Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1556results about How to "Enable recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

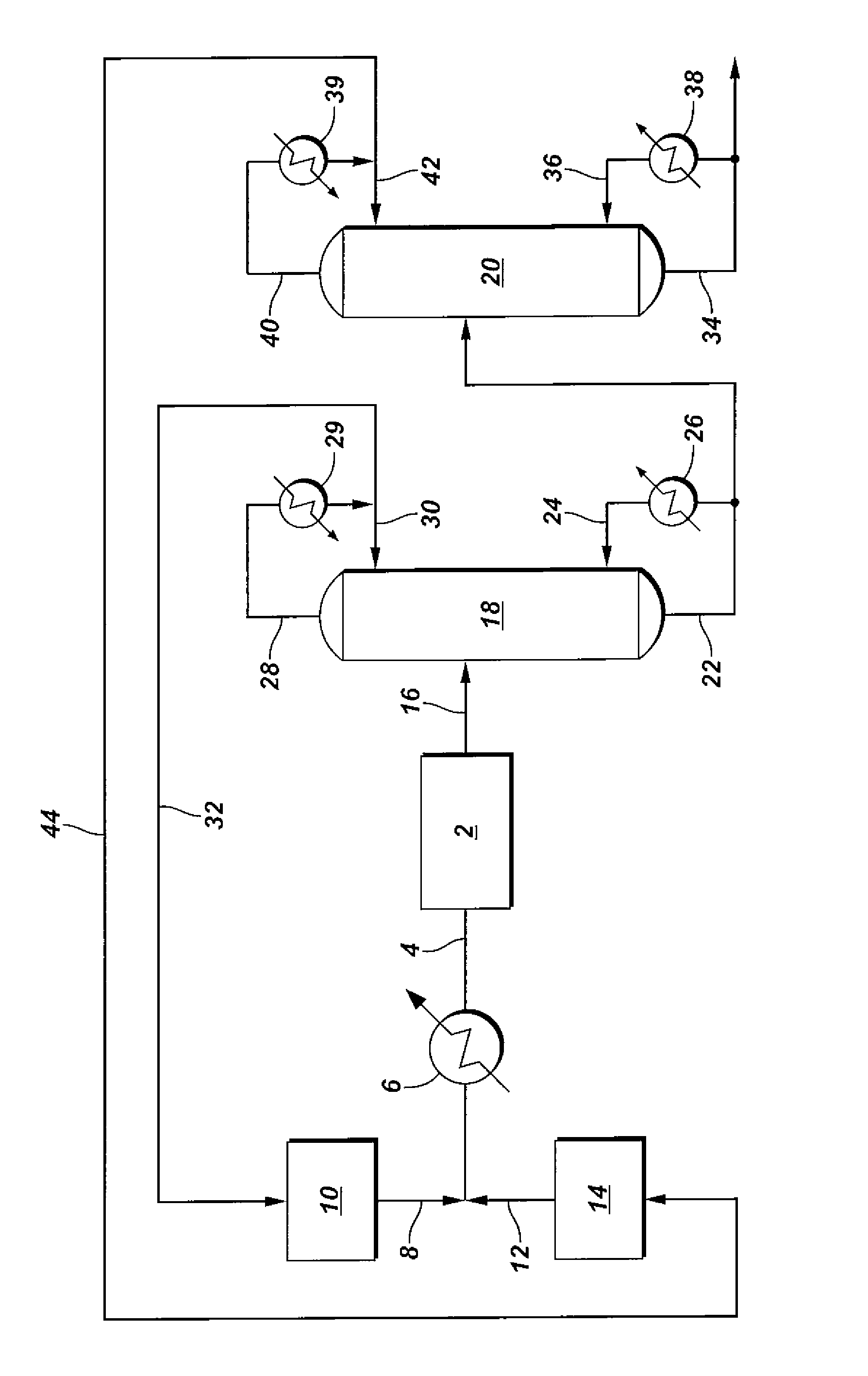

Compositions and methods of using same in producing heavy oil and bitumen

InactiveUS7691788B2Maximize the effectLarge volumeWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

Owner:SCHLUMBERGER TECH CORP

Compositions and Methods of Using Same in Producing Heavy Oil and Bitumen

InactiveUS20070295640A1Reduce energy consumptionMinimal heat lossWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

deposition in a formation, wellbore, near wellbore region, and production tubing. Compositions of the invention comprise an asphaltene solvent and a viscosity reducing agent, the asphaltene solvent and viscosity reducing agent present in a ratio so as to substantially reduce viscosity of an asphaltene-containing material while substantially negating deposition of asphaltenes either in a reservoir, in production tubing, or both when mixed or otherwise contacting the asphaltene-containing material Methods of the invention comprise forcing a composition comprising an asphaltene solvent and a viscosity reducing agent to contact an asphaltene-containing hydrocarbon in an underground geologic formation, and producing from the formation a production composition comprising at least some of the treatment composition and at least some of the asphaltene-containing hydrocarbon under conditions sufficient to substantially negate deposition of asphaltenes in the formation.

Owner:SCHLUMBERGER TECH CORP

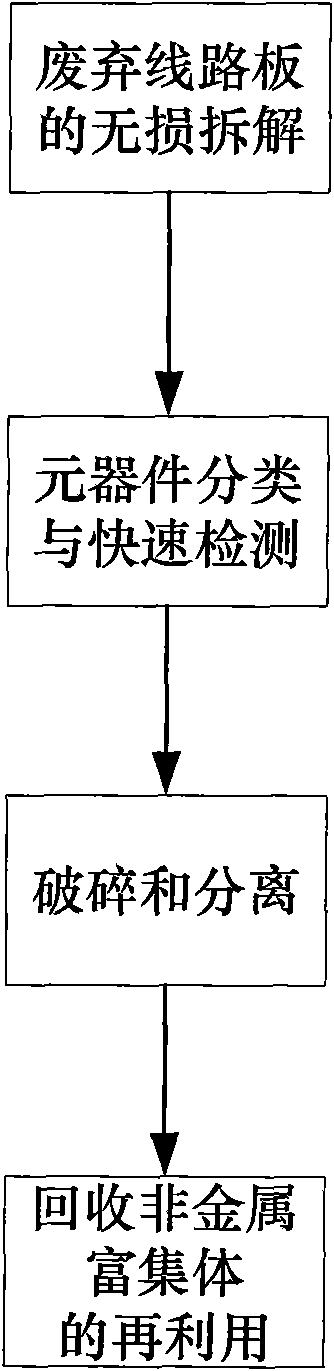

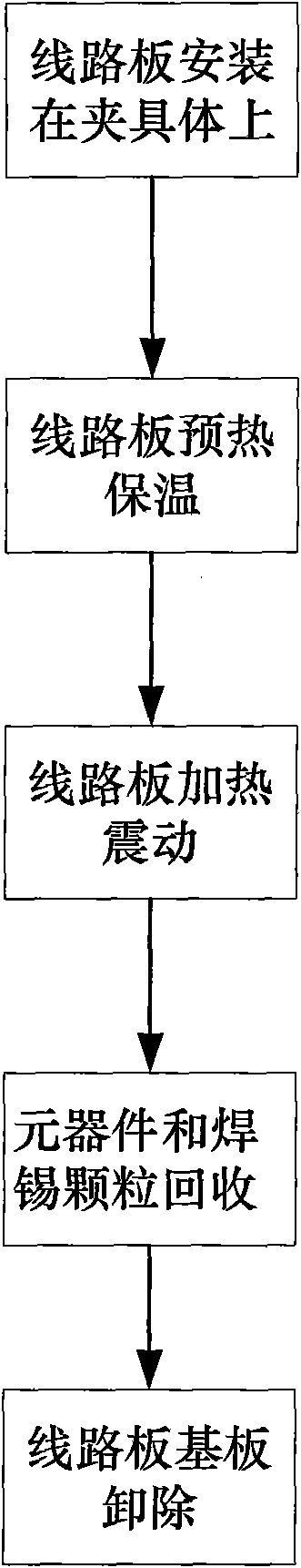

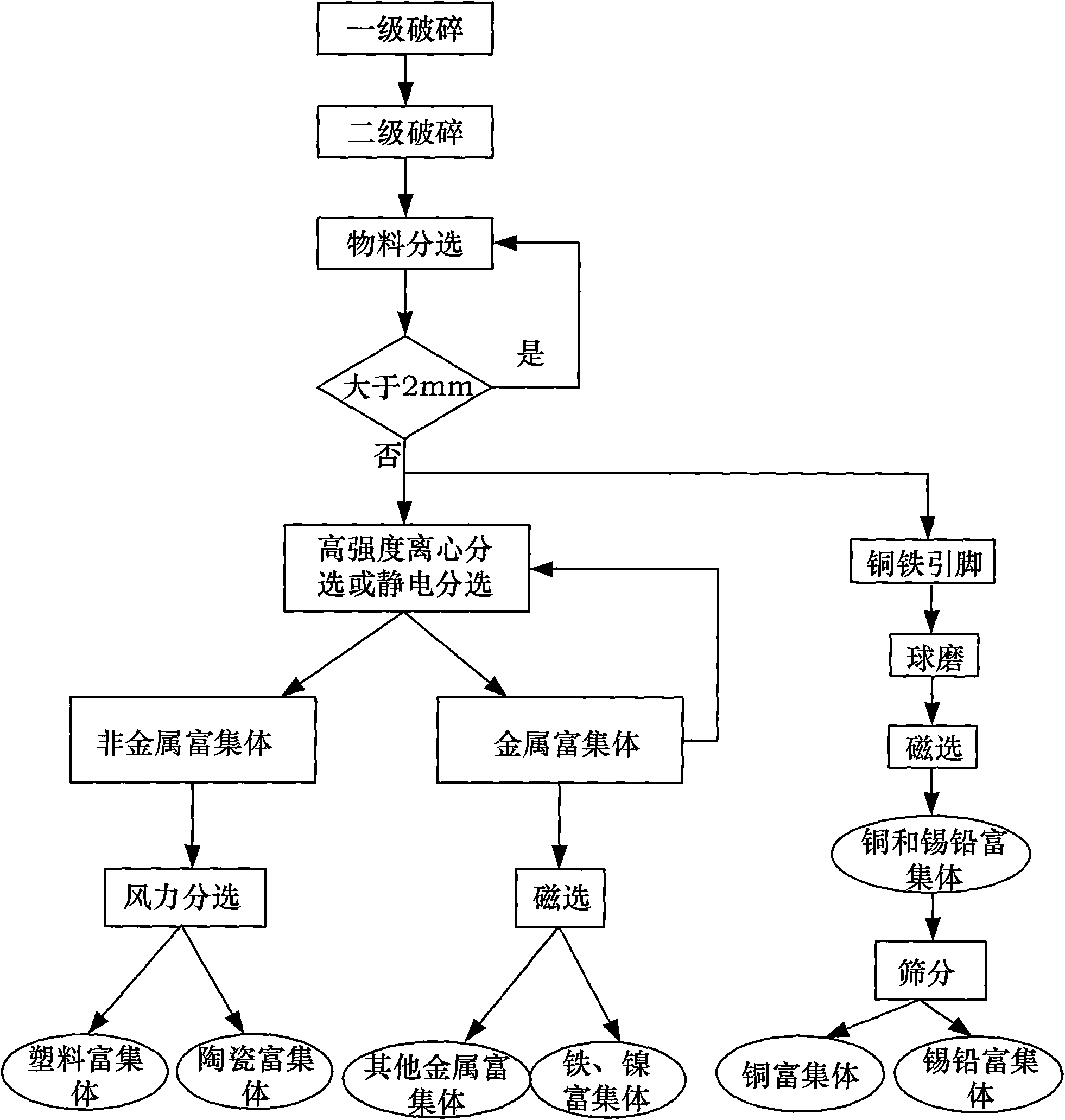

Recycling method of discarded circuit board

InactiveCN101642765ARealize separation and recoverySimplified brokenSolid waste disposalSoldering apparatusEngineeringMetal powder

The invention discloses a recycling method of discarded circuit boards, comprising the following steps: disassembling a discarded circuit board into three parts: a base plate, components and solder, then carrying out sorting and rapid detection on disassembled components; respectively crushing and separating the base plates and various loss-of-function components, and recycling the crushed and separated various powders, wherein the metal powder can be directly reused, and the recycled non-metal powder is used for being prepared into compound material. The method provided by the invention can realize sorting recycling of all resources of the discarded circuit boards; the recycled material can be reused, and therefore, the secondary pollution can not be generated.

Owner:BEIHANG UNIV

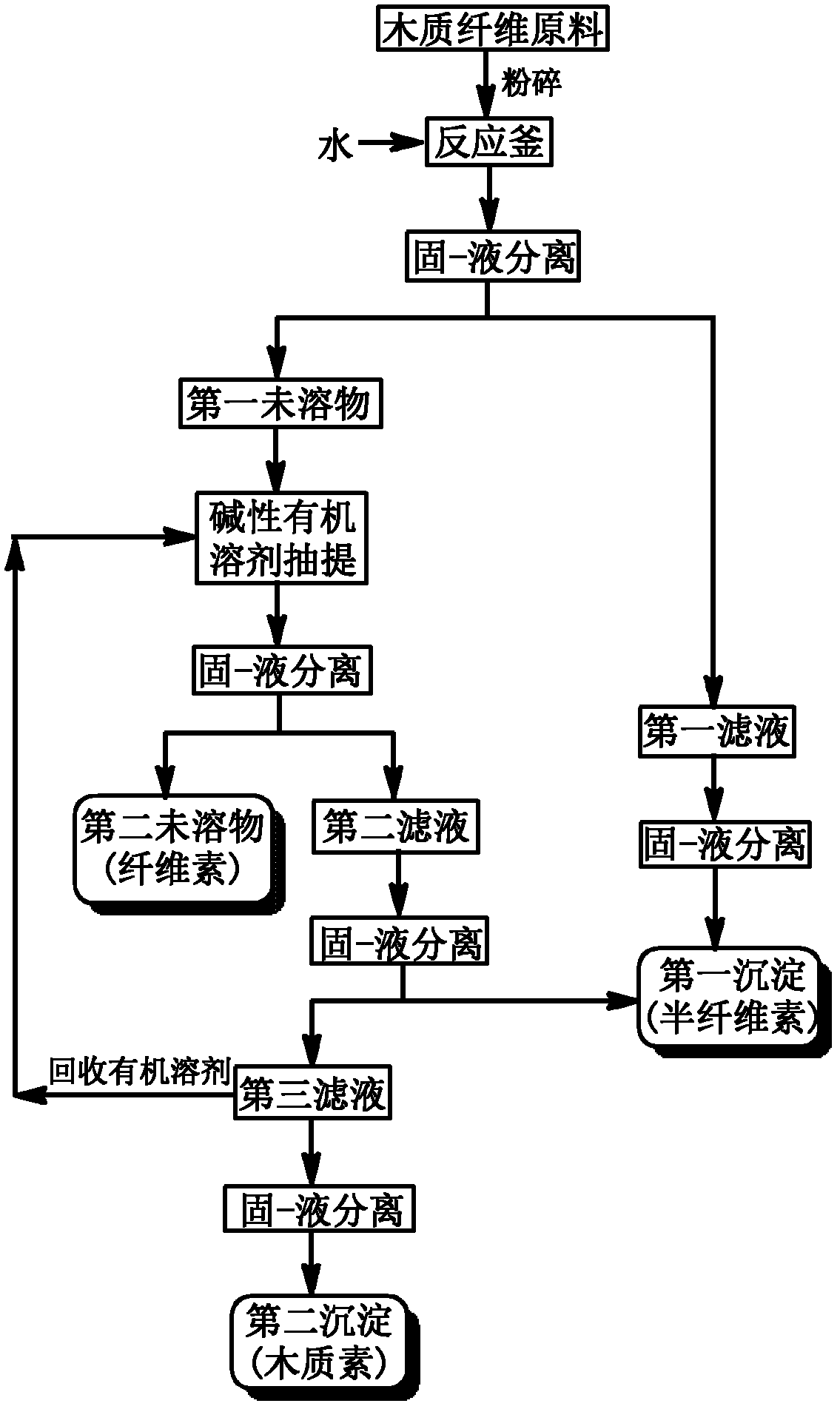

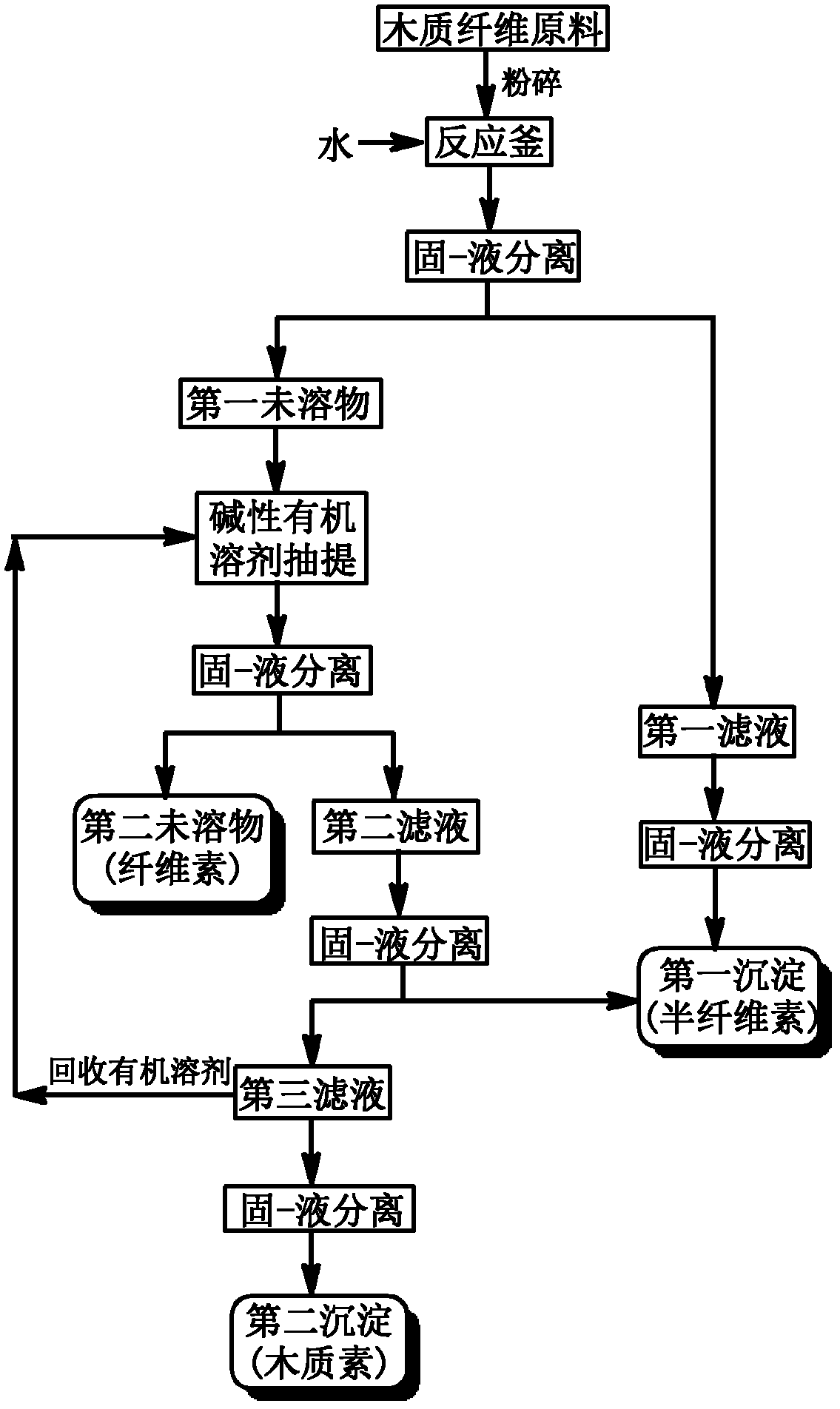

Method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials

The invention relates to a method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials and belongs to the field of utilization and technology of biomass resources of agriculture and forestry. In the method, the hemicellulose is extracted from the wood fiber raw materials by using hot water, then the lignin is extracted by using alkaline organic solvent under mild conditions; and residual ingredients rich in the cellulose are further used for enzyme hydrolysis to prepare fermentable sugar solution, thereby achieving full-ingredient utilization of the hemicellulose, cellulose and lignin in the biomass resources of the agriculture and forestry. The method has simple process, and is environmentally friendly, the organic solvent can be recycled, thereby promoting the development of the green agriculture and forestry, and the method has wide social and economic benefits.

Owner:BEIJING FORESTRY UNIVERSITY

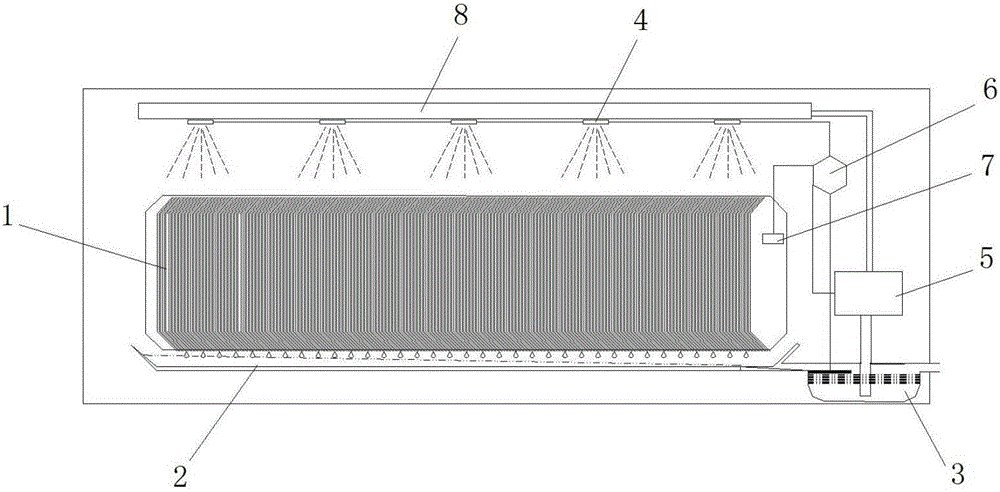

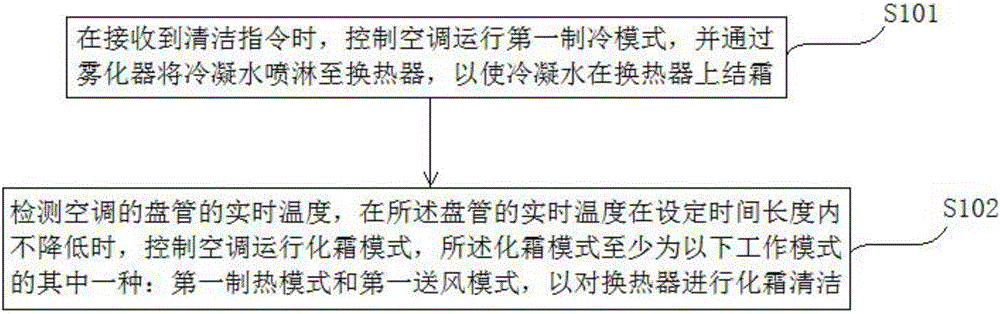

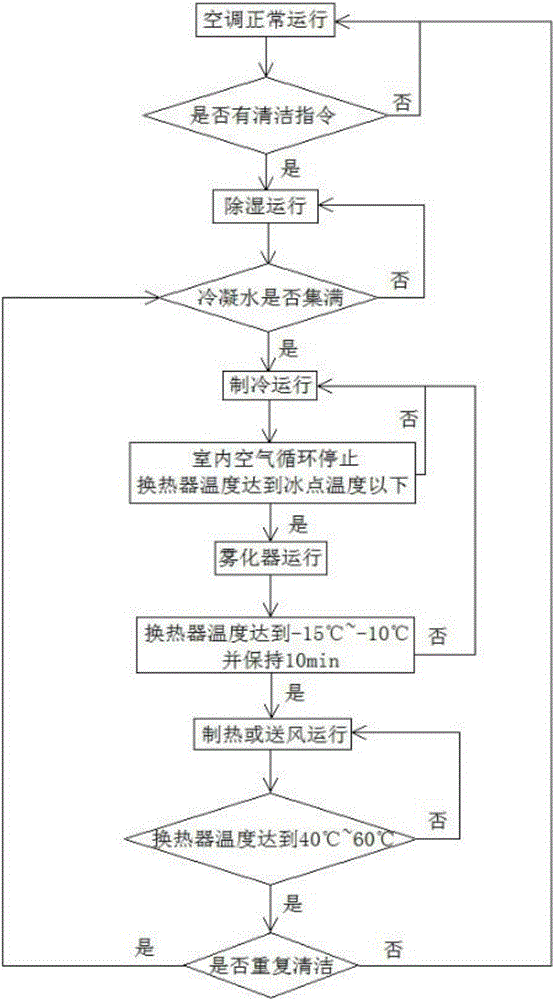

Air conditioner cleaning device and cleaning method

InactiveCN106568173AEasy to cleanEnable recyclingMechanical apparatusSpace heating and ventilation safety systemsCondensed waterFrost

The invention discloses an air conditioner cleaning device and cleaning method, and belongs to the technical field of air conditioner cleaning. An air conditioner comprises a heat exchanger and a water receiving disk. The cleaning device comprises a water storage which communicates with the water receiving disk, atomizers and an actuator, wherein the water storage is used for storing condensed water in the water receiving disk, the atomizers are located above the heat exchanger, and the actuator is connected with the water storage and the atomizers, and used for conveying the condensed water in the water storage to the atomizers. The air conditioner cleaning device can store part of the condensed water in the original water receiving disk, when the air conditioner needs frost condensation for cleaning, the moisture content inside an indoor unit is increased with condensed water, then, the thickness of the ice layer of frost condensation of the air conditioner is increased, and therefore, the cleaning effect of the air conditioner is improved; and meanwhile, condensed water can be recycled, and the product ideas of economization and environmental protection are met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

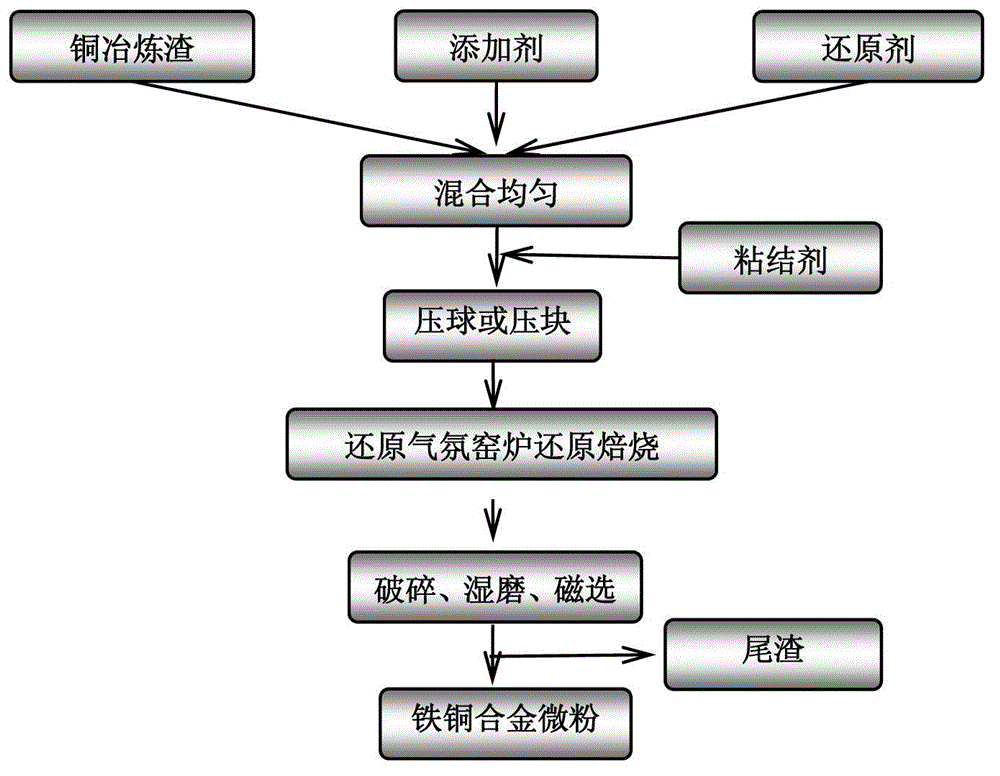

Method for rapidly reducing copper slags to produce iron-copper alloys in kiln in reducing atmosphere

ActiveCN102719676AIncrease added valueAchieve restorationProcess efficiency improvementSilicic acidReducing atmosphere

A method for rapidly reducing copper slags to produce iron-copper alloys in a kiln in a reducing atmosphere is characterized by including the steps: proportionally mixing the copper slags, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20%-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, uniformly mixing, producing the uniformly mixed mixture to pellets with the diameters ranging from 15mm to 30mm and small cylindrical briquettes with all the heights ranging from 15mm to 30mm by a pellet press or a briquetting machine, and drying the pellets or small cylindrical briquettes; flatly laying the dried pellets or small cylindrical briquettes at the bottom of the kiln, wherein the material layer thickness ranges from 20mm to 45mm, the material layer reducing temperature ranges from 1250 DEG C to 1450 DEG C, and the reducing time is 10-40min; and subjecting the reduced pellets or the briquettes to cooling, crushing, wet grinding and wet separation so that iron-copper alloy powder with the iron recovery rate of 85%-99% is obtained. According to the method, iron in a great quantity of silicate iron in the copper slags, which cannot be separated out by the traditional technology, is extracted and turns into the iron-copper alloy micro powder with high added value so that iron and copper in the copper slags are extracted and used simultaneously, and physical and chemical heat energy in strong reducing waste gas can be completely recovered during rapid depth reduction.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

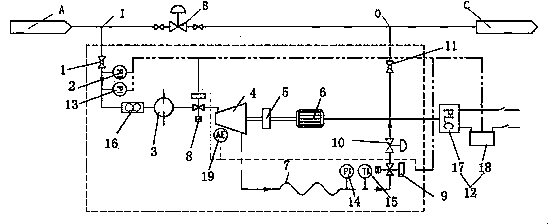

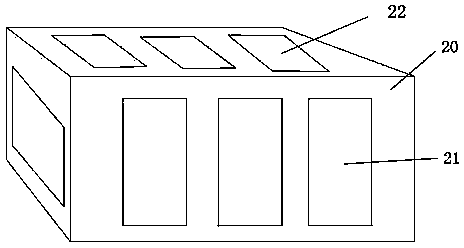

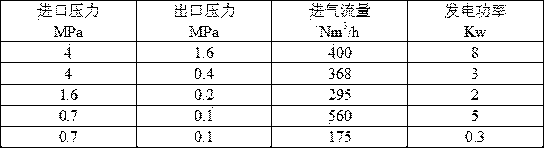

A pressure energy-recycling generation device for a natural gas pipe network

InactiveCN104213939AReduce wasteEnable recyclingMachines/enginesSafety/regulatory devicesElectricitySolenoid valve

The invention provides a pressure energy-recycling generation device for a natural gas pipe network. The device can efficiently transform the pressure energy in the natural gas pipe network into electricity, thereby realizing recycling. The operation state of the generation device can be automatically real-time monitored by combining a PLC and a solenoid valve, a pressure transmitter, a leakage detector and a sealing machine pry. The device can automatically forewarn and interlock to shut off when conditions like excess pressure and gas leakage occur, so the device has superior security and stability. The device can produce outstanding economic benefit, and has important meaning to reducing resource waste and accelerating establishment of resource-saving and environmentally friendly society.

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

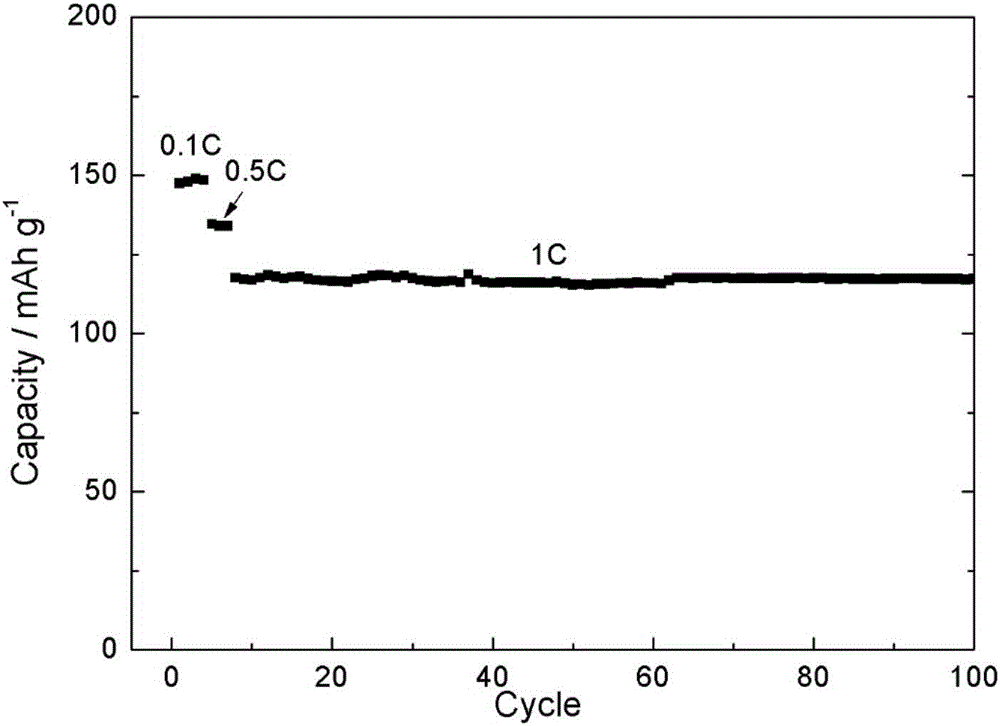

Recovery method of positive active material in lithium ion battery waste material

InactiveCN103794832AHigh charge and discharge capacityImprove charge and discharge efficiencyWaste accumulators reclaimingBattery recyclingElectrochemistryLithium electrode

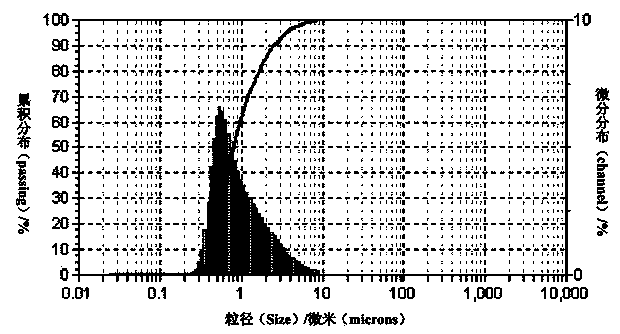

The invention provides a recovery method of a positive active material in a lithium ion battery waste material. The method includes the following steps: S1, heat treatment of the waste material is performed at 350-500DEG C in inert gas or reducing gas atmosphere; S2, powder product obtained in the step S1 is sintered at 600-800DEG C in the inert gas or reducing gas atmosphere; and the positive active material is obtained by recovery; the positive active material is one or multiple substance selected from lithium phosphate, lithium silicate or a vanadium material of lithium. The positive active material obtained by recovery is high in charge and discharge capacity, and high in charge and discharge efficiency, the obtained positive active material is even in particle size distribution, and complete in crystal structure, the technical process of the recovery method is simple, the requirement on equipment is low, the process is easy to control, at the same time, the recovery process may not cause a negative impact on the active material, physical and chemical properties and electrochemical activity of the active material may not be affected, the recovery and reuse of the positive active material raw material can be realized, the cost can be saved, and the recovery method has environmental-friendly benefits.

Owner:BYD CO LTD

Method and apparatus for quickly and deeply purifying air or water or other fluid at low cost

InactiveCN101055106AStrong catalytic reaction abilityQuick breakdownWater/sewage treatment by irradiationLighting and heating apparatusChemistryDecomposition

Owner:蒋遂安

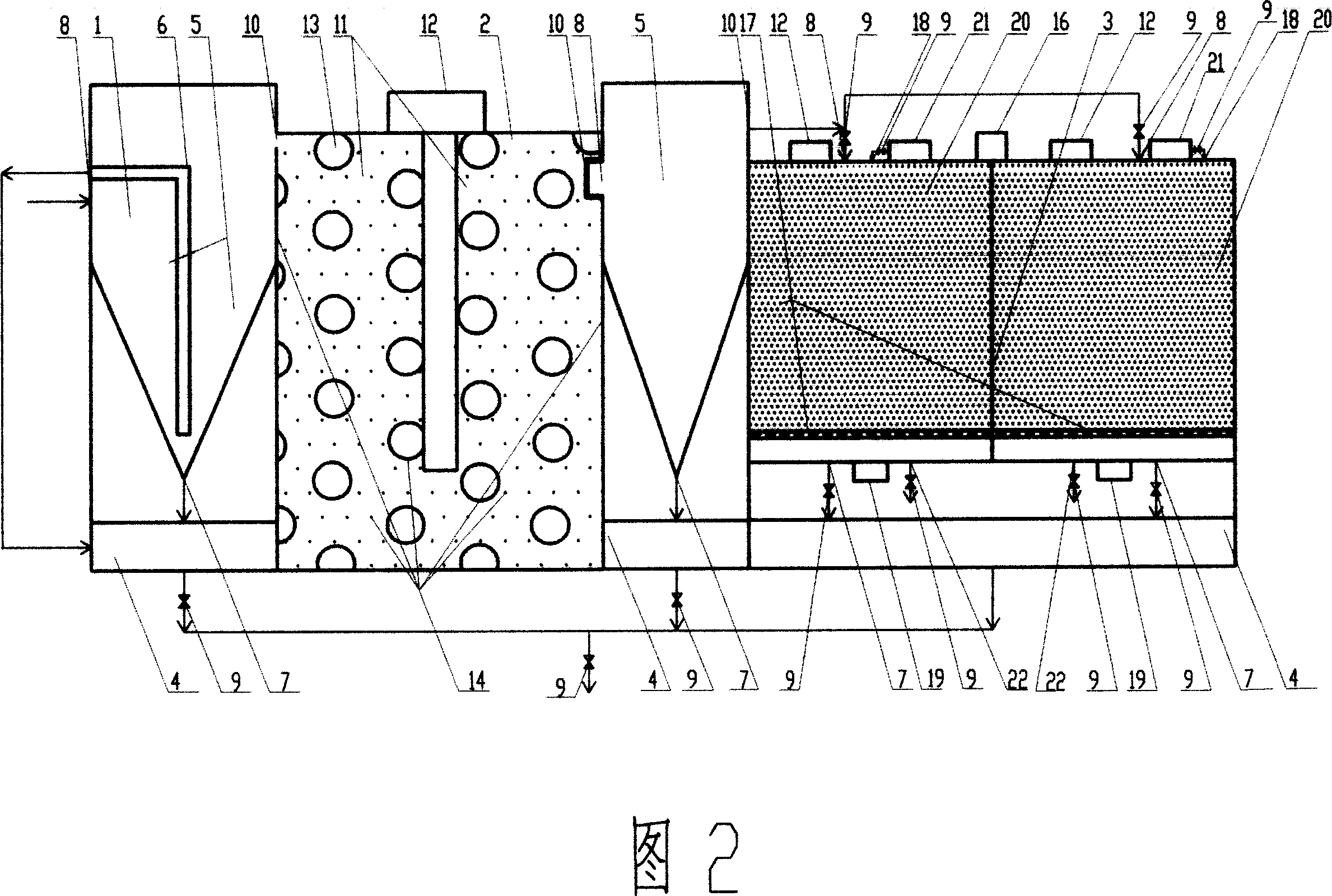

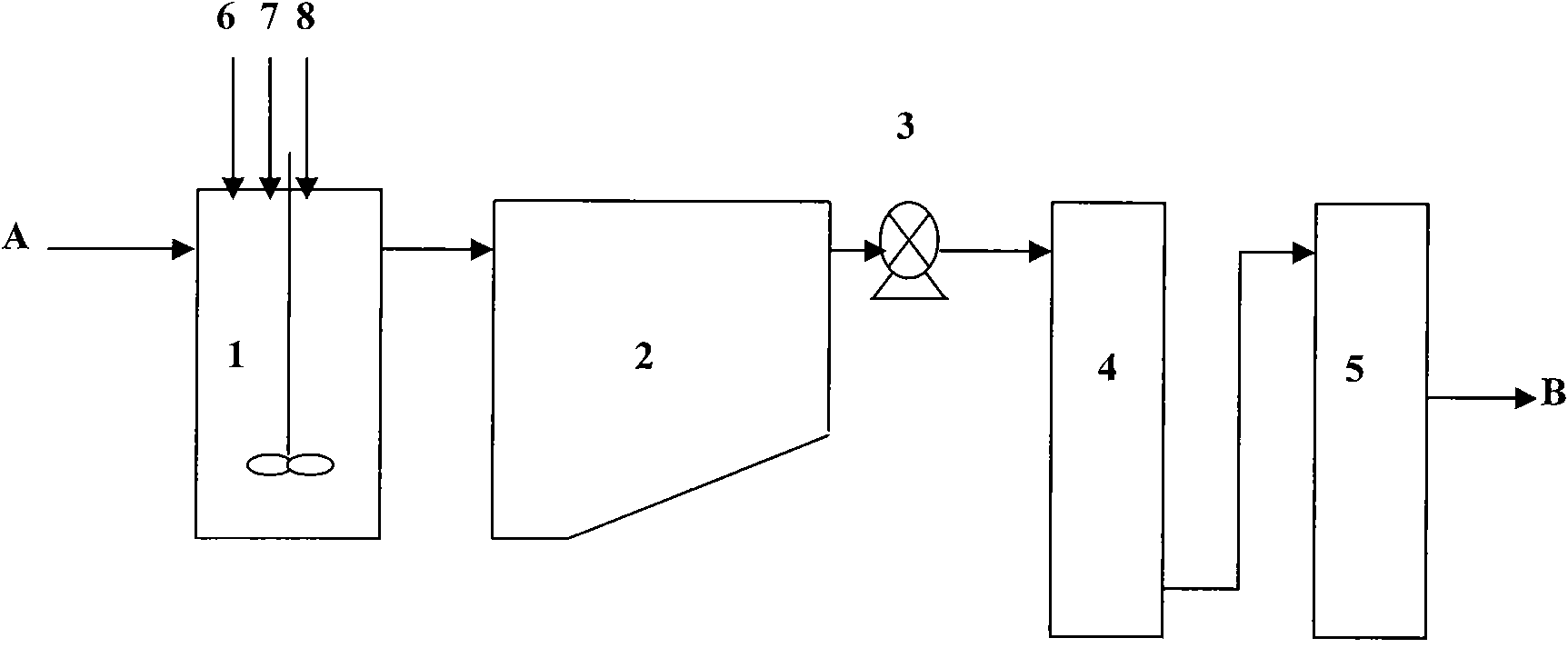

Method and device for treating a great variety of waste emulsion of high concentration using hyperfiltration membrane method

ActiveCN101311127AGood demulsification effectEasy to handleUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh concentrationLiquid waste

The invention discloses a method for treating the waste emulsion with high concentration and a plurality of varieties by an ultrafiltration membrane method and a device thereof, which belongs to the technical field of waste water and waste liquid treatment. The main technique of the invention is 'dissolved air flotation-ultrafiltration membrane-electrolysis floatation', which can effectively reduce the dosage of medicament and improve emulsion breaking effect by adopting an efficient dissolved air flotation system, moreover, the water for dissolved air flotation, which is taken from a subsequent intermediate water tank, can flexibly adjust and dilute the concentration of the waste water, thus improving the running stability and the shock resistant loading capability of the system. An ultrafiltration membrane with large flux, high separative efficiency and long service life is adopted in an ultrafiltration system to realize oil-water separation and to concentrate the emulsion for a plurality of times and then floating oil is recovered, the waste water generated in ultrafiltration washing is treated again after reflow, thus reducing waste liquid discharging. Electrolysis floatation can remove residual emulsified oil and dissolved oil in the waste water, thus further lowering the COD value of yielding water. When the quality of raw water is changed, an activated carbon adsorption unit can guarantee the quality of the yielding water to be standard. The method and the device of the invention can process waste emulsion with high concentration and a plurality of varieties and have simple and reasonable technique, good quality of yielding water, compact layout of the device, thus facilitating automatic control and realizing recovery of emulsion and recycle economy as well as changing waste to be profitable simultaneously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

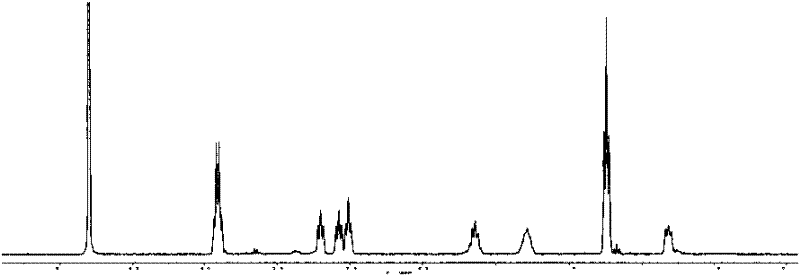

Ionic liquid precursors and their supported mesoporous materials, synthesis and applications

InactiveCN102276642AReduce usageReduce use costGroup 4/14 element organic compoundsOrganic compound preparationChemical reactionIonic conductance

The invention relates to an ionic liquid precursor and a mesoporous material for supporting the ionic liquid precursor, synthesis and application. A preparation method comprises the following steps of: 1) synthesizing the ionic liquid precursor; 2) synthesizing the mesoporous material for supporting the ionic liquid precursor; and 3) acidizing or alkalifying the synthesized mesoporous material for supporting the ionic liquid precursor according to the requirements so as to obtain a target product. The loading capacity of the mesoporous material for supporting the ionic liquid precursor is relatively adjusted, and a mesoporous material for supporting functionalized ionic liquid can be obtained by further acidizing or alkalifying the material according to the requirements. The amount, strength of acid and alkali, properties, variety and the like of ionic liquid supported on the material are adjustable, so that the material can meet the demand of application such as various acid and alkaline catalytic reactions, chemical adsorption and separation and the like. By the material, the using amount of the ionic liquid is greatly reduced, the better catalytic effect is achieved when the material is applied to aldol condensation reactions, and the recycling of a catalyst can be realized. The kind of material is expected to be used for catalyzing more chemical reactions, and may be applied in the fields of adsorption, separation, ionic conductance and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

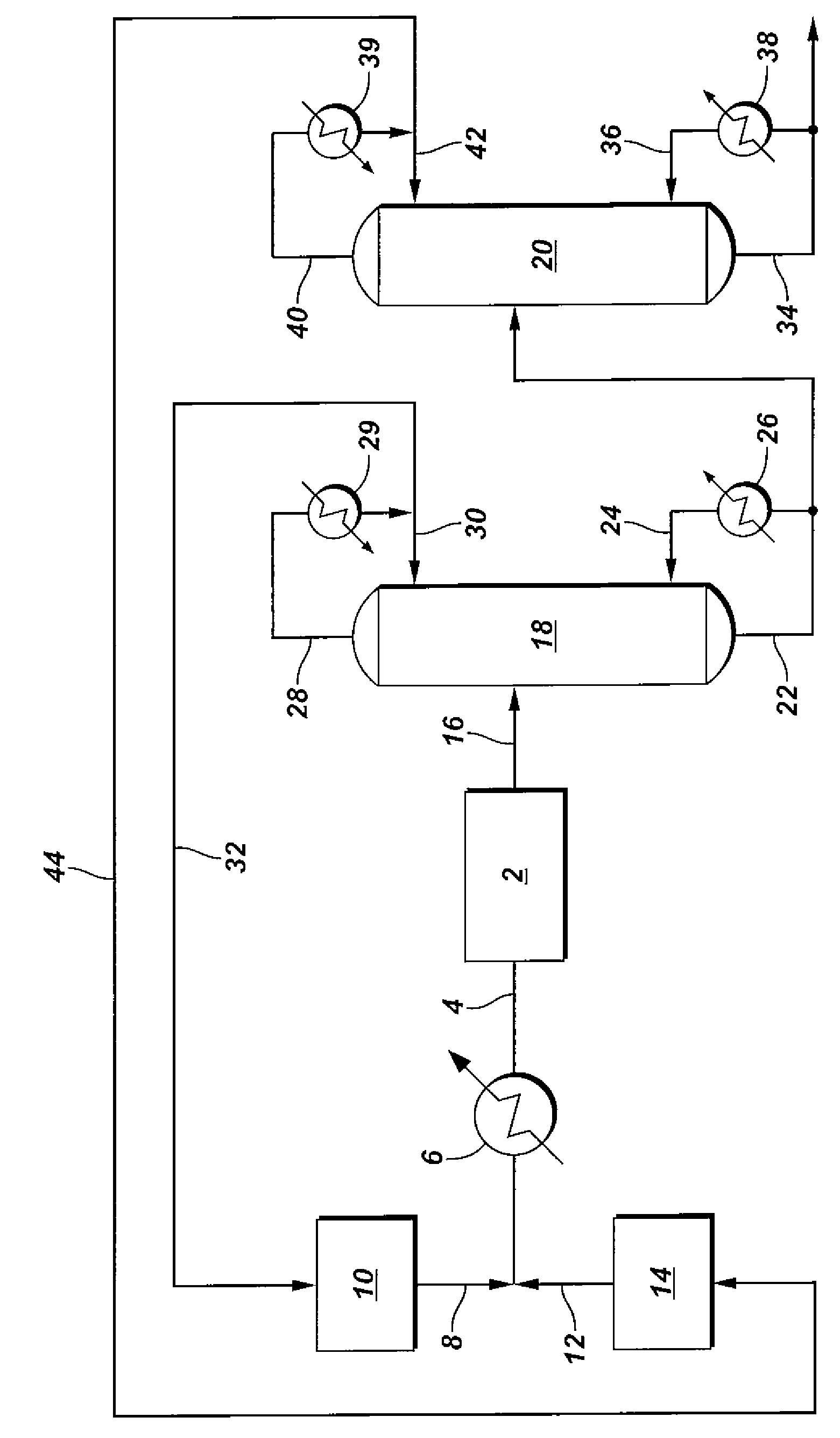

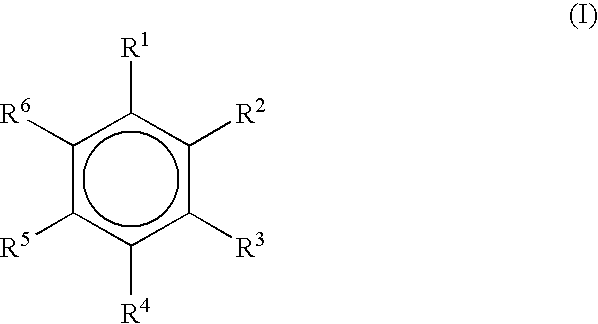

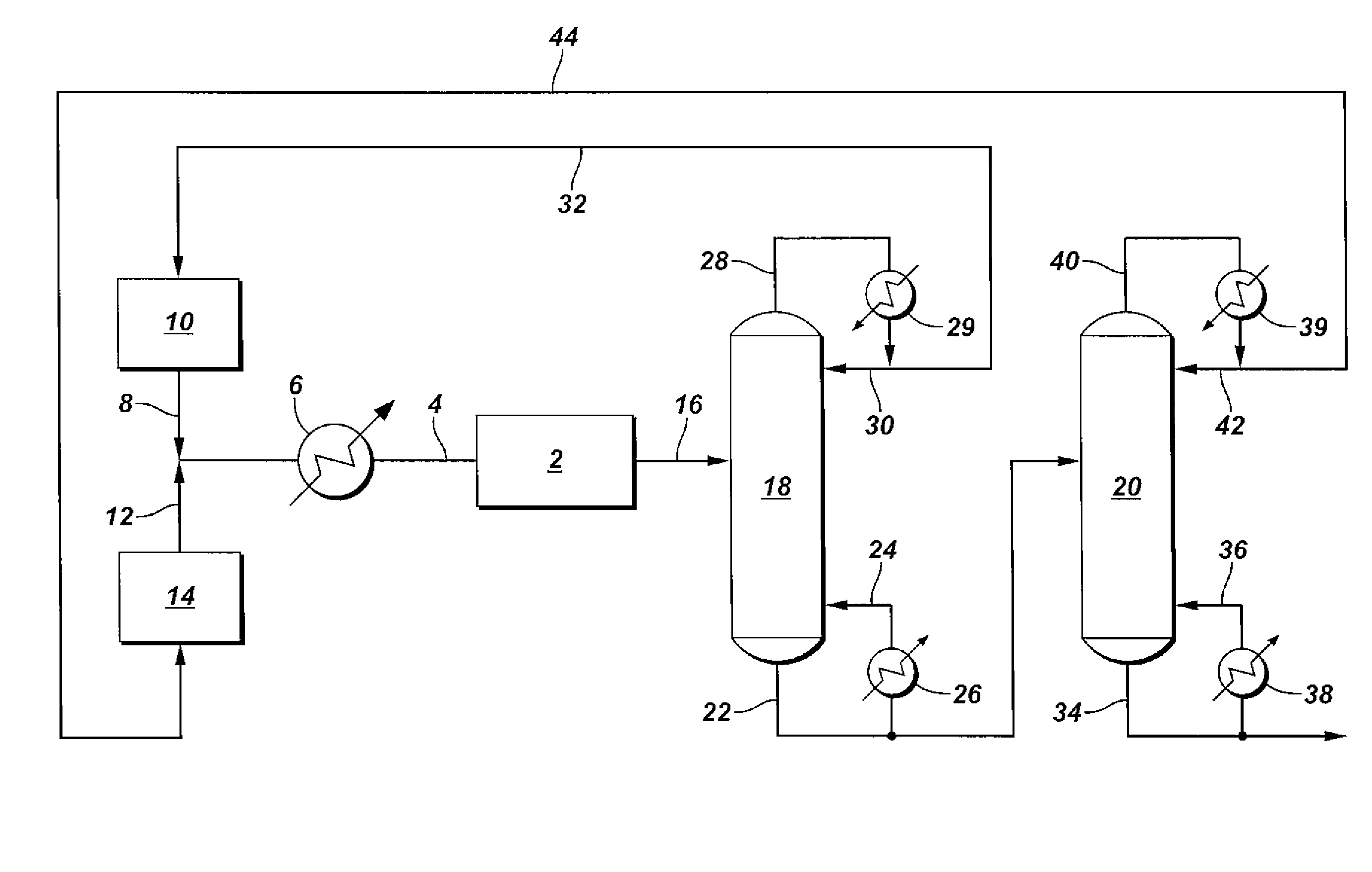

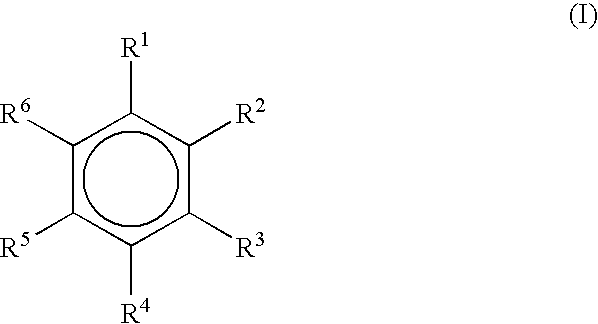

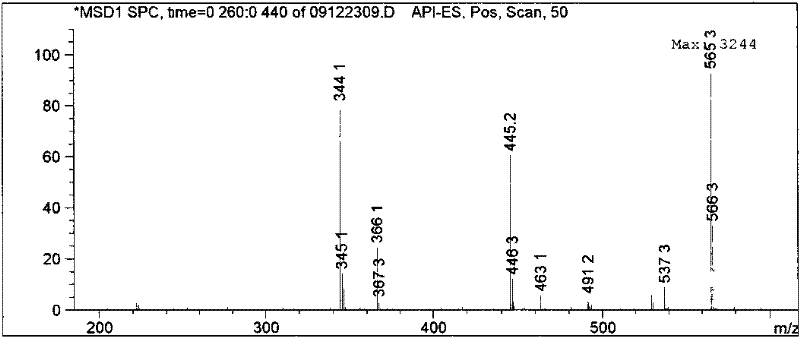

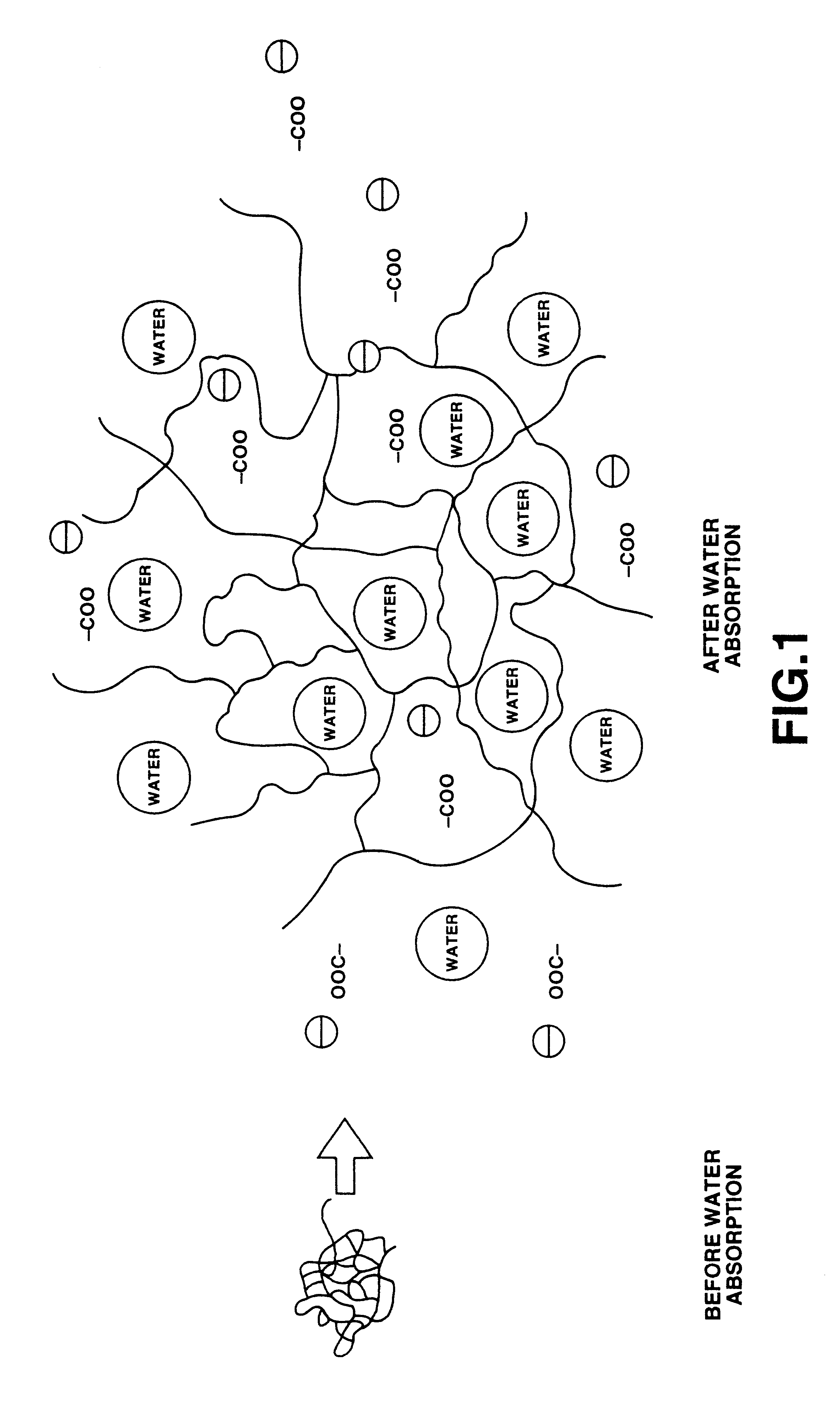

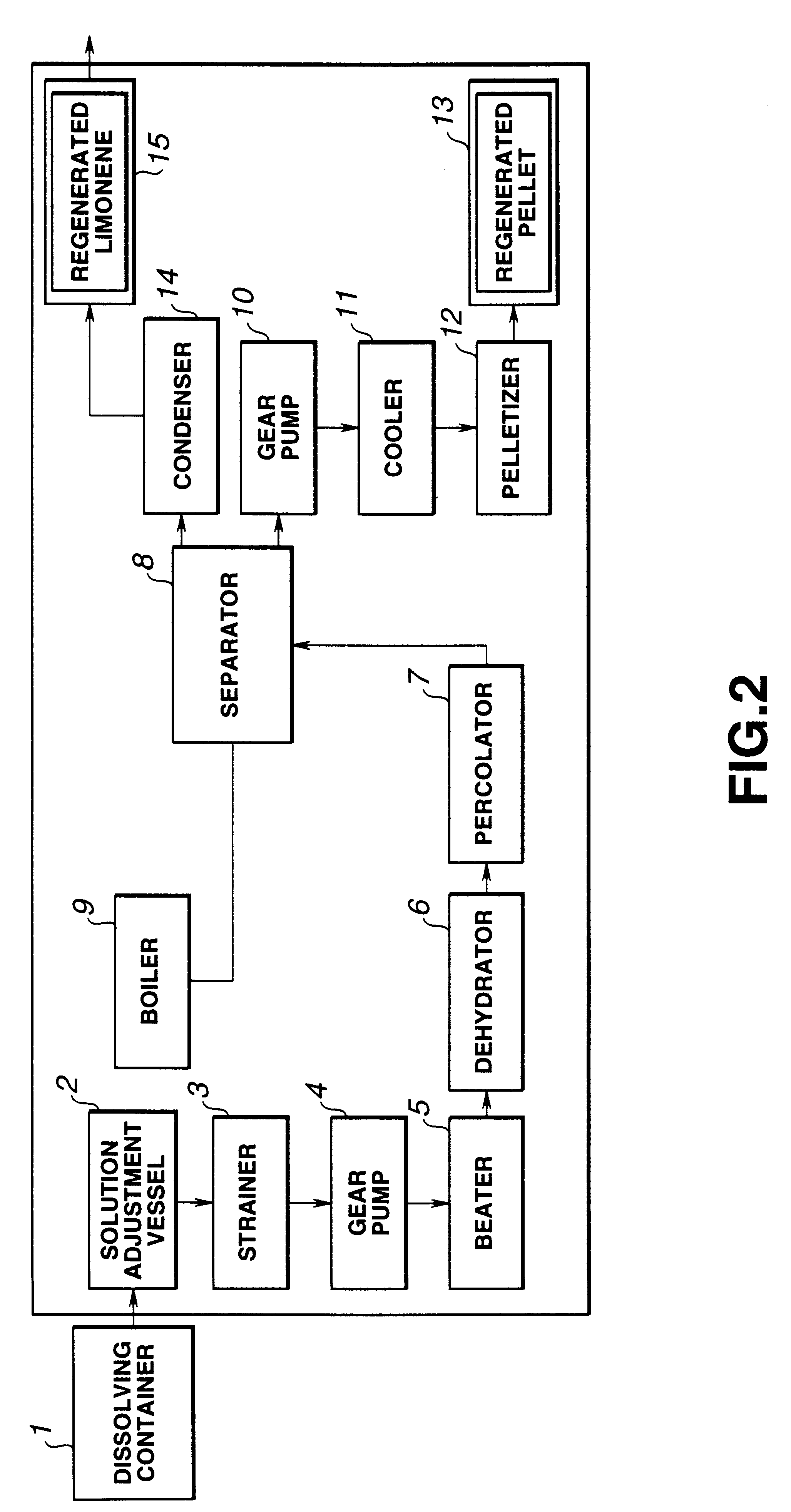

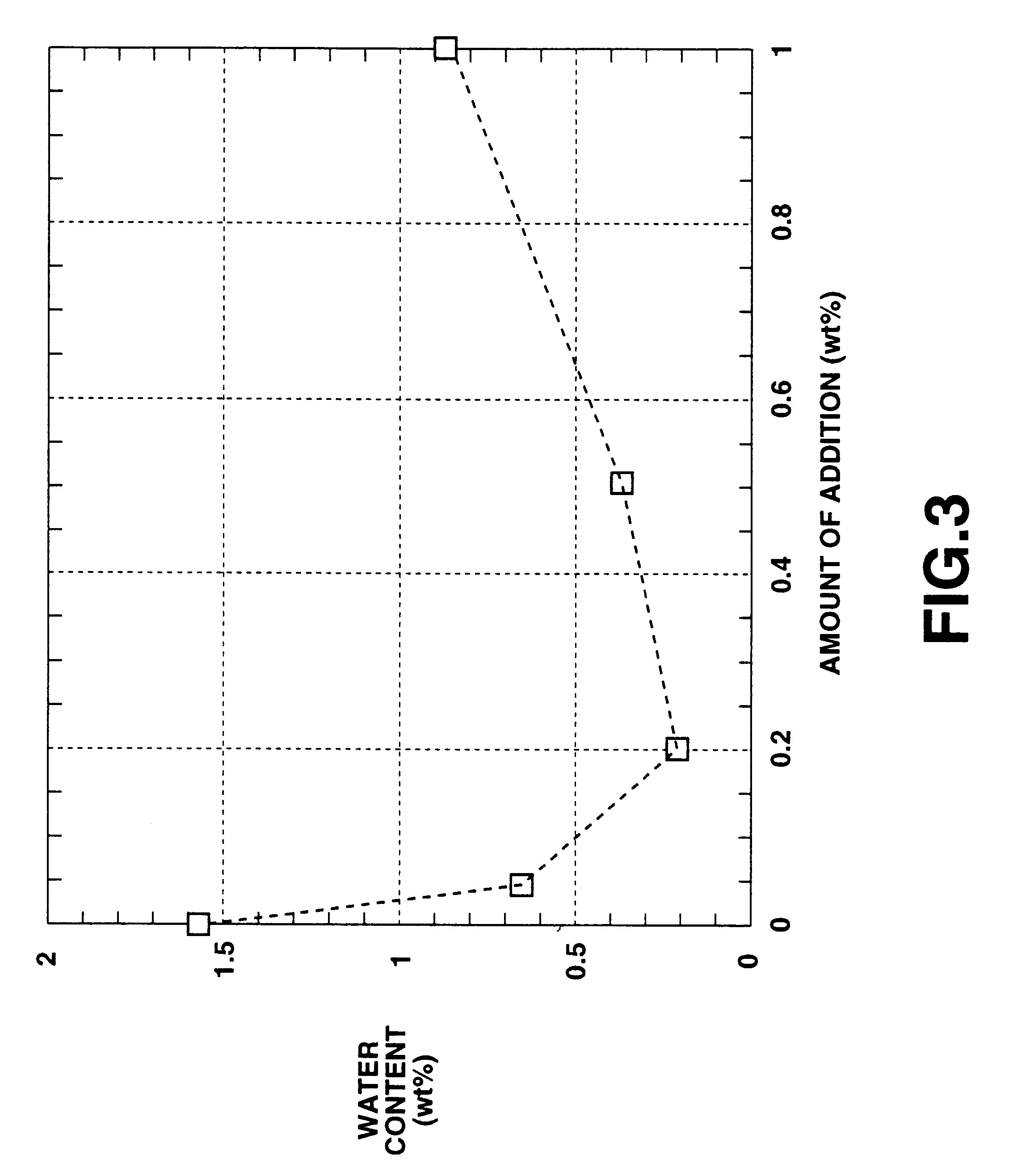

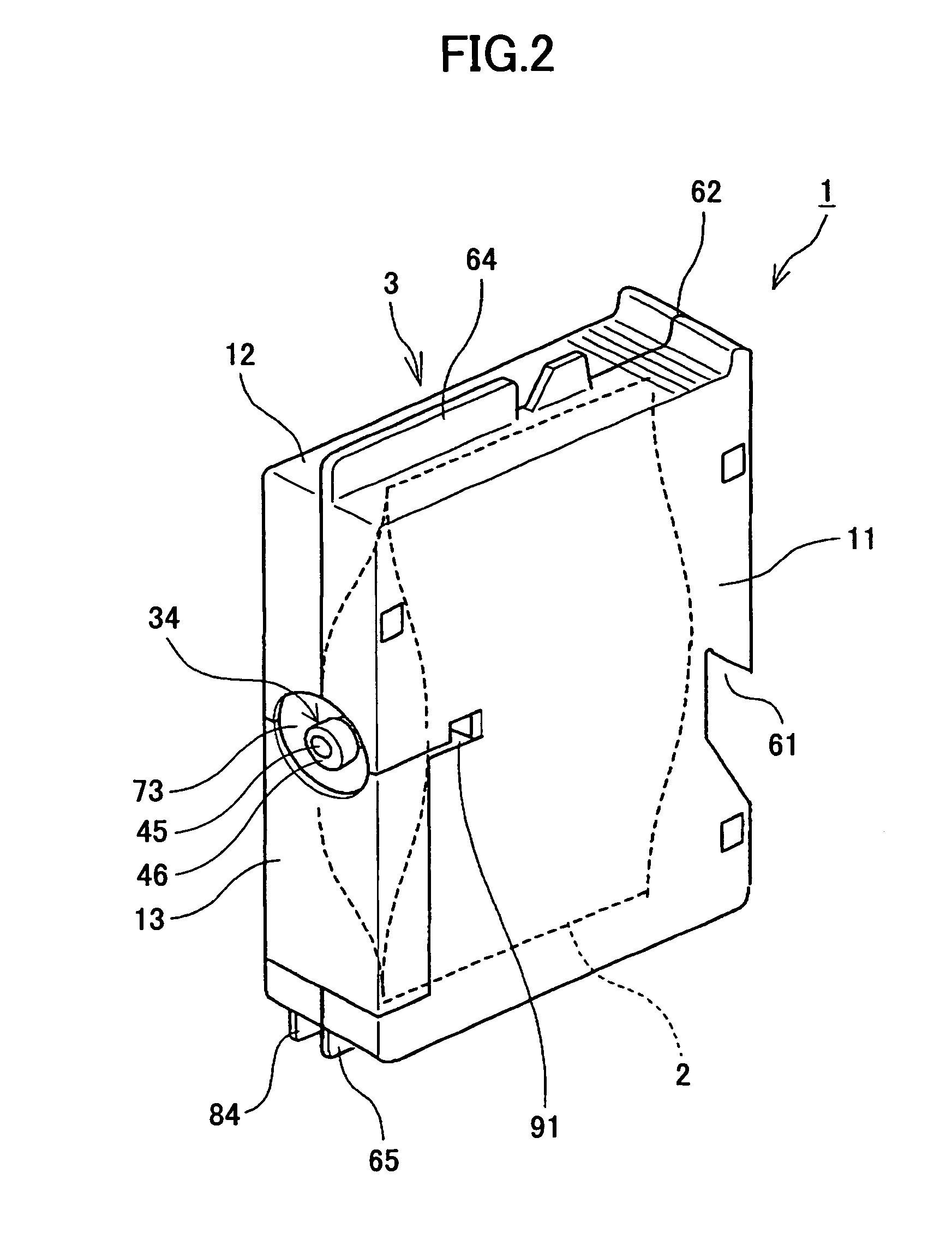

Method and apparatus for recycling styrene resin

InactiveUS6169121B1High-quality regeneratedEnable recyclingPlastic recyclingEnergy based chemical/physical/physico-chemical processesForeign matterOrganic solvent

There is provided a processing method for effectively and promptly removing insoluble components contained in a solution of a styrene resin waste material to enable regeneration of high-quality regenerated styrene. To this end, a solution of the styrene resin waste material in an organic solvent is processed with, for example, a dehydrating agent, to remove insoluble components. The resulting clarified solution is degasified on heating in vacuum to remove the organic solvent for recycling the resulting mass as a regenerated styrene resin. The insoluble components include foreign matter, such as moisture, sludge and colorant agents. By this processing method, it becomes possible to recycle high-quality regenerated styrene.

Owner:SONY CORP

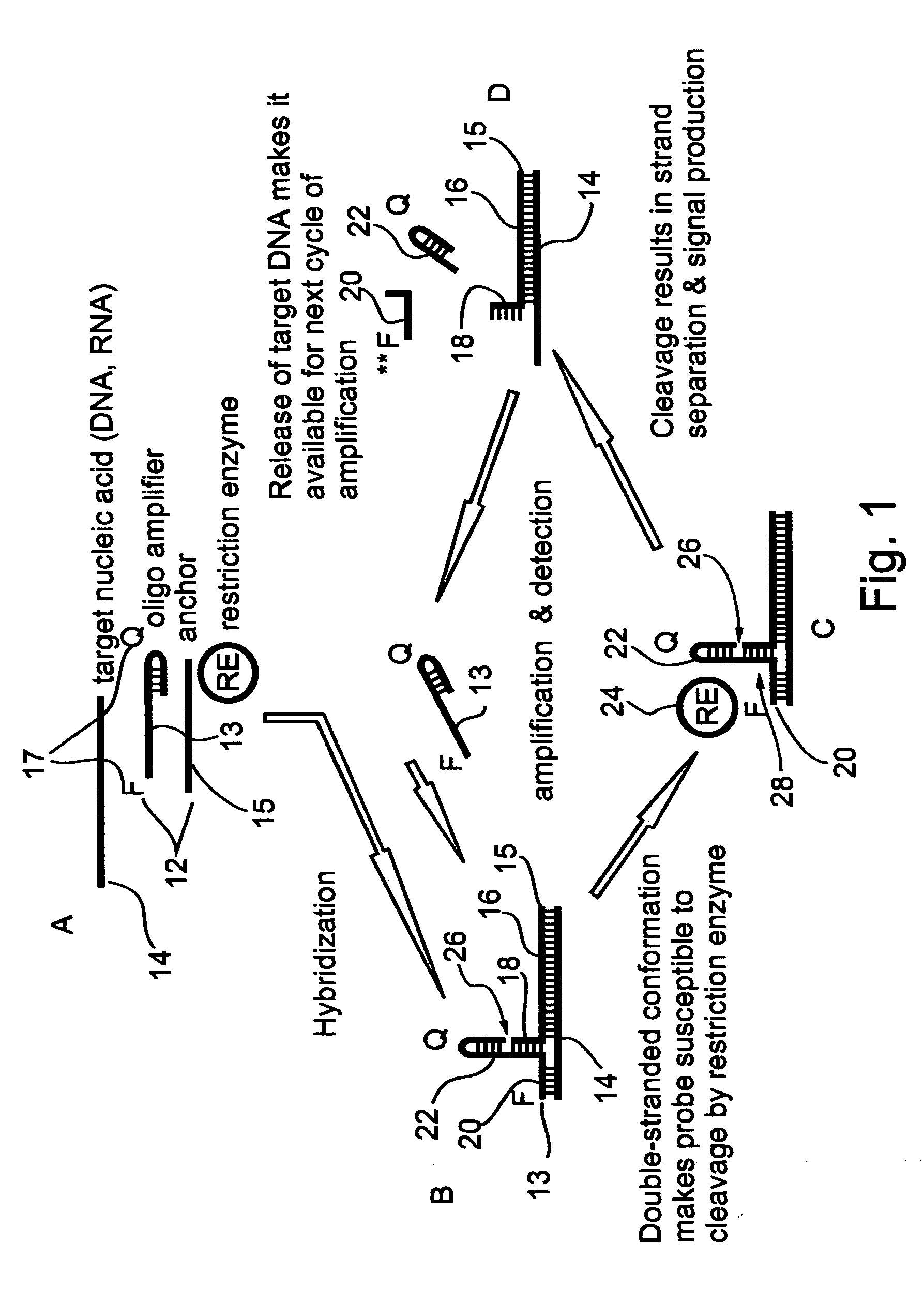

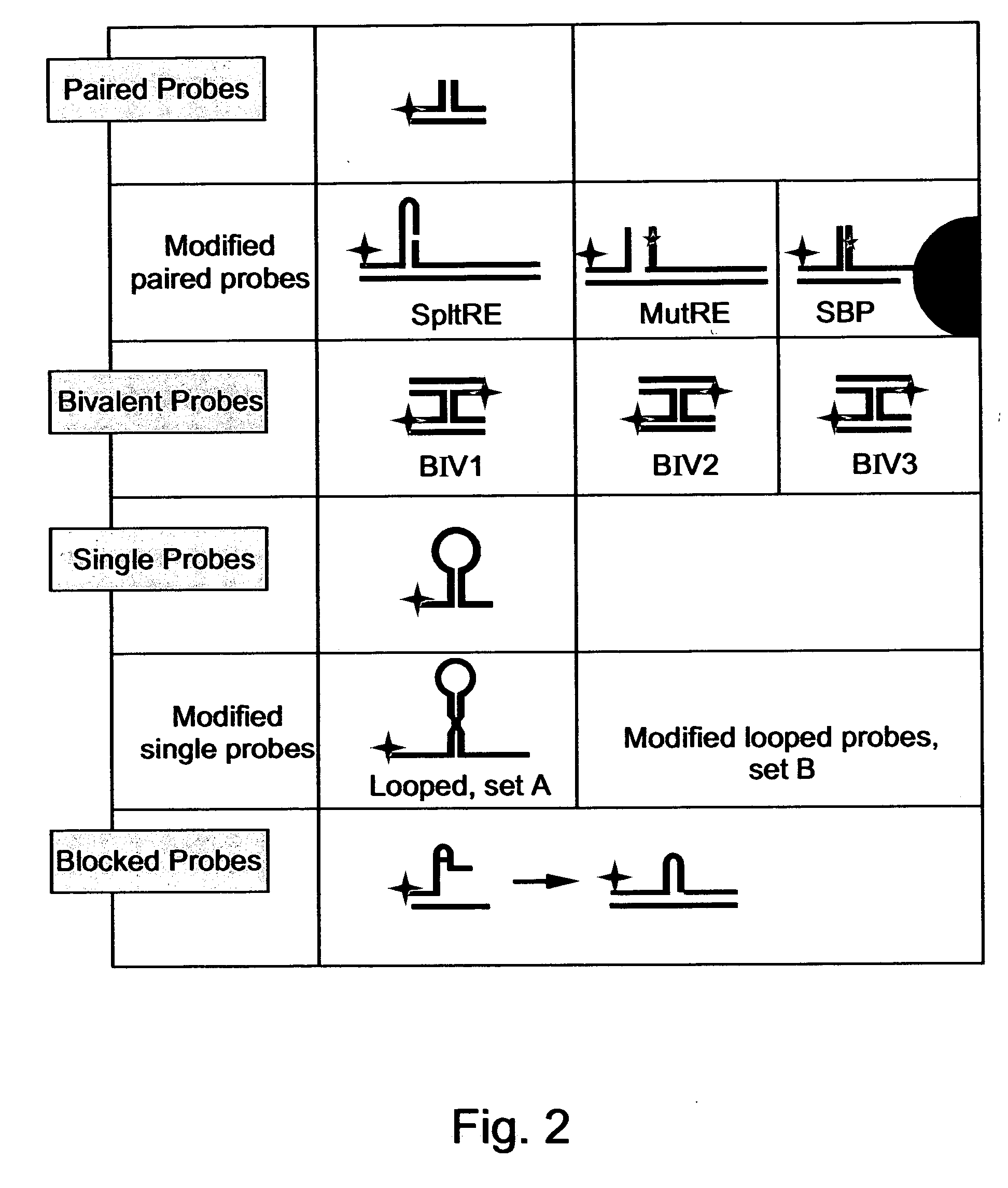

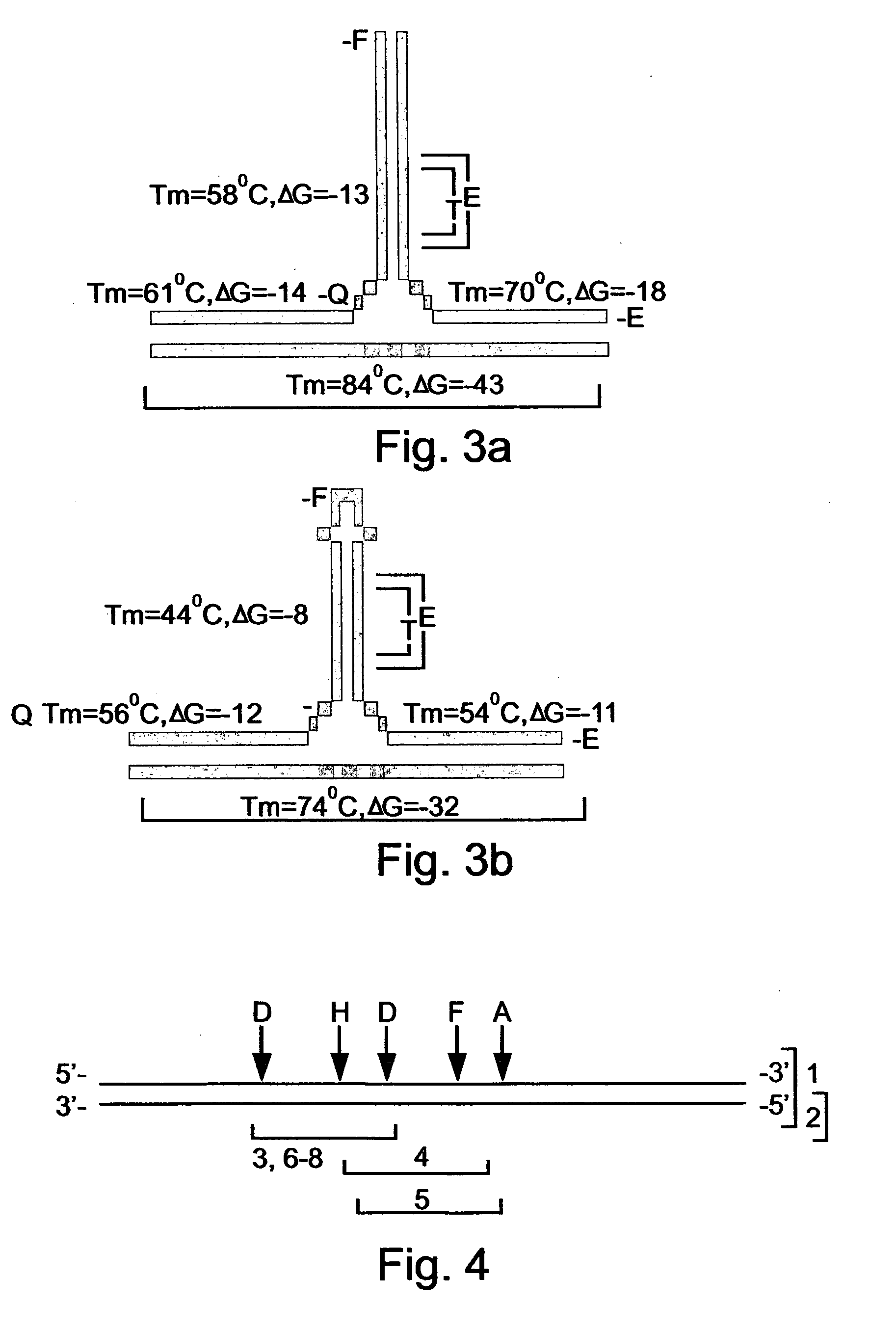

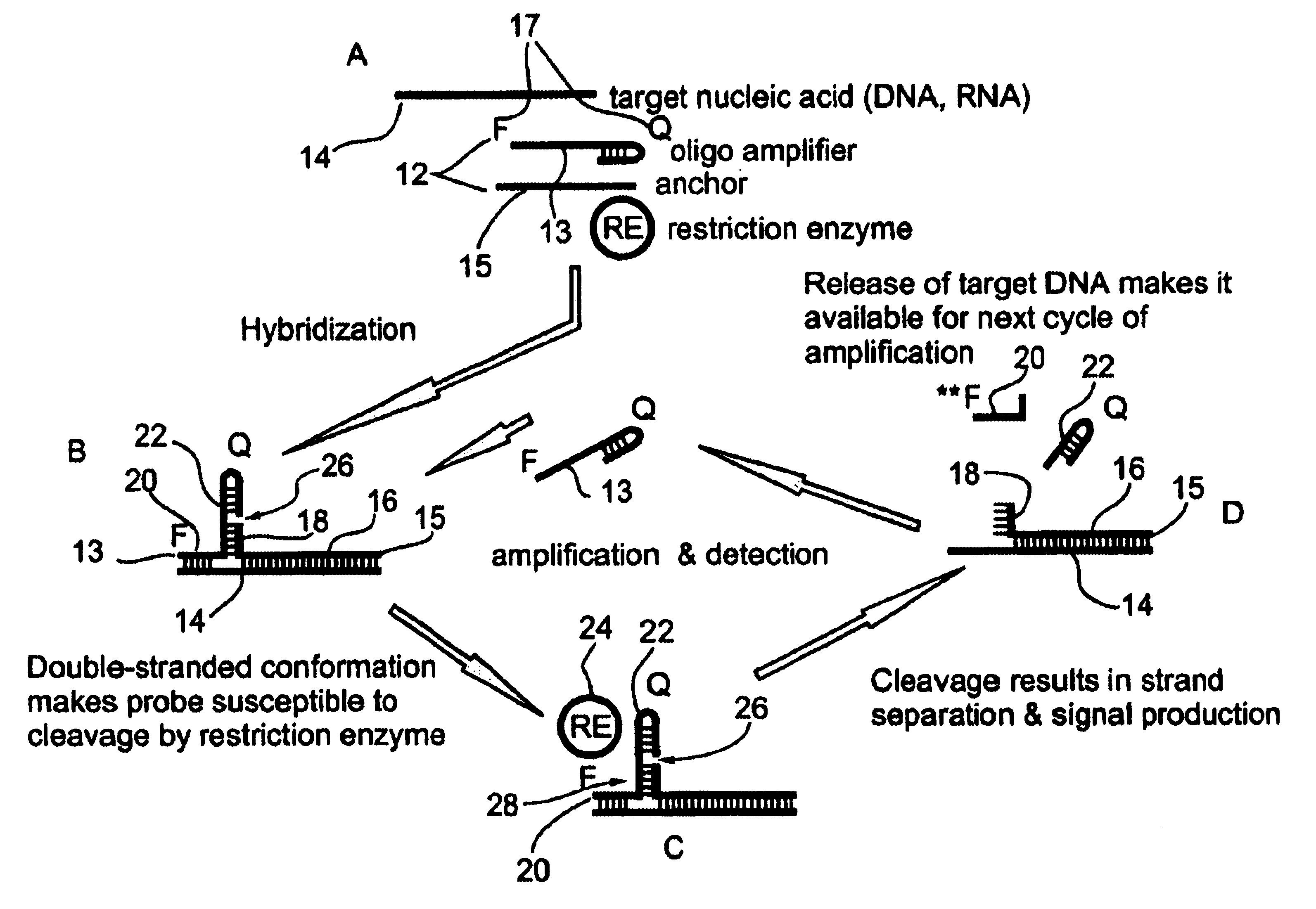

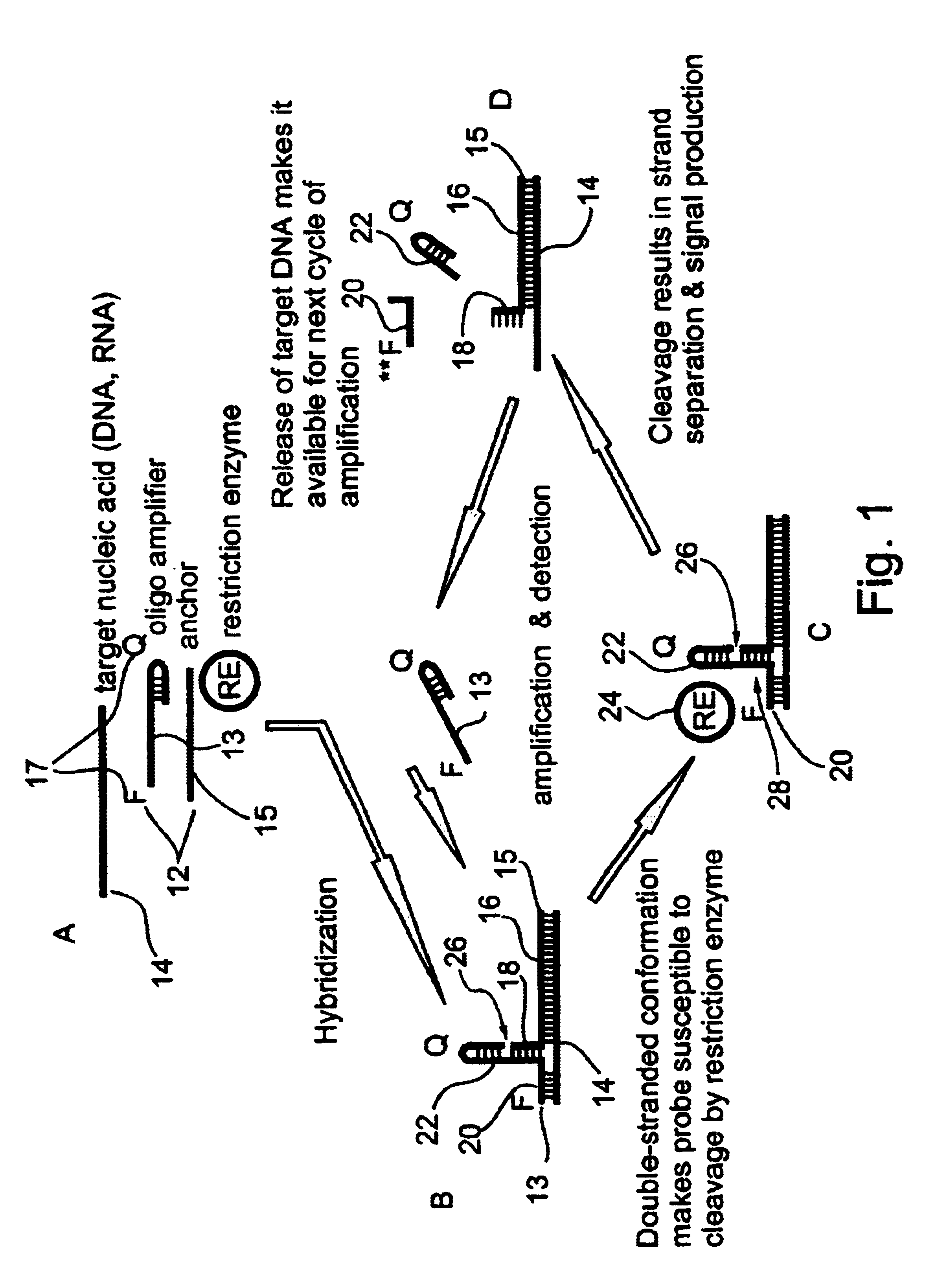

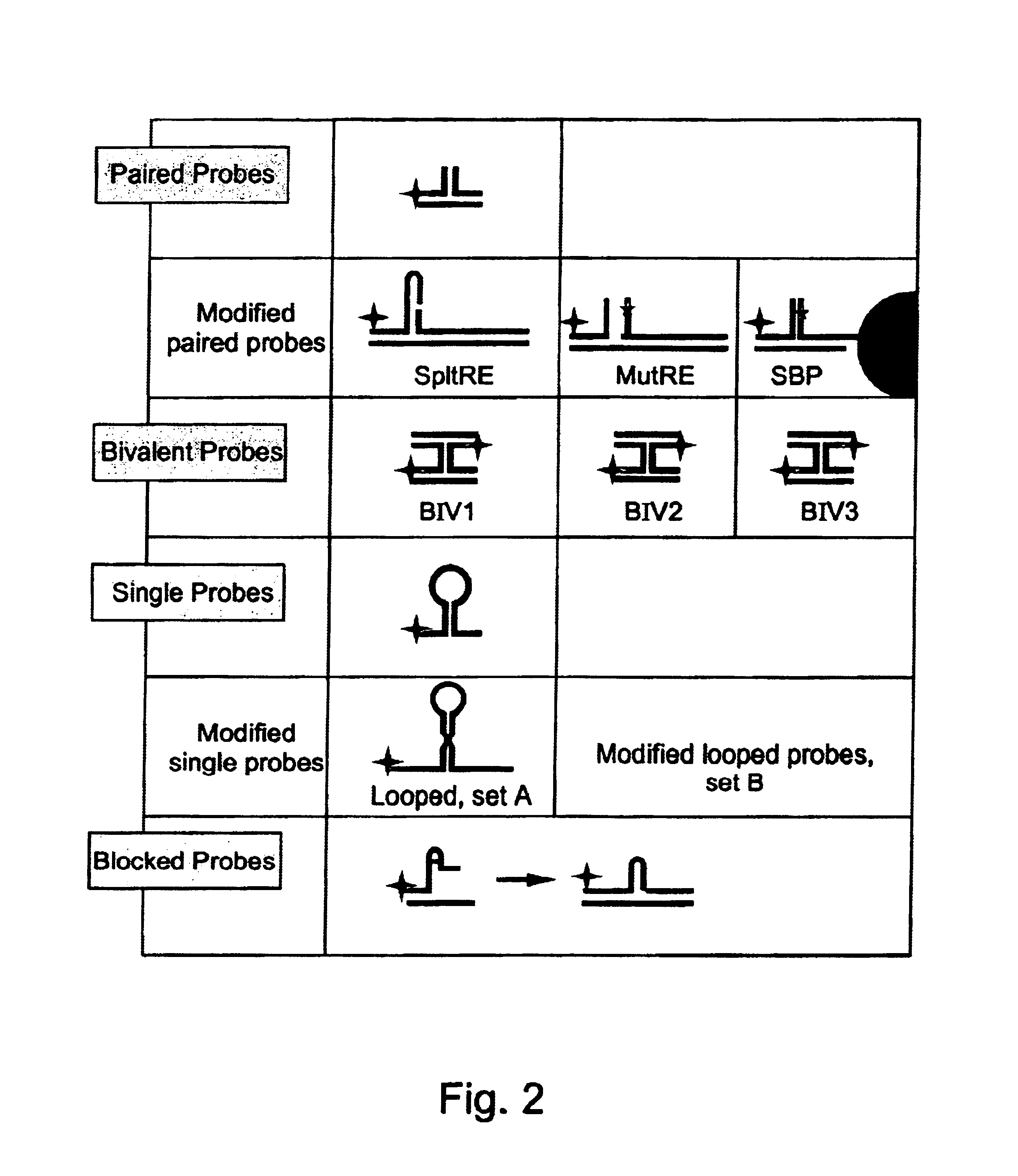

Oligonucleotides and assemblies thereof useful in the detection of the presence or absence of target nucleic acid sequences in a sample

InactiveUS20040142369A1Enable recyclingConvenient and efficient detectionSugar derivativesMaterial analysis by observing effect on chemical indicatorNucleic acid sequencingOligonucleotide

Owner:ALAJEM SARA +2

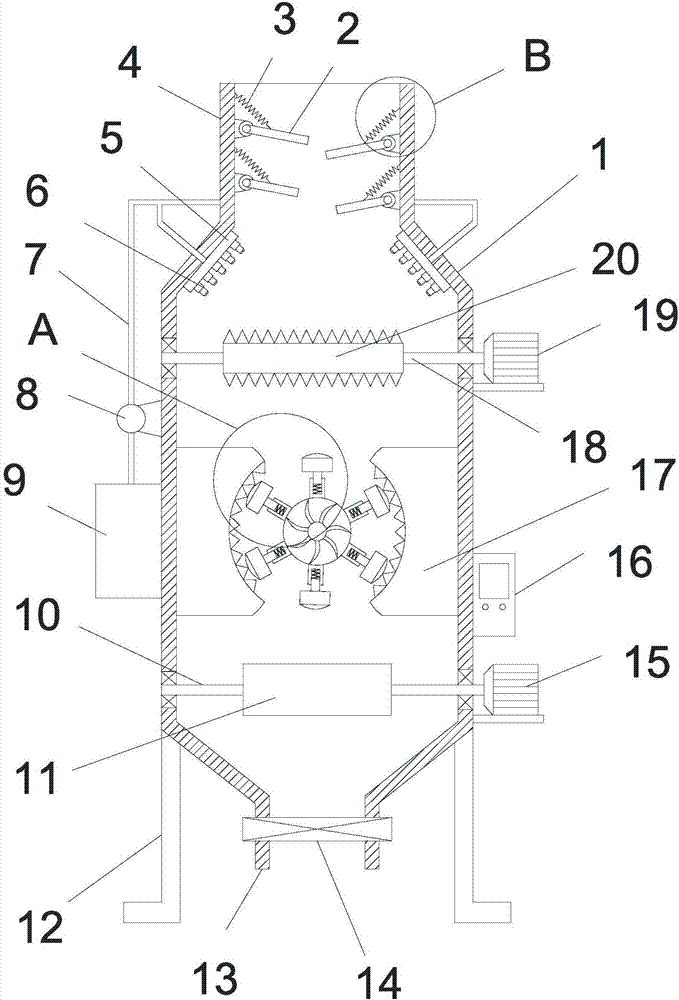

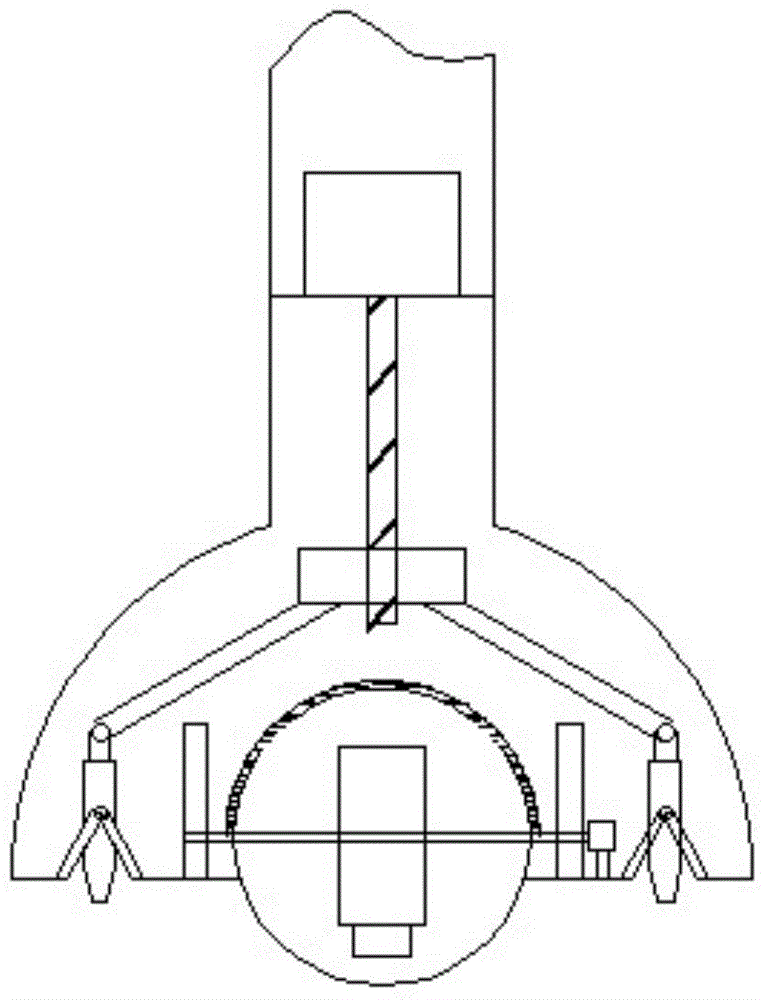

Efficient crushing device for construction waste

InactiveCN107457030AReduce the impactImprove crushing efficiencyUsing liquid separation agentDirt cleaningFailure rateArchitectural engineering

The invention discloses a high-efficiency crushing device for construction waste, which comprises a crushing box, a feeding pipe is arranged on the top of the crushing box, a water collecting tray is arranged on the inner wall of the crushing box, and several nozzles are uniformly arranged on the surface of the water collecting tray, and the crushing box There is a water tank on the outer wall on the left side, and a catheter is connected between the water tank and the water collection tray, and a water pump is installed on the catheter; the left and right inner walls of the crushing box are symmetrically equipped with limiting extrusion plates, and the sliding device inside the sleeve There is a sliding shaft, a damping spring is arranged in the sleeve, and the crushing pressure head is in contact with the sawtooth; a control box is provided on the outer wall on the right side of the crushing box, and the control box is electrically connected with the electromagnet plate; The crushing efficiency is high and the crushing effect is sufficient; the buffer plate buffers and absorbs the garbage entering the crushing box, reduces the impact on the crushing roller, improves the stability of the device, reduces mechanical loss and failure rate, and avoids construction The concentrated falling of garbage leads to uneven crushing.

Owner:李明超

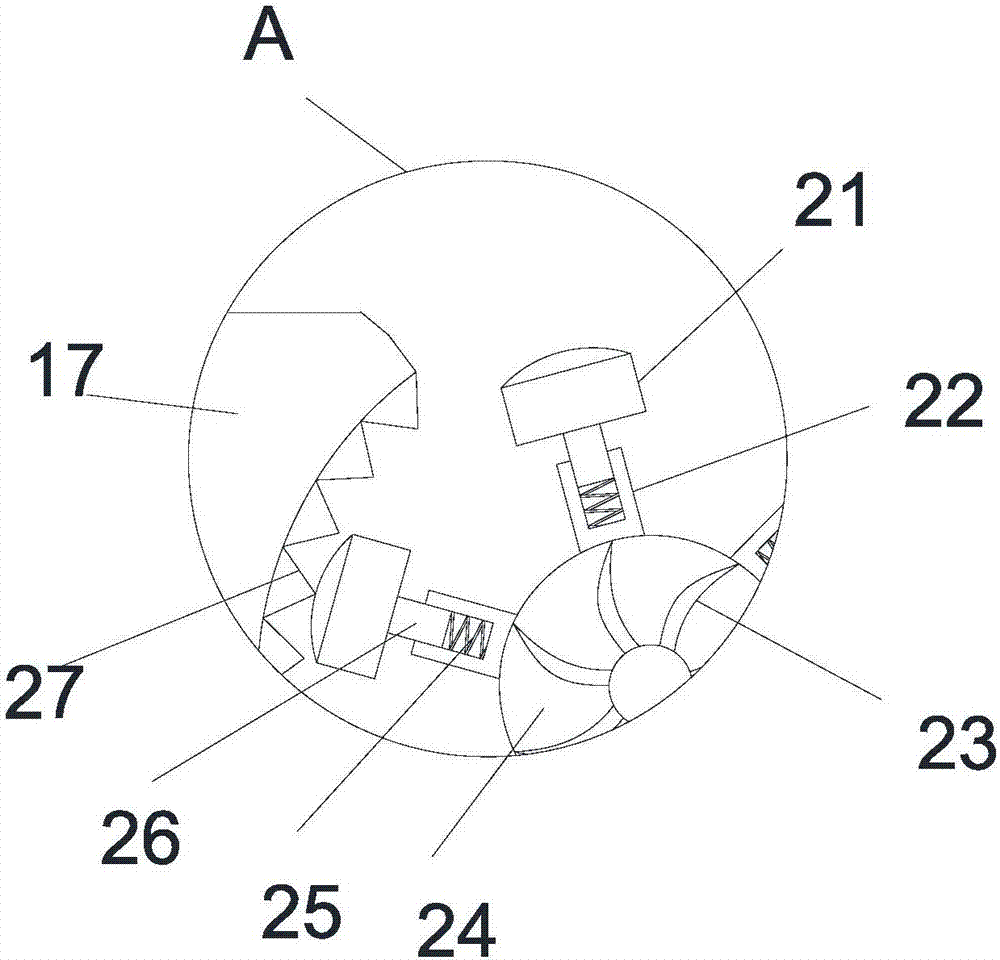

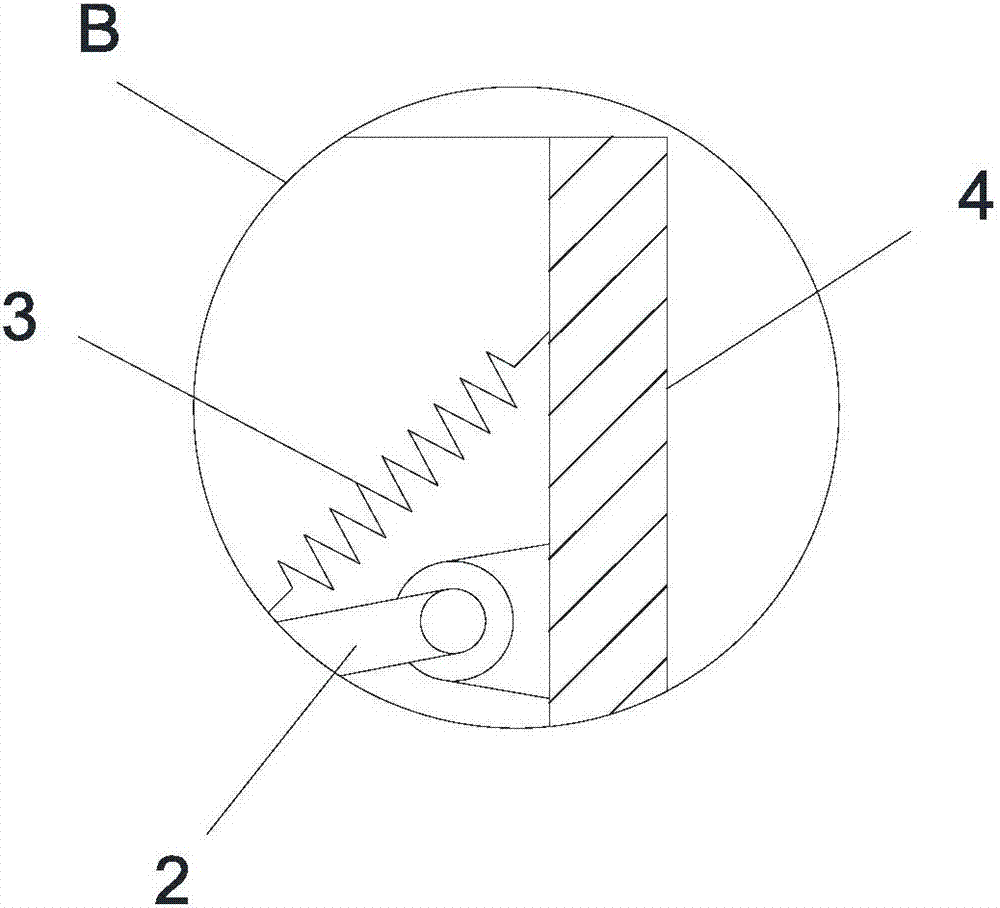

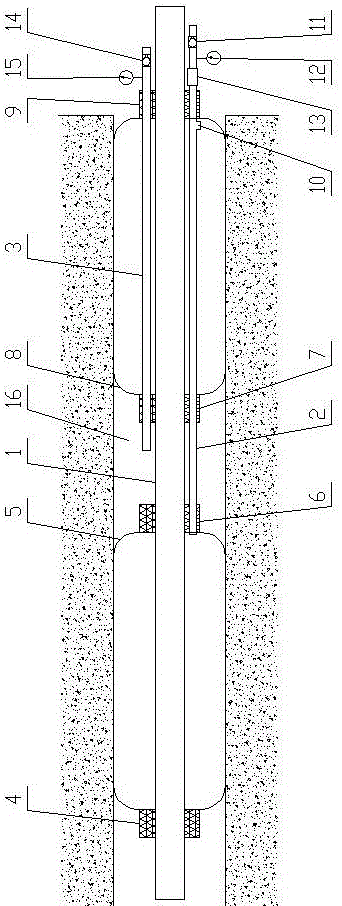

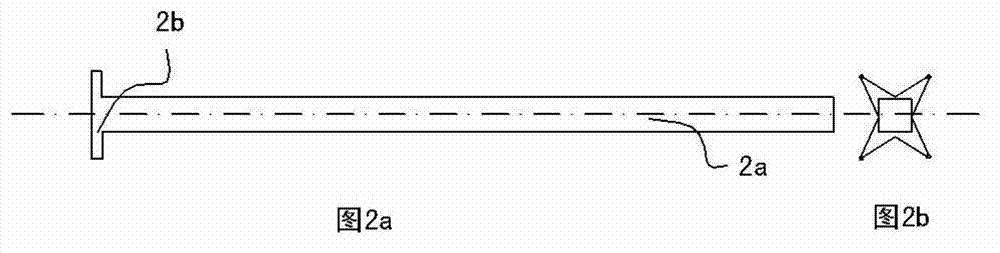

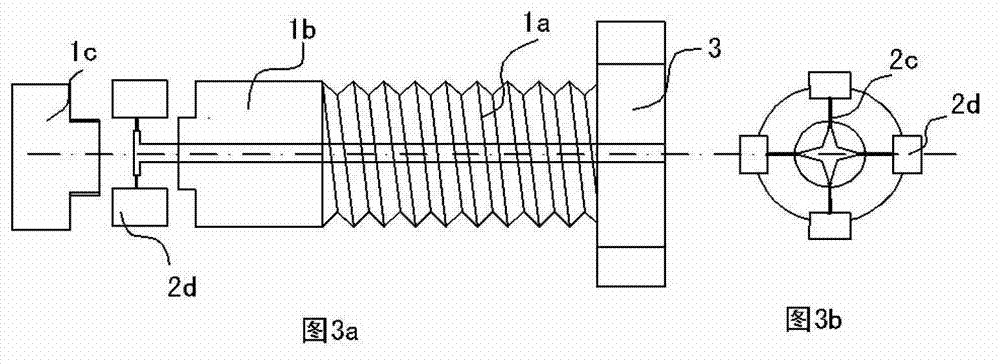

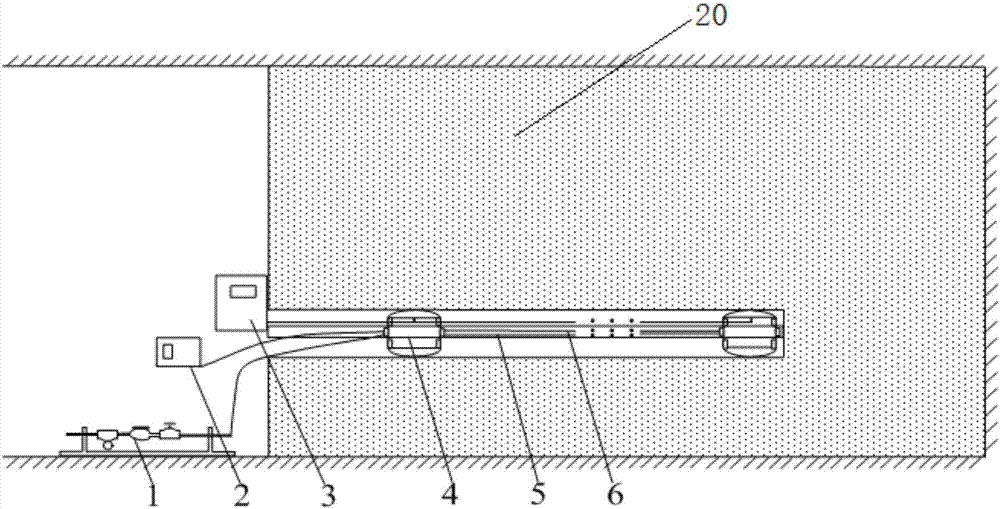

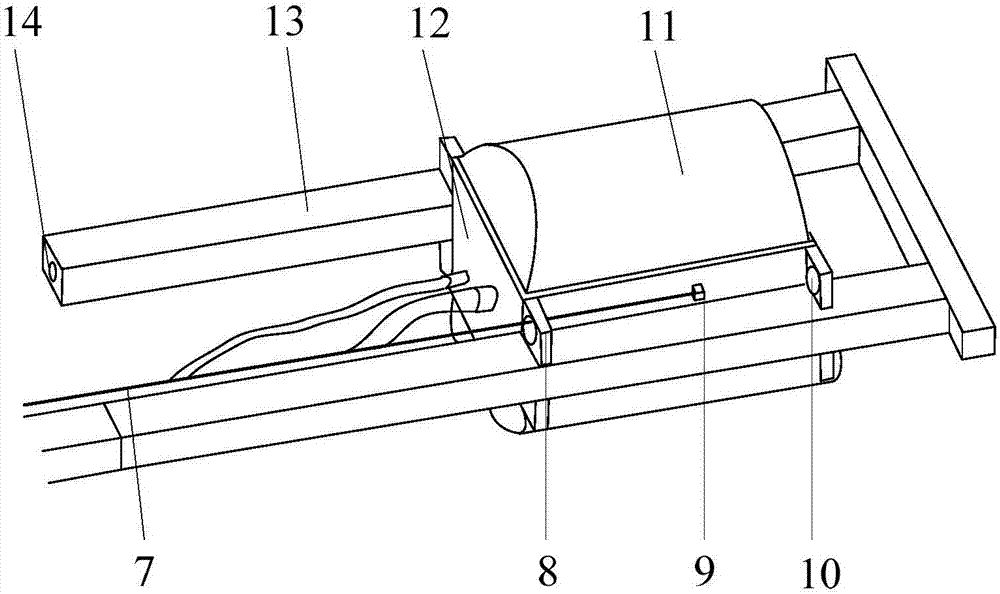

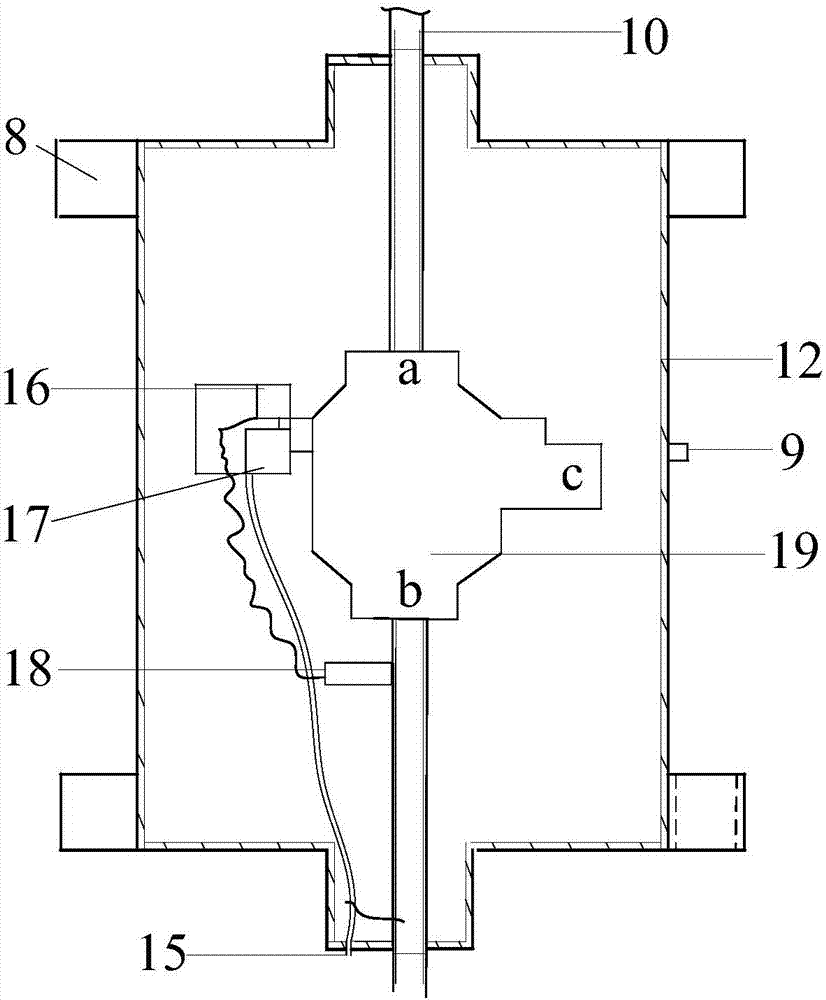

Coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device and method

InactiveCN105756599ALow costEasy to operateGas removalSealing/packingAir compressionCoal mine methane

A coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device comprises a gas extraction pipe, a gas injection pipe and a water injection pipe which are arranged in parallel.A first limiting block, a first expansion gas bag, a second limiting block, a third limiting block, a second expansion gas bag and a fourth limiting block are sequentially arranged on the gas extraction pipe from inside to outside, an inner end opening of the gas injection pipe is communicated with the interior of the first expansion gas bag, a gas injection hole communicated with the interior of the second expansion gas bag is formed in the gas injection pipe, and an inner end opening of the water injection pipe is located between the second limiting block and the third limiting block.The invention further discloses a hole sealing method.Cheap water and air are adopted as hole sealing materials in the device and the method and can be supplemented through an underground air compression system and a water supply system as needed to ensure good hole sealing quality, the whole device can be recycled and reused after the extraction work is finished, pollution to a coal body, underground water and underground air can be avoided, the safety level of a mine is improved, and popularization of the novel coal mine gas treatment technology can be easily promoted.

Owner:关红星

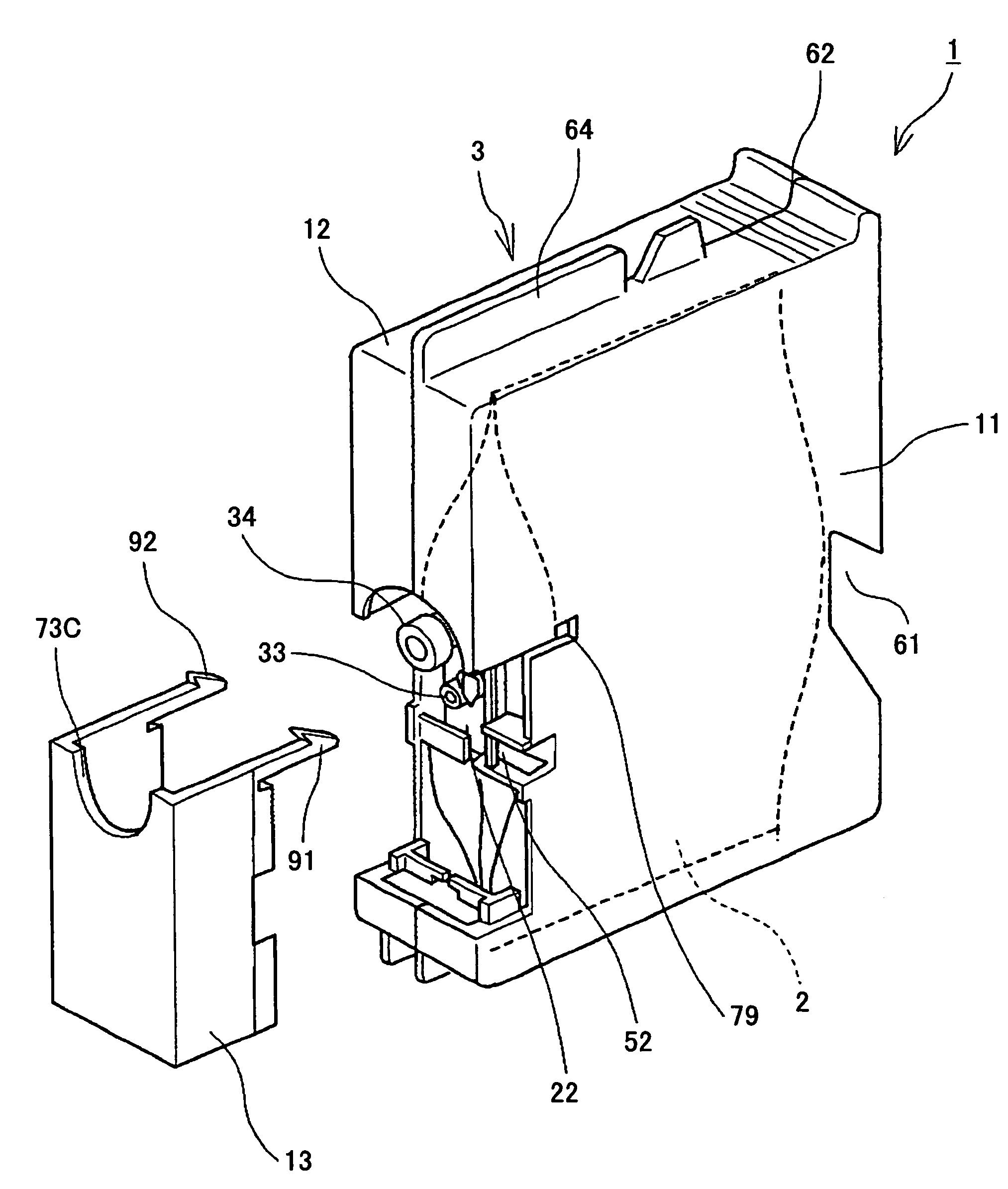

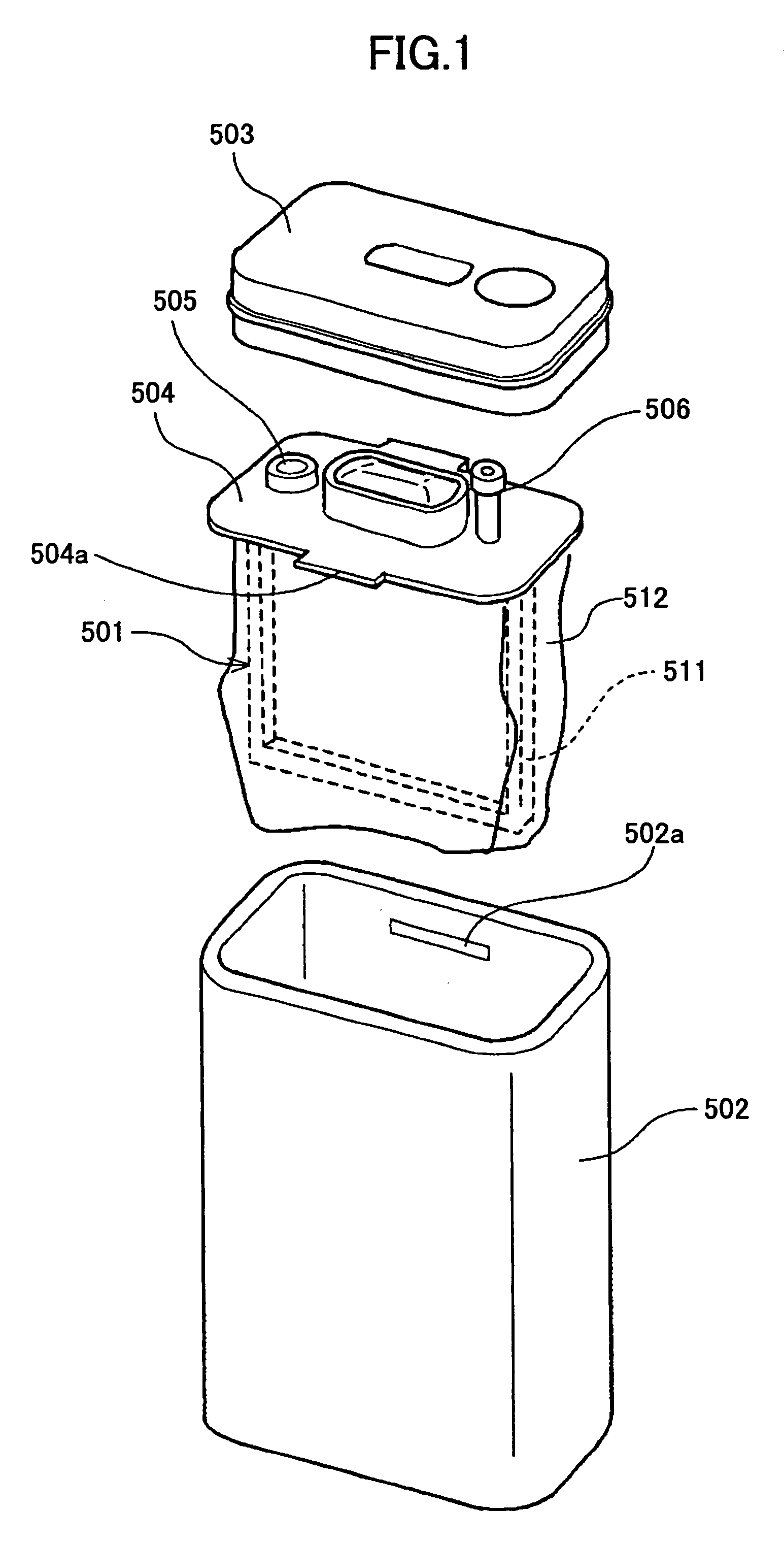

Ink bag, ink cartridge and ink-jet recording apparatus, ink filling method, ink refilling method, manufacturing method of ink cartridge, and recycling method of ink cartridge

An ink bag comprises a flexible bag body of a generally rectangular form and a holding member attached to one edge of the bag body, wherein the holding member includes: an ink filling opening for filling the bag body with ink; an ink discharging opening for discharging the ink inside the bag body; and an engaging part for holding the ink bag to a cartridge case in which the ink bag is accommodated.

Owner:RICOH KK

Solar panel cleaning vehicle with rotary spray head

InactiveCN104307784AGuaranteed cleanlinessImprove heat collection efficiencyCleaning using liquidsWastewaterSolar power

Owner:ZHEJIANG ZHONGXIN NEW ENERGY TECH CO LTD

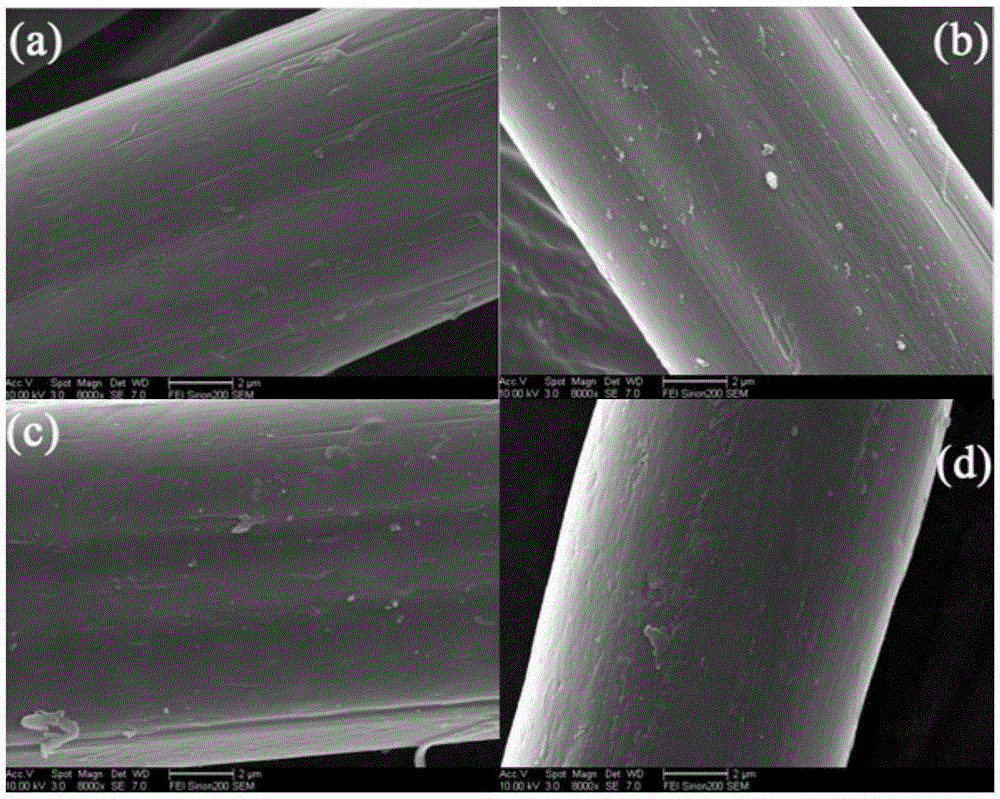

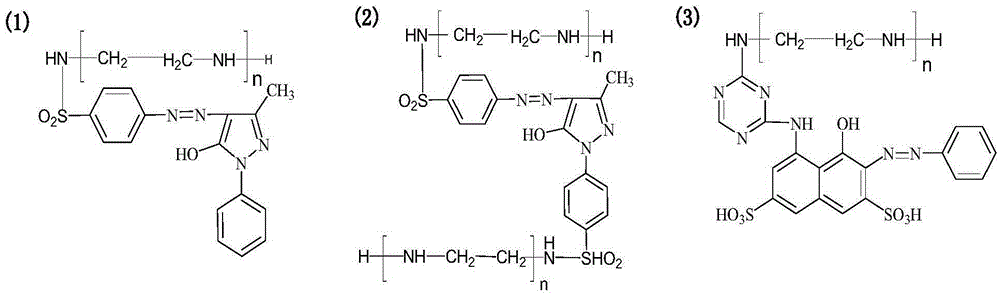

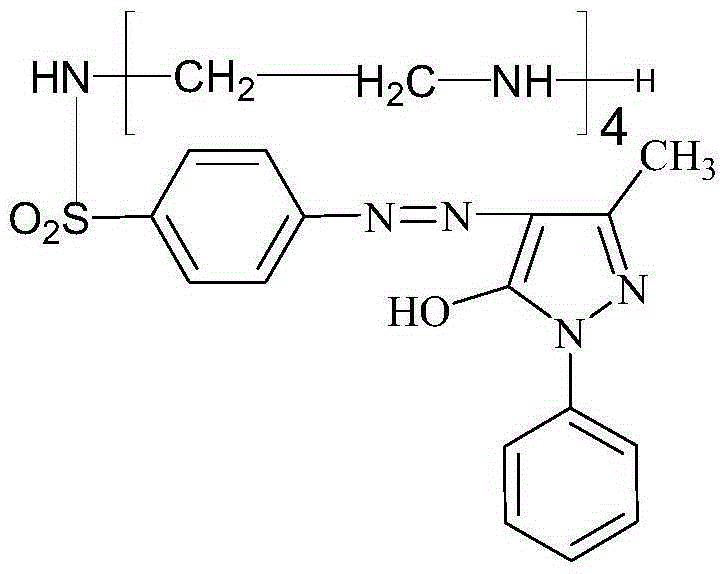

Dyeing method for calcium alginate fibers

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

Method for recycling high-iron red mud as steelmaking slag former/dephosphorizing agent

The invention discloses a method for recycling high-iron red mud as a steelmaking slag former / dephosphorizing agent. The red mud is solid waste generated when alumina is produced by adopting a Bayer process, and the existing treatment method of the solid waste is to be stored in a yard. The method comprises the following step: mixing the air-dried and levigated mud red with lime at the mass ratio of 1:(0.6-0.8), as a slag former / dephosphorizing agent during a steelmaking process. The invention provides a conception of recycling the iron element in waste red mud in an aluminum plant and removing elements of Si, P and the like in molten iron, desiliconization and dephosphorization can be carried out by fully utilizing the high oxidization and high alkalinity of the high-iron red mud, and the iron element in the red mud can be recycled. Silicon element in the iron can be removed to be below 0.1% and the phosphorous removal rate can achieve more than 76% under the condition of no oxygen blowing, the majority of Fe element in the high-iron red mud enters a molten iron melting pool, so that the recycling of red mud can be realized, the production cost can be lowered, and further multiple purposes of changing wastes into valuables, protecting the environment and the like can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

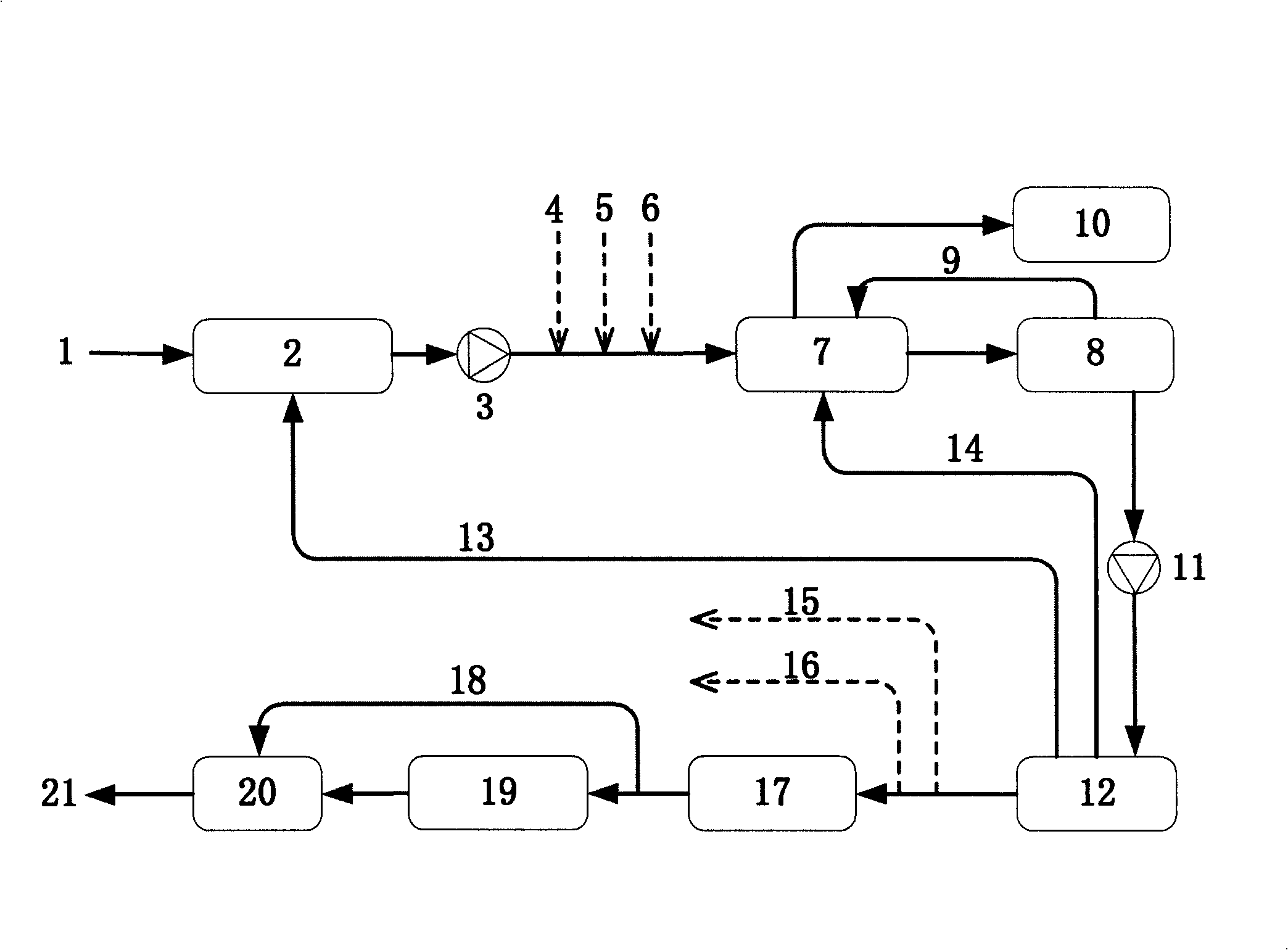

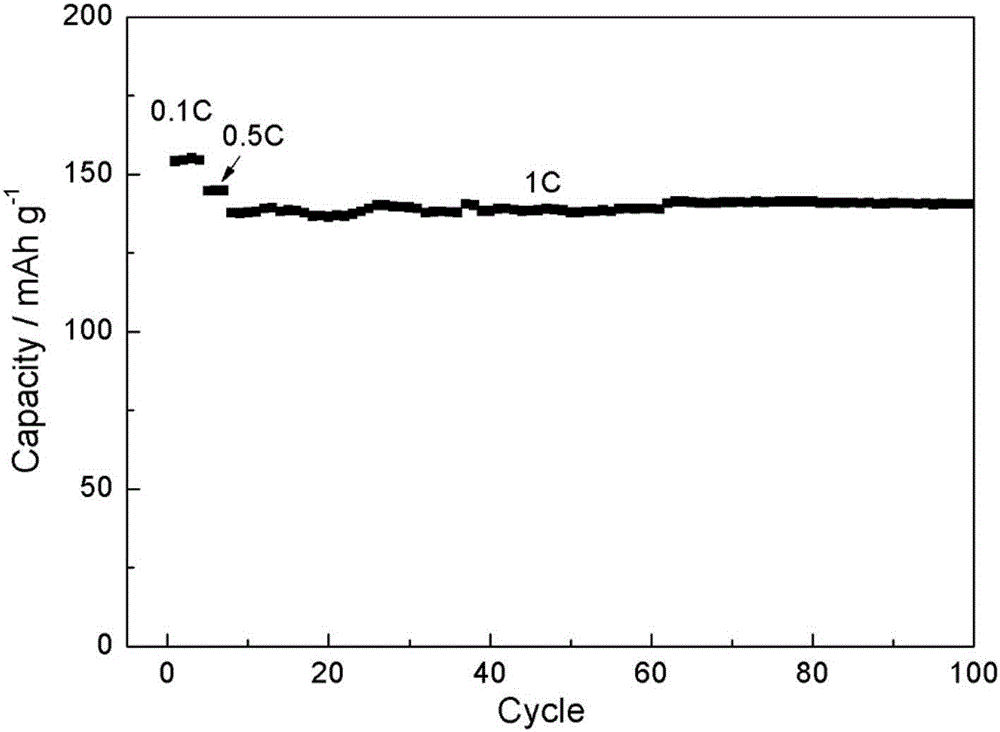

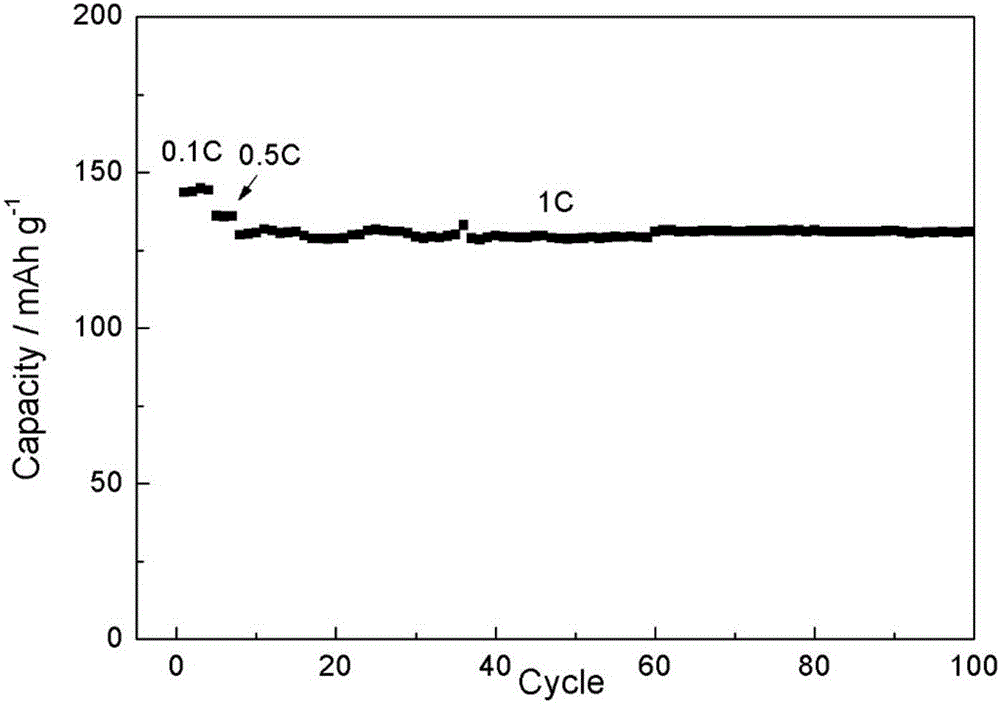

Method for recycling lithium iron phosphate in waste lithium ion batteries

ActiveCN106276842AReduce manufacturing costEnable recyclingWaste accumulators reclaimingPhosphorus compoundsOrganic acidLithium iron phosphate

The invention belongs to the technical field of recycling and cyclic utilization of waste power lithium ion batteries, and particularly relates to a method for recycling lithium iron phosphate in waste lithium ion batteries. The method includes the following steps that firstly, dried waste lithium iron phosphate powder is added into a 0.1-5 mol / L aqueous solution mainly containing organic acid to be processed, and an acidic solution containing Li+, Fe2+ and PO43- is obtained after filtering; secondly, an organic solvent is added into mother liquor to obtain lithium iron phosphate precursor coarse precipitate; thirdly, the lithium iron phosphate precursor coarse precipitate is filtered and collected and dispersed in an organic dispersing agent to be subjected to high-energy ball milling for 0.5-8 hours, the obtained slurry is dried to remove the solvent and then forged for 2-8 hours in atmosphere at 600-800 DEG C, and a recycled lithium iron phosphate cathode material is obtained; fourthly, filtrate obtained in the third step is recycled and used for dissolving of lithium iron phosphate in the first step again in the concentrated mixed organic acid with the organic solvent / dispersing agent separated out.

Owner:BEIJING BEIDA MINGDE CHEM PHARMA

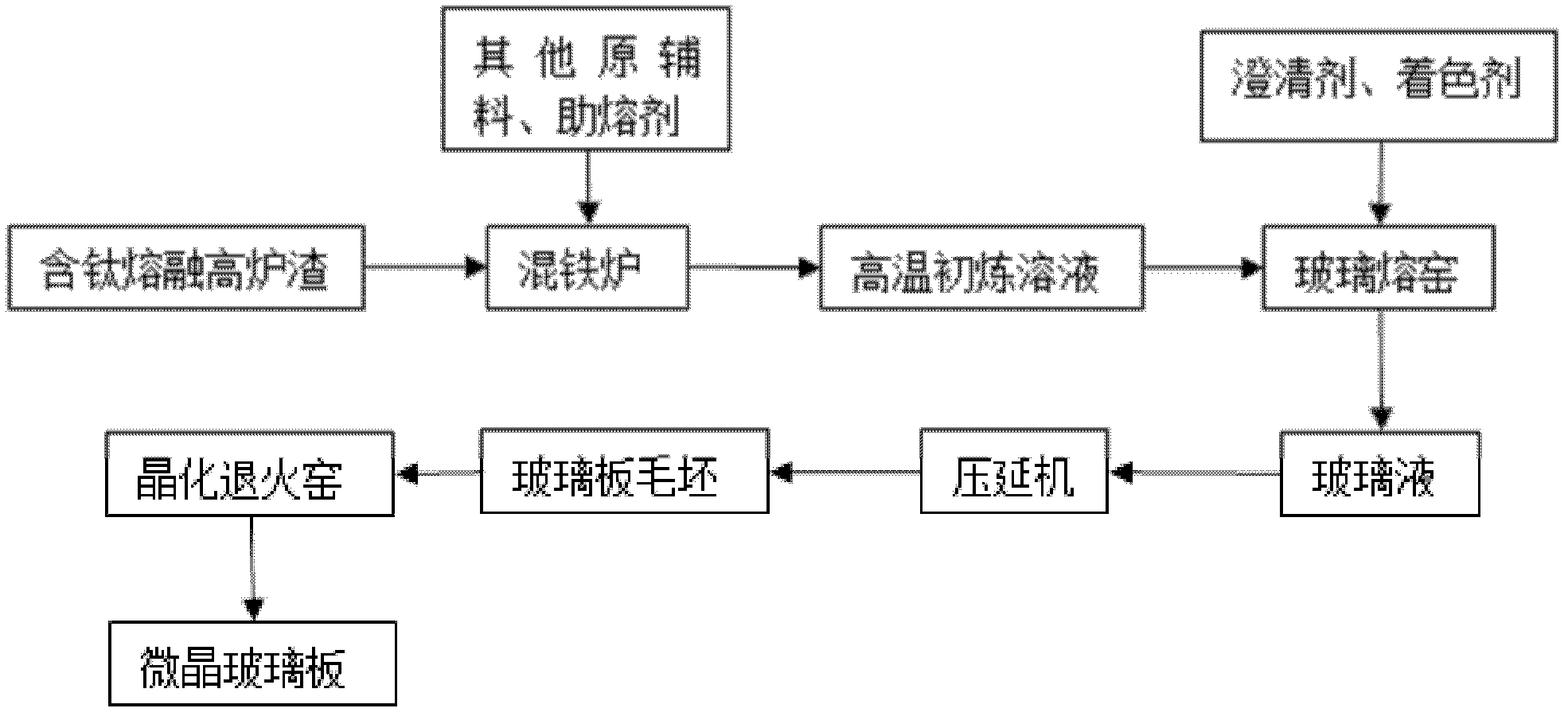

Method for manufacturing glass ceramic by titanium-containing melting blast furnace slag

The invention discloses a method for manufacturing glass ceramic by titanium-containing melting blast furnace slag. The method comprises the following steps of: directly feeding titanium-containing high-temperature melting blast furnace slag flowed out of a blast furnace into a metal mixer, mixing the slag with other auxiliary raw materials and a fluxing agent, feeding high-temperature initial-refining solution into a glass melting furnace and also adding a clarifying agent and a coloring agent, refining in the glass melting furnace to form the smelted glass with uniform elements, uniform temperature and good flowability, feeding the smelted glass into a calendar to form red and hot glass blanks by pressing, and feeding the pressed glass blanks into a crystallization annealing kiln to carry out thermal treatment to manufacture the glass ceramic which takes diopside as a main crystalline phase. Compared with the prior art, the method for manufacturing the glass ceramic by the titanium-containing melting blast furnace slag has the advantages that the blast furnace slag with high titanium content is taken as the raw material for preparing the glass ceramic, thus the effectively utilization rate of the blast furnace slag with the high titanium content is improved, the discharge of the blast furnace slag with the high titanium content is further reduced, and the recovery of an industrial solid waste resource is also realized when the environment is improved.

Owner:达州市海蓝冶金设备制造有限公司

Method of treating epoxy resin-cured product

InactiveUS6962628B1Promote recoveryEasy to separatePlastic recyclingChemical recyclingEpoxyOrganic solvent

A method of treating a composite material of epoxy resin-cured product and inorganic matter to easily recover the resin components in a recyclable state without causing thermal decomposition. A method of separating the inorganic matter. The epoxy resin-cured product is treated with a treatment liquid which contains a decomposition catalyst for epoxy resin-cured products and an organic solvent to decompose and dissolve the epoxy resin-cured product. A composite material of epoxy resin-cured product and inorganic matter is also treated to decompose and dissolve the epoxy resin-cured product in the above-mentioned manner and the inorganic matter is then separated from the liquid.

Owner:HITACHI CHEM CO LTD

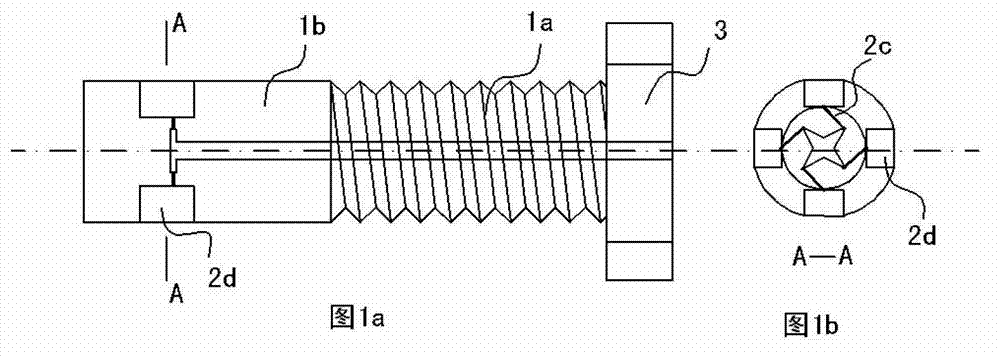

Pop-up single-side bolt fastener

The invention discloses a pop-up single-side bolt fastener which is characterized in that a tail rod body of a screw rod is a threaded rod and a front rod body of the screw rod is a cylinder polish rod; a slot is arranged on the outer peripheral surface of the cylinder polish rod in a cross shape; a T-shaped cavity is arranged in the screw rod, a top plane of the T-shaped cavity is communicated with the slot on the same plane, a longitudinal axle hole in the T-shaped cavity starts from the top plane of the T-shaped cavity and extends and penetrates through the screw rod; a T-shaped rotation piece is configured in the T-shaped cavity, and each support block is embedded into the slot or protrudes out of the outer peripheral surface of the cylinder polish rod due to the rotation of a top rotation plate of the T-shaped rotation piece. The pop-up single-side bolt fastener can implement single-side fastening from one side and can be repeatedly used through a pop-up structure.

Owner:HEFEI UNIV OF TECH

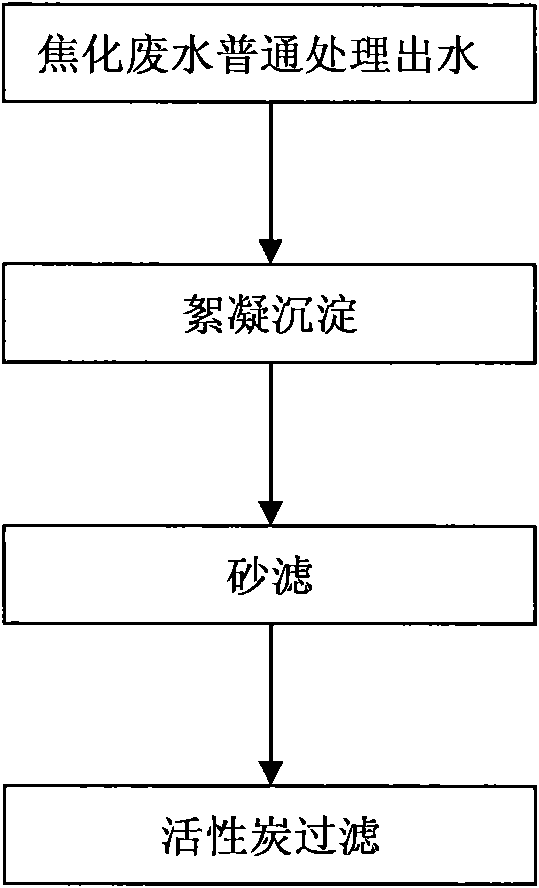

Coking wastewater treatment device and coking wastewater posttreatment method

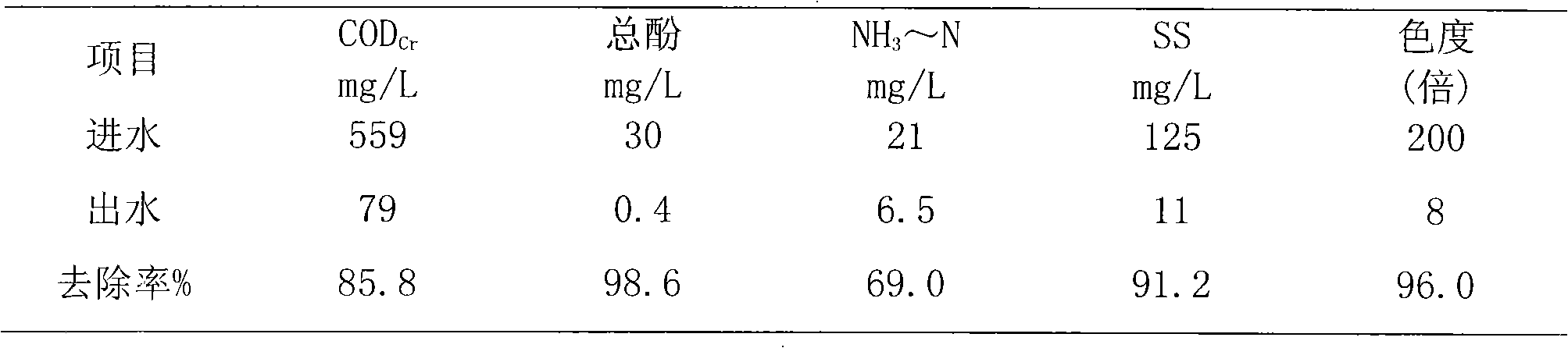

InactiveCN101987762AReduce CODAchieve emission standardsMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemical oxygen demandActivated carbon filtration

The invention relates to a coking wastewater treatment device which comprises a flocculation reaction tank, wherein the flocculation reaction tank is connected with a flocculation settling pond, the flocculation settling tank is connected with a sand filter, and the sand filter is connected with an active carbon filter. A coking wastewater posttreatment method comprises the steps of: adding an efficient composite flocculating agent, a polymer coagulant aid and a mineral powder absorbing agent into the coking wastewater subjected to common treatment; regulating the pH value to be 8-9 with alkali, wherein the flocculation reaction settling time is 1-2.5h; and then carrying out sand leaching and active carbon filtration, wherein the effluent quality fully reaches the standard for emission or recycling. The COD (Chemical Oxygen Demand), the total phenol, the ammonia nitrogen, SS (Suspended Substances) and the chromaticity in the coking wastewater subjected to the treatment with the method are respectively reduced by above 80 percent, 90 percent, 60 percent, 90 percent and 95 percent; and by treating the coking wastewater according to the invention, the purposes of good effect, simple operation and convenience in management are achieved.

Owner:SHANGHAI WEILAI ENTERPRISE

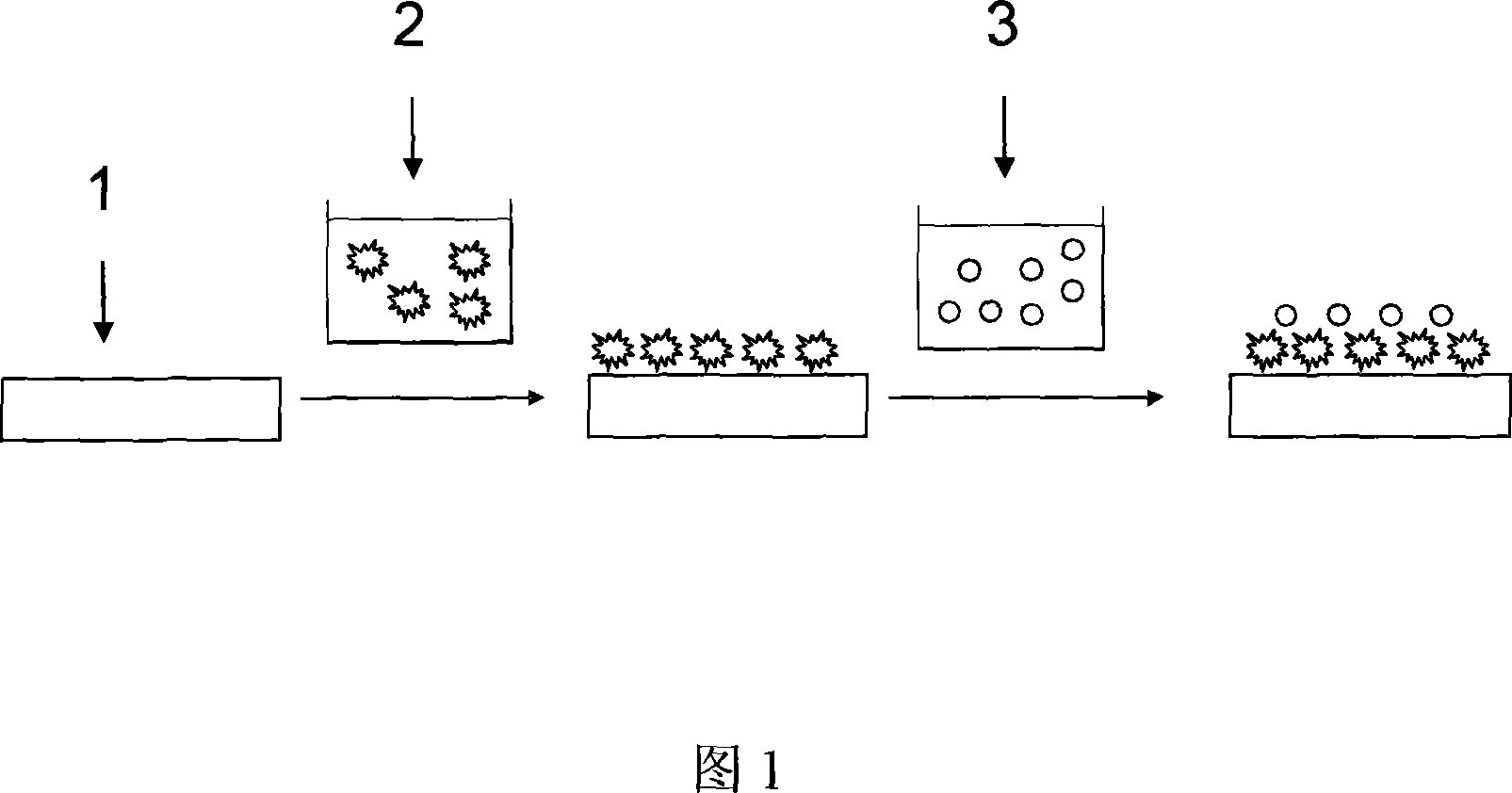

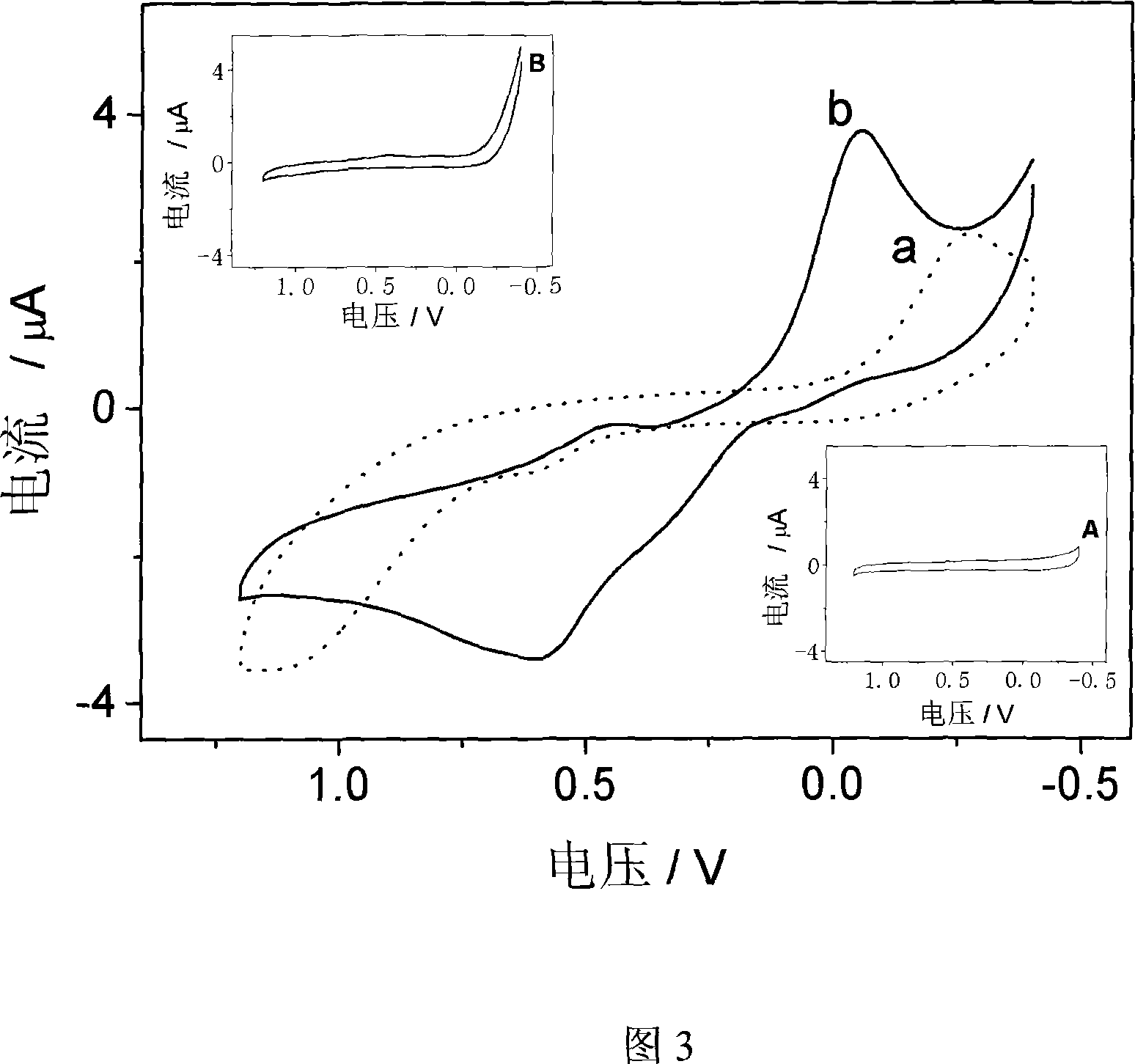

Method for assembling block copolymer for preparing gold nano array electrode in water phase

InactiveCN101059472AEliminate pollutionEliminate distractionsMaterial electrochemical variablesMultilayer membranePolystyrene

The invention relates to a method for assembling embedded polymer to prepare metal nanometer array electrode in water phase, belonging to nanometer electrode technical field. The invention assembles polythene pyridine-polystyrene embedded polymer in water phase, uses the static function between cation micelle and the metal nanometer particle with negative charge to prepare metal nanometer array electrode. The inventive method is simple which lead in organic solvent, repeatedly applied electrode surface, and reduced cost. The metal nanometer array electrode has better dispersion, improved transmission speed of electrode surface, and better catalysis ability on catechin. The surface of the prepared metal nanometer particle has same charge, applied in the preparation of other metal nanometer array electrode, and self-assemble multilayer membrane, to build complex multi-element nanometer structure, with significant benefit in the research and application of nanometer electrochemistry and biological sensor.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

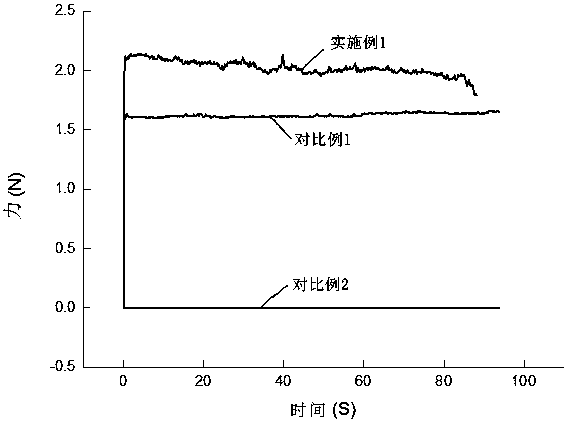

Integrated monitoring device of oriented stress distribution and deformation of single-hole coal-rock masses and monitoring method

ActiveCN106989849AReduce the number of drilled holesAvoid disturbanceUsing fluid meansHydraulic/pneumatic force measurementSingle holeDrill hole

The invention discloses an integrated monitoring device of oriented stress distribution and deformation of single-hole coal-rock masses and a monitoring method. The integrated monitoring device consists of multiple capsule pressure sensors, a three-way magnetic valve, a connection pipe, a multi-channel displacement monitor, a multi-channel pressure monitor, a steel filament rope and an installation guide rail. According to the invention, the capsule pressure sensors are arranged in drilling holes; through liquid injection devices, the hydraulic pressure of each capsule pressure sensor is allowed to reach a preset value; the capsule pressure sensors are well coupled to the coal-rock masses; deformation monitoring points are attached to the housings of the capsule pressure sensors so that reliable fixation of the deformation monitoring points is achieved; consistency of the stress monitoring and deformation monitoring of the coal-rock masses is ensured; and after the monitoring is finished, all electromagnetic control valves are opened, liquid in the capsules flows back, and the installation guide rail is moved out from detection holes, so recycling is finished. Thus, problems of poor applicability to mining induced stress and deformation of the coal-rock masses, poor consistency, high monitoring cost and unrecyclable devices in the current drilling hole stress monitoring devices are overcome.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation process of high-performance coating diaphragm having surface coated with organic layer

PendingCN110148699AImprove fitInhibit sheddingCell seperators/membranes/diaphragms/spacersSecondary cells servicing/maintenancePolymer scienceOrganic solvent

The invention discloses a preparation process of a high-performance coating diaphragm having a surface coated with an organic layer, and relates to the technical field of production of lithium ion battery microporous membranes. The process comprises the steps of: dissolving organic viscous high-temperature resin and an additive in an organic solvent to form a polymer solution; then coating the surface of a diaphragm substrate with a polymer solution in a dip-coating or gravure-coating mode; and finally, performing drying in an oven at a temperature of 50-120 DEG C. According to the high-performance coating diaphragm prepared by employing the method, the surface of the substrate is coated with a layer of viscous high-temperature resin so that the problem of bonding of a microporous membraneand a pole piece is solved, and meanwhile, the falling of stepless particles can be well avoided, and therefore, the safety of a lithium battery is solved, and the performance of the lithium batteryis fully played.

Owner:扬州中锂新能源有限公司

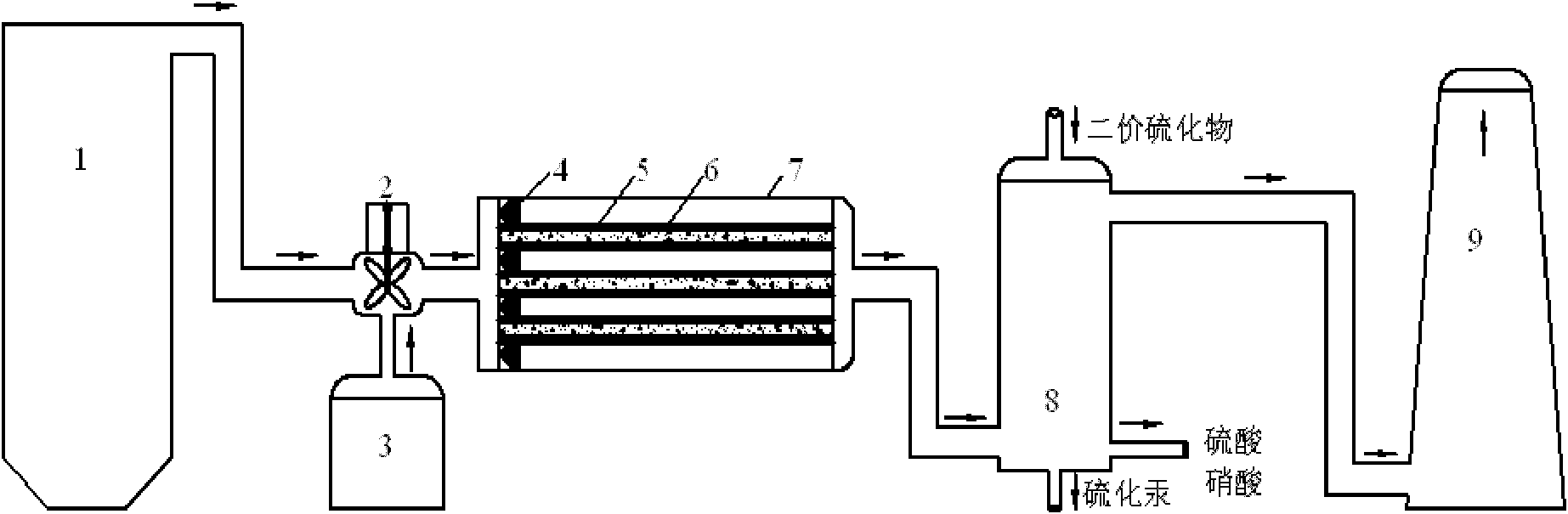

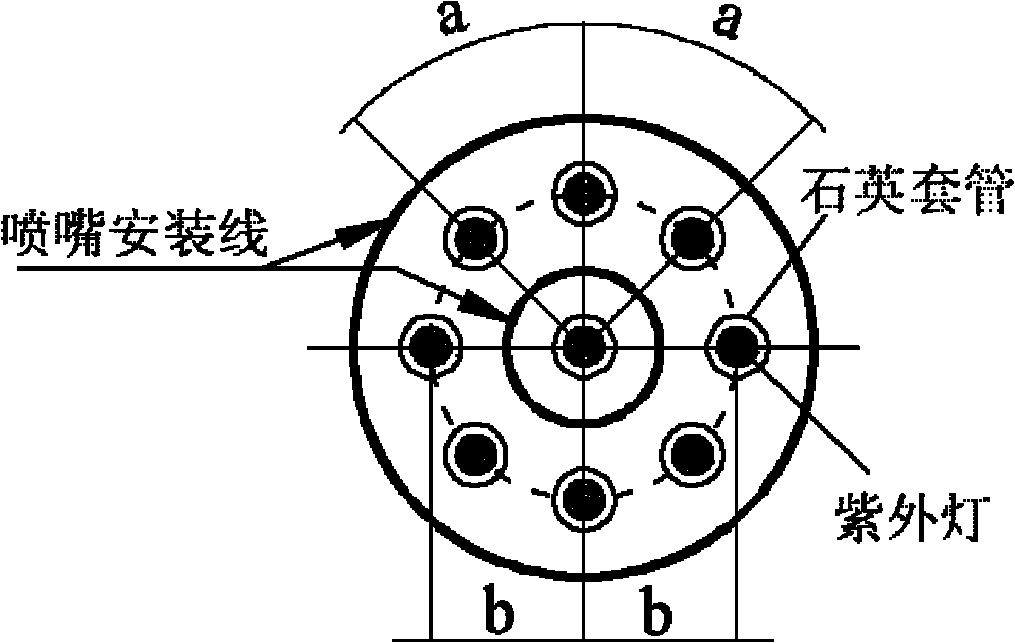

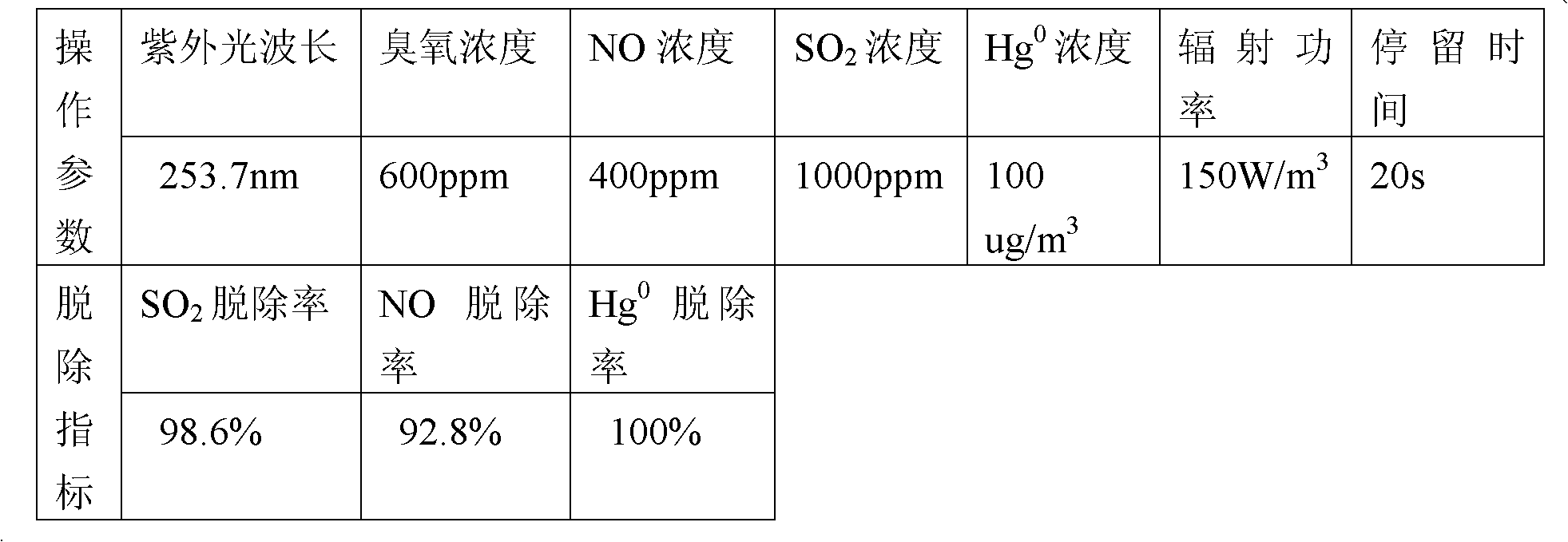

Fume purification system based on advanced oxygenation combining wet scrubbing

InactiveCN102160959AHigh reaction rate constantEasy attackDispersed particle separationSolubilityEngineering

The invention provides a fume purification system based on advanced oxygenation combining wet scrubbing. The system is a combustion and exhaust system formed by a boiler, an ozone generator, a stirrer, a swirl nozzle, a reactor, a gas-liquid absorption tower and a chimney, wherein fume containing sulfur oxide, nitric oxide and mercury generated by combustion of the boiler and O3 generated by the ozone generator enter the stirrer together, are mixed, flow through the swirl nozzle, and are sprayed into the reactor with an ultraviolet lamp tube; and hydroxyl radical (.OH) with strong oxidability generated under excitation of ultraviolet radiation, SO2 in the fume, indissoluble NO and HgO are oxidized into gaseous products with higher dissolubility and enter the gas-liquid absorption tower to be absorbed and removed by water; Hg<2+> generated in the gas-liquid absorption tower captures and retrieves mercuric sulfide by adding sulfidion S<2-> in equal molar ratio; and the residual sulfuric acid and nitric acid mixed solution is used as an industrial raw material for recycling, and the cleaned fume enters the chimney so as to be exhausted.

Owner:SOUTHEAST UNIV

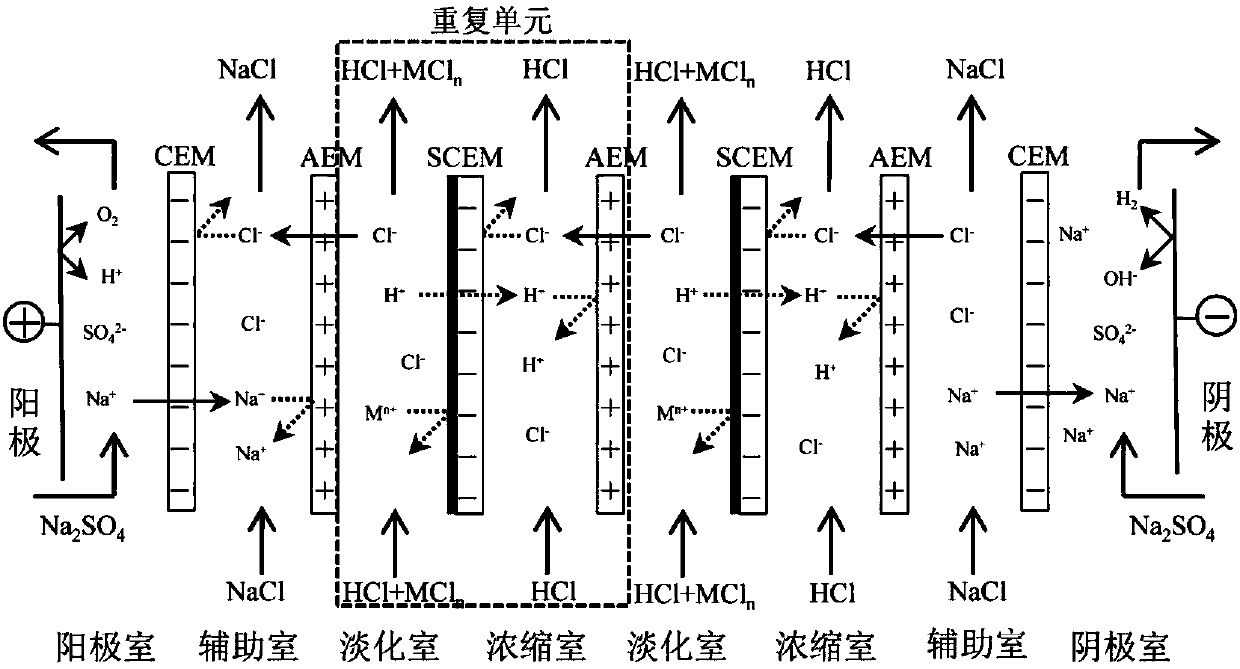

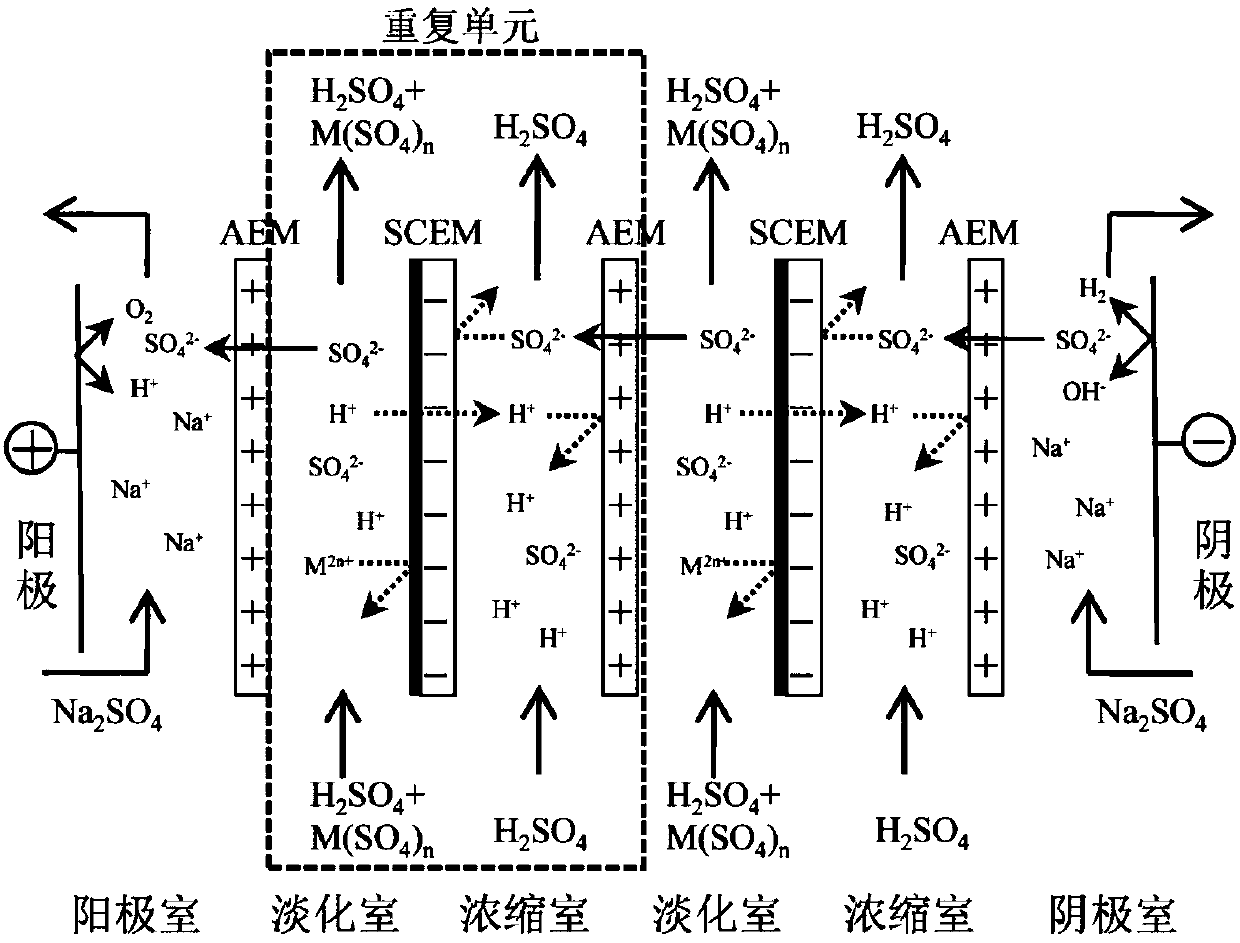

Device and method for recovering acid from waste liquid containing low-concentration acid and high-concentration metal ions through hydrogen-ion selective electrodialysis

InactiveCN107746098AEnable recyclingSolve the deep separation problemGeneral water supply conservationWater contaminantsLiquid wasteHigh concentration

The invention provides a device for recovering acid from a waste liquid containing low-concentration acid and high-concentration metal ions through hydrogen-ion selective electrodialysis. The waste liquid containing low-concentration acid and high-concentration metal ions is separated through the hydrogen ion selective electrodialysis device, selective separation of hydrogen ions and the metal ions is realized, recycling of the low-concentration acid in the waste liquid can be realized, and meanwhile, the metal ions in the waste liquid can be directly recycled, or pure metal can be obtained through electrodeposition. The method is simple to operate, and is economical and environmentally friendly, and the low-concentration acid and the high-concentration metal ions in the waste liquid can be recycled and reused, so that the device has good application values, the problem that acid and metal ions cannot be separated from the waste liquid containing low-concentration acid and high-concentration metal ions at present is solved, the problem of deep separation of the low-concentration acid in a diffusion dialysis leachate is also solved, and thus the problem of hydrogen evolution existedwhen the metal ions in the diffusion dialysis leachate are treated by the electrodeposition method is also solved.

Owner:UNIV OF SCI & TECH OF CHINA

Oligonucleotides and assemblies thereof useful in the detection of the presence or absence of target nucleic acid sequences in a sample

InactiveUS6887662B1Enable recyclingConvenient and efficient detectionSugar derivativesMaterial analysis by observing effect on chemical indicatorNucleic acid sequencingOligonucleotide

Owner:DIASORIN ITALIA SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com