Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "No loss of productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

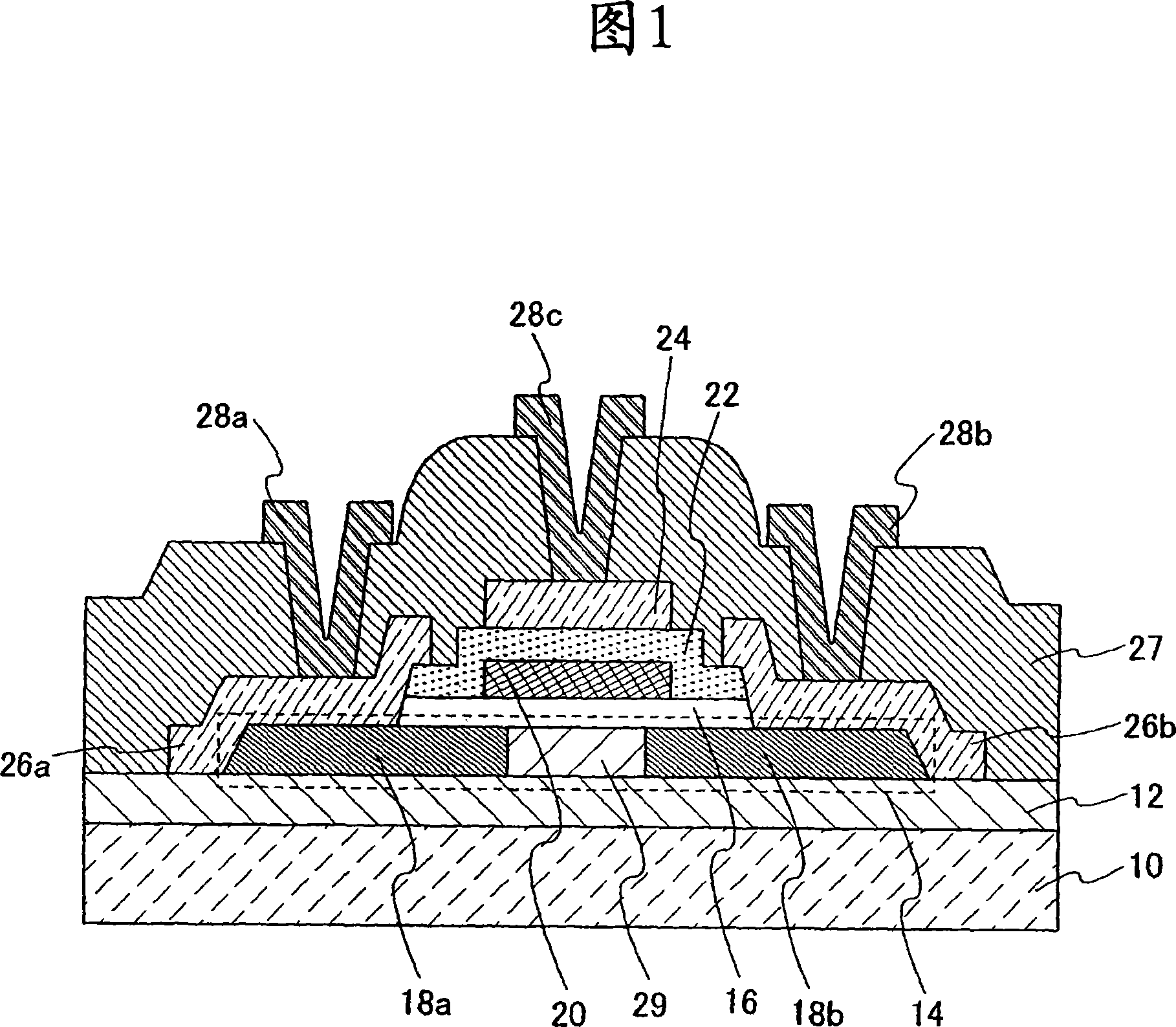

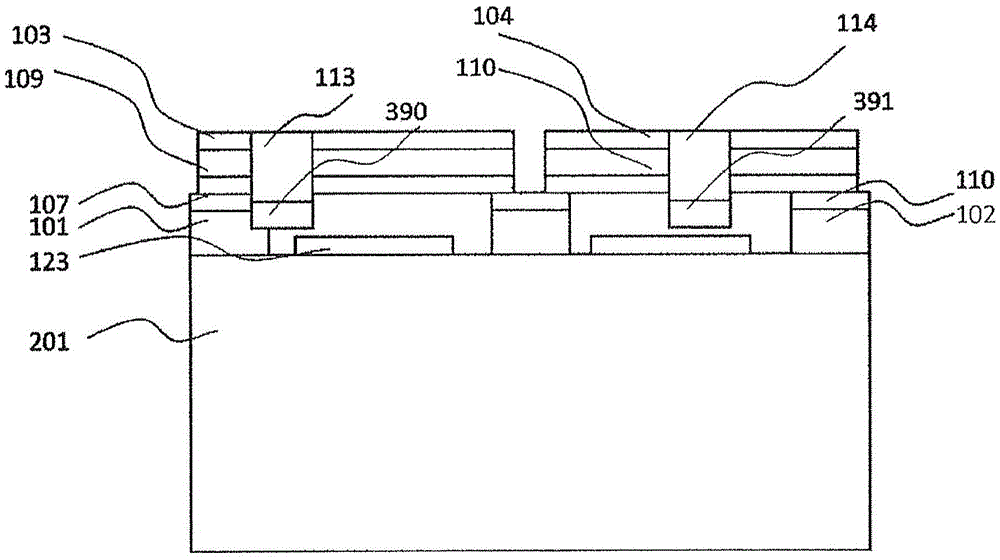

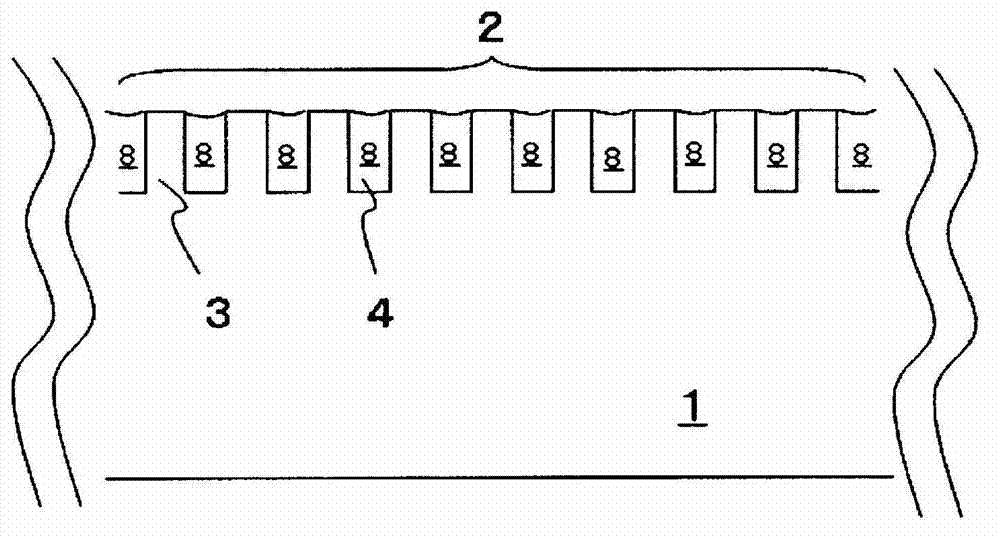

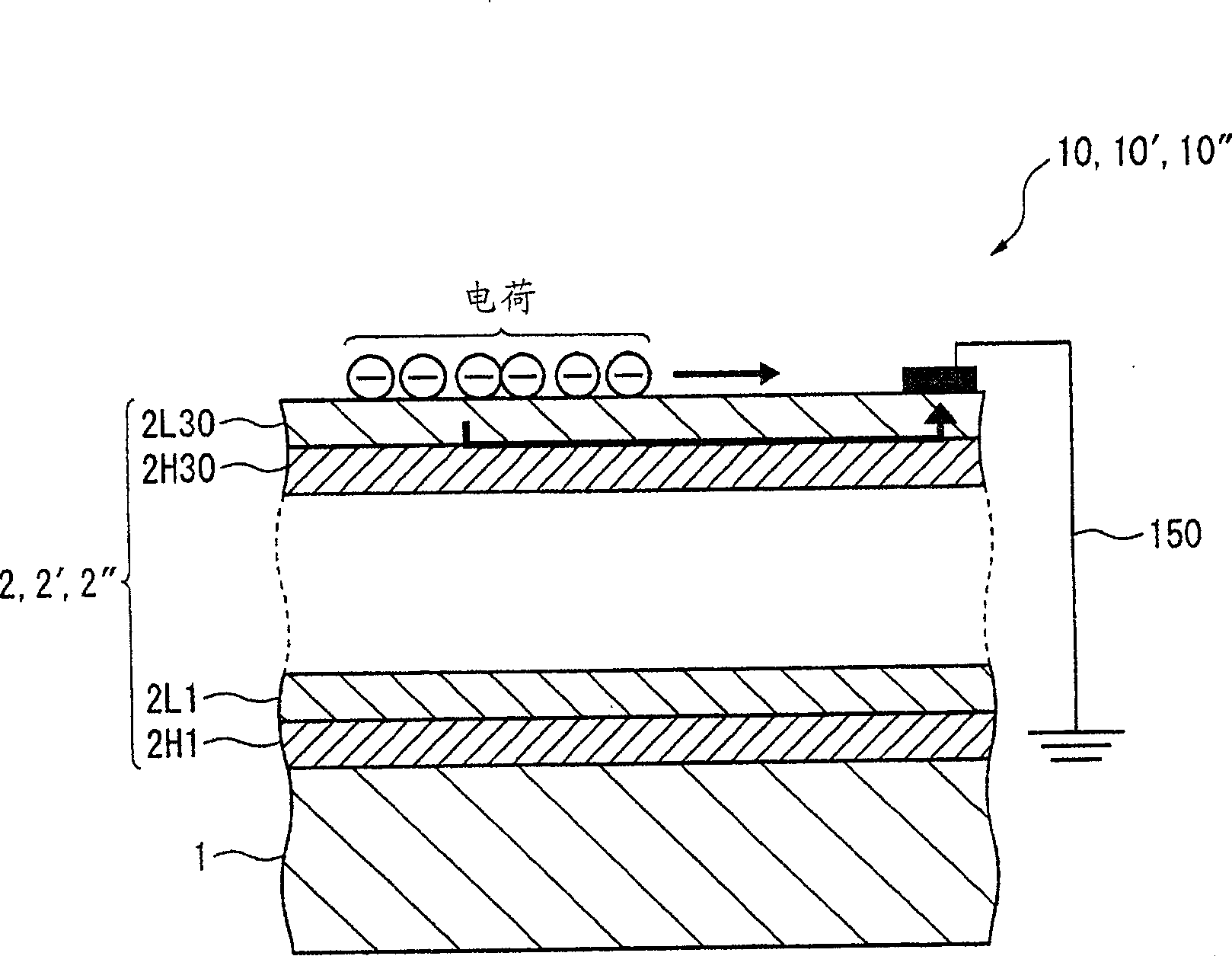

Nonvolatile semiconductor storage device and method for manufacturing the same

InactiveCN101047190AIncrease the contact resistance valueWrite efficientlyTransistorSolid-state devicesElectrical resistance and conductanceCharge retention

It is an object to provide a nonvolatile semiconductor storage device that prevents increase in a contact resistance value due to etching of a semiconductor layer when etching an interlayer insulating film and that has superiority in a writing characteristic and an electric charge-holding characteristic, and a manufacturing method thereof. A conductive layer is provided between a source or drain region and a source or drain wiring. The conductive layer is made of the same conductive layer that forms a control gate electrode. An insulating film is provided so as to cover the conductive layer, and the insulating film has a contact hole for exposing part of the conductive layer. The source or drain wiring is formed so that the contact hole is filled.

Owner:SEMICON ENERGY LAB CO LTD

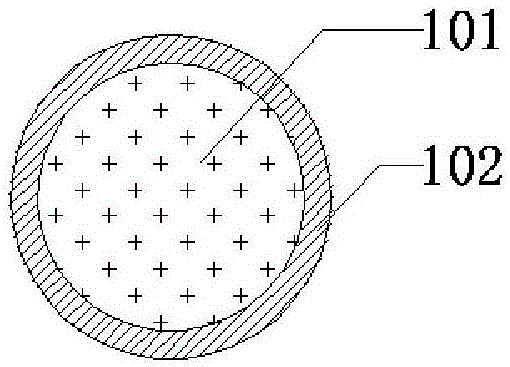

Edge-self-sealing quantum dot film

ActiveCN106189826APlay a closed roleNo loss of productivityLayered productsPolyurea/polyurethane coatingsQuantum dotUltraviolet irradiation

The invention relates to a quantum dot film, particularly an edge-self-sealing quantum dot film. The edge-self-sealing quantum dot film is provided with a quantum dot layer, wherein a water oxygen barrier layer is respectively arranged on the upper and lower surfaces of the quantum dot layer; the quantum dot layer is composed of liquid microcapsules, quantum dots, dispersed particles, a matrix resin and a film forming aid; the liquid microcapsules are uniformly distributed in the quantum dot layer; each of the liquid microcapsules is provided with a liquid capsule core; and a solid capsule wall is arranged outside each liquid capsule core. After the edge-self-sealing quantum dot film is cut off, the liquid microcapsules at the notch can be cut off, the film forming liquid in the liquid microcapsules can seep and be fused mutually, and the liquid can implement homogeneous immersion on the film edge under the action of surface tension; and the liquid can be cured to form a film under the condition of normal temperature, heating or ultraviolet irradiation, thereby performing a sealing function on the edge of the quantum dot film. The sealing process is not limited by the edge contour of the film, and the edge-self-sealing quantum dot film can also have a sealing effect on the internal edges of complicated film edge contours or locating hole films.

Owner:XIAMEN BOHR TECH CO LTD

Moulding, filling and sealing appts. for self-standing bags

InactiveCN1519102AEfficient productionHigh speed manufacturingEnvelopes/bags making machineryWrappingThin membranePlastic bag

A shaping, filling and sealing apparatus for making the plastic bags able to stand up by itself is composed of three thermally sealing units, a folding mechanism, and a filling tube for filling the filler. The third sealing unit can also cut the thermally sealed part.

Owner:ORIHIRO ENGINEERING CO LTD

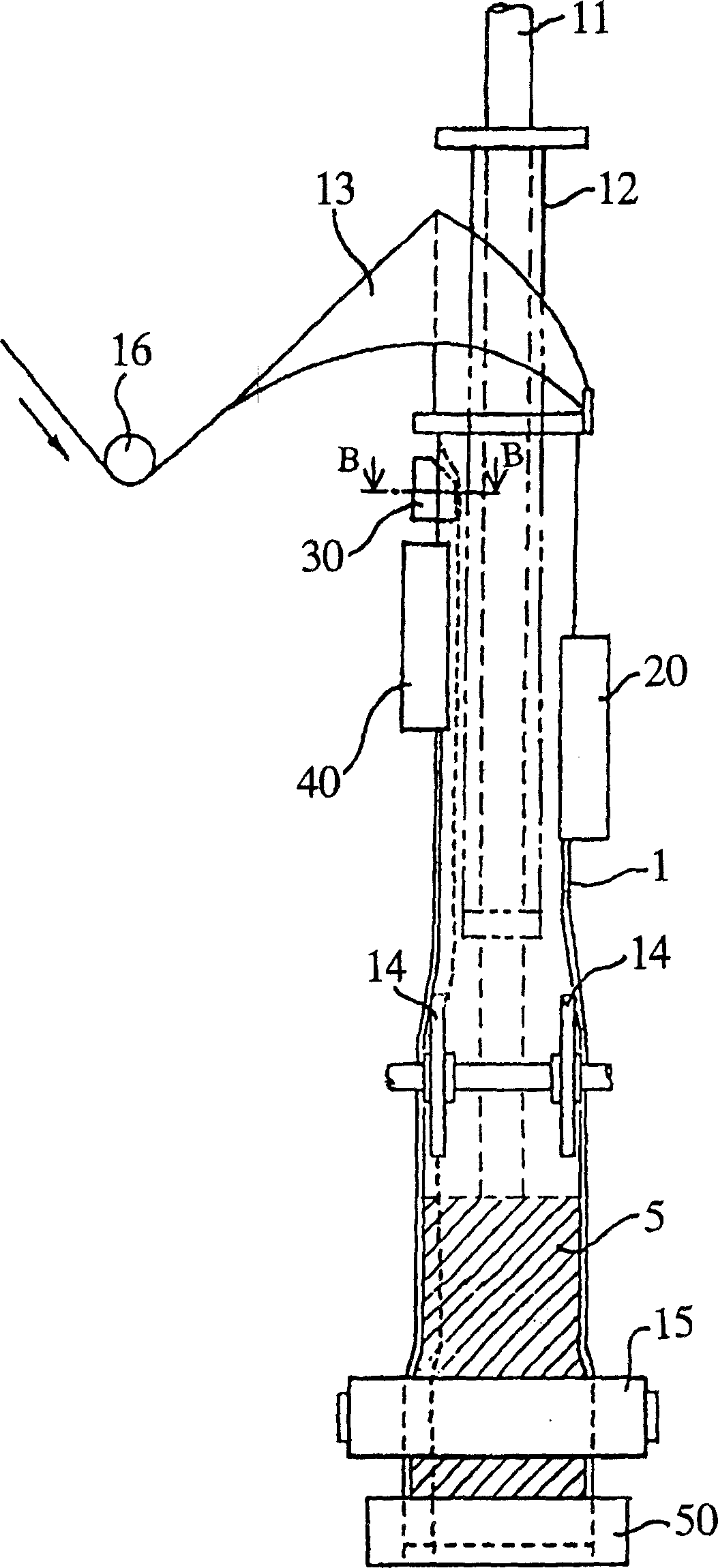

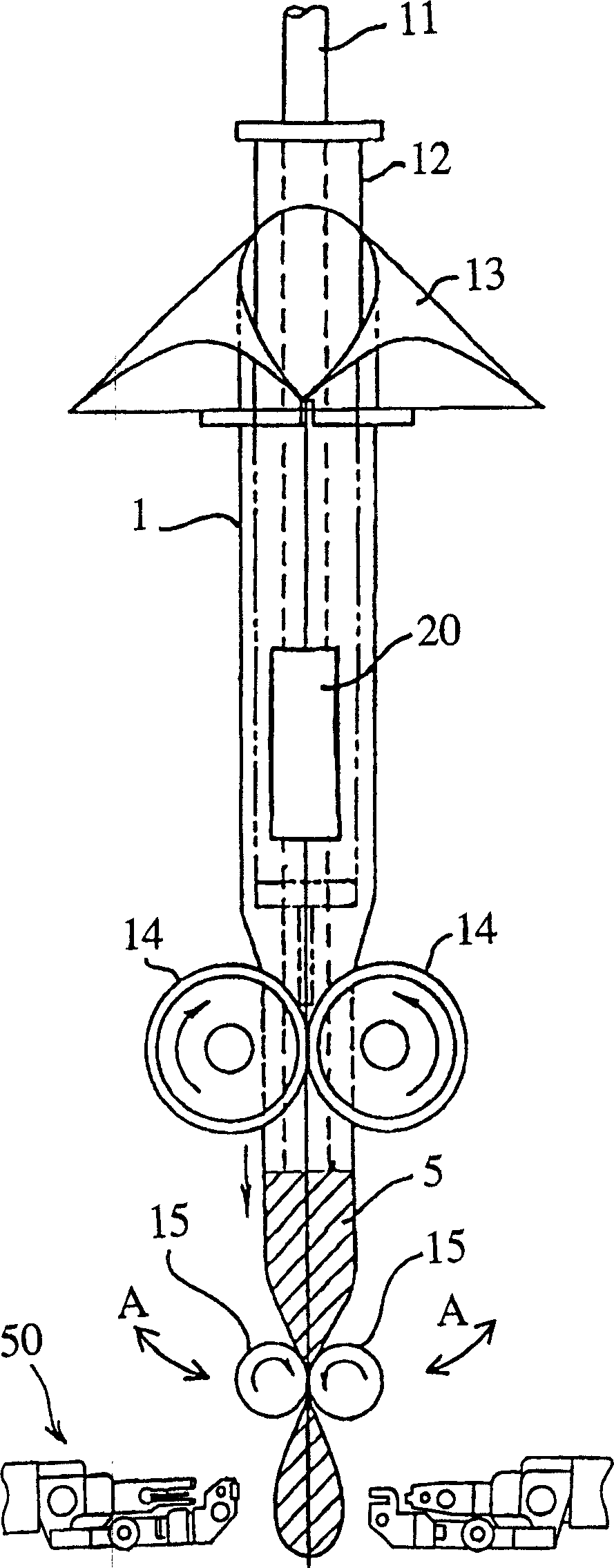

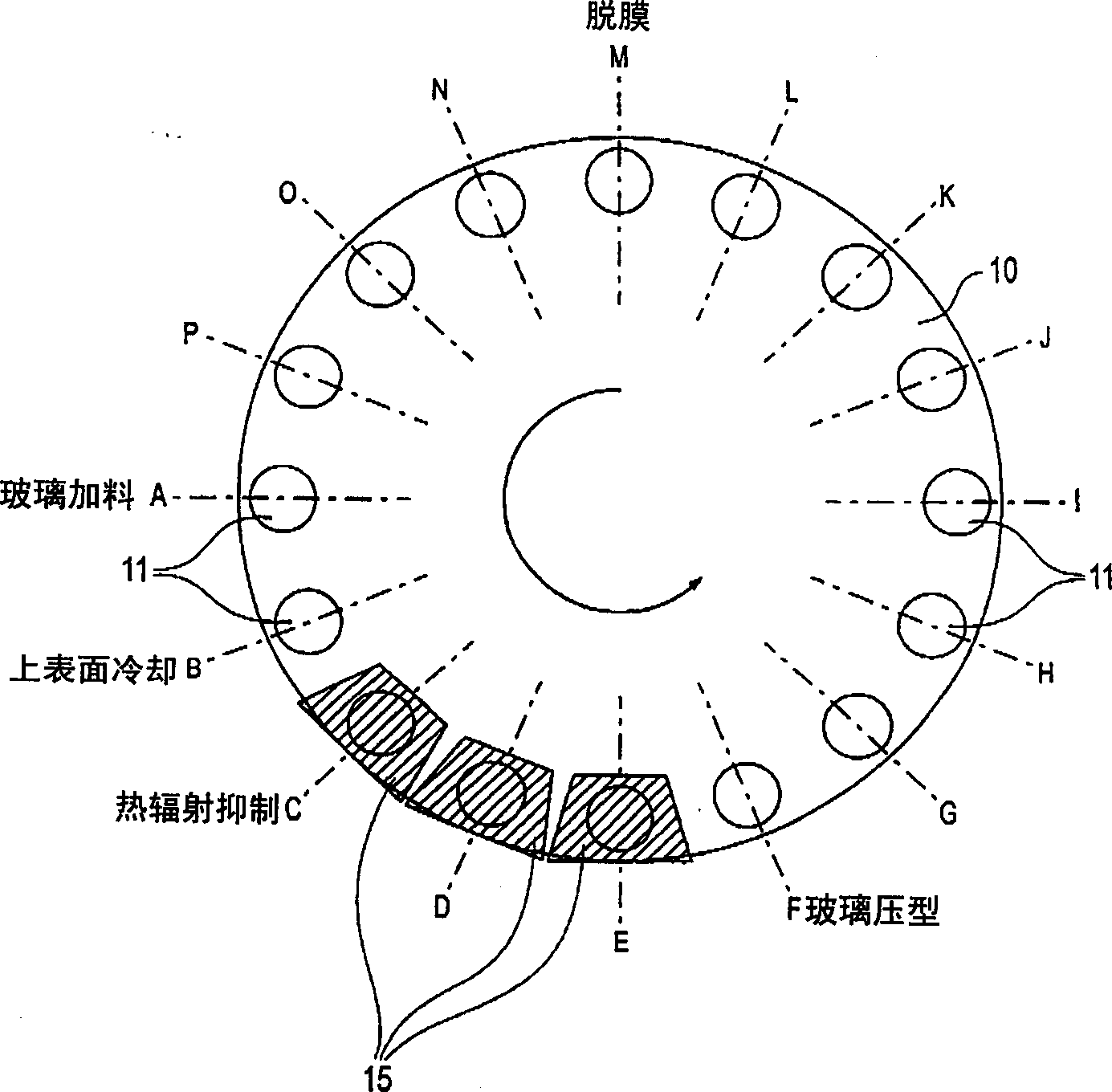

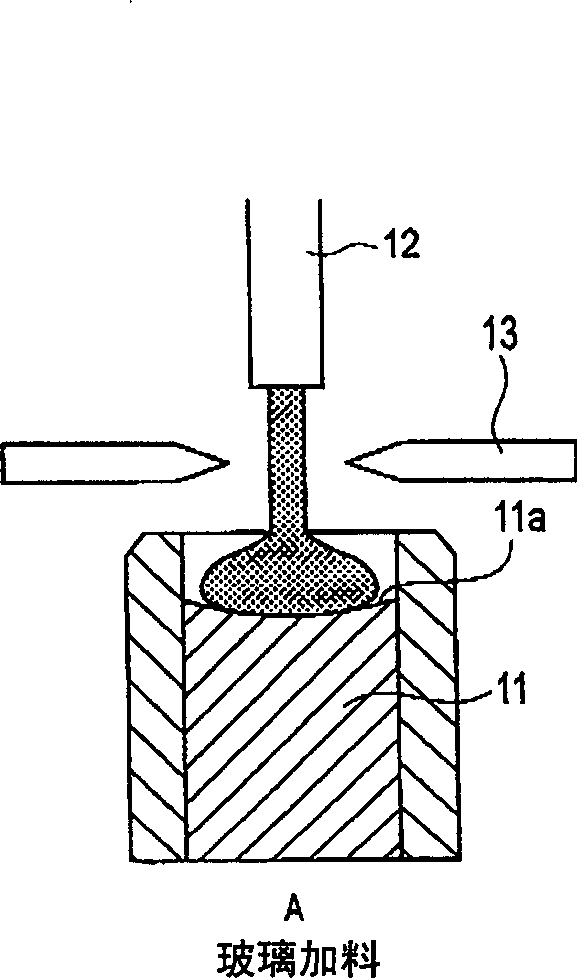

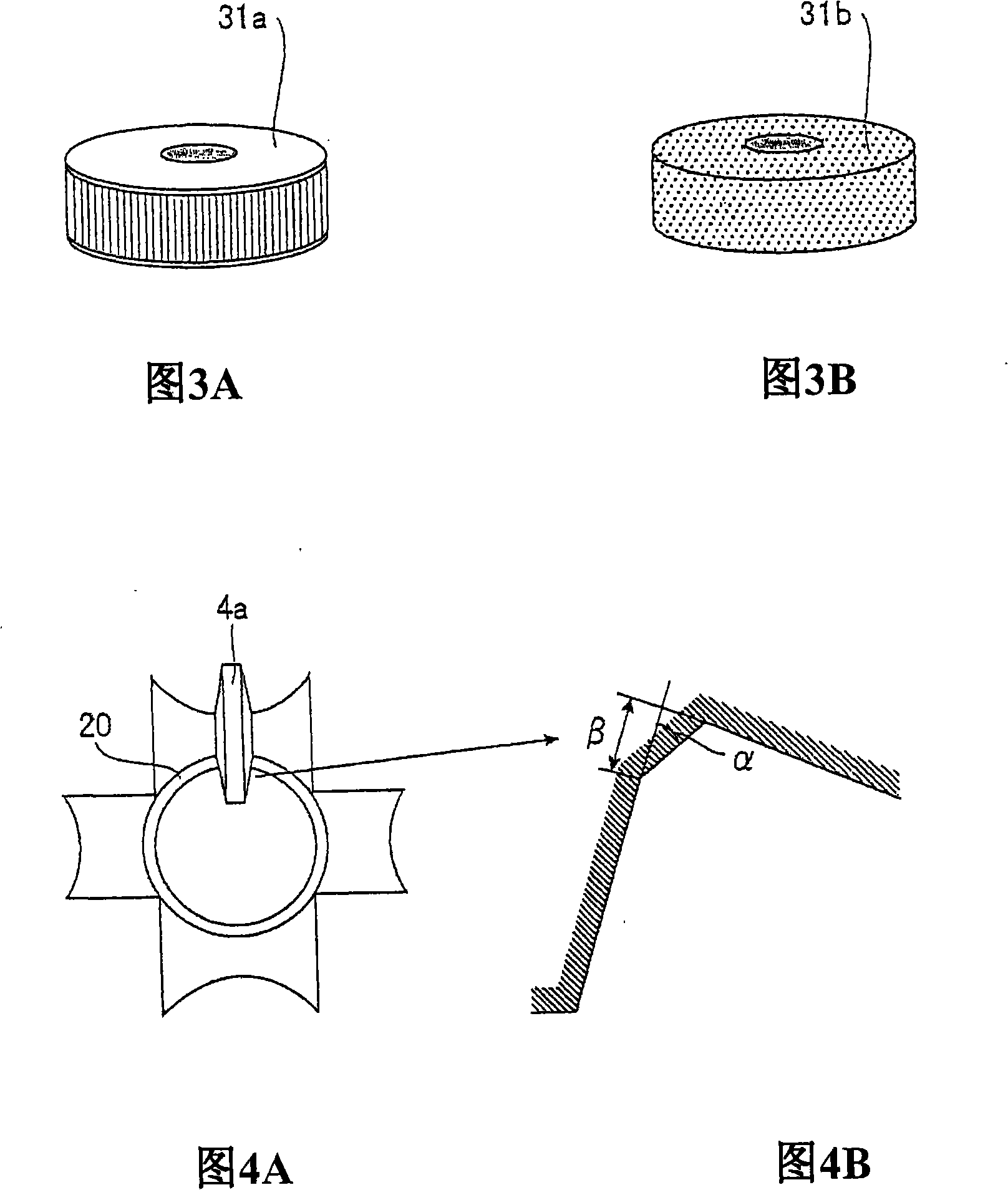

Method and equipment for mould-pressed glass product

InactiveCN1340467ASave heatSmall temperature differenceGlass pressing apparatusGlass productionThermal radiationPoise

On molding a glass product by pressing a glass gob by the use of a mold composed of upper and lower dies each of which has a molding surface, a molten glass is supplied as the glass gob onto the molding surface of the lower die. Cooling is carried out for an upper surface of the glass gob supplied onto the molding surface of the lower die. After the cooling, heat radiation suppression is carried out to suppress heat radiation from the glass gob so that an inner part and an upper part of the glass gob are close in temperature to each other. Thereafter; the glass gob is pressed by the molding surfaces of the upper and the lower dies when the glass gob has a viscosity within a range between 103.5 and 106.5 poises (dPa.s). Preferably, the heat radiation suppression is carried out by making a heat shielding member lower in temperature than the inner part of the glass gob approach the upper part of the glass gob in a non-contact state.

Owner:HOYA CORP

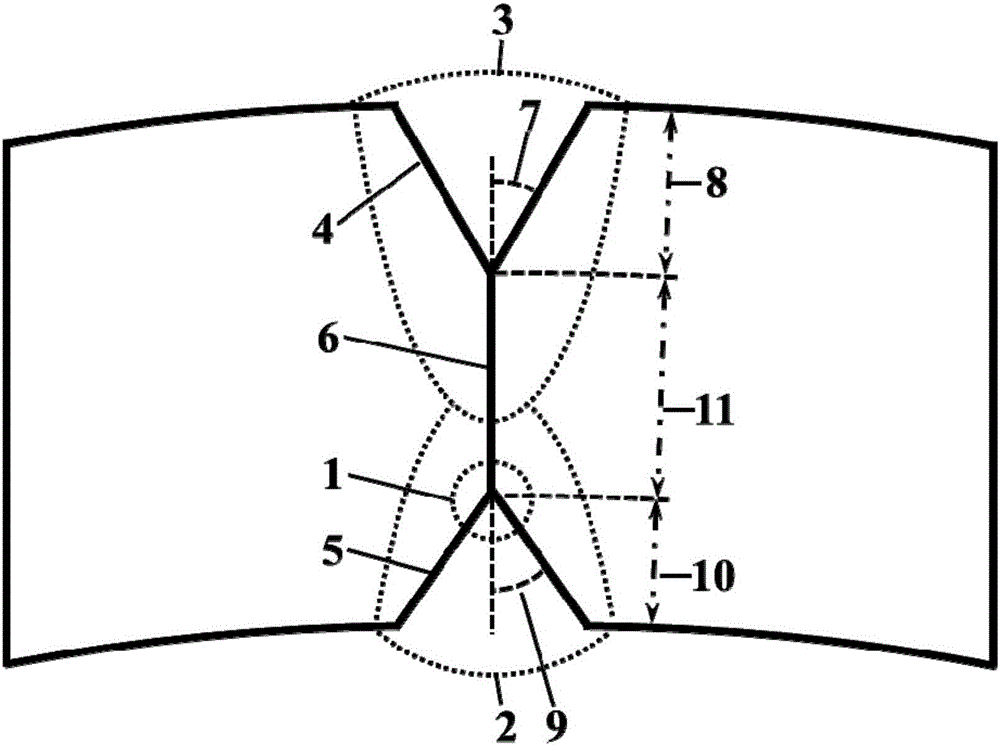

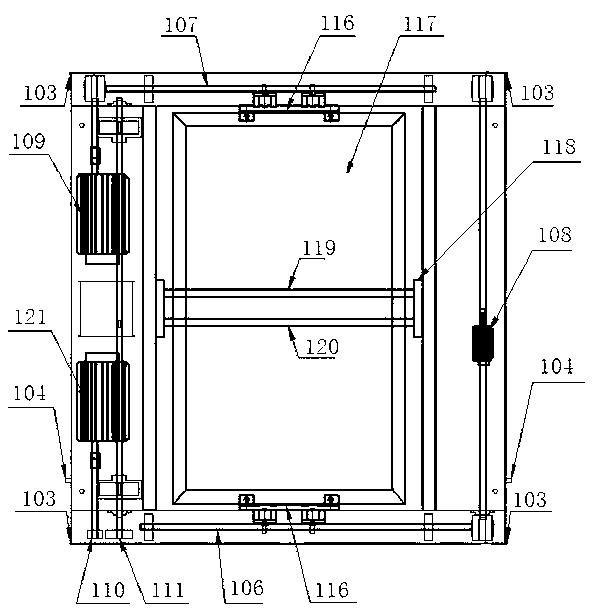

Manufacturing method for X80 pipeline steel spiral welded pipe

The invention belongs to the field of mechanical equipment manufacturing and particularly relates to a manufacturing method for a spiral submerged arc welded pipe. A manufacturing method for an X80 pipeline steel spiral welded pipe includes the following technological steps that uncoiling and flattening of an X80 pipeline steel plate coil are conducted; edge milling is conducted; pre-bending is conducted; forming is conducted; pre-welding is conducted; internal welding is conducted; external welding is conducted; pipe end expanding is conducted; and product inspection is conducted. Brand new design is conducted on a welding groove type, and therefore energy of a welding line of an inner weld bead and energy of a welding line of an outer weld bead are distributed again, the energy of the welding line of the outer weld bead is improved, and the energy of the welding line of the inner weld bead is reduced. The grain size in a critical coarse-grain area in a heat-affected area can be obviously reduced due to the reduction of the energy of the welding line of the inner weld bead, scattering of distribution of chain-shaped M-A components is facilitated, meanwhile, the size of the M-A components can be reduced, and therefore the toughness of the welding heat-affected area is obviously improved. In addition, although the filling amount of the outer weld bead is increased to some extent, a double-wire tandem sequence is changed into a three-wire tandem sequence for welding, the welding speed can be ensured, and the production efficiency cannot be reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +3

Water-absorbable polyacrylic acid (salt) resin and process for production thereof

ActiveCN102015777AHigh whitenessNo loss of productivityAbsorbent padsBandagesPolymer scienceALLYL SUCROSE

The object aims to provide a water-absorbable resin which is prevented from the occurrence of gelatinization of a monomer before polymerization, hardly causes discoloration over time, has a remarkably improved surface color, and also has excellent absorption properties. For achieving the object, provided is a process for producing a water-absorbable polyacrylic acid resin, which comprises: a step of preparing a monomer by using acrylic acid having a hydroxyacetone content of 300 ppm by mass or less; a polymerization step of polymerizing the monomer to produce a hydrogel; and a drying step of drying the hydrogel. Also provided is a process for producing a water-absorbable polyacrylic acid resin, which comprises: a step of preparing a monomer by using acrylic acid; a step of polymerizing the monomer in the presence of phenol to produce a hydrogel; and a drying step of drying the hydrogel.

Owner:NIPPON SHOKUBAI CO LTD

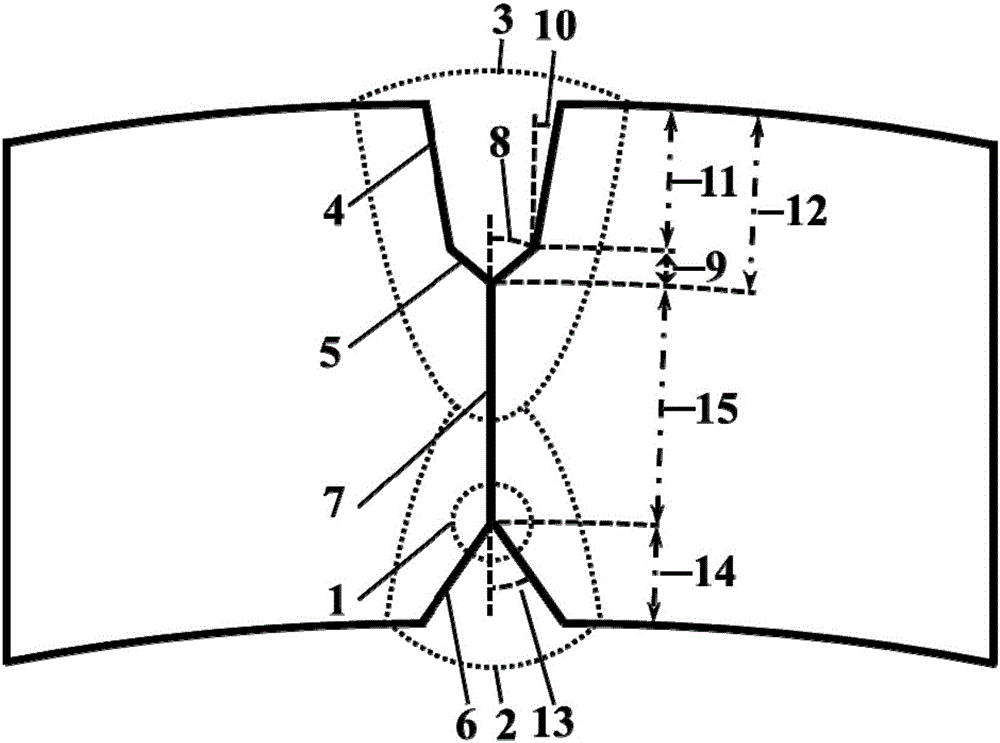

Vacuum processing system and substrate transfer method

InactiveCN101688296AAvoid cross contaminationTransfer realizationVacuum evaporation coatingSemiconductor/solid-state device manufacturingEngineeringGate valve

A vacuum processing system (1) is provided with a first processing section (2) wherein PVC processing chambers (12-15) are connected to a first transfer chamber (11) to which a wafer (W) is to be transferred; a second processing section (3) wherein CVD processing chambers (22, 23) are connected to a second processing chamber (21) to which the wafer is to be transferred; a buffer chamber (5a), which is arranged between the first transfer chamber (11) and the second transfer chamber (12) through a gate valve (G), stores the wafer (W), and is capable of adjusting pressure therein; and a control section (110) for controlling opening / closing of a gate valve (G) and pressure in the buffer chamber (5a) so that the buffer chamber (5a) is selectively communicated with either the first transfer chamber (11) or the second transfer chamber (12) and that pressure inside matches with pressure inside the communicating transfer chamber.

Owner:TOKYO ELECTRON LTD

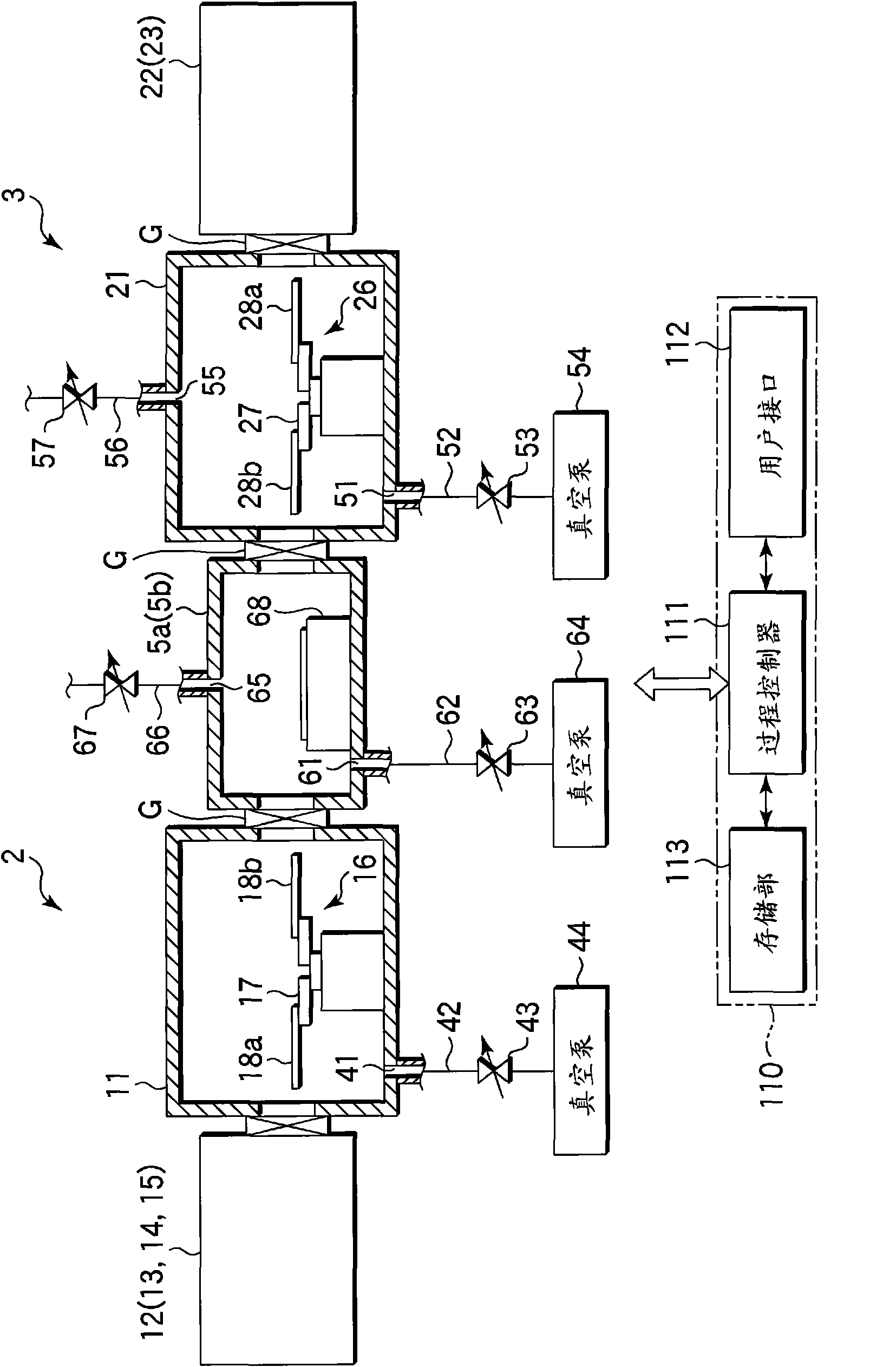

Ferritic stainless steel sheet for water heater excellent in corrosion resistance at welded part and steel sheet toughness

ActiveCN101578385AImprove corrosion resistanceReduce productivityFurnace typesHeat treatment furnacesSheet steelCorrosion

Disclosed is a ferritic stainless steel sheet for a water heater, which shows excellent corrosion resistance at a welded part and has an excellent steel sheet toughness. Specifically disclosed is a ferritic stainless steel sheet for a water heater, which comprises the following components (by mass): C: 0.020% or less, Si: 0.30-1.00%, Mn: 1.00% or less, P: 0.040% or less, S: 0.010% or less, Cr: 20.0-28.0%, Ni: 0.6% or less, Al: 0.03-0.15%, N: 0.020% or less, O: 0.0020-0.0150%, Mo: 0.3-1.5%, Nb: 0.25-0.60%, and Ti: 0.05% or less, with the remainder being Fe and unavoidable impurities, and which satisfies the requirements expressed by the following formulae (1) and (2). 25 <= Cr+3.3Mo <= 30 (1) 0.35 <= Si+Al <= 0.85 (2), wherein 'Cr', 'Mo', 'Si' and 'Al' represent the contents (expressed by mass%) of Cr, Mo, Si and Al, respectively.

Owner:JFE STEEL CORP

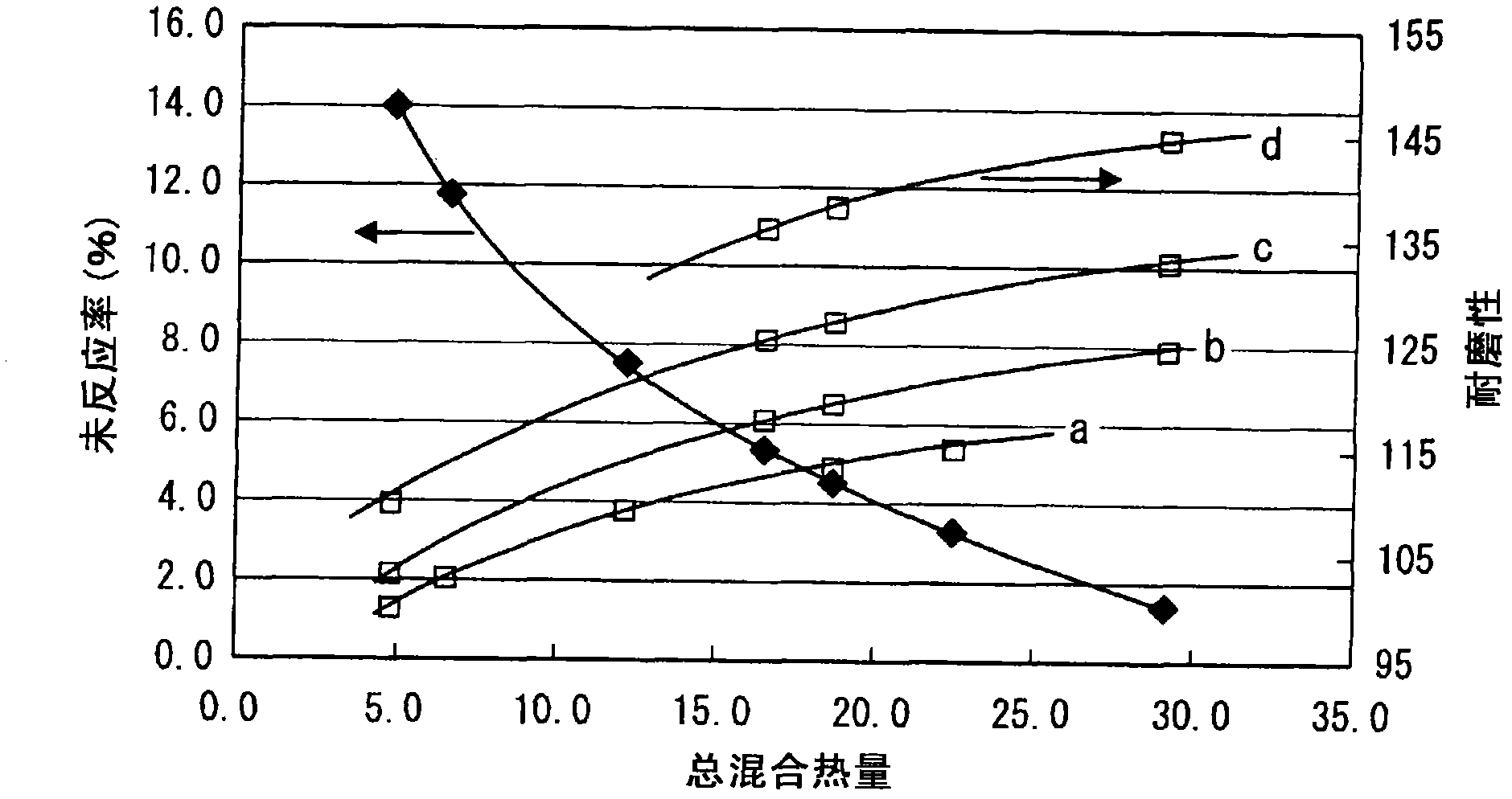

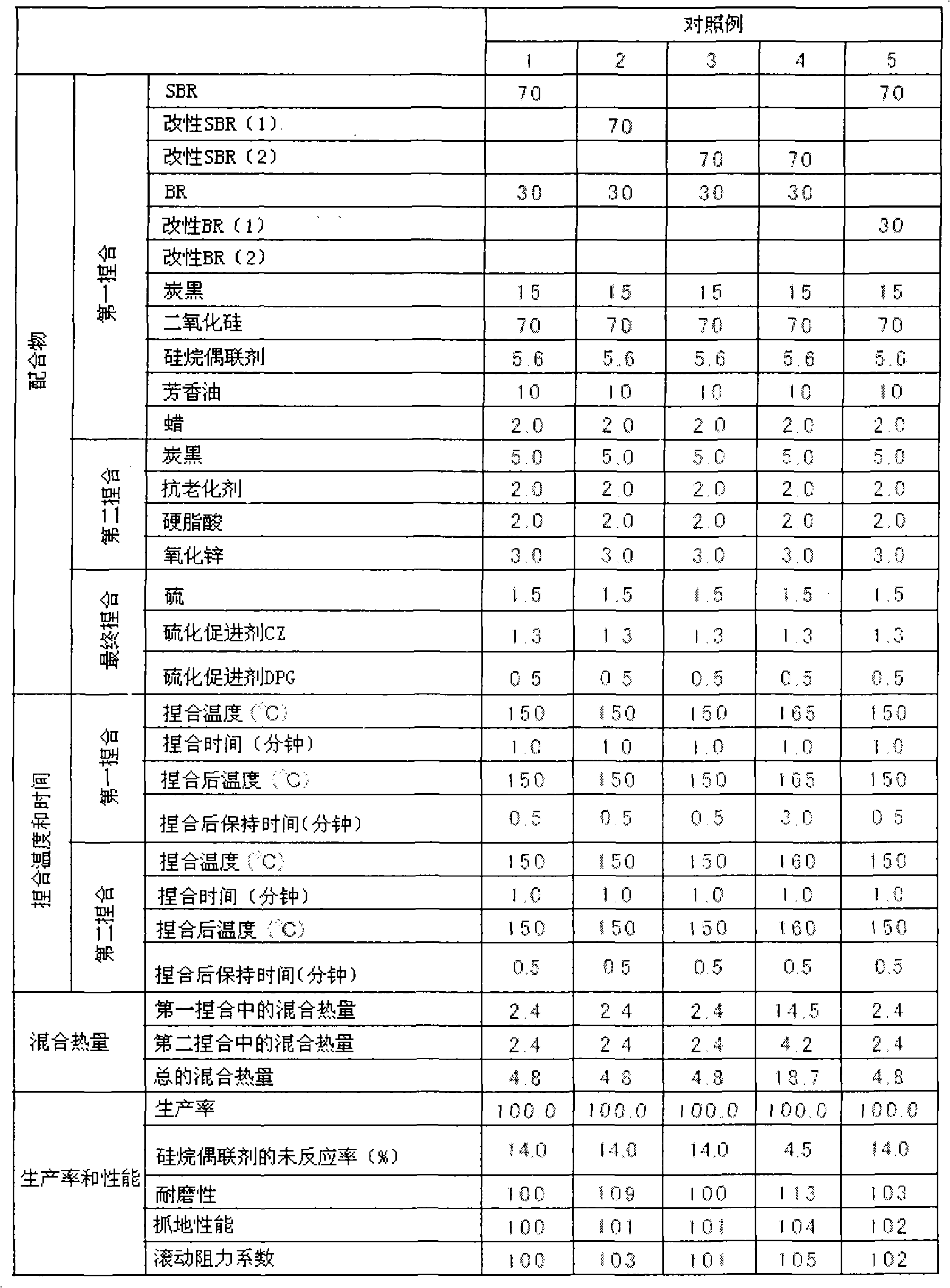

Rubber composition for tire, manufacturing method thereof and pneumatic tire using the rubber composition for tire

The invention provides a method for manufacturing a rubber composition for a tire, and the method comprises: a kneading step, wherein a closed kneading machine is used to knead a rubber material and a silane coupling agent together, the rubber material is obtained by mixture of 100 mass parts of raw material rubber for the tire and 5-150 mass parts of silicon dioxide; and a holding step, wherein at the lower part of the closed kneading machine, under high temperature, a rubber block obtained by kneading is kept for a predetermined time, therefore, heat required for reaction of silicon dioxide and the silane coupling agent is provided for the rubber block, wherein in the 100 mass parts of raw material rubber for the tire, 5-100 mass parts of styrene butadiene rubber with the molecular weight distribution Mw / Mn being below 2.3 and end modification, and / or 10-60 mass parts of tin modified polybutadiene rubber by lithium initiator polymerization, the in modified polybutadiene rubber is provided with 50-3000 ppm of tin atom content ratio, 5-50 mass% of ethylene combination amount, and less-than 2.0 of molecular weight distribution Mw / Mn.

Owner:SUMITOMO RUBBER IND LTD

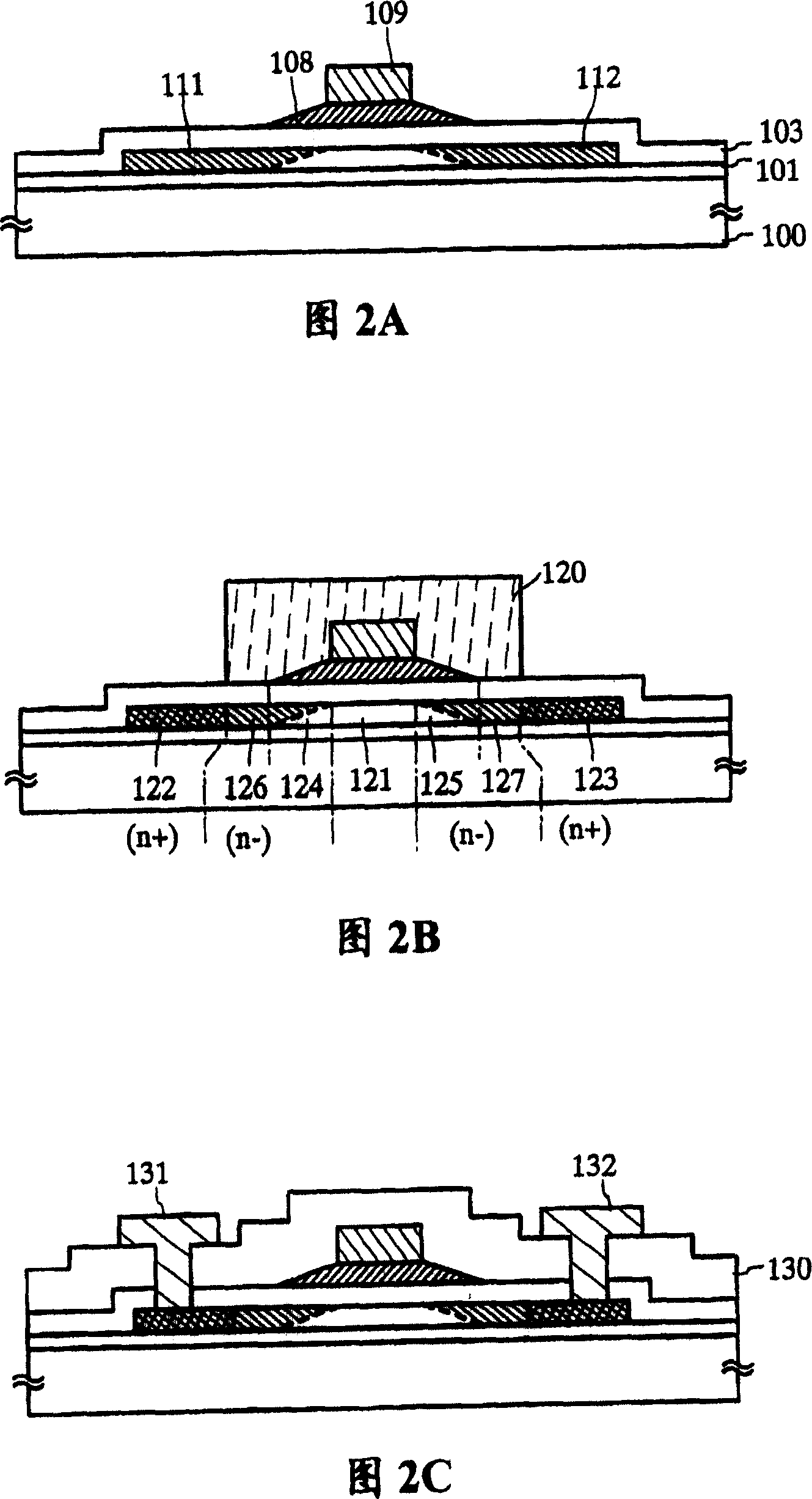

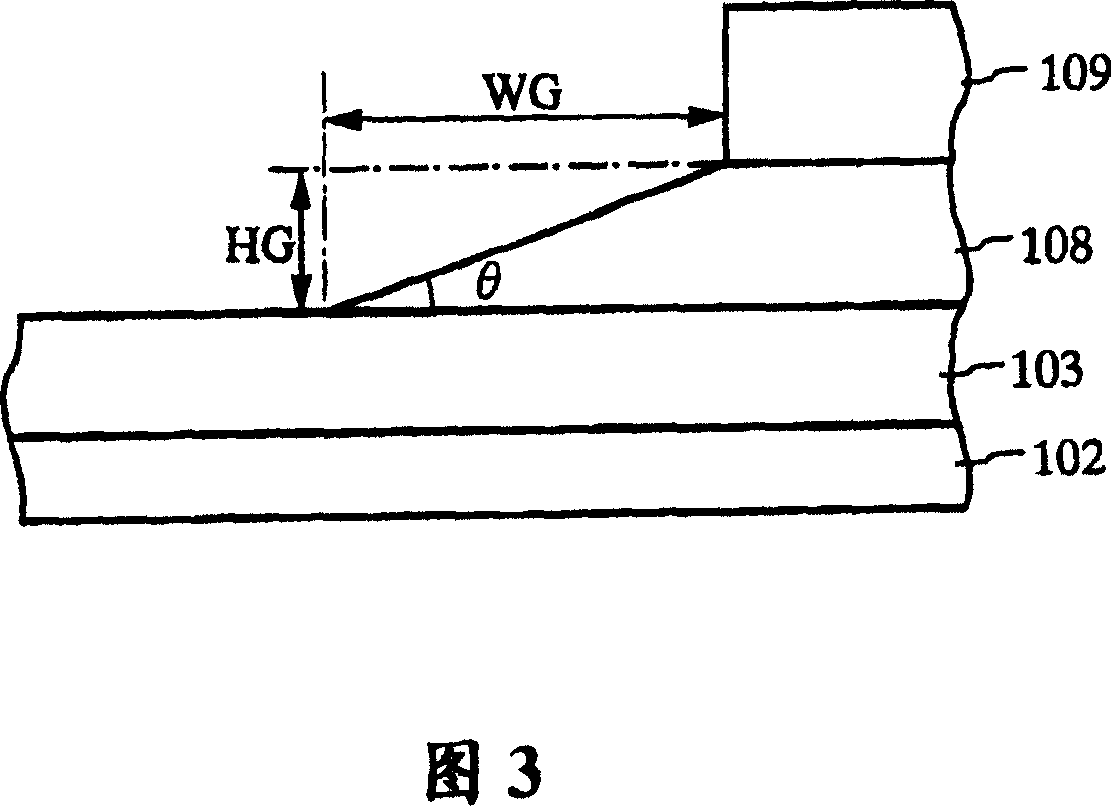

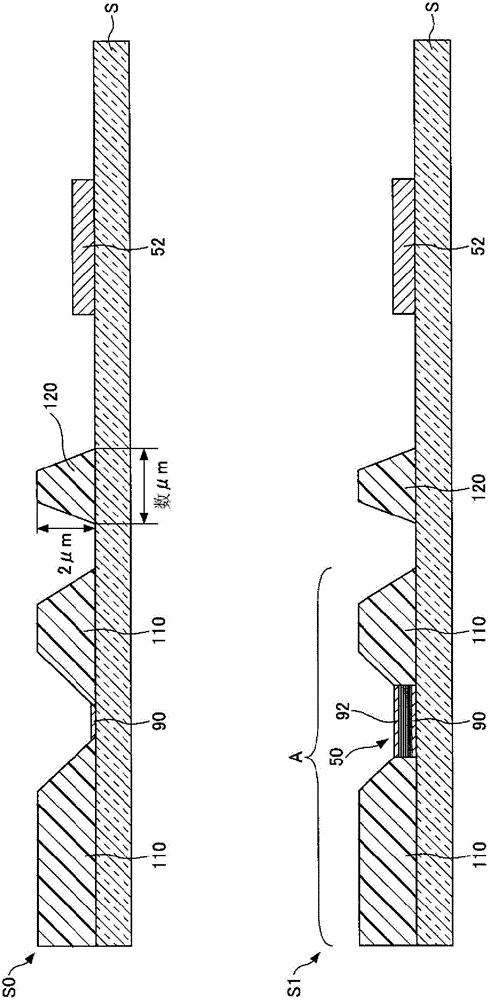

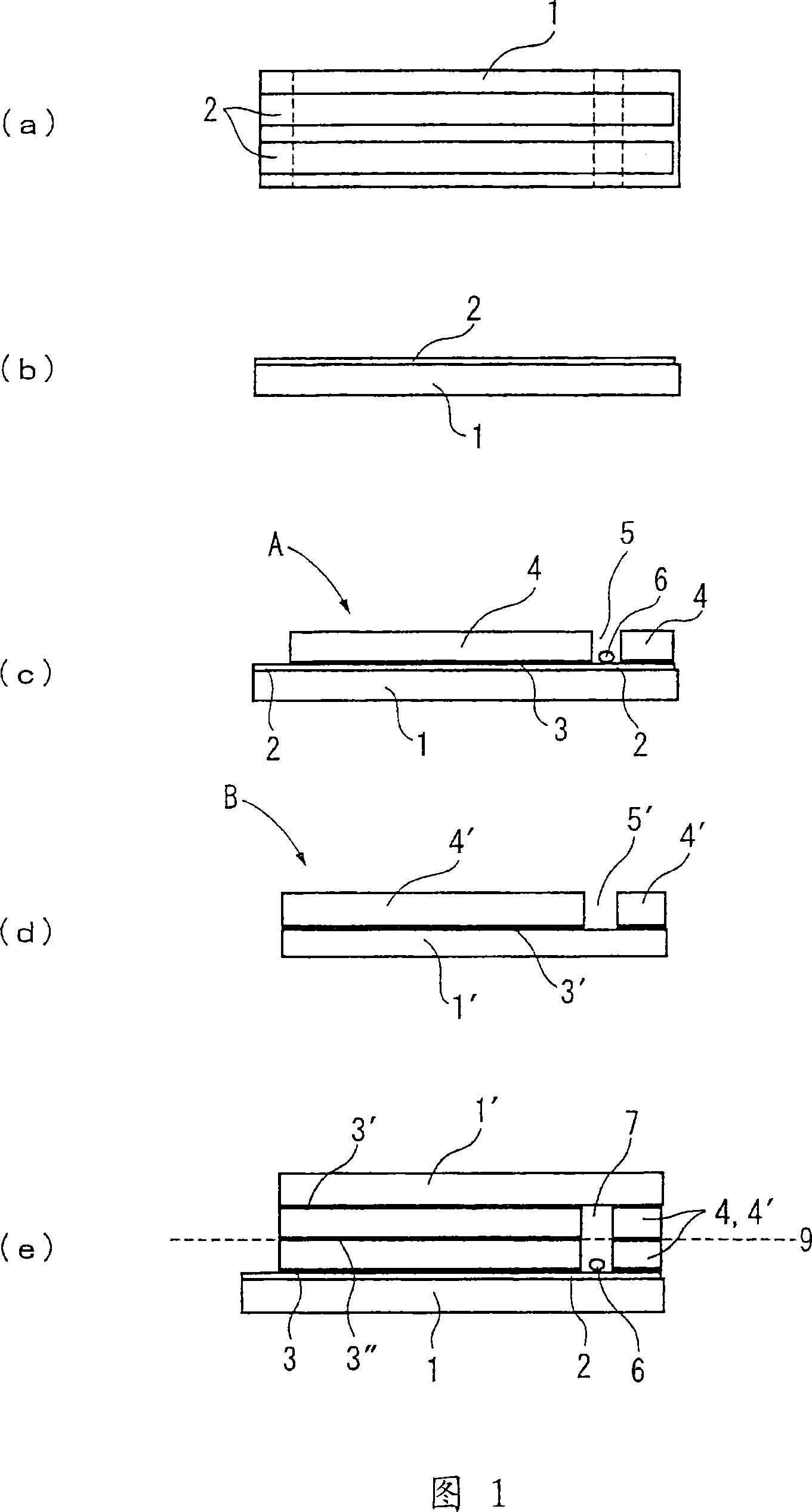

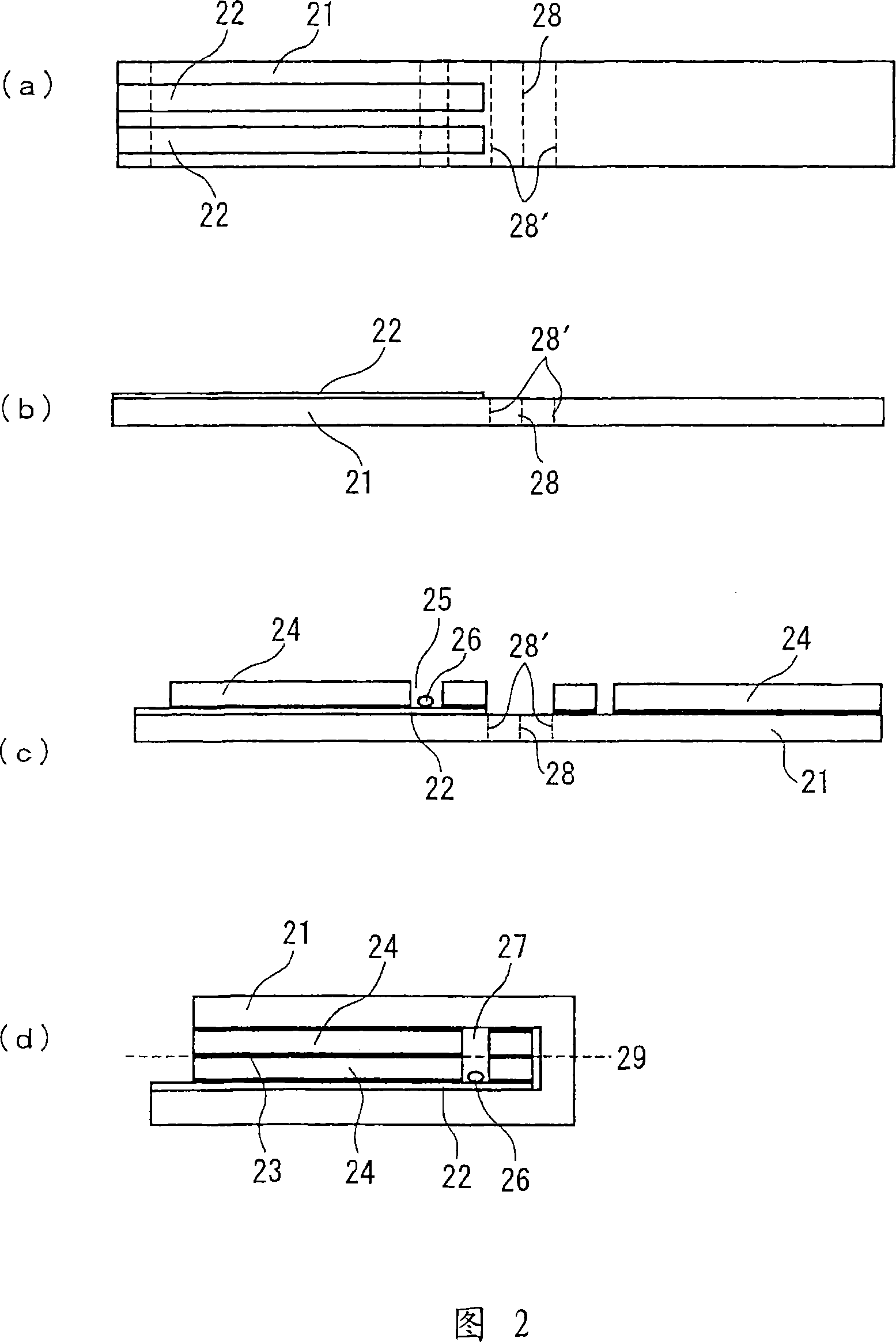

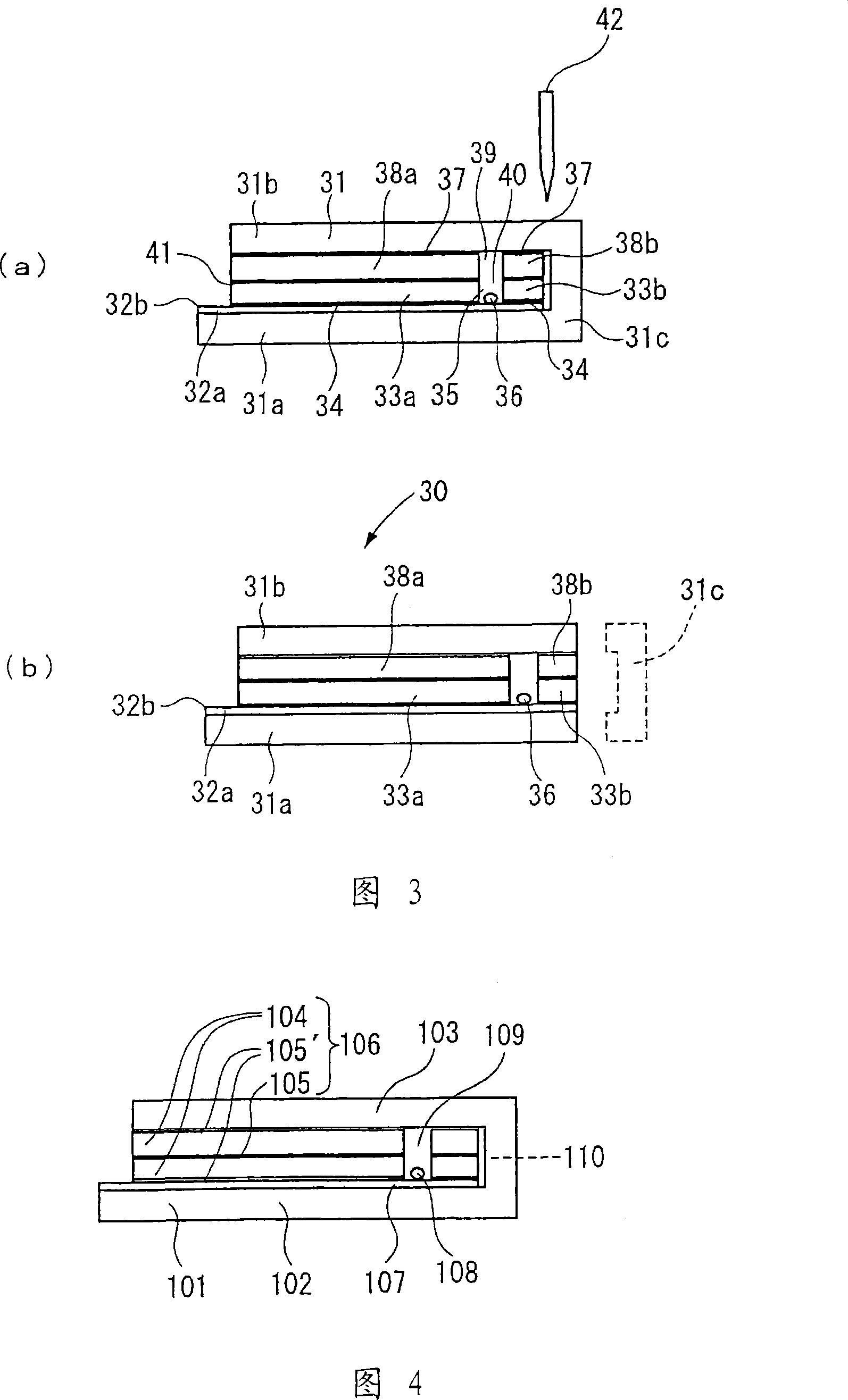

Method of fabricating a semiconductor device

There is provided a thin film transistor having improved reliability. A gate electrode includes a first gate electrode having a taper portion and a second gate electrode with a width narrower than the first gate electrode. A semiconductor layer is doped with phosphorus of a low concentration through the first gate electrode. In the semiconductor layer, two kinds of n-type impurity regions are formed between a channel formation region and n-type impurity regions. Some of the n-type impurity regions overlap with a gate electrode, and the other n-type impurity regions do not overlap with the gate electrode. Since the two kinds of n-type impurity regions are formed, an off current can be reduced, and deterioration of characteristics can be suppressed.

Owner:SEMICON ENERGY LAB CO LTD

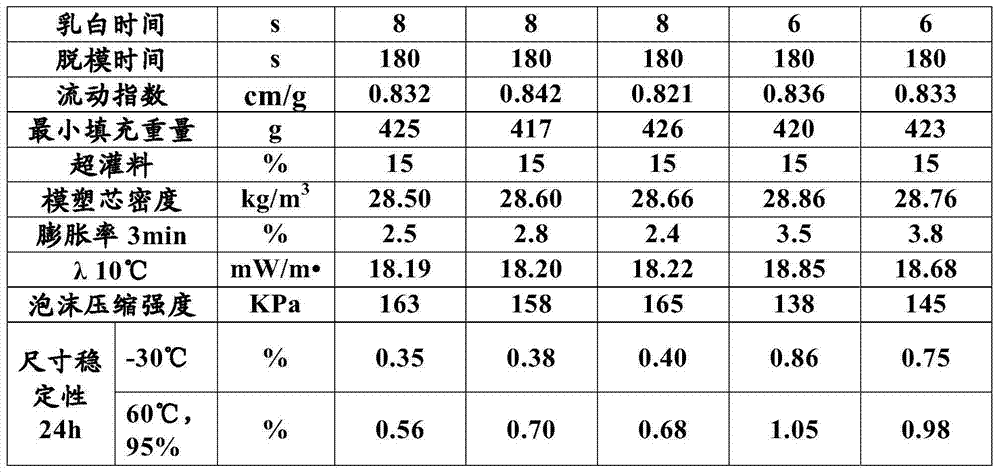

Polyalcohol composition, application thereof and rigid polyurethane foam prepared from polyalcohol composition

The invention relates to a polyalcohol composition containing the following components in parts by weight: 5-45 parts of polyether polyol (a1) formed by toluenediamine and oxyalkylene polymerization, 7-50 parts of polyether polyol (a2) formed by toluenediamine, triethanolamine and oxyalkylene polymerization, 3-25 parts of polyether polyol (a3) formed by glycerin and oxyalkylene polymerization, 15-65 parts of polyether polyol (a4) formed by saccharose and oxyalkylene polymerization and 3-20 parts of polyether polyol (a5), wherein the total weight part of the components from (a1) to (a5) is 100. The invention also relates to an application of the polyalcohol composition to the preparation of rigid polyurethane foam and rigid polyurethane foam prepared from the polyalcohol composition.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

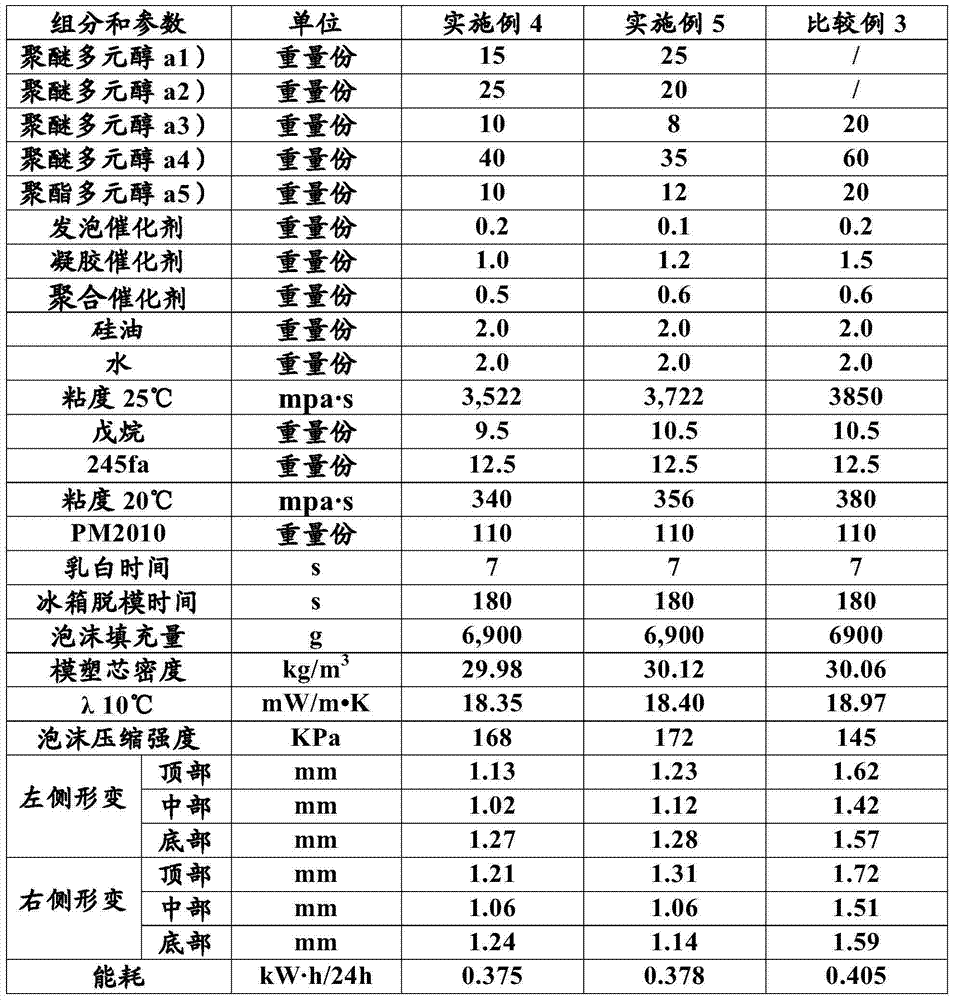

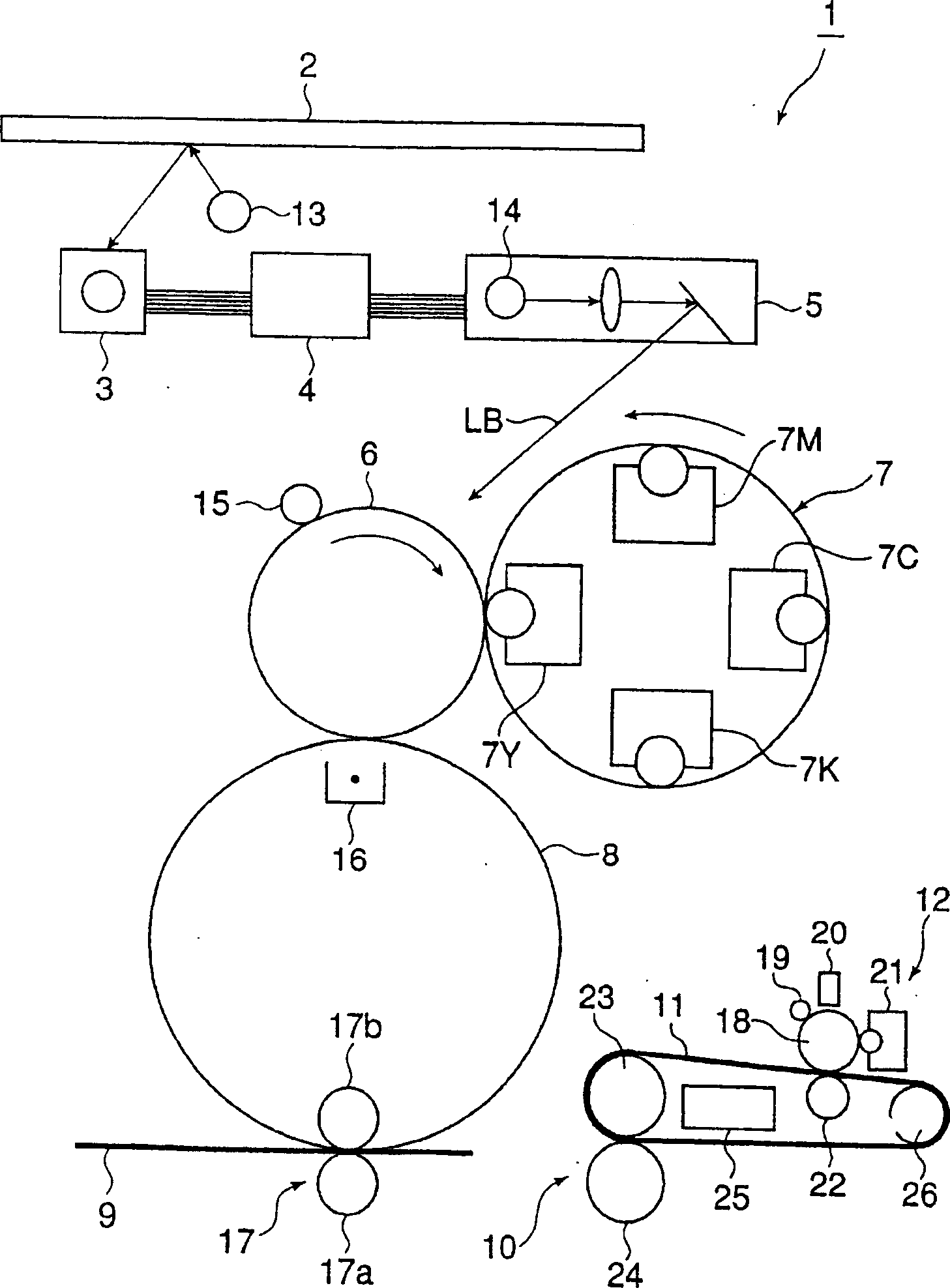

Apparatus for forming transparent coating and colour imaging apparatus using the same

InactiveCN1493929AWon't increase in sizeNo loss of productivityElectrographic process apparatusImage transferEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

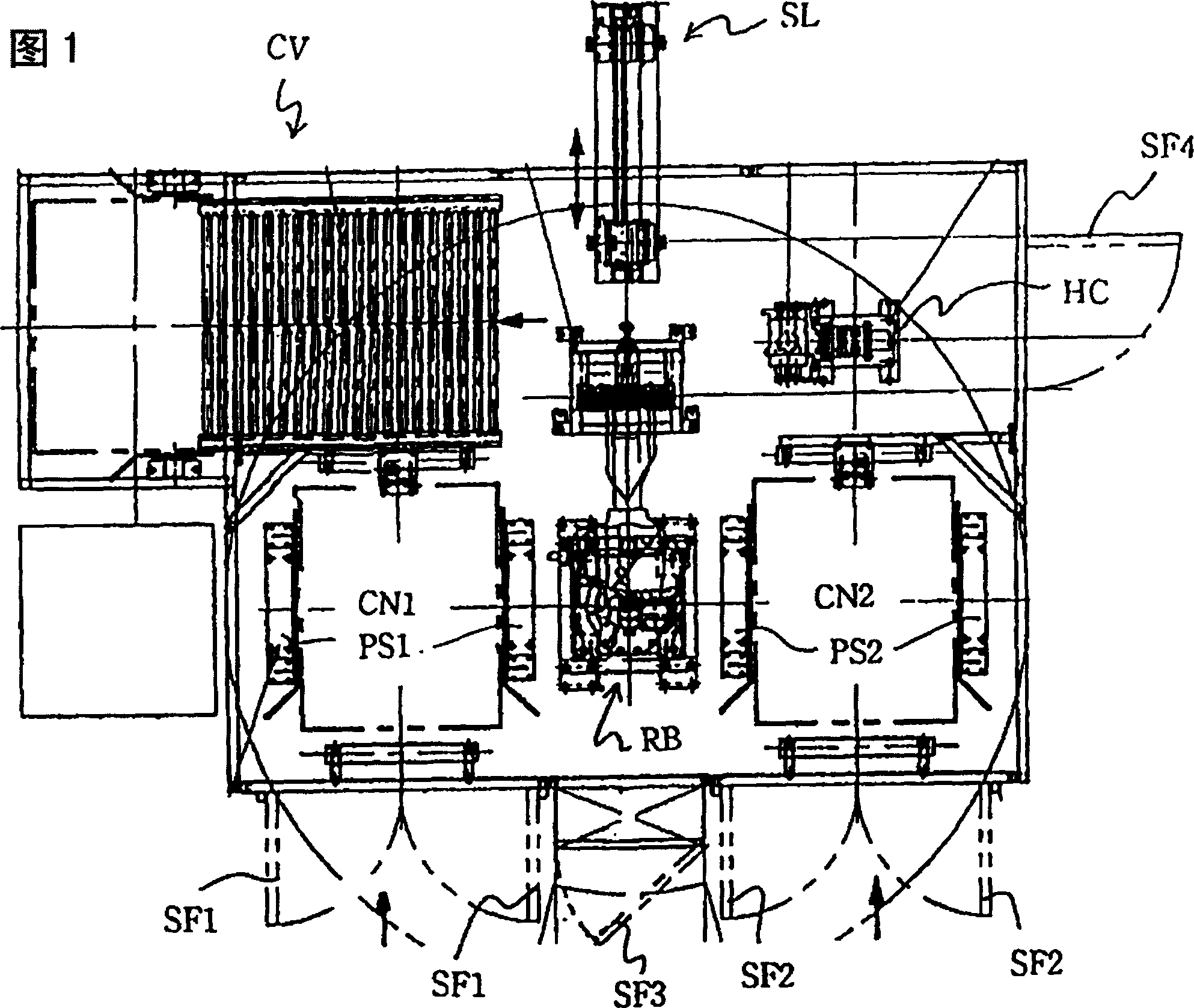

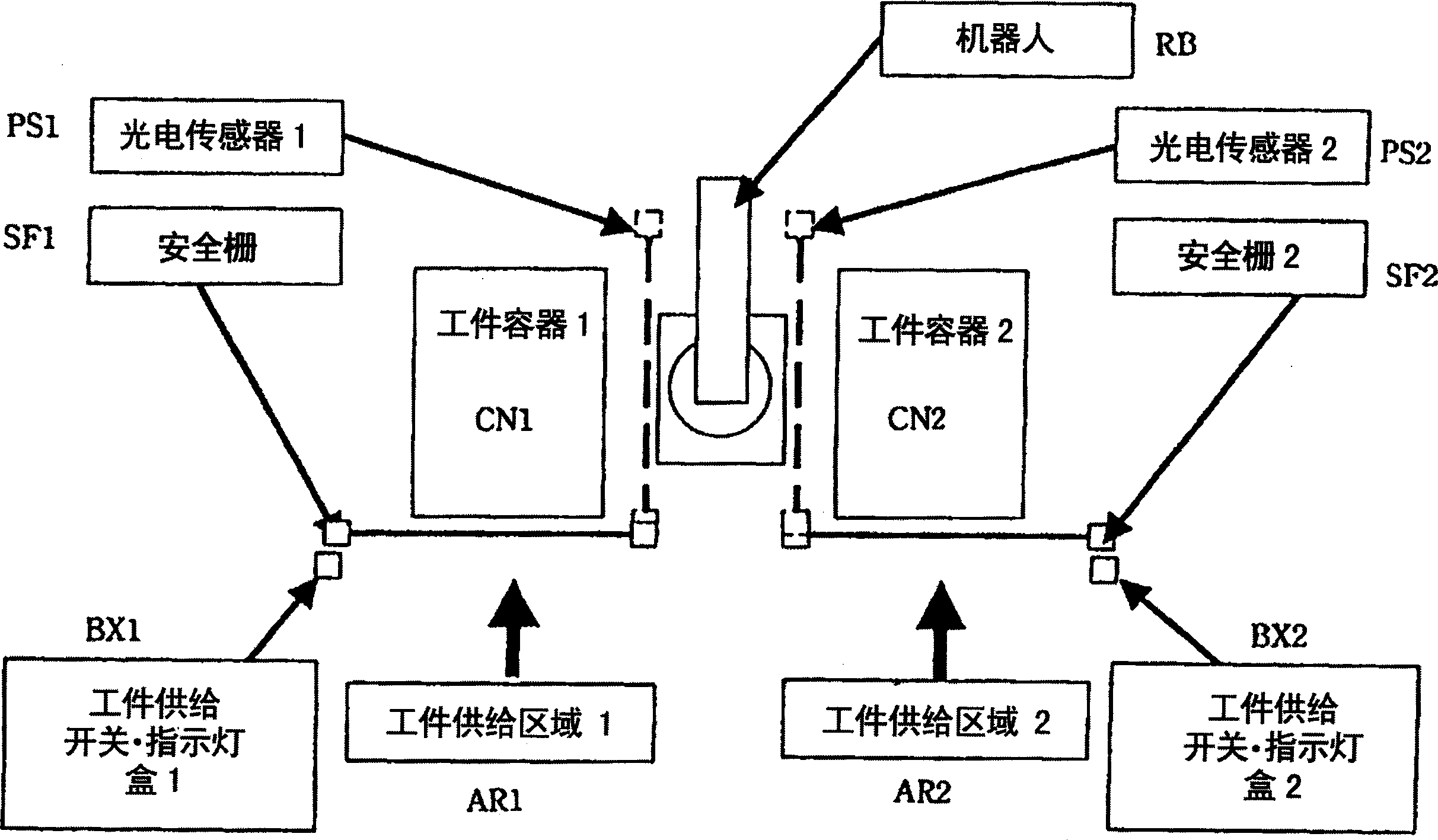

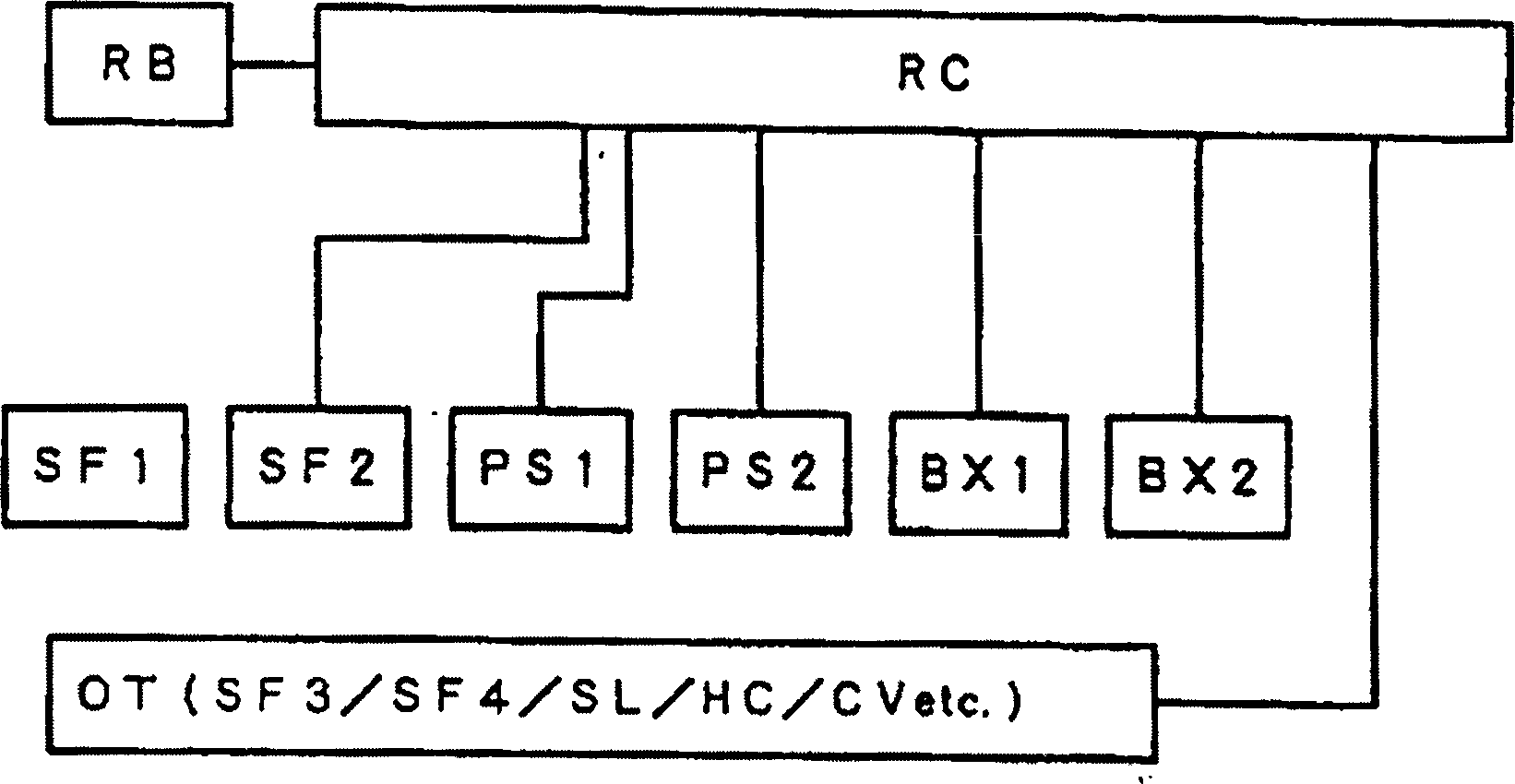

Safety device of automatic machinery system

InactiveCN1498733ANo loss of productivityReduced run rateEngineering safety devicesManipulatorSwitch boxPhotoelectric sensor

During a robot taking workpieces out of a workpiece container 2, a safety fence 2 and a photoelectric sensor 1 are valid and the robot is stopped when the safety fence 2 is opened or a beam from the photoelectric sensor 1 is cut off. A safety fence 1 and a photoelectric sensor 2 are invalid and do not hinder operation of the robot. Operation feasible state indicating lamps of workpiece feeding lamp / switch boxes 1 and 2 are turned on and off, respectively. If an operator replaces a workpiece container 1, he / she actuates an operating area entrance switch or the box 1 into an ON state to make OFF state an operation feasible signal for the robot RB on a side of the workpiece container 1. When the robot is operating on the side of the workpiece container 1, the robot can continue to operate while similarly ensuring safety of the operator.

Owner:FANUC LTD

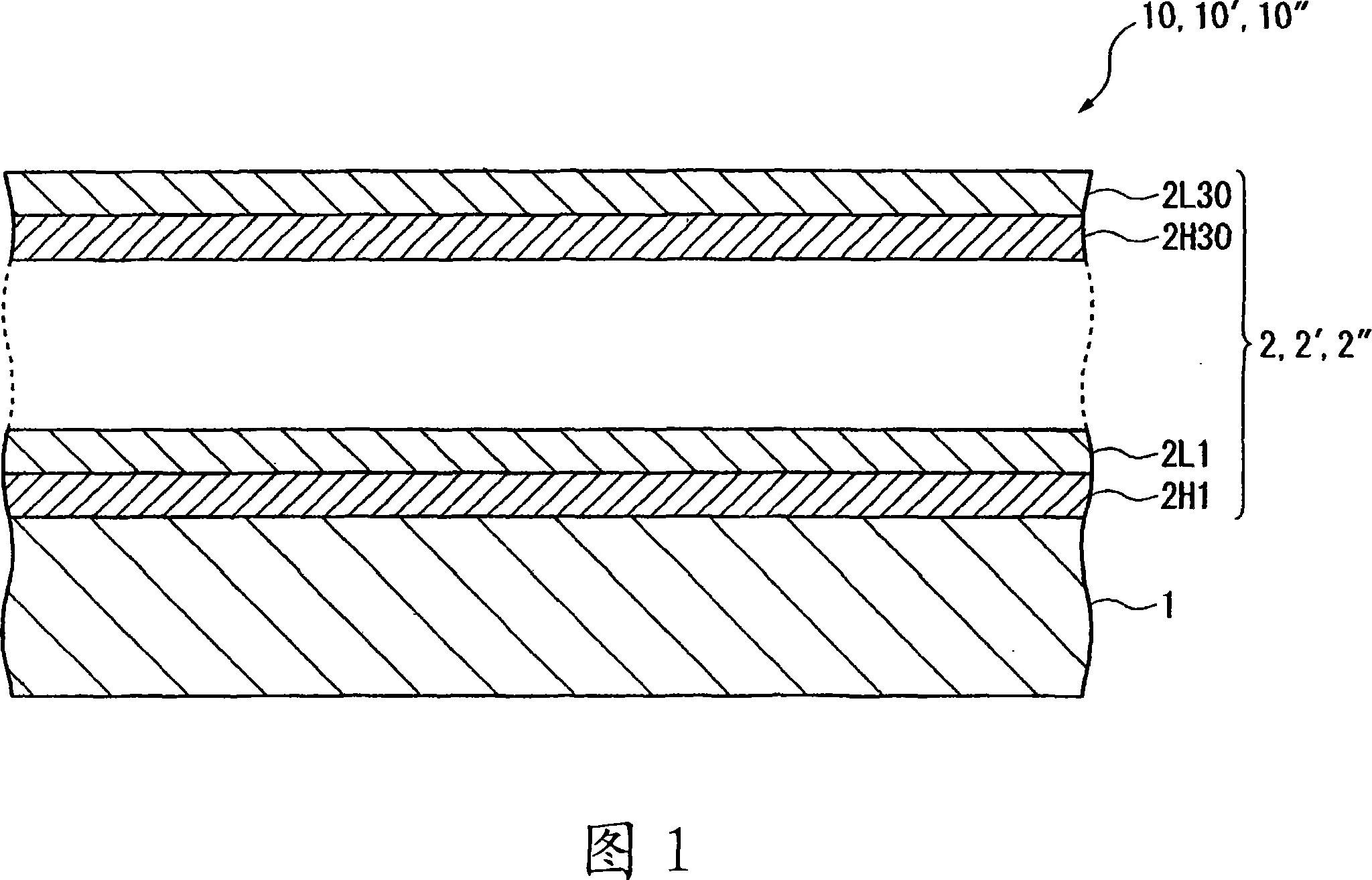

Optical multilayer filter, method for manufacturing the same, and electronic apparatus

InactiveCN101051093AReduce the amount of adhesionEfficient manufacturingOptical filtersCamera filtersElectricitySurface layer

An optical multilayer filter comprises a substrate, and an inorganic thin film that is composed of a plurality of layers and formed on the substrate. An uppermost surface layer of the inorganic thin film is a silicon oxide layer having a density of from 1.9 g / cm<3 >to 2.2 g / cm<3>.

Owner:SEIKO EPSON CORP

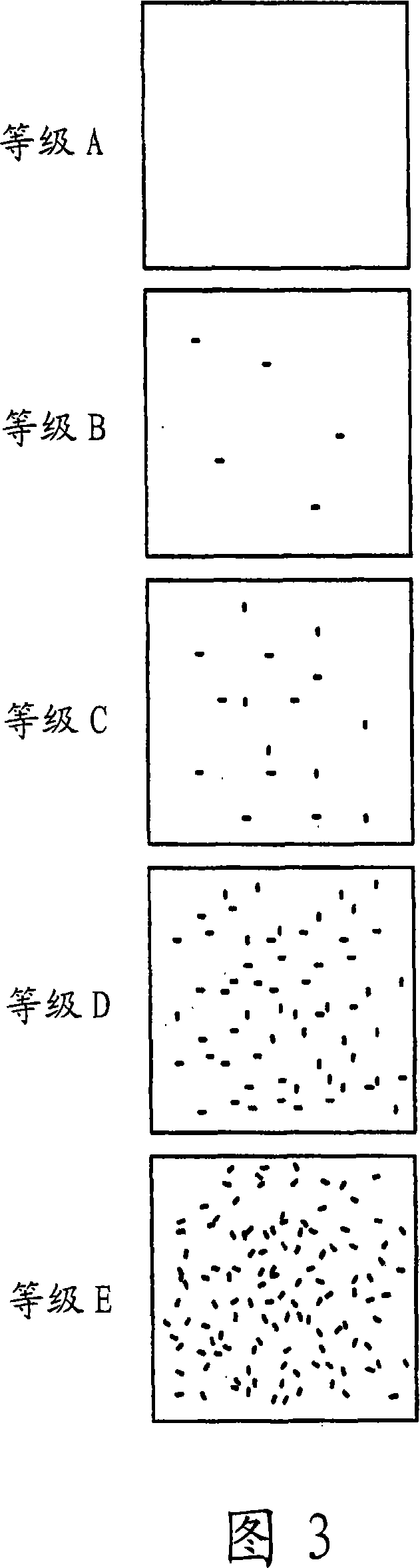

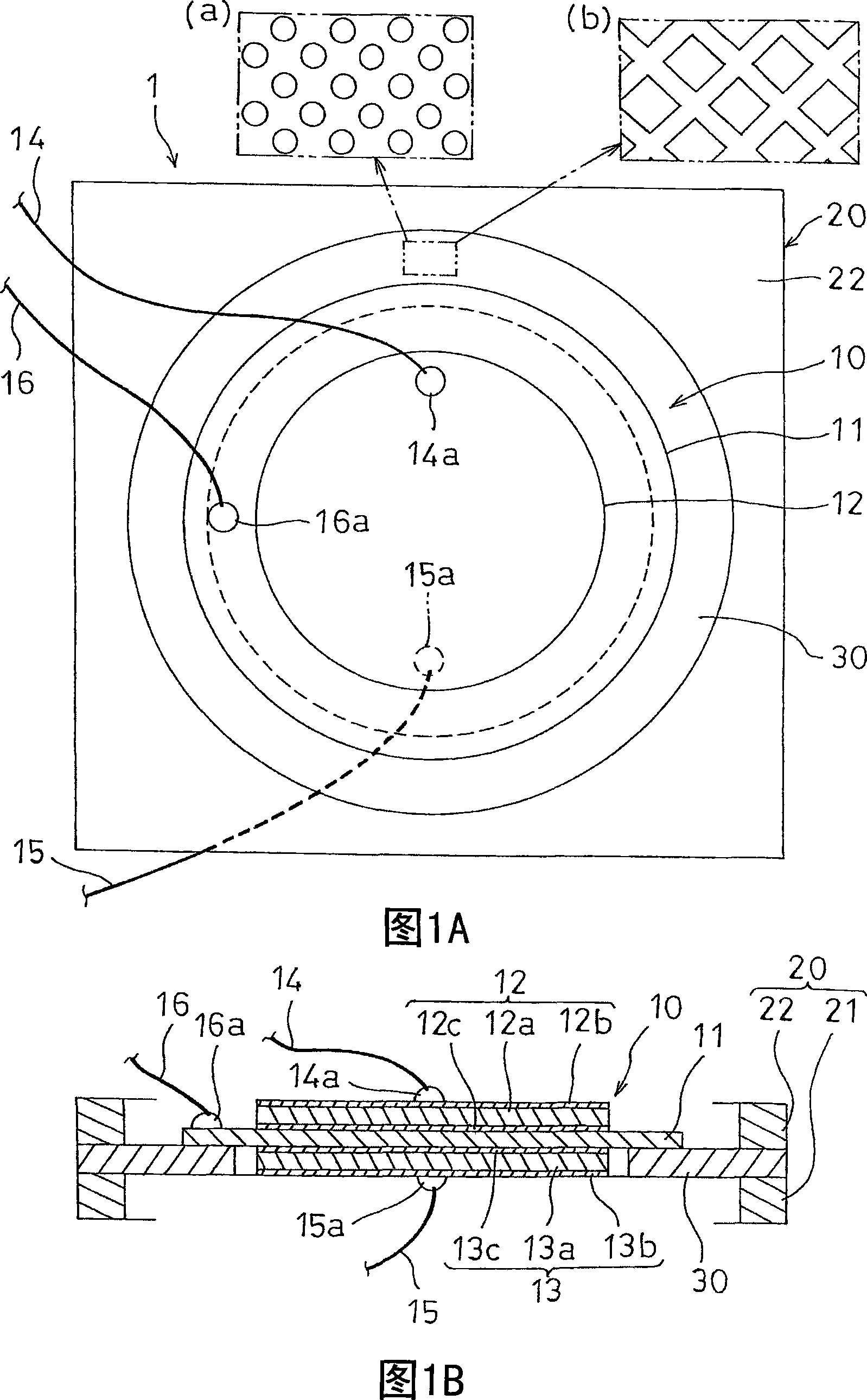

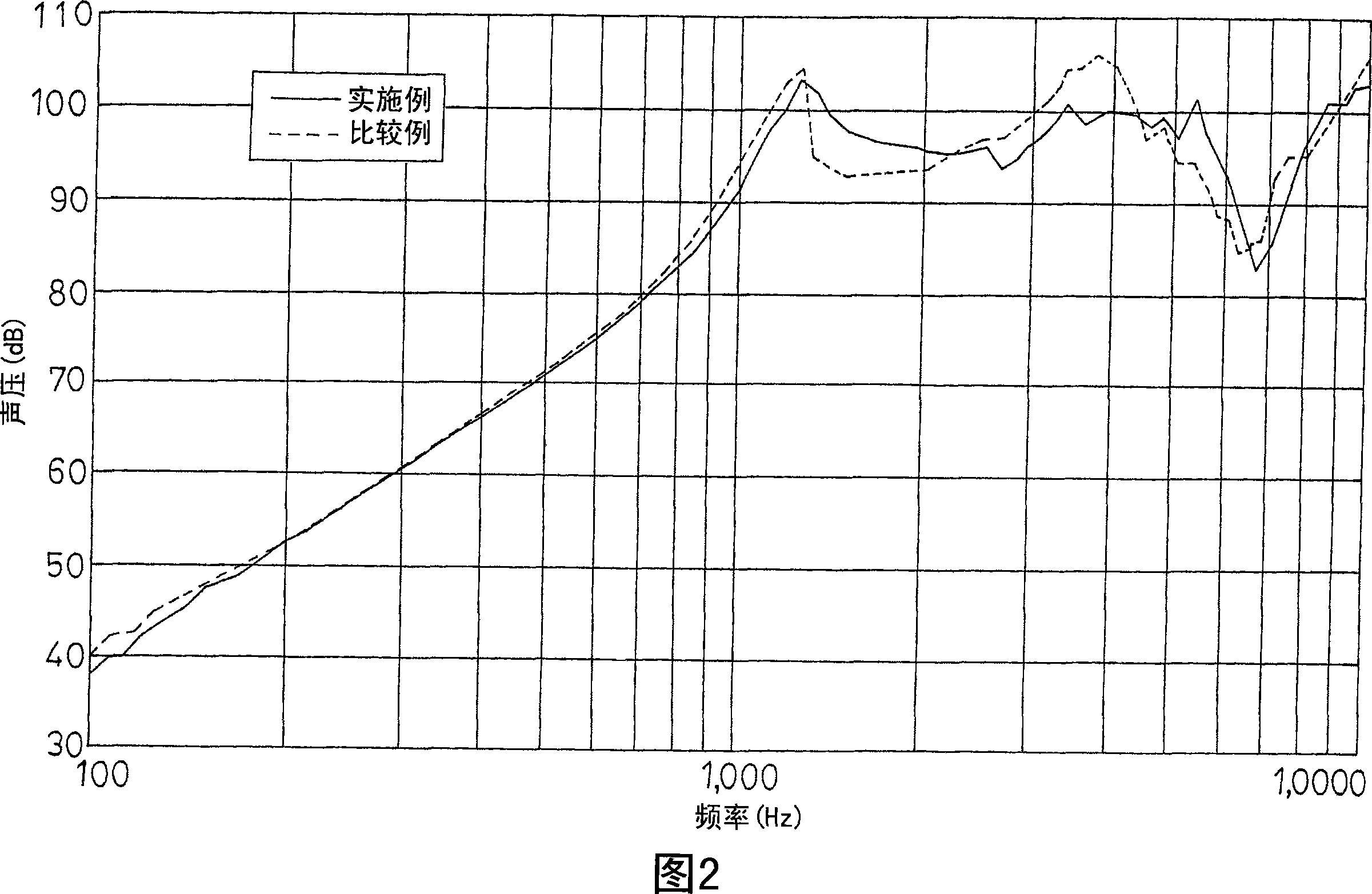

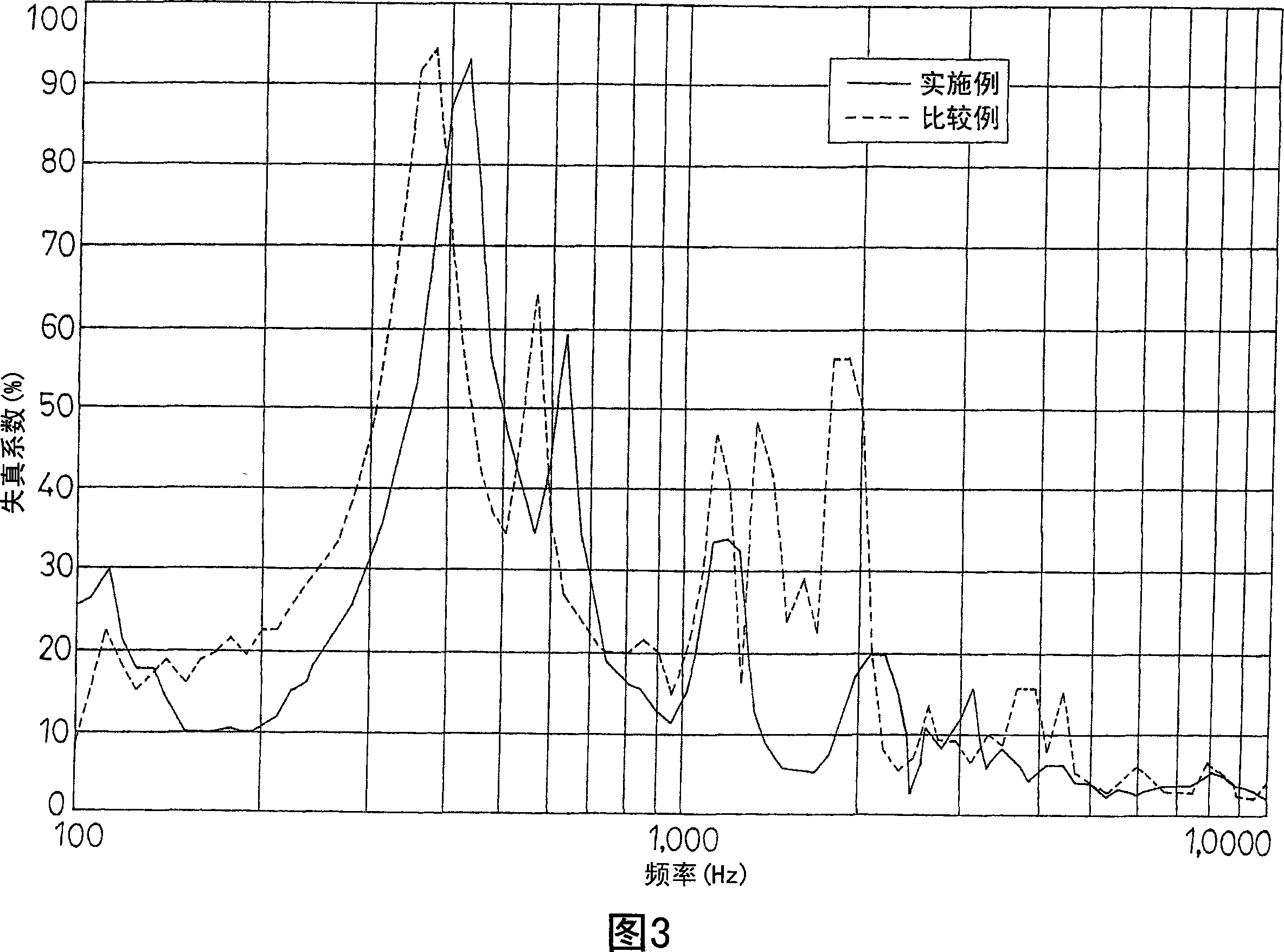

Piezoelectric electroacoustic transducing device

InactiveCN101111099ALossless sizeNo loss of productivityLoudspeaker diaphragm dampingPiezoelectric/electrostrictive transducersConvex structurePiezoelectric actuators

In order to improve the sound pressure level and the sound quality of a piezoelectric electroacoustic transducing device without impairing the size, the productivity, the cost, and the like of the device, the piezoelectric electroacoustic transducing device 1 has: a frame 20; a piezoelectric vibrator 10 in which piezoelectric elements 12, 13 are bonded to a metal plate 11; and a support member 30which supports a peripheral portion of the piezoelectric vibrator 10 on the frame 20, and which is made of a resin film such as a ring-like PET resin, and a mesh or embossed concave and convex structure is formed on the surface of the support member 30. While maintaining the external shape of the support member 30, the support member 30 is provided with a flexibility at which a large displacementof the piezoelectric vibrator 10 is not impeded.

Owner:HOSIDEN CORP

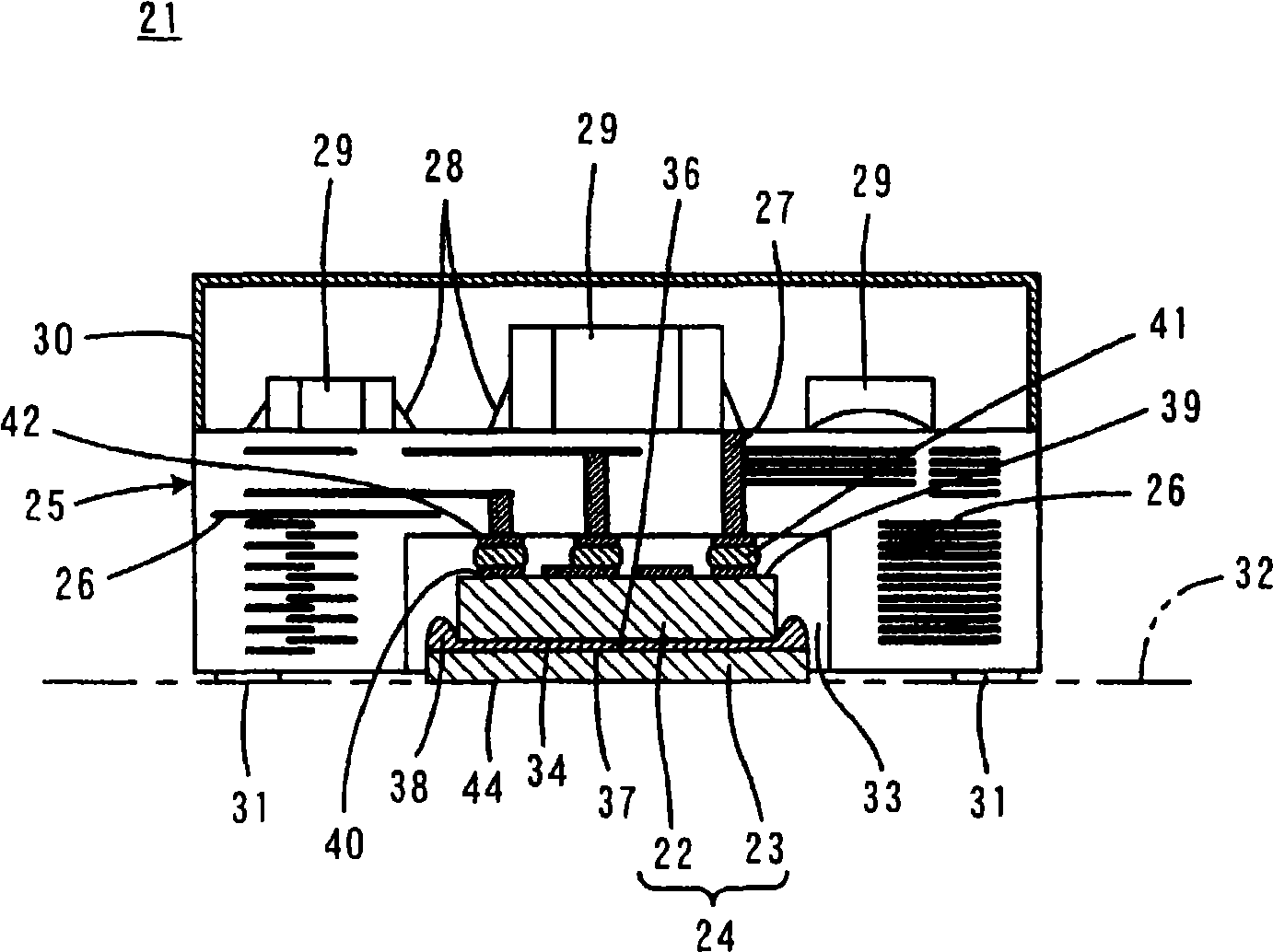

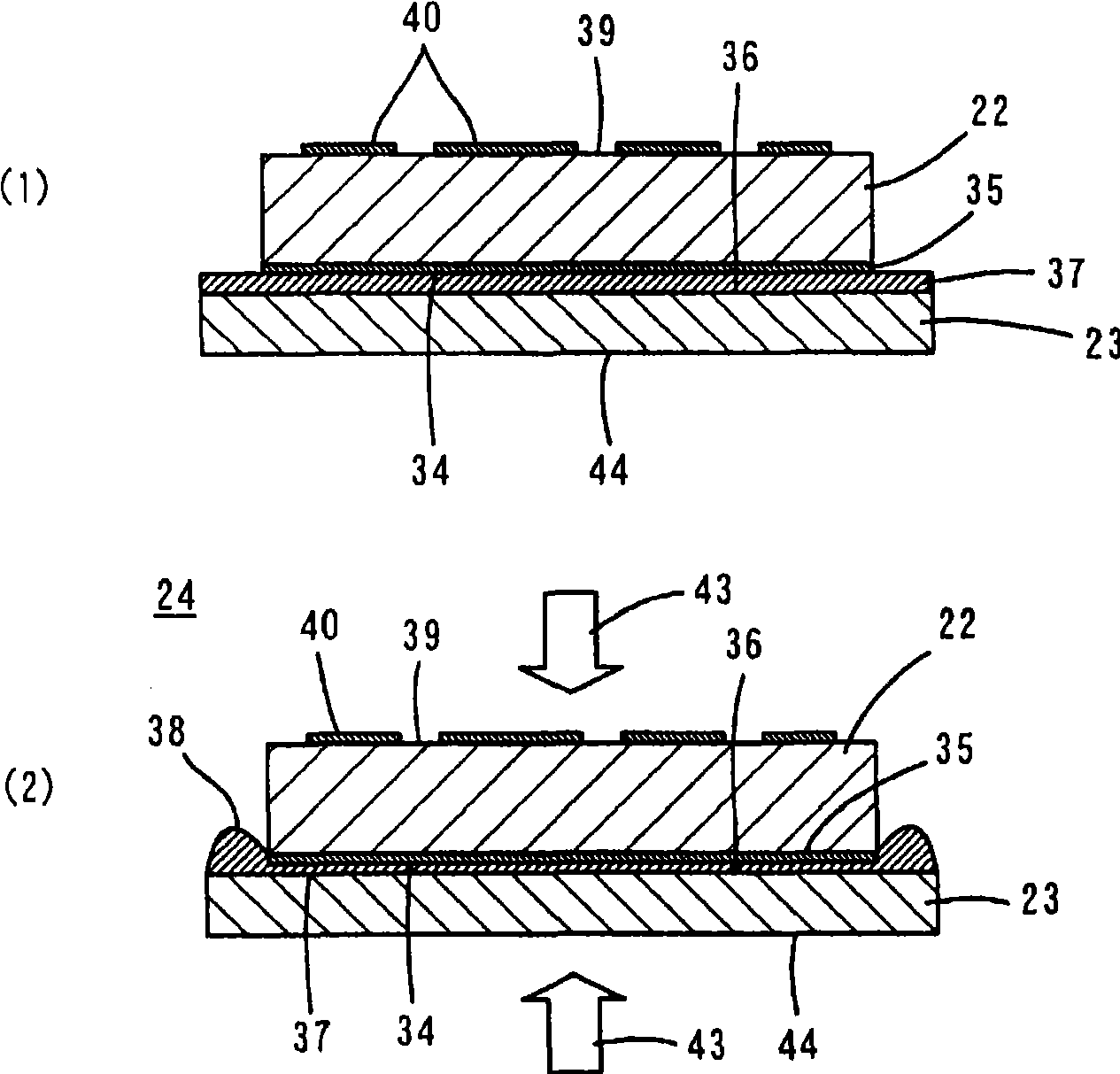

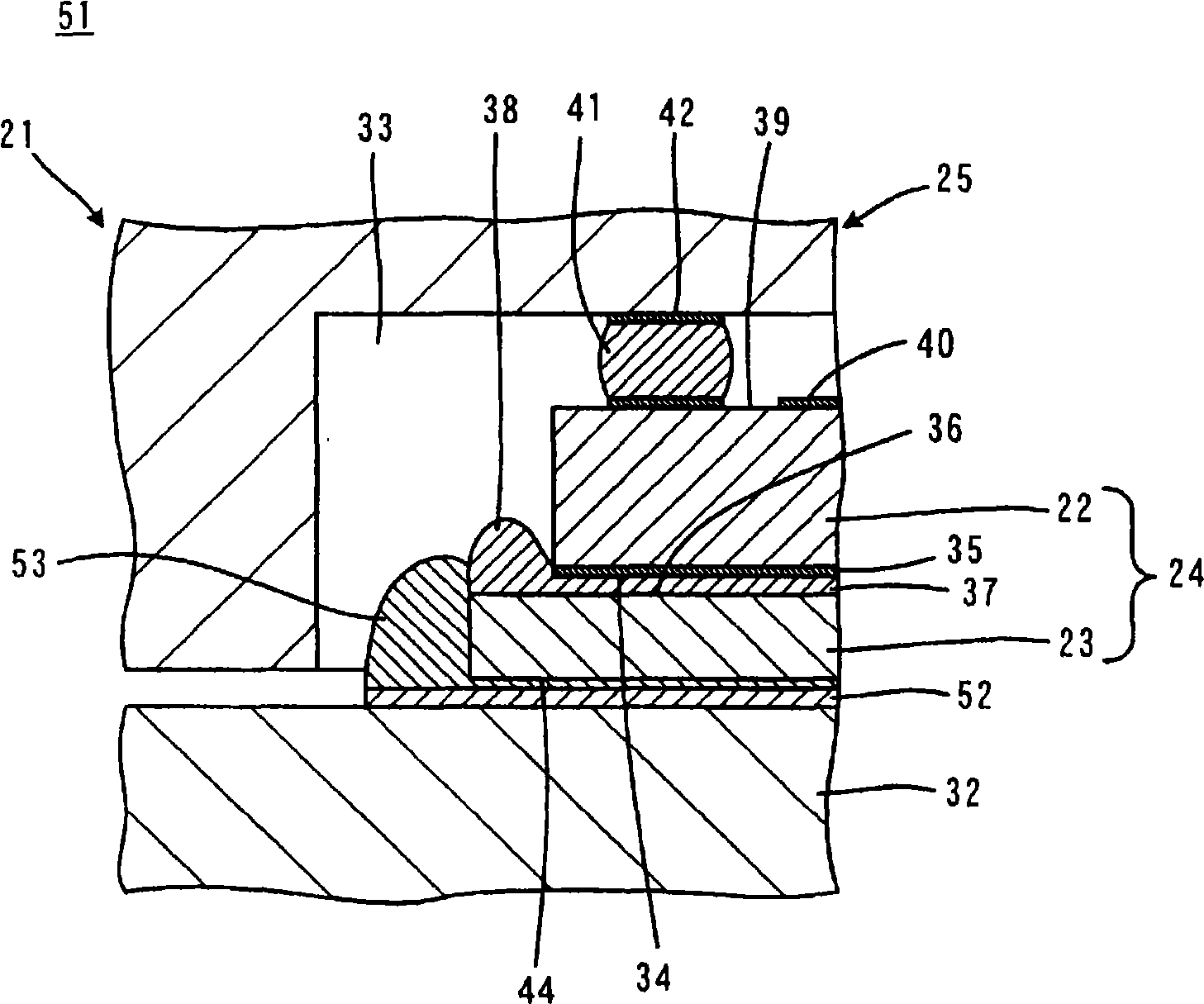

Electronic part device and method of manufacturing it and electronic part assembly and method of manufacturing it

InactiveCN101512761APrevent molten erosionGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesMetal sheetEngineering

If solder for joining a metal sheet to the metal surface of a board melts and erodes solder for joining an electronic part element to the metal sheet when an electronic part device in which the metal sheet is joined to the electronic part element is mounted on the board, the reliability of joining between the electronic part element and the metal sheet is lowered. A ridge (38) extending along the periphery of the bottom surface (34) of the electronic part element (22) is formed by a part of a first solder (37) for joining the electronic part element (22) to the metal sheet (23). The ridge (38) intercepts a second solder (53) for joining the metal sheet (23) to a board (32) serving as a mother board to prevent the first solder (37), which contributes to the joining of the electronic part element (22) to the metal sheet (23), from being melted and eroded.

Owner:MURATA MFG CO LTD

Full-automatic embossing machine

InactiveCN103158340AImprove efficiencyReduce the number of plate changesScreen printersPrinting press partsEngineeringUltimate tensile strength

The invention discloses a full-automatic machine which comprises an embossing machine body and a plurality of clamps used for locating the embossing machine body. The embossing machine body is arranged on table boards, an operating rail of the embossing machine body is arranged on the table boards, the number of the table boards is plural, and the table boards are arranged side by side and connected through turning systems, a shifting car and turning rails of the shifting car are arranged on the turning systems, the shifting car is used for shifting the embossing machine body, a signal emission device is arranged on the shifting car, the turning rails are rectilinear rails and perpendicular to the plane of the table boards, and included angles of 90 degrees are formed between the turning rails and the table boards. The full-automatic machine has the advantages of being high in automation degree and capable of enlarging product category, improving efficiency for dozens of times, improving product quality, reducing labor intensity and reducing production cost and complexity of labor.

Owner:山东宏美数码科技股份有限公司

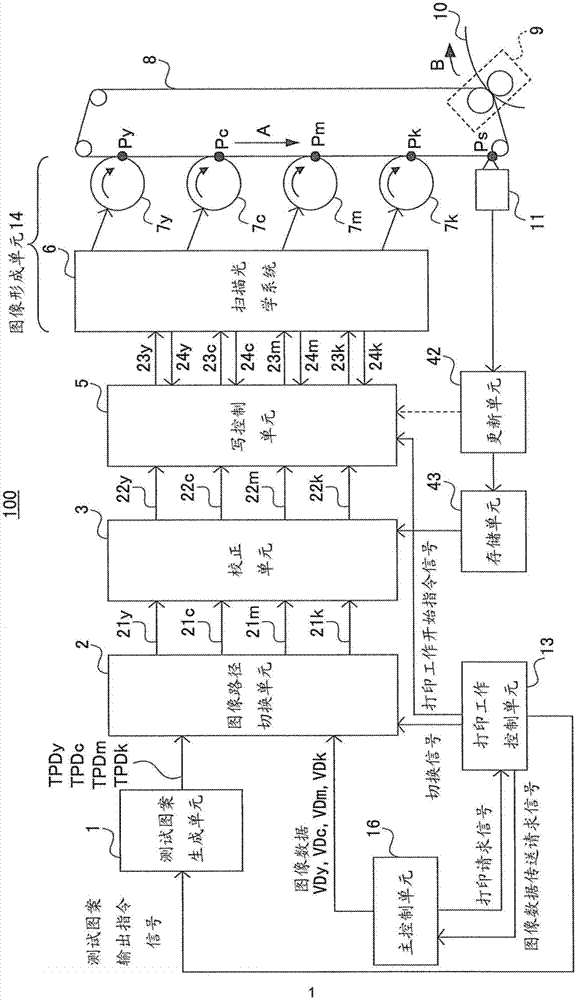

Image forming apparatus and image forming method

InactiveCN103168276ANo loss of productivityElectrographic process apparatusImage data processing detailsComputer scienceImaging data

Owner:RICOH KK

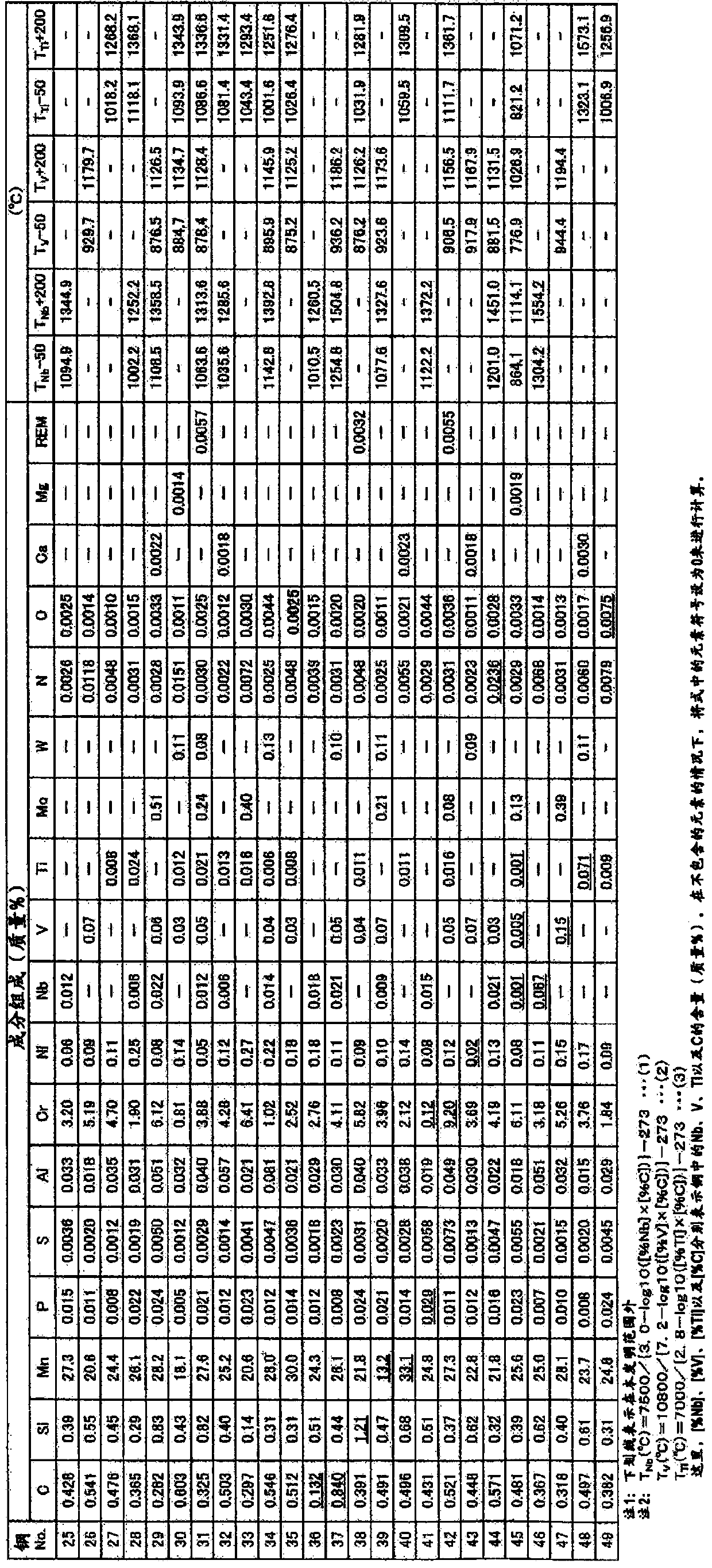

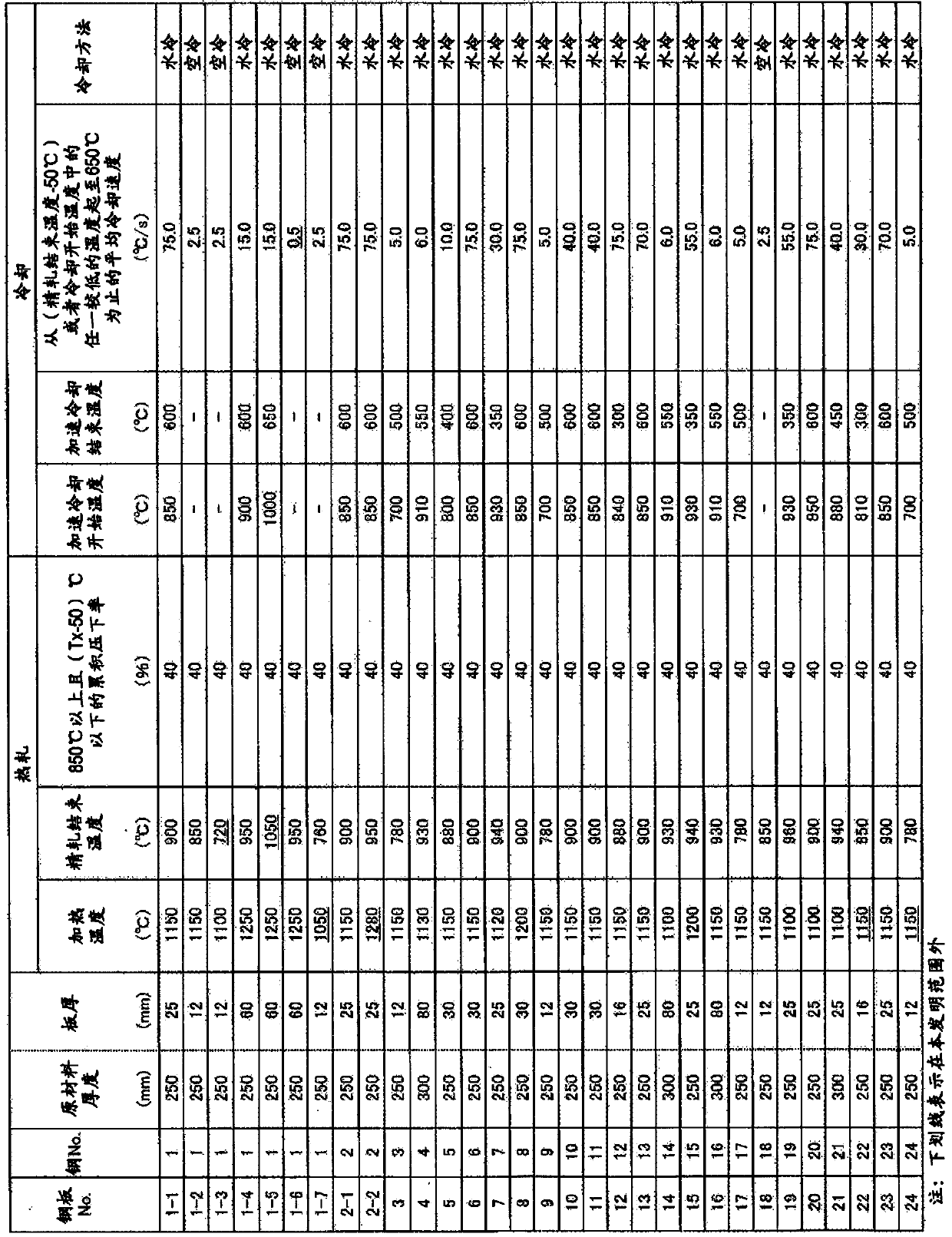

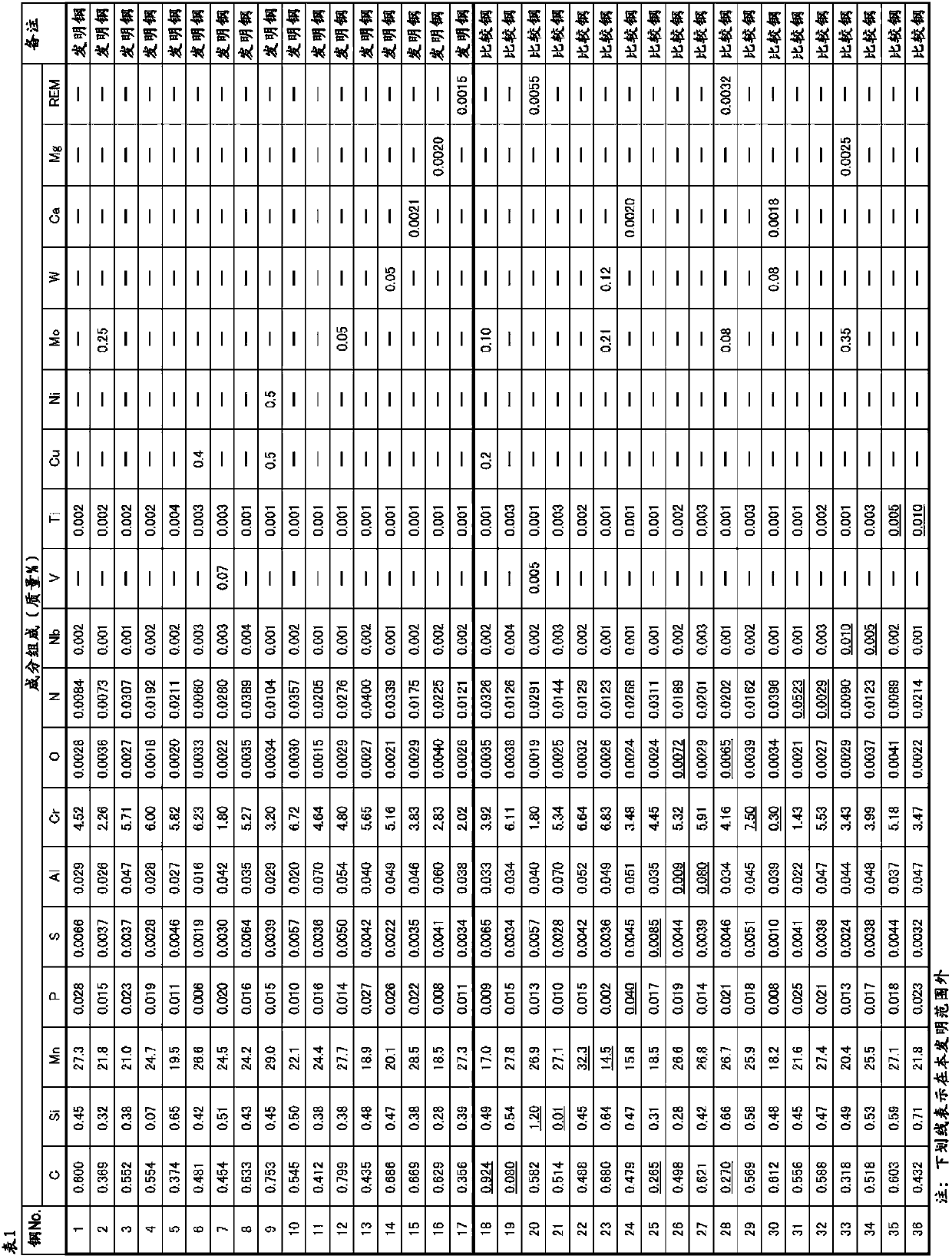

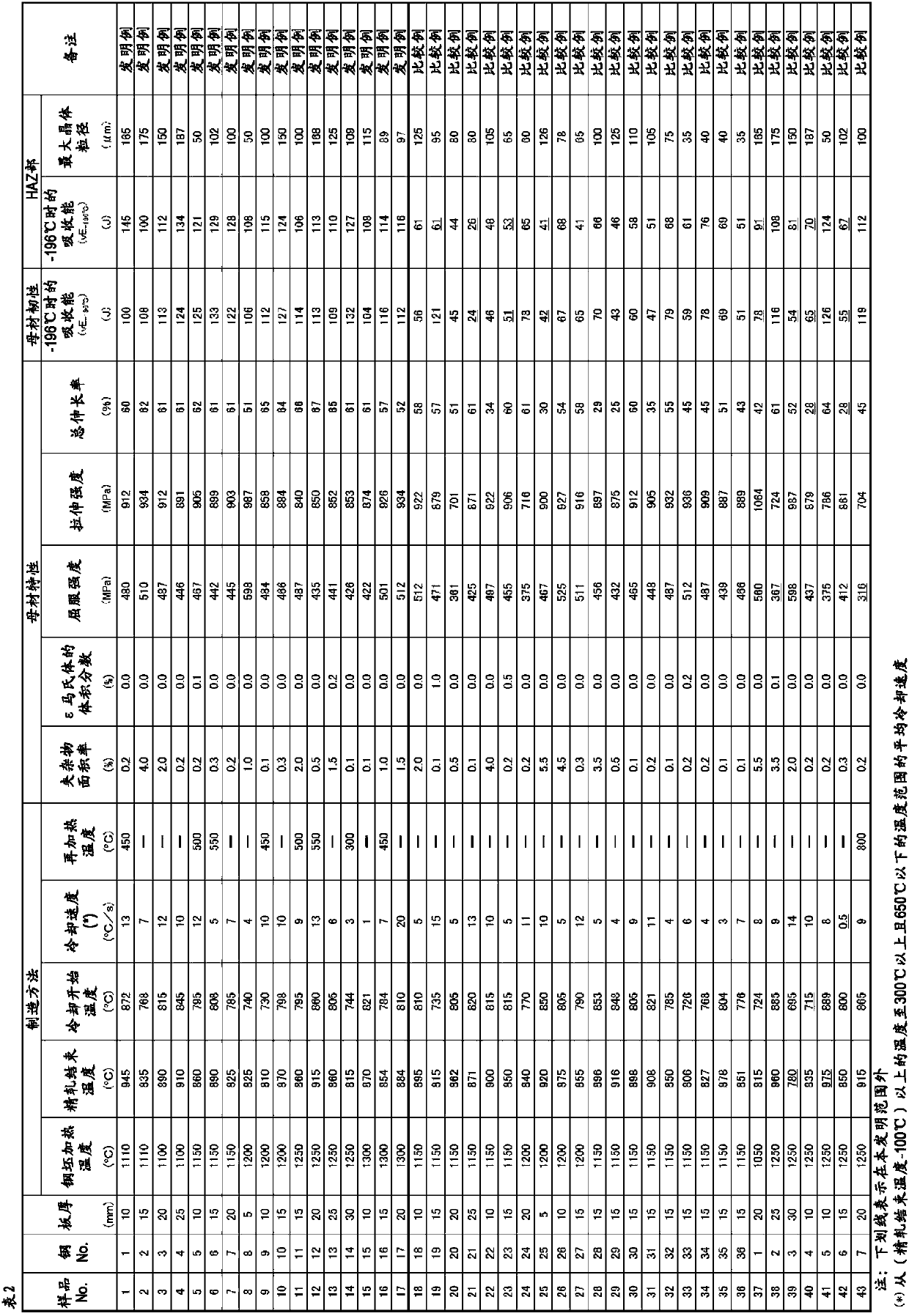

High mn steel sheet and method for producing same

ActiveCN110050082AExcellent resistance to stress corrosion crackingImprove securityFurnace typesHeat treatment furnacesAspect ratioAustenite

Provided are a high Mn steel sheet and a method for producing this high Mn steel sheet. This high Mn steel sheet has a component composition which contains, in mass%, 0.20-0.70% of C, 0.05-1.0% of Si,15-30% of Mn, 0.028% or less of P, 0.02% or less of S, 0.01-0.1% of Al, 0.5-7.0% of Cr, 0.03-0.30% of Ni and 0.0010-0.0200% of N, while containing one or more of 0.003-0.030% of Nb, 0.03-0.10% V and0.003-0.040% of Ti, with the balance made up of Fe and unavoidable impurities. With respect to this high Mn steel sheet, the microstructure at 0.5 mm below the steel sheet surface has a matrix phase of austenite; and 25% or more of the austenite in terms of area ratio has a circle-equivalent diameter of 10 um or more, while having an aspect ratio of the length to the breadth of 3 or more.

Owner:JFE STEEL CORP

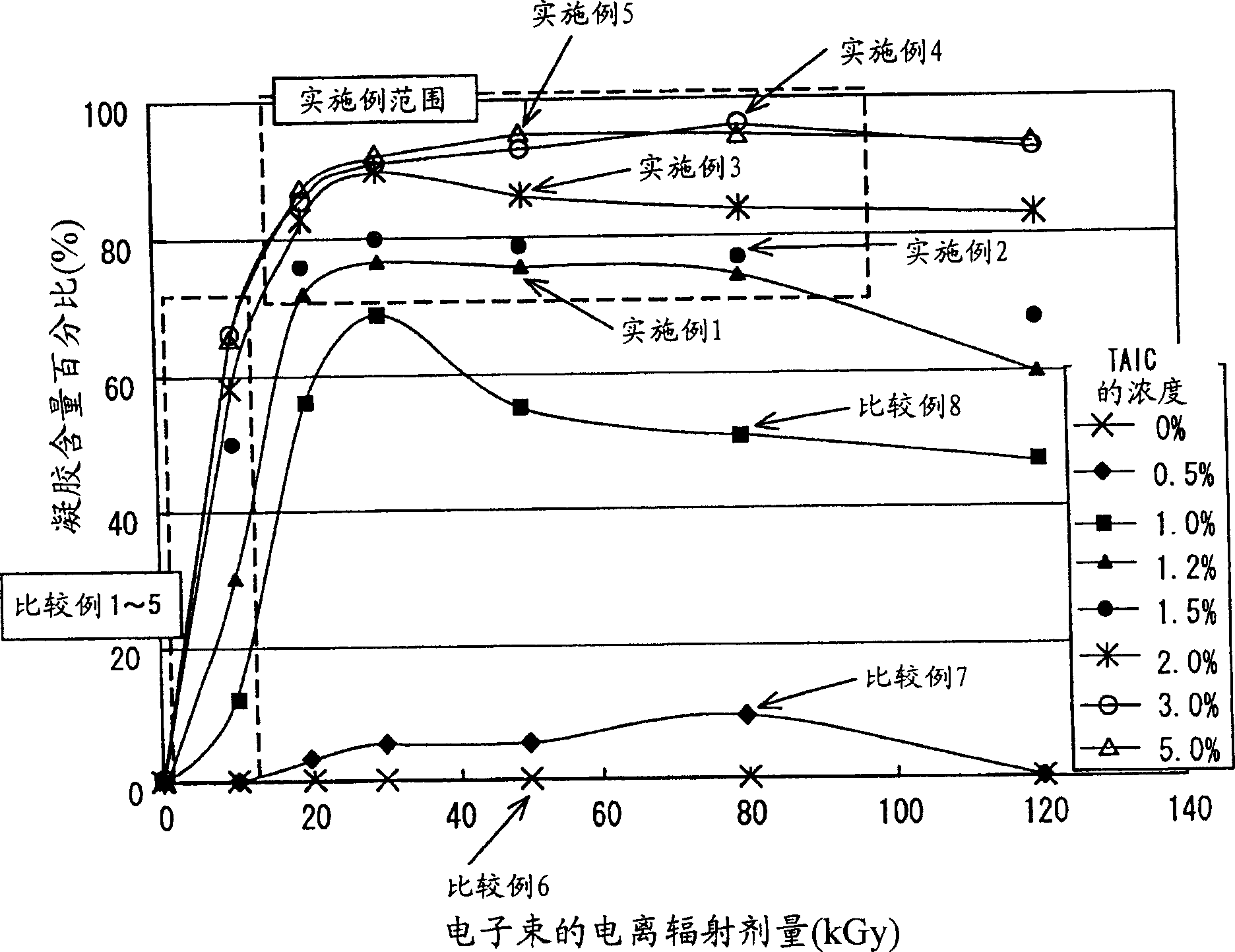

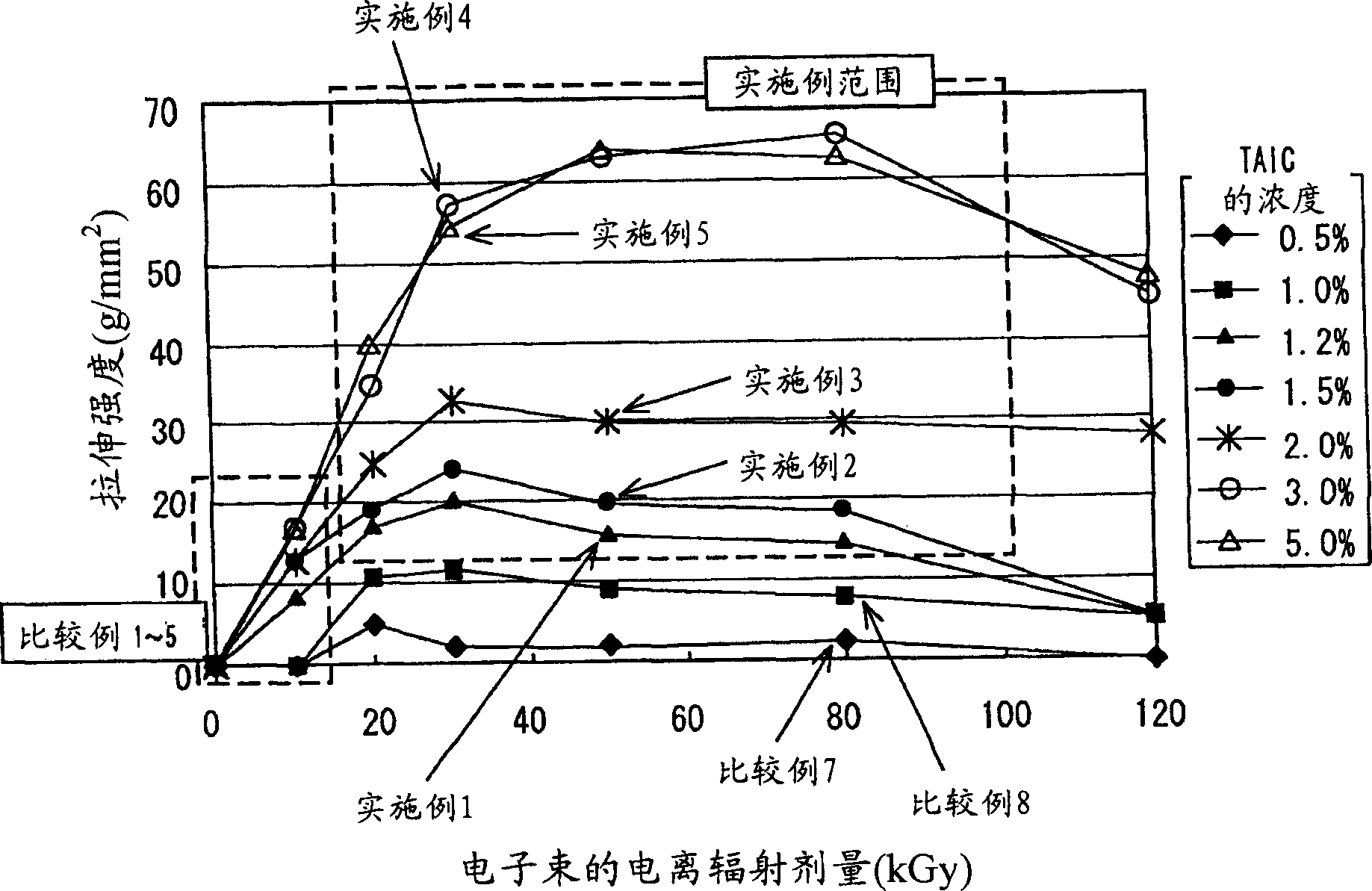

Biodegradable material and process for producing the same

A biodegradable aliphatic polyester, such as polylactic acid, is mixed with a monomer having allyl and molded into a molding having the crosslinking degree of the biodegradable aliphatic polyester increased. Thereafter, the molding is exposed to ionizing radiation to thereby obtain a molding excelling in heat resistance. Triallyl isocyanurate or triallyl cyanurate is used as the monomer having allyl.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

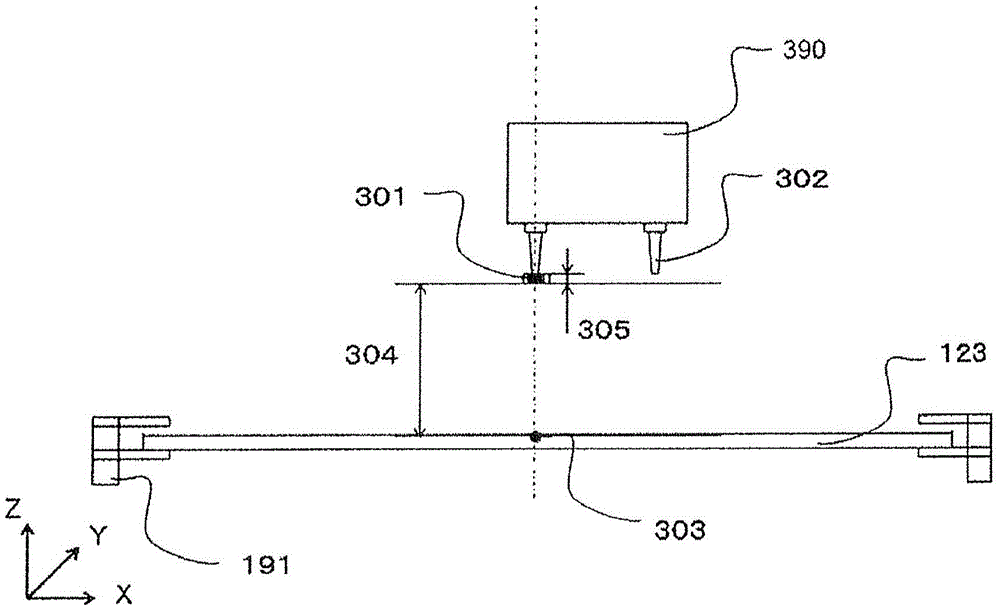

Component mounting device

ActiveCN105532084AAvoid breakingHigh positioning accuracyUsing optical meansElectrical componentsEngineering

Prior art discloses the feature of measuring the height of the entire substrate for each substrate prior to a production operation for mounting a component on a substrate (component mounting). However, time for inspection was necessary besides production time because each substrate was subjected to inspection, thereby causing productivity to decrease. The present invention has a component mounting unit containing a nozzle and a distance detection unit for optically obtaining the distance between a substrate and a component held by the aforementioned nozzle, and is characterized in that an illumination region formed by the distance detection unit is formed in the vicinity of a section in which the nozzle is projected onto the substrate.

Owner:YAMAHA MOTOR CO LTD

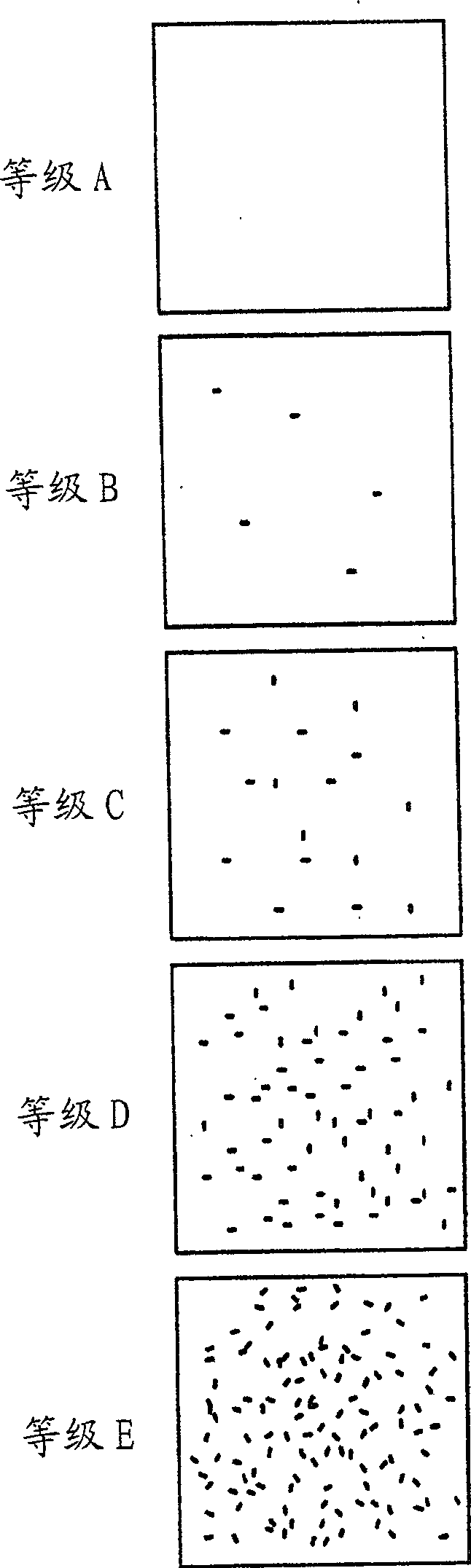

Water-repellent protective film formation agent, chemical solution for forming water-repellent protective film, and wafer cleaning method using chemical solution

InactiveCN102971836AStable cleaningPrevent collapseGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingChemical solutionTantalum nitride

[Problem] To provide a water-repellent protective film formation agent, a chemical solution that contains the agent and is used for forming a water-repellent protective film, and a cleaning method for wafers that uses the chemical solution, wherein it is possible in the manufacturing of semiconductor devices to efficiently clean wafers while preventing pattern collapse of: wafers (1) in which a substance containing silicon atoms is included on at least the surface of the recesses in an unevenly patterned (2) wafer surface; or wafers (1) in which at least one type of substance selected from a group consisting of titanium, titanium nitride, tungsten, aluminum, copper, tin, tantalum nitride, and ruthenium, is included on part of at least the surface of the recesses in an unevenly patterned (2) wafer surface. [Solution] A water-repellent protective film formation agent that is used in wafer cleaning for forming a water-repellent protective film on at least the surface of the recesses of wafers, the agent being a silicon compound represented by the formula [1]. [1] R1aSiX4-a

Owner:CENT GLASS CO LTD

Optical multilayer filter, and electronic apparatus

InactiveCN100474003CReduce the amount of adhesionEfficient manufacturingOptical filtersCamera filtersElectricitySurface layer

Owner:SEIKO EPSON CORP

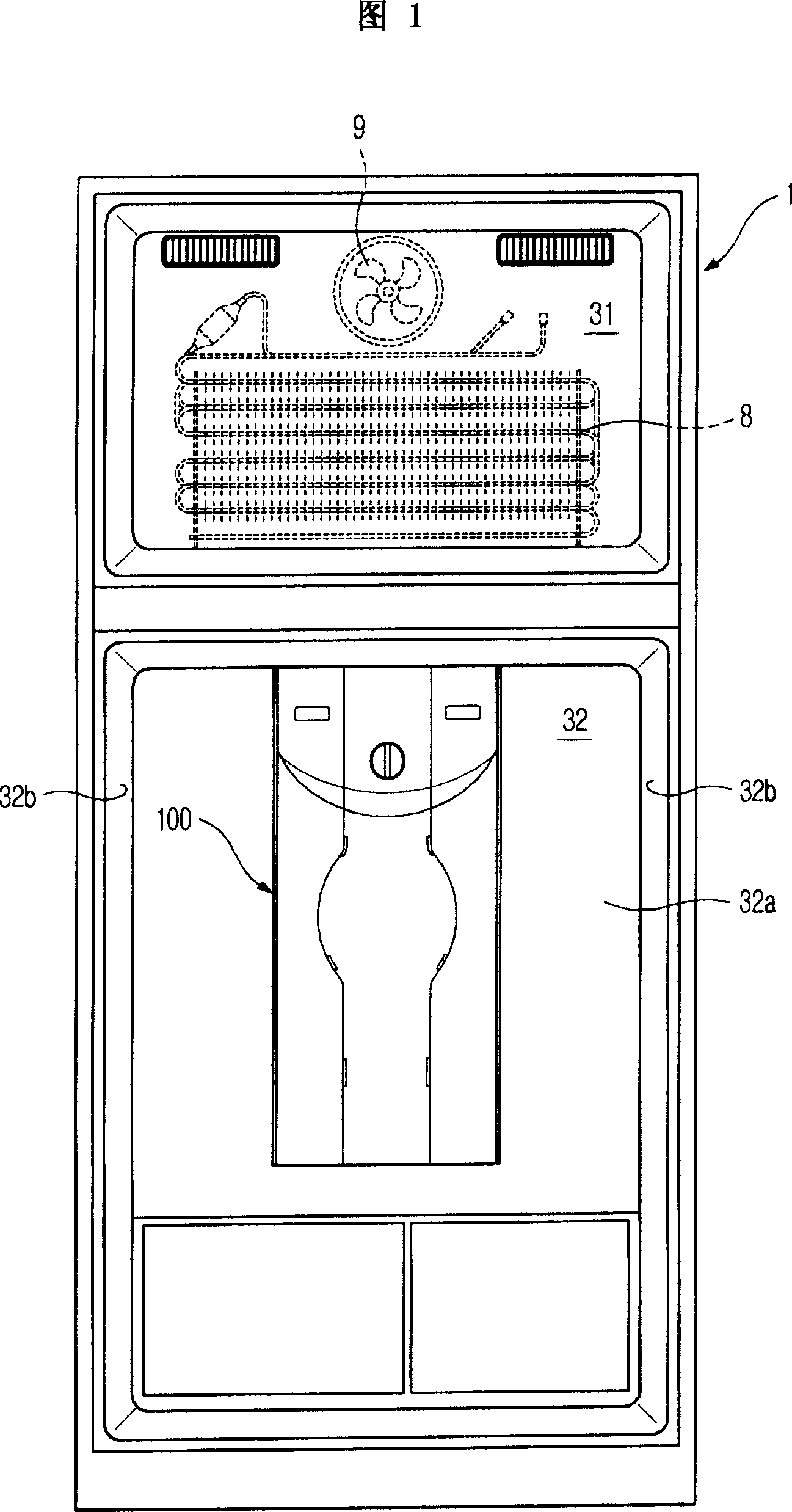

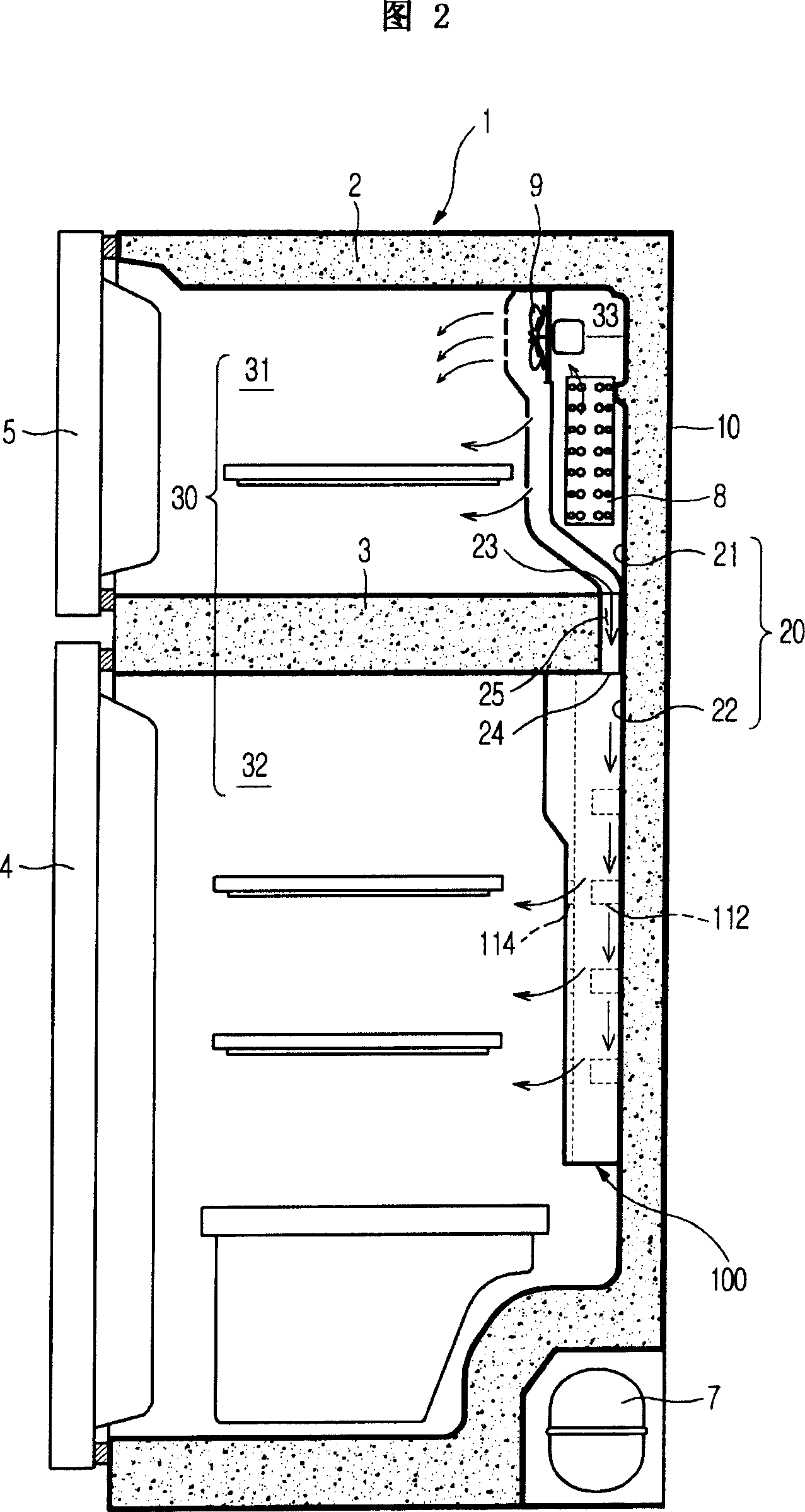

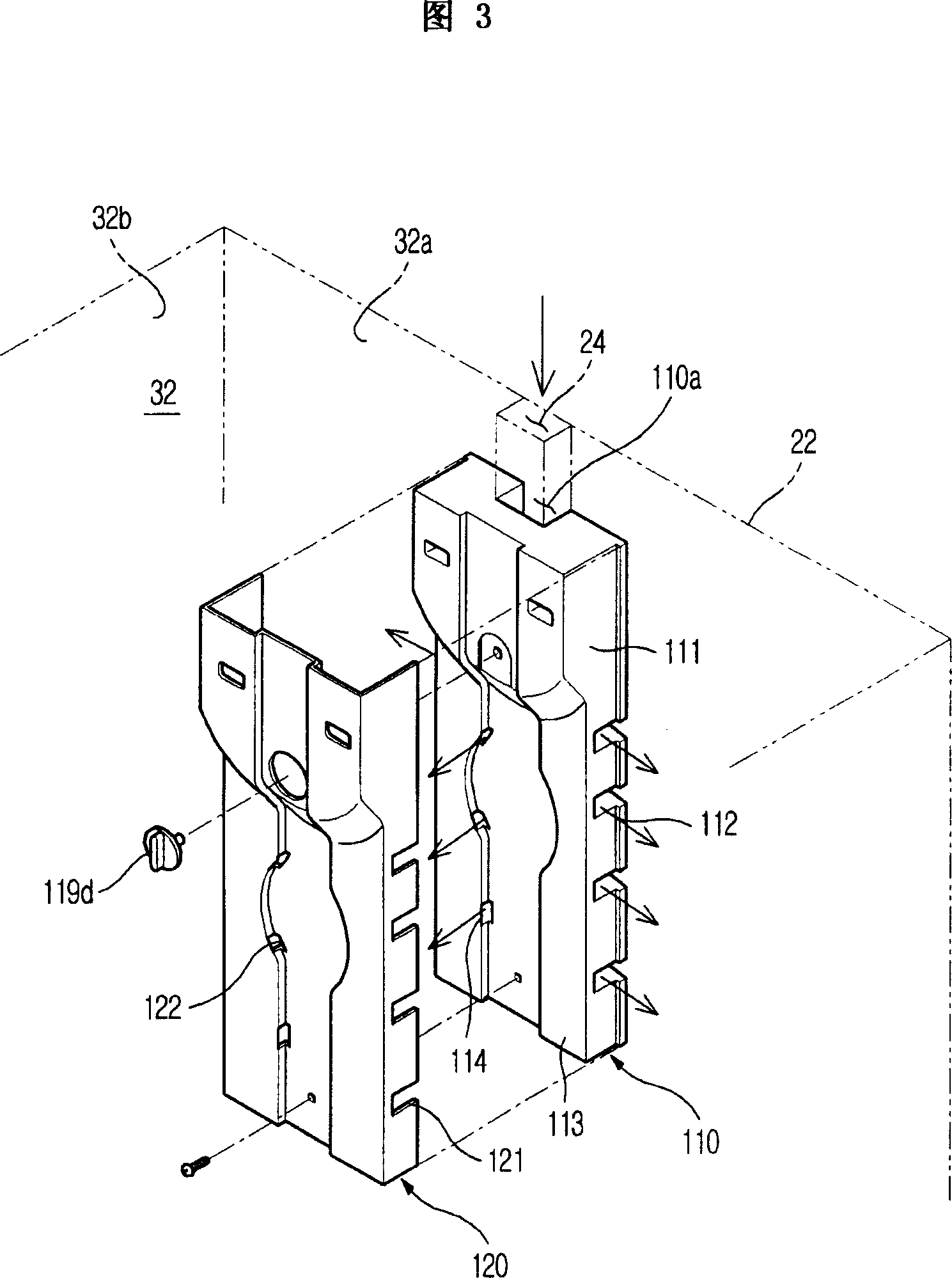

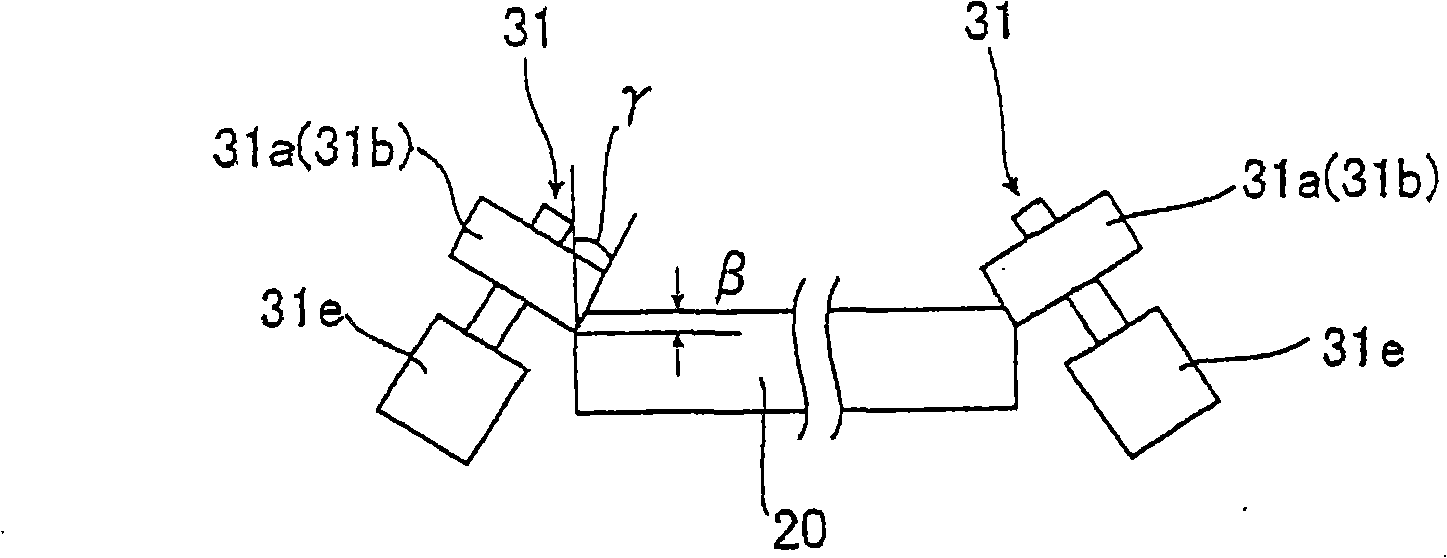

Refrigerator

InactiveCN1932420AUniform supplyReduce manufacturing costLighting and heating apparatusDomestic refrigeratorsProduction rateCooling chamber

The invention provides a refrigerator capable of uniformly supplying cooling air to an entire storeroom without increasing production cost and decreasing productivity. The refrigerator comprises a cooling air distributing unit having passage forming components. The passage forming components consists of a plurality of restrictive passages which are used for inducing the cooling air transferred from a cooling chamber to the store room. A plurality of side discharging slots are formed on opposite side surfaces of the passage forming components used for discharging the cooling air toward opposite side direction. Furthermore, a plurality of front discharging slots are formed on front surfaces of the passage forming components used for discharging the cooling air toward the front surface of the passage forming components. The cooling air from the side discharging slots moves along the side and back surfaces opposite to the cooling chamber as well as cools margin area of the cooling chamber. In addition, the cooling air from the front discharging slots cools central area of the cooling chamber. Thus, the cooling chamber is uniformly cooled and shows an improved temperature distribution.

Owner:SAMSUNG ELECTRONICS CO LTD

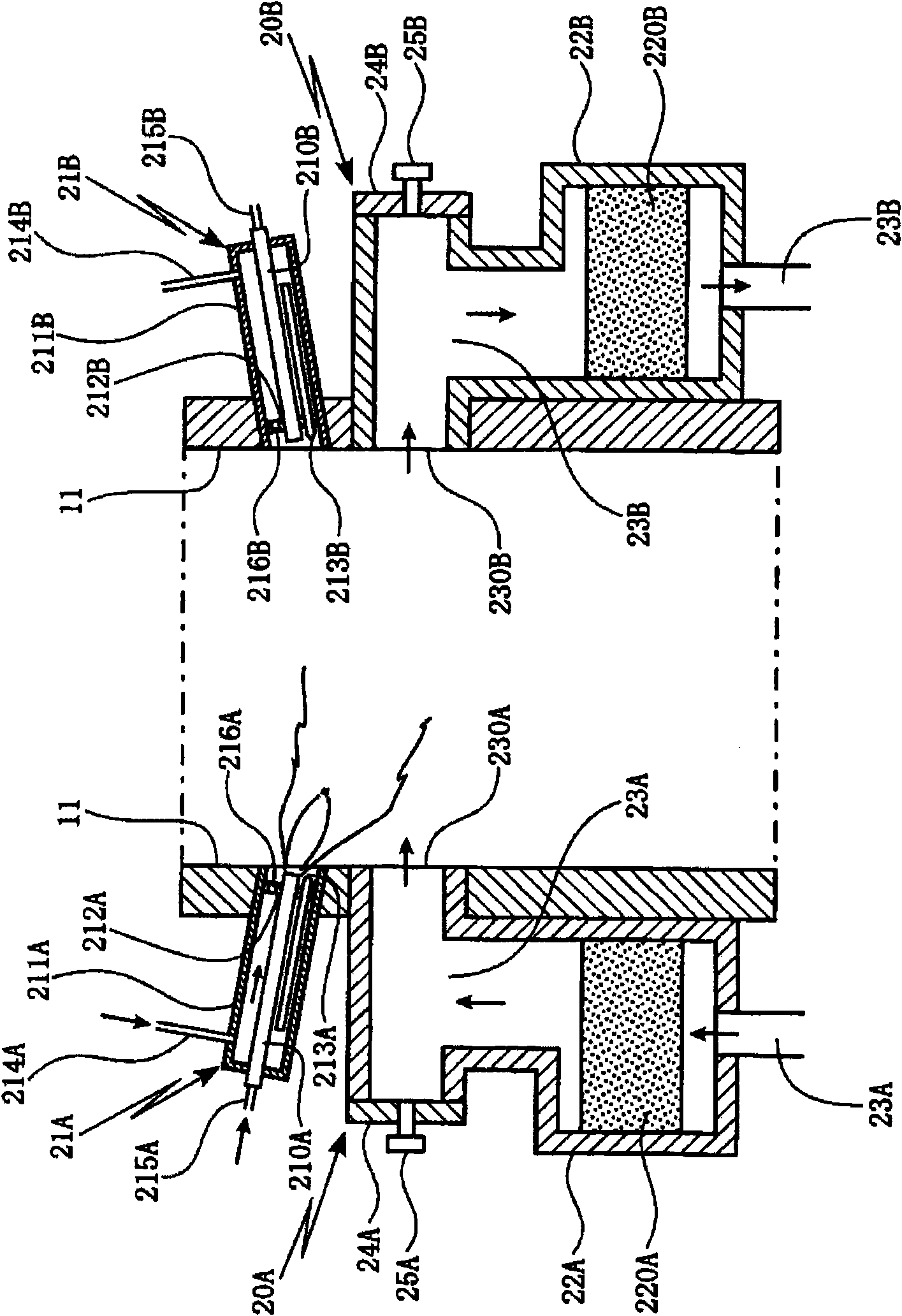

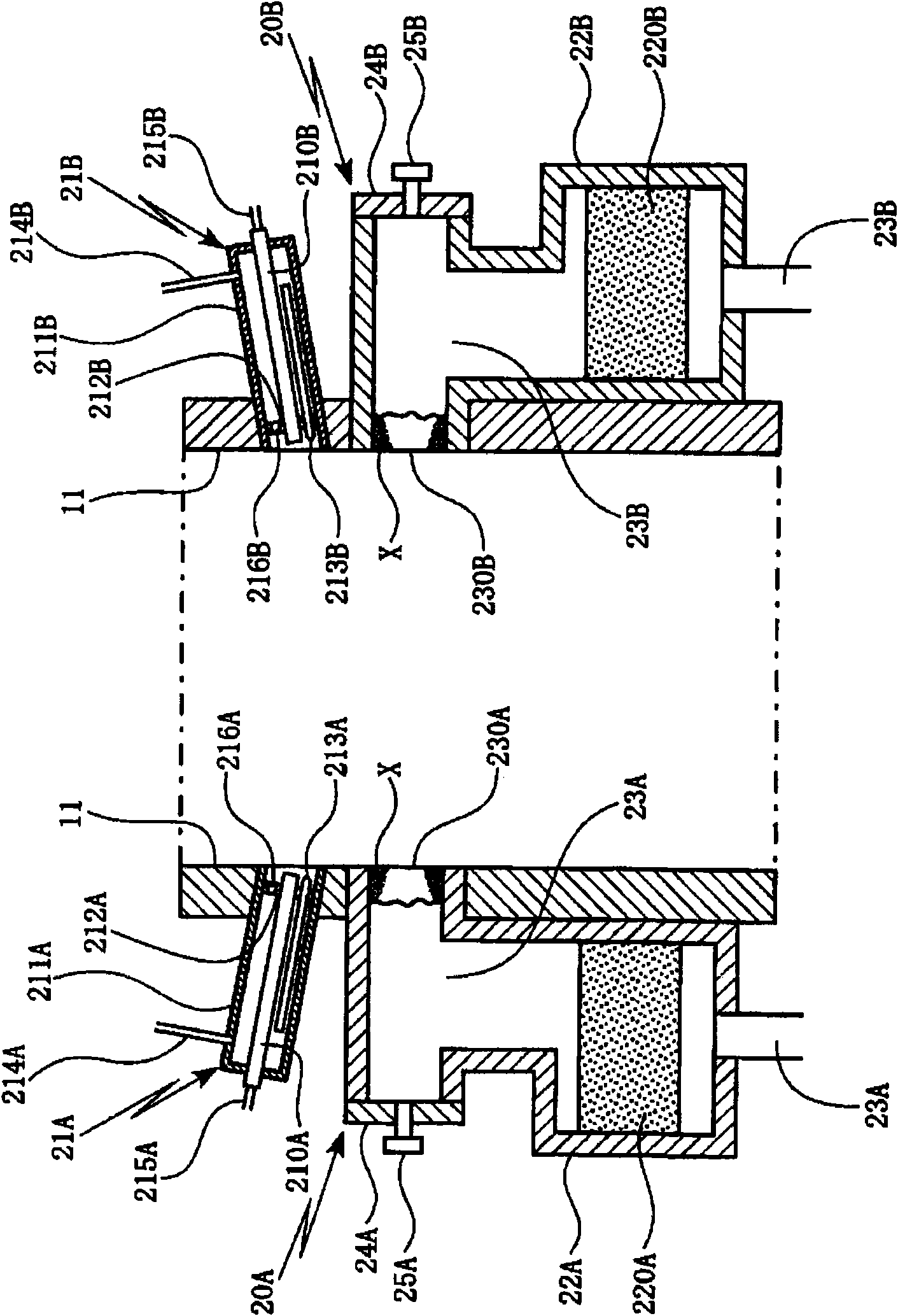

Method of producing seam-welded pipe having good welded portion characteristics

ActiveCN101300103AExcellent weld propertiesNo loss of productivityHigh frequency current welding apparatusTubular articlesElectrical resistance and conductanceEngineering

The invention provides a method of efficiently manufacturing electric resistance welding pipes having excellent characterization of welded seams, by which each lateral edge of a rounded strip immediately before electric resistance welding is securely shaped with desired tapering flexibly in response to change in strip thickness, so that welding quality may be kept to be excellent. A method of manufacturing electric resistance welding pipes, in which a strip material (20) is subjected to forming, then edges thereof are formed to substantially face each other, and then the edges are subjected to electric resistance welding to form a pipe (30), wherein an edge and an edge opposed thereto at one of an upper-surface side and a lower-surface side of the strip are shaped with tapering before theforming by means of cutting or shaving (3), or fin-pass (4) forming.

Owner:JFE STEEL CORP

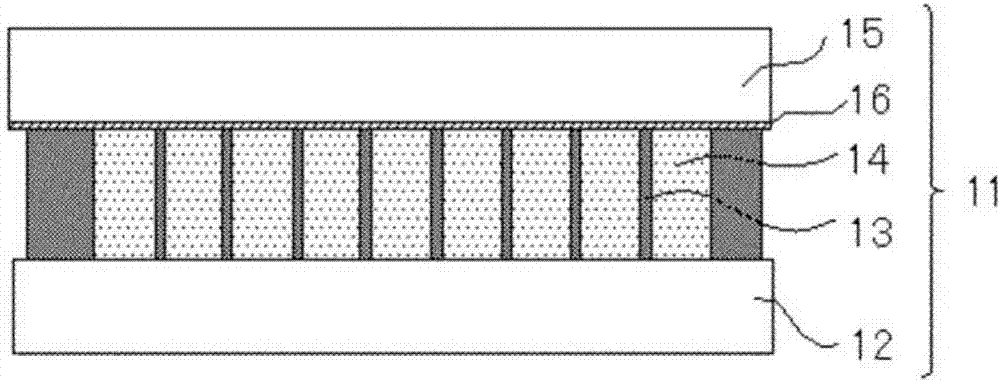

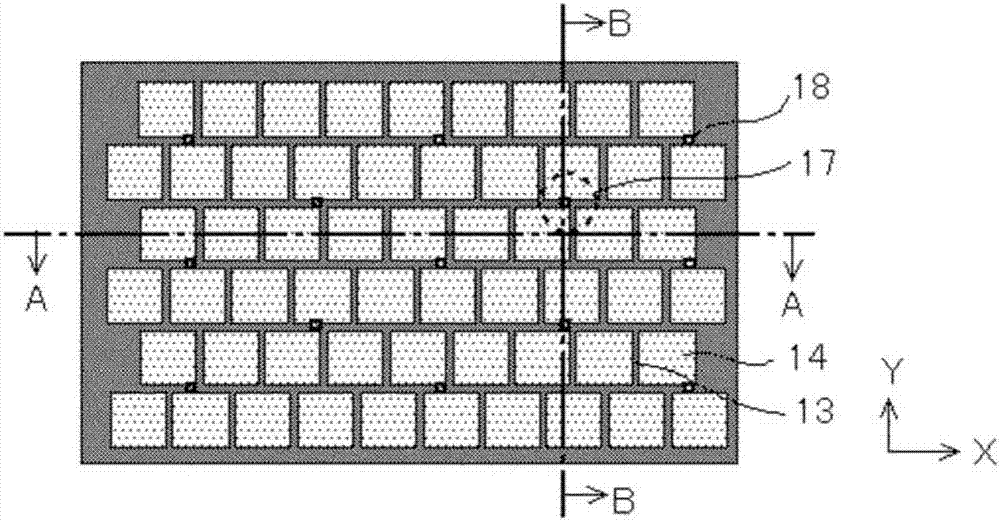

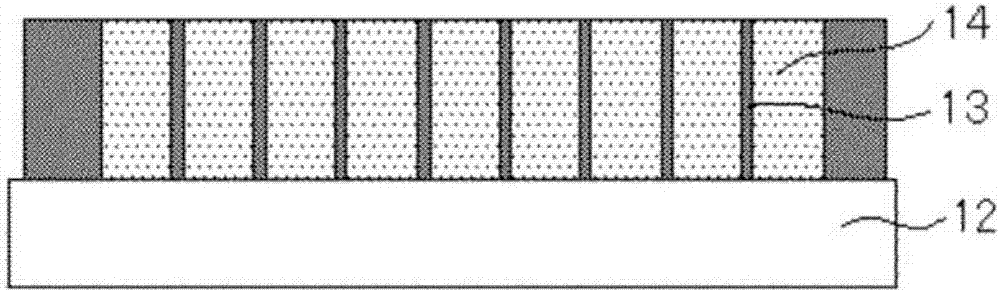

Light beam direction controlling element and display device

InactiveCN107209290AGood adhesionImprove reliabilityMountingsNon-linear opticsProduction rateDisplay device

Provided are a light beam direction controlling element and a display device configured such that warpage due to the thermal contraction of a light absorbing material is minimized, and such that adhesion between transparent substrates is enhanced, thereby improving reliability without decreasing productivity. The light beam direction controlling element comprises light transmission regions composed of a light transmission material arrayed on a substrate, and light absorbing regions composed of a light absorbing material filled in the gaps between the light transmission regions, the light absorbing regions restricting the direction of the light beam passing through the substrate. The light absorbing regions extend on the substrate surface in a first direction and a second direction orthogonal to each other. The light absorbing regions extending in the first direction and the light absorbing regions extending in the second direction intersect each other to have an L-shaped or a T-shaped intersected portion, while having at least one structure that divides the light absorbing regions in the regions extending in the first direction or in the second direction excluding the intersected portion.

Owner:TIANMA MICRO ELECTRONICS CO LTD

HIGH-Mn STEEL AND PRODUCTION METHOD THEREFOR

PendingCN110573642AImprove low temperature toughnessImprove ductilityFurnace typesHeat treatment furnacesNon-metallic inclusionsUltimate tensile strength

The present invention proposes a method for imparting better ductility to high-Mn steel that has superior cryogenic toughness in both a welding heat-affected part and a matrix after being welded. Thishigh-Mn steel has a component composition comprising, in mass%, 0.30-0.90% of C, 0.05-1.0% of Si, 15-30% of Mn, not more than 0.030% of P, not more than 0.0070% of S, 0.01-0.07% of Al, 0.5-7.0% of Cr, 0.0050-0.0500% of N, not more than 0.0050% of O, the respective contained amounts of Ti and Nb being at suppressed levels of less than 0.005%, with the remaining portion being Fe and unavoidable impurities, wherein the high-Mn steel has a microstructure including austenite as a matrix phase, the area fraction of non-metal inclusion in the microstructure is less than 5.0%, and the high-Mn steel has a yield strength of at least 400 MPa and an absorption energy (vE-196) of at least 100 J.

Owner:JFE STEEL CORP

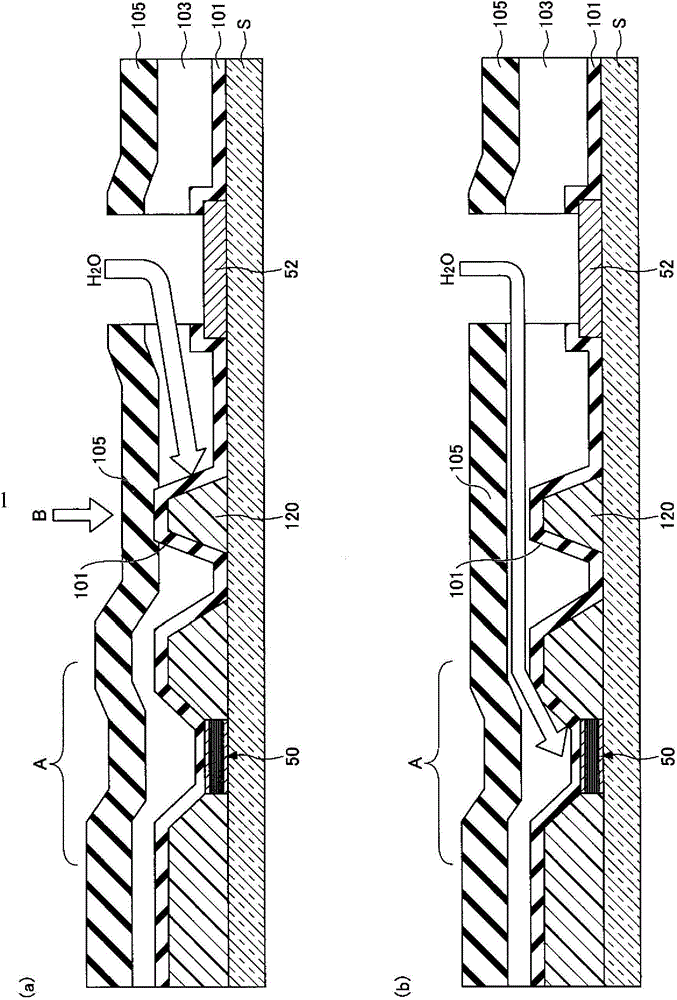

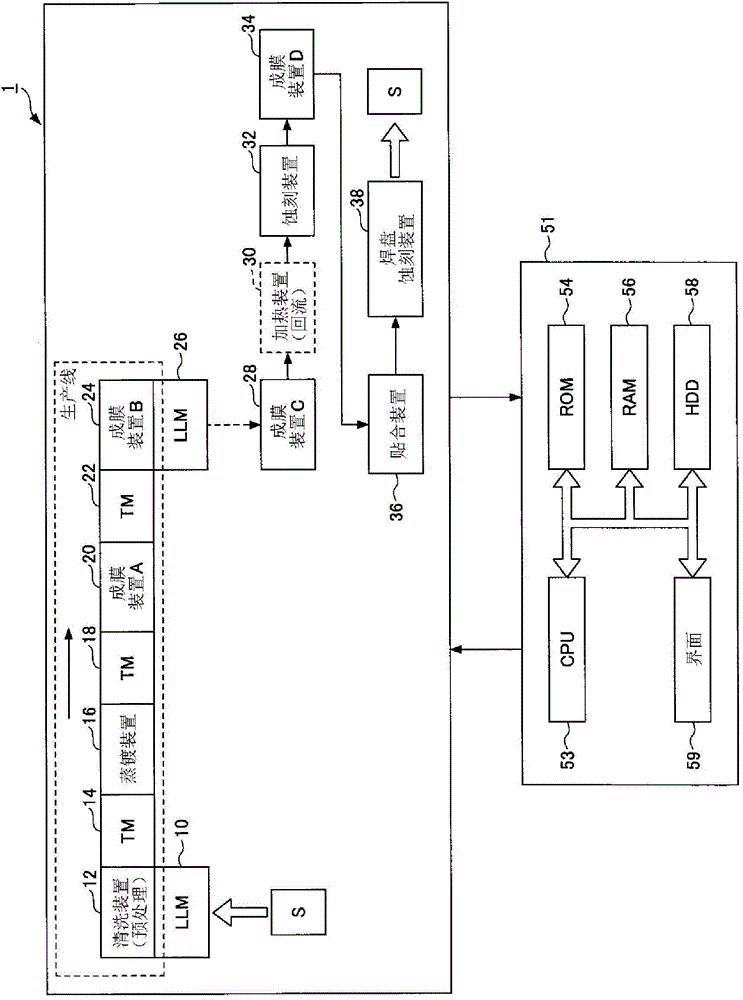

Manufacturing method and manufacturing apparatus of organic device and organic device

ActiveCN104051673AImprove sealingLow costElectroluminescent light sourcesSolid-state devicesInter layerManufactured apparatus

The invention provides a manufacturing method and a manufacturing apparatus of an organic device and the organic device capable of inhibiting water from immersing into an organic EL element. The method comprises an input step and an etch-back step. In the input step, a substrate with an intermediate layer formed above a first sealing layer is inputted, and the first sealing layer is used for sealing an organic layer on an anode of one or multiple separating wall portions. In the etch-back step, the intermediate layer formed in the substrate is etched back until at least one part of the first sealing layer of at least one of the one or multiple separating wall portions is exposed from the intermediate layer and can contact with a second sealing layer formed in the next step.

Owner:TOKYO ELECTRON LTD

Sensor chip and production method therefor

InactiveCN101006337ANo warpingSatisfied with the appearanceMaterial analysis by electric/magnetic meansElectrical and Electronics engineeringHumidity

A sensor chip is provided. The sensor chip is provided with the board, the cover layer, the spacer layer sandwiched between the board and the cover layer, the hollow reacting part between the board and the cover layer, and a detecting means in the hollow reacting part. The board and the cover layer are made of the same material and have the same thickness. The material and the shape of the spacer layer are symmetric to a flat plane which is parallel to the board at equal distances from the board and the cover layer. The sensor chip does not warp due to changes of temperature and humidity in the environment. A method for manufacturing such sensor chip is also provided.

Owner:SUMITOMO ELECTRIC IND LTD +1

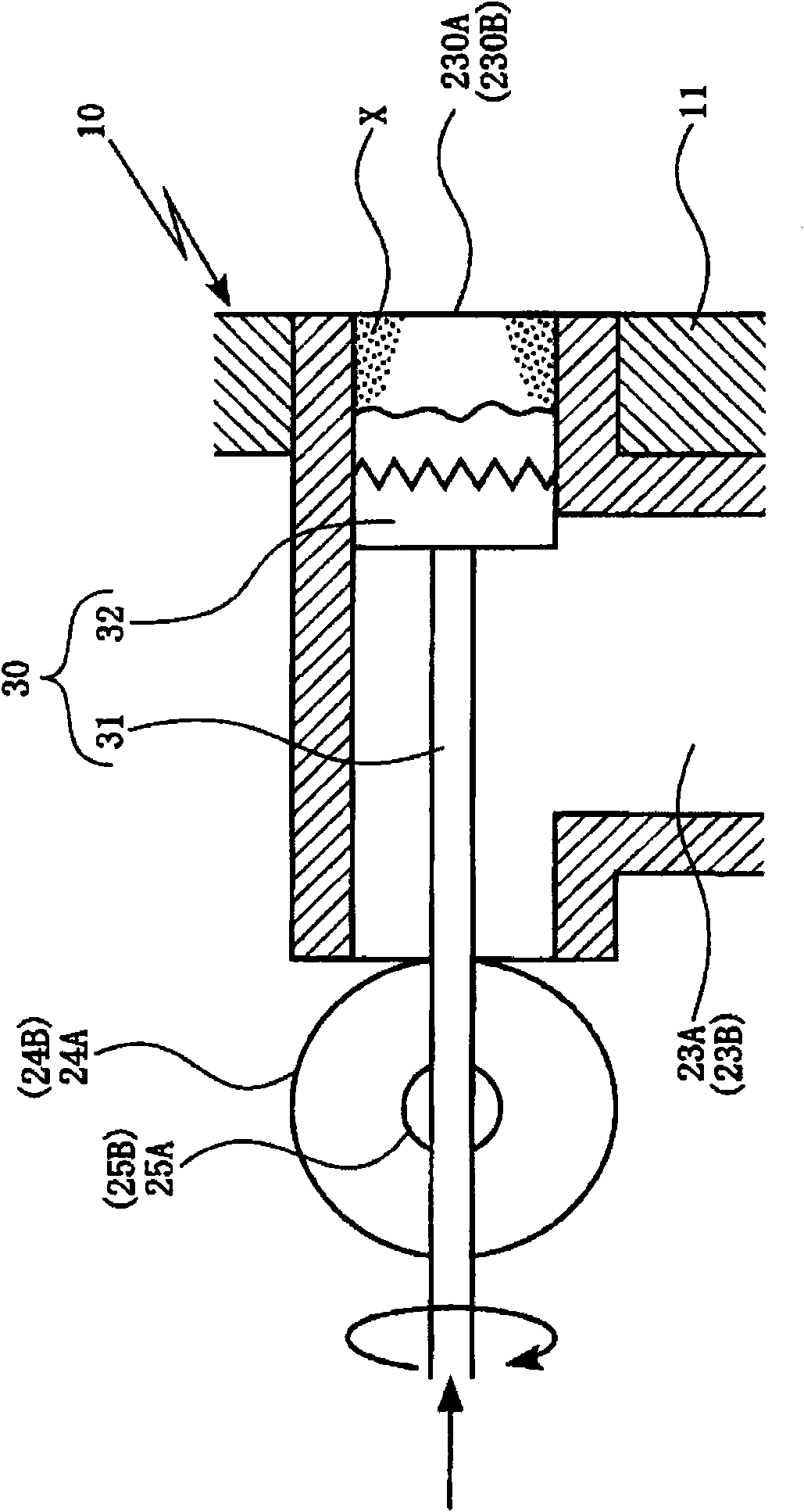

Regenerative burner and heat treating furnace

ActiveCN101986033AEfficient cleaningNo loss of productivityFurnace componentsIndirect carbon-dioxide mitigationNozzleHeat treated

A heat treating furnace employing a regenerative burner, wherein the regenerative burner includes: a burning part configured to eject fuel from a fuel ejecting nozzle to burn; a regenerative chamber configured to accept regenerative material; and an exhaust path configured to discharge from the regenerative chamber to the heat treating furnace through an exhaust outlet, in the heat treating furnace, attachment attached to the exhaust outlet can be removed simply. In the regenerative burner (20) having the burning part (21), the regenerative chamber (22) and the exhaust path (23), a door (24) for maintenance is arranged on the exhaust path between the exhaust outlet and the regenerative chamber, the door for maintenance is opened and the attachment (X) attached to the exhaust outlet is cleaned by a cleaning component (30), wherein the burning part (21) is configured to make the fuel to be ejected from the fuel ejecting nozzle (210) to burn, the regenerative chamber (22) accepts regenerative material (220), and the exhaust path (23) discharges from the regenerative chamber to the heat treating furnace (10) through the exhaust outlet (230).

Owner:CHUGAI RO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com