Central beam tube type optical cable and central beam tube type ribbon optical cable

A bundled tube and optical cable technology, which is applied in the field of central bundled tube optical cable and central bundled tube ribbon optical cable, can solve the problems of electrical heating affecting optical fiber communication, difficulty in recovering costs, and the need for production personnel, so as to achieve stable and reliable product quality. , The effect of less investment in production equipment and higher communication density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

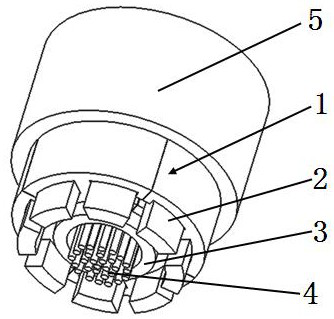

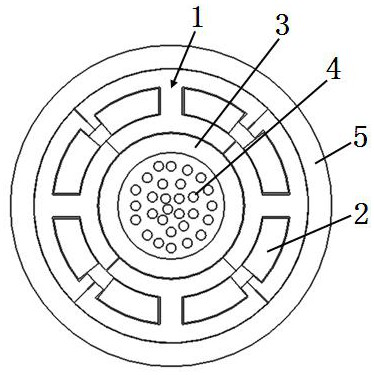

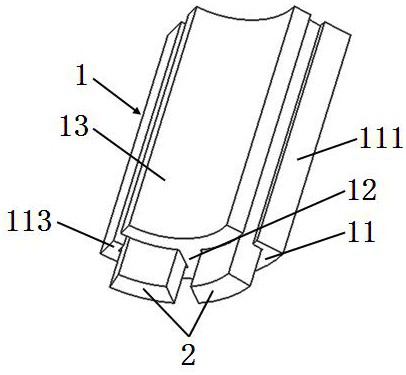

[0028] please see Figure 1 to Figure 4 , a central bundle tube type optical cable, has four accommodating parts 1, a plurality of strengthening parts 2, a central loose tube 3, a plurality of optical fibers 4, and an outer sheath 5, and the optical fiber 4 is located in the central loose tube 3 , the reinforcing part 2 is located outside the central loose tube 3, the reinforcing part 2 is located in the housing part 1, the housing part 1 is located outside the central loose tube 3, and the outer sheath 5 is located outside the housing part 1; its characteristics That is: the accommodating part 1 is composed of a first arc-shaped part 11, a connecting part 12, a second arc-shaped part 13, a first limiting part 111, and a second limiting part 113. The first arc-shaped part 11 and the second The two arc parts 13 are all in the shape of an arc cylinder, and the connecting part 12 is located between the first arc part 11 and the second arc part 13 and connects the two together. Th...

Embodiment 2

[0038] please see Figure 5 to Figure 8 ,refer to Figure 1 to Figure 4 , a central bundle tube type ribbon optical cable, which is basically the same as that of Example 1, except that: one of them is that the first accommodating chamber 112 and the second accommodating chamber 114 all have surrounding loose tubes 6, and the surrounding There are multiple light guide fibers 7 in the loose tube 6; there is at least one loose tube around each first accommodating cavity or in each second accommodating cavity; the second is: there is no central loose tube, all The upper surface of the second arc-shaped part 13 of the accommodating part 1 encloses a central cavity; in the central cavity there are a plurality of optical fiber ribbons 8 stacked together, and each optical fiber ribbon 8 has a plurality of optical conductors 9 in it.

[0039] That is: a central bundle tube type ribbon optical cable, which has a plurality of accommodating parts 1, a plurality of surrounding loose tubes...

Embodiment 3

[0041] please see Figure 9 ,refer to Figure 1 to Figure 8 , a central bundle tube type ribbon optical cable, basically the same as the implementation example 1, the difference is that: one of them is: there is no reinforcing part 2, and there are surroundings in the first accommodating cavity 112 and the second accommodating cavity 114. The loose tube 6 has a plurality of light guide fibers 7 in the surrounding loose tube 6; each first accommodating cavity or each second accommodating cavity has at least one surrounding loose tube 6; the second is: the center The loose tube 3 has a plurality of optical fiber ribbons 8 stacked together, and each optical fiber ribbon 8 has a plurality of optical conductors 9 in it.

[0042] That is: a central bundle tube type optical cable, which has four accommodating parts 1, a central loose tube 3, a plurality of surrounding loose tubes 6, a plurality of optical fibers 7, a plurality of optical fiber ribbons 8, and a plurality of optical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com