Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

414 results about "Increased thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle interior trim panel with a soft-touch foam layer, and a method and apparatus for making the same

InactiveUS6136415ALow densityFlexible of partLamination ancillary operationsSynthetic resin layered productsDashboardPolyolefin

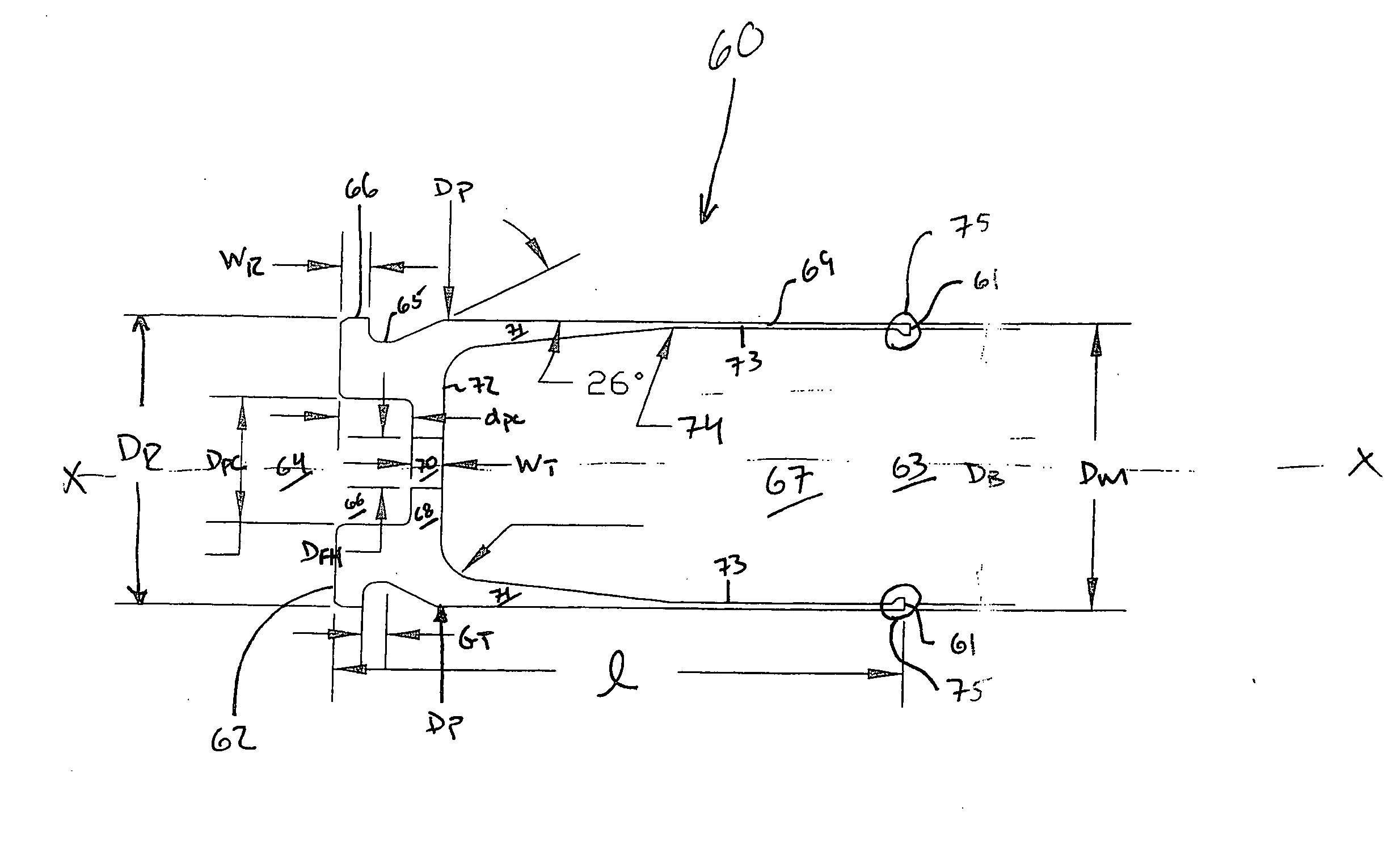

An interior trim component such as a vehicle dashboard includes a substantially rigid and form-stable substrate of polypropylene and natural fibers, a supporting halo skeleton and other frame components heat fused onto the backside of the substrate, and a polyolefin foam layer as well as a decorative polyolefin cover film laminated onto the front side of the substrate. The foam layer has an increased thickness and a decreased foam density at sharply contoured or curved areas of the trim component, in comparison to the flat surfacial areas. As a result, the trim component has a desirable soft-touch characteristic and impact absorbing properties at all areas including protruding curves and edges. A method for forming such a trim component involves steps of pre-molding the foam layer and cover film by vacuum thermoforming, pre-molding the substrate by vacuum thermoforming, and then heat laminating the pre-heated, pre-molded substrate onto the pre-molded foam layer and cover film. The sharply curved or contoured areas of the component are provided with a greater tolerance spacing between the substrate and the cover film, which are held to the respective mold contours by vacuum. Under the effect of heat and the applied vacuum, the foam layer expands to have a greater thickness and a lower density in these sharply contoured areas.

Owner:HERBERT OLBRICH

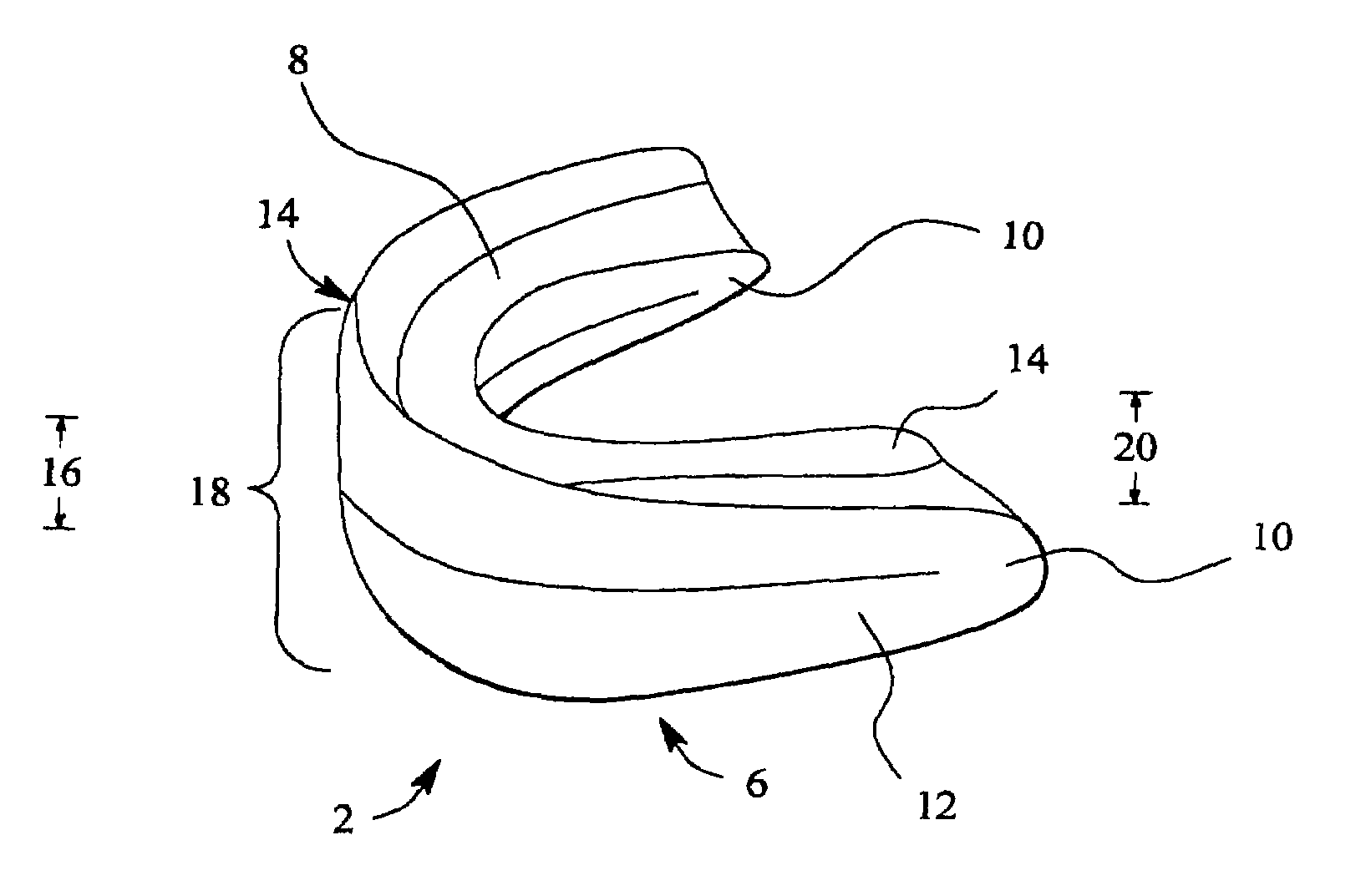

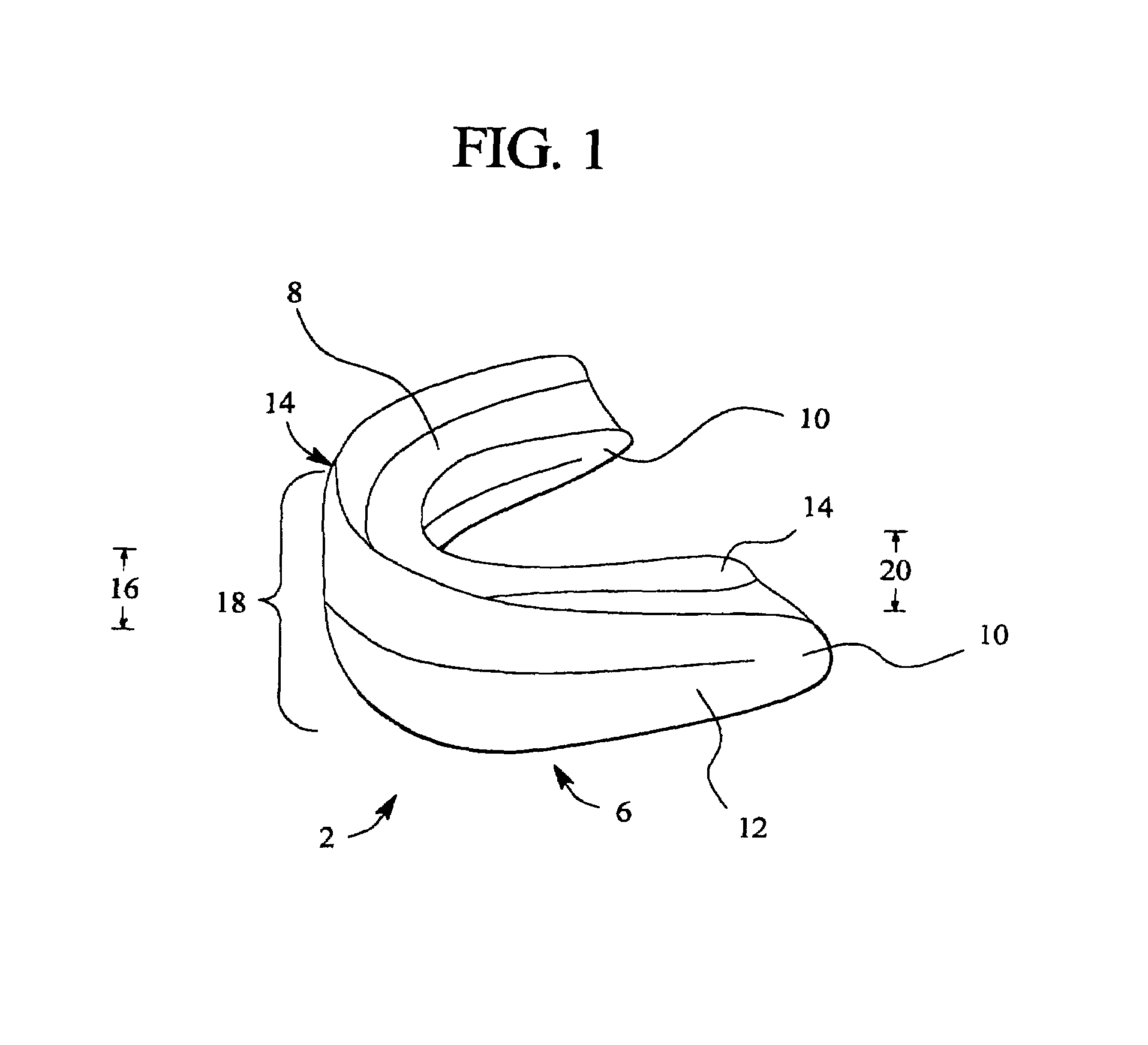

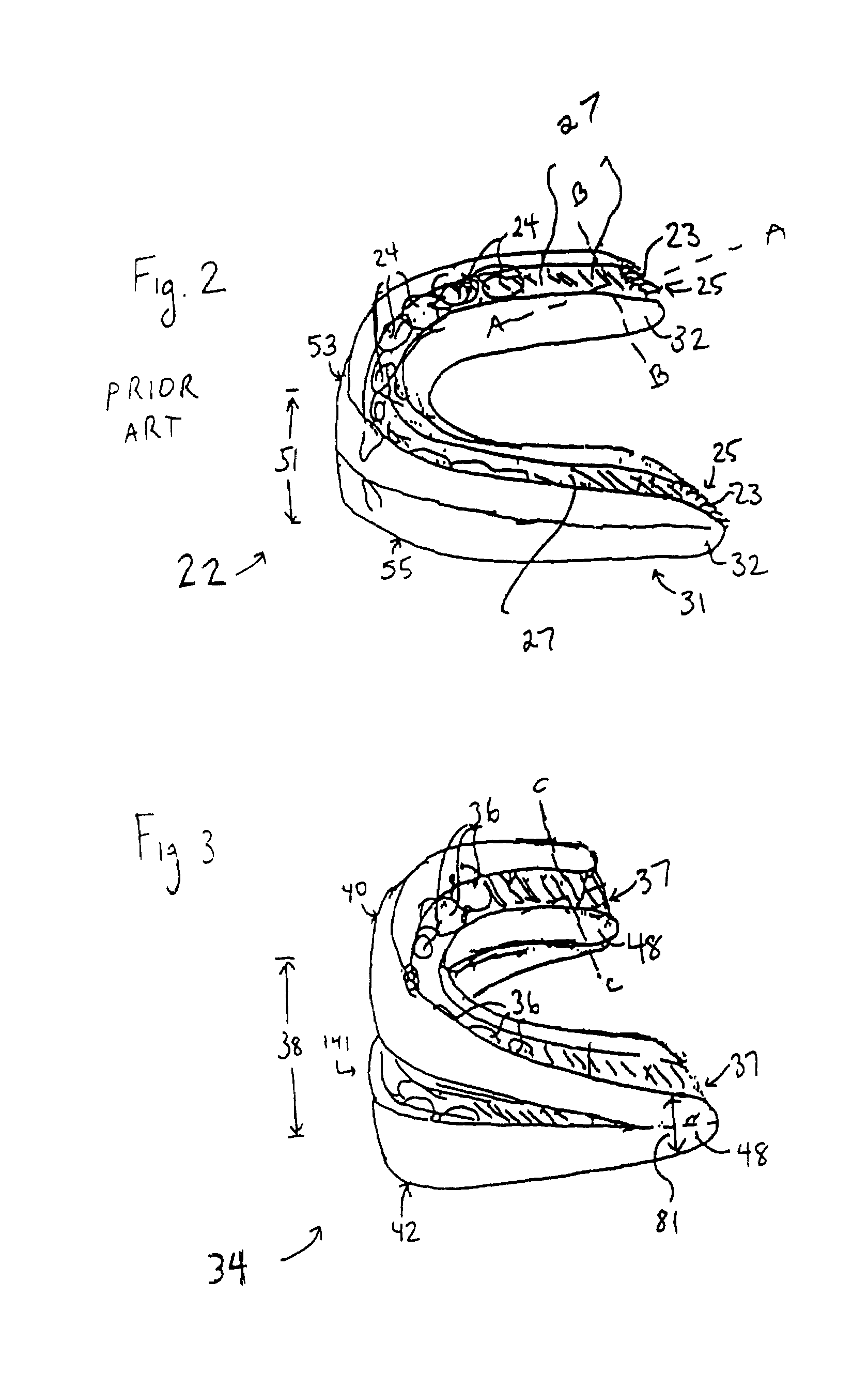

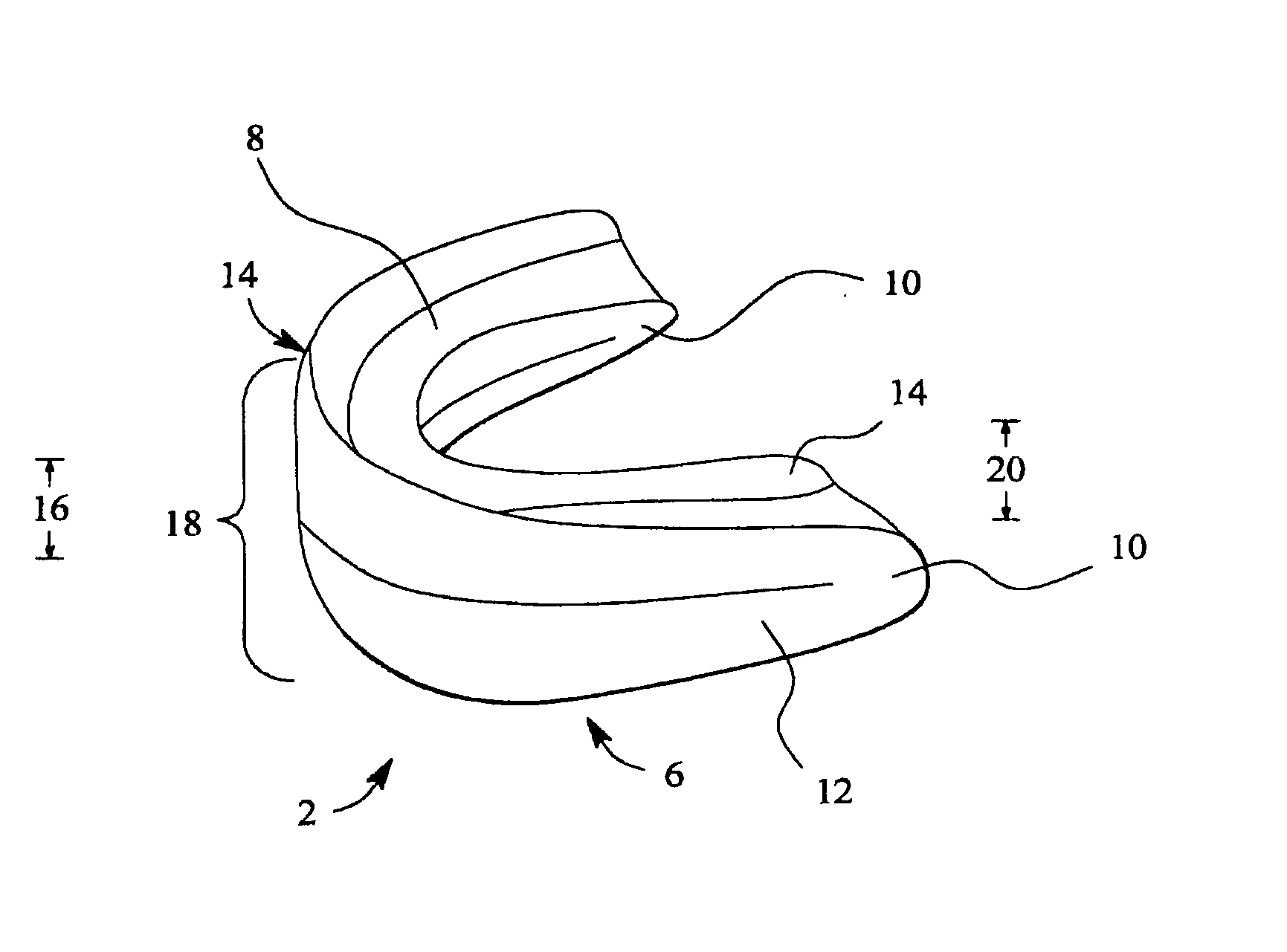

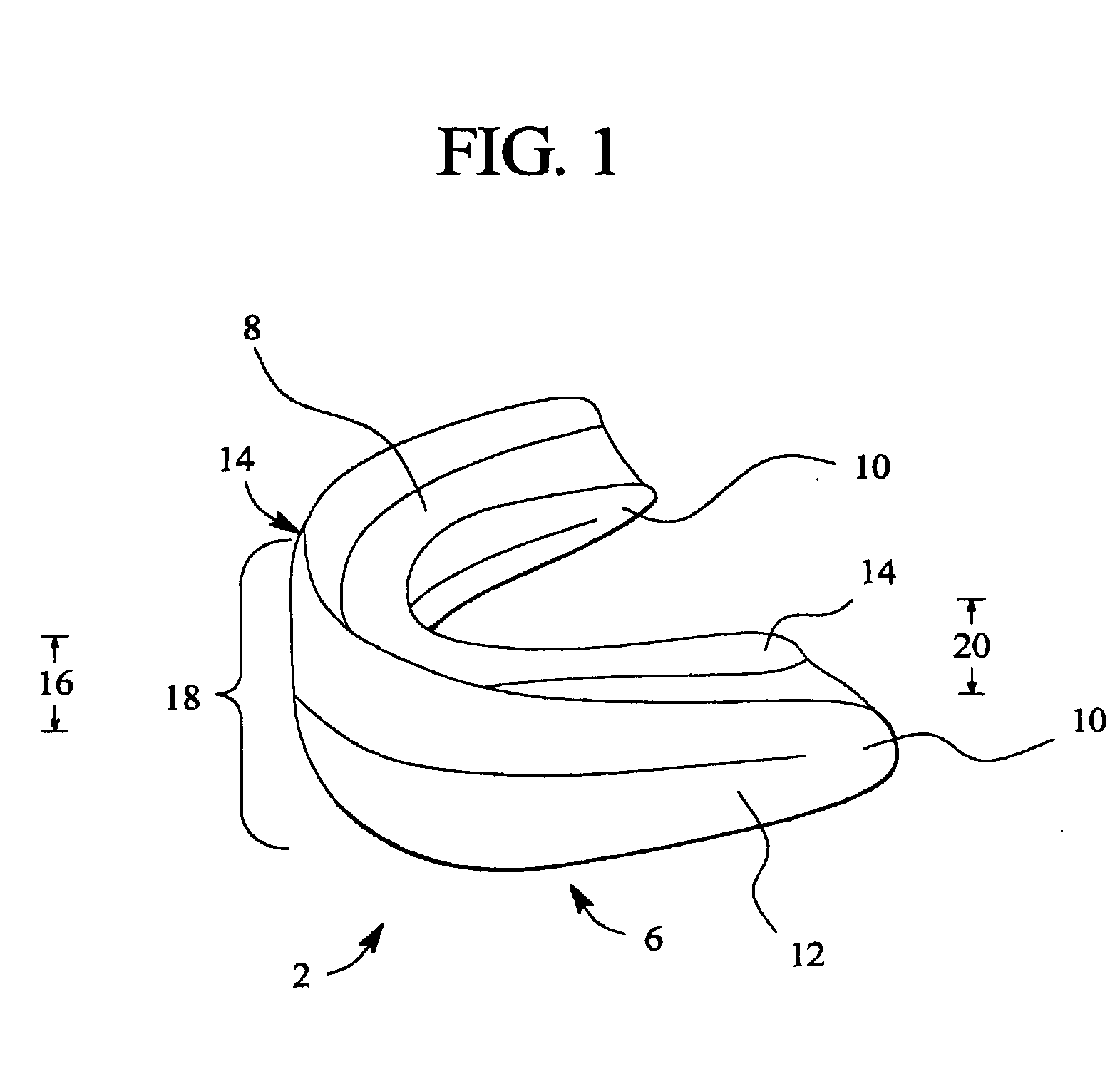

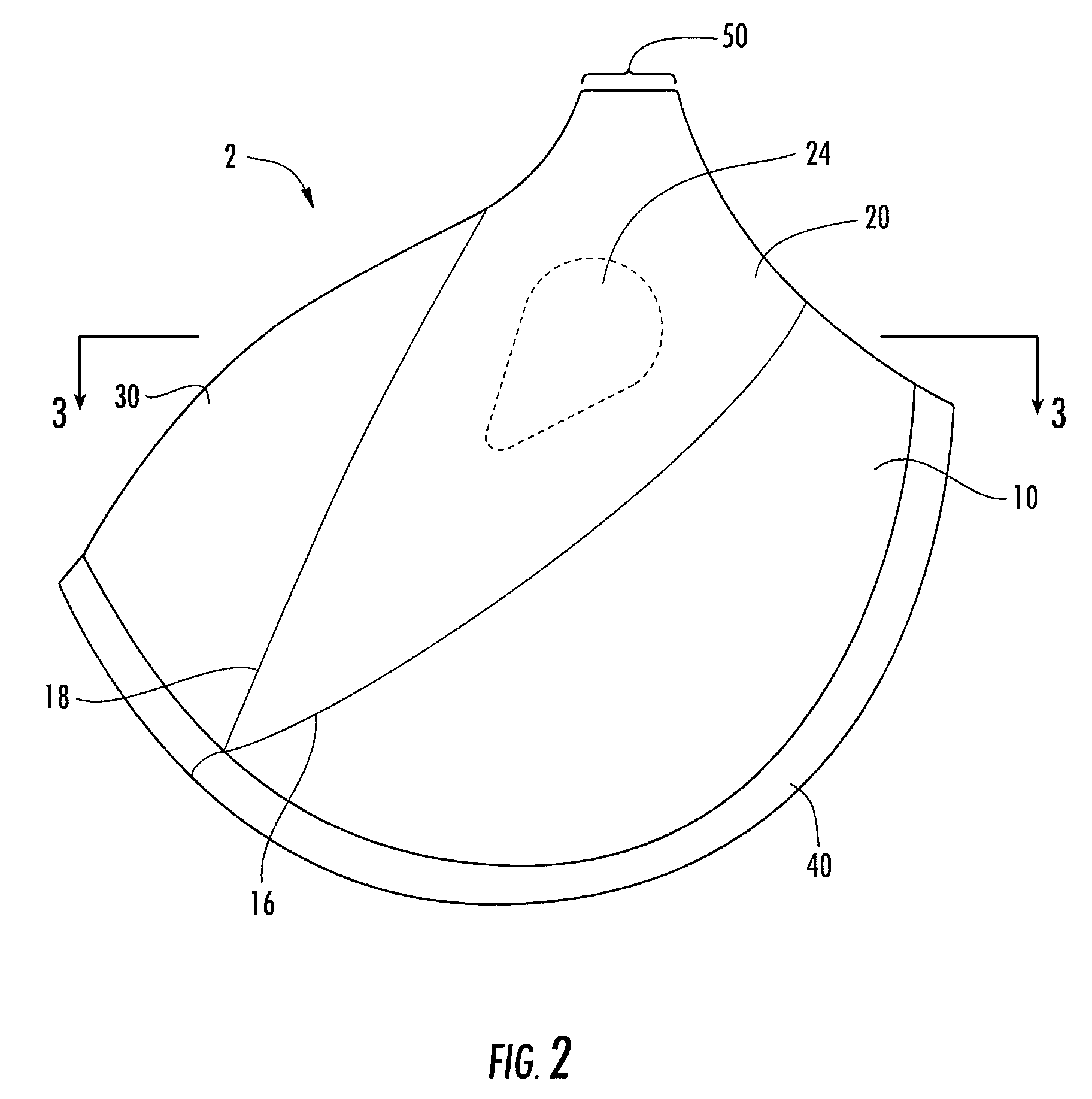

Dental appliance having an altered vertical thickness between an upper shell and a lower shell with an integrated hinging mechanism to attach an upper shell and a lower shell and a system and a method for treating malocclusions

ActiveUS7458810B2Increasing the thicknessMaintain positionAdditive manufacturing apparatusOthrodonticsOpen biteDecreased thickness

A dental appliance having increased or decreased thickness between an upper shell and a lower shell in combination with a hinging mechanism and a system and a method for treating malocclusions are provided. The dental appliance may have an upper shell and a lower shell which receive upper teeth and lower teeth, respectively, of a user. The upper shell and the lower shell may be attached at a hinge. The dental appliance may have an increased thickness between the upper shell and the lower shell as well as an increased thickness of the hinge. In an embodiment, the dental appliance may have a decreased vertical thickness and an insertable hinging mechanism. The dental appliance may then extend treatment of malocclusions to the rear teeth of the user and may correct a dental condition, such as, for example, overbite, overjet, open bite, crowding, rotations, spacing, cross-bites, gummy smiles and temporomandibular joint problems.

Owner:ORTHO TAIN INC

Nonwoven fabrics with advantageous properties

InactiveUS7060149B2Increasing the thicknessIncrease opening spacingEnvelopes/bags making machineryLaminationEngineeringNonwoven fabric

This invention relates to nonwoven fabrics with advantageous characteristics and the method to produce these fabrics. Advantageously, the fabrics of the subject invention have increased thickness (loft) compared to conventional nonwoven fabrics and have high air permeability and open space while maintaining softness and strength at the same basis weight.

Owner:THE PROCTER & GAMBLE COMPANY

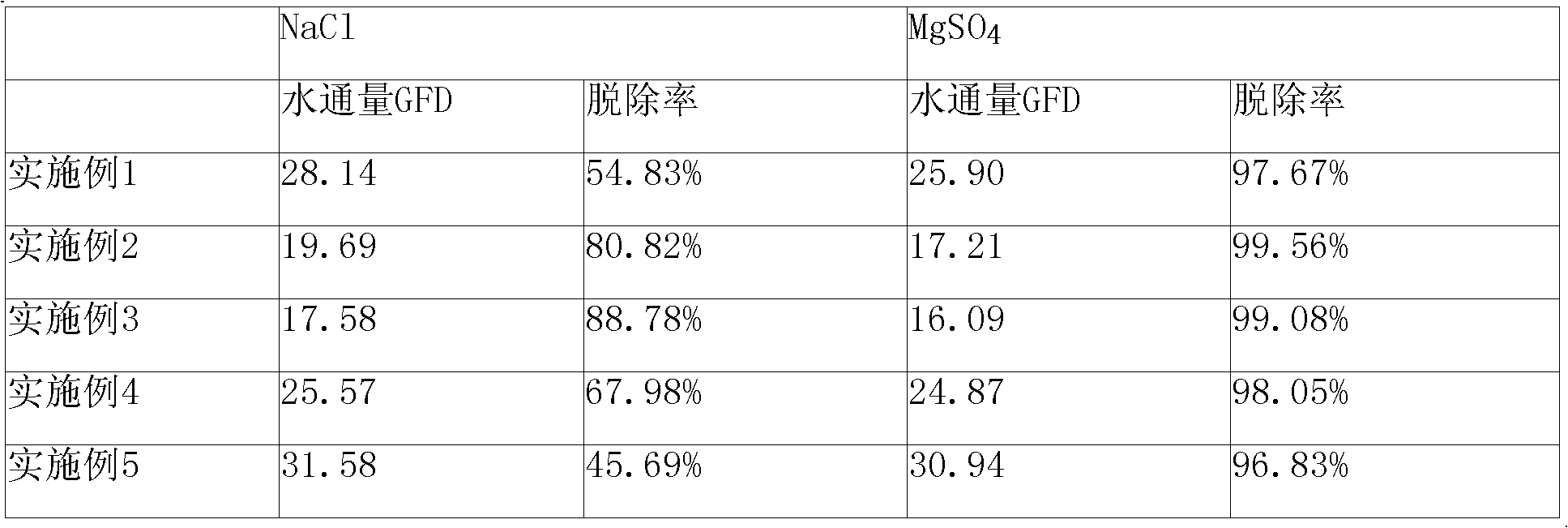

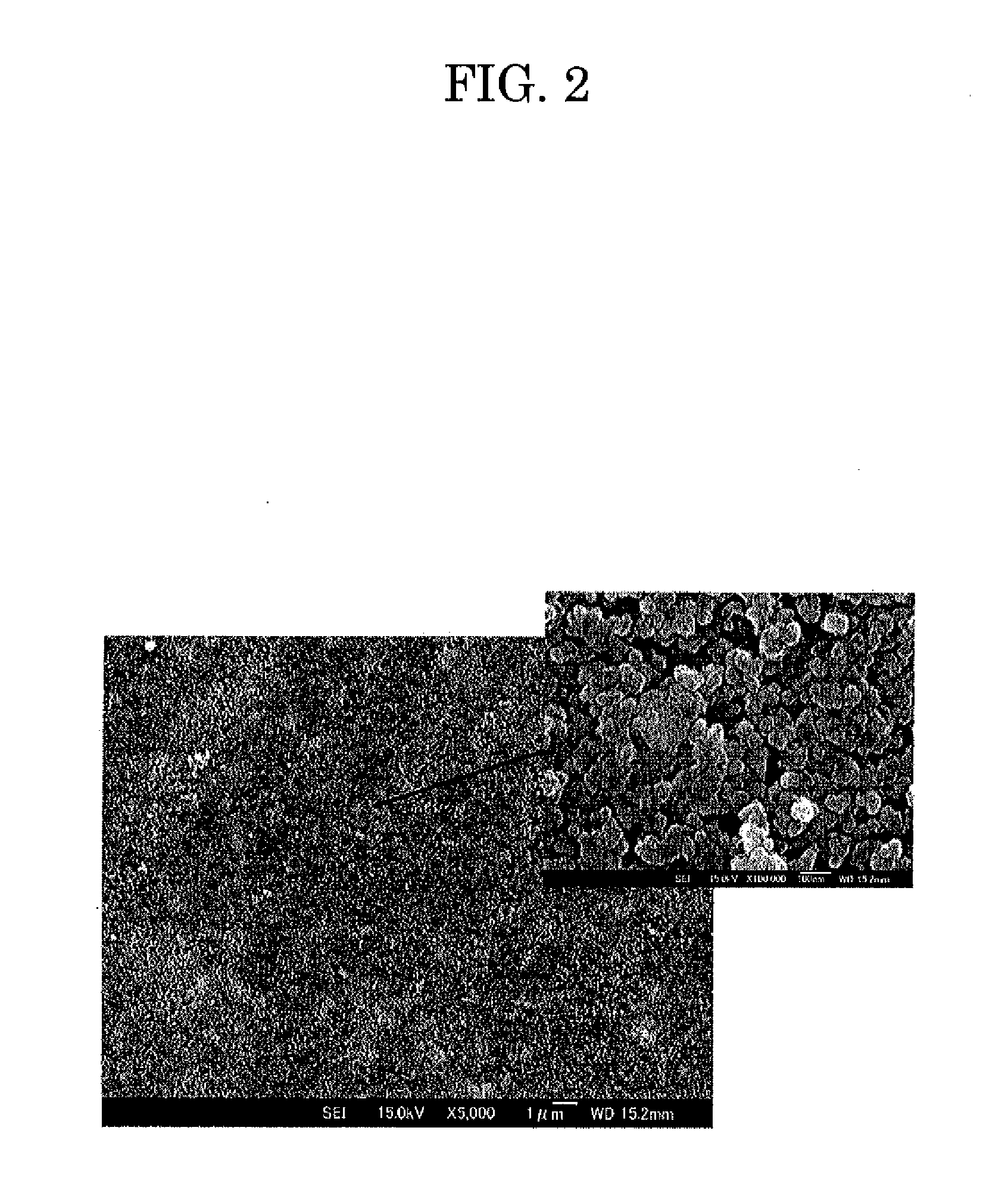

High-selectivity composite nanofiltration membrane and preparation method thereof

InactiveCN101934201AIncreasing the thicknessImproves stain resistanceSemi-permeable membranesPolyamideOxidation resistant

The invention discloses a high-selectivity composite nanofiltration membrane and a preparation method thereof. The high-selectivity composite nanofiltration membrane comprises a nonwoven layer and a polymer porous supporting layer; and the porous supporting layer is provided with one or two polyamide surface layers prepared by reacting polyamine and / or amine polyalcohol with chlorine polyacyl. Compared with the prior art, by forming one or two polyamide surface layers on the porous supporting layer through an interfacial polymerization method, the nanofiltration membrane has increased thickness of a surface layer, has more smooth, hydrolysis-resistant, oxidation-resistant and scratch-resistant surface, and improves pollution resistance; and the surface of the membrane can carry negative or positive charges, so that the composite nanofiltration membrane has a high-selectively functional desalting layer; besides, the method for preparing the composite nanofiltration membrane is simple to operate, high water flux and desalination rate are ensured under low pressure, and the service life of the membrane component is prolonged.

Owner:北京时代沃顿科技有限公司

Low-temperature doping processes for silicon wafer devices

InactiveUS20080000521A1Quality improvementImprove concentrationPolycrystalline material growthFinal product manufactureGas phaseSystem configuration

A low temperature method and system configuration for depositing a doped silicon layer on a silicon substrate of a selected grade. The silicon substrate for functioning as a light absorber and the doped silicon layer for functioning as an emitter. The method comprises the acts of: positioning the silicon substrate in a chamber suitable for chemical vapour deposition of the doped silicon layer on the silicon substrate, an external surface of the silicon substrate suitable for promoting crystalline film growth; using a plurality of process parameters for adjusting growth of the doped silicon layer, the plurality of process parameters including a first process parameter of a process temperature for inhibiting diffusion of dopant atoms into the external surface of the silicon substrate, and a second process parameter of a hydrogen dilution level for providing excess hydrogen atoms to affect a layer crystallinity of the atomic structure of the doped silicon layer; exposing the external surface of the silicon substrate in the chamber to a vapour at appropriate ambient chemical vapour deposition conditions, the vapour including silicon atoms, dopant atoms and the excess hydrogen atoms, the atoms for use in growing the doped silicon layer; and originating growth of the doped silicon layer on the external surface to form an interface between the doped silicon layer and the silicon substrate, such that the doped silicon layer includes first atomic structural regions having a higher quality of the layer crystallinity next to the interface with adjacent second atomic structural regions having a lower quality of the layer crystallinity with increasing concentrations of crystal defects for increasing thickness of the doped silicon layer from the interface. The resultant silicon substrate and doped layer (or thin film) can be used in solar cell manufacturing.

Owner:SIVOTHTHAMAN SIVA +1

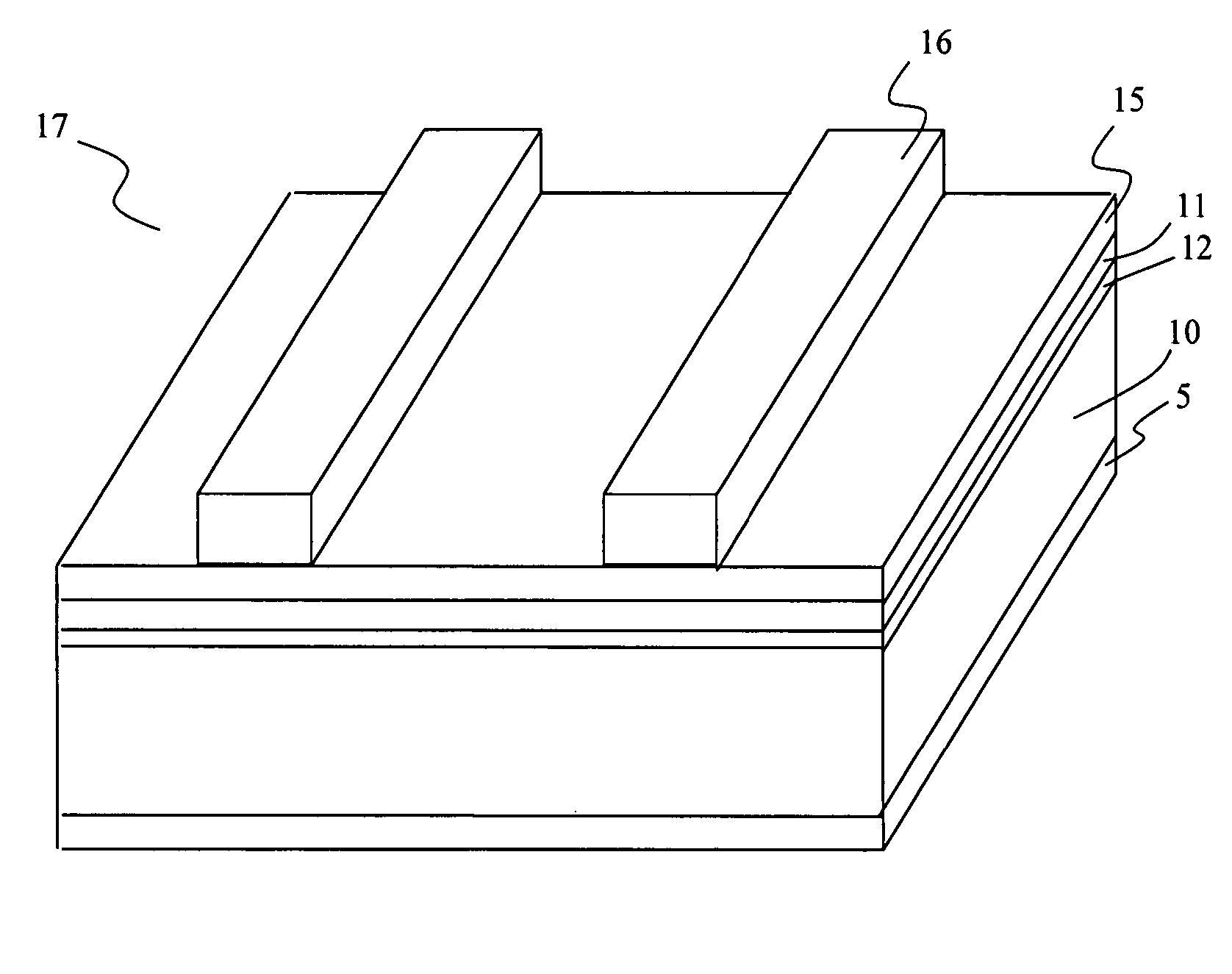

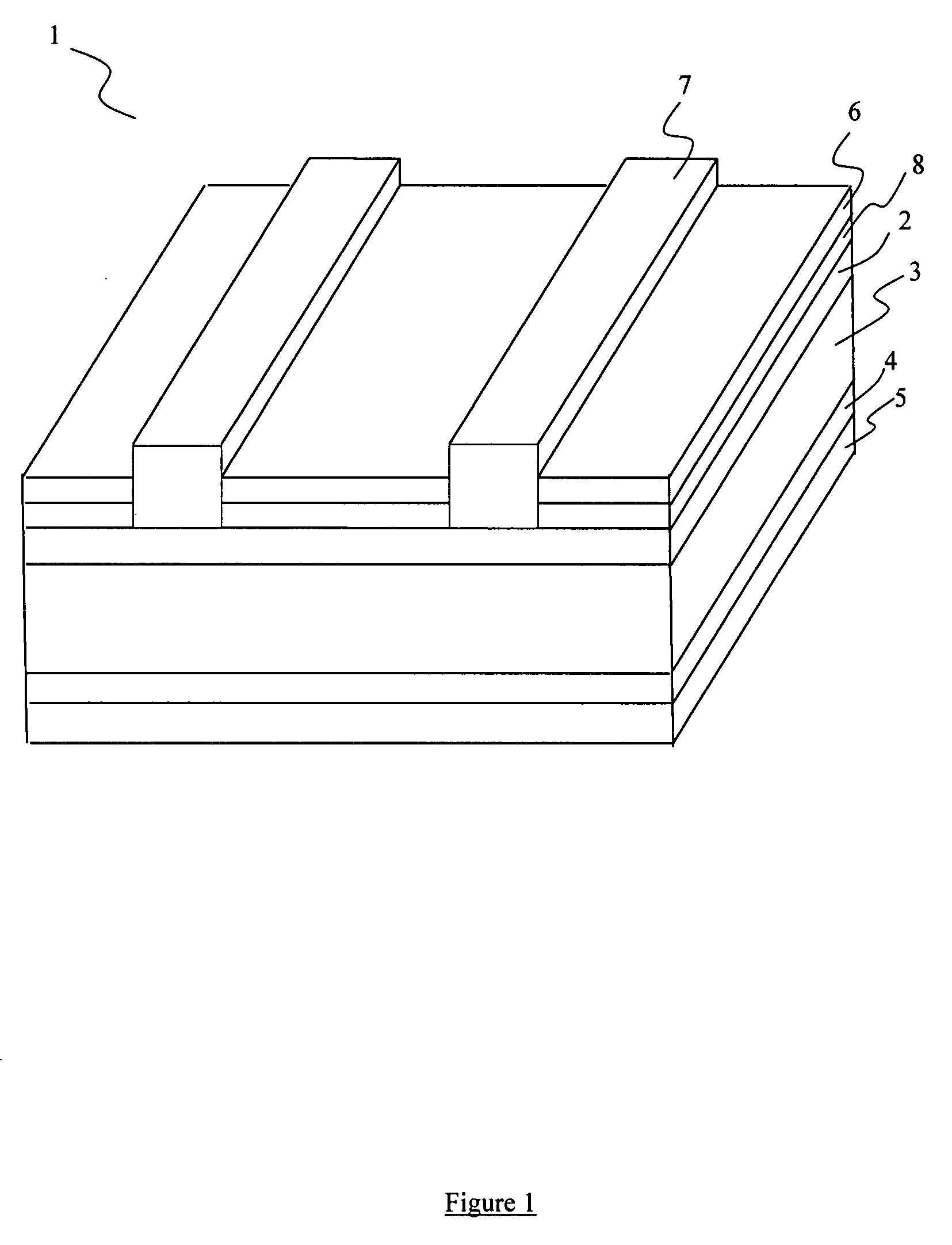

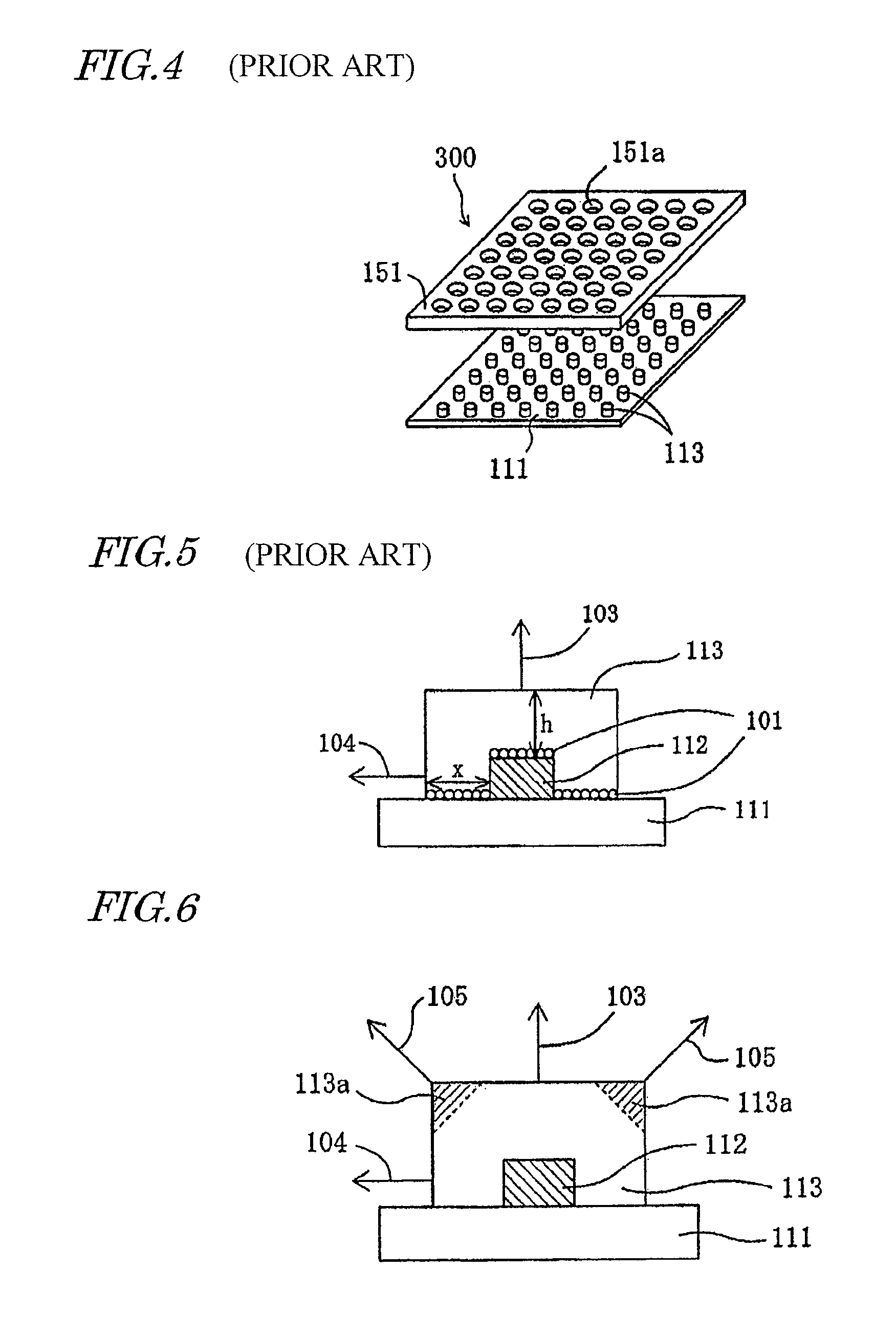

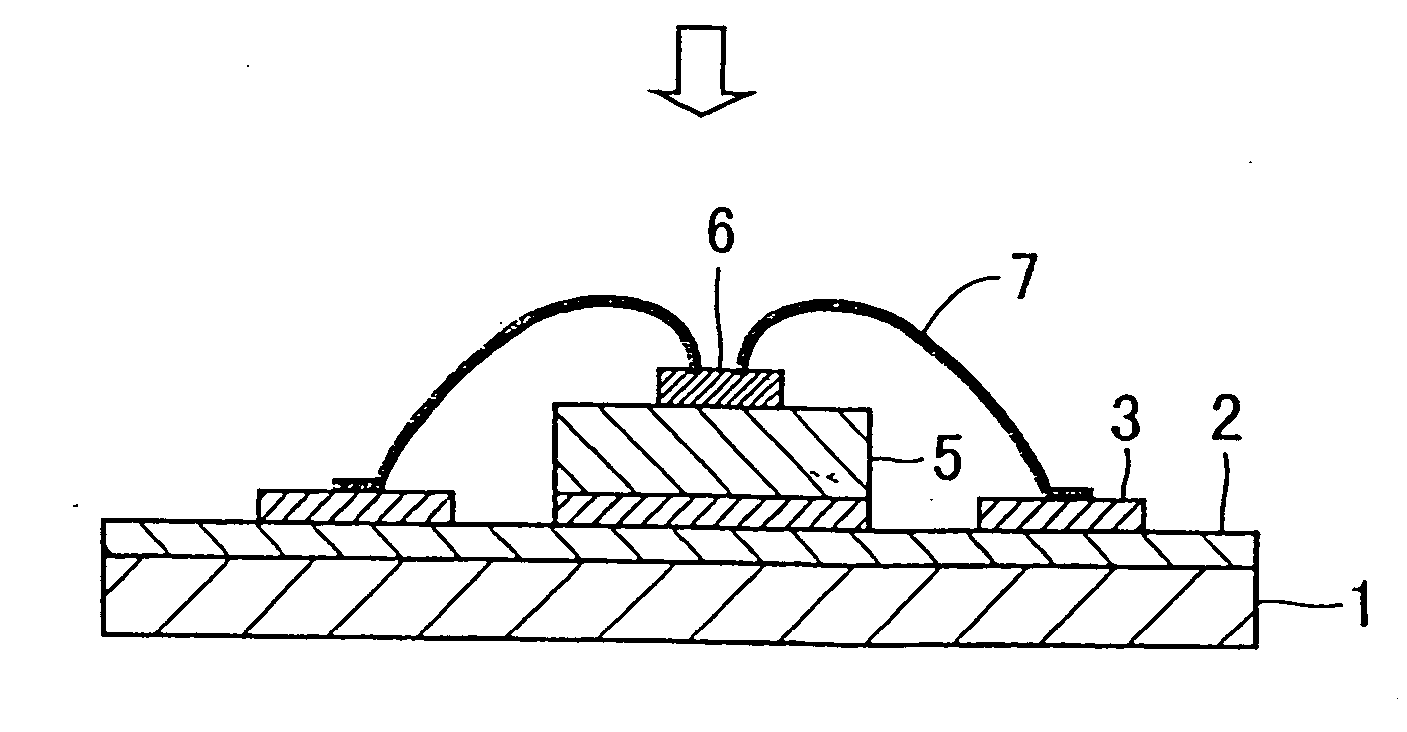

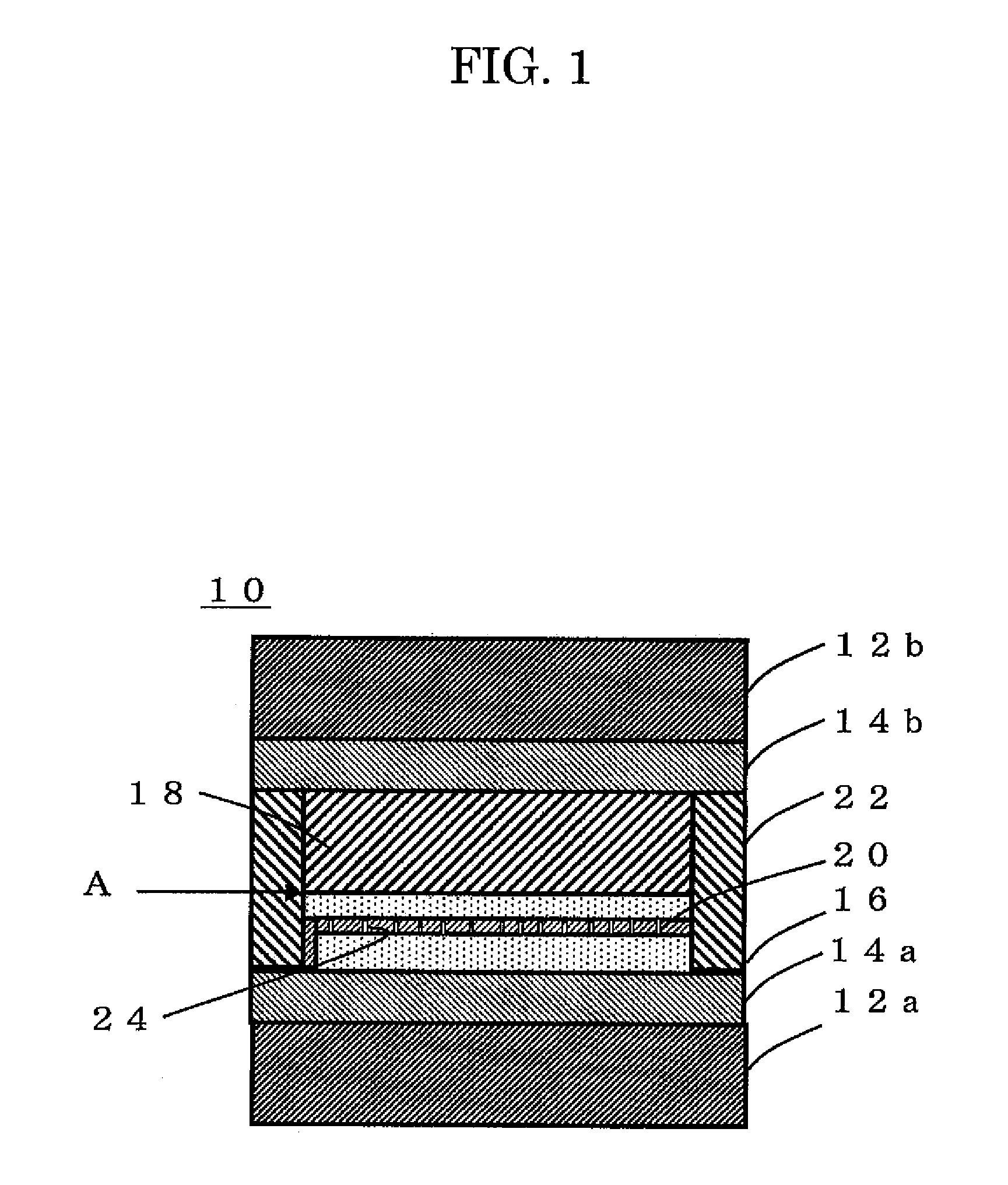

LED lamp provided with optical diffusion layer having increased thickness and method of manufacturing thereof

InactiveUS7514867B2Reduced color unevenness can be fabricated more easilyRemove colorPlanar light sourcesPoint-like light sourcePhosphorFluorescence

An LED lamp according to the present invention includes: at least one LED chip 12 that is mounted on a substrate 11; a phosphor resin portion 13 that covers the LED chip 12; a lens 22 to act on the outgoing light of the phosphor resin portion 13; and an optical diffusion layer (light-transmissive resin portion 20), which is arranged between the phosphor resin portion 13 and the lens 22 and in which particles to scatter the light are dispersed.

Owner:SOVEREIGN PEAK VENTURES LLC

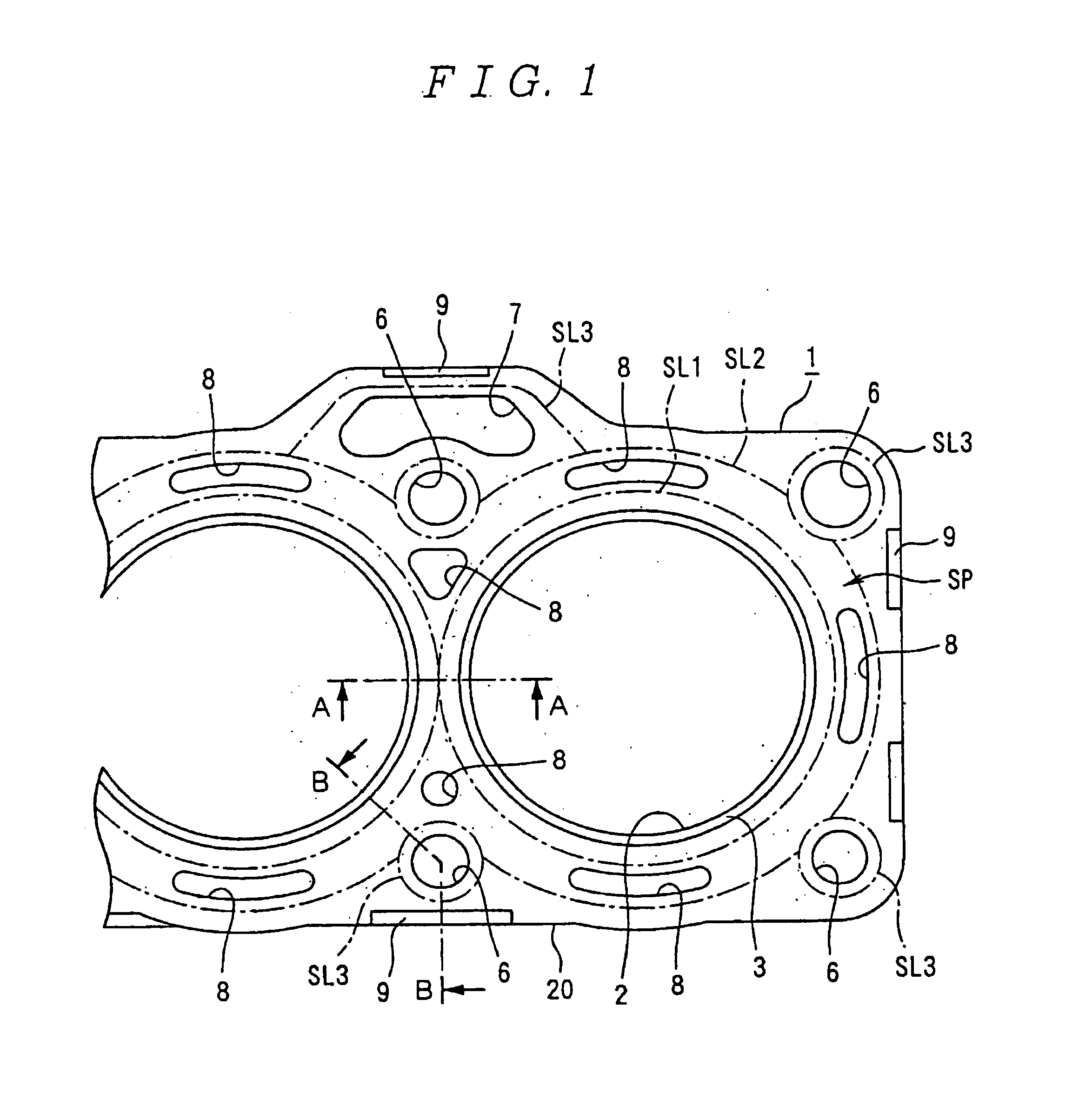

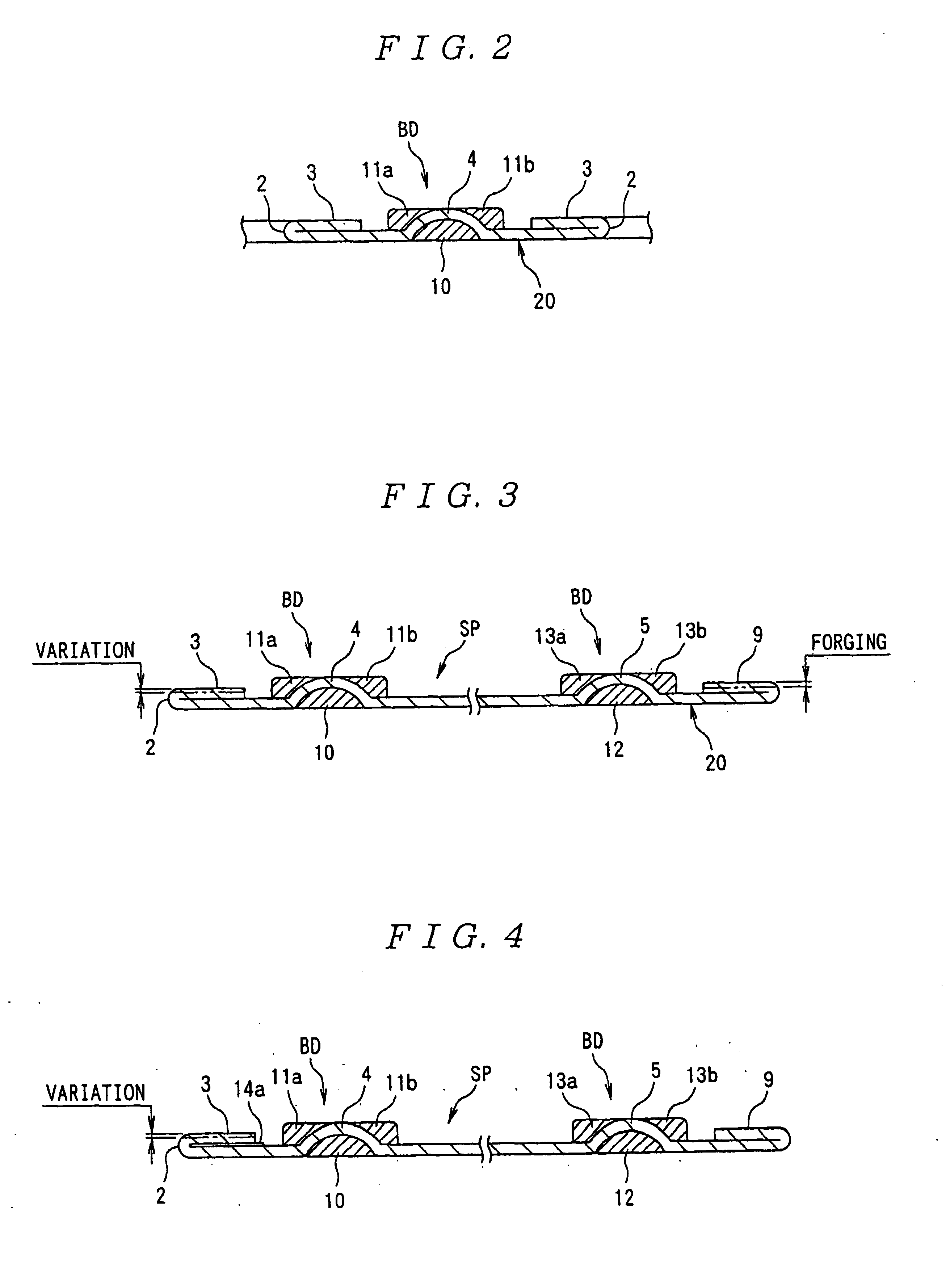

Metallic gasket

InactiveUS7025358B2Improve machining accuracyImprove cooling effectEngine sealsSealing arrangements for enginesCombustion chamberCooling effect

A metallic gasket comprising a base plate having a first thickness-increased portion 3 formed at a peripheral edge on a combustion chamber opening 3 side of a base plate, and a first seal line SL1 and a second seal line SL2 arranged on the outer side of said first thickness-increased portion 3. No openings other than a cooling water hole 8 exist between said two seal lines. Beads formed along said seal lines SL1 and SL2 each consist of a convex metal bead raised only upward from an upper surface of said base plate and a rubber bead made of an elastic sealing material fixed to a convex portion and a concave portion of said metal bead. This structure of said metallic gasket can improve a processing accuracy of said metal bead and also enhance cooling effects on said metallic gasket itself and said joint surfaces of an engine, between which said metallic gasket is disposed.

Owner:JAPAN METAL GASKET CO LTD

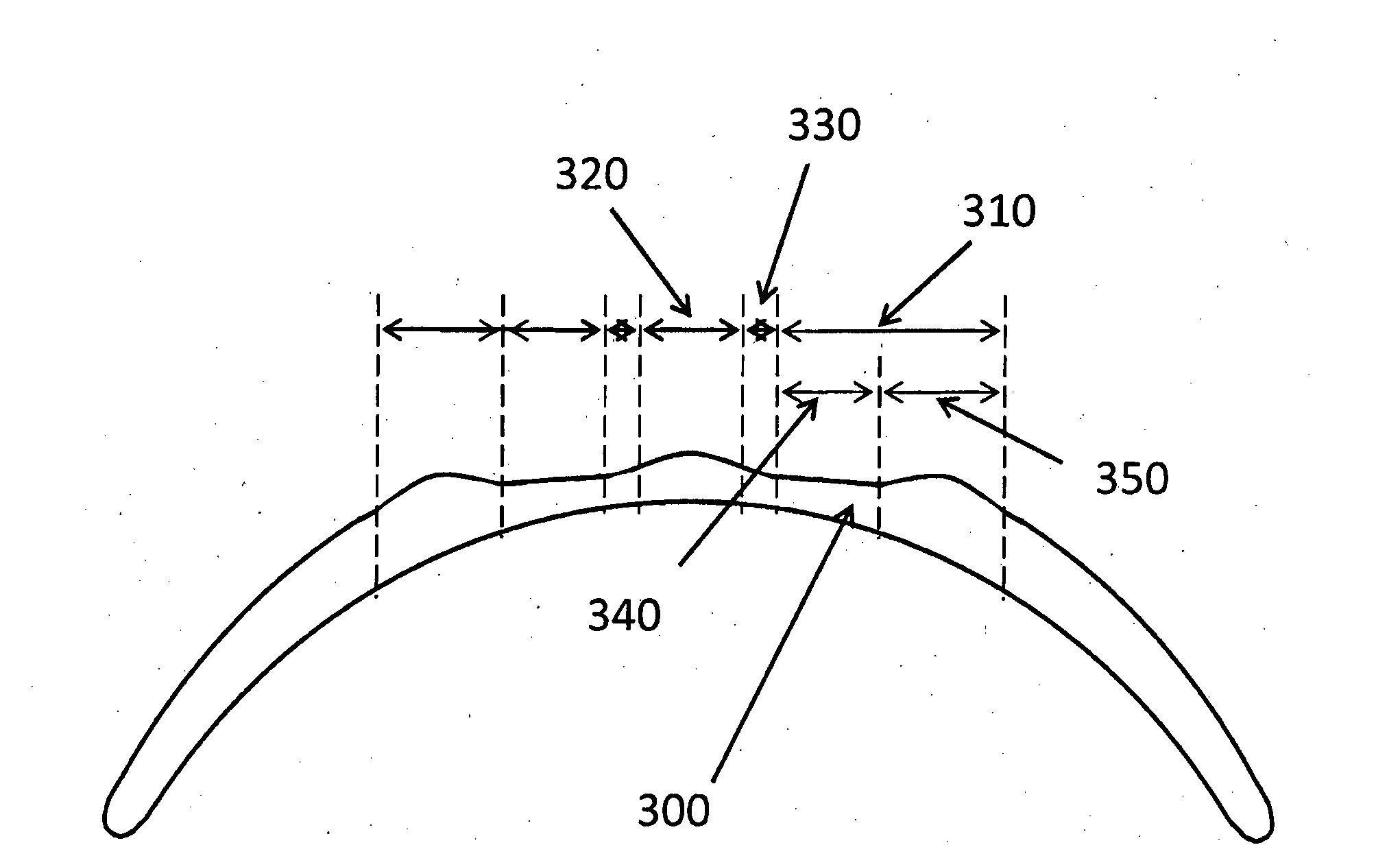

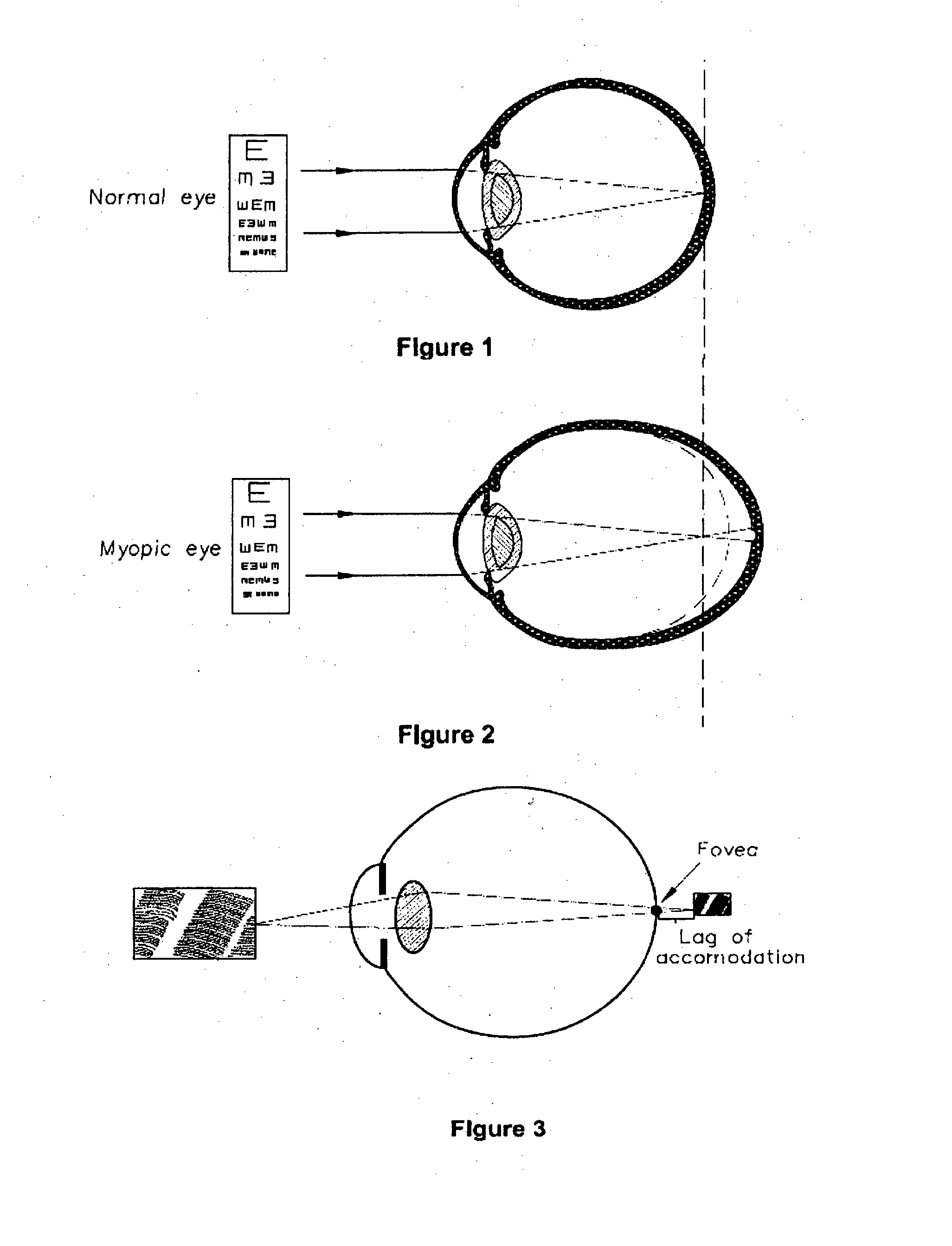

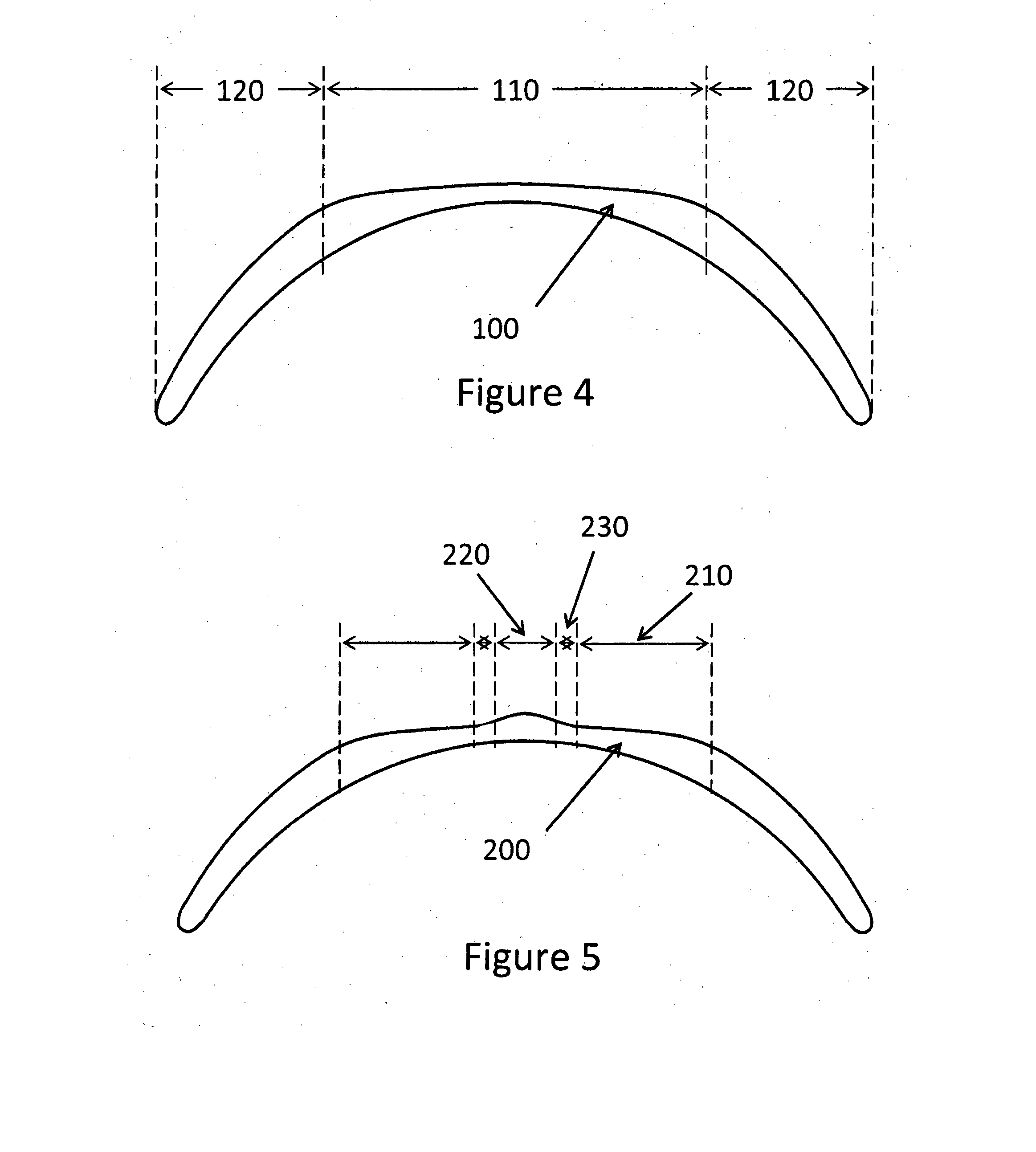

Corneal remodelling contact lenses and methods of treating refractive error using corneal remodelling

InactiveUS20120320334A1Enhanced ability to affect progression of myopiaConvenient treatmentSpectales/gogglesEye treatmentRefractive errorRefraction errors

Contact lenses are described with a corneal remodelling effect. This corneal remodelling effect is one or both of broad-area corneal remodelling and localised remodelling. The contact lenses may also have a refractive power. The refractive power may vary across the lens and for myopia may have increased power centrally. The increased power may be provided over a lens area that has increased thickness due to localised remodelling.

Owner:BRIEN HOLDEN VISION INST (AU)

Side-gored bag having a first zipper tape with an area of increased thickness and with an area of progressively reduced thickness

A side-gored bag is provided which includes: a first panel film, a second panel film; a pair of V-members forming side gussets; and a zipper device including a first zipper tape, and a second zipper tape. The upper edges of the V-members are situated so as to be downwardly displaced by a distance w from the upper edges of the first and second panel films. The first zipper tape has a first meshing rib and the first zipper tape is bonded in a horizontal position to the first panel film over an area of the panel film which extends by a distance W (wherein W>w) from the upper edge in such a manner that both the lower side of the zipper tape and the first meshing rib are situated below the upper edges of the V-members so as to cover an upper part of each V-member. The second zipper tape has a second meshing rib and the second zipper tape is bonded to the second panel film in such a manner that the second meshing rib is aligned with the first meshing rib. The side-gored bag also includes an area adjacent to the upper side of the first zipper tape, which is of an increased thickness as compared with a remaining area of the tape, and an area adjacent to the lower side of the first zipper tape, which is progressively reduced in thickness toward the lower side.

Owner:MEIWA PAX

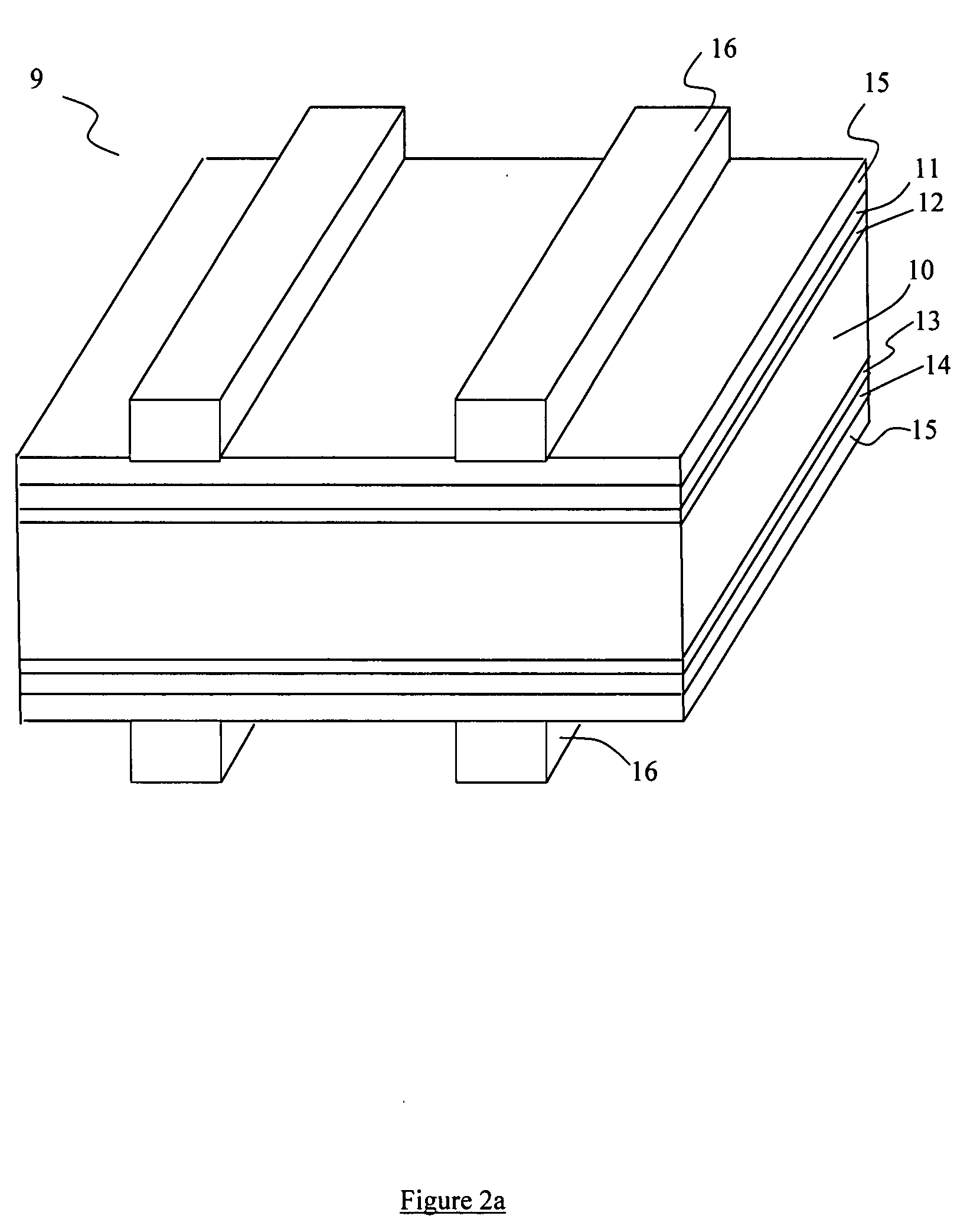

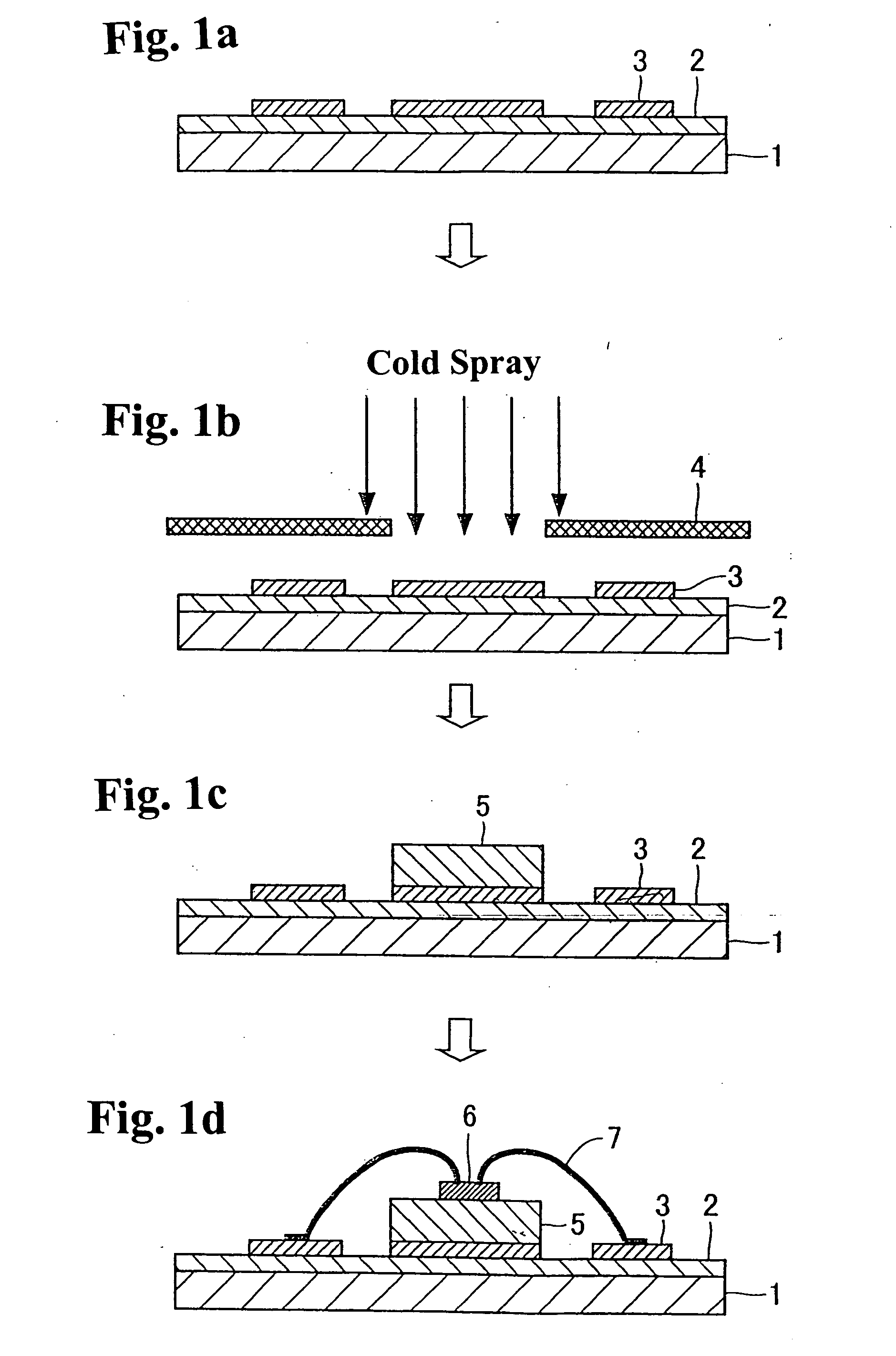

Wiring board and method of manufacturing the same

ActiveUS20060258055A1Improve cooling effectLess thermal resistanceSemiconductor/solid-state device detailsPrinted electric component incorporationMetal foilSemiconductor

A wiring board has a circuit pattern that includes metal foil attached to an insulating layer, and a built-up circuit pattern disposed on top of the metal foil circuit pattern. The built-up circuit pattern is an increased thickness laminate of cold spray processed metal material. Even when a power semiconductor is mounted on the built-up circuit pattern, the heat that is generated by losses therein can be diffused by the built-up circuit pattern. The wiring board has excellent heat dissipation, can be manufactured by a small number of process steps, and is of low cost.

Owner:FUJI ELECTRIC HLDG CO LTD

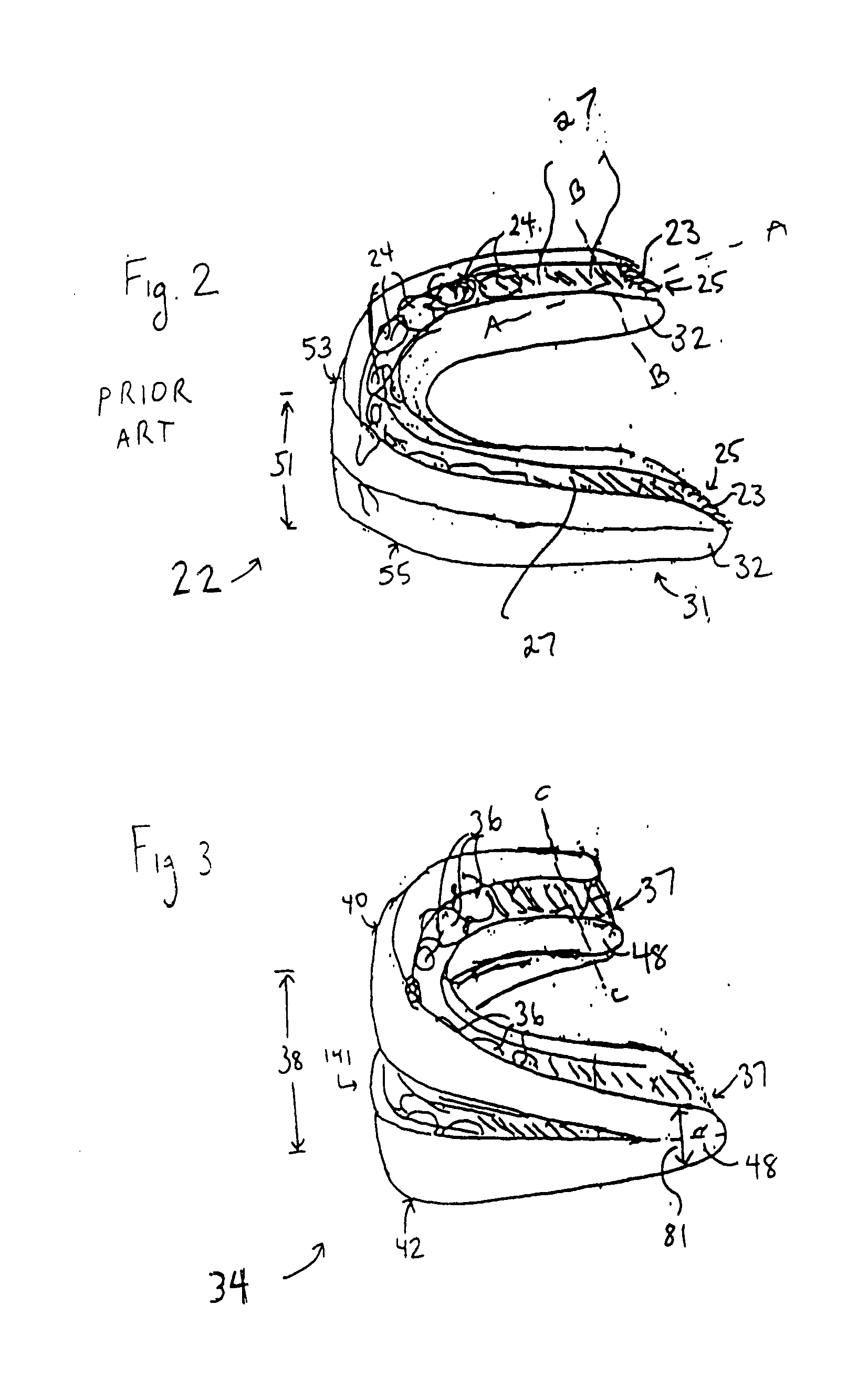

Tidal flow hydroelectric turbine

InactiveUS20090278357A1Increasing the thicknessReduce contactPump componentsFinal product manufactureElectricityWater flow

A hydroelectric turbine for the production of electricity from tidal flow forces, the turbine having a rotor with an open center such that the blades are mounted between an inner rim and outer rim, wherein retaining members and anti-friction members are provided to limit movement of the rotor relative to the housing in either axial direction, such that water flow in either direction operates the turbine, but wherein the retaining members and the anti-friction members allow the rotor to shift in either axial direction in response to water flow. The anti-friction members limiting rotor travel in the axial direction are preferably of increased thickness, such that as the anti-friction members wear down, the rotor is able to shift relative to the housing in the axial direction.

Owner:OPENHYDRO GRP LTD

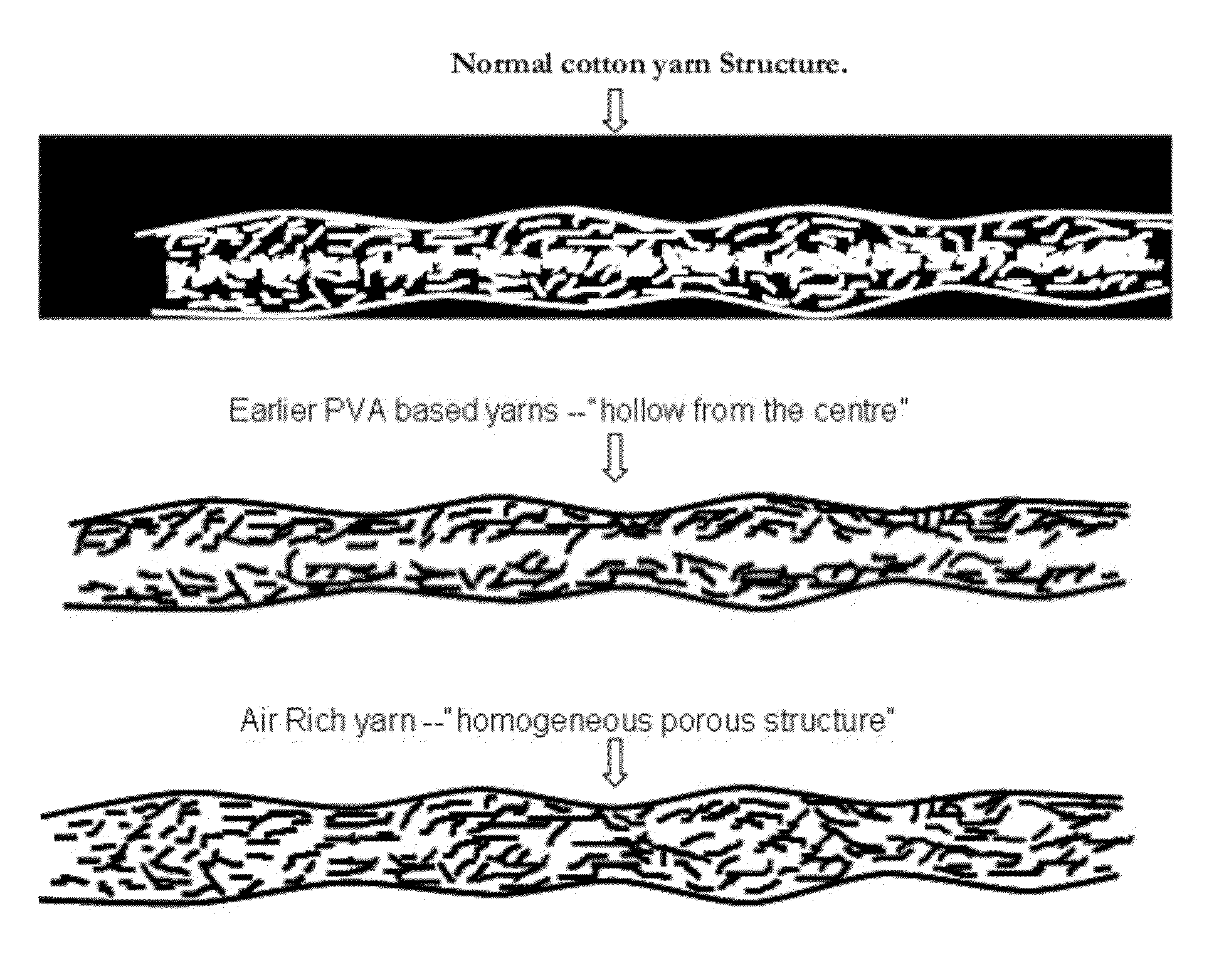

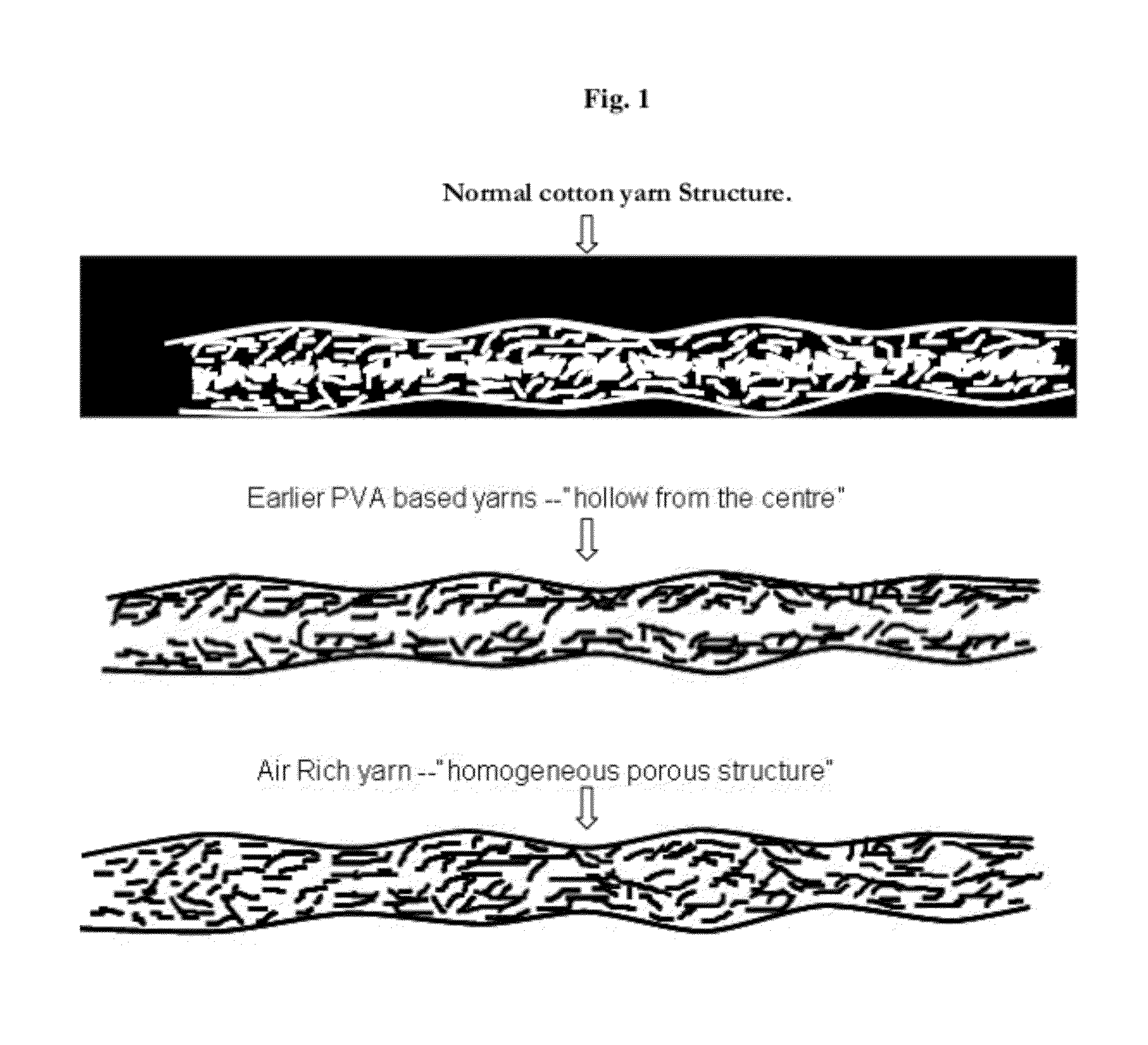

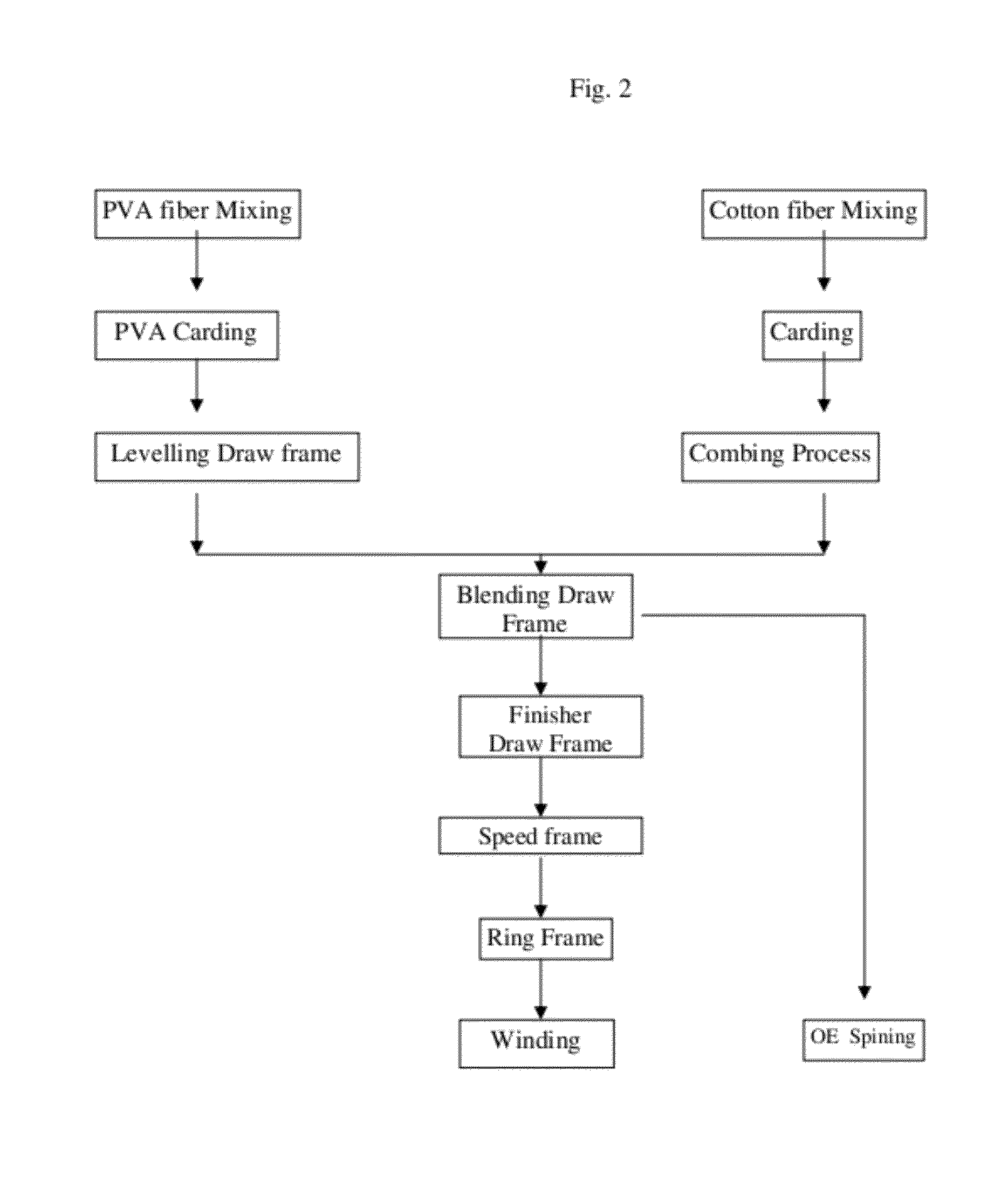

Air rich yarn and fabric and its method of manufacturing

The present invention relates to air rich yarn and fabric with pores throughout the cross-section. Air rich yarn and fabric have high wettability, easy dryability, quick absorbency and increased thickness. When air rich yarn is used to make terry fabric it makes thicker fabric with increased capacity to absorb water and also release moisture faster while drying.

Owner:TRIDENT

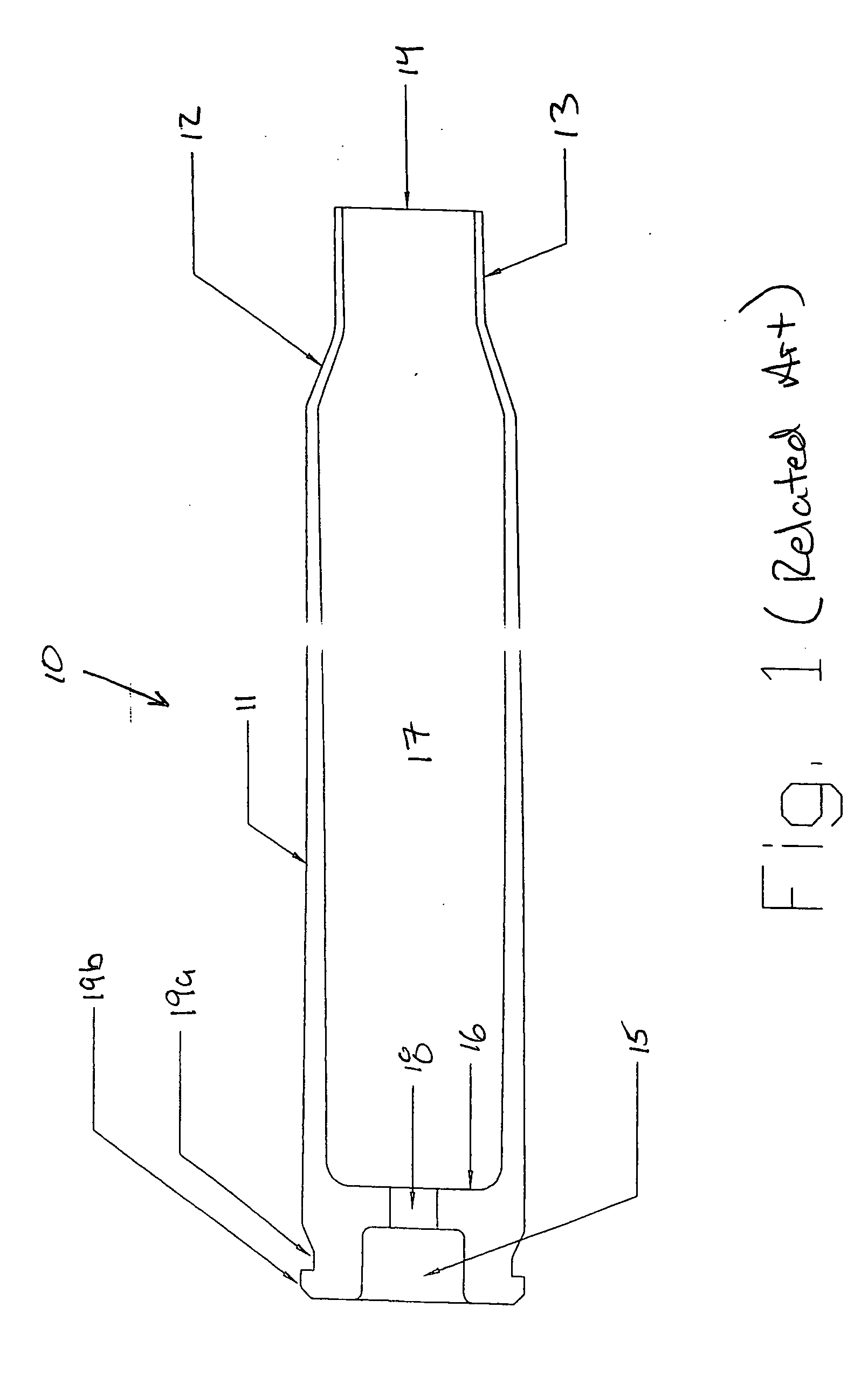

Lead free, composite polymer based bullet and cartridge case, and method of manufacturing

InactiveUS20050188879A1High strengthImprove reinforcementAmmunition projectilesShotgun ammunitionDouble wallEngineering

A lead-free, composite polymer based bullet and cartridge case, wherein the cartridge case is formed by matingly engaging a cylindrical body and a corresponding base. A belted cartridge case has a double wall design, which provides the cartridge with increased thickness, and in turn, a reinforced structure useful for withstanding breakage from an impact caused by high pressure loads. The belt is formed to have an inner diameter at a first end of the base that is larger than the outer diameter of any portion of the cylindrical body. A nested cartridge case allows the second end of the case to nest in a first end of the base at an engaging region.

Owner:POLYTECH AMMUNITION

Transistor gate forming methods and transistor structures

ActiveUS20070048941A1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectric layerMetal

A transistor gate forming method includes forming a metal layer within a line opening and forming a fill layer within the opening over the metal layer. The fill layer is substantially selectively etchable with respect to the metal layer. A transistor structure includes a line opening, a dielectric layer within the opening, a metal layer over the dielectric layer within the opening, and a fill layer over the metal layer within the opening. The metal layer / fill layer combination exhibits less intrinsic less than would otherwise exist if the fill layer were replaced by an increased thickness of the metal layer. The inventions apply at least to 3-D transistor structures.

Owner:MICRON TECH INC

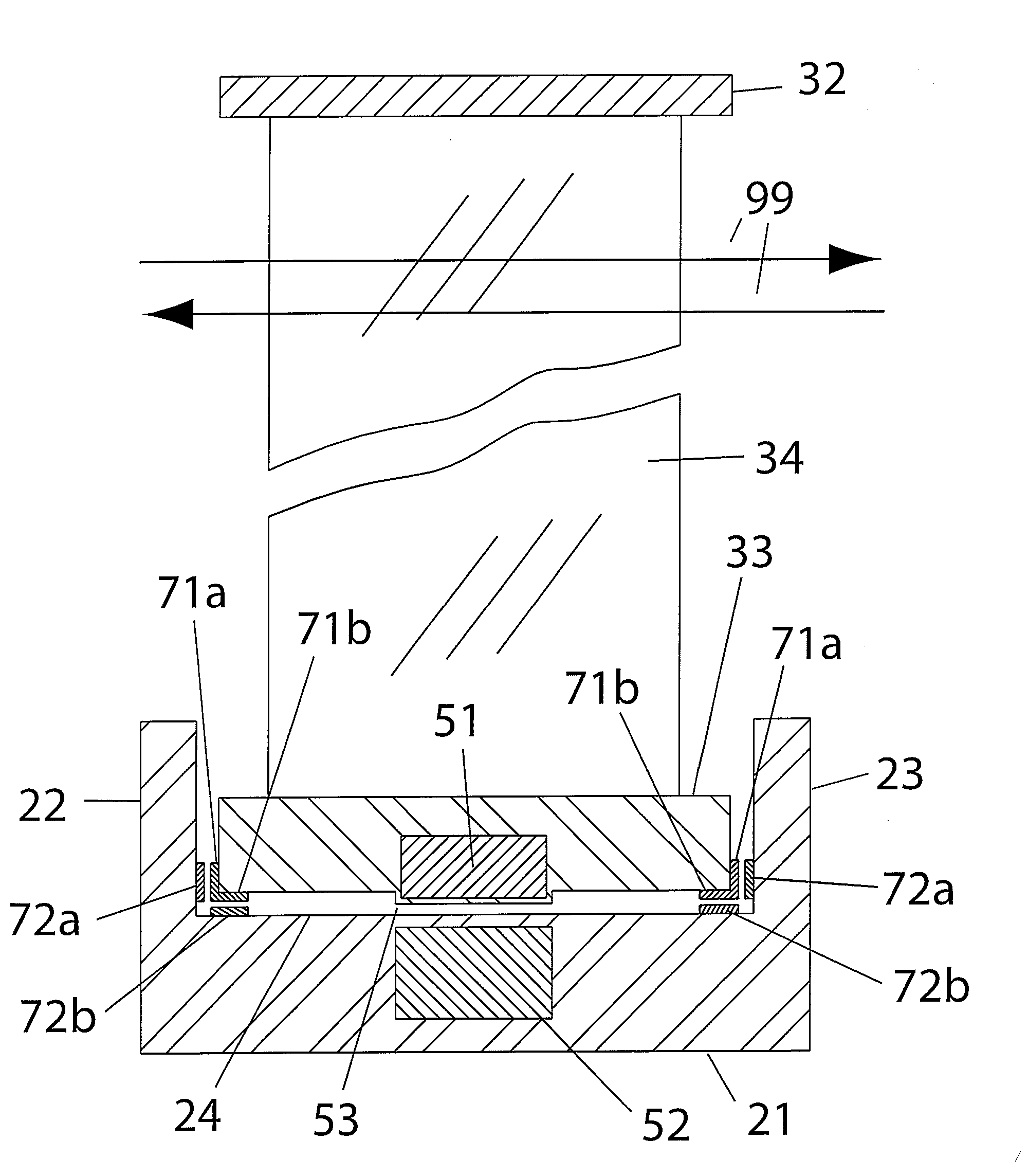

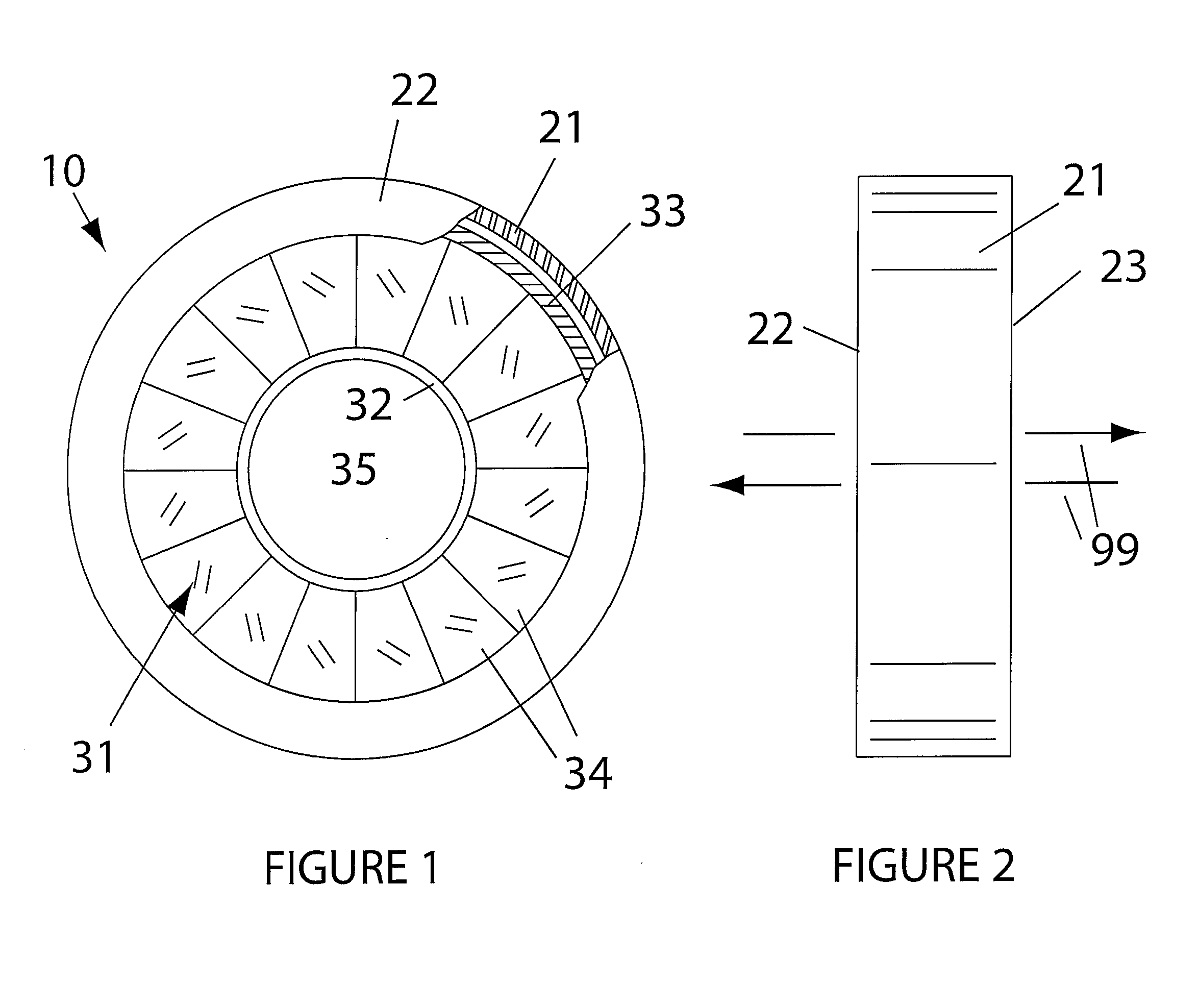

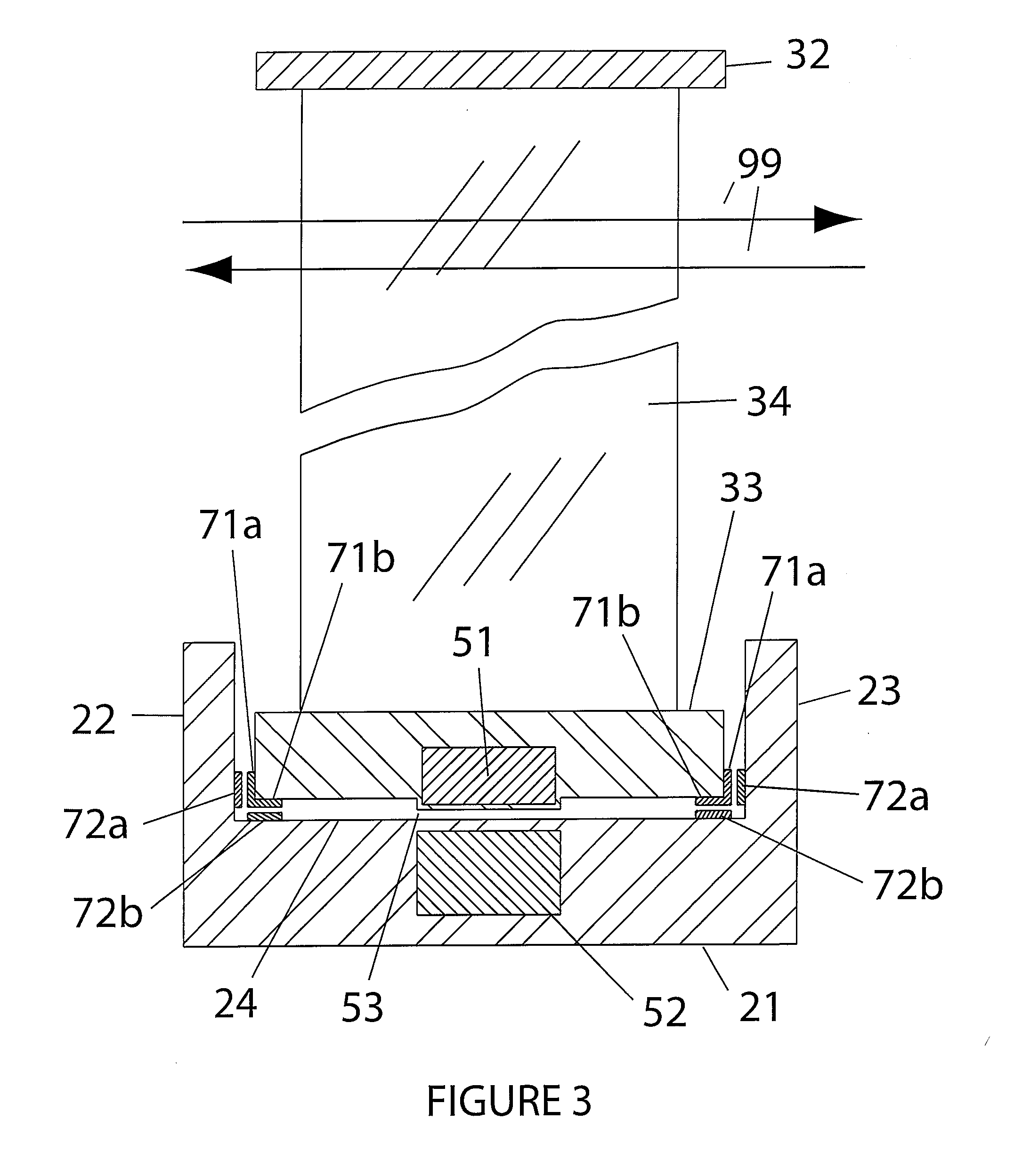

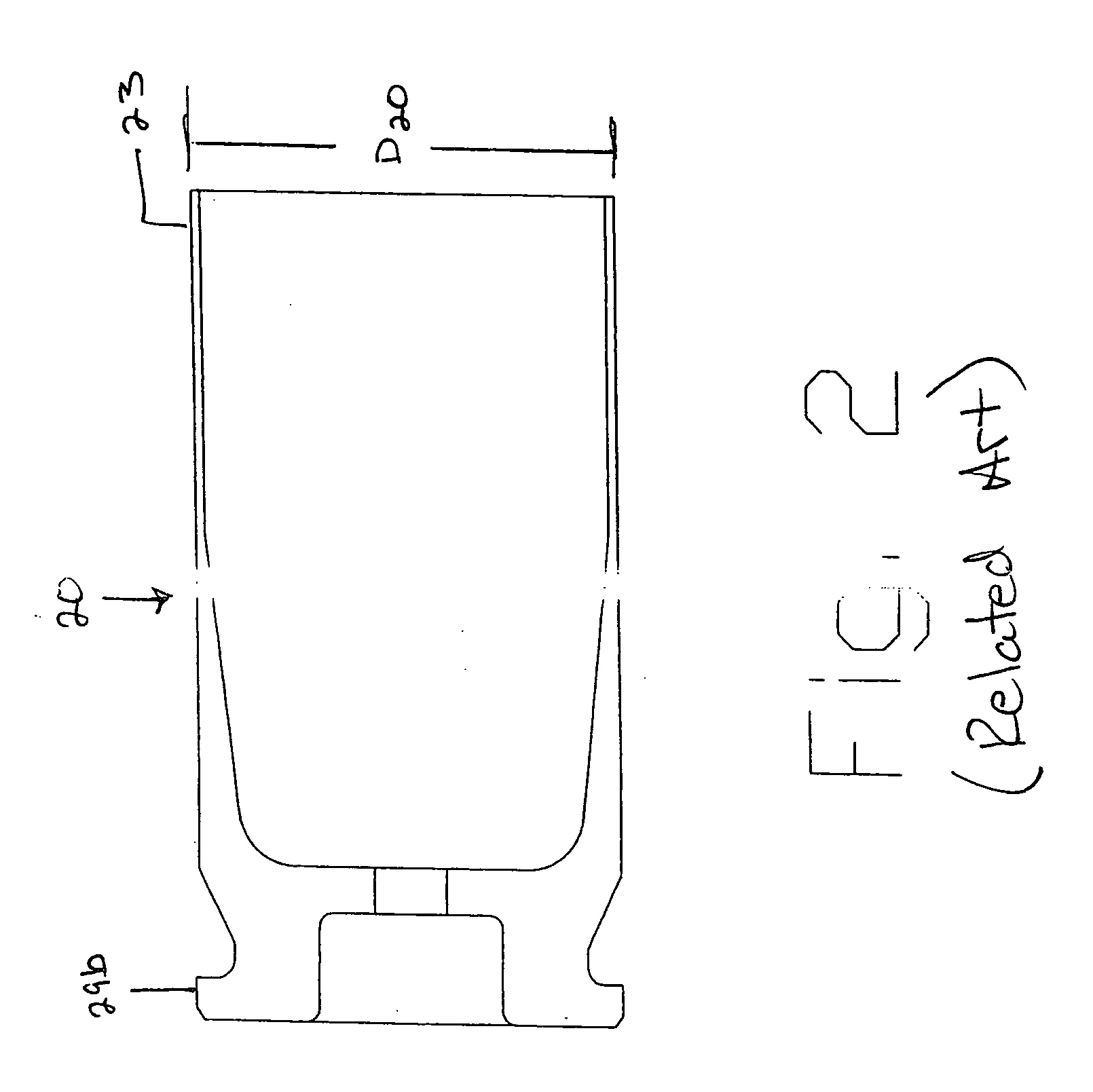

Method and system for shaped glasses and viewing 3D images

ActiveUS20100067108A1Reduce the wavelength shiftStereoscopic photographySteroscopic systems3d imageComplementary filter

Shaped glasses have curved surface lenses and spectrally complementary filters disposed on the curved surface lenses configured to compensate for wavelength shifts occurring due to viewing angles and other sources. The spectrally complementary filters include guard bands to prevent crosstalk between spectrally complementary portions of a 3D image viewed through the shaped glasses. In one embodiment, the spectrally complementary filters are disposed on the curved lenses with increasing layer thickness towards edges of the lenses. The projected complementary images may also be pre-shifted to compensate for subsequent wavelength shifts occurring while viewing the images.

Owner:DOLBY LAB LICENSING CORP

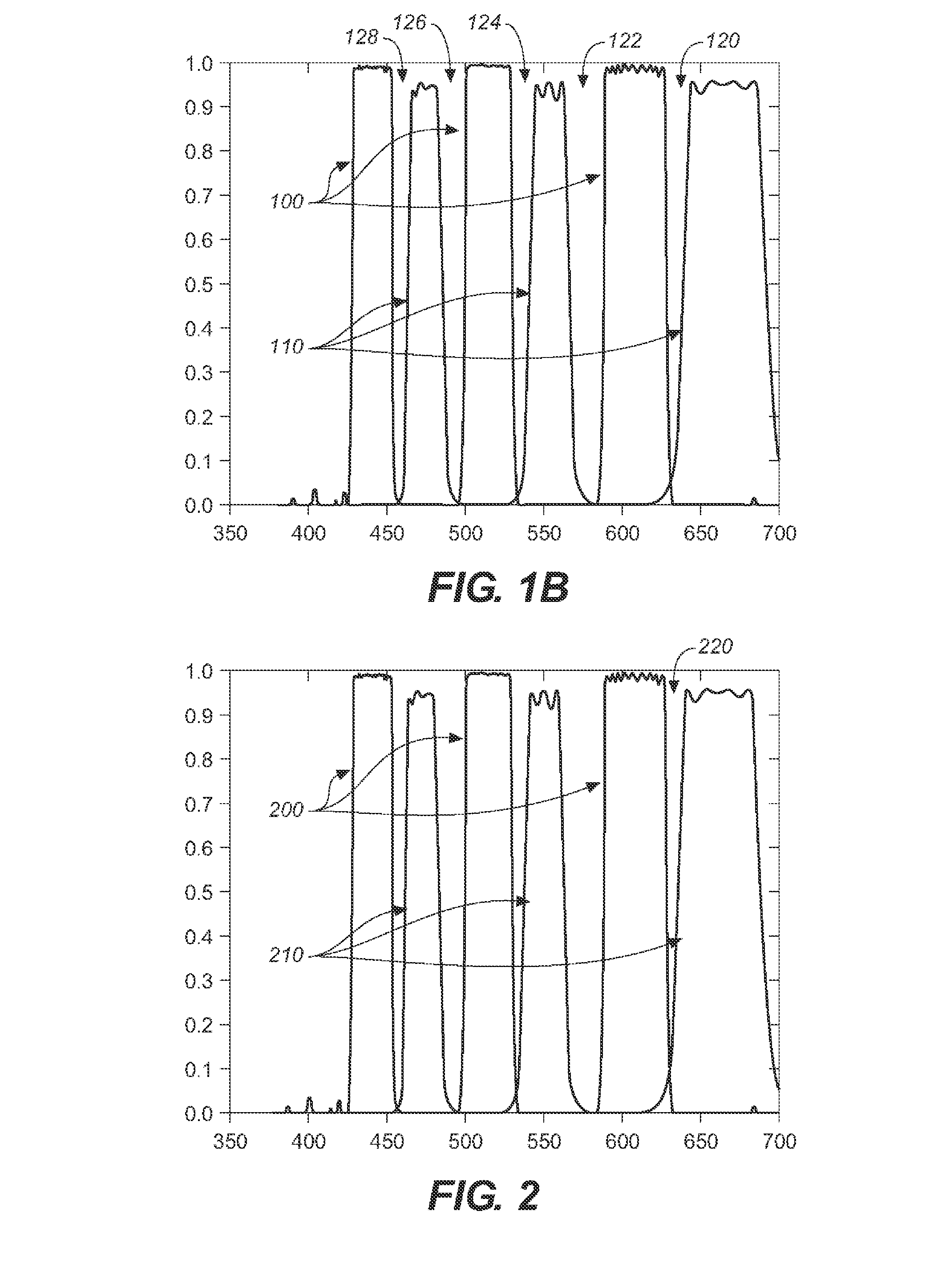

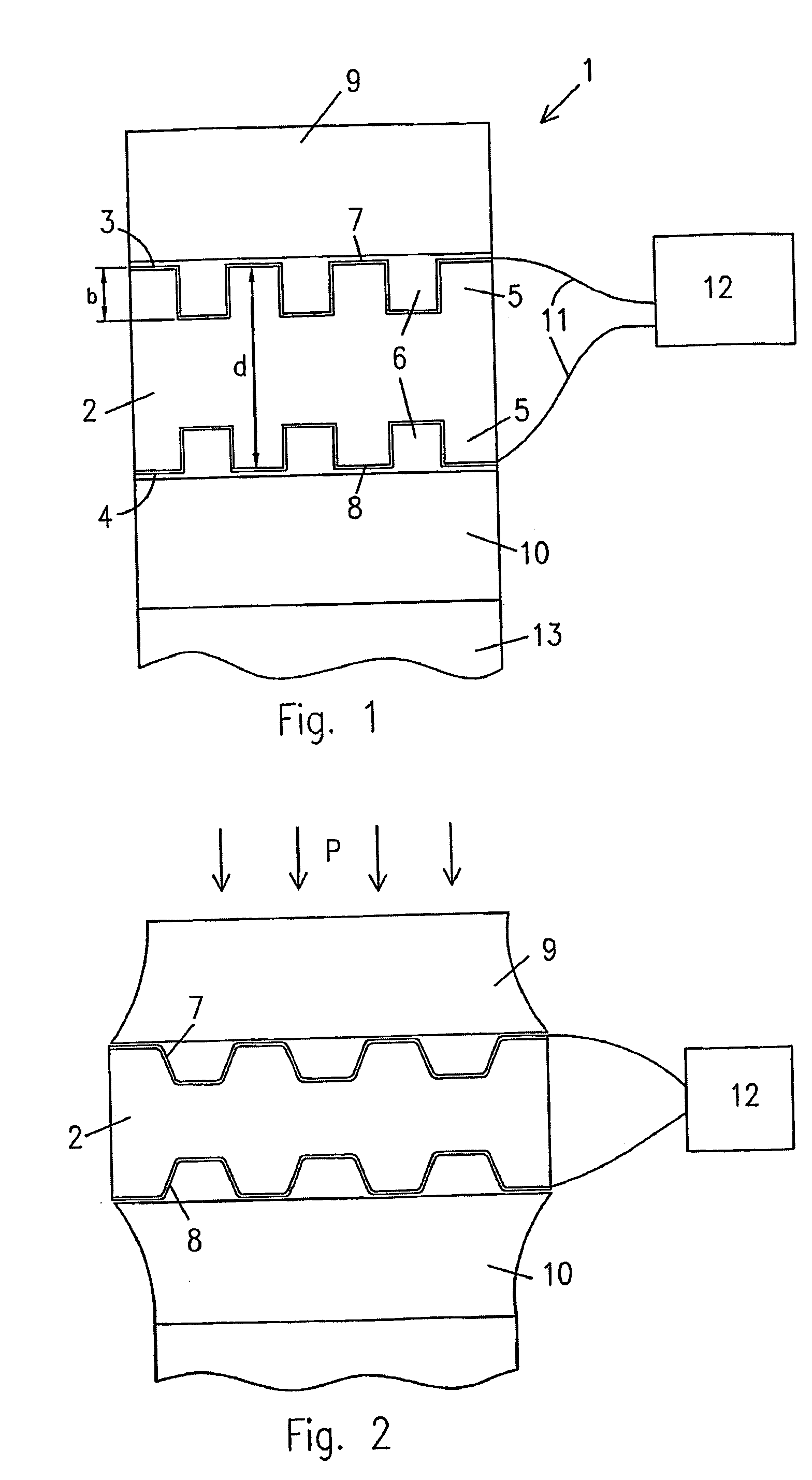

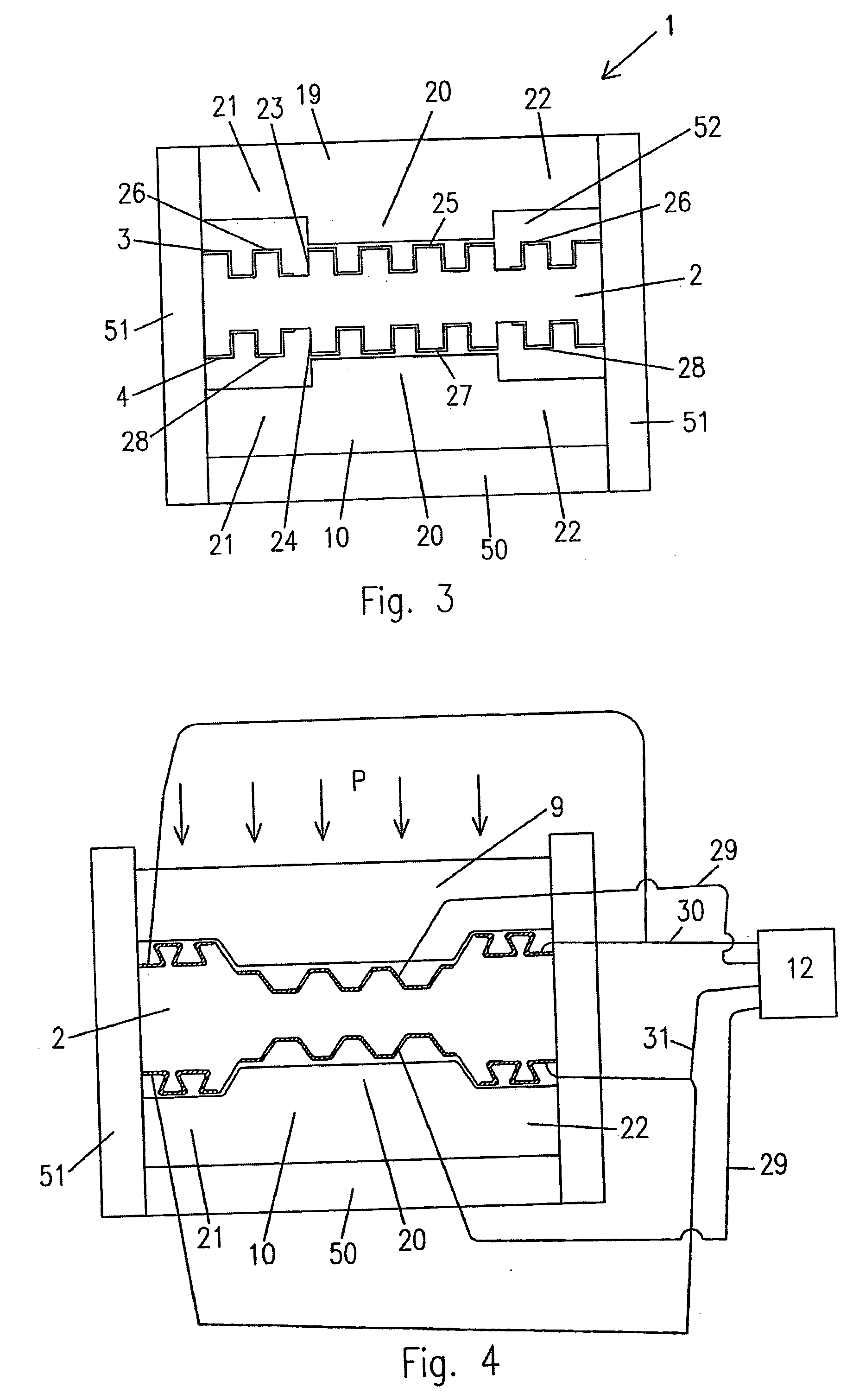

Tactile sensor element and sensor array

InactiveUS20060016275A1High sensitivityLow costForce measurementTension measurementSensor arrayElastomer

A tactile sensor element includes a first pressure transfer layer and a second pressure transfer layer, an elastomeric body arranged between the first and second pressure transfer layers, the body having a first and a second surface opposed to each other, the first and second surfaces having corrugations to allow displacement of elastomeric body material in a predetermined direction perpendicular to the corrugations when exposed to a contact pressure on at least one of the surfaces, a first electrode arranged on the first surface and a second electrode arranged on the second surface, the first and the second electrodes being connectable to external means for determining the capacitance of a capacitor formed by the elastomeric body and the electrodes, where at least one pressure transfer layer has at least one portion of increased thickness. Further disclosed is a tactile sensor array comprising a plurality of sensor elements.

Owner:LEAP TECH APS

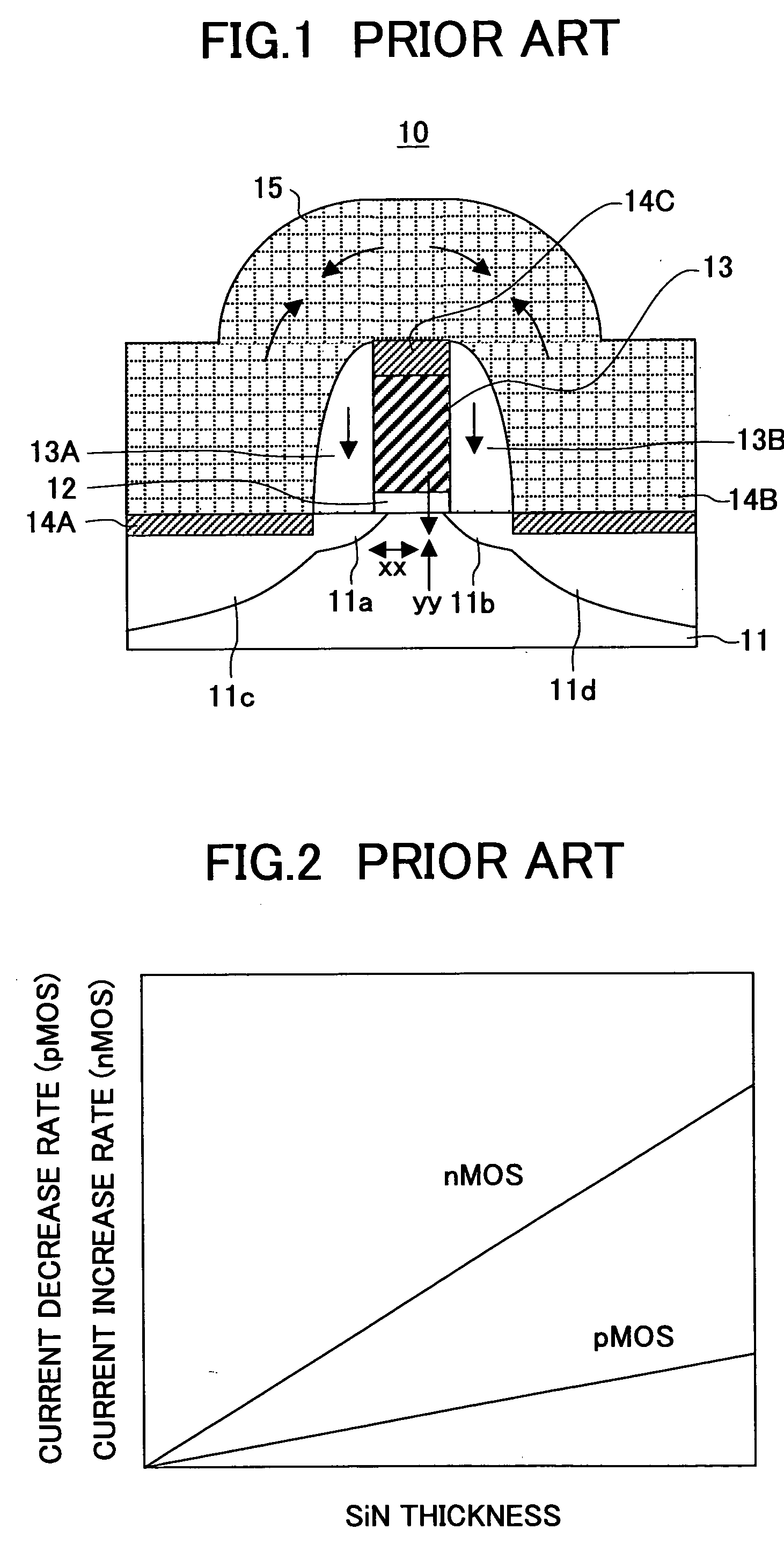

Semiconductor device and a CMOS integrated circuit device

InactiveUS20060006420A1Improve mobilityIncrease speedSolid-state devicesSemiconductor/solid-state device manufacturingCMOSDevice material

A semiconductor device includes a stress-accumulating insulation film formed on a semiconductor substrate so as to cover a gate electrode and sidewall insulation films, the stress-accumulating insulation film accumulating a stress therein, wherein the stress-accumulating insulation film including a channel part covering the gate electrode and the sidewall insulation films and outer parts extending outside of the channel part, the stress-accumulating insulation film having an increased thickness in the channel part as compared with the outer part.

Owner:FUJITSU MICROELECTRONICS LTD

Dental appliance having an altered vertical thickness between an upper shell and a lower shell with an integrated hinging mechanism to attach an upper shell and a lower shell and a system and a method for treating malocclusions

ActiveUS20050037311A1Increasing the thicknessMaintain positionAdditive manufacturing apparatusOthrodonticsOpen biteDental malocclusion

A dental appliance having increased or decreased thickness between an upper shell and a lower shell in combination with a hinging mechanism and a system and a method for treating malocclusions are provided. The dental appliance may have an upper shell and a lower shell which receive upper teeth and lower teeth, respectively, of a user. The upper shell and the lower shell may be attached at a hinge. The dental appliance may have an increased thickness between the upper shell and the lower shell as well as an increased thickness of the hinge. In an embodiment, the dental appliance may have a decreased vertical thickness and an insertable hinging mechanism. The dental appliance may then extend treatment of malocclusions to the rear teeth of the user and may correct a dental condition, such as, for example, overbite, overjet, open bite, crowding, rotations, spacing, cross-bites, gummy smiles and temporomandibular joint problems.

Owner:ORTHO TAIN INC

Sectional wind turbine blade

ActiveUS20110293432A1Increase widthSame chord-to-thickness ratioWind motor assemblyReaction enginesTurbine bladeMoment of inertia

Wind turbine blade comprising two or more blade sections each of which defines a non-joint zone and, at one or each of its ends, a joint zone. The blade sections are connected in pairs such that the joint zones of each pair are connected at a joint, whereby the joint is positioned between two non-joint zones. At least one of the joints have an increased thickness and a wider chord relative to the thickness and the chord of the two non-joint zone between which the joint is positioned so as to increase the second moment of inertia in the area of the joint.

Owner:VESTAS WIND SYST AS

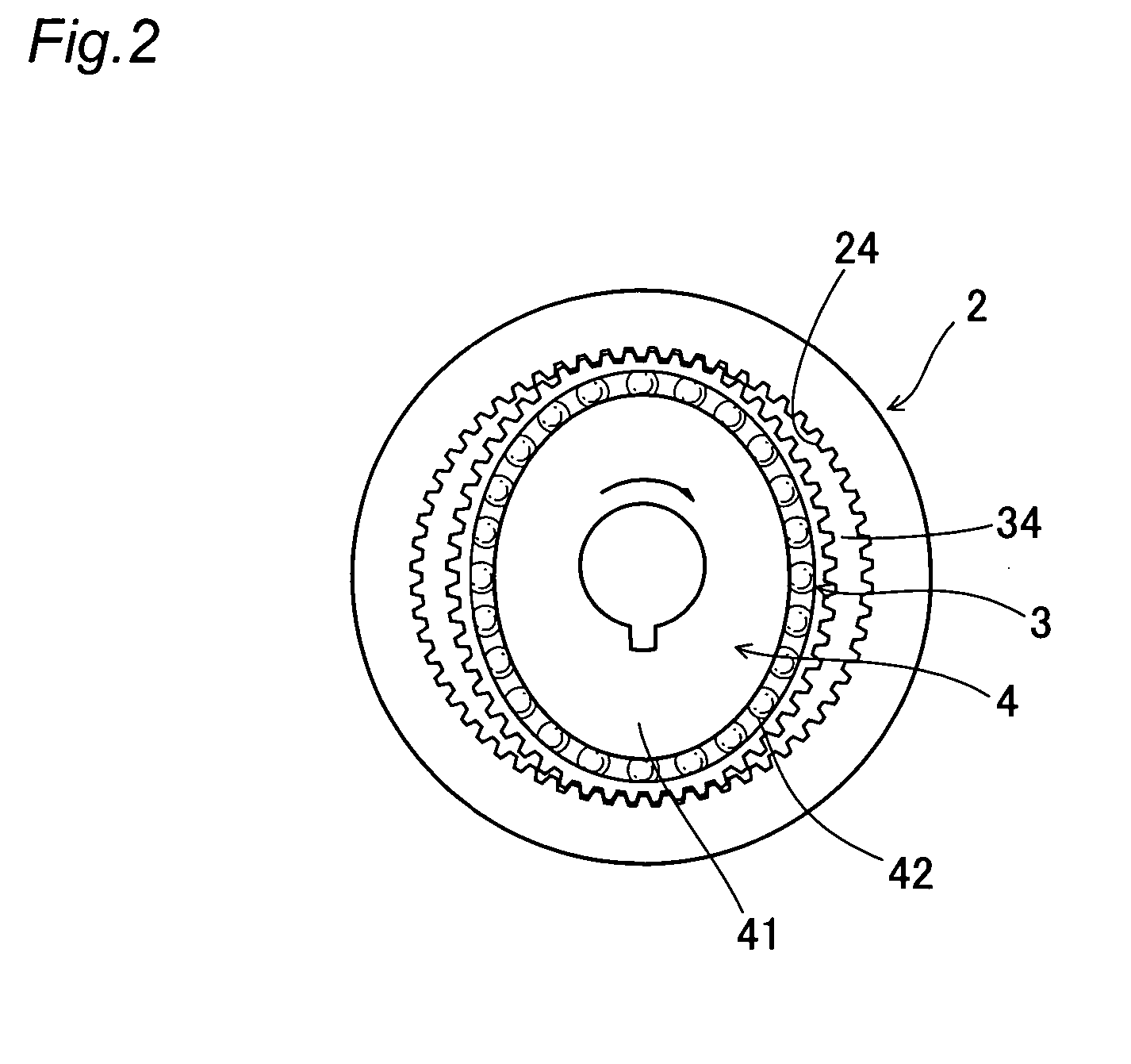

Wave gear device

InactiveUS20050066769A1Increasing the thicknessPrevent degradationPortable liftingToothed gearingsGear wheelEngineering

A wave gear device has a rigid internal gear, a flexible external gear, and a wave generator. The tooth profiles of both gears are initially defined by a basic rack tooth profile shape. The lower parts of the dedendum portions of these tooth profiles are modified by curves C2 and C3 having pressure angles α2 and α3 that are less than the standard pressure angle α1 of the basic rack tooth profile shape C1. An increase in thickness of the tooth bottom side can be minimized even if the tooth depth is increased and the tooth thickness / tooth space ratio changed to increase the tooth thickness. Hence, the ratcheting torque of a wave gear device having a high reduction gear ratio can be increased without reducing the service life and strength of a pinion cutter for the rigid internal gear, or the fatigue strength of the flexible external gear.

Owner:HARMONIC DRIVE SYST IND CO LTD

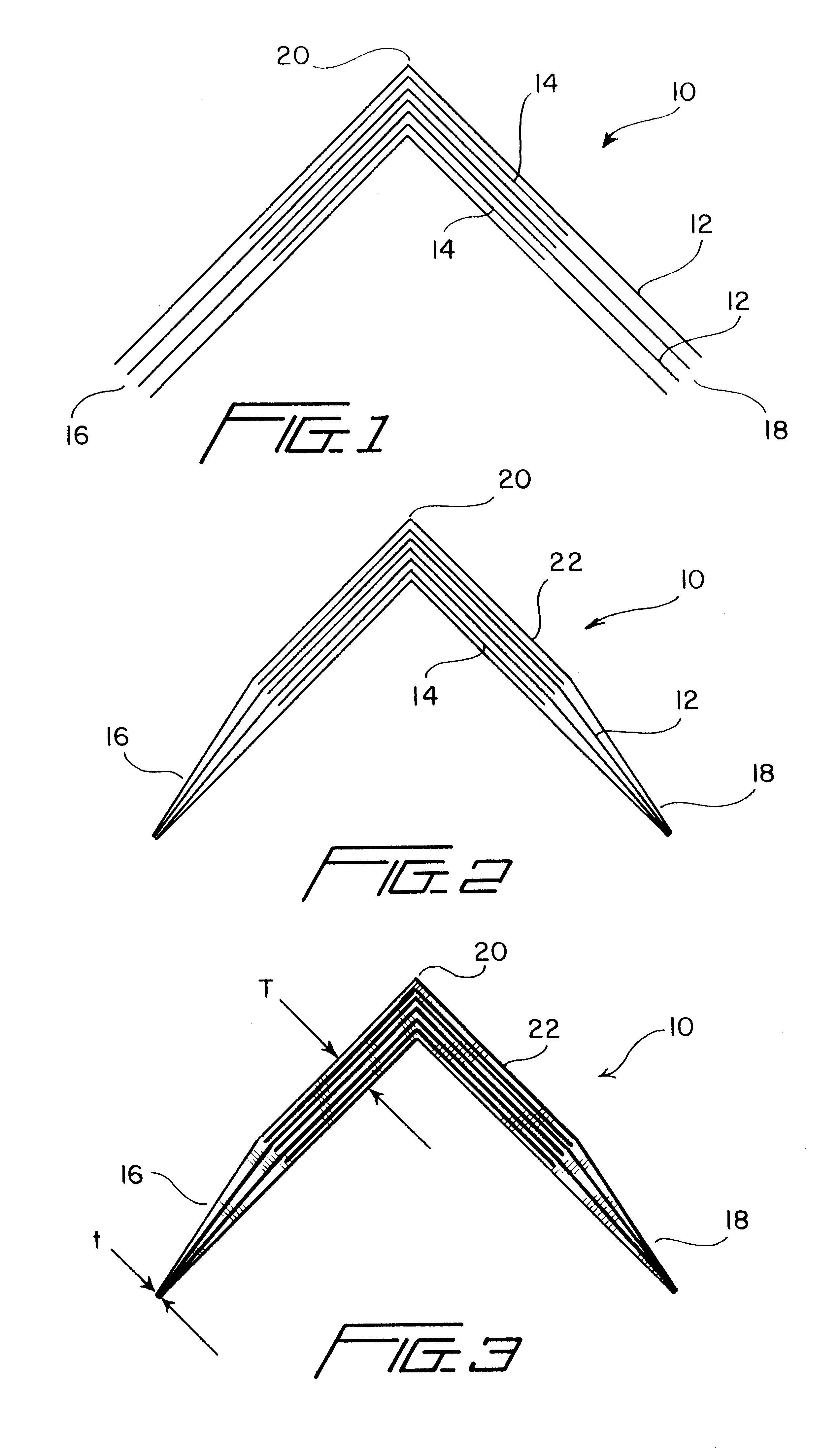

Angleboard edge protector

InactiveUS6527119B1Easy to handleGood orientationOther accessoriesContainer/bottle contructionDistal portionEngineering

An edge or corner protector comprises an apex portion and a pair of leg members extending away from the apex portion so as to define an angle of approximately 90° therebetween. The apex portion and leg members are defined by a plurality of paper plies which have at least two different width dimensions. Relatively narrow and relatively broad paper plies are alternatively arranged with respect to each other whereby the apex portion and proximal portions of the leg members are formed by both the broad and narrow paper plies whereas distal portions of the leg members are formed only by the broad paper plies. In this manner, increased thickness and strength is provided within the apex and proximal portions of the leg members as needed, the distal portions of the leg members nevertheless facilitate mounting, positioning, and orientation of the edge or corner protectors upon edge or corner regions of articles to be protected, and a substantial reduction in the overall raw material cost is achieved.

Owner:SIGNODE IND GRP

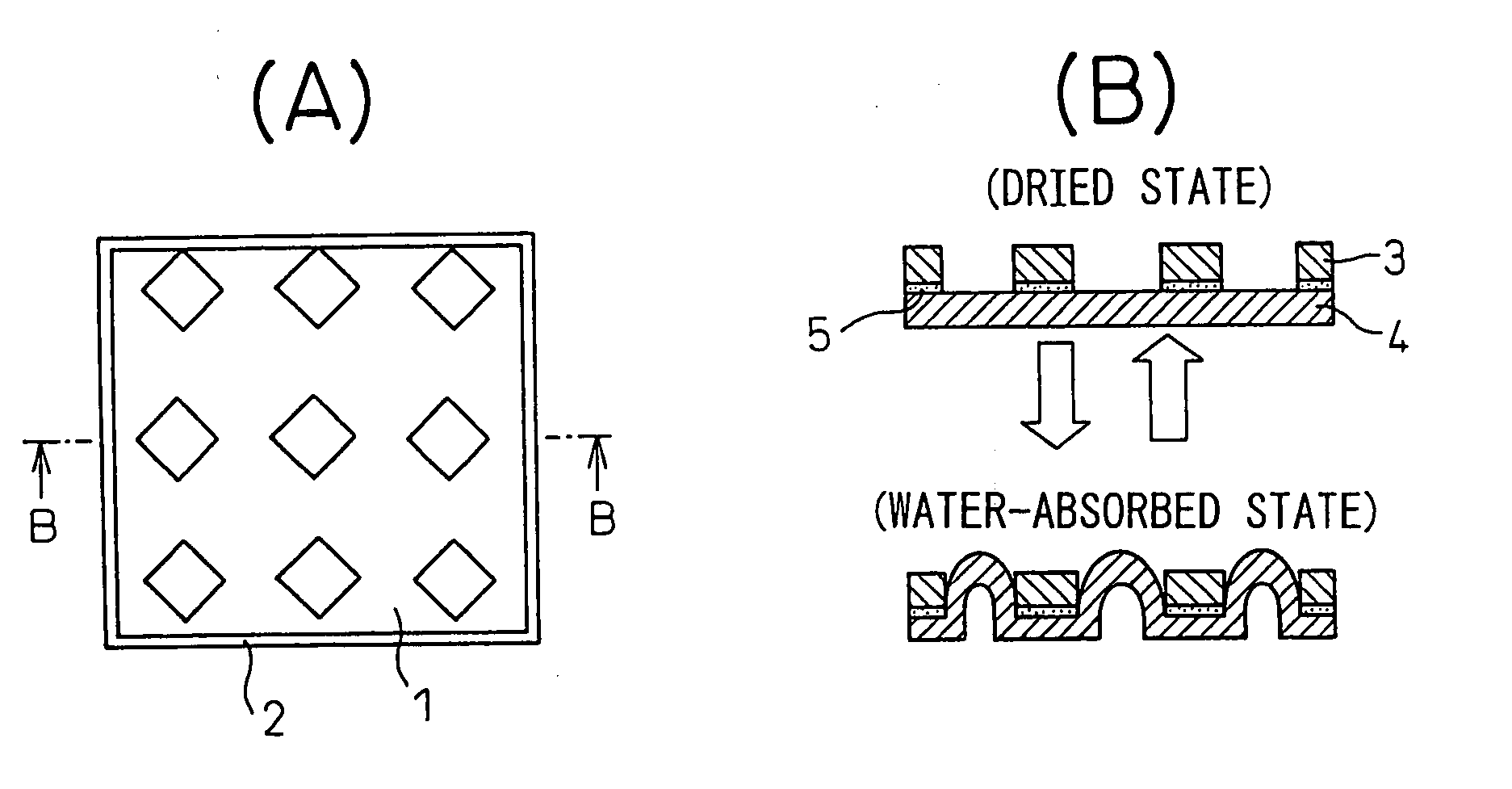

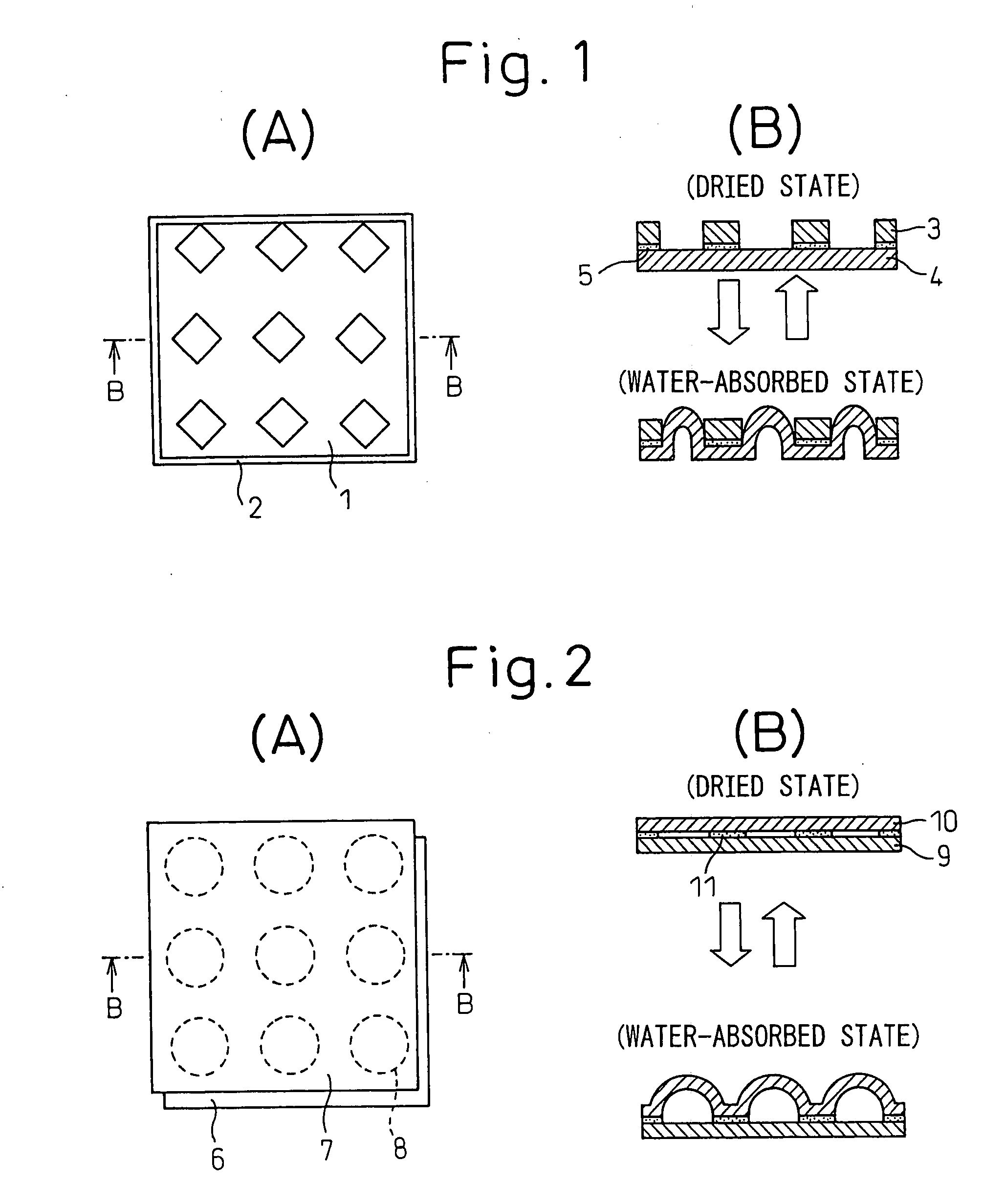

Composite Fabric Material Exhibiting Three-Dimensional Structural Change Upon Water Absorption, and Textile Products

InactiveUS20080254263A1Increasing the thicknessImprove breathabilityGarment special featuresLayered productsEngineeringResin coating

The composite fabric material of the invention comprises a water-absorbing woven or knitted fabric, the area and thickness of which, or the area or thickness of which, increases by at least 10% in its water-absorbed state relative to its dried state; and an area change-restricting means composed of a woven or knitted fabric, nonwoven fabric, resin film or resin coating, the area and thickness of which does not substantially change in its water-absorbed state relative to its dried state, the area change-restricting means being bonded or sewn onto at least one side of the water-absorbing woven or knitted fabric over a partial region so as to leave a plurality of other partial regions separated from each other, or over the entire region, the means serving to restrict change in area by water absorption at the bonded or sewn portions of the water-absorbing woven or knitted fabric. Upon wetting with water, the area and thickness, or the area or thickness, of the water-absorbing woven or knitted fabric at the plurality of the partial regions that are separated from each other increases, thereby changing the three dimensional structure of the composite fabric material.

Owner:TEJIN FIBERS LTD

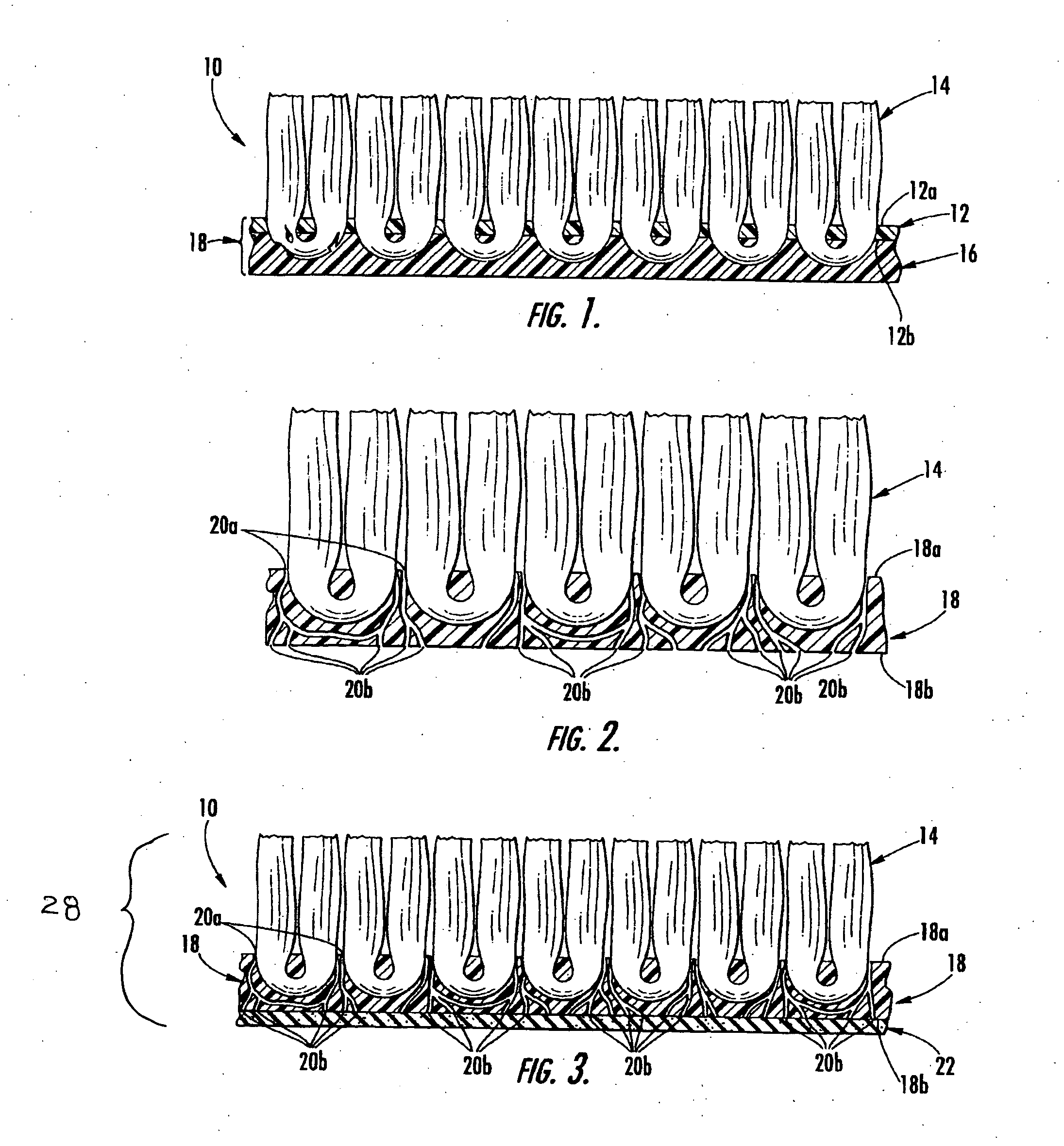

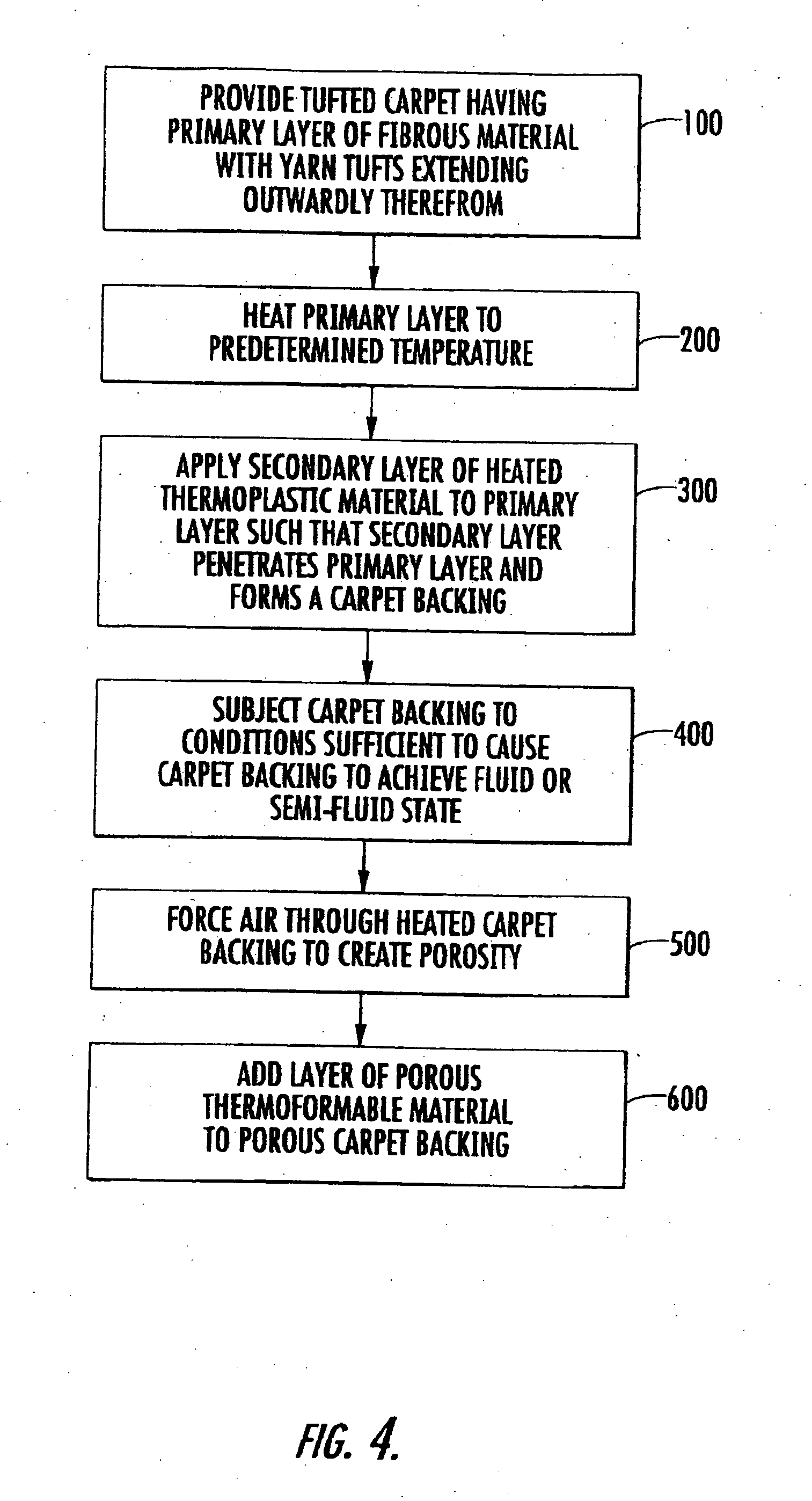

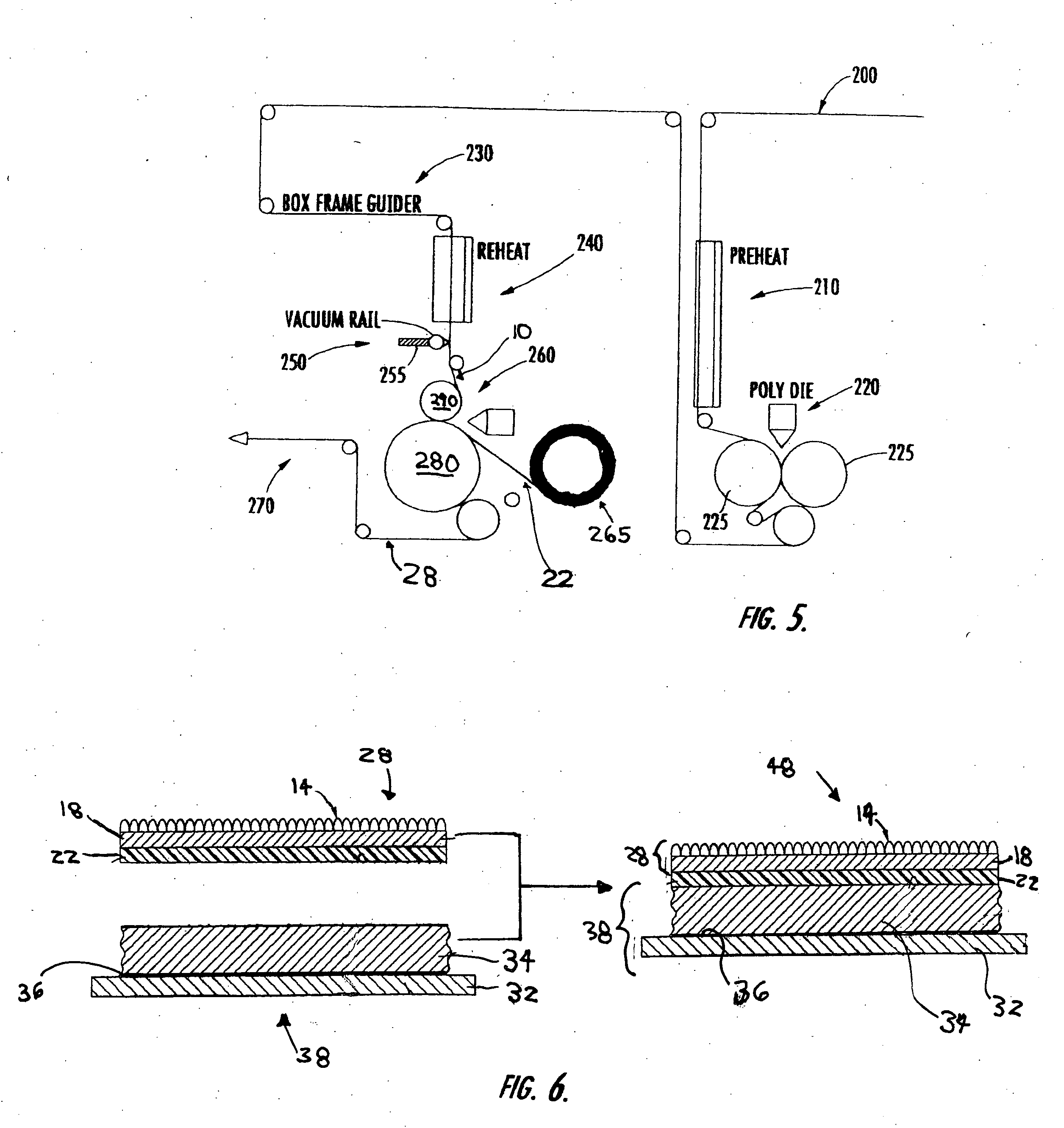

Sound absorbing/sound blocking automotive trim products

InactiveUS20050064779A1High mechanical strengthMaintain porosityVehicle arrangementsBristleUltrasound attenuationEngineering

Sound absorbing / sound blocking products, including trim products formed from a porous fibrous layer backed by a sound absorbing layer and a sound blocking layer for use within vehicles, and methods of making same, are provided. A porous fibrous layer structure including a fibrous layer backing is heated to achieve a fluid or semi-fluid state and then subjected to vacuum to draw air through the fibrous layer backing to create a porous structure. A layer of sound absorbing and a layer of sound blocking material may be applied to the porous fibrous layer backing to provide improved acoustic properties. An underlayment may further be included to provide selected areas of increased thickness and provide tailoring of sound attenuation.

Owner:AURIA SOLUTIONS UK I LTD

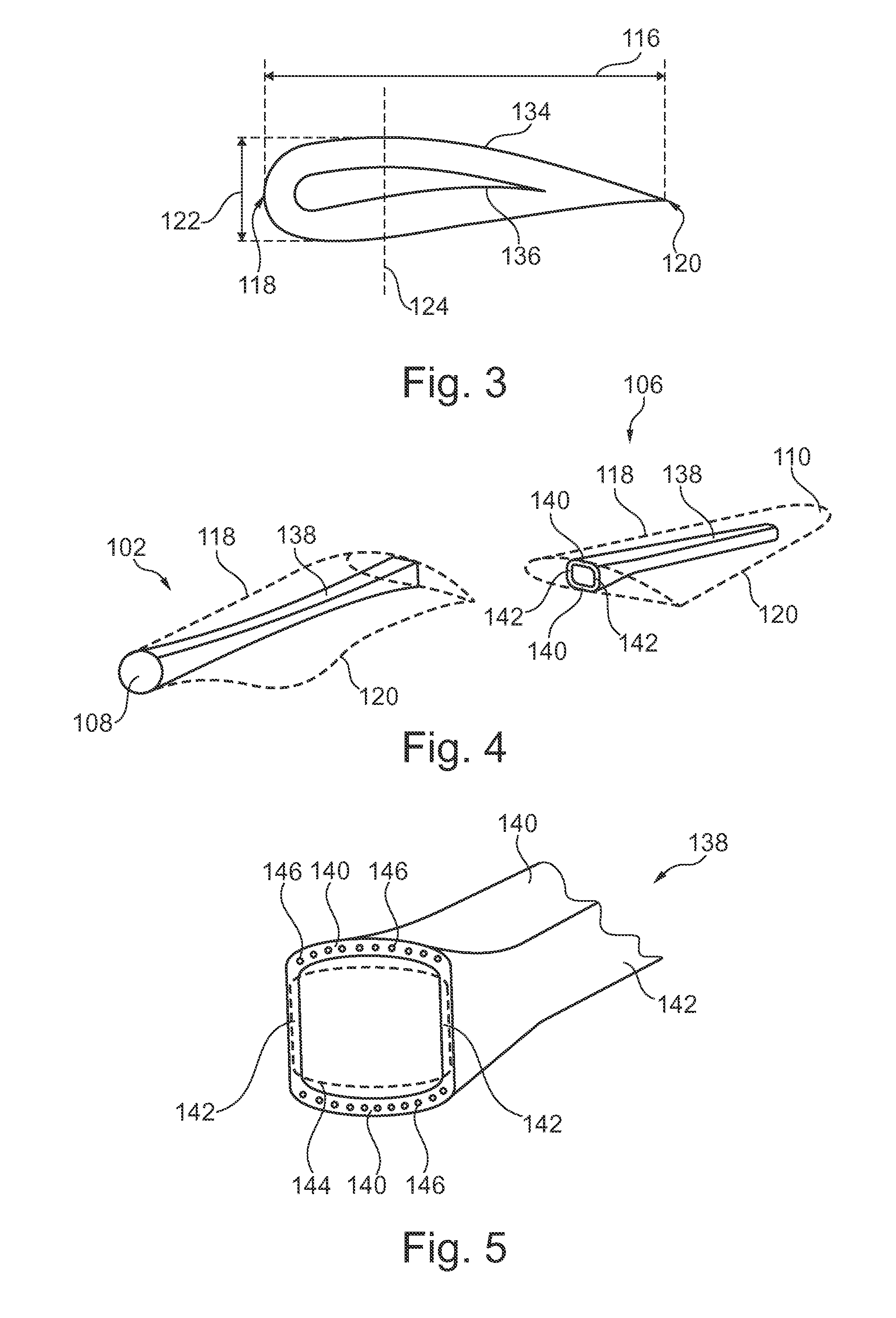

Three-dimensional design lasts for footwear

Systems and methods for generating three-dimensional design lasts for footwear include: (a) generating a three-dimensional last structure on a computer display (e.g., having the appearance of a conventional footwear last structure); (b) receiving user input indicating offset values for various zones of the last structure, wherein the user input indicates offset values for one or more of: a toe region, a heel region, an ankle region, a forefoot region, and / or an instep region; and (c) generating a three-dimensional design last for the footwear on the computer based on the three-dimensional last structure and the user input indicating the desired offset values. The three-dimensional design last may constitute a modified version of the three-dimensional last structure that has an increased thickness to simulate a desired thickness of an upper material placed on the last structure and / or to more closely simulate an appearance of an actual footwear upper.

Owner:NIKE INNOVATE CV

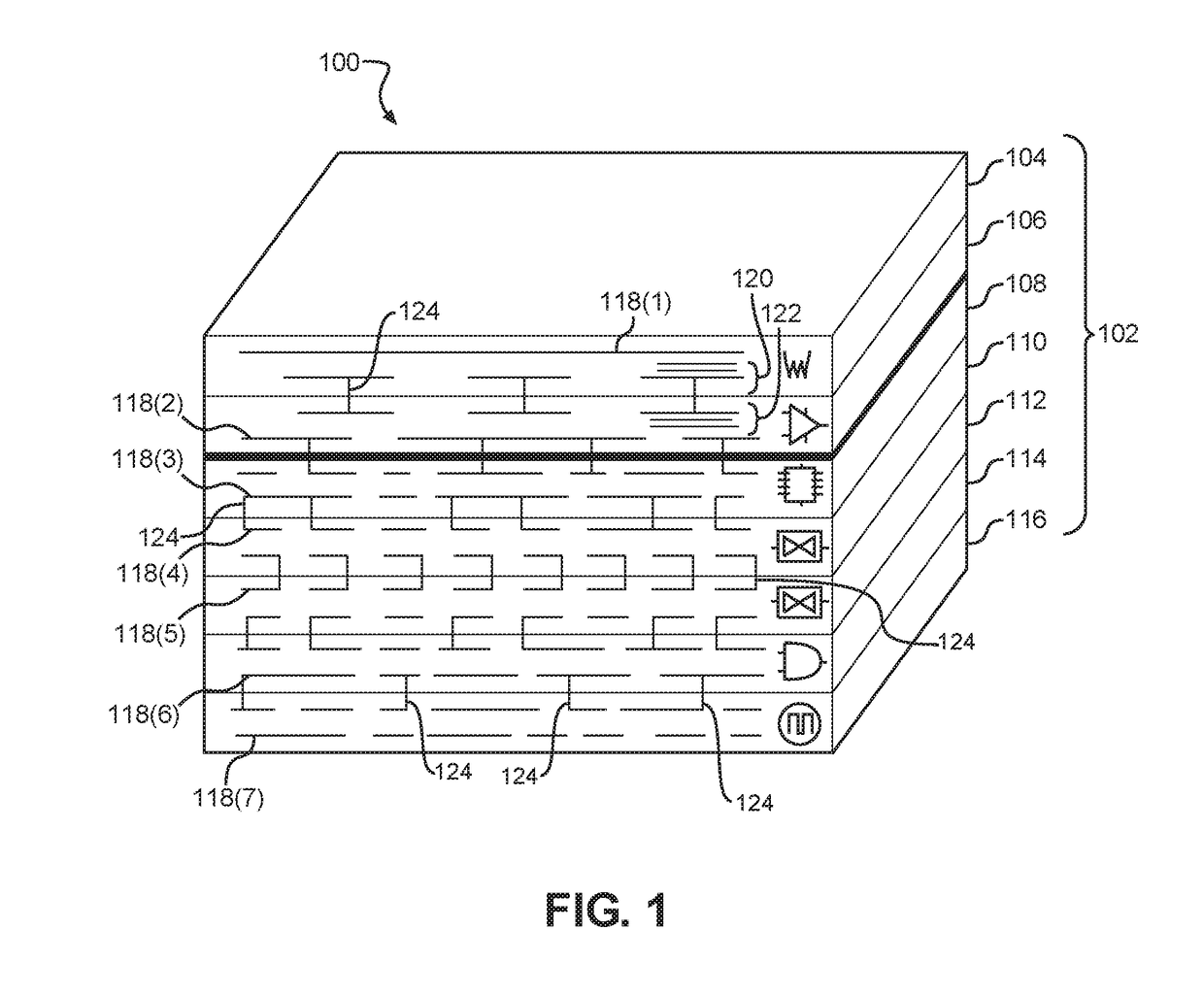

Power distribution networks for a three-dimensional (3D) integrated circuit (IC) (3DIC)

InactiveUS20180286800A1Reduce voltage dropImprove battery performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceVoltage drop

Power distribution networks in a three-dimensional (3D) integrated circuit (IC) (3DIC) are disclosed. In one aspect, a voltage drop within a power distribution network in a 3DIC is reduced to reduce unnecessary power dissipation. In a first aspect, interconnect layers devoted to distribution of power within a given tier of the 3DIC are provided with an increased thickness such that a resistance of such interconnect layers is reduced relative to previously used interconnect layers and also reduced relative to other interconnect layers. Further voltage drop reductions may also be realized by placement of vias used to interconnect different tiers, and particularly, those vias used to interconnect the thickened interconnect layers devoted to the distribution of power. That is, the number, position, and / or arrangement of the vias may be controlled in the 3DIC to reduce the voltage drop.

Owner:QUALCOMM INC

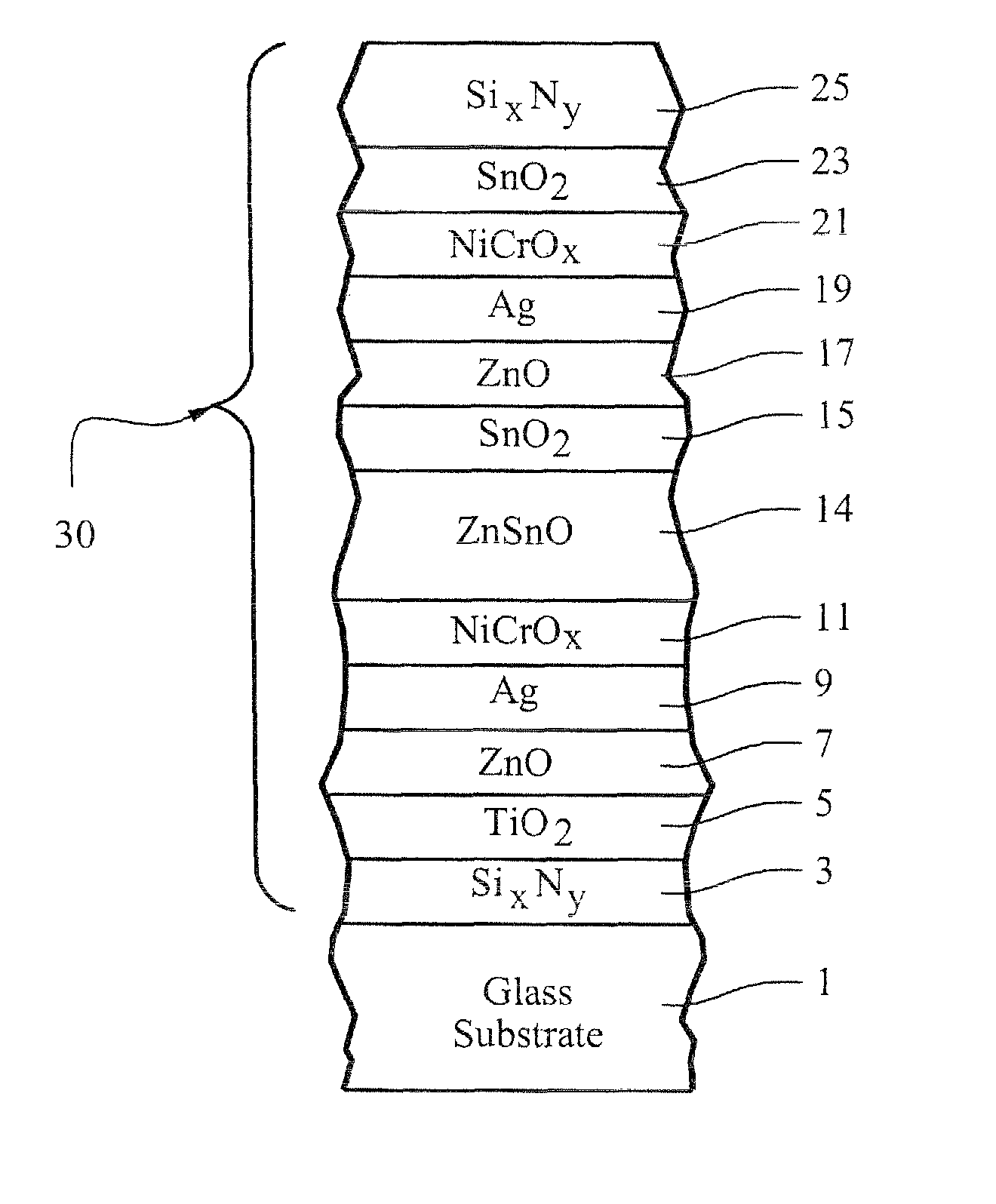

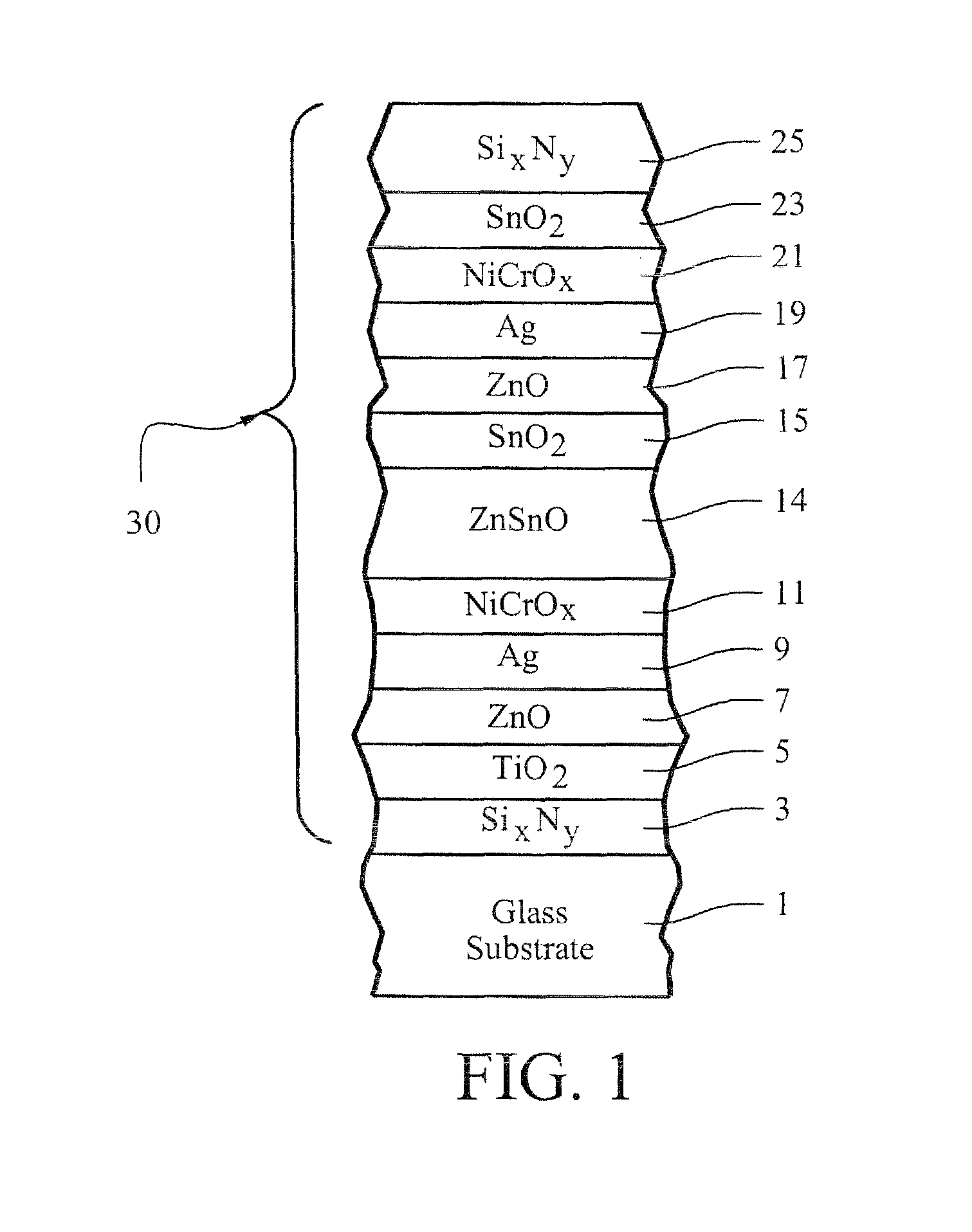

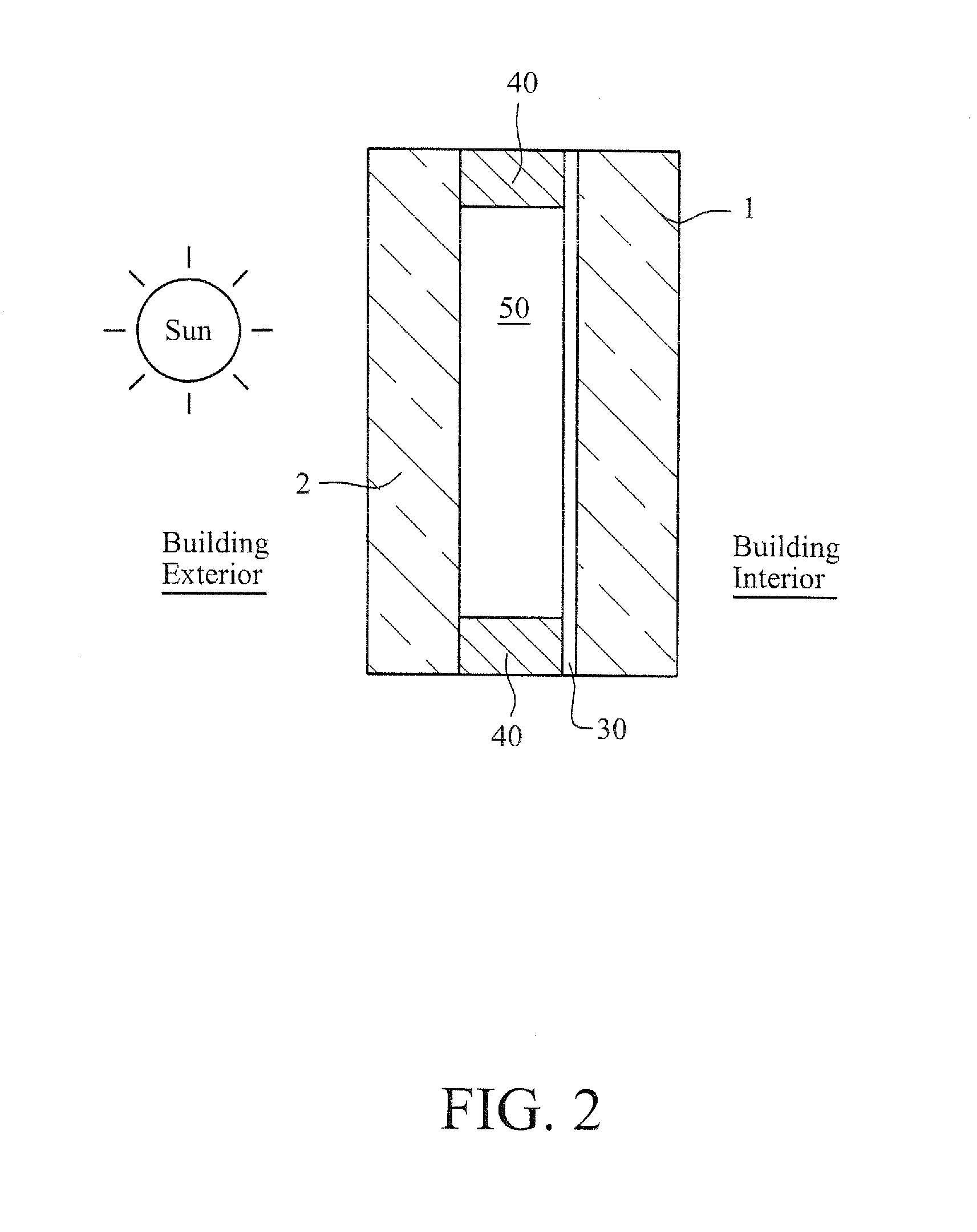

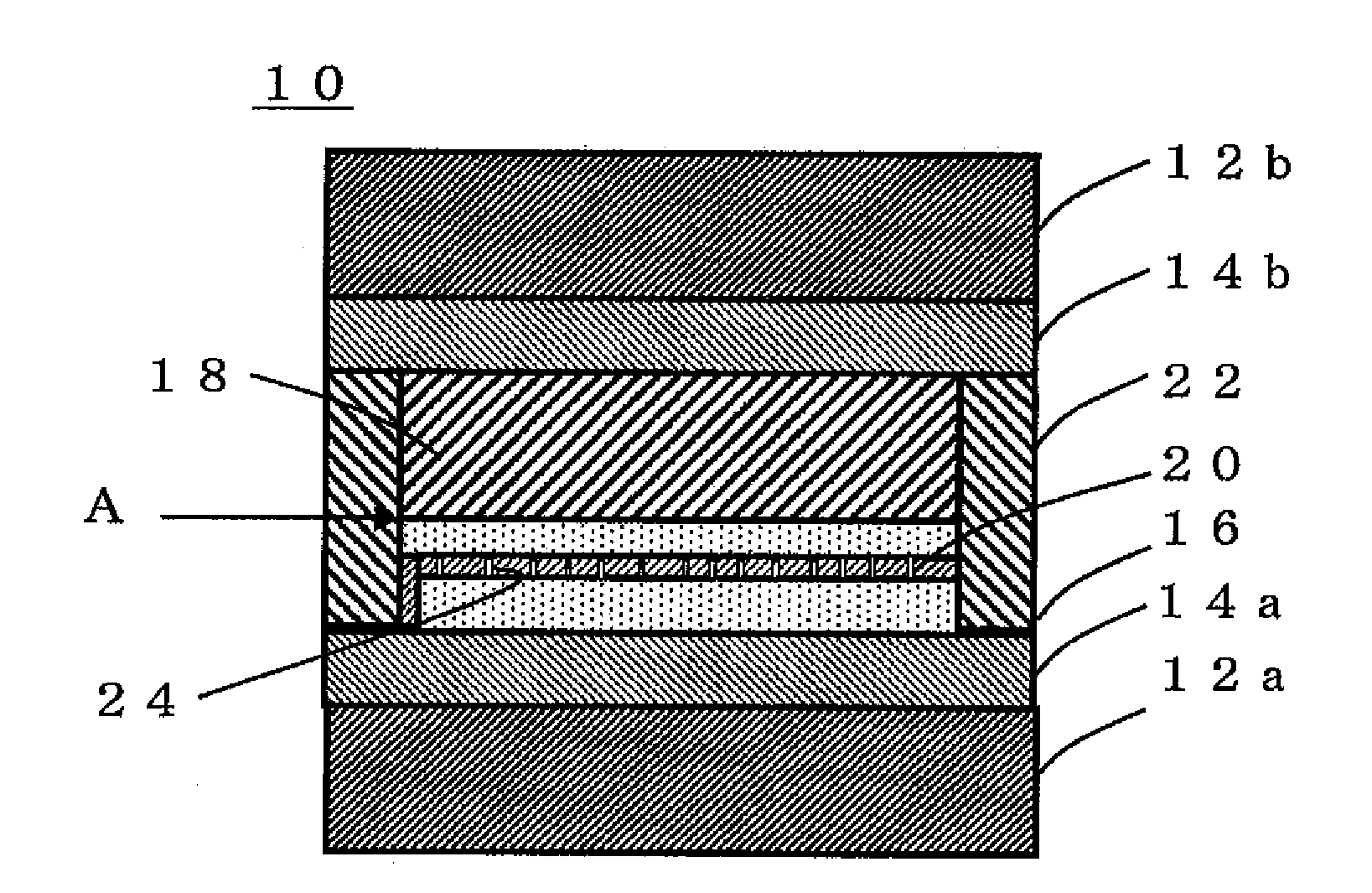

IG window unit including double silver coating having increased SHGC to U-value ratio, and corresponding coated article for use in IG window unit or other window

ActiveUS8940400B1Increase Light to Solar Gain (LSG) coefficientHigh film-side reflectanceLight protection screensGlass/slag layered productsInsulated glazingLow emissivity

An insulating glass (IG) window unit includes first and second substrates, and a low-emissivity (low-E) coating supported by one of the substrates. The low-E coating has two silver based infrared (IR) reflecting layers and allows the IG window unit to realize an increased SHGC to U-value ratio, and an increased thickness ratio of an upper silver based layer of the coating to a bottom silver based layer of the coating. The low-E coating is designed to have a low film-side reflectance, so that for example when the low-E coating is used on surface number three of an IG window unit the IG window unit can realize reduced visible reflectance as viewed from the outside of the building on which the IG window unit is mounted or is to be mounted.

Owner:GUARDIAN GLASS LLC

Dye-sensitized solar cell and process for producing the same

InactiveUS20090314339A1Easy to produceImprove conversion efficiencyElectrolytic capacitorsFinal product manufactureMicroparticleSolvent

Owner:NIPPON STEEL CHEMICAL CO LTD +1

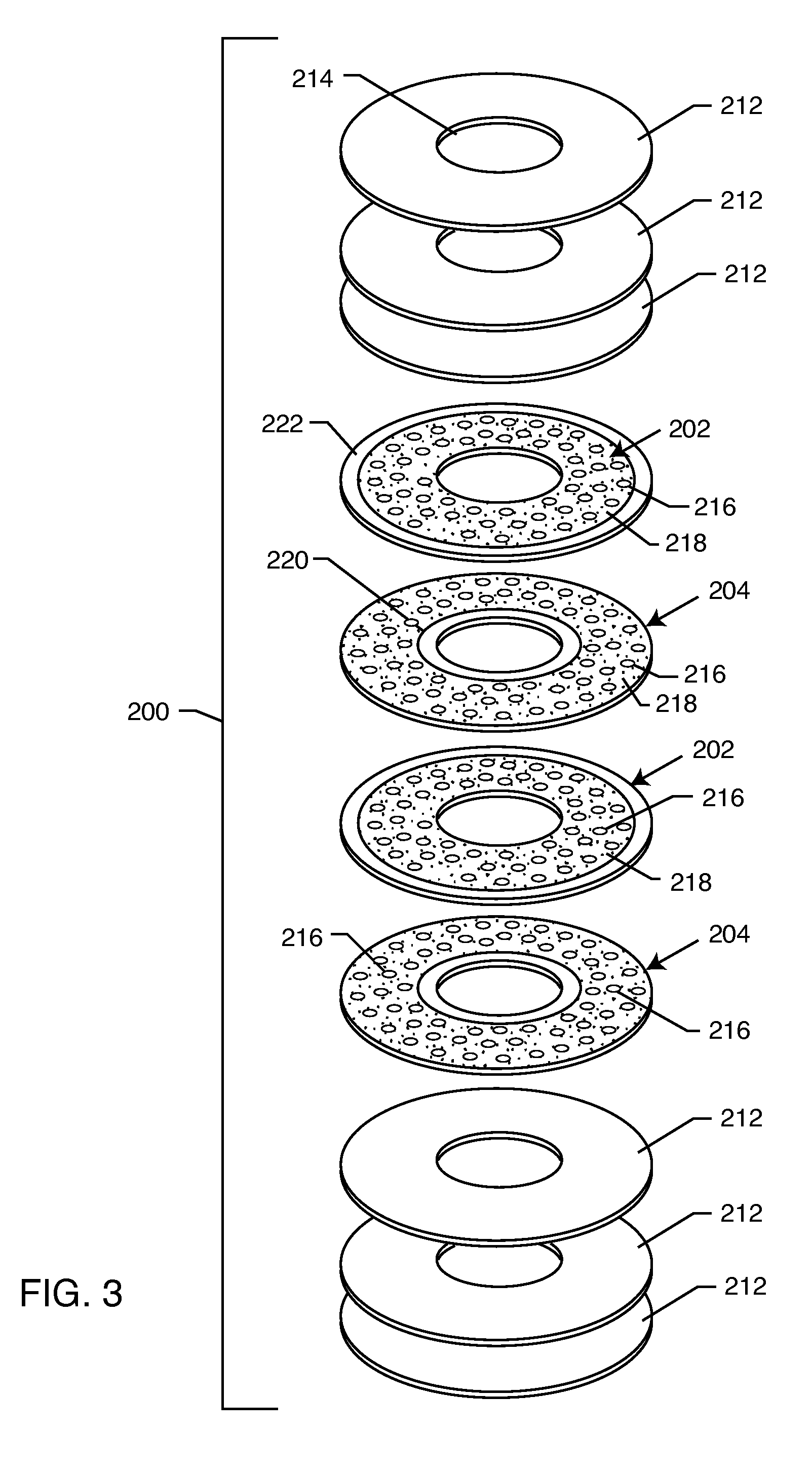

Feedthrough capacitor having reduced self resonance insertion loss dip

InactiveUS7623336B2Capacitor Quality Factor (Q) is relatively minimizedSelf-resonance insertion loss dip of the capacitor is reduced or eliminatedAnti-noise capacitorsElectrotherapySelf resonanceHigh resistivity

The self-resonance insertion loss dip of a feedthrough capacitor is reduced or eliminated by raising the equivalent series resistance of the capacitor, thus minimizing the capacitor Q. The equivalent series resistance of the capacitor can be raised by forming voids in the active and / or ground electrode plates of the capacitor. The electrode plates may be formed so as to have a relatively reduced thickness, or a relatively increased thickness. A conductive material having a relatively high resistivity may be used to form the active and / or ground electrode plates of the capacitor. Alternatively, the conductive material forming the electrode plates may have a dielectric material added thereto.

Owner:WILSON GREATBATCH LTD

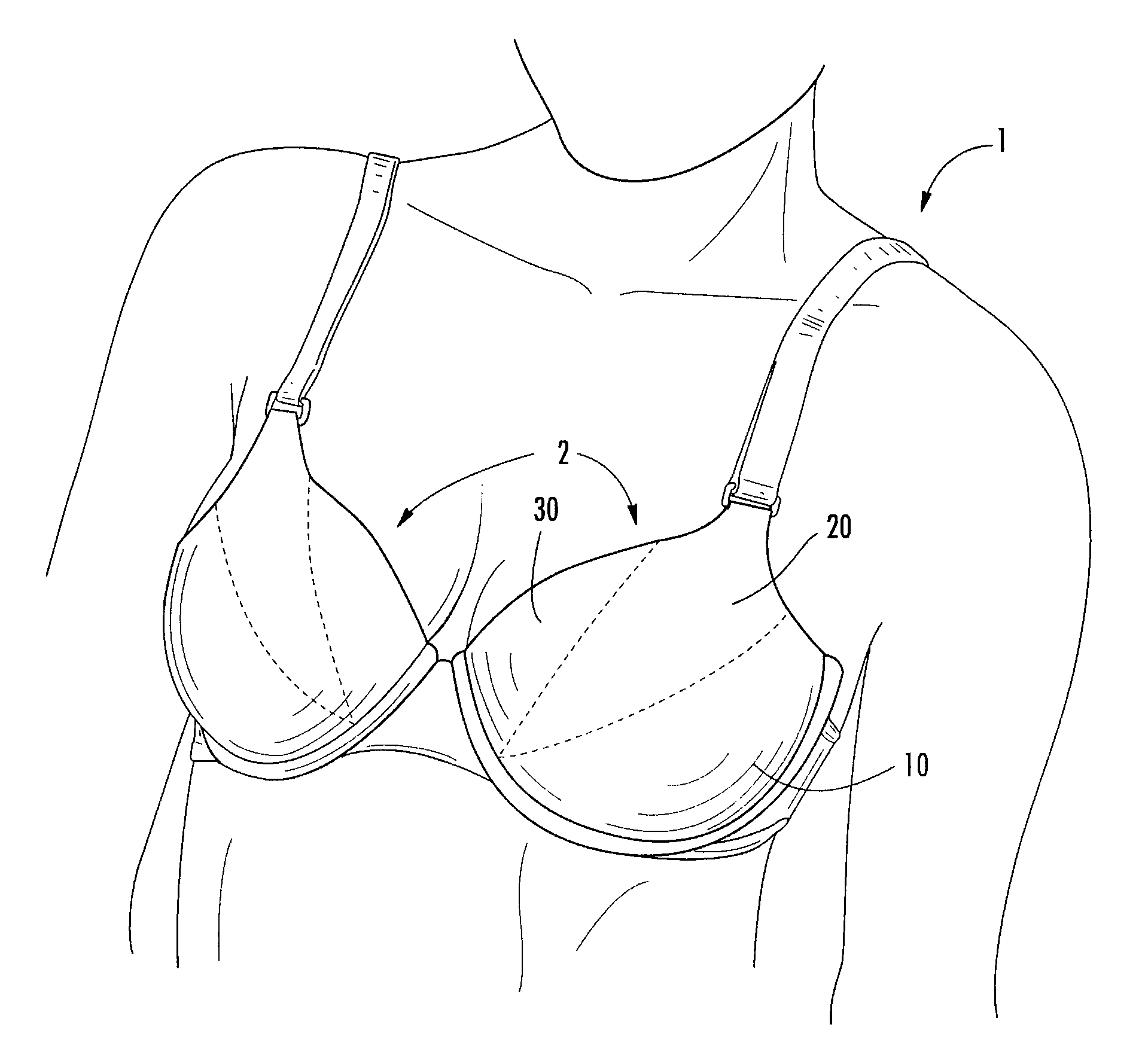

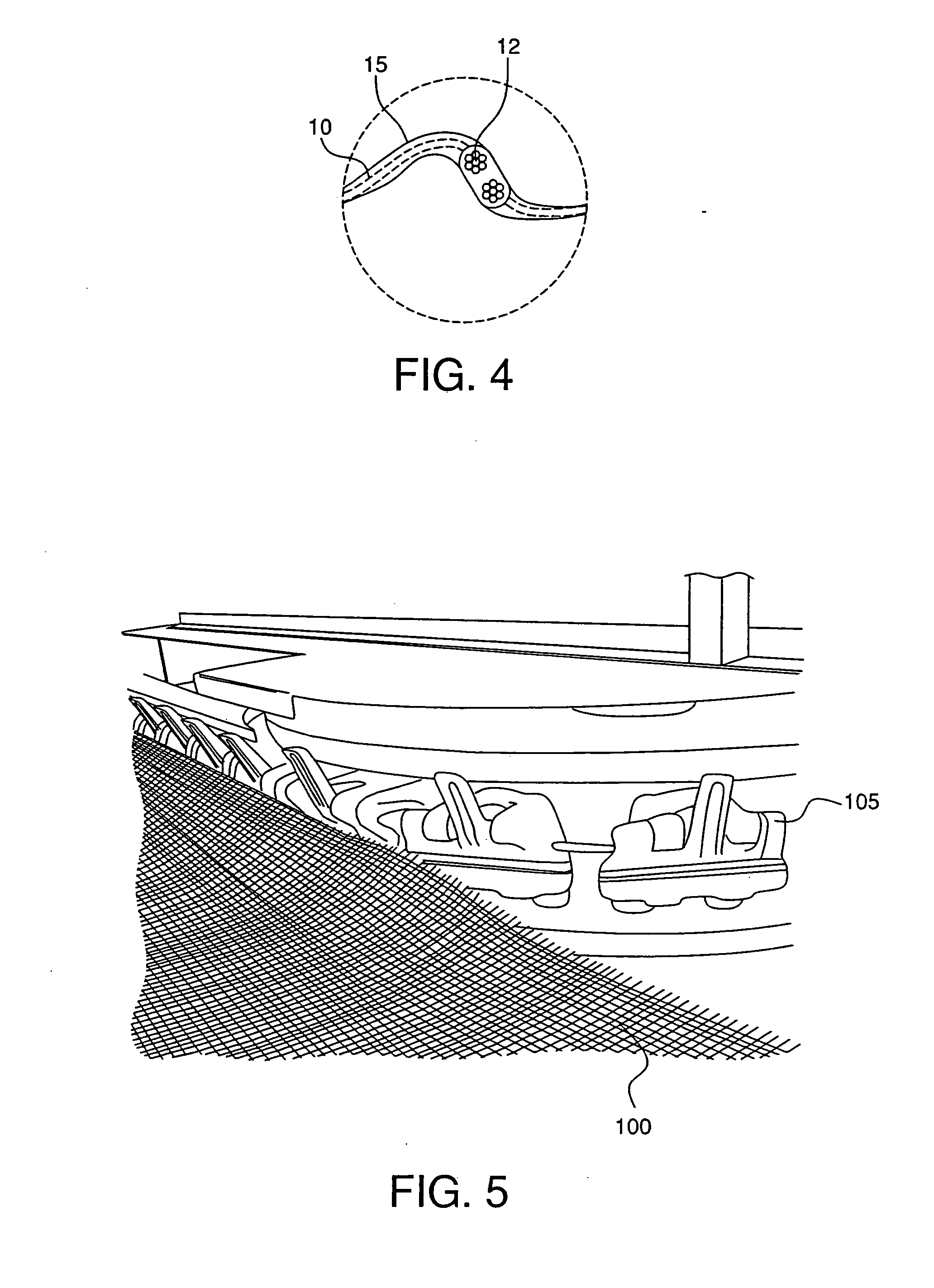

Bra Cup for Augmenting Breasts and Brassiere Having the Same

ActiveUS20100041313A1Convenient to accommodateCharacteristic is differentBrassieresBiomedical engineeringIncreased thickness

A bra cup that supports and augments different areas of the breast. The bra cup includes different sections having different combinations of multilayer fabric and foam materials to create a round, smooth, silhouette underneath the clothing of the wearer without sacrificing the comfort of the wearer or the accuracy of the fit. The bra cup includes two or more discrete sections that are attached together and then covered on an outward facing surface with a continuous foam and fabric layer that provides a smooth outer surface. The first section includes a stabilizer material that creates a sling-like mechanism that causes the first section to cradle the breasts of a wearer, while pushing the breasts simultaneously upwards towards the neckline and inwards towards the other breast. The second section includes an area of increased thickness in a location corresponding to the superior lateral quadrant of the breast. The combination of the stabilizer in the first section and the area of thicker cross section in the second section cooperate to create a rounded overall appearance to the breasts of the wearer. The addition of the continuous foam layer and laminated fabric layer cooperate with the first and second sections in the bra cup to create a round and smooth silhouette underneath the clothing of the wearer.

Owner:MAIDENFORM

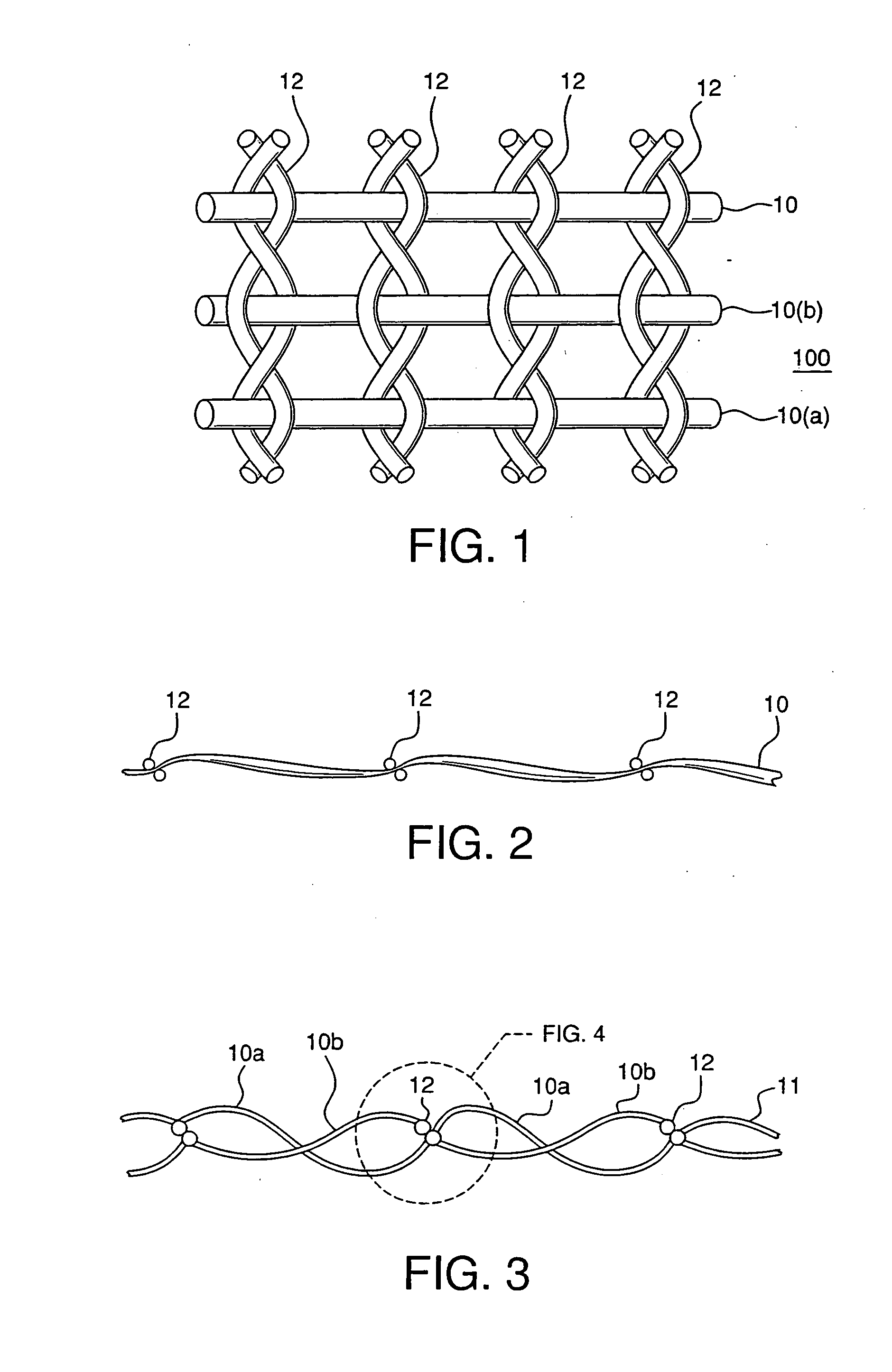

Enhanced thickness fabric and method of making same

ActiveUS20050136758A1Easily penetrate fabricIncreasing the thicknessSynthetic resin layered productsGauze-woven fabricsGlass fiberPolymer resin

The present invention provides thickened fabrics and reinforcements for use as a spacer or reinforcement for a matrix system. The fabric includes in a first embodiment a woven fabric comprising weft and warp yarns containing glass fibers. A portion of the weft yarns are undulated, resulting in an increased thickness for the fabric. The fabric is coated with a polymeric resin or bonding agent, for substantially binding the weft yarns in the undulated condition. This invention also includes methods for making such fabric by increasing the thickness of a woven or non-woven material by such methods as applying tension during weaving operations, or using unbalanced yarns.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com