Ferritic stainless steel sheet for water heater excellent in corrosion resistance at welded part and steel sheet toughness

A stainless steel plate and water heater technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as material corrosion, and achieve the effects of improved corrosion resistance, improved corrosion resistance, and excellent toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Hereinafter, the present invention will be described in more detail based on examples.

[0085] The steel (steel numbers 1 to 17 are examples of the present invention, 18 to 22, A and B are comparative examples, and 23 and 24 are steels composed of components shown in Table 1 are smelted with a 50 kg small scale vacuum melting furnace). Existing example). After heating these steel ingots to 1050-1250°C, they are hot-rolled at a finishing temperature of 750-950°C and a coiling temperature of 650-850°C. rolling plate.

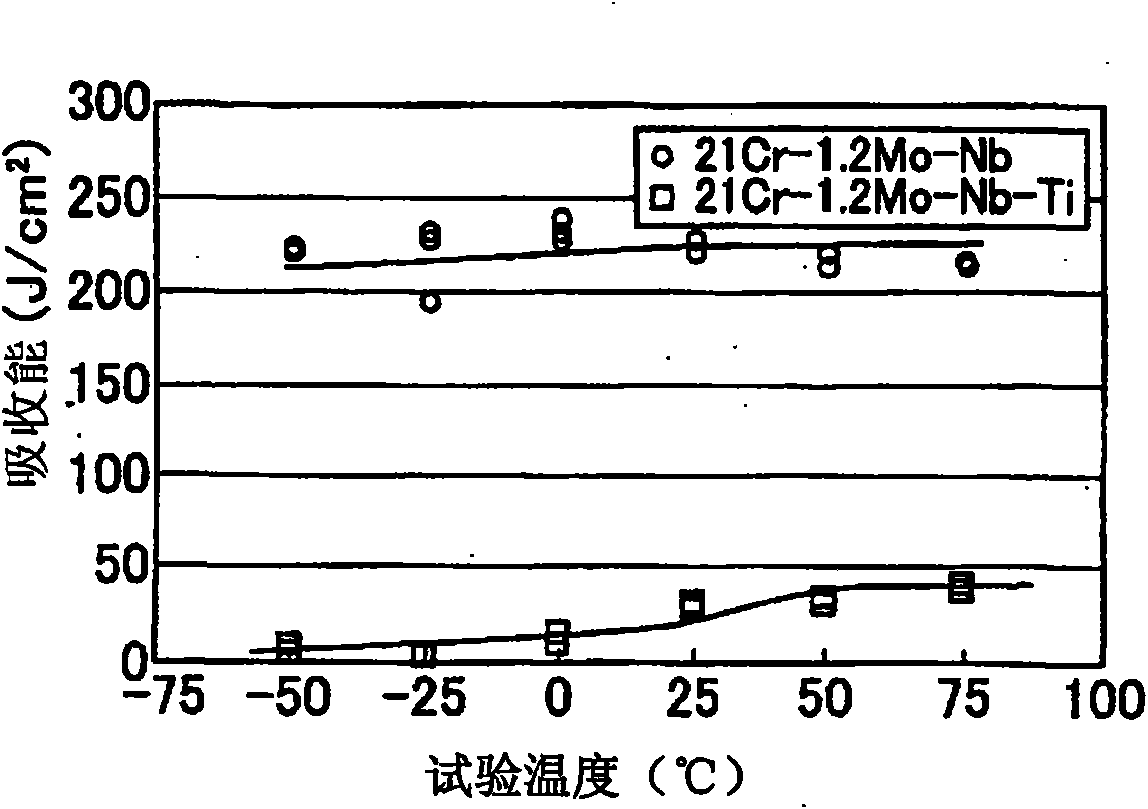

[0086] First, the toughness of the obtained hot-rolled sheet was investigated at this time. In the study, the shape of the test piece was No. 4 of JIS Z2202, and the V-notch was processed so that the direction of the V-notch was perpendicular to the rolling direction (C direction), and the pendulum impact was performed. test. The toughness was evaluated by observing the fracture (fracture cross section) with a microscope (microscope) and SEM (scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com