Glass pressing machine

A calender, glass technology, applied in glass calendering, glass forming, glass manufacturing equipment and other directions, can solve the problems of rolling, even wrapping, high surface temperature of rollers, rising production costs, etc. Uniform thickness and small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

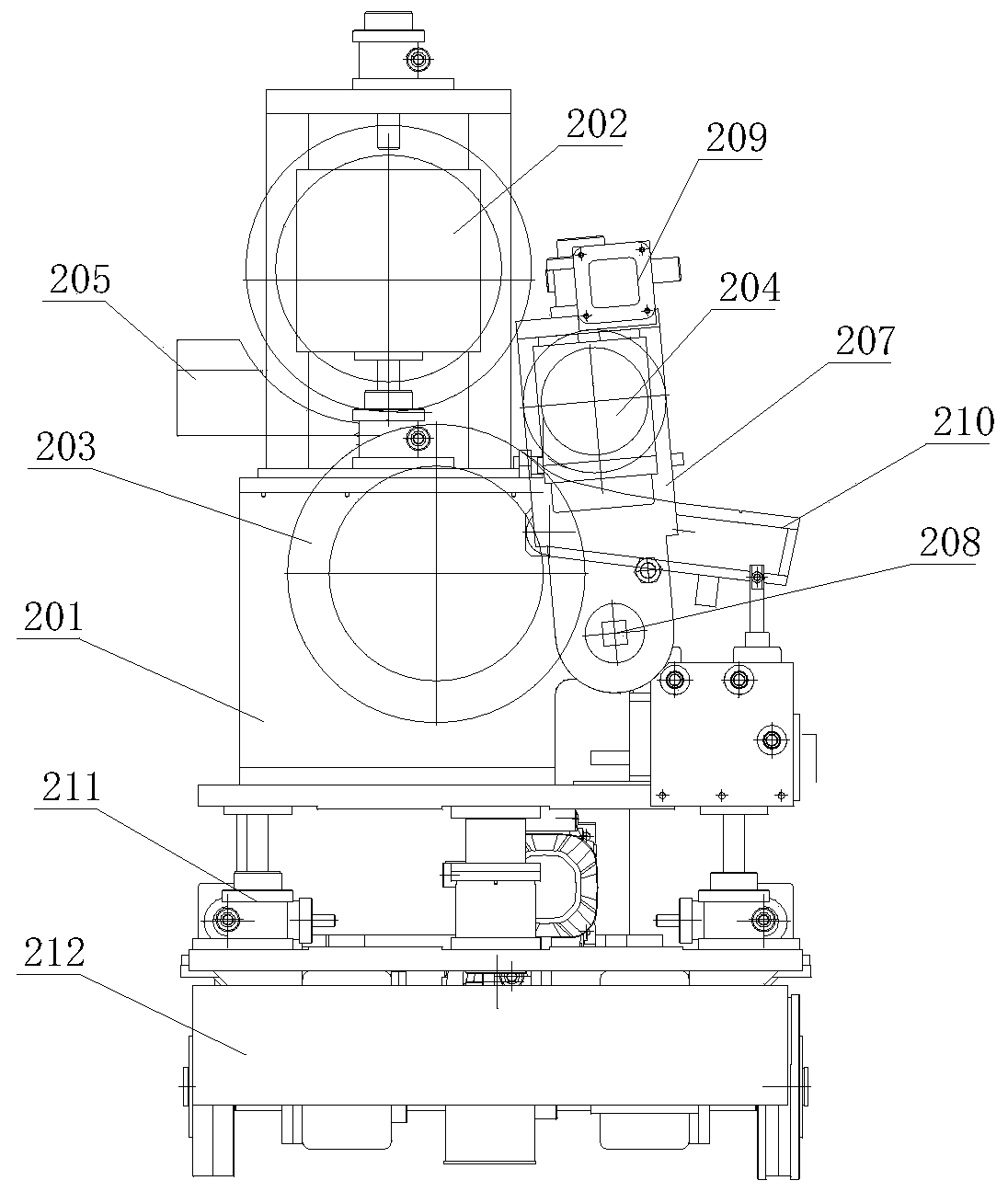

[0029] This embodiment provides a glass rolling machine, such as figure 2 , Figure 4 As shown, it includes base 201, upper main roller 202, lower main roller 203, secondary pressure roller 204, lip brick 205 and drag roller 206, upper main roller 202, lower main roller 203, secondary pressure roller 204 and drag roller 206 Both are installed on the top of the base 201, the upper main roller 202 is arranged on the top of the lower main roller 203, and the lip brick 205 is arranged on the head end of the upper main roller 202 and the lower main roller 203, for the upper main roller 202 and the lower main roller 203 The glass liquid is transported between them, and the lip brick 205 can be fixed directly on the top of the base 201, or can be installed on the kiln in front of the calender; the secondary pressure roller 204 and drag roller 206 are arranged on the upper main roller 202 and the lower main roller 203 at the tail end of the main roller 204, the secondary pressing ro...

Embodiment 2

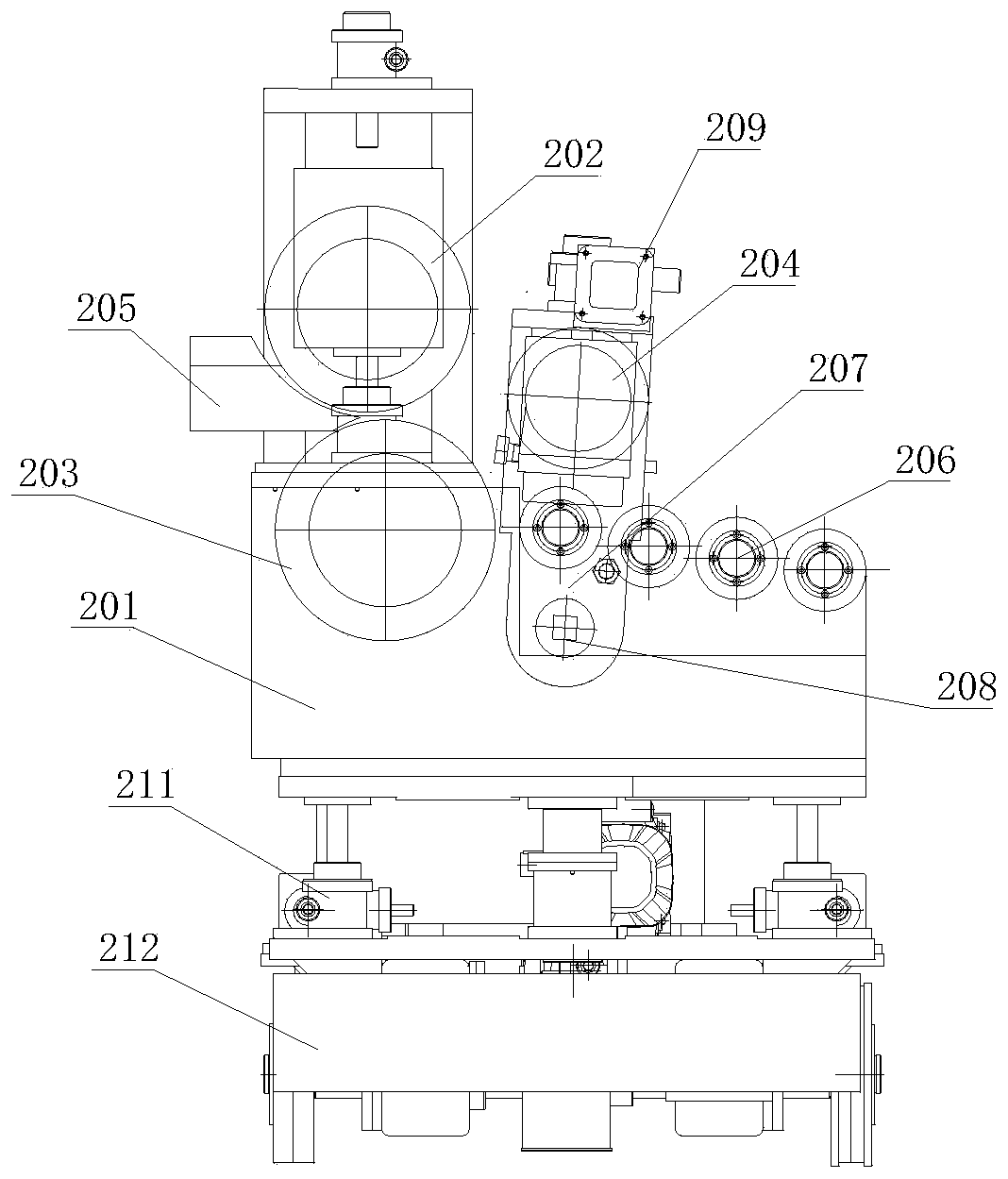

[0035] Such as image 3 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, no supporting plate water bag 210 is provided, and the secondary pressure roller 204 is arranged on the top of the drag roller 206, which is connected to the first end of the drag roller 206. The knuckle rollers are opposite and rotate in opposite directions. The specific working process is as follows:

[0036] Such as Figure 5 As shown, the liquid glass in the molten state is pressed into a certain thickness by the upper main roller 202 (driven by a separate frequency conversion motor, rotating in the V1 direction) and the lower main roller 203 (driven by a separate frequency conversion motor, rotating in the V2 direction) of the calender. The glass is pressed into a plate of final thickness by the secondary pressing roller 204. The plate passes through the drag roller 206 (rotated by a separate frequency conversion motor), and then passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com