Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88 results about "Stripping (fiber)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stripping is the act of removing the protective polymer coating around optical fiber in preparation for fusion splicing. The splicing process begins by preparing both fiber ends for fusion, which requires that all protective coating is removed or stripped from the ends of each fiber. Fiber optical stripping can be done using a special stripping and preparation unit that uses hot sulphuric acid or a controlled flow of hot air to remove the coating. There are also mechanical tools used for stripping fiber which are similar to copper wire strippers. Fiber optical stripping and preparation equipment used in fusion splicing is commercially available through a small number of specialized companies, which usually also design machines used for fiber optical recoating.

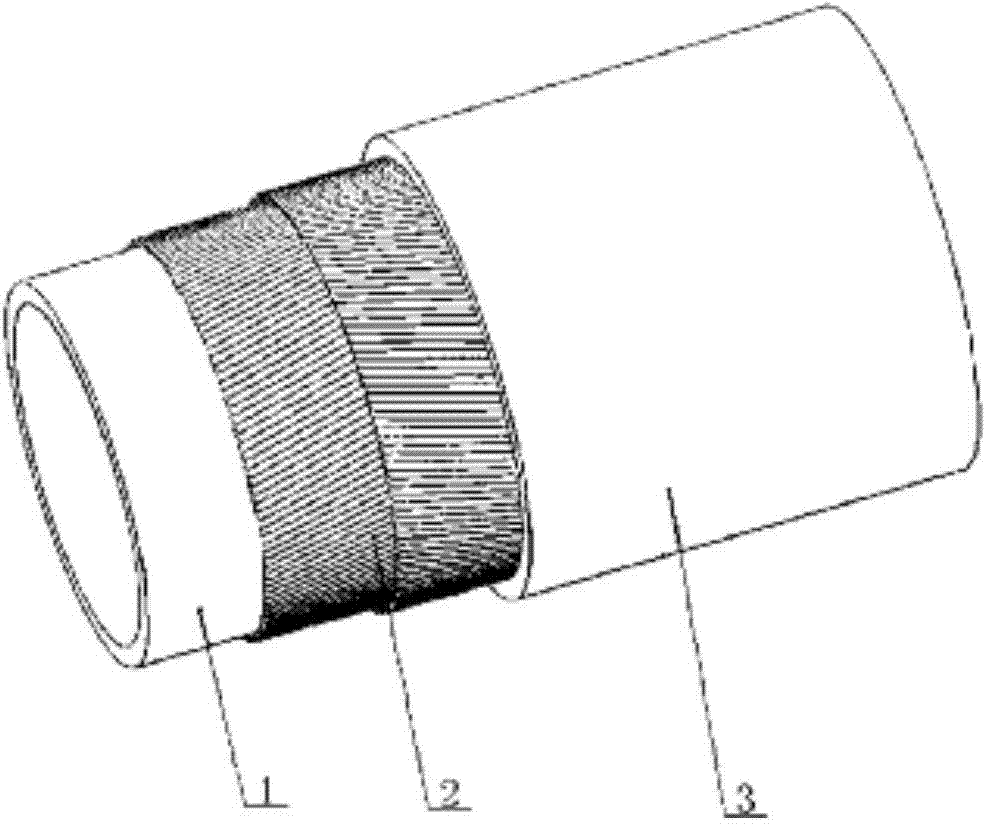

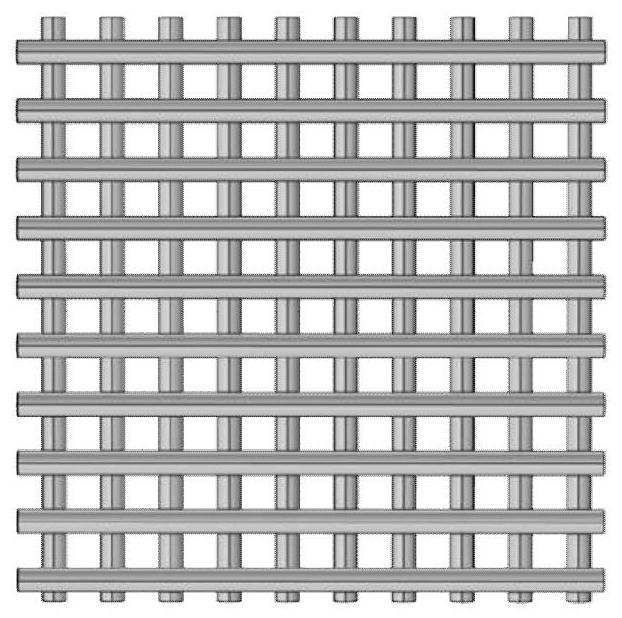

Flexible ultra-high molecular weight polyethylene composite tube as well as preparation method and production system thereof

The invention discloses a flexible ultra-high molecular weight polyethylene composite tube as well as a preparation method and a production system thereof. The composite tube comprises an ultra-high molecular weight polyethylene inner pipe, a middle layer of a bidirectional wound glass fiber composite belt, and an outer polyethylene cladding layer, wherein the ultra-high molecular weight polyethylene inner tube, the glass fiber composite belt and the polyethylene outer layer are respectively compounded in a surface softening or melting state, so that all composite layers are compact in structure and totally fused into a whole. The preparation method of the composite tube mainly comprises the steps of extrusion molding of the ultra-high molecular weight polyethylene inner tube, winding of the glass fiber composite belt, heating and compounding and cladding of the fused polyethylene on the outer wall. The ultra-high molecular weight polyethylene composite tube has the advantages of no cracking of the inner tube, no stripping of the composite layers, capacity of coiling, low production cost, high compression strength and uniform and stable pressure resistant values in all places, and is suitable for oil pumping tubes and gathering and transportation tubes of land oil fields and underwater oil gas conveying tubes for offshore oil production.

Owner:四川高德特科技有限公司

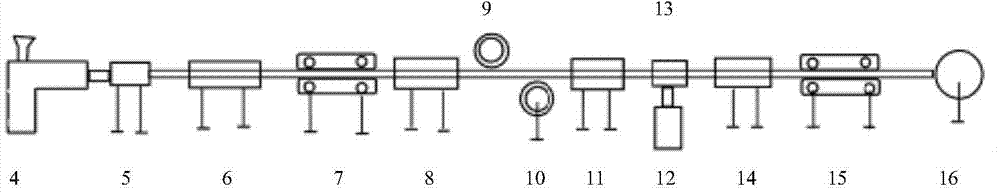

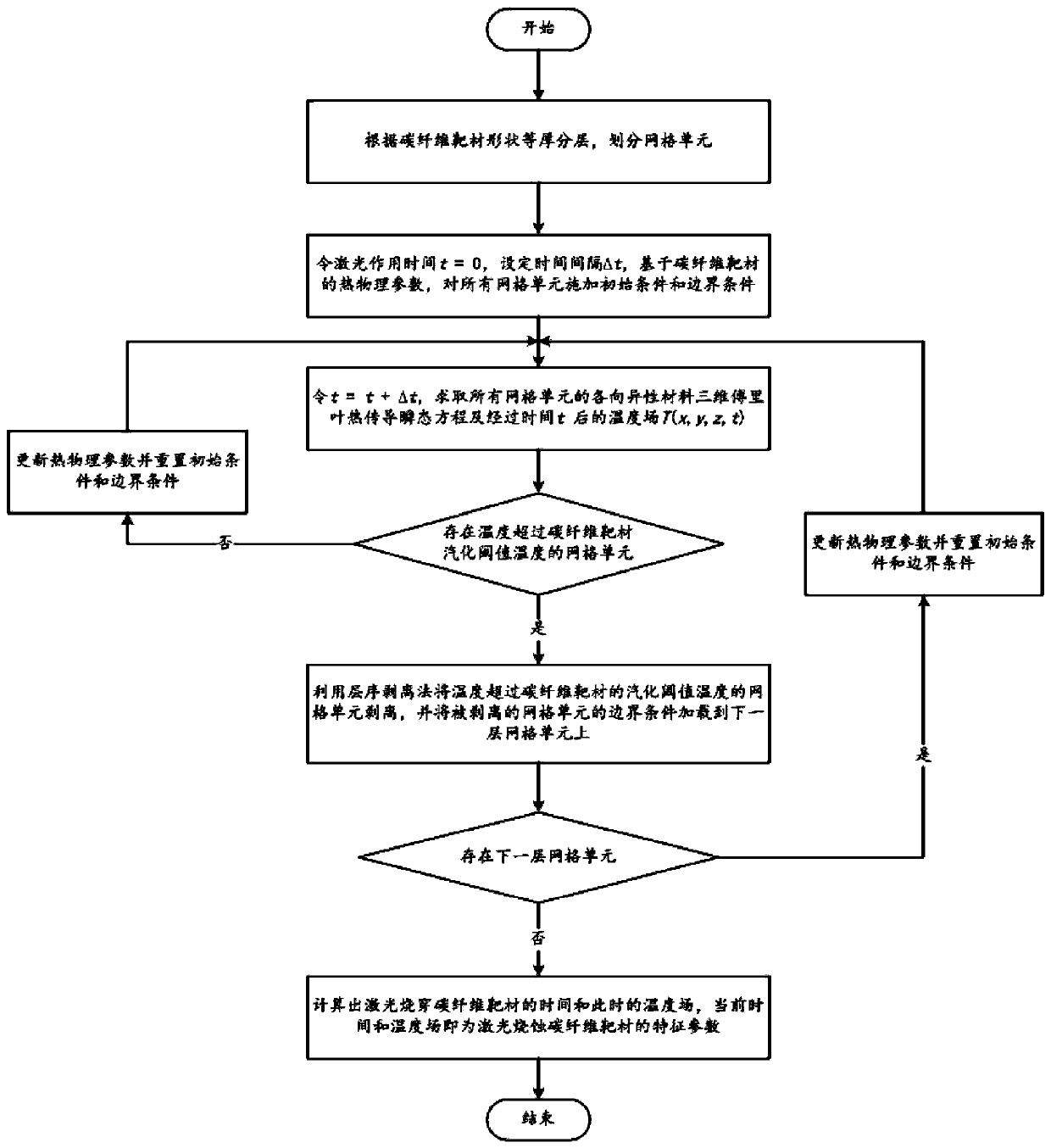

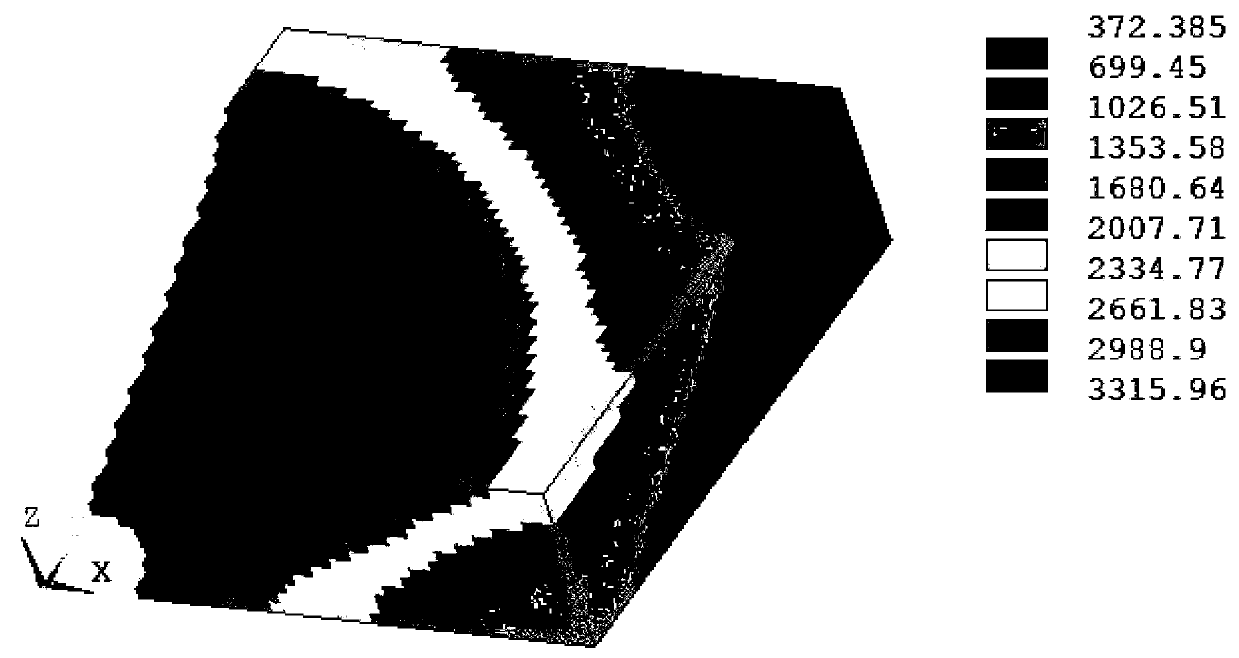

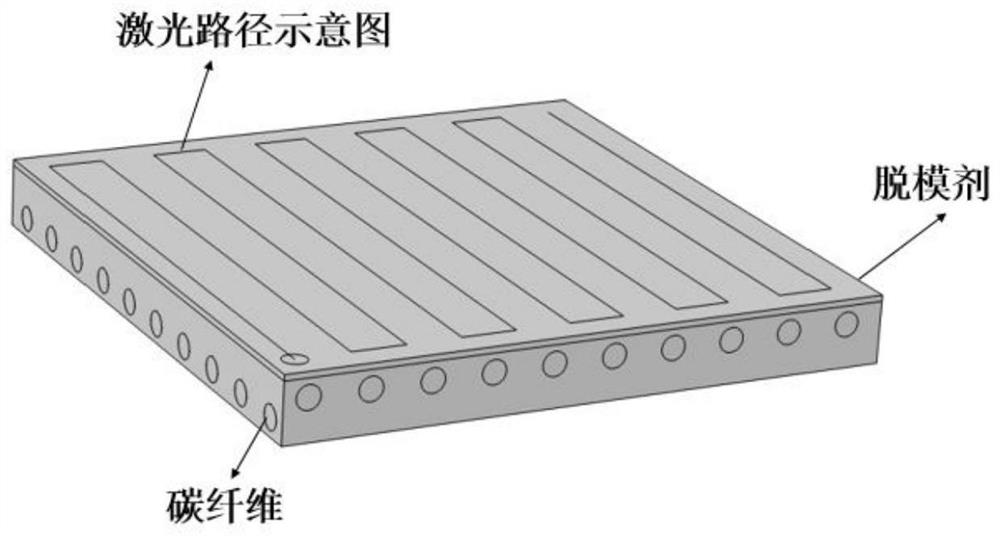

Method for calculating temperature field of laser ablation carbon fiber target material

The invention discloses a method for calculating a temperature field of a laser ablation carbon fiber target material, and relates to the field of laser damage effect research, and the method comprises the following steps: 1, carrying out the equal-thickness layering according to the shape of the carbon fiber target material, and dividing grid units; 2, setting the laser action time t to be equalto 0, setting a time interval delta t, and applying an initial condition and a boundary condition to the unit according to the thermophysical parameters of the carbon fiber target material; 3, settingt= t + delta t, solving three-dimensional heat conduction transient equations of anisotropic materials of all units, and calculating a target material temperature field after time t; 4, if a grid unit with the temperature exceeding the vaporization threshold temperature of the carbon fiber target exists, vaporizing the unit according to a meta-order stripping method, loading the corresponding boundary condition to the next layer of unit, and then executing the step 5; 5, traversing the grid units: judging whether a next layer of unit exists, if yes, adjusting the thermophysical parameters ofthe target material, updating the boundary condition and the initial condition, and then executing the step 3; otherwise, determining a fact that the time and the temperature field are the characteristic parameters of the laser damaged carbon fiber target material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

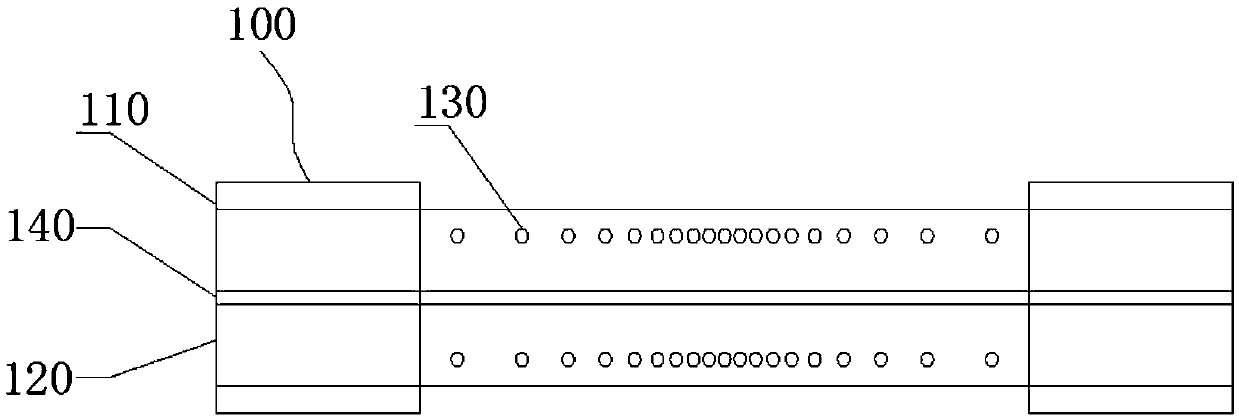

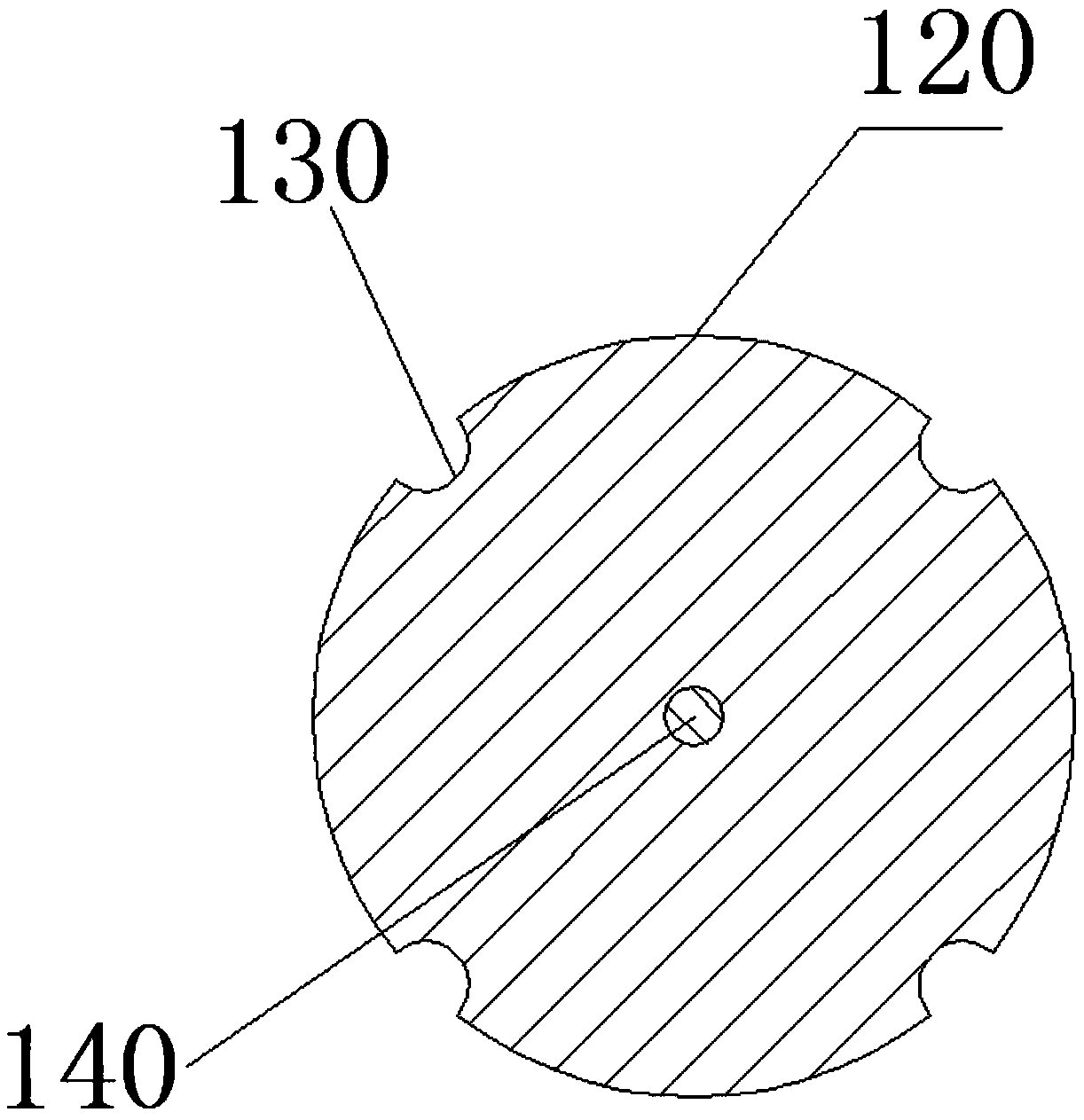

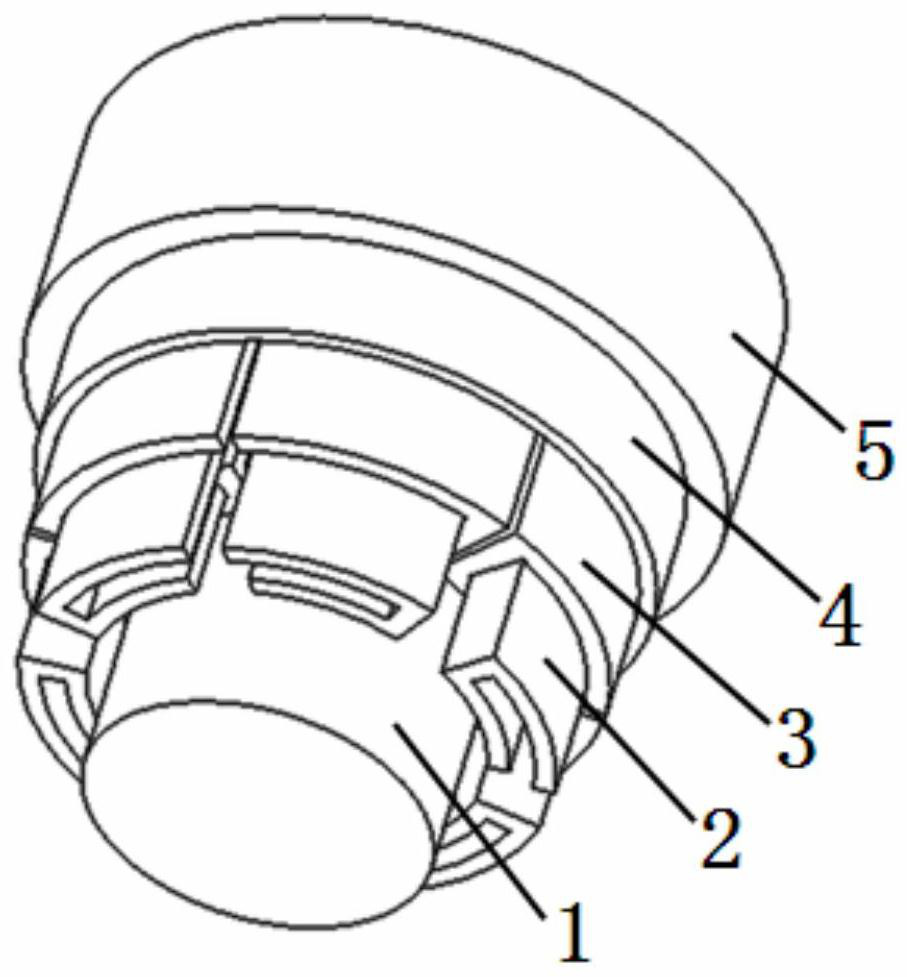

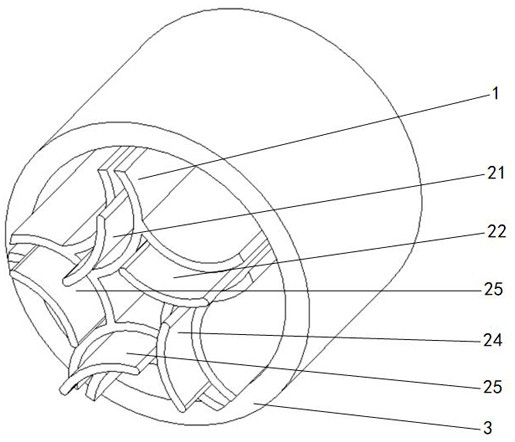

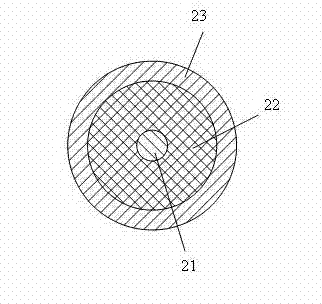

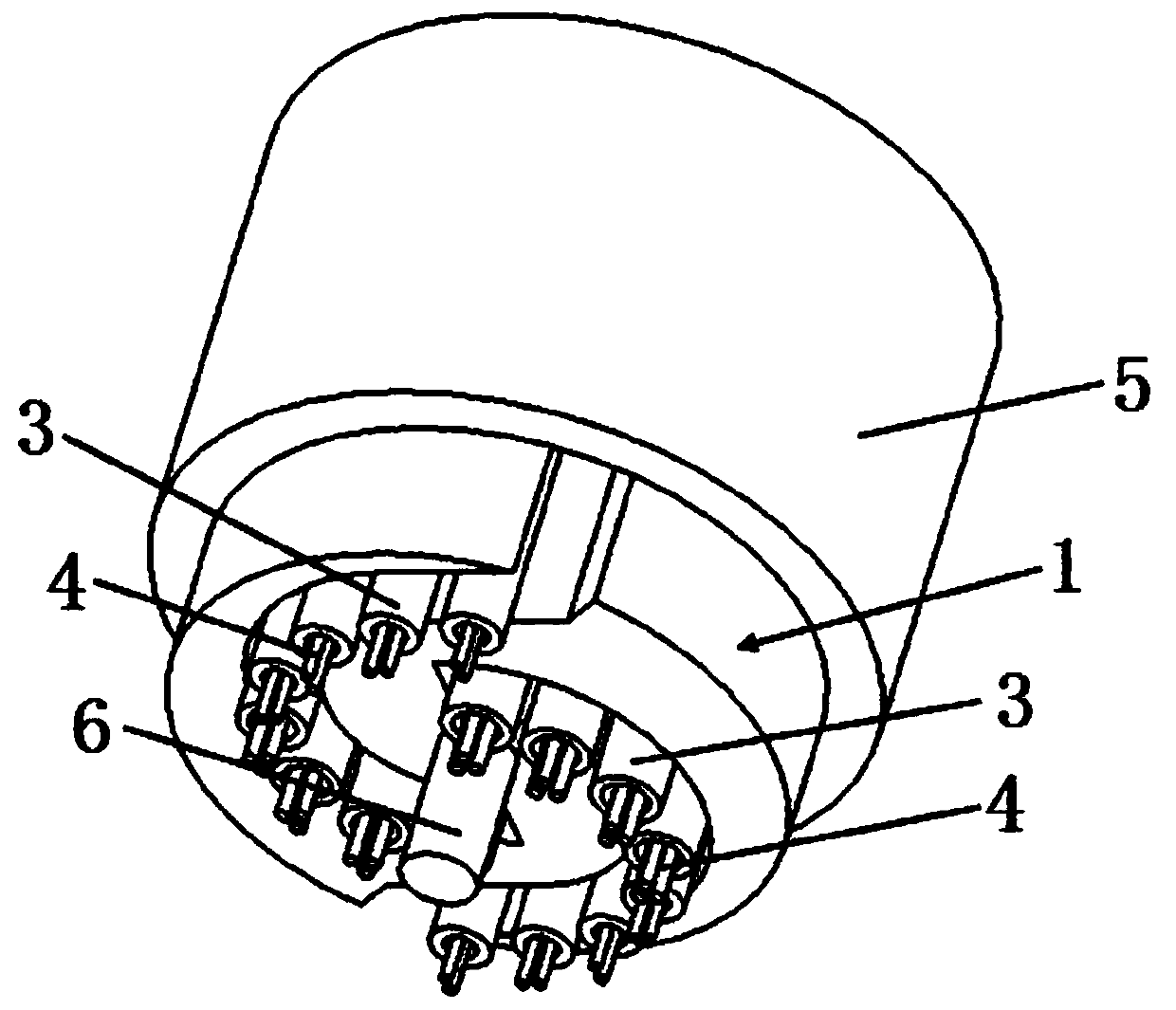

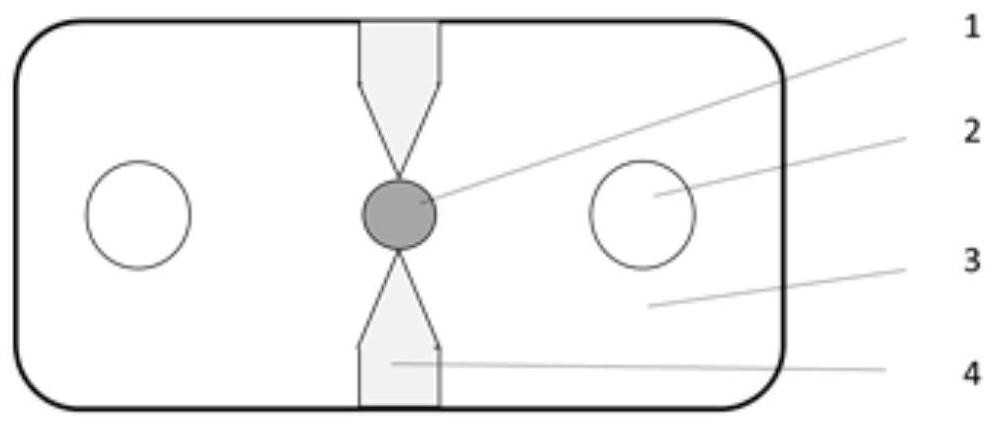

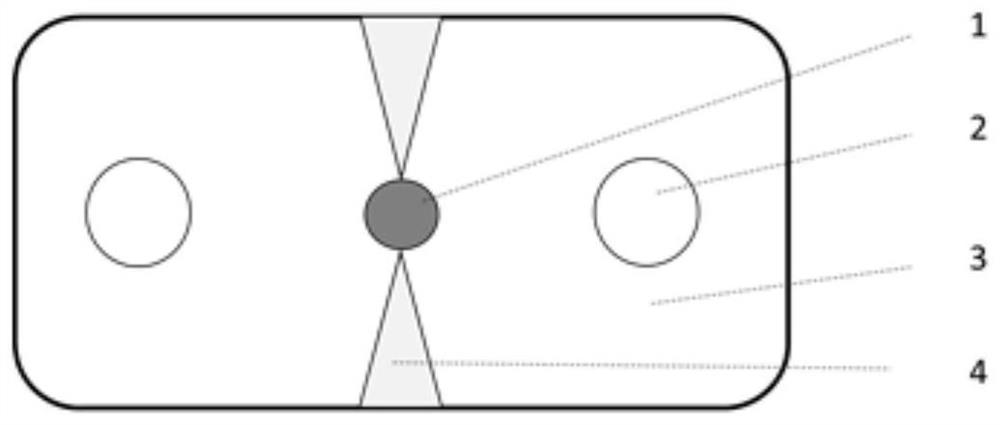

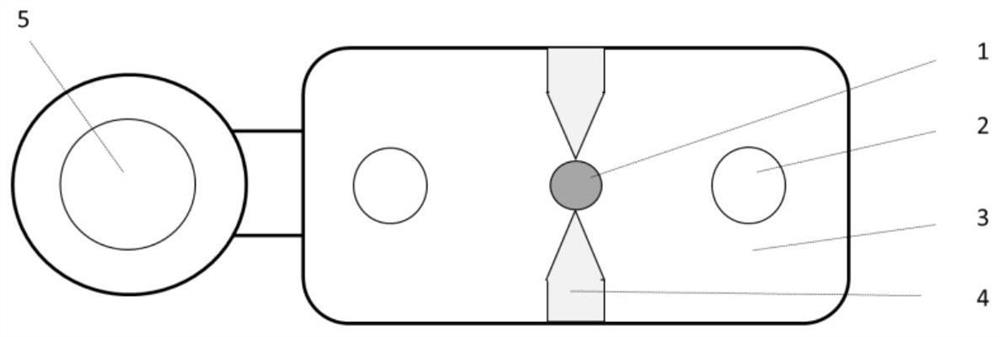

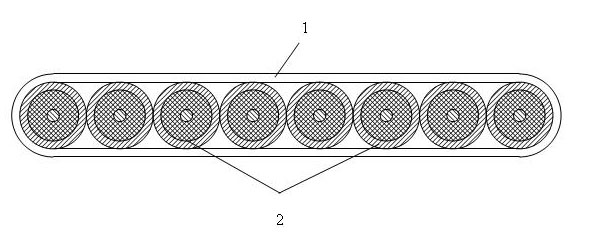

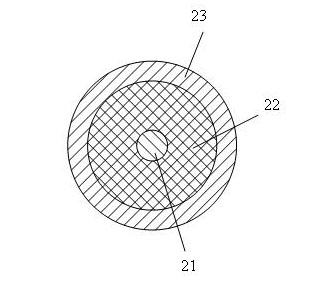

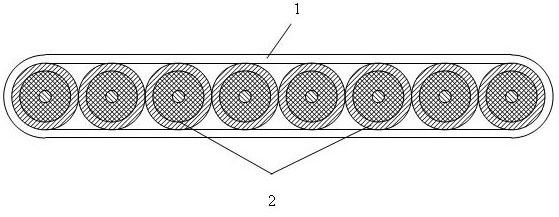

Manufacturing method and package structure of optical fiber stripper

InactiveCN109541750AImprove stripping efficiencyIncrease the withstand powerActive medium shape and constructionLaser cooling arrangementsHeat conductingComputer module

The invention provides an optical fiber stripper, a manufacturing method and package structure of the optical fiber stripper. The optical fiber stripper has the advantages such as high stripping efficiency, high withstand power, uniform temperature distribution, long service life, high stability and the like. The package structure of the optical fiber stripper is characterized in that: the opticalfiber stripper is placed in a glass tube to provide preliminary package protection for the optical fiber stripper; and then the glass tube is arranged in an accommodating cavity surrounded by a heatconducting cover plate and a heat conducting bottom plate to perform thermal conductive packaging on the optical fiber stripper; therefore, on one hand, the package structure is conveniently installedon a water-cooled plate of an external water-cooling device, the heat emitted by the optical fiber stripper is uniformly transmitted to the water-cooled plate, and then the heat is taken away by thewater-cooling device; on the other hand, the thermal conductive packaging of the optical fiber stripper can prevent the stripped light from leaking into an optical path module; therefore, the damage of the stripped light to the optical path is avoided, the stability and working efficiency of the optical fiber stripper is greatly improved, and the stability of an entire optical fiber laser system is maintained.

Owner:CELOX PHOTONICS TECH CO LTD

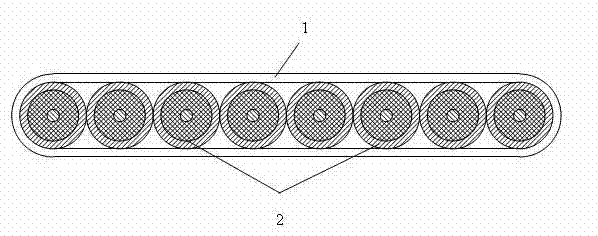

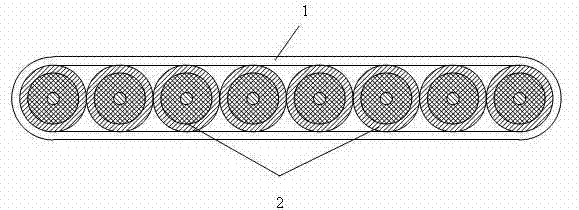

Novel compression-resistant rat-bite-proof optical cable

The invention belongs to the technical field of communication, and discloses a novel compression-resistant and rat-bite-proof optical cable, which is provided with a plurality of loose tubes and a plurality of loose sleeve parts, a plurality of light guide fibers are arranged in the loose tubes, and a plurality of light guide fibers are arranged in the loose sleeve parts. The novel compression-resistant and rat-bite-proof optical cable is also provided with compression-resistant and rat-proof parts, wherein the pressure-resistant and rat-proof part is of an integrated structure and is of a characteristic structure; and the loose sleeve and the loose sleeve part are positioned in the compression-resistant rat-proof component. The invention has the following main beneficial effects: the structure is simpler, the manufacture is easier, the qualified rate of finished products is higher, and the compression resistance and the rat-bite-proof performance are better; In addition, the stripping, construction and maintenance performances are better.

Owner:EZHOU POWER SUPPLY COMPANY STATE GRID HUBEI ELECTRIC POWER +1

Self-stripping waterproof coating and preparation method thereof

The invention discloses a self-stripping waterproof coating and a preparation method thereof, and belongs to the technical field of waterproofness, a self-stripping net can be pre-buried in the coating in advance, the strength, especially the crack resistance, of the coating can be improved in an assisted mode, meanwhile, a tight water seepage sensing net can be formed, and once a water seepage phenomenon occurs on the surface of the coating, the water absorption fiber rods on the self-stripping net can rapidly absorb water, convey the water into the water collection base balls and then indirectly convey the water to the hydrolysis balls in the trigger pipes, impact is formed on a water seepage area on the surface of the coating from the edge of the self-stripping net by means of the characteristic that the hydrolysis balls react with water to release a large amount of gas, and then self-stripping of the water seepage area is achieved. Meanwhile, when the gas is released to the outside, the permeation water can flow back and does not easily continue to permeate, so that an excision operation similar to a lesion part is realized, further erosion of the permeation water to the coating is reduced, and technicians can be prompted to repair the coating in time.

Owner:福州盛世凌云环保科技有限公司

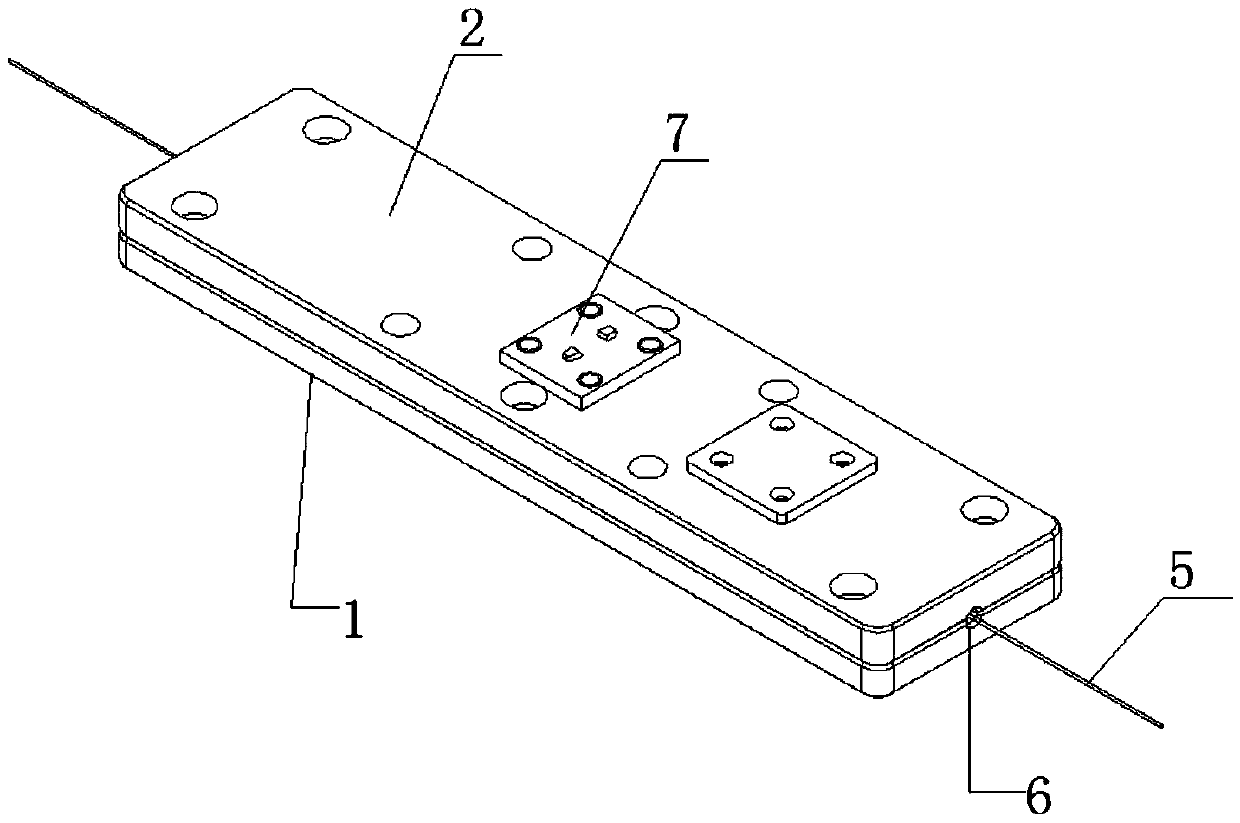

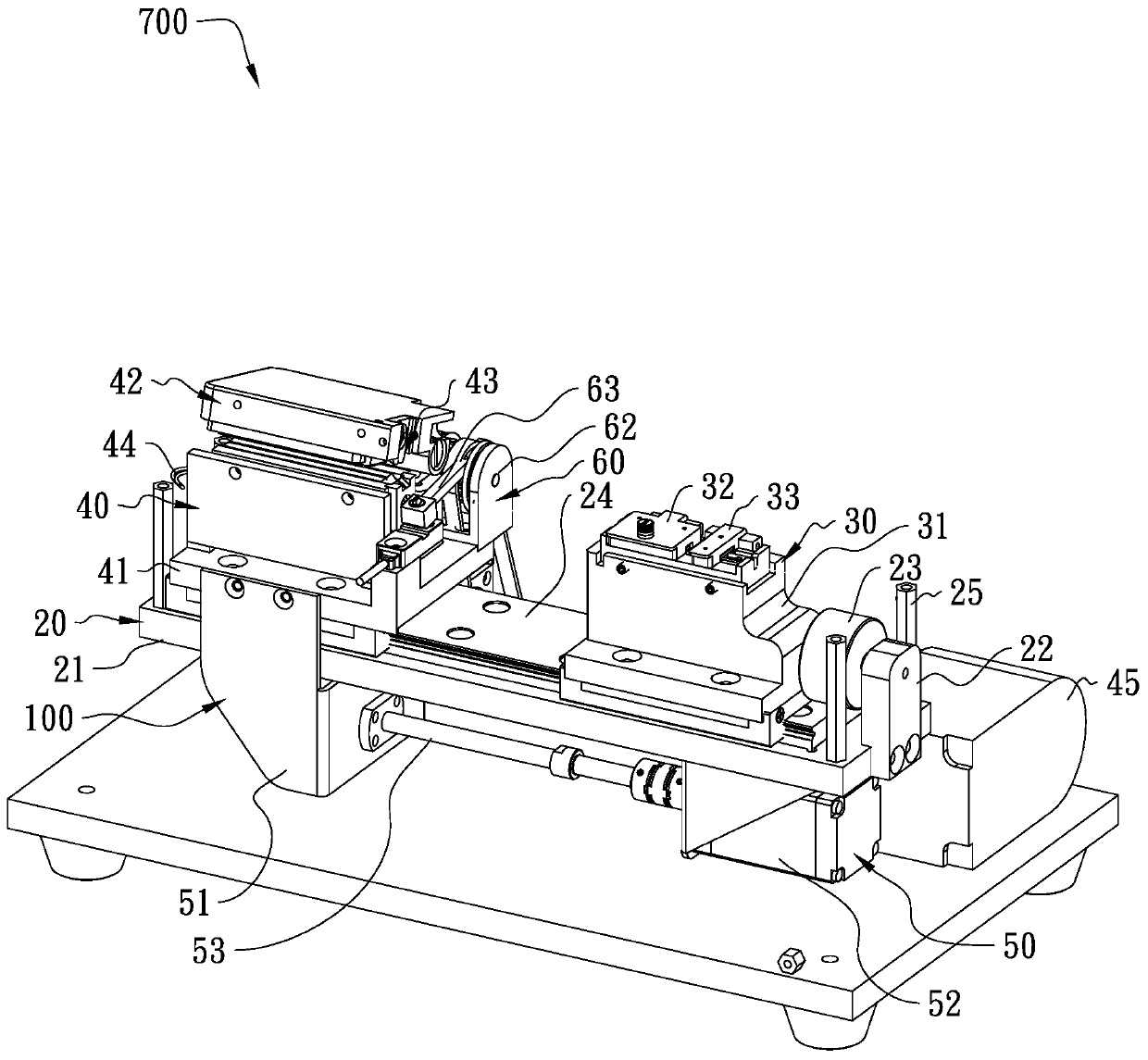

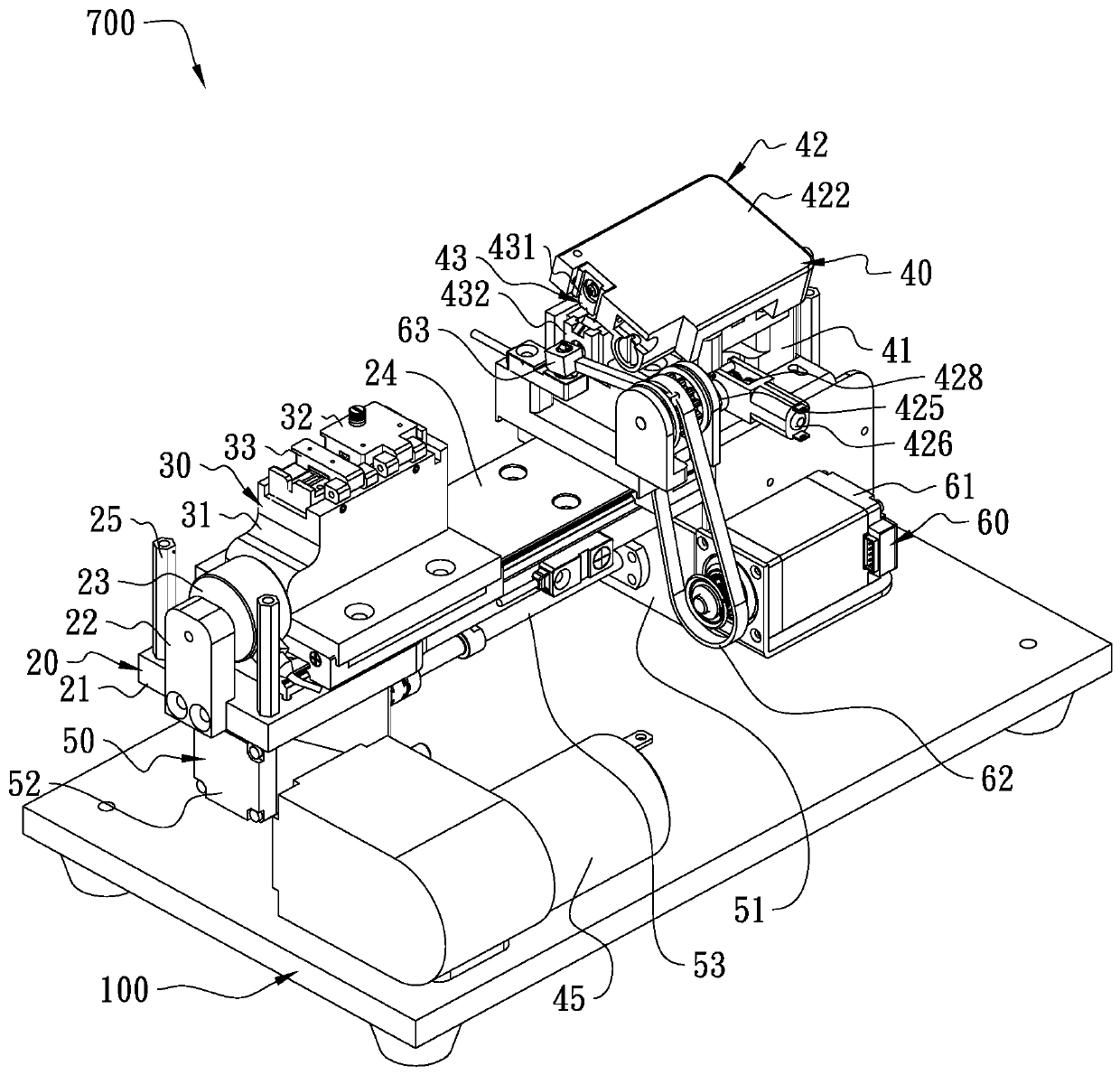

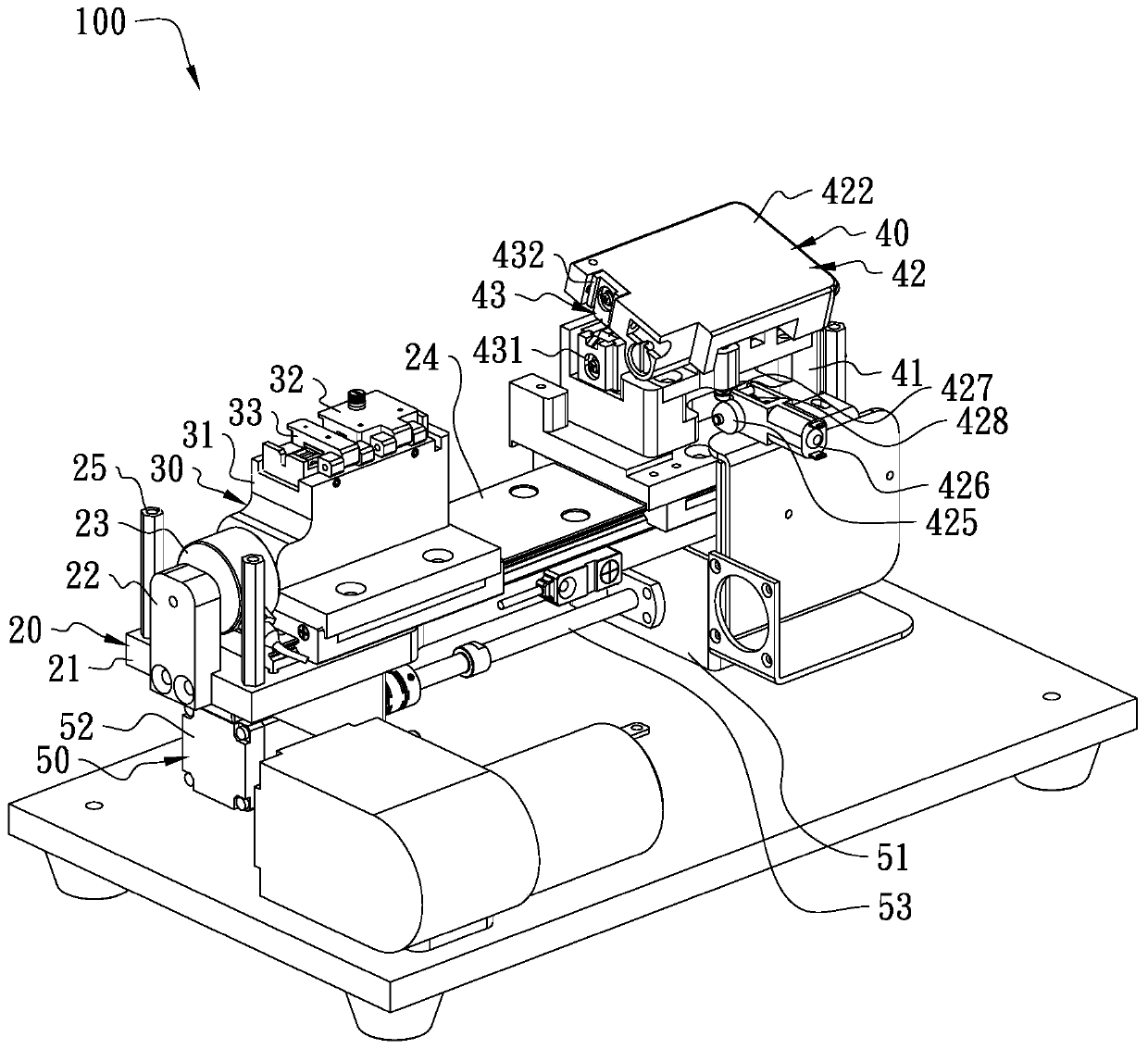

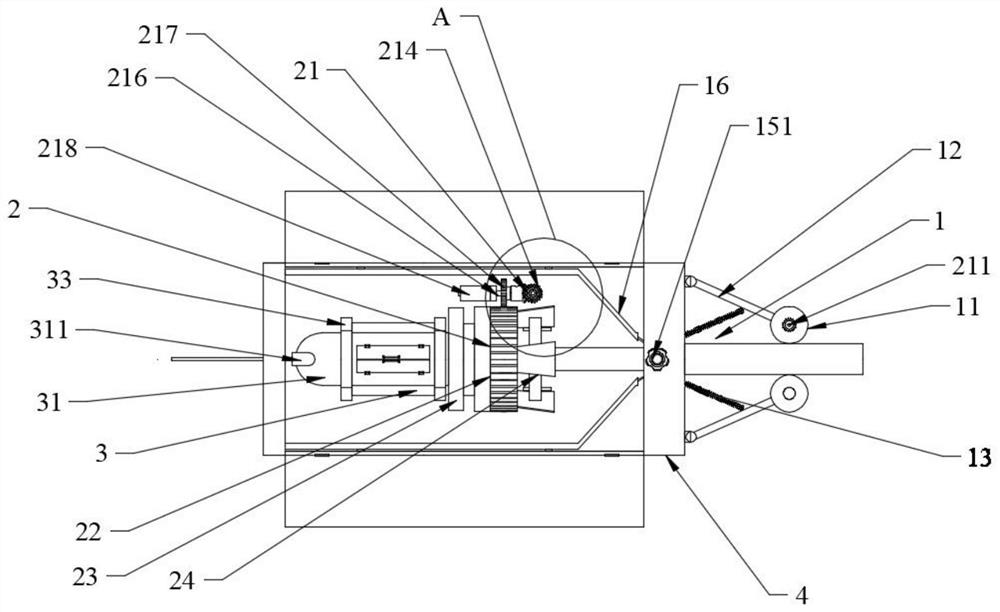

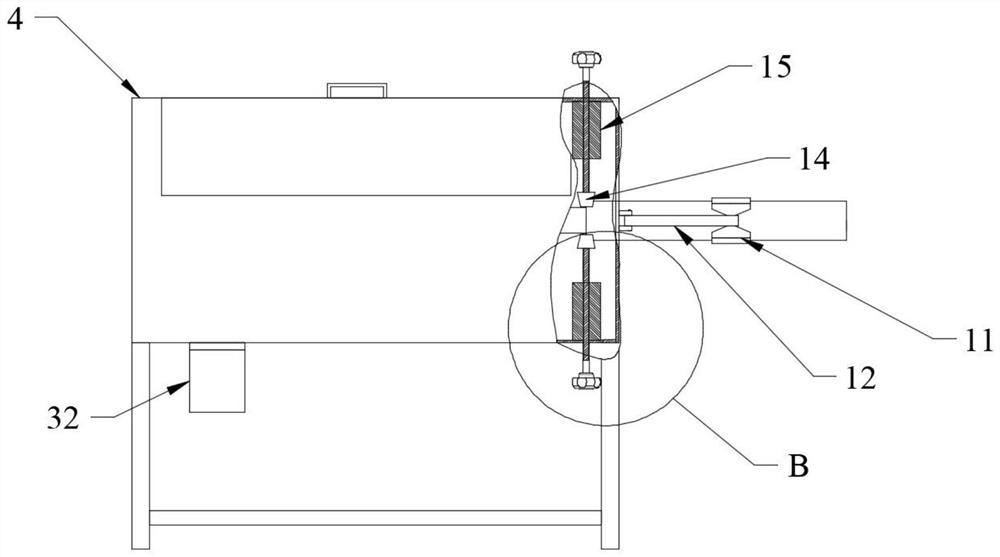

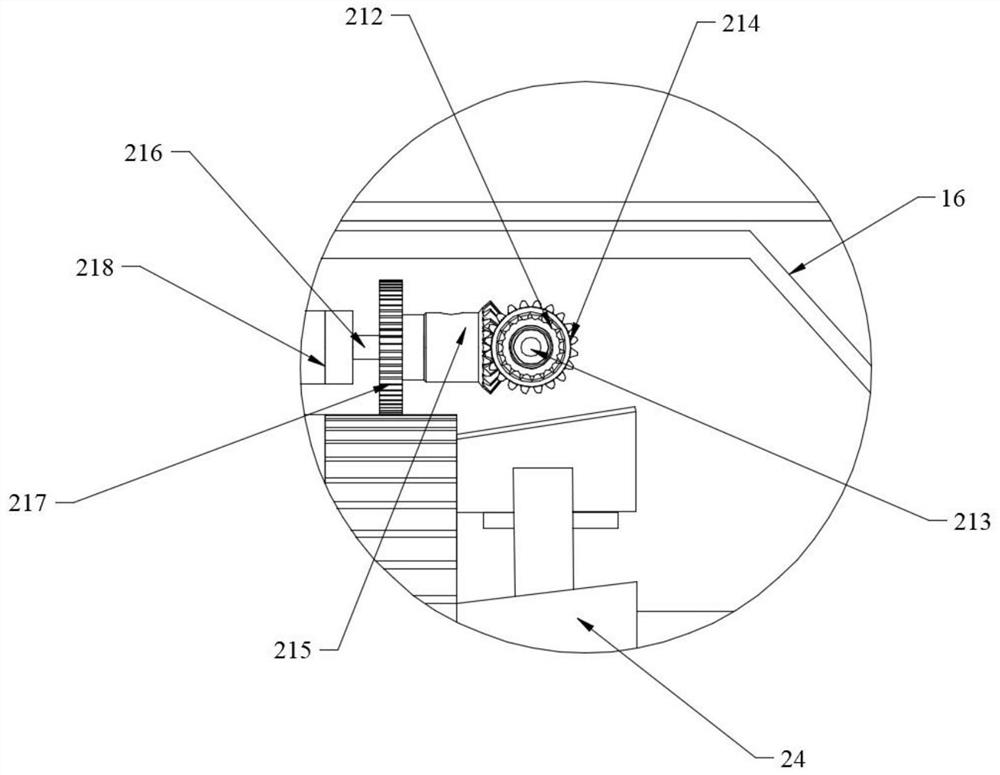

Coating layer stripping equipment and coating layer stripping method

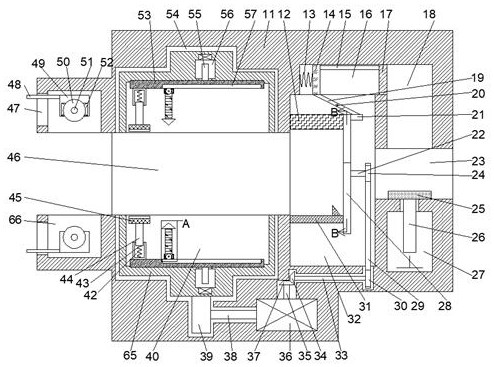

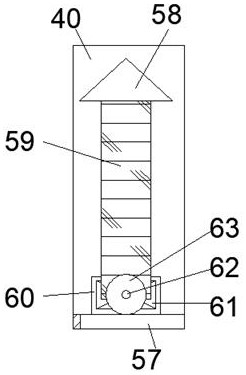

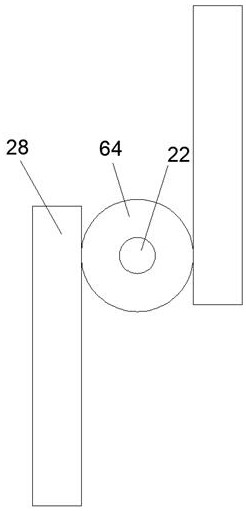

The invention discloses coating layer stripping equipment and a coating layer stripping method. The coating layer stripping equipment comprises a bottom plate, an axial moving mechanism mounted on thebottom plate, an optical fiber rotating mechanism mounted on the axial moving mechanism, an optical fiber positioning mechanism for supporting an optical fiber, and a cutting mechanism arranged on the bottom plate, the optical fiber rotating mechanism comprises an axial base plate connected with the axial moving mechanism, a first rotating assembly arranged on the axial base plate and a second rotating assembly arranged on the axial base plate; the first rotating assembly and the second rotating assembly are respectively used for clamping the optical fiber; the first rotating assembly and thesecond rotating assembly are also used for synchronously driving the optical fiber to rotate; and the cutting mechanism and the optical fiber positioning mechanism are correspondingly arranged, so that the section left after the coating layer is stripped is smooth and flat, and the cladding light filtering effect is improved.

Owner:GZ PHOTONICS CO LTD

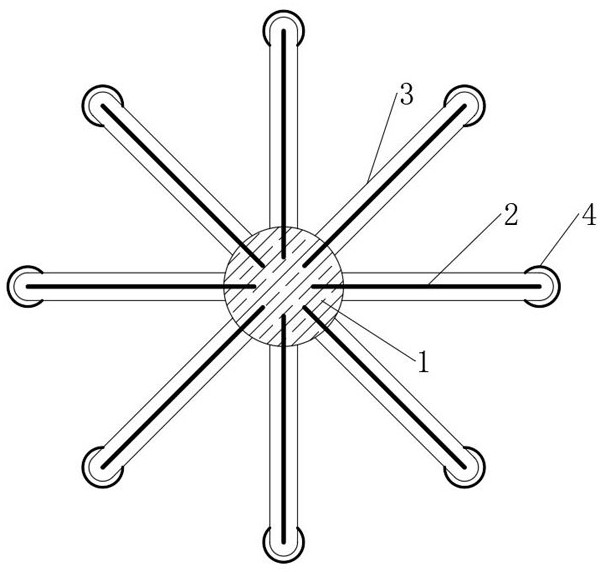

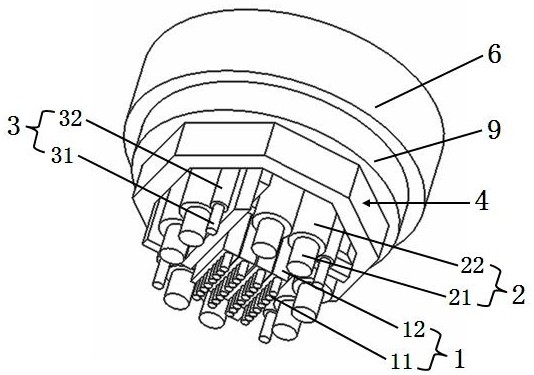

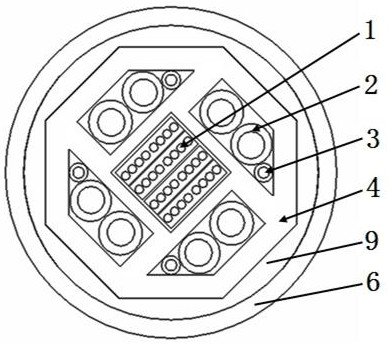

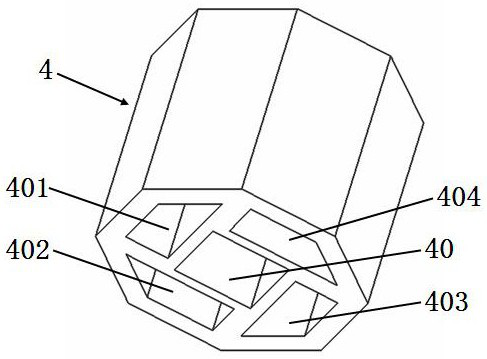

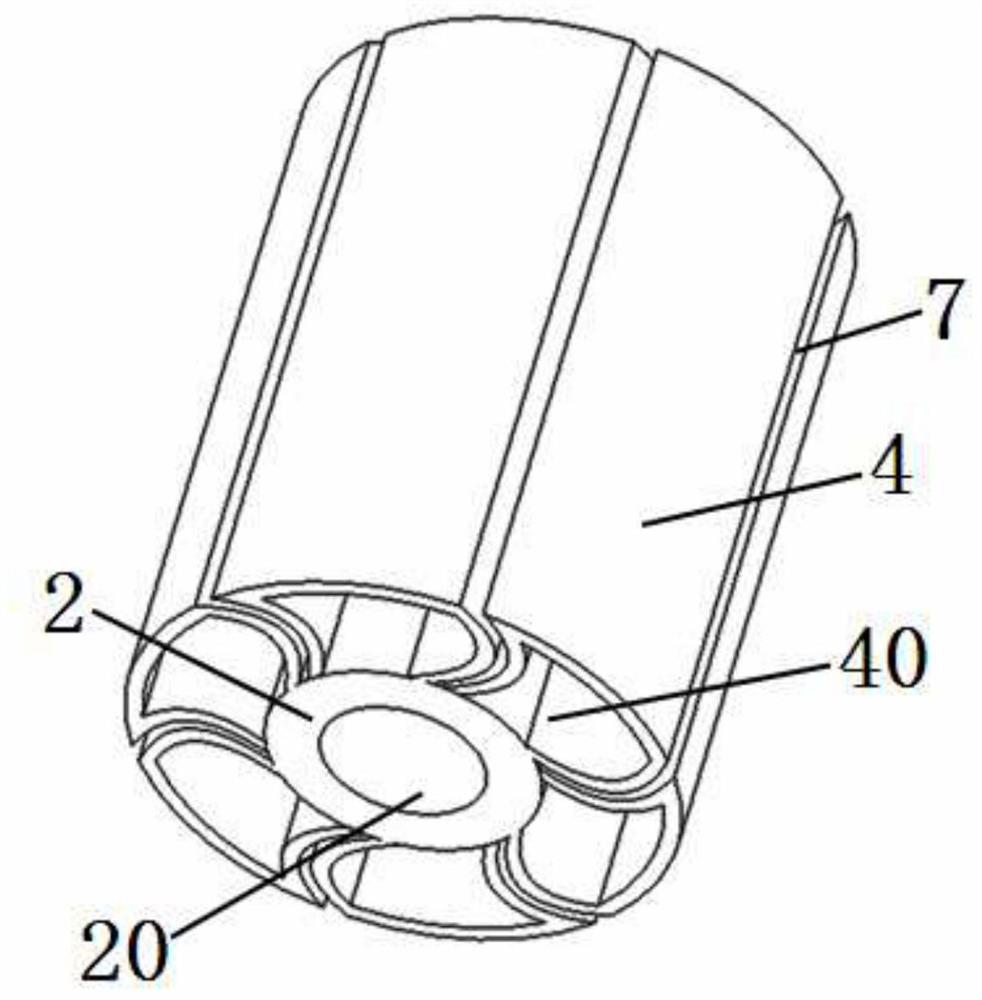

Optical fiber ribbon optical cable with octahedral cylinder structure shell

ActiveCN113611453AImprove convenienceSo as not to damageCommunication cablesPower cablesFiberEngineering

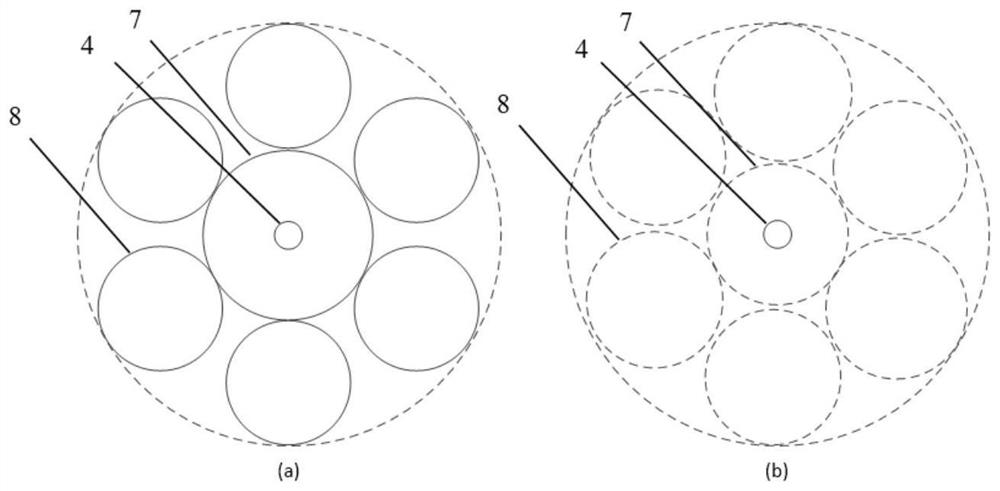

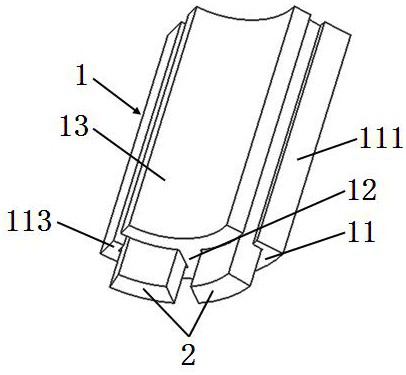

The invention belongs to the technical field of optical cables and discloses an optical fiber ribbon optical cable with an octahedral cylinder structure shell. The optical fiber ribbon optical cable is provided with a central optical fiber ribbon body and a shell (4), wherein the central optical fiber ribbon body is composed of a plurality of central optical fiber ribbons (1); the optical cable is characterized in that the shell (4) is of an octahedral cylinder structure, and a shell inner cavity (45) is formed in the shell (4); the optical cable further comprises four isolation components (5), the isolation components (5) are located in an inner cavity (45) of the shell, first to fourth containing cavities are formed between the isolation components (5) and the shell (4), a central containing cavity (40) is formed among the isolation components (5), the central optical fiber ribbons are located in the central containing cavity (40), and at least one of the first to fourth containing cavities is internally provided with an external optical fiber ribbon (7). The optical cable is advantaged in that the optical cable has characteristics of convenient stripping of the electrical unit and the optical fiber ribbon, high fiber core density, high space utilization rate, good compression resistance and the like, and can better adapt to the width and height of the optical fiber ribbon body.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD

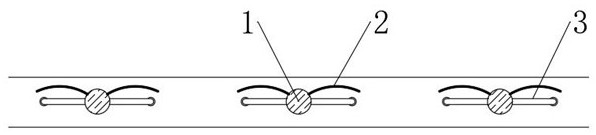

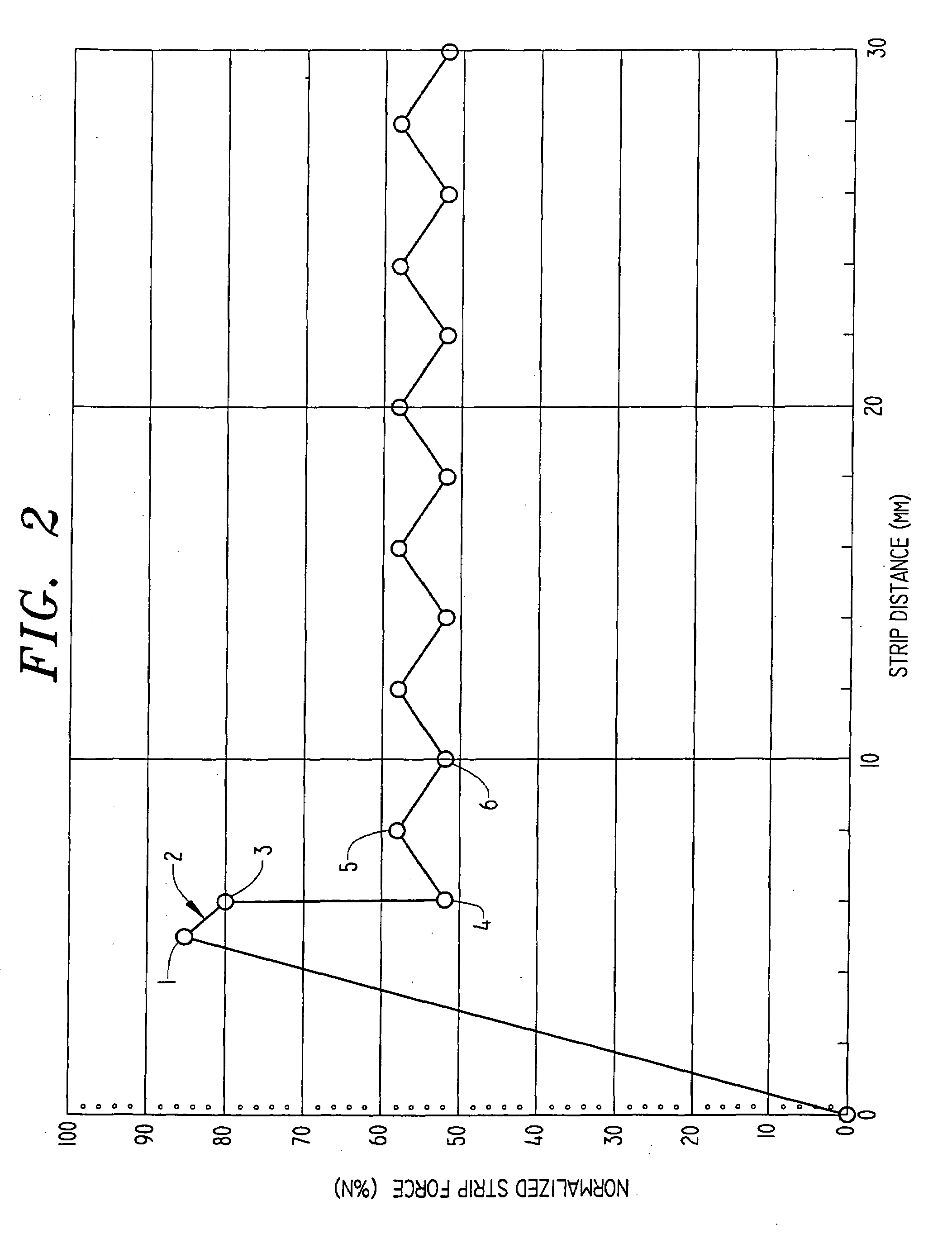

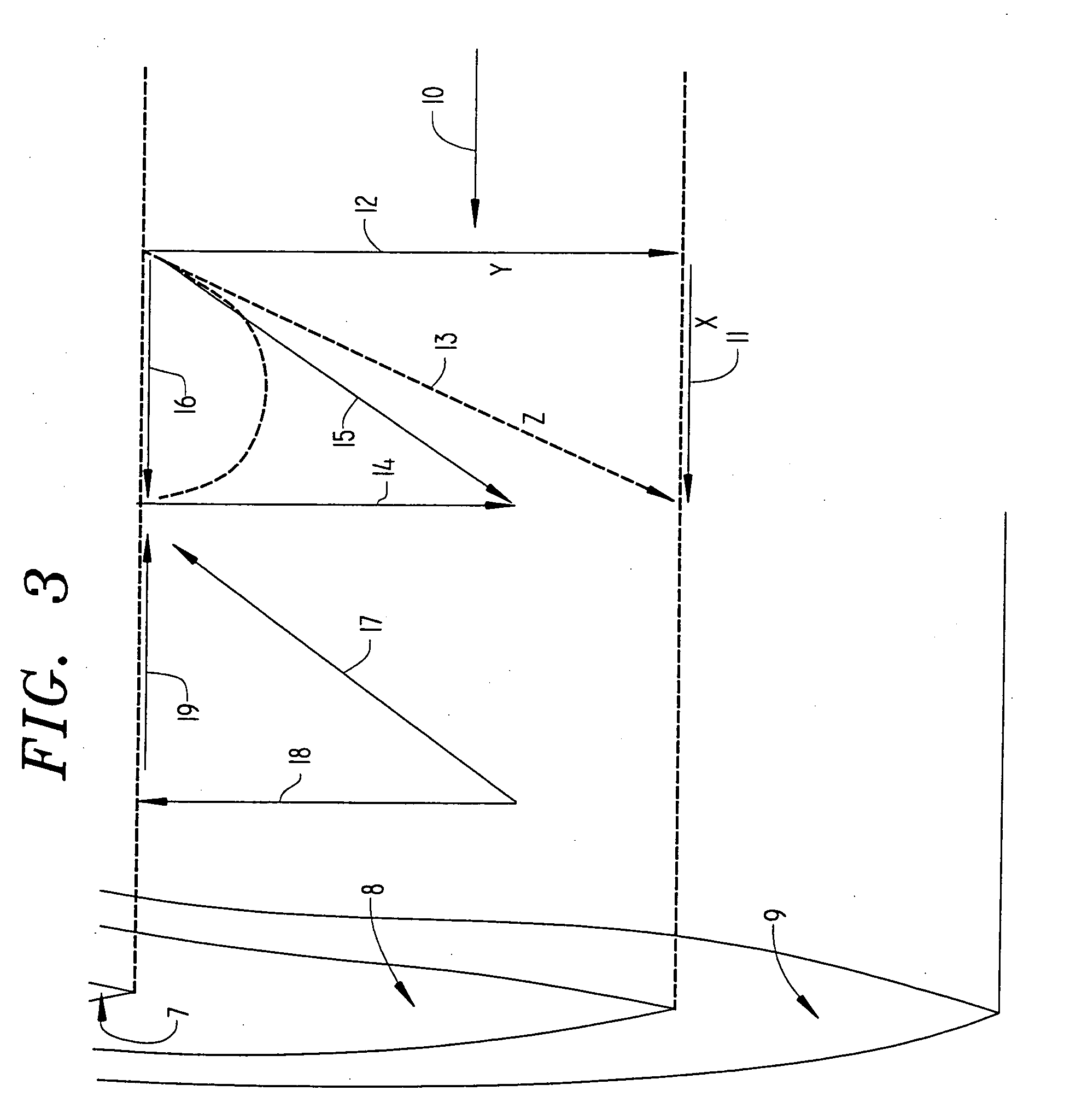

Radiation-curable optical glass fiber coating compositions, coated optical glass fibers, and optical glass fibers, and optical glass fiber assemblies

InactiveUS20090171011A1Improved ribbon stripping capabilitySufficient adhesionFibre mechanical structuresGlass fiberOligomer

Optical fiber coatings are disclosed having excellent ribbon stripping and adhesion behavior. The coatings are radiation-curable. The excellent stripping and adhesion behavior can be achieved by several means which include by use of additives, by use of radiation-curable oligomers having higher molecular weight, or by use of coatings having certain thermal properties. Combination of means can be employed. Stripping behavior can be measured by crack propagation and fiber friction measurements.

Owner:DSM IP ASSETS BV

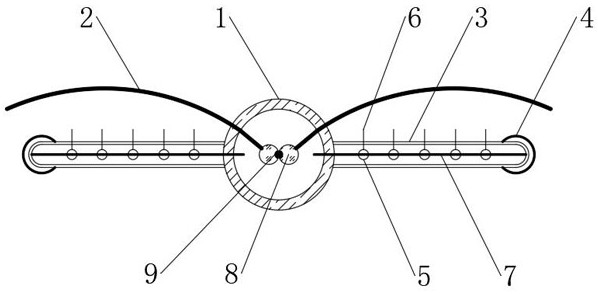

Power cable, photoelectric composite cable, communication optical cable and optical fiber ribbon

PendingCN113903526ASimple structureEasy to peelCommunication cablesInsulated cablesPower cableProtection layer

The invention belongs to the technical field of electric power and cables, and relates to a power cable. The power cable is provided with a reinforcing component, an accommodating component, a protective layer and an outer protective layer, and a power transmission component is arranged in the accommodating component. The power cable is characterized in that the accommodating component is composed of a third bent part, a second connecting part, a fourth bent part, a third connecting part and a fifth bent part; a second cavity, a fourth cavity and a third cavity are formed in the accommodating component; the third cavity and the second cavity are communicated with each other; the third cavity and the fourth cavity are communicated with each other; the accommodating component is of an integrated structure; the power transmission component is composed of a first bending part, a first connecting part and a second bending part, and a first cavity is formed among the first bending part, the first connecting part and the second bending part; and the second bending part is arranged in the fourth cavity, the first connecting part is arranged in the third cavity, and the first bending part is arranged in the second cavity. The invention also discloses a communication optical cable, a photoelectric composite cable and an optical fiber ribbon. The power cable of the invention has the advantages of simple structure, easy stripping, good heat dissipation, lighter weight, lower cost and more flexible use.

Owner:王爱华

Power cable, photoelectric composite cable, communication optical cable and optical fiber ribbon

InactiveCN112151216ASimple structureEasy to peelInsulated cablesCommunication cablesPower cableEngineering

The invention belongs to the technical field of electric power and cables, and relates to a power cable, which is provided with a reinforcing component, an accommodating component, a protective layerand an outer protective layer, wherein a power transmission component is arranged in the accommodating component, the accommodating component is composed of a third bent part, a second connecting part, a fourth bent part, a third connecting part and a fifth bent part, a second cavity, a fourth cavity and a third cavity are formed in the accommodating component, the second cavity is communicated with the third cavity, the third cavity is communicated with the fourth cavity, the accommodating component is of an integrated structure, the power transmission component is composed of a first bent part, a first connecting part and a second bent part, a first cavity is formed among the first bent part, the first connecting part and the second bent part, the second bent part is arranged in the fourth cavity, the first connecting part is arranged in the third cavity, and the first bent part is arranged in the second cavity. The invention also discloses a communication optical cable, a photoelectric composite cable and an optical fiber ribbon. According to the invention, the main beneficial effects of simple structure, easy stripping, good heat dissipation, lighter weight, lower cost and moreflexible use are achieved.

Owner:CHANGSHU BAILIAN PHOTOELECTRIC TECH CO LTD

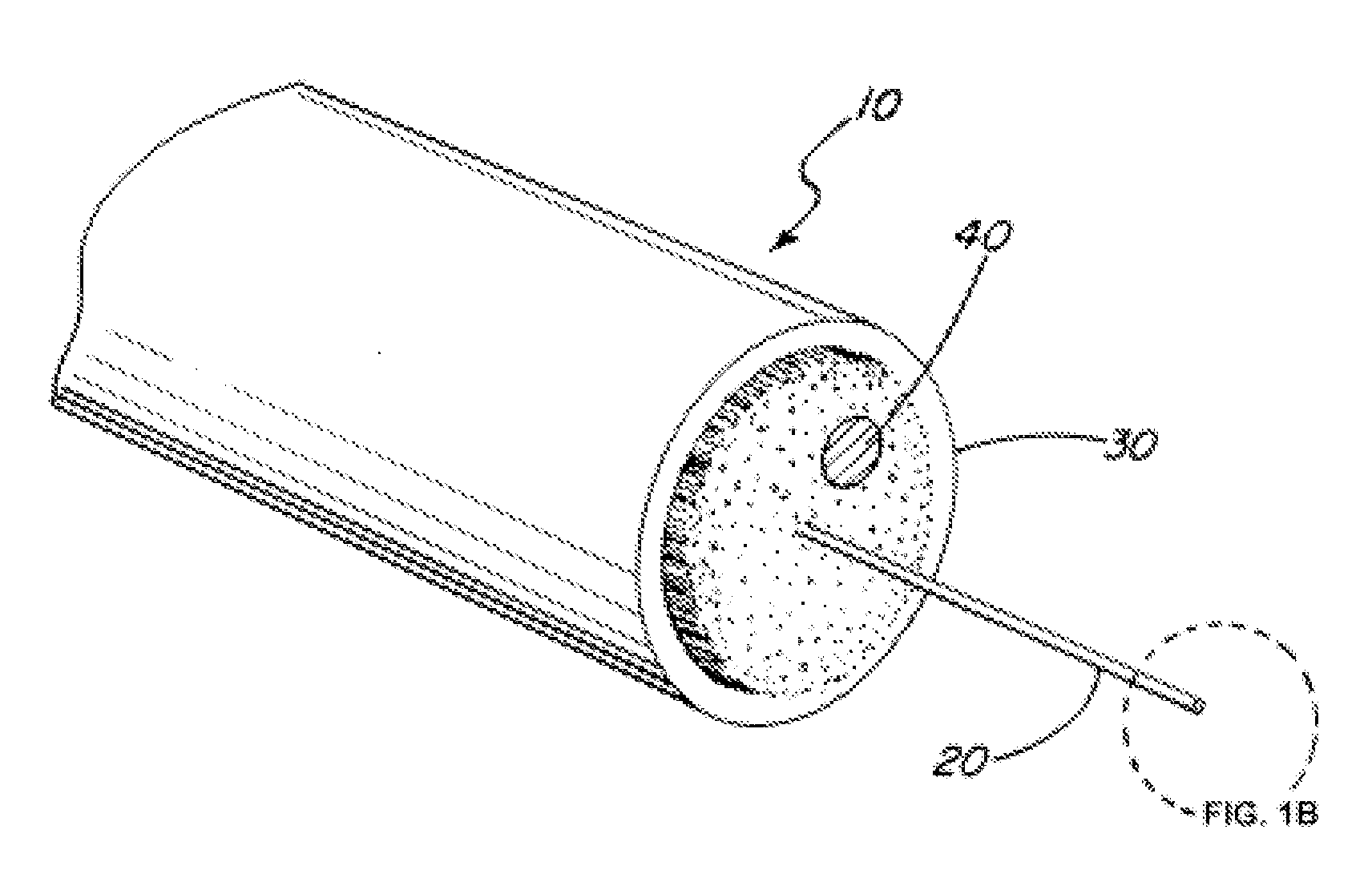

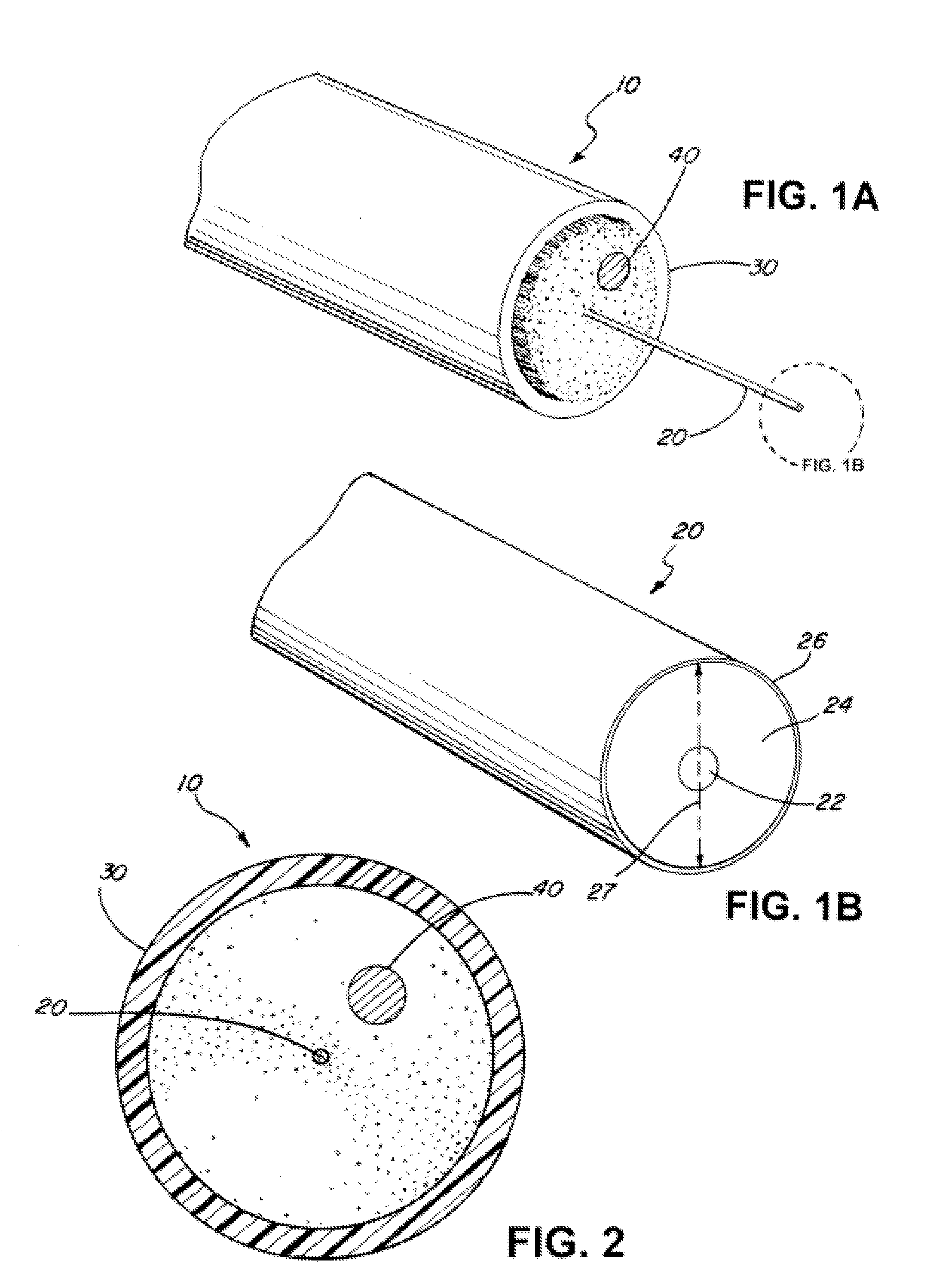

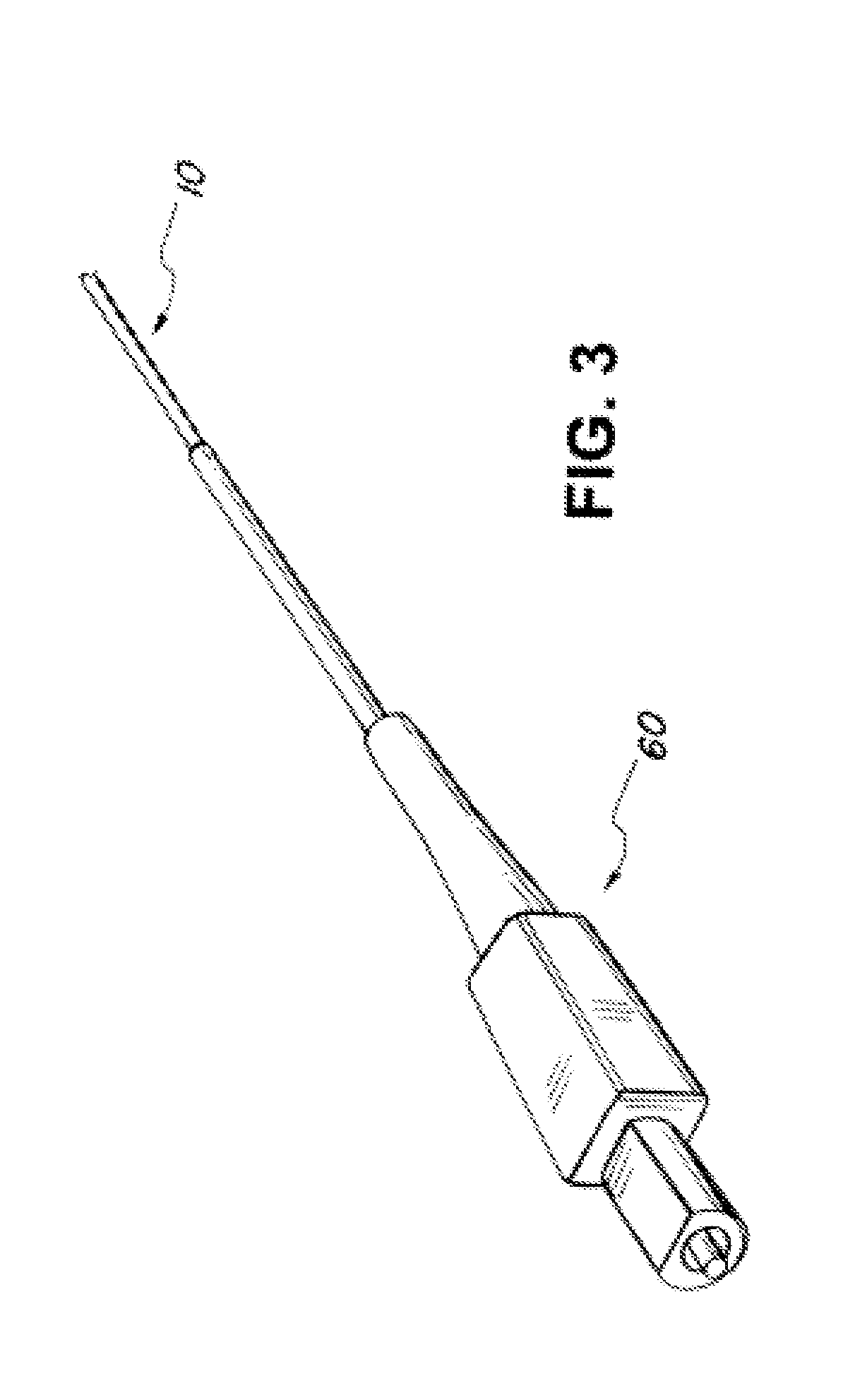

Cable with non-stripping optical fiber

Cables having non-stripping, or buffer-free, optical fibers are disclosed. The cables each have a buffer-free optical fiber including a core, cladding layer and a thin protective coating enclosing the cladding and having an overall diameter of 125 μm. This protective coating protects the cladding and core from moisture and provides structural integrity to prevent physical damage to the fiber during installation and termination with connectors. Embodiments of this non-stripping fiber do not require removal of a buffer layer during field termination so connections can be formed using simple cleaving techniques. As such, the field termination process for embodiments is simplified compared with conventional approaches.

Owner:TZENG SHING WU PAUL

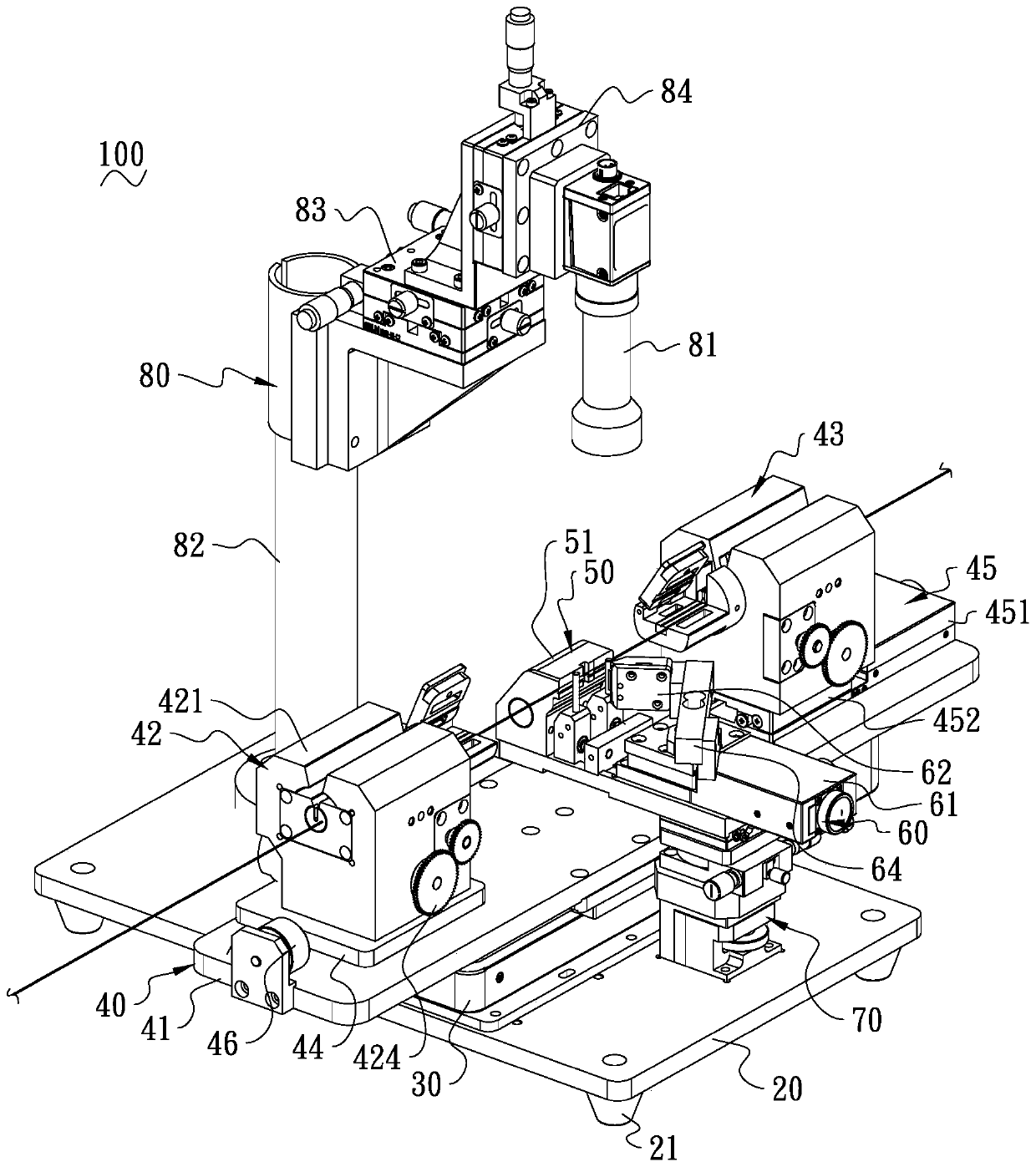

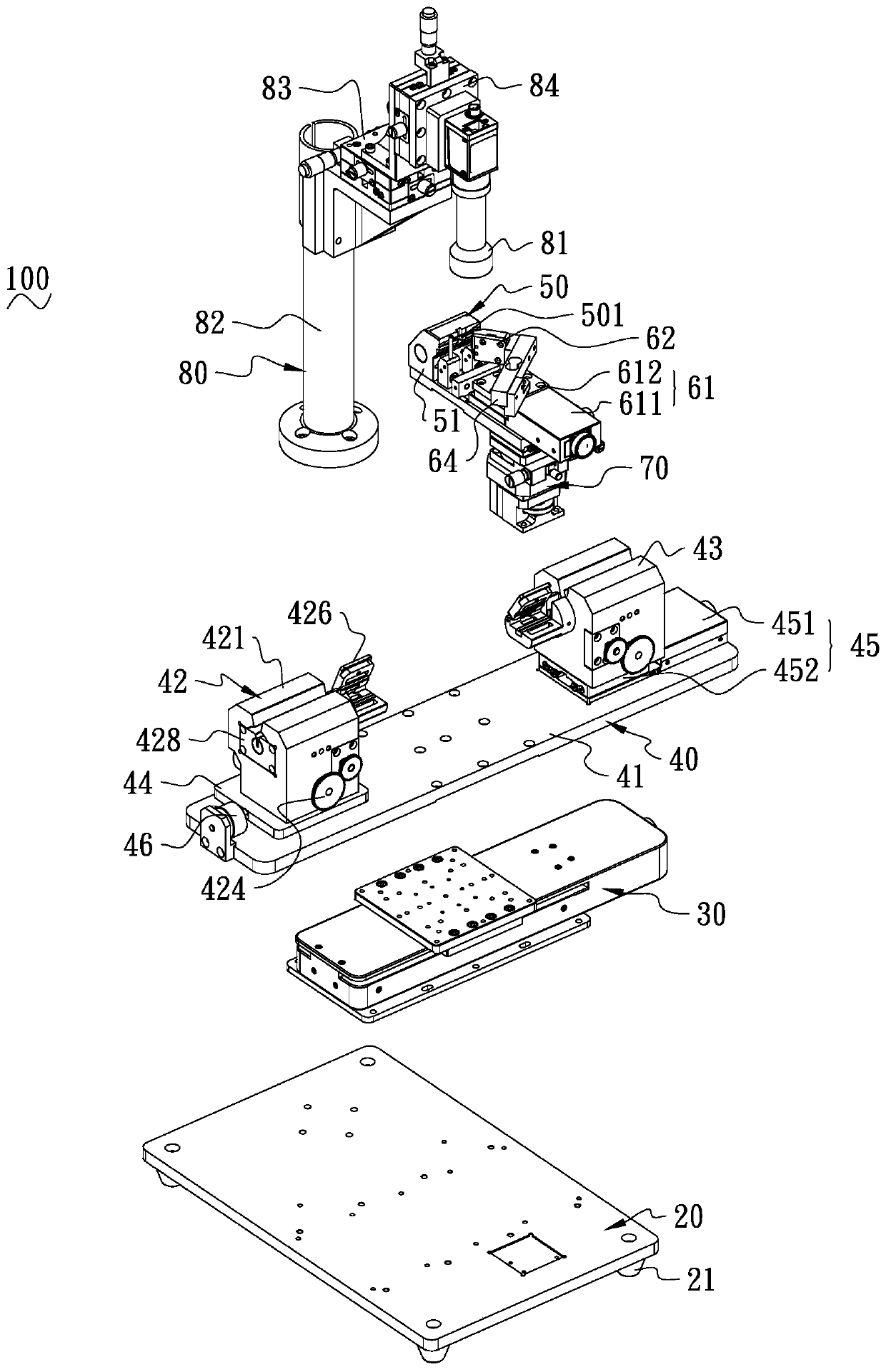

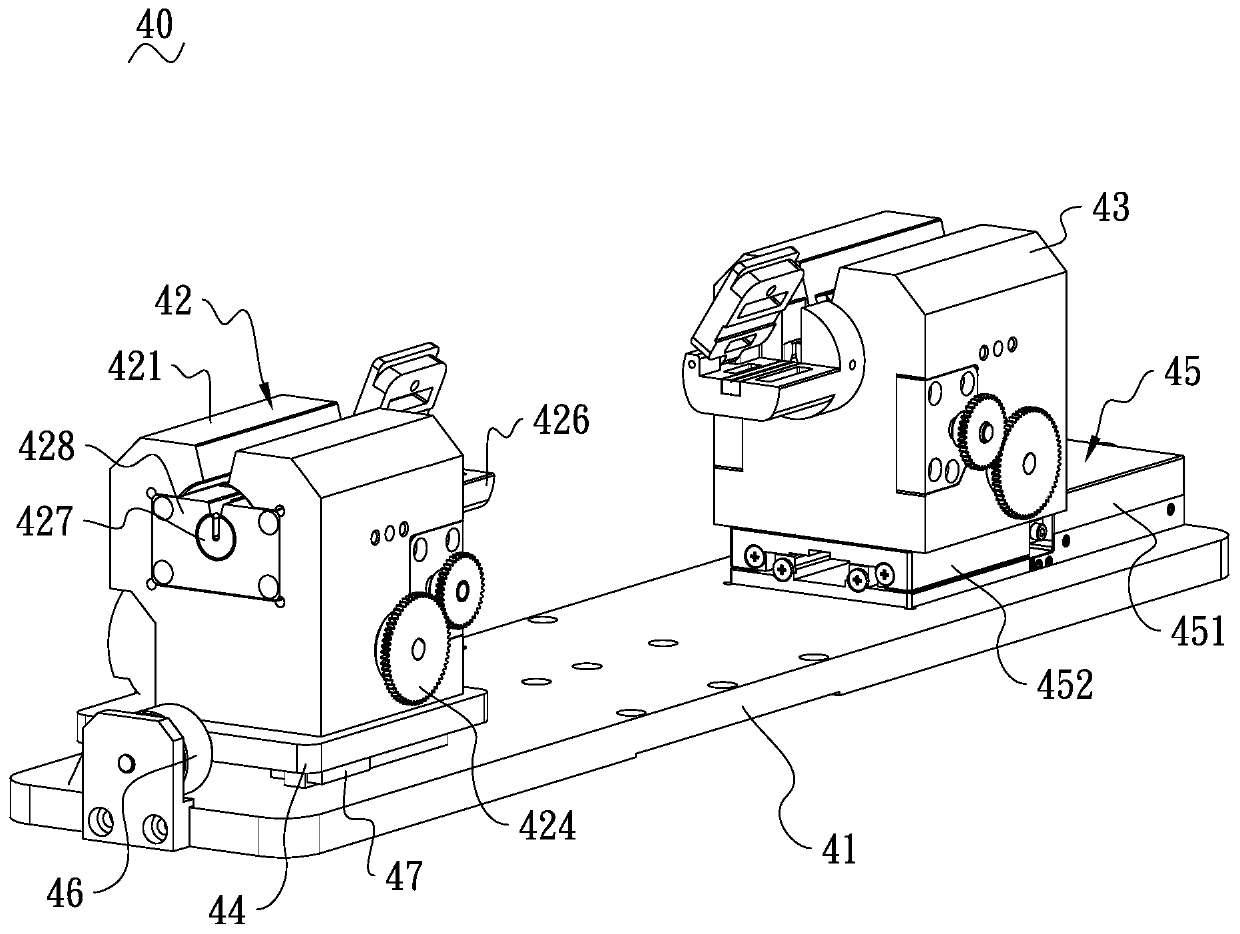

Optical fiber stripping equipment and optical fiber stripping and cutting system

The invention discloses optical fiber stripping equipment and an optical fiber stripping and cutting system. The optical fiber stripping equipment comprises a supporting device, a clamping device connected with the supporting device, a stripping device connected with the supporting device, and a transverse movement driving device used for driving the clamping device and the stripping device to beaway from each other. The clamping device is used for fixing part of the optical fiber. The stripping device comprises a first base installed on the supporting device, a folding mechanism installed onthe first base, and a stripping blade mechanism connected with the folding mechanism. The folding mechanism is used for driving the stripping blade mechanism to open and close. The stripping blade mechanism is used for scraping and stripping the coating layer. The folding mechanism or the blade stripping mechanism is used for positioning the optical fiber. The optical fiber is fixed on the clamping device, and then the other part of the optical fiber is positioned. Meanwhile, the folding mechanism enables the stripping blade mechanism to be attached to the coating layer of the optical fiber,then the stripping blade mechanism is far away from the clamping device through the transverse movement driving device, the coating layer of the optical fiber is separated from the fiber core under scraping and stripping of the stripping blade mechanism, and thus stripping of the coating layer is completed automatically.

Owner:GZ PHOTONICS CO LTD

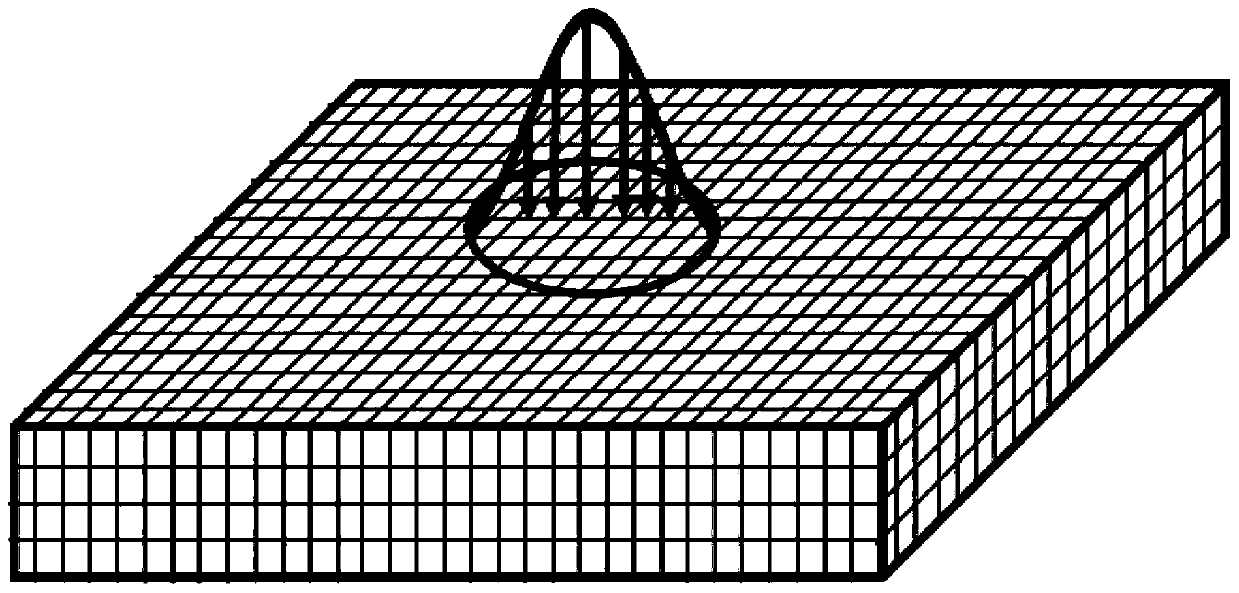

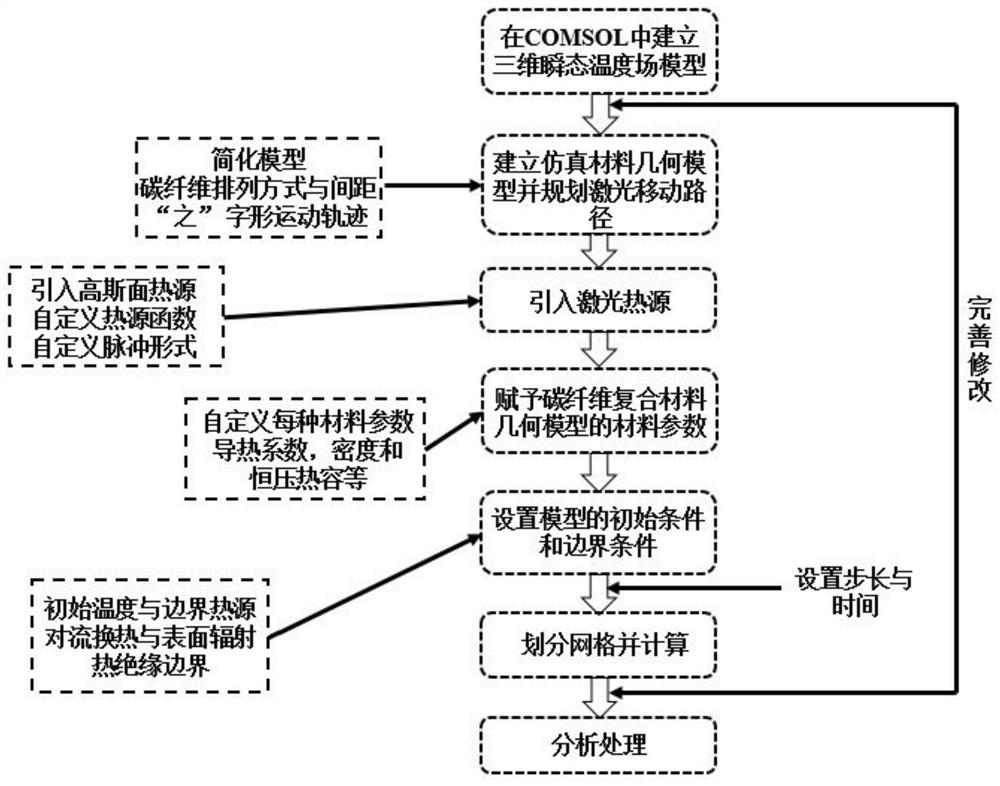

Method for simulating temperature field in carbon fiber material release agent based on laser cleaning stripping

PendingCN112380677AReal-time temperature changeGeometric CADDesign optimisation/simulationFiberResin matrix

The invention relates to the field of pretreatment of glued carbon fiber composite materials in aerospace and automobile industries, in particular to a method for simulating temperature field in a carbon fiber material release agent based on laser cleaning stripping. The method comprises the following steps: 1) establishing a three-dimensional transient temperature field model through COMSOL; 2) scanning the to-be-detected carbon fiber composite material through a three-dimensional laser scanner, constructing a geometric model of the carbon fiber composite material, and planning a moving pathof laser in the geometric model through a COMSOL model development module; 3) introducing a pulse laser heat source to establish a heat source model; 4) setting material parameters of the geometric model of the carbon fiber composite material; 5) setting initial conditions and boundary conditions of the geometric model of the carbon fiber composite material; and 6) dividing different grids for thegeometric model of the carbon fiber composite material, and obtaining the relationship between the laser scanning speed and the temperature field after completion through a COMSOL analysis module. According to the invention, COMSOL software is utilized to be suitable for numerical simulation of temperature field distribution of laser cleaning of the carbon fiber resin matrix composite material.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Optical fiber ribbon optical cable easy to strip

PendingCN113625404AReduce consumptionCompact structureFibre mechanical structuresRibbon cableEngineering

The invention belongs to the technical field of communication optical cables, and discloses an easy-to-strip optical fiber ribbon cable, which is provided with an accommodating shell and first to fifth optical fiber ribbon units, wherein the accommodating shell is composed of first to fifth protection units; an accommodating cavity is formed in each protection unit, the optical fiber ribbon unit is positioned in the accommodating cavity, the width of the outer end of the accommodating cavity is minimum, the optical fiber ribbon unit cannot escape from the accommodating cavity under normal conditions, the protection units are mutually inclined and connected, and the bending directions of all the protection units are consistent, namely clockwise or anticlockwise; the connecting parts of all the protection units define a pentagonal center cavity located in the center. The product has the main beneficial effects of more compact structure, less material consumption, lower cost, more convenience in stripping and separation, better heat dissipation effect and more convenience in test and construction.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD

Optical fiber stripping solution and preparation method thereof, and optical fiber stripping method

The invention relates to optical fiber stripping solution and a preparation method thereof, and an optical fiber stripping method. The optical fiber stripping solution comprises chloroform, formic acid, acetophenone, paraffin, benzoic acid and a thickener. The optical fiber stripping method comprises the following steps of: heating the optical fiber stripping solution to 40 to 50 DEG C, soaking astrip optical fiber needing to be stripped in the optical fiber stripping solution for 2 to 3 seconds, taking out, waiting for 2 to 4 seconds for full reaction, and cleaning the optical fiber to remove an encapsulating layer. By the method, the encapsulating layer of the optical fiber can be quickly removed, the optical fiber is completely stripped, and a fiber core, a cover layer and a coating layer are not damaged, so that the optical fiber is prevented from being broken or damaged in the stripping process; and compared with the conventional manual stripping process, the method improves thespeed by 30 times, saves a large amount of labor and improves production efficiency.

Owner:SHANGHAI HUIJUE NETWORK COMM EQUIP

Flame-retardant cable, flame-retardant optical cable and flame-retardant optical fiber ribbon optical cable

PendingCN113744922AImprove pass rateSimple structureInsulated cablesFibre mechanical structuresElectrical conductorEngineering

The invention belongs to the technical field of electric power and communication, and discloses a flame-retardant cable, which is provided with a plurality of conductors, a protection part and a central reinforcing part, and is characterized in that the protection part is of a special structure, the protection part is of an integrally formed integrated structure, the conductors are positioned in the protection part, and the central reinforcing part is positioned in the protection part. The invention further discloses a flame-retardant optical cable and a flame-retardant optical fiber ribbon optical cable. The cable and the optical cables have the following main advantages: the structure is simpler, the production is easier, the qualified rate of finished products is higher, the storage is easier, the assembly is more flexible, the heat dissipation is better, the stripping is more convenient, the assembly and maintenance are faster, the investment is less, the cost recovery is faster, and the product performance is more stable and more reliable.

Owner:周立芳

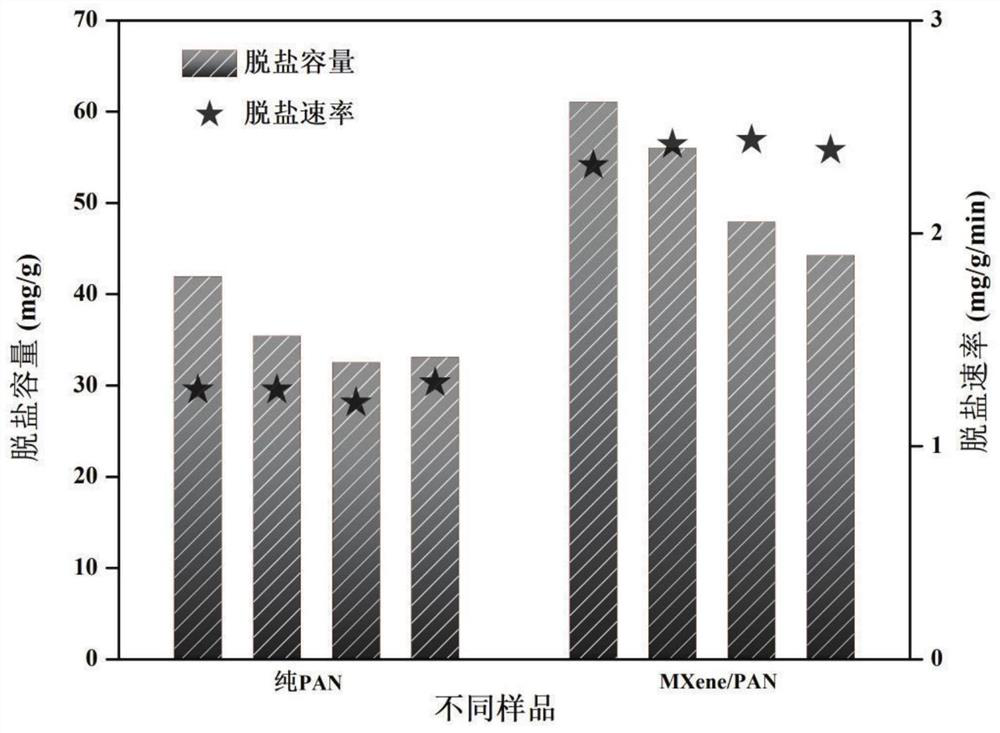

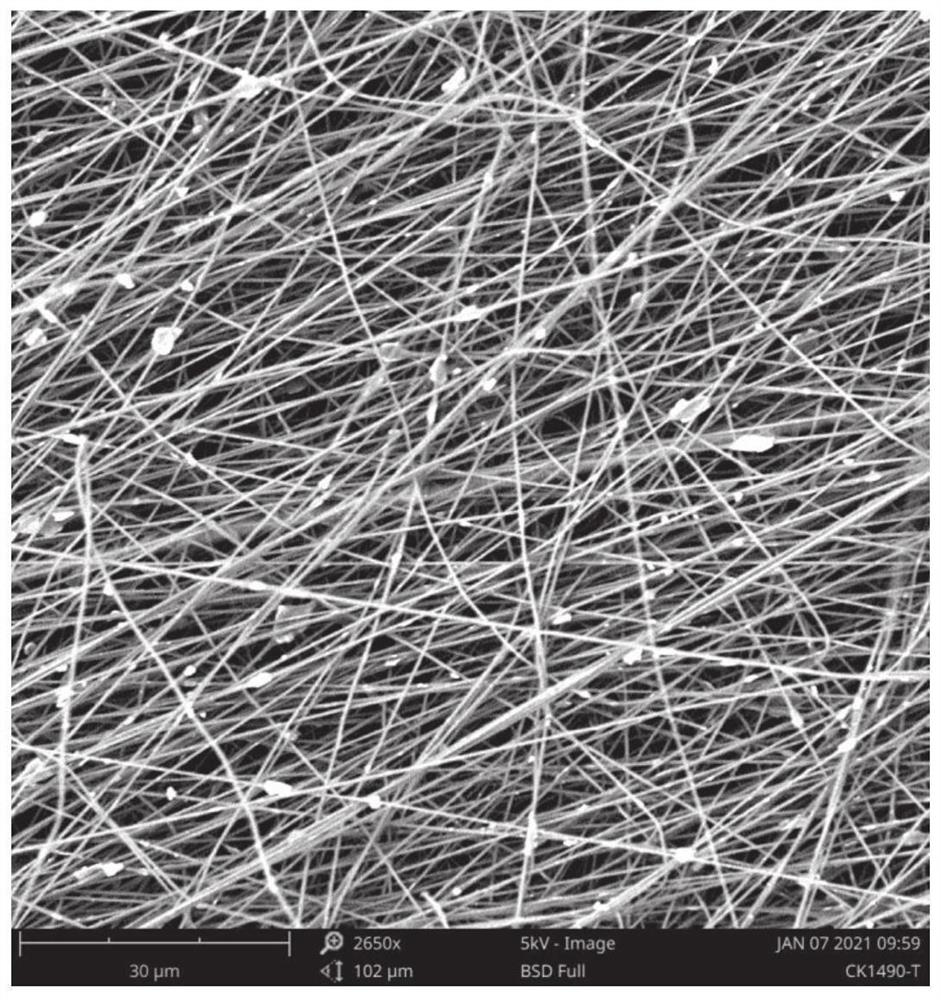

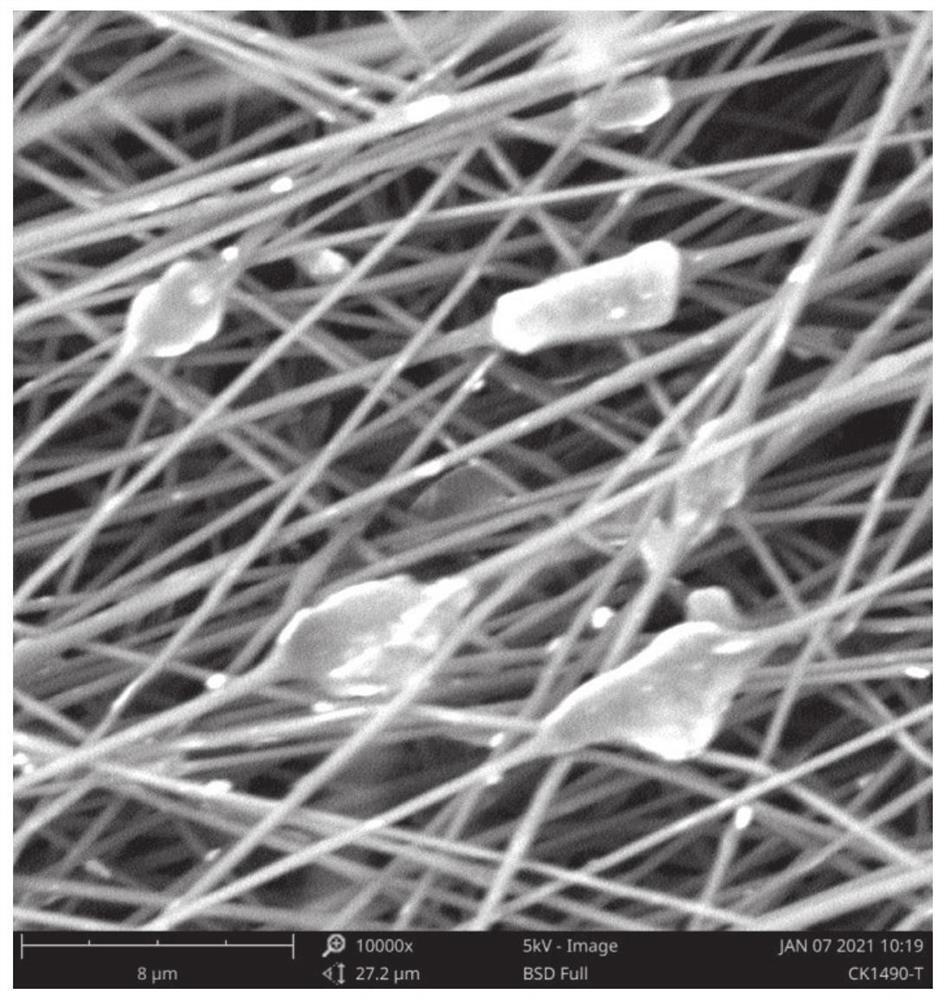

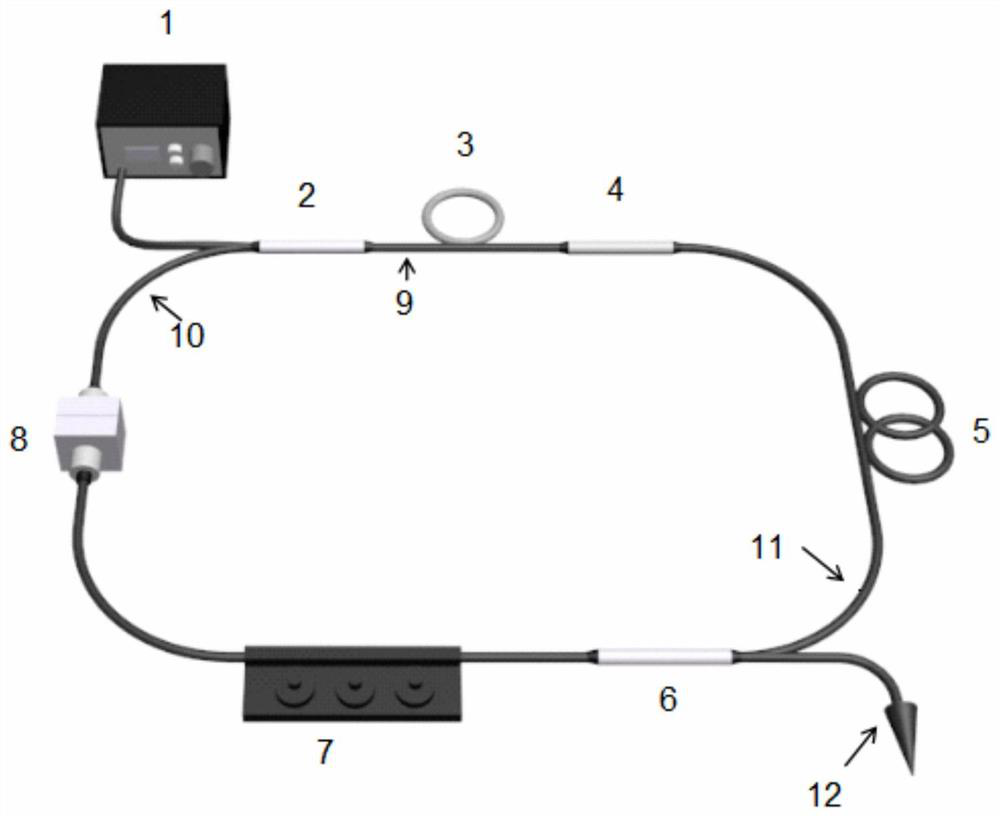

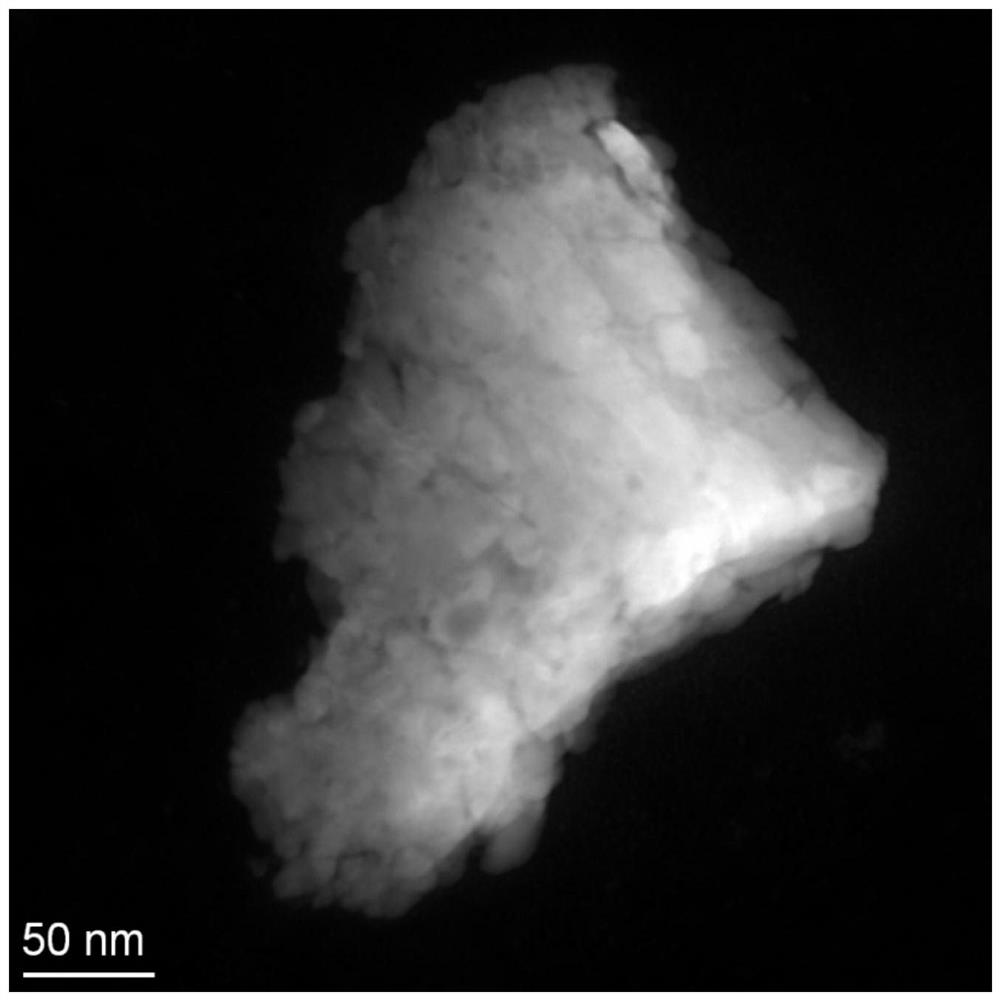

Preparation and application of novel MXene modified porous carbon fiber composite electrode

InactiveCN113005567ARich chemical propertiesUnique Morphological StructureDispersed particle separationWater/sewage treatmentFiberCapacitance

The invention provides preparation and application of a novel MXene modified porous carbon fiber composite electrode. The preparation method comprises the steps of carrying out etching treatment on an MAX phase, and obtaining two-dimensional layered MXene; enabling mXene to be centrifuged, washed and dissolved in an organic solvent DMF for ultrasonic stripping layering, and obtaining an organic solution of a single-layer MXene nanosheet; adding PAN into a MXene / DMF mixed solution, and fully mixing and stirring to obtain a spinning precursor solution; injecting the spinning solution into an electrostatic spinning device, and performing electrostatic spinning to obtain an MXene / PAN nanofiber membrane; and performing pre-oxidation and carbonization on the composite nanofiber membrane to obtain an electrode material capable of being used for desalination. An MXene / PAN film provided by the invention simultaneously has double electrode layers of a carbon material and a pseudocapacitance desalination mechanism of a Faraday electrode material, is high in desalination speed and high in desalination capacity, and can be widely applied to the fields of seawater desalination, industrial wastewater treatment and the like.

Owner:TONGJI UNIV

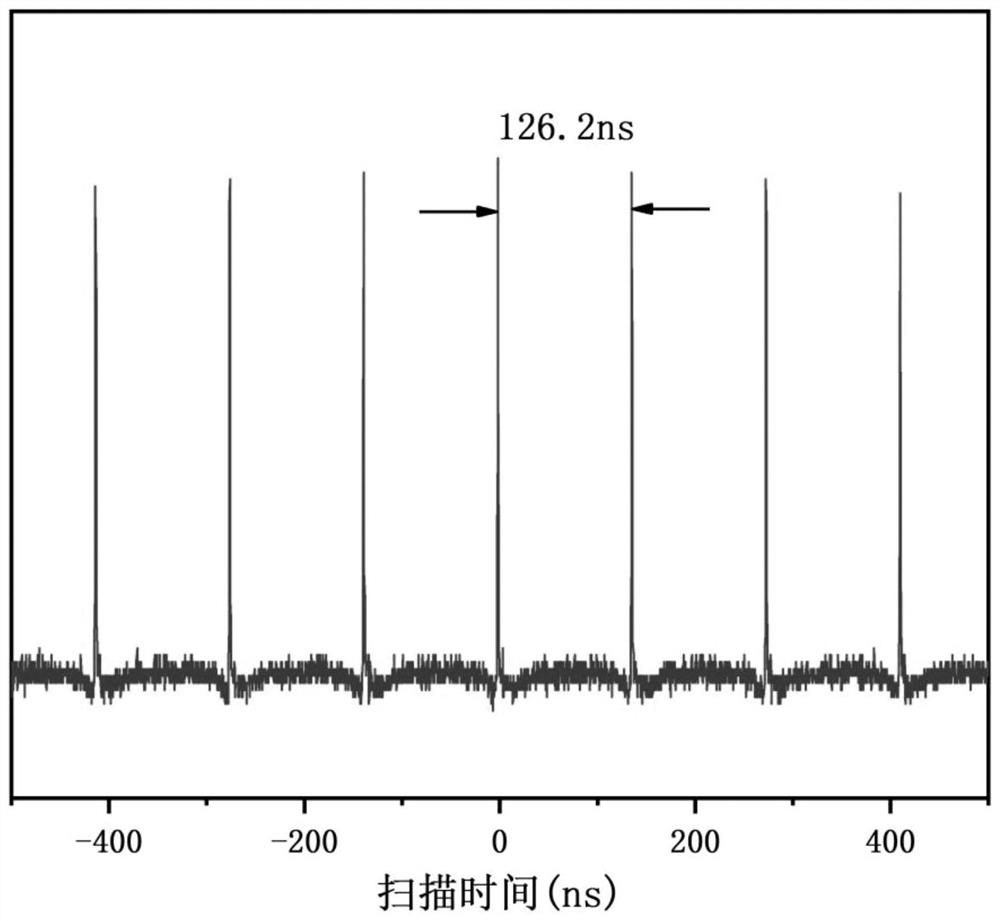

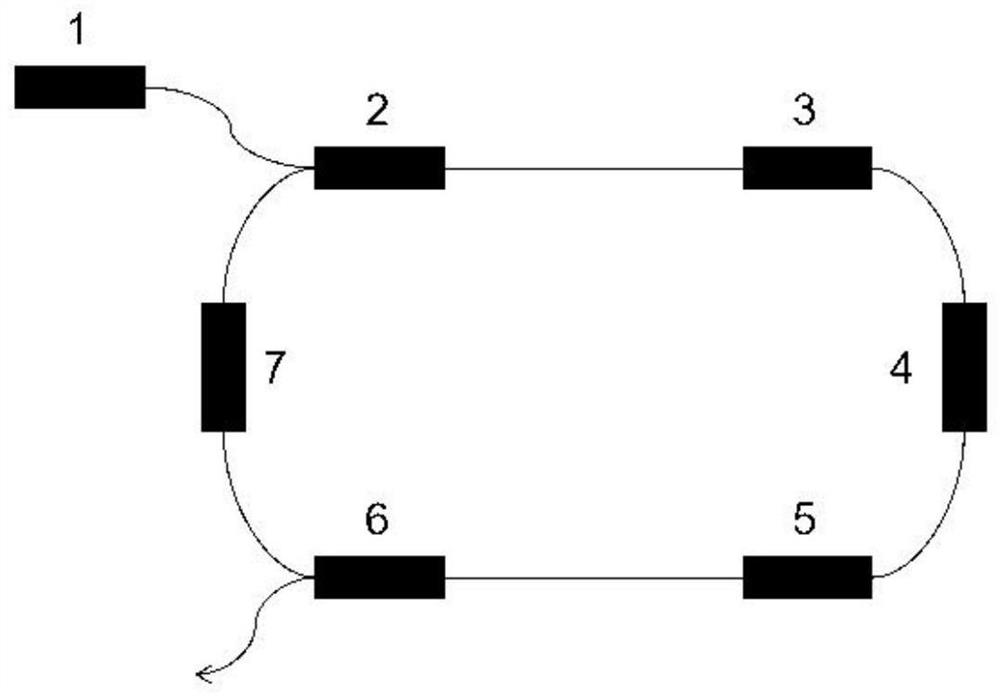

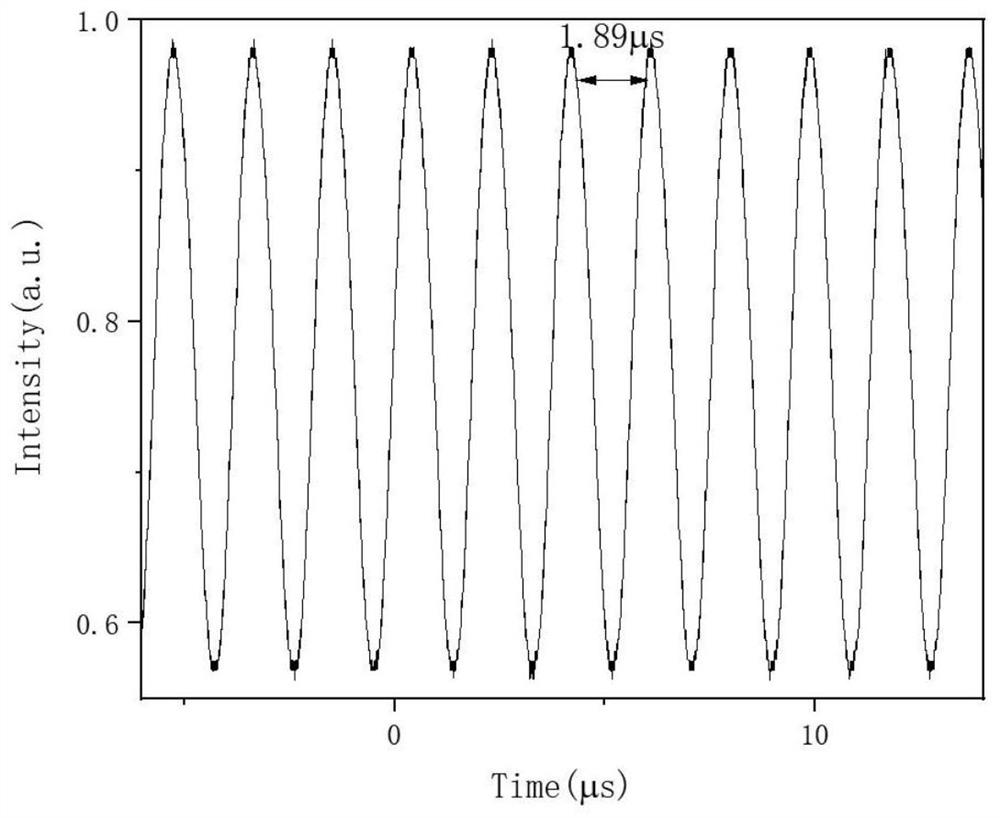

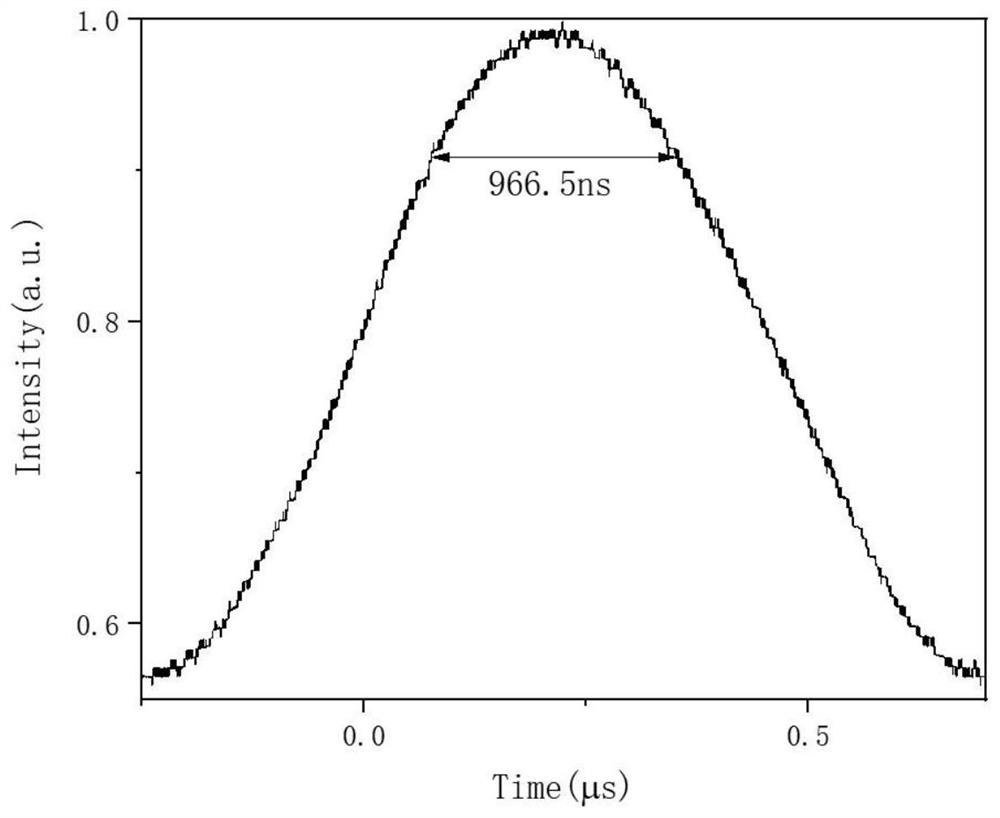

Saturable absorber based on palladium telluride, preparation method and mode-locked fiber laser prepared from saturable absorber

PendingCN112688153AEvenly distributedQuality improvementMaterial nanotechnologyActive medium shape and constructionMode locked fiber laserComposite film

The invention belongs to the technical field of passive mode-locked ultrafast fiber lasers, and discloses a saturable absorber based on palladium telluride, a preparation method and a mode-locked fiber laser prepared from the saturable absorber. The preparation method of the saturable absorber based on palladium ditelluride comprises the following steps: stripping by a liquid phase stripping method, fusing with polyvinyl alcohol, drying to form a composite film, cutting the composite film into small pieces, transferring to the end surface of an optical fiber jumper, connecting with another optical fiber jumper by a flange plate, and transferring to the end surface of the optical fiber jumper, connecting with another optical fiber jumper through a flange plate, arranging in the optical fiber flange, and generating picosecond-level ultrashort pulse laser. The saturable absorber based on palladium telluride is small in size, simple in preparation method, wide in working wavelength and short in recovery time, industrial production can be achieved, and the ultrashort pulse laser based on the material is stable in performance.

Owner:GUANGDONG UNIV OF TECH

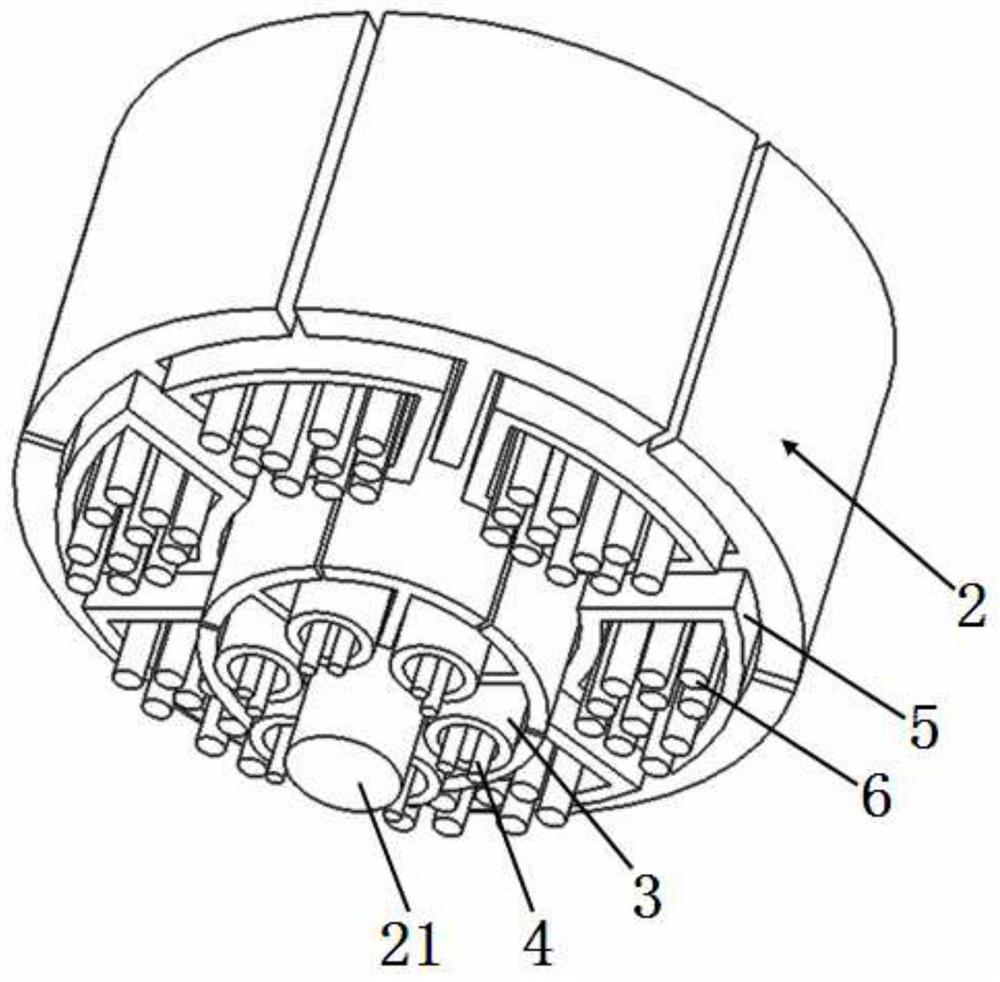

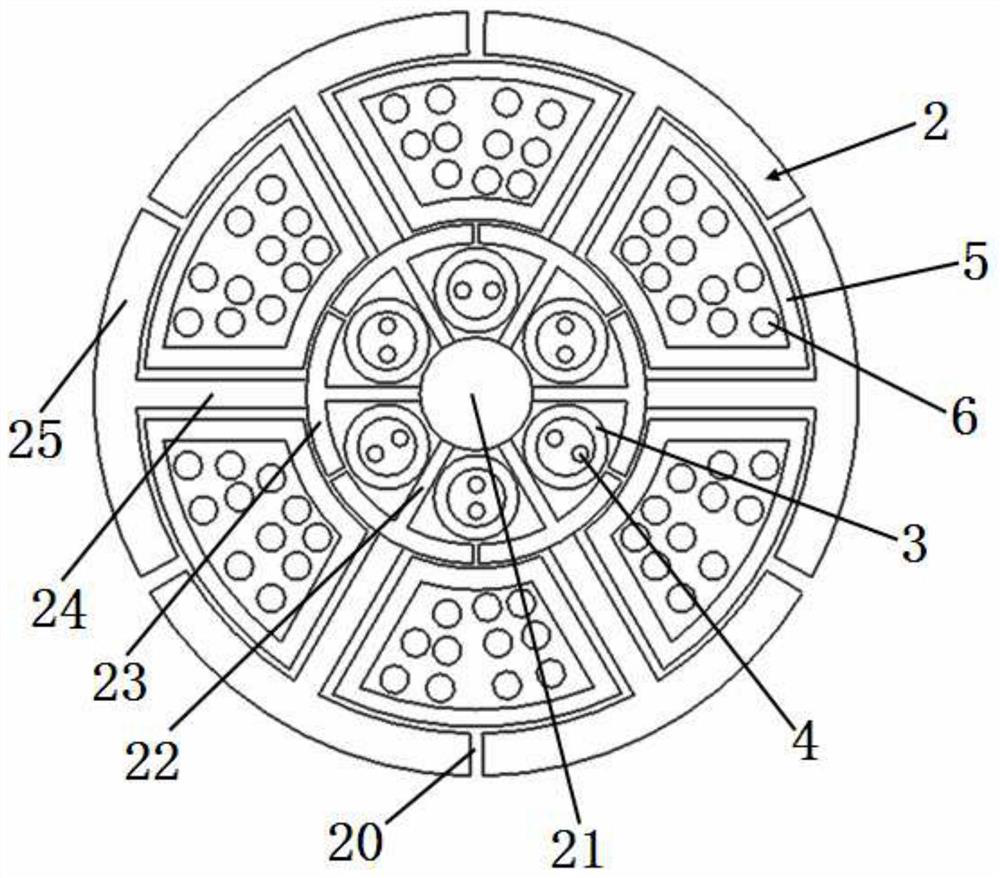

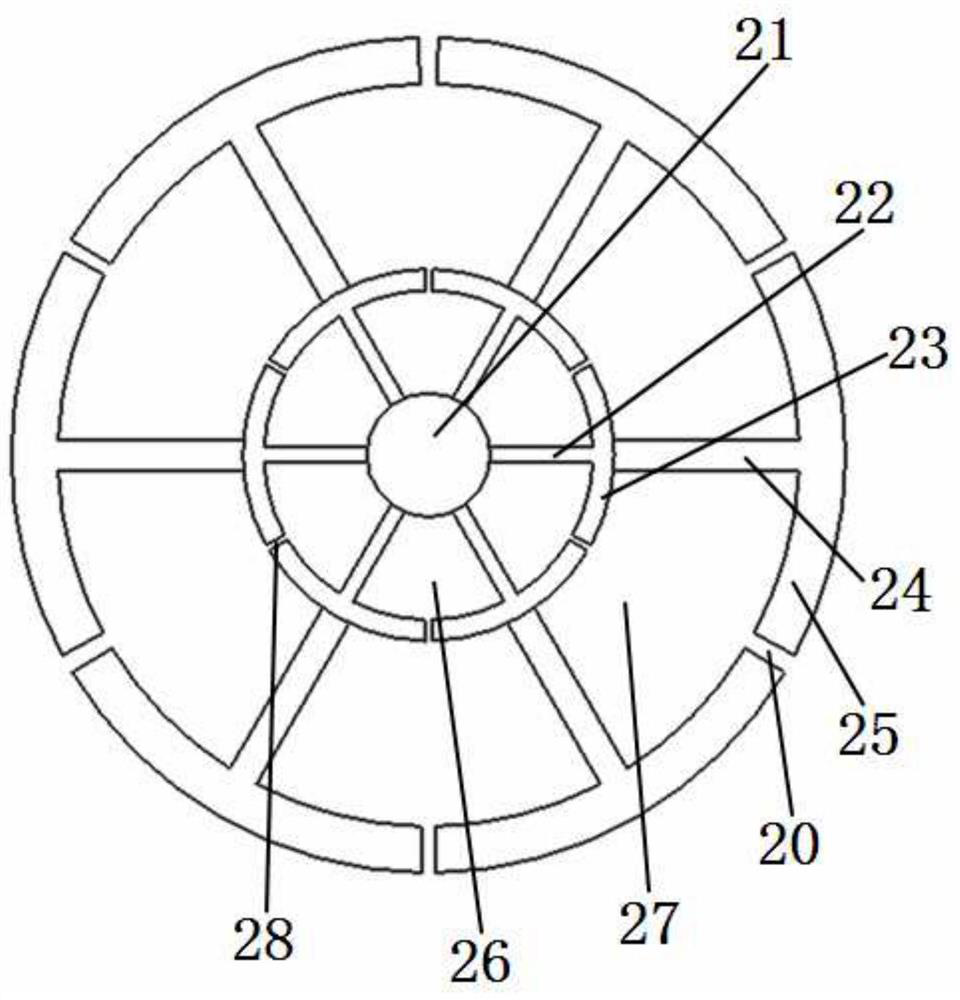

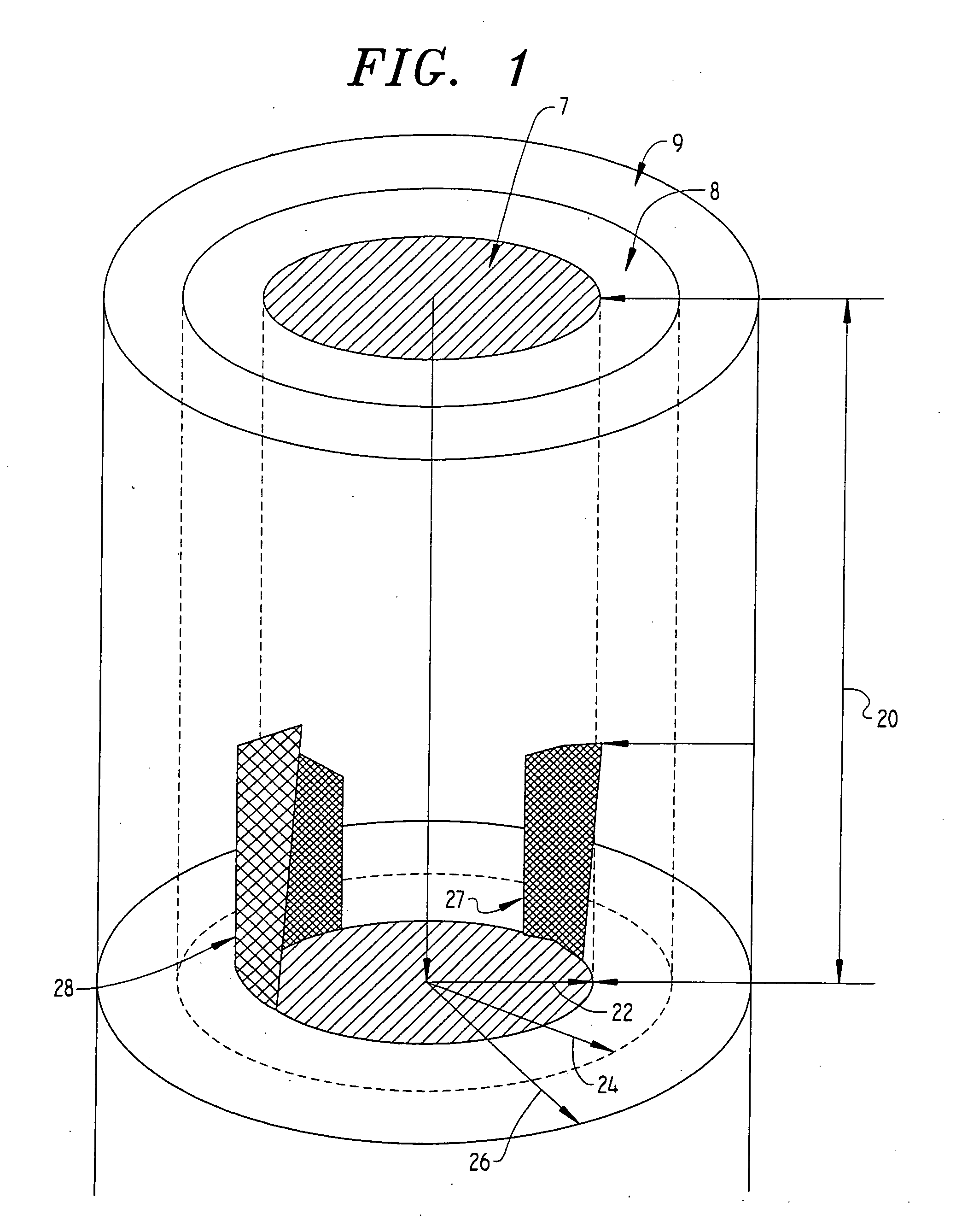

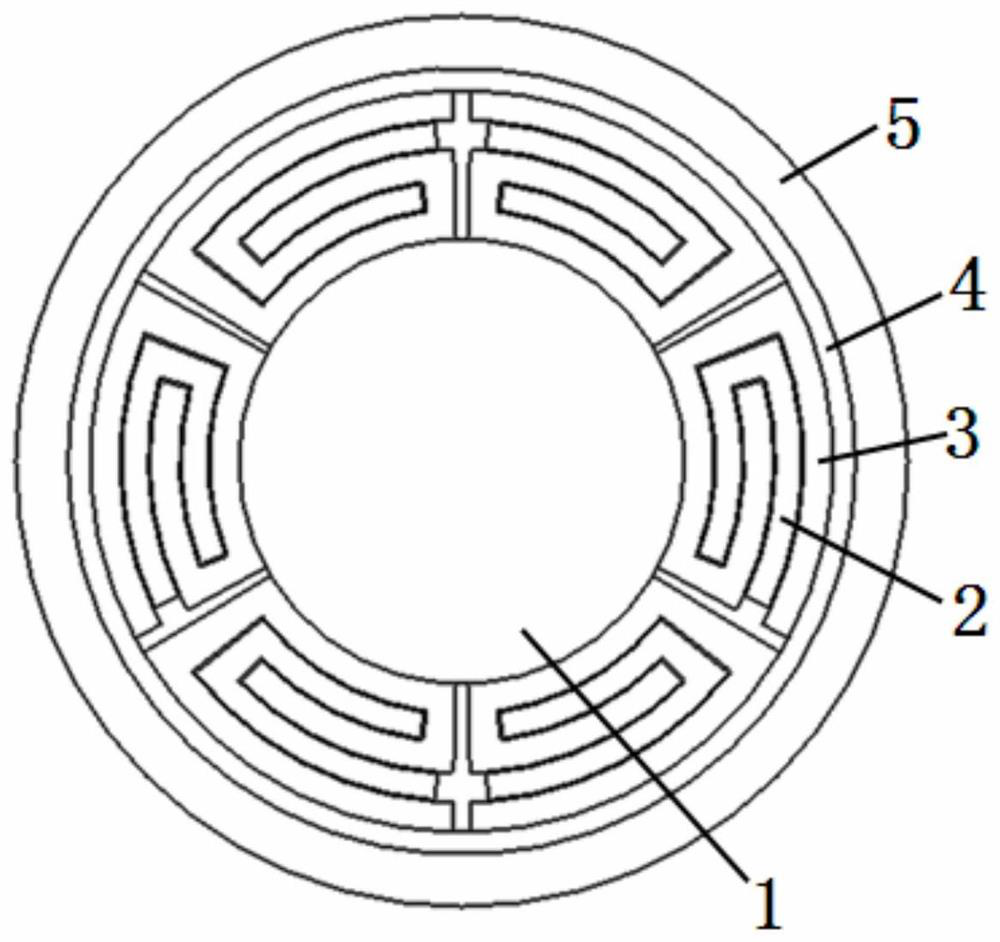

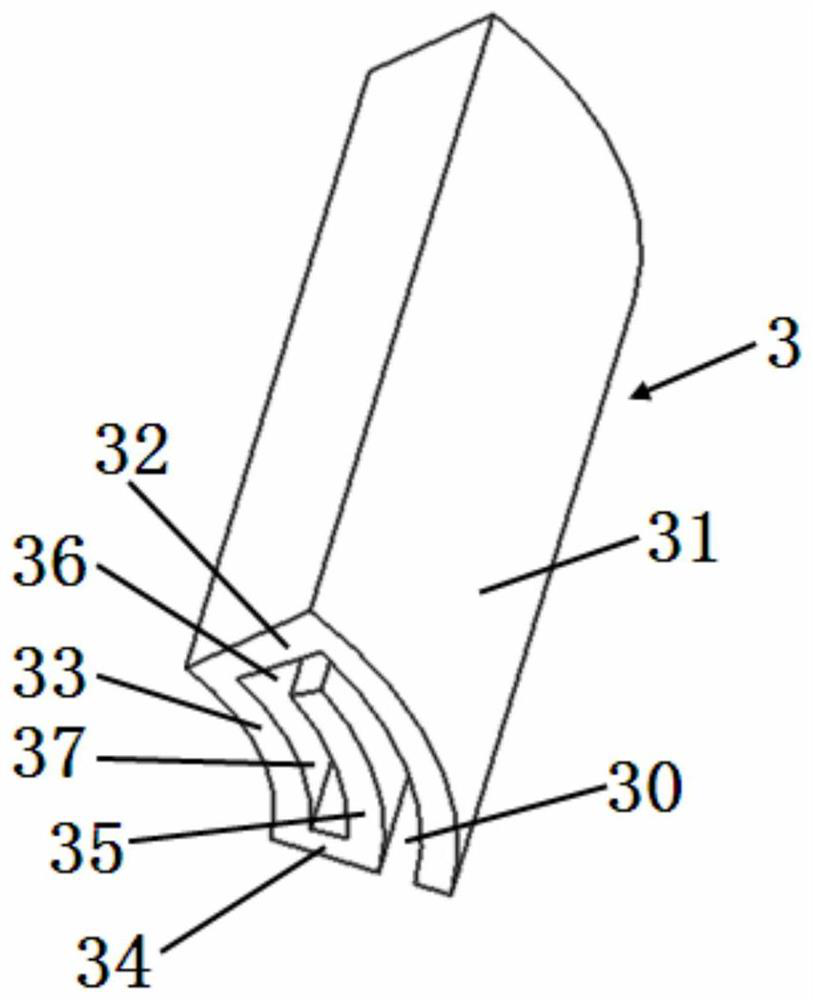

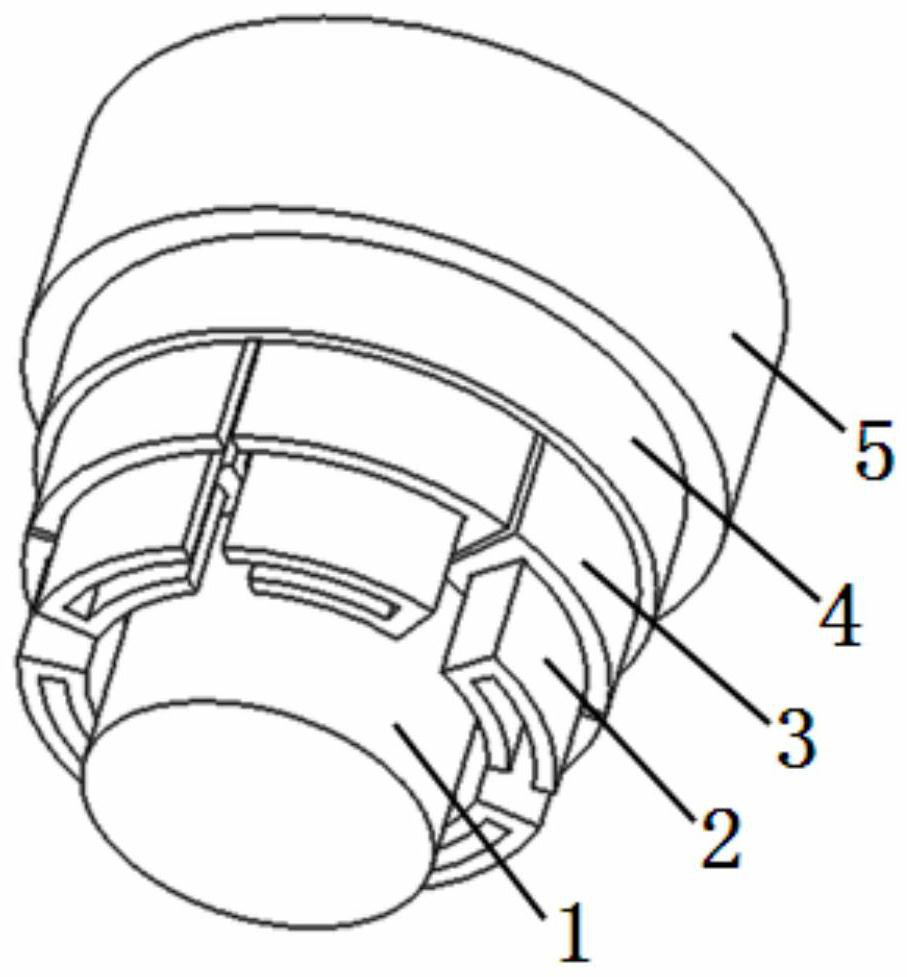

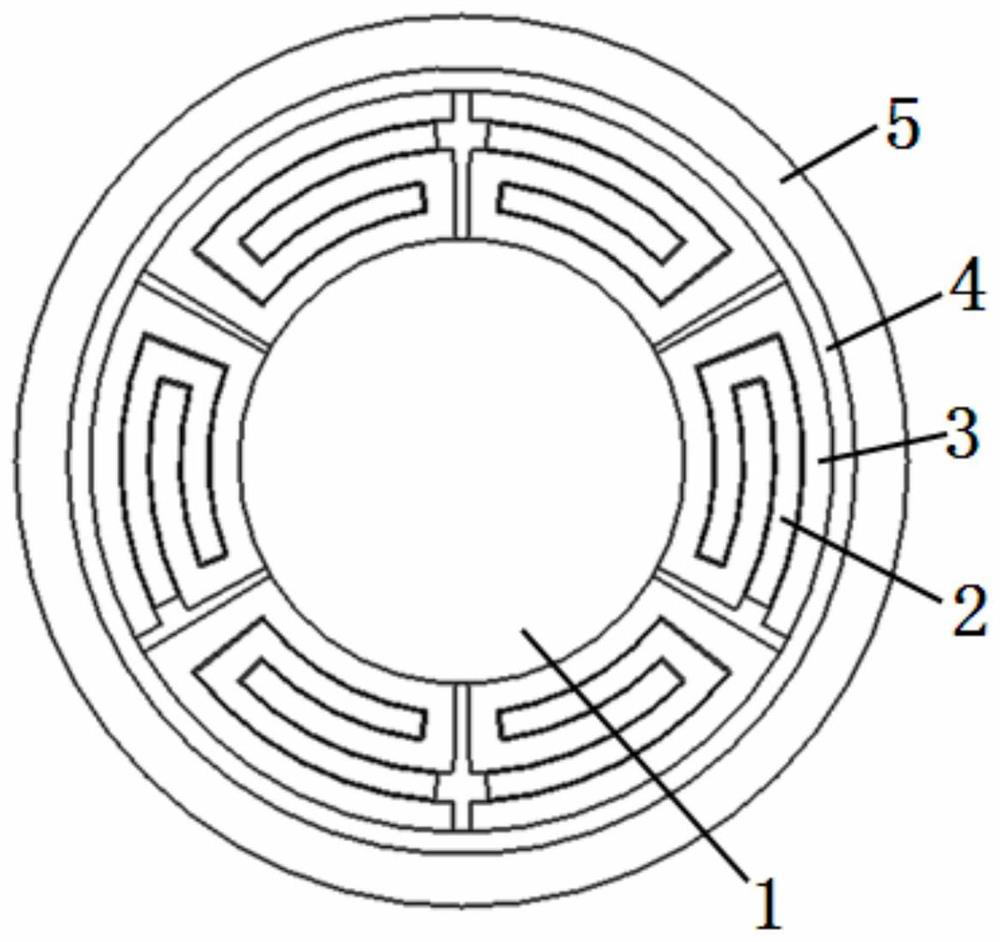

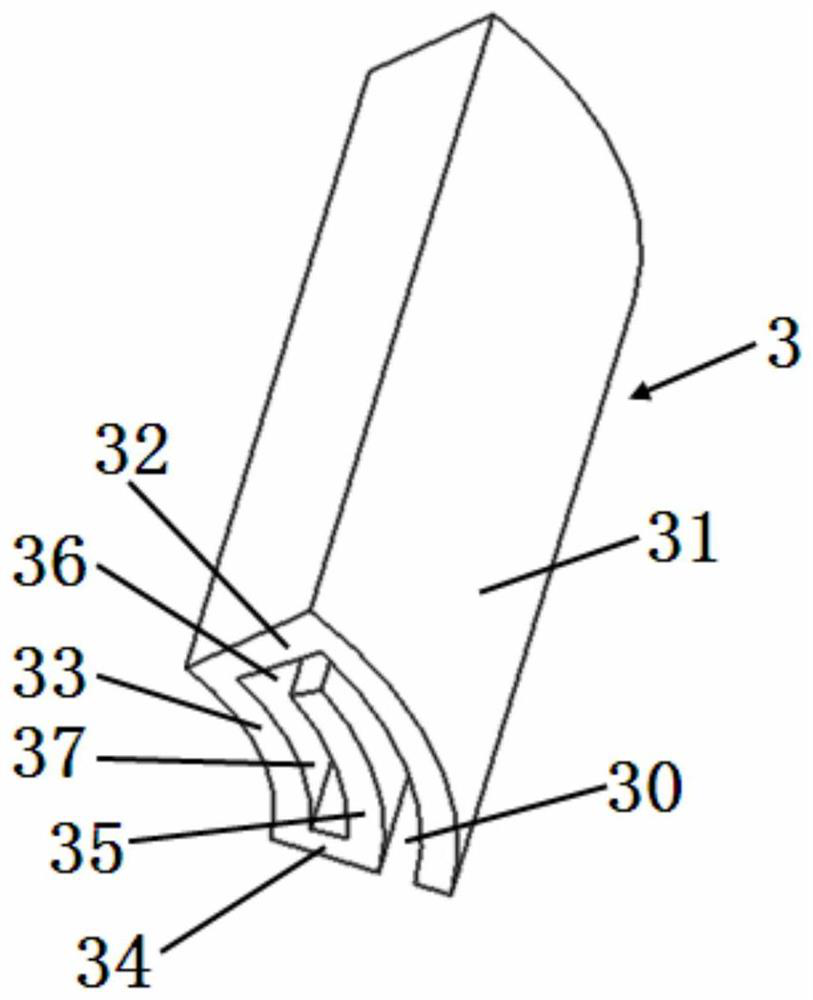

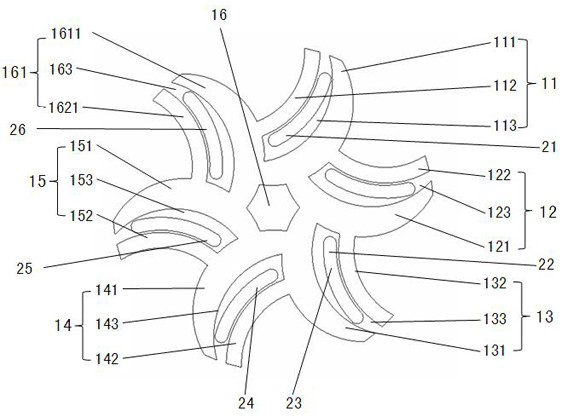

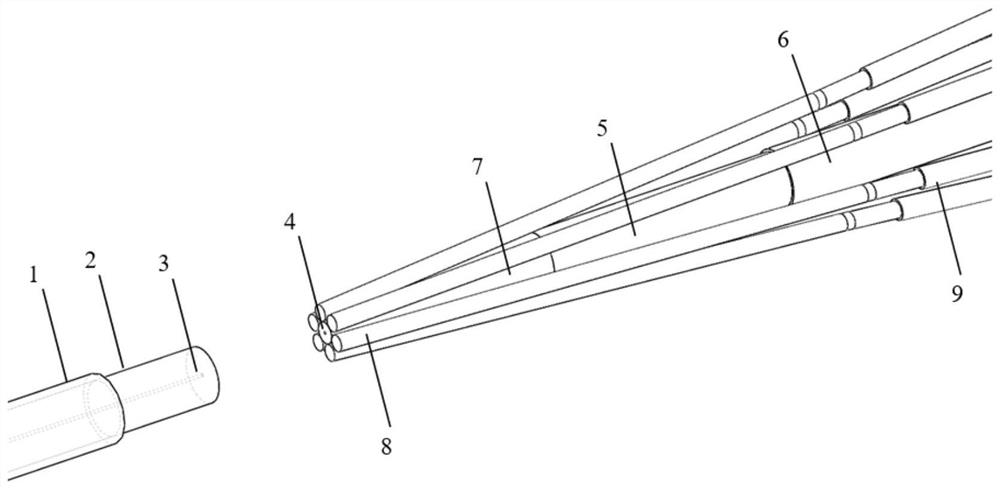

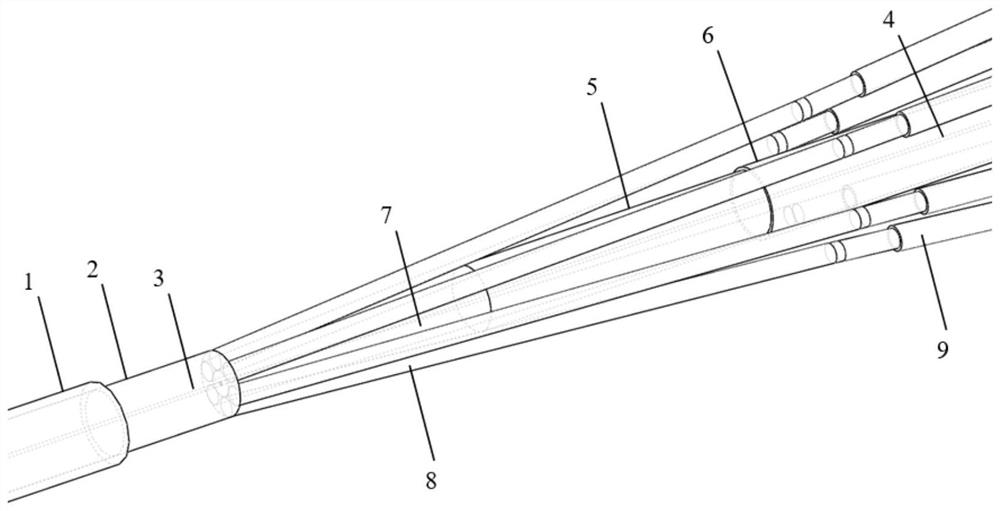

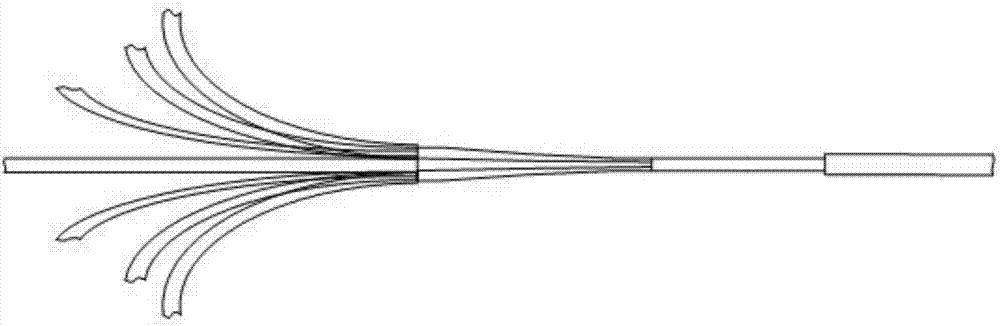

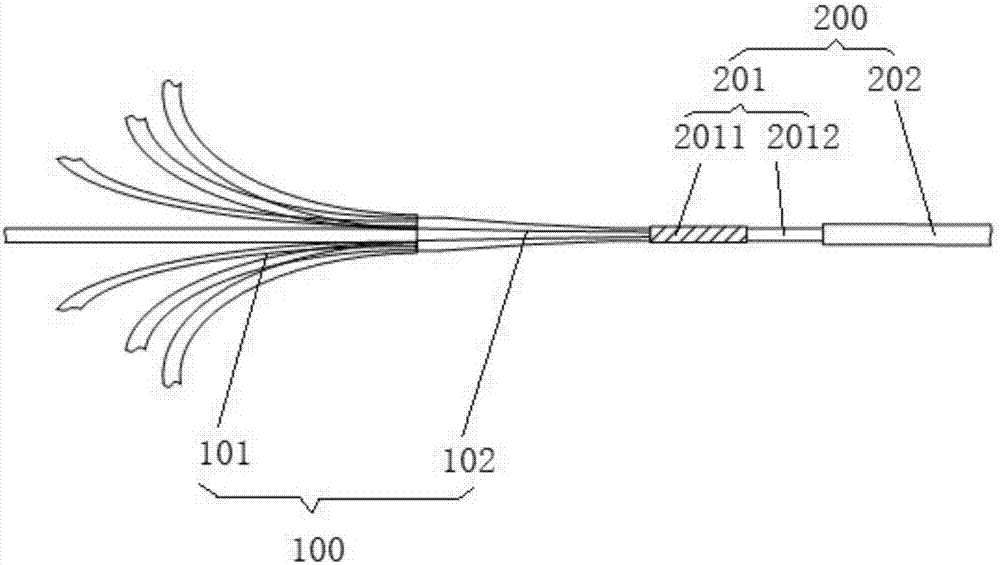

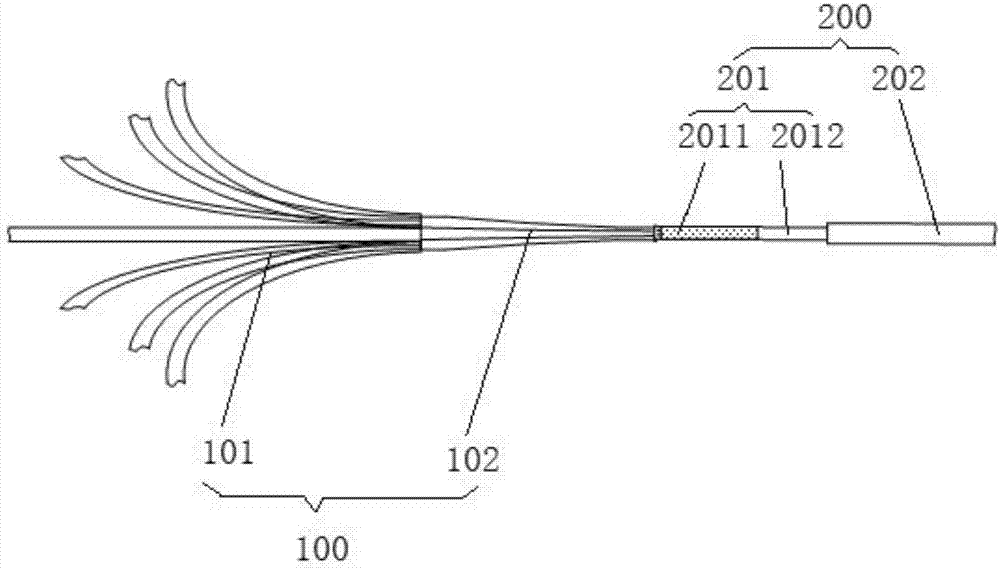

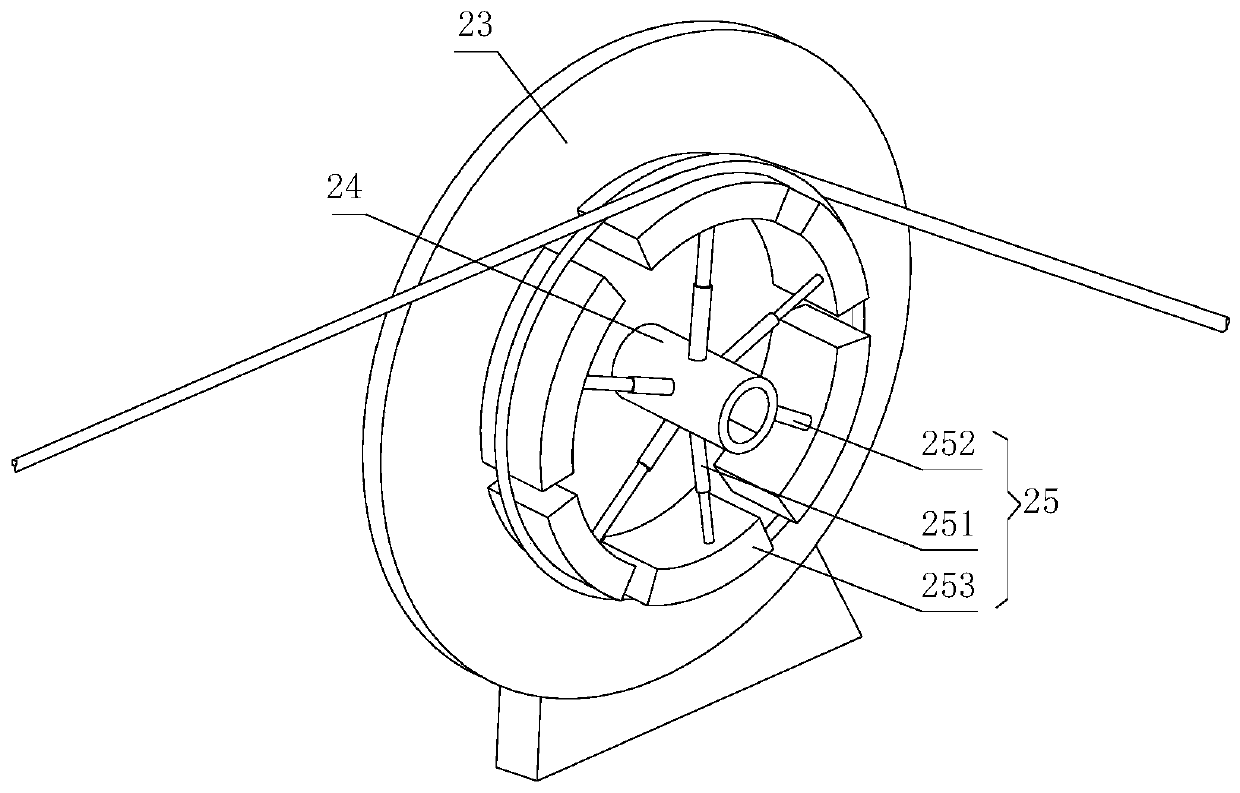

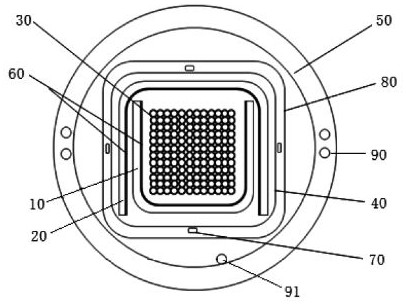

Optical fiber guide type high-power optical fiber cladding light stripper for deep stripping

InactiveCN112213821AAvoid affecting laser transmissionIncrease powerCoupling light guidesActive medium shape and constructionDouble-clad fiberLight guide

The invention discloses a deep-stripping optical fiber guide type high-power optical fiber cladding light stripper. A novel method of guiding leakage through a plurality of optical waveguides is employed, so that most leaked cladding light is not accumulated on a double-cladding transmission optical fiber any more, but is transmitted to any place through the optical fiber for sufficient heat dissipation and dissipation. The stripping depth of the cladding light stripper is controlled through the diameter of the optical fiber cone at the output end of the cladding light stripper and the diameter of the leakage light guide optical fiber, residual pump light in the cladding optical fiber can be filtered out, and a high-order laser mode in the cladding optical fiber can also be filtered out. The light stripper can be suitable for higher bearing power, waste light can be guided to any place through the optical fiber, and thermal management design is more convenient; meanwhile, the problem of high temperature of the double-clad optical fiber in the traditional stripper is avoided, so high-power laser transmission in the fiber core and cladding light stripping in the cladding are safer and more reliable.

Owner:SOUTH WEST INST OF TECHN PHYSICS

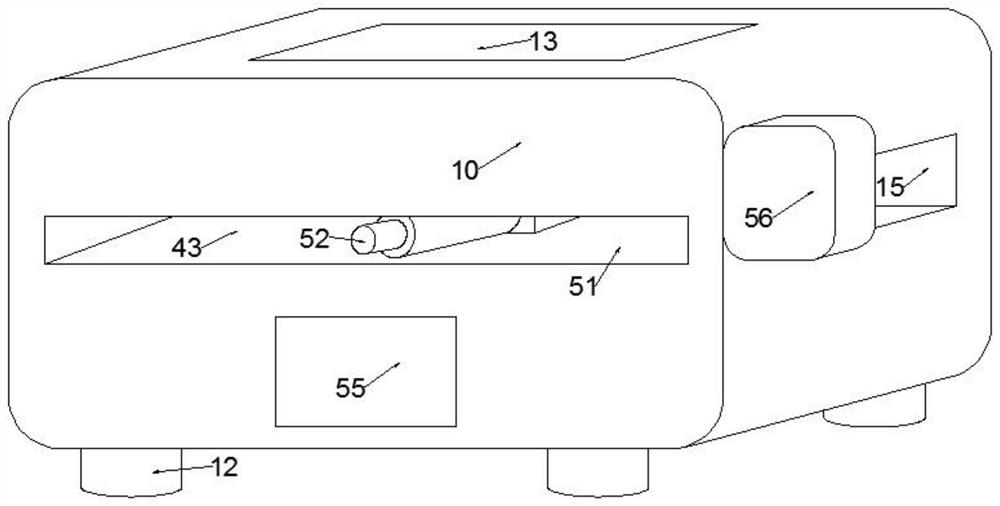

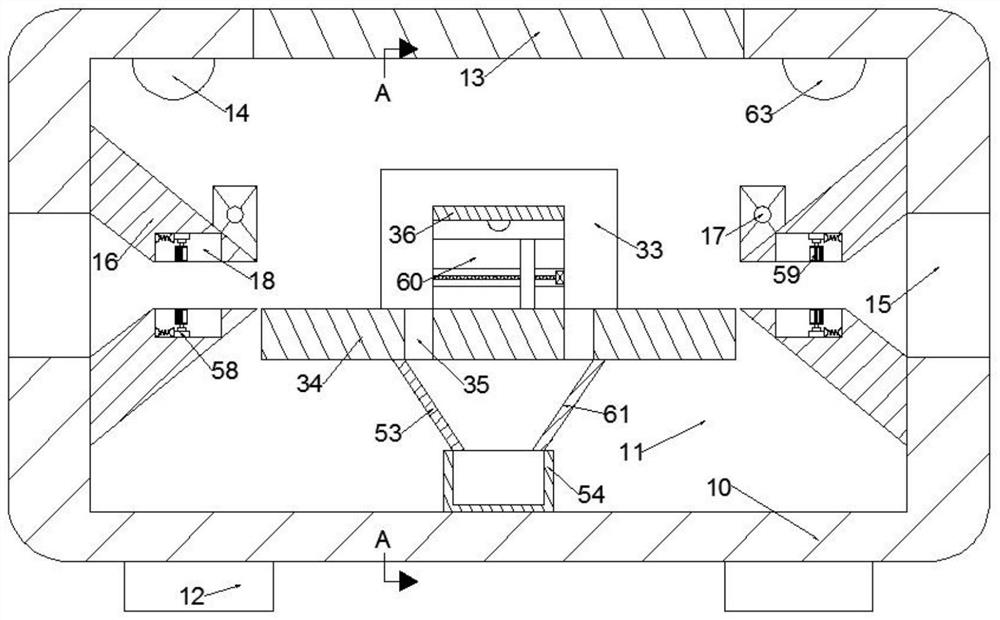

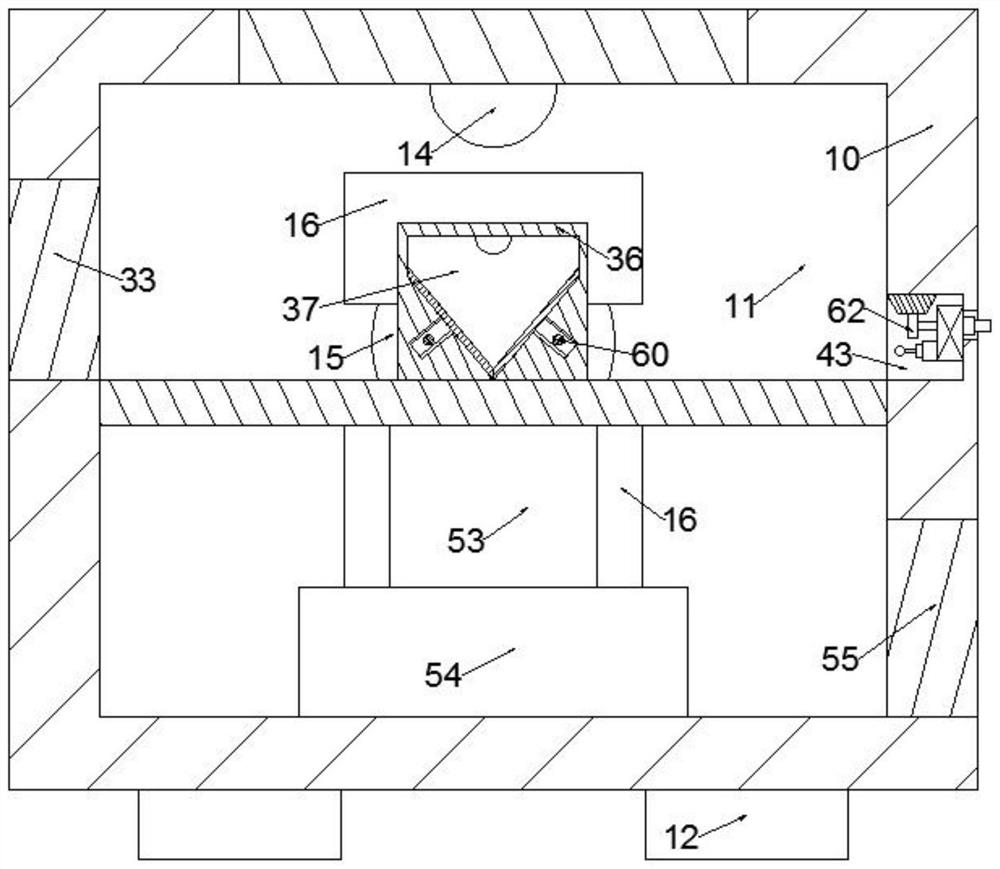

Apparatus for connecting optical fiber to port

InactiveCN112034551AImprove connection efficiencyReduce the number of situations where work cannot be performedCoupling light guidesEngineeringSlide plate

The apparatus for connecting the optical fiber to the port comprises a mounting box, an extending cavity with a leftward opening is formed in the mounting box, a rotating block is rotationally arranged on the outer side circumference of the extending cavity, a movable cavity is formed in the rotating block, and the end, close to the extending cavity, of the movable cavity communicates with the extending cavity; and two sliding plates are fixedly arranged on the inner side wall of the end, away from the extending cavity, of the movable cavity, and the two sliding plates are symmetrical up and down with the extending cavity as the symmetry center. Therefore, cutting and stripping of the outer skin of the optical fiber can be completed without any manpower. According to the apparatus for connecting the optical fiber to the port, the situation that when people peel off the outer skin of an optical fiber cable, work cannot be conducted due to lack of tools is reduced, the situation that thework efficiency is low due to the fact that an optical fiber port is not large is effectively avoided through the arranged installation cavity, and the connection efficiency of the optical fiber andthe port is improved to a large extent.

Owner:YIWU WANJU ELECTRONICS CO LTD

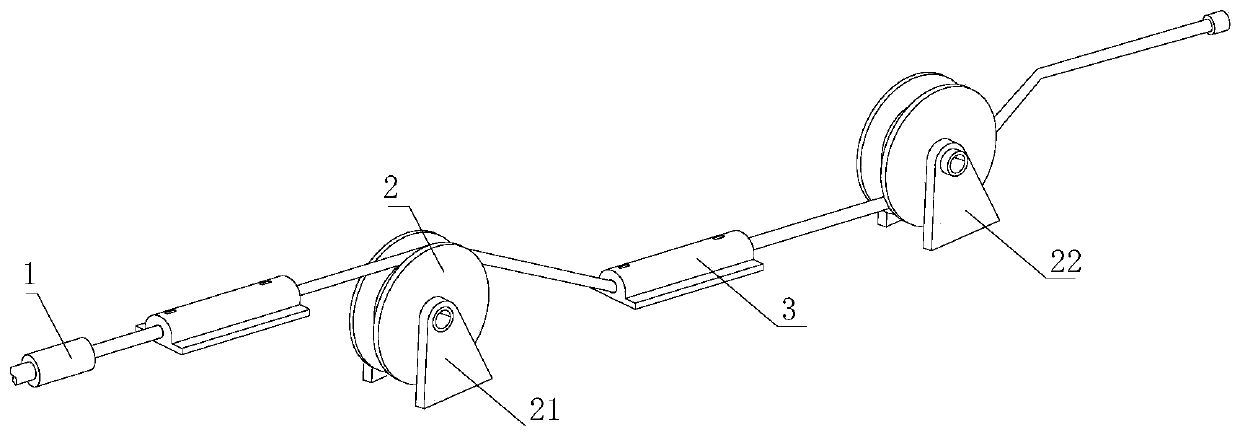

Novel multi-mode pumping optical fiber beam combiner and manufacturing method thereof

PendingCN107515472AReduce thermal effectsIncrease powerExcitation process/apparatusSemiconductor laser excitation apparatusRough surfaceRefractive index

The invention relates to a novel multi-mode pumping optical fiber beam combiner and a manufacturing method thereof. The novel multi-mode pumping optical fiber beam combiner comprises an input optical fiber and an output optical fiber, and the input optical fiber is connected with the output optical fiber in a welded mode; the output optical fiber comprises a coating layer stripping section, the coating layer stripping section is divided into a first section and a second section in the length direction of the coating layer stripping section, the first section is adjacent to the input optical fiber, and a light leakage layer is arranged on the outer surface of the first section and used for filtering away laser in a fluorine-doped layer. According to the beam combiner, the surface of the coating layer stripping section is subjected to roughening treatment or sleeved with quartz glass in a melting mode so that the laser can leak from the high-refractive-index quartz glass or the rough surface, the laser in the fluorine-doped layer is filtered out, therefore the heat effect of the beam combiner is reduced, and the beam combiner can bear higher power.

Owner:四川思创激光科技有限公司

Optical cable and electric cable easy to strip

InactiveCN111158097ACompact structureReduce weightInsulated cablesFibre mechanical structuresEngineeringElectric cables

Owner:常熟虞星光电科技有限公司

High-energy mode-locked fiber laser based on chromium-silicon-tellurium saturable absorber

InactiveCN114024202AStrong nonlinear absorption performanceImprove stabilityActive medium materialActive medium shape and constructionHigh energyNonlinear absorption

The invention discloses a high-energy mode-locked fiber laser based on a chromium-silicon-tellurium saturable absorber, and relates to the technical field of fiber lasers. The implementation of the invention comprises the following steps: S1, adding 1g of chromium-silicon-tellurium nanocrystal into 60ml of 75% ethanol solution to prepare chromium-silicon-tellurium dispersion liquid; and S2, putting the mixture into an ultrasonic cleaning machine to be subjected to ultrasonic stripping for 10 h, and carrying out centrifugation for 30 min in a centrifugal machine with the rotating speed being 1500 rmp. The chromium-silicon-tellurium saturable absorber has very high nonlinear absorption performance and can cover a wide absorption area of mid-infrared visible light, the chromium-silicon-tellurium saturable absorber has the advantages of being high in stability, not prone to being oxidized and capable of achieving laser mode locking operation for a long time, chromium-silicon-tellurium is prepared through a liquid phase stripping method, the process is simple, and when in use, only the chromium-silicon-tellurium film needs to be transferred to the end face of the optical fiber connector, and the operation is convenient.

Owner:台州同合激光科技有限公司

High-power fiber laser indication light protection device and implementation method thereof

ActiveCN111596408ATimely removalFree from damageCoupling light guidesFibre mechanical structuresErbium lasersMaterials science

The invention discloses a high-power fiber laser indication light protection device and an implementation method thereof, and belongs to the fiber laser field; the device comprises an indicating lightlaser, optical fiber winding mechanisms and cladding light stripping mechanisms, an optical fiber connected to the indicating light laser is connected with the two sets of optical fiber winding mechanisms and the cladding light stripping mechanisms, the optical fiber winding mechanisms are used for changing the winding diameter of an optical fiber and the bending angle change of the optical fiber, fiber core light in the optical fiber enters a cladding from a fiber core, and the optical fiber winding mechanisms convert the fiber core light into cladding light. Reverse fiber core light and cladding light of the high-power optical fiber laser can be effectively stripped through two cladding light stripping mechanisms and step-by-step stripping, the indication light laser is protected against damage, and attenuation of the intensity of indication light cannot be caused.

Owner:GW (SHANGHAI) LASER TECH CO LTD

Rubber-covered wire optical cable easy to strip

ActiveCN113064239AAvoid damageAvoid \"broken fiber\" phenomenonFibre mechanical structuresEngineeringContinuous operation

The invention relates to a rubber-covered wire optical cable easy to strip, which comprises a sheath with a rectangular cross section, wherein an optical fiber unit is coated at the middle part in the sheath, reinforcers are arranged at two sides in the sheath and correspond to the optical fiber unit, and grooves contracting from outside to inside are arranged at the middle parts of the upper and lower surfaces outside the sheath corresponding to the optical fiber unit. The optical cable is characterized in that the bottom of the groove reaches or is close to the optical fiber unit to form a deep groove, the deep groove is filled with a separation filling layer, and the resin material of the separation filling layer is different from the resin material of the sheath. According to the invention, when the sheath is subjected to external stress or self-contraction, the top point of the bottom of the groove body extrudes the optical fiber, so that the attenuation of the optical fiber is prevented from being increased; and the stripping performance of the sheath of the rubber-covered wire optical cable is improved, so that the continuous operation is convenient, the fiber protection performance is good, the defect that the sheath is difficult to strip due to bonding of the sheath layer and the optical fiber unit can be avoided, and the phenomena of damage to the optical fiber unit and fiber breakage in the stripping process are avoided.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Optical fiber stripping solution and preparation method thereof, and optical fiber stripping method

The invention relates to optical fiber stripping solution and a preparation method thereof, and an optical fiber stripping method. The optical fiber stripping solution comprises chloroform, formic acid, acetophenone, paraffin, benzoic acid and a thickener. The optical fiber stripping method comprises the following steps of: heating the optical fiber stripping solution to 40 to 50 DEG C, soaking a strip optical fiber needing to be stripped in the optical fiber stripping solution for 2 to 3 seconds, taking out, waiting for 2 to 4 seconds for full reaction, and cleaning the optical fiber to remove an encapsulating layer. By the method, the encapsulating layer of the optical fiber can be quickly removed, the optical fiber is completely stripped, and a fiber core, a cover layer and a coating layer are not damaged, so that the optical fiber is prevented from being broken or damaged in the stripping process; and compared with the conventional manual stripping process, the method improves the speed by 30 times, saves a large amount of labor and improves production efficiency.

Owner:SHANGHAI HUIJUE NETWORK COMM EQUIP

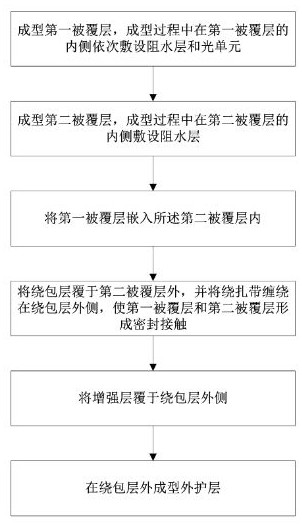

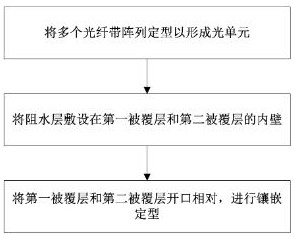

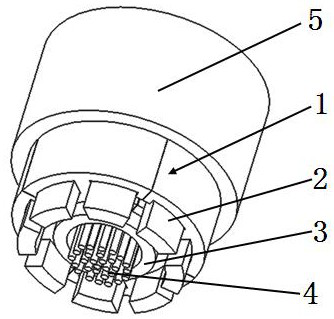

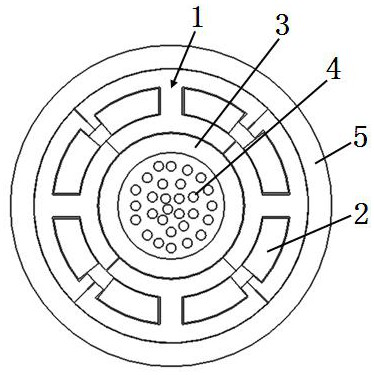

Optical fiber ribbon cable and manufacturing method thereof

ActiveCN114879329ALow tear strengthGuaranteed stabilityFibre mechanical structuresRibbon cableEngineering

The invention provides an optical fiber ribbon cable and a manufacturing method thereof. The optical fiber ribbon cable comprises: a coating layer comprising a first coating layer and a second coating layer, the first coating layer being detachably accommodated in the second coating layer and cooperating with the second coating layer to form an installation cavity; the light unit is mounted in the mounting cavity; the wrapping layer is wound on the second coating layer; and an outer protection layer which is coated on the outer side of the wrapping layer. The first coating layer and the second coating layer are both of a U-shaped structure, the opening end of the first coating layer is embedded into the second coating layer, and the opening of the first coating layer and the opening of the second coating layer are opposite in direction; the wrapping layer is wound around the periphery of the second coating layer in the axial direction of the optical unit and applies extrusion acting force to the second coating layer so that the second coating layer and the first coating layer can form sealing fit. The optical fiber ribbon optical cable of the technical scheme can solve the problem of low connection efficiency caused by difficult stripping of the existing optical cable.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Central beam tube type optical cable and central beam tube type ribbon optical cable

ActiveCN113640932AReduce investmentSimple structureFibre mechanical structuresBeam tubeStructural engineering

The invention belongs to the technical field of communication optical cables, and discloses a central beam tube type optical cable, which is provided with a plurality of accommodating components, a plurality of reinforcing components, a central loose tube, a plurality of light-guide fibers and an outer sheath, the light-guide fibers are positioned in the central loose tube, the reinforcing components are positioned outside the central loose tube, the reinforcing components are positioned in the accommodating components, the accommodating components are located outside the central loose tube, and the outer sheath is located outside the accommodating components; the optical cable is characterized in that the accommodating components are of an integrated structure and has a special structure; and the upper surfaces of the accommodating components are attached to the outer wall of the central loose tube, and all the accommodating components wrap the periphery of the outer wall of the central loose tube. The invention also discloses a central beam tube type ribbon optical cable. The cable has the main beneficial effects of simple structure, easiness in manufacturing, stripping and heat dissipation, higher communication density, more stable and reliable product quality and less production equipment investment.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD

Axial stripping and lateral wire arrangement continuous optical cable stripping device

PendingCN113031178AAvoid damageConvenient for centralized processingFibre mechanical structuresStructural engineeringMechanical engineering

The invention discloses an axial stripping and lateral wire arrangement continuous optical cable stripping device, which comprises a protective sleeve cutting assembly, a reinforcer removing assembly, an optical fiber traction assembly and a shell, and is characterized in that the protective sleeve cutting assembly is fixedly connected with the shell, the protective sleeve cutting assembly is located at one side of the shell, the reinforcer removing assembly is located in the shell, the reinforcer removing assembly is connected with the protective sleeve cutting assembly, one part of the optical fiber traction assembly extends into the shell, one end, extending into the shell, of the optical fiber traction assembly is fixedly connected with the reinforcer removing assembly, and the partial side edge, located outside the shell, of the optical fiber traction assembly is fixedly connected with the shell. According to the invention, the layer-stranded optical cable is reversely unwound according to an original winding angle by the reinforcer removing assembly, so that a steel wire serving as a reinforcer can be separated from an optical fiber; and the inner diameter can be freely adjusted by the inner diameter adjusting component, so that optical cables with different diameters can be stripped by the stripping device.

Owner:马泽睿

Combined optical fiber welding operation box

InactiveCN114460690AImprove welding efficiencyImprove efficiencyCleaning using toolsCoupling light guidesBare fiberEngineering

The invention provides a combined optical fiber welding operation box which comprises a shell, a cavity is formed in the shell, and a stripping mechanism, a second cleaning mechanism, a first cleaning mechanism, a collecting mechanism, a cutting mechanism and a monitoring mechanism are arranged in the cavity. According to the invention, optical fibers can be automatically fused, the fusion splicing efficiency of the optical fibers is improved, meanwhile, an optical fiber jacket can be automatically stripped through the stripping latch, manual stripping of the optical fibers is avoided, the fusion splicing efficiency is improved, the working intensity of workers is reduced, bare fibers are automatically cleaned through the arc-shaped cotton slivers, and the labor intensity of the workers is reduced. A coating layer which is not easy to clean on the surface of a bare fiber is removed, the optical fiber can be automatically or manually cut through the motor and the cutting knife, an operator can select different cutting modes according to different environments, and finally, the interior of the fusion splicer can be automatically cleaned through the scraper before the bare fiber is fused.

Owner:鲍丽娜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com