Experimental device for researching influence of roughness on heat transfer of wall surface of spray pipe

An experimental device and roughness technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as uncertainty and difficulty in ensuring the consistency of gas parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

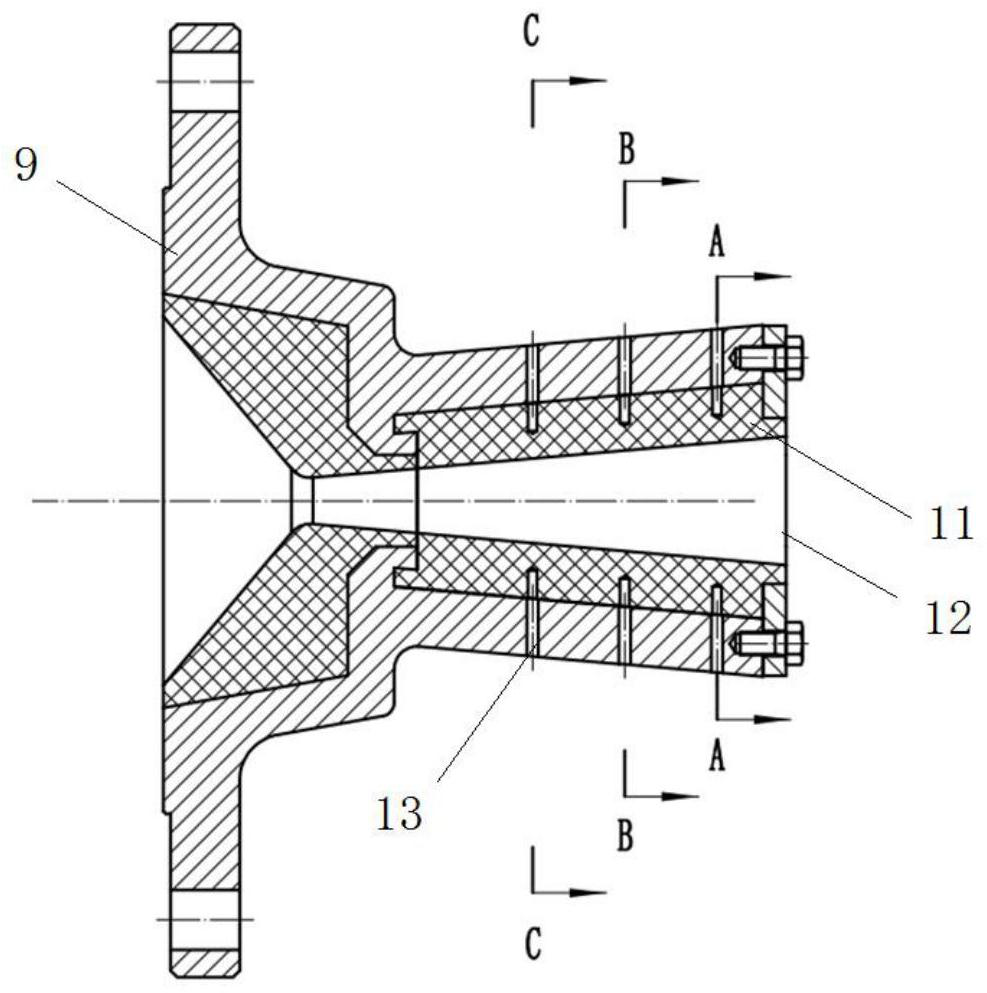

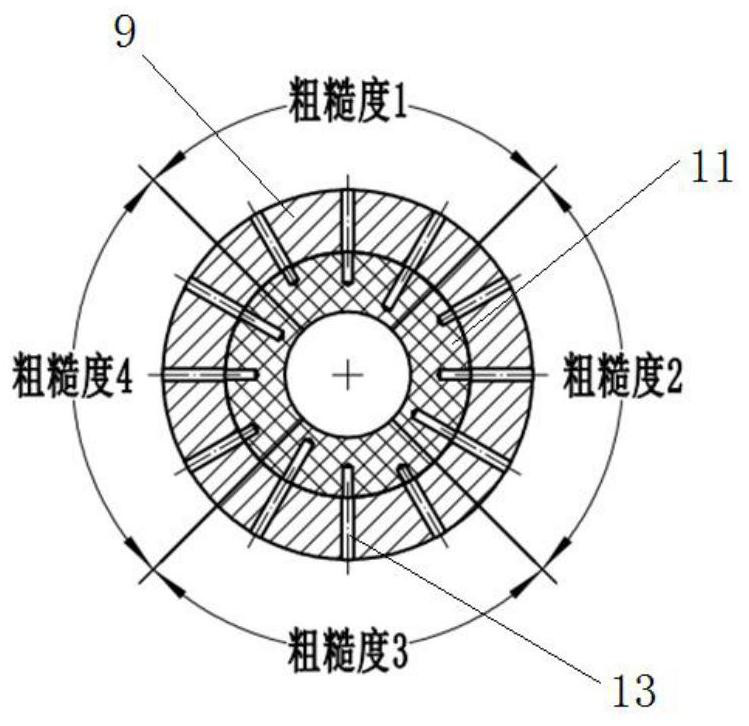

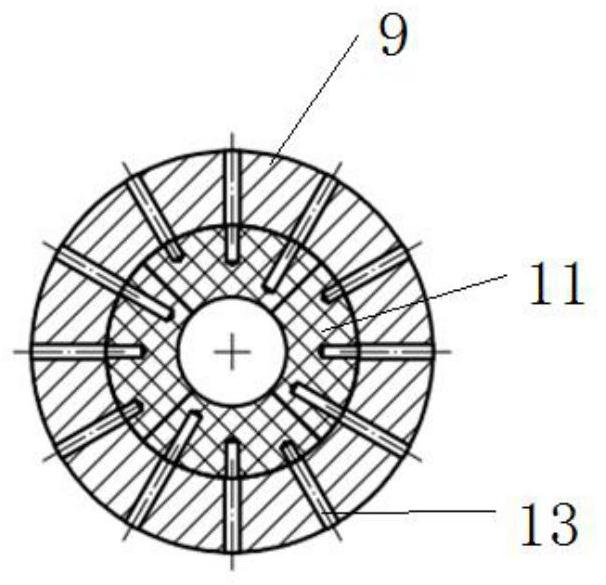

[0038] The expansion section of the nozzle is spliced by four graphite temperature measuring parts with different surface roughness, and the parts are bonded with high temperature resistant epoxy resin to achieve the sealing effect. Four graphite temperature measuring parts with different roughness are evenly distributed in the circumferential direction to form a complete nozzle expansion section. At the same time, temperature measuring points of different depths are arranged at different expansion ratio sections along the axial direction of the expansion section, such as figure 1 In the three sections of A, B, and C, the thermocouple at the temperature measuring point can measure the change rate of the internal temperature of the nozzle wall with the engine working time during the engine working process. After the splicing of the nozzle, it is placed in the nozzle casing as a whole. The nozzle casing is made of steel material, which can ensure the overall strength. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com