Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

729 results about "Plastic compounding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compounding consists of preparing plastic formulations by mixing and/or blending polymers and additives in a molten state, these blends are automatically dosed with fixed setpoints usually through feeders/hoppers. It is mostly a blend of copolymers such as ABS, SAN, SMA etc. with additives such as anti-oxidants, UV-stabilizers and other value adding agents and sometimes a strengthening component is added such as glass fibre.

Sealed cartridge for making a beverage

InactiveUS6849285B2Easy to produceSatisfactory resistanceReady-for-oven doughsLiquid flow controllersBiotechnologyMechanical engineering

The invention relates to a sealed cartridge, provided to be extracted under pressure, containing a substance (15) for preparing a beverage, comprising a dish (9) with a bottom (10) and a side wall (11), having substantially the shape of a frustum of a cone, and a circular edge with a diameter greater than the bottom, and a cover (12) welded to the periphery of the edge of the dish, in which the cover (12) consists of a flexible material which is impermeable to oxygen, chosen from the group consisting of aluminum, an aluminum / plastic composite, an aluminum / plastic / paper composite, pure or multi-layer plastic, the said cartridge not comprising a filter or a weakening zone and the cover being intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the said cartridge comprising, in the dish at the level of the bottom, a barrier (13) that is automatically resealable against leakage of the substance upon withdrawal of the fluid injection needle.

Owner:SOC DES PROD NESTLE SA

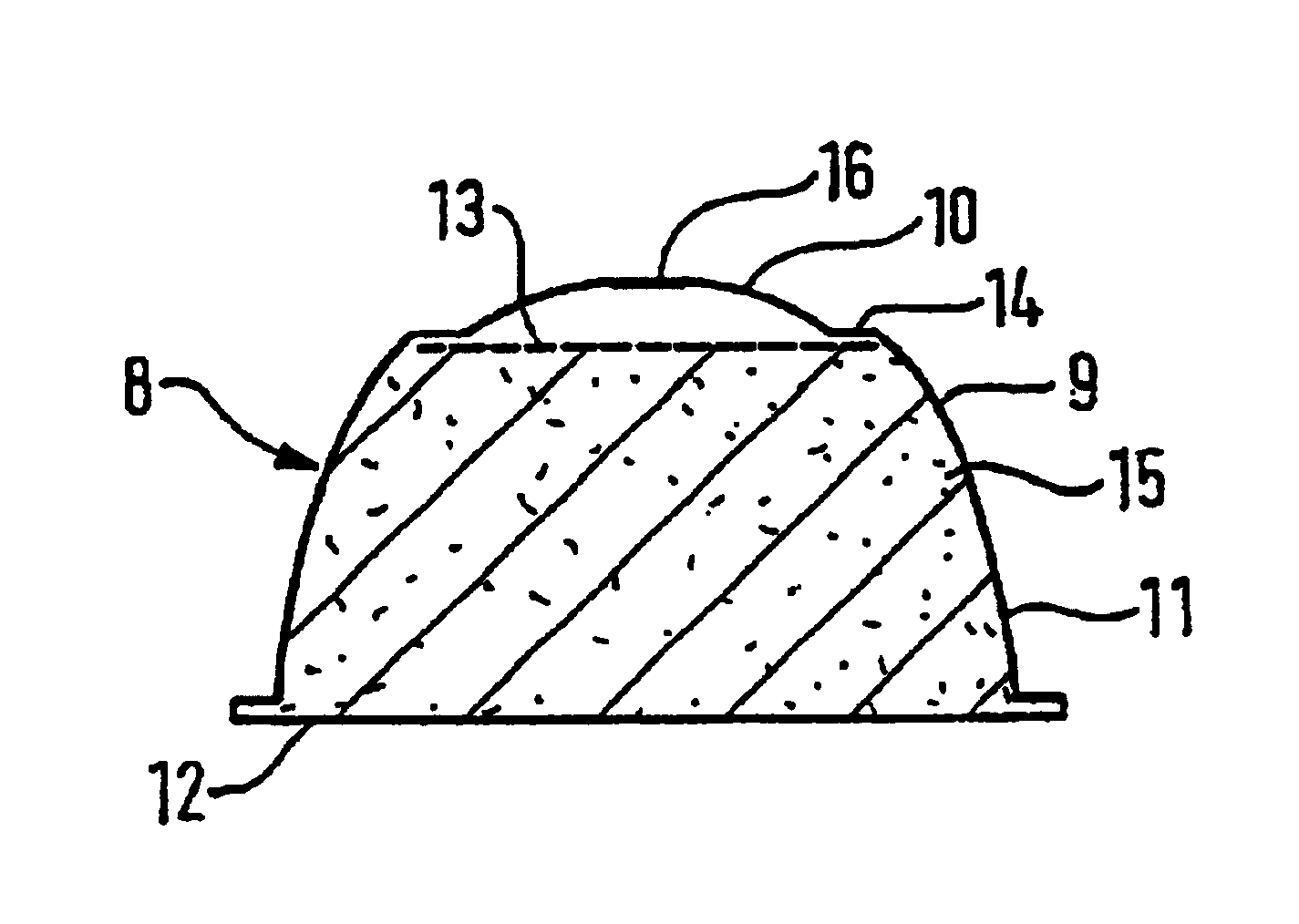

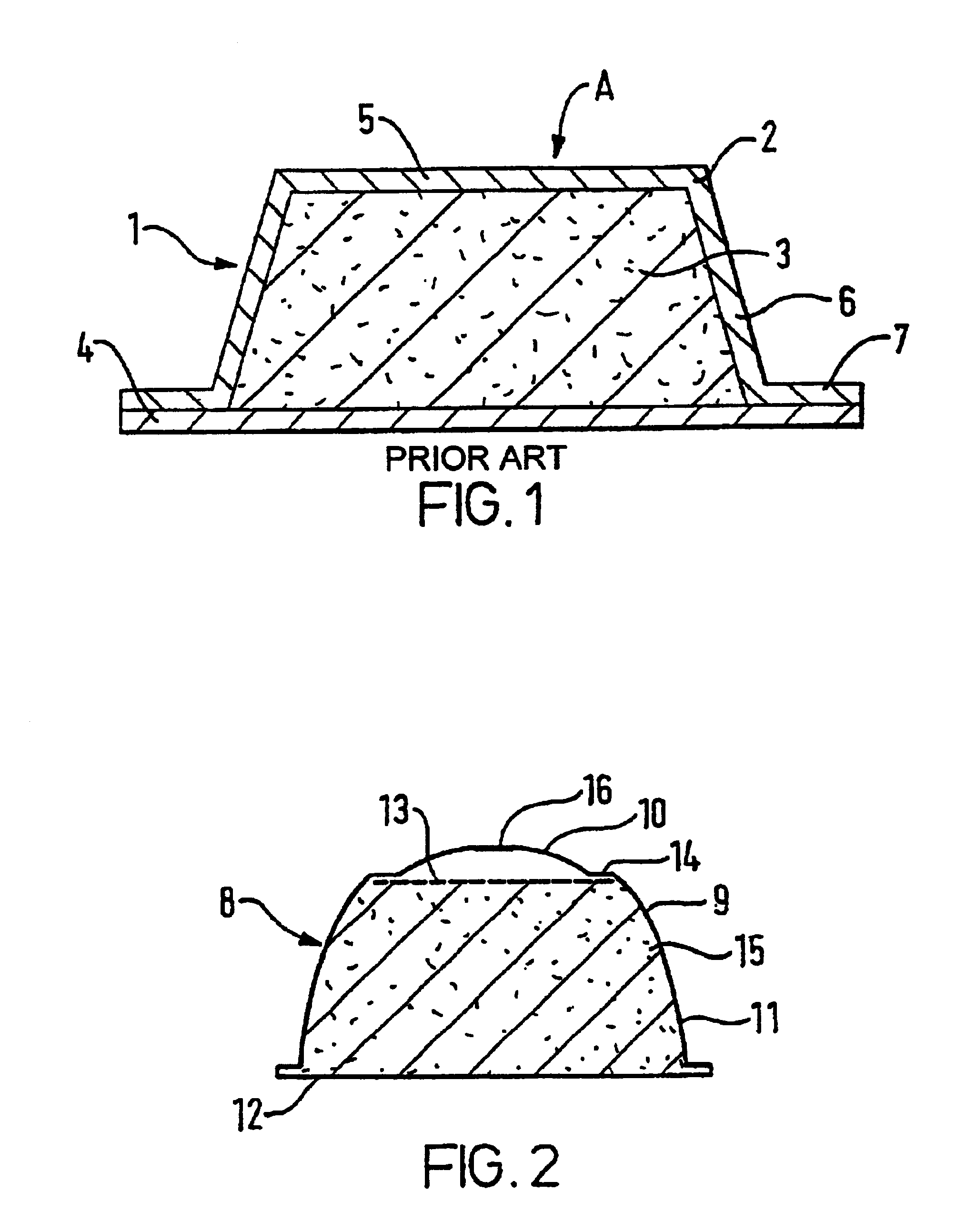

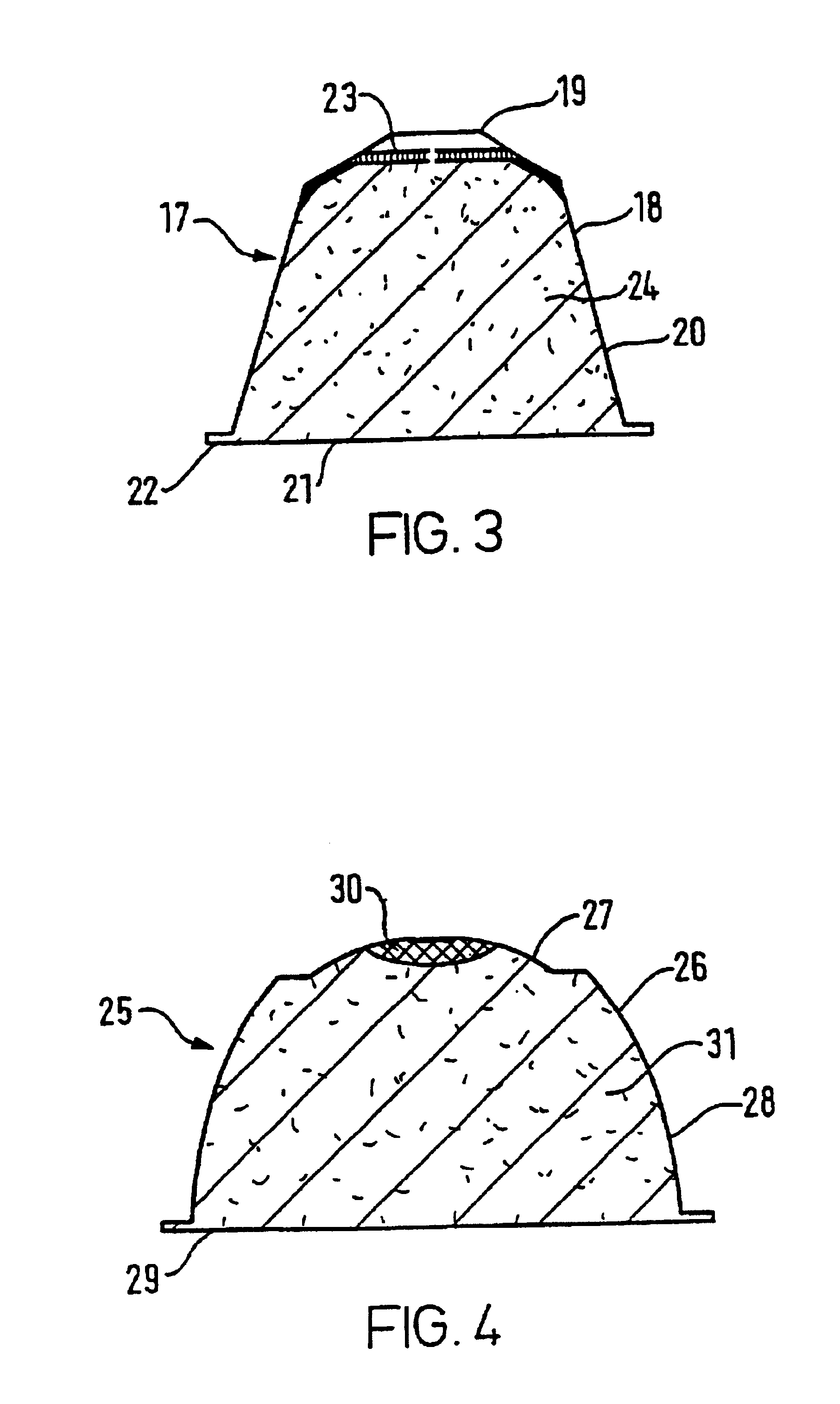

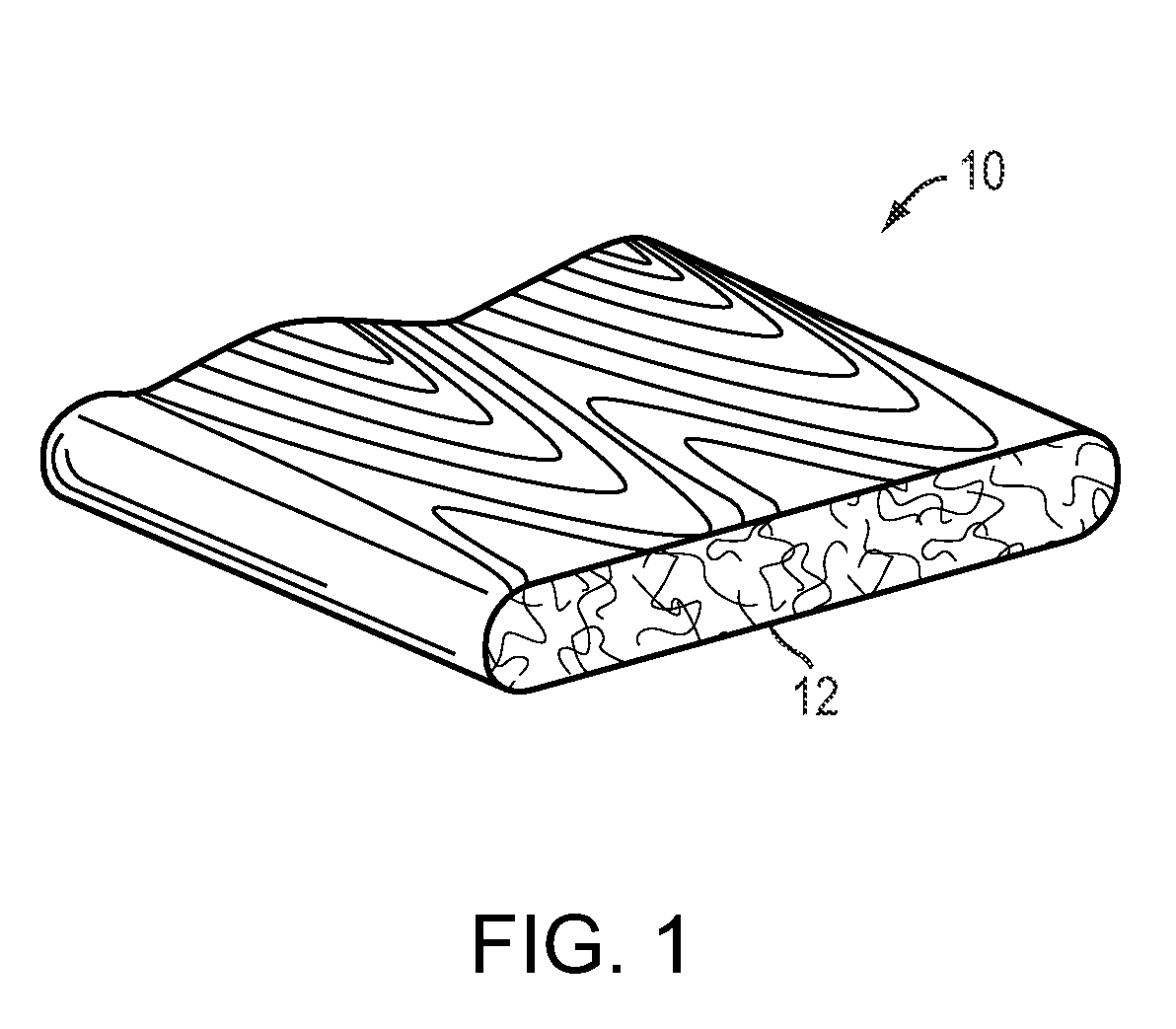

Plastic Composites Using Recycled Carpet Waste and Systems and Methods of Recycling Carpet Waste

InactiveUS20080213562A1Reduce material costsLamination ancillary operationsSynthetic resin layered productsNatural fiberInorganic materials

An extruded composite utilized as a building material includes a base polymer, unseparated processed recycled carpet waste, and a filler material, which may be a wood filler or other natural fiber. Carpet waste may be separated into components that may be utilized in a variety of plastics applications, including extruded composites utilized as building materials. Separation may include shaving face fiber from bound fiber secured in a backing fiber and / or may include separating fiber pile and backing fibers from carpet adhesive to remove inorganic materials such as calcium carbonate.

Owner:MATERIAL INNOVATIONS LLC

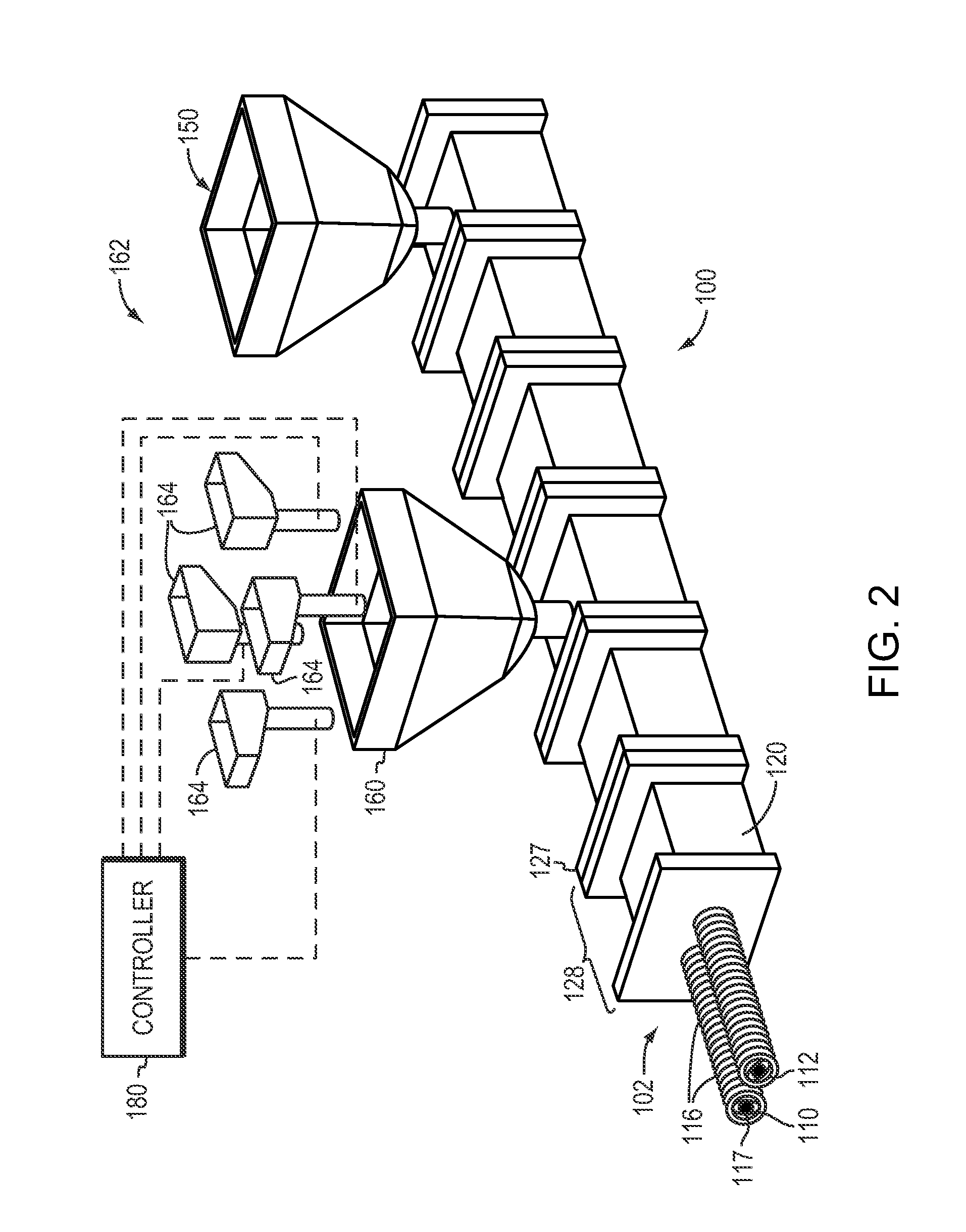

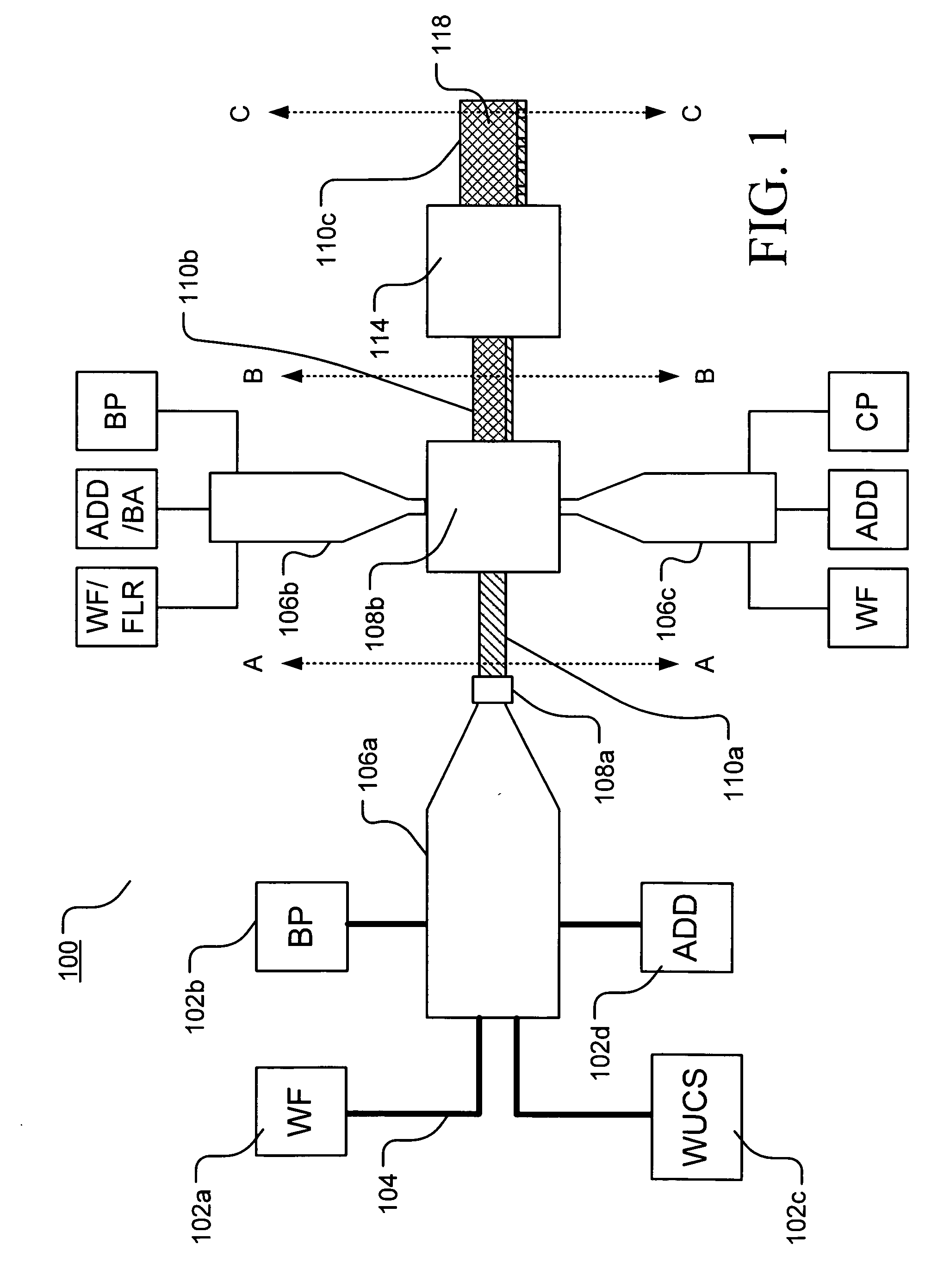

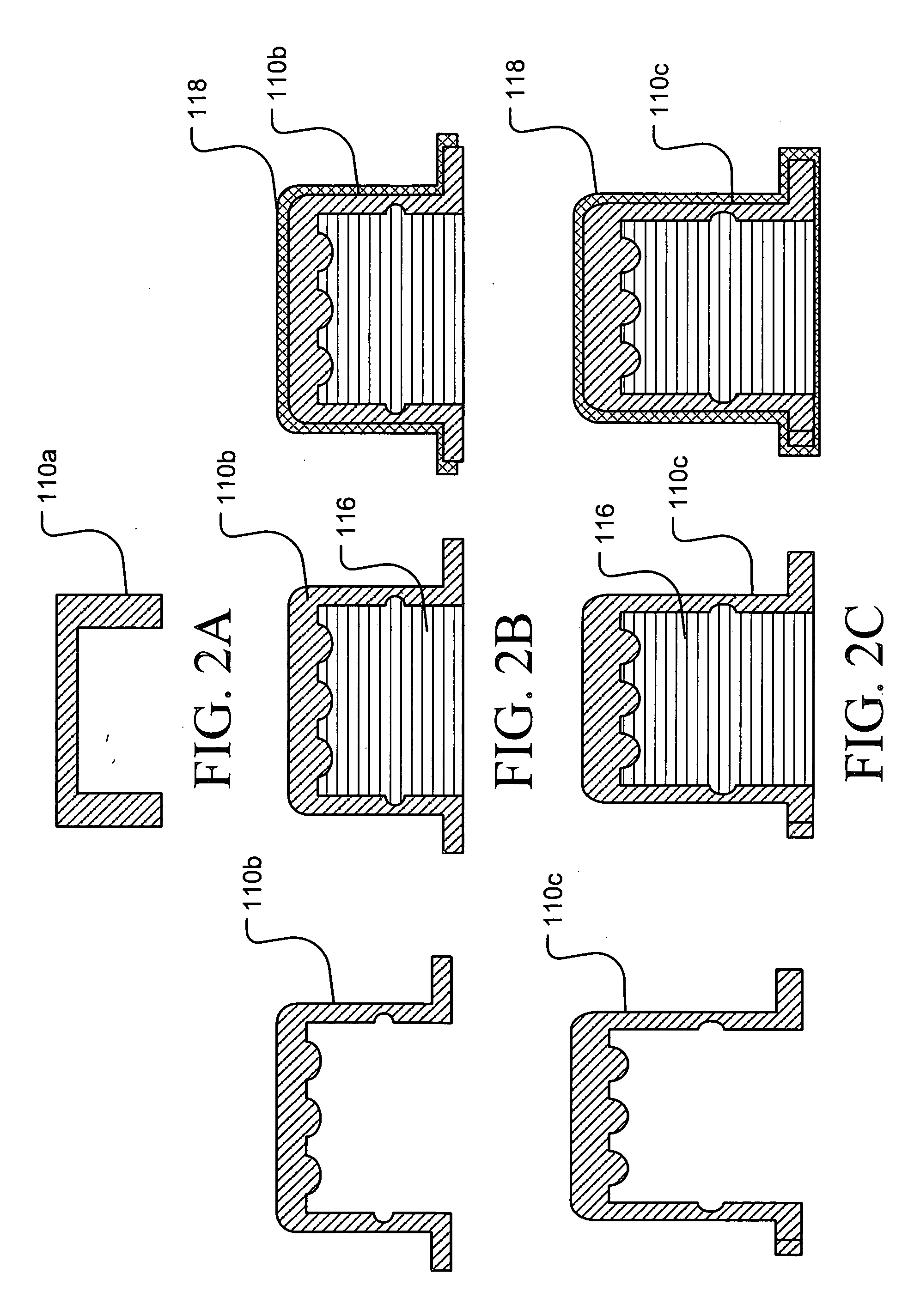

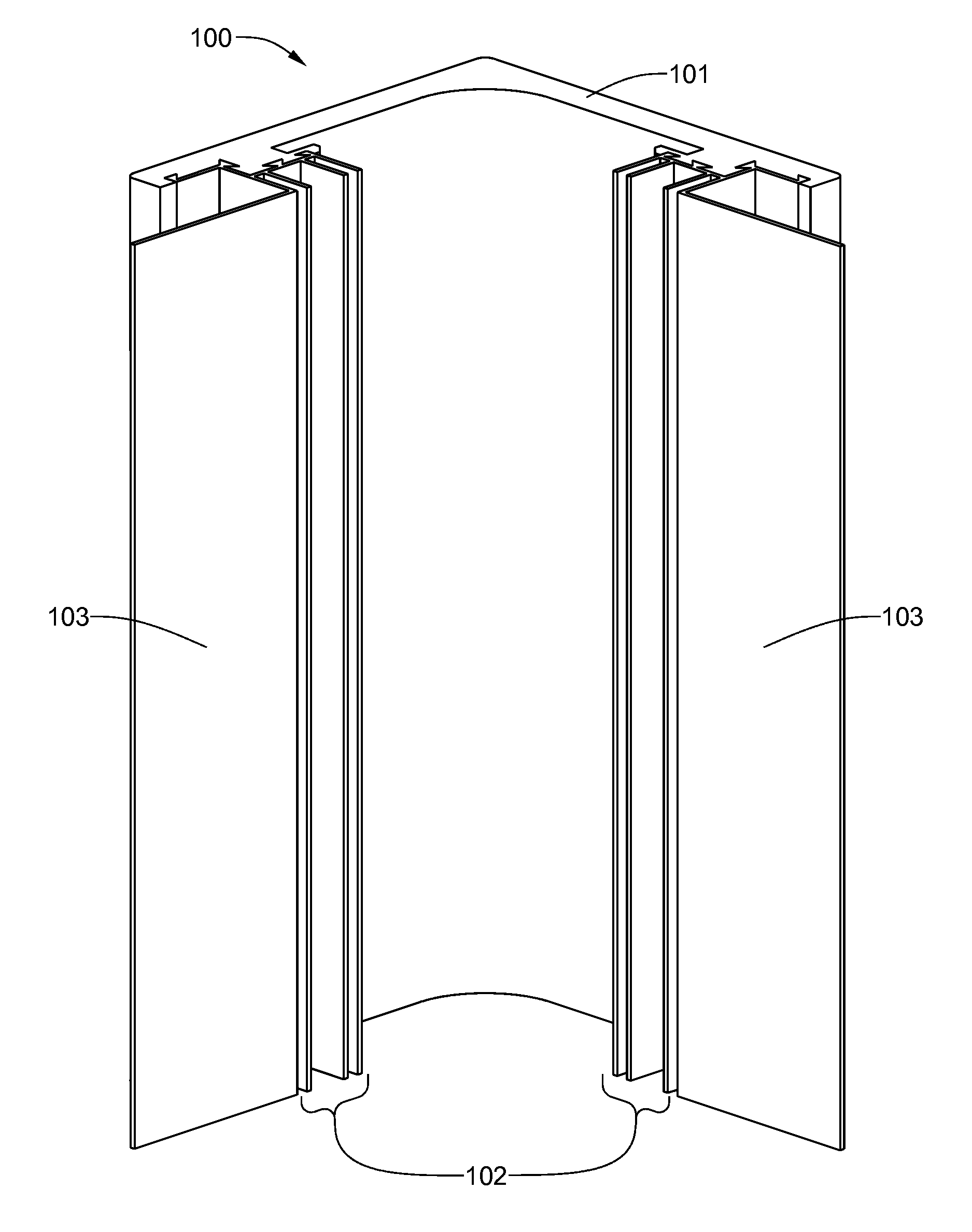

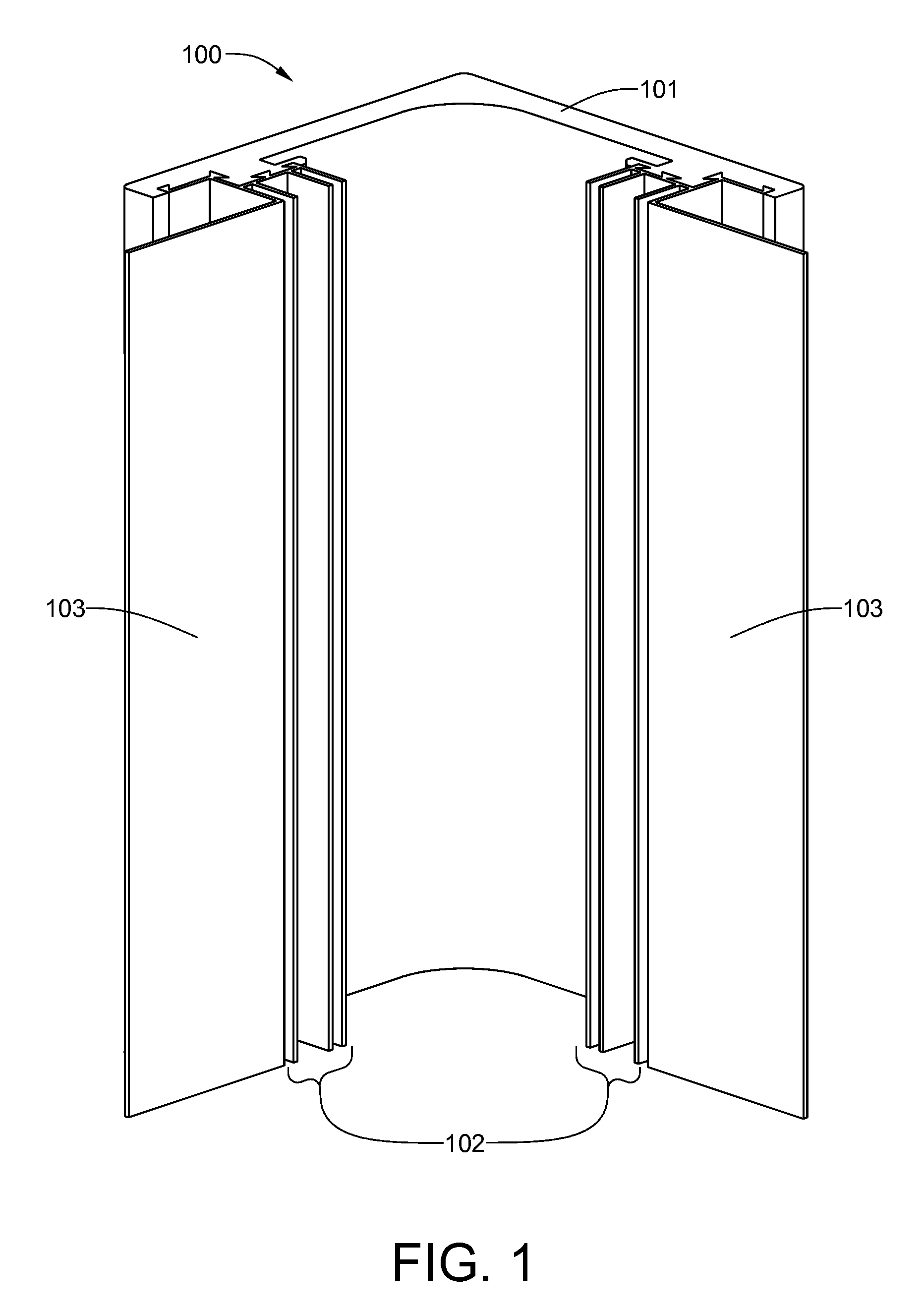

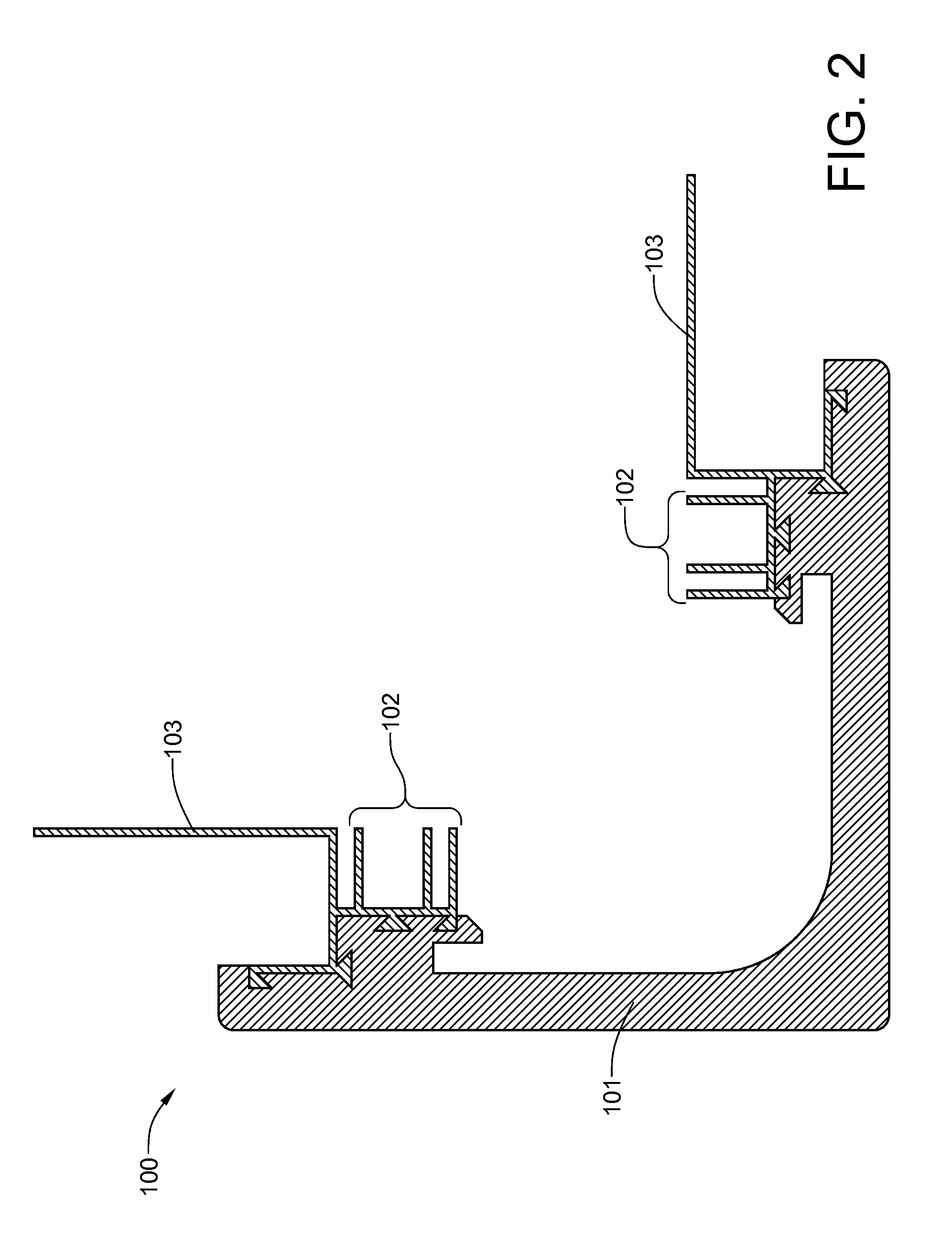

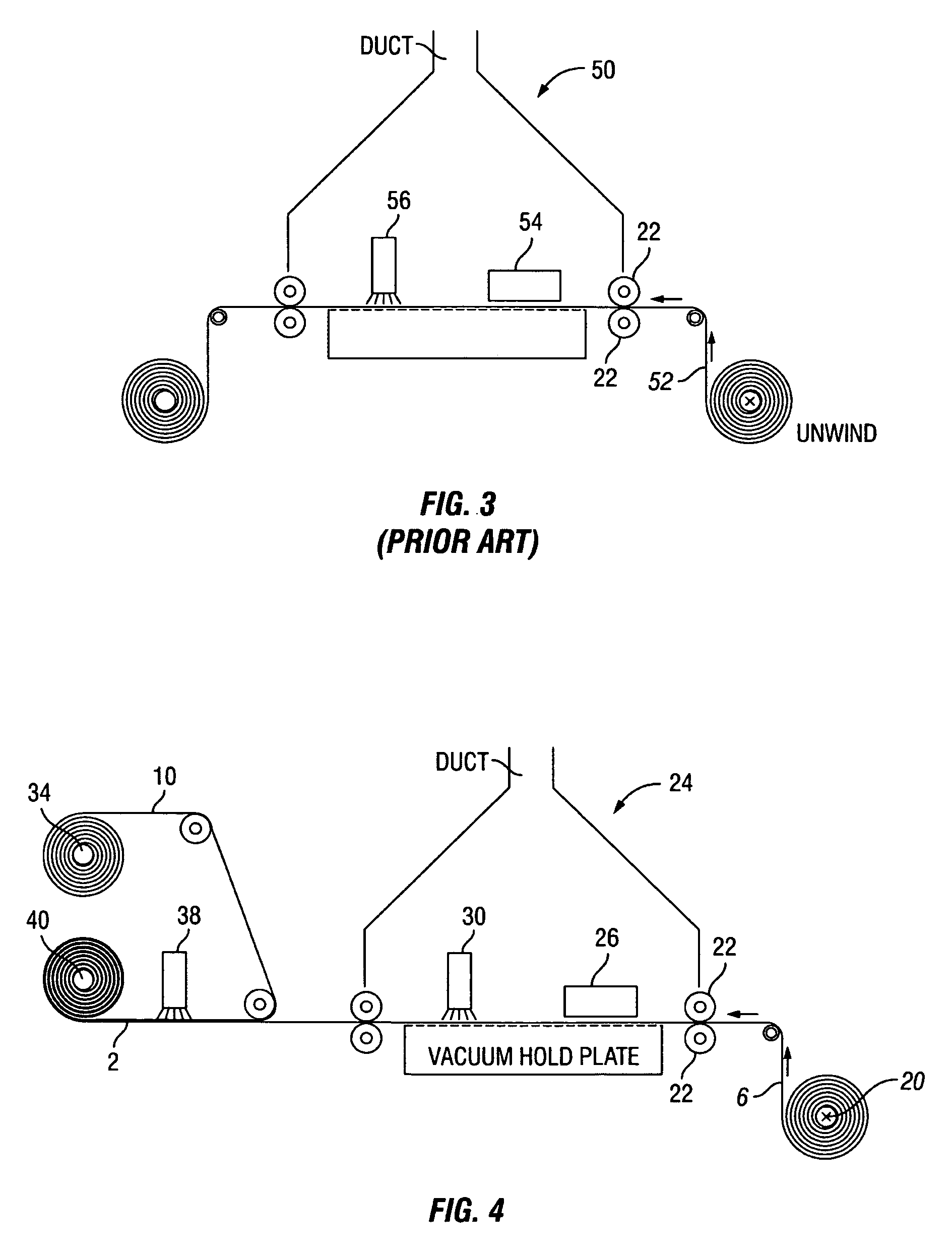

Tri-extruded WUCS glass fiber reinforced plastic composite articles and methods for making such articles

Disclosed are a series of composite polymer composite structures formed by the coextrusion of at least two distinct polymeric compositions including a structural composition and a coating composition whereby the primary structural frame formed from the structural composition includes at least one, and typically a plurality, of longitudinal recesses or cavities. These recesses or cavities may, in turn, be filled with a third distinct polymeric composition that may include wood byproducts and / or a foaming or blowing agent.

Owner:OCV INTELLECTUAL CAPITAL LLC

Charcoal-containing polyurethane foam composite material

Disclosed is carbon-containing urethane foam composite material, relating to urethane foam composite material. The composite material is carbon-containing soft urethane foam, or carbon-containing slowly-recoverable urethane foam or carbon-containing hard urethane foam. Apart from the necessary foam source and the auxiliary material, the raw material for preparing the urethane foam includes super-thin bamboo powder or charcoal powder. Furthermore, far-infrared powder, sterilized powder, silver ion powder, organic germanium powder, tea powder or Chinese herbal powder can be added into the raw material for preparing the urethane foam. The urethane foam can be made into bath sponge and washing sponge with the capabilities of adsorbing and degrading noxious gas, disinfecting and sterilizing, radiating far infrared rays and adjusting humidity or be made into pillows, cushions, mattresses and indoor decorations with medical and health care functions in daily life.

Owner:林文炳

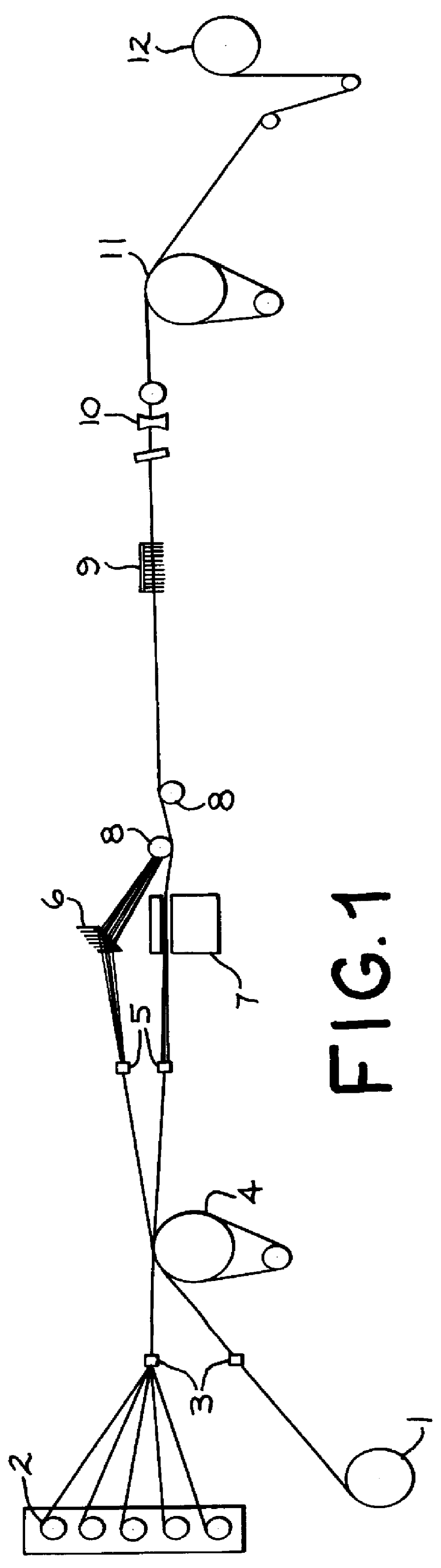

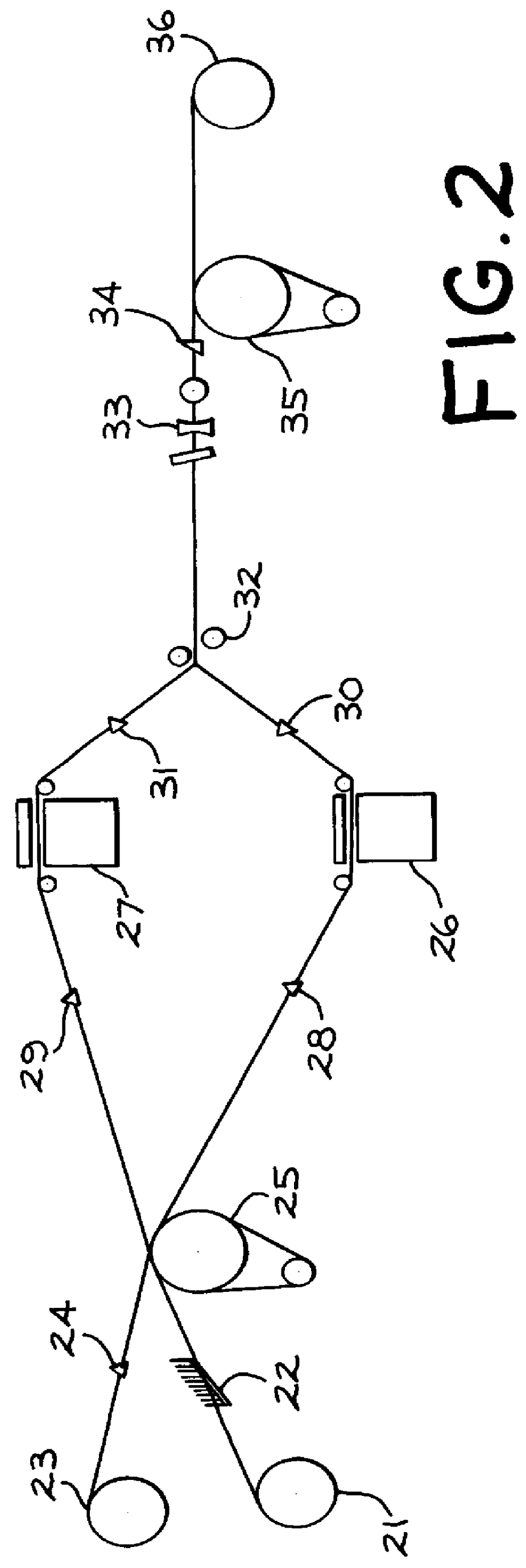

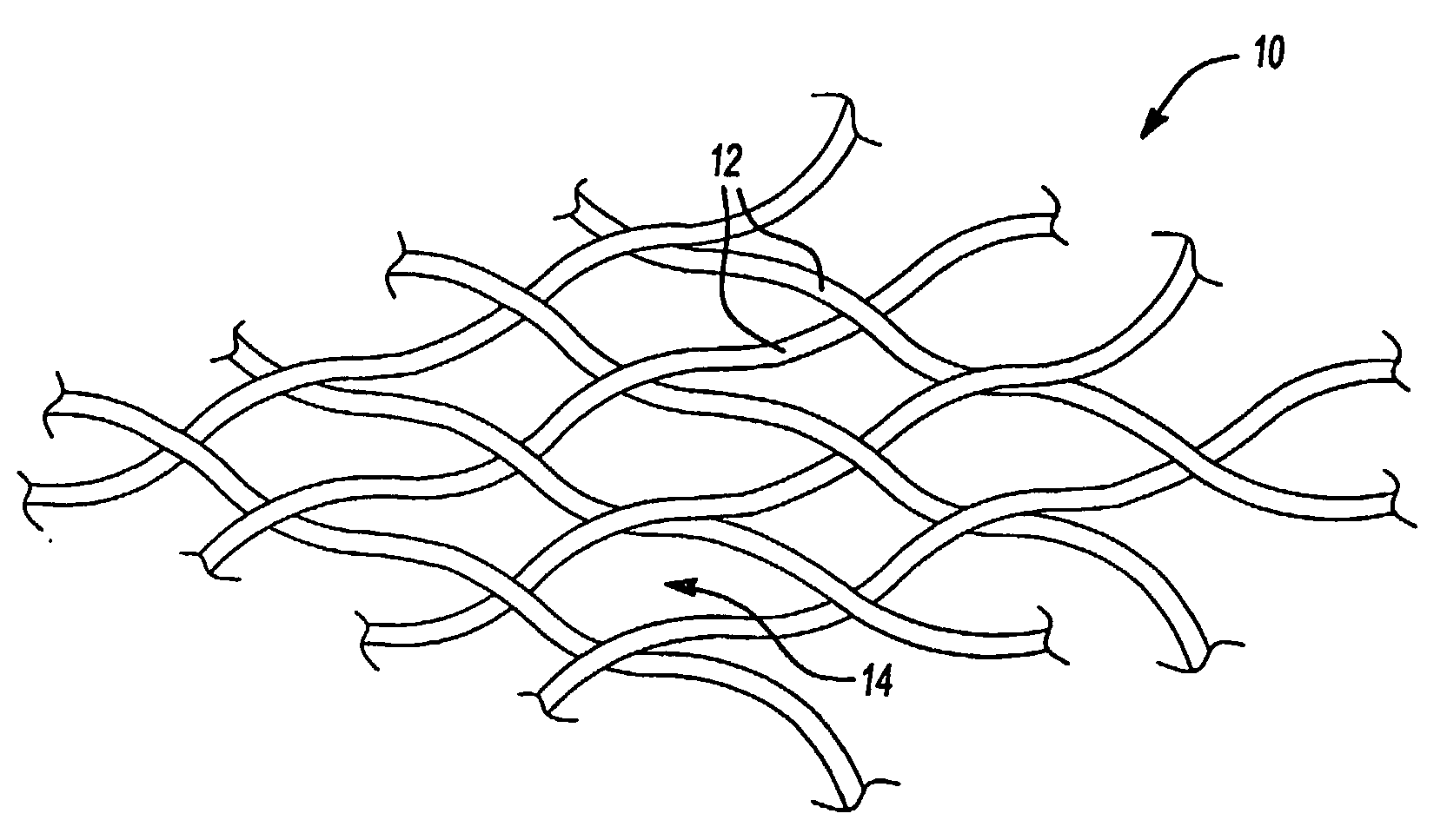

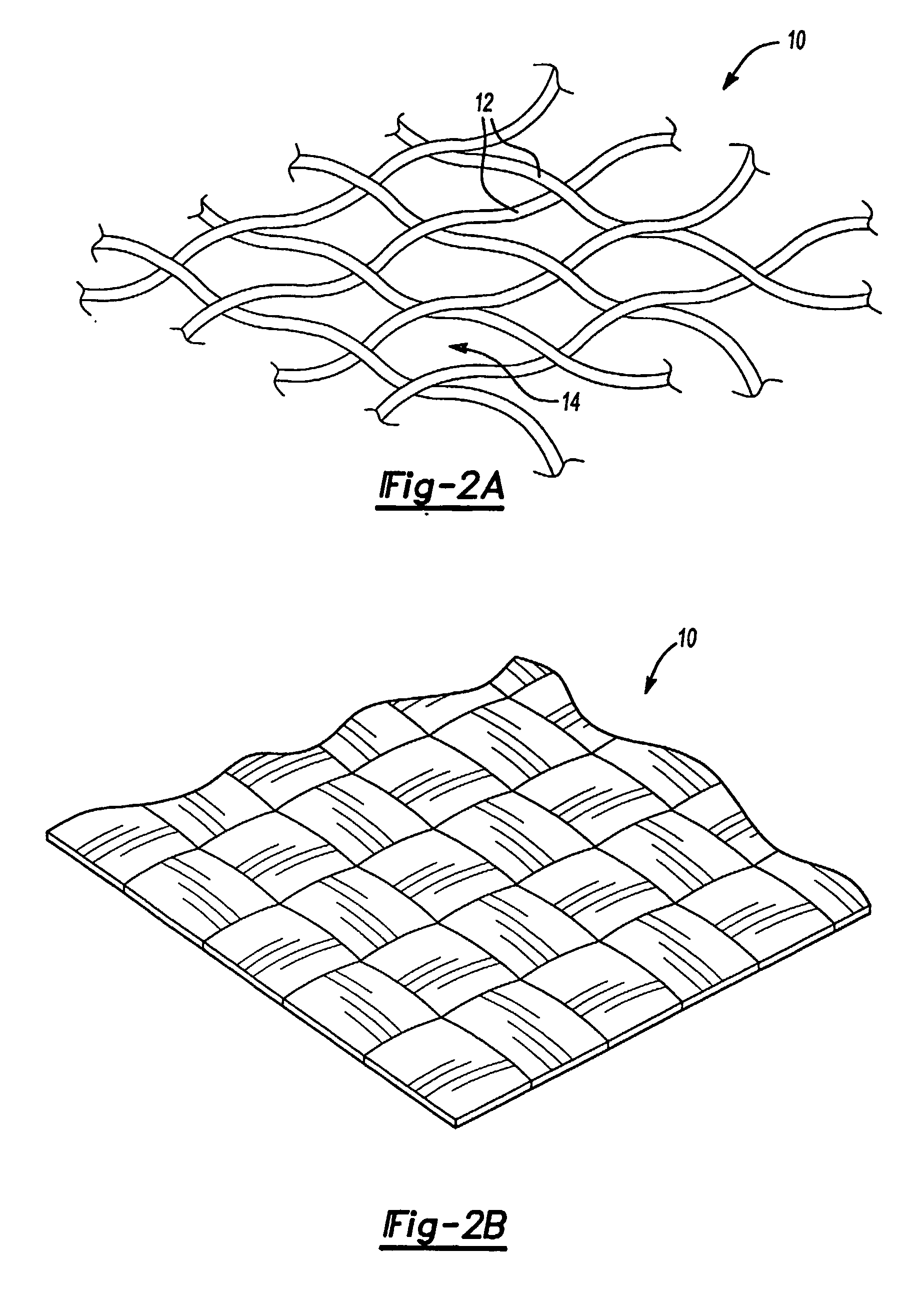

Continuous, linearly intermixed fiber tows and composite molded article thereform

InactiveUS6045906AGood drapabilityImprove wettabilityLayered productsWoven fabricsFiberPolymer science

The instant invention involves a process used in preparing fibrous tows which may be formed into polymeric plastic composites. The process involves the steps of (a) forming a carbon fiber tow; (b) forming a thermoplastic polymeric fiber tow; (c) intermixing the two tows; and (d) withdrawing the intermixed tow for further use.

Owner:CYTEC TECH CORP

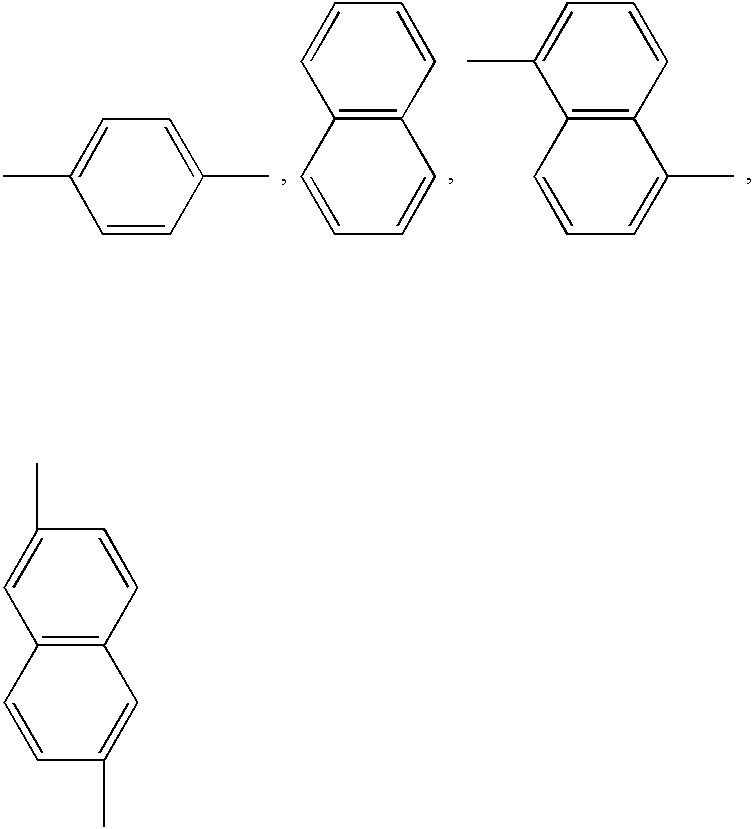

Benzoxazine colophony based on renewable resources, its composition and preparing method thereof

The invention relates to a kind of benzoxazine colophony whose materials come from renewable resources, its composition and preparing method. This kind of benzoxazine colophony is prepared with phenols stemmed from the renewable resources, such as eugenol, guaiacol and cardanol, and diamine stemmed from the renewable resources such as decamethylene diamine, and cavaform or triformol or formaldehyde liquid. The relevant composition is prepared with this kind of benzoxazine colophony and other heat-convertibleresin. The benzoxazine and its composition can be used in many fields such as coatings, thermosetting plastics, matrix colophony of composite materials and so on.

Owner:BEIJING UNIV OF CHEM TECH

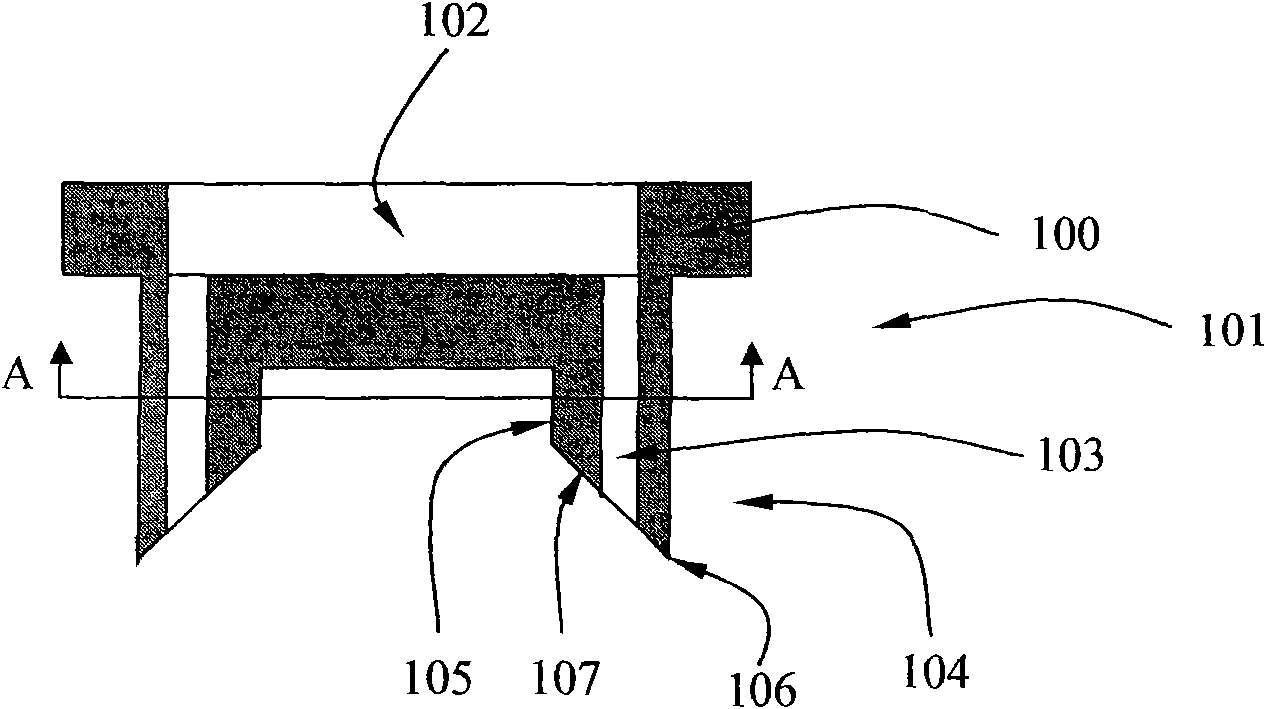

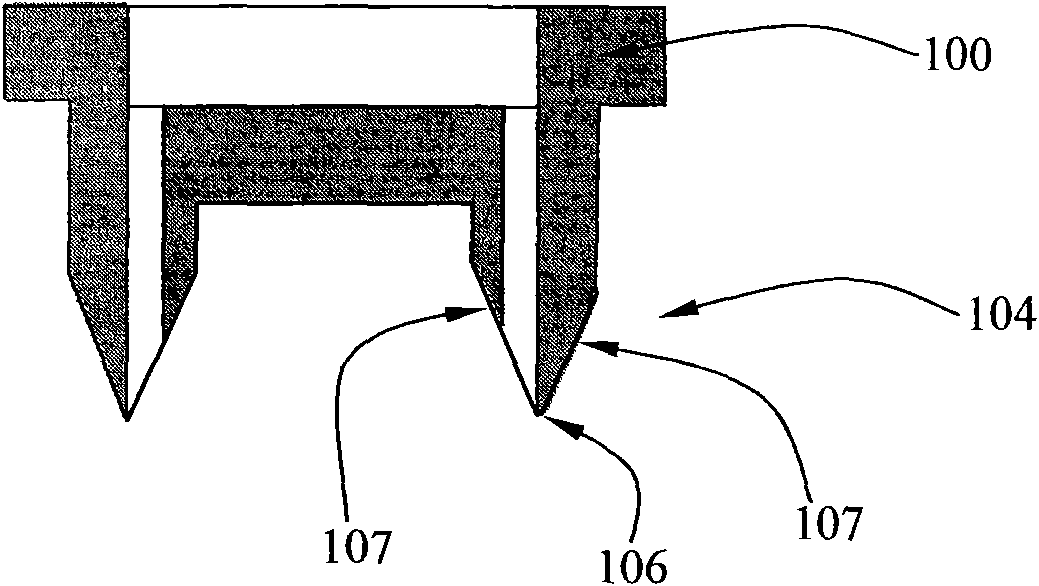

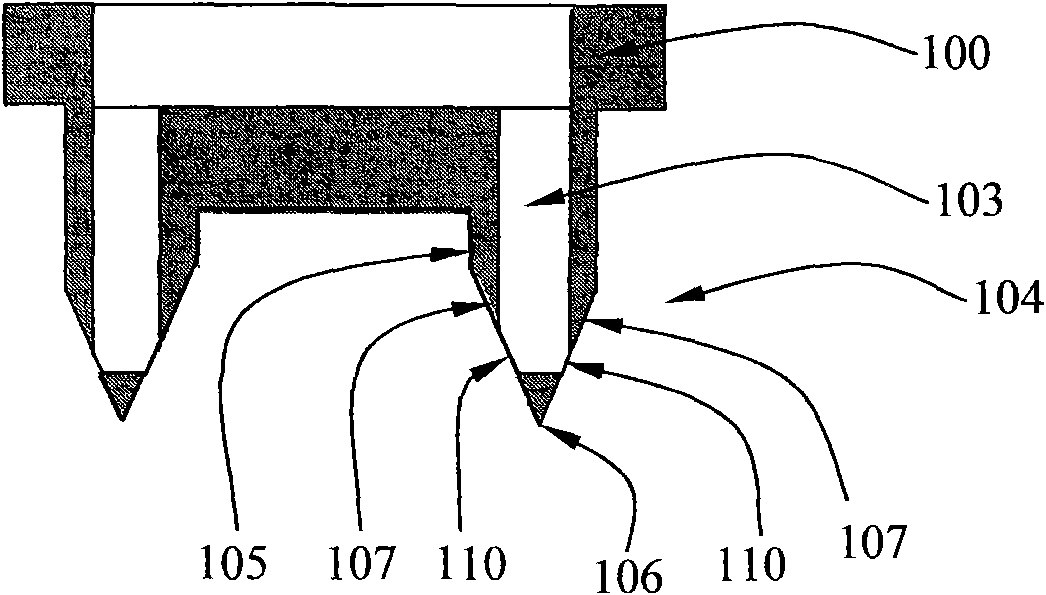

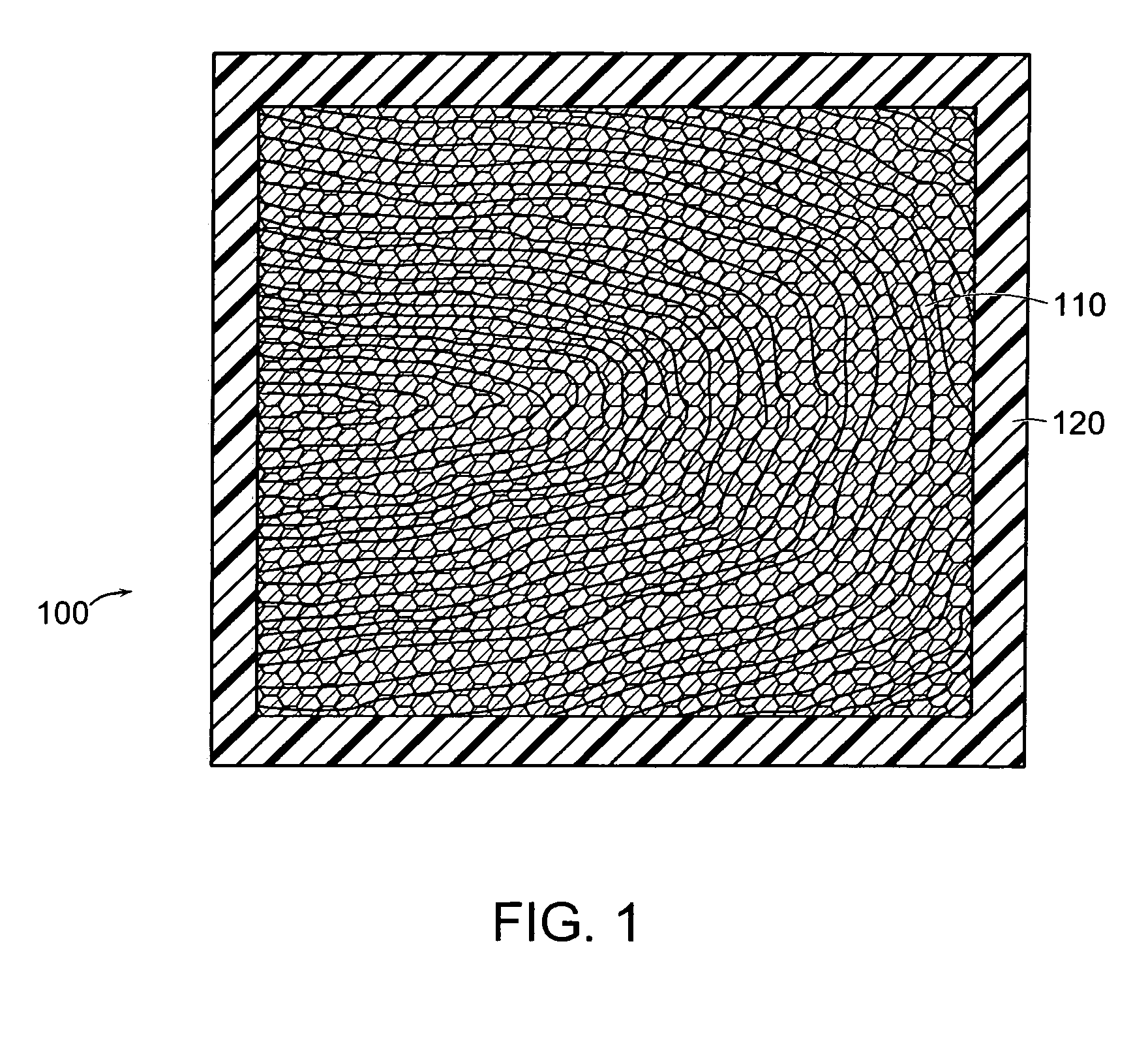

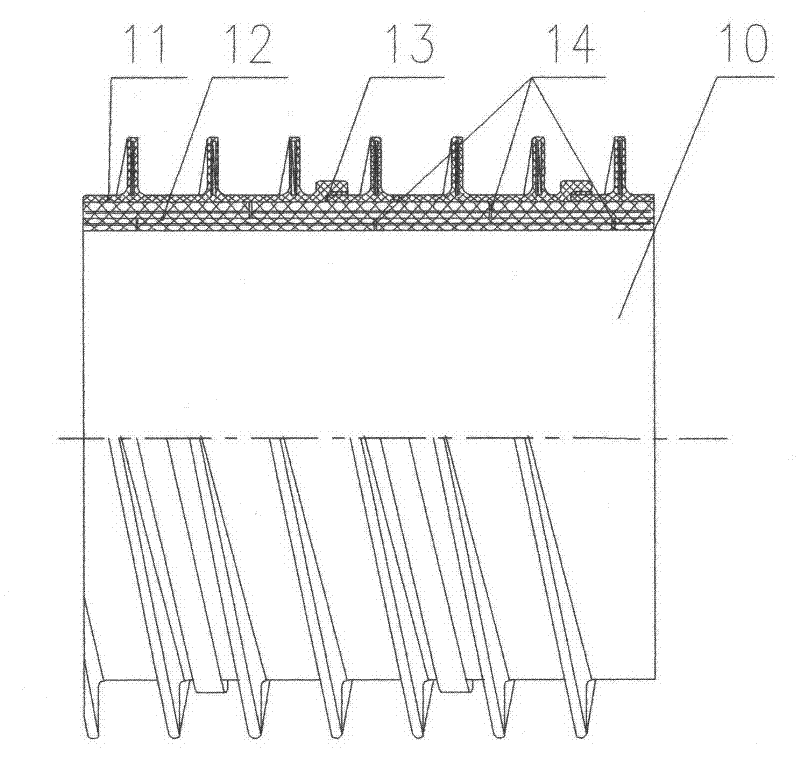

Microneedles array, die casting method for manufacturing microneedle array and die for manufacturing microneedle array

ActiveCN101856538AReduce manufacturing costLow priceMicroneedlesMedical devicesMetallic materialsDie casting

The invention provides a microneedles array, a method for manufacturing the microneedles array and a die for manufacturing the microneedles array. The microneedles array comprises a base and a plurality of microneedles which are integrated with the base, wherein a liquid storage cavity is arranged in the base, and each microneedle are provided with micro-pinholes which are communicated with the liquid storage cavity; the microneedles array is made of plastics, composite materials, and ceramics or metal materials by injection molding; and each microneedle has at least one inclined surface which is inclined towards the central line of the microneedle, and the outlet of each micro-pinhole is positioned on at least one inclined surface, so that the end of the outlet of the microneedle forms a pinnacle part. The die specialized for the invention comprises an upper die, a middle die and a lower die, wherein the middle die and the lower die are provided with cavities for forming the microneedles; and the upper die and the middle die are provided with grooves for forming the base. The three-plate die of the invention can be used for conveniently manufacturing the microneedles array with the pinnacles. Since the stripping process in the injection molding method is carried out step by step, the method has the advantages of small die drawing resistance and low manufacturing cost.

Owner:THE HONG KONG POLYTECHNIC UNIV

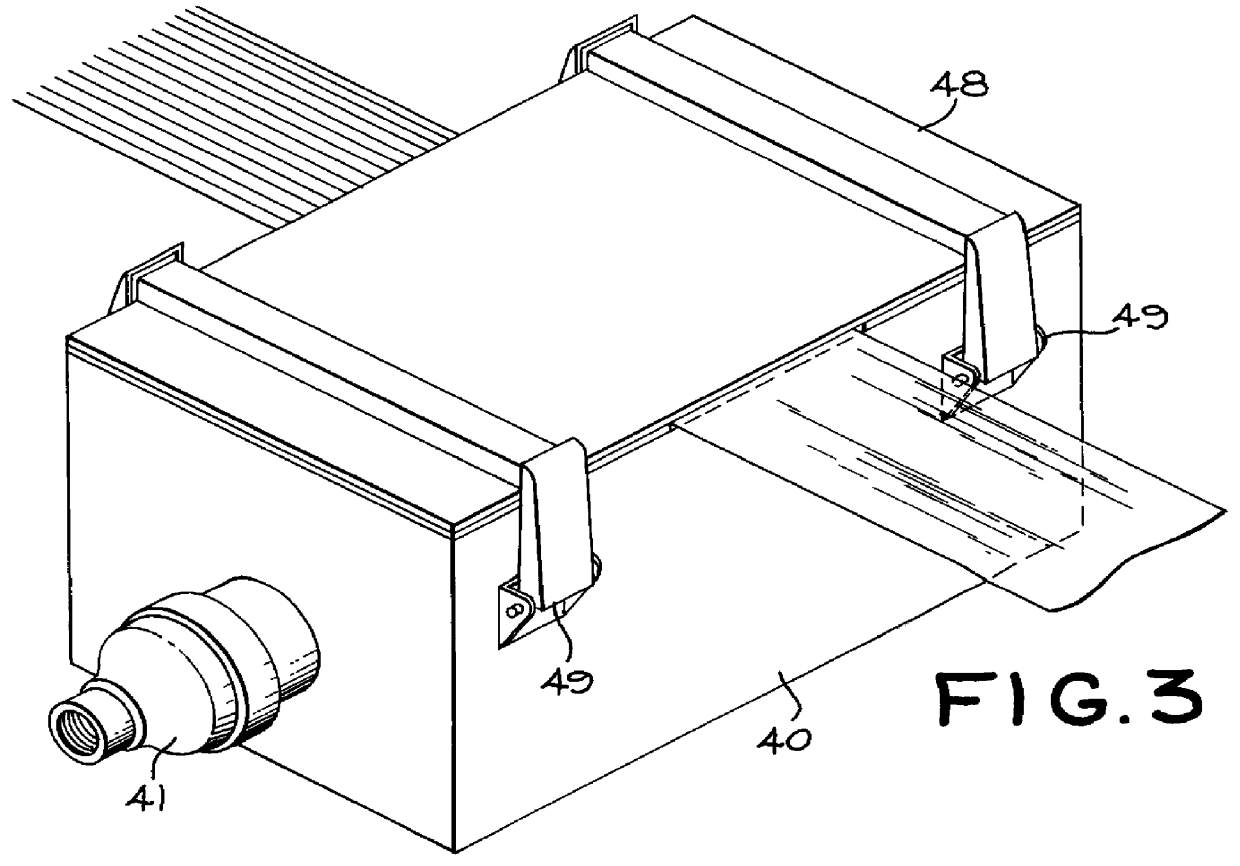

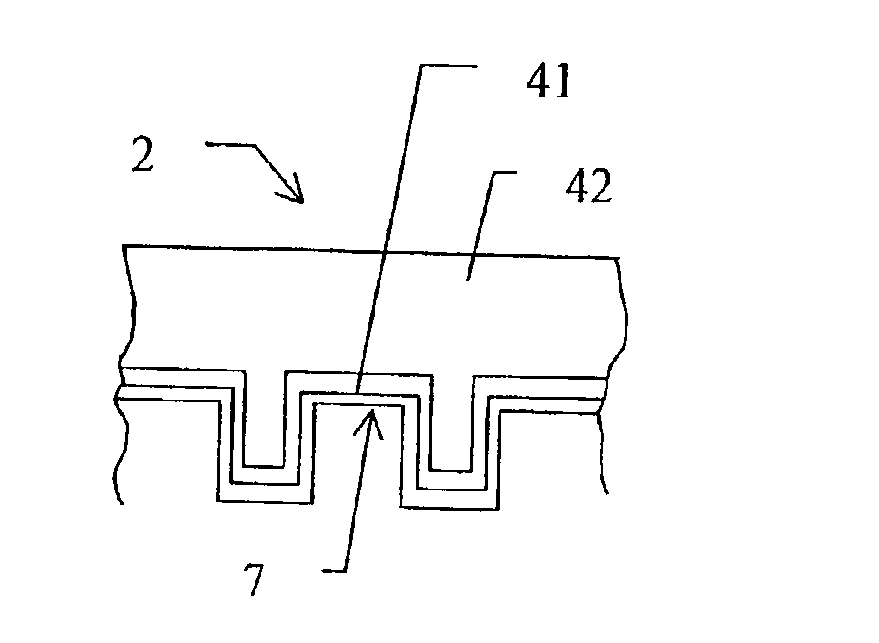

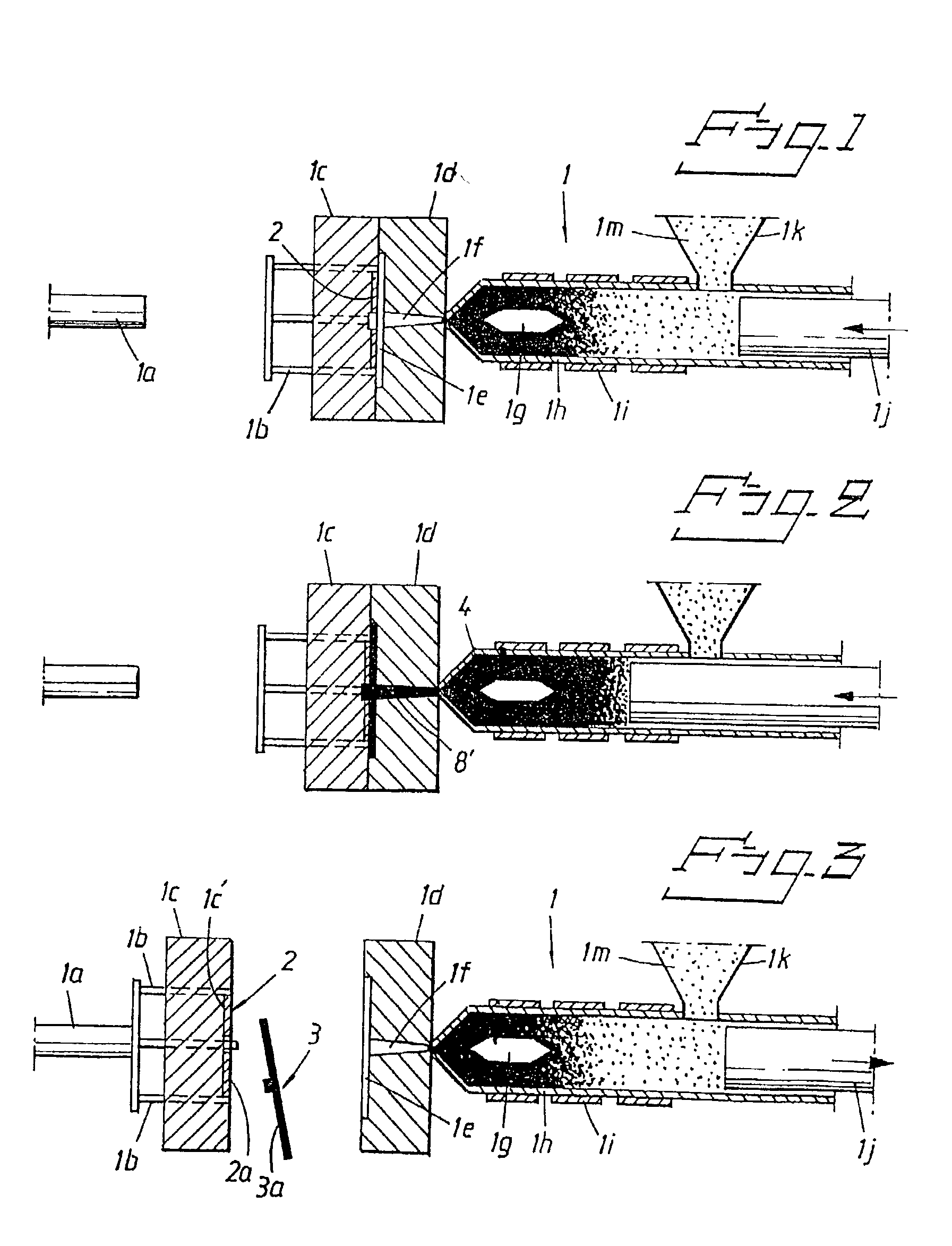

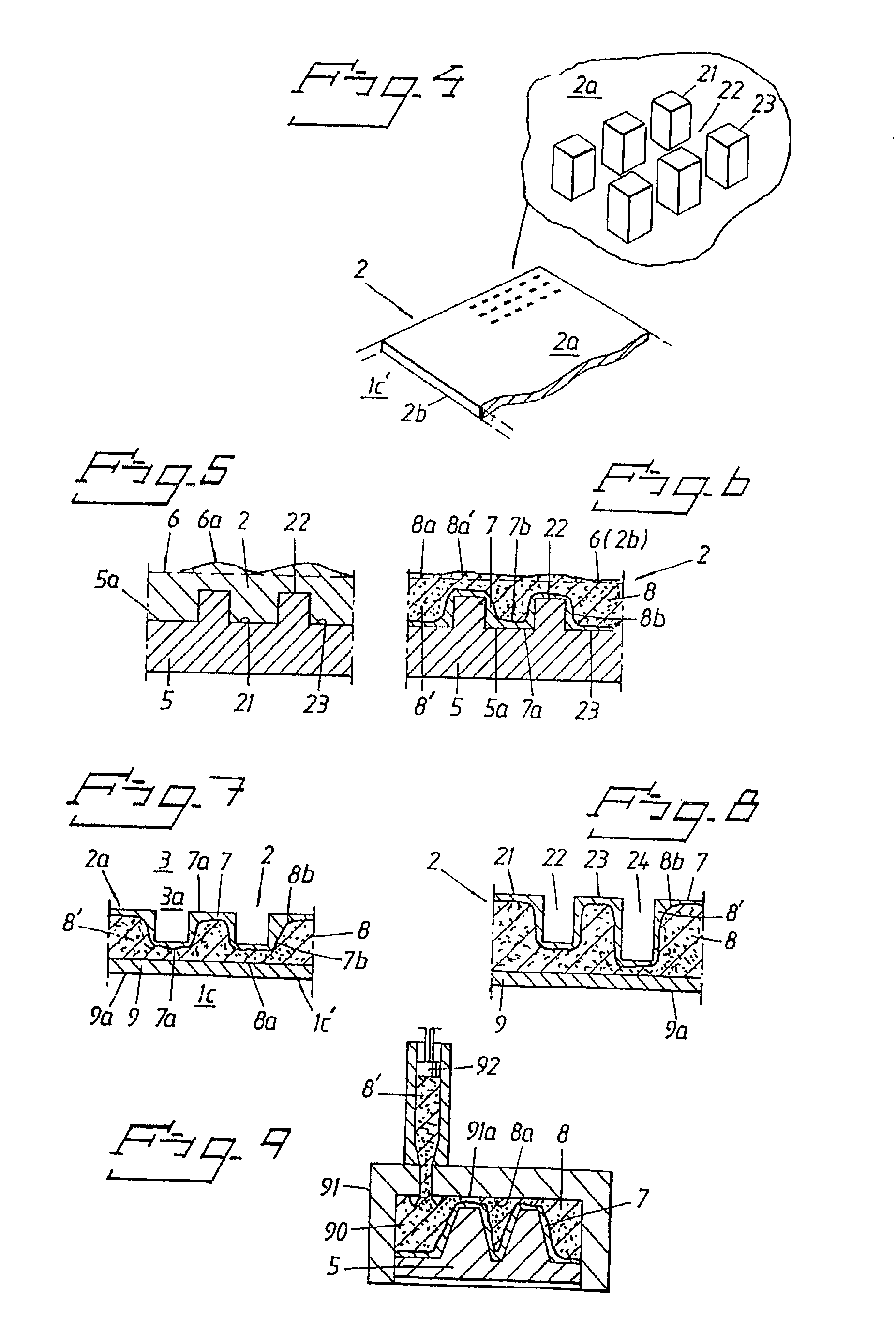

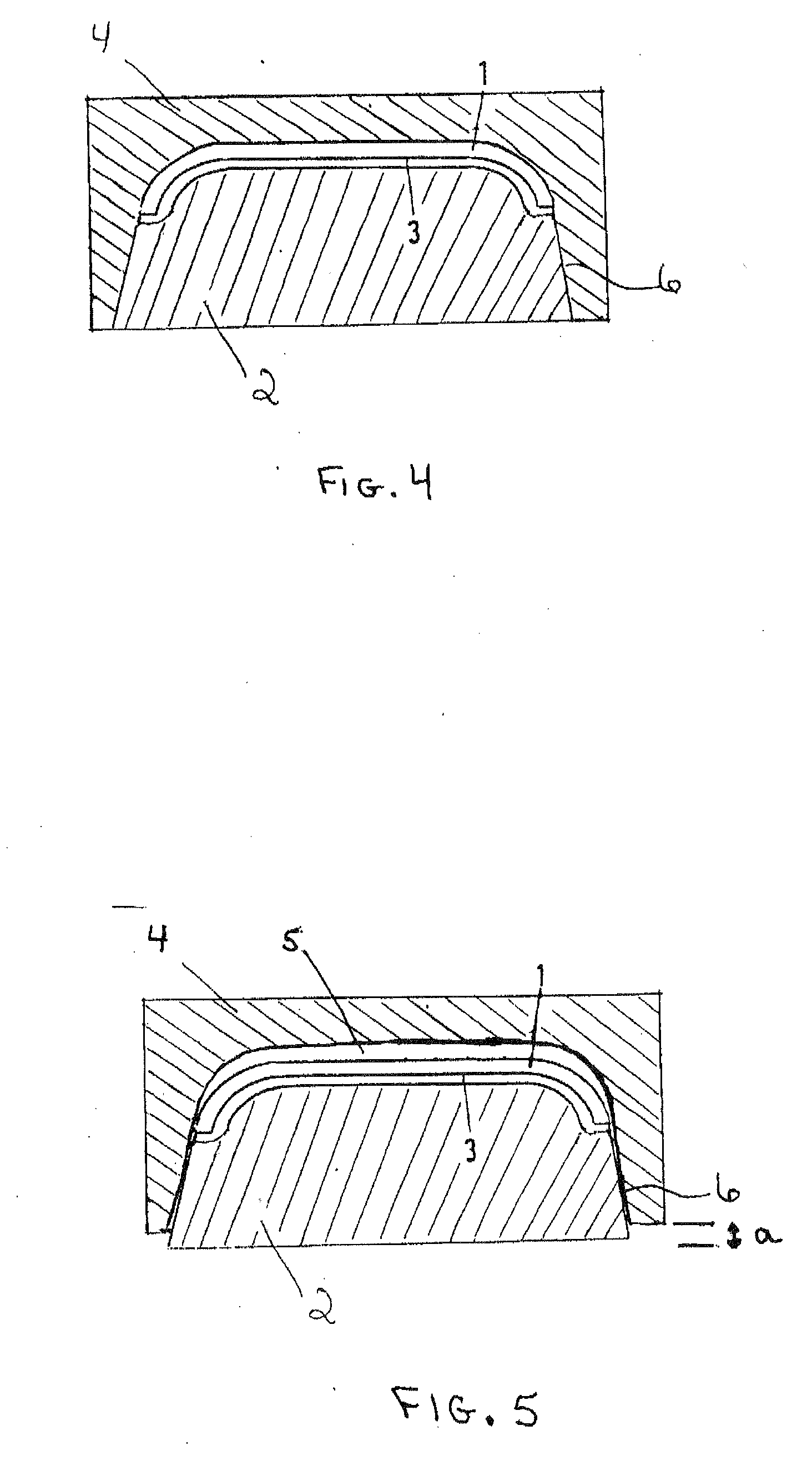

Matrix and method of producing said matrix

InactiveUS20030047823A1Simply produceReduce needRecord carriersLayered productsWear resistantMicrostructure

The invention relates to a method of producing a matrix suitable for use in a plastic element-producing machine, a matrix produced in accordance with the method and the use of such a matrix to form a plastic element. One side of the matrix (2) is provided with a negative microstructure (2a) which is replicated in plastic material (3) to form a positive microstructure (3a) on a plastic element (3), wherewith the matrix (2) can be produced by applying a layer of material (7) to the positive microstructure side of a master. The positive microstructure side of the master has a thin wear-resistant layer (7) which serves as a first wear surface, wherewith said layer will present irregularities (7a) which correspond essentially to the microstructure, and wherein at least said irregularities are filled-in with a plastic composite (8') so as to form a carrier element (8) for supporting the first wear layer (7). The layer (7) can further be provided with means for supplying heat energy to said matrix.

Owner:GYROS

Hydrotalcite-rare earth-calcium zinc stablizer for PVC and its preparation method

InactiveCN101007878AImprove long-term thermal stabilityGood initial colorabilityChemical synthesisHydrotalcite

The invention discloses a PVC hydrotalcite- rare earth- calcium zinc stabilizing agent and the method for preparing the same, which in detail erlates to plastic composite stabilizing agent and the preaparing method, belonging to chemical field. The main component for stabilizing comprises column- supported hydrotalcite, unsaturated rare earth, and epoxy aliphatic acid calcium zinc, and it is prepared through chemical synthesis, reformed treatment and optimization compound. The product is characterized by outstanding thermal stabilizing effect, good first stage coloring property, sound plasticizing property, good transparenty, weatherability, improved quality, high effeciciency, no toxicity, no pollution, low cost. It can replace expensive organotin thermal stabilizing agent and is widely used in PVC product preparation, such as water- supply pipes, section bar, transparent granulate, film, medical apparatus, toy, fridge stamp and box sheet material.

Owner:扬州科宇化工有限公司

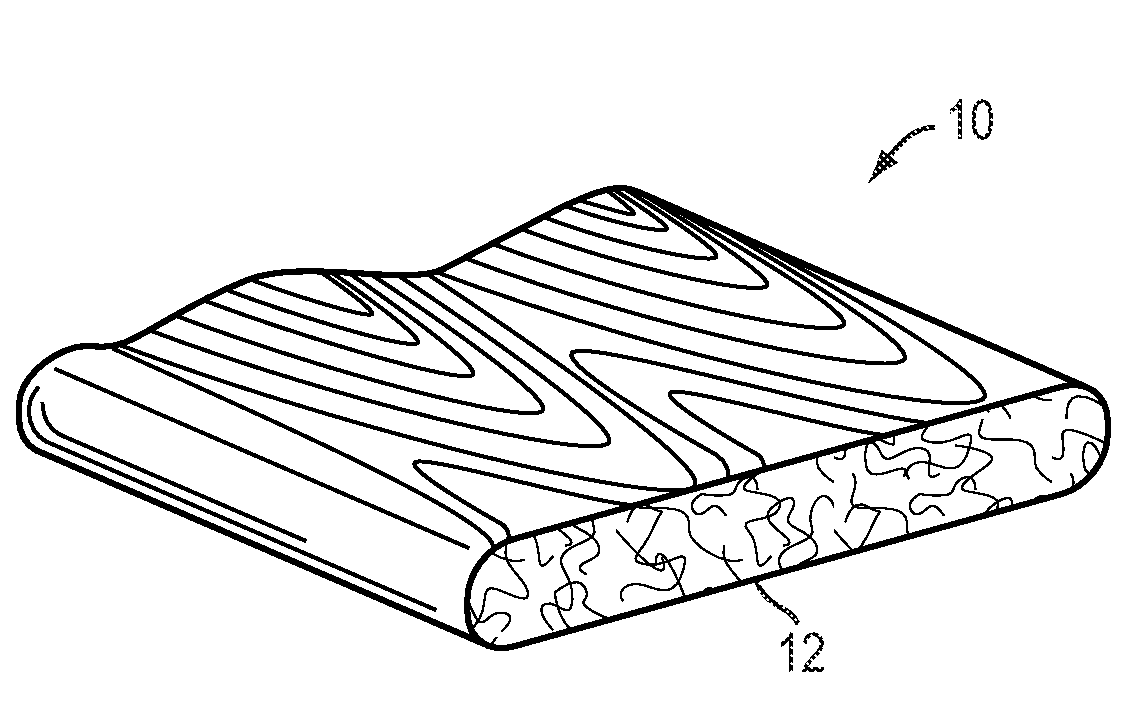

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

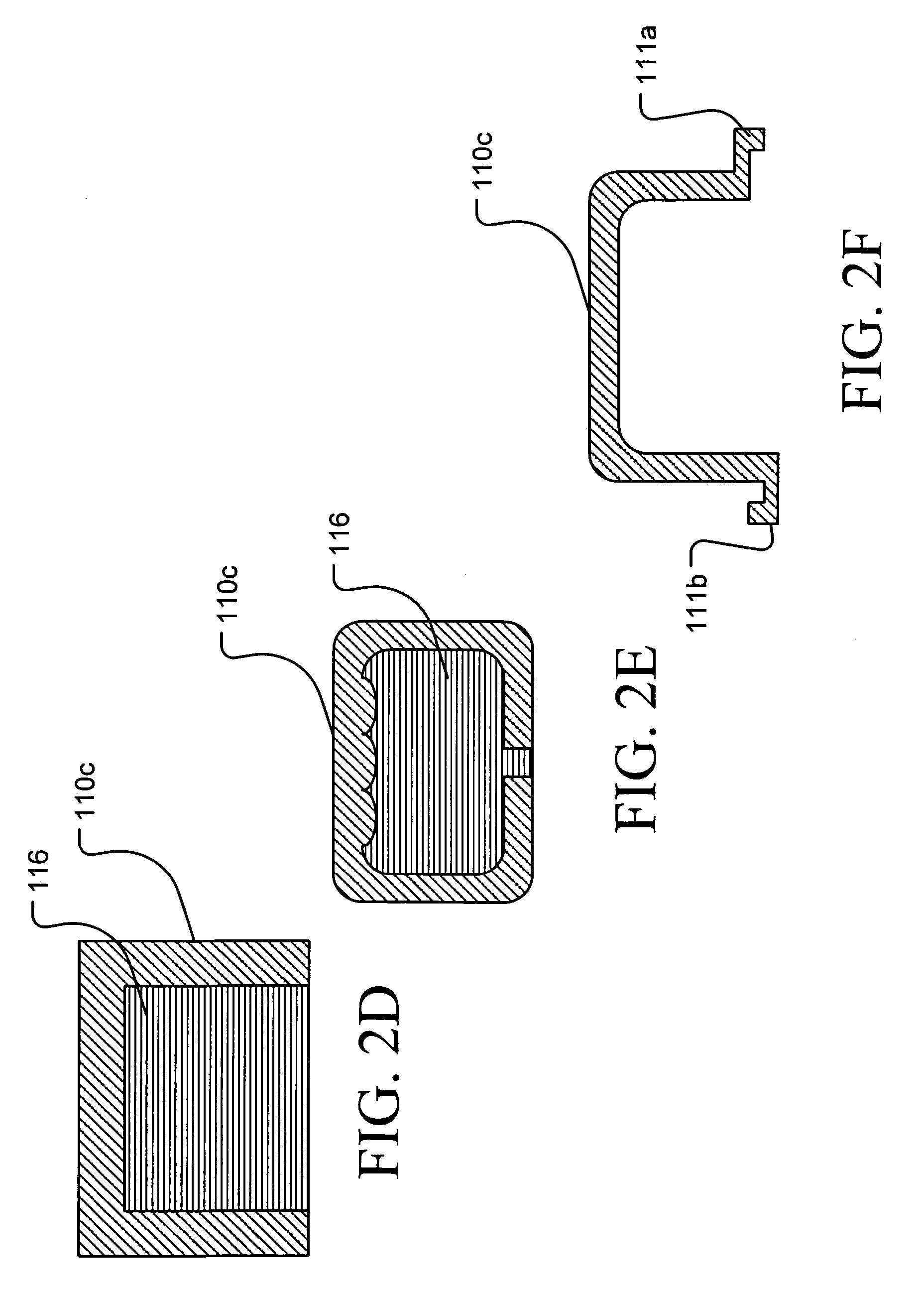

Trim components for lapboard siding that are co-extruded from wood-plastic composites and polyvinyl chloride

ActiveUS20120328823A1Reduce installation costsUse amountCovering/liningsSynthetic resin layered productsPolyvinyl chlorideEngineering

A lapboard siding and trim system is provided in which trim siding components for board-and-batten siding and associated trim components are manufactured using a co-extrusion process, whereby wood / thermoplastic resin composite material and polyvinyl chloride thermoplastic resins are co-extruded through a single die assembly, thereby producing a trim piece having a plastic composite component, that will be visible following installation, fused under heat and pressure to the polyvinyl chloride standoff and attachment fins, that will be hidden following installation. Also provided is a lapboard siding and trim system in which siding components for clapboard siding are manufactured by extruding wood / thermoplastic resin composite material through a die. Associated trim components are manufactured using the co-extrusion process described above. The siding and trim components are completely waterproof, and installation proceeds with almost no face nailing and almost no caulk.

Owner:MONTEER SHAUN ROBERT

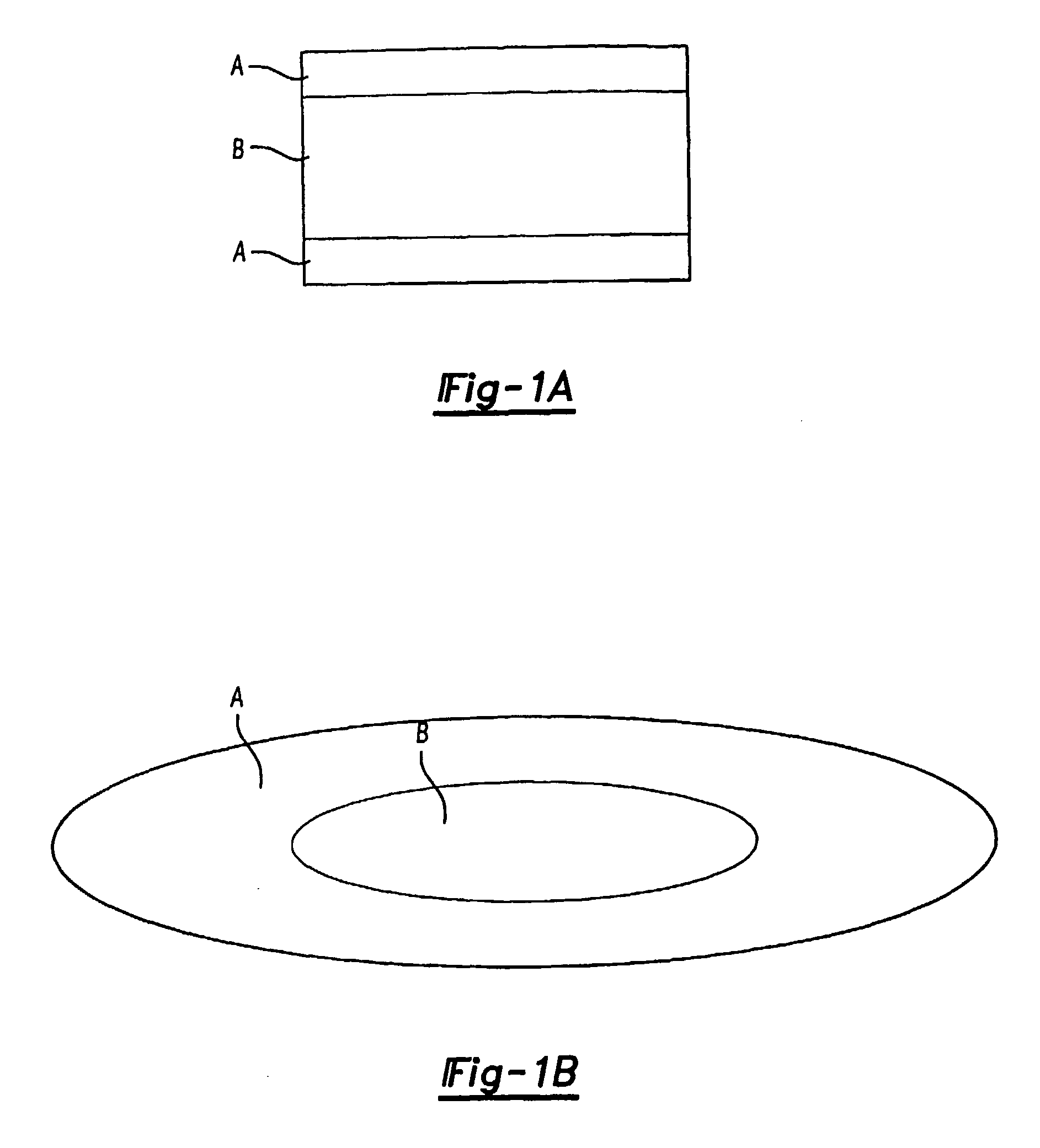

Formable composite films of plastic and composite elements of plastic coated with soft touch coating, and the production thereof

InactiveUS20060078745A1Synthetic resin layered productsPolyurea/polyurethane coatingsComposite filmComposite element

The present invention relates to composite plastic moldings containing A) a thermoplastically formable, heat-resistant composite film having A1) a carrier film of a thermoplastic resin and A2) a layer of a heat-resistant soft touch coating on one side of the carrier film (A1) and B) a thermoplastic layer on the side of the carrier film (A1) facing away from the soft touch coating, wherein the soft touch coating (A2) is obtained from a composition containing i) polyurethanes and / or polyurethane-ureas which are free from hydroxyl and / or amine groups, ii) ionically modified polyurethanes and / or polyurethane-ureas which contain hydroxyl and / or amine groups, iii) at least one crosslinking agent, iv) optionally film-forming resins other than A1) or A2), and v) optionally additives. The present invention also relates to a process for the production of these composite moldings and their use in telecommunications equipment and in vehicle, ship and aircraft construction.

Owner:BAYER MATERIALSCIENCE AG

PVC (polyvinyl chloride)-based wood plastic and preparation method thereof

Owner:山西峰岩新型建材股份有限公司

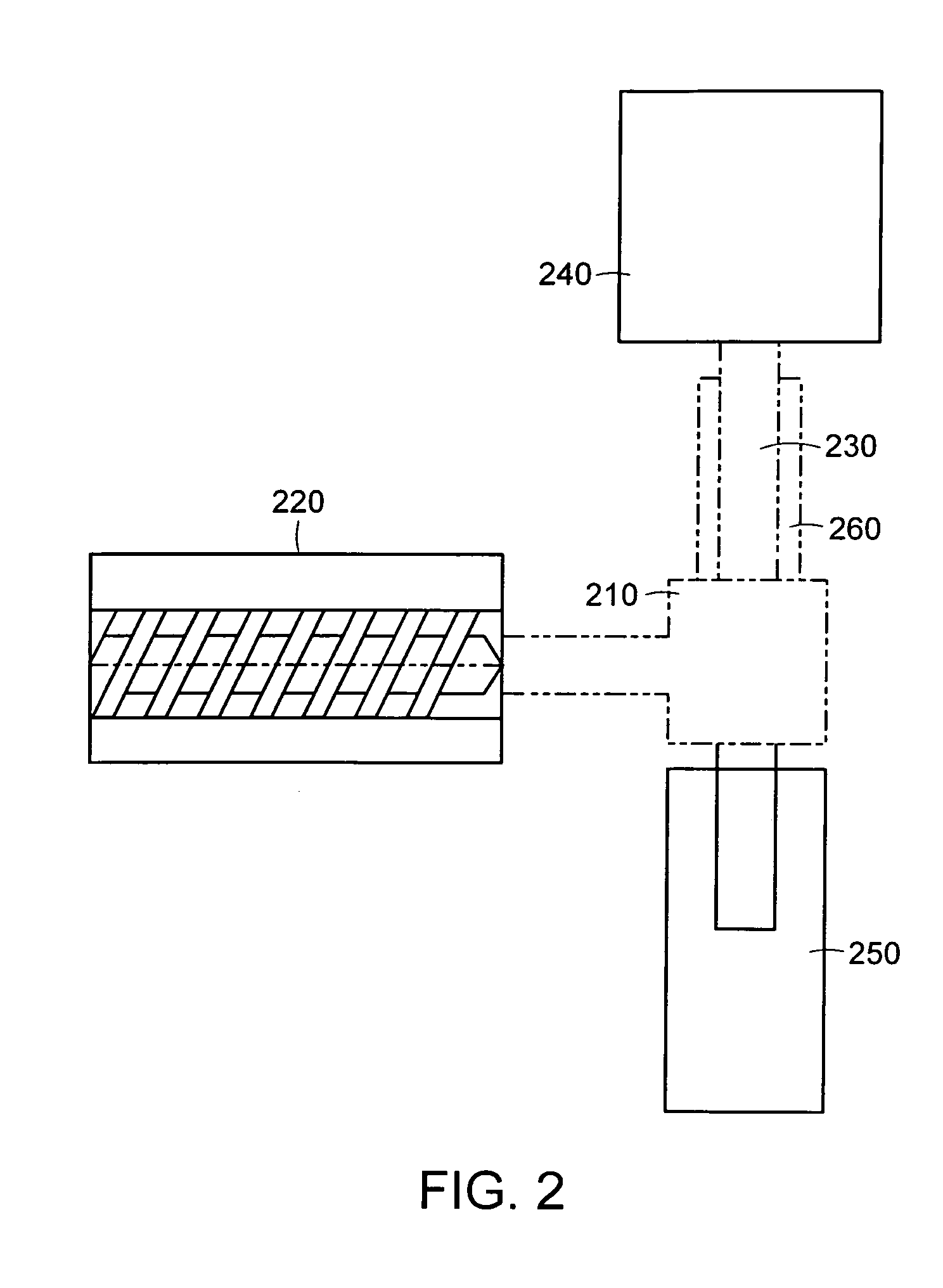

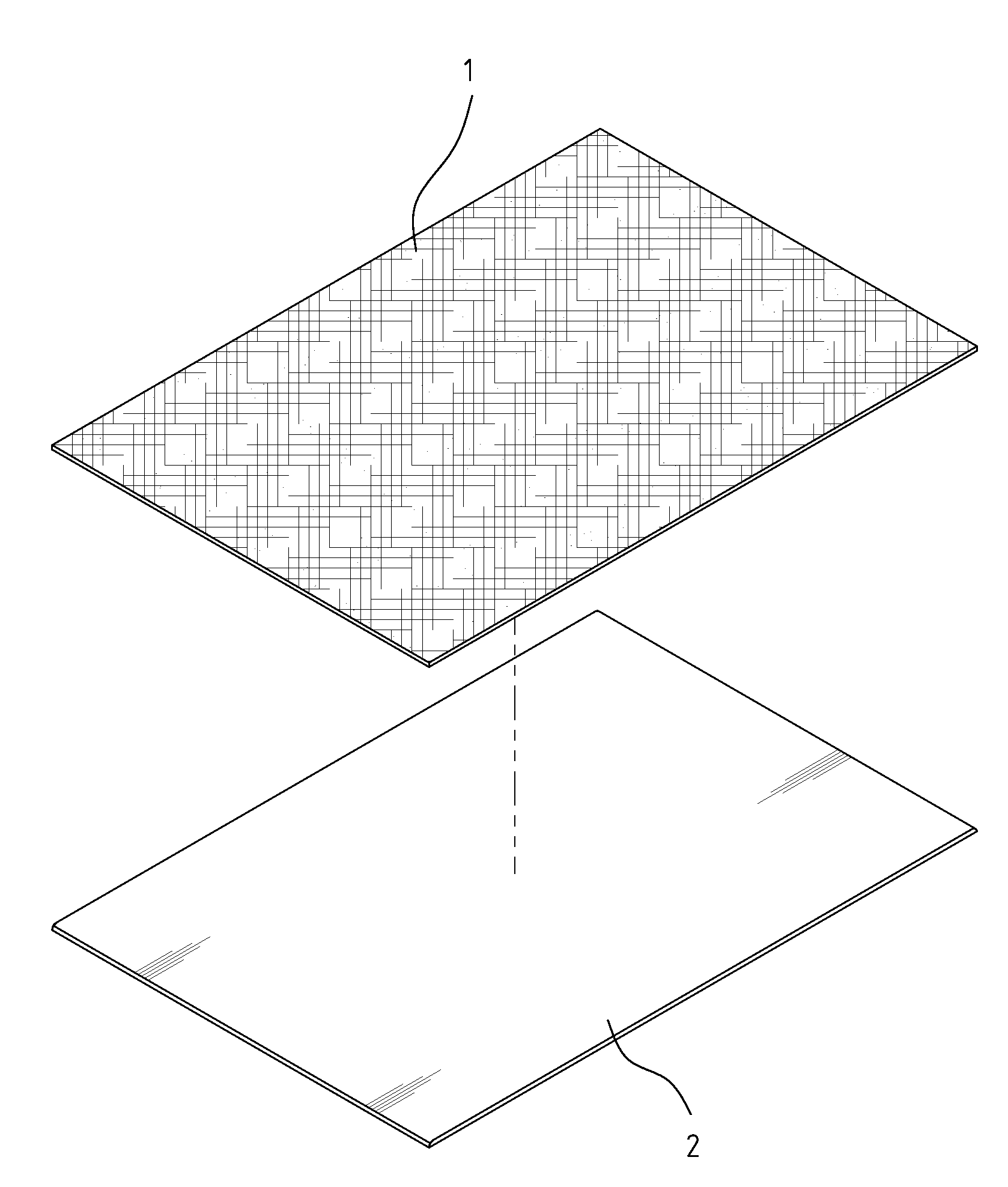

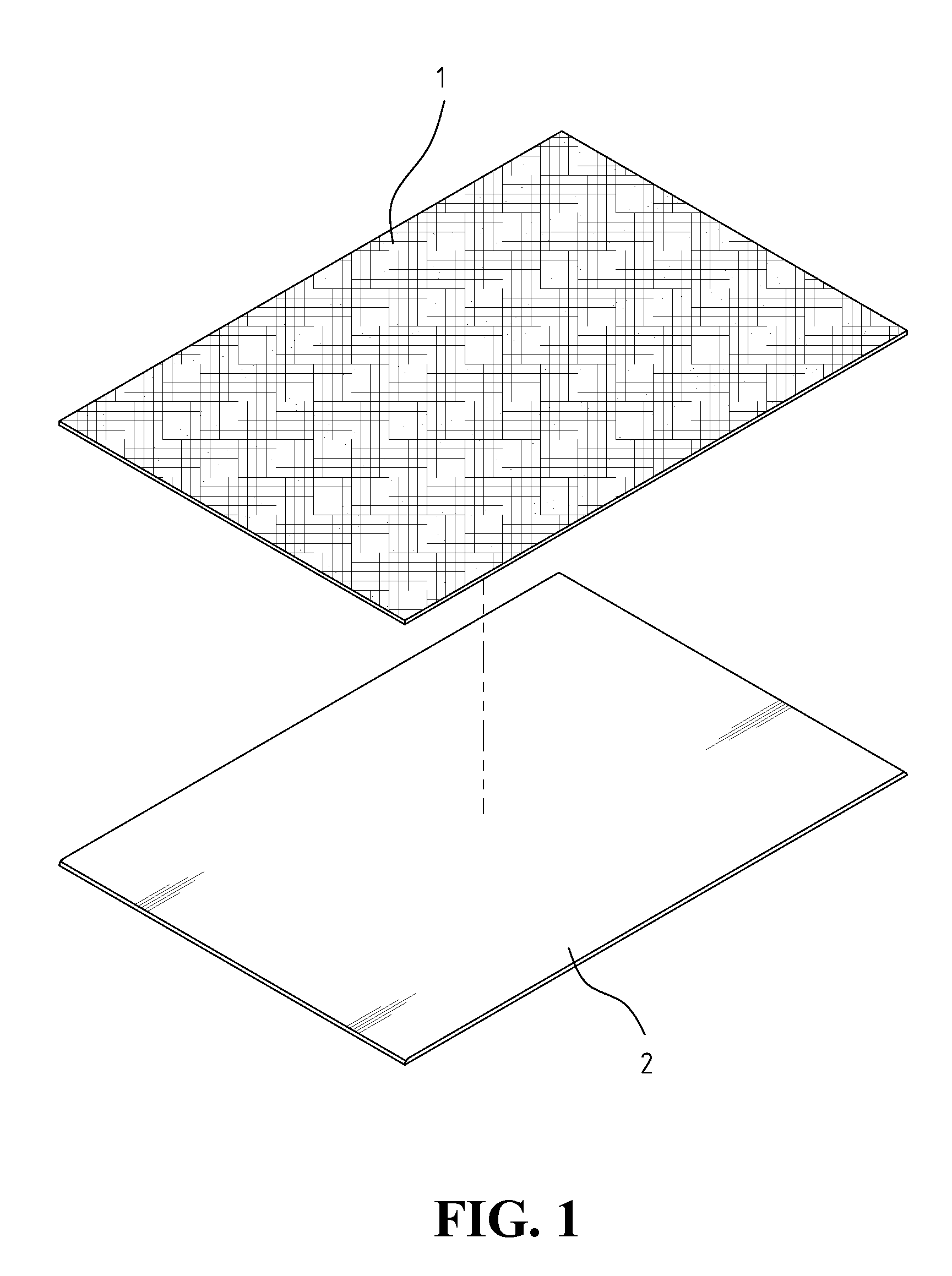

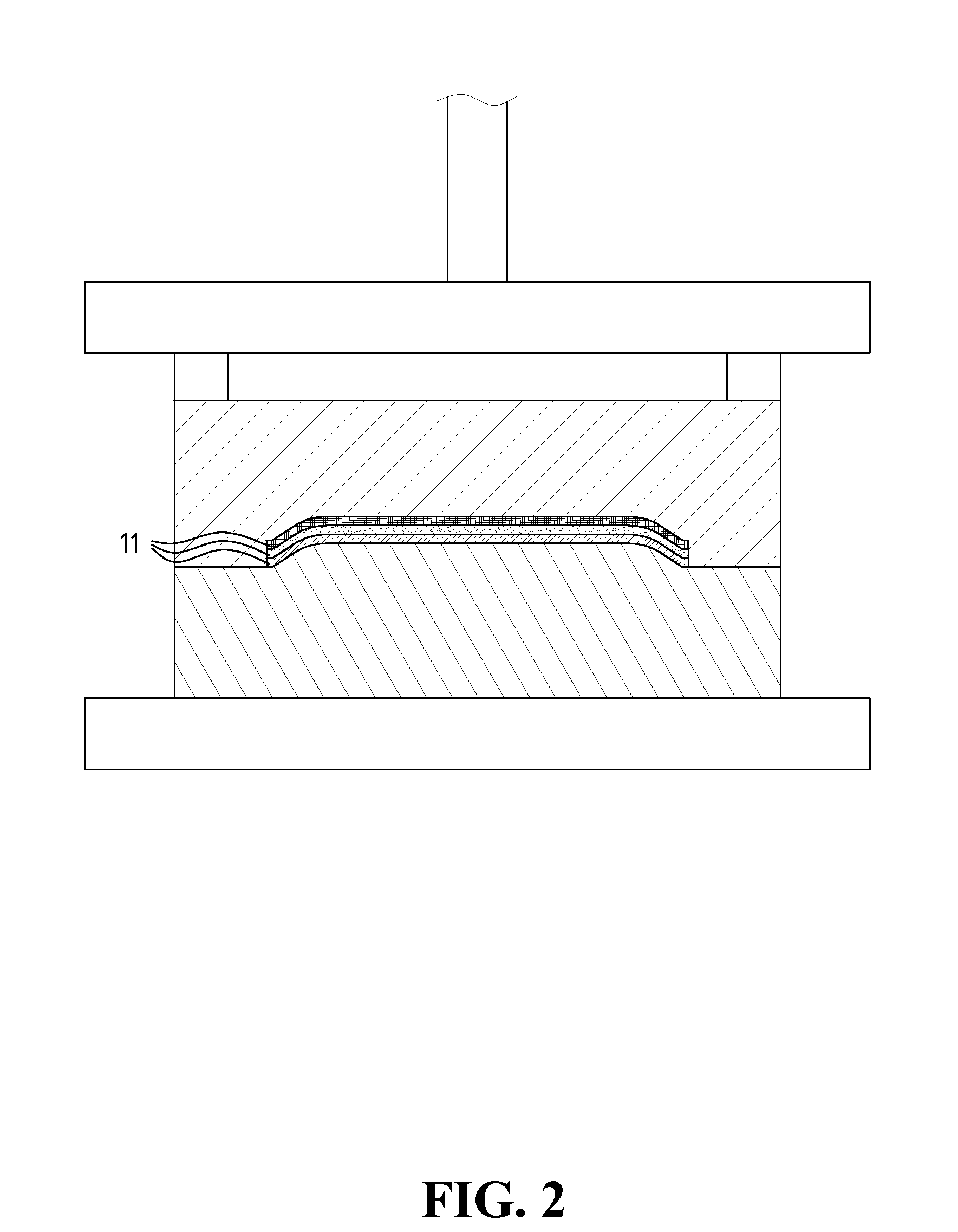

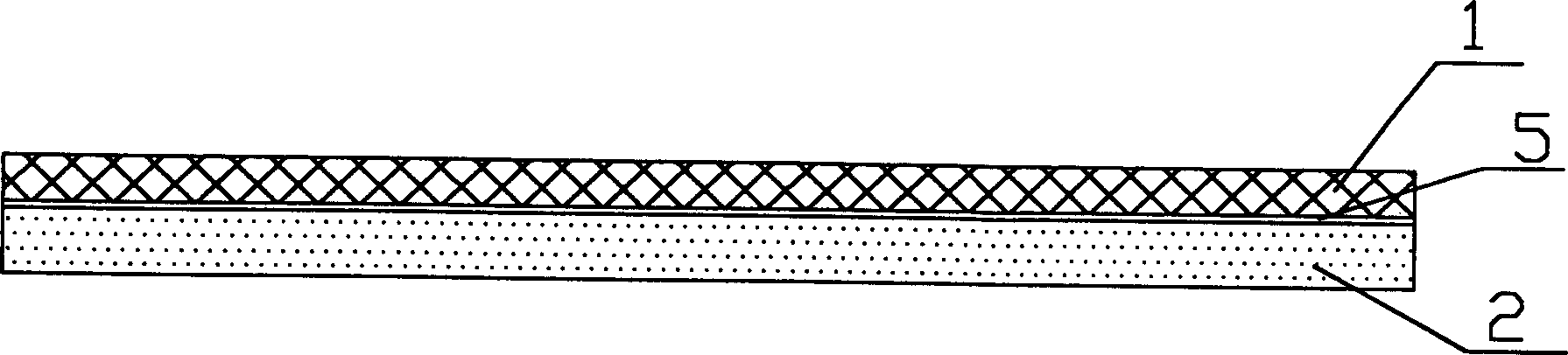

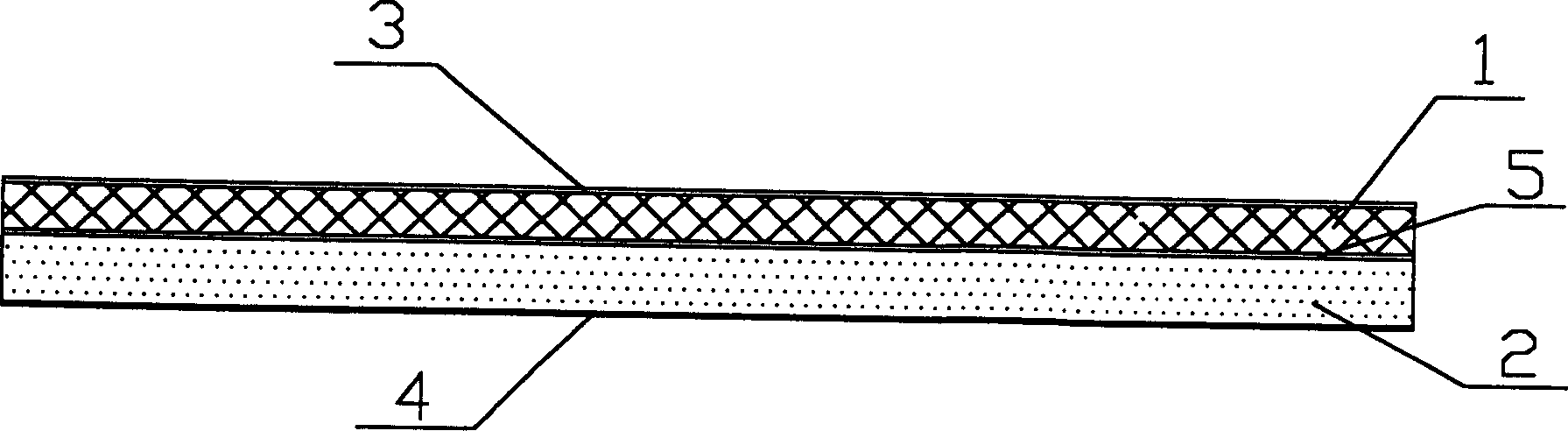

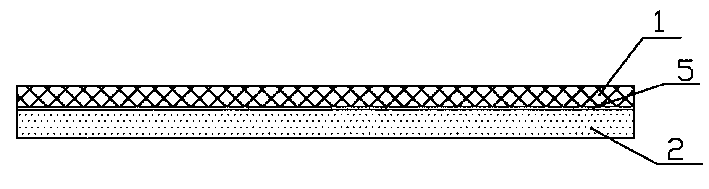

Composite Structure Of Composite Substrate And Plastic Material

InactiveUS20090136708A1Improve adhesionAvoid problemsSynthetic resin layered productsElectrical equipmentCompression moldingPlastic injection molding

A composite structure of a composite substrate and a plastic material is provided. The composite structure is fabricated by a method including the steps of: preparing a plurality of fiber layers weaved in different directions and laminating the fiber layers to configure a stack; soaking the stack in a resin, and drying the soaked stack to obtain a composite substrate; conducting a compression molding process to the composite substrate to achieve a predetermined shape; putting the compression molded composite substrate in a mold of a plastic injection molding machine; injecting a melting plastic material obtained from plastic particles melted by an extrusion machine into the mold, for combining with the composite substrate; and water cooling for hardening the combination, thus achieving a product of the composite structure.

Owner:HUANG CHUN YING +1

Composite fiber blends

The instant invention involves a process used in preparing fibrous tows which may be formed into polymeric plastic composites. The process involves the steps of (a) forming a carbon fiber tow; (b) forming a thermoplastic polymeric fiber tow; (c) intermixing the two tows; and (d) withdrawing the intermixed tow for further use.

Owner:CYTEC TECH CORP

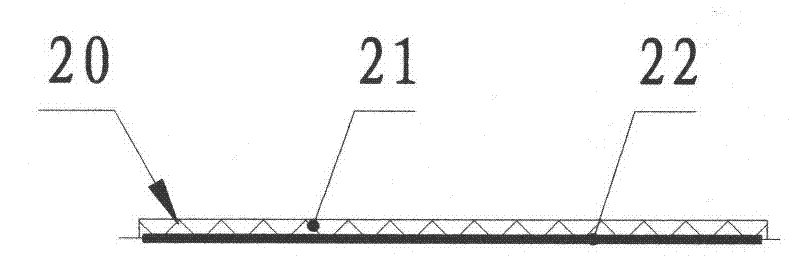

Plastic composite sheet and its producing method

InactiveCN1457981AGood adhesionGood matting effectSynthetic resin layered productsInter layerEngineering

The composite plastic sheet includes facing layer, middle layer and base layer, the facing layer is made of PVC, modified PP or modified PE; the middle layer is made of PVA film or polyurethane thermosol film; and the base layer is made of foamed PVC, modified PP or modified PE. Over the facing layer, there is one layer of coated dulling agent with pressed pattern. The composite plastic sheet has good comprehensive performance and its adhering middle layer combines the facing layer and the base layer well. The composite plastic sheet has the advantages of excellent heat insulating and sound isolating performance, high shock resistance, high anticorrosive performance, high electric insulating performance, high strength, beautiful appearance and easy cleaning.

Owner:长春一塑汽车内饰材料有限公司

Aqueous plastic compound ink

The water-thinned plastic composite printing ink consists of anionic polyurethane dispersing liquid, acrylic ester emulsion, pigment, dispersant, defoaming agent, polyethylene wax, water and small amount of isopropanol. The self made acrylic ester emulsion well compatible with the anionic polyurethane dispersing liquid results in good comprehensive performance and low cost of the water-thinned printing ink. The addition of crosslinking agent raises the wear resistance, attaching strength and stripping strength of ink layer. The trial water-thinned printing ink has a printing speed on a processed bi-directional polypropylene film of 30-50 m / min and stripping strength after compounding of 180 N / in. The water-thinned printing ink has fast drying speed and high wear resistance, and is especially suitable for printing on polypropylene, polyester film and other soft food packing material.

Owner:SUN YAT SEN UNIV

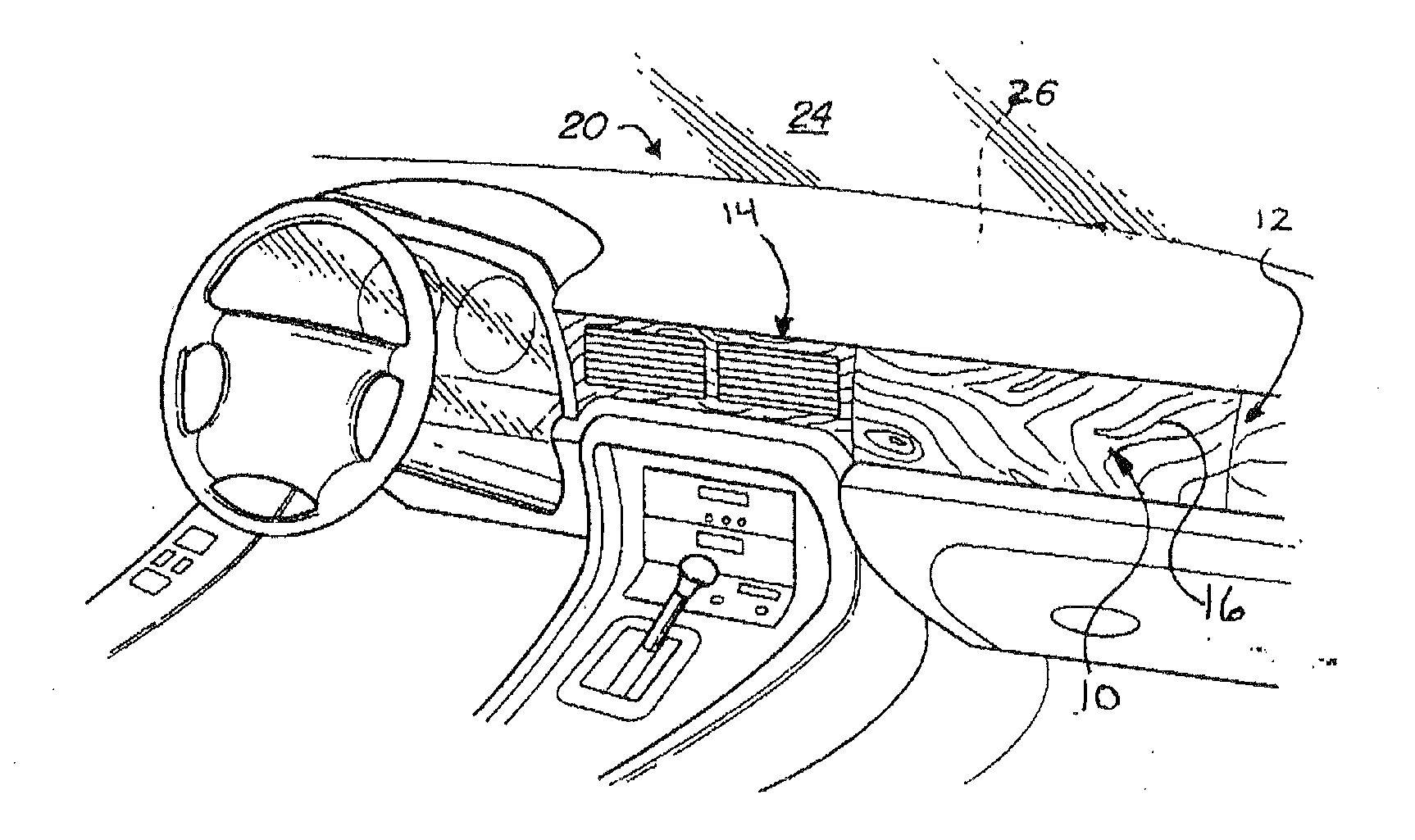

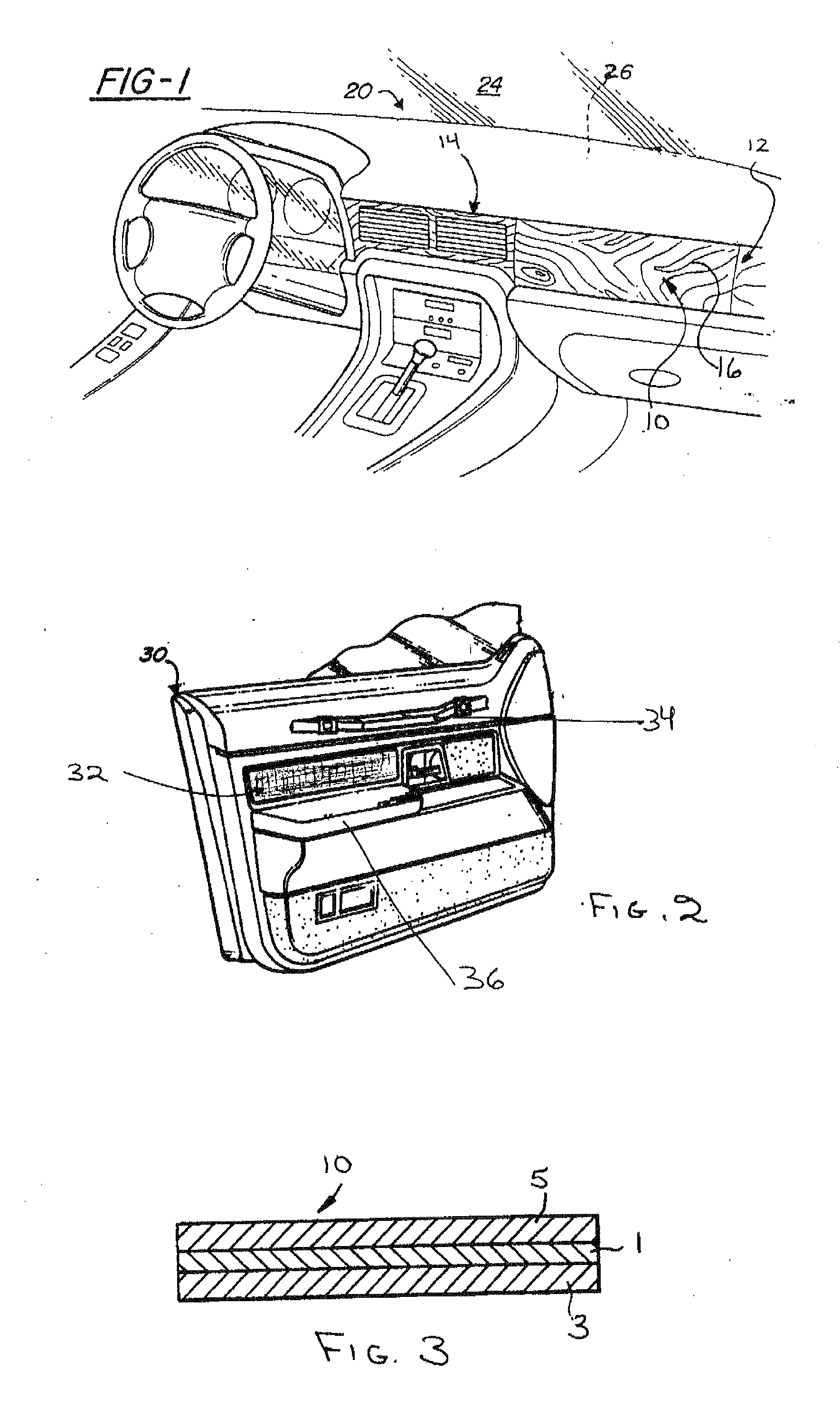

In mold lamination of decorative products

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a decorative layer, the decorative layer comprising a relatively thin metal foil, film, fabric, veneer or sheet of paper having a digital image from an inkjet printer deposited on a front surface thereof. In one exemplary embodiment, the appearance of a wood veneer may be modified by digitally printing a burl pattern over the wood grain surface of the veneer prior to injection molding.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Fire-retardant cellulose reinforced plastic composite material and preparation method thereof

InactiveCN101885871AReduce smoke productionImprove flame retardant performancePolymer sciencePolyvinyl chloride

The invention discloses a fire-retardant cellulose reinforced plastic composite material and a preparation method thereof. The composite material is characterized by comprising 100 parts of thermoplastic high polymer and 20 to 50 parts of cellulosic material in part by weight, wherein at least one of the thermoplastic high polymer or the cellulosic material is a material after fire-retardant modification; the thermoplastic high polymer is polyethylene, polypropylene, polyvinyl chloride or polystyrene; and the cellulosic material is one of or a mixture of more than two of the following materials in a mass ratio: wood flour, bamboo powder, wheat straw powder, corn straw powder, bran or rice chaff of which the grain size is 50 to 400 meshes, and cellulose fibers having no textile processing value. The preparation method comprises the following steps of: firstly, performing corresponding fire-retardant modification on the thermoplastic high polymer or / and the cellulosic material; secondly, uniformly mixing the thermoplastic high polymer and the cellulosic material by using a screw extruder; thirdly, extruding the mixture out after fusion; and finally, performing compression molding forming.

Owner:TIANJIN POLYTECHNIC UNIV

Production method for composite material of cotton lever and plastics

The invention discloses a preparation method of a cotton stalk and plastic composite material. The steps of the method is that: the cotton stalk is grinded into cotton stalk powders with 40 to 160 meshes, then the cotton stalk powders are dried until the moisture content is less than or equal to 3 percent, and the dried cotton stalk powders are stirred and sprayed with coupling agent solution simultaneously, and the modified cotton stalk powders are prepared; the modified cotton stalk powders are then mixed evenly with plastic resin, compatilizer, lubricant, stabilizer, antioxidant, filling materials and flame retardant, then mixed material is prepared; after the mixed material is extruded from an extruding machine, the cotton stalk and plastic composite material is obtained. The invention properly solves the problems of compatibility between the cotton stalk and the plastic and treatment technology of surface of raw materials, realizes comprehensive utilization of cotton stalk waste which can be used for replacing lumbers which are at the state of shortage, increases the added value of the cotton planted by a cotton grower, and solves the problem of utilization of the cotton stalk wastes.

Owner:GUANGZHOU SCUT BESTRY TECHNOLOGY CO LTD

Isocyanate strengthened agricultural residue fiber/plastic composite material and its preparation method

This invention relates to a agricultural remainder / plastic composite enhanced by isocyanate. The weight percentage of its components is that agricultural remainder fabric material 10-60%, plastic 10-60%, couplant 0.3-10% which is percentage weighed by bone dry weight of agricultural remainder fabric material. It is complex made by the technology of wood based panel. Its preparation is that at first agricultural remainder fabric material is pretreated into paring, fiber or powder and dried with water content 0-25%, and then thermoplastic is classified and shattered into lamellar or granular; At last, two kinds of materials, together with 0.3-10% couplant, are mixed for pretreatment in ordinary temperature, then a mixed powder is made. Pavement and thermocompression are conducted at 130-223DEG C and 1-20MPa about 1-20min, then the plate is received by cutting-edge at ordinary temperature.

Owner:LANGFANG HUARI FURNITURE CO LTD

Modification and use methods for straw biomass

The invention discloses a straw-derived composite material, i.e., proper-plasticity modified straw biomass obtained through carrying out modification on straw powder by using ore powder and adjuvants, new materials formed through further compounding the modified straw biomass and plastics and a method for producing straw-plastics products by using the new materials. According to the method, firstly, the straw biomass is crushed to certain fineness, then, the straw biomass powder is mixed with the ore powder in the presence of an esterifying agent and a coupling agent so as to form modified straw powder, and the modified straw powder is further compounded with the plastics in the presence of the adjuvants such as a grafting agent so as to form the new materials, which replace wood-plastics and plastics, and new products.

Owner:NANJING UNIV OF TECH

Decorative glass laminate containing an ultraviolet printed image thereon and a method for preprating said decorative glass laminate

This invention is directed to a plastic composite comprising color images printed onto a polymeric support film using UV ink. The polymeric support film layer may be bonded to a polymeric film selected from the group consisting of aliphatic polyurethane and ethyl vinyl acetate. The combined laminate can then optionally be disposed between two layers of plasticized PVB, forming the plastic composite. The plastic composite can then be placed between two sheets of glass forming the final laminated glass product. Preferably, when the UV image is printed on the polymeric support film, the image is only partially cured by a UV lamp. After the polymeric support film is contacted with the polymeric film, with the partially cured UV image therebetween, the laminate is exposed to a second UV lamp operating at full power so as to completely cure the UV image.

Owner:SOLUTIA INC

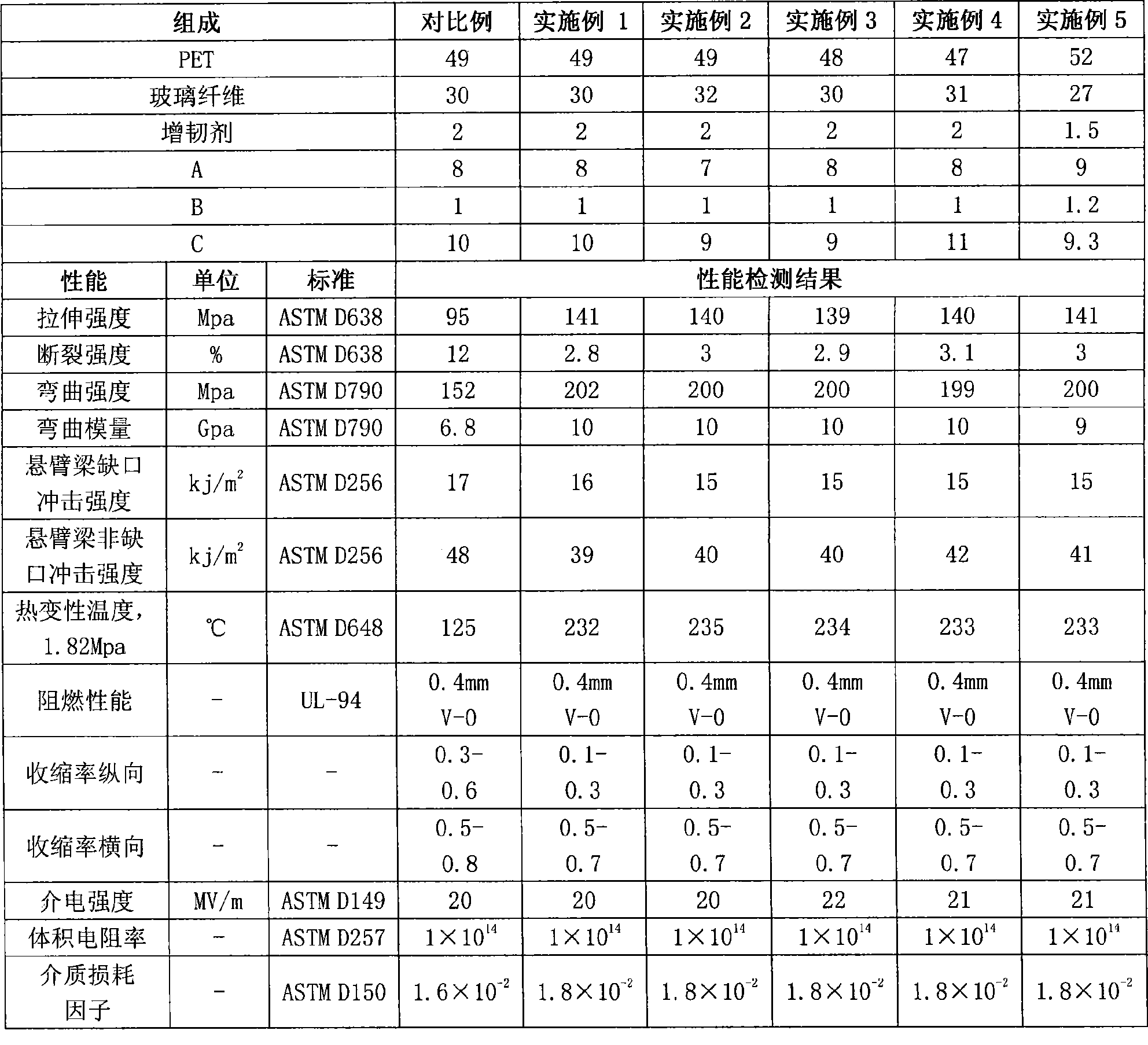

Halogen-free flame-retardant polyethylene terephthalate engineering plastic composite material and preparation method thereof

ActiveCN101445650AShortened nucleation induction periodPromote crystallizationPolyethylene terephthalate glycolPhosphate

The invention relates to a halogen-free flame-retardant polyethylene terephthalate engineering plastic composite material and a preparation method thereof. The halogen-free flame-retardant polyethylene terephthalate engineering plastic composite material is prepared by commonly introducing PET resin, glass fiber, flexibilizer and additional three components of A, B and C into a twin-screw extruder and carrying out extrusion, cooling and pelletizing; wherein, the A component is mother particles which are prepared after mixing organic rare earth phosphate salt nucleating agent, antioxidant, external lubricant and polyethylene; the B component is the mother particles which are prepared after mixing pigment and PE; the C component is a flame-retardant system which is obtained by complexing phosphorus-containing inorganic material melamine pyrophosphate and phosphorus-containing organic material ammonium polyphosphate to form phosphonate salt and then using rare earth coupling agent for treatment. The PET in the invention is characterized by rapid crystallization rate and good mobility, and the prepared product is characterized by excellent comprehensive performance, environmental friendliness and content of environment-associated substances which is in line with the EU RoHS standards, thereby being applicable to electronic and electrical appliance products.

Owner:BEIJING HUATENG NEW MATERIAL CO LTD

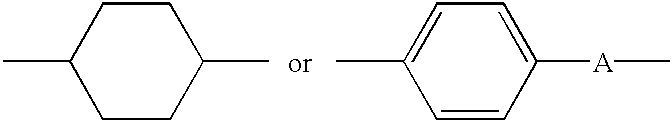

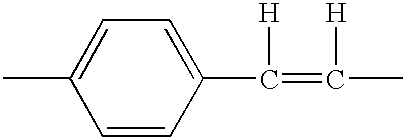

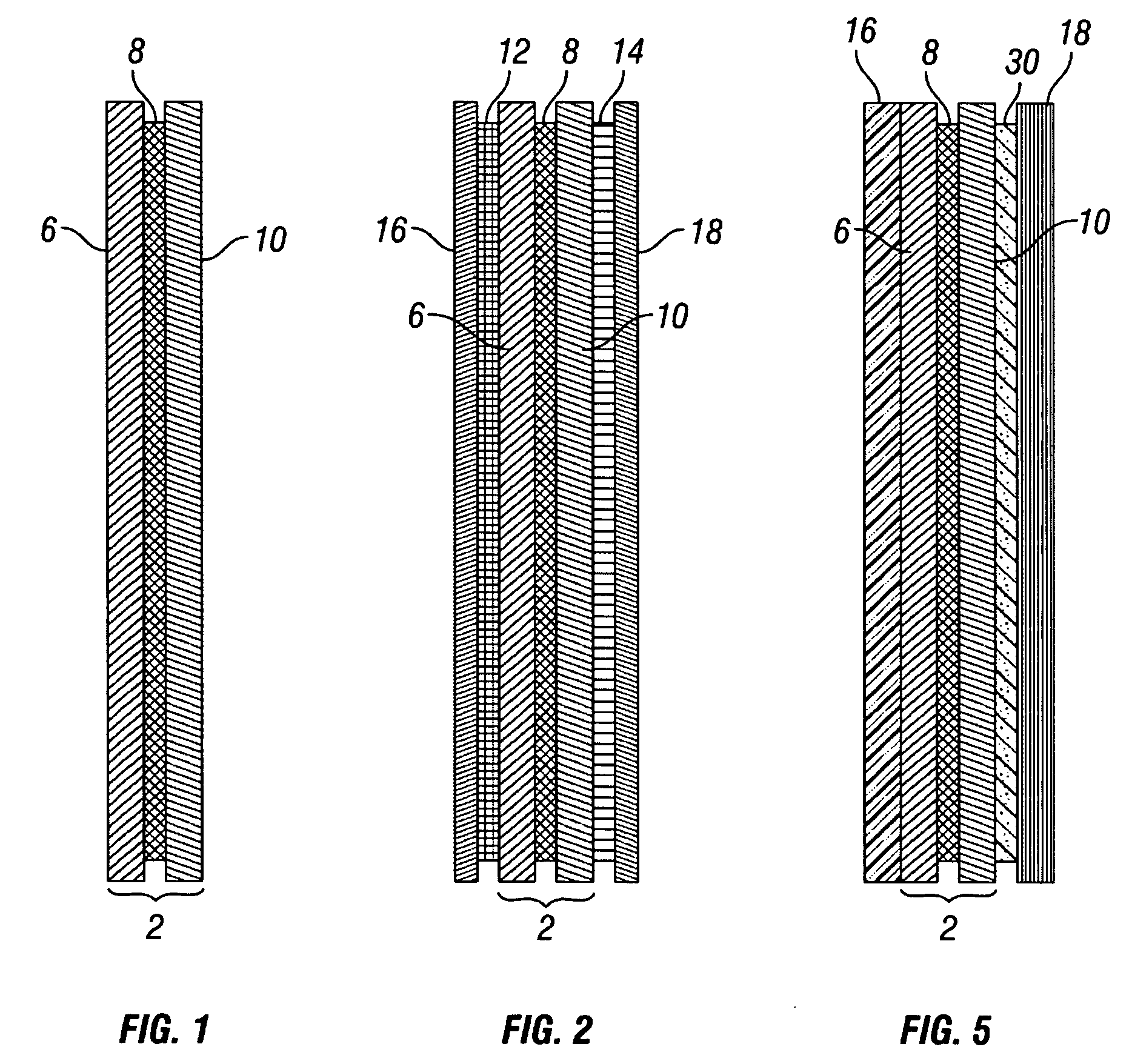

Polyolefinic Materials for Plastic Composites

InactiveUS20080261471A1High degreeEasy to storeSynthetic resin layered productsWoven fabricsPolyolefinEthylene Homopolymers

A reinforced composite article and method for making the same. The article and method employ at least one elongated member as a reinforcement phase. Specific elongated members are multiple layer structures wherein the layers are each polyolefinic (e.g., at least one of the layers may be a propylene-based polymer, such as a propylene-ethylene copolymer, an isotactic polypropylene homopolymer, or a combination thereof). Optionally, at least one of the layers may include a non-migratory process aid or surface modifier agent. An intermediate form including the elongated member may made and processed (for example, with a step of consolidation) to form a composite article.

Owner:DOW GLOBAL TECH LLC

Method for preparing flavored dried poultry egg

InactiveCN101744311ASimple processThe process is simple and easy to controlFood preparationComposite filmMicrowave

The invention relates to a method for preparing a flavored dried poultry egg, which is characterized by comprising the following steps: mixing 100 parts of whole poultry egg liquid by weight and auxiliary materials uniformly according to a proportion, and standing the mixture at the temperature of between 0 and 25 DEG C; pouring the stood liquid into a non-viscous die, shaping the liquid through two process parameters of adjusting the pH value to between 4 and 6 or between 9 and 11 and adjusting the temperature to between 60 and 121 DEG C to form protein gel with good elasticity and hardness; taking out the shaped material from the die, and cutting the materials into chips with different shapes and sizes as required; baking the material for 5 to 50 minutes at the temperature of between 120 and 200 DEG C or frying the material for 30 seconds to 5 minutes at the temperature of between 120 and 200 DEG C; taking the baked or fried dried poultry egg out, and flavoring the product; then packing the flavored product by using a plastic composite film packing bag; sterilizing the packed product by using microwave; and cooling, labeling, coding and encasing the sterilized product to obtain the flavored dried poultry egg.

Owner:王建华

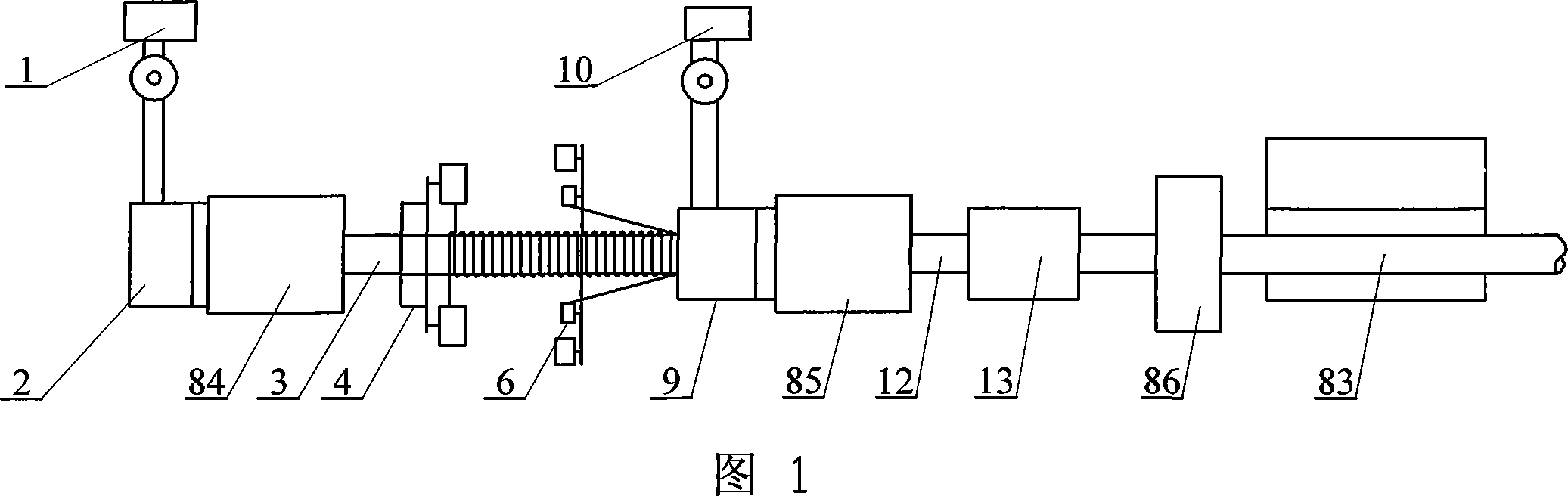

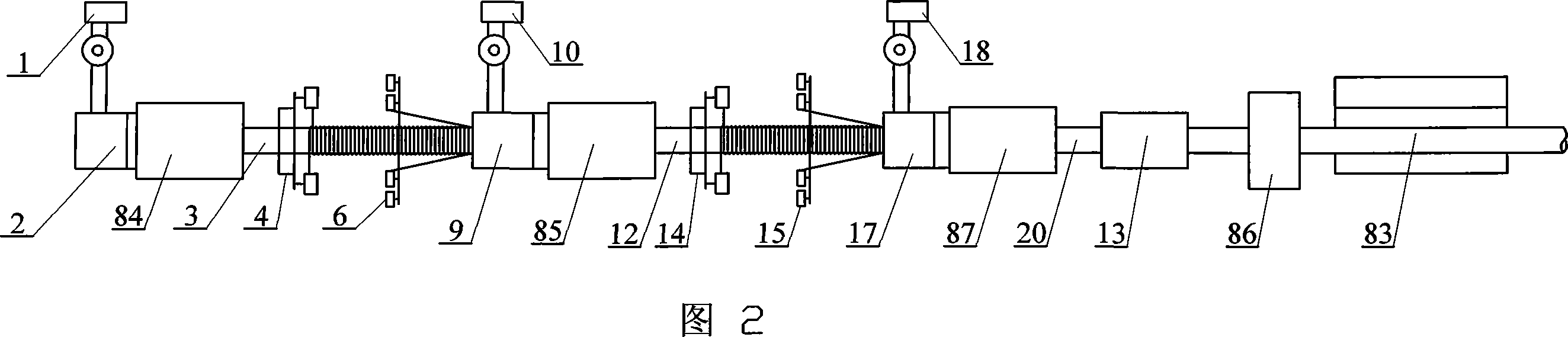

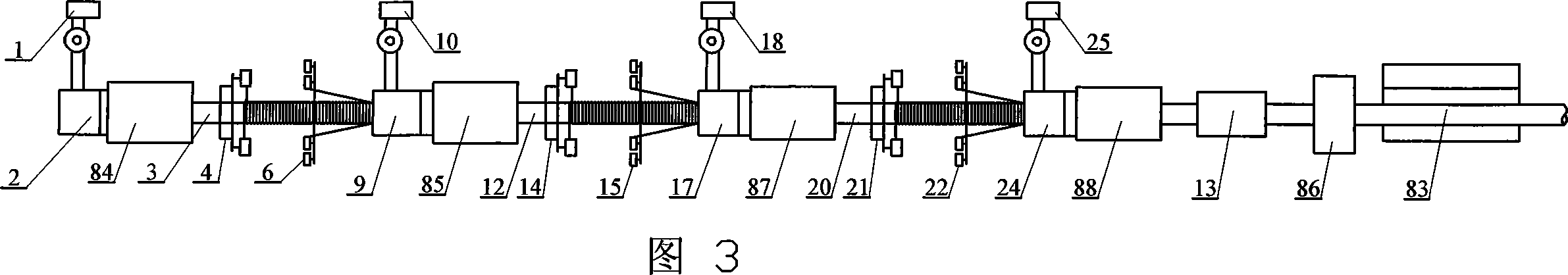

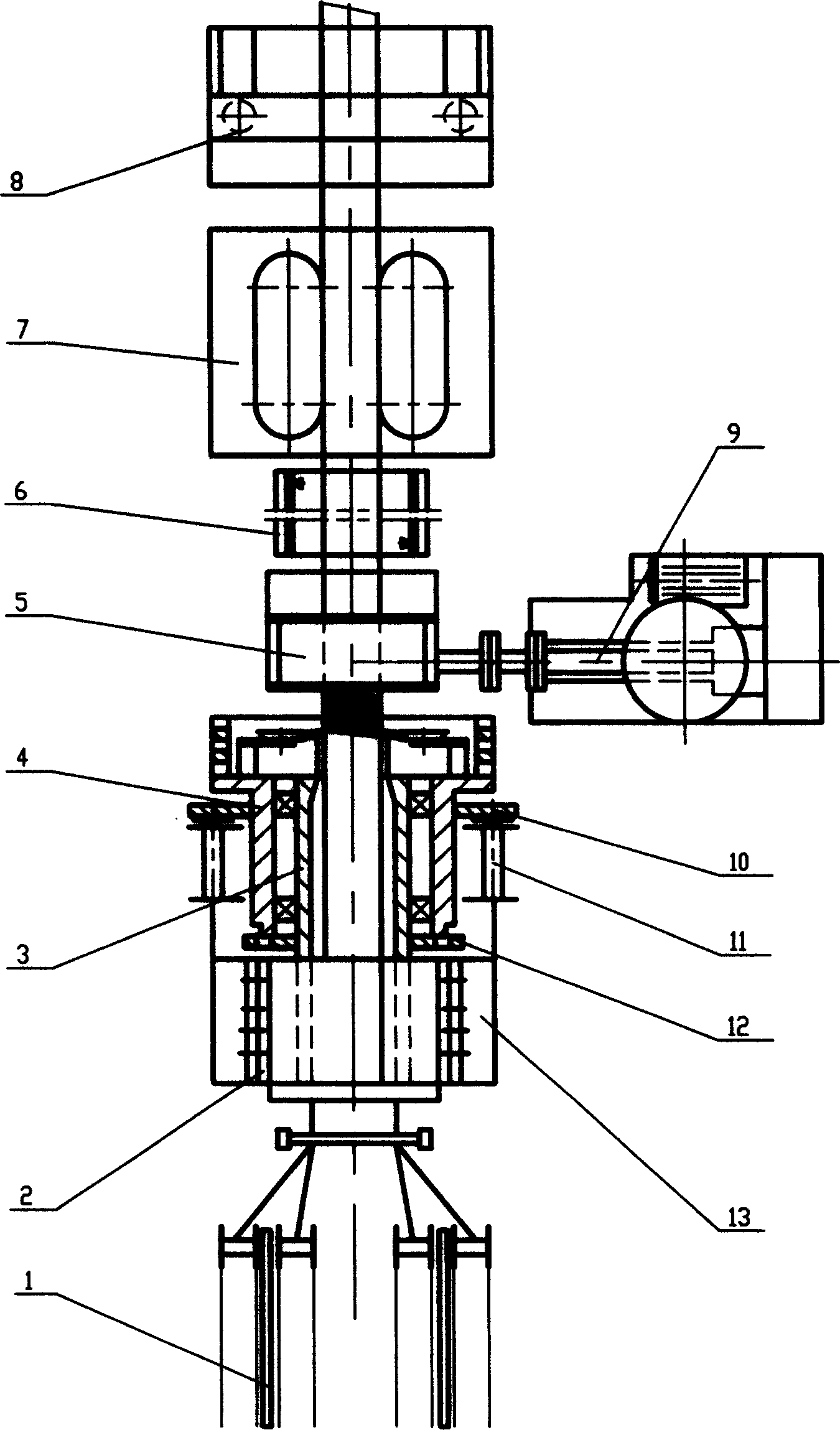

Method for producing steel mesh reinforced plastic composite pipes and its self-contained equipment

InactiveCN101077613AFast shapingEasy to shapeTubular articlesPlastic forming machineProcess configuration

The present invention is process and apparatus for producing steel net reinforced plastic composite pipe as one kind of steel structure reinforced plastic composite pipe. The process includes: extruding hot molten plastic into the inner plastic forming machine and cooling to obtain the inner plastic pipe blank layer, winding steel wire and arranging longitudinal wire onto the inner plastic pipe blank layer to form steel net, setting inside the first plastic pipe forming machine and extruding hot molten plastic into the first plastic pipe forming machine to form the composite plastic blank comprising one inner plastic pipe blank layer, one steel net layer and one outer plastic coating layer, and cutting to obtain the steel net reinforced plastic composite pipe. The equipment includes also one cooling water tank.

Owner:李富春

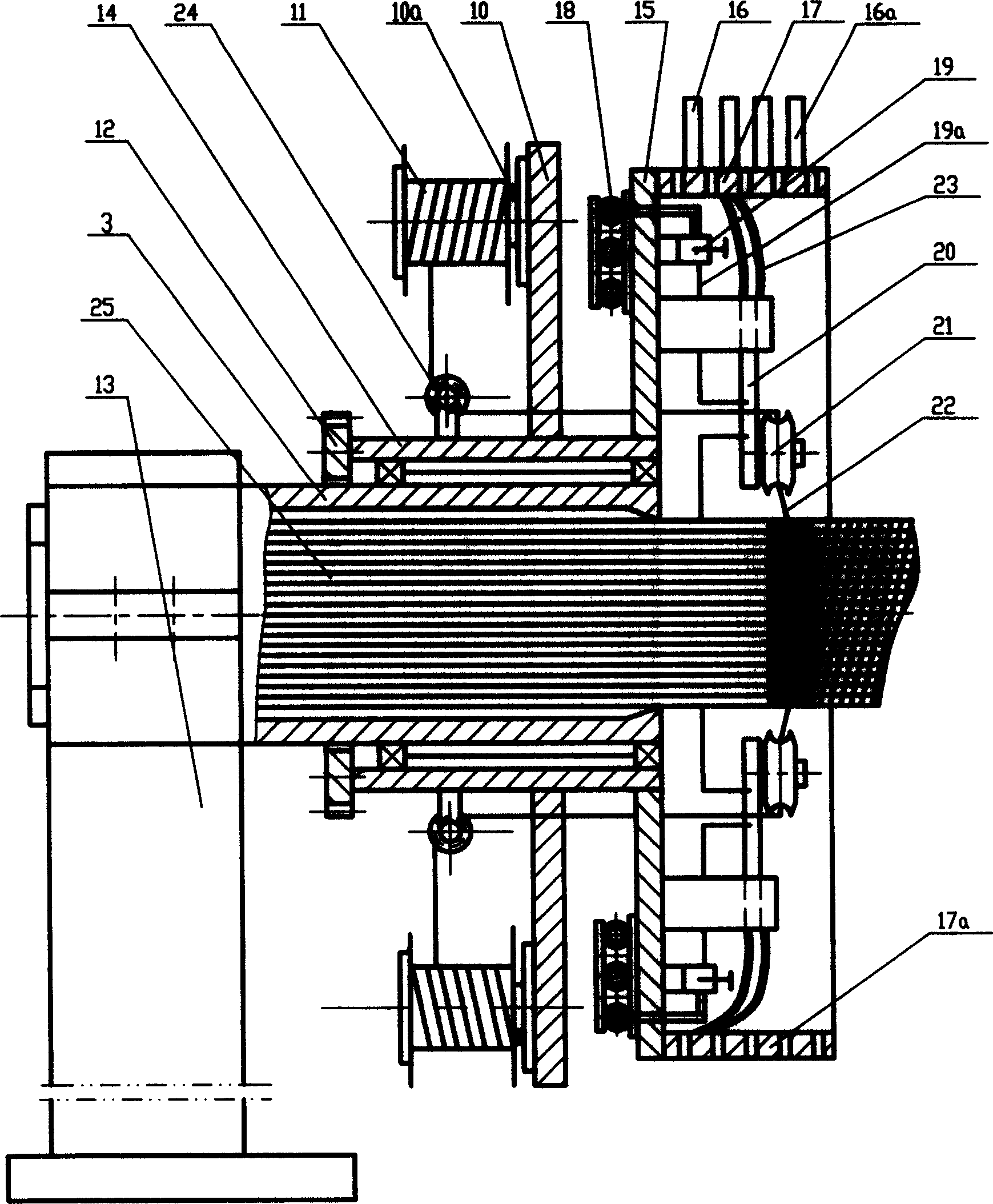

Pipeline containing compound pipe of steel skeleton-plastic, and manufacture of compound pipe

InactiveCN1562617AFirmly connectedConsistent corrosion resistanceButtonsRecord carriersThermoplasticMetallurgy

A composite steel skeleton-plastic pipe is prepared through welding the warp steel wires with the weft steel wires by net shaper and fuzzy resistance welding technology to form a netted steel skeleton, feeding it in a pipe shaping unit while extruding the fused plastics in it for combining the steel skeleton with the fused plastic, and cooling. Its making machine and the pipeline of said pipe are also disclosed.

Owner:ハルビンスターウェイマシーナリーマニュファクチャリングカンパニーリミテッド

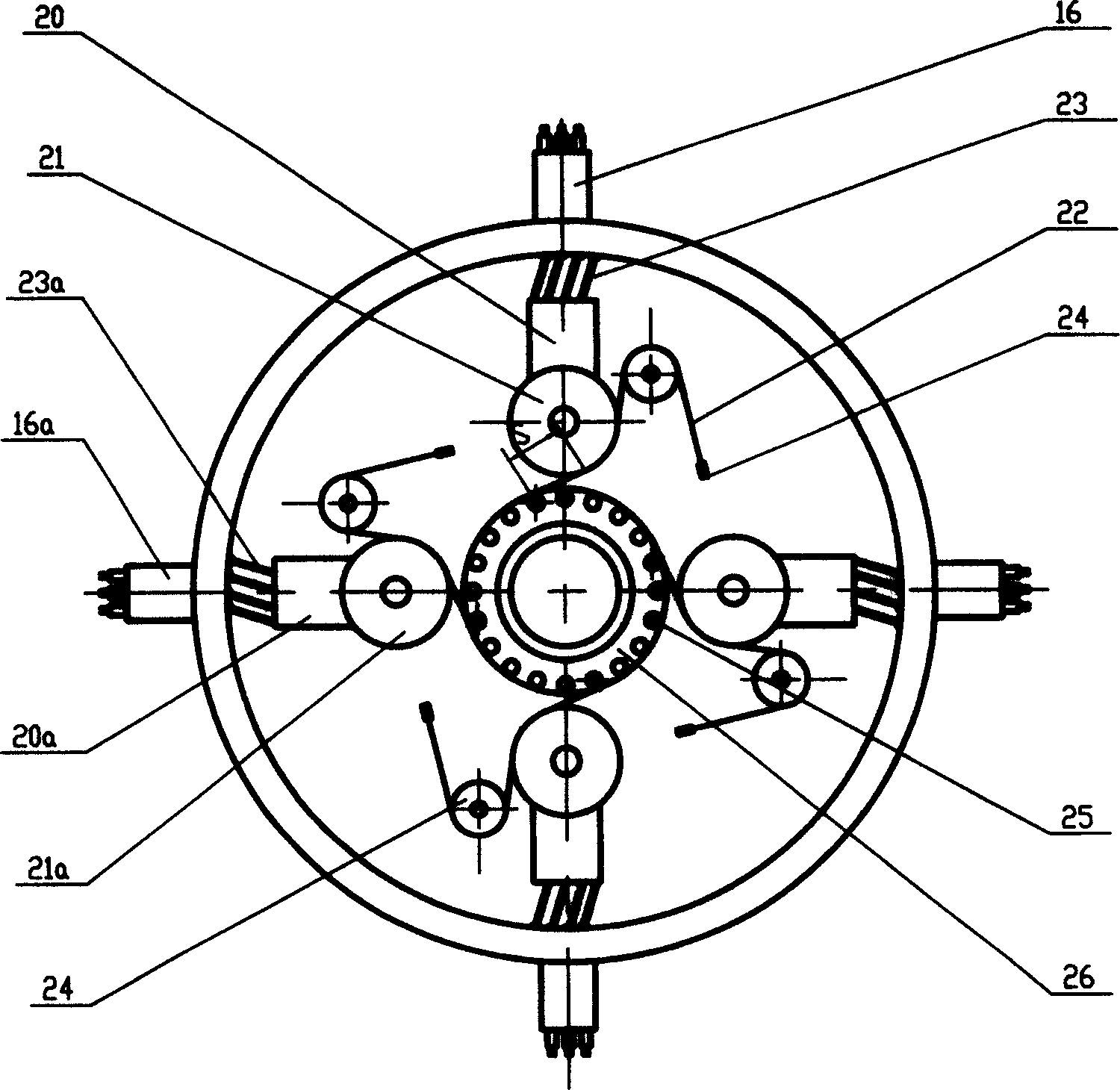

Water pipe, strip material, method and apparatus for manufacturing water pipe

ActiveCN102269298ALess material consumptionLarge caliberSynthetic resin layered productsRigid pipesWater sourceSpiral wound

A water conveying pipe includes a composite reinforced outer pipe formed by spiral winding, and a composite reinforced inner lining pipe formed by spiral winding. The outer tube is a metal-reinforced plastic composite corrugated tube structure or a tube structure with metal-reinforced plastic composite vertical ribs. The inner lining pipe is formed by at least two layers of fiber-reinforced plastic composite strips that are continuously spirally wound along the inner wall of the outer pipe and attached to the inner wall of the outer pipe, and the inner lining pipe covers the helically wound seam of the outer pipe . The present invention also provides strips, methods and devices for manufacturing the above-mentioned water delivery pipe lining pipes. The pipeline can be used as a large and medium-sized water pipeline in the water source transmission of urban water plants.

Owner:ハルビンスターウェイマシーナリーマニュファクチャリングカンパニーリミテッド

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com