Method and equipment for mould-pressed glass product

A technology of glass products and molding, which is applied in the field of direct pressing system and can solve undisclosed problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

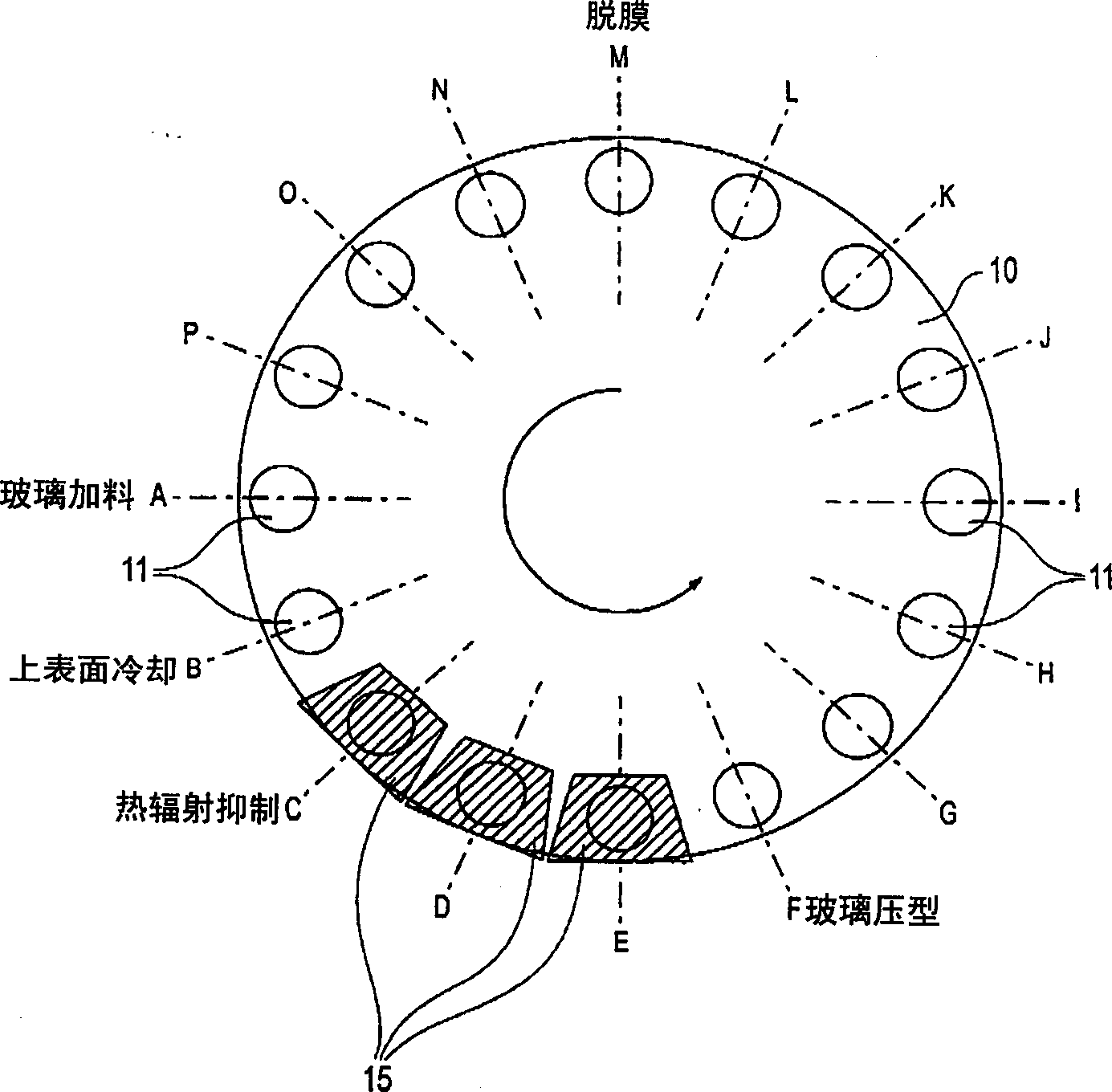

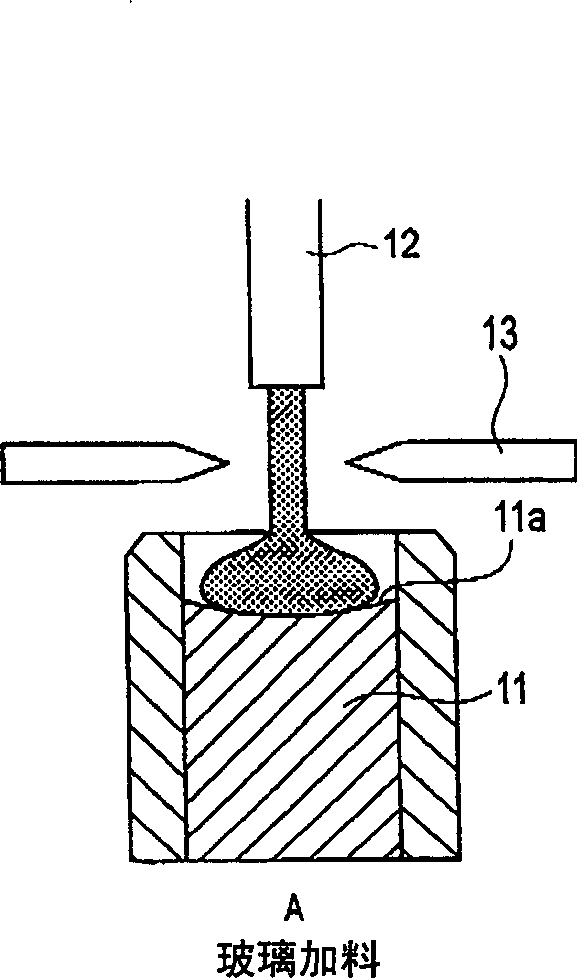

[0026] An embodiment of the present invention will be described below with reference to the accompanying drawings. Among them, a method of molding an optical lens blank as a glass product by using a turntable as a conveying device and sixteen lower molds arranged on the circumference of the turntable will be aimed at. According to the temperature of the glass gob, the area in contact with the molding surface of the lower mold and its surroundings are called the lower part of the glass, and the other area exposed to the ambient atmosphere that is not in contact with the molding surface of the lower mold and its surroundings are called glass. the upper part. In addition, a part of the upper part of the glass surface-molded by the upper die is called an upper surface.

[0027] Such as figure 1 As shown, a plurality of stations A to P for the various steps of the method of the invention are arranged on the turntable 10 . As shown in the figure, a plurality of lower dies 11 , si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com