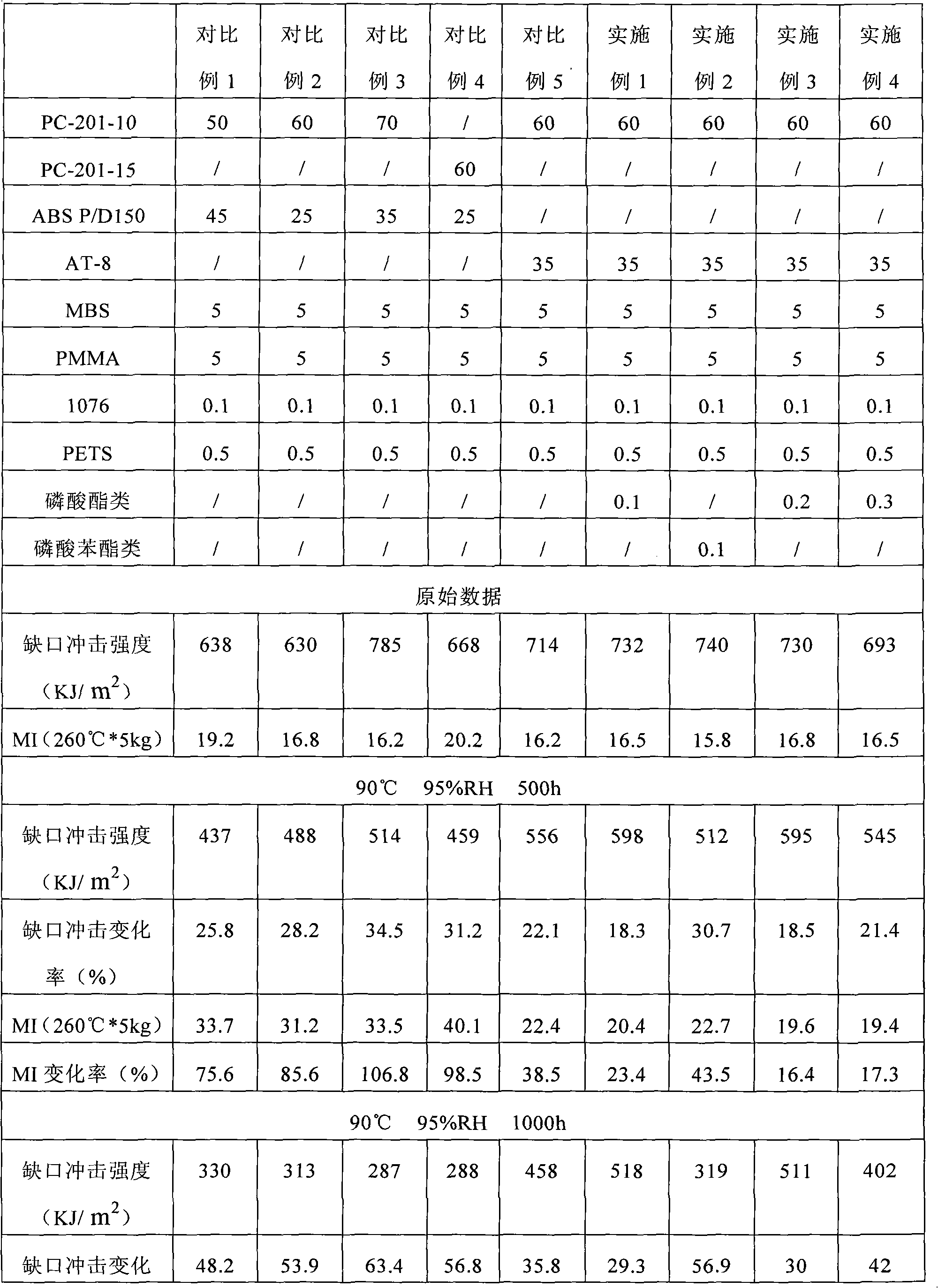

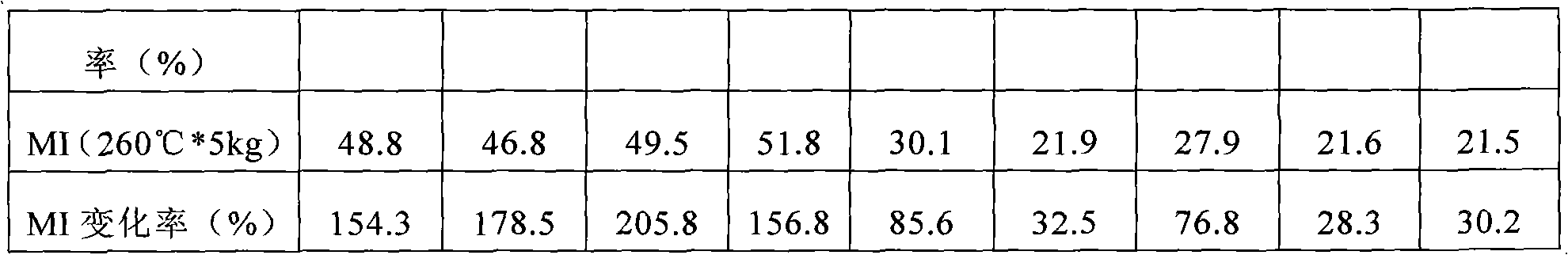

PC/ABS alloy with excellent hydrolysis resistance and preparation method thereof

InactiveCN101787193AImprove mechanical propertiesImprove hydrolysis resistanceState of artAntioxidant

The invention relates to a PC / ABS alloy with excellent hydrolysis resistance and a preparation method thereof; the alloy comprises the following components in parts by weight: 50 to 70 parts of PC, 30 to 40 parts of ABS, 5 to 10 parts of compatibilizer, 5 to 10 parts of toughener, 0.1 to 1 part of hydrolysis agent, 0.1 to 1 part of lubricant and 0.1 to 1 part of antioxidant; the components are prepared in the parts by weight, put into a medium-speed mixer to be mixed for 20min, to prepare mixed material; and finally the mixed material is put into a twin-screw extruder, the rotating speed of the screws is controlled to be 180 to 600rpm, the material is melted, extruded and granulated, and the product is prepared. Compared with the prior art, the PC / ABS provided by the invention adopts ABS and the hydrolysis agent which are specially synthesized, thereby not only improve the mechanical performance of the material, but also improving the hydrolysis resistance of the PC / ABS alloy.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

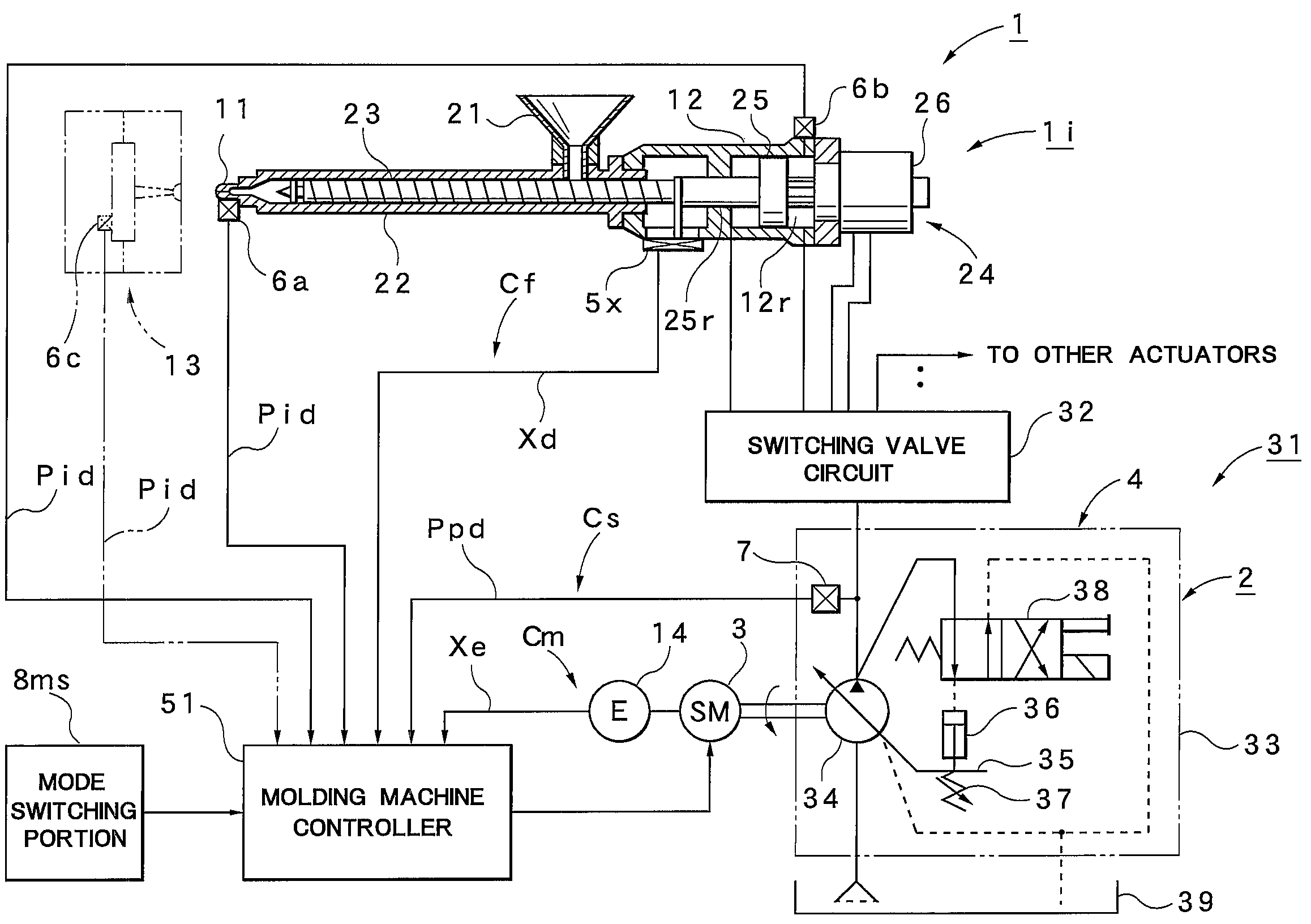

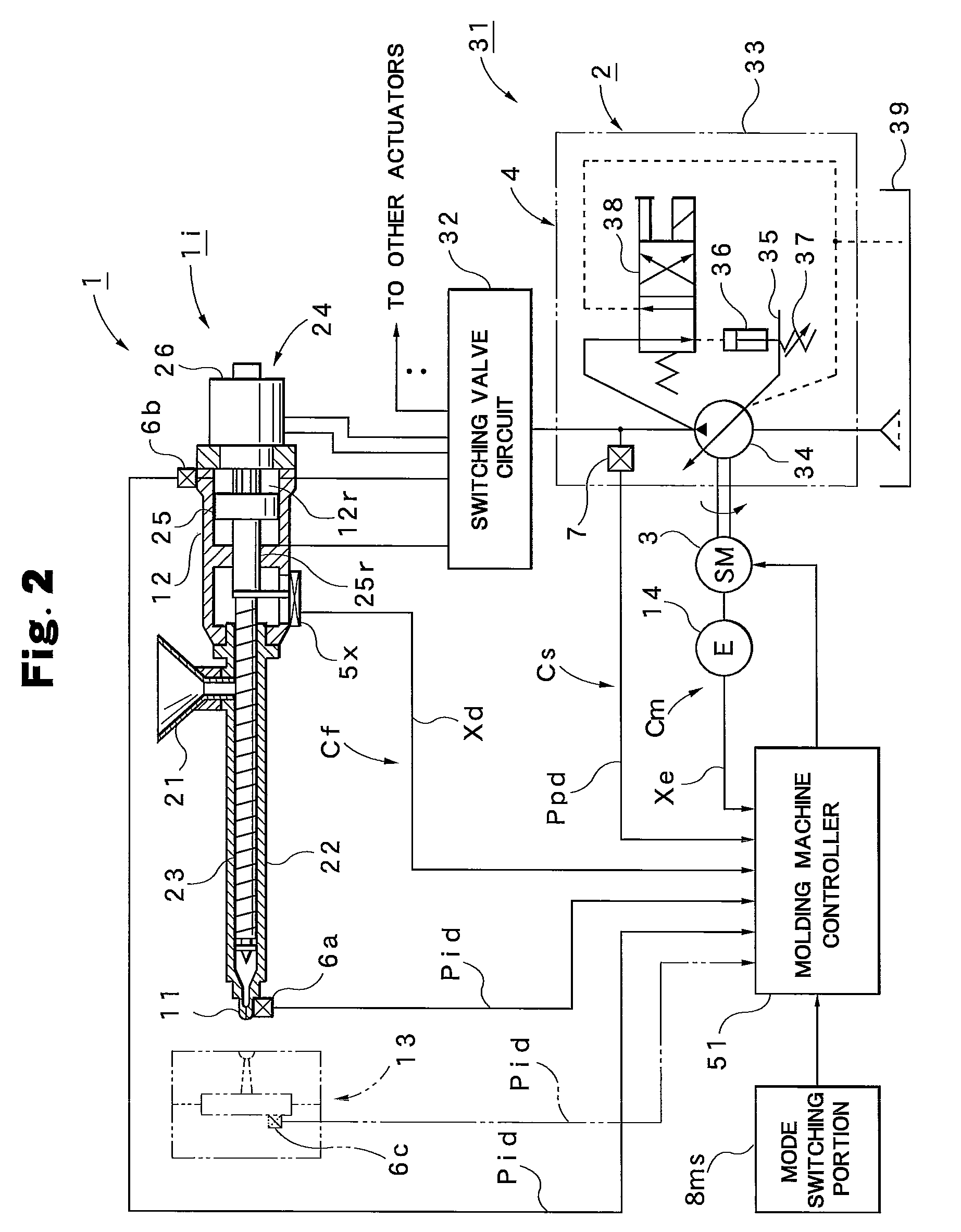

Injection molding machine and method of controlling the same

ActiveUS20090218710A1CostLow costAuxillary shaping apparatusFood shapingInjection pressureLoop control

An injection molding machine 1 includes mode selection means 8 that can selectively switch between a first control mode M1 and a second control mode M2. In the first control mode M1, control is performed by a first control system Cf in which a screw speed is controlled by feedback with a speed detection value Vd that is detected by screw speed detection means 5 and a speed target value Vfc, and an injection pressure is controlled by feedback with a pressure detection value Pid that is detected by injection pressure detection means 6 and a pressure target value Pic, whereas, in the second control mode M2, control is performed by a second control system Cs in which the screw speed is open-loop controlled with a speed target value Vsc, and a pump pressure is controlled by feedback with a pressure detection value Ppd that is detected by pump pressure detection means 7 and that is related to the pump pressure of the hydraulic pump 4 and a pressure target value Ppc.

Owner:NISSEI PLASTIC IND CO LTD

Preparation method of luminescent polyamide composite material

InactiveCN105419309AGood dispersionImprove uniformity of light emissionLuminescent compositionsGlass fiberNylon material

The invention discloses a preparation method of a luminescent polyamide composite material. The method comprises the following steps of (1) preparing a graphene / red-light phosphor / SiO2 composite material; (2) weighing the following materials in parts by weight: 60 to 70 parts of nylon resin, 30 to 40 parts of hybrid glass fiber reinforcement, 1 to 5 parts of nylon master batch, 1 to 5 parts of graphene / red-light phosphor composite material and 0.1 to 0.3 part of antioxygen; extruding the materials by a double-screw extruder and pelleting, wherein the hybrid glass fiber reinforcement is added through a side-feeder, the screw speed of the double-screw extruder is 120 to 150r / min, the temperature is 265 to 280 DEG C, and then the polyamide composite material is obtained. The preparation method of the luminescent polyamide composite material can enhance the dispersity and the luminance uniformity of phosphor in the luminescent polyamide composite material, and the high luminescent intensity is obtained.

Owner:黄志华

High impact resistance fiberglass reinforced fire retardant engineering plastics and preparation method

The invention discloses a high-impact glass fiber reinforced flame retardant engineering plastic and a preparation method thereof. Besides glass fiber, 30-60 parts of polycaprolactam, 8-25 parts of acrylonitrile-butadiene-styrol copolymer, 3-6 parts of compatilizer, 4-10 parts of toughener, 12-16 parts of flame retardant, 0.3-0.5 parts of antioxidant and 0.3-0.8 parts of lubricant are put in a high-mixing machine to blend for 2-5 minutes, then the blending material is put in a double screw extruder; meanwhile, 18-30 parts of glass fiber are put in the rear half section of the double screw extruder to mix together to be granulated and molded; wherein, the processing temperature is 180-245 DEG C and the screw speed is 240-560 revolutions per minute. The prepared high-impact glass fiber reinforced flame retardant engineering plastic is characterized by high size stability, large mechanical strength, excellent heat resistance, high combustibility that is up to UL94 V-0(1.6mm), etc.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

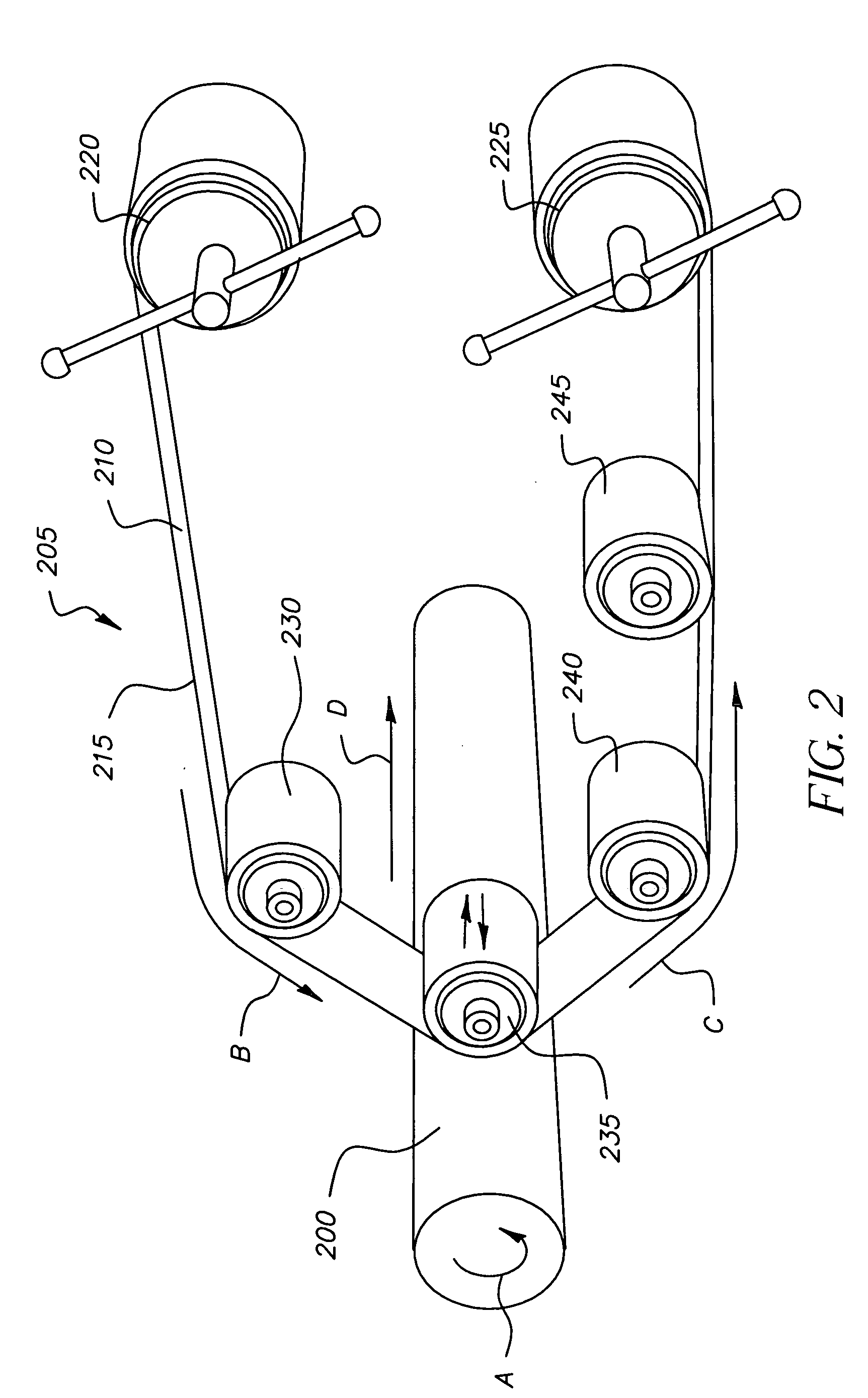

Metering roller for fuser release oil applicator

InactiveUS20050015987A1Avoiding image quality defectPrecise maintenanceShaft and bearingsMetal-working apparatusPulp and paper industryScrew speed

A metering roller, for a fuser release oil applicator, which enables precise and consistent application of a predetermined target amount of release oil to the fuser roller. Starting with tubing stock that has been machined and course ground to a final outside diameter, the metering roller is produced by initial pre-finish polishing, electroplating with Nickel, heat treatment to achieve a hardened surface, and final post-finish polishing. Both pre-finish and post-finish polishing steps are performed on a lathe with continuously fed polishing paper according to a parameter recipe that includes lathe spindle rpm and lead screw speed, and polishing paper grit, feed rate, pressure, and oscillatory rate.

Owner:EASTMAN KODAK CO

Thermoplastic elastomer materials

InactiveCN101486818AAchieve high transparencyPharmaceutical containersMedical packagingPolyolefinThermoplastic elastomer

The invention provides a thermoplastic elastomer material which consists of the following ingredients according to weight percentage: (A) 30-80% of polyolefin resin and 20-70% of hydriding styrenic thermoplastic elastomer. The MFR of the polyolefin resin is 2-7, which is measured according to ISO1133 standard (the temperature is 230 DEG C, the load is 2.16kg). The thermoplastic elastomer material is obtained by mixing the ingredient (A) and the ingredient (B) at the melt temperature of 210-220 DEG C and the screw speed of 300-450rpm.

Owner:常州美迪塑料科技有限公司

Method for preparing high-toughness degradable material by using melt-grafting blending method

The invention relates to a method for preparing a high-toughness degradable material by using a melt-grafting blending method, which comprises the following steps: (1) carrying out melt-grafting on polycaprolactone PCL, anhydride and an initiator, and then obtaining modified polycaprolactone by way of extrusion granulation, wherein the mass ratio of the polycaprolactone PCL to the anhydride to the initiator is 100: (1 to 10): 0.5; and (2) carrying out melt-grafting blending on poly (3-hydroxybutyrate-3-hydroxyvalerate) PHBV, the modified polycaprolactone, methyl acrylate and an initiator, and then obtaining the high-toughness PHBV-class degradable material by way of extrusion granulation, wherein the mass ratio of the poly (3-hydroxybutyrate-3-hydroxyvalerate) PHBV to the modified polycaprolactone to the methyl acrylate to the initiator is 100: (5 to 50): (0.5 to 10):0.5, the processing temperature is 100 to 170 DEG C, and the screw speed is 50-80 R.P.M. The method is simple in process, low in cost, and suitable for industrialization, and the elongation at break of the produced PHBV-class degradable material can reach 560 percent; therefore, the method of the invention has good application prospect.

Owner:DONGHUA UNIV

Hydrotalcite flame-retardant polypropylene (PP) composite material and preparation method thereof.

The invention relates to a hydrotalcite flame-retardant polypropylene (PP) composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 50-85% of PP, 1-10% of compatilizer, 10-35% of flame retardant, 1-10% of hydrotalcite, 0.1-1% of antioxidant and 0.1-0.5% of lubricating-dispersing agent. The preparation method comprises the following steps: weighing raw materials based on the weight ratio; sequentially putting the PP, the compatilizer, the flame retardant, the hydrotalcite, the antioxidant and the lubricating-dispersing agent in a high-speed mixer, and mixing for 2-7 minutes; discharging; and placing the mixed raw materials in a double screw extruder, and carrying out extrusion and granulation at the temperature of 170-210 DEG C, wherein, the screw speed is maintained at 160-600RPM (revolutions per minute). Compared with the prior art, the obtained flame-retardant PP composite material has the advantages of good and stable flame-retardant effect, good glossiness, low specific gravity, good mechanical properties, simple processing technique, wide application range and high economic value.

Owner:SHANGHAI SUNNY

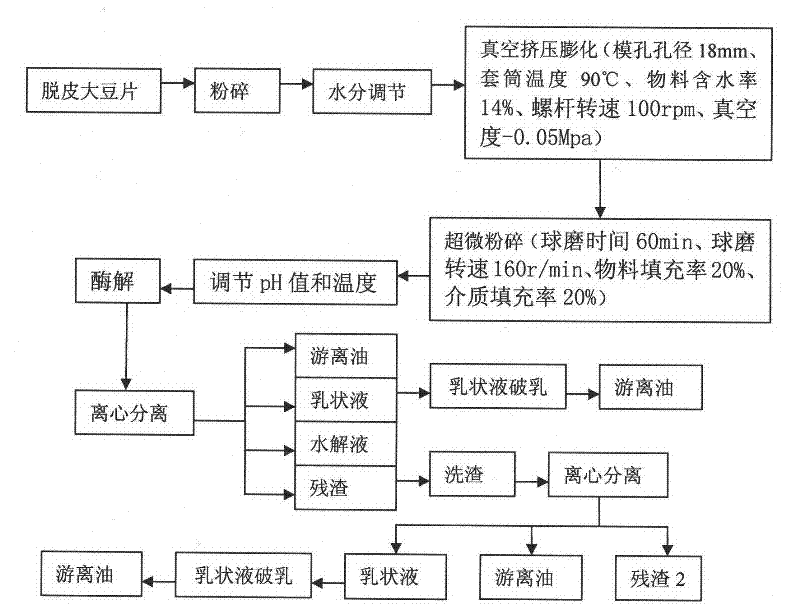

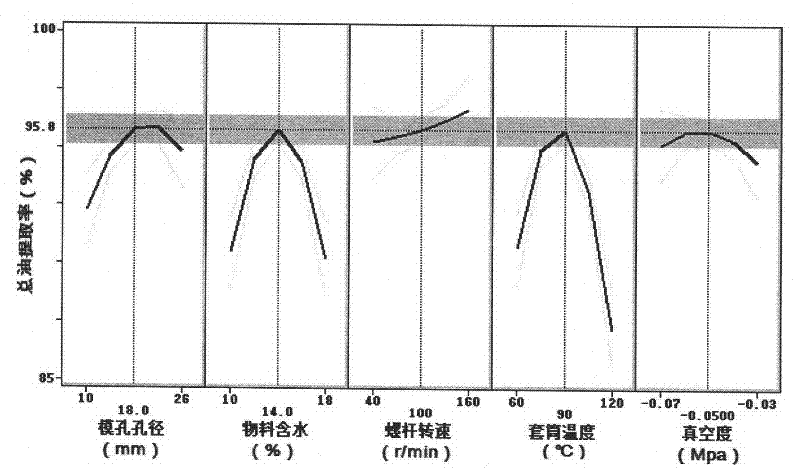

Extraction method of soybean oil

InactiveCN102229851AEffective contactFacilitated releaseFatty-oils/fats productionSoybean productFilling rate

The invention discloses an extraction method of soybean oil and belongs to the technical field of extraction and processing of plant oil. The extraction method comprises the following steps that: dehulled soybean pieces as a raw material are pretreated by a vacuum extrusion-expansion process and a superfine ball-grinding process to form a soybean product; the soybean product is mixed with water; a protease is added into the mixture obtained the previous step and undergoes an enzymolysis reaction with the mixture; and the reaction products are subjected to a centrifugal separation process and soybean oil is obtained. Parameters of the vacuum extrusion-expansion process comprise that a mould aperture size is in a range of 14 to 26 mm; a screw speed is in a range of 70 to 160 rotations per minute; a sleeve temperature is in a range of 75 to 120 DEG C; and a vacuum degree is in a range of -0.03 to -0.07 MPa. Parameters of the superfine ball-grinding process comprise that a ball-grinding time is in a range of 20 to 100 min; a ball-grinding speed is in a range of 100 to 220 rotations per minute, a material filling rate is in a range of 10 to 30%; and a medium filling rate is in a range of 10 to 30%. The extraction method has the advantages of simple used equipment, safe operation, good soybean oil product properties of no solvent residue and high nutritional values, and high total oil extraction rate reaching to about 97.48%.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Polylactic acid modified material and preparation method thereof

The invention discloses a polylactic acid modified material which comprises the following components in percentage by mass: 40-90% of polylactic acid, 5-30% of polyether type polyamide elastomer and 5-30% of montmorillonite. The preparation method of the polylactic acid modified material comprises the following steps: drying polylactic acid and polyether type polyamide elastomer in a vacuum drying oven at 70 DEG C for 24 hours, drying montmorillonite in a vacuum drying oven at 100 DEG C for 24 hours, and carrying out melt blending on the polylactic acid, polyether type polyamide elastomer and montmorillonite in a twin-screw blender to obtain a blend system, wherein the blending temperature is 170-190 DEG C, the screw speed of the twin-screw blender is 40-100 rpm, and the blending time is 5-10 minutes; and after drying the blend system, and carrying out injection molding with an injection molding machine to obtain the modified material, wherein the cylinder temperature of the injection molding machine is 170-190 DEG C, the mold temperature is 50 DEG C, and the injection molding cycle is 40-60 seconds. The invention has the advantages of high tensile strength and excellent elongation at break.

Owner:NANTONG UNIVERSITY

Walnut meal composite nutrition powder and preparation technology thereof

The invention discloses walnut meal composite nutrition powder and a preparation technology of the walnut meal composite nutrition powder. The preparation technology of the walnut meal composite nutrition powder comprises the steps that (1) pearl barley powder and walnut meal powder serve as main raw materials, extrusion processing is carried out on the raw materials through a bulking machine under the conditions that the extrusion temperature is 150DEG C-170DEG C, and the screw speed is 540-580r / min, and pearl barley and walnut powder extruded materials are obtained; (2) the extruded materials are smashed to form powdery materials with the specification of being larger than 100 meshes, the powdery materials are placed into a homogenizer, sucrose and water are added, high-pressure homogeneity processing is carried out under the conditions that the pressure is 20-25MPa, and the temperature is 70-80DEG C, then, composite probiotics inoculated fermentation processing is carried out on the materials to form walnut meal composite fermentation liquid, and spray drying processing is carried out on the walnut meal composite fermentation liquid to obtain the walnut meal composite nutrition powder. The walnut meal composite nutrition powder and the preparation technology of the walnut meal composite nutrition powder have the advantages of being simple in processing technology, low in manufacturing cost, capable of making full use of the nutrition complementary advantage of the raw materials, capable of achieving all nutritional functions of the walnut meal raw materials, good in quality of products, good in taste of the products, rich in nutrient of the products, stable in quality and performance of the products and the like.

Owner:GUIZHOU UNIV

Method for processing demersal pufted granular feed of river crab

The invention is a sinkable bulked granular river-crab feed and its making method, additionally arranging a variable-frequency speed regulator on the main electric machine of an ordinary screw squeezer to regulate the speed of the screw, combining with related control process conditions, making better waterproof sinkable bulked granular river-crab feed. According to the nutrition needs of the river crabs, it selects and compounds fish meal, soybean dregs, wheat and other raw materials, and makes it by the working procedures of micro-crushing, mixing, regulating quality, extruding, drying and cooling, etc and by the control of the conditions of crushed particle size, material water and temperature after quality-regulating, the screw speed of the squeezer, segment barrel temperature, etc. It has good waterproof property, high gelatination degree, very quickly absorbs water to turn soft after entering in water, suitable for the river crabs to ingest.

Owner:JIANGNAN UNIV

Wheat bran twin-screw extruding treatment method and twin-screw extruding machine thereof

The present invention relates to a twin-screw extrusion processing treatment method for wheat bran and its twin-screw extruder. Said treatment method includes the following steps; thermal refining wheat bran; extruding treatment, adopting twin-screw extruder to treat thermal refined wheat bran, the draw ratio of screw rod is 15-30:1, compression ratio of twin-screw is 2-8:1, the rotating speed of screw rod is 150-500 rpm; rotary cutting; and pulverizing. Said invention can make the microorganism, biological enzyme and injurious insect eggs being in the wheat bran be completely killed and inactivated so as to make the wheat bran obtain further development and utilization.

Owner:河北黑马面粉有限责任公司

Extrusion process for polyethylene polymers

A method for the improved extrusion of polyethylene polymers comprising passing polyethylene through a single stage, twin screw extruder comprising a solid polymer conveying zone, a polymer melting zone, a dispersive mixing zone, and a distributive mixing / pumping zone, in which the throughput and screw speed are optimized to reduce the number of gels present, ensure complete polymer melting within the polymer melting zone, and to minimize polymer degradation.

Owner:NOVA CHEM (INT) SA

Polypropylene modified material for expansion water tank of automobile and preparation method thereof

InactiveCN102775718AImprove low temperature impact strengthImprove high temperature creep resistanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polypropylene modified material for an expansion water tank of an automobile and a preparation method thereof and belongs to the technical field of auto part manufacturing. The polypropylene modified material for the expansion water tank for the automobile comprises the following components in percentage by weight: 75-85 percent of propylene-ethylene block polypropylene copolymer, 10-20 percent of linear low density polyethylene (LLDPE) resin, 2-5 percent of ethylene propylene diene monomer (EPDM), 0.1-0.5 percent of nucleating agent and 0.1-0.5 percent of antioxidant. After being mixed according to the proportion, the materials are extruded and granulated by a double screw extruder under the conditions that the processing temperature is 210-240 DEG C, and the screw speed is 210-240 revolutions / minute. The polypropylene modified material has the beneficial effects that polypropylene is modified by the reasonable components according to the mixing proportion, so that the material has higher low-temperature impact strength and higher high-temperature creep resistance; and meanwhile, the hot plate welding performance of the material is improved, the material transparency is improved, and the production processing requirements and the use requirements of the expansion water tank for the automobile are completely satisfied.

Owner:SHANDONG HUA TONG AUTOMOBILE MOLDS PLASTICS TECH

Method for producing drawing protein by utilizing compound vegetable protein containing peanut and soybean

The invention discloses a method for producing a drawing protein by utilizing a compound vegetable protein containing peanut and soybean. The method comprises the following steps: mixing and tempering 73-85 parts of low-temperature degreased peanut protein powder, 5-15 parts of soy isolate protein, 1-15 parts of vital gluten and 1-15 parts of starch at the ratio of raw materials and then performing extruding tissue treatment under the conditions of extruding temperature of 60-160 DEG C, screw speed of 180-240r / min, feeding rate of 80-140g / min, cooling temperature of extruding mold of 62-75 DEG C and moisture content of materials in the extruding process of 50%-62%. High-moisture peanut drawing protein prepared according to the invention can overcome the difficulty in preparing the high-moisture drawing protein by taking peanut protein as the raw material; the acquired product requires no rehydration, has uniform and bright color and is free from bean flavor; compared with a tissue product taking a single protein as the raw material, the product has the advantage of rich nutrition.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

High-heat-resistant high-binding-force electroplating PC/ABS alloy material and preparation method thereof

The invention relates to a high-heat-resistant high-binding-force electroplating PC / ABS alloy material and a preparation method thereof. The PC / ABS alloy material comprises the following components by weight: 30-60 parts of PC resin, 20-50 parts of ABS gelatine powder, 15-35 parts of Alpha-SAN resin, 1-5 parts of a compatilizer, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method comprises the following steps: adding the PC resin, the ABS gelatine powder, the Alpha-SAN resin, the compatilizer, the antioxidant and the lubricant to a mixer for mixing by weight in the preparation process; feeding a prepared mixture from the main feeding opening of a extruder, controlling the temperature of a machine cylinder to be 220-270 DEG C, and controlling the screw speed to be 300-600 circles / minute, mixing and pelleting to obtain the PC / ABS alloy material. Compared with the prior art, the used Alpha-SAN resin modified by Alpha-vinyltoluene has the more excellent heat resistance, and is capable of effectively improving the heat-resisting level of the material under the situation without reducing the glue amount. The compatilizer is introduced for improving the compatility of the Alpha-SAN and PC phases, improving the dispersibility of the rubber, and improving the heat resistance and binding force performance of the material system advantageously.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Method for producing semi-moist sucking pig feed

ActiveCN101103776AImprove qualityEfficient killingAnimal feeding stuffAccessory food factorsStarch gelatinizationSolid particle

The invention relates to a production method for a semi-humid porket feed belonging to the pig feed processing technical field. The invention is a general weaned piglets feed: the raw materials is dry powder feed and solid particle feed; after being crushed, sieved and weighed, fungicide and quantitative water are added in the raw materials, and then are blended with a water content of 25 percent to 55 percent; the semi-humid porket feed is made by extruding, refrigerating and packing the particles; when the extrusion method is used for the production, an extruder with a kneading area temperature of 80 DEG C to 150 DEG C, a cooling temperature of 50 DEGC to 100 DEG C, and an extrusion condition of the screw speed of 200 -1000r / min is adopted for producing the semi-humid porket feed with a starch gelatinization of 75 percent to 90 percent. Preservative with a certain concentration is added into the feed formula, so that the semi-humid porket feed will not mildew within 6 months.

Owner:SHANGHAI XINNONG FEED

Physical stripping graphene-plastic composite and preparation method

The invention relates to the technical field of heat conducting plastic and provides a physical stripping graphene-plastic composite which comprises the following components in percentage by weight: 5-60% of heat conducting powder, 40-90% of plastic and 1-5% of auxiliary, wherein the heat conducting powder is physical stripping graphene which is mixed by a twin-screw extruder to prepare graphene-plastic composite masterbatch; the particle size of the graphene is 50-5000 meshes, the layer number of the graphene is 2-50, and the carbon content of the graphene is 85-99.8%. The invention also provides a preparation method of the composite, which comprises the following steps: drying the plastic masterbatch; setting the working temperature of the twin-screw extruder and the twin-screw speed; adding the graphene from an area I; adding a coupling agent from an area II; adding an antioxidant from an area III; and performing blending, extrusion and granulation. The physical stripping graphene-plastic composite and the preparation method thereof have the following beneficial effects: through physical stripping of graphene and plastic compounding preparation, the material has excellent heat conducting property and is reasonable in proportion, and the technology is simple and suitable for mass production and has a broad application prospect.

Owner:上海多希石墨烯材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com