Saturable absorber based on palladium telluride, preparation method and mode-locked fiber laser prepared from saturable absorber

A technology of saturable absorption and fiber lasers, applied in the field of passive mode-locked ultrafast fiber lasers, which can solve the problems of low optical damage threshold, easy oxidation, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

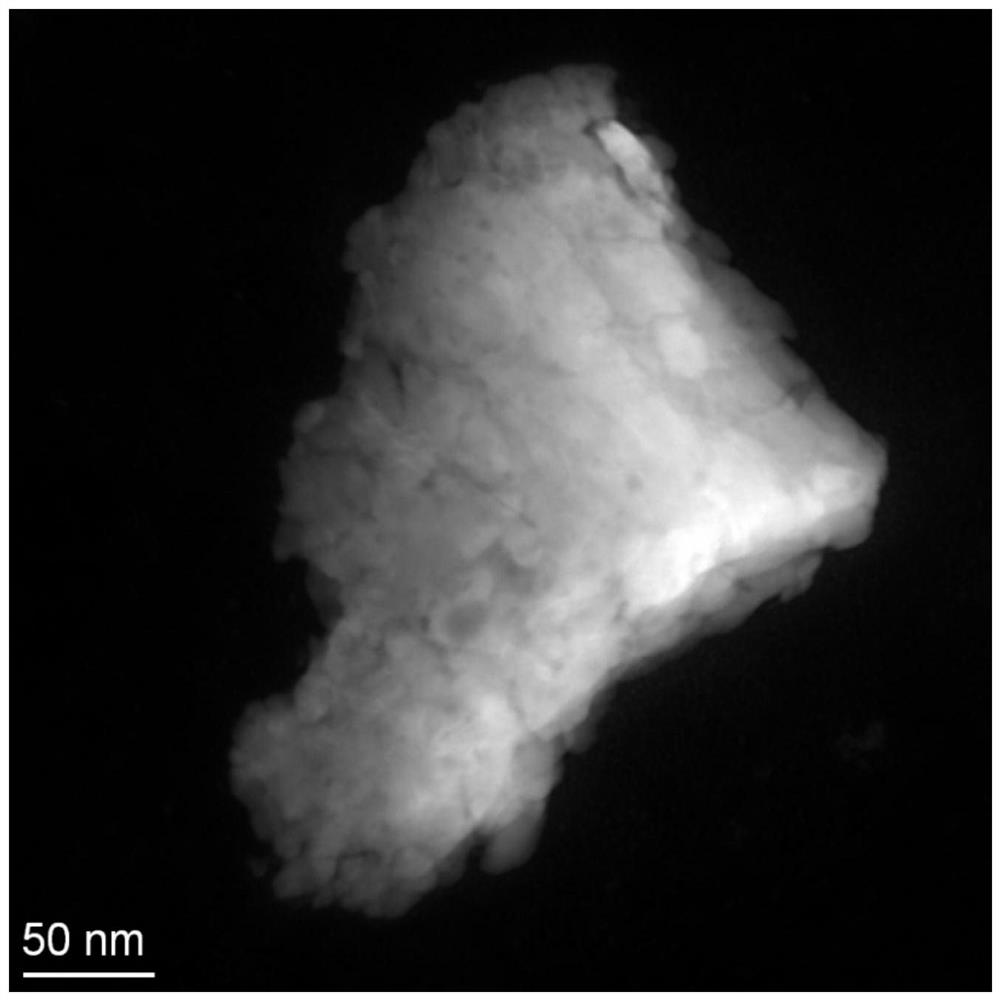

[0030] Step 1: Put 20 mg of palladium ditelluride powder into 40 milliliters of N-methylpyrrolidone (NMP) solution, sonicate for 36 hours in a high-power (400W) continuous ultrasonic cleaner, then centrifuge at 2000 rpm for 3 minutes, remove palladium ditelluride nanosheets with more layers, and take the supernatant to obtain a solution of palladium ditelluride nanosheets.

[0031] Step 2: Take 3 milliliters of the palladium ditelluride nanosheet solution obtained above, then put 1 milliliter of 4wt% polyvinyl alcohol (PVA) solution into ultrasonic vibration for 5 minutes to make it mix evenly, and then pour the mixed solution into a disposable petri dish and placed in a drying oven to dry at 60°C for more than 24 hours, and the film was taken out with tweezers after cleaning with alcohol to obtain a saturable absorber based on palladium ditelluride, which was cut into small pieces of 2×2mm, and then Transfer to fiber end face.

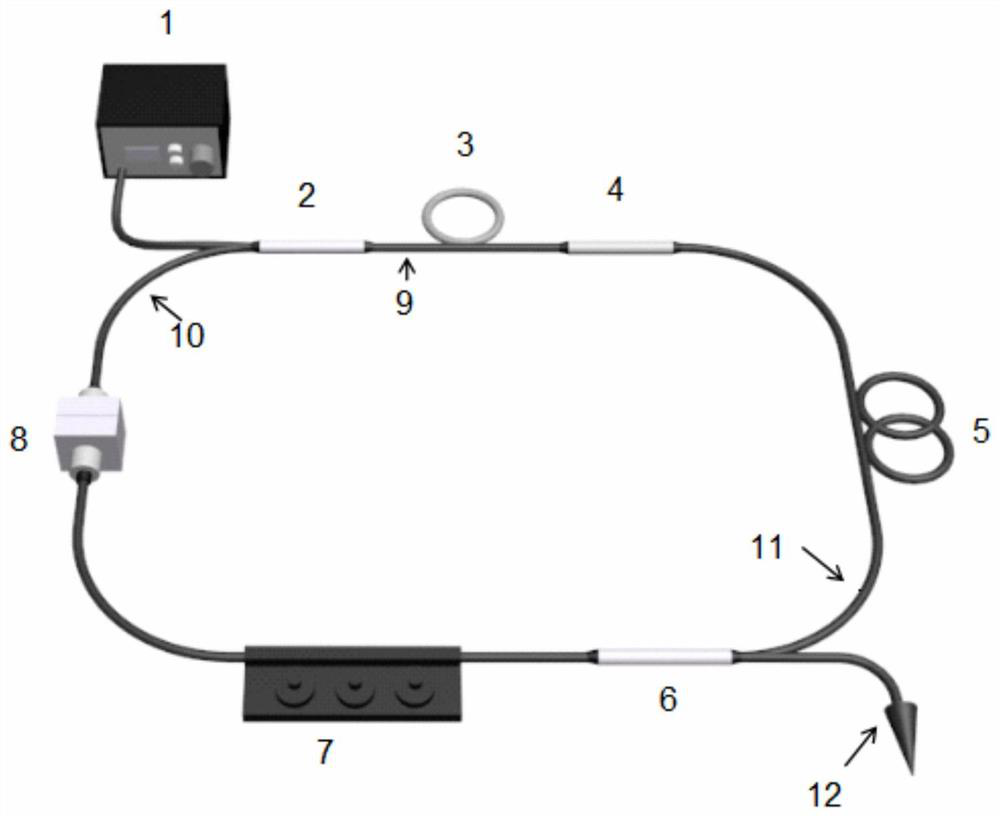

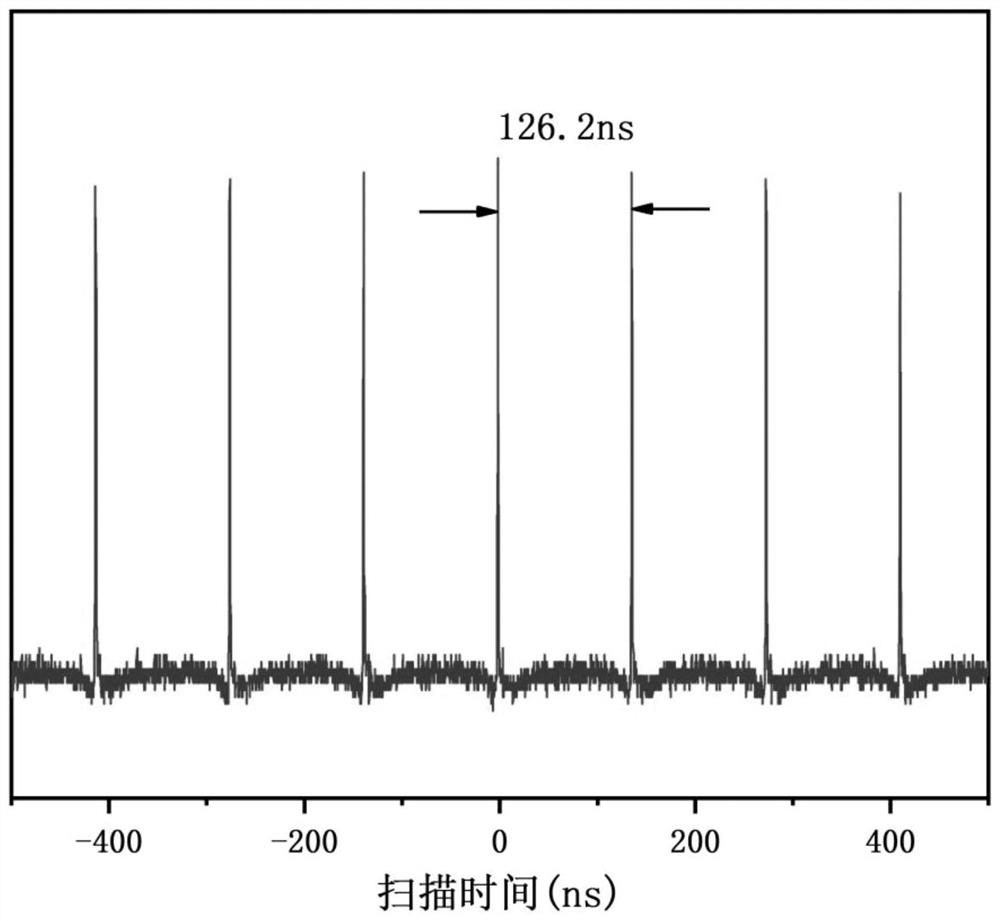

[0032] Such as figure 1 As shown, the mode-lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com