Injecting molding grade natural fiber composite material and preparation method thereof

A natural fiber and composite material technology, applied in the field of natural fiber composite materials and their preparation, can solve the problems of natural fiber composite materials not suitable for injection molding parts, poor fluidity of natural fibers, poor appearance quality, etc., to achieve lightweight, high density Low, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

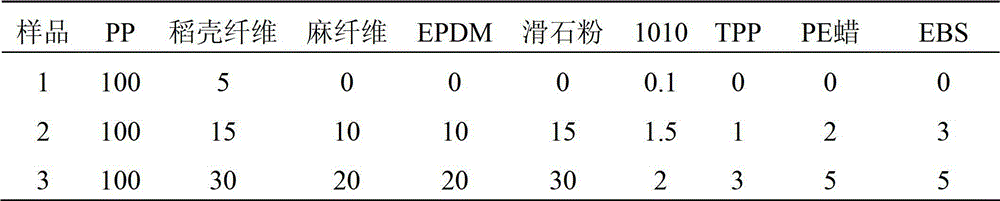

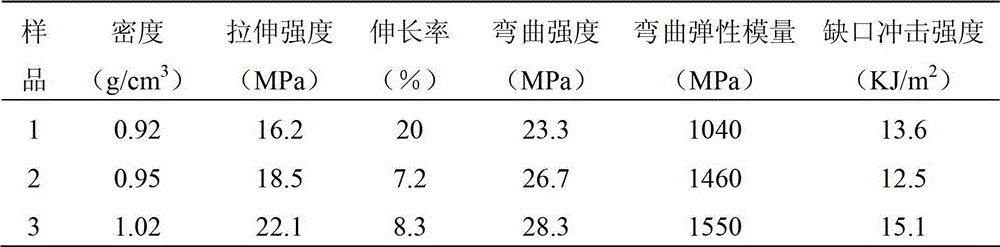

[0022] Embodiment 1, a kind of injection molding grade natural fiber composite material

[0023] A kind of injection molding grade natural fiber composite material, comprises the following component preparation of proportioning by weight:

[0024] Polypropylene (thermoplastic resin) 10kg;

[0025] 500 g of wood fibers (natural fibers) with an average length or particle size of less than 3 mm;

[0026] Triphenyl phosphite (anti-aging agent) 10g.

[0027] The natural fibers are treated with a silane coupling agent.

Embodiment 2

[0028] Embodiment 2, a kind of injection molding grade natural fiber composite material

[0029] A kind of injection molding grade natural fiber composite material, comprises the following component preparation of proportioning by weight:

[0030] Polypropylene (thermoplastic resin) 10kg;

[0031] 5 kg of wood fibers (natural fibers) with an average length or particle size of less than 3 mm;

[0032] Triphenyl phosphite (anti-aging agent) 500g.

[0033] The natural fibers are treated with a silane coupling agent.

Embodiment 3

[0034] Embodiment 3, a kind of injection molding grade natural fiber composite material

[0035] A kind of injection molding grade natural fiber composite material; Comprise the following component preparation of weight portion proportioning:

[0036] Polypropylene (thermoplastic resin) 10kg;

[0037] 2.5 kg of wood fibers (natural fibers) with an average length or particle size of less than 3 mm;

[0038] Triphenyl phosphite (anti-aging agent) 250g.

[0039] The natural fibers are treated with a silane coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com