Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3724 results about "Micro holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

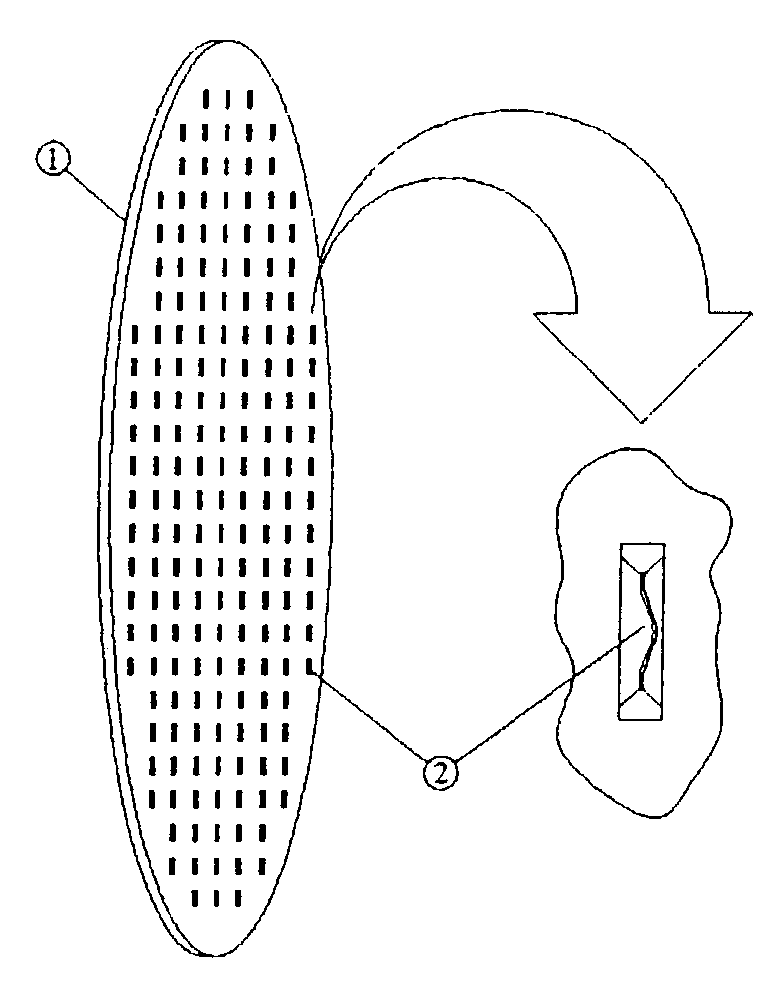

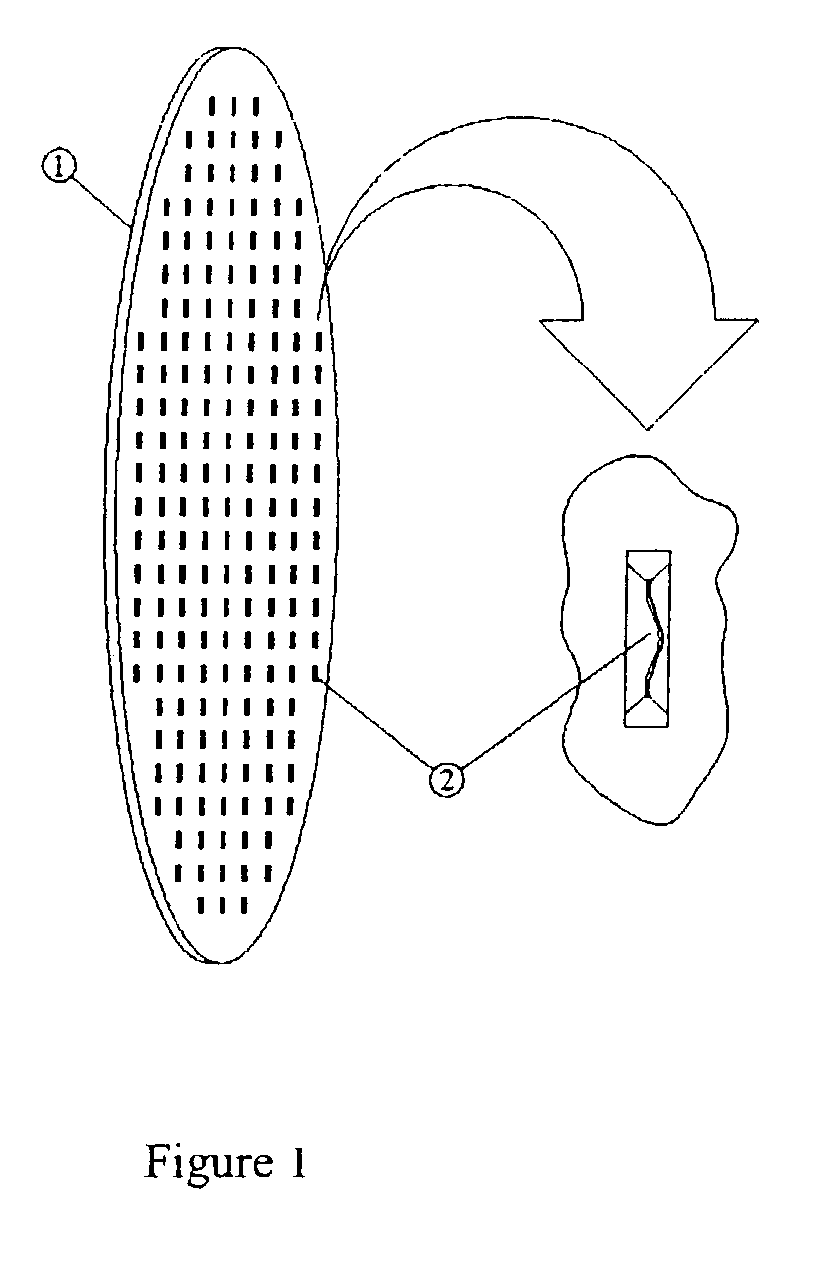

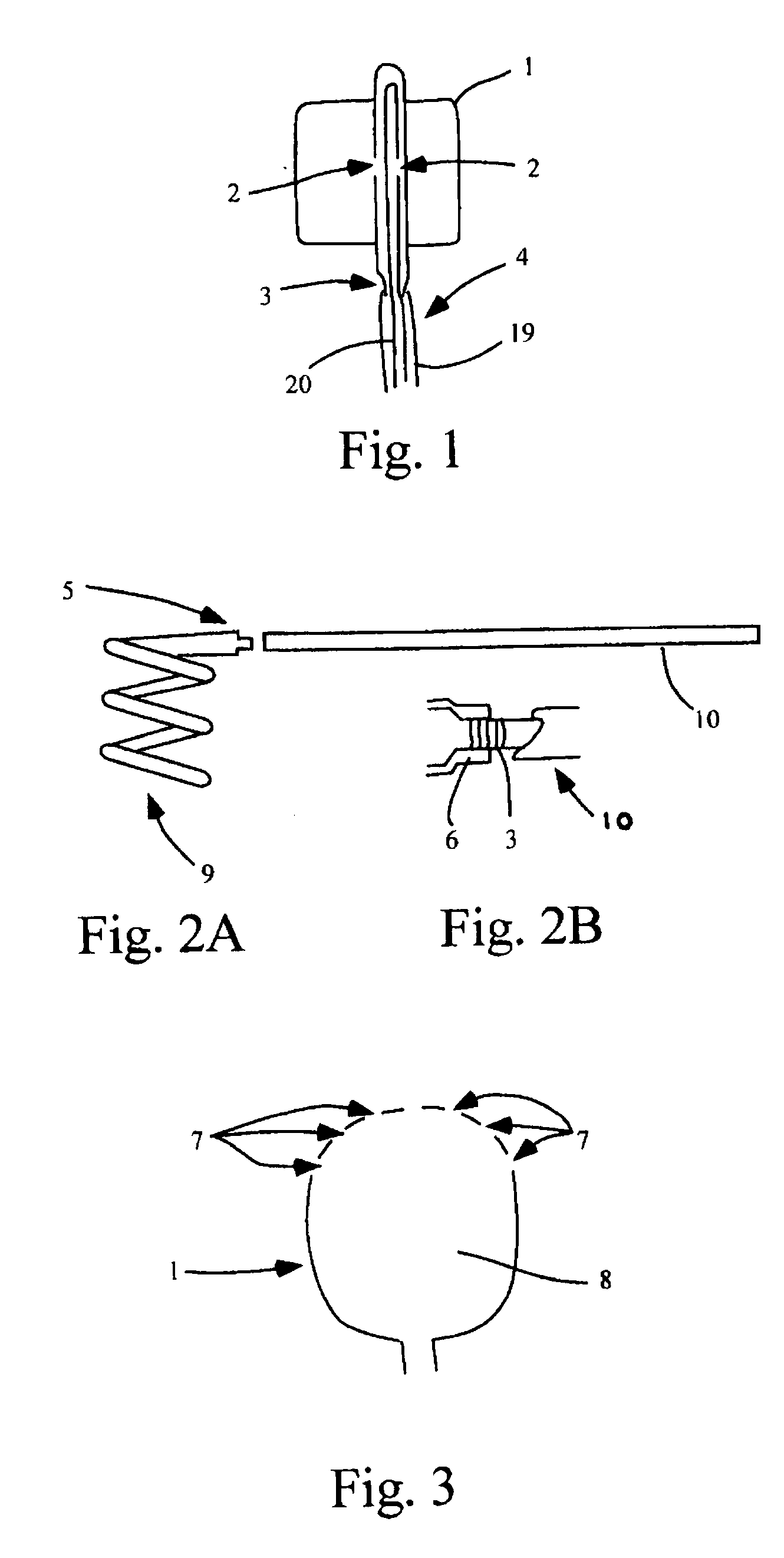

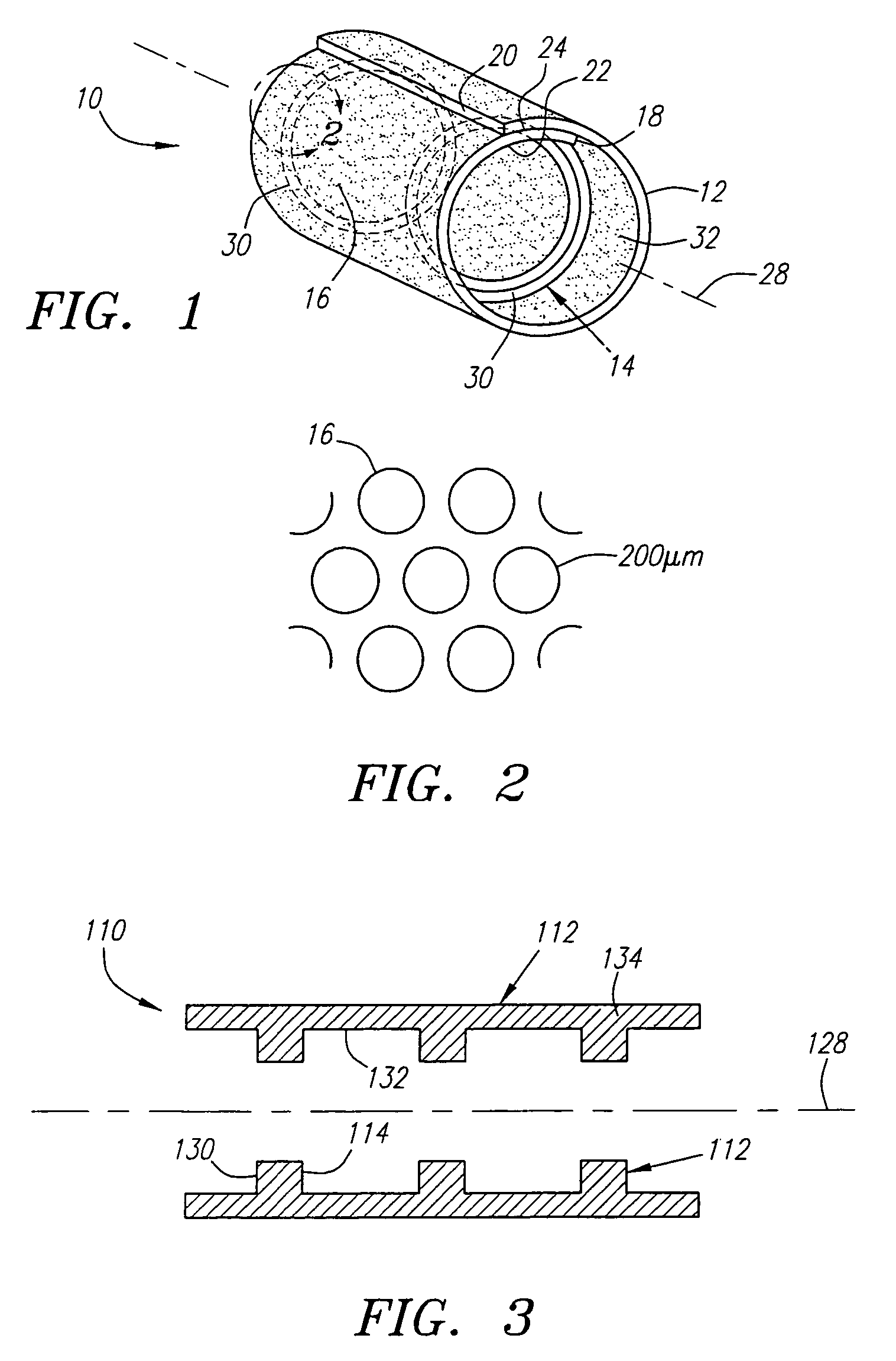

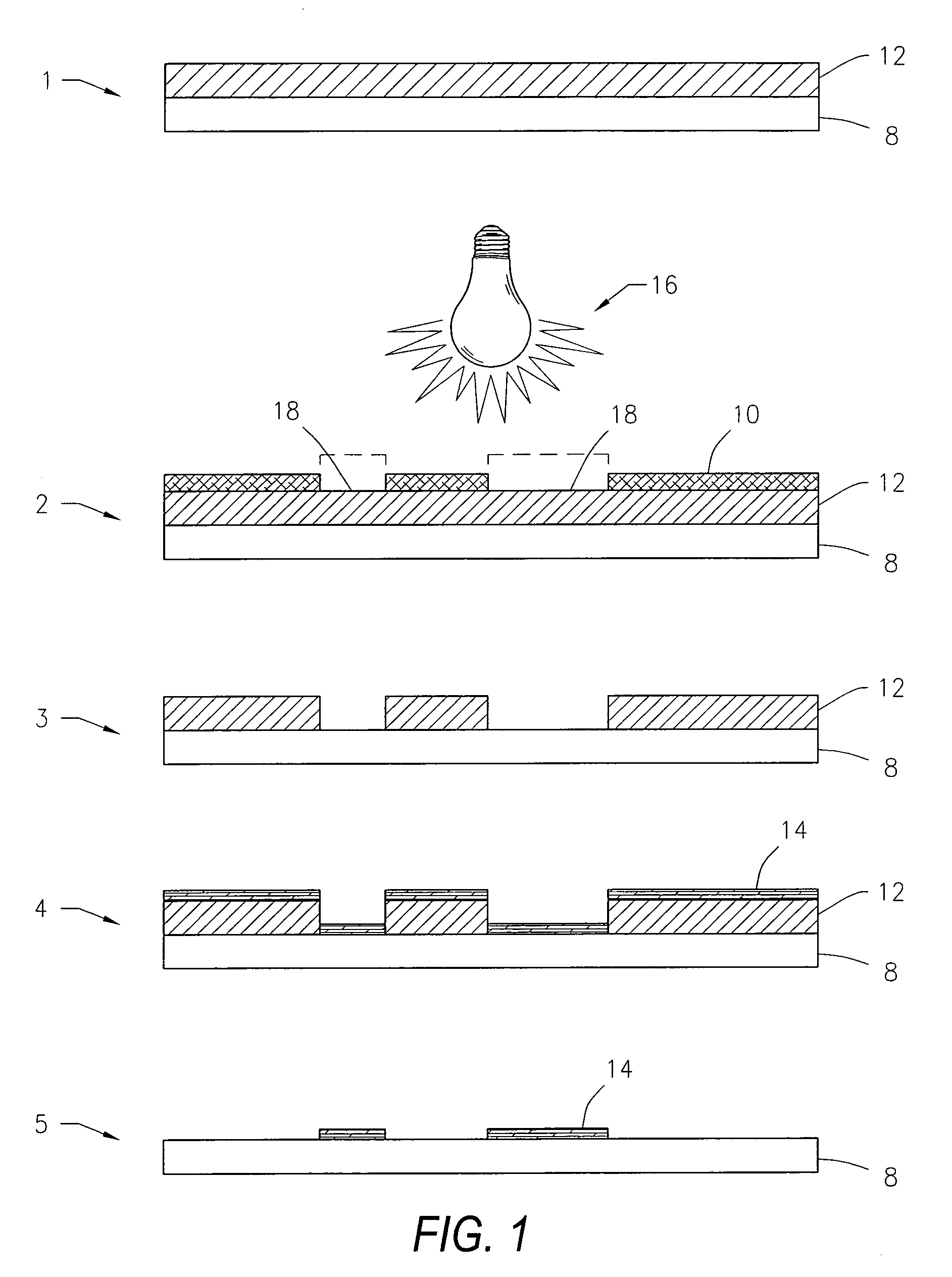

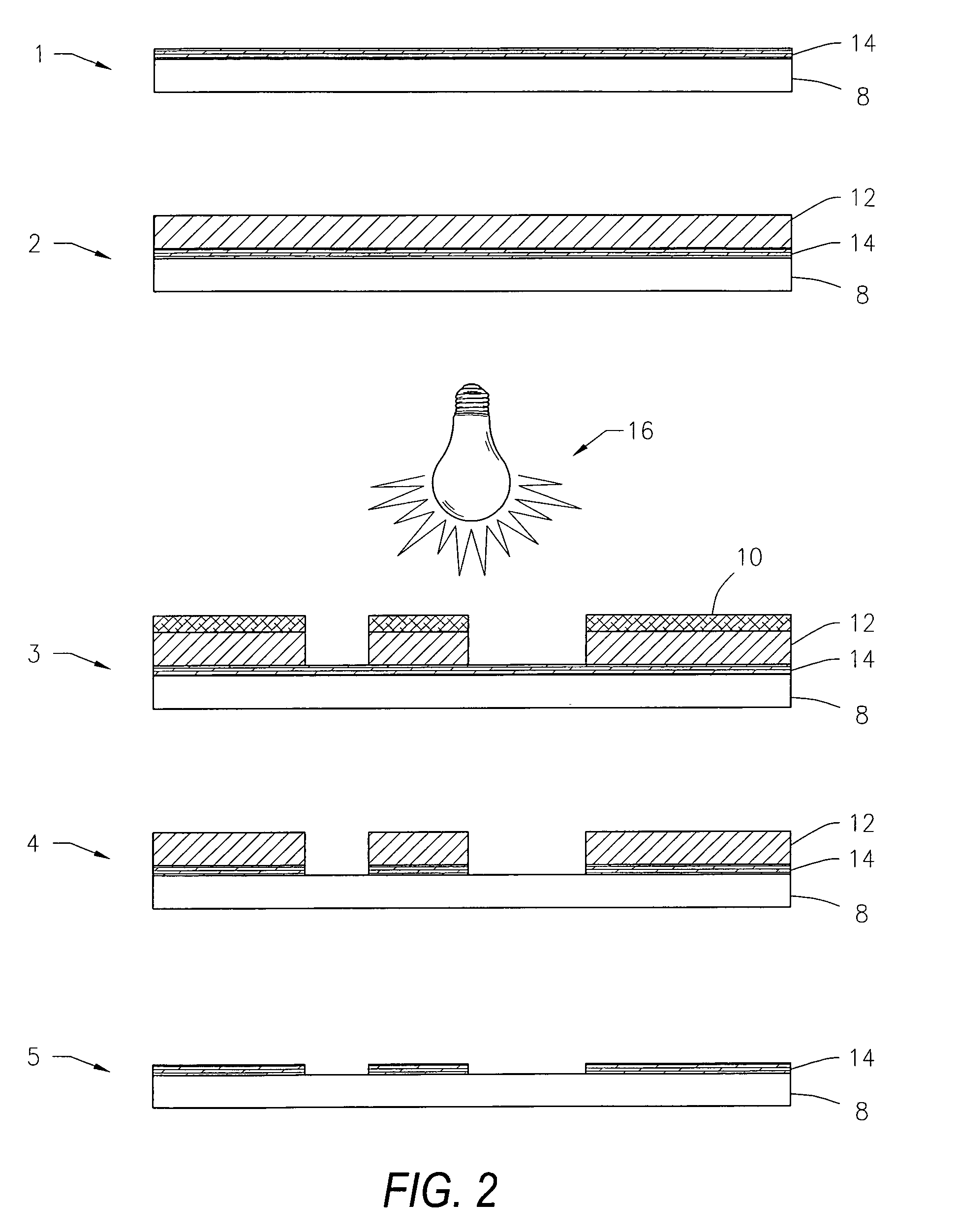

Transdermal drug delivery device, method of making same and method of using same

InactiveUS7141034B2Broaden applicationAmpoule syringesElectrotherapyTissue membraneBiomedical engineering

A transdermal drug delivery device for forming a micropore in a tissue membrane of an animal comprising a substrate and a porator that is located on or within the substrate. The porator is constructed of a material that is destroyed upon forming the micropore. The transdermal drug delivery device also comprises at least one reservoir and a controller for controlling the formation of said micropore by the porator and destroying the porator after the formation of the micropore.

Owner:PASSPORT TECH +2

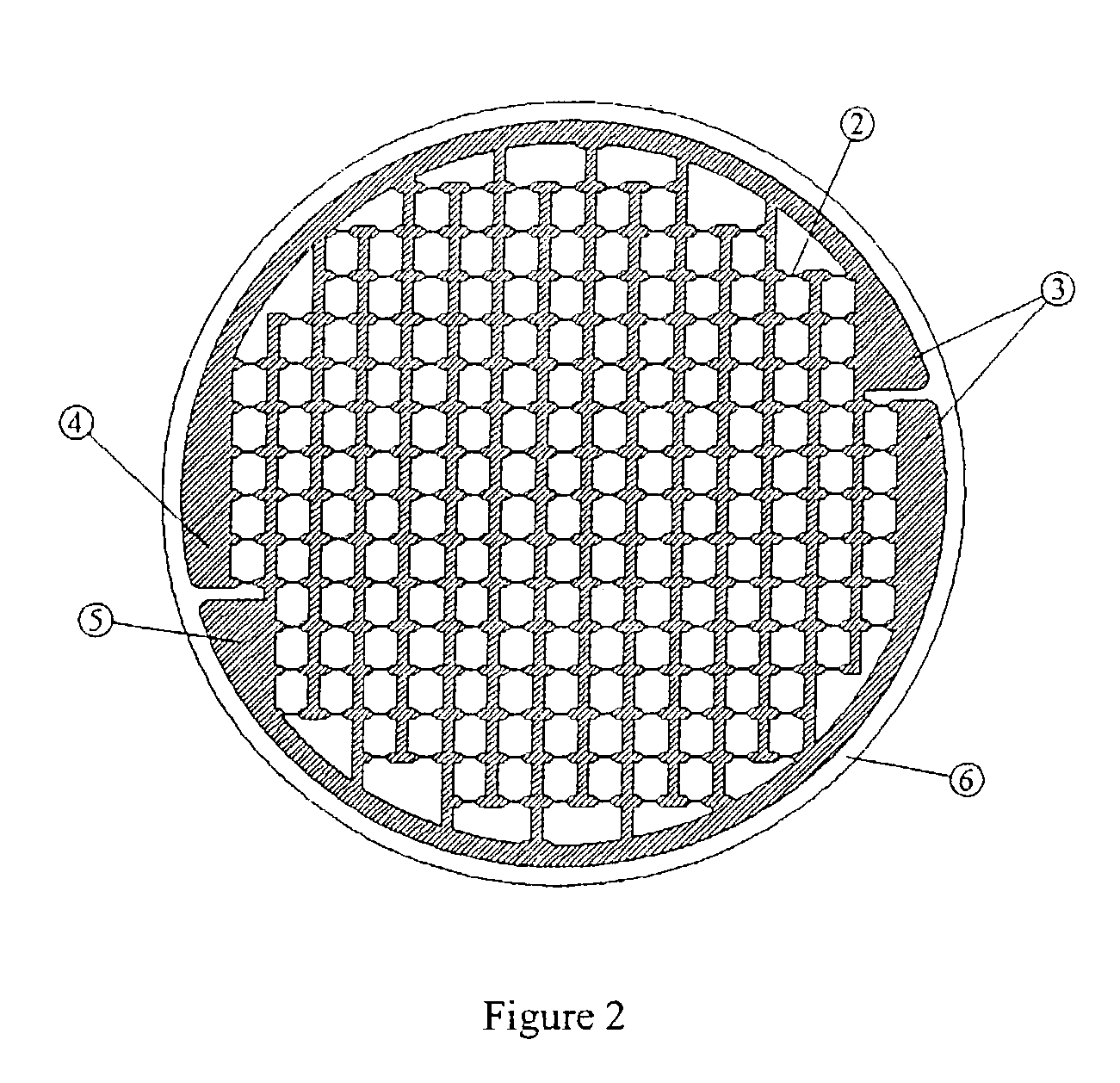

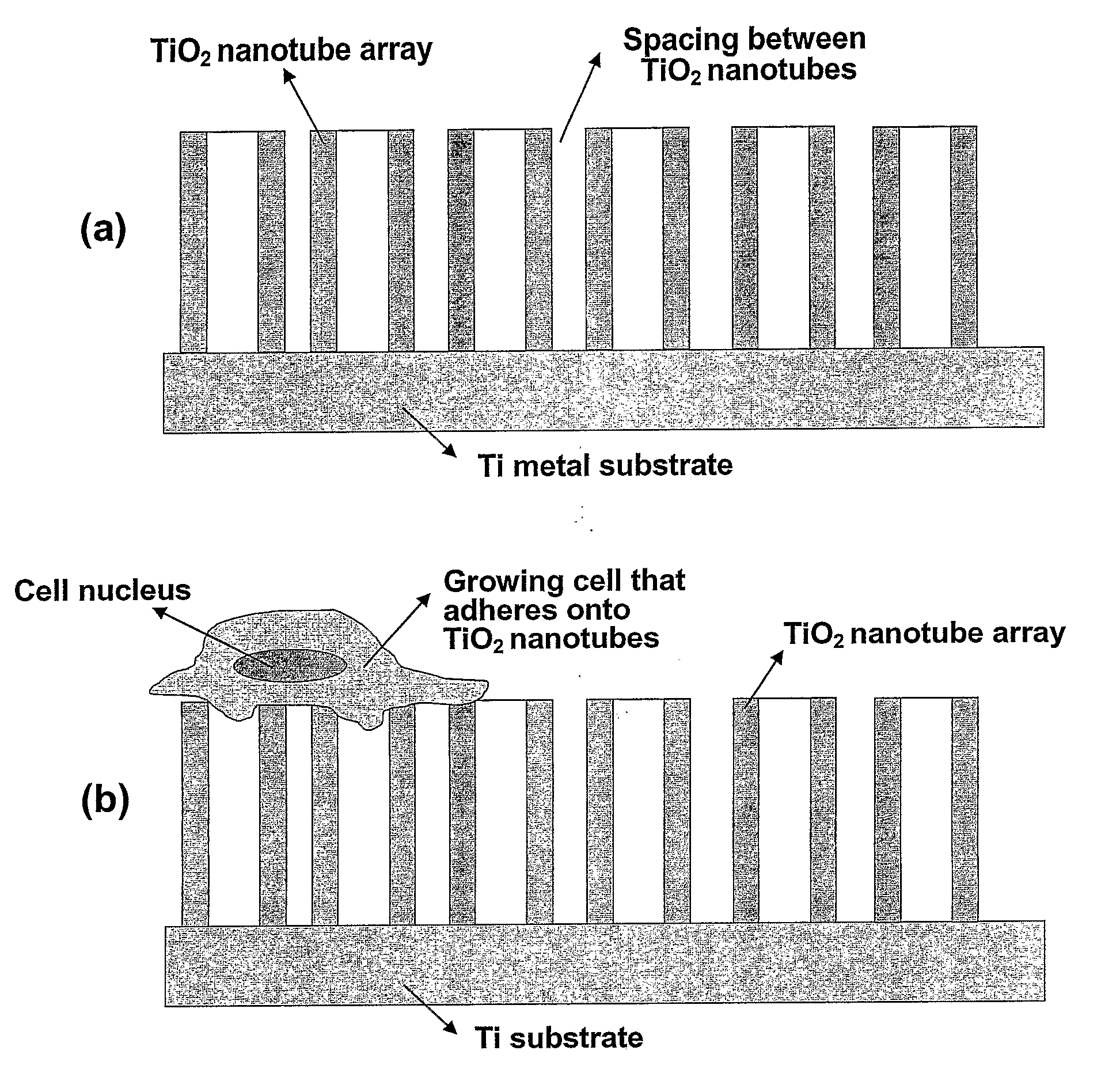

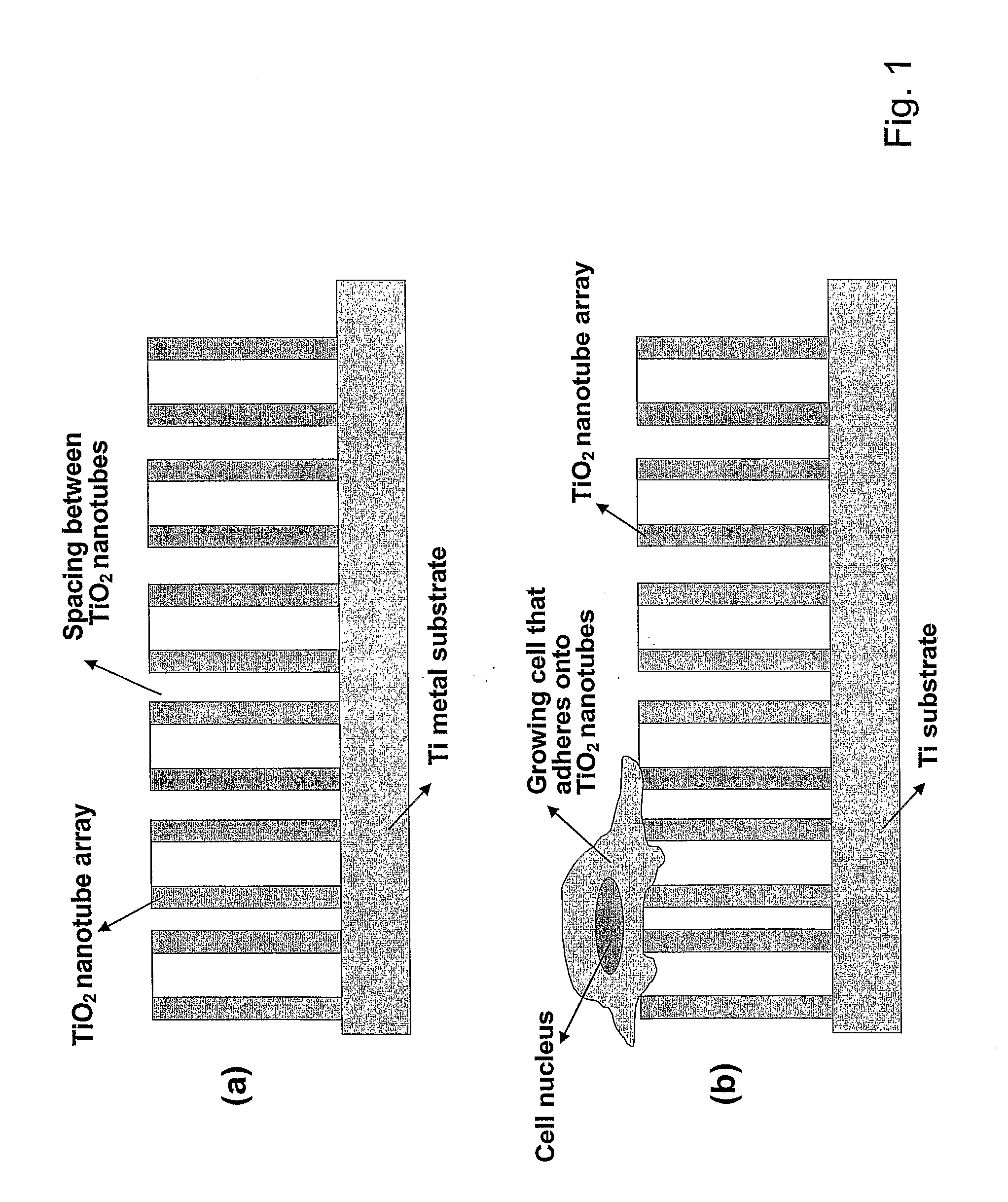

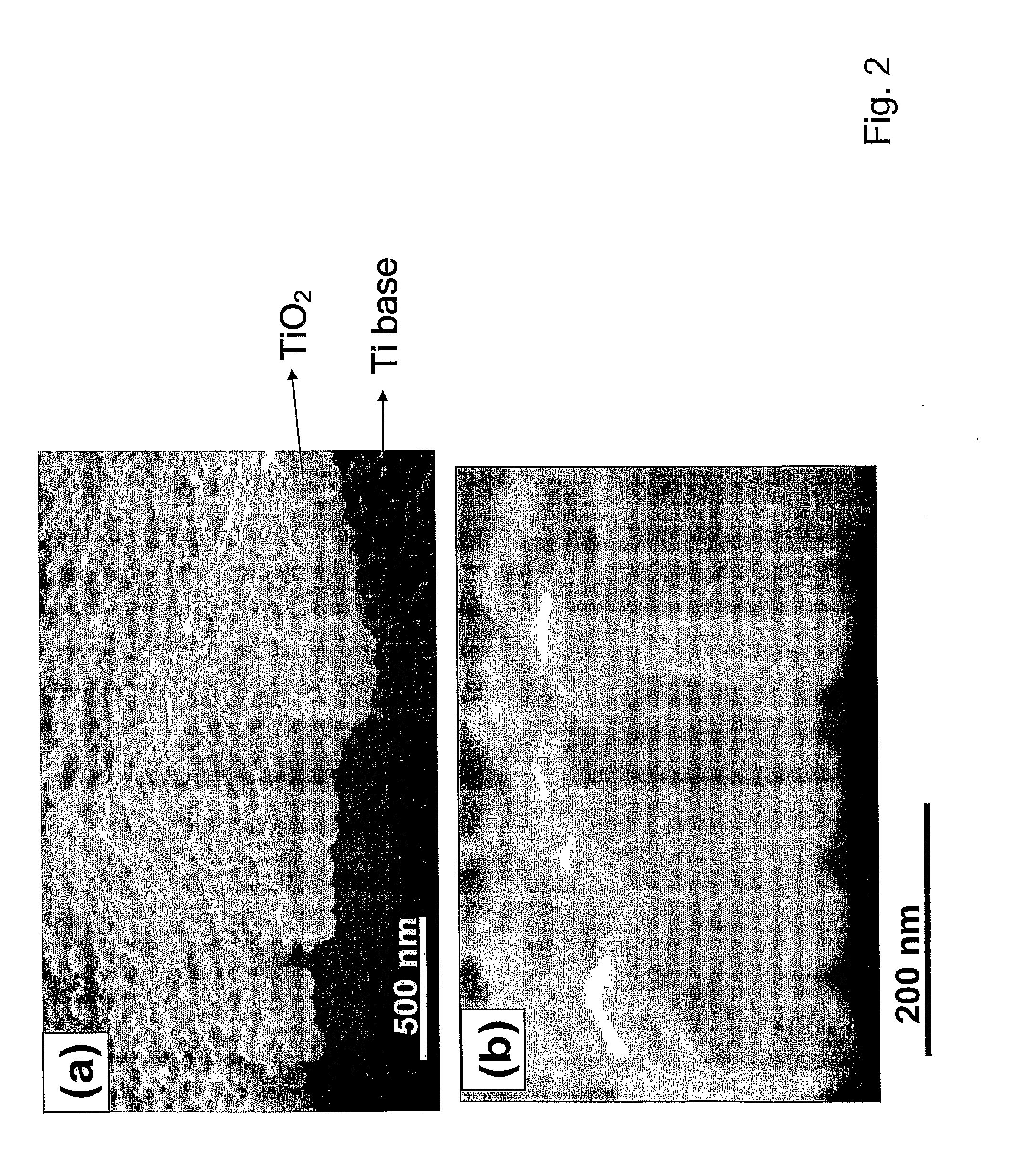

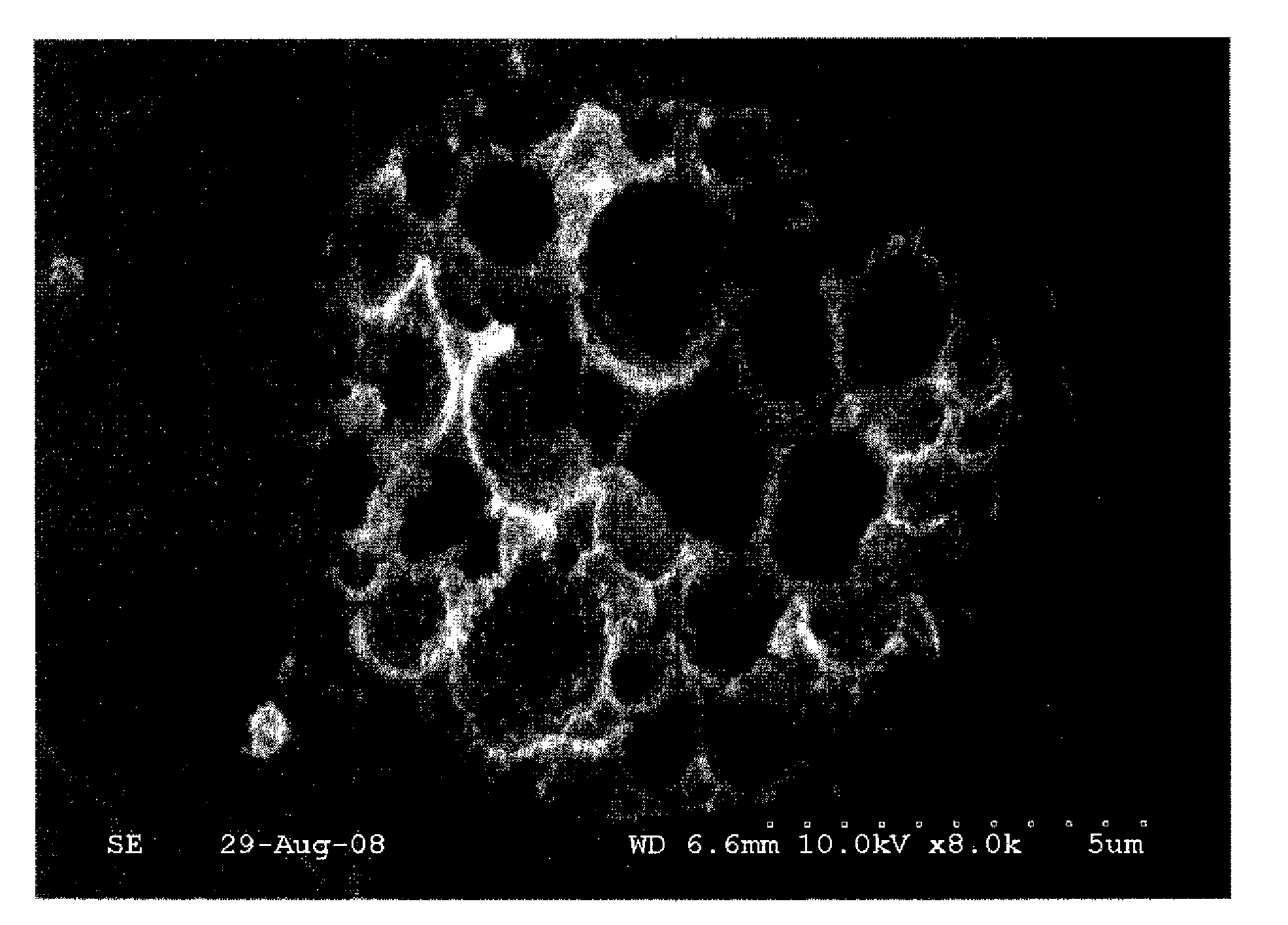

Compositions comprising nanostructures for cell, tissue and artificial organ growth, and methods for making and using same

ActiveUS20090220561A1Improve bone formationIncreased durabilityBioreactor/fermenter combinationsElectrolysis componentsIn vivoNanostructure

The invention provides articles of manufacture comprising biocompatible nanostructures comprising nanotubes and nanopores for, e.g., organ, tissue and / or cell growth, e.g., for bone, kidney or liver growth, and uses thereof, e.g., for in vitro testing, in vivo implants, including their use in making and using artificial organs, and related therapeutics. The invention provides lock-in nanostructures comprising a plurality of nanopores or nanotubes, wherein the nanopore or nanotube entrance has a smaller diameter or size than the rest (the interior) of the nanopore or nanotube. The invention also provides dual structured biomaterial comprising micro- or macro-pores and nanopores. The invention provides biomaterials having a surface comprising a plurality of enlarged diameter nanopores and / or nanotubes.

Owner:RGT UNIV OF CALIFORNIA

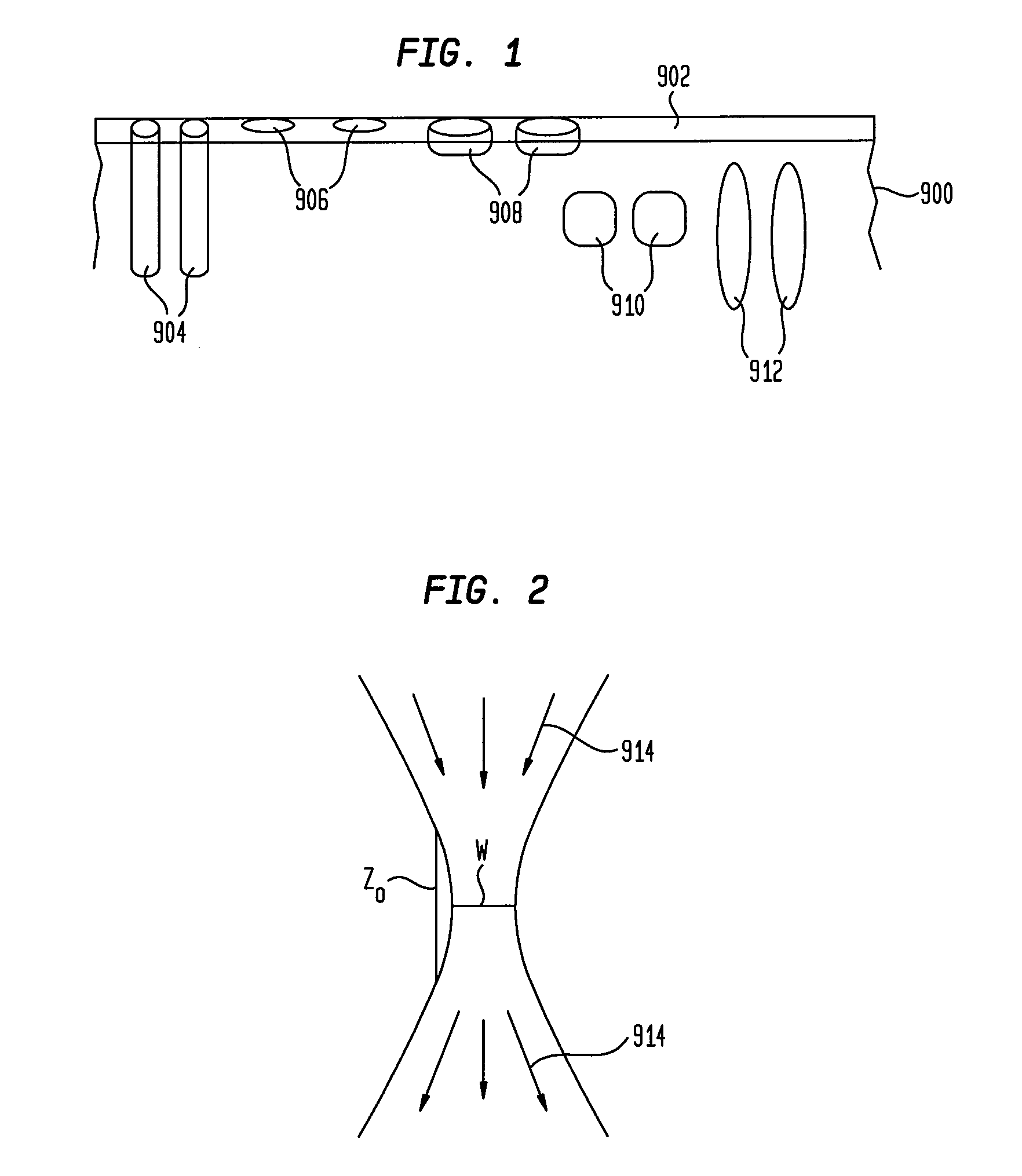

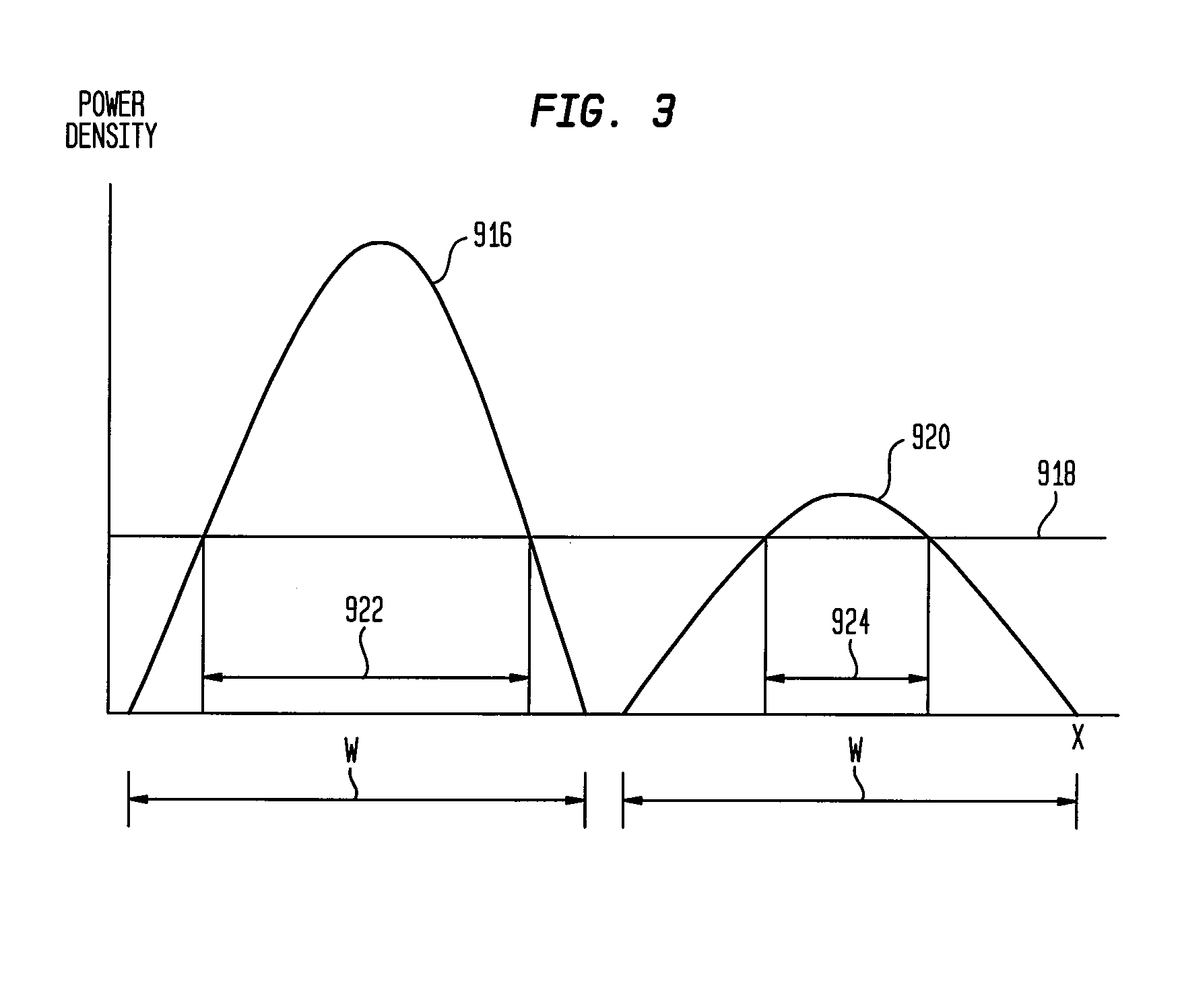

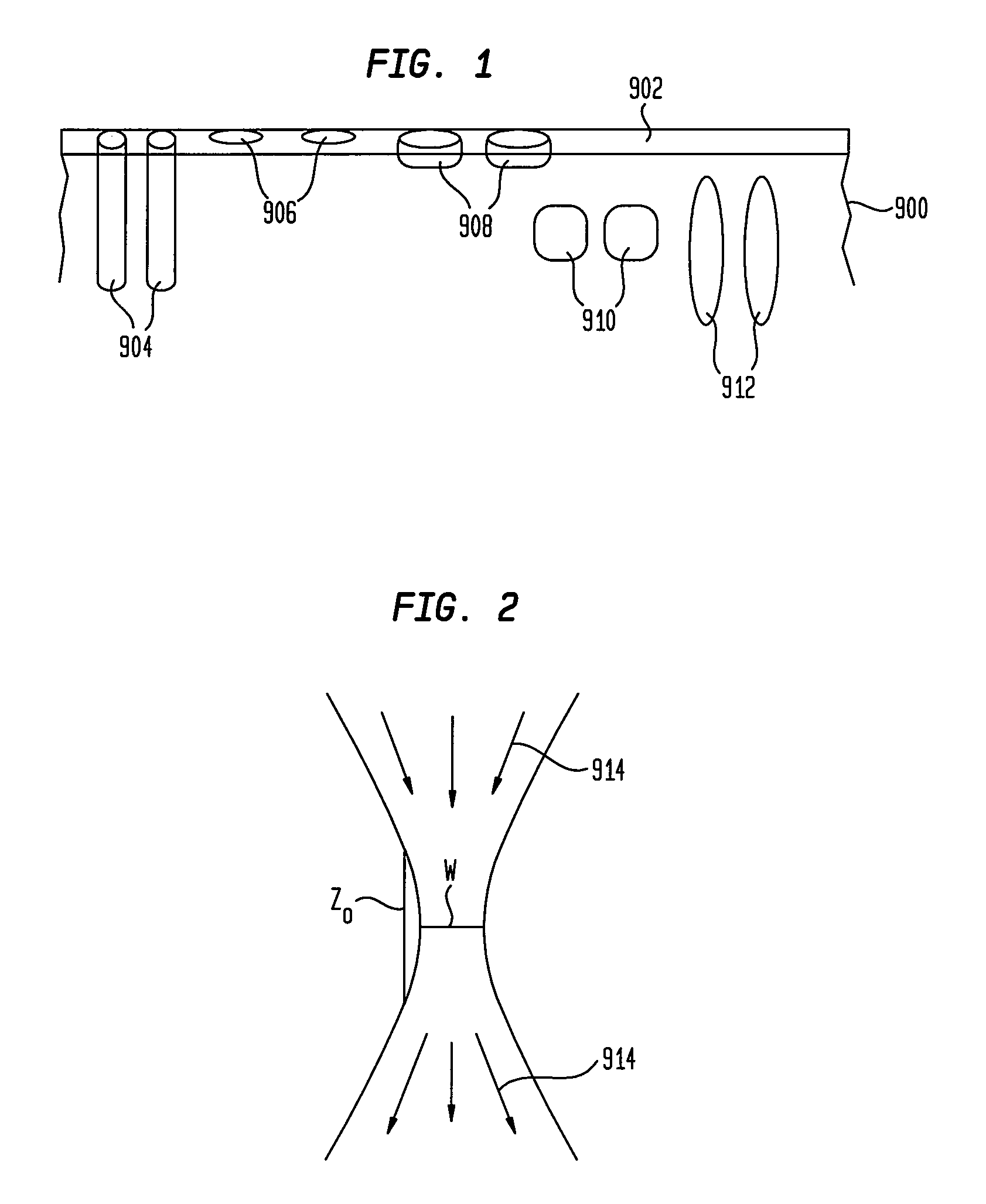

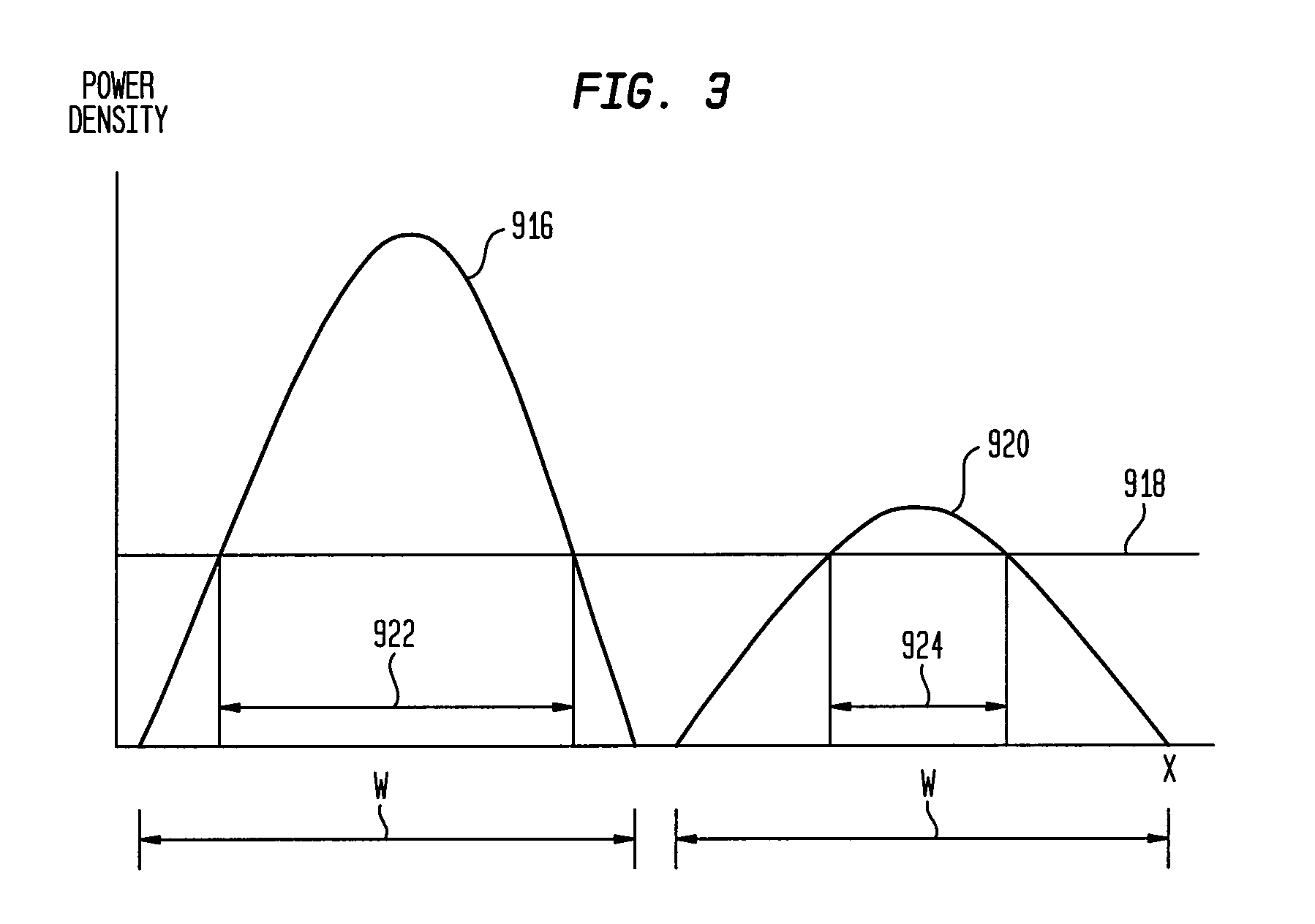

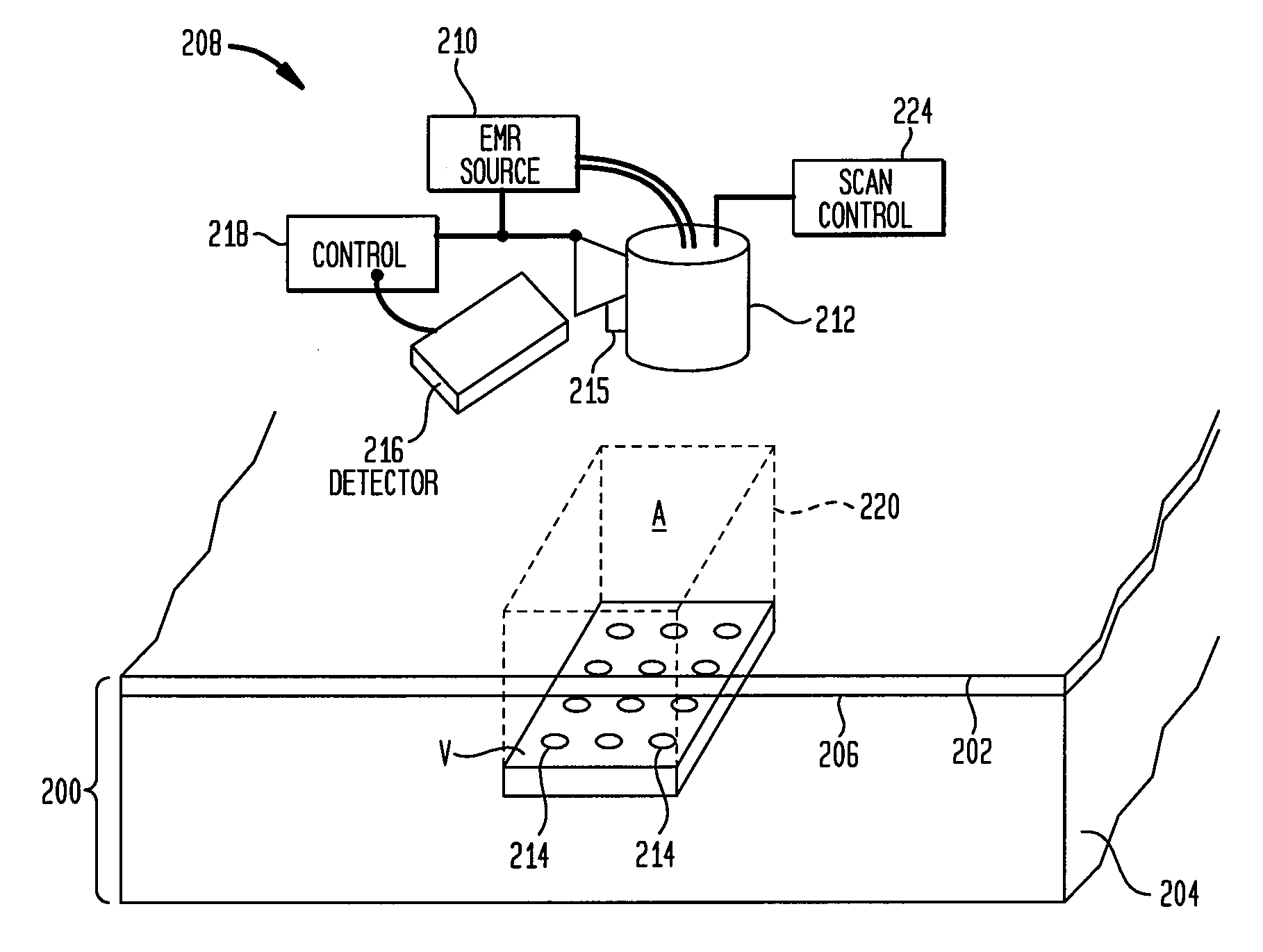

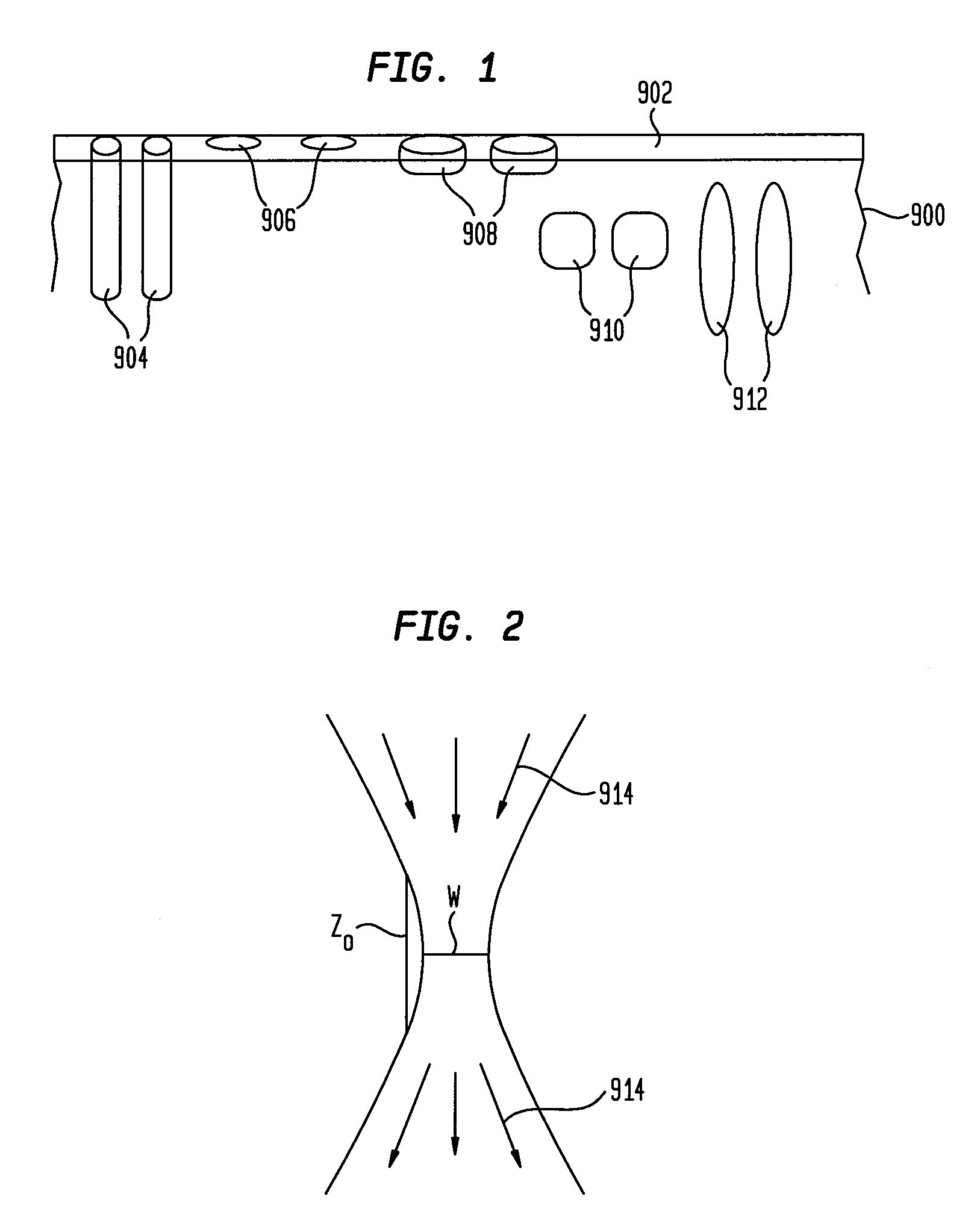

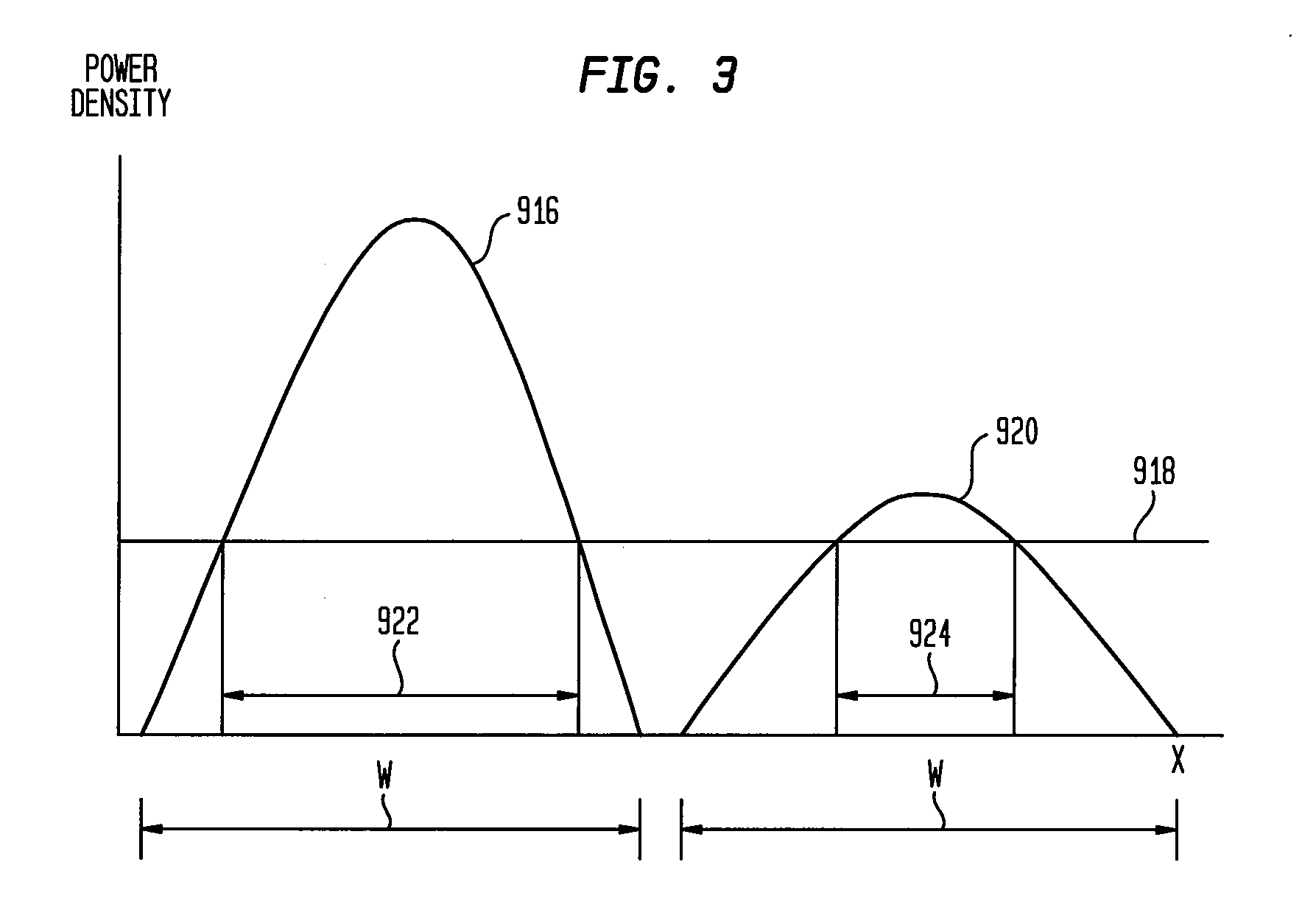

Methods And Devices For Fractional Ablation Of Tissue

InactiveUS20080172047A1Fine wrinklesImprove textureUltrasound therapyElectrotherapyElectromagnetic radiationChromophore

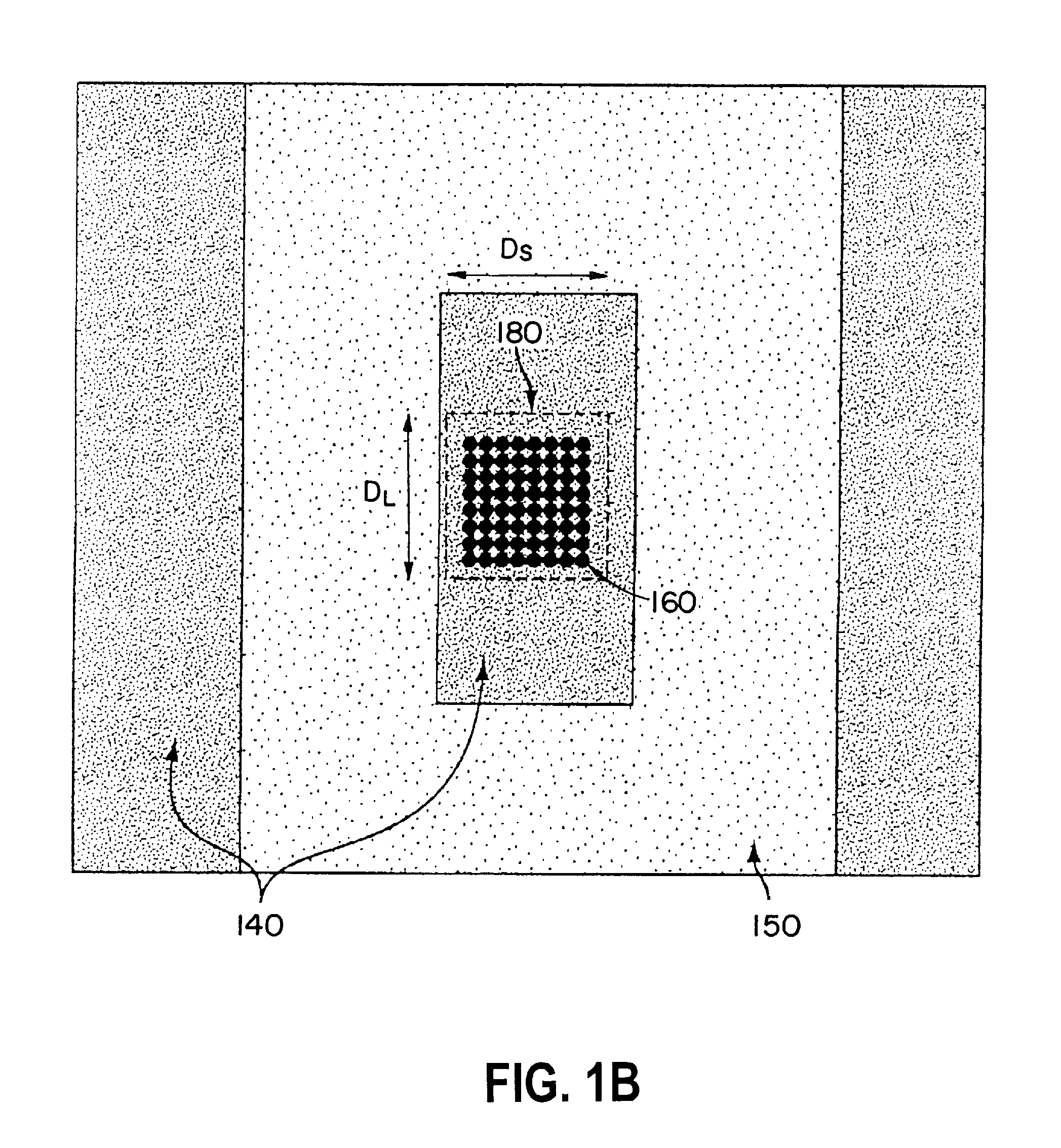

Methods and devices for ablating portions of a tissue volume with electromagnetic radiation (EMR) to produce lattices of EMR-treated ablation islets in the tissue are disclosed, including lattices of micro-holes, micro-grooves, and other structures. Also, methods and devices for using the ablated islets are disclosed, including to deliver chromophores, filler, drugs and other substances to the tissue volume.

Owner:PALOMAR MEDICAL TECH

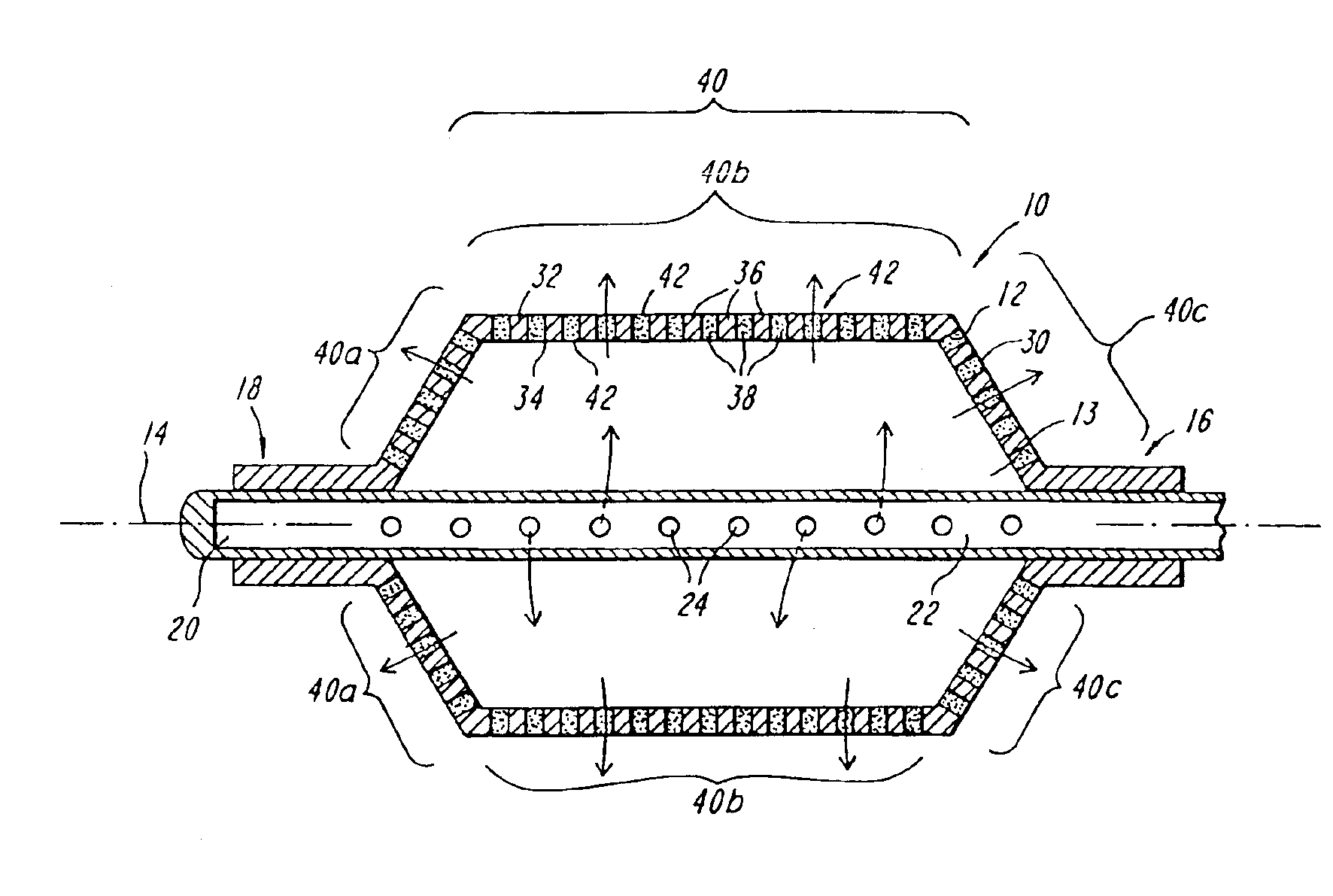

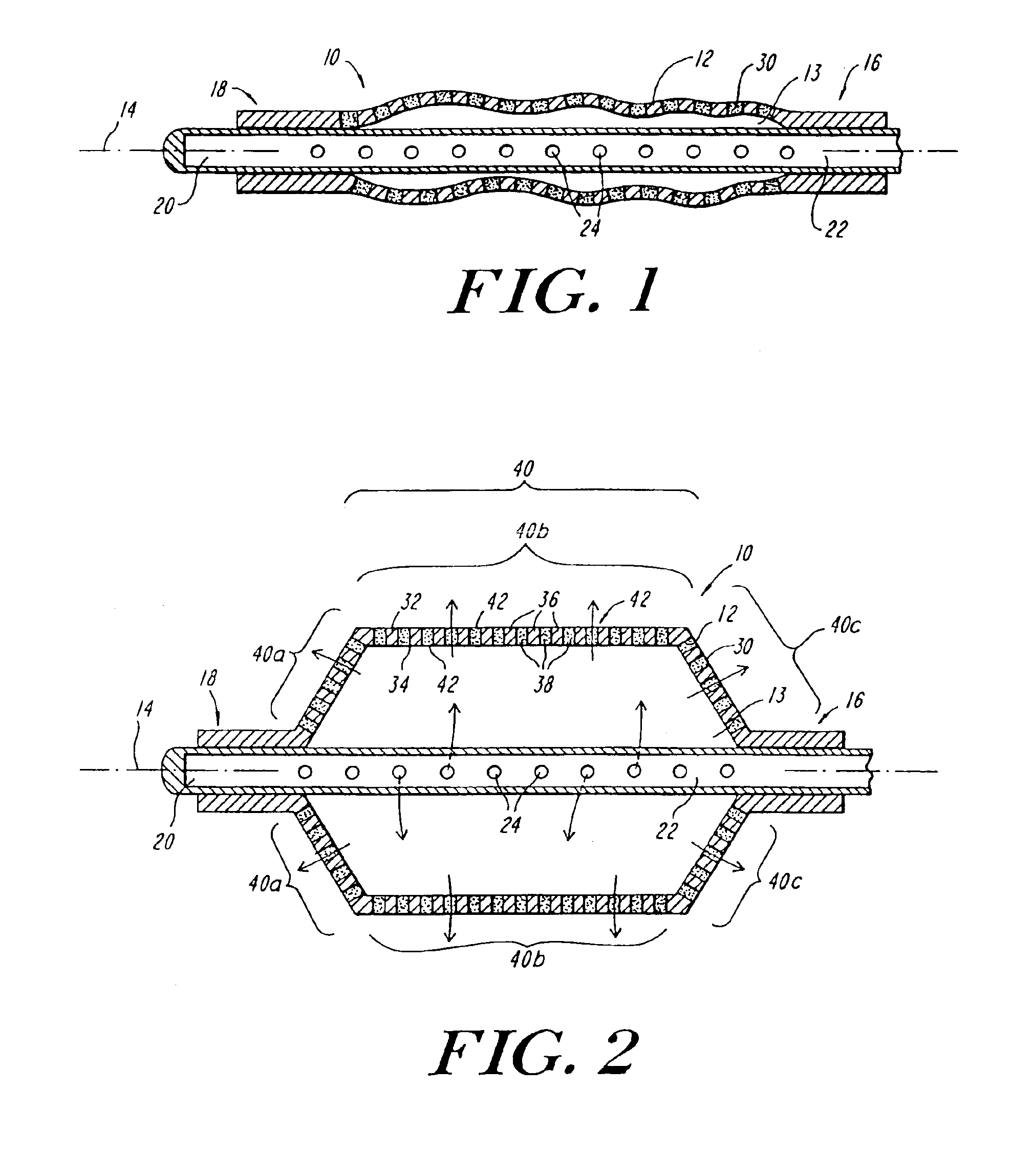

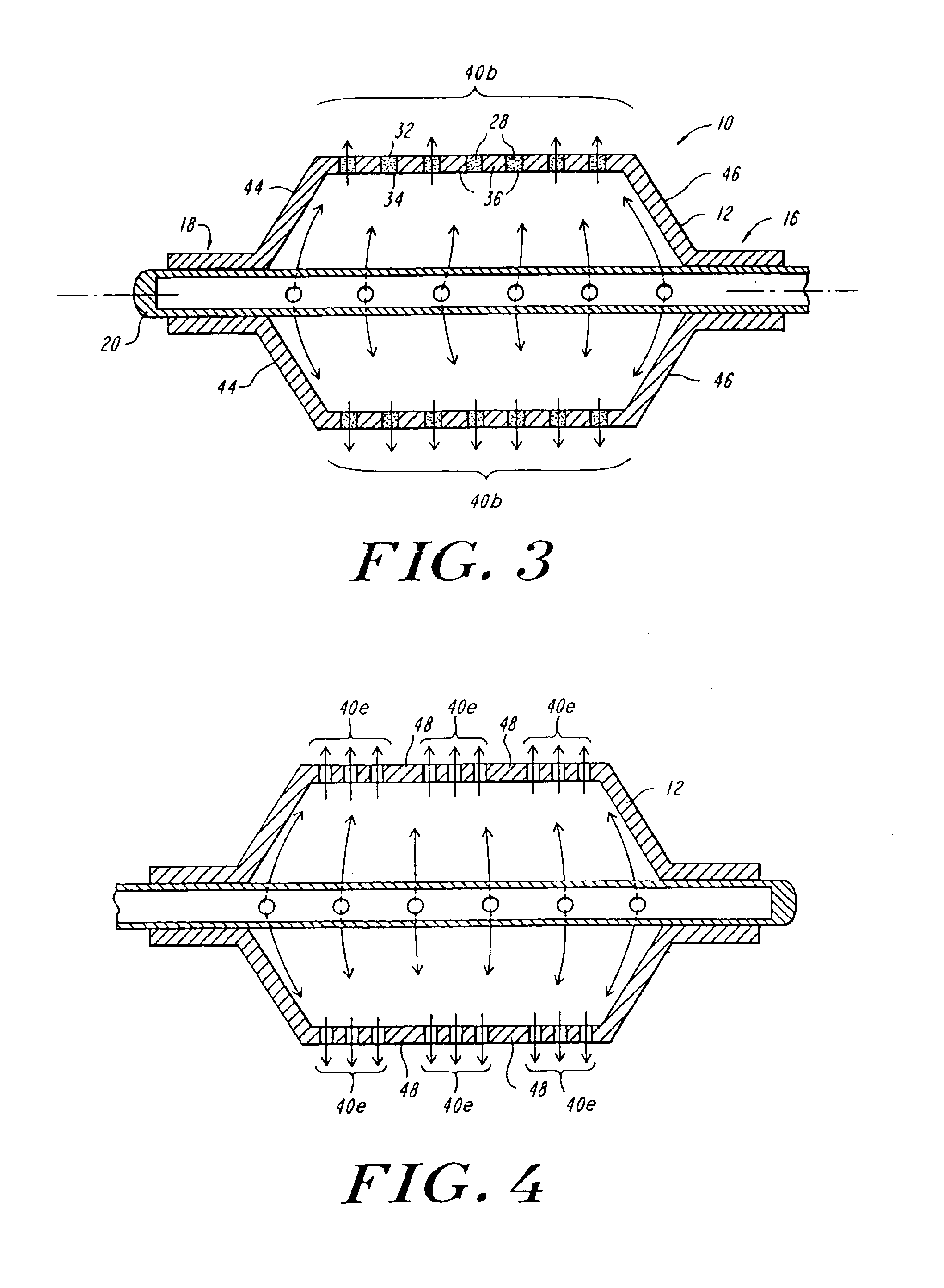

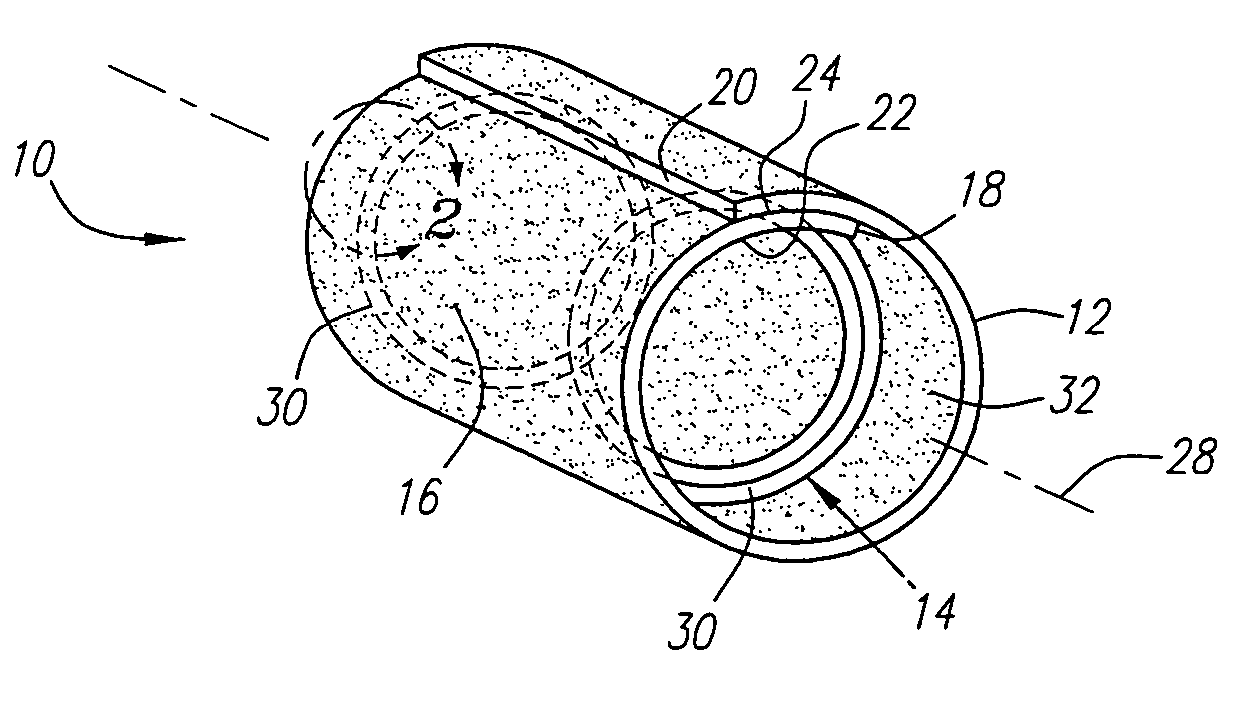

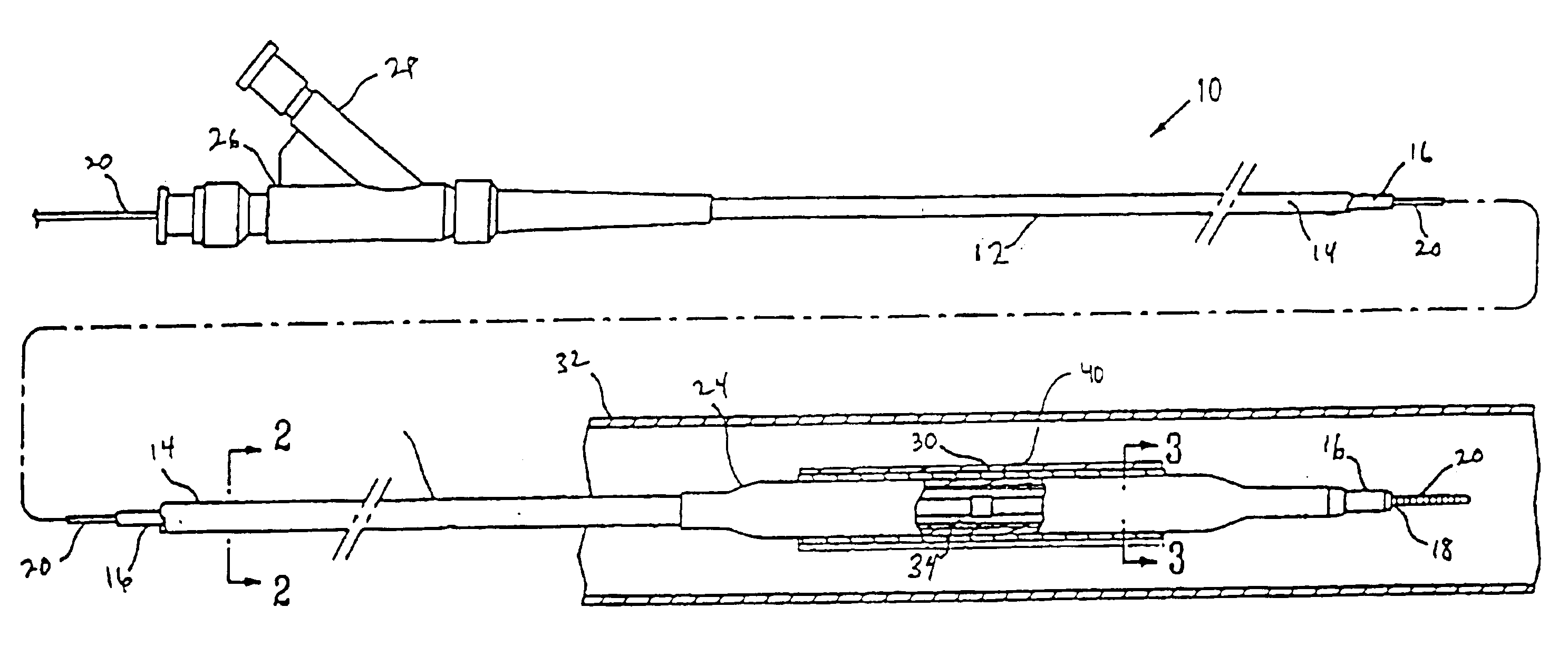

Expandable fluoropolymer device for delivery of therapeutic agents and method of making

A radially expandable fluid delivery device for delivering a fluid to a treatment site within the body is disclosed. The fluid delivery device is constructed of a microporous, biocompatible fluoropolymer material having a microstructure that can provide a controlled, uniform, low-velocity fluid distribution through the walls of the fluid delivery device to effectively deliver fluid to the treatment site without damaging tissue proximate the walls of the device. The fluid delivery device includes a tubular member defined by a wall having a thickness transverse to the longitudinal axis of the tubular member and extending between an inner and an outer surface. The wall is characterized by a microstructure of nodes interconnected by fibrils. The tubular member is deployable from a first, reduced diameter configuration to a second, increased diameter configuration upon the introduction of a pressurized fluid to the lumen. The tubular member includes at least one microporous portion having a porosity sufficient for the pressurized fluid to permeate through the wall. Substantially all of the nodes within the microporous portion are oriented such that spaces between the nodes form micro-channels extending from the inner surface-to the outer surface of the wall.

Owner:ATRIUM MEDICAL

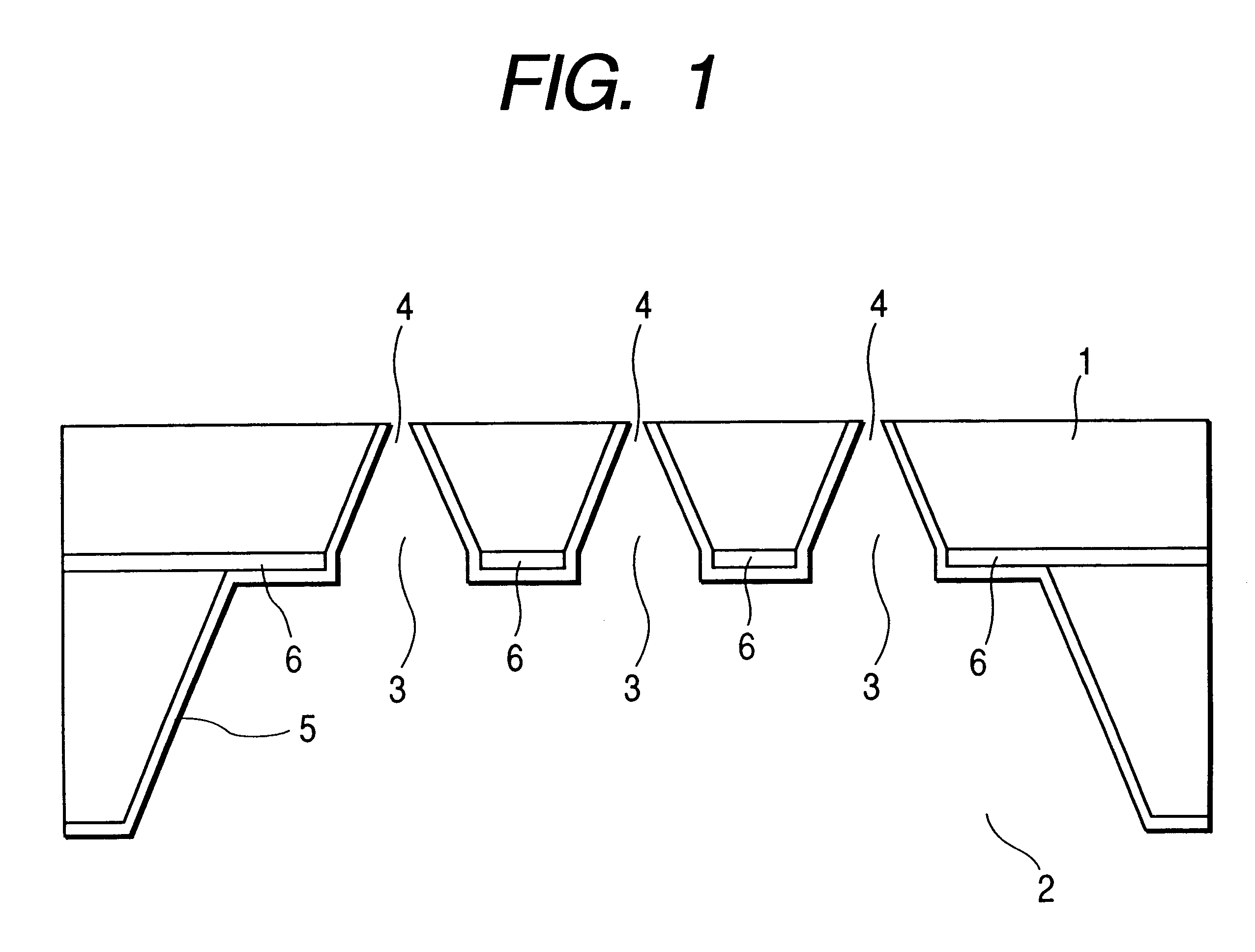

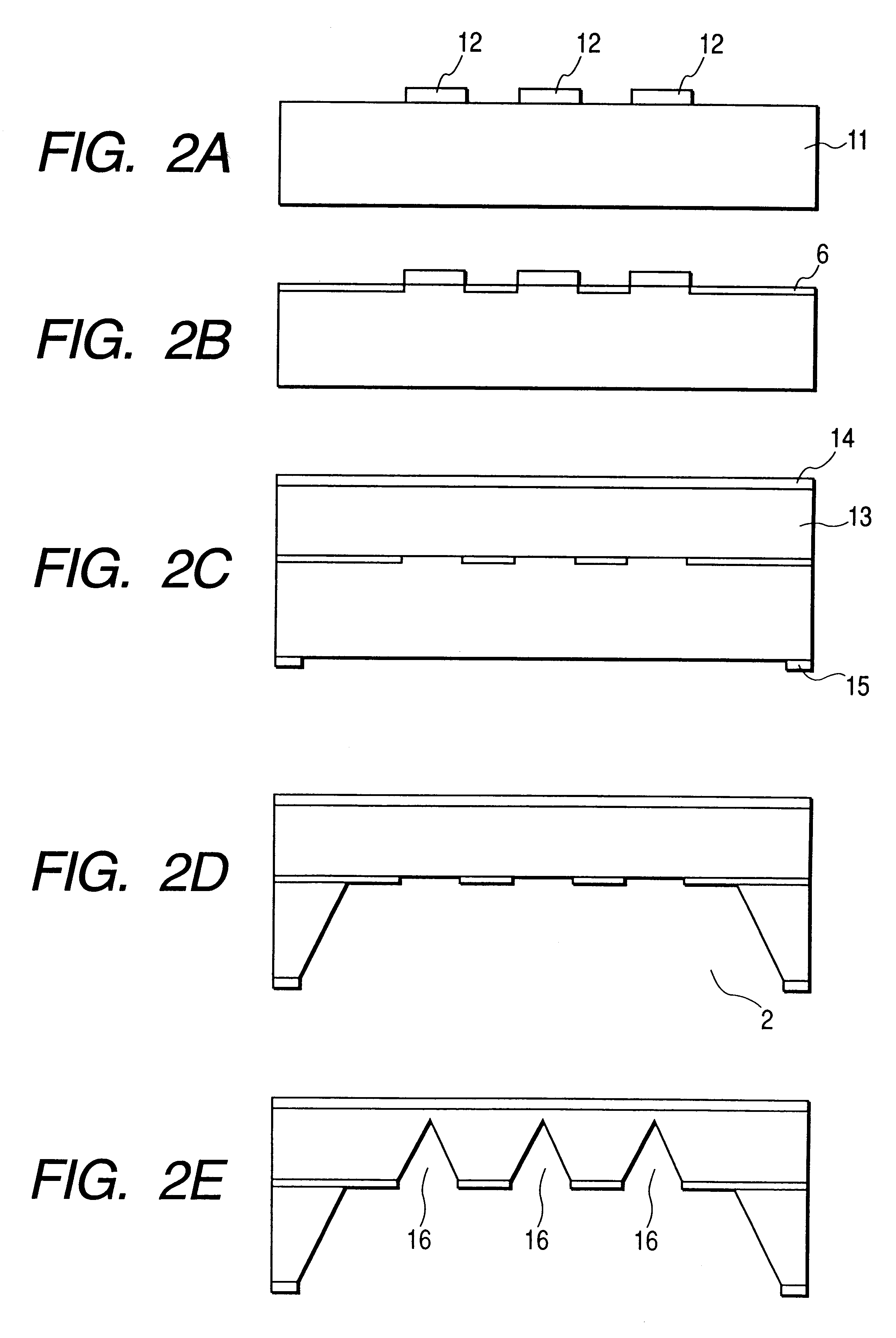

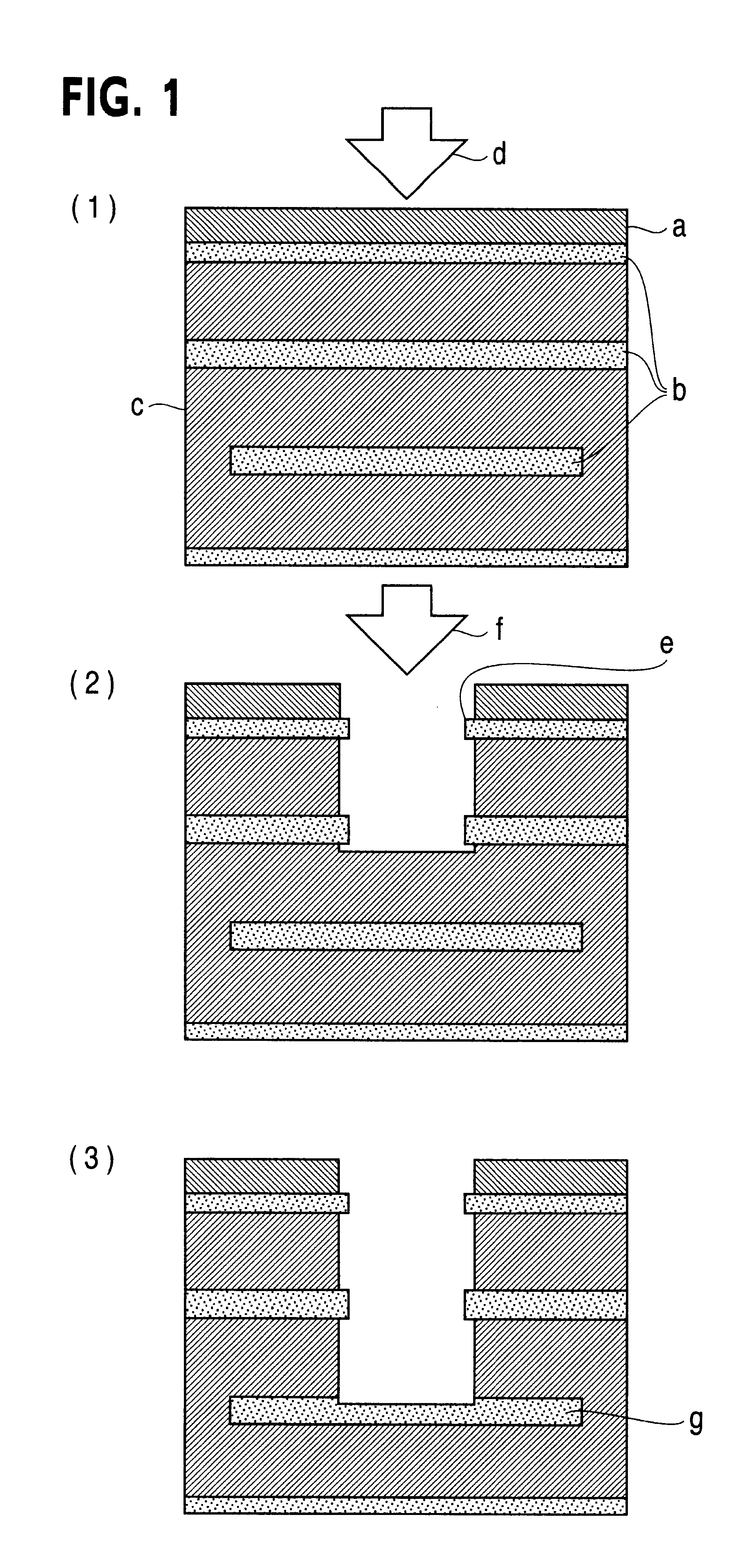

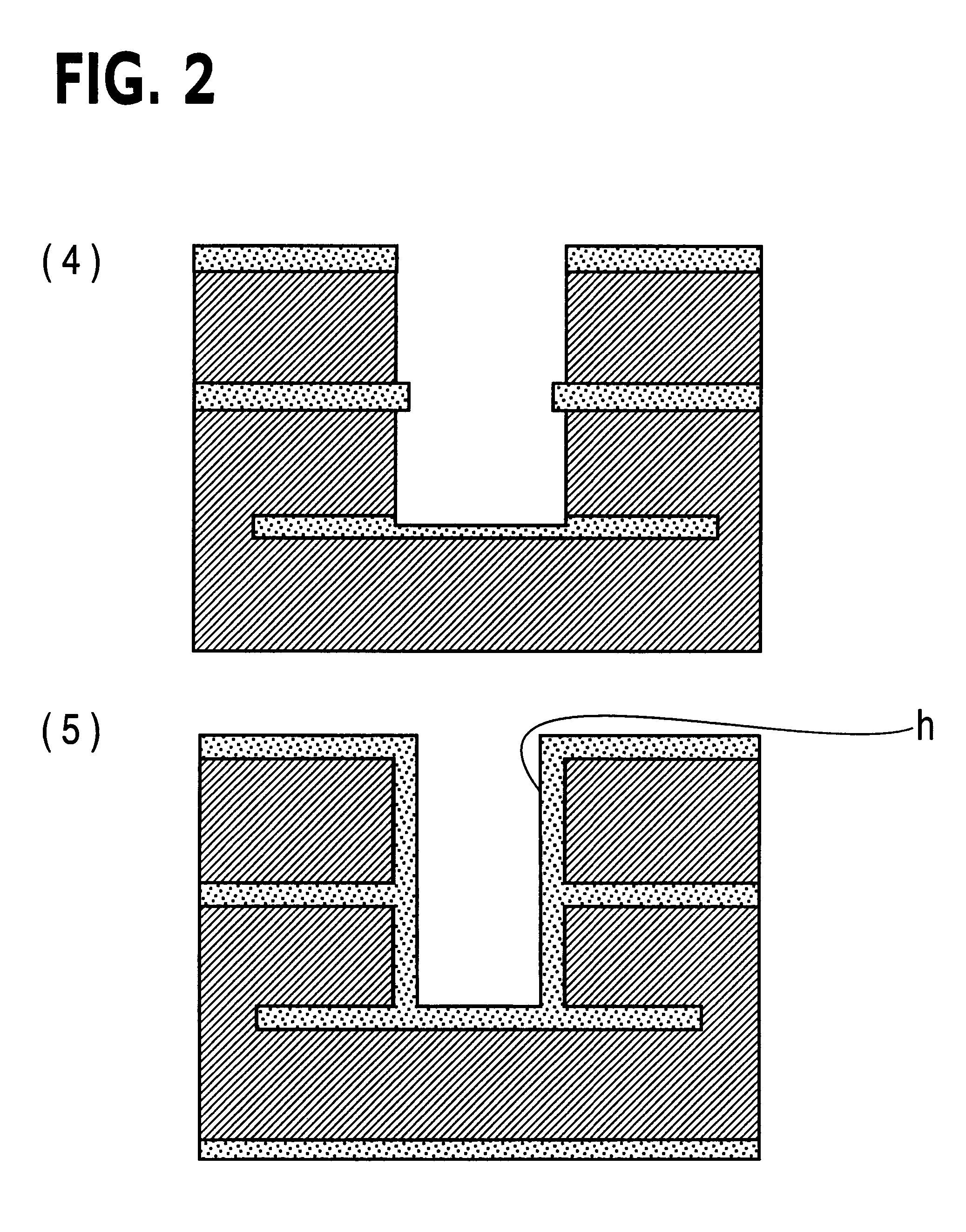

Optical probe for detecting or irradiating light and near-field optical microscope having such probe and manufacturing method of such probe

InactiveUS6215114B1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansLight irradiationNear field optical microscope

An optical prove for detecting or irradiating evanescent light is manufactured by forming a film having a regulated film thickness on a substrate, then forming a recess from the rear surface of the substrate, and forming a through hole in the film from the side of the recess by etching. The obtained optical probe has a micro-aperture at the tip of the through hole and usually, a plurality of optical probes each having a micro-aperture of uniform profile are formed on a single substrate. In the recess, light-receiving or light-irradiating means may be provided.

Owner:CANON KK

Methods And Devices For Fractional Ablation Of Tissue

InactiveUS20080214988A1Promote disseminationAlters optical propertyUltrasound therapyElectrotherapyElectromagnetic radiationChromophore

Methods and devices for ablating portions of a tissue volume with electromagnetic radiation (EMR) to produce lattices of EMR-treated ablation islets in the tissue are disclosed, including lattices of micro-holes, micro-grooves, and other structures. Also, methods and devices for using the ablated islets are disclosed, including to deliver chromophores, filler, drugs and other substances to the tissue volume.

Owner:PALOMAR MEDICAL TECH

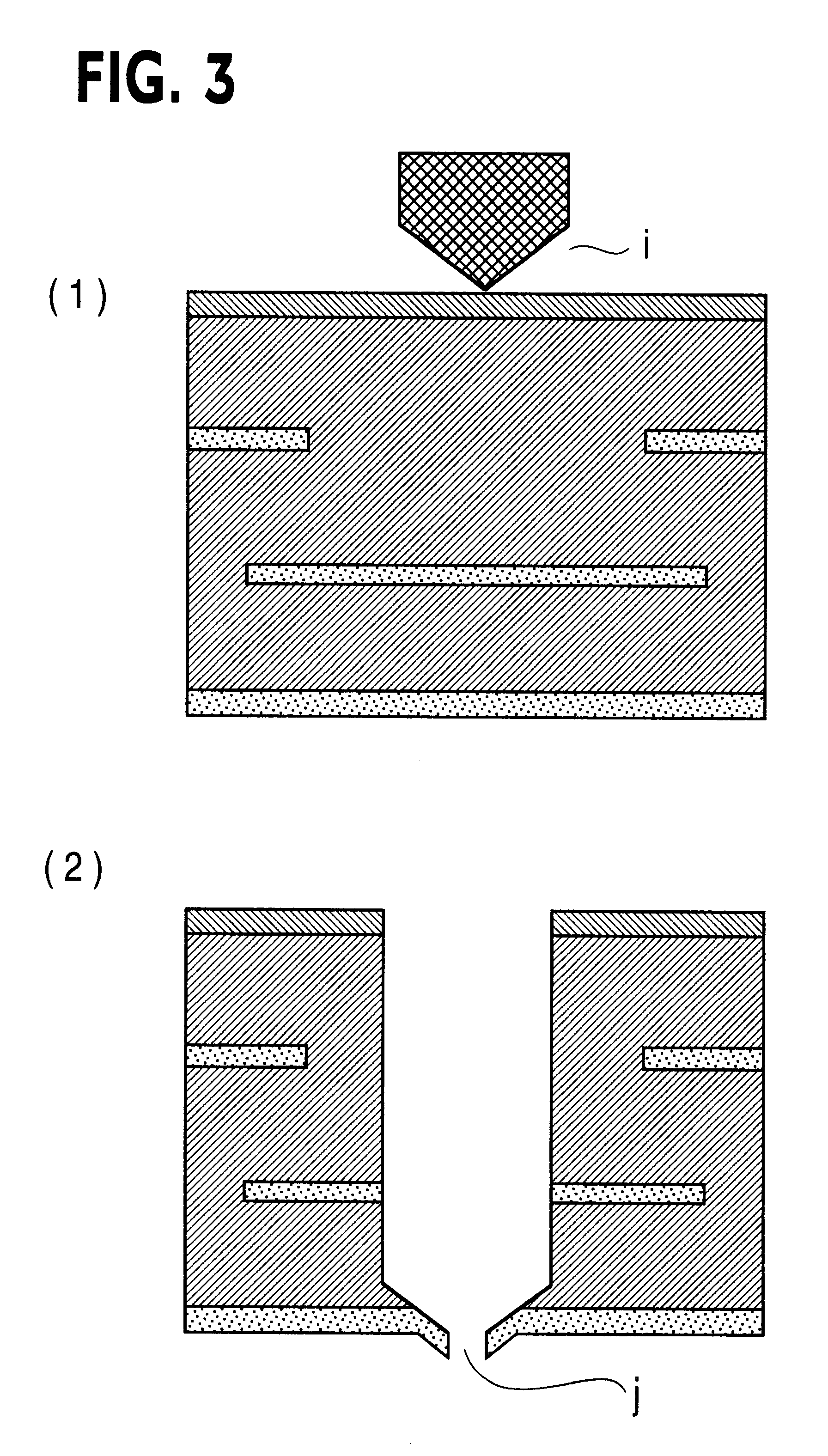

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

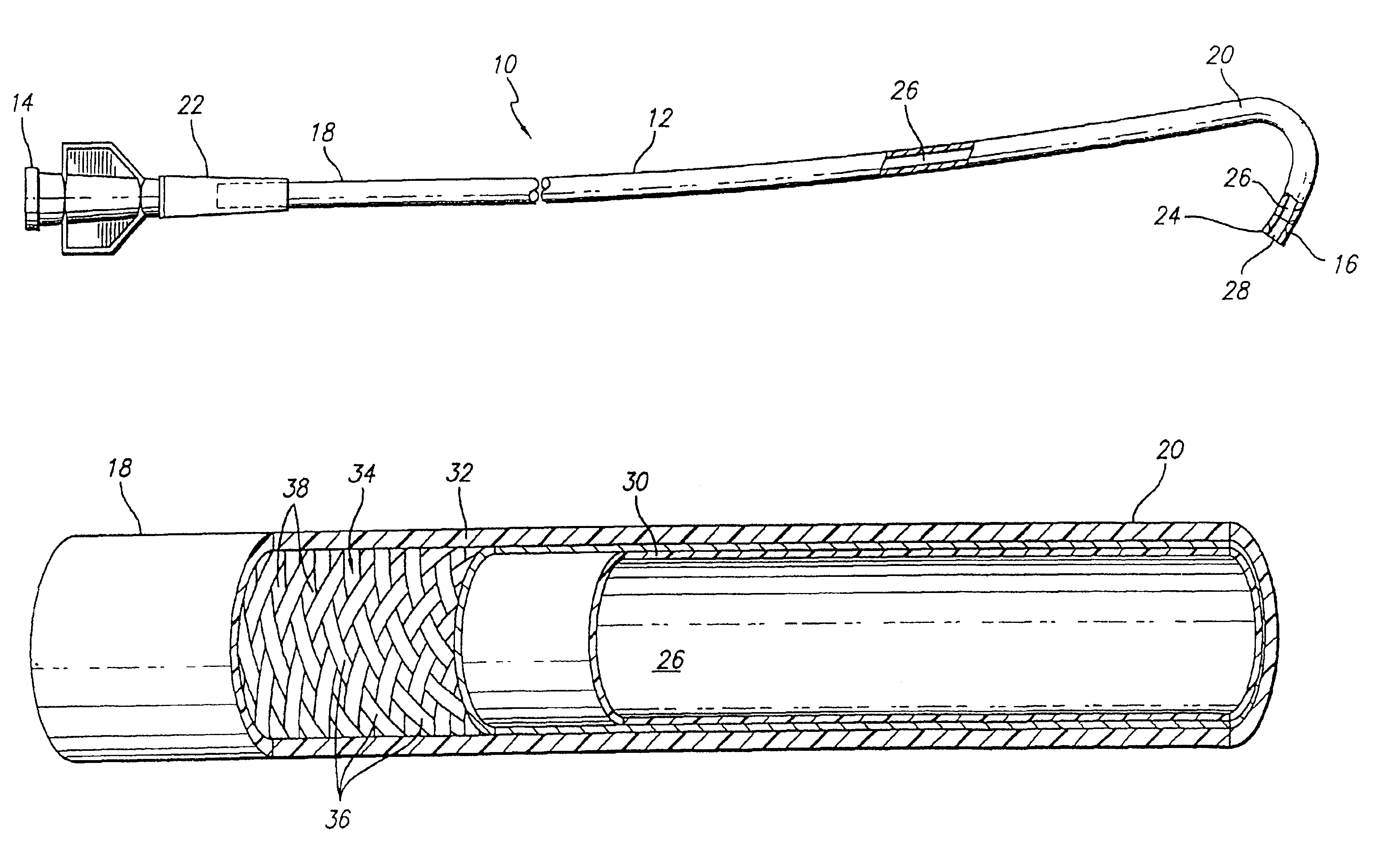

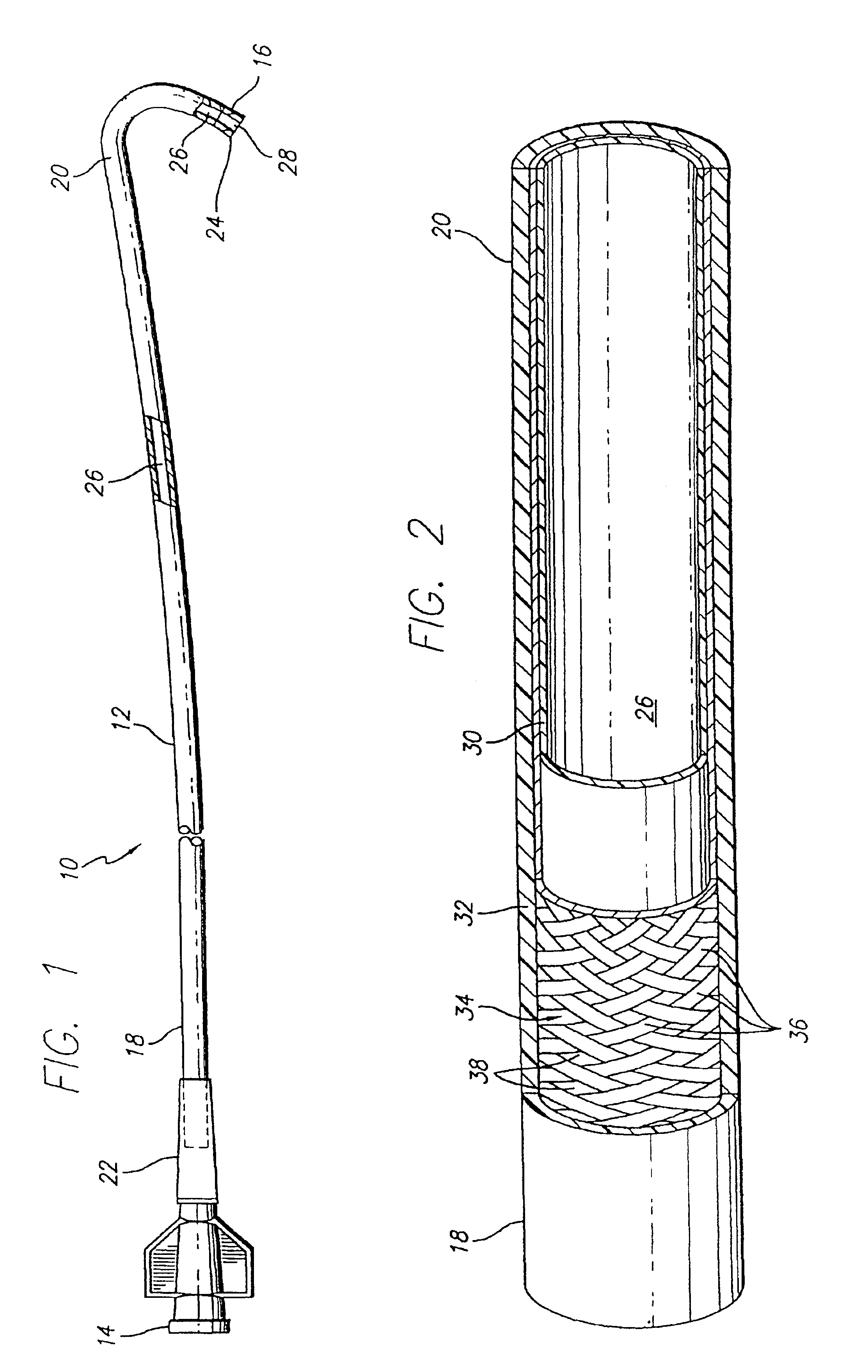

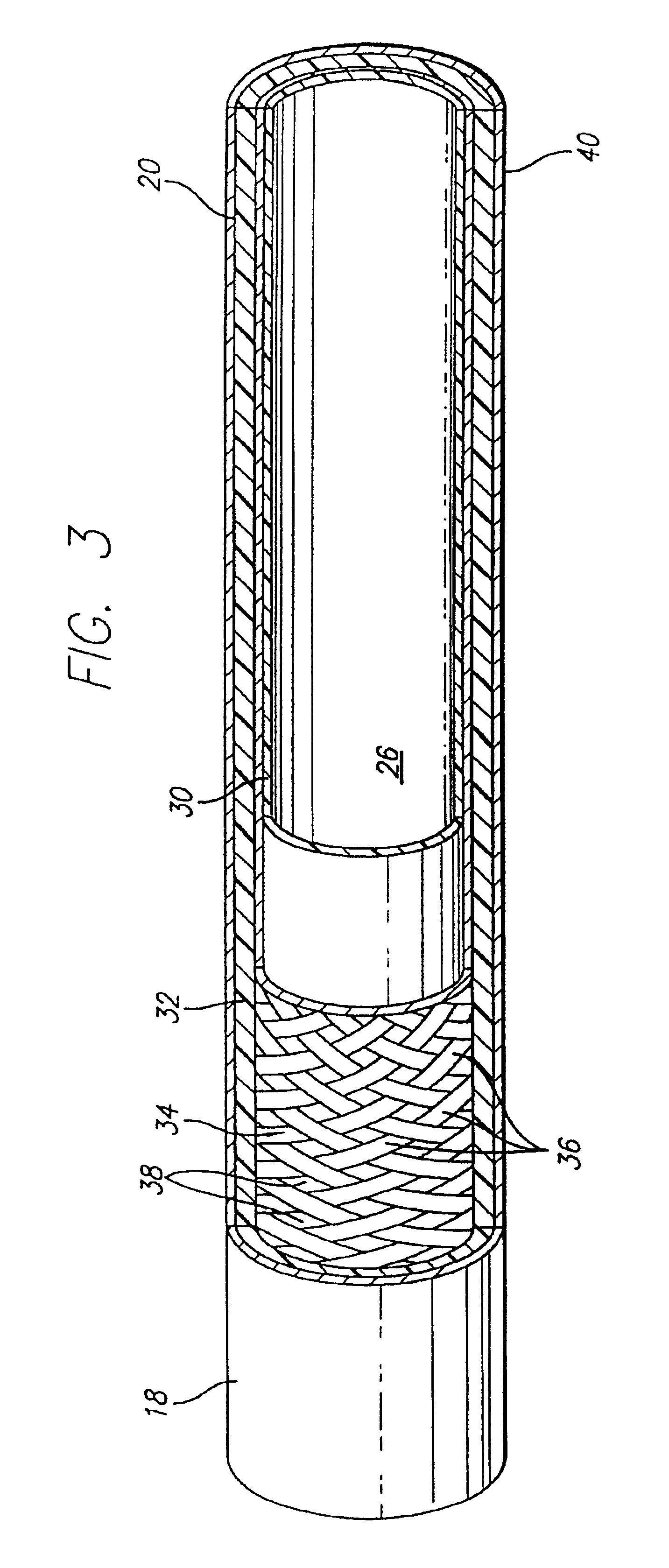

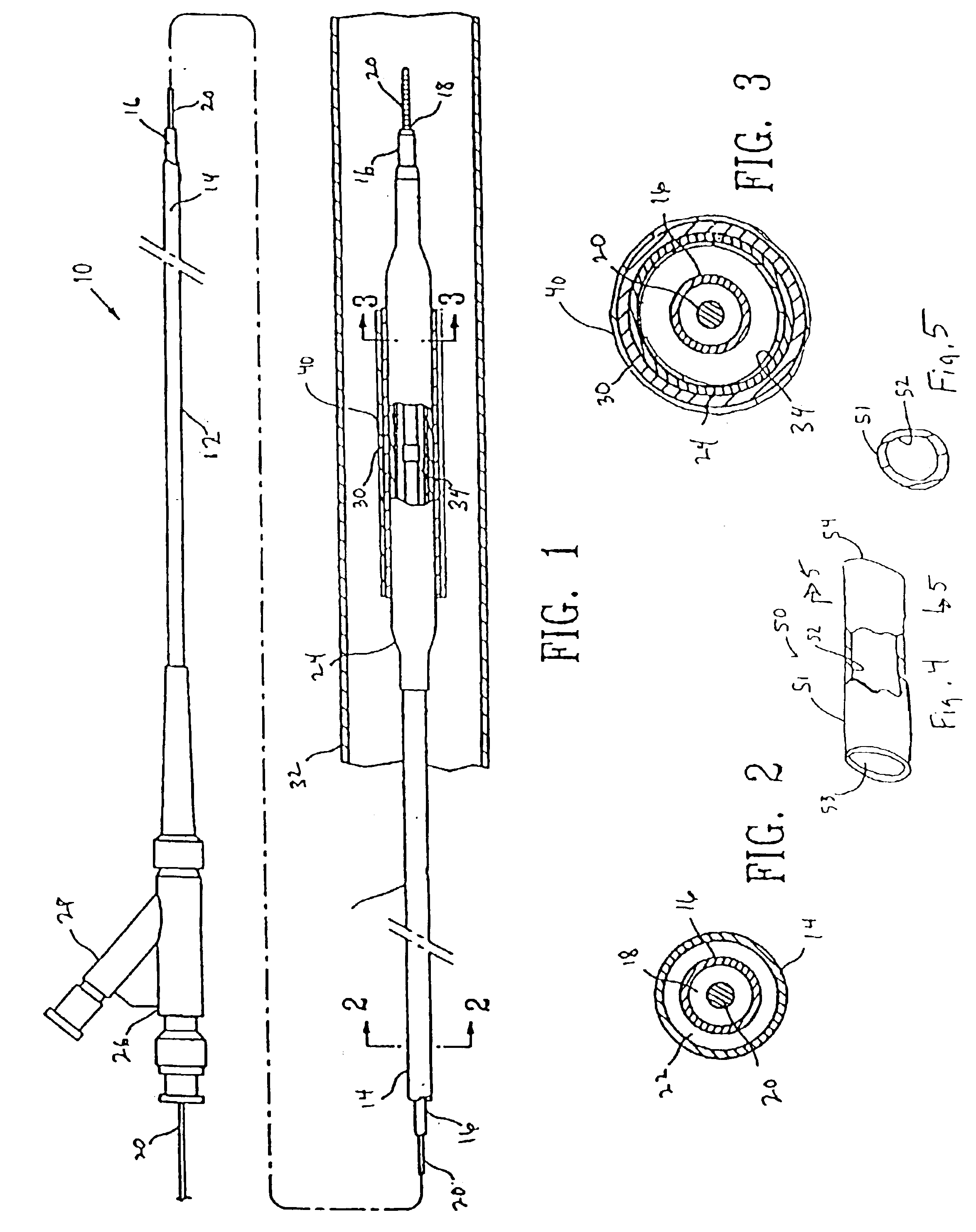

Expanded UHMWPE for guiding catheter liners and other lubricious coatings

An intraluminal catheter, such as a guiding catheter, employed for intravascular procedures and having an inner liner formed of expanded Ultra High Molecular Weight Polyethylene (UHMWPE) is disclosed. The expanded UHMWPE is microporous and has an oriented microstructure structure characterized by nodes interconnected by fibrils. The inner liner formed of expanded UHMWPE is very thin to maximize the inner lumen diameter and has excellent mechanical properties.

Owner:ABBOTT CARDIOVASCULAR

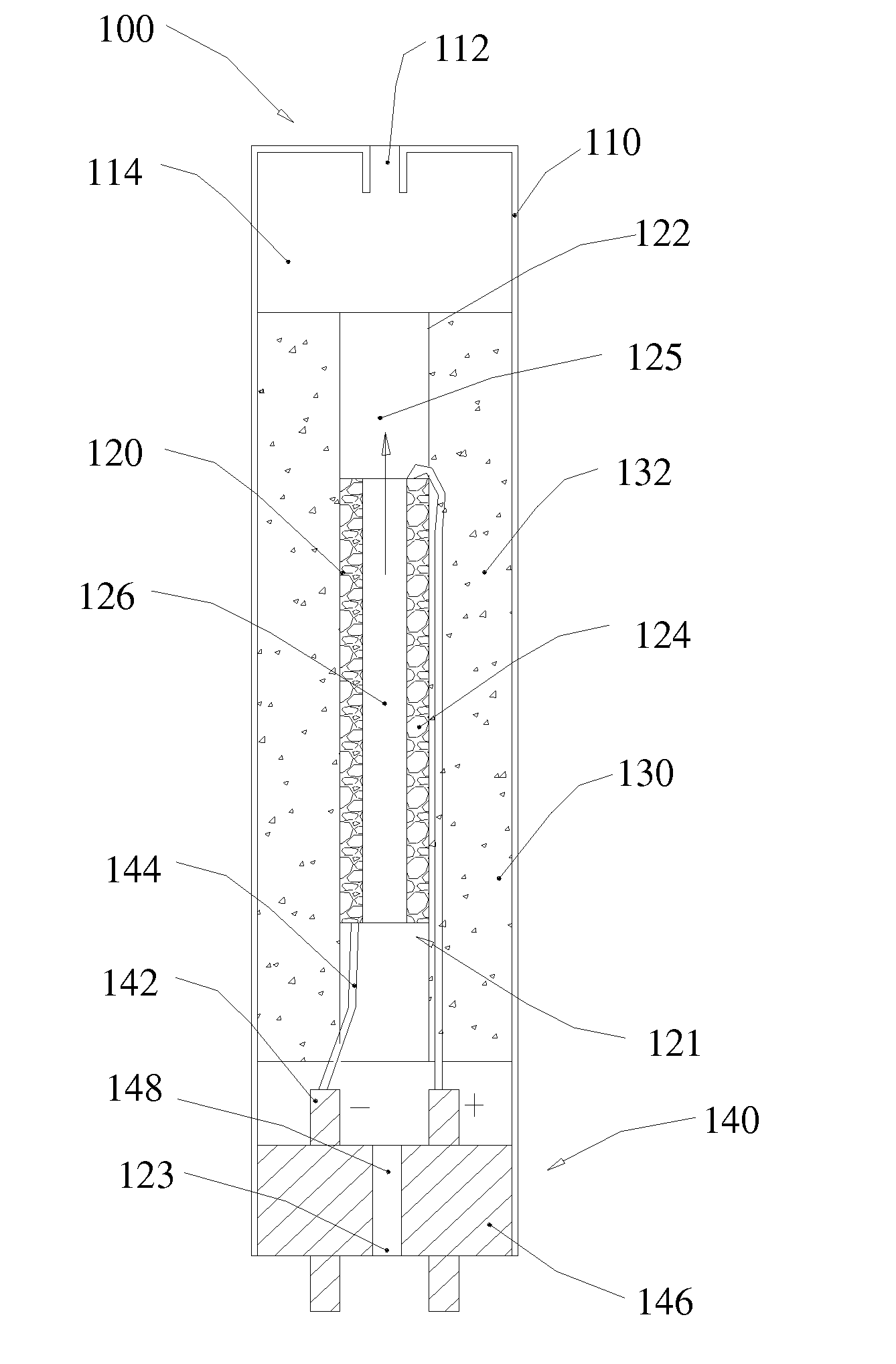

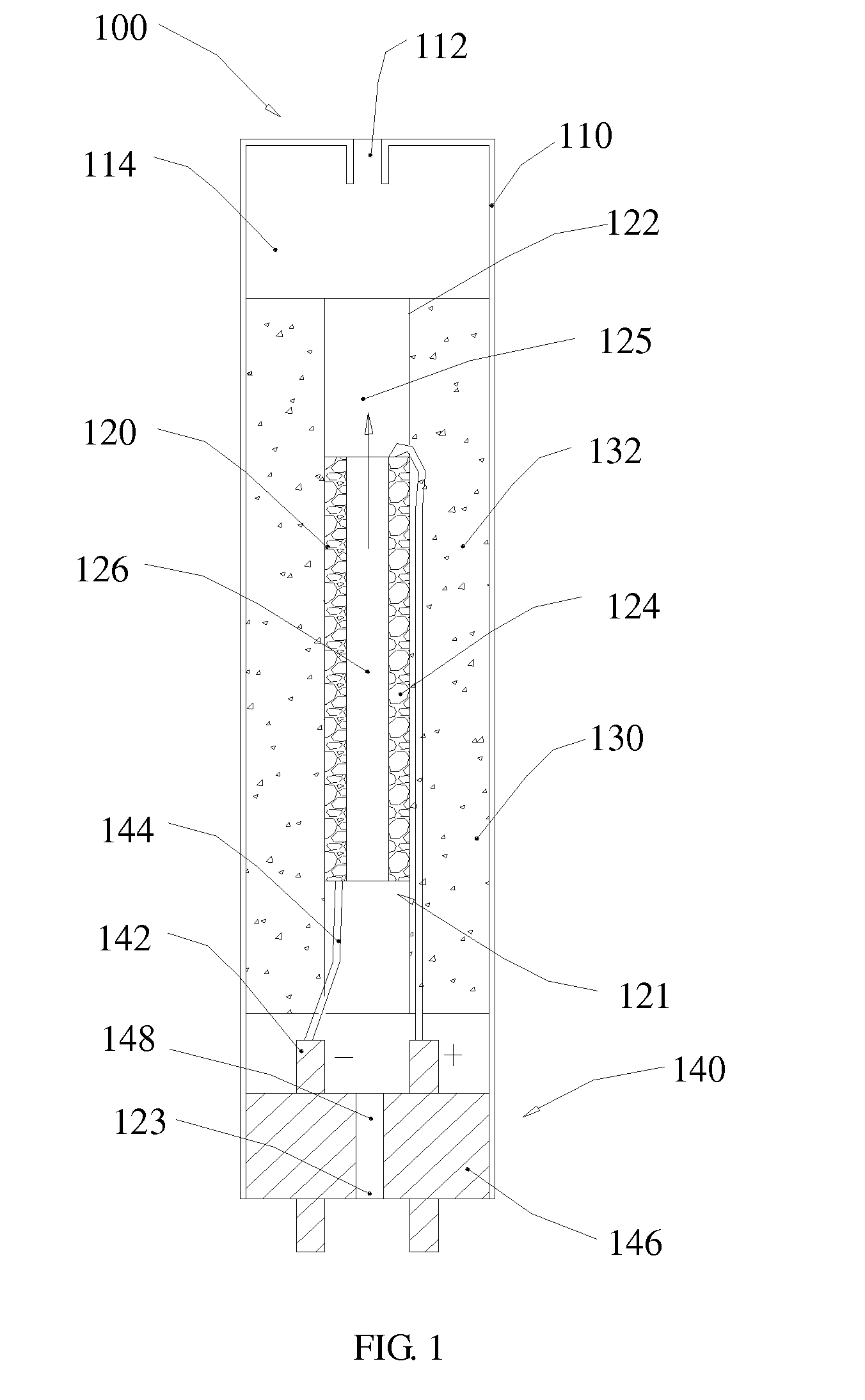

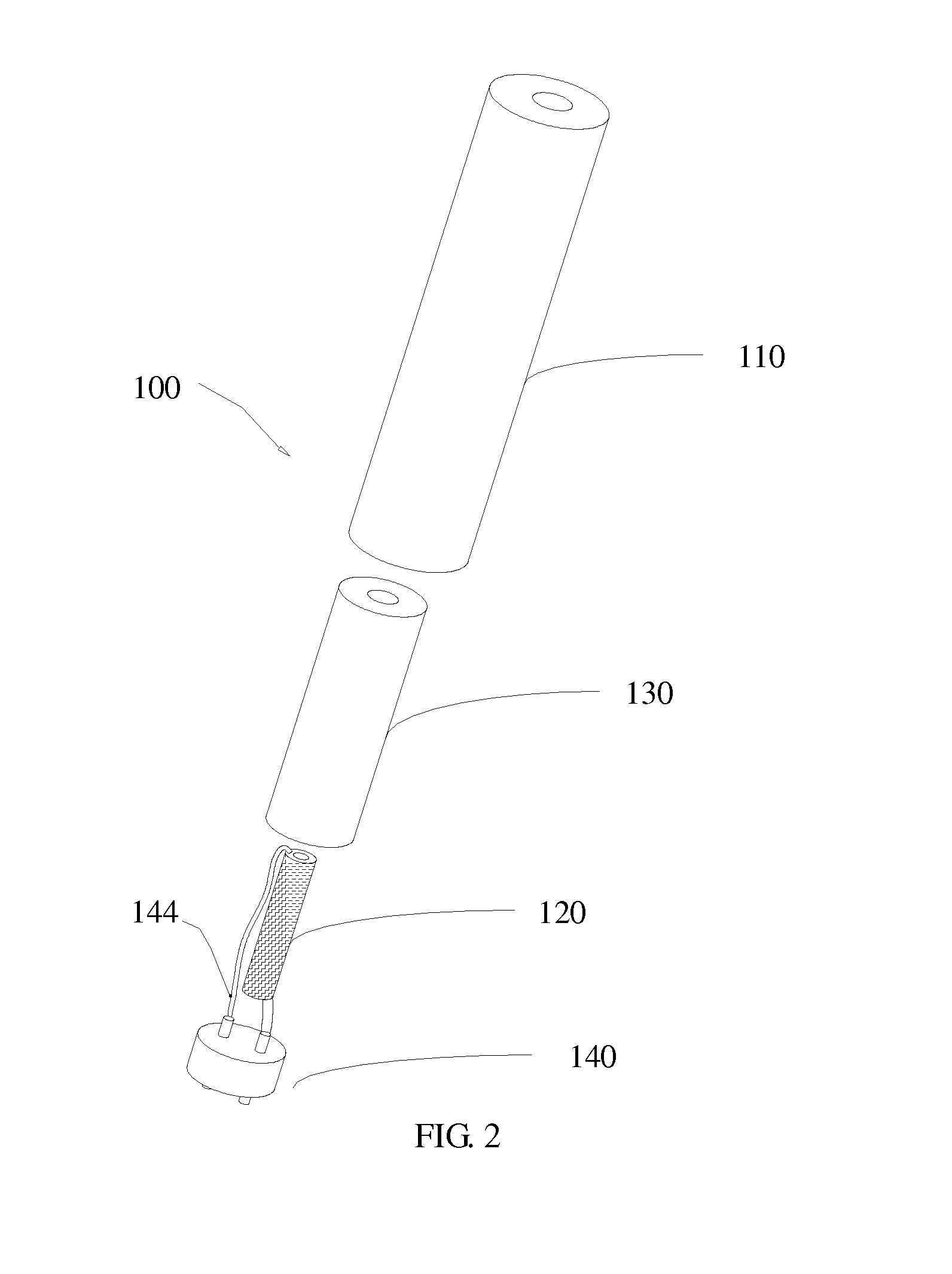

Electronic cigarette

ActiveUS20150090280A1Increase the number ofImprove heating efficiencyRespiratorsTobacco pipesElectronic cigaretteEngineering

An electronic cigarette is provided, which includes: a housing having a chimney formed therein; a liquid reservoir for storing liquid in the housing; and an atomizer assembly received in the housing. The atomizer assembly includes a heating tube capable of absorbing liquid. The heating tube defines a plurality of micropores on a wall thereof; an inner surface of the heating tube is in contact with the air in the chimney.

Owner:SHENZHEN SMOORE TECH LTD

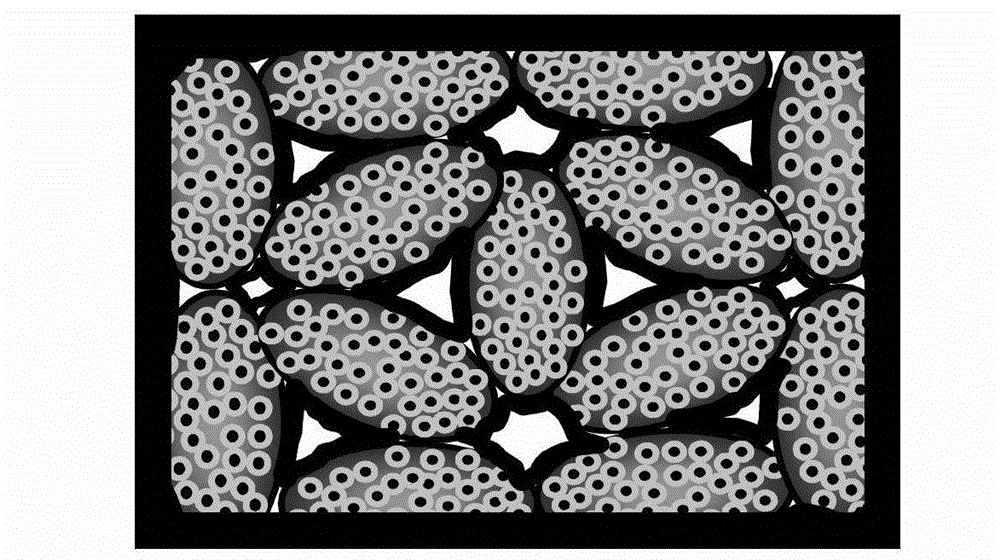

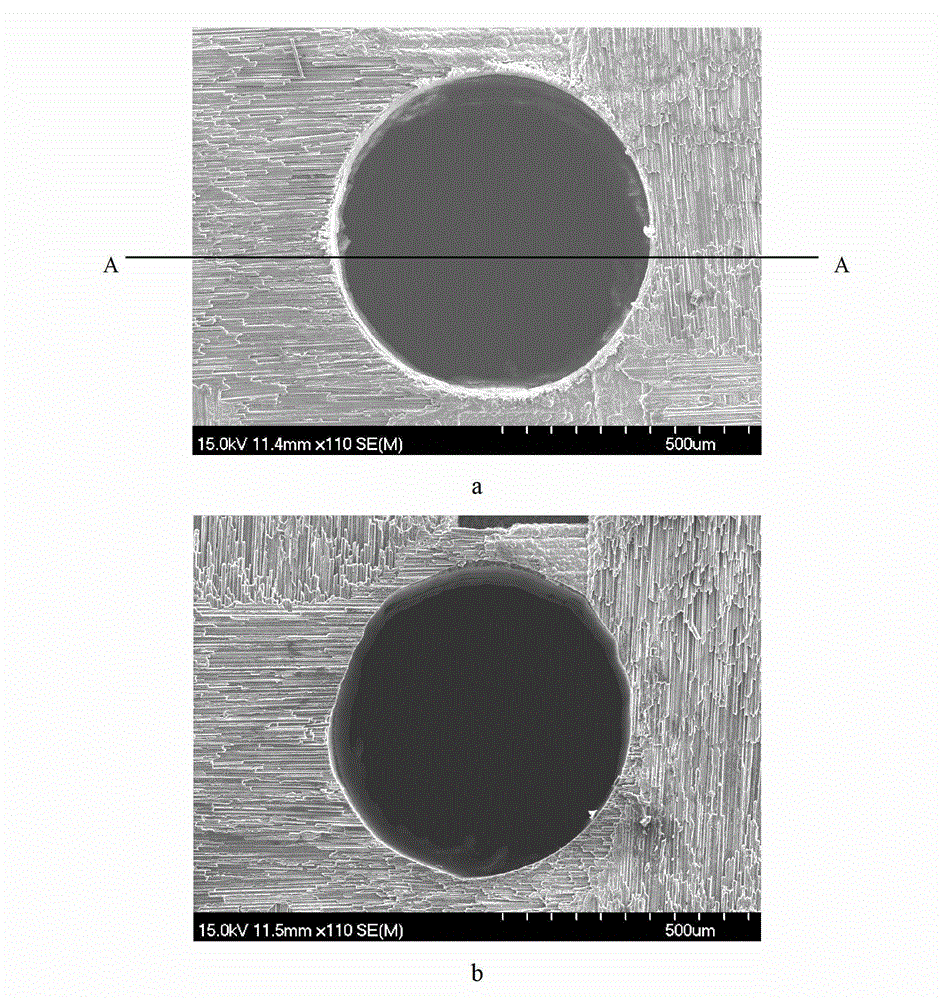

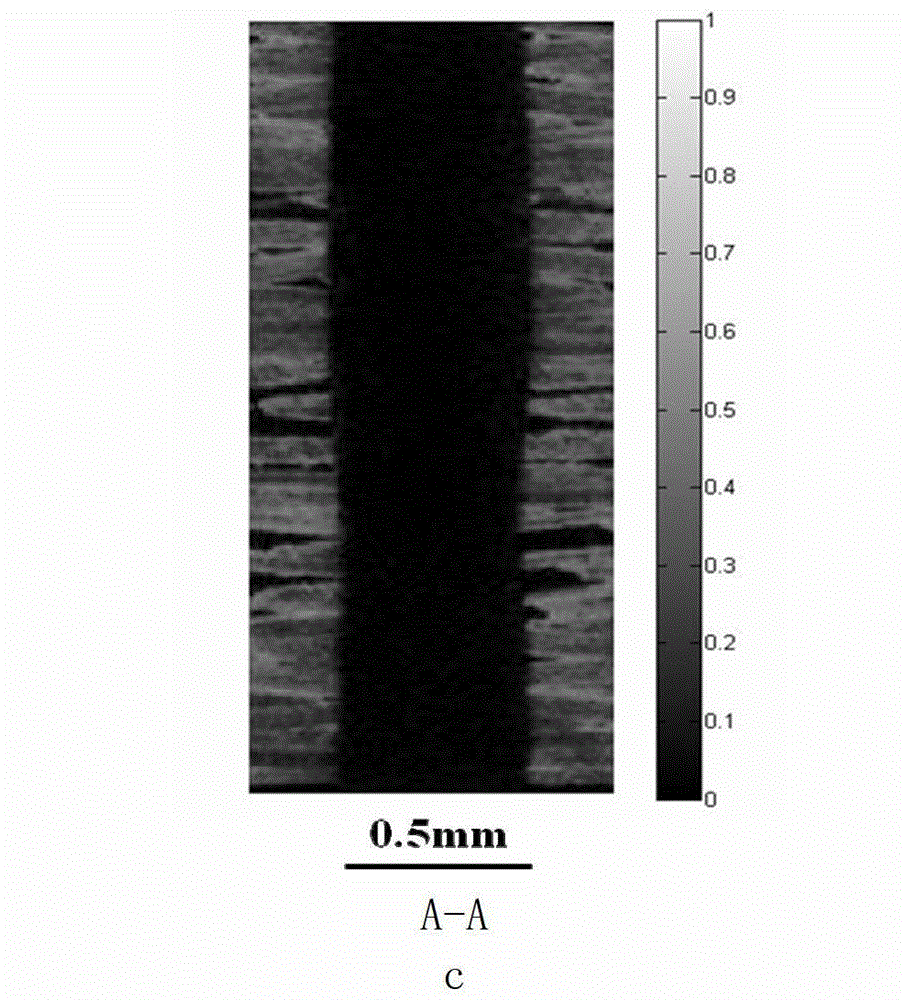

Method for hole machining with picosecond laser

ActiveCN103143841AImprove forming qualityGood processing designabilityLaser beam welding apparatusPicosecond laserOptoelectronics

A method for hole machining with picosecond laser realizes hole machining on CMC-SiC (Ceramic Matrix Composite-Silicon Carbide) material according to the characteristics of fiber composite materials and the machining feature that picosecond laser is suitable for various materials due to superhigh peak power of picosecond laser. According to the method, round holes or square holes are machined in the CMC-SiC material layer by layer in a distributed machining mode; the influence of tiny cracks can be ignored during machining; the stability is good; and the method is particularly suitable for mass repeated micro-hole machining. Layer-by-layer machining in a heliciform way is adopted when round holes are machined; and layer-by-layer machining in a linear scanning way is adopted when square holes are machined. The method has the advantages of good stability of the machining technology, strong designability, high precision and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Voided polymer film containing layered particulates

Disclosed is an optical element comprising a polymer film containing a dispersion of minute layered particulates and microvoids.

Owner:SKC HI TECH & MARKETING CO LTD CO REGISTRATION NO 161511 0225312

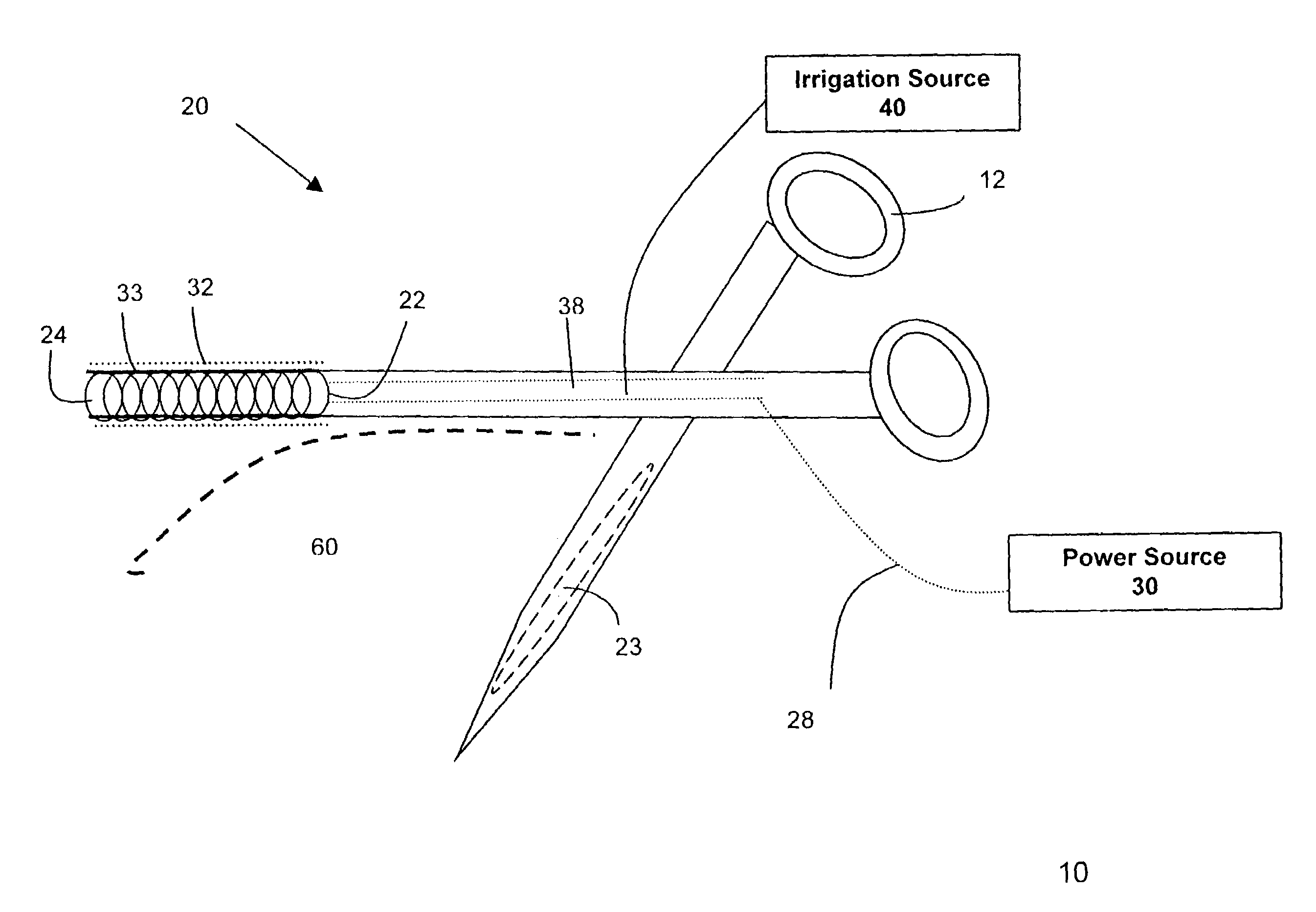

Method and apparatus for tissue ablation

Owner:MEDTRONIC INC

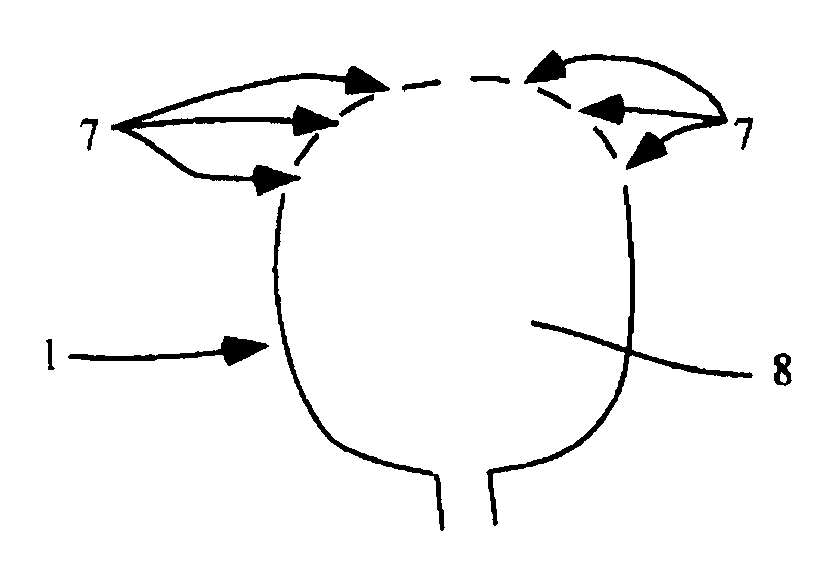

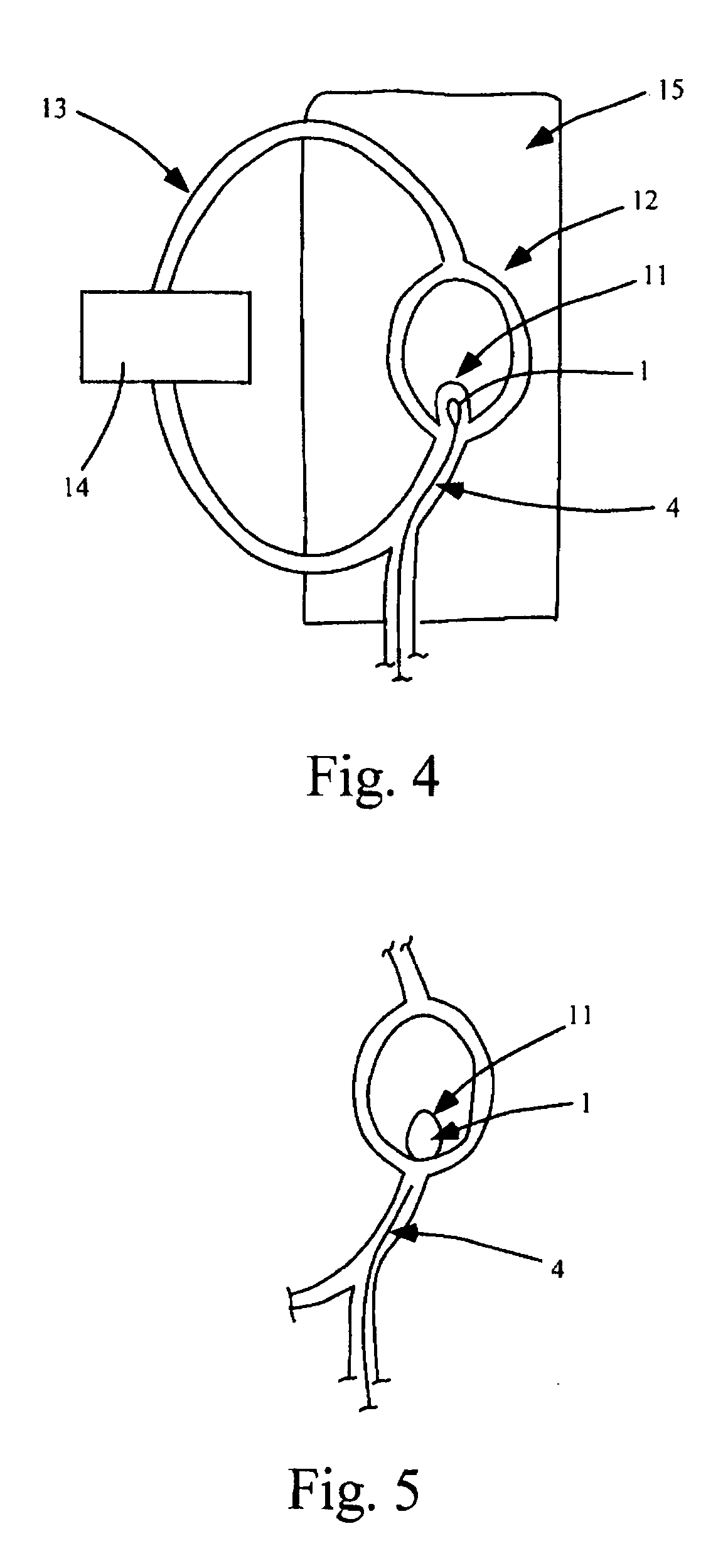

Aneurysm treatment using semi-compliant balloon

InactiveUS20060079923A1Simple procedureBalloon catheterDilatorsAneurysm treatmentAnterior Cerebral Artery Aneurysm

A device for occluding an aneurysm comprising: a detachable, semi-compliant, radially-expanding balloon mounted on a catheter, wherein the balloon is in fluid communication with the catheter, wherein the balloon comprises a plurality of micropores, and wherein the micropores in the balloon allow expression of a bio-adhesive fluid at a defined pressure from the inside to the outside of the balloon.

Owner:BOARD OF REGENTS THE LELAND STANFORD JR UNIV THE

Micro-porous mesh stent with hybrid structure

Owner:ENDOTEX INTERVENTIONAL SYST

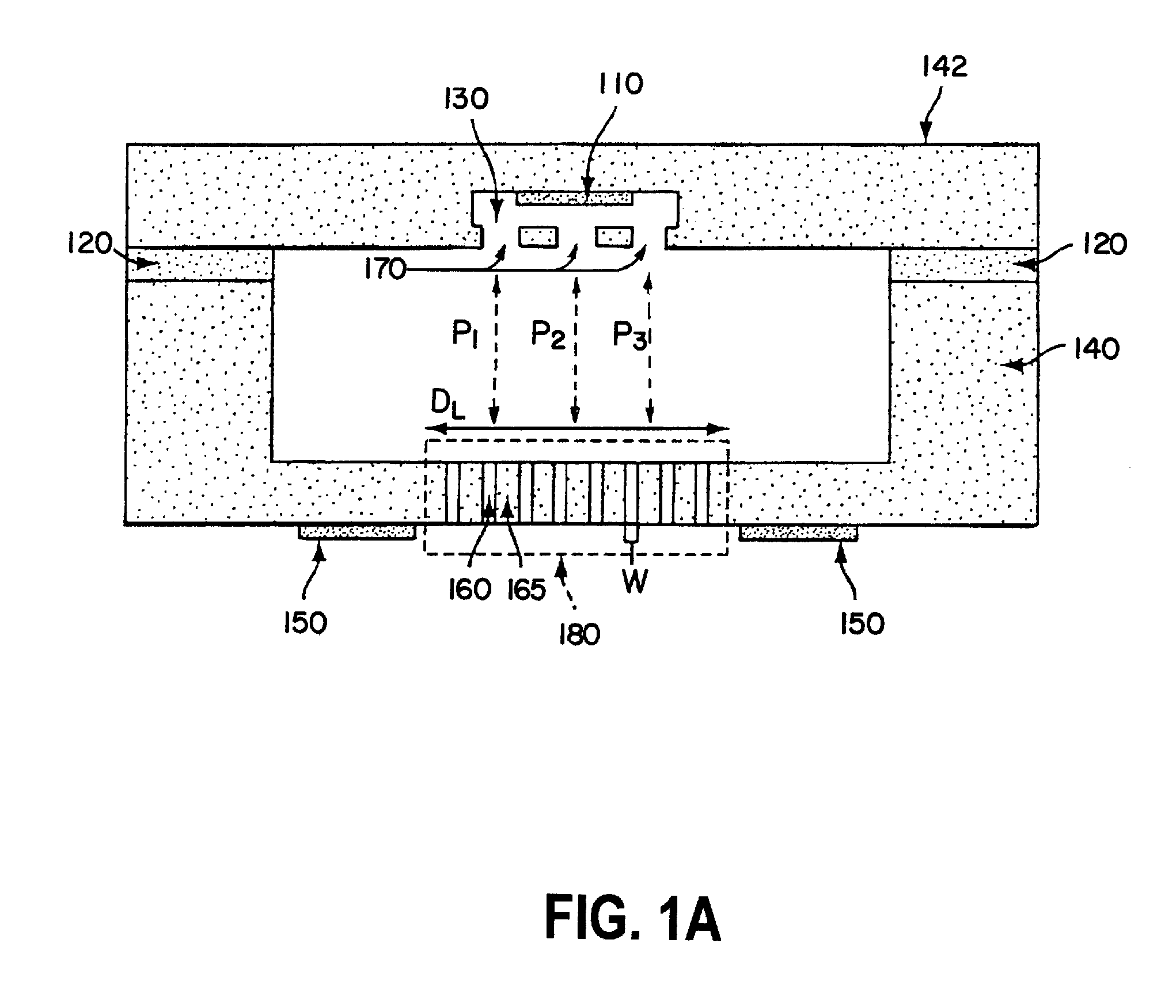

Rapid Ink-Charging Of A Dry Ink Discharge Nozzle

InactiveUS20100171780A1Sufficient materialSolid-state devicesMachines/enginesMulti materialSuspended particles

The present teachings relate to methods and apparatus for depositing one or more materials (e.g., one or more films, such as one or more solids) on one or more substrates, which may form part of an OLED or other type(s) of display. In some embodiments, the disclosure relates to apparatus and methods for depositing ink on one or more substrates. The apparatus can include, for example, one or more chambers for receiving ink, and plural orifices configured in the one or more chambers which are adapted for ejecting droplets of the ink; a discharge nozzle comprising an array of micro-pores (e.g., configured in a rectangular array), with each micro-pore having an inlet port and an outlet port, and the discharge nozzle receiving plural quantities (e.g., droplets) of ink from the chamber(s) via the orifices at the inlet ports and dispensing the ink from the outlet ports. The droplets of ink can be received at unique, spaced-apart locations on the inlet ports of the discharge nozzle. In some embodiments, a single liquid ink-holding chamber, which includes plural orifices (e.g., three), receives ink in liquid form having a plurality of suspended particles, and droplets of the ink are ejected substantially simultaneously from the chamber to respective, spaced-apart locations on the discharge nozzle; and the discharge nozzle evaporates the carrier liquid and deposits the solid particles on one or more substrates.

Owner:KATEEVA

Medical device formed of ultrahigh molecular weight polyolefin

Medical devices having at least a component, such as a catheter balloon, stent cover and vascular graft, formed of ultrahigh molecular weight polyolefin, such as ultrahigh molecular weight polyethylene. The device component is formed from ultrahigh molecular weight polyethylene that has been processed so that it is microporous and has an oriented node and fibril structure. The device component expands compliantly at low strains and are substantially less compliant at higher strains. The invention also comprises methods for making such medical devices, including the steps of compacting a polyethylene powder and deforming it to impart the oriented structure.

Owner:ABBOTT CARDIOVASCULAR

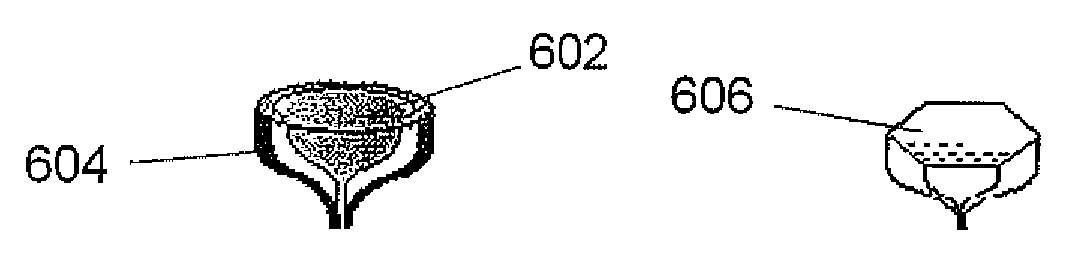

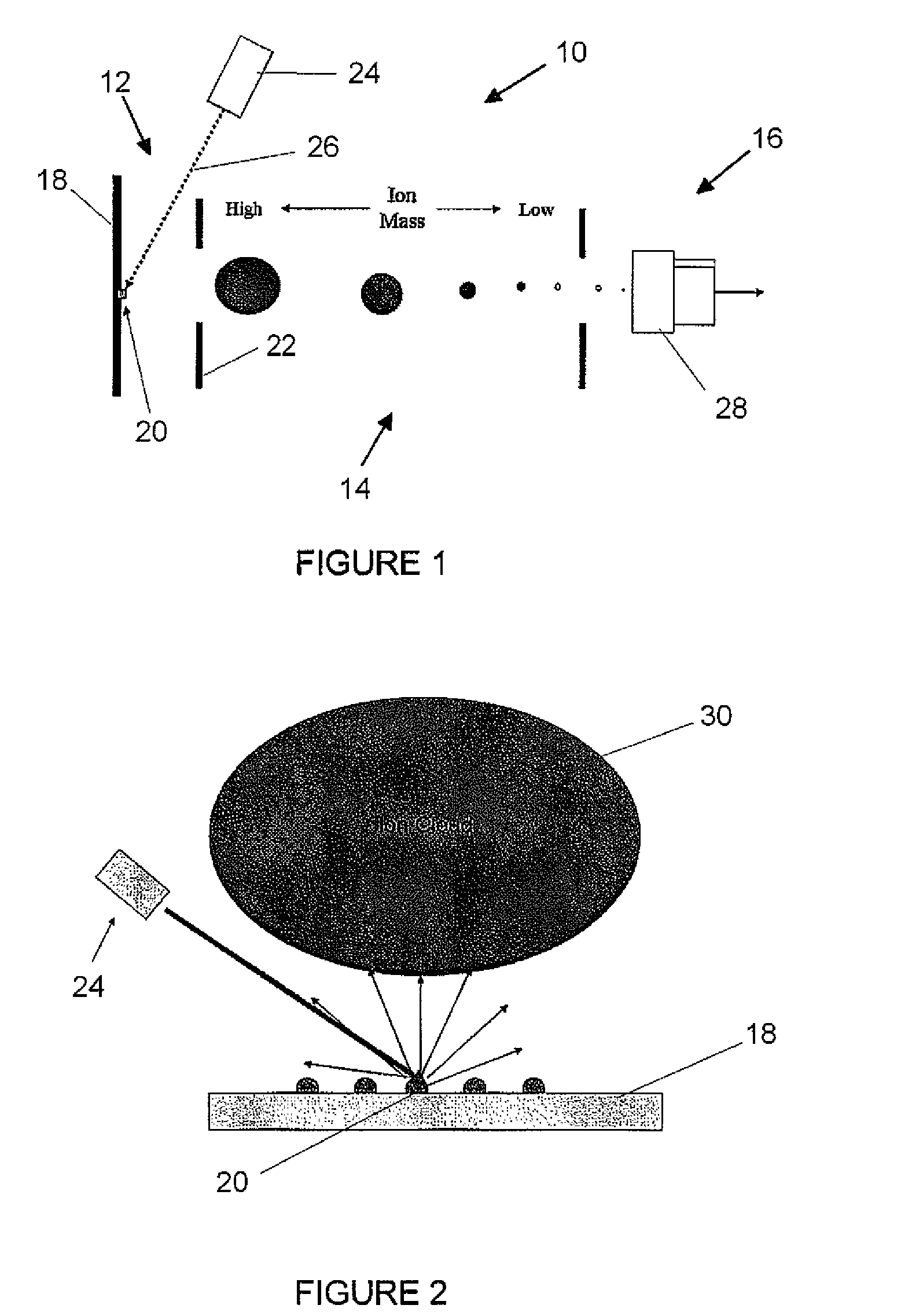

MALDI target plate utilizing micro-wells

ActiveUS7695978B2Bioreactor/fermenter combinationsBiological substance pretreatmentsGlass fiberSpectroscopy

An arrangement for a MALDI sample plate for ion mass spectroscopy is disclosed. The sample is configured to shape the hypersonic explosion which creates the ions generated in a MALDI-type time-of-flight mass spectrometer. The MALDI sample plate includes a glass wafer formed from a plurality of clad glass fibers and has a first planar surface. The plate also has a plurality of micro-wells formed in the glass wafer. The micro-wells extend to a depth that is less than the thickness of the glass wafer and act to hold a spot sample in a manner that prevents spreading, maximizes the formation of ions, and shapes the resulting ion cloud to improve ion migration.

Owner:PHOTONIS SCI INC

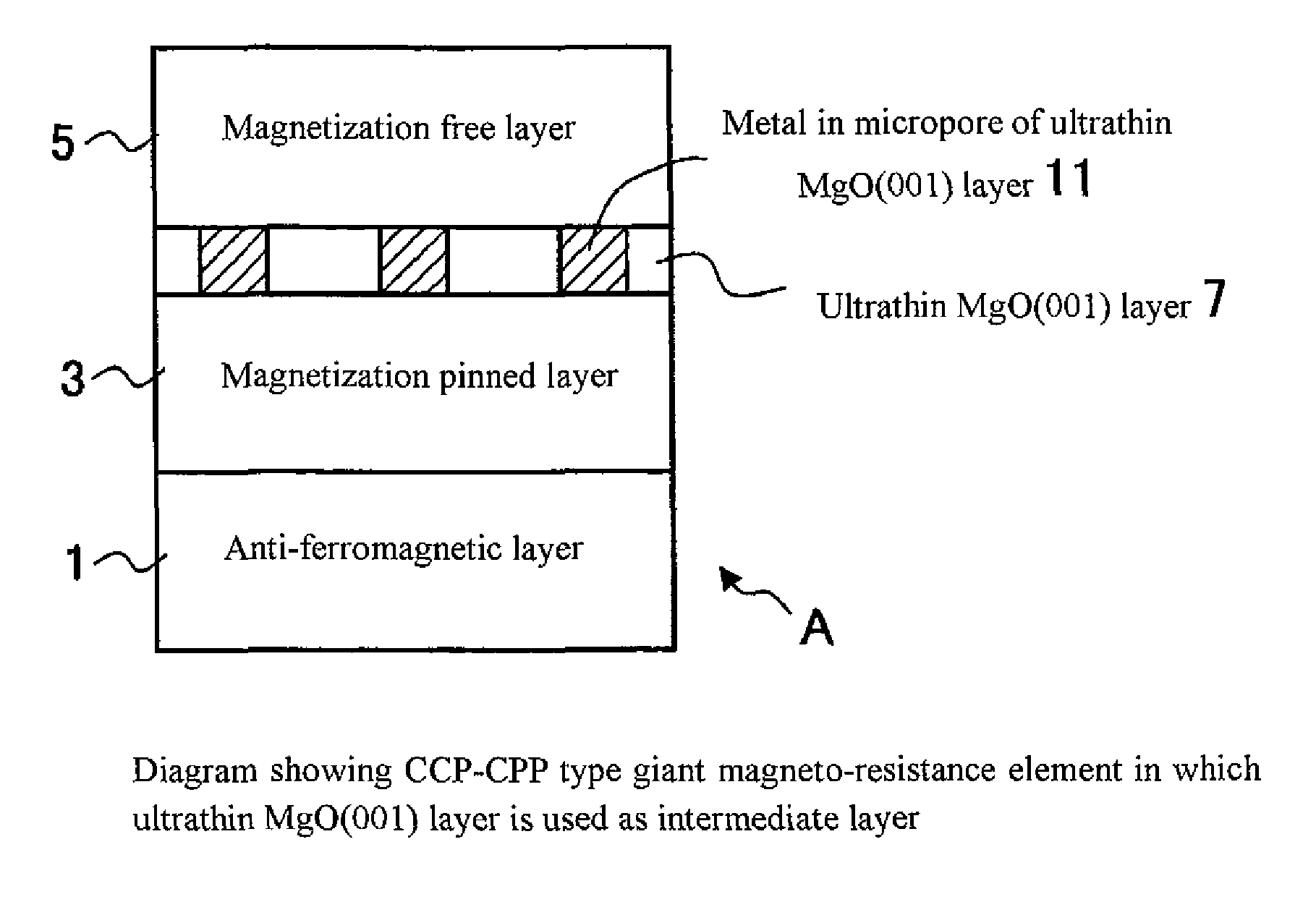

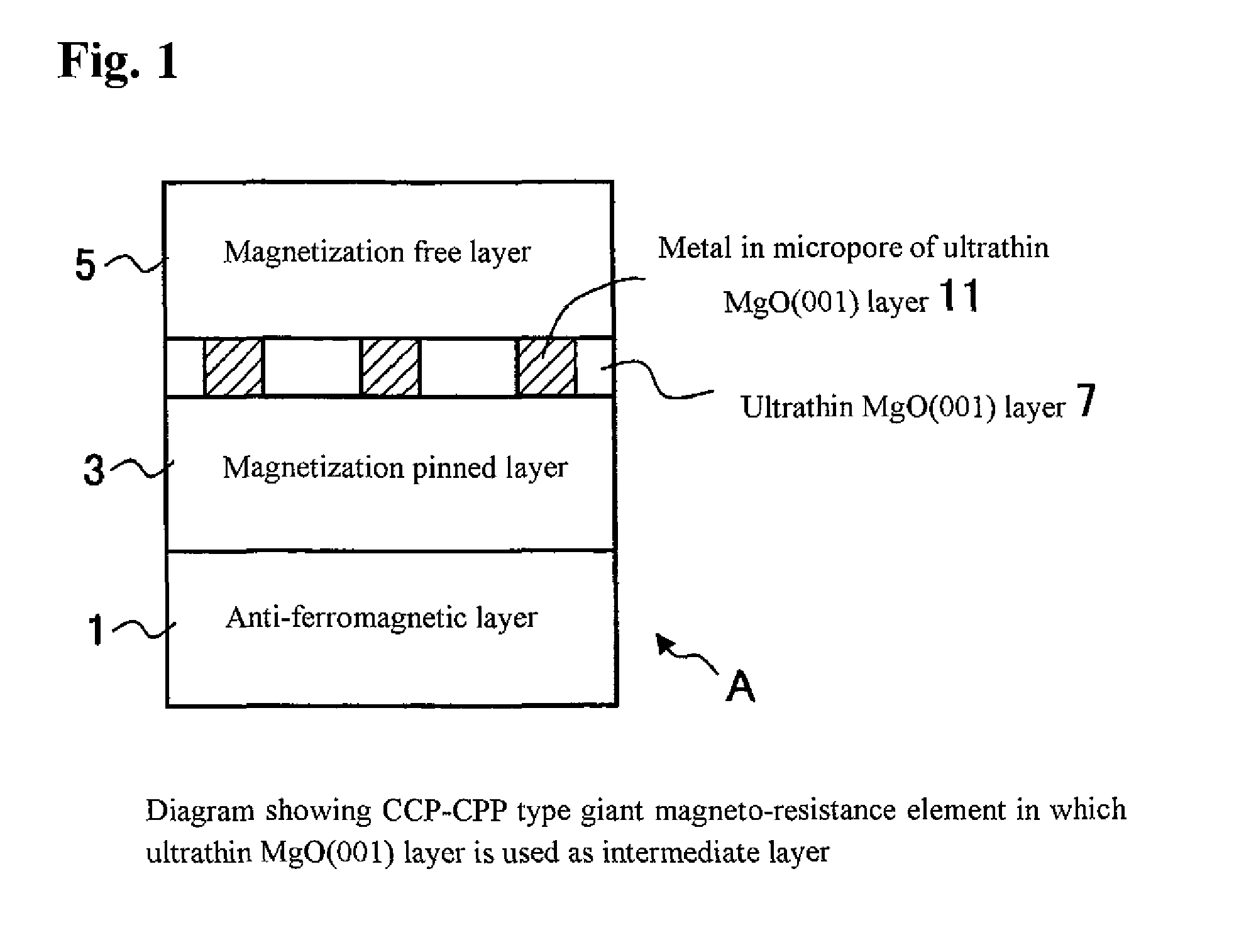

Cpp type giant magneto-resistance element and magnetic sensor

InactiveUS20080026253A1Lower resistanceRaise the ratioNanomagnetismMagnetic measurementsMagnetic reluctanceMagnetization

Provided are a CCP (current confined path)-CPP (current-perpendicular-to-plane) type giant magneto-resistance (GMR) element having a giant magneto-resistance ratio in a low resistance region (a region of not more than 1 ohm per square micrometer) and a magnetic sensor using this GMR element. The CCP-CPP type GMR element A has a laminated structure of an anti-ferromagnetic layer, a magnetization pinned layer, an intermediate layer and a magnetization free layer, and is formed to have a construction in which a current flows perpendicularly to a film plane. By using an ultrathin magnesium oxide layer having micropores that is preferentially oriented in the (001) direction as the intermediate layer, the magneto-resistance ratio is enhanced, because a current flowing from the magnetization free layer to the magnetization pinned layer (or in the opposite direction) is confined by the metal in the micropores.

Owner:NAT INST OF ADVANCED IND SCI & TECH

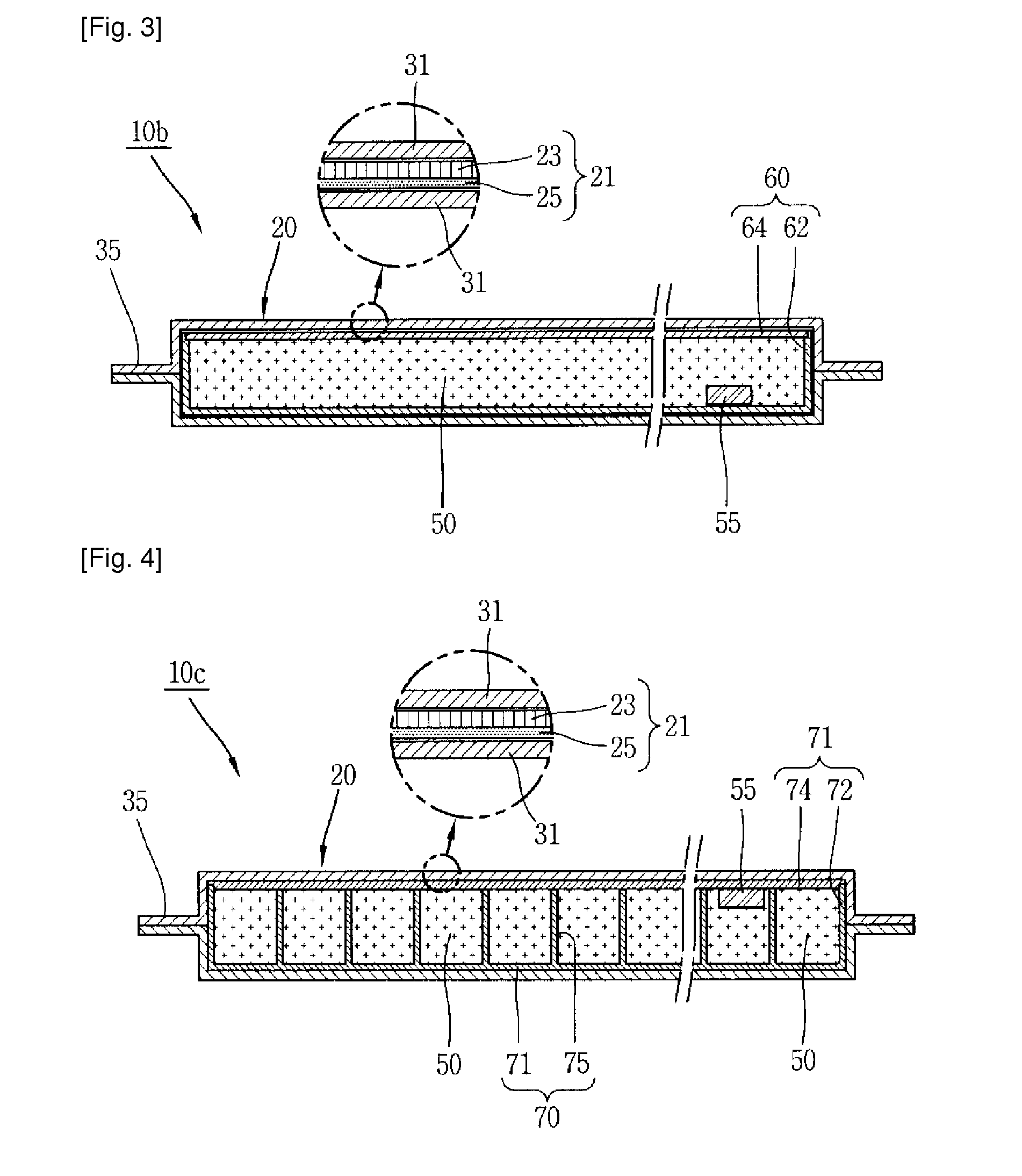

Vacuum insulation member, refrigerator having vacuum insulation member, and method for fabricating vacuum insulation member

ActiveUS20120118002A1Easy to manufactureReduce manufacturing costLamination ancillary operationsThermal insulationGlass fiberEngineering

Disclosed are a vacuum insulation member, a refrigerator having a vacuum insulation member, and a method for fabricating a vacuum insulation member. The vacuum insulation member includes: an envelope having gas impermeability and having a certain decompressed space therein; a core formed as a structure for maintaining a certain shape and disposed at an inner side of the envelope to support the envelope; and a filler formed as powder having micro pores and filled at the inner side of the envelope. The use of a glass fiber core can be avoided, an internal vacuum degree can be easily maintained, and a life span can be lengthened.

Owner:LG ELECTRONICS INC

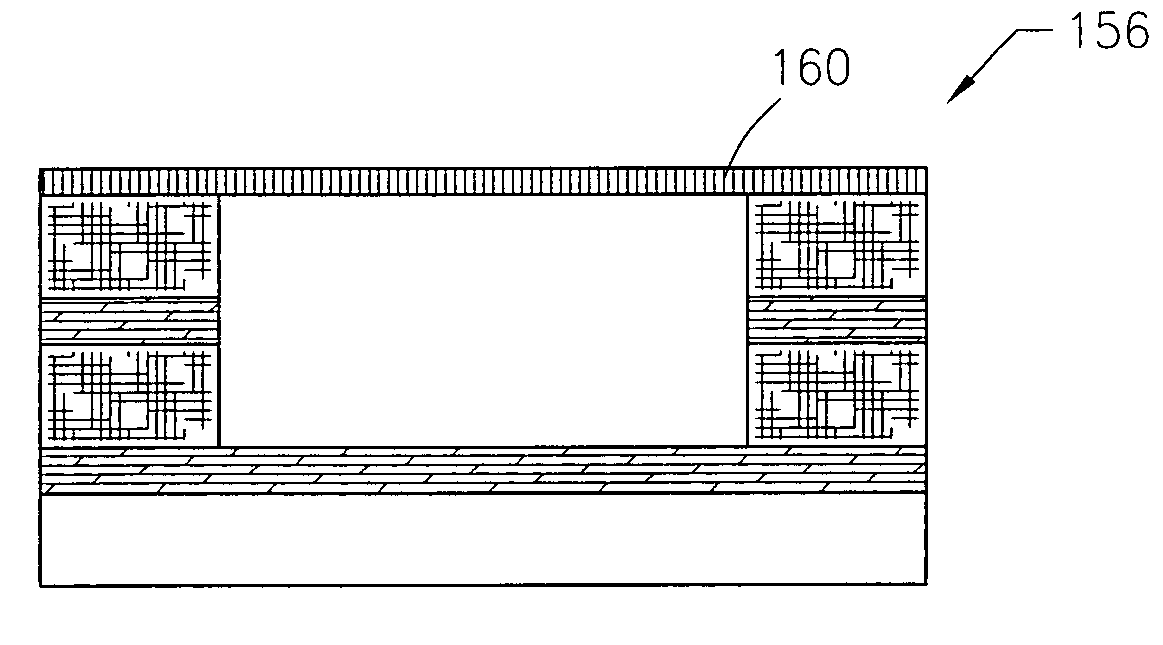

Multilayer microcavity devices and methods

InactiveUS7144486B1Rapid Detection AnalysisImmobilised enzymesBioreactor/fermenter combinationsConductive materialsPolyimide membrane

Microcavities and micropores that are microscopic (<1 mm) in width and depth and contain any number of individually-addressable electrodes, separated by insulators, along the walls of each cavity. The conducting materials, and the insulator materials can be deposited alternately onto a starting substrate, which is typically an oxidized silicon wafer or polyimide film, but may be any substrate that shows good adhesion to the materials layered on it. The cavities are etched through these layers, perpendicular to the plane of the substrate, exposing the layers at their edges. Pores may be carved entirely through the device.

Owner:SMITHKLINE BECKMAN CORP +1

Methods And Devices For Fractional Ablation Of Tissue

InactiveUS20080183162A1Altered mechanical propertyTighten the skinUltrasound therapyElectrotherapyMedicineElectromagnetic radiation

Owner:PALOMAR MEDICAL TECH

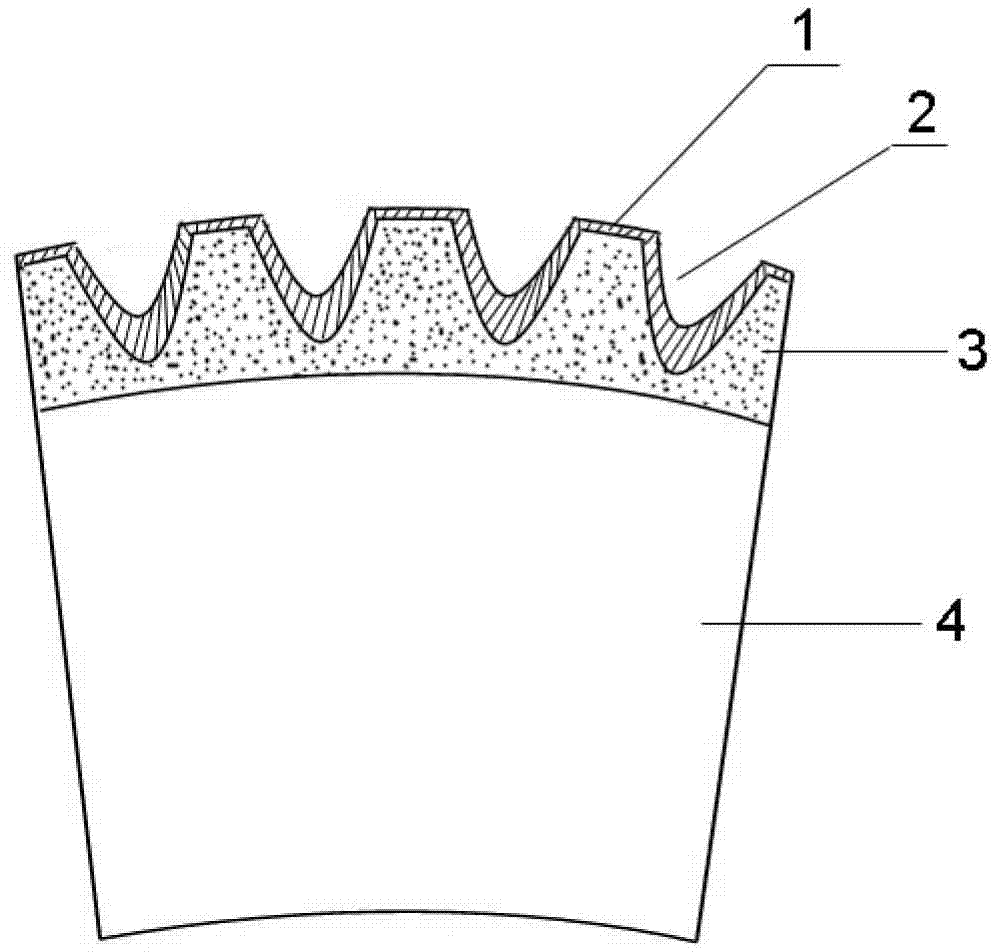

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

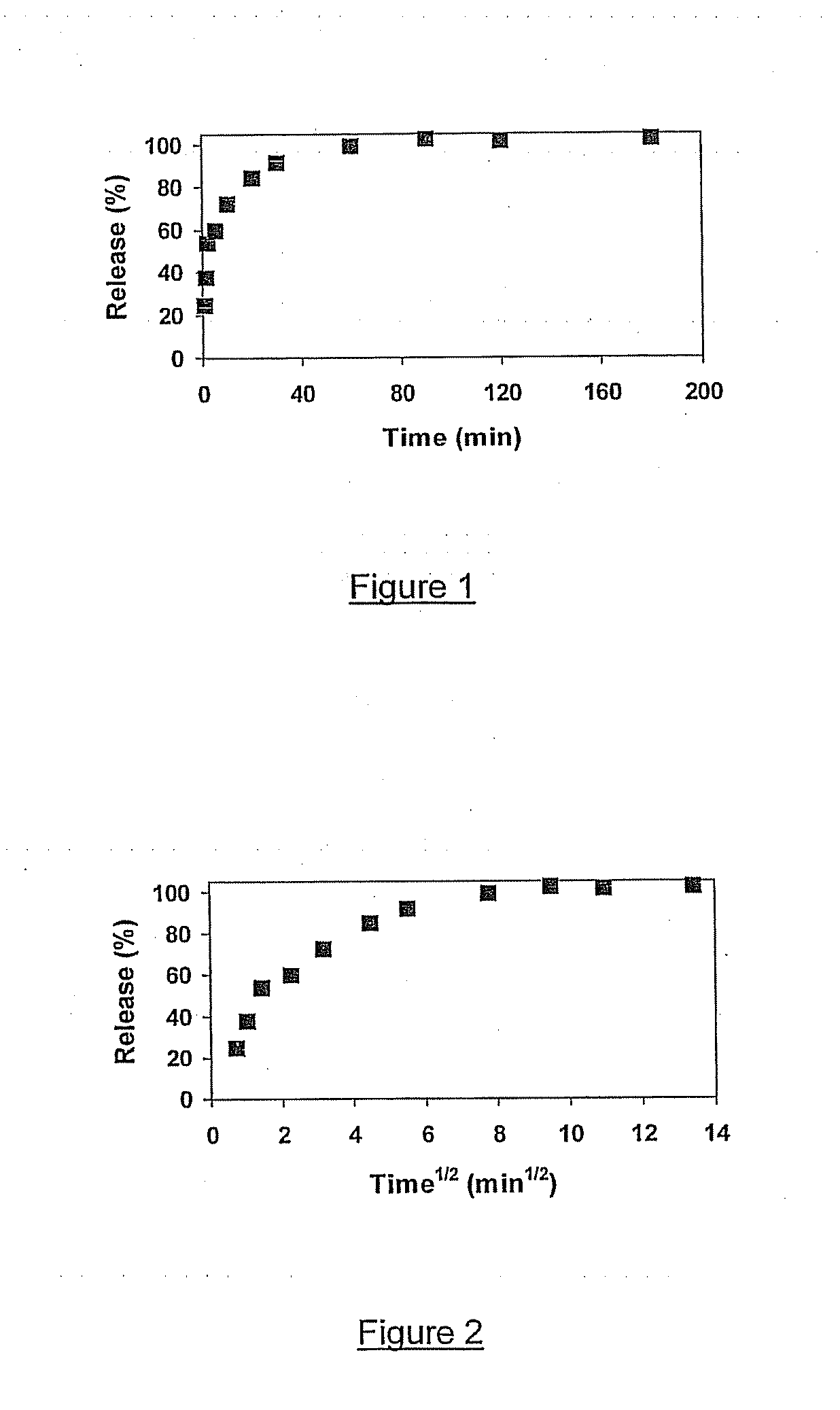

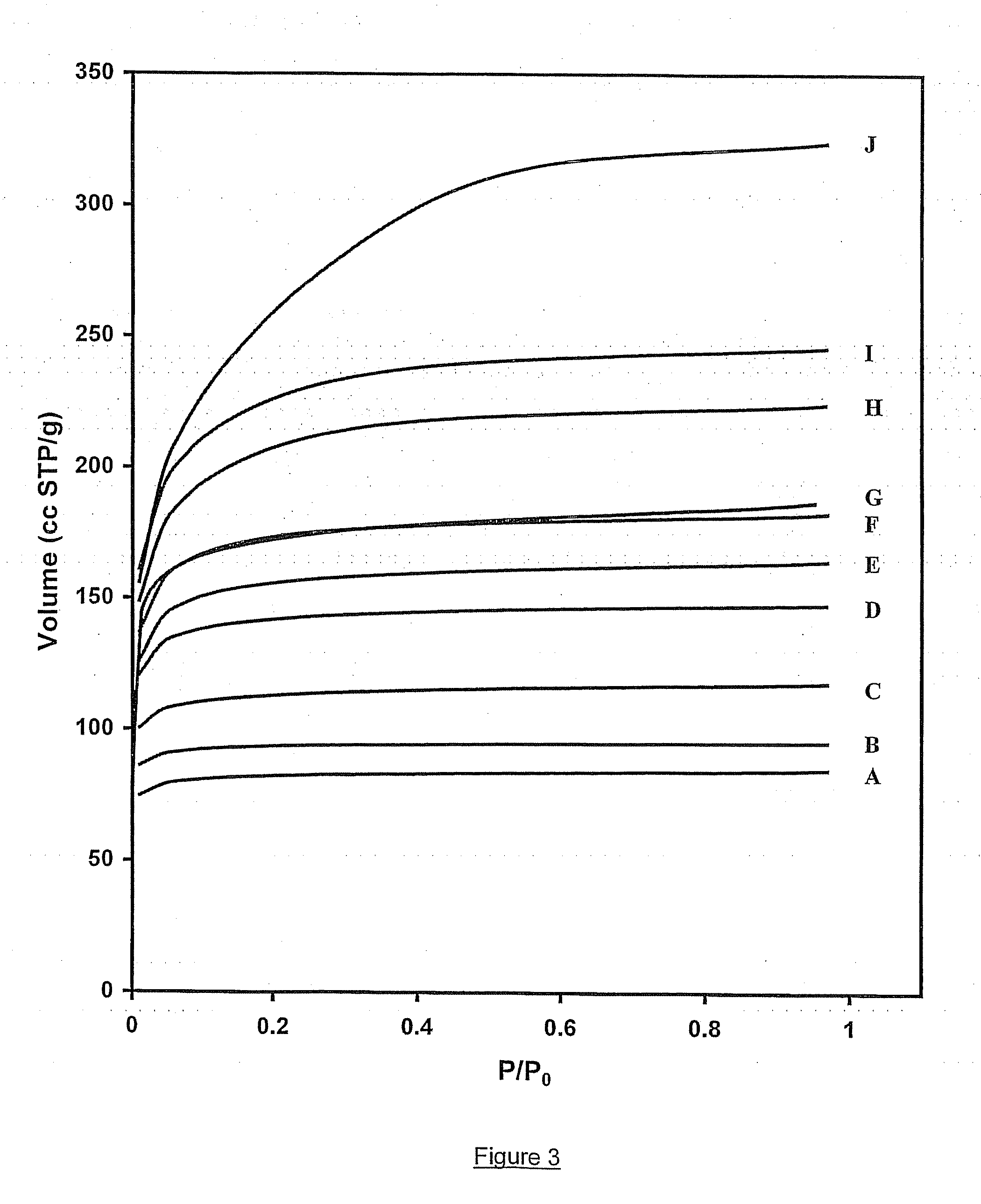

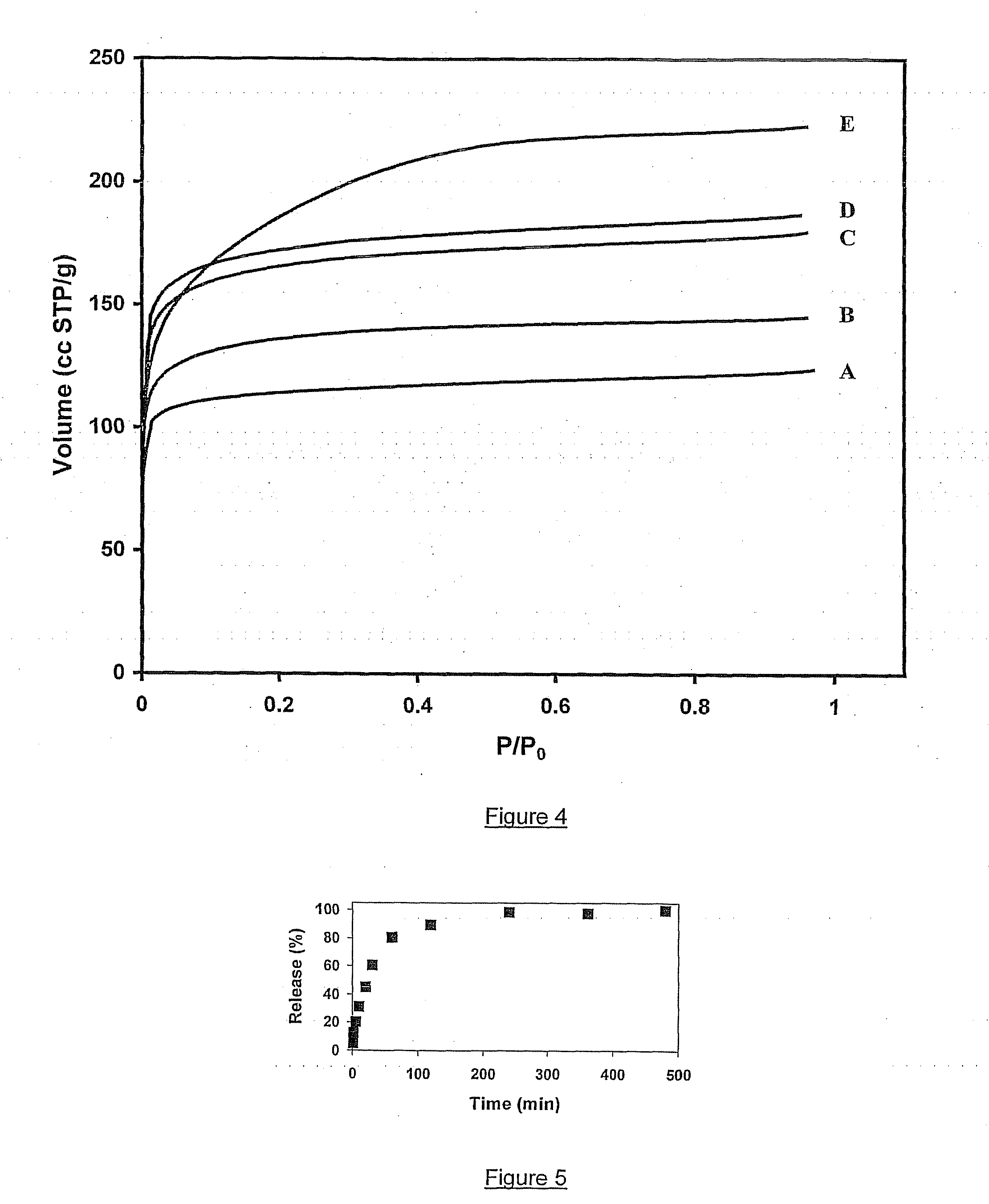

Controlled Release Delivery System for Bio-Active Agents

ActiveUS20070275068A1Easy loadingEasy to optimizePowder deliverySilicaControlled releaseActive agent

The invention provides a controlled release delivery system comprising a bio-active compound and a matrix carrier, wherein said matrix carrier is an amorphous microporous non-fibrous silicon or titanium oxide being loaded with said bio-active compound and wherein the micropores of said matrix carrier have a mean size in the range of 0.4 to 2.0 nm.

Owner:K U LEUVEN RES & DEV

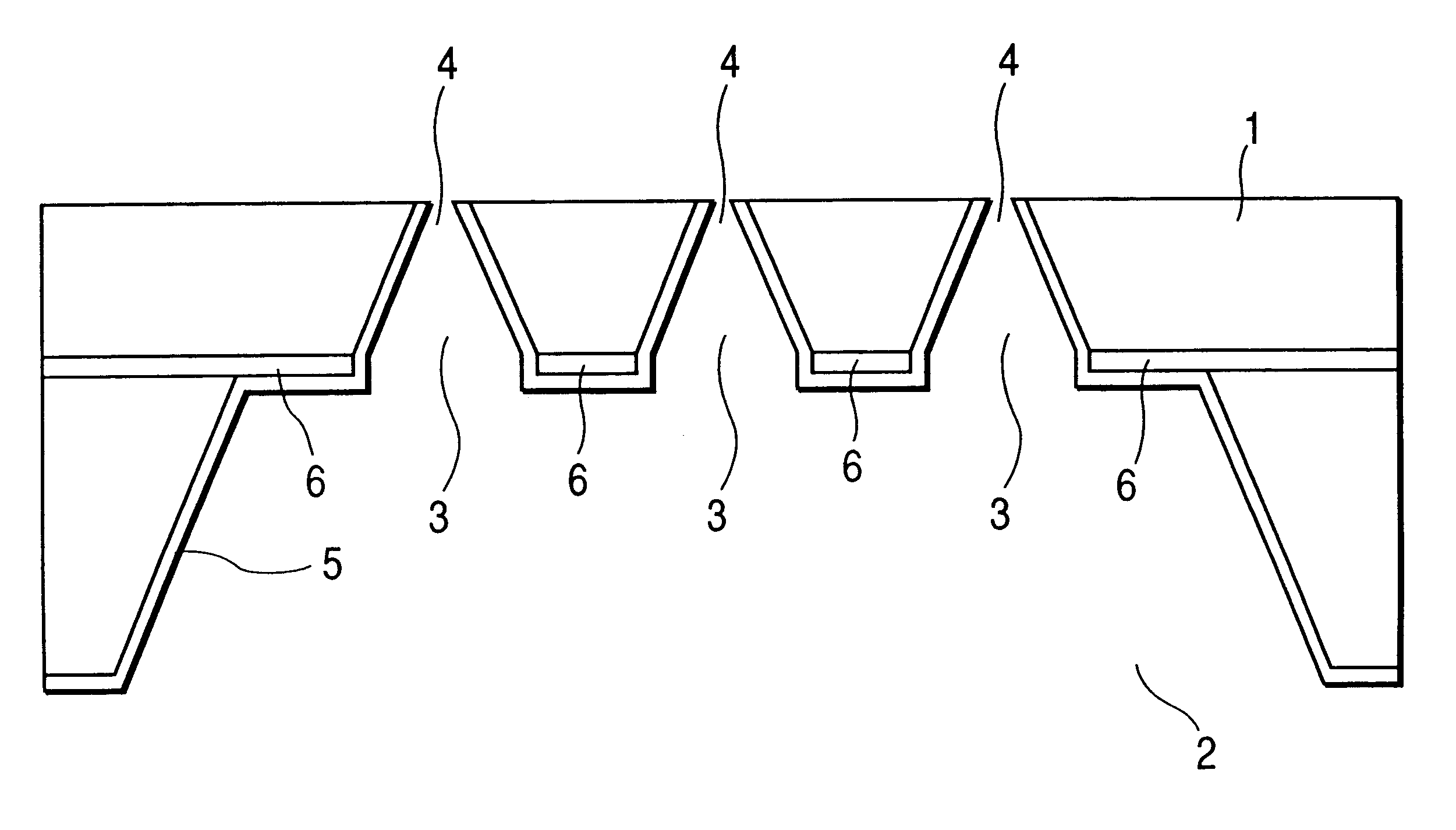

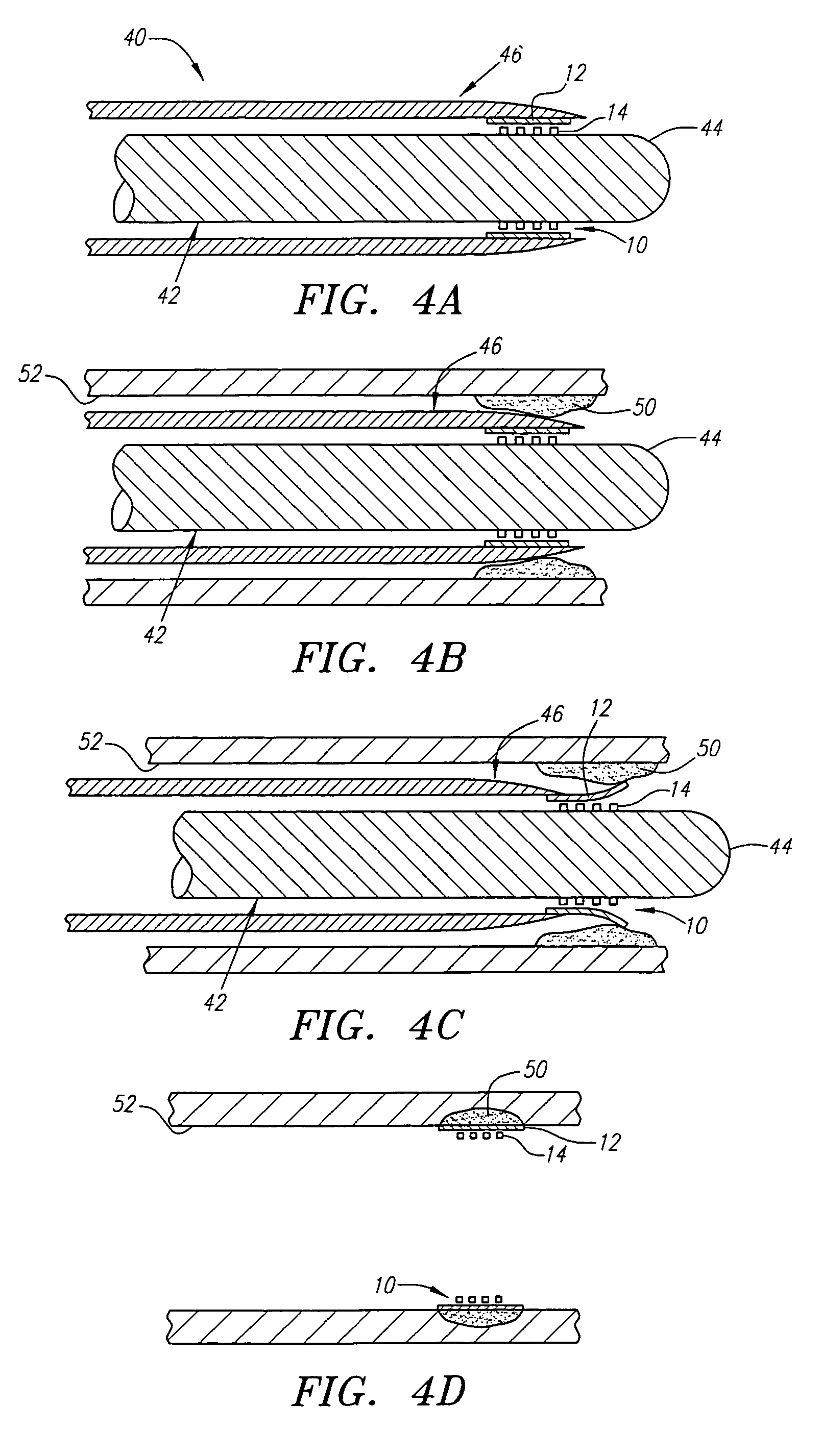

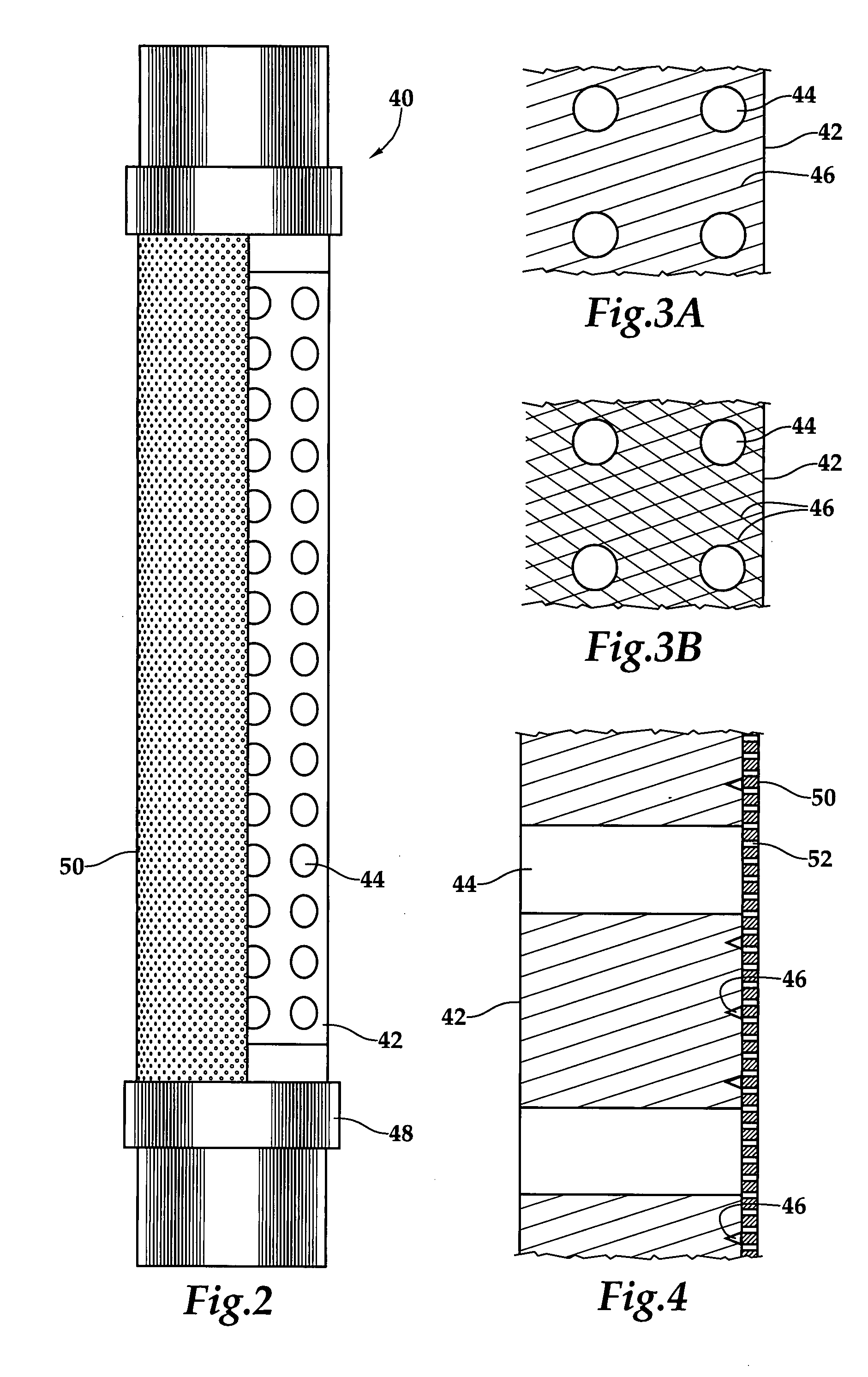

Sand control screen having a micro-perforated filtration layer

InactiveUS20080217002A1Easy to cleanEasy to manufactureFluid removalDrinking water installationFiltrationMaterial Perforation

A sand control screen (40) includes a perforated base pipe (42) and a filter layer (50) that has micro-perforations (52) therein. The filter layer (50) is attached to the base pipe (42) along the entire length of the filter layer (50). Channels (46) are formed between the base pipe (42) and the filter layer (50) to allow fluid to flow therebetween. The sand control screen (40) is formed by micro-perforating a length of material, such as sheet metal, to form the filter layer (50), creating channels (46) that will allow fluids to flow between the base pipe (42) and filter layer (50), wrapping the filter layer (50) around the base pipe (42), attaching the filter layer (50) to the base pipe (42) along the length of the filter layer (50) and creating a seam between the two edges of the filter layer (50).

Owner:HALLIBURTON ENERGY SERVICES INC

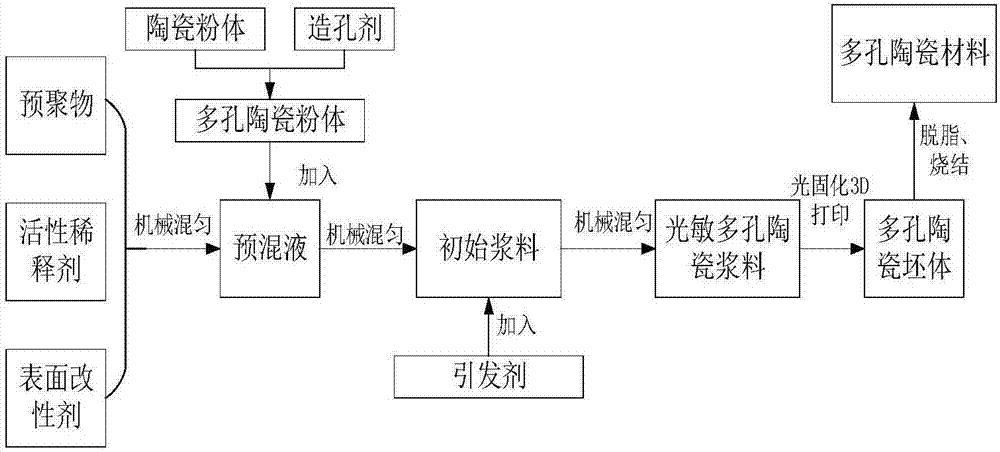

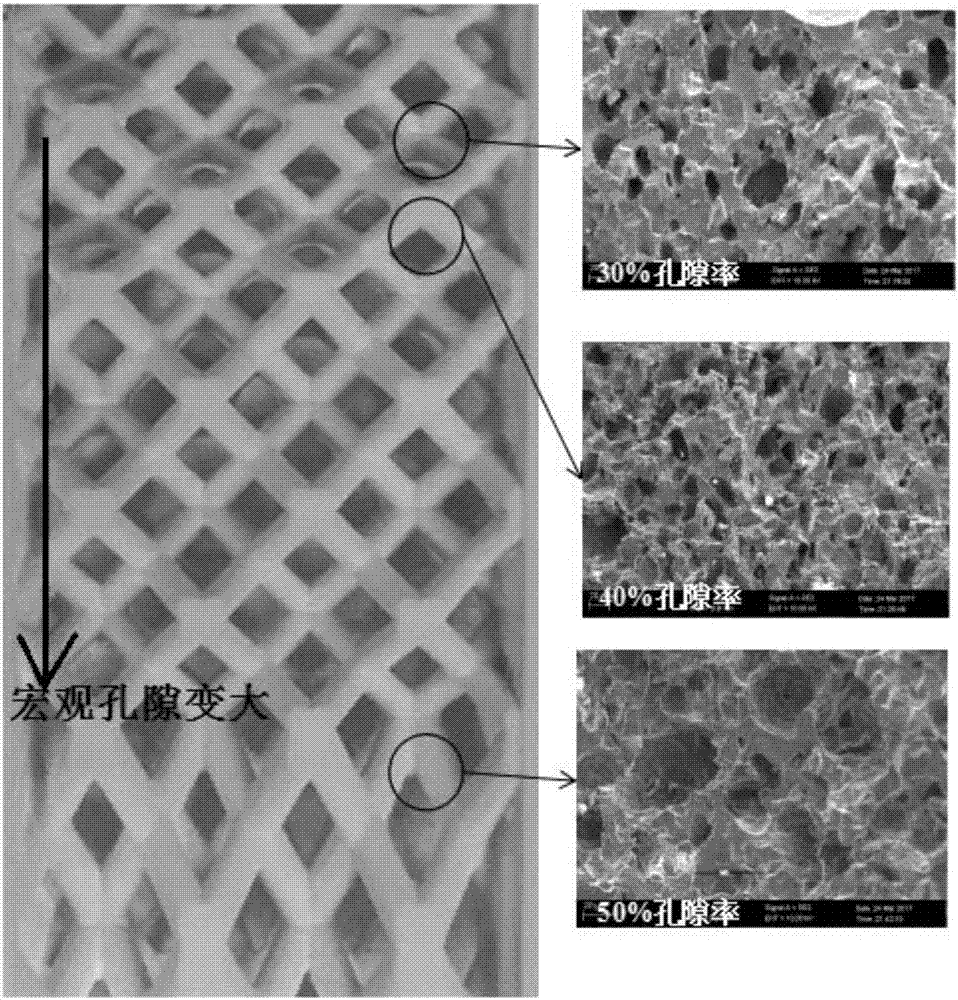

Preparation method of porous ceramic material rapidly formed based on photocuring

InactiveCN107032798AHigh porosityControllable shapeAdditive manufacturing apparatusCeramicwareDiluentSlurry

Provided is a preparation method of a porous ceramic material rapidly formed based on photocuring. The preparation method comprises the steps that firstly, a photo-cured resin prepolymer, an active diluent and a surface modifier are evenly mixed to obtain a premixed solution, ceramic powder and a pore-forming agent are mixed to obtain porous ceramic powder, then the porous ceramic powder is mixed in the premixed solution to obtain primary slurry, and then a photoinitiator is added to prepare a photocured porous ceramic slurry; the ceramic slurry is put in a photocuring forming device to prepare a photocuring forming blank; finally the blank is degreased and sintered to obtain the porous ceramic material. By designing and optimizing the components and proportion of the photocured porous ceramic slurry and using a photocuring 3D printing device, the limitations of traditional mold processing to shapes are overcome. The micropores formed by adopting the pore-forming agent and macropores for 3D printing are combined, and the high-porosity foam ceramic material can be prepared. In addition, the macropores are controllable in shape and distribution, and gradient porous ceramic material can be prepared.

Owner:TSINGHUA UNIV

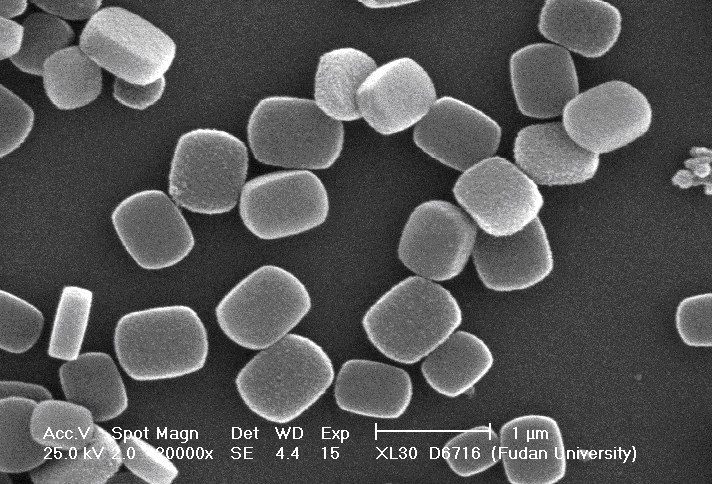

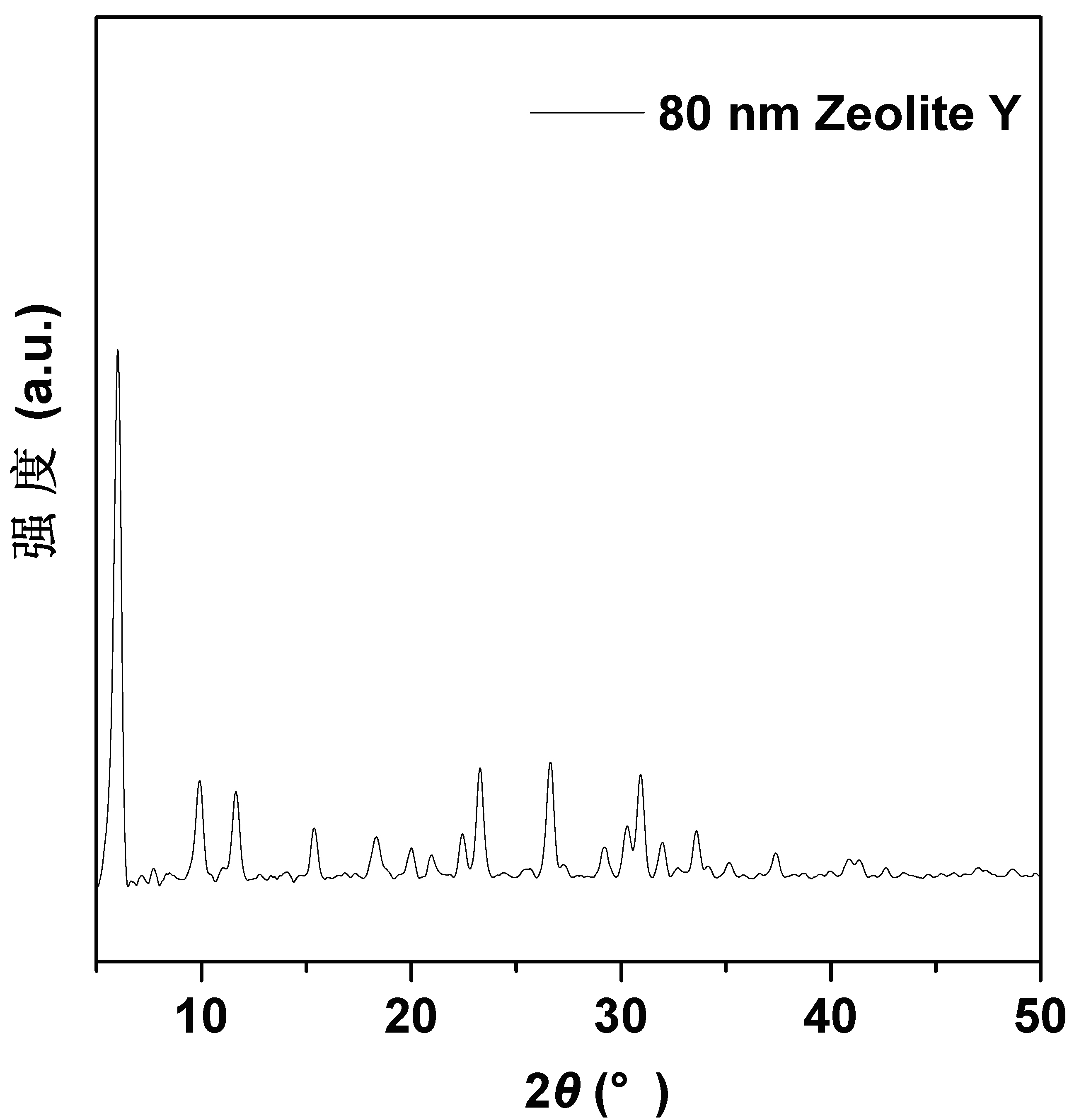

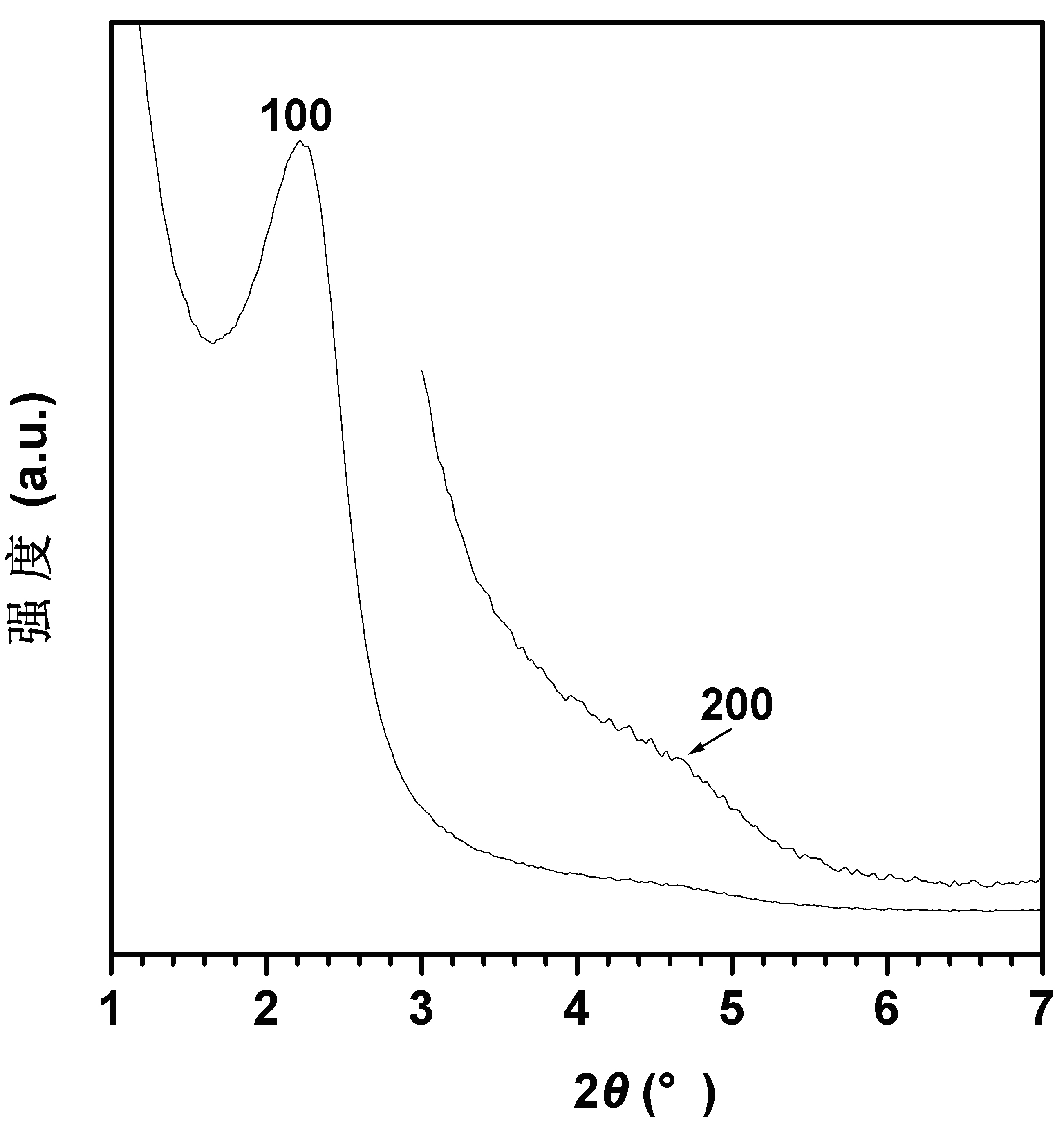

Preparation method for mesopore-micropore core-shell composite molecular sieve catalyst

ActiveCN101890363AMaintain microporosityHigh and adjustable microporosityMolecular sieve catalystsSilicon oxideSolution phase

The invention belongs to the technical field of material preparation and oil chemical engineering, and in particular discloses a preparation method for a mesopore-micropore core-shell composite molecular sieve catalyst. Zeolite particles are dispersed in organic solvent / water mixed solution which contains cationic surfactant and alkali under the action of ultrasound, and then silicon or silicon-aluminum species are introduced into the mixed solution to obtain a mesopore-micropore core-shell composite molecular sieve by solution phase self-assembly and a sol-gel process, wherein micropore zeolite serves as a core, and mesopore silicon oxide or aluminum-containing mesopore silicon oxide serves as a shell layer. The obtained composite molecular sieve has a retained zeolite micropore framework and an ordered two-dimensional hexagonal mesopore structure, a mesopore path is vertical with the surface of the zeolite particles, the path has high openness, the thickness of the mesopore shell layer is adjustable, and after the mesopore shell is packed, the mesopore-micropore can maintain high un-obstruction. The method has the advantages of simple operation, low raw material cost, low equipment requirement and the like.

Owner:上海介孔谷新材料发展有限公司

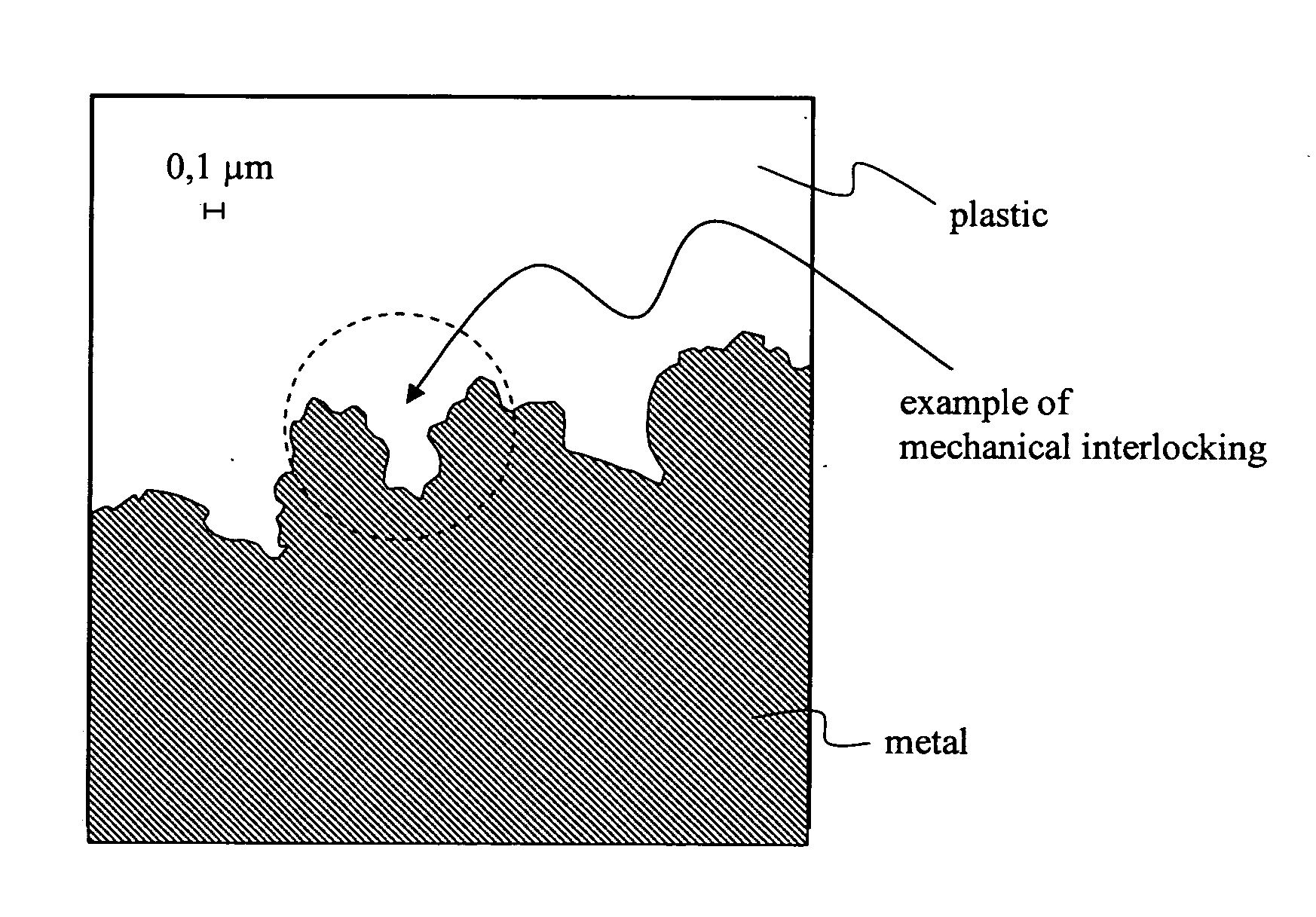

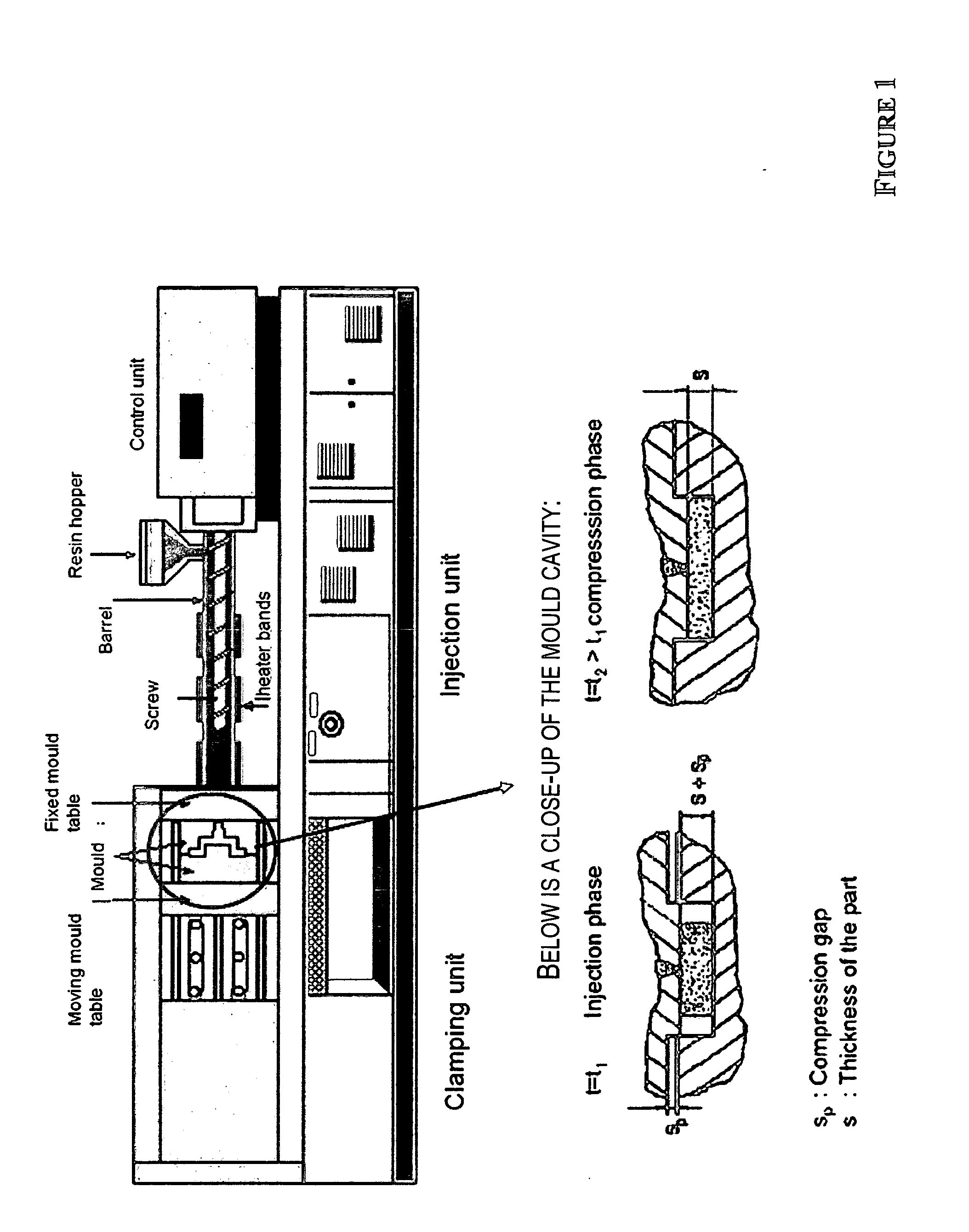

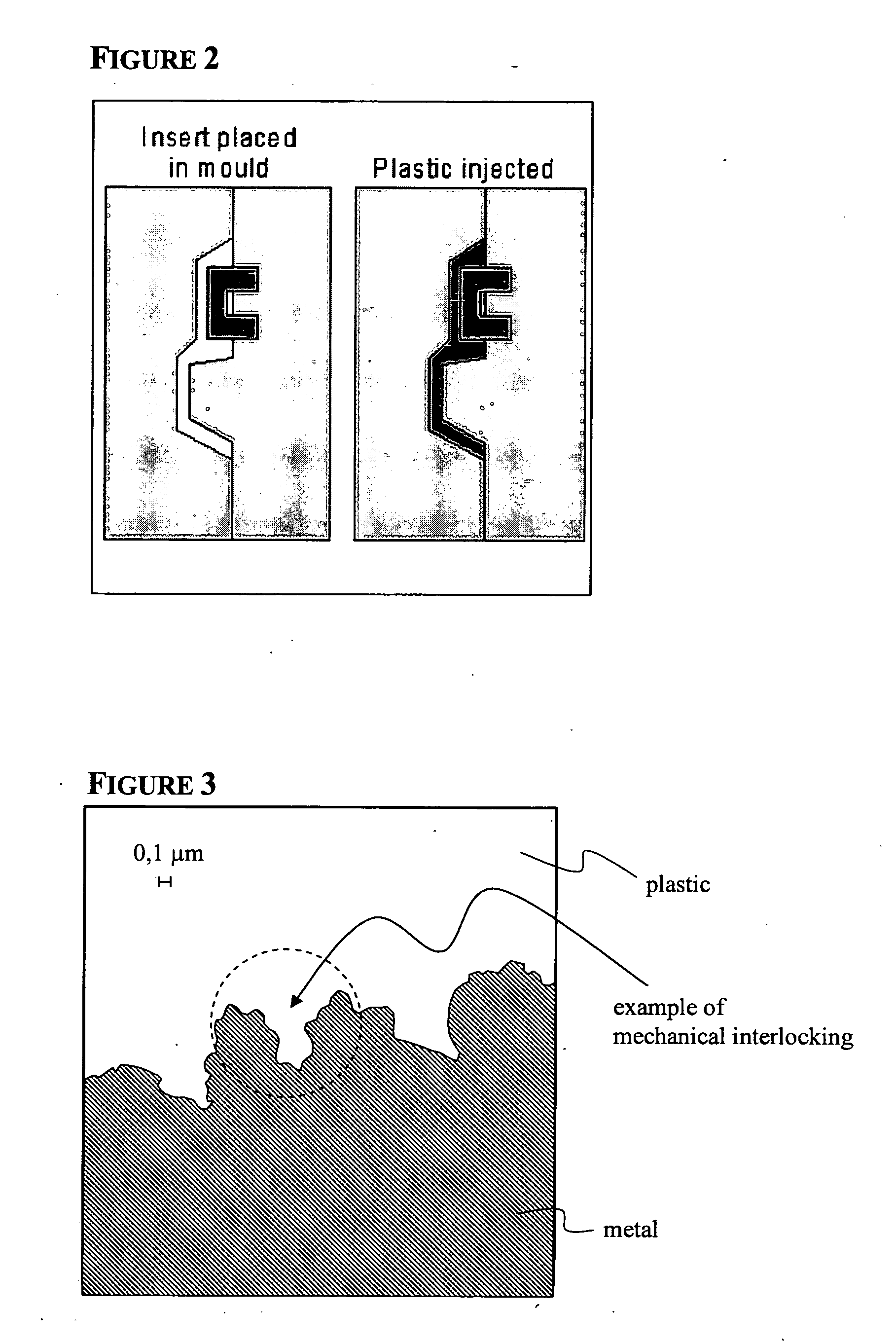

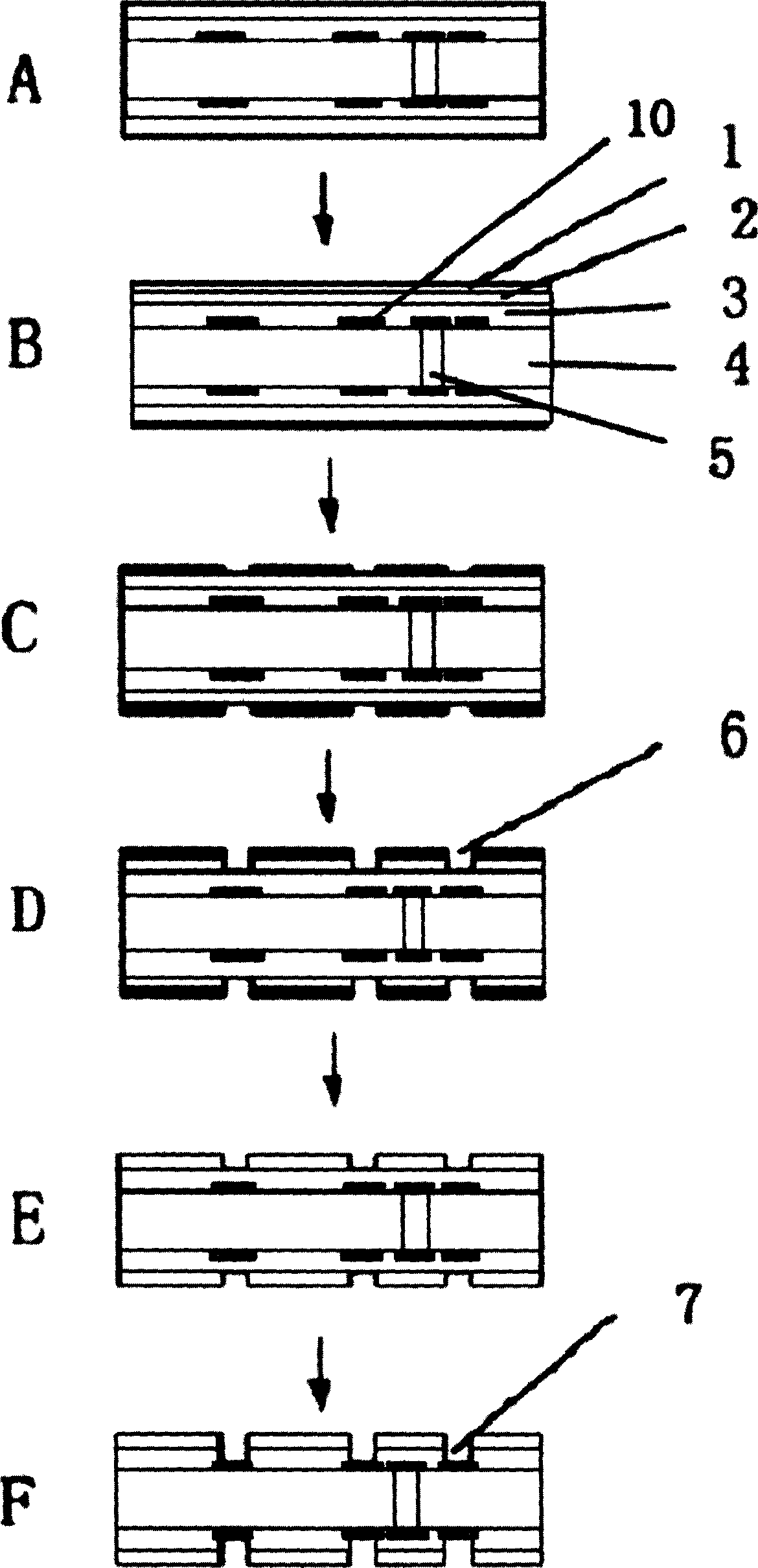

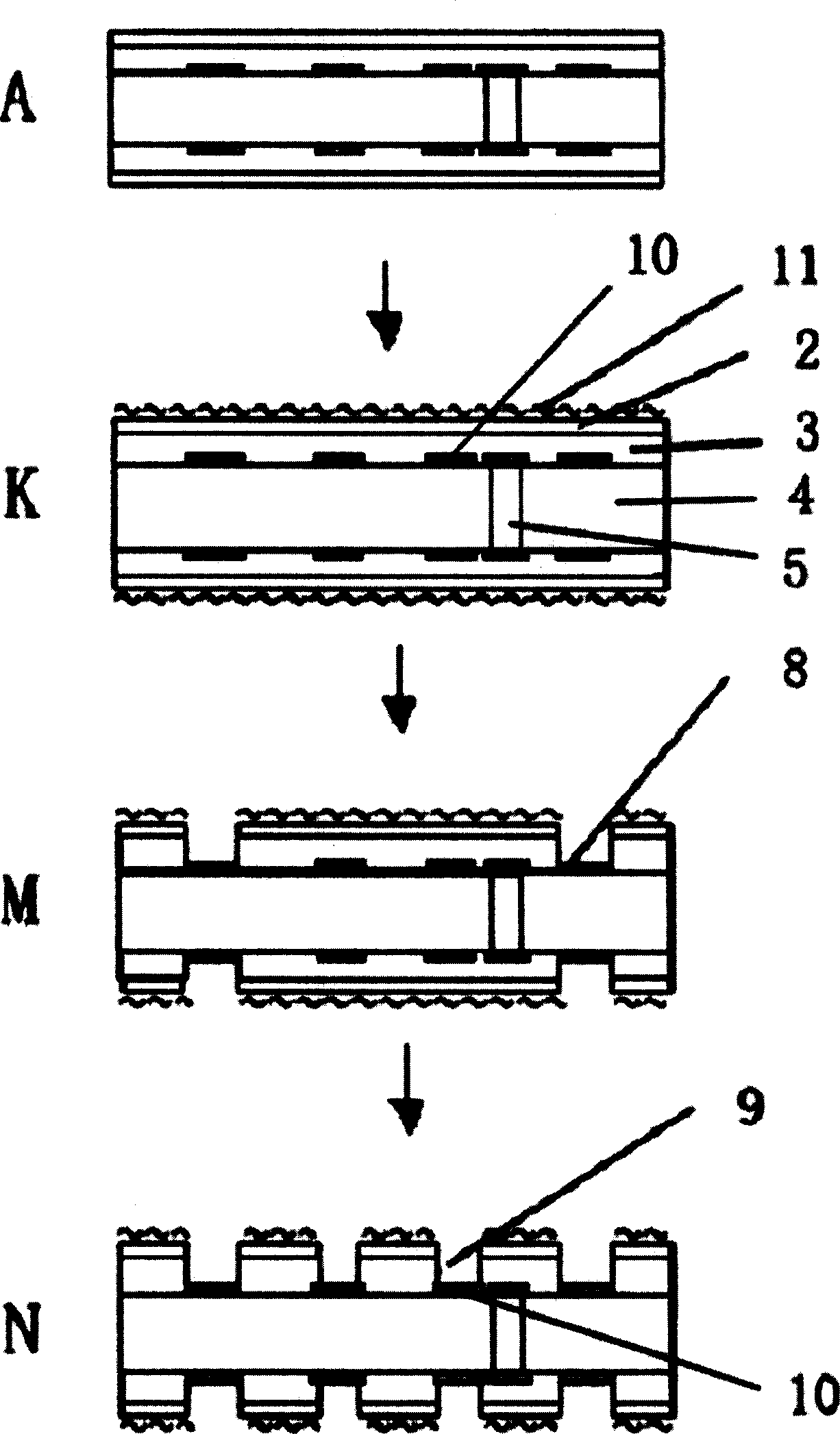

Plastic-acceptor hybrid components

InactiveUS20080070001A1High bonding strengthLess internal stressRecord information storageMagnetic recordingEngineeringInjection moulding

The present invention relates generally to plastic-acceptor hybrid components and, more particularly, to the direct bonding of over-moulded plastics to an acceptor insert, such as a metal, in an injection moulding tool. A method and apparatus are provided allowing the production of the present plastic-acceptor hybrid components in which the bonding of said components is obtained by anchoring the plastic component in micro-holes formed in the surface of an acceptor component.

Owner:NOKIA CORP

Method of drilling a hole through Co2 laser directly

InactiveCN1761378AHigh precisionGuaranteed alignmentConductive material chemical/electrolytical removalLaser beam welding apparatusEtchingCopper foil

Drilling method of carbon dioxide laser includes steps: preparing locating point on layer next to the outer layer; before pressfitting added layer, browning oxidizing surface of target bonding pad; after pressfitting added layer, milling location hole / polishing edge, washing surface under high pressure; browning front surface of copper, thinning and coursing the surface before drilling hole by layer; first time to drill hole by laser; positioning film perforation by using plate location hole in original etching method for making window of copper, burning through copper foil and resin above the locating point on layer next to the outer layer so as to expose the locating point; second time to drill hole by laser; using the exposed locating point as position fixing to make micro hole inplate; washing surface under high pressure to remove browning layer after drill hole. The invention saves dry film and etching liquid, and raises process precision.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

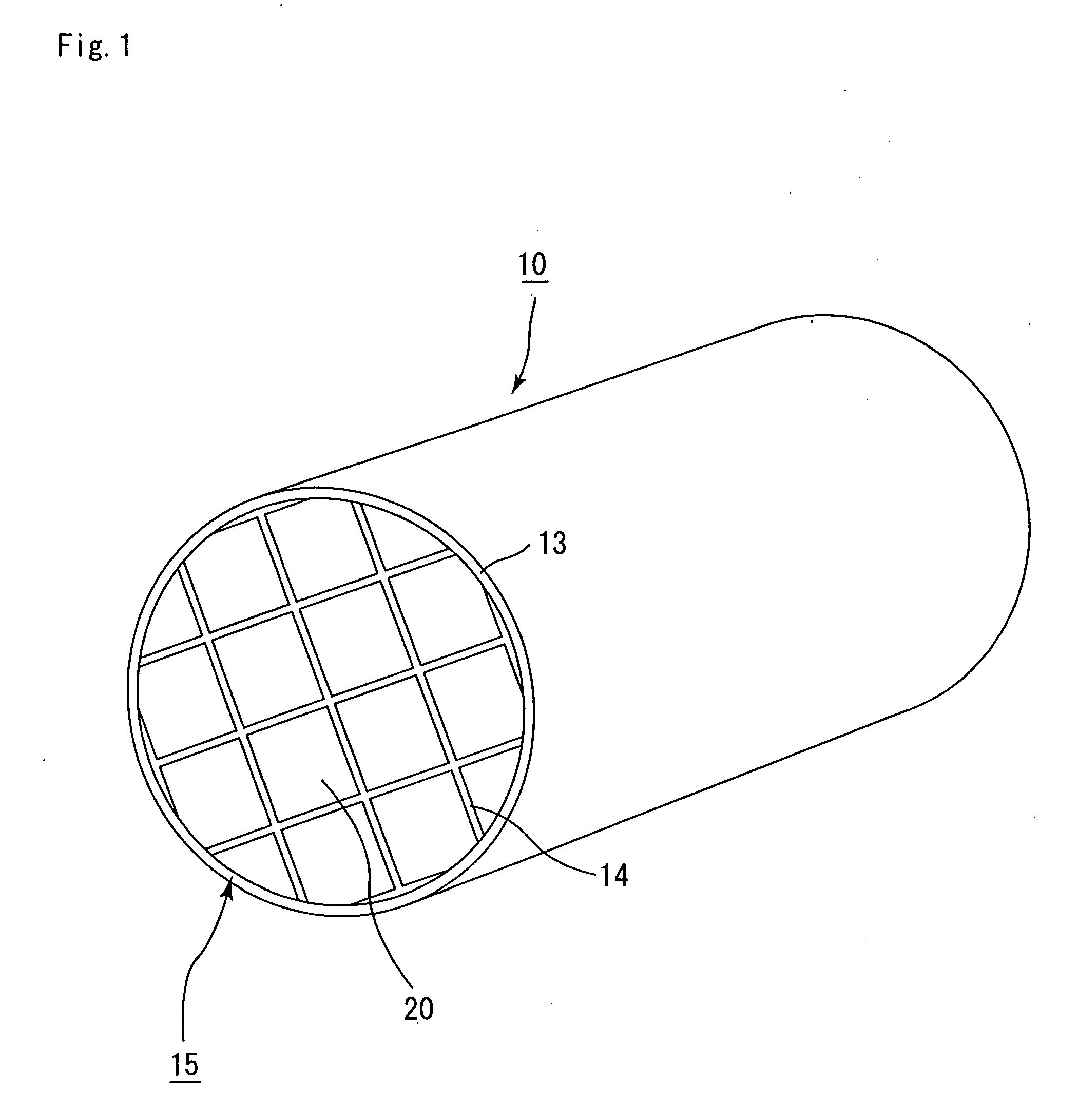

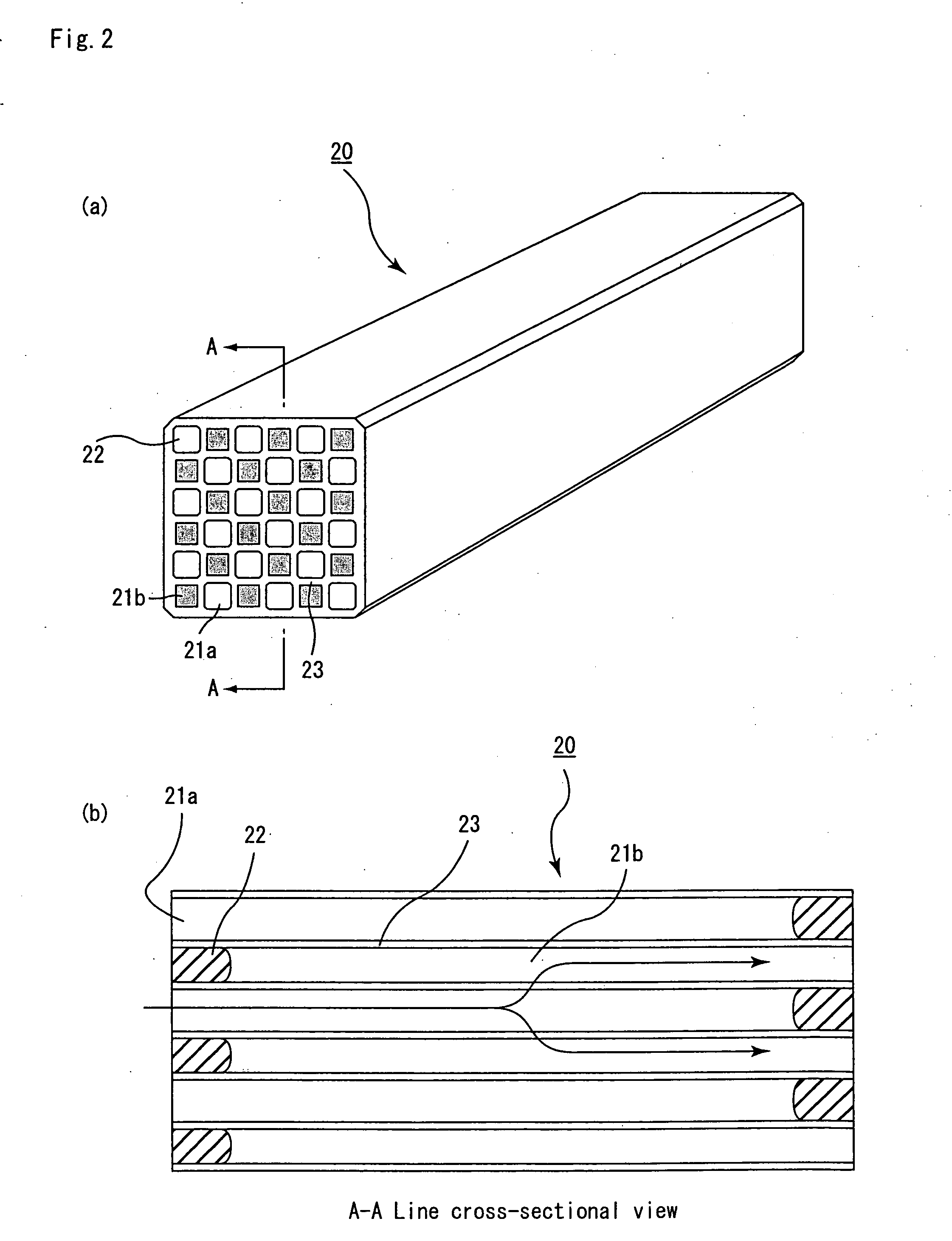

Honeycomb structural body

ActiveUS20060093784A1Made thinnerTransmission easilyPhysical/chemical process catalystsDispersed particle filtrationPore diameterHoneycomb structure

An object of the present invention is to provide a honeycomb structural body which is low in pressure loss and can prolong a period up to a regenerating process. The present invention is directed to a columnar honeycomb structural body comprising a large number of through holes placed in parallel with one another in a length direction with wall portion interposed therebetween, wherein: each of the through holes has one of ends sealed; one end face of the through hole differs in opening area from the other end face thereof; a ceramic material which constitutes the wall portion has an average pore diameter in a range from 5 to 30 μm; and the rate of capacity of micro pores each having a pore diameter two or more times larger than the average pore diameter is set to 30% or less of the capacity of the entire micro pores.

Owner:IBIDEN CO LTD

Polymer particles with additives encapsulated in microvoids

ActiveUS20100021838A1Synthetic resin layered productsCellulosic plastic layered productsPolymer sciencePorous particle

Porous particles comprising a polymer binder and at least one additive distinct from any pore stabilizing compound present in the particle, wherein: the polymer binder comprises a solid compositionally continuous phase having an external particle surface; discrete pores are dispersed within the solid compositionally continuous phase, forming internal pore surfaces; and the at least one additive is present primarily in the discrete pores. The additive may further preferably not be present in the solid compositionally continuous phase, and be substantially absent from the external particle surface. A toner set for forming a color electrophotographic image comprising a plurality of different colored toners, where at least one of the different colored toners comprise such porous particles comprising additives, and in a particular embodiment wherein at least two different colored toners each comprise different pigments present primarily in the internal pores. A process of making such porous particles.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com