Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

338 results about "Shear viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The shear viscosity. The shear viscosity of a system measures is resistance to flow. A simple flow field can be established in a system by placing it between two plates and then pulling the plates apart in opposite directions. Such a force is called a shear force, and the rate at which the plates are pulled apart is the shear rate.

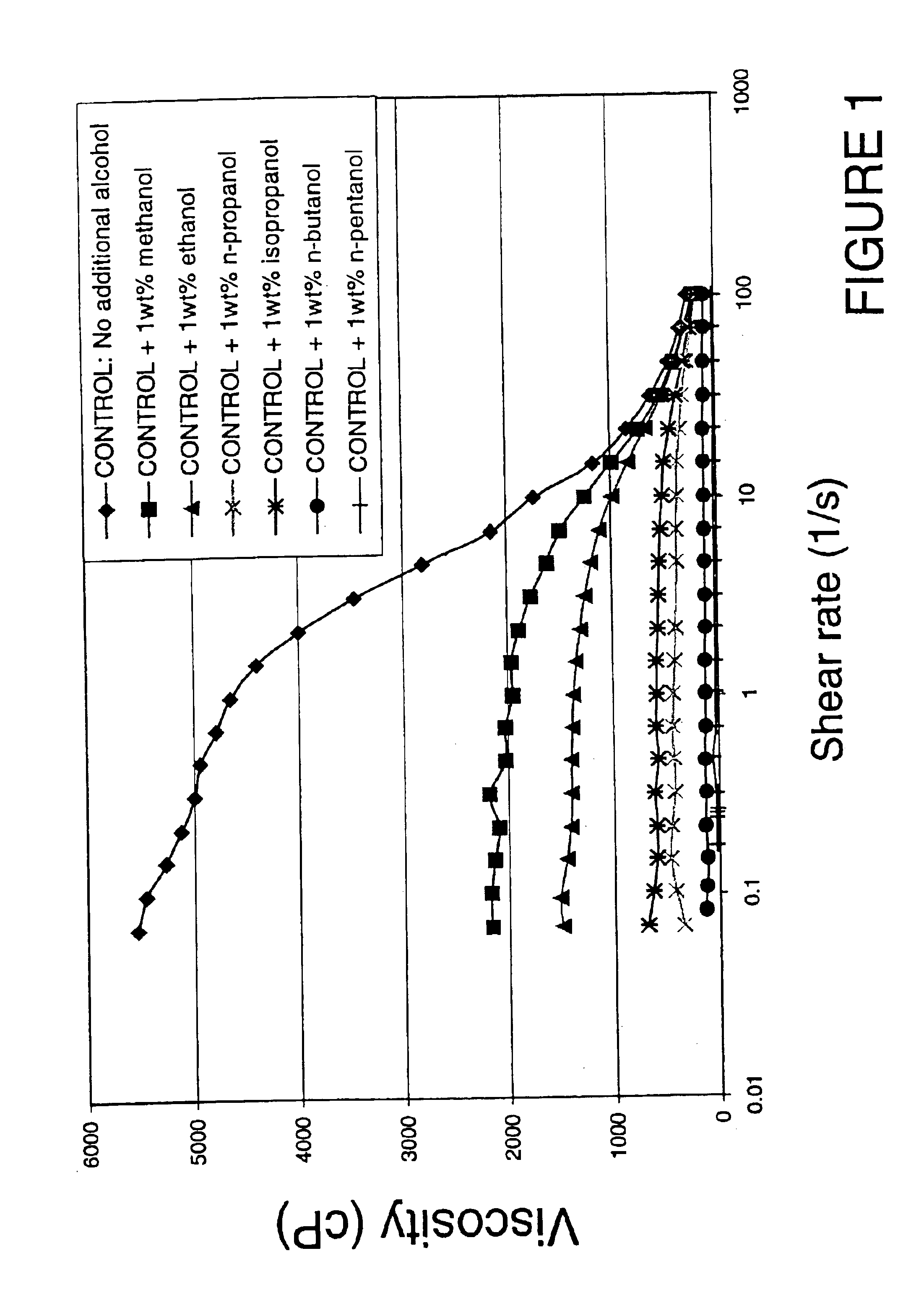

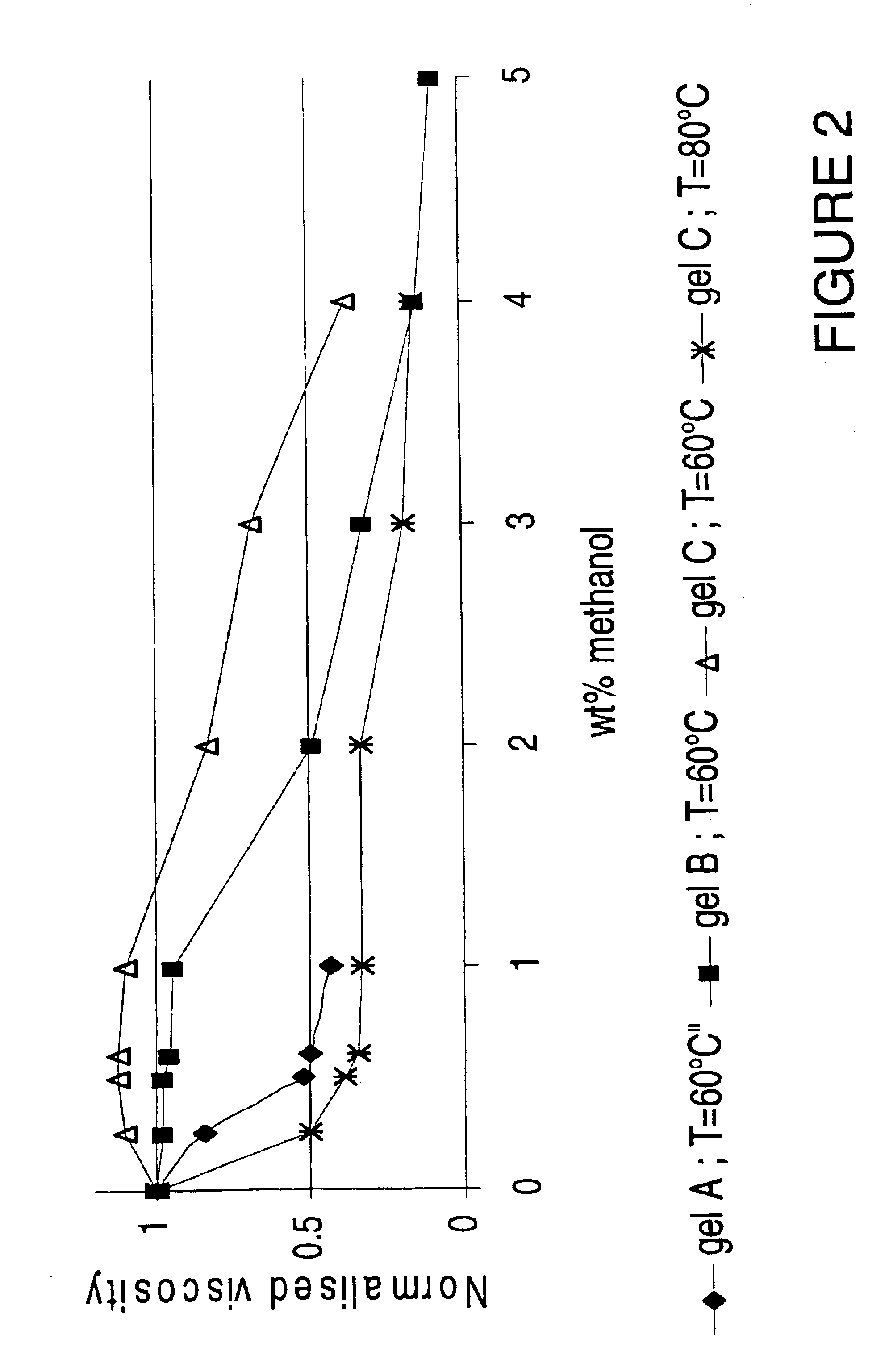

Viscosity reduction of viscoelastic surfactant based fluids

InactiveUS6881709B2Improve efficiencyImproves and optimizes conditionOther chemical processesFluid removalAlcoholSolid particle

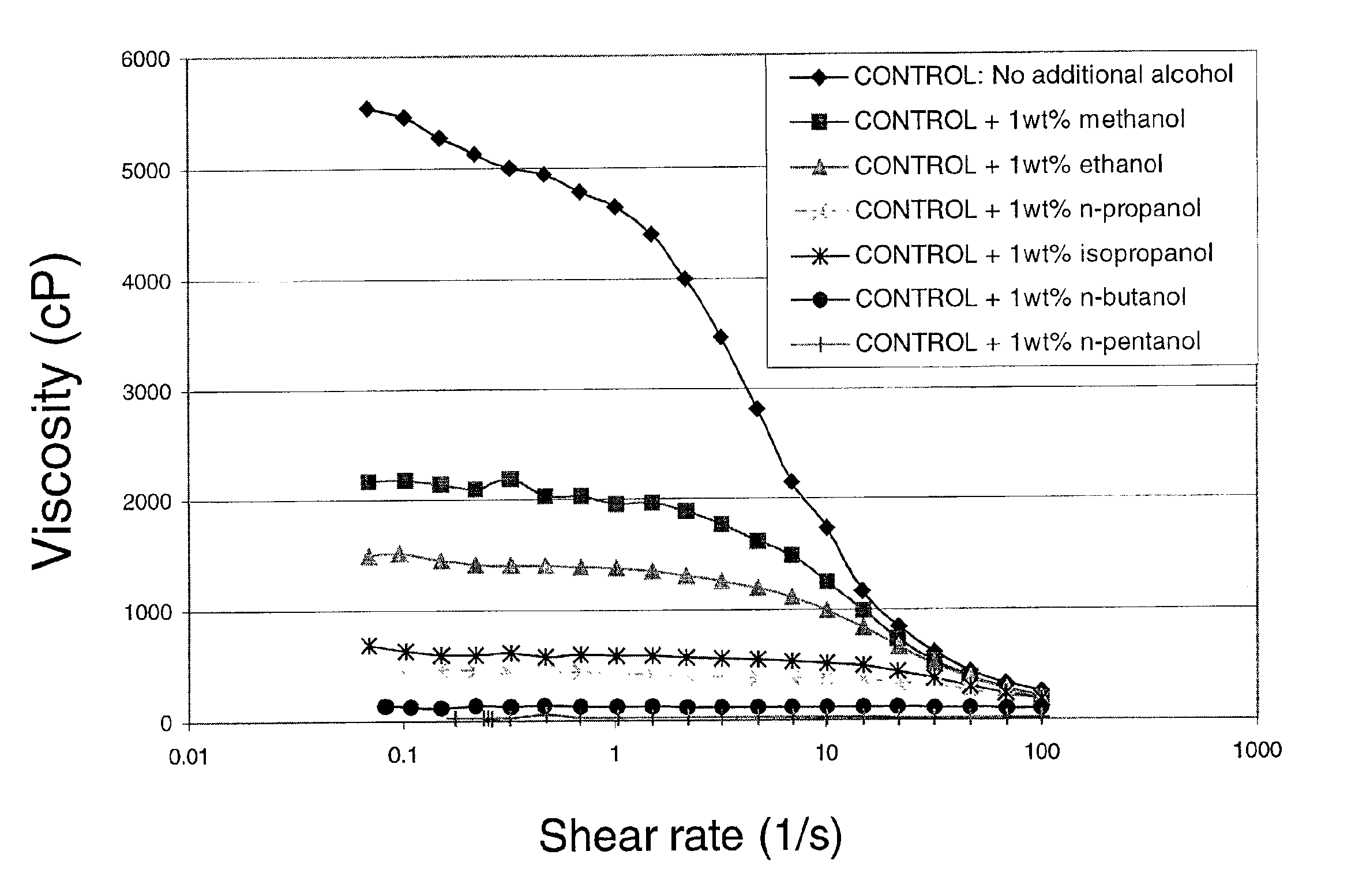

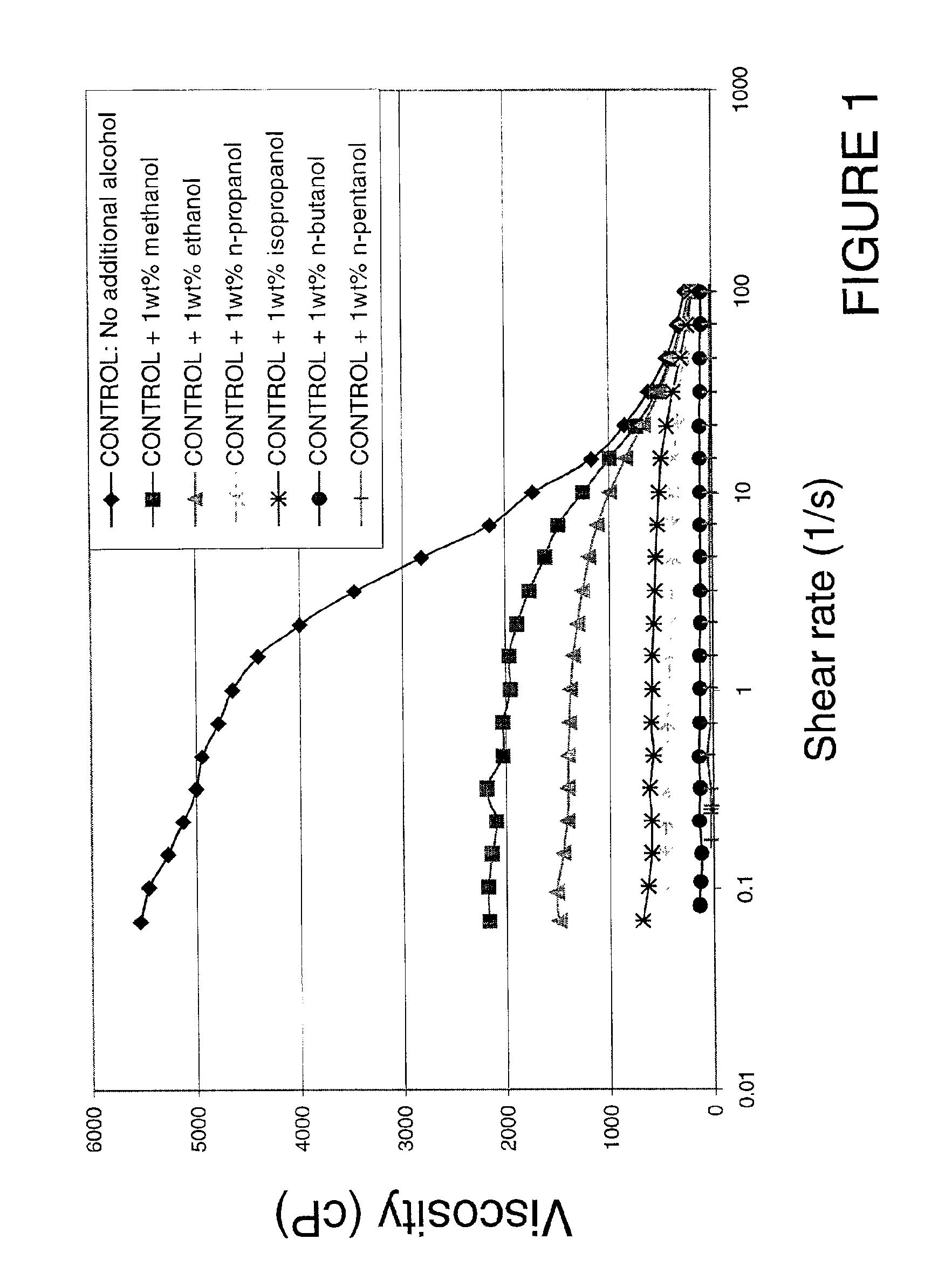

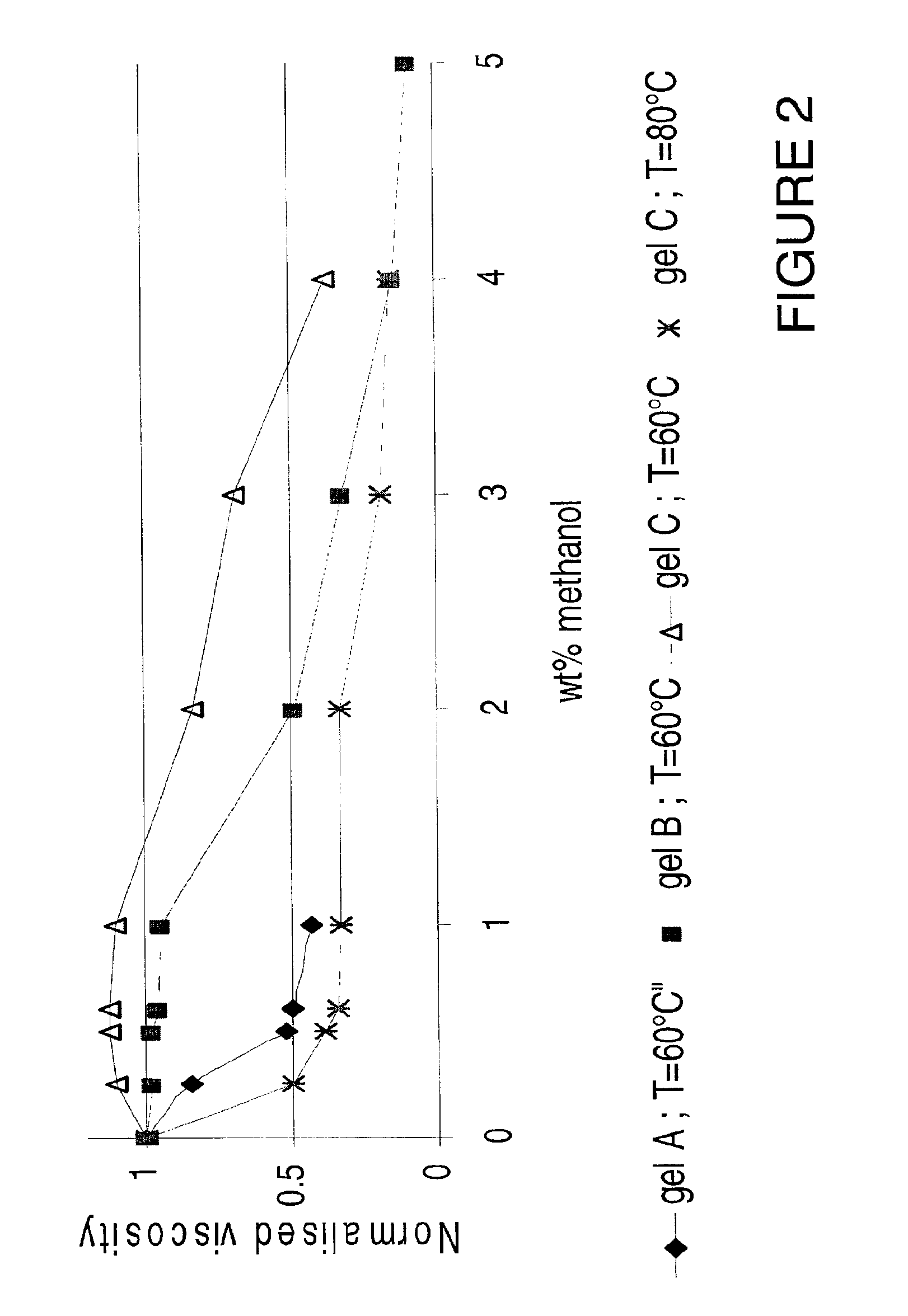

Methods and compositions are disclosed for controlled addition of components that decrease the viscosity of the viscoelastic surfactant fluids or for controlled changes in the electrolyte concentration or composition of the viscoelastic surfactant fluids. One aspect of the invention relates to the use of internal breakers with a delayed activation. Another aspect of the invention relates to the use of precursors that release a breaking system such as alcohol by a process such as melting, slow dissolution, reaction with a compound present in the fluid or added to the fluid during or after the step of injecting, rupture of an encapsulating coating and de-adsorption of a breaking agent absorbed into solid particles. In another aspect of the invention, alcohols are included in a pad to reduce the low-shear viscosity and reduce the resistance to flow of the treatment fluids during a desired phase of the treatment.

Owner:SCHLUMBERGER TECH CORP

Viscosity reduction of viscoelastic surfactant based fluids

InactiveUS6908888B2Improve efficiencyImproves and optimizes conditionOther chemical processesFluid removalAlcoholSolid particle

Methods and compositions are disclosed for controlled addition of components that decrease the viscosity of the viscoelastic surfactant fluids or for controlled changes in the electrolyte concentration or composition of the viscoelastic surfactant fluids. One aspect of the invention relates to the use of internal breakers with a delayed activation. Another aspect of the invention relates to the use of precursors that release a breaking system such as alcohol by a process such as melting, slow dissolution, reaction with a compound present in the fluid or added to the fluid during or after the step of injecting, rupture of an encapsulating coating and de-adsorption of a breaking agent absorbed into solid particles. In another aspect of the invention, alcohols are included in a pad to reduce the low-shear viscosity and reduce the resistance to flow of the treatment fluids during a desired phase of the treatment.

Owner:SCHLUMBERGER TECH CORP

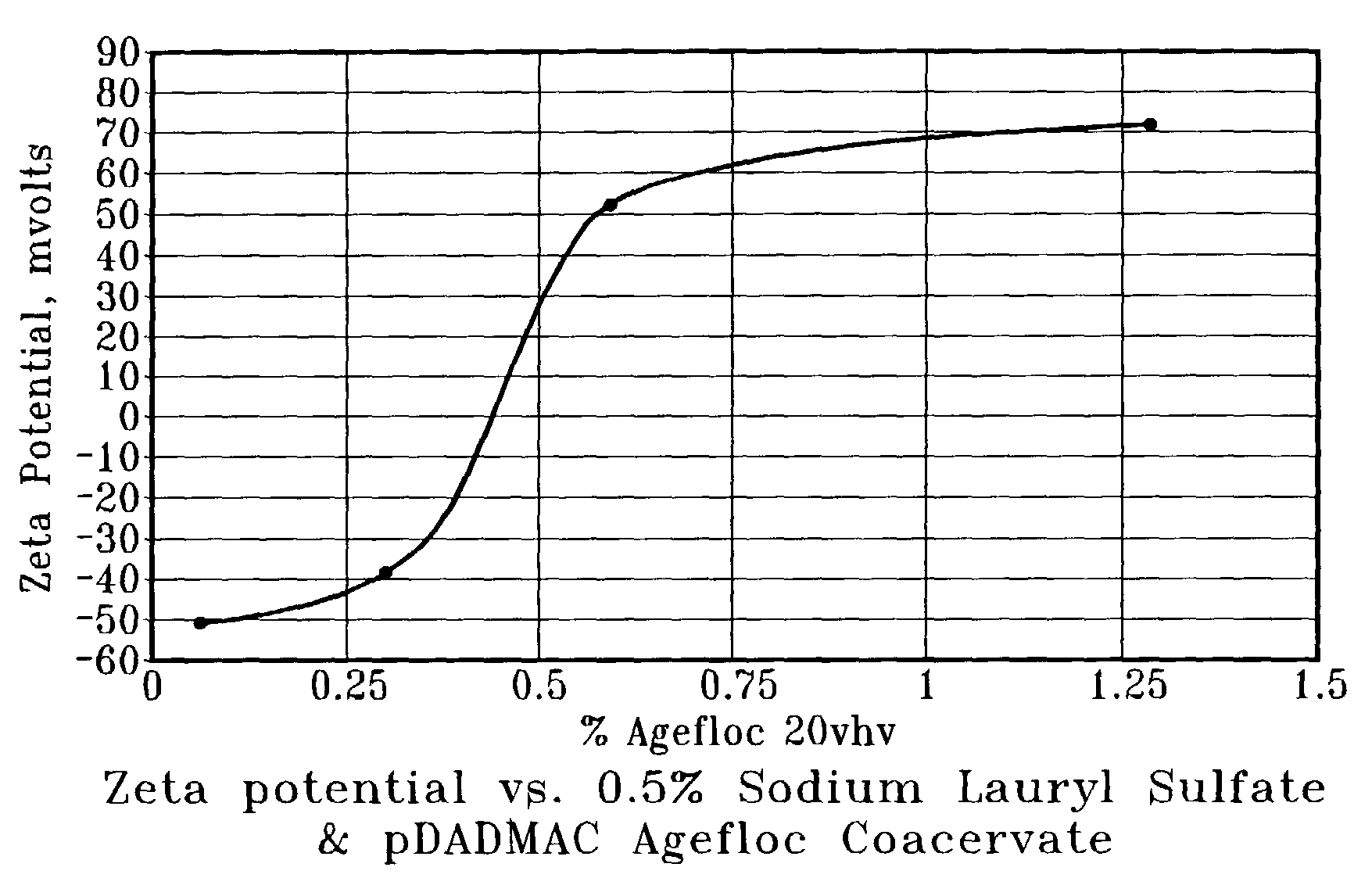

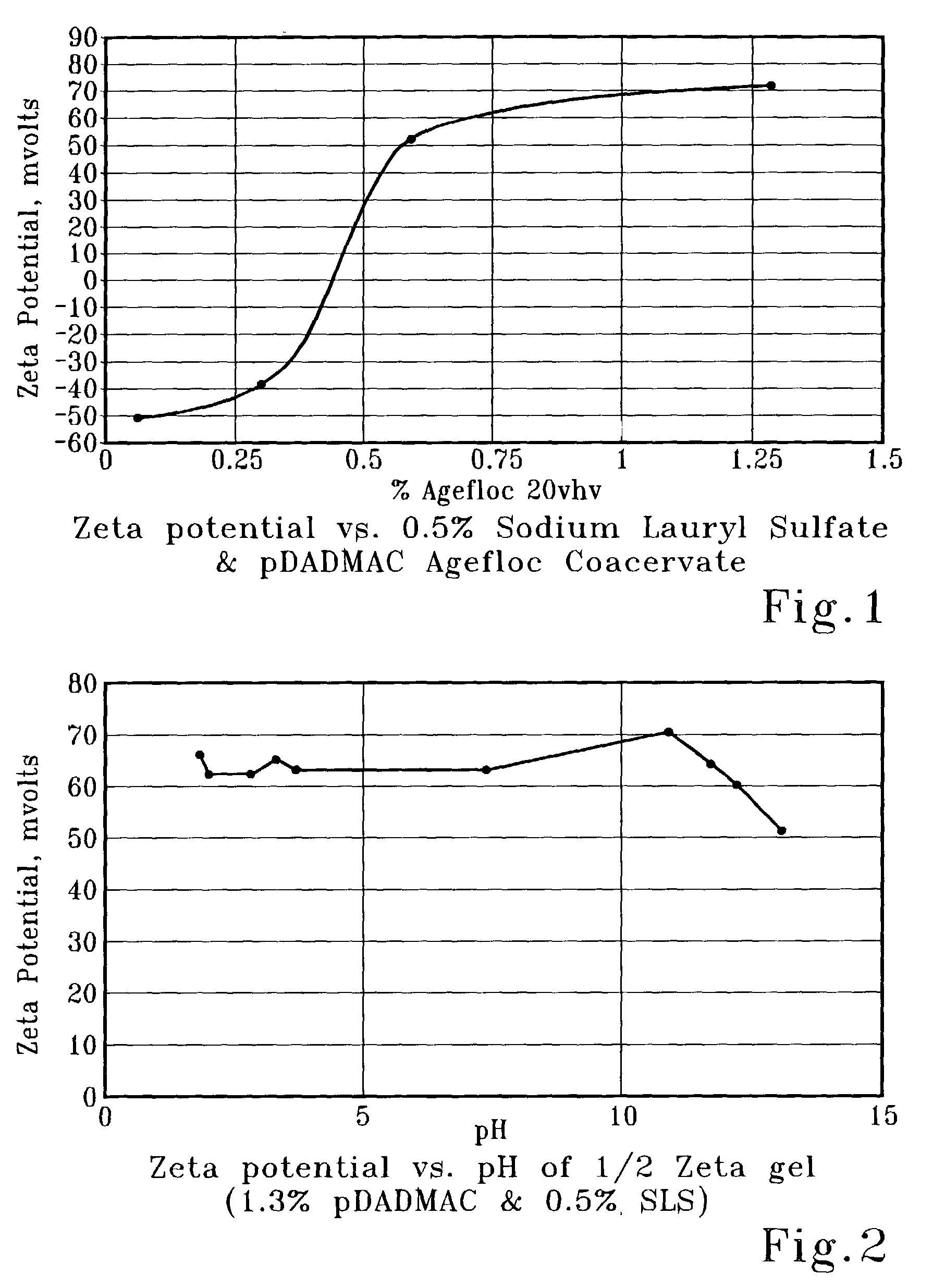

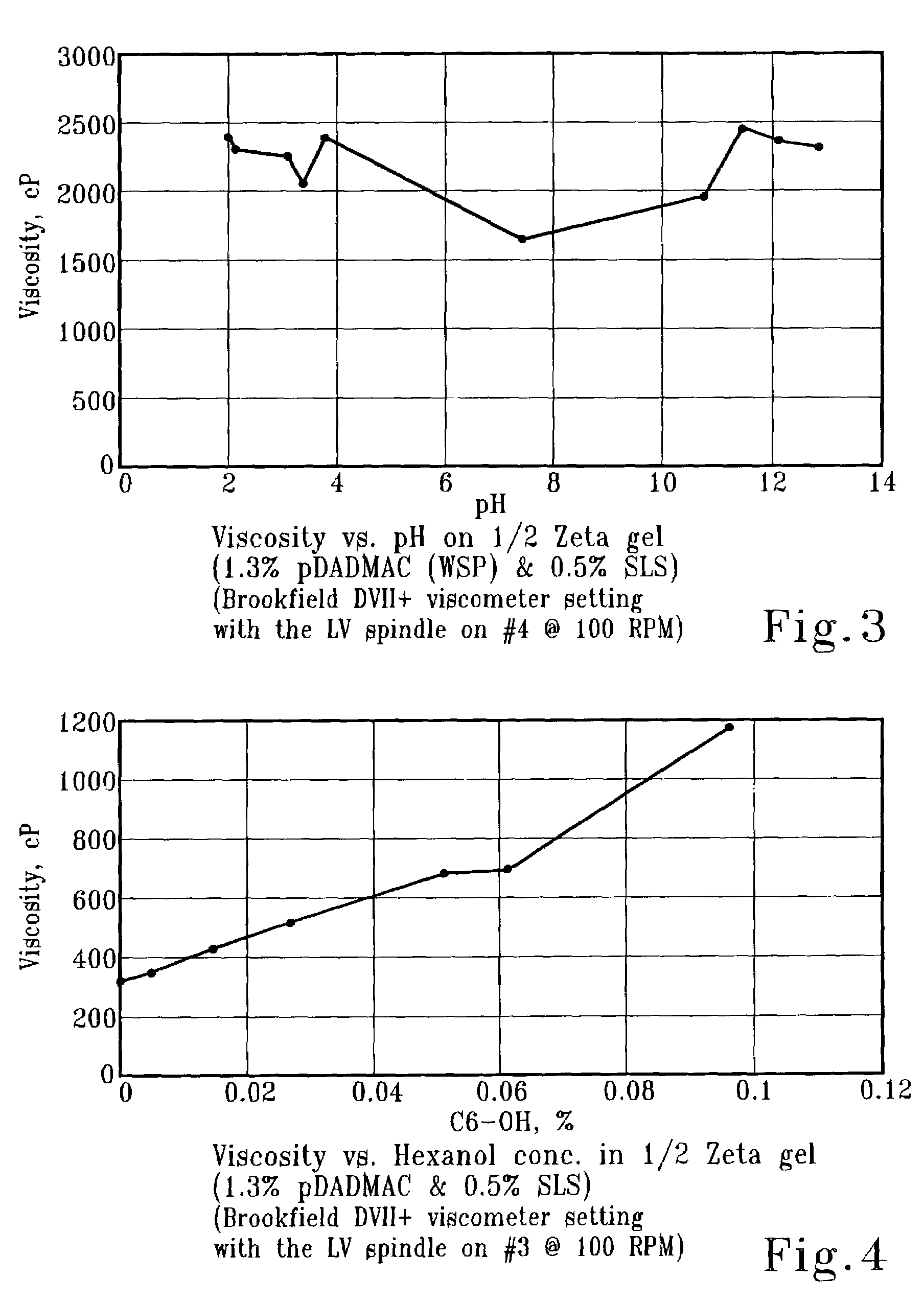

Friction reducing composition and method

InactiveUS7205262B2Easy to pumpReduce frictionDrilling rodsHollow article cleaningShear viscosityDodecylsulfonic acid

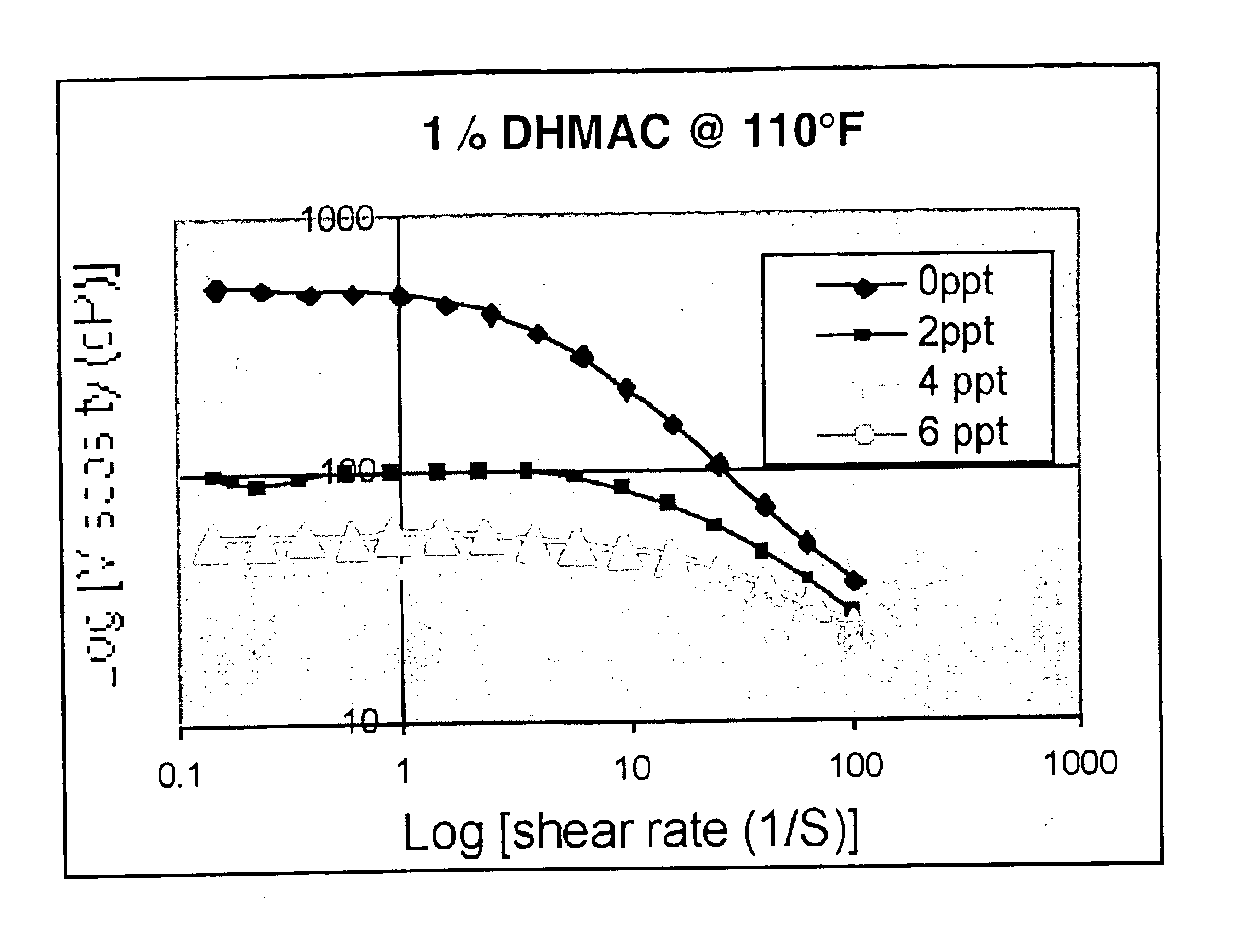

Water soluble nonionic friction reducers and added to coacervate gels having excellent shear viscosities and other properties. A preferred gel comprises poly diallyl dimethyl ammonium chloride, a lesser amount of sodium lauryl sulfonate, and lauryl alcohol. Excellent friction reducing properties are manifested; a particularly practical use for the compositions is in subterranean formation fracturing.

Owner:LUBRIZOL OILFIELD SOLUTIONS

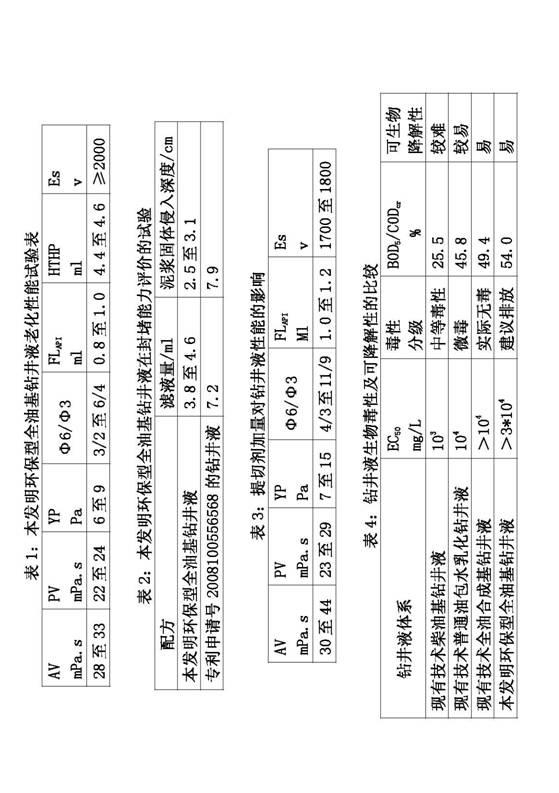

Environmental-friendly type oil-based drilling fluid and preparation method thereof

ActiveCN102304353AAvoid damageImprove the blocking effectDrilling compositionHorizontal wellsPetroleum

The invention relates to the technical field of an oil-based drilling fluid for petroleum drilling, in particular to an environmental-friendly type oil-based drilling fluid and a preparation method therefore. The environmental-friendly type oil-based drilling fluid is prepared from the following raw materials: base liquid white oil, calcium chloride water solution, an emulsifying agent, a wetting agent, organic oil for drilling fluid, a composite plugging agent, a shear strength improving agent, a basicity regulating agent and a fluid loss additive; and a weighting agent is added into a mixture of the raw materials. The oil-based drilling fluid has the following advantages of: good plugging property, high shear viscosity and strong rock carrying capability; the EC 50 (median effect concentration) of the drilling fluid is larger than 3*104mg / L; the drilling fluid has good environmental safety; the return permeability of the drilling fluid can reach 90%-98%; the drilling fluid has little damage to reservoirs; the preparation process of the drilling fluid is simple; the drilling fluid is mainly applied to a special construction technology such as underbalance, horizontal wells and the like, water sensitivity reservoirs and low-pressure low permeability gas wells.

Owner:克拉玛依市金鑫科技有限公司

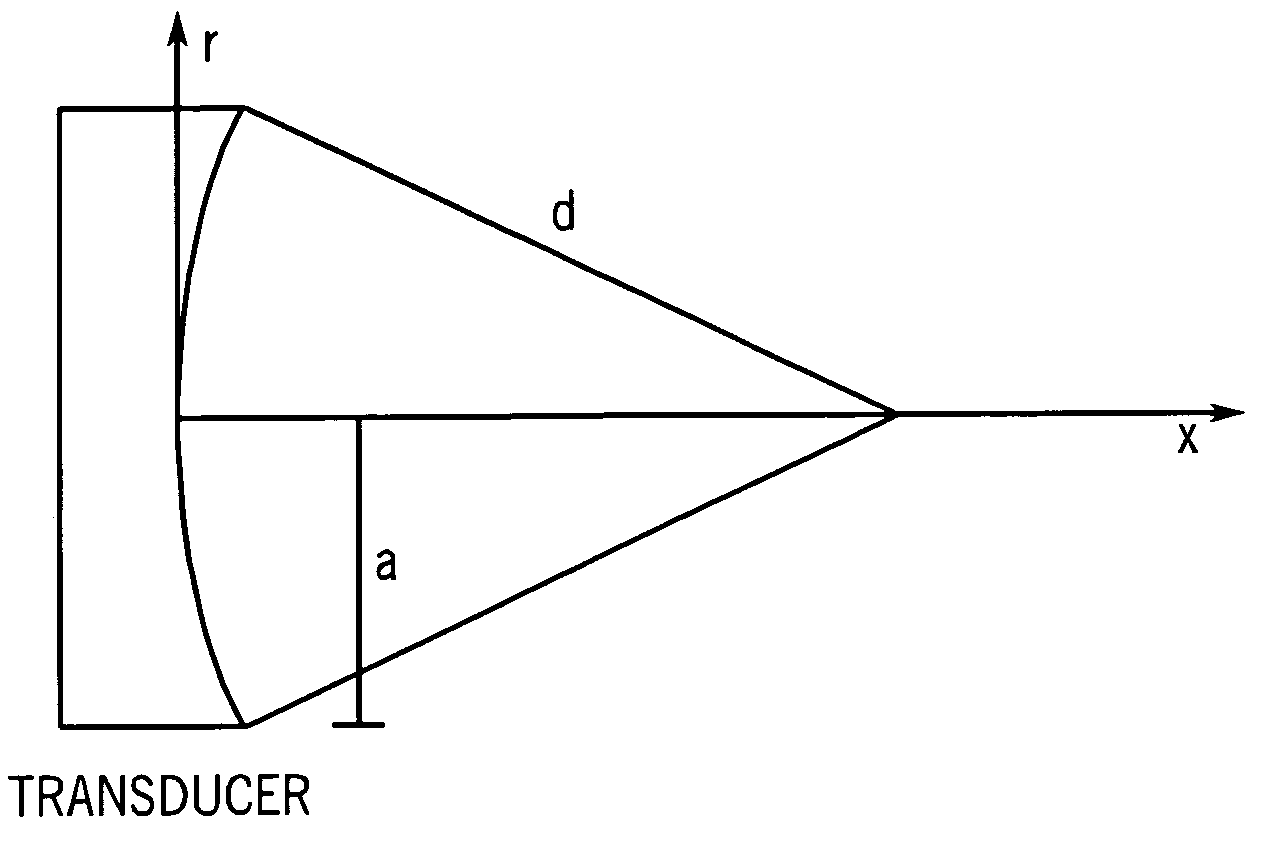

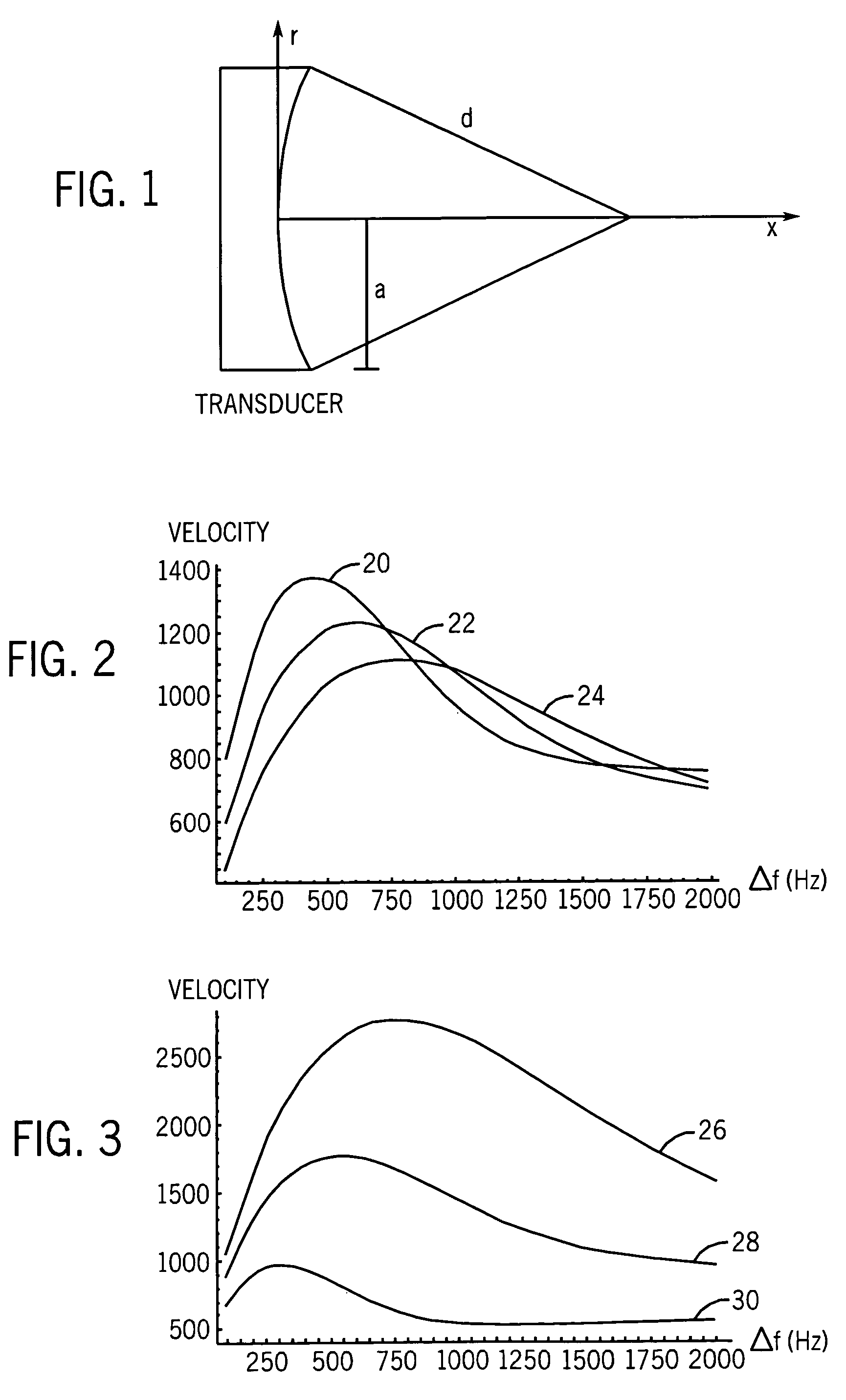

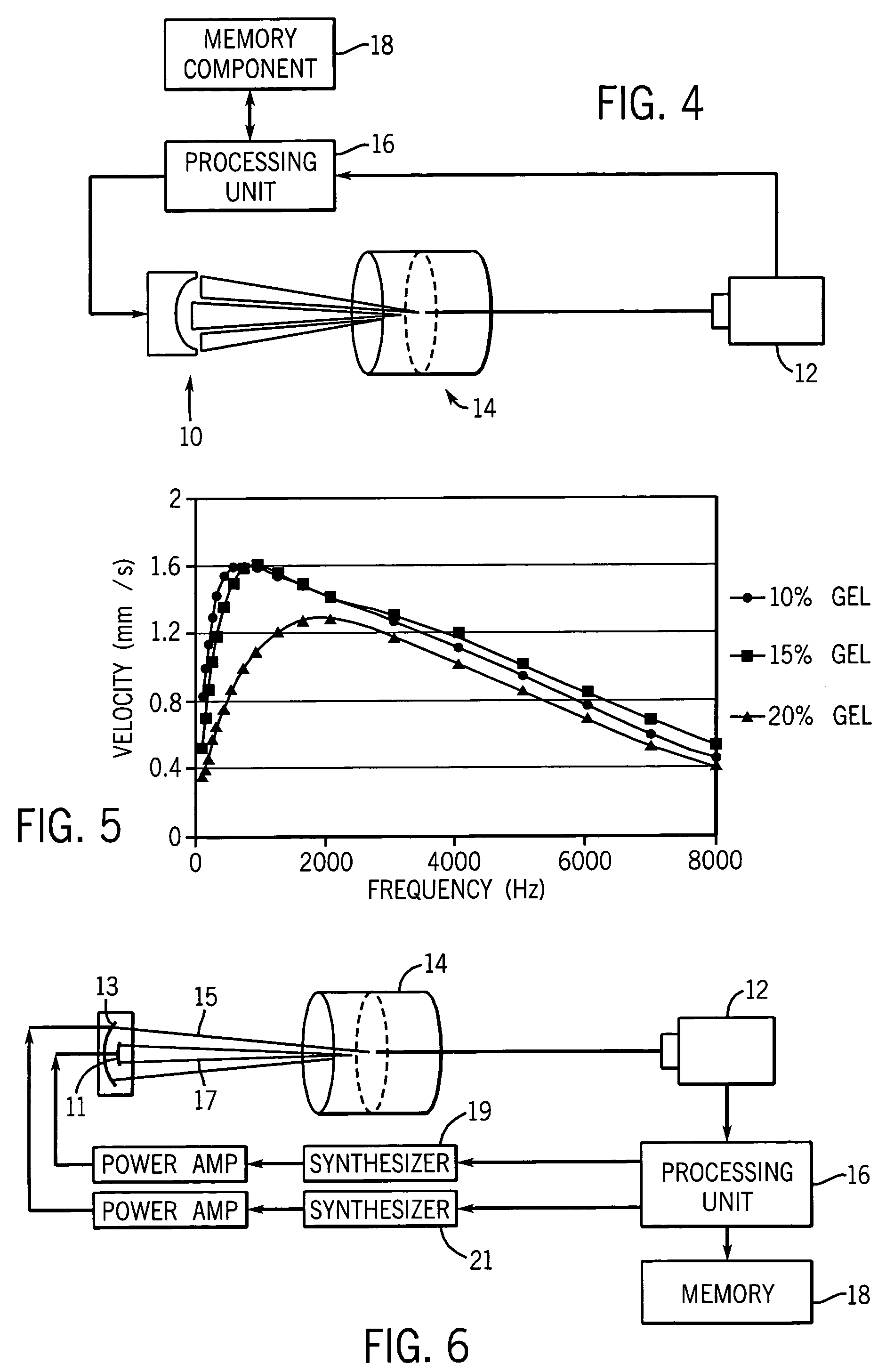

Method and apparatus for shear property characterization from resonance induced by oscillatory radiation force

ActiveUS20050004463A1Analysing solids using sonic/ultrasonic/infrasonic wavesSurgeryFrequency spectrumResonance

A method for determining a shear elasticity and shear viscosity of a material based on resonance characteristics. A focused ultrasound wave is directed at the material to induce oscillations in the material, and a velocity of the material is measured. A spectrum of frequency of oscillation versus velocity is developed, and the resonance characteristics exhibited by the spectrum are used to estimate the shear elasticity and viscosity of the material.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

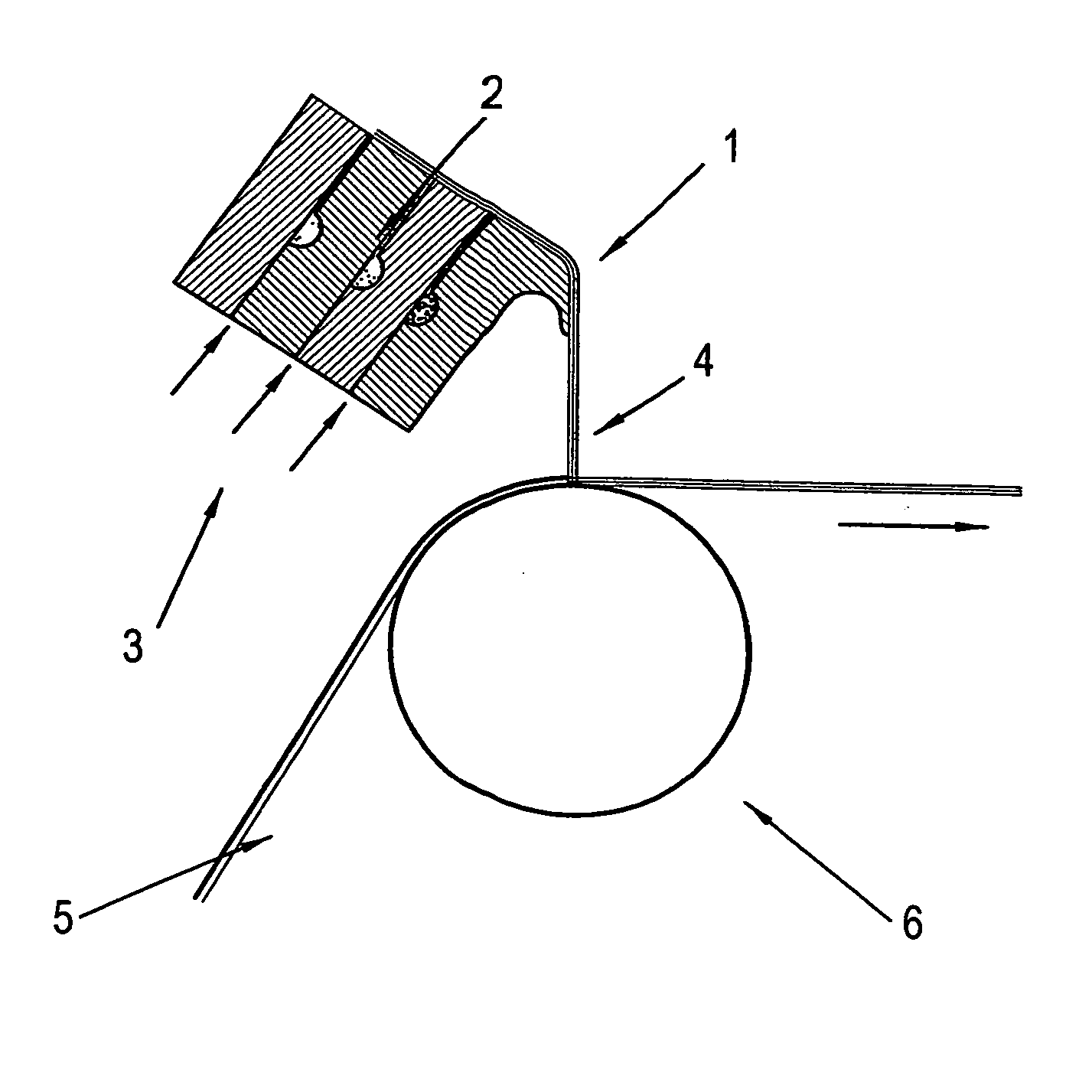

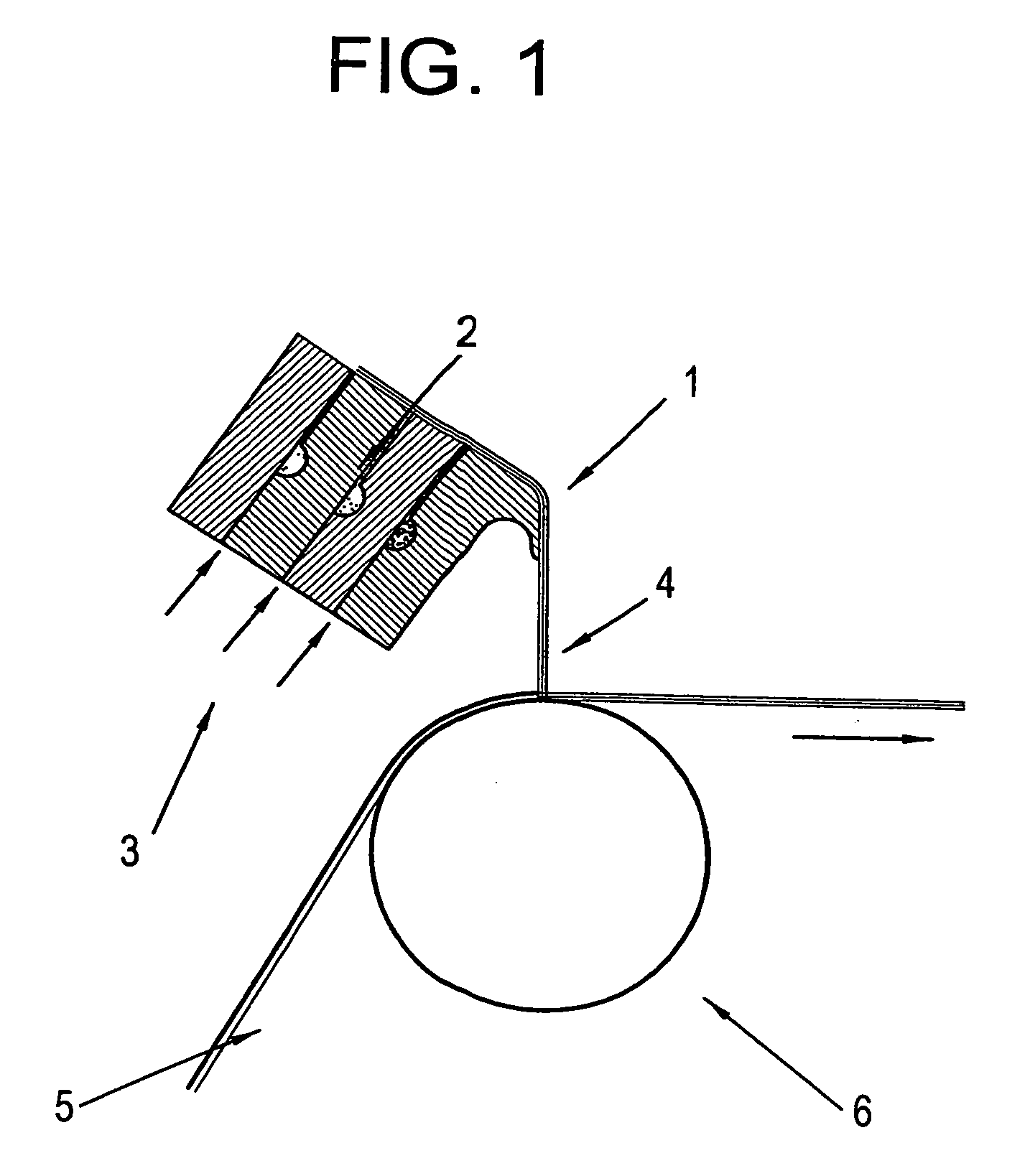

Process for making coated paper or paperboard

InactiveUS20050039871A1Increase shear viscosityEfficient use ofNon-fibrous pulp additionLiquid surface applicatorsPaperboardEngineering

The present invention refers to a method of producing a coated paper or paperboard, but excluding photographic papers, comprising the steps of: (a) forming a free flowing curtain comprising at least one layer, whereby the composition forming at least one layer of the free flowing curtain has a high shear viscosity of at least about 50 mPa.s, and (b) contacting the curtain with a continuous web substrate of basepaper and paperboard.

Owner:DOW GLOBAL TECH LLC

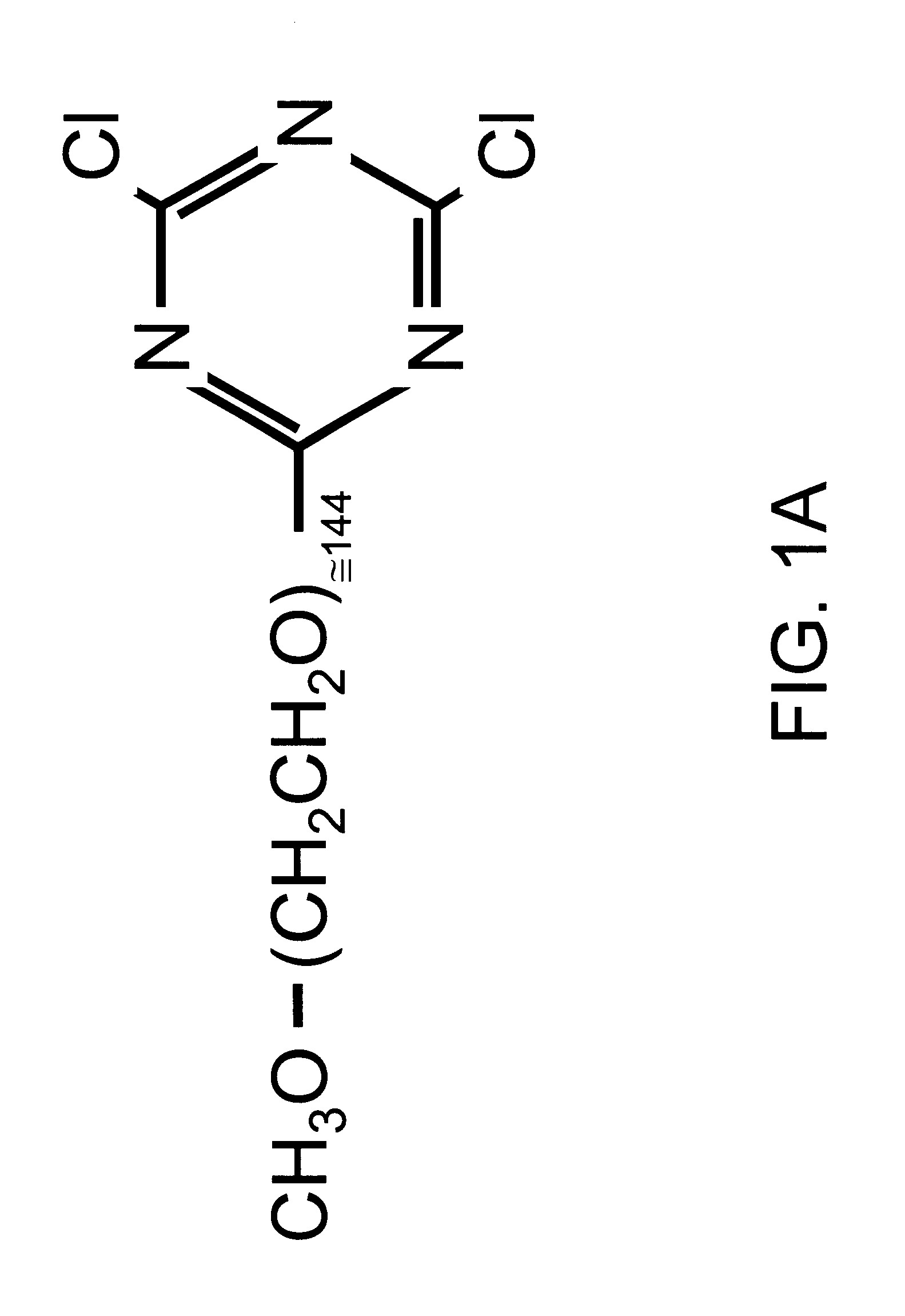

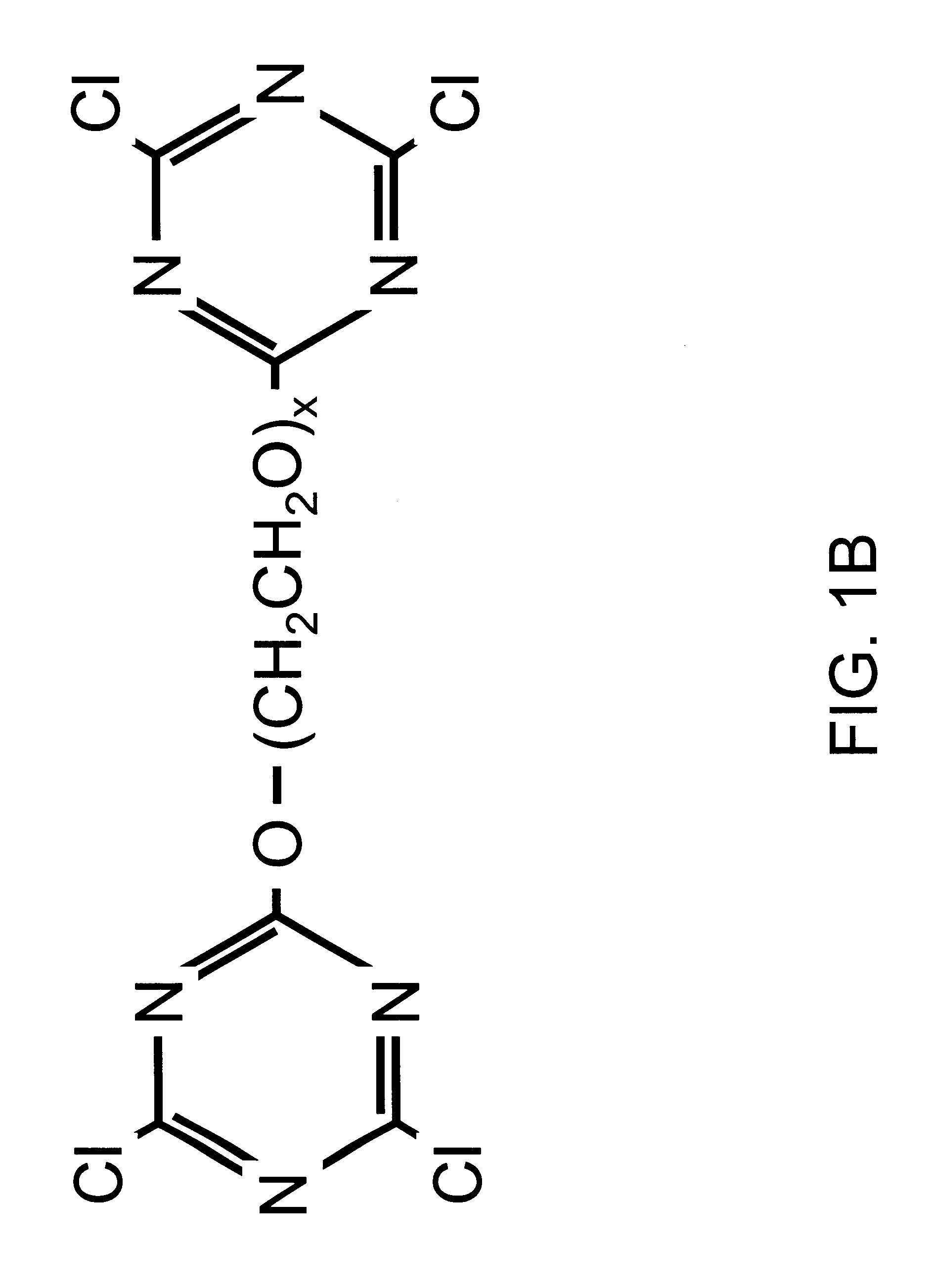

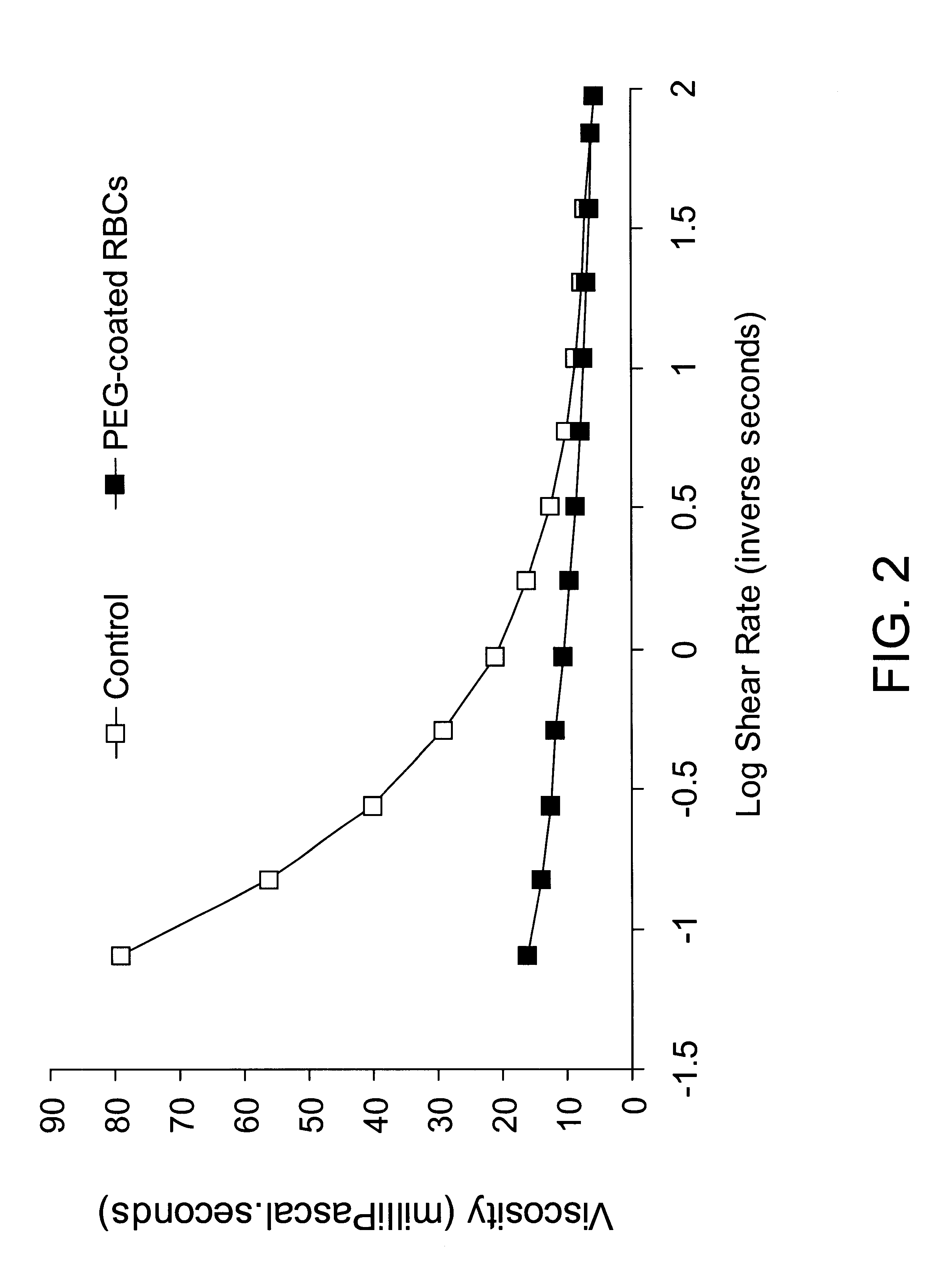

Red blood cells covalently bound with two different polyethylene glycol derivatives

InactiveUS6312685B1Reduce decreaseSignificant comprehensive benefitsBiocideDead animal preservationDiseaseBlood plasma

Living cells are modified at their surface with specially selected polymers. Covalently attaching specially selected polyethylene glycol (PEG) derivatives to the surface of red blood cells (RBC) in aqueous media under mild conditions is a preferred example. The selected PEG derivatives dramatically reduced aggregation and low shear viscosity of RBC resuspended in autologous plasma, and inhibited RBC agglutination by blood group-specific antibodies. The morphology and deformability of the PEG-treated cells were unaltered. PEG coating of the RBC surface is applicable to the treatment of a variety of diseases characterized by vaso-occlusion or impaired blood flow, e.g., myocardial infarction, shock, and sickle cell disease. An infusion solution is prepared containing red blood cells covalently bound to a PEG derivative having a molecular weight of between 2,000 and 5,000 Daltons and a PEG derivative having a molecular weight between 10,000 and 35,000 Daltons.

Owner:FISHER TIMOTHY C +1

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS7025821B2Starch dervative coatingsAmylose/amylopectin derivative coatingsFiberThermoplastic

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal·Seconds to about 80 Pascal·Seconds and an apparent extensional viscosity in the range of from about 150 Pascal·Seconds to about 13,000 Pascal·Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:PROCTER & GAMBLE CO

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS20050076809A1Starch dervative coatingsAmylose/amylopectin derivative coatingsThermoplasticFiber

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal.Seconds to about 80 Pascal.Seconds and an apparent extensional viscosity in the range of from about 150 Pascal.Seconds to about 13,000 Pascal.Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of hollow multi-micropore polyester filament yarn

InactiveCN1908259AStrong moisture absorption and quick drying performanceEasy to useHollow filament manufactureMonocomponent polyesters artificial filamentProduction lineReduction treatment

The invention relates to a method for producing polyester filament yarn with hollow porous structure and better wet adsorption function, wherein it uses two kinds of soluble polyester chips with high and low shearing viscosities to be high-speed spinned with normal polyester chip, to change the components of polyester chip, to be dried and processed via hollow ejection plate, POY-DT production line or FDY one-time production time to obtain the hollow polymer filament yarn. Via alkali reduction treatment, and watched under electric scanning fiber scope, the surface of fiber is uniformly distributed with micro concaves, the section has through micro holes, while its wet adsorption property is better than present one.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

Copolymers, compositions thereof, and methods for making them

Provided are amorphous ethylene propylene copolymer, compositions thereof, and methods for making same, whereby the copolymer can include of from about 40 wt. % to about 60 wt. % ethylene derived units; and of from about 60 wt. % to about 40 wt. % propylene derived units. The copolymer can be characterized by having no discernable melting point as measured by DSC, an MFRR (MI (21.6 kg; 230° C.) / MI (2.16 kg; 230° C.)) (MI (2.16 kg; 230° C.)) of about 38 or more, a molecular weight distribution (MWD) of from about 1.5 to about 2.5, and a shear viscosity η* at 0.01 rad / sec measured at 70° C. that satisfies the relation |η*|(70° C.; 0.01 rad / sec)>1.2*106*|MFR|−0.77, wherein MFR is the melt flow rate.

Owner:EXXONMOBIL CHEM PAT INC

Thickener for high-surfactant aqueous systems

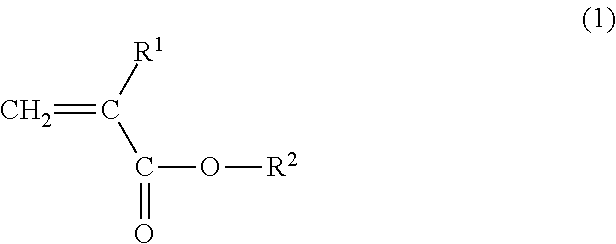

ActiveUS20040063855A1Low shear viscosityLack of clarityInorganic/elemental detergent compounding agentsCosmetic preparationsMeth-Colloid

An aqueous composition comprising at least 18% surfactant and colloidal inorganic clay. This composition is stable with regard to phase separation at 40° C. for at least three months and exhibits increased low-shear viscosity relative to a composition without clay. The composition comprises at least one lipophilically-modified copolymer containing acrylic acid residues and C2-C4 alkyl (meth)acrylate residues.

Owner:ROHM & HAAS CO

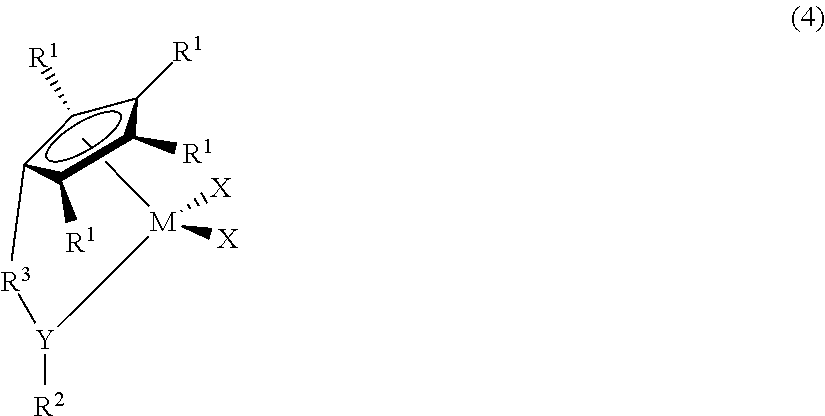

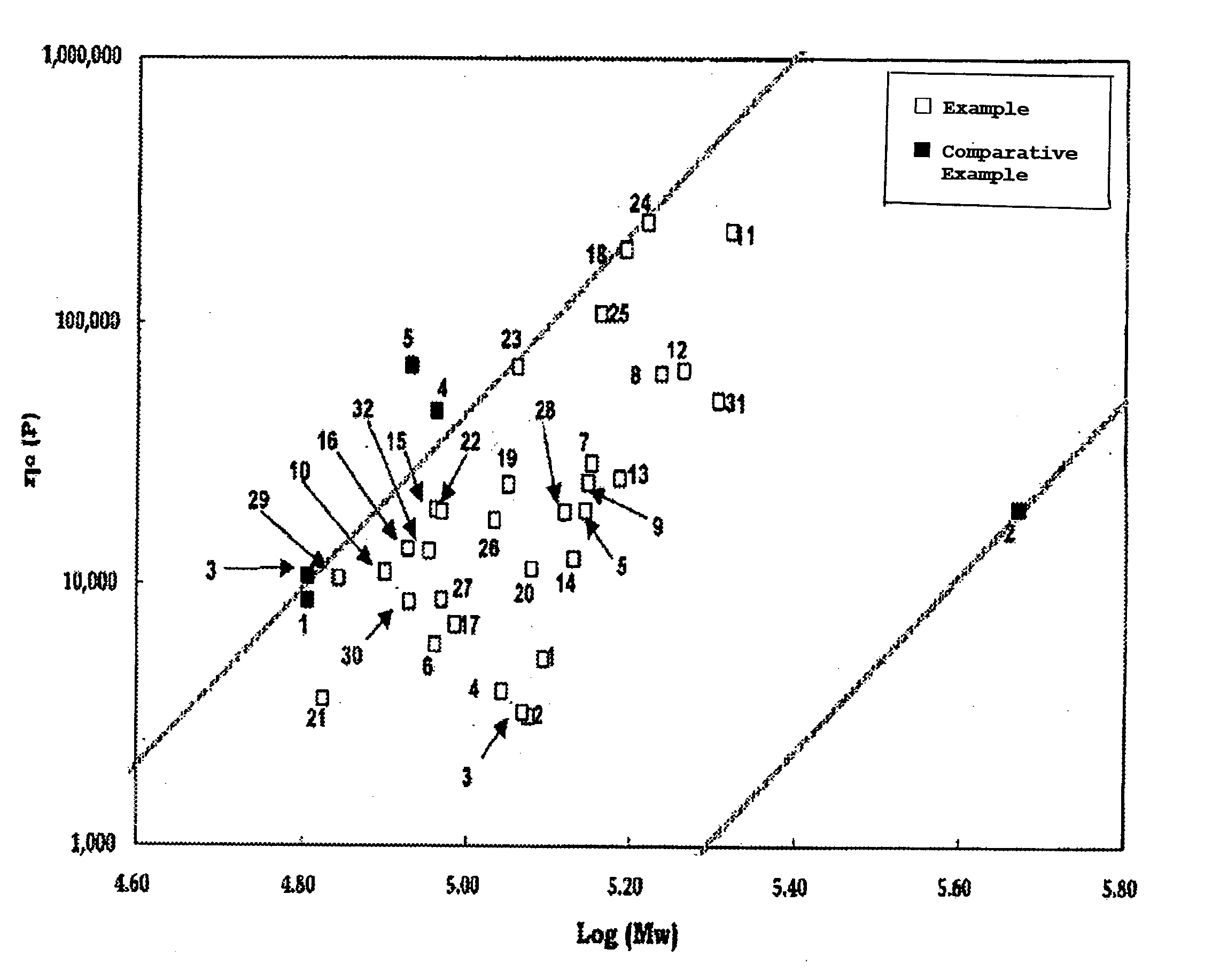

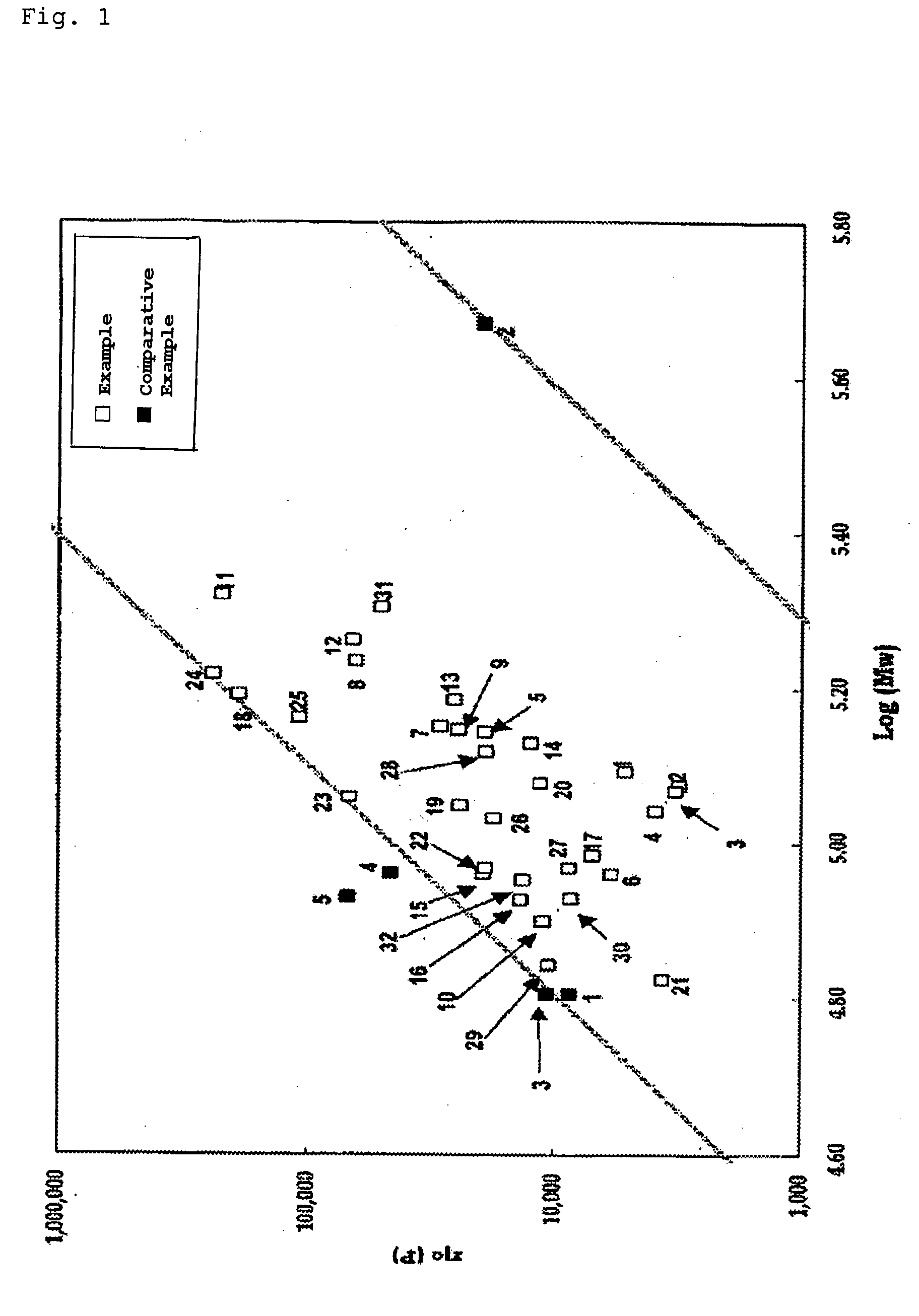

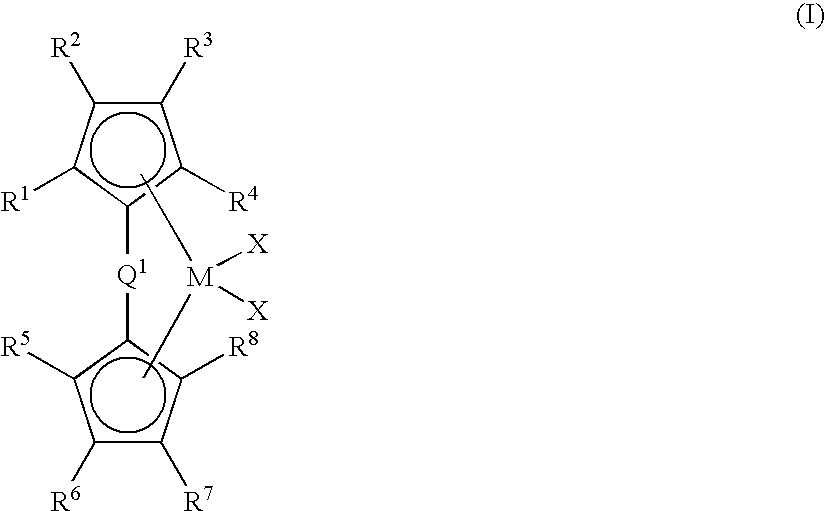

Ethylene-Based Resin and Molded Object Obtained Therefrom

Ethylene-based resin, which exhibits a satisfactorily high melt tension and can provide a molded object excellent in mechanical strength, the ethylene-based resin characterized in simultaneously satisfying the requirements [1] to [5] described below: [1] melt flow rate (MFR) under a loading of 2.16 kg at 190° C. is in the range of 0.1 to 100 g / 10 minutes; [2] density (d) is in the range of 875 to 970 kg / m3; [3] ratio [MT / η*(g / P)] of melt tension [MT(g)] at 190° C. to shearing viscosity [η*(P)] at 200° C. at an angular velocity of 1.0 rad / sec. is in the range of 1.50×10−4 to 9.00×10−4; [4] sum [(A+B)( / 1000C)] of the number of methyl branches [A( / 1000C)] and the number of ethyl branches [B( / 1000C)] per 1000 carbon atoms measured by 13C-NMR is 1.8 or less; and [5] zero shear viscosity [η0(P)] at 200° C. and weight-average molecular weight (Mw) measured by GPC-viscosity detector method (GPC-VISCO) satisfy the following relational expression (Eq-1): 0.01×−13×Mw3.4≦η0≦4.5×10−13×Mw3.4 (Eq-1)

Owner:MITSUI CHEM INC

Zwitterionic gemini viscoelasticity surfactant, preparing method thereof and clean fracturing fluid with zwitterionic viscoelasticity surfactant as thickening agent

InactiveCN106268496AEasy to prepareHigh yieldTransportation and packagingMixingShear viscosityViscoelasticity

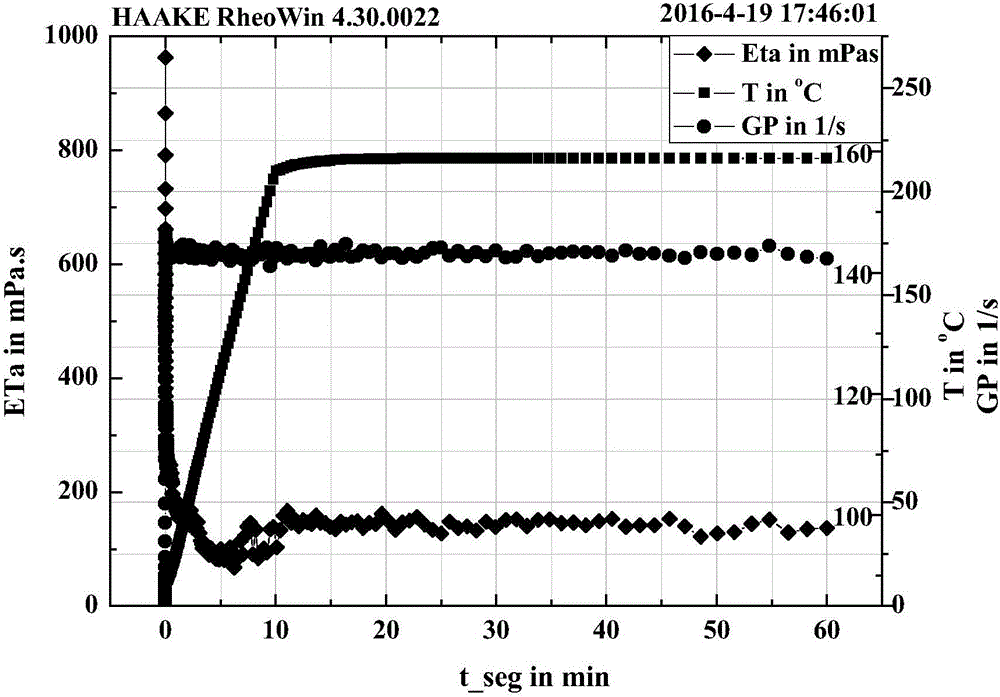

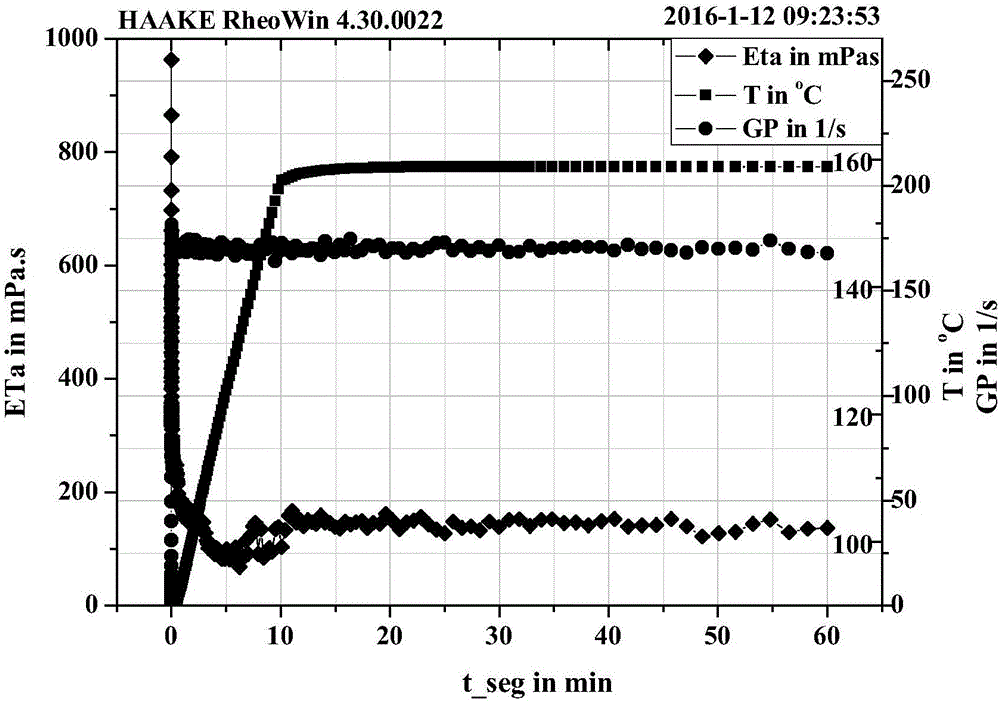

The invention provides a zwitterionic gemini viscoelasticity surfactant, a preparing method thereof and clean fracturing fluid with the zwitterionic viscoelasticity surfactant as a thickening agent. The clean fracturing fluid prepared with the method is simple in material, low in cost, obvious in microcosmic net structure, good in viscoelasticity, excellent in sand suspending performance and thorough in gel breaking, and the clean fracturing fluid has the maximal advantage of being good in temperature resistance; the shear viscosity of the best product at the temperature below 160 DEG C is larger than or equal to 130 mPa.s, and is much larger than 25 mPa.s of the site construction requirement of the clean fracturing fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Thickener for high-surfactant aqueous systems

An aqueous composition comprising at least 18% surfactant and colloidal inorganic clay. This composition is stable with regard to phase separation at 40° C. for at least three months and exhibits increased low-shear viscosity relative to a composition without clay. The composition comprises at least one lipophilically-modified copolymer containing acrylic acid residues and C2–C4 alkyl (meth)acrylate residues.

Owner:ROHM & HAAS CO

Method of printing a fluid material using a continuous jet printing technique and curable compositions for use in said method

The invention relates to a method for printing a fluid material using a continuous jet printing technique, wherein the material is passed under pressure from a reservoir through a channel to at least one outflow opening of the channel, after which the material is passed through the outflow opening, whereby the pressure in at least a part of the channel upstream of the outflow opening is in the interval of 15-600 bars [≡15·105 to 600·105 Pa], and whereby the fluid material comprises a curable composition which comprises: a) a component A in an amount in the range of from 1-15 wt % which component A has a dielectric constant larger than 15 (at 0° C.); b) an ionically dissolved lipophilic salt in an amount in the range of from 1-15 wt %, c) optionally (a) coating additive(s) in an amount of at most 10 wt %, and d) for the remaining part a liquid component B which comprises a curable monomer and / or a curable oligomer, which liquid component B has a low shear viscosity (at 22° C.) in the range of from 50-1500 mPas, whereby liquid components A and B are compatible with each other, and all amounts are based upon total composition. The invention further relates to said curable composition and articles comprising said composition.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

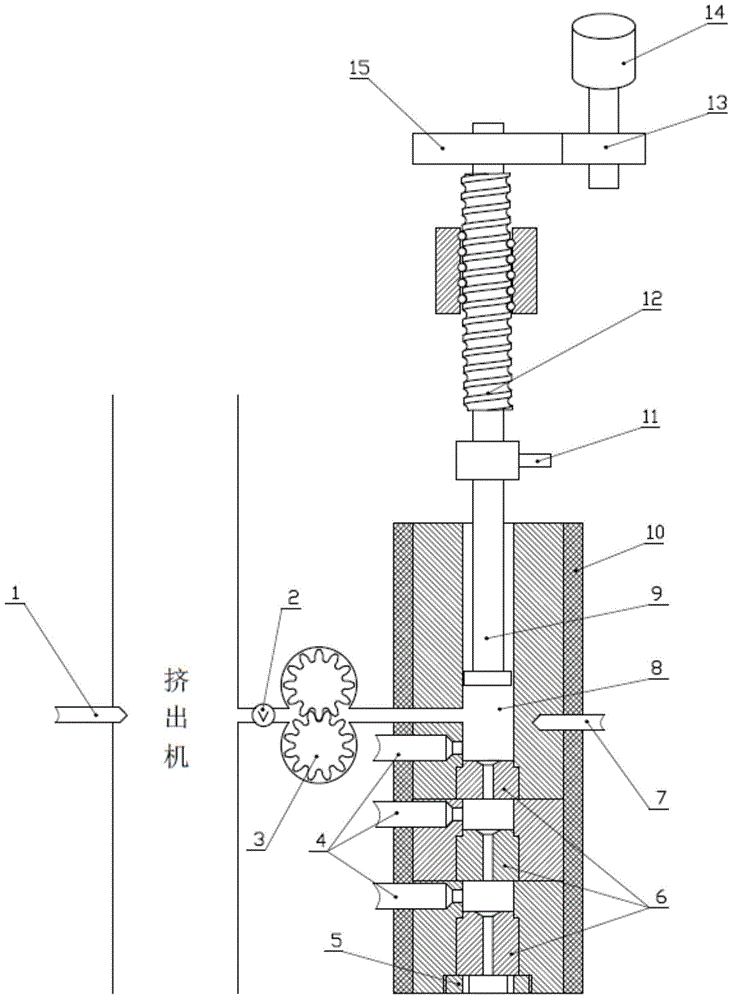

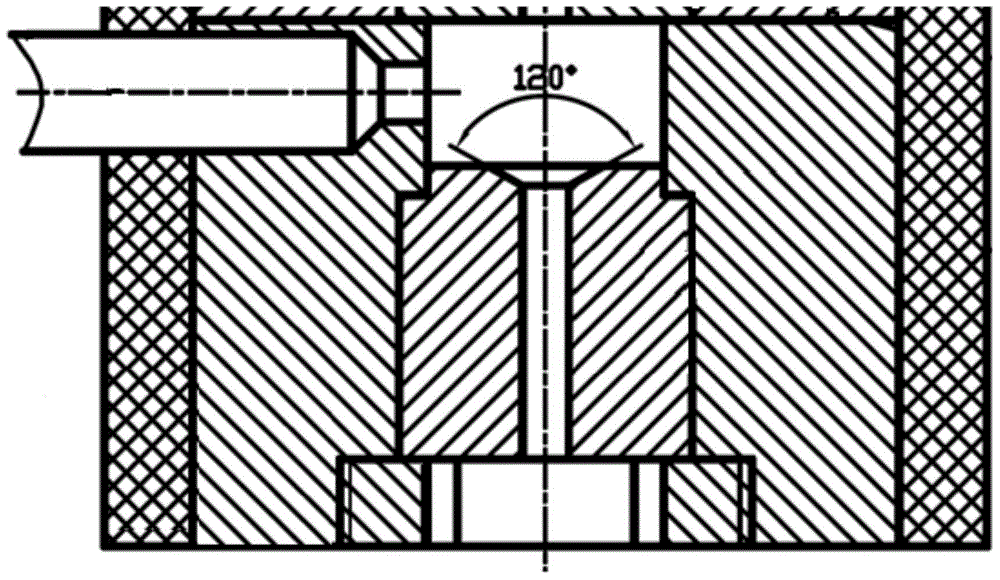

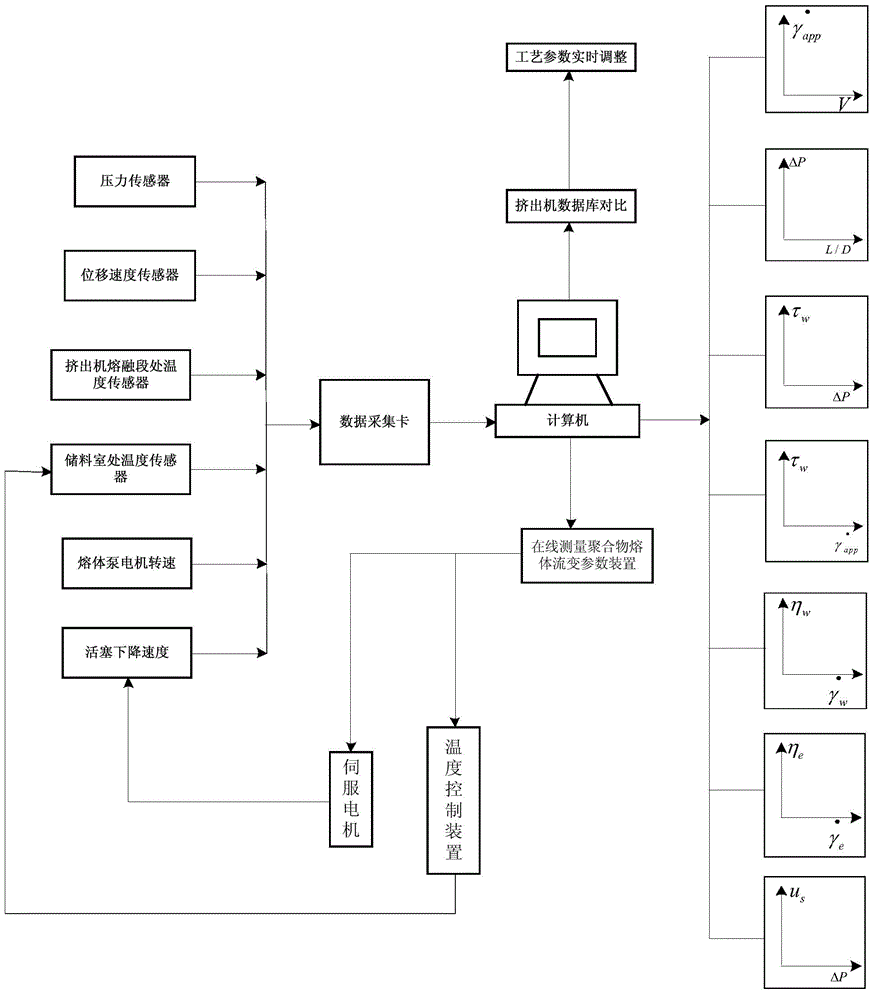

Device and method for online measuring polymer melt rheological parameter

InactiveCN104568663AReduce the effect of trial errorStudying Instantaneous Extensional ViscosityDirect flow property measurementTemperature controlEngineering

The invention discloses a device and a method for online measuring a polymer melt rheological parameter. The device comprises a temperature control device, wherein a storage chamber is formed in the temperature control device; a piston is arranged above the storage chamber, and a plurality of capillary opening molds which are spaced to one another are sequentially arranged below the storage chamber from top to bottom; the storage chamber is connected to a fused plasticizing section of an extruder through a melt pump, the melt pump is used for introducing the polymer melt into the storage chamber from the fused plasticizing section of the extruder, and the polymer melt in the storage chamber can be sequentially extruded from a plurality of capillary opening molds under the extrusion of the piston. By adopting the device, the Bagley and Rabinowitsch correction can be synchronously carried out, the real shear viscosity of the material can be measured in real time, and the instantaneous tensile viscosity of the melt can be measured by utilizing a Cogswell method; in addition, the wall slippage phenomenon of the melt can be researched by replacing different capillary opening molds in different sizes. Compared with the traditional offline measurement method, the device and the method have the advantages that the rheological behavior of the material in a processing device can be really reflected.

Owner:SOUTH CHINA UNIV OF TECH +1

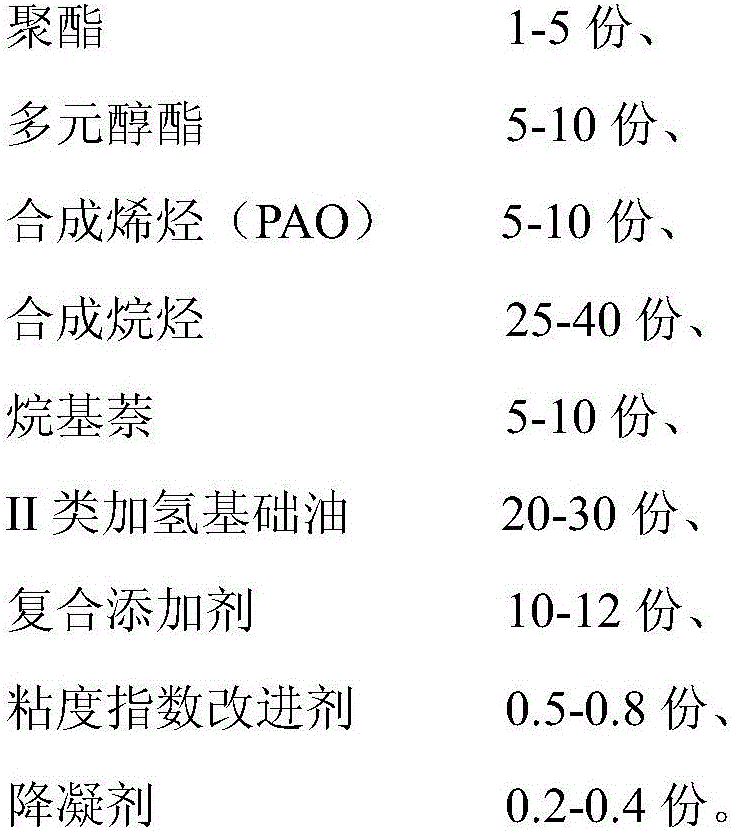

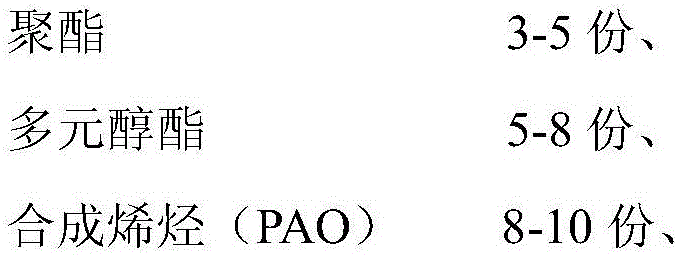

Special engine oil for improving engine oil combustion phenomenon of turbocharged engine and preparation method thereof

The invention relates to a lubricating oil, and specifically discloses a special engine oil for improving the engine oil combustion phenomenon of turbocharged engine and a preparation method thereof. The special engine oil includes base oil and additives; the base oil includes polyester, polyol ester, synthetic olefin (PAO), synthetic alkane, alkyl naphthalene and class II hydrotreated base oil; and the additives include a compound agent, a viscosity index improver and a pour point depressant. The invention also provides a preparation method of the special engine oil. The special engine oil provided by the invention has high flash point and high temperature-high shear viscosity, and has greatly reduced evaporation loss. At the same time, the engine oil meets the grade requirements of API SN. The special engine oil provided by the invention can greatly reduce the engine oil combustion phenomenon of turbocharged engine.

Owner:青岛冠军石油化学有限公司

Resist stripping compositions and methods for manufacturing electrical devices

ActiveUS20120058644A1Good dispersionImprove solubilityDetergent mixture composition preparationSemiconductor/solid-state device manufacturingTetramethylammonium hydroxideHydroxylamine

A liquid composition free from N-alkylpyrrolidones and hydroxyl amine and its derivatives, having a dynamic shear viscosity at 50° C. of from 1 to 10 mPas as measured by rotational viscometry and comprising based on the complete weight of the composition, (A) of from 40 to 99.95% by weight of a polar organic solvent exhibiting in the presence of dissolved tetramethylammonium hydroxide (B) a constant removal rate at 50° C. for a 30 nm thick polymeric barrier anti-reflective layer containing deep UV absorbing chromophoric groups, (B) of from 0.05 to <0.5% of a quaternary ammonium hydroxide, and (C) <5% by weight of water; method for its preparation, a method for manufacturing electrical devices and its use for removing negative-tone and positive-tone photoresists and post etch residues in the manufacture of 3D Stacked Integrated Circuits and 3D Wafer Level Packagings by way of patterning Through Silicon Vias and / or by plating and bumping.

Owner:BASF AG

A method for manufacturing modified extra fine heavy calcium carbonate powder

ActiveCN101544852AImprove lipophilicityImprove wettabilityCoatingsPigment treatment with macromolecular organic compoundsShear viscosityChemistry

The invention relates to a method for manufacturing modified extra fine heavy calcium carbonate powder; polyglycol and water are evenly mixed according to a mass ratio of 1:1 to get fluid A which is added from an inlet orifice of a muller and enters the muller together with coarse fodder entering the muller; the coarse fodder is continuously grinded to be fine, ceaselessly mixed to be even with the fluid A, and evenly wrapped simultaneously; wrapped modified extra fine heavy calcium carbonate powder is separated after entering a grader through wind, thus obtaining modified extra fine heavy calcium carbonate powder. The modified extra fine heavy calcium carbonate of the invention not only ensures retaining of characteristics of modified extra fine heavy calcium carbonate powder, but can improve lipophilicity, wettability and disperse stability of powder body. After applied to a latex system, the modified extra fine heavy calcium carbonate powder obtained by the invention can improve hydrophobic mature of a dope system, rinse resistant times, high shear viscosity of a latex system, construction property, and reduce dosage of moistening dispersant and foam suppressor in the meanwhile.

Owner:广福建材(蕉岭)精化有限公司

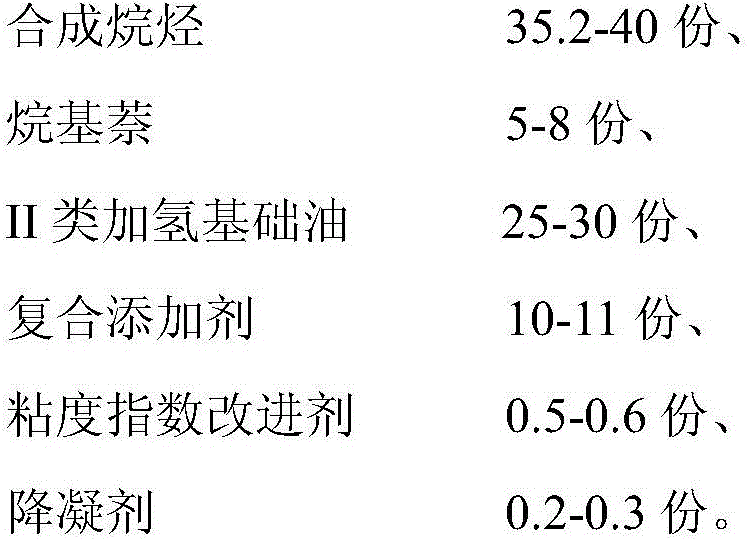

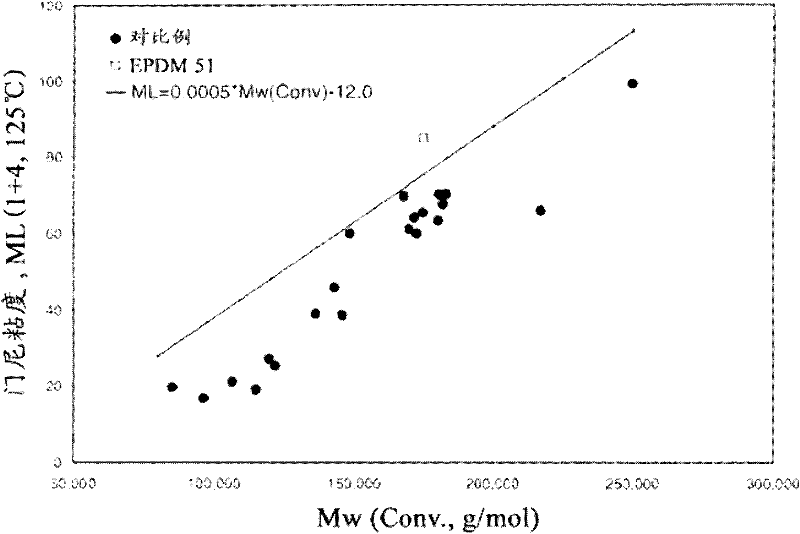

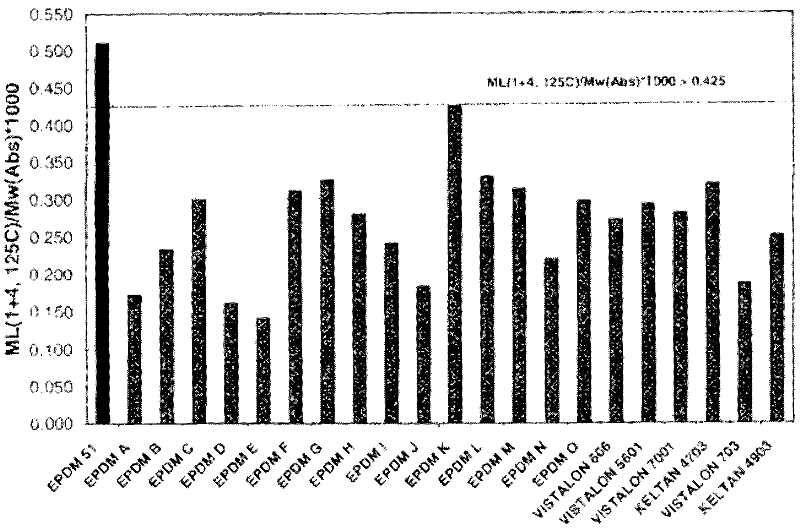

Polymer compositions, methods of making the same, and articles prepared from the same

The invention provides a composition comprising a first composition, which first composition comprises the following: A) a first interpolymer comprising, in polymerized form, ethylene, an a-olefin and a nonconjugated polyene; B) a second interpolymer comprising, in polymerized form, ethylene, an a-olefin and a nonconjugated polyene; and wherein the first composition has an [(ML(1+4, 125 DEG C)) / Mw(conv)]*1000 greater than 0.429 mole / g. The invention also provides a composition comprising a first composition, which first composition comprises the following: A) a first interpolymer comprising, in polymerized form, ethylene, an a-olefin and a nonconjugated polyene; B) a second interpolymer comprising, in polymerized form, ethylene, an a-olefin and a nonconjugated polyene; and wherein the first composition has a Mooney Viscosity (ML, 1+4, 125 DEG C) greater than, or equal to, 70, and has a low shear viscosity (Eta at 0.1 rad / sec) less than, or equal to, 100,000 Pa DEG sec. The invention also provides a composition comprising a first composition, which first composition comprises the following: A) a first interpolymer comprising, in polymerized form, ethylene, an a-olefin and a nonconjugated polyene; B) a second interpolymer comprising, in polymerized form, ethylene, an a-olefin and a nonconjugated polyene; and wherein the first composition has a Mooney Viscosity (ML(1+4, 125 DEG C)) greater than, or equal to, 70, and has an [Mw(abs)] / [Mw(conv)] less than 1.2.

Owner:DOW GLOBAL TECH LLC

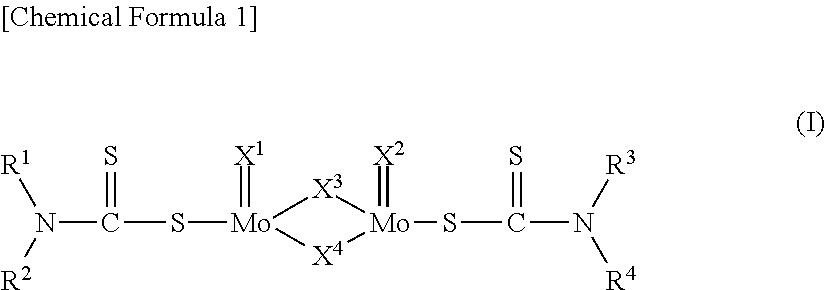

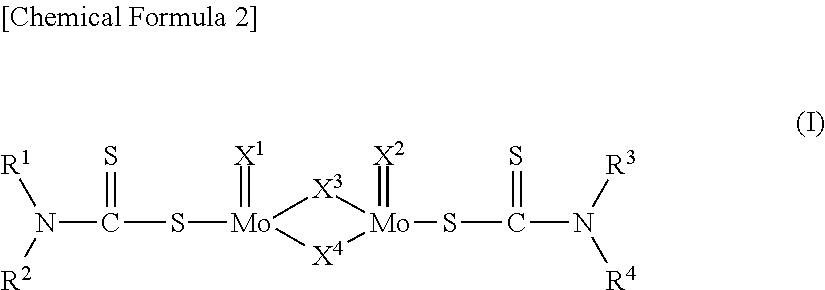

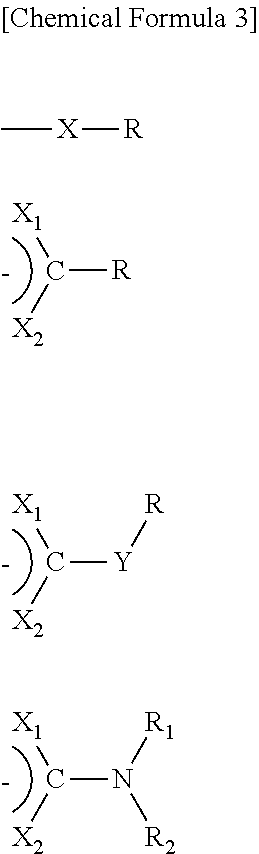

Lubricant composition for internal combustion engine

A lubricating oil composition of the present invention for an internal combustion engine is prepared by blending (A) a perbasic calcium sulfonate and / or a perbasic calcium phenate having a TBN of 200 mgKOH / g or higher, (B) predetermined binuclear and / or trinuclear organic molybdenum compounds, and (C) a polyalkyl (meth)acrylate having an SSI of 30 or lower into a lubricating base oil composed of a mineral oil and / or a synthetic oil, in which the total content of molybdenum derived from the binuclear and trinuclear organic molybdenum compounds is 0.025% by mass or higher based on the total amount of the composition, and in which the lubricating oil composition has a high-temperature high-shear viscosity at 100° C. of 4.0 to 5.0 mPa·s, a high-temperature high-shear viscosity at 150° C. of 2.5 mPa·s or lower and a NOACK value (250° C., 1 hr) of 15% by mass or less.

Owner:IDEMITSU KOSAN CO LTD

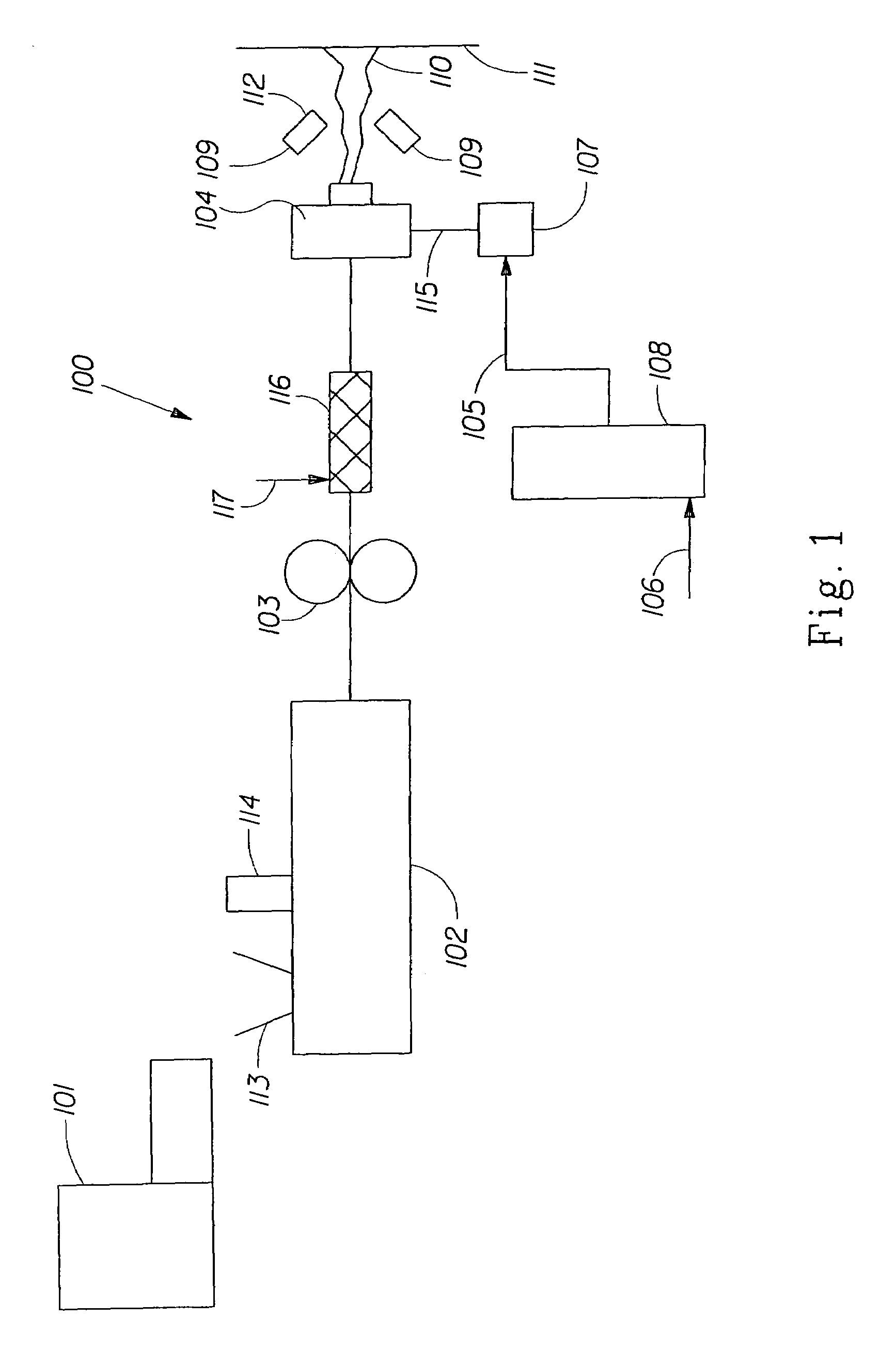

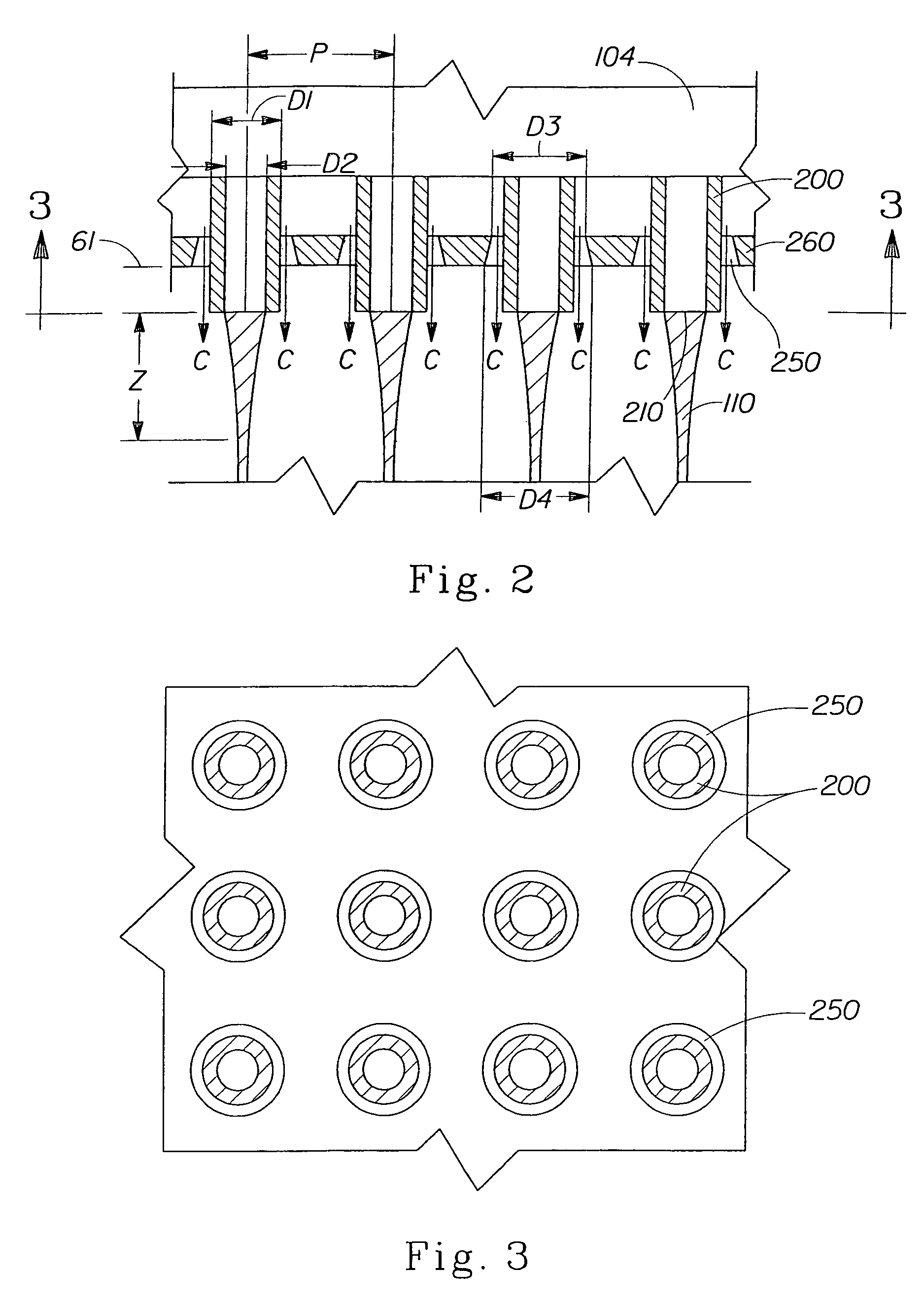

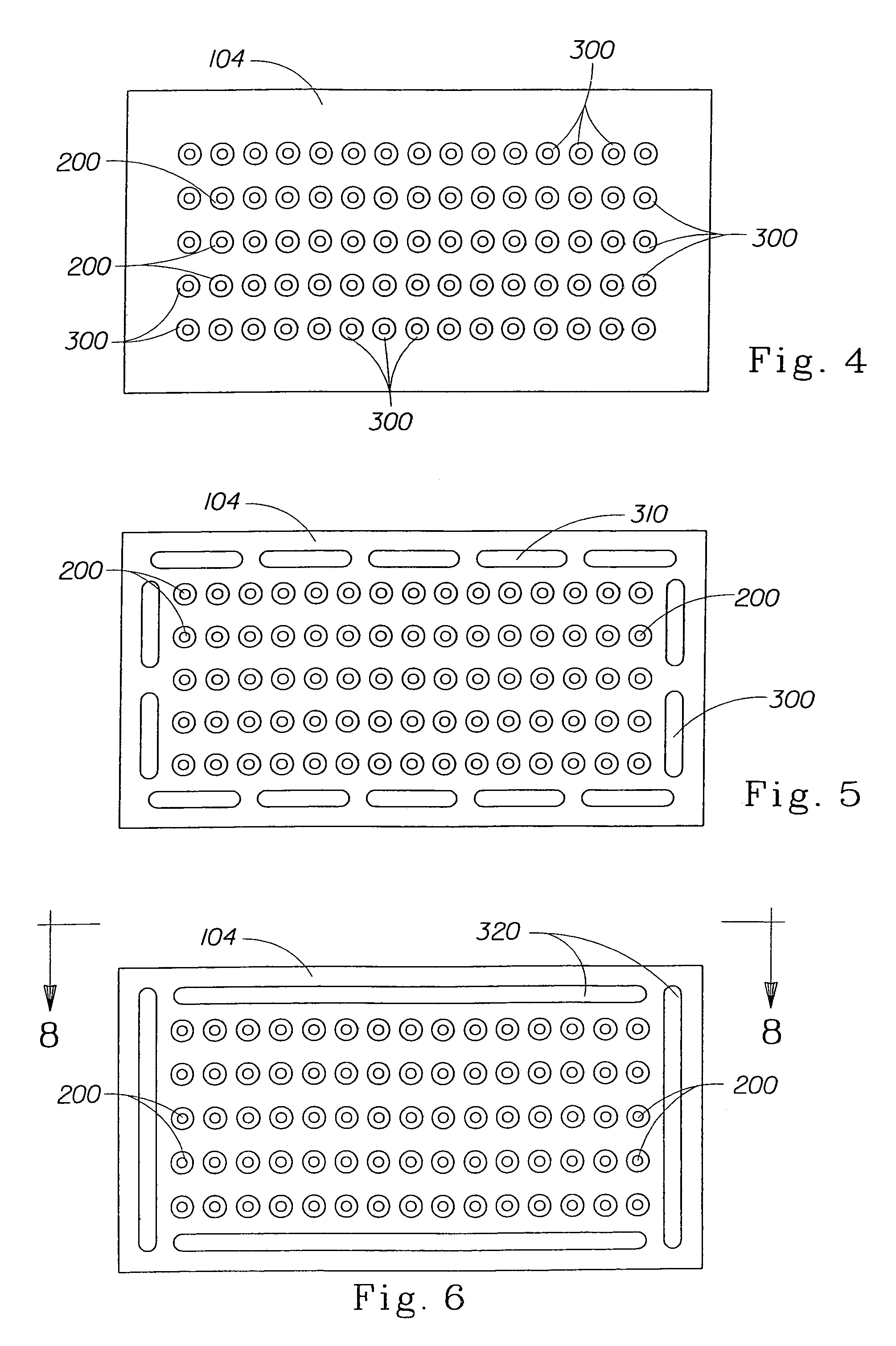

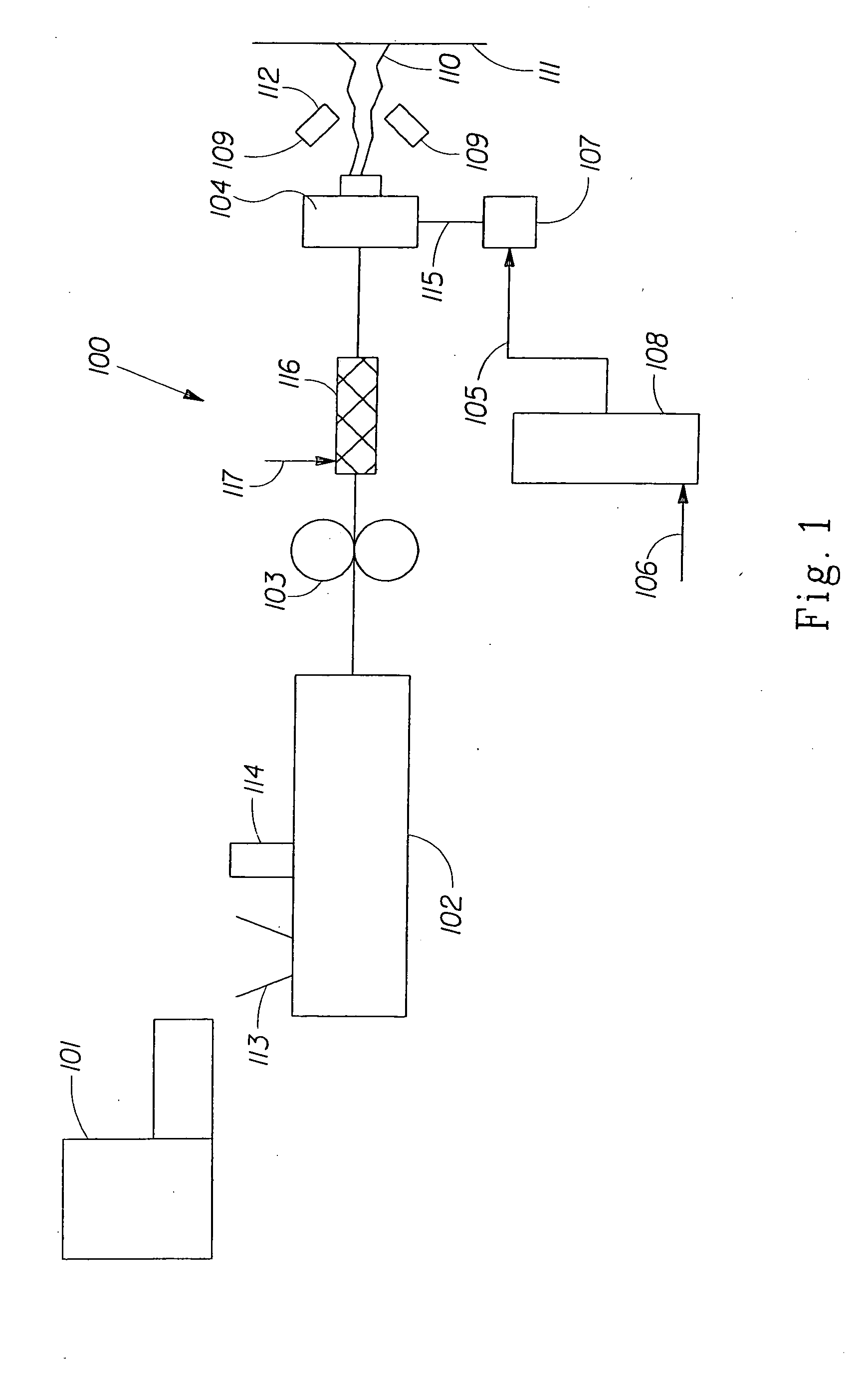

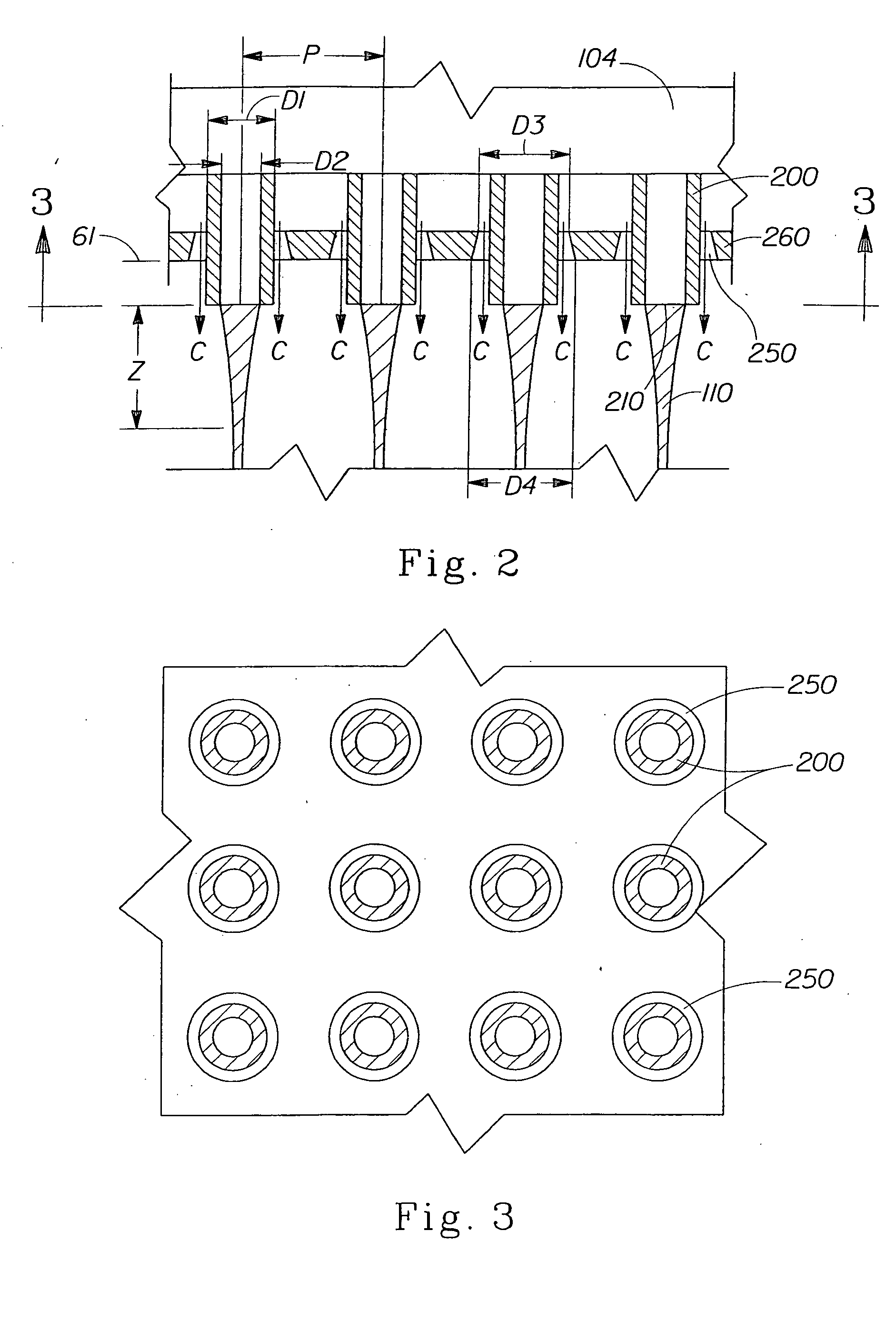

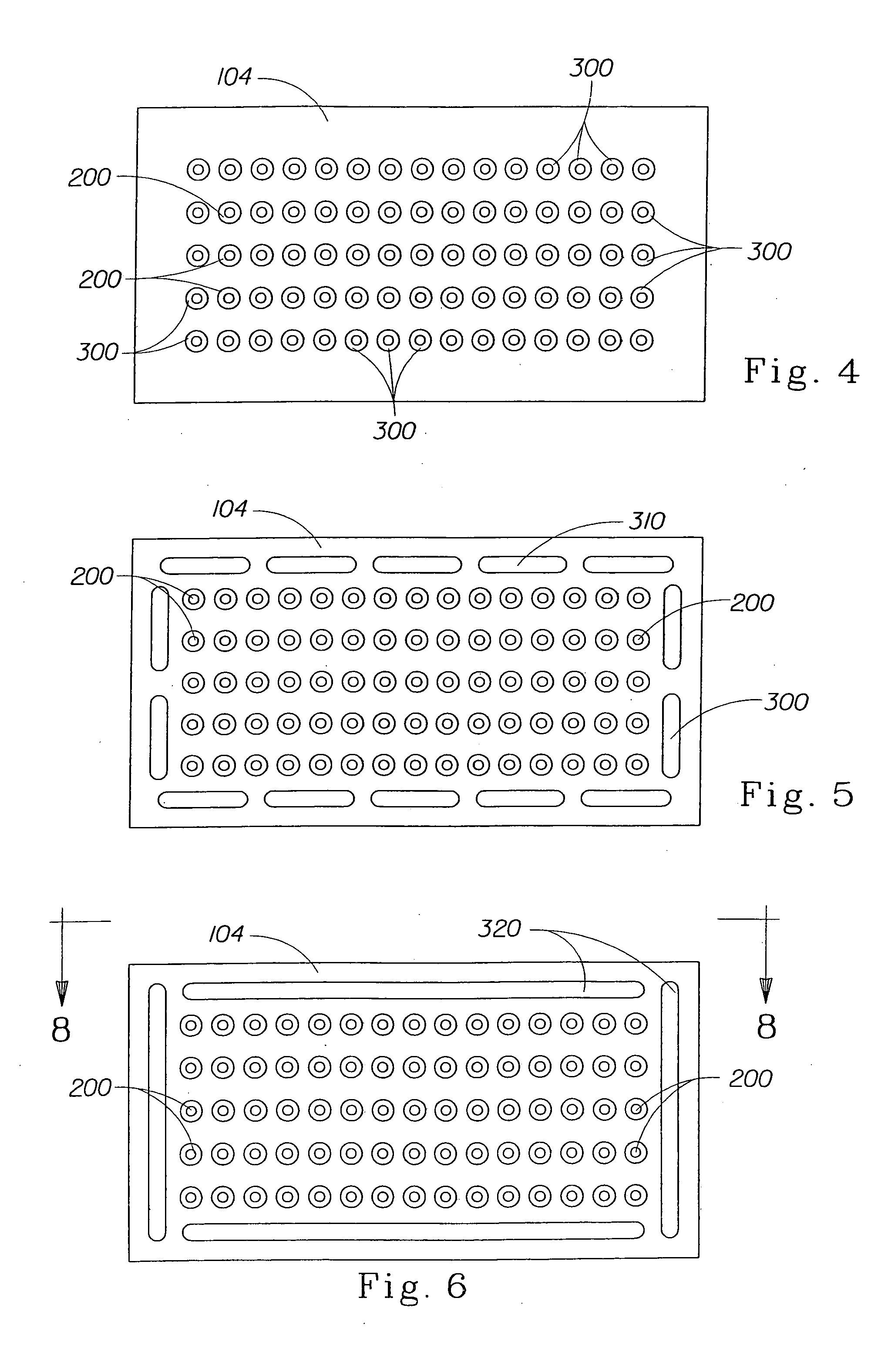

Fuel cell separator and a method for manufacturing the same

InactiveUS20050277009A1Lower resistanceLow costFinal product manufactureElectrode carriers/collectorsFuel cellsShear viscosity

A first resin is prepared which has a content of electrically conductive particles adjusted in the range from 60 wt % to 90 wt %, and a melt shear viscosity adjusted in the range from 1×103 Pa.sec to 1×107 Pa.sec. A second resin is prepared which has a content of electrically conductive particles that is adjusted in the range from 50 wt % to less than 90 wt % and that is less than that of the first resin. The second resin has a melt shear viscosity adjusted in the range from 1×102 Pa.sec to less than 1×105 Pa.sec. A resin block prepared from the first resin is placed in a mold, and the second resin is injection molded into the mold while heating the mold to the melting temperature of the first resin or above.

Owner:MITSUBISHI ELECTRIC CORP

Thermotropic Liquid Crystalline Polymer with Improved Low Shear Viscosity

A thermotropic liquid crystalline polymer melt polymerized in the presence of a viscosity modifier that can help increase the “low shear” viscosity of the resulting composition is provided. The increased “low shear” viscosity can minimize drooling of the polymer composition during processing and also allow it to possess a greater melt strength, which facilitates its ability to be processed in a wide variety of applications without losing its physical integrity. Despite having a relatively high “low shear” viscosity, the present inventors have discovered that the viscosity modifier does not substantially increase the “high shear” melt viscosity of the polymer composition. In this regard, the ratio of the “low shear” viscosity to the melt viscosity is generally very high, such as within a range of from about 50 to about 1000.

Owner:TICONA LLC

Water emulsion coating and preparation method thereof

InactiveCN101143980AEvenly distributedMeet the requirements of low low shear viscosityEmulsion paintsEmulsionLatex particle

The invention discloses an aqueous latex paint with high solid and low-viscosity, wherein the coating viscosity is regulated by associative thickeners, such as hydrophobic modified polyaminoester HEUR, hydrophobic modified Polyether HPE and / or hydrophobic modified alkaline expansive emulsion HASE, and the pigment and filler ground paint-pulp is dispersed by associative dispersants, and the moderate-high-low PVC aqueous latex paint used is 20-60 percent in total paint by weight of bonding emulsion. In the invention, the organic pigment and filler particle surface is modified by associative dispersant to enable the organic pigment and filler particle surface to be drawn into the thickening-network, so as to meet requires for lower shear viscosity of the coating and direct construction without dilution with water. The coating abandons conventional hydration thickening method, and all adopts associative thickeners to regulate the coating viscosity, so the coating has good low thixotropy; while the bonding latex particles and pigment and filler particle with function of fill and color are homogeneously distributed more ideally, therefore the coating has no layer phenomenon appeared which is caused by syneresis.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Artificial turf yarn

InactiveUS20140242304A1Dead plant preservationArtificial flowers and garlandsYarnZero shear viscosity

An artificial turf comprising a turf yarn prepared from an ethylene-based polymer composition comprising less than or equal to 100 percent by weight of the units derived from ethylene; and less than 30 percent by weight of units derived from one or more α-olefin comonomers; wherein said ethylene-based polymer composition is characterized by having a Comonomer Distribution Constant of equal to or greater than 40, a vinyl unsaturation of less than 100 vinyls per one million carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) equal to or greater than 1.75; a density in the range of 0.915 to 0.930 g / cm3, a melt index (12) in the range of from 0.8 to 5 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2 to 3.6, and a molecular weight distribution (Mz / Mw) equal to or less than 3; and wherein the turf yarn exhibits one or more of the following properties (a) shrink of less than 4.8%, and (b) curl of less than 0.5 is provided.

Owner:SANDKUEHLER PETER +1

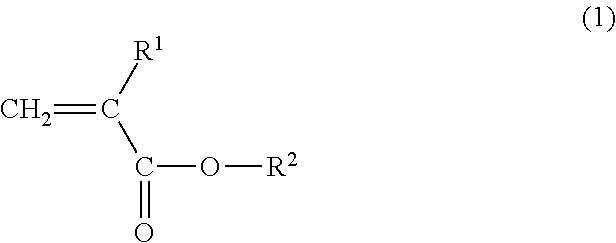

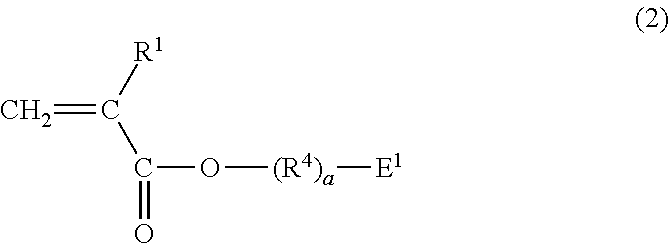

Lubricating oil composition

InactiveUS20150218482A1Increased durabilityImprove efficiencyAdditivesFuel efficiencyInternal combustion engine

[Problem]To provide a lubricating oil composition capable of attaining high-level fuel efficiency, durability and piston detergency in internal-combustion engines.[Means for Resolution]The lubricating oil composition according to the present invention contains a viscosity index improver and a metallic detergent in at least one base oil selected from mineral oils and synthetic oils therein, wherein the viscosity index improver contains a polymethacrylate viscosity index improver and an olefin copolymer viscosity index improver, the polymethacrylate viscosity index improver is contained in an amount of from 3.0% by mass to 9.5% by mass based on the total amount of the lubricating oil composition, the metallic detergent is at least one selected from calcium sulfonate, calcium phenate and calcium salicylate, the calcium amount derived from the metallic detergent is from 500 ppm to 1500 ppm based on the total amount of the lubricating oil composition, the high-temperature high-shear viscosity at 150° C. of the lubricating oil composition is 2.6 mPa·s or more, the high-temperature high-shear viscosity at 80° C. of the lubricating oil composition is 7.8 mPa·s or less, and the ratio of the high-temperature high-shear viscosity at 100° C. of the lubricating oil composition to the high-temperature high-shear viscosity at 150° C. thereof is 2.05 or less.

Owner:IDEMITSU KOSAN CO LTD +1

Lubricating oil composition

InactiveUS20140011724A1Reduce resistance to lubricationImprove fuel efficiencyLubricant compositionContact pressureViscosity index

A lubricating oil composition which exceeds the fuel saving performance of a conventional low viscosity lubricating oil composition, contains (A) a lubricating base oil having a % CA of 2 or less, adjusted to a 100° C. kinematic viscosity of 1.5 to 4.5 mm2 / s and (B) a viscosity index improver including (B1) a poly(meth)acrylate having a weight-average molecular weight of 50,000 or less in an amount of 1 to 10 percent by mass and (B2) a poly(meth)acrylate having a weight-average molecular weight of 100,000 to 250,000 in an amount of 0.1 to 5 percent by mass of the total composition. The composition has a 80° C. high-shear viscosity (Vs: mPa·s) and a 80° C. kinematic viscosity (Vk: mm2 / s) ratio (Vs / Vk) of less than 1, a coefficient of traction of 0.02 or less at 40° C., an average speed of 3.0 m / s, a slip ratio of 10%, and a contact pressure of 0.4 GPa.

Owner:JX NIPPON OIL & ENERGY CORP

Method for producing an adhesive tape, comprising an open textile carrier and a pressure-sensitive adhesive

The invention relates to a method for producing an adhesive tape intended more particularly for wrapping cables, comprising an open textile carrier and a pressure-sensitive adhesive coated on one side thereof. A shear viscosity of the pressure-sensitive adhesive, at a temperature of 25 DEG C. during coating from dispersion, is 200 to 100 000 Pa*s at a shear rate of 10-2 s-1 and is 0.1 to 10 Pa*s at a shear rate of 100 s-1.

Owner:TESA SE

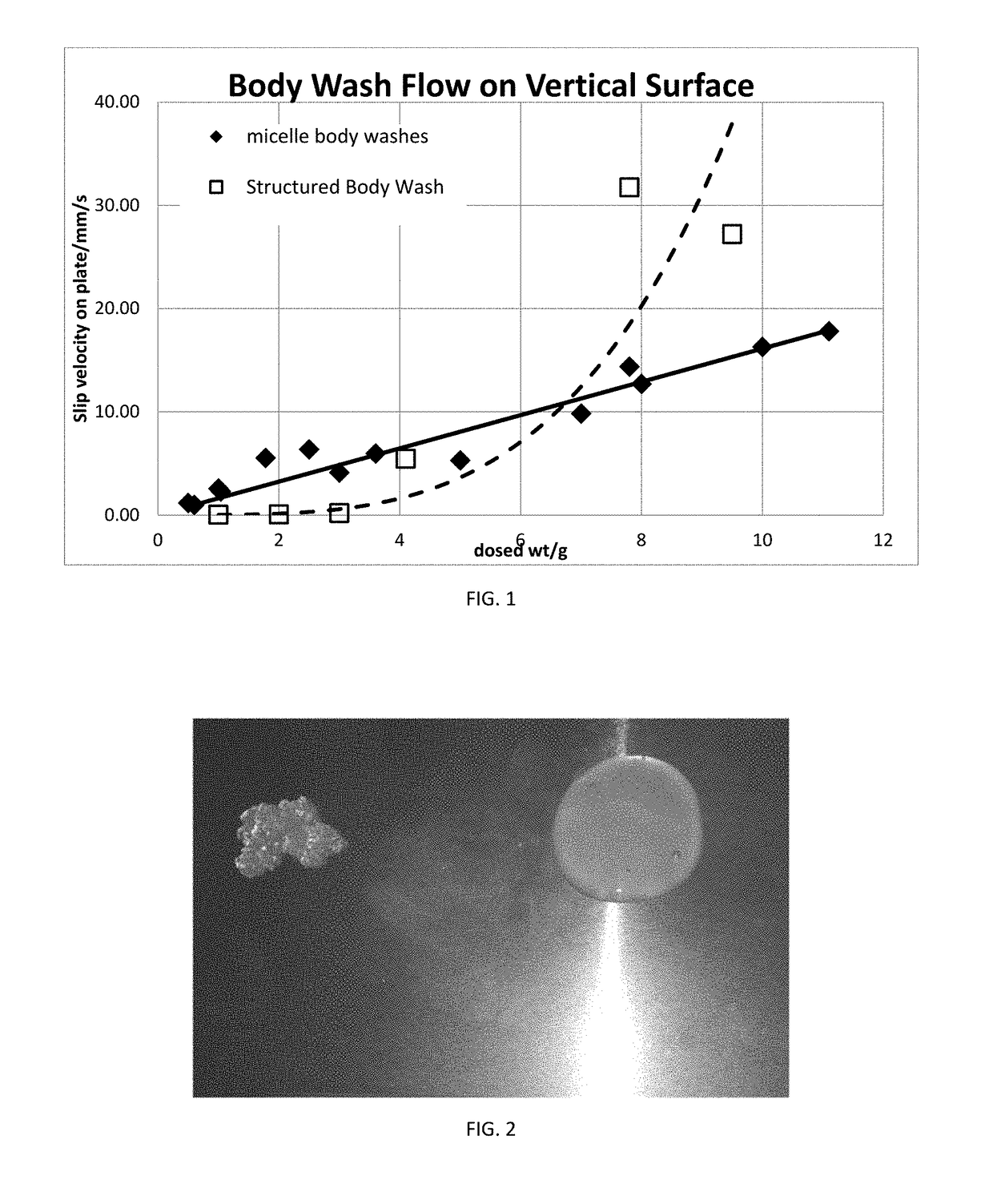

Packaged Personal Cleansing Product

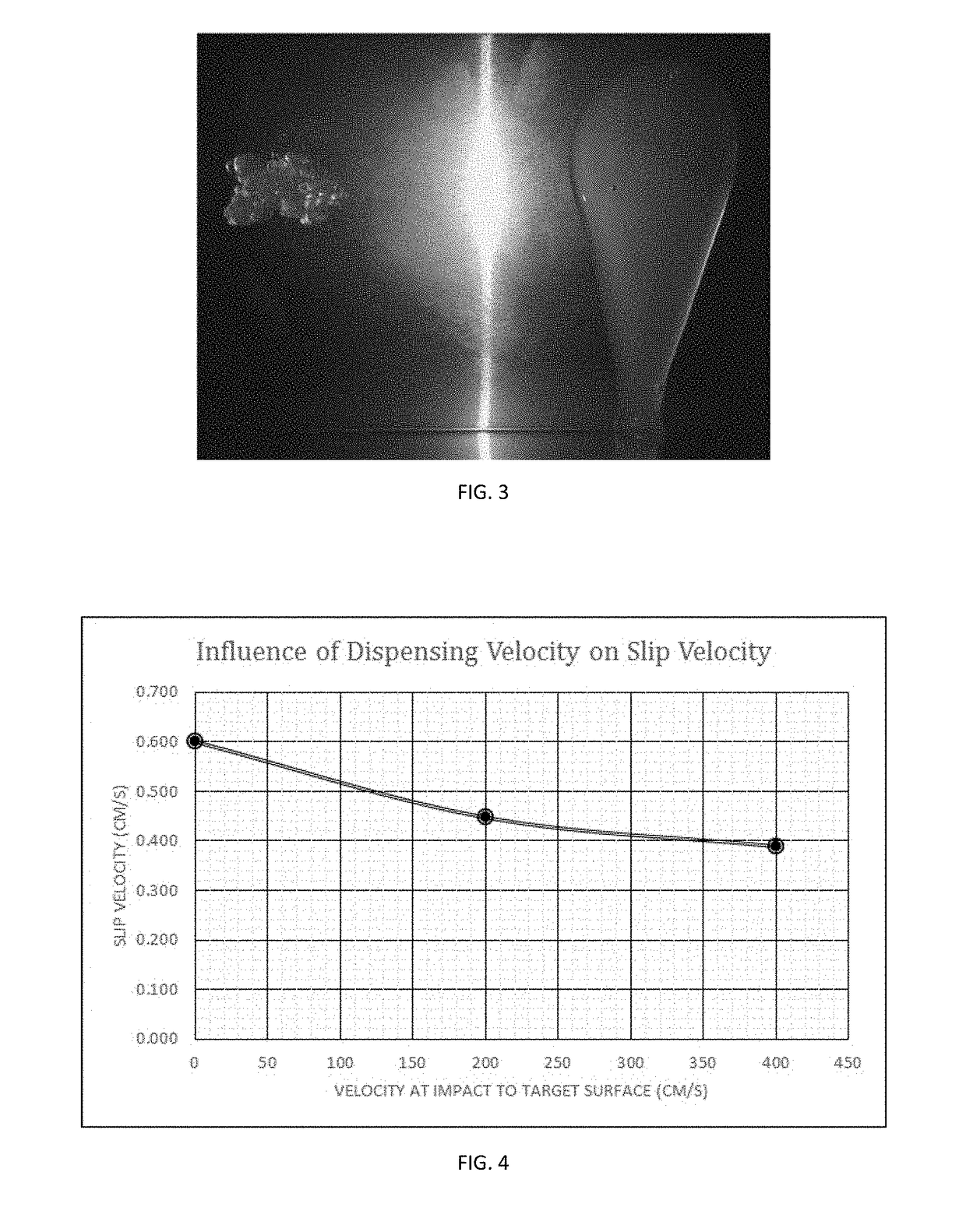

A method of formulating a personal cleansing product that will adhere to skin, includes: combining a cleansing composition with from about 18% to about 70%, by weight of the composition, of a surfactant; wherein the composition has a low shear viscosity of 100 Pa*s or more and a high shear viscosity 5 Pa*s or less; and a package with an orifice, wherein the package has a dispensing velocity of 50 cm / s or more.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com