Method for measuring band steel surface total residual and residual ferrous powder

A measurement method and technology of iron powder, which can be applied in the application of material absorption and weighing, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc. Contaminate the effective area of the steel plate, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Sampling:

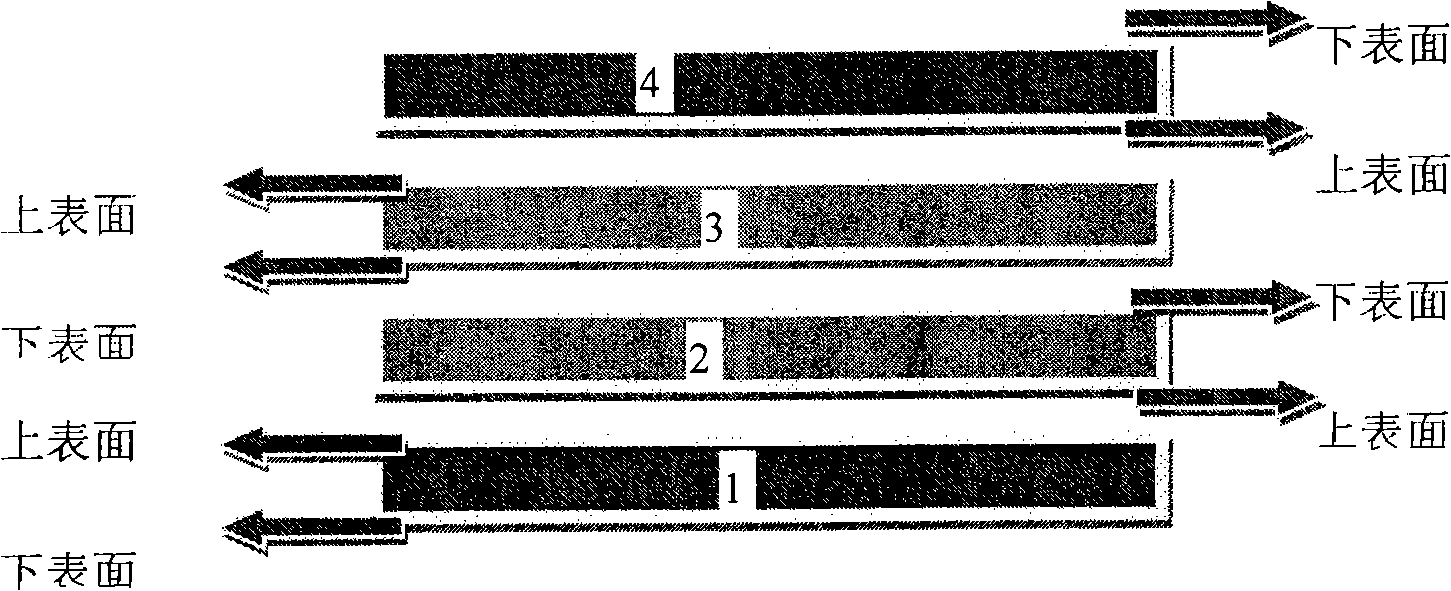

[0028] Take four samples continuously, each piece of specification: plate width × 500mm; after cutting, put them flat, and put them in the following way:

[0029] The upper surface of the first board and the upper surface of the second board, the lower surface of the second board and the lower surface of the third board, the upper surface of the third board and the upper surface of the fourth board are stacked together in turn, taking the middle The two blocks are tested.

[0030] 2. Use methyl ethyl ketone to clean the residue on the board surface. The cleaning method is:

[0031] (1) 250ml beaker treatment: put the clean beaker (with zeolite inside) in an oven at 100°C for 1 hour at a constant temperature, then take it out and cool it at room temperature for 5 minutes, put it in a desiccator and cool it down to room temperature (about 30 minutes), Weigh to get G1.

[0032] (2) Place the steel plate to be tested horizontally on the table, select a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com