Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

874 results about "Fibrous layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uveitis is the inflammation of the uvea, the pigmented layer that lies between the inner retina and the outer fibrous layer composed of the sclera and cornea.

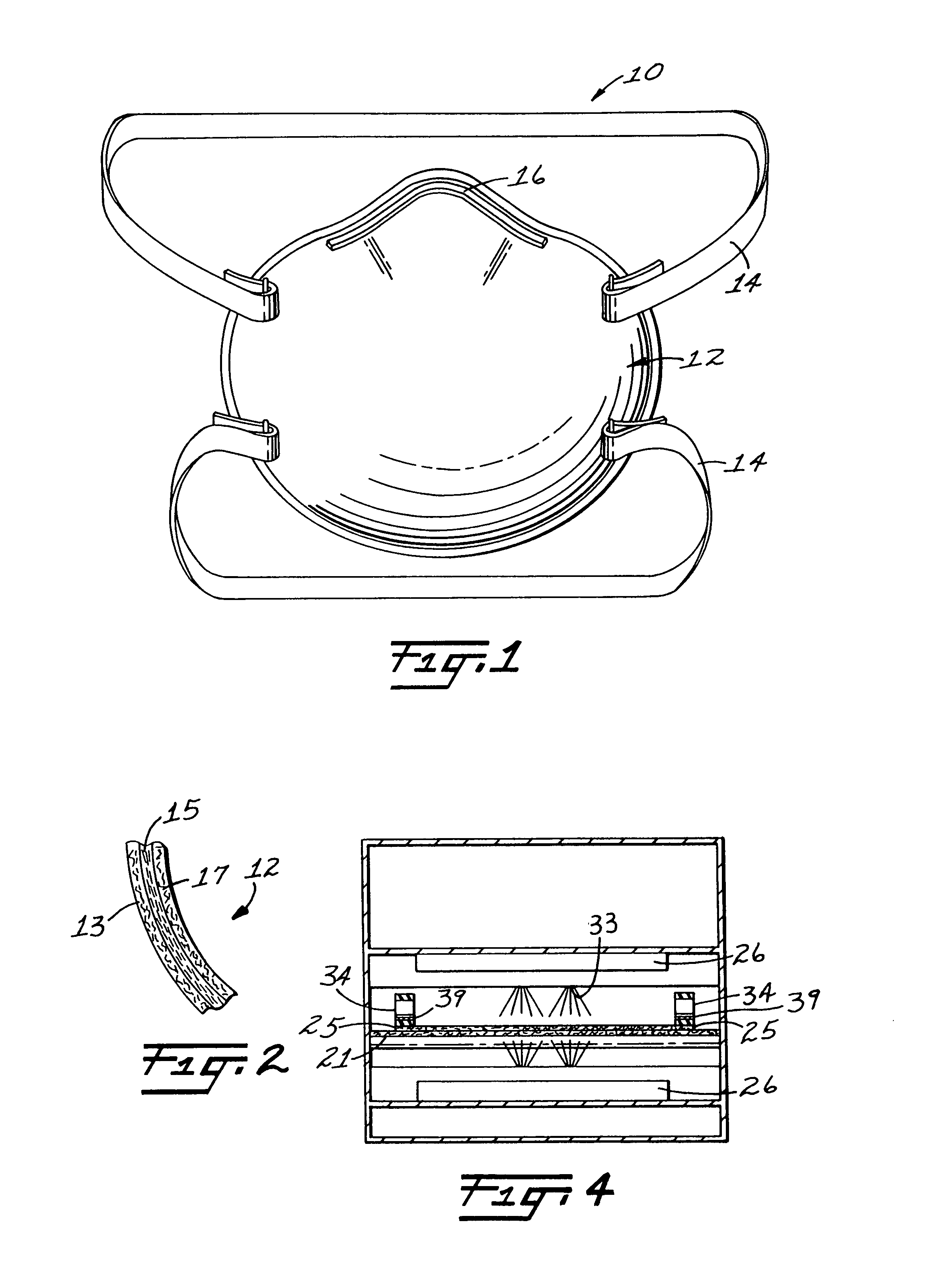

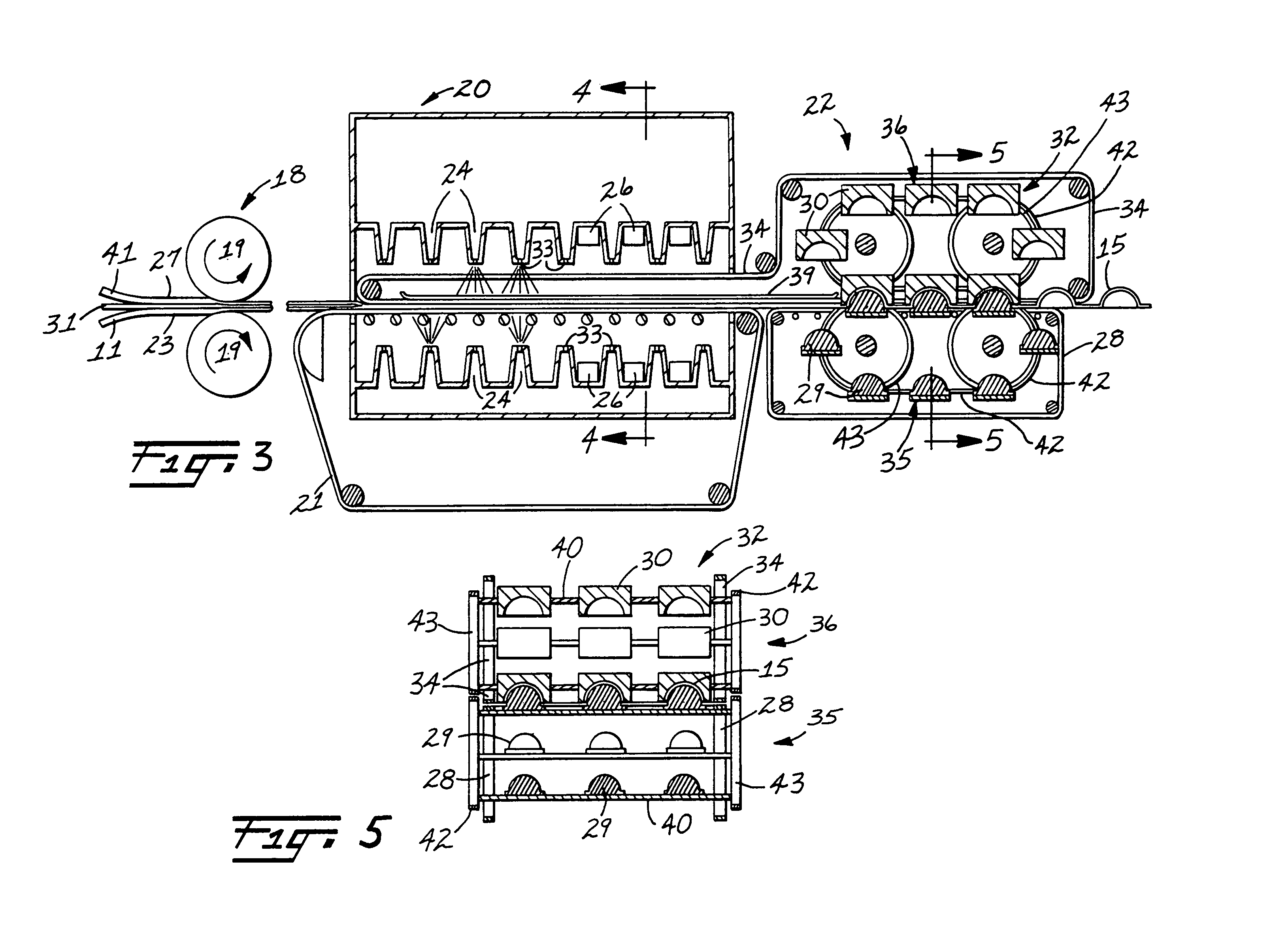

Foam composite for the repair or regeneration of tissue

InactiveUS6306424B1Variable mechanical strengthFacilitate cell migrationPowder deliveryPeptide/protein ingredientsTissue engineeringFibrous layer

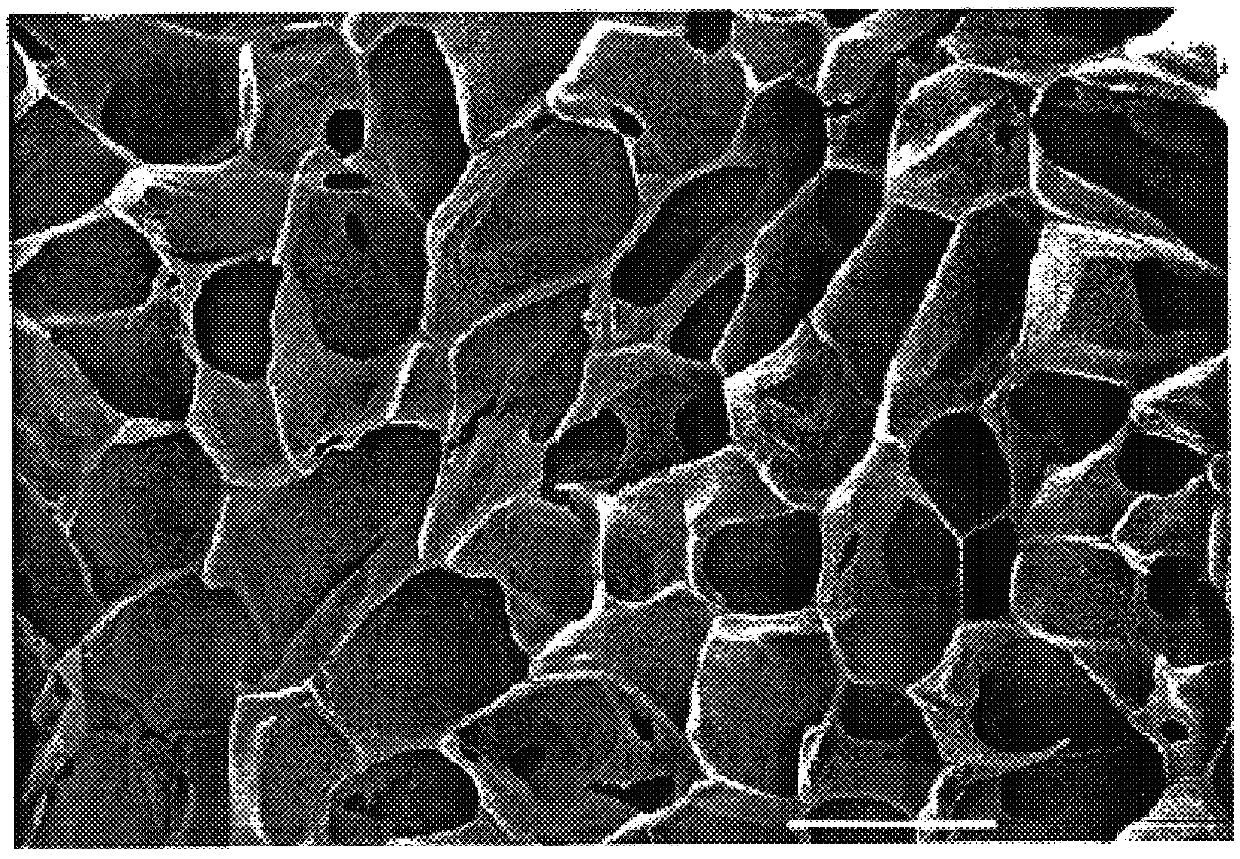

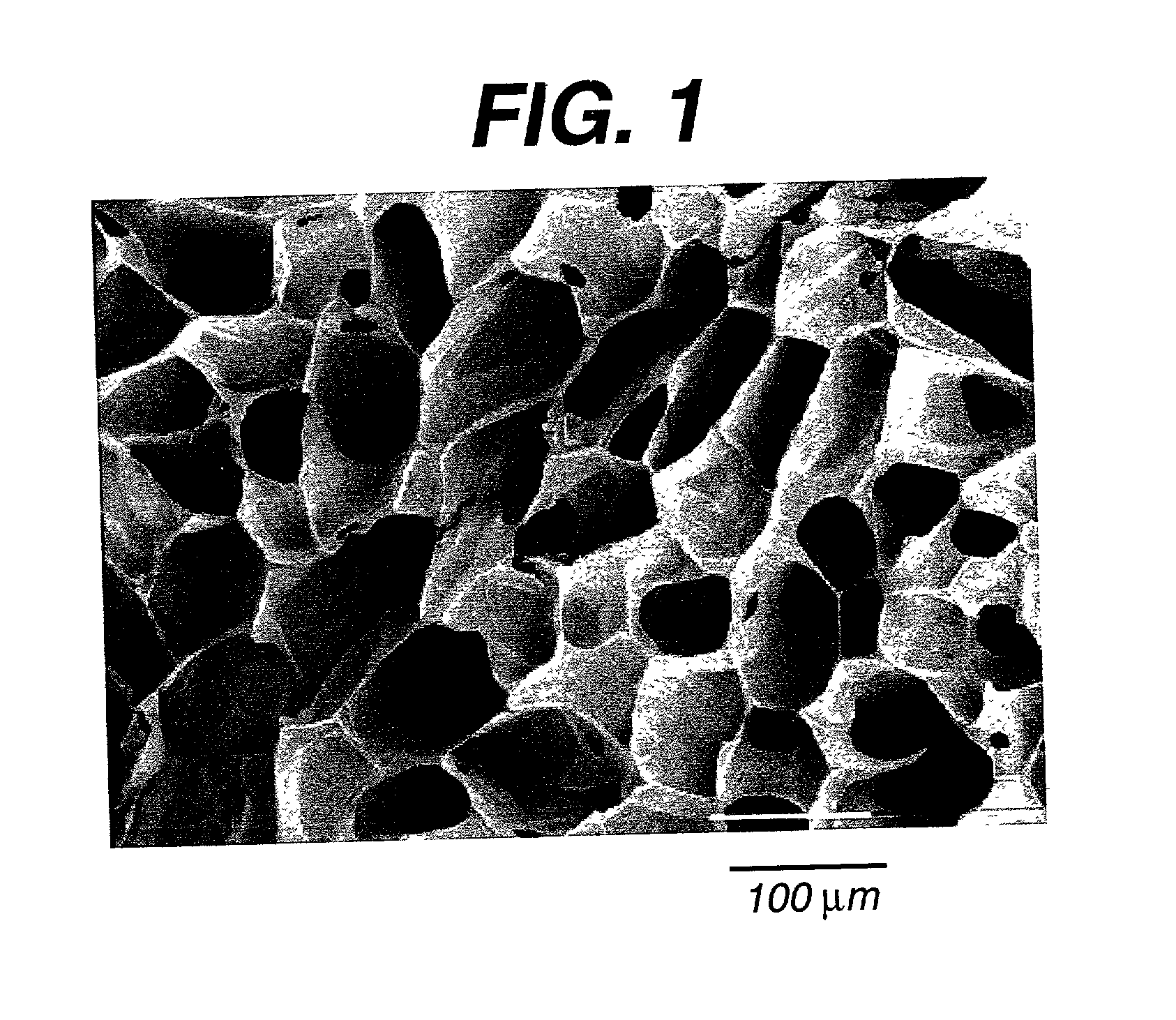

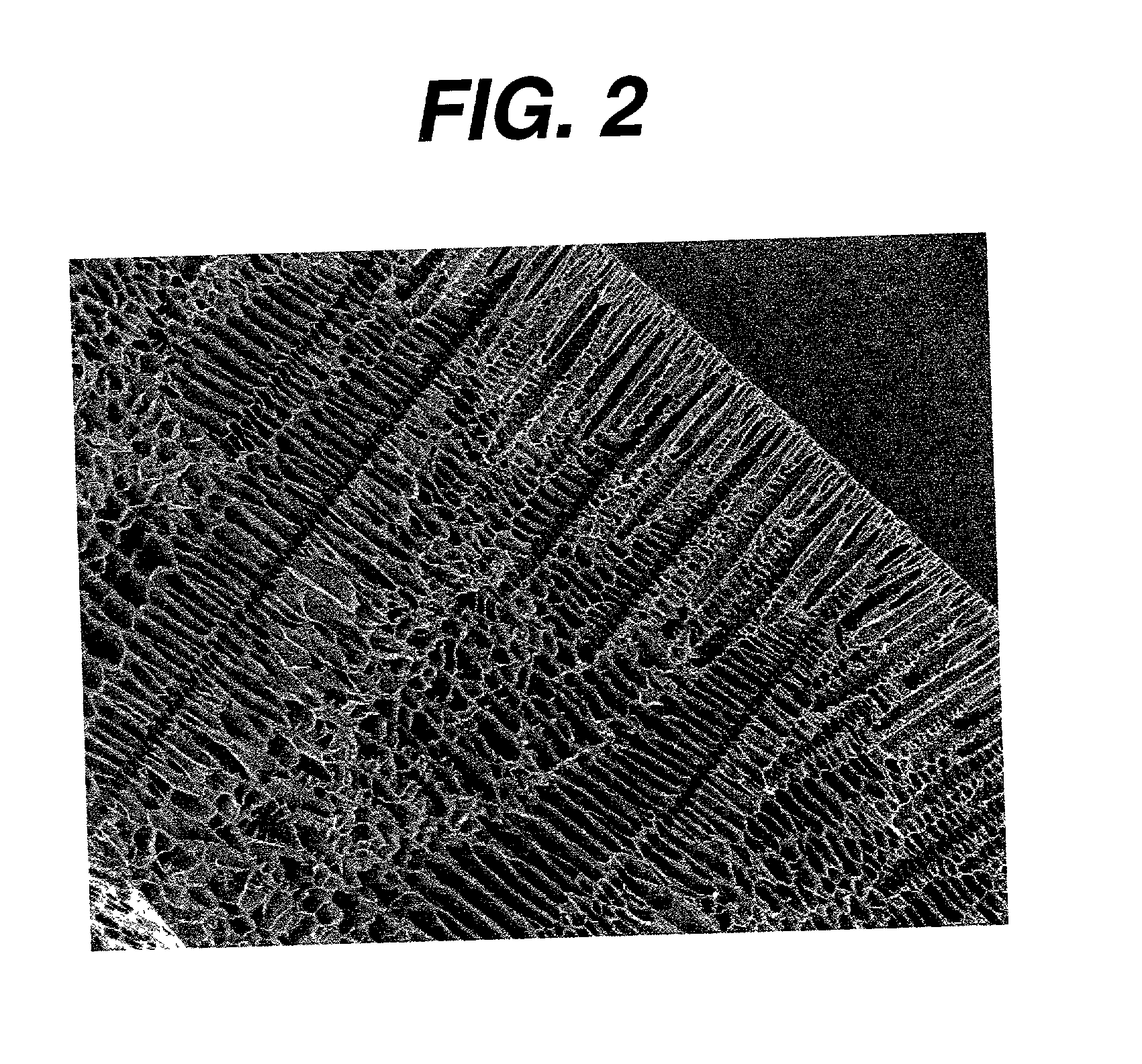

The present patent describes a biocompatible composite made of a first fibrous layer attached to a three-dimensional inter-connected open cell porous foams that have a gradient in composition and / or microstructure through one or more directions. These composites can be made from blends of absorbable and biocompatible polymers. These biocompatible composites are particularly well suited to tissue engineering applications and can be designed to mimic tissue transition or interface zones.

Owner:ETHICON ENDO SURGERY INC

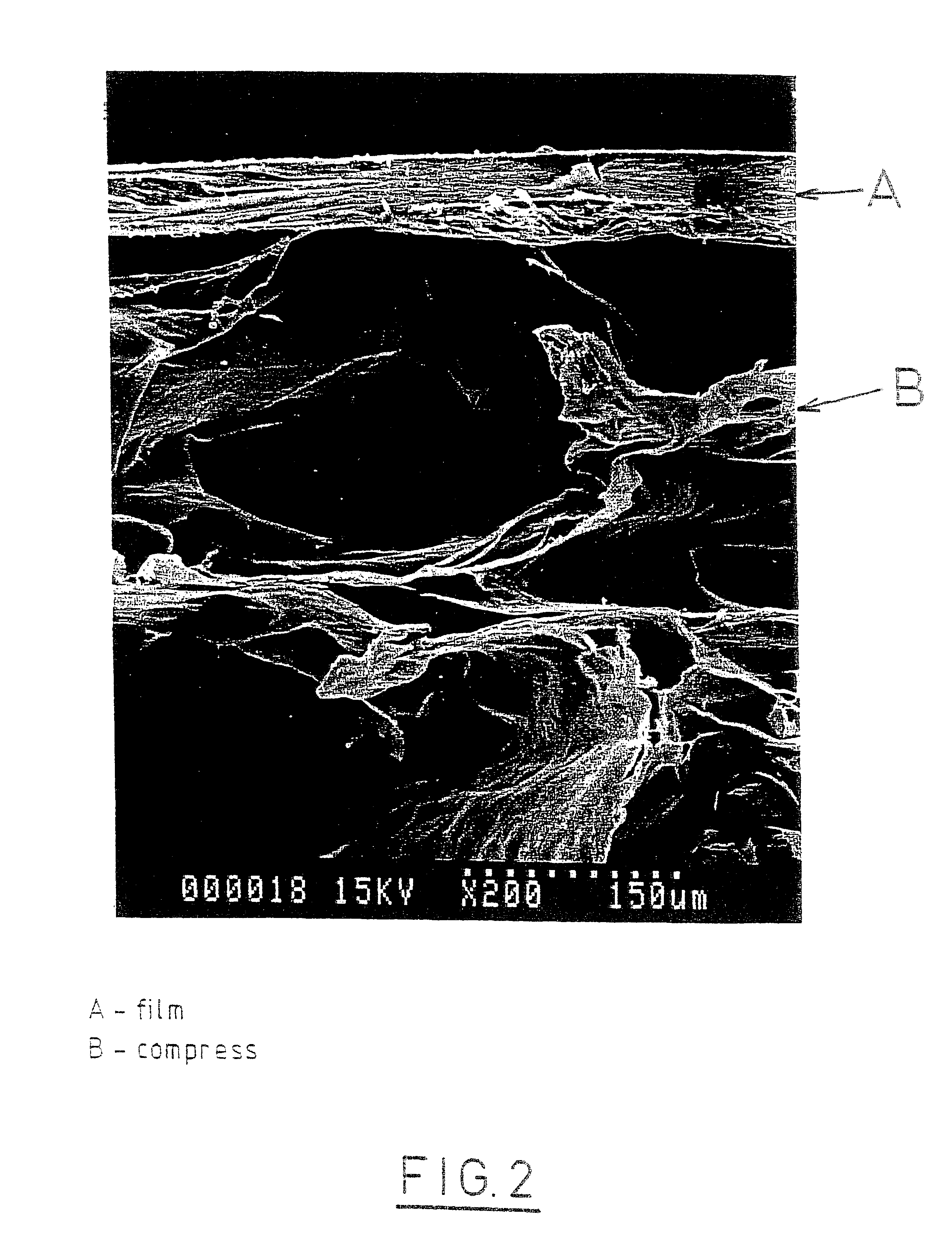

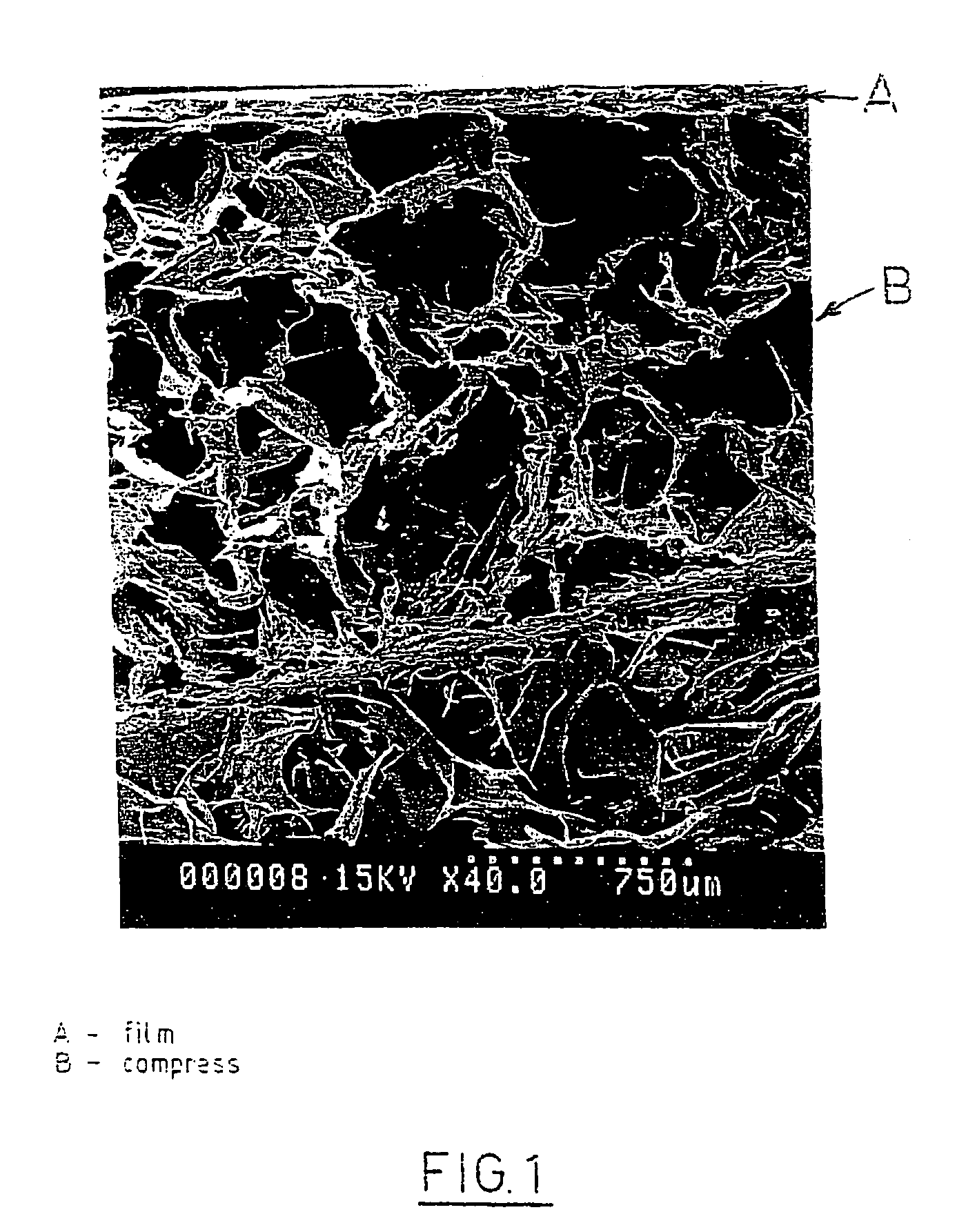

Method for preparing two-layer bicomposite collagen material for preventing post-operative adhesions

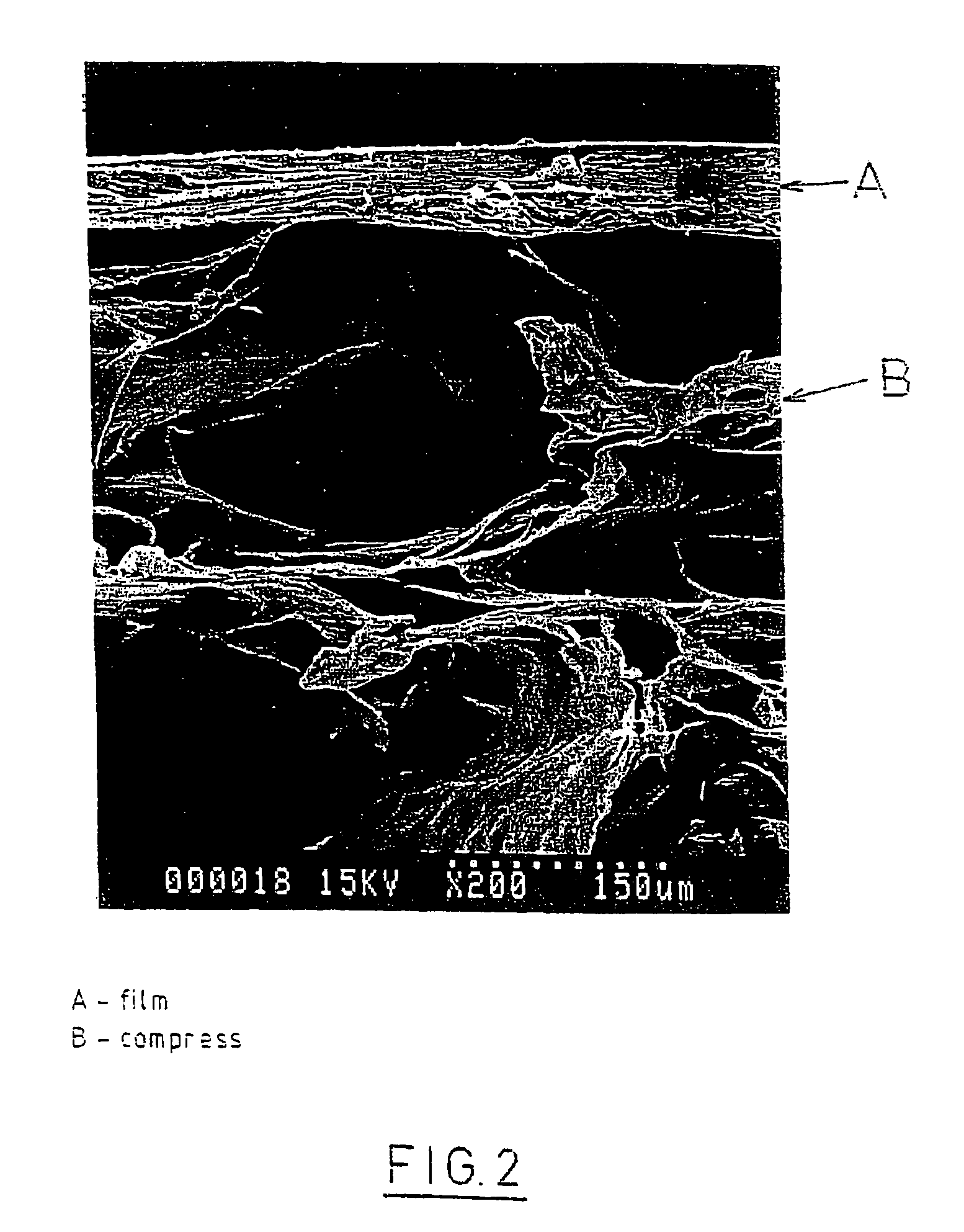

InactiveUS6596304B1Improve propertiesAvoid stickingPeptide/protein ingredientsSurgerySurgical operationPost operative

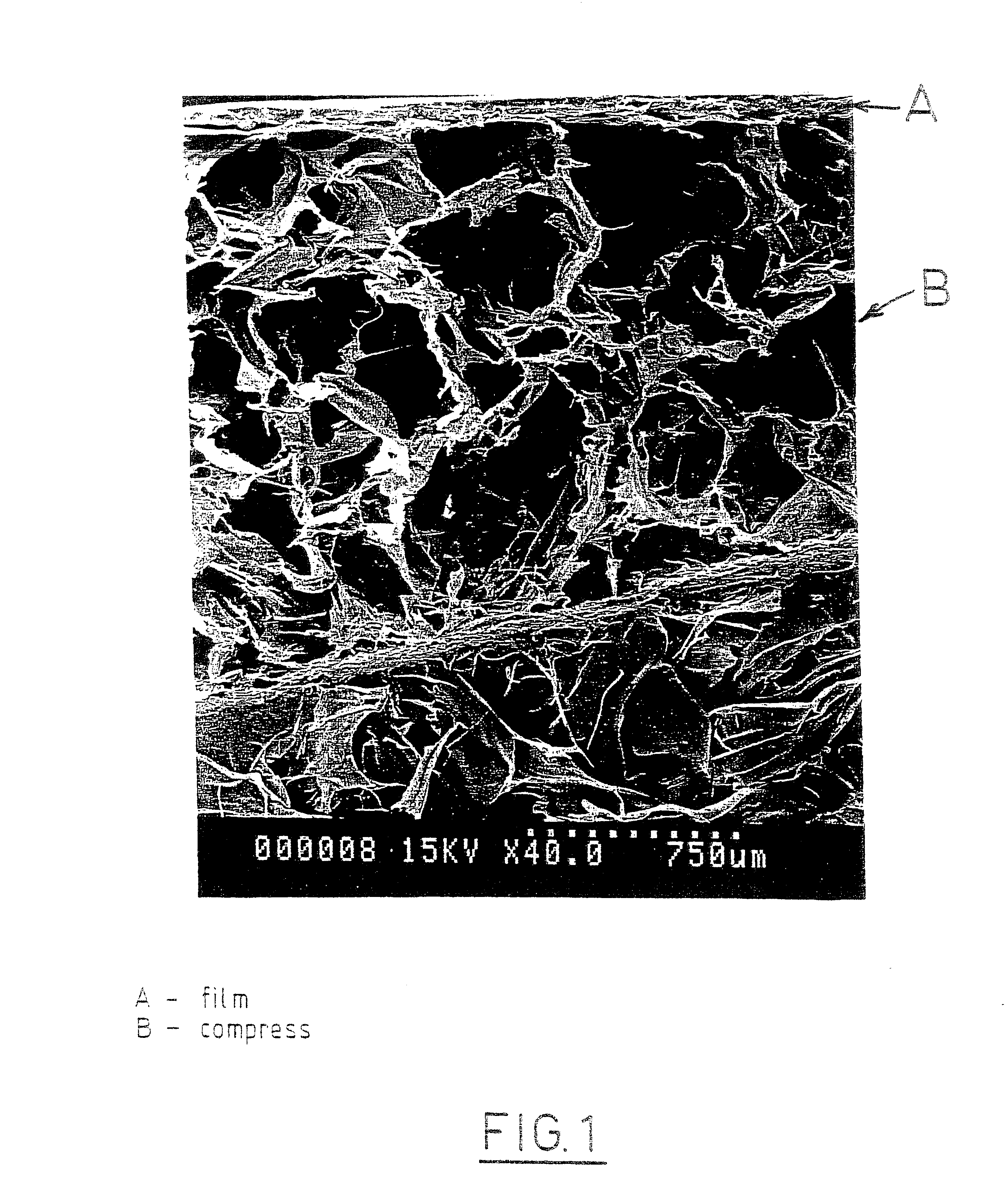

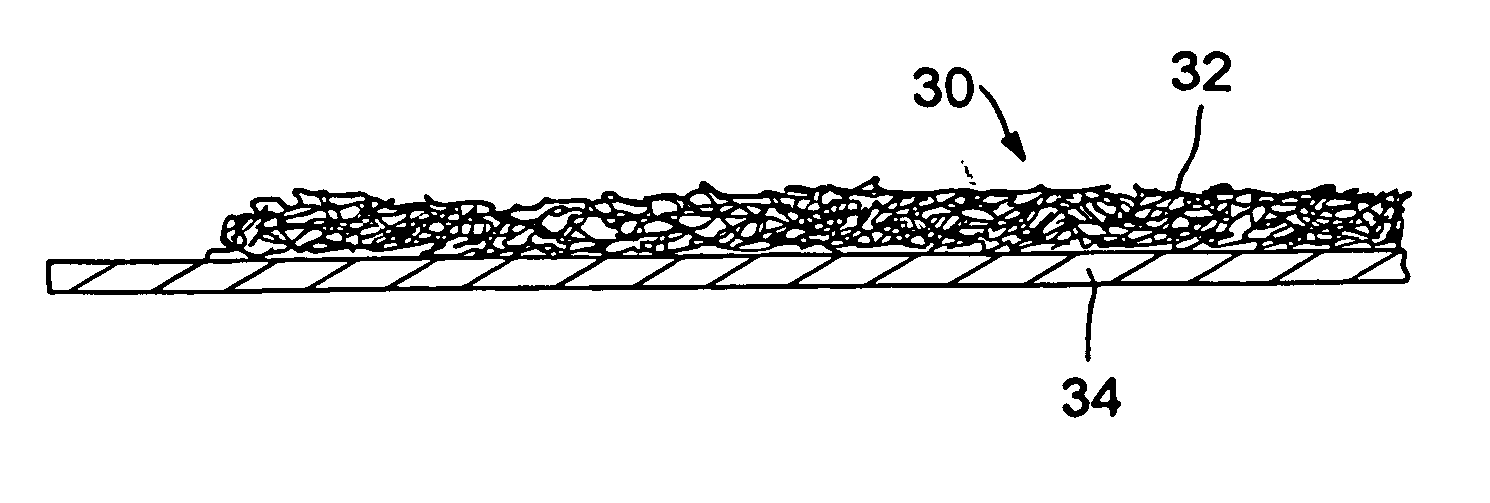

A bicomposite material based on collagen is prepared which has two closely bound layers and is biocompatible, non-toxic, hemostatic and biodegradable in less than a month, and can be used in surgery to achieve hemostasis and prevent post-surgical adhesion. To prepare the material, a solution of collagen or gelatin, which may contain glycerine and a hydrophilic additive such as polyethylene glycol or a polysaccharide, is poured onto an inert support to form a layer 30 .mu.m to less than 100 .mu.m thick. Then a polymeric porous fibrous layer is applied during gelling of the collagen or gelatin, and the resultant material is dried. The polymeric porous fibrous layer may be made of collagen or a polysaccharide, and have a density of not more than 75 mg / cm.sup.2, a pore size from 30 .mu.m to 300 .mu.m and a thickness of 0.2 cm to 1.5 cm.

Owner:IMEDEX BIOMATERIAUX CHAPONOST

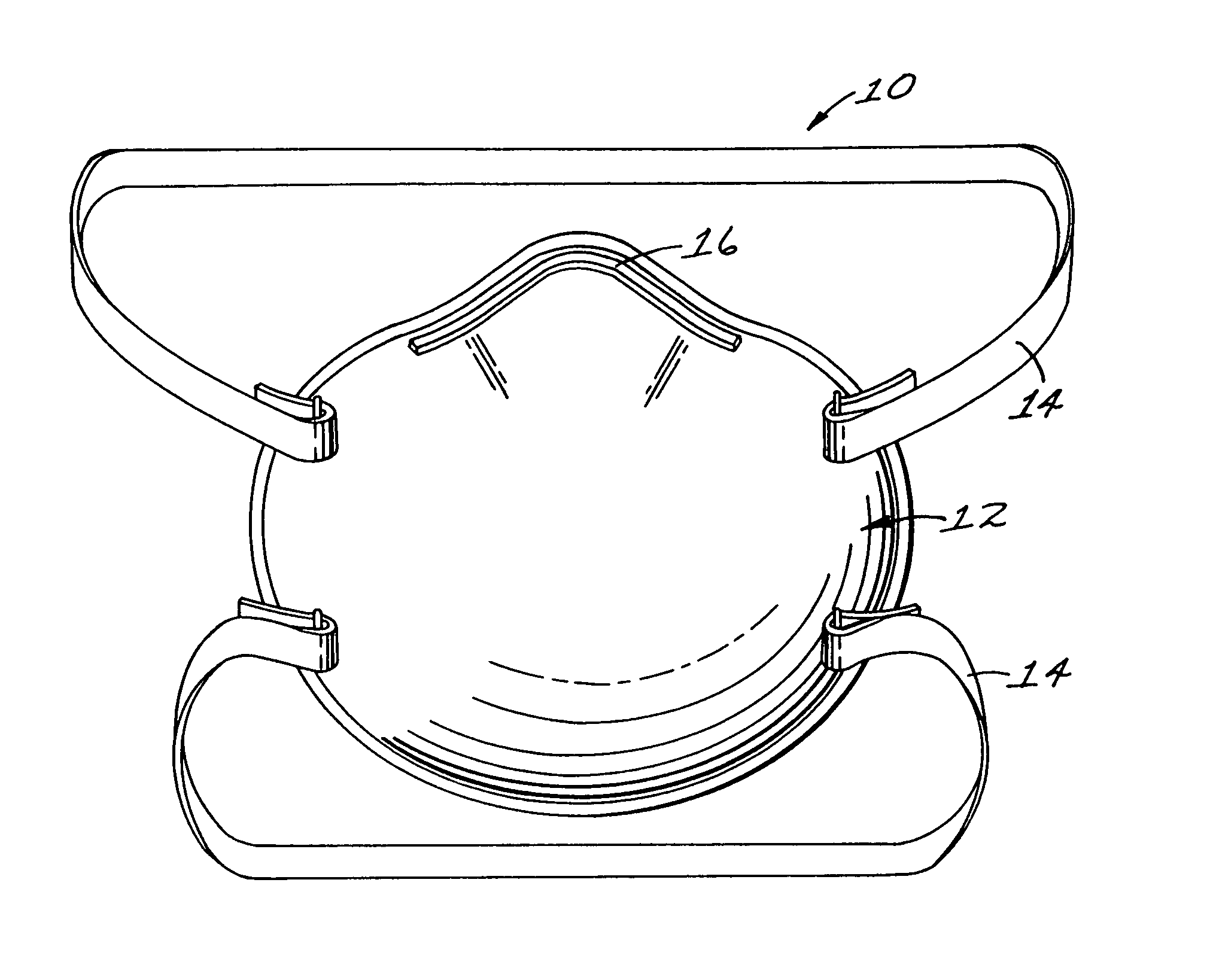

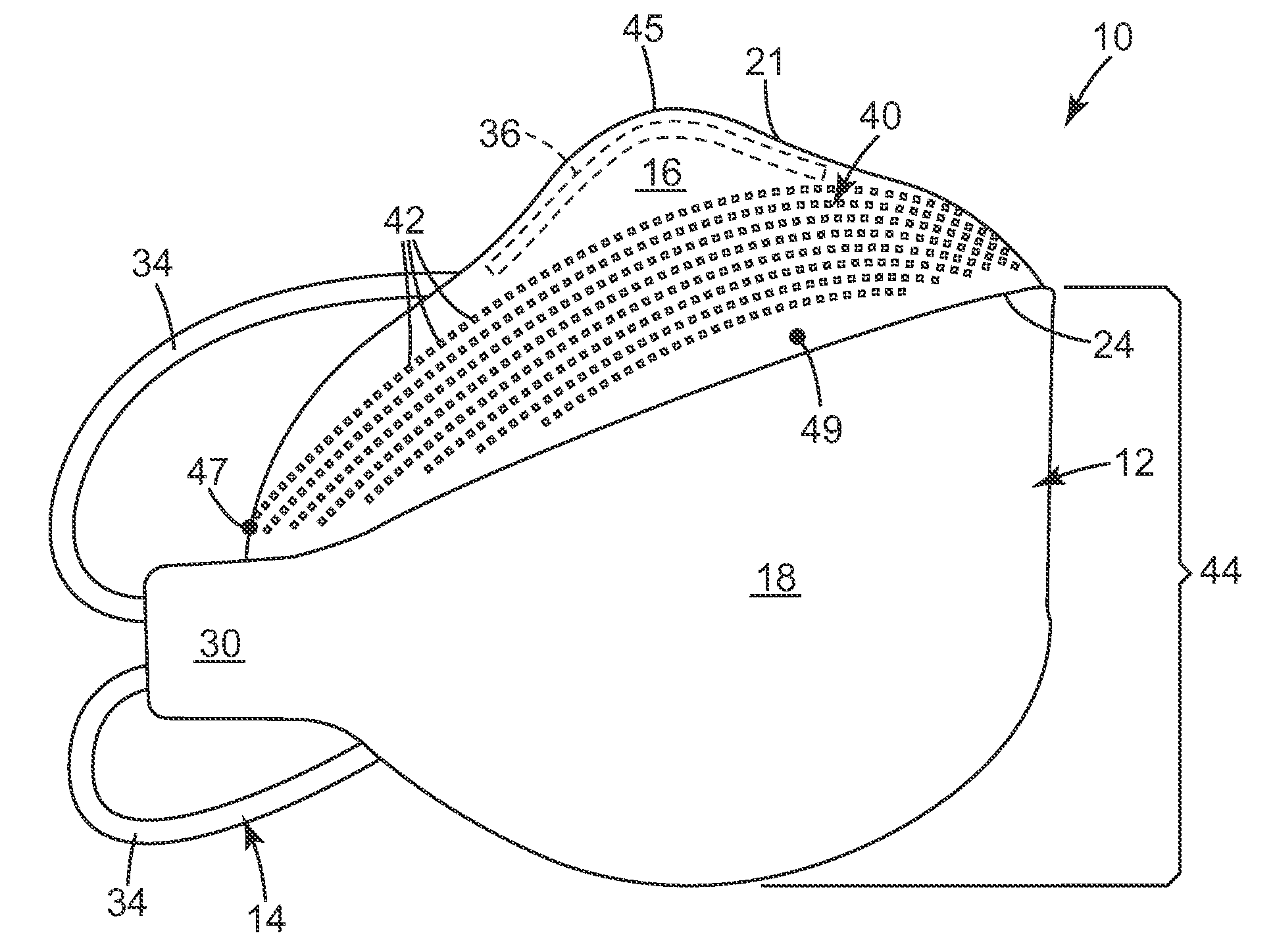

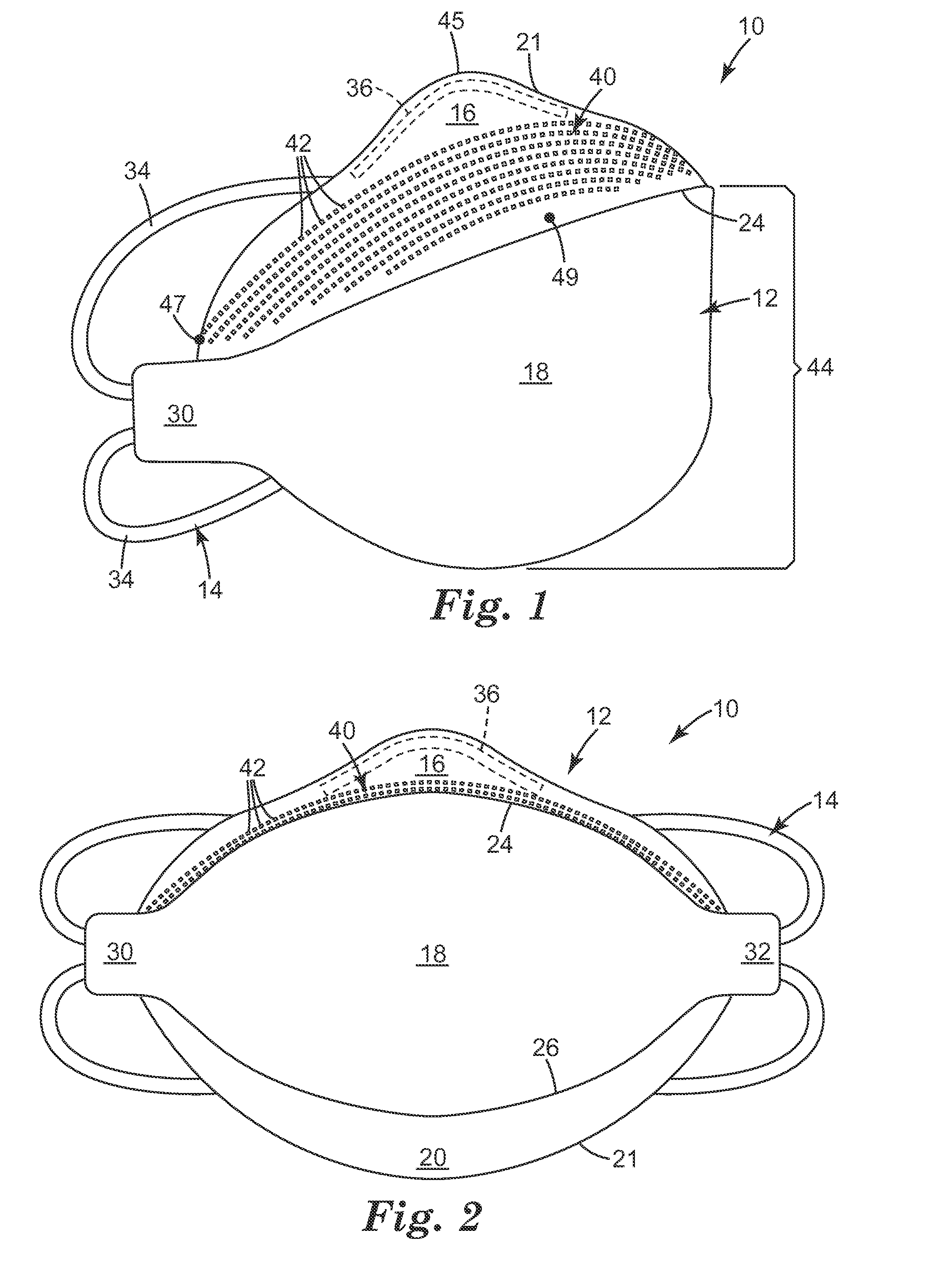

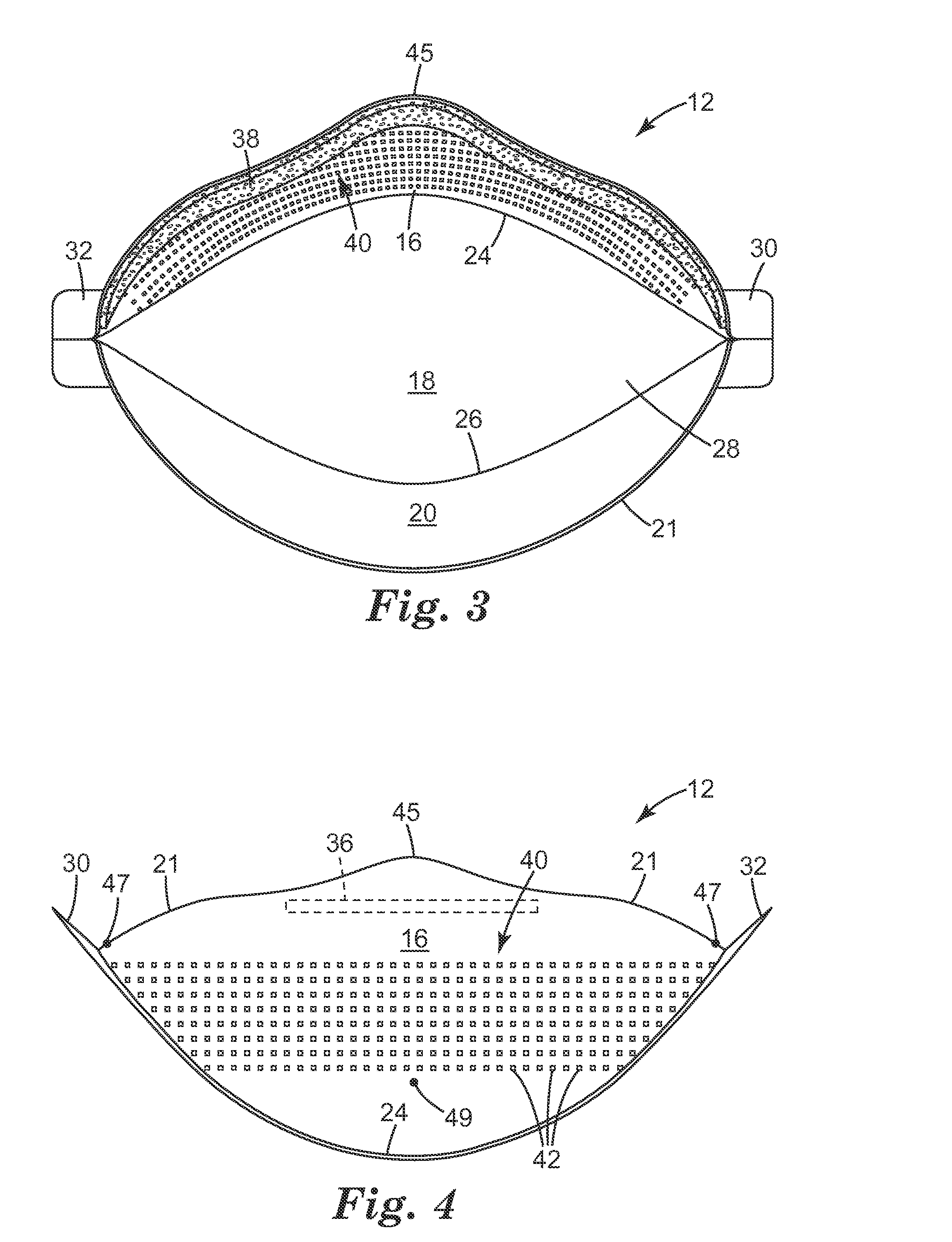

Fibrous filtration face mask

InactiveUS7131442B1Improved surface fuzz propertyReduce creationBreathing filtersBreathing masksPolymer scienceNose

A face mask for filtering contaminants from the air. The face mask includes a harness for securing the mask over the nose and mouth of the wearer and a nonwoven fibrous layer attached to the harness. The nonwoven fibrous layer contains at least 40 weight percent thermally bonding fibers, where at least 10 weight percent of the fibers in the nonwoven fibrous layer are bicomponent fibers. The nonwoven fibrous layer is molded in a cup-shaped configuration and has a surface fuzz value of not less than 7.5 after being subjected to a surface fuzz abrasion test.

Owner:3M CO

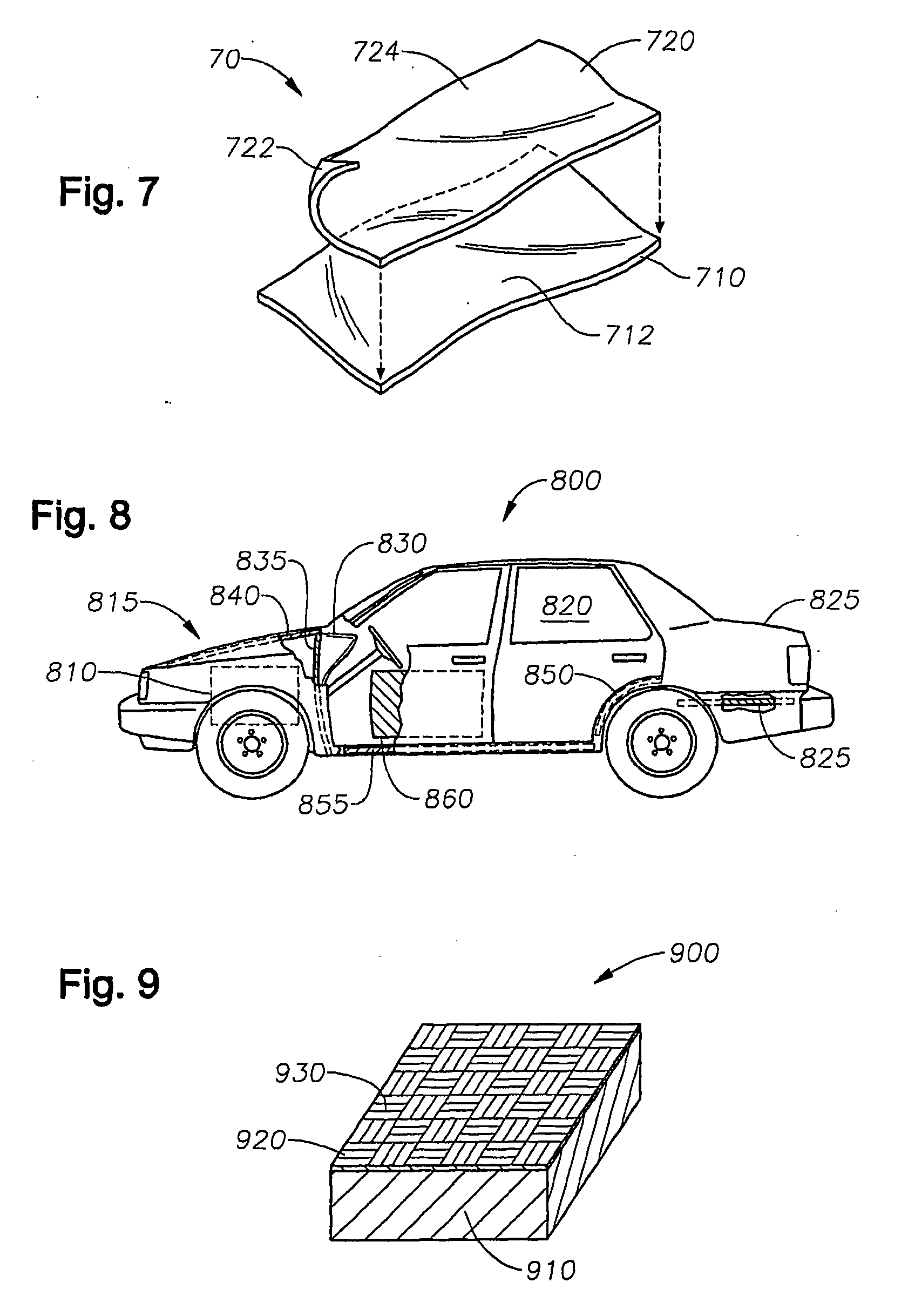

Nonwoven material for acoustic insulation, and process for manufacture

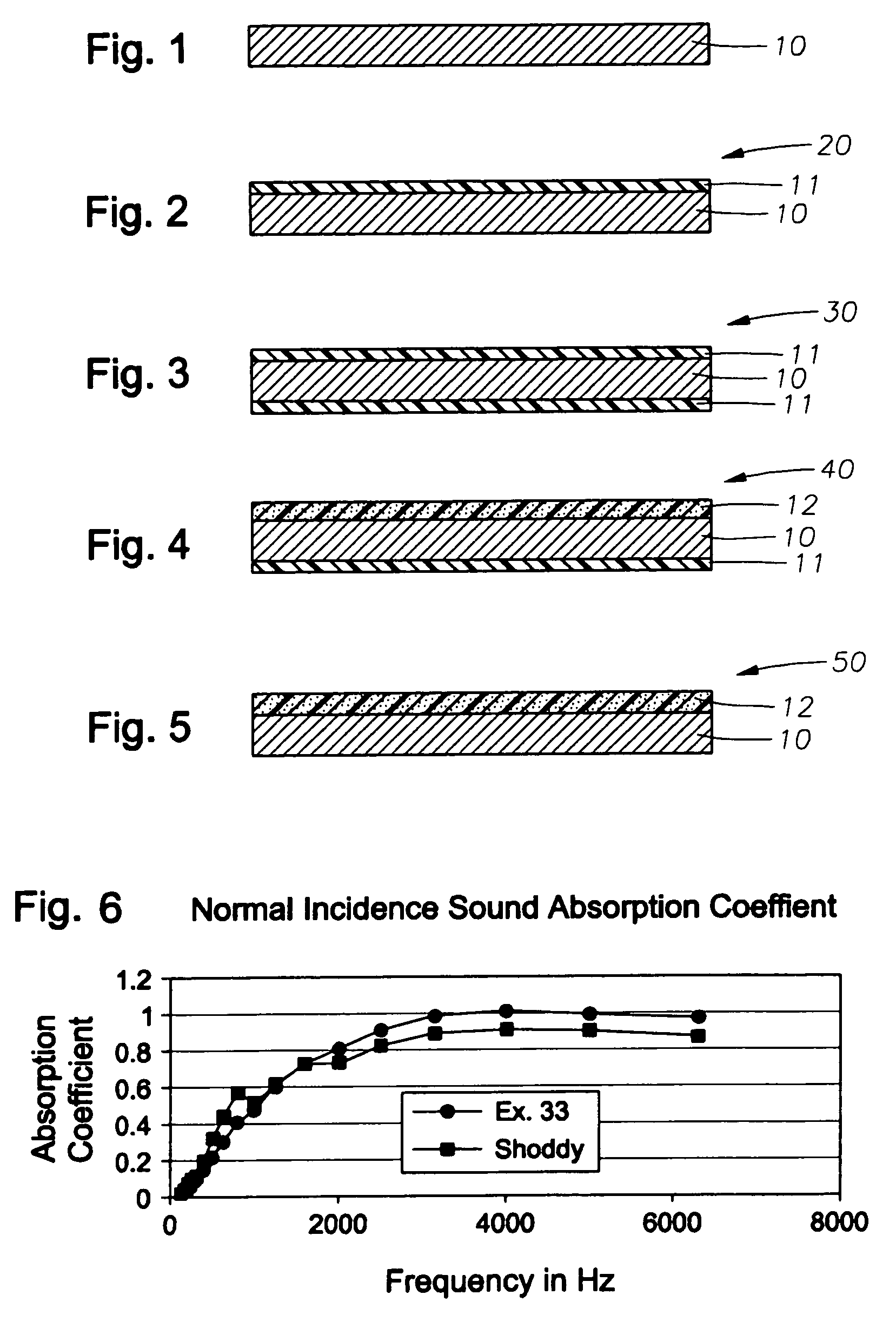

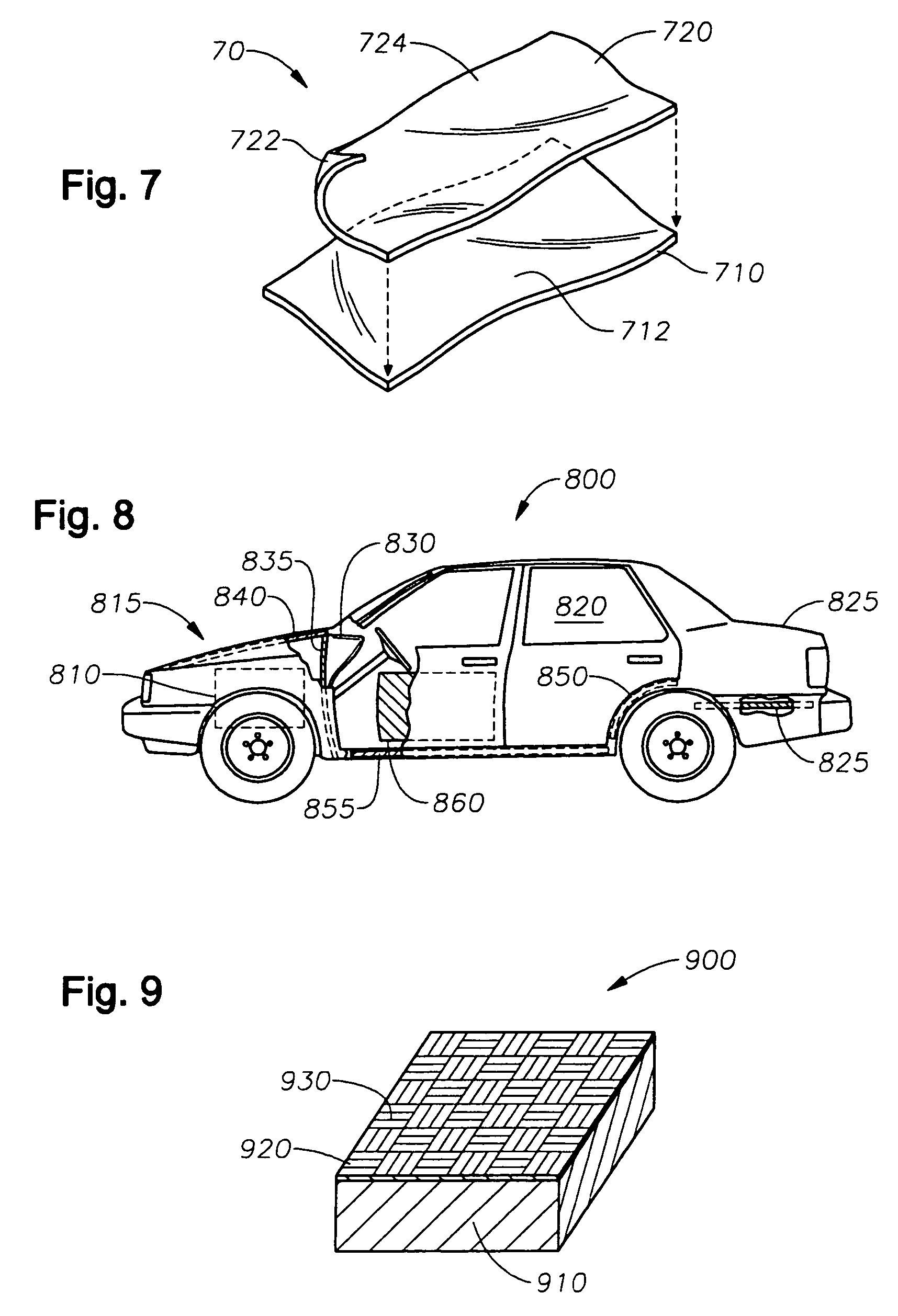

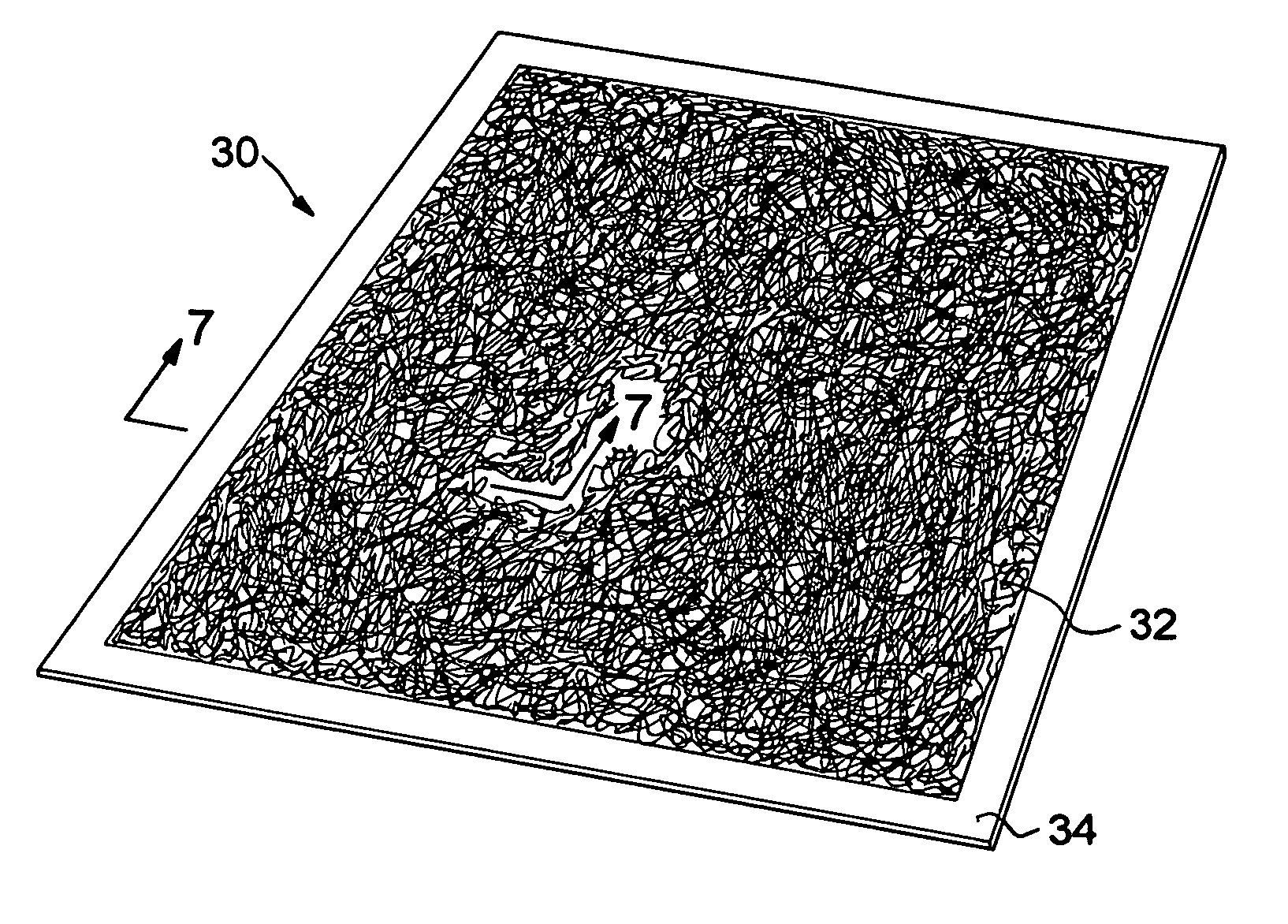

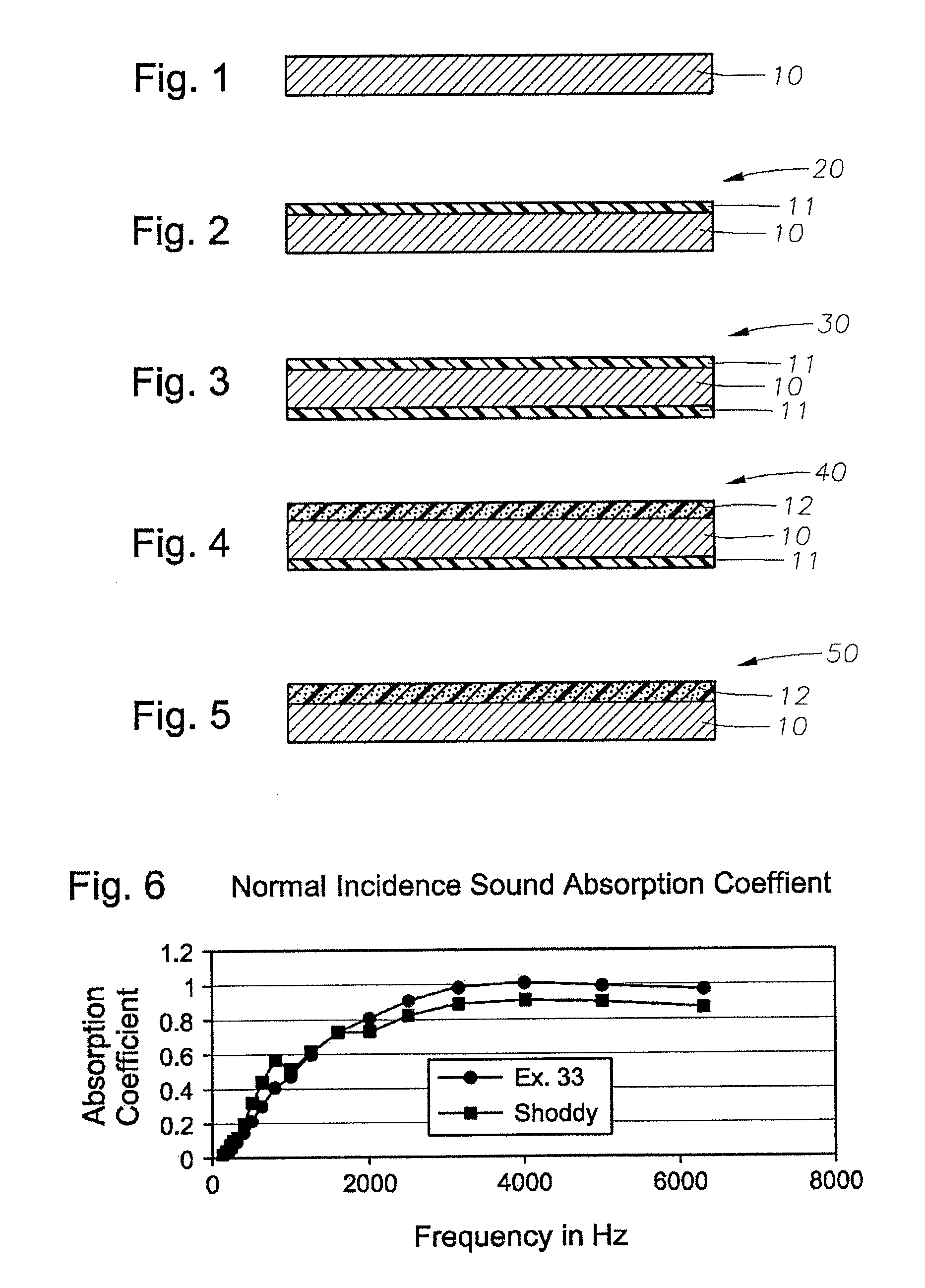

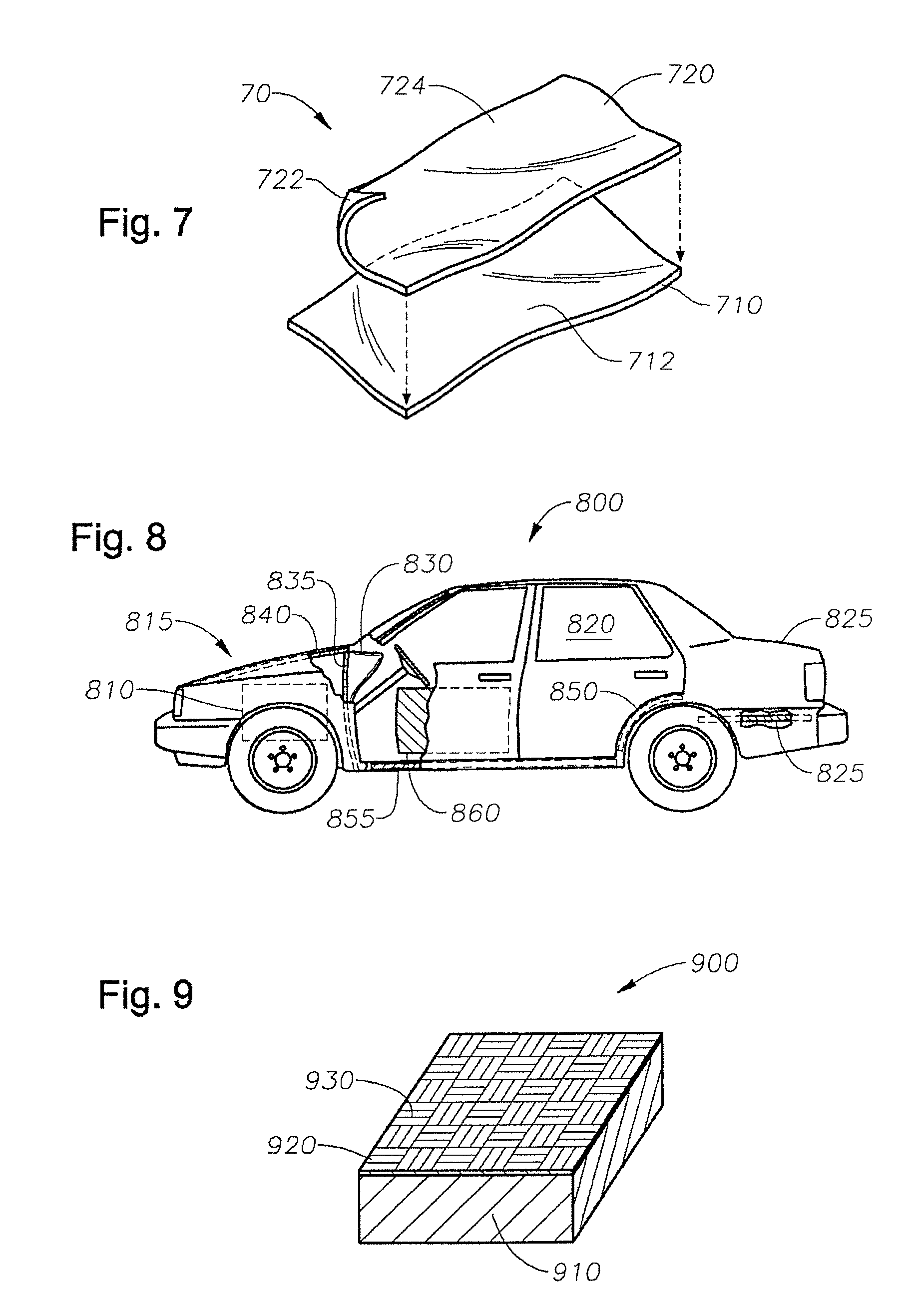

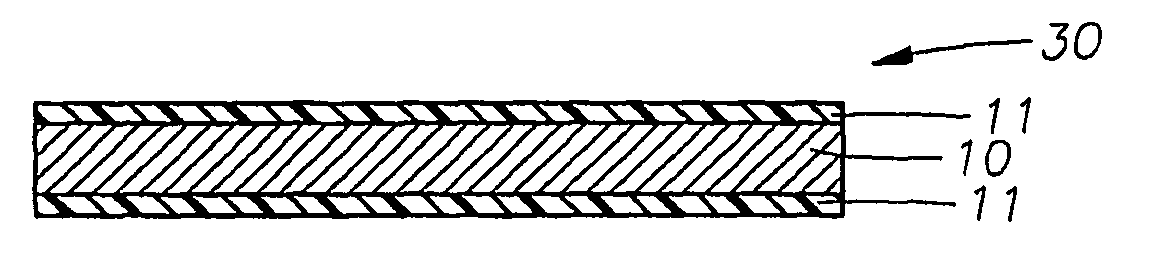

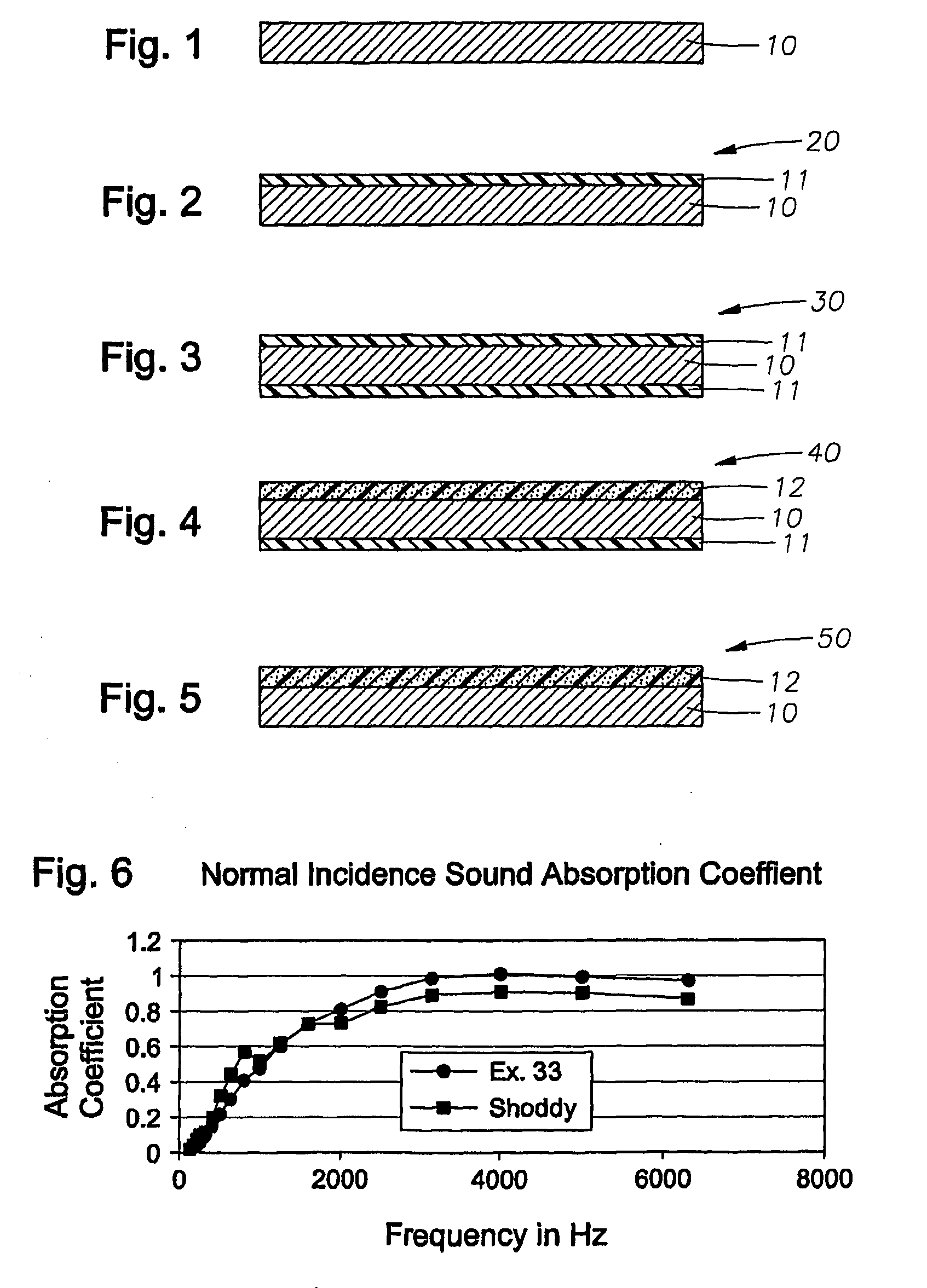

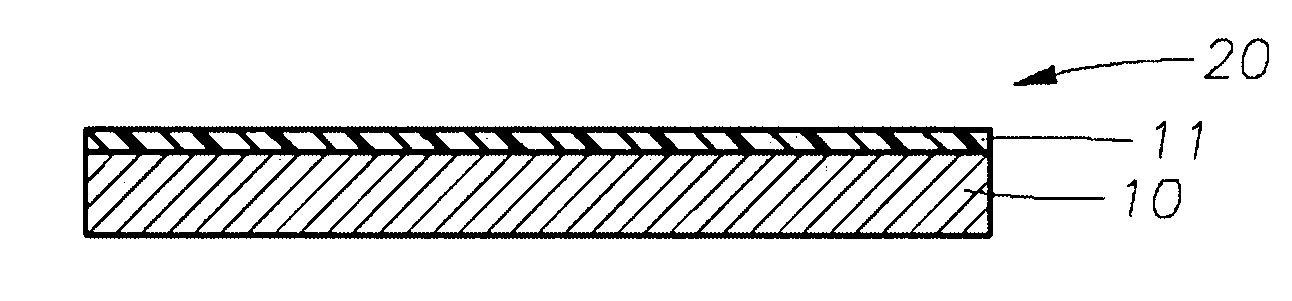

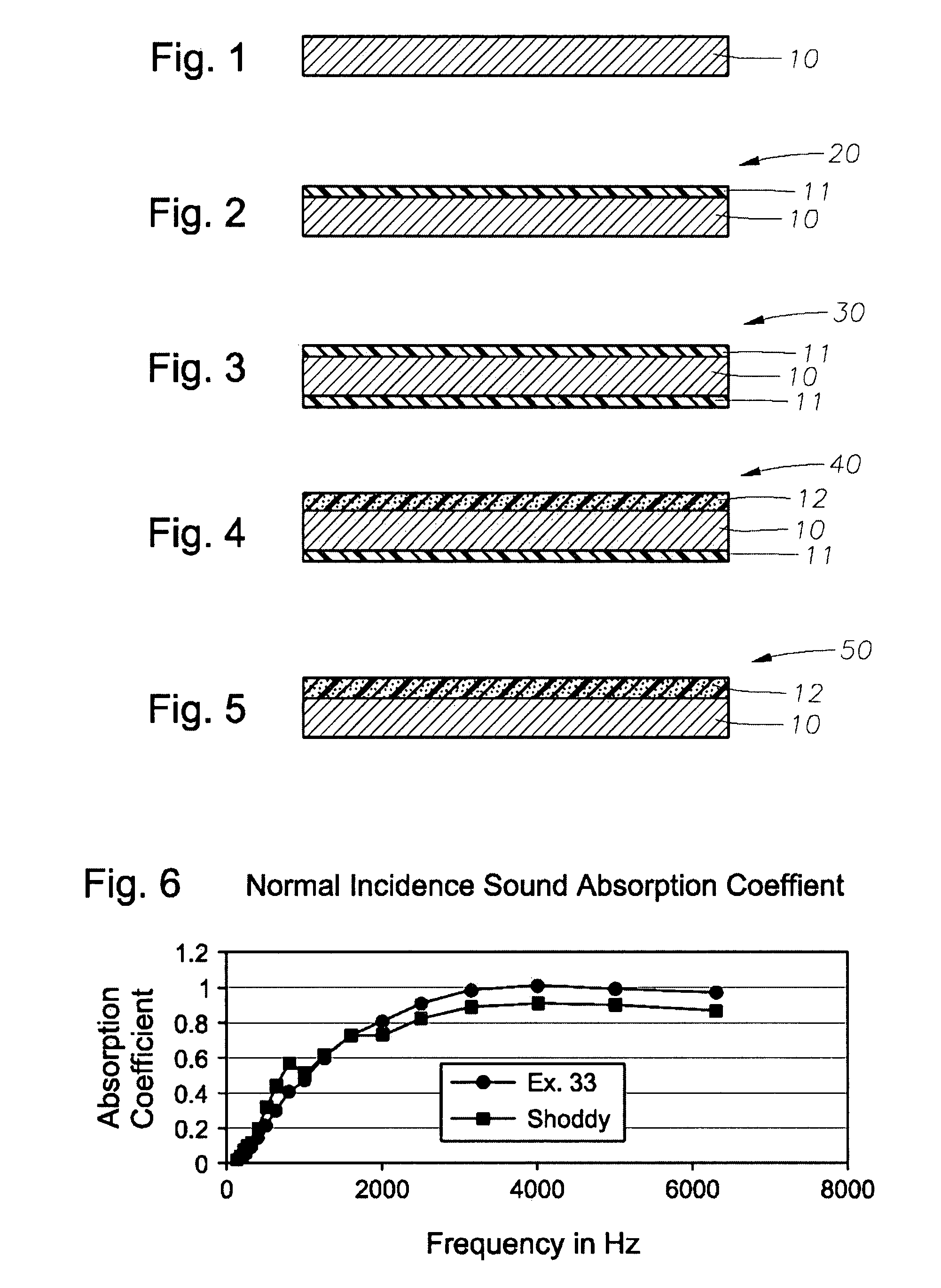

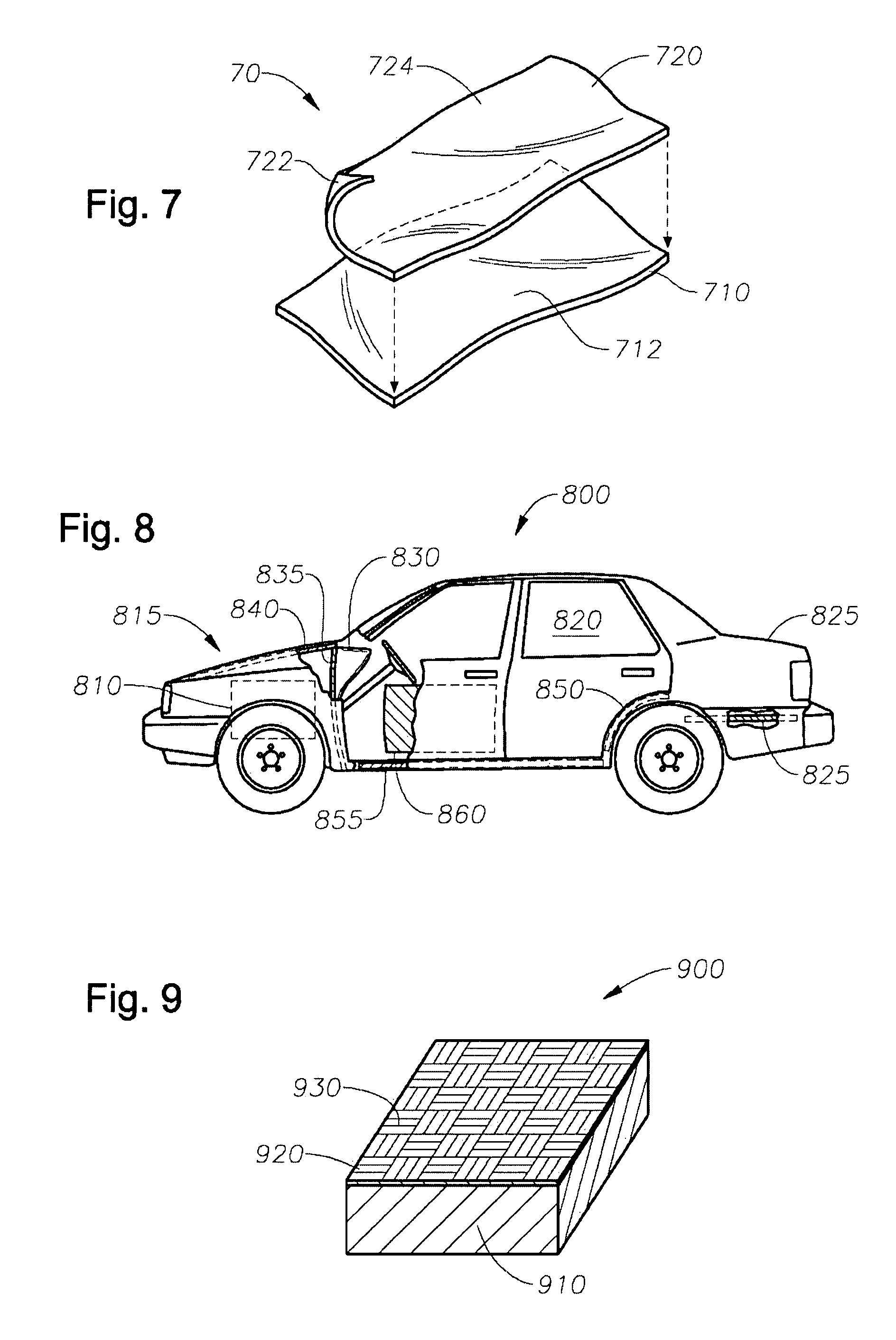

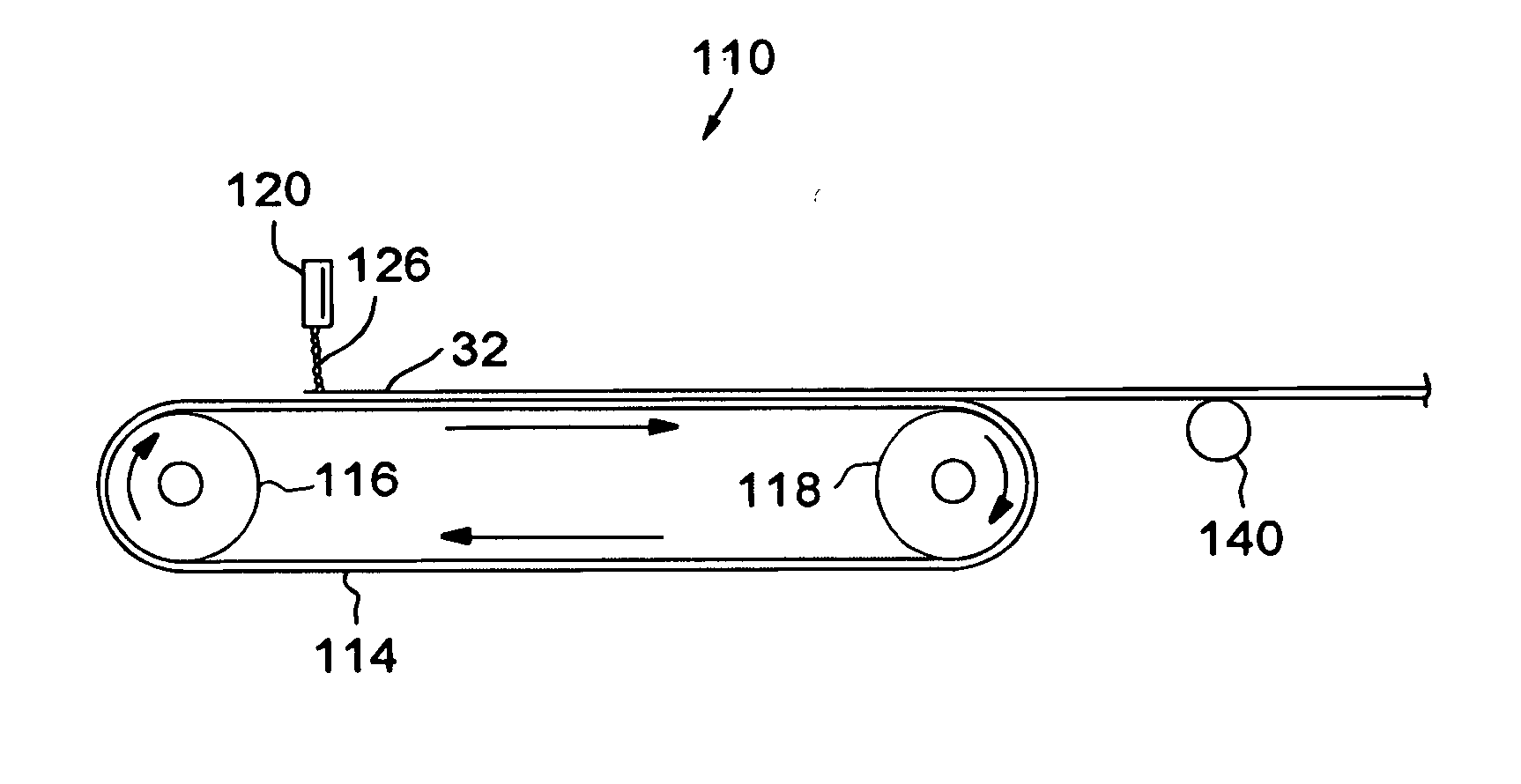

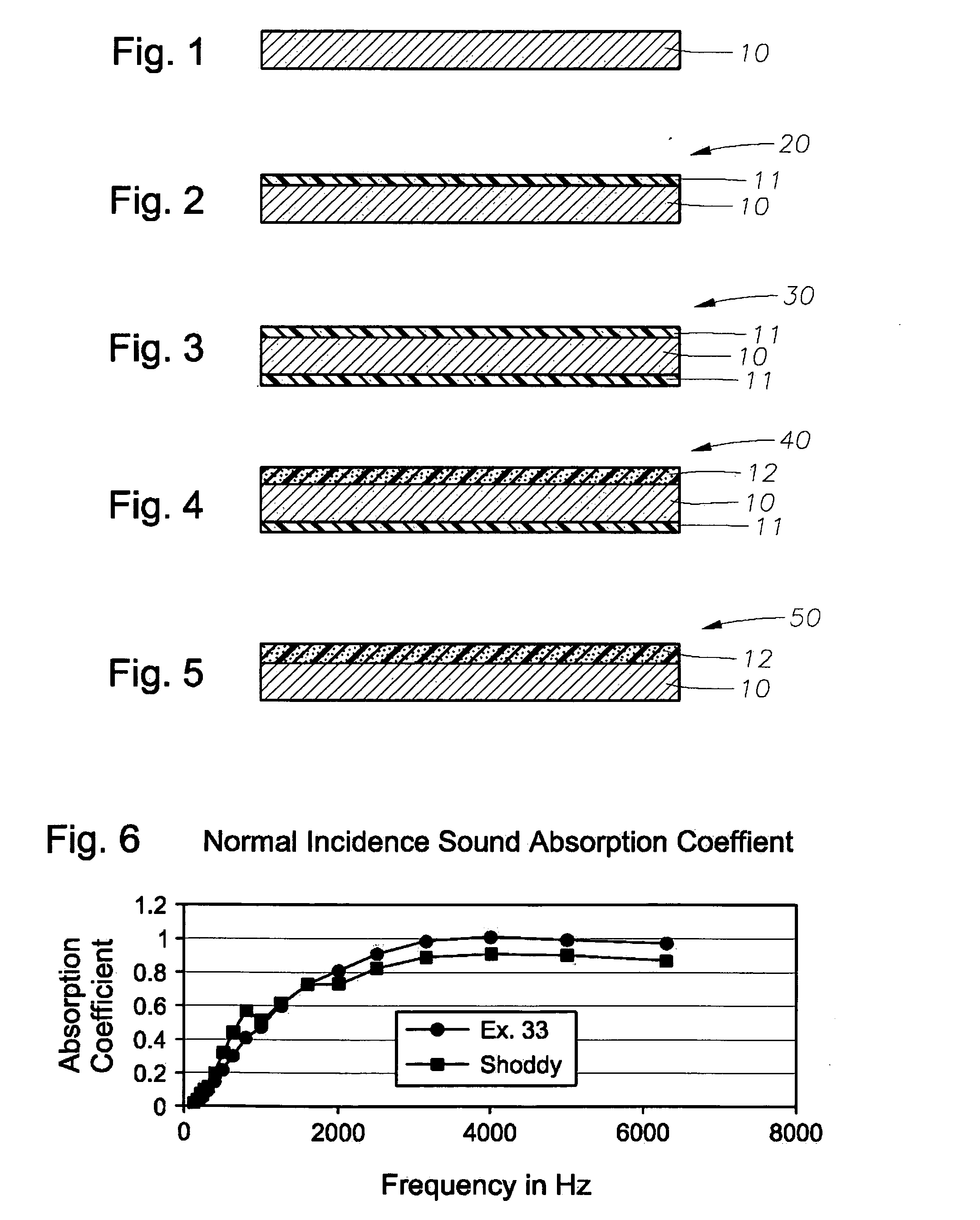

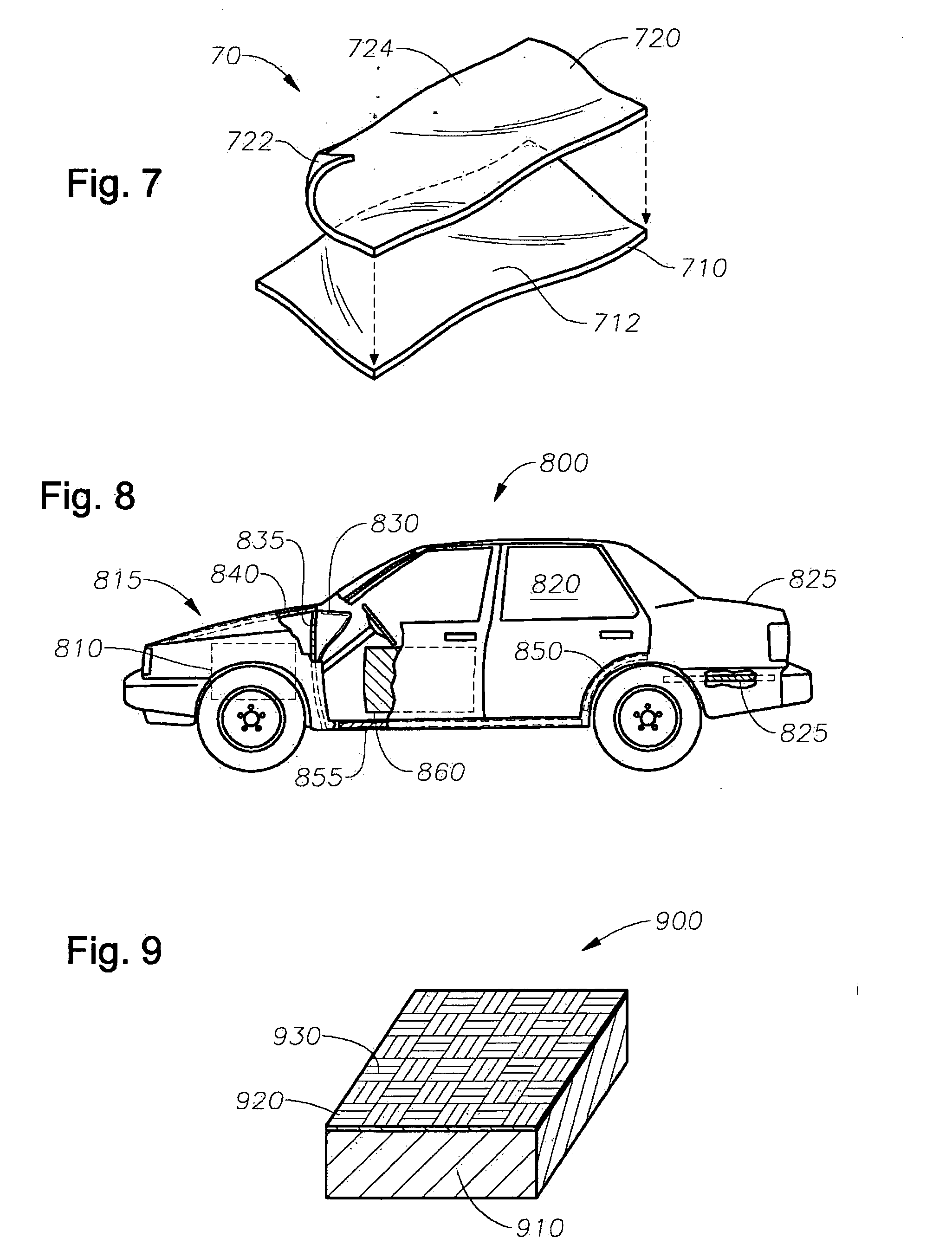

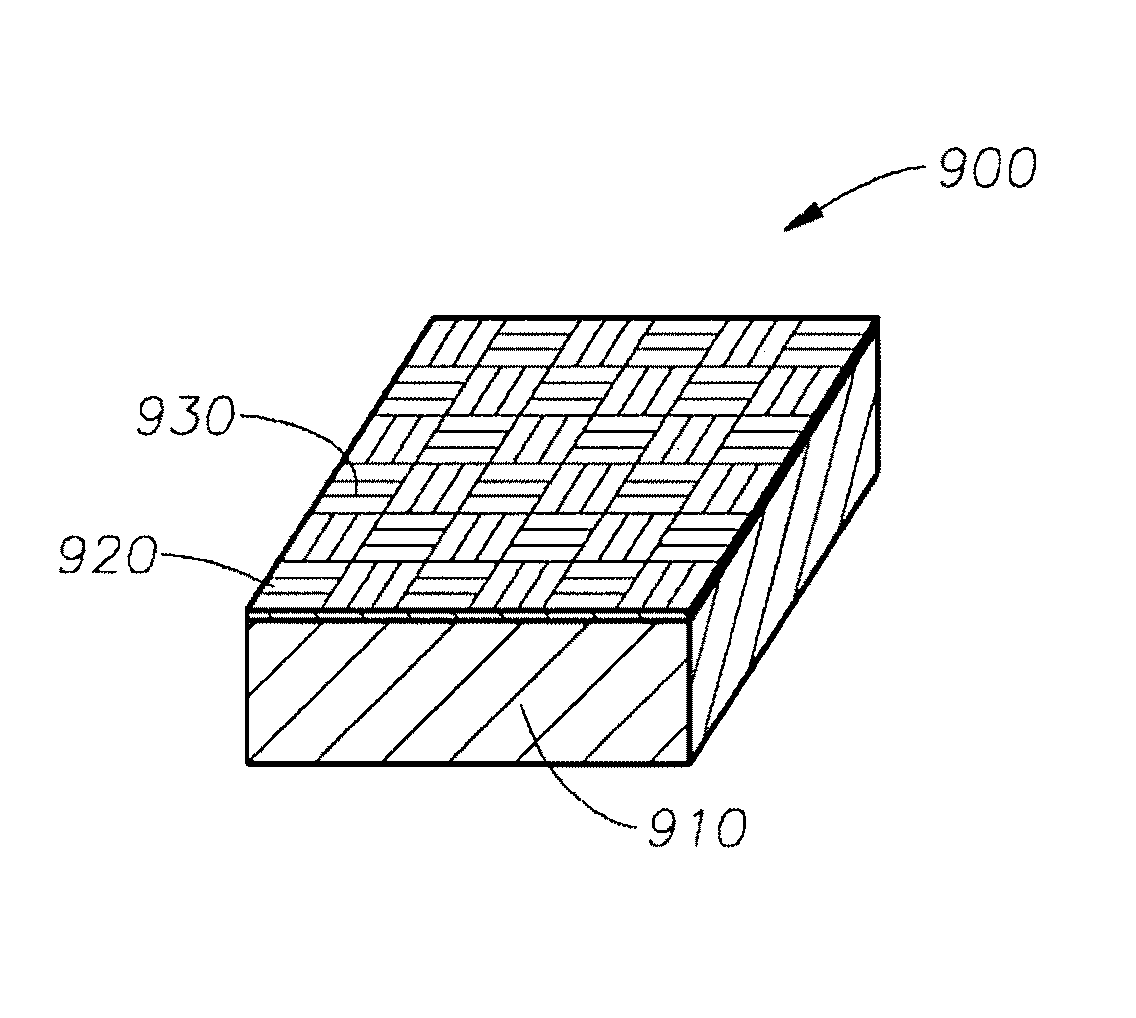

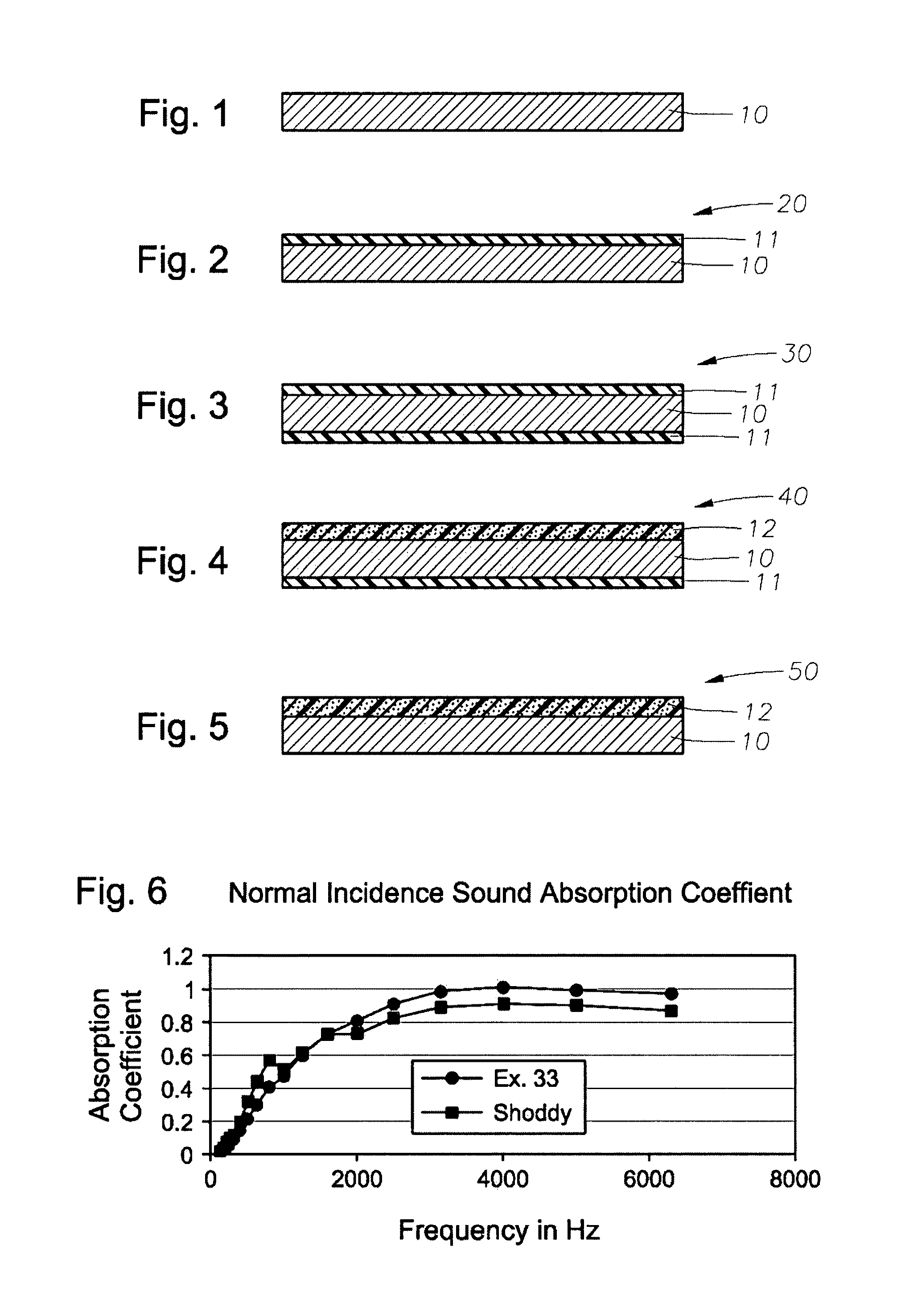

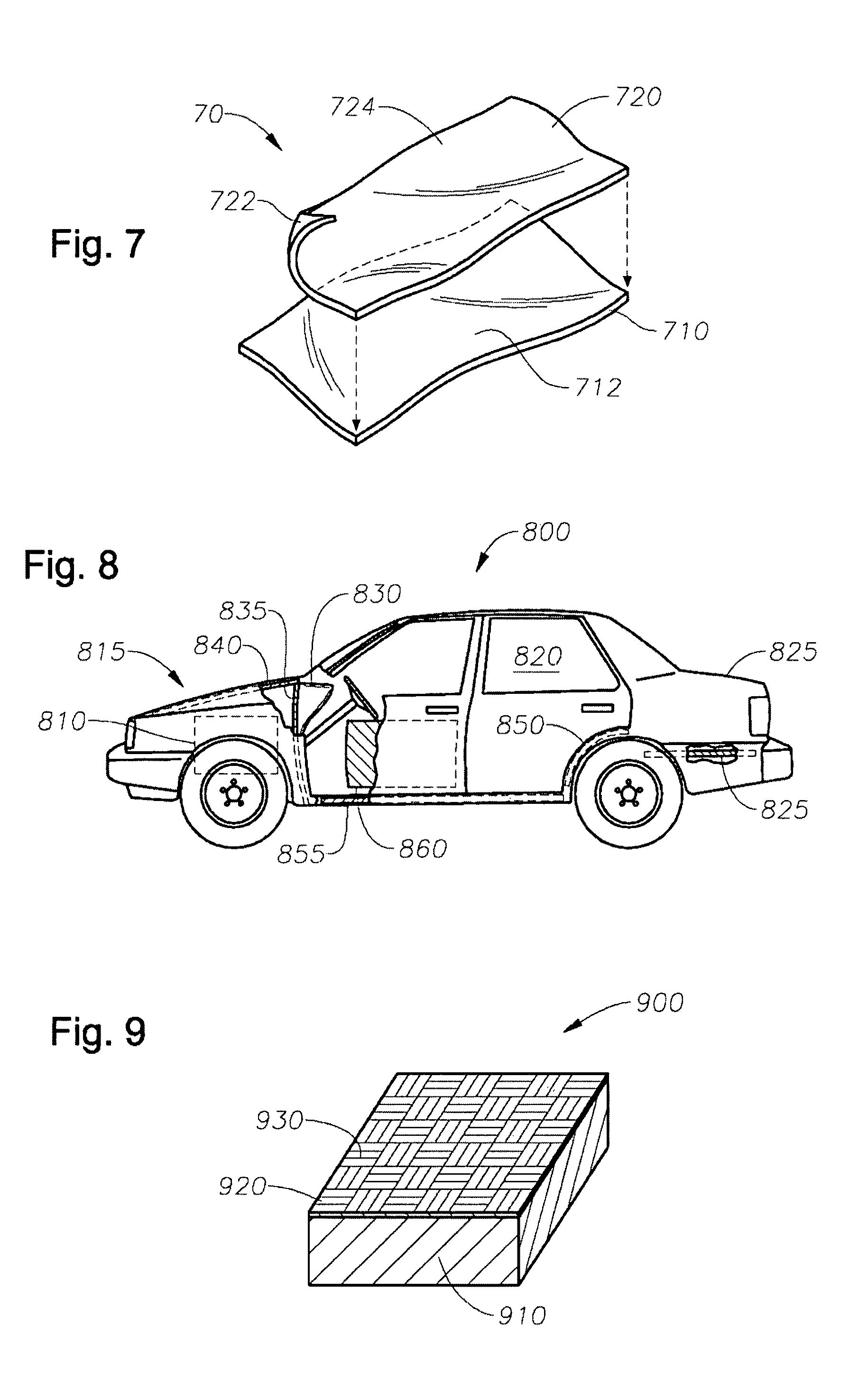

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

Disposable scrubbing product

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Foam composite for the repair or regeneration of tissue

InactiveUS20030077311A1Variable mechanical strengthFacilitate cell migration and nutrient flowBiocidePowder deliveryRegeneration tissueBiology

The present patent describes a biocompatible composite made of a first fibrous layer attached to a three-dimensional inter-connected open cell porous foams that have a gradient in composition and / or microstructure through one or more directions. These composites can be made from blends of absorbable and biocompatible polymers. These biocompatible composites are particularly well suited to tissue engineering applications and can be designed to mimic tissue transition or interface zones.

Owner:ETHICON ENDO SURGERY INC

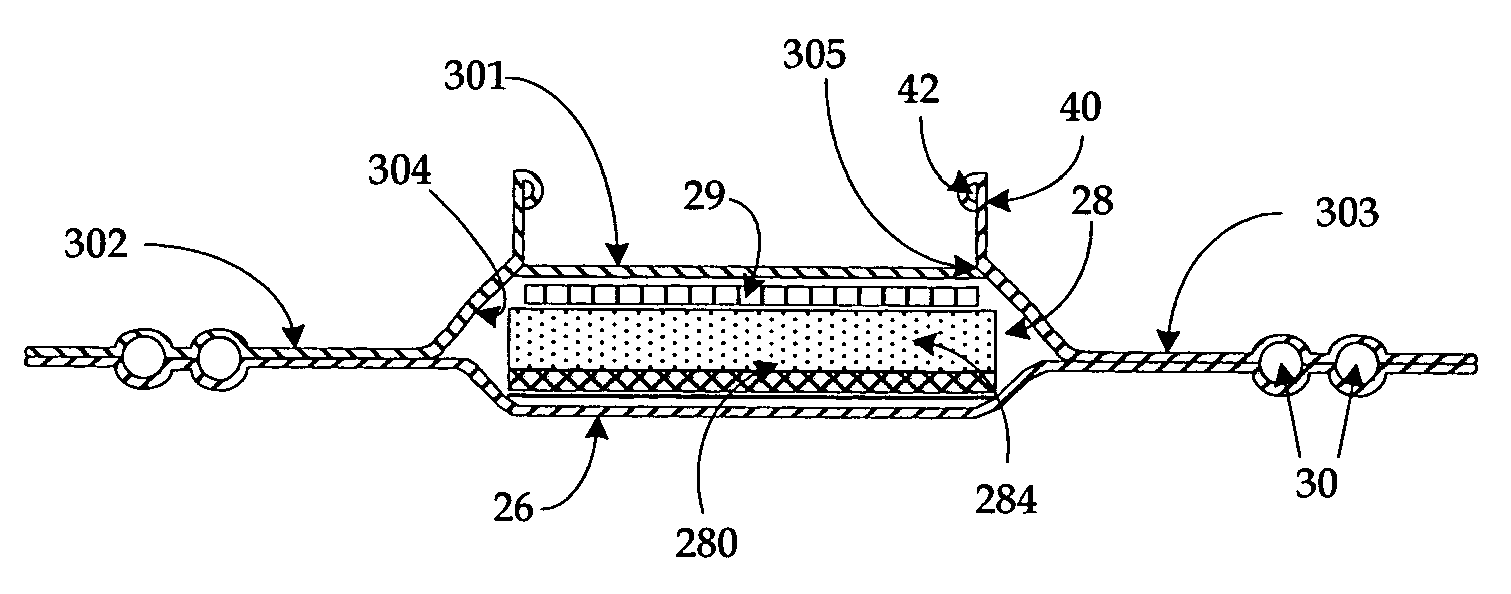

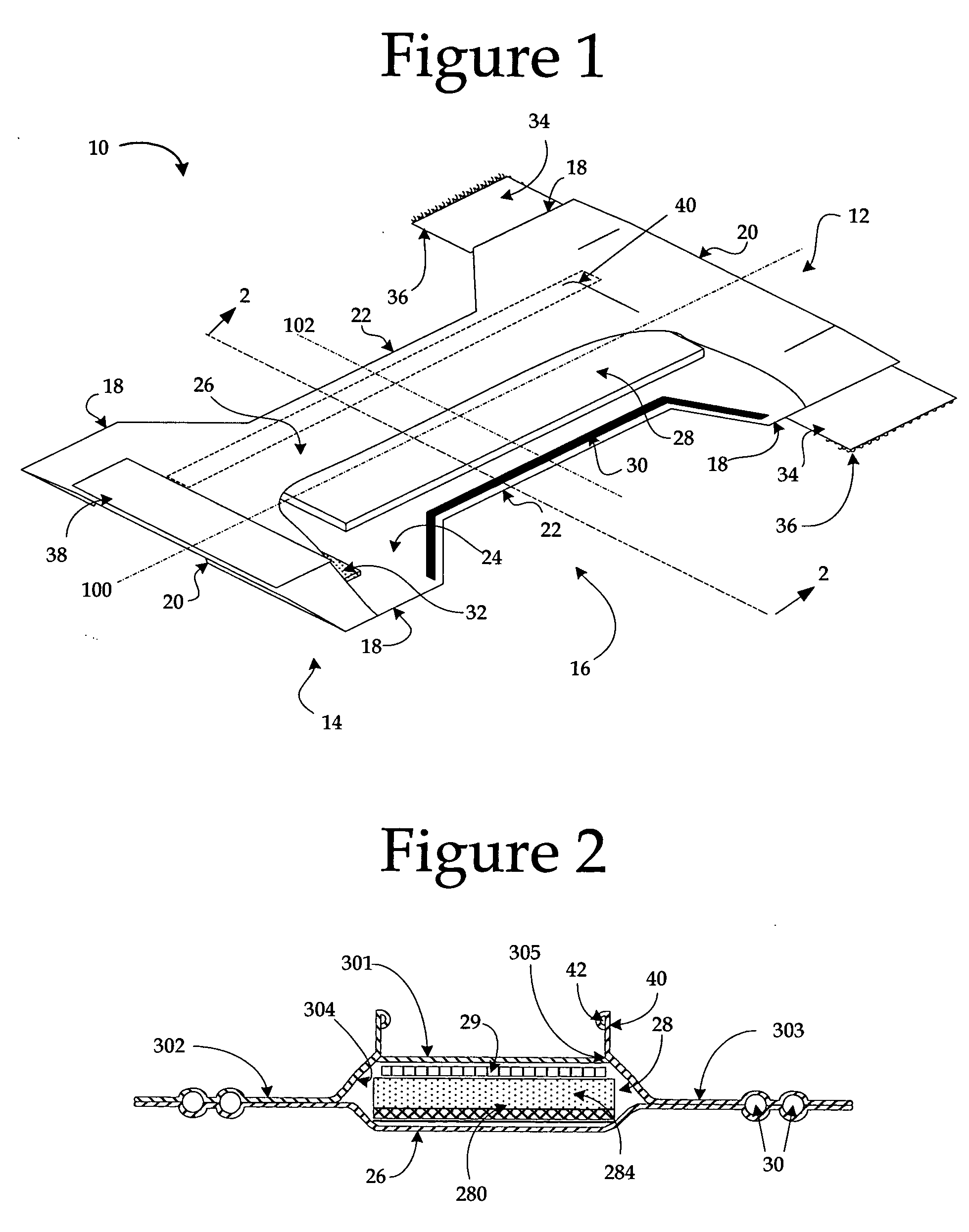

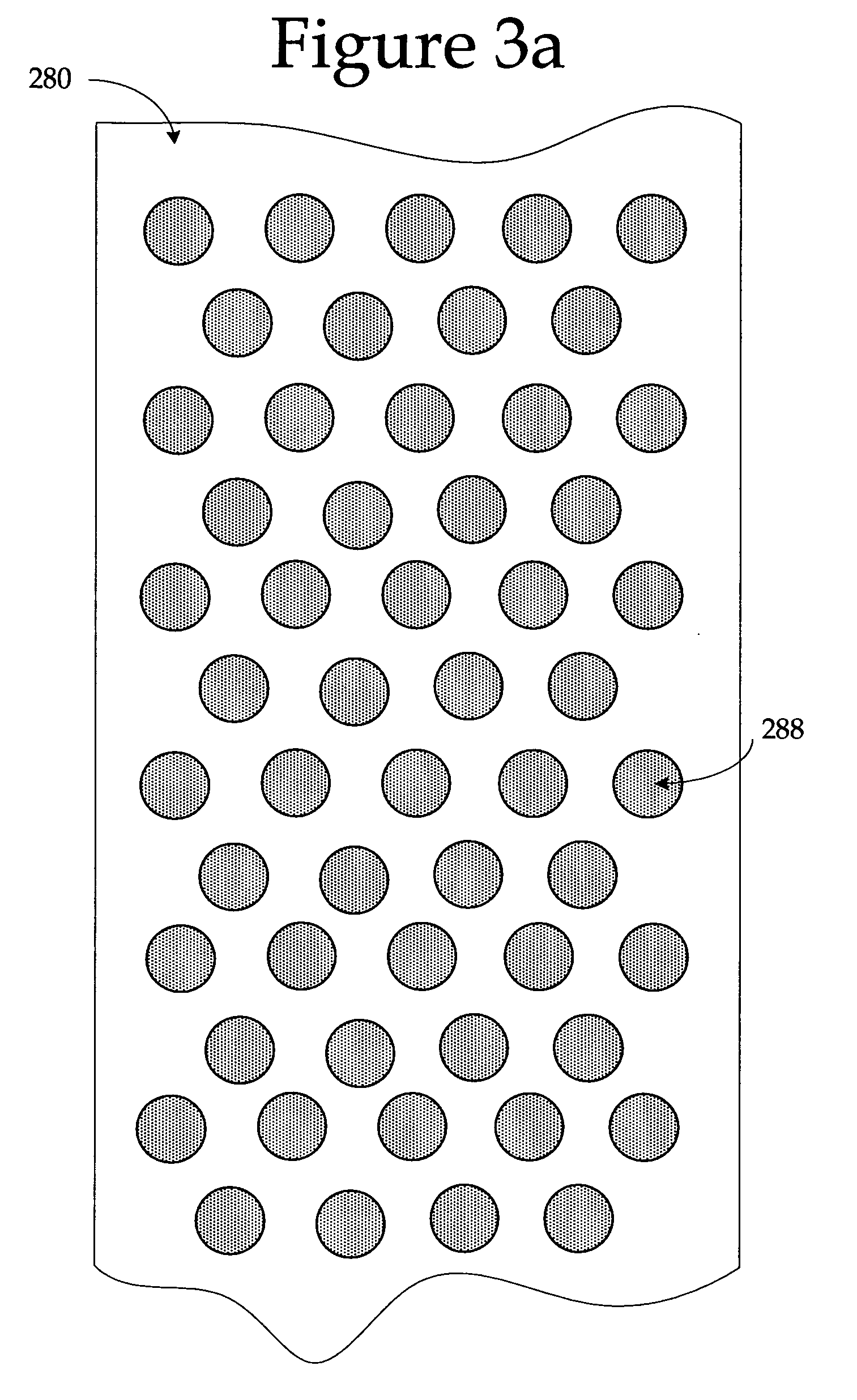

Absorbent core with three-dimensional sub-layer

InactiveUS20050101929A1Improved ability to retain fluidPrevent leakageBaby linensTamponsEngineeringFibrous layer

An absorbent core for use in an absorbent article, having a central fibrous layer having synthetic fibers, and a three-dimensional sub-layer having a plurality of small pockets that contain superabsorbent particles. Superabsorbent particles are deposited and partially enclosed in the discrete small pockets, and are prevented from shifting to other portions of the absorbent core. An absorbent article including the absorbent core, and a method for providing an absorbent article including the absorbent core are also described.

Owner:FIRST QUALITY RETAIL SERVICES

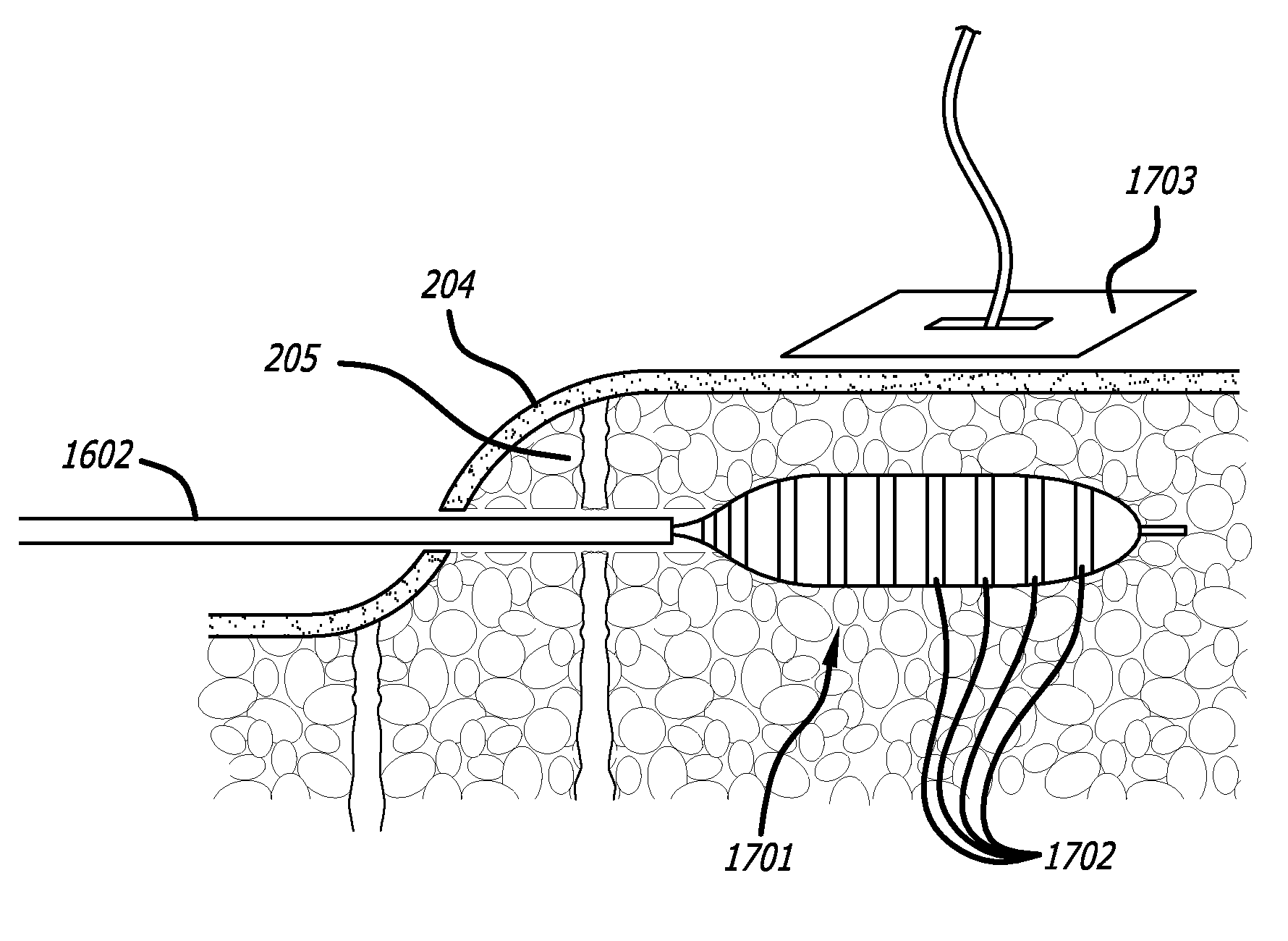

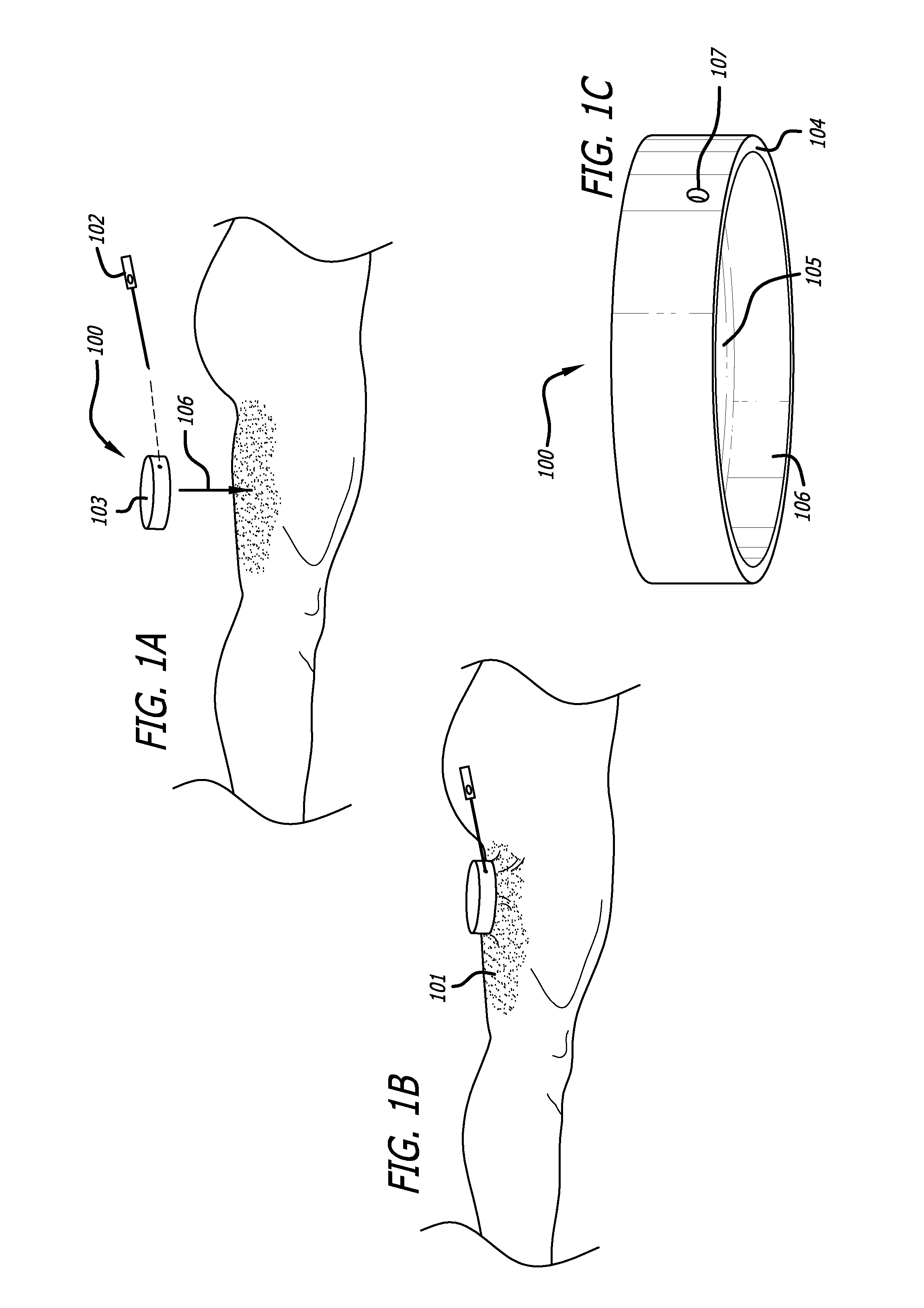

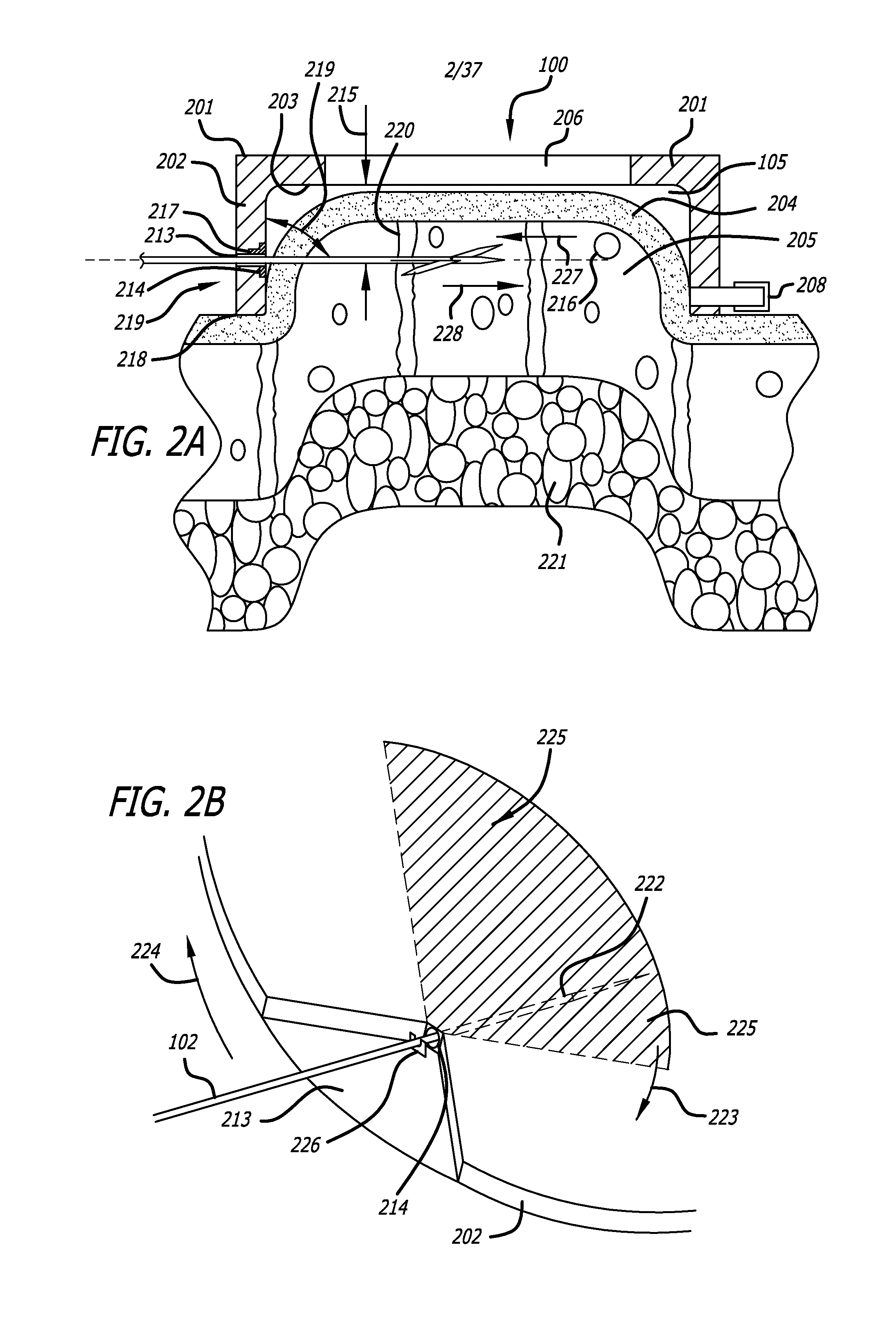

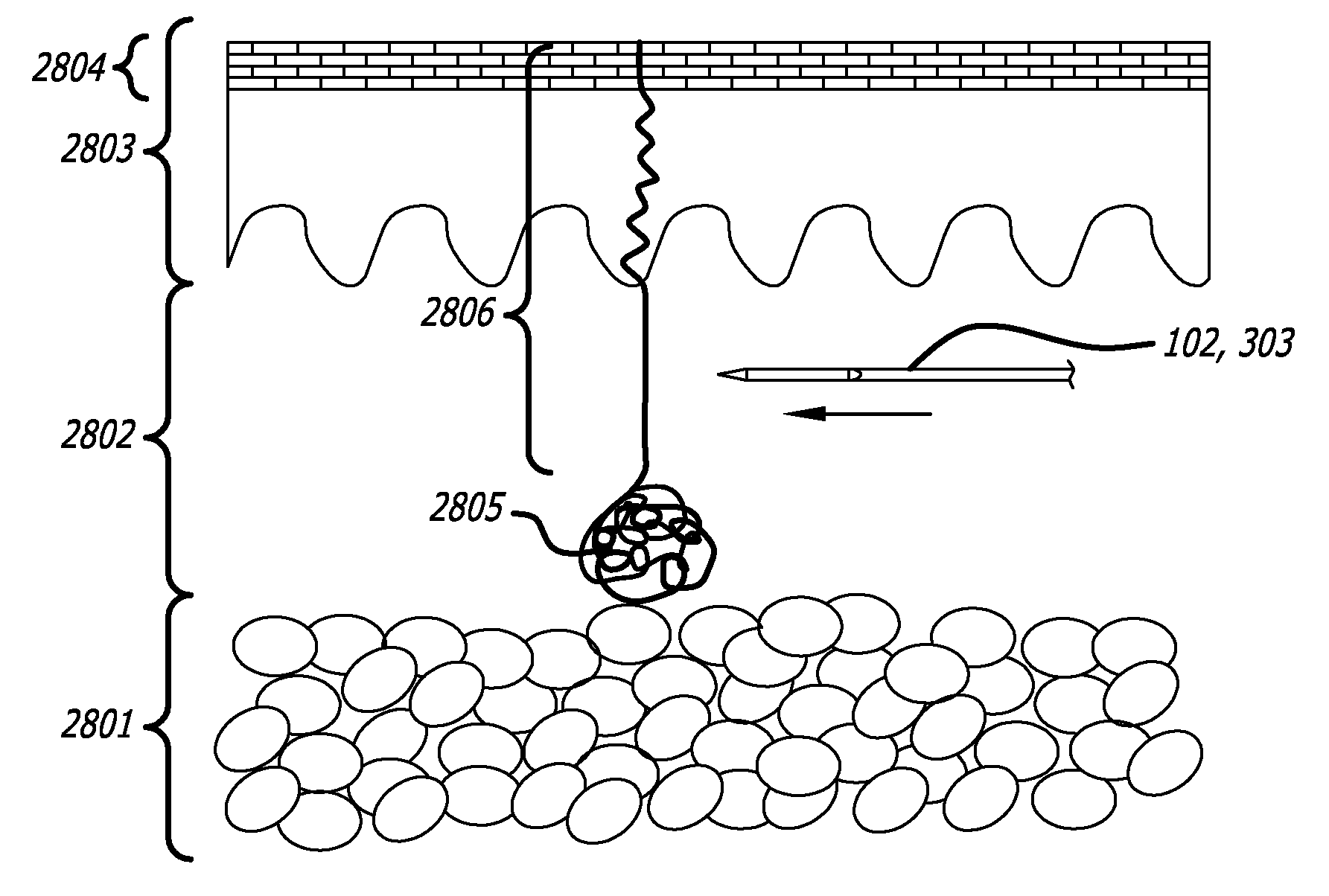

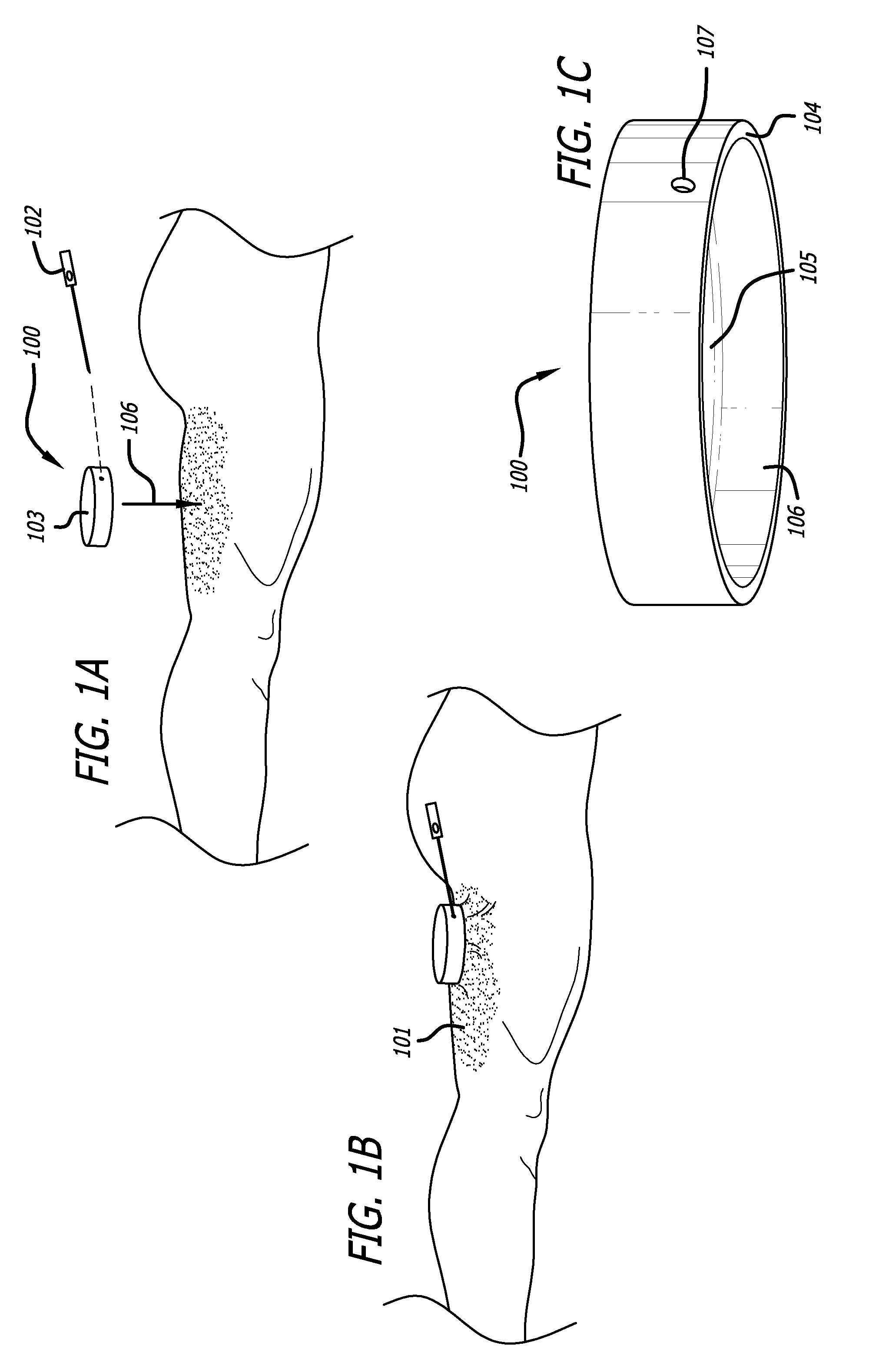

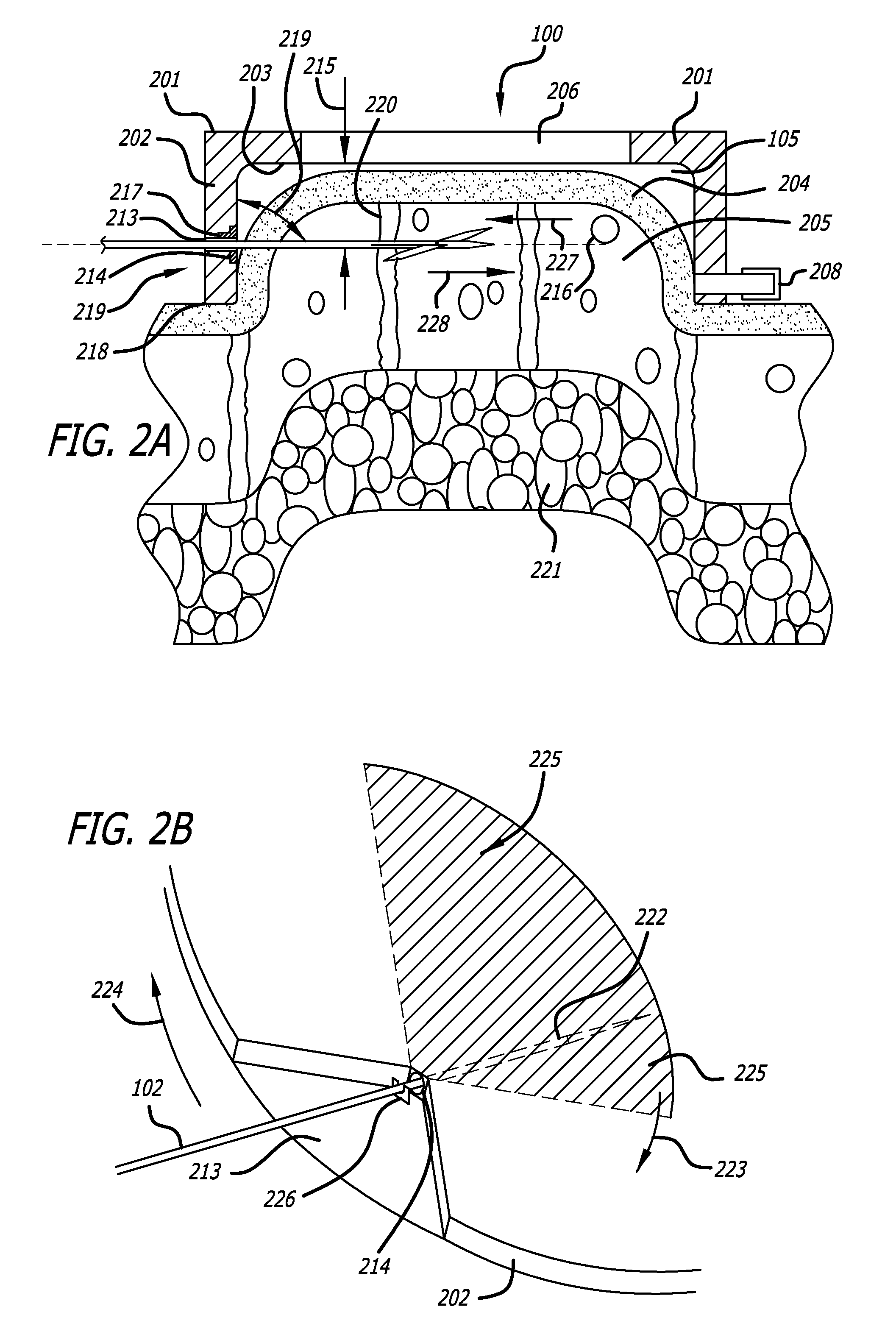

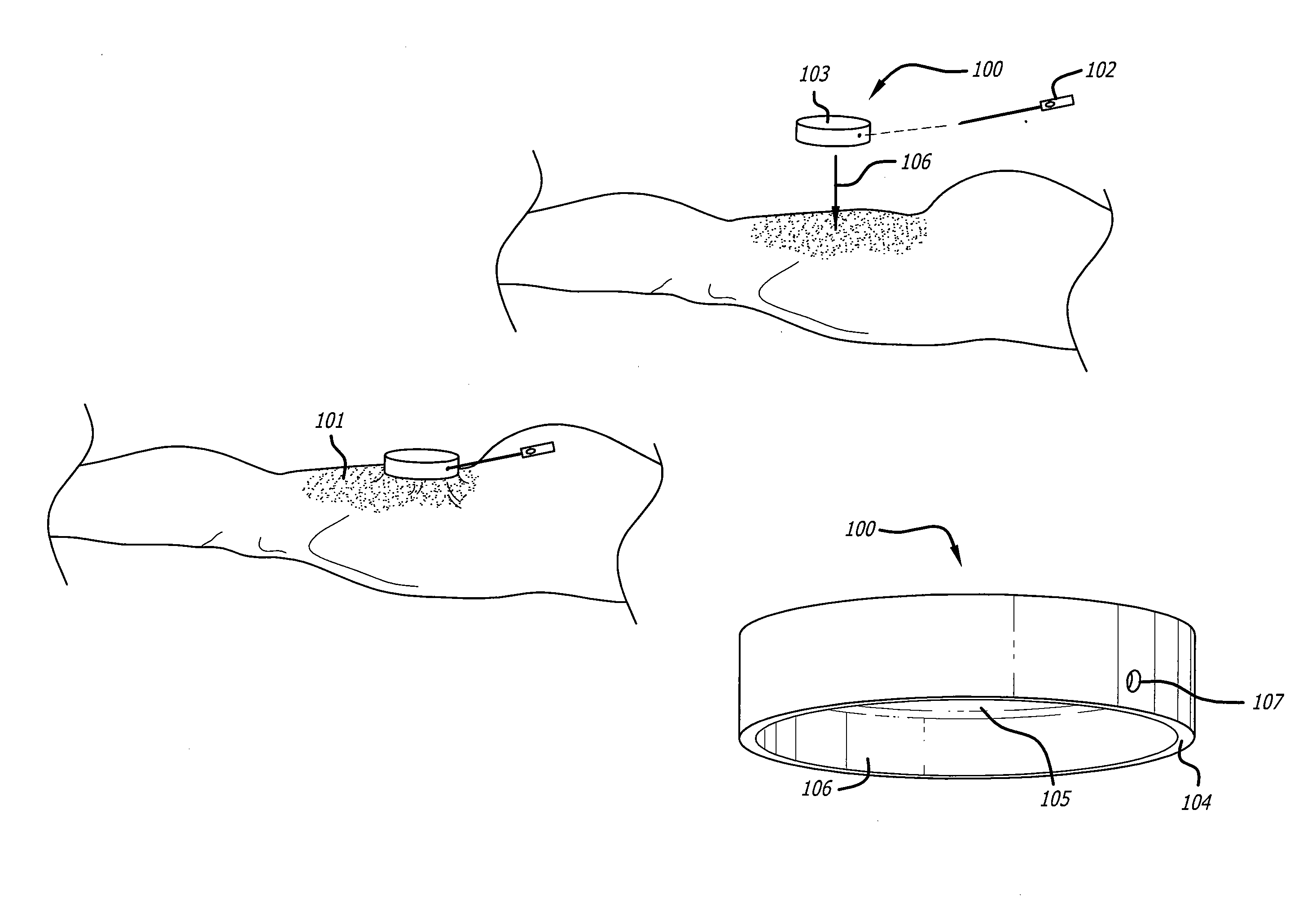

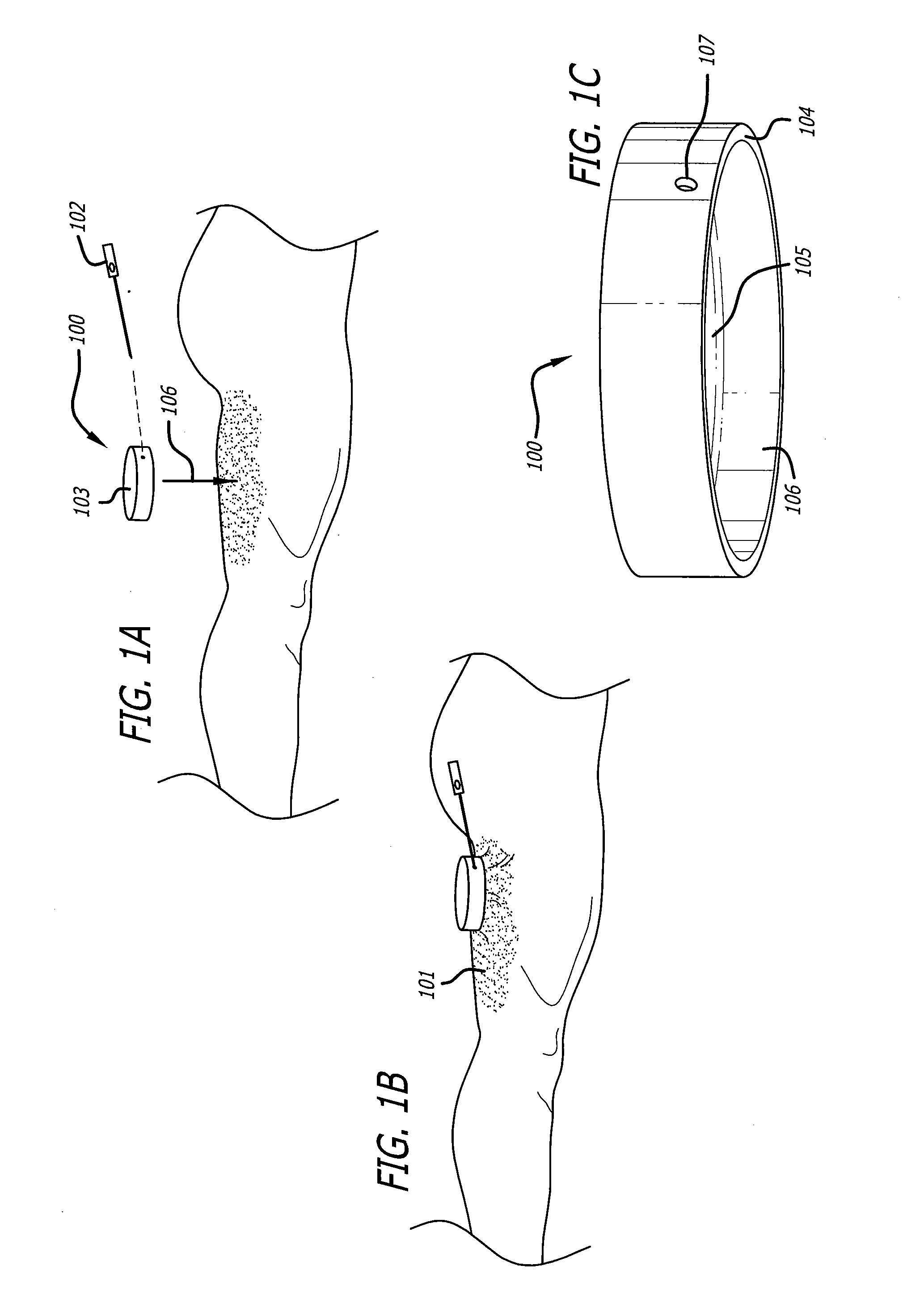

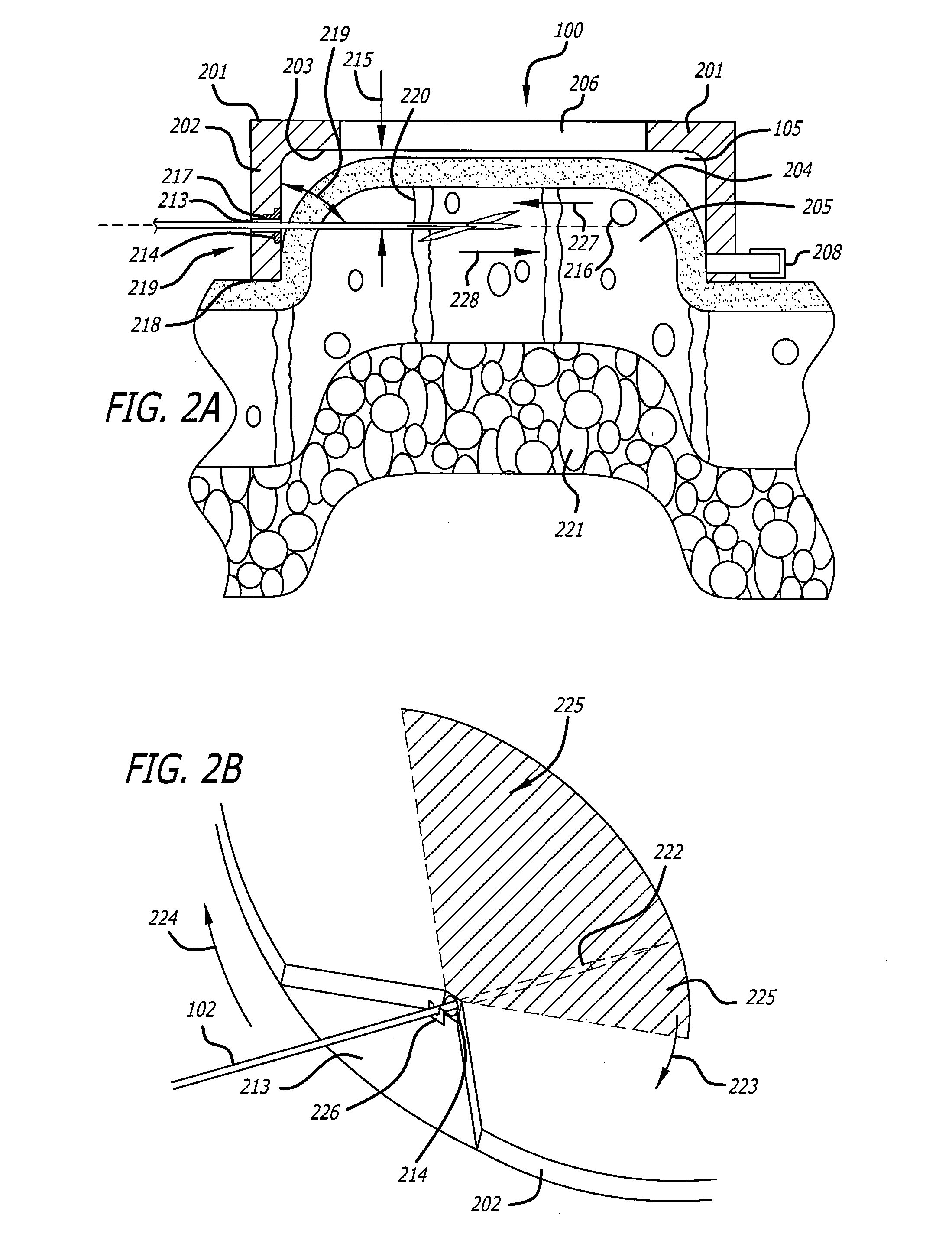

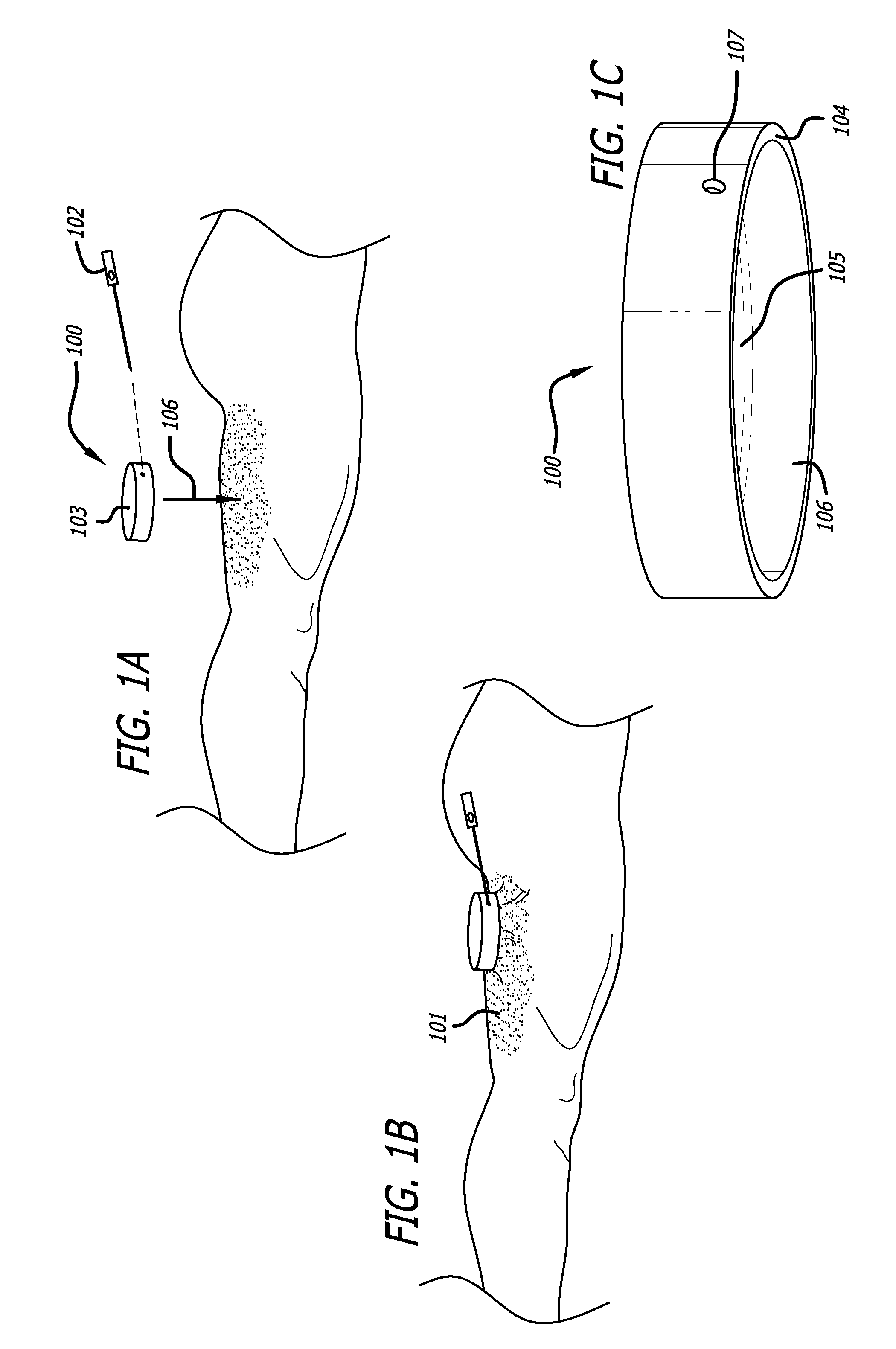

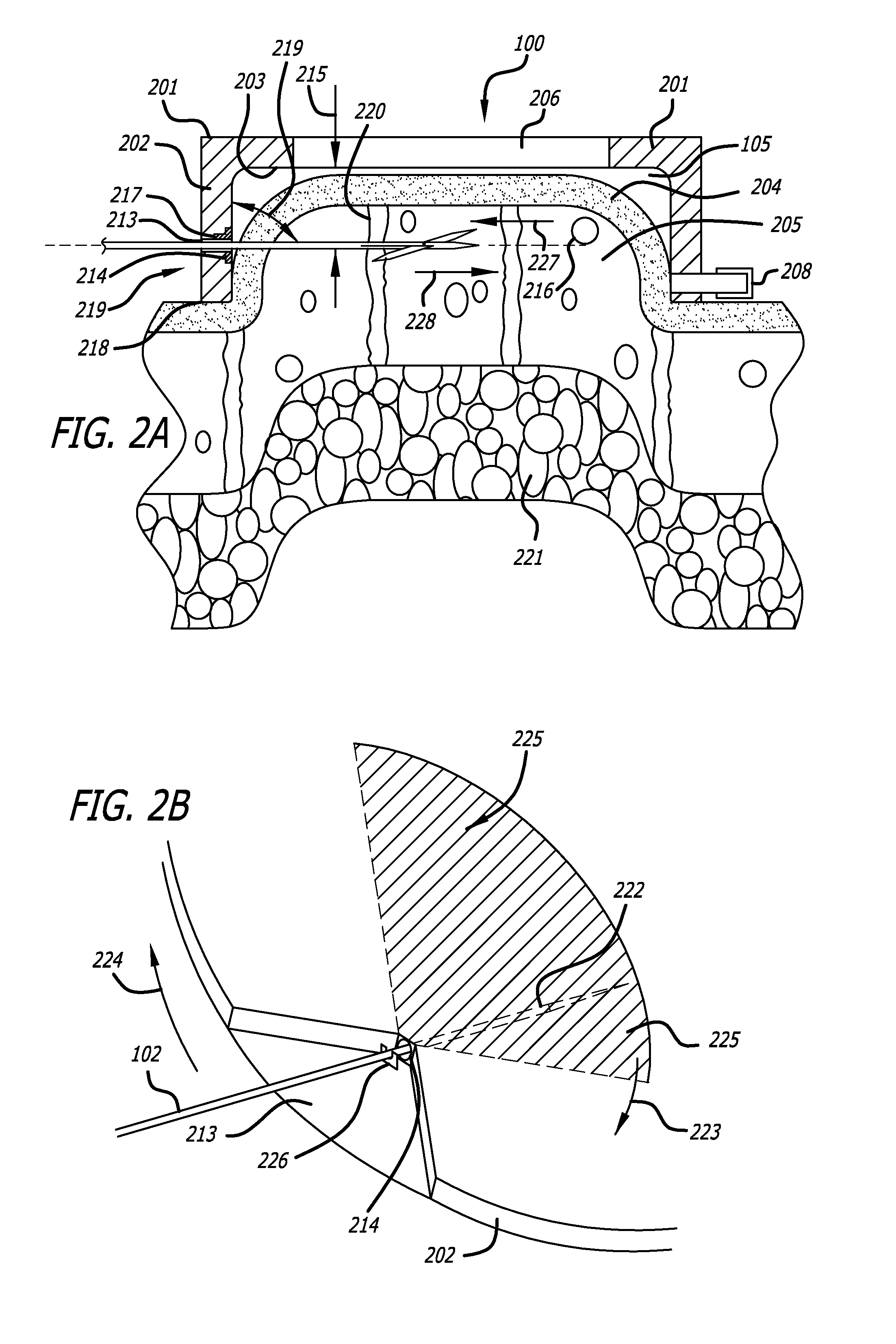

Dissection handpiece and method for reducing the appearance of cellulite

ActiveUS20110028898A1Prevent removalIncrease kinetic energyAnti-cellulite devicesDiagnosticsWound healingSkin treatments

A dermatological skin treatment device is provided. The device comprises a handpiece and a cutting tool, wherein the tool is inserted through the conduit and percutaneously inserted into a tissue disposed within a recessed area of the handpiece. The device and method cut the fibrous structures under the skin that cause cellulite at an angle substantially parallel to the surface of the skin and replace these structures with a non-cellulite forming structure by deploying a highly fibrous mesh through a single needle hole to create a highly fibrous layer directly or through wound healing processes.

Owner:ULTHERA INC

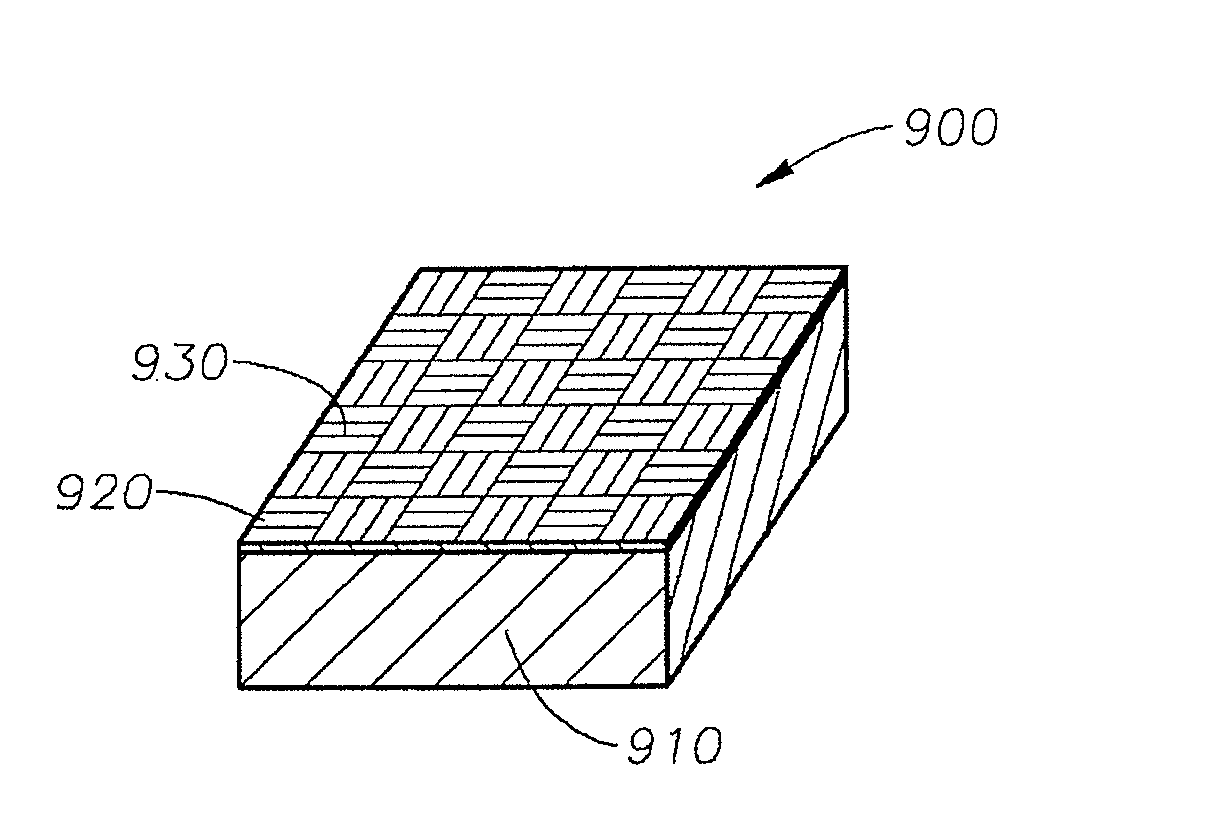

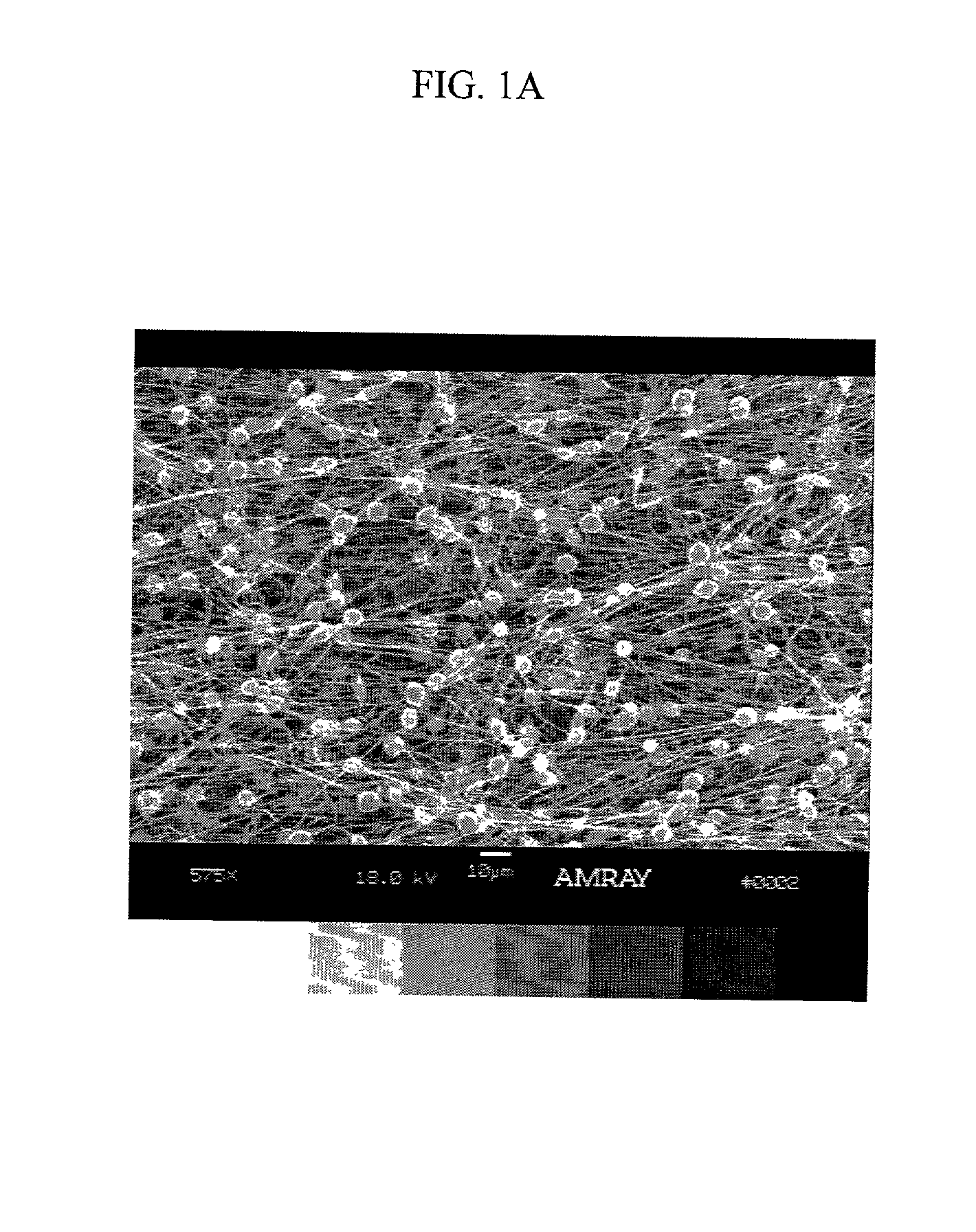

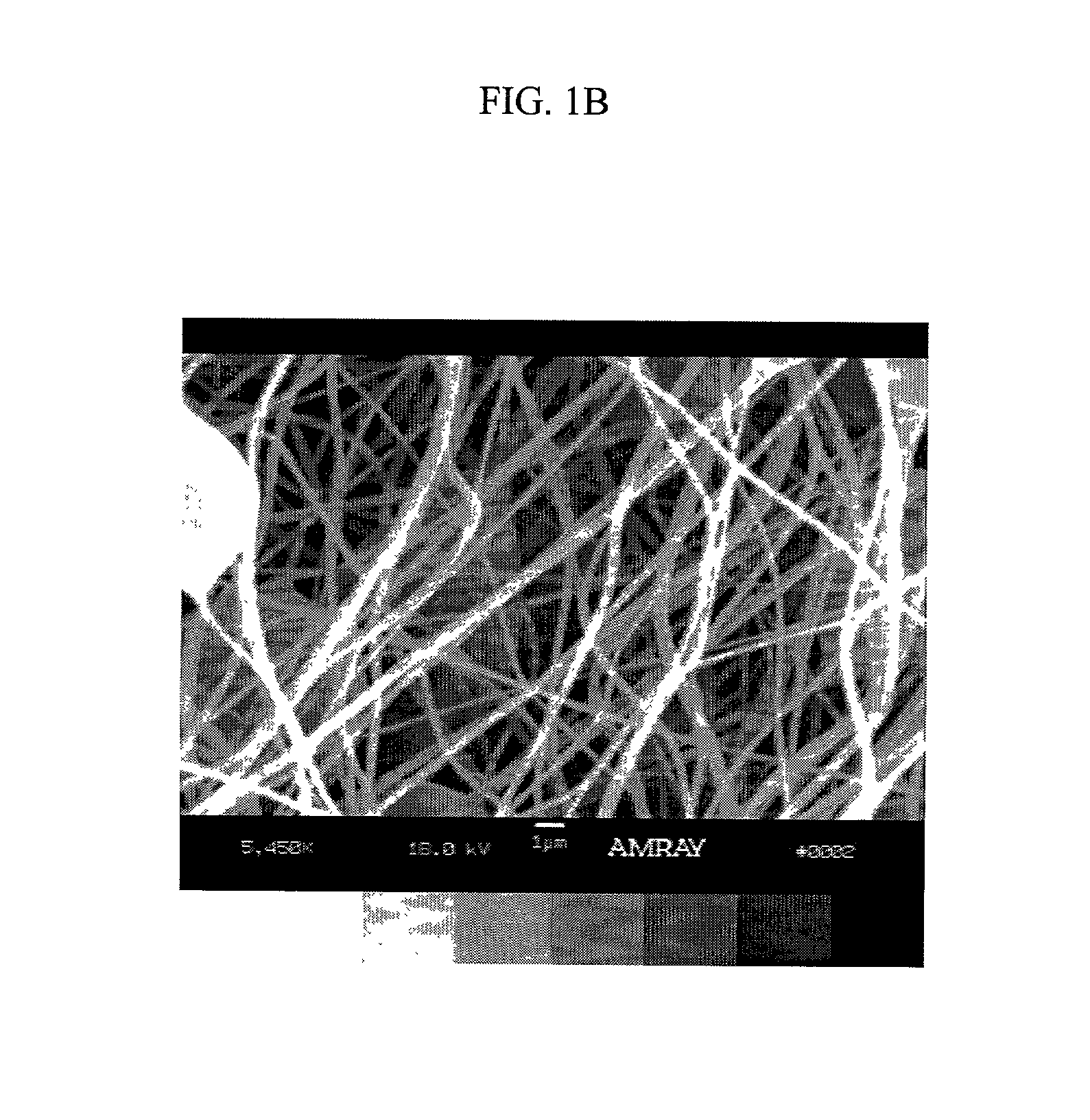

Enhanced ballistic performance of polymer fibers

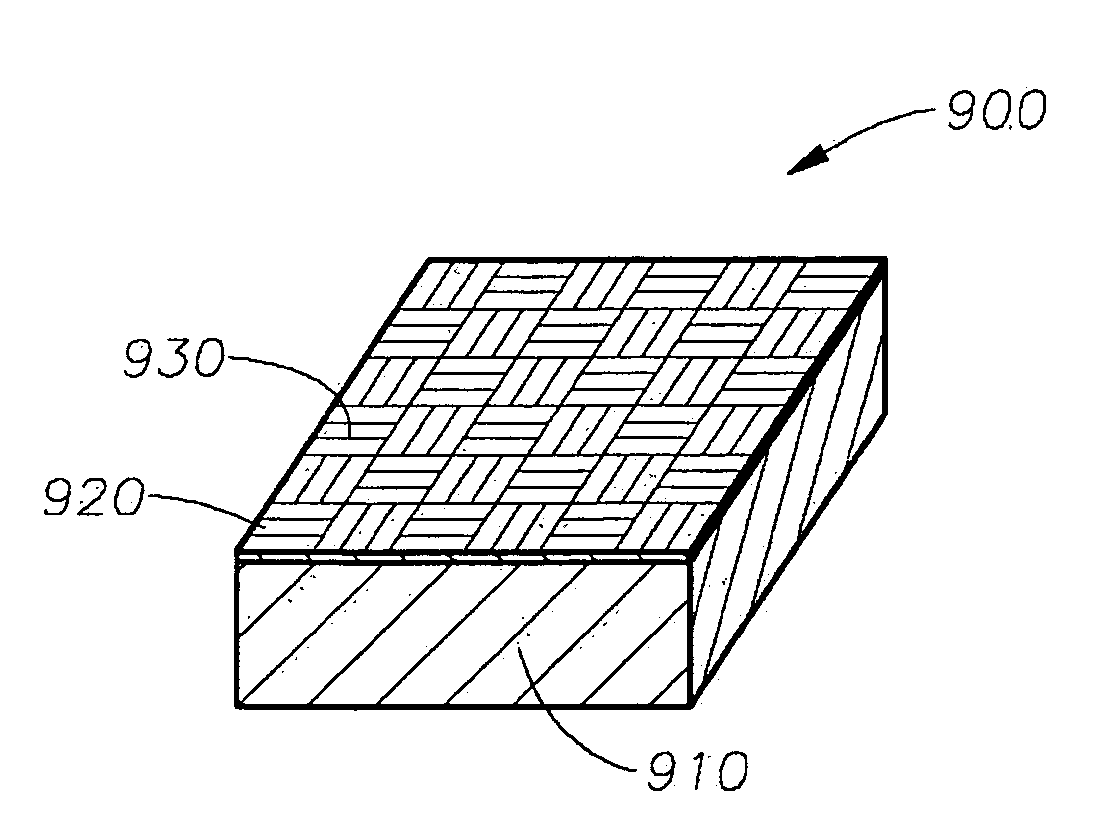

ActiveUS7964518B1Synthetic resin layered productsPersonal protection gearFiber ChemistryPhysical strength

Ballistic resistant materials having improved strength and lighter weights. More particularly, improved ballistic resistant fabrics produced from drawn, high modulus fibers having a reduced fiber diameter and improved physical strength properties, without changing other properties such as fiber chemistry, binder resin type and binder resin content. The fabrics incorporate low denier per filament monofilament fibers, low denier per filament multifilament fibers, or a combination of low denier per filament monofilament fibers and low denier per filament multifilament fibers in a specialized fabric construction to form fine fiber layers and fabrics having enhanced strength and fiber areal density without altering the fabric weight, or having reduced fabric weight without a corresponding reduction in ballistic performance.

Owner:HONEYWELL INT INC

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS7837009B2Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsMildewEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

Nonwoven material for acoustic insulation, and process for manufacture

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

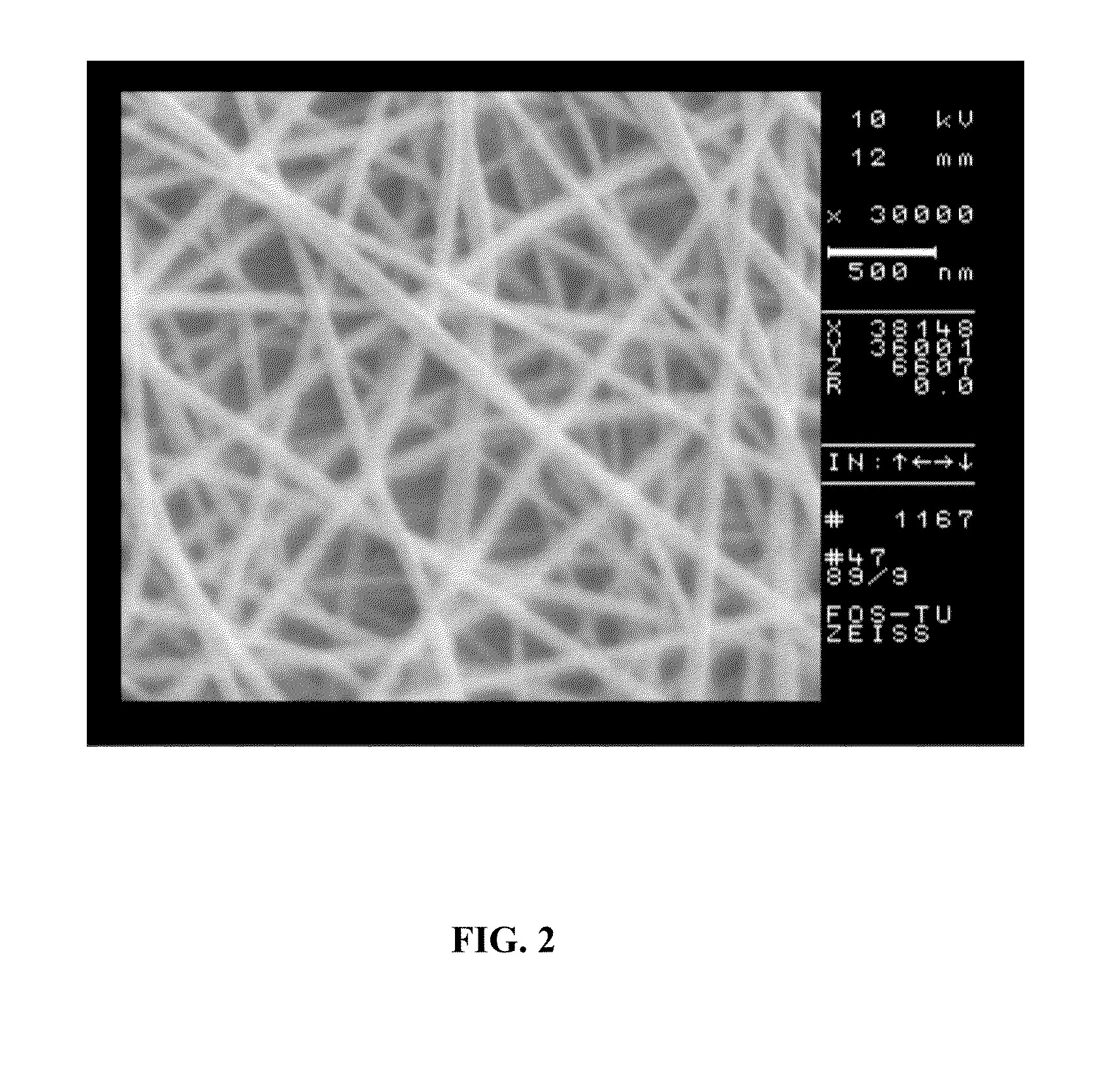

Vascular graft having a chemicaly bonded electrospun fibrous layer and method for making same

InactiveUS20030100944A1Improve surface morphologyGood tissue responseNon-woven fabricsCoatingsChemical LinkageElectrospinning

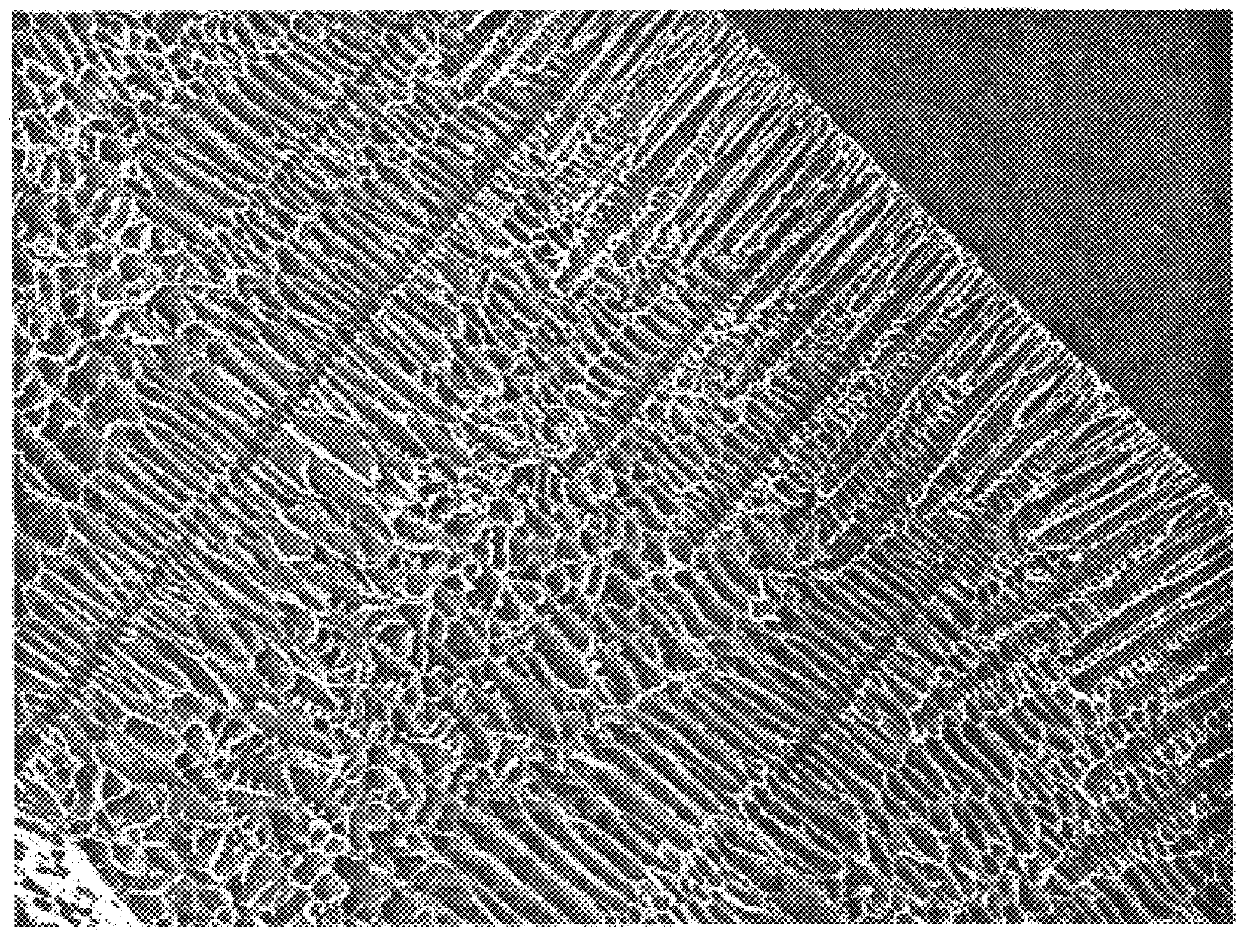

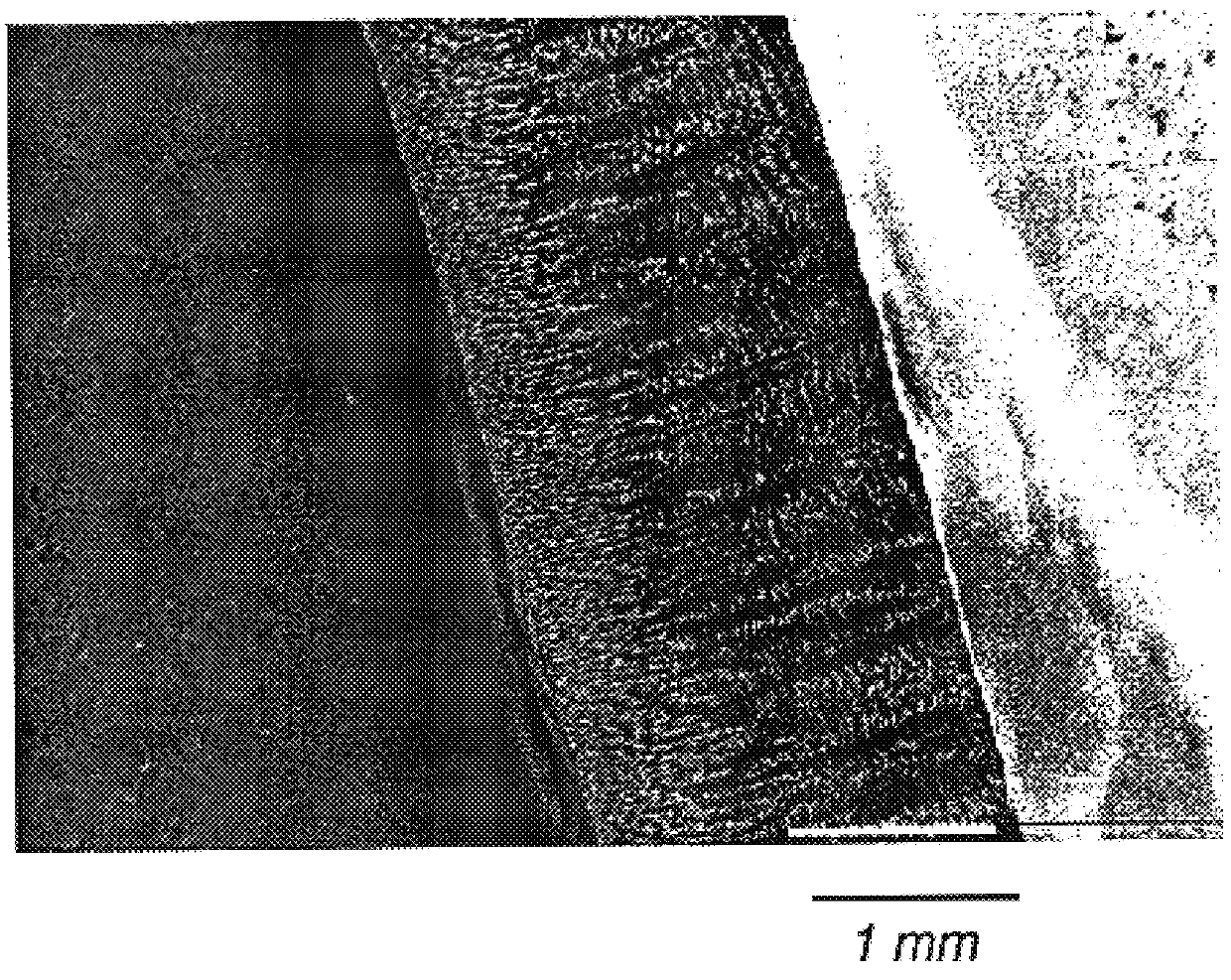

A vascular graft comprising a traditional graft material and an electrospun fibrous layer. The solvent used to reduce the material for the electrospun layer is also capable of reducing the graft material to a liquid solution. The electrospun layer is chemically bonded to the graft material, without adhesives, by either spraying the graft with the solvent prior to electrospinning or by assuring that a sufficient amount of residual solvent reaches the graft while electrospinning.

Owner:DATASCOPE INVESTMENT

Fire retardant nonwoven material and process for manufacture

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GLATFELTER CORP

Composite structures containing tissue webs and other nonwovens

InactiveUS20050136772A1Resists effect of waterMaintain stiffnessPersonal careCarpet cleanersEngineeringPolymer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a tissue layer made from papermaking fibers. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, an anchoring agent, such as synthetic fibers, are incorporated into the tissue layer that form a bond with the abrasive layer when forming a laminate in accordance with the present invention.

Owner:KIMBERLY-CLARK WORLDWIDE INC

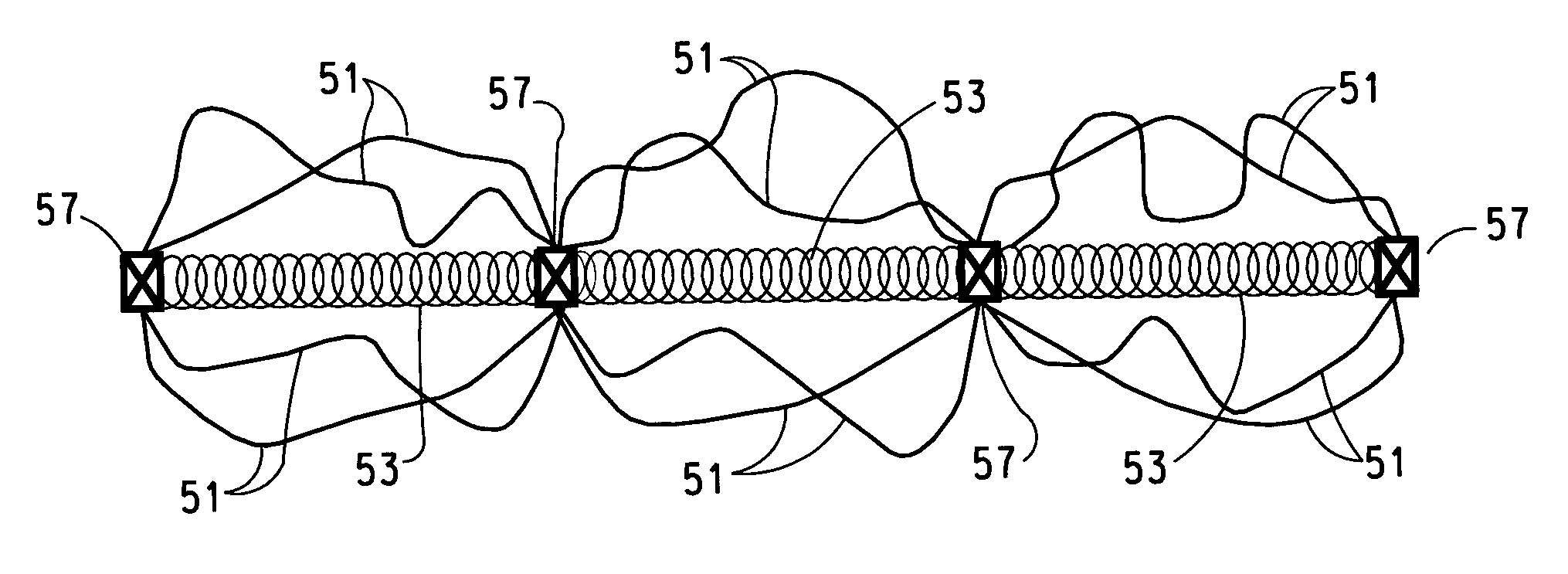

Stretchable composite sheets and processes for making

This invention relates to an improved method for preparing stretchable multiple-component bonded composite sheets which involves bonding a fibrous layer of spirally-crimpable multiple-component continuous filaments or staple fibers to one or more non-spirally-crimpable layers using an array of intermittent mechanical, chemical, or thermal bonds, and heating the bonded composite to activate the spiral crimp of the fibers in the spirally-crimpable layer. Multi-layer nonwoven fabrics prepared according to the method of the current invention have an improved combination of strength, aesthetics, stretch-recovery properties, and textile hand and drape compared to multiple-component nonwoven fabrics known in the art.

Owner:THE LYCRA CO LLC

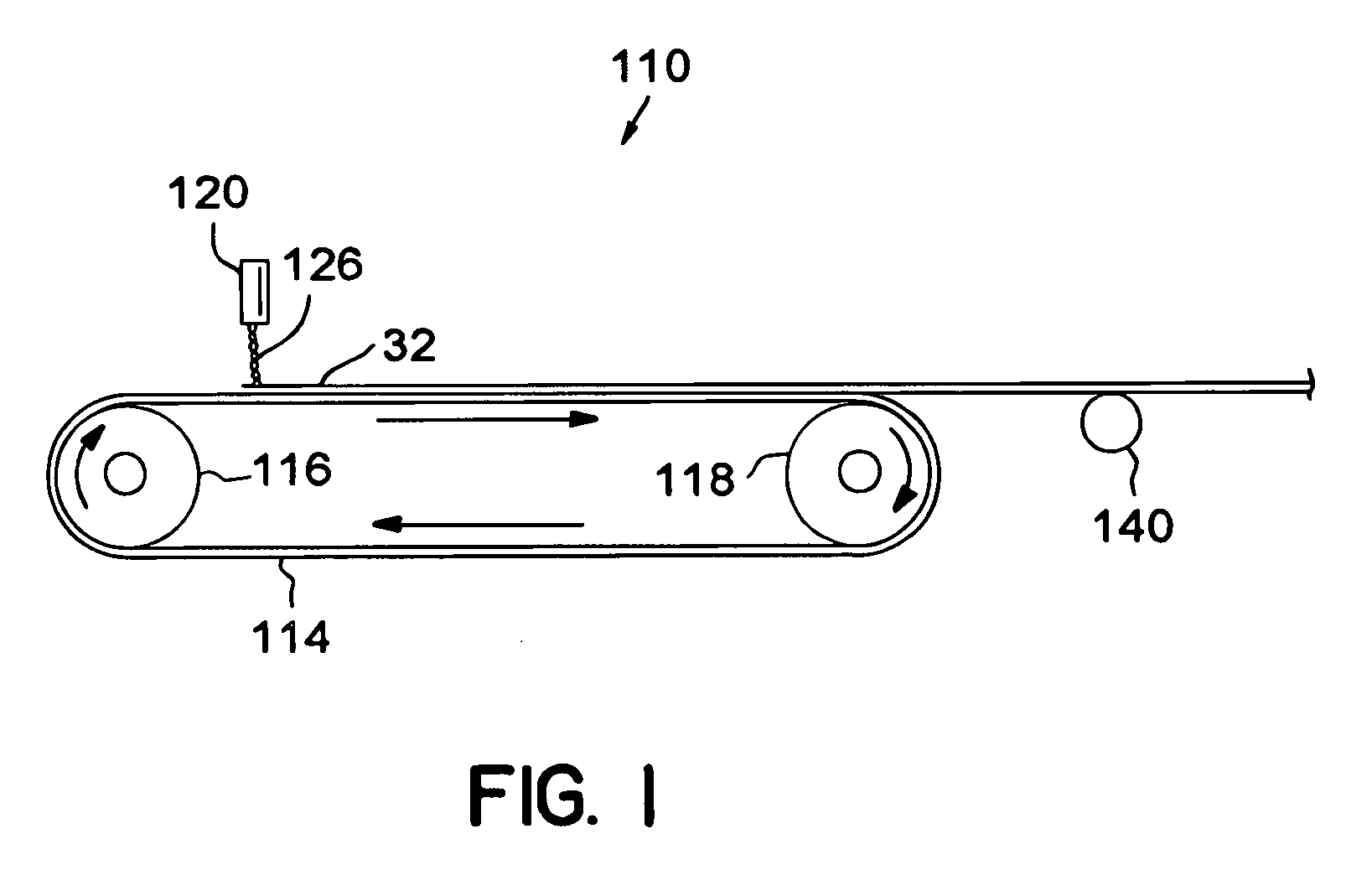

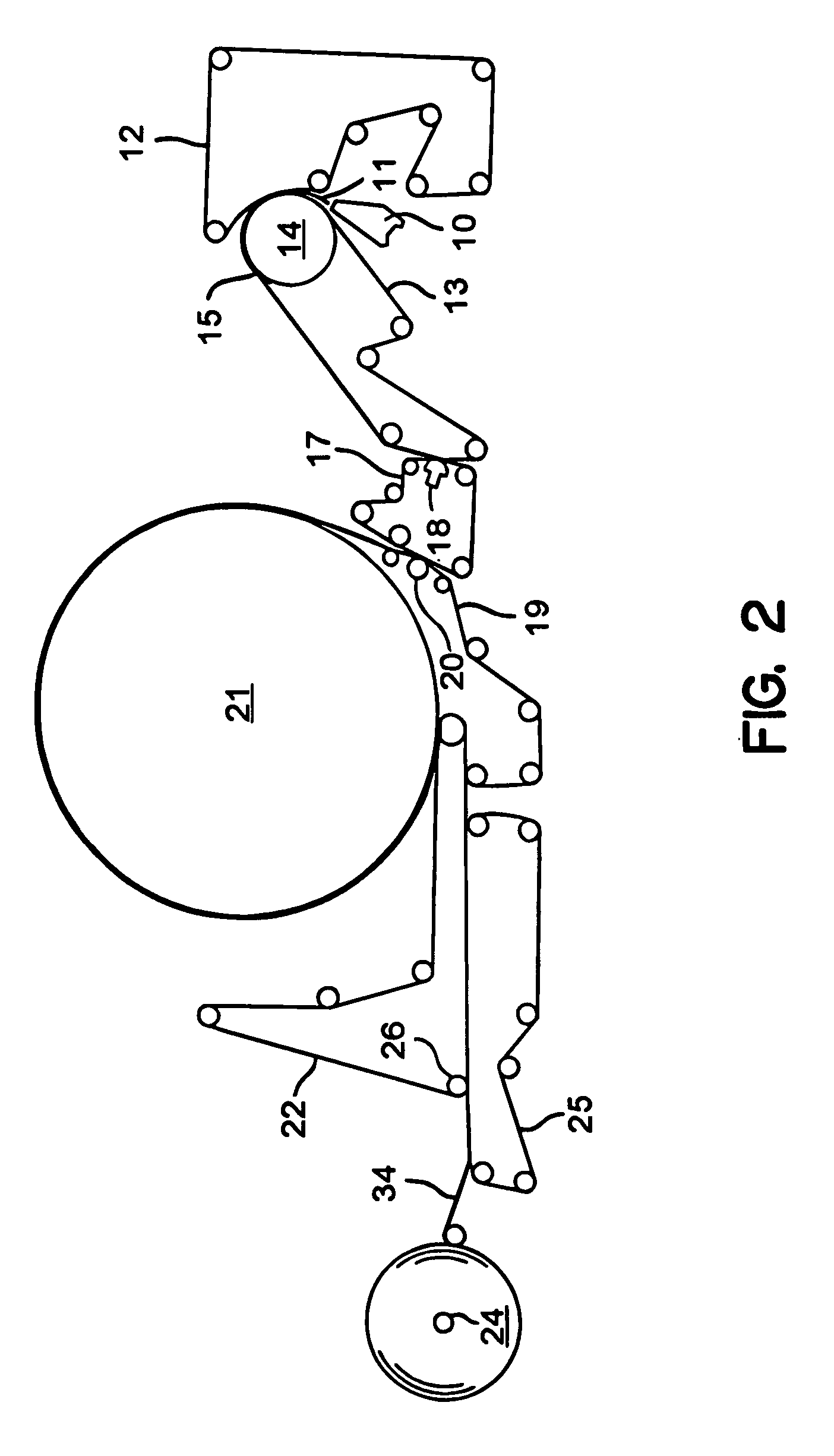

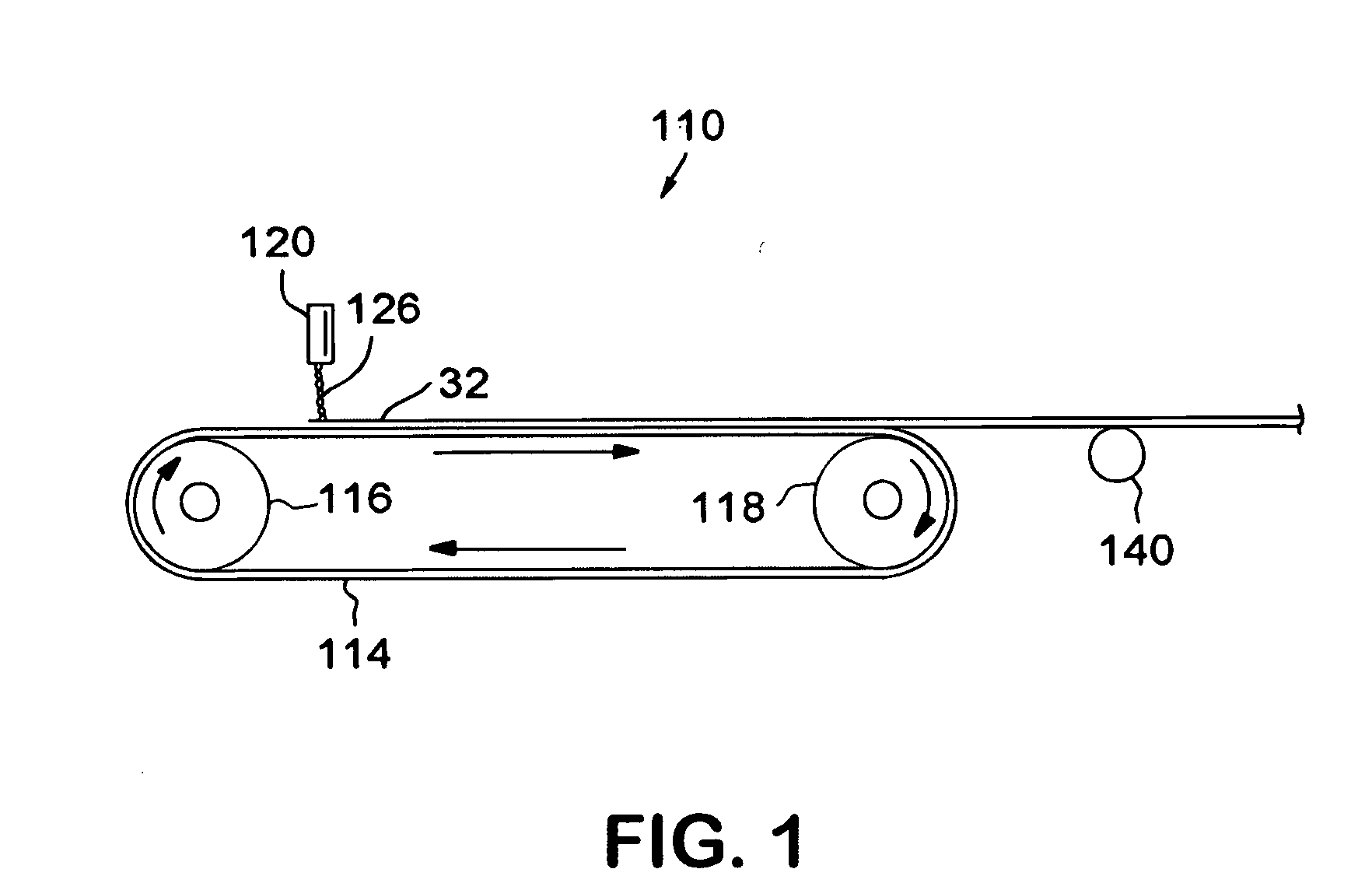

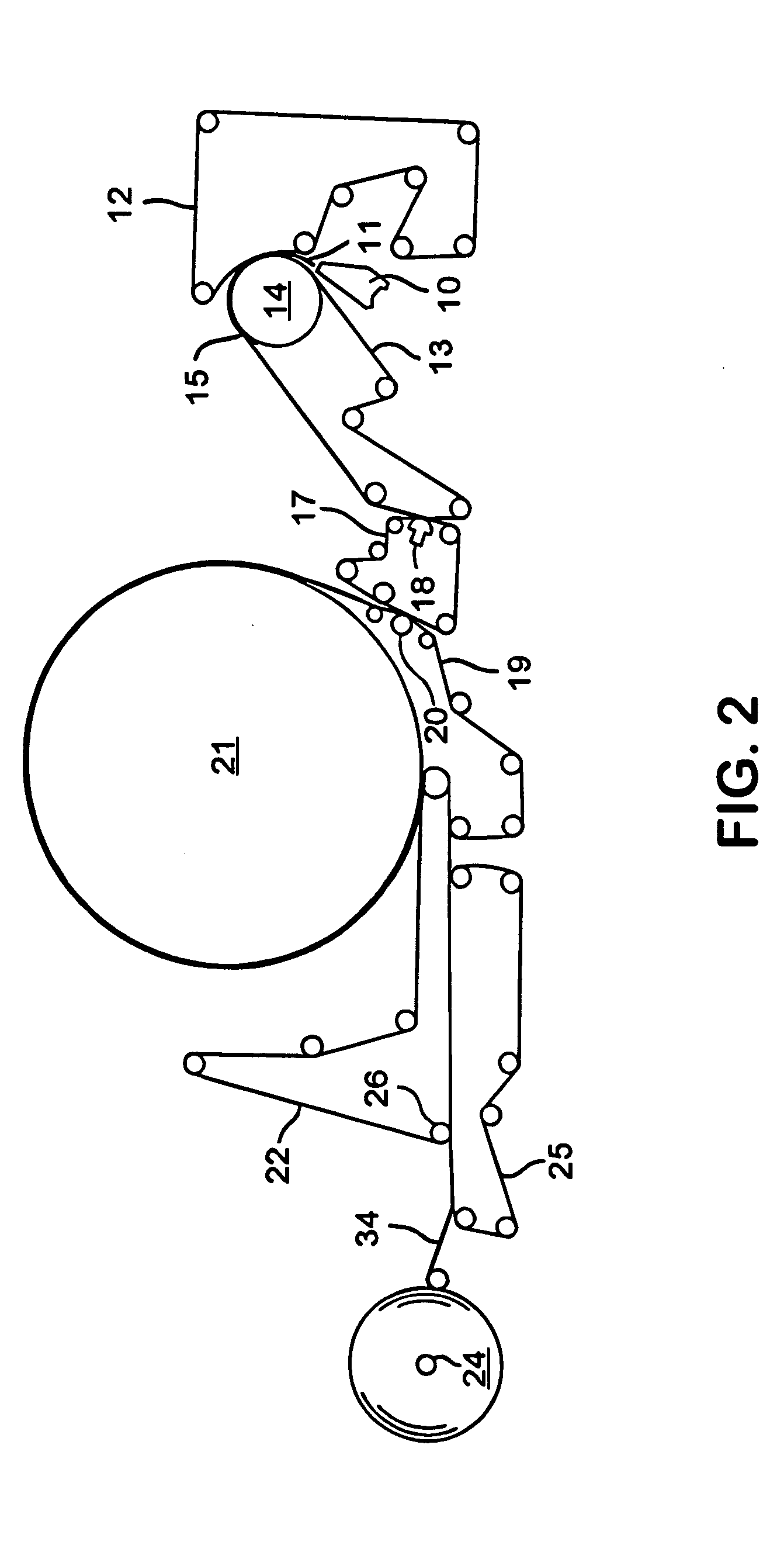

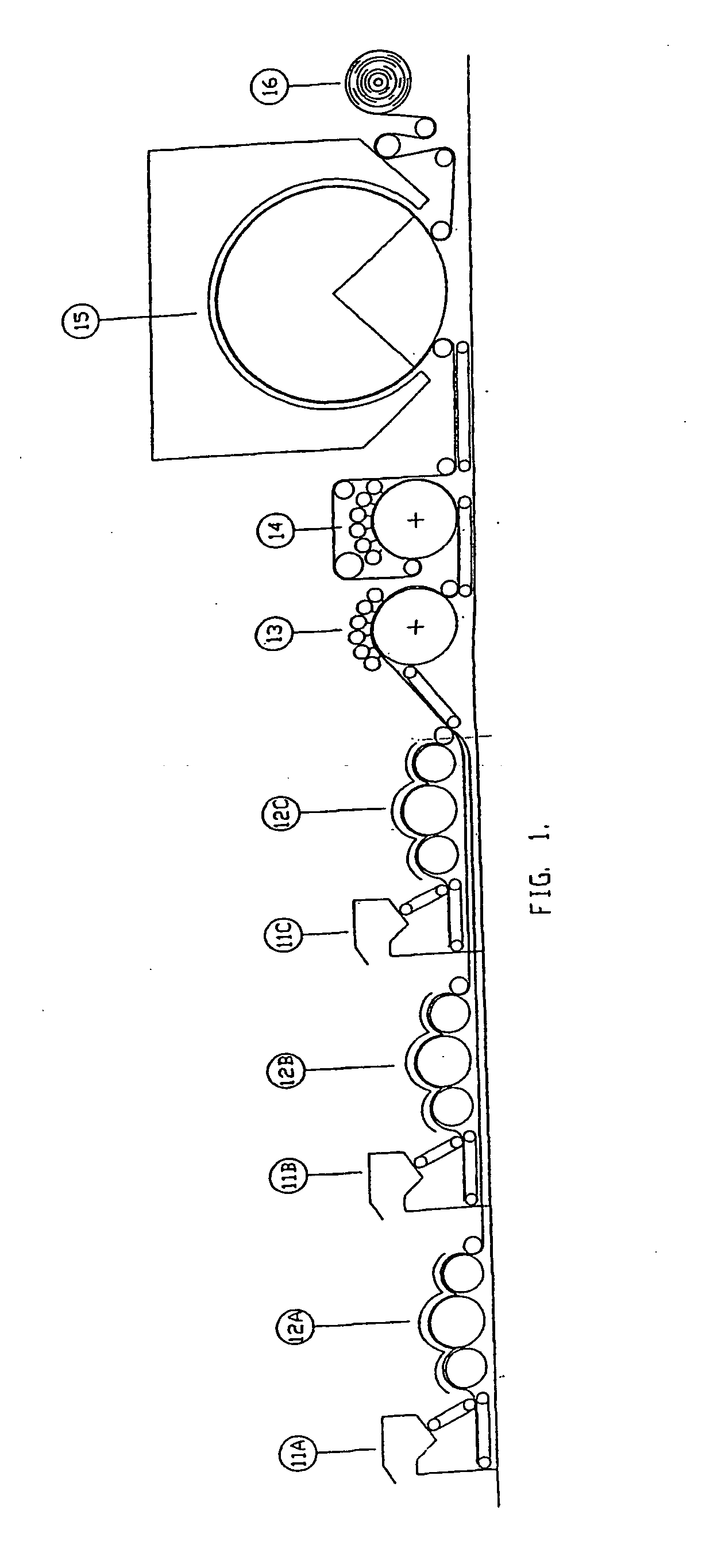

Method and apparatus for opening continuous filaments

InactiveUS7003856B2Simple conditionsUniform openingFilament manufactureFibre cleaning/openingEngineeringMechanical engineering

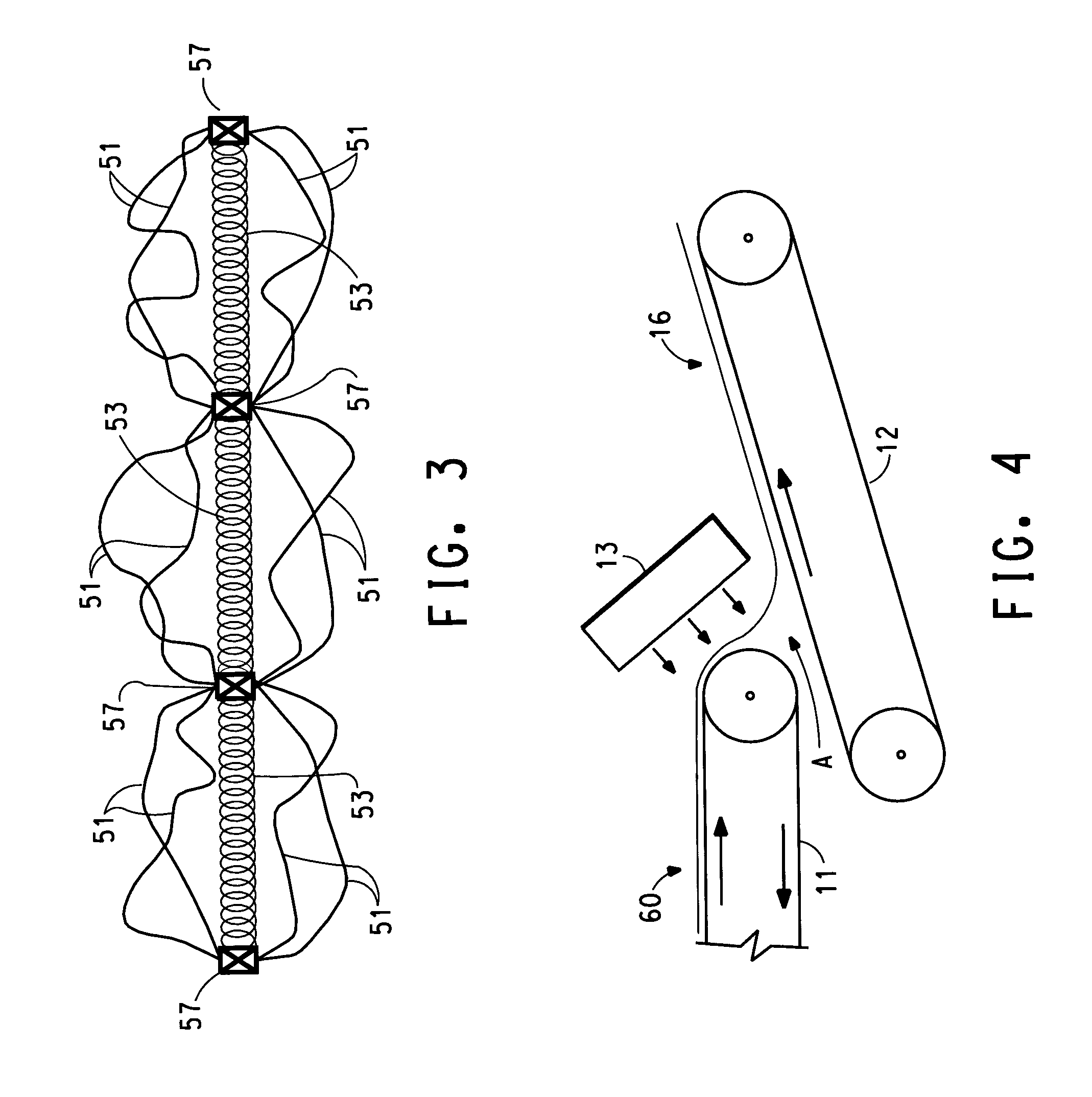

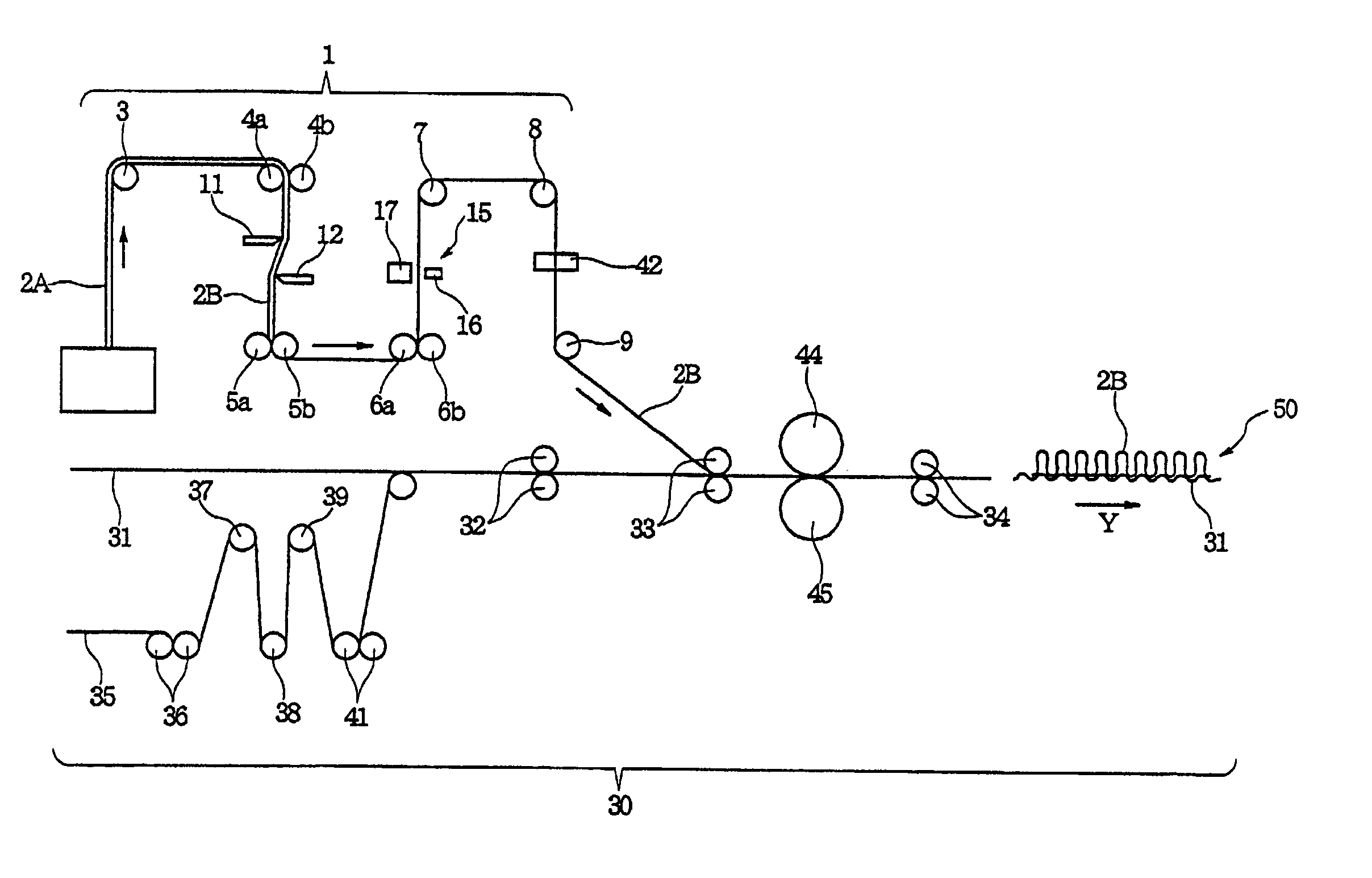

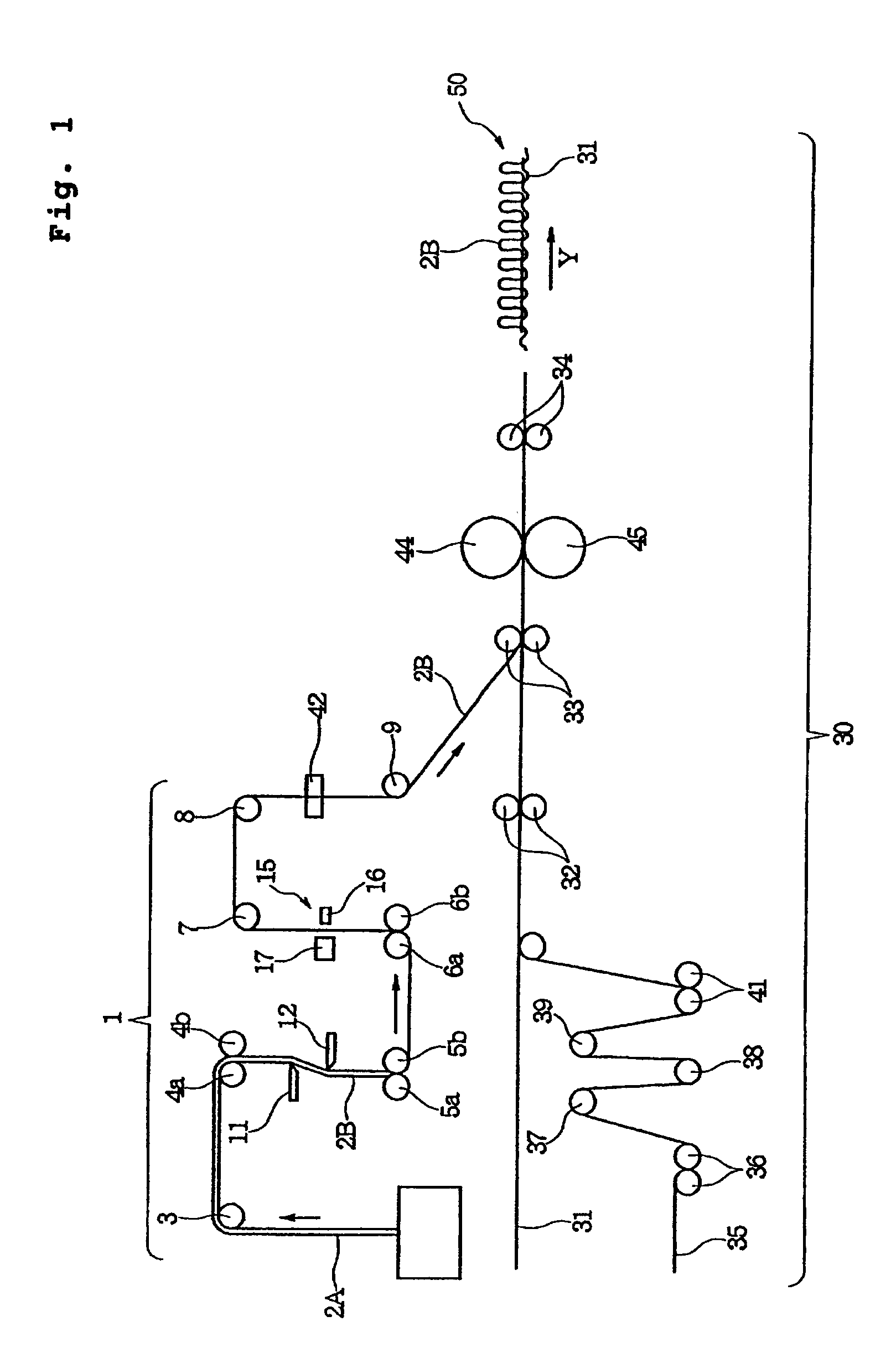

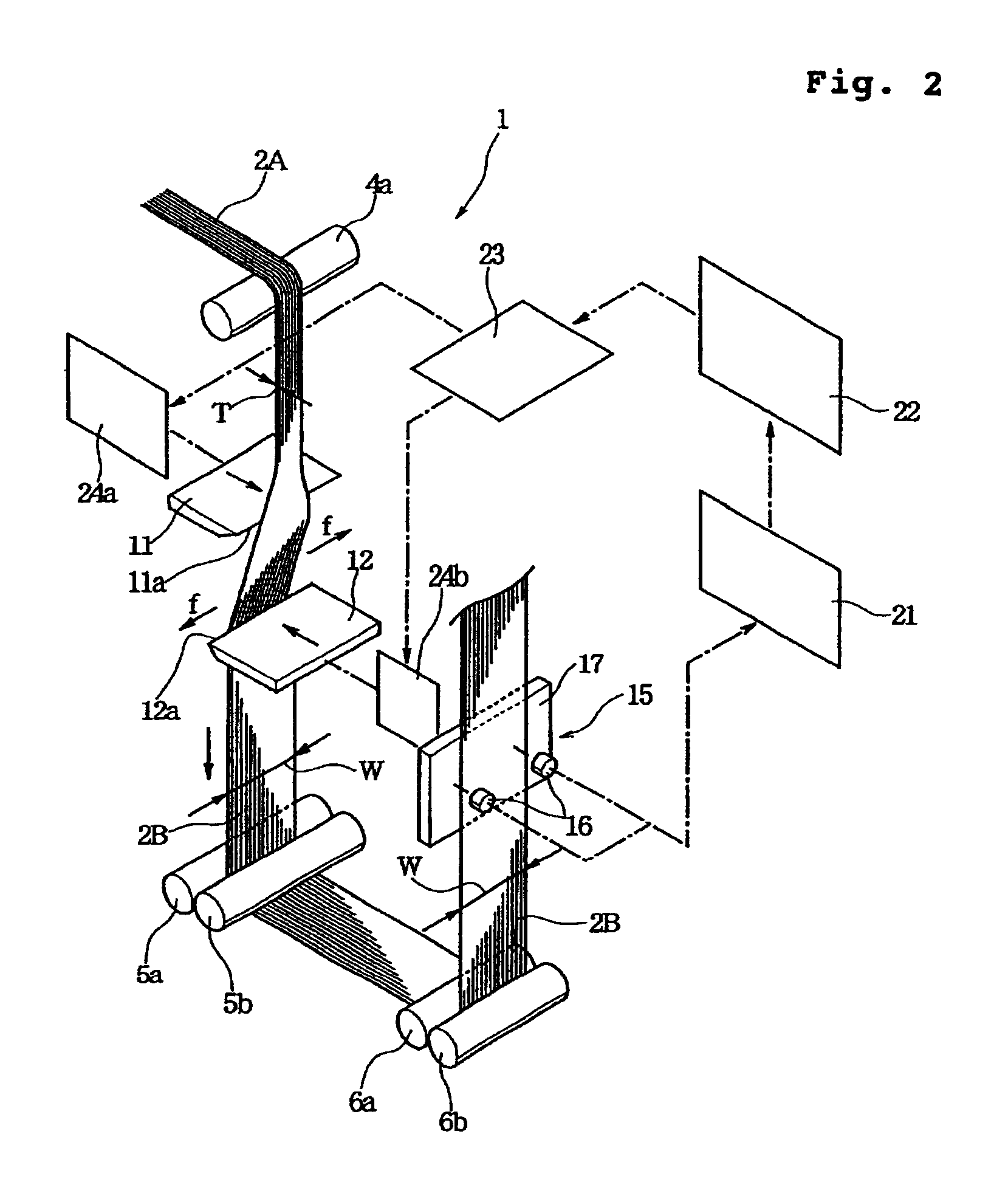

A method and an apparatus for opening continuous filaments provide stable quality of fibrous layer after opening crimped TOW. The TOW is transported by means of a plurality of rolls. While transported, the TOW is applied a resistance on one side of the TOW by slidingly contacting a sliding body onto the TOW at between rolls. As a result, continuous filaments stacked in a thickness direction of the TOW are caused to sift in a transporting direction of the TOW. Thus, the TOW is opened and the continuous filaments are spread in a width direction of the TOW.

Owner:UNI CHARM CORP

Disposable scrubbing product

InactiveUS20050129897A1Resists effect of waterMaintain stiffnessStampsWrappersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, multiple layers of an abrasive structure are releasably attached together. In this manner, the top or outermost layer may be removed after being used in order to expose an unused abrasive structure located below the discarded layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS20080121461A1Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsVolumetric Mass DensityEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

Electro spun nanofibrous wound dressing and a method of synthesizing the same

InactiveUS20130150763A1Improve mechanical propertiesGood chemical propertiesNon-adhesive dressingsAdhesive dressingsCross-linkWound dressing

The various embodiments herein provide an electro spun wound dressing comprising three nano fibrous layers and a method of synthesizing the same. The outer polymeric layer acts as a support layer for the other two layers and is hydrophilic in nature. The middle layer comprises a genipin cross linked reservoir layer loaded with a herbal extract of Melilotus officinalis and is hydrophobic or hydrophilic in nature. The second layer is cross-linked to control a release of the Melilotus officinalis extract in an aqueous environment. The third layer is a wound contacting inner layer comprising a non-cross-linked chitosan based nanofibrous layer that is hydrophilic in nature. Various additives are provided to enhance the mechanical or the chemical properties of the wound dressing and to control a release profile of the herbal extract.

Owner:MIRZAEI ESMAEIL +3

Dissection handpiece and method for reducing the appearance of cellulite

ActiveUS20100228182A1Prevent removalIncrease kinetic energyElectrotherapyAnti-cellulite devicesWound healingSkin treatments

A dermatological skin treatment device is provided. The device comprises a handpiece and a cutting tool, wherein the tool is inserted through the conduit and percutaneously inserted into a tissue disposed within a recessed area of the handpiece. The device and method cut the fibrous structures under the skin that cause cellulite at an angle substantially parallel to the surface of the skin and replace these structures with a non-cellulite forming structure by deploying a highly fibrous mesh through a single needle hole to create a highly fibrous layer directly or through wound healing processes.

Owner:ULTHERA INC

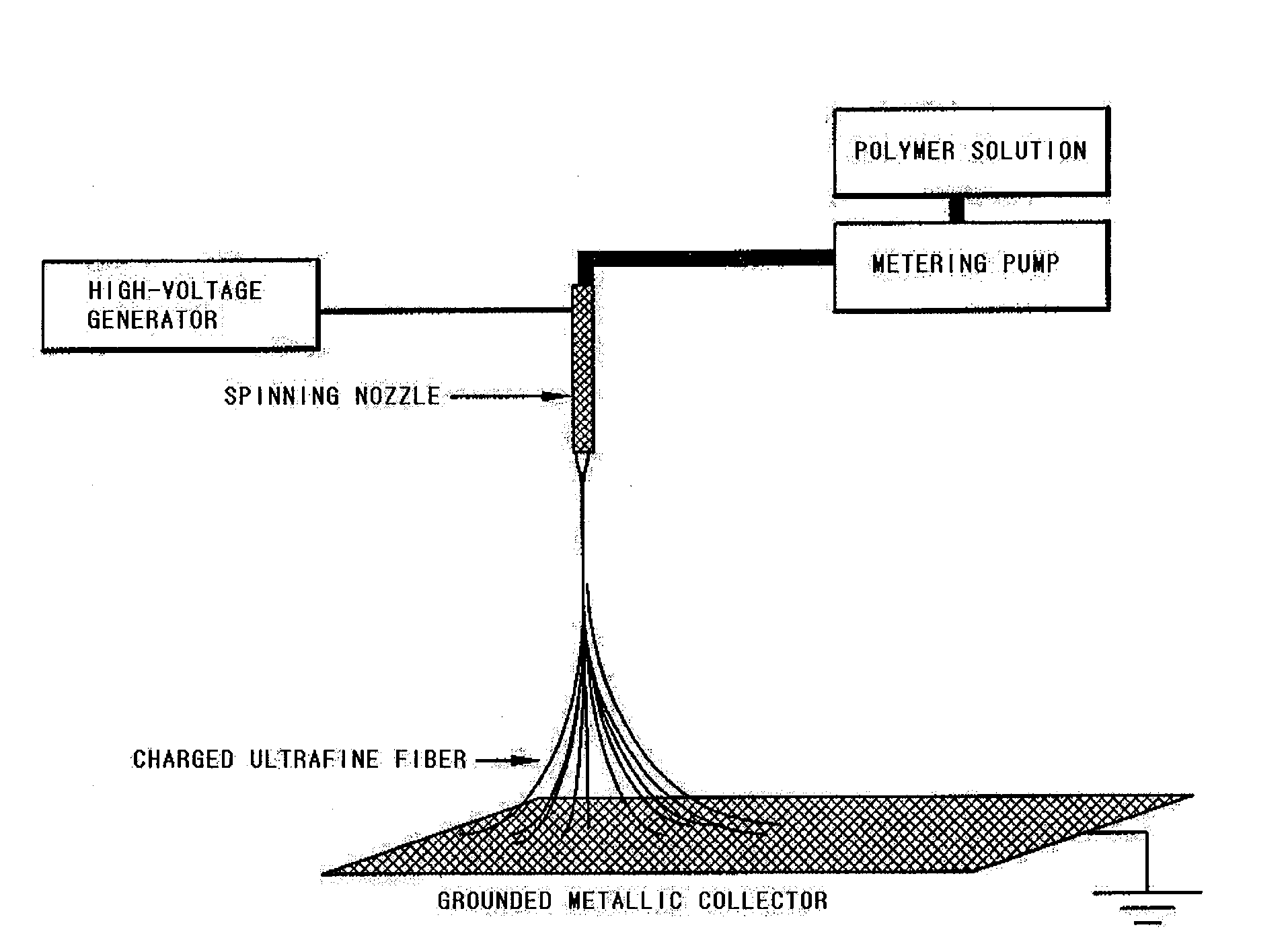

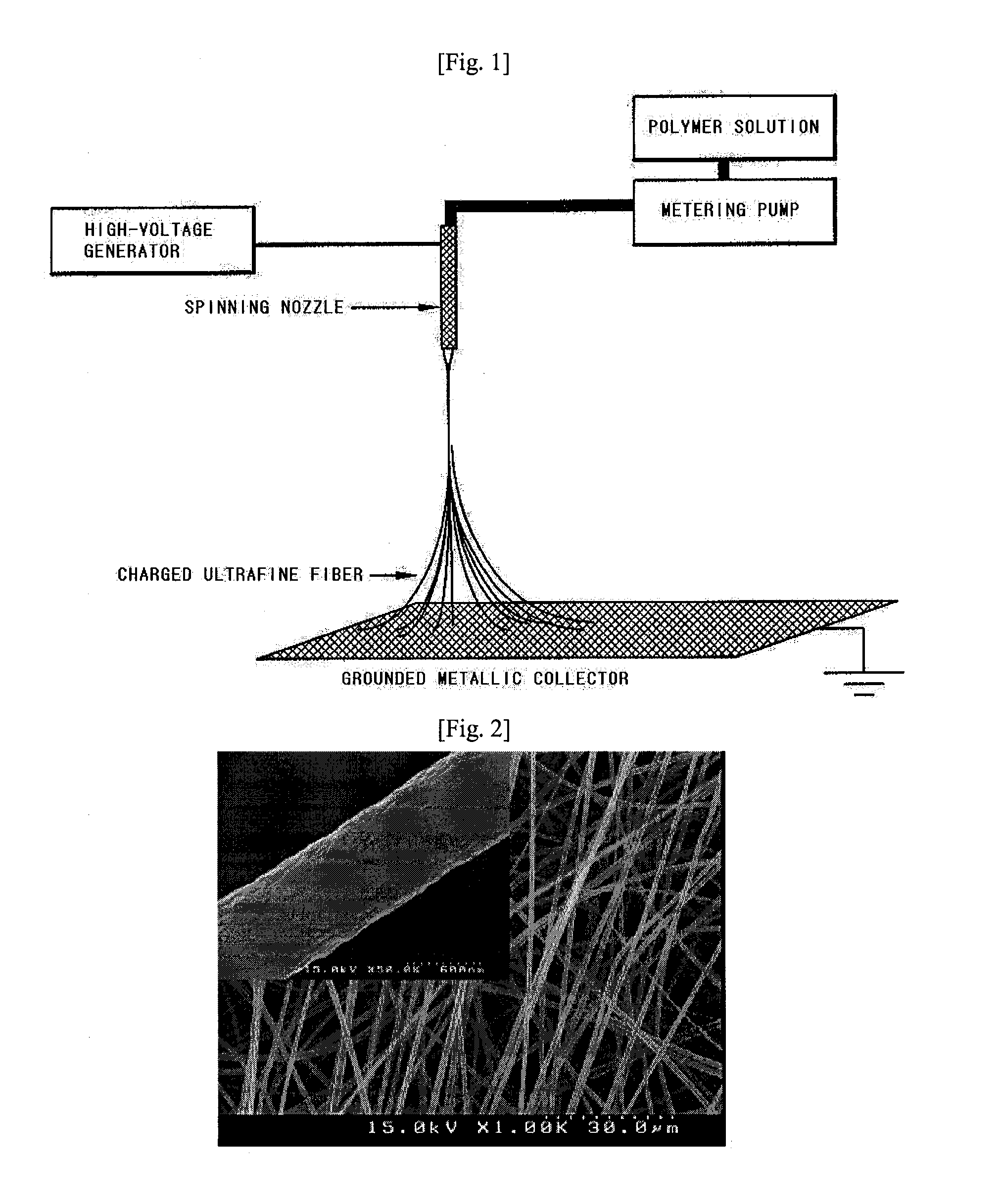

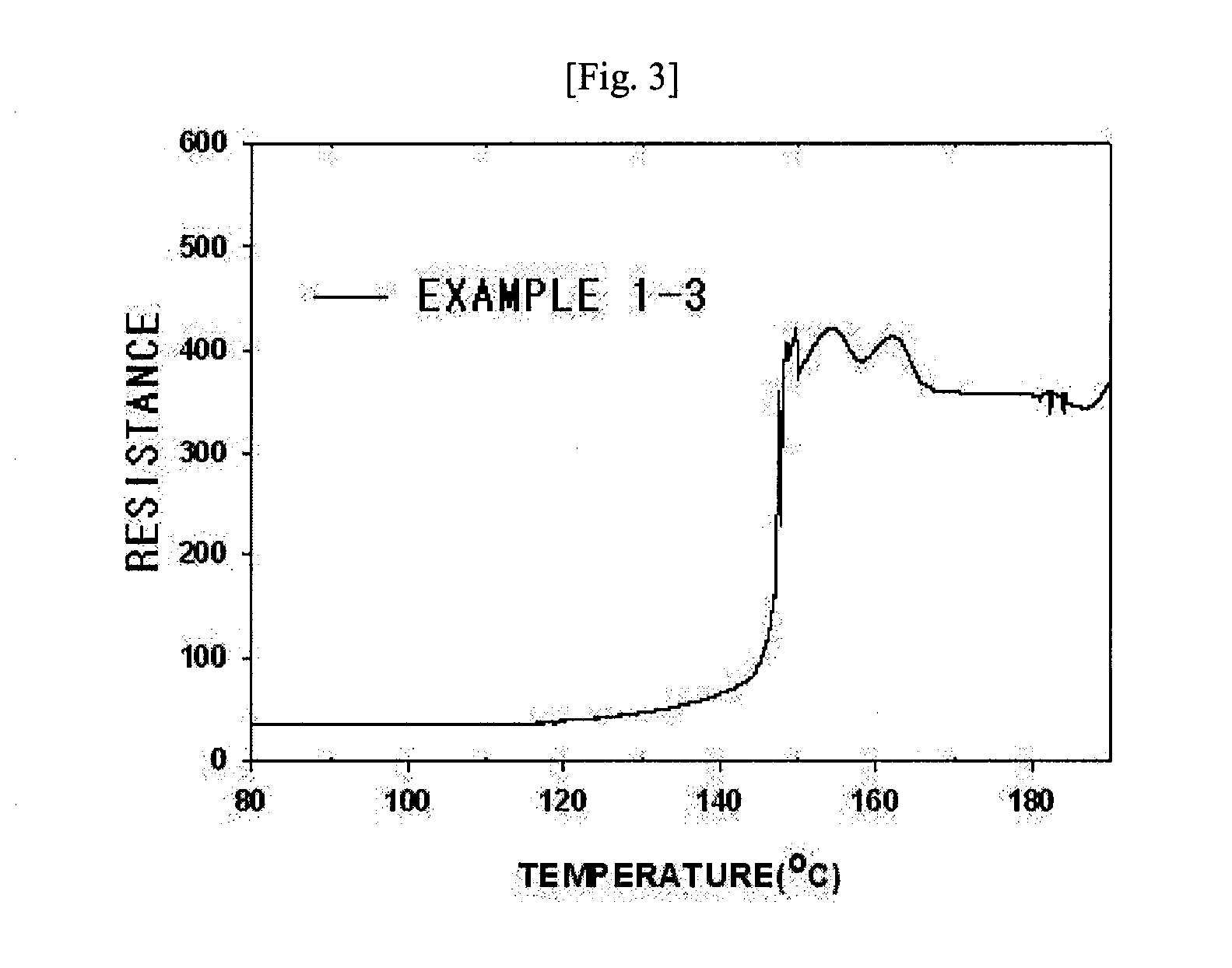

Heat resisting separator having ultrafine fibrous layer and secondary battery having the same

InactiveUS20100304205A1High suppression characteristicsImprove ionic conductivityHybrid capacitor separatorsProtecting/adjusting hybrid/EDL capacitorPolyolefinFuel cells

A polyolefin separator having an heat-resistant ultrafine fibrous layer and a secondary battery using the same, in which the separator has a shutdown function, low thermal contraction characteristics, thermal endurance, excellent ionic conductivity, excellent cycling characteristics at the time of battery construction, and excellent adhesion with an electrode. The present N invention adopts a very simple and easy process to form an ultrafine fibrous layer through an electrospinning process, and at the same time, to remove solvent and to form pores. Accordingly, the separator of the present invention is useful particularly for electrochemical devices used in a hybrid electric automobile, an electric automobile, and a fuel cell automobile, requiring high thermal endurance and thermal stability.

Owner:KOREA INST OF SCI & TECH

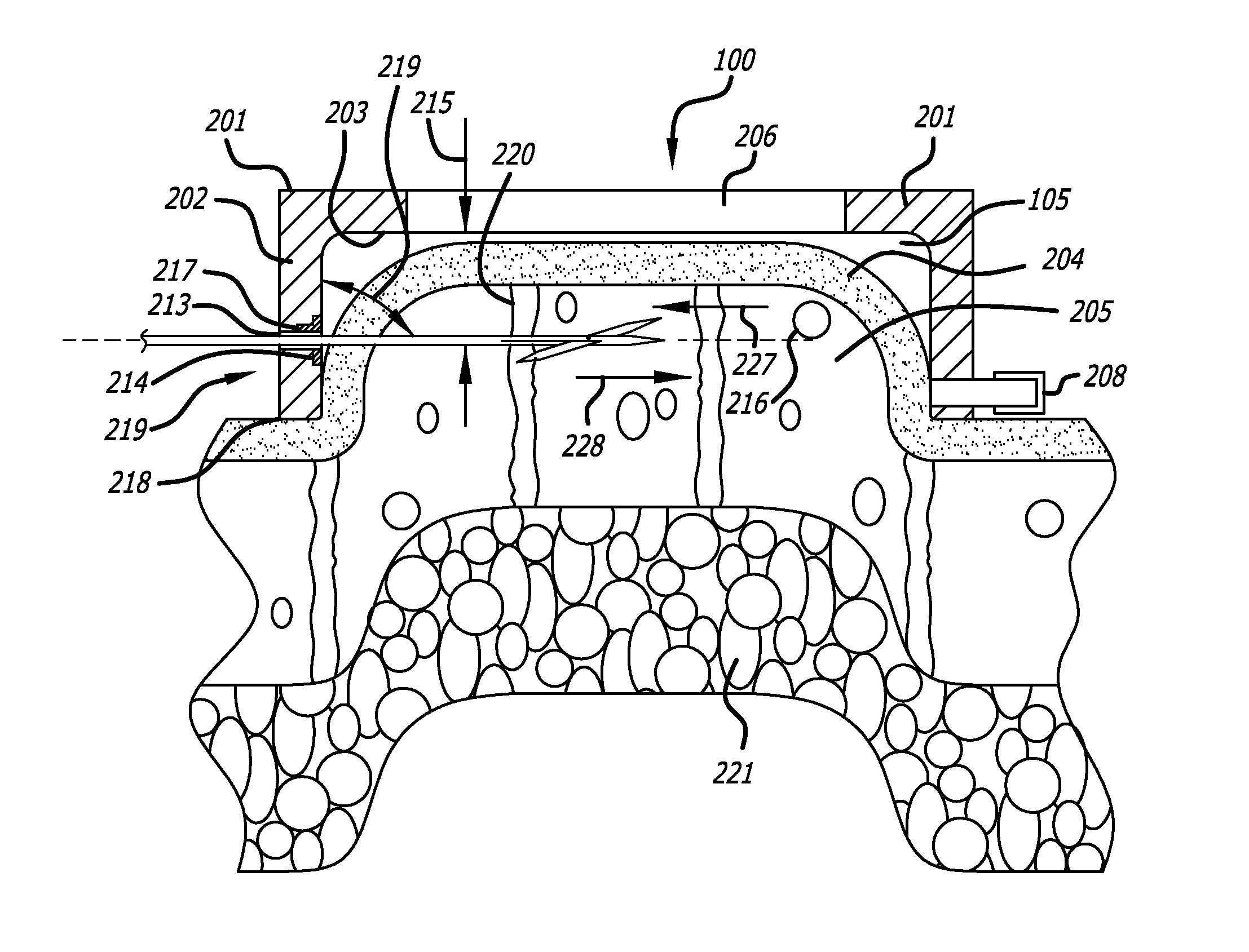

Dissection handpiece with aspiration means for reducing the appearance of cellulite

ActiveUS20120165725A1Prevent removalIncrease kinetic energyIncision instrumentsExcision instrumentsWound healingSkin treatments

A dermatological skin treatment device is provided. The device comprises a handpiece and a cutting tool, wherein the tool is inserted through the conduit and percutaneously inserted into a tissue disposed within a recessed area of the handpiece. The device and method cut the fibrous structures under the skin that cause cellulite at an angle substantially parallel to the surface of the skin and replace these structures with a non-cellulite forming structure by deploying a highly fibrous mesh through a single needle hole to create a highly fibrous layer directly or through wound healing processes. A tool is provided to aspirate excess fluid and tissue from the treatment area.

Owner:ULTHERA INC

Maintenance-free Anti-fog respirator

ActiveUS20080271737A1Improve fitImprove wearer comfortGarment special featuresBreathing filtersRespiratorFilter media

A respirator 10 that includes a harness 14 and a mask body 12 that is air permeable. The mask body 12 has a sinus region 40 and a primary filtering region 44 and comprises at least one nonwoven fibrous webs, which web includes a layer of filter media. The sinus region 40 of the mask body 12 exhibits a resistance to airflow that is greater than the primary filtering region 44. This resistance to airflow is achieved through an alteration of the intrinsic structure of the plurality of nonwoven fibrous layers in the sinus region 40 without adding additional material to the mask body. The alteration of the intrinsic structure assists in preventing eyewear fogging.

Owner:3M INNOVATIVE PROPERTIES CO

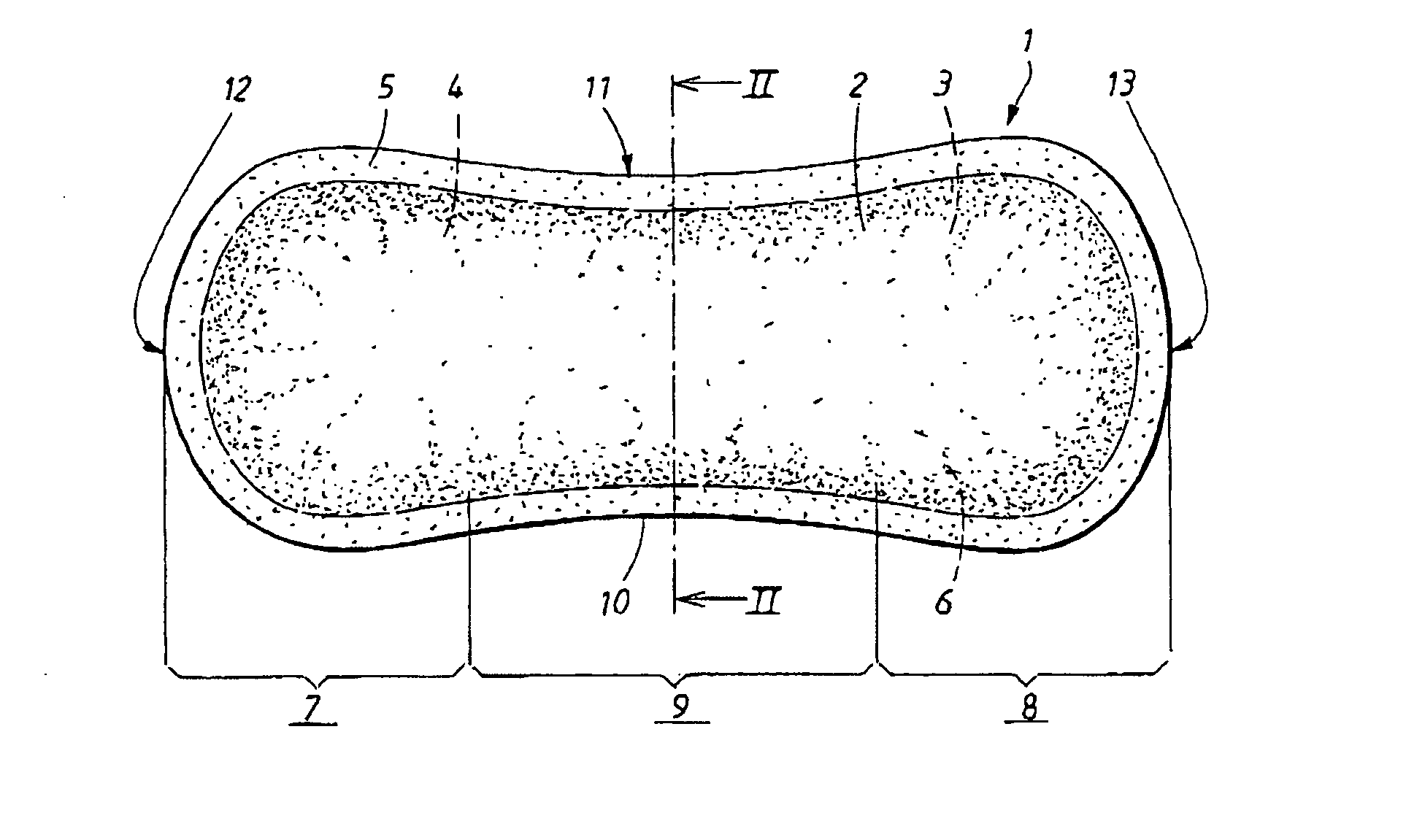

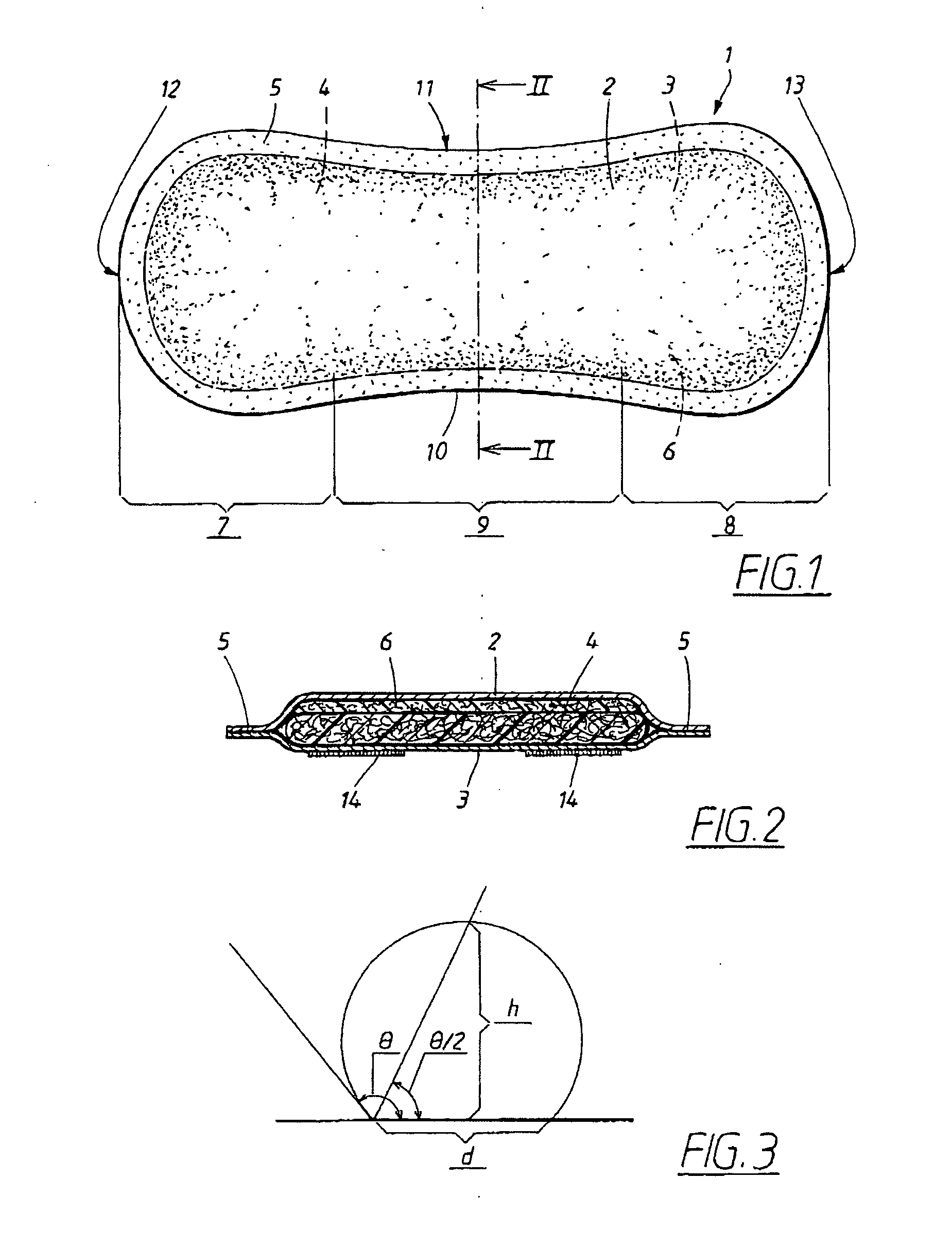

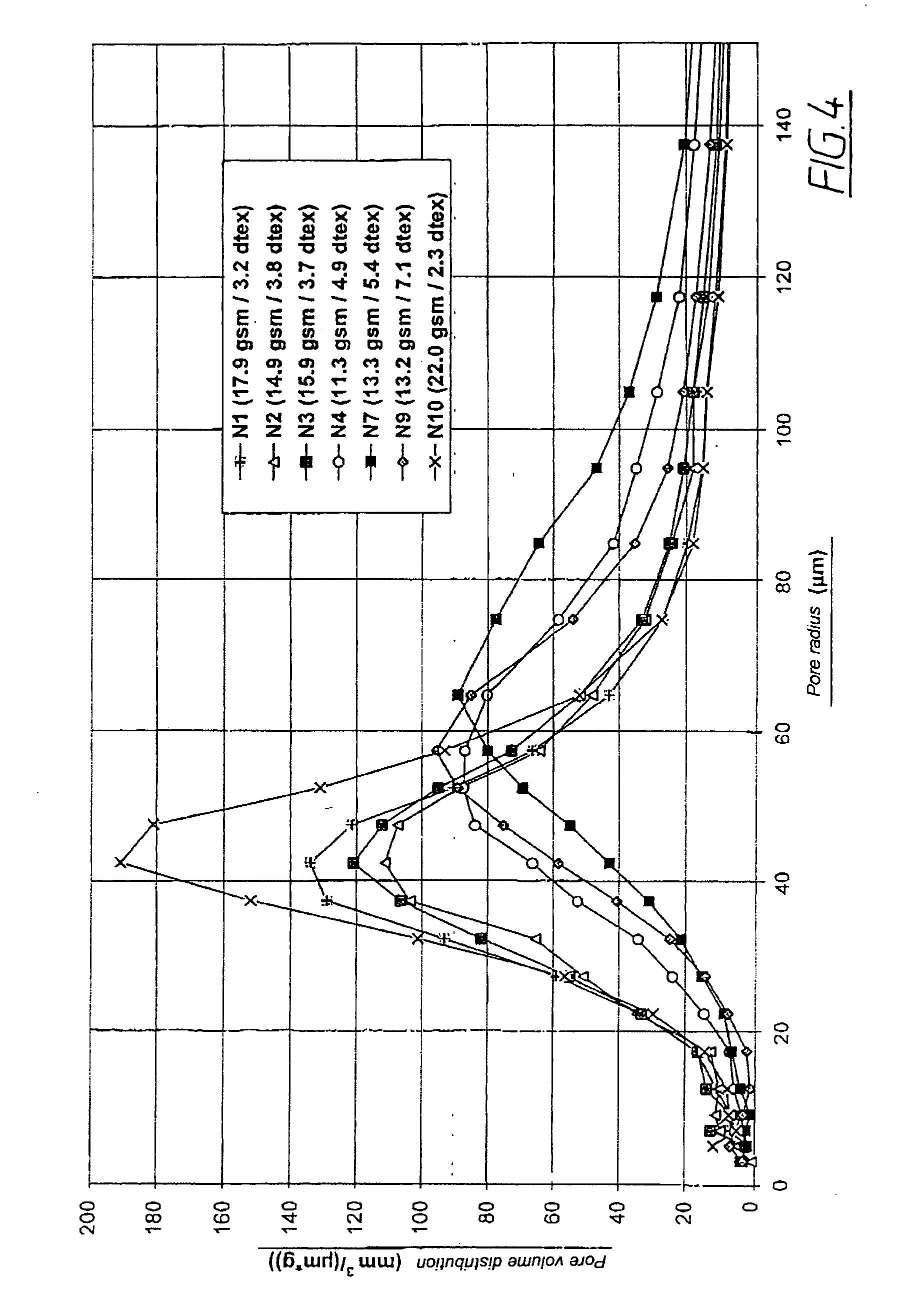

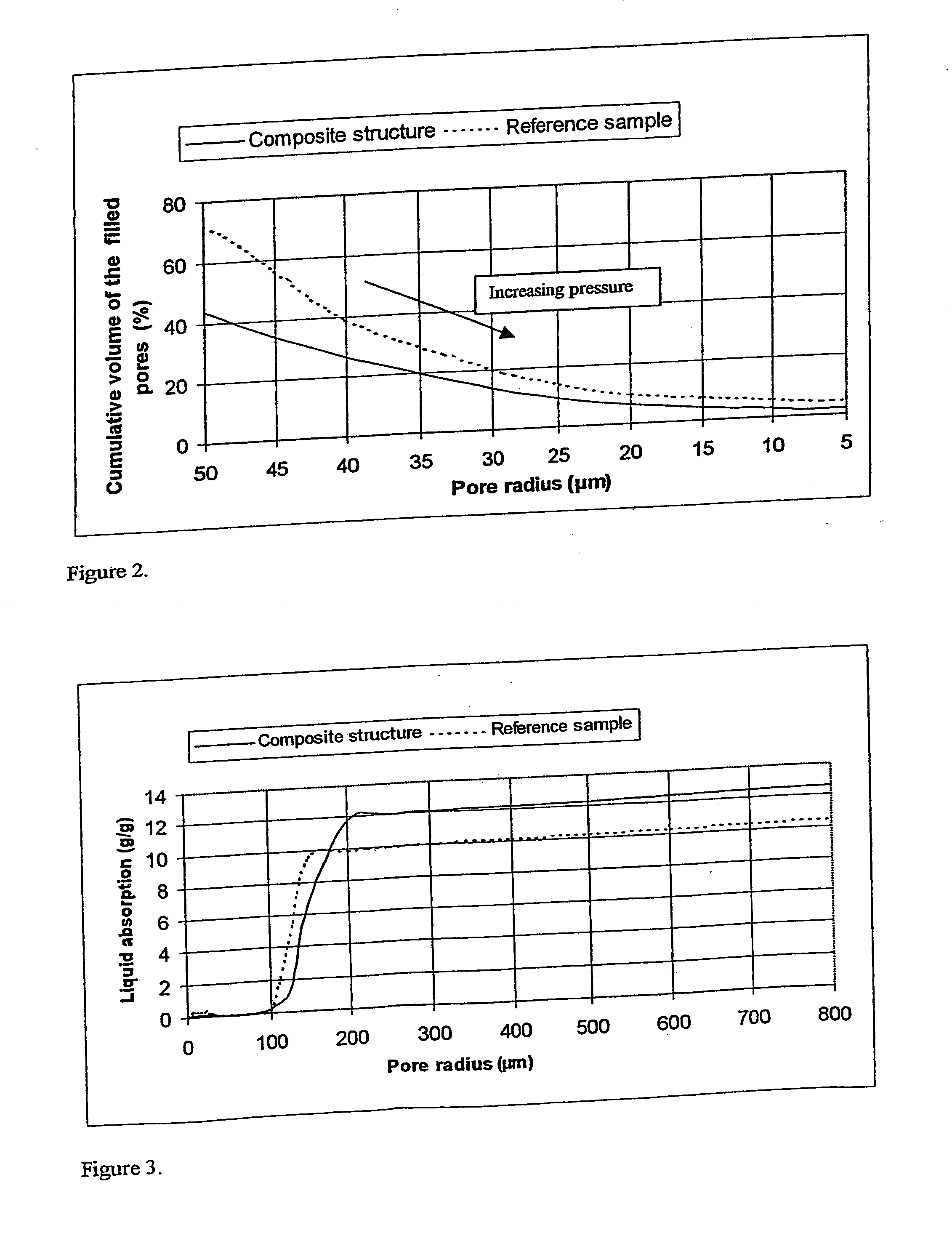

Absorbent article with improved surface material

An absorbent article comprises an absorbent body, a liquid-permeable covering layer arranged over a first surface on the absorbent body, and a liquid-permeable liquid-transfer layer arranged between the absorbent body and the liquid-permeable covering layer. The liquid-permeable covering layer comprises a nonwoven material with a pore volume distribution curve with a maximum at a pore radius greater than or equal to 50 mum and with a wetting angle of at least 120°. The liquid-transfer layer comprises a fibrous layer with a pore volume distribution curve with a maximum at a pore radius of from 105 to 325 mum.

Owner:ESSITY HYGIENE & HEALTH AB

Fire retardant nonwoven material and process for manufacture

Owner:GLATFELTER CORP

Method for preparing two-layer bicomposite collagen material for preventing post-operative adhesions

InactiveUSRE39172E1Improve propertiesAvoid stickingBiocidePeptide/protein ingredientsMedicinePolyethylene glycol

A bicomposite material based on collagen is prepared which has two closely bound layers and is biocompatible, non-toxic, hemostatic and biodegradable in less than a month, and can be used in surgery to achieve hemostasis and prevent post-surgical adhesion. To prepare the material, a solution of collagen or gelatin, which may contain glycerine and a hydrophilic additive such as polyethylene glycol or a polysaccharide, is poured onto an inert support to form a layer 30 μm to less than 100 μm thick. Then a polymeric porous fibrous layer is applied during gelling of the collagen or gelatin, and the resultant material is dried. The polymeric porous fibrous layer may be made of collagen or a polysaccharide, and have a density of not more than 75 mg / cm2, a pore size from 30 μm to 300 μm and a thickness of 0.2 cm to 1.5 cm.

Owner:IMEDEX BIOMATERIAUX CHAPONOST

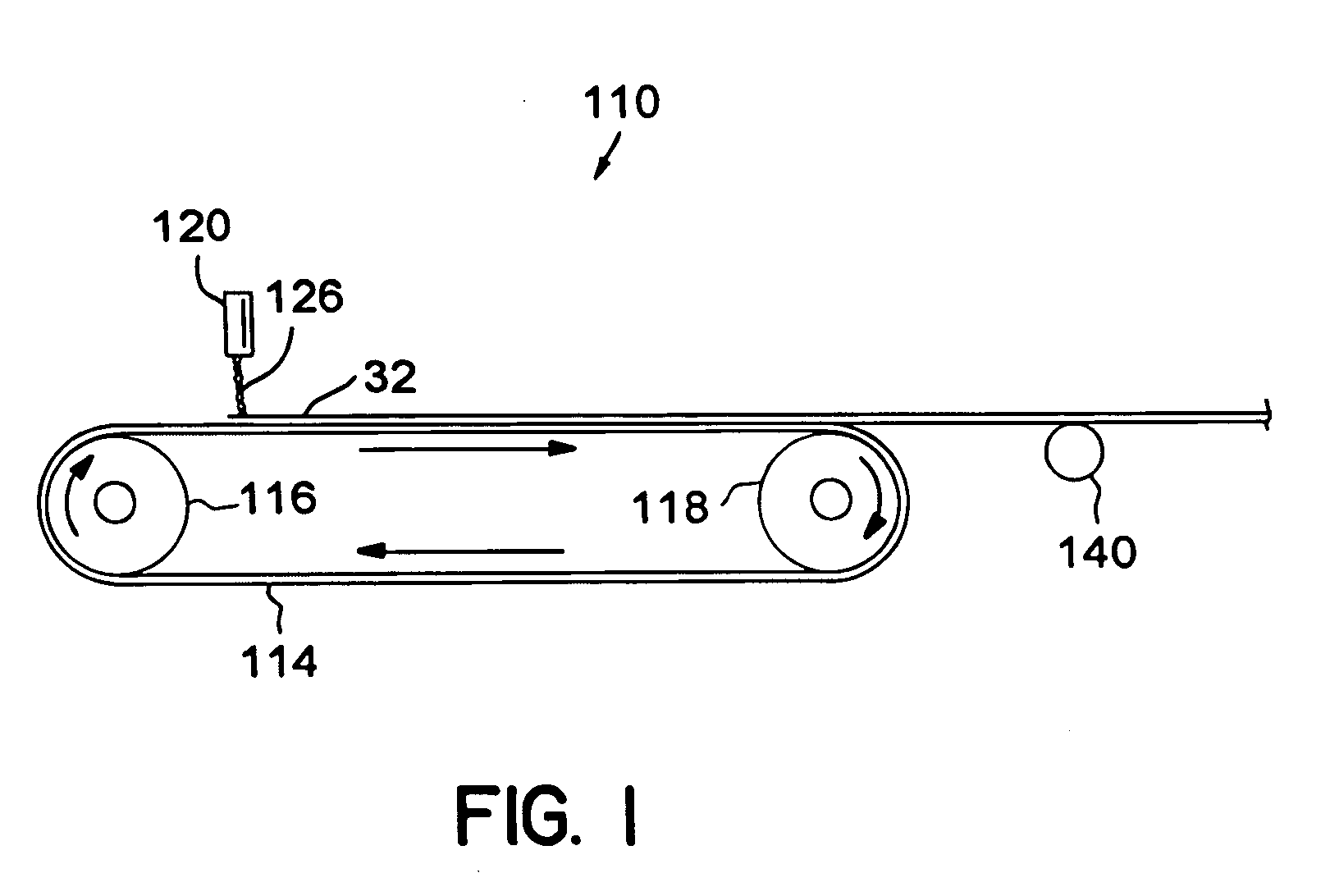

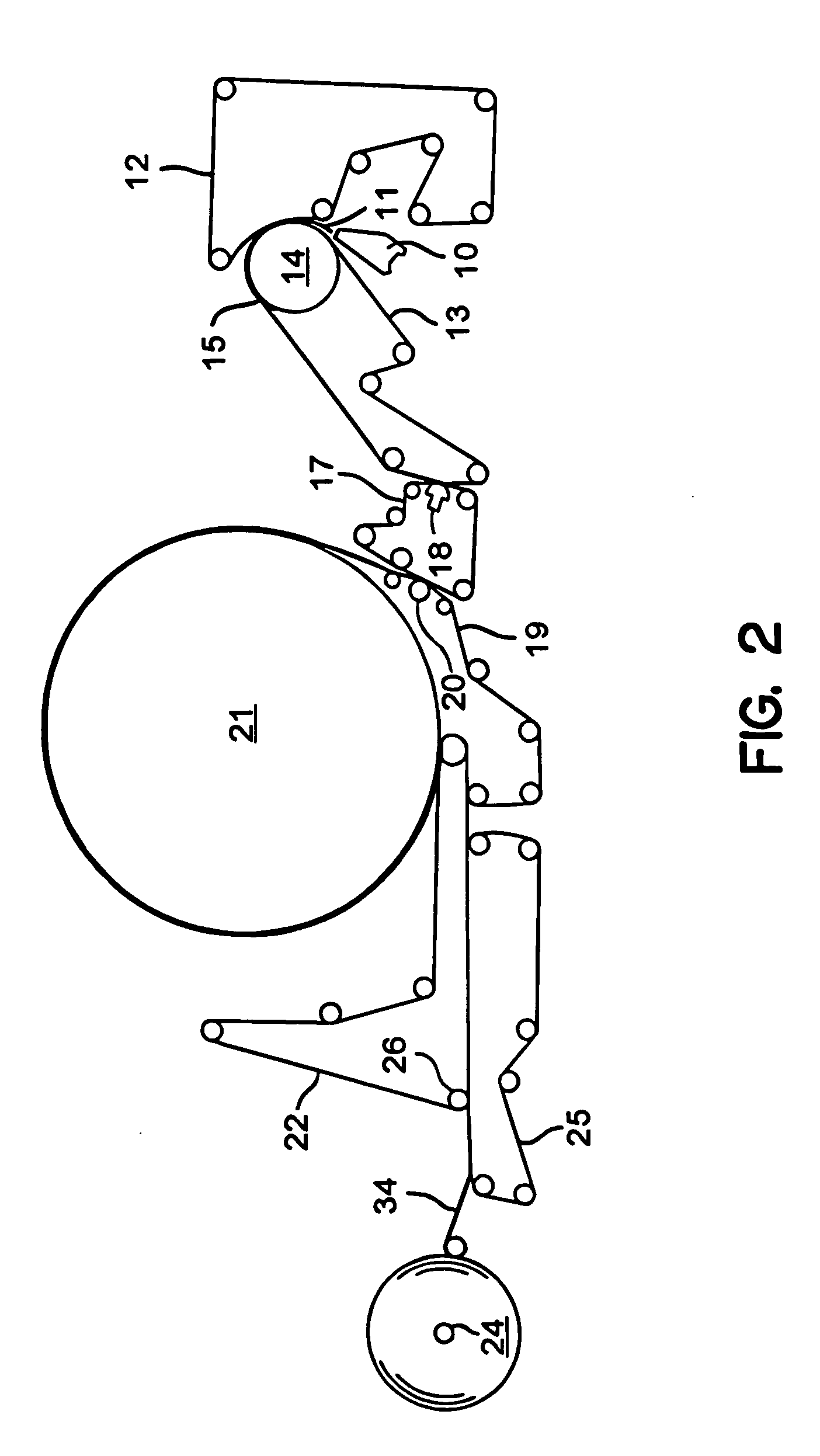

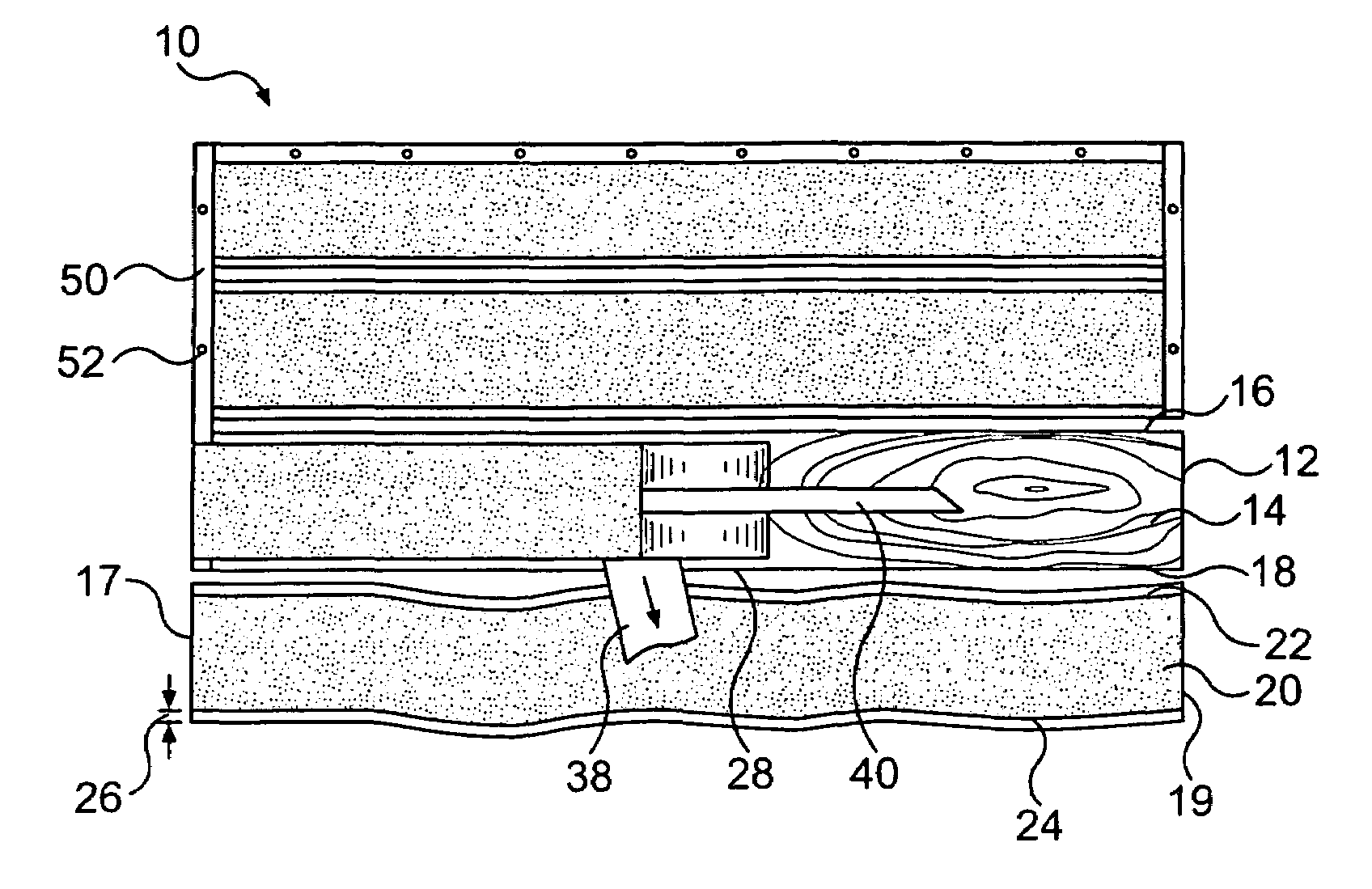

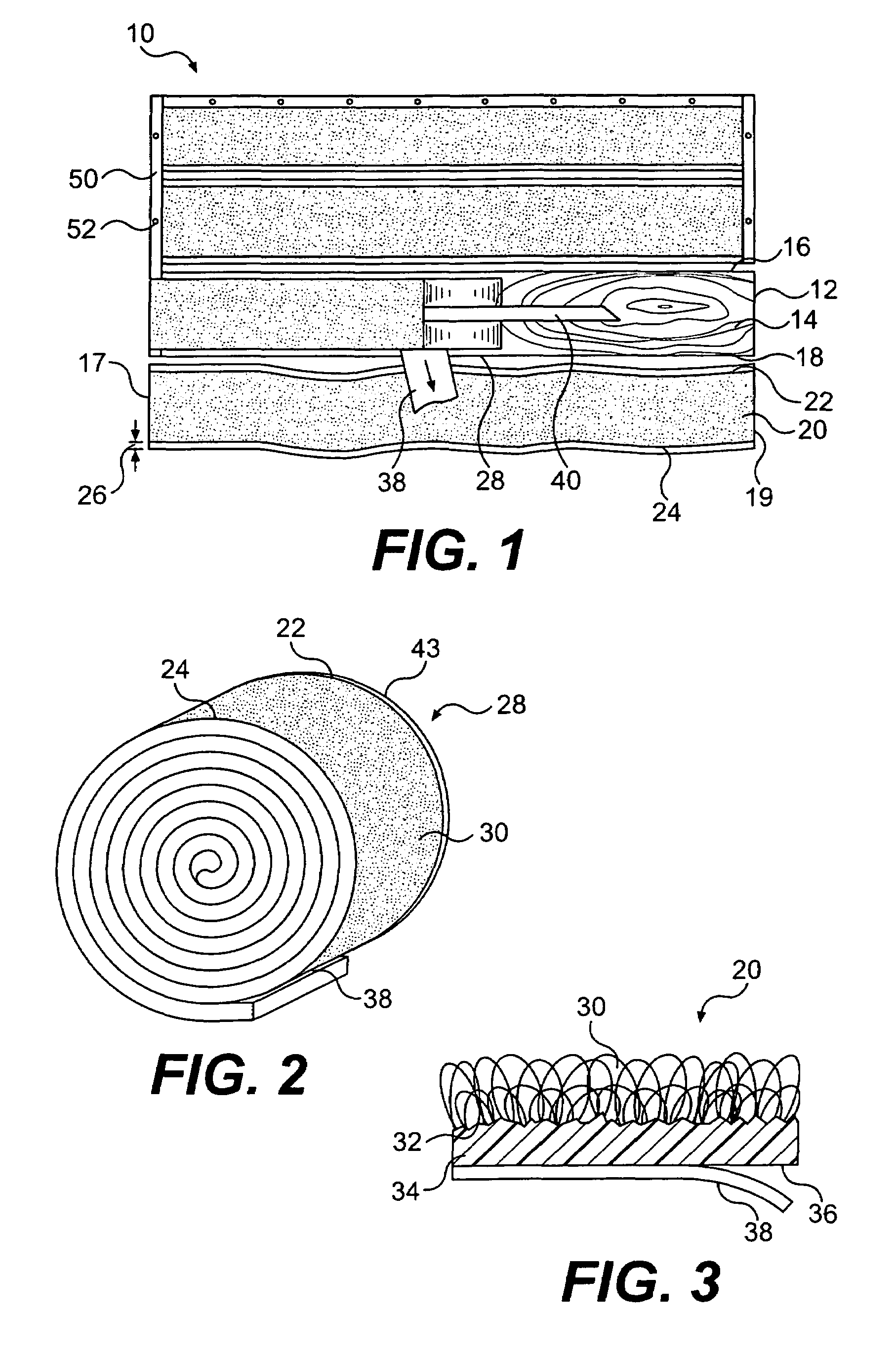

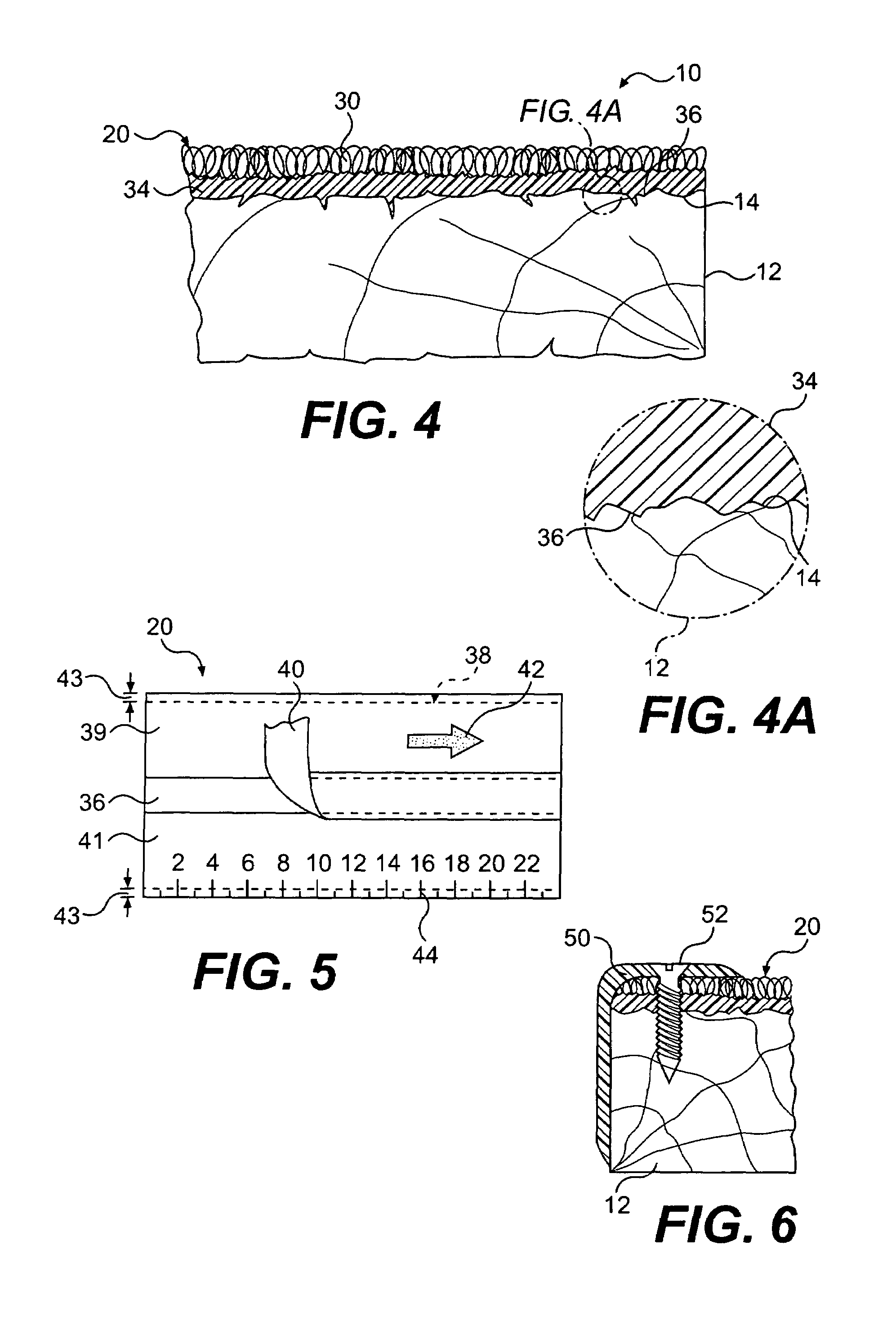

Method of applying a covering for boards

A covering system is designed as an elongated strip of covering material having a fibrous layer and an integral moldable layer for mounting on the upper surface of boards, such as deck planks. In a preferred embodiment, strips are preferably secured to the length of the boards solely by a layer of a hot melt pressure sensitive adhesive carried by the strip. The moldable material is applied in a volume of about at least 185 grams per square meter. A removable release sheet covers the adhesive surface of the moldable material. The release sheet can include a positioning mechanism and indicia such as the direction of the pile and measuring guides. The moldable material provides sufficient adhesion across the width of the strip for both initial application and sufficient thickness for subsequently molding to the board surface for long term adhesion.

Owner:OCONNOR INVESTMENT CORP

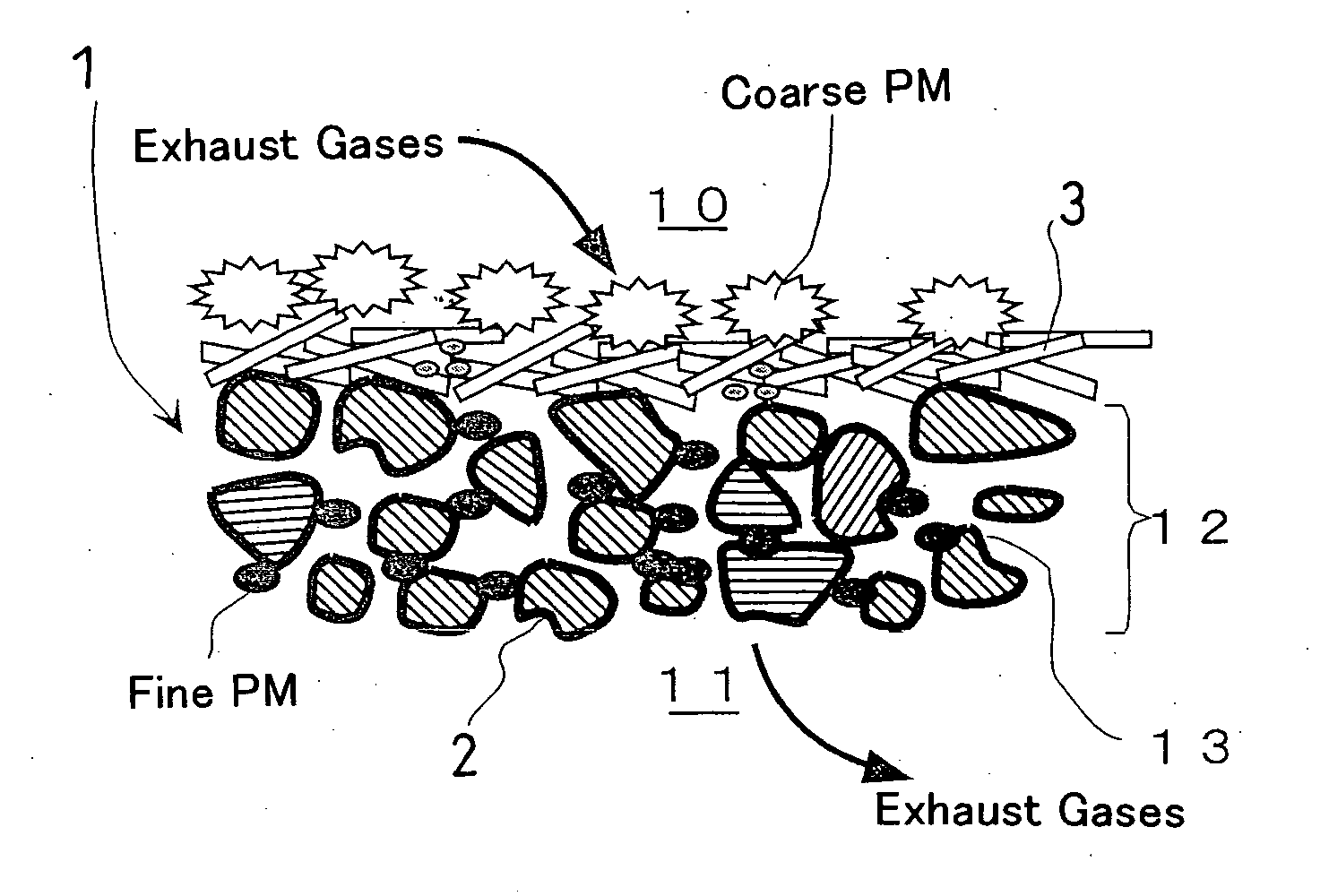

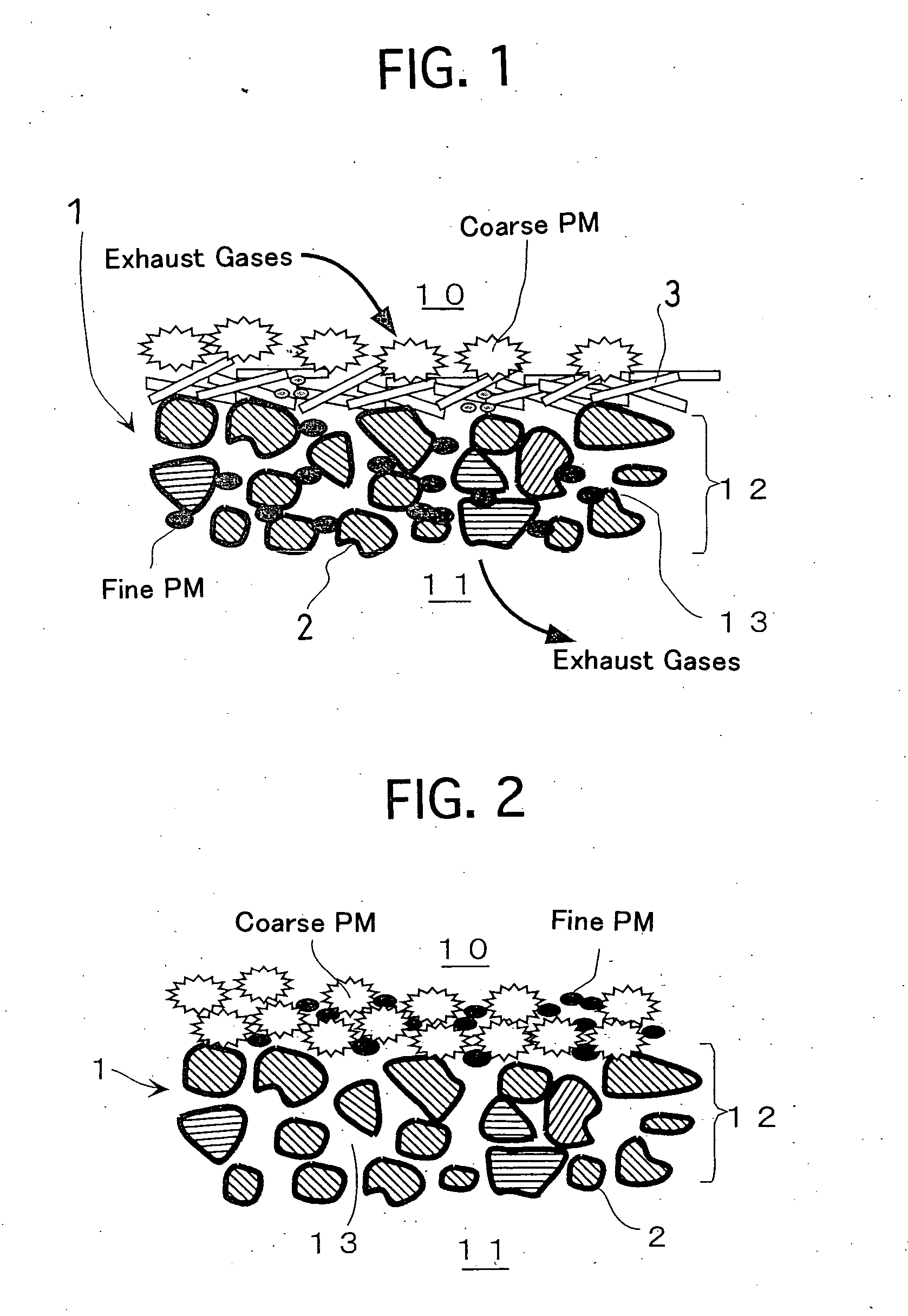

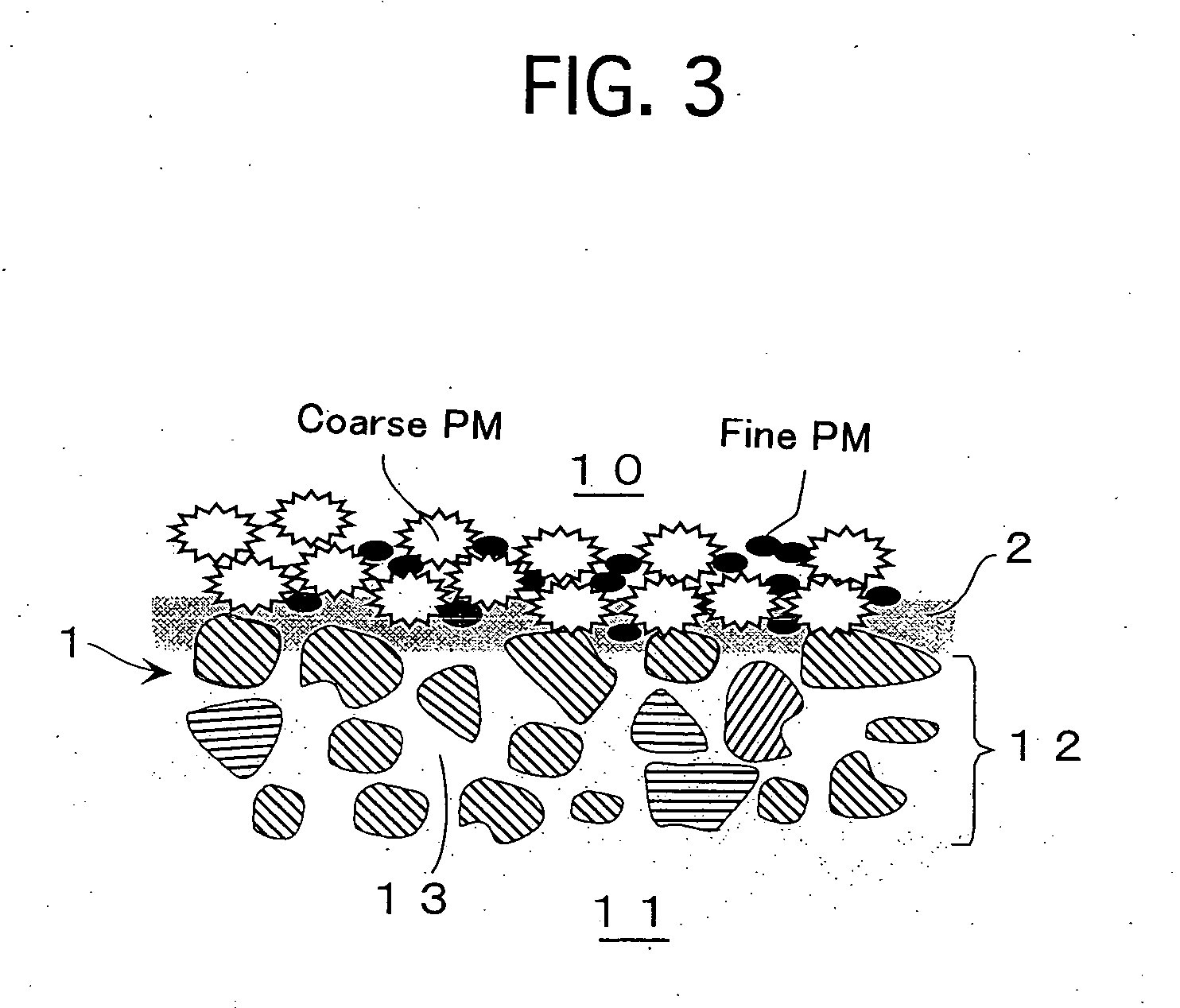

Filter catalyst for purifying exhaust gases

InactiveUS20050074374A1Oxidizing rateIncrease ratingsCombination devicesInternal combustion piston enginesAdditive ingredientExhaust fumes

A filter catalyst is for purifying exhaust gases, and comprises a honeycomb structure, a catalytic layer and a fibrous layer. The honeycomb structure comprises inlet cells clogged on a downstream side of a flow of the exhaust gases, outlet cells neighboring the inlet cells, and clogged on an upstream side of the flow of the exhaust gases, and cellular walls demarcating the inlet cells and the outlet cells, and having pores. The catalytic layer is formed on a surface of the cellular walls and an inner surface of the pores, and includes a porous oxide and a catalytic ingredient loaded on the porous oxide. The fibrous layer is formed on the outermost surface of the cellular walls of the inlet cells at least, and includes entangled fibrous substances composed of a heat-resistant material. The filter catalyst inhibits the pressure loss from increasing and upgrades the oxidizing rate of PMs greatly.

Owner:TOYOTA JIDOSHA KK

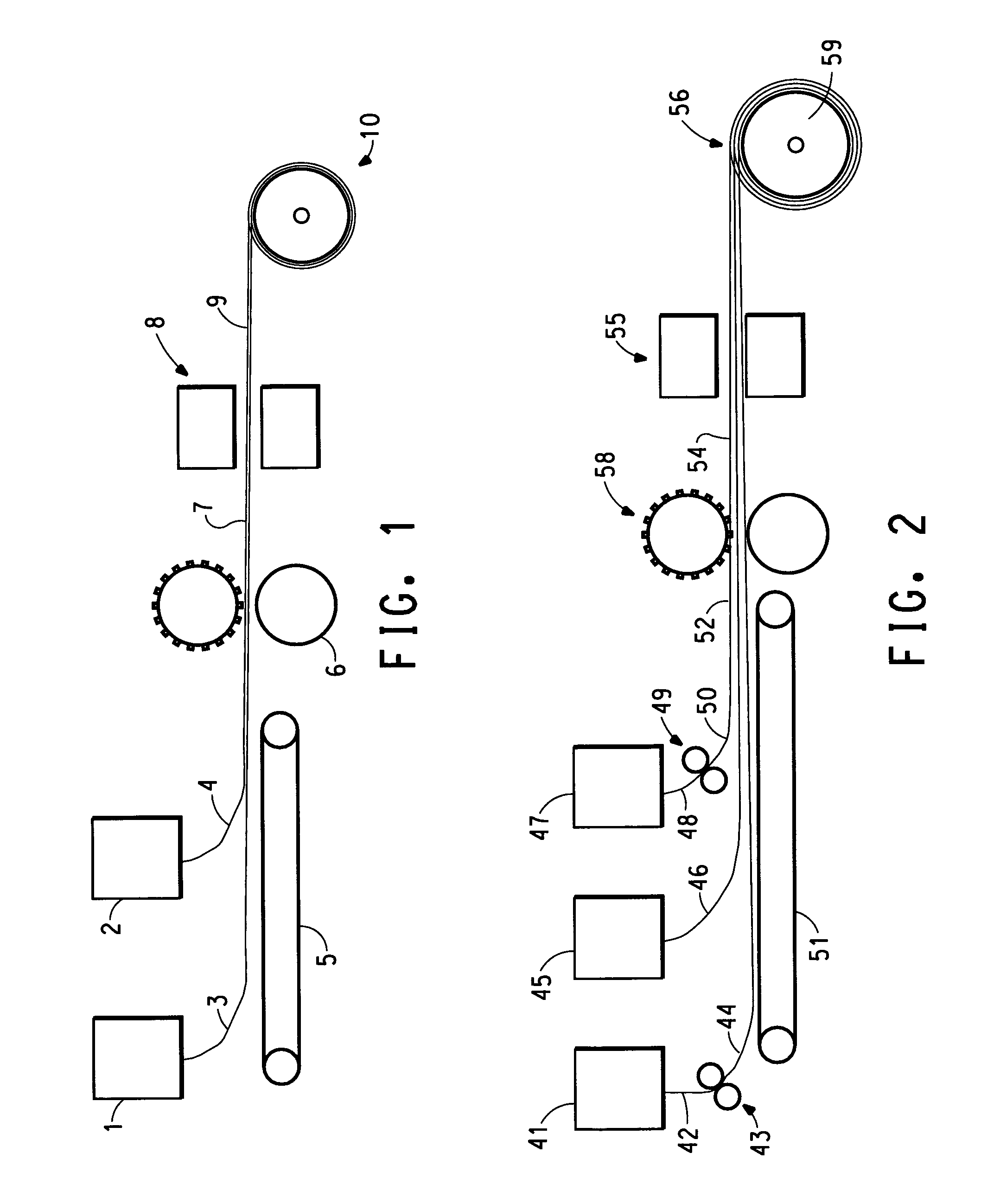

Composite nonwoven its use and method of manufacture

InactiveUS20050090175A1Excellent liquid absorptionGood release effectPattern makingNeedling machinesPolymer scienceFibrous layer

The invention concerns a composite nonwoven formed from fibrous layers bonded together by entanglement of fibers of the layers, wherein the fibrous layers comprise first and second outer layers each comprising a mixture of hydrophobic and hydrophilic fibers, as well as an intermediate layer of hydrophobic fibers sandwiched between the first and the second outer layers, the weight ratio between the hydrophobic and hydrophilic fibers in the first and the second layers being 20:80 to 80:20. The invention also concerns the manufacture of the nonwoven, as well as its use, especially as a wet wipe.

Owner:SUOMINEN NONWOVENS

Dissection handpiece and method for reducing the appearance of cellulite

ActiveUS20120277674A1Increase kinetic energyPrevent leakageElectrotherapyAnti-cellulite devicesWound healingSkin treatments

A dermatological skin treatment device is provided. The device comprises a handpiece and a cutting tool, wherein the tool is inserted through the conduit and percutaneously inserted into a tissue disposed within a recessed area of the handpiece. The device and method cut the fibrous structures under the skin that cause cellulite at an angle substantially parallel to the surface of the skin and replace these structures with a non-cellulite forming structure by deploying a highly fibrous mesh through a single needle hole to create a highly fibrous layer directly or through wound healing processes.

Owner:ULTHERA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com