Optical cable and electric cable easy to strip

An optical cable and stripping technology, applied in the field of optical cables and cables that are easy to open and strip, can solve the problems of optical fiber breakage, inconvenient heat dissipation, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

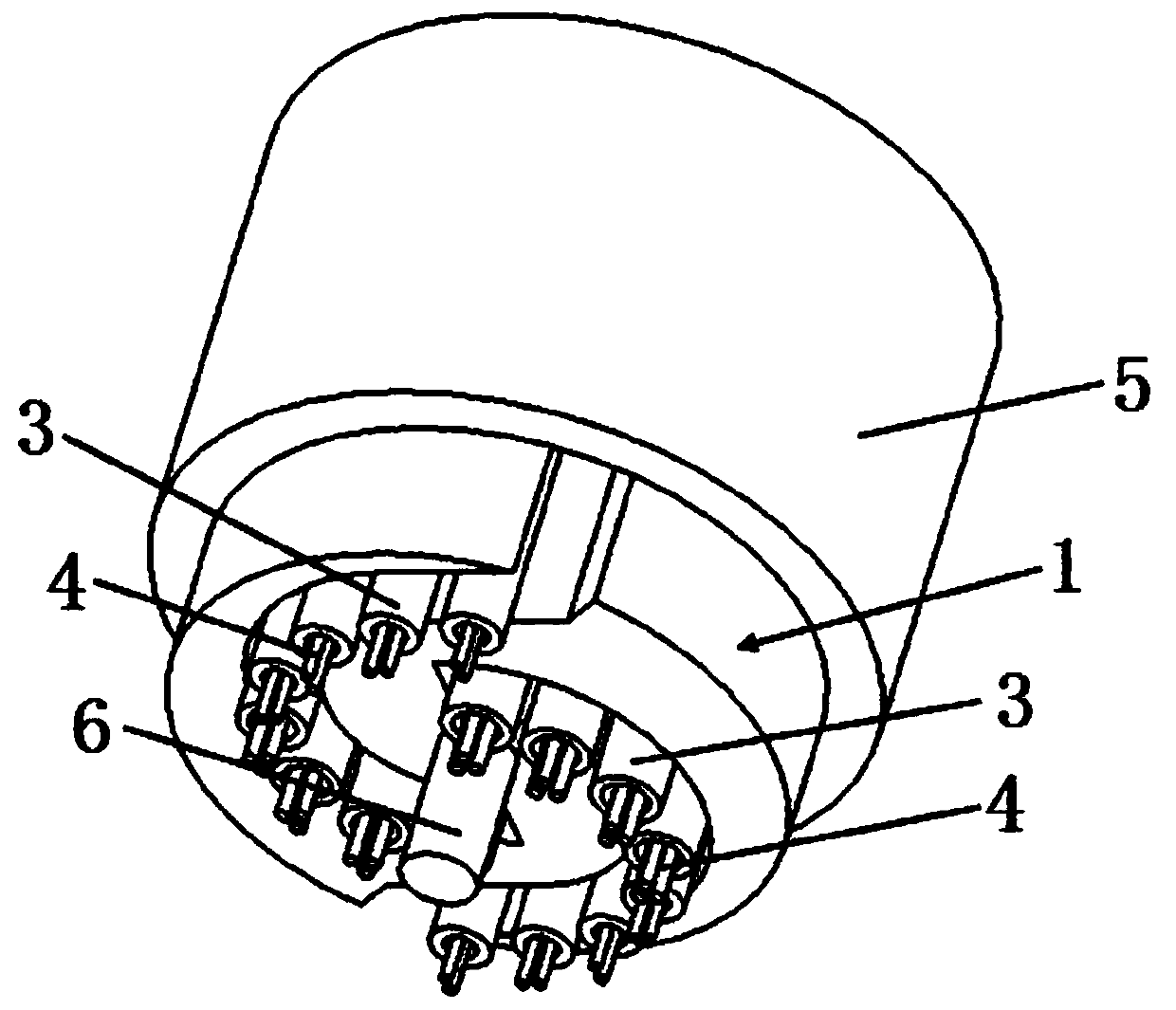

[0046] please see Figure 1 to Figure 4 , and see Figure 5 to Figure 9 , an optical cable that is easy to peel, has a support body 1, an outer sheath 5 covering the support body, a reinforcement member 6 located in the center of the support body, and a plurality of loose tubes 3 located in the support body, each loose There is an optical fiber 4 in the sleeve; it is characterized in that the stent body 1 is composed of a first stent body 11, a second stent body 12, and a body connecting portion 13, and the first stent body 11 is located on the left side of the body connecting portion 13, The second bracket body 12 is located on the right side of the body connecting part 13, the lower right part of the first bracket body 11 is connected with the lower part of the body connecting part 13, and the upper left part of the second bracket body 12 is connected with the upper part of the body connecting part 13. , the body connecting portion 13 is formed by combining two semi-cylindr...

Embodiment 2

[0052] please see Figure 10 with Figure 11 , and refer to Figure 1 to Figure 9 , a cable that is easy to peel, has a support body 1, an outer sheath 5 covering the support body, a reinforcement member 6 located in the center of the support body, a plurality of first power transmission units 21 located in the support body, and a plurality of first power transmission units 21 located in the support body. Two power transmission units 22, multiple third power transmission units 23, and multiple fourth power transmission units 24; it is characterized in that the support body 1 is composed of a first support body 11, a second support body 12, and a body connecting part 13. A bracket body 11 is positioned at the left side of the body connecting portion 13, and a second bracket body 12 is positioned at the right side of the body connecting portion 13. The upper left part is connected with the upper part of the main body connecting part 13, and the main body connecting part 13 is ...

Embodiment 3

[0057] please see Figure 12 to Figure 14 , and refer to Figure 1 to Figure 11 , an optical cable that is easy to peel, has a support body 1, an outer sheath 5 covering the support body, a reinforcement member 6 located in the center of the support body, a first power transmission unit 21 and a second power transmission unit 22 located in the support body , a plurality of loose tubes 3, optical fibers 4 positioned in the loose tubes; it is characterized in that the support body 1 is composed of a first support body 11, a second support body 12, and a body connecting portion 13, and the first support body 11 is located on the left side of the body connecting portion 13, and the second bracket body 12 is positioned on the right side of the body connecting portion 13. The lower right part of the first bracket body 11 is connected with the lower part of the body connecting portion 13, and the upper left part of the second bracket body 12 is connected to the bottom of the body con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com