Technological process of ramie bast fiber

A bast fiber and processing technology technology, applied in the field of hemp bast fiber processing technology, can solve the problems of backward production equipment, low fiber utilization rate, difficult to make high-grade products, etc., to reduce difficulty and pressure, improve fiber Fragmentation, the effect of reducing consumption and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] First of all, it is stated that the processing technology of the hemp bast fiber in the present invention is mainly explained by taking the processing of hemp as an example, but its application in the processing of other hemp bast fibers is not excluded.

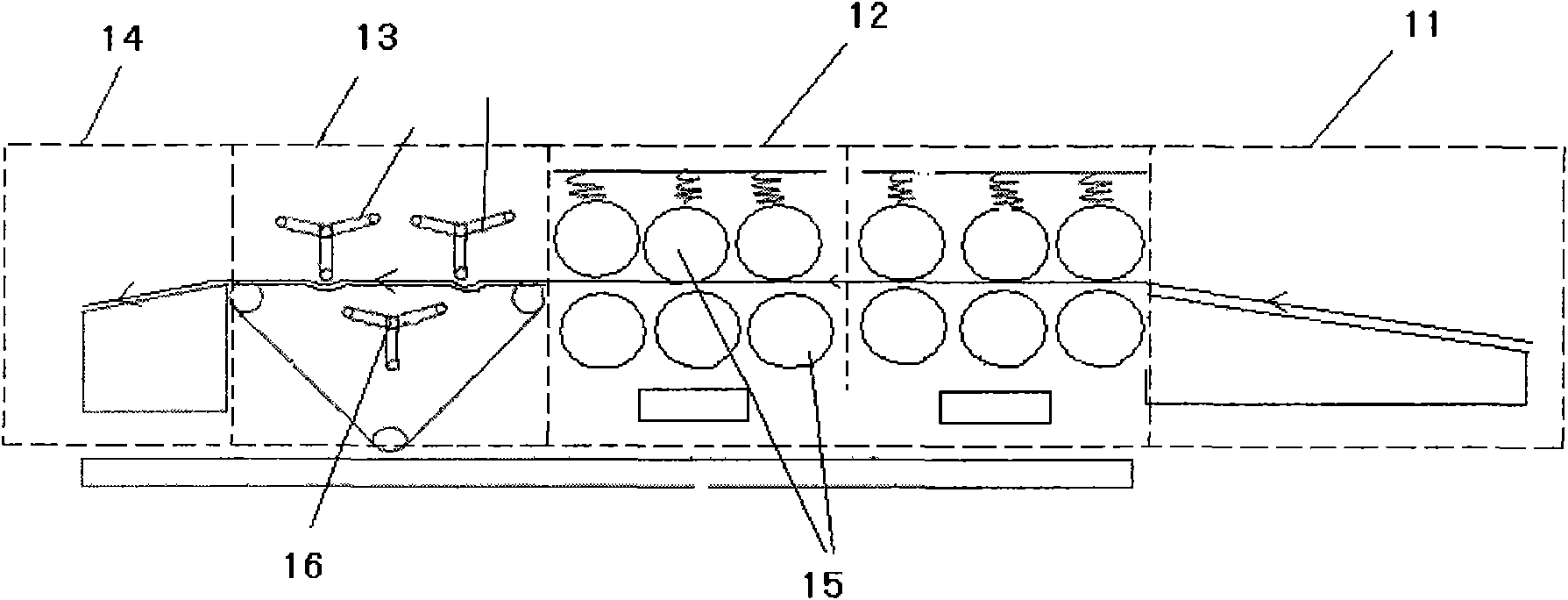

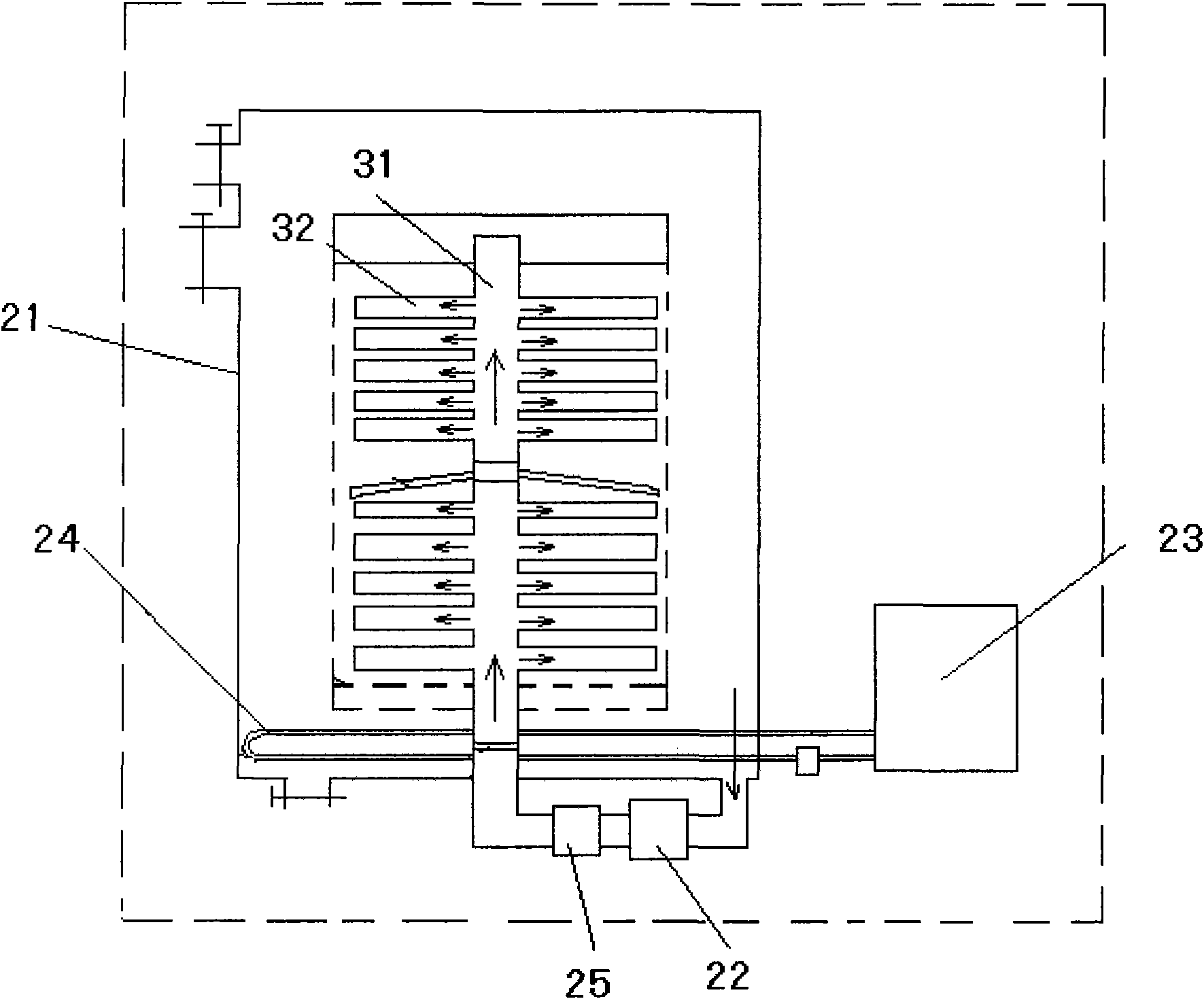

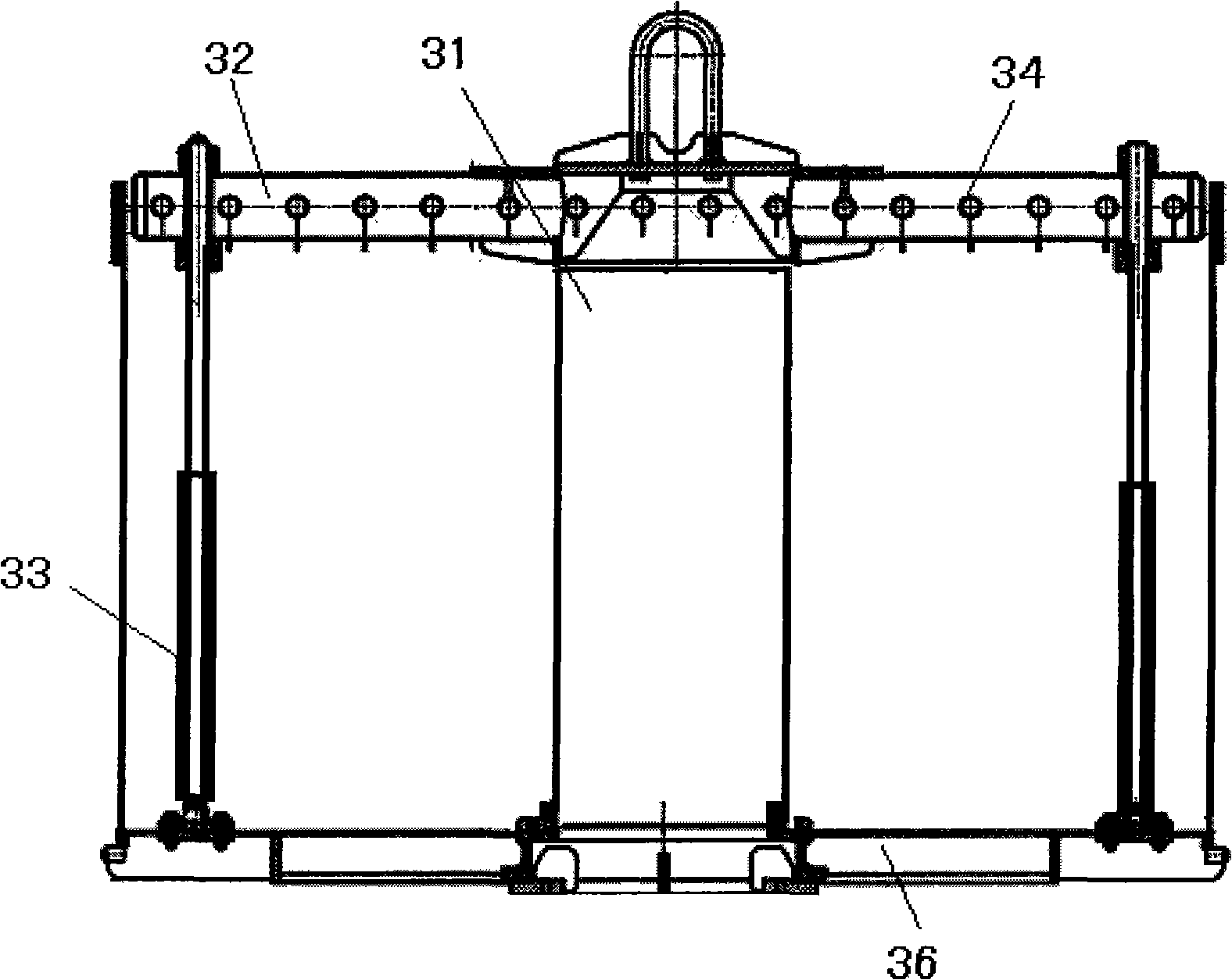

[0070] The hemp class bast fiber processing technology provided by the invention comprises the following processing steps:

[0071] Unpack and sort the raw hemp husk, cut off the root and apex, perform mechanical degumming on the mechanical degumming equipment, put the bast fibers after mechanical degumming into cages, perform biological degumming and / or high-temperature cooking degumming, and then undergo high-temperature degumming After rinsing, the cage is unloaded, and after fiber separation, washing, rinsing, softness, and radio frequency drying, it is made into dry flax; then the lean flax is mechanically softened, oiled, infiltrated and maintained, and then sorted by stretching, needle combing, and combing. , A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com