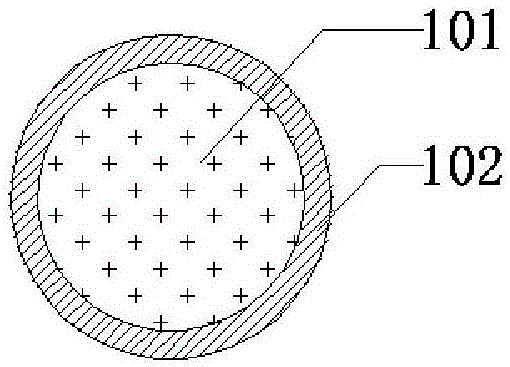

Edge-self-sealing quantum dot film

A quantum dot film and self-sealing technology, which can be used in electronic equipment, applications, coatings, etc., can solve the problems of increasing the coating edge banding process, poor size adaptability, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of liquid microcapsules

[0030] Add 10 parts by mass of polyester polyol and 2.5 parts by mass of emulsifier into 100 parts by mass of water, and emulsify with an emulsifier for 10 minutes to form an emulsion. The emulsion was transferred into a reaction kettle, heated to 60° C. with stirring by a stirrer, and then 0.02 parts by mass of initiator and 8 parts by mass of polyacrylate monomer were added dropwise at the same time. After reacting for 3 hours, the emulsion was transferred into a container, centrifuged with a centrifuge, and the precipitate was washed with ethanol to obtain polyester polyol liquid microcapsules with a particle size of 1 μm.

[0031] 5 parts by mass of isocyanate and 1.4 parts by mass of emulsifier were added to 100 parts by mass of water, and emulsified by an emulsifier for 11 minutes to form an emulsion. The emulsion was transferred into a reaction kettle, heated to 50° C. under stirring by a stirrer, and then 0.01 parts by m...

Embodiment 2

[0040] 1. Preparation of liquid microcapsules

[0041]8 parts by mass of epoxy resin and 7 parts by mass of ethylene-vinyl acetate copolymer were dissolved in 110 parts by mass of toluene as oil phase; 3 parts by mass of emulsifier were dissolved in 200 parts by mass of water as water phase. Add the oil phase dropwise to the water phase under stirring to make it into an emulsion, then heat to 60°C and continue to stir for 8h, so that the toluene is slowly volatilized. Phase separation occurs due to different phases, and the ethylene-vinyl acetate copolymer migrates to the interface between the oil phase and the water phase to become the wall of the microcapsules. After the toluene volatilized, the emulsion was transferred into a container, centrifuged with a centrifuge, and the precipitate was washed with ethanol to obtain epoxy resin liquid microcapsules with a particle size of 8 μm.

[0042] 9 parts by mass of polythiol and 9 parts by mass of ethylene-vinyl acetate copolyme...

Embodiment 3

[0051] 1. Preparation of liquid microcapsules

[0052] Add 11 parts by mass of photocurable resin, 6 parts by mass of isocyanate, and 4 parts by mass of emulsifier into 120 parts by mass of water, and emulsify with an emulsifier for 20 minutes to form an emulsion. Transfer the emulsion into a reaction kettle, slowly add 0.02 parts by mass of catalyst triethylenetetramine and 9 parts by mass of polyethylene glycol under stirring by a stirrer, stir for 8 minutes and then heat to 70°C. After reacting for 1 hour, the emulsion was transferred into a container, centrifuged with a centrifuge, and the precipitate was washed with ethanol to obtain photocurable resin liquid microcapsules with a particle size of 3 μm.

[0053] 2. Preparation of edge self-sealing quantum dot film

[0054] 6 parts by mass of photocurable resin liquid microcapsules, 1.1 parts by mass of green quantum dots, 0.1 parts by mass of red quantum dots, 50 parts by mass of silicone resin, 0.06 parts by mass of cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com