Method and device for rinsing and softening fiber bundles

A fiber bundle and softening technology, applied in the field of fiber bundle rinsing, can solve the problems of unclean cleaning, low fiber production rate, uneven softness, etc., so as to improve processing efficiency and quality, improve fiber utilization rate and good washing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

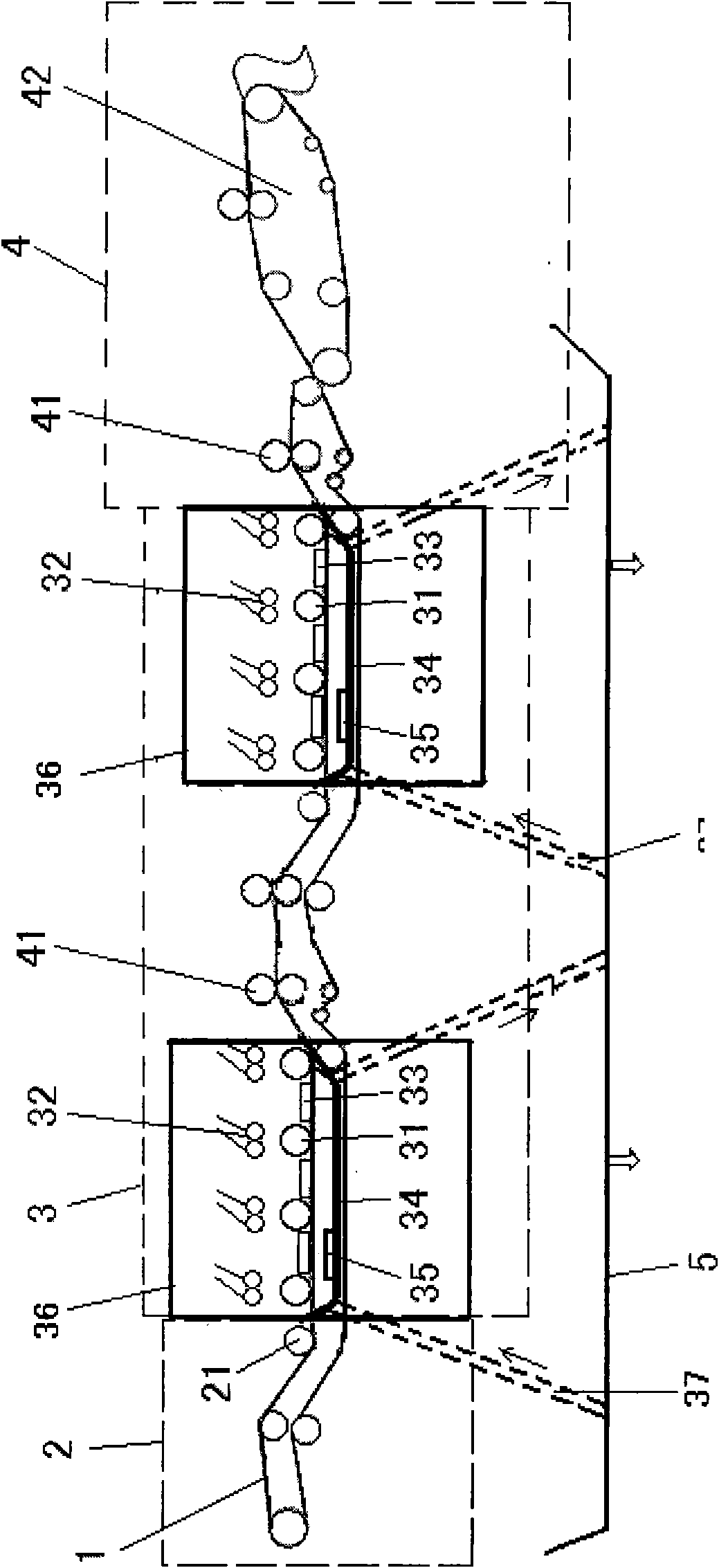

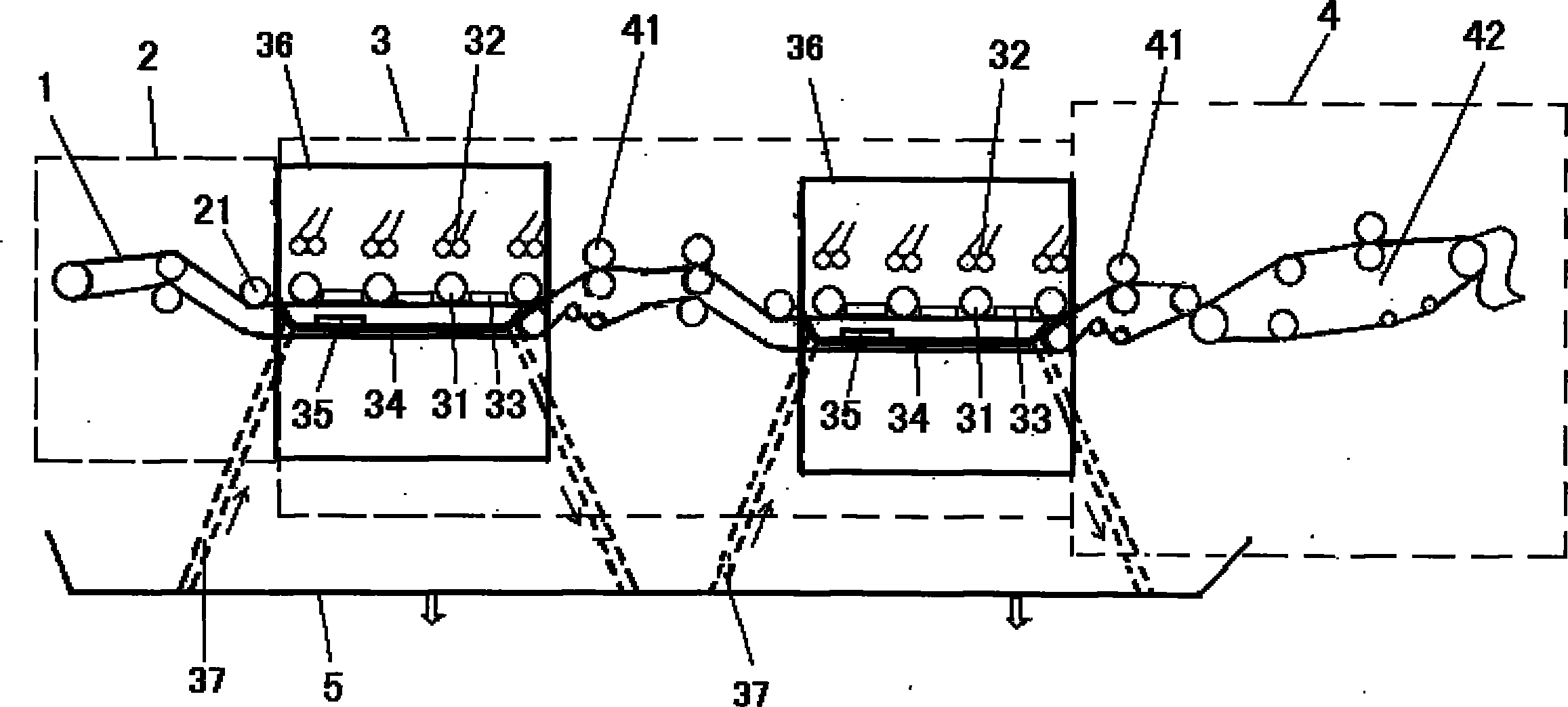

[0016] like figure 1 Shown, the present invention comprises a frame (not marked in the figure), is provided with the conveying crawler belt 1 driven by electricity on the frame. Crawler 1 adopts mesh crawler with seamless interface throughout the whole process. There are different parts on the upper and lower sides of crawler 1. According to the function, it is divided into feeding area 2, rinsing soft area 3 and output area 4. The parts in each working area are controlled by the frame Support, and the crawler 1 will link each work area. The lower part of the frame is provided with a water circulation treatment device 5 . A variable frequency motor (not shown in the figure) is installed on the outside of the frame to control the operation of each component.

[0017] The feeding zone 2 is located at the conveying starting end of the crawler belt 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com