Display method for metallographic structure of austenite and ferrite dissimilar steel joint

A technology of metallographic structure and display method, which is applied in the field of physical and chemical inspection, can solve the problems such as difficult single etchant structure morphology, difficulty in grasping the degree of etching, over-corrosion of ferrite, etc., and achieves a stable and easy-to-control reaction process, Simple etching method and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

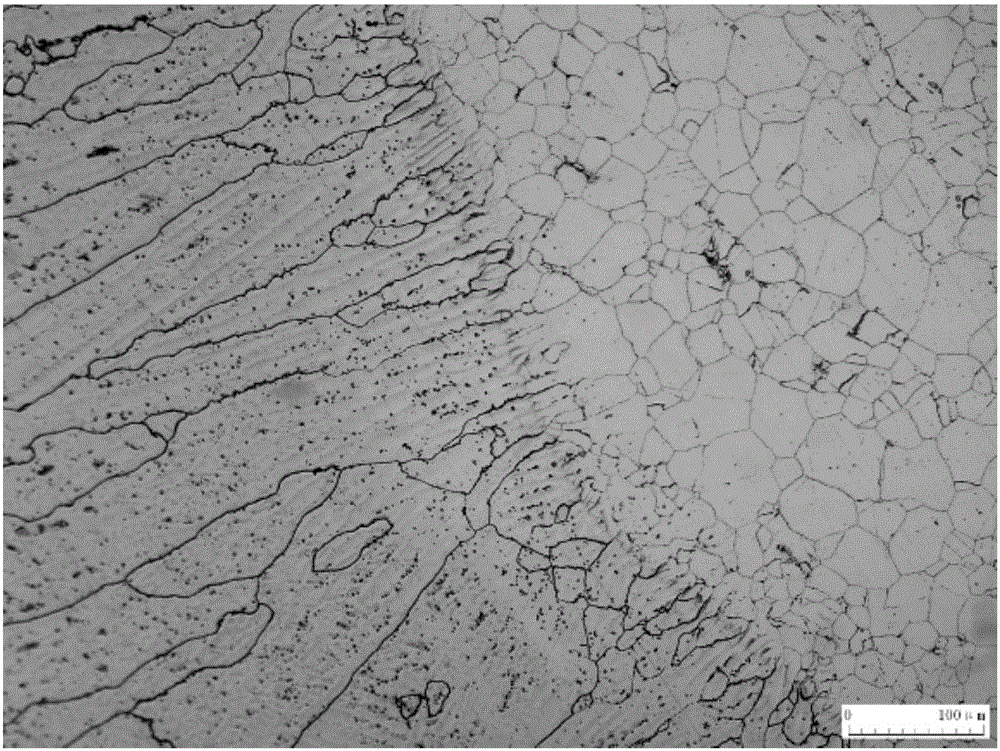

[0037] Take S30432 stainless steel and T91 steel joint structure as an example

[0038] (1) Sampling: Take an analysis sample with two-sided metal at the joint of S30432 stainless steel and T91 steel dissimilar steel, take the cross-section of the joint surface of S30432 stainless steel and T91 steel dissimilar steel as the analysis surface, and grind and polish until the surface Smooth and scratch-free sample to be tested;

[0039] (2) Preparation of etching solution

[0040] The etching solution includes electrolytic etching solution, intermediate treatment etching solution, and chemical etching solution, wherein the electrolytic etching solution is an oxalic acid aqueous solution with a mass percent of 3%; the intermediate treatment etching solution is a 14% mass percent dilute hydrochloric acid solution The chemical etching solution is a picric hydrochloric acid ethanol solution, which is made by adding 0.2 g of picric acid to 100 ml of 2% concentrated hydrochloric acid a...

Embodiment 2

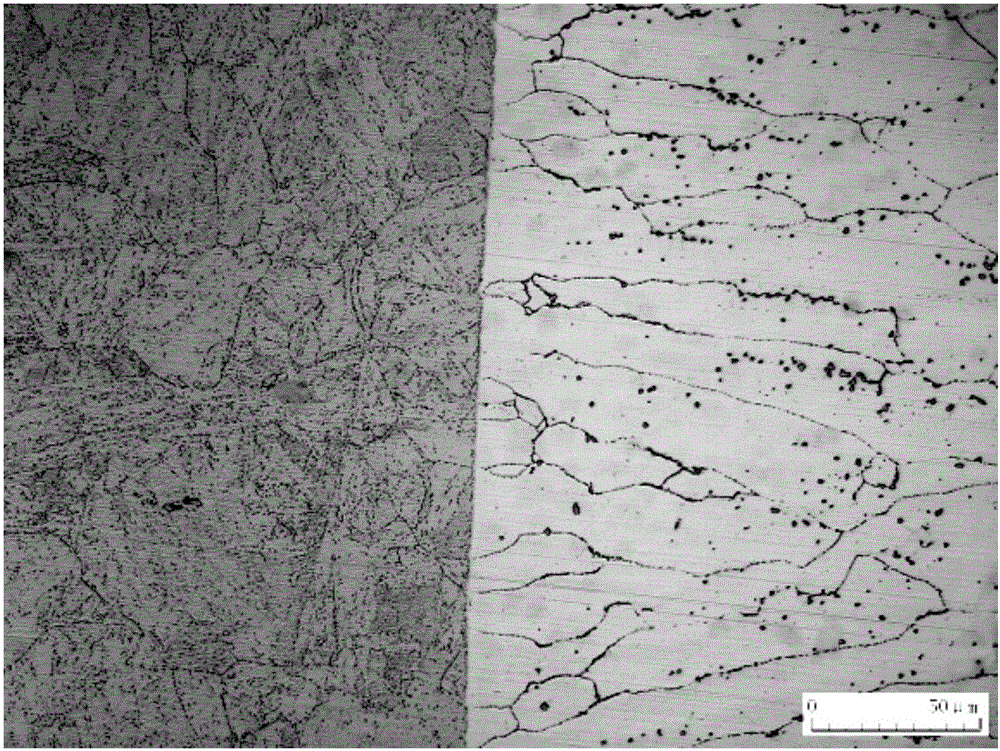

[0046] Take S30432 stainless steel and T92 steel joint structure as an example

[0047](1) Sampling: Take an analysis sample with two-sided metal at the joint of S30432 stainless steel and T92 steel dissimilar steel, take the cross-section of the joint surface of S30432 stainless steel and T92 steel dissimilar steel as the analysis surface, and grind and polish until the surface Smooth and scratch-free sample to be tested;

[0048] (2) Preparation of etching solution

[0049] The etching solution includes electrolytic etching solution, intermediate treatment etching solution, and chemical etching solution, wherein the electrolytic etching solution is an oxalic acid aqueous solution with a mass percentage of 10%; the intermediate treatment etching solution is a dilute hydrochloric acid solution with a mass percentage of 22% The chemical etching solution is a picric acid ethanol solution, which is made by adding 2.5g of picric acid to 100ml of concentrated hydrochloric acid abs...

Embodiment 3

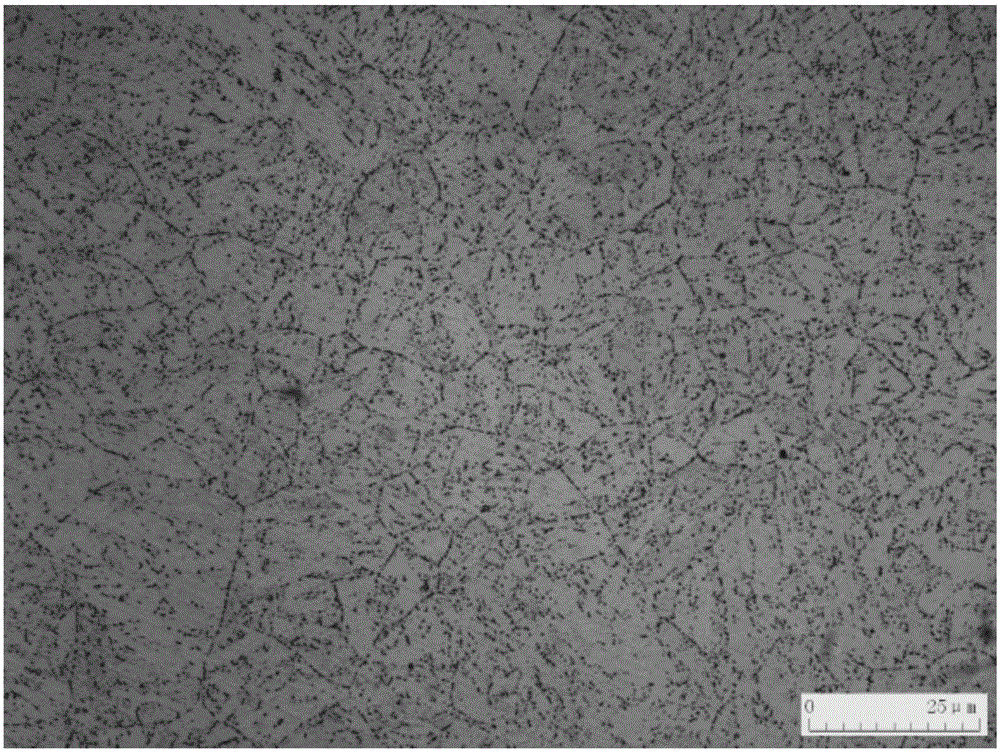

[0055] Take S30432 stainless steel and T91 steel joint structure as an example

[0056] (1) Sampling: Take an analysis sample with two-sided metal at the joint of S30432 stainless steel and T91 steel dissimilar steel, and use the cross-section of the joint surface of S30432 stainless steel and T91 steel dissimilar steel as the analysis surface for grinding and polishing;

[0057] (2) Preparation of etching solution

[0058] The etching solution includes electrolytic etching solution, intermediate treatment etching solution, and chemical etching solution, wherein the electrolytic etching solution is an aqueous oxalic acid solution with a mass percentage of 5%; the intermediate treatment etching solution is a dilute hydrochloric acid solution with a mass percentage of 20% The chemical etching solution is a picric hydrochloric acid ethanol solution, which is made by adding 0.5 g of picric acid to 100 ml of 3% concentrated hydrochloric acid absolute ethanol solution;

[0059] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com