Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

548results about "Fibre cleaning/opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

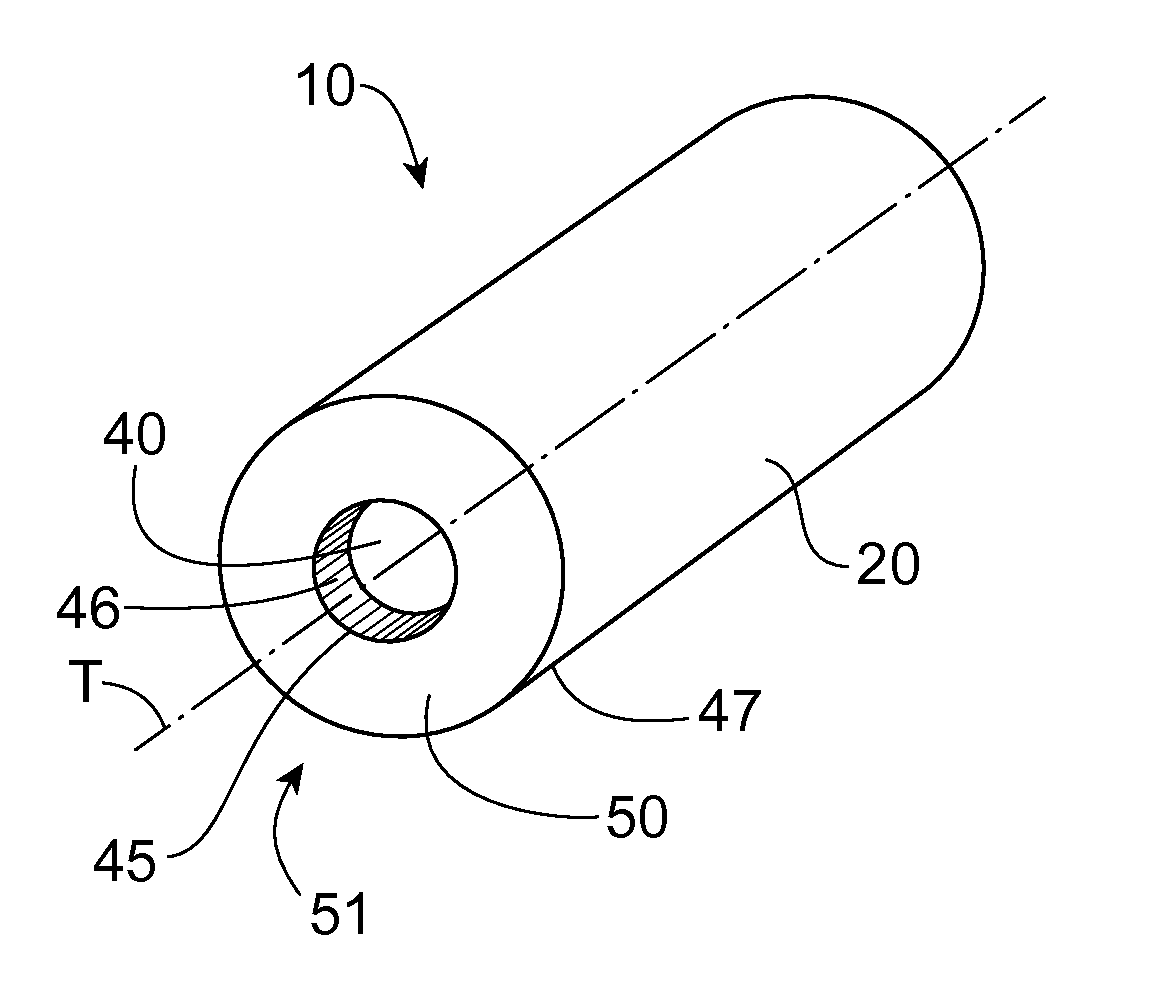

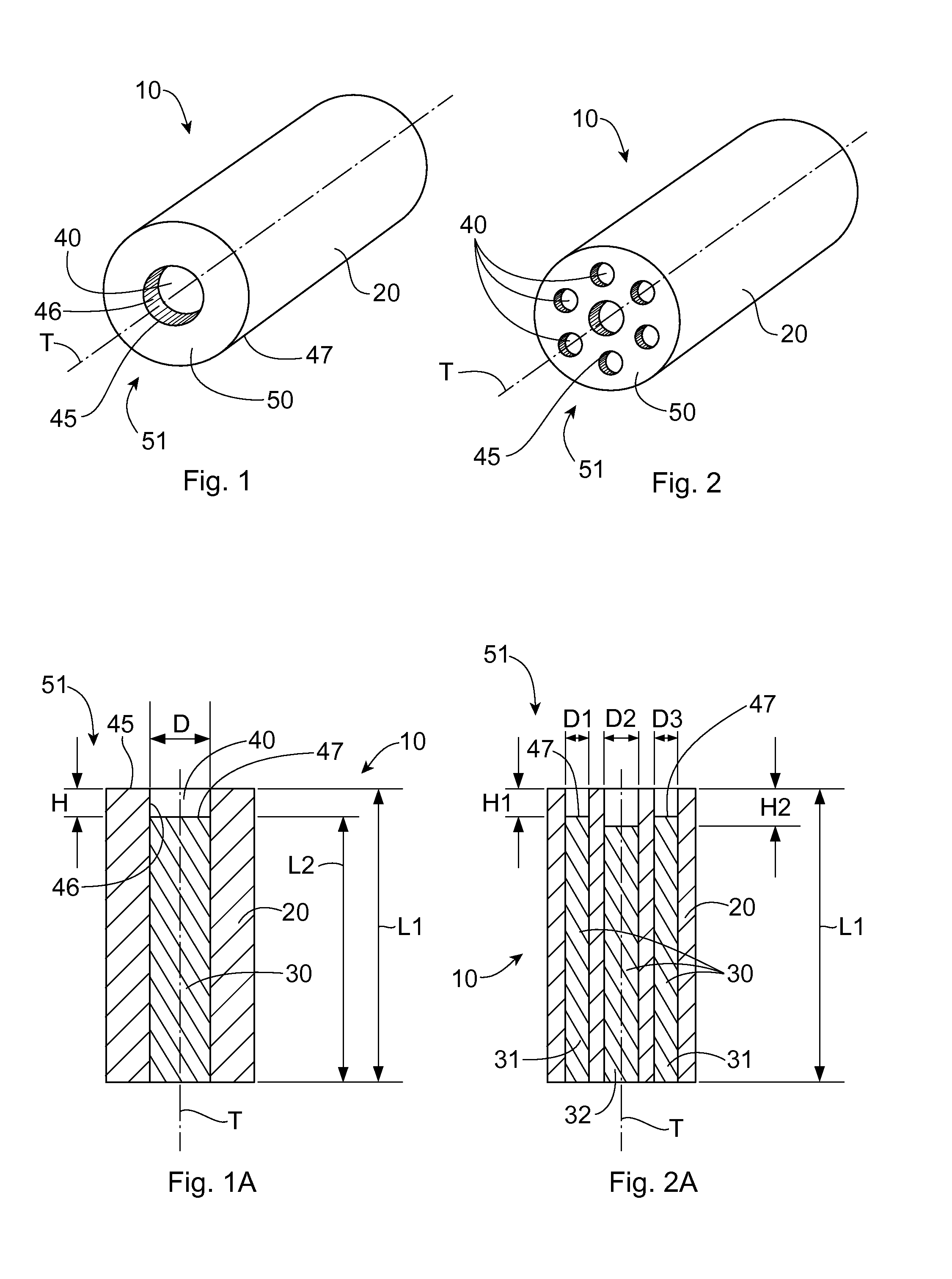

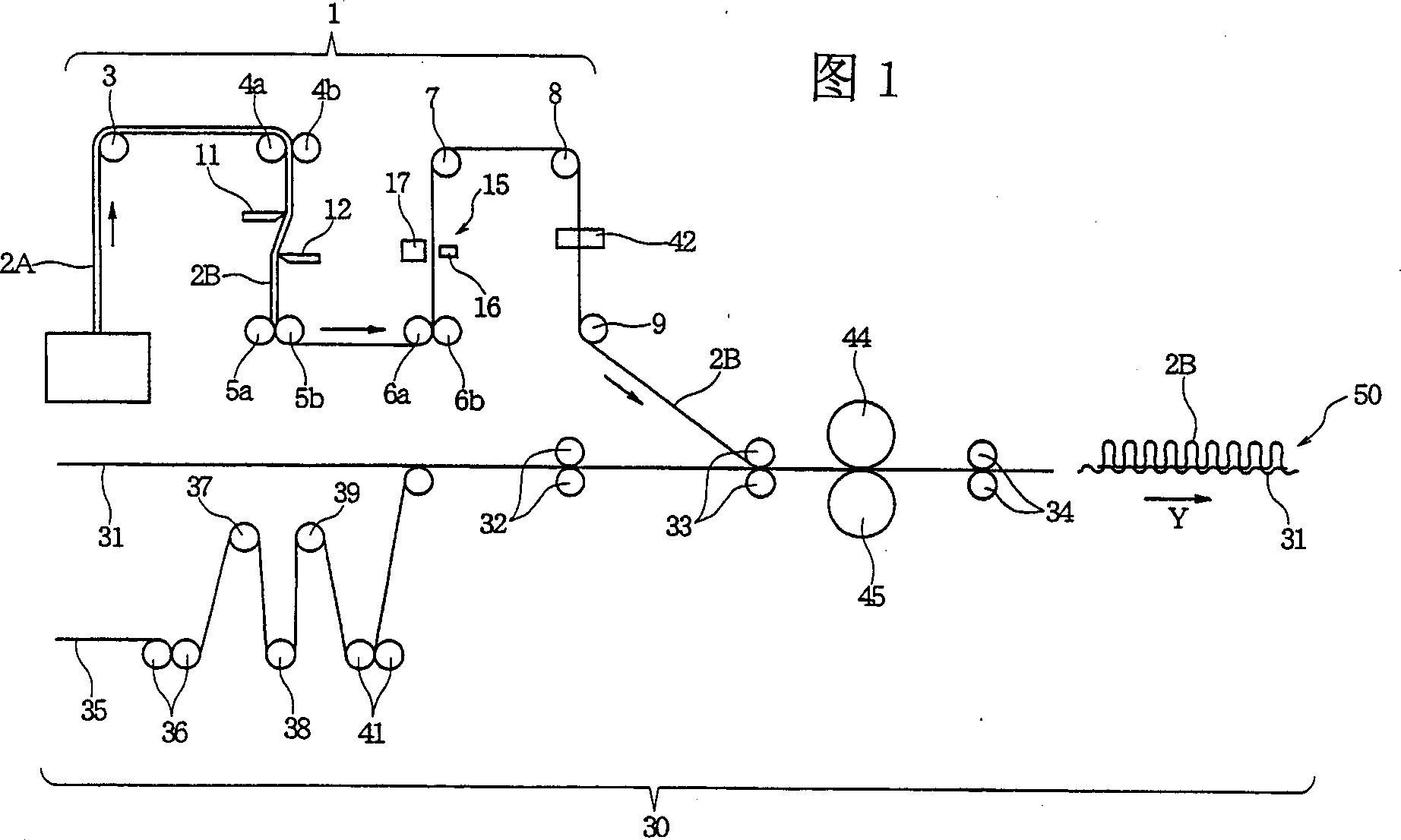

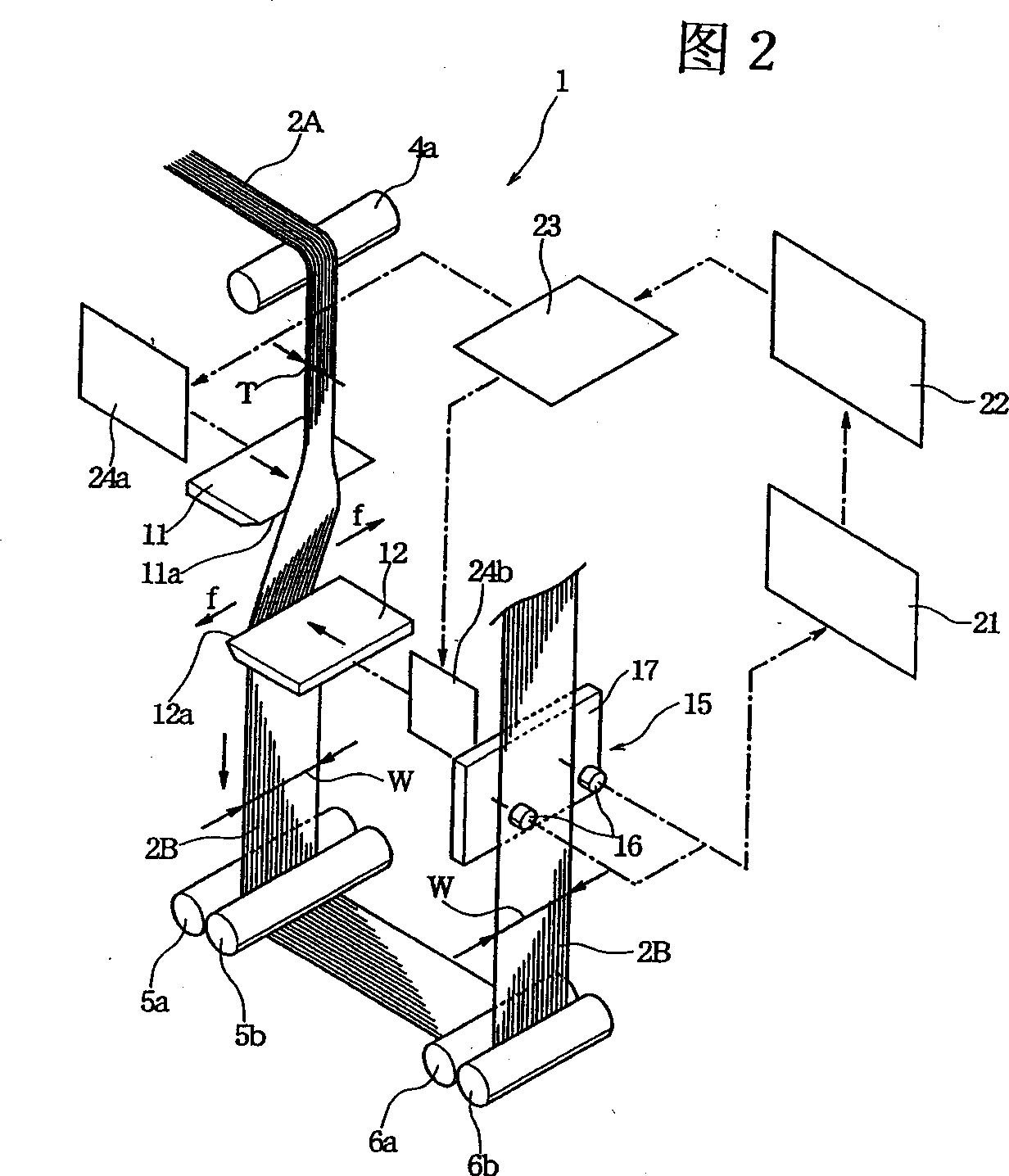

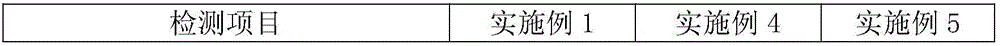

Method and apparatus for opening continuous filaments

InactiveUS7003856B2Simple conditionsUniform openingFilament manufactureFibre cleaning/openingEngineeringMechanical engineering

A method and an apparatus for opening continuous filaments provide stable quality of fibrous layer after opening crimped TOW. The TOW is transported by means of a plurality of rolls. While transported, the TOW is applied a resistance on one side of the TOW by slidingly contacting a sliding body onto the TOW at between rolls. As a result, continuous filaments stacked in a thickness direction of the TOW are caused to sift in a transporting direction of the TOW. Thus, the TOW is opened and the continuous filaments are spread in a width direction of the TOW.

Owner:UNI CHARM CORP

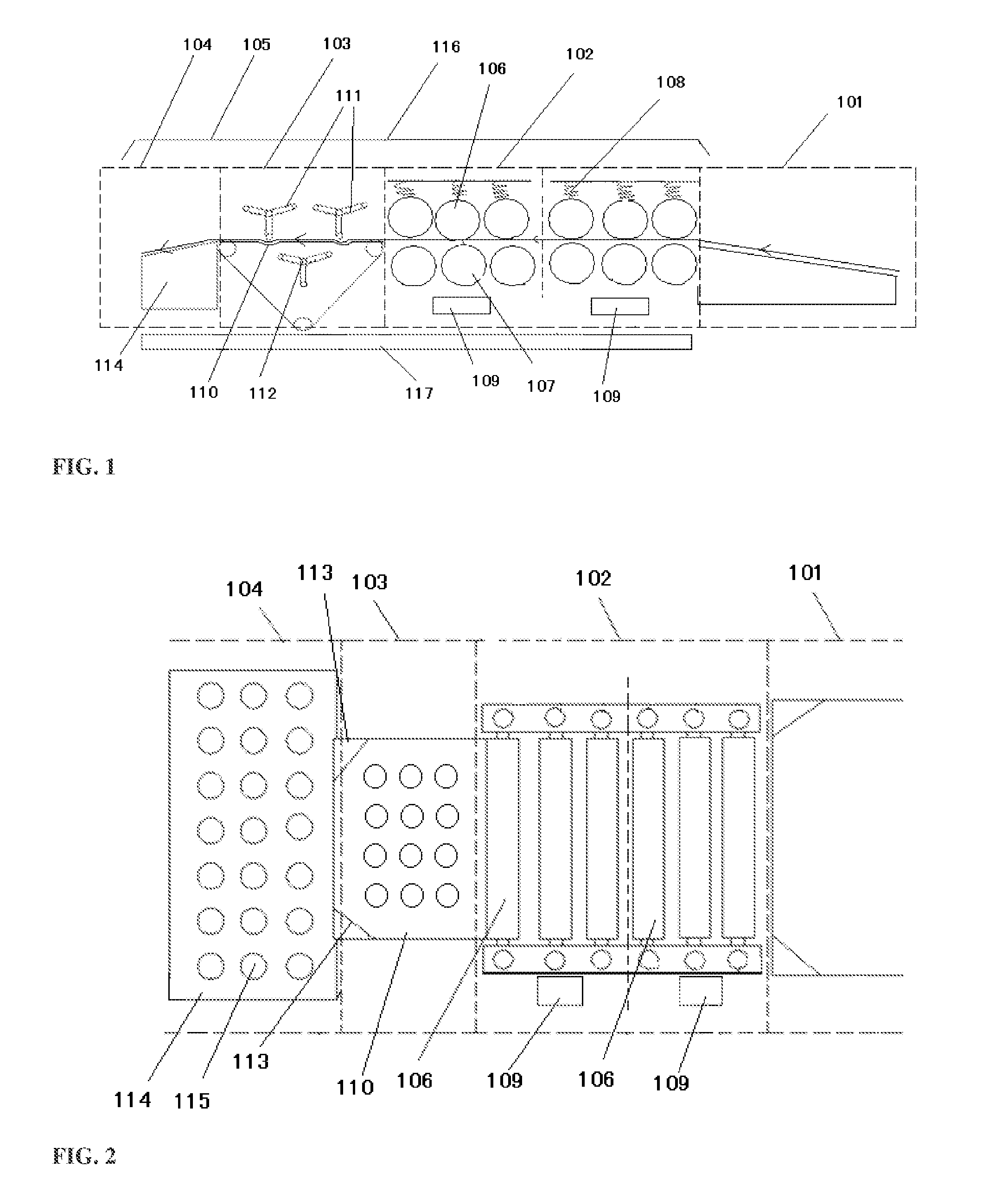

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

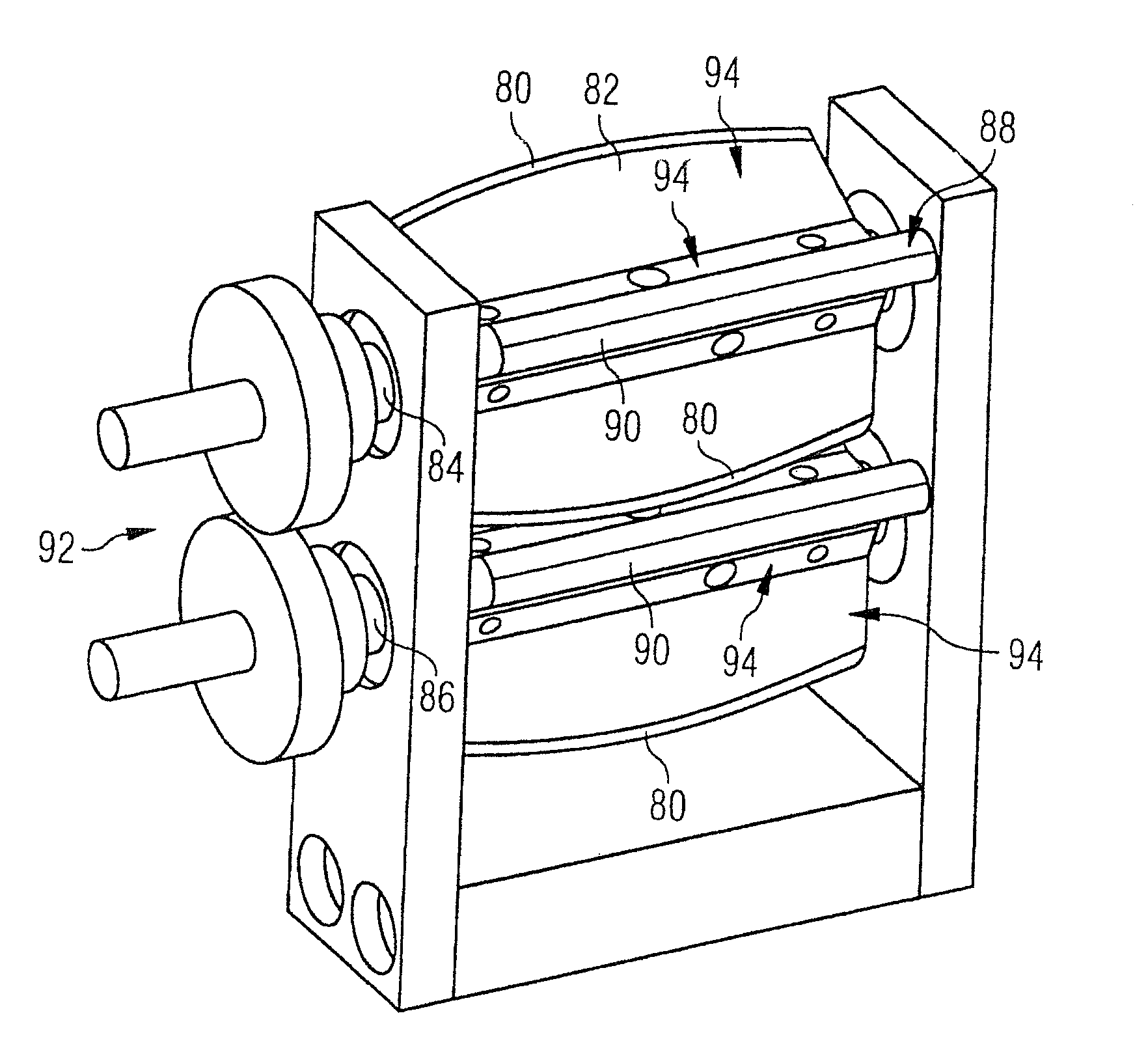

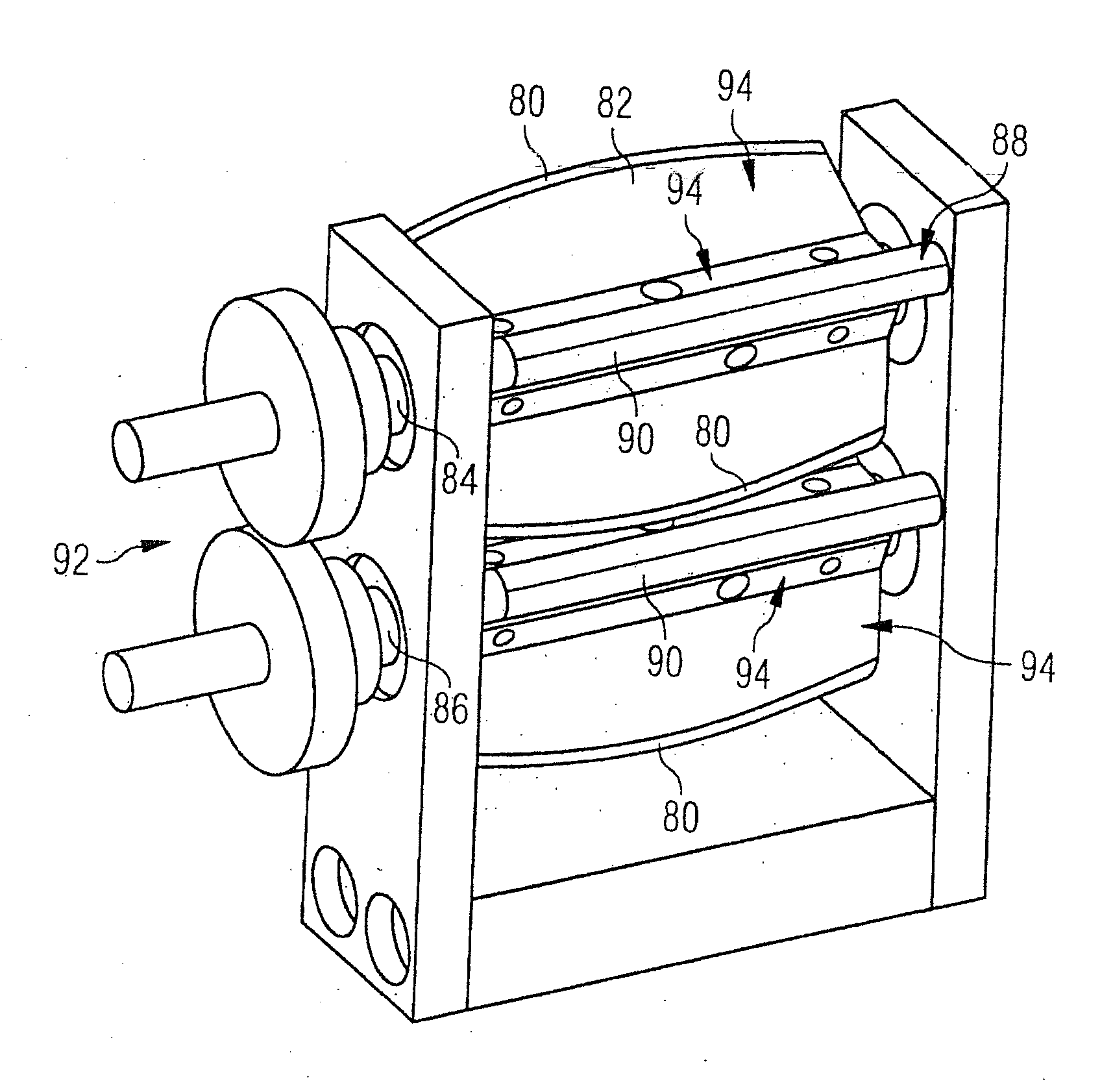

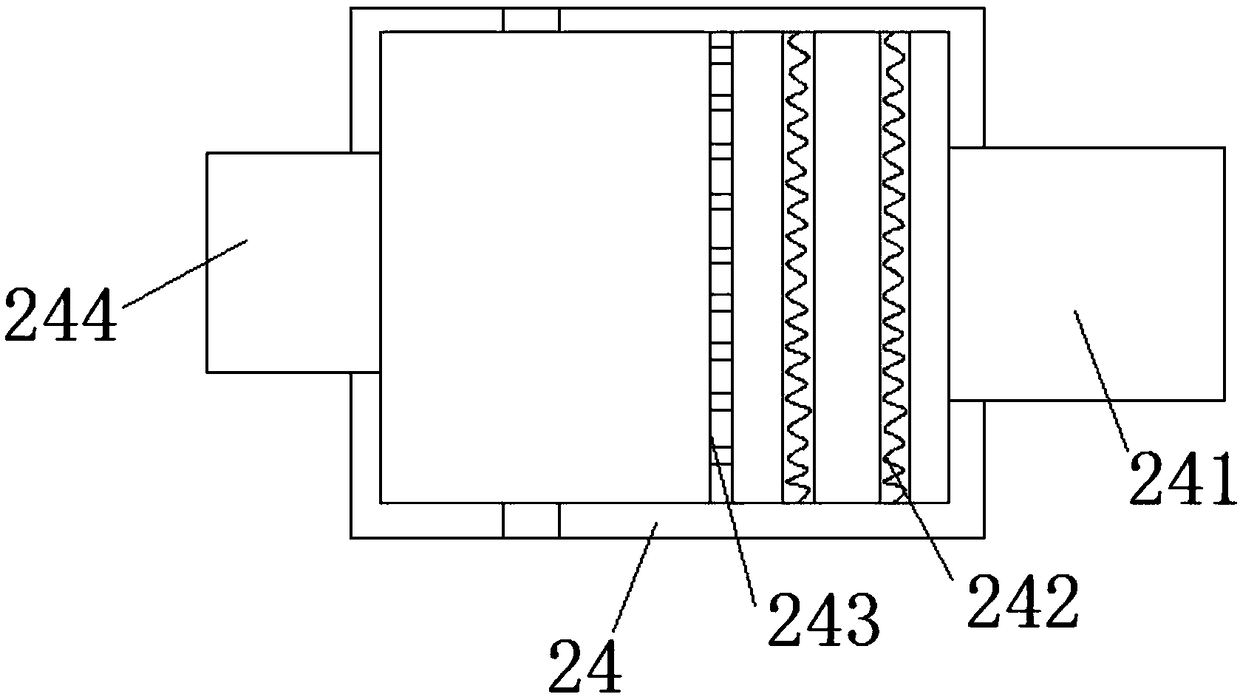

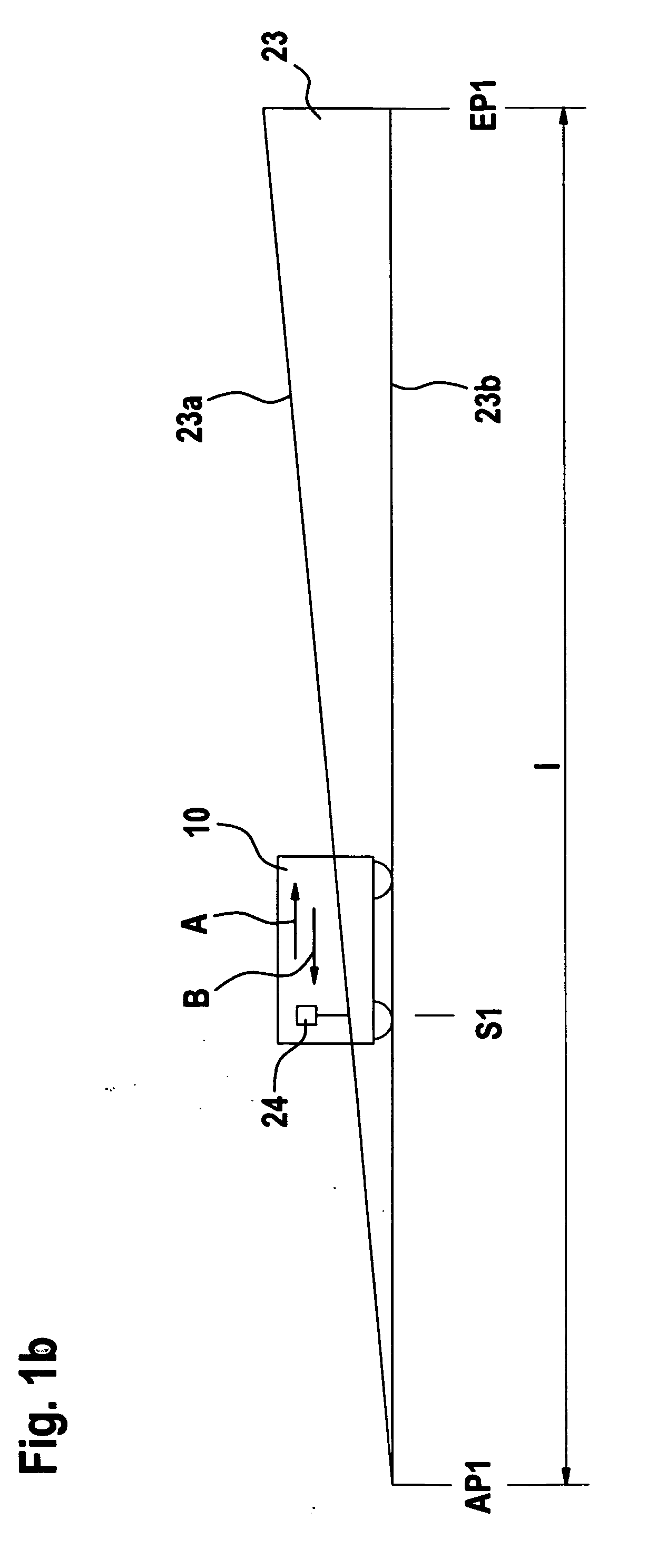

Spreading device for spreading out fiber filament bundles and spreading method carried out using the same

ActiveUS8191215B2Avoid concentrationEmbedded in matrixFilament manufactureFibre cleaning/openingFiberEngineering

A spreading device (20) for spreading a fiber filament bundle (32) to form a flat fiber band (14) has at least one convexly bent spreading edge (80) that is movable. The convexly bent spreading edge has at least one direction component perpendicular to a longitudinal extension of the fiber filament bundle (32) to be spread relative to the convexly bent spreading edge. The fiber filament bundle is configured to be placed under tension onto the convexly bent spreading edge (80) and thereafter is configured to be moved again with the at least one direction component perpendicular to the fiber filament bundle (32) away from the fiber filament bundle to release the fiber filament bundle from the convexly bent spreading edge (80).

Owner:EADS DEUT GMBH

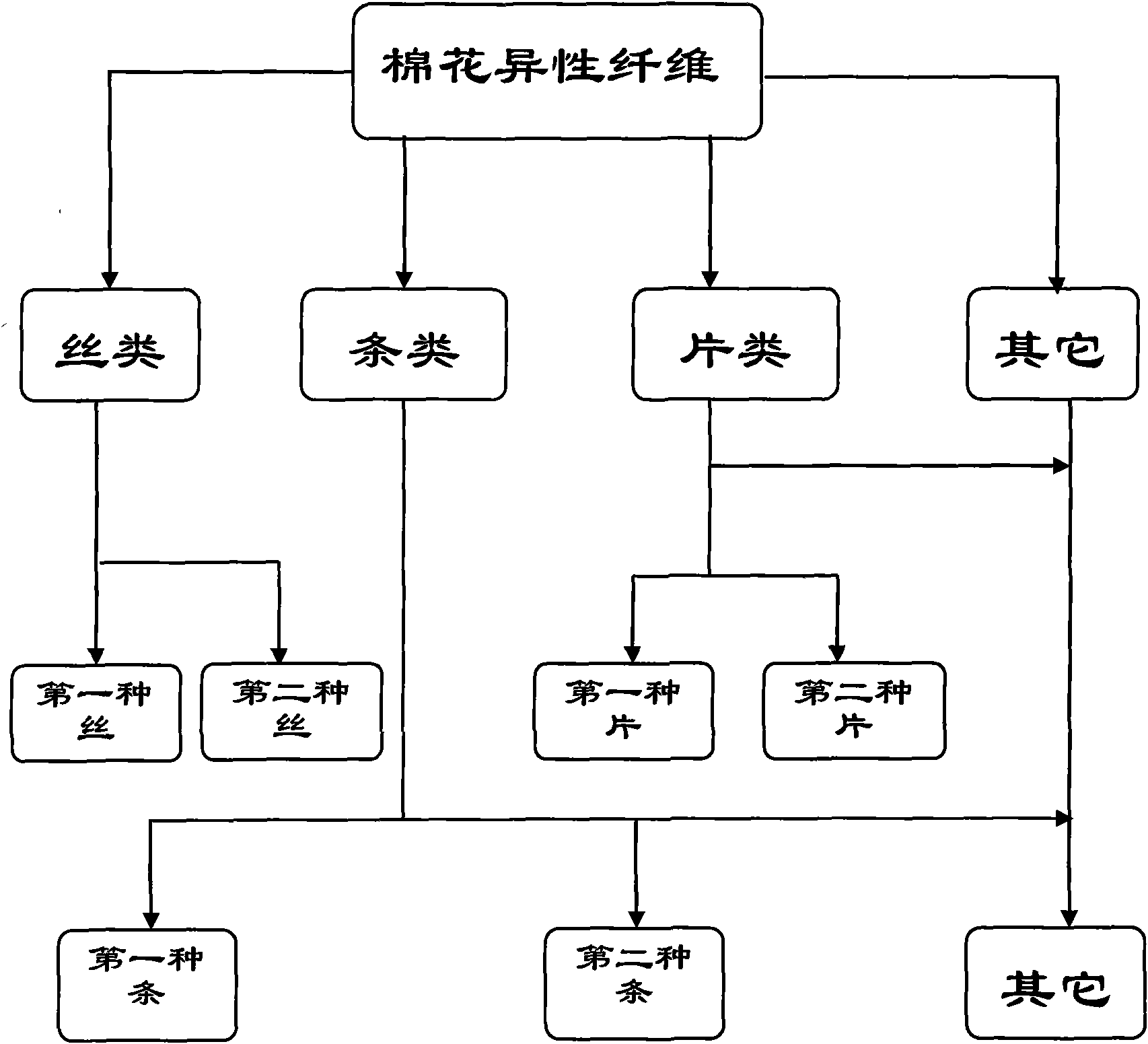

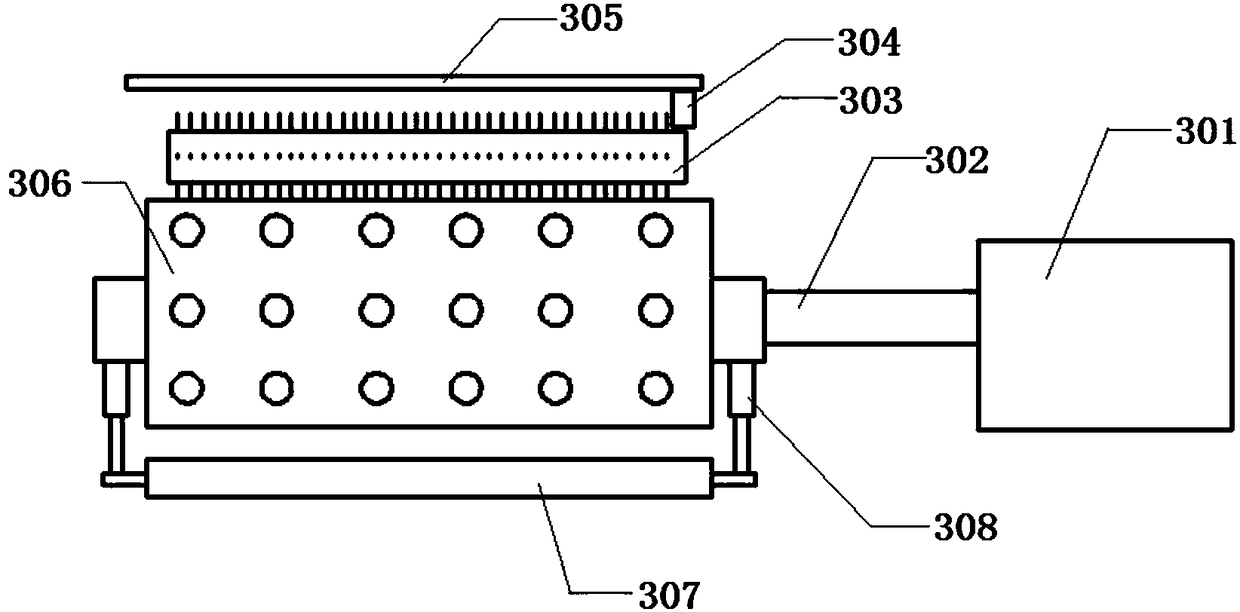

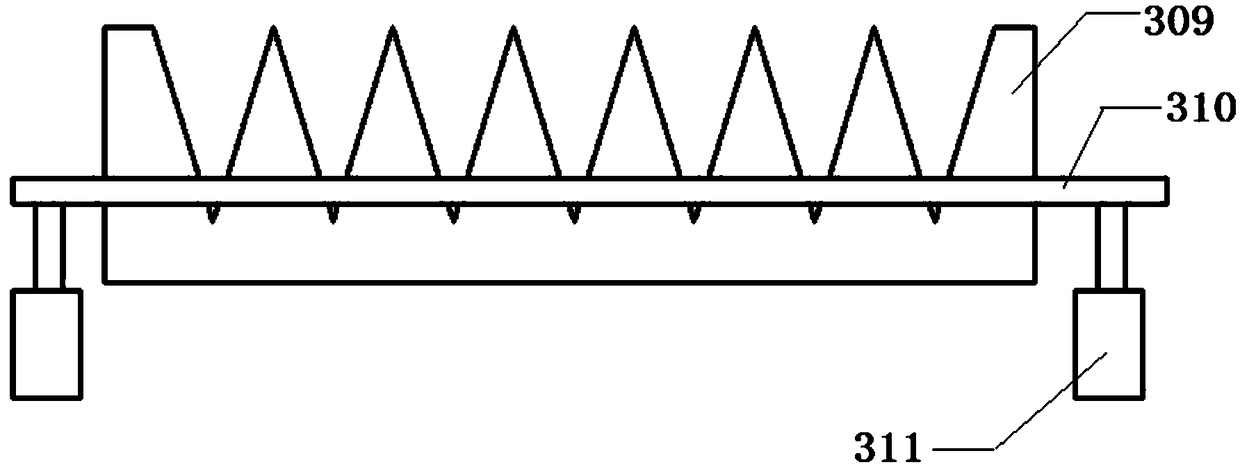

Seed cotton foreign fiber separator

ActiveCN101570905AEfficient removalImprove cleanlinessVegetable fibre separation from seedsFibre cleaning/openingFiberState of art

The invention discloses a seed cotton foreign fiber separator which comprises a separating chamber consisting of an electrode plate set and a case body, a feeding port, a discharge port, an impurity discharge port, a fan and a wind chamber. The electrode plate set consists of an anode plate and a cathode plate. The electrode plate of the electrode plate set, which is positioned between the separating chamber and the wind chamber, is a wind-evening network-shaped structure. The seed cotton foreign fiber separator is characterized in that a stirring device is arranged between the anode plate and the cathode plate in the separating chamber, and at least one stirring and shifting roller constitutes a stirring and shifting roller set. Compared with the prior art, the seed cotton foreign fiber separator can effectively clear foreign fibers such as mulching films, and the like during cotton picking, and meanwhile can clear other impurities, and the clearing effect is good.

Owner:SHIHEZI UNIVERSITY

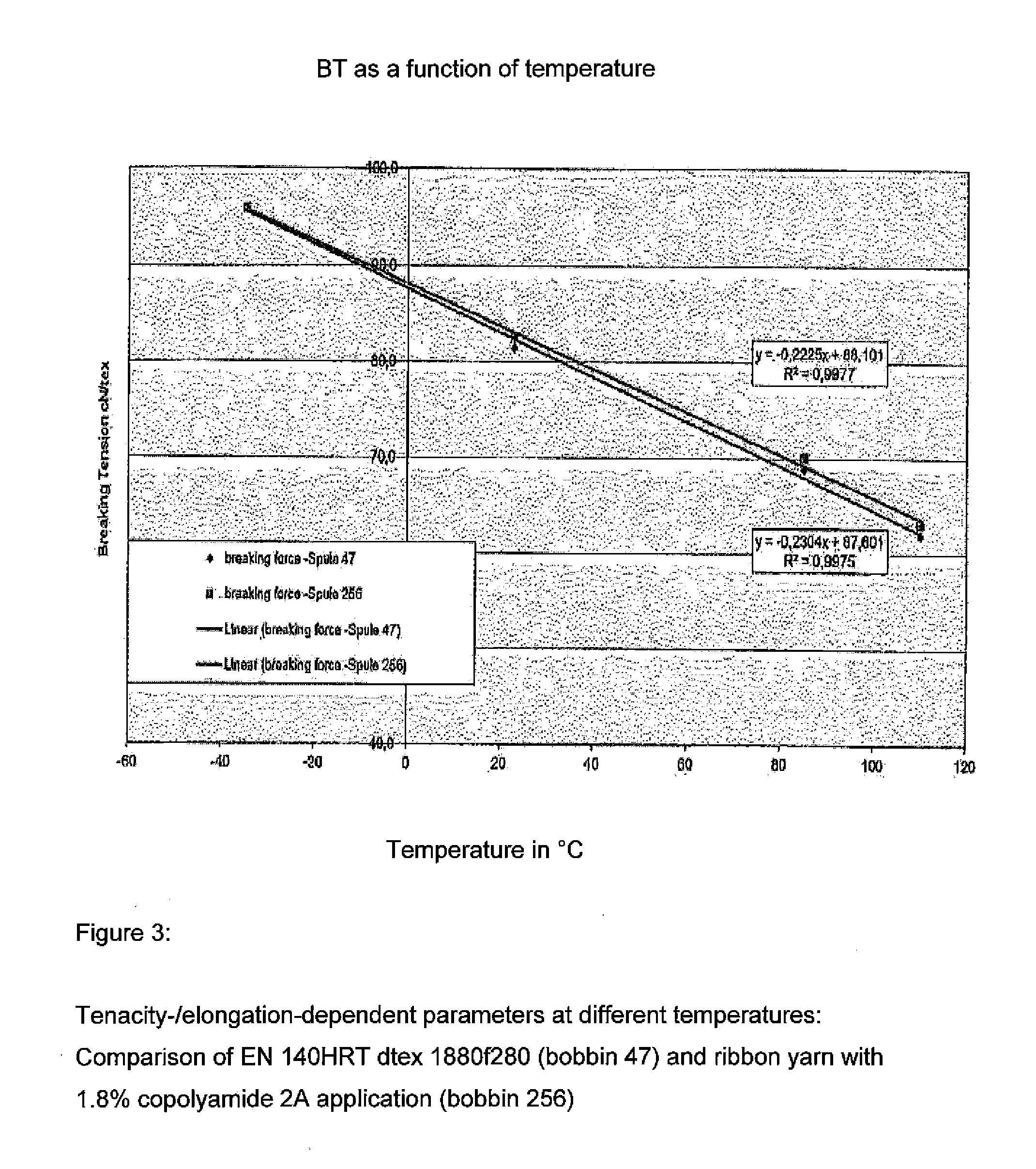

Ribbon yarn

ActiveUS20150167207A1Broaden applicationExcellent combustion resistanceMechanical impurity removalFilament handlingBand shapeEngineering

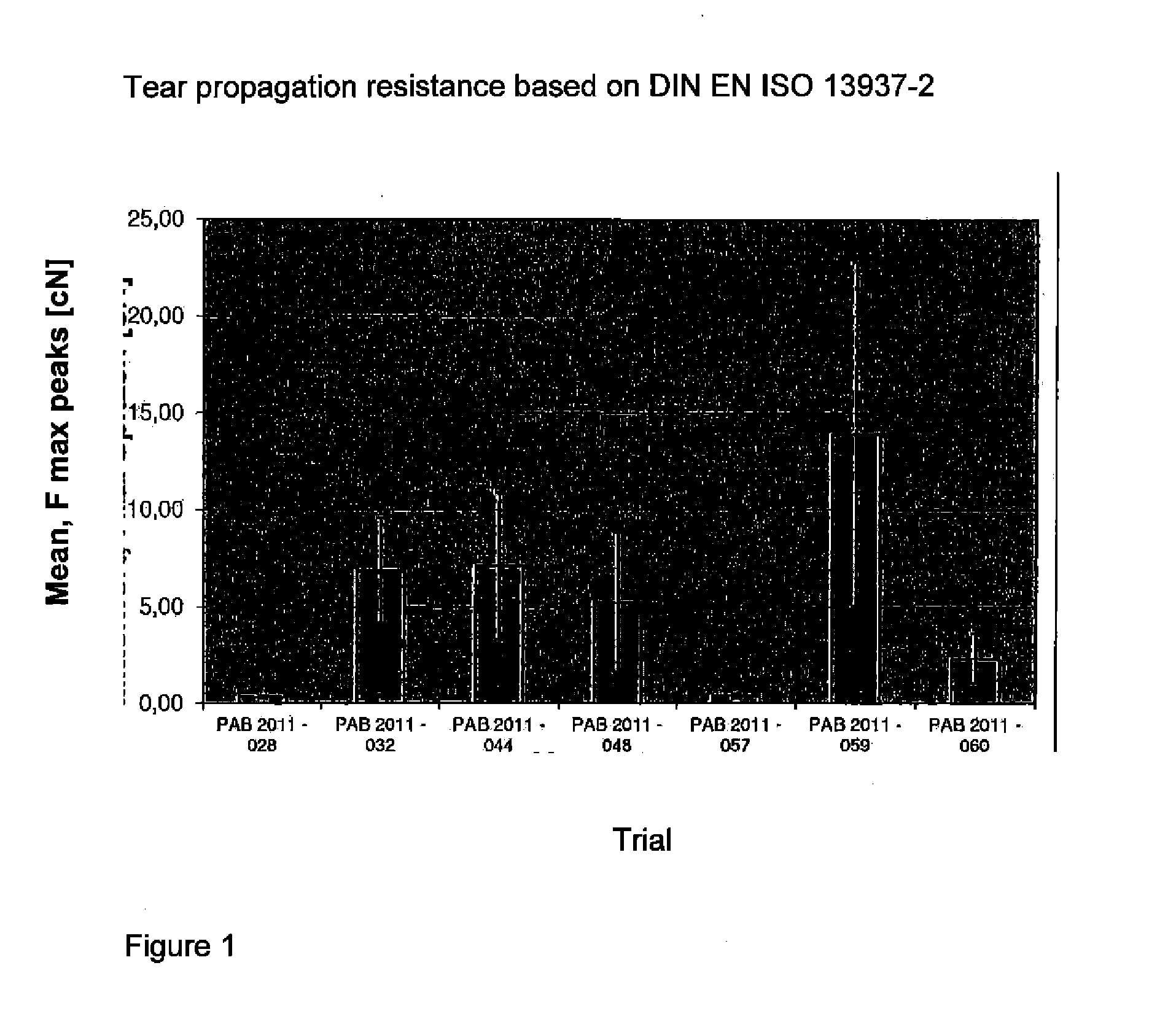

A method is disclosed for fabricating a ribbon yarn, the method including: spreading the yarn such that not more than five filaments are lying over one another, fixing the yarn by forming a matrix of one or more fixatives, winding the fixed yarn, wherein the fixative or fixatives are selected from a group consisting of copolyamides, copolyesters and silicones and also mixtures or blends thereof. Also described is the ribbon yarn and the application of the ribbon yarns for airbag fabrics, as a tire reinforcement and in textile construction.

Owner:PHP FIBERS GMBH

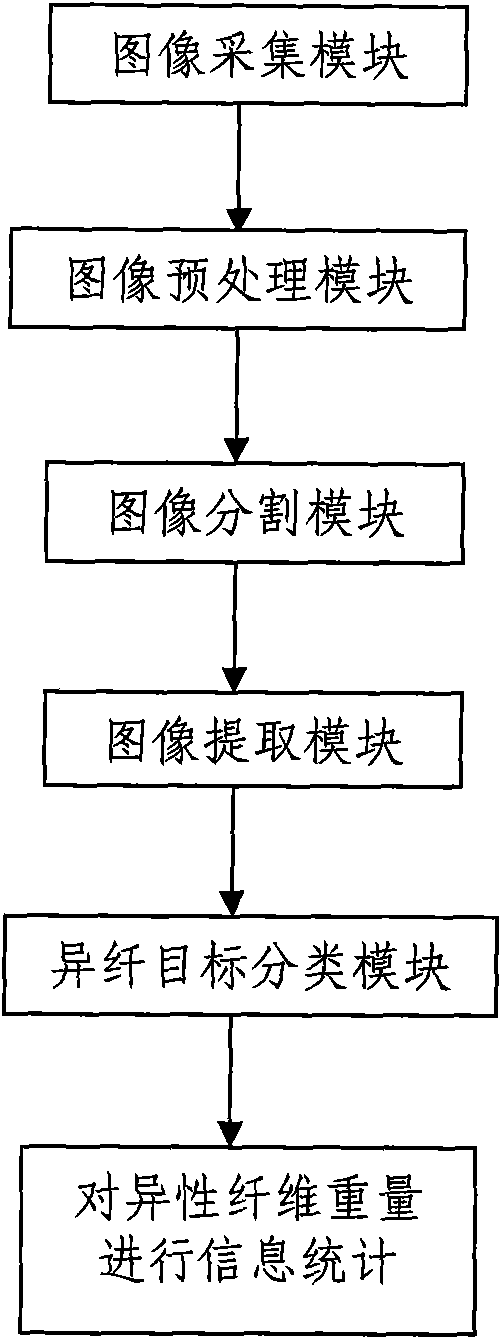

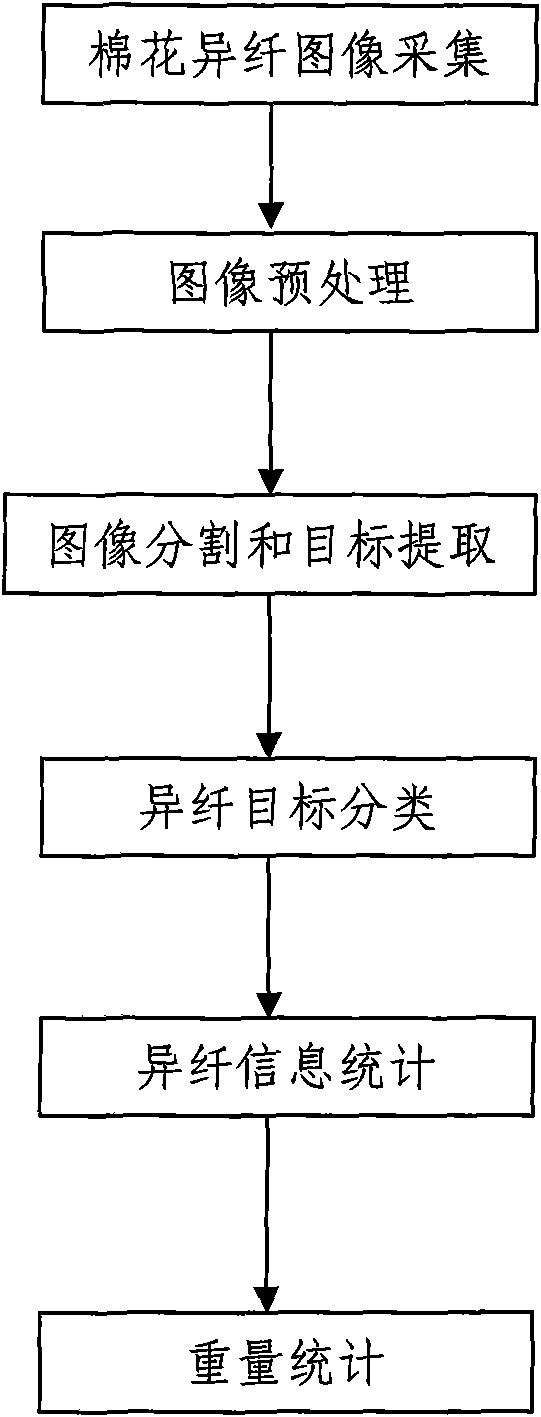

Measuring method and system for weight of cotton foreign fiber based on machine vision technique

InactiveCN101555661AHigh speedImprove accuracyInspecting textilesFibre cleaning/openingImage basedFiber

The invention relates to a measuring method and system for the weight of cotton foreign fiber based on machine vision technique. The measuring system for the weight of cotton foreign fiber comprises a cotton foreign fiber image acquisition module, an image processing module used for preprocessing acquired images, a module used for carrying out target division and extraction for the preprocessed images, a module used for classifying the extracted targets and a module used for carrying out statistical operation for the classified result. The system can accurately obtain the unit area weight of cotton foreign fiber based on image processing technique and can be used for intelligent identification and weight measurement of the cotton foreign fiber combining with on-site image processing technique. The invention also provides a measuring method for the weight of cotton foreign fiber based on the machine vision technique. By utilizing the method and the system, the accuracy, the periodicity, the timeliness of the diction of the foreign fiber as well as the detection efficiency are all improved, and the harm of the foreign fiber is efficiently reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

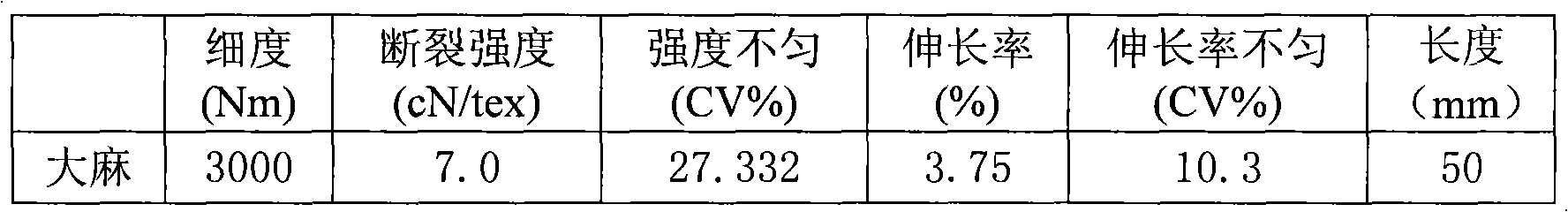

Hemp fiber and preparation method thereof

ActiveCN101831715AShorten the timeReduce processFibre cleaning/openingCarding machinesHempcreteSoftening

The invention provides a hemp fiber with a fineness of 1,500-4,000 Nm and the strength of 4-10cN / dtex. The hemp fiber has higher fineness and strength and can be used for spinning by using a dry method and preparing various grades of textile products by blending with other fibers. The invention also provides a preparation method of the hemp fiber, comprising the following steps of: chemical degumming, aftertreatment, stamping, oil feeding, softening, oil feeding and humidification, stowing and mechanical opening, wherein the step of chemical degumming specifically comprises the following steps of: adding hydrogen peroxide, alkali metal silicates, urea and a penetrating agent to water and uniformly stirring; then adding hemp peels; heating up, preserving heat and washing by using clear water; adding alkali, the alkali metal silicates, urea and the penetrating agent to water and uniformly stirring; adding oxidized hemps; and heating up, preserving heat and washing by using clear water. The method can prepare hemp fibers with an extremely high fineness and has low environmental pollution.

Owner:CHINA GARMENT BUYITIANXIA BEIJING TRADING

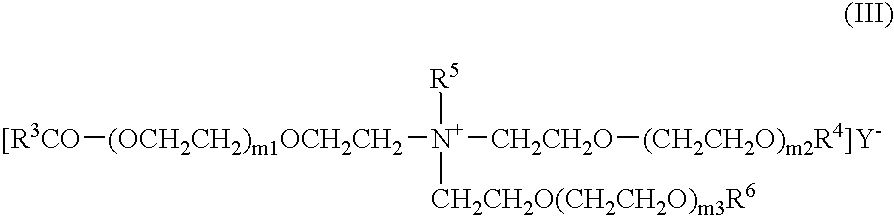

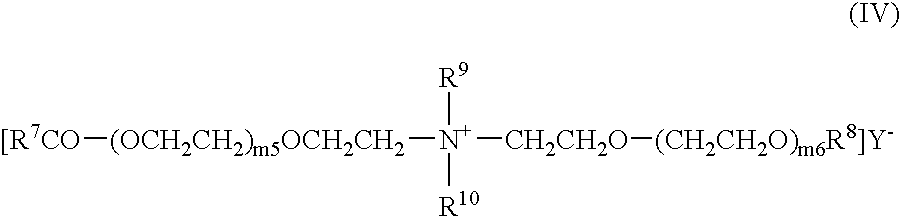

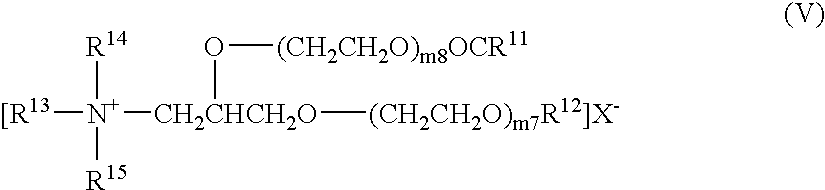

Textile finishing agents

InactiveUS20060258558A1Organic detergent compounding agentsNon-ionic surface-active compoundsFiberYarn

A method for treating fibers, yarns or textiles to improve the sensory effect for a user or weaver of a fabric article. The method treats the fiber, yarns or textiles with an emulsion containing 15-30% by weight of a mixture of waxes having melting points in the range of 35° C. to 60° C. including a lipophilic wax matrix; 10%-20% by weight of emulsifier which are at least one of alkyl or alkenyl oligoglycosides or alkyl ether sulfates, 1%-10% by weight of a crystal regulator which can be partial esters of C12-22 fatty acids with at least one of glycerol, polyglycerol and sorbitan. The mean particle size of the wax crystals is not greater than 6 μm. The emulsion includes water and auxiliaries and additives.

Owner:COGNIS IP MANAGEMENT GMBH

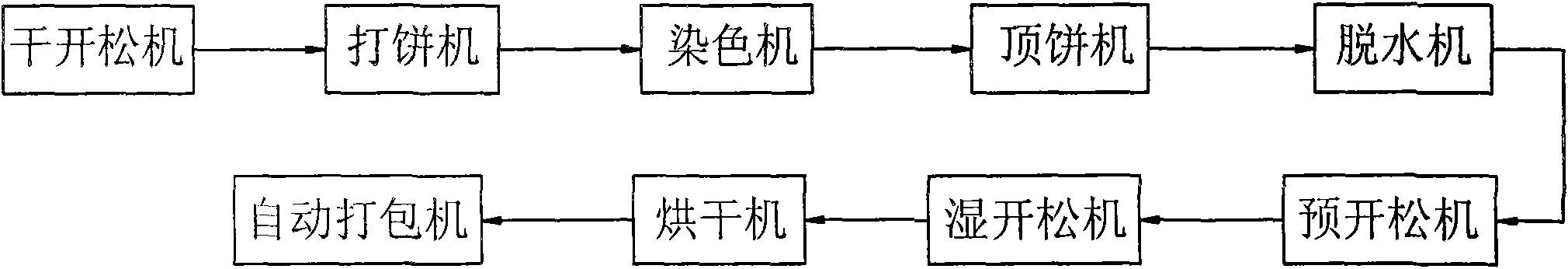

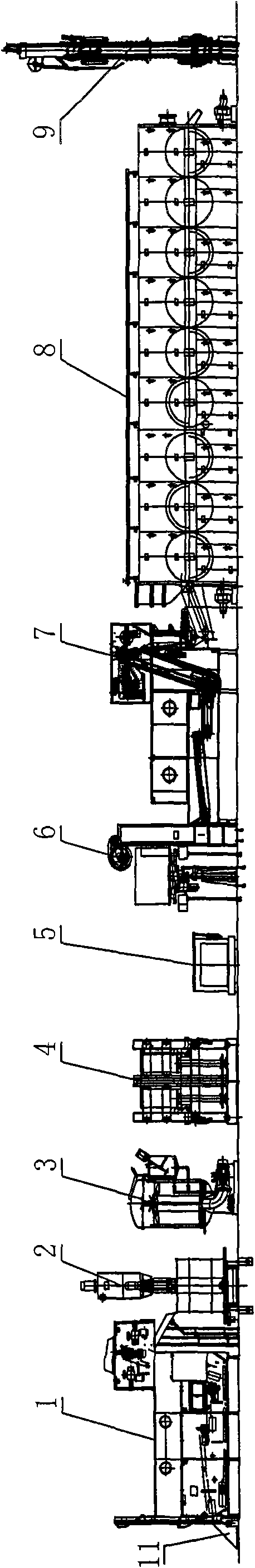

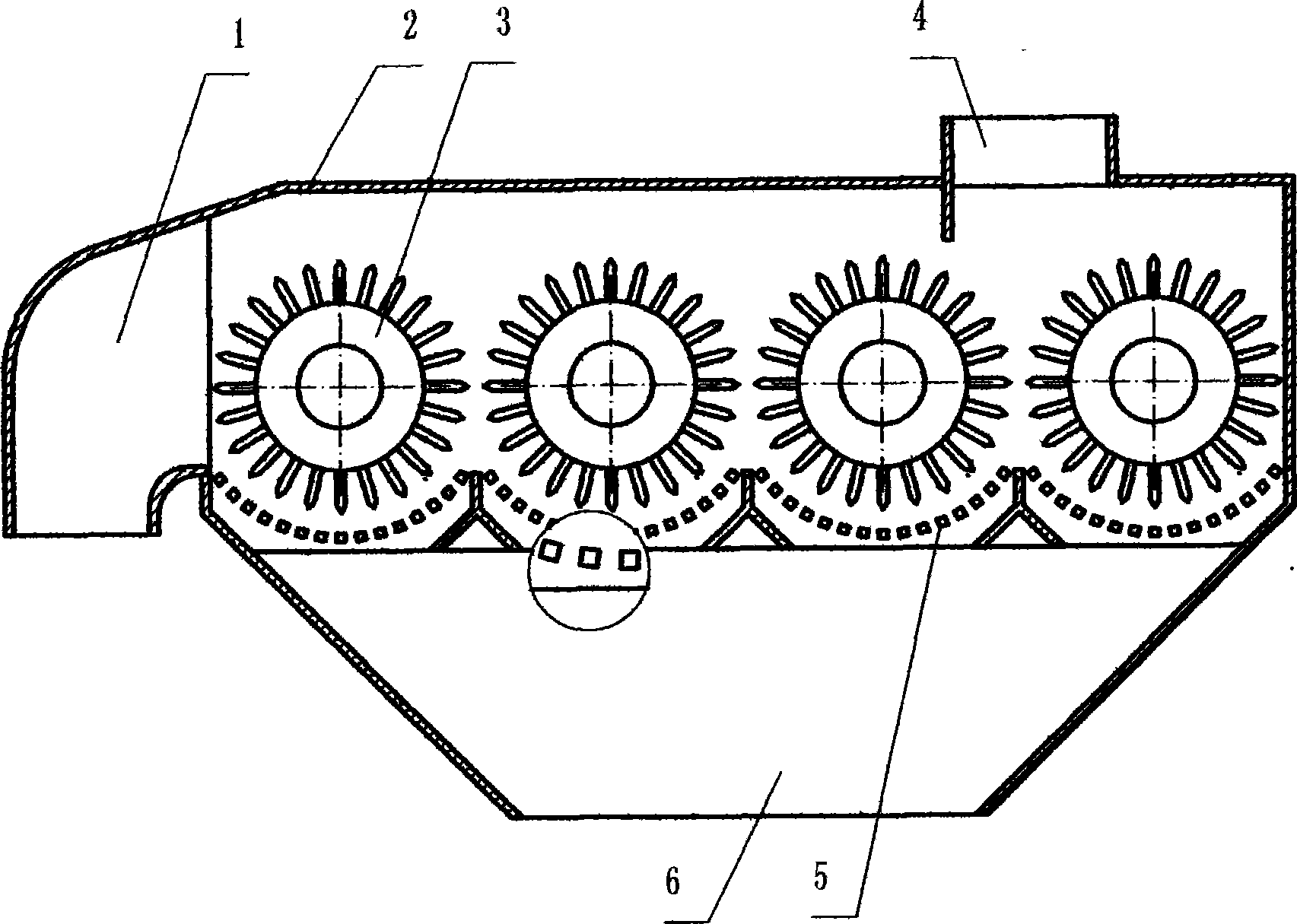

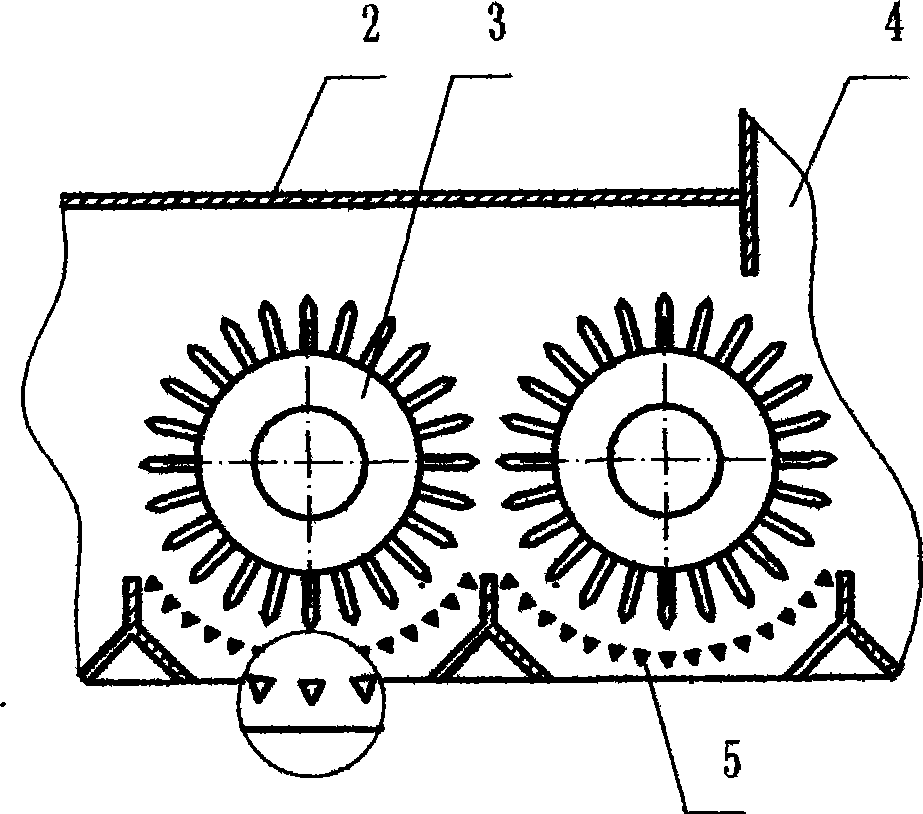

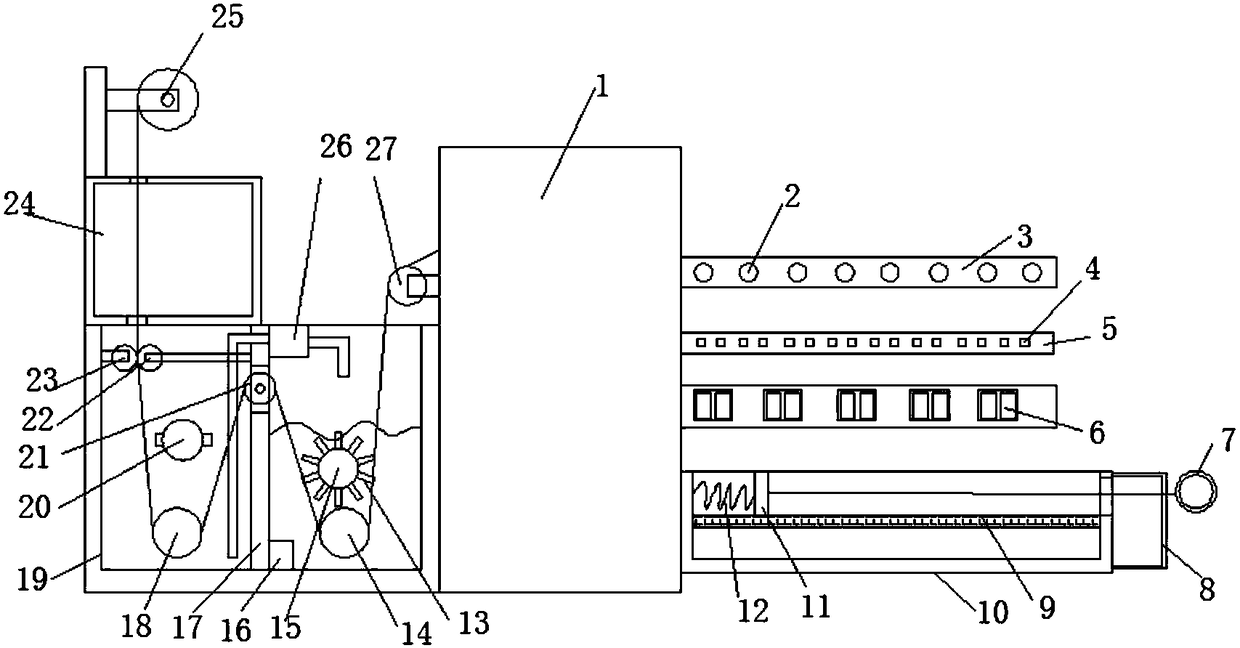

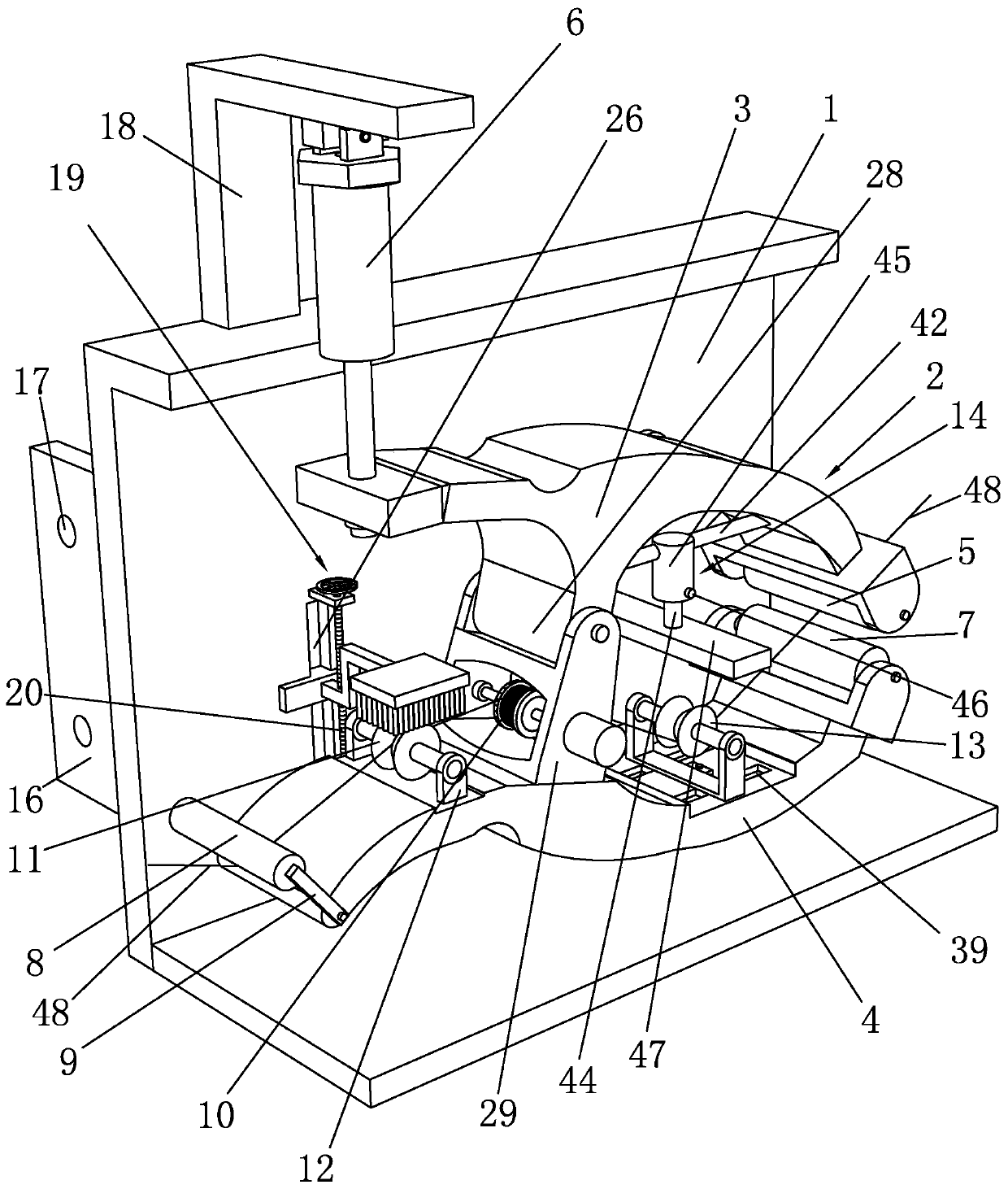

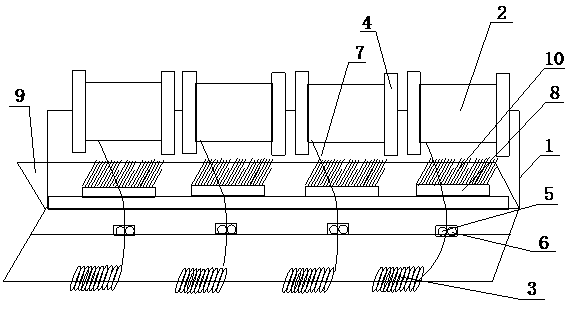

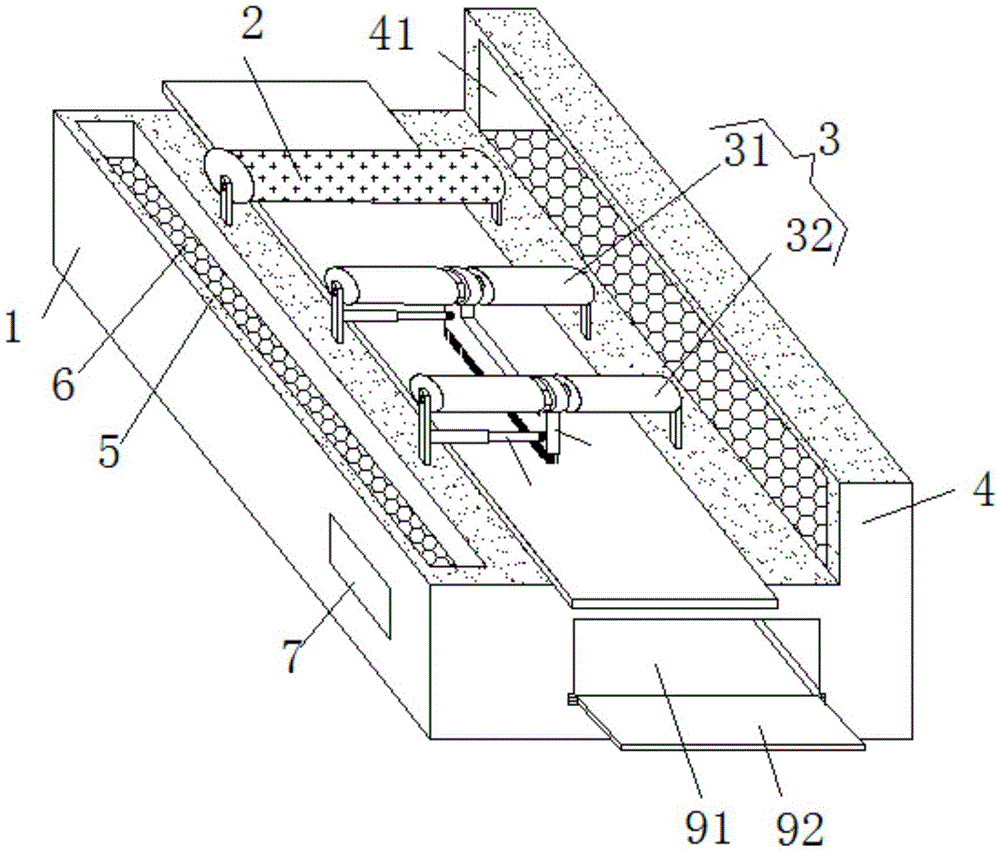

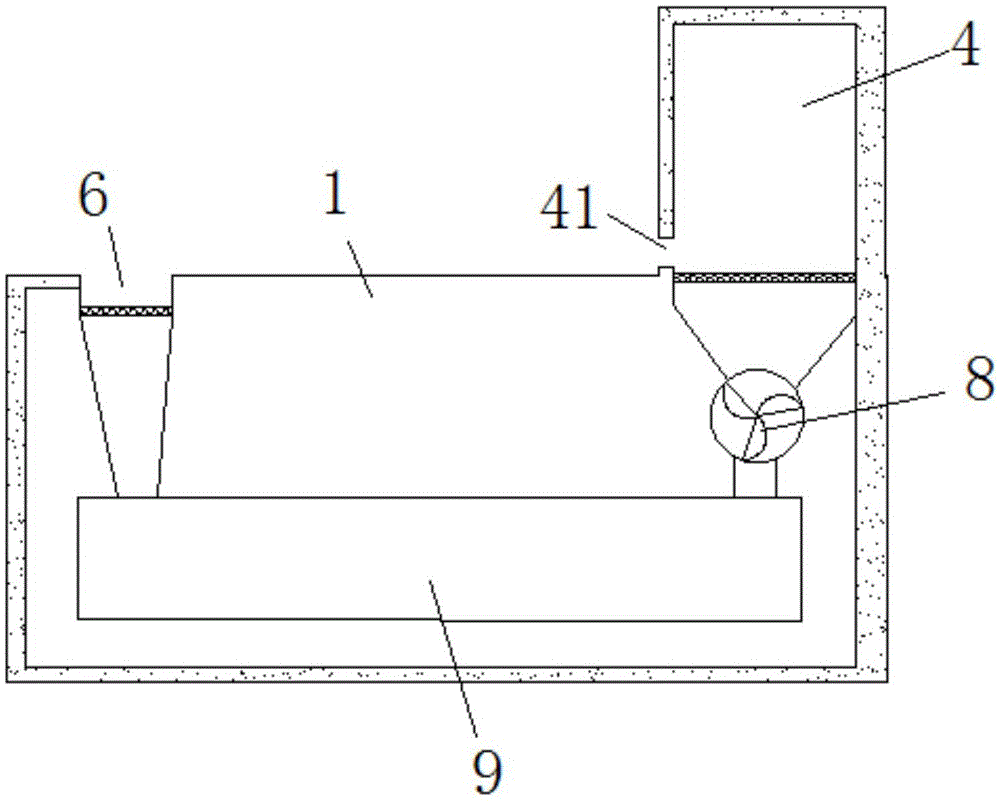

Automatic processing system for dyeing loose fibers

ActiveCN101629365AImprove the degree of automated productionIncrease productivityTextile treatment machine partsFibre cleaning/openingCircular discProduction line

The invention discloses an automatic processing system for dyeing loose fibers. The system comprises a dry opening machine, a disk forming machine, a dyeing machine, a dewatering machine, a wet opening machine, a drying machine and an automatic packing machine which are sequentially connected, wherein, a pre-opening machine is connected between the dewatering machine and the wet opening machine, the pre-opening machine comprises a rotatable disk, the disk is installed on a lifting rack, and a cotton peeling roller is arranged above the disk. A hydraulic disk jacking machine can also be arranged between the dyeing machine and the dewatering machine. The invention is the first automatic production line for dyeing the loose fibers, can be suitable for dyeing various fibers, and can increase the degree of automatic production, shortens the production period of entire dyeing processing, increases the production efficiency, reduces the intensity of labor production, and especially greatly increases safety.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

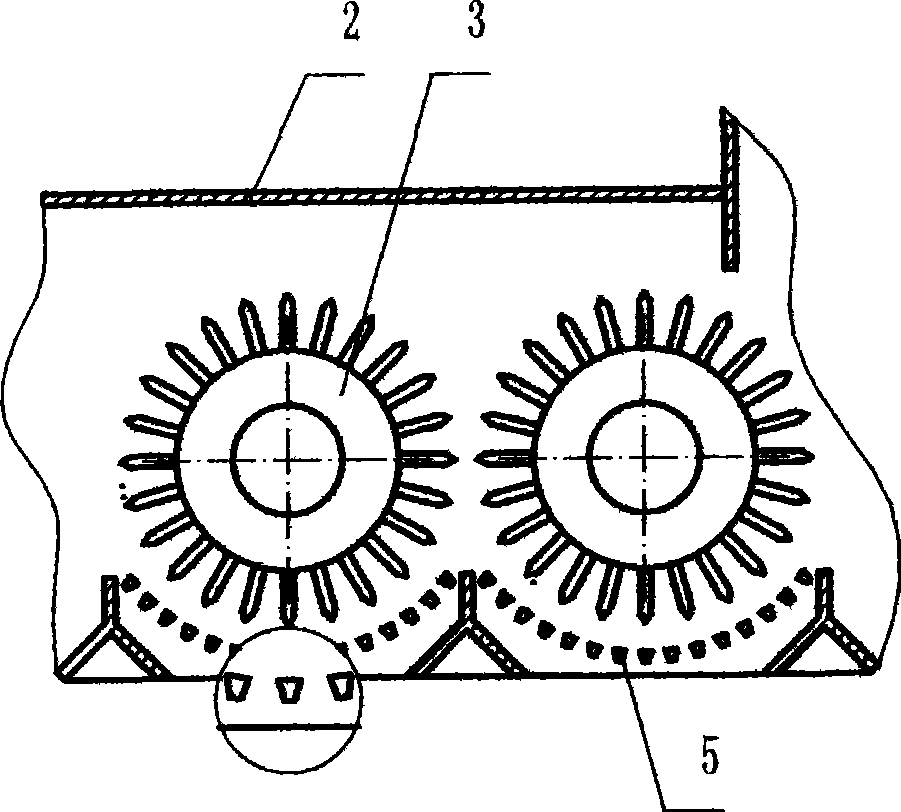

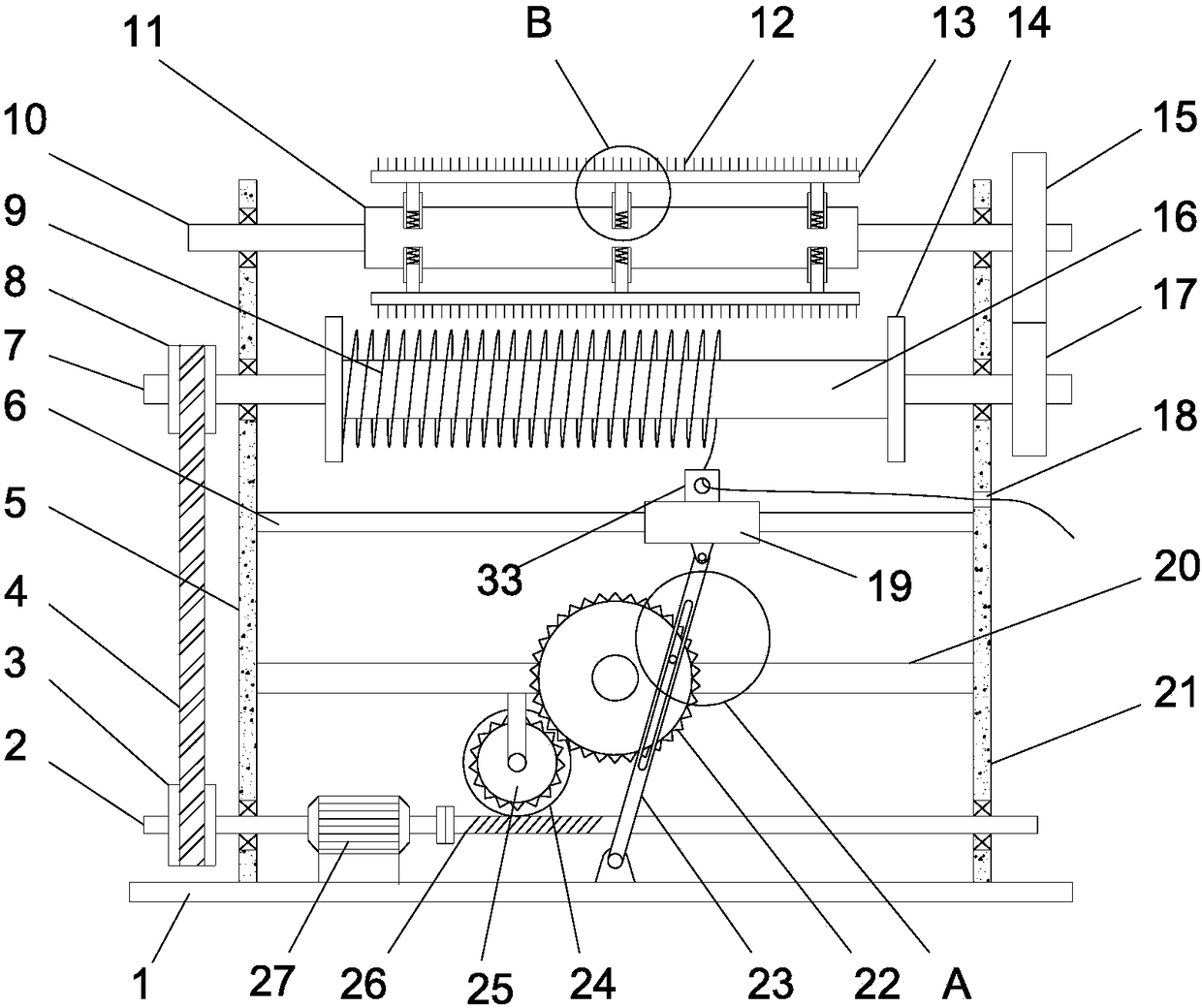

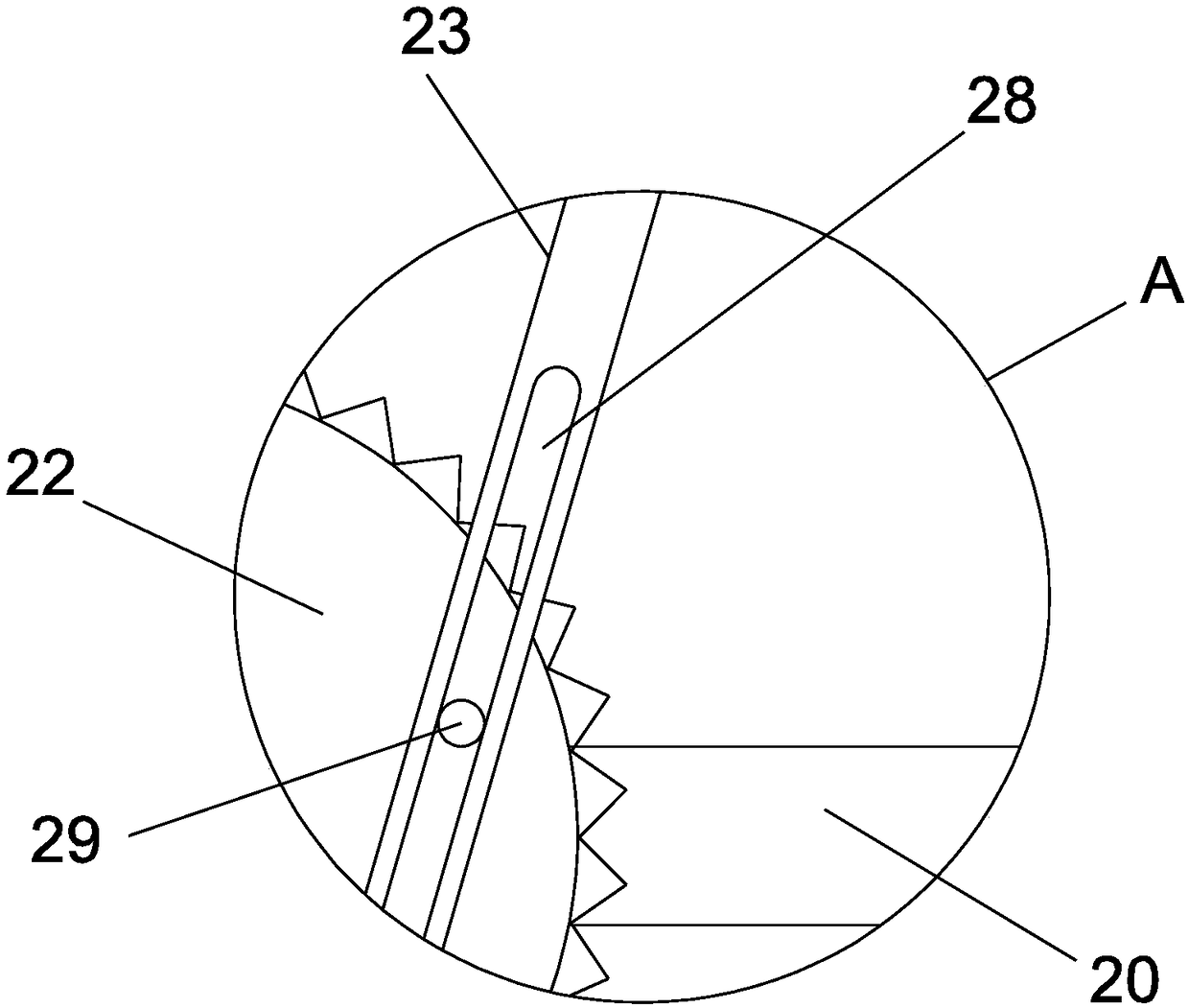

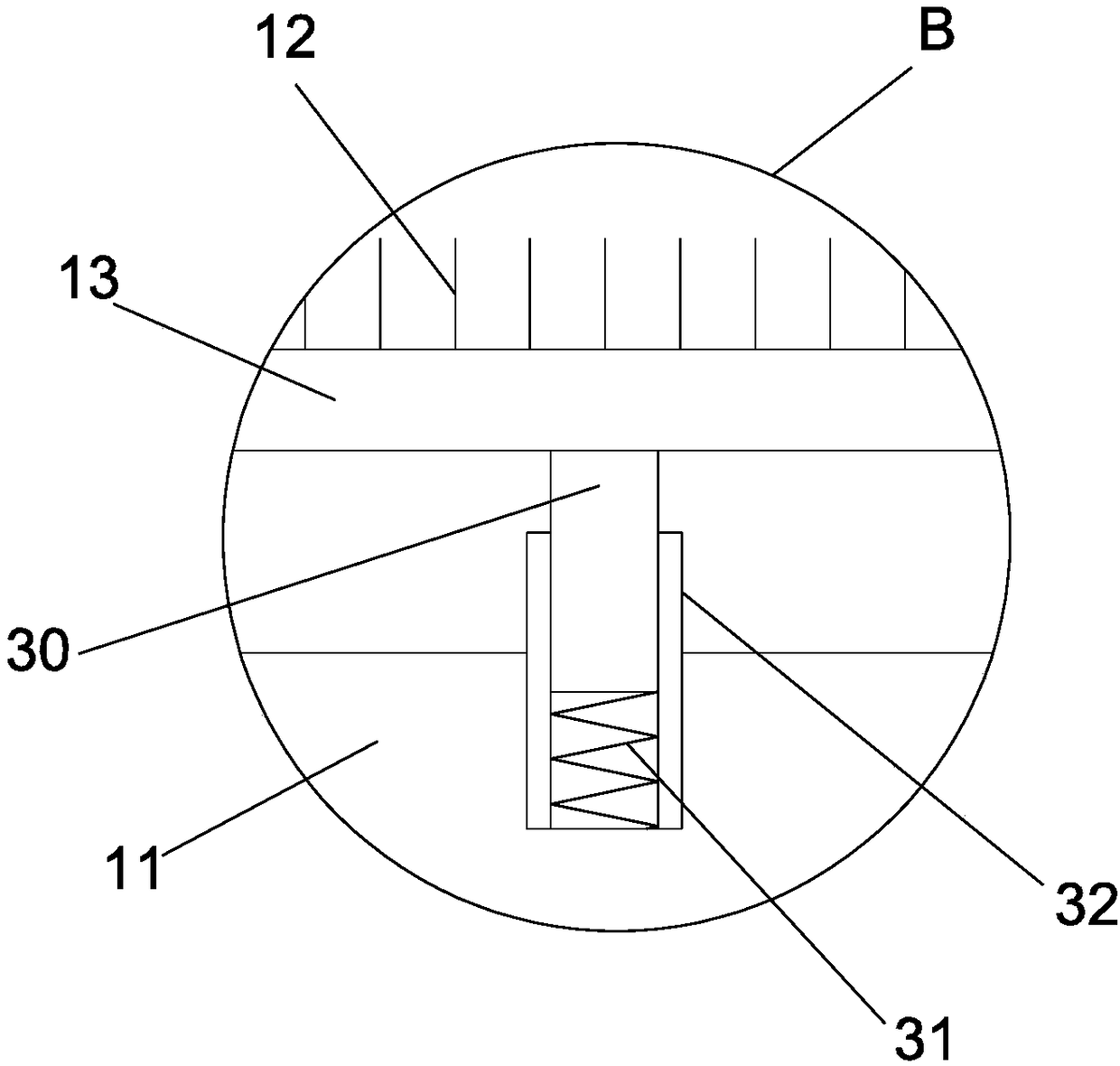

Cotton cleaning mechanism and constituted cotton-picker

InactiveCN101451280AReduce complexityReduce damageFibre cleaning/openingPicking devicesCotton fibreEngineering

Owner:黄军干

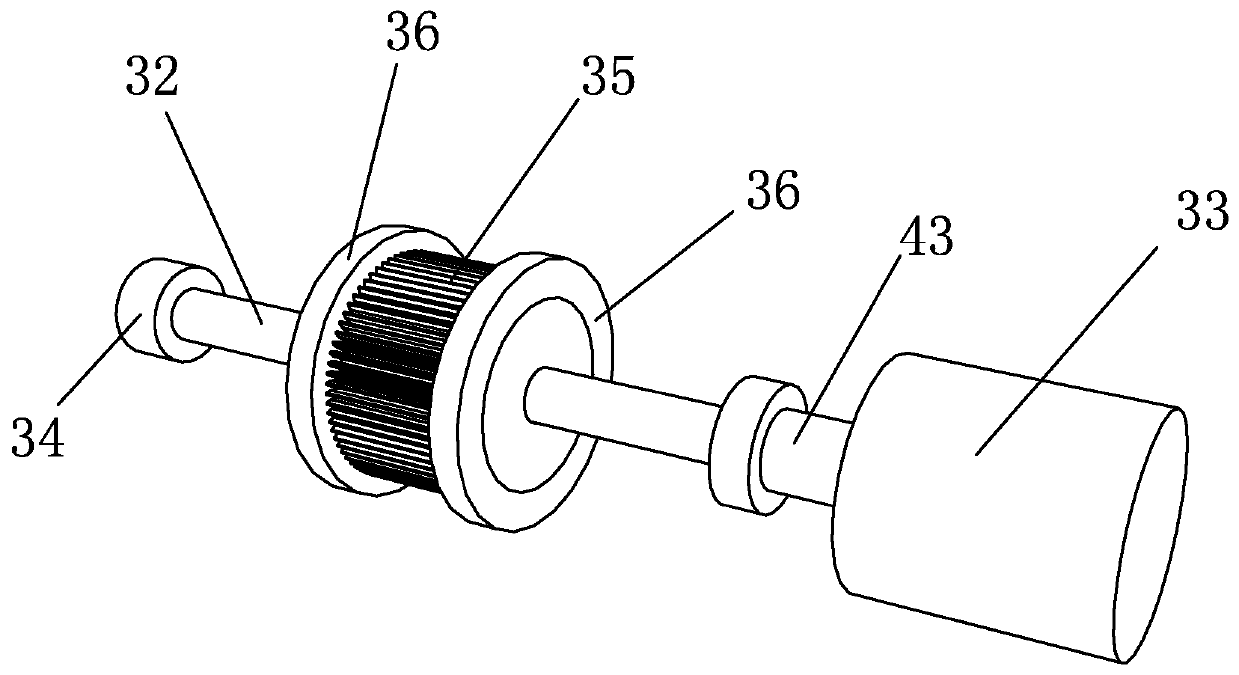

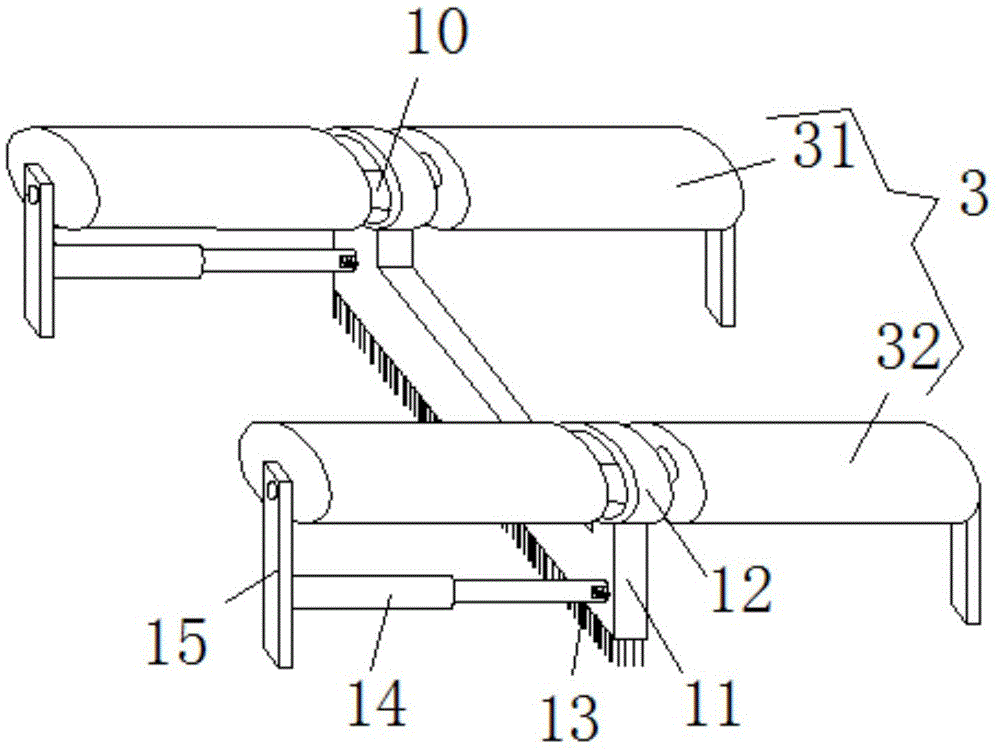

Uniform spinning silk yarn winding device

InactiveCN108516403AAvoid concentrated windingAchieve regulationFilament handlingFibre cleaning/openingYarnDrive shaft

The invention discloses a uniform spinning silk yarn winding device. The uniform spinning silk yarn winding device comprises a bearing plate. A supporting plate I and a supporting rod II are vertically fixedly arranged on the bearing plate, and a double-shaft motor is fixedly arranged on the bearing plate. A first drive shaft is fixedly arranged on an output shaft of the double-shaft motor. A swinging strip plate is provided with a guiding groove, and the surface of a second driven shaft is sleeved with and fixedly provided with a cleaning rotation roller. The end, away from the cleaning rotation roller, of a sliding rod is horizontally and fixedly provided with a brush plate, and a soft brush is fixedly arranged on the surface of the brush plate. Through rotation of a winding rotation roller, silk yarn winding is achieved; through the left-right reciprocating motion of a sliding casing pipe along a guiding rod, the silk yarn position is adjusted through a silk yarn limiting block, theuniform silk yarn winding effect is achieved, the silk yarn is prevented from being wound around one position of the winding rotation roller in a centralized manner, and the winding quality is improved; and meanwhile, through rotation of the soft brush, rotating cleaning is conducted on dust attached to the silk yarn, and the cleanliness of the silk yarn is guaranteed.

Owner:绍兴柯桥涵雷服饰科技有限公司

Spreading device for spreading out fiber filament bundles and spreading method carried out using the same

ActiveUS20100107384A1Embedded in matrixAvoid concentrationFilament manufactureFibre cleaning/openingFiberEngineering

A spreading device (20) for spreading a fiber filament bundle (32) to form a flat fiber band (14) has at least one convexly bent spreading edge (80) that is movable. The convexly bent spreading edge has at least one direction component perpendicular to a longitudinal extension of the fiber filament bundle (32) to be spread relative to the the convexly bent spreading edge. The fiber filament bundle is configured to be placed under tension onto the convexly bent spreading edge (80) and thereafter is configured to be moved again with the at least one direction component perpendicular to the fiber filament bundle (32) away from the fiber filament bundle to release the the fiber filament bundle from the convexly bent spreading edge (80).

Owner:EADS DEUT GMBH

Cleaning-conveniently spinning device

InactiveCN108118420AAvoid pollutionReduce pollutionLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingYarnEngineering

The invention belongs to the field of a spinning device, and particularly to a cleaning-conveniently spinning device. For a textile machine is polluted by massive spreading of fluff dust and unable toclean the interwoven cloth for the fluff on a yarn is easy to drop when the yarn of the existing textile machine passes through a roll wheel and other guide devices, the following plan is presented;the spinning device comprises a device main body; one side of the device main body is orderly equipped with a horizontal fixing plate, a teasing plate, an ultra-wear-resisting thread crossing device and a collecting box with an opened top end from top to bottom orderly; multiple rotary shafts are rotationally connected to the fixing plate, and multiple comb teeth are connected to the teasing plate; the side wall at one side of the collecting box is equipped with an exhaust fan. The cleaning-conveniently spinning device can collect and clean fluff and dust on the yarn, prevent fluff from polluting the spinning device, reduce the maintenance of the spinning device in later period while clean and dry the interwoven cloth; thus the cloth does not need to clean in later period, the spinning effect is good.

Owner:苏州朦井纺织科技有限公司

Apparatus for stripping fibre material from textile fibre bales of spinning material, for example cotton, synthetic fibres and the like

InactiveUS20060207064A1Reduce light lossNo wearFibre cleaning/openingCarding machinesTextile fiberEngineering

An apparatus for stripping fiber material from textile fiber bales has a tower, which can be moved to and fro in relation to the fiber material by means of a carriage having a travel motor or the like, and has at least one boom, which is provided with the stripping apparatus. The boom together with the stripping apparatus can be moved in the height direction of the tower by means of a lifting motor or the like. A movable distance sensor is provided for determination of the location in the length direction. In order to make possible, by simple means, an exact determination of location in the length and / or height direction, a movable distance sensor scans, for location determination in the length and / or height direction, the distances to a counterpart element and calculates from those distances the location.

Owner:TRUETZSCHLER GMBH & CO KG

Yarn guiding device for textile machinery yarn

ActiveCN109693971ASmooth and smooth entryEasy to handleFilament handlingFibre cleaning/openingYarnFixed frame

The invention discloses a yarn guiding device for textile machinery yarn. The yarn guiding device comprises a fixed frame and a yarn guiding frame; the yarn guiding frame comprises an arc-shaped rotating plate and an arc-shaped fixed plate; an upper pressure roller is arranged at the right end of the arc-shaped rotating plate, and the left end of the arc-shaped rotating plate is connected with anadjusting air cylinder; a lower pressure roller is arranged at the right end of the arc-shaped fixed plate, and a yarn arranging wheel is arranged on the arc-shaped fixed plate; and a first yarn guiding roller is arranged between the yarn arranging wheel and a yarn leading roller, and a second yarn guiding roller is arranged between the yarn arranging wheel and the lower pressure roller. The yarntransferred from different angles can be led, the yarn is prevented from being broken in the transferring process, burrs and impurities on the surface of the yarn can be removed in the yarn leading process through the design of the yarn arranging wheel, thus the surface of the yarn is smoother and flatter, and the quality of the yarn is improved; and meanwhile, electrostatic friction generated inthe yarn transferring process can be removed through a electrostatic eliminating assembly, and the problems of yarn fault increasing, yarn breaking and flying are reduced.

Owner:绍兴华清化纤纺织有限公司

Yarn cleaning device

InactiveCN108060480AGuaranteed cleanlinessPiercing arrangementsFibre cleaning/openingYarnElectrical and Electronics engineering

The invention discloses a yarn cleaning device. The yarn cleaning device comprises a first sliding rail, a sliding block, cleaning devices, pressing devices, yarn detection wire take-up devices and yarn junction devices, the sliding block is slidingly arranged on the first sliding rail, a resetting device is arranged between the first sliding rail and the sliding block, the upper surface of the sliding block is provided with the yarn junction devices, the yarn detection wire take-up devices are arranged between the yarn junction devices, the yarn penetrates through the yarn junction devices and the yarn detection wire take-up devices, the cleaning devices which are used for cleaning yarn flocs are arranged on the sliding block, and the pressing devices are arranged between the yarn junction devices and the cleaning devices. The yarn cleaning device can achieve continuous yarn detection, in the case of continuous yarn movement, cutting off and connecting are conducted, and adsorption processing is conducted on the flocs on the yarn through the cleaning device.

Owner:颍上鑫鸿纺织科技有限公司

Process for making filament having unique tip and surface characteristics

InactiveUS20150361590A1Facilitate plaque-removal performanceAdd depthBrush bodiesLayered productsMaterials science

A process for making a filament for use in a brush implement comprises providing a composite filament comprising an external material and at least one internal material, wherein the tip surface comprises the internal material surrounded by the external material, the internal material having longitudinal shrinkage characteristics that differ from those of the external material; and causing the internal material to shrink inside the external material, whereby the internal material comprising the tip surface sinks relative to the external material comprising the tip surface so that at least one crater is formed at the tip surface of the filament, the at least one crater comprising a bottom formed by the internal material and walls formed by the external material, the at least one crater having a surface edge of a predetermined size and a predetermined shape.

Owner:THE PROCTER & GAMBLE COMPANY

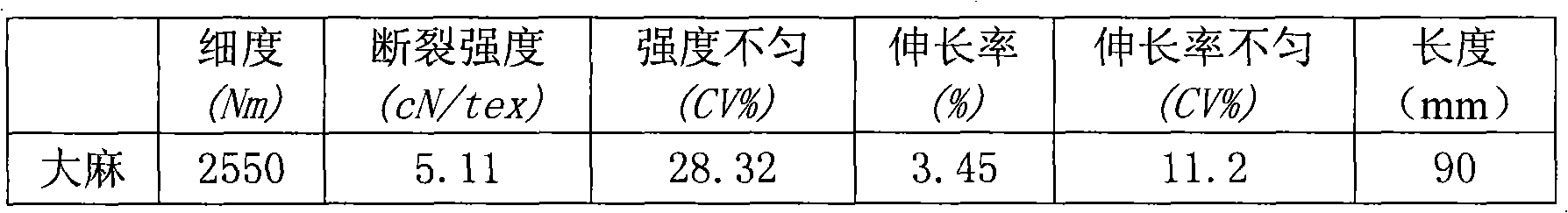

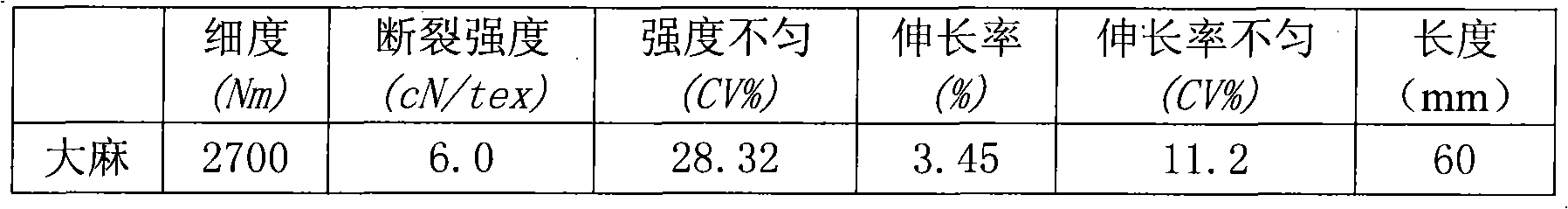

Flax fibers and preparation method thereof

ActiveCN101818379AImprove finenessOvercome the defect of only spinning coarse-count yarns of about 24-36 public countsFibre cleaning/openingCarding machinesFlax fiberFineness

The invention relates to flax fibers. The strength of the flax fibers is 3.0 to 8.0cN / dtex and the fineness of the flax fibers is 1,500 to 3,500 Nm; preferably, the strength of the flax fibers is 4.0 to 7.0cN / dtex and the fineness of the flax fibers is 1,500 to 3,000Nm; more preferably, the strength of the flax fibers is 4.5 to 6.5cN / dtex and the fineness of the flax fibers is 1,800 to 2,800Nm; and optimally, the strength of the flax fibers is 5.0 to 6.0cN / dtex, and the fineness of the flax fibers is 2,300 to 2,700Nm. The invention also relates to the preparation method of the flax fibers, which comprises the steps of acid impregnation, washing, oxidization, fiber spinning, oil feeding, oil and water removal, fiber softening, oil feeding and wetting, stowing and mechanical loosing. The flax fibers provided by the invention have high strength and fineness. The preparation method is short in process and light in pollution.

Owner:CHINA GARMENT BUYITIANXIA BEIJING TRADING

Silk yarn winder

InactiveCN103848280AReduce tensionQuality assuranceFilament handlingFibre cleaning/openingYarnBiochemical engineering

The invention discloses a silk yarn winder comprising a frame, wherein a roller for fixing raw material silk yarns is fixed on the upper part of the frame, a silk yarn winding tube for winding silk yarns is fixed on the lower part of the frame, a tension mechanism is mounted on the frame between the roller and the silk yarn winding tube and in contact fit with the surface of the raw material silk yarns, a brush fixing plate is arranged on the frame under the roller, a smoothing brush is arranged on the brush fixing plate, and a dust collection chute is fixed on the frame under the smoothing brush. The silk yarn winder has the advantages that the smoothing brush is capable of clearing away impurities on the silk yarns, and as a result, the tension of the silk yarns is reduced and the quality of the product is guaranteed.

Owner:倪立俊

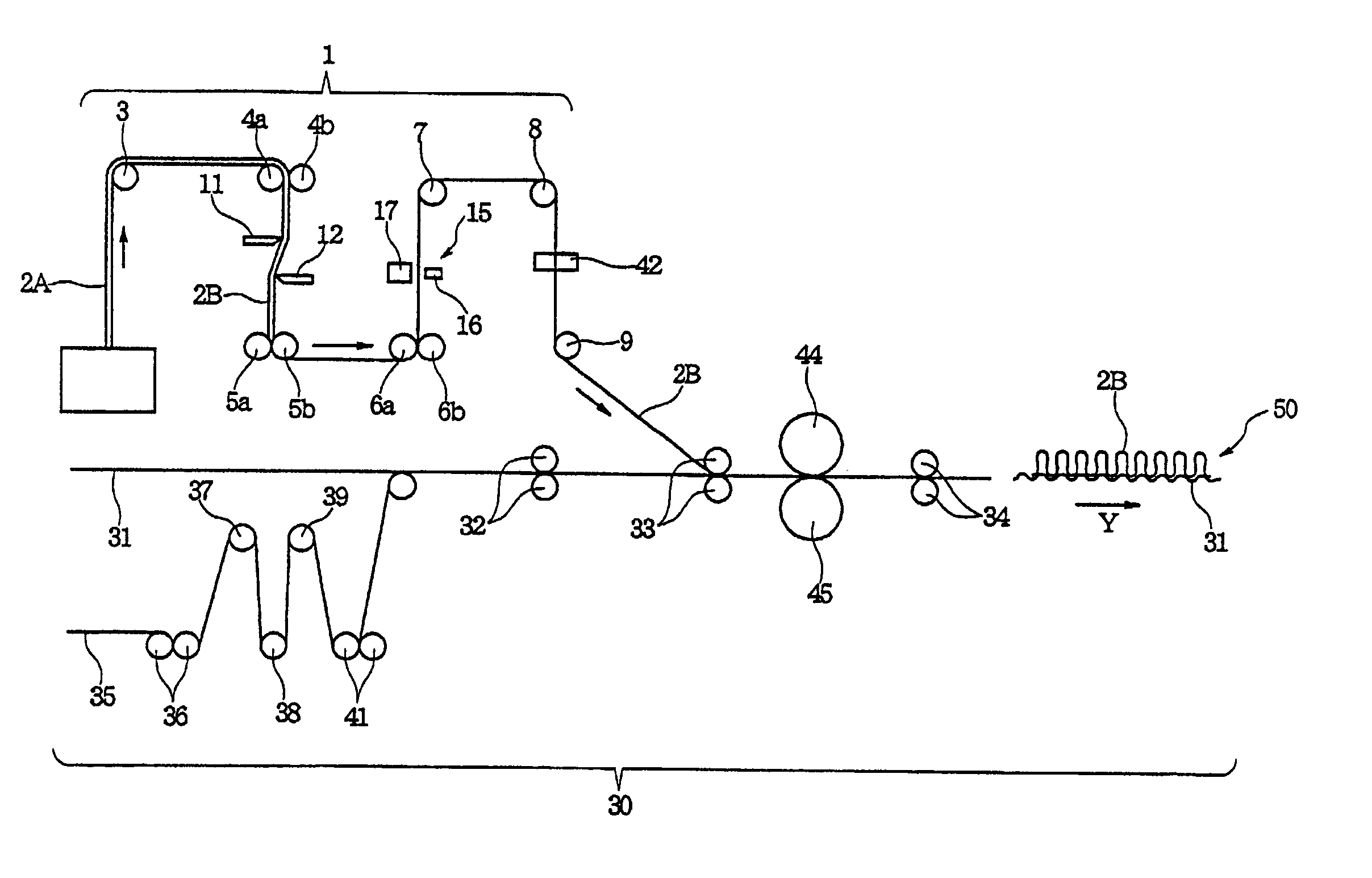

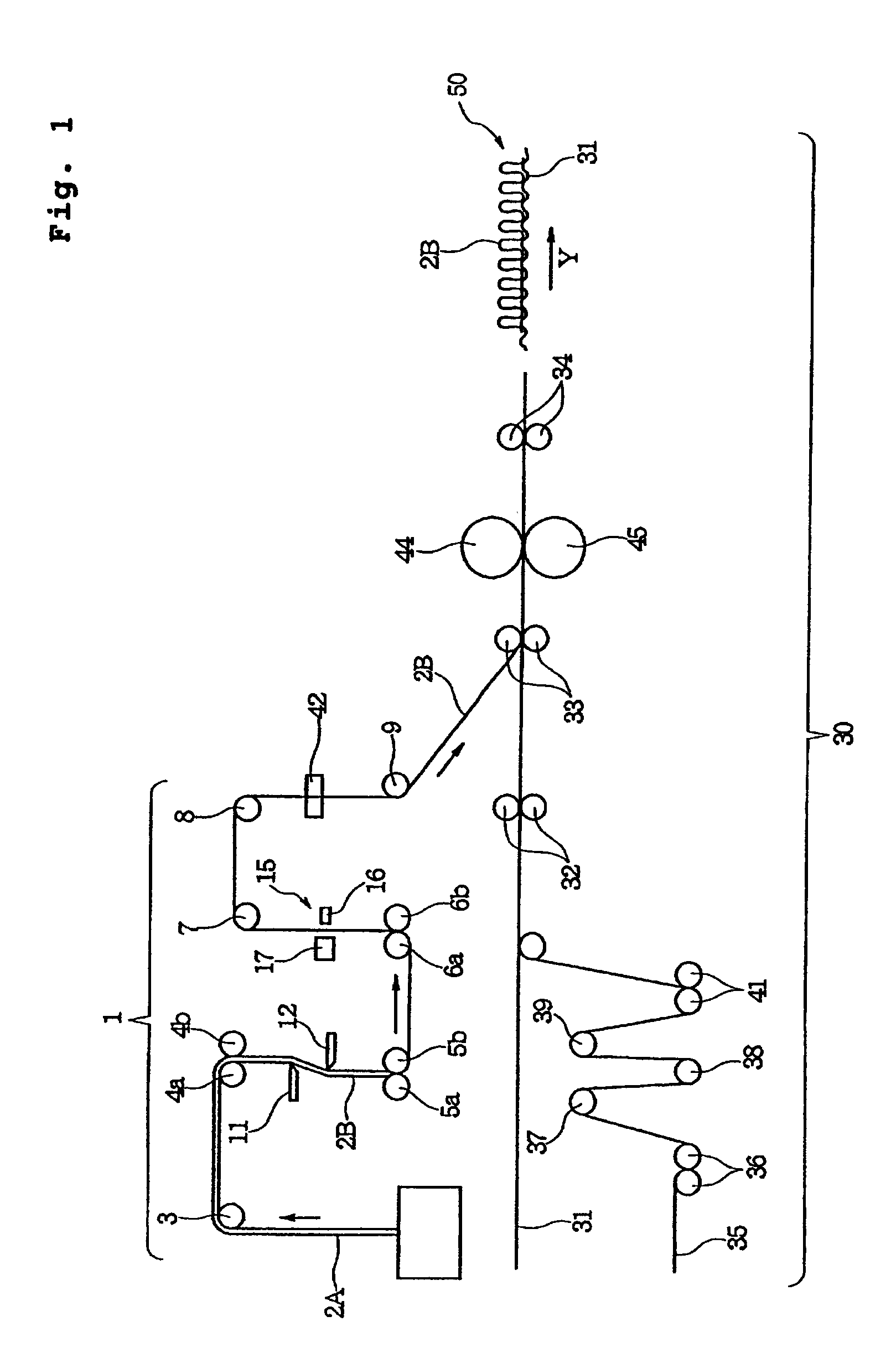

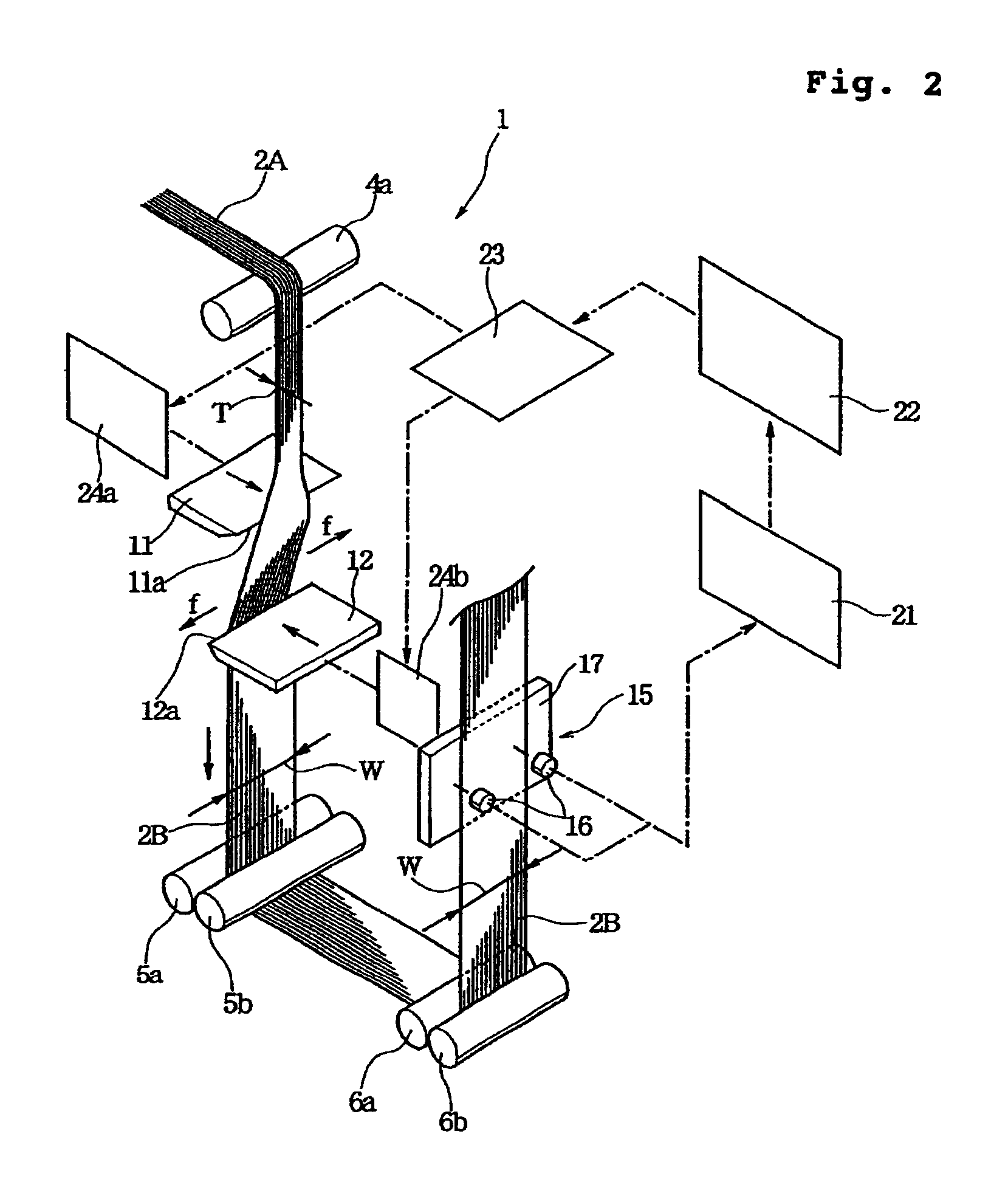

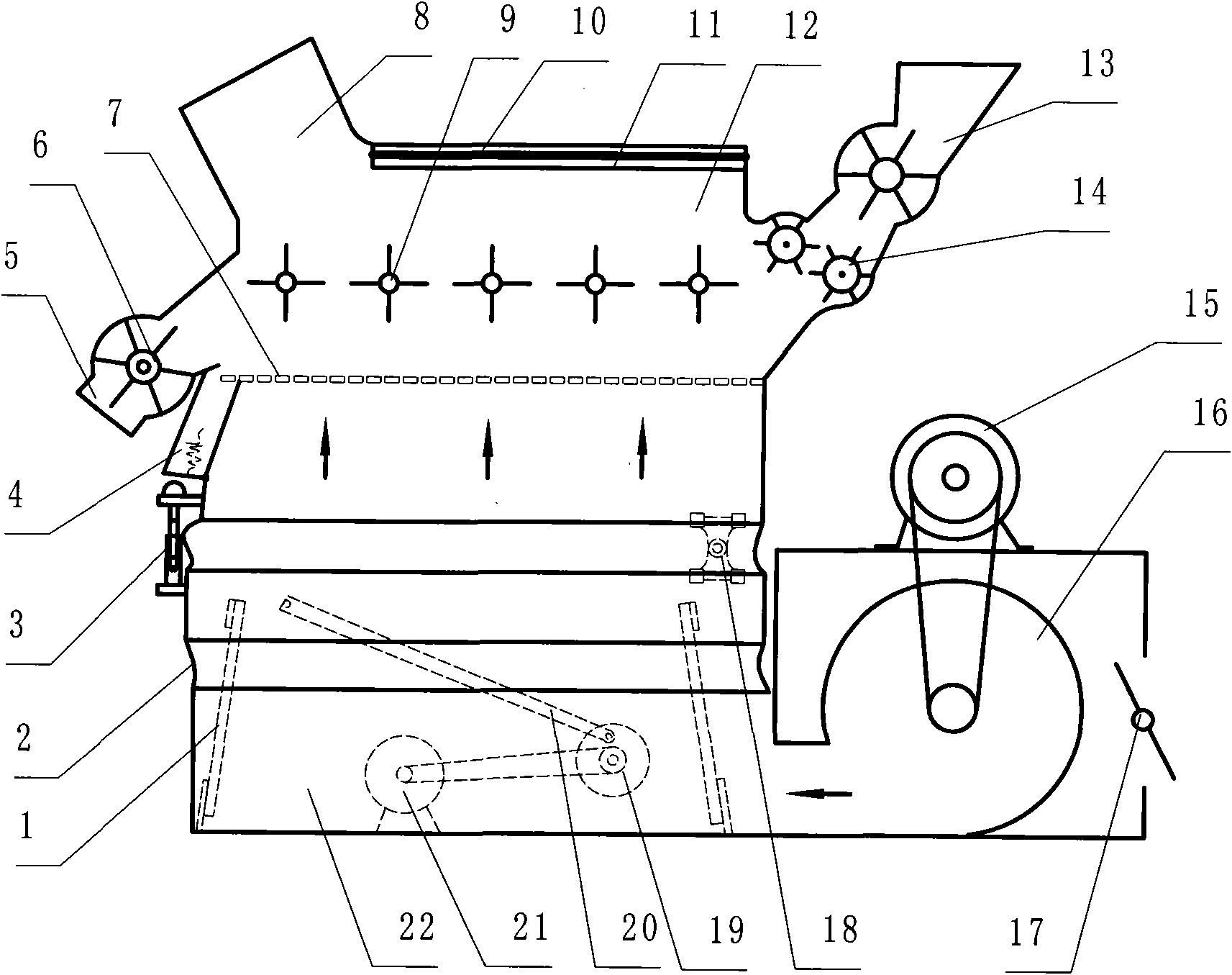

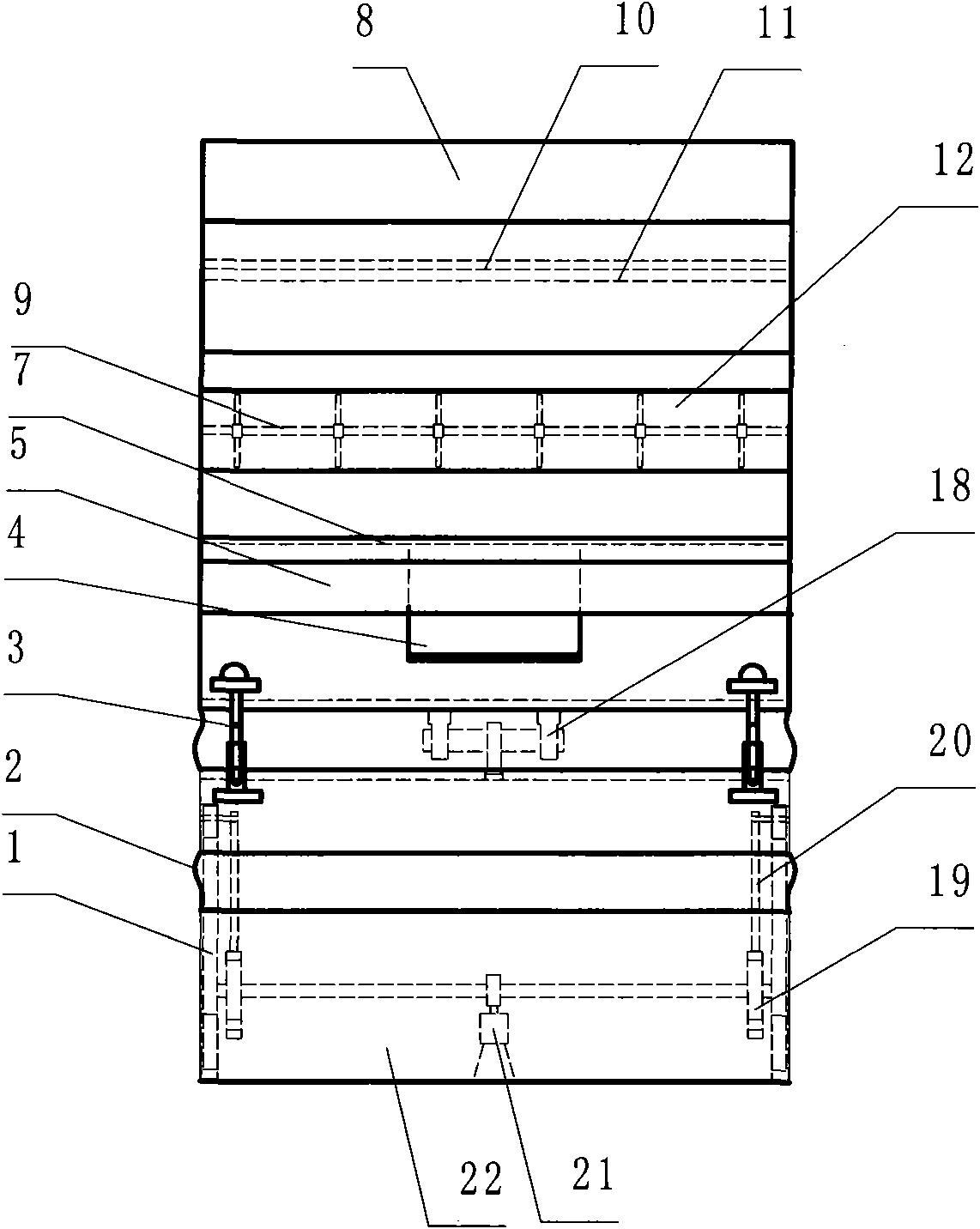

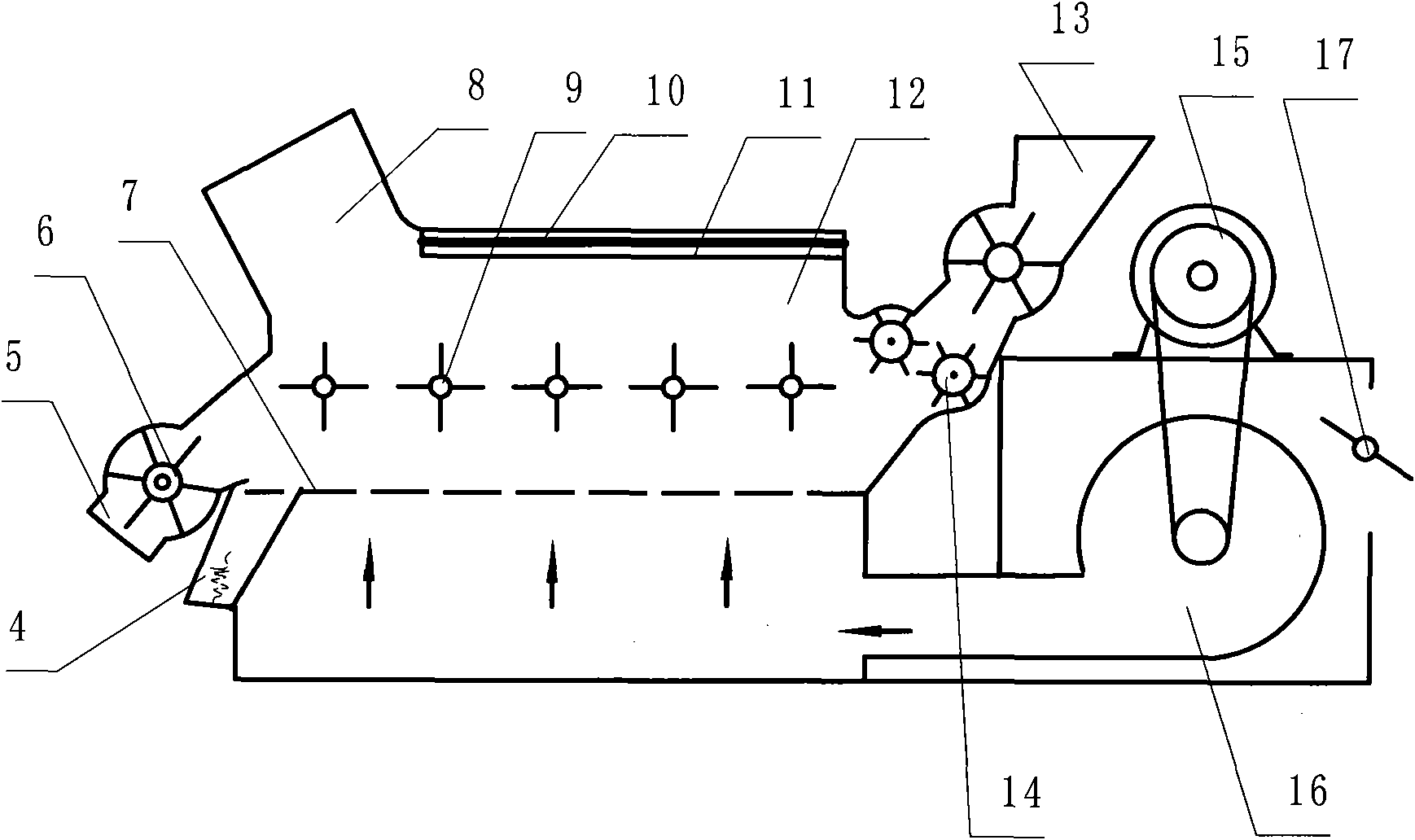

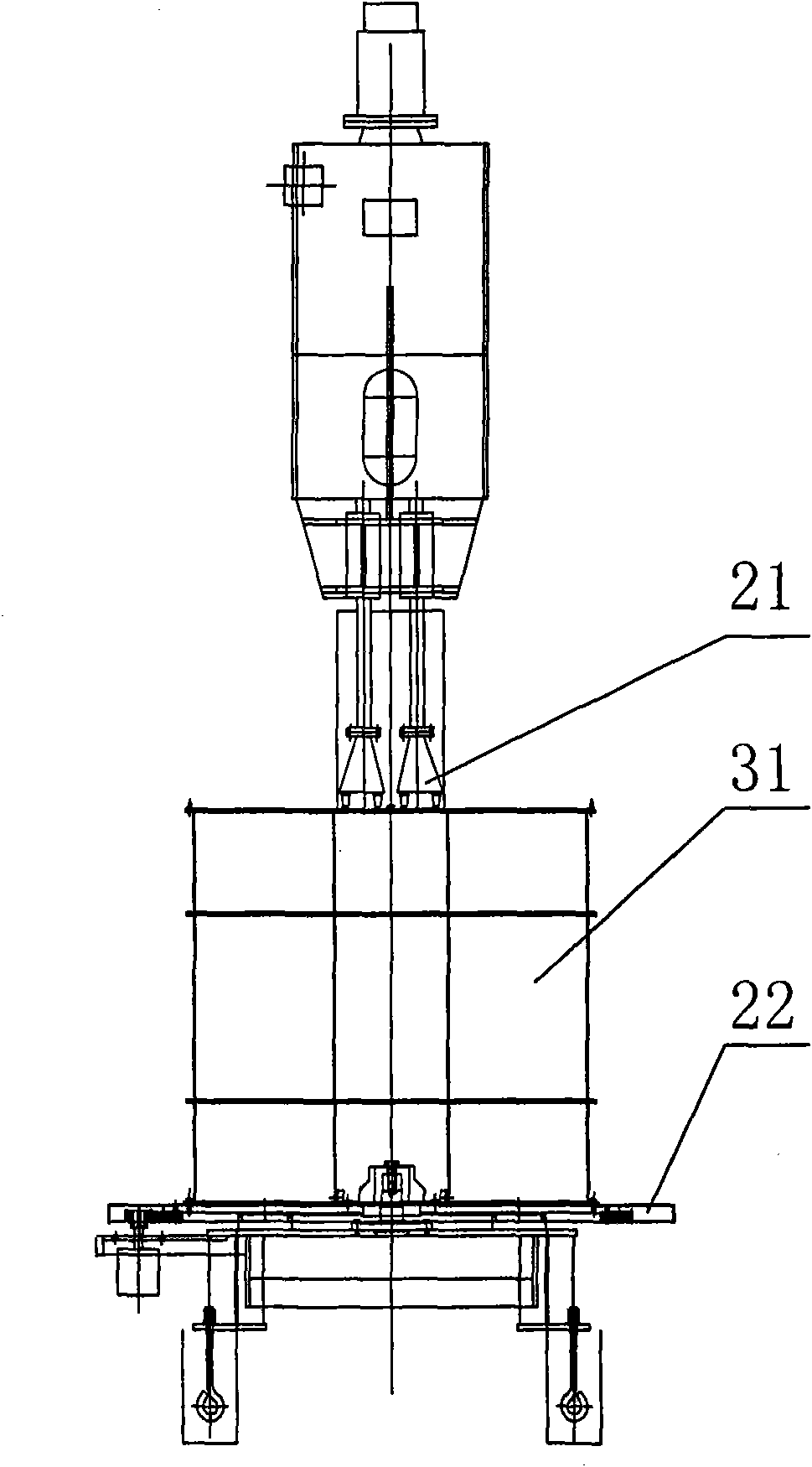

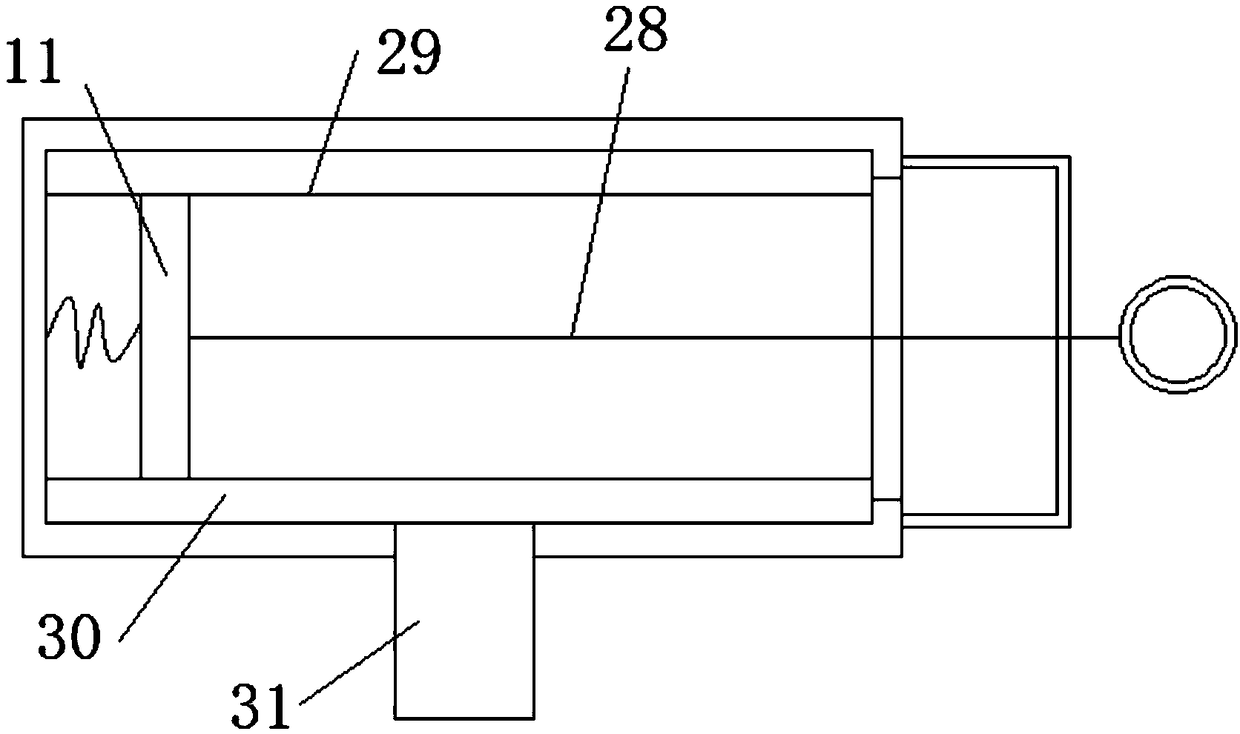

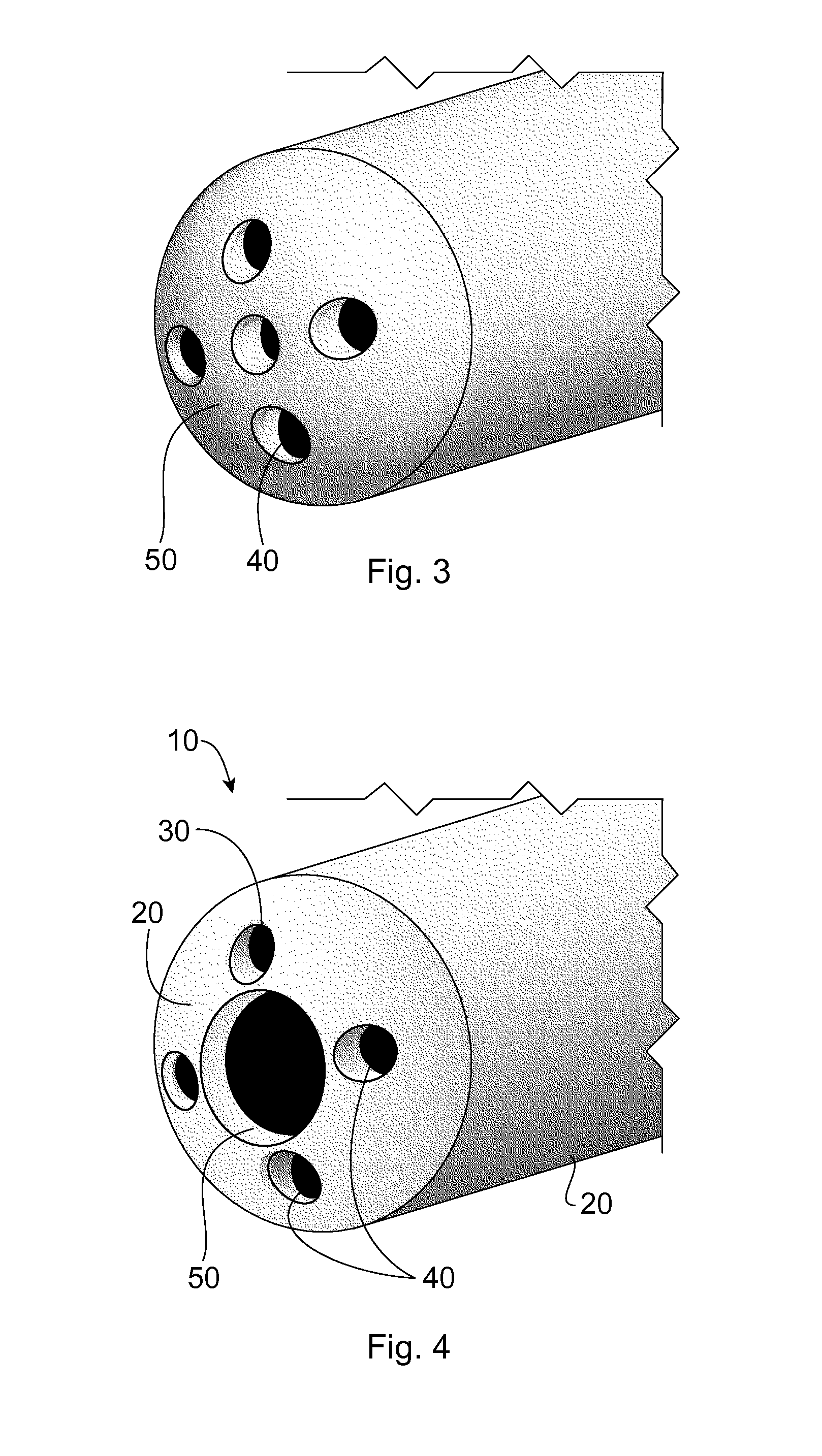

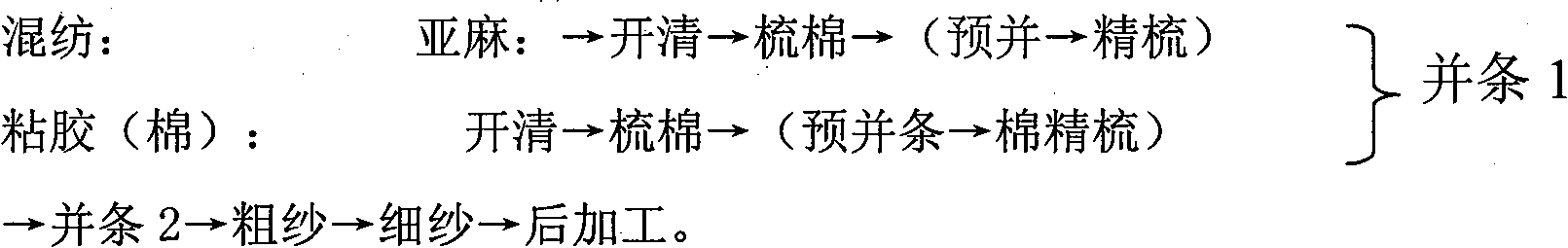

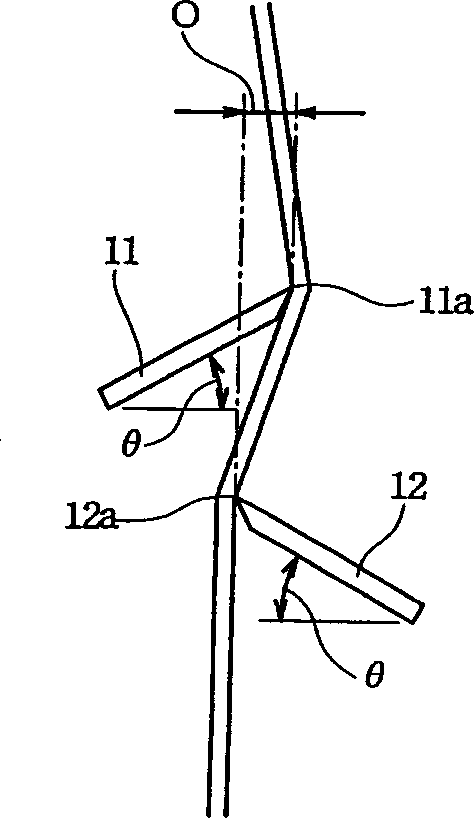

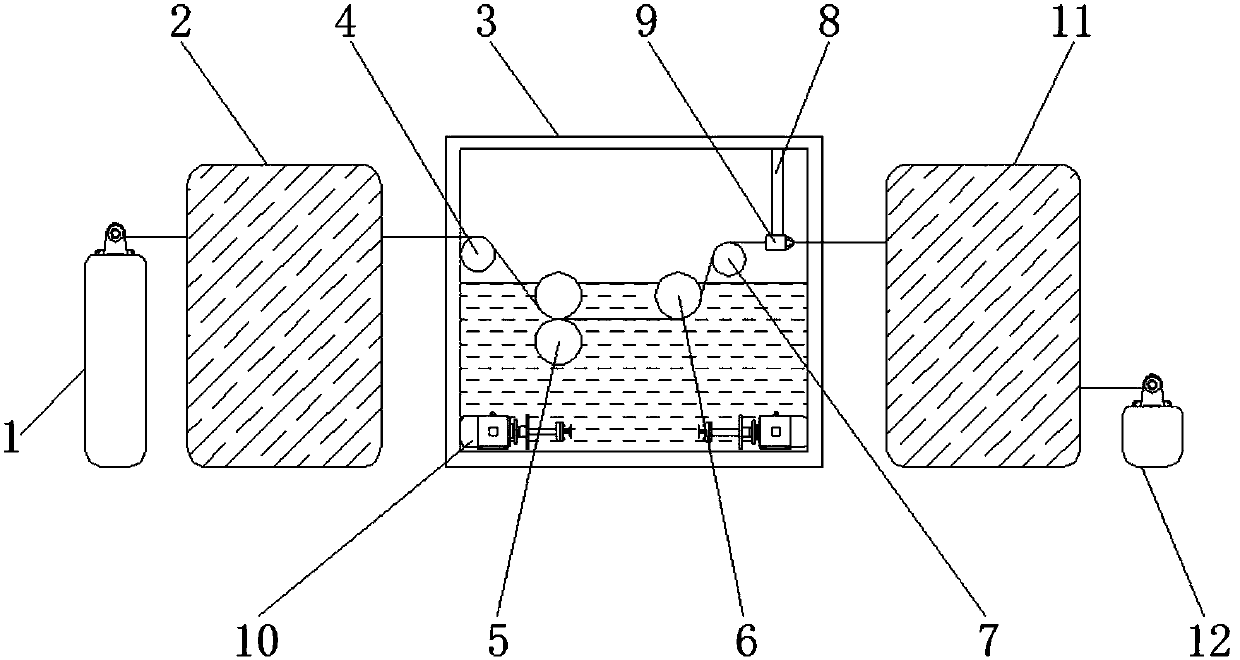

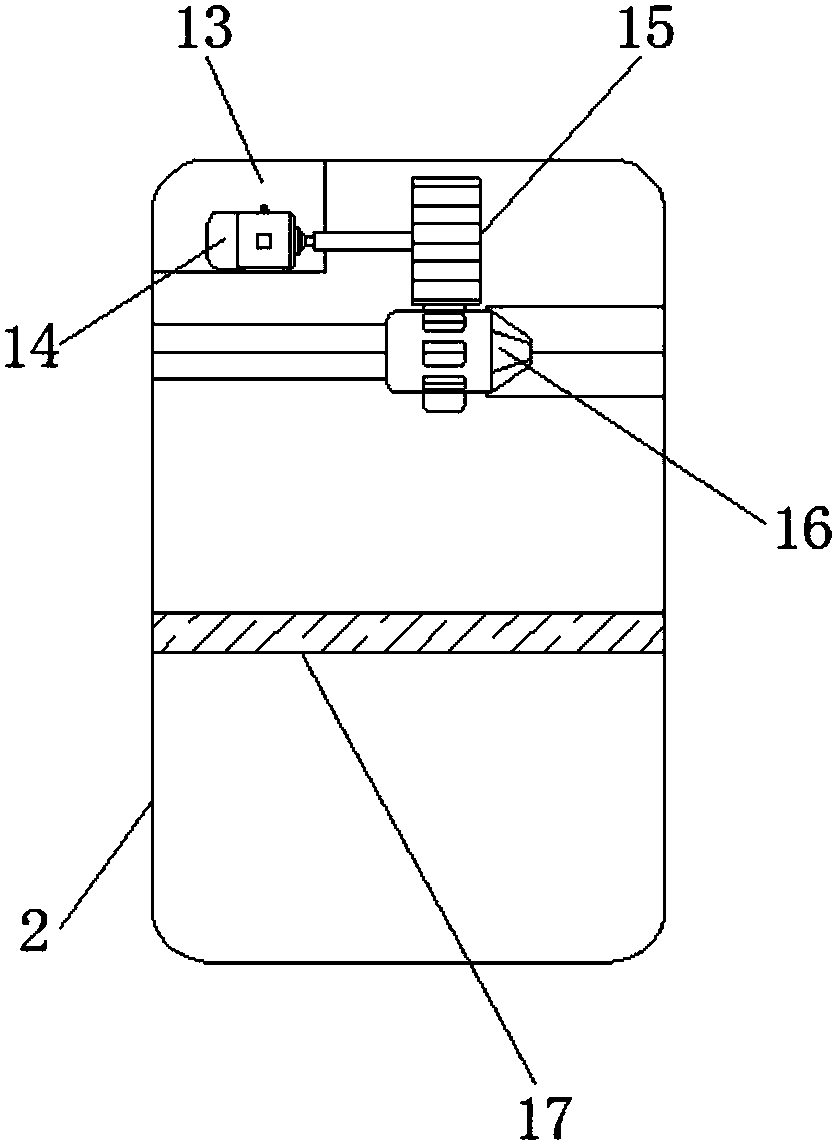

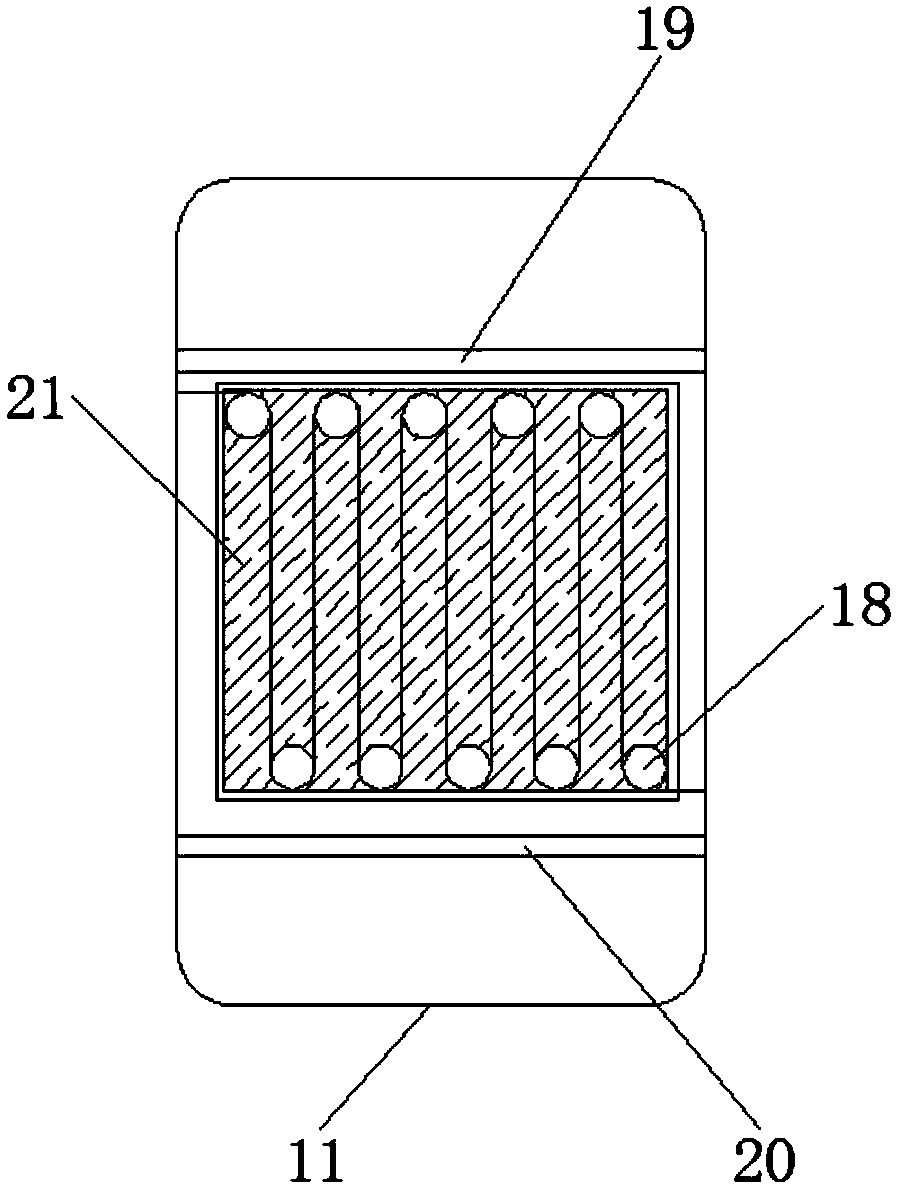

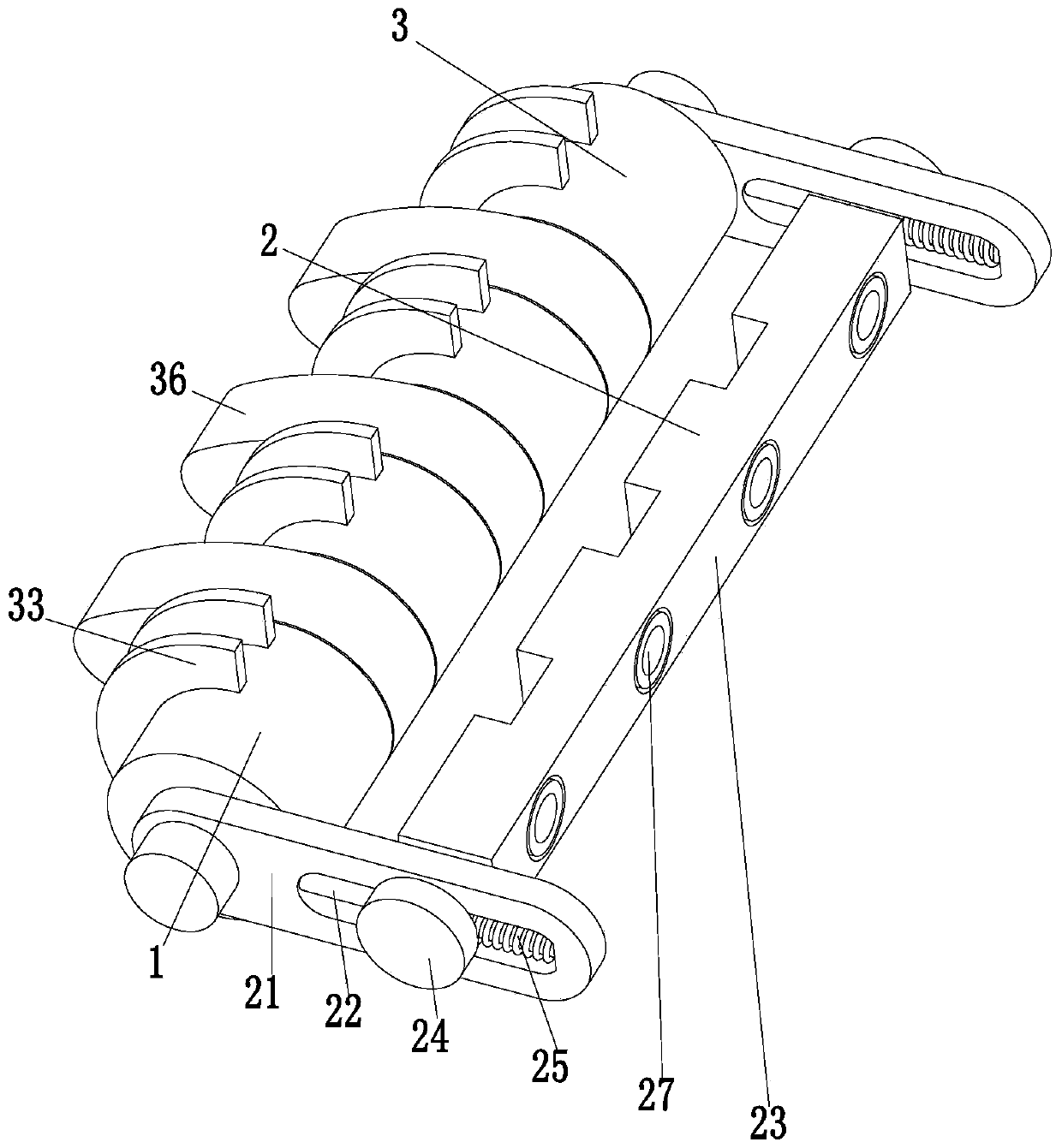

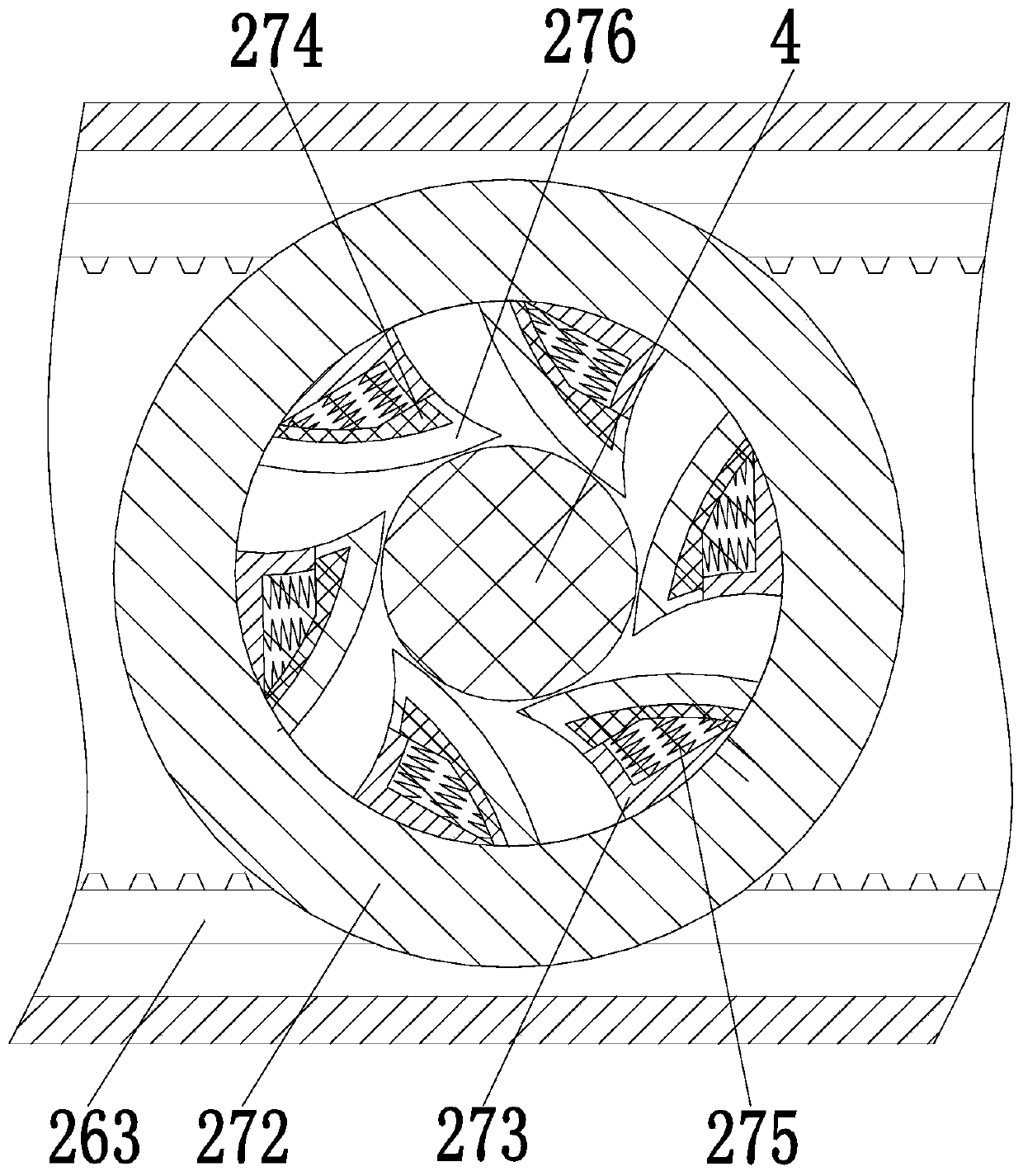

Continuous filament-yarn opening method and apparatus thereof

A method and an apparatus for opening continuous filaments to solve a problem that in opening a crimped tow, qualities of a fiber layer after opening are not stabilized and the change of various opening conditions is difficult when the kind of the tow is changed. Sliding plates 11 and 12 are brought into contact with a crimped tow 2A being transported between a transfer roll 4a and transfer rolls 5a and 5b. Continuous filaments arranged in the thickness direction of the tow 2A are provided with a shear by a sliding force produced when the tow 2A is slid on the sliding plates 11 and 12 and opened so that a fiber layer 2B in which the continuous filaments are dispersed in the width direction can be obtained.

Owner:UNI CHARM CORP

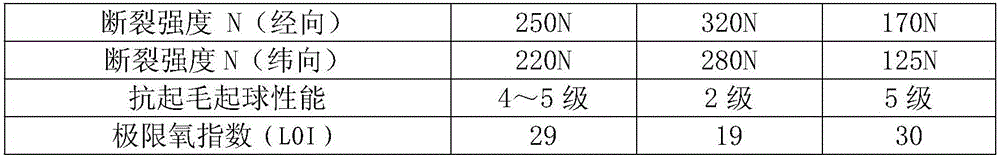

Preparation method of protective clothing blended fabric

ActiveCN105862204AImprove insulation effectImprove antistatic performanceSolvent-treatmentFibre cleaning/openingPolyesterEnvironmental resistance

The invention provides a preparation method of a protective clothing blended fabric. The fabric is formed by blending modified polyester fibers, wool and linen fibers, and the modified polyester fibers are formed by adding raw vermiculite powder to the preparation process of polyester fibers, cost is low, the modification effect is excellent, and in addition, the whole preparation process is environmentally friendly; the heat preservation performance of the fabric can be improved by adding the wool; antistatic performance and anti-ultraviolet performance of the fabric can be improved by adding the linen fibers.

Owner:SHENZHEN ELLASSAY FASHION CO LTD

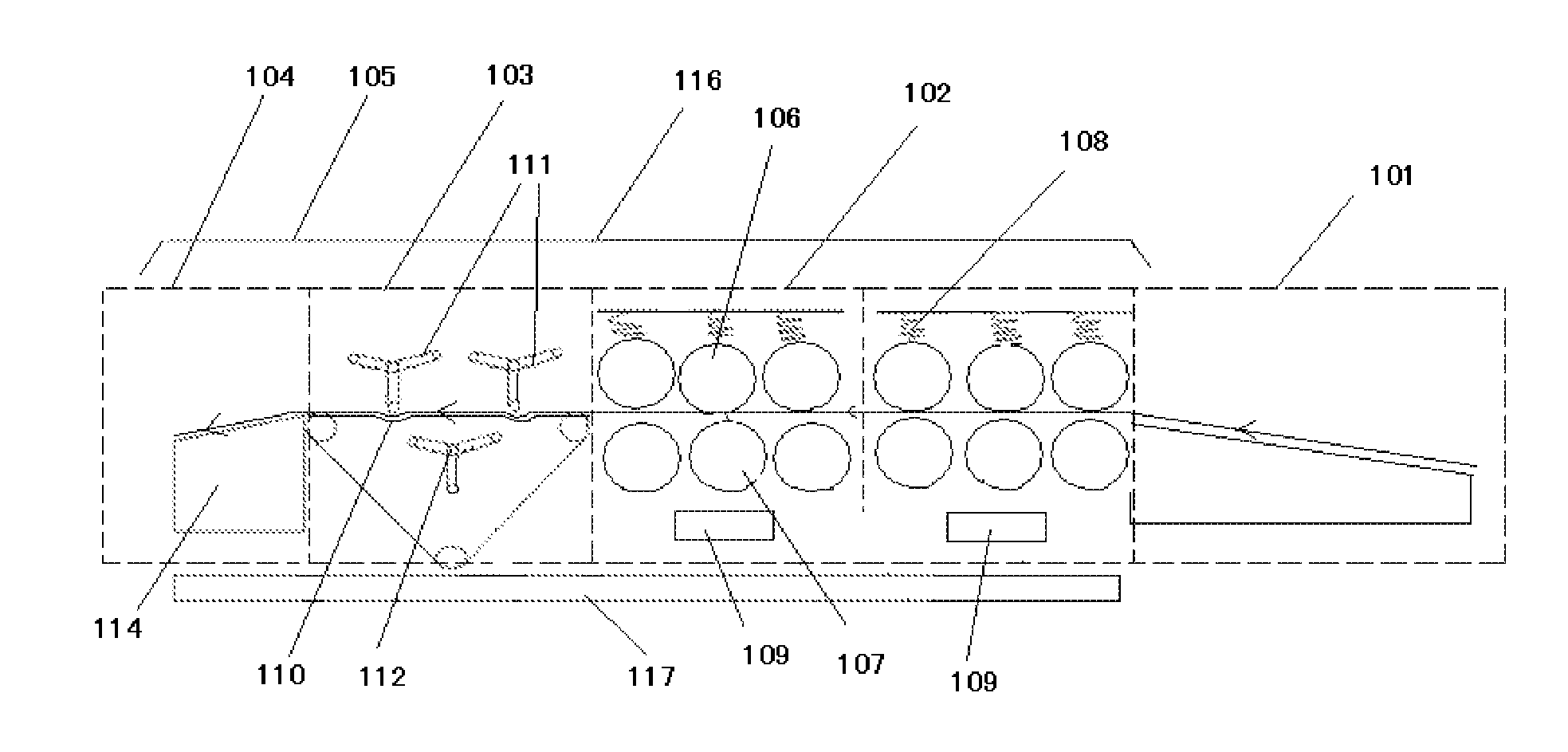

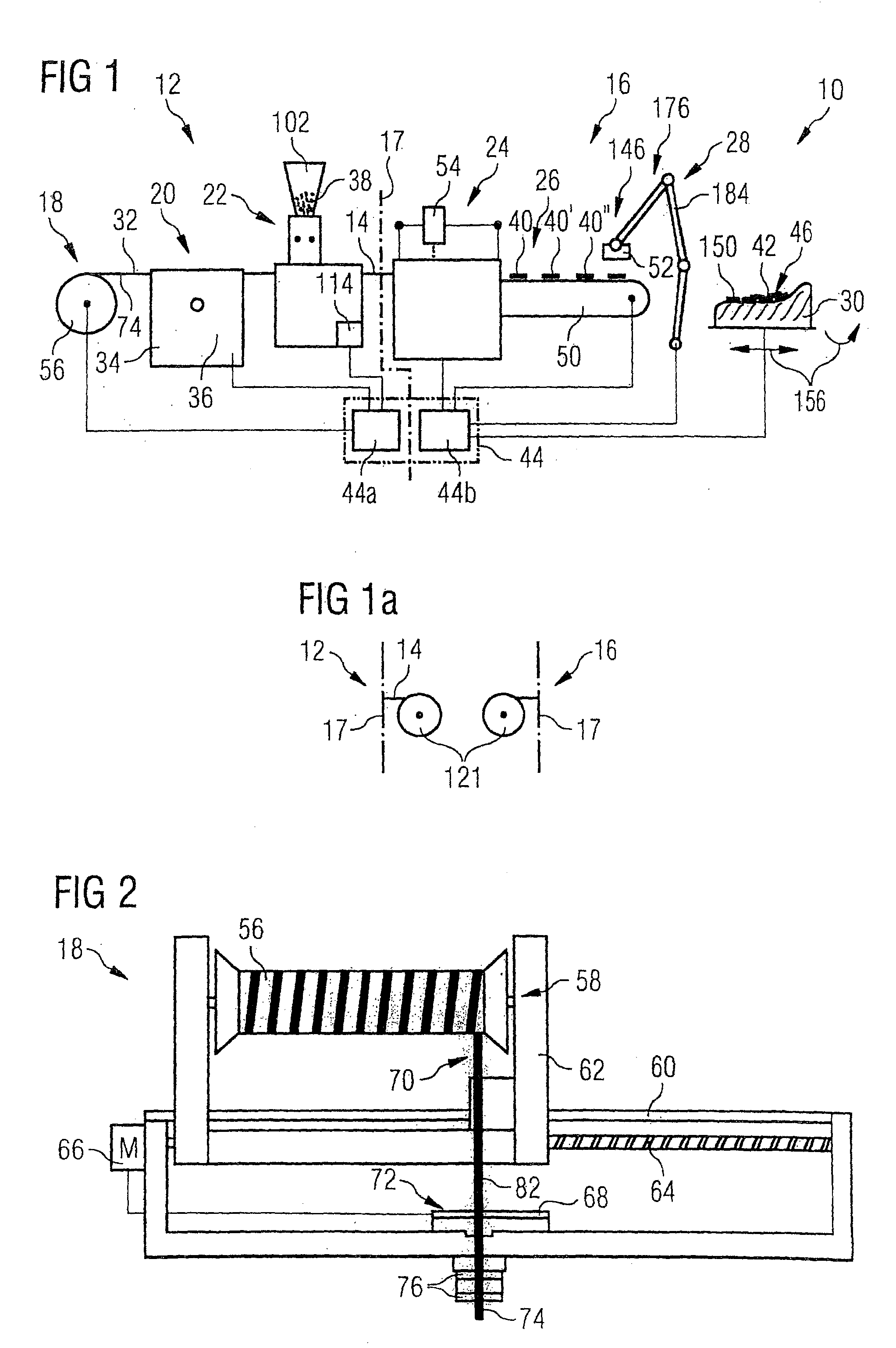

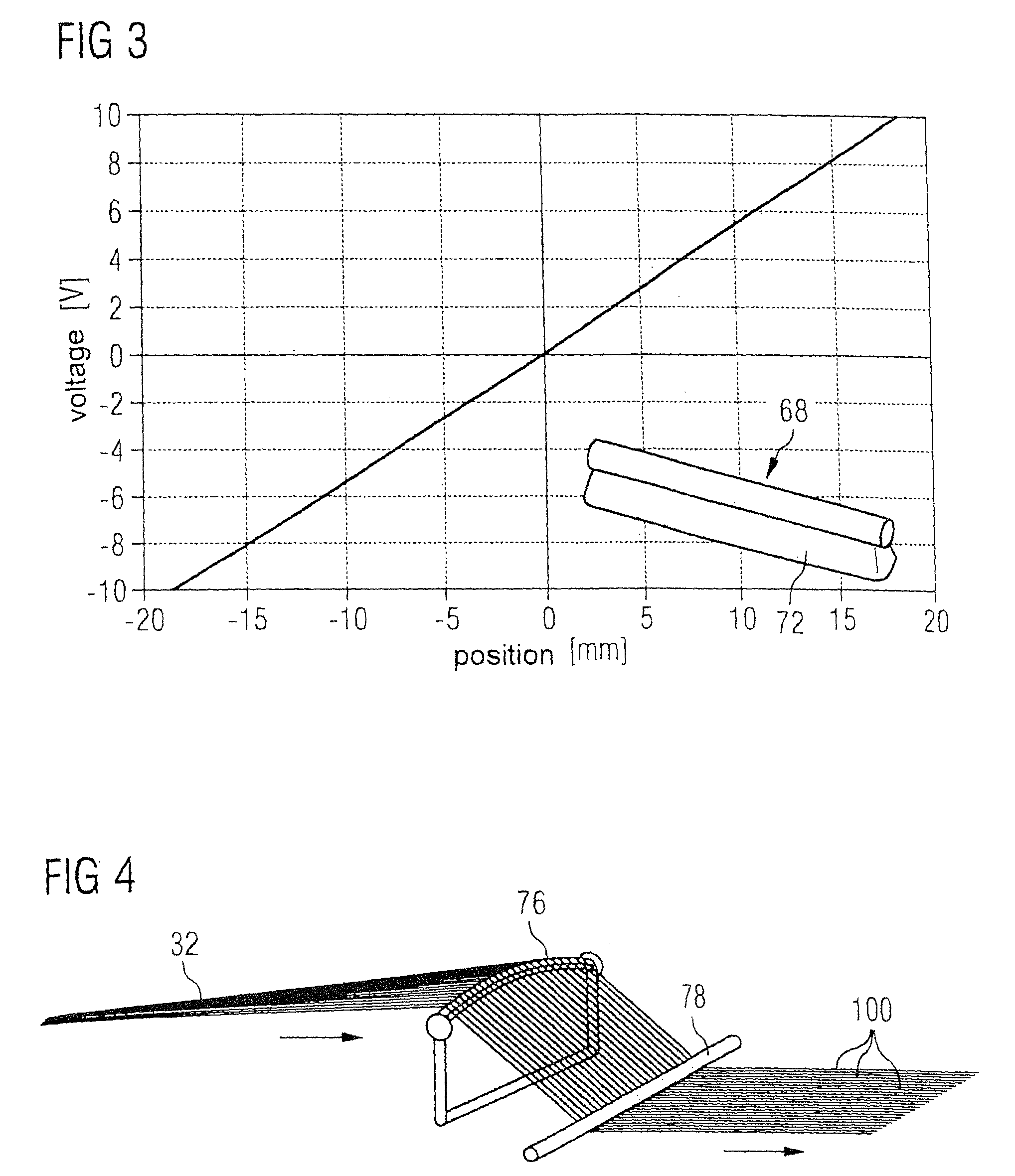

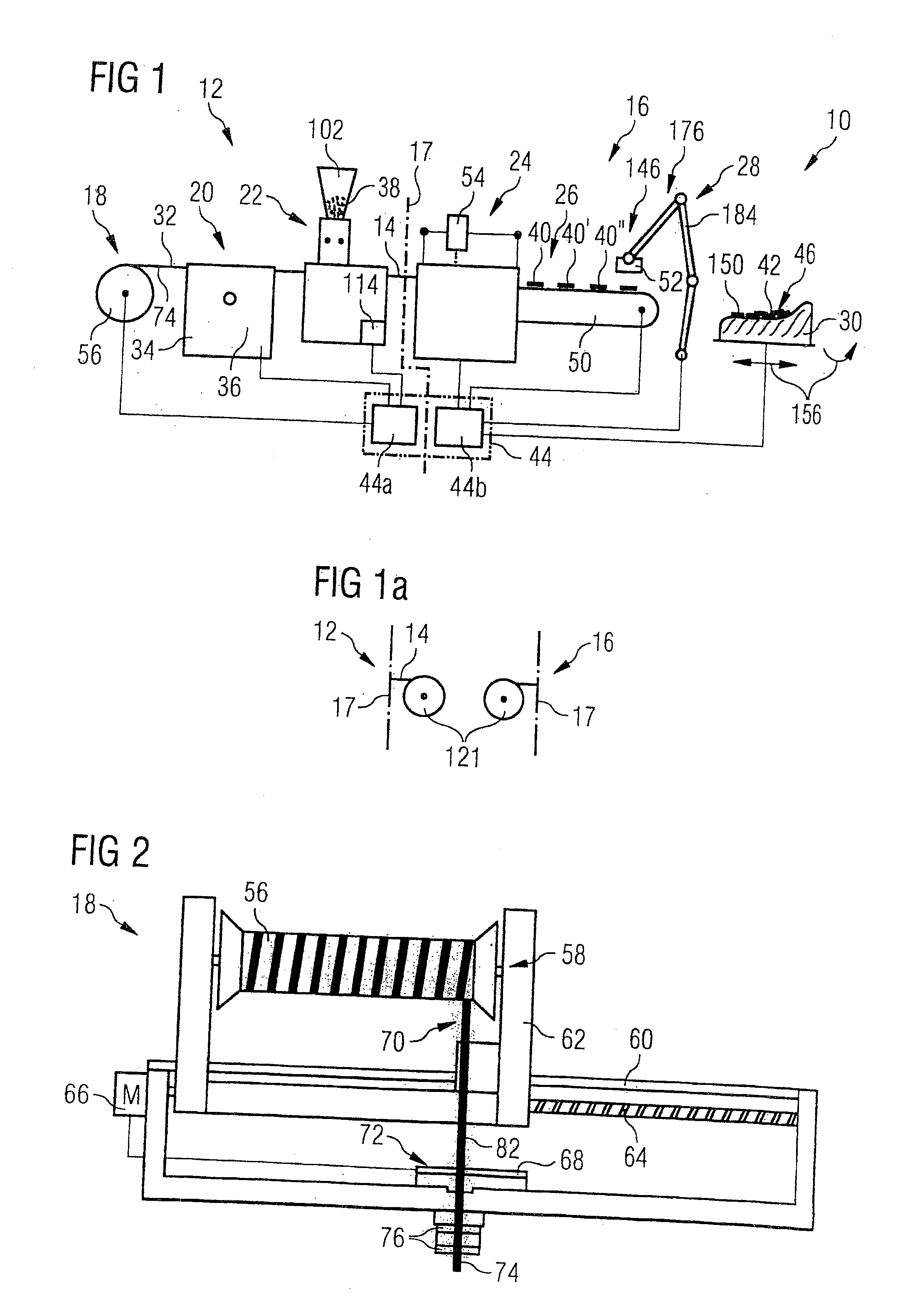

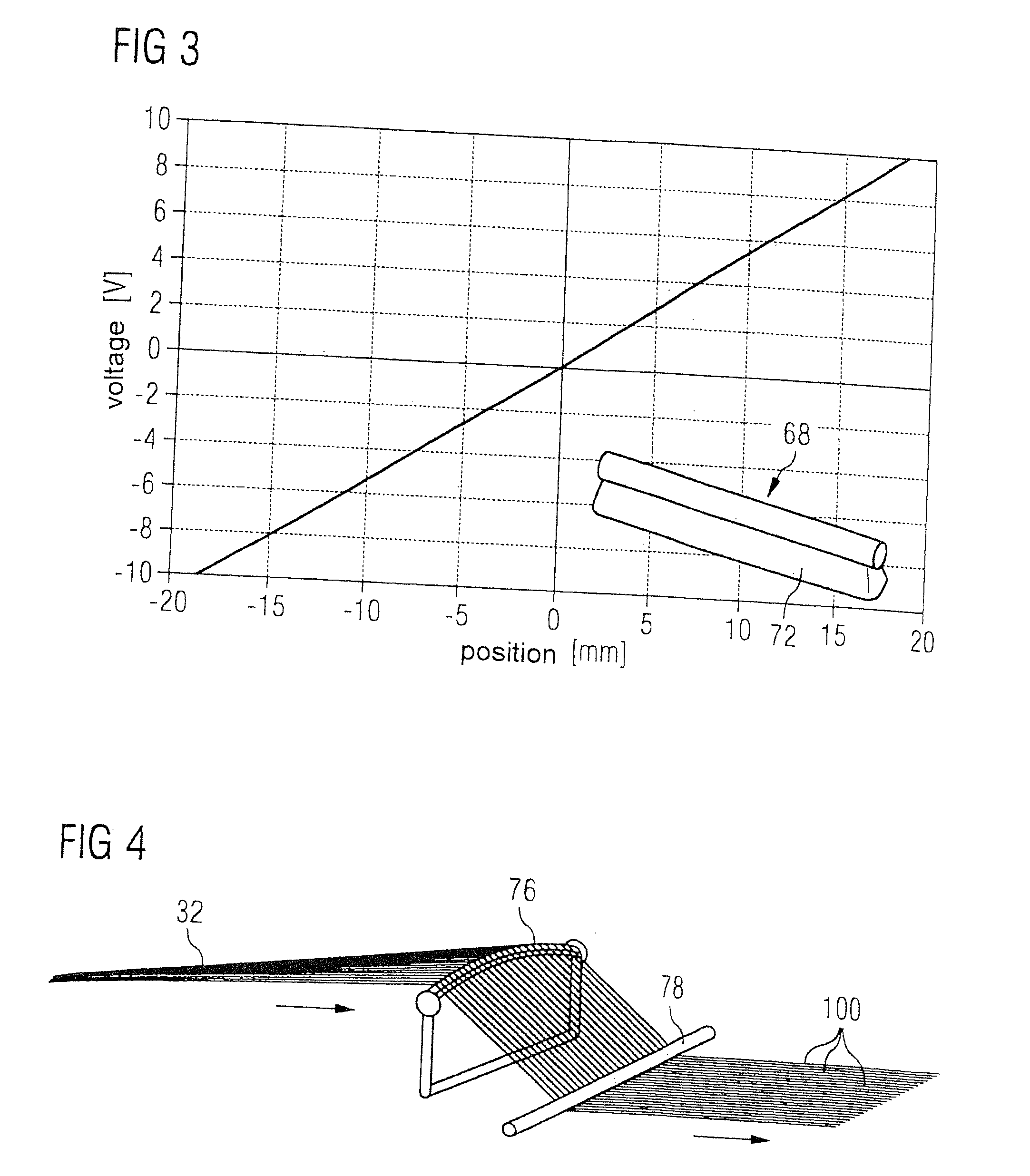

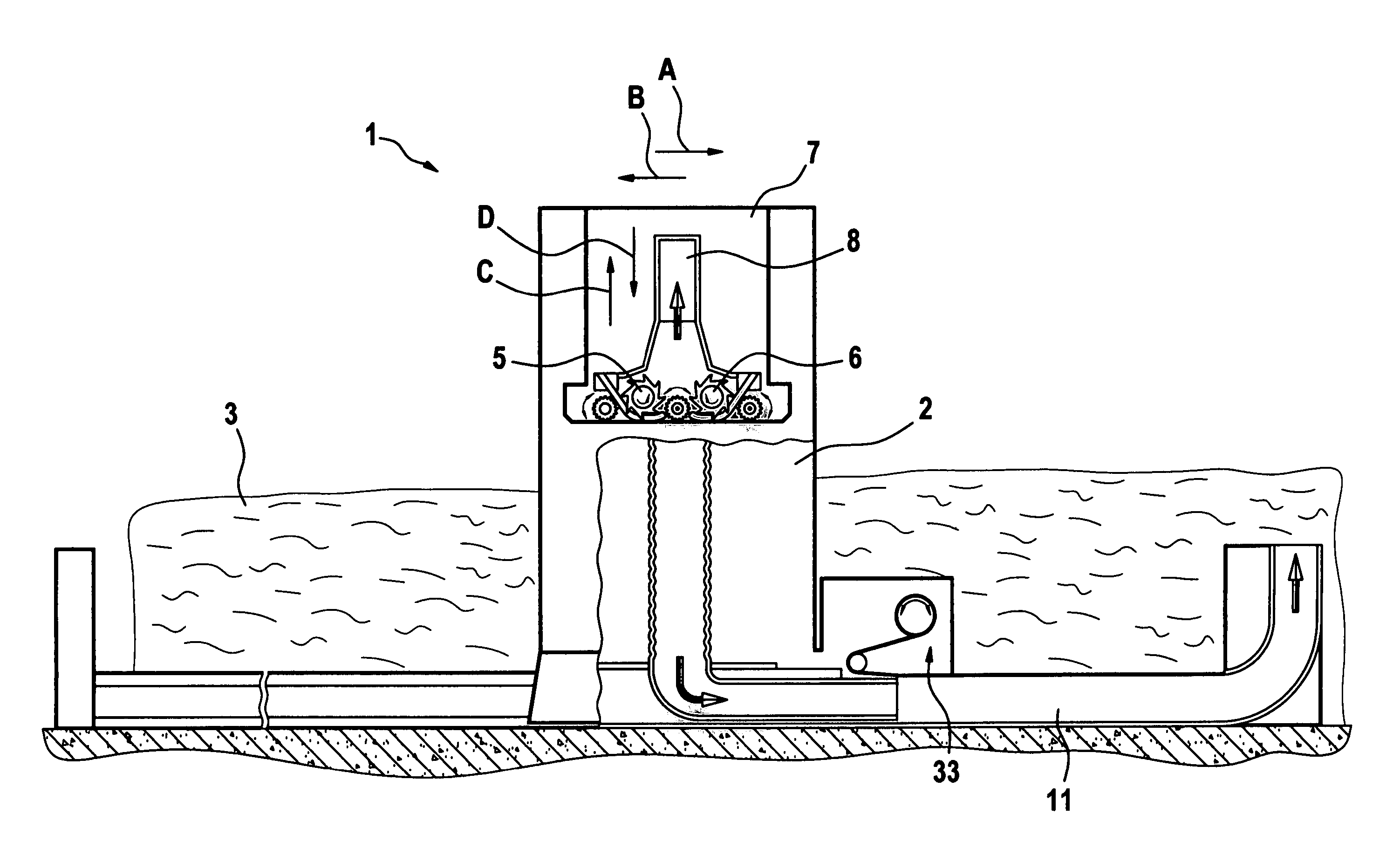

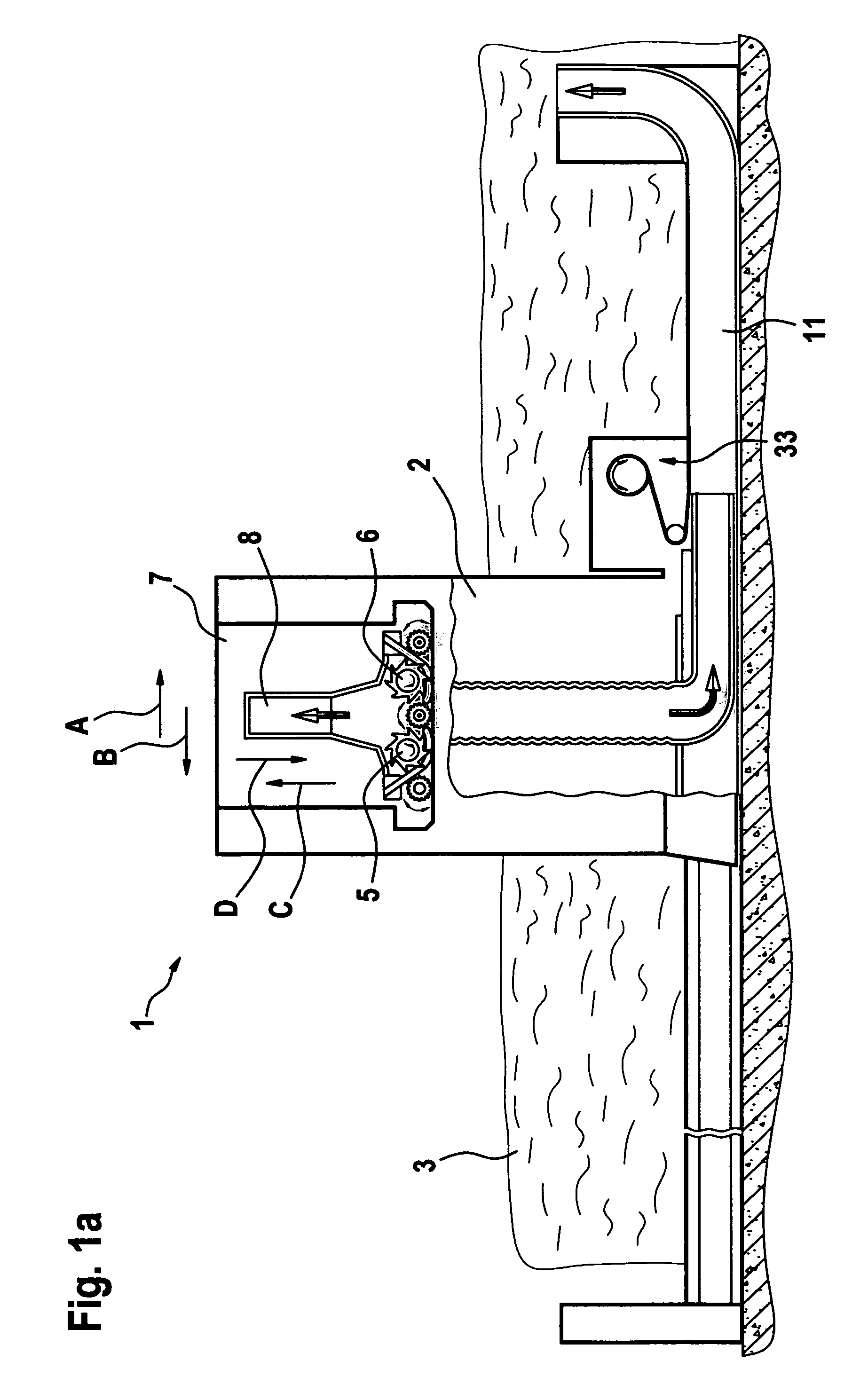

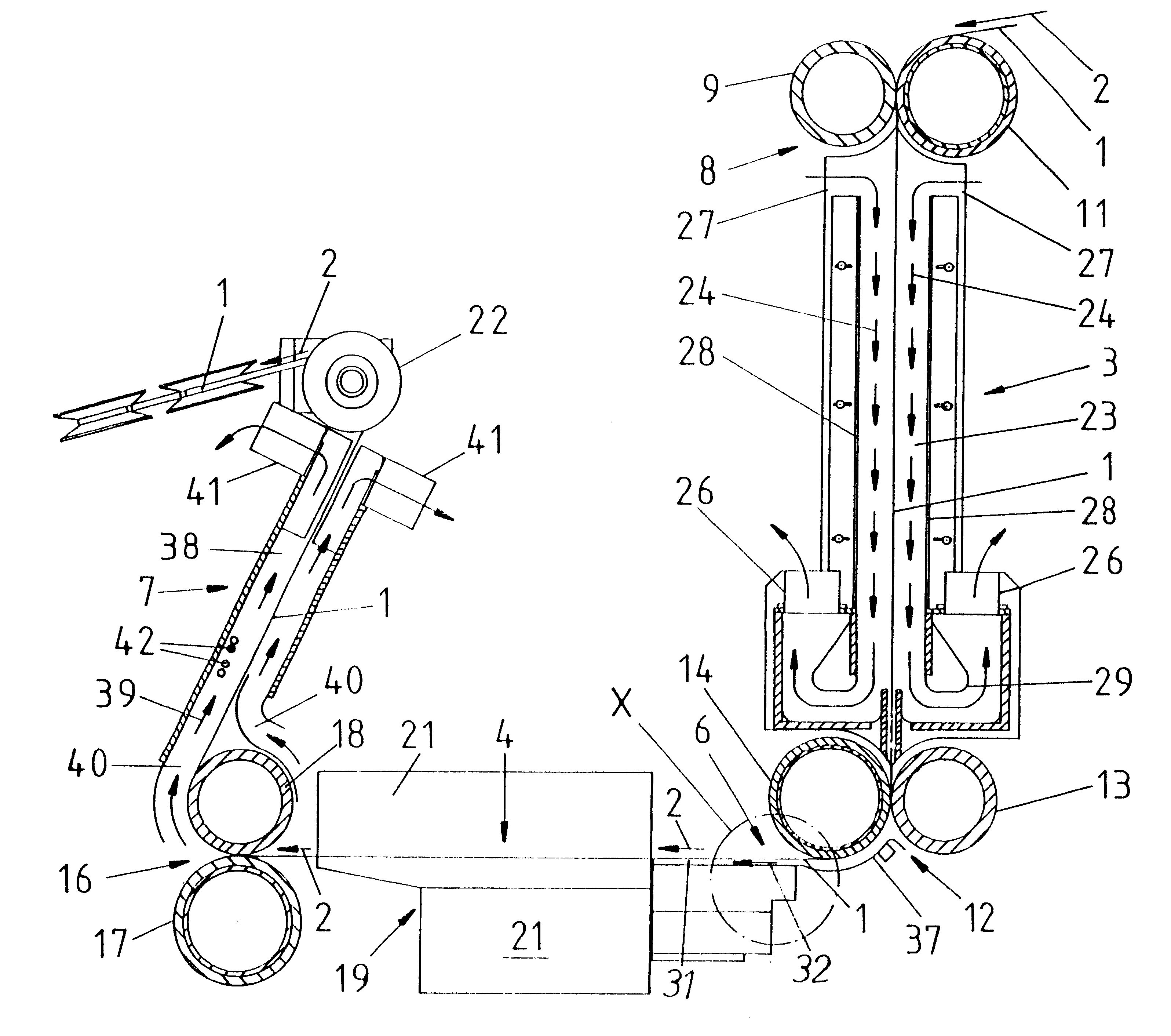

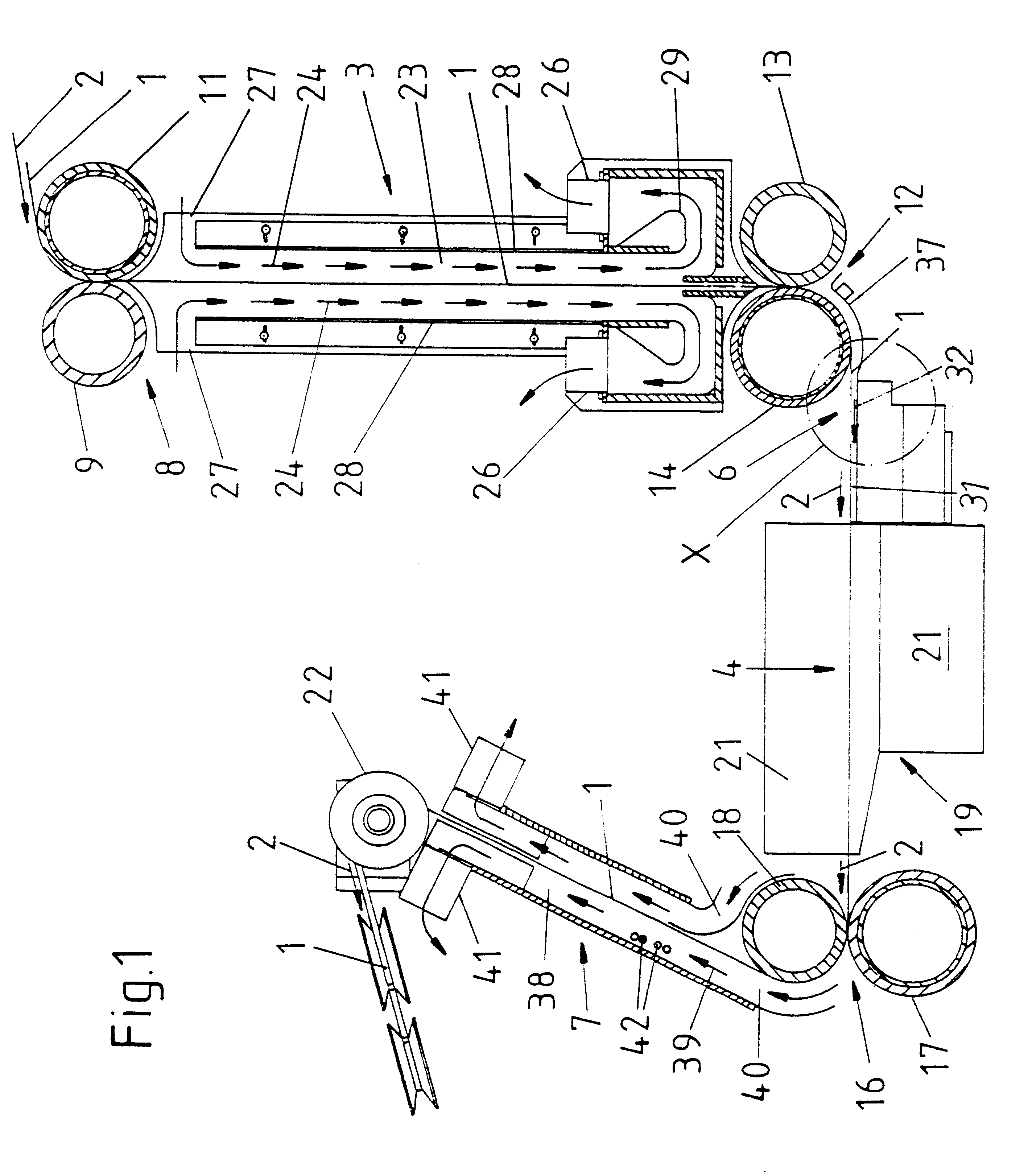

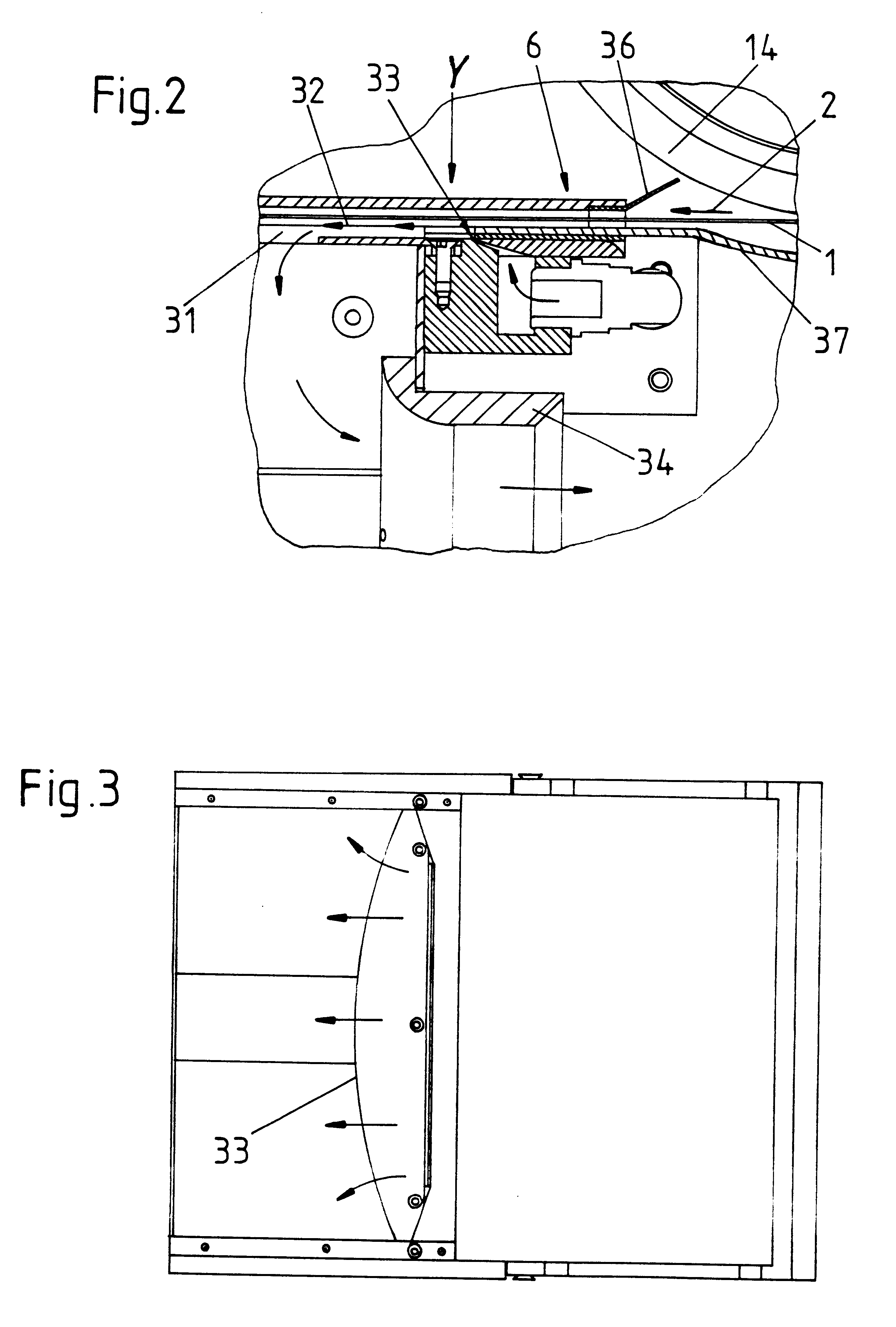

Method of and apparatus for making filter mouthpieces for rod-shaped articles of the tobacco processing industry

InactiveUS6263882B1Take up small amountReduce widthCigar manufacturePaper/cardboard wound articlesPlasticizerFilter material

A tow of filamentary filter material for tobacco smoke which is to be converted into a rod-like filler of a filter rod is conveyed along an elongated path first through a stretching or tensioning zone where the filaments are stretched and the tow is converted into a relatively wide flat web, thereupon along a relaxing portion of the path wherein the tensioning action upon the filaments is reduced, thereupon along a third portion wherein at least one side of the running web is contacted by droplets of an atomized plasticizer, and thereafter along a fourth portion of the path wherein the web is gathered by reducing its width so that it more closely resembles a rod which is thereupon draped into a web of cigarette paper or other suitable wrapping material. A wind tunnel surrounds at least one portion of the path to confine at least one stream of air which is caused to flow in the direction of advancement of the tow. A tunnel can surround the stretching zone, the relaxing and / or the fourth portion of the path.

Owner:HAUNI MASCHINENBAU AG

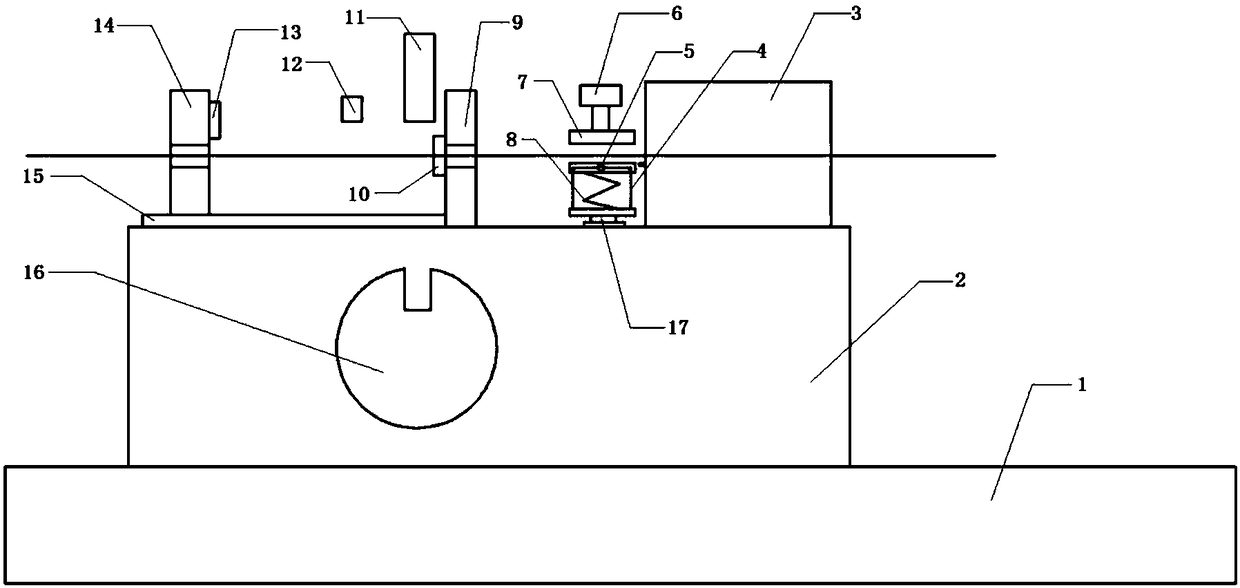

Yarn sizing machine capable of uniformly conducting sizing

InactiveCN107675388AExtended drying timeFully dryFibre cleaning/openingTextile treatment machine arrangementsPulp and paper industry

The invention discloses a yarn sizing machine capable of uniformly conducting sizing. The yarn sizing machine comprises a yarn putting device, a cleaning device shell is arranged at the right of the yarn putting device, a driving bin is arranged inside the cleaning device shell, a driving motor is installed inside the driving bin, the front end of the driving motor is connected with a dust tightening device through a gear, a static electricity dust remover is installed inside the cleaning device shell, a size tank is arranged at the right of the cleaning device shell, a first yarn guide rolleris arranged inside the size tank, a yarn extruding roller is arranged at the right of the first yarn guide roller, a sizing roller is installed at the right of the yarn extruding roller, and a secondyarn guide roller is arranged at the upper right portion of the sizing roller. According to the yarn sizing machine capable of uniformly conducting sizing, design of the dust tightening device, the gear, the static electricity dust remover, the yarn extruding roller, an air draft device and an air suction device is adopted, the speed for yarn to absorb sizing agent can be increased, and thereforethe work efficiency of the sizing machine is improved so that the yarn can be more fully dried.

Owner:杭州依翰丝绸文化创意有限公司

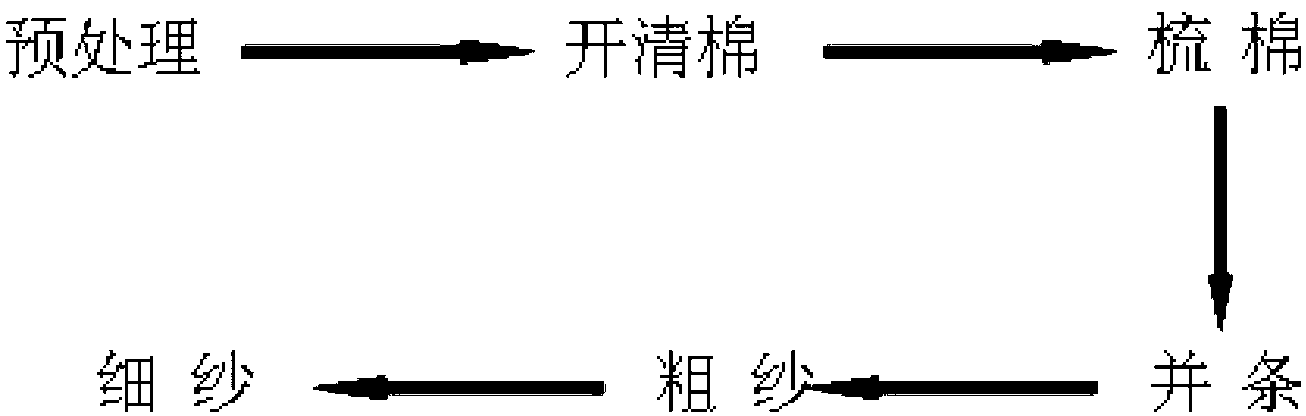

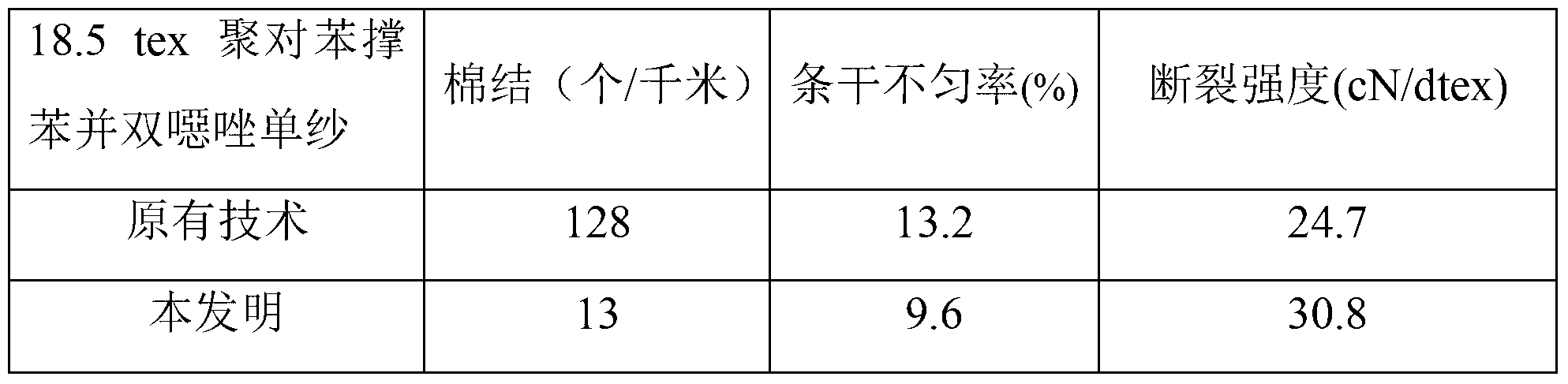

Method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres

The invention discloses a method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres. The method comprises the steps of pre-treatment, cotton opening and picking, cotton teasing, drawing, rough spinning and fine spinning. The method solves the difficult problem of spinning the poly-p-phenylenebenzobisthiazole fibres, and establishes a technical foundation of pure spinning of the PBO fibres, which is performed on cotton spinning equipment; yarns obtained via spinning have the advantages of glabrous surface, smoothness, less neps, uniform evenness and the like, can be widely applied to high-grade protective textiles and industrial textiles.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

Cotton quilt production method

InactiveCN109763256ASufficient inventoryEasy to controlFibre cleaning/openingNon-woven fabricsFiberAgricultural science

The invention discloses a cotton quilt production method. The method comprises steps of blowing, carding, spreading, forming, webbing and grinding. The method comprises specific steps as follows: blowing: opening and mixing cotton obtained after separation of cotton seeds, and removing impurities until the impurity content is 0.85%-0.95%; carding: carding conveyed cotton flow by a carding machine,performing impurity removal and uniform mixing, and carding cotton; spreading: spreading cotton fiber carded by the carding machine into webs with width and length meeting requirements by a cotton spreading machine according to required cotton quilt parameters set by a computer; forming: cutting spread cotton quilts in step c) according to the cotton quilt length requirement by cotton cutting equipment; webbing: defining the front and back sides of cut cotton quilts in step d) into webs with the same spacing by defining equipment, producing cotton rolls, and cutting the webs after cotton cutting by a cutter; grinding: after the cotton is well spread, performing grinding once, arranging cotton sheets, and removing uneven cotton balls. The method has the advantages of high filling power, sufficient air holding, good dust removal effect, high efficiency and high benefits.

Owner:江西欧孕母婴用品有限公司

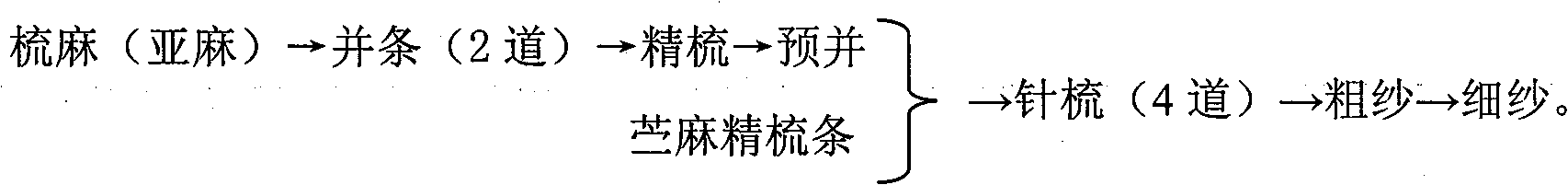

Method for producing ramie cotton blended yarn by using cotton-spinning equipment

This invention discloses a method for producing gunny-cotton blend yarn with a cotton spinning device including the following steps: pretreatment of fine dry gunny, cleaning cotton, combing cotton, fine combing, merging slivers, roving, spinning and winding process, which is advantaged that hemp yarn number is high reaching to 60-80 British yarn with 55-80% hemps, dry yarn is increased greatly and faults are reduced greatly.

Owner:CHANGSHANZHAOZHOU TEXTILE

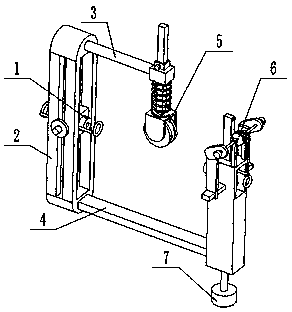

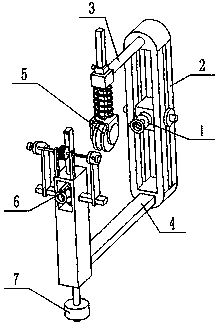

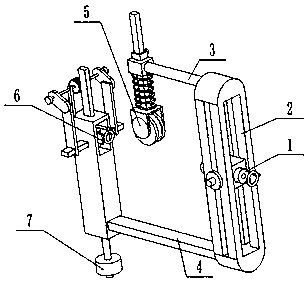

Yarn inlet and guiding device for textile machine

InactiveCN108455376AAvoid disconnectionEasy to disconnectFilament handlingFibre cleaning/openingYarnEngineering

The invention relates to the field of textile processing equipment, in particular to a yarn inlet and guiding device for a textile machine. The yarn inlet and guiding device for the textile machine comprises a yarn guiding pipe mechanism, a mounting frame, a cylinder connection rod, a rectangular connection rod, a yarn guiding wheel mechanism, a dust removing brush assembly and a dust collecting pipe assembly; a through rectangular groove I is formed in the front and back side faces of the mounting frame; the left side face and the right side face of the mounting frame are each provided with one rectangular groove II; the rectangular groove I and the two rectangular grooves II communicate with each other; the yarn guiding pipe mechanism is connected to the inner sides of the rectangular groove I and the two rectangular grooves II of the mounting frame; the upper end of the rear side face of the mounting frame is fixedly connected with the cylinder connection rod; and the rear end of the cylinder connection rod is fixedly connected with the yarn guiding wheel mechanism. The yarn guiding pipe mechanism inside the yarn inlet and guiding device is used for guiding yarns and properly adjusting the guiding height and direction of the yarns, and requirements of different textile machines are met conveniently.

Owner:佛山市冠康隆纺织有限公司

Spinning roller capable of removing burrs on surface of yarn

The invention relates to a spinning roller capable of removing burrs on the surface of a yarn. The spinning roller comprises a round roller, a scraping unit, a cleaning unit and the spinning yarn, wherein the scraping unit is mounted at the right end of the round roller, the cleaning unit is arranged in the round roller, and the spinning yarn is placed on the round roller and the scraping unit. Bysimultaneously performing left-and-right reciprocating scraping on the yarn, the scraping effect is enhanced in a rotating mode, the burrs on the spinning yarn are basically removed, and meanwhile, alarge amount of floating hairs is removed; and the surface of the spinning yarn is cleaned through a brush to remove the floating hairs adhered to the spinning yarn by hooking, so that removal of theburrs on the surface of the yarn is completed through improvement of the roller and one process is omitted.

Owner:佛山维彩纺织有限公司

Cleaning device for spinning machine

ActiveCN105603592AAffect qualityAffect normal workFibre cleaning/openingTextile treatment cleaning apparatusEngineering

The invention discloses a cleaning device for a spinning machine. The cleaning device comprises a workbench, a sweeping device, an ash intake cavity, a colleting cavity and a fixing part. The collecting cavity is arranged in the inner cavity of the workbench. A groove is formed in the left end of the upper portion of the workbench. The sweeping device and a cleaning roller are arranged in the middle of the upper portion of the workbench. The sweeping device comprises a first fixing shaft and a second fixing shaft. A fixing rod is arranged in the middle of each of the first fixing shaft and the second fixing shaft. A sweeping plate is arranged at the lower ends of the first fixing shaft and the second fixing shaft. Two ends of the upper portion of the sweeping plate are respectively provided with clamp rings corresponding to the fixing rods. A brush is arranged at the lower end of the sweeping plate. The left side of the sweeping plate is connected with the fixing part through a telescopic rod. The ash intake cavity is arranged in the right end of the upper portion of the workbench. The lower end of the inner cavity of the ash intake cavity is connected with one end of an exhaust fan through a pipeline. The cleaning device is novel in structure, high in practicality, convenient to use and evident in cleaning effect.

Owner:南通景群纺织品有限公司

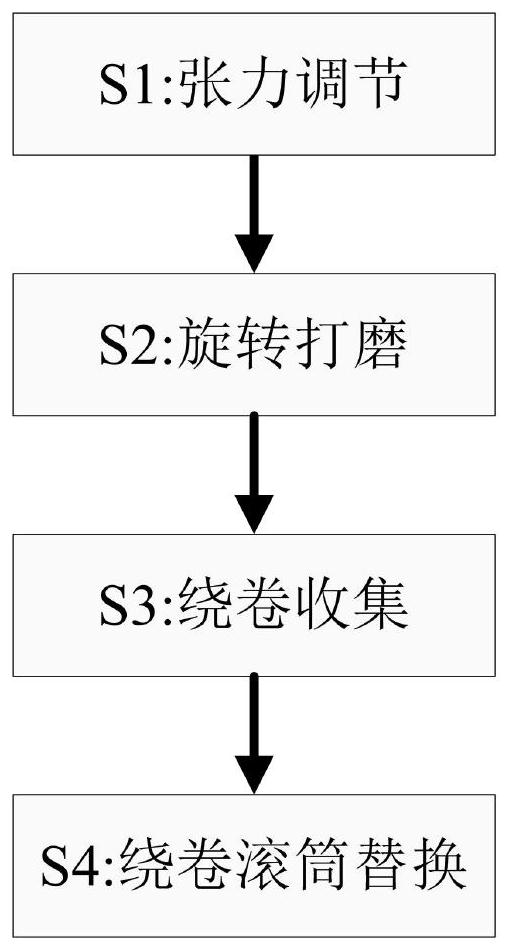

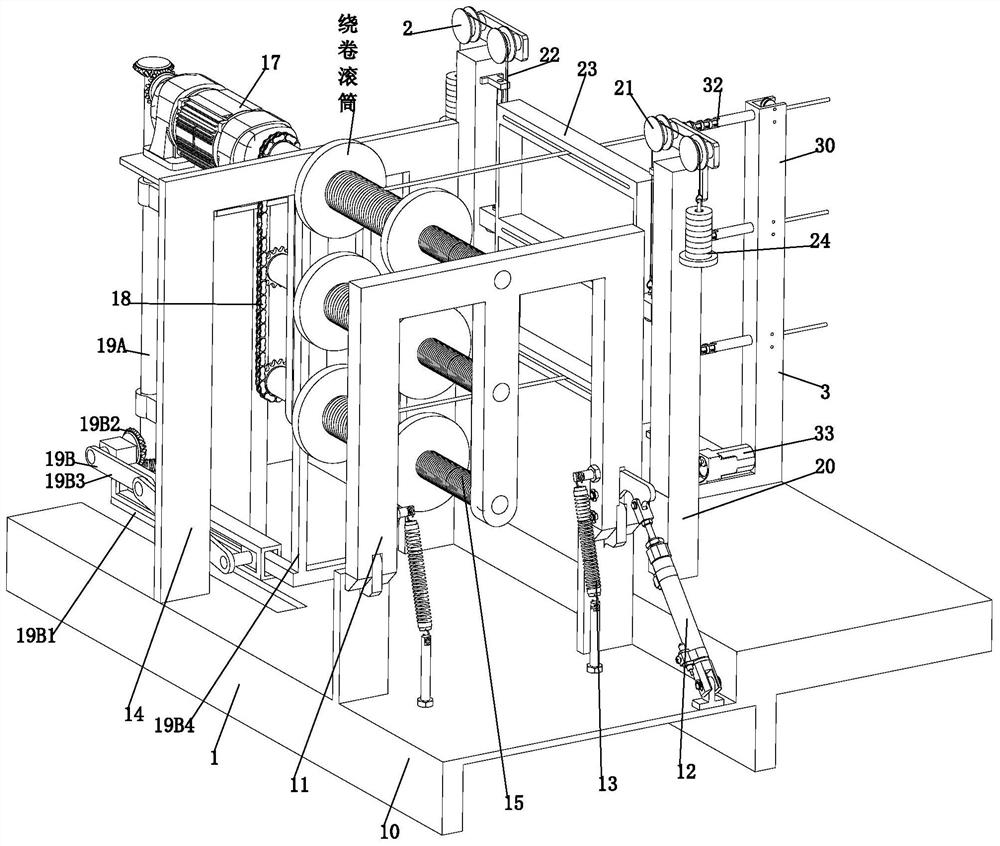

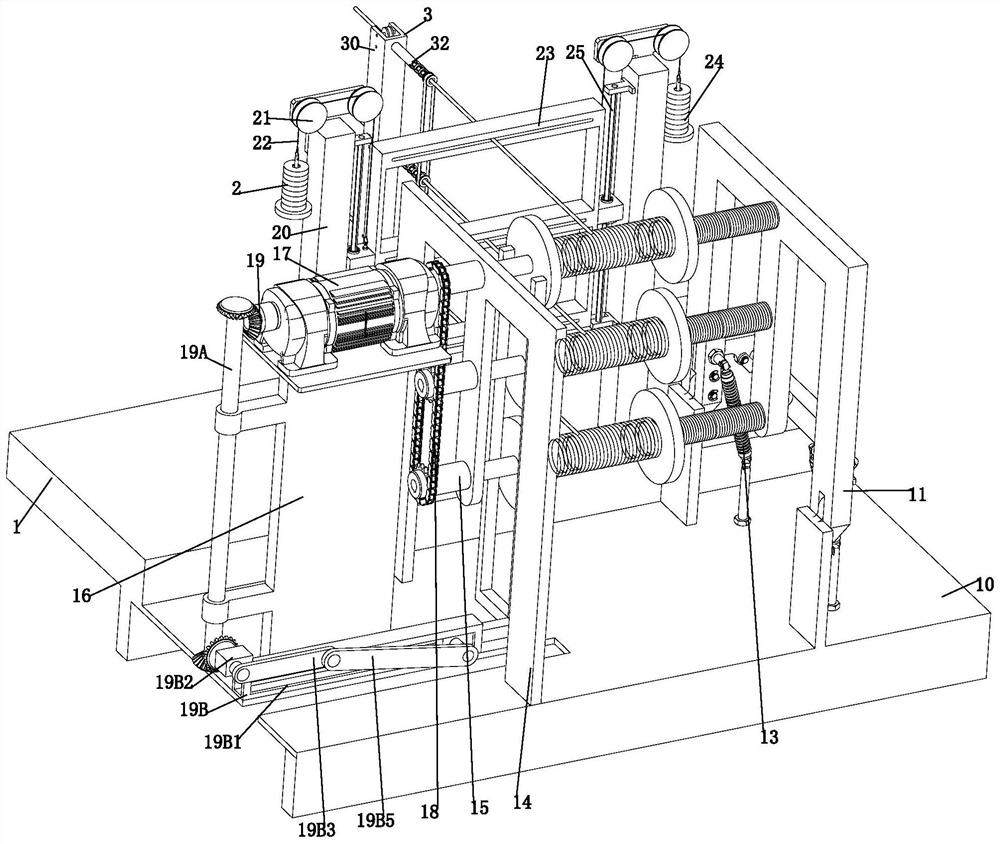

Cotton yarn textile yarn surface cleaning process

InactiveCN111717729AEasy to update and replaceReduce work intensityFilament handlingFibre cleaning/openingFiberMachine parts

The invention provides a cotton yarn textile yarn surface cleaning process. The cotton yarn textile yarn surface cleaning process involves a winding mechanism, a tension mechanism and a rotary grinding mechanism, wherein the rotary grinding mechanism is installed on the winding mechanism, the tension mechanism is located between the middle of the winding mechanism and the middle of the rotary grinding mechanism, and the tension mechanism is installed on the winding mechanism. According to the cotton yarn textile yarn surface cleaning process, the problems that in a weaving process, flyings arecaused due to the fact that fluff on the surface of yarn falls off, so that weaving of textile production, especially knitting production, is difficult to conduct smoothly, and the phenomenon that aproduct quality problem is caused are solved, in the knitting production, the yarn rubs with a looping machine part at a high speed in the knitting looping process, loose fibers on the surface of theyarn and the fluff on the surface of the yarn fall off to form the flyings, and the flyings stain moving parts of a machine, so that the movement of the parts such as knitting needles is influenced, and finally the parts are damaged and defective cloth is generated.

Owner:卫平山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com