Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3538results about "Textile shaping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

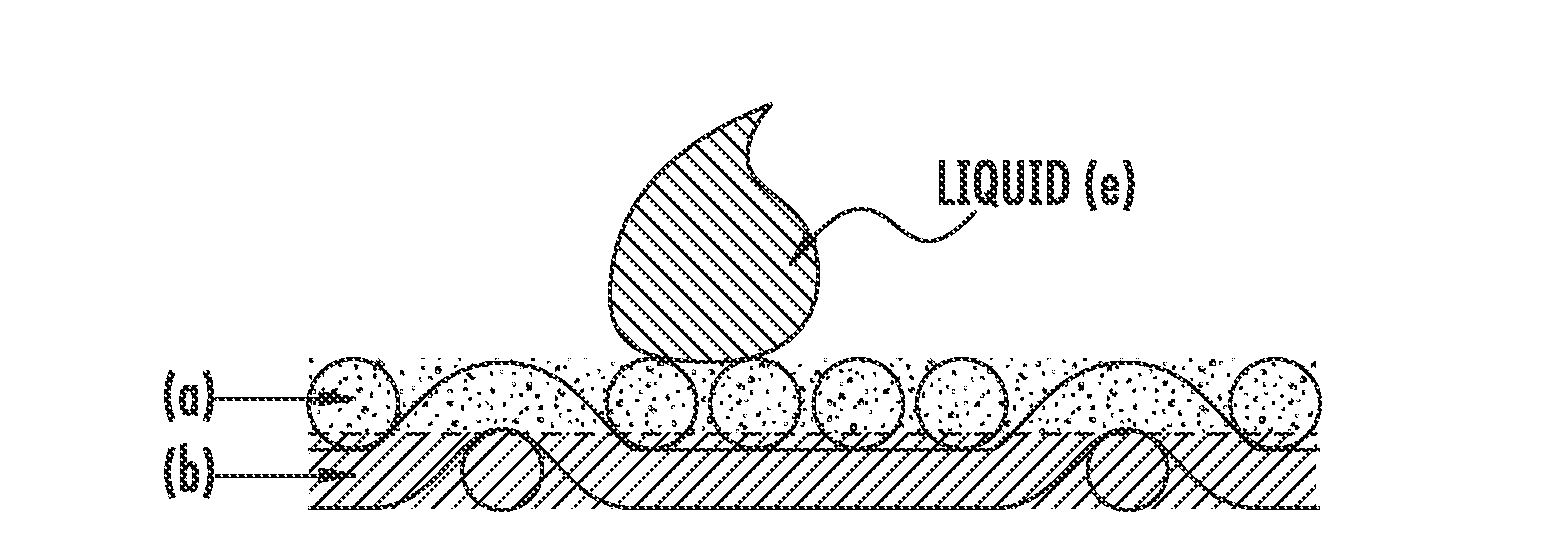

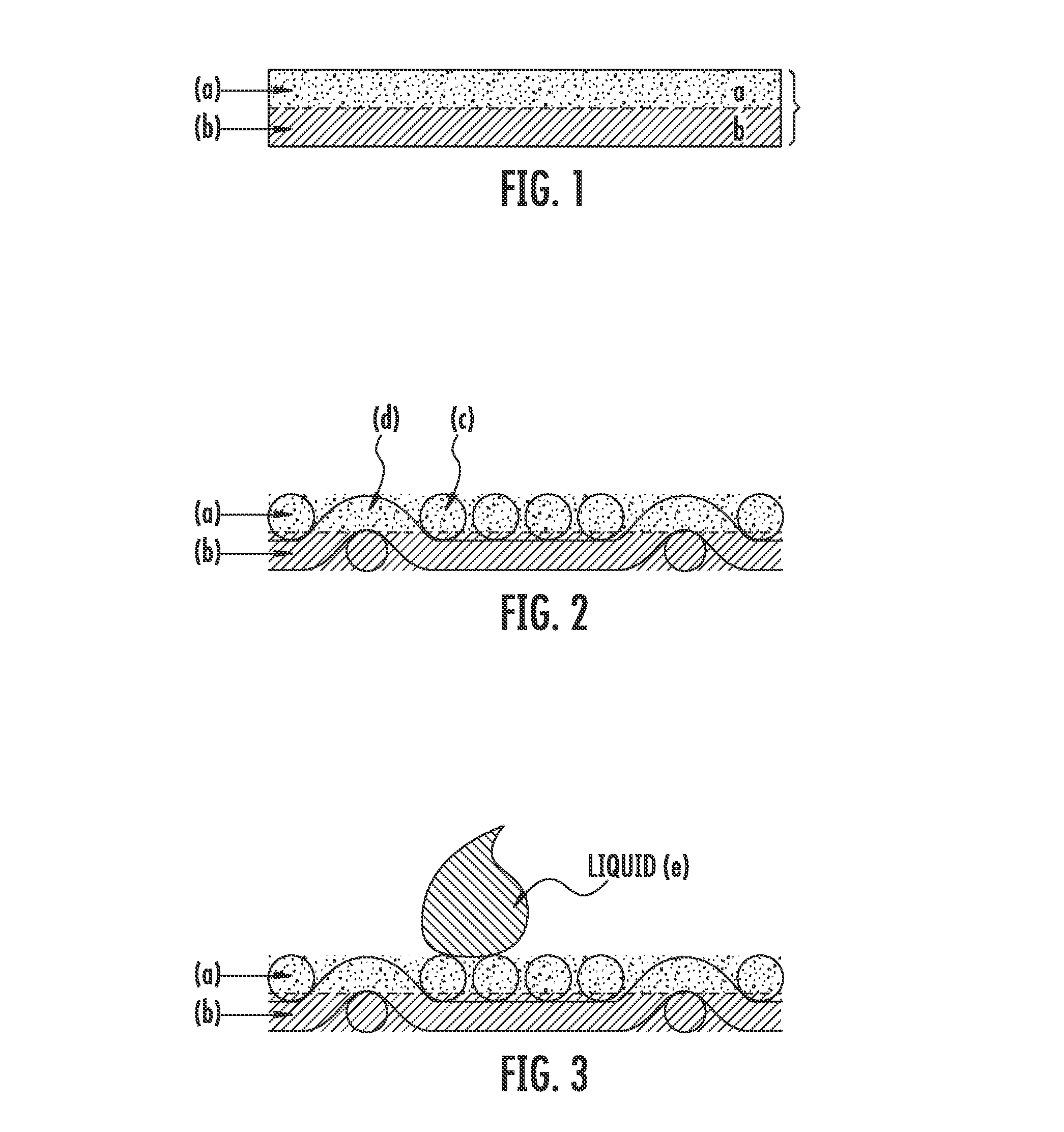

Enhancement of color on surfaces

InactiveUS6872444B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsPigmenting treatmentNanoparticleMaterials science

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

Protection product

A protection product made of (i) a woven fabric woven with a high-performance fiber, in which the opening rate of thread-opening treatment is 0 to 5%, and the width of a thread constituting the woven fabric is 10-fold or more relative to the thread thickness, (ii) a woven fabric in which the cross-sectional shape of a thread constituting the woven fabric is thinner on an edge side of both ends as compared with an intermediate part in the width direction, or (iii) a woven fabric woven with a twistless high-performance fiber having a fineness of 200 to 15,000 dtex, in which the ratio of the thread width to the thread thickness of at least one of a warp and a weft is 10 to 100, and the opening rate is 0 to 5%.

Owner:SOWA TEXTILE +2

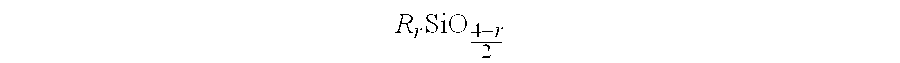

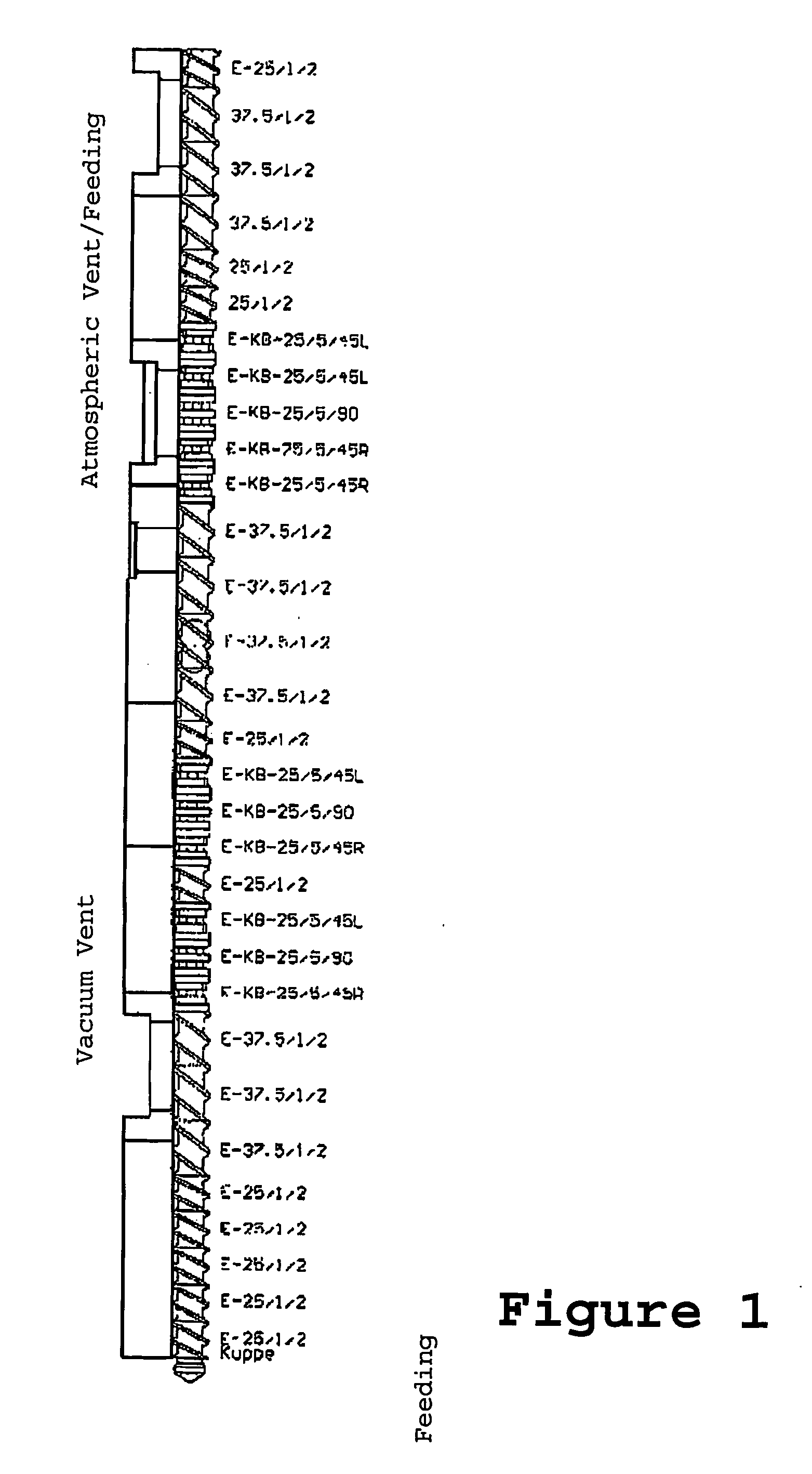

Fire resistant polymeric compositions

InactiveUS20060068201A1Improve water resistanceLow thermal conductivityInsulated cablesCeramic layered productsPassive fire protectionSilicate minerals

Owner:OLEX AUSTRALIA

Mirror face synthetic leather and production method thereof

InactiveCN101498106AImprove wear resistanceIncrease brightnessSolvent-treatmentSynthetic resin layered productsPolyesterSurface layer

The invention relates to a mirror face synthetic leather and a manufacturing method thereof, belonging to the technical filed of synthetic leather and manufacturing methods. The manufacturing method is characterized in that the manufacturing method comprises the following steps: manufacturing polyester or daiamid short fiber and sea-island fiber into non-woven fabrics, immersing the non-woven fabrics in polyvinyl alcohol or ironing the non-woven fabrics by hot pressing, processing raw fabrics, immersing and coating polyurethane, solidifying, extracting, obtaining basic fabrics, embossing, removing film by a dry method, curing and inspecting for entering warehouses. The mirror face synthetic leather manufactured by the manufacturing method has high wearing resistance, high brightness, excellent performance and technological improvements on base layers and surface layers, effectively develops the use valve that the original single sea-island fiber does not have, and combines the characteristics of sea-island fiber and daiamid or polyester fiber. The manufacturing method widens the technical routes of synthetic leather development and has wide prospects of popularization and application.

Owner:QUANZHOU WANHUA SEWANG MICRO FIBER CO LTD

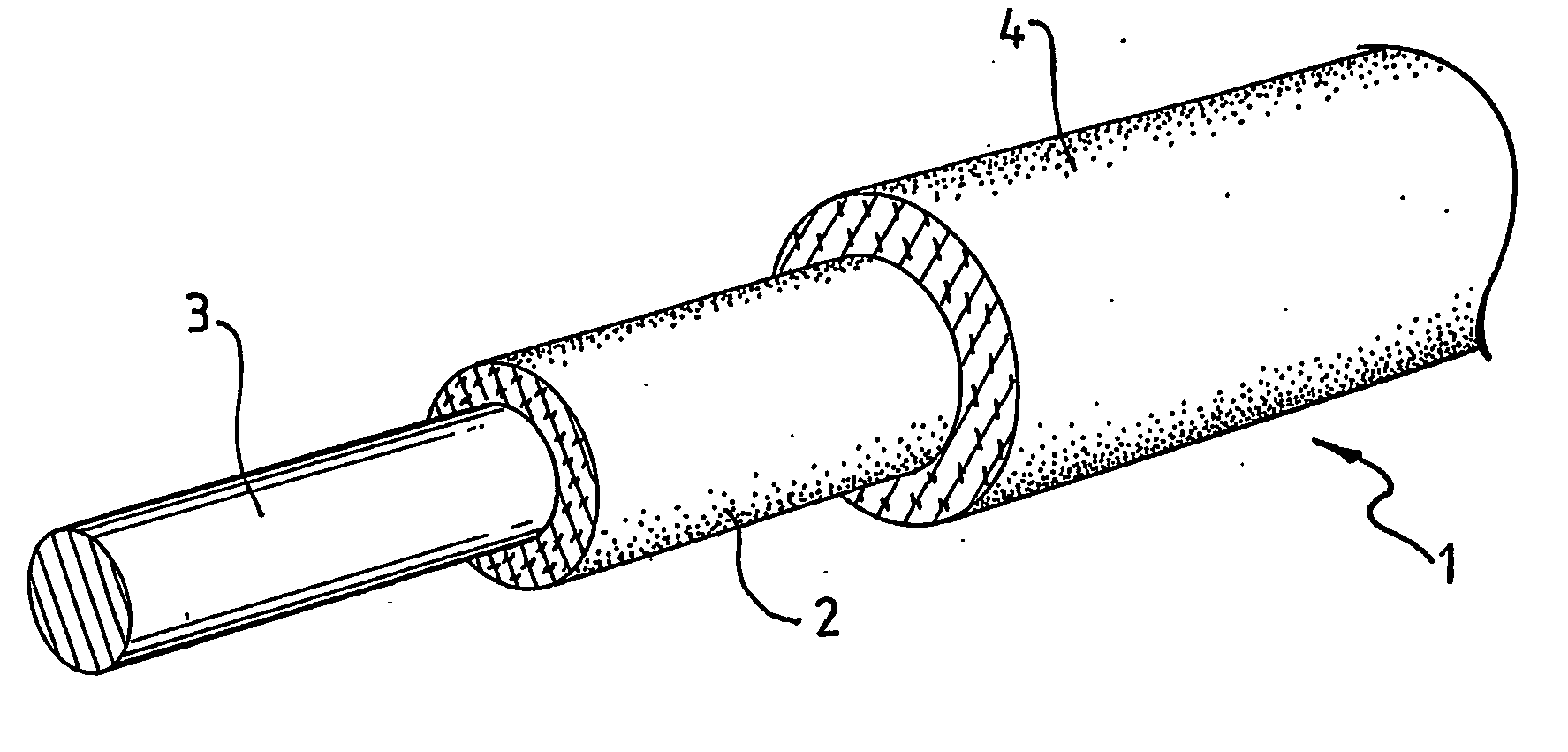

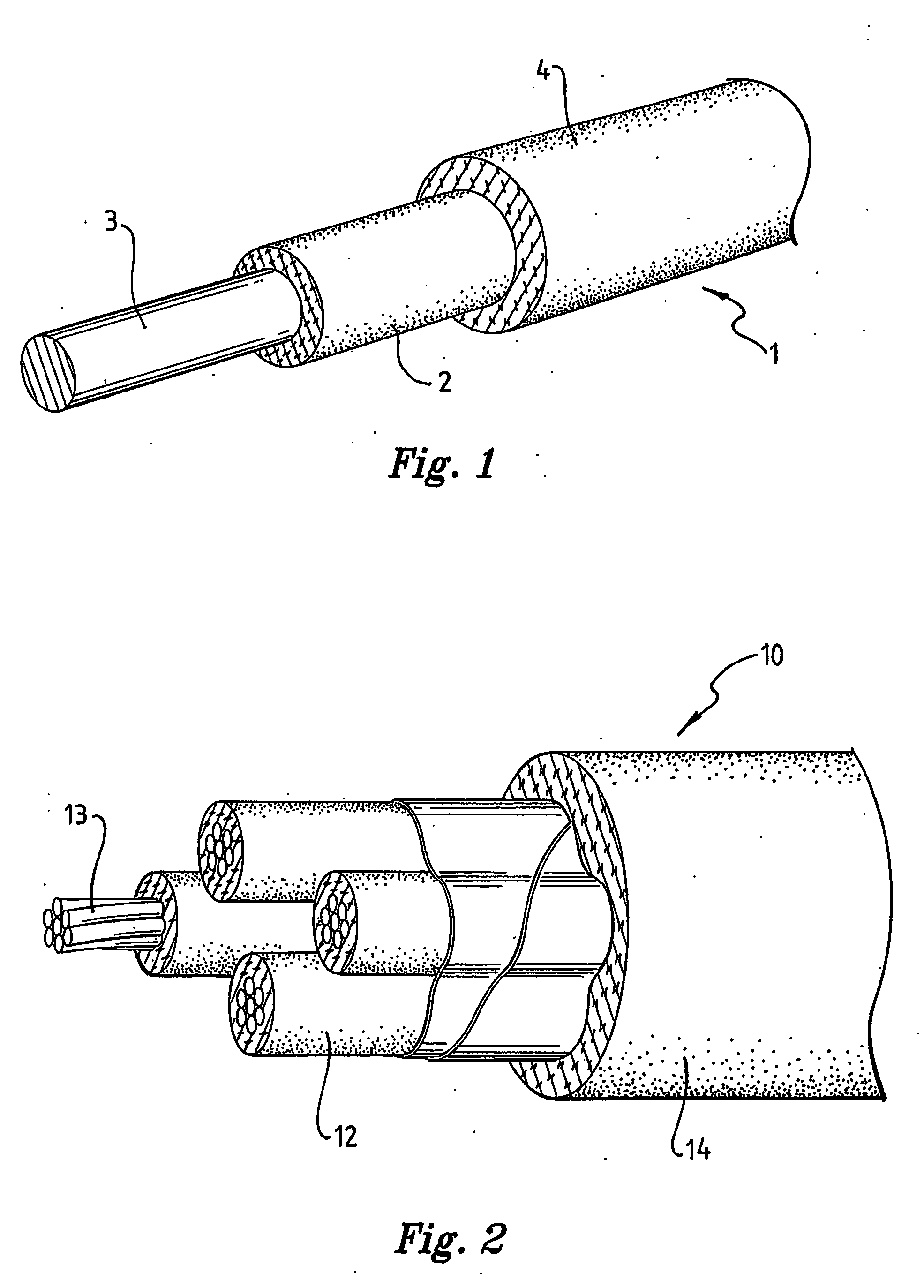

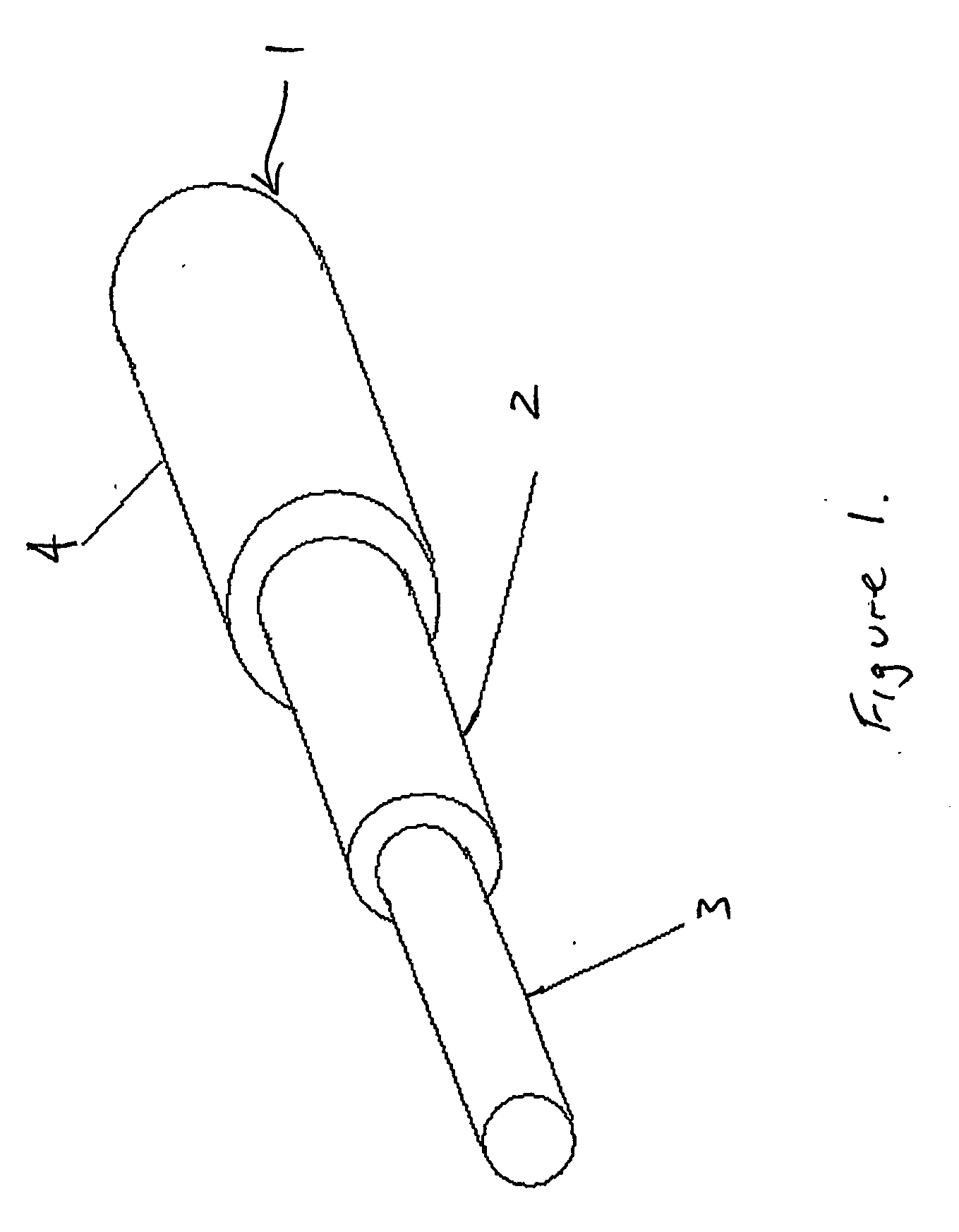

Fire-resistant silicone polymer compositions

InactiveUS20060155039A1High mechanical strengthPlastic/resin/waxes insulatorsSpecial tyresFire protectionElectrical conductor

A fire resistant composition comprising: a silicone polymer; mica in an amount of from 5% to 30% by weight based on the total weight of the composition; and a limited amount of glass additive sufficient to enable the formation of a self supporting ceramic material at temperatures above the decomposition temperature of the silicone polymer and below the fire rating temperature of the composition. The glass additive addition required to produce the self supporting ceramic material has been found to be preferably from 0.3% to 8% by weight based on the total weight of the composition. The composition is applicable to products formed for fire wall linings, fire partitions, screens, ceilings or linings, structural fire protection, fire door inserts, window or door seals, intumescent seals, in electrical switchboard cabinets or cables. In one cable application, the composition may be used as the extruded intermediate material (2) between the conductor (3) and extruded sheath (4).

Owner:OLEX AUSTRALIA

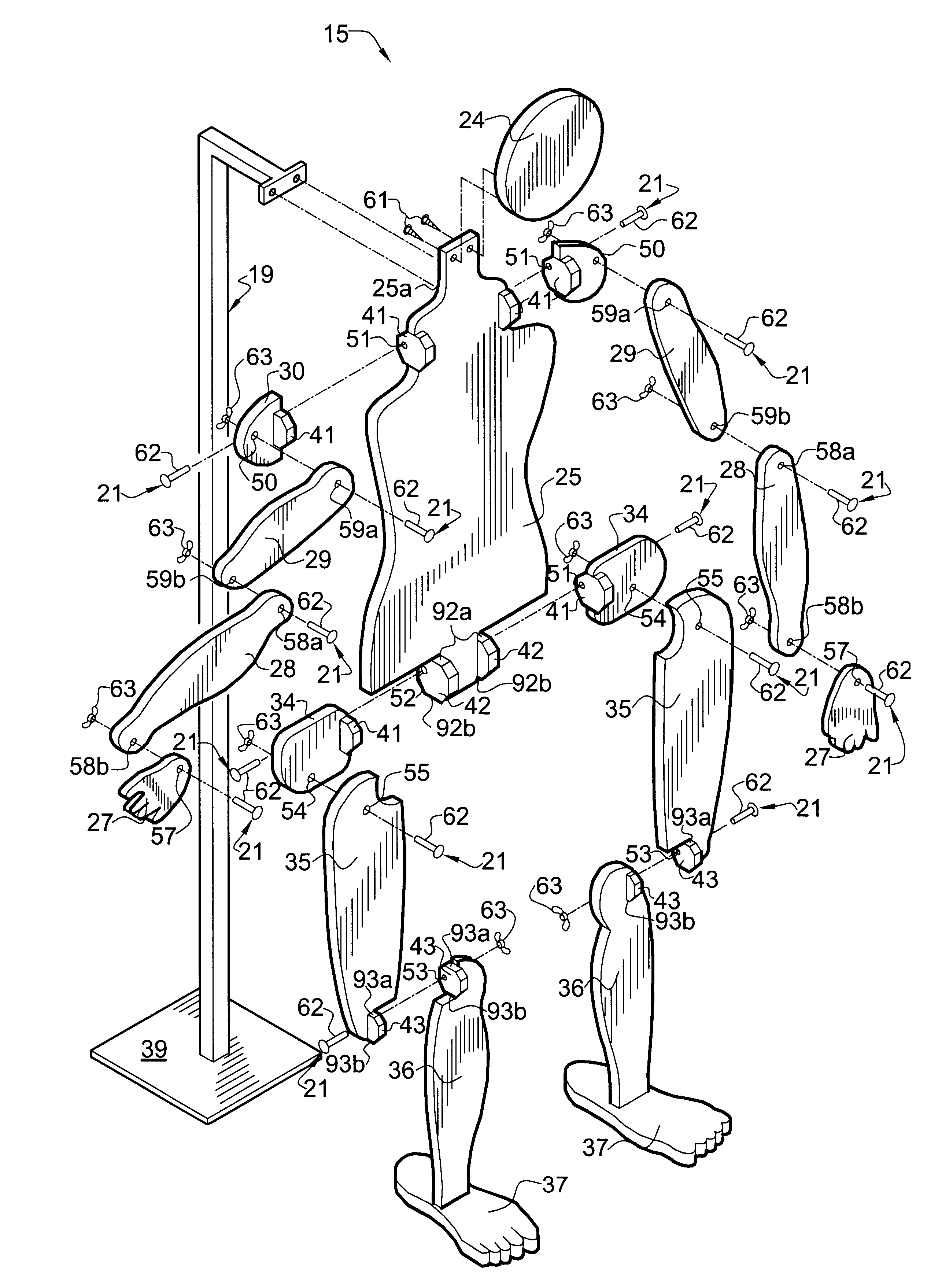

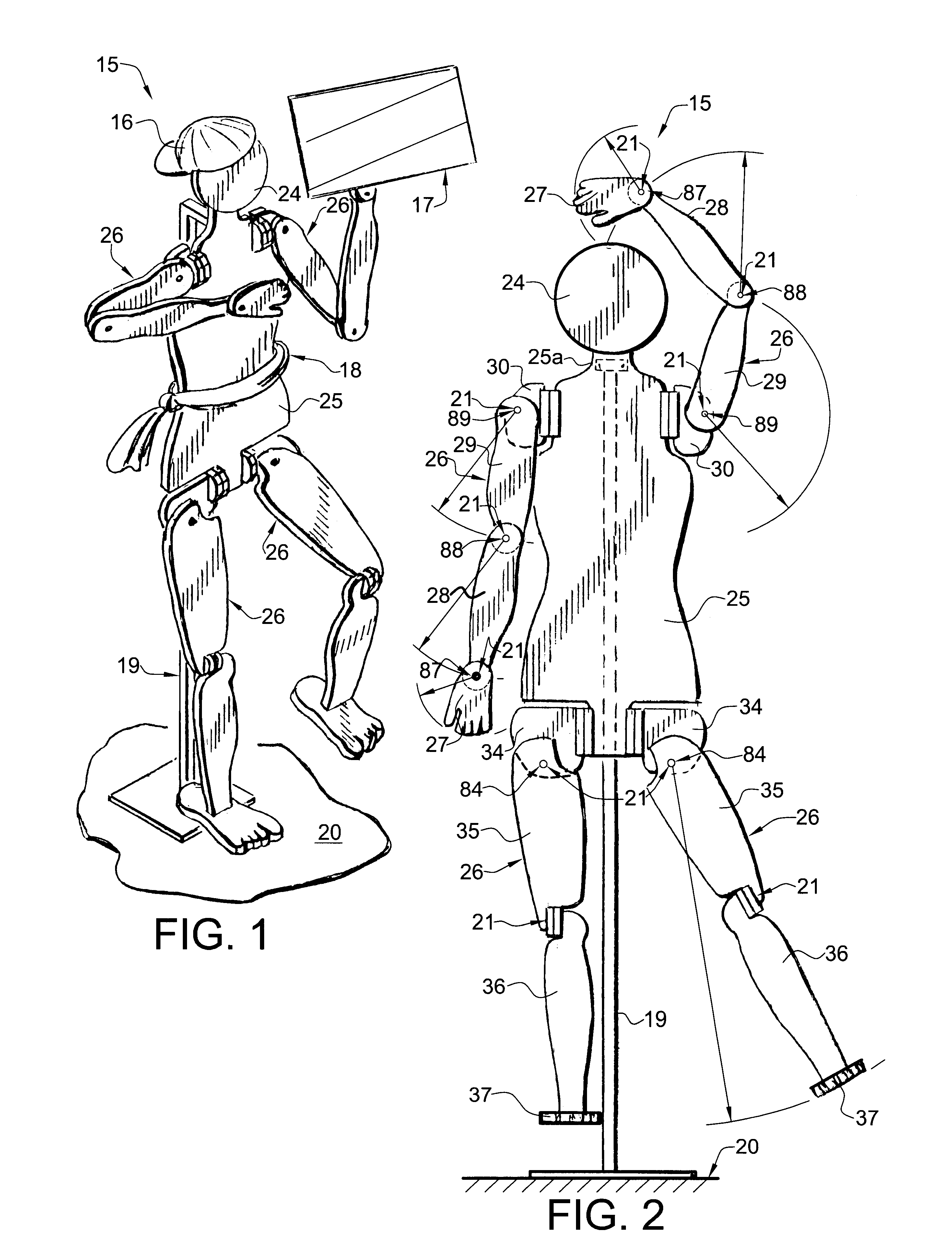

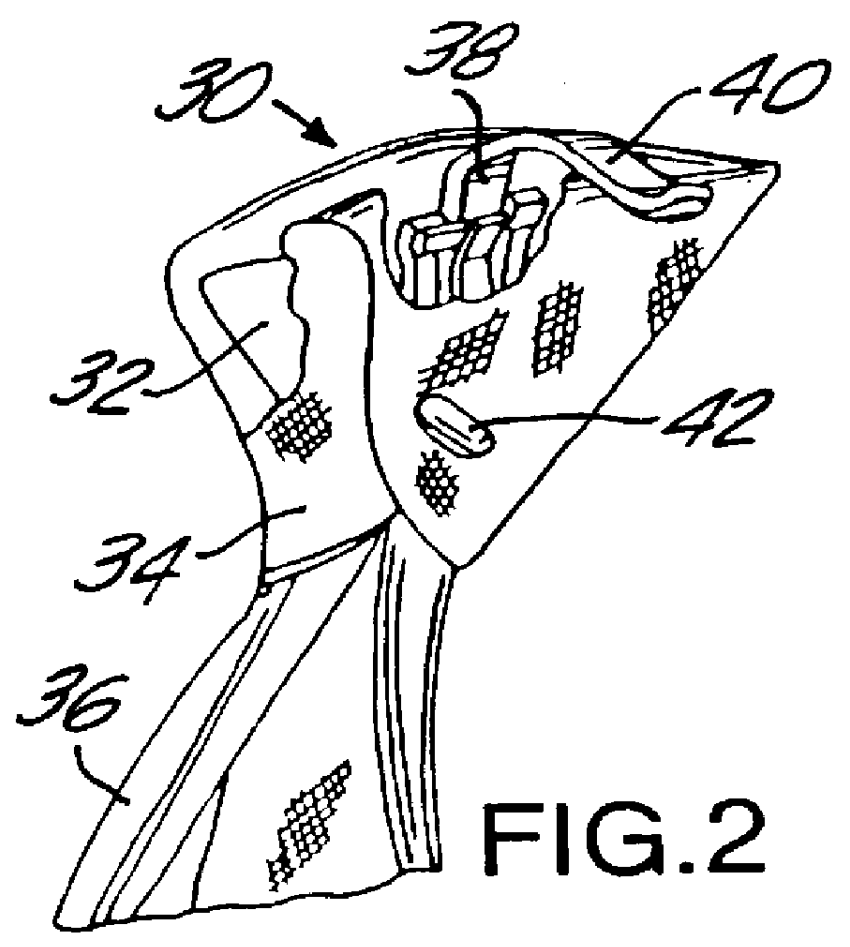

Human-figure display system

A repositionable display system in the shape of a human figure that can be used to communicate information by holding signs or by making simple gestures; or it can be used to support various items such as clothing or accessories. The repositionable display is in the shape of a life-size human form comprising a head, torso, arms, and legs. A two-pin connection forms each shoulder and hip joint, thereby allowing for positioning of the arm and legs in multiple planes. A single-pin connection forms the wrist, elbow, and knee joints. Each of the pin connections are removable, thereby allowing for assembly and disassembly of the repositionable display system. A stand may be provided to maintain the repositionable display system in a substantially upright position. Cedar wood may be used to construct the repositionable display system which assists in repelling insects while emitting a pleasing aroma.

Owner:BUBLITZ REBECCA J +1

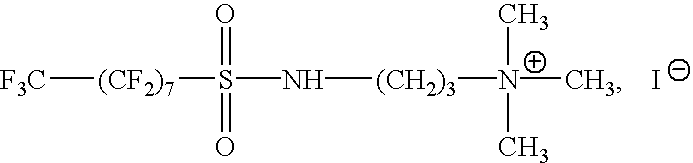

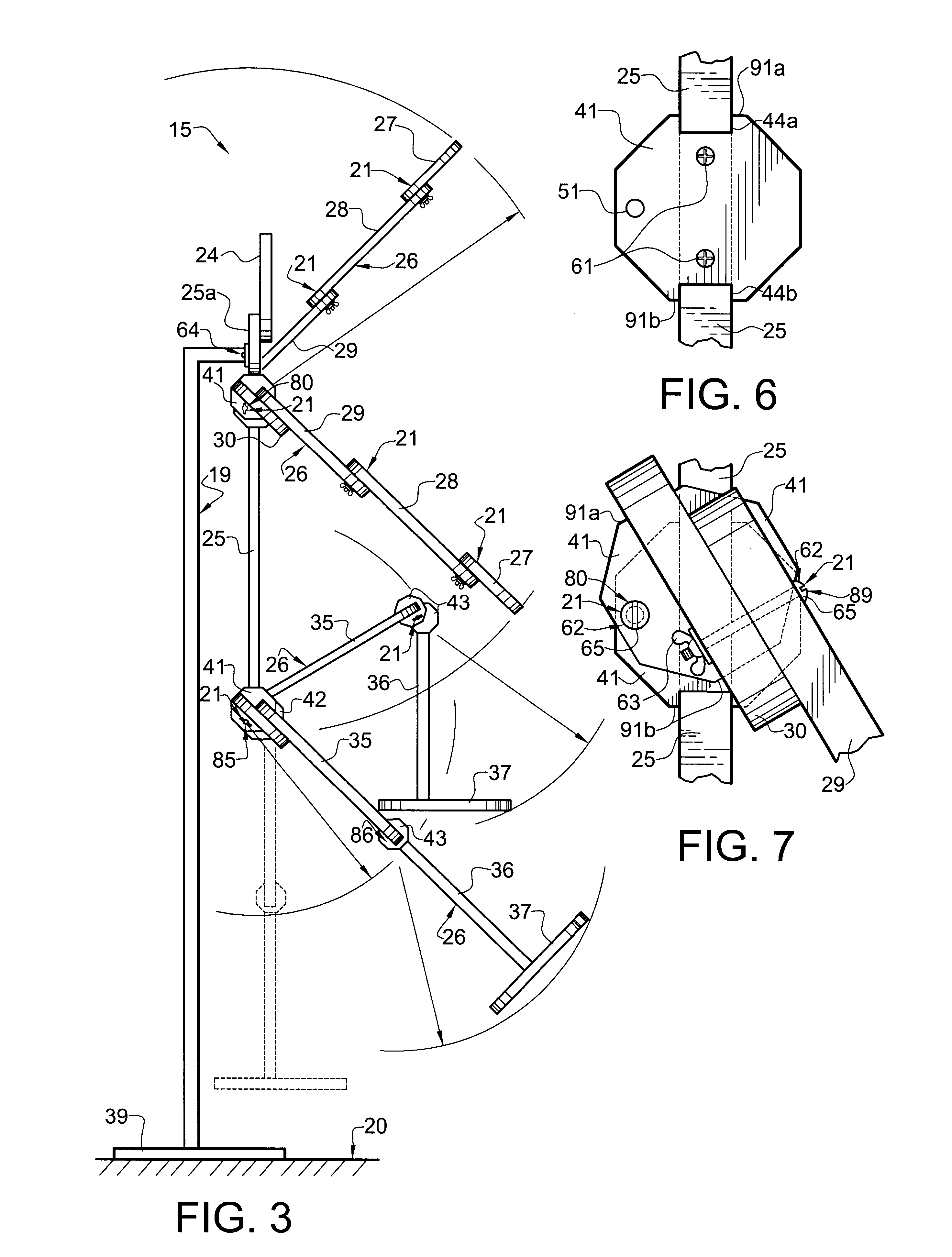

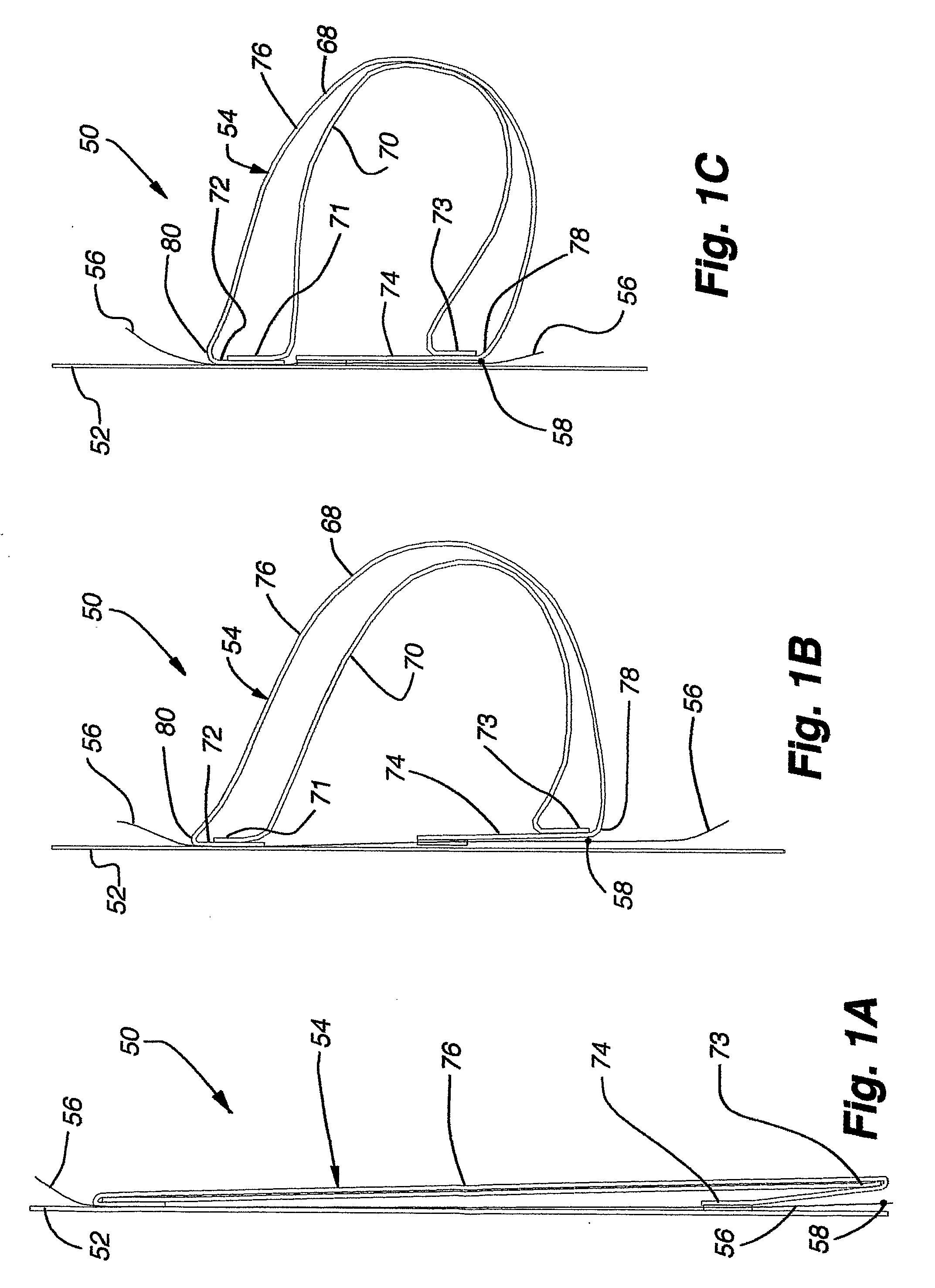

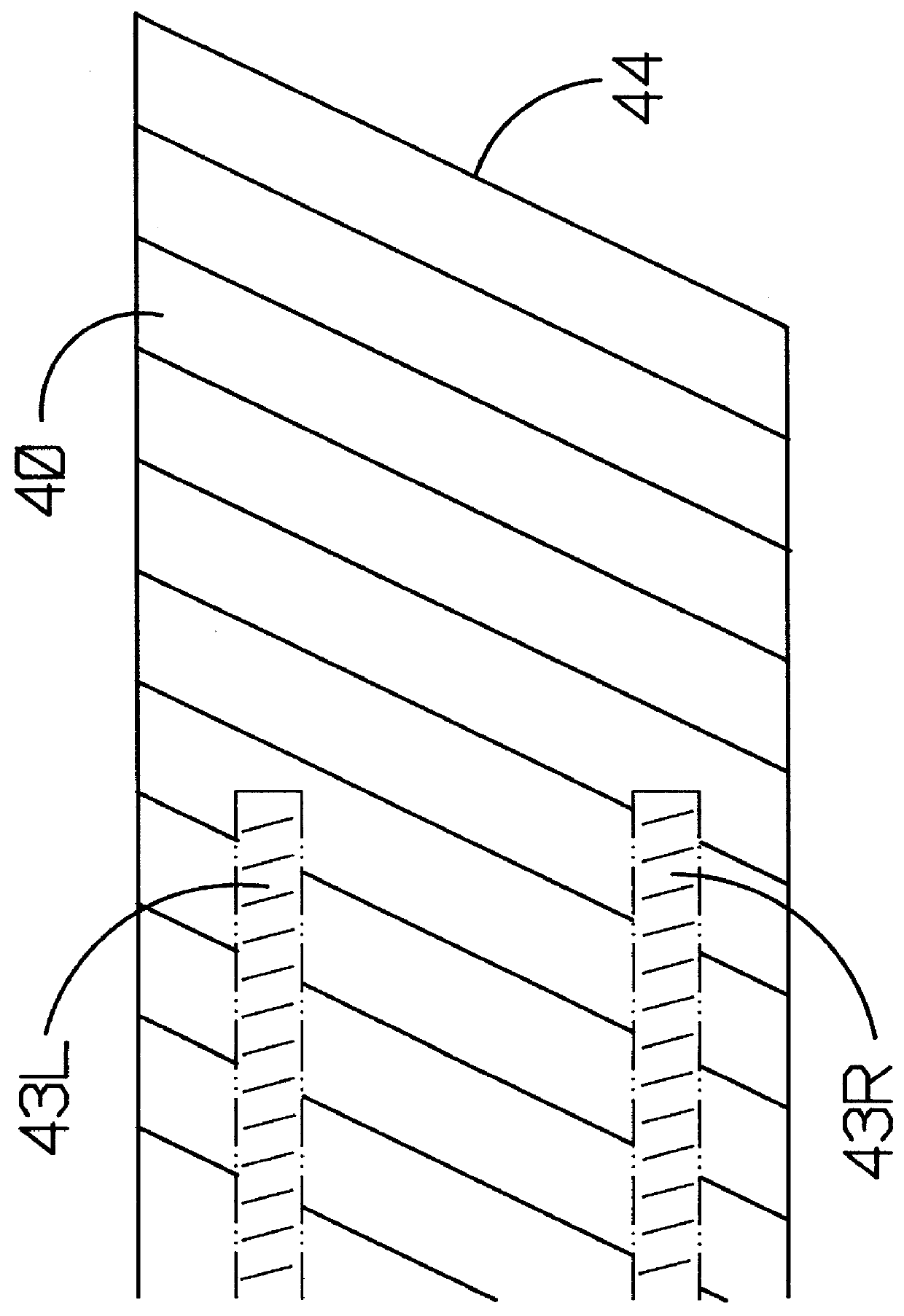

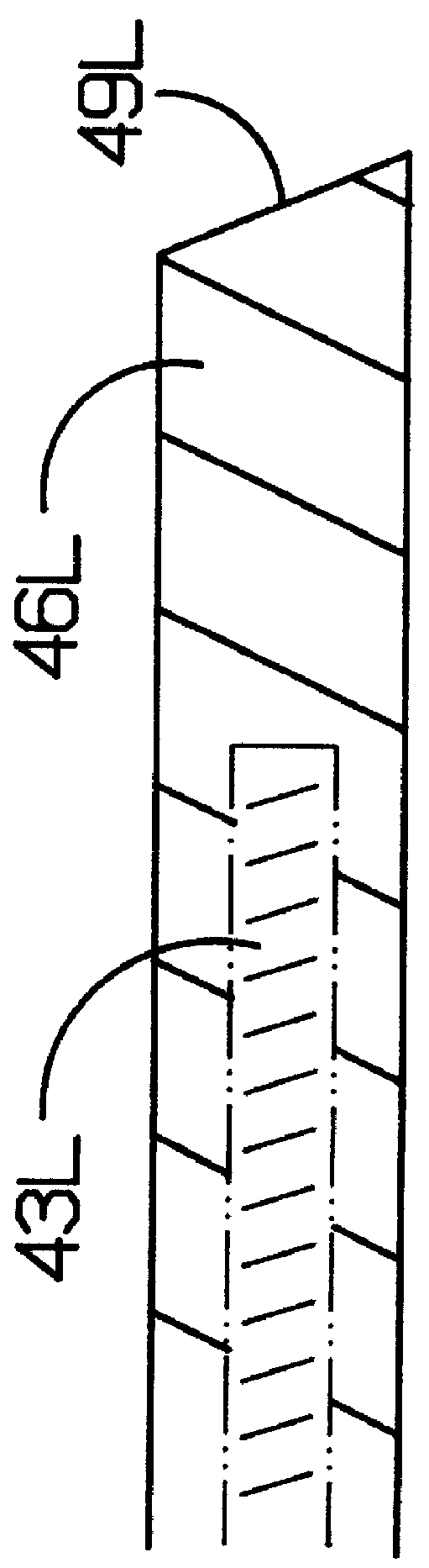

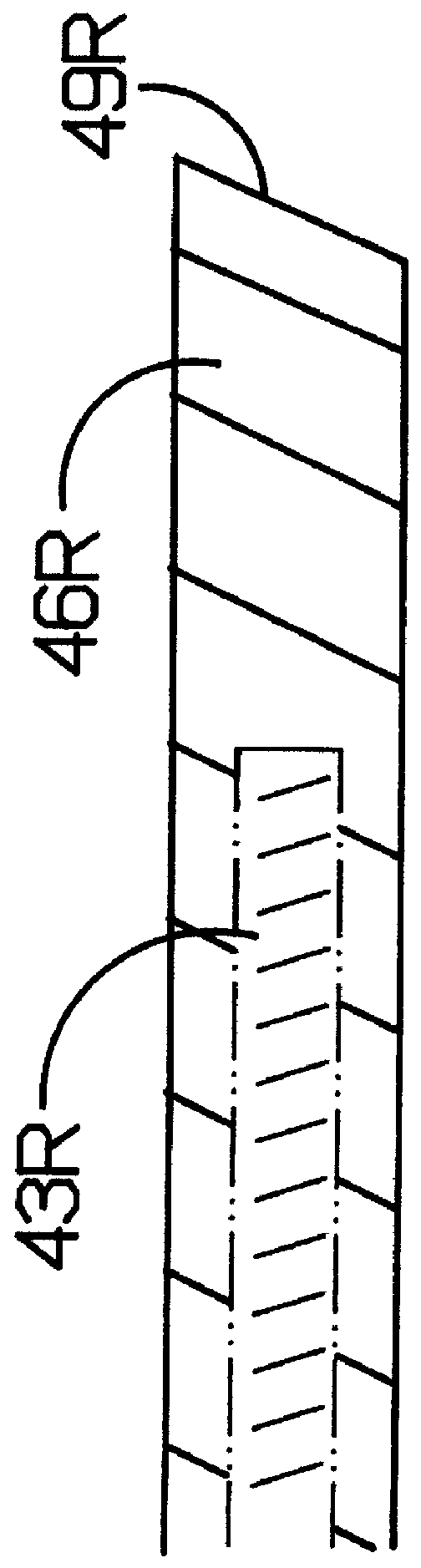

Appparatus and Method for Making a Window Covering Having Operable Vanes

An apparatus and associated method for manufacturing a window covering 50 for an architectural opening. The apparatus includes a support structure handling assembly 92, an operating element handling assembly 94, and a vane handling assembly 96. The handling assemblies process the respective materials to an assembly station 100 to attach one portion of a vane 54 to the operating elements 56, and another portion of the vane 54 to the support structure 52, allowing movement of one portion of the vane 54 relative to other portion of the vane.

Owner:HUNTER DOUGLAS INC

Full-surface bonded multiple component melt-spun nonwoven web

InactiveUS20050130545A1Synthetic resin layered productsWoven fabricsNonwoven fabricUltimate tensile strength

A full-surface bonded multiple component nonwoven fabric is provided that has an improved combination of tear strength and tensile strength at lower thicknesses than known in the art. The full-surface bonded multiple component webs have a void percent between about 3% and 56% and a Frazier permeability of at least 0.155 m3 / min-m2. The full-surface bonded multiple component nonwoven fabrics can be prepared in a smooth-calendering process.

Owner:EI DU PONT DE NEMOURS & CO

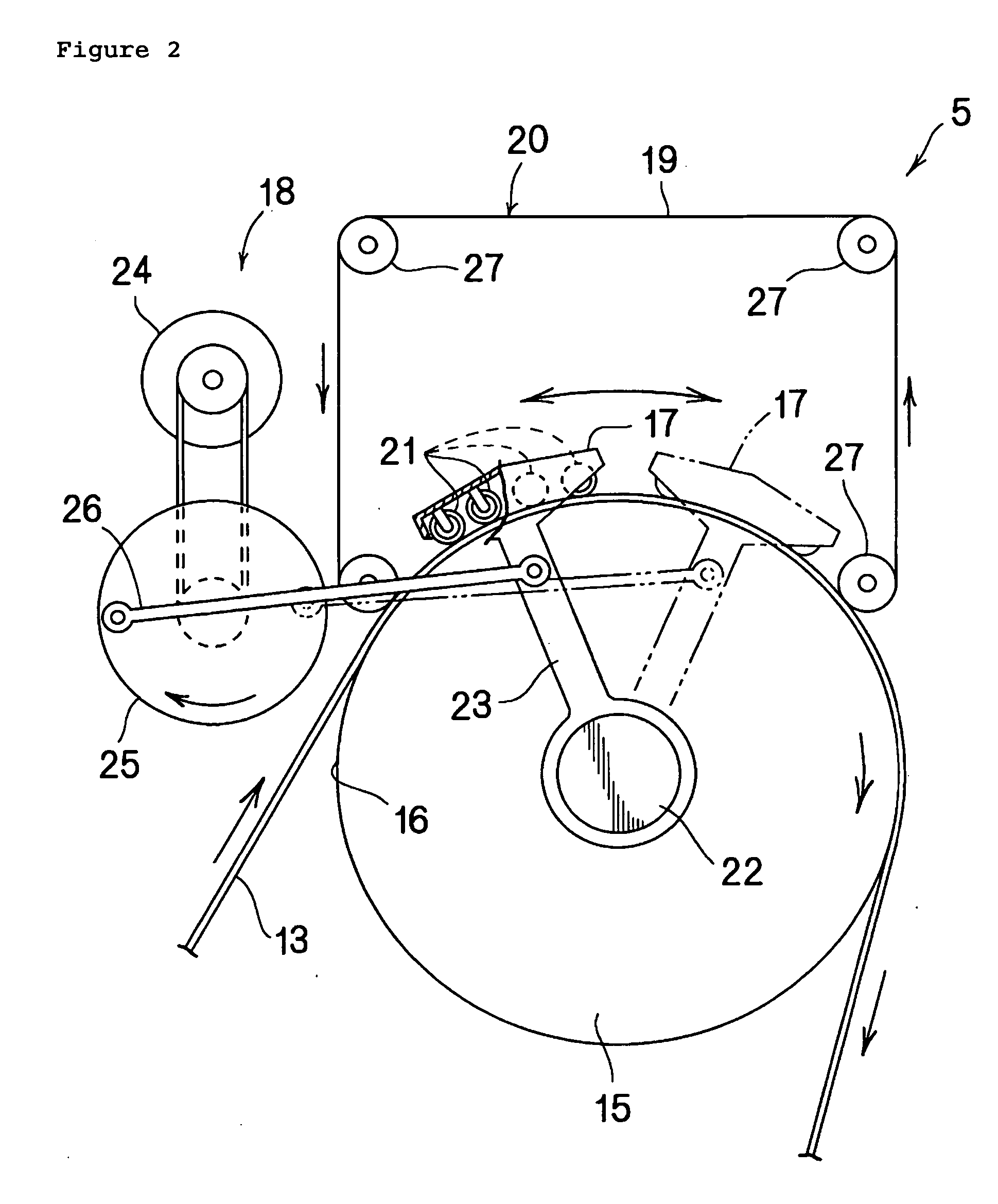

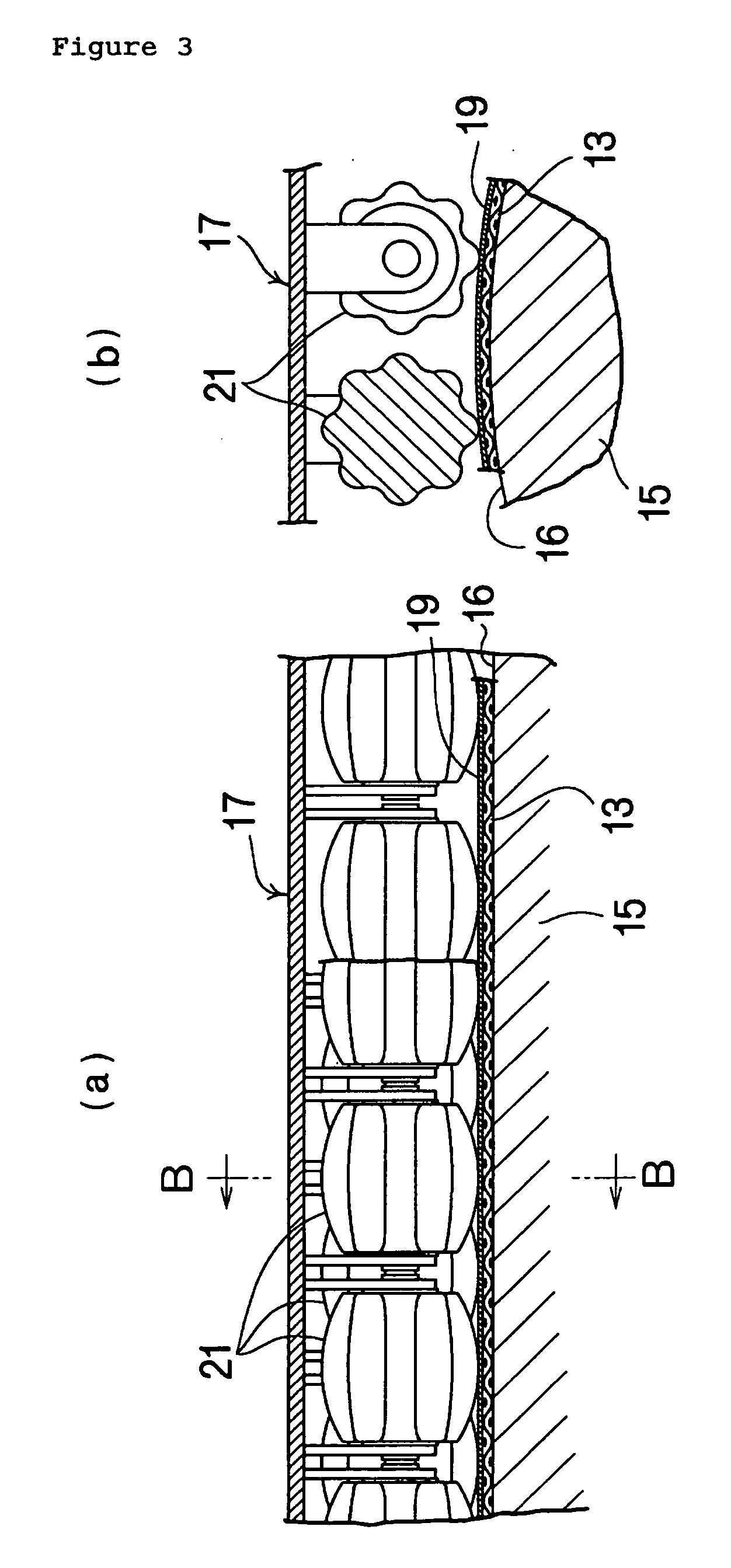

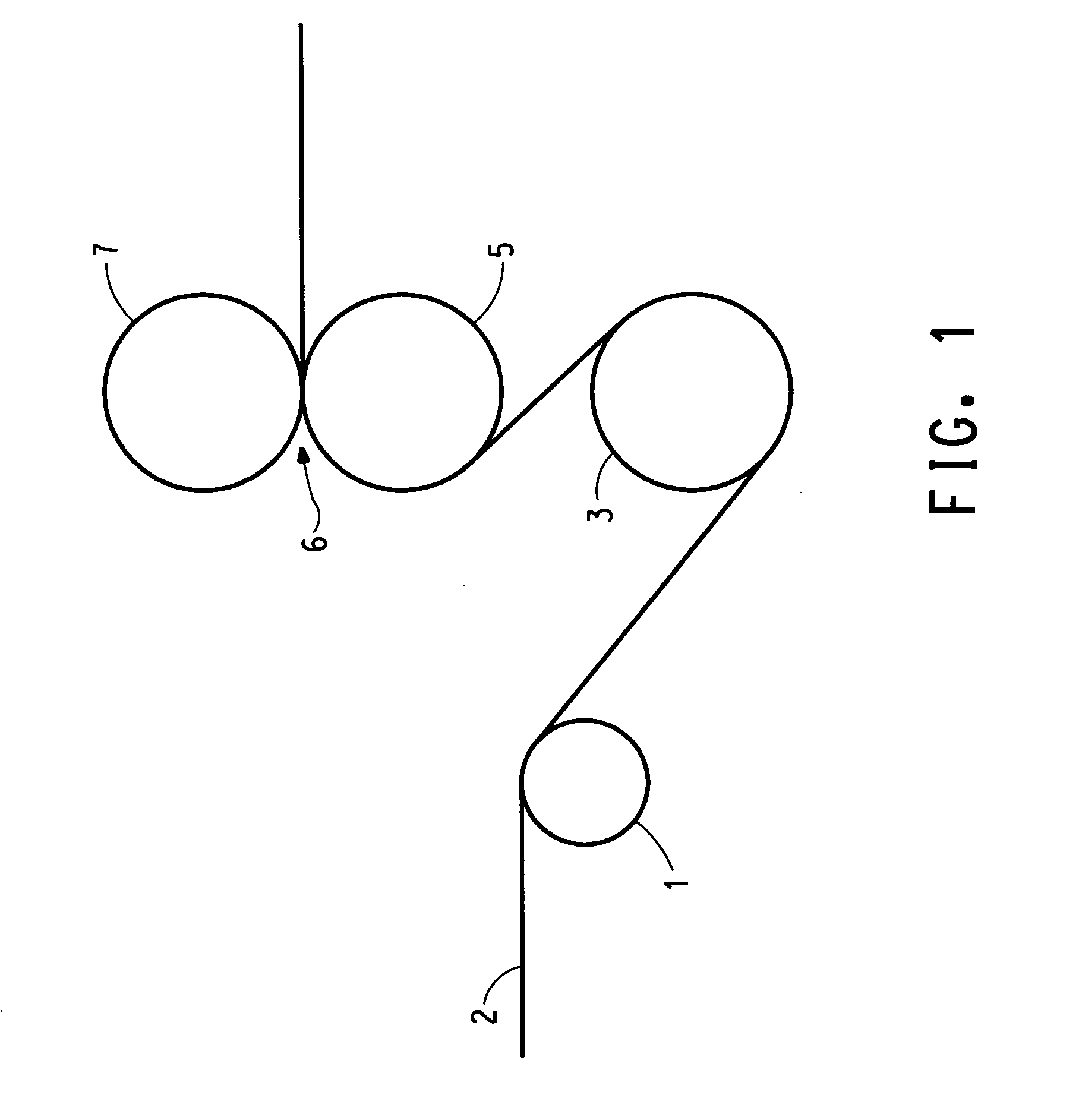

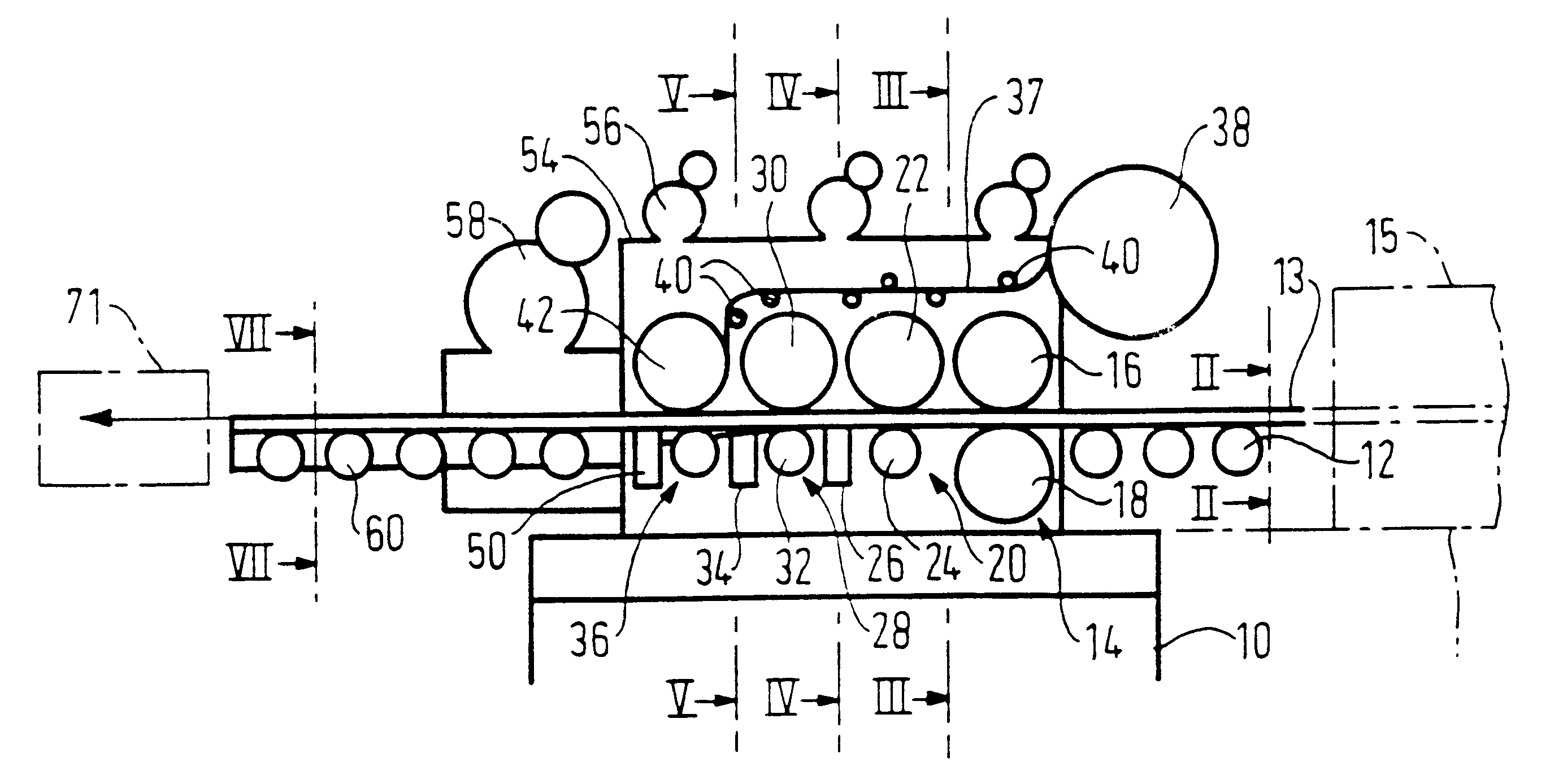

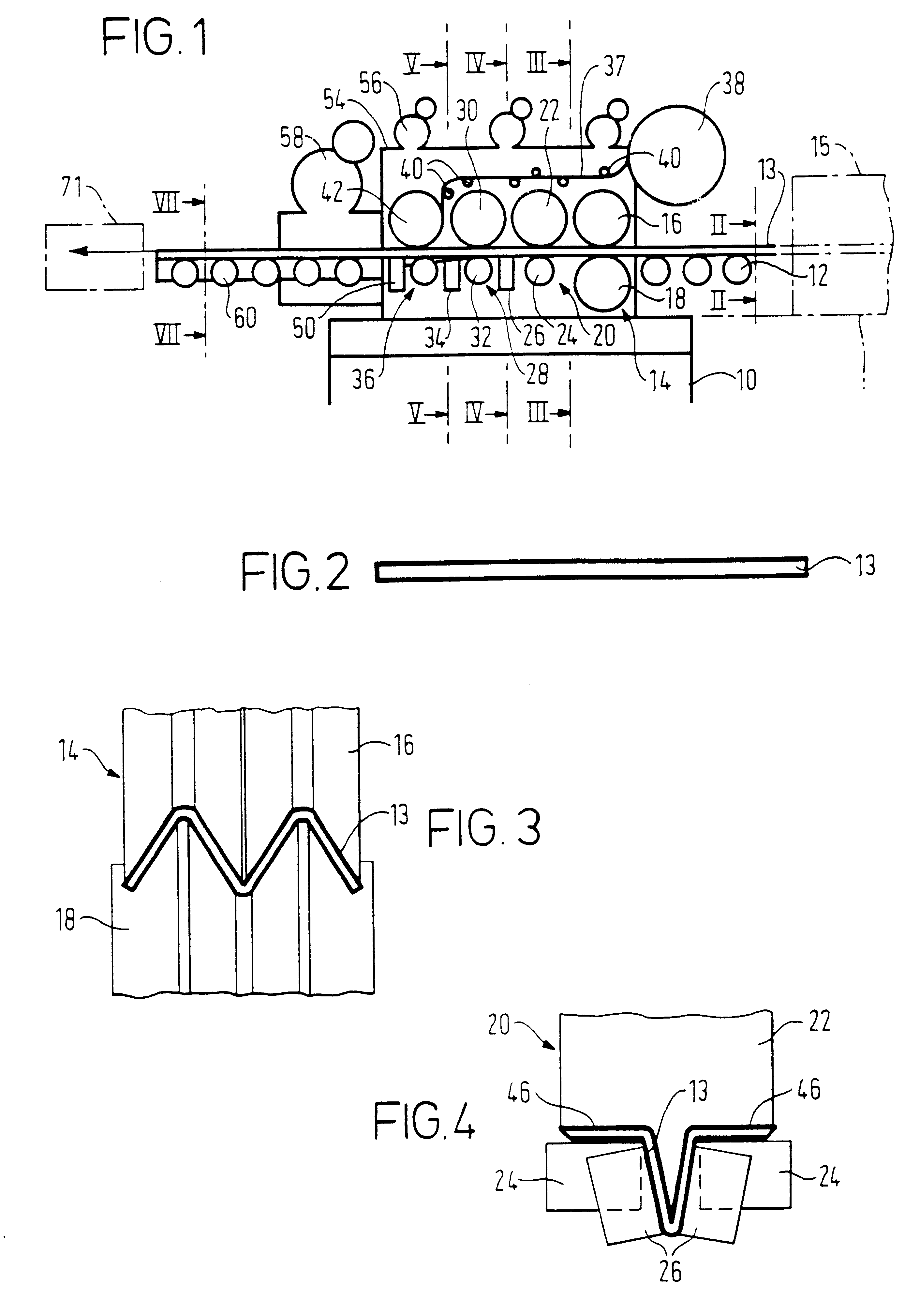

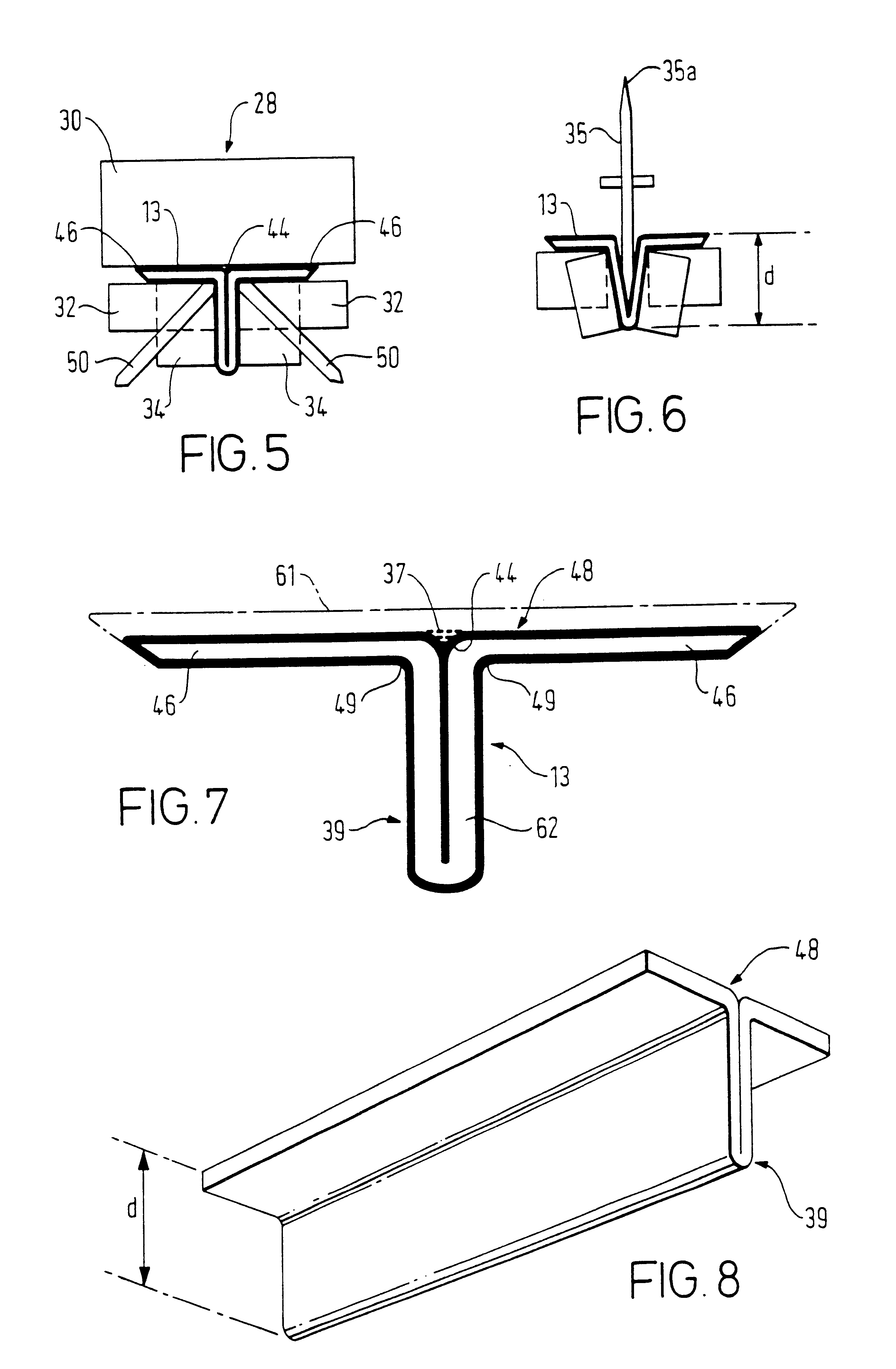

Roll forming machine

The roll forming machine comprise a series of rollers 14, 20, 28 and 36 for shaping a fabric 13 such as a fabric impregnated with a curable matrix. A feed roller 36 is provided for feeding a length of material 37 such as a tow of fibres onto the fabric during or subsequent to the shaping process. The roll forming process is particularly useful in the manufacture of blade stiffeners for an aircraft wing.

Owner:AIRBUS OPERATIONS LTD

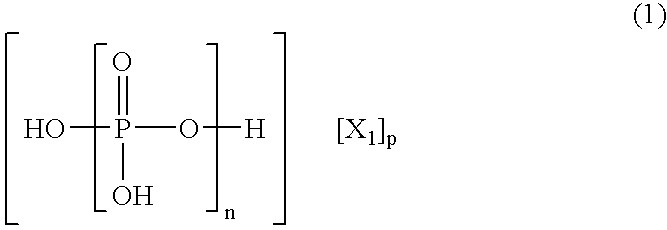

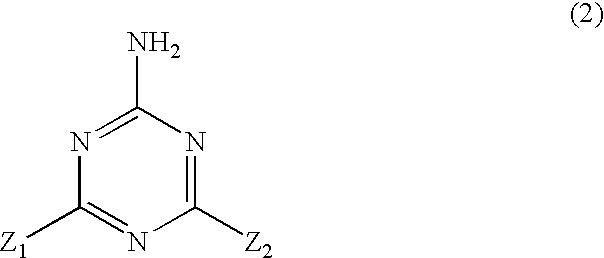

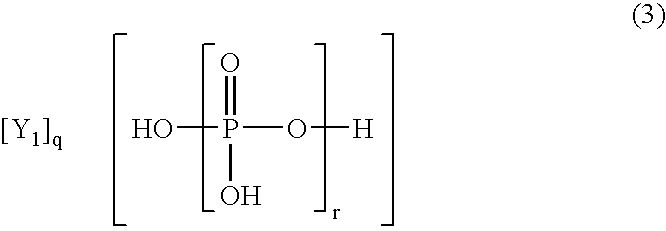

Flame retardant composition and flame retardant resin composition containing the composition

InactiveUS20050256234A1Improve flame retardant performanceTextile shapingCarboxylic acidFire retardant

A flame retardant composition includes, as essential components having two specified types of phosphate compounds; silicon dioxide or metal oxides; and at least one member selected from among higher aliphatic carboxylic acids, metal salts of higher aliphatic carboxylic acid, higher fatty acid amide compounds, and esters between mono- or polyhydric alcohols and higher aliphatic carboxylic acids. This flame retarder composition is free from secondary agglomeration, and does not need incorporation of a halogenated flame retarder that when blended in a synthetic resin, releases harmful gas at combustion. The flame retardant composition enables imparting flame retardant properties to synthetic resins with the use of a small amount of flame retarder.

Owner:ADEKA CORP

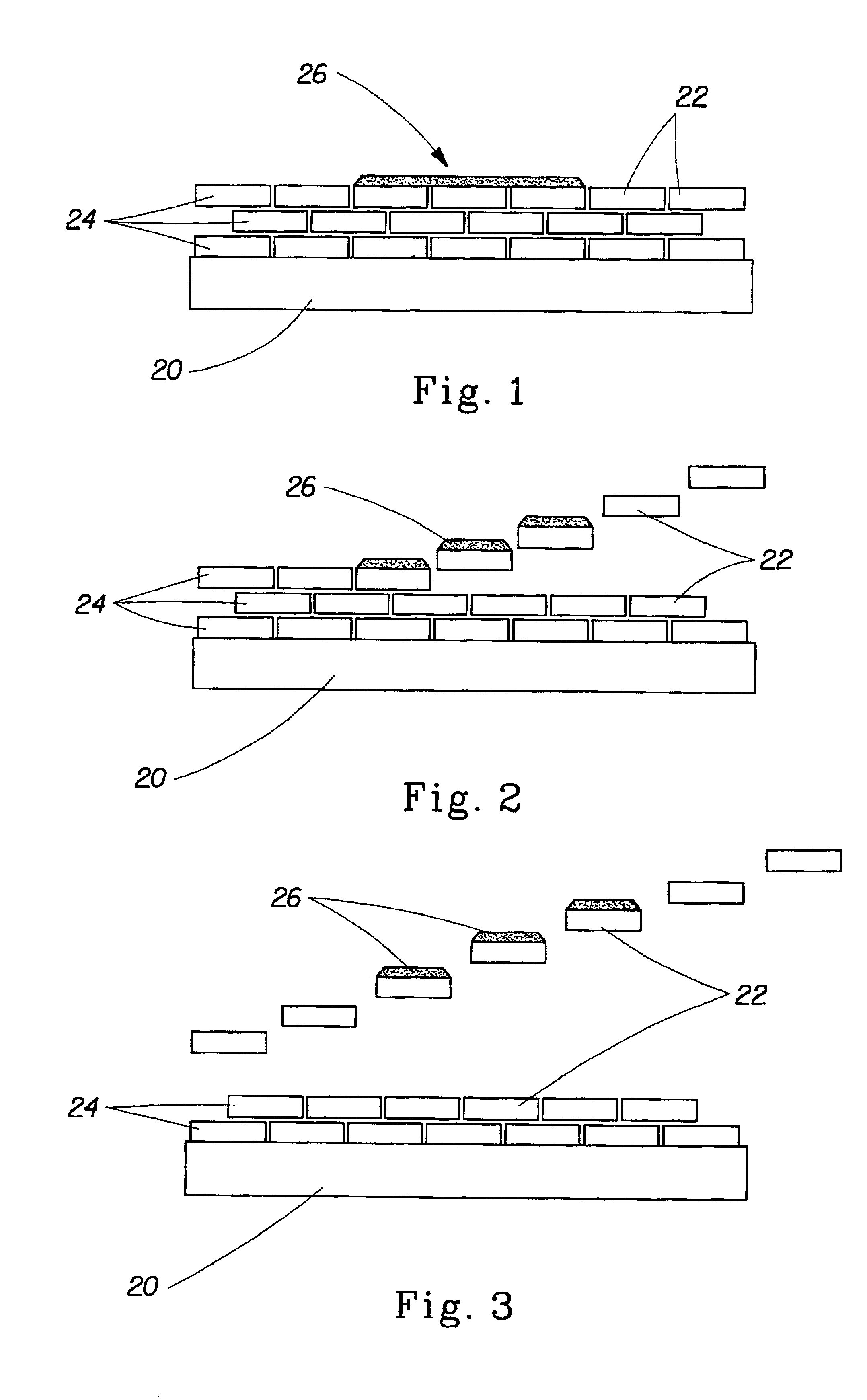

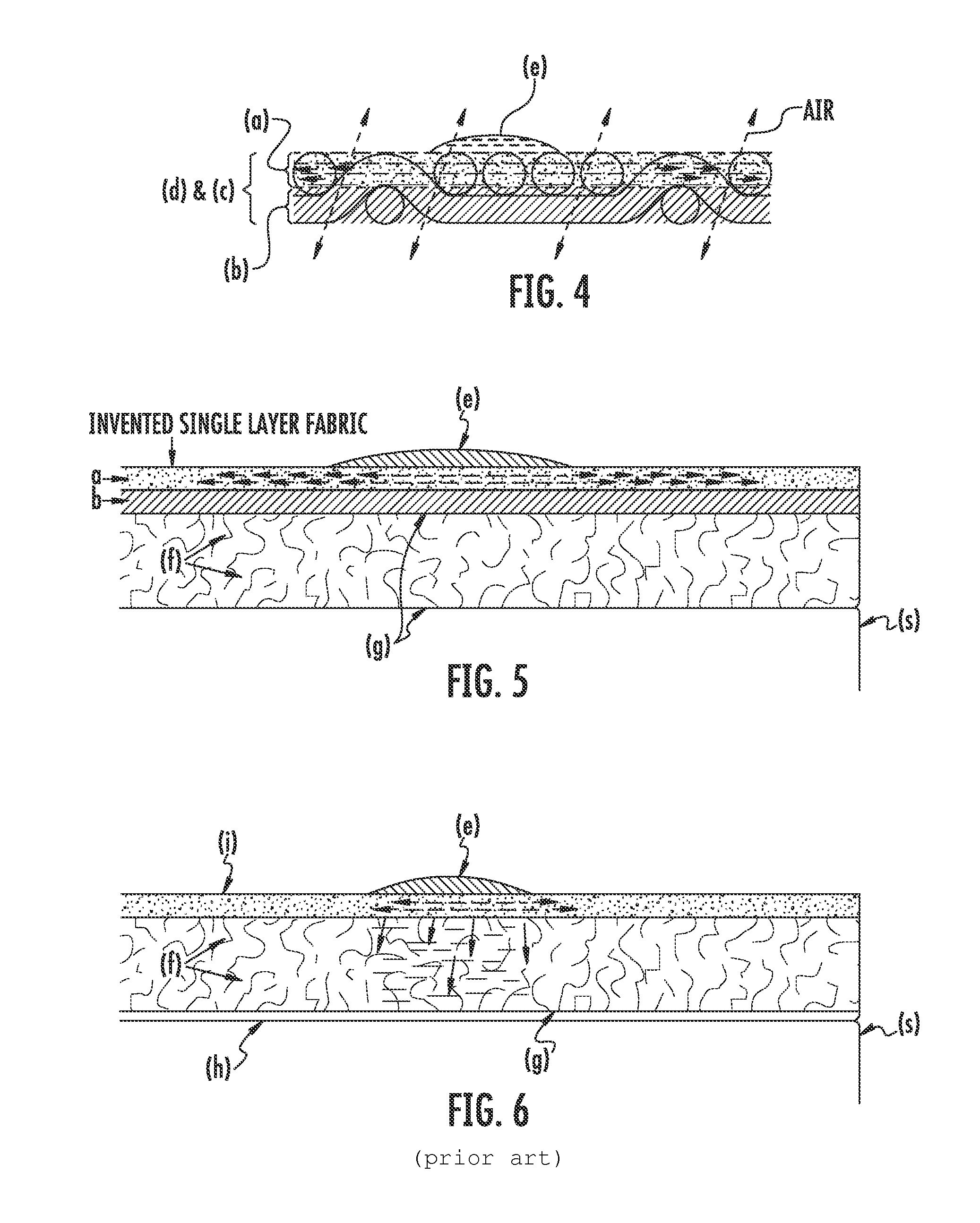

Semi-absorbent, semi-resistant, breathable fabric

A semi-absorbent, semi-resistant, breathable fabric includes a single-layer having a first, hydrophilic side that absorbs water, and a second, hydrophobic side; wherein the first, hydrophilic side of the single-layer fabric quickly spreads out a liquid that is absorbed laterally to a wider area such that the absorbed liquid does not seep or pass through to the second, hydrophobic side of the single-layer fabric under gravitational force. A method of making a semi-absorbent, semi-resistant, breathable fabric includes: subjecting a first side of a single-layer fabric to a hydrophilic amino functional polysiloxane softener; treating a second opposite side of the fabric with a fluorocarbon compound under low pressure such that the fluorocarbon compound penetrates no more than half of the fabric thickness; and drying and curing the fabric, preferably at a temperature of about 145° C. to 155° C. for about three minutes to about five minutes.

Owner:WELSPUN INDIA LTD

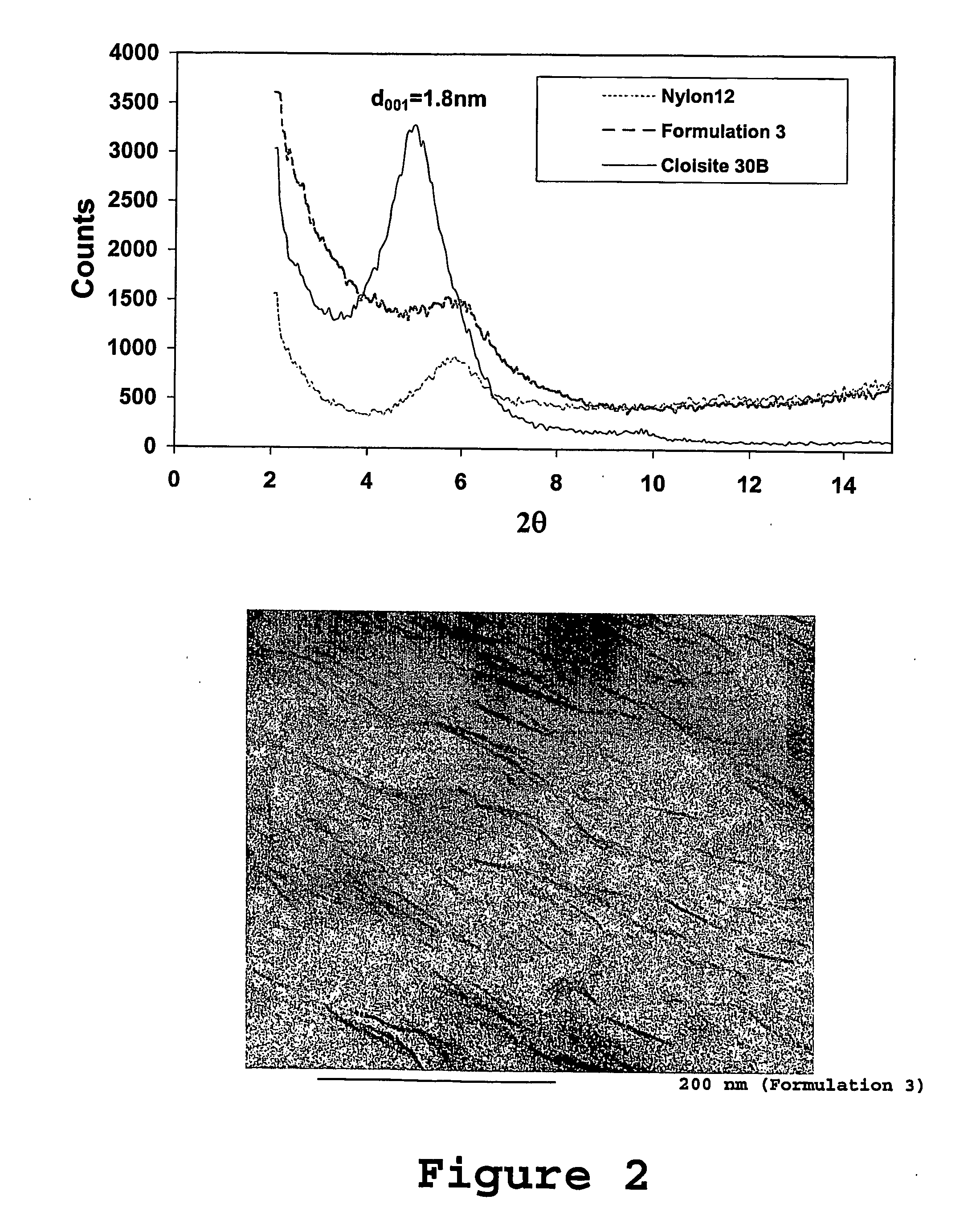

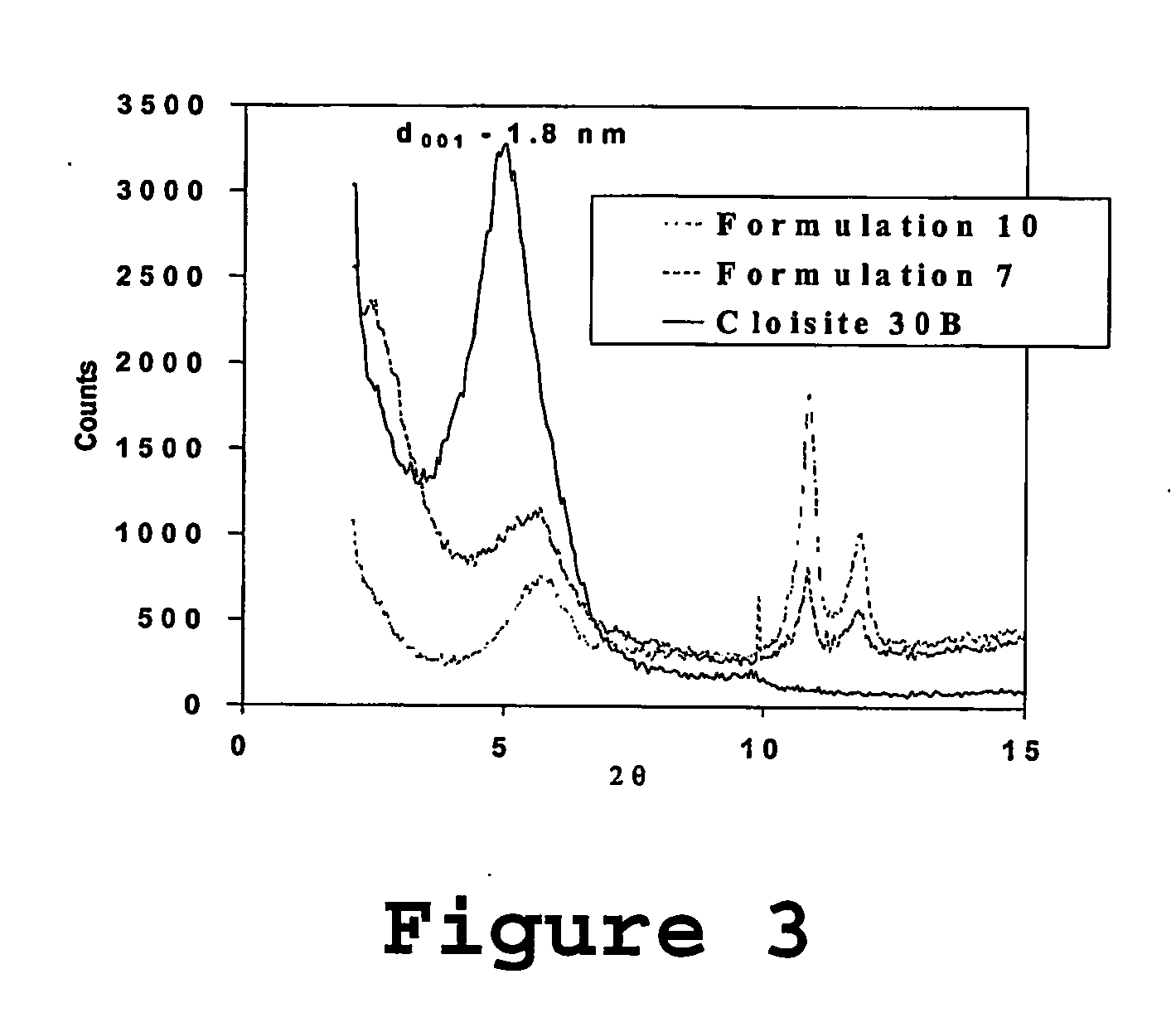

Fire resistant material

InactiveUS20070194289A1Improve compatibilityImprove rheologySilicon compoundsTextile shapingPolyamideMaterials science

The present invention relates to inorganic-organic hybrids (IOHs), methods for their preparation and their use as fire resistant materials or components of fire resistant materials. More specifically, the invention relates to polyamide fire resistant formulations containing IOHs which have application in the production of fire resistant articles or parts thereof for use in the transportation, building, construction and electrical or optical industries.

Owner:THE BOEING CO

Physical and mechanical properties of fabrics by hydroentangling

InactiveUS20050125908A1Reducing surface pilling tendencyExcellent abrasion resistancePhysical treatmentDetergent compounding agentsFiberFibril

Methods for reducing the surface pilling tendency and improving abrasion resistance of a pillable fabric are disclosed. The methods include providing a pillable fabric including fibrils extending from the surfaces thereof, supporting the fabric, and exposing the fabric to a hydroentanglement process that imparts an energy in the range of at least about 4000 to 5000 KJoules / Kg of fabric using pressures of 200 bars or greater. The presence of fibrils on the fabric surface are reduced to an amount wherein the pilling production on the fabric is less than about 20% after 5,000 cycles of abrasion on a Martindale device according to ASTM D4970 testing standard and the fabric remaining mass is at least about 80% to 90% after 50,000 cycles of abrasion on a Martindale device according to ASTM D4966 testing standard.

Owner:NORTH CAROLINA STATE UNIV

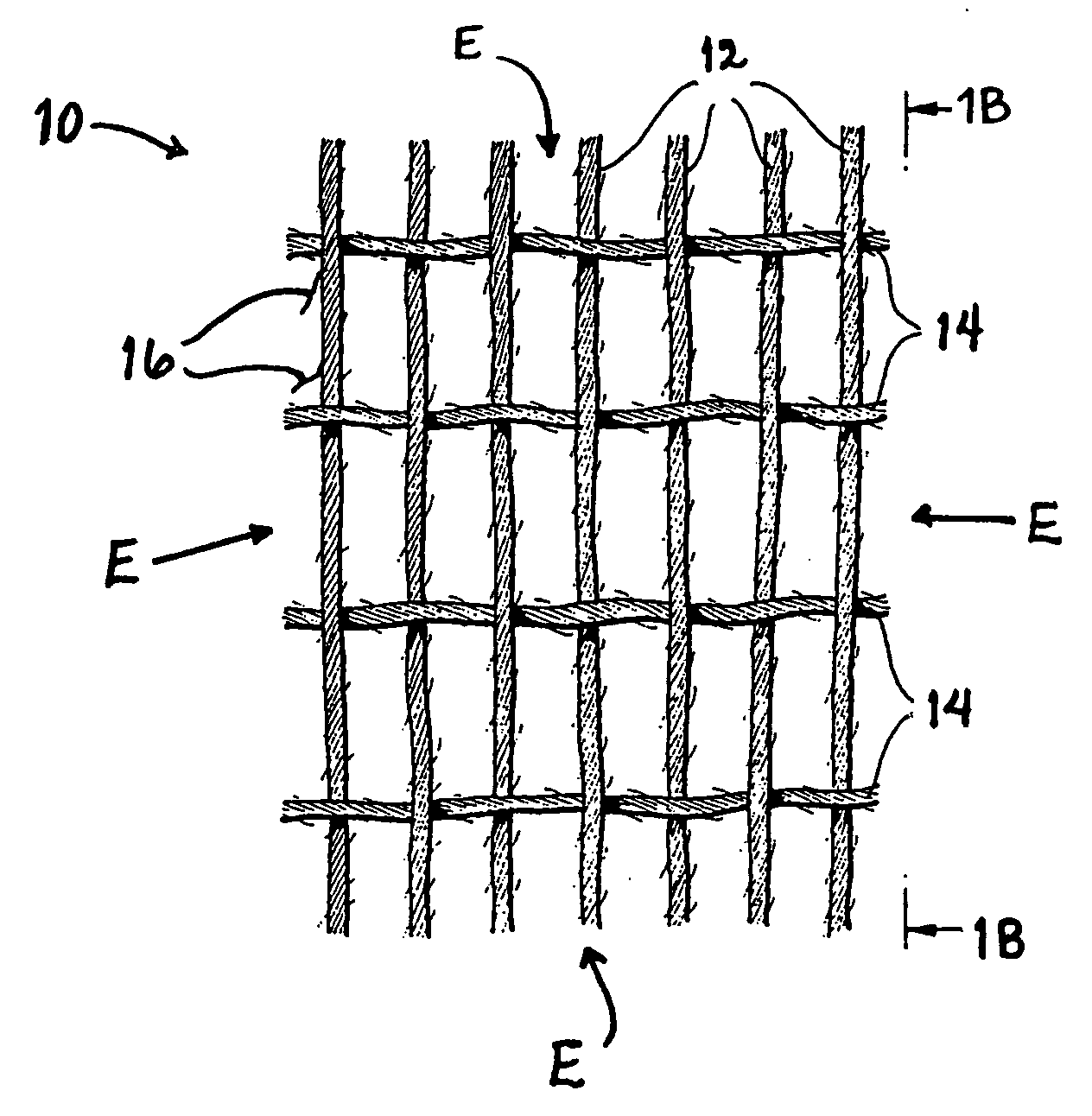

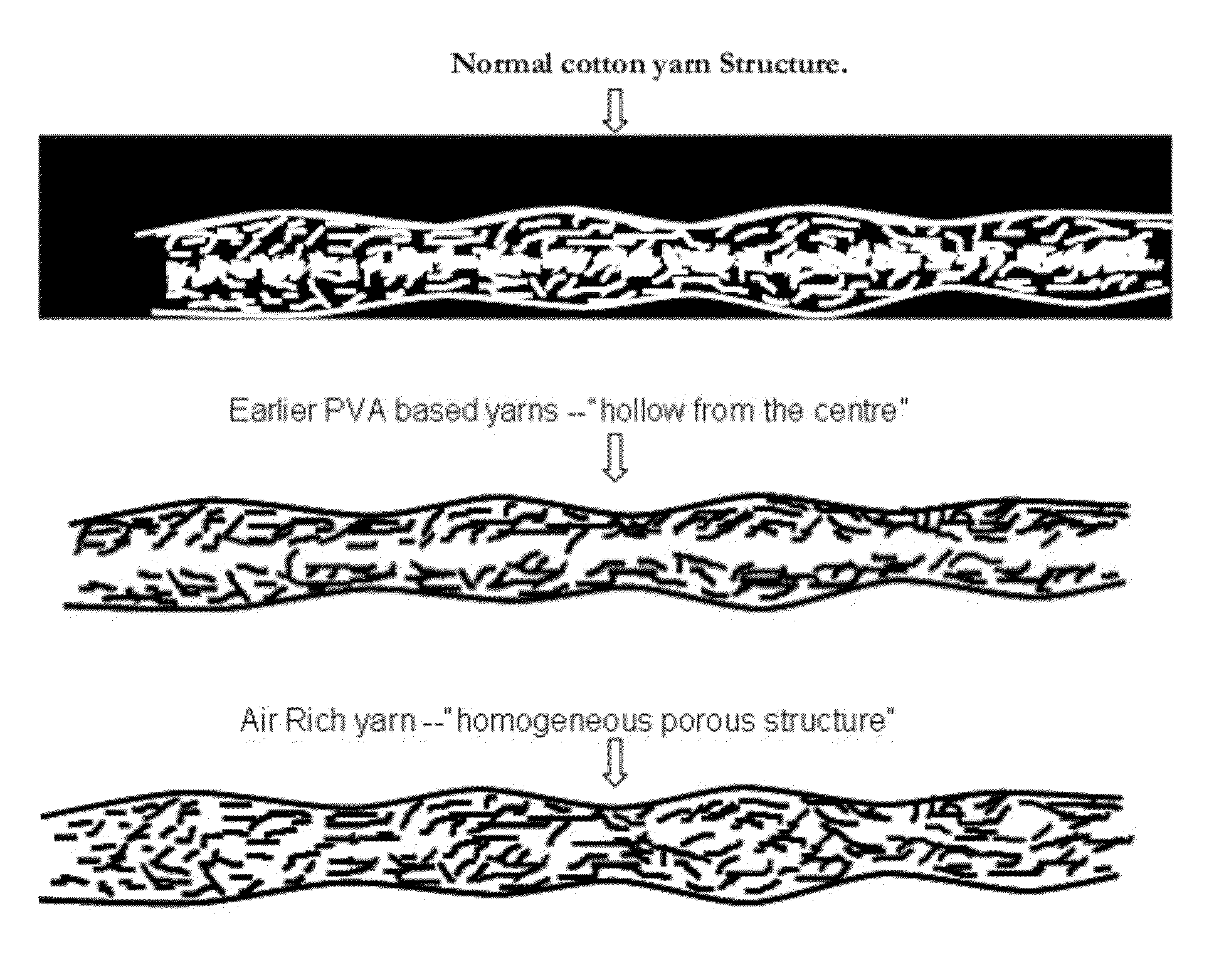

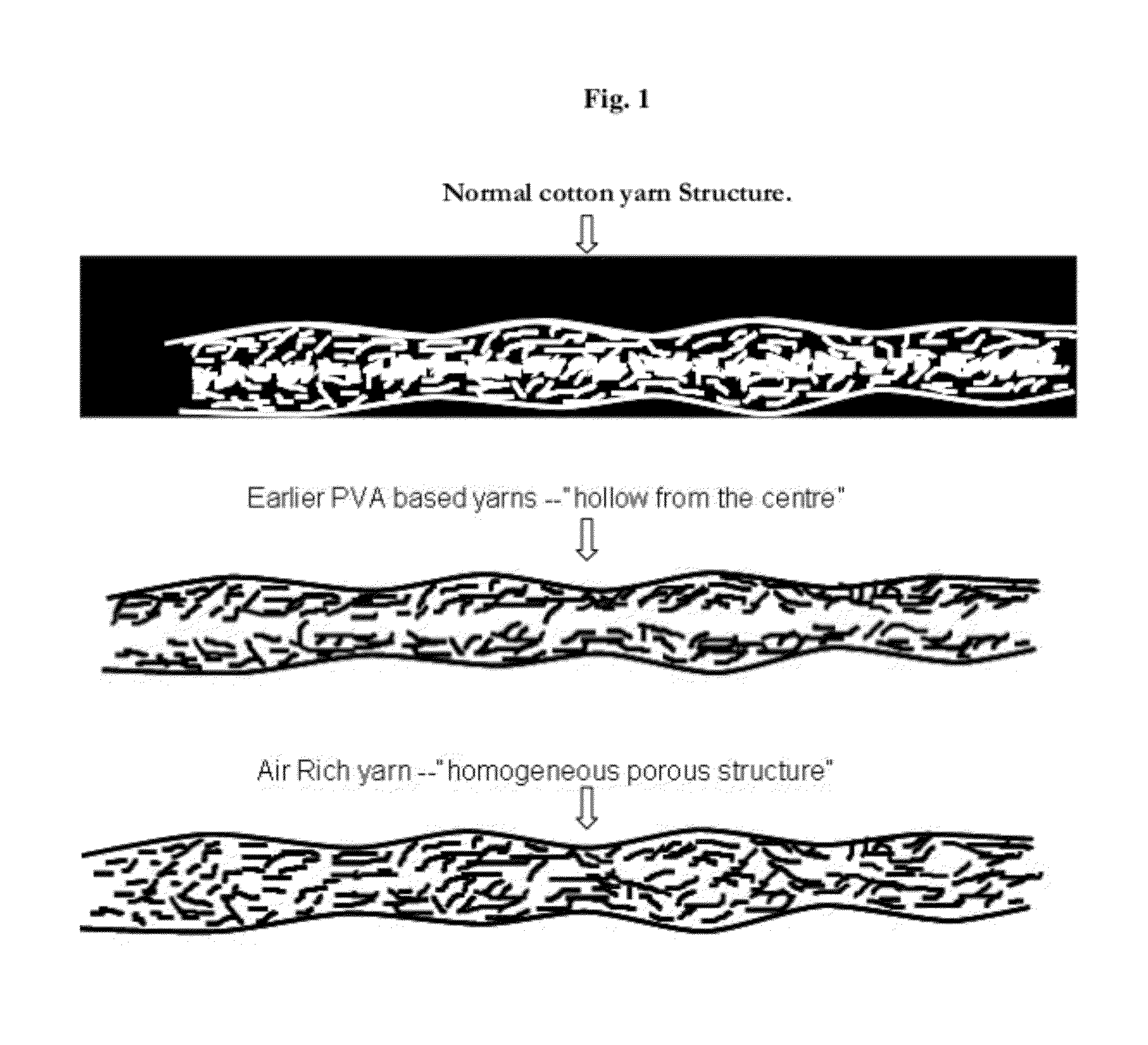

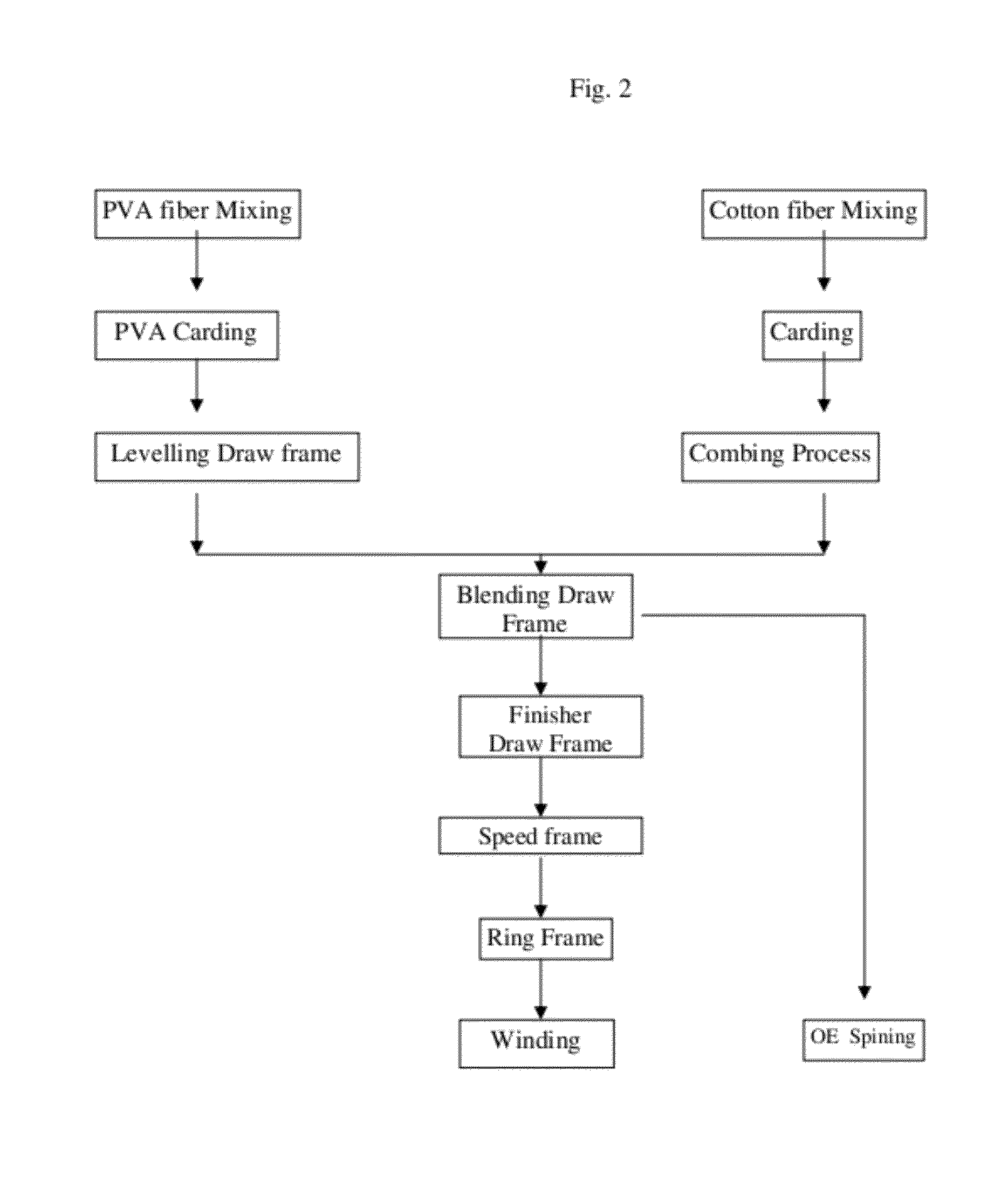

Air rich yarn and fabric and its method of manufacturing

The present invention relates to air rich yarn and fabric with pores throughout the cross-section. Air rich yarn and fabric have high wettability, easy dryability, quick absorbency and increased thickness. When air rich yarn is used to make terry fabric it makes thicker fabric with increased capacity to absorb water and also release moisture faster while drying.

Owner:TRIDENT

Homeowner's method of snow removal with a motor vehicle

This method provides various high-power-ratio snow removal devices which clear paths narrower than the motor vehicles. We use small, light, low-priced, yet also safe, durable devices to clear the narrow swaths. High power ratios result from applying motor vehicle horsepower to small snow removal devices similar to those found on lawn tractors. Such devices may comprise moldboard plows (FIGS. 3, 9, 10, 11, 15, 16), snow throwers (FIGS. 7 and 13), or combinations of both types (FIG. 12 and 17). Quick-connect and quick-release fittings (FIGS. 3A, 3B, 6, 8, 9A, 9B, 14) position each device for temporary propulsion by a vehicle. The connectors allow quick conversion of the family car to a plowing machine, and when plowing is done, quick re-conversion. A moldboard plow of about half the car's width (FIG. 3) is our preferred embodiment. The mini-moldboard (FIG. 10) is least expensive. Deepest snow can be handled by our tall, narrow moldboard (FIG. 15). We protect homeowners, their cars and their plows from injury when plows strike hidden objects. Protection devices comprise safety springs (60) and pivots (63, 67 and 69) of FIG. 3B, the tension-release mechanism mentioned but not detailed in FIG. 15, annor shields (396, 398) of FIG. 16 and various others mentioned or provided for in our drawings but not detailed. We prefer cars' chassis tie-down ears (72) in FIG. 3A, as connector points for our plow or thrower arms. For cars lacking such ears, we propose add-on ears. For example, tie-down ear (126) in FIG. 6.

Owner:NUGENT GORDON W

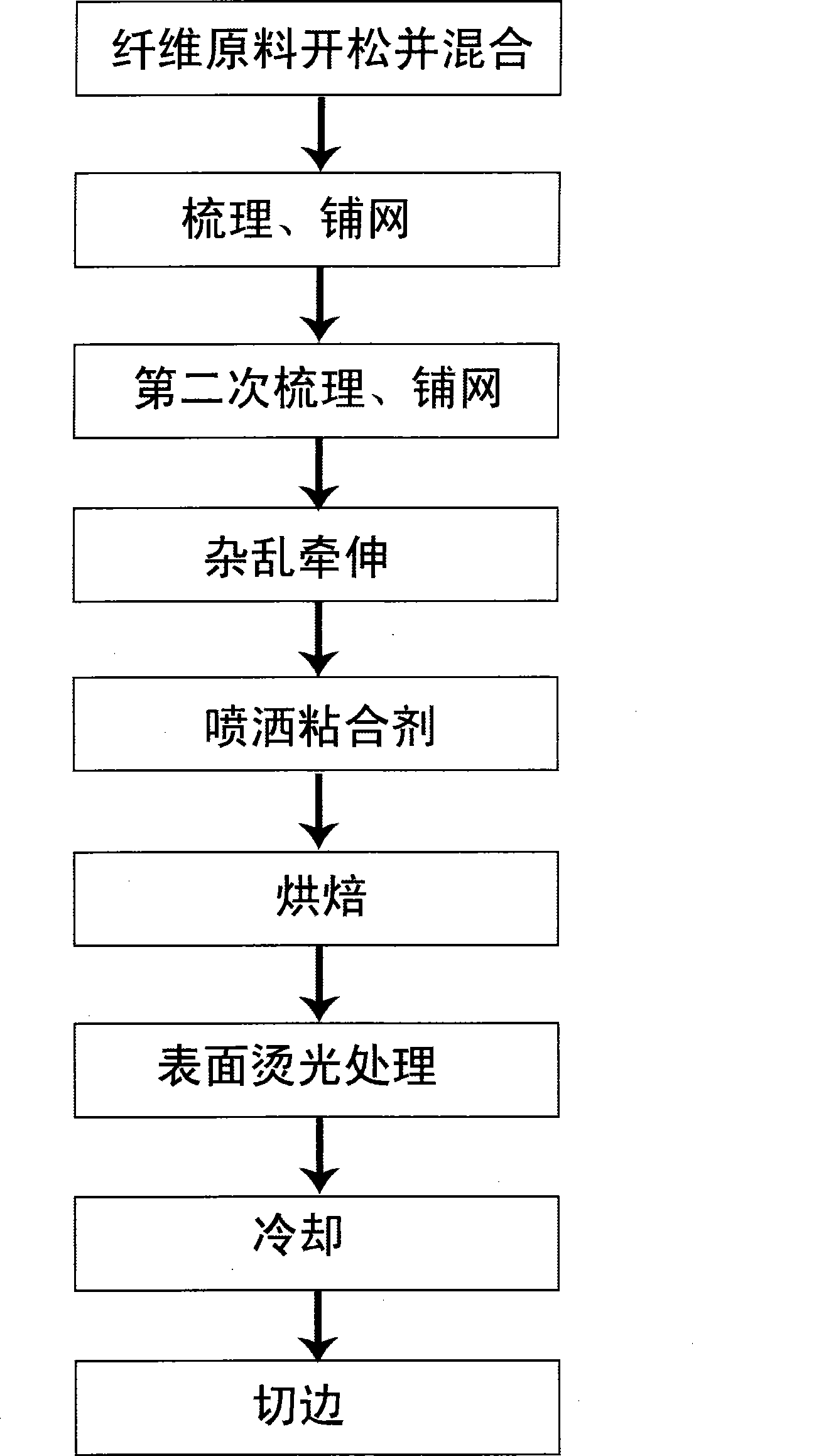

Thermal protection flocculus and manufacturing method thereof

InactiveCN101476212AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberNet shape

The invention provides a keeping warm flocculus which is prepared from raw material by weight including 56%-85% fine denier fibre and / or super fine denier fibre, 0-30% hollow fibre, 5-30% felt fibre. The preparing method includes steps as follows: loosing and mixing various fibre raw material; then combing, lapping for forming fibre net; then processing disorder drafting to the felt net for forming solid net shape crossing struture; then heating and baking the felt net, at least melting surface of the felt fibre for felting surrounding fibre. The fine denier fibre can increase content of still air in the keeping warm flocculus, reduce heat quantity conduction, and can divide space in the keeping warm flocculus into smaller space for avoiding or reducing air convection, accordingly increase warm keeping property of the keeping warm flocculus; the hollow fibre can increase filling power and compress rebound property of the warm keeping flocculus; filling power and compress rebound property of the warm keeping flocculus are increased after being disorder draft.

Owner:汕头市奥山服饰有限公司

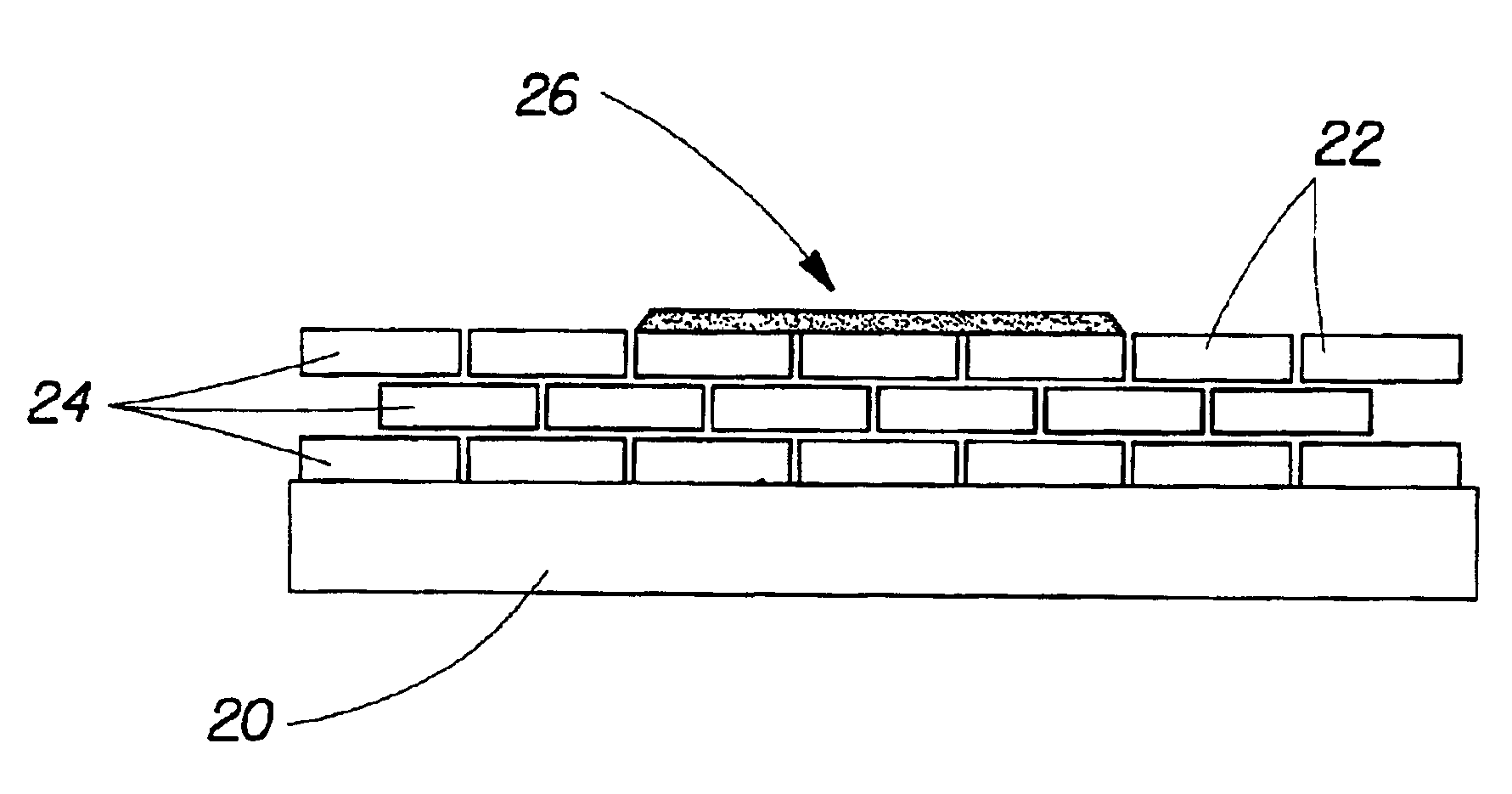

Stab resistant and anti-ballistic material and method of making the same

The invention relates to a fabric having both stab resistant and anti-ballistic properties. The fabric is made of yarn of a weight greater than about 500 dtex, and the fabric has a minimum shrinkage factor of at least about 1% achieved through a densification treatment. The invention further relates to a method of producing a such a fabric having the steps of agitating a fabric made of a yarn of a weight greater than about 500 dtex, substantially removing a spin finish from the fabric before, during or after the agitating step, and drying the fabric.

Owner:TEIJIN TWARON GMBH

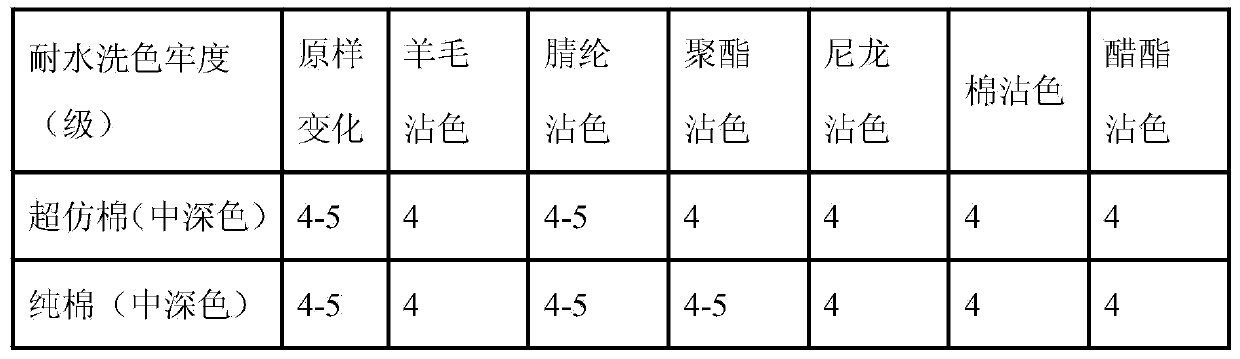

Preparation method of high-imitation cotton printed fabric

InactiveCN103741417AReduce tensionFully swollenSucessive textile treatmentsWoven fabricsPolyesterYarn

The invention discloses a preparation method of a high-imitation cotton printed fabric. The preparation method comprises the following steps: (1) weaving cloth; (2) sizing and oiling; (3) desizing and refining; (4) reducing alkaline amount; (5) shaping; (6) sanding; (7) printing; (8) post-shaping and drying; and (9) absorbing moisture, sweating and finishing. According to the preparation method, superfine denier fiber is used for weaving; warps and wefts adopt high-fischer yarns; compared with normal polyester cotton fabric, the high-imitation cotton printed fabric s better in moisture absorption and air permeability, and smoother in hand feeling; according the preparation method, raw material selection and structure design are used; and the processes of loosing and desizing, shaping, sanding, padding, absorbing moisture, sweating and finishing are used for preparing the high-imitation cotton printed fabric; the preparation method is simple and practical in process and strong in adaptability; the overall process has the characteristics of obviously saving energy and water; test of performances of colour fastness, strength and anti-static property proves that the high-imitation cotton printed fabric completely achieves the effect of the cotton.

Owner:浙江弘晨印染科技股份有限公司

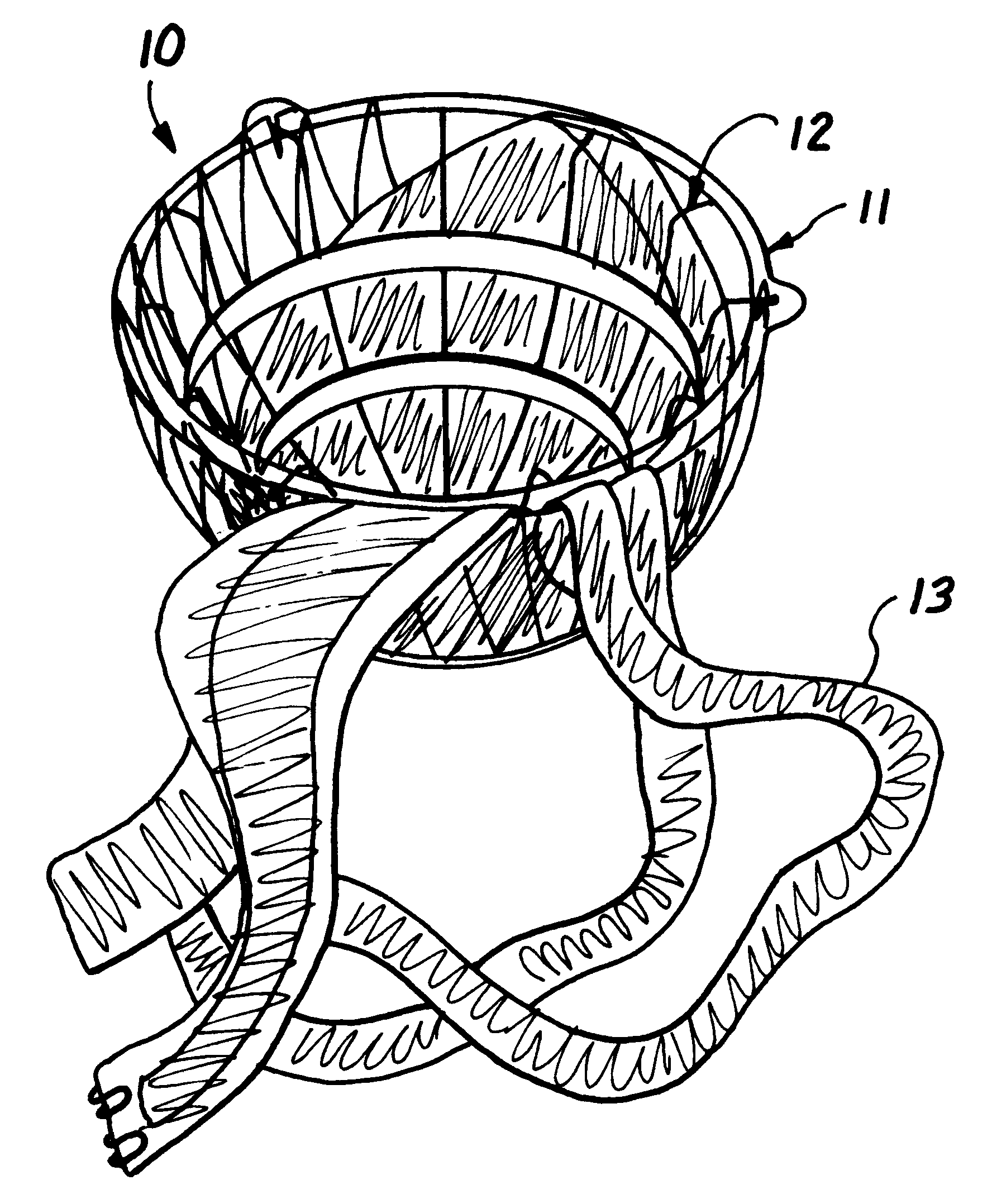

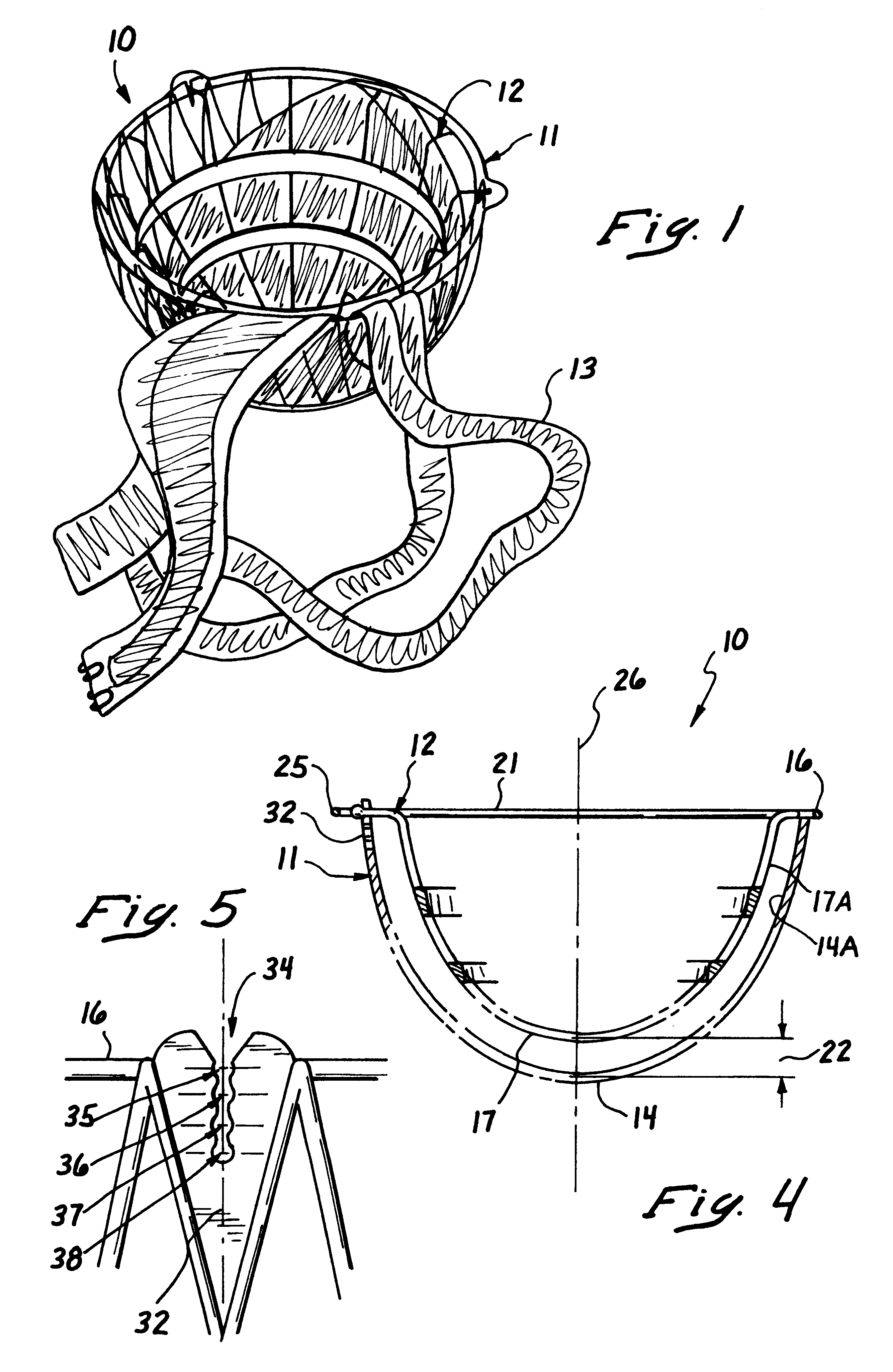

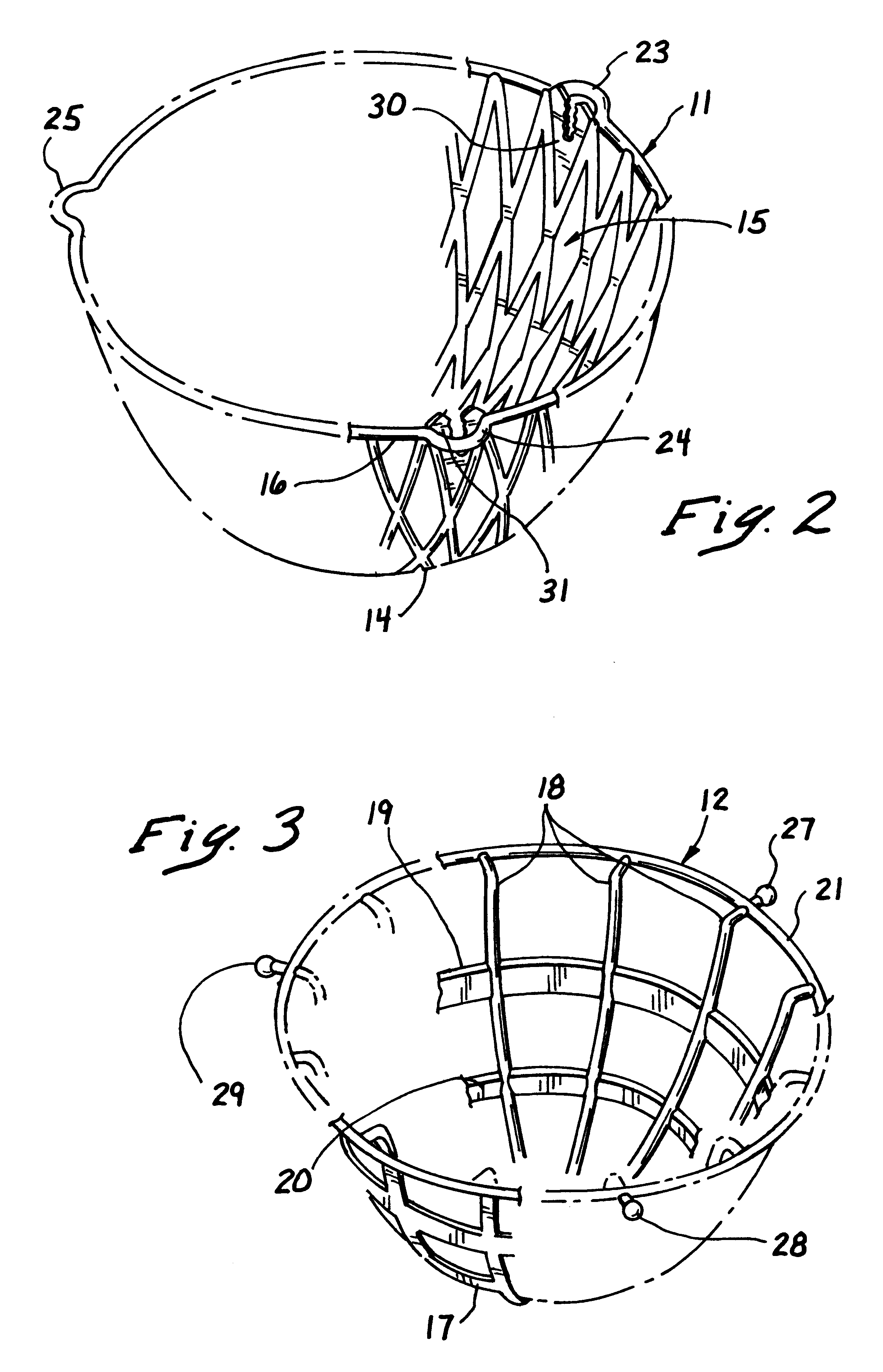

Protective bra cage device for laundering delicate undergarments

InactiveUS6234368B1Easy and less-costly to fabricateConvenience to workIroning apparatusLaundry apparatusCage deviceEngineering

Owner:DESFORMERYL J +1

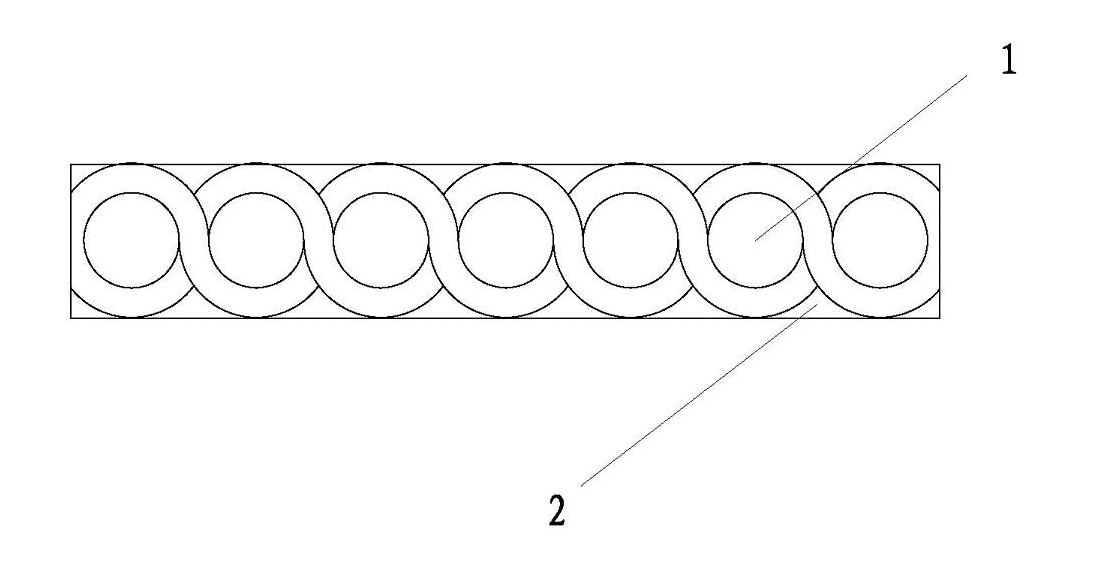

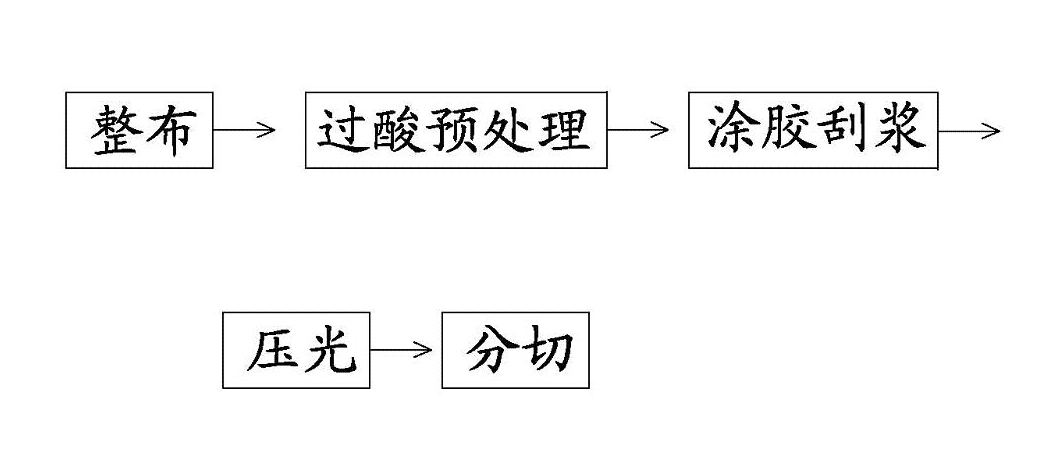

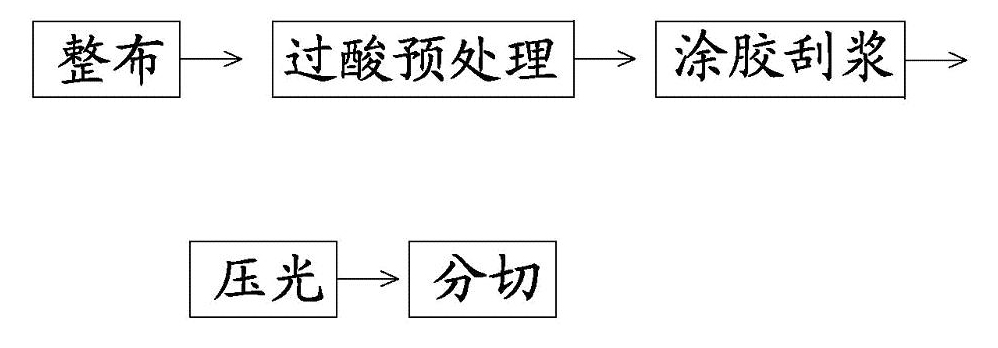

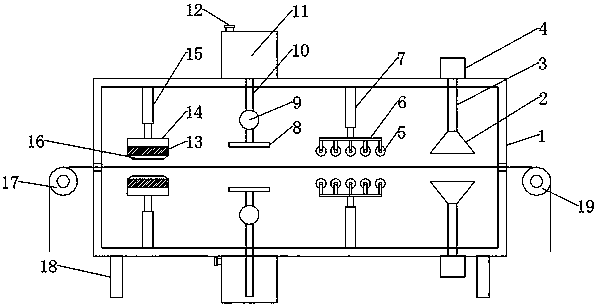

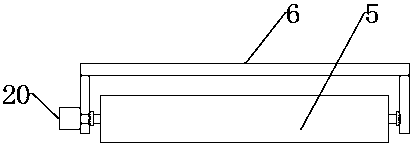

Environment-friendly non-fraying printed label tape and manufacturing method thereof

The invention relates to an environment-friendly non-fraying printed label tape and a manufacturing method thereof, belonging to the technical field of label tape manufacturing. The environment-friendly non-fraying printed label tape comprises a substrate layer and a colloid layer, the thickness of the substrate layer is within 150-170 microns, and the thickness of the colloid layer is within 20-30 microns; and the colloid layer is a synthetic resin scraping layer. The manufacturing method of the environment-friendly non-fraying printed label tape sequentially comprises the steps of cloth arranging, gelatinizing and scraping, calendering and cutting, wherein the gelatinizing and scraping step is as follows: gelatinizing a piece of grey cloth, in which the gelatinizing quantity is controlled within 20-40g / m<2>, and scraping the grey cloth by a scraping machine after gelatinizing, wherein the gelatinizing formula is as follows: 80-89wt% of synthetic resin, 10-15wt% of water and 1-5wt% of thickening agent. In the invention, the manufacturing method needs low production cost; and the product has the technical effect of non-fraying and meets the 0eko-tex standard100.

Owner:HUZHOU SINY LABEL MATERIAL

Cloth processing equipment for weaving

InactiveCN108374278ATimely stereotypesImprove qualityMechanical cleaningPressure cleaningEngineeringBrush device

The invention discloses cloth processing equipment for weaving. The cloth processing equipment comprises a dustproof box, a material inlet roller, a material outlet roller, a float hair attracting device, a float hair brushing device, a humidifying device and a wrinkle eliminating device. The float hair attracting device comprises a dust collector, an air pipe and an attracting head. The float hair brushing device comprises a first electric push rod, a mounting board and a hairbrush roller. The humidifying device comprises a water tank, a hard water pipe, a booster pump and a nozzle. The wrinkle eliminating device comprises a second electric push rod, a mounting box, a heater and a winkle eliminating board. The cloth processing equipment is provided with the float hair attracting device and the float hair brushing device, thereby eliminating the float hair on the surface of the cloth and preventing entering of the float hair into body of personnel through breathing in postprocessing oftextile. The cloth processing device is provided with the humidifying device and the wrinkle eliminating device for performing ironing and wrinkle elimination on the humidified cloth. The cloth is pulled out of the bottom of the wrinkle eliminating board through the pulling force of the material outlet roller and is stretched. The wrinkle-eliminated cloth is cooled and molded in air, thereby ensuring in-time cloth fixing after wrinkle elimination and improving cloth quality.

Owner:陈雪莲

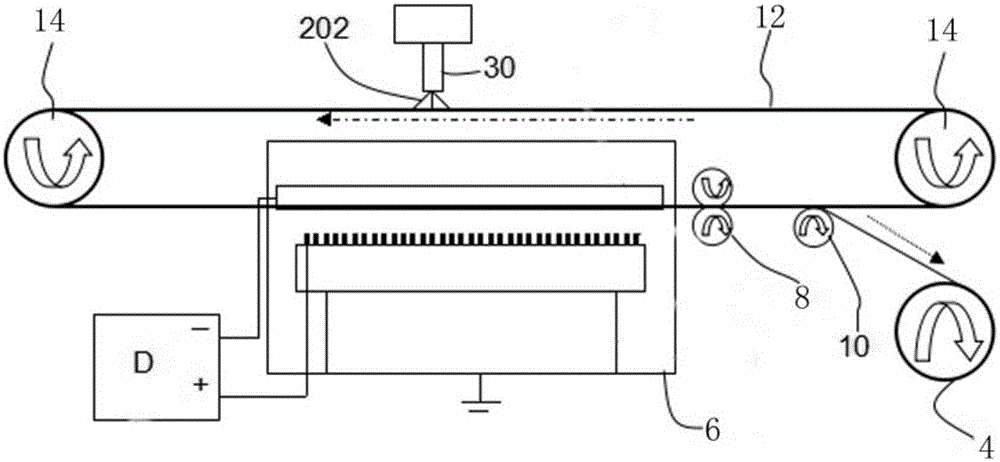

Waterproof and breathable paper diaper base membrane and manufacturing method thereof

ActiveCN105063896ASolve leaking urineSolve the problem of red and swollen buttocksNon-woven fabricsBandagesWater vaporAdult diaper

The invention provides a waterproof and breathable paper diaper base membrane which comprises a base material layer and a waterproof and breathable layer composited with the base material layer. The waterproof and breathable paper diaper base membrane is characterized in that the base material layer is a non-woven fabric fiber layer with the breathability being 100-700 CFM and the thickness being 5-20 GSM, and the waterproof and breathable layer is a nanometer fiber stacking body layer. The invention further provides a manufacturing method of the waterproof and breathable paper diaper base membrane. Hydrophobic high polymer resin is utilized for passing through quantity production high pressure electrostatic spinning equipment, and electrostatic spinning is directly performed on an ultrafine fibber non-woven fabric to form a nanometer fiber stacking body. According to the paper diaper base membrane produced by compositing the nanometer fiber and the ultrafine fiber non-woven fabric, the water pressure resistance can reach more than 4000 mm H2O, meanwhile, the breathability can reach more than 3 CFM, and the water vapor permeance can reach more than 10000 g / cm<2>.24h. A gap for production of the waterproof and breathable base membrane in China is filled, and the problems of urine leakage and red and swollen buttocks caused when a baby wears a paper diaper are completely solved; meanwhile, the base membrane formed by compositing the nanometer fiber and the non-woven fabric can be applied to the market of adult diapers and woman sanitary towels and has the good market development prospect.

Owner:SOOCHOW BOYOO NANO TECH CO LTD

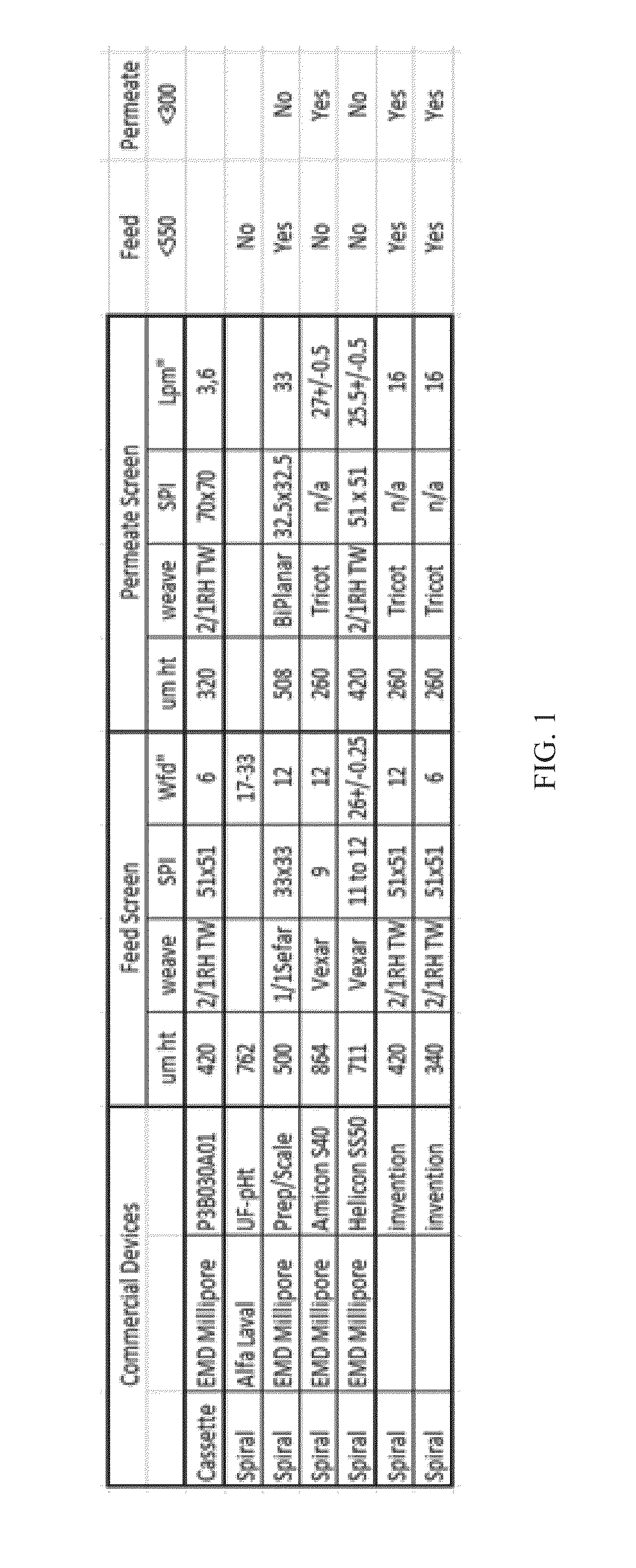

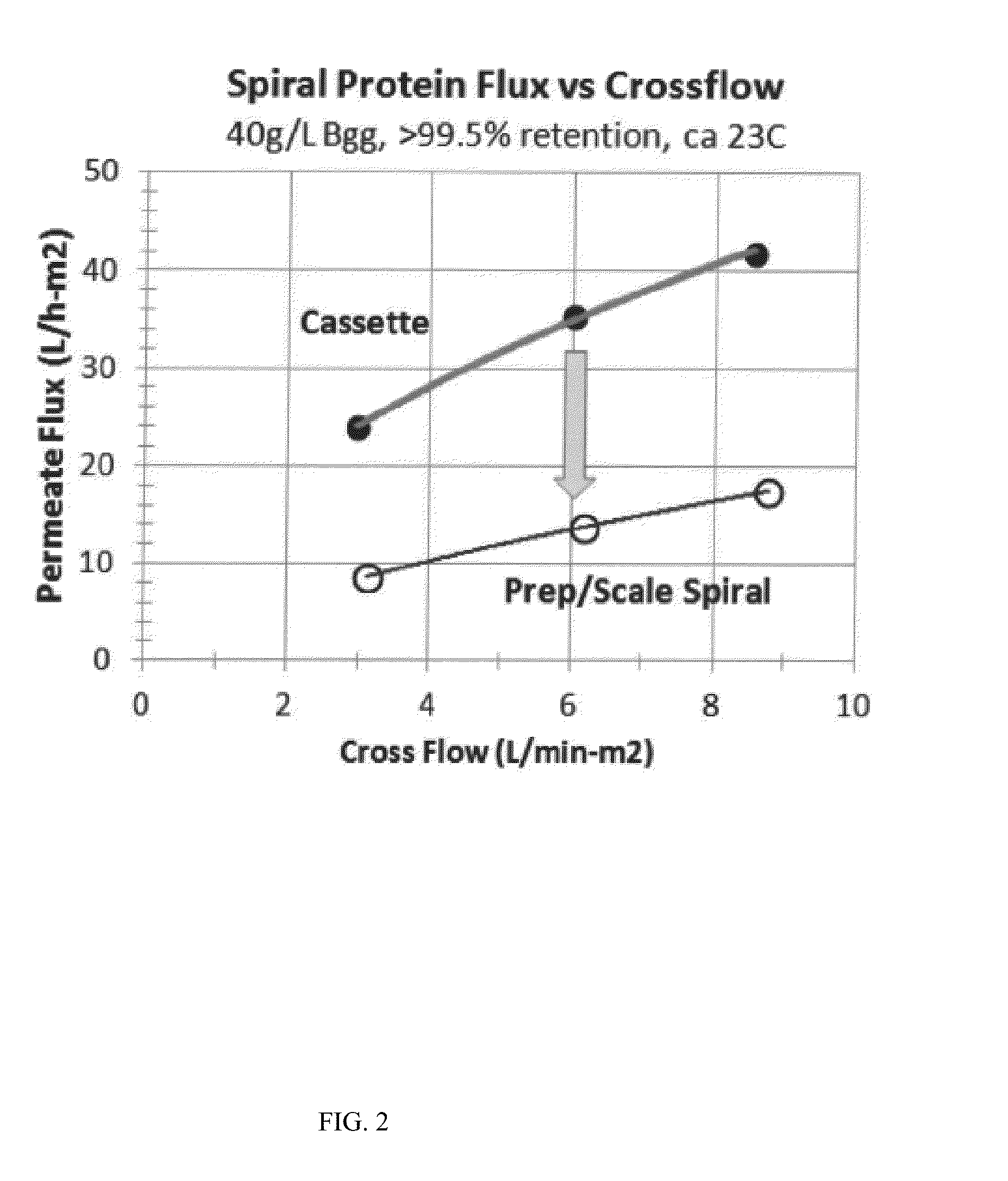

Compact spiral-wound filter elements, modules and systems

ActiveUS20150375173A1Increased feed channel pressure dropEasy to mergeUltrafiltrationReverse osmosisFiltrationSpiral wound

The present invention provides compact spiral-wound filter elements having cassette-like performance. The invention further provides filtration systems (e.g., TFF systems) and processes (e.g., SPTFF processes) employing compact spiral-wound filter elements having cassette-like performance.

Owner:MILLIPORE CORP

End-Fray Resistant Heat-Shrinkable Woven Sleeve, Assembly Therewith and Methods of Construction Thereof

ActiveUS20140272218A1Excellent abrasion resistanceIncreased crush strengthWrappers shrinkageProtective fabricsPliabilityArchitectural engineering

A woven sleeve, sleeve assembly and methods of construction thereof are provided. The sleeve has a flexible, abrasion resistant, circumferentially closed and continuous elongate wall extending lengthwise along a central axis between opposite ends. The wall is woven with warp yarns extending generally parallel to the central axis and at least one heat-shrinkable weft yarn extending generally transversely to the warp yarns. The warp yarns provide the sleeve with coverage, abrasion resistance and flexibility and the weft yarn provides the ability to shrink the wall about an elongate member being protected within a cavity of the sleeve, as well as providing enhanced crush strength and abrasion resistance. At least one of the warp yarns and / or weft yarn includes at least one low melt, heat-fusible yarn served therewith to enhance resistance to end-fray during a cutting operation.

Owner:FEDERAL MOGUL POWERTAIN LLC

Multifunctional thermal underwear fabric and processing method thereof

InactiveCN102312342AFunction increaseGood warmth retentionWeft knittingFibre treatmentPolyesterTextile technology

The invention relates to a multifunctional thermal underwear fabric and a processing method thereof, belonging to the field of textile technology. The multifunctional thermal underwear fabric comprises a face weave and a bottom weave, wherein the face weave consists of cotton fibers, polyester fibers, spandex fibers, bamboo charcoal fibers, viscose fibers, wool fibers and plant protein fibers; and the bottom weave consists of polyester fibers. The content of the cotton fibers accounts for 34-60 percent of the total components, the content of the polyester fibers accounts for 26-39 percent of the total components, the content of the spandex fibers accounts for 5-6 percent of the total components, the content of the bamboo charcoal fibers accounts for 0.5-6 percent of the total components, the content of the viscose fibers accounts for 1-17 percent of the total components, the content of the wool fibers accounts for 1-5 percent of the total components, and the content of the plant protein fibers accounts for 0.5-7 percent of the total components. The multifunctional thermal underwear fabric has the advantages that the functions of the fabric are expanded by guaranteeing an excellent warmth keeping performance through the cotton fibers, by guaranteeing ideal elasticity through the spandex fibers, by reflecting a good moisture absorbing performance and air permeability through the polyester fibers and by reflecting a good antibiotic property through the bamboo charcoal fibers; and since function processing, baking and secondary ironing processes are increased, the fabric has an aromatic long-lasting effect.

Owner:CHANGSHU MENGXI FURNISHINGS

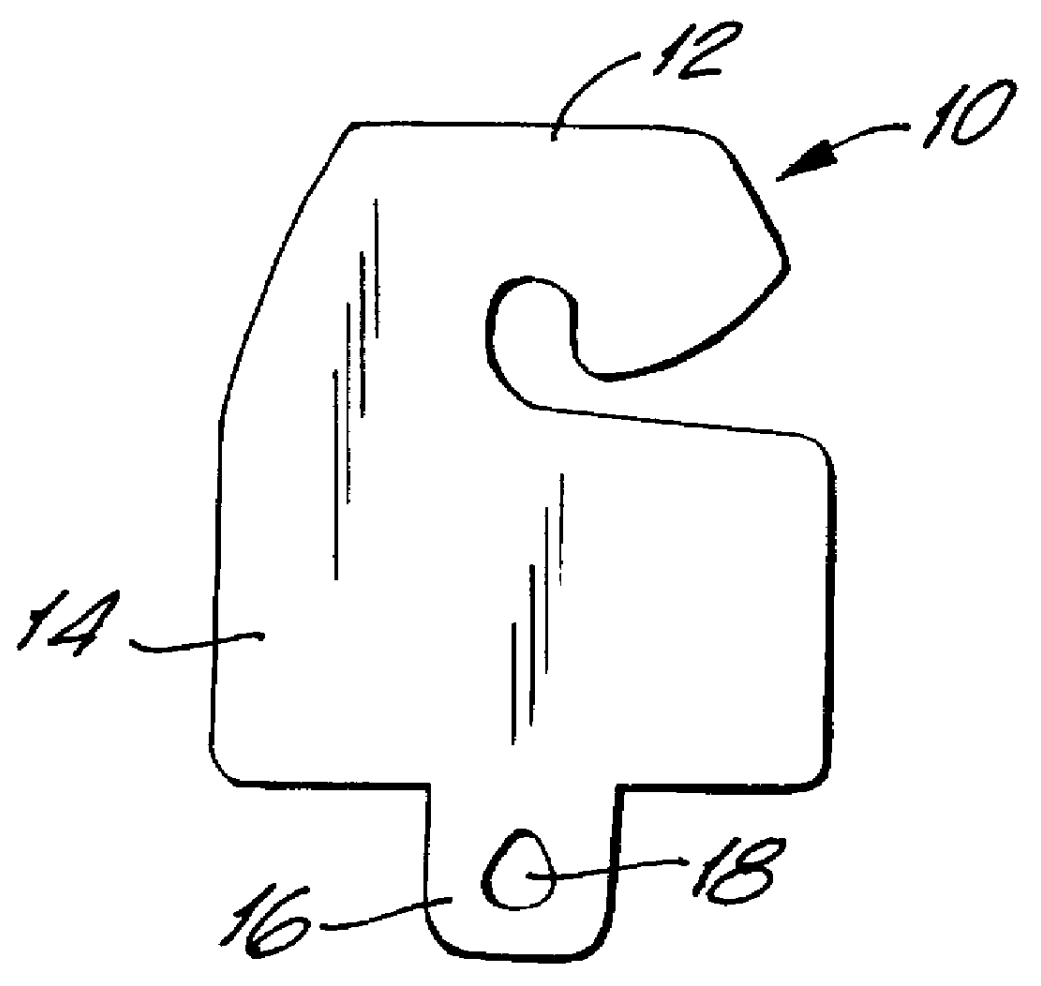

Hanger for a pre-tied necktie assembly

InactiveUS6105833AEasy and economical to manufactureApparel holdersGarmentsEngineeringMechanical engineering

A hanger for a pre-tied knotted necktie assembly includes an upper hook portion, a central body portion coupled to the upper hook portion, and a lower stem portion coupled to the central body portion. The lower stem portion includes an opening therethrough that is adapted to receive and selectively retain the pre-tied knotted necktie assembly's clip. To connect the hanger to a necktie assembly, the necktie assembly's clip is disengaged, the necktie assembly and hanger are aligned at right angles relative to one another, the necktie assembly's clip is slid through the opening in the hanger's lower stem portion, the hanger and necktie assembly are turned relative to one another to place them in alignment, and the necktie assembly's clip is engaged.

Owner:EASTERN CREATIVE INDS +1

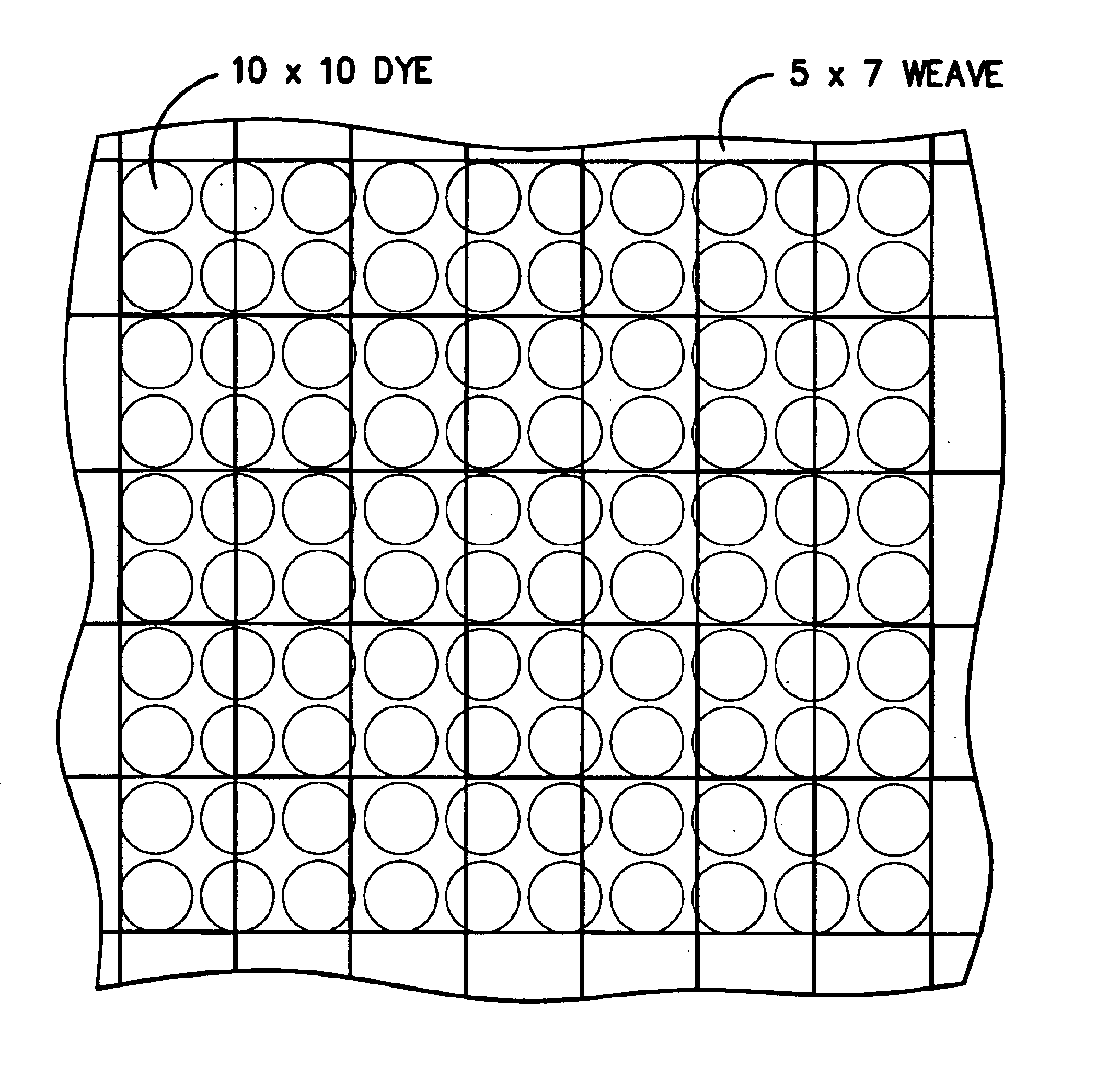

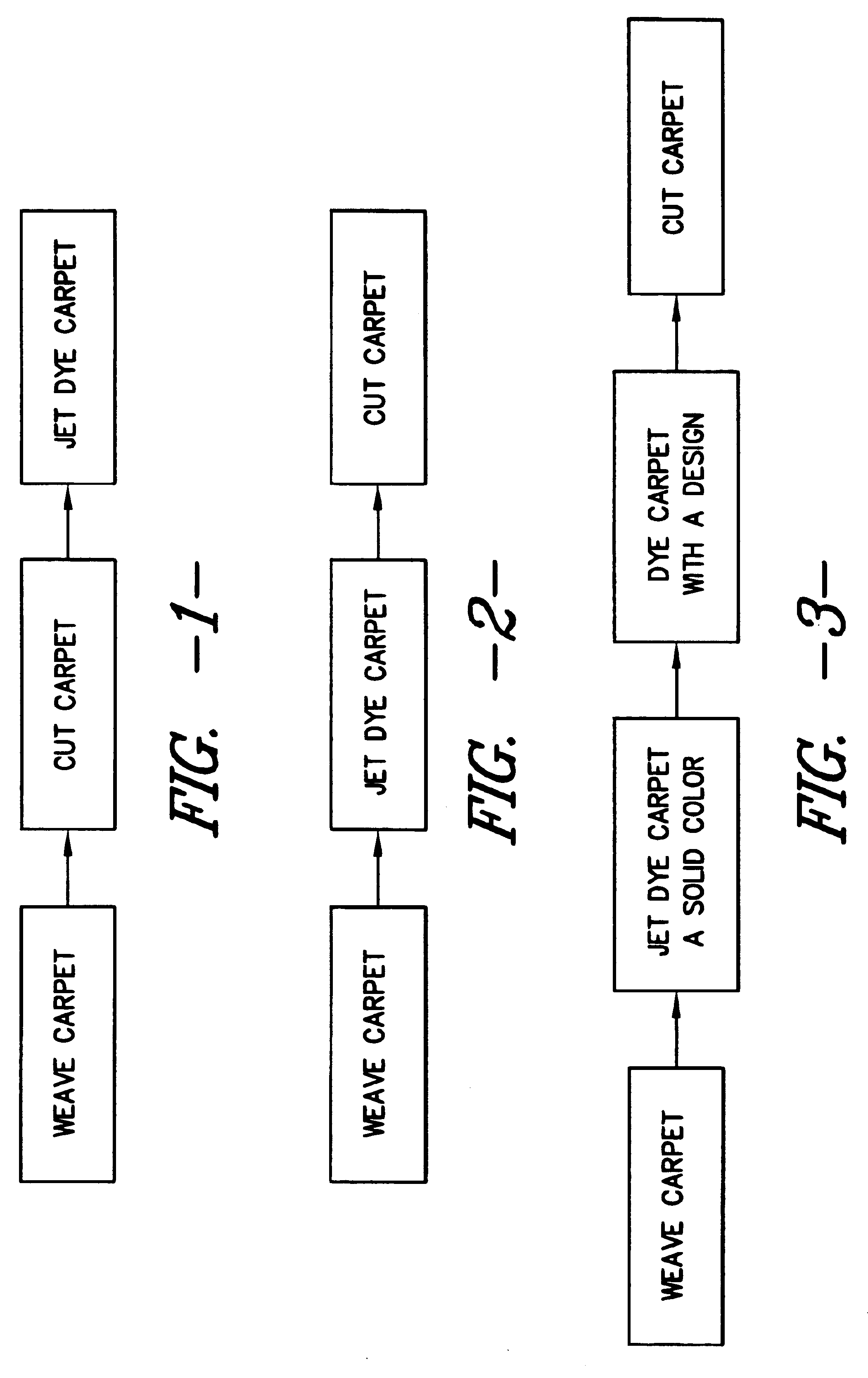

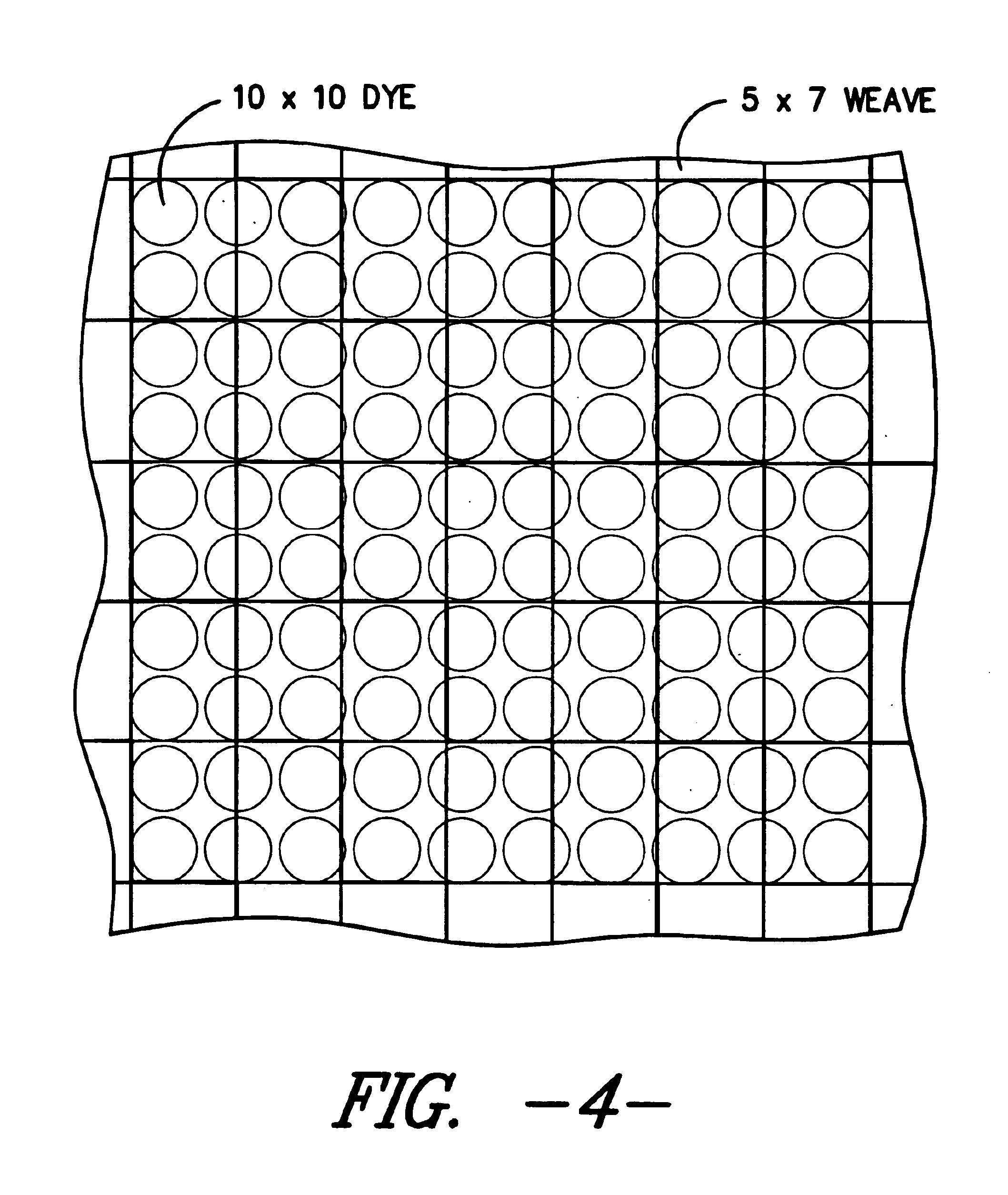

Patterned carpet and method

InactiveUS6884493B2Designed withImprove finenessFibre treatmentSynthetic resin layered productsYarnScreen printing

Owner:MILLIKEN & CO

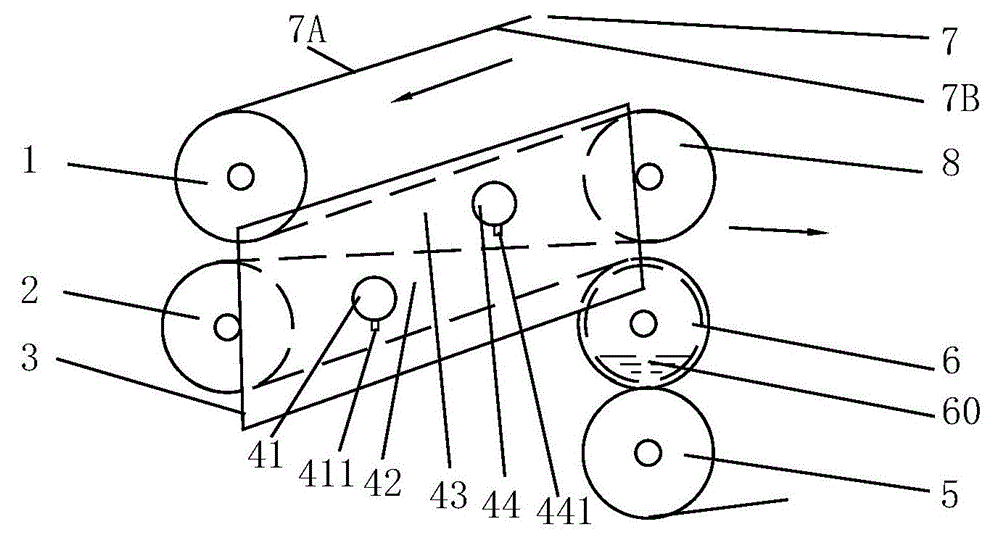

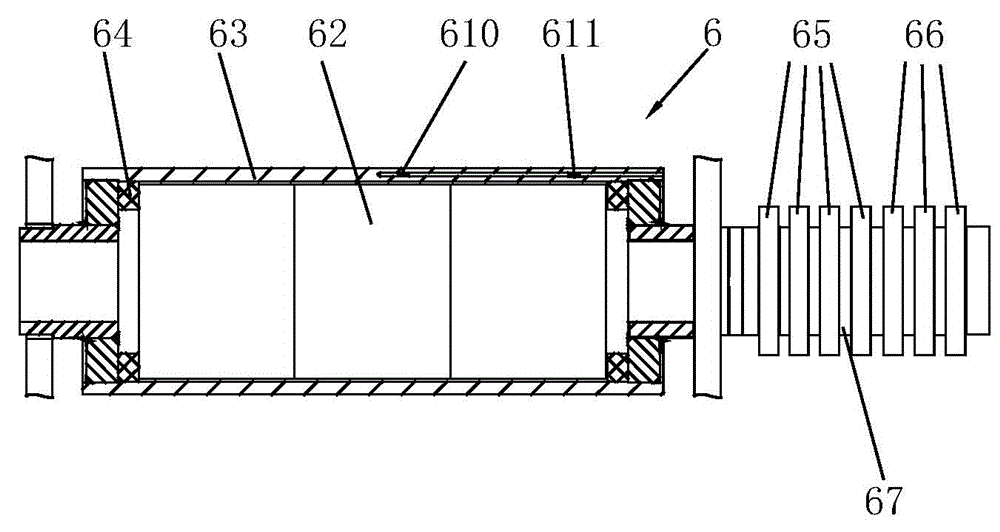

Ironing equipment for synthetic leather processing

InactiveCN104313827AReasonable structureLow costLiquid spraying apparatusTextile treatment by spraying/projectingElectricityWater saving

The invention discloses ironing equipment for synthetic leather processing. The ironing equipment includes a coating machine, and ironing equipment installed before the coating machine. The ironing equipment includes a heating roller and a pressing roller; the heating roller presses the pressing roller; the cloth is conveyed to the coating machine through a third driving roller, a second driving roller, a first driving roller, a heating roller and a pressure roller; the third driving roller, the second driving roller, the first driving roller and the heating roller respectively form a first cavity and a second cavity, which are respectively sealed by sealing steam plates; the first cavity and the second cavity are provided with a first steam pipe and a second steam pipe, which are communicated with the an ultrasonic water atomization generator; the water mist humidifies the cloth; the pressure roller is equipped with at least three electric heating bodiesa first temperature sensor and a second temperature sensor, which are connected with an electric heating controller. The invention has the beneficial effects of reasonable structure, low cost, electricity saving, water saving, space saving, and high temperature, high humidity and high pressure shaping and ironing of cloth.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

Secure display necktie holder

Provided is a necktie holder for attachment to a shirt under a shirt button. The shirt button is attached to the shirt by a threading having a width. The necktie holder comprises a flexible body having a tie slot sized for the placement of a tie therein, a channel defined in the flexible body and extending to an interior mouth, and first and second shoulders opposedly positioned within the channel. The shoulders define a constriction proximate the interior mouth, the constriction being smaller than the width of the threading. As a result, the button can be manually urged beyond the first and second shoulders while causing the constriction to resiliently flex the flexible body to momentarily permit passage of the shirt button into the interior mouth. Also provided is a method for securing a necktie to a shirt.

Owner:PEACOCK APPAREL GROUP

Dacron simulation crepe yarn process

InactiveCN101748545ARich in styleElegant style on canvasWoven fabricsTextile shapingEngineeringSizing

The invention mainly discloses a dacron simulation crepe yarn process, wherein a weaving working procedure comprises the steps of raw-material mixing, rewinding, twisting, sizing, sectionally warping, drafting and denting that are carried out on warp yarns as well as the steps of raw-material mixing, rewinding, twisting, sizing, spooling that are carried out on weft yarns; then weaving the warp yarns and the weft yarns, drying and checking; a printing and dyeing working procedure comprises the steps of white body unwinding sewing, cotton-ginning, desizing, high-temperature preshrinking, water-absorbing and scutching, drying, presizing, reducing the alkali content, dyeing, scutching, finishing resin, sizing and checking. The warp density of a finished product is 405 pieces / 10cm, and the weft density thereof is 220-275 pieces / 10cm. The alkali content in the textile is reduced by adopting a high-temperature preshrinking and loose immersion method. The invention realizes that the dacron simulation crepe yarn is produced by using a water-jet loom; and the textile has even winkling and blistering streaks, soft hand feeling and gentle gloss, and reaches the excellent simulation effect.

Owner:章金龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com