Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Good initial colorability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

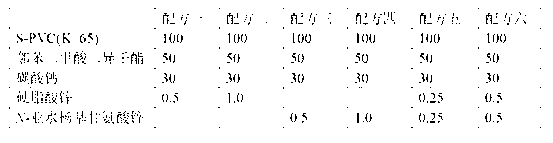

Hgdrotalcite base chlorine containing high polymer composite heat stabilizing agent

A hydrotalcite-based composite thermal stabilizer for PVC and chlorine-contained high polymer is prepared from hydrotalcite, calcium soap and zinc soap through proportionally mixing.

Owner:BEIJING UNIV OF CHEM TECH

Hydrotalcite-rare earth-calcium zinc stablizer for PVC and its preparation method

InactiveCN101007878AImprove long-term thermal stabilityGood initial colorabilityChemical synthesisHydrotalcite

The invention discloses a PVC hydrotalcite- rare earth- calcium zinc stabilizing agent and the method for preparing the same, which in detail erlates to plastic composite stabilizing agent and the preaparing method, belonging to chemical field. The main component for stabilizing comprises column- supported hydrotalcite, unsaturated rare earth, and epoxy aliphatic acid calcium zinc, and it is prepared through chemical synthesis, reformed treatment and optimization compound. The product is characterized by outstanding thermal stabilizing effect, good first stage coloring property, sound plasticizing property, good transparenty, weatherability, improved quality, high effeciciency, no toxicity, no pollution, low cost. It can replace expensive organotin thermal stabilizing agent and is widely used in PVC product preparation, such as water- supply pipes, section bar, transparent granulate, film, medical apparatus, toy, fridge stamp and box sheet material.

Owner:扬州科宇化工有限公司

Composite heat stabilizer for hydrophobic nano-hydrotalcite PVC and preparation method thereof

The invention relates to a composite heat stabilizer for hydrophobic nano-hydrotalcite PVC, comprising the following raw materials according to the mass percent: 30-50 of calcium stearate, 10-20 of zinc stearate, 10-30 of hydrophobic nano-hydrotalcite, 5-15 of lubricant, 4-7 of surface modifier and 5-15 of auxiliary heat stabilizer. With the method of coprecipitation, the hydrophobic nano-hydrotalcite is added with eunatrol to prepare hydrophobic nano-hydrotalcite including Mg and Al with the mol ratio of 2-3:1. The nano-hydrotalcite prepared by the invention has good hydrophobic nature. Good compatibility with a PVC basal body can be achieved if the nano-hydrotalcite is used in a composite heat stabilizer for PVC. Advantages of difficult precipitation and good stabilizing effect can be achieved when the nano-hydrotalcite is used as a stabilizer for plastic processing of PVC, and the like. The addition of the hydrophobic nano-hydrotalcite can reduce the balance torque, improve the processing property and reduce the cost. The preparation method causes no pollution and has low energy consumption.

Owner:慧科高新科技股份有限公司

High weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer and preparation method thereof

InactiveCN101735532AImprove hydrophobicityGood miscibilityOxygen/ozone/oxide/hydroxidePolymer sciencePolyethylene glycol

The invention discloses a high weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer which is composed of the following raw materials in percentage by weight: 20-40% of calcium stearate, 15-25% of zinc stearate, 10-30% of hydrophobicity nano-hydrotalcite, 1-1.5% of hyperdispersant, 5-15% of lubricating agent, 4-7% of surface modifier and 5-15% of assistant heat stabilizer, wherein, hydrophobicity nano-hydrotalcite is prepared with a coprecipitation method by adding sodium oleate, and the molar ratio of Mg to AL in hydrophobicity nano-hydrotalcite is 2-3:1; the hyperdispersant is copolymer of maleic anhydride-sodium allyl sulfonate-crylic acid polyethylene glycol monoester. The nano-hydrotalcite prepared by the invention has better hydrophobic property and favorable compatibility with PVC matrix. Hydrophobicity nano-hydrotalcite and hyperdispersant are added to lower balancing torque, improve handling characteristics and weather resistance and lower cost. The preparation method of the invention has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

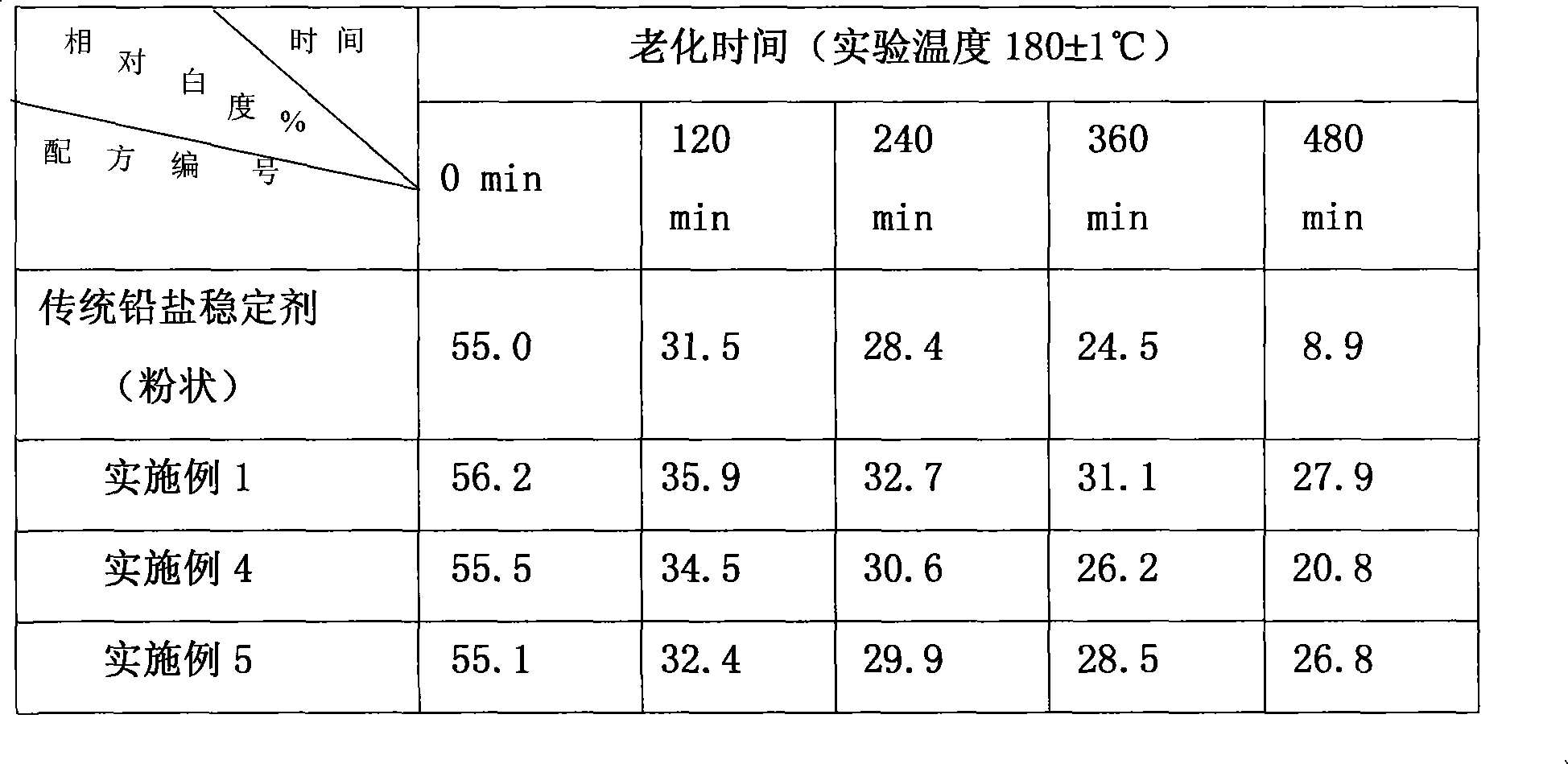

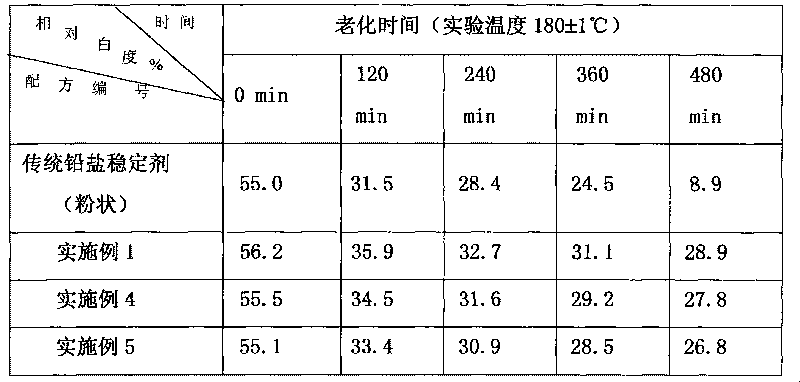

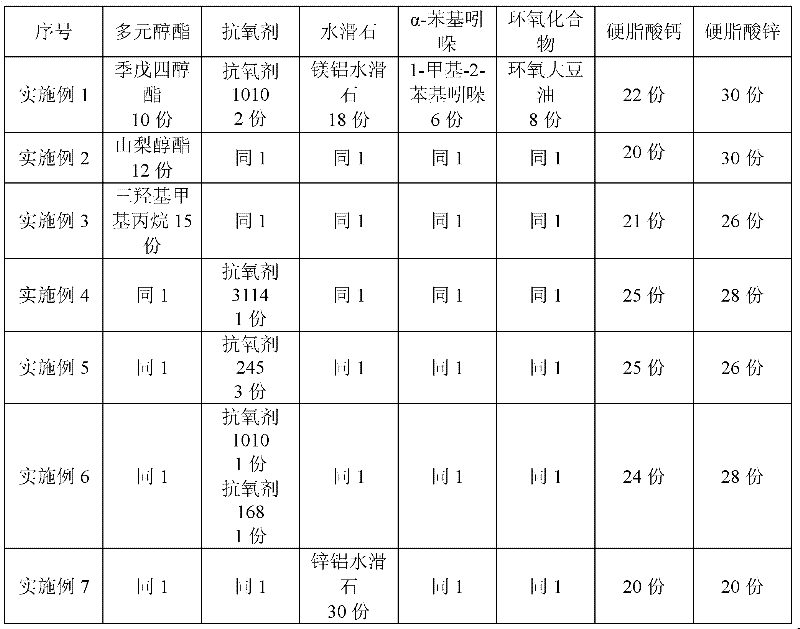

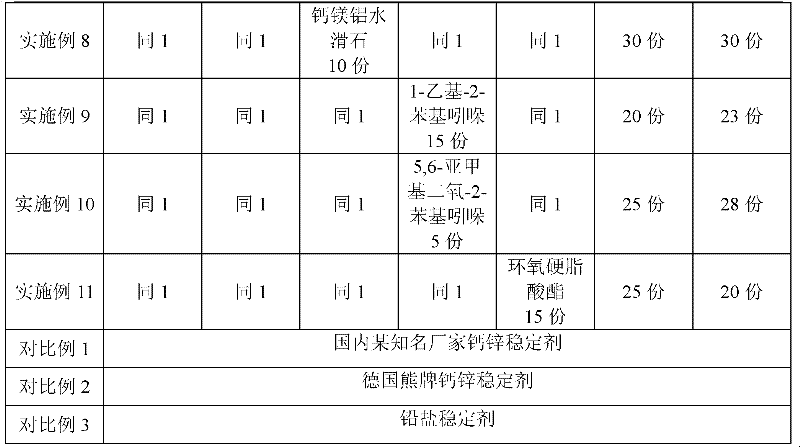

High-efficiency environment-friendly stabilizing agent used for PVC section bars

The invention relates to a high-efficiency environment-friendly stabilizing agent used for PVC section bars, which belongs to the technical field of PVC processing aids. The stabilizing agent comprises the following raw materials by weight: 20 to 30 of calcium stearate, 20 to 30 of zinc stearate, 10 to 15 of polyol ester, 1 to 3 of an anti-oxidant, 0.5 of an ultraviolet ray absorber, 10 to 30 of hydrotalcite, 3.5 of beta-diketone, 5 to 15 of alpha-phenylindole and 8 to 15 of epoxy compounds. The invention enables the problem of thermal decomposition of PVC section bars during processing to beovercome and the problem of discoloring because of long-term illumination and exposure in air during daily usage of PVC section bars to be solved, meeting developmental needs of section bars in China.

Owner:SHANDONG RUIFENG CHEM

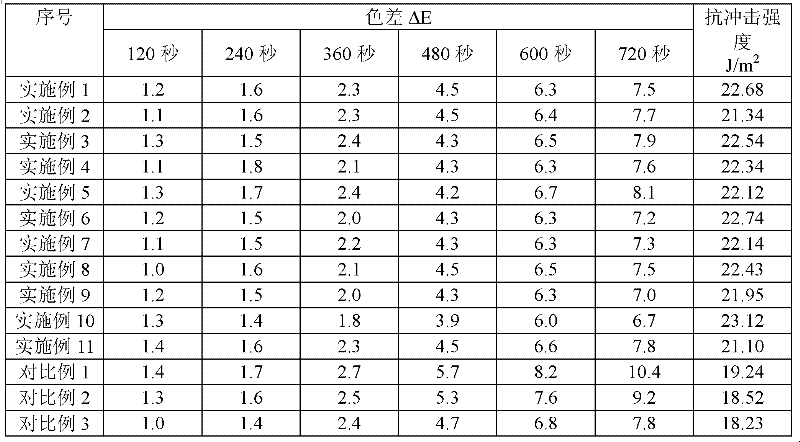

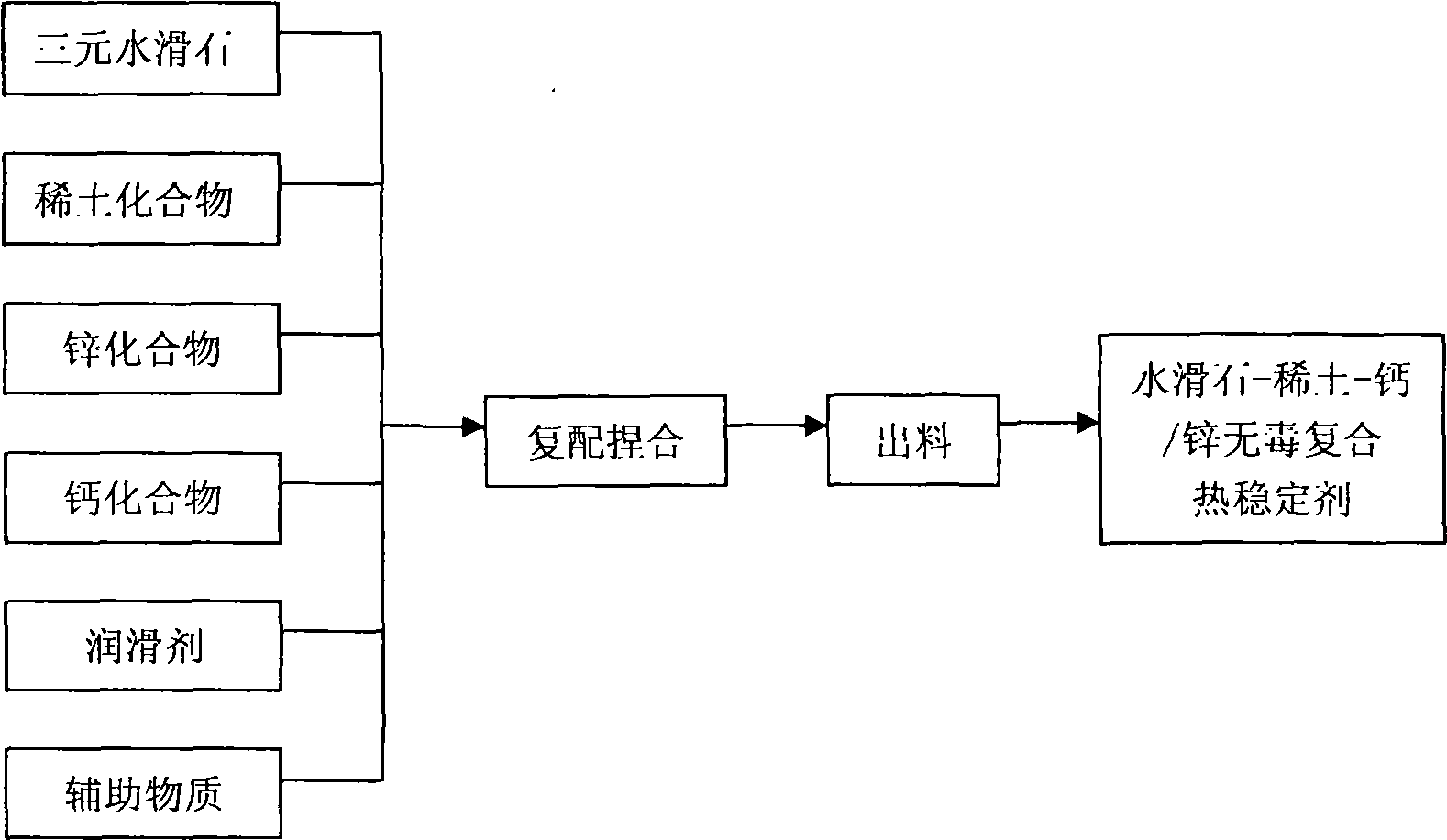

Ternary hydrotalcite-rare earth-calcium/zinc nontoxic composite heat stabilizer and preparation thereof

The invention relates to a preparation method of compound thermal stabilizer in plastic processing additive and pertains to the technical field of plastic processing additive. The invention discloses a ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer and a preparation method thereof. The invention comprises the materials of the stabilizer such as ternary hydrotalcite, organic rare earth compound, Ca compound and Zn compound, a synthetic preparation method thereof and an optimal compounding method of ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer. The ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer provided by the invention serves as a new generation high-efficiency innoxious stabilizer, can replace the traditional lead salt and expensive organic stannum thermal stabilizer and can be widely applied to the fields of PVC pipe material, section material, wire and cable, medical instrument and membrane, etc.

Owner:江西宏远化工有限公司

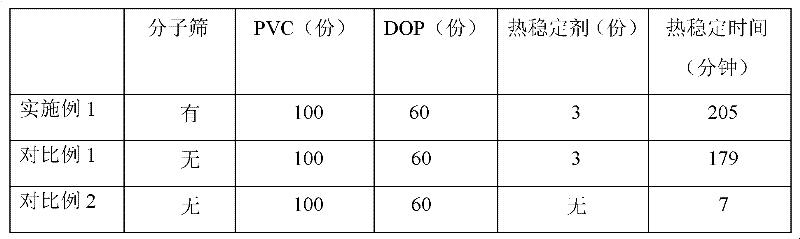

Novel molecular sieve PVC composite stabilizing agent and its preparation method

ActiveCN102477196AImprove thermal stabilityNo pollution in the processMolecular sievePolyvinyl chloride

The invention relates to a novel molecular sieve PVC (polyvinyl chloride) composite stabilizing agent and its preparation method. The stabilizing agent is characterized by comprising the following raw materials by mass percent: 20-40% of calcium stearate; 15-25% of zinc stearate; 5-15% of a molecular sieve; 8-20% of a lubricating agent; 8-15% of a surface modification agent; and 5-15% of an auxiliary heat stabilizing agent. The preparation method has no pollution and low energy consumption. According to the national standard GB2113-82 ''test for whiteness of plastics'', the prepared novel modification composite stabilizing agent, compared with traditional stabilizing agents, has excellent thermal stability. And the prepared molecular sieve in the invention has a micropore structure, and diameters of the pores are uniform in size.

Owner:慧科高新科技股份有限公司

Composite heat stabilizer for PVC, preparation and application thereof

The invention relates to a composite heat stabilizer used in PVC, the preparation and application thereof. The composite heat stabilizer is prepared by compounding mg-al hydrotalcite and zn-al hydrotalcite according to a certain proportion. The mg-al hydrotalcite and the zn-al hydrotalcite are reasonably modified and excellently compounded by stearic acid, which can greatly save the energy consumption, increases the efficiency, and increases the thermal stability performance. In the aspect of heat stability performance, the product is non-toxic and efficient, has low cost, good initial coloration, transparency, and excellent weather resistance and plasticity, and good compatibility with PVC. The use level of an additive in the course of processing does not influence the performance of products and is difficult to wear down process equipment. The products can directly use no-toxic products to finish the substitutions of cadmium free, lead free and bromine free of export products, further is applicable to other relative industries and fields, has wide application prospect.

Owner:CENT SOUTH UNIV

Heat stabilizer containing liquid barium and zinc, preparation method thereof and application thereof

The invention relates to a heat stabilizer containing liquid barium and zinc, a preparation method thereof, and application thereof. The heat stabilizer consists of the following components in percentage by weight: 10%-30% of liquid carboxylate with the percentage by weight of barium as 5%-20%, 5%-30% of liquid carboxylate with the percentage by weight of zinc as 2%-15%, 10%-40% of composite phosphite ester, 1.5%-5% of beta-diketone, 0.5%-3% of antioxygen1010, 10%-40% of DOP (dioctyl phthalate), and 1.0%-5% of odourless kerosene. Liquid carboxylic acid metallic soap and auxiliary stabilizer are adopted to exert the synergistic effect, excellent heat stability and excellent initial-stage dyeing property and transparency are achieved for PVC (polyvinyl chloride) soft products, the production process is simple, only two steps are required, the production cost is low, the investment is low, and the heat stabilizer containing liquid barium and zinc is applicable to large-scale industrial production.

Owner:湖北犇星新材料股份有限公司

Environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and preparation method of environmental-friendly high-efficiency composite heat stabilizer

InactiveCN102153824AImprove thermal stabilityGood initial colorabilityPreparation of metal alcoholatesEnvironmental resistancePentaerythritol

The invention belongs to the field of a heat stabilizer for PVC (polyvinyl chloride) and relates to an environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and a preparation method of the environmental-friendly high-efficiency composite heat stabilizer. The environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) is prepared by performing a reaction of tribasic zinc, calcium stearate, a lubricant and an auxiliary heat stabilizer, wherein the tribasic zinc is prepared by mixing pentaerythritol and zinc oxide according to a weight ratio of 6-8:3 and performing a reaction for 4 to 6 hours at a temperature of 140 to 180 DEG C. The preparation method comprises the following steps of: adding the tribasic zinc and the calcium stearate into a reaction kettle for sufficiently mixing; adding the mixed materials into a kneading machine to knead for 15 to 25 minutes at a temperature of 100 to 120 DEG C; adding a lubricating agent and the auxiliary heat stabilizer in the kneading machine to knead and stir for 25-35min; and carrying out discharging, tabletting, sieving and packaging to obtain the finished product. The prepared environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the characteristics that the environmental-friendly high-efficiency composite heat stabilizer is difficult to separate out and has good stabilizing effect; the balancing torque can be reduced; and the processing property is improved. Moreover, the environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the advantages of high efficiency and environment protection.

Owner:慧科高新科技股份有限公司

Zinc-based heat stabilizer for polyvinyl chloride, composition with same and application of zinc-based heat stabilizer for polyvinyl chloride

The invention relates to zinc-based heat stabilizer for polyvinyl chloride, a composition with the same and an application of the zinc-based heat stabilizer for polyvinyl chloride. The zinc-based heat stabilizer is prepared from urea organic matter and zinc salt through a liquid phase reaction. According to the composition independently prepared from the zinc-based heat stabilizer or prepared by mixing the zinc-based heat stabilizer, calcium carboxylate, beta-diketone, phosphite ester and polyhydric alcohols raw materials, the thermal stability of PVC can be effectively improved. The raw materials of the zinc-based heat stabilizer are easy to obtain, the synthetic process is simple, industrial application prospects are achieved, and the zinc-based heat stabilizer has the important guiding function on research and development of novel urea heat stabilizer.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Polyvinyl chloride fiber reduced in initial coloration

InactiveCN101031676AImprove convenienceImprove thermal stabilityWigsMonocomponent halogenated hydrocarbon artificial filamentFiberHeat resistance

Owner:KANEKA CORP

Novel composite heat stabilizer and application thereof in polyvinyl chloride material

The invention relates to a novel composite heat stabilizer which is characterized by containing phthalic acid metal salt, fatty acid rare earth, beta-diketone, calcium acetylacetonate, a composite antioxidant, PE wax and hexadecanol. The novel composite heat stabilizer provided by the invention can be used for comprehensively and effectively enhancing the heat stability of polyvinyl chloride, for instance, a polyvinyl chloride material with the composite heat stabilizer added has longer Congo red discoloring time and more excellent initial colorability and dynamic heat stability, has good processing property and is capable of promoting the plasticization, reducing the torque of a fusant, free of toxicity, environmental-friendly, capable of substituting an organic tin heat stabilizer, a lead heat stabilizer or other heat stabilizers with higher toxicity.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

Method for synthesizing PVC thermal stabilizer dicarboxylic acids rear earth salt and uses thereof

InactiveCN101200556AGood initial colorabilityImprove long-term thermal stabilityCarboxylic acid salt preparationRare earthCarboxylic acid

The present invention discloses a synthetic method of PVC thermal stabilizer dyadic carboxylic acid rare-earth salt. The method is characterized in that absolute ethyl alcohol is solvent; hydrogen peroxide is reducing agent; soluble rare-earth inorganic salt, alkali and dyadic carboxylic acid are reacted according to the mol ratio of 1: 2.5-3.5:0.3-2 under the temperature of 40 to 80 DEG C so as to produce the dyadic carboxylic acid rare-earth salt. The purpose is to be used as the thermal stabilizer of PVC plastic processing. The dyadic carboxylic acid rare-earth salt as the thermal stabilizer provided by the present invention not only overcomes the settlement of the prior thermal stabilizer but also increases the preliminary tinctorial property and long-term thermal stability; in addition, the present invention also greatly promotes the PVC plastication and has low cost, therefore, the present invention has the prospect of industrial application.

Owner:ANHUI UNIVERSITY

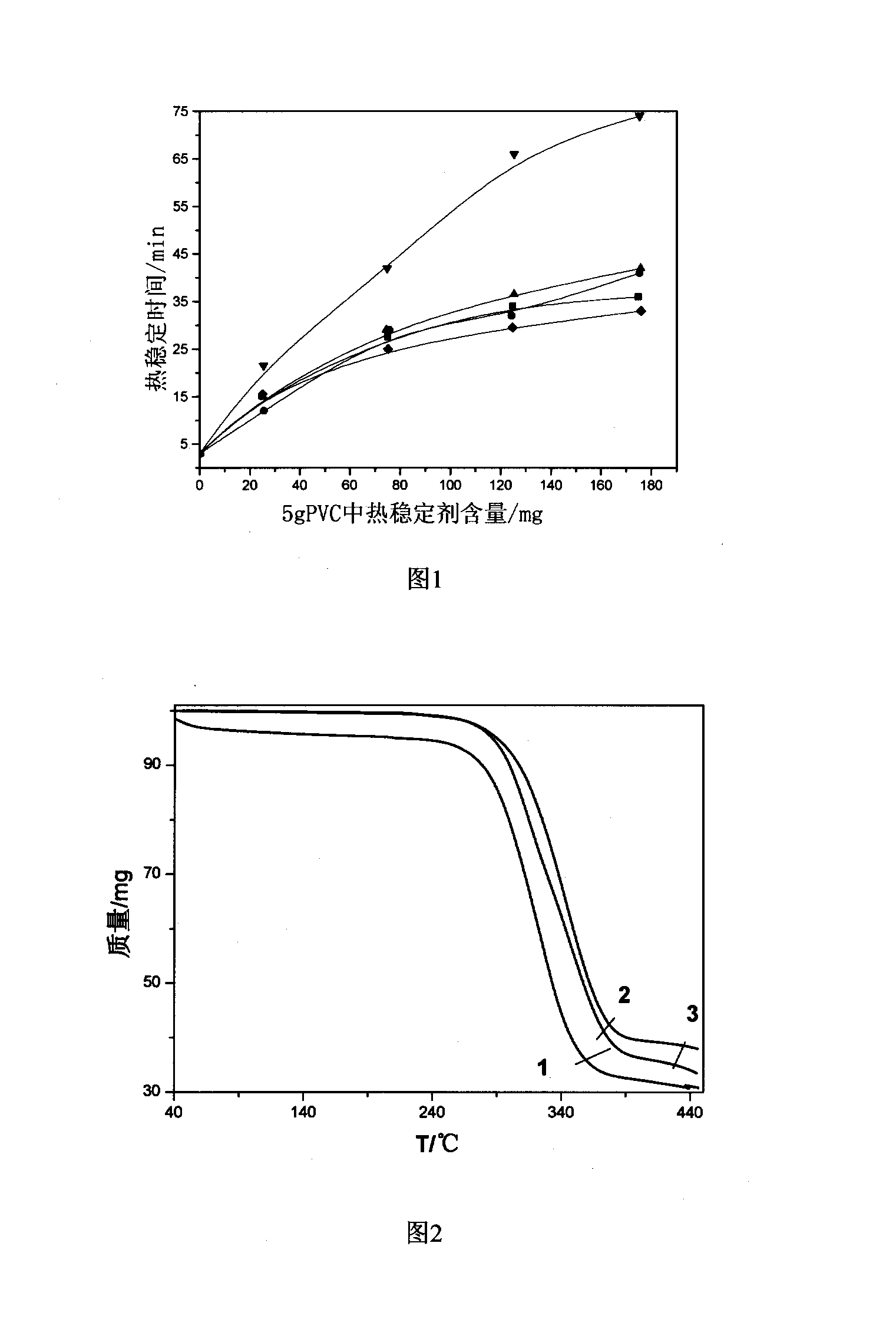

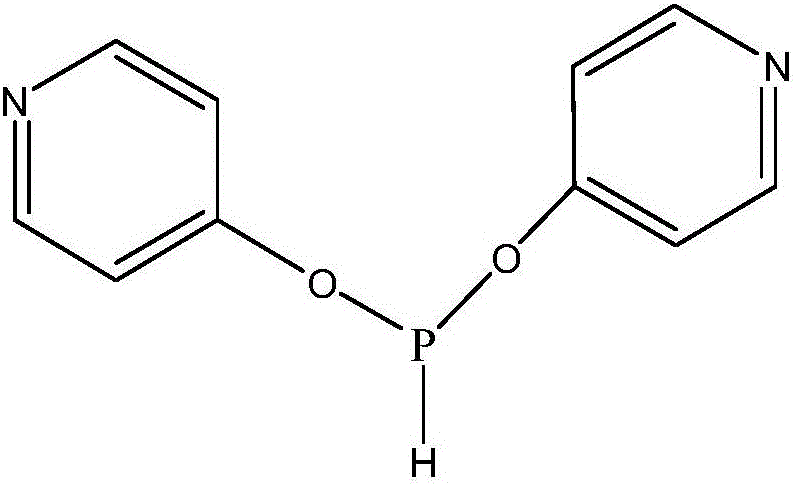

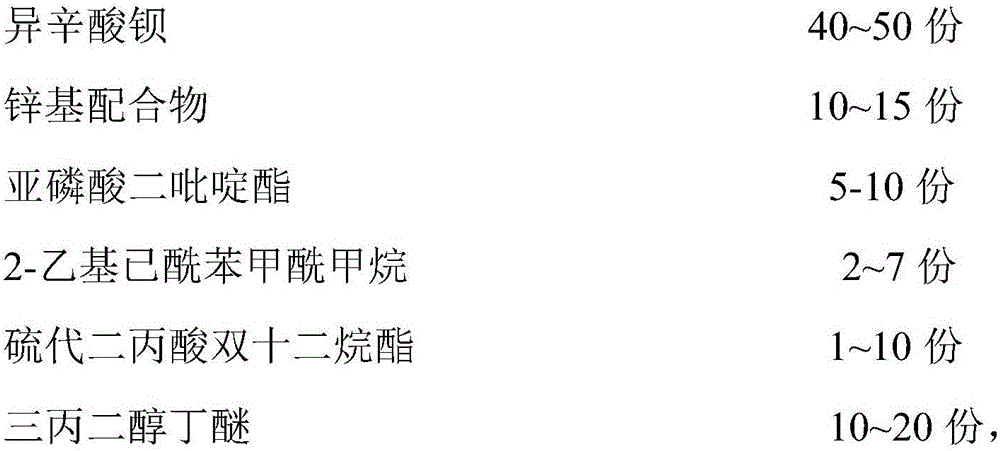

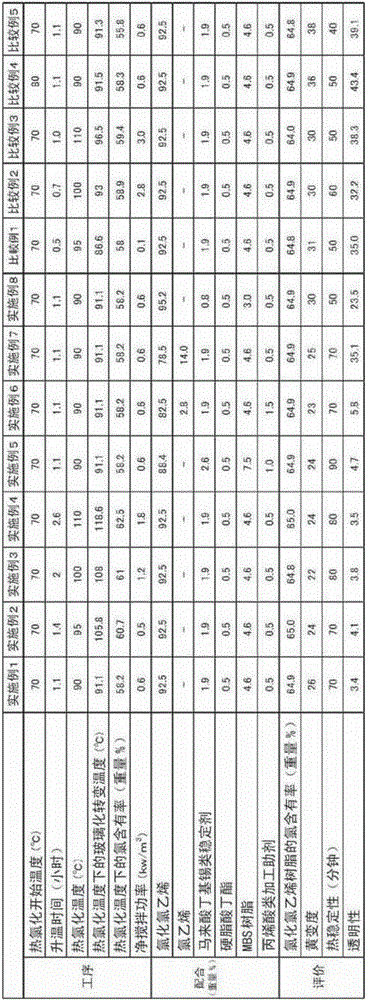

Application of bipyridine ester phosphite to PVC heat stabilizer

ActiveCN106046618AExcellent resistance to precipitationAuxiliary Stabilization ImprovementNitrogen atomEther

The invention relates to the application of bipyridine ester phosphite to a PVC heat stabilizer. bipyridine ester phosphite can be applied to preparation of a liquid barium-zinc stabilizer, a liquid barium-cadmium-zinc stabilizer and a liquid calcium-zinc stabilizer. The liquid barium-zinc stabilizer is prepared from, by weight, 40-50 parts of barium isotanoate, 10-15 parts of zinc-based complex, 5-10 parts of bipyridine ester phosphite, 2-7 parts of 2-ethyl acetyl benzoyl methane, 1-10 parts of thiodipropionicacid dilauryl ester and 10-20 parts of tripropylene glycol n-butyl ether. The bipyridine ester phosphite compound has a higher anti-precipitation property than aliphatic or aromatic phosphite ester by means of a novel heterocyclic perssad replacing the aliphatic or aromatic perssad during preparation of the liquid barium-zinc stabilizer, the liquid barium-cadmium-zinc stabilizer and the liquid calcium-zinc stabilizer. By introducing nitrogen atoms to the heterocyclic ring, the auxiliary stabilization effect on phosphite ester is improved remarkably, and then the printing performance and stability of a modified PVC product are improved.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

Production method for chlorinated vinyl chloride resin

The present invention provides a production method for a chlorinated vinyl chloride resin that has excellent heat stability (initial colorability, and heat-resistance stability) and that can be used to obtain a transparent molded product. The present invention is a production method for a chlorinated vinyl chloride resin wherein a reaction liquid that comprises a vinyl chloride aqueous suspension that contains a vinyl chloride resin is thermally chlorinated in a sealable reaction vessel, the production method having a step (1) wherein the reaction liquid is heated, chlorine is introduced into the reaction vessel when the temperature is 55-70 DEG C, and thermal chlorination is started, a step (2) wherein the temperature inside the reaction vessel is increased while being kept at or below the glass transition temperature of a partially chlorinated vinyl chloride resin, and a step (3) wherein, after the chlorine content percentage of the partially chlorinated vinyl chloride resin is 58 weight% or more, thermal chlorination is performed at a prescribed temperature that is 85 DEG C or more but less than 115 DEG C. In steps (1)-(3), the net agitation power (Pv) inside the reaction vessel is 0.2-2.5 w / m3 per 1 m3 of the reaction liquid.

Owner:SEKISUI CHEM CO LTD +1

N-salicylidene zinc glycinate compound and application thereof as PVC heat stabilizer

ActiveCN103183619AImprove thermal stabilityGood initial colorabilityOrganic chemistryGlycineSalicylaldehyde

The invention relates to a novel N-salicylidene zinc glycinate compound for improving heat stability of PVC. The novel N-salicylidene zinc glycinate compound has a chemical formula of [ZnL].H2O, wherein L represents coordination negative ions generated by a reaction of salicylaldehyde and glycine. The N-salicylidene zinc glycinate or a composition composed of the N-salicylidene zinc glycinate and a conventional stabilizer component can be used as a stabilizer that enables the PVC to have relatively good heat stability, thereby ideally improving initial dyeing property and the long-term heat stability of the PVC. Besides, the N-salicylidene zinc glycinate has the advantages of convenience for synthesis, easily available raw materials, etc. Therefore, the N-salicylidene zinc glycinate compound has good industrial application prospects.

Owner:SHENZHEN AIMSEA IND

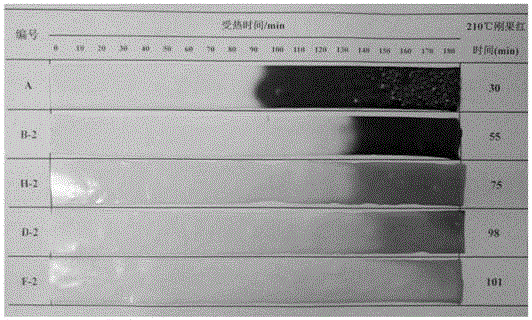

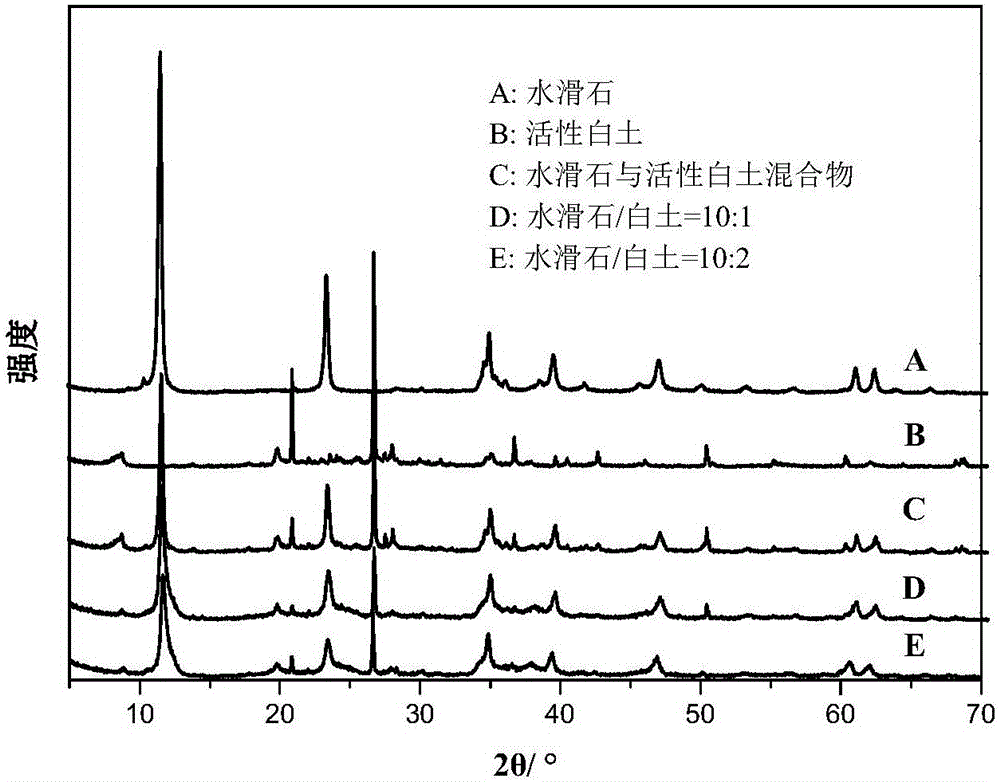

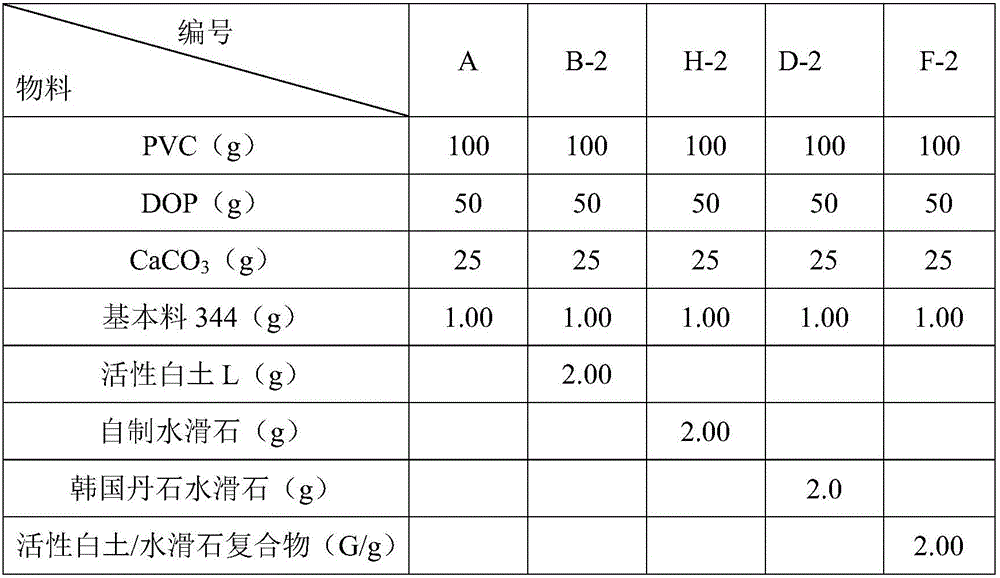

Composite material used for PVC heat stabilizers, and preparation method thereof

The invention relates to a composite material used for PVC heat stabilizers. The novel composite material Hangjin 2# soil / hydrotalcite is produced from Hangjin 2# soil with abundant reserves and low price and self-made hydrotalcite through using a silane coupling agent grafting technology, and has a good effect when used in the PVC heat stabilizers. Adoption of the cheap Hangjin 2# soil as a raw material reduces the production cost of the composite material and makes the composite material have better performances than imported DANSUK hydrotalcite.

Owner:ZHAOQING UNIV

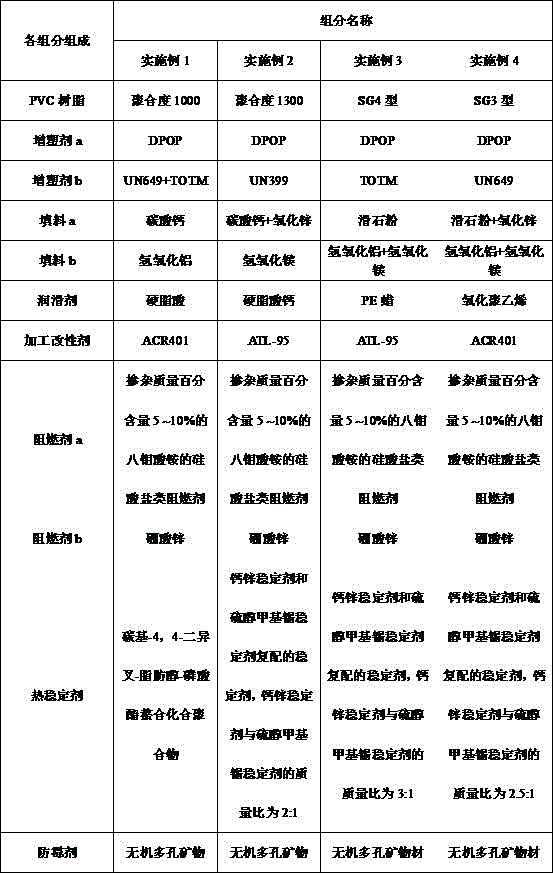

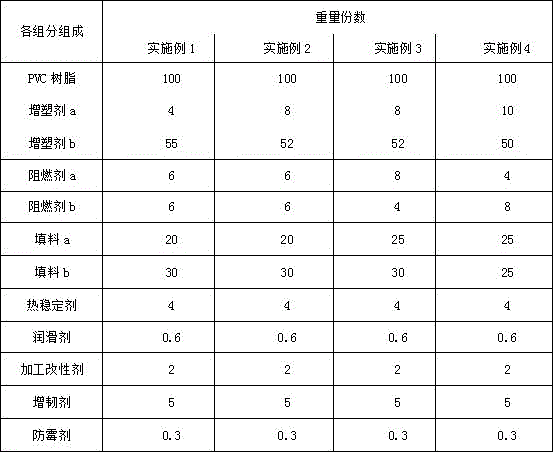

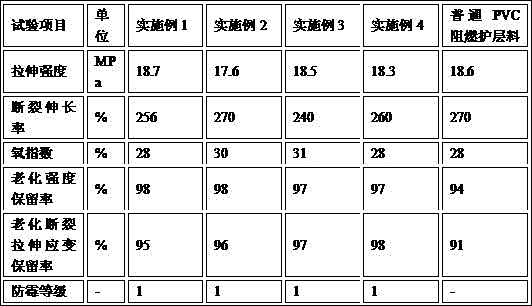

Novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material

ActiveCN106496863AGood compatibilityGood weather resistancePlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention discloses a novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 2-8 parts of a plasticizer a, 30-55 parts of a plasticizer b, 5-10 parts of a flame retardant a, 5-10 parts of a flame retardant b, 10-40 parts of packing a, 20-30 parts of packing b, 2-10 parts of a thermal stabilizer, 0.5-2 parts of a lubricant, 1-3 parts of a processing modifier, 0.2-0.4 part of an anti-mold agent and 5-10 parts of a toughening agent, wherein the anti-mold agent is an antibacterial anti-mold agent which is compounded from an inorganic porous mineral material loaded with inorganic antibacterial factors and organic anti-mold factors. Compared with a common PVC flame-retardant protection layer material, the novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material disclosed by the invention is very good in anti-mold property, and the service life of the protection layer material is greatly prolonged.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

Transparent powder calcium-zinc composite heat stabilizer for PVC and preparation method thereof

The invention provides a transparent powder calcium-zinc composite heat stabilizer for PVC and a preparation method thereof. The transparent powder calcium-zinc composite heat stabilizer comprises the following raw materials in parts by weight: 30-35 parts of a calcium-zinc composite main heat stabilizer, 25-30 parts of an auxiliary heat stabilizer, 10-20 parts of hydrotalcite, 5-10 parts of silicon dioxide, 5 parts of an antioxidant and 5 parts of an ultraviolet light absorber. The calcium-zinc composite main heat stabilizer is formed by compounding epoxy zinc oleate and epoxy calcium oleate, the auxiliary heat stabilizer is formed by magnesium acetylacetonate, the hydrotalcite is formed by modified ternary hydrotalcite, and the silicon dioxide is formed by fumed silica. The calcium-zinc composite main heat stabilizer, the magnesium acetylacetonate auxiliary heat stabilizer and the modified ternary hydrotalcite and fumed silica are used as fillers to be combined according to the proportion, and the transparency of the heat stabilizer is effectively improved according to the efficient coloring inhibition characteristic of the heat stabilizer.

Owner:黄山佳宝新材料科技有限公司

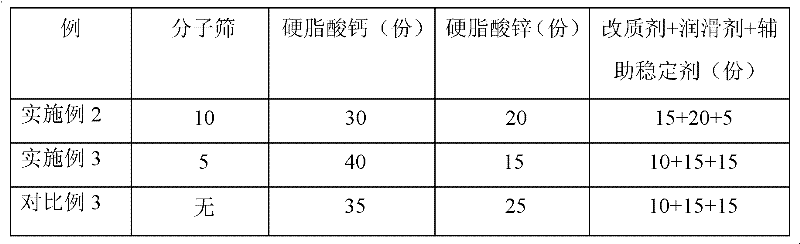

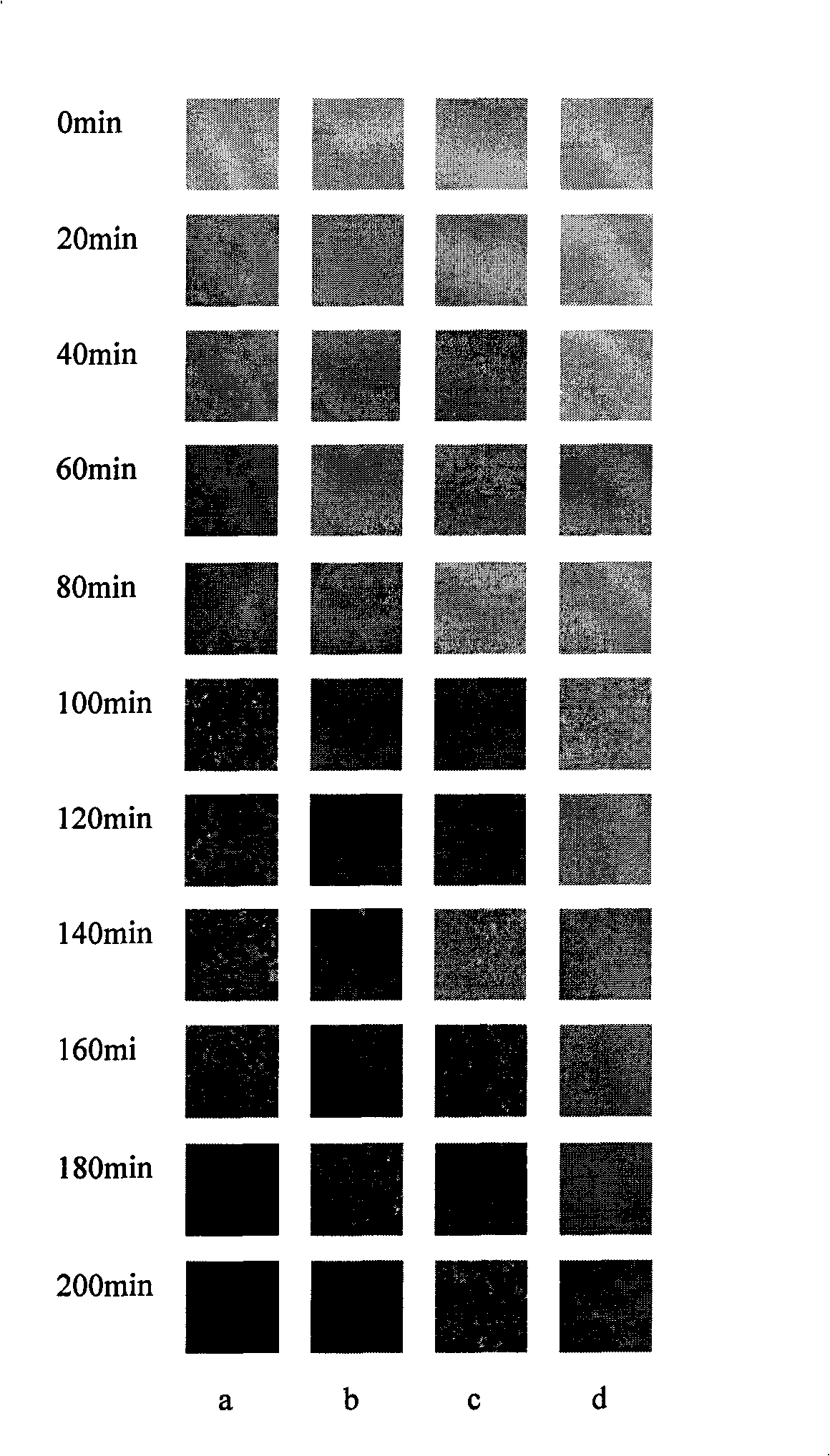

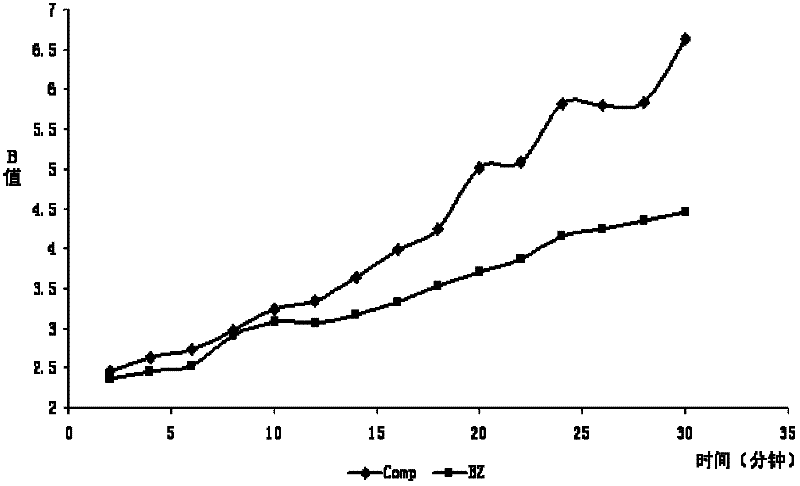

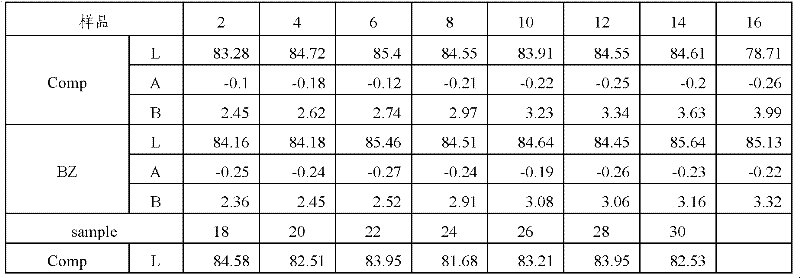

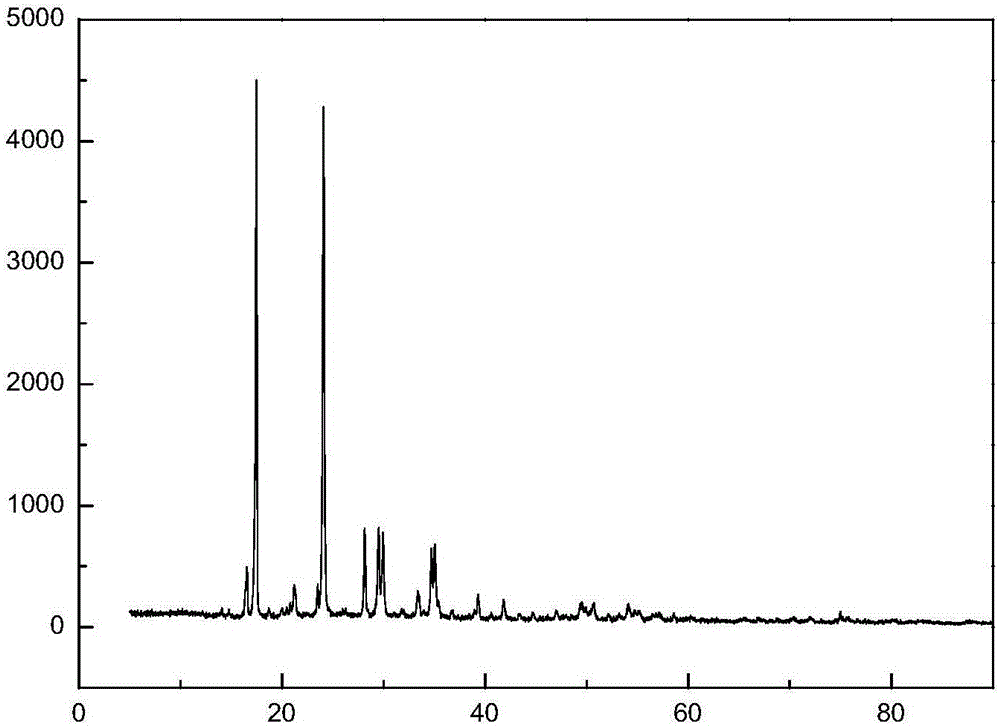

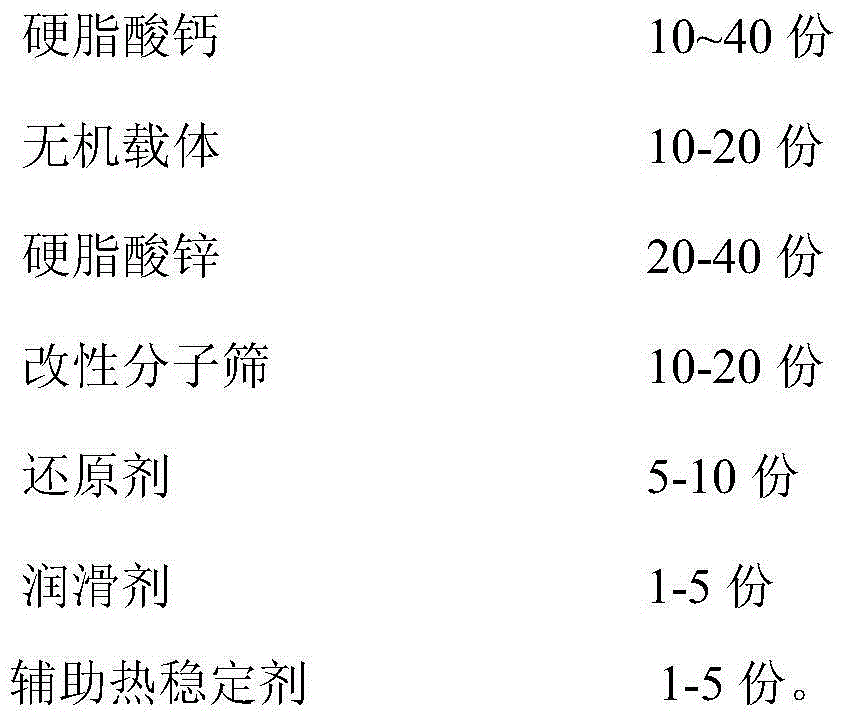

Modified molecular sieve heat stabilizer for PVC and preparation method thereof

The invention relates to a modified molecular sieve heat stabilizer for PVC (polyvinyl chloride) and a preparation method thereof, and belongs to the technical field of chemical industry. The heat stabilizer comprises the following raw materials by the mass percentage: 10-40 parts of calcium stearate, 10-20 parts of an inorganic carrier, 20-40 parts of zinc stearate, 10-20 parts of a modified molecular sieve, 5-10 parts of a reducing agent, 1-5 parts of a lubricant, and 1-5 parts of an auxiliary heat stabilizer. A prepared novel molecular sieve is good in effect, and good in intersolubility with an organic solvent; and as a stabilizer for processing plastics such as PVC, the heat stabilizer has the characteristics of being hardly to precipitate and good in stabilization effect. Through the addition of the prepared novel molecular sieve, the processing performance is improved, and the cost is reduced. Through carrying out static aging experiments on PVC into which the novel modified molecular sieve composite heat stabilizer is added, results show that the added composite stabilizer disclosed by the invention can significantly improve the heat stability of PVC.

Owner:淄博龙沙高分子材料科技有限公司

Preparation method of rare earth heat stabilizer used for PVC

InactiveCN106977841AImprove long-term stabilityGood initial colorability3-Hydroxypropionic acidEnvironmental resistance

The invention discloses a preparation method of a rare earth heat stabilizer used for PVC, and belongs to the technical field of plastic assistants. The preparation method comprises the following steps: protecting the hydroxyl group of 3-hydroxypropionic acid used as a raw material with trimethylchlorosilane, reacting the hydroxyl group protected 3-hydroxypropionic acid with thionyl chloride to generate acyl chloride, reacting the acyl chloride with glutamic acid to generate an amine substance, oxidizing the amine substsance to obtain a substance containing an amino group and a carboxyl group, saponifying the substance containing an amino group and a carboxyl group, reacting the saponified substance with an inorganic rare earth salt to generate organic rare earth with generated HCl neutralized by the amino group in order to prevent automatic oxidation, mixing the organic rare earth with a heat stabilization assistant, and drying the obtained mixture to obtain the rare earth heat stabilizer used for PVC. The rare earth heat stabilizer used for PVC overcomes the disadvantages of large toxicity, poor initial heat stability and slow speed of existing heat stabilizers, and has the advantages of improvement of the long-term stability and the initial coloring property of the PVC, non-toxicity, environmental protection, low energy consumption, low dosage, low price and broad industrial application prospect.

Owner:CHANGZHOU UNIV

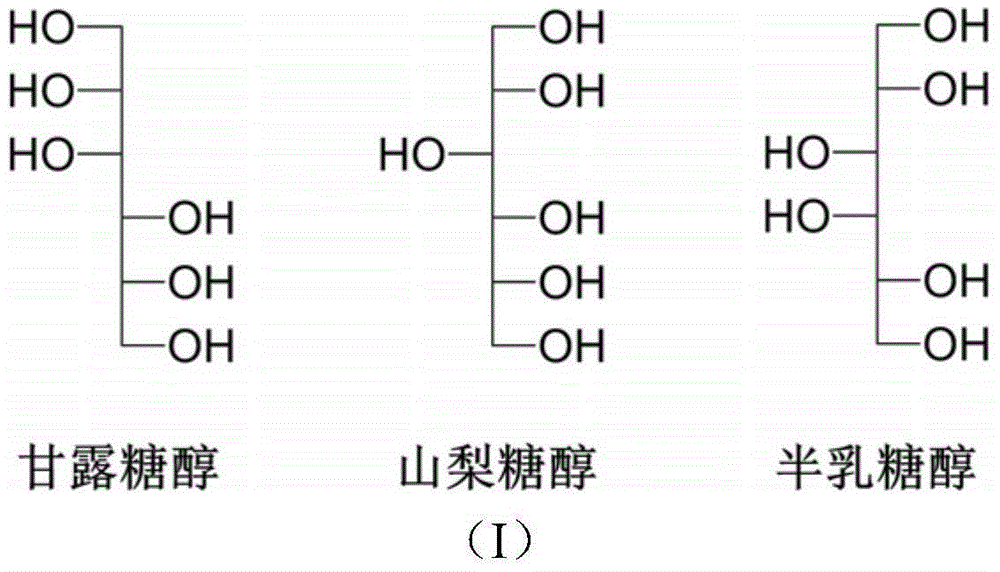

Metal oxide-hexanehexol compound heat stabilizer, preparation method and application in PVC

The invention discloses a metal oxide-hexanehexol compound heat stabilizer, a preparation method and application in PVC. The heat stabilizer is composed of compounds generated after hexanehexol reacts with metal oxide, and the compounds comprise hexanehexol metal salt, the metal oxide, the hexanehexol and dehydrated hexanehexol. The synthesized metal oxide-hexanehexol compound heat stabilizer is non-toxic and environmentally friendly, low in melting point and easy to disperse, the compatibility between the heat stabilizer and a PVC base body is good, initial coloration is good, long-term stability is good, lubrication performance is good, and the problem that an existing environment-friendly PVC heat stabilizer is poor in heat stabilizing effect is solved. When zinc oxide-mannitol compounds prepared under preferred conditions are applied to PVC, heat stabilizing time can be 240 minutes, and the problem that the existing environment-friendly PVC heat stabilizer is poor in heat stabilizing effect is solved.

Owner:ZHEJIANG UNIV +1

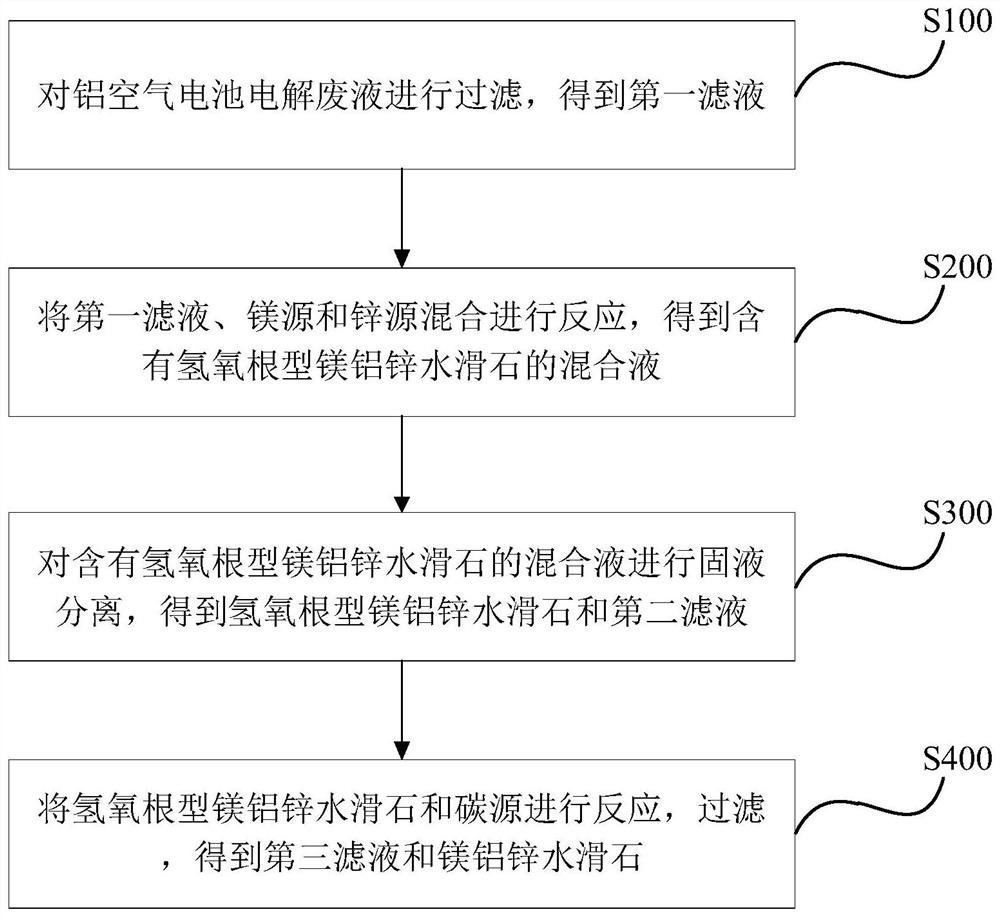

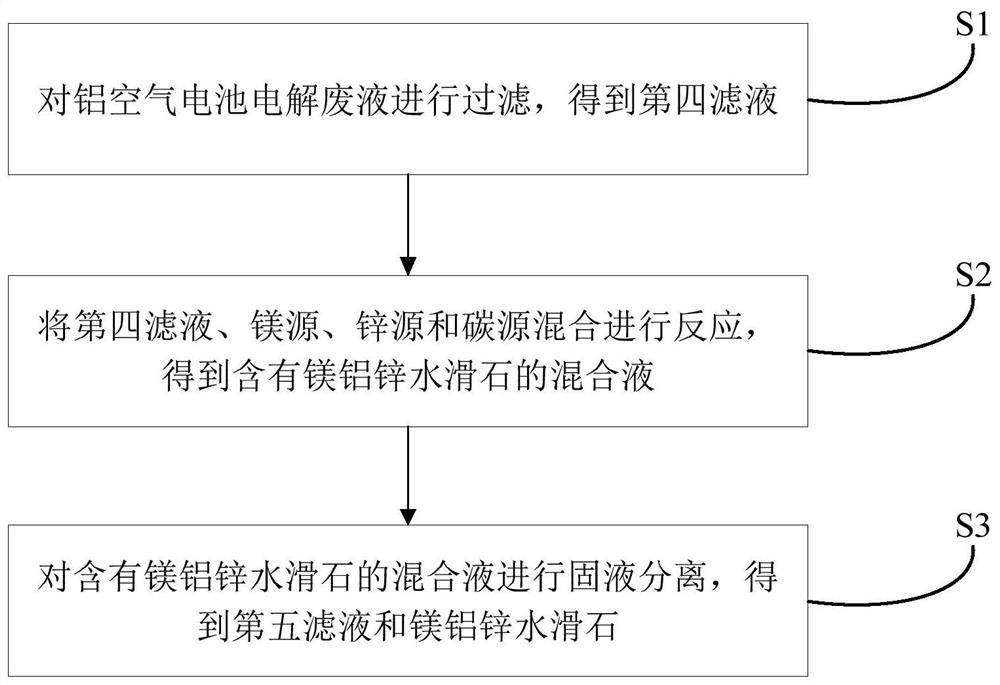

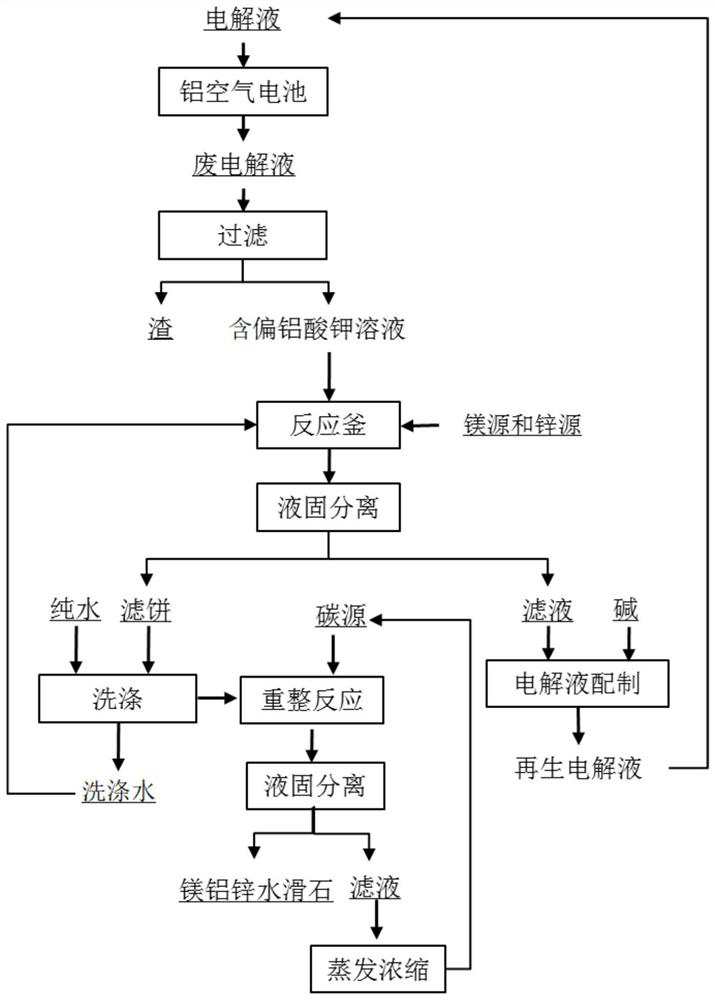

Method for preparing magnesium-aluminum-zinc hydrotalcite from aluminum-air battery electrolytic waste liquid, and application thereof

InactiveCN113620326AEnable recyclingLow impurity contentAluminium compoundsAlkali metal carbonatesElectrolysisPhysical chemistry

The invention discloses a method for preparing magnesium-aluminum-zinc hydrotalcite from aluminum-air battery electrolytic waste liquid, and application thereof. The preparation method comprises a scheme 1 or a scheme 2, and the scheme 1 comprises the following steps: filtering the aluminum-air battery electrolytic waste liquid in advance, reacting filtrate with a magnesium source and a zinc source, carrying out solid-liquid separation to obtain hydroxyl type magnesium-aluminum-zinc hydrotalcite, reacting the hydroxyl type magnesium-aluminum-zinc hydrotalcite with a carbon source, and filtering to obtain magnesium-aluminum-zinc hydrotalcite; and the scheme 2 comprises the following steps: directly reacting filtrate obtained by filtering the aluminum-air battery electrolytic waste liquid with the magnesium source, the zinc source and the carbon source, and performing solid-liquid separation to obtain magnesium-aluminum-zinc hydrotalcite. By adopting the method, resource utilization of the aluminum-air battery electrolytic waste liquid can be realized, the magnesium-aluminum-zinc hydrotalcite with a relatively high additional value can be obtained, the production cost of the hydrotalcite can be reduced, and the prepared magnesium-aluminum-zinc hydrotalcite is relatively low in impurity content, easy in crystal form control, simple in equipment operation, relatively low in production cost, energy-saving and environment-friendly, and is easy to realize industrial production.

Owner:云南创能斐源金属燃料电池有限公司

Hgdrotalcite base chlorine containing high polymer composite heat stabilizing agent

Owner:BEIJING UNIV OF CHEM TECH

Stabilizing agent used for producing PVC plastic products and preparation technique thereof

InactiveCN101691428AReduces rednessMitigates the rate at which thermal stability degradesDiketoneOrganic acid

The invention belongs to the technical field of the processing of chlorine-containing polymer products, which discloses a stabilizing agent used for producing PVC plastic products and a preparation method thereof. The preparation method is mainly and technically characterized by comprising the following steps: putting organic acid into a reaction kettle sequentially, heating to dissolve the organic acid, putting a catalyst and dissolving the catalyst; then, putting each metal compound sequentially, preparing an intermediate after dewatering, heating, discharging and cooling, then putting the intermediate, other lamellar compounds, an antioxidant, a light stabilizing agent, pentaerythritol ester, diketone, amino crotonate and a lubricant into a compounding kettle and producing the stabilizing agent used for producing the PVC plastic products after compounding and stirring. The stabilizing agent has the characteristics of no toxicity, high stability, superior consistency performance with resin and good weatherability.

Owner:张保发

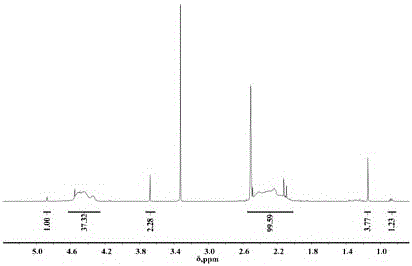

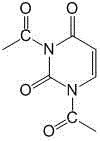

Novel preparation method of orotic acid hydrate zinc PVC stabilizer by heterogeneous system

InactiveCN106518782AImprove thermal stabilityRaw materials are easy to getOrganic chemistryPrecipitationEthanol

By the technology of a heterogeneous system, orotic acid hydrate zinc is prepared to enhance stability of PVC. The preparation method comprises the following steps: adding proper amounts of uracil and deionized water into a four-mouth flask, heating and fully stirring, adding proper amounts of ammonia water and a phase-transfer catalyst, letting the phase-transfer catalyst be uniformly dispersed in the solution, and cooling the solution to room temperature; adding zinc pyrrolidone carboxylate and glycerol while stirring, stirring at constant temperature at room temperature for several hours, pouring the reaction solution into lots of ethanol to obtain white precipitate, separating with cold water, and washing and drying. The orotic acid hydrate zinc is used as a PVC heat stabilizer and can reduce initial coloration of PVC and prolong later zinc burning. According to the technology, cold water is used for separation and purification of the product. Thus, traditional technological flow is greatly simplified, and resource waste and environmental pollution are avoided. The raw materials are easily available, and the preparation technology is simple. Therefore, the technology has a good industrial application prospect.

Owner:SHENZHEN AIMSEA IND

Preparation method of environment-friendly thermal stabilizing agent

The invention relates to preparation of an environment-friendly thermal stabilizing agent, and belongs to the technical field of plastic industry. Castor oil and soybean oil are taken and are added into a four-opening flask; the flask is put into a water bath pot; preheating is performed; maleic anhydride is taken and is poured into methyl ethyl ketone; the obtained mixed liquid is dripped into the flask; after the dripping is completed, the temperature is controlled; stirring is performed; solvents are removed in a vacuum way; modified mixed oil is obtained; the modified mixed oil is poured into a three-opening flask; formic acid, dibenzoyl methane and pentaerythritol are poured; a hydrogen peroxide solution is dripped into the flask; the temperature is regulated; the rotating speed is regulated; after the reaction, still standing and cooling are performed to the room temperature; layering is performed; upper layer oily materials are obtained; sodium hydroxide solution is heated; the upper layer oily materials are dripped into the sodium hydroxide solution; stirring is performed; emulsion is obtained; a zinc oxide solution is added into the emulsion; stirring is performed; products are filtered; filter slag is washed by distilled water and is then put into a baking oven to be baked; the environment-friendly thermal stabilizing agent is obtained.

Owner:戴琪

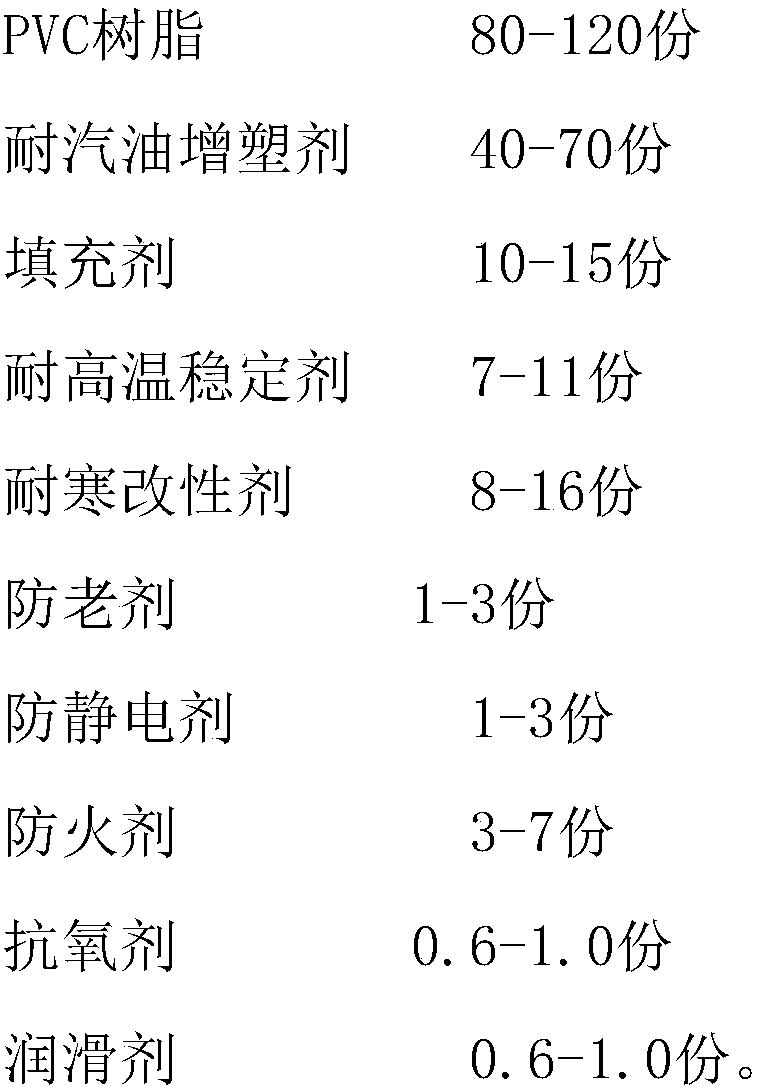

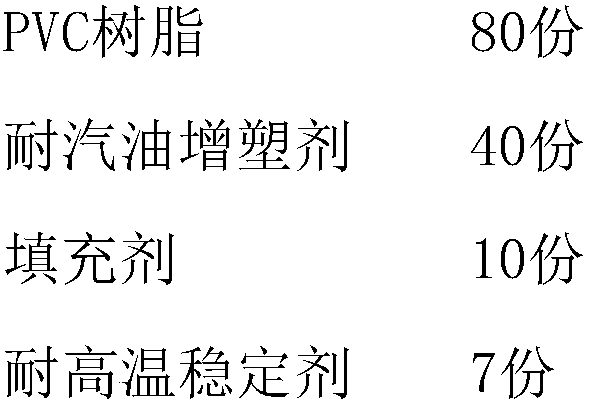

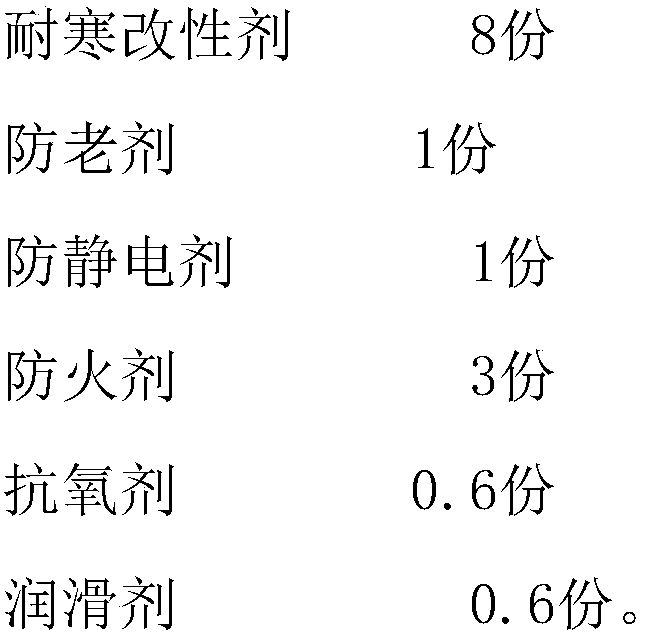

PVC modified material used for automobile charging pile and preparation method thereof

The invention relates to the technical field of PVC materials, and specially relates to a PVC modified material used for an automobile charging pile and a preparation method thereof. The PVC modifiedmaterial includes, by weight, the following raw materials: 80-120 parts of PVC resin, 40-70 parts of a gasoline resistance plasticizer, 10-15 parts of a filler, 7-11 parts of a high temperature resistance stabilizer, 8-16 parts of a cold resistance modifier, 1-3 parts of an anti-aging agent, 1-3 parts of an antistatic agent, 3-7 parts of a fire retardant, 0.6-1.0 part of an antioxidant, and 0.6-1.0 part of a lubricant. The PVC modified material has the characteristics of good antistatic effect, environmental protection, excellent performance of high temperature resistance and low temperature resistance, good effects of gasoline resistance, antioxidation and fire prevention, and good processing properties; and the PVC modified material is suitable for the automobile charging pile.

Owner:广东祺龙科技有限公司

Use of dicarboxylate as PVC heat stabilizer

The invention relates to a new use of dicarboxylates as PVC heat stabilizer. The aliphatic dicarboxylates is nontoxic and environment-friendly, is of cheap price, lubricating quality and high metal content, and can improve inherent heat stability, paintability and long-term stability of PVC, so it has a good industry application prospect.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com