Extraction method of soybean oil

A technology of soybean oil and extraction method, which is applied in the direction of oil/fat production and fat production, and can solve the problems of low oil yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

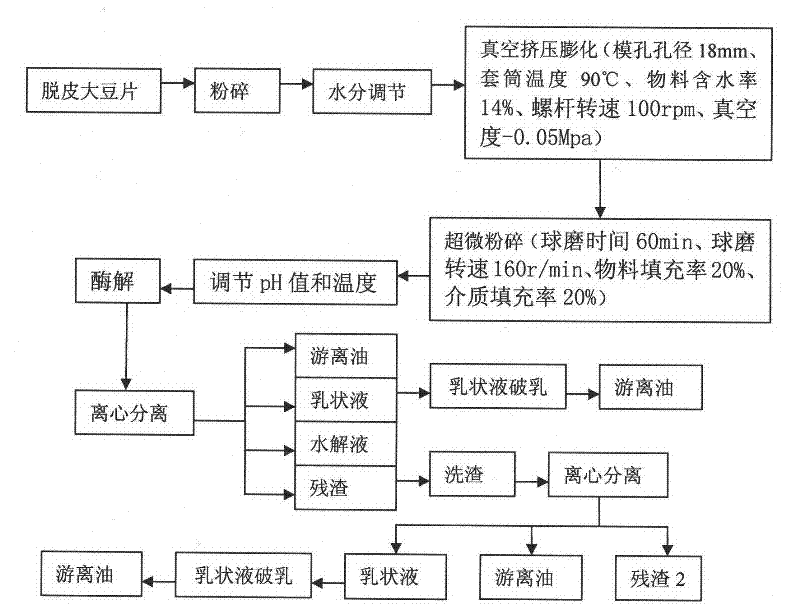

Method used

Image

Examples

Embodiment 1

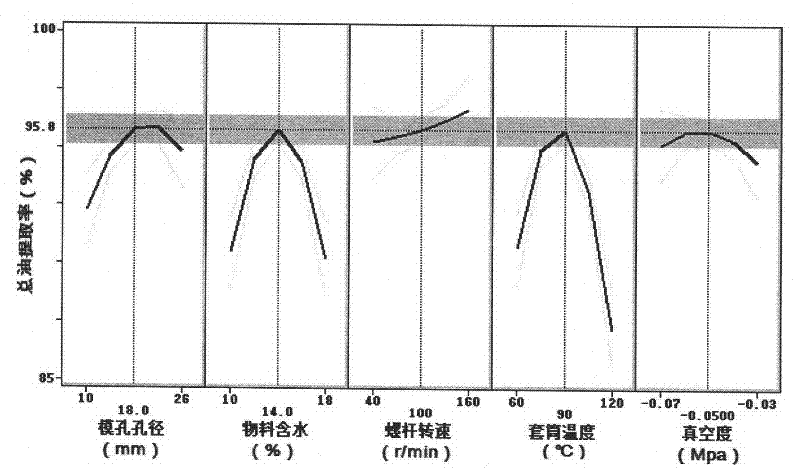

[0024] Example 1: Screening experiment of optimal parameters for vacuum extrusion puffing of peeled soybean flakes

[0025] 1 Materials and methods

[0026] 1.1 Materials and reagents

[0027] Dehulled soybean flakes Harbin Jiusan Oil Group

[0028] protex-6L alkaline endoprotease Danish novo company

[0029] 1.2 Main instruments and equipment

[0030] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0031] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0032] Centrifuge Beijing Medical Centrifuge Factory

[0033] Precision Electric Mixer Jiangsu Jintan City Ronghua Instrument Manufacturing Co., Ltd.

[0034] Electric constant temperature water bath Yuyao Dongfang Electrical Instrument Factory

[0035] Semi-automatic azotometer Shanghai Xinjia Electronics Co., Ltd.

[0036] Digester Shanghai Fiber Inspection Instrument Co., Ltd.

[0037] Hammer Mill China Tianjin Test Instrument Co., Ltd.

[0038] Soxhlet Extractor Tianjin Glas...

Embodiment 2

[0073] Example 2: Screening experiment for optimal parameters of vacuum puffed soybean micronization

[0074] Based on the best vacuum extrusion technique for extracting soybean oil determined in Example 1, a single-factor micro-sized pulverization test was carried out to determine the micro-sized process parameters (ball milling time, ball milling speed, material filling rate, medium filling rate) scope. Taking the total oil extraction rate as the investigation index, a response surface design experiment with 4 factors and 5 levels was carried out.

[0075] 1 Materials and methods

[0076] 1.1 Materials and reagents

[0077] Dehulled soybean flakes Harbin Jiusan Oil Group

[0078] protex-6L alkaline endoprotease Danish novo company

[0079] 1.2 Main instruments and equipment

[0080] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0081] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0082] Centrifuge Beijing Medical Centrifuge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com