Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13636 results about "Anti ageing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin Firming Anti-Aging Cosmetic Mask Compositions

InactiveUS20040161435A1Promote excess fat reductionPromote cellulite controlBiocideCosmetic preparationsAdditive ingredientPhase mask

I have discovered cosmetic mask compositions suitable for face, neck, chin or body applications. These compositions synergistically combine at least one skin beneficial cosmetic or drug composition with at least one composition to promote excess fat reduction, cellulite control, or muscle toning benefits. The mask composition also contains at least one binder composition that binds with other beneficial ingredients by electrostatic, atomic, or ionic charges to synergistically enhance their topical site-specific benefits. These mask compositions are suitable for a variety of delivery system methods that include peel-off mask, leave-in mask, moisturizing mask, exfoliating mask, prosthetic mask, soaking mask, depilatory mask, foaming mask, rinse-off mask, sloughing mask, rub-off mask, two-phase mask, dual-chamber mask, and self-heating (heat releasing) mask.

Owner:GUPTA SHYAM K

Methods and topical formulations comprising colloidal metal for treating or preventing skin conditions

In preferred embodiments, the present invention relates to compositions comprising colloidal metals and / or metals for the treatment and prevention of skin conditions and / or diseases. More specifically, the disclosed metal containing compositions are useful as antioxidants, anti-aging agents, anti-wrinkle agents, anti-peroxidation agents, antimicrobial agents, anti-inflammatory agents, pain-relieving agents, wound recovery agents, sun-screens, sunblocks, and integument and skin-supporting agents when applied to the skin / integument, or administered generally to an animal or human body.

Owner:MARGULIES JOEL +1

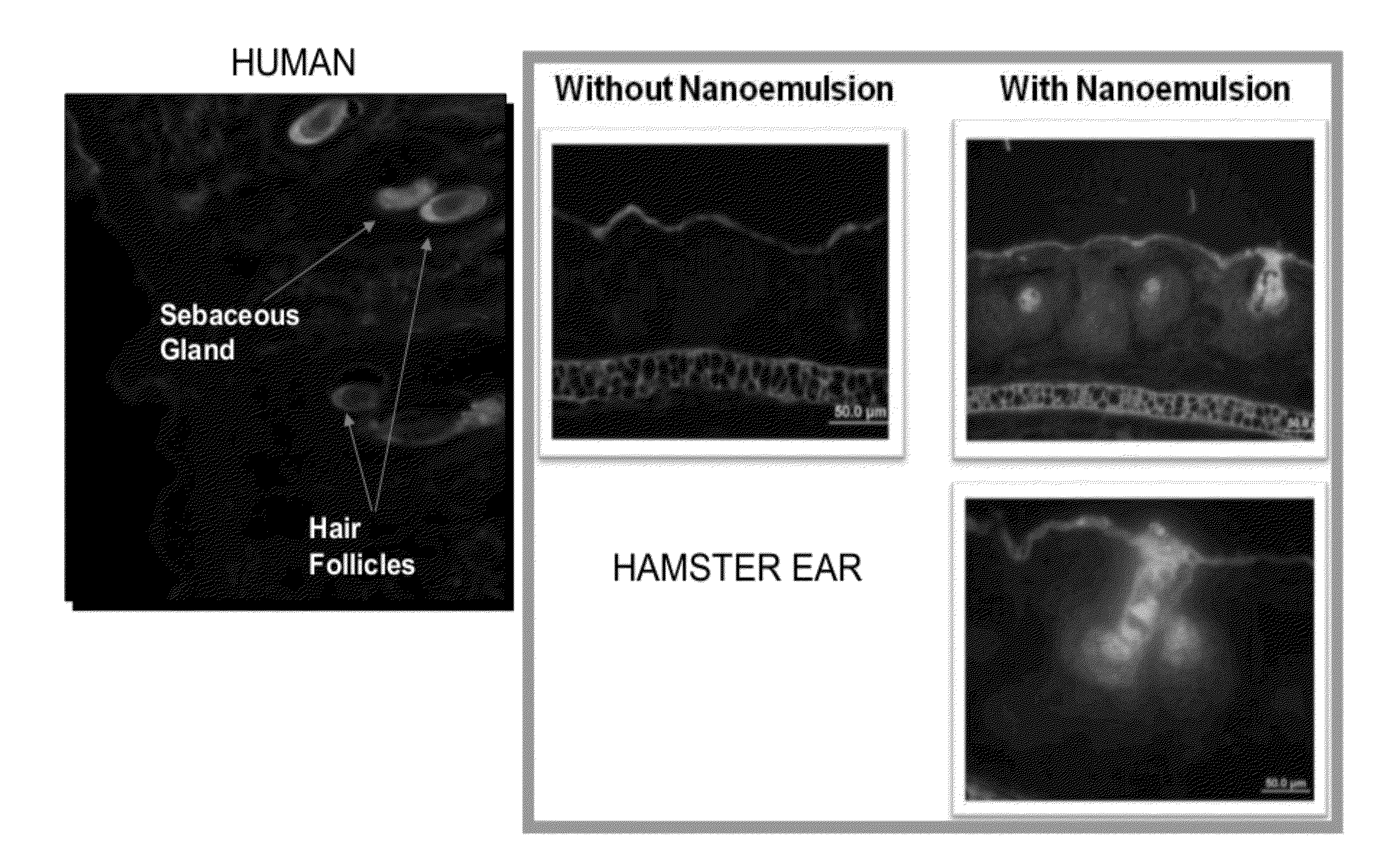

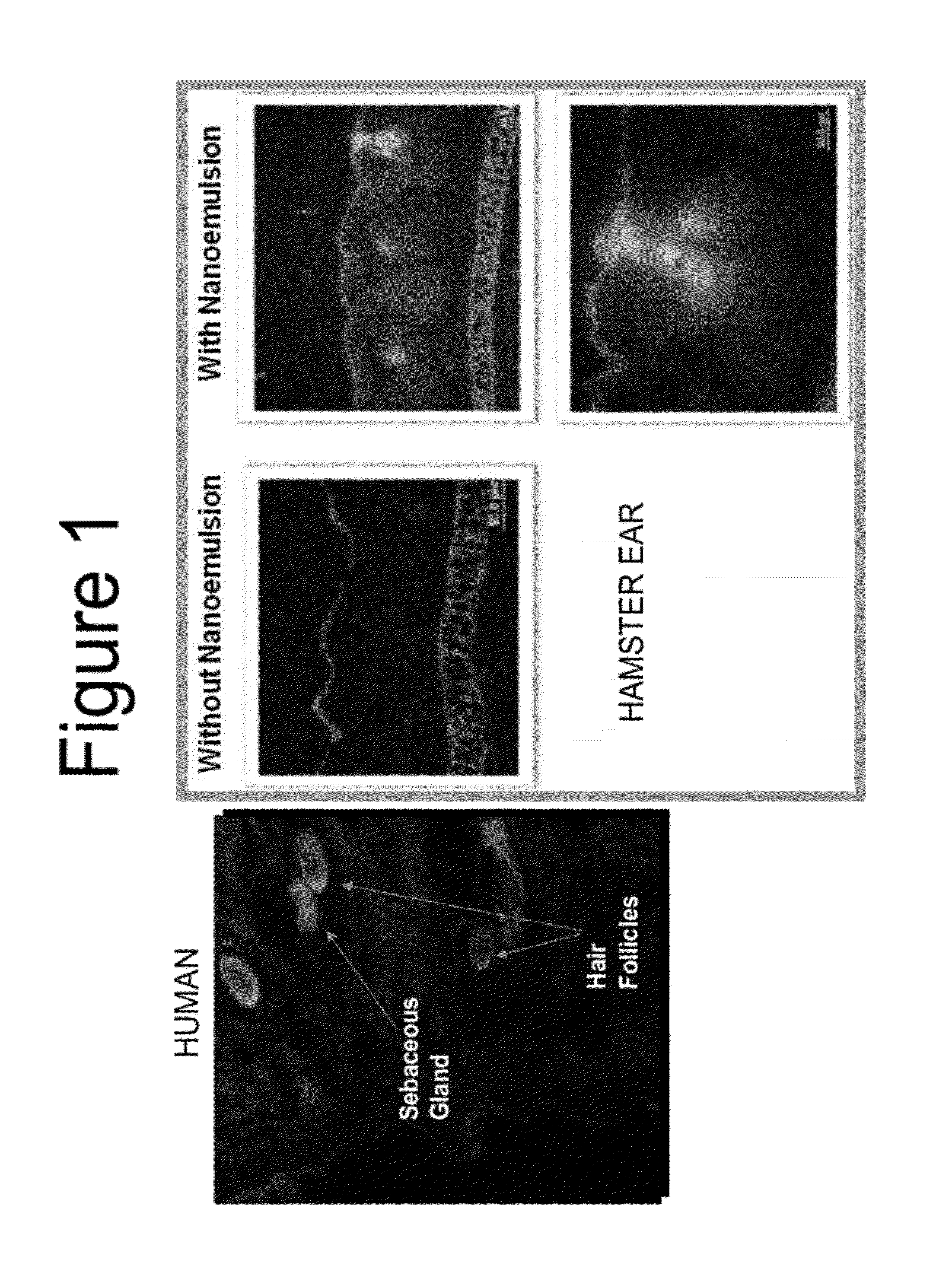

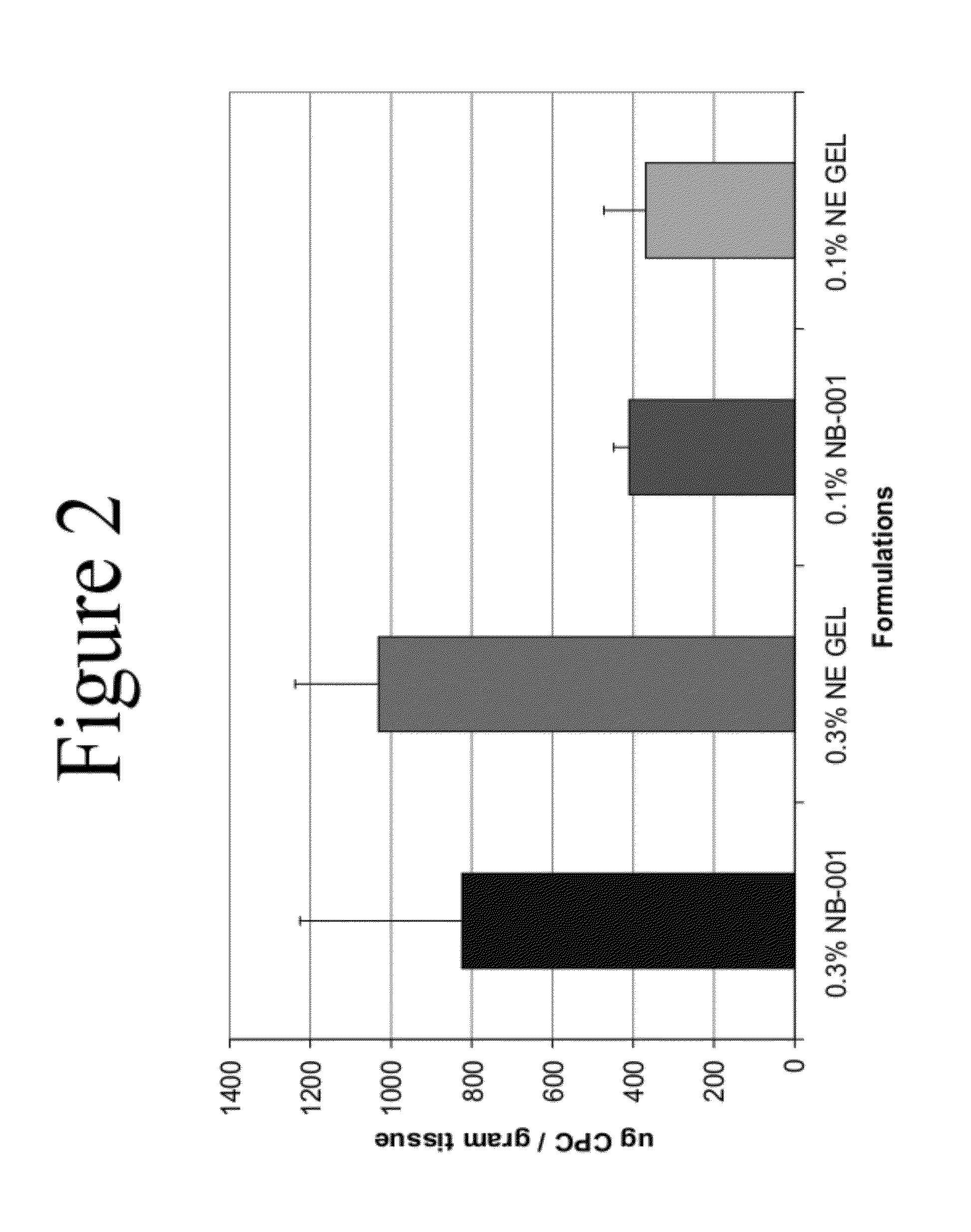

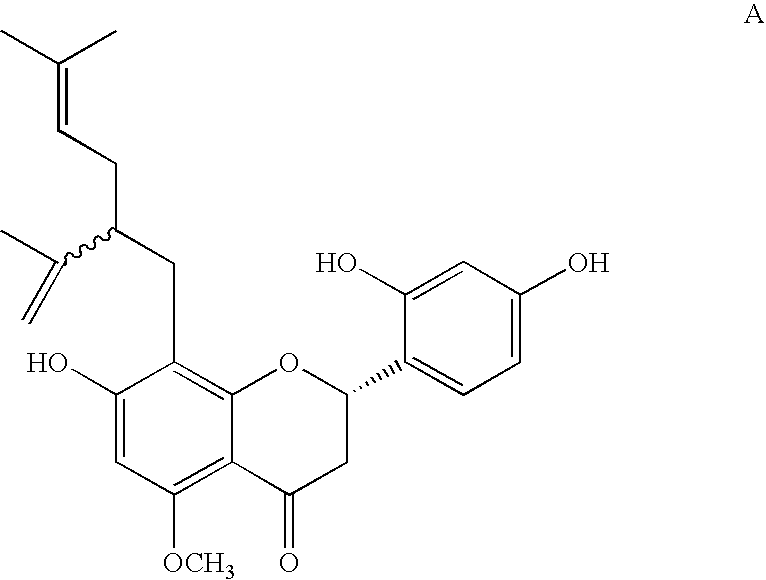

Anti-aging and wrinkle treatment methods using nanoemulsion compositions

InactiveUS20120064136A1Effective treatmentEffective preventionBiocideCosmetic preparationsWrinkle skinMedicine

The present invention relates to methods for treating, preventing, minimizing, and / or diminishing signs of aging in the skin comprising administering to the subject in need thereof a nanoemulsion composition.

Owner:NANOBIO CORP

Oral Compositions Containing Botanical Extracts

The disclosure provides oral compositions having at least two botanical active ingredients derived from plants. The oral composition also includes an orally acceptable vehicle to deliver an effective amount of the at least two active ingredients in vivo. The botanical active ingredients provide particularly efficacious antimicrobial (antibacterial, antiviral, and / or antifungal), antioxidant, anti-inflammatory, anti-ageing, and or healing properties to the oral compositions.

Owner:COLGATE PALMOLIVE CO

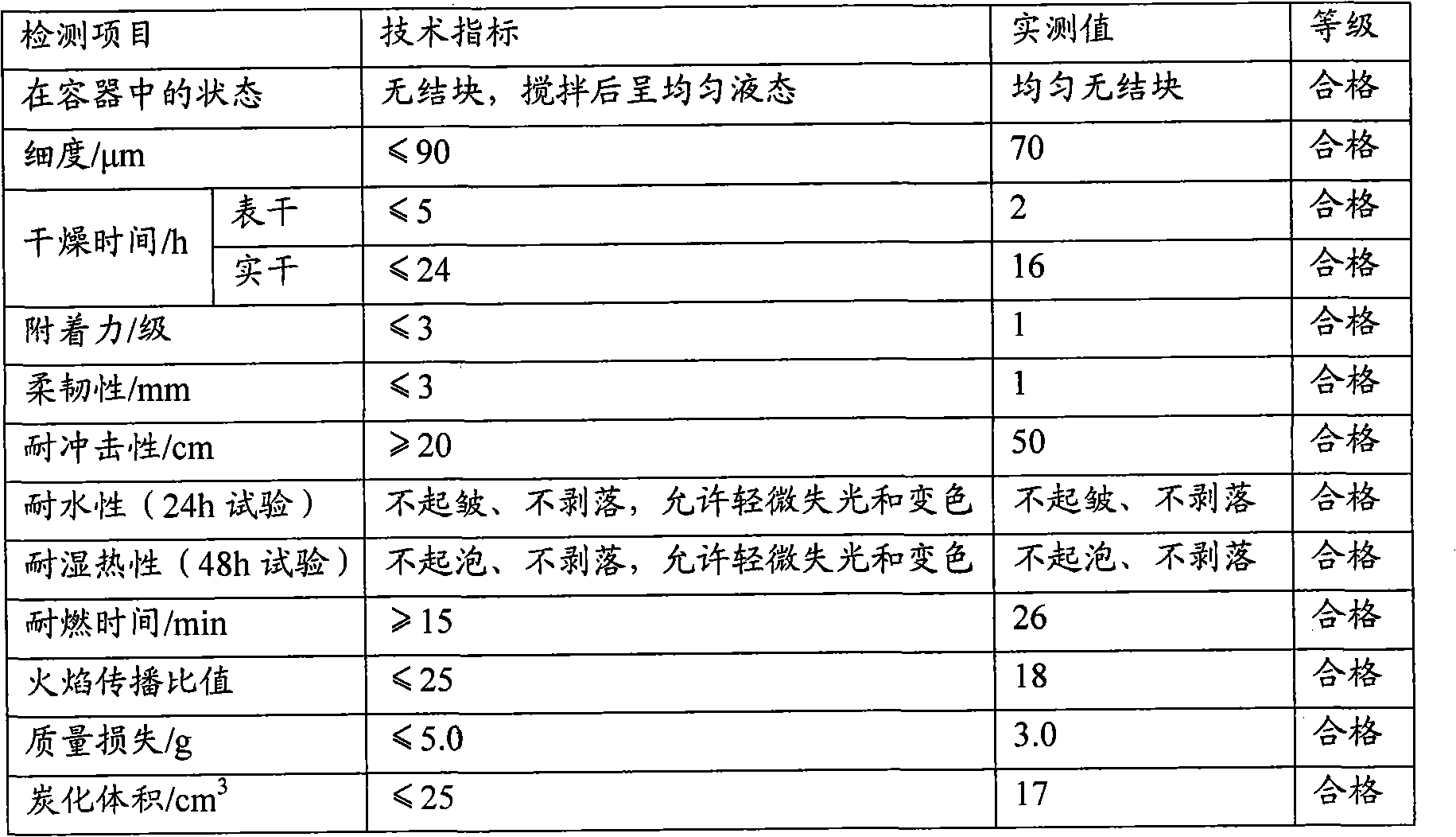

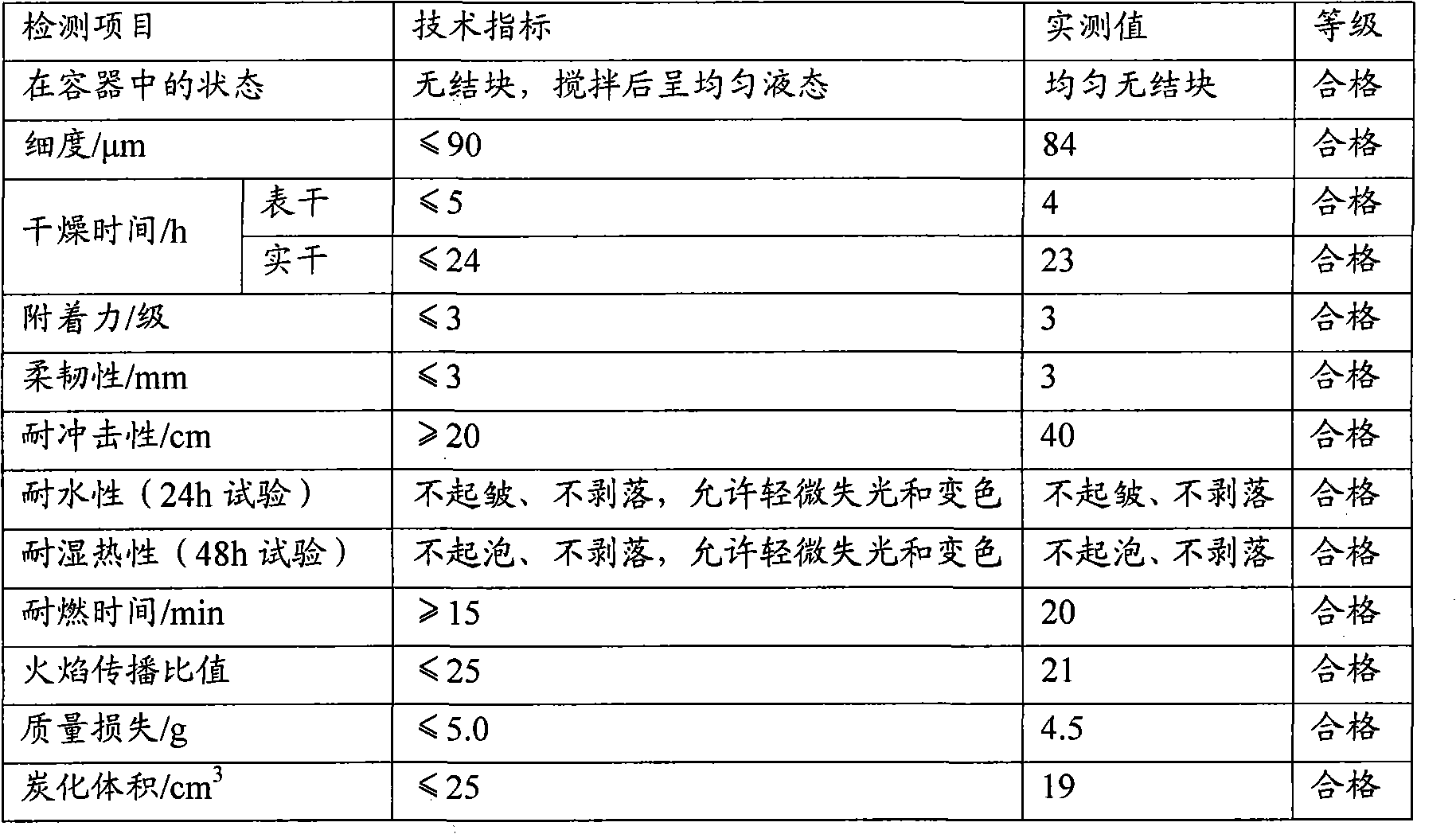

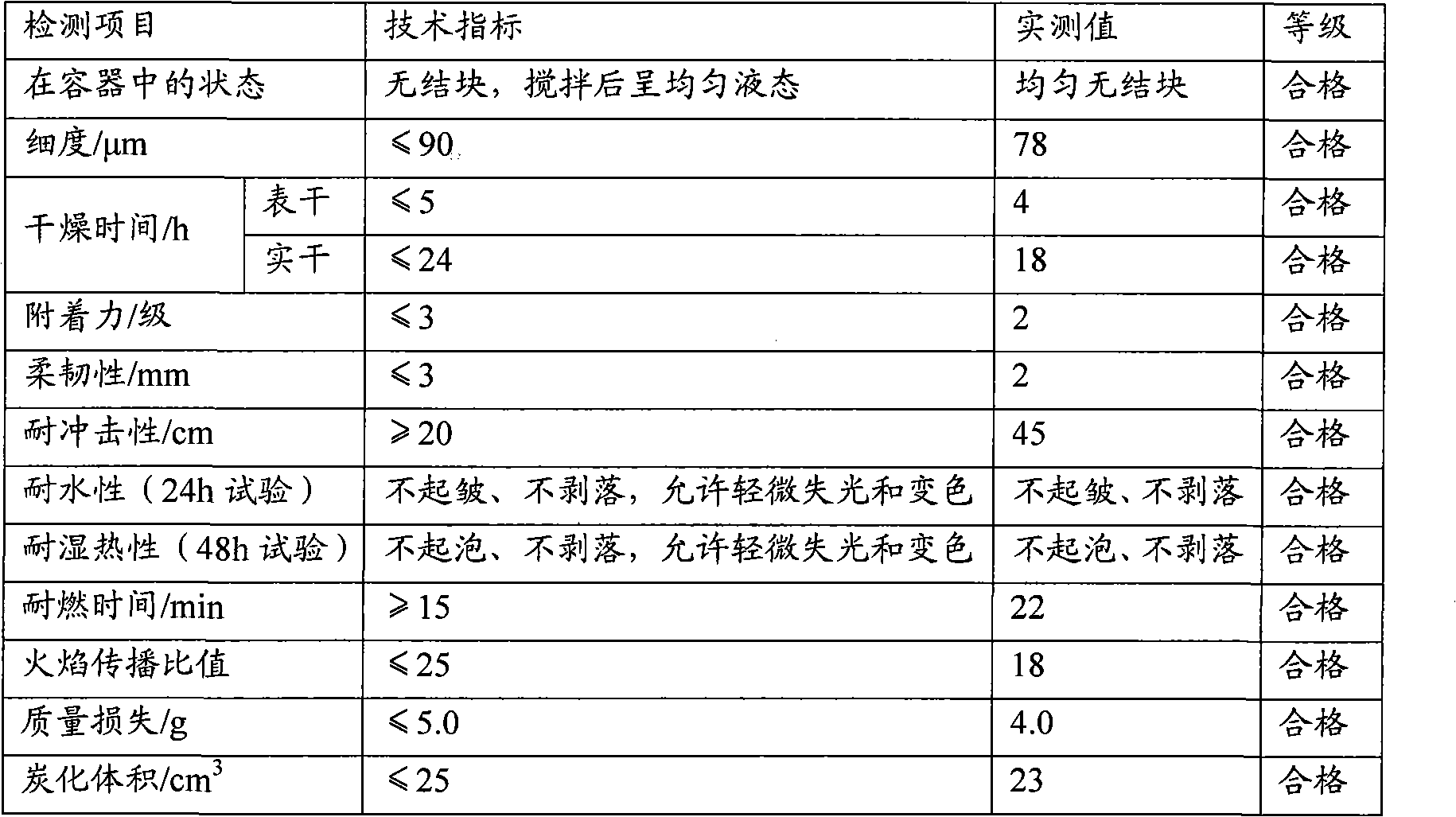

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

Topical anti-wrinkle and anti-aging moisturizing cream

InactiveUS20100098794A1Restoring skinRestoring to stateOrganic active ingredientsBiocideWater basedMedicine

The present invention relates to a topical anti-wrinkle and anti-aging moisturizing cream designed (formulated) to repair and restore human adult skin to its original youthful state. This has successfully been achieved by using a water based molecular mixture of high molecular weight (0.5 to 2.0 million Daltons) hyaluronic acid (HA) and of low molecular weight hyaluronic acid oligosaccharides (small HA fragments less than 12000 Daltons molecular weight) to create this unique anti-aging moisturizer. An equal mixture of high molecular HA and HA-oligosaccharides at concentrations of 0.1-0.2% was found to be essential for providing our moisturizer its unique ability to repair and rejuvenate adult human skin.

Owner:ARMAND GERARD

Physically unclonable function with tamper prevention and Anti-aging system

ActiveUS20120179952A1Avoids freezing attackReduce the impactMemory adressing/allocation/relocationInternal/peripheral component protectionComputer hardwarePhysical unclonable function

Owner:INTRINSIC ID

Anti-aging skin care composition and uses thereof

The present invention is directed toward anti-aging skin care compositions comprising Vitamin B1, Vitamin B5, Vitamin C, N-acetyl-cysteine and, optionally, lipoic acid. The present invention is further directed toward methods for therapeutically or prophylactically treating the consequences of aging on the condition or appearance of the skin. The present invention further provides one or more kits that are useful for delaying, treating or preventing the consequences of aging on the condition or appearance of the skin.

Owner:KLYSZ BEATRICE M

Anti-aging composition, kit and method of use

InactiveUS20070237735A1Reducing and preventing age-related skin symptomReducing and preventing symptomBiocideCosmetic preparationsMADECASSIC ACIDAntioxidant

An anti-aging composition comprising: (i) at least one biomimetic oligopeptide having a sequence of 20 amino acids or less; (ii) at least one lipoaminoacid; (iii) at least one pentacyclic triterpenoid selected from the group consisting of asiaticoside, madecassic acid, asiatic acid and madecassoside; (iv) at least one antioxidant; and (v) tetrahydropiperine; a kit comprising such composition and a method of use.

Owner:LABES DERMO COSMETIK

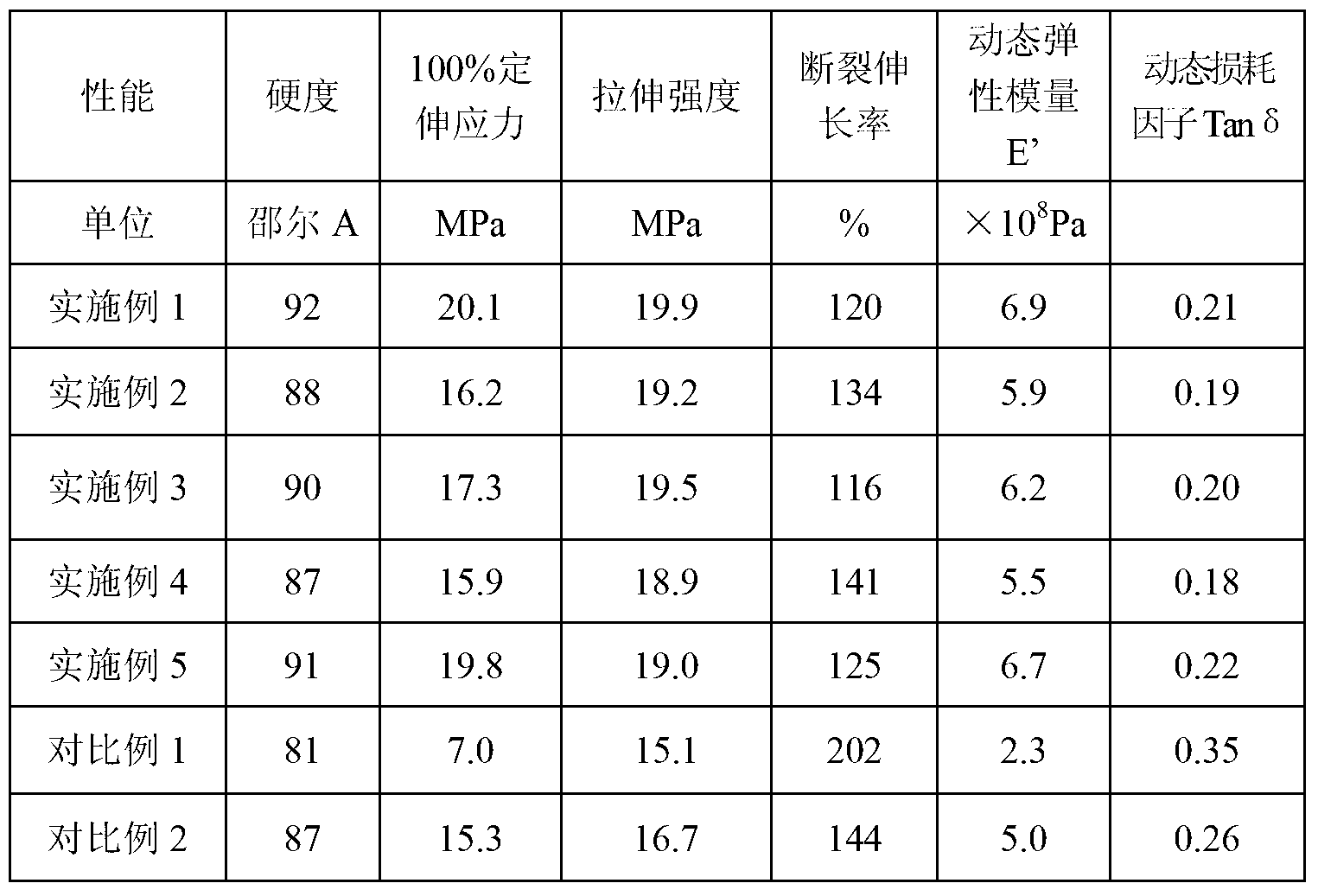

Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

The invention provides an oxidized grapheme / carbon black rubber nanocomposite and preparation method thereof, which belongs to the field of rubber nanocomposite technology. The nanocomposite comprises the following basic compositions by mass: 100 parts of diene series rubber matrix, 0.5-5 parts of oxidized grapheme, 30-70 parts of hard carbon black of average particle size 11-30nm, 1-10 parts of plasticizer, 6-10 parts of activator, 0.5-4 parts of anti-aging agent, 1-4 parts of sulfuration promoter and 1-6 parts of insoluble sulphur; oxidized grapheme modifier. The oxidized grapheme powder is dispersed in deionized water for ultrasound, and a natural rubber emulsion is added, and masterbatch after flocculation, washing and drying is mixed uniformly with other additives, after sulfuration, the product is obtained. The oxidized grapheme / carbon black rubber nanocomposite has the advantages of excellent processing performance and obviously reduced dynamic themogenesis, thereby improving the usage life of tyre.

Owner:BEIJING UNIV OF CHEM TECH

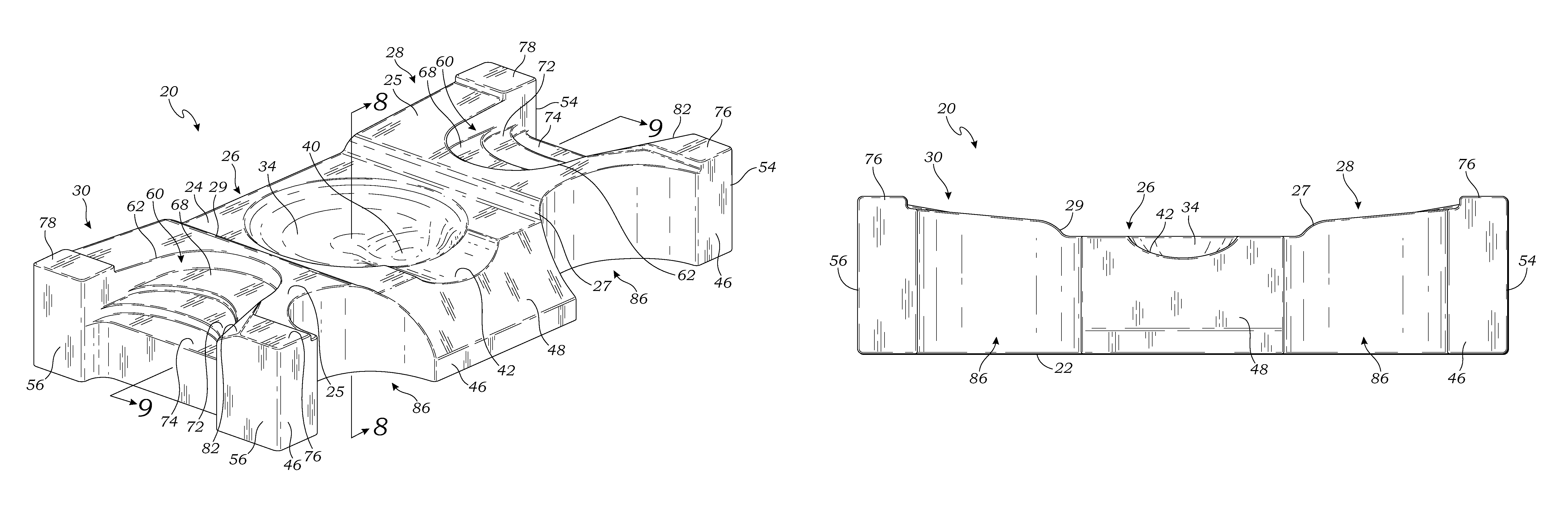

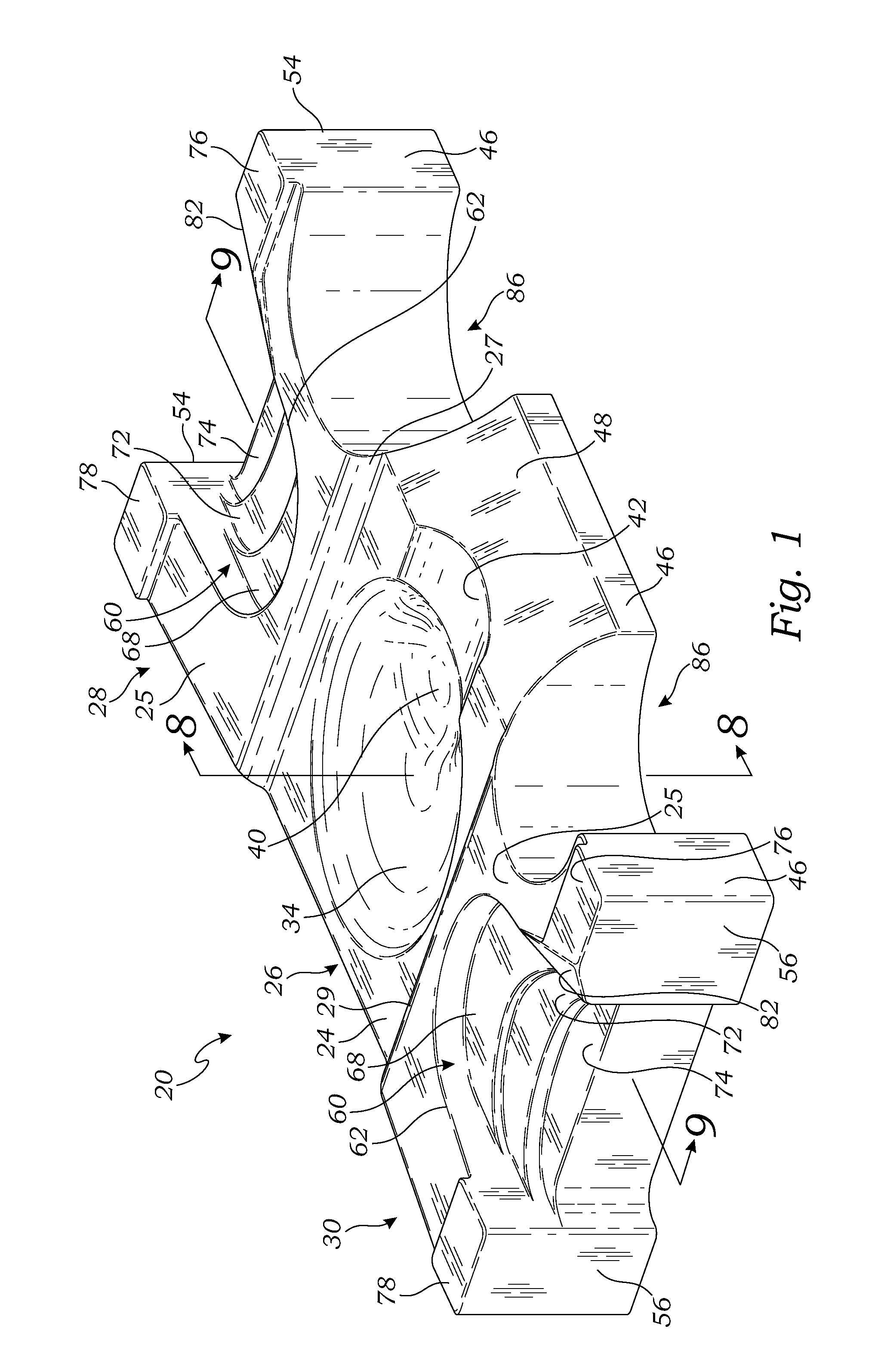

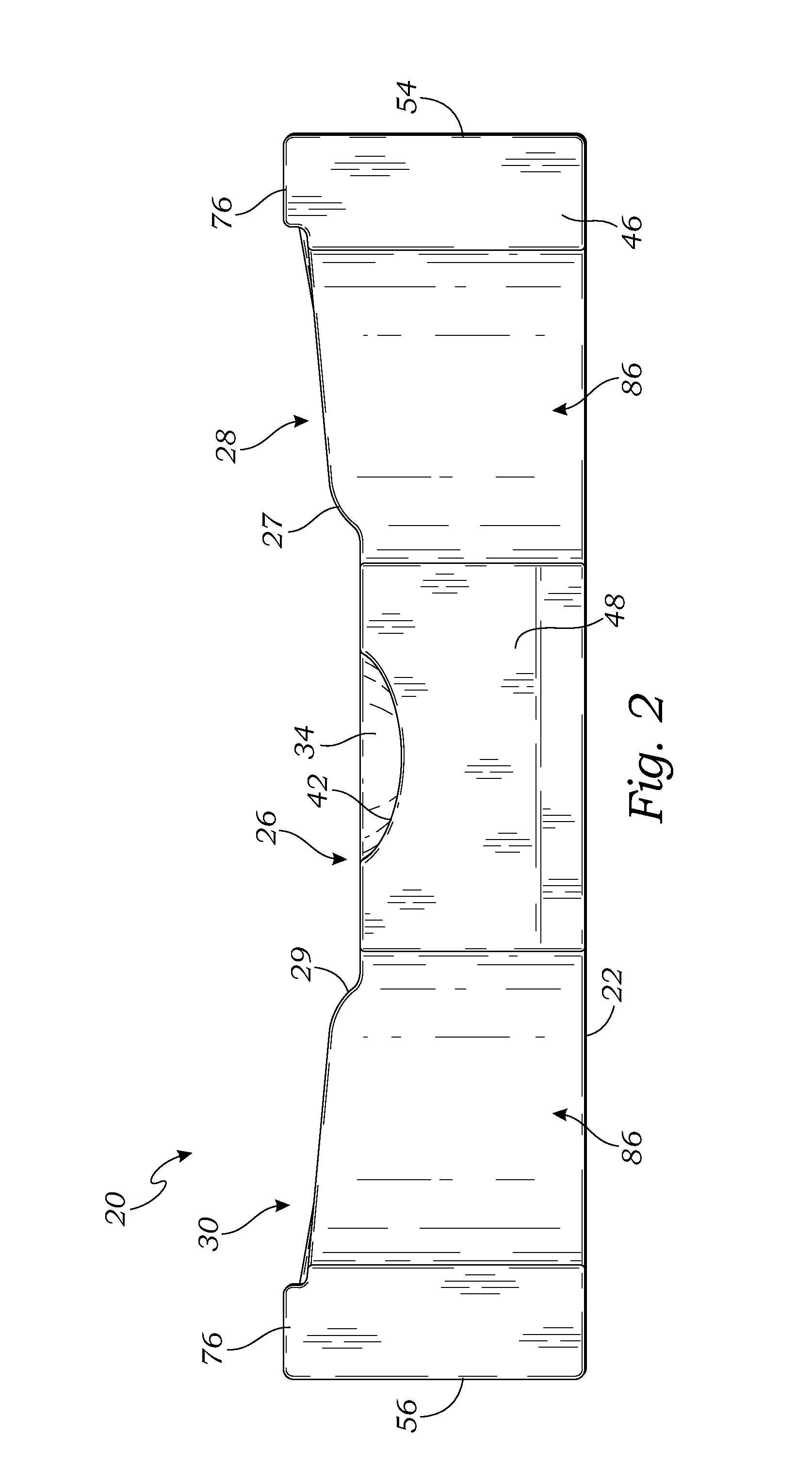

Anti-aging pillow

ActiveUS8161588B1Reducing facial wrinklingPreventing sleep-associated appearancePillowsSofasEngineeringAnti ageing

An anti-aging pillow provides, in the exemplary embodiment, a top surface providing a substantially central supine section flanked by an upwardly sloping left side section and a substantially symmetrical right side section, the left and right side sections elevated relatively higher than the supine section. The supine section is configured for accommodating a user when lying in a supine position, while each of the left and right side sections is configured for accommodating the user when lying in a respective side position. This configuration enables the pillow to both substantially prevent the user from unintentionally changing sleep positions as well as substantially assist in physically directing the user in selectively transitioning between each of the supine position and left and right side positions as desired, while substantially maintaining the user's head, neck, shoulders, and back in neutral alignment and substantially preventing facial contact with the pillow or underlying sleeping surface.

Owner:JUVEREST

Preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes

ActiveCN102134360ADoes not show brittlenessExcellent low temperature toughnessRigid pipesPolymer scienceChlorinated polyvinyl chloride

The invention discloses a preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes, which is characterized in that the tubes are made by the following steps: 75 to 100 portions of chlorinated polyvinyl chloride resin, 0 to 25 portions of vinyl chloride resin, 3 to 10 portions of ABS, 1 to 8 portions of acrylic acid resin, 3 to 8 portions of bismaleimides, 1 to 5 portions of plasticizing accelerator, 1 to 5 portions of compatibilizer, 10 to 25 portions of engineering plastics, 1 to 3 portions of lubricant, 1 to 5 portions of nanometer materials, 4 to 8 portions of stabilizing agent, 2 to 15 portions of filler, 0 to 1 portion of cross-linking agent, 1 to 5 portions of processing modifier and 3 to 10 portions of impact modifier are mixed and blended according to weight proportion, and then extruded by a mould. Compared with the prior art, the super-strong high temperature-resistant chlorinated polyvinyl chloride tubes has the advantages of being high in vicat softening point, being capable of meeting the high-temperature requirement of more than 120 DEG C, and having good anti-aging performance, antiflaming and insulation performance, and compression resistance, and long service life.

Owner:SHANGHAI YUANZHOU PIPE

Self-adhesive waterproof coiled material having high initial stickiness and preparation method thereof

ActiveCN103361025AEfficient productionEfficient production lineNon-macromolecular adhesive additivesBituminous material adhesivesBasementAnti ageing

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

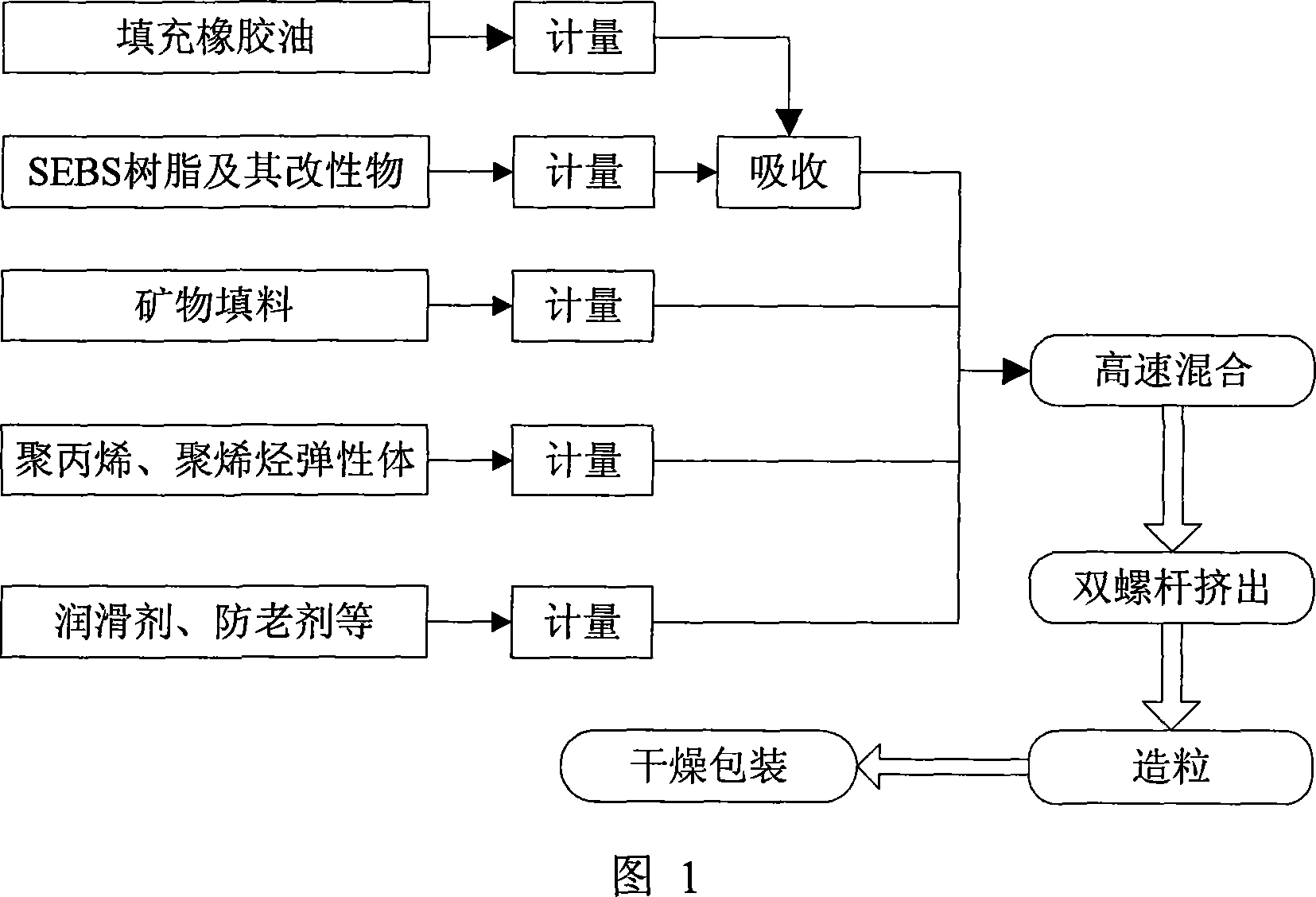

Environmental protection type SEBS thermoplastic elastic body sealing strip material and preparation method thereof

InactiveCN101100593AHigh/low temperature resistantGood mechanical propertiesOther chemical processesElastomerEngineering

An evrionmental-protecting SEBS thermoplastic elastic sealing strip and its production are disclosed. It consists of SEBS resin and modifier 100 proportion, rubber filling oil 75-125 proportion, polypropylene 20-40 proportion, poly-olefine elastomer 10-30 proportion, mineral filler 150-250 proportion, lubricant 0.4-0.8 proportion, and anti-ageing agent 0.45-0.60 proportion. The process is carried out by: weighing, mixing and granulating to obtain final product. It's cheap, simplified, safe, convenient and efficient. It has excellent high / low temperature resistances and anti-ageing performance and can be used to manufacture vehicle, refrigirator and freezer.

Owner:东莞市盛家橡塑科技有限公司

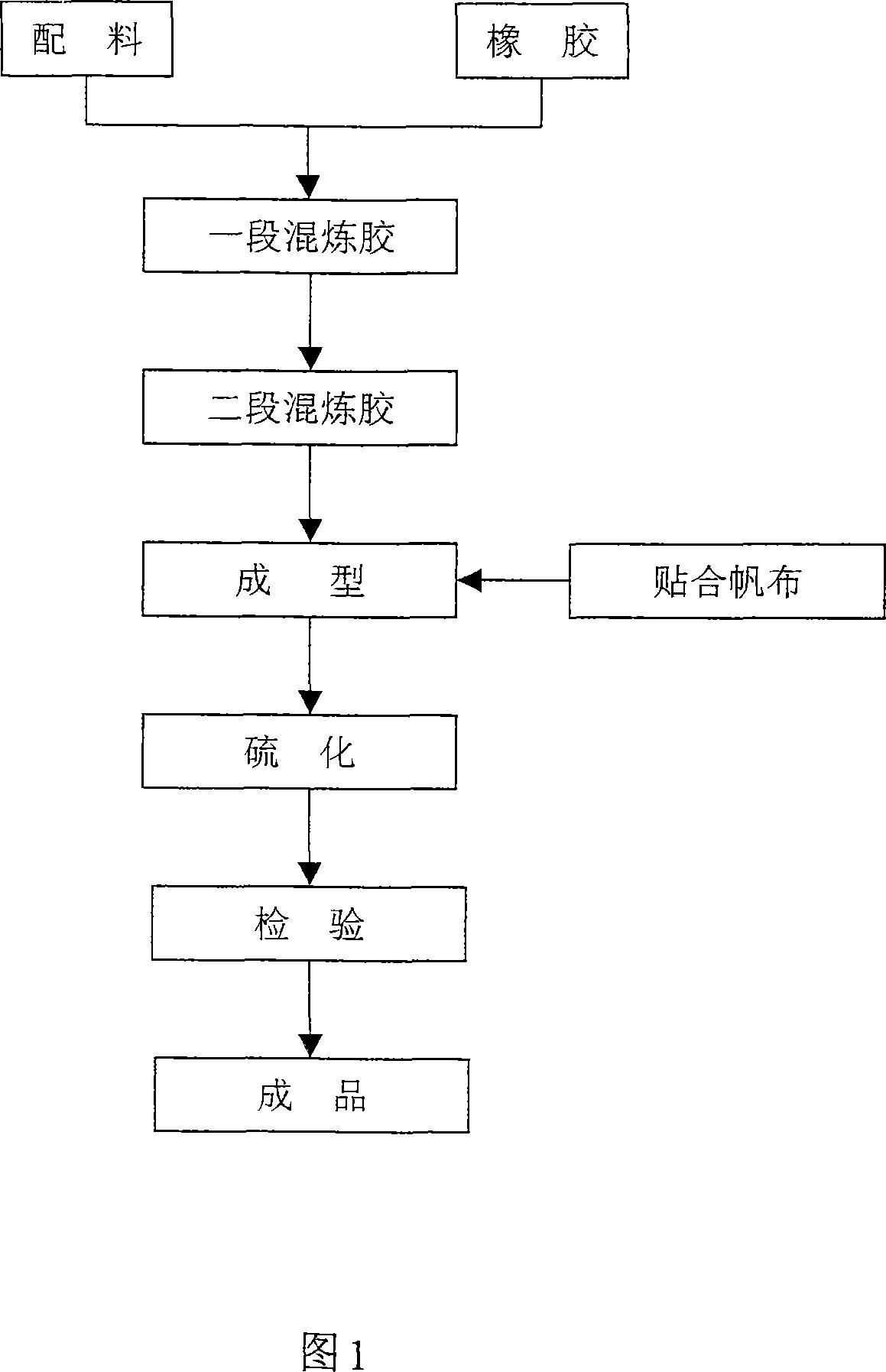

High-heat-conductivity rubber composite material and preparation method thereof

InactiveCN102504358AImprove thermal conductivitySimple preparation processRubber materialVulcanization

The invention discloses a high-heat-conductivity rubber composite material and a preparation method of the high-heat-conductivity rubber composite material. The high-heat-conductivity rubber composite material consists of the following ingredients in parts by mass: 100 of rubber, 4 to 6 of zinc oxide, 1 to 3 of stearic acid, 1 to 2 of anti-aging agents, 40 to 60 of carbon black, 1 to 1.5 of promoters, 1 to 3 of sulphur and 50 to 170 of heat conducting agents. The manufacture method comprises the following process steps that: the rubber is added into an open mill, the zinc oxide, the stearic acid, the anti-aging agents, the promoters, the carbon black and the heat conducting agents are sequentially added after the roll recovering, and finally, the sulphur is added. After rubber materials are uniformly mixed, the thin conduction is carried out, triangle bag packing and rolling are respectively carried out for five times, and the roll distance is regulated to 1.5mm for sheet output. The material sheets are placed into a mold, the vulcanization is carried out on a flat plate vulcanization machine, the vulcanization time is 15 to 20 minutes, the vulcanization temperature is 160 to 165 DEG C, and the vulcanization pressure is 10 to 12MPa. The material disclosed by the invention has an excellent physical and mechanical property and a high heat conduction factor.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Modified, weather resisting polypropylene material

This invention discloses a modified polypropylene material used as elements of home appliances, such as outdoor hulls of air-conditioners and panels of automobiles. The modified polypropylene material comprises: polypropylene resin 65-85 wt.%, toughening modifier 1-18 wt.%, mineral reinforcer 0-25 wt.%, coupler 0.1-0.8 wt.%, processing auxiliary 0.2-2 wt.%, photostabilizer 0.2-2 wt.% and colorant 0.1-1.5 wt.%. Compared with present polypropylene material, the modified polypropylene material has improved weathering resistance and anti-aging property.

Owner:CGN JUNER NEW MATERIALS

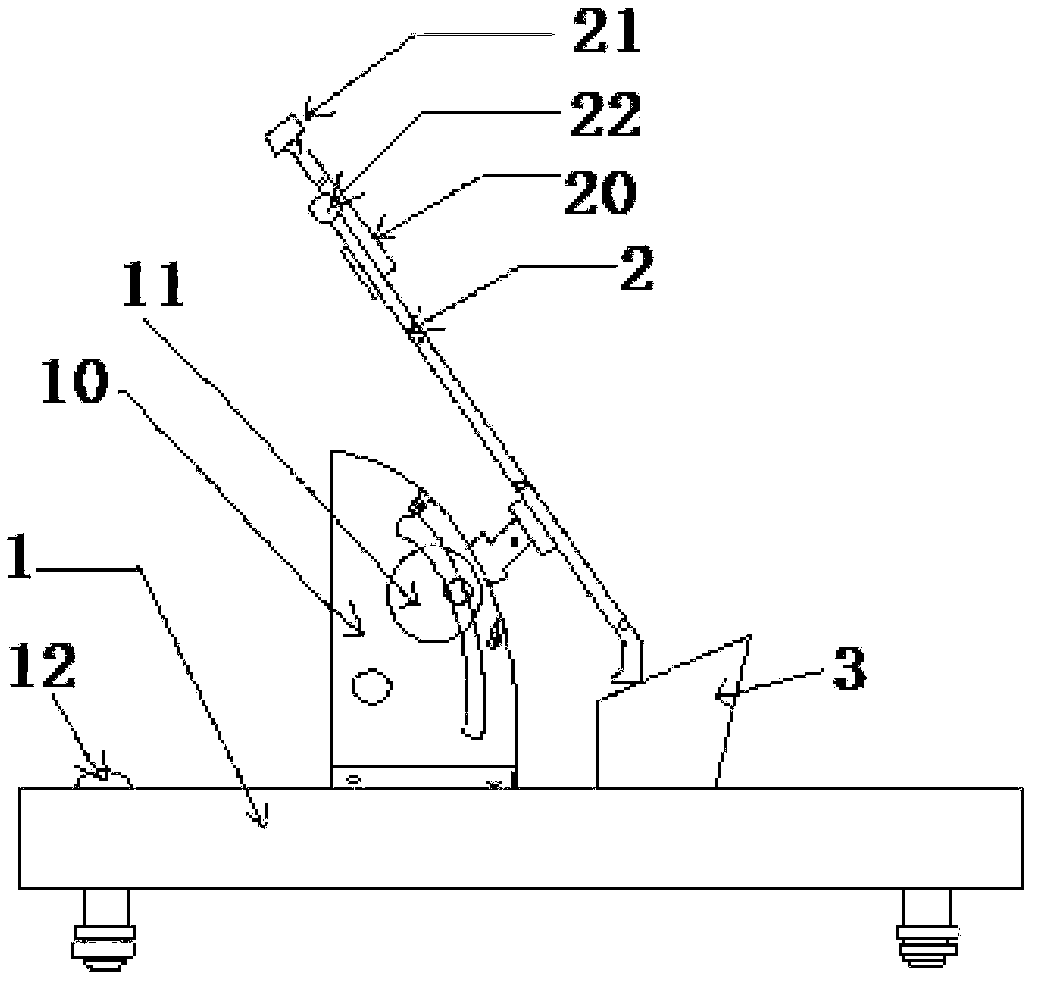

High-temperature-resisting conveyer belt

ActiveCN101028888AImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

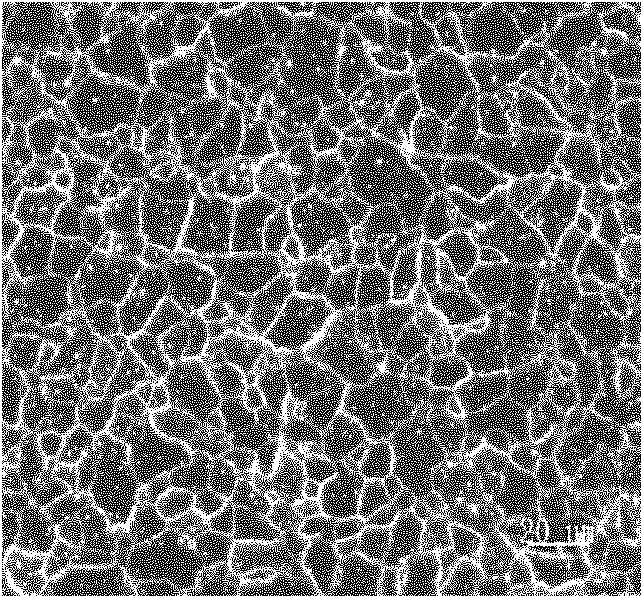

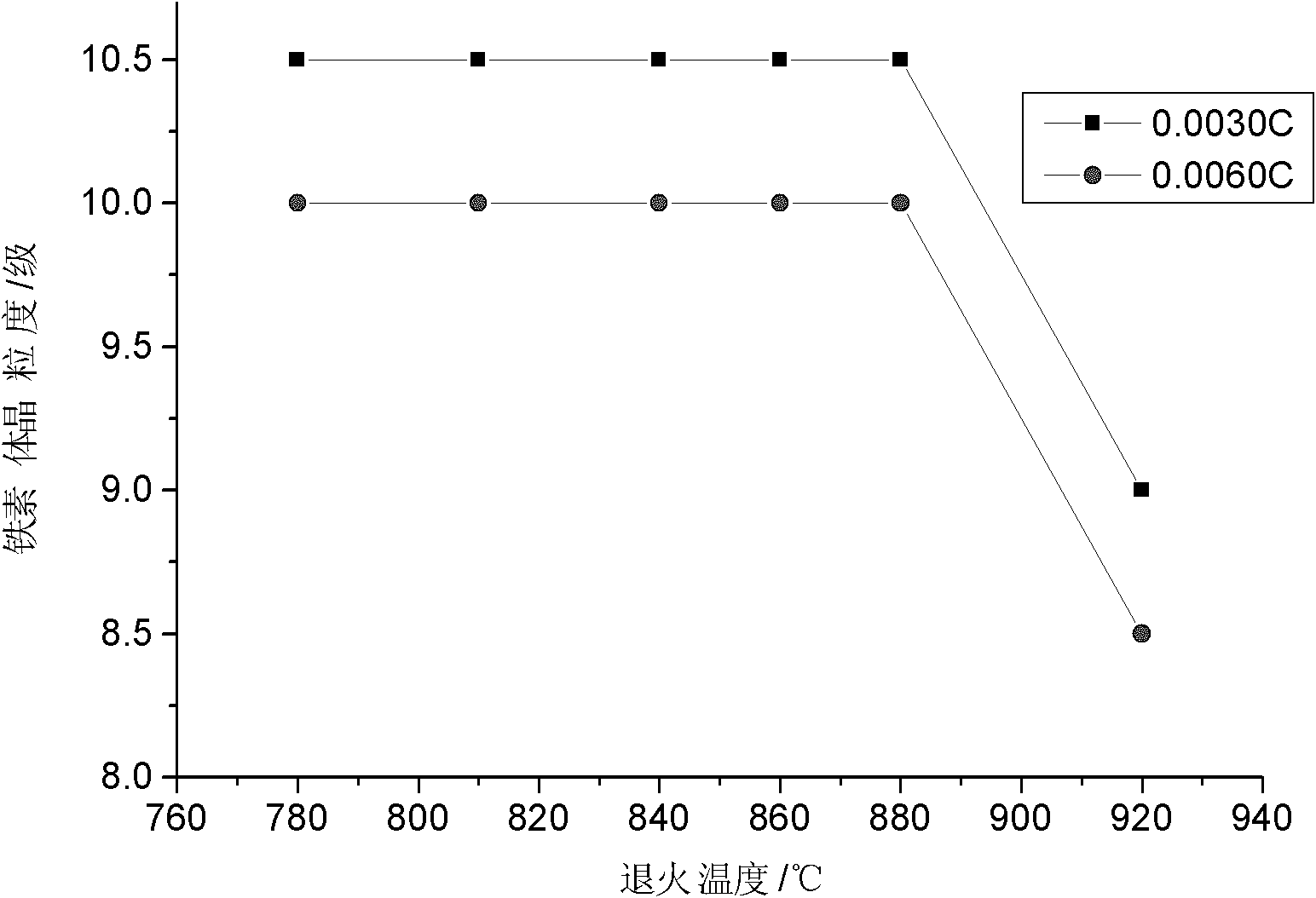

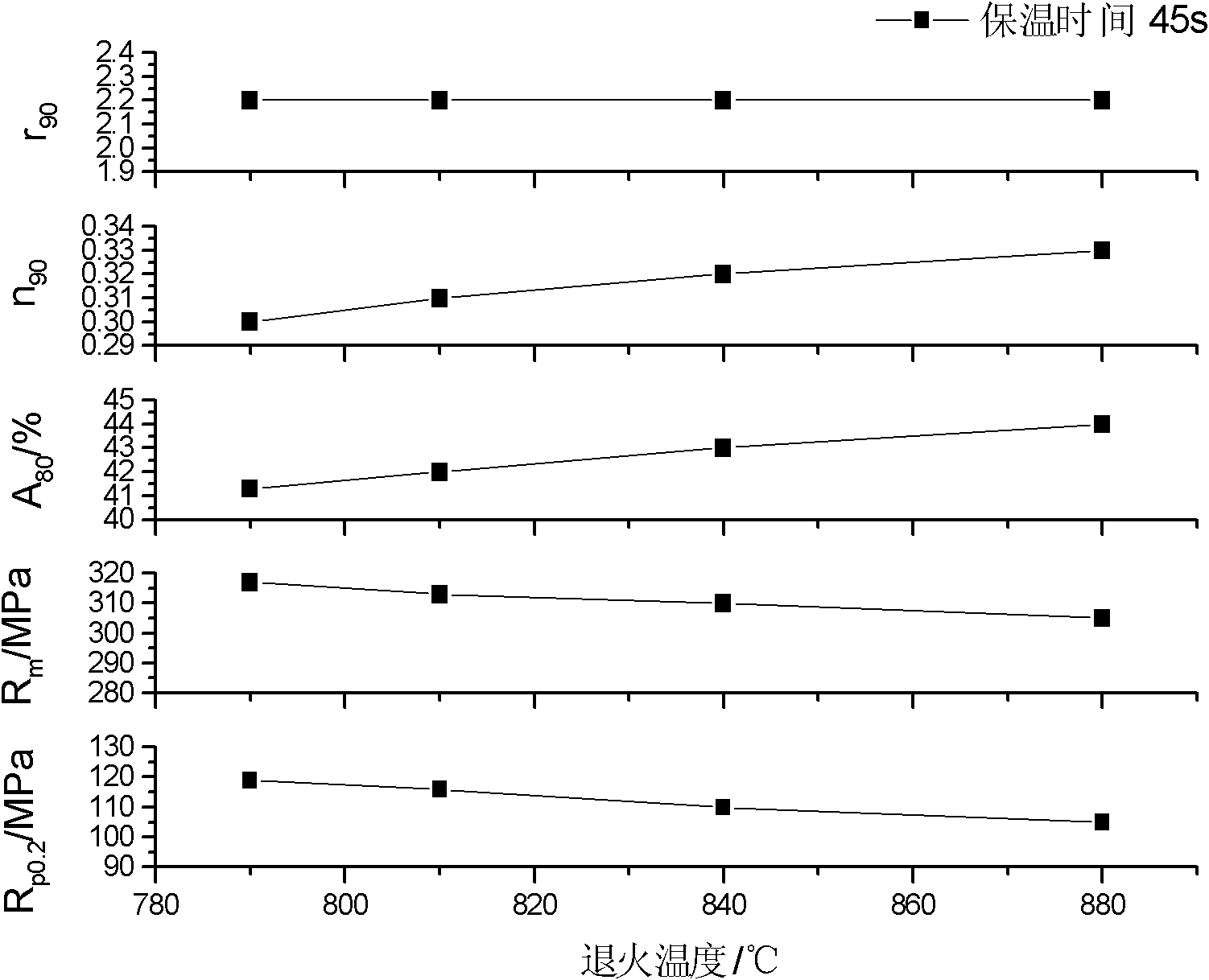

Low-yield strength anti-ageing continuous annealing cold-roll steel sheet and production method thereof

InactiveCN101956133ARefine and stabilize crystal sizeLower yield strengthSheet steelContinuous annealing

The invention belongs to the field of roll steel, in particular to a low-yield strength anti-ageing continuous annealing cold-roll steel sheet and a production method thereof, which solves the technical problem that stable-performance low-yield strength anti-ageing cold-roll steel sheets are difficult to be produced on a machine set with worse equipment level. The technical scheme of the invention is characterized by providing the low-yield strength anti-ageing cold-roll steel sheet and the production method thereof. The method of the invention can be implemented on the machine set with worse equipment level; and by adopting the method of the invention, the stable-performance low-yield strength anti-ageing cold-roll steel sheet can be produced, and the technical problem existing in the field of roll steel for a long term can be overcome.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

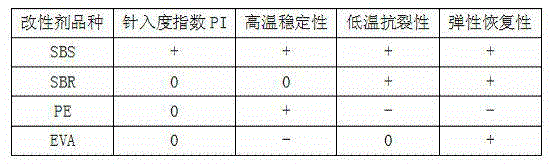

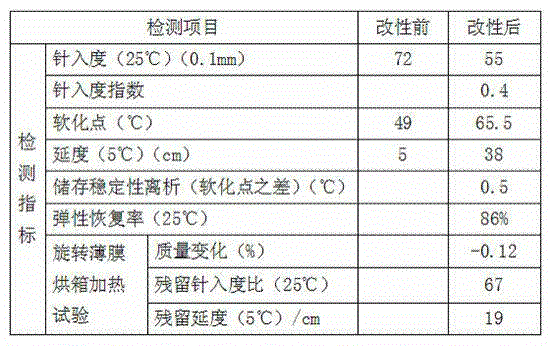

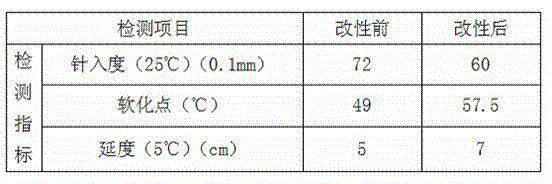

Composite asphalt modifier as well as preparation method and application method of composite asphalt modifier

InactiveCN102911507AEasy to useGood compatibilityBuilding insulationsHigh temperature storageAnti ageing

The invention discloses a composite asphalt modifier as well as a preparation method and an application method of the composite asphalt modifier. The composite asphalt modifier comprises a polymer, a compatilizer, an anti-aging agent, a nano material and a chemical additive, and is prepared by evenly mixing the components at the temperature of 0-200 DEG C. The application method of the composite asphalt modifier comprises two ways of: 1. mixing the composite asphalt modifier with matrix asphalt at the temperature of 120-210 DEG C for 10-500minutes to prepare modified asphalt composition; and 2, mixing the compatilizer, the matrix asphalt, the polymer, crosslinking body and the composite asphalt modifier at the temperature of 120-210 DEG C for 10-500minutes to prepare another modified asphalt composition. The modified asphalt compositions prepared by the method have good high, low temperature performance and high-temperature storage stability.

Owner:江柳

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

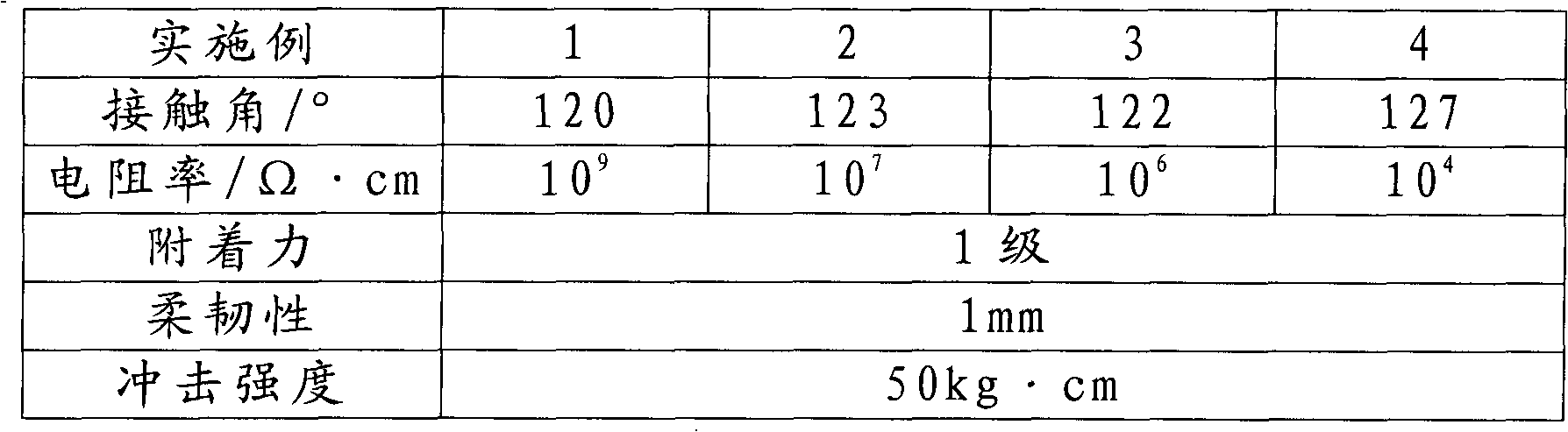

High hydrophobic static-electricity conducting anti-icing coating and method for producing same

ActiveCN101792631AHas electrostatic propertiesReduce formationInsulated cablesElectrically-conductive paintsElectric wireStatic electricity

The invention provides high hydrophobic static-electricity conducting anti-icing coating and a method for producing the same, aiming at solving the problem existing in the prior art that the common low surface energy coating can not balance both hydrophilic characteristic and static-electricity conducting function. According to the technical scheme adopted to solve the problem, the high hydrophobic static-electricity conducting anti-icing coating comprises component A and component B, wherein the weight ratio of the component A to the component B is 9-16:1. The component A comprises the following materials by weight percent: 35-60 percent of the fluorocarbon resin, 10-40 percent of conductive powder, 1-8 percent of organic silicon compound, 0.5-3 percent of anti-aging agent, 0.5-5 percent of dispersant, 0.5-3 percent of anti-sedimentation agent and 10-40 percent of organic solvent. The component B is aliphatic and / or aromatic curing agent. After being coated on the surface of an electric wire, the high hydrophobic static-electricity conducting low surface energy anti-icing coating can delay the icing and reduce the adhesion force of the ice and the surface of the electric wire. In addition, with the static-electricity conducting performance, the high hydrophobic static-electricity conducting low surface energy anti-icing coating can protect the electric wire against lightning stroke.

Owner:STATE GRID CORP OF CHINA +1

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

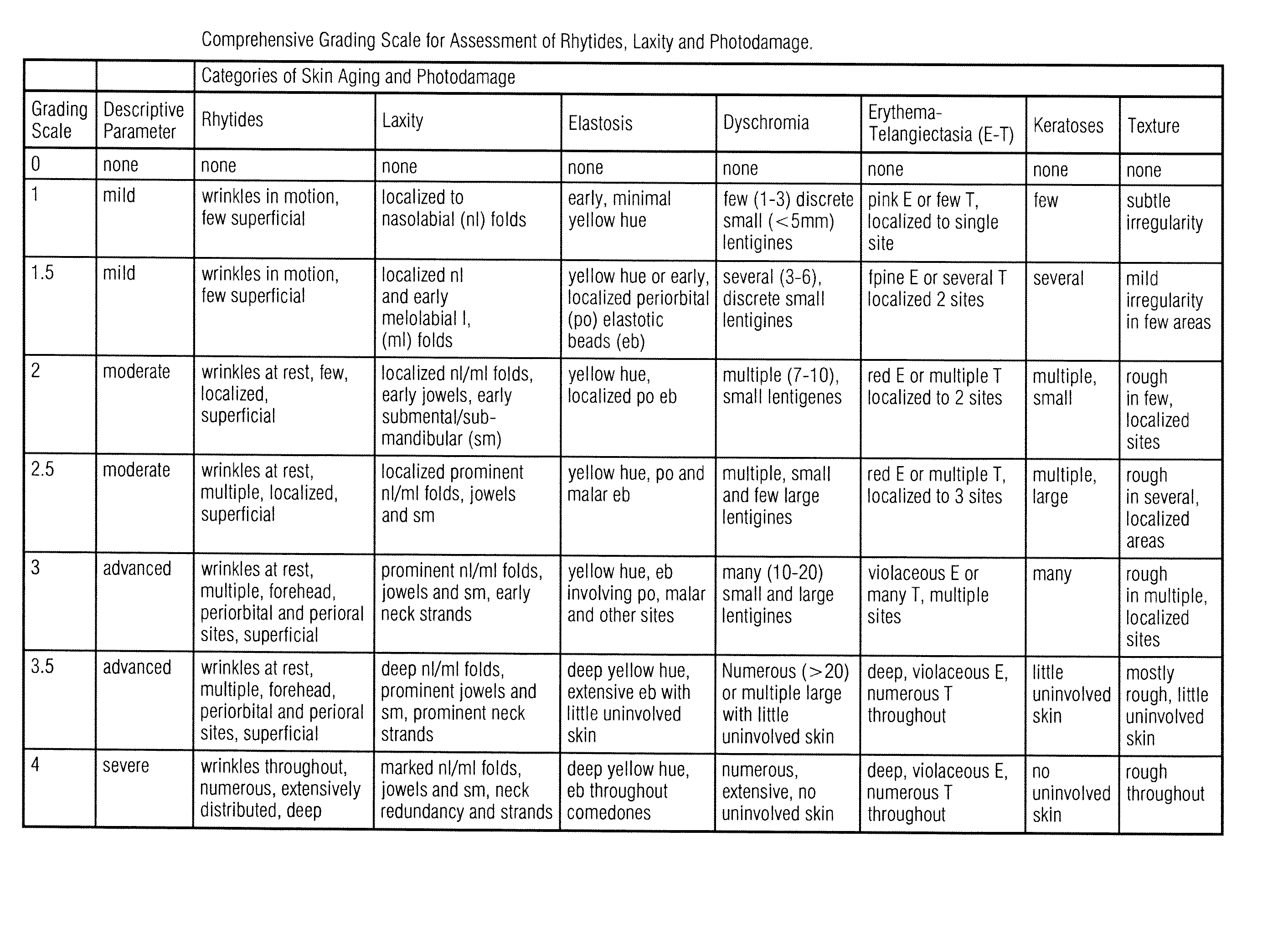

Multi-Active Microtargeted Anti-Aging Skin Cream Polymer Technology

InactiveUS20110305737A1Reduction in signWithout exacerbating acneCosmetic preparationsBiocideCosmetic creamLotion

A comprehensive, single agent cosmetic cream or lotion containing a high number of ingredients that target anti-aging in a defined manner. The cream or lotion contains a high number and variety of active substances that demonstrate excellent safety and efficacy in all of the various defined categories of skin aging, including but not limited to wrinkles, abnormal pigment or brown spots due to aging of the skin and an unexpectedly high efficacy in the reduction of redness and acne and rosacea blemishes.

Owner:MACRENE ACTIVES LLC

Application of nicotinamide mononucleotide in preparation of anti-aging drugs or health care products

InactiveCN104814974AImprove securityObvious effect and easy to stabilizeOrganic active ingredientsAntinoxious agentsDiseaseIntracellular substance

The invention discloses application of nicotinamide mononucleotide in preparation of anti-aging drugs or health care products, wherein nicotinamide mononucleotide is applied to preparation of anti-aging drugs or health products. The nicotinamide mononucleotide (NMN) provided by the invention is used as an active ingredient in preparation of anti-aging drugs or health products. The specific dose can be decided according to the severity degree of diseases, drug delivery approaches and related factors. NMN itself is a body intracellular substance, has high safety as a drug or health product, and the NMN is a monomer molecule, the efficacy is obvious and stable.

Owner:BONTAC BIO ENG SHENZHEN

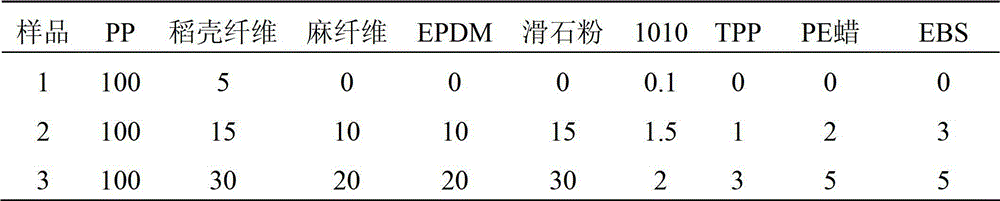

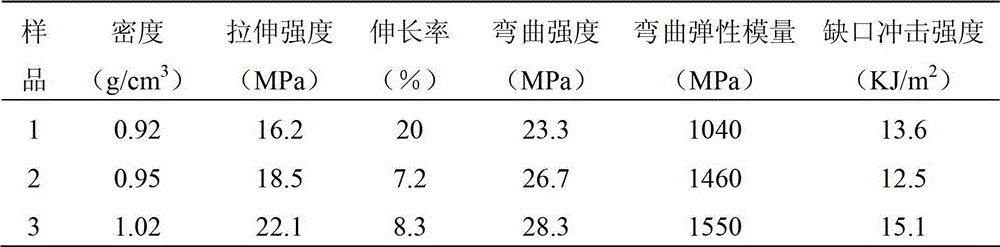

Injecting molding grade natural fiber composite material and preparation method thereof

The invention relates to a natural fiber composite material and a preparation method of the composite material. The composite material comprises the following components in parts by weight: 100 parts of thermoplastic resin, 5-50 parts of natural fiber, 0-20 parts of impact modifier, 0-30 parts of inorganic filler, 0.1-5 parts of anti-aging agent, and 0-10 parts of processing aid. The preparation method of the composite material comprises the steps of adding the natural fiber into an aqueous solution of a saline coupling agent to soak, then drying the natural fiber, mixing the natural fiber with the other processing aids, feeding the mixed material into a double-screw extruder to subject to the melting extrusion, and granulating to obtain the composite material. Compared with the prior art, the preparation method is simple in process and environment-friendly. More importantly, the problems that the composite material, into which a large amount of natural fiber is added, is poor in material mobility, low in intensity of parts, and poor in appearance quality, are solved. The current situation that the natural fiber composite material cannot adapt to the injection moldings of complex structures is changed.

Owner:CHERY AUTOMOBILE CO LTD

Anti-aging essence and preparation method thereof

ActiveCN109464342AUnique textureMoisturized skinCosmetic preparationsToilet preparationsWrinkle skinSkin complexion

The invention discloses anti-aging essence. The anti-aging essence is prepared from components in percentage by mass as follows: 0.01%-2% of active peptide, 3%-15% of polyol, 0.01%-10% of a moisturizer, 0.5%-1.2% of a plant preservative, 0.1%-10% of a skin conditioner, 0.02%-0.1% of a chelating agent, 0.1%-2% of an anti-inflammatory repair agent and the balance of deionized water. The invention further provides a preparation method of the anti-aging essence and an application of the anti-aging essence to preparation of skin care products. The anti-aging essence can be used for daily skin careand has the functions of moisturizing skin, resisting inflammation, relieving skin, reducing wrinkles and brightening complexion, meanwhile, the problem of inactivation of the active peptide when being combined with a traditional chemical preservative is solved by adopting the natural plant preservative, and stability of product functions is guaranteed.

Owner:广州市盛美化妆品有限公司

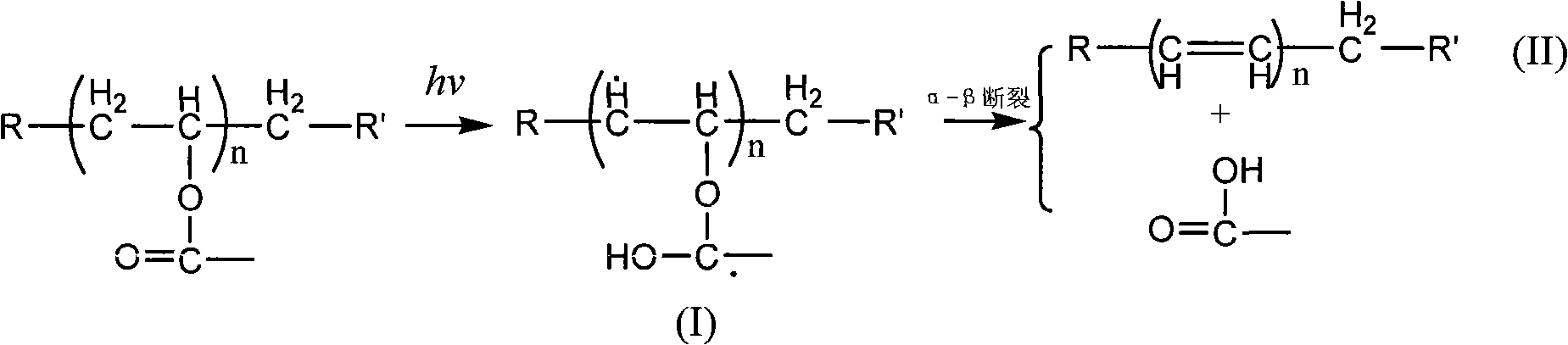

Novel EVA adhesive film

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

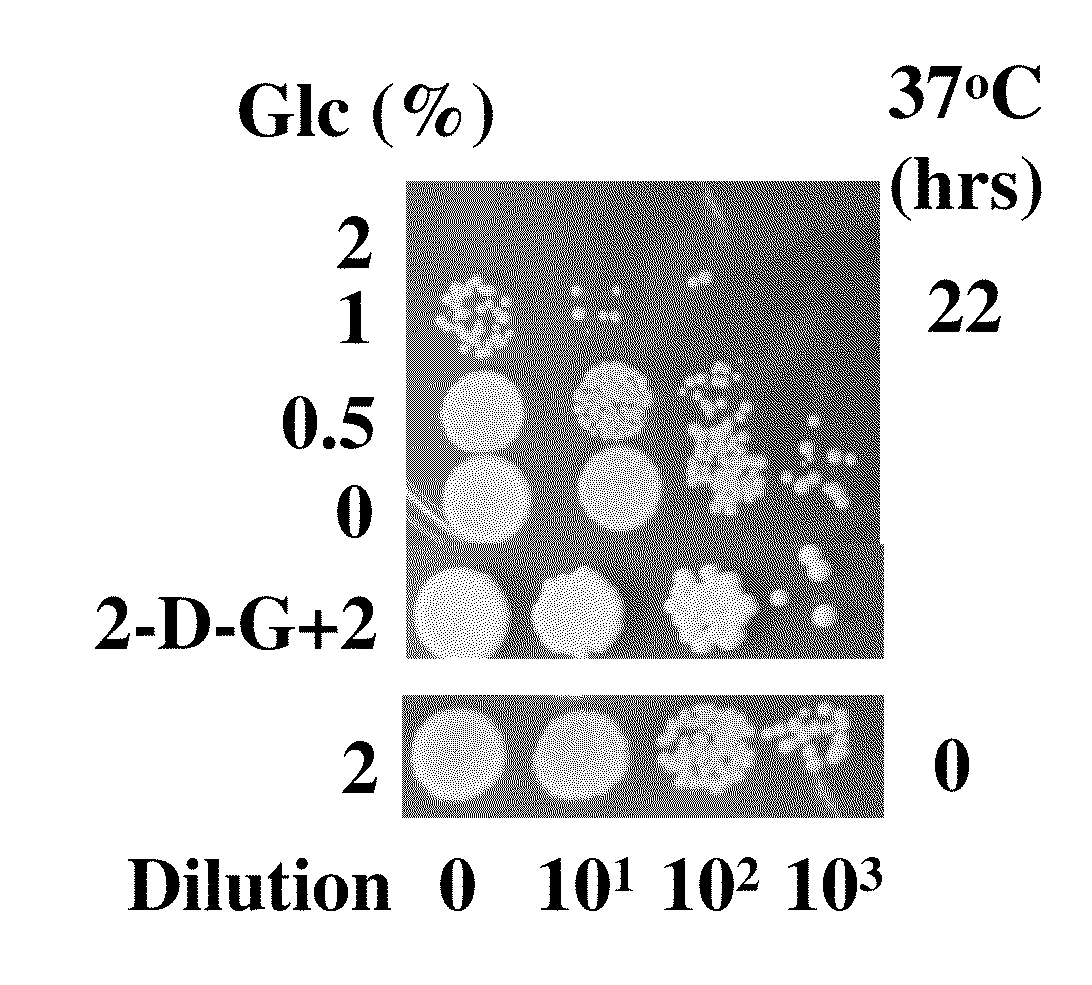

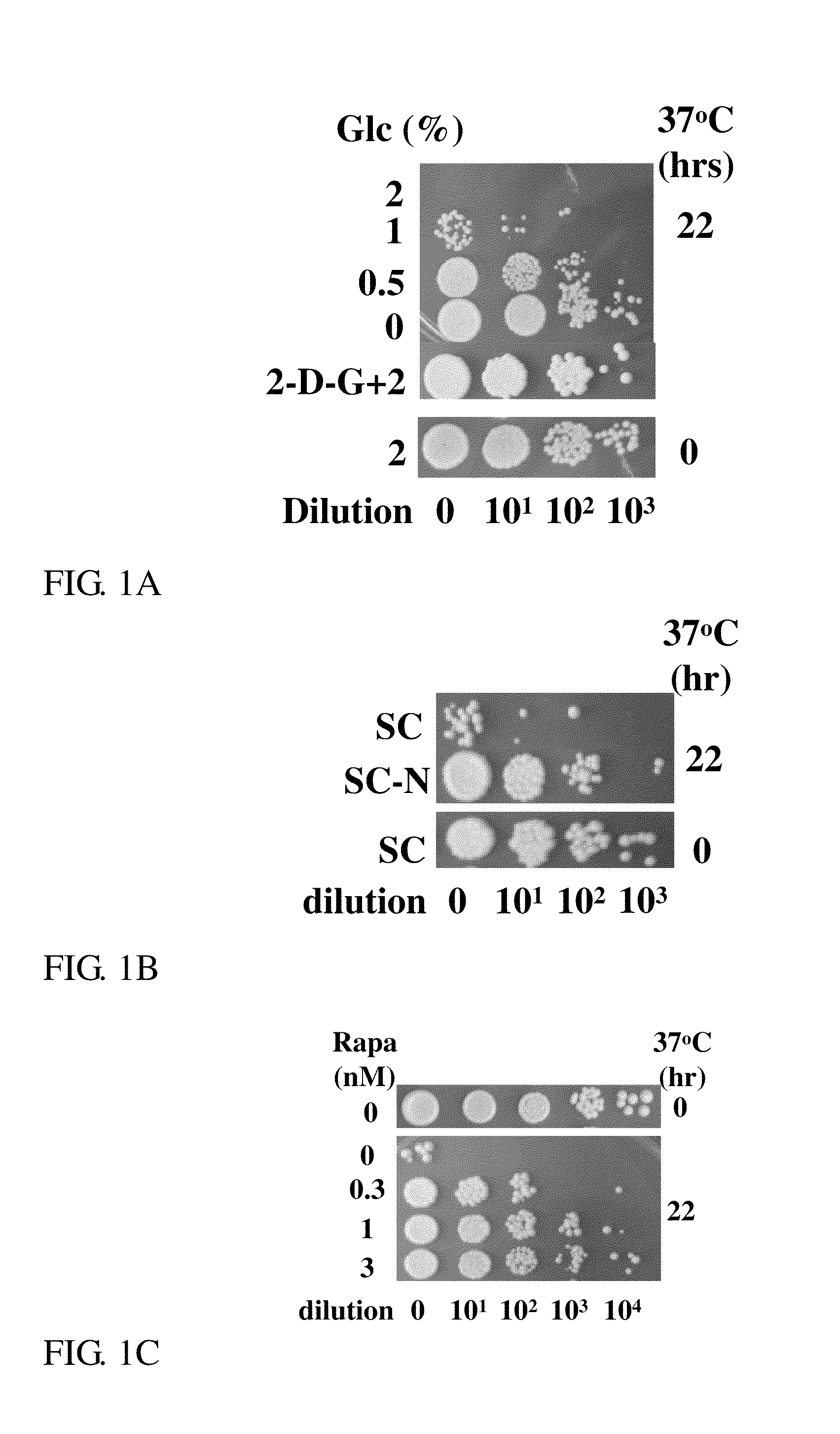

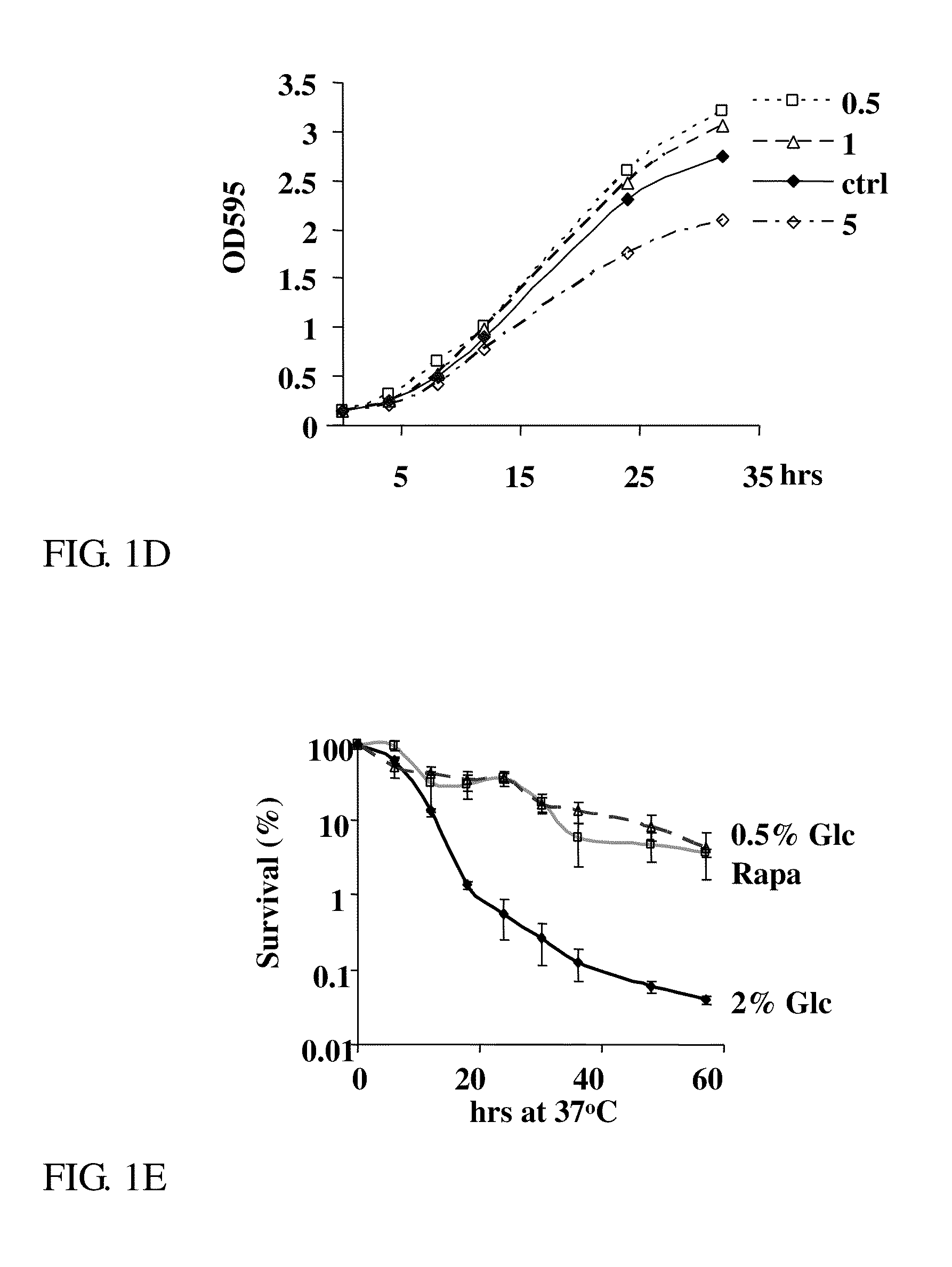

Novel anti aging agents and methods to identify them

ActiveUS20100260733A1Stimulate mitochondrial functionPrevent and treat deteriorationOrganic active ingredientsSenses disorderAge related diseaseHigh-Throughput Screening Methods

The present invention discloses novel mechanisms in the aging process and describes novel methods for high-throughput screening to identify, detect, and purify agents to be used for improving mitochondrial function, maintaining the cell cycle-arrested state in senescent and post mitotic cells, and thus preventing or treating age-related diseases or disorders associated with accelerated mitochondrial function loss, telomere dysfunction, and / or deterioration of the growth-arrested state. The present invention also discloses a number of compounds or compositions identified from this method. The present invention further provides the use of low doses of rapamycin or its analogs as a mimic of caloric restriction in preventing age-related diseases or disorders.

Owner:QI HAIYAN

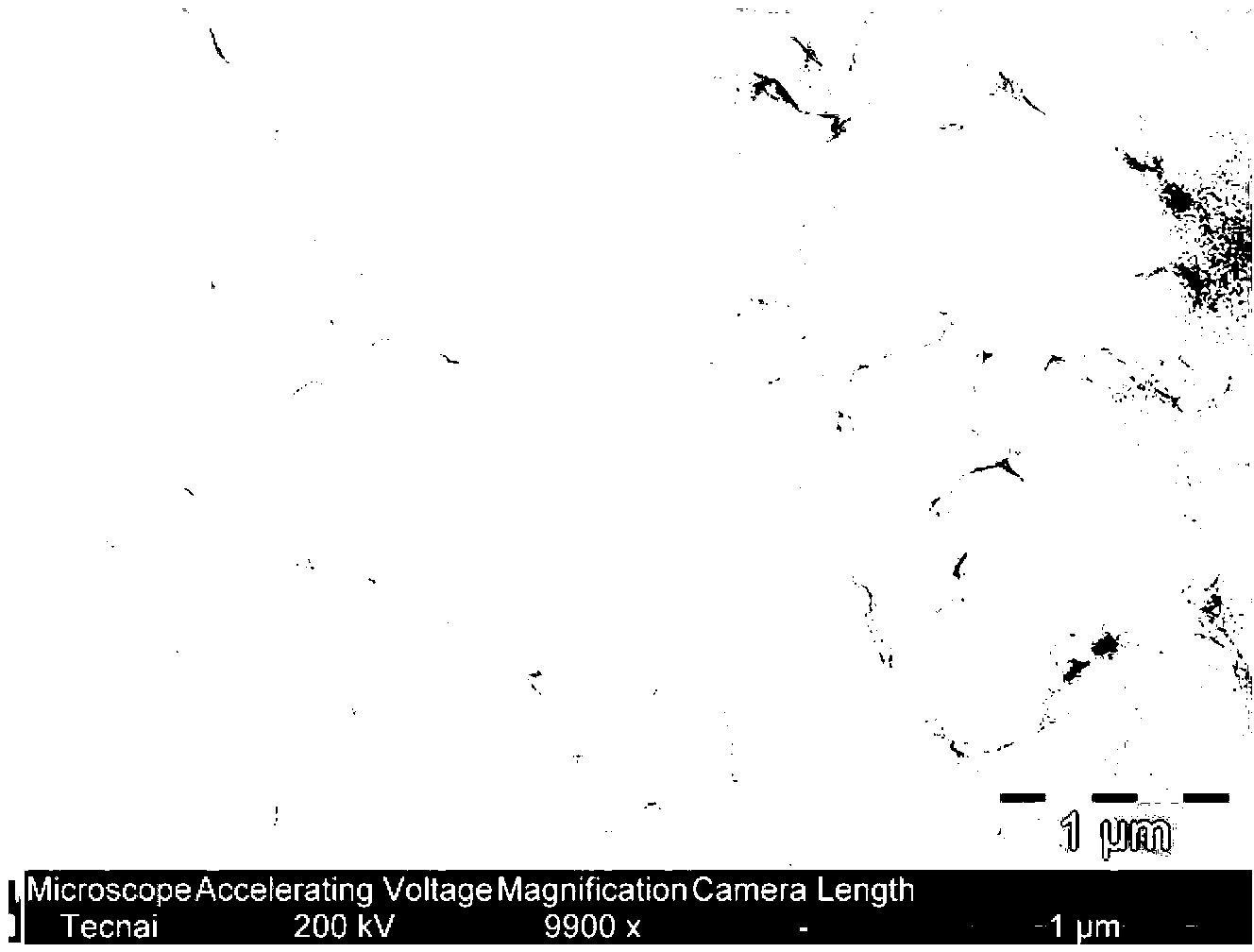

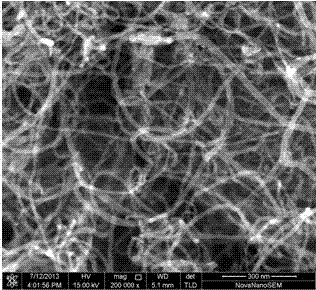

Preparation method of pre-dispersed carbon nano-tube rubber masterbatches

ActiveCN104513410AHigh tear strengthWear volume reductionSpecial tyresMicron scaleHigh concentration

The invention belongs to the field of materials and specifically relates to a preparation method of pre-dispersed carbon nano-tube rubber masterbatches. The method is characterized in that the rubber masterbatches comprise the following ingredients, by weight, 5-100 parts of carbon nano-tube, 5-100 parts of rubber, 5-100 parts of wax, 0.5-50 parts of a dispersing aid, 0.5-5 parts of an anti-aging agent and 0.1-10 parts of an activator. The preparation method of the rubber masterbatches comprises the following specific steps: carrying out high-speed shearing on the above ingredients, mixing, carrying out in situ activated modification on carbon nano-tube such that carbon nano-tube is uniformly dispersed and has no micron-scale aggregate, and pelleting so as to obtain the pre-dispersed high-concentration carbon nano-tube rubber masterbatches. By the use of the pre-dispersed carbon nano-tube rubber masterbatches prepared by the above formula and method, tear strength of tire tread rubber can be raised by about 5-10% and even more, wear volume of Akron is reduced by about 30% and even more, volume resistivity is minimized by two orders of magnitudes, and mechanical properties such as tensile strength, elongation at break and the like are basically unchanged or increased a little.

Owner:SHANDONG DAZHAN NANO MATERIALS

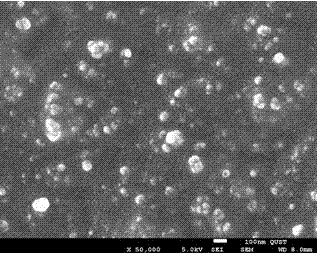

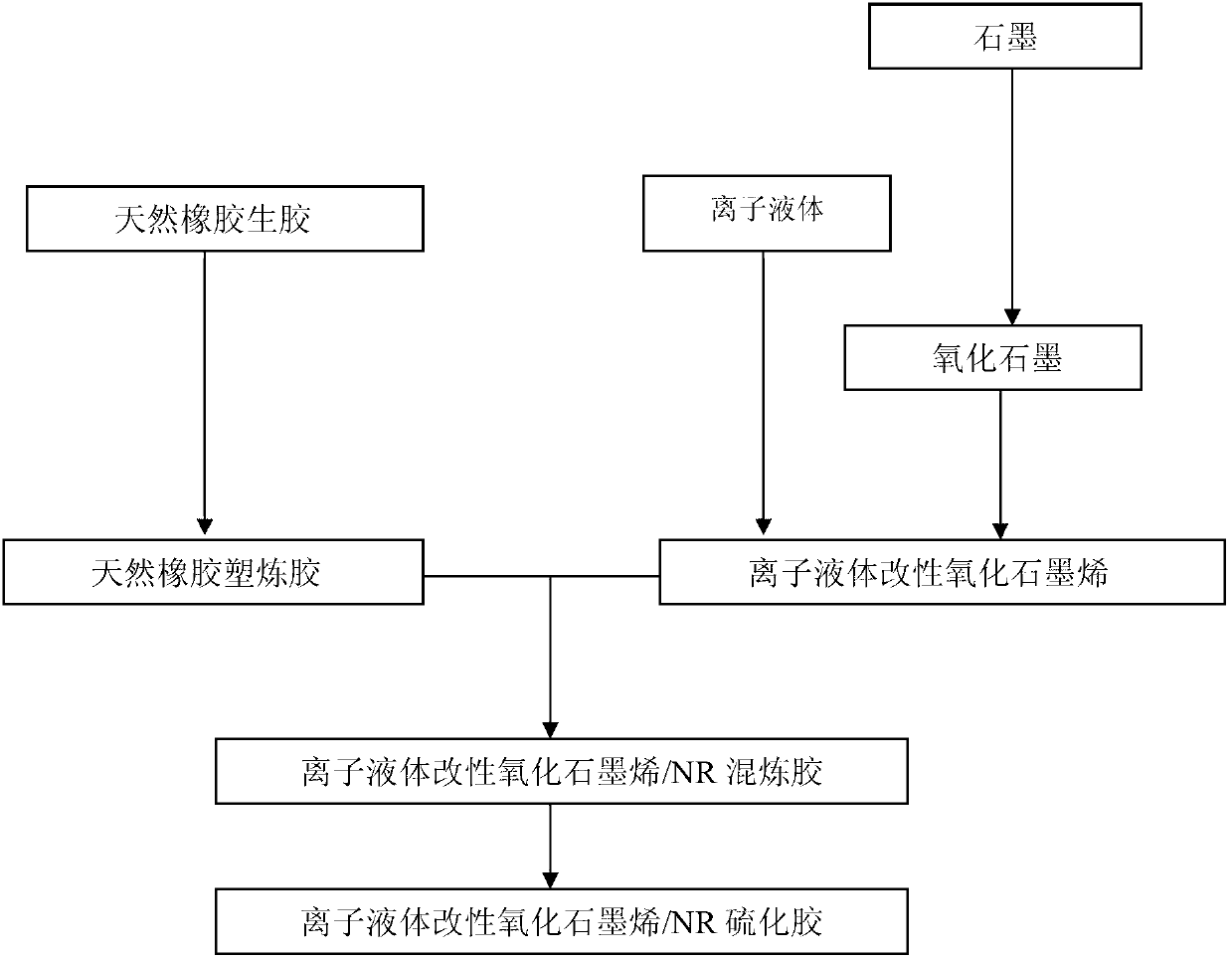

Ionic liquid modified graphene oxide/natural rubber vulcanized rubber and preparation method thereof

The invention relates to ionic liquid modified natural rubber vulcanized rubber containing graphene oxide. Graphene oxide is modified by use of ionic liquid through a solid grinding method, the modified graphene oxide and natural rubber are mechanically mixed in an open mill or internal mixer, and the formulas such as zinc oxide, stearic acid, an anti-aging agent, an accelerant, a vulcanizing agent, carbon black and the like are added at the same time to obtain natural rubber compound containing ionic liquid modified graphene oxide; and the ionic liquid modified graphene oxide / natural rubber vulcanized rubber provided by the invention can be obtained through vulcanization processing. According to the invention, modified graphene oxide is prepared by use of ionic liquid through the solid grinding method. Under the synergistic effect of the ionic liquid modified graphene oxide and carbon black, the heat conduction coefficient and the mechanical performance of the vulcanized rubber can be improved at the same time. The invention provides a preparation method of novel modified graphene oxide / natural rubber vulcanized rubber with simple technology and excellent performance.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com