Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

878results about "Glass optical fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

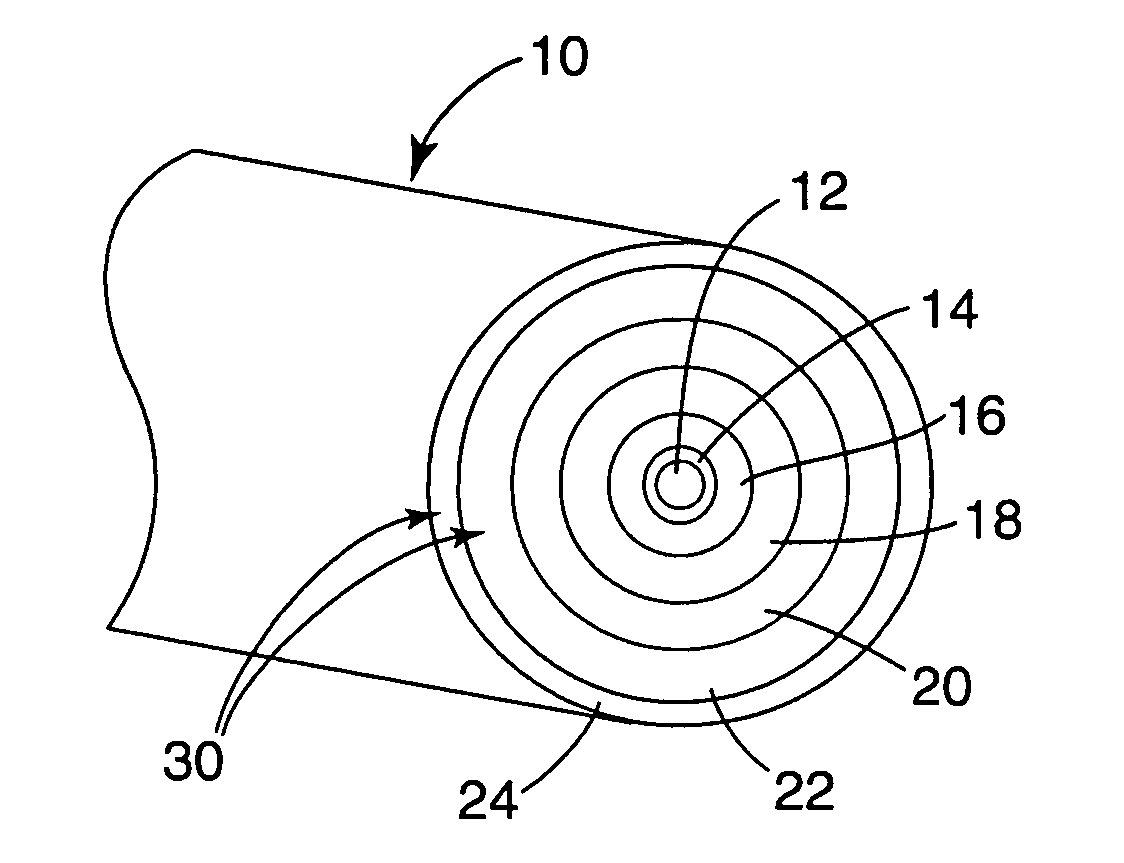

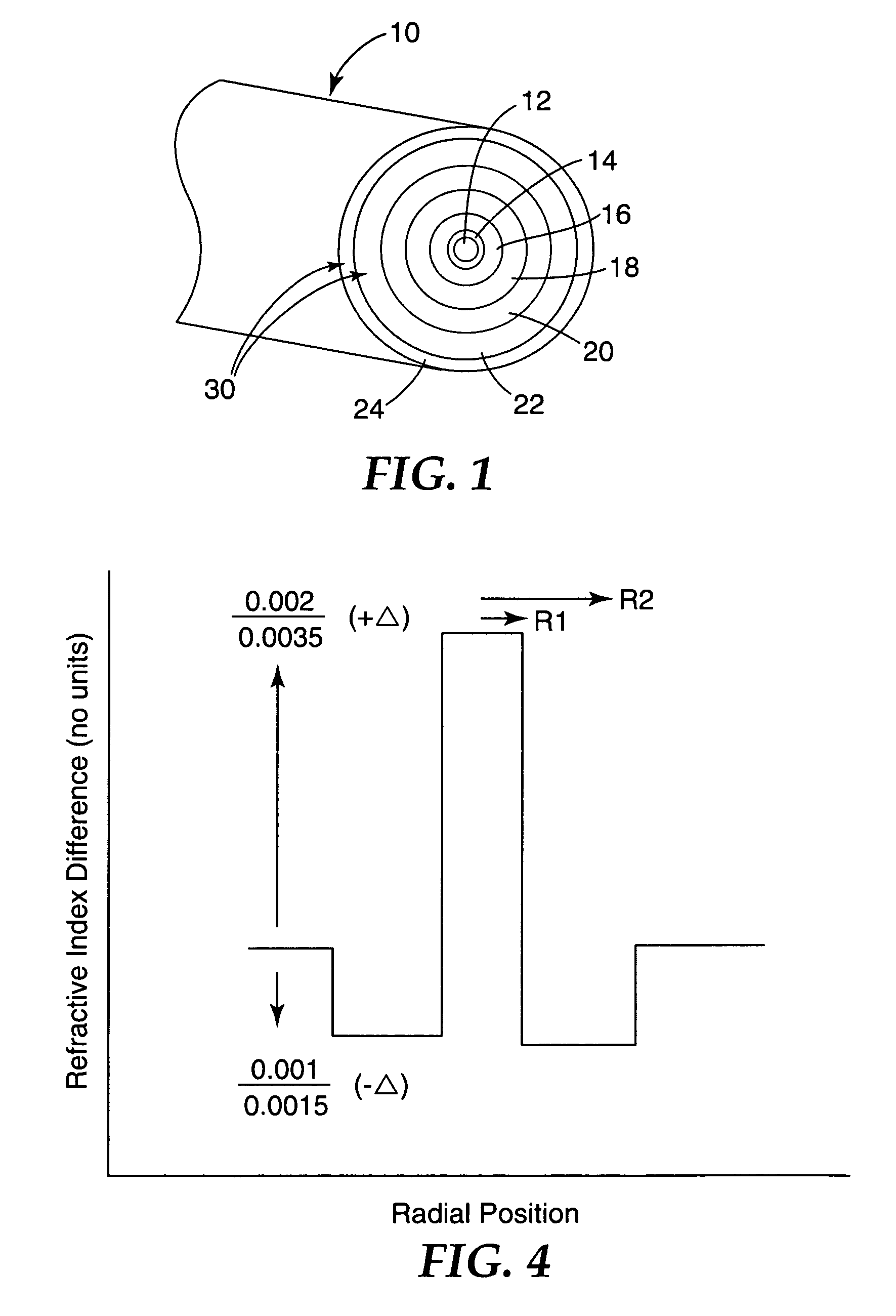

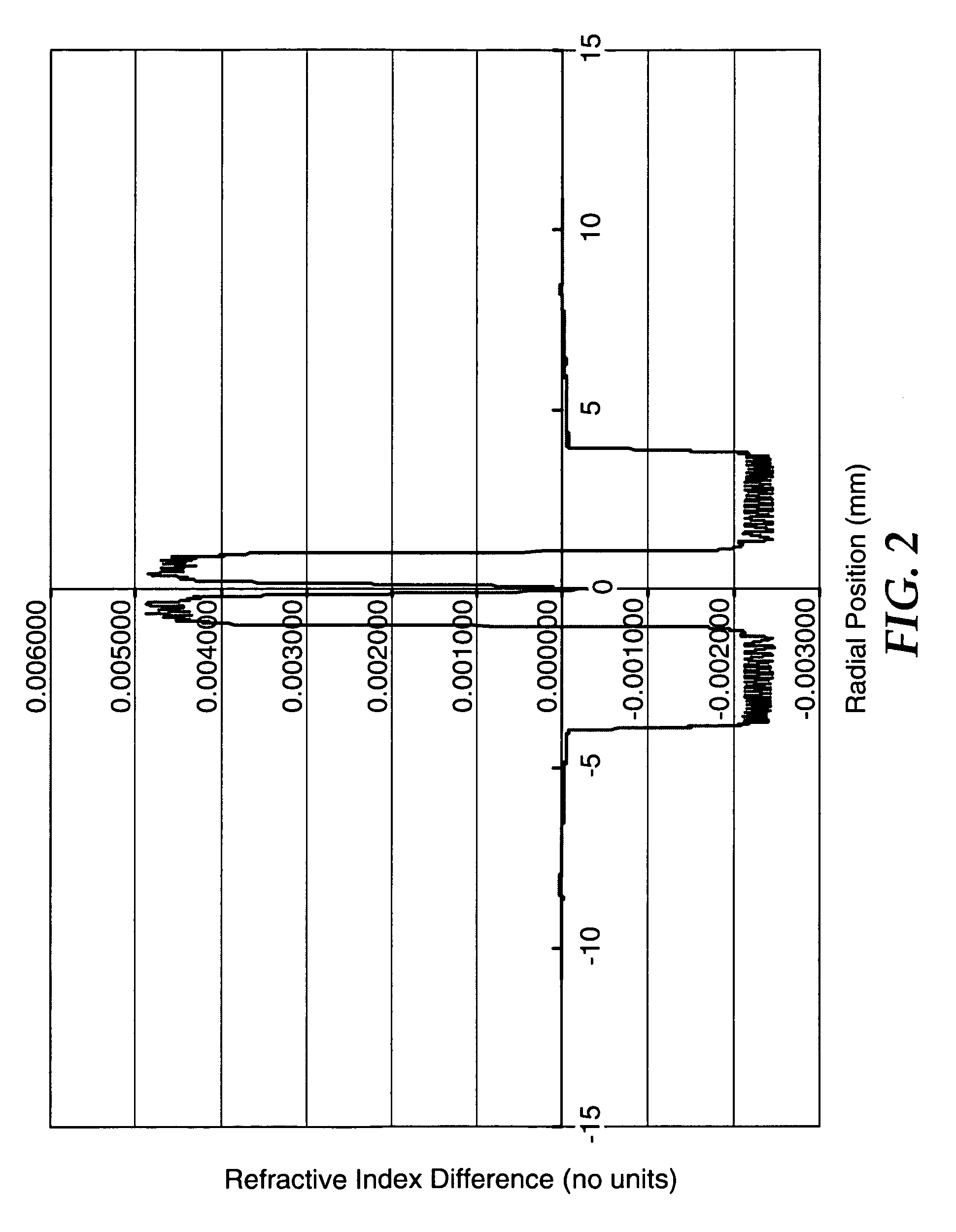

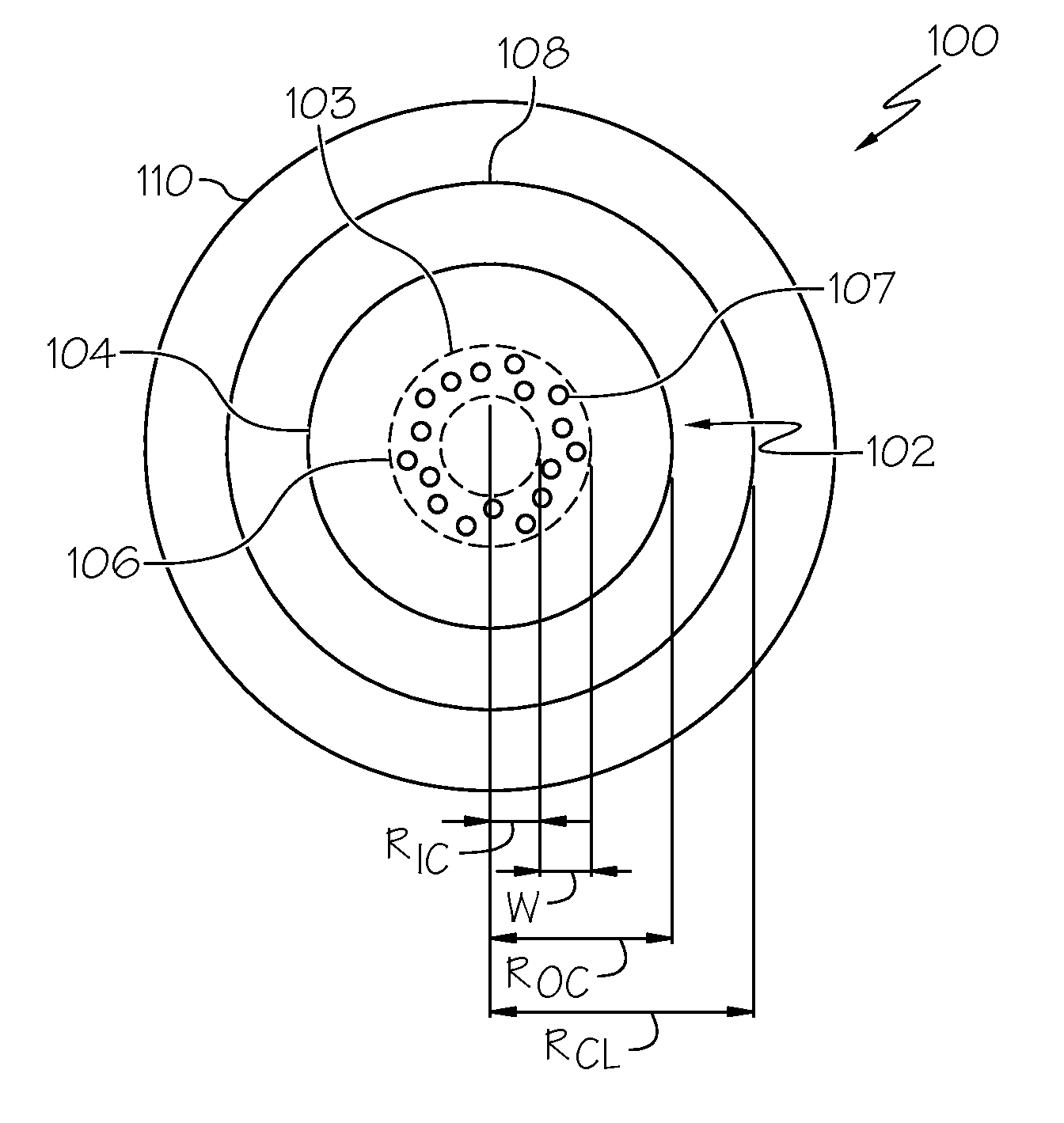

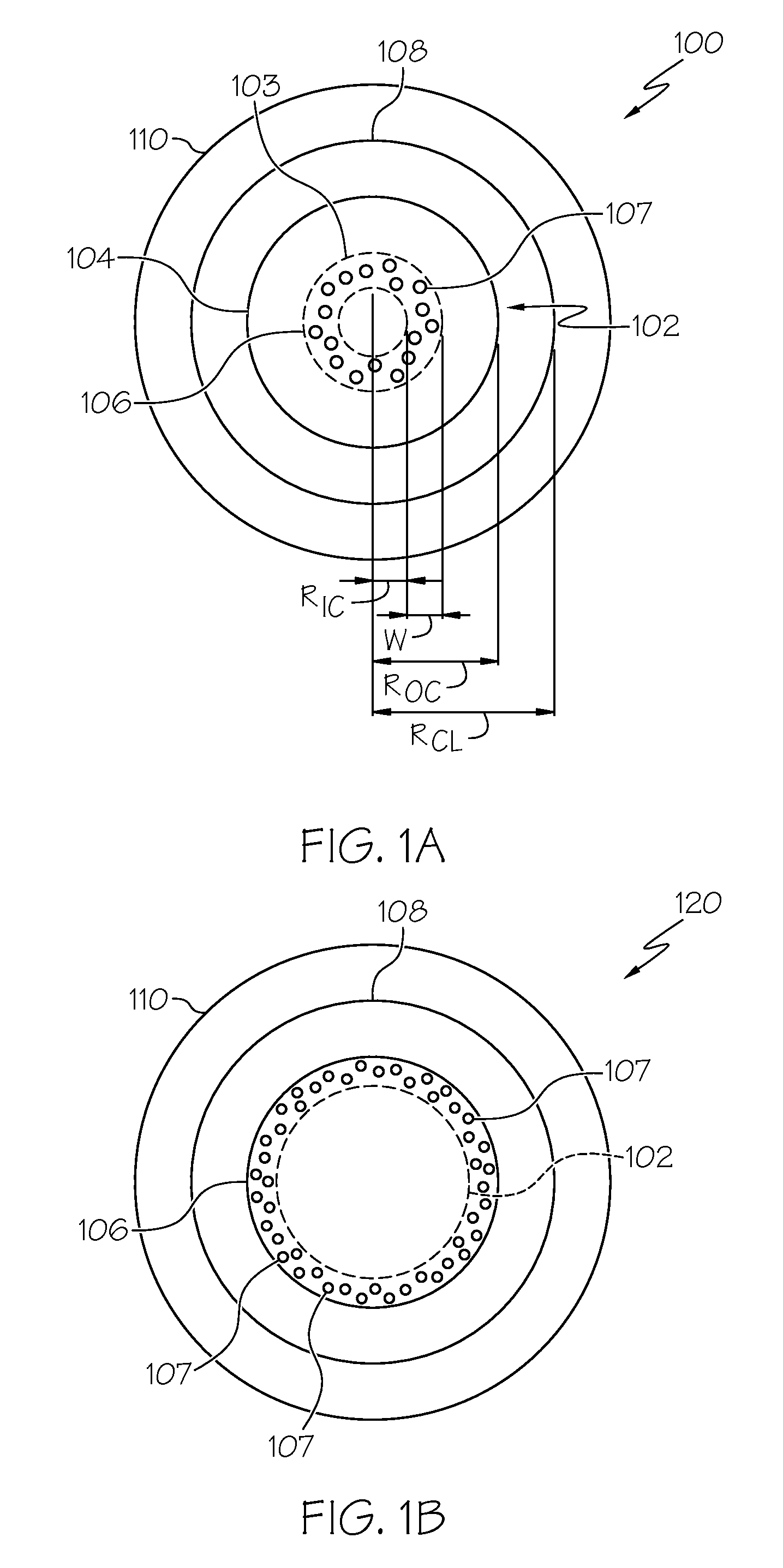

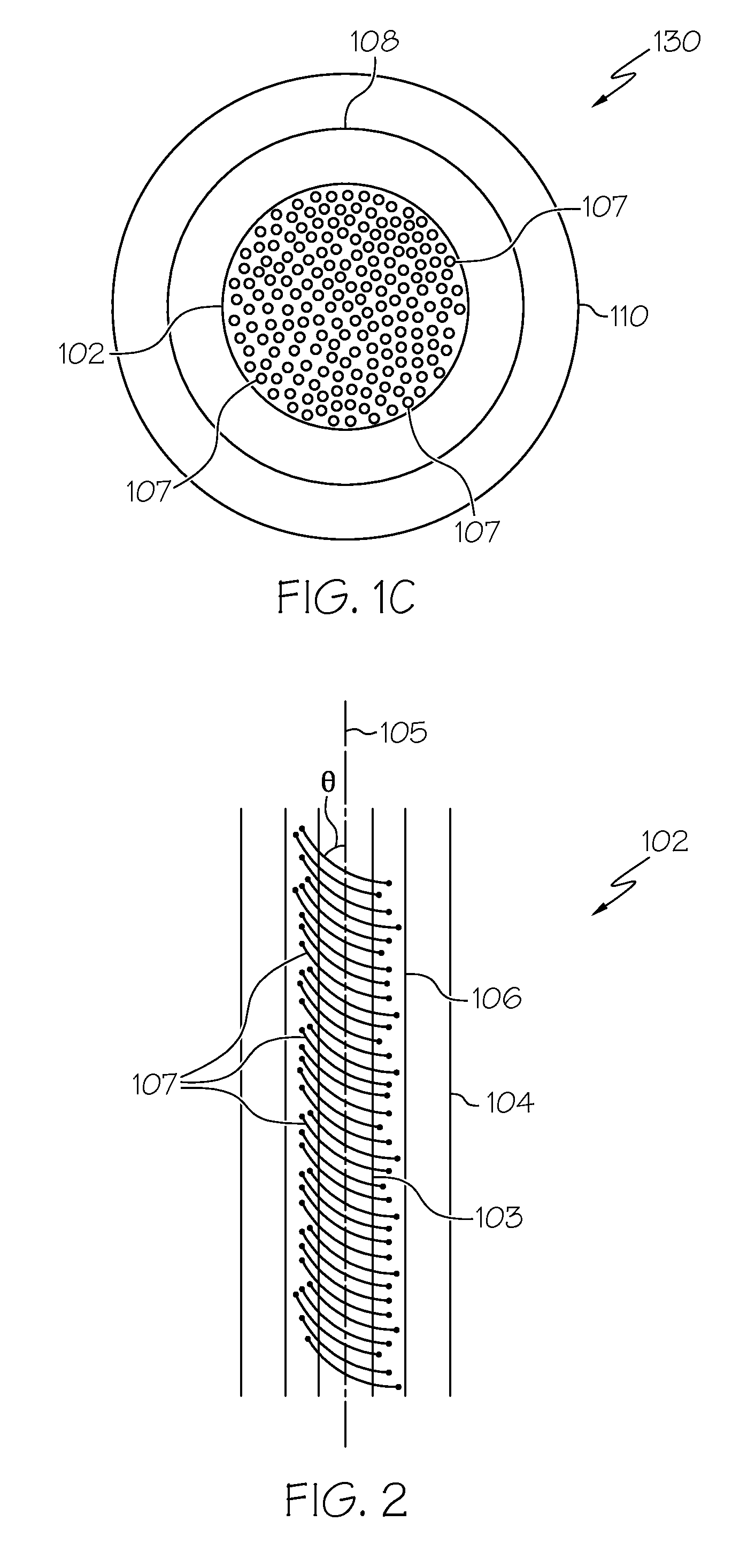

Triple-band bend tolerant optical waveguide

ActiveUS7130516B2Minimal splice lossesGlass optical fibreOptical fibre with multilayer core/claddingBand bendingLength wave

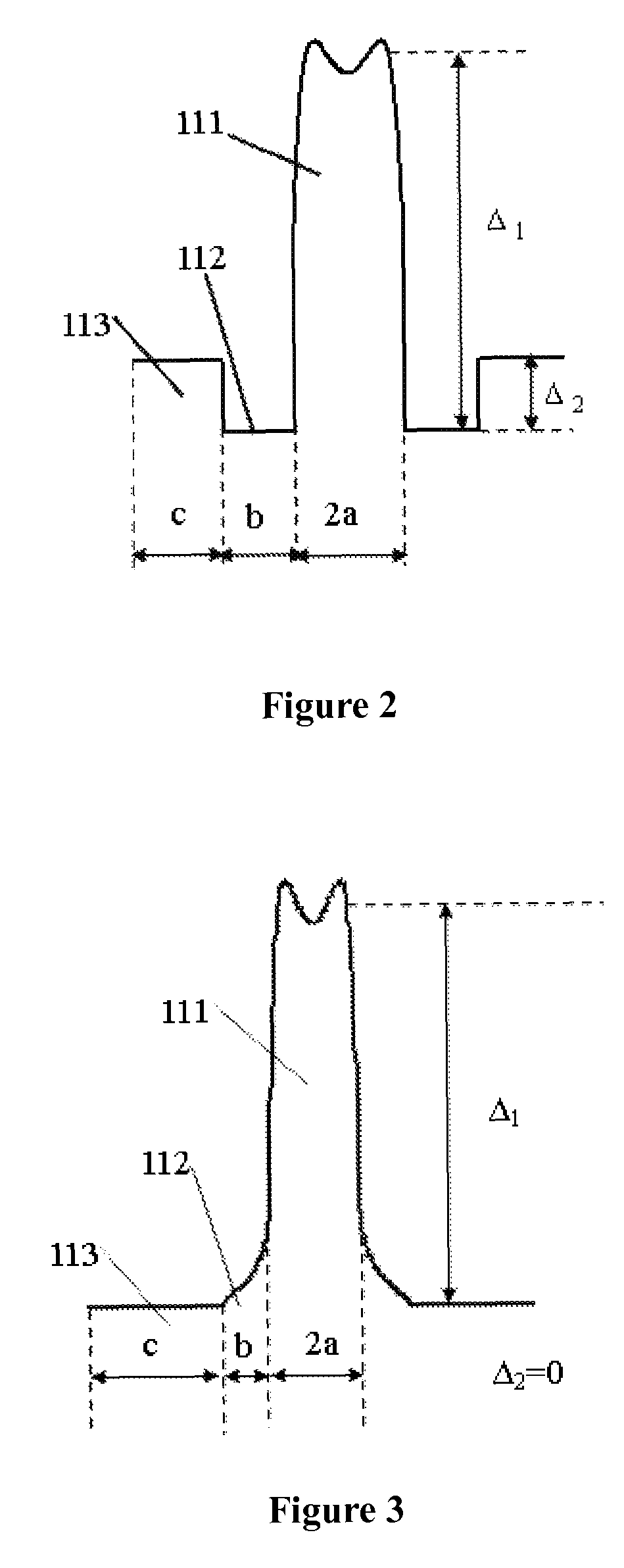

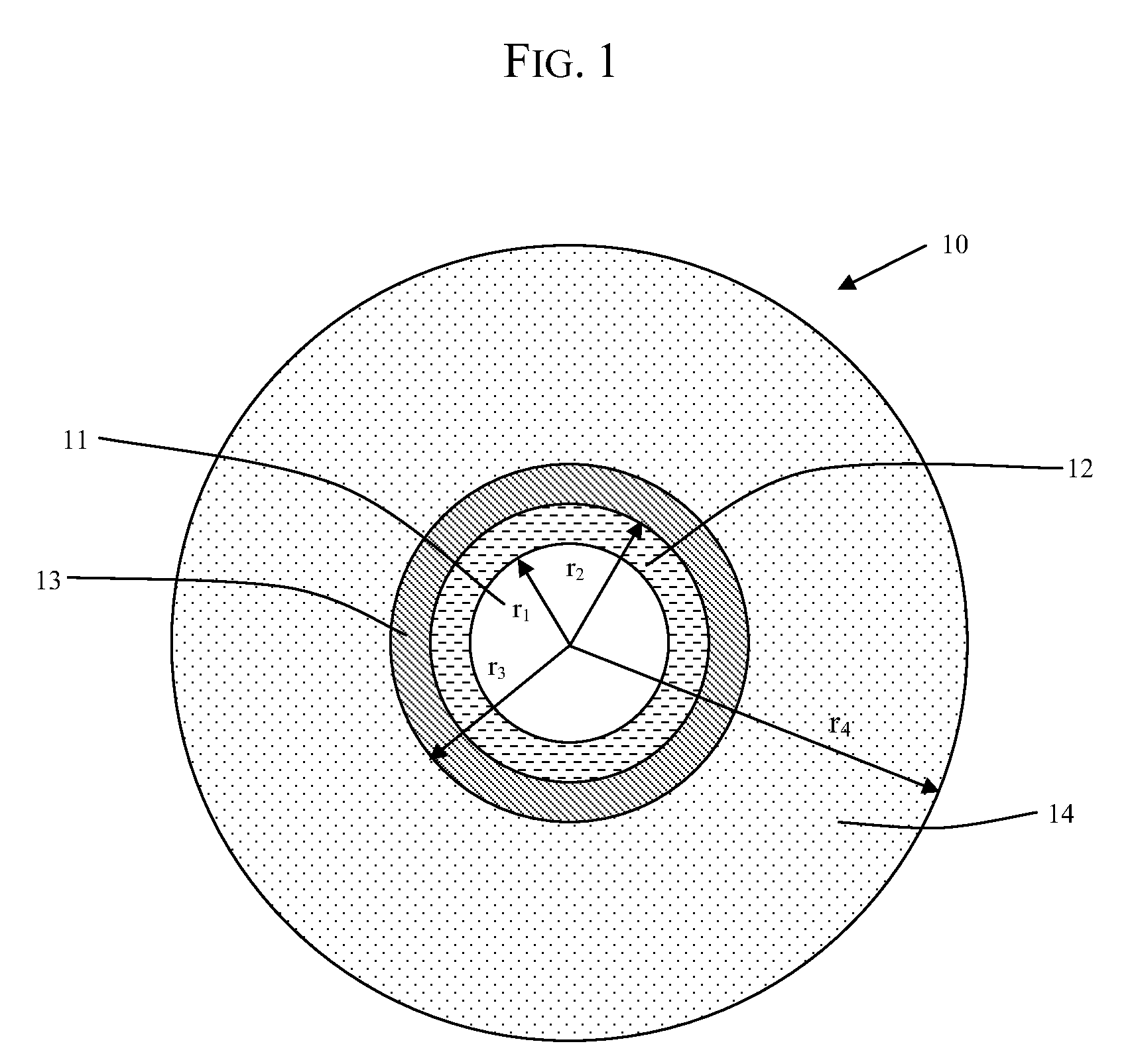

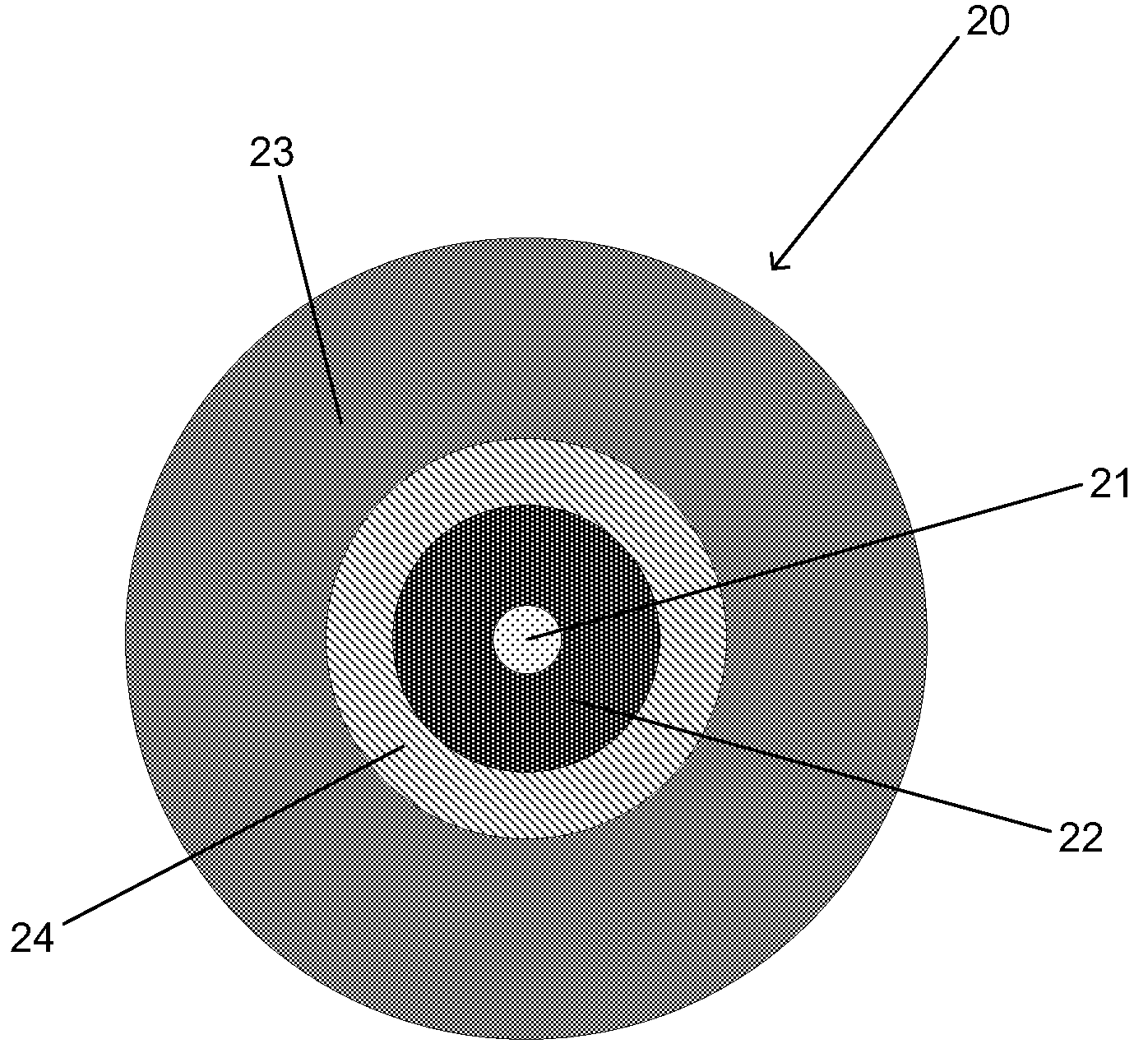

An optical waveguide comprises a core, an inner cladding laterally surrounding the core, and an outer cladding laterally surrounding the inner cladding, wherein the core, inner cladding, and outer cladding have a depressed well configuration. The waveguide operates in three or more wavelength bands, wherein a first wavelength band is centered at about 1300 nm, and wherein a second wavelength band is centered at about 1625 nm. The waveguide has bend losses that are less than or equal to 1.0 dB / turn when measured on a 5 mm radius bend at 1625 nm and bend losses that are less than or equal to 1.5 dB / turn when measured on a 5 mm radius bend at 1650 nm.

Owner:CORNING RES & DEV CORP

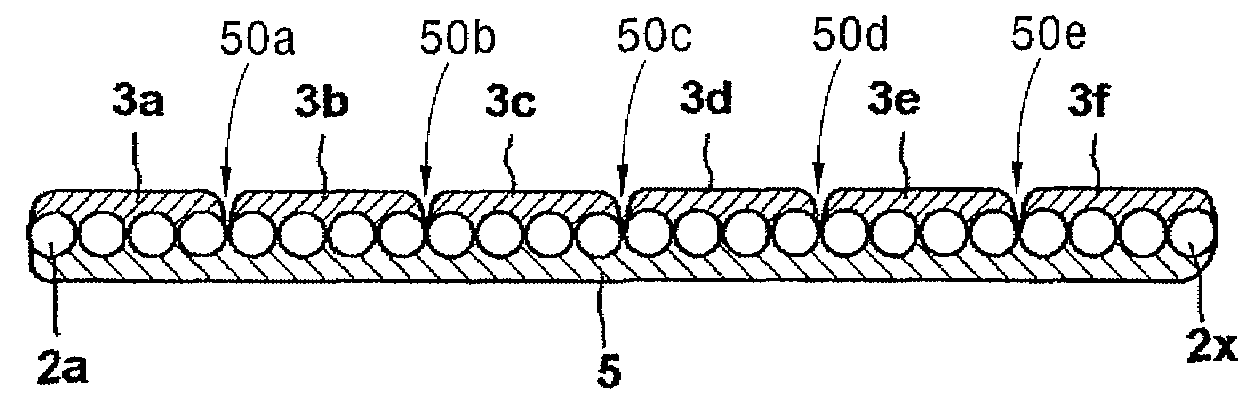

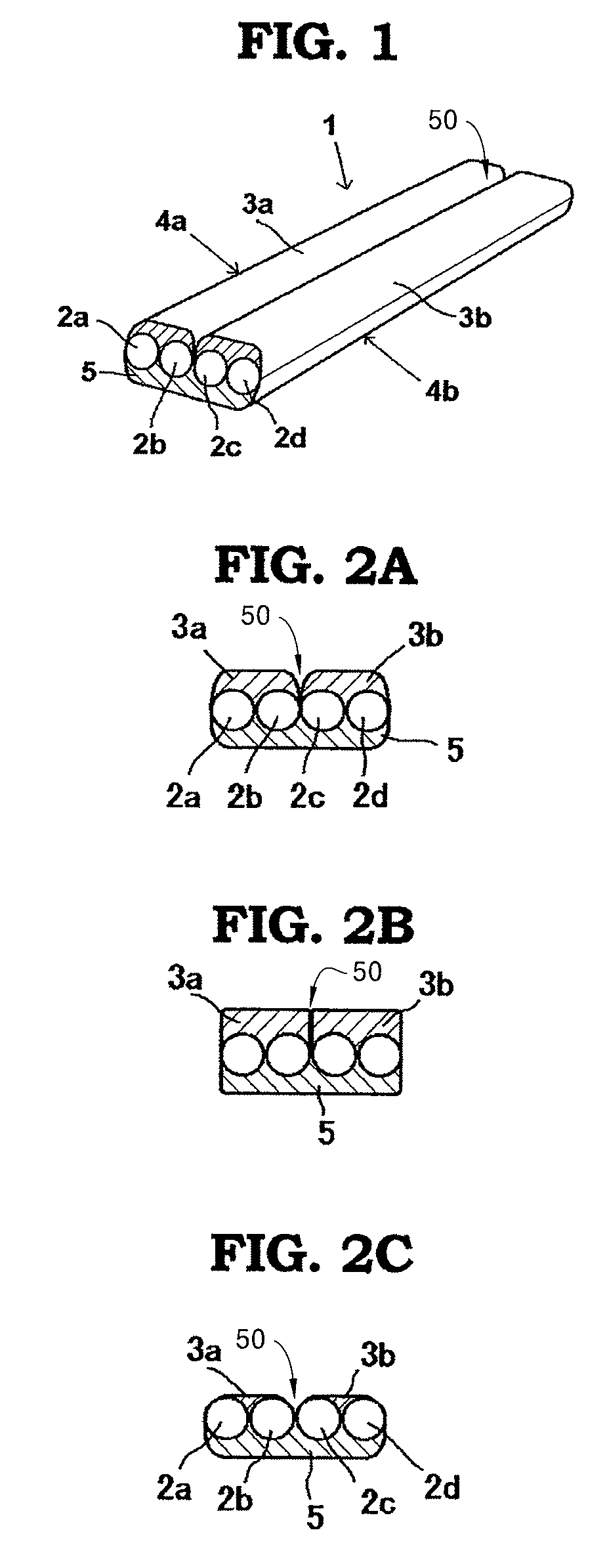

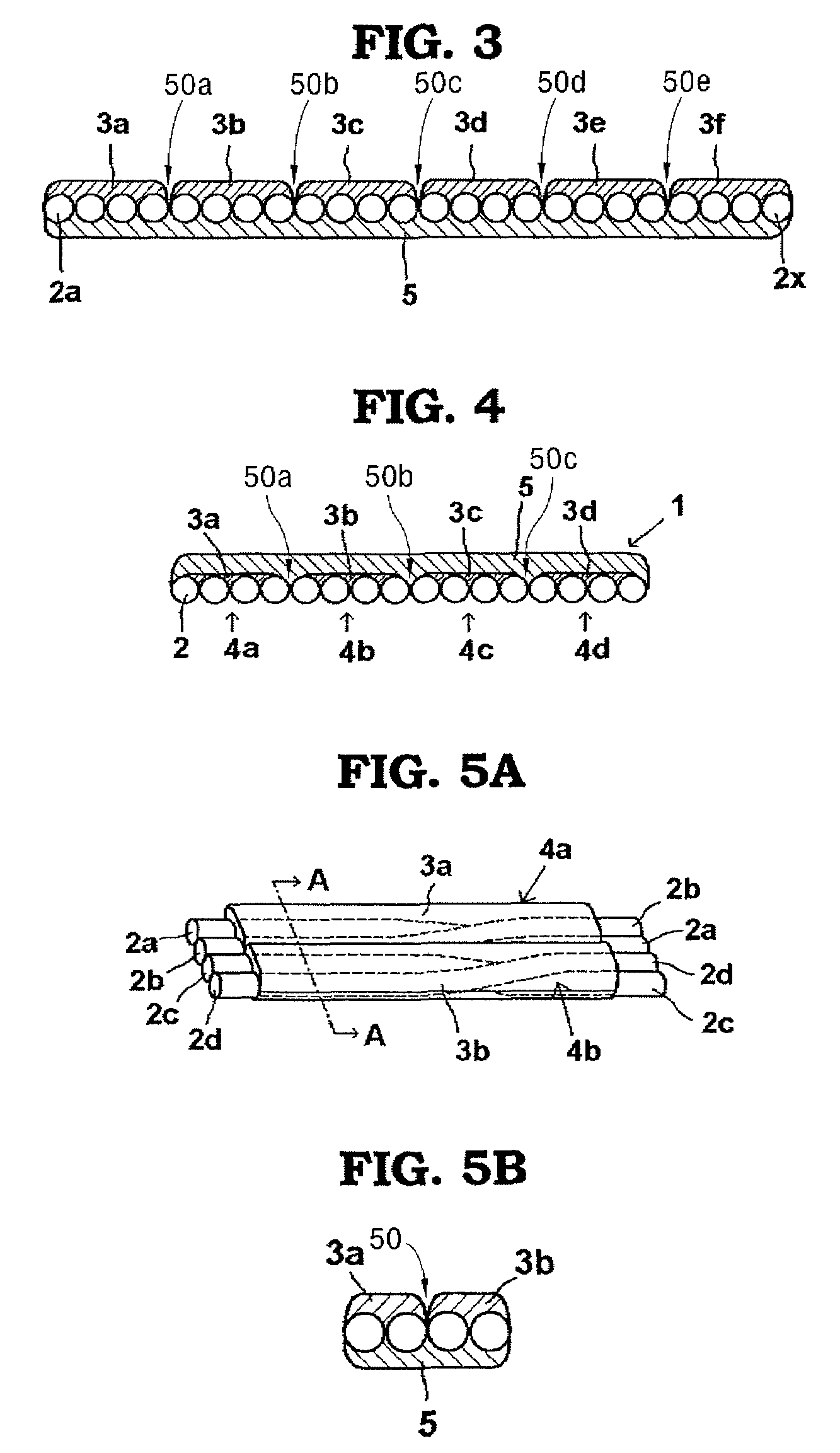

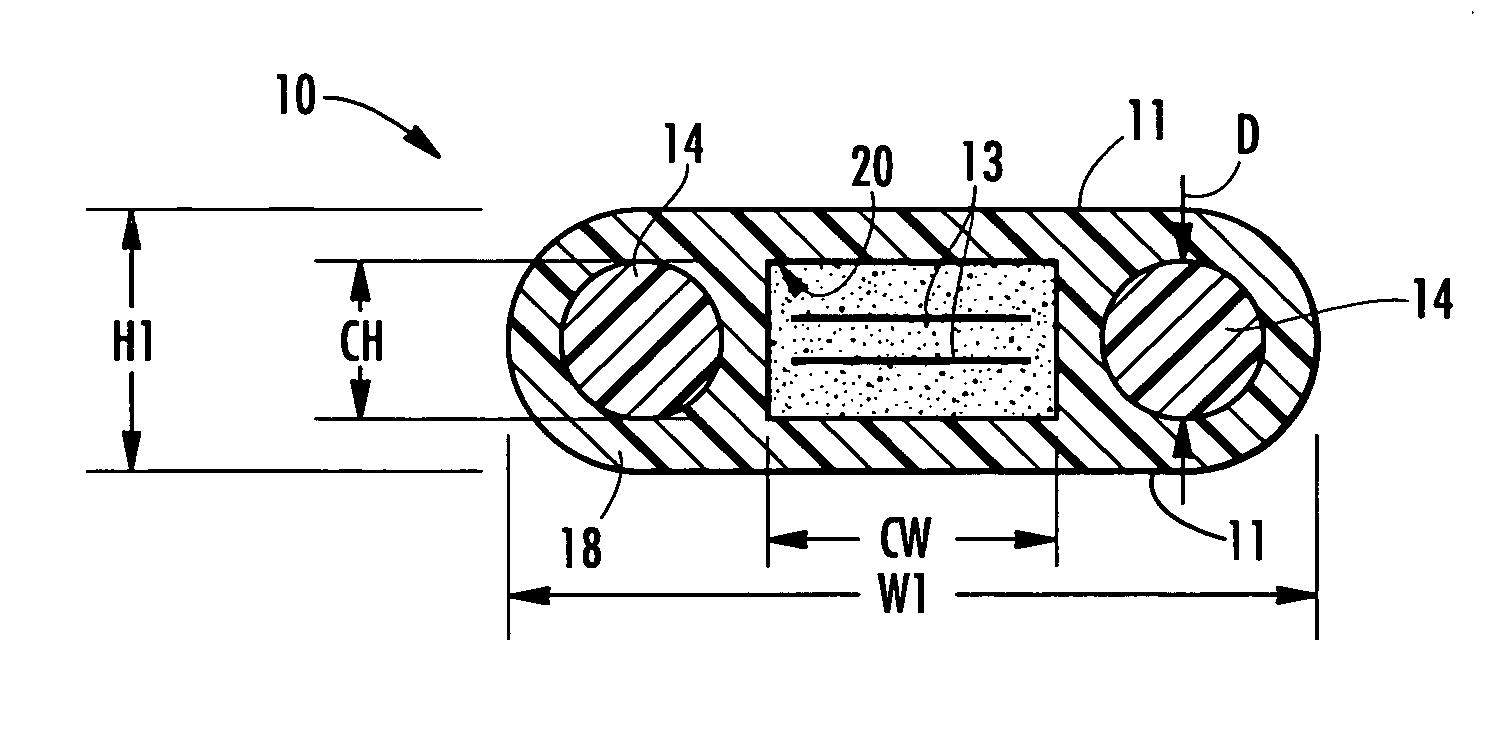

Optical fiber structure and method of manufacturing same

InactiveUS7509009B2Easily branchedPromote divisionGlass optical fibreFibre mechanical structuresEngineeringUltimate tensile strength

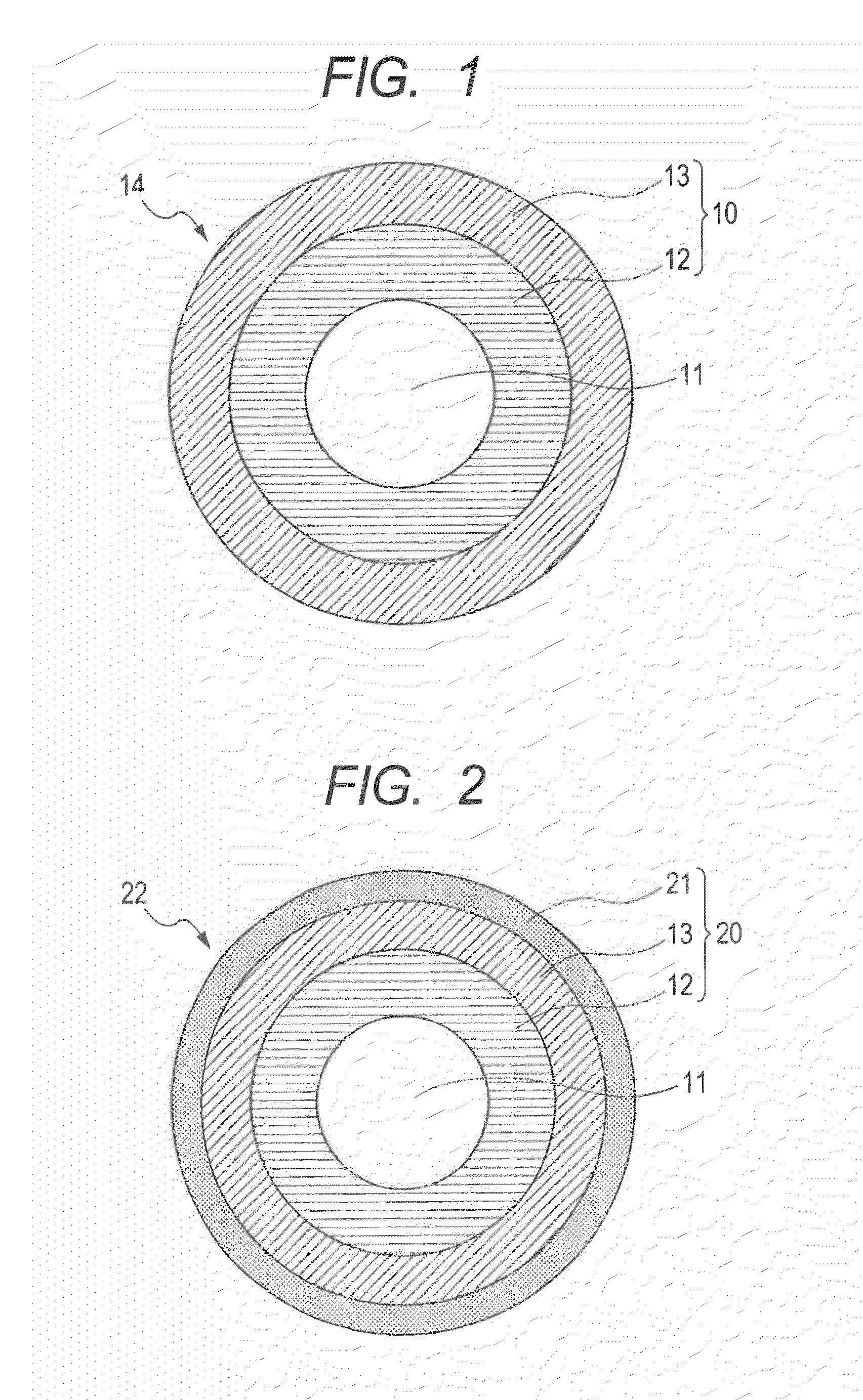

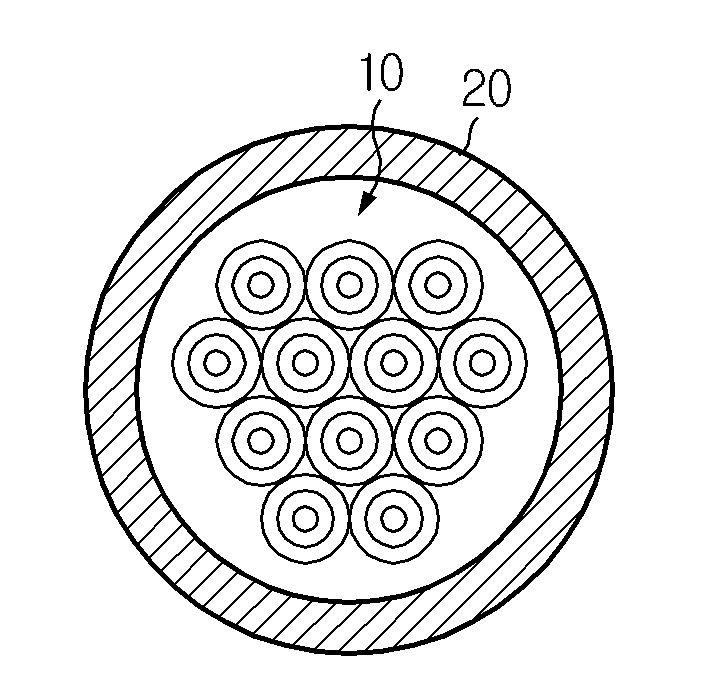

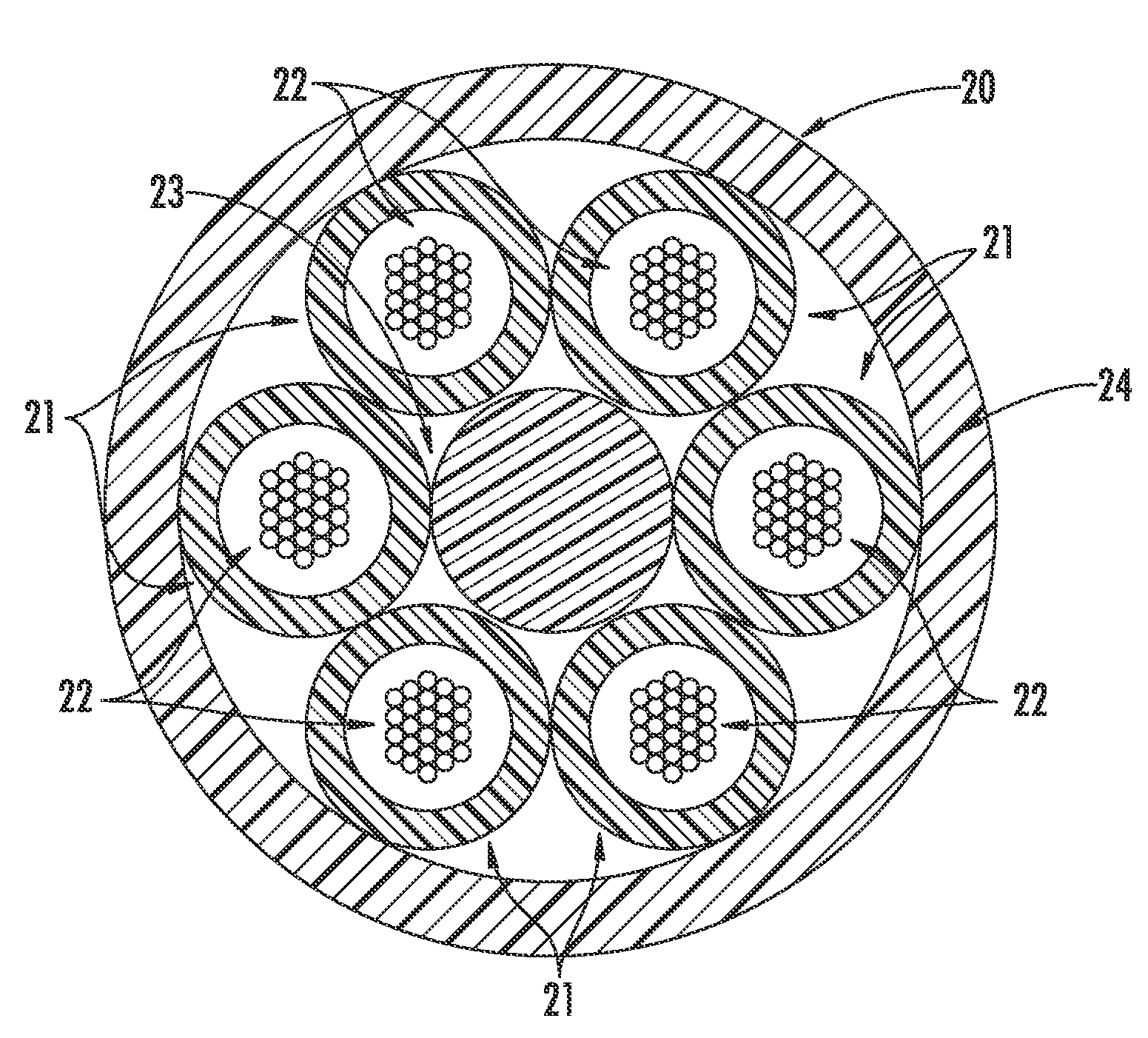

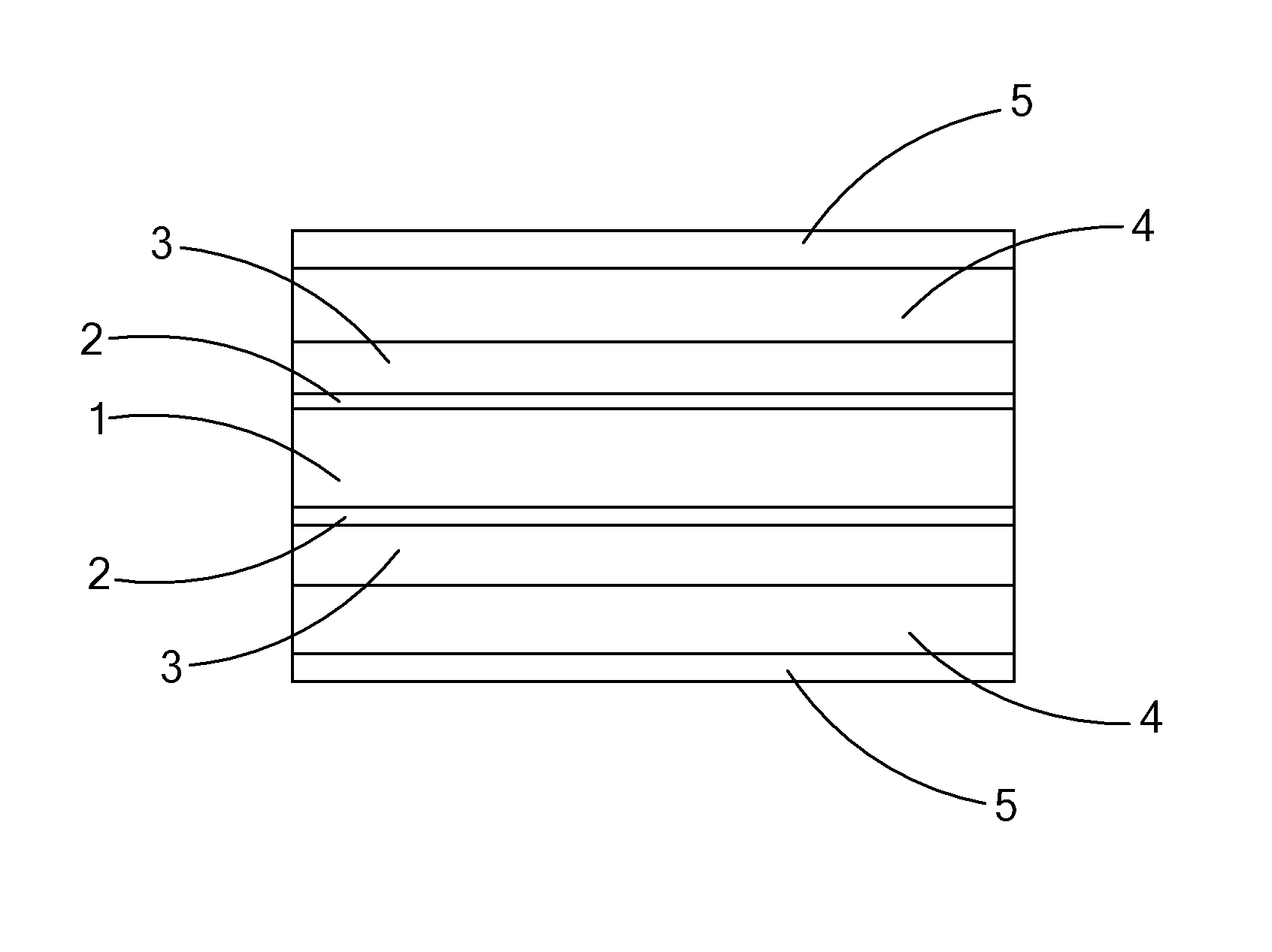

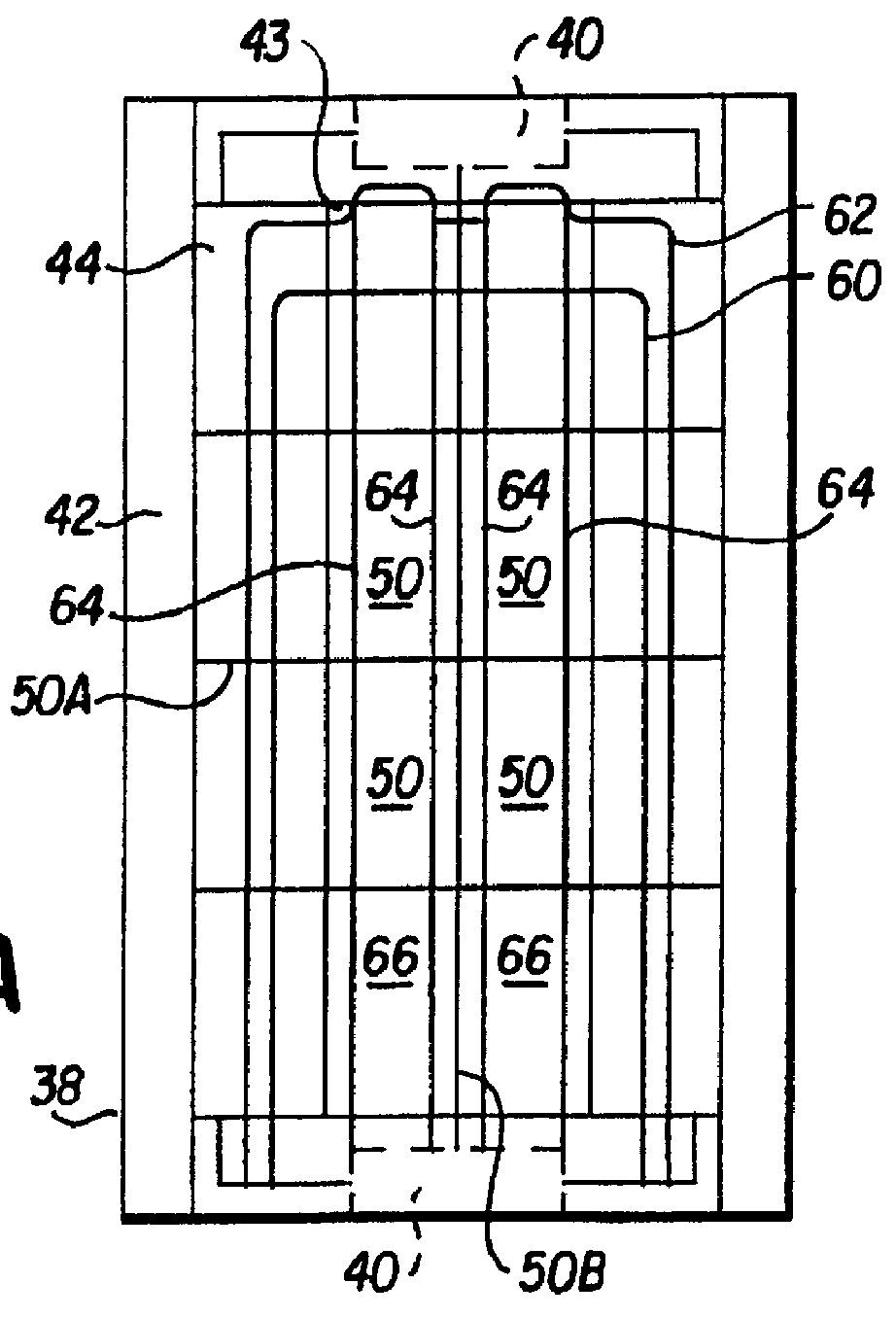

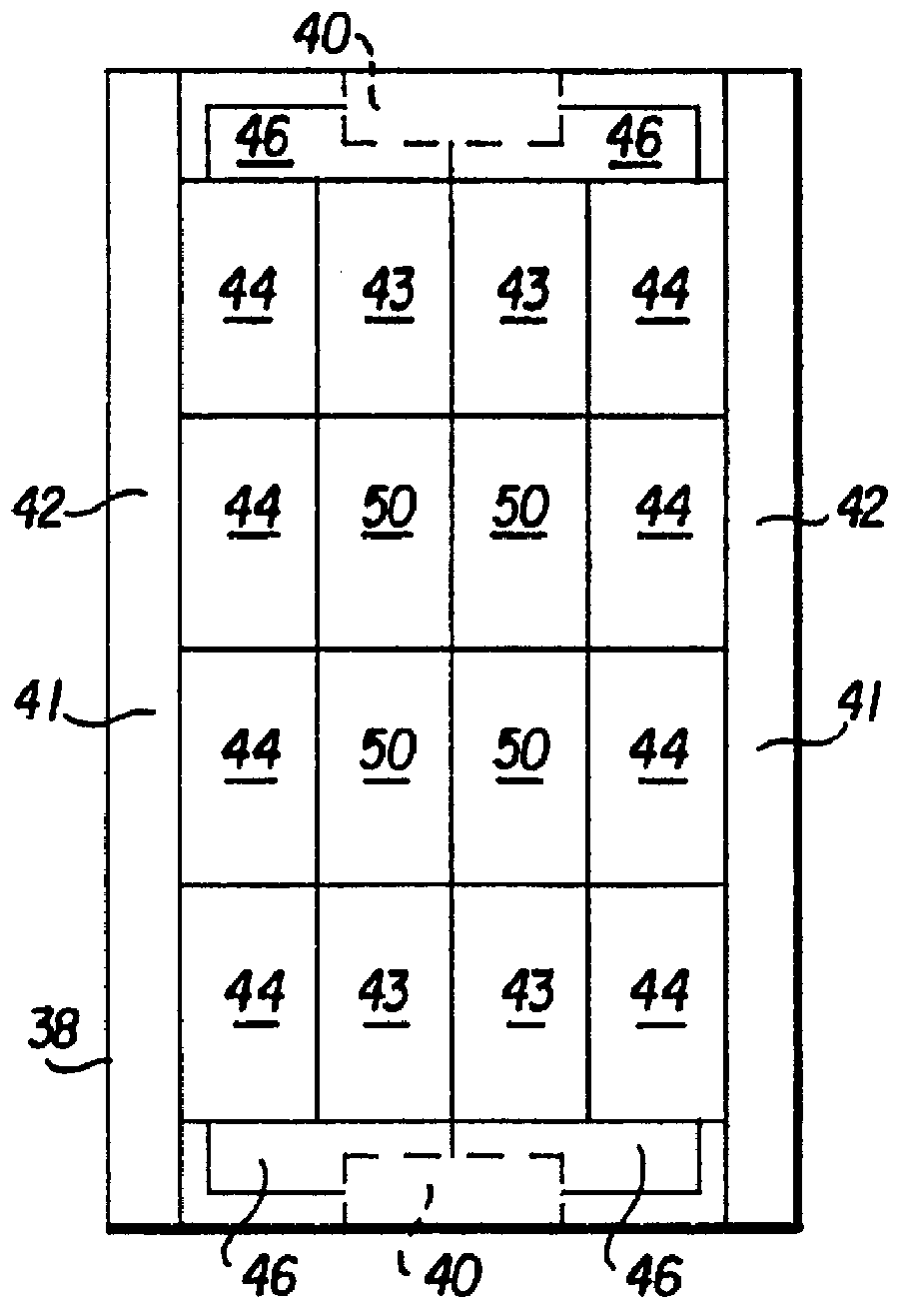

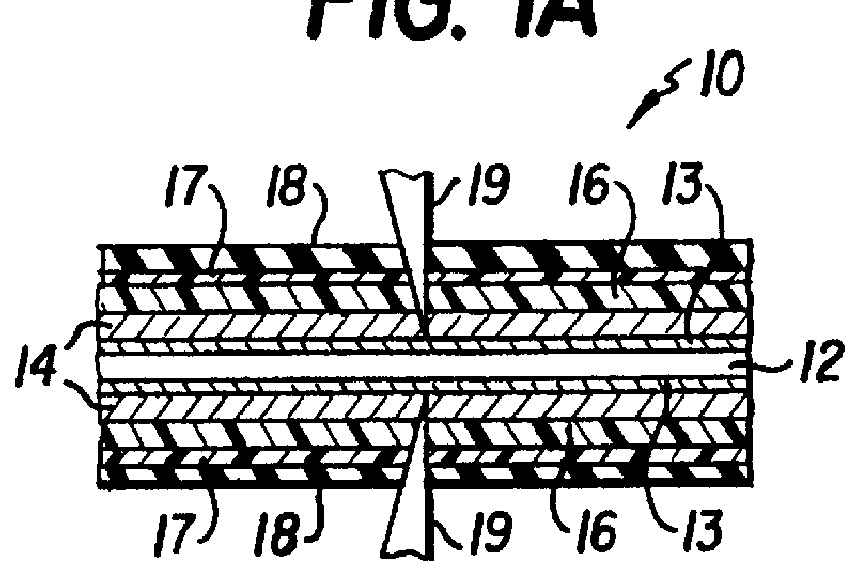

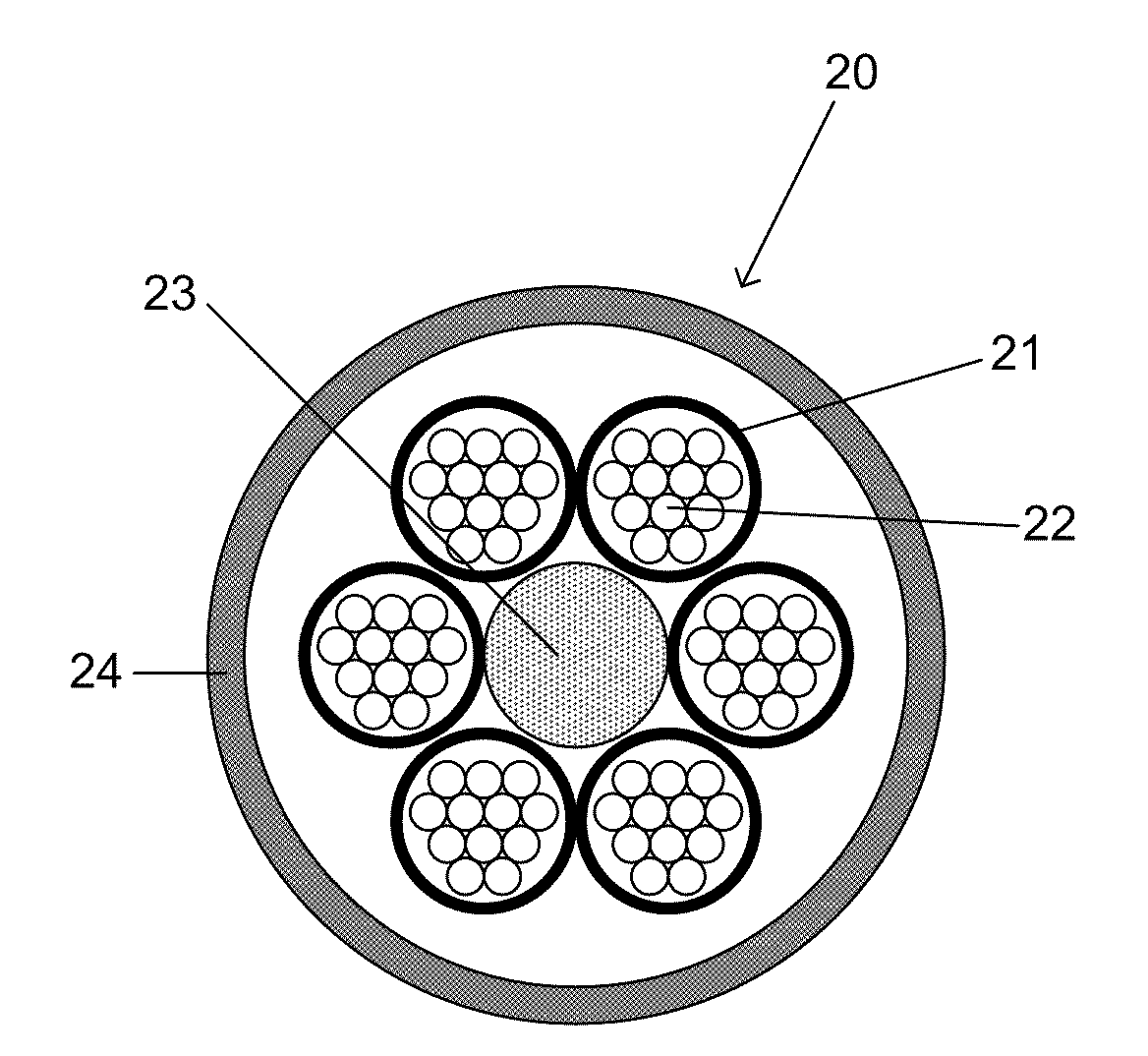

The present invention provides an optical fiber structure that allows for reliable and easy branching of optical fibers, as well as a method of manufacturing such optical fiber structure. The optical fiber structure proposed by the present invention is characterized by a structure wherein multiple optical fiber units, each comprising multiple optical fibers that are aligned two-dimensionally in such a way that one side is covered by a first covering body, are aligned so that the covered surfaces face the same direction, and the covered or uncovered surfaces of the multiple optical fiber units are integrally covered by a second covering body. The second covering body should preferably be made of silicone rubber having a tearing strength of 29 kgf / cm or below.

Owner:TOMOEGAWA PAPER CO LTD

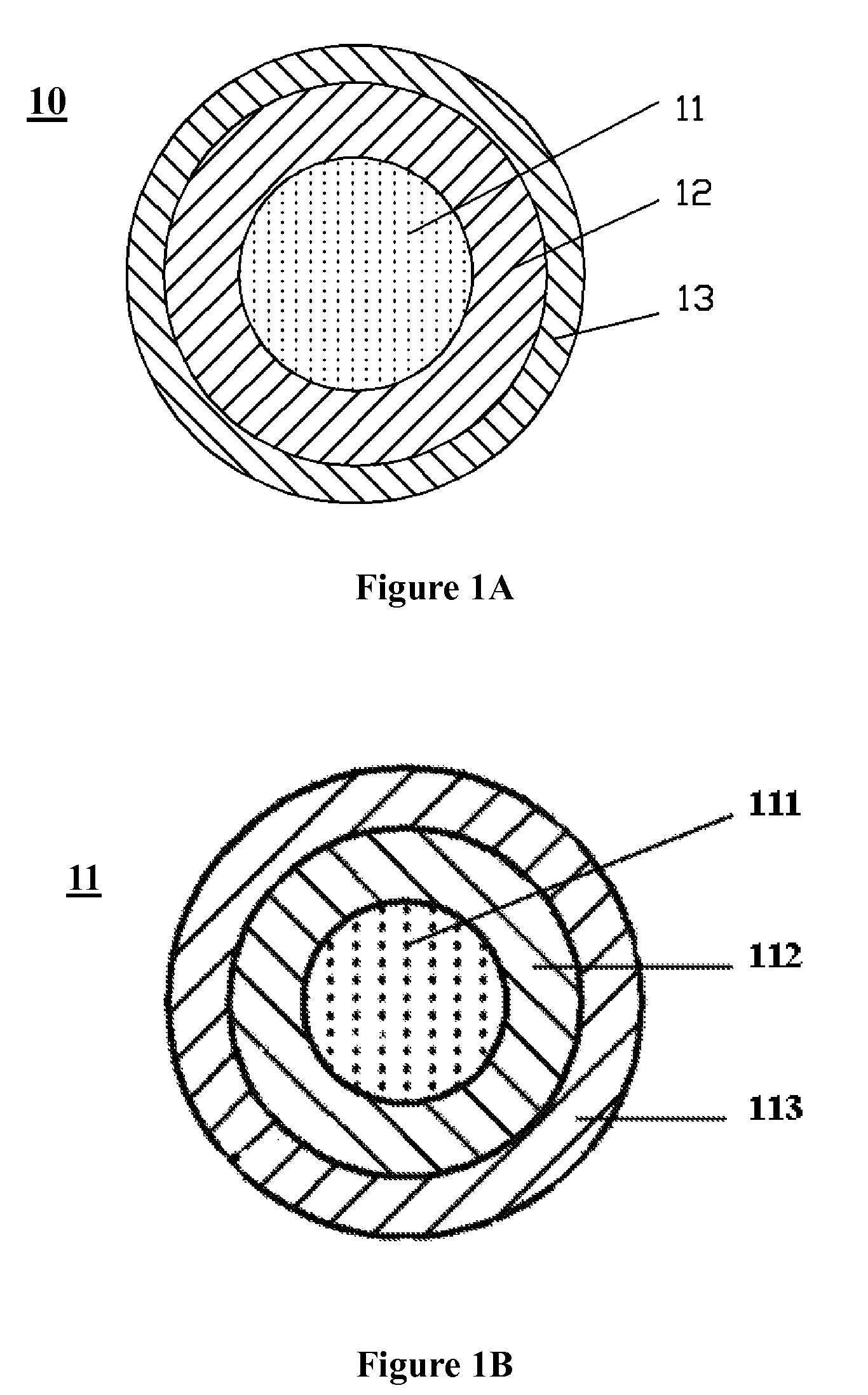

Bend insensitive single mode fiber

ActiveUS8750664B2Manufacturing toleranceReduce manufacturing costGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberAccess network

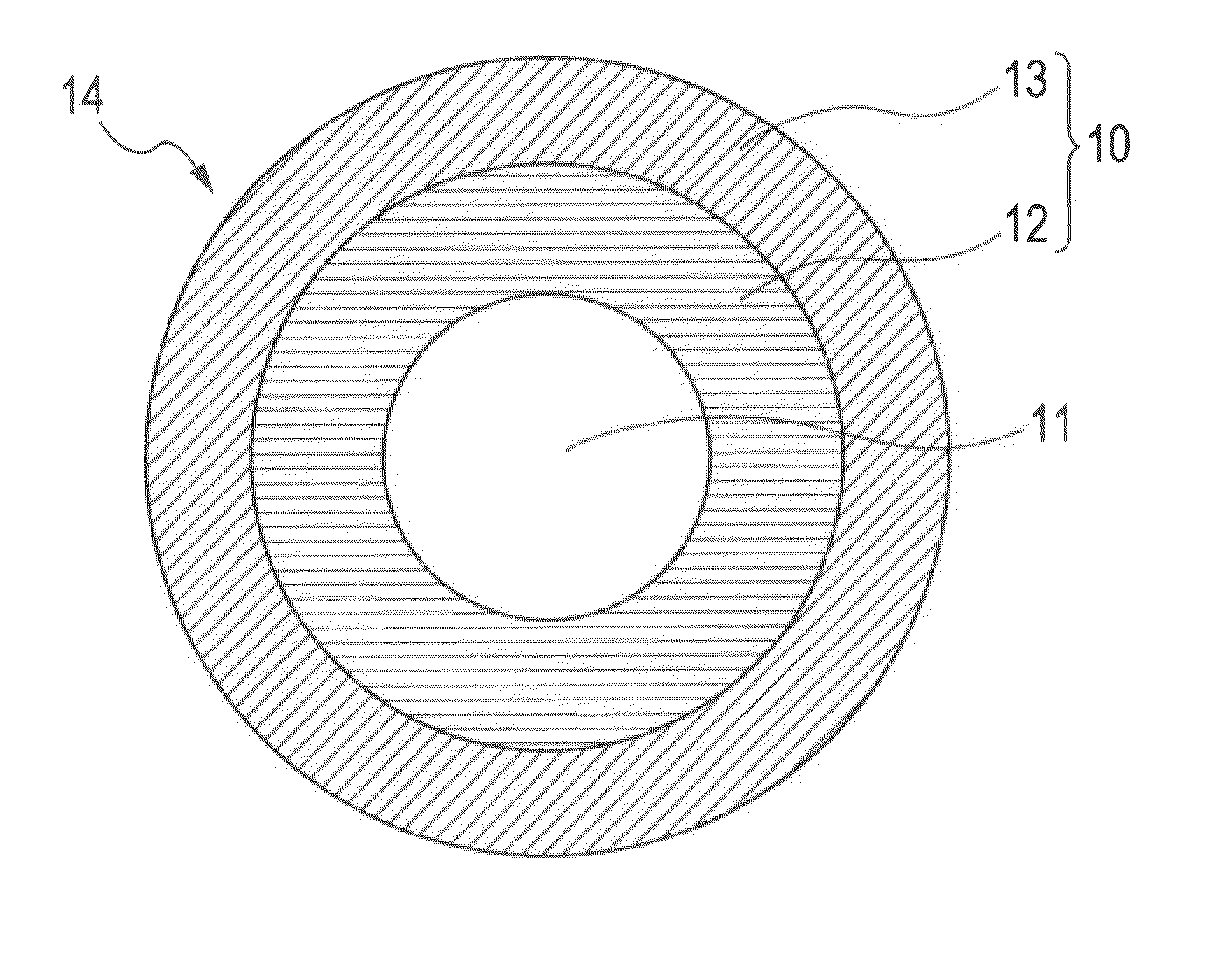

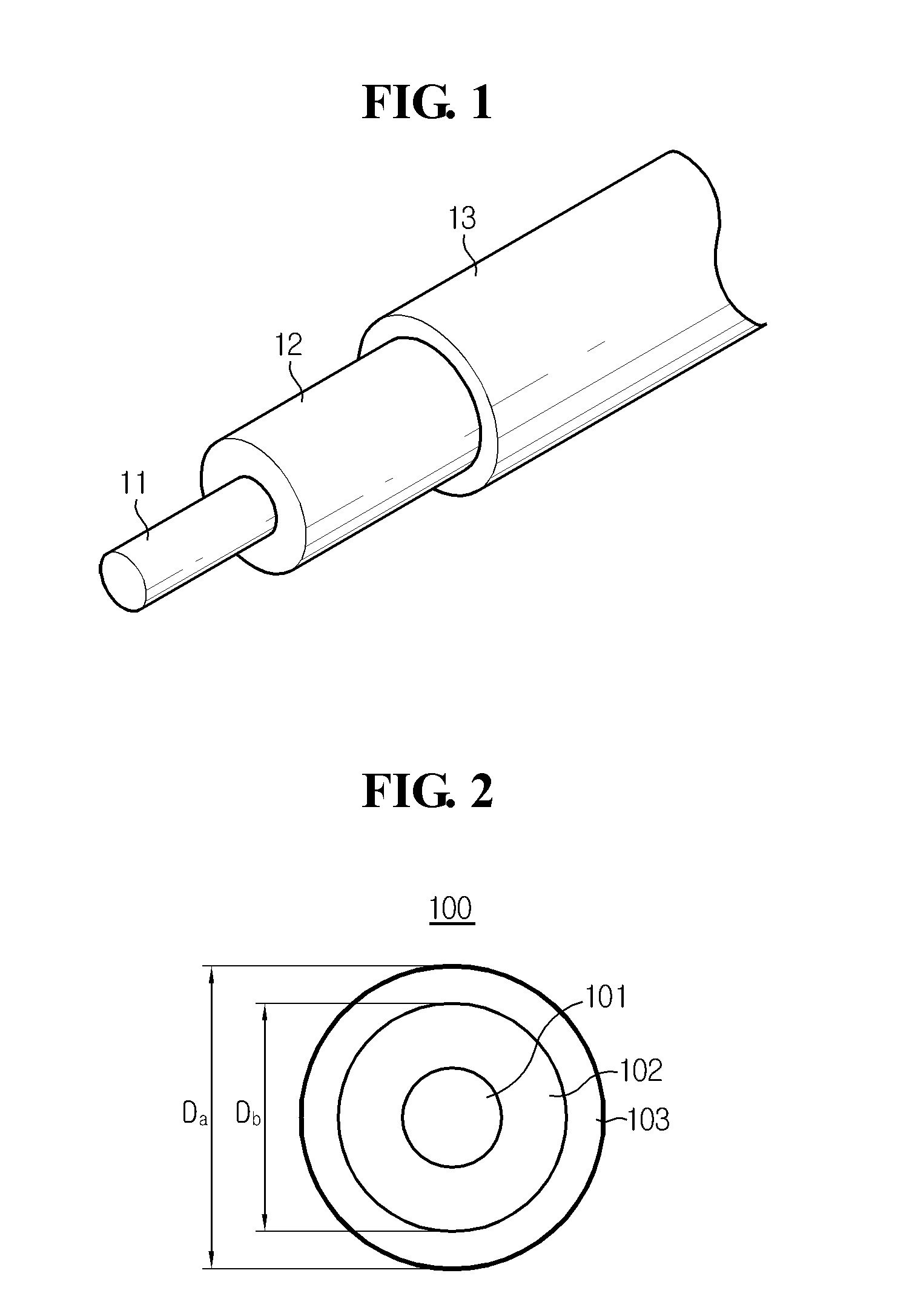

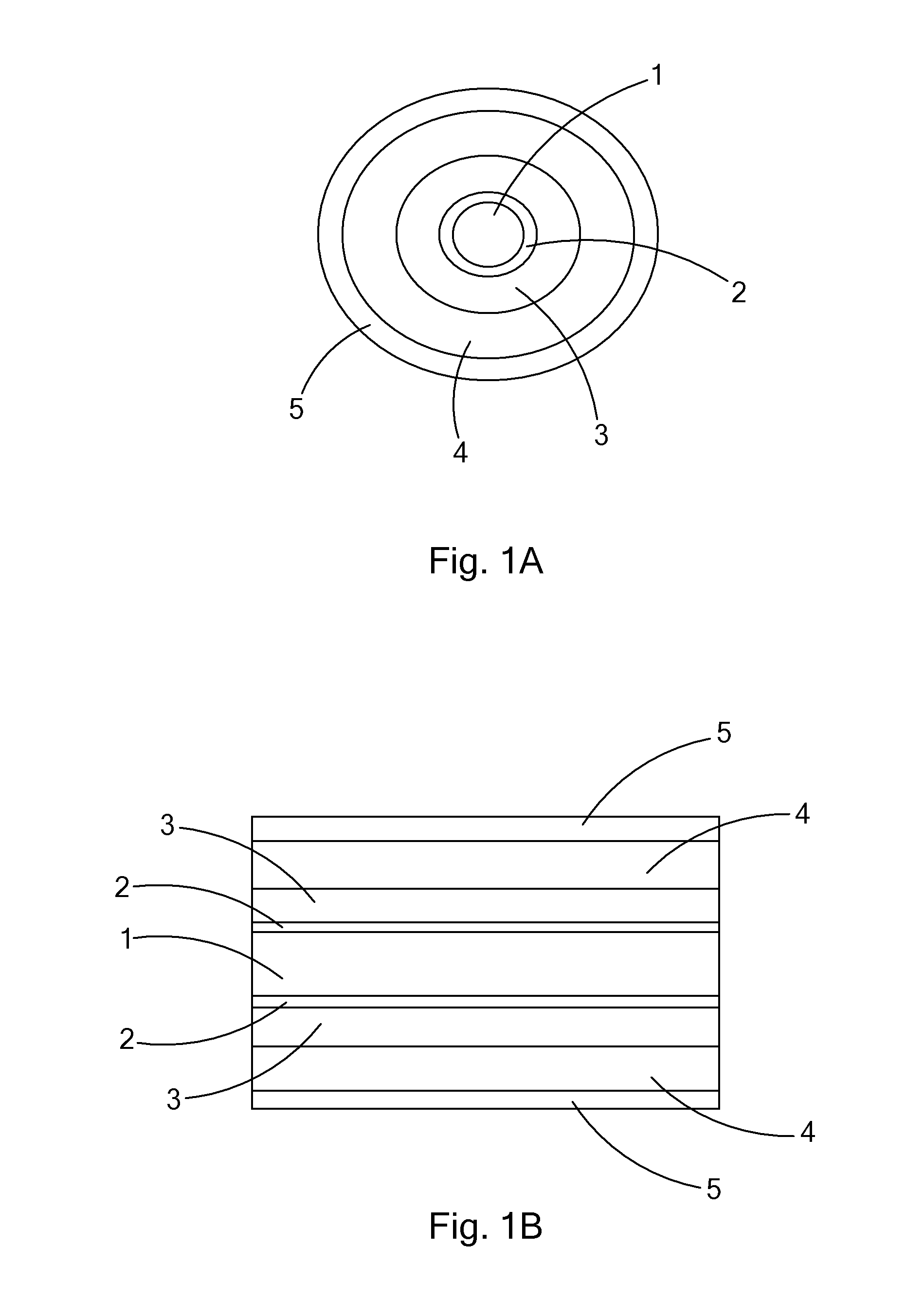

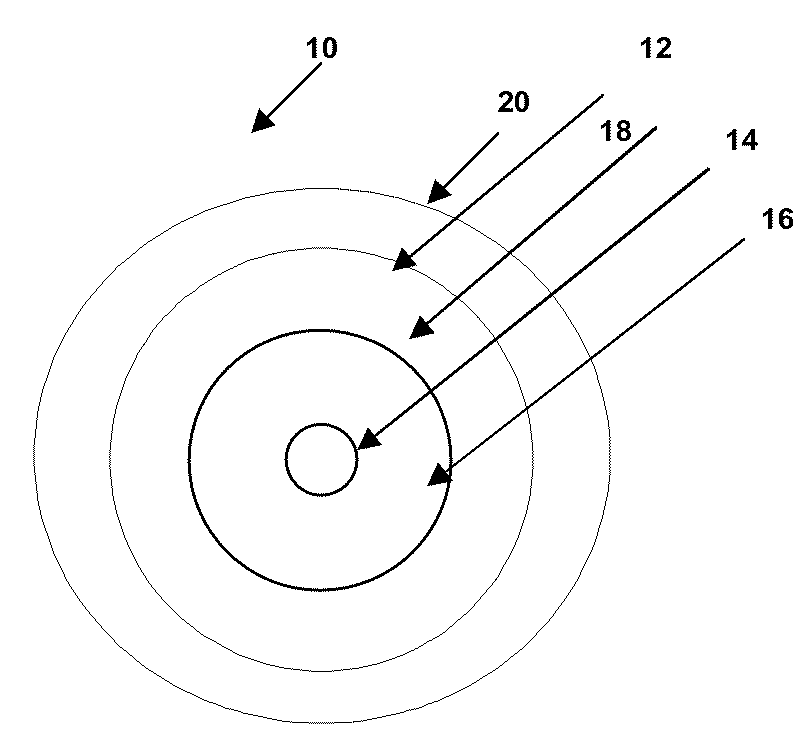

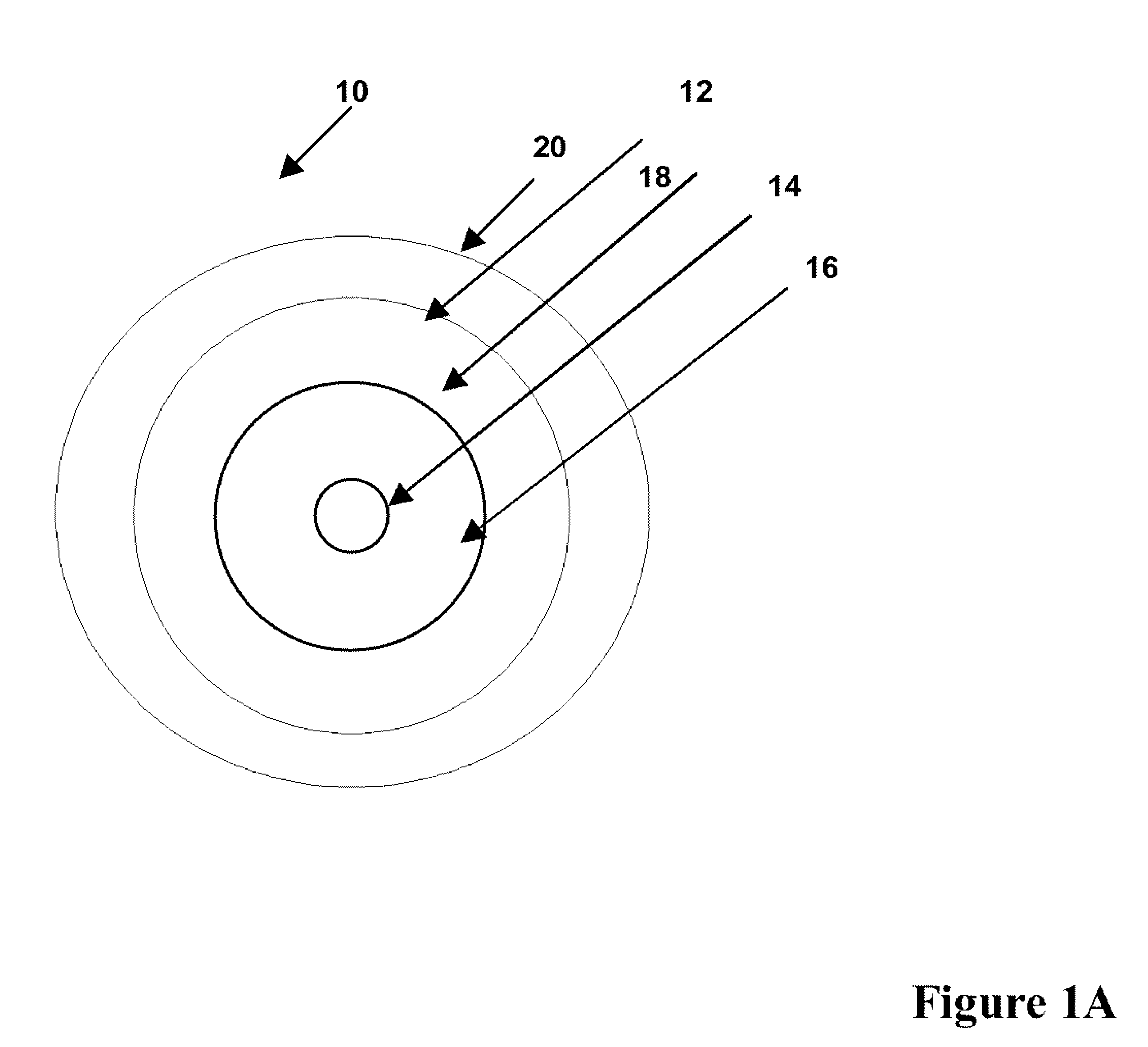

This invention discloses a bend insensitive single mode fiber, which is composed by a bare glass fiber with a round cross section and two resin protective layers with circular cross sections surrounding the outer of the bare glass fiber. It is characterized in that the bare glass fiber is composed by a core layer with a round cross section and two claddings with circular cross sections. The refractive index of the core layer is higher than the index of the two claddings and the refractive index difference between the core layer and the first cladding is larger than the difference between the first and second claddings. The second cladding is made of pure SiO2. The refractive index profile of the core layer follows a power function, and the refractive index profile of the two claddings follow a ladder-type distribution. The loss of the invented fiber is insensitive to the bending of the fiber, which meets the requirements of ITU.T G.657.A and G.657.B standards, respectively. It is applicable to the Fiber To The Home (FTTH) and other local area network and the access network systems.

Owner:FUTONG GROUP CO LTD

Optical fiber

ActiveUS20110274396A1Increased transmission lossTransmission loss is hardGlass optical fibreOptical fibre with multilayer core/claddingHigh humidityThermal expansion

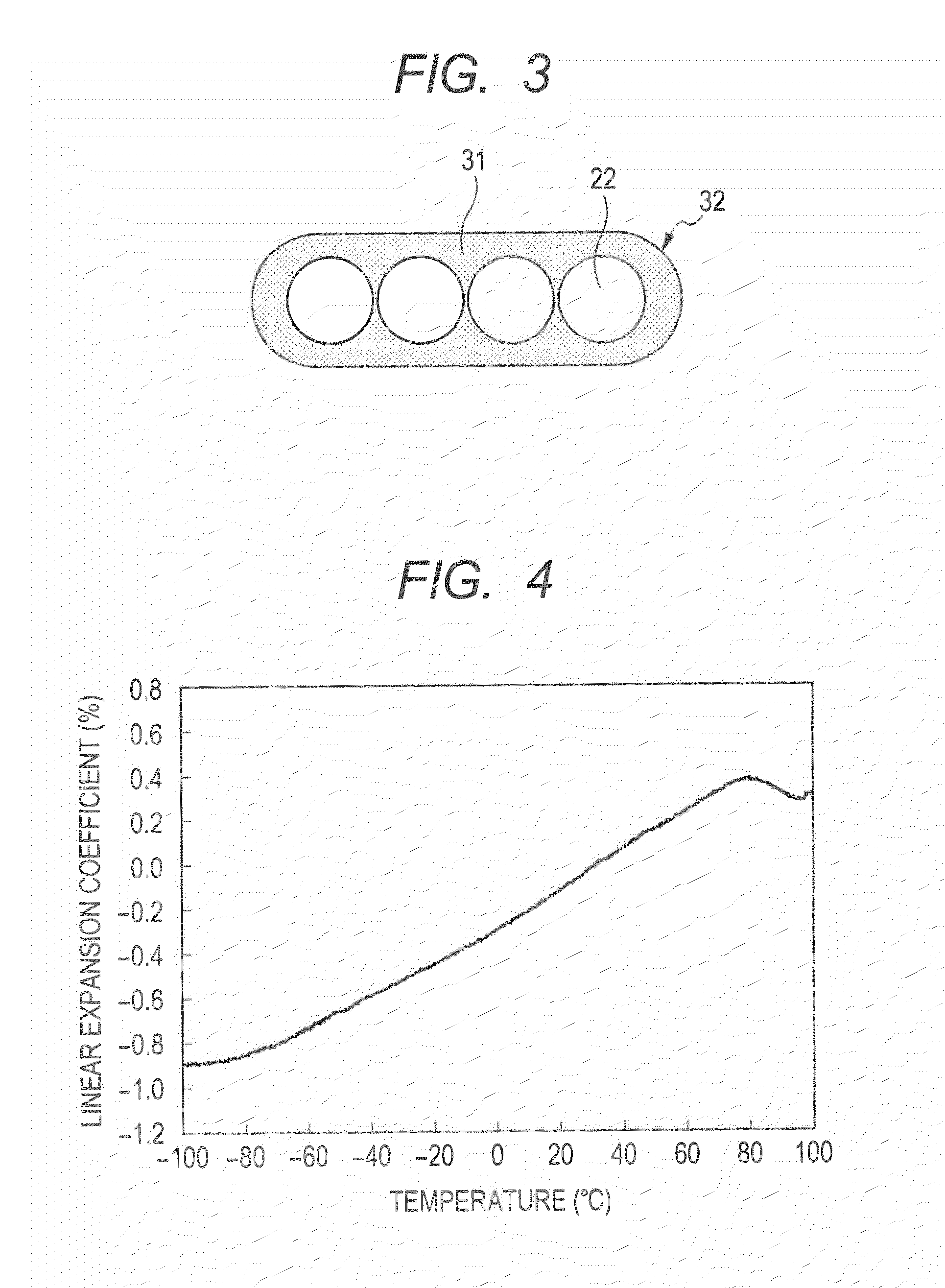

The present invention provides an optical fiber in which the transmission loss increase is suppressed even under a high-humidity condition or under a water-immersed condition. A colored optical fiber (22) according to an embodiment of the present invention is a colored optical fiber (22) formed by applying a colored layer to an optical fiber (14) including a glass optical fiber coated with at least a double-layered coating layer of a soft layer and a hard layer, and the ratio of thermal expansion coefficient between the coating layer after the colored layer of the colored optical fiber (22) is applied and the coating layer of the optical fiber (14) before the colored layer is applied is 0.87 or more. Furthermore, an optical fiber ribbon (32) according to another embodiment of the present invention is an optical fiber (32) formed by arranging a plurality of the colored optical fiber (22) in the form of a plane and coating them all together with a ribbon resin and the ratio of thermal expansion coefficient between the coating layer after the colored layer of the colored optical fiber (22) is applied and the coating layer of the optical fiber before the colored layer is applied is 0.90 or more.

Owner:FURUKAWA ELECTRIC CO LTD

Bend-insensitive optical fiber having small coating diameter and optical cable comprising the same

InactiveUS20130330050A1Improve bending loss characteristicMinimized volumeGlass optical fibreOptical fibre with multilayer core/claddingRefractive indexCoating

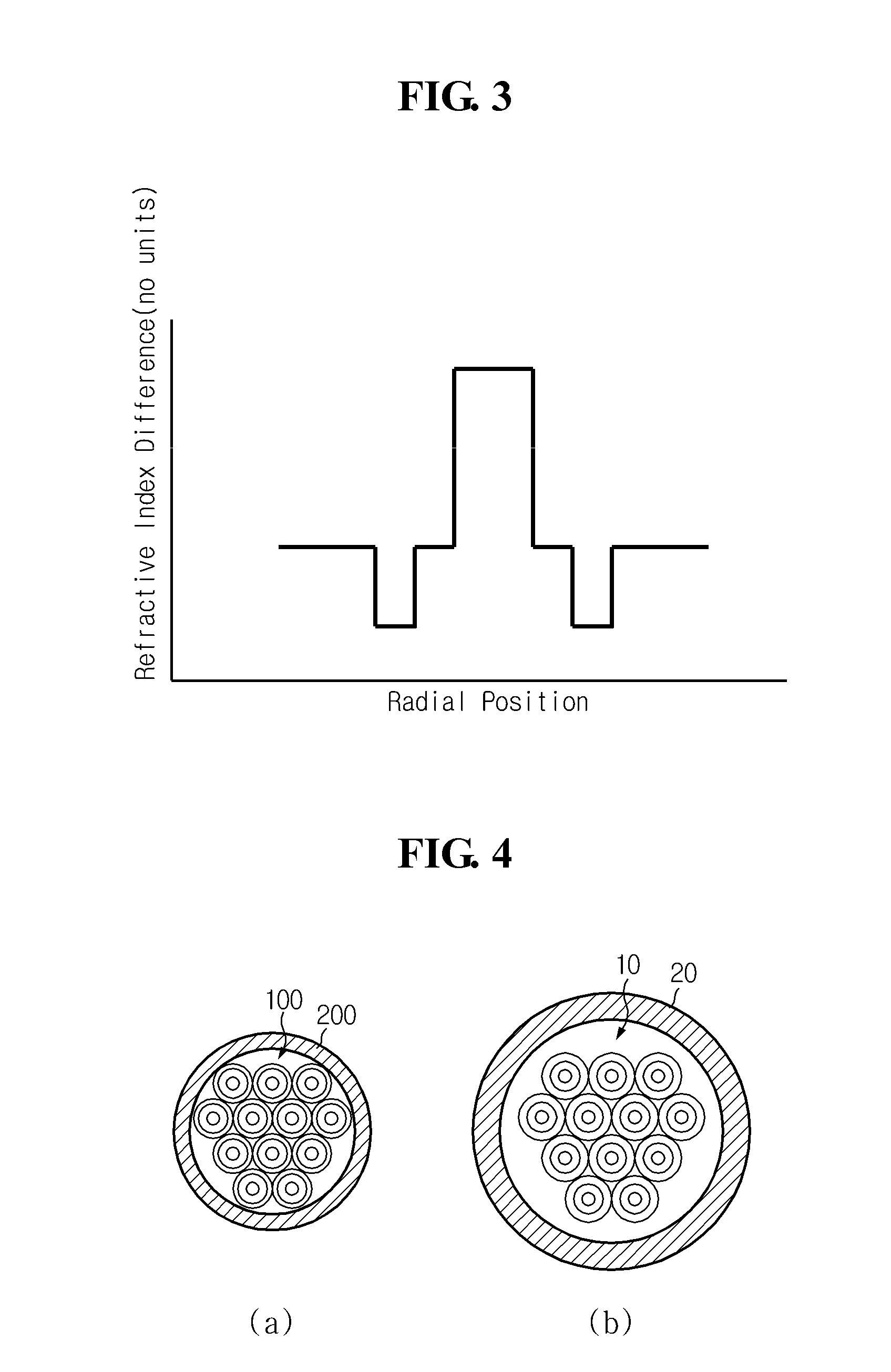

Provided is a bend-insensitive optical fiber including a core centered at the optical fiber, a cladding surrounding the core and having a lower refractive index than the core, a coating layer surrounding the cladding, and a region formed in the cladding and having a lower refractive index than the cladding, wherein the coating layer has a multilayered structure and a total outer diameter of 240 μm or less, and a bend-insensitive optical cable comprising the same.

Owner:LG CABLE LTD (KR)

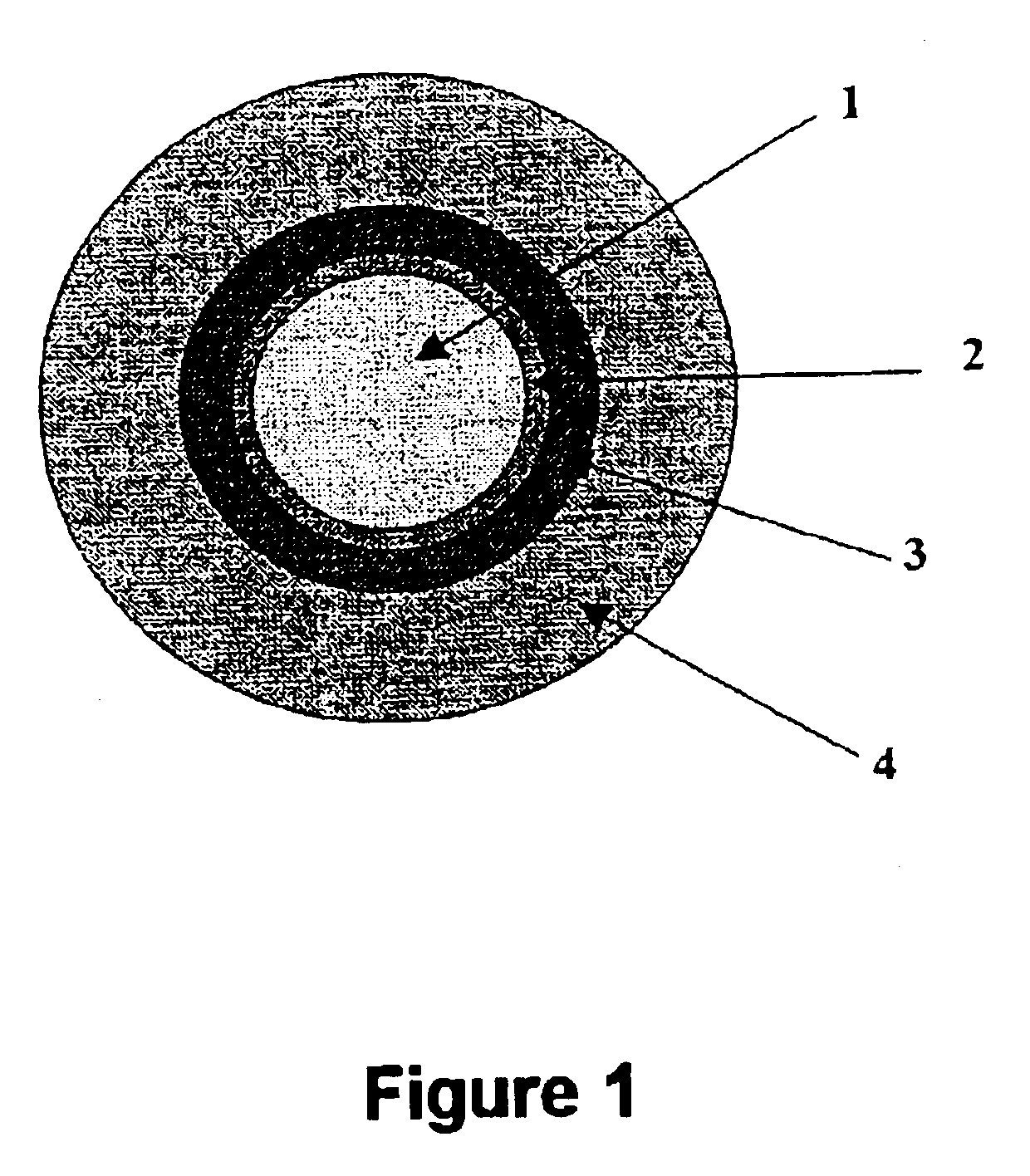

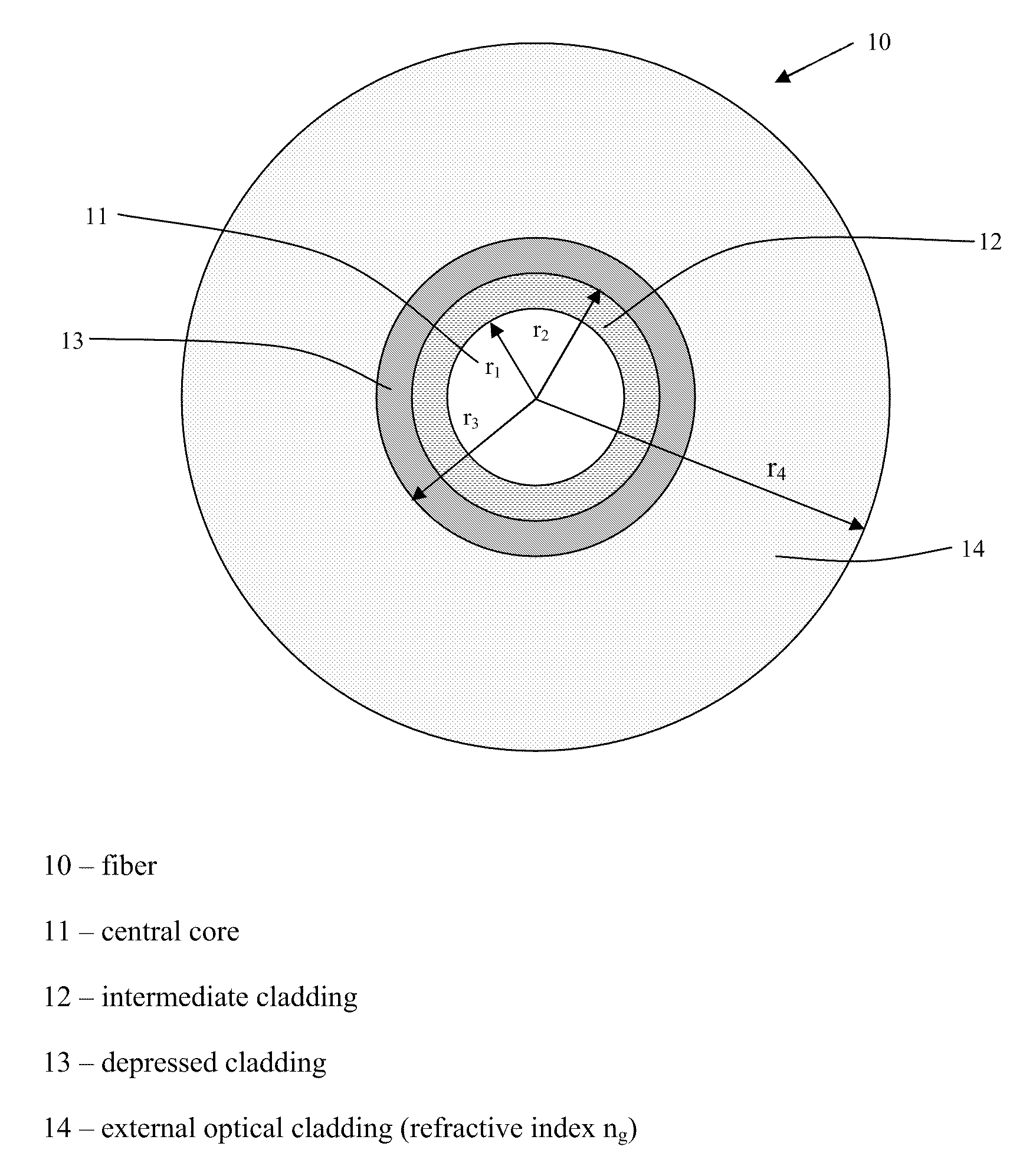

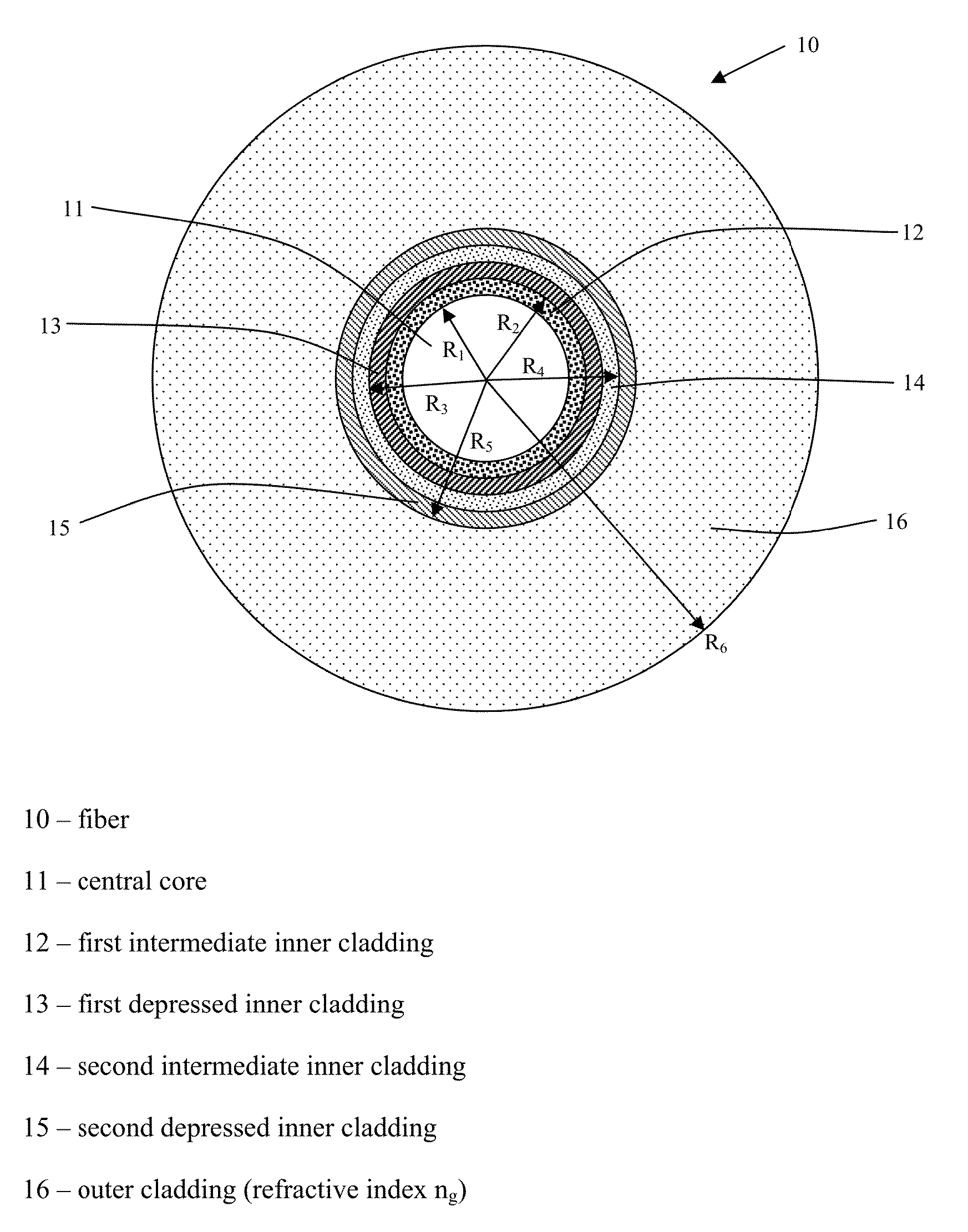

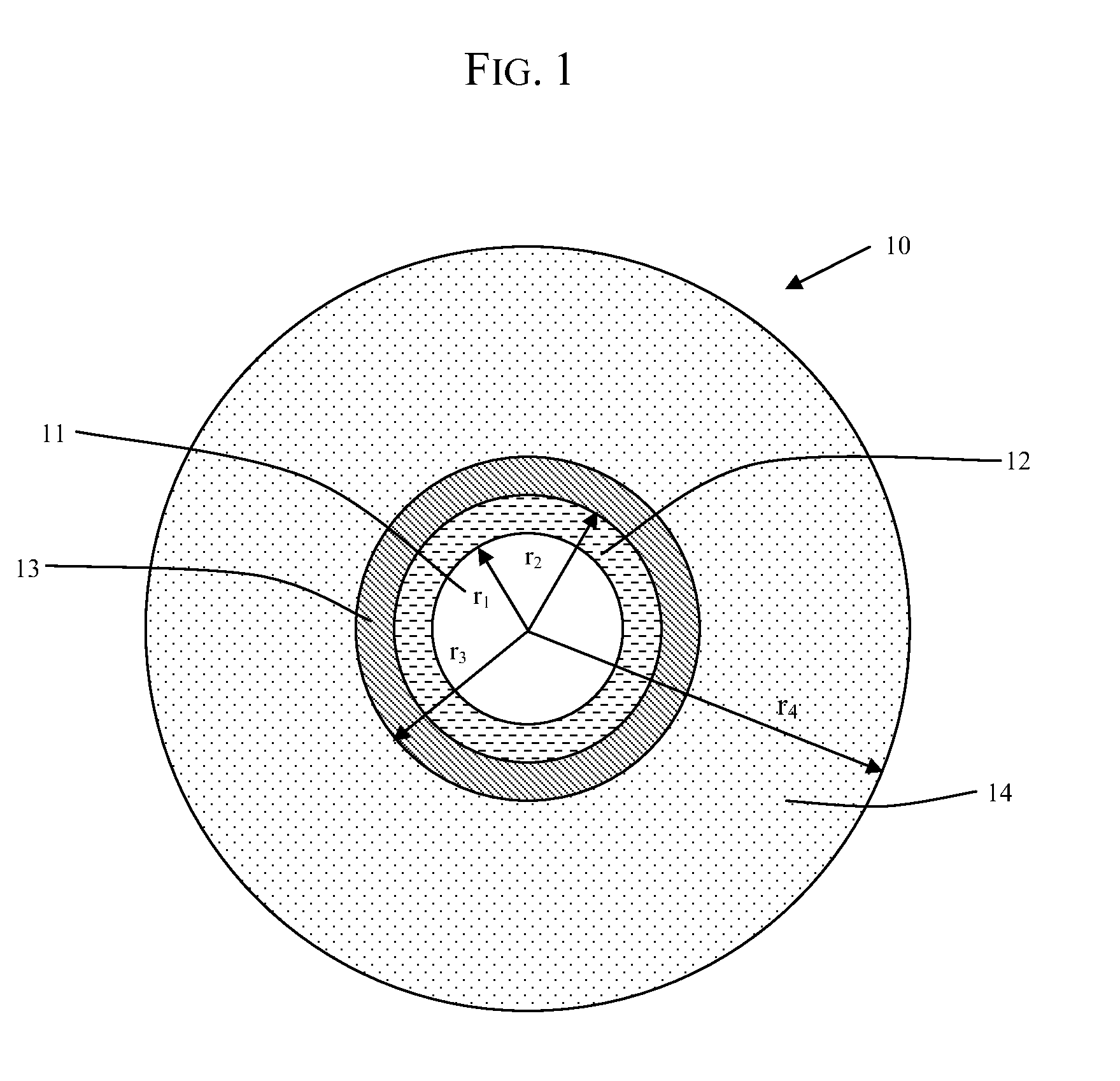

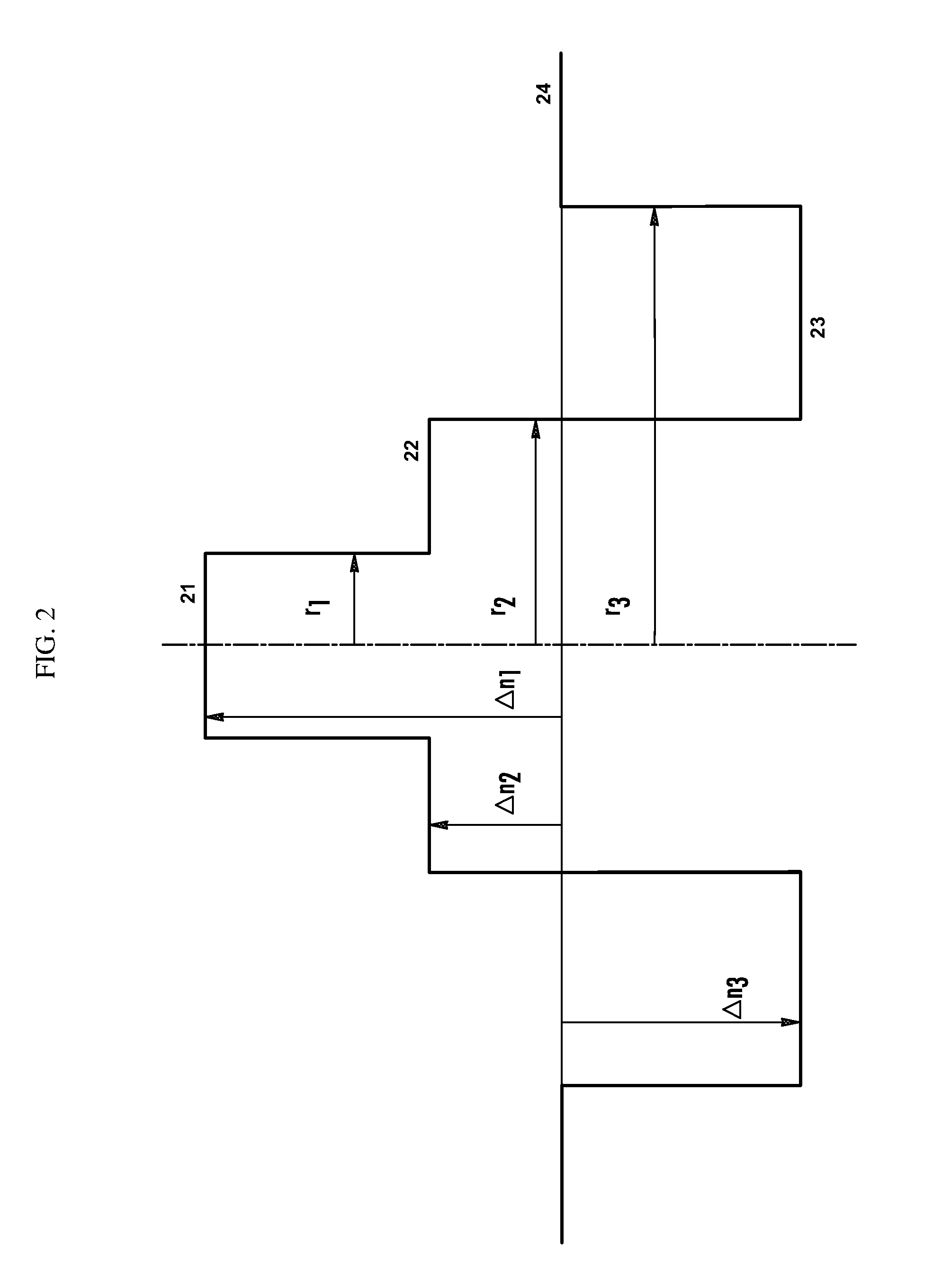

Single-Mode Optical Fiber Having Reduced Bending Losses

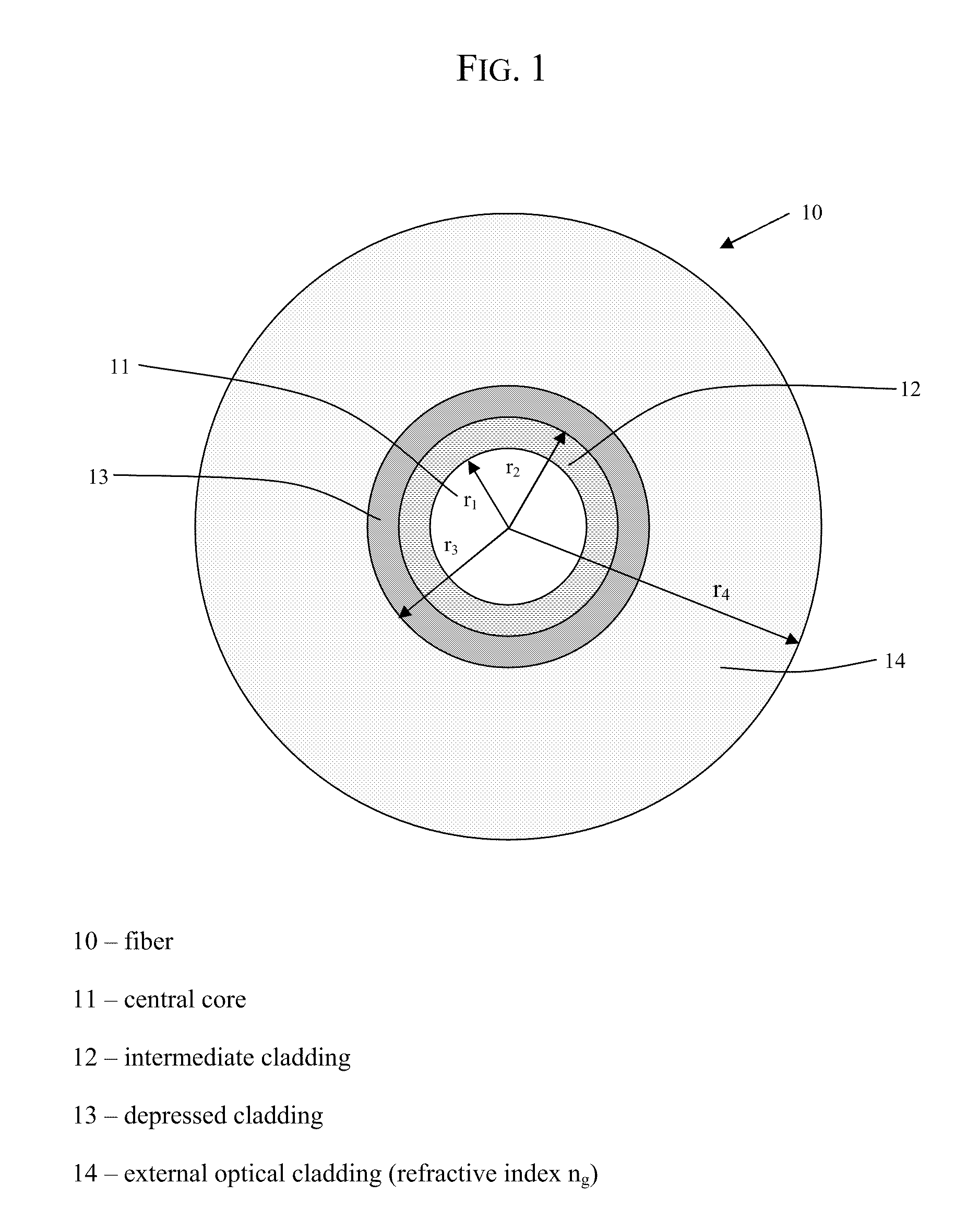

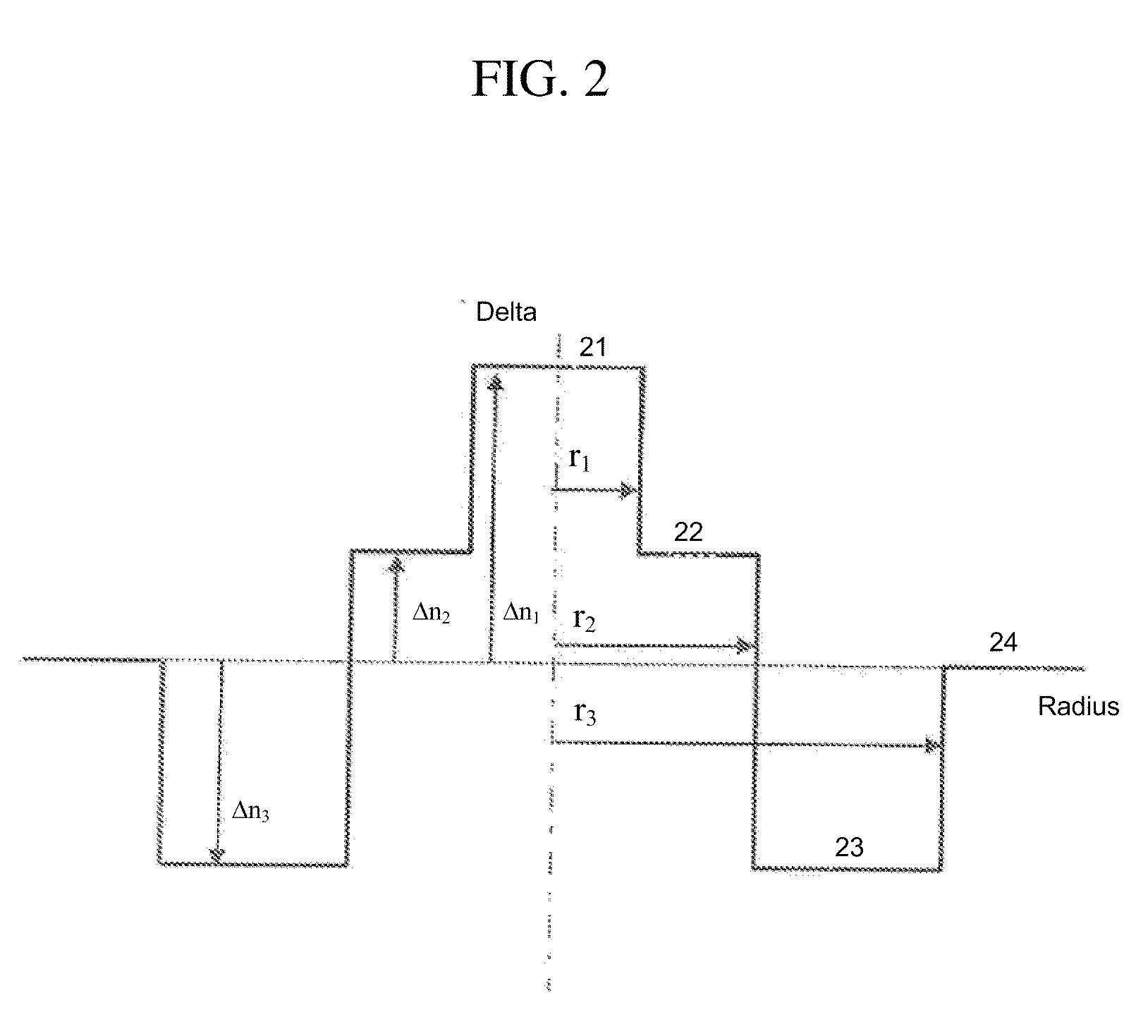

ActiveUS20090279835A1Improves bending lossSufficient attenuationGlass optical fibreOptical fibre with graded refractive index core/claddingLength waveMode field diameter

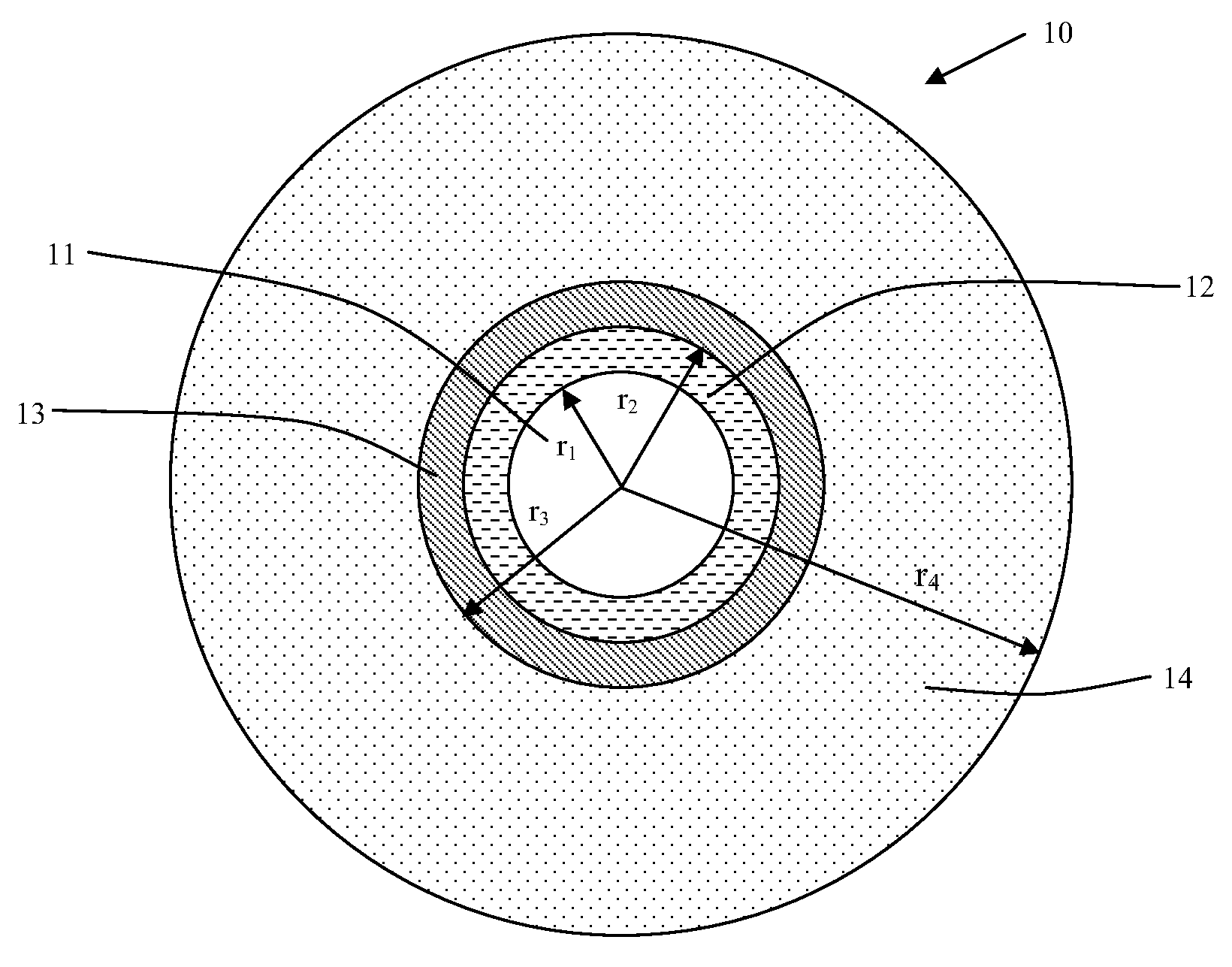

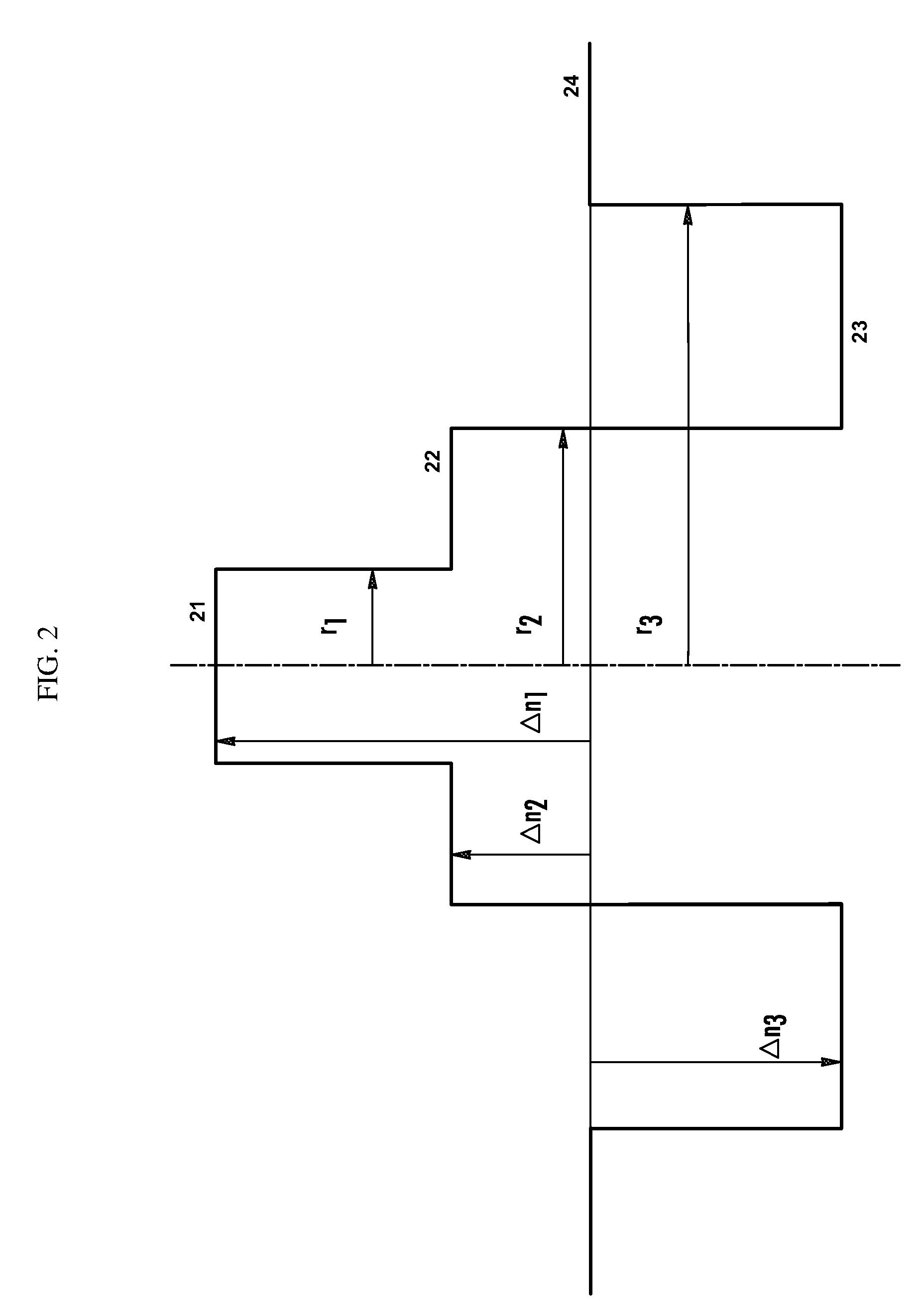

A single-mode optical fiber includes a central core, an intermediate cladding, a depressed trench, and an external optical cladding. The central core has a radius r1 and a positive refractive index difference Δn1 with the optical cladding. The intermediate cladding has a radius r2 and a positive refractive index difference Δn2 with the optical cladding, wherein Δn2 is less than Δn1. The depressed trench has a radius r3 and a negative index difference Δn3 with the optical cladding. At a wavelength of 1310 nanometers, the optical fiber has a mode field diameter (MFD) between 8.6 microns and 9.5 microns and, at a wavelength of 1550 nanometers, the optical fiber has bending losses less than about 0.25×10−3 dB / turn for a radius of curvature of 15 millimeters. At a wavelength of 1260 nanometers, attenuation of the LP11 mode to 19.3 dB is achieved over less than 90 meters of fiber.

Owner:DRAKA COMTEQ BV

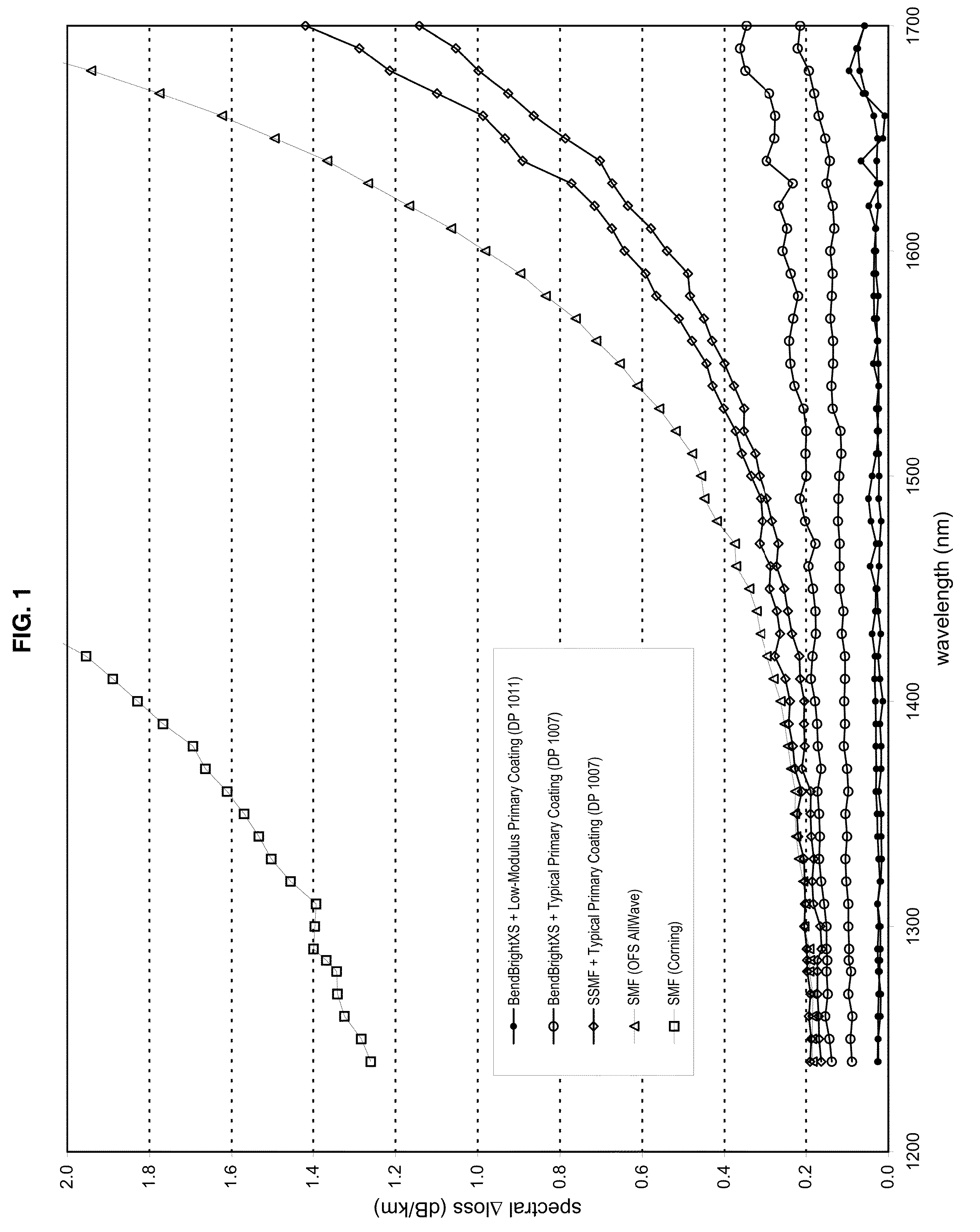

Reduced-Diameter Optical Fiber

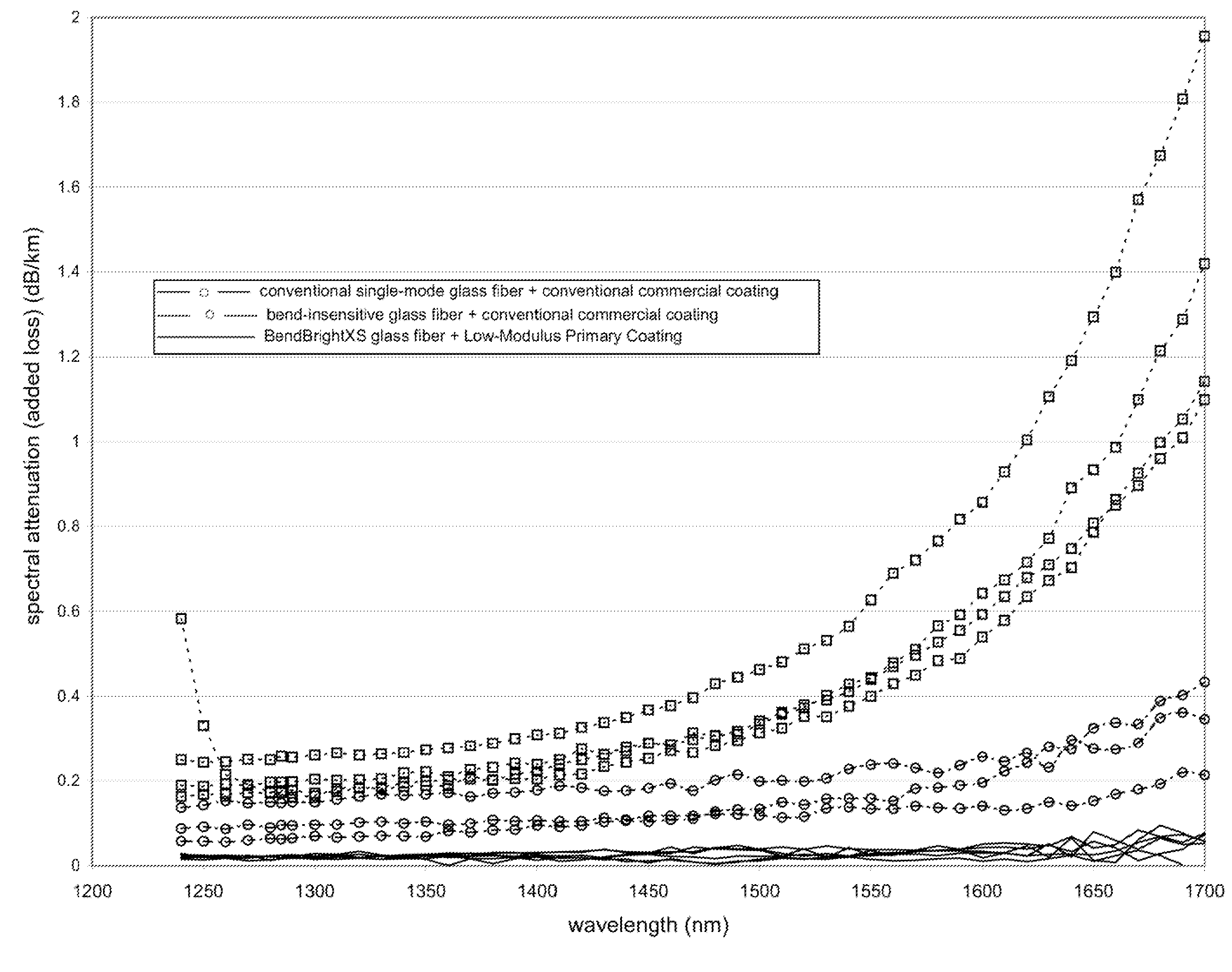

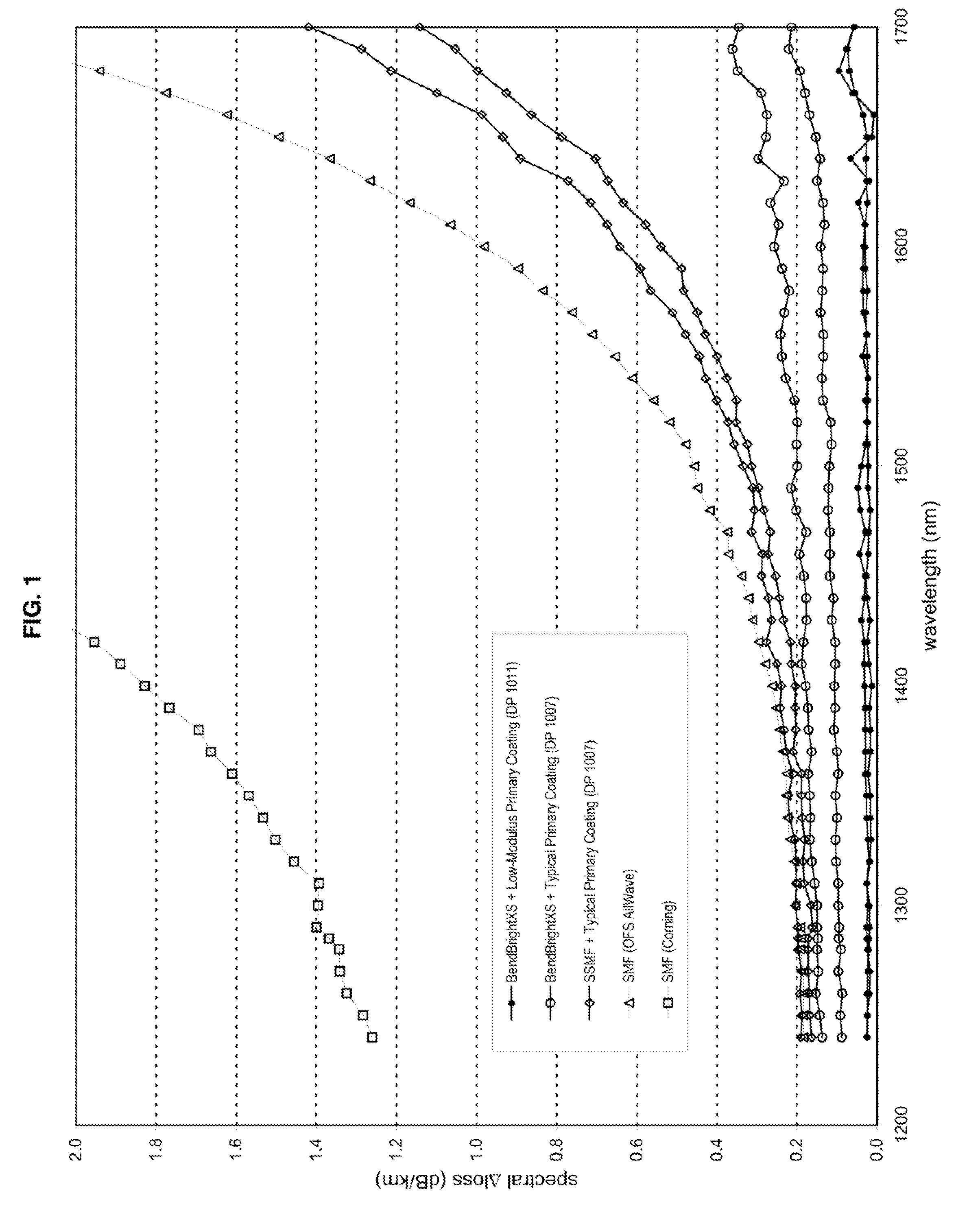

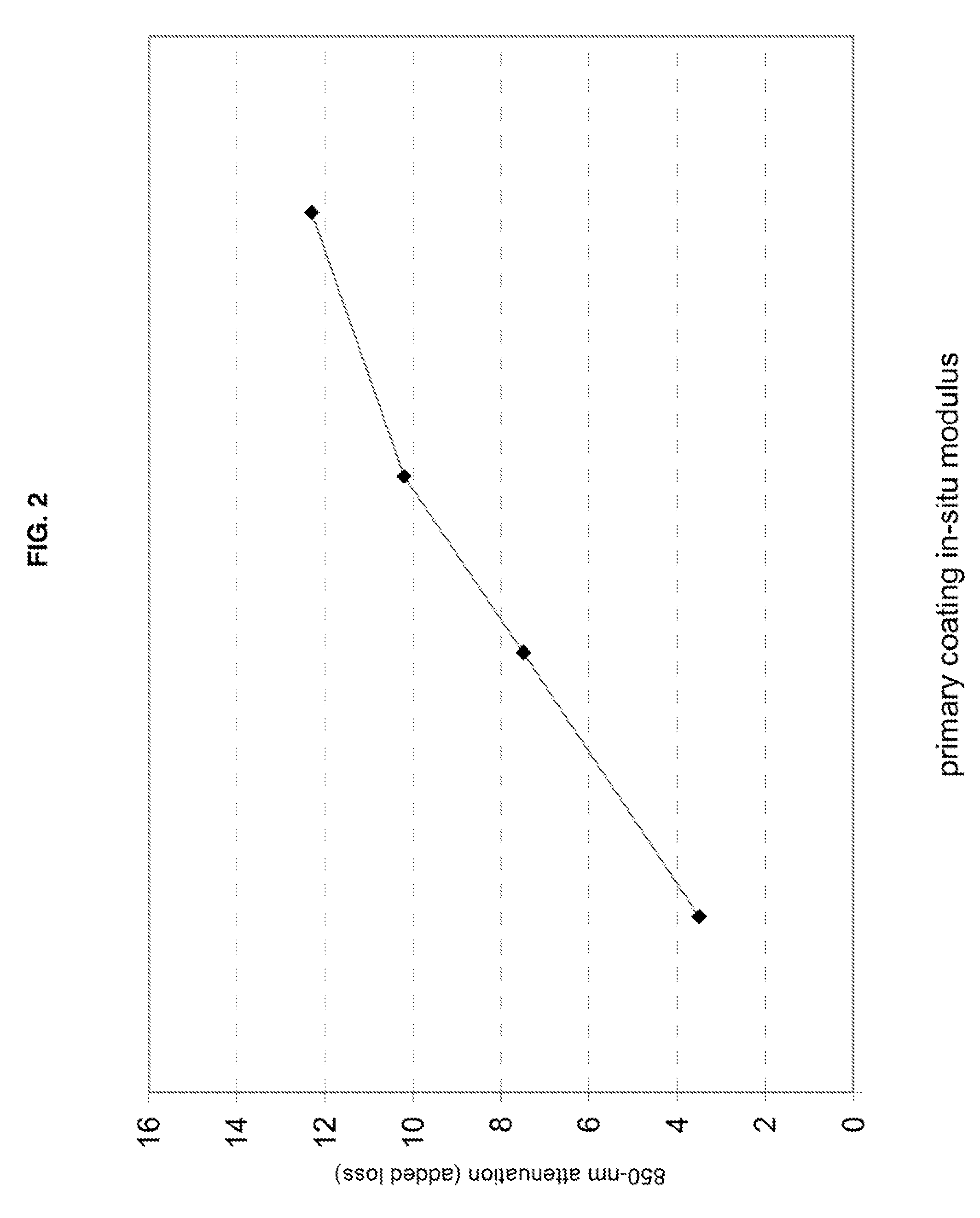

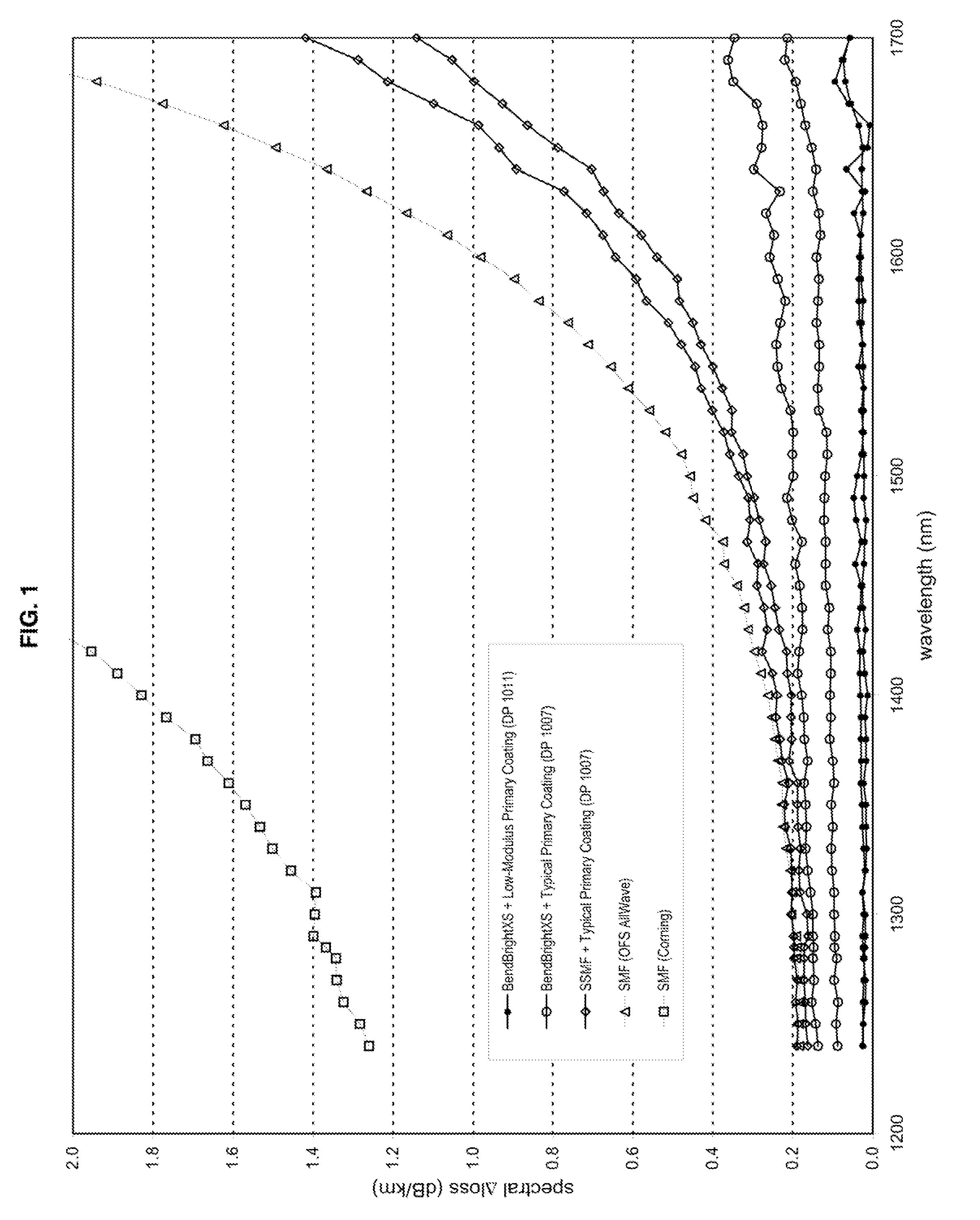

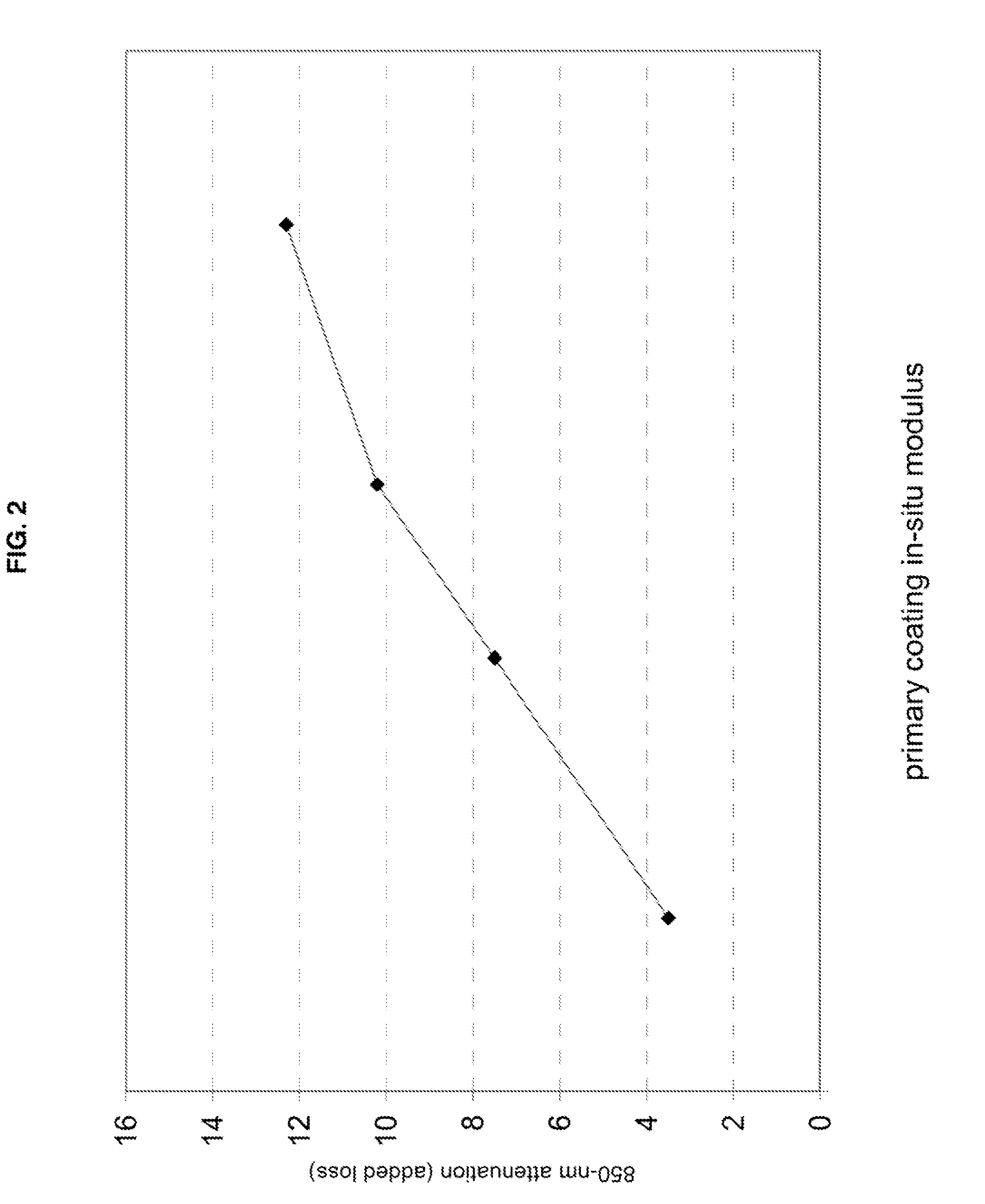

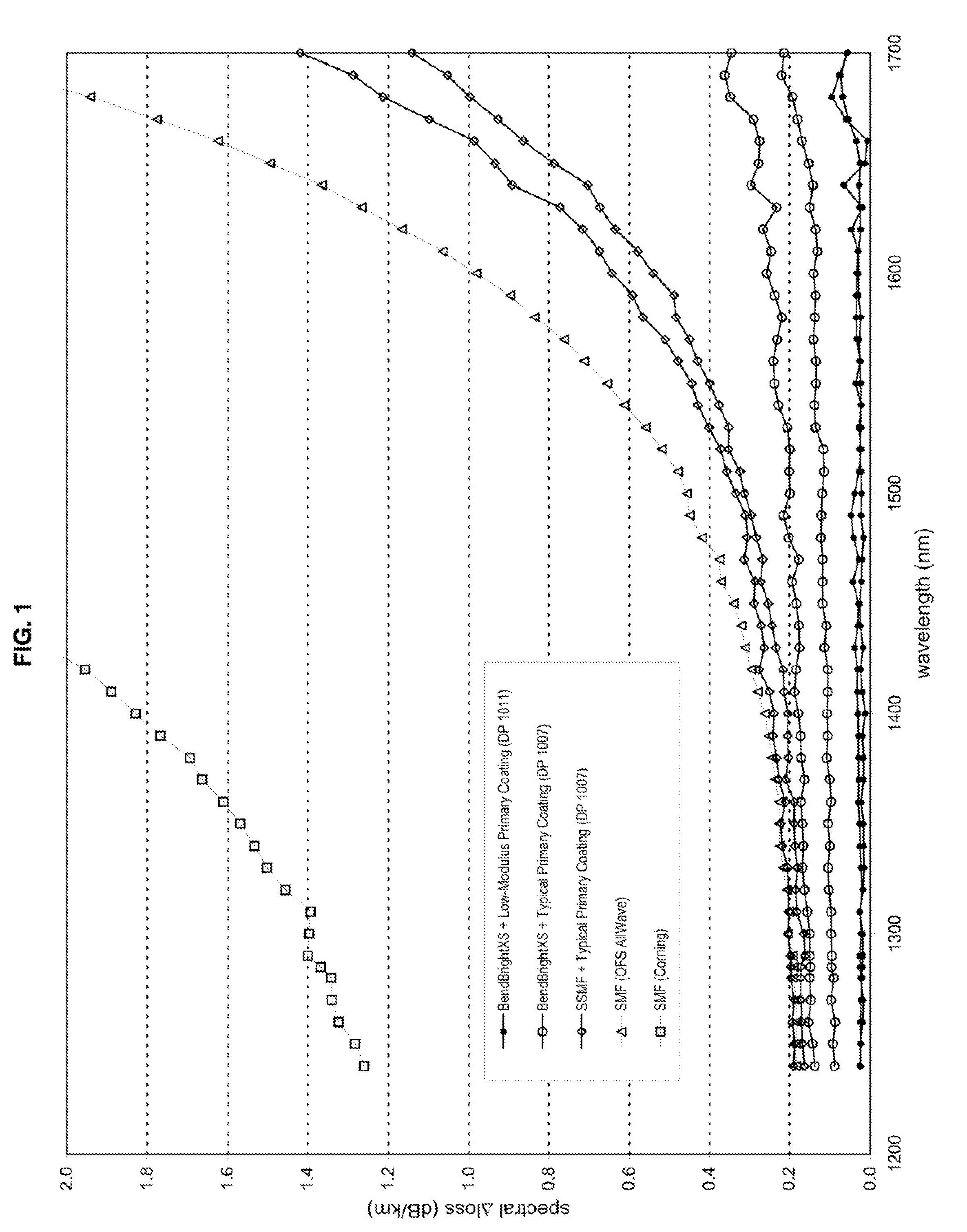

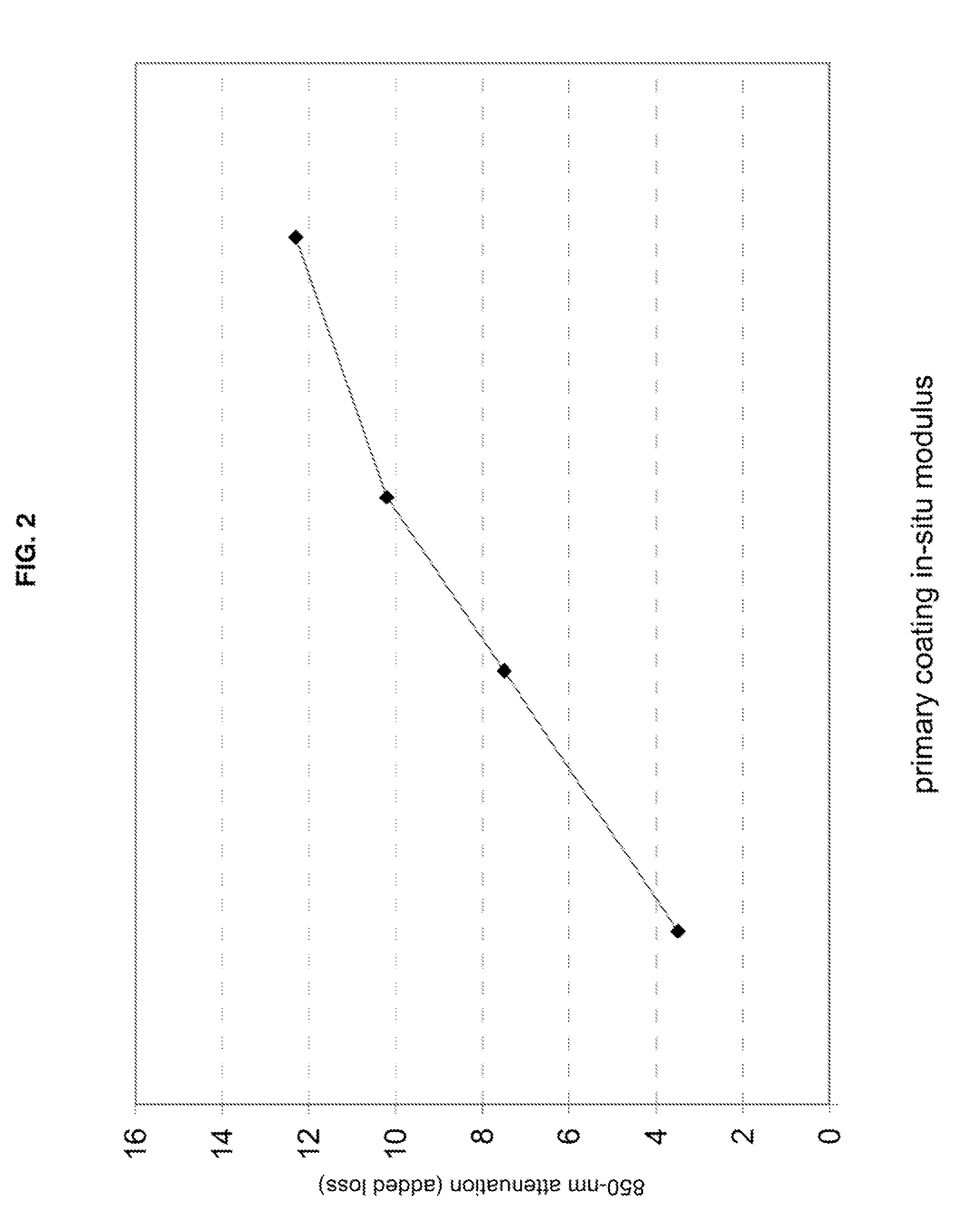

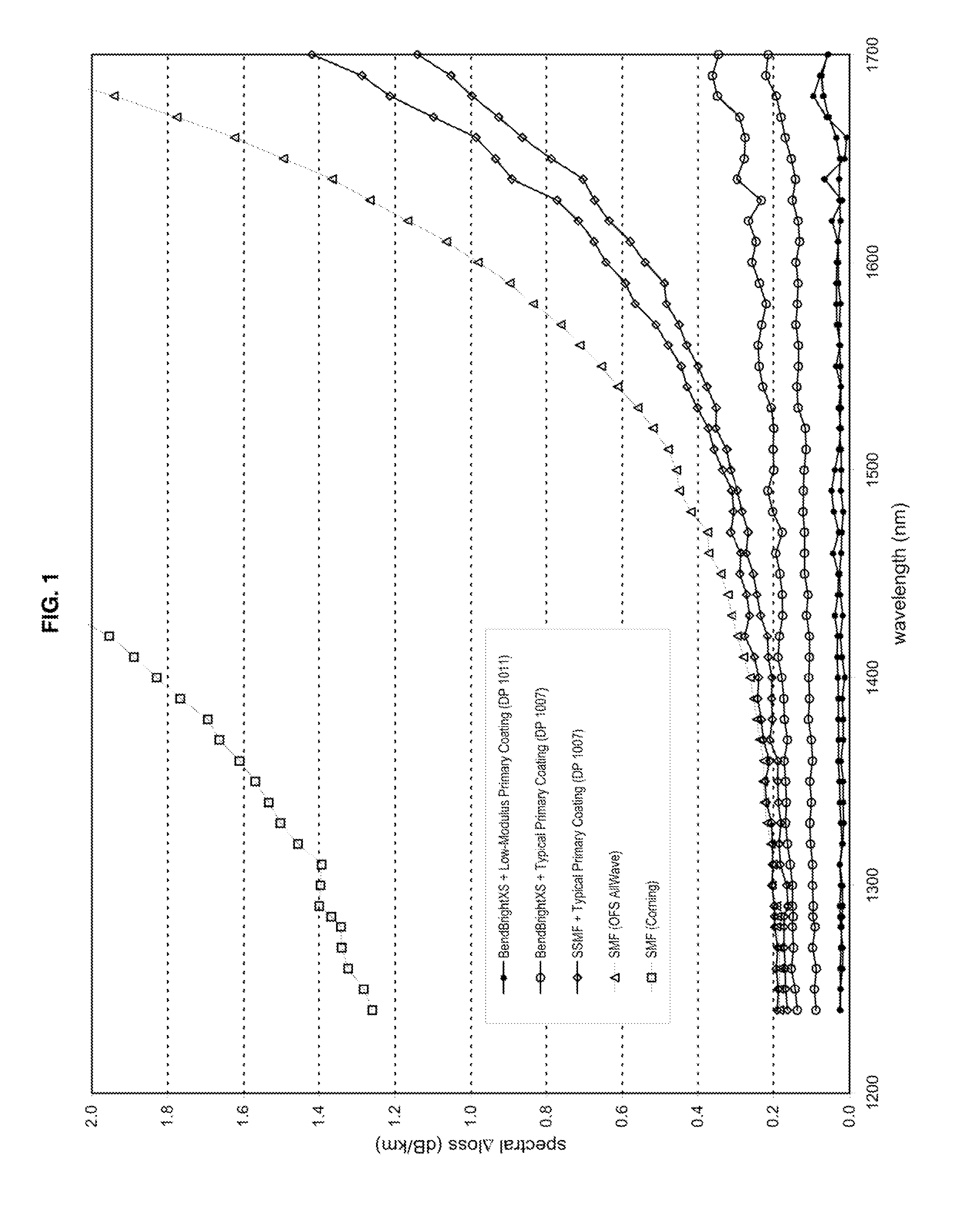

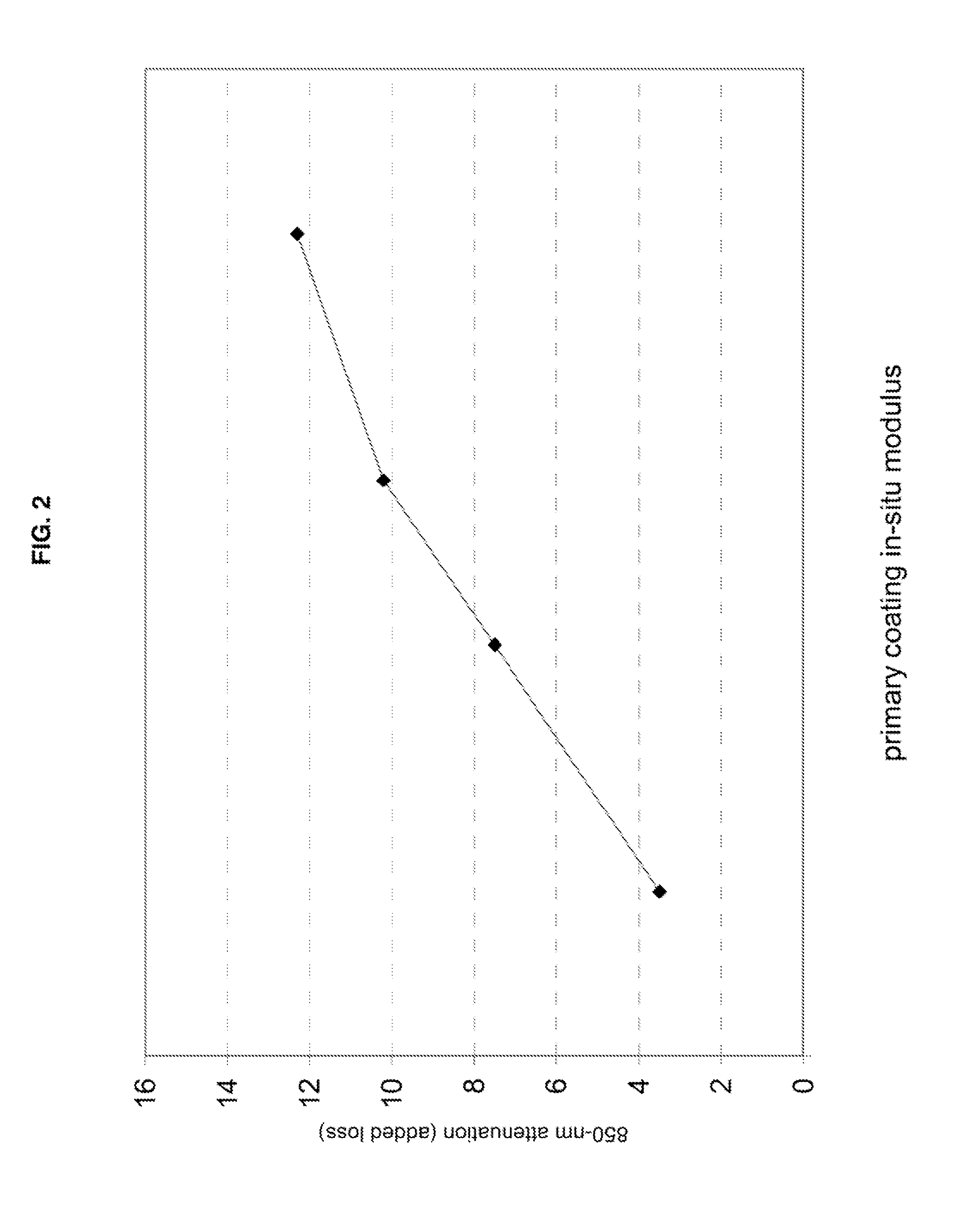

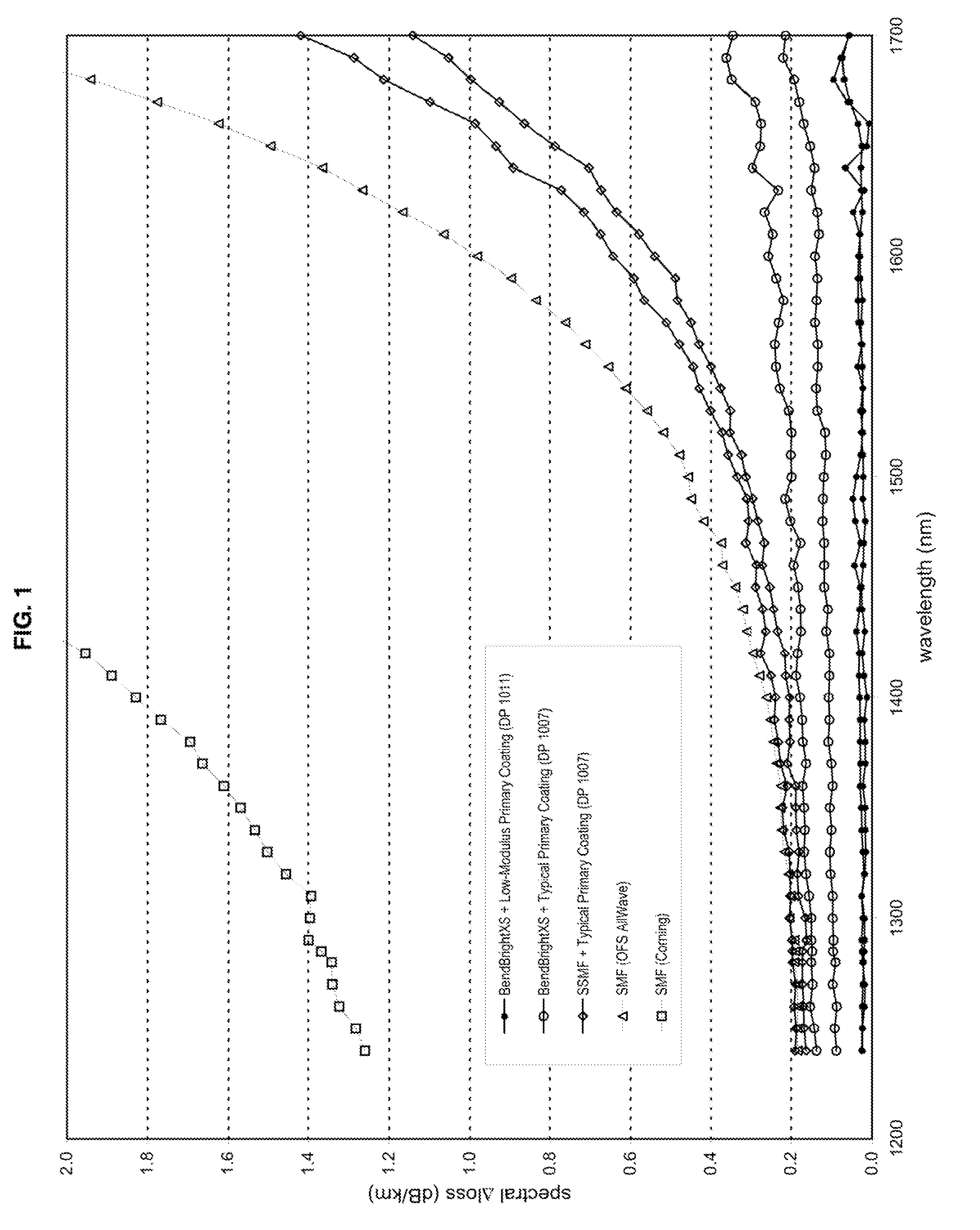

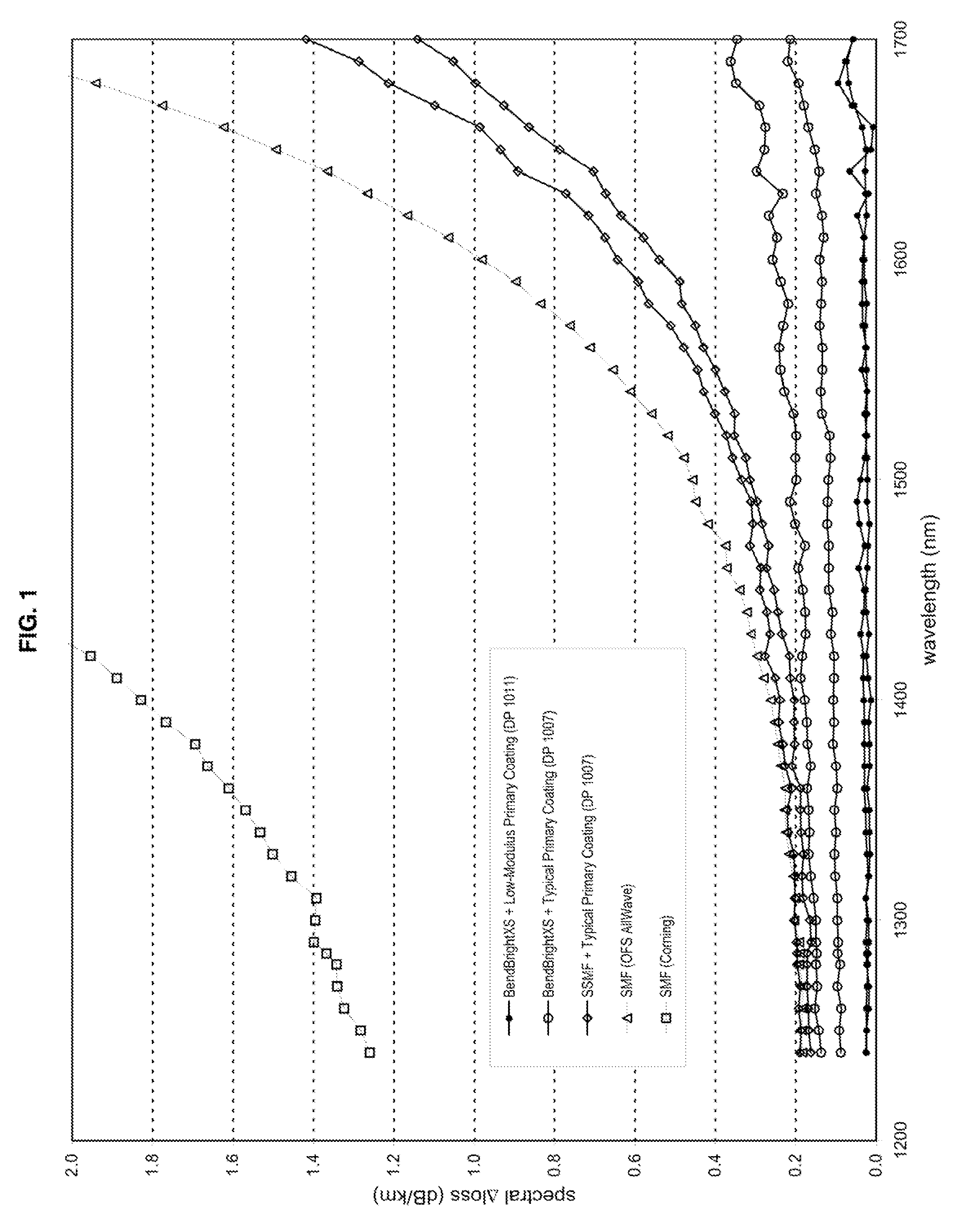

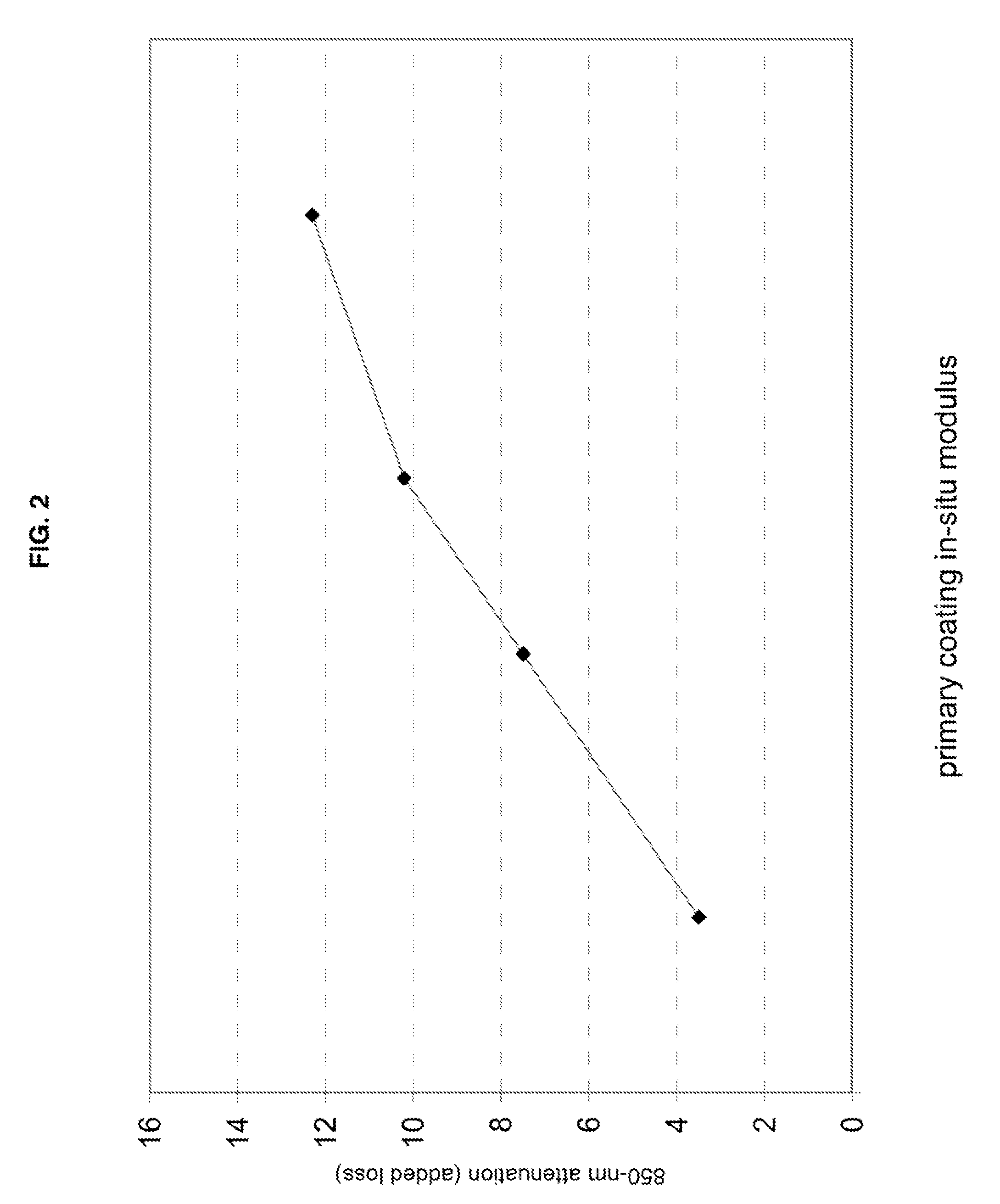

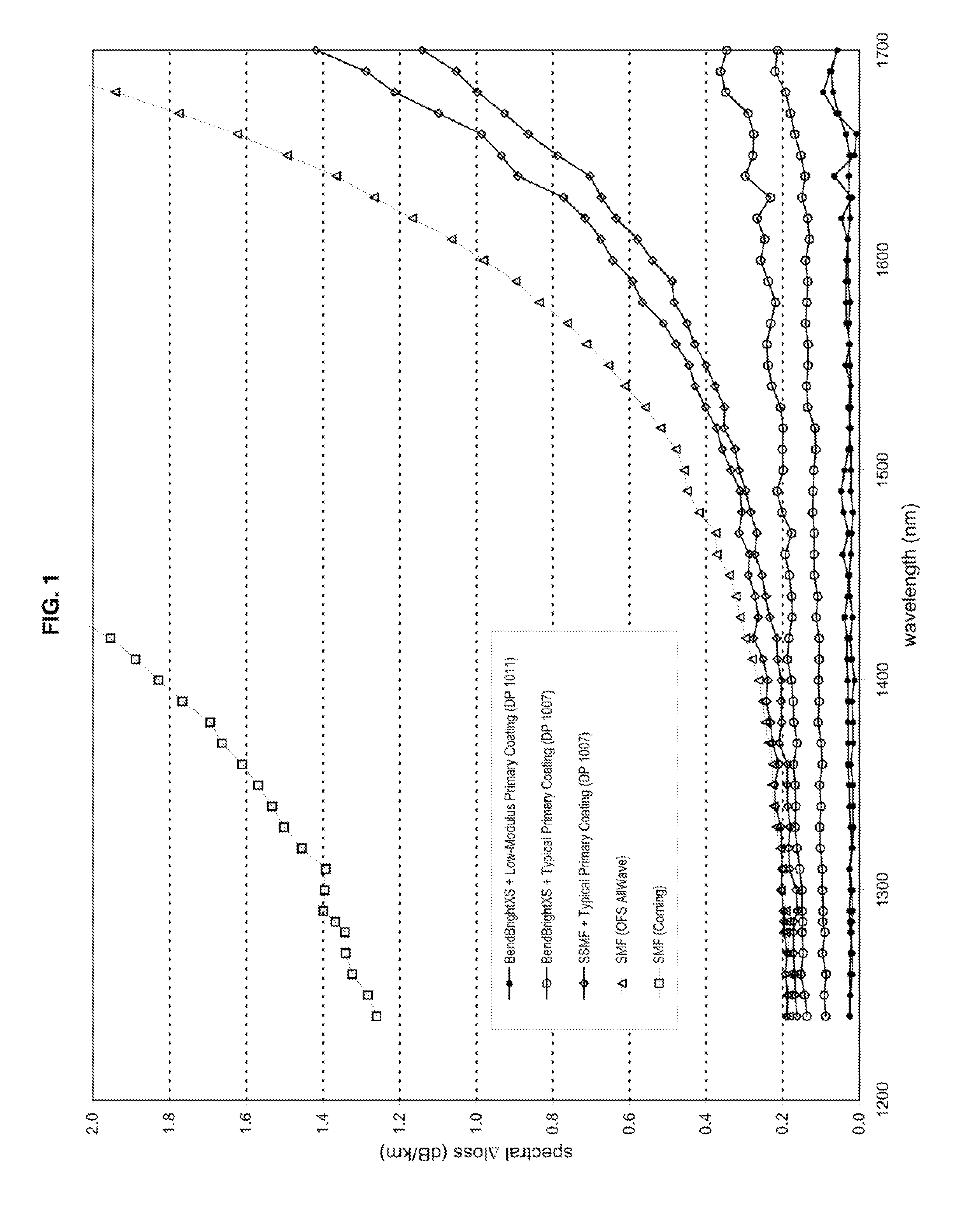

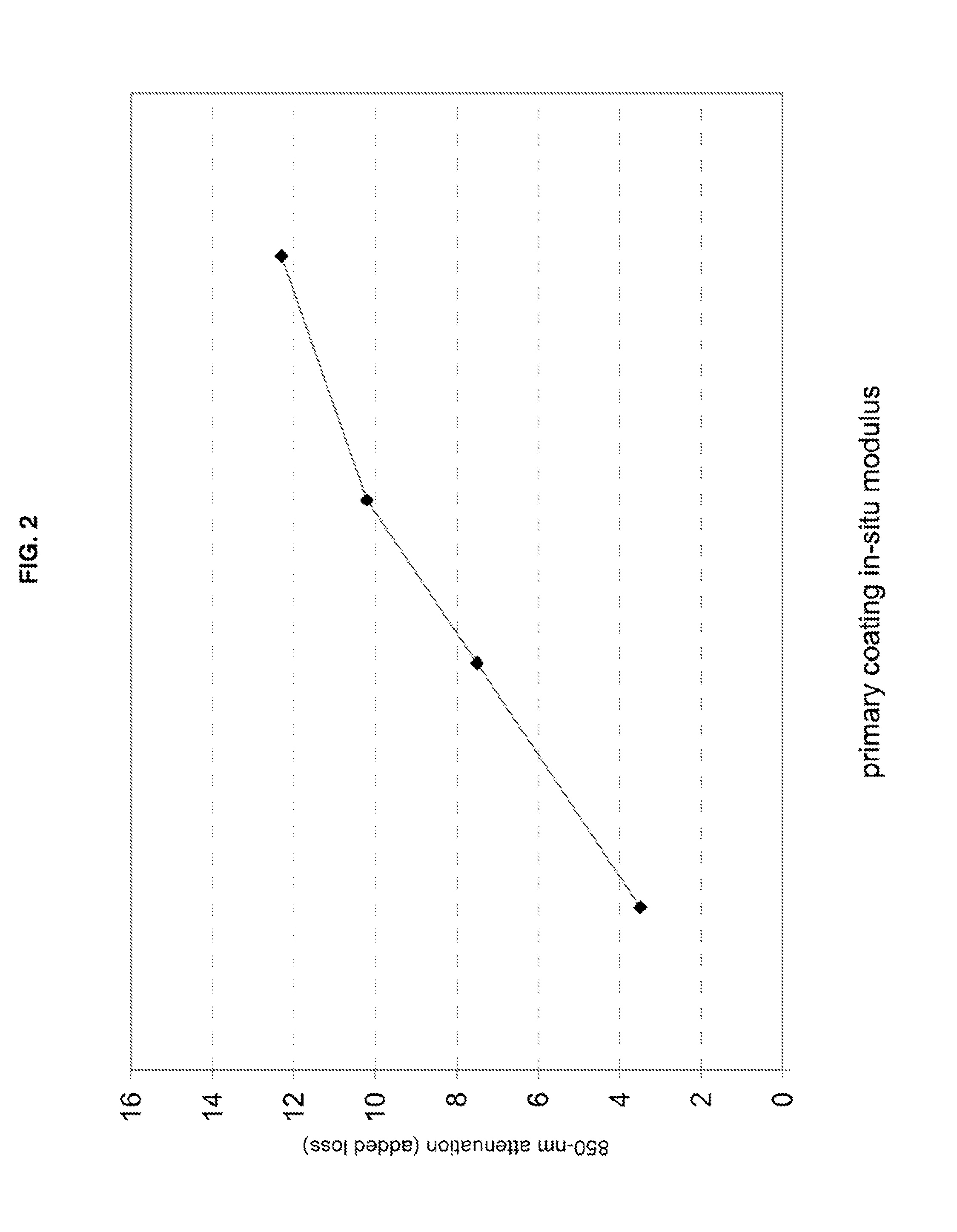

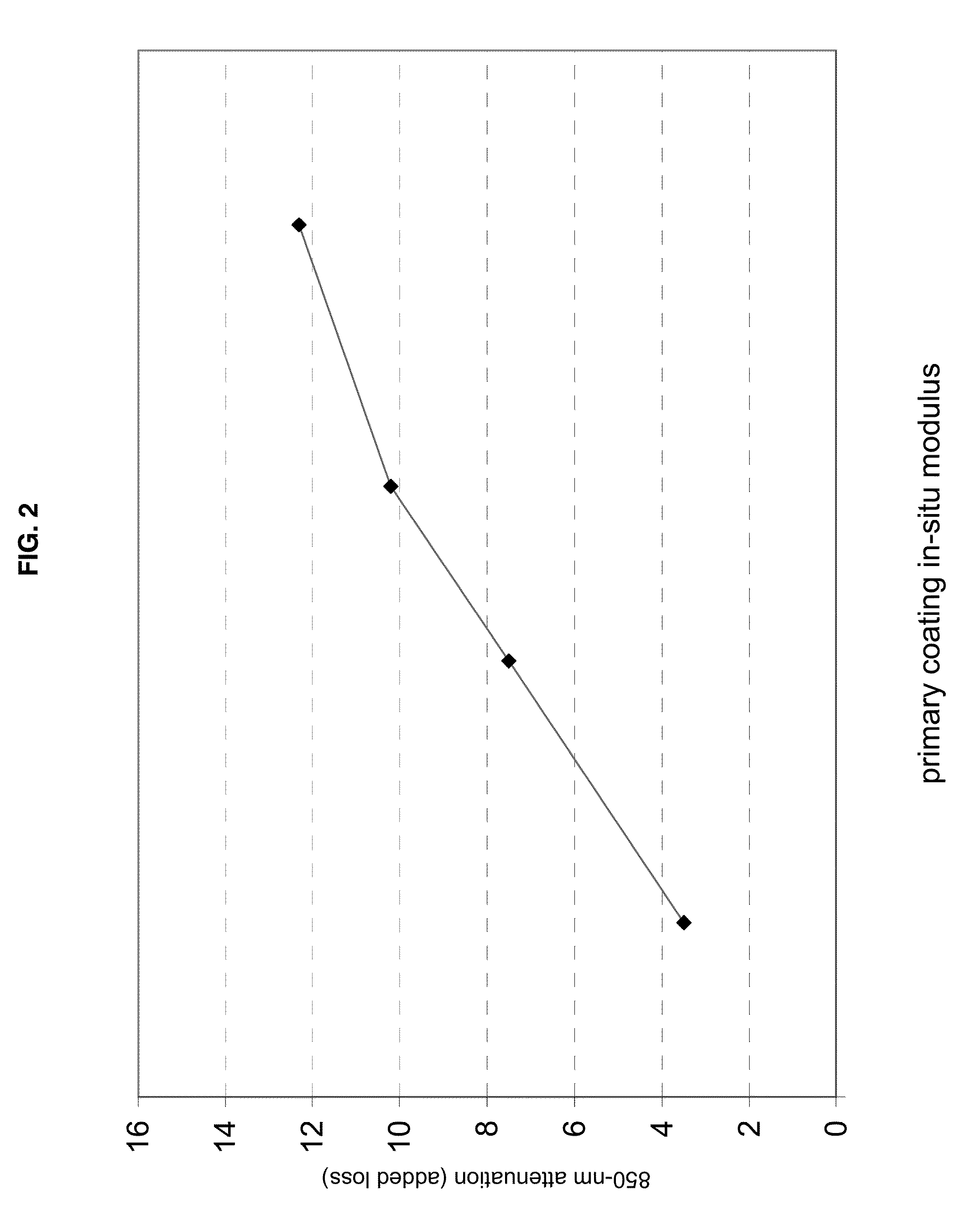

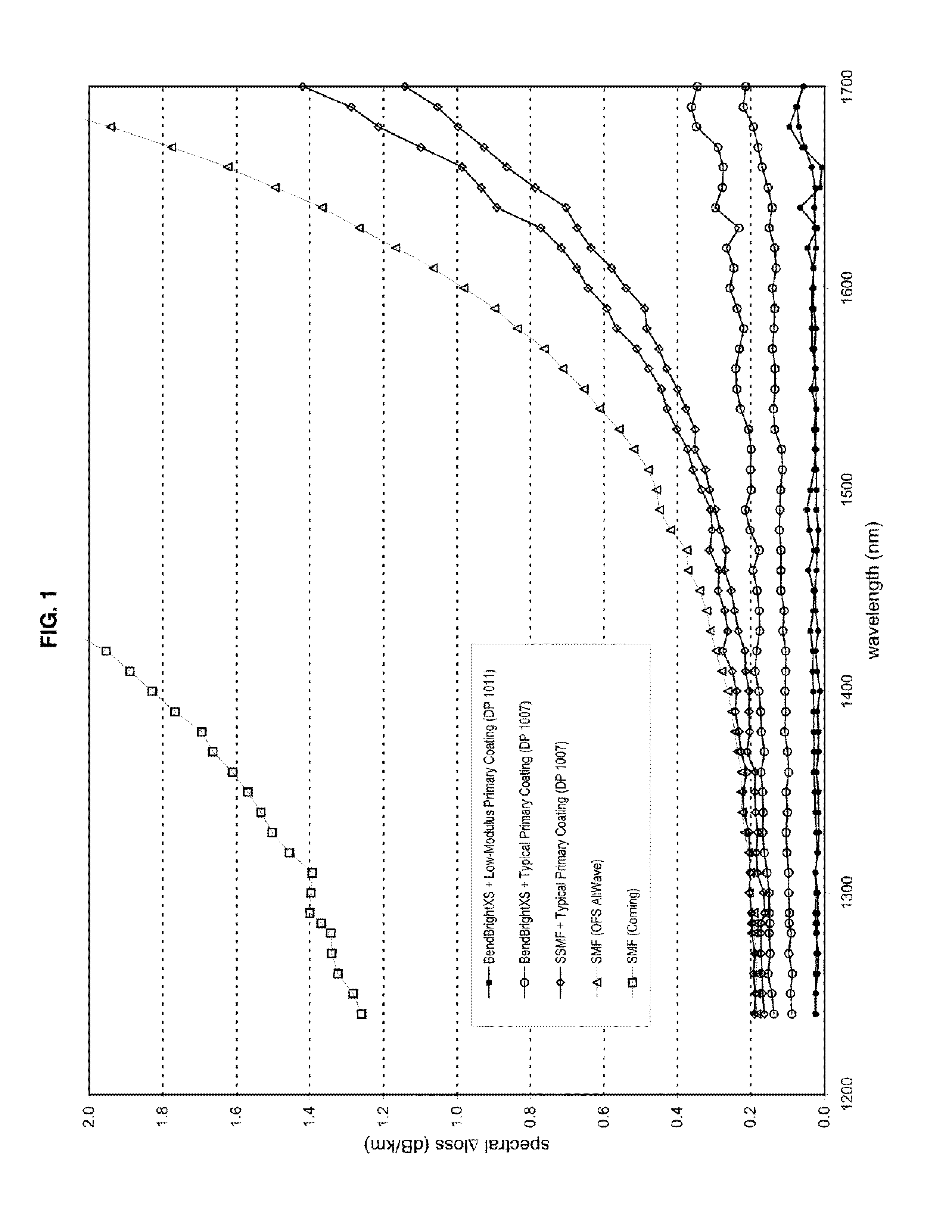

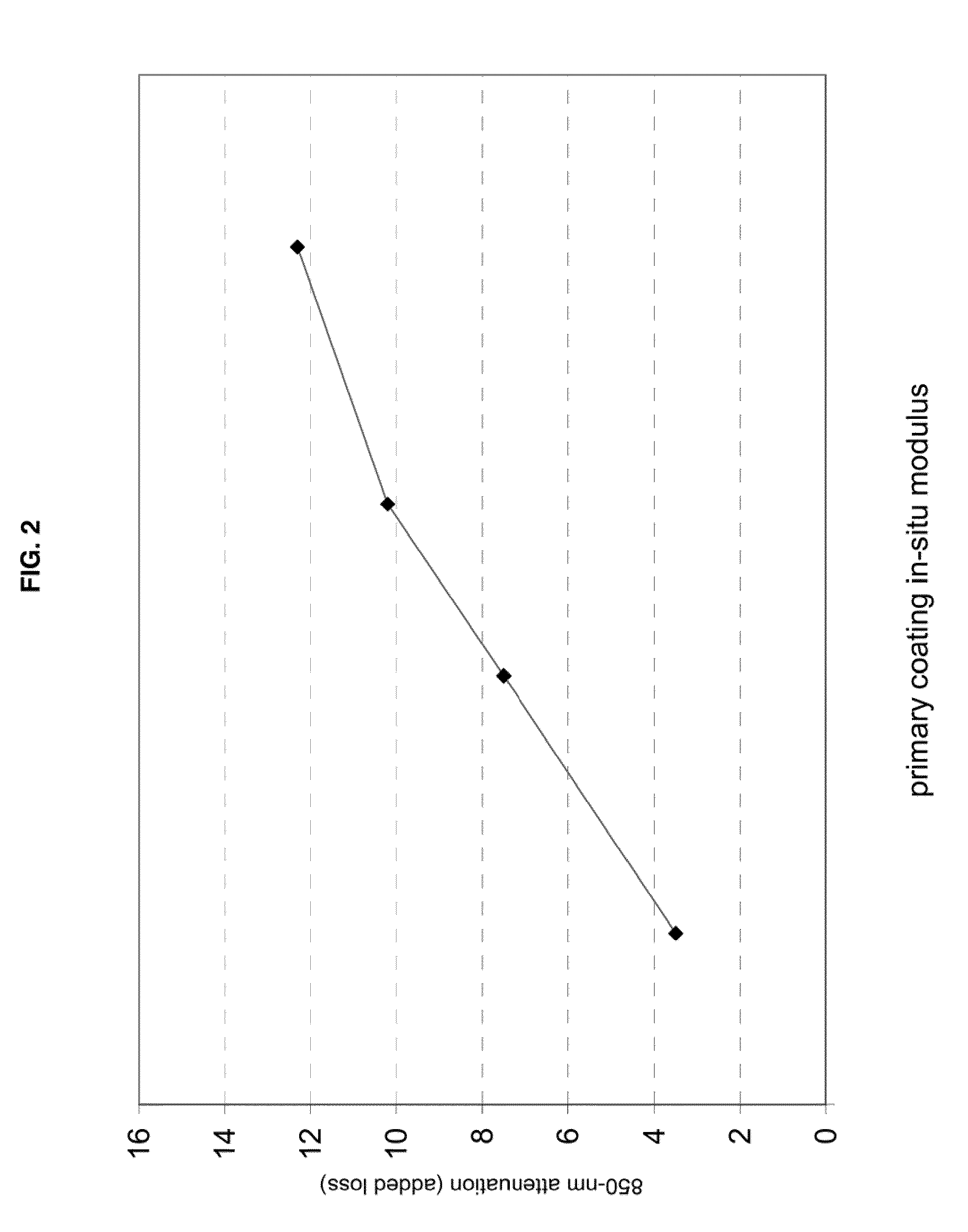

ActiveUS20100119202A1Improve protectionEasily matedGlass optical fibreCoupling light guidesFiberGlass fiber

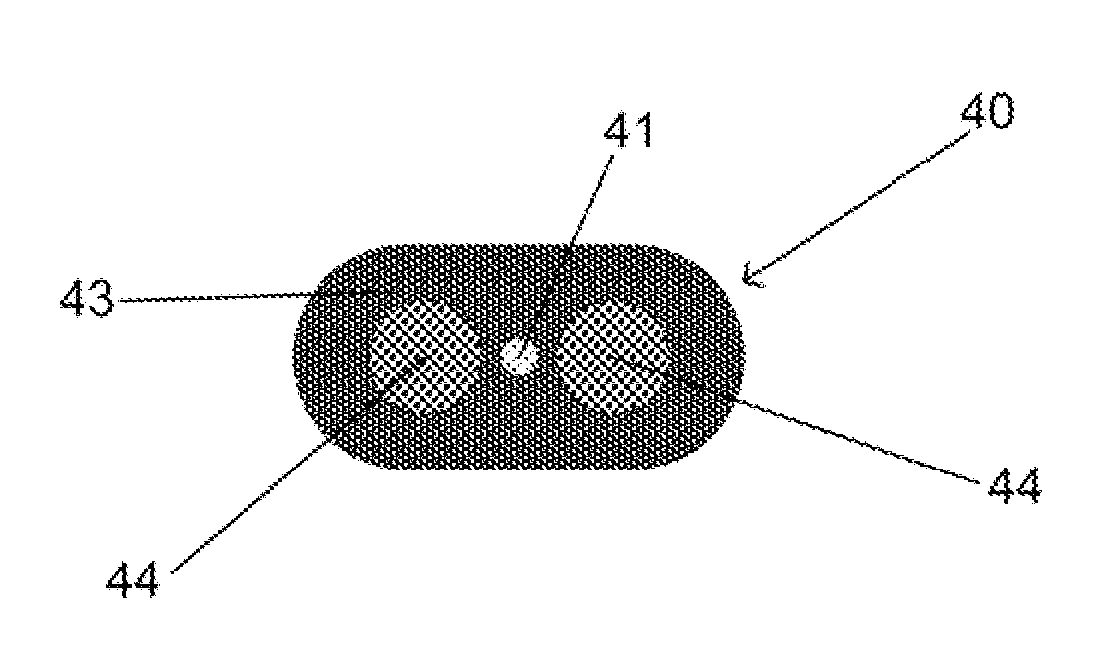

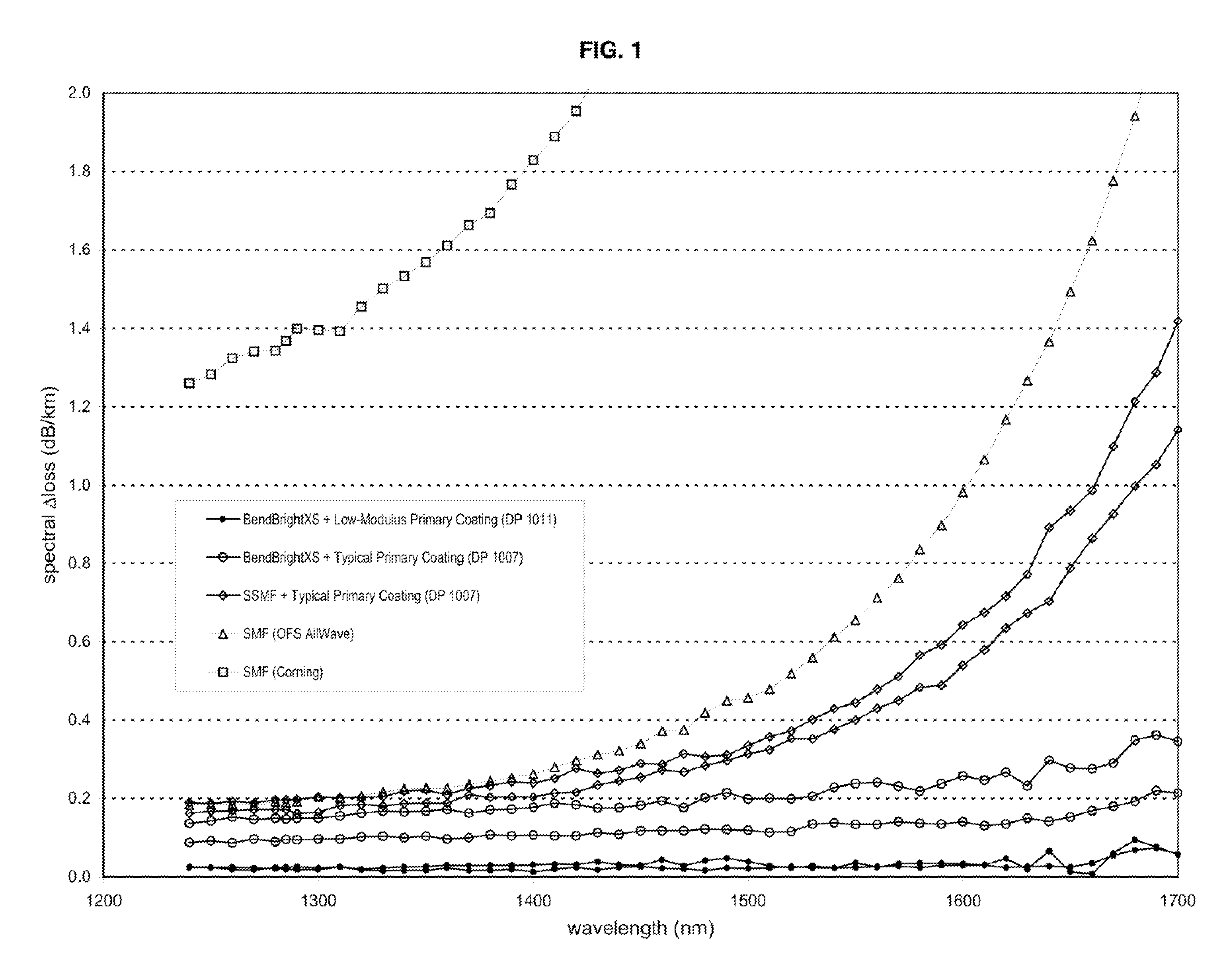

Disclosed is a reduced-diameter optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

Polymeric optical conductors

InactiveUS6766091B2Glass optical fibreOptical fibre with graded refractive index core/claddingFiberZero shear viscosity

An optical cable, which is flame-retardant, and has excellent adhesion of the protective covering to the fiber cladding and uniform thickness of the fiber cladding, contains a polymer optical conductor containing a fiber core; a single-layer or multi-layer fiber cladding; an inner external layer which adheres to the fiber cladding with a peel force of at least 50 N; and an outer external layer which adheres to the inner external layer with a peel force of not more than 30 N. The inner external layer contains a molding composition having a first polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, and f) mixtures thereof. The first polyamide contains at least 50 mueq / g of amino end groups. The first molding composition has a zero-shear viscosity of from 400 to 6000 Pas. The outer external layer contains a second molding composition which has the following i)-iii): i) from 20 to 95% by weight of a second polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, f) a polyetheramide of at least one of a)-e), and g) mixtures thereof, ii) from 5 to 45% by weight of a flame retardant, and iii) from 0 to 60% by weight of an impact modifier.

Owner:EVONIK DEGUSSA GMBH

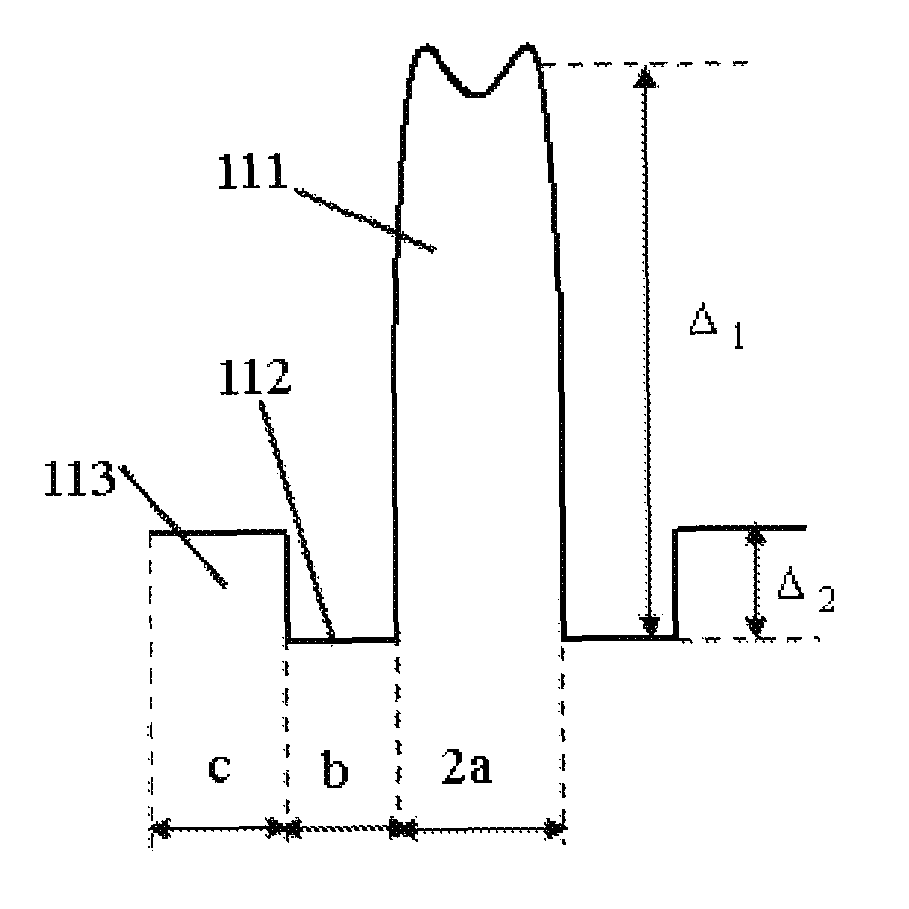

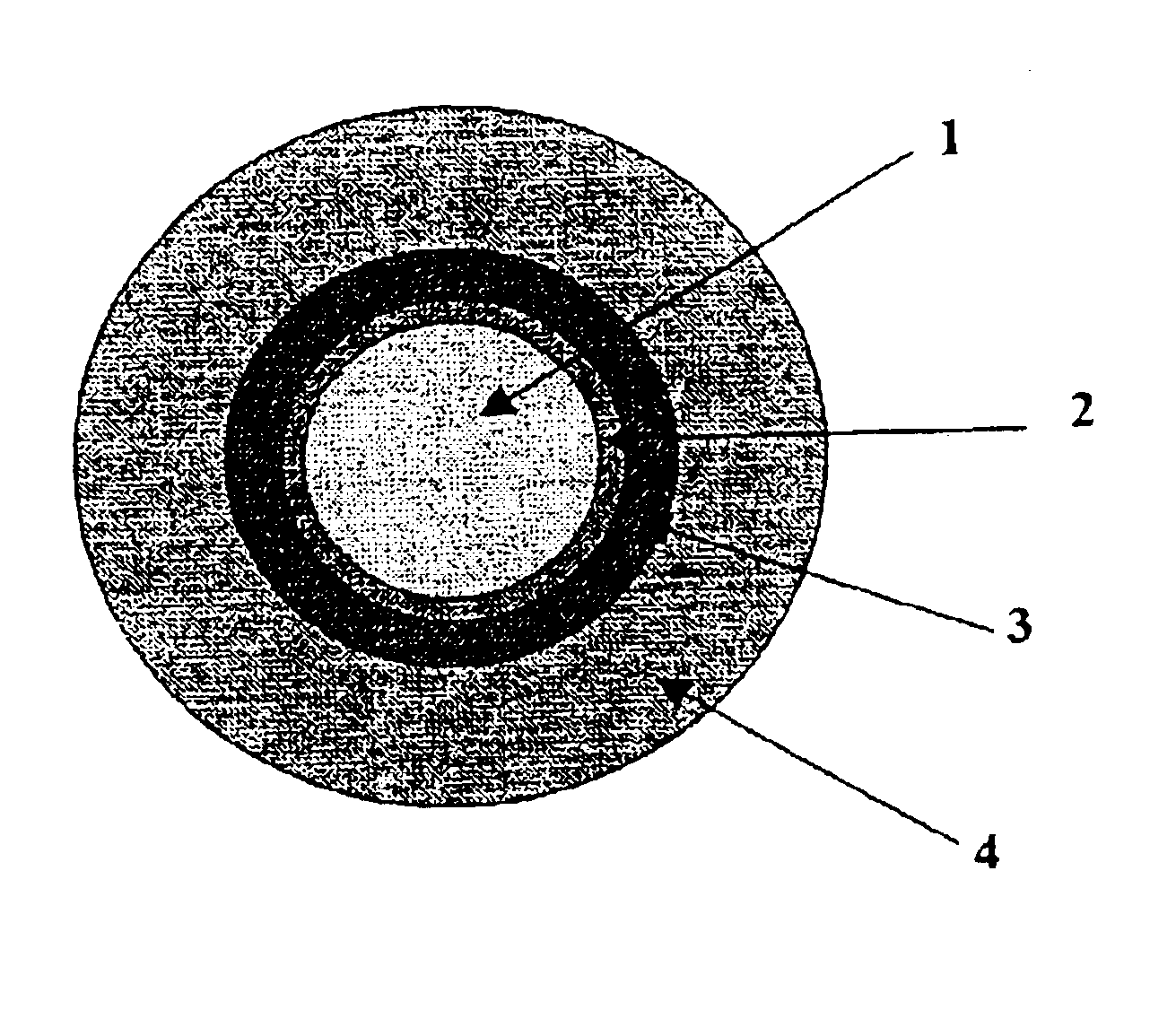

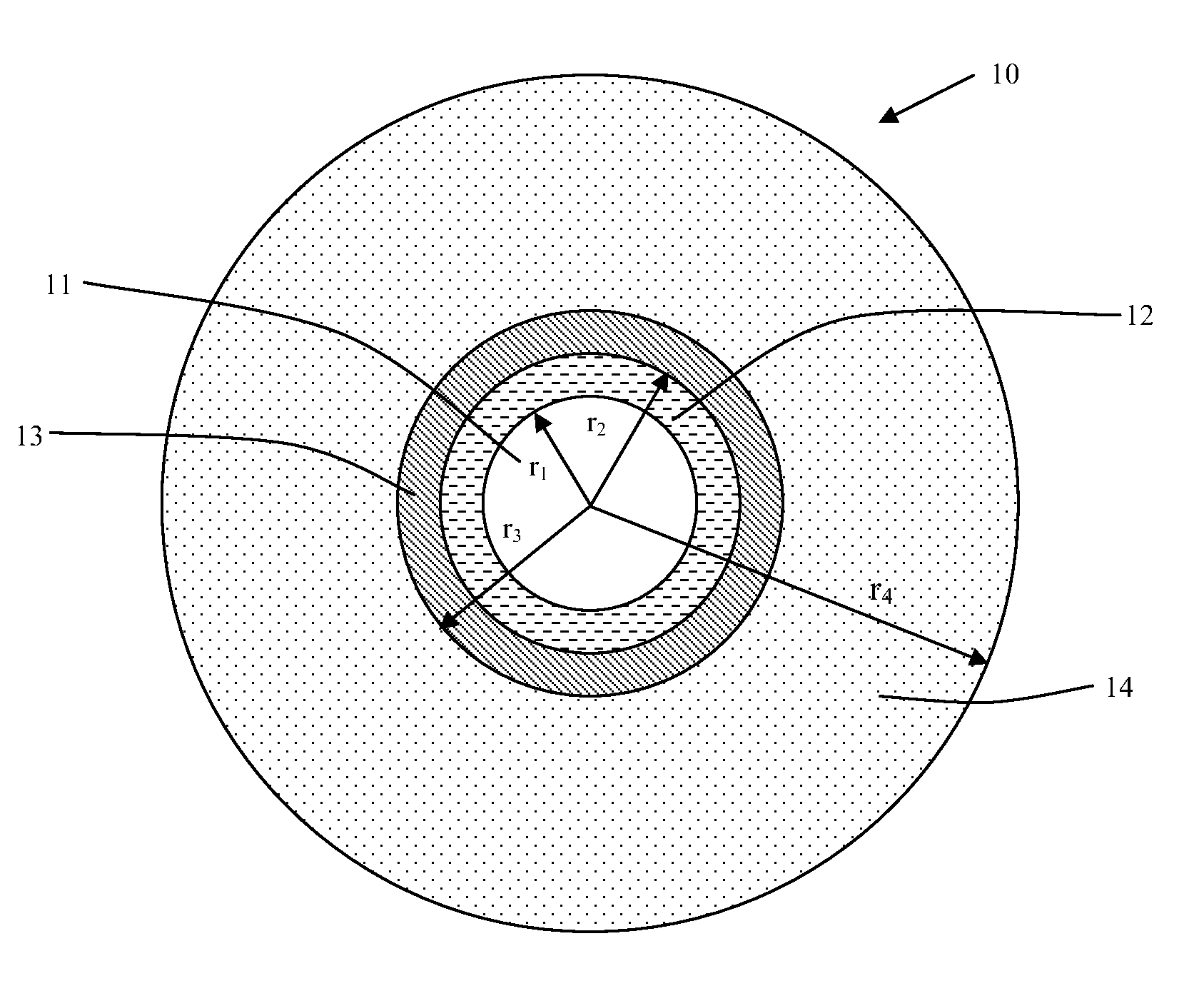

Bend-Insensitive Single-Mode Optical Fiber

ActiveUS20090279836A1Sufficient attenuationImproves the bending lossesGlass optical fibreOptical fibre with graded refractive index core/claddingWavelengthLength wave

A single-mode optical fiber includes a central core, an intermediate cladding, a depressed trench, and an external optical cladding. The central core has a radius r1 and a positive refractive index difference Δn1 with the optical cladding. The intermediate cladding has a radius r2 and a refractive index difference Δn2 with the optical cladding, wherein Δn2 is less than the central core's refractive index difference Δn1. The depressed trench has a radius r3 and a negative index difference Δn3 with the optical cladding. The optical fiber has a nominal mode field diameter (MFD) between 8.6 microns and 9.5 microns at a wavelength of nanometers, and at a wavelength of 1550 nanometers, the optical fiber has bending losses less than 0.15 dB / turn for a radius of curvature of 5 millimeters and cable cut-off wavelengths of less than or equal to nanometers.

Owner:DRAKA COMTEQ BV

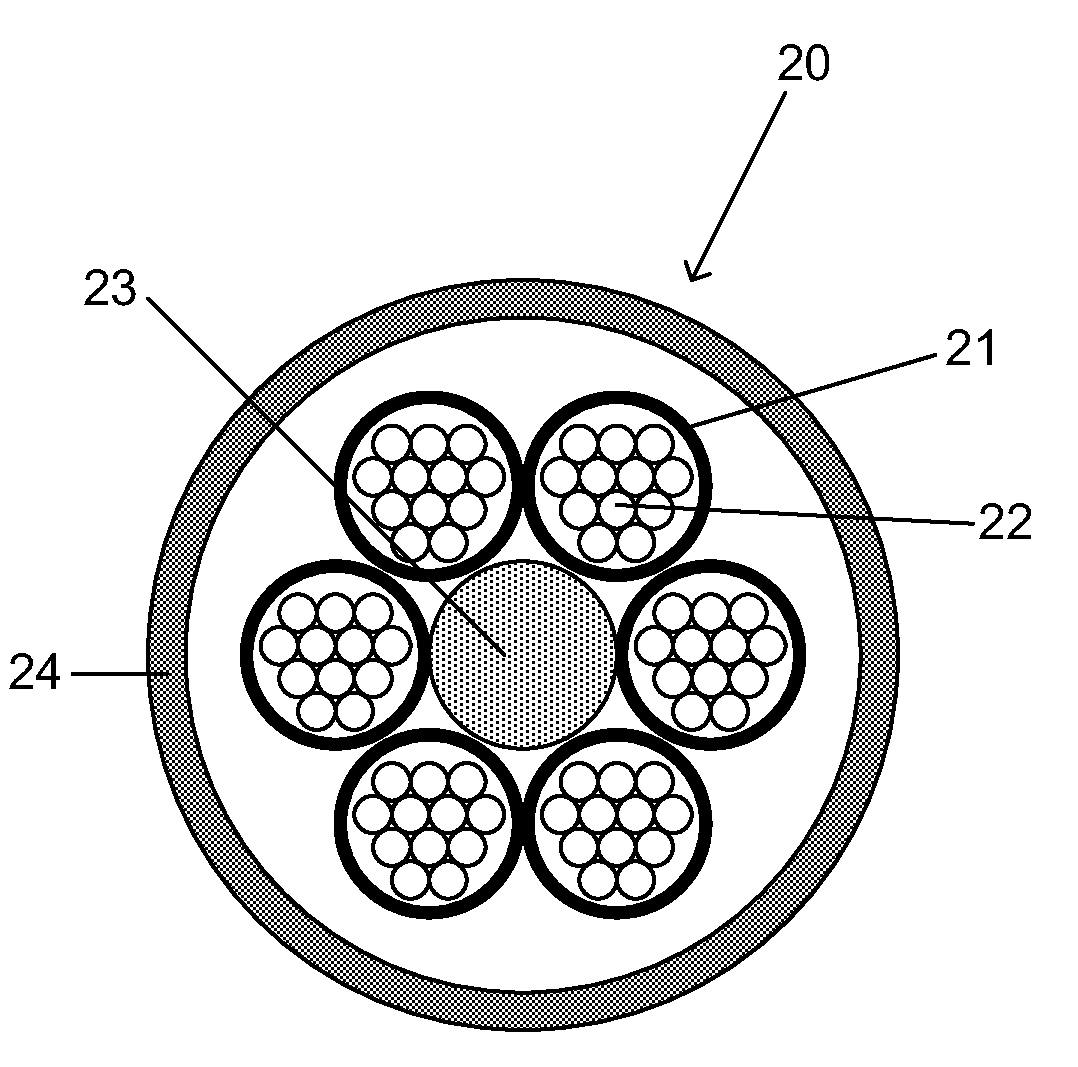

Optical-Fiber Loose Tube Cables

ActiveUS20100092140A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberFiber

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in buffer tubes and cables having relatively high filling coefficients and fiber counts.

Owner:DRAKA COMTEQ BV

ADSS Cables with High-Performance Optical Fiber

ActiveUS20100092138A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in all-dielectric self-supporting (ADSS) cables.

Owner:DRAKA COMTEQ BV

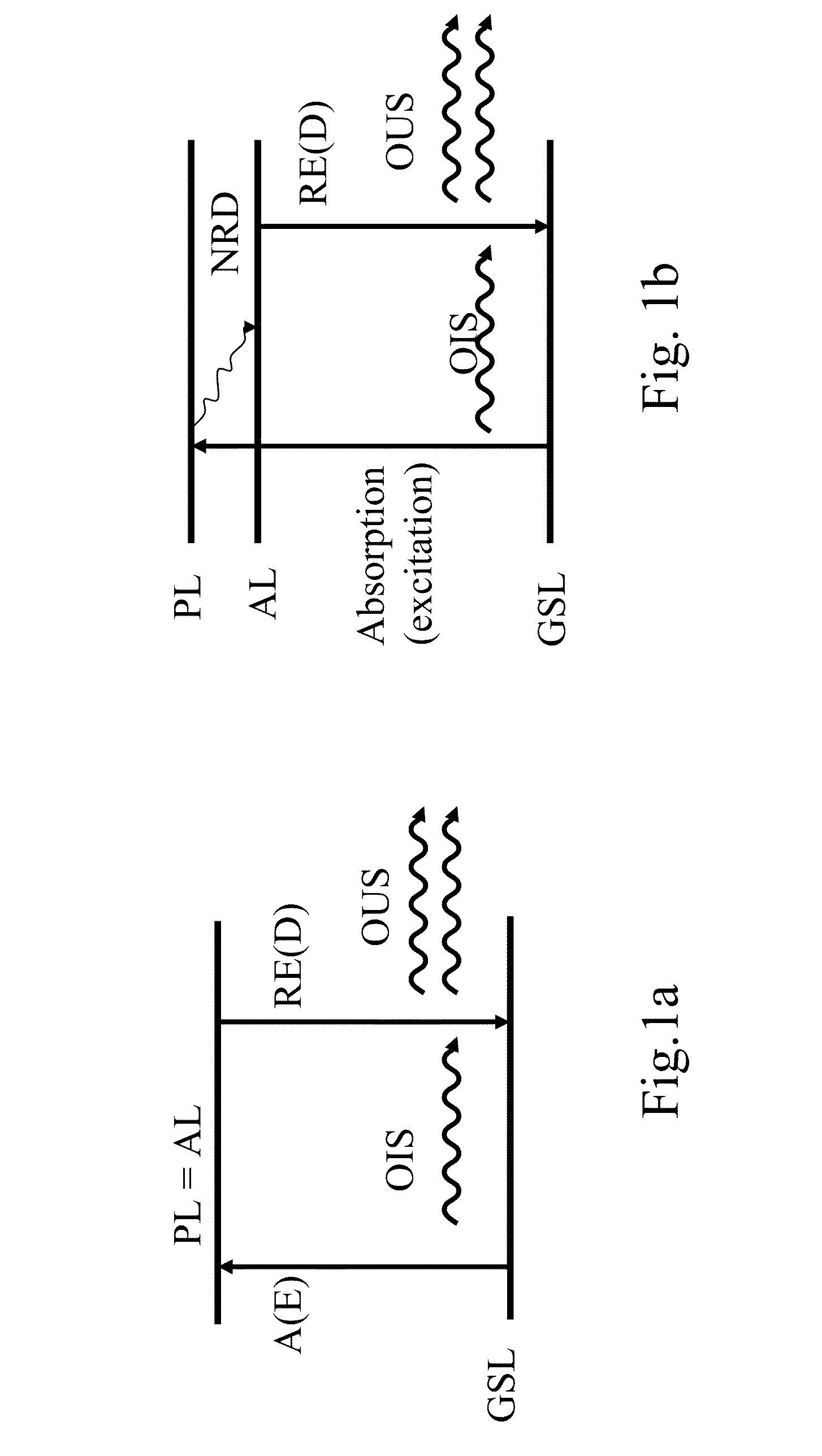

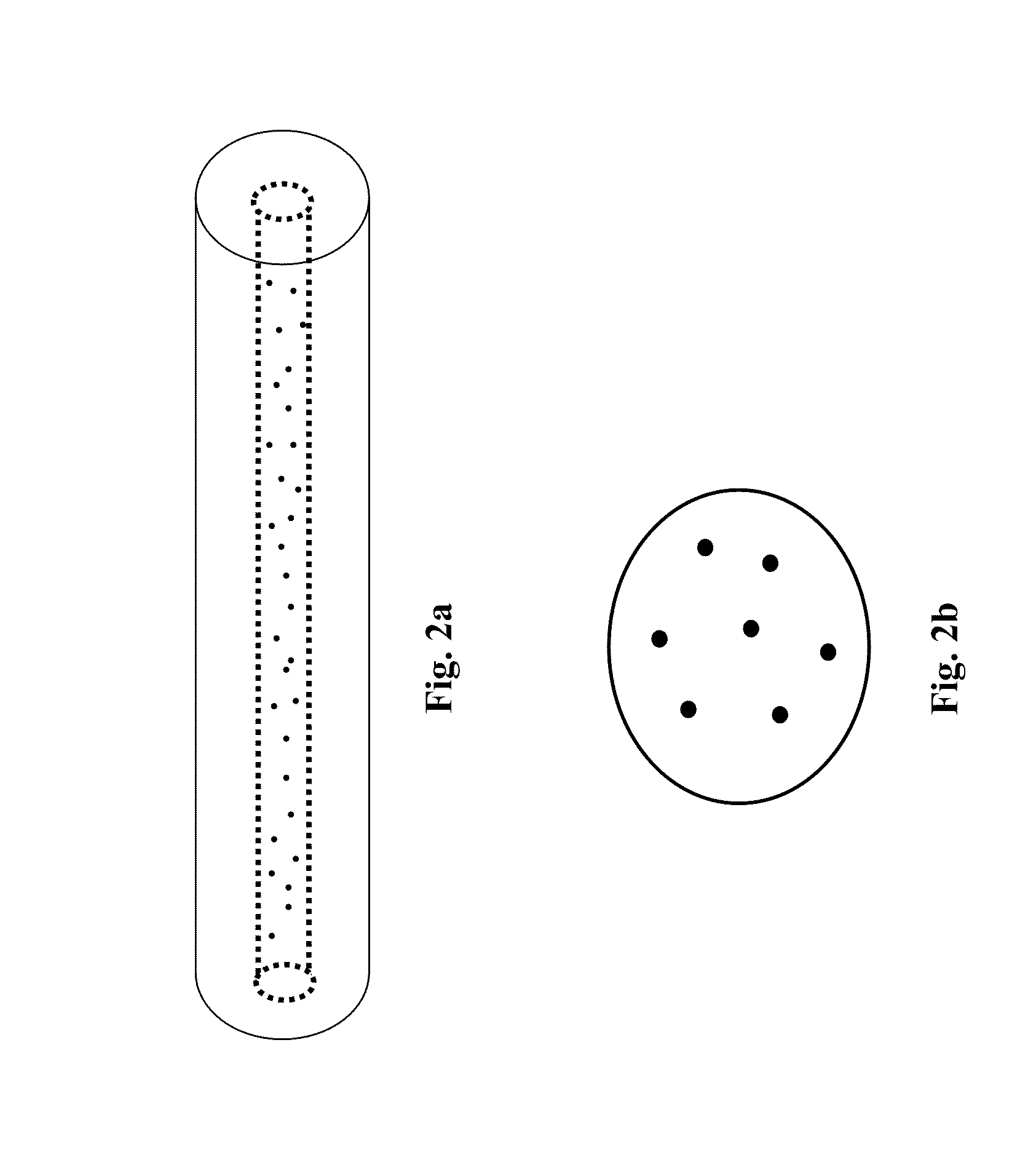

Amplifying Optical Fiber and Method of Manufacturing

InactiveUS20100118388A1Improve efficiencyIncrease output powerGlass optical fibreMaterial nanotechnologyRare-earth elementNanoparticle

Disclosed is an amplifying optical fiber having a central core and an optical cladding surrounding the central core. The central core is based on a silica matrix that includes nanoparticles, which are composed of a matrix material that includes doping ions of at least one rare earth element. The amplifying optical fiber can be employed, for example, in an optical amplifier and an optical laser.

Owner:DRAKA COMTEQ BV

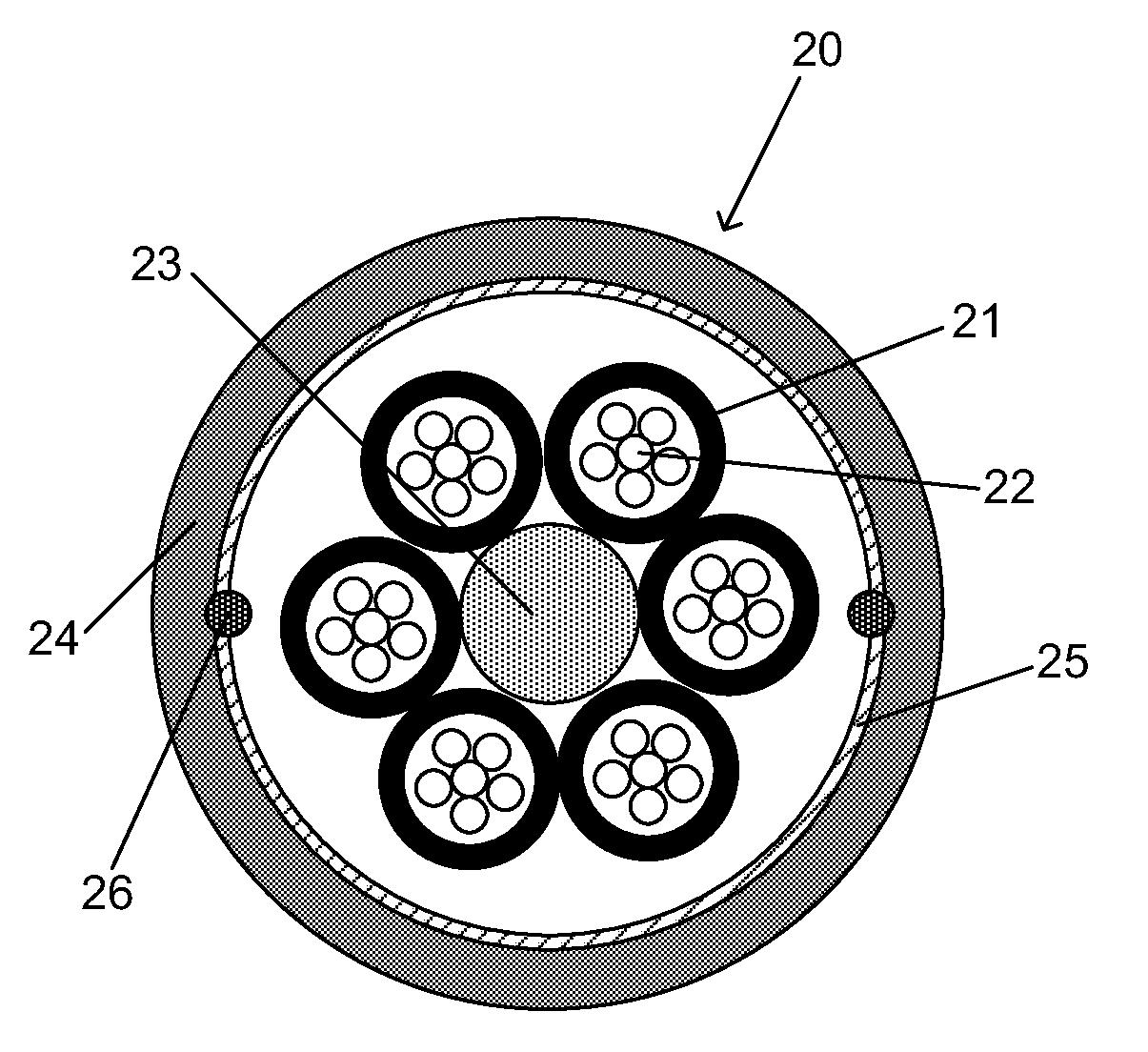

Reduced-Diameter Ribbon Cables with High-Performance Optical Fiber

ActiveUS20100135625A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberFiber

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

Reduced-Diameter, Easy-Access Loose Tube Cable

ActiveUS20100092139A1Improve protectionEasily matedGlass optical fibreOptical fibre with multilayer core/claddingLow modulusCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in relatively thin-walled, low-modulus buffer tubes (i.e., “flextubes”) that can be readily accessed without special tools.

Owner:DRAKA COMTEQ BV

Reduced-Size Flat Drop Cable

ActiveUS20100135624A1Improve protectionEasily matedGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that are useful in reduced-size drop cables.

Owner:DRAKA COMTEQ BV

Single-Fiber Drop Cables for MDU Deployments

ActiveUS20100135623A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness.The improved coating system provides optical fibers that offer significant advantages to single-fiber drop cables, such as those employed for Multiple Dwelling Unit (MDU) applications.

Owner:DRAKA COMTEQ BV

Optical Fiber Cable for Transmission of High Power Laser Energy Over Great Distances

ActiveUS20100215326A1Easy to transportIncrease powerGlass optical fibreDrill bitsHigh power lasersEngineering

There is provided a system and apparatus for the transmission of high power laser energy over great distances without substantial power loss and without the presence of stimulated Raman scattering. There is further provided systems and optical fiber cable configurations and optical fiber structures for the delivering high power laser energy over great distances to a tool or surface to perform an operation or work with the tool or upon the surface.

Owner:FORO ENERGY

Coated optical fibers having strippable primary coatings and processes for making and using same

InactiveUS6014488ACleanly strippableHigh modulusGlass optical fibreGlass making apparatusFiberSilicon dioxide

PCT No. PCT / US98 / 01289 Sec. 371 Date Sep. 1, 1998 Sec. 102(e) Date Sep. 1, 1998 PCT Filed Jan. 23, 1998 PCT Pub. No. WO98 / 33081 PCT Pub. Date Jul. 30, 1998The invention relates to coated optical fibers which are coated with a particular radiation-cured primary coating layer composition. The fibers which are coated comprises a glass core and a glass cladding layer. The core, for example may comprises silica doped with oxides of germanium or phosphorous and the cladding, a pure or doped silicate such as fluorosilicate. Alternatively, the fibers may comprises a polymerclad silica glass core. Examples of such claddings include organosiloxanes such as polydimethylsiloxane or a fluorinated acrylic polymer.

Owner:HEXION INC

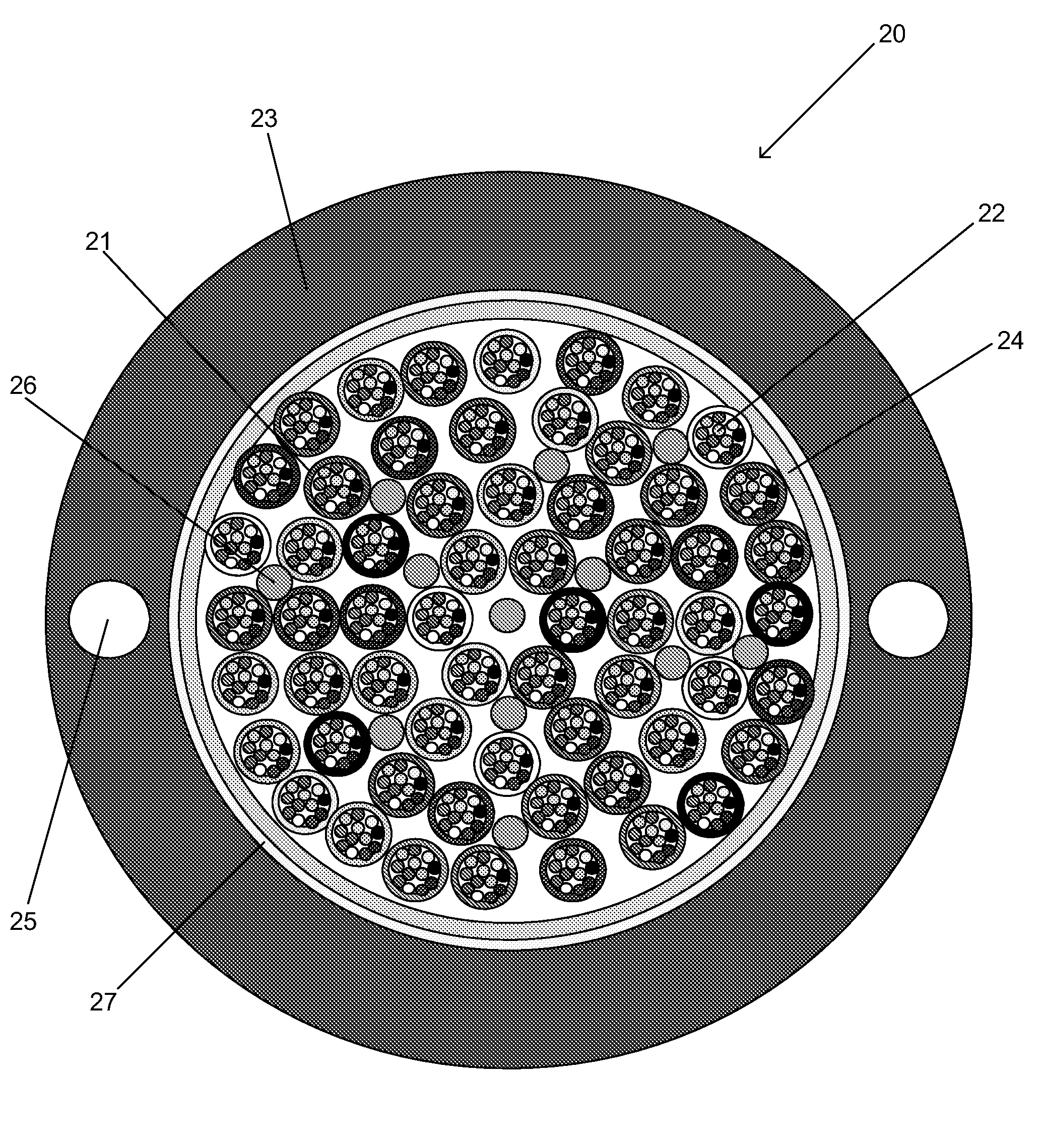

High-Fiber-Density Optical-Fiber Cable

ActiveUS20110069932A1Improve protectionGlass optical fibreOptical fibre with multilayer core/claddingUltrasound attenuationGlass fiber

Disclosed is an improved optical fiber possessing a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optical fibers in accordance in the present invention may be incorporated into a reduced-diameter optical-fiber cable that possesses a high fiber count and a high cable fiber density. The high-fiber-density optical-fiber cable, which is suitable for deployments in ducts, is capable of achieving outstanding attenuation performance when subjected to temperature variations of between about −40° C. and 70° C.

Owner:DRAKA COMTEQ BV

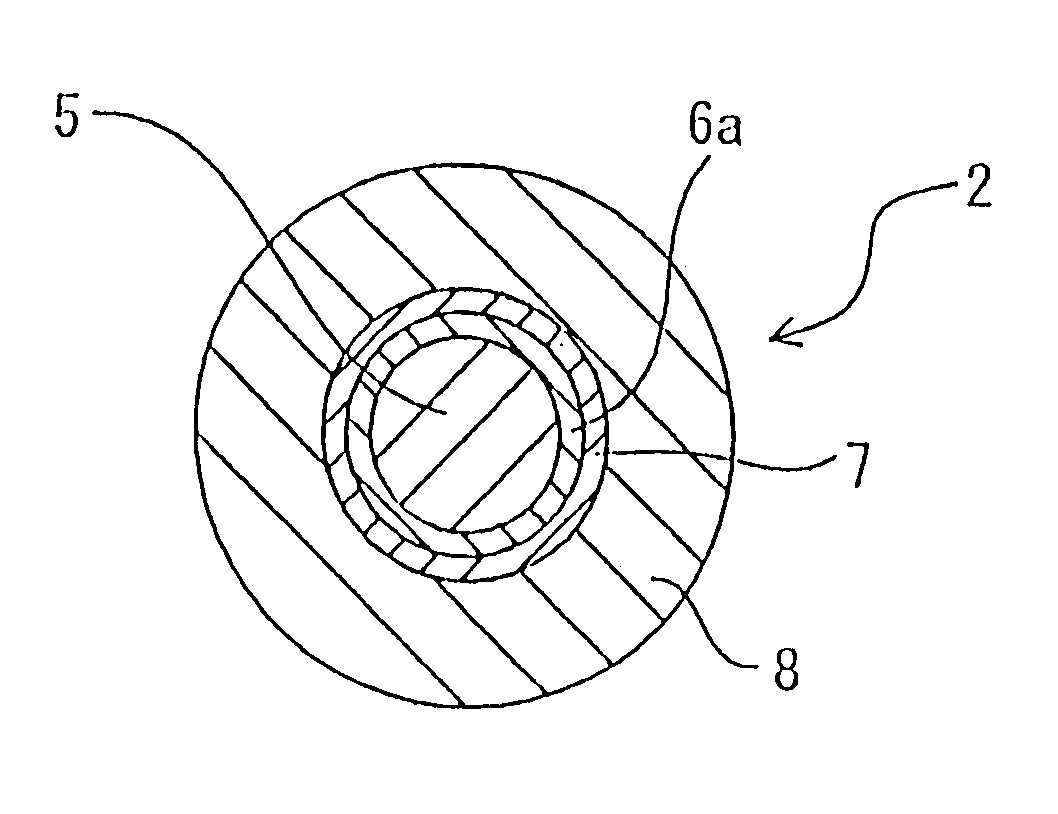

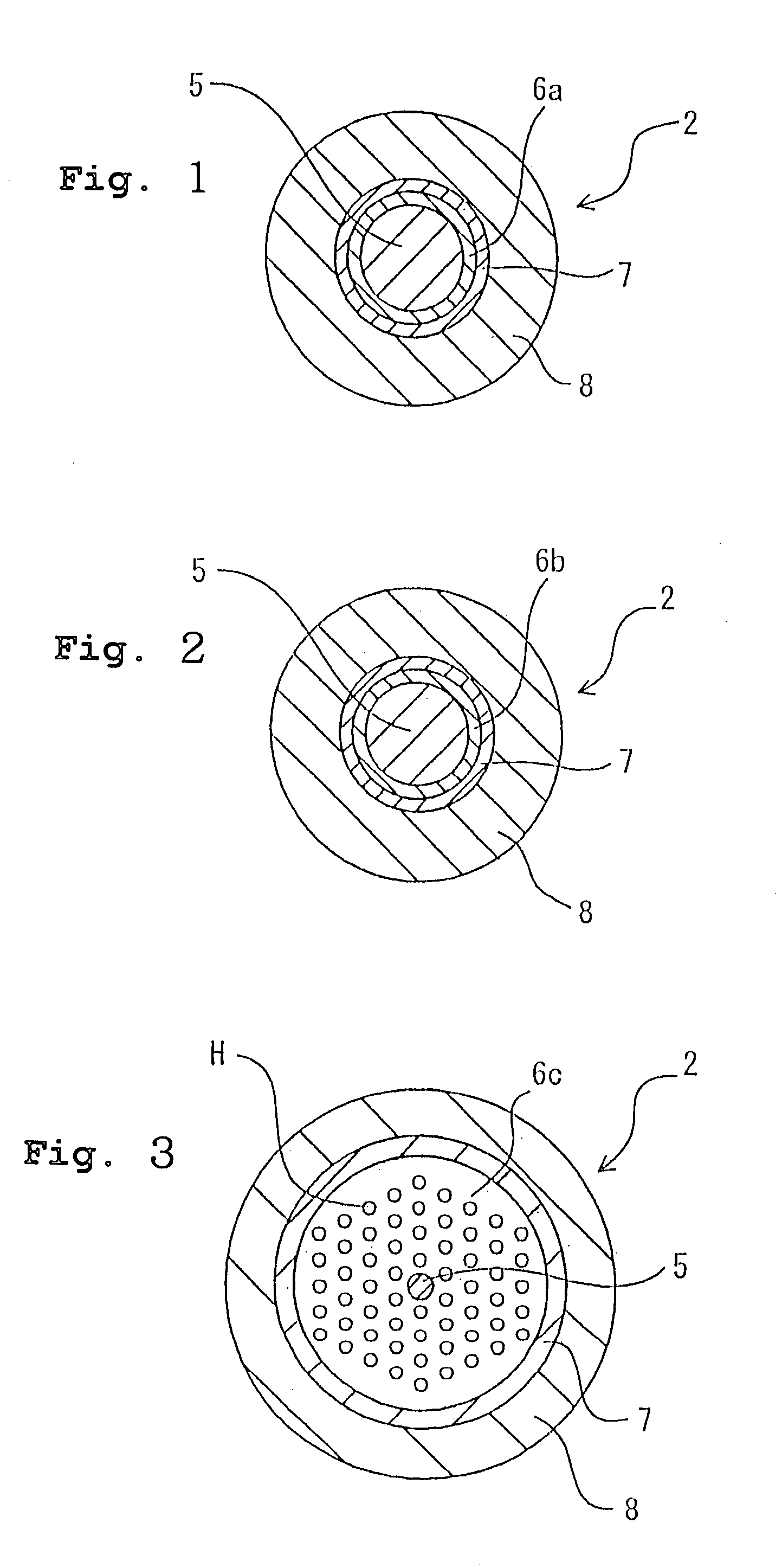

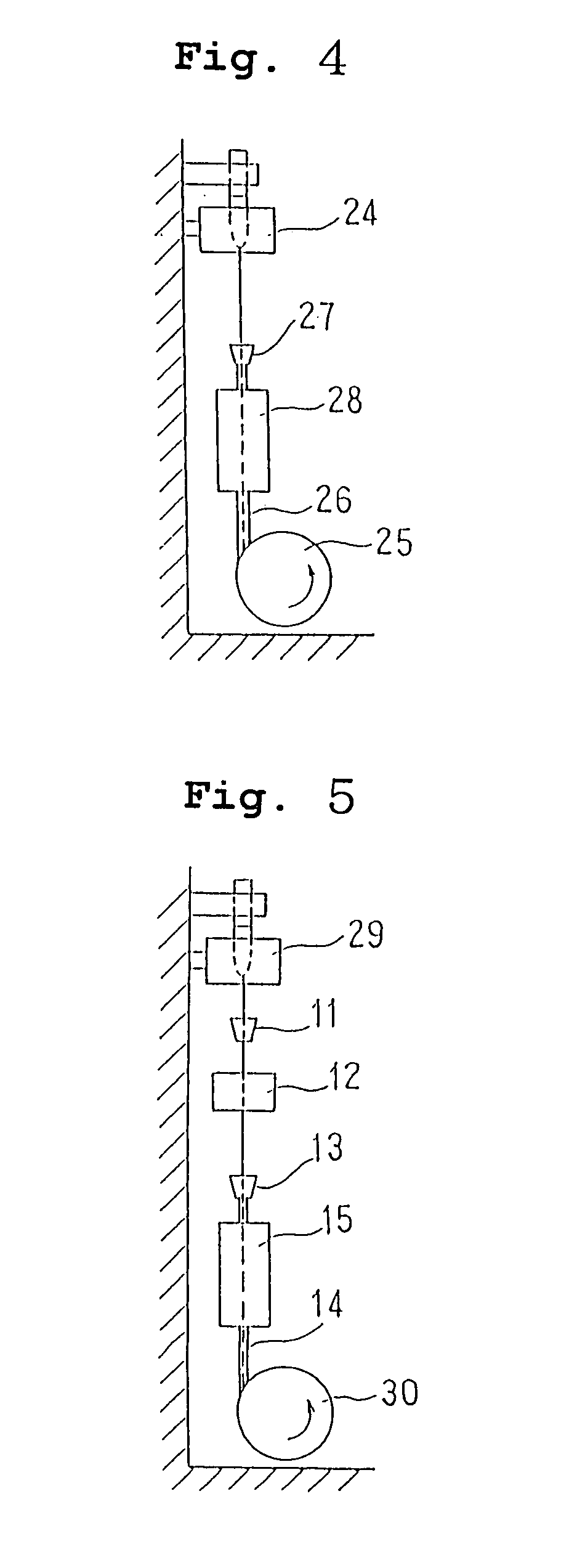

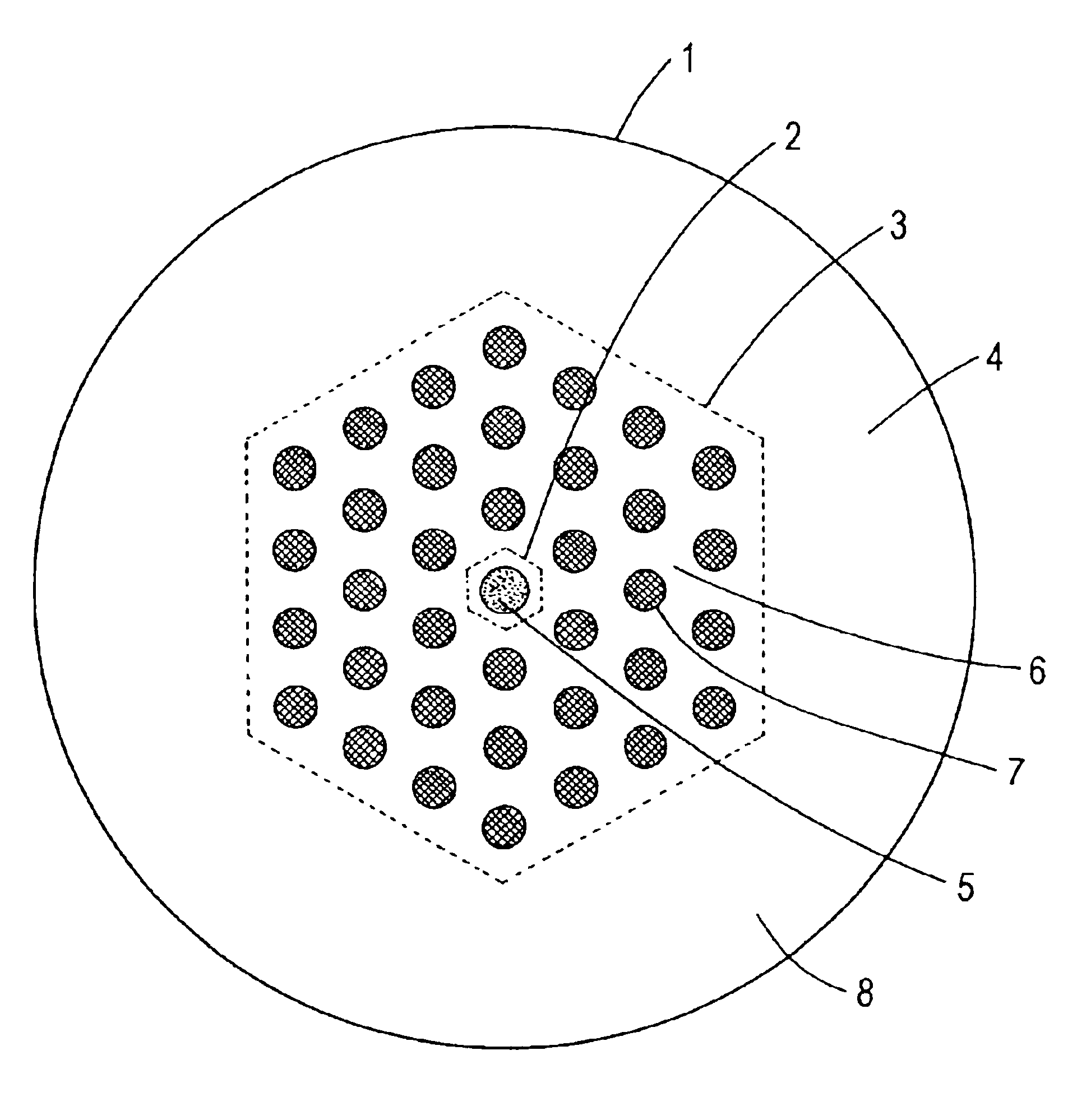

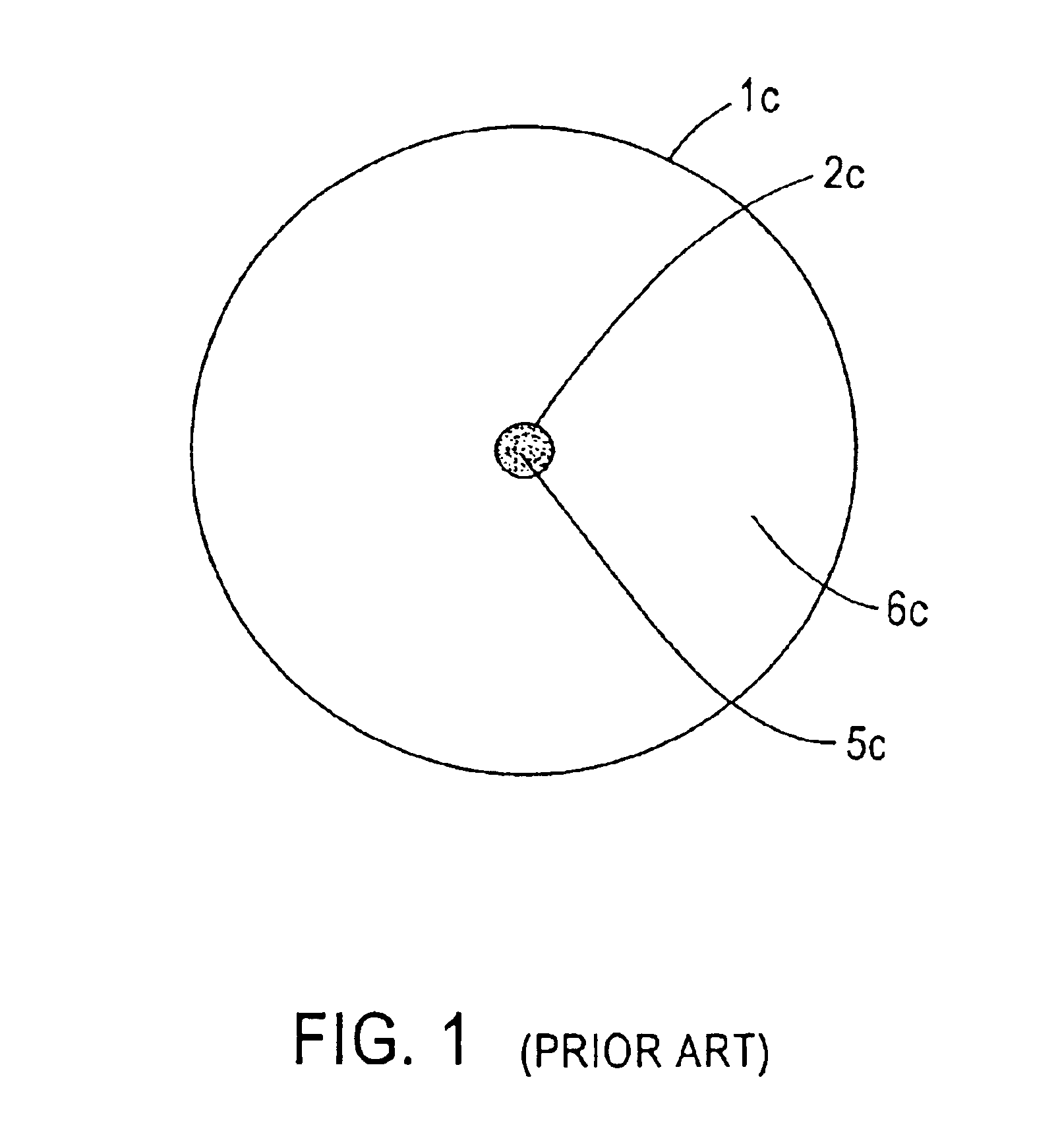

Optical fiber for transmitting ultraviolet ray, optical fiber probe, and method of manufacturing the optical fiber probe

InactiveUS6944380B1High light transmittanceResistant to deteriorationGlass optical fibreGlass making apparatusFiberHydrogen

It is an object of the present invention to provide an optical fiber for transmitting ultraviolet ray which has an improve transmittance and is prevented from deterioration by ultraviolet ray with which it is irradiated. It is another object of the present invention to provide an optical fiber probe which can propagate vacuum ultraviolet ray and deep ultraviolet ray at a high transmittance, is deteriorated only to a limited extent when irradiated with ultraviolet ray and can be etched to have a desired shape of the sharpened section at the fiber end.The present invention provides the optical fiber for transmitting ultraviolet ray which has a core 5 of silica glass containing a given content of fluorine and a clad 6a of silica glass containing a given content of fluorine or boron, a clad 6b of a resin which transmits ultraviolet ray or a clad 6c having air holes H. The clad may be coated with a protective layer and further with a covered layer for protection. In particular, the core, clad and protective layer have a high transmittance for ultraviolet ray and resistance to ultraviolet ray with which they are irradiated, when treated with hydrogen.An optical fiber probe 1 has an optical fiber 2 provided with a sharpened section 3 at the end, which is sharpened with an etchant solution, the sharpened section 3 being coated with a light-shielding metallic film 4.

Owner:JAPAN SCI & TECH CORP

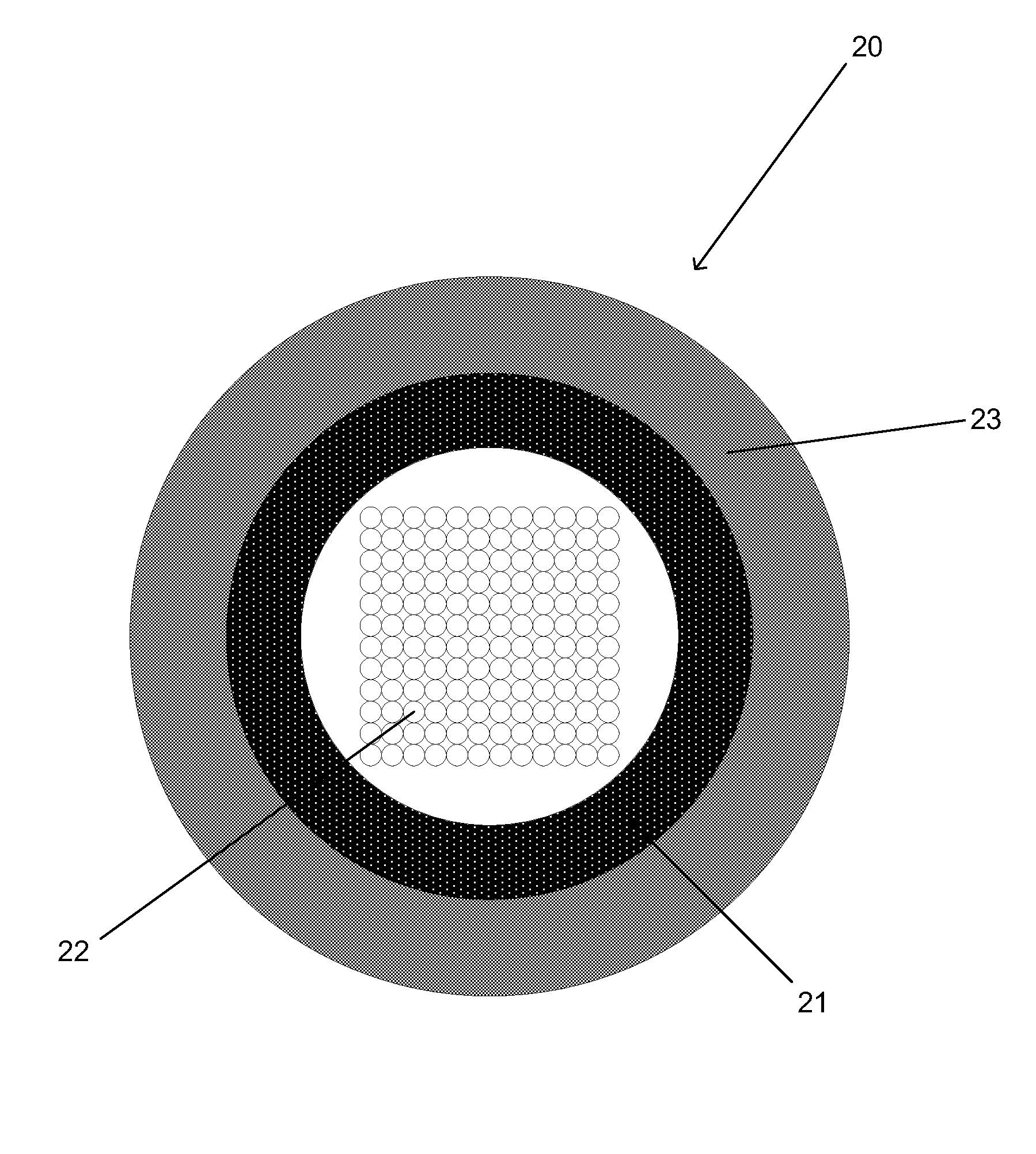

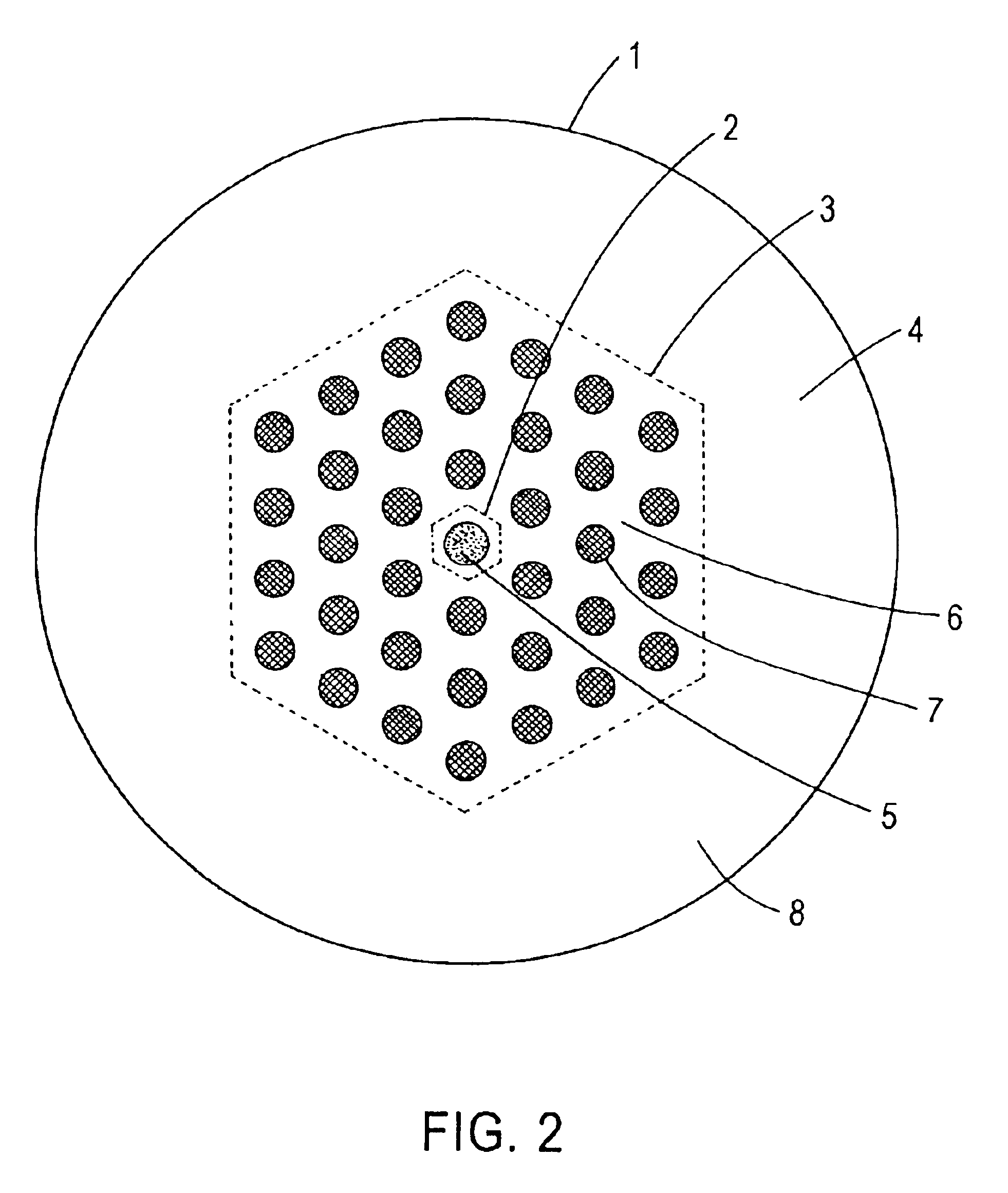

Microstructured optical fiber

An optical fiber suitable for use in a single fiber or multifiber optical connector or array is structured with a core region and a cladding region surrounding the core region, and exhibits a bending loss of a fundamental mode of the fiber at a wavelength λ is lower than 0.1 dB / m at a diameter of 15 mm, a mode-field diameter of the fundamental mode at an end of the fiber at the wavelength λ is between 8.0 μm and 50 λ, and a bending loss of a first higher-order mode at the wavelength λ is higher than 1 dB / m at a diameter of 30 mm. The fiber may be multistructured, wherein the cladding region comprises a main medium and a plurality of sub medium regions therein to form a spatially uniform average refractive index.

Owner:SUMITOMO ELECTRIC IND LTD

Microbend-Resistant Optical Fiber

ActiveUS20100290781A1Improve protectionGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberCoating system

Disclosed is an improved, single-mode optical fiber possessing a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

Bend-insensitive single-mode optical fiber

ActiveUS7889960B2Sufficient attenuationImproves the bending lossesGlass optical fibreOptical fibre with graded refractive index core/claddingRefractive indexLength wave

Owner:DRAKA COMTEQ BV

Light Diffusing Fibers and Methods for Making the Same

Light diffusing optical fibers and methods for producing light diffusing optical fibers are disclosed. In one embodiment, a light diffusing optical fiber includes a core portion formed from silica glass and comprising a plurality of helical void randomly distributed in the core portion of the optical fiber and wrapped around the long axis of the optical fiber. A pitch of the helical voids may vary along the axial length of the light diffusing optical fiber in order to achieve the desired illumination along the length of the optical fiber. A cladding may surround the core portion. Light guided by the core portion is scattered by the helical voids radially outward, through the cladding, such that the light diffusing optical fiber emits light with a predetermined intensity over an axial length of the light diffusing optical fiber, the light diffusing optical fiber having a scattering induced attenuation loss greater than about 0.2 dB / m at a wavelength of 550 nm.

Owner:CORNING INC

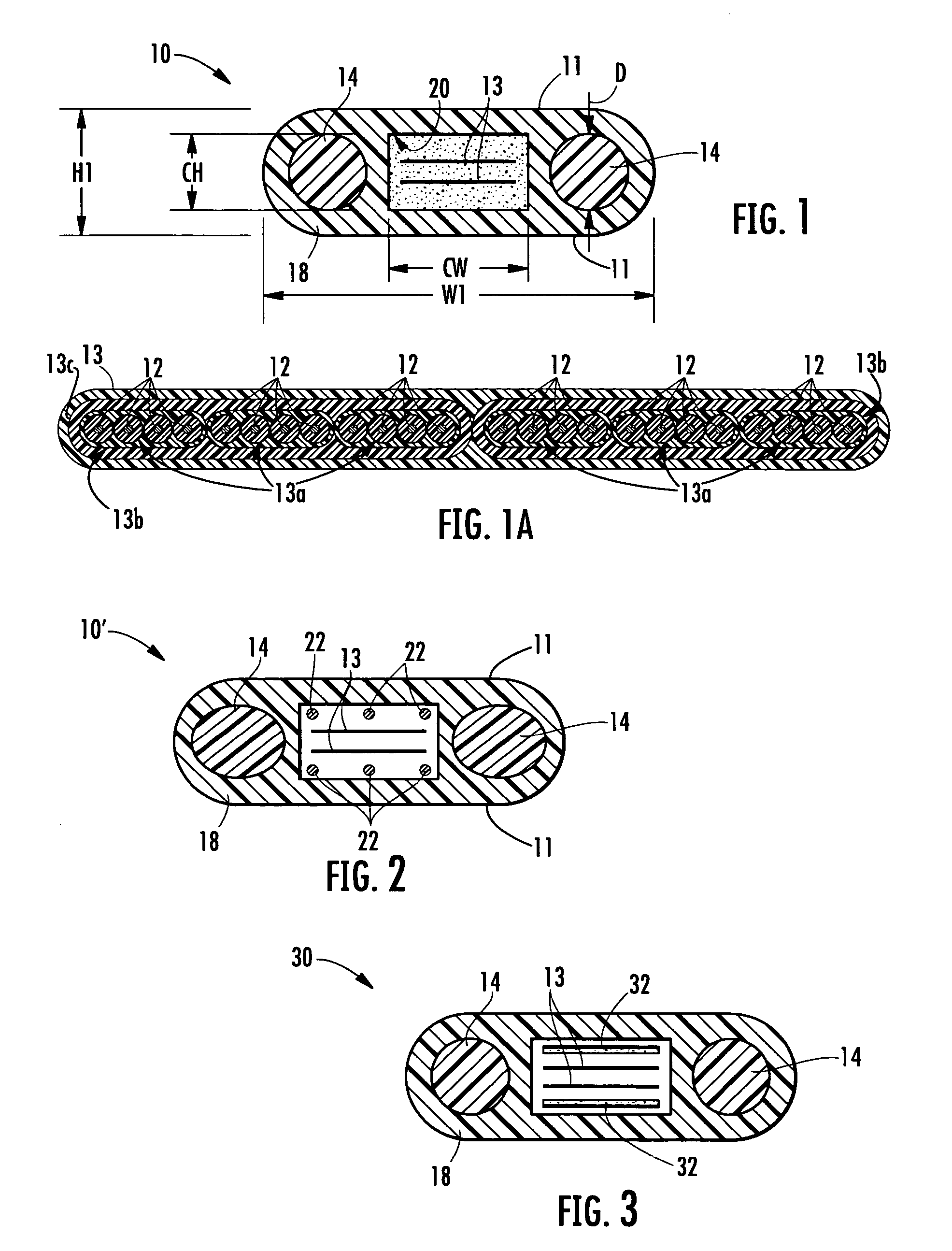

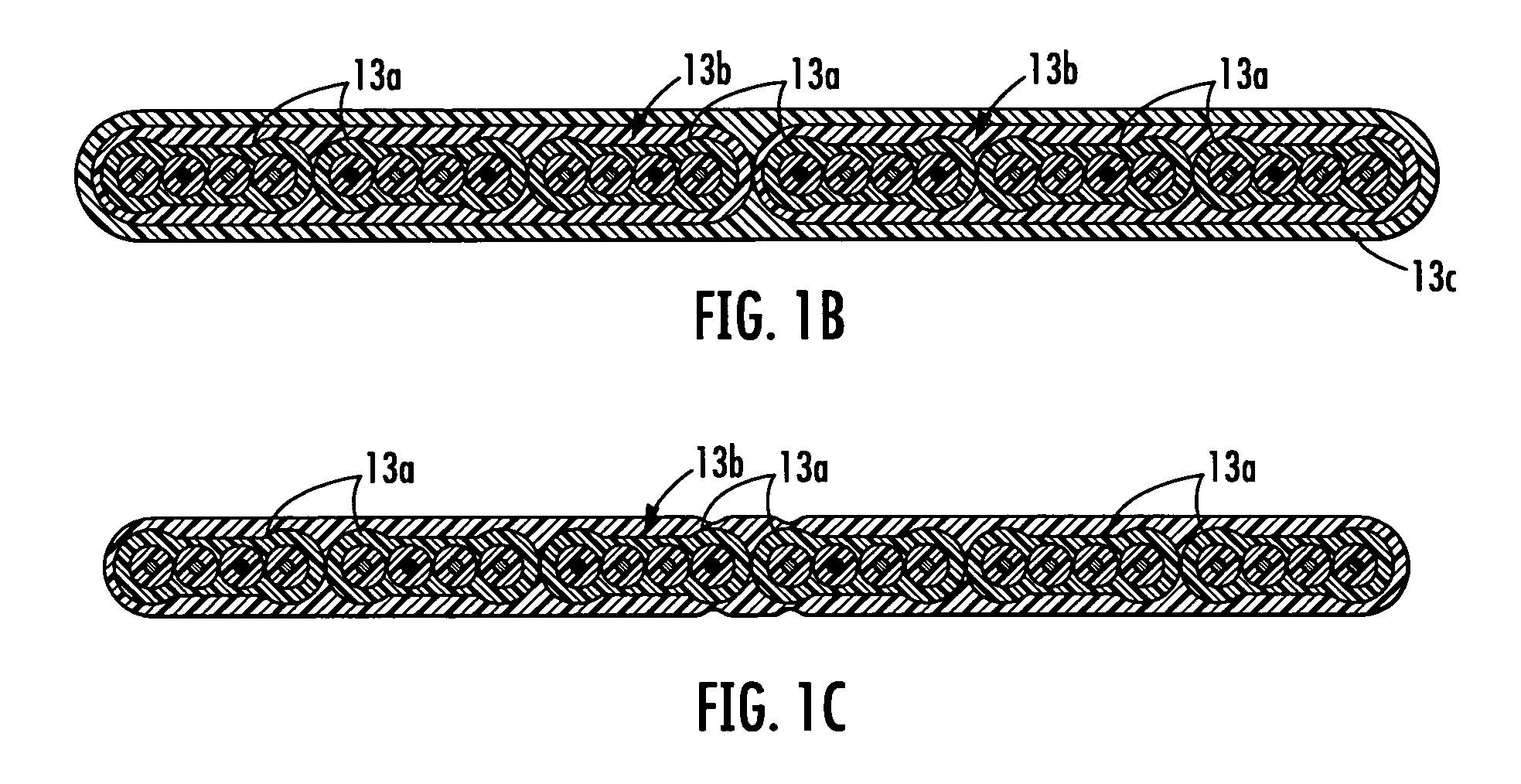

Dry fiber optic cables and assemblies

A fiber optic cable includes at least one optical fiber, at least one strength member, at least one dry insert, and a cable jacket. The cable jacket has a cavity with a generally rectangular cross-section with the at least one optical fiber and the at least one dry insert disposed therein. The at least one optical fiber has a predetermined level of coupling to the cable jacket that is provided by the at least one dry insert within the cavity of cable jacket. The predetermined level of coupling is about 0.1625 Newtons or more per optical fiber for a thirty meter length of fiber optic cable. Additionally, fiber optic cables of the present invention are also suitable as a portion of a cable assembly.

Owner:BELDEN TECHNOLOGY INC +1

Large effective area fiber with graded index GE-free core

ActiveUS7929818B1Glass optical fibreOptical fibre with graded refractive index core/claddingUltrasound attenuationSilica measurement

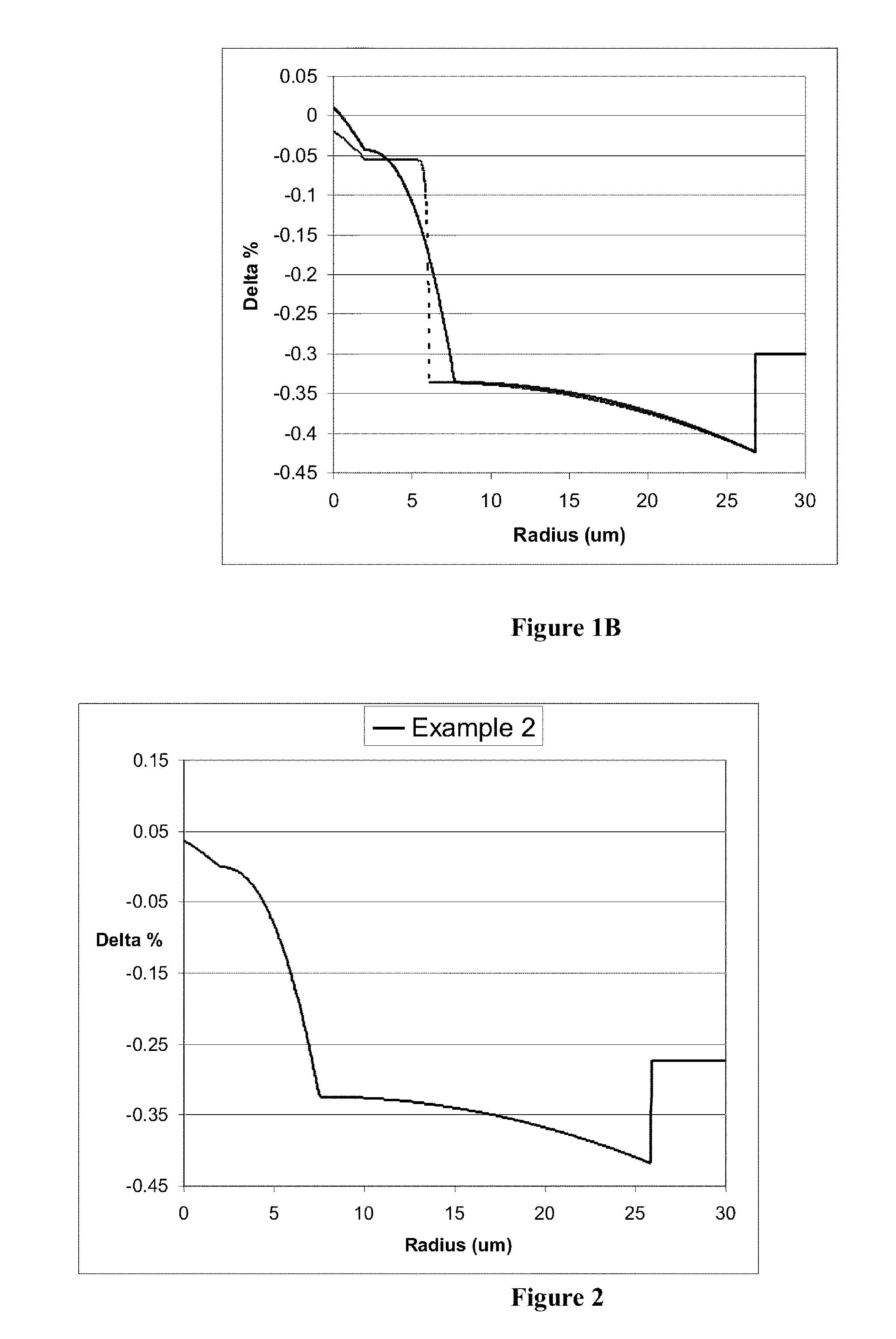

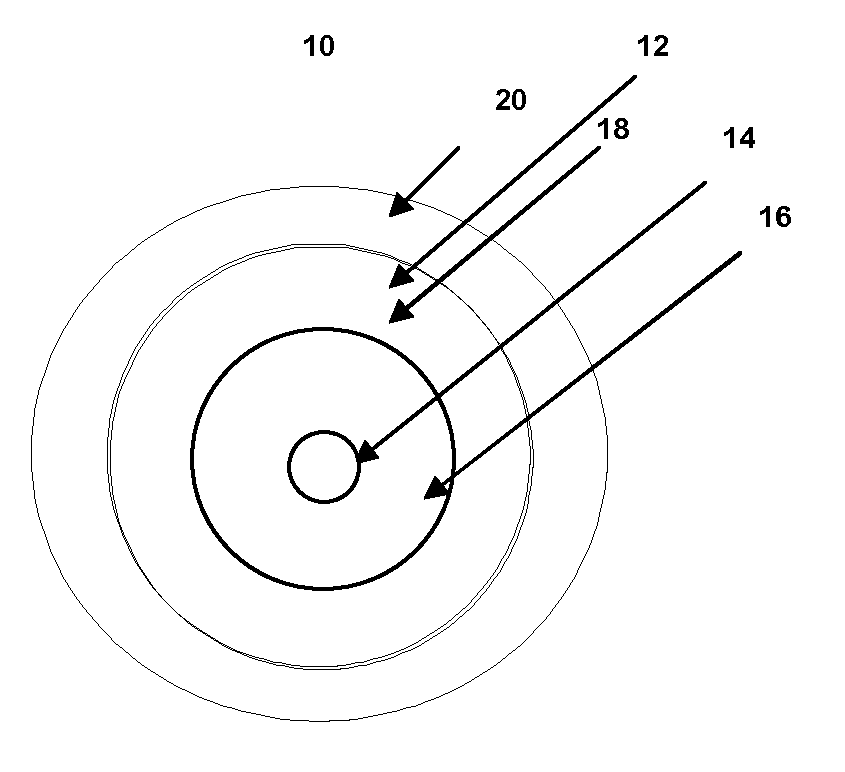

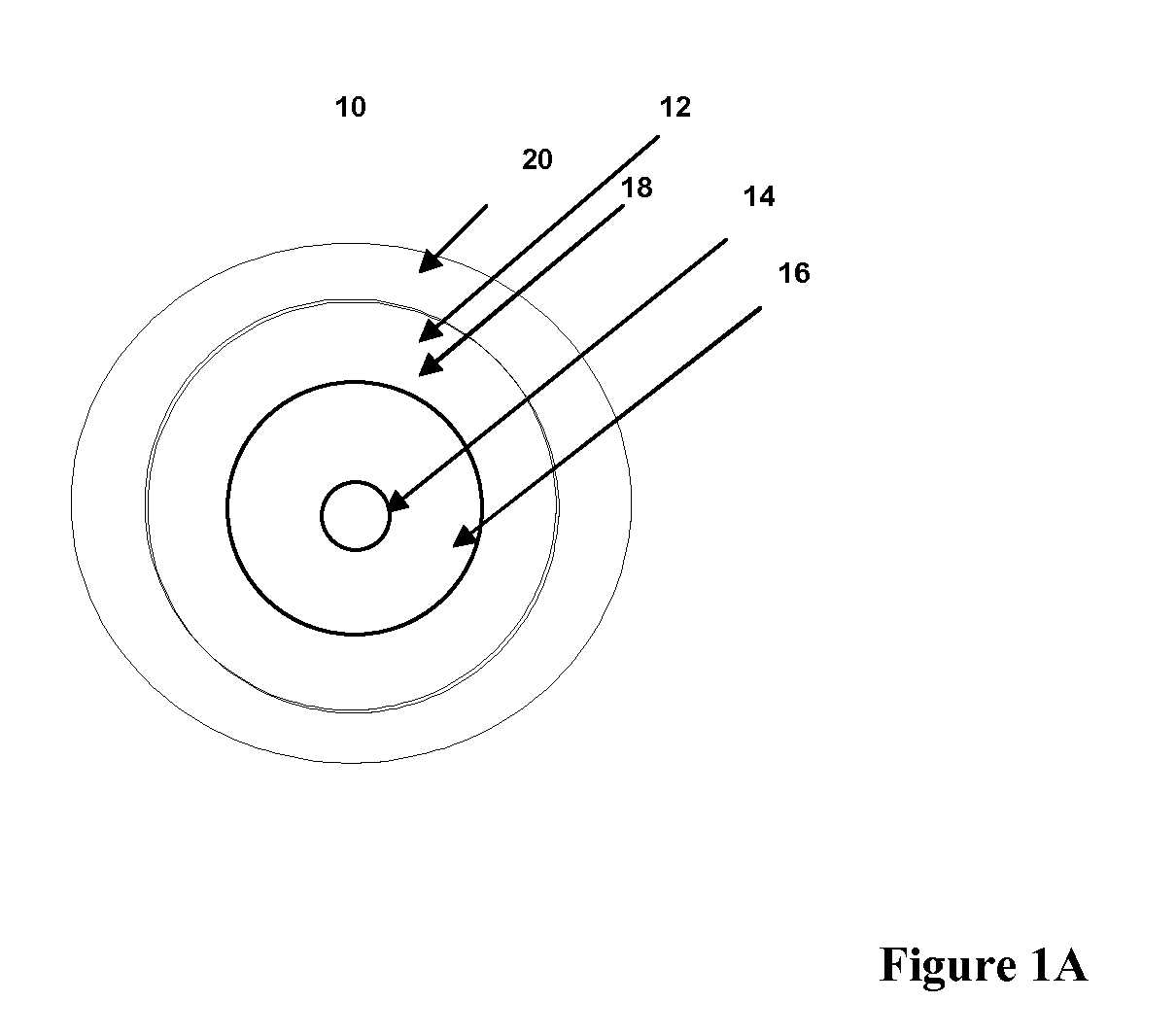

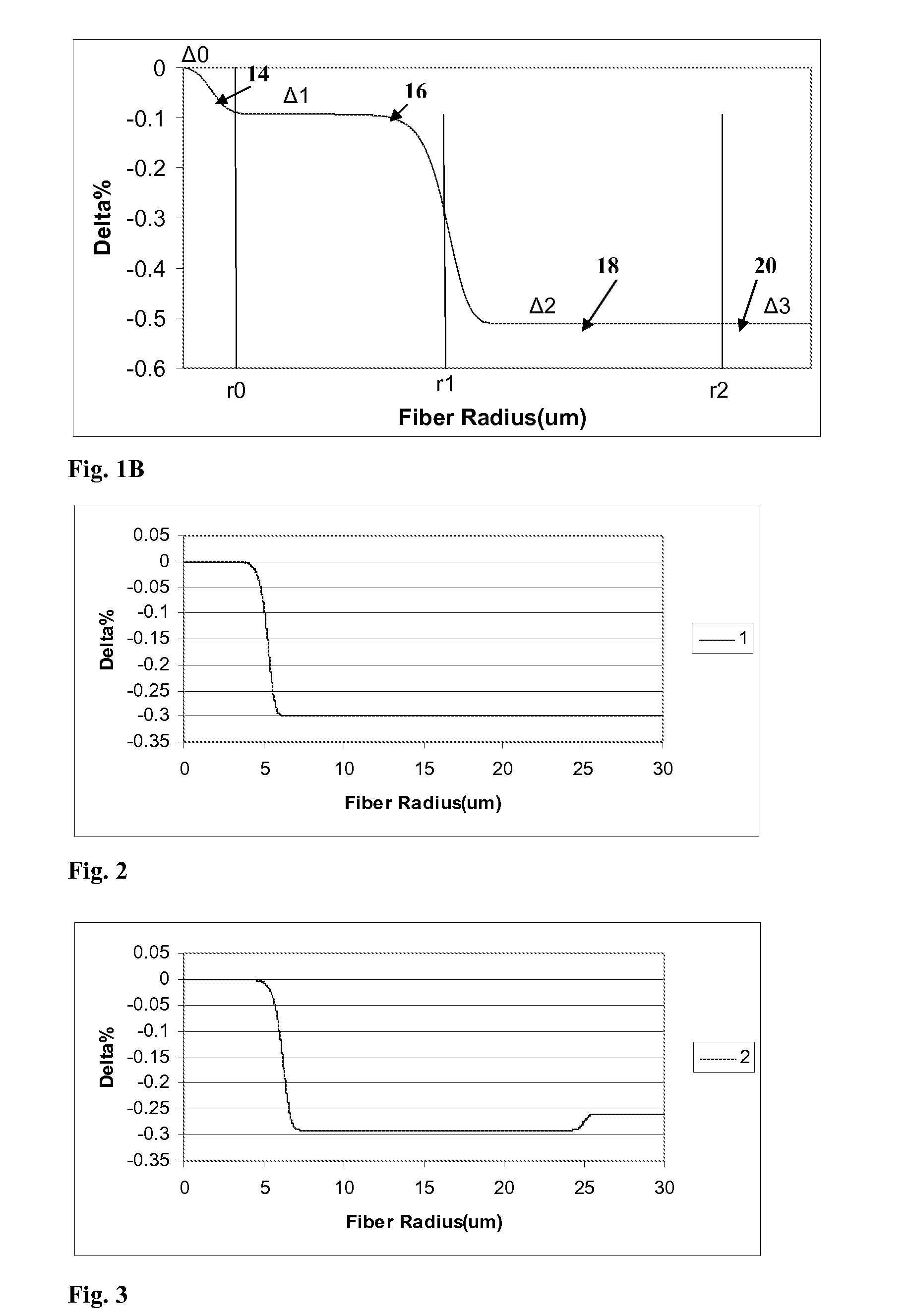

According to some embodiments an optical waveguide fiber comprises (i) a Ge free core having an effective area of 100 μm2to 150 μm2, at 1550 nm wavelength, said core comprising: a) a central core region extending radially outwardly from a centerline to a radius r1, and having a relative refractive index percent profile Δ1(r) in % measured relative to pure silica, wherein −0.1%≦Δ1(r)≦0.12%, wherein the central core region has a maximum relative refractive index percent, Δ1MAX; (b) a first annular core region surrounding and directly adjacent to the central core region, having an α value 1.5≦α≦10, and extending to an outer radius r2, wherein 6 μm≦r2≦10 μm, and having a relative refractive index percent profile, Δ2(r) in % measured relative to pure silica, a minimum relative refractive index Δ2MIN, a maximum relative refractive index Δ2MAX and the relative refractive index measured at a radius r=2 μm, wherein 0.45≦Δ2≦0; −0.25≧Δ2MIN≧−0.45 and Δ1MAX≧Δ2(r=2 μm); (c) a fluorine doped second annular region surrounding and directly adjacent to the first annular core region and extending to a radius 20 μm≦r3≦30 μm and having a negative relative refractive index percent profile, Δ3(r) in %, measured relative to pure silica, with a minimum relative refractive index percent Δ3MIN and −0.5%<Δ3MIN<−0.25%; and Δ3MIN≦Δ2MIN; (ii) a cladding surrounding the core and having a relative refractive index percent Δ4(r) in % measured relative to pure silica and a minimum refractive index delta Δ4MIN, and −0.4%<Δ4<−0.2%; wherein the relative refractive index profile of the optical fiber is selected to provide attenuation of no more than 0.17 dB / km at the 1550 nm wavelength.

Owner:CORNING INC

Large Effective Area Fiber With GE-Free Core

ActiveUS20100195966A1Glass optical fibreOptical fibre with graded refractive index core/claddingUltrasound attenuationSilica measurement

According to some embodiments an optical waveguide fiber comprises:(i) a Ge free core having an effective area of 90 μm2 to 160 μm2, at a 1550 nm wavelength, and α value 12≦α≦25, said core comprising:(a) a central core region extending radially outwardly from a centerline to a radius 0 μm≦r0≦2 μm, and having a relative refractive index percent profile Δ0(r) in % measured relative to pure silica, wherein −0.1%≦Δ0(r)≦0.1%, wherein the central core region has a maximum relative refractive index percent, Δ0MAX,(b) a first annular core region surrounding and directly adjacent to the central core region and extending to an outer radius r1, wherein 4.8 μm≦r1≦10 μm, and having a relative refractive index percent profile, Δ1(r) in % measured relative to pure silica, and a minimum relative refractive index, Δ2MIN, and the relative refractive index measured at a radius r=2.5 μm being:−0.15≦Δ1(r=2.5 μm)≦0, and Δ0MAX≧Δ1(r=2.5 μm);(c) a fluorine doped second annular region surrounding and directly adjacent to the first annular core region and extending to a radius 13 μm≦r2≦30 μm and having a negative relative refractive index percent profile, Δ2(r) in %, measured relative to pure silica,with a minimum relative refractive index percent Δ2MIN being:Δ2MIN≦Δ1(r=2.5 μm), and −0.7%≦Δ2MIN≦−0.28%;(ii) a cladding surrounding the core and having a relative refractive index percent Δc(r) in % measured relative to pure silica, and Δc(r)=Δ2MIN±0.3%;wherein the relative refractive index profile of the optical fiber is selected to provide attenuation of no more than 0.175 dB / km at the wavelength of 1550 nm.

Owner:CORNING INC

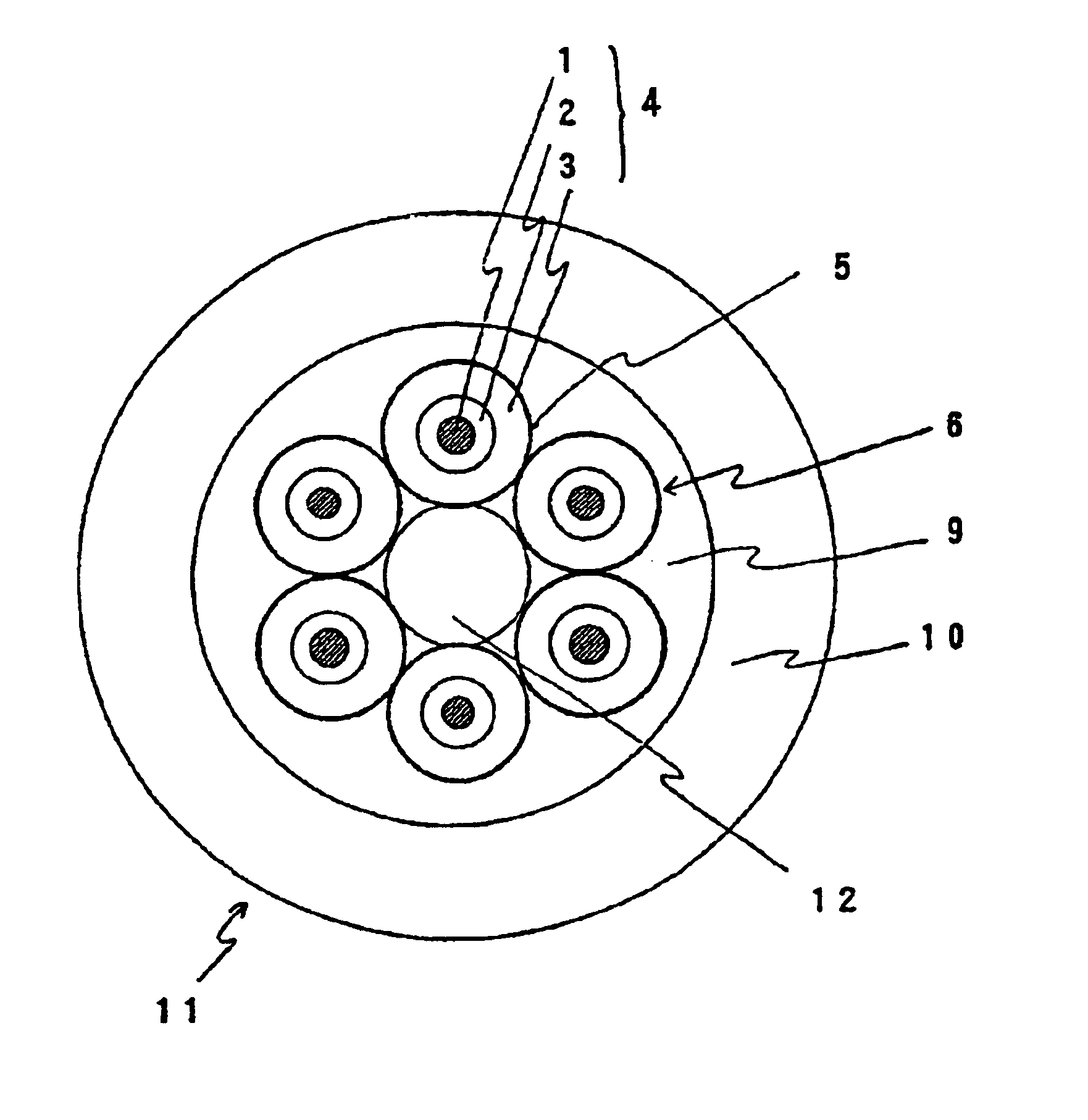

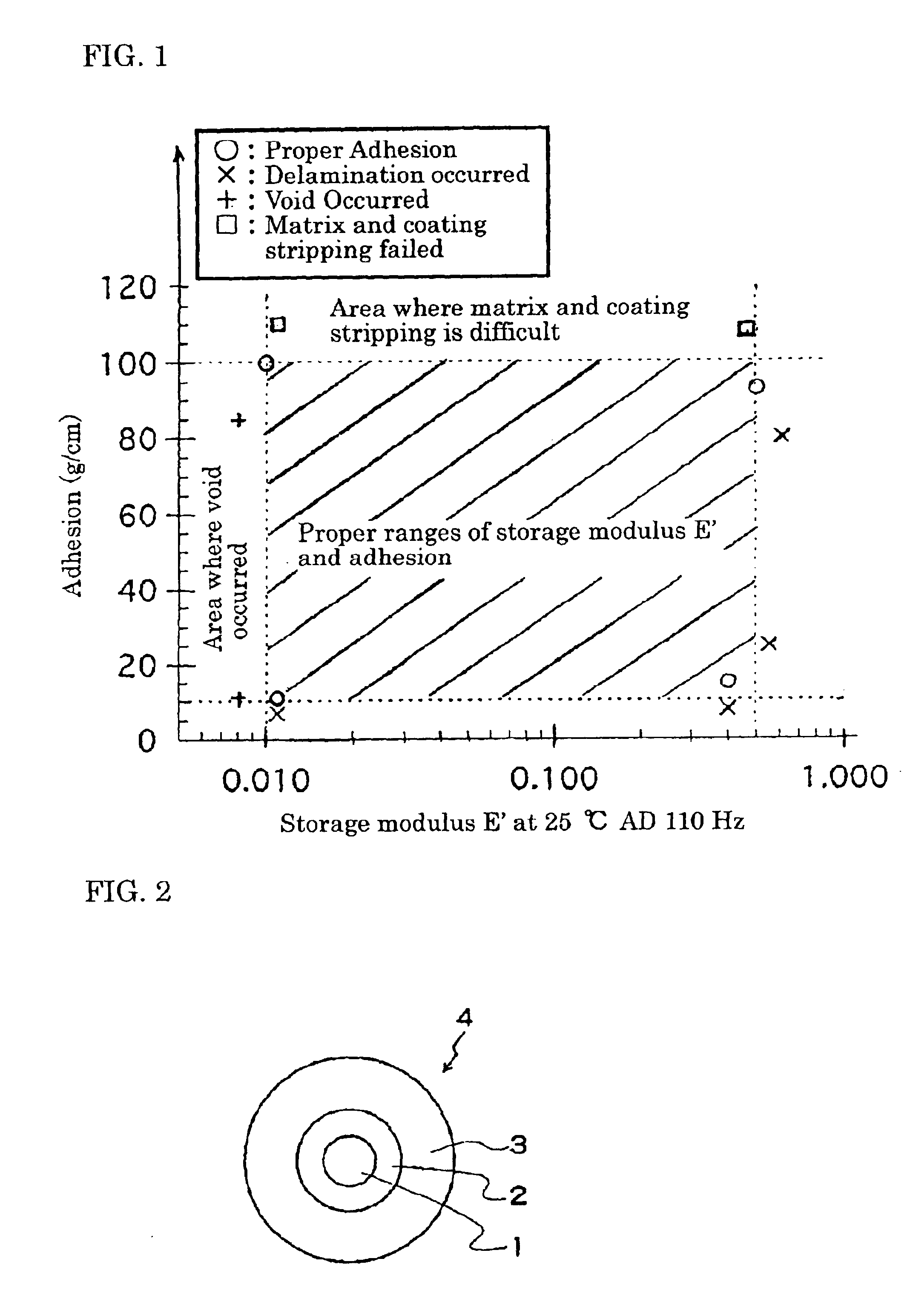

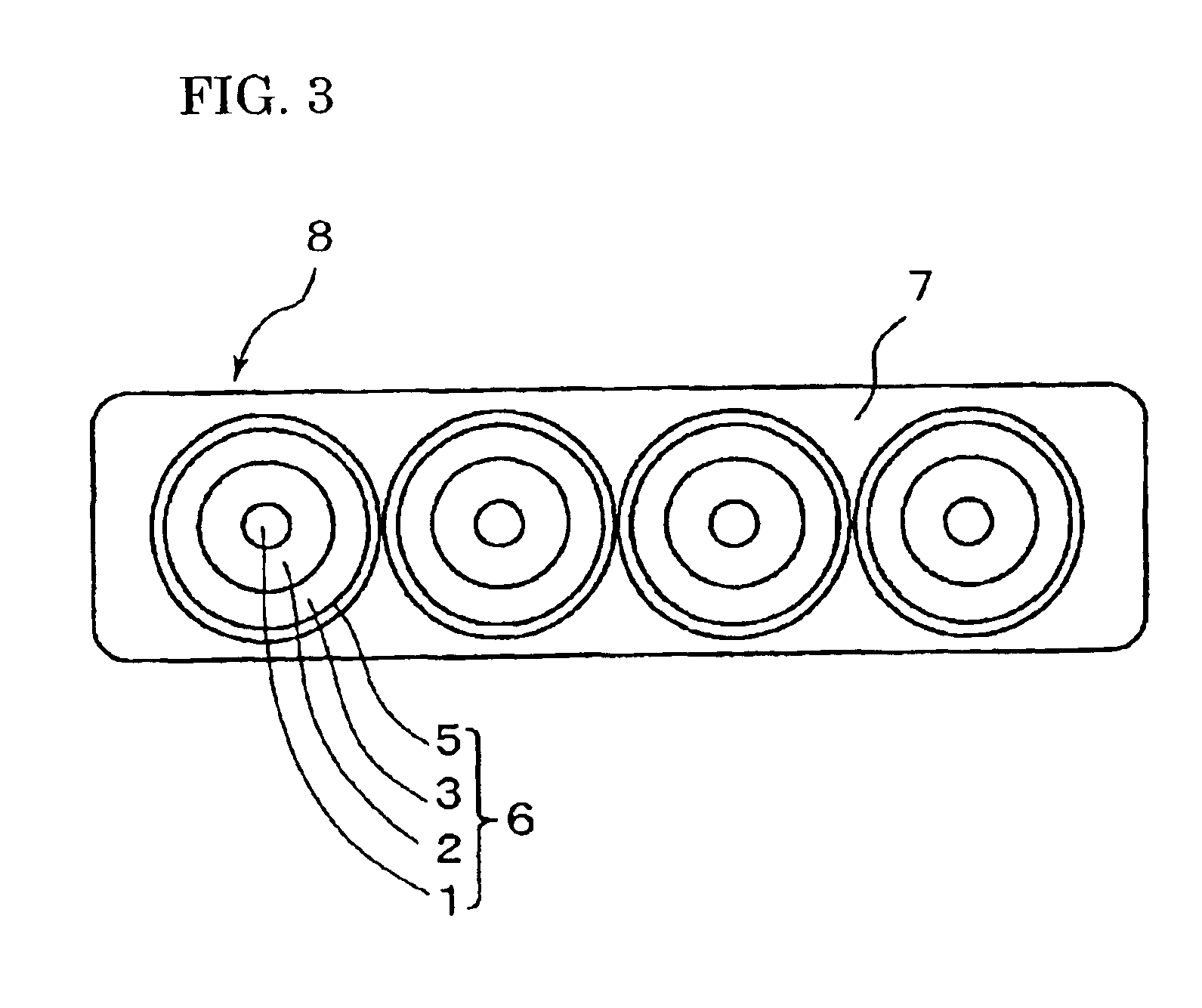

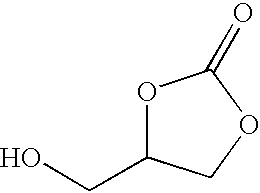

Coated optical fiber

InactiveUS6810188B1Shorten the production lineExcellent peelabilityGlass optical fibreOptical fibre with multilayer core/claddingOptoelectronicsPlastic optical fiber

A coated optical fiber is shown in which, by coating a glass optical fiber with a primary coating having a storage modulus E' of 0.01 kg / mm<2 >to 2.0 kg / mm<2 >at 25° and 110 Hz and an adhesion of 10 g / cm to 200 g / cm to the glass optical fiber, delamination at the interface between the glass optical fiber and the primary coating, and voids are prevented during and after the production, for example, on the line during drawing and winding. An optical fiber ribbon of the present invention, which is formed by collectively coating the coated optical fibers each including a primary coating with a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 10 g / cm to 100 g / m, has a high delamination resistance and a good collective strippability of coatings. In an optical fiber unit of the present invention which is formed by collectively coating the coated optical fibers having a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 100 g / cm to 200 g / cm, delamination and voids will not occur.

Owner:SUMITOMO ELECTRIC IND LTD

Coated optical fibers

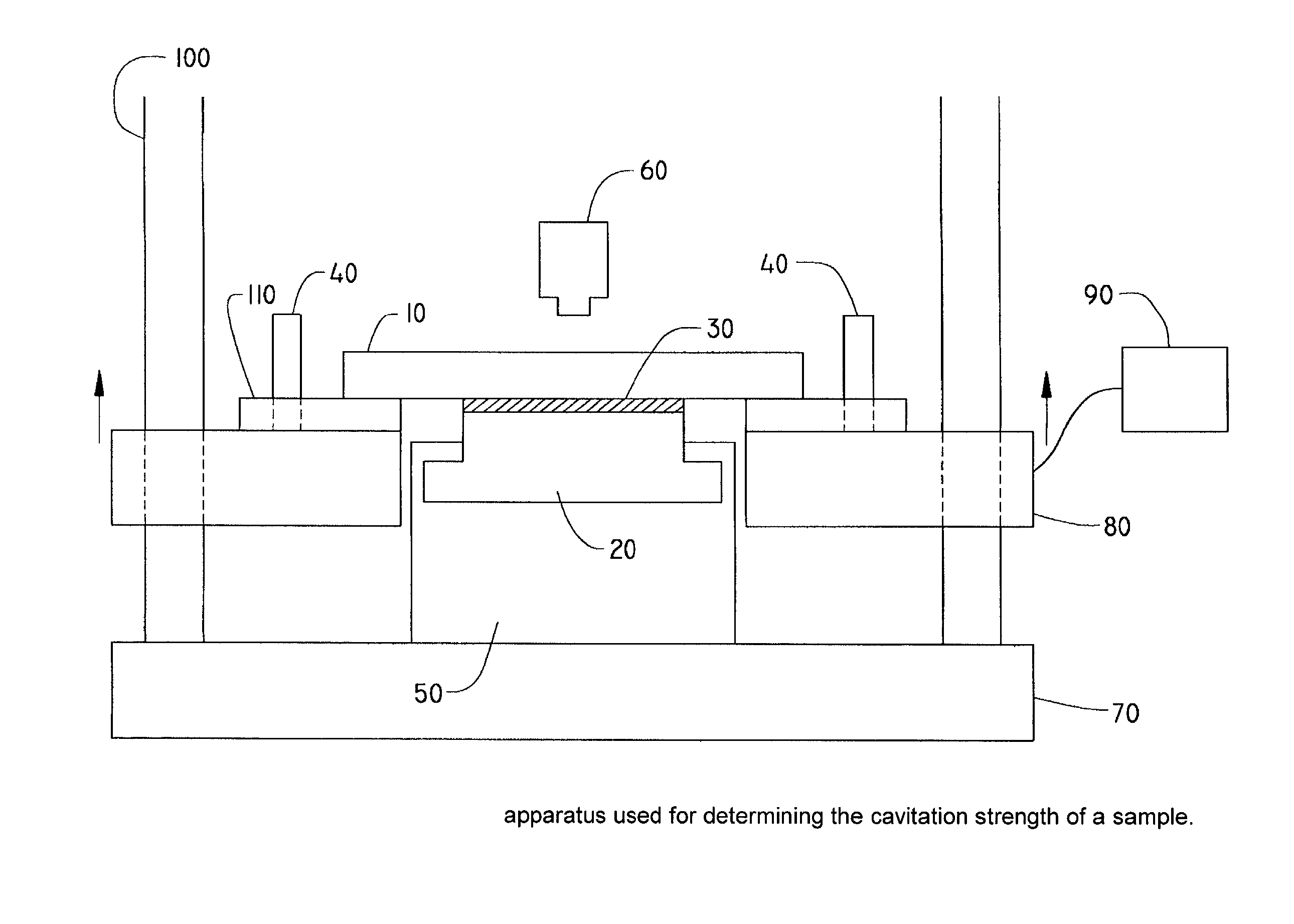

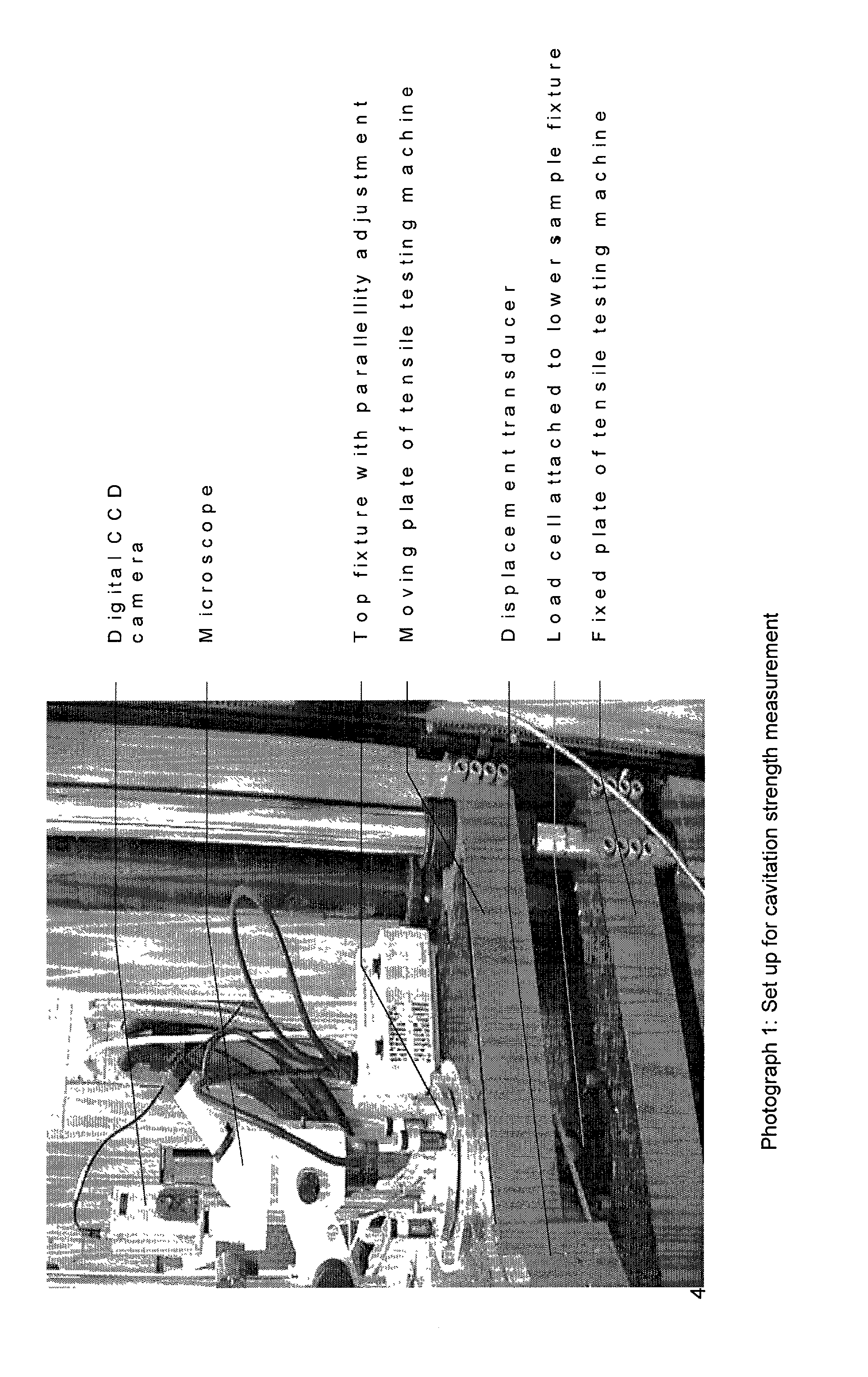

InactiveUS20020146225A1Sufficient high cavitation strengthLow modulusGlass optical fibreSynthetic resin layered productsHigh resistanceCavitation

The invention relates to coated optical fibers comprising soft primary coatings and to such primary coatings for protecting glass optical fibers having a sufficient high resistance against cavitation. In particular, the primary coatings have a cavitation strength at which a tenth cavitation appears (sigma10cav) of at least about 1.0 MPa as measured at a deformation rate of 0.20% min-1 and of at least about 1.4 times their storage modulus at 23° C. The coating preferably shows strain hardening in a relative Mooney plot, preferably has a strain energy release rate Go of about 20 J / m2 or more, and preferably has a low volumetric thermal expansion coefficient. The invention furthermore provides a method and apparatus for measuring the cavitation strength of a primary coating.

Owner:DSM IP ASSETS BV

Reduced-diameter, easy-access loose tube cable

ActiveUS8031997B2Improve protectionEasily matedGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberCoating system

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses. The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The improved coating system provides optical fibers that are useful in relatively thin-walled, low-modulus buffer tubes (i.e., “flextubes”) that can be readily accessed without special tools.

Owner:DRAKA COMTEQ BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com