Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205 results about "Bast fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

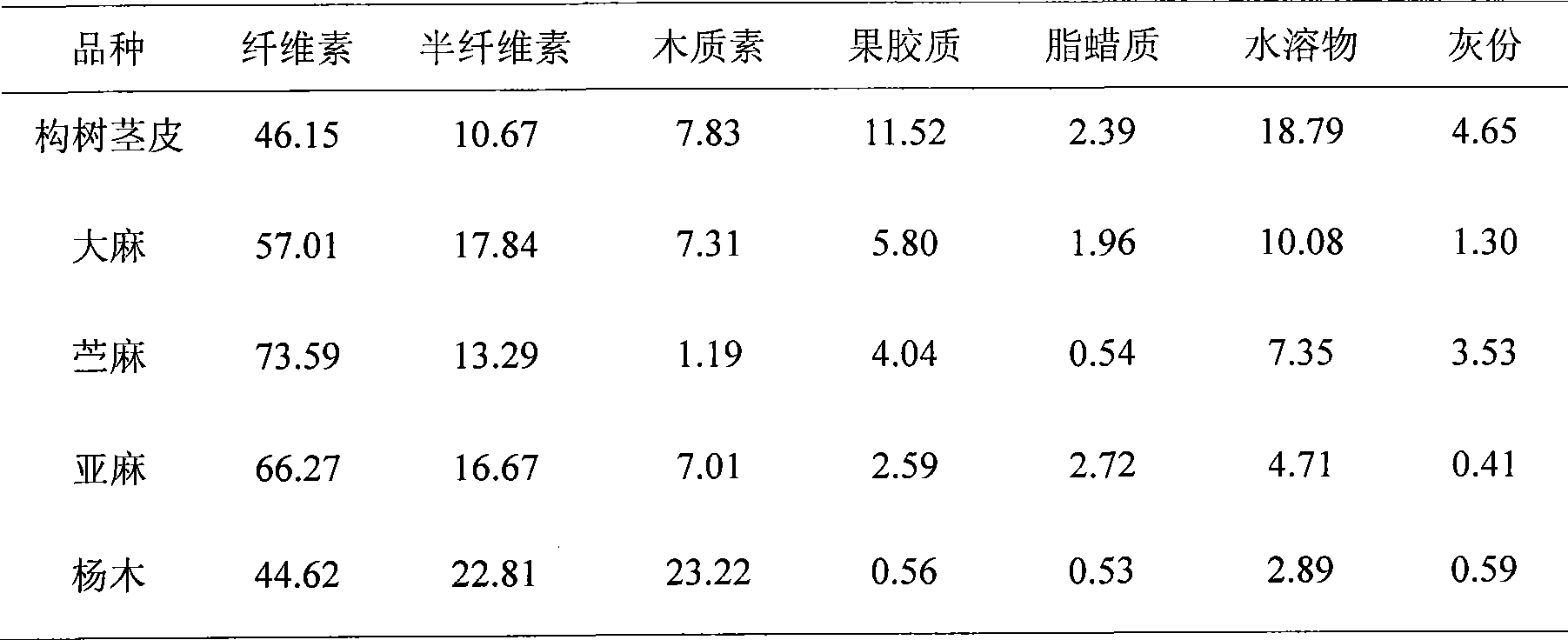

Bast fibre (also called phloem fibre or skin fibre) is plant fibre collected from the phloem (the "inner bark", sometimes called "skin") or bast surrounding the stem of certain dicotyledonous plants. It supports the conductive cells of the phloem and provides strength to the stem. Some of the economically important bast fibres are obtained from herbs cultivated in agriculture, as for instance flax, hemp, or ramie, but also bast fibres from wild plants, as stinging nettle, and trees such as lime or linden, wisteria, and mulberry have been used in the past. Bast fibres are classified as soft fibres, and are flexible. Fibres from monocotyledonous plants, called "leaf fibre", are classified as hard fibres and are stiff.

Fluorescent pseudomonad DA4 strain as well as acquisition method and application thereof

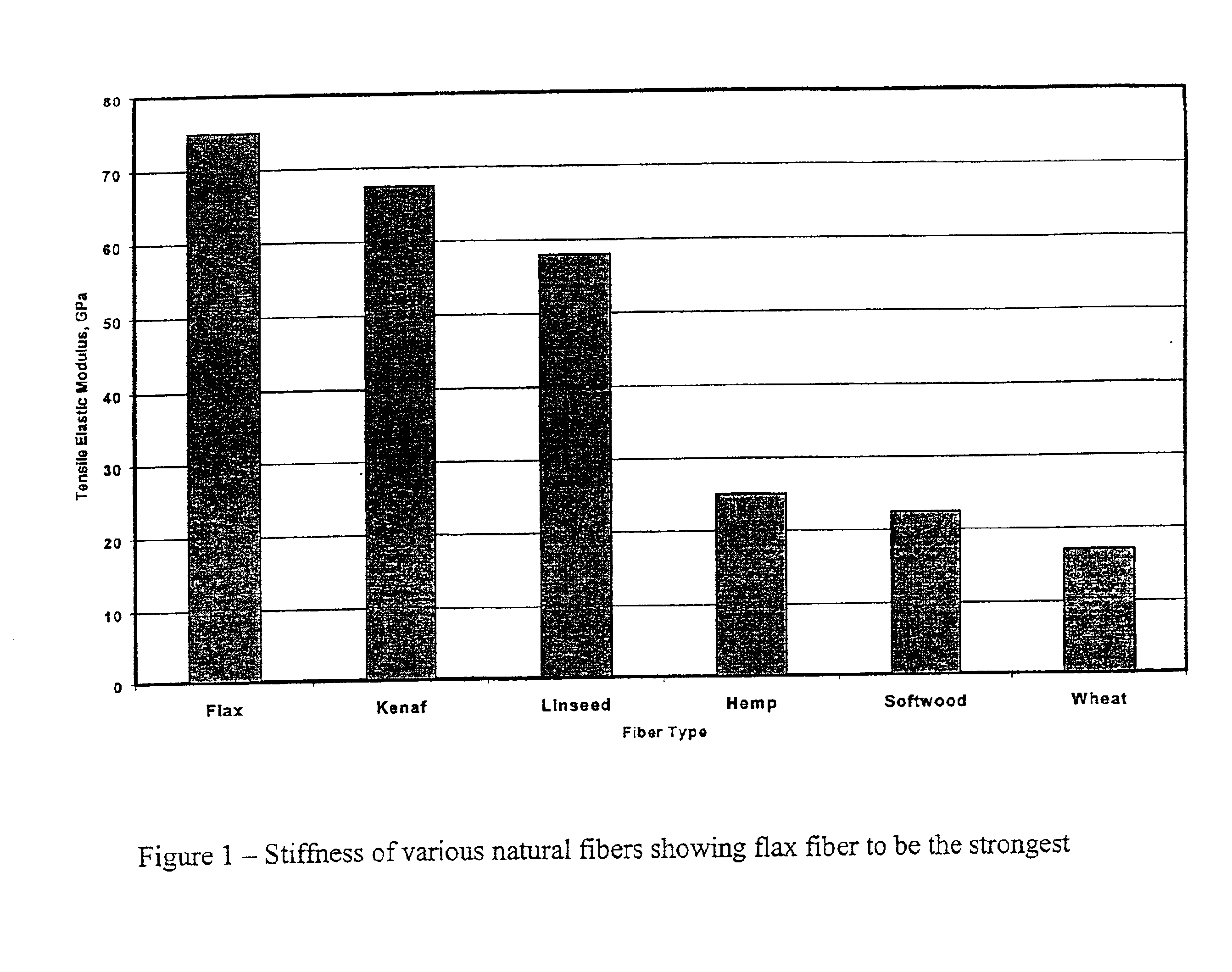

InactiveCN102002468AHigh enzyme productionEnzyme richBacteriaBiochemical fibre treatmentFlax fiberUltimate tensile strength

The invention relates to a fluorescent pseudomonad DA4 strain as well as an acquisition method and application thereof. The fluorescent pseudomonad DA4 strain has pectase and hemicellulase producing capacity and flax degumming activity. The fluorescent pseudomonad strain screened by the invention has fast propagation, high antipollution capacity and good heat and alkali resistance; since a composite degumming enzyme solution is used for flax degumming, the degumming period is shortened greatly, and the system and the culturing process is safe for operation without toxicity or environmental pollution; the invention can shorten the flax degumming period, enhance the flax yield and the strength of flax fibers, improve the quality of the flax fibers by adopting the composite degumming enzyme solution for flax microbial degumming, thereby being beneficial to popularization; in addition, the invention can not only be used for flax raw stem degumming, roving scouring and the biological pretreatment of flax fabrics, but also can be used for the degumming and the biological pretreatment of hemp bast fibers, i.e. ramie, jute, hemps, and the like.

Owner:DONGHUA UNIV

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

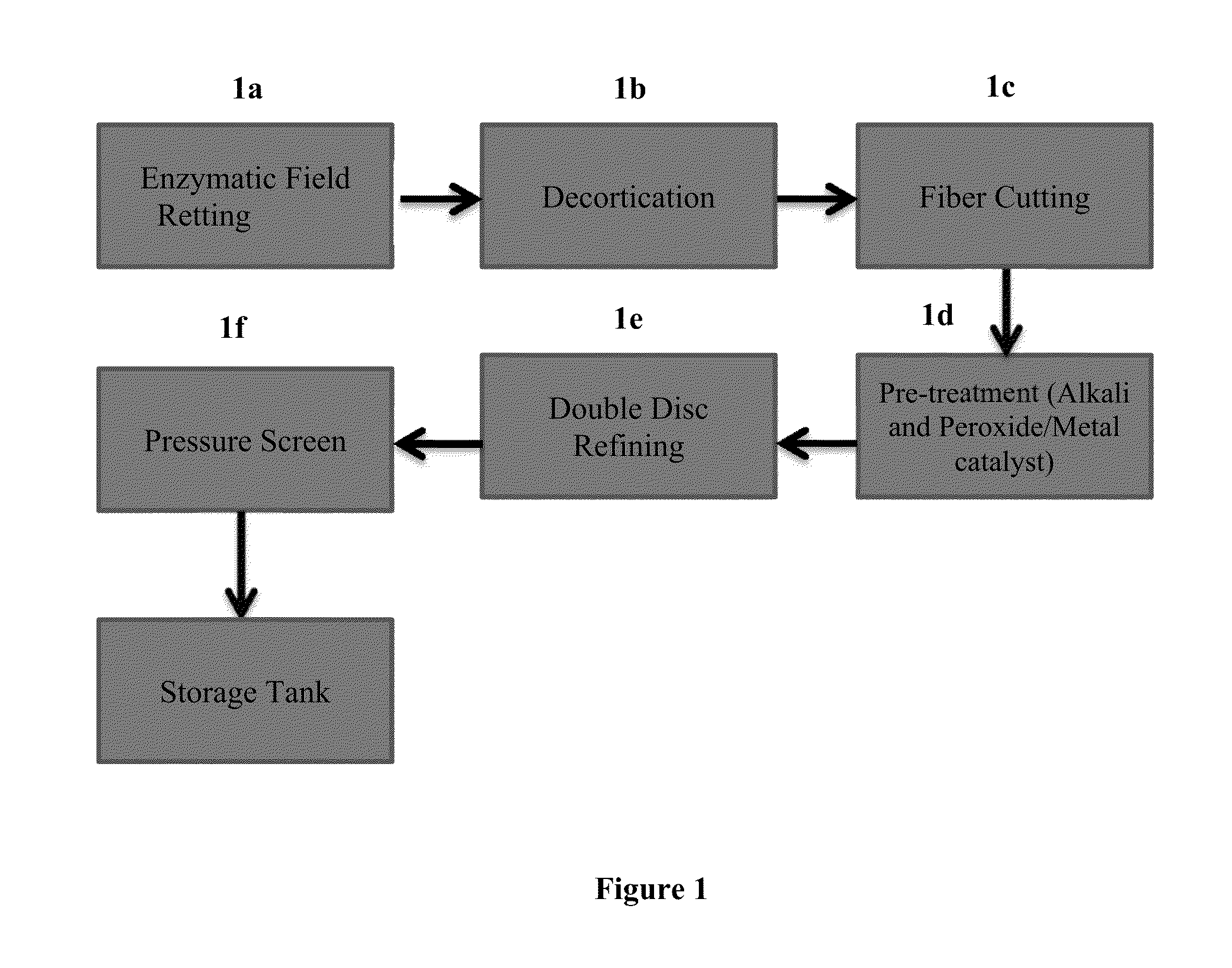

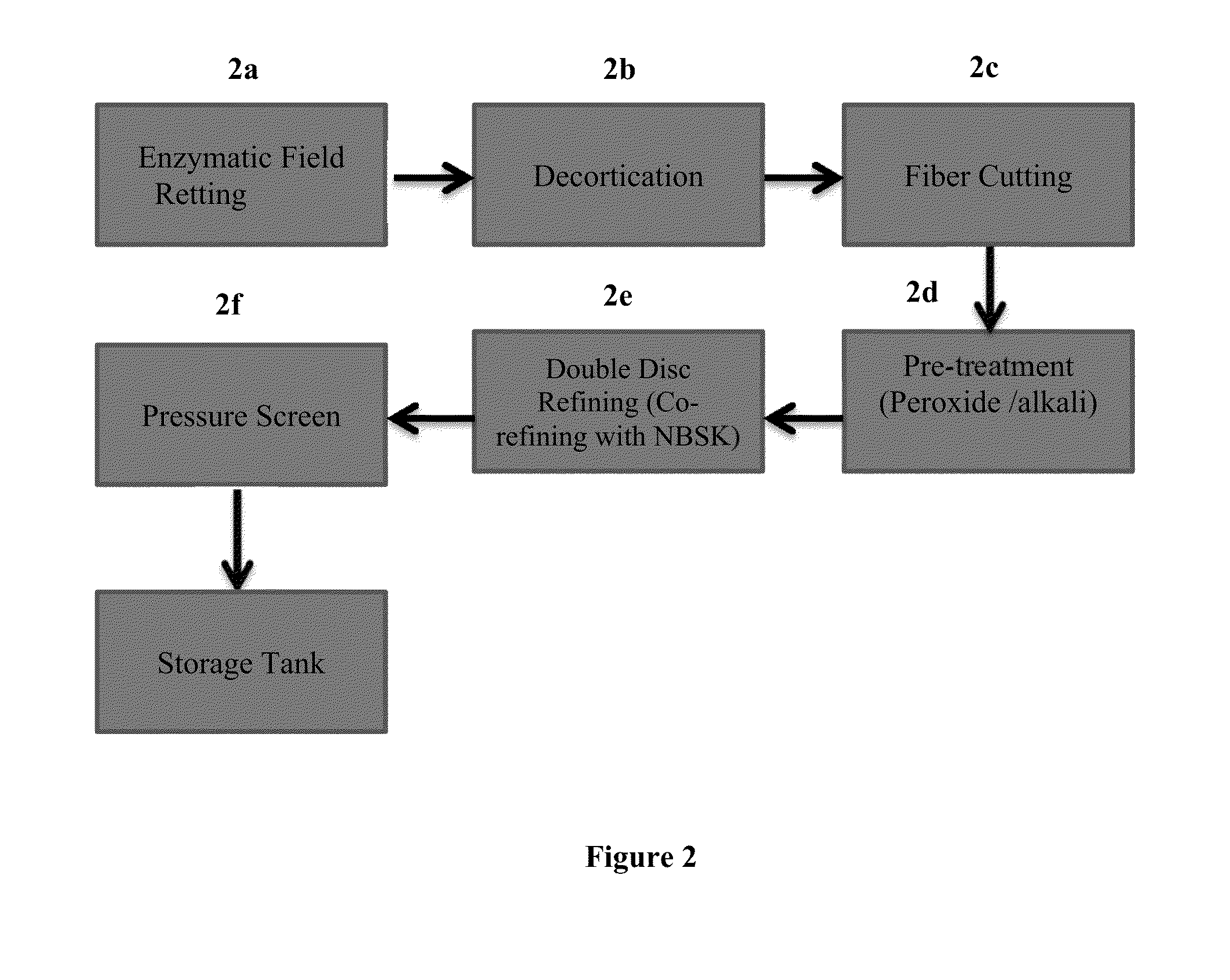

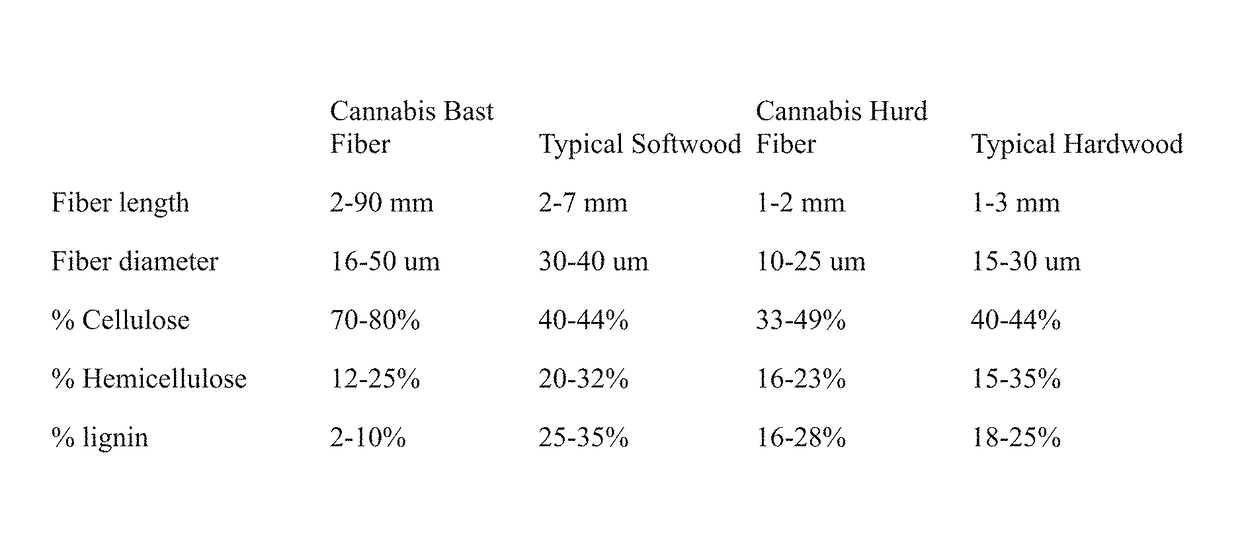

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS20160130762A1Reduce manufacturing costLose weightNon-fibrous pulp additionPaper after-treatmentCelluloseBleach

A method to prepare, pulp, and bleach cannabis bast and hurd fibers to allow for the fiber to be incorporated into absorbent cellulosic structures on a wet-laid paper machine while keeping the pectin within the fibers. The wet laid paper machine can use the ATMOS, NTT, ETAD, TAD, or UCTAD method to produce the absorbent cellulosic structure. Absorbent cellulosic structures are produced with the cannabis bast and hurd fibers or with the bast fibers alone with the hurd fibers being combined with paper mill sludge or dust to form a fuel pellet.

Owner:FIRST QUALITY TISSUE

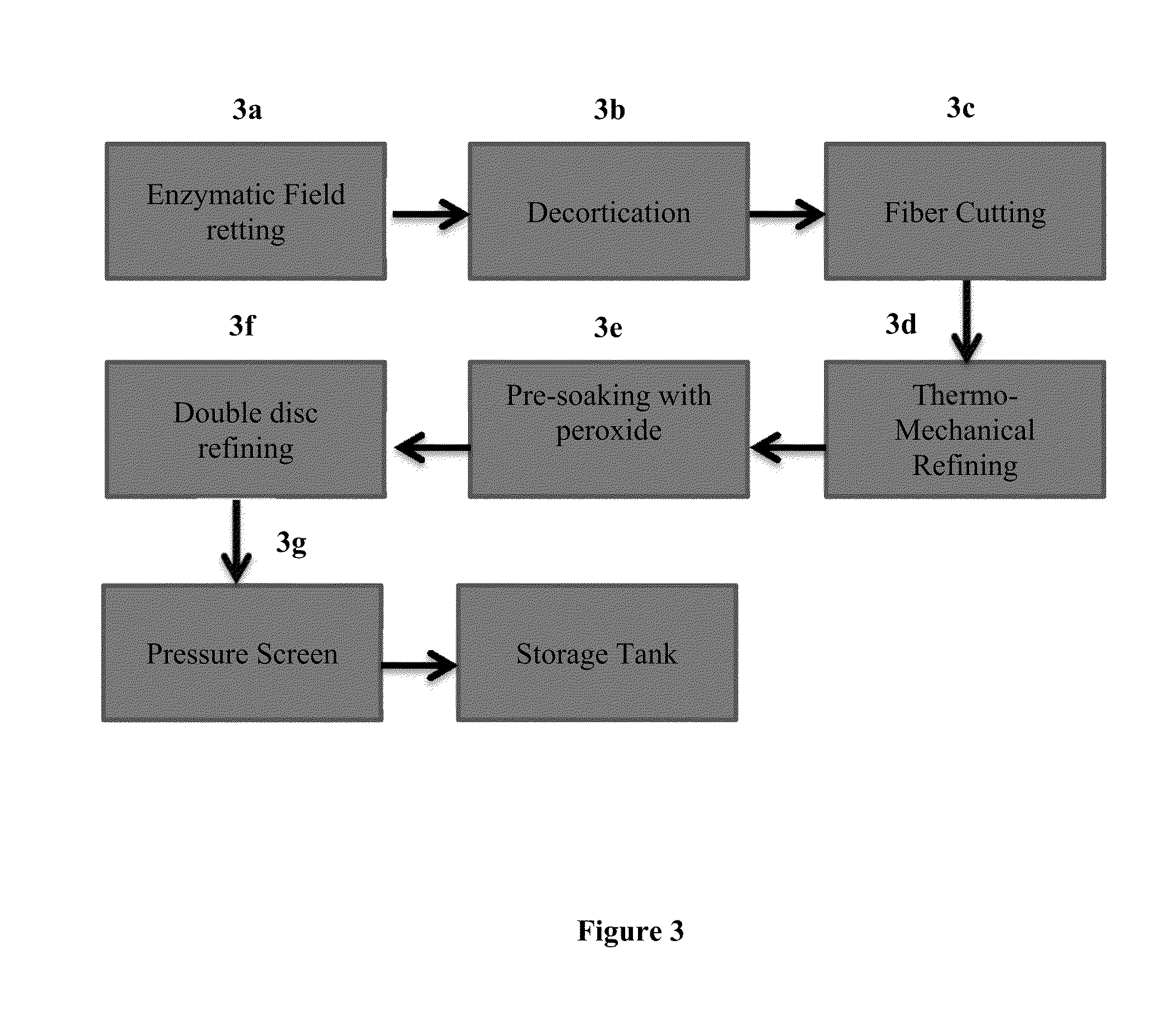

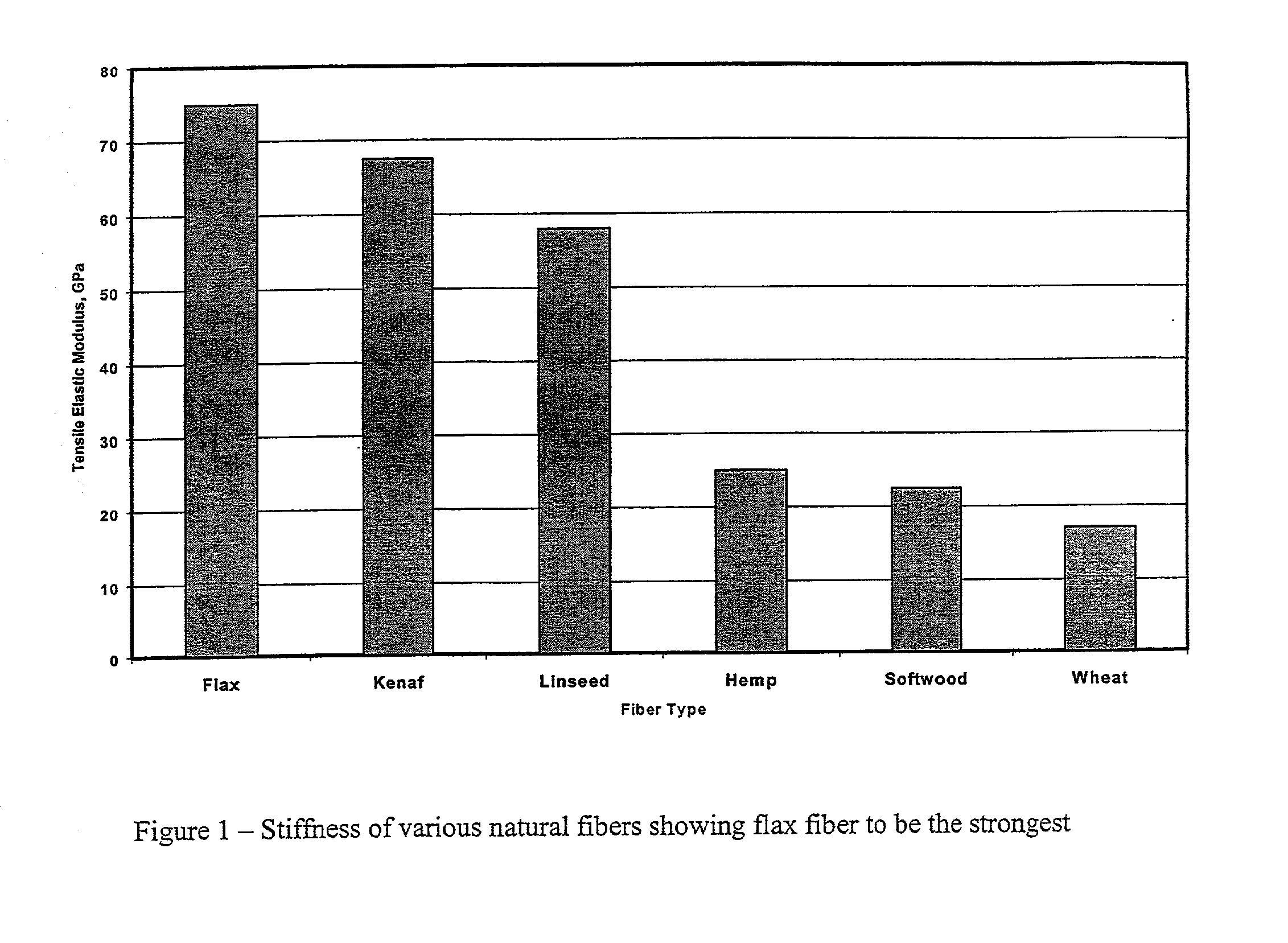

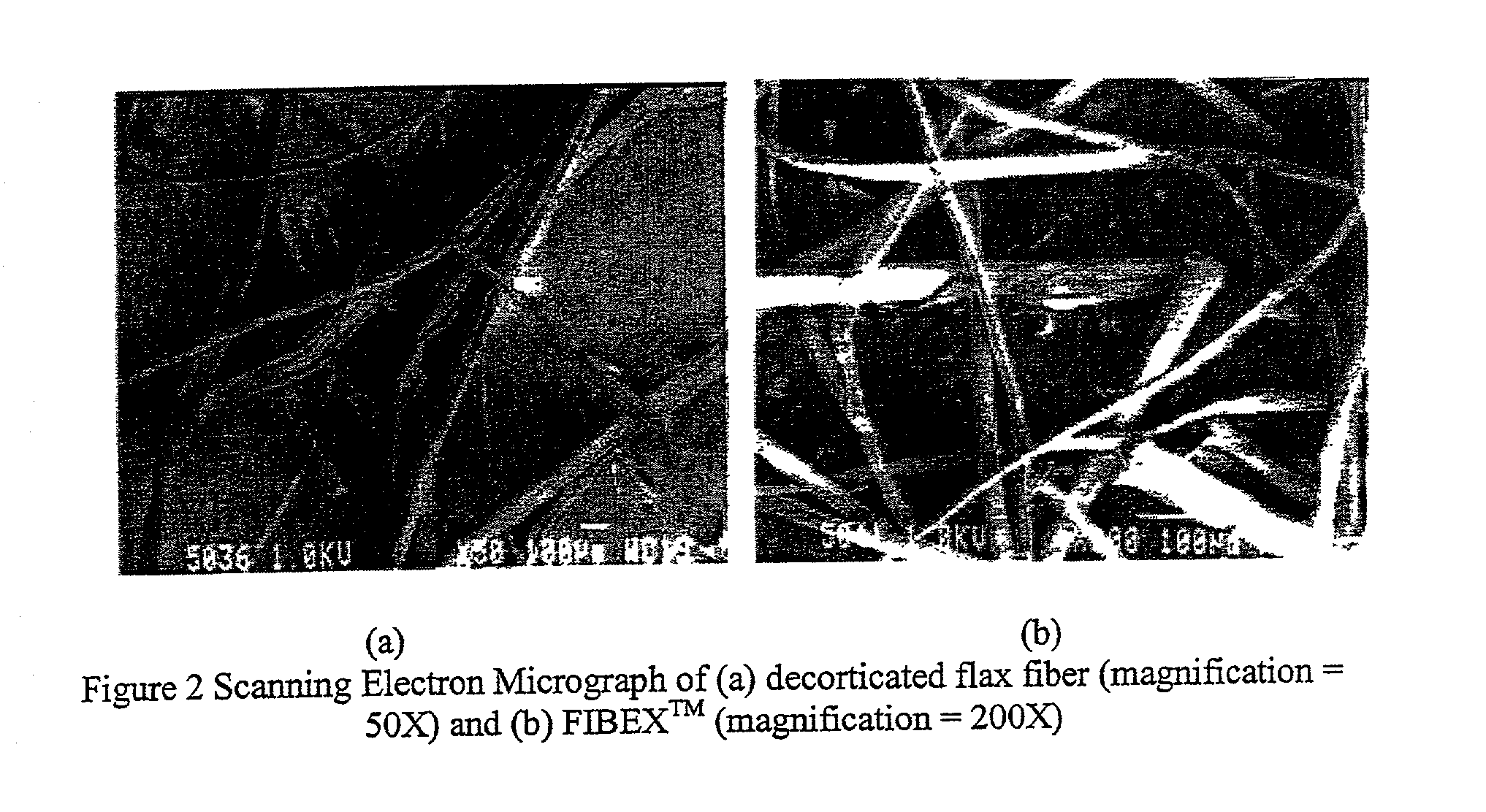

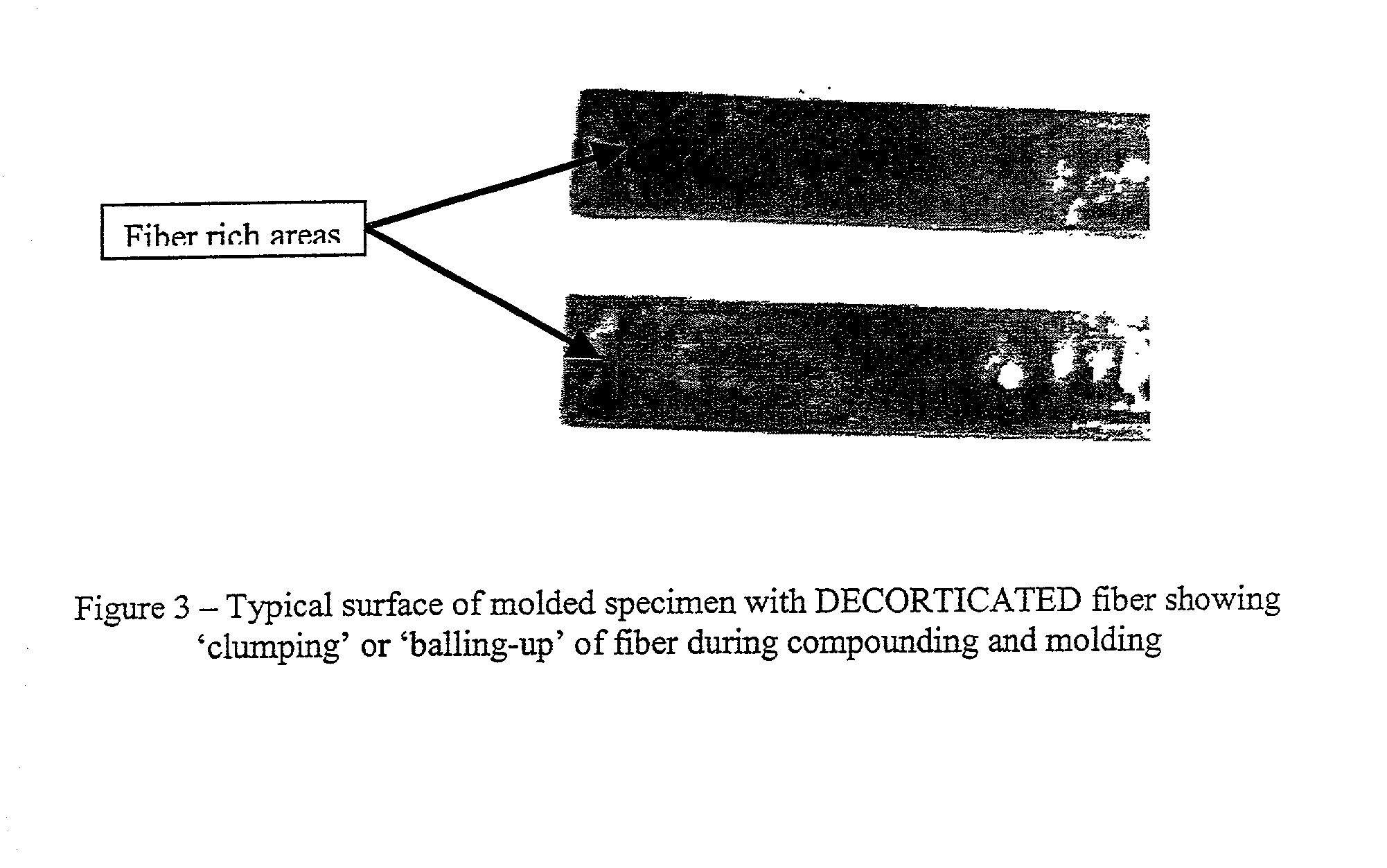

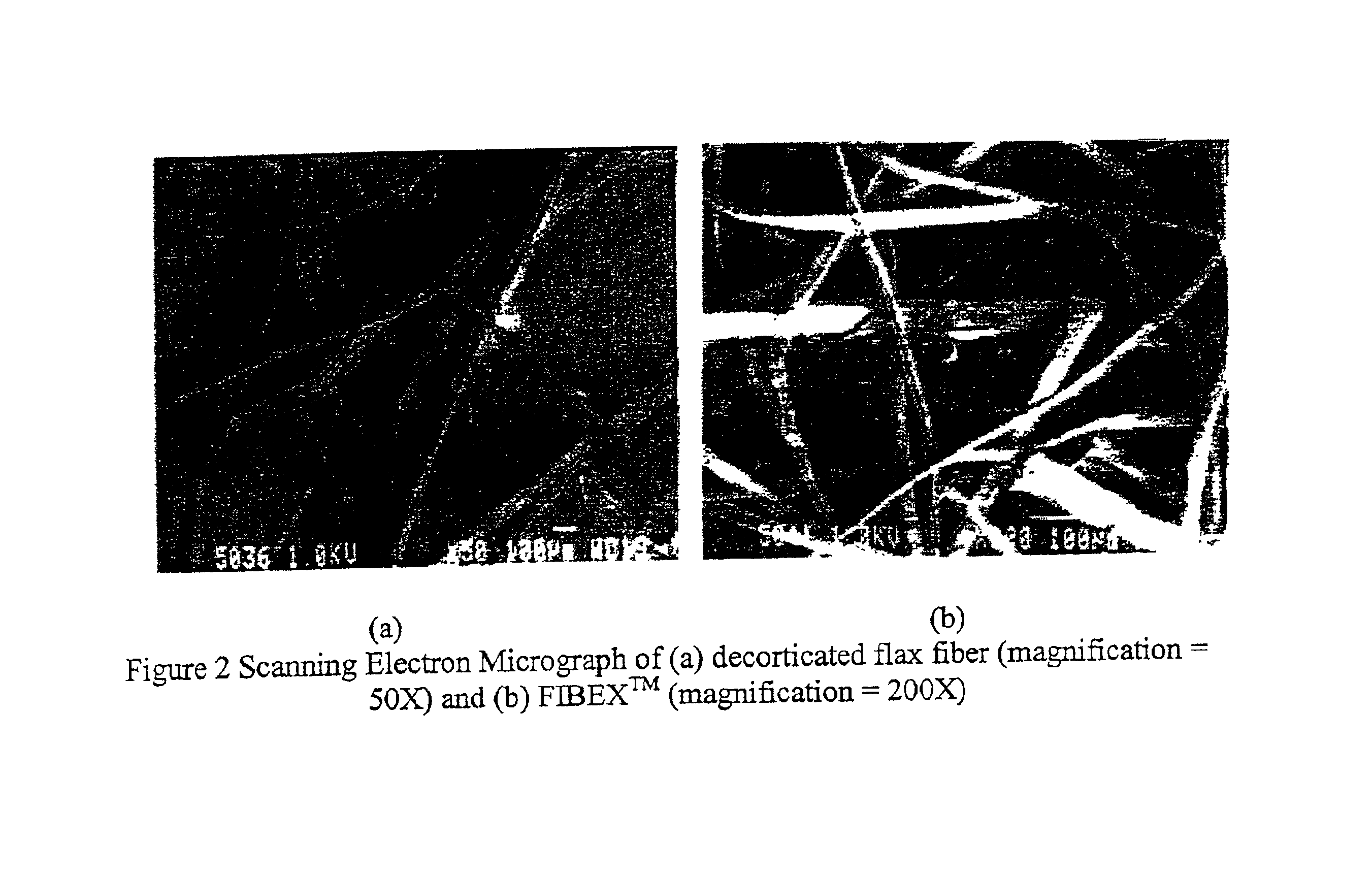

Fibrillated bast fibers as reinforcement for polymeric composites

A decorticated bast fiber such as from flax that is particularly suitable as a reinforcement for polymeric resins, thermoplastic, and thermoset composites. The invention specifically overcomes past difficulties involving compounding and injection molding of composite specimens with bast fiber reinforcements. In one form, ultrasonic energy is applied to decorticated bast fibers to cause fibrillation.

Owner:ENG MECHANICS CORP OF COLUMBUS

Environmental protection type base fibre film, and its mfg. process

ActiveCN1559176AHigh strengthLose weightOrganic fertilisersPlant protective coveringsAdhesiveEngineering

An environmental protection type bast fibre film which is air permeable and impervious is prepared from bast fibres through opening fibres, removing dust and impurities, carding, stripping for netting, airflow netting, chemical sticking by adhesive to become film, applying the hydrophobic agent onto its surfaces, and cold rolling.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Fibrillated bast fibers as reinforcement for polymeric composites

InactiveUS6767634B2Ultrasonic/sonic fibre treatmentMonocomponent synthetic polymer artificial filamentThermoplasticPolymer resin

A decorticated bast fiber such as from flax that is particularly suitable as a reinforcement for polymeric resins, thermoplastic, and thermoset composites. The invention specifically overcomes past difficulties involving compounding and injection molding of composite specimens with bast fiber reinforcements. In one form, ultrasonic energy is applied to decorticated bast fibers to cause fibrillation.

Owner:ENG MECHANICS CORP OF COLUMBUS

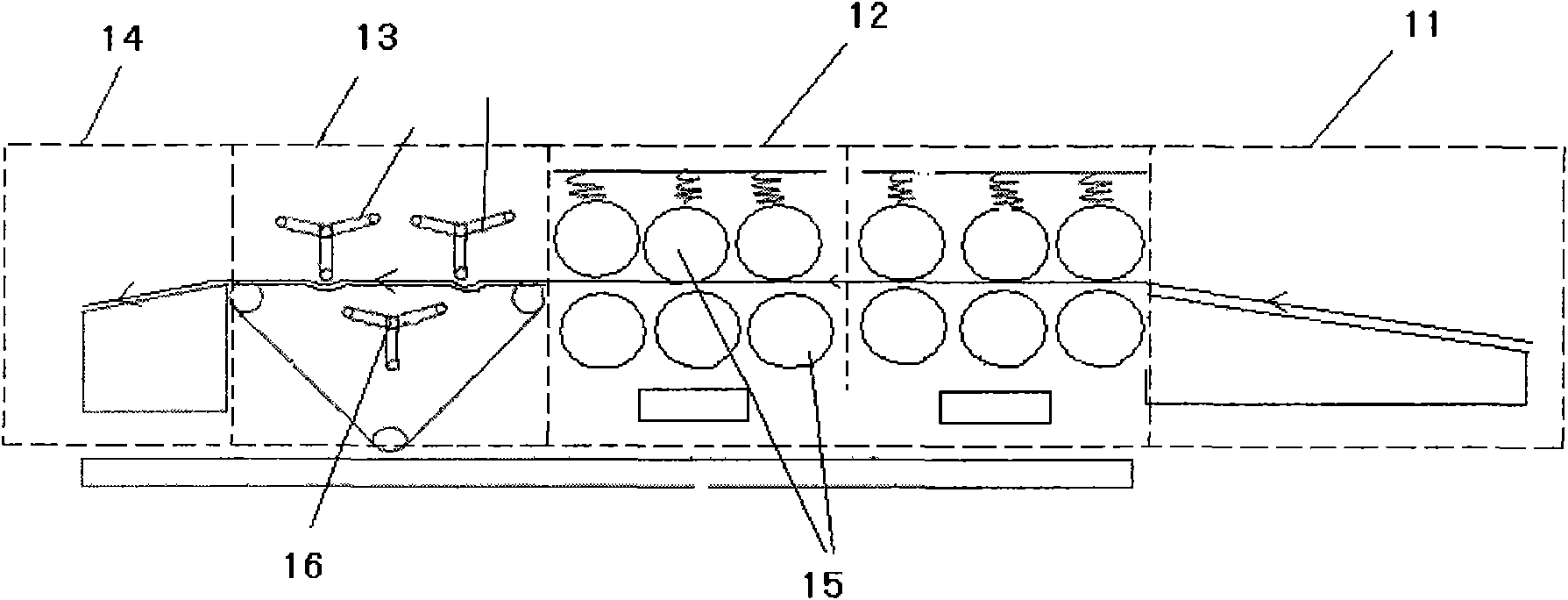

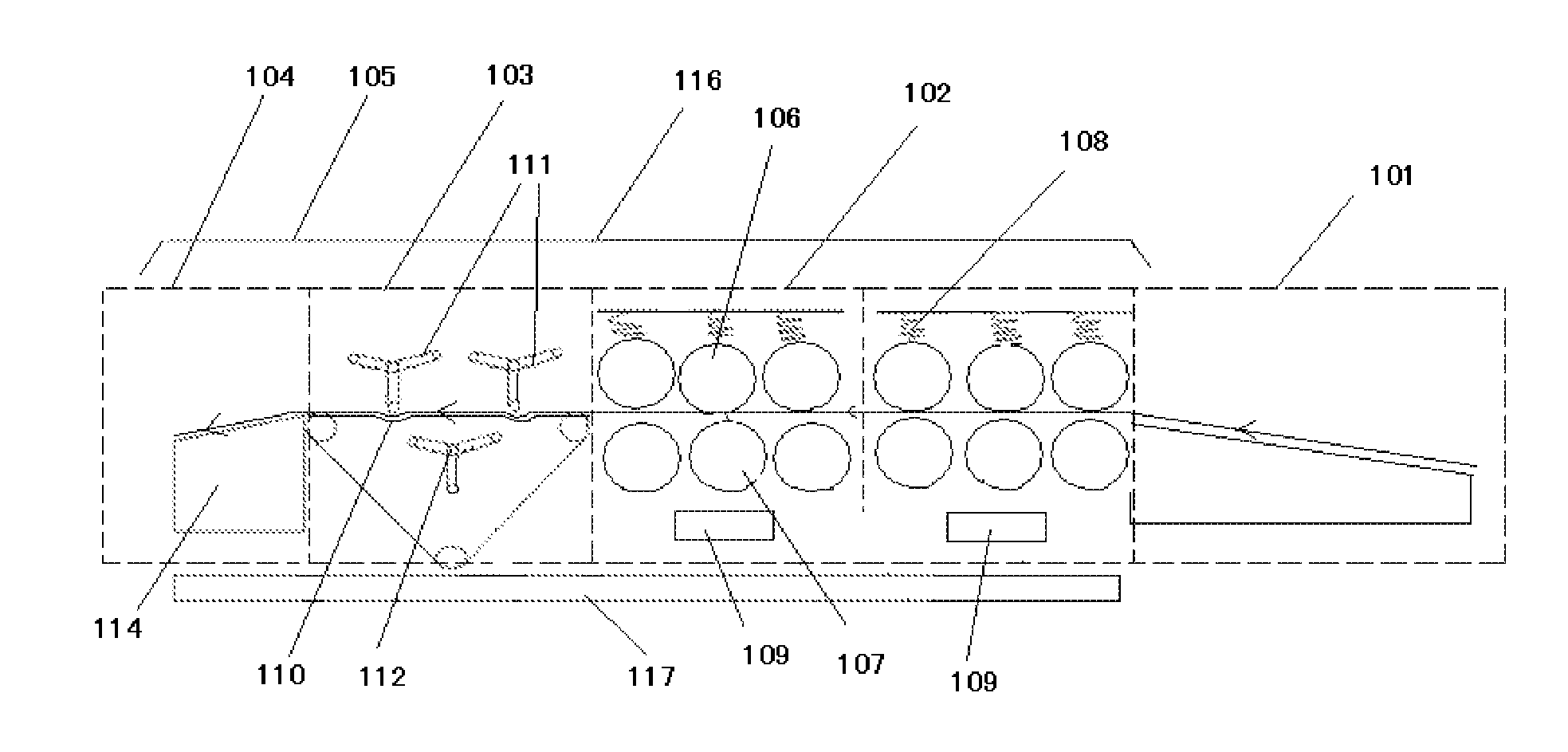

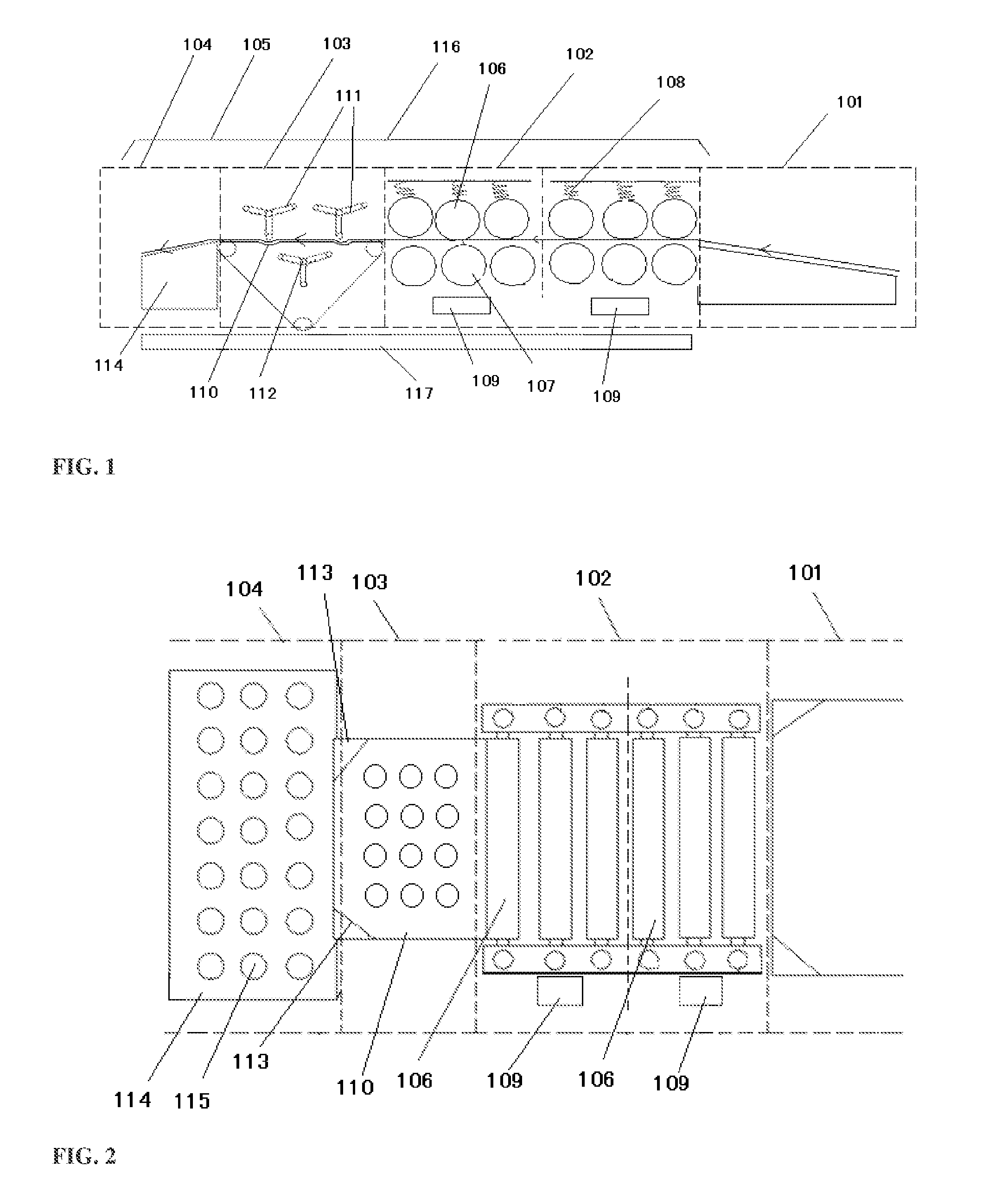

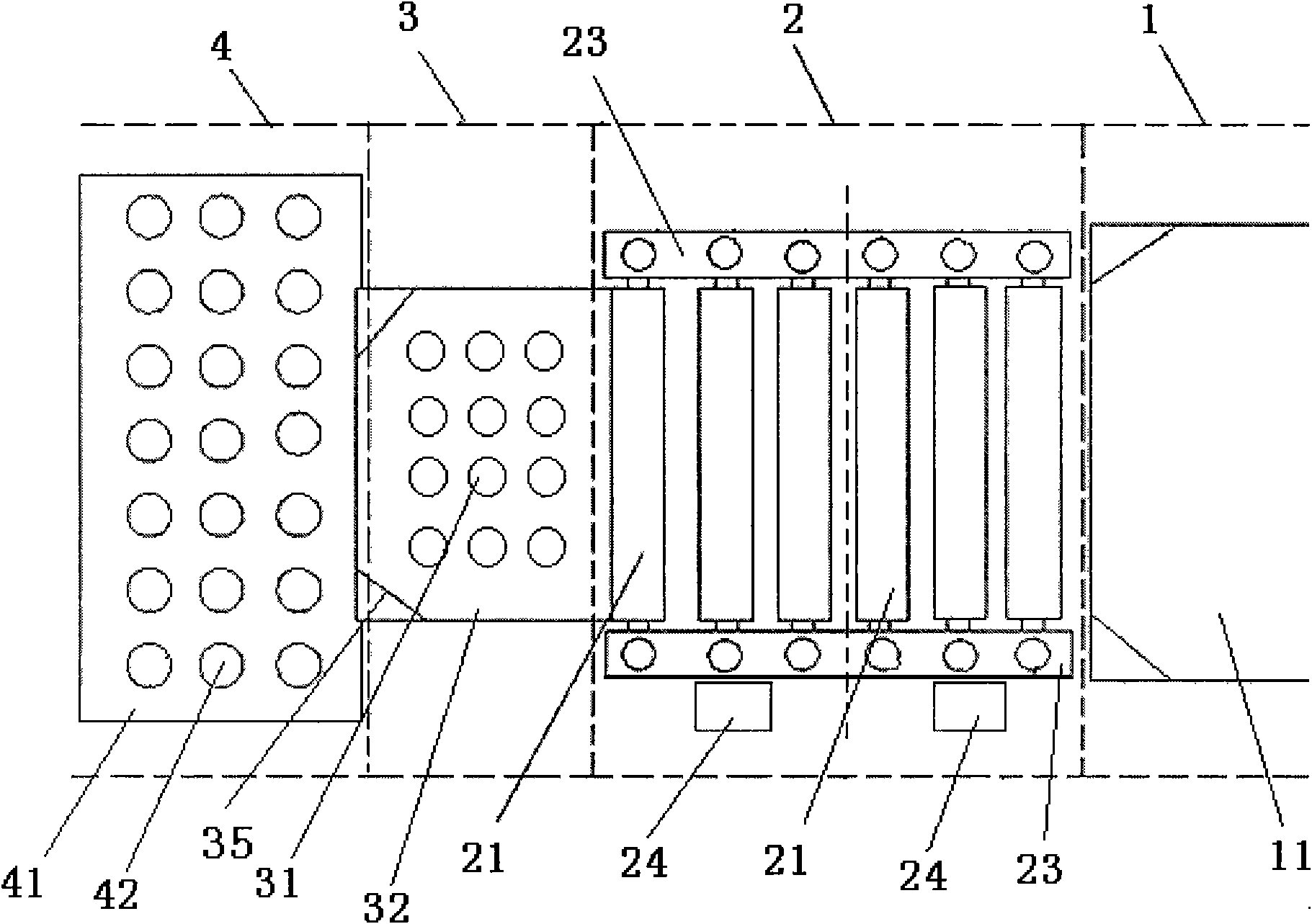

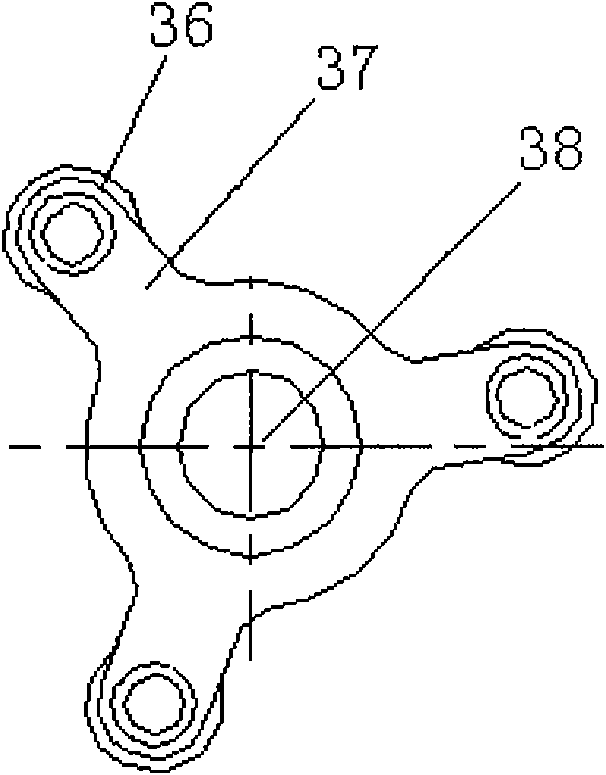

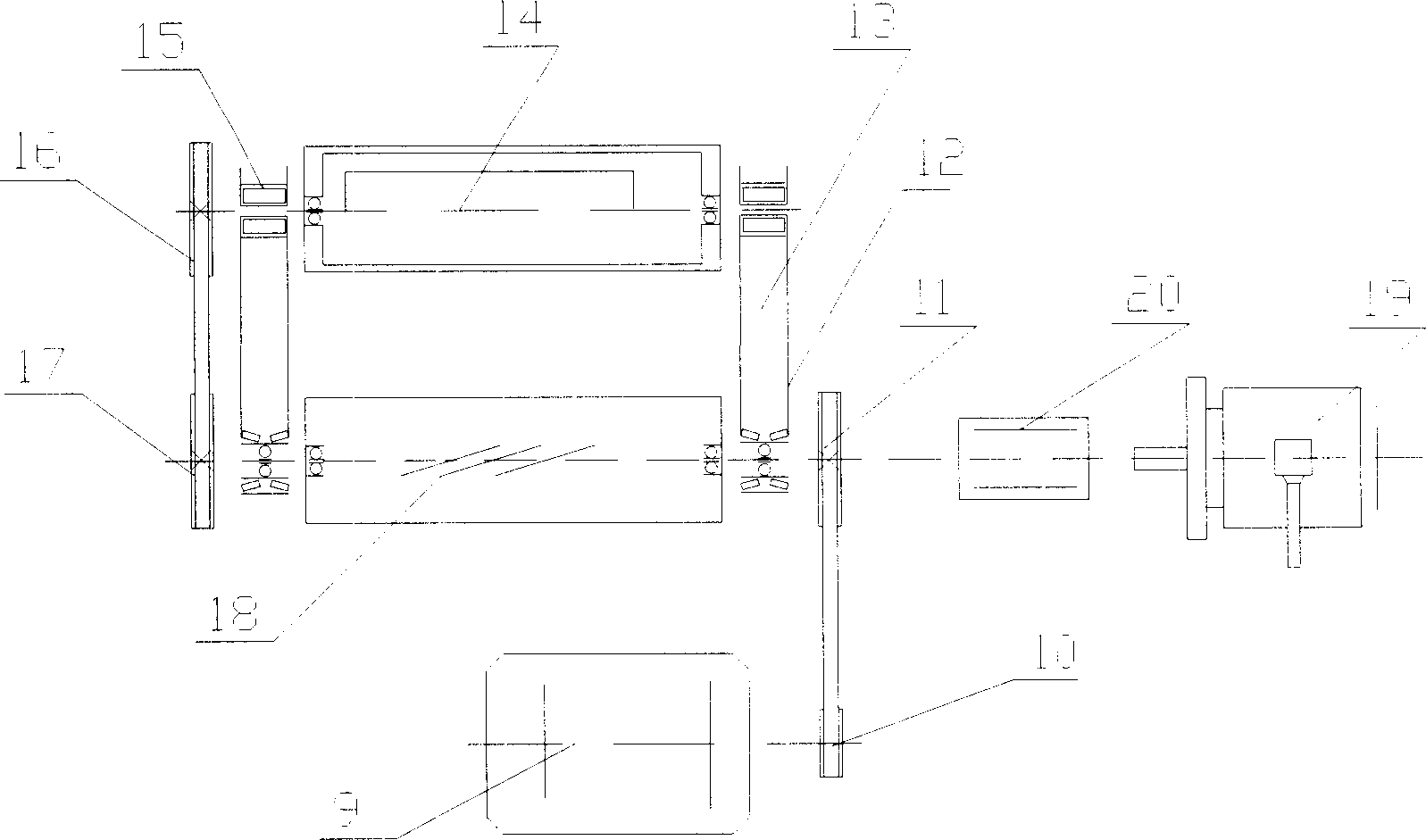

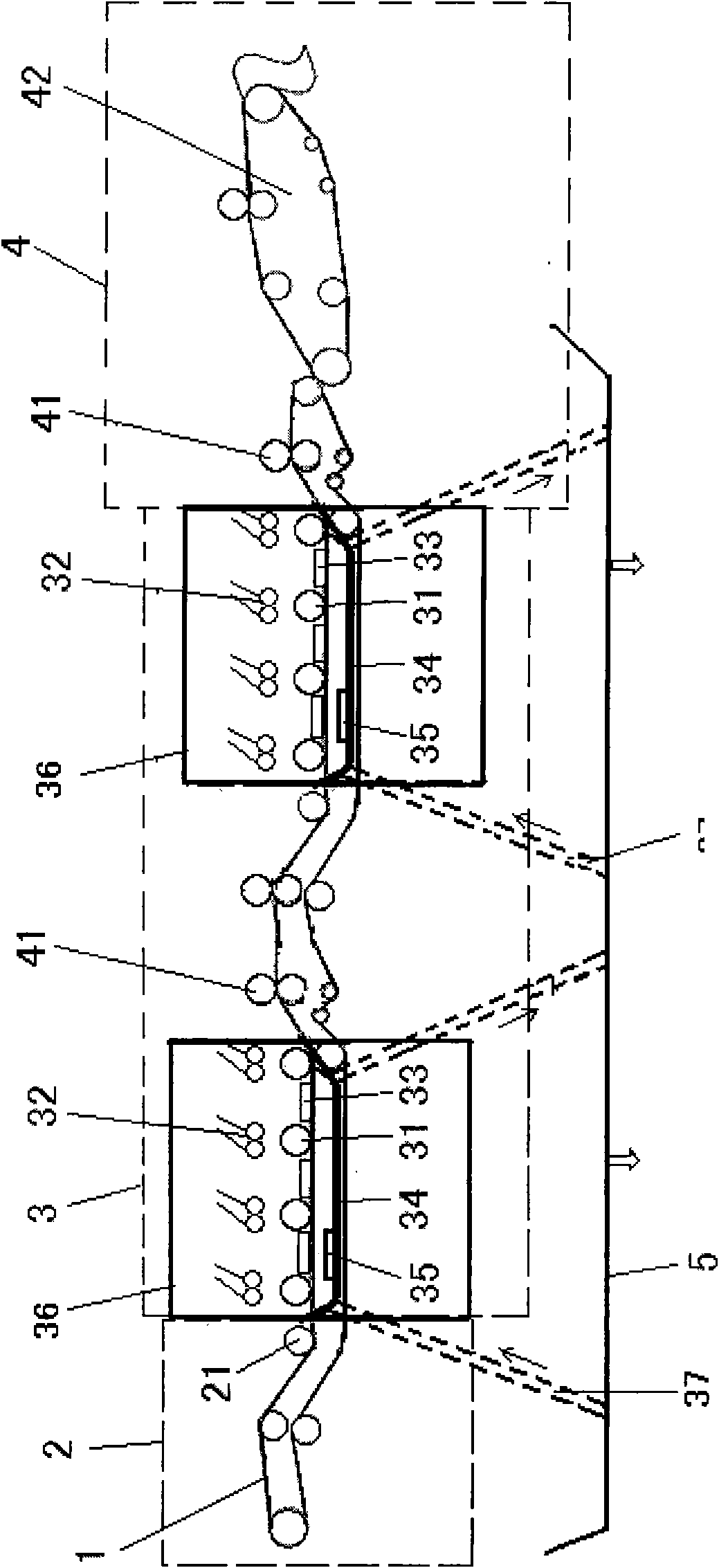

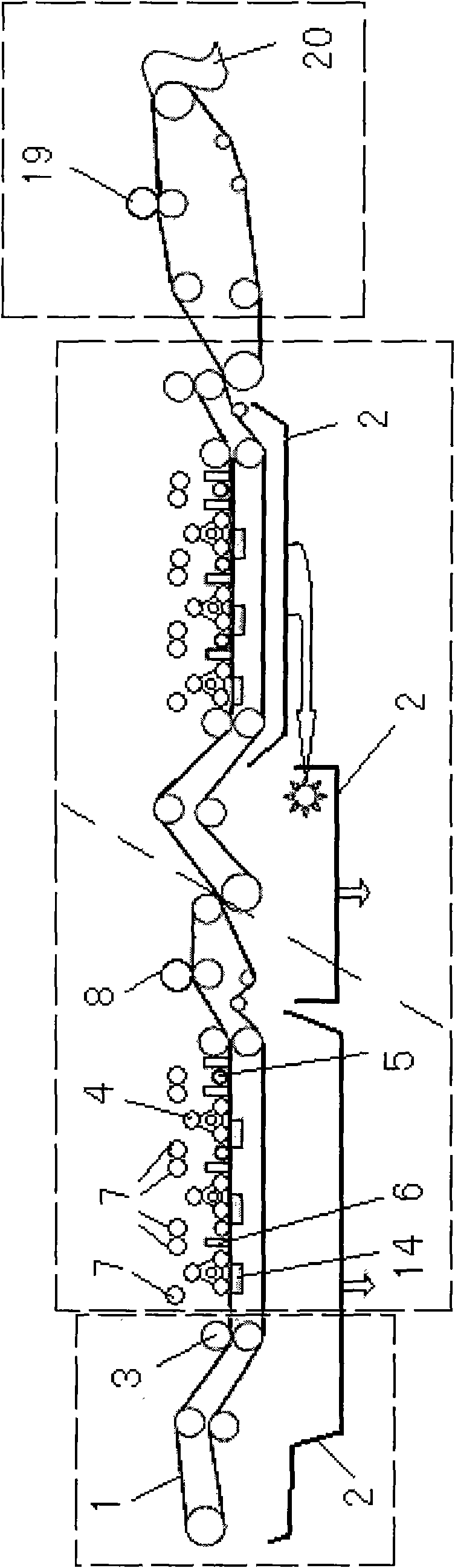

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

Process for the extraction and preparation of bast fibers, bast fibers obtained therefrom and their use

ActiveUS7481843B2Good bulkinessEasy crimpingBleaching apparatusDetergent compounding agentsYarnPolymer science

The present invention generally relates to a process for the extraction and preparation of bast fibers with high quality and high counts. The process is suitable for ramie, hemp and flax. The present invention also relates to bast fibers with high counts produced according to the process, as well as pure yarns and mixed, blended yarns made from said bast fibers.

Owner:XU MEIRONG

Active biological medical fertilizer and preparation method thereof

InactiveCN101139233AGrowth spurtAmazing growth abilityBiocideBio-organic fraction processingMonkshoodsDisease

The present invention discloses an active biological drug fertilizer, which is characterized in that: the present invention is prepared with the fermenting process by photosynthetic bacteria, yellow corrupted acid and the extraction from Azadirachtin, Langdu Root and kusnezoff monkshood. The present invention is with an especial function for killing insect and preventing disease as well as accelerating the growth for the plant, protecting flower and fruit, enhancing the output and improving the integrative performance for the product quality and so on. The present invention is adaptable to the crops including rice, wheat, cotton, cole, bean, earthpea, corn, bast fibre plants, watermelon, fruit tree, vegetable, tobacco leaf, tea leaf, medicinal materials, flower, and pasture and seeding wood and so on. Besides, the present invention has also the function for accelerating the output for the pecan. The prevention and cure objects include: lepidopterans, orthopteran, Diptera, Coleoptera, ring vein, Hymenoptera and acarid and so on. The present invention has the much higher sensitivity to the following pests including: prodenia litura, asparagus caterpillar, cabbage butterfly, tea geometrid, tea smaller green leaf hopper, pecan peachblossom maggot and locust and so on.

Owner:袁进

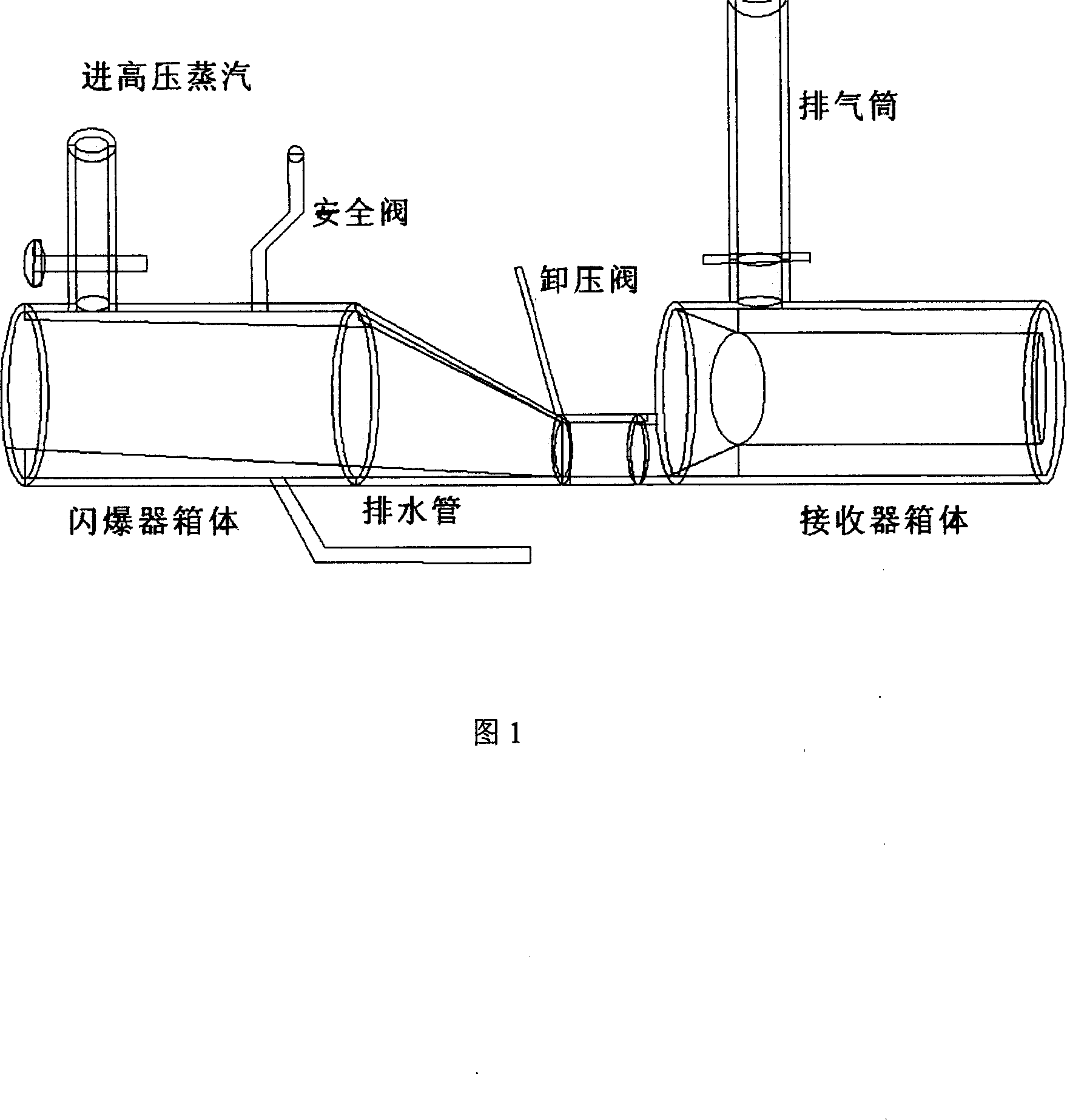

Hemp-like bast fibre flash explosion-high temperature boiling combination degumming technique

The flash bursting and high temperature digesting process for degumming hemp bast fiber includes pre-treatment, flash bursting and high temperature digesting to eliminate residual pectin, hemicellulose and lignin from hemp bast fiber, and raise the fiber fracturing degree and softness. The flash bursting and high temperature digesting process has ideal degumming effect, obvious non-fiber component eliminating effect and less pollution, and the degummed hemp bast fiber has high cellulose rate, high fiber fracturing degree and high fiber flexibility.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Boiling-off method for bast fibre and bast fibre produced by the same

InactiveCN1772976AAchieve economyFully reflect the scientific concept of developmentVegetable materialEngineeringWater content

The present invention discloses a degumming method of bast fibre. Said method includes the following steps: soaking bast fibre in water for 40-80 min, making its water content is 60-100%, then placing the water-contained bast fibre into a steam explosion tank, making steam explosion under the condition of that its pressure is 1.3-1.7 MPa and the pressure-retaining time is 3-8 min, taking out the bast fibre, washing said bast fibre with water and drying so as to obtain the invented degummed bast fibre.

Owner:北京赛特瑞科技发展有限公司

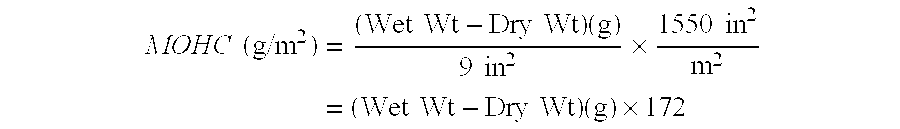

Nonwoven fabrics of short individualized bast fibers and products made therefrom

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin having a mean length less than 6 millimeters. The nonwoven fabric can include staple fibers and / or pulp fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

Cutting device of phloem fiber

The invention relates to a cutting device of phloem fiber, which is characterized in that the cutting device comprises a reverse U-shaped machine frame, one side of the machine frame is provided with a motor, the motor drives a group of worm and gear mechanisms through a transmission mechanism, worm wheels in the worm and gear mechanisms are coaxially connected with a crank disc of a crank connecting rod mechanism, a connecting rod is eccentricly connected on the crank disc, the other end of the connecting rod is connected with a cutter, the cutter spans between two vertical beams of the machine frame and is movably supported on the cross beam of the machine frame, the cutter is provided with a guide block and a guide groove in inclined movement correspondingly to the cross beams of the machine frame, both sides of the machine frame under the cutter are respectively provided with a material inlet support plate and a material outlet support plate, a cutter falling groove right aligned with the cutter is connected between the material inlet support plate and the material outlet support plate, and a hard pad block is arranged in the cutter falling groove. When the device provided by the invention is used for cutting the phloem fiber, the time and the labor can be saved, the cutting length required by the technology can be realized, the manual operation error can be reduced, and the production efficiency is high.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

Paper of electrolytic capacitor and preparation method

InactiveCN1626731AExtend your lifeReduce energy consumptionSpecial paperPaper/cardboardElectrolysisPulp and paper industry

The invention relates to an electrolytic capacitor paper. It adopts multilayer structure formed from one layer of pressure-resisting layer and several layers of absorption layers, and the pulp of pressure-resisting layer paper is one kind selected from wood pulp, agave fiber and grass fiber or their mixture, and the absorption layer paper can be one layer or multilayer structure, and its pulp is one kind selected from fibrila, bast fibre and grass fibre or their mixture. Said invention also provides a method for preparing said electrolytic capacitor paper.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL

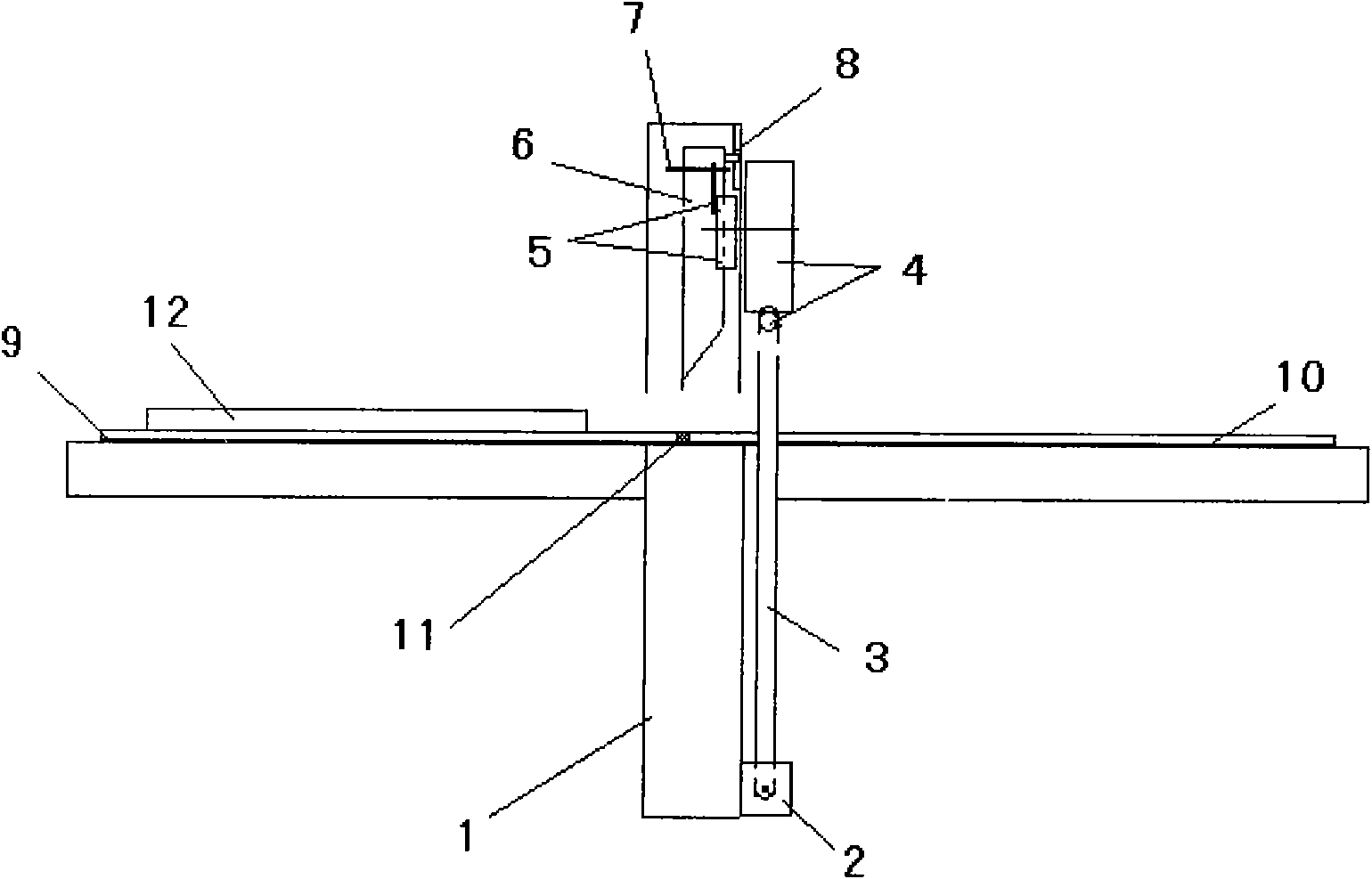

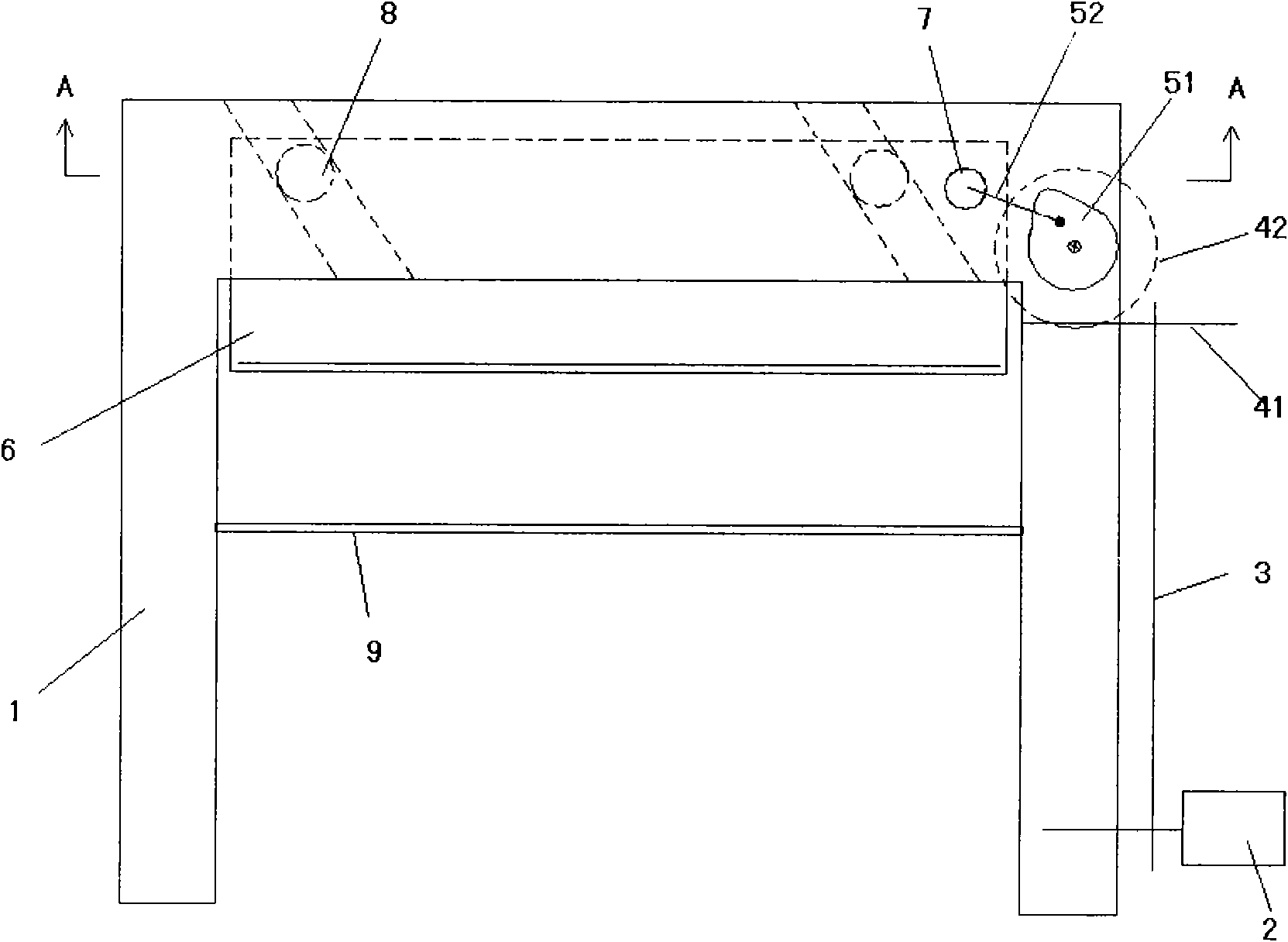

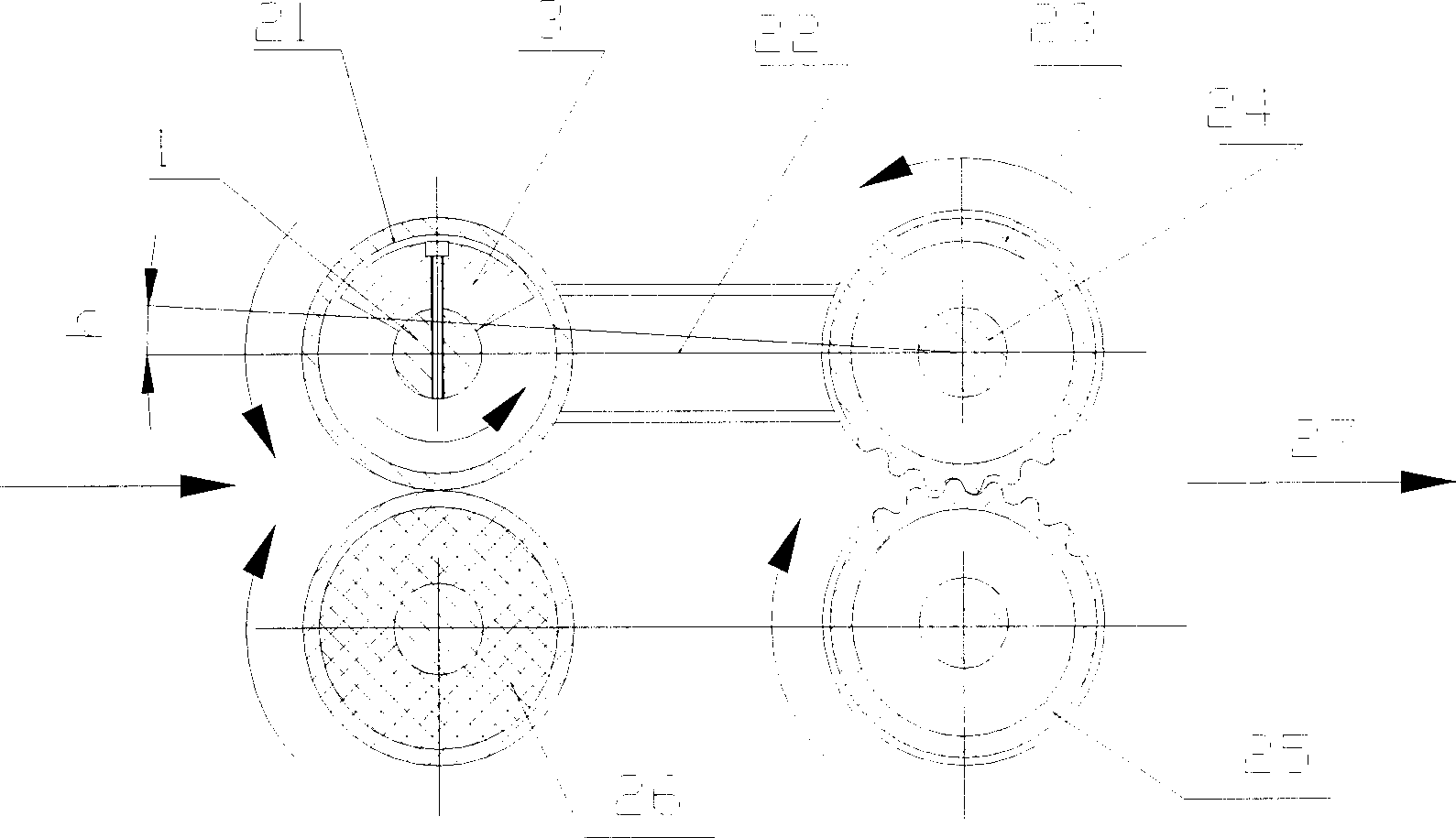

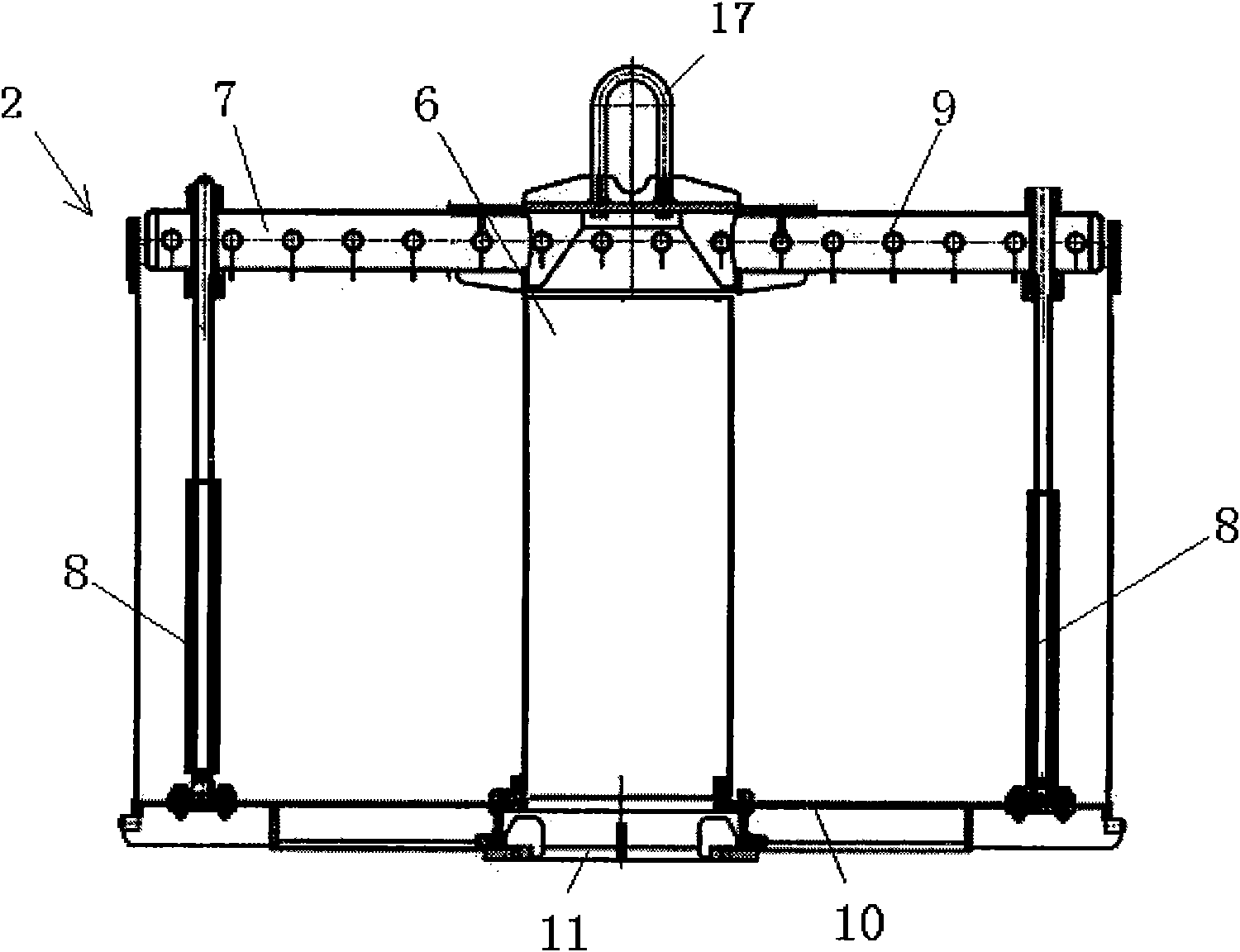

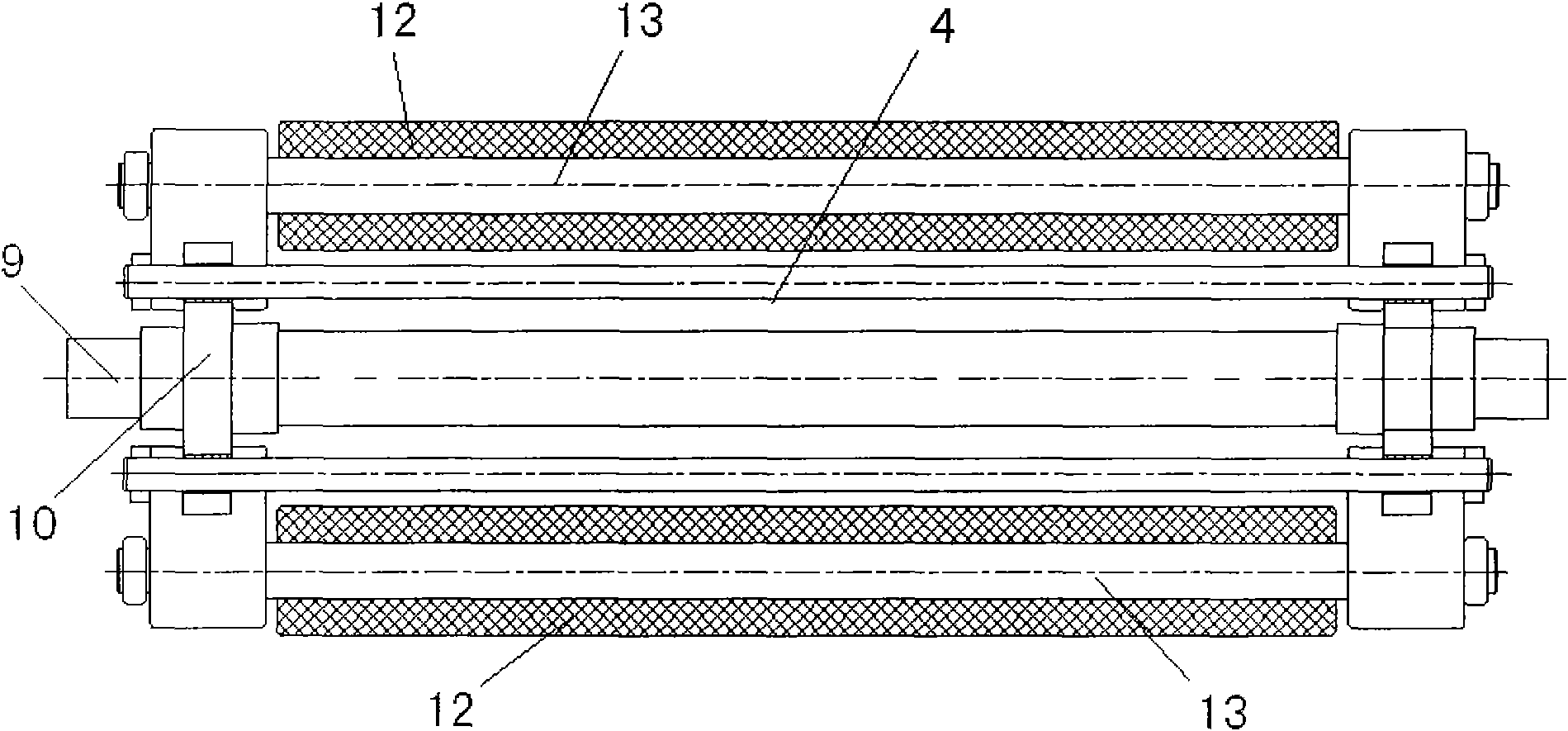

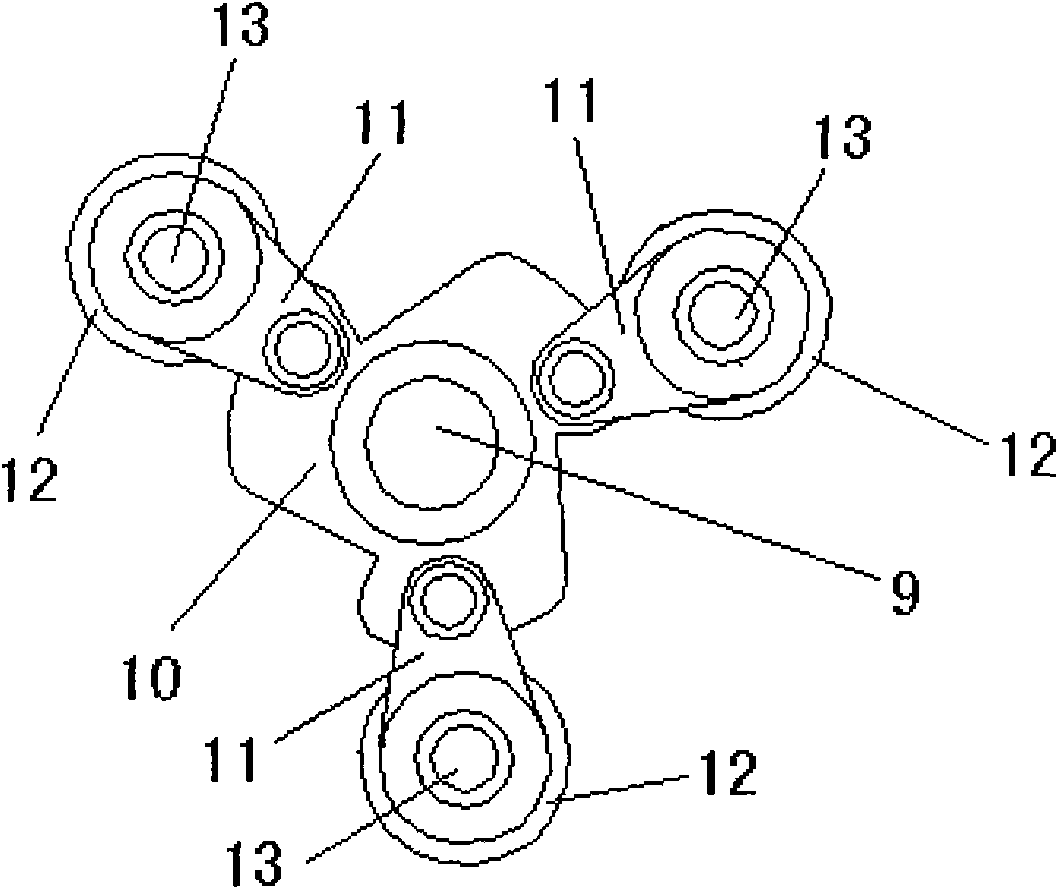

Mechanical degluing method and device of phloem fiber

ActiveCN101824657AHas penetrationUniform degummingMechanical fibre separationElectric machineryEngineering

The invention relates to a mechanical degluing method and a device of phloem fiber. The method of the invention comprises the following steps: 1) spreading and flatly paving phloem fiber in bundles, manually or mechanically feeding the phloem fiber between two rows of upper rollers and lower rollers in arrangement in pairs; 2) driving the upper rollers and the lower rollers to do alternating movement in the positive direction and the reverse direction through a motor, in addition, ensuring that the movement time in the positive direction is longer than the movement time in the reverse direction, and repeatedly extruding, kneading and forwards conveying the phloem fiber; 3) carrying out manual or mechanical oscillation and impurity removal through flapping on colloidal particles and dust on the phloem fiber at the same time of conveying the processed phloem fiber in the second step by a conveying belt; and 4) carrying out manual and mechanical shaking for further impurity removal on the processed phloem fiber in the third step, and then, packing the phloem fiber into bundles. The invention has the advantages of reasonable structural design, ideal degluing effect, small degluing pollution and safe and reliable operation, and can be widely used in the degluing process of phloem fiber, leaf fiber and gramineae fiber raw materials and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

Cationic dye for copolyester slice and fiber and its prepn.

The present invention relates to a kind of cation-dyeable copolyester chip of fibre produced by copolymerization of terephthalic acid monomer, ethylene ester isophthalate-5-sodium sulfonate (potassium sulfonate) monomer and glycol monomer and its preparation method. Said ivnention fibre features cation-dyeability of normal temp. and normal pressure, high contractility, soft hand touch and resisting fuzzy and pilling, can be extensively used for pure yarn or blending with natural fibres of silk, cotton, wool and bast fibre to obtain various shell fabrics.

Owner:DONGHUA UNIV

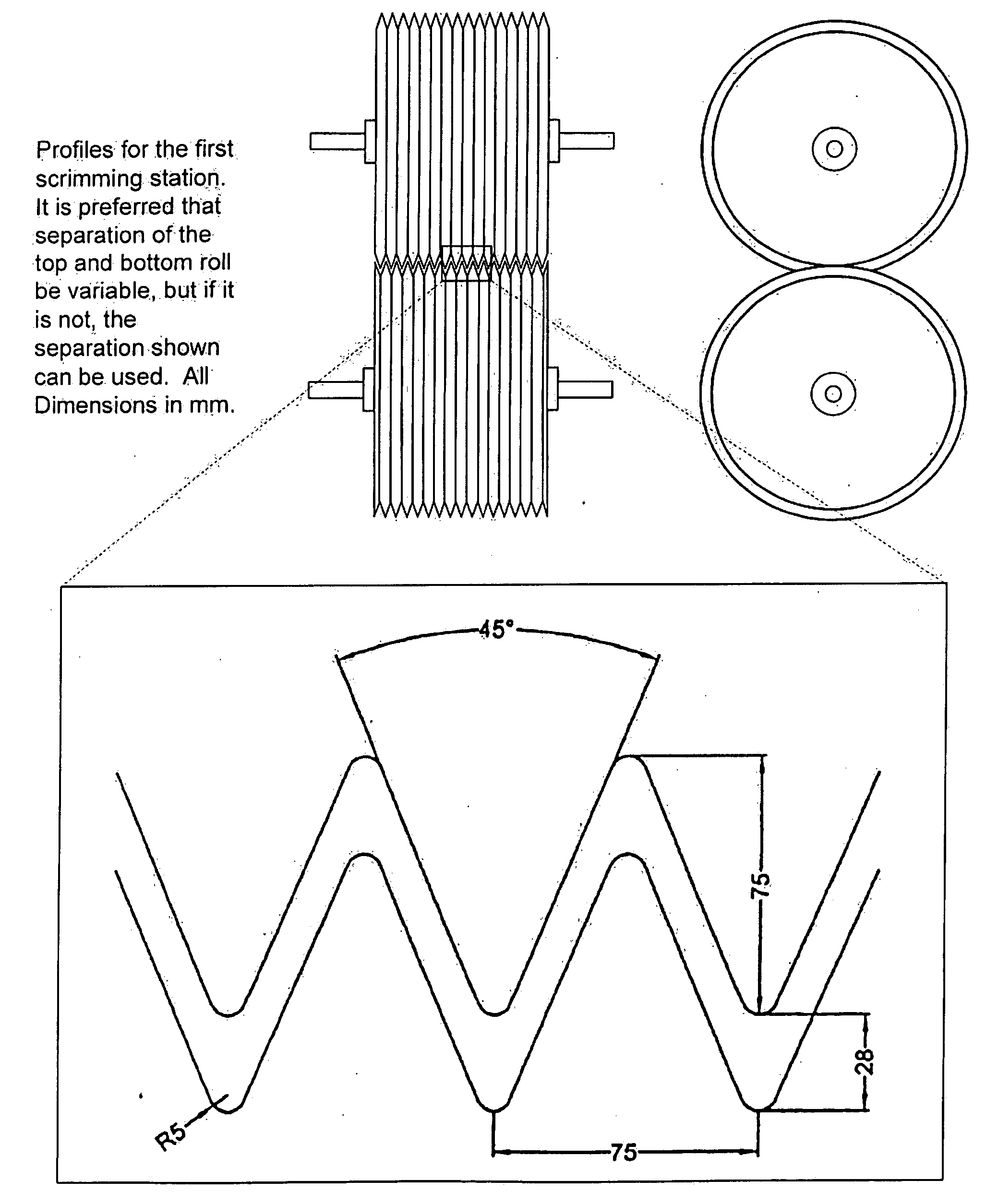

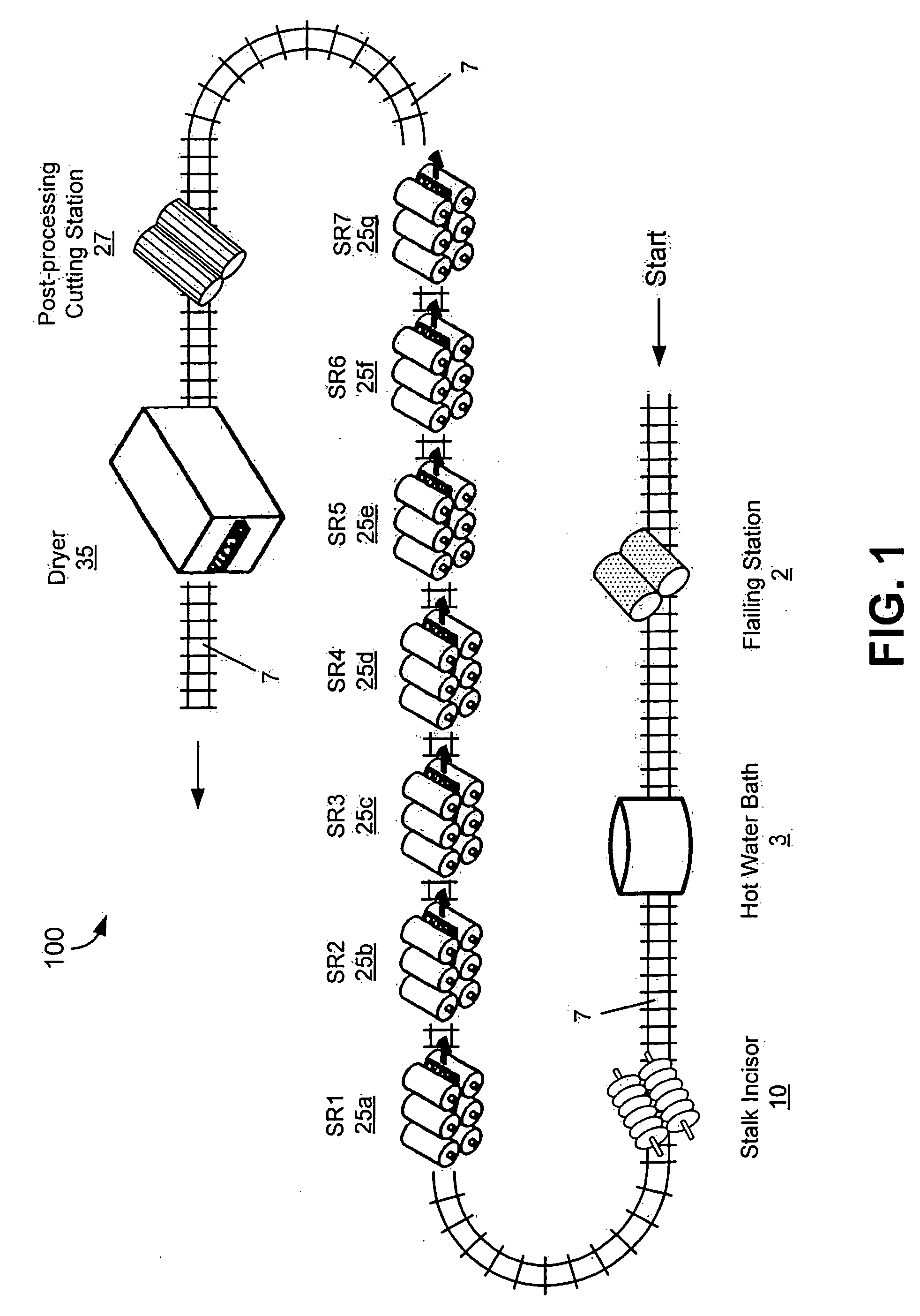

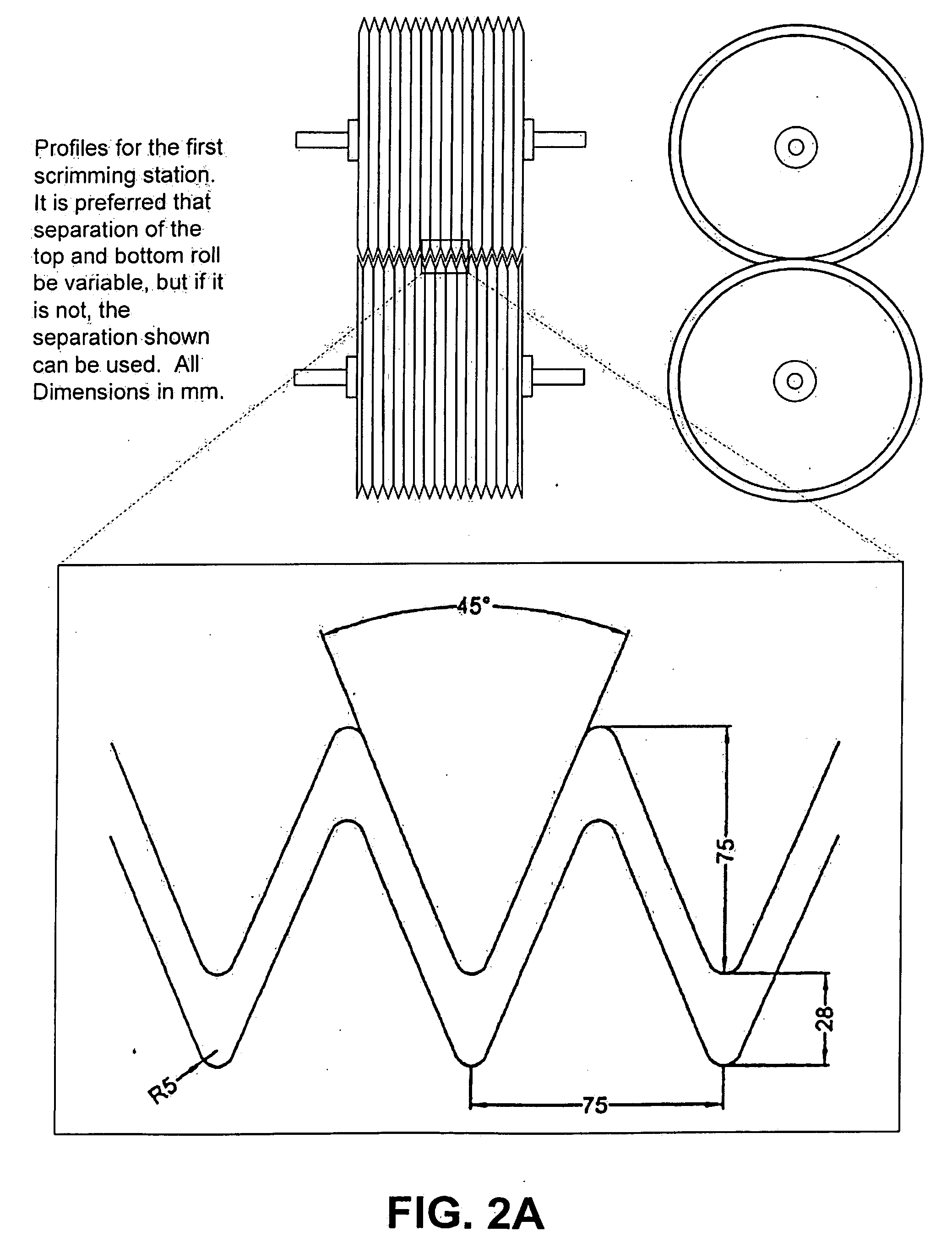

System and method for the separation of bast fibers

InactiveUS20090145563A1Quality improvementEfficient separationFibre cleaning/opening by toothed membersWood working apparatusEngineeringBast fibre

The present invention relates generally to the timber products industry, and particularly to methods and apparatus for the separation of bast fibers. More particularly, the present invention relates to methods and apparatus for use in the separation of inner core from outer bast of bast plants using soaking, cutting, and scrimming methods and apparatuses.

Owner:TIMTEK

Bacterial strain producing phloem fibre degumming enzyme and its application in ramie and hemp degumming

The present invention relates to a strain capable of producing bast fiber degumming enzyme and its application for degumming ramie and hemp, belonging to the field of microbial technology. Said strain is bacillus subtilis No.13, and its preservation number is CCTCC, No.M200038. Its degumming rate can be up to 95%, its degumming effect is good, and its degumming process can be completed within 2-6hr., and the fibre separation index is 100%.

Owner:SHANDONG UNIV

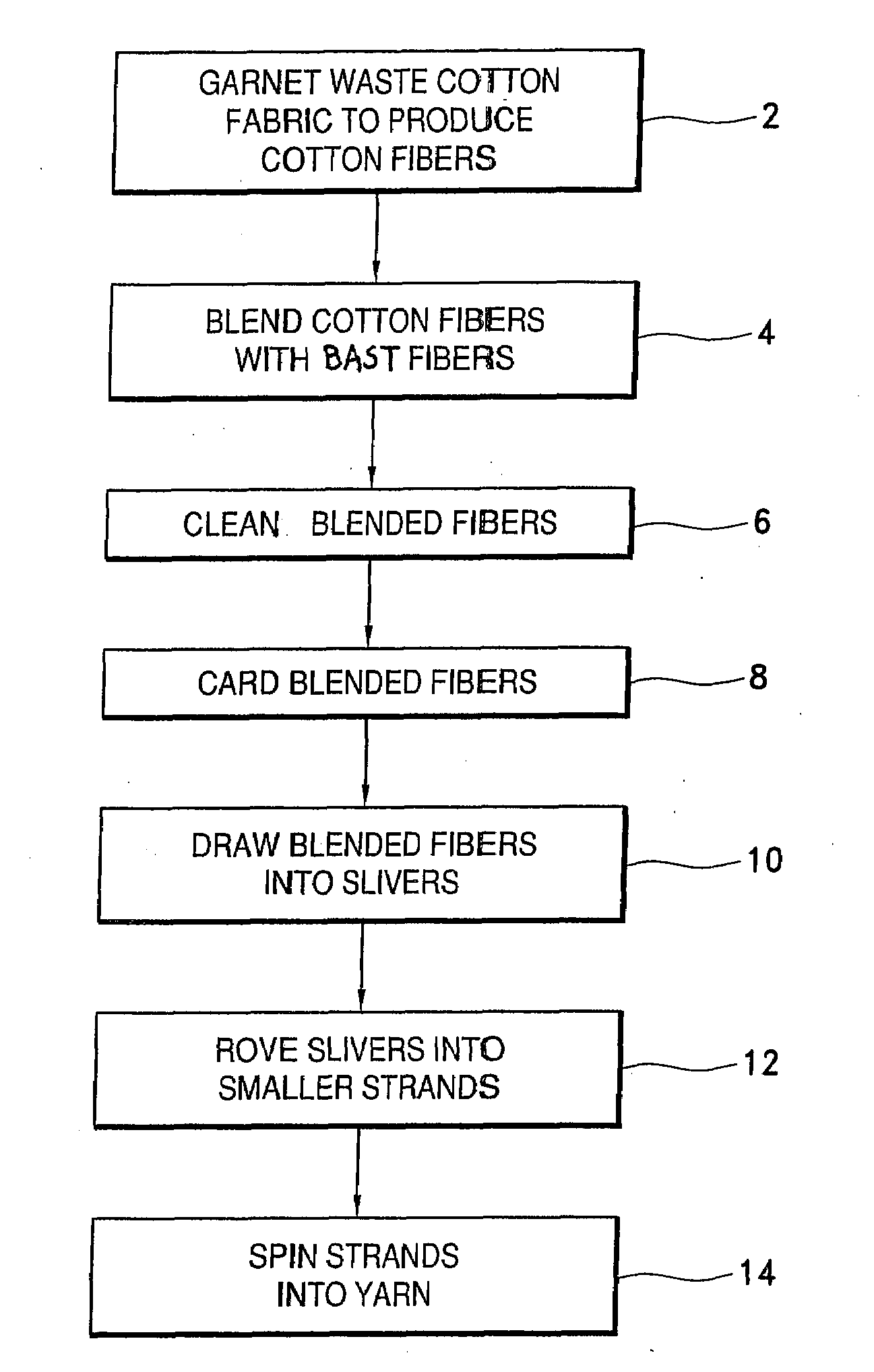

Composite regenerated cotton and bast fiber yarn and method for making the same

A composite bast fiber and cotton yarn is formed by blending natural bast fibers with cotton fibers which have been regenerated from waste cotton material such as trimmings and cuttings from the apparel manufacturing industry. The regenerated cotton and bast fibers are cleaned and blended, then carded to align the fibers into strands. Depending on the size and texture of the desired yarn, the fibers are stretched and drawn into slivers prior to spinning to join the fibers together. The natural bast fibers are up to two and one half to three time longer than the regenerated cotton fibers, so that the natural bast fibers overlap and braid onto the regenerated cotton fibers during spinning. The resultant yarn is stronger and more absorbent than yarns made solely out of regenerated cotton fibers, a blend of regenerated cotton and acrylic fibers, or regenerated cotton and polyester fibers currently available.

Owner:SILVER SCOTT H

Method for producing paper pulp used in rice paper production by broussonetia papyrifera bark through steam-exploding degumming

InactiveCN101487195ALow cost of industrializationHigh yieldFats/resins/pitch/waxes removal in pulpWashing/displacing pulp-treating liquorsCuticleResource utilization

The invention belongs to the field of phloem fiber resource utilization, in particular relates to a method for preparing high-quality paper pulp such as rice paper and the like by steam-explosion, degumming and cleaning of broussonetia papyrifera bark. The method comprises the steps as follows: firstly, the steam-explosion treatment of the broussonetia papyrifera bark is carried out; subsequently, rinsing and bleaching are carried out, thus obtaining the high-quality paper pulp. The no-pollution steam-explosion treatment degrades 80% of the pectin and hemicellulose and part of the lignin in the broussonetia papyrifera bark fiber, completely separates the external epidermis (black skin) of the broussonetia papyrifera from the internal layer phloem thereof simultaneously, and removes the black tissue of the external epidermis by the bleaching; furthermore, during the steam-explosion process, the bark fiber is torn to a loose structure, which leads the chemical drug to sufficiently permeate during the bleaching process and improves the whiteness of the paper pulp. The method reduces the industrial cost of the papermaking by broussonetia papyrifera bark, avoids the environmental pollution caused by chemical pulp preparation process and can improve the yield and quality of the paper pulp; and the paper pulp can be used for preparing high-quality paper such as rice paper, bank paper and the like. The invention provides a new method for clean high-value utilization of the broussonetia papyrifera bark resource and generates greater economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for raising dyeing performance of linen through modification by use of 1-butyl-3-methylimidazolium chloride ionic liquid

According to the invention, bast-fibre or fabric is used as a raw material and can be modified by the use of a 1-butyl-3-methylimidazolium chloride ionic liquid ([Bmim]Cl) to substantially raise the dyeing performance of direct dyestuff or reactive dye on linen. The advantage of the invention lies in that 1-butyl-3-methylimidazolium chloride ionic liquid ([Bmim]Cl) is a high-efficiency cellulose swelling agent and has a simple treatment process. In addition, it is safe and nontoxic when processing by the use of the ionic liquid, and the ionic liquid can be recovered and utilized after the treatment, so as to reduce discharge of a large amount of high-density alkali waste liquid after traditional treatment. The dyeing performance of the modified bast-fibre or fabric, such as ramie, flax and hemp can be raised. High dye uptake can be also reached even without the addition of salt, which helps minimize the amount of salt during the dyeing process and reduce the dyeing cost.

Owner:JIANGNAN UNIV

Vibration roller fiber-opening method and fiber-opening machine

InactiveCN1667162AIncrease productivityReduce labor intensityMechanical fibre separationBand shapePulp and paper industry

The invention discloses a mode of vibration roller fiber separating method and the machine. There are several pairs of vibration roller in fiber separating box, the upper roller is vibration that is vibrating at a certain frequency, and the down roller is a steel anvil roller. The upper roller and the down roller are arranged interval. The fiber raw material after boiling-off would pass the vibration roller through the upper roller and the down roller, and would be beaten continuously, equably and fast by vibration roller in water.

Owner:SICHUAN TEXTILE SCI RES INST

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS9988763B2Reduce manufacturing costLose weightNon-fibrous pulp additionPulp bleachingCelluloseBleach

Owner:FIRST QUALITY TISSUE LLC

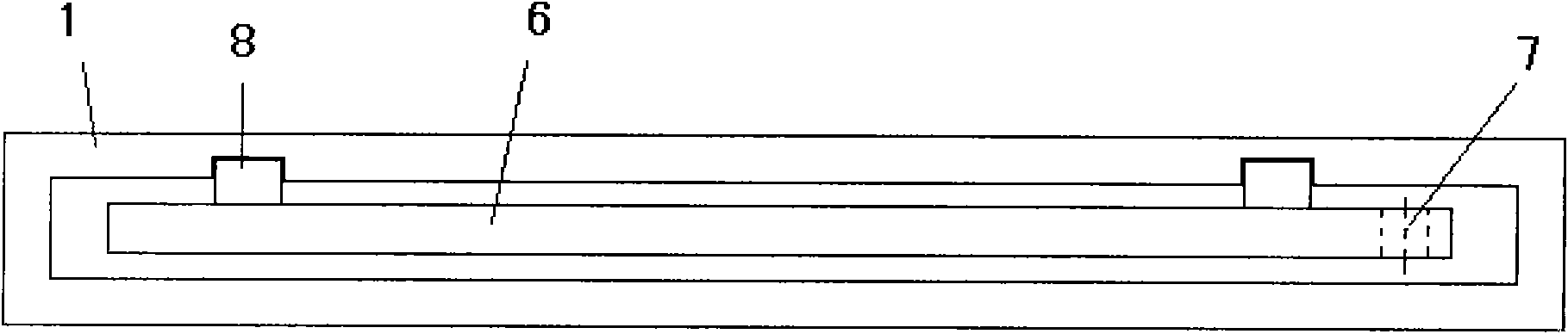

Method and device for rinsing and softening fiber bundles

ActiveCN101824715AGuaranteed to be straightIncrease profitTextile treatment machine arrangementsDry-cleaning apparatus for textilesFiber bundleBand shape

The invention relates to a method and a device for rinsing and softening fiber bundles, which is characterized in that a rotatably running mesh pedrail is arranged on a stander, and at an input end of the pedrail, fibers are conveyed forwards through a feed roller along with the pedrail, and are carded through a group of splitting rollers arranged at intervals, sprayed with water through a water spray pipe, soaked in hot water in a hot water tank, and conveyed forwards through the pedrail simultaneously; at an output end of the pedrail, water is squeezed from the fibers by a pair of water squeezing rollers, and then the fibers are sent to a cloth arrangement machine; and the zonary fibers are processed into folded fibers through the cloth arrangement machine to fall into a fiber storage box. The invention can be widely used in the processing of washing, softening, bleaching and the like of various degummed bast fibers, grass fibers, leaf fibers and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

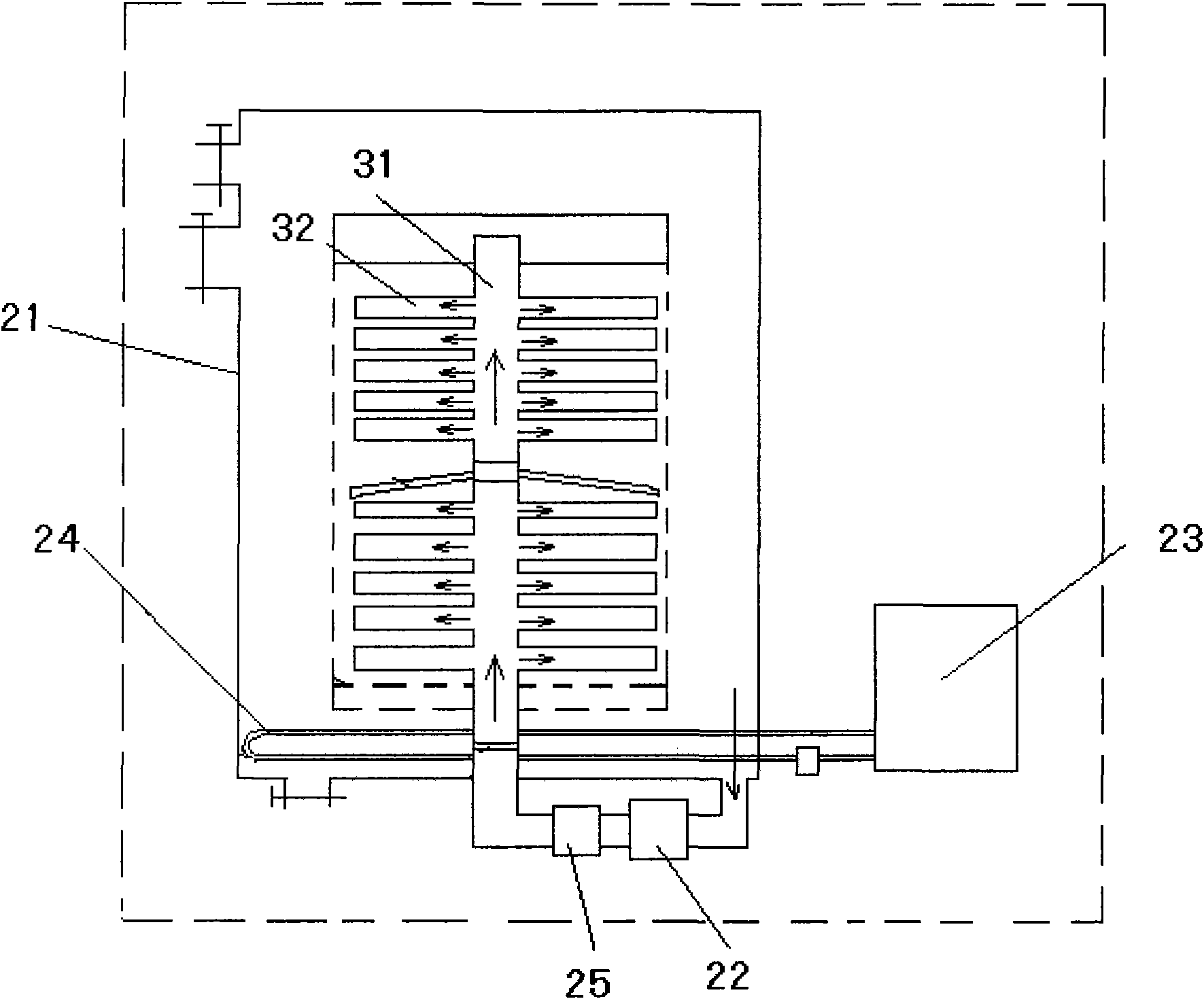

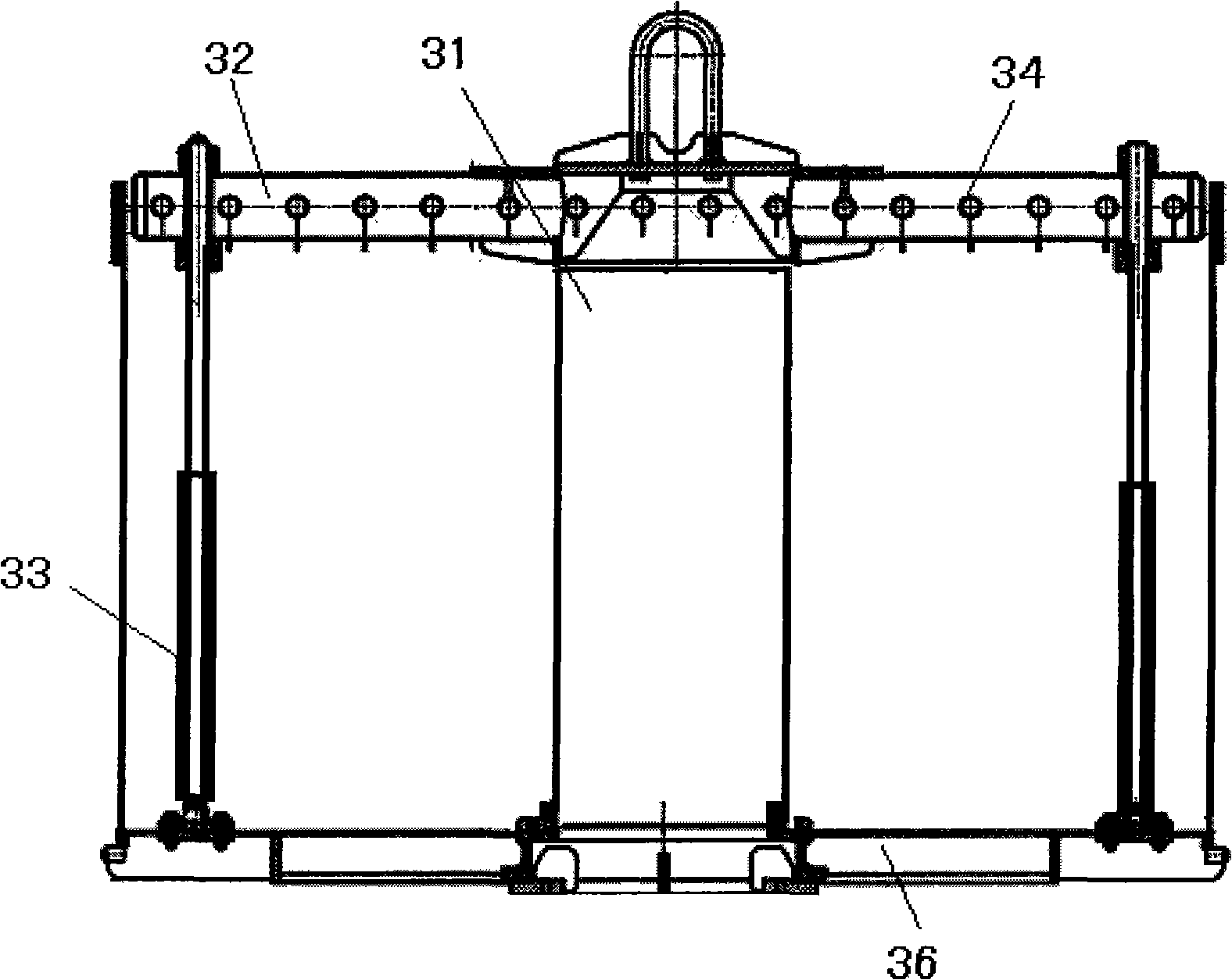

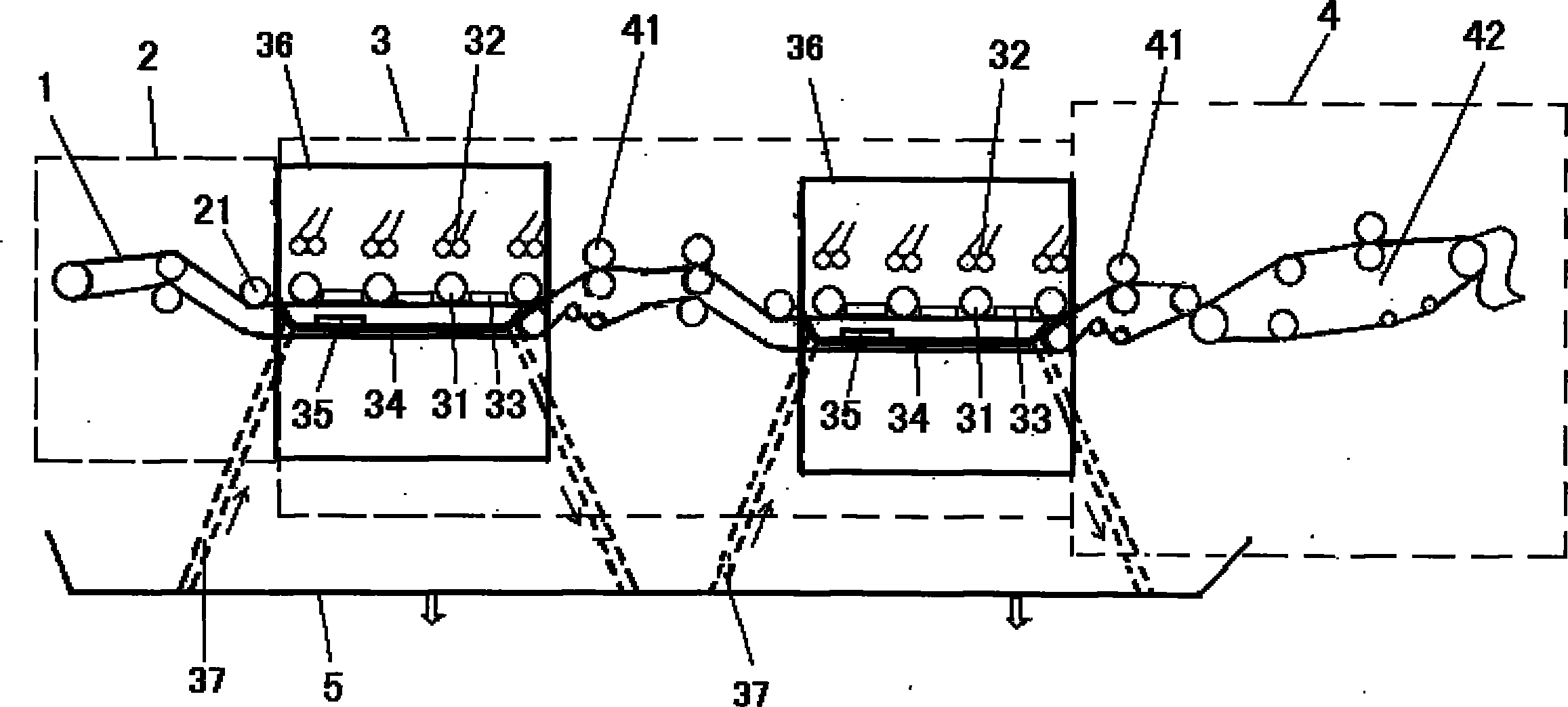

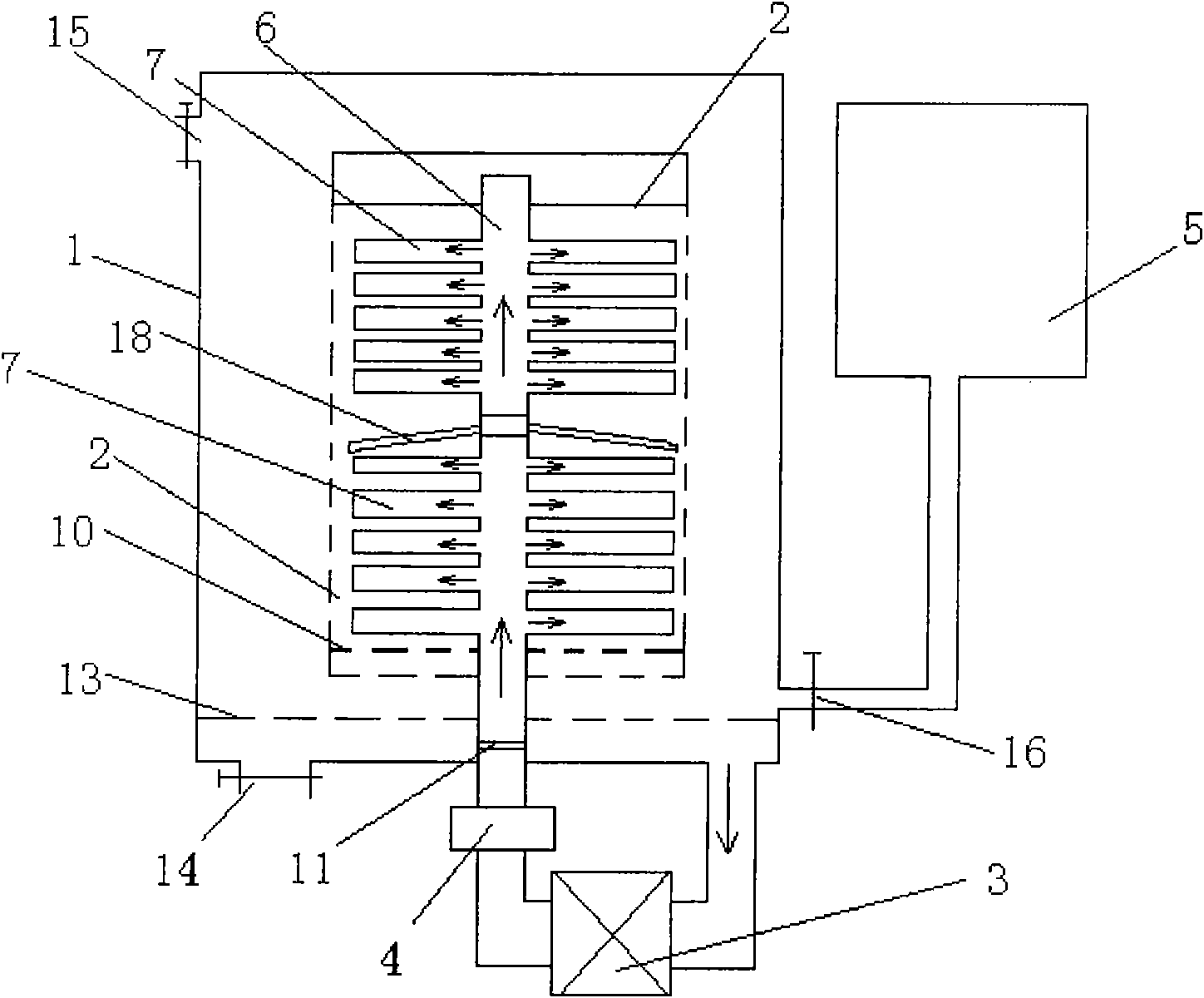

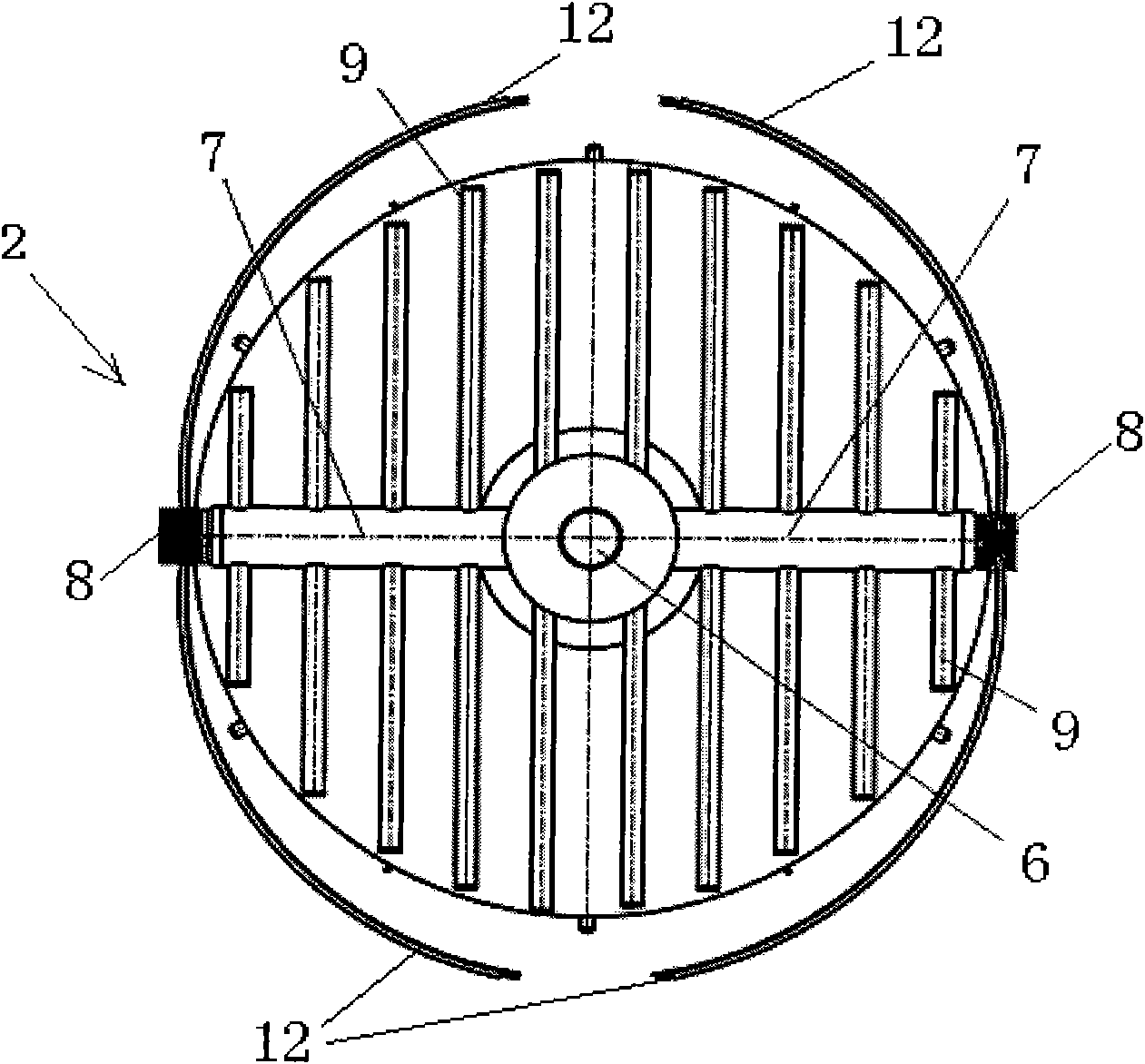

Liquid circulation processing device and method for bast fibers

ActiveCN101838895AReduce dosageGuaranteed normal needsTextile treatment machine arrangementsTextile treatment with treating outlet contectYarnAfter treatment

The invention relates to a liquid circulation processing device and a liquid circulation processing method for bast fibers. The method comprises the following steps of: 1) hanging the bast fibers or yarns in bunches on an extension bar of a yarn hanging device in parallel; 2) serially connecting a plurality of yarn hanging devices, and putting the yarn hanging devices in a main vat; 3) adding chemical agents into the main vat through an auxiliary vat, and opening a main pump and a heat exchange device; and 4) after treatment fluid is pumped into a hollow column of each yarn hanging device, spraying the treatment fluid on the bast fibers or yarns through holes on each extension bar and spraying holes on each extension bar. The device used by the liquid circulation processing method for the bast fibers and yarns is characterized by comprising a barrel-shaped main vat; the yarn hanging devices are arranged inside the main vat; the main pump is arranged outside the main vat; a water inlet of the main pump is connected with a water outlet of the main vat; a water outlet of the main pump is connected with the heat exchange device; a water outlet of the heat exchange device is connected with a water inlet of each yarn hanging device inside the main vat; and the auxiliary vat is arranged outside the main vat. The liquid circulation processing device and the liquid circulation processing method for the bast fibers can be widely applied to degumming, washing, bleaching and dyeing the bast fibers, scouring, dyeing, bleaching and washing the yarns, and other processes.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

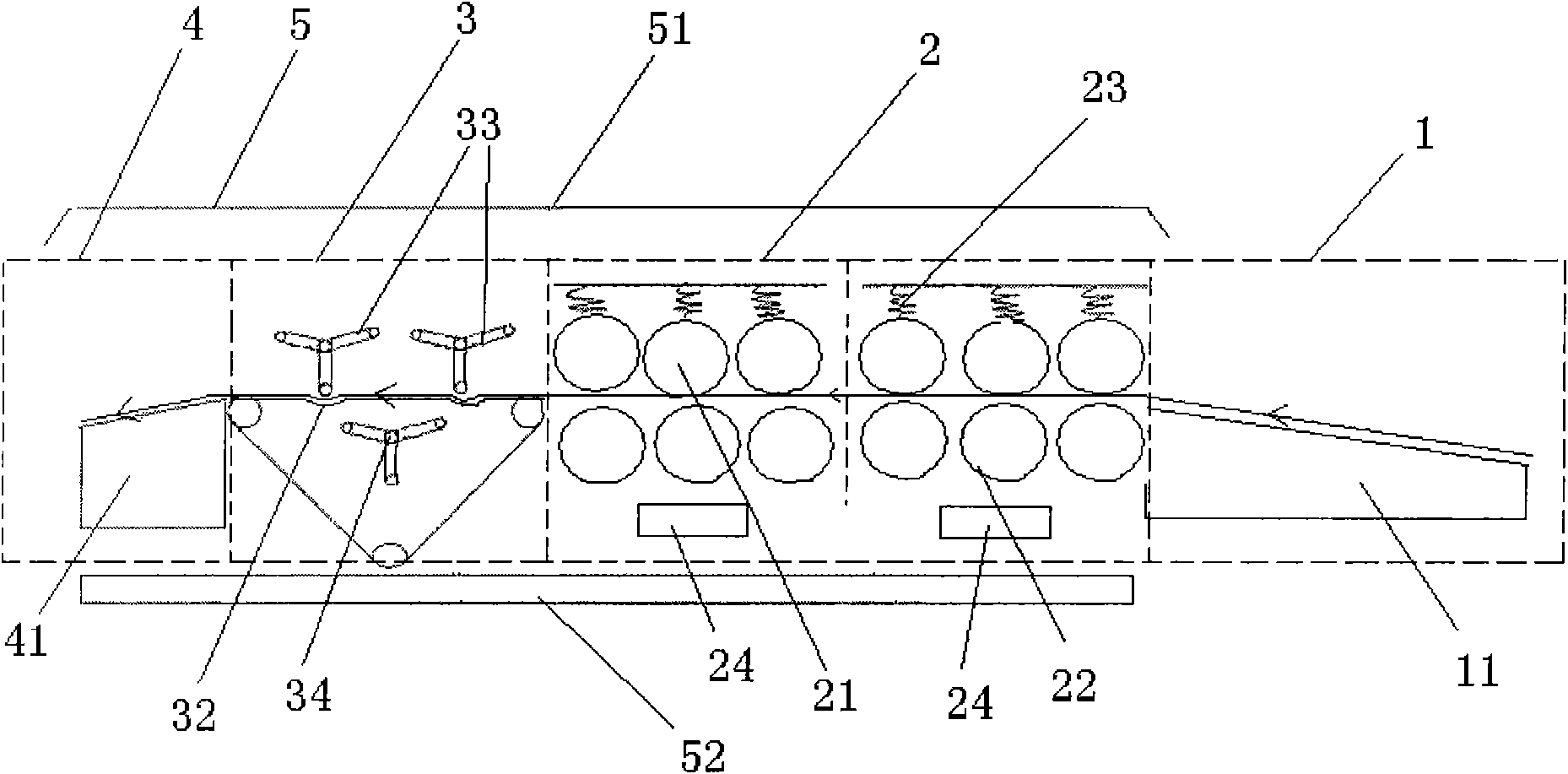

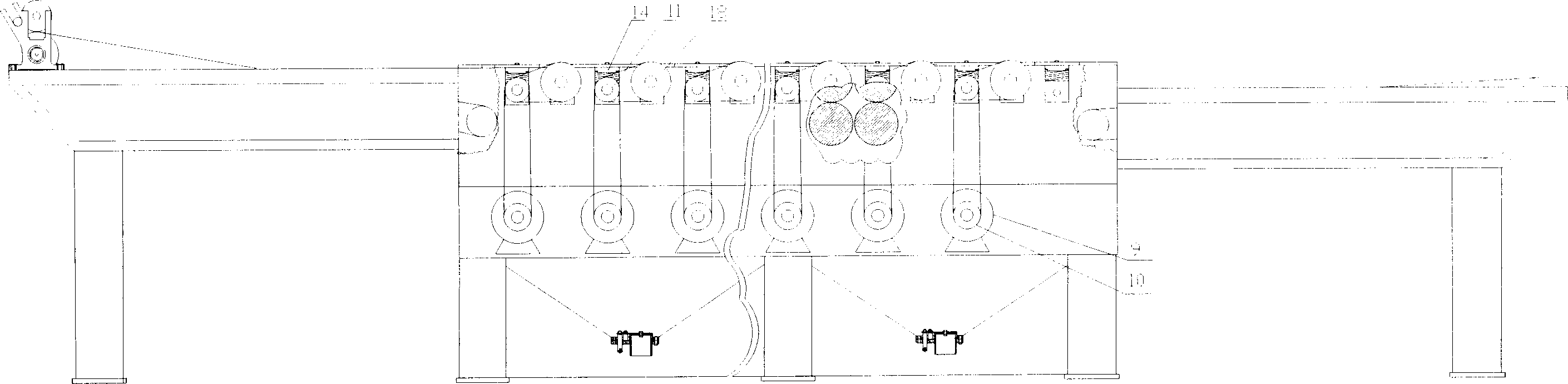

Fiber bundle dividing and washing method and device

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

Entangled substrate of short individualized bast fibers

Nonwoven textile fabrics in accordance with the present invention include a web of entangled polymeric fibers with substantially pectin-free, individualized bast fibers having a mean length less than 9 millimeters (mm). A method of making a nonwoven fabric includes forming a web of polymeric fibers, forming a randomly arrayed fiber web of the substantially individualized bast fibers having a mean length less than 9 mm, disposing the web of the substantially individualized bast fibers onto the web of polymeric fibers, and entangling the polymeric fibers with the substantially individualized bast fibers to form the nonwoven fabric. In addition, laminates include the nonwoven fabric, a film, and an adhesive disposed between the fabric and the film to bond the nonwoven fabric to the film.

Owner:GPCP IP HLDG LLC

High-strength carbon fiber shielding paper and preparation method thereof

InactiveCN103726394AImprove shielding effectExcellent chemical stabilitySpecial paperPaper/cardboardFiberCarbon fibers

The invention discloses high-strength carbon fiber shielding paper and a preparation method thereof. The shielding paper comprises carbon fibers, plant fibers and conductive particles, wherein the carbon fibers and the plant fibers are randomly and uniformly distributed in a plane, micron-sized holes are formed among the plurality of fibers to form a three-dimensional reticulated structure, and the conductive particles are existent between the surfaces and the holes of the fibers; the carbon fibers are 1 mm to 20 mm in length; the plant fibers comprise wood fibers, grass plant fibers, bast fibers, seed hair fibers or combination of the wood fibers, the grass plant fibers, the bast fibers and the seed hair fibers; the conductive particles comprise carbon black with the particle size of 1 nm to 100 nm, silver coated copper powder, conductive rubber or combination of the carbon black, the silver coated copper powder and the conductive rubber. The shielding paper has the advantages of uniform porous structure and excellent ventilation property, shielding performance and mechanical strength; in addition, air filter paper can be used to the fields of energy resources, electromagnetic wave shielding, antistatic packaging, adsorption separation, aerospace and the like.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Process for the extraction and preparation of bast fibers, bast fibers obtained therefrom and their use

ActiveUS20070094810A1Maintain good propertiesGood bulkinessBleaching apparatusDetergent compounding agentsYarnPolymer science

The present invention generally relates to a process for the extraction and preparation of bast fibers with high quality and high counts. The process is suitable for ramie, hemp and flax. The present invention also relates to bast fibers with high counts produced according to the process, as well as pure yarns and mixed, blended yarns made from said bast fibers.

Owner:XU MEIRONG

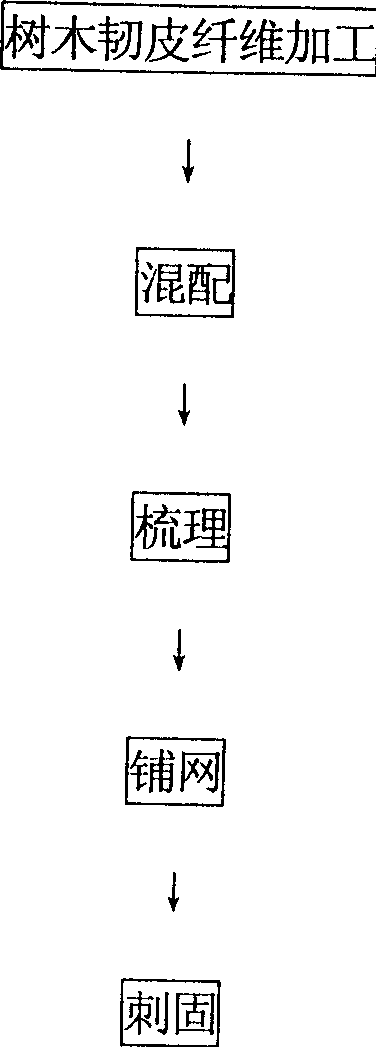

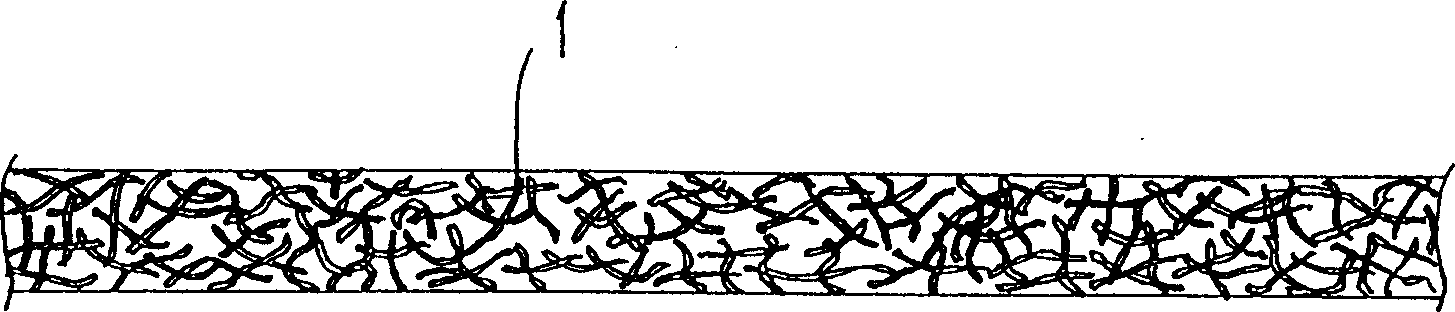

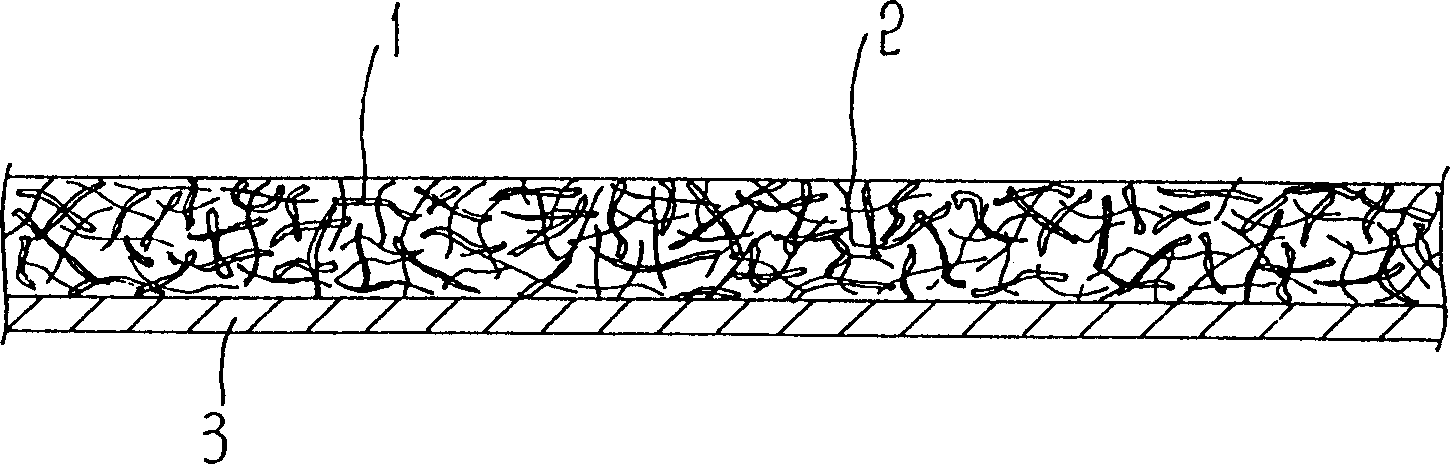

Tree bast fiber non-woven cloth and its processing method

This invention discloses non-woven fabric of tee bast fiber and its process method, among which, the non-woven fabric is composed of 1-100% weight proportion of tree bast fibers and 0-99% other spinning fiber, fibers are mixedly woven among tree bast fibers, the spinning fibers, the bast and spinning fibers to form a cubic net woven structure including the following steps: process tree base fibres, mixing, combing, spreading the net and transfixation.

Owner:TIANWEI TEXTILE TECH SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com