Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

862 results about "Tweezers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tweezers are small tools used for picking up objects too small to be easily handled with the human fingers. The word is most likely derived from tongs, pincers, or scissors-like pliers used to grab or hold hot objects since the dawn of recorded history. In a scientific or medical context they are normally referred to as forceps.

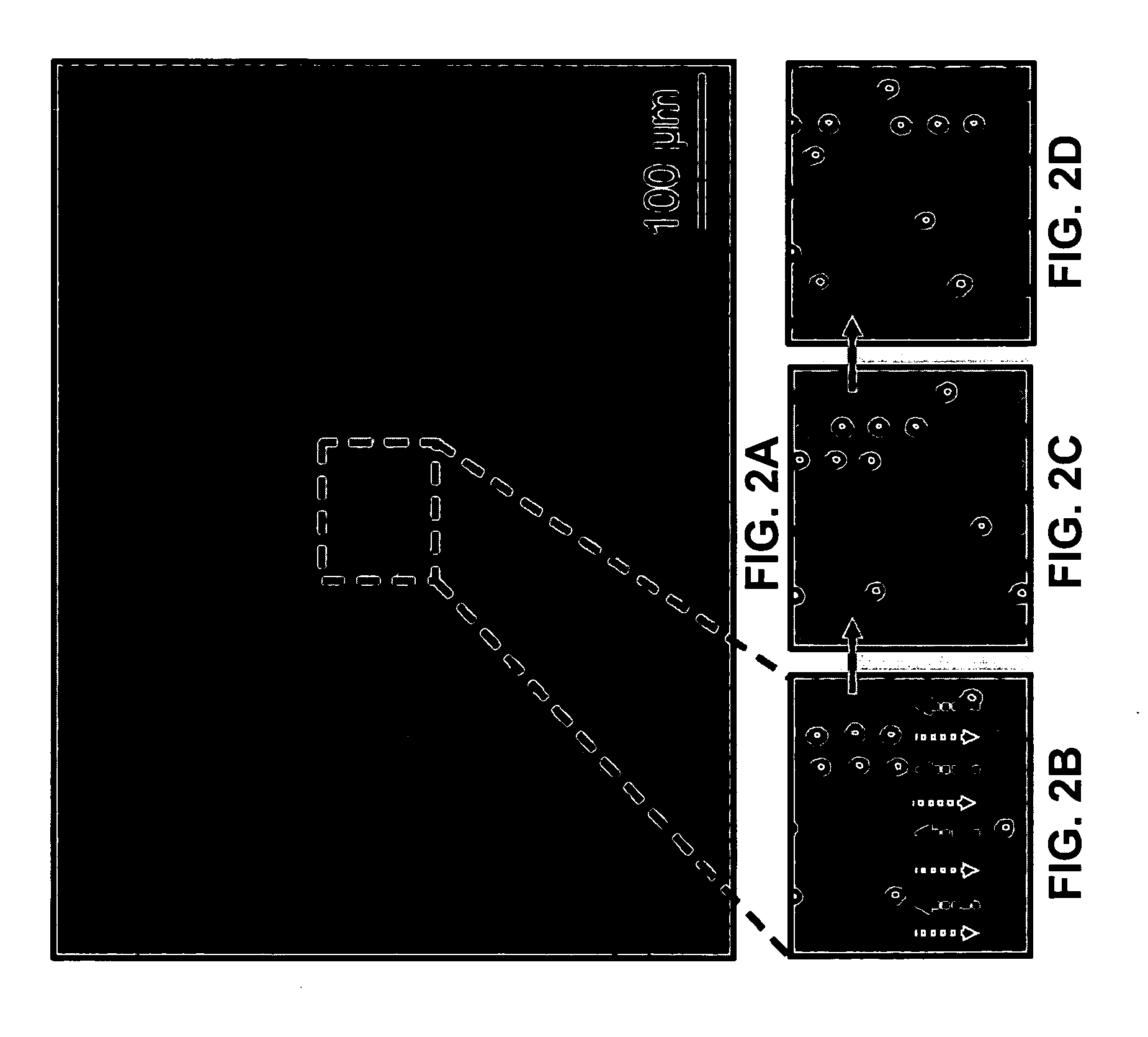

Optoelectronic tweezers for microparticle and cell manipulation

ActiveUS7612355B2Easy to operateEasy to createElectrostatic separatorsSludge treatmentMicroparticleOpto electronic

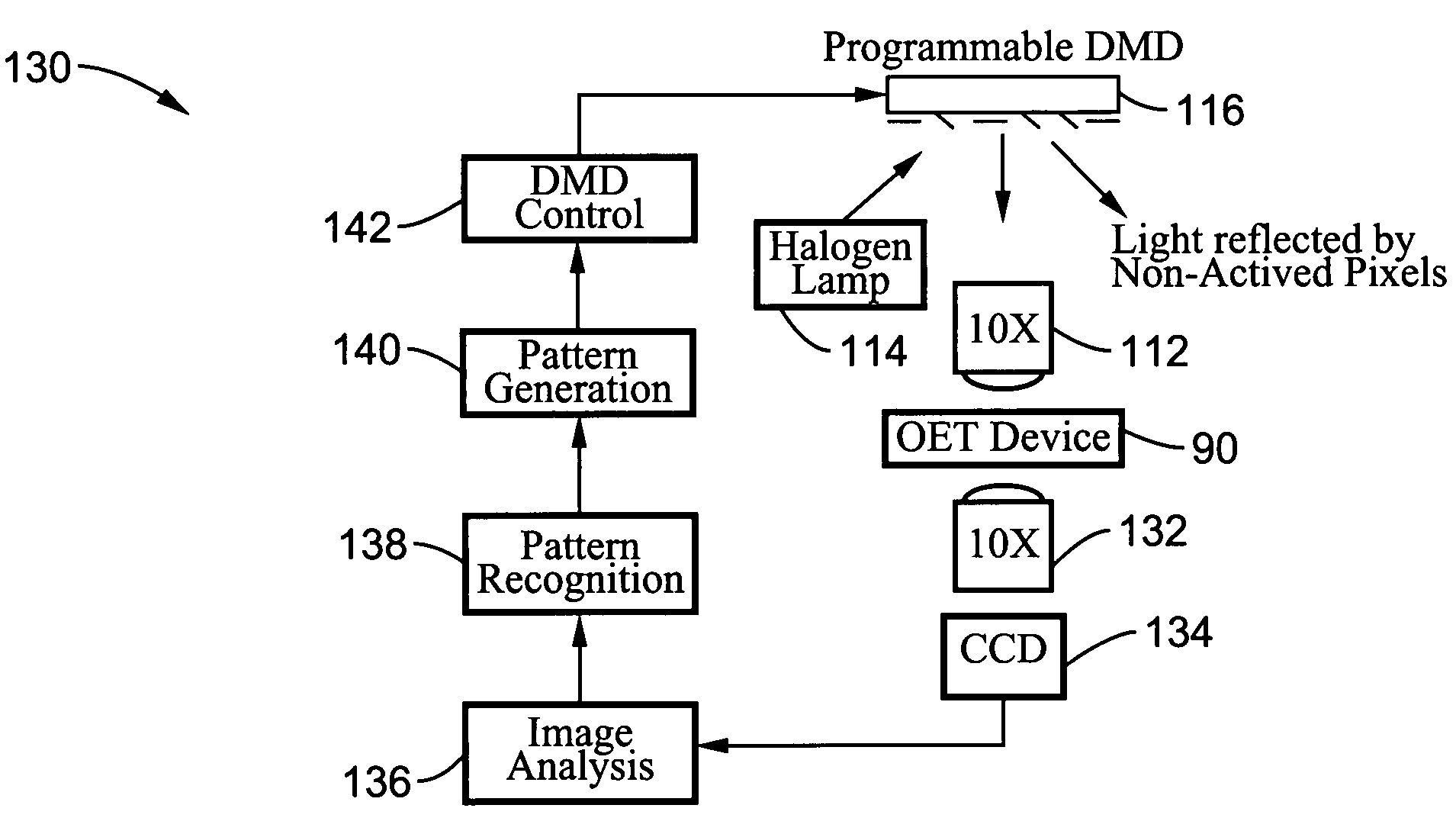

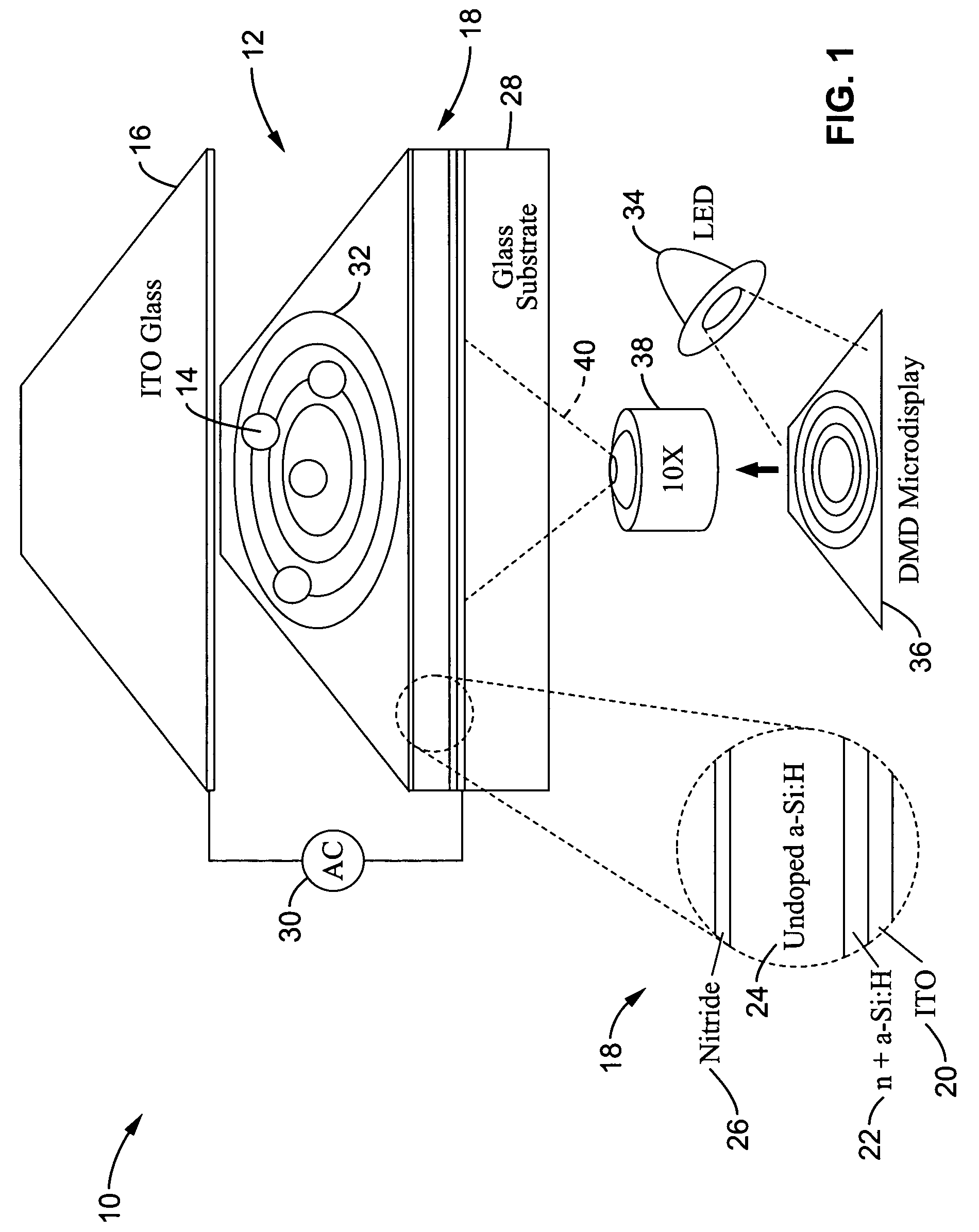

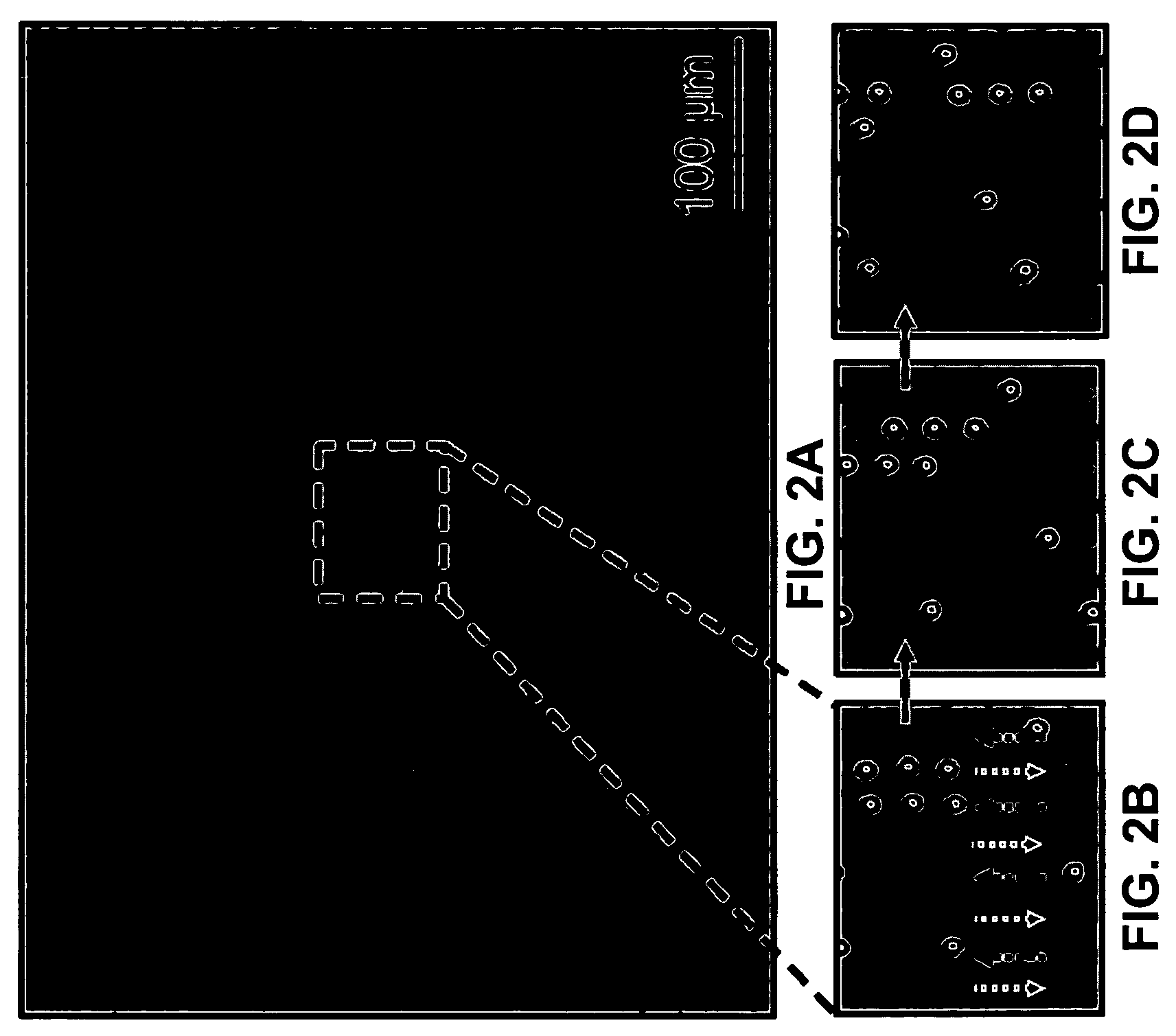

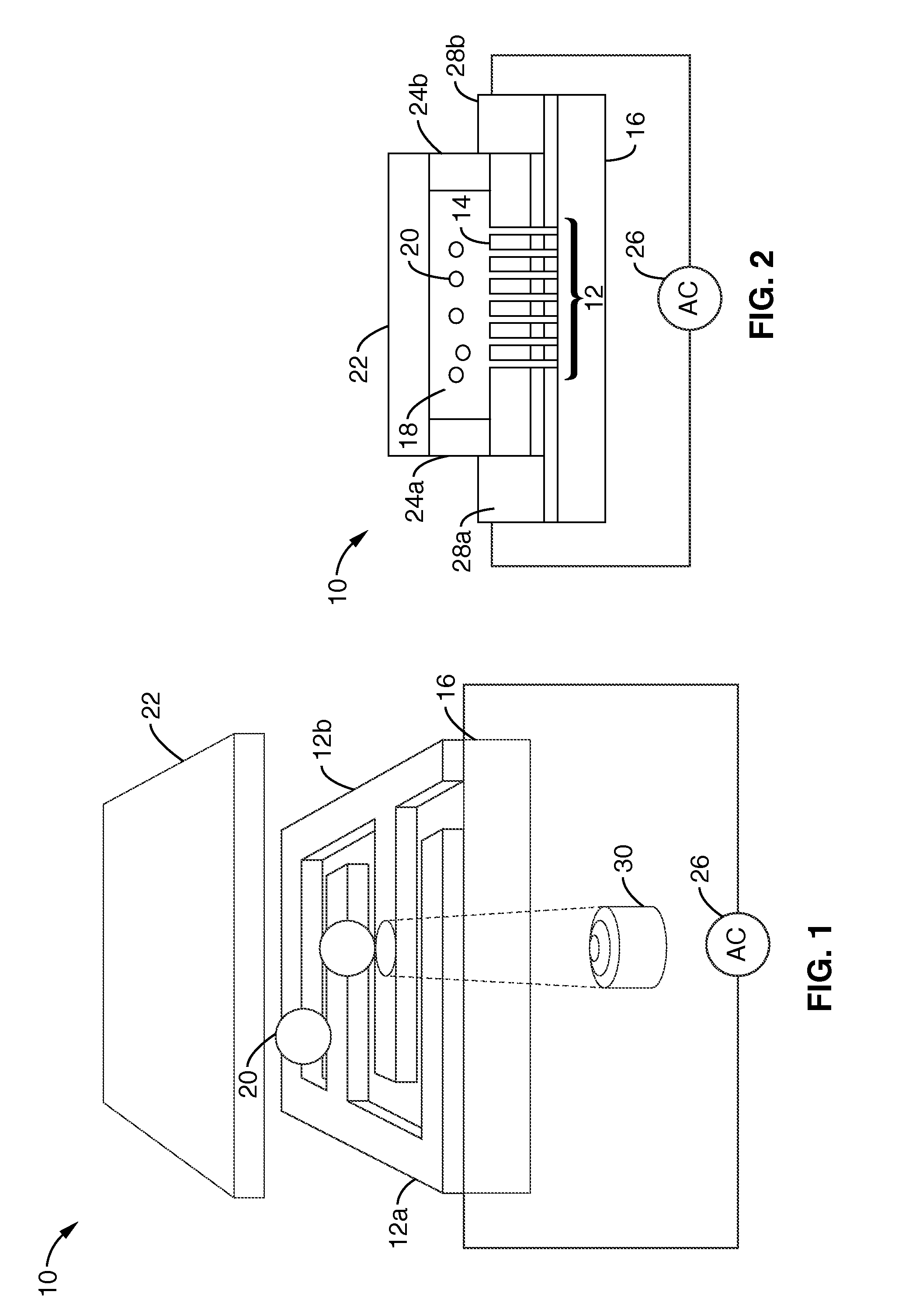

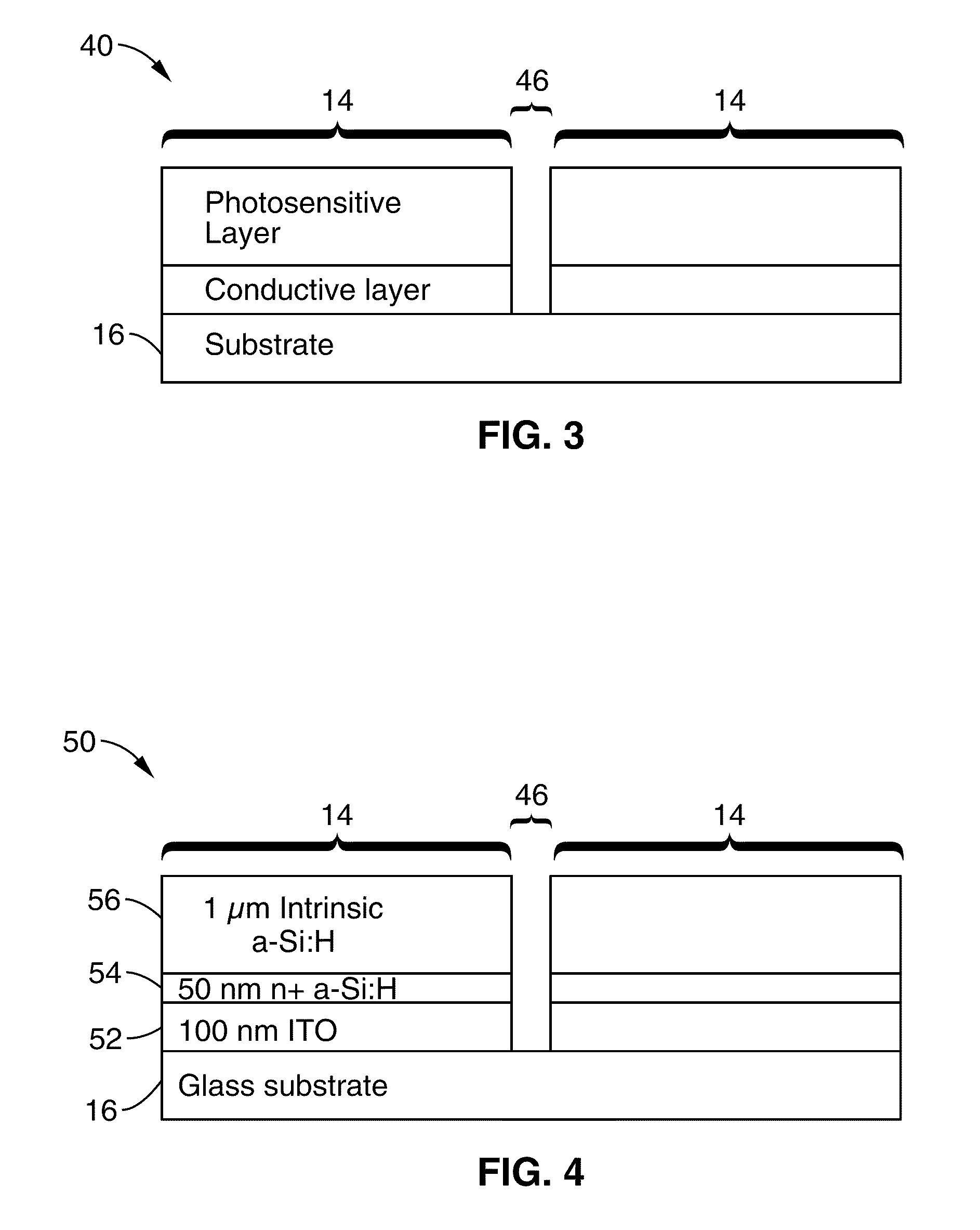

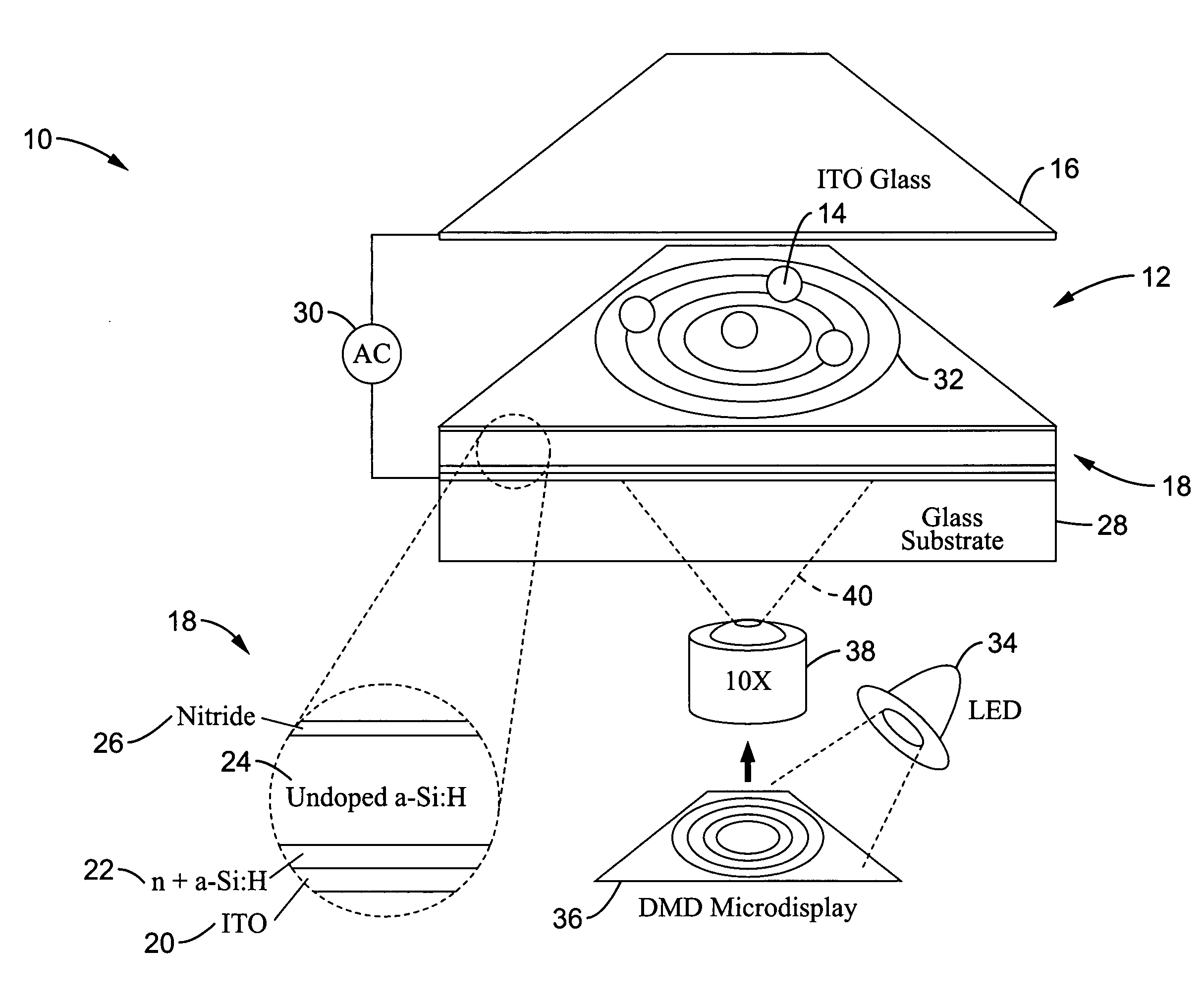

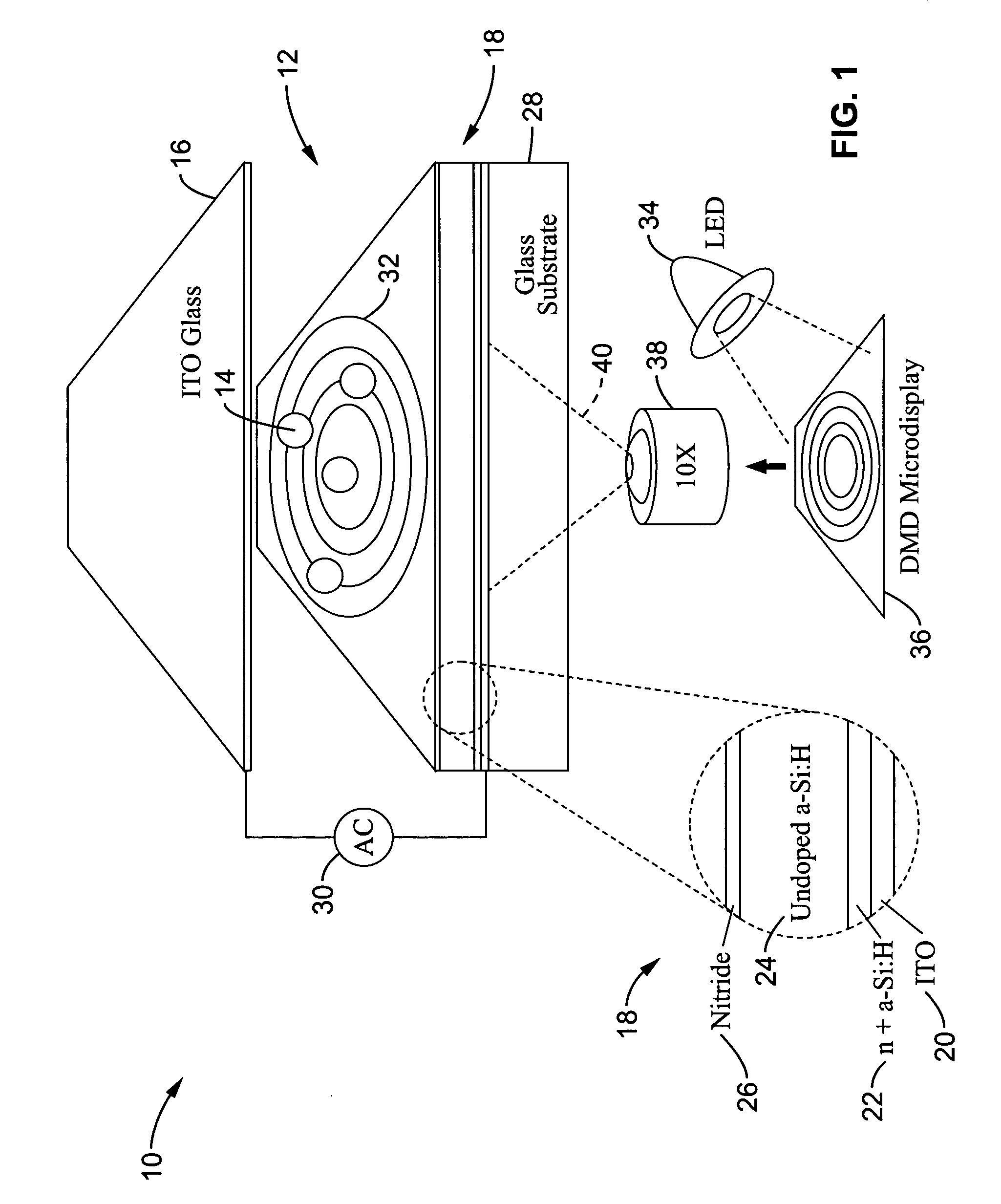

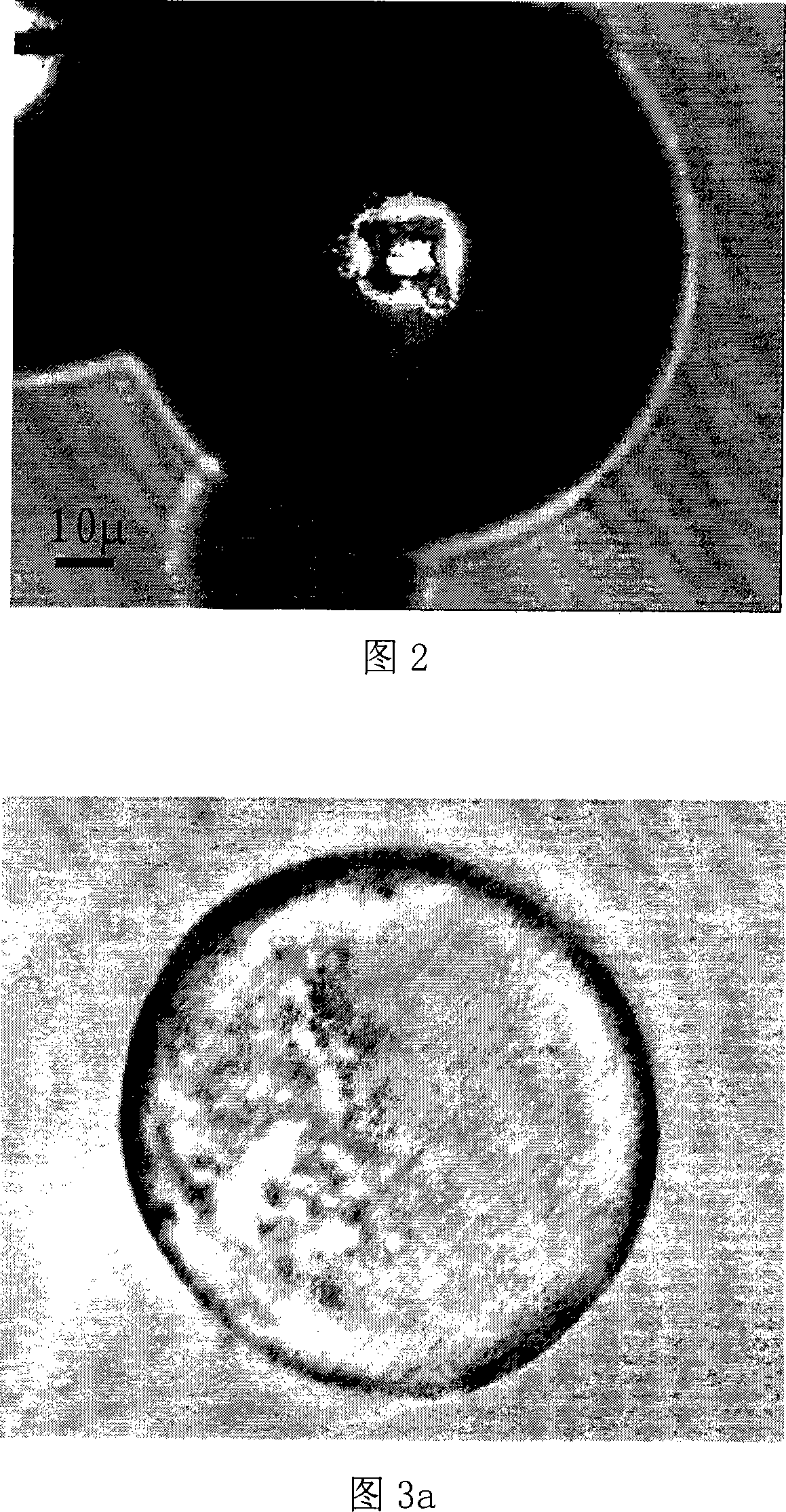

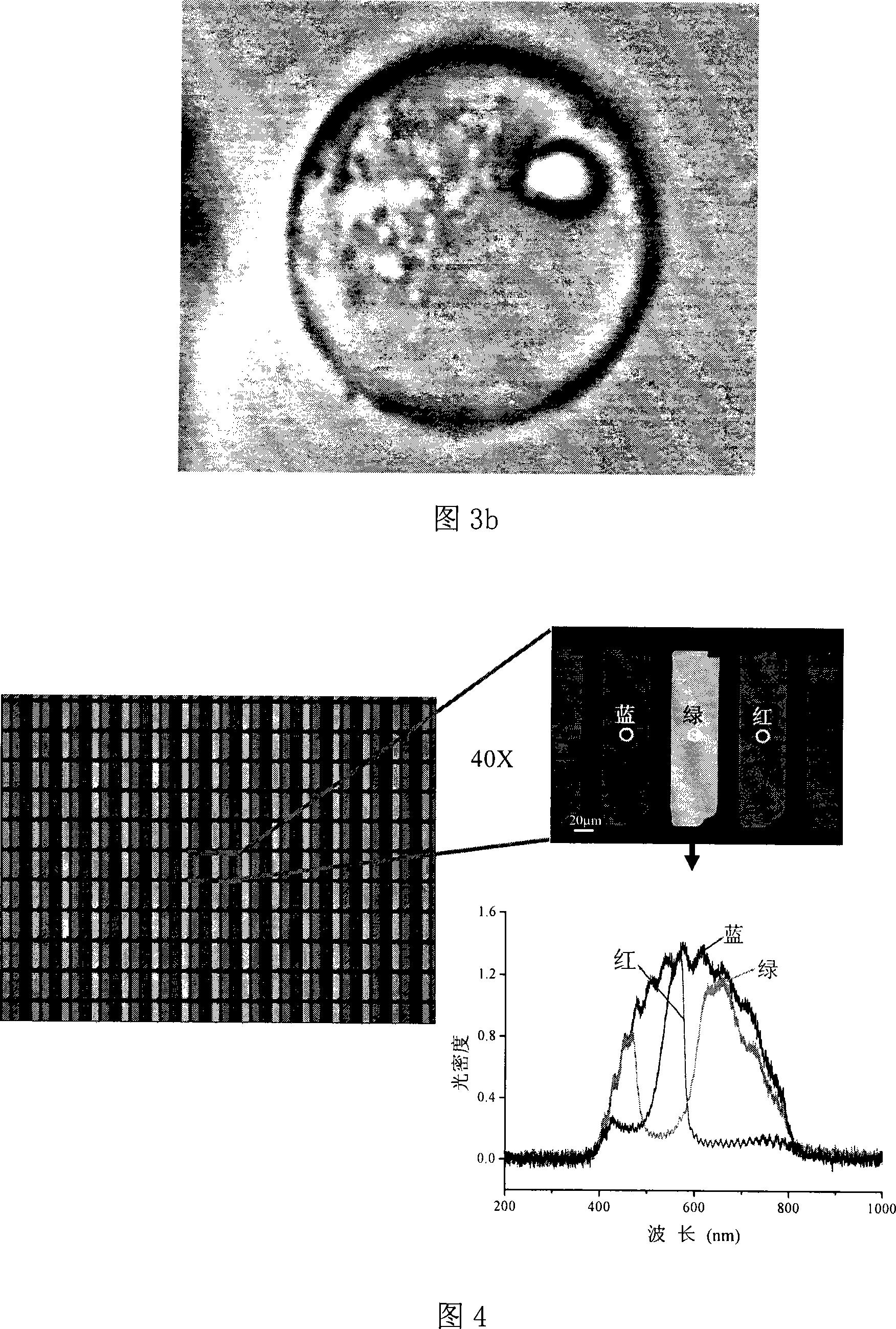

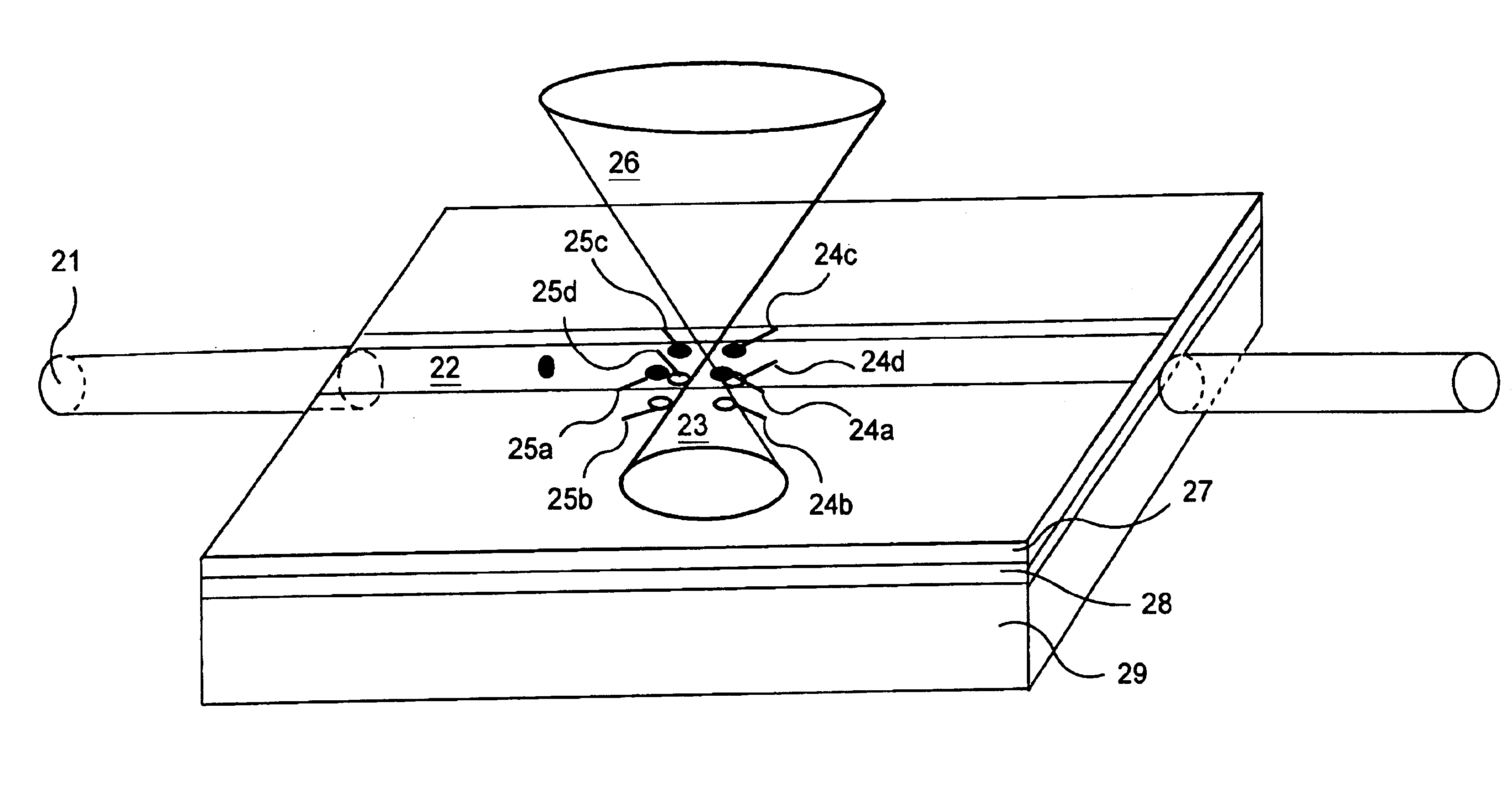

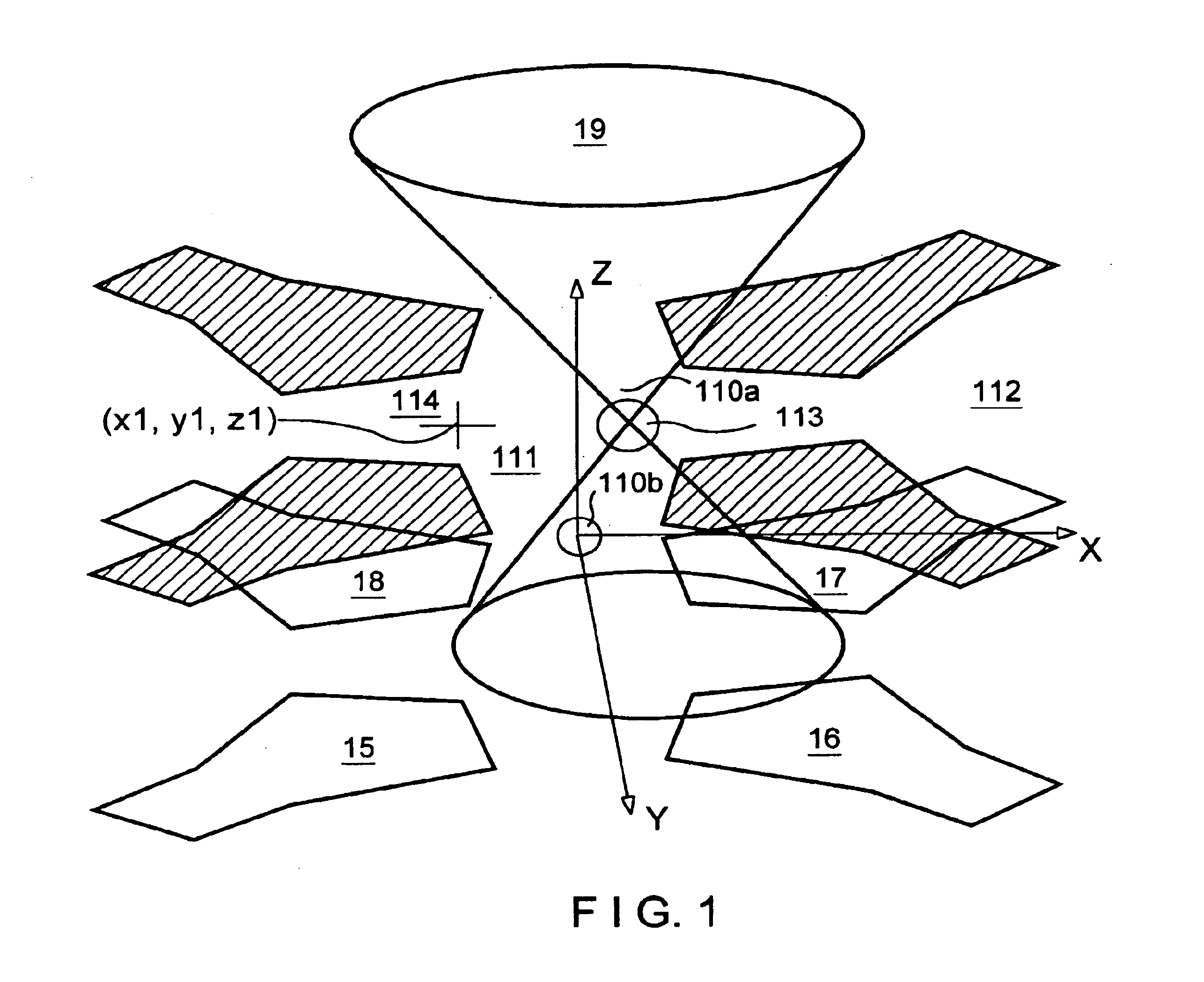

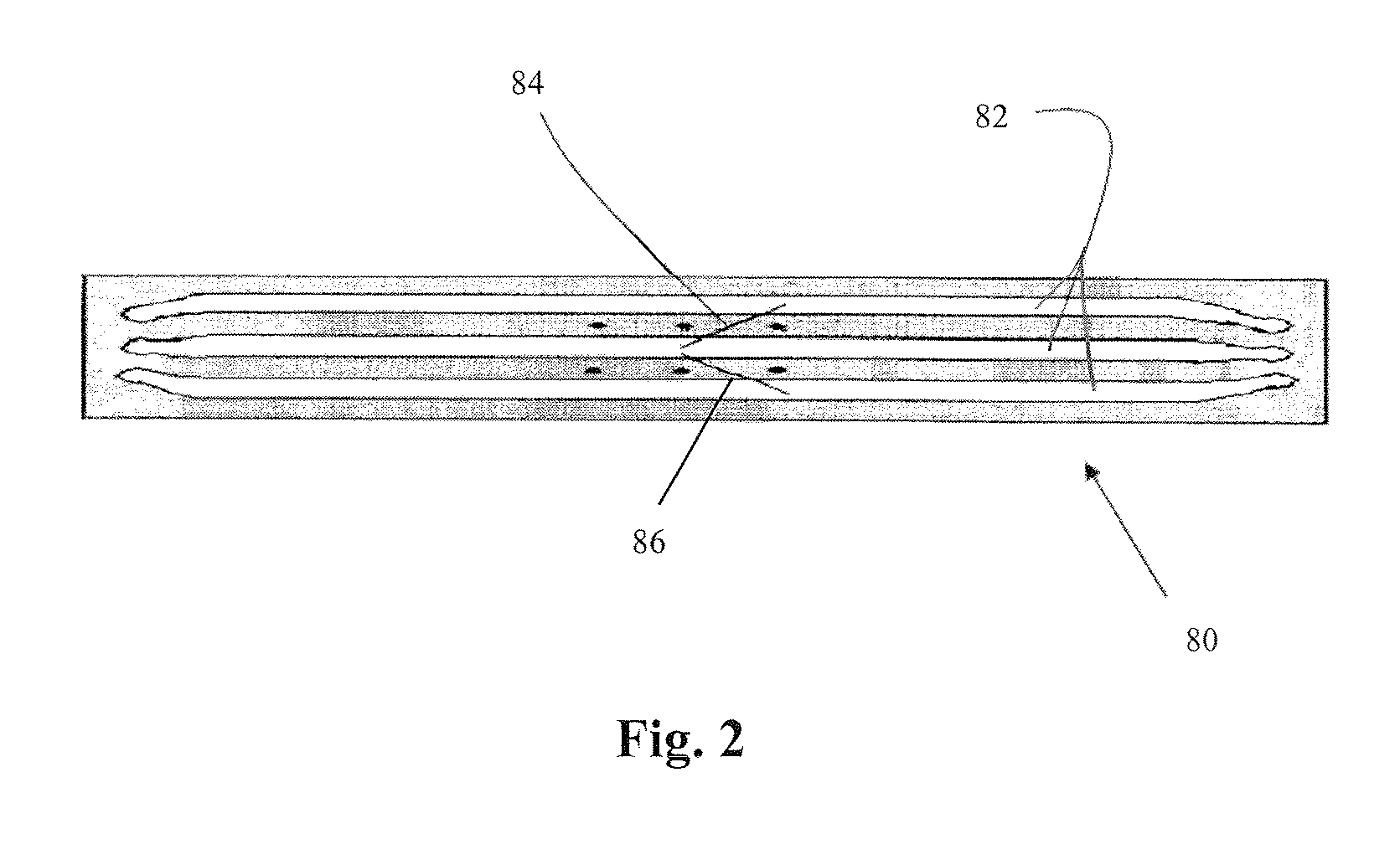

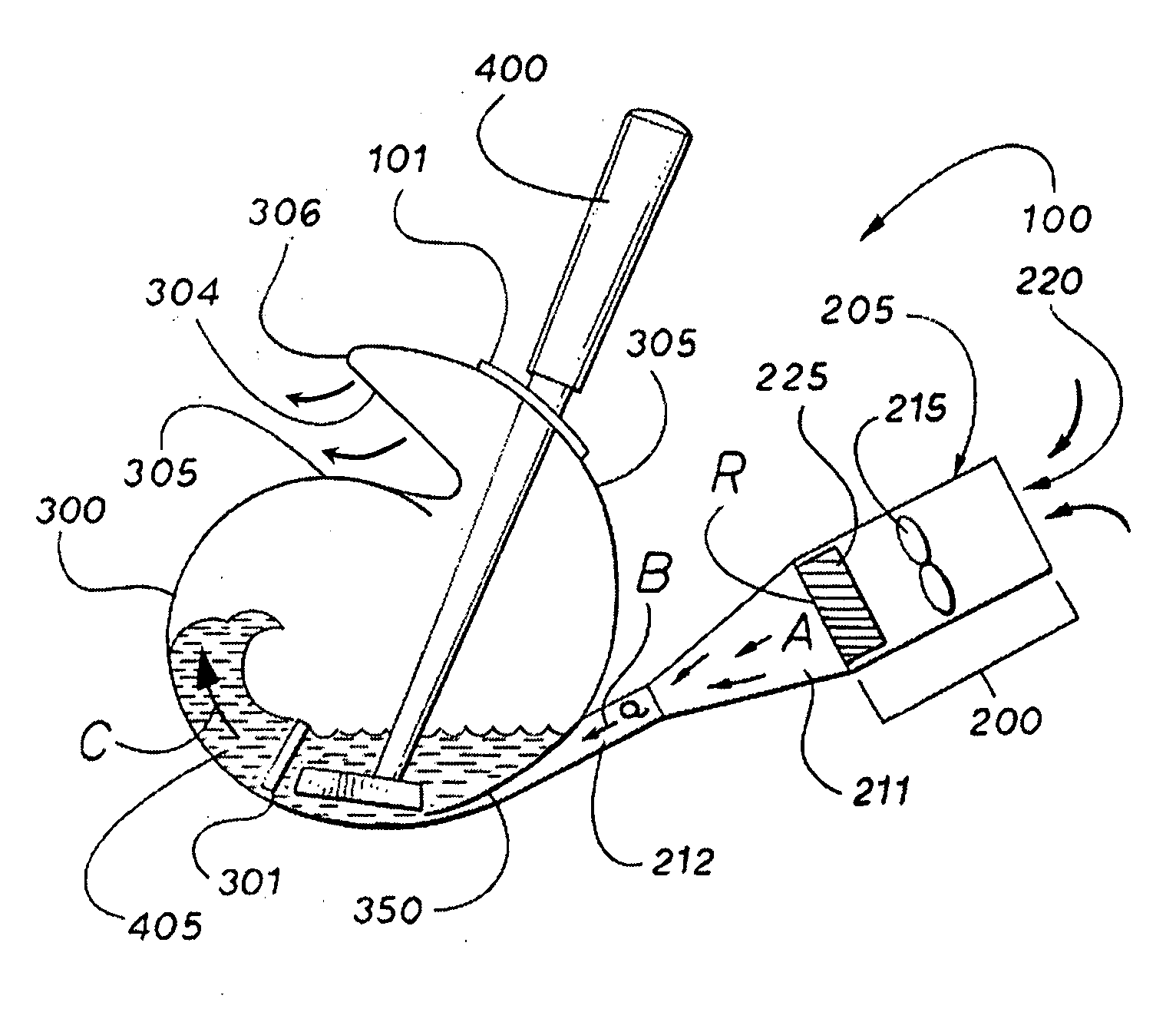

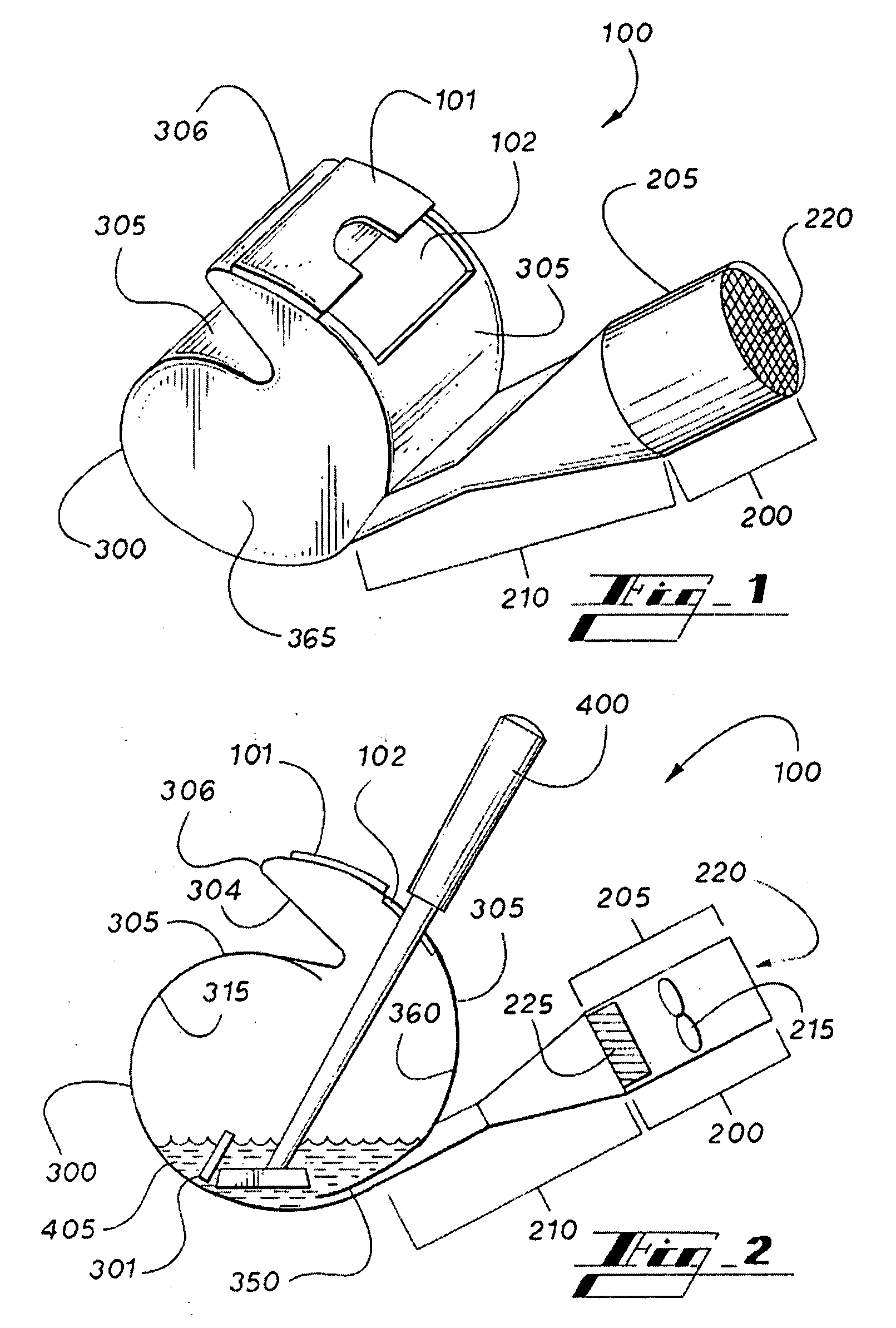

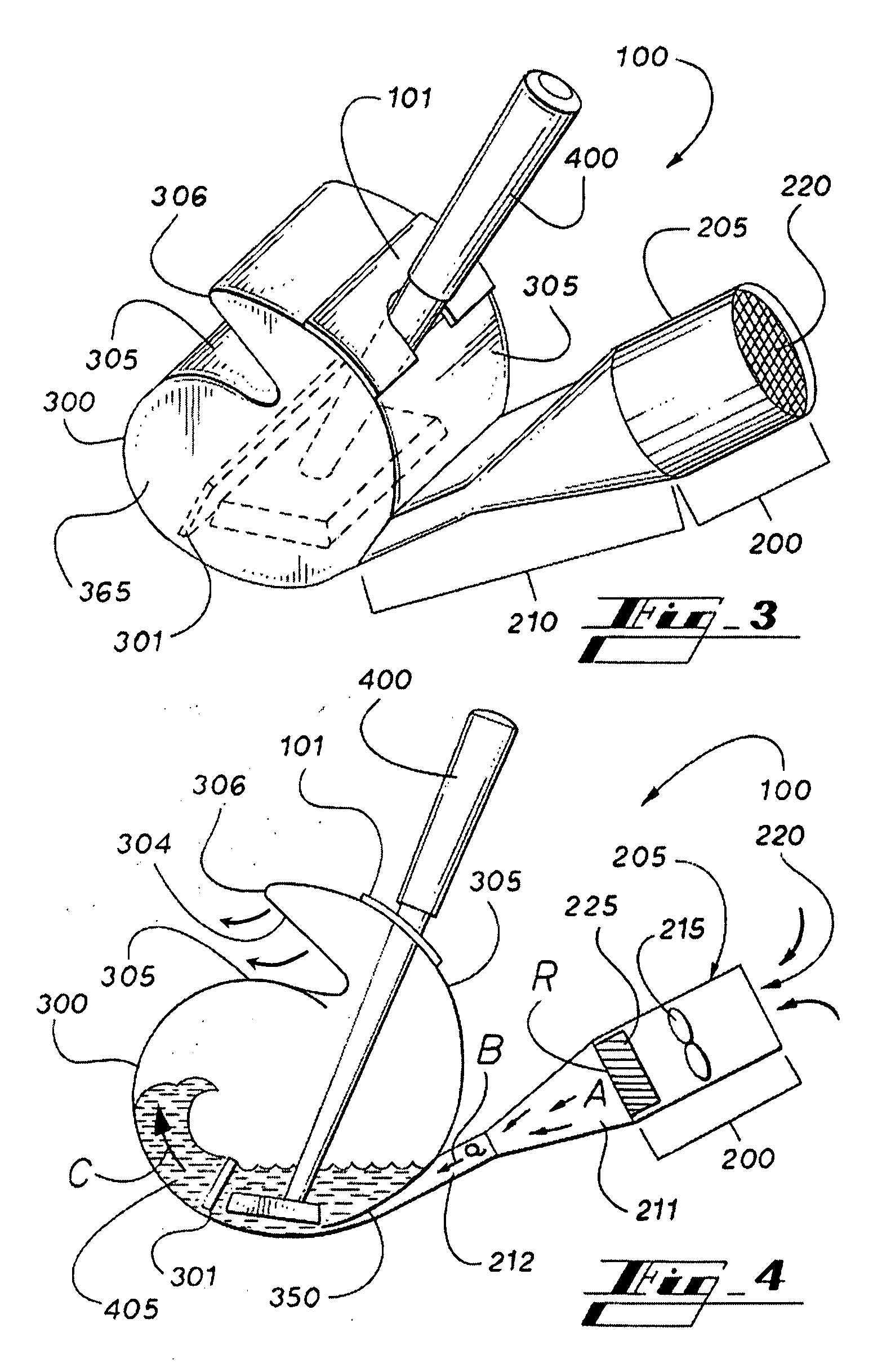

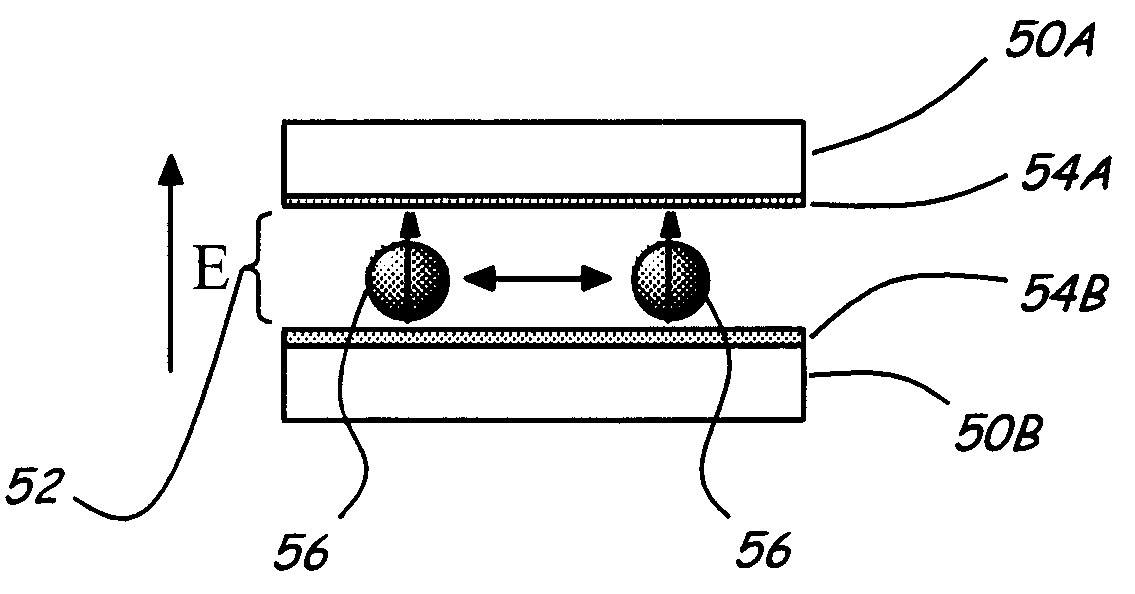

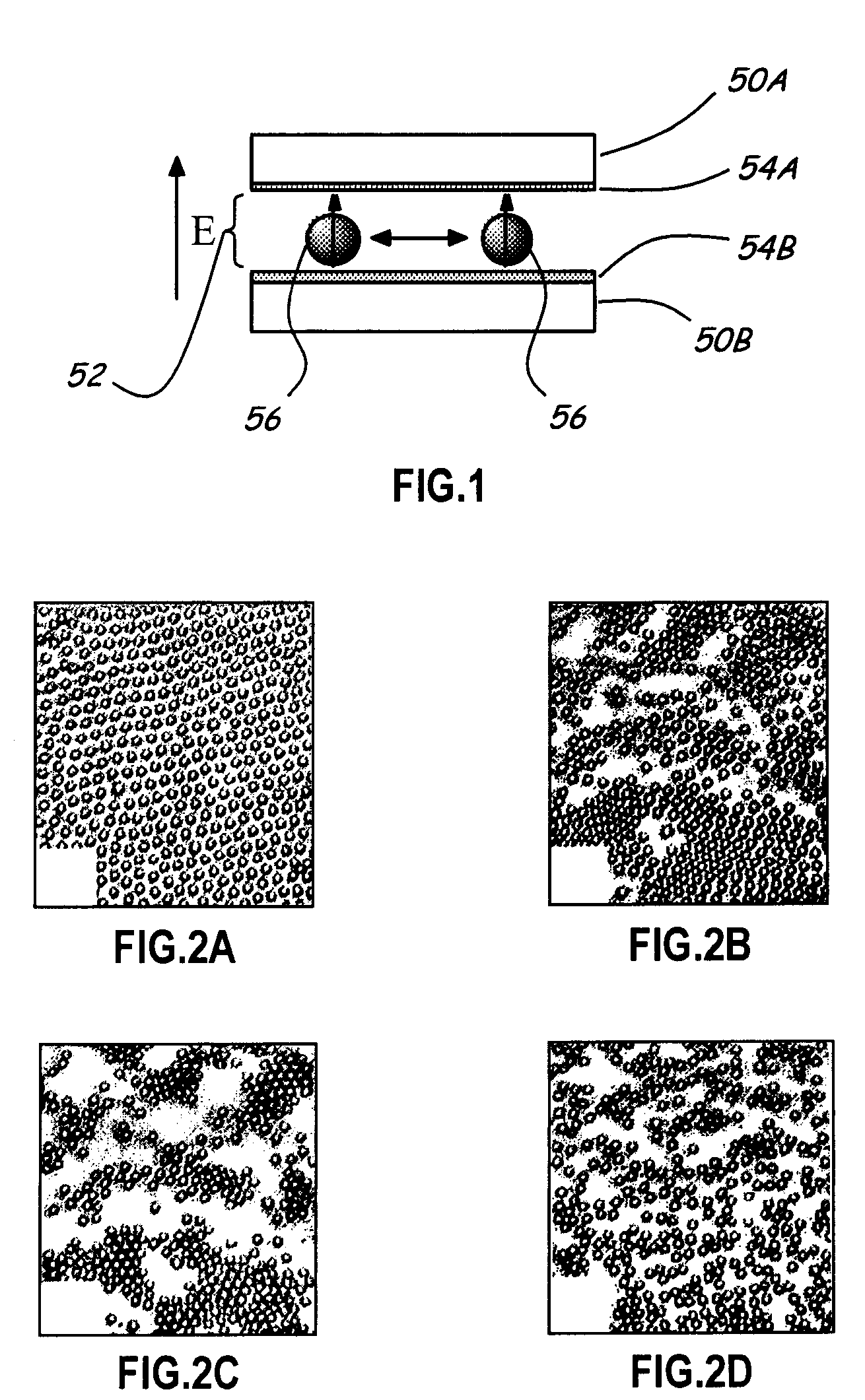

An optical image-driven light induced dielectrophoresis (DEP) apparatus and method are described which provide for the manipulation of particles or cells with a diameter on the order of 100 μm or less. The apparatus is referred to as optoelectric tweezers (OET) and provides a number of advantages over conventional optical tweezers, in particular the ability to perform operations in parallel and over a large area without damage to living cells. The OET device generally comprises a planar liquid-filled structure having one or more portions which are photoconductive to convert incoming light to a change in the electric field pattern. The light patterns are dynamically generated to provide a number of manipulation structures that can manipulate single particles and cells or groups of particles / cells. The OET preferably includes a microscopic imaging means to provide feedback for the optical manipulation, such as detecting position and characteristics wherein the light patterns are modulated accordingly.

Owner:RGT UNIV OF CALIFORNIA

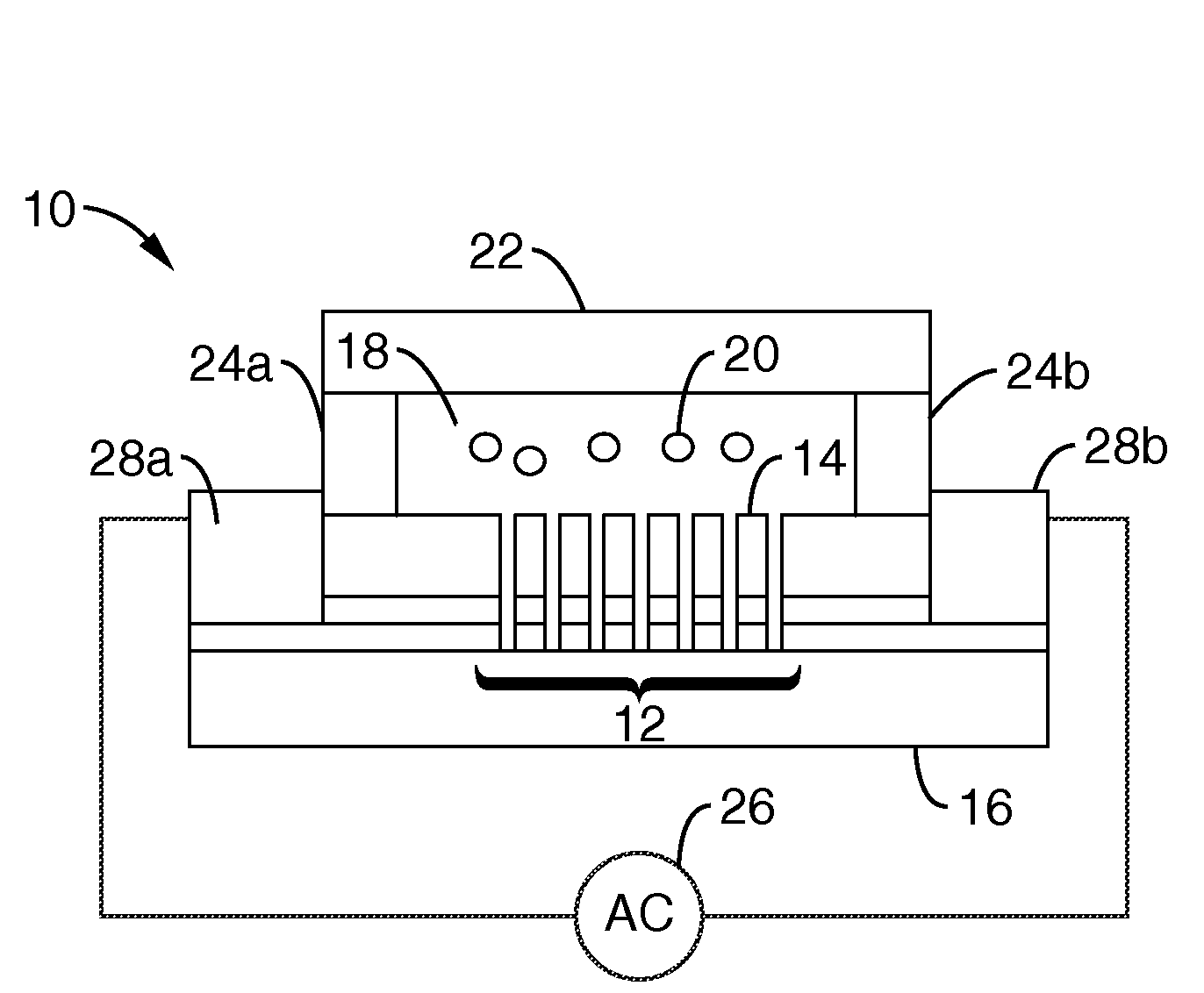

Single-sided lateral-field and phototransistor-based optoelectronic tweezers

ActiveUS7956339B2Good flexibilityElectrostatic separatorsSludge treatmentDielectrophoretic forceCell culture media

Owner:RGT UNIV OF CALIFORNIA

Optoelectronic tweezers for microparticle and cell manipulation

ActiveUS20090170186A1Easy to operateEasy to createElectrostatic separatorsSludge treatmentMicroparticleDielectrophoresis

An optical image-driven light induced dielectrophoresis (DEP) apparatus and method are described which provide for the manipulation of particles or cells with a diameter on the order of 100 μm or less. The apparatus is referred to as optoelectric tweezers (OET) and provides a number of advantages over conventional optical tweezers, in particular the ability to perform operations in parallel and over a large area without damage to living cells. The OET device generally comprises a planar liquid-filled structure having one or more portions which are photoconductive to convert incoming light to a change in the electric field pattern. The light patterns are dynamically generated to provide a number of manipulation structures that can manipulate single particles and cells or groups of particles / cells. The OET preferably includes a microscopic imaging means to provide feedback for the optical manipulation, such as detecting position and characteristics wherein the light patterns are modulated accordingly.

Owner:RGT UNIV OF CALIFORNIA

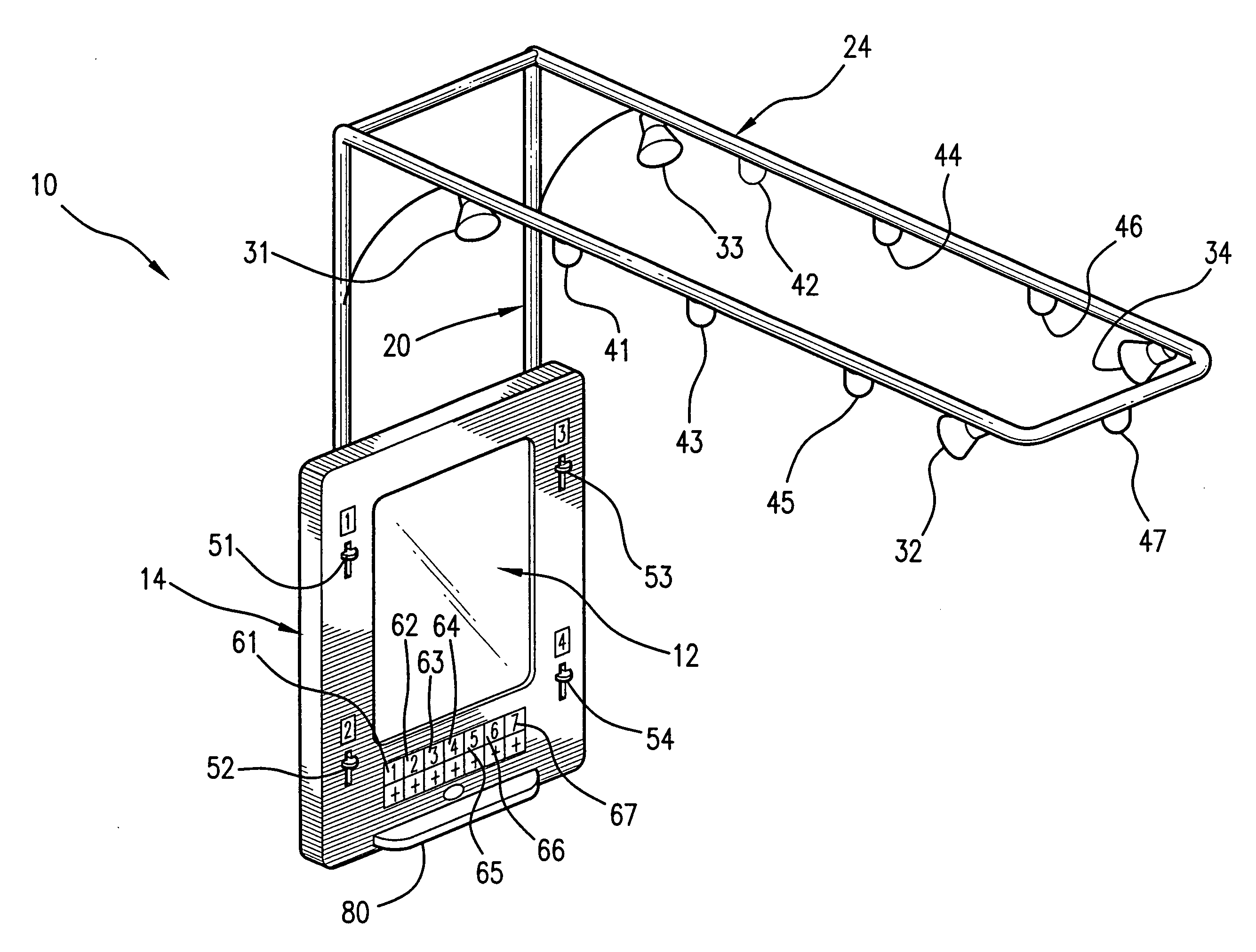

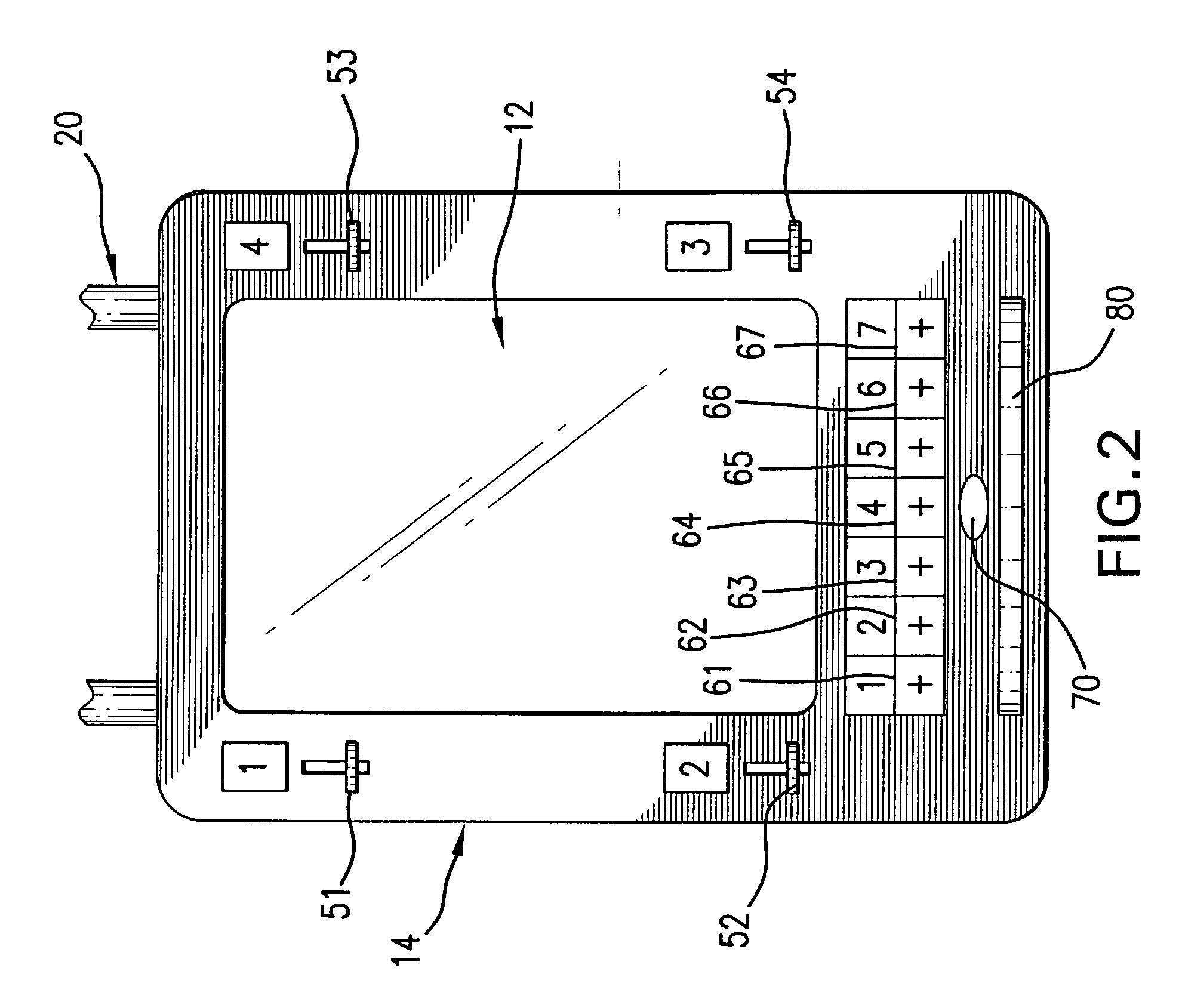

Personal grooming visual display system

InactiveUS20090303320A1Improve portabilityColor television detailsClosed circuit television systemsDocking stationEffect light

A personal grooming apparatus includes a high definition monitor, an overhead bracket providing a canopy above the monitor, one or more cameras supported on the overhead bracket for viewing a user's face, as well as the sides and back of the user's head, and possibly other areas of the user's body. An arrangement of lights supported on the bracket illuminate the various camera views. Controls are provided for independent control of the several lights (e.g., ON / OFF, dimming) the cameras (e.g., camera activation, zoom function, camera view selection), and the monitor. A docking station accommodates a handheld unit. The docking station is provided with a wireless receiver port for communicating with the handheld unit. The handheld unit includes a camera and LED lighting for close-up views that are displayed on the monitor. The handheld unit is adapted for receiving various attachment tools and devices, such as, but not limited to, a nose hair trimmer, a beard and moustache trimmer, tweezers, and a nail buffer. A carry case holds the handheld unit and includes a mini monitor, a docking station with a docking port and a control pad. Power is supplied by a removable A / C power cord and an internal rechargeable battery.

Owner:DAVIS RICK

Single-sided lateral-field and phototransistor-based optoelectronic tweezers

ActiveUS20100101960A1Good flexibilityElectrostatic separatorsSludge treatmentDielectrophoretic forceCell culture media

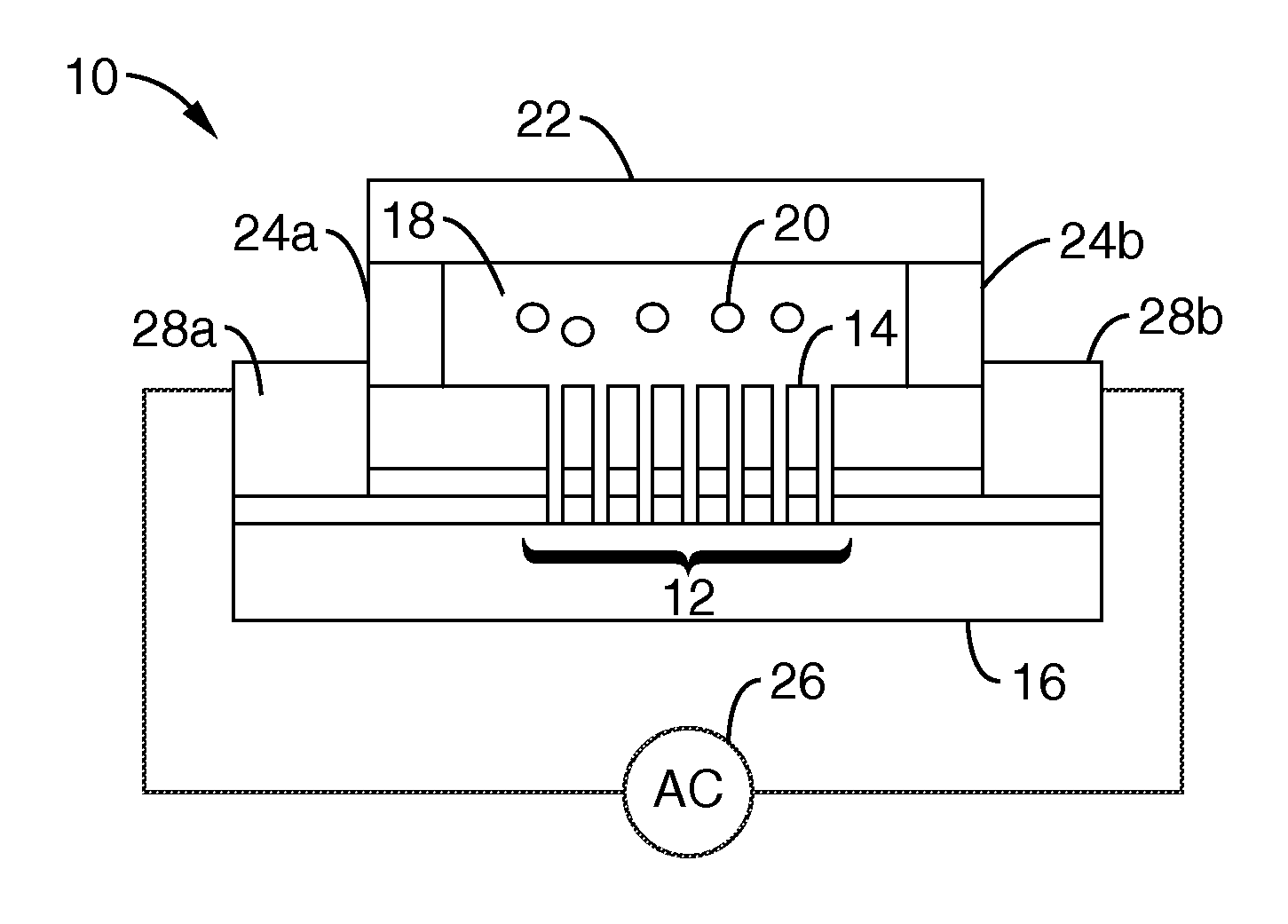

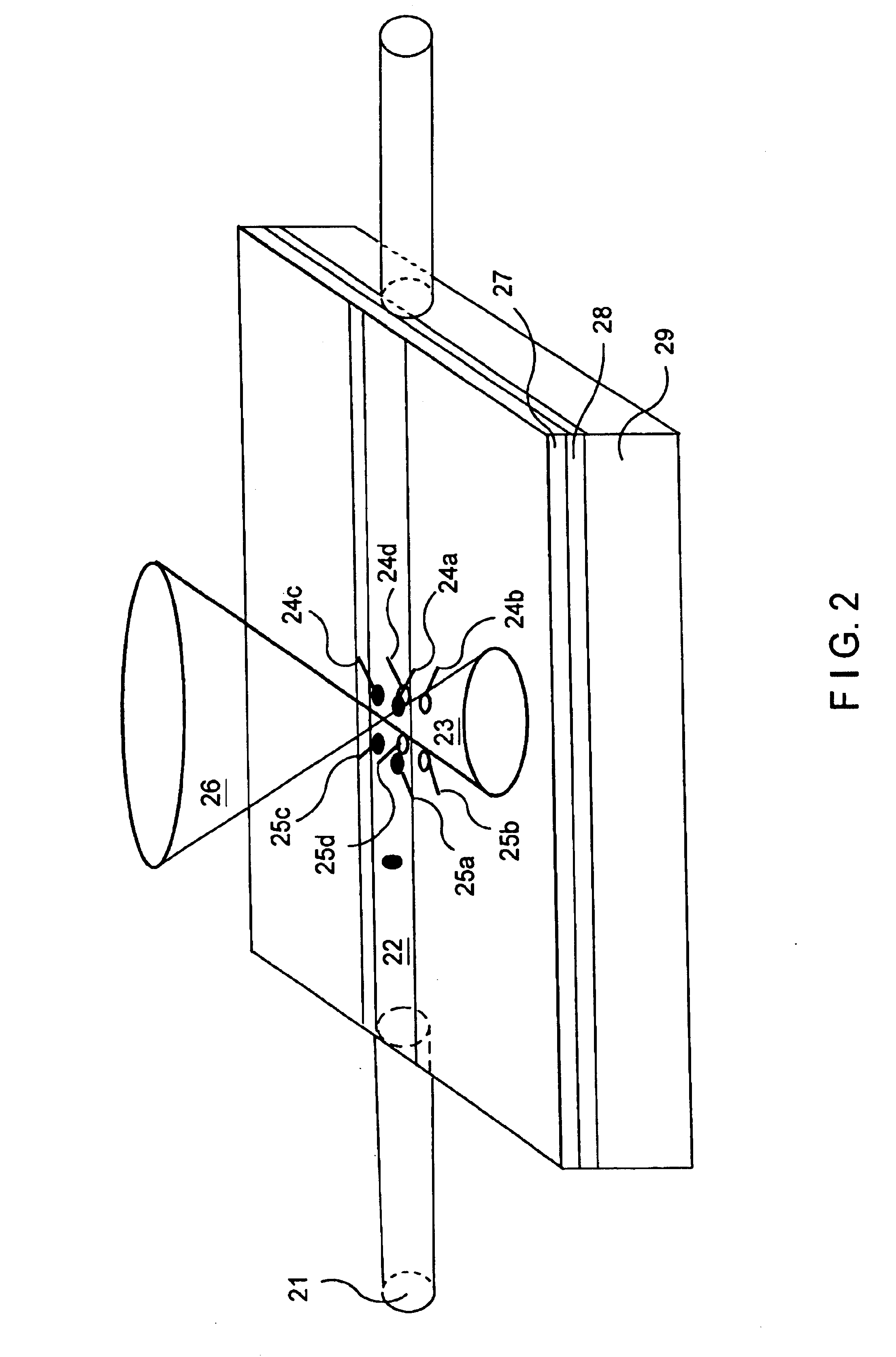

Described herein are single-sided lateral-field optoelectronic tweezers (LOET) devices which use photosensitive electrode arrays to create optically-induced dielectrophoretic forces in an electric field that is parallel to the plane of the device. In addition, phototransistor-based optoelectronic tweezers (PhOET) devices are described that allow for optoelectronic tweezers (OET) operation in high-conductivity physiological buffer and cell culture media.

Owner:RGT UNIV OF CALIFORNIA

Multifunctional optical micro-control device

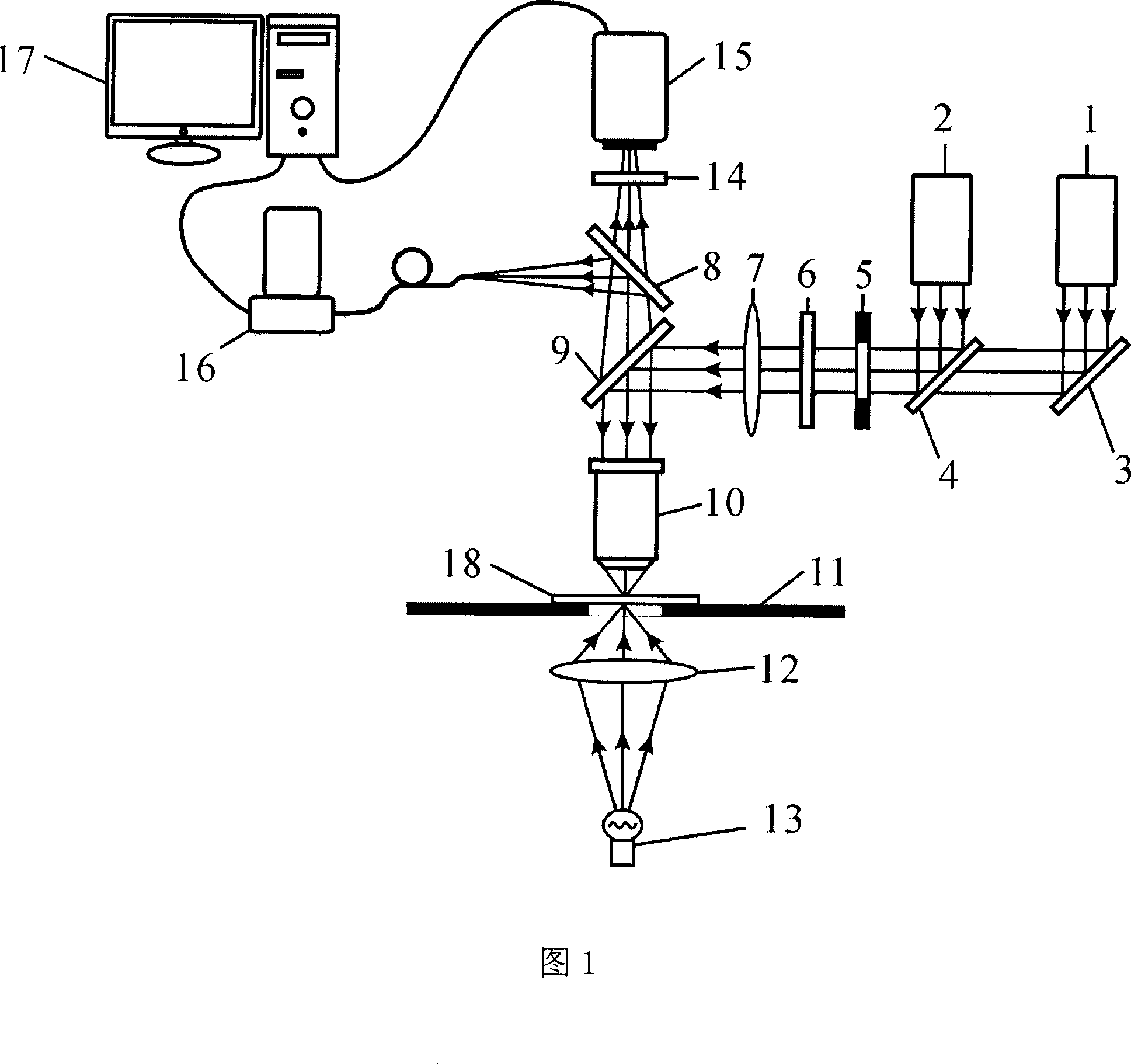

InactiveCN101216414AOvercome singleOvercome deficienciesSurface/boundary effectMaterial analysis by optical meansFemto second laserCcd camera

A multifunctional optical micro-manipulation device comprises a femtosecond laser, an optical tweezers laser, an optical system, a stage, a light source system, an imaging system, a spectral measurement system and a computer, wherein the optical system comprises a shutter, an attenuator, a focusing lens, a near IR reflector and a microscopic objective lens; the light source system comprises an illumination light source and a condenser lens; the microscopic objective lens is arranged on the stage for condensing a laser beam emitted by a laser generator onto a sample; the condenser lens is arranged below the stage for condensing a visible light emitted by the illumination light source onto the sample; and the imaging system includes an IR filter and CCD camera sequentially disposed on the projection light path of the near IR reflector. By integrating three functions of laser tweezers, femtosecond laser scissors and microspectrometer in one system, the invention can overcome the singleness and the disadvantages of the prior laser micro-beam technology and can be widely used for studying in biological, medical, biophysical, material chemistry and nano-technology fields.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Small core diameter ultra-high numerical aperture cone optical fiber optical tweezers and manufacturing method thereof

InactiveCN101118300ALow loss connectionAchieving 3D capture with a single fiberRadiation/particle handlingCoupling light guidesHigh numerical apertureTweezers

The present invention discloses a pair of small core and ultra-large numerical aperture taper fiber tweezers and a fabricating method thereof. The present invention is a pair of small core and ultra-large numerical aperture taper fiber tweezers, using the small core and ultra-large numerical aperture fiber to be processed, with the end of the fiber polished into a cone shape and the angle of the cone tip formed between 30 degrees and 120 degrees, and connected by means of the thermal thawing diffusion numerical aperture matching technology. Due to the large numerical aperture at the fiber tip, a divergent optical field is formed to cause a larger gradient force potential well of the optical field, thereby overcoming the deadweight of particles, realizing the single fiber three-dimensional trap of minute particles and such operations like fixing, moving, and transporting the trapped particles and so on. The small core and ultra-large numerical aperture taper fiber tweezers in the present invention can be used for trapping living biological cells or moving and assembling minute particles.

Owner:HARBIN ENG UNIV

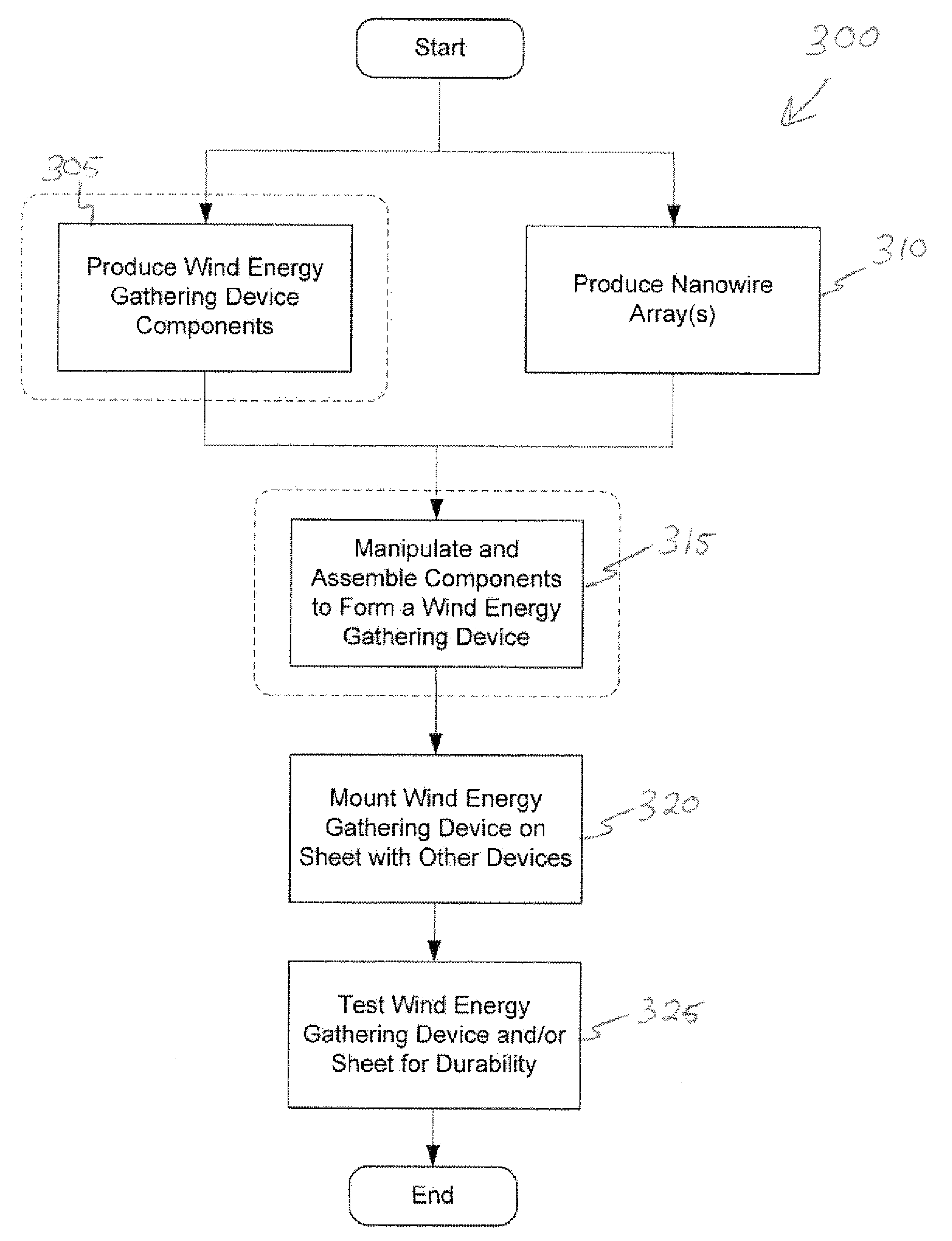

System and Method for Creating Micro/Nano Wind Energy Gathering Devices

ActiveUS20080148549A1Effective installationIntroducing energyNanostructure manufacturePiezoelectric/electrostriction/magnetostriction machinesChemical compositionEngineering

Method and system for manufacturing small wind energy gathering devices, for example, of geometrical dimensions tip to ⅛th of an inch (microdevices), employing micro-fabrication techniques. For example, three-dimensional single chemical composition parts of a small wind energy gathering device are manufactured using two-photon three dimensional lithography. Preferably, a plurality of such parts are manufactured in parallel, thereby optimizing the production process. The plurality of parts may be handled and assembled using precision instruments such as micro-tweezers, micro-scissors, and holographic lasers. Nanowires may be used to interconnect a plurality of the microdevices together, or to connect components of a particular microdevice. These nanowires are produced in nanowire arrays and are attached to a common base structure. Additionally, a form of injection molding and polymer materials may be utilized in the manufacturing of the small wind energy gathering devices (microdevices), which provide protective coatings and surfaces of reduced friction.

Owner:TAMIRAS PER PTE LTD LLC

Tweezers

A hand tool includes a main body, a pair of arms connected to the main body, first tips connected to the arms and configured to grasp an object, and second tips connected to the arms and configured to grasp an object. The first tips are connected to the second tips. Another aspect of the invention is directed to a hand tool including a main body, a pair of arms connected to the main body, and a scoop portion at one end of the main body.

Owner:STITCH ACQUISITION CORP

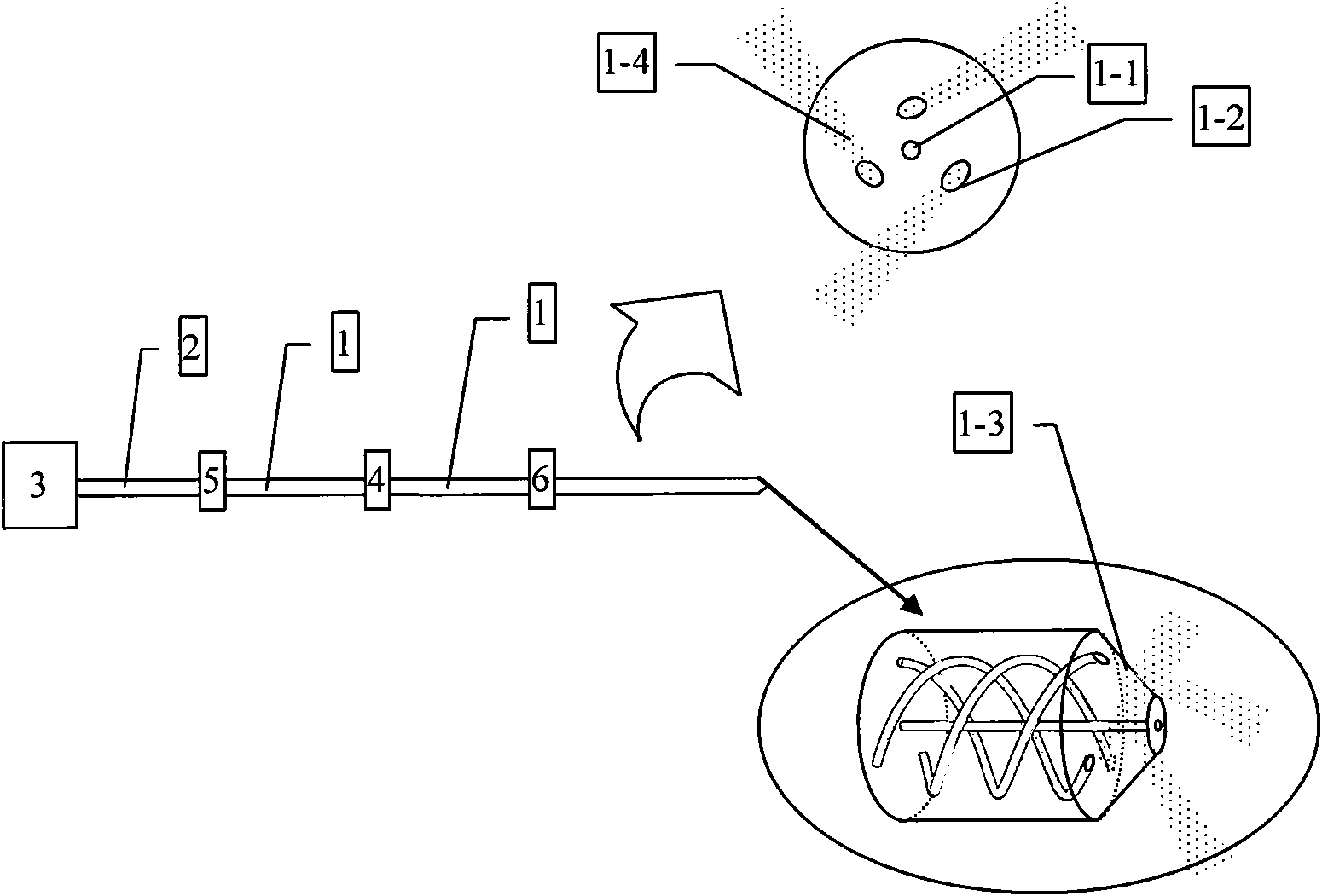

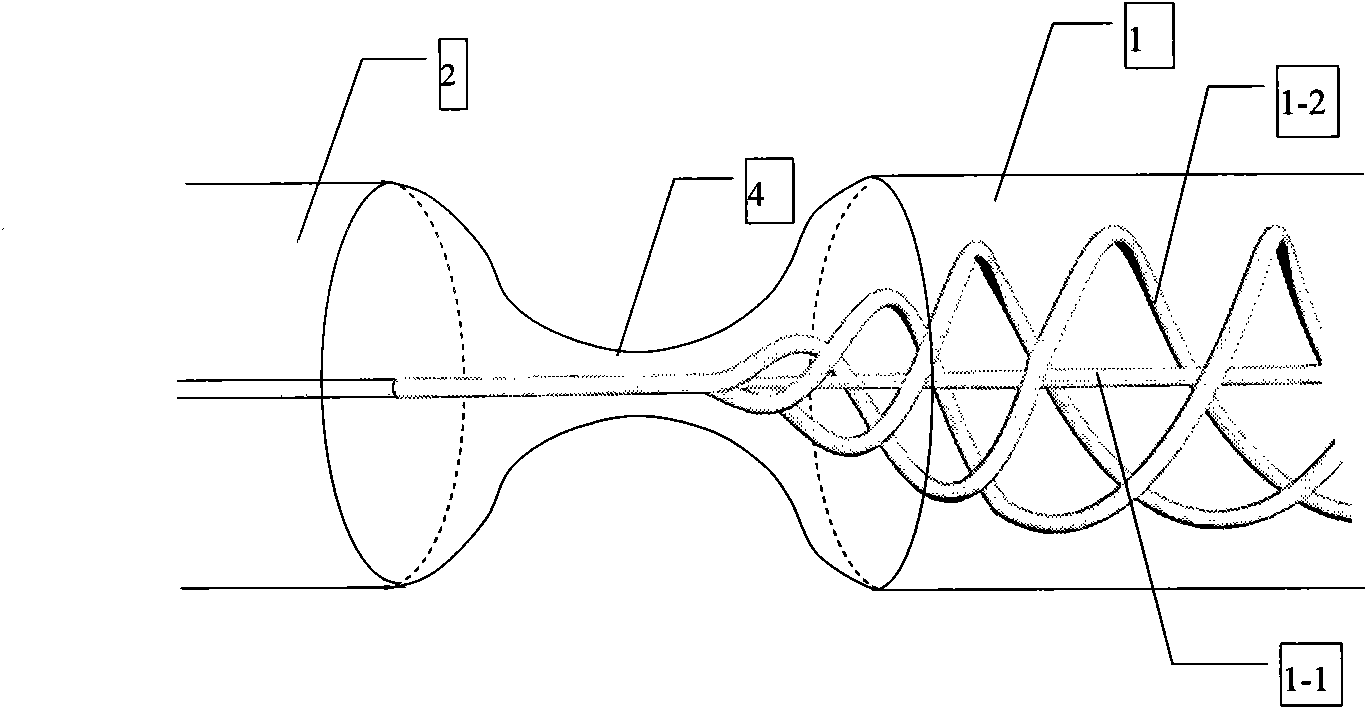

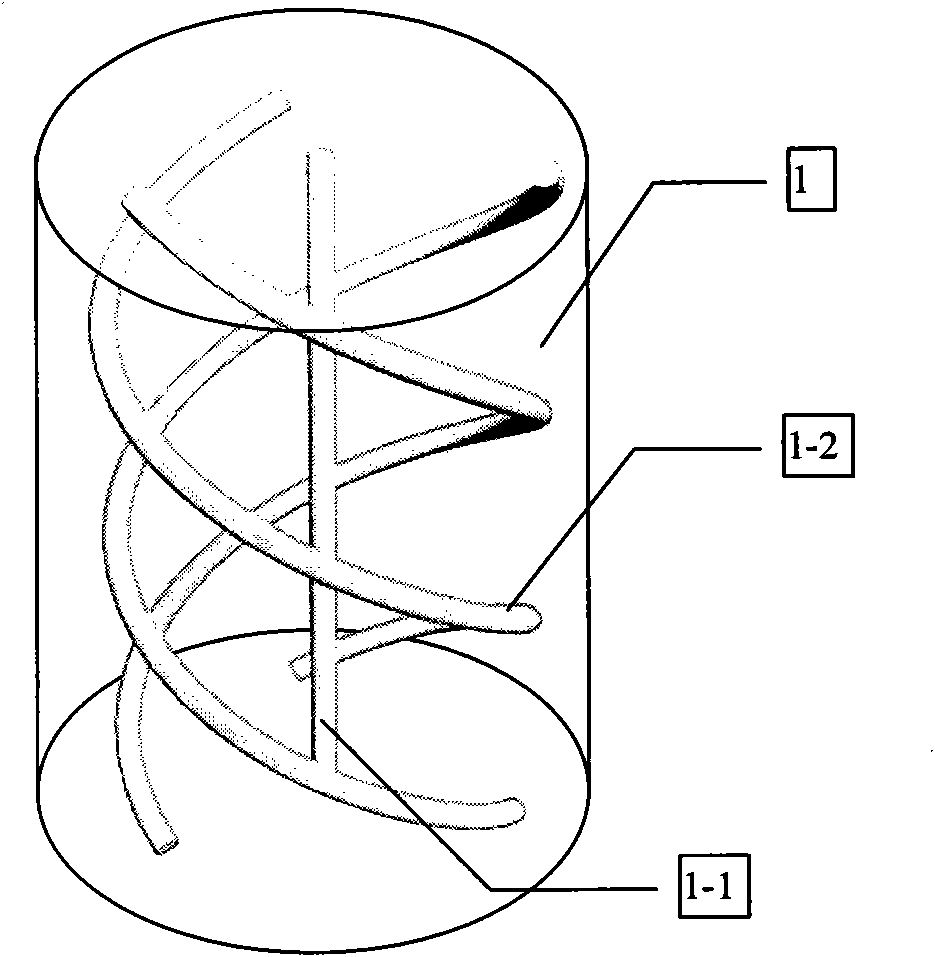

Satellite-type helical multi-core fiber optical micro-tweezers capable of achieving rotation of small particles and preparation method thereof

InactiveCN101881858AAchieve rotationCapture flexibleCladded optical fibreRadiation/particle handlingPhysical spaceEngineering

The invention provides satellite-type helical multi-core fiber optical micro-tweezers capable of achieving the rotation of small particles and a preparation method thereof. A laser source is connected with one end of a standard single-mode fiber, and the other end of the standard single-mode fiber is coupled with the satellite-type helical multi-core fiber by thermal-fused bi-conical taper to form a first thermal-fused bi-conical taper position; the satellite-type helical multi-core fiber is attached to an optical-path changing device, and the satellite-type helical multi-core fiber passing through the optical-path changing device is further subjected to the thermal-fused bi-conical taper operation to form a second thermal-fused bi-conical taper position; and the other end of the satellite-type helical multi-core fiber is prepared into a pyramidal shape in a processing manner of finely grinding. Therefore, the invention can save the physical space and greatly reduce the optical input power of the system, so as to reduce the damage on the particles to be trapped; the particles can be trapped in a more flexible, more accurate and adjustable manner; and the vortex-shaped optical trap can be naturally formed at the fiber end, thus achieving the rotation of the particles and the motor function of the operated particles.

Owner:HARBIN ENG UNIV

Combination pocket mirror and magnifier

A combination illuminated magnifier and mirror device comprises a compact and low-profile case of a resilient material, a separate magnifying assembly, a separate mirror assembly, a release mechanism for releasing both assemblies, and an illuminating device for viewing ease. Both magnifying and mirror assemblies are separately functional from each other; however the combination thereof provides the greatest benefit to the user. Accessories for the present invention are anticipated and may include a tool slot for tweezers and an exterior flashlight.

Owner:BRIGHT PATRICIA P +1

Method and device for measuring, calibrating and using laser tweezers

InactiveUS6991906B1Increase amplitudeAccurate thresholdImmobilised enzymesOptical radiation measurementElectricityLight beam

To measure or exert optically-induced forces on at least one particle in the focus of an optical cage, the following steps are taken:a) the focus is positioned in a microelectrode arrangement with a three-dimensional electrical field that has a field gradient which forms an electrical capture area, and the focus is at a distance from the capture are andb) the amplitude of the electrical field, the light power of the light beam forming the optical cage, and / or the distance of the capture area from the focus are varied to detect which varied field property moves the particle from the focus to the capture area or vice versa, or at least to temporarily move the particle into the capture area.

Owner:EVOTEC BIOSYST +1

Throughput type fiber optical tweezers based on coaxial dual-waveguide structure and dynamic control method

InactiveCN101950049ACapture flexibleAccurate captureRadiation/particle handlingOptical fibre with multilayer core/claddingCoaxial cableMicrostructure fiber

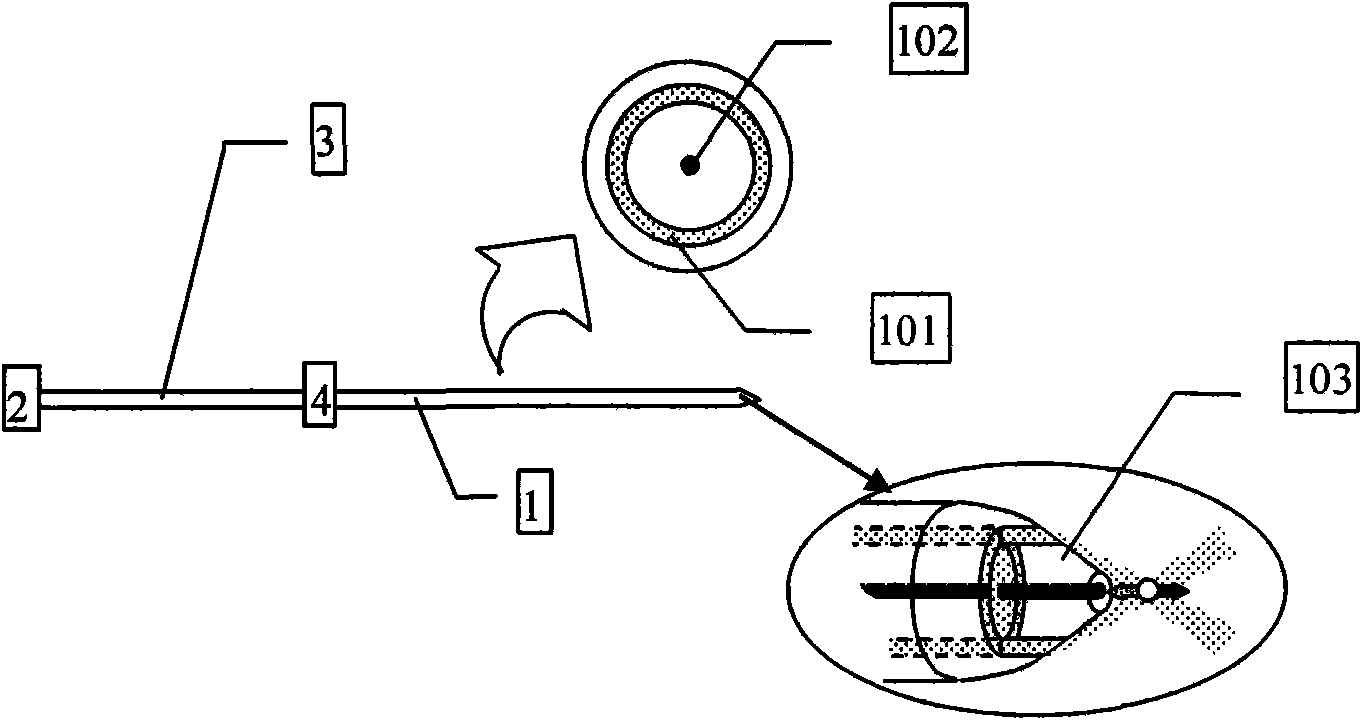

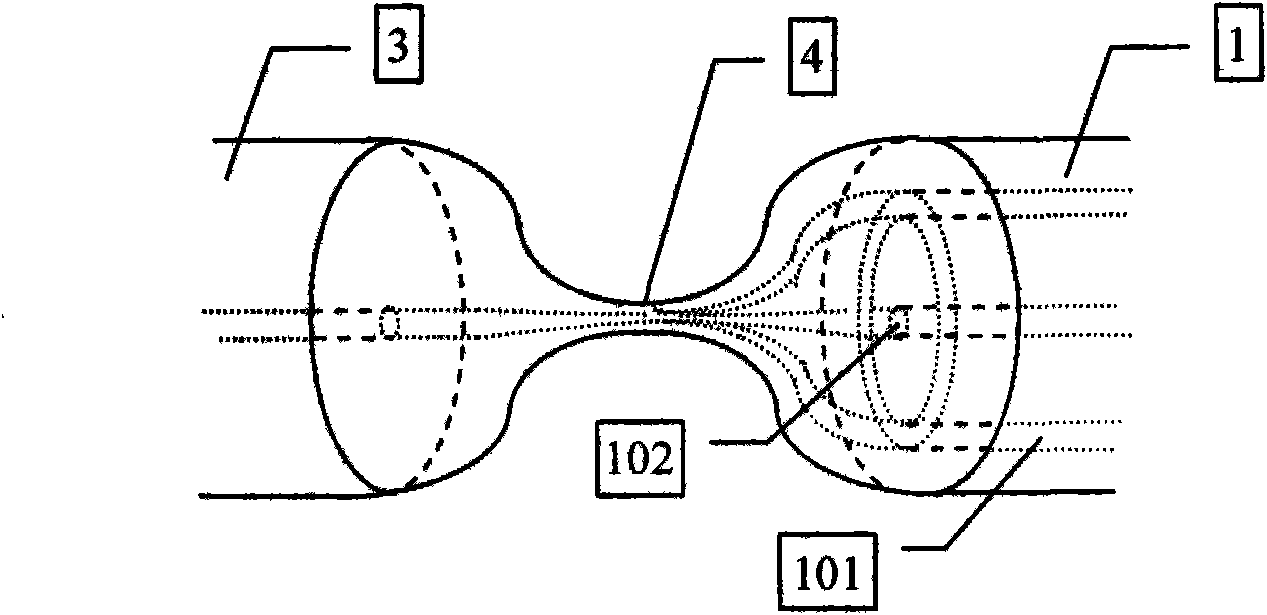

The invention provides throughput type fiber optical tweezers based on a coaxial dual-waveguide structure and a dynamic control method. The tweezers mainly comprise a coaxial double-waveguide microstructure fiber (1), a wavelength-adjustable LD light source (2) and a standard single-mode single-core fiber (3), and are characterized in that the coaxial double-waveguide microstructure fiber (1) is coupled with the standard single-mode single-core fiber (3) in a fused-tapered mode; the other side of the standard single-mode single-core fiber (3) is connected with the wavelength-adjustable LD light source (2); and the other end of the coaxial double-waveguide microstructure fiber (1) is finely ground into a cone shape (103). Coaxial double-waveguide fiber is utilized to control particles, the throughput, emission and even resorption of the particles can be stably captured; and meanwhile, the throughput type fiber optical tweezers based on the coaxial dual-waveguide structure can capture the particles more flexibly and accurately and has adjustability, thereby greatly improving the practicability of the technology of the fiber optical tweezers.

Owner:HARBIN ENG UNIV

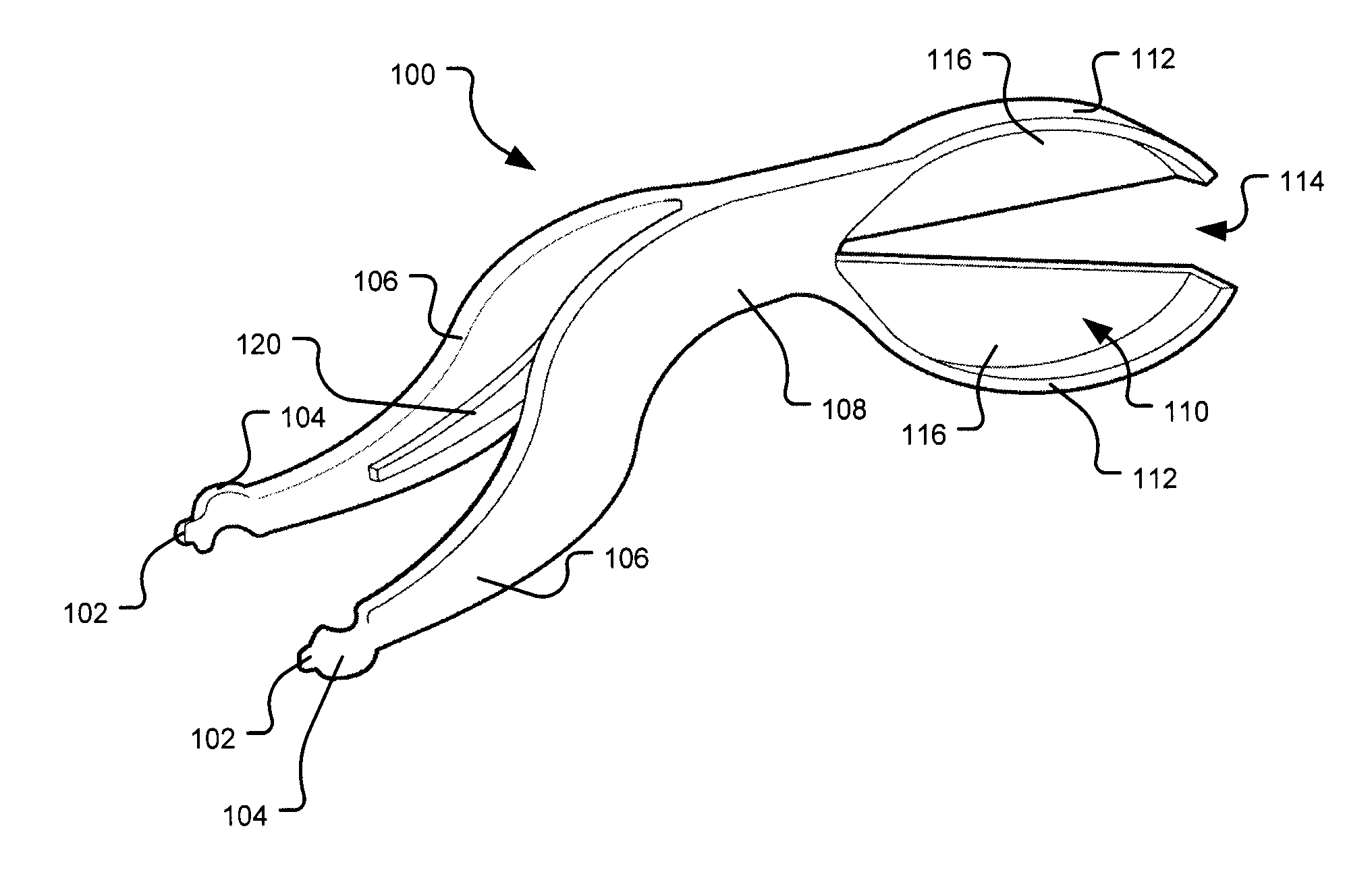

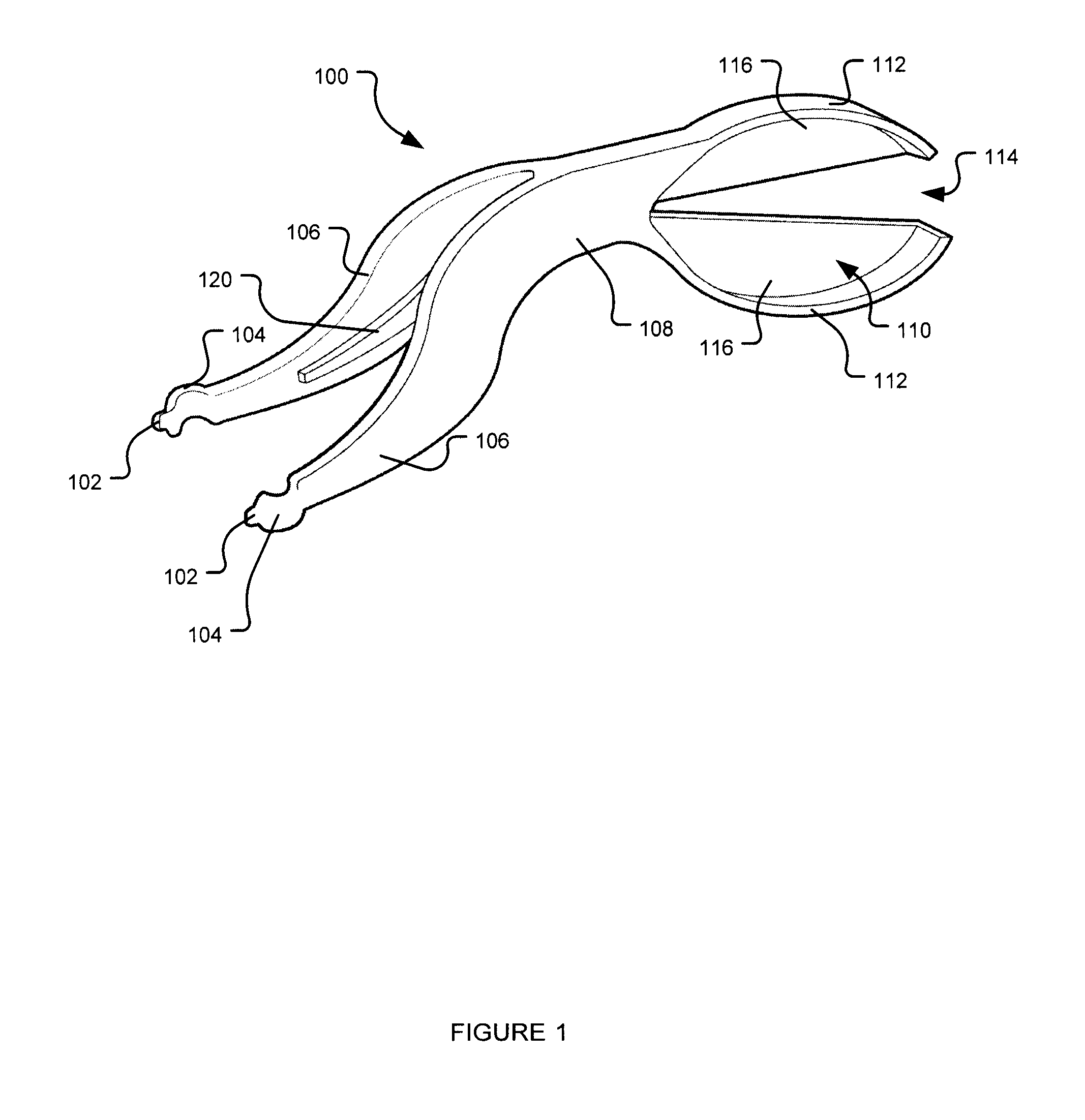

Combination tweezer and eye hair grooming device and method

A combination tweezer and eye hair care device and method. A combination device includes a tweezer along a first portion of the length thereof and an eye hair care device along a second portion. The eye hair care device may be an eyebrow brush or an eyelash comb In one embodiment, the eye hair care device is removable. The tweezer may have a straight, angled or pointed cutting tip.

Owner:ROSS RICHARD

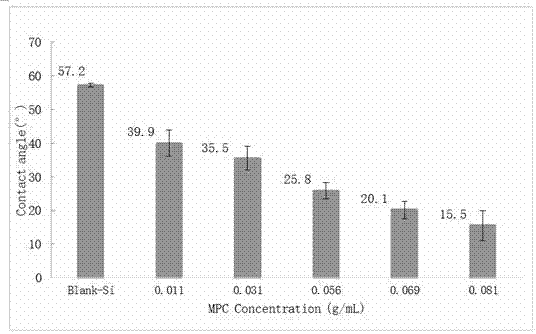

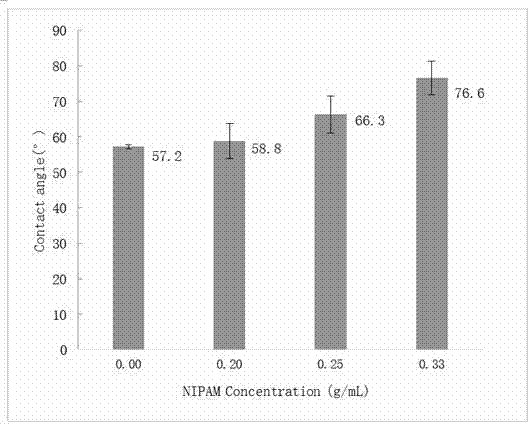

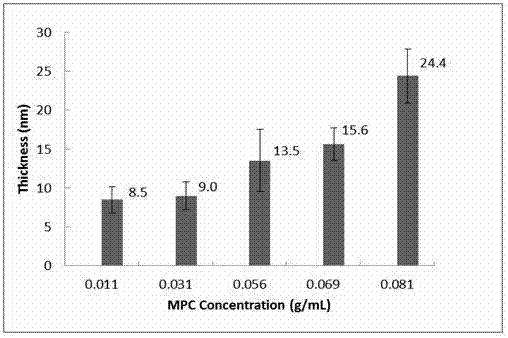

Universal and efficient material surface modification method

InactiveCN106967228AOptimize experimental conditionsAdhesion is gentleCoatingsSurface modificationSubstrate surface

The invention discloses a universal and efficient material surface modification method which comprises the following steps: 1) preparing a dopamine solution; 2) treating a substrate surface, washing, and preserving for later use; drying a substrate material in a blowing manner before being used; putting a substrate into the dopamine solution, and drying in the blowing manner for later use; 3) grafting a PEI (Polyethyleneimine) layer on the basis of a dopamine coating, preparing a Tris*HCl solution, and sealing for preservation; preparing a polyethyleneimine (PEI) solution for later use; putting the substrate coated by a PDA layer into the polyethyleneimine (PEI) solution, sealing the opening with a preservative film, stirring at room temperature for reaction, grafting the polyethyleneimine (PEI) layer, performing reaction, taking out by using tweezers, and blowing for later use; 4) inoculating an activated initiator; 5) performing surface initiation polymerization, immobilizing the initiator on surfaces of different substrates, and preparing different types of polymer brushes on the surfaces of different substrates by using a surface initiation polymerization method. The method has the advantages of being gentle and universal.

Owner:NORTHWEST UNIV

Dual Ended Tweezer

Owner:HUSSAIN MUHAMMAD +1

Tweezers with magnetically pivotal illumination device

A tweezers includes two joined metal legs comprising a forward gripping end and a force exertion portion extending from a rear end of the leg to the gripping end wherein a projection is formed on an inner surface of a head part joining the legs; a battery powered light source having a forward portion pivotably secured to the legs and comprising an on / off switch; a magnet disposed in a rear end of the light source and adapted to attach to the projection; and a plastic member covered the head part and the force exertion portions of the legs. An angle of light emitted from the light source can be adjusted to illuminate an area being worked therewith.

Owner:CHEN MING NAN

Miniaturized Optical Tweezer Array

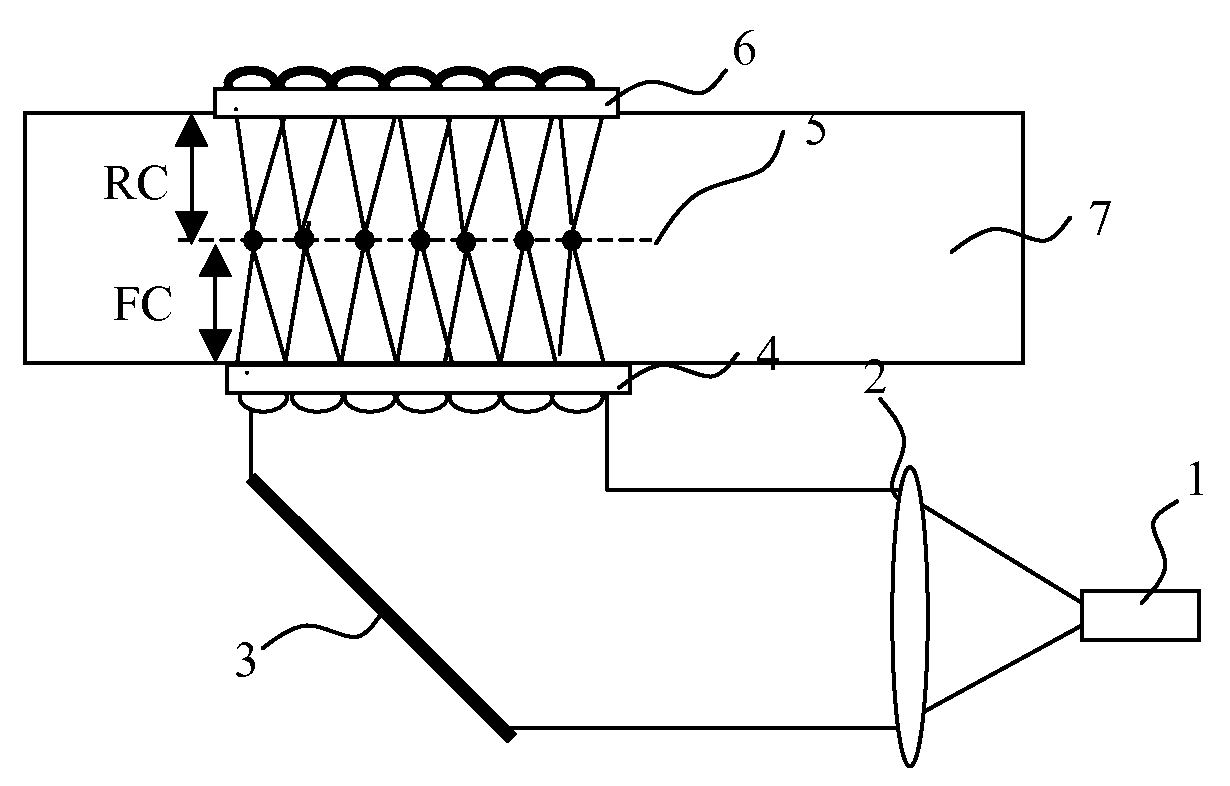

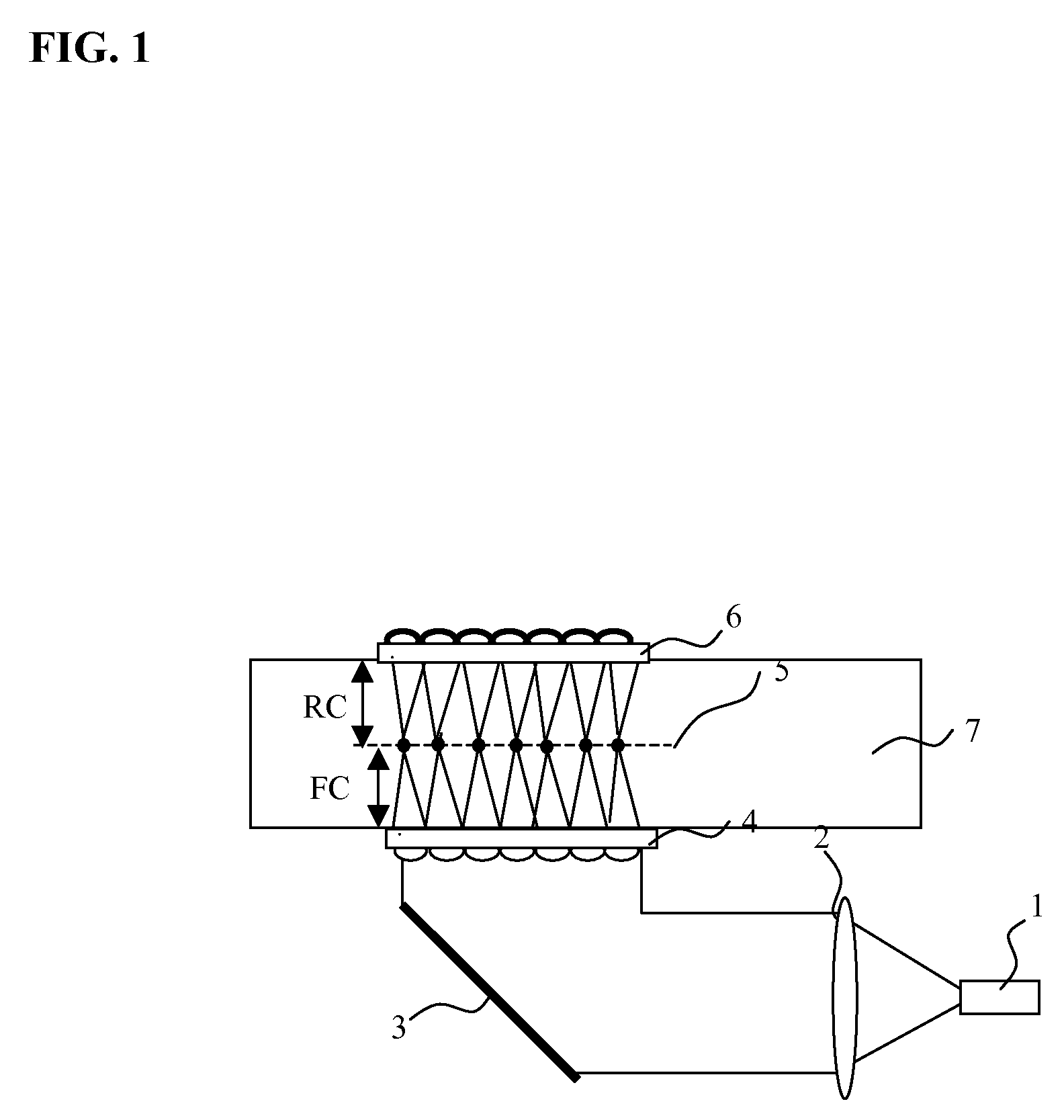

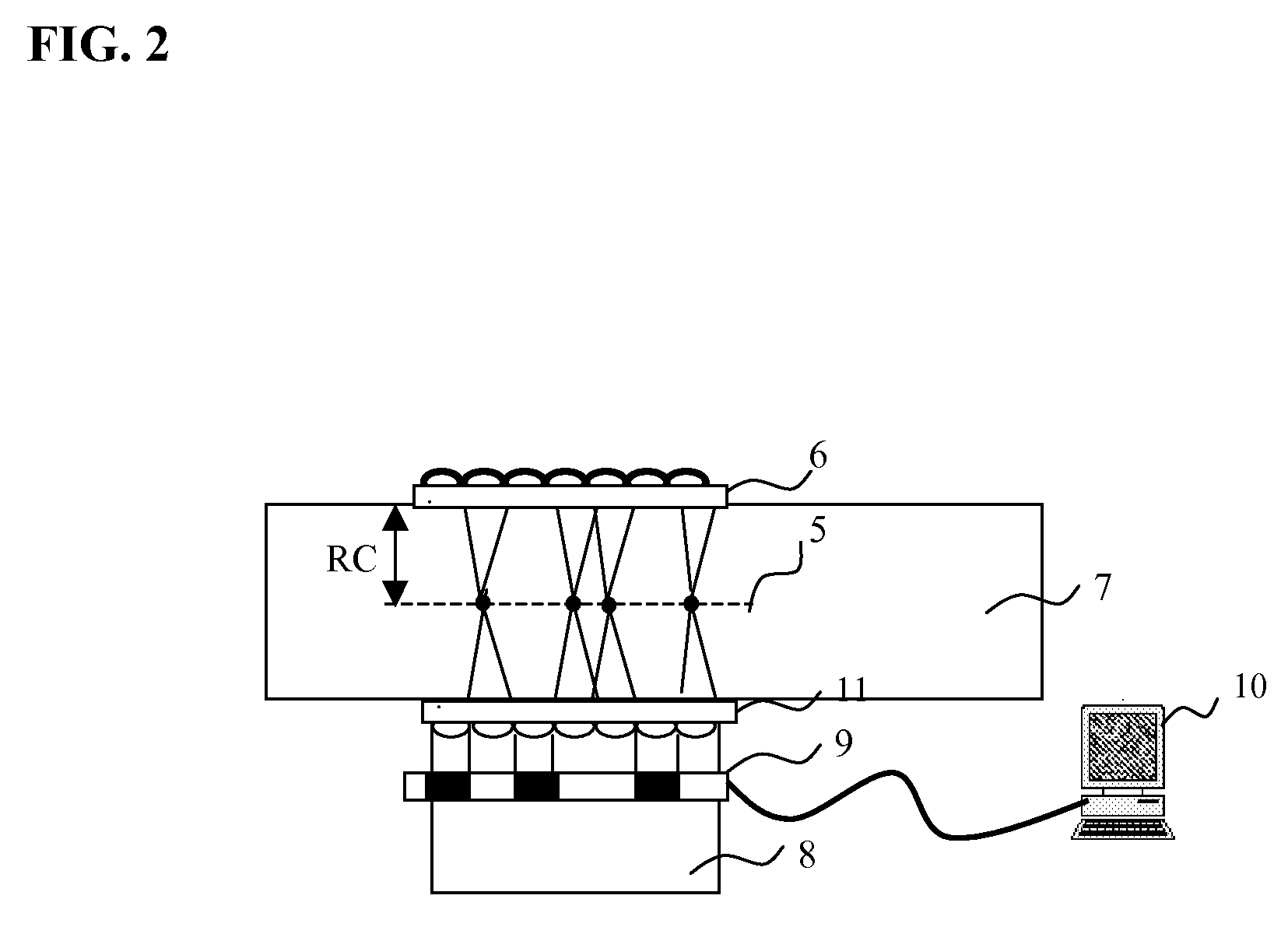

ActiveUS20090190221A1Little useLaser detailsMaterial analysis by optical meansOptoelectronicsTweezers

Apparatus for forming a single or a plurality of threedimensional optical traps, the apparatus comprising: a. A collimated light source that is directed onto an array of focalizing refractive or diffractive elements providing a single or a plurality of focal areas, and b. An array of reflective elements, placed opposite to the said focalizing elements described in a), which reflect back the light into the said focal area. The invention also relates to a method for using this apparatus.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

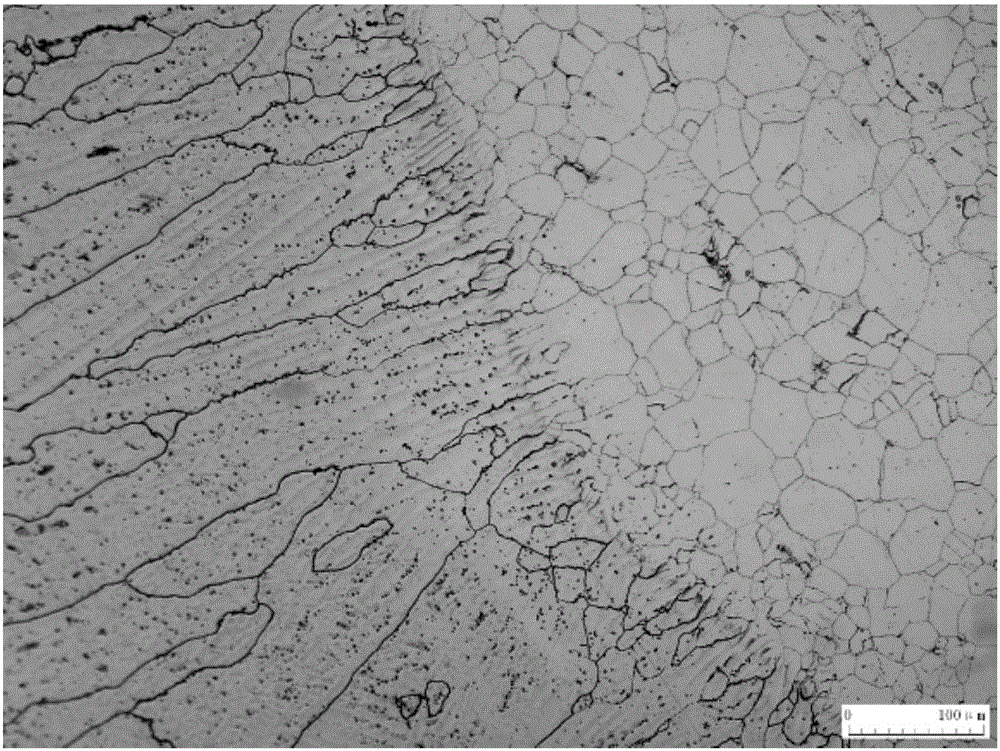

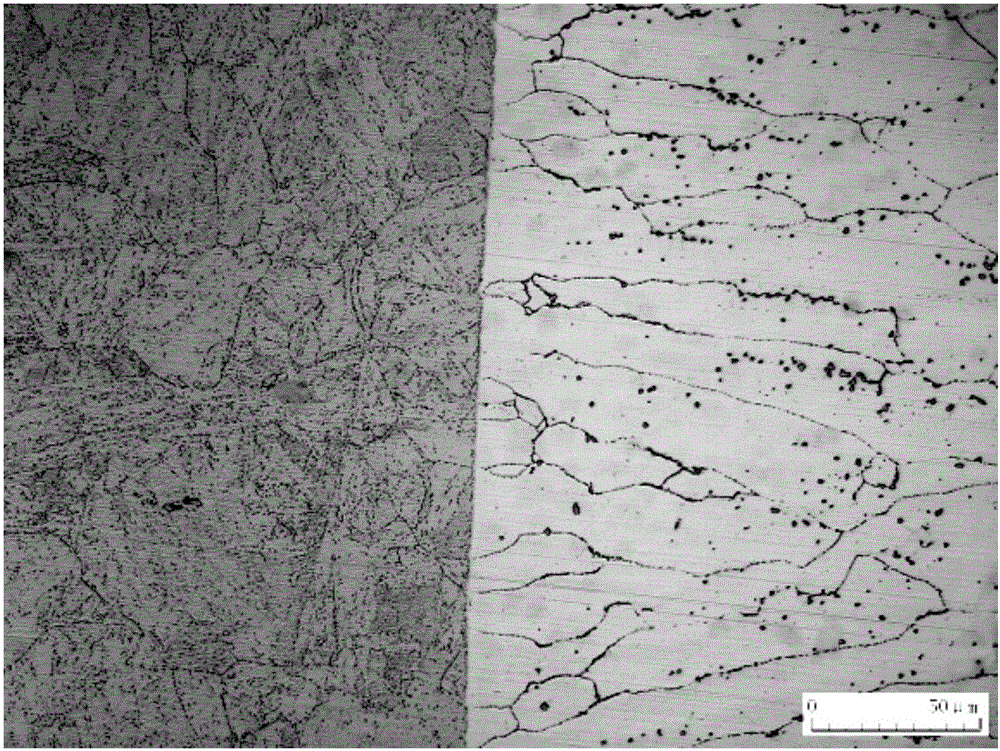

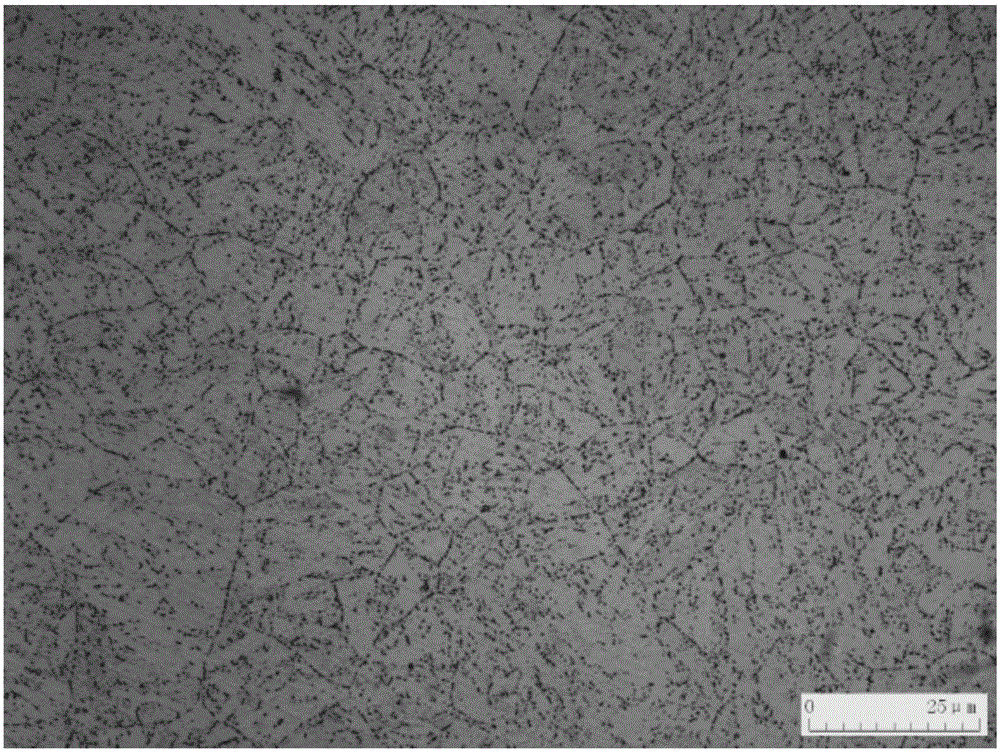

Display method for metallographic structure of austenite and ferrite dissimilar steel joint

ActiveCN106092710AEasy to prepareConvenient and accurate inspectionPreparing sample for investigationMaterial analysis by optical meansElectrolysisAlcohol

The invention discloses a display method for a metallographic structure of an austenite and ferrite dissimilar steel joint. According to the display method, the operation is simple, rapid and safe, and an etching process is easy to control. The display method comprises steps as follows: (1), sampling: sampling is performed at the austenite and ferrite dissimilar steel joint; (2), preparation of etching solutions: the etching solutions comprise an electrolysis etching solution, an intermediate treatment etching solution and a chemical etching solution; (3), etching treatment of a dissimilar steel joint sample: a to-be-detected sample is clipped by a pair of anodic stainless steel tweezers and soaked into the electrolysis etching solution, the distance between an analysis surface of the to-be-detected sample and a cathode is enabled to be 5-20 mm, and the to-be-detected sample is etched for 2-10 s; the sample is soaked into the intermediate treatment etching solution, and the surface is wiped for 2-10 s; then the sample is soaked into the chemical etching solution and wiped until the surface is silver gray; finally, the sample is washed with clean water, absolute ethyl alcohol is dropwise added to the sample, and the sample is blow-dried by a blower; (4), the sample is subjected to microexamination. The display method is simple to operate, convenient and rapid to use, good in repeatability and suitable for daily batch inspection and has great guiding significance for production.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

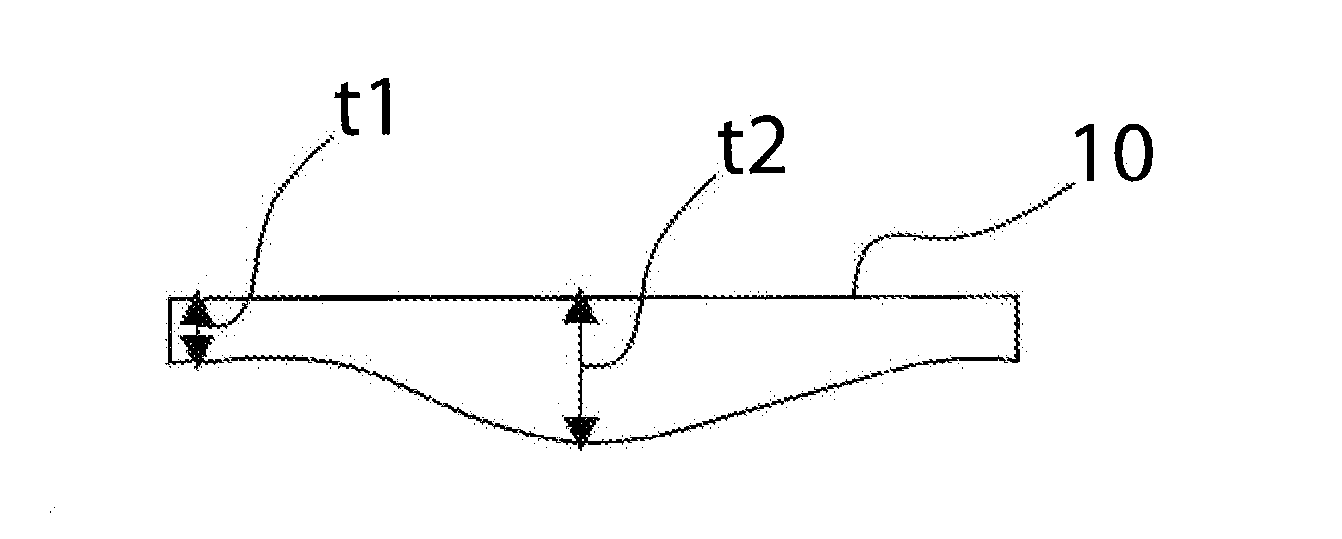

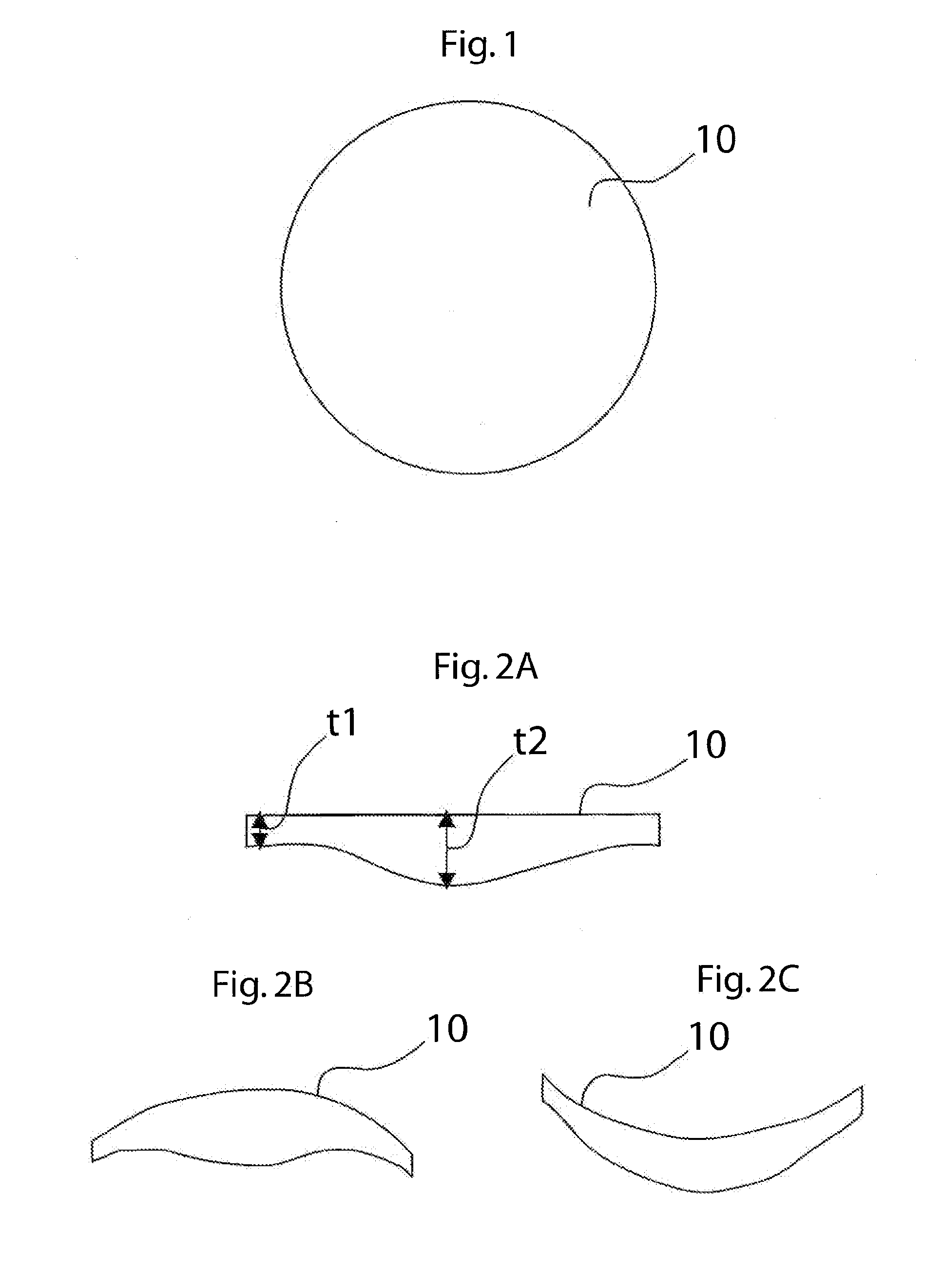

Method and apparatus for correcting optical aberrations using a deformable mirror

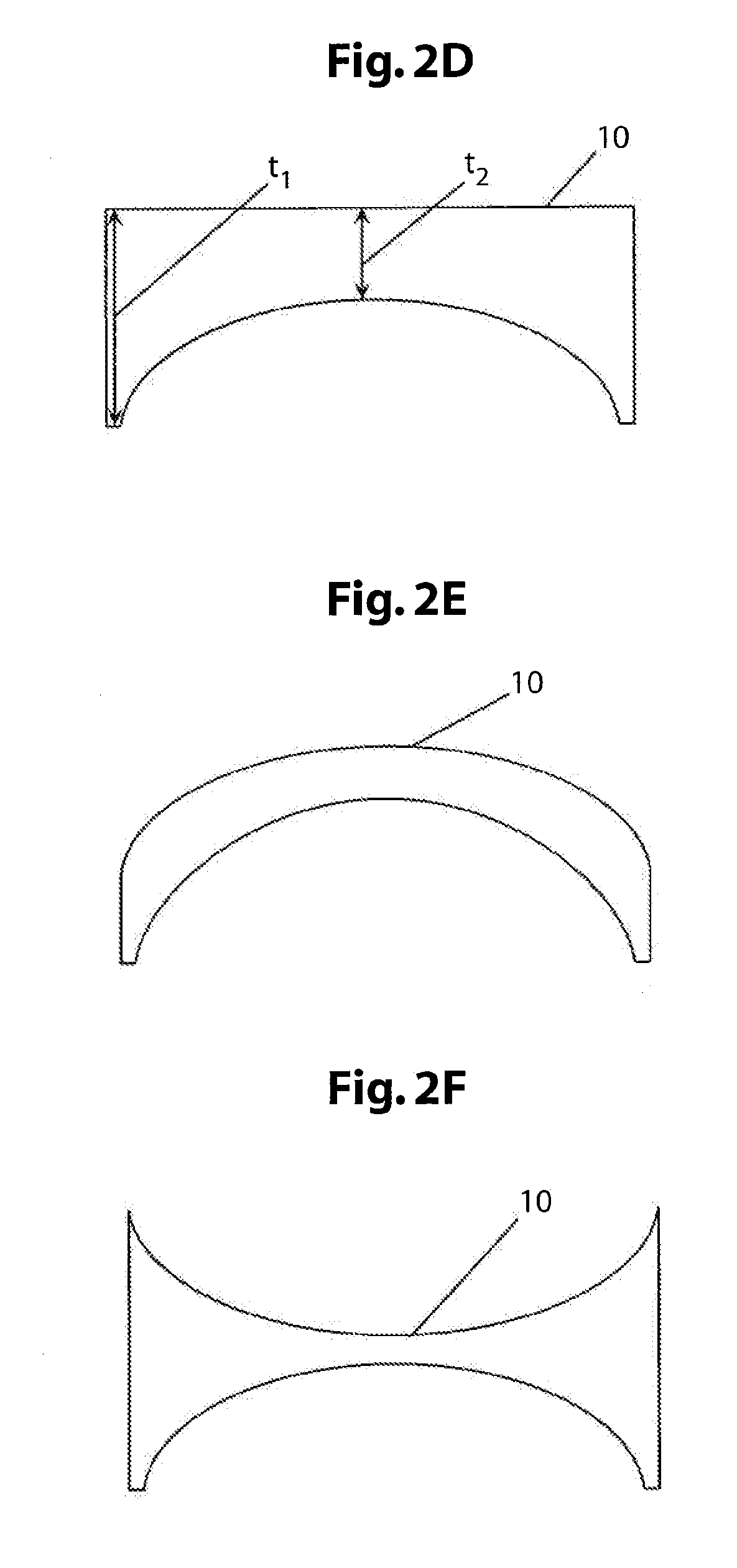

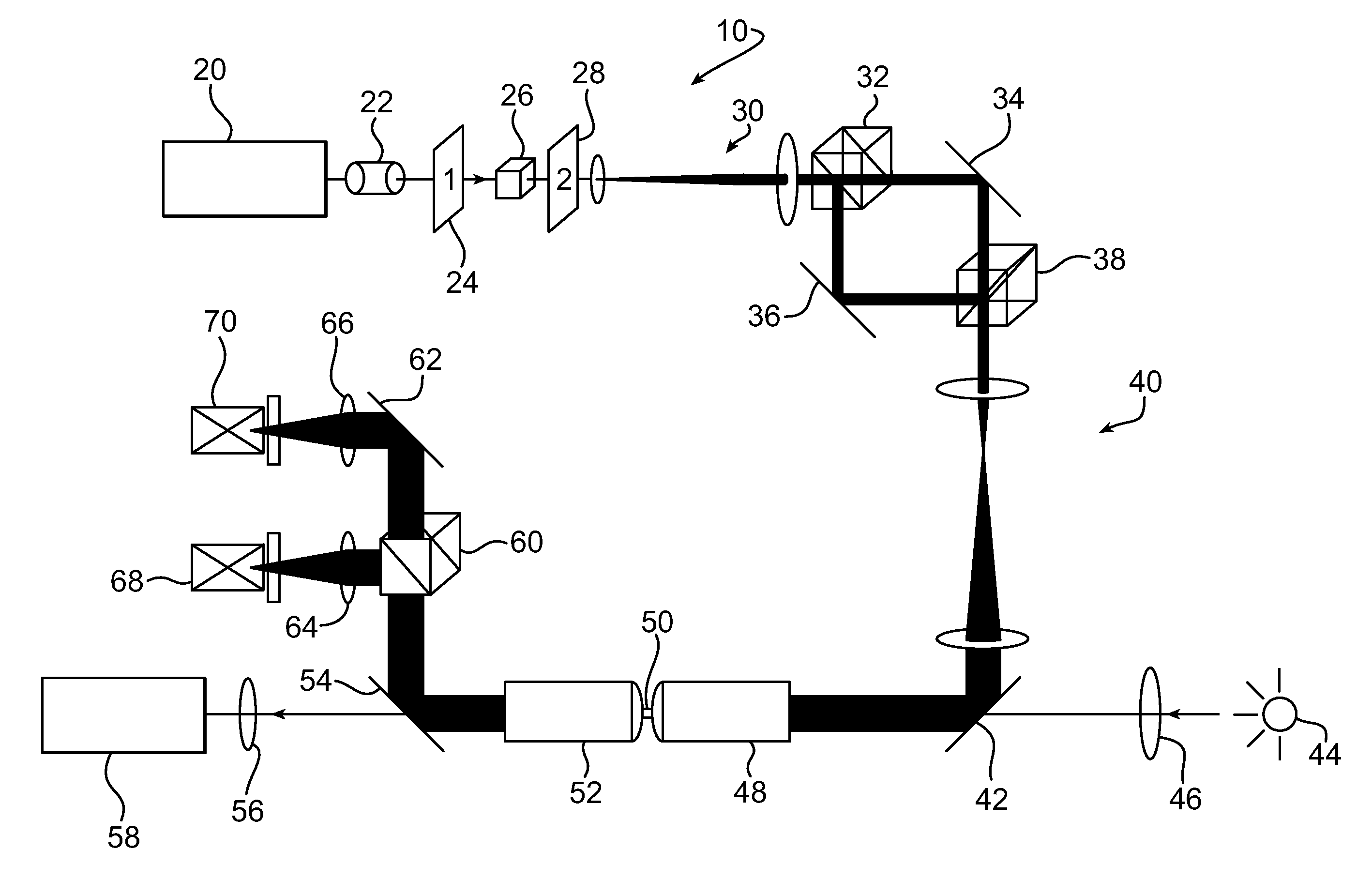

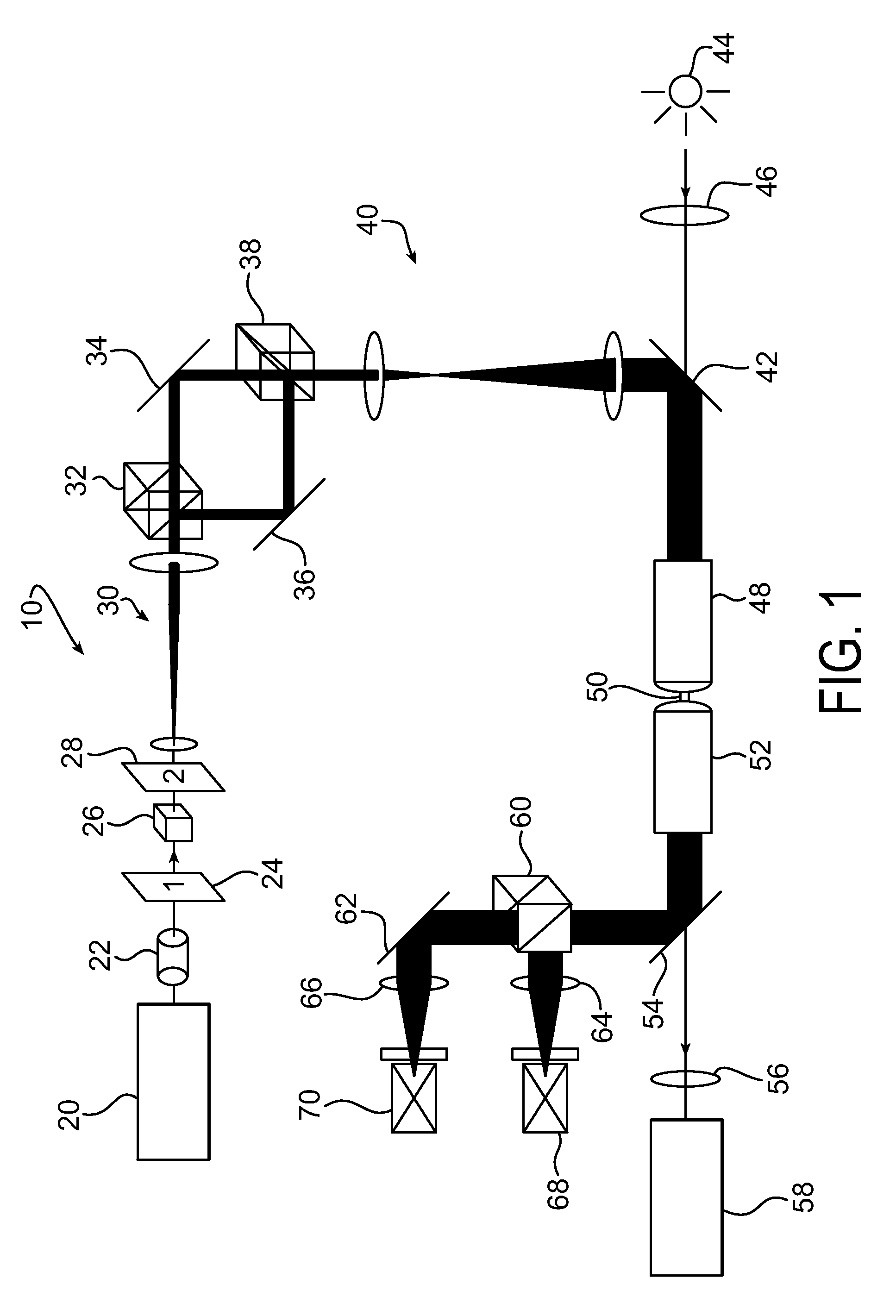

InactiveUS20110134552A1Simple and preciseNecessary functionMirrorsMountingsTweezersSpherical aberration

A method and apparatus for correcting optical aberrations in an optical device using a deformable mirror. An actuator is provided which applies a deforming force to the deformable mirror. By selecting particular thickness profiles of the deformable mirror and force configurations of the actuator, the optical device can be configured to correct for different optical aberrations. The actuator may be configured to apply the deforming force peripherally, centrally, non-centrally or homogenously across the surface of the deformable mirror. The deformable mirror may be a flat disk mirror, a convex mirror, or a concave mirror, and may include a membrane having a variable flexibility. The optical device may be a wide-field microscope, an optical read / write device, laser tweezers, or any other optical device in which correction of optical aberrations is desirable.

Owner:YEDA RES & DEV CO LTD +1

Sensitive and rapid detection of viral particles in early viral infection by laser tweezers

InactiveUS20100099076A1Decrease of viral levelImprove the level ofBioreactor/fermenter combinationsBiological substance pretreatmentsMicrospherePhotodetector

The present system and methods allow for low level detection of as little as single pathogen particles, such as viral or bacterial particles, during the early stage of infection. An optical trapping system, such as laser tweezers, are used to trap a substrate to which an analyte has been bound to detect and record the thermal motion of an antibody-antigen interaction that may occur between an anti-viral antibody-coated microsphere and a viral particle for example. The system may be equipped with a detection system such as a position sensitive photodetector (PSD) to record the thermal motion of a trapped microsphere and particle at a certain frequency. The thermal motion data may be Fourier transformed into a power spectrum, which may be transformed into an output value using a Lorentzian equation. The power spectrum of the trapped microsphere may be recorded before and after binding of the pathogenic particle to determine the presence thereof.

Owner:KENT STATE UNIV

Cleaning and drying system for a personal hygiene device

InactiveUS20080060671A1Remove debrisReduce corrosionInternal framesBrushesTweezersMechanical engineering

An apparatus, system and method to clean and dry a personal hygiene device, such as a razor, tweezers, a comb, a toothbrush or other dental apparatuses, such as a dental pick. Typically, the system includes dryer generally coupled to a curved-wall chamber. The dryer generally includes a housing coupled to a duct, which, in turn is coupled to the curved-wall chamber. The housing includes a fan for pulling intake air into a housing via an air-intake. The housing further may include a heating element for heating air before entry into the curved-wall chamber. Thus, a personal hygiene device placed into a curved-wall chamber having a cleaning fluid can advantageously be cleaned and dried via circulating heated air and fluid within the curved-wall chamber under the circulation force of air provided by the fan.

Owner:RUFFIN STEPHEN

Powder metallurgy composite antimicrobial stainless steel instrument and its preparation method

InactiveCN101007351ASimplified adjustment processDiffusion is easy to achieveThermal treatmentMetal powder

The invention involves preparation method of powder metallurgy composite antibiotic non-corrodible steel equipment, it includes: shaping non-corrodible steel powder and preparing green compact; adding antibiotic metal powder into non-corrodible steel powder and preparing mixing powder; shaping the green compact and mixing powder in one time, coating the outside of green compact with mixing powder uniformly, then adglutinating, preparing the powder metallurgy composite antibiotic non-corrodible steel equipment after thermal treatment, the equipment includes the integral body of knives, scissors, clamps, forks, bowls, pans, spoons, tweezers, cups or its combinations. The antibiotic metal ion in the surface antibiotic layer can make the equipment play antibiotic role in the utilization process.

Owner:SOUTH CHINA UNIV OF TECH

Devices Employing Colloidal-Sized Particles

The present invention relates to the use colloidal particles to realize photonic and microfluidic devices. In particular embodiments, colloidal particles are used to realize microfluidic a two-way valve, three-way valve, check valve, three-dimensional valve, peristalsis pump, rotary pump, vane pump, and two-lobe gear pump. In certain embodiments, actuation of an active element in the microfluidic structure is accomplished by electrophoresis, the use of an optical trap or “tweezer”, or the application of an electric field or magnetic field. In other embodiments, the application of an electrical field to colloidal particles that are substantially constrained to two dimensional movement is used to realize wave guides, filters and switches for optical signals.

Owner:COLORADO SCHOOL OF MINES

Tweezers with pivotal slidable illuminating device

A tweezer assembly for handling minute objects includes two prongs comprising a rear opening having an upward inclined proximal end, an arcuate, enlarged distal end, and an elongated straight portion; a fulcrum member integrally formed with the prongs and having a through hole; a handle comprising two half portions including a grooved rail with the prong secured thereto and a trough aligned with the opening, and an intermediate member having a projection inserting into the through hole to secure the handle and the fulcrum member together; and a lamp comprising two side projections having a peripheral groove and a flat on the groove. The lamp is adapted to slide by sliding the projections along the troughs. The sliding will be stopped when the grooves enter the proximal ends with the flats being inclined to engage the proximal ends so as to pivot the lamp.

Owner:CHEN MING NAN

Nanometer biological optical tweezers based on optical micro-flow annular resonant cavity

InactiveCN103592782ALocalized manipulationSolving localized manipulation problemsRadiation/particle handlingCoupling light guidesBeam splitterBottle neck

The invention belongs to the technical field of optics and particularly relates to nanometer biological optical tweezers based on optical micro-flow annular resonant cavity. The tweezers comprise a silicon substrate chip type annular micro-cavity and a beam splitter or a multi-mode interference beam splitter. A tunable laser source is used to couple an optical field into the annular micro-cavity through the beam splitter and form an echo wall standing wave mode, and the optical gradient force generated by the standing wave mode is utilized to achieve localization operation of nanometer particles. The optical tweezers have the advantages that the technical bottle neck of nonlocality operation in the prior art is broken through, the features of the micro-flow and the high-quality factor optical micro-cavity are combined, low power consumption is achieved, localization operation of biological molecules in 100 nanoscale is achieved, and the like.

Owner:FUDAN UNIV

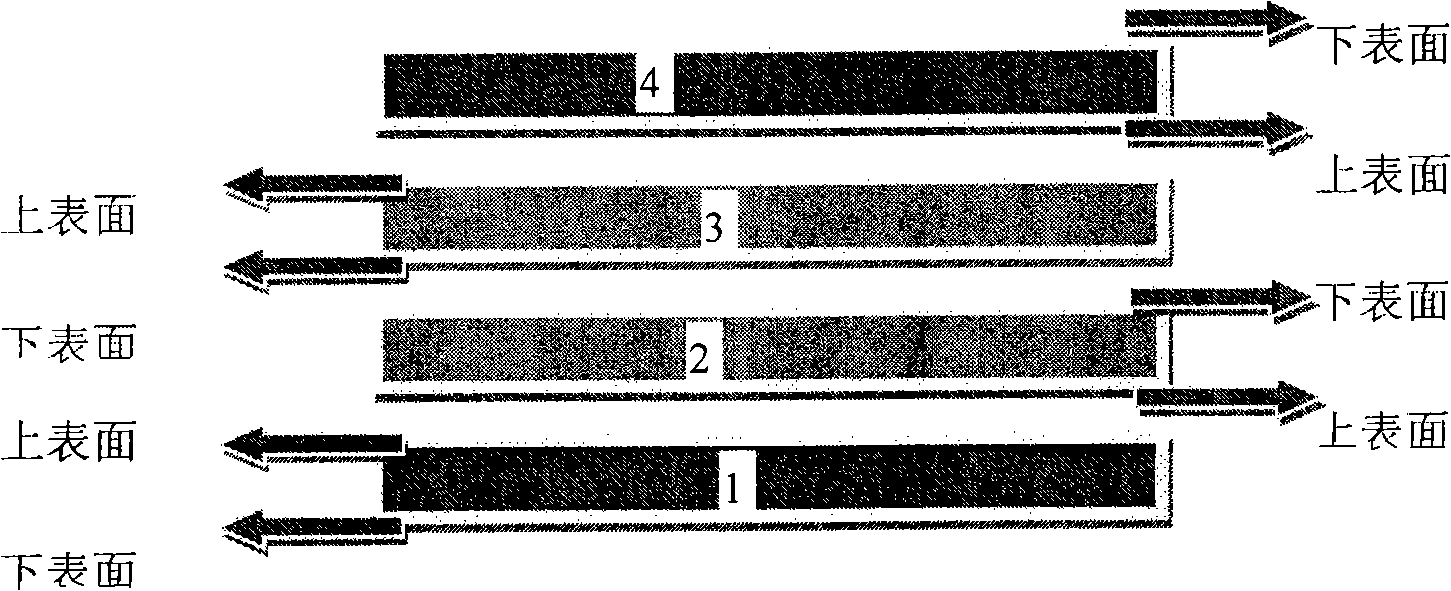

Method for measuring band steel surface total residual and residual ferrous powder

ActiveCN101354329AGuaranteed accuracyMaterial analysis by observing effect on chemical indicatorWeighing by absorbing componentSteel platesTweezers

The invention pertains to the field of metal material detecting and particularly provides a measuring method of total residues and residual iron powder on the strip surface. The measuring method of the invention is characterized in that a sampling mode that the upper surfaces of a first plate and a second plate, the lower surfaces of the second plate and a third plate, the upper surfaces of the third plate and a fourth plate are stacked together in sequence; when in measuring, two plates in the middle are taken to be detected. Butanone is used for cleaning the residues on the surface of the plate; a small amount of absorbent cotton is nipped by a tweezer to be dipped into little butanone so as to scrub the residues on the surface of the steel plate into a 250ml beaker till no dark mark can be scrubbed out by absorbent cotton; the absorbent cotton and the tweezer are washed by Ketone with small amount repeatedly to ensure accuracy of residues. When in analysis, total amount of residues is calculated by the formula: Oil(mg / m<2>single surface)=(G2-G1) / S, and the content of residual iron powder is calculated by the formula: Fe(mg / S<2> / single surface) is equal to V multiplied by C multiplied by 55.85 / 1.2 multiplied by 10<-1> multiplied by 2 multiplied by 10<-1>. The invention has the advantages that the effective area of a steel plate is ensured without being polluted when sampling is carried out and the effective area of the steel plate can not be polluted in the whole course of the experiment, thus ensuring the accuracy of the analysis result.

Owner:SHOUGANG CORPORATION

Trachea foreign body tweezers and tweezer body

The invention discloses trachea foreign body tweezers and a tweezer body. The tweezer body is integrally molded by use of elastic rubber or plastics; the tweezer body is structurally composed of a circularly tubular pipe joint b, a circularly tubular support ring, a spherical surface-shaped claw connecting surface and three claws, all of which are orderly and integrally connected together; the three claws are evenly connected to the external surface of the claw connecting surface and located in the same circle; a piston body is slidingly connected to the inner wall of the pipe joint b, and a connecting rod is connected between the piston body and the center of the claw connecting surface; through holes are evenly formed in the claw connecting surface and distributed in a circumferential array with the connecting rod as the center. The tweezer body is integrally molded by use of the elastic rubber or plastics, and thus is convenient to manufacture and low in manufacturing cost. The piston body is driven by negative pressure to move toward a piston barrel so that the claw connecting surface can be recessed, and then the three claws are driven by the claw connecting surface to realize a clamping action so as to clamp a foreign body.

Owner:邱兆友

Electric part handling device

ActiveUS7269892B2Delicate positioningMinimizes dead anglePrinted circuit assemblingLine/current collector detailsHand heldEngineering

Owner:HAKKO CO LTD

Liquid phase laser three-dimensional printing system and method based on nanoparticles

The invention relates to a liquid phase laser three-dimensional printing system and a liquid phase laser three-dimensional printing method based on nanoparticles. The system comprises a laser light source, a transmission control unit, a scanning focusing unit, a monitoring device, a liquid tank, a bearing substrate, an objective table, a moving table and a computer. The method comprises the following steps: establishing a geometrical model by utilizing computer drawing software, slicing and delaminating data, and planning a scanning path; putting liquid which contains to-be-printed nanoparticles into the liquid tank; adjusting the moving table, adjusting the upper surface of the bearing substrate placed on the objective table to a position which approaches the upper surface of the liquid in the liquid tank, so as to be positioned on the laser focusing plane after focusing; enabling the nanoparticles in the solution to move towards a laser focus by utilizing the action of laser tweezers, and generating fusion under the photothermal action, so as to form single-layer structures by virtue of laser scanning; lowering the objective table by the thickness of one single-layer structure, and scanning the other single-layer structure until the design structure is printed; taking out the printed structure, and cleaning residual nanoparticles on the surface of the structure.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com