Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Pressed glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressed glass (or pattern glass) is a form of glass made using a plunger to press molten glass into a mold. It was first patented by American inventor John P. Bakewell in 1825 to make knobs for furniture.

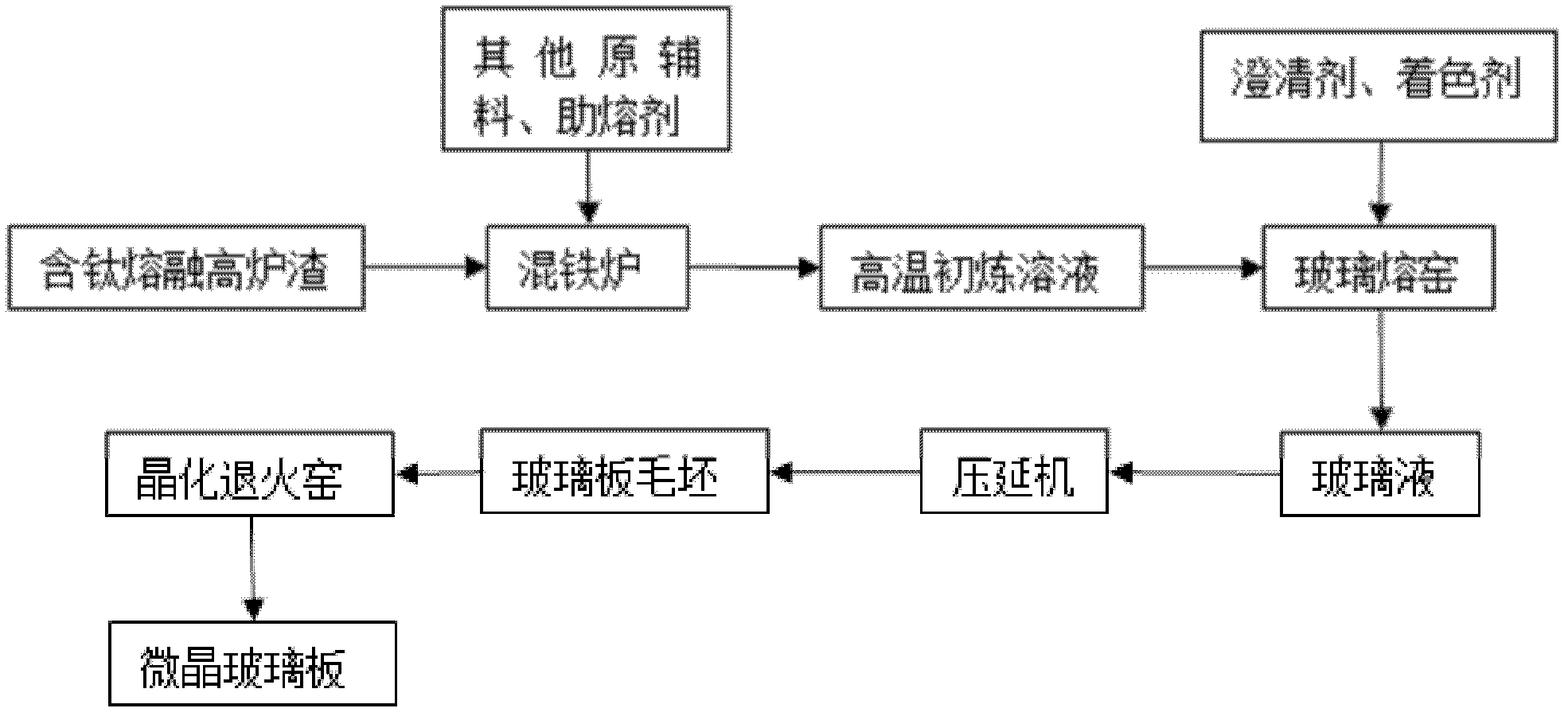

Method for manufacturing glass ceramic by titanium-containing melting blast furnace slag

The invention discloses a method for manufacturing glass ceramic by titanium-containing melting blast furnace slag. The method comprises the following steps of: directly feeding titanium-containing high-temperature melting blast furnace slag flowed out of a blast furnace into a metal mixer, mixing the slag with other auxiliary raw materials and a fluxing agent, feeding high-temperature initial-refining solution into a glass melting furnace and also adding a clarifying agent and a coloring agent, refining in the glass melting furnace to form the smelted glass with uniform elements, uniform temperature and good flowability, feeding the smelted glass into a calendar to form red and hot glass blanks by pressing, and feeding the pressed glass blanks into a crystallization annealing kiln to carry out thermal treatment to manufacture the glass ceramic which takes diopside as a main crystalline phase. Compared with the prior art, the method for manufacturing the glass ceramic by the titanium-containing melting blast furnace slag has the advantages that the blast furnace slag with high titanium content is taken as the raw material for preparing the glass ceramic, thus the effectively utilization rate of the blast furnace slag with the high titanium content is improved, the discharge of the blast furnace slag with the high titanium content is further reduced, and the recovery of an industrial solid waste resource is also realized when the environment is improved.

Owner:达州市海蓝冶金设备制造有限公司

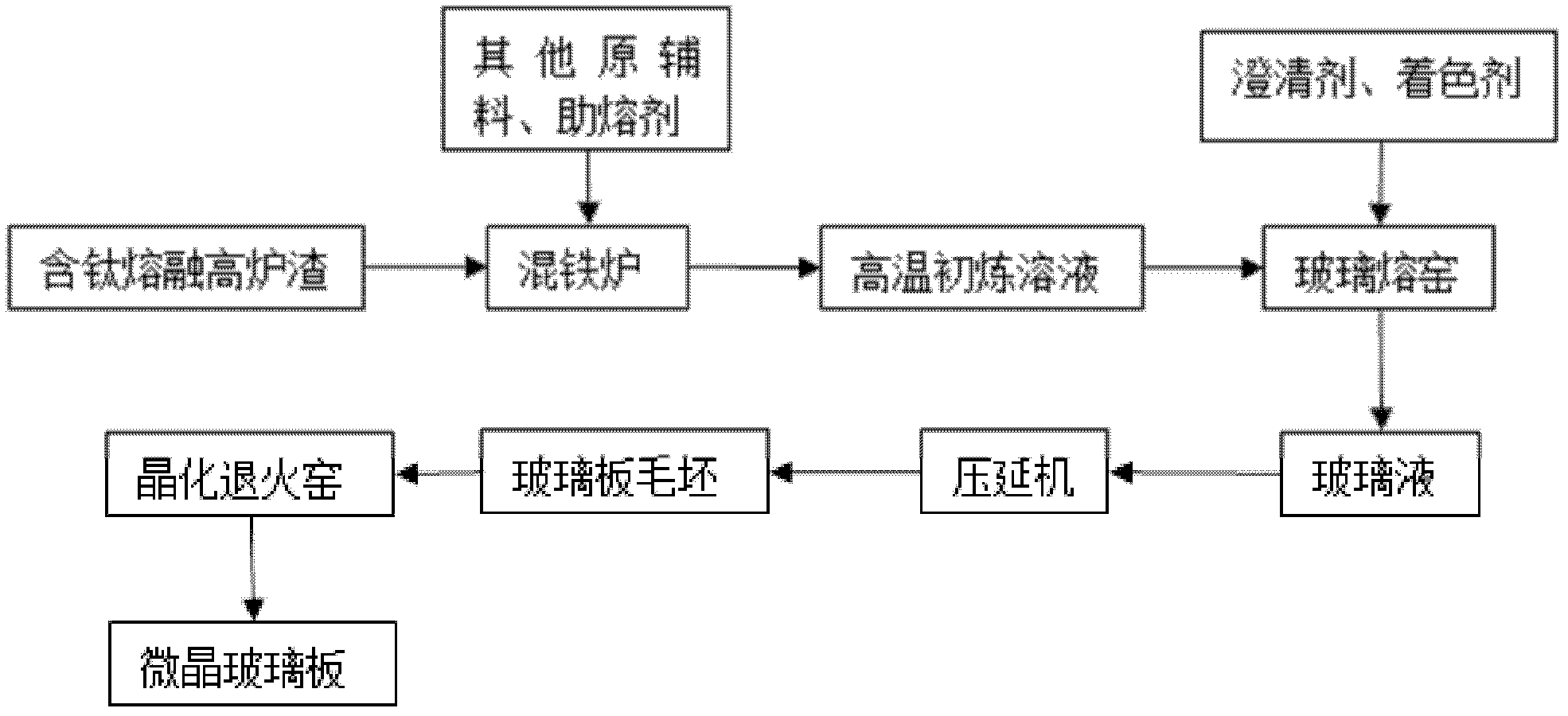

Methods of forming a glass wiring board substrate

InactiveUS20130239617A1Low CTEWell-matchedSolid-state devicesGlass reforming apparatusMicrometerIntegrated circuit

Disclosed is a method or process for forming a glass wiring board substrate for integrated circuit wiring boards, including providing a first molding surface (20) positioned on a first mold (22) having truncated conical pins (24) protruding therefrom, the pins (24) having a diameter at the top end (26) thereof of 150 micrometers or less, and a minimum pitch (28) of 400 micrometers or less, providing a glass sheet (30) having first and second surfaces (32,34) on opposite major sides thereof, pressing the first surface (32) of the glass sheet against the molding surface (20), heating the glass sheet (30) and the first molding surface (20) together to a temperature sufficient to soften a glass of which the glass sheet (30) is comprised, such that the pattern of the first molding (20) surface is replicated in the first surface (32) of the glass sheet (30), thereby producing a formed glass sheet (30′) having an array of holes (40) therein, cooling the formed glass sheet (30′) and the molding surface (20) together to a temperature below the softening point of said glass, and separating the formed glass sheet (30) from the molding surface (20). The forming may press the glass sheet using one mold surface or two mold surfaces simultaneously. For embodiments using a single mold, the holes may be blind holes after pressing, and may then be opened to form through-holes by back side lapping. Alternatively, the glass is pressed up to through-hole formation, avoiding the need of back side lapping.

Owner:CORNING INC

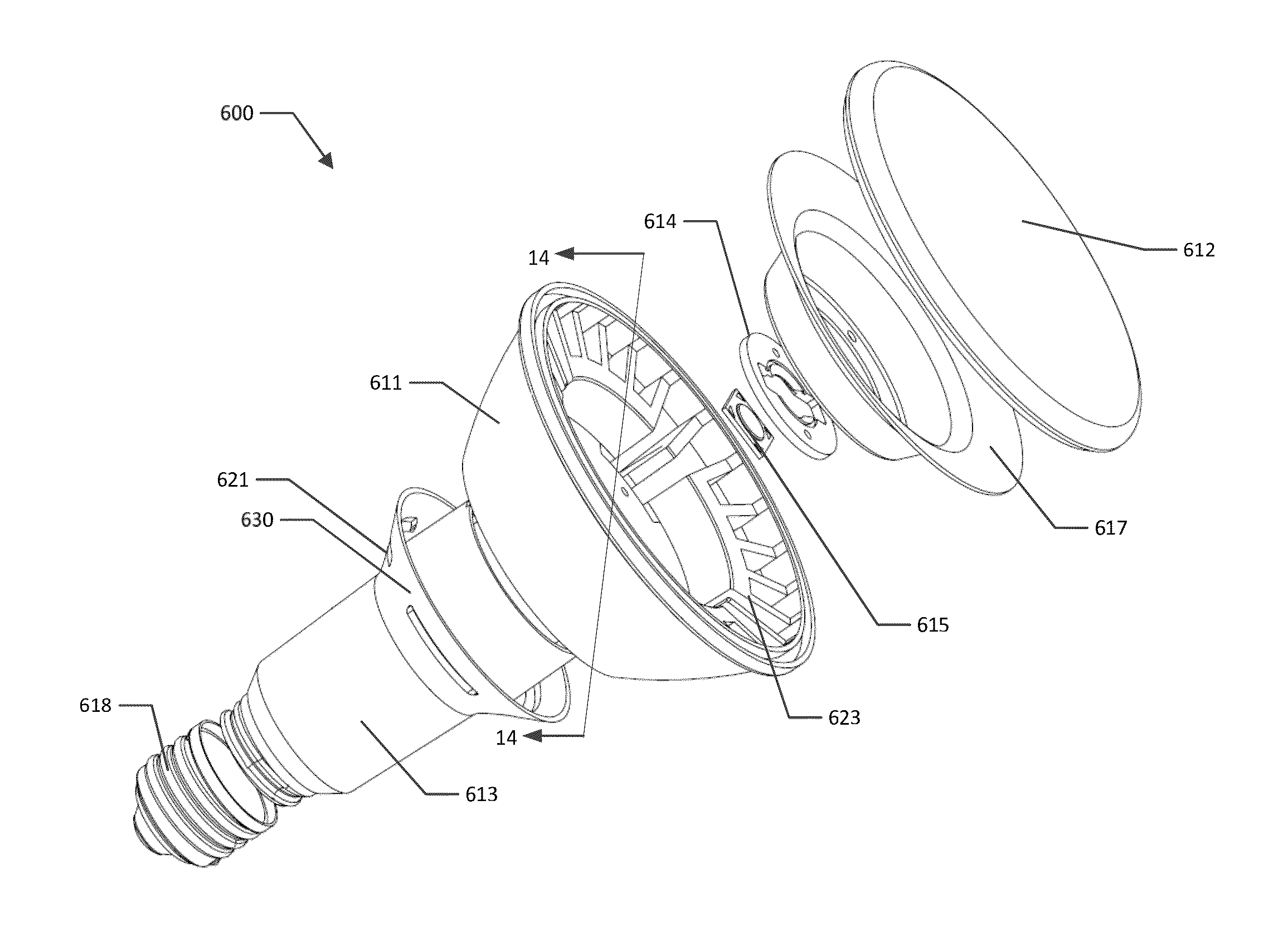

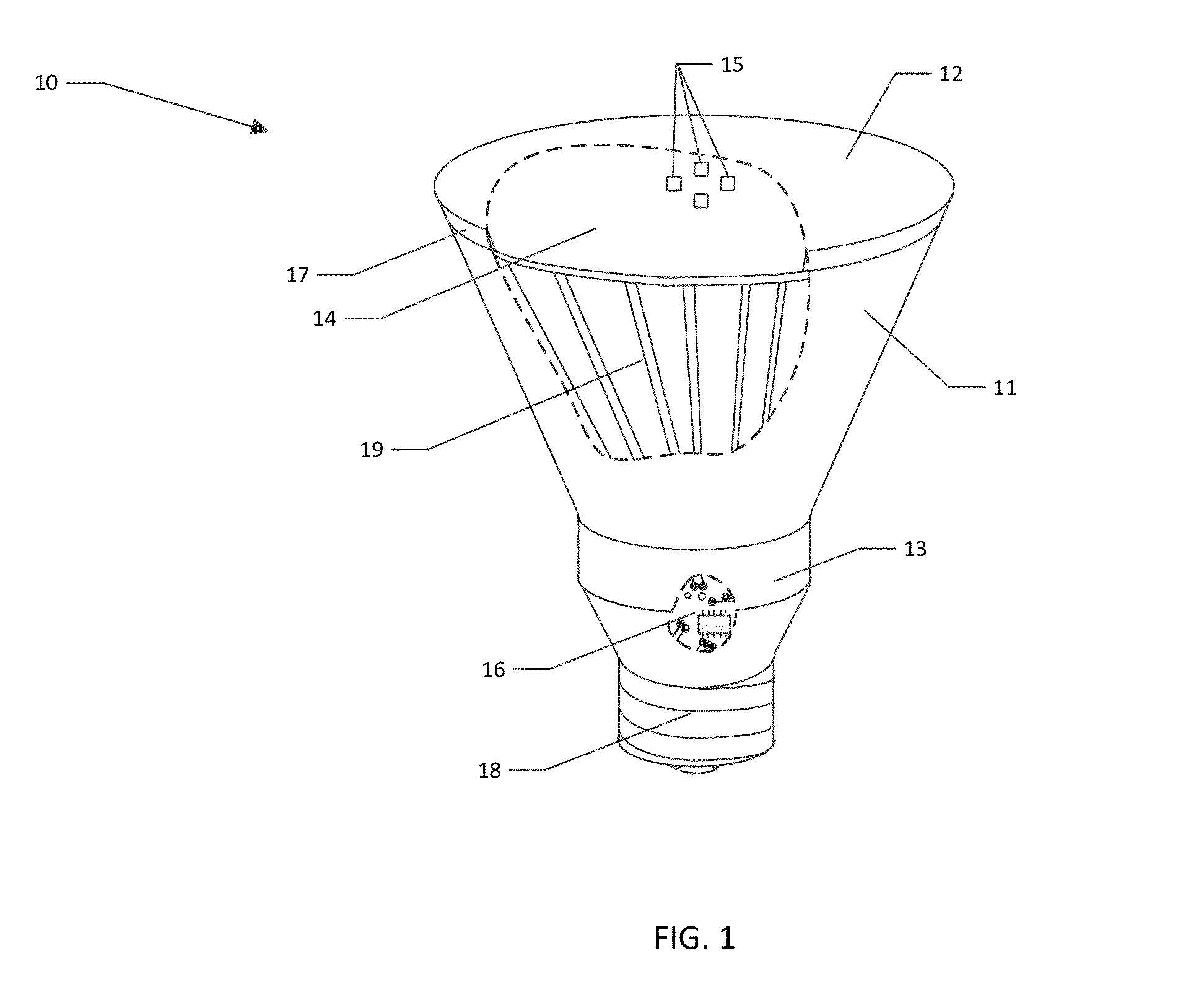

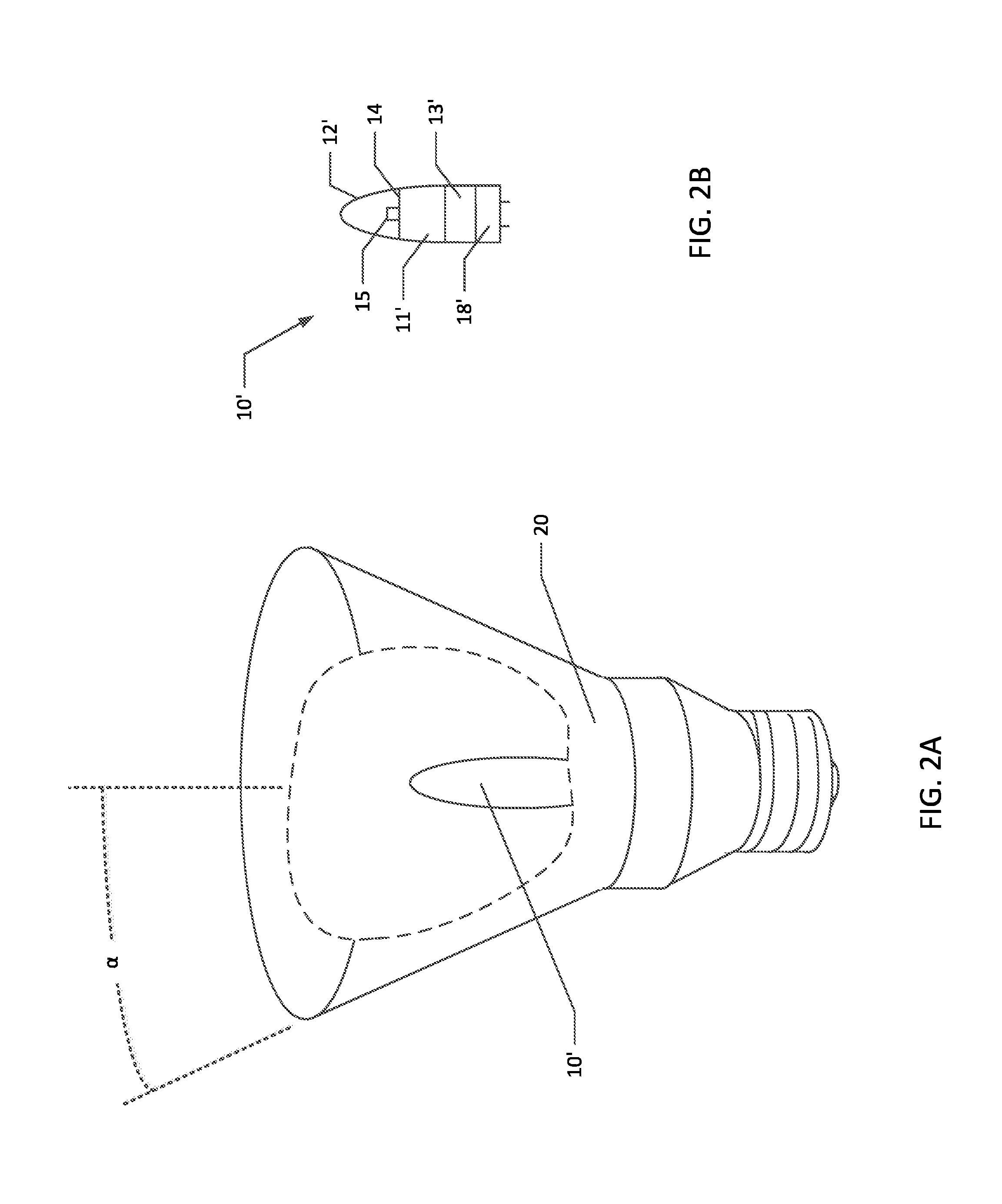

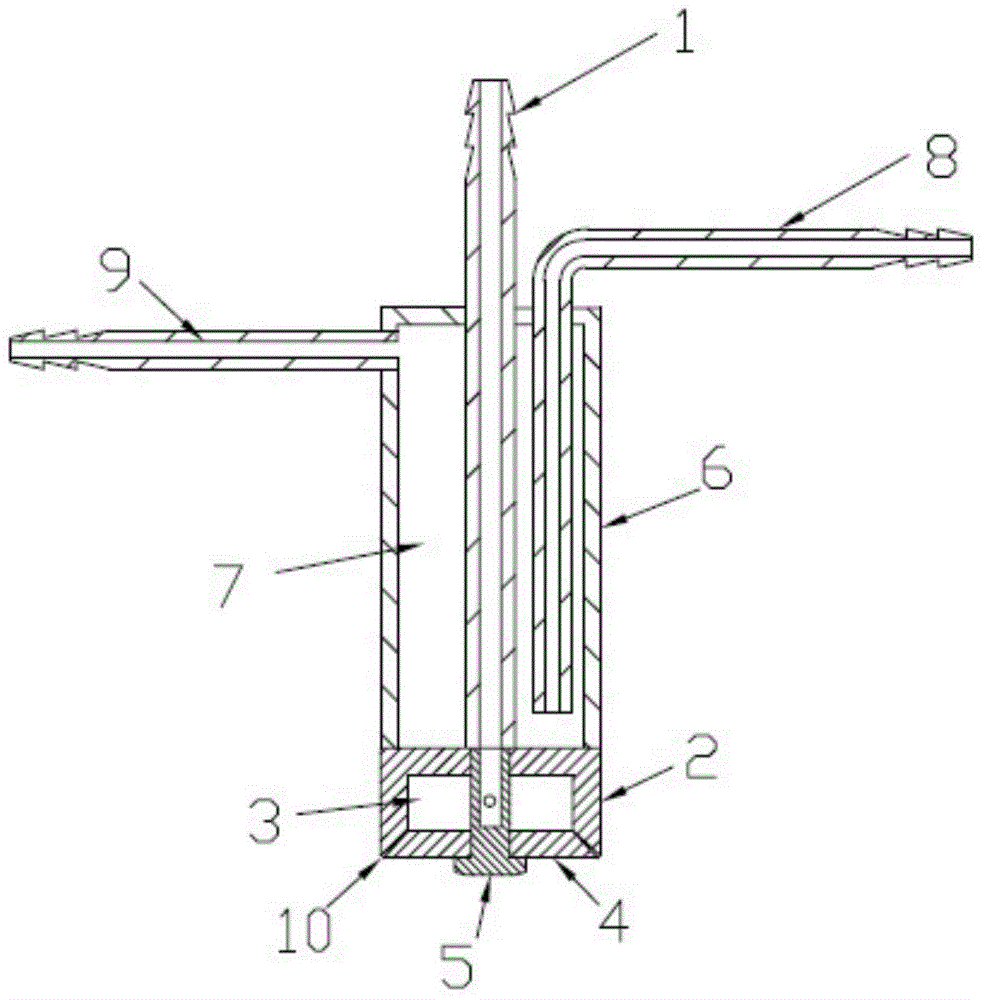

Hard-pressed glass light emitting diode flood lamp

ActiveUS9103510B2Heat dissipationEasy to operateElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLight-emitting diode

In various embodiments, a light emitting diode (LED) flood lamp is provided. The LED flood lamp may include a base cap; a first housing having a first end and a second end, the first end secured to the base cap; a second housing having at least in part a partially conical shape, an end of the second housing having a smaller diameter secured to the second end of the first housing; at least one LED secured within the second; driver circuitry secured within the LED flood lamp between the end of the base cap and the at least one LED; a reflector having a partially conical shape; and a diffuser element secured to at least one of a wider end of the reflector or the end of the second housing having the larger diameter. In some embodiments, the first or second housing may include one or more vents.

Owner:FEIT ELECTRIC CO INC

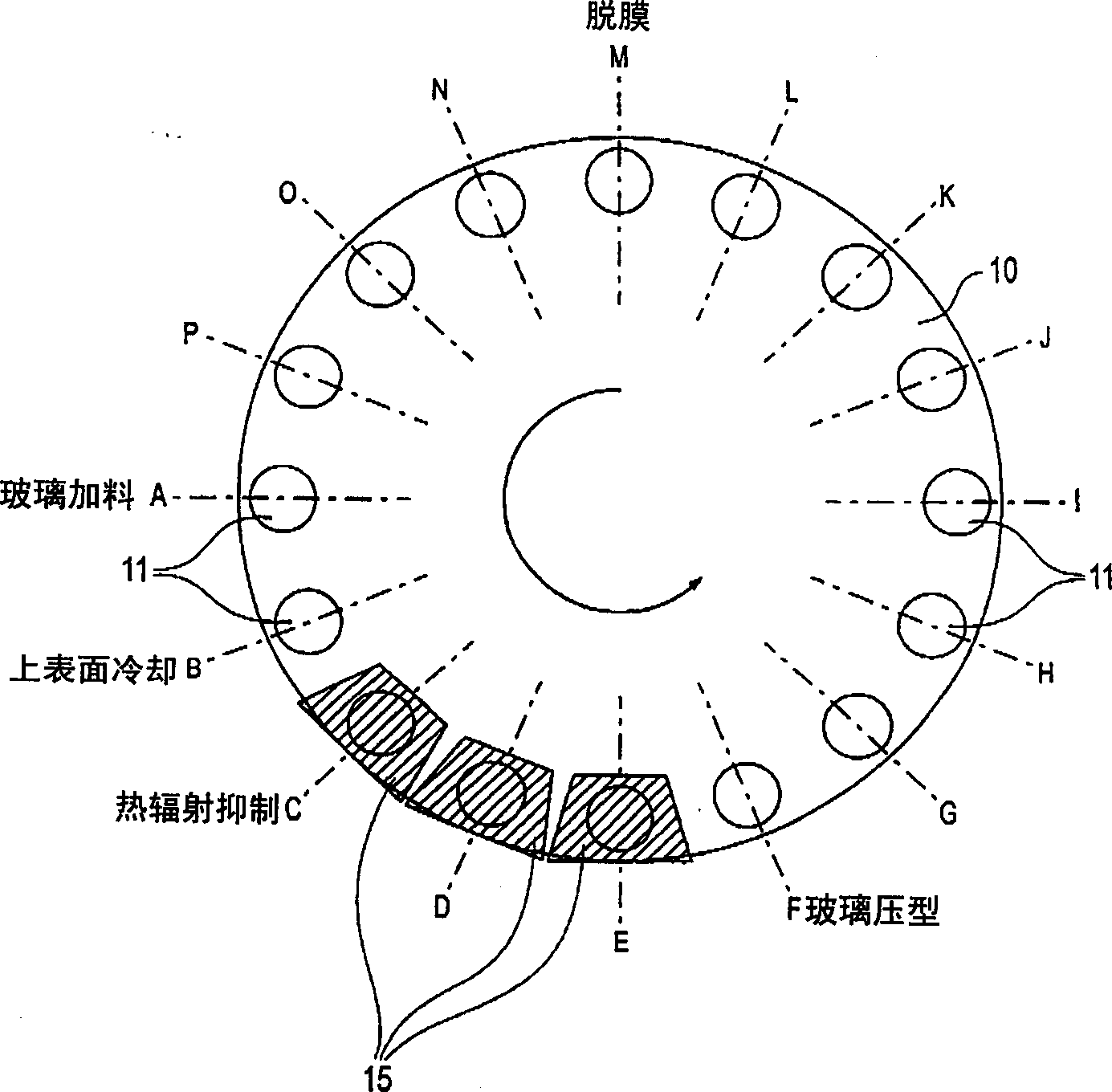

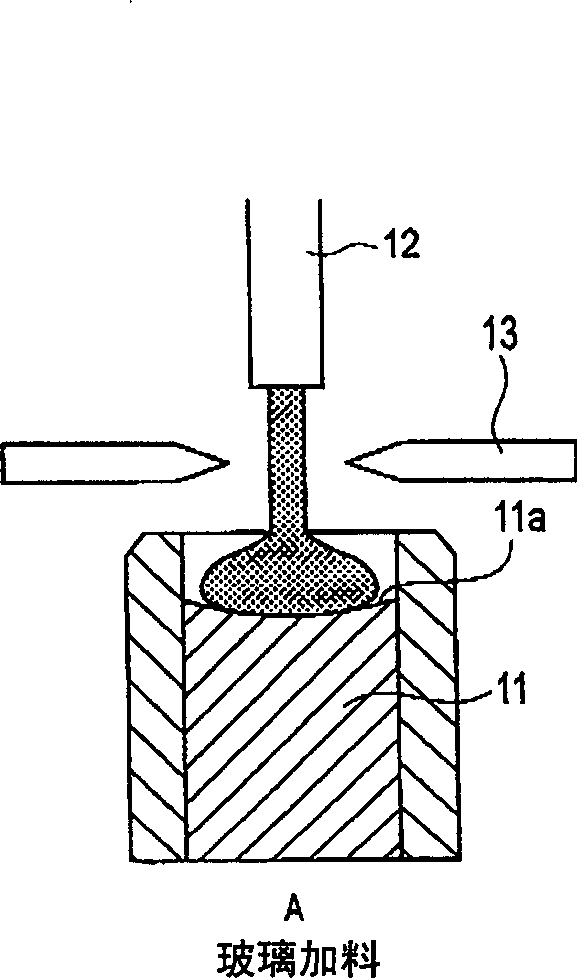

Method and equipment for mould-pressed glass product

InactiveCN1340467ASave heatSmall temperature differenceGlass pressing apparatusGlass productionThermal radiationPoise

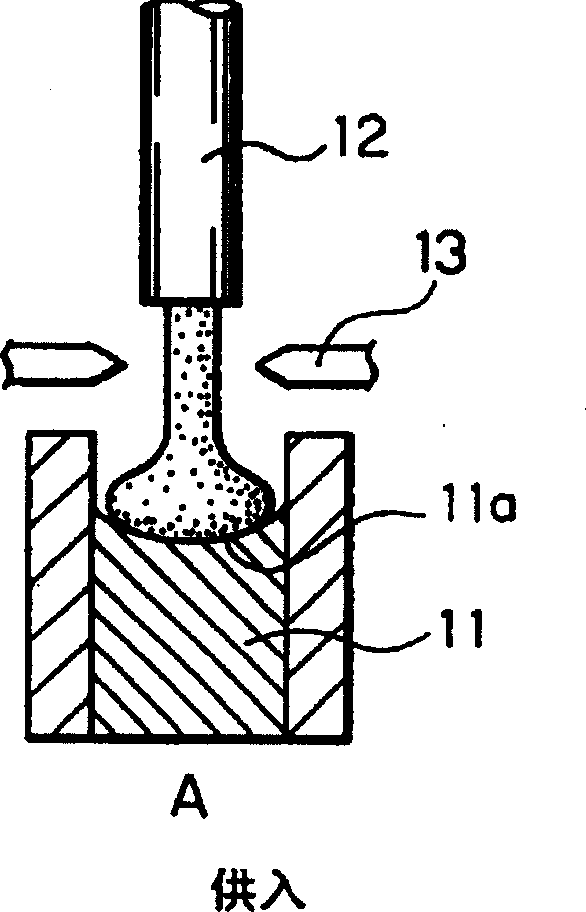

On molding a glass product by pressing a glass gob by the use of a mold composed of upper and lower dies each of which has a molding surface, a molten glass is supplied as the glass gob onto the molding surface of the lower die. Cooling is carried out for an upper surface of the glass gob supplied onto the molding surface of the lower die. After the cooling, heat radiation suppression is carried out to suppress heat radiation from the glass gob so that an inner part and an upper part of the glass gob are close in temperature to each other. Thereafter; the glass gob is pressed by the molding surfaces of the upper and the lower dies when the glass gob has a viscosity within a range between 103.5 and 106.5 poises (dPa.s). Preferably, the heat radiation suppression is carried out by making a heat shielding member lower in temperature than the inner part of the glass gob approach the upper part of the glass gob in a non-contact state.

Owner:HOYA CORP

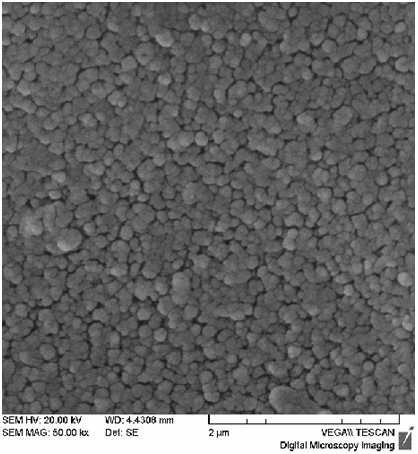

Method for preparing calcium aluminosilicate nanometer microcrystal glass by utilizing natrium silica calcium glass waste slag

InactiveCN101973709AIncreased crystallization tendencyImprove mechanical propertiesSlagSilicon oxide

The invention provides a method for preparing calcium aluminosilicate nanometer microcrystal glass by utilizing natrium silica calcium glass waste slag. The method comprises the following steps: 1) classifying, grinding and screening natrium silica calcium glass waste slag to prepare glass powder; 2) adding silicon dioxide, calcium oxide, aluminum oxide, boron oxide, TiO2 / P2O5 composite nucleating agent and rare-earth oxide to ensure that component requirement of the calcium aluminosilicate (CAS) microcrystal glass can be fulfilled; 3) filling the uniformly mixed glass materials into a high-alumina crucible, and pouring into a die to press and mold; and 4) putting the pressed glass plate in a muffle furnace for heat treatment, cooling to room temperature with the furnace after heat treatment to obtain the CAS nanometer microcrystal glass. The method has the advantages that: (1) the mechanical performance of the microcrystal glass is greatly improved; and (2) the additive dosage is adjusted according to the component composition of the glass residues to ensure that the glass achieves the regulated formula proportion. The method is suitable for the conventional various civil natrium silica calcium glass waste slag.

Owner:NANCHANG HANGKONG UNIVERSITY

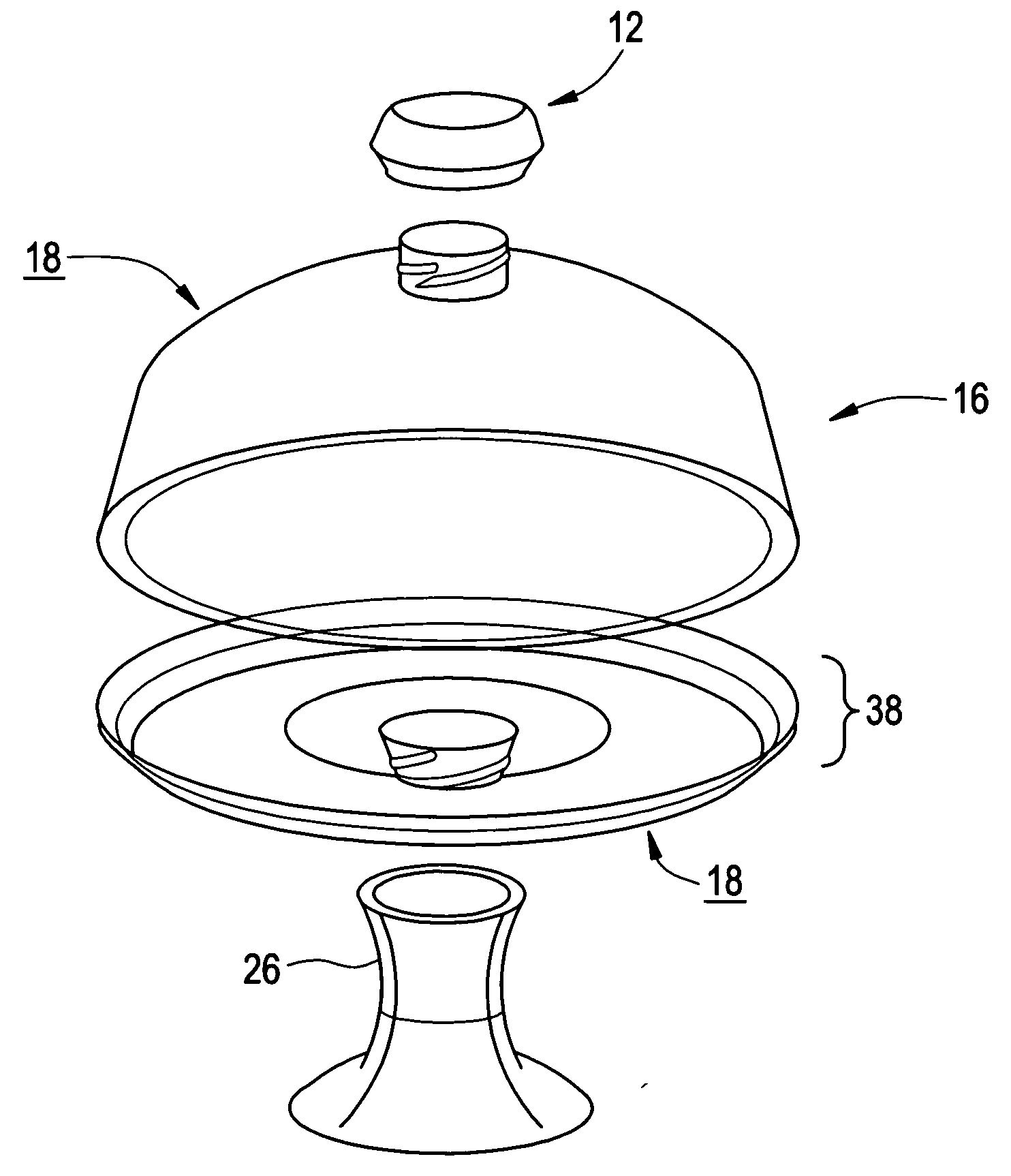

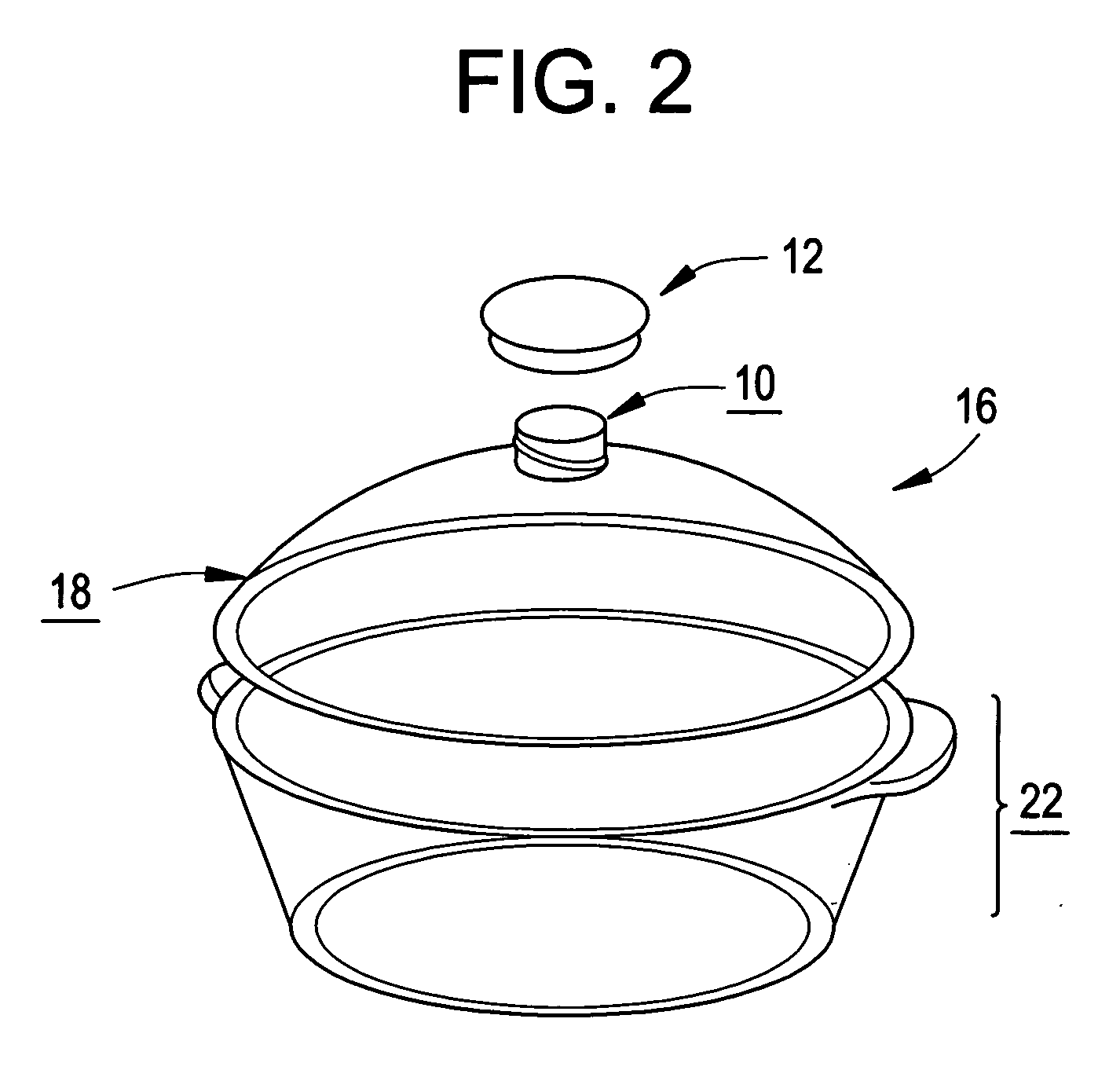

Glass lid

A pressed glass lid with an attachable knob. A threaded post is molded in glass for purposes of attaching a knob. The threaded post is integrally formed on a surface portion of a lid. The surface portion may be a lid or formed of a conical body. The internal threaded channel of the knob has a diameter greater than the diameter of the threaded post.

Owner:ANCHOR HOCKING OPERATING

Glass lamp shade forming process by machine pressuring and blowing

InactiveCN101793376AShorten molding timeIncrease productionGlass pressing apparatusGlass blowing apparatusCrucibleEngineering

The invention discloses a glass lamp shade forming process by machine pressing and blowing. The process is characterized by comprising the following steps of: a, melting the glass material; b, preheating dies to 400-600 DEG C; c, starting the air compressor: starting the air compressor to introduce the compressed air into the work system; d, selecting material: selecting the boiled glass material from the crucible according to the appropriate weight by a selector and placing the glass material in the center of the bed die of the flat-plate air compressor pressing die; e, pressing the glass material cake with the flat-plate air compressor; f, forming the semi-finished product with paddle table; g, forming the finished product by blowing: reversely covering the blowing forming die on the sub-opening of the semi-finished product by a former, starting the compression air switch of the forming paddle table to blow the semi-finished product to the finished product, and starting the blowing forming die; h, annealing: taking the finished product from the paddle table forming die by a shade taker and sending the shade to a shade sender, and sending the the shade to an annealing furnace for annealing; and I, drilling: drilling a hole at the bottom of the lamp shade by a driller. The invention has the advantages of no fire finishing, low energy consumption, no false bobble, high use rate of glass material, low production cost, short forming time and the like.

Owner:宋春烨

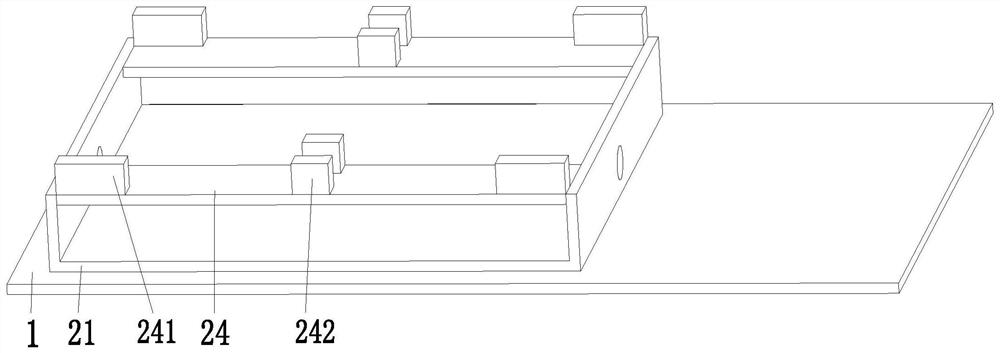

Conveniently-charging and high-security glass movable stand

InactiveCN107285032APrevent crashEasy loadingCharge manipulationConveyor partsFritArchitectural engineering

The invention discloses a glass moving frame which is convenient for loading materials and has high safety, which comprises a horizontal plate and two central columns, support frames are arranged on both sides of the end surface of the horizontal plate, and inclined support blocks are arranged on both sides of the central column , a plurality of rollers are installed on the support frame, two side columns are arranged on both sides of the end surface of the horizontal plate, and a support rod is arranged between the opposite faces of the two side columns on the same side, and the two ends of the support rod pass through The sliding mechanism is connected with the two side columns, the upper end of the support rod is equipped with a support roller, the lower end of the support rod is connected with the hydraulic cylinder arranged on the horizontal plate through the hydraulic rod, and two Compression brackets, the upper ends of the two compression brackets are equipped with compression rollers, and the upper ends of the compression brackets are connected with the central column through compression springs. The invention has the advantages of simple structure, firm glass pressing, convenient glass feeding, improved feeding efficiency, high stability during feeding of the moving frame, and strong practicability.

Owner:安庆海维环保设备有限公司

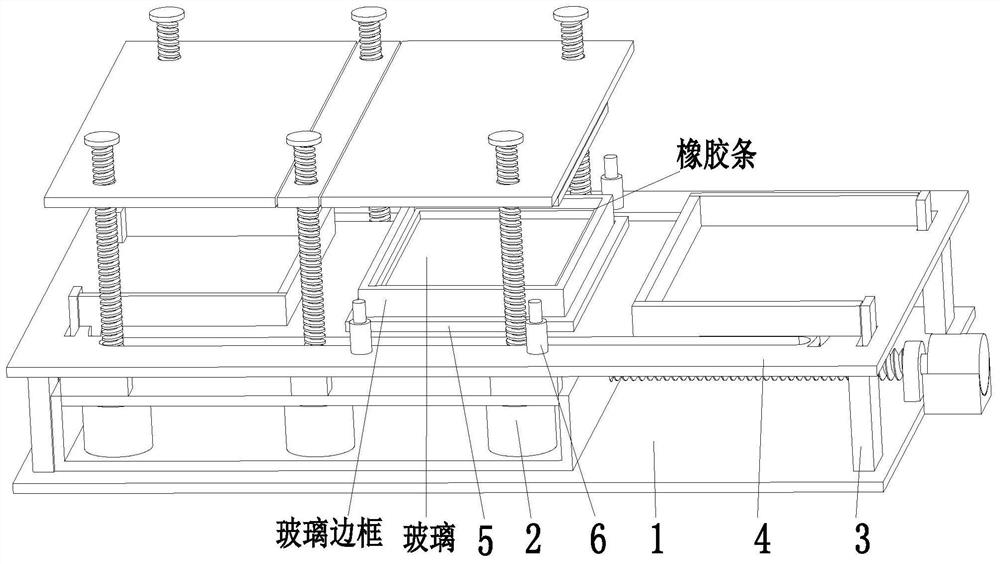

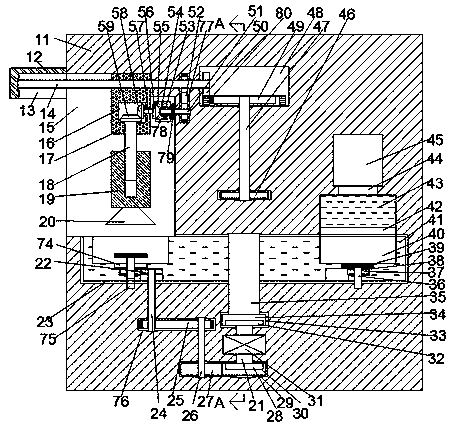

Automatic vacuum glass assembling machine and assembling method

ActiveCN111958542AHigh scrap rateReduce the pressing effectWork holdersMetal-working hand toolsEngineeringPressed glass

The invention relates to an automatic vacuum glass assembling machine. The automatic vacuum glass assembling machine comprises a base, a displacement mechanism, a supporting plate, a bearing plate, amaterial storage mechanism and a spring rod, and is characterized in that the displacement mechanism is installed on the upper end face of the base, the supporting plate is installed at the corner position of the upper end face of the base, the bearing plate is installed on the upper end face of the supporting plate, the material storage mechanism is installed on the upper end face of the bearingplate, spring rods are evenly arranged in the middle of the upper end face of the bearing plate, and scales are arranged on the outer side faces of the contraction ends of the spring rods. According to the automatic vacuum glass assembling machine and the assembling method, the problems that when an existing vacuum glass assembling machine is used for assembling vacuum glass, the corners of the pressed glass cannot be aligned, the unaligned parts of the corners of the glass are prone to being broken in the pressing process, when the glass surface is pressed, the stress is not uniform, so thatthe pressed glass surface is in an inclined state, and the effect of assembling the vacuum glass is reduced are solved.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

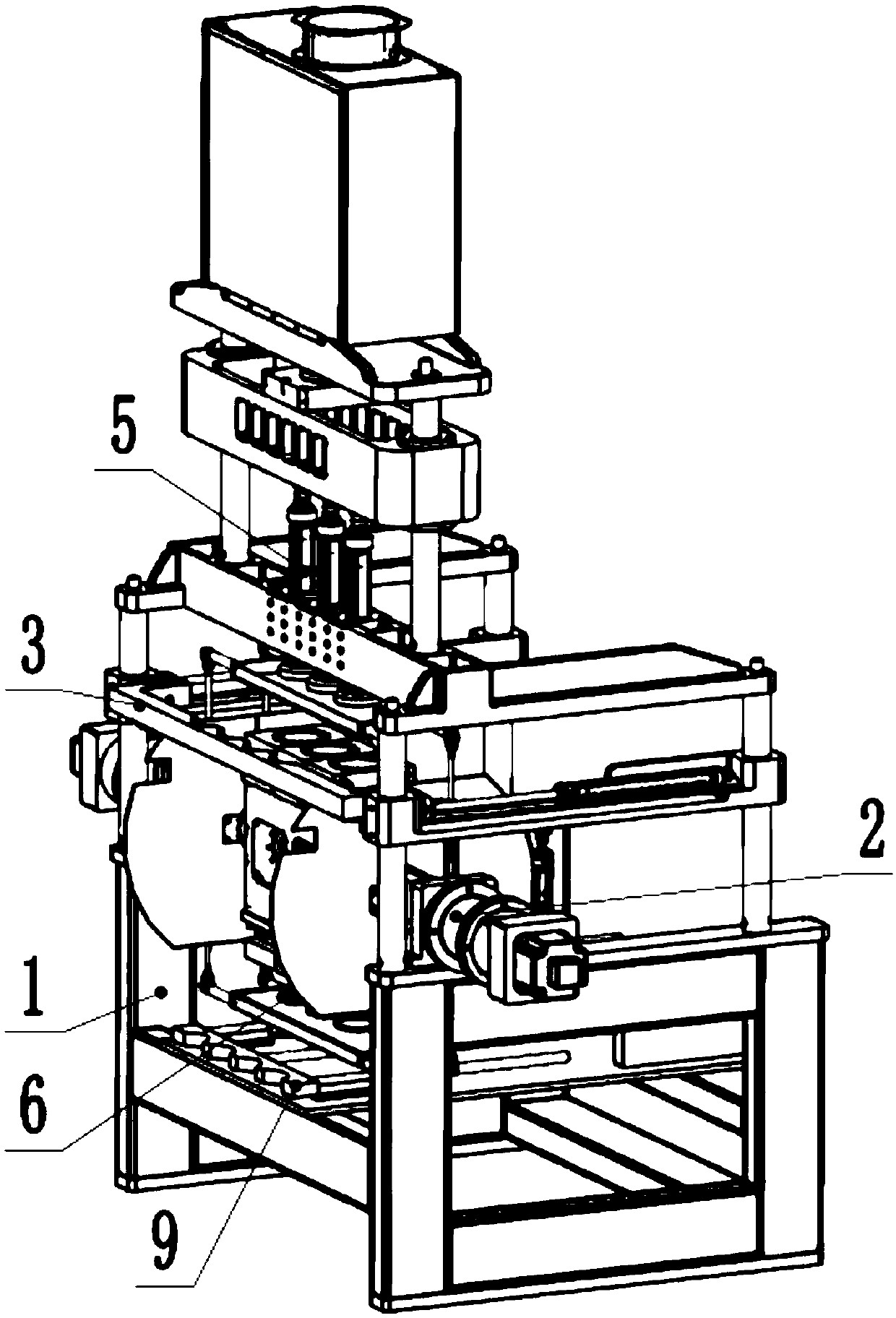

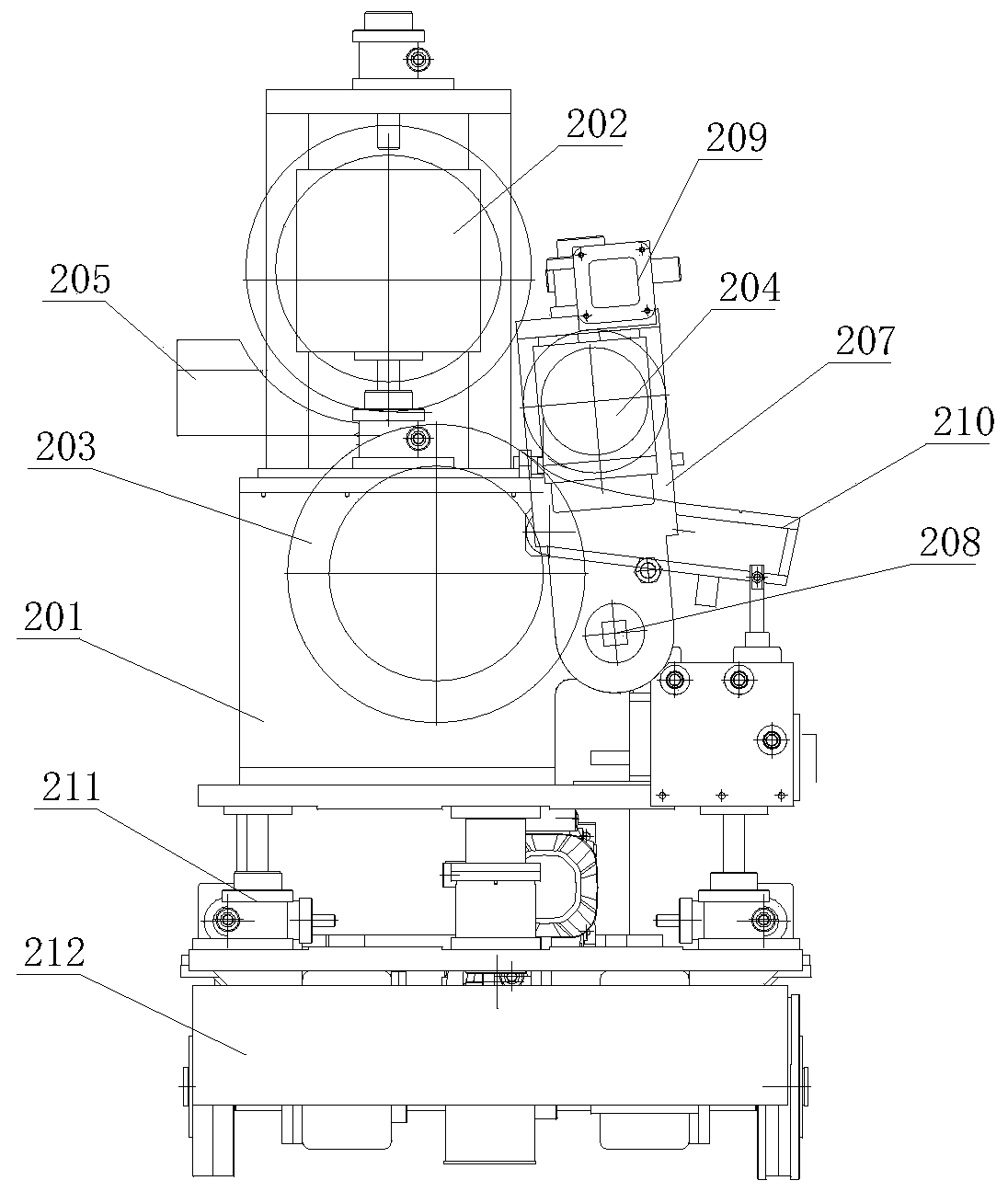

Glass forming press

The invention provides a glass forming press, and relates to the technical field of glass forming. The glass forming press comprises a frame. A punching mechanism is arranged on the upper side of theframe, and the frame is internally provided with a plurality of molds and a mold turning mechanism for driving the molds to turn over, wherein the molds are located below the punching mechanism; the mold turning mechanism comprises a driving device and a horizontal rotating shaft, the driving device is mounted on the frame, and the rotating shaft is connected to the output end of the driving device; the molds are evenly and symmetrically arranged on two sides of the rotating shaft around the axis of the rotating shaft. The glass forming press has the advantages that finished pressed glass products can be rotated through the rotating shaft to be separated from the molds, discharge ends do not need to be provided additionally on the end faces of the molds, the finished pressed glass productsare conveniently taken out, and the processing efficiency is improved.

Owner:重庆重科智能装备研究院有限公司

Processing method for 3D net-free glass film

ActiveCN107382037AGood touch effectEasy to operateLaminationLamination apparatusNumerical controlCutting glass

The invention protects a processing method for a 3D net-free glass film. The method comprises the following steps: (S1) cutting a piece of glass into approximate shape according to the size of a to-be-processed 3D net-free glass film; (S2) for carving holes corresponding to the glass film in the cut glass plate by using a numerical control machine tool; (S3) coating sweeping powder onto the glass film cut by CNC, driving a vacuum chuck to press the glass plate onto the sweeping machine by utilizing a vacuum pump in a sweeping machine and performing sweeping operation; (S4) placing the swept glass into different cleaning agents for cleaning in turn; (S5) placing the cleaned glass into a hot briquetting mold for thermally pressing, thereby changing the edge of the glass to be an arc hook face; (S6) placing the thermally pressed glass into a high-temperature chemical toughening furnace and performing temperature sensing treatment at 650 DEG C; (S7) placing the toughened glass into an AF workshop and coating nanometer anti-fingerprint oil; (S8) adhering a layer of anti-explosion glue to the glass film surface; and (S9) adhering a double faced adhesive tape to the inner layer of the glass film, thereby acquiring the end product.

Owner:SHENZHEN KANGCHENGTAI IND CO LTD

Machine blowing molding technology for glass lamp shade

The invention relates to a machine blowing molding technology for a glass lamp shade. The process feature lies in the following steps: a, melting frit; b, pre-heating a die to 400-600 DEG C; c, starting up an air compressor to enable compressed air to enter a working system; d, gathering materials in the way that a gatherer picks the cooked frit out of a crucible according to a proper weight and places the cooked frit in the bottom die center of a stamping die of a flat-plate aerostatic press; e, using the flat-plate aerostatic press to press glass cakes; f, forming a semi-finished product through a tread table; g, blowing to form a finished product in the way that a molding worker places a blowing molding die at the opening part of the semi-finished product in a back-off manner, starts up a compressed air switch of the molding tread table to blow the semi-finished product into the finished product and then starts up the blowing molding die; h, annealing in the way that a shade taking worker takes the finished product out of a tread table shaping die and gives the finished product to a shade delivery worker and the shade delivery worker feeds the finished product into an annealing furnace for annealing; and i, drilling in the way that a drilling worker performs drilling on the bottom of a lamp shade. The machine blowing molding technology has the advantages that fire finishing is not required, so that the energy consumption is reduced; counterfeit bubbles are not needed, so that the frit usage rate is high; the production cost is low; and the molding time is shortened.

Owner:纪宗耀

Rapid forming device for pressed glass

InactiveCN109133582ASuppression efficientSimple structureGlass pressing apparatusEngineeringPower apparatus

The invention discloses a rapid forming device for pressed glass. The rapid forming device comprises a device main body, a transmission device arranged inside the device main body, a conveying devicearranged inside the device main body and a pressing device arranged inside the device main body, wherein the transmission device is internally provided with a power device; the power device is connected with a rotating block through power; a forming cavity is arranged inside the rotating block in annular array; the conveying device is connected with the power device through a belt and is driven through a bevel gear; a conveying block capable of moving up and down is arranged inside the conveying device; and the lower end of the conveying block is fixedly connected with a sucking disc. The device can automatically drive the pressed glass to be formed, the automatic structure is compact, through a four-side working cavity of the circular rotating block, the pressing of the formed glass, cooling ejection and conveying can be carried out synchronously, the device can operate for long time, the automation efficiency is high, the interior of the device is sealed, the pressing temperature iscontrollable, the glass pressing is more efficient, and the same power driving guarantees synchronous operation of each working step.

Owner:HANGZHOU KANGYAN STATIONERY CO LTD

Method for preparing ultraviolet fluorescent red plastic film by taking rare earth phosphate glass as photochromic agent and application of ultraviolet fluorescent red plastic film in aspect of anti-counterfeiting

InactiveCN104262781AGive full play to the fluorescent functionIncrease incorporationStampsIdentification meansRare-earth elementIce water

The invention discloses a method for preparing an ultraviolet fluorescent red plastic film by taking rare earth phosphate glass as a photochromic agent and an application of the ultraviolet fluorescent red plastic film in the aspect of anti-counterfeiting. For solving the problems of large polarity difference between an inorganic rare earth fluorescent agent and a high polymer material, fluorescent concentration quenching and fluorescent stability and the like of a doped rare earth fluorescent high polymer material, by taking phosphate glass as a matrix, taking Eu<3+> ions as a fluorescent activator and taking Ce<3+> ions as a sensitizer, through the synergistic effect of the phosphate glass matrix, the Eu<3+> and the Ce<3+> in a formula, a fluorescent concentration quenching phenomenon is overcome, thereby improving the adding amount and fluorescence efficiency of rare earth element Eu; glass fragments are prepared by pressing through using a melting method and an ice-water mixture cooling glass sheeter, and then the glass fragments are subjected to high-pressure grinding by using an air-current mill so as to prepare phosphate glass with a particle size of less than 300 nm and containing Eu<3+>, Ce<3+> and fluorescent powder; and a surface modifier is added and fluorescent powder and polymer masterbatches are subjected to melt blending, then a plastic film prepared by film blowing is white and transparent in daylight, and emits bright red light under ultraviolet-irradiation, and the plastic film has special transmission spectrum, and can be used as an anti-counterfeiting packaging film, an anti-counterfeiting label printing base material and an anti-counterfeiting safety line base material.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Thick glass cup forming mechanism

The invention discloses a thick glass cup forming mechanism in the technical field of glassware production and manufacturing, and the thick glass cup forming mechanism comprises a forming machine body, the top of the forming machine body is fixedly provided with a material containing mechanism, the material containing mechanism comprises a feeding mechanism and an ejection mechanism, and the top of the material containing mechanism is rotatably provided with a material containing disc; the top of the material containing disc is fixedly provided with four lower die bases distributed in a circle, the top of the forming machine body is fixedly provided with a hydraulic rod, the bottom end of the hydraulic rod is fixedly provided with a connecting plate, the connecting plate is located over the material containing disc, and the bottom of the connecting plate is fixedly provided with a cooling cylinder and a pressing die core. In the process of pressing and forming a glass blank, a formed glass cup can be cooled, so that the glass cup can be quickly cooled and formed, the glass cup and a pressing mold can be quickly separated, workers can conveniently unload the glass cup, the glass blank can be continuously pressed and formed at a time, and a secondary processing process is avoided.

Owner:南通明艺玻璃科技有限公司

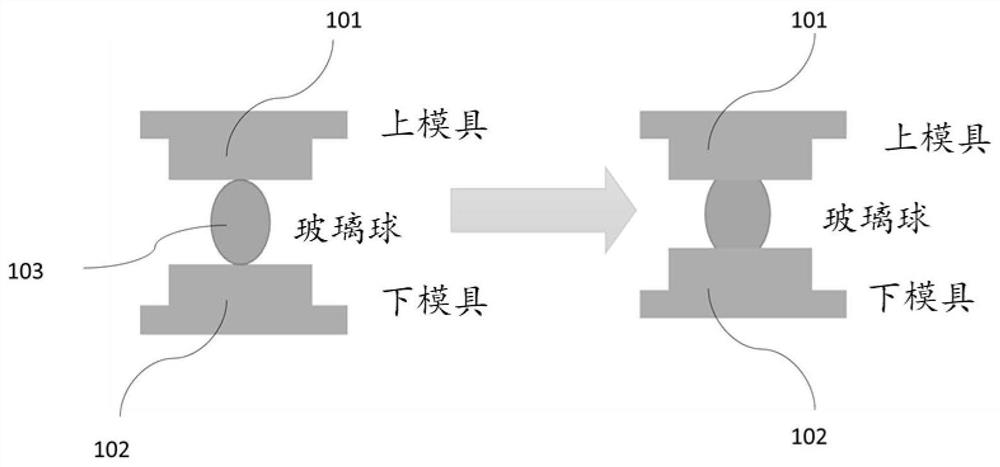

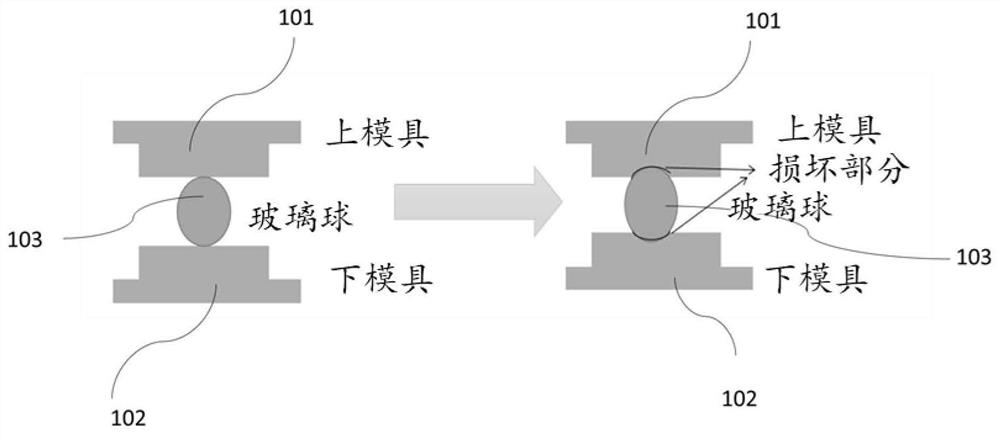

Non-isothermal glass mold pressing method

PendingCN113651522AKeep shapeExtended service lifeGlass pressing apparatusGlass reforming apparatusSilicon moldElectric machine

The invention relates to a mold pressing method for prolonging the service life of a mold in a non-isothermal glass mold pressing process. The method comprises the following steps: placing a to-be-pressed glass product (103) on a lower mold (102), driving the lower mold (102) to rise at a certain speed by a motor, and heating the lower mold (102) by utilizing voltage so as to transfer heat to the glass product (103), so that the temperature of the glass product (103) rises to the conversion temperature (Tg) of glass or above; enabling the motor to continues drive the lower mold (102) to continue to ascend and carry the glass product (103) to move at the same time, so that the glass product (103) makes contact with the upper mold (101), and the pressing process is completed; wherein the upper mold (101) and the lower mold (102) are made of monocrystalline silicon materials. By adopting the mold pressing method provided by the invention, only the glass material is subjected to mold pressing deformation in the mold pressing process of the lens, and the shape and form of the silicon mold are kept unchanged, so that the service life of the silicon mold is prolonged, and the overall production cost is reduced.

Owner:李莉华 +5

Clamping apparatus back side adhesive tape pasting working station

The invention relates to a glue sticking workstation on the back of a clamp, which includes a suction cup lifting unit, a transmission unit, a compacting unit and a tape sticking unit. The adsorption module includes an adsorption unit containing a suction cup for absorbing the panel glass on the glass fixture through the through hole on the glass fixture and a thimble support unit for supporting the glass fixture; one side of the suction cup lifting unit is provided with the A compacting unit, the compacting unit includes a clamp compacting module for pressing the clamp with panel glass delivered by the transfer unit on the transfer unit through the compacting block and passing through the side of the panel glass on the clamp The glass compacting module pressed by the compacting rod; the tape sticking unit includes two tape sticking modules that are moved and glued by a lateral transfer mechanism, and are respectively arranged on opposite sides of the conveying unit. The invention improves the work efficiency of pasting glue.

Owner:TIANJIN ZHONGSHENGDA TECH CO LTD

Impact-resistant high-strength bulletproof glass and preparation method thereof

ActiveCN111452457AFit tightlyNot easy to produceLamination ancillary operationsProtective equipmentToughened glassPressed glass

The invention discloses a preparation method of impact-resistant high-strength bulletproof glass. The preparation method comprises the following steps: S1, cleaning and air-drying a semi-tempered glass substrate; S2, performing lamination according to the superposing sequence of the semi-tempered glass substrate and the PVB film; S3, placing the superposed glass combination on a roller press for pre-pressing; S4, feeding the pre-pressed glass combination into an autoclave for autoclaving to obtain a semi-finished product glass substrate interlayer combination; S5, overlapping according to an overlapping sequence of the semi-finished product glass substrate interlayer combination, the PU film and the PC board to obtain a combined material; S6, the laminated combined material is put into a vacuum bag to be subjected to edge sealing treatment; and S7, autoclaving the combined material for 4-6 h under the conditions that the temperature is 110-120 DEG C and the pressure is 1.1-1.25 Mpa, thus producing the bullet-proof glass. The invention also discloses the bullet-proof glass prepared by the method. According to the bulletproof glass prepared by the invention, the overall dead weight can be reduced by about 20%-30%, and meanwhile, the impact resistance and bulletproof performance are kept unchanged.

Owner:WUJIANG GOLDEN GLASS TECH

Production method of sandwich glass with colored pattern

The invention discloses a production method of a sandwich glass with a colored pattern. The production method comprises the following steps: determining a colored pattern, drawing the pattern in a computer, then manufacturing a plate; determining the glass size, cutting glass, trimming the glass edges, washing and drying the glass; drawing the colored pattern on the prepared glass according to the plate; aligning the edges of two pieces of glass with the colored pattern, sealing the two pieces of glass by neutral silicone sealant; subjecting the sealed glass to vacuum pressing by a vacuum ring or a vacuum bag, wherein the vacummizing constant temperature is 85 to 165 DEG C, and the pressure is 1-1.3 MPa; and finally washing the pressed glass by clean water. The glass is well sealed, thus the harmful substances in the colored pattern will not be leaked out of the sandwich glass, and moreover, the sandwich glass is beautiful, fashion, and elegant.

Owner:QINGDAO SHOUSHENG IND

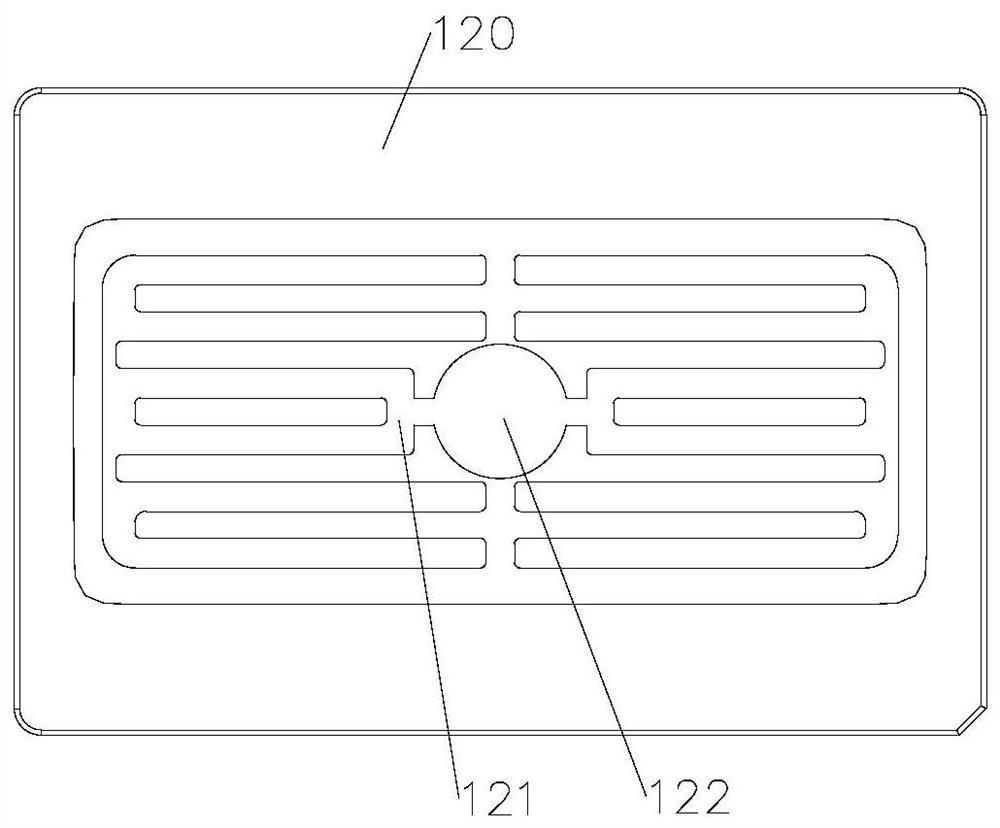

Method, mold and system for forging-adsorption composite molding of surface textures of glass

ActiveCN113024092ANo stencil transferProtection ridge straightnessGlass reforming apparatusGlass productionPressed glassGlass forming

The invention provides a method, a mold and a system for forging-adsorption composite molding of surface textures of glass, belonging to the technical field of 3D glass molding. The method provided by the invention comprises the following steps: pre-pressing glass into a bent shape; and conducting forging-adsorption composite molding on the pre-pressed glass, wherein the glass is forged and pressed through an upper die, and vacuumizing adsorption is conducted between a lower die and the glass. The method can ensure that the ridge of a texture area of a product is clear, and meanwhile, an appearance surface is almost free of mold printing transfer.

Owner:ONEPLUS TECH SHENZHEN

Pressed glassware bottom cutting technology, product and special-purpose fire gun thereof

InactiveCN104876433AEasy resectionExtended service lifeGlass severing apparatusEngineeringFlame cutting

The invention discloses a pressed glassware bottom cutting technology and a product thereof. A heating device is stretched into the bottom of the inner wall of a glass cup body without an opening at the bottom. A to-be-cut part of the glassware is fused and cut by the heating device. The glass bottom is cut off to obtain a finished product cup body with an opening at the bottom. A flame cutting method of the invention is used for removing the lower bottom of the glass cup body, and has the advantages of simple technology, convenient operation and good processing effect. A cut surface is smooth, easy to clean and more healthy. The invention also relates to a special fire gun for the bottom cutting technology. The fire gun of the invention has simple and compact structure, and strong practicality, and is especially suitable for being placed in the cup body to process the bottom wall in the case that the inner chamber size of the glass cup is limited.

Owner:郑罗三 +1

Glass pressing machine

PendingCN110272184AUniform thicknessNot easy to bendGlass rolling apparatusBrickPulp and paper industry

The invention discloses a glass pressing machine. The glass pressing machine comprises a base, an upper main roller, a lower main roller, a secondary pressing roller, a lip tile and pulling rollers. The upper main roller, the lower main roller, the secondary pressing roller and the pulling rollers are installed at the top of the base, the upper main roller is arranged at the top of the lower main roller, and the lip tile is arranged at the head ends of the upper main roller and the lower main roller and used for conveying glass liquid to the portion between the upper main roller and the lower main roller; the secondary pressing roller is arranged at the tail end of the upper main roller, the pulling rollers are arranged at the tail end of the lower main roller, the secondary pressing roller is used for conducting secondary pressing on glass pressed by the upper main roller and the lower main roller, and the pulling rollers convey the pressed glass to other processes. The provided glass pressing machine has a secondary pressing function, the thickness of a liquid glass material pressed by the glass pressing machine is more uniform, products with various flower types can be obtained through pressing, and the roller wrapping phenomenon cannot occur.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

Roundness control method for pressed glass insulator

ActiveCN111128486AAvoid deformationImprove roundnessSievingScreeningVitrificationMechanical engineering

The invention discloses a roundness control method for a pressed glass insulator, which is used for controlling the roundness of a glass insulator discharged by glue discharging and vitrifying equipment. The method comprises the following steps that: 1, the glue discharging and vitrifying equipment discharges glue in an effective temperature area with a uniform temperature field and generates theglass insulator; 2, a heat insulation device is used as a glue discharging carrier to bear the glass insulator; and 3, unqualified glass insulators is rejected by using shaking type rejecting equipment. By controlling the temperature uniformity degree of an effective temperature zone of production equipment, the screen tray is used for bearing the glass insulators, so that the glass insulators arenot prone to deformation after glue discharging and vitrification, the glass insulators with the sizes reaching the standard are screened out through screening equipment, and the roundness of products is guaranteed.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

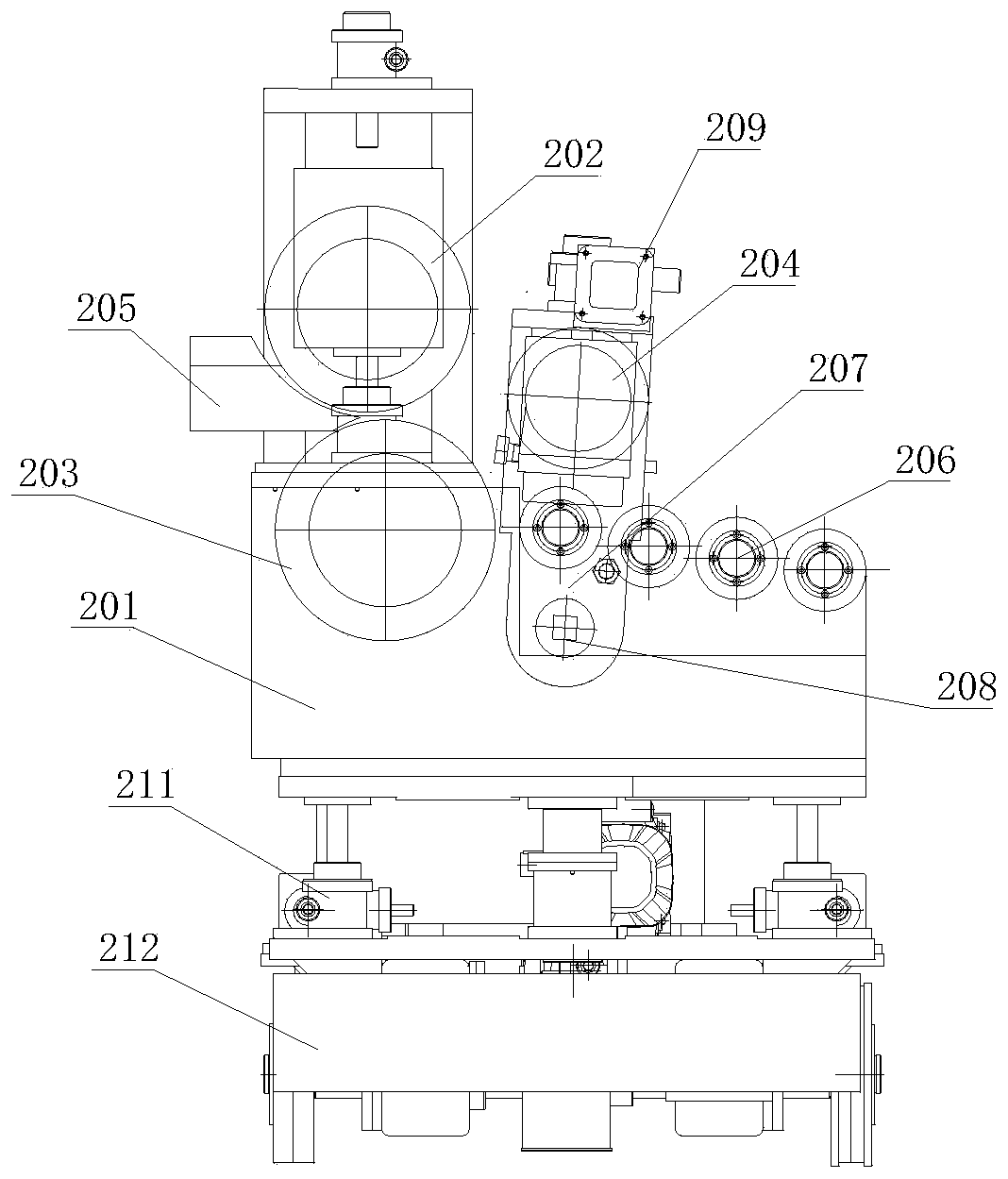

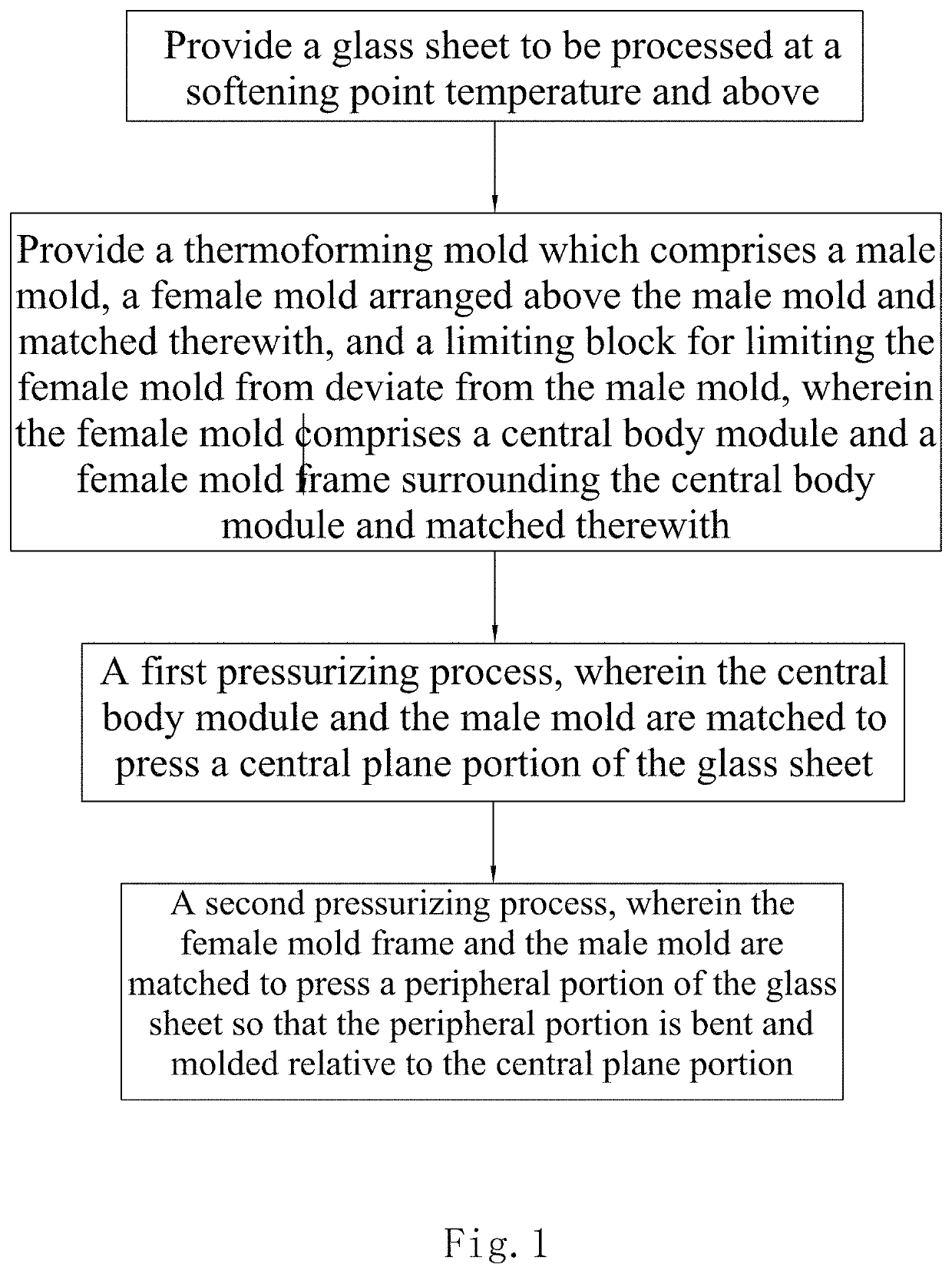

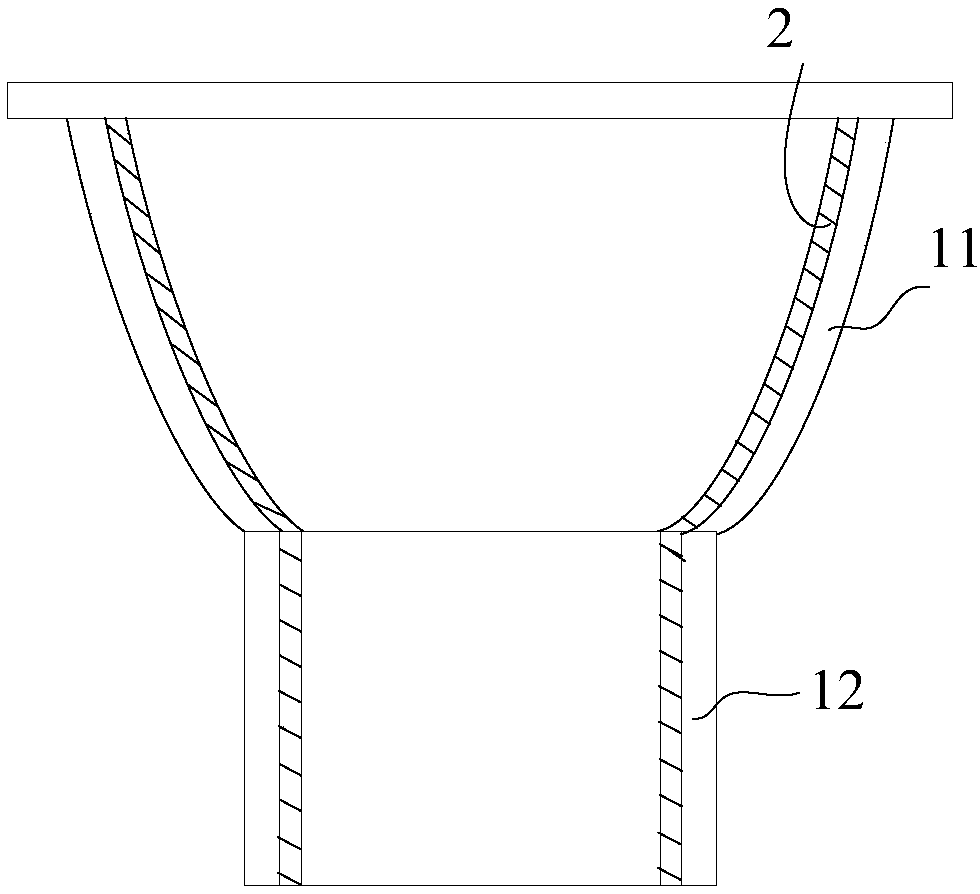

Thermoforming method, thermoforming mold and thermoforming device for glass product

ActiveUS10913676B2Improve glass qualityImprove manufacturing yieldGlass transportation apparatusGlass/slag layered productsGlass chipThermoforming

The present disclosure relates to a thermoforming method, a thermoforming mold, and a thermoforming device. The method comprises: providing a glass sheet to be processed at a softening point temperature and above; providing a thermoforming mold which comprises a male mold, a female mold arranged above the male mold and matched therewith, and a limiting block for limiting the female mold from deviate from the male mold, wherein the female mold comprises a central body module and a female mold frame surrounding the central body module and matched therewith; a first pressurizing process, wherein the central body module and the male mold are matched to press a central plane portion of the glass sheet; and a second pressurizing process, wherein the female mold frame and the male mold are matched to press a peripheral portion of the glass sheet so that the peripheral portion is bent and molded relative to the central plane portion; wherein the central plane portion is always pressed by the central body module in the second pressurizing process. The method improves the quality of a molded glass product and enhances the manufacturing yield of the glass product.

Owner:AAC TECH PTE LTD

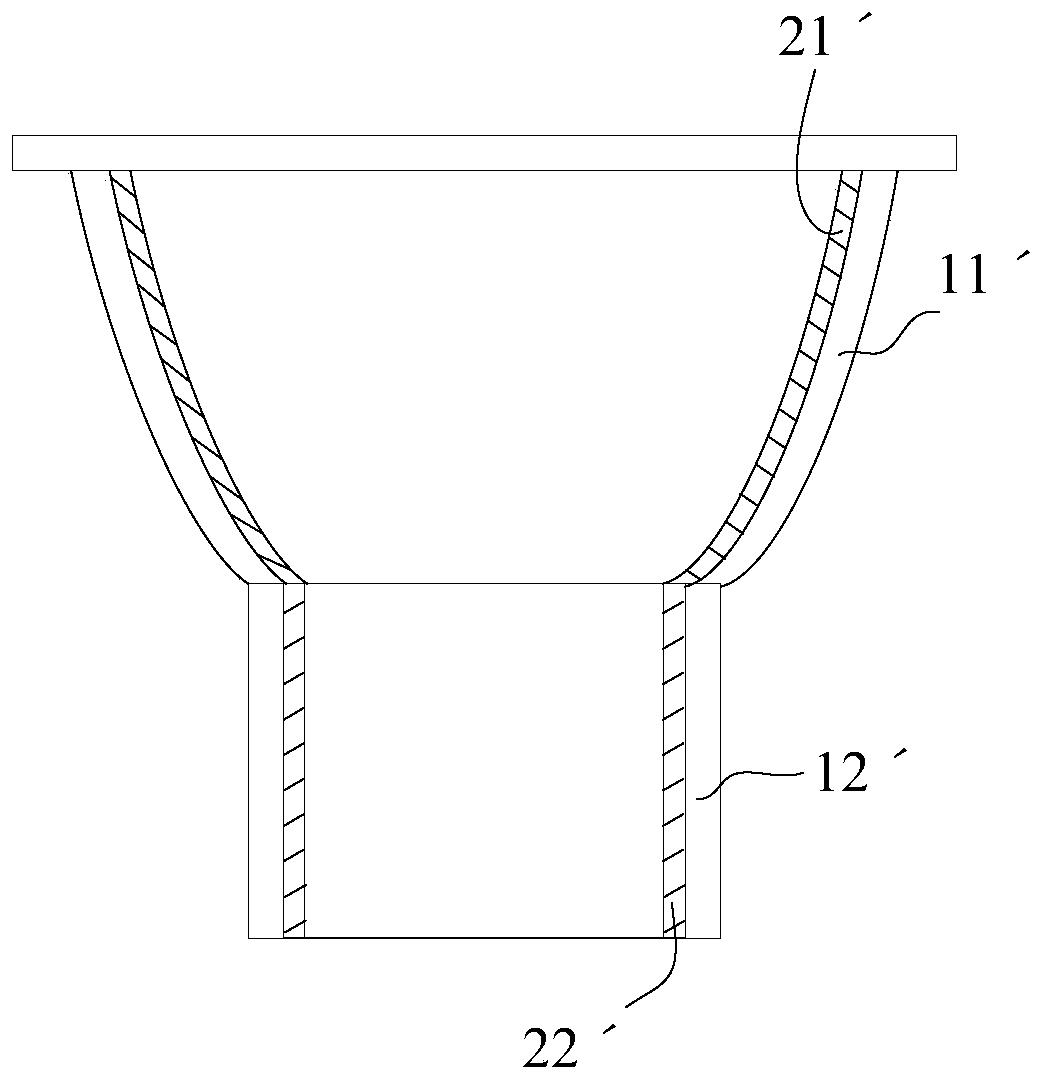

Pressed glass lamp cup, preparation method thereof and lamp

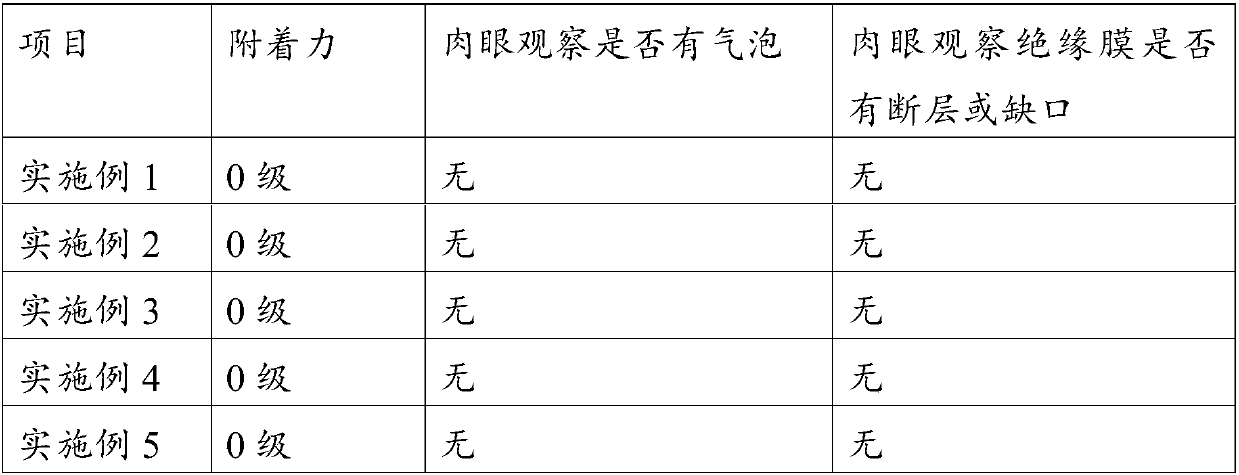

ActiveCN107726252ARealize one-time moldingImprove insulation performanceNon-electric lightingPoint-like light sourceEngineeringPressed glass

The invention discloses a pressed glass lamp cup. The pressed glass lamp cup comprises a cup body and an insulating film arranged on the inner surface of the cup body. The insulating film is arrangedon the inner surface of the cup body through insulating paint, and the coating range of the insulating film covers the whole inner surface from a cup opening to a cup bottom. The insulating paint comprises a component A and a component B, and the mixing ratio of the component A to the component B is 100:(1-10). Correspondingly, the invention further provides a preparation method of the pressed glass lamp cup and a lamp adopting the pressed glass lamp cup. According to the pressed glass lamp cup, the insulating film arranged on the pressed glass lamp cup can be formed at a time and is uniformlyand completely smeared on the whole inner surface from the cup opening to the cup bottom, and the inner electroconductive problem is solved.

Owner:FOSHAN ELECTRICAL & LIGHTING

Method and device for mould pressing glass products

InactiveCN1244508CGlass pressing apparatusGlass press-moulding apparatusForming faceTemperature control

This method is composed of a stage for supplying molten glass on the forming faces of a lower die, a stage for controlling the glass temp. so that the temp. of the inside of glass is brought close to that of the peripheral part and a stage for pressing the glass by the forming faces of the upper die and lower die, when viscosity of the temp.-controlled glass is within 103.5-106.5 poise. Since the temp. of the inside of glass is brought close to that of the peripheral part and the glass is pressed with a relatively high viscosity, the heat contraction quantity of the pressed glass is made small, and the difference in heat contraction quantity between the inside and peripheral part of the glass is decreased. Consequently, the generation of shrinks on the glass surface is reduced.

Owner:HOYA CORP

A vacuum glass automatic assembly machine and assembly method

ActiveCN111958542BHigh scrap rateReduce the pressing effectWork holdersMetal-working hand toolsEngineeringPressed glass

The invention relates to a vacuum glass automatic assembly machine and an assembly method, comprising a base, a displacement mechanism, a support plate, a support plate, a storage mechanism and a spring rod, characterized in that: a displacement mechanism is installed on the upper end of the base, and the corner of the upper end of the base is There are support plates installed at all places, a support plate is installed on the end surface of the support plate, a material storage mechanism is installed on the end surface of the support plate, and a spring rod is uniformly arranged in the middle of the end surface of the support plate, and the outer surface of the contracted end of the spring rod There are scales on the top; the present invention can solve the problem that existing vacuum glass assembly machines exist when assembling vacuum glass: the corners of the glass after lamination cannot be aligned, which may easily lead to misalignment of the corners of the glass during the lamination process. Fragmentation of some parts occurs; the glass surface is in an inclined state after being pressed due to uneven force when the glass surface is pressed, which reduces the effect of assembling the vacuum glass.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

A thick glass forming mechanism

The invention discloses a thick glass forming mechanism in the technical field of glassware production and manufacturing, which comprises a forming machine body. The top of the mechanism is rotatably installed with a tray, and the top of the tray is fixed with four lower mold seats distributed in a circle. The top of the molding machine body is fixed with a hydraulic rod, and the bottom of the hydraulic rod is fixed with a connecting plate. , the connection plate is located directly above the material tray, and the bottom of the connection plate is fixedly equipped with a cooling tube and a die core. The present invention can also lower the temperature of the formed glass during the molding process of the pressed glass body, so that it can be quickly cooled and formed, and can quickly separate the glass from the pressing mold, which is convenient for workers to unload. Moreover, the glass body can be pressed and formed continuously at one time, avoiding the process of secondary processing.

Owner:南通明艺玻璃科技有限公司

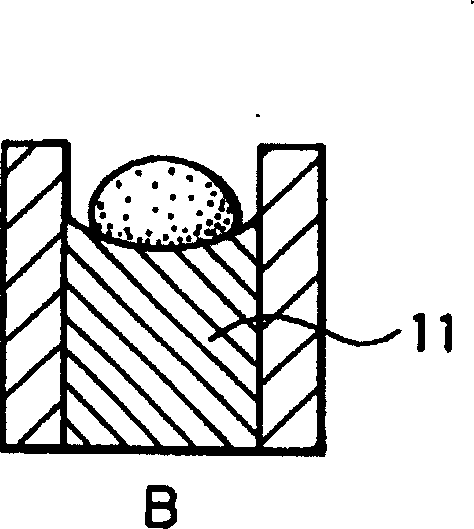

Method and device for blank pressing glass bodies

The invention relates to a method for producing blank-pressed glass bodies for optical components, according to preforming technology, whereby a liquid glass gob is supplied to a levitation preform mould in which said glass gob is preformed to form a parison, without touching the mould surface. After a defined period of time, said parison is transferred to a separate compression mould and is pressed therein by means of a press tool in order to form the end shape. The parison (1) is transferred to the compression mould (2) in such a way that it falls freely from the preform mould into the compression mould (2). According to the invention, the preform mould (1) is displaced above the compression mould (2) for the transfer of the glass gob, is maintained in said transfer position, and is downwardly pivoted away from the glass gob.

Owner:DOCTER OPTICS

Pressed glass lamp cup and its preparation method and lamp

ActiveCN107726252BRealize one-time moldingImprove insulation performanceNon-electric lightingPoint-like light sourceInsulative paintPressed glass

The invention discloses a pressed glass lamp cup. The pressed glass lamp cup comprises a cup body and an insulating film arranged on the inner surface of the cup body. The insulating film is arrangedon the inner surface of the cup body through insulating paint, and the coating range of the insulating film covers the whole inner surface from a cup opening to a cup bottom. The insulating paint comprises a component A and a component B, and the mixing ratio of the component A to the component B is 100:(1-10). Correspondingly, the invention further provides a preparation method of the pressed glass lamp cup and a lamp adopting the pressed glass lamp cup. According to the pressed glass lamp cup, the insulating film arranged on the pressed glass lamp cup can be formed at a time and is uniformlyand completely smeared on the whole inner surface from the cup opening to the cup bottom, and the inner electroconductive problem is solved.

Owner:FOSHAN ELECTRICAL & LIGHTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com