Zero-discharge treatment method of salt-containing organic wastewater

A treatment method and organic wastewater technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as high salt content and high organic wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is used to illustrate the zero discharge treatment method of saline organic wastewater of the present invention.

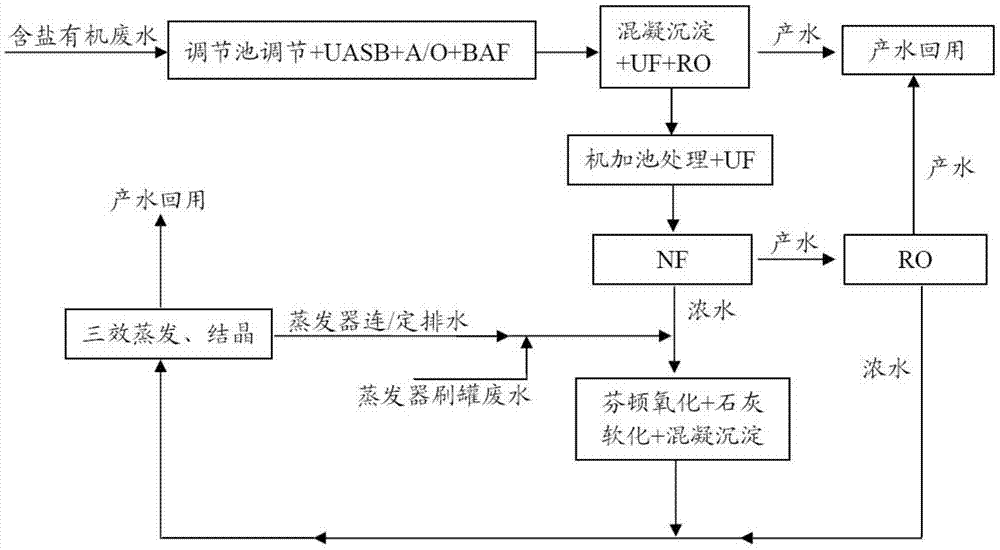

[0044] Such as figure 1 The zero-discharge treatment method for waste water produced by pressurized gasification of crushed coal is shown. The equipment used to implement the method includes a main biochemical treatment unit, a recycling unit, an advanced treatment unit, a Fenton oxidation unit and a three-effect evaporation connected in sequence crystal unit. Among them, the main biochemical treatment unit includes regulating tank, UASB (upflow anaerobic sludge bed), anoxic / aerobic (A / O) treatment tank, biological aerated filter (BiologicalAeratedFilter, BAF), through the main biochemical treatment The process efficiently degrades organic matter. The recycling unit concentrates the waste water through coagulation sedimentation, ultrafiltration and reverse osmosis, and the concentrated product water is reused. The advanced treatment unit inc...

Embodiment 2

[0079] This example is a comparative example, and it differs from Example 1 in that the treatment method of this example does not include a Fenton oxidation unit, and the nanofiltration concentrated water of the advanced treatment unit is mixed with the seawater reverse osmosis concentrated water of the advanced treatment unit Then directly enter the evaporation crystallization unit. In this case, the water inflow to the evaporative crystallization unit is 83m 3 / h, COD is 575mg / L; set the effective volume of the evaporator to 500m 3 , after one month of operation, the COD in the evaporator accumulated to about 68724mg / L, causing serious foam problems, and the high content of calcium and magnesium in the evaporator led to serious scaling problems, which ultimately affected the production load and stability of the evaporator run. The quality of the produced water is reduced, and the saturated saline solution waste water has nowhere to be discharged when cleaning the tank, whi...

Embodiment 3

[0081] This example is used to illustrate another method for zero discharge treatment of saline organic wastewater of the present invention.

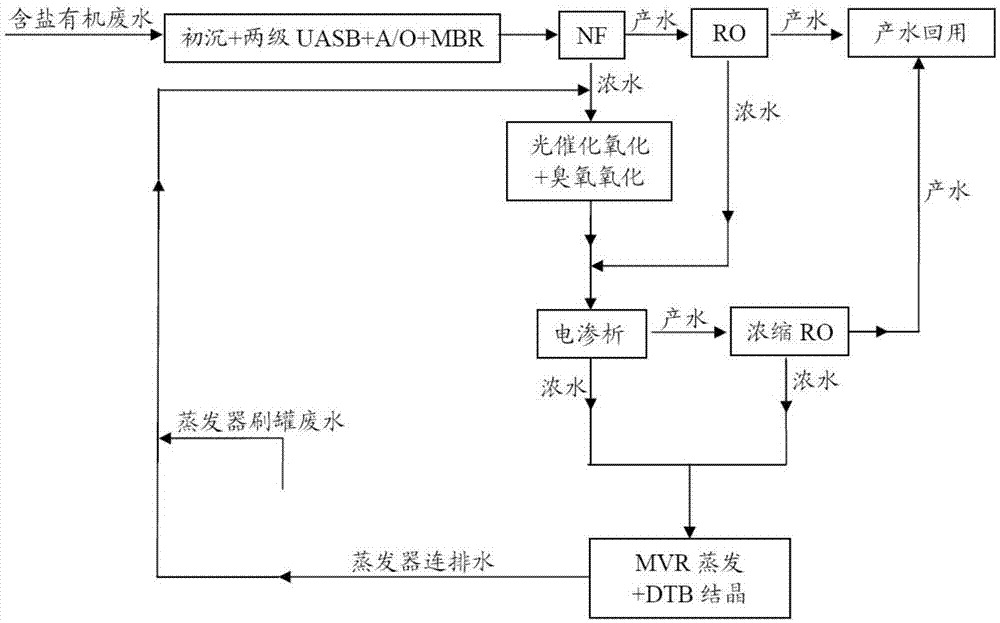

[0082] Such as figure 2 The zero-discharge treatment method for pharmaceutical wastewater shown, the main equipment used to implement the method includes a main biochemical treatment unit, a reuse unit, an advanced oxidation unit, a concentration unit and an evaporation crystallization unit connected in sequence. Among them, the main biochemical treatment unit includes primary sedimentation tank, UASB (two-stage upflow anaerobic sludge bed), A / O unit, and MBR unit to remove suspended solids and organic matter; the recycling unit includes nanofiltration, reverse osmosis, etc. The unit concentrates the salt-containing organic wastewater and obtains pure product water, which is recycled; the advanced oxidation unit includes a combination unit of ozone oxidation and photocatalytic oxidation to treat the evaporation of nanofiltration concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com