Method for simulating temperature field in carbon fiber material release agent based on laser cleaning stripping

A carbon fiber material, laser cleaning technology, used in 3D modeling, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

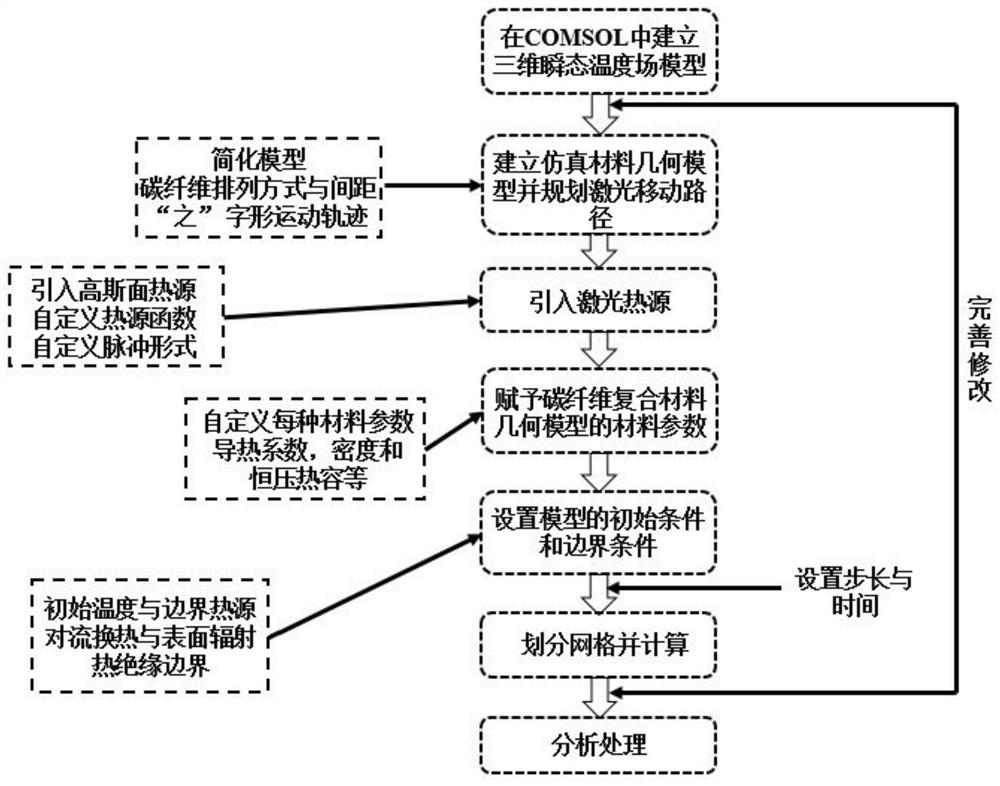

Method used

Image

Examples

Embodiment 2

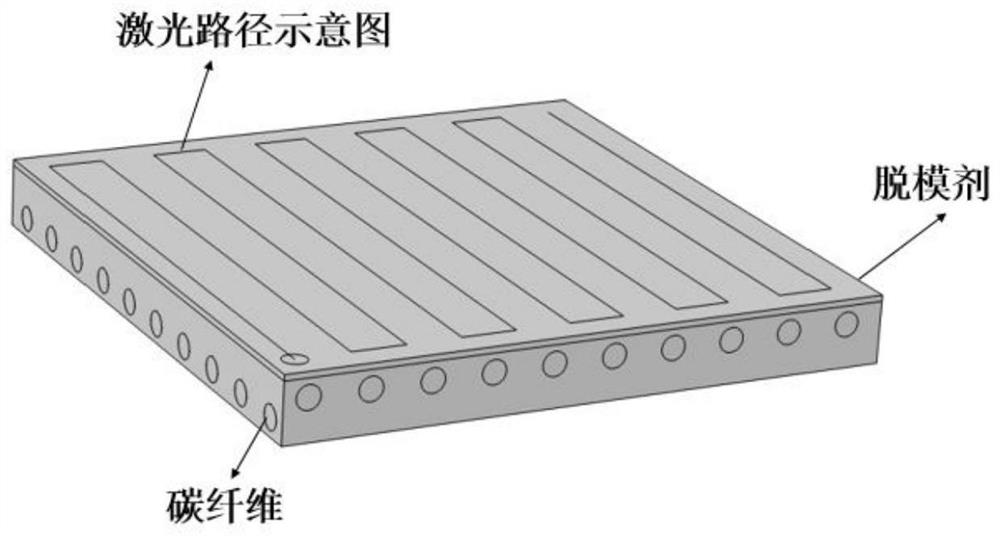

[0087] (1) Establishment of geometric model

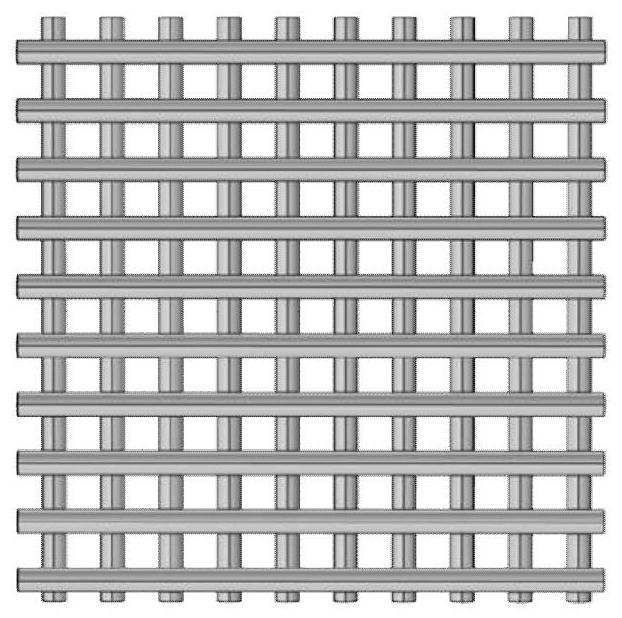

[0088] A cuboid with a size of 10mm×10mm×1.1mm is set to represent the geometric model of the simulated release agent. In the layer option, set the top 0.1mm as the release layer. Set the carbon fiber size of a single 0° alignment as a long cylinder with a radius of 0.2mm and a height of 10mm. Using the array option, a single carbon fiber is distributed along the x-axis direction into 10 identical long cylinders, each with an interval of 1mm. In the same way, when setting a single 90°-aligned carbon fiber of the same size, use the array option to distribute a single carbon fiber along the y-axis direction in 10 identical long cylinders, each with an interval of 1mm. The carbon fibers arranged in the 0° direction and the 90° direction are selected to be "merged", so that the two are closely connected, simulating the vertical weaving method of the actual resin-based carbon fiber composite material, and evenly distributed in the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com