Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7777results about "Magnetic recording" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified Molecular Arrays

InactiveUS20110059865A1Less reactiveAccelerated programSequential/parallel process reactionsNucleotide librariesMolecular array(Hydroxyethyl)methacrylate

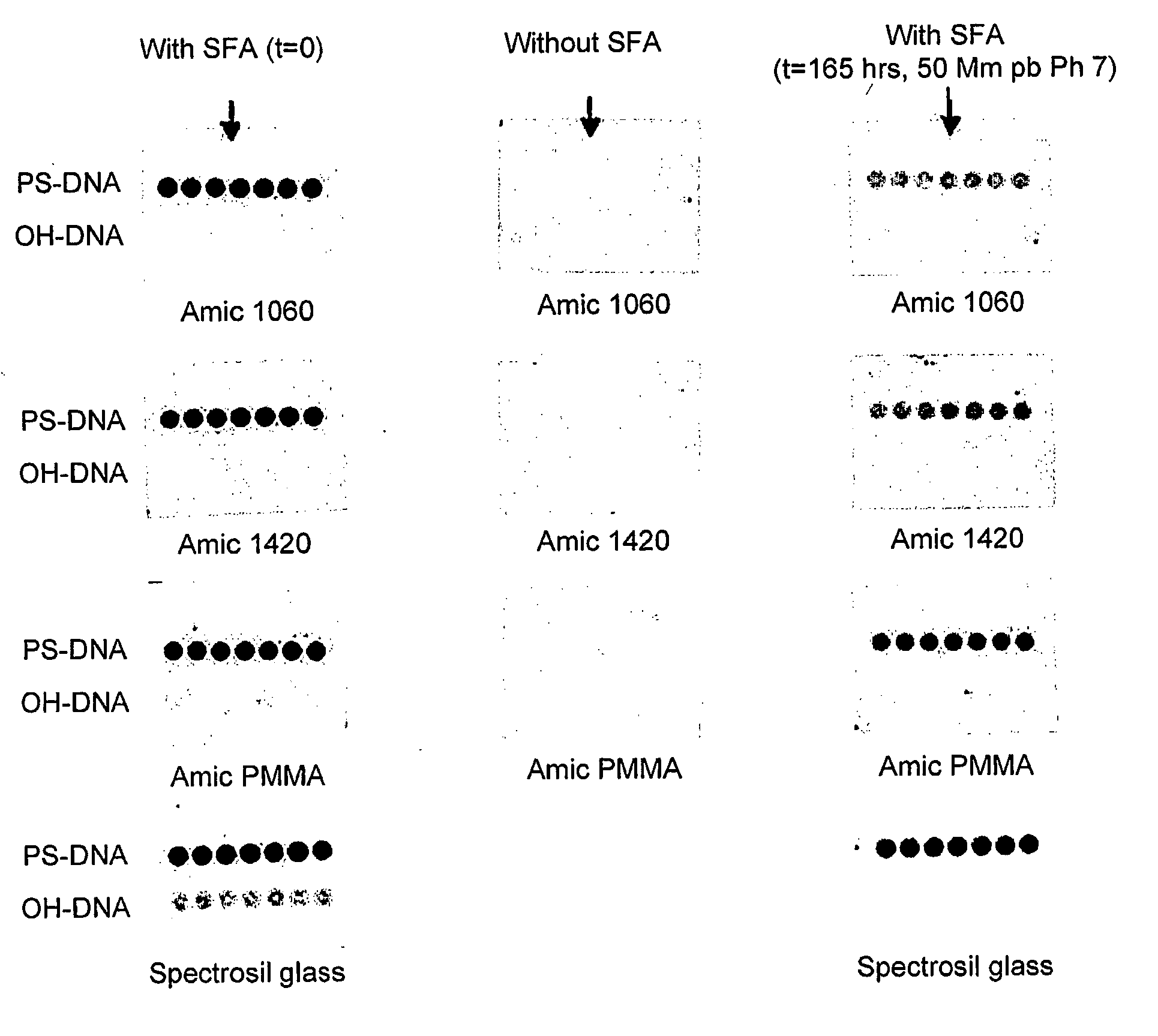

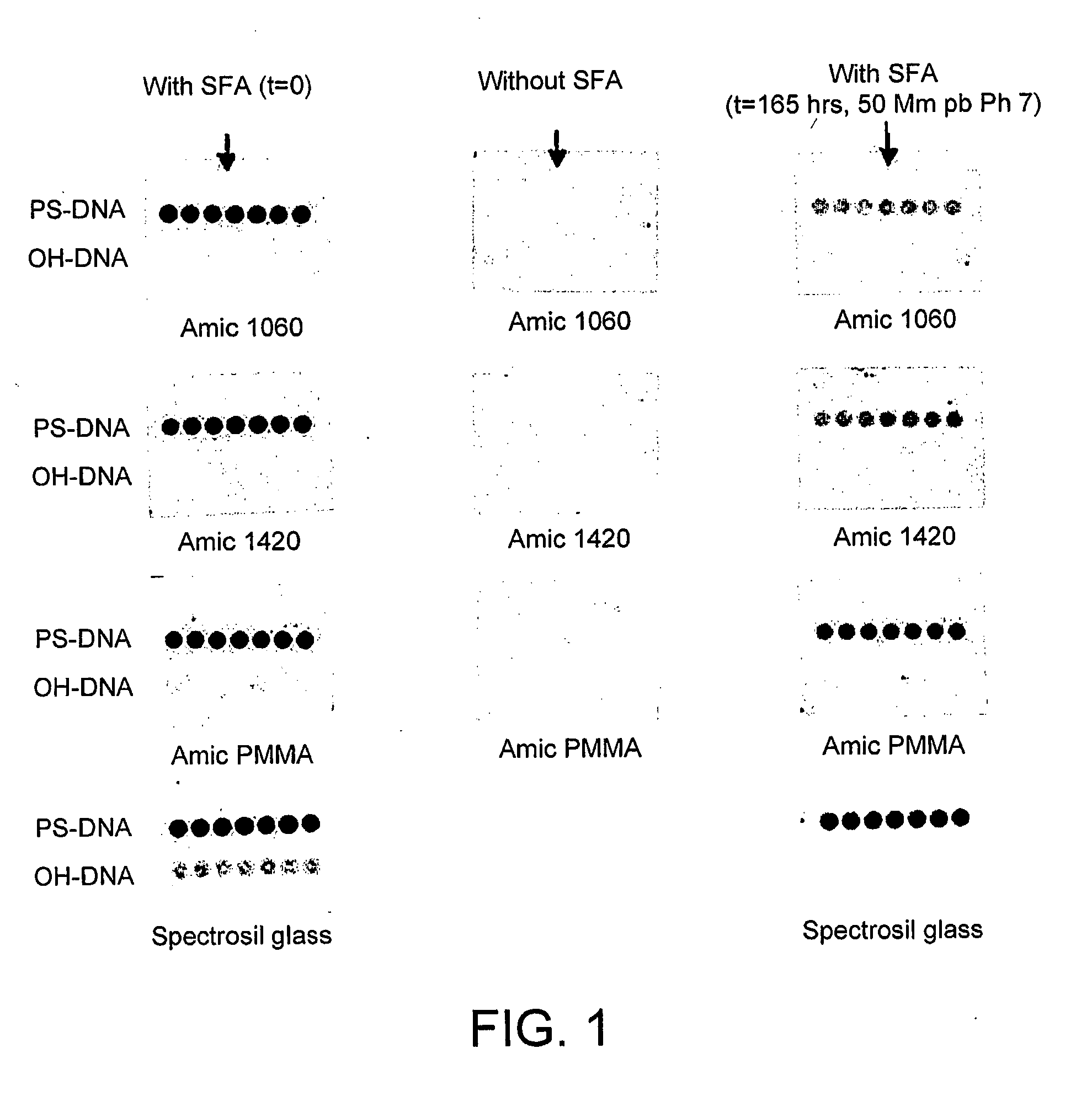

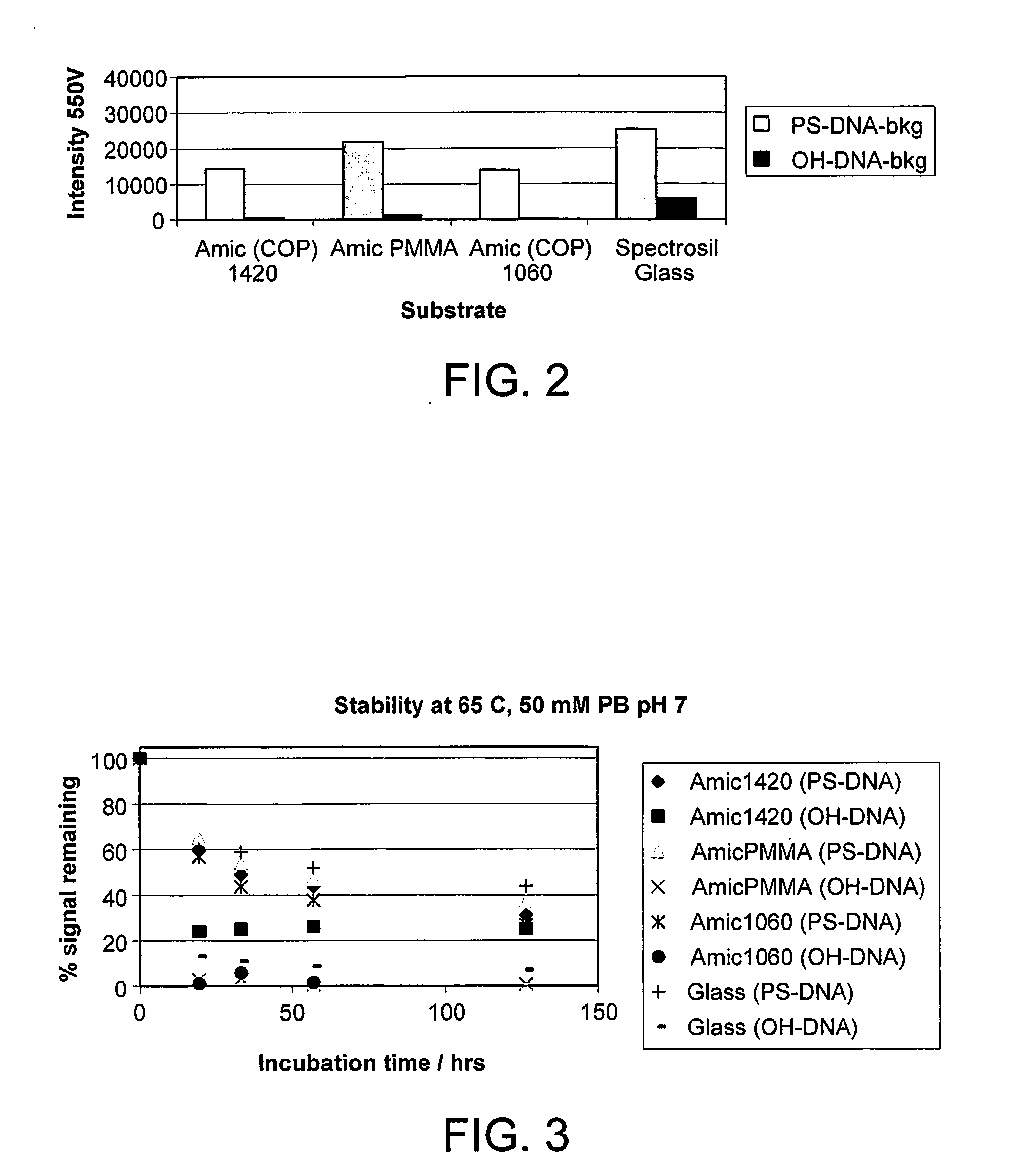

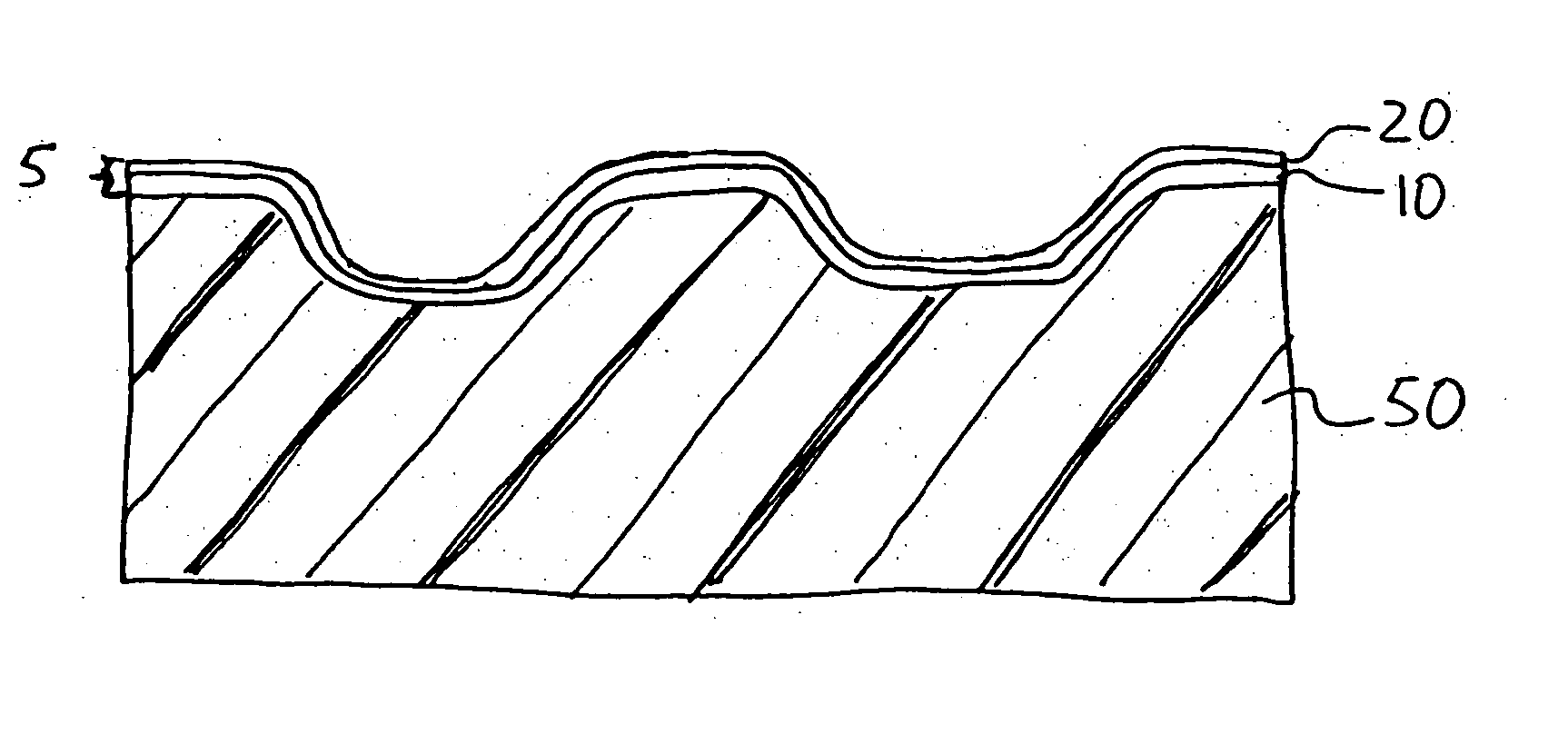

The invention relates to the preparation of a hydrogel surface useful in the formation and manipulation of arrays of molecules, particularly polynucleotides and to the chemical modification of these and other arrays. In particular, the invention relates to a method of preparing a hydrogel immobilised to a solid support comprising polymerising on the support a mixture of a first comonomer which is acrylamide, methacrylamide, hydroxyethyl methacrylate or N-vinyl pyrrolidinone and a second comonomer which is a functionalised acrylamide or acrylate.

Owner:ILLUMINA CAMBRIDGE LTD

Nanoparticle coatings for flexible and/or drawable substrates

ActiveUS20050287348A1Better able to withstandHigh glossPretreated surfacesRecord information storageNanometreMaterials science

Owner:PPG IND OHIO INC

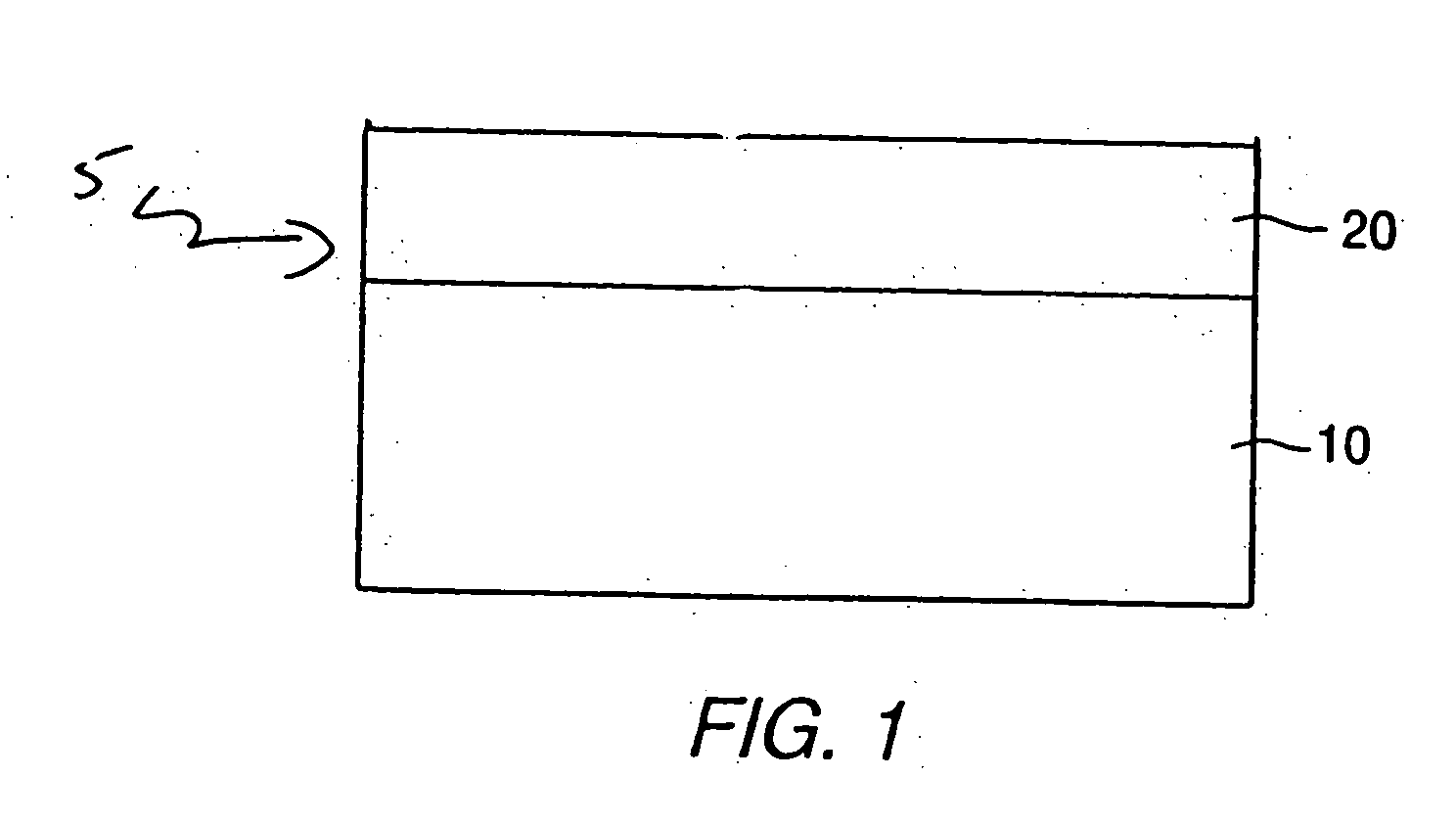

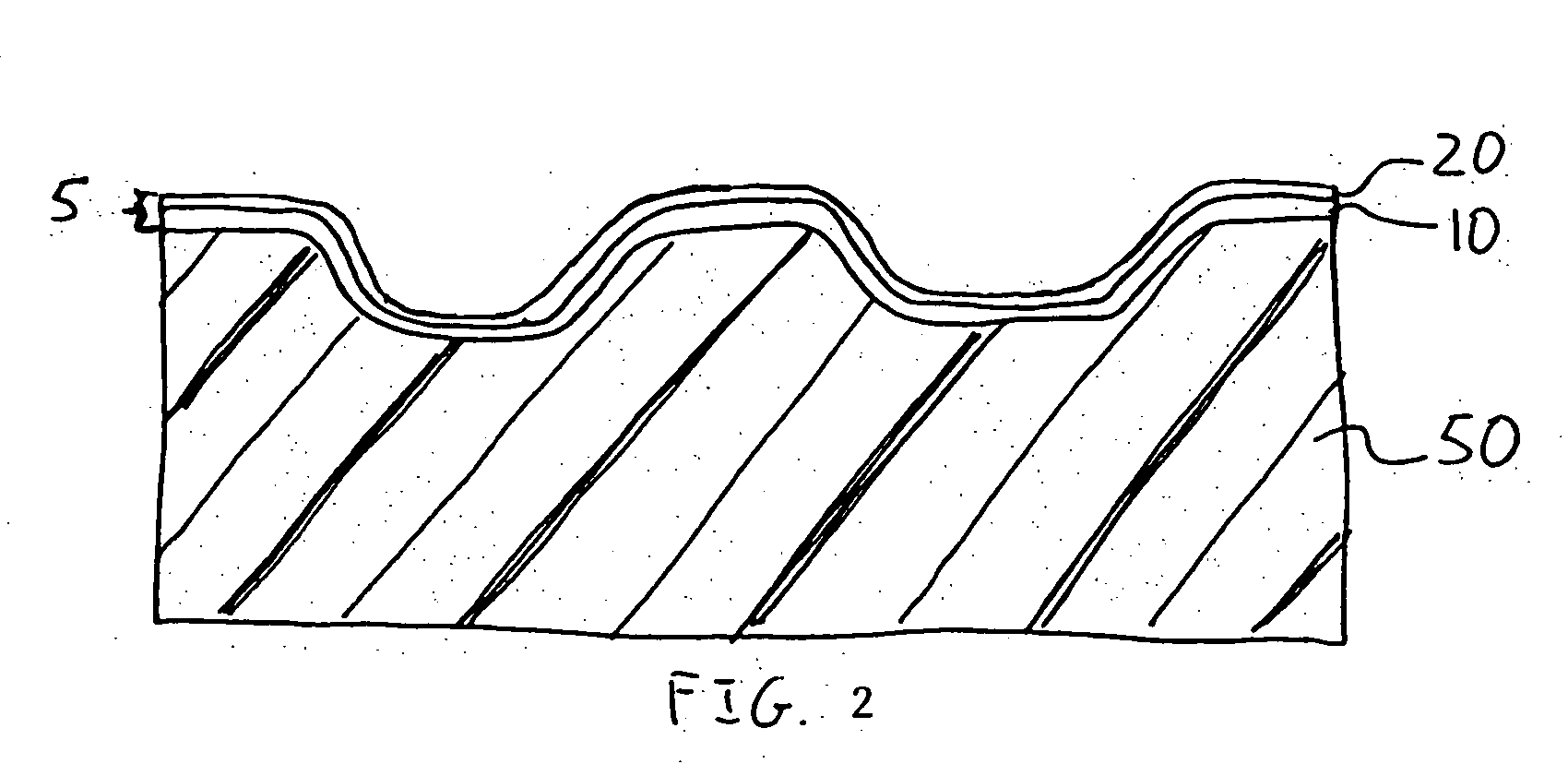

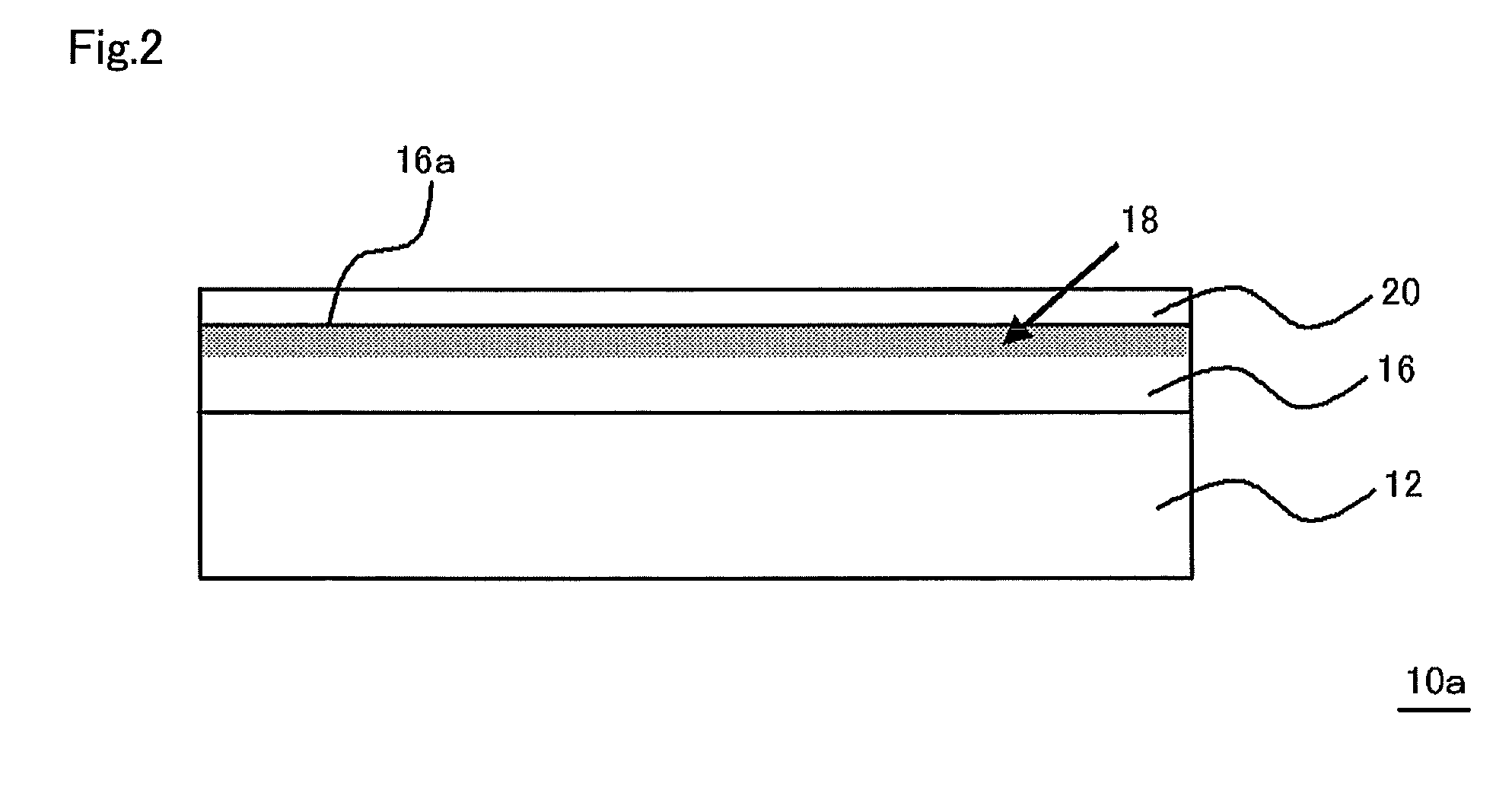

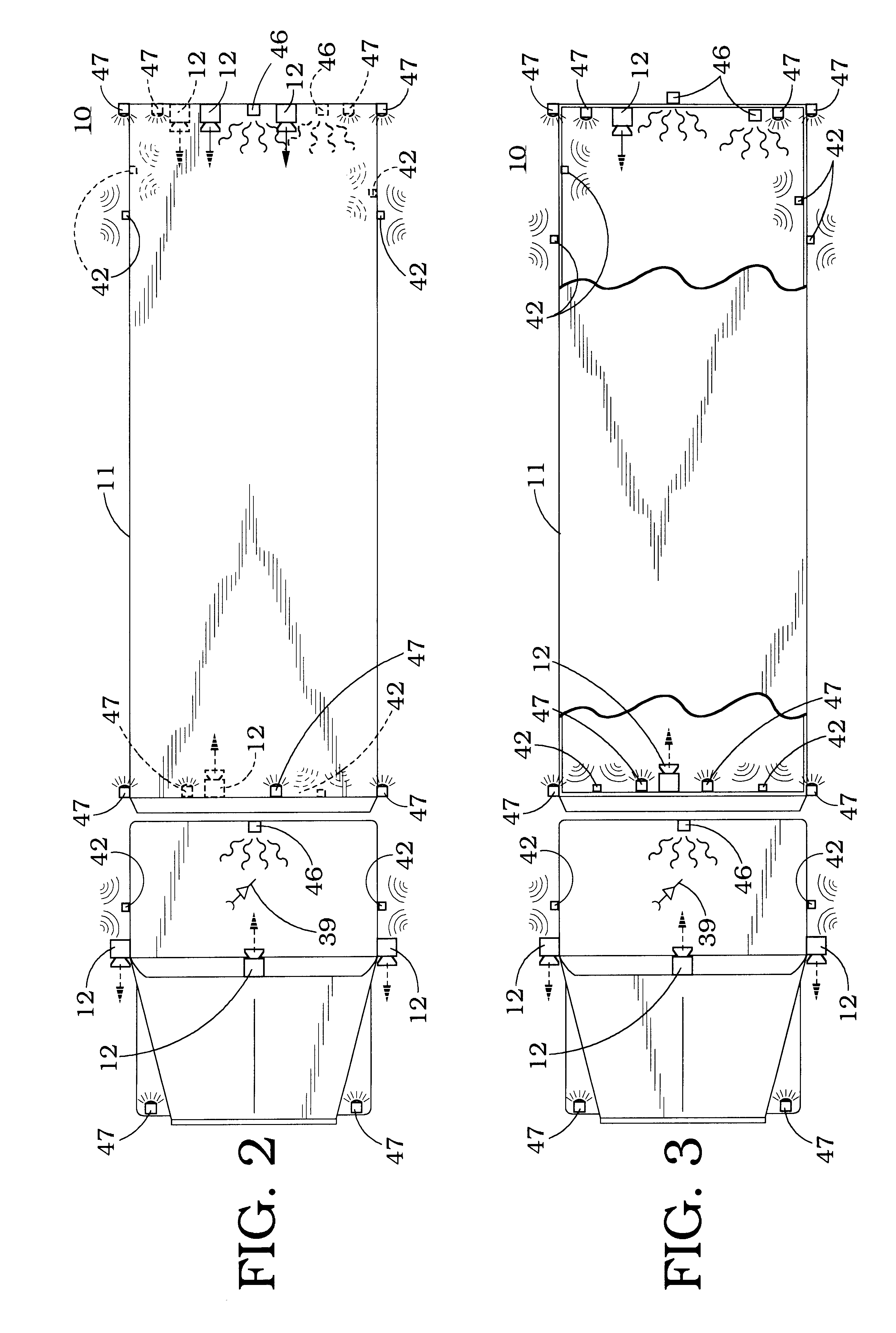

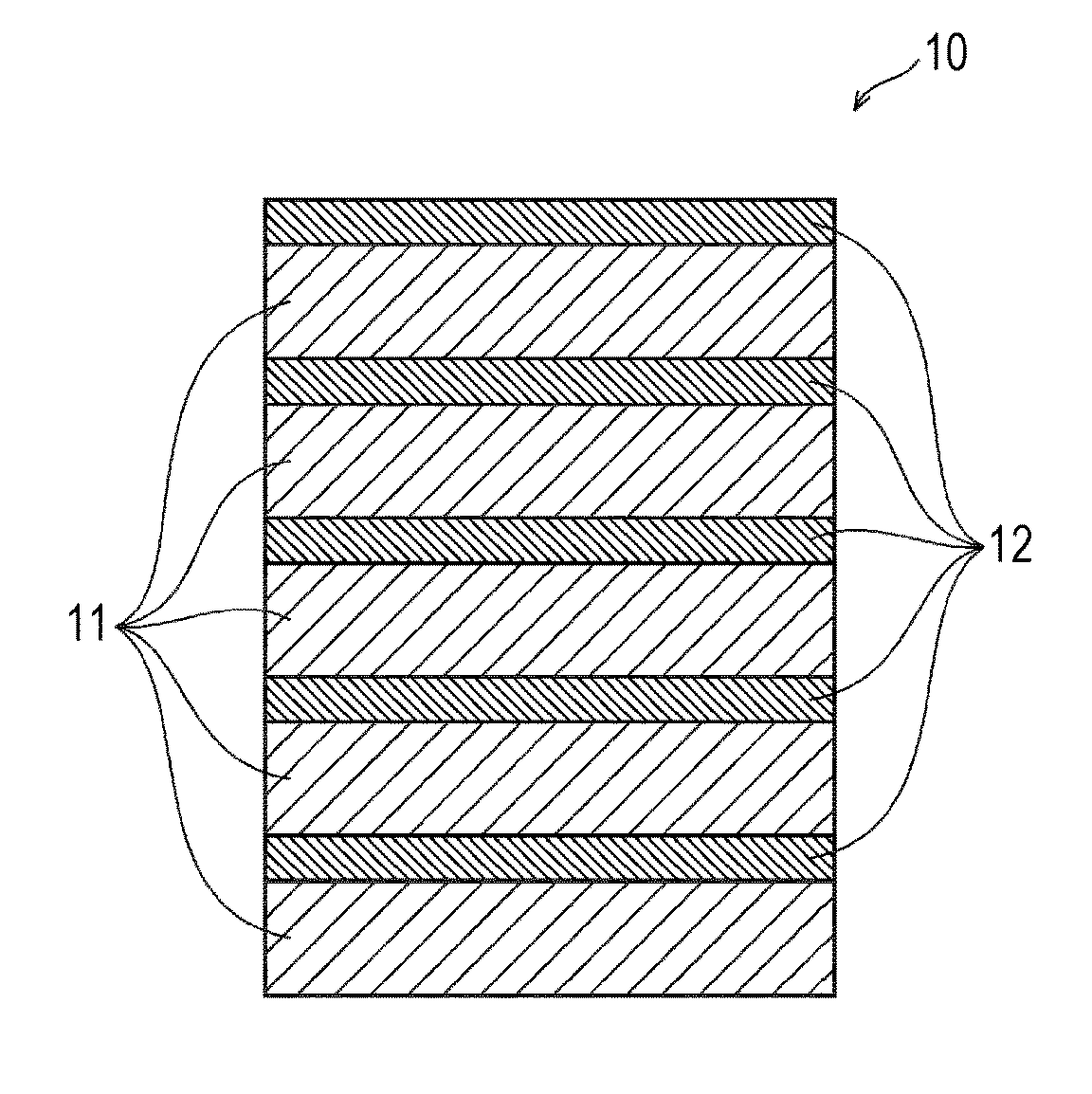

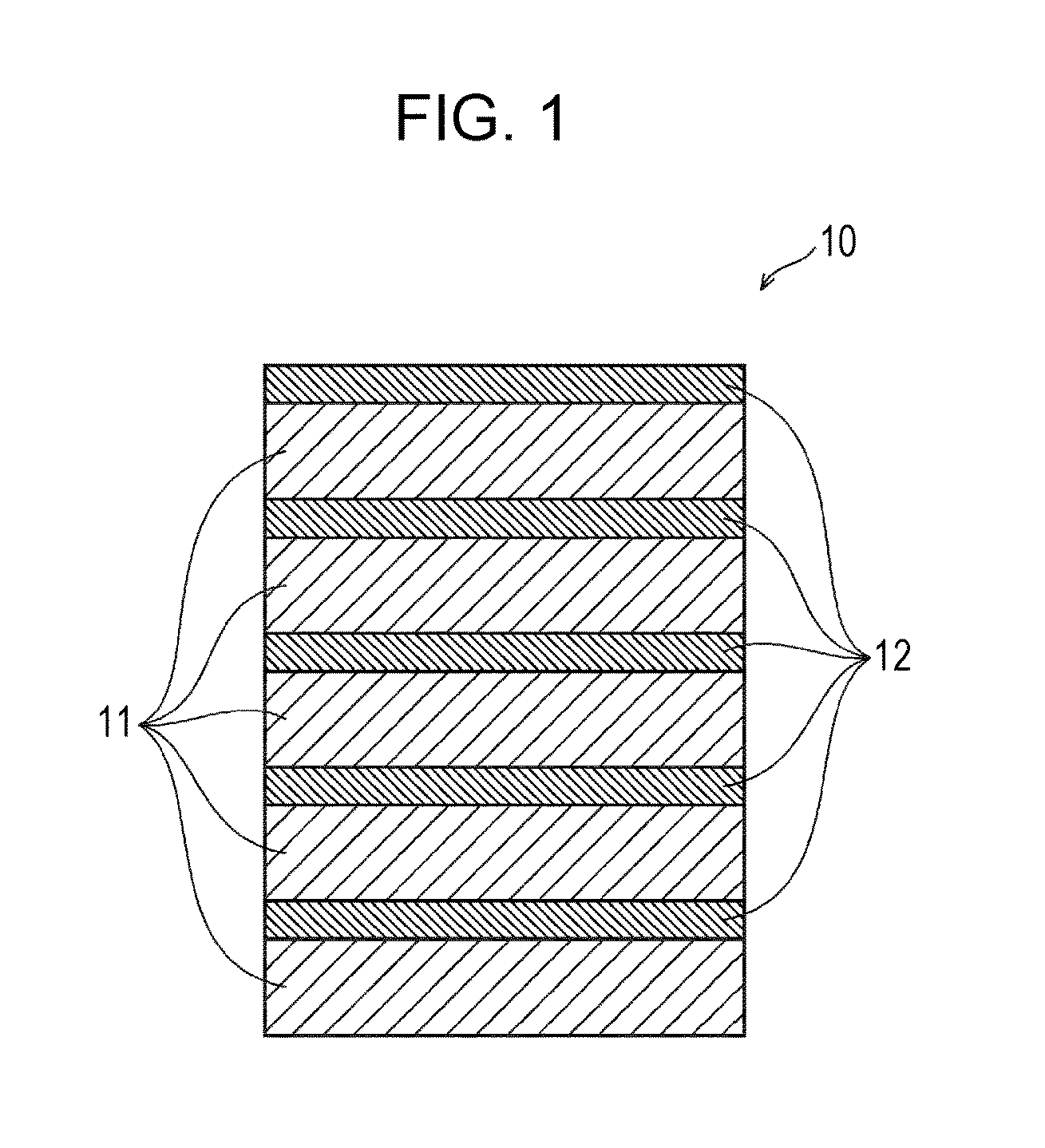

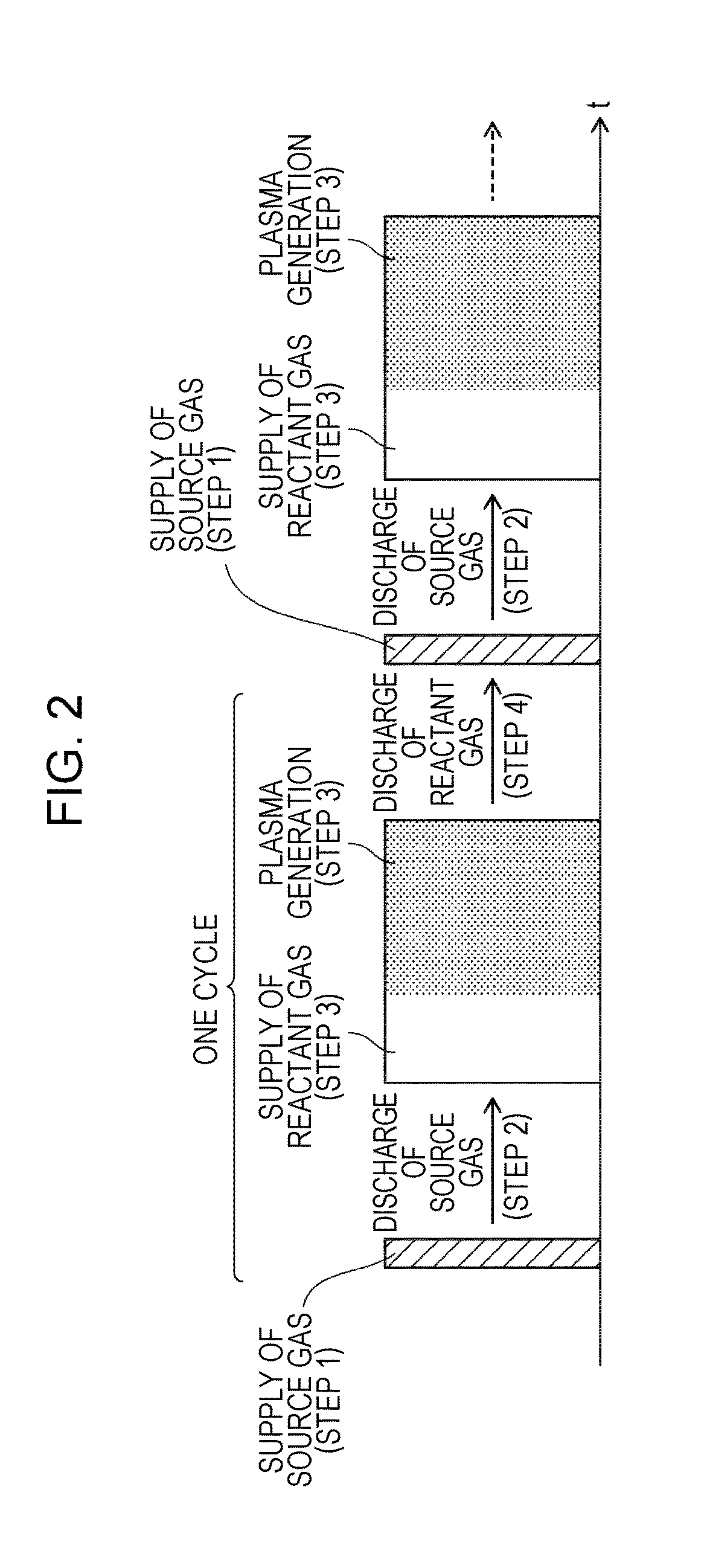

Multilayered material and method of producing the same

InactiveUS20120107607A1Reduce the impactIncrease production capacityRadiation applicationsPretreated surfacesWater vaporPolysilazane

A multilayered material is provided which includes a substrate and a silicon-containing film formed on the substrate, wherein the silicon-containing film has a nitrogen-rich area including silicon atoms and nitrogen atoms, or silicon atoms, nitrogen atoms, and an oxygen atoms and the nitrogen-rich area is formed by irradiating a polysilazane film formed on the substrate with an energy beam in an atmosphere not substantially including oxygen or water vapor and denaturing at least a part of the polysilazane film. A method of producing the multilayered material is also provided.

Owner:MITSUI CHEM INC

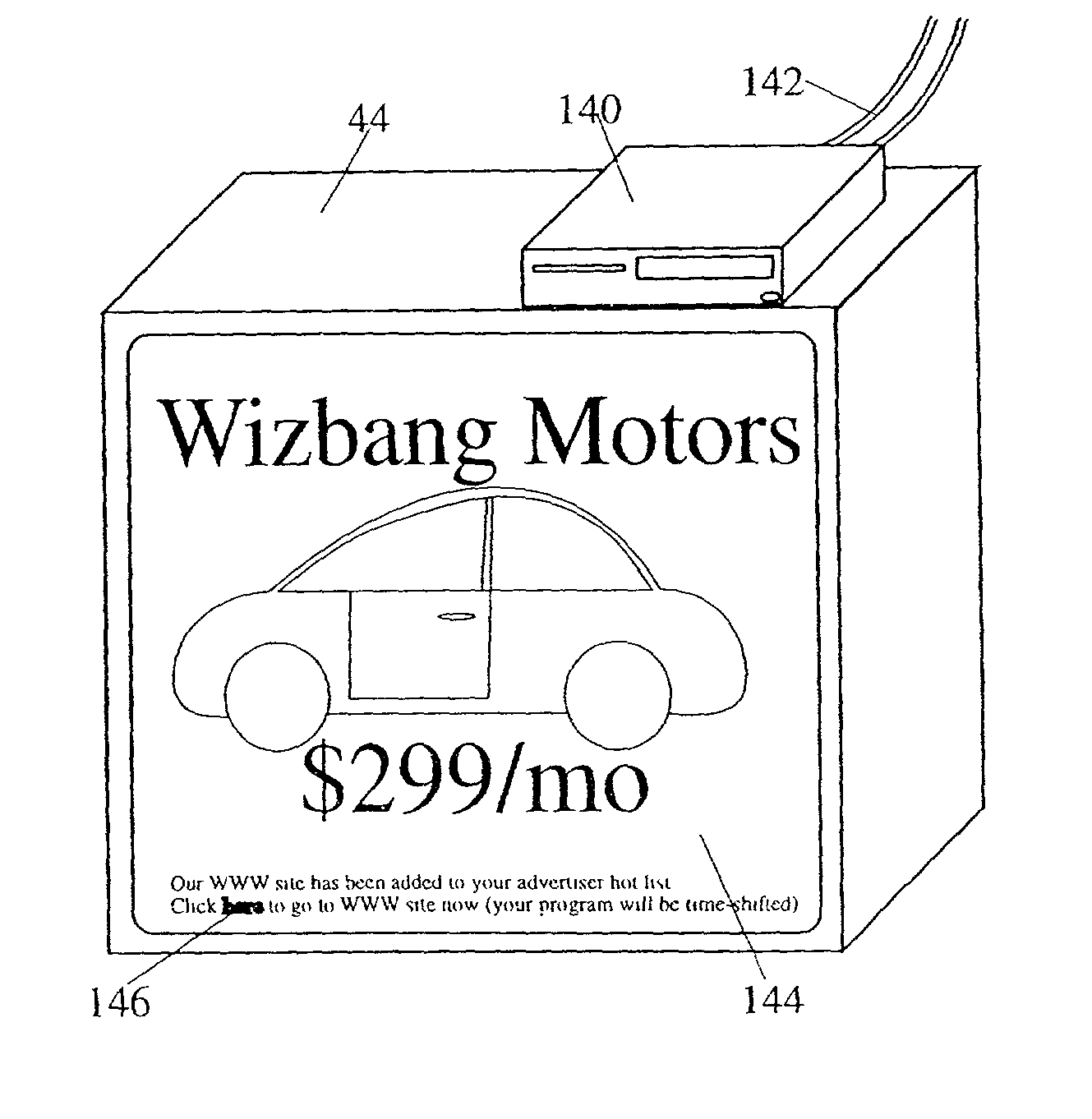

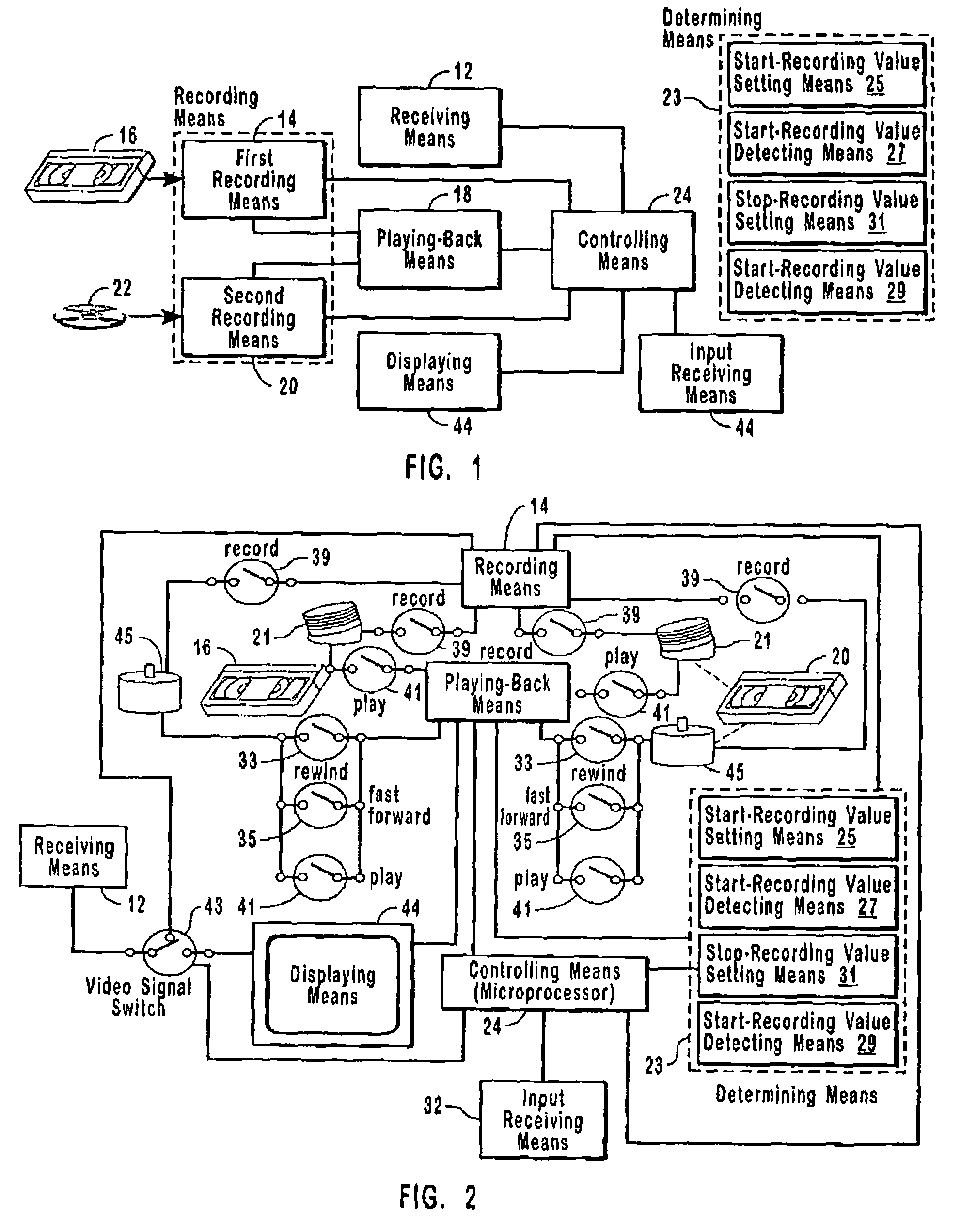

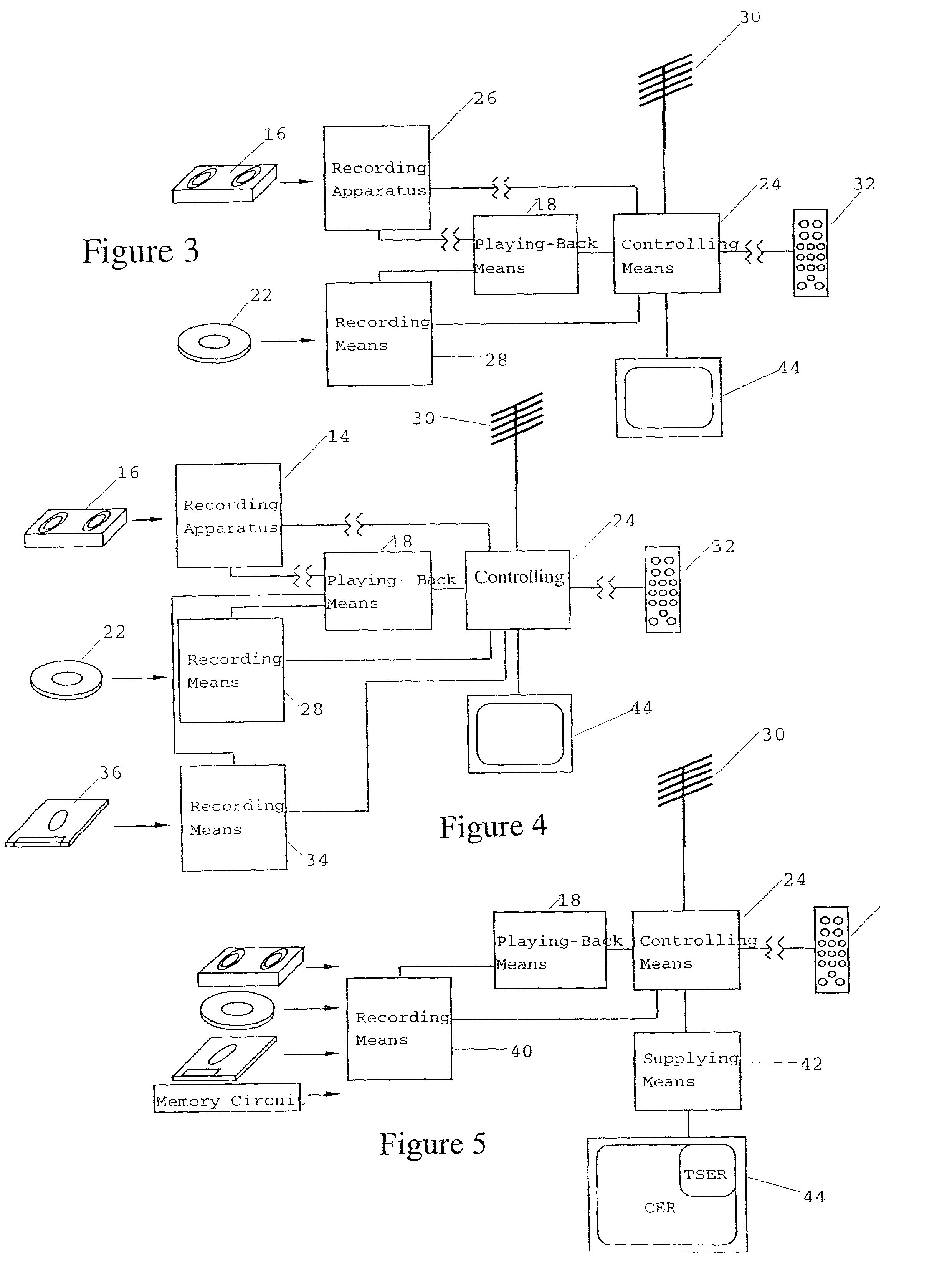

Pausing television programming in response to selection of hypertext link

InactiveUS6973669B2Television system detailsColor television signals processingHyperlinkRecording duration

A time sequential signal comprising audiovisual content and hyperlinks is received and displayed on a display device by the systems of the invention in a time sequential manner. The display of the time sequential signal is paused whenever a displayed hyperlink is selected. While pausing the display, data corresponding to any selected hyperlink is accessed and displayed on the display device. The corresponding data may comprise a web page accessed through the Internet or an interval page that is transmitted within the vertical blanking intervals of the time sequential signal. While pausing the display of the time sequential signal, the time sequential signal is recorded so that it can be viewed in the order it was recorded as soon as a resume display command is received by the system.

Owner:ROVI TECH CORP

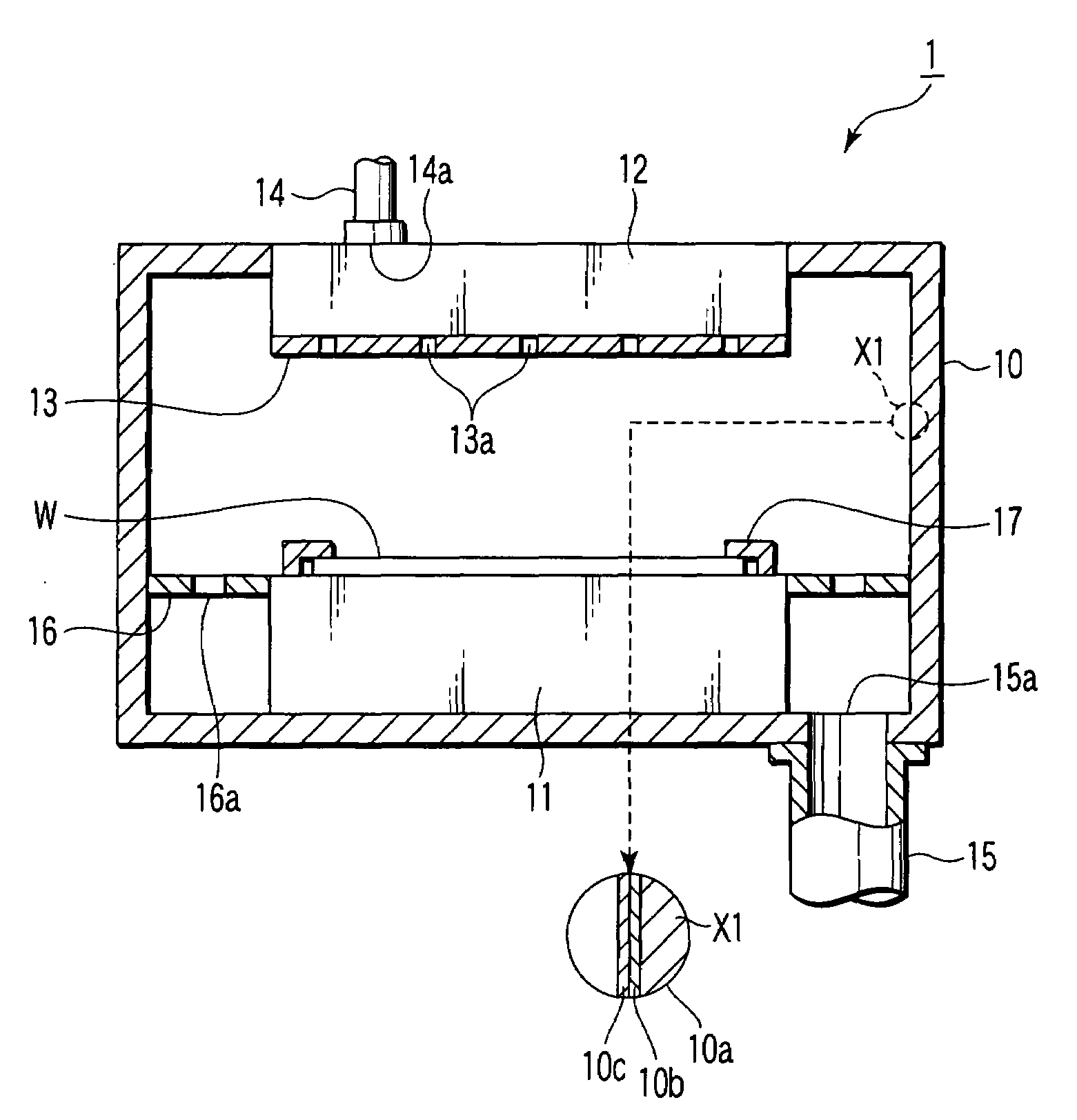

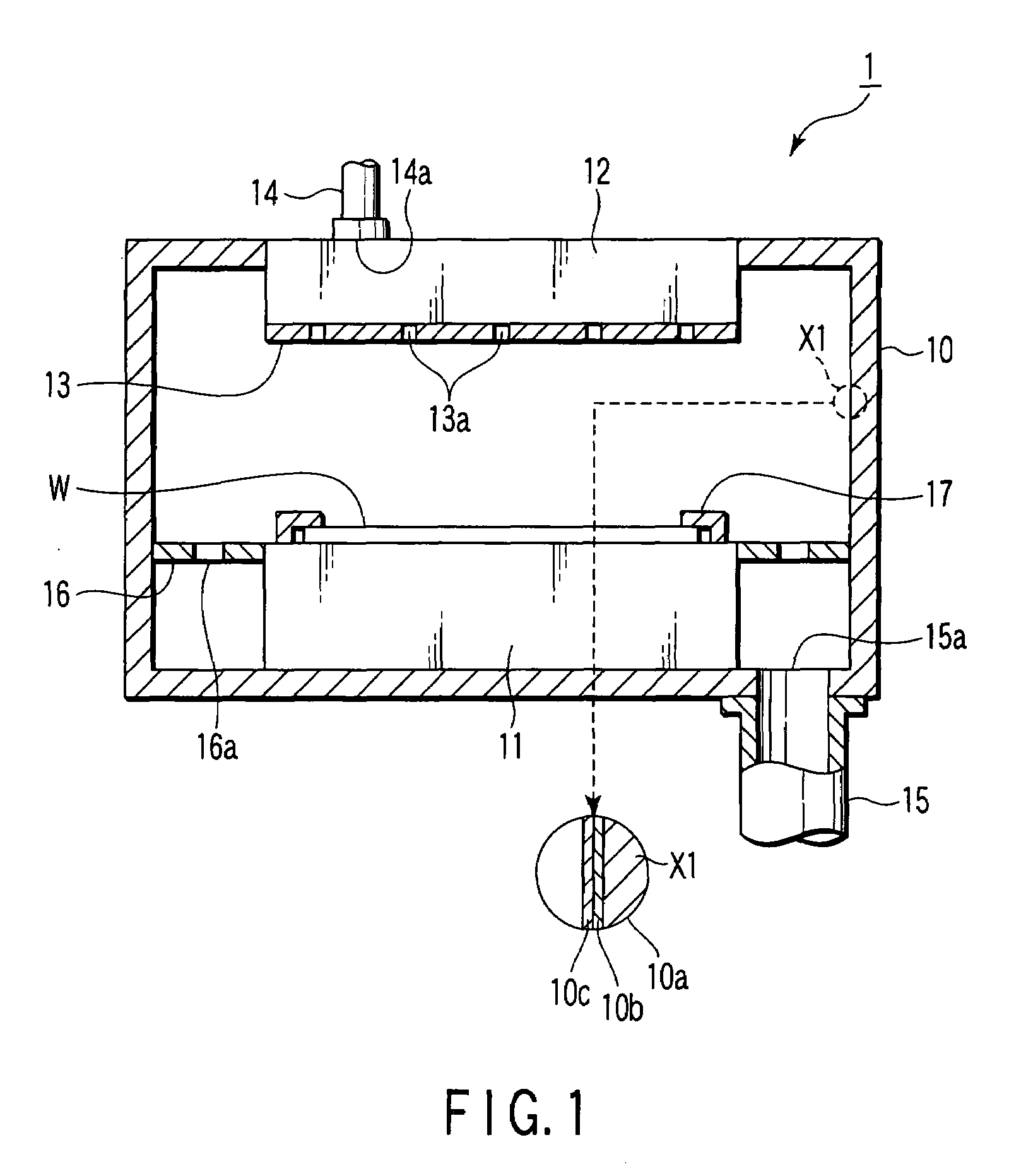

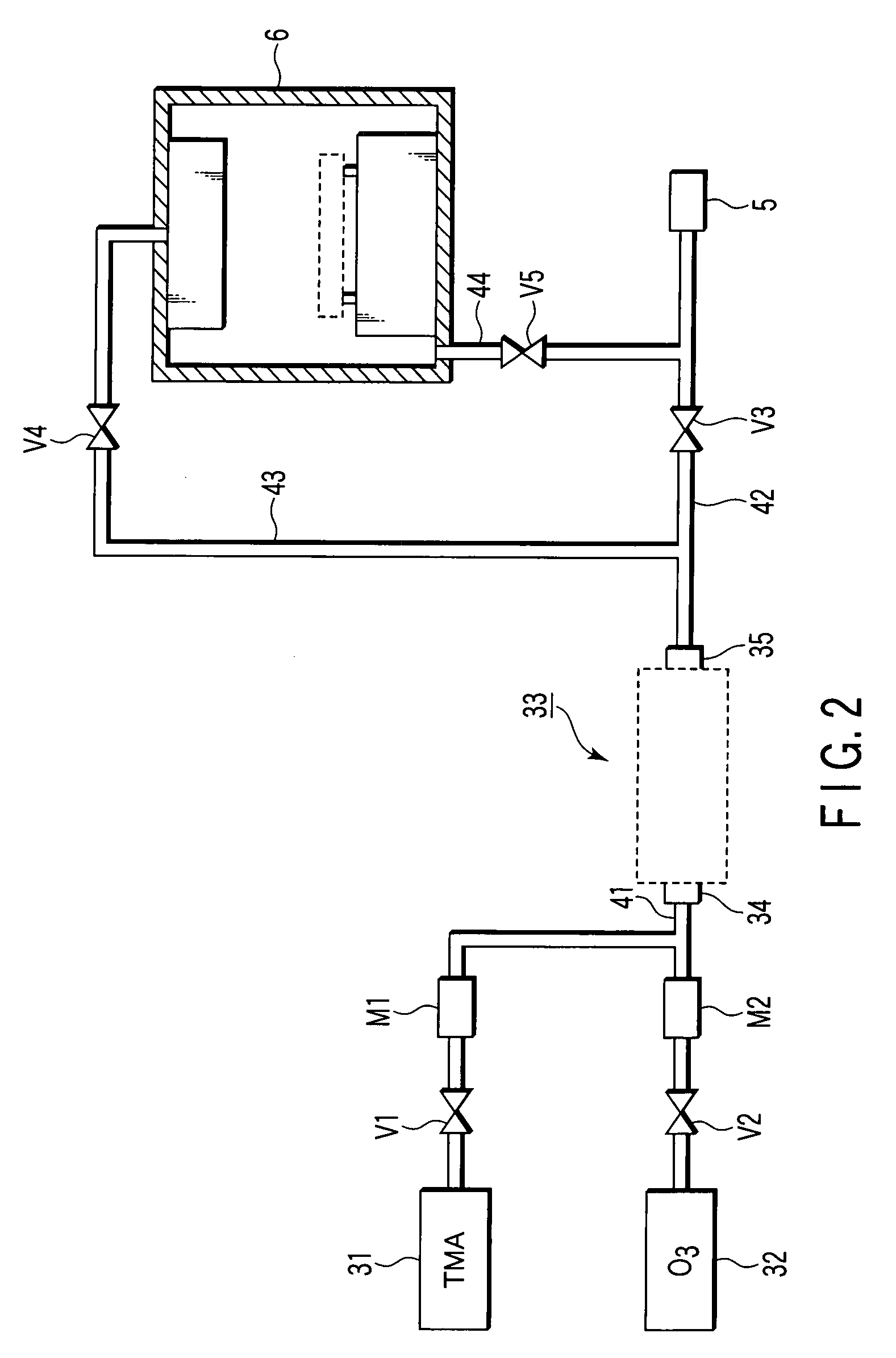

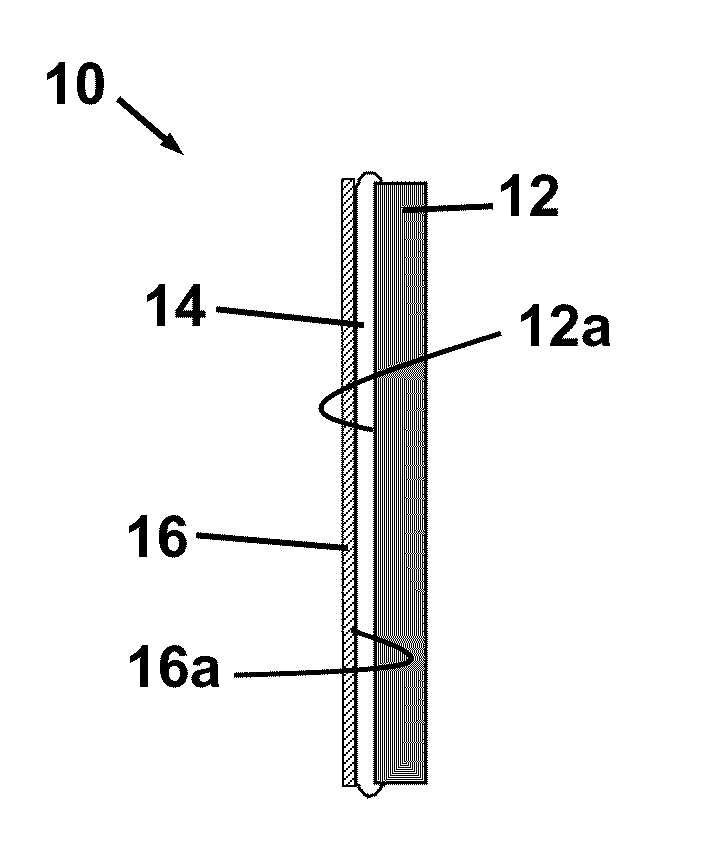

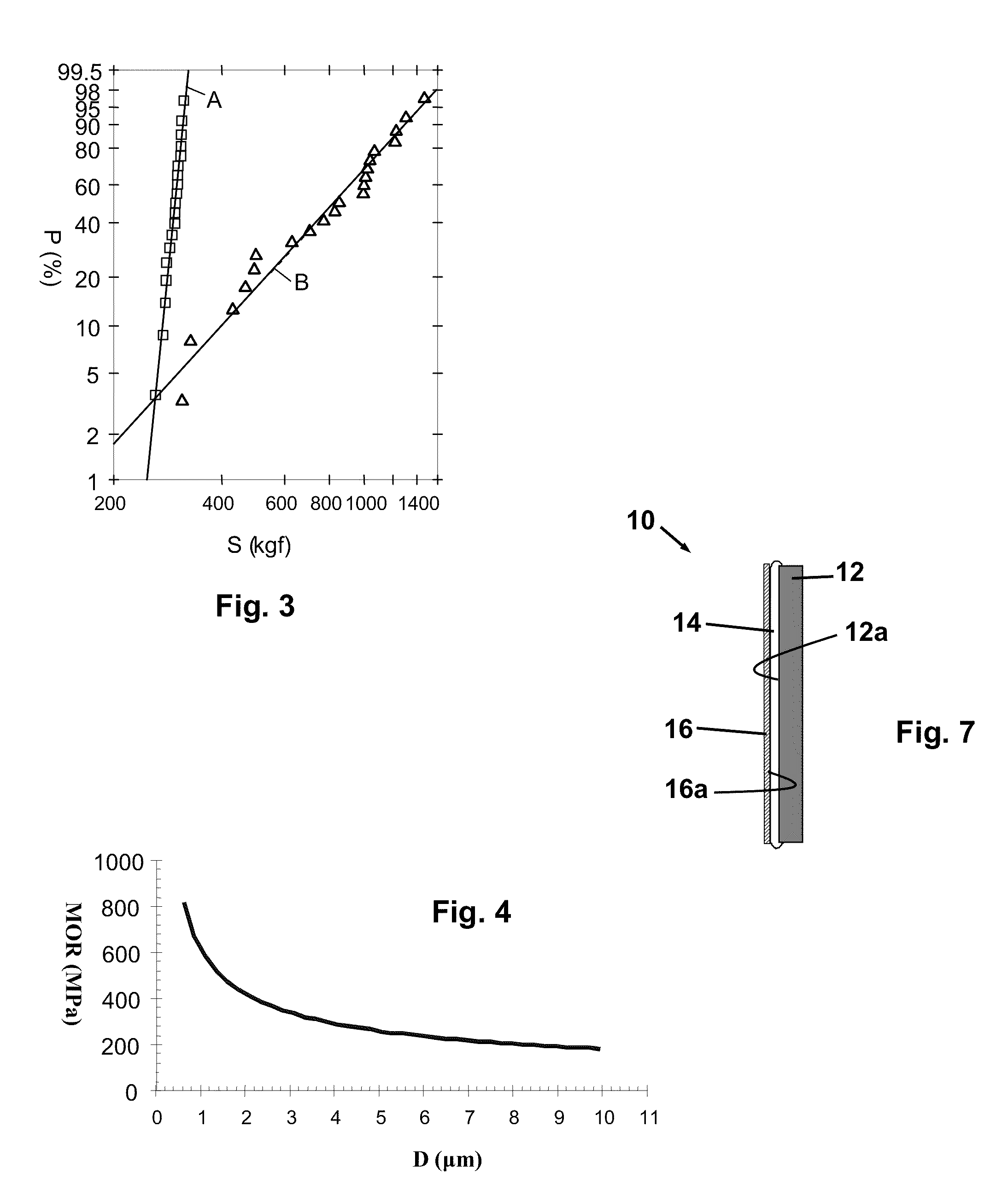

Component for semicondutor processing apparatus and manufacturing method thereof

InactiveUS20090194233A1Increased durabilityLiquid surface applicatorsSemiconductor/solid-state device manufacturingTectorial membranePorosity

A component (10) for a semiconductor processing apparatus includes a matrix (10a) defining a shape of the component, and a protection film (10c) covering a predetermined surface of the matrix. The protection film (10c) consists essentially of an amorphous oxide of a first element selected from the group consisting of aluminum, silicon, hafnium, zirconium, and yttrium. The protection film (10c) has a porosity of less than 1% and a thickness of 1 nm to 10 μm.

Owner:TOKYO ELECTRON LTD

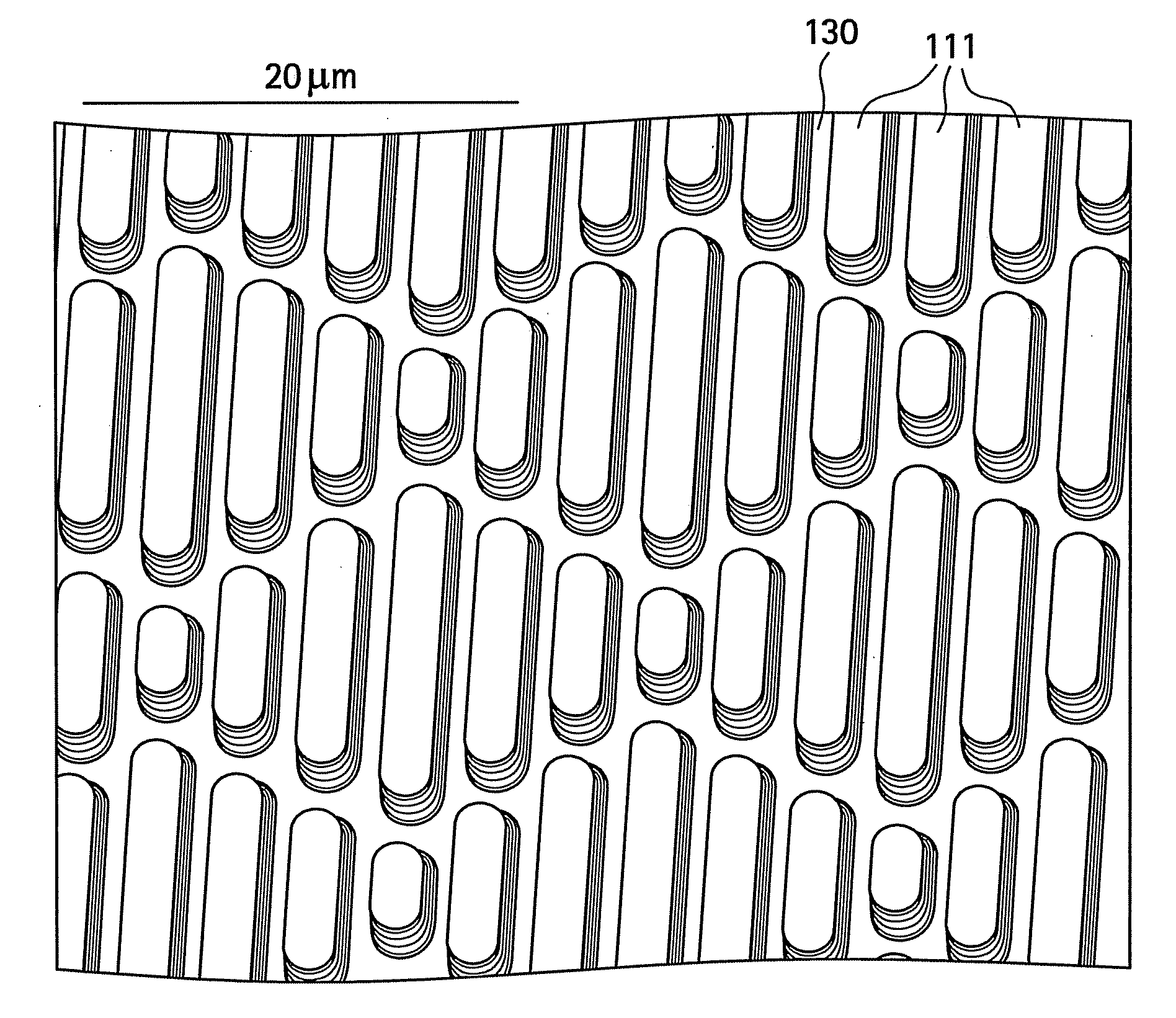

Surface topographies for non-toxic bioadhesion control

Owner:UNIV OF FLORIDA RES FOUNDATION INC

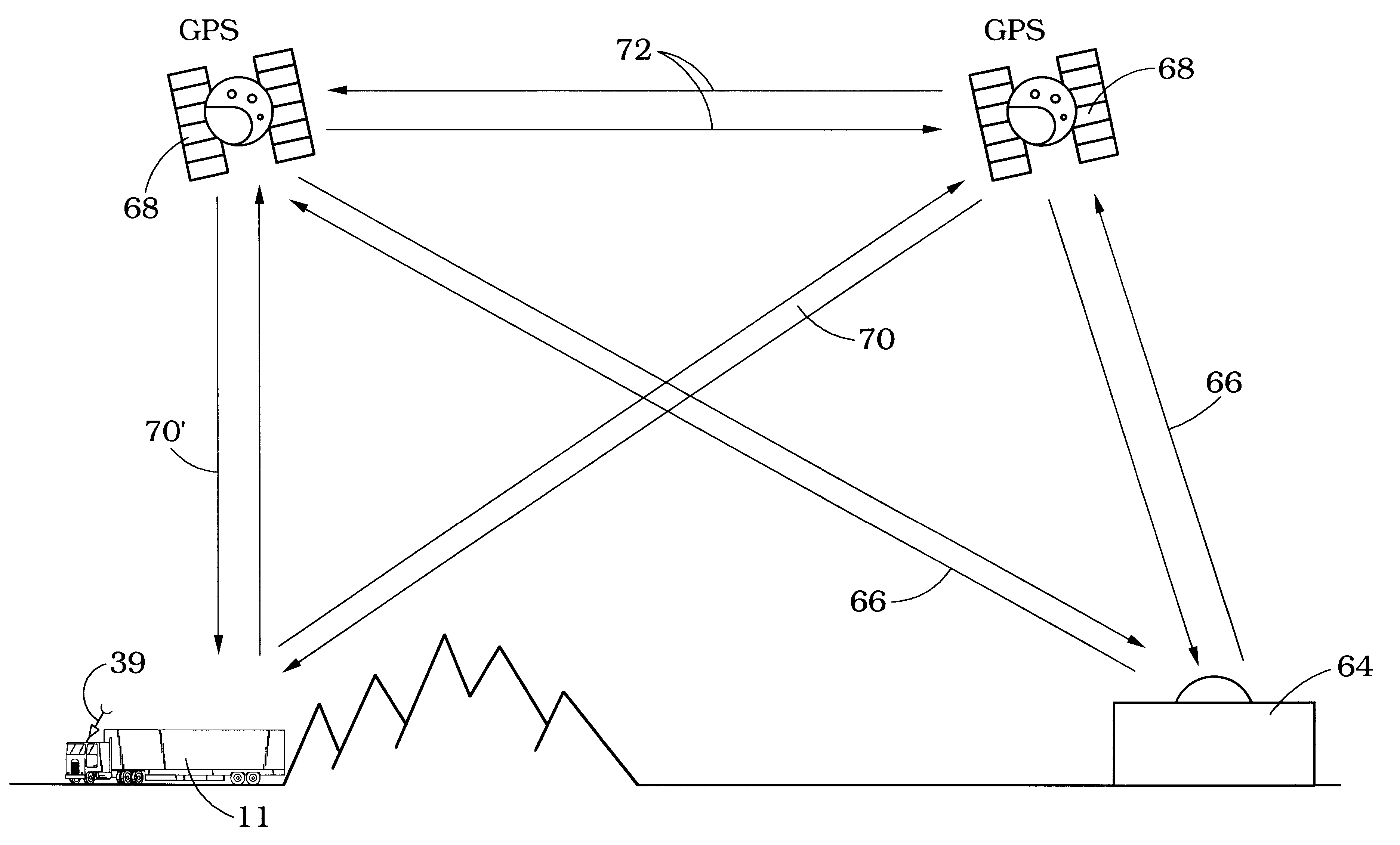

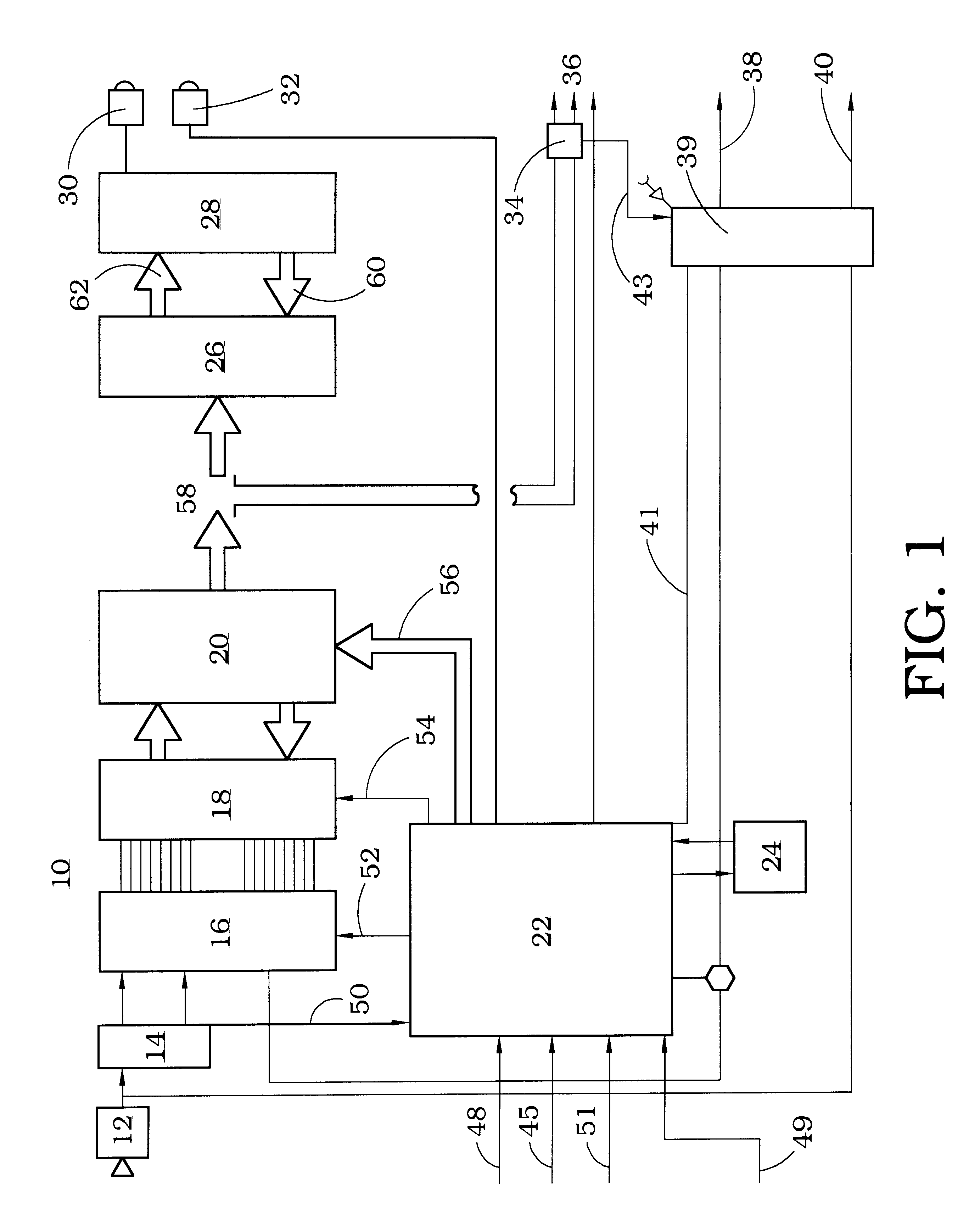

Secure, vehicle mounted, surveillance system

InactiveUS6211907B1Allow accessRegistering/indicating working of vehiclesAnti-theft devicesTransceiverData file

A novel system for gathering, analyzing and storing information for the purpose of motor vehicle theft and vandalism investigations. An on board secure vehicle mounted surveillance system, that can monitor the vehicle for brief or extended periods of time that can operate whether the vehicle is on or off, having a video camera for generating video signals of an incident proximate the vehicle, having an audio device for monitoring events proximate the vehicle, motion sensor to activate the system and lights activated by the system to illuminate the area viewed by the camera. The video signals are digitized into a synchronized data file, carrying a unique vehicle identification and a time indicator with other input data occurring on or about the vehicle such as audio recordings and the like. The file is encrypted and stored on a large capacity, code accessible device or transmitted, via a transceiver, real time to authorities and / or an off vehicle storage site. Once written, the encrypted file cannot be altered or corrupted, decrypted without the encryption key, or accessed without the access authorization code. The stored data file can be down loaded to be used as evidence.

Owner:EVICAM INT

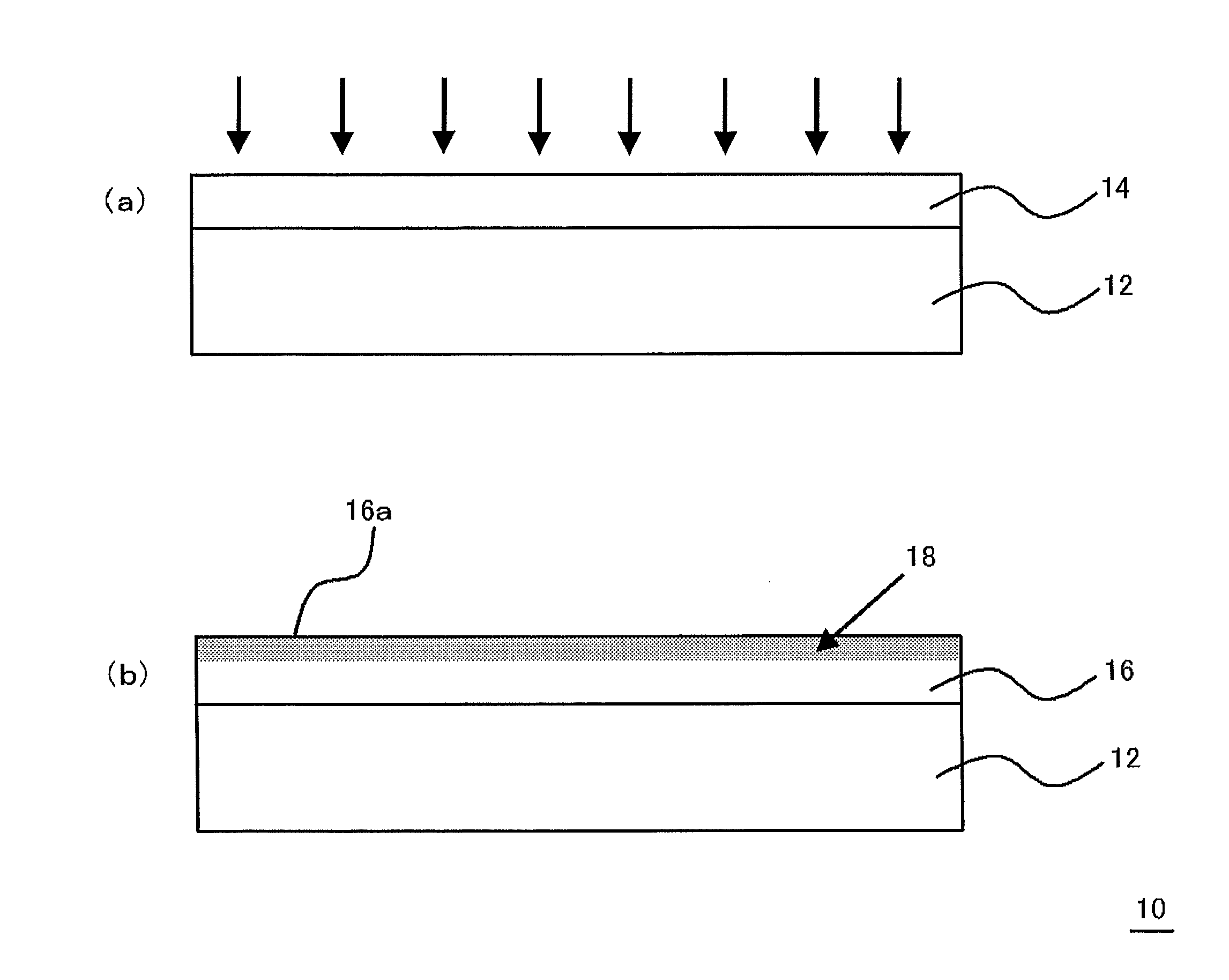

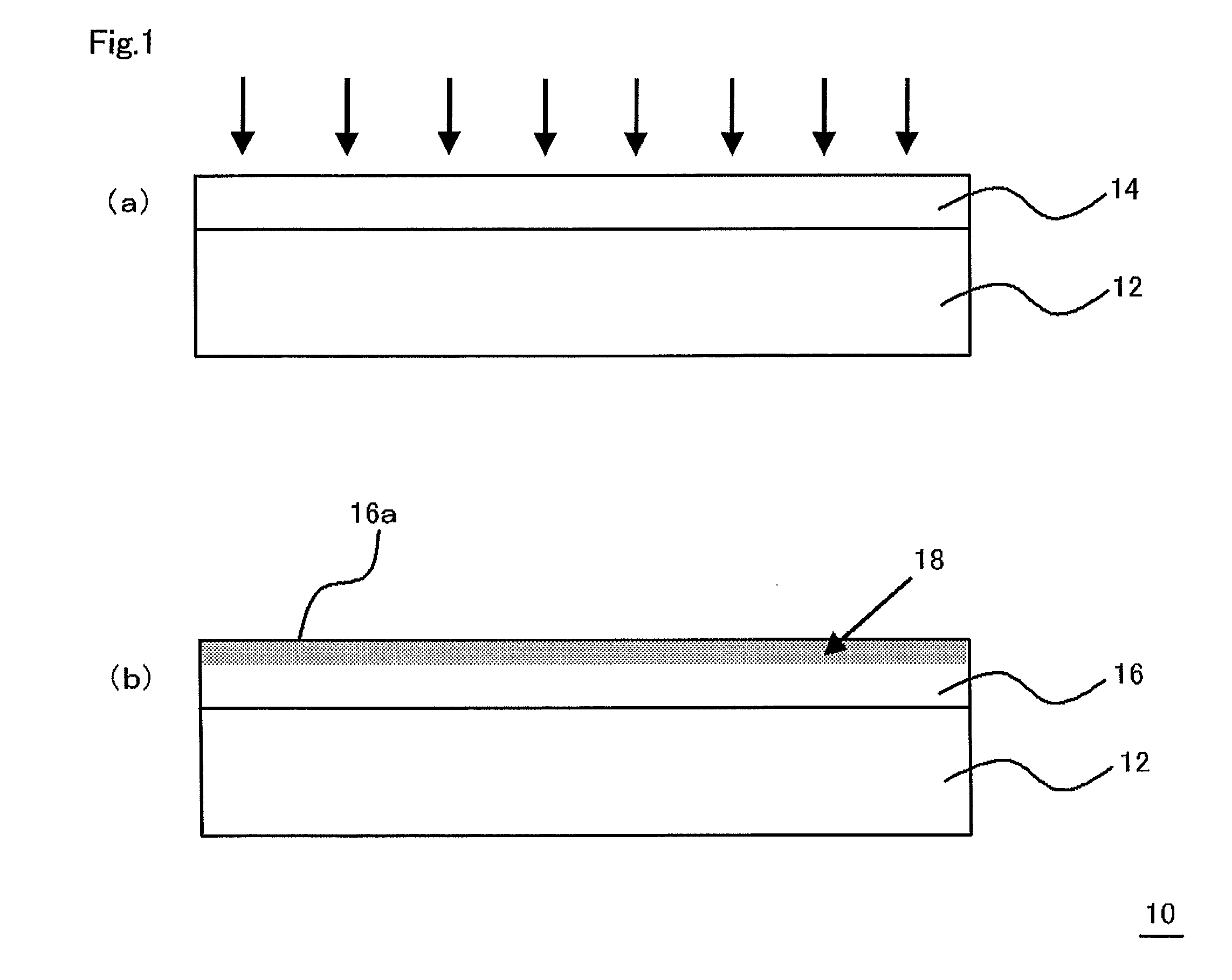

Gas barrier film, film substrate provided with gas barrier film, and electronic device including the film substrate

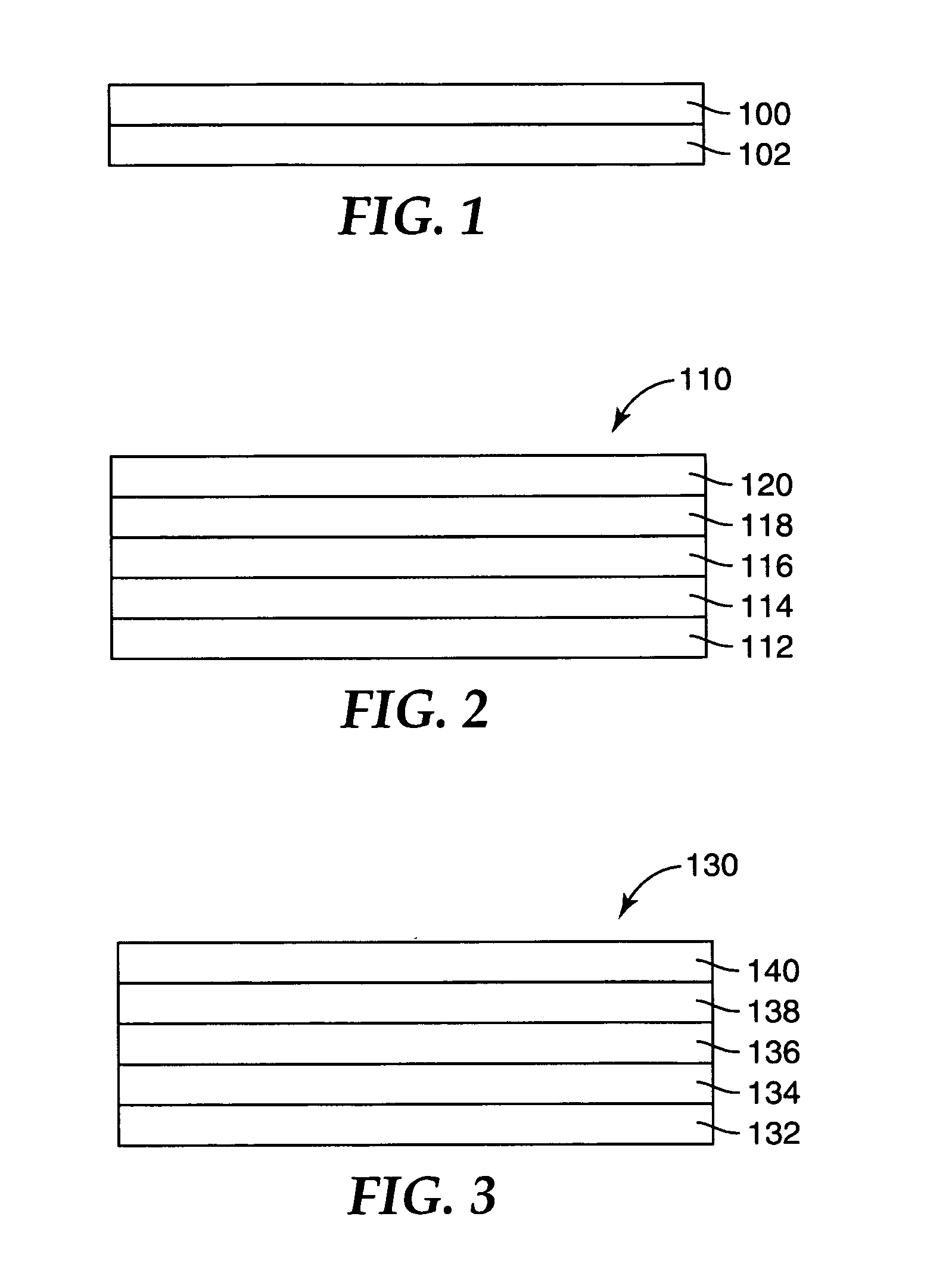

ActiveUS20150343741A1Excellent gas barrier performanceIncrease resistanceLayered productsRecord information storageThin membraneElectric devices

A gas barrier film includes two or more first barrier layers each made of a first inorganic material and one or more second barrier layers each made of a second inorganic material different from the first inorganic material. Each of the two or more first barrier layers and each of the one or more second barrier layers are alternately stacked. The first inorganic material comprises aluminum oxide. Each of the two or more first barrier layers has a thickness of 3 nm or more. The total thickness of the two or more first barrier layers is 20 nm or less. The two or more first barrier layers and the one or more second barrier layers are formed by atomic layer deposition.

Owner:SAMSUNG DISPLAY CO LTD

Diamond capsules and methods of manufacture

InactiveUS20100297391A1Reduce temperature differenceImprove conductivityLayered productsShaftsNanocrystalAccess port

Capsules and similar objects are made from materials having diamond (sp3) lattice structures, including diamond materials in synthetic crystalline, polycrystalline (ordered or disordered), nanocrystalline and amorphous forms. The capsules generally include a hollow shell made of a diamond material that defines an interior region that may be empty or that may contain a fluid or solid material. Some of the capsules include access ports that can be used to fill the capsule with a fluid. Capsules and similar structures can be manufactured by growing diamond on suitably shaped substrates. In some of these methods, diamond shell sections are grown on substrates, then joined together. In other methods, a nearly complete diamond shell is grown around a form substrate, and the substrate can be removed through a relatively small opening in the shell.

Owner:SUNSHELL

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

Polycrystalline group iii metal nitride with getter and method of making

ActiveUS20100151194A1Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

Magnetic data recording device

Owner:FITBIT INC

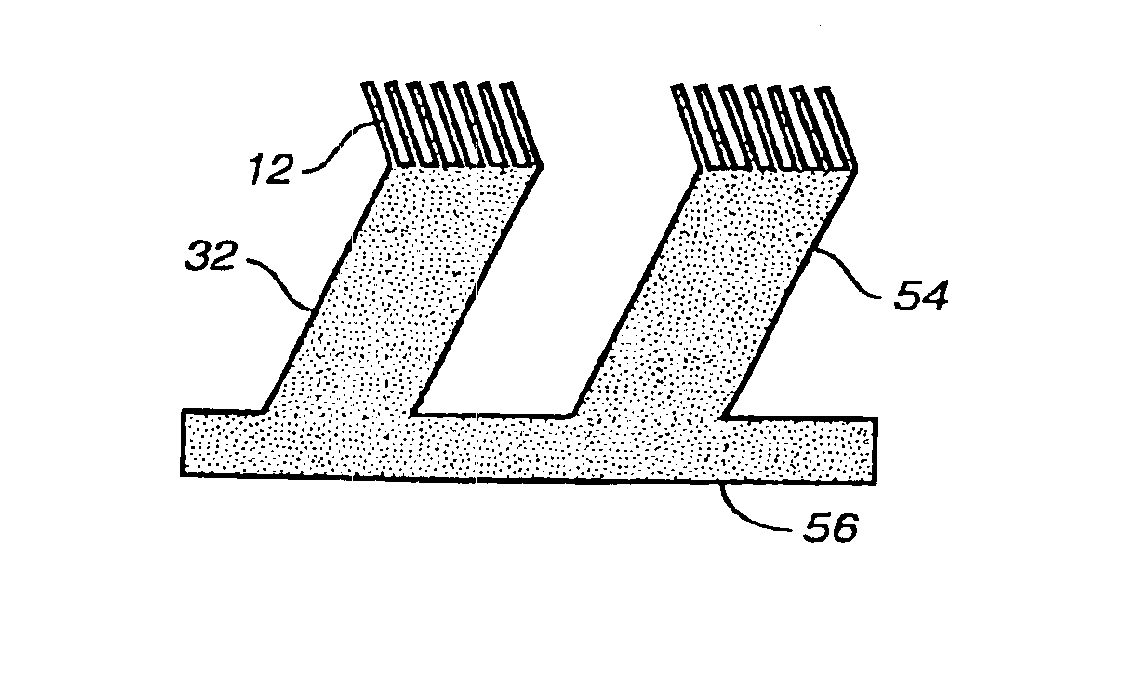

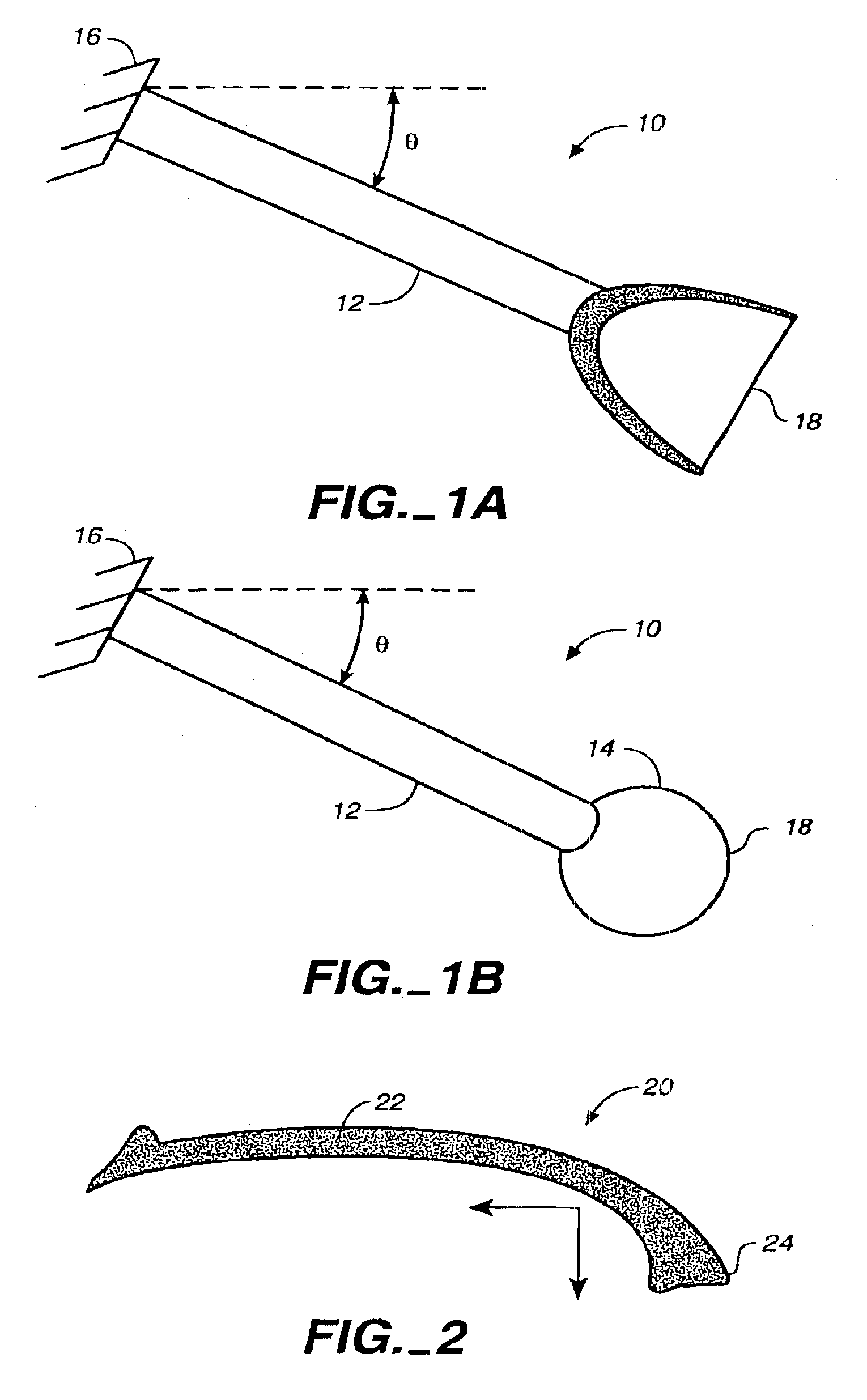

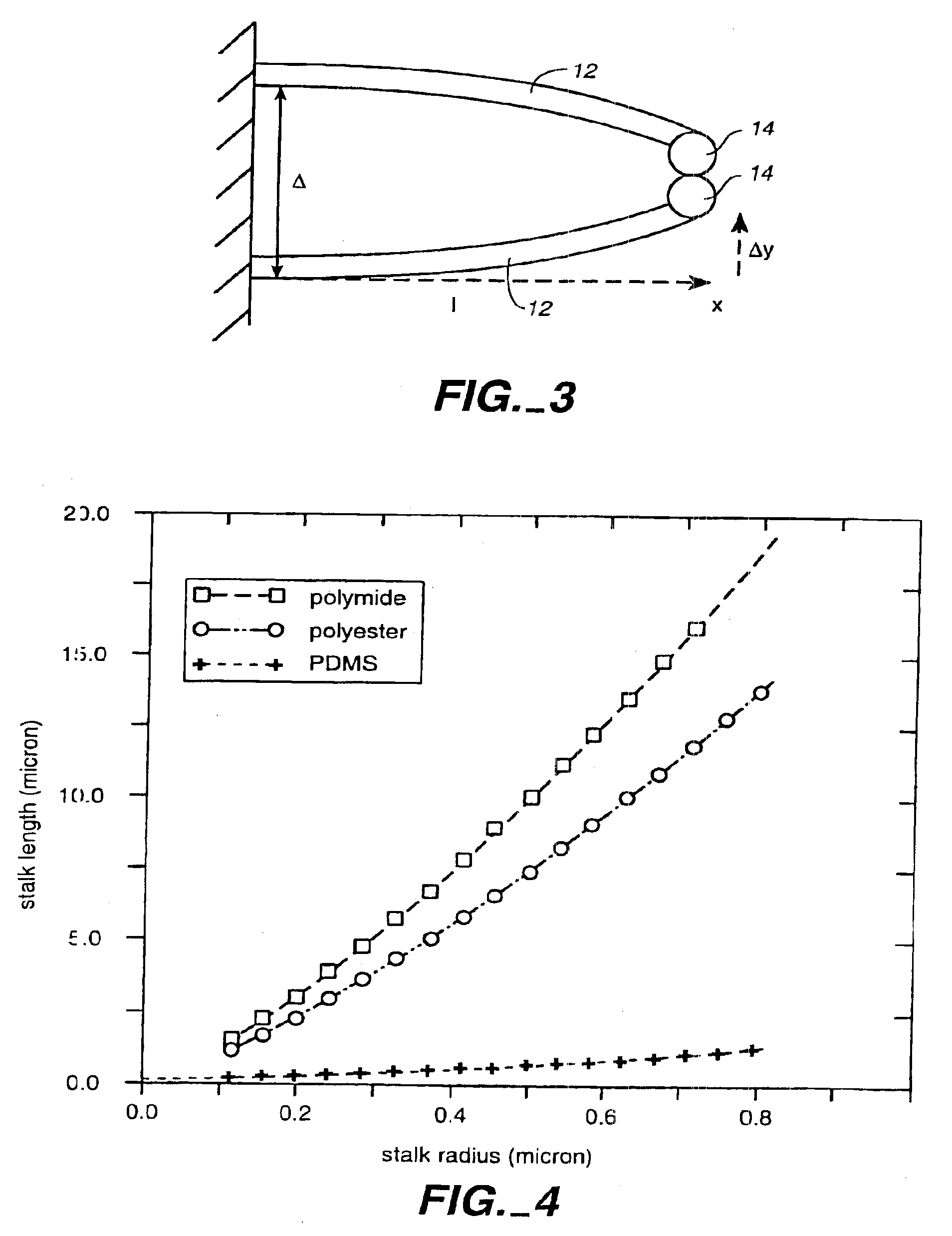

Adhesive microstructure and method of forming same

InactiveUS6872439B2Improve adhesionEasy to disengageSnap fastenersMaterial nanotechnologyMicroscopic scaleOblique angle

A fabricated microstructure comprising at least one protrusion capable of providing an adhesive force at a surface of between about 60 and 2,000 nano-Newtons. A stalk supports the protrusion at an oblique angle relative to a supporting surface. The microstructure can adhere to different surfaces.

Owner:RGT UNIV OF CALIFORNIA

Method and system for finding approximate matches in database

InactiveUS6061680A "chat roGood serviceDigital data processing detailsCoin-freed apparatusNetwork linkRemote computer

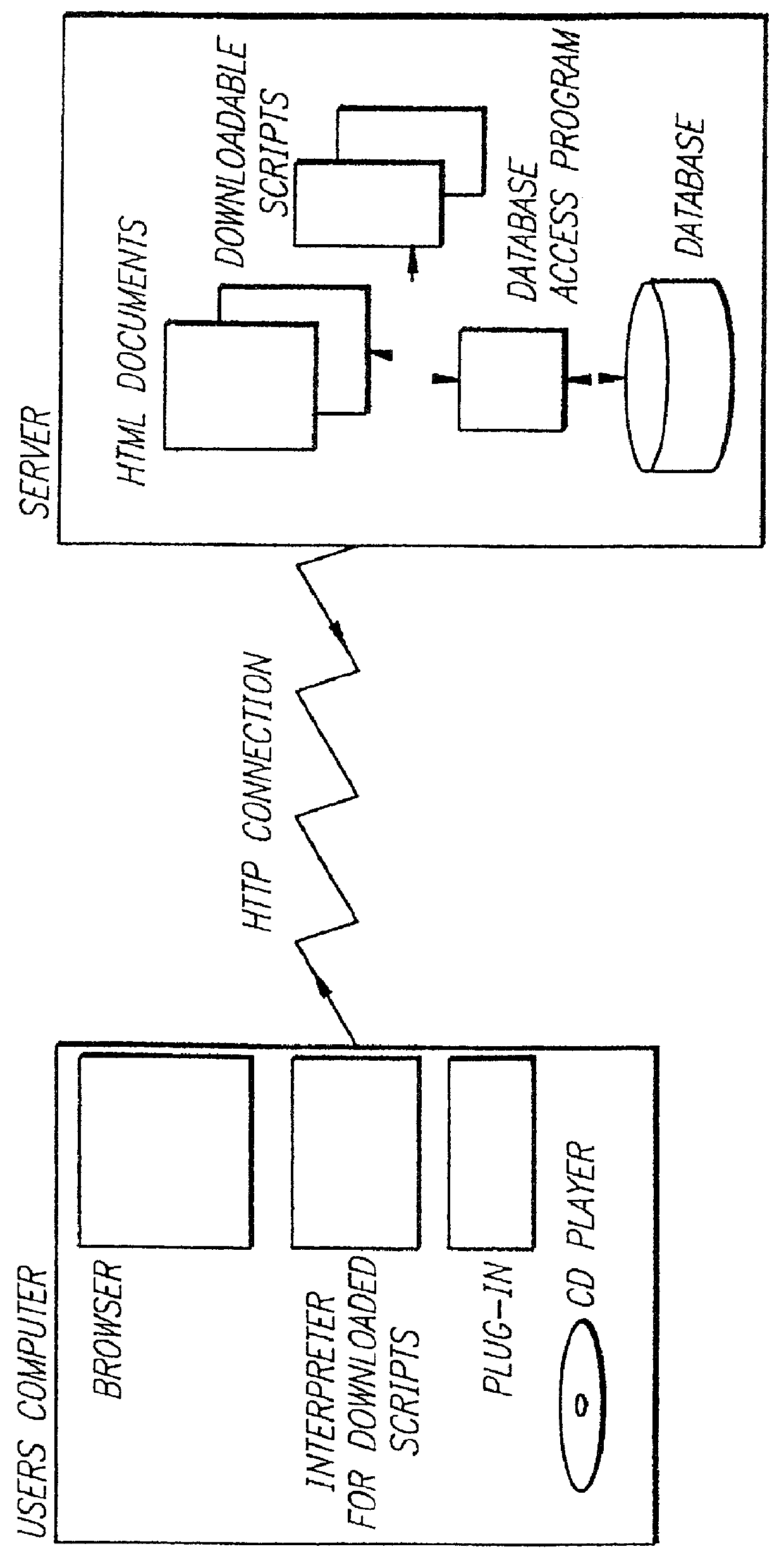

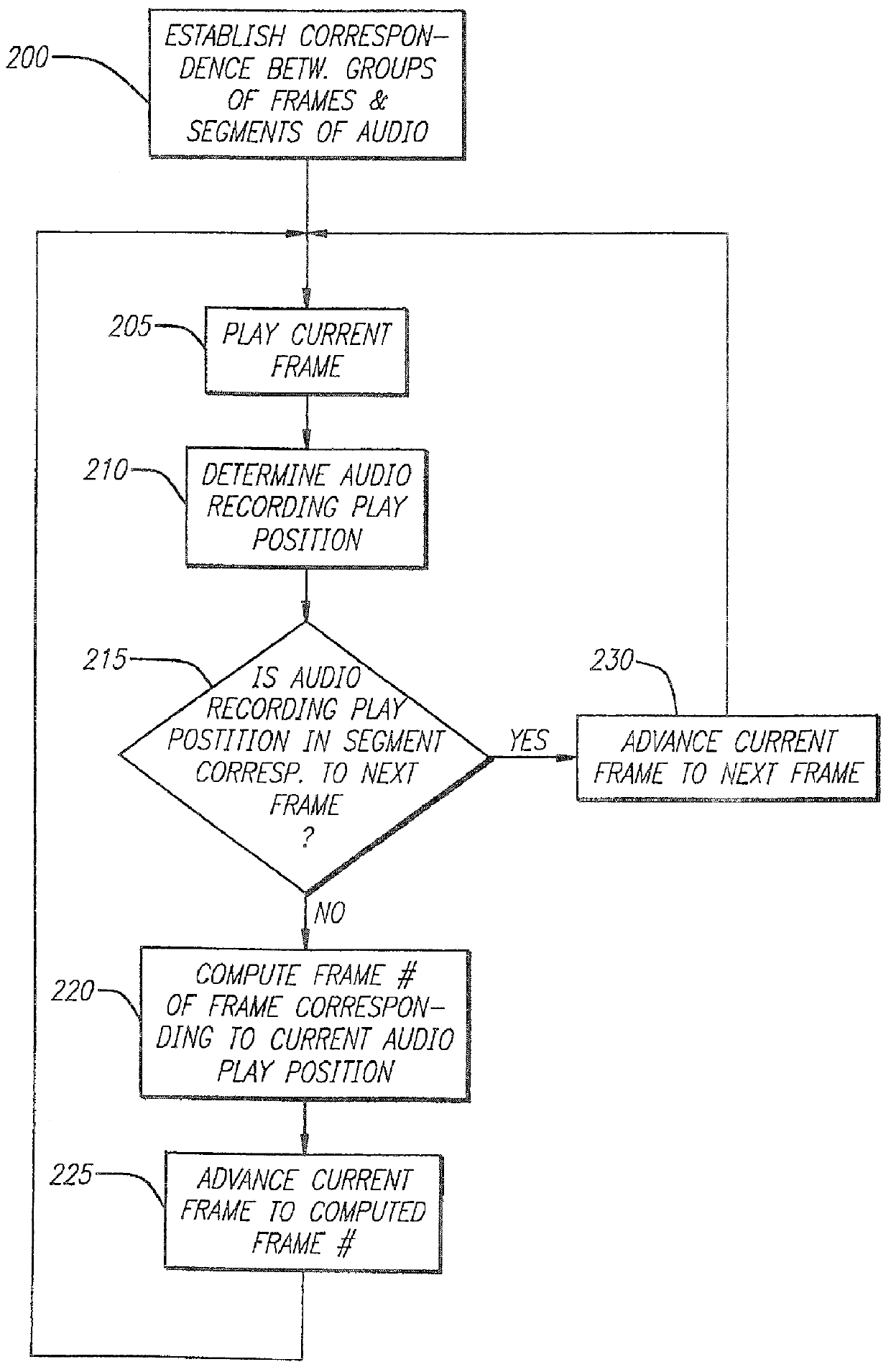

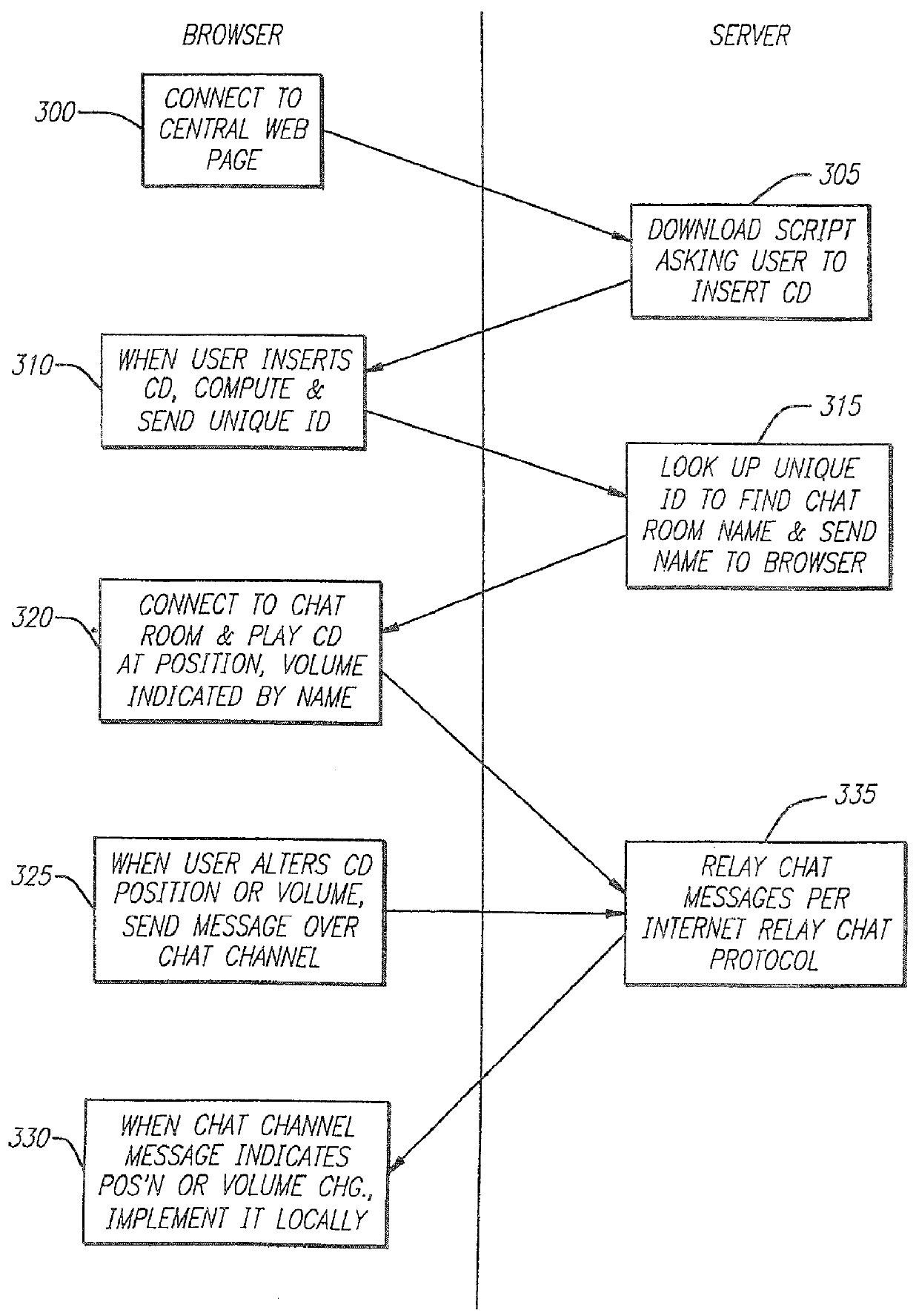

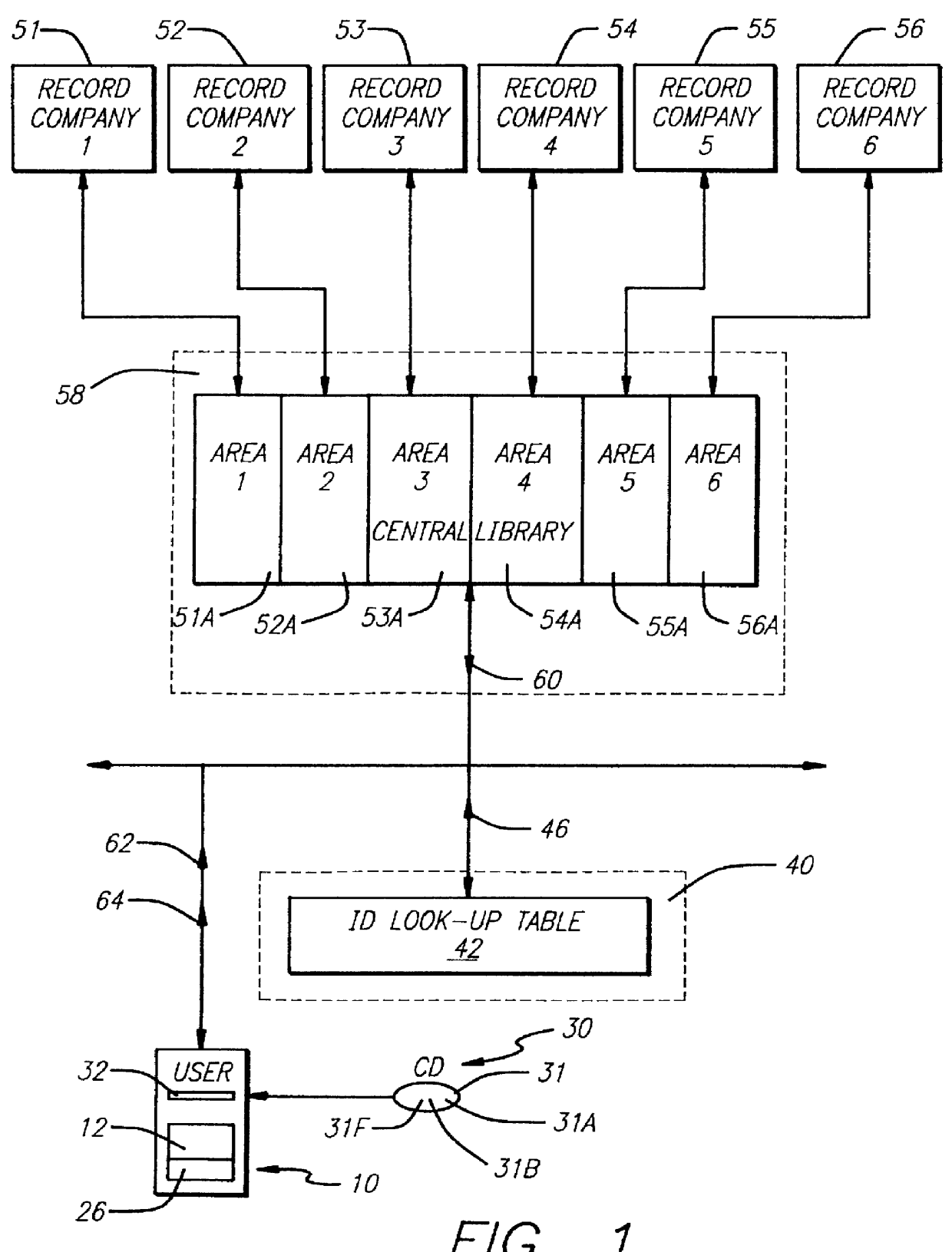

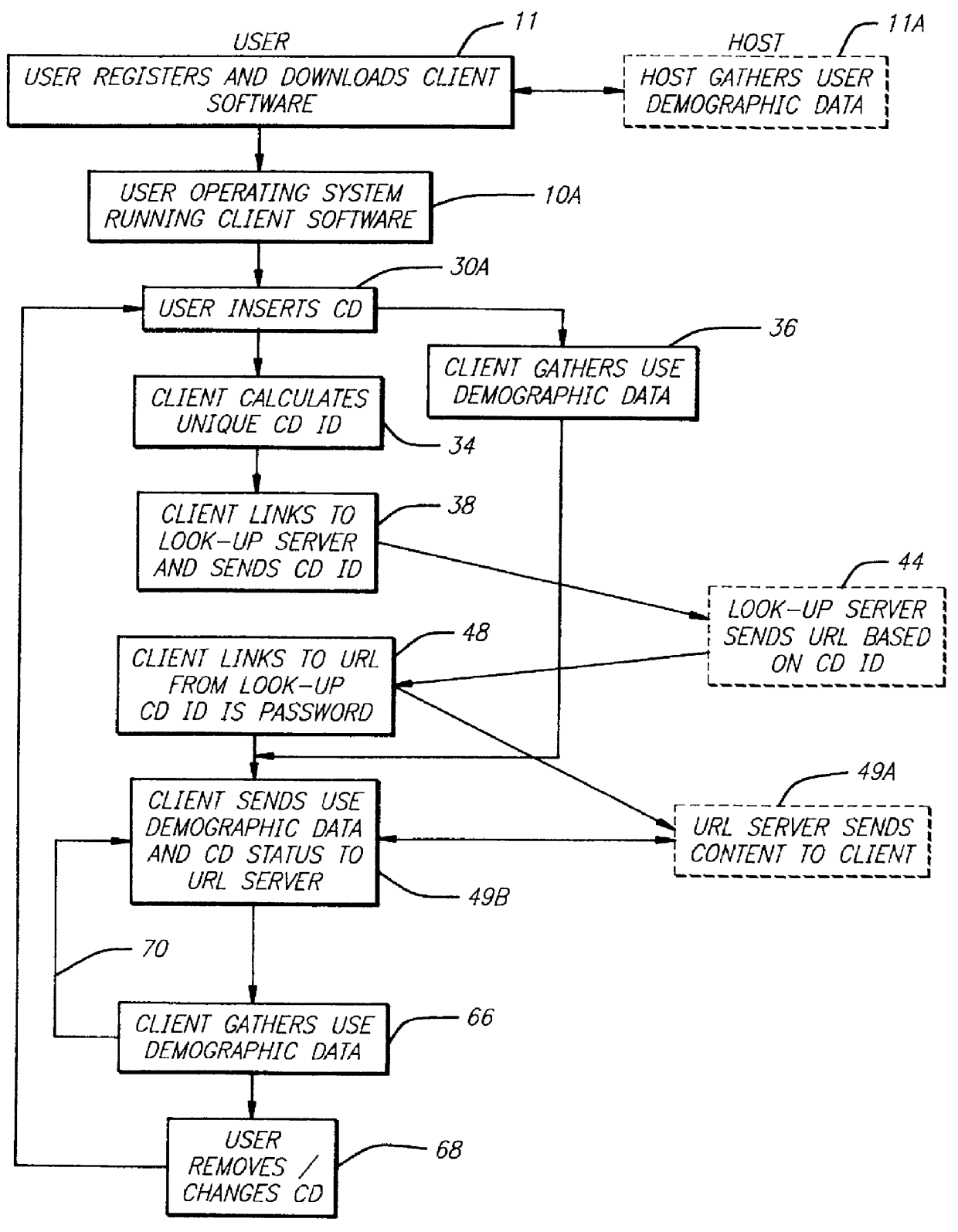

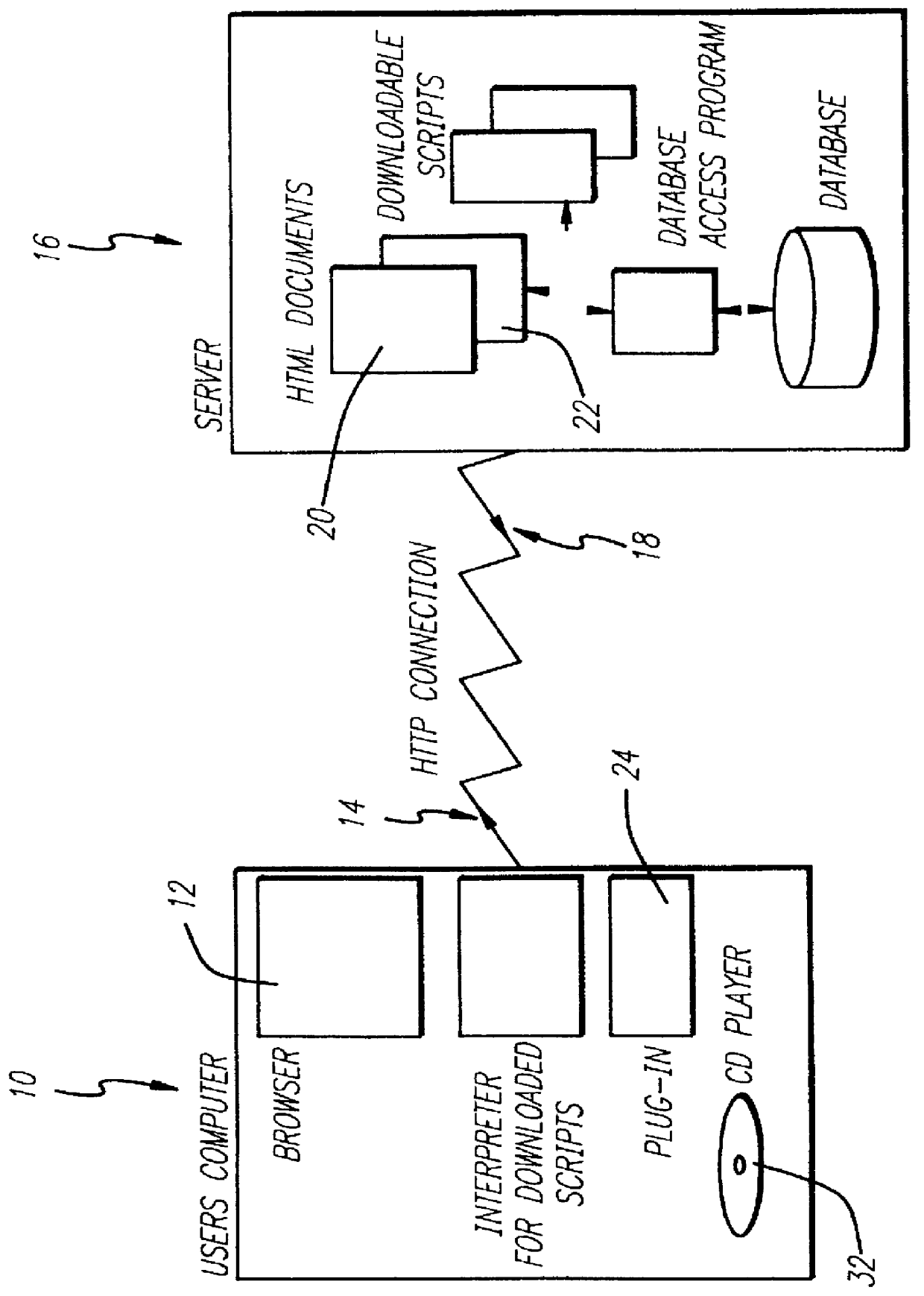

Entertainment content complementary to a musical recording is delivered to a user's computer by means of a computer network link. The user employs a browser to access the computer network. A plug-in for the browser is able to control an audio CD or other device for playing the musical recording. A script stored on the remote computer accessed over the network is downloaded. The script synchronizes the delivery of the complementary entertainment content with the play of the musical recording.

Owner:GRACENOTE

Network delivery of interactive entertainment complementing audio recordings

InactiveUS6154773A "chat roGood serviceCoin-freed apparatusBroadcast transmission systemsNetwork linkRemote computer

Owner:GRACENOTE

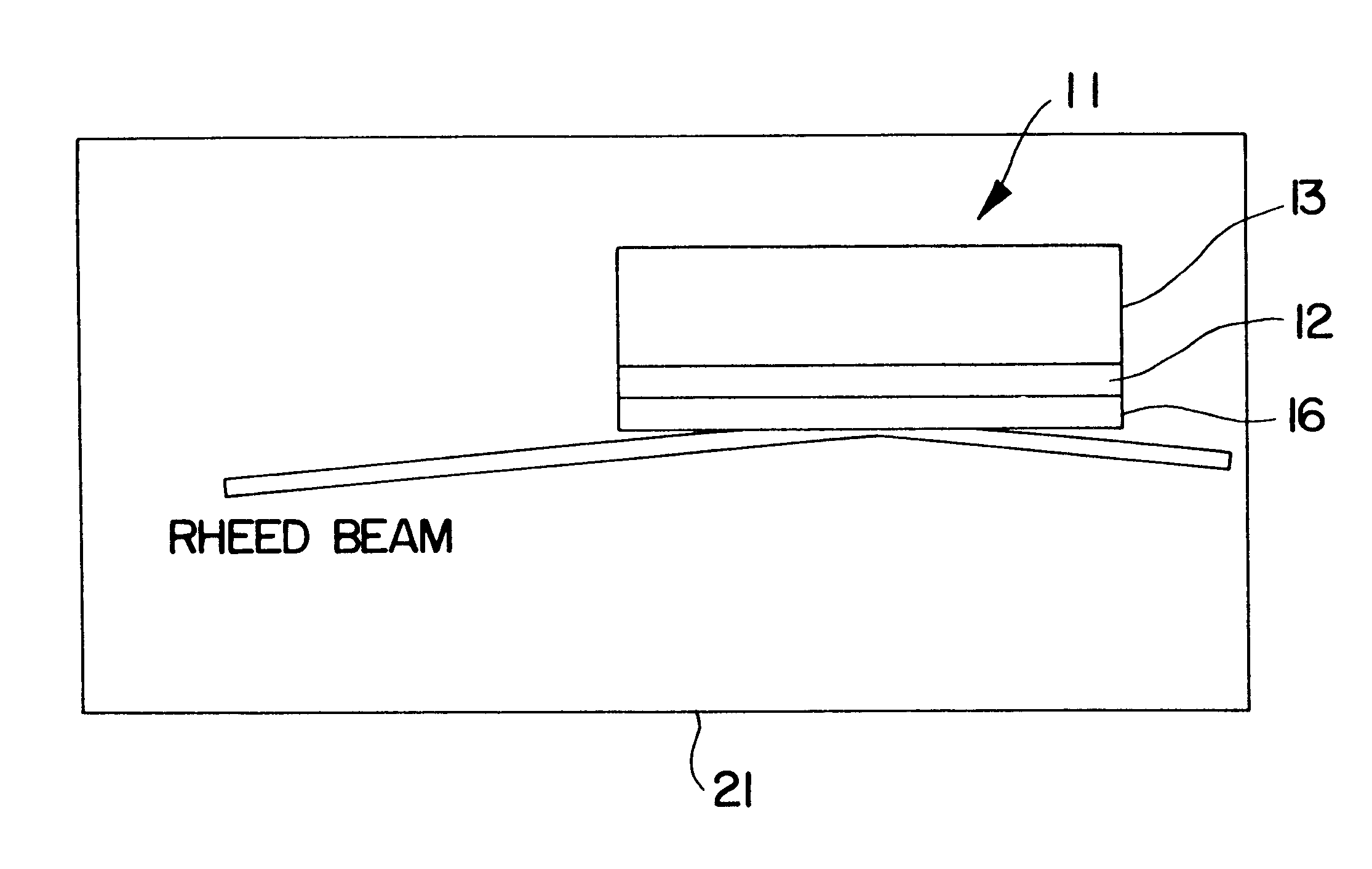

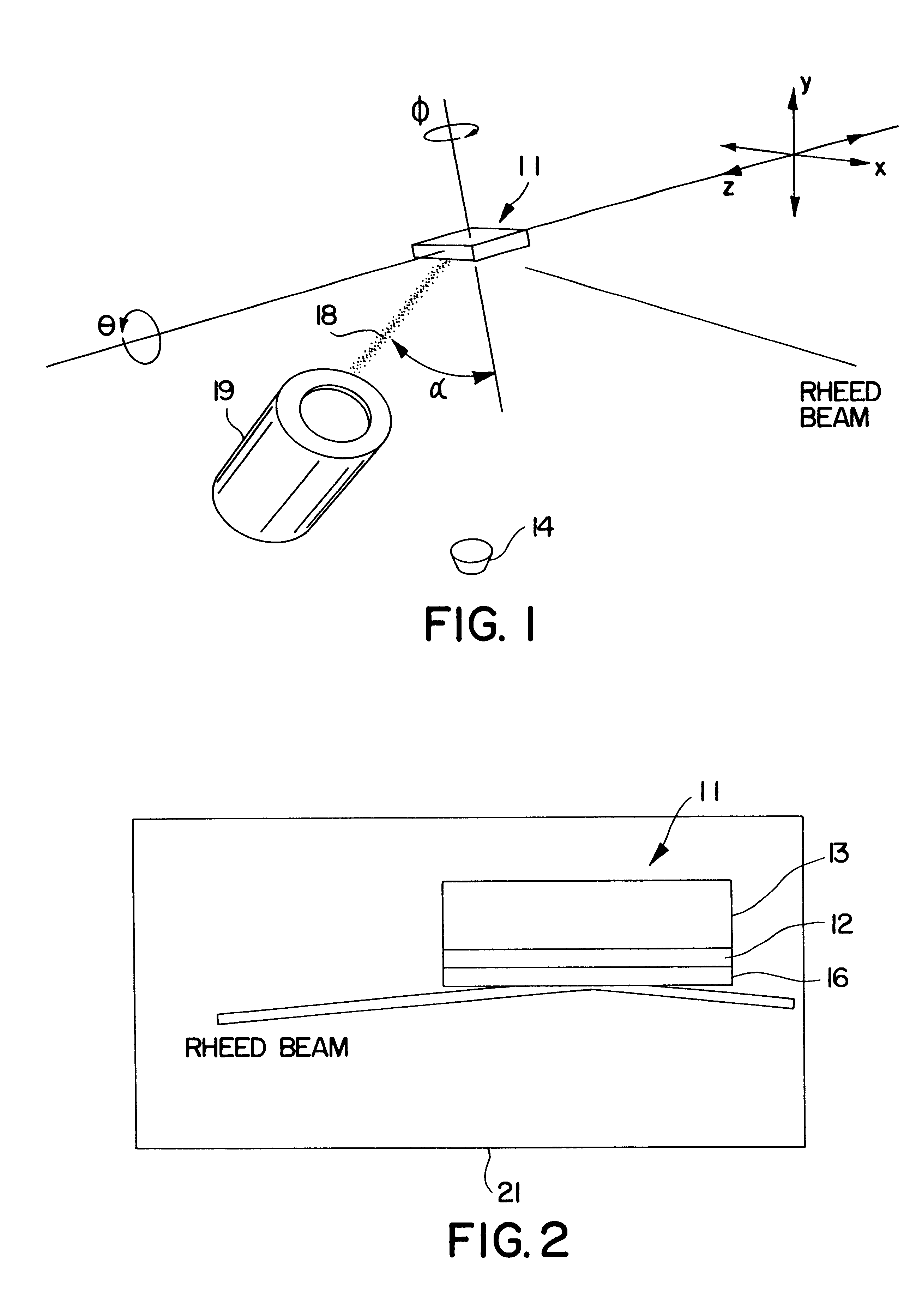

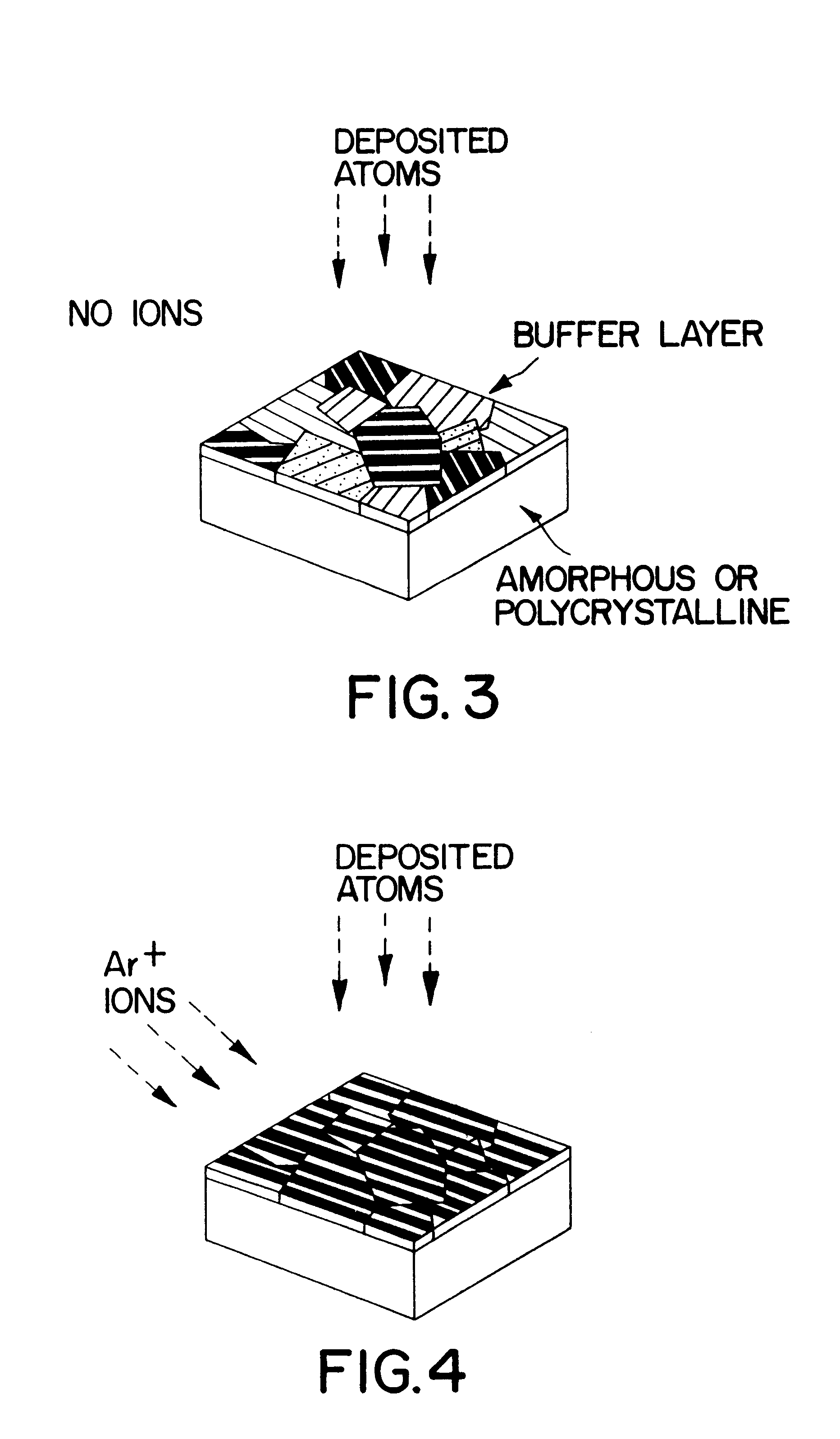

Thin films having rock-salt-like structure deposited on amorphous surfaces

InactiveUS6190752B1Simple technologyLow production costVacuum evaporation coatingSputtering coatingIon beam-assisted depositionOptoelectronics

A thin film of material having a rock-salt-like structure is deposited on a smooth amorphous substrate surface by ion beam assisted deposition.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

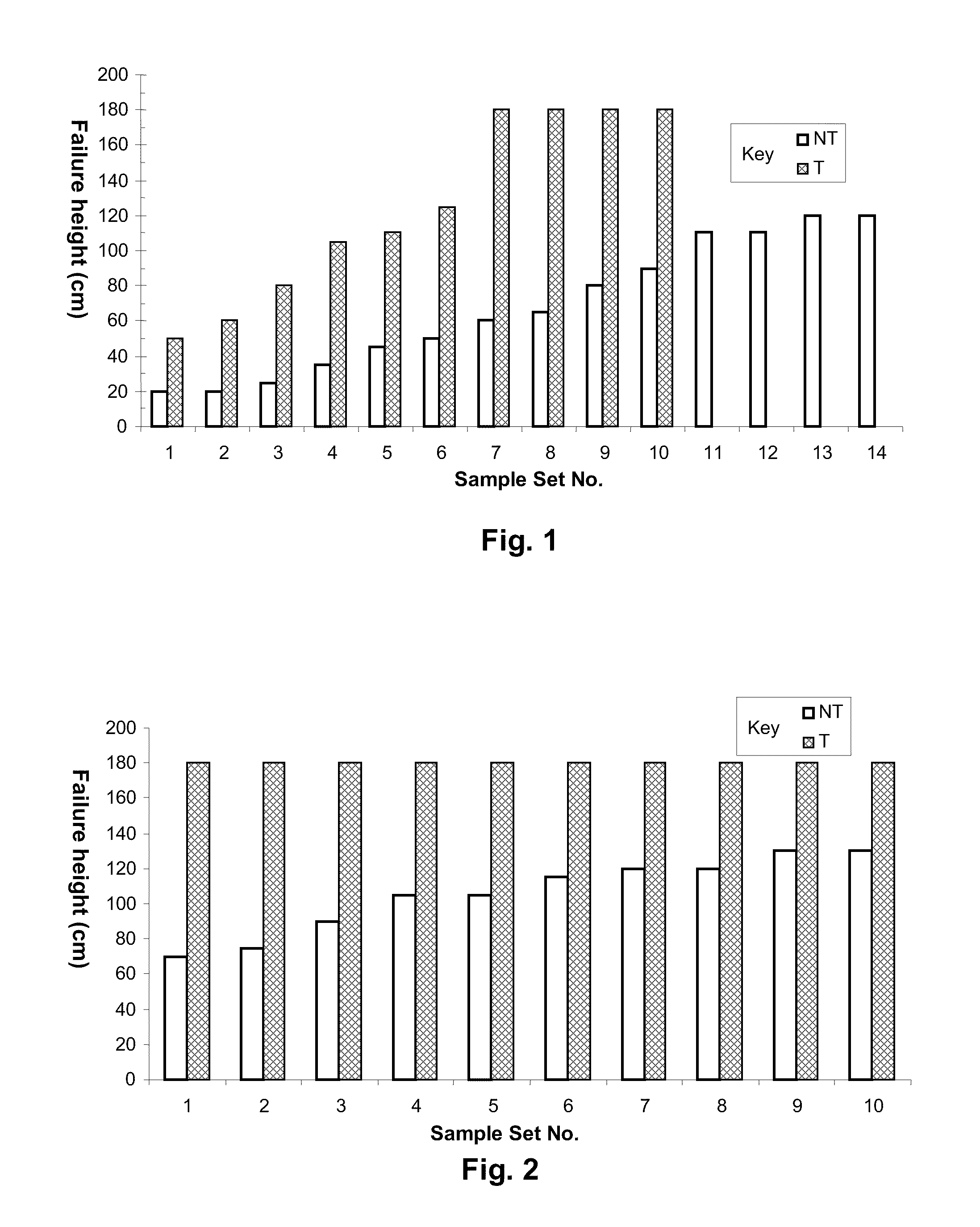

Impact-damage-resistant glass sheet

ActiveUS20110165393A1Increased and more consistent resistanceImprove flexural strengthSynthetic resin layered productsRecord information storageGlass coverDisplay device

Impact-damage-resistant glass sheet comprising at least one chemically etched surface in combination with a tempering surface compression layer, the glass sheet exhibiting a high standardized ball drop failure height and a high flexural modulus of rupture strength, useful to provide damage-resistant glass cover sheets for consumer electronic video display devices, is provided by subjecting thin glass sheet to a combination of a surface tempering treatment and a surface etching treatment that improves strength while maintaining the optical glass sheet properties required for video display applications.

Owner:CORNING INC

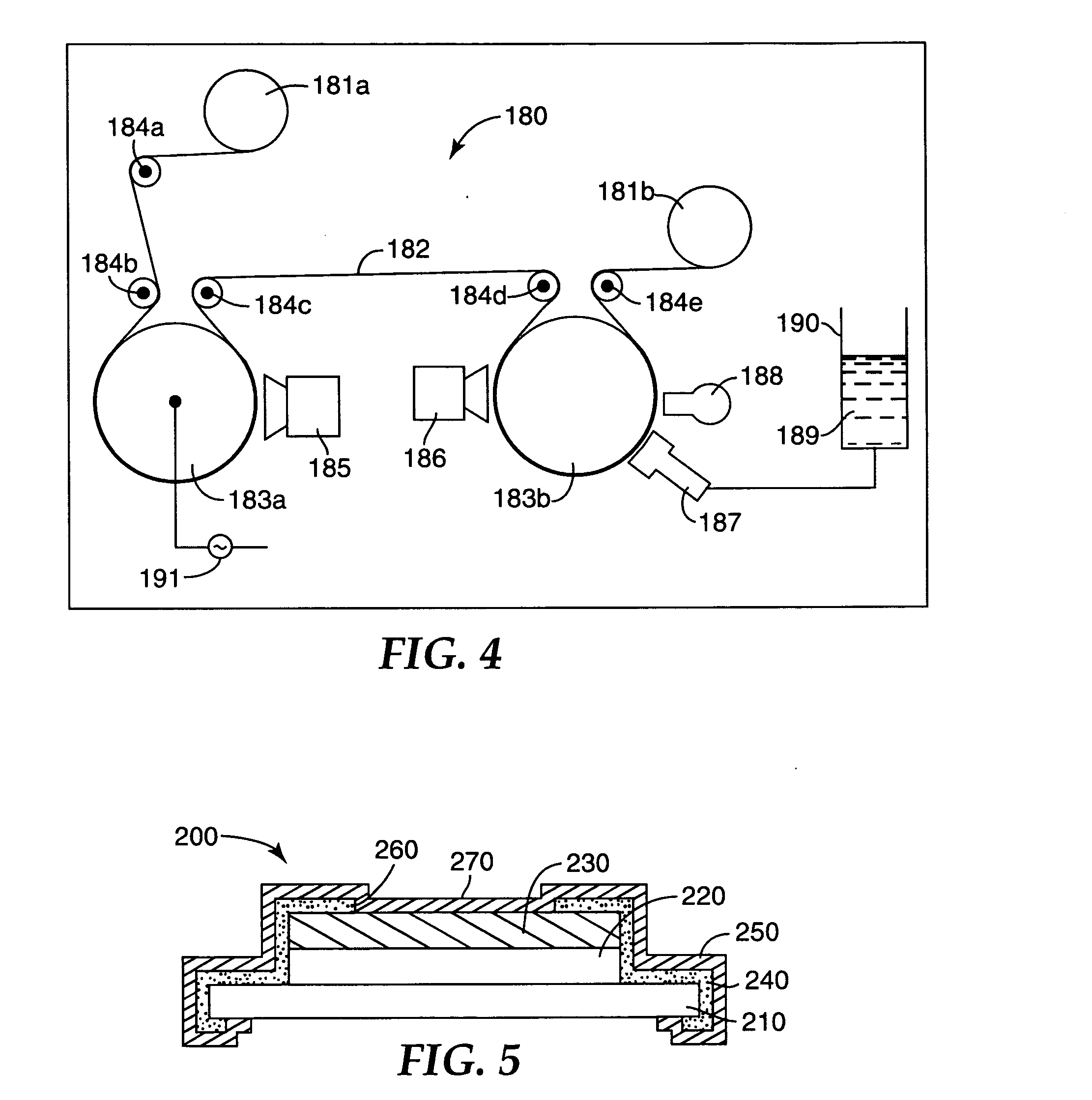

Moisture barrier coatings

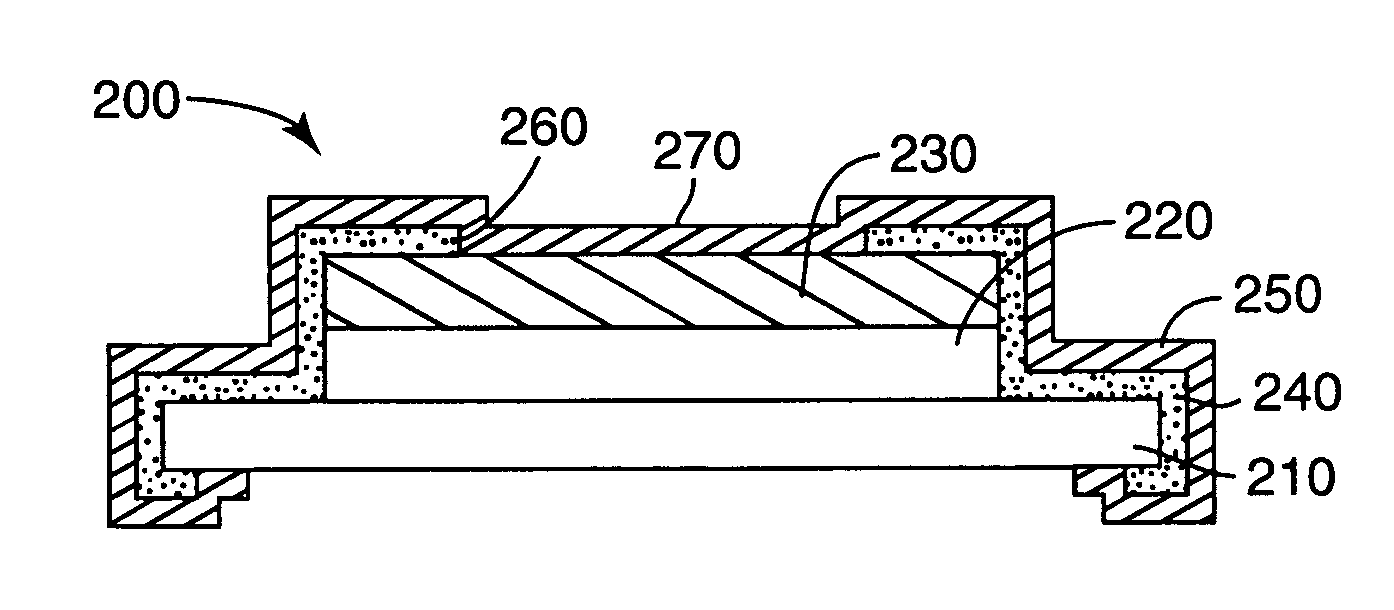

InactiveUS20070020451A1Liquid surface applicatorsSynthetic resin layered productsCarbon layerMoisture barrier

A barrier assembly having a flexible or rigid substrate overcoated with an all polymer multilayer stack. A multilayer on the substrate includes alternating diamond-like glass or carbon layers with polymer layers. Another multilayer includes alternating polymer layers using different types of polymers. The barrier layers can be used to mount, cover, encapsulate or form composite assemblies for protection of moisture or oxygen sensitive articles

Owner:3M INNOVATIVE PROPERTIES CO

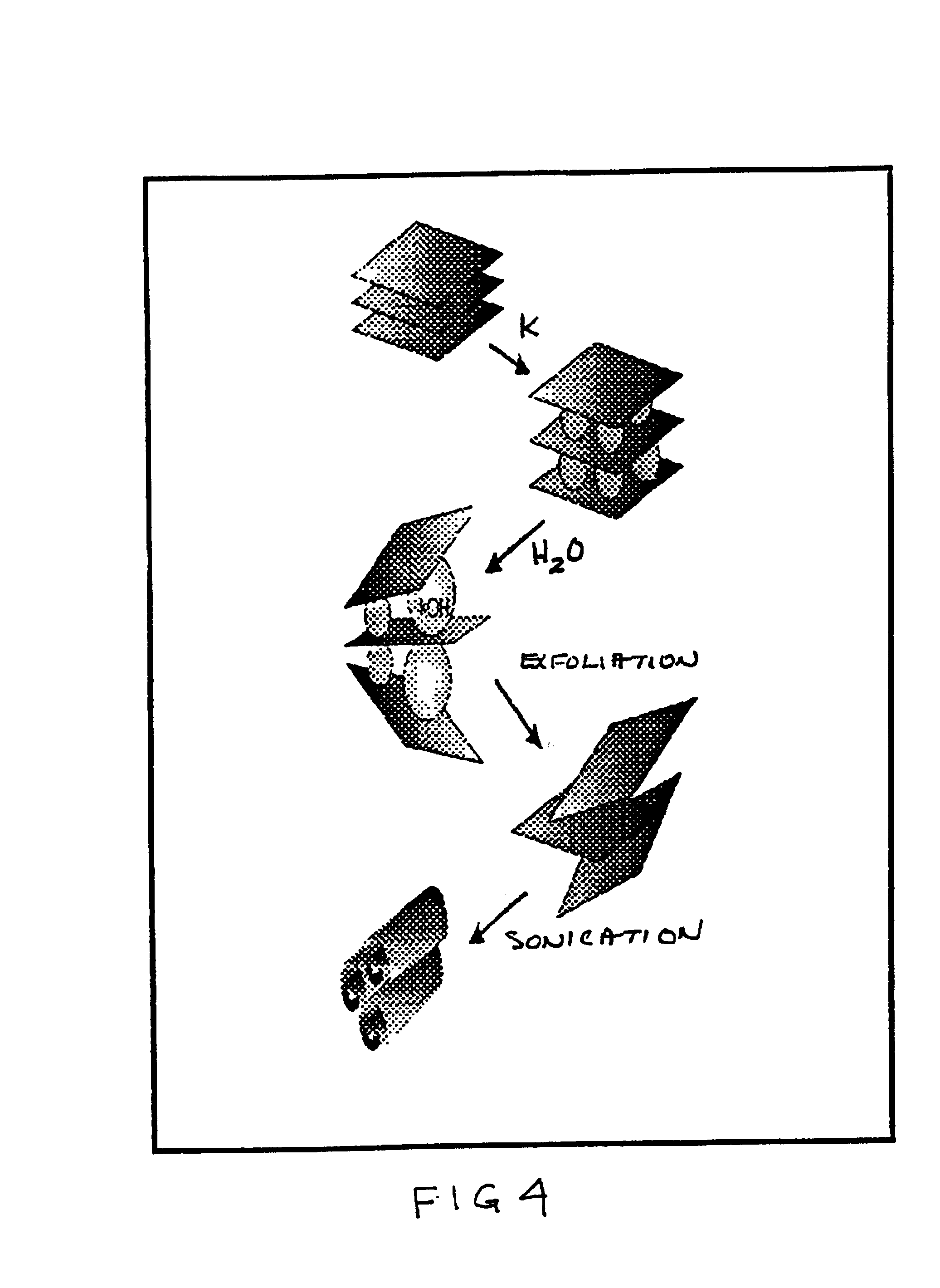

Chemical manufacture of nanostructured materials

InactiveUS6872330B2High strengthIncrease volumeMaterial nanotechnologyOxide/hydroxide preparationInorganic compoundTe element

A low temperature chemical route to efficiently produce nanomaterials is described. The nanomaterials are synthesized by intercalating ions into layered compounds, exfoliating to create individual layers and then sonicating to produce nanotubes, nanorods, nanoscrolls and / or nanosheets. It is applicable to various different layered inorganic compounds (for example, bismuth selenides / tellurides, graphite, and other metal complexes, particularly transition metal dichalcogenides compounds including oxygen, sulfur, tellurium or selenium).

Owner:RGT UNIV OF CALIFORNIA

Activatable material

InactiveUS6846559B2Assist in flow controlPreventing fatigue crack growthSynthetic resin layered productsRecord information storageEpoxyElastomer

An activatable (e.g., heat expandable) material and articles incorporating the same is disclosed. The material includes an epoxy resin; an epoxy / elastomer hybrid or reaction product; a blowing agent; a curing agent; and optionally, a filler. In preferred embodiments, the material includes aramid fiber, nanoclay or both.

Owner:ZEPHYROS INC

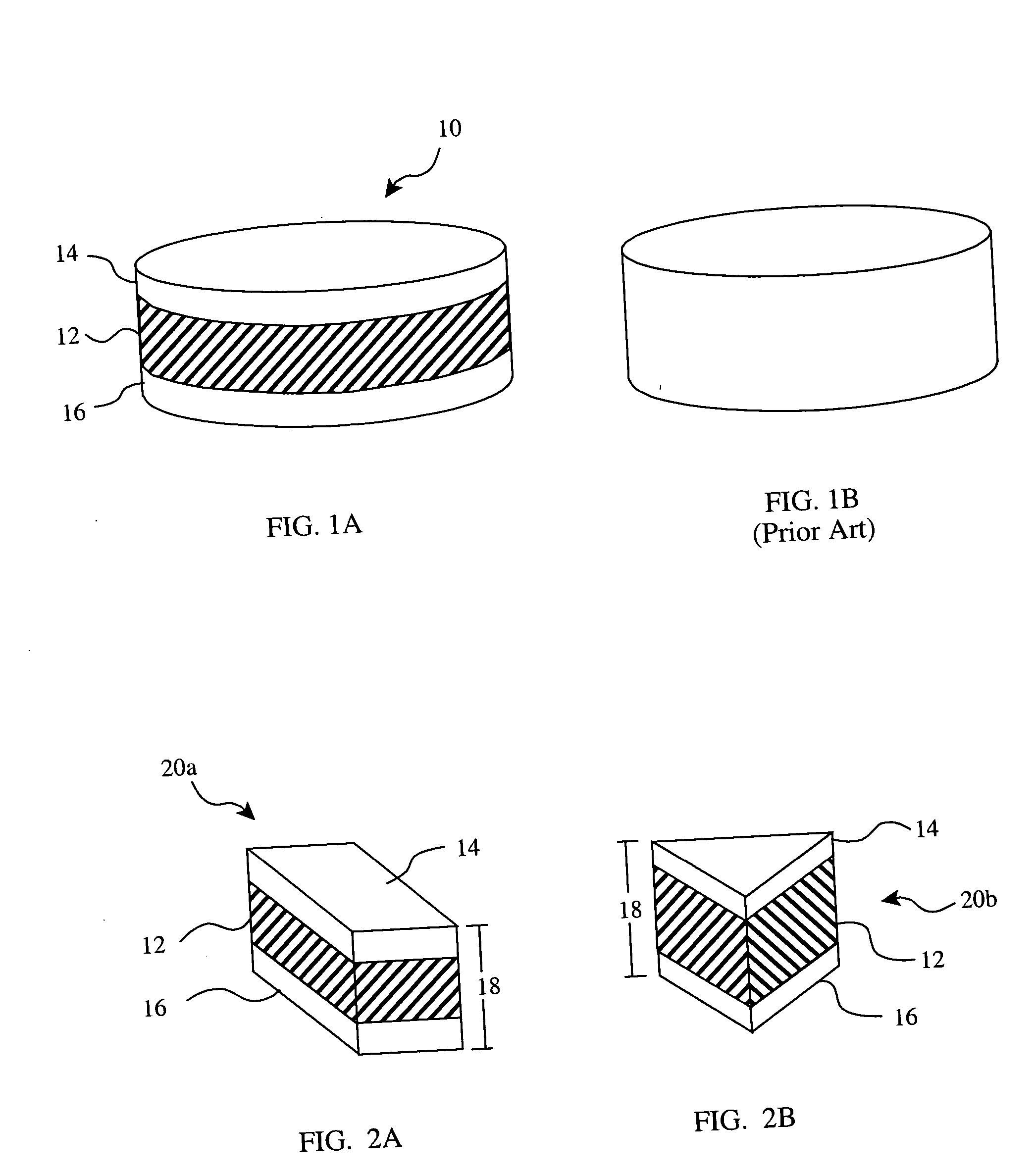

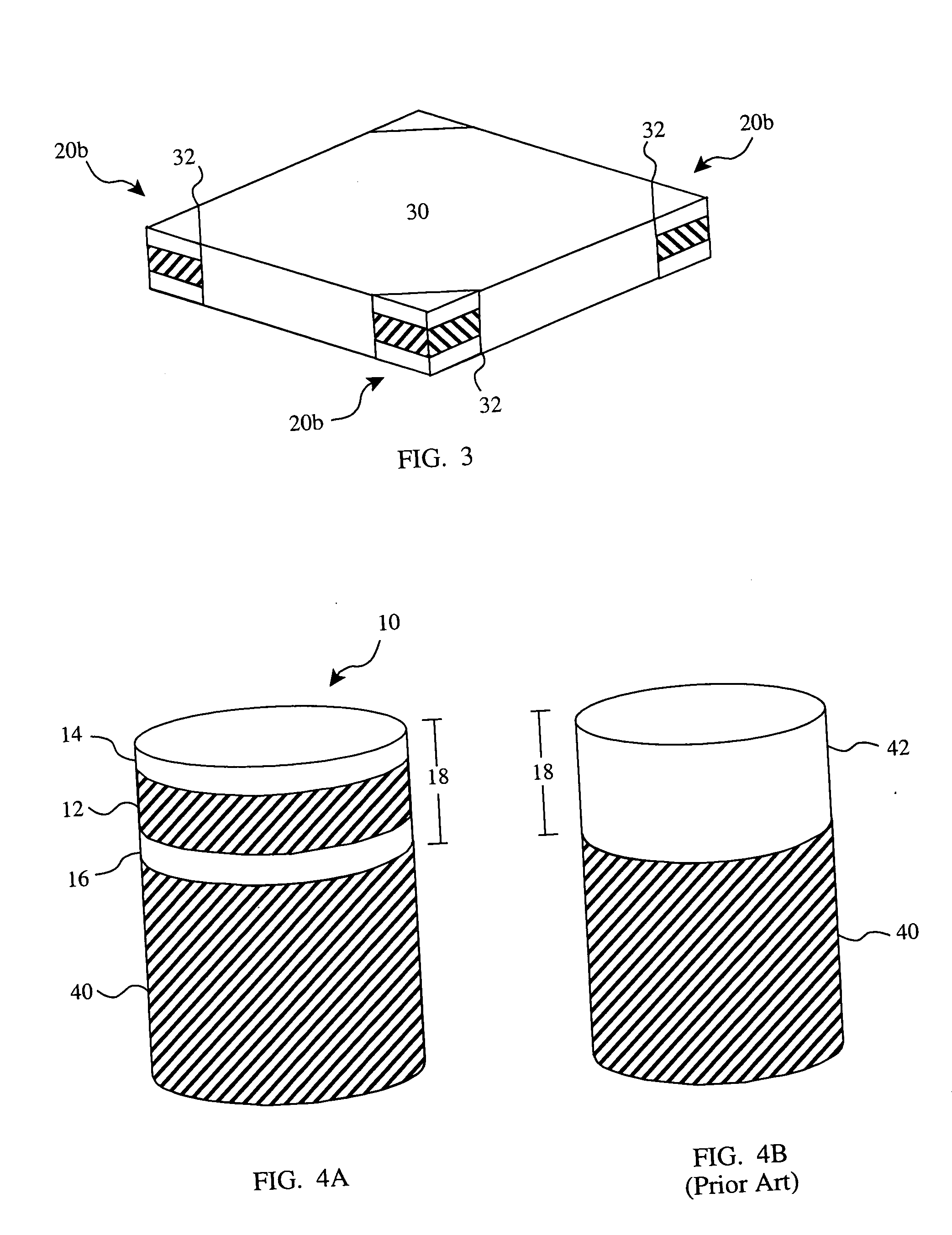

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

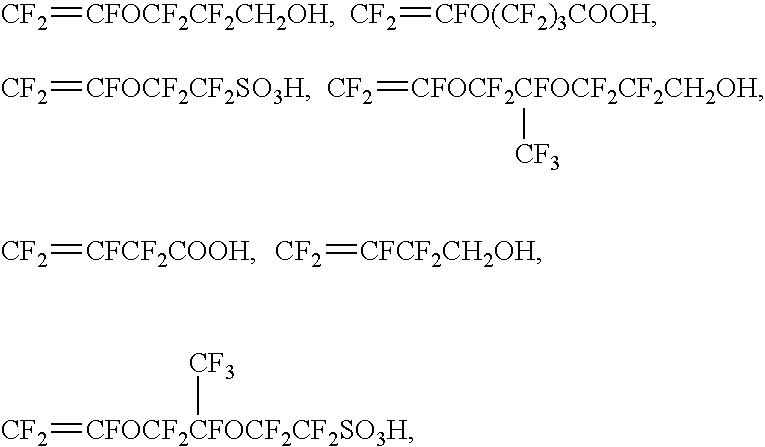

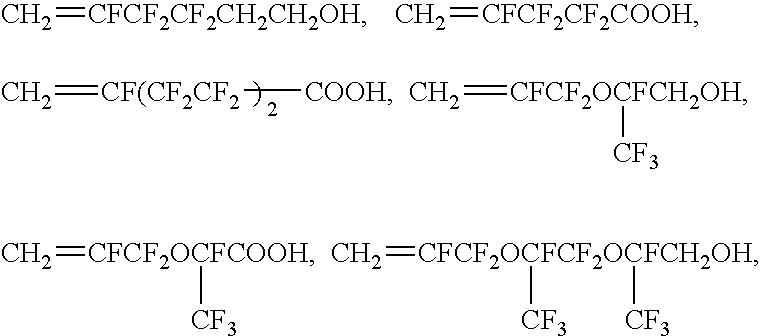

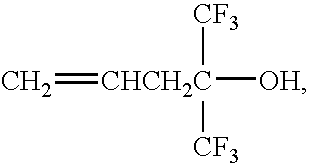

Thin coating film comprising fluorine-containing polymer and method of forming same

InactiveUS6794027B1High propertyLowering transparencySynthetic resin layered productsPretreated surfacesHeat resistanceFluorine containing

To provide the method of forming the thin coating film of fluorine-containing polymer having heat resistance and non-sticking property by adhering directly to a substrate without lowering characteristics such as reflection and light transmission which the substrate has. The thin coating film is a film which comprises a continuous layer of fluorine-containing polymer formed by adhering directly to the substrate and has a thickness of less than 3 mum, wherein the fluorine-containing polymer in the coating film has a hydrophilic functional group and a crystalline melting point of not less than 200° C.

Owner:DAIKIN IND LTD

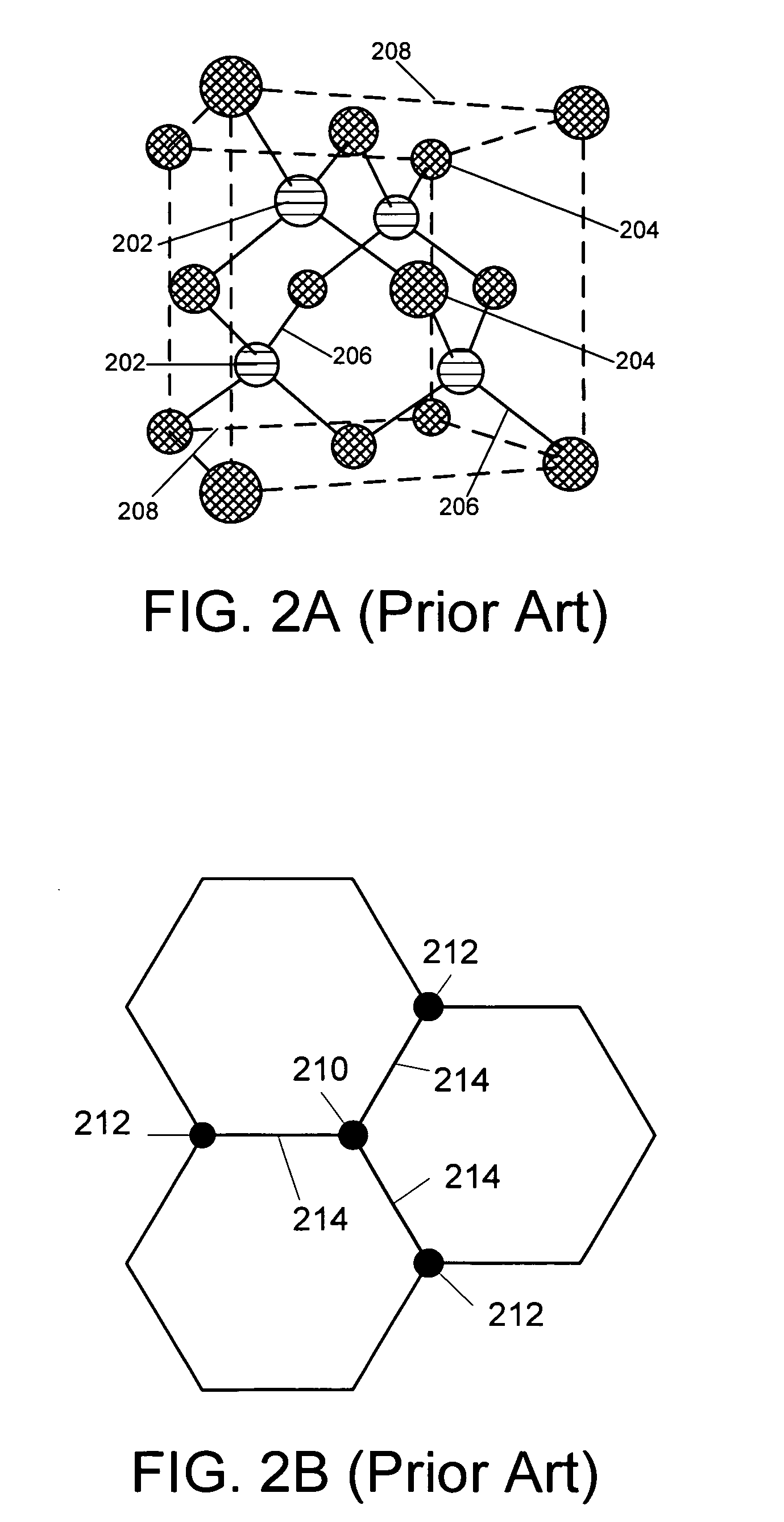

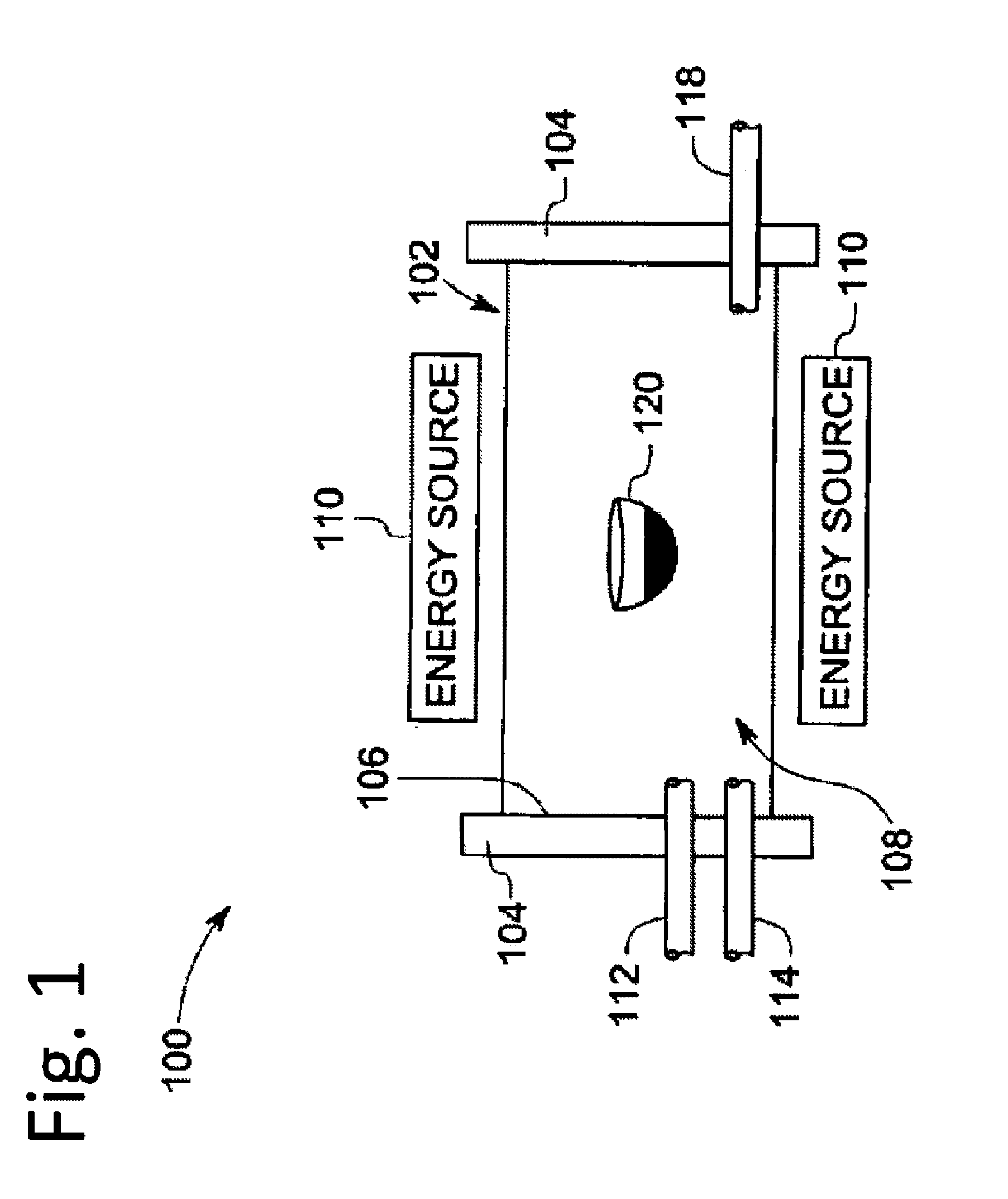

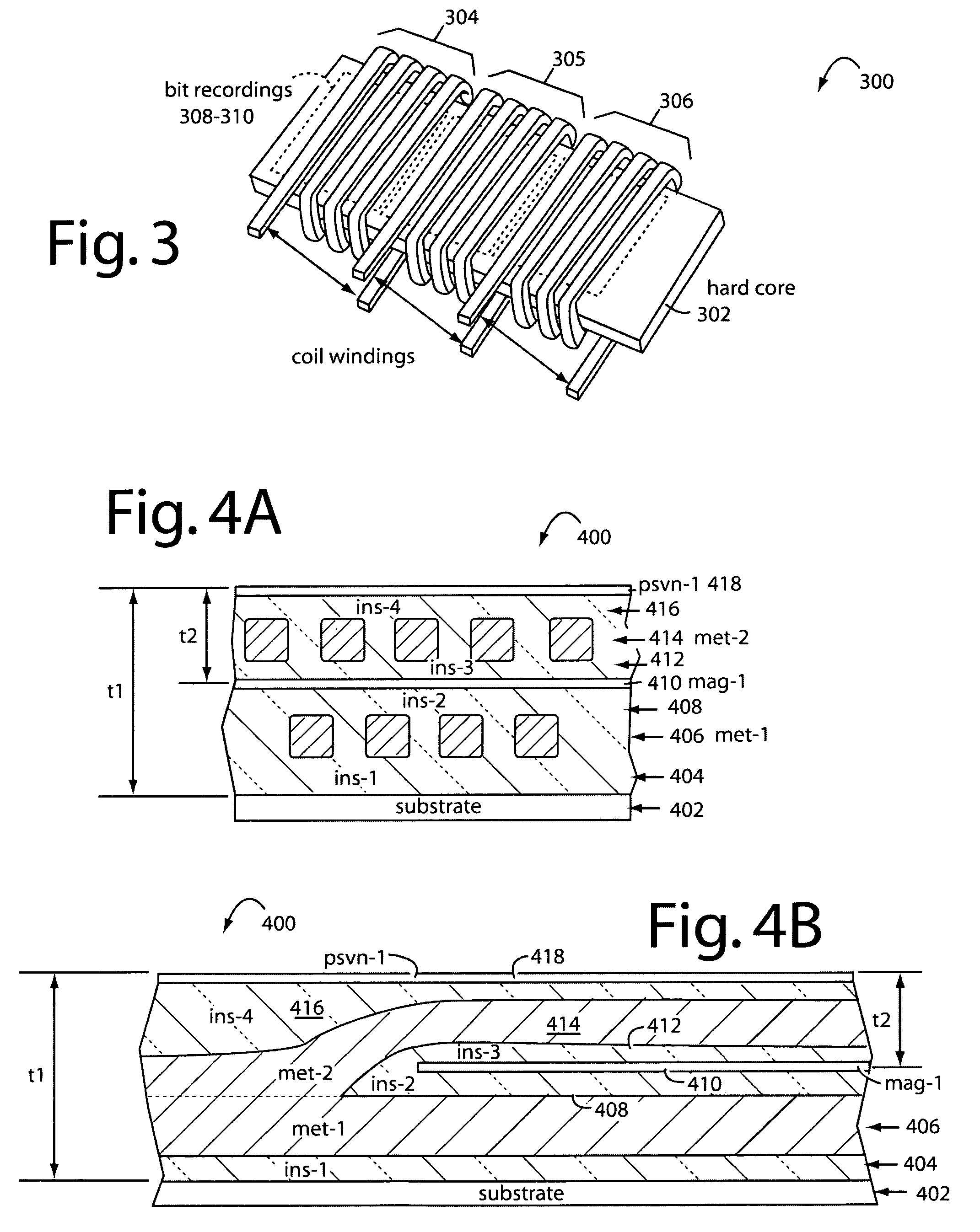

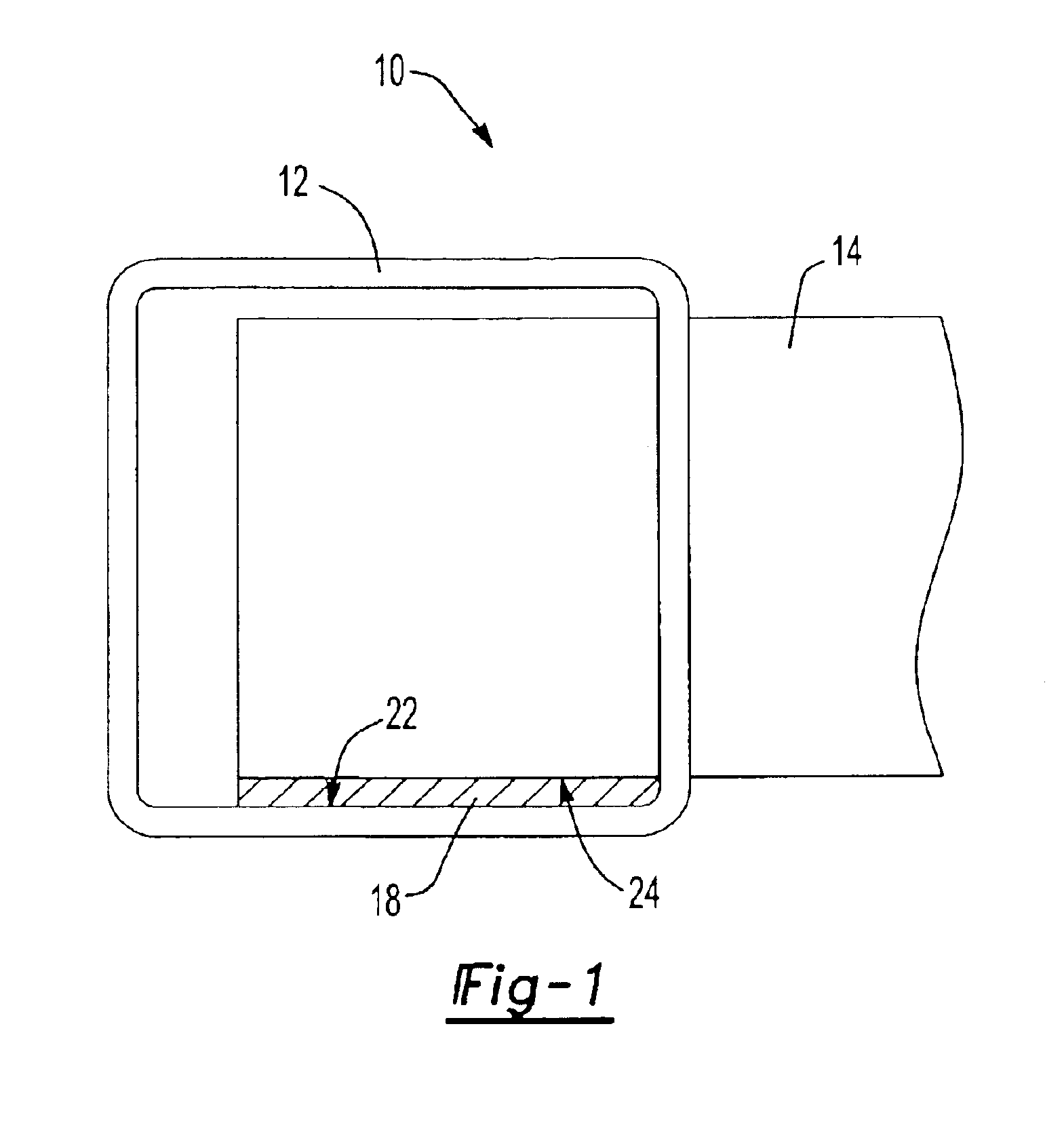

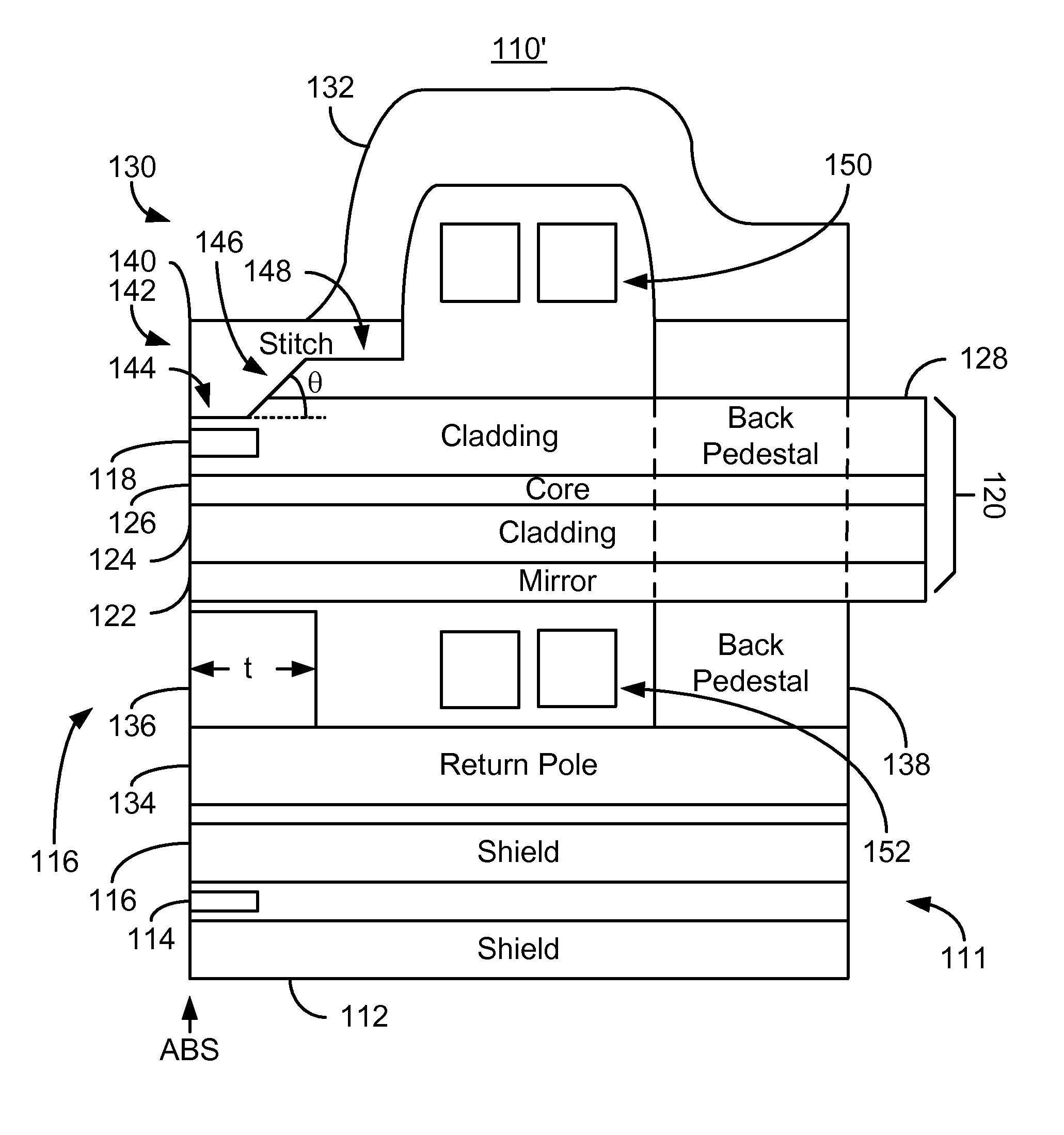

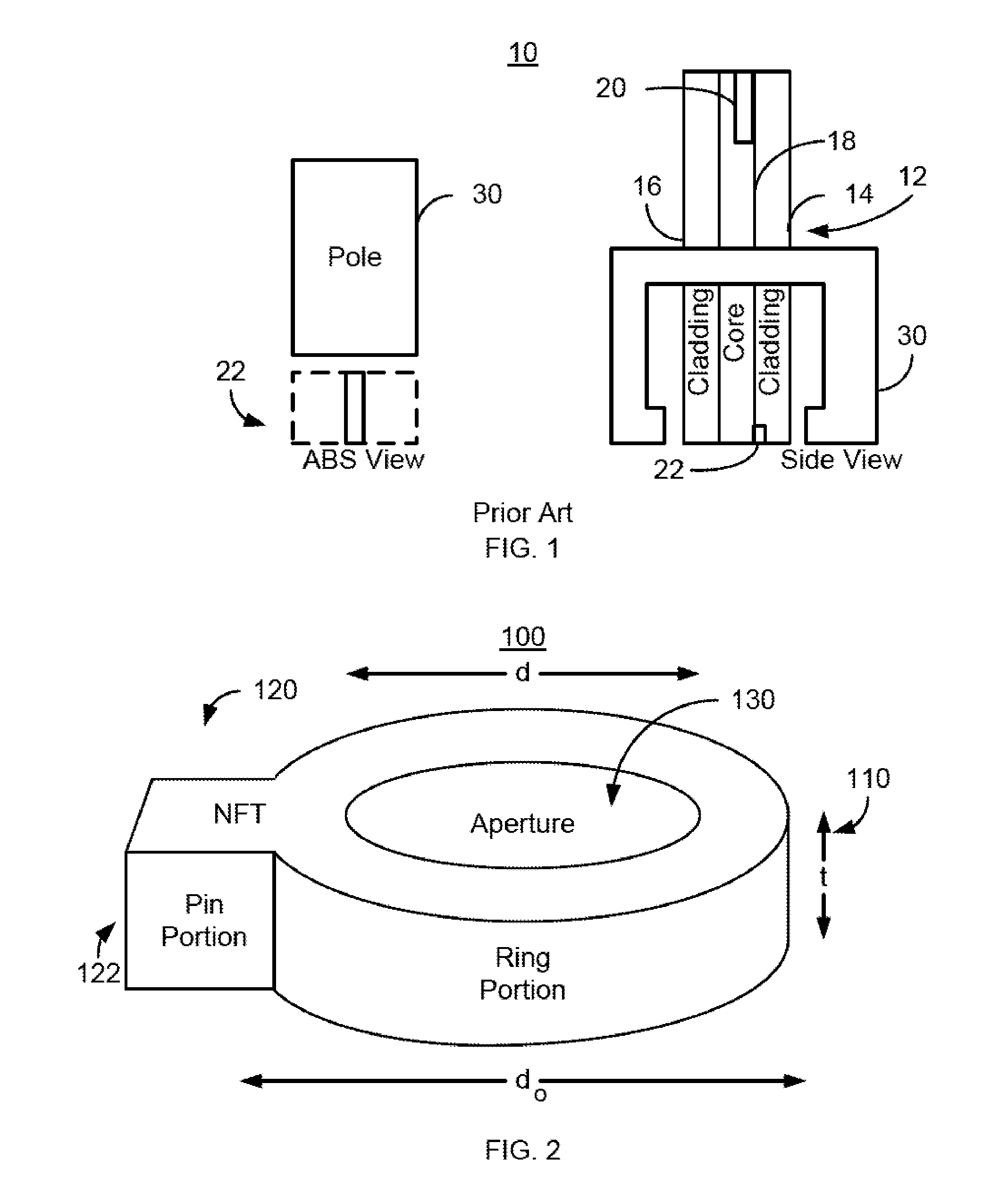

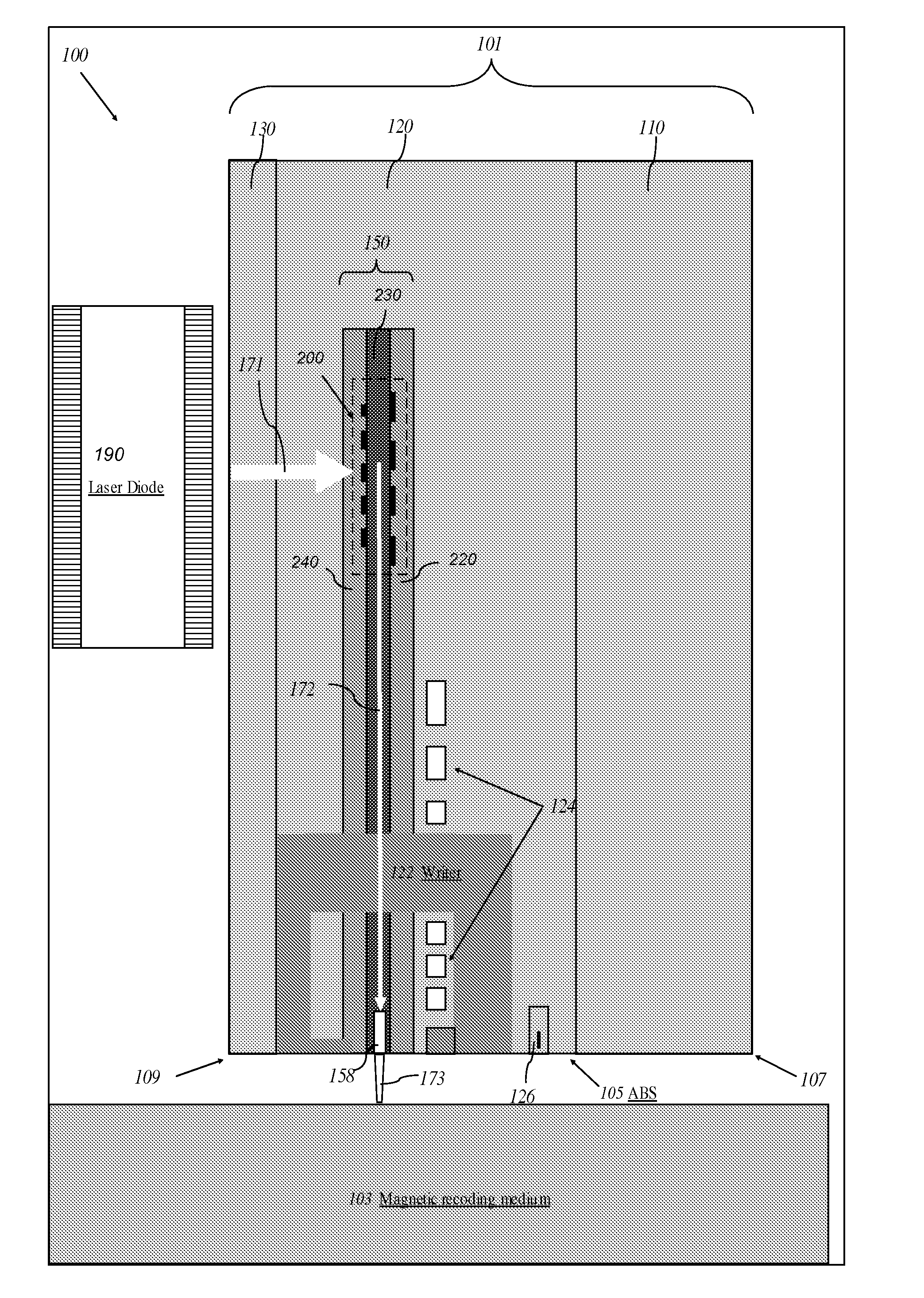

Method and system for providing a write pole in an energy assisted magnetic recording disk drive

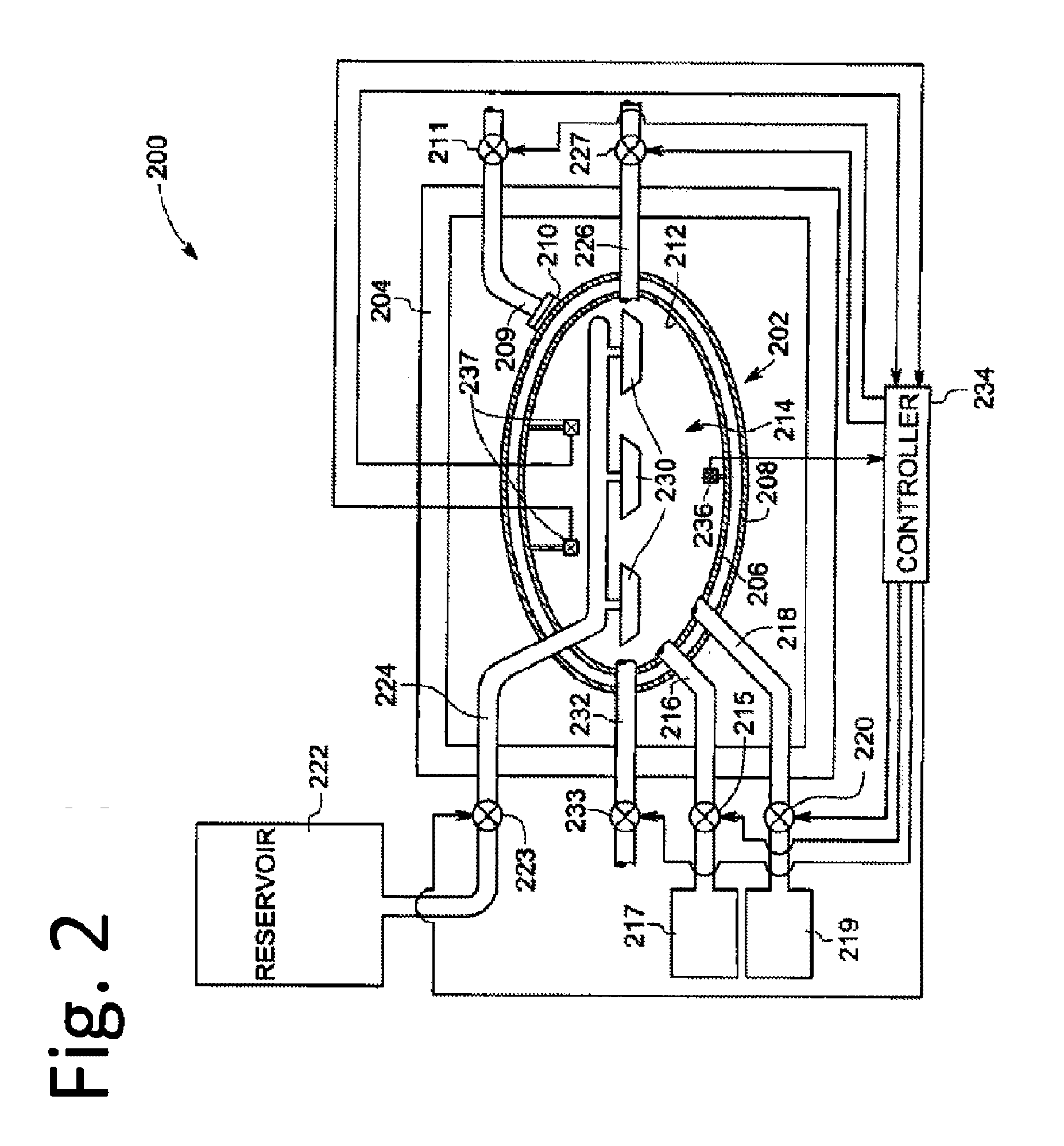

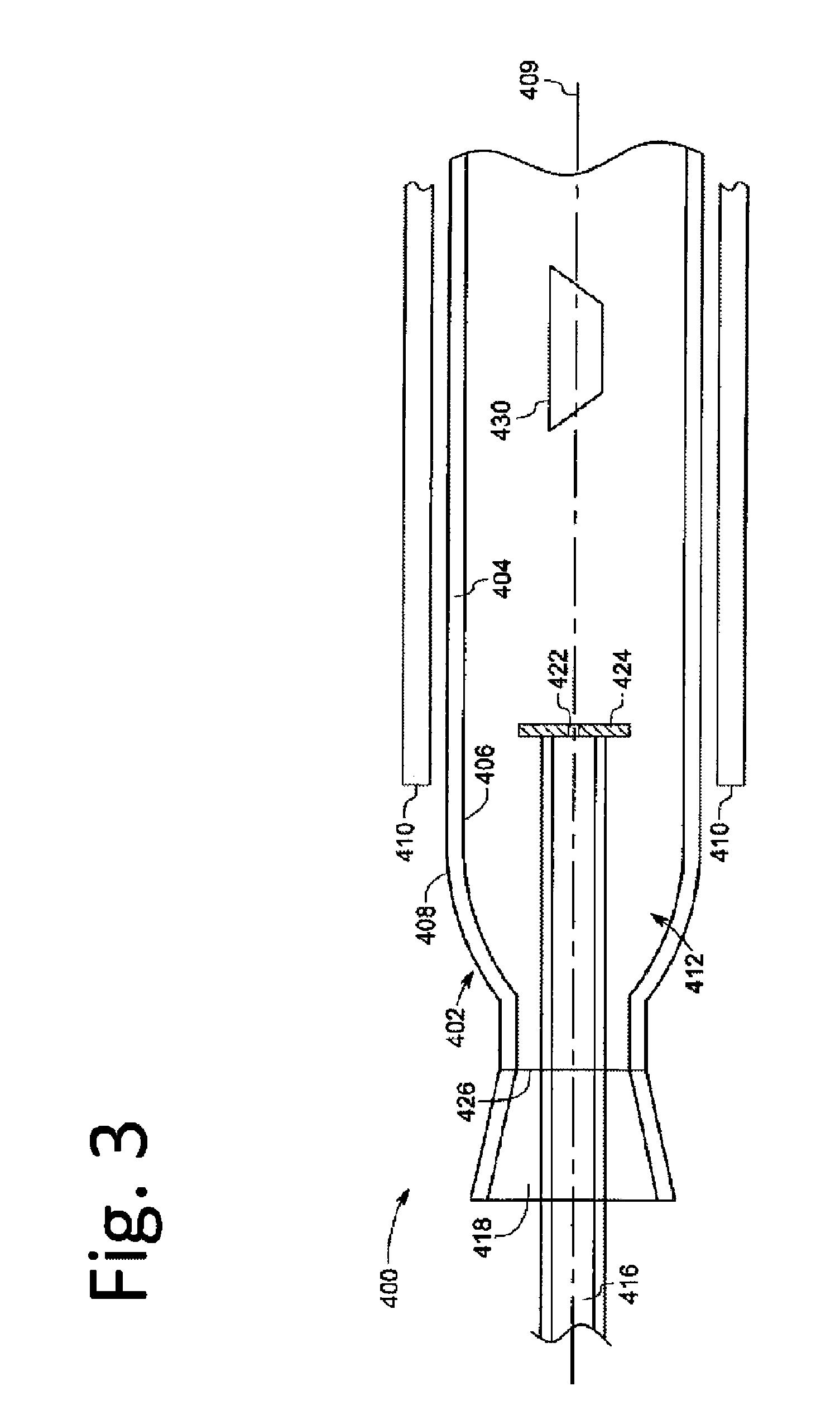

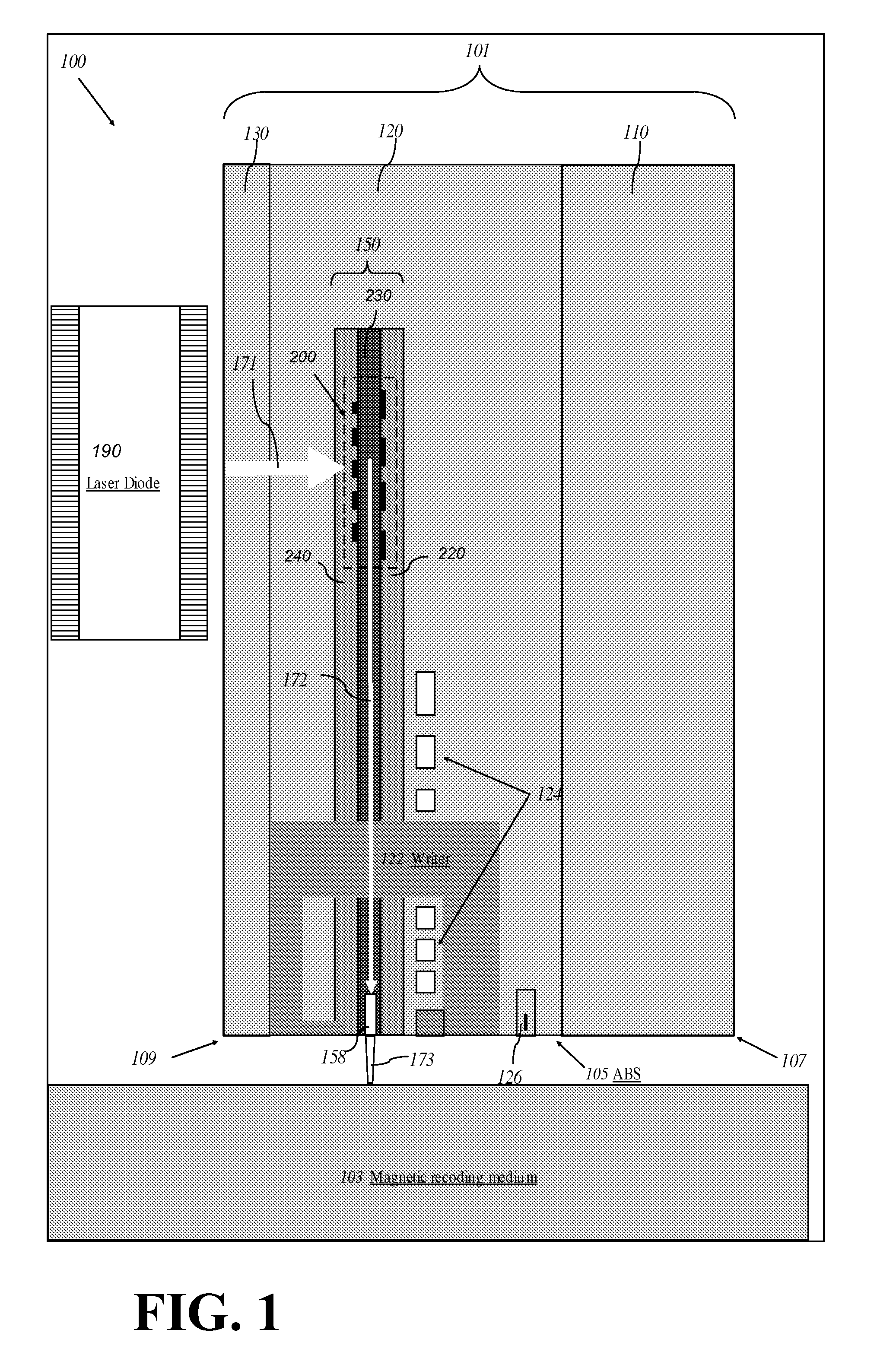

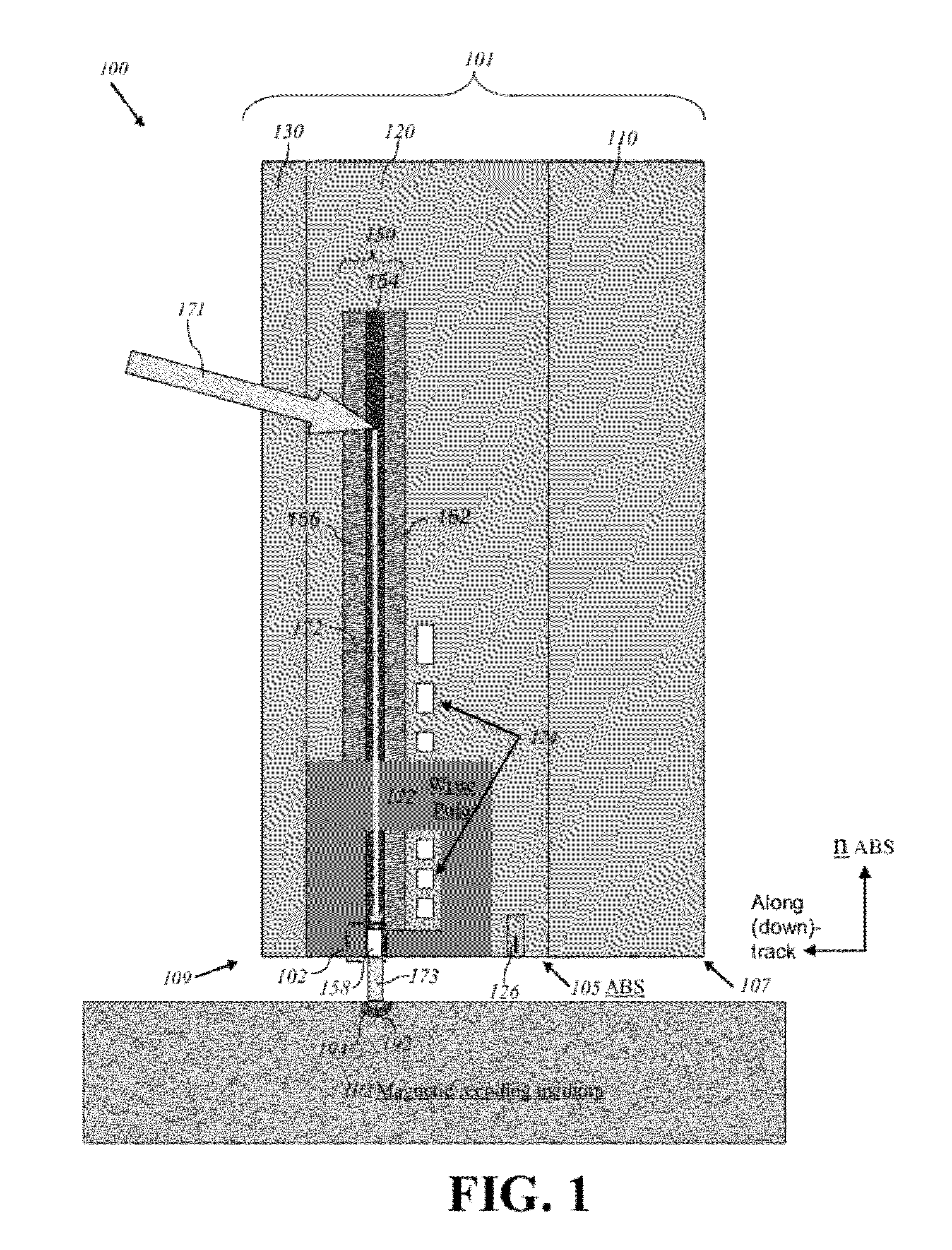

A method and system for providing an energy assisted magnetic recording (EAMR) transducer coupled with a laser are described. The EAMR transducer has an air-bearing surface (ABS) residing in proximity to a media during use. The method and system include providing waveguide(s), a near-field transducer (NFT), write pole(s), and coil(s). The waveguide(s) direct energy from the laser toward the ABS. The NFT is coupled with the waveguide and focuses the energy onto the media. The write pole(s) include a stitch for providing a magnetic field to the media and a yoke coupled to the stitch. The stitch includes an ABS-facing surface, a sloped surface, and an NFT-facing surface between the ABS-facing and sloped surfaces. The NFT-facing surface is substantially parallel to the NFT. The sloped surface is sloped at least twenty-five and not more than sixty-five degrees with respect to the NFT-facing surface. The coil(s) energize the write pole(s).

Owner:WESTERN DIGITAL TECH INC

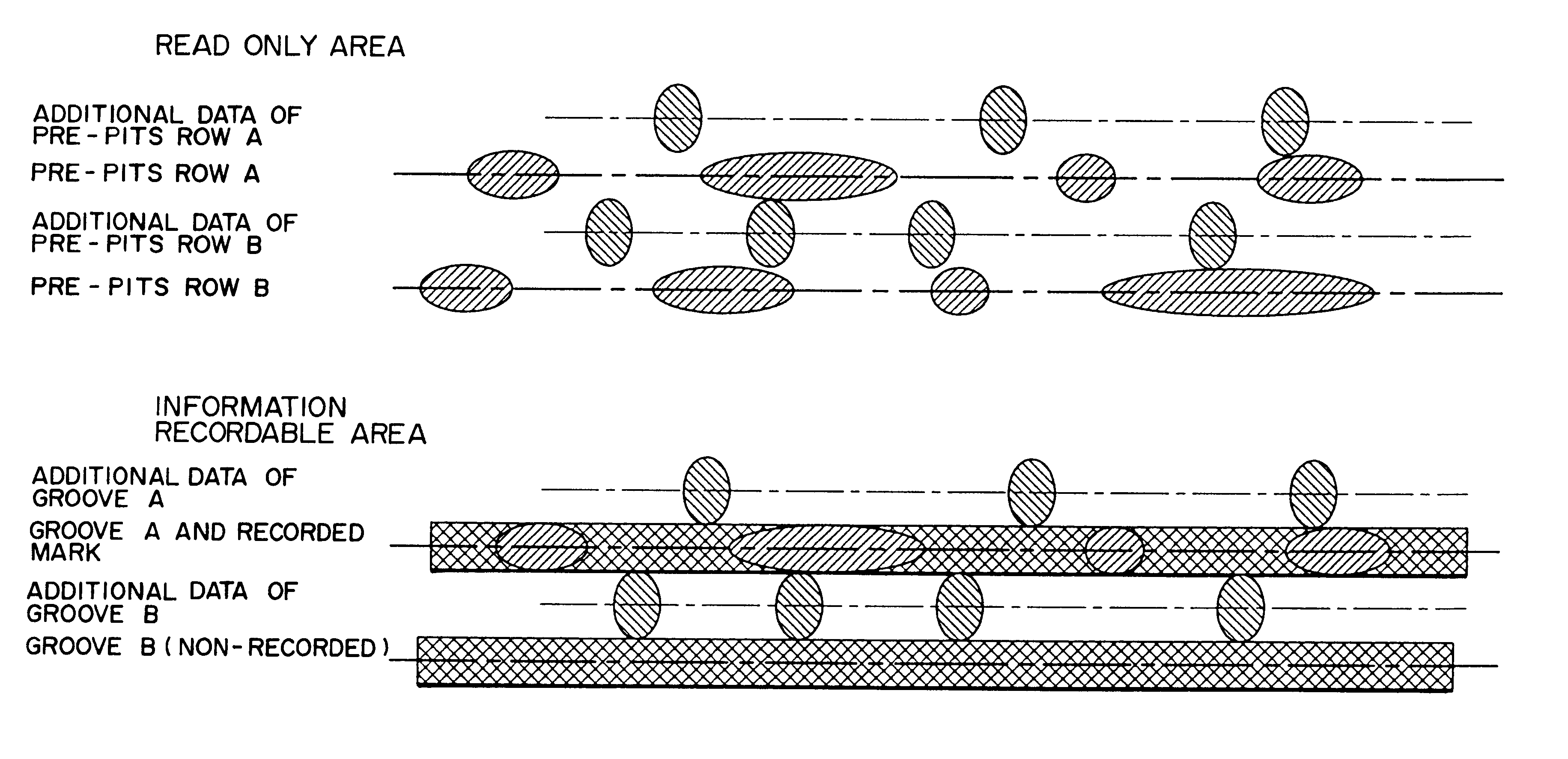

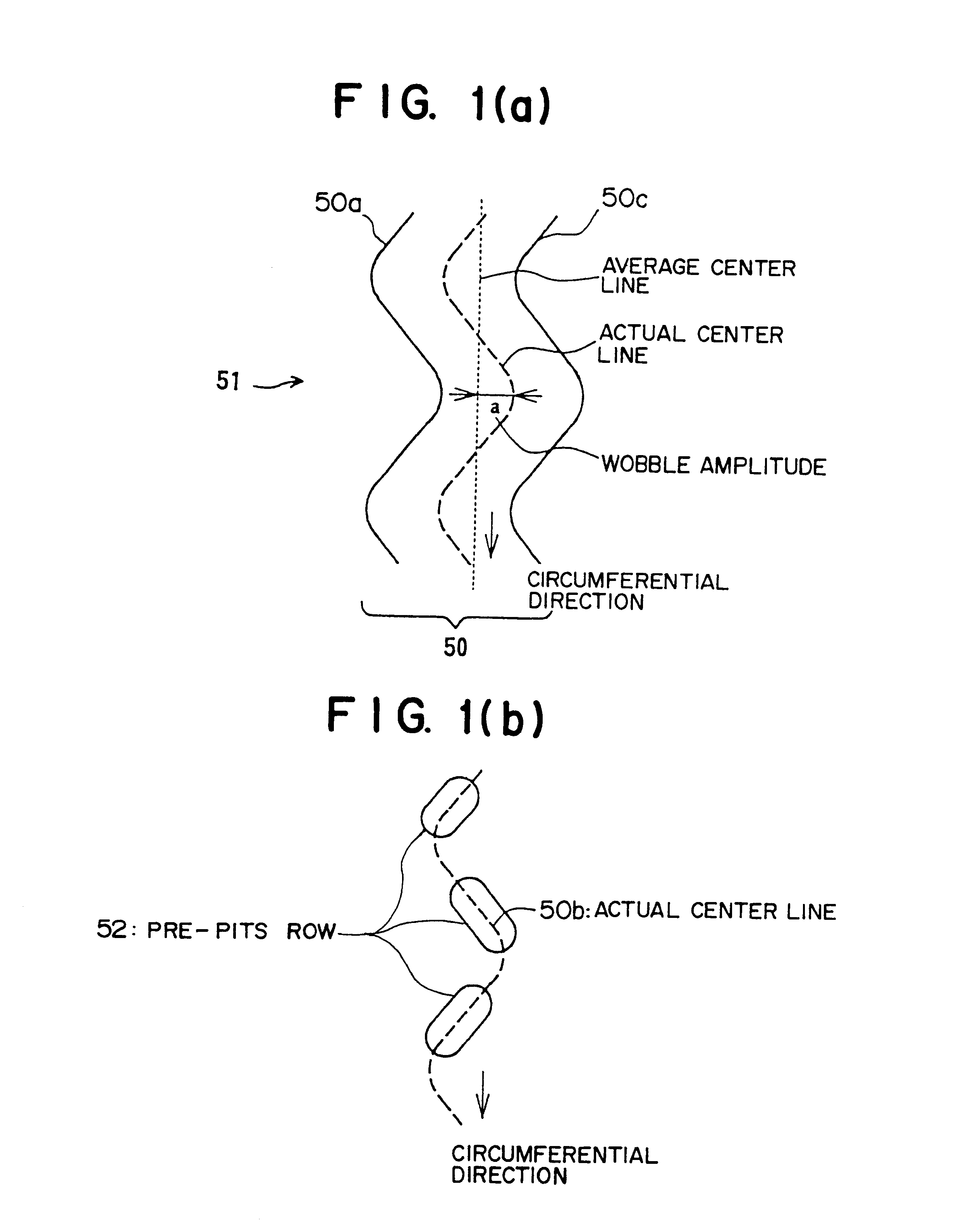

Optical recording medium, data recording method for rewritable-type phase change type optical disc, data erase method for rewritable compact disc, data erase method for rewritable phase change type recording medium, read only data erase method, and recording/readout apparatus

InactiveUS6671249B2Prevent destruction and falsificationReduce the possibilityCombination recordingRecording carrier detailsComputer hardwareRewritable compact disc

For an optical recording medium having a phase change type recording layer on its a substrate and having as read only area and a writable area in a recording area, a data recording method is provided which records data in the writable area. This data recording method comprises a transfer step of transferring program data recorded in the read only area in a practical form to an external computer, and an execution step (step A10) of automatically executing the program data in the external computer to record data in the writable area, which can facilitate manufacturing and reduce the possible of destruction or falsification of ROM data.

Owner:CMC MAGNETICS CORPORATION

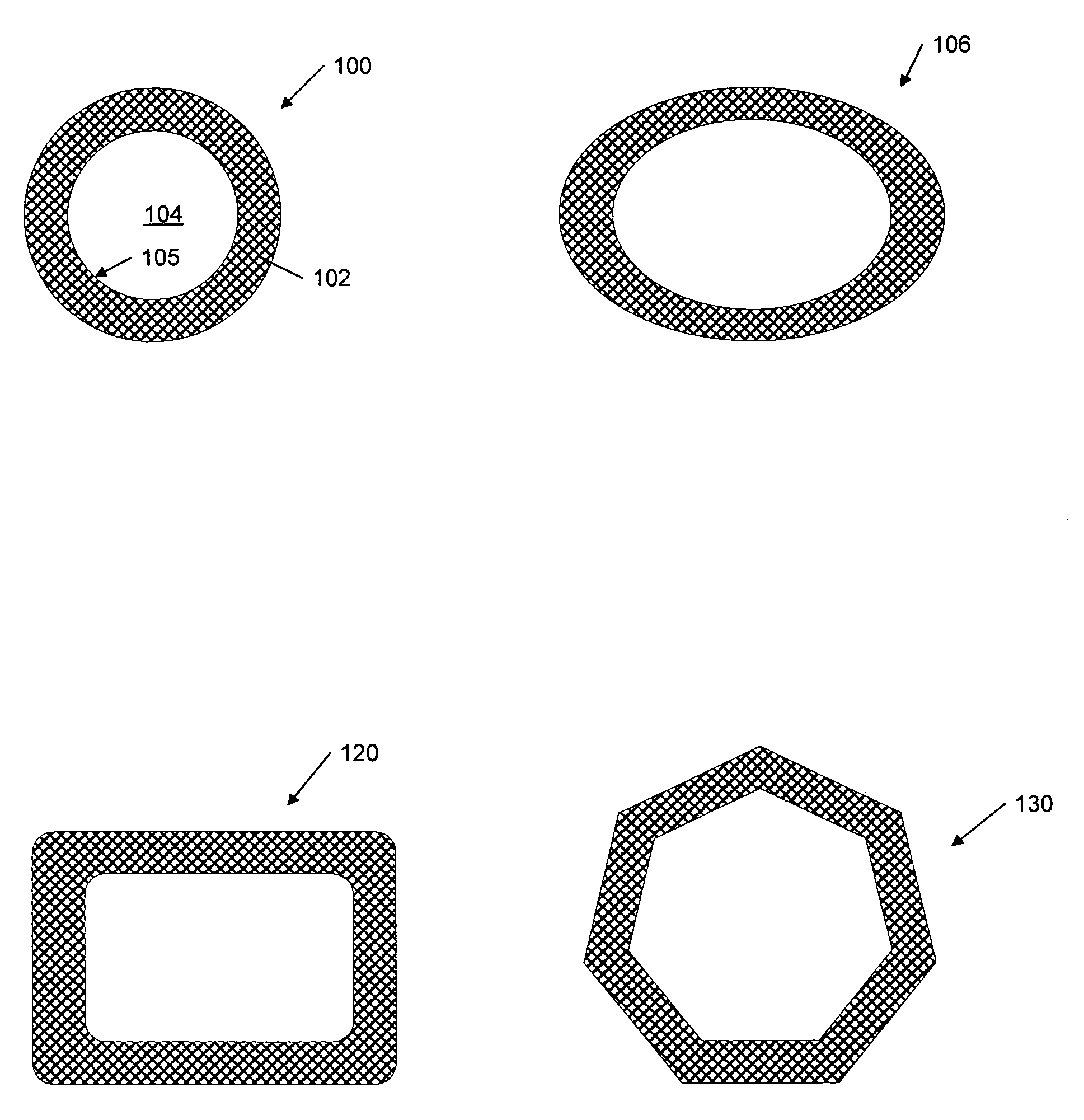

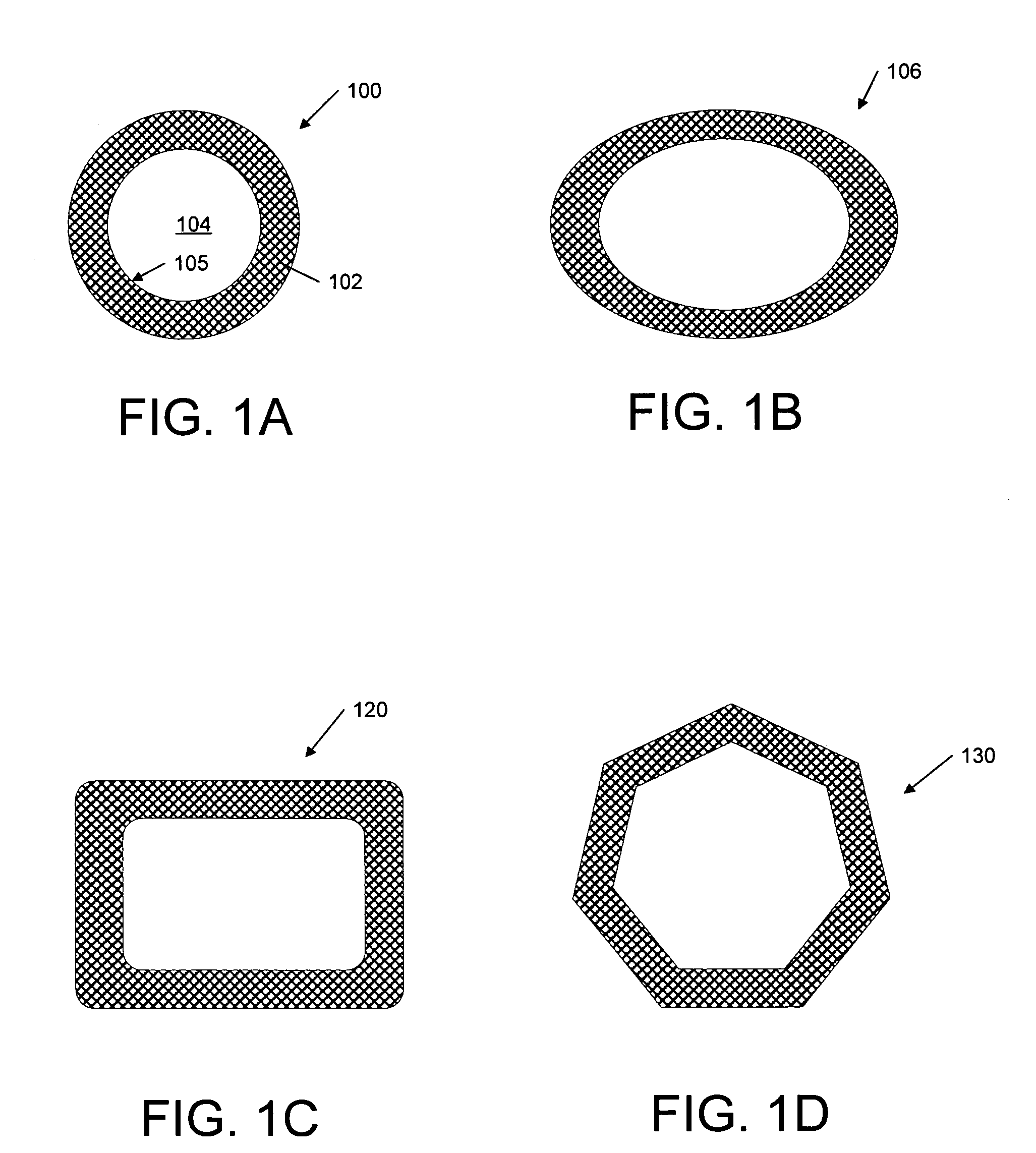

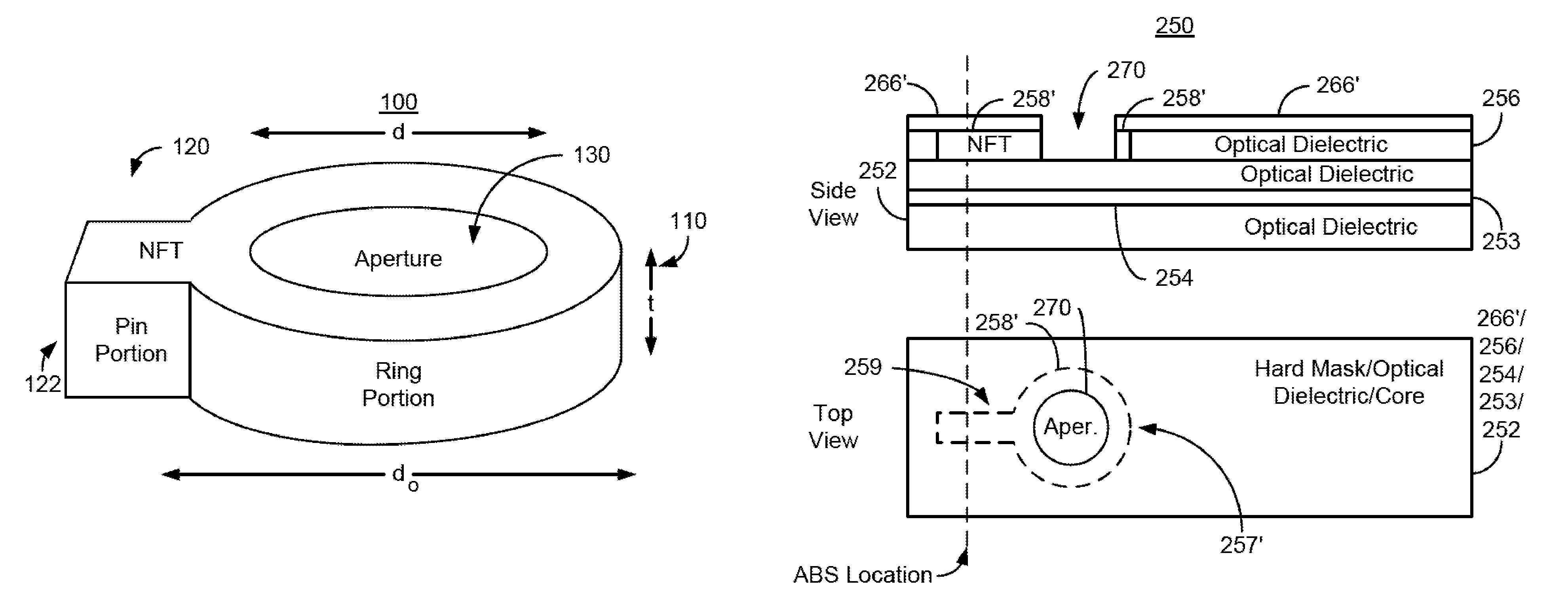

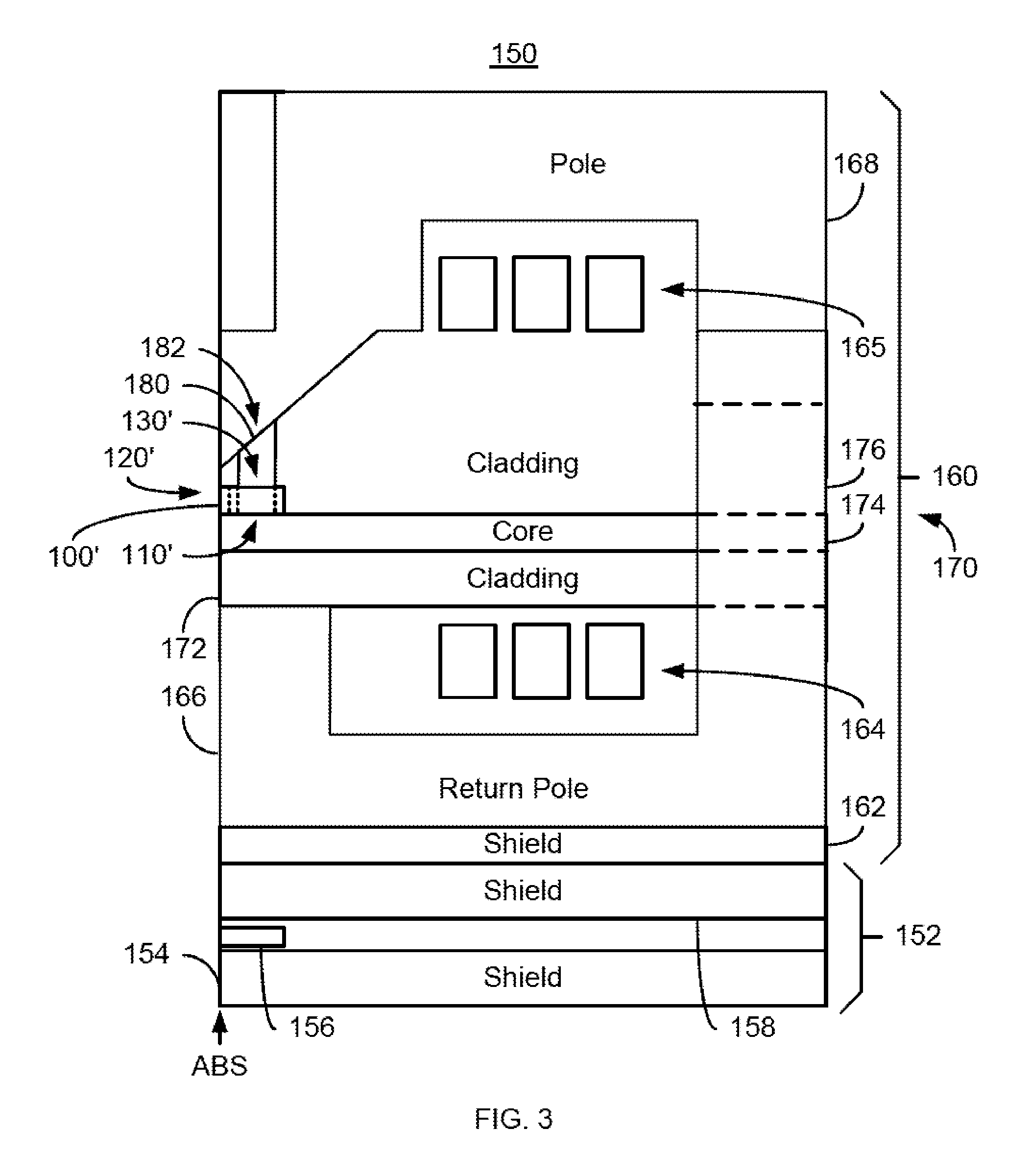

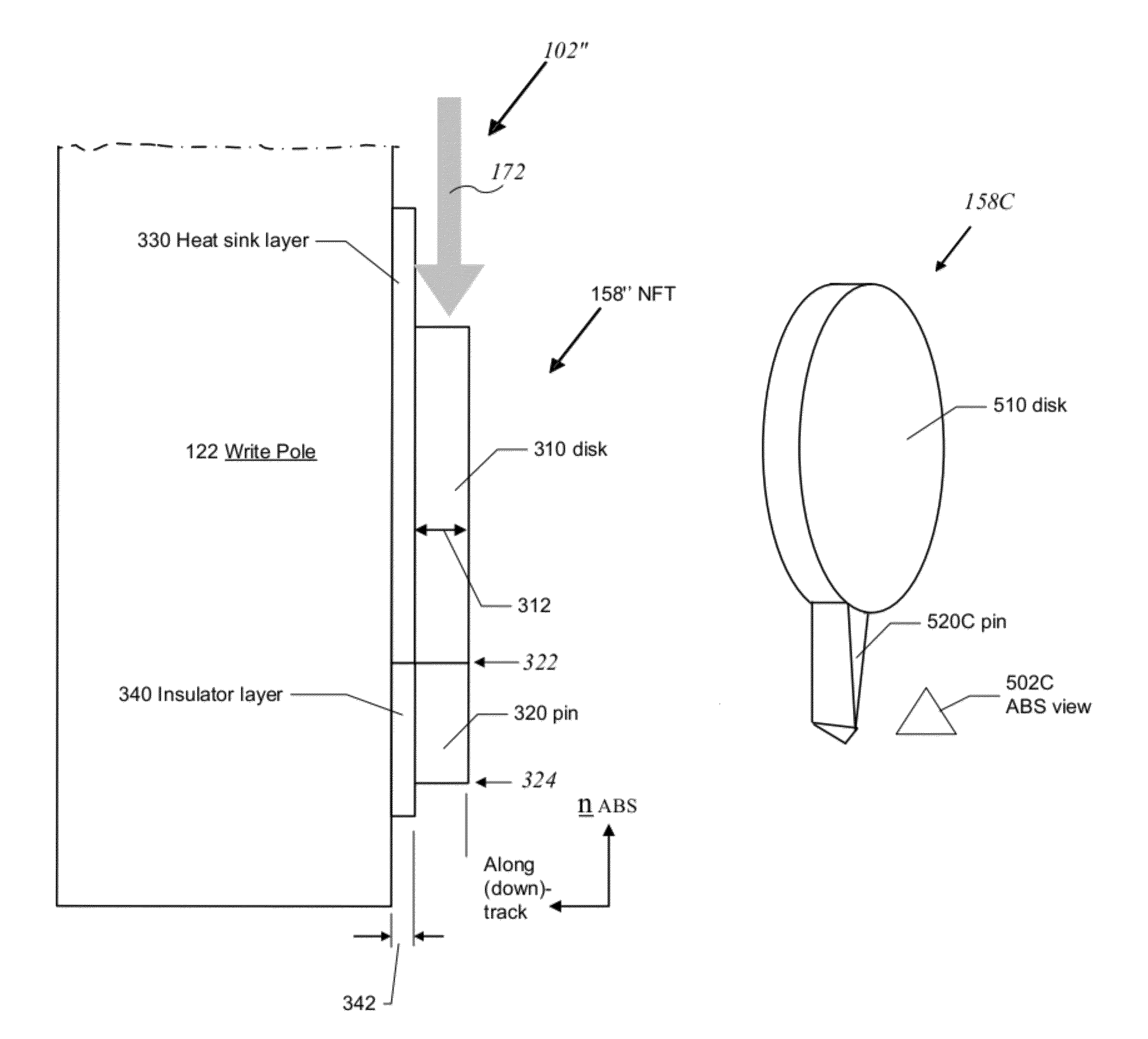

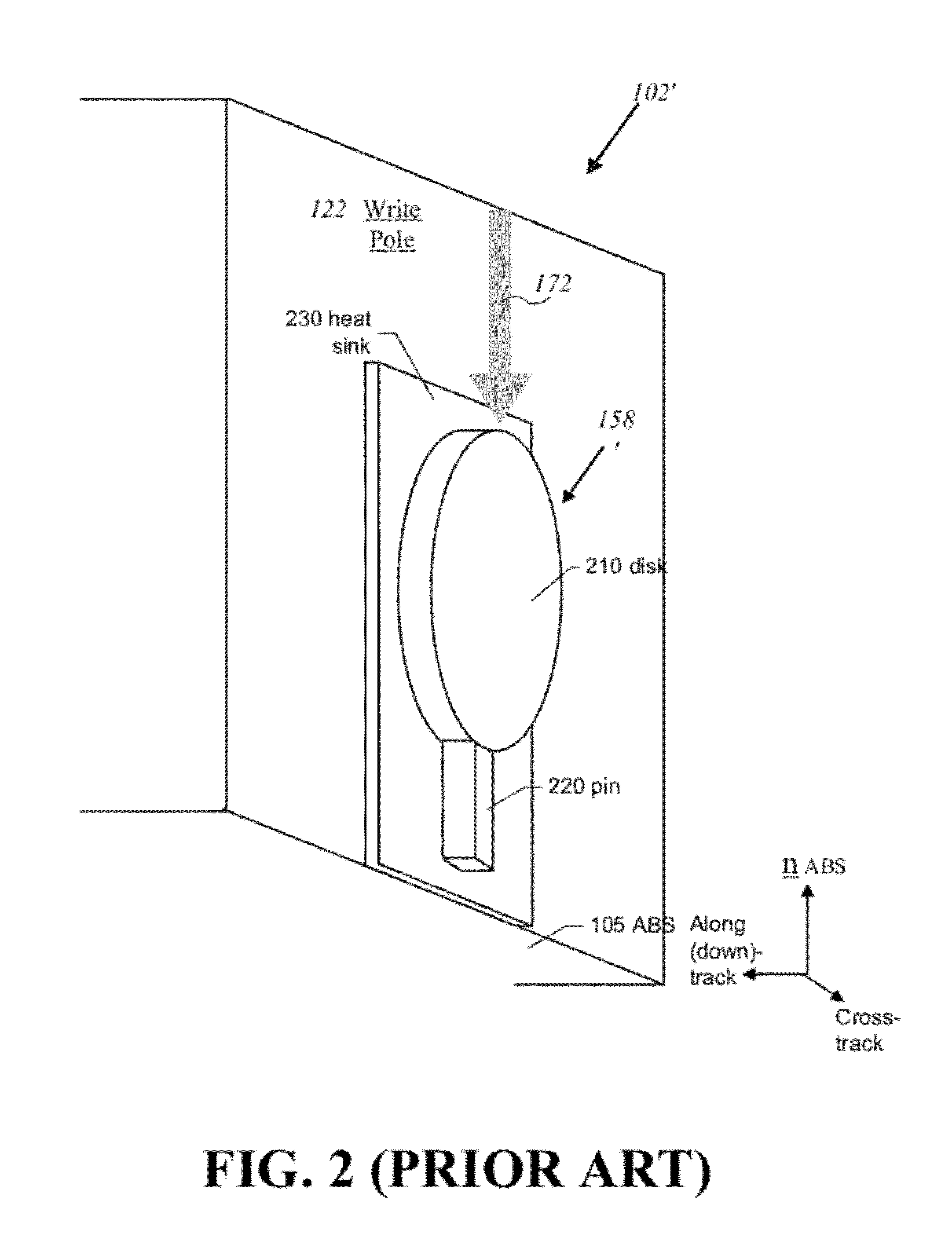

Method and system for providing an energy assisted magnetic recording writer having a ring shaped NFT

A method and system provides an EAMR transducer. The transducer is coupled with a laser for providing energy and has an air-bearing surface (ABS) configured to reside in proximity to a media during use. The EAMR transducer includes a near field transducer (NFT) for focusing the energy onto the region of the media, a write pole, and at least one coil for energizing the write pole. The NFT includes a ring portion having an aperture therein and a pin portion proximate to the ABS. The write pole is configured to write to a region of the media.

Owner:WESTERN DIGITAL TECH INC

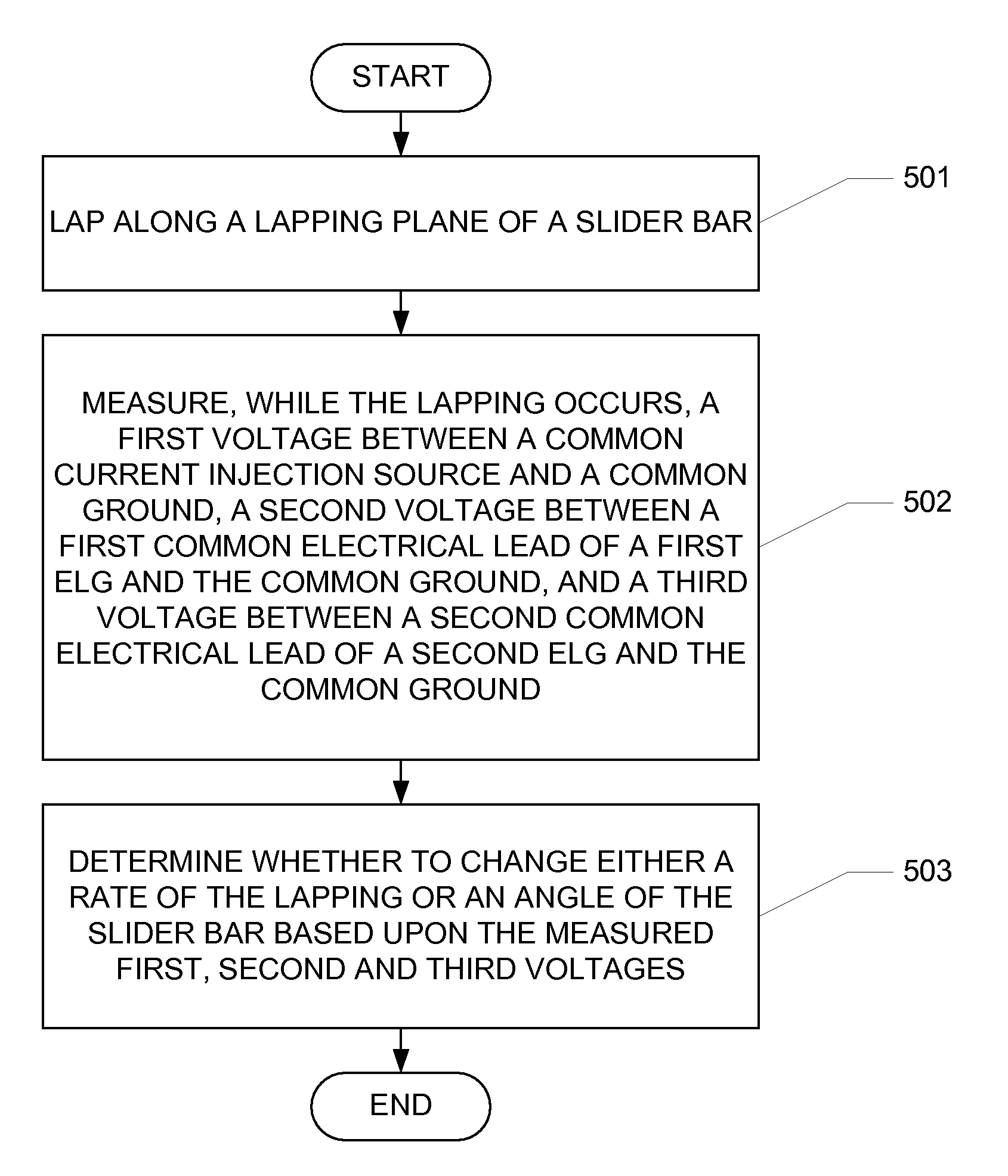

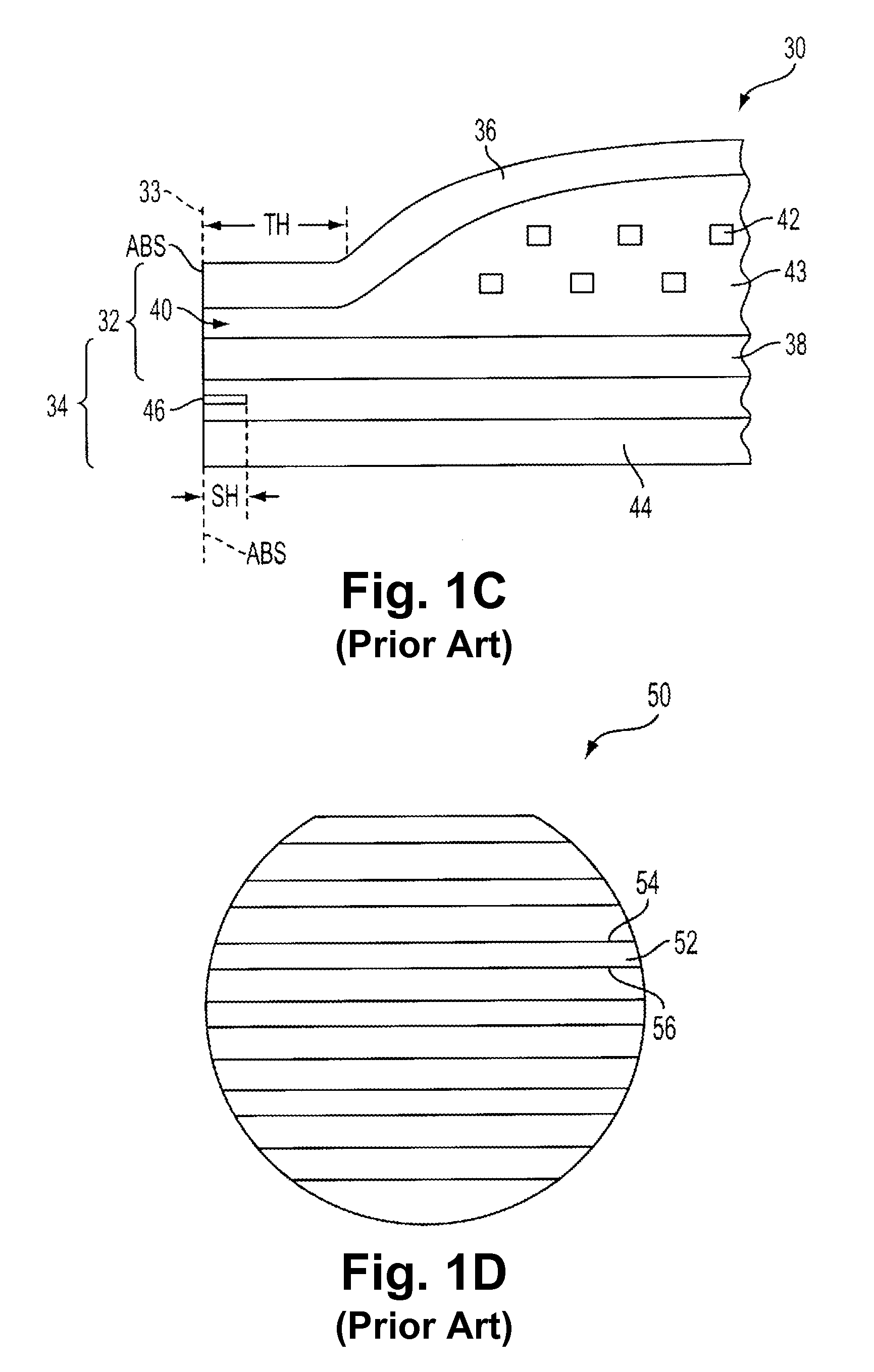

Four pad self-calibrating electronic lapping guide

Lapping guides for use in fabrication of a magnetic recording head are provided. The lapping guides comprise a first differential electronic lapping guide (ELG) disposed in a first layer of the magnetic recording head. The first differential ELG has a first resistive element and a second resistive element between which is disposed a first common electrical lead. The lapping guides further comprise a second differential ELG disposed in a second layer of the magnetic recording head. The second differential ELG has a third resistive element and a fourth resistive element between which is disposed a second common electrical lead. The first and second differential ELGs share a common ground and a common current injection source. Remaining lapping distances at the first and second layers of the magnetic recording head are determined by measuring changing voltages across the first, second, third and fourth resistive elements, respectively.

Owner:WESTERN DIGITAL TECH INC

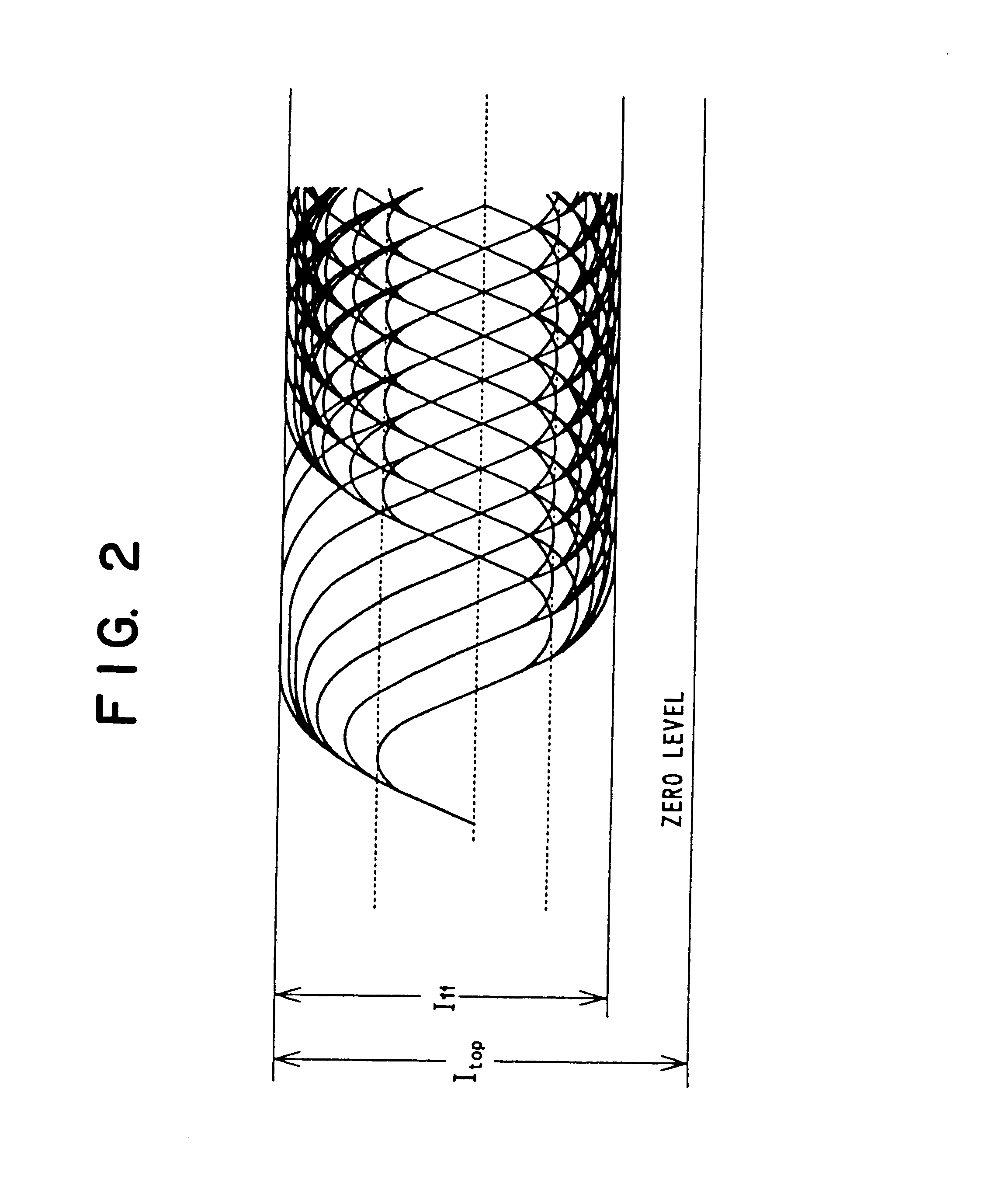

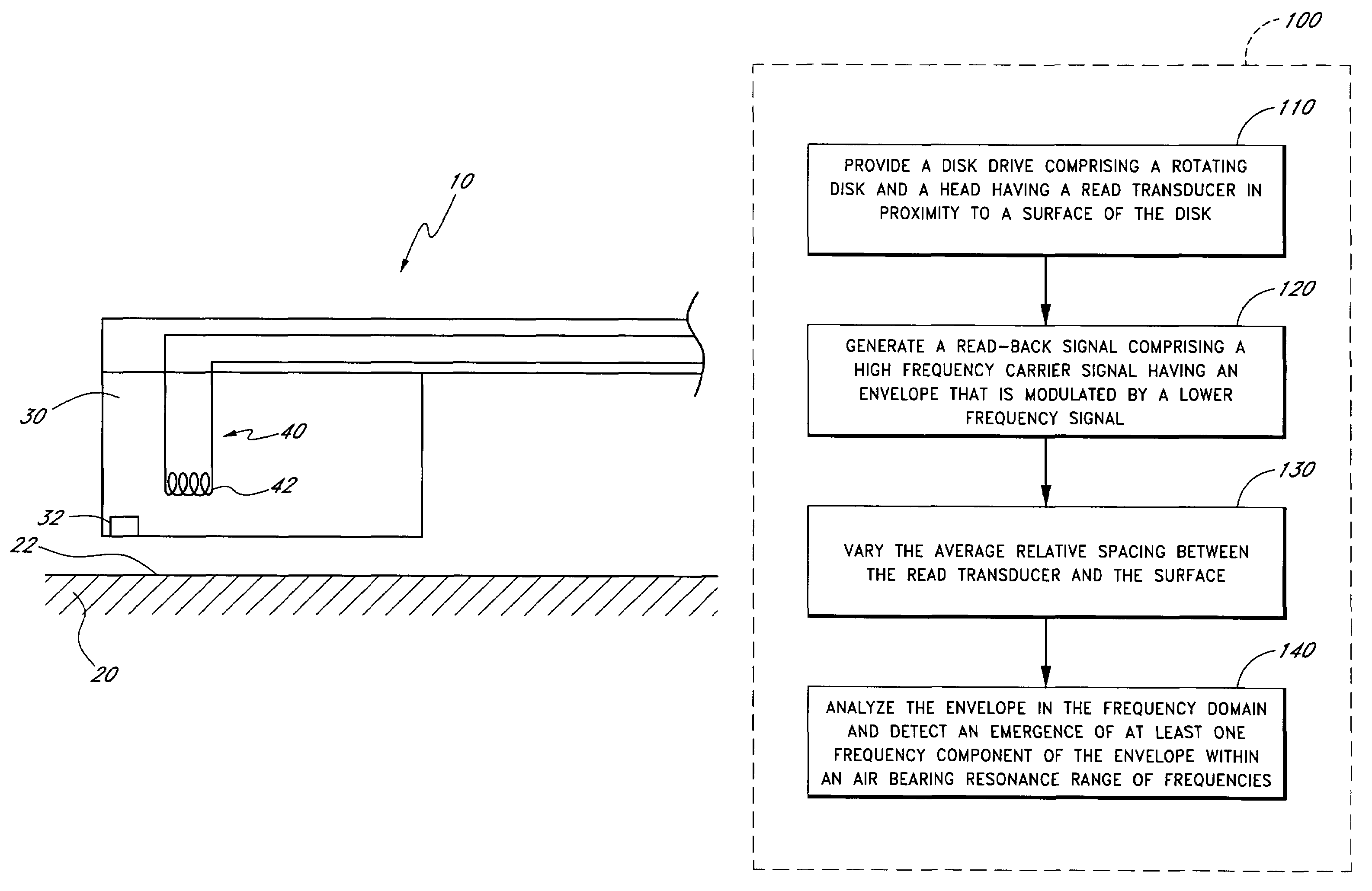

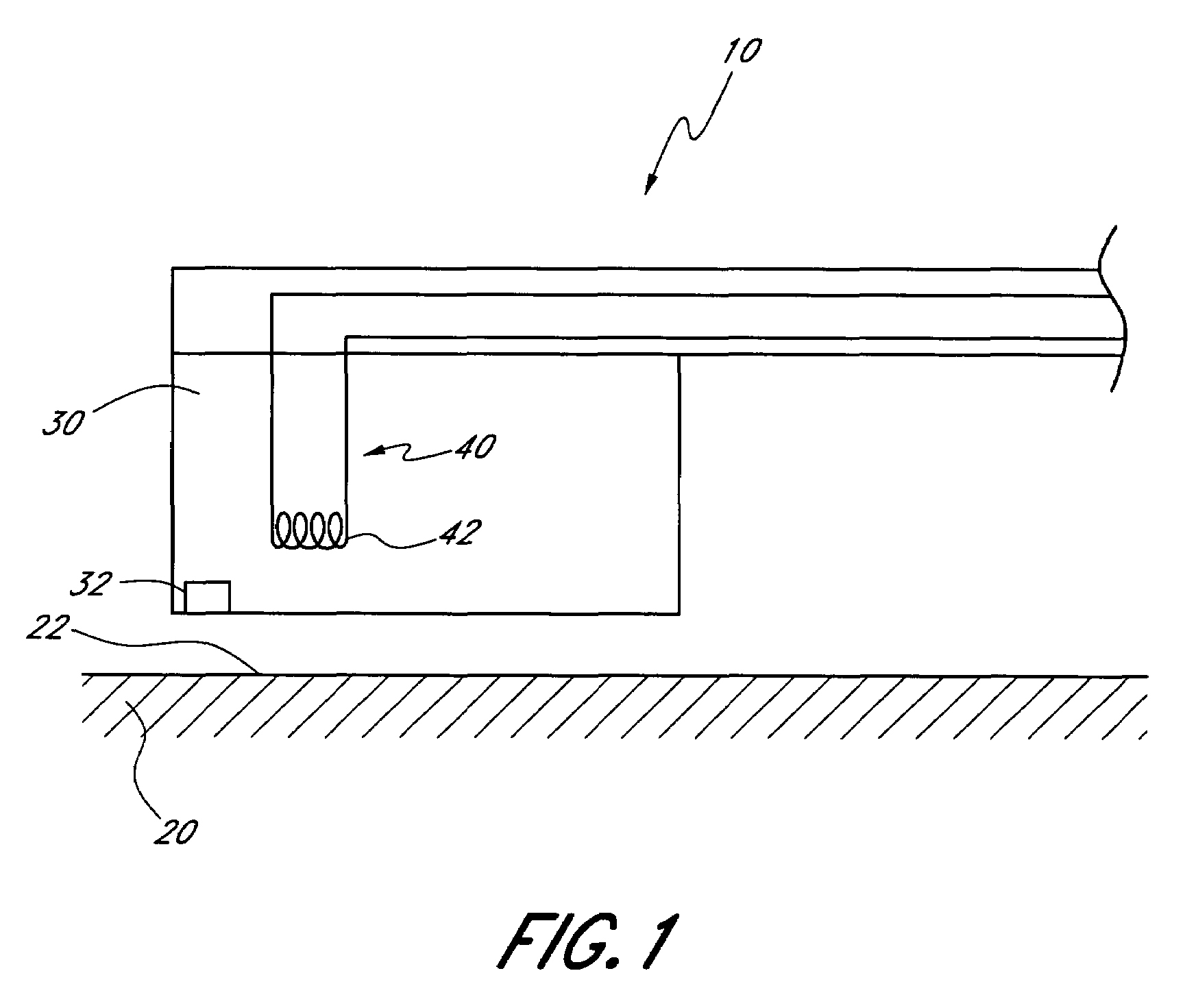

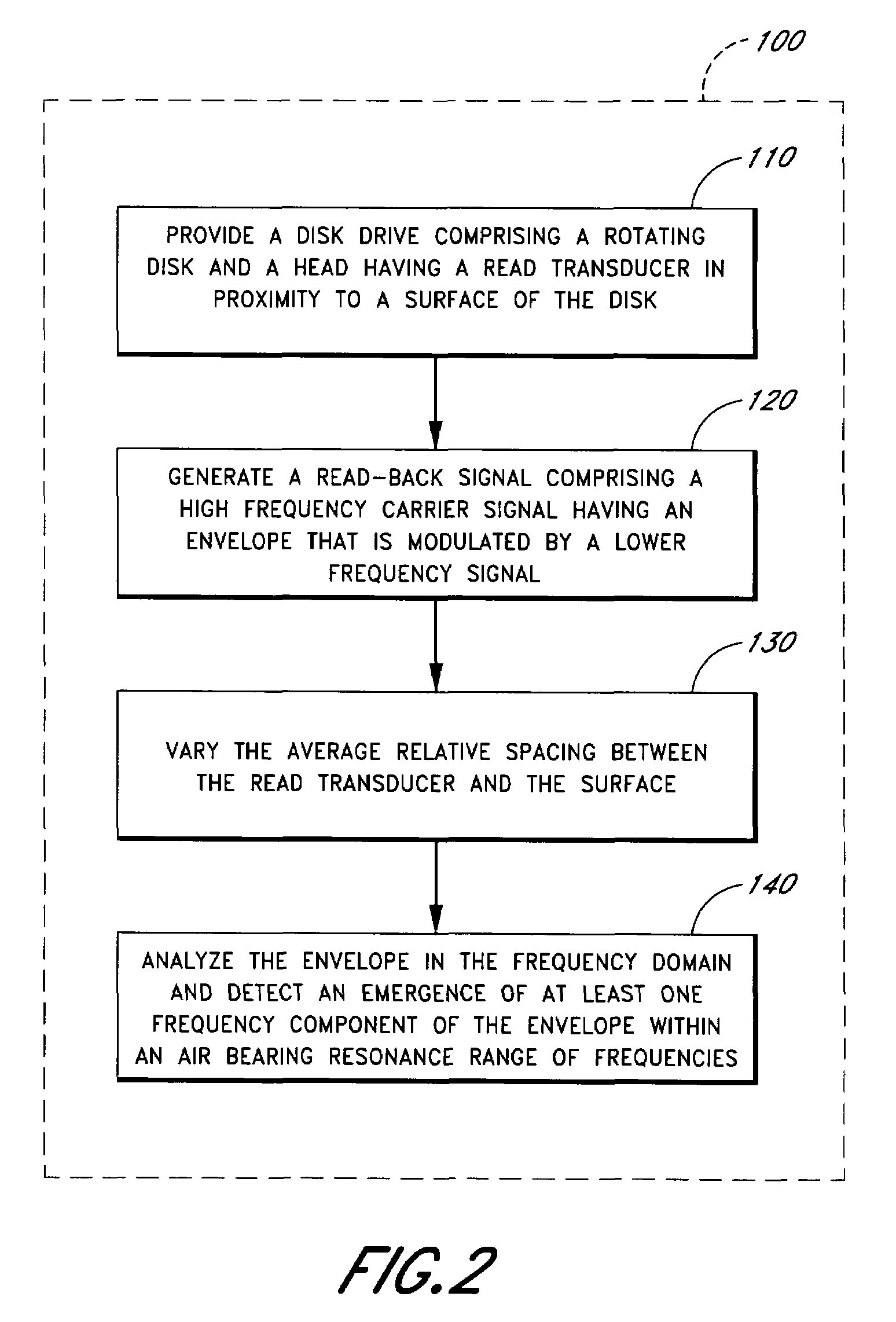

Method of monitoring operation of a disk drive by analyzing the envelope of a read-back signal in the frequency domain

A method monitors operation of a disk drive. The method includes providing a disk drive which includes a rotating disk and a head having a read transducer in proximity to a surface of the disk and an adjustment mechanism which controllably adjusts an average relative spacing between the read transducer and the surface. The method further includes generating a read-back signal by reading from the surface using the read transducer. The read-back signal includes a high frequency carrier signal having an envelope that is modulated by a lower frequency signal. The method further includes varying the average relative spacing between the read transducer and the surface using the adjustment mechanism. The method further includes analyzing the envelope in the frequency domain and detecting an emergence of at least one frequency component of the envelope within an air bearing resonance range of frequencies.

Owner:WESTERN DIGITAL TECH INC

Optical disk, an optical disk barcode forming method, an optical disk reproduction apparatus, a marking forming apparatus, a method of forming a laser marking on an optical disk, and a method of manufacturing an optical disk

InactiveUS6052465APossible to separateDigitally marking record carriersDigital data processing detailsOptical pickupBarcode

Disclosed is an optical disk barcode forming method wherein, as information to be barcoded, position information for piracy prevention, which is a form of ID, is coded as a barcode and is recoded by laser trimming on a reflective film in a PCA area of an optical disk. When playing back the thus manufactured optical disk on a reproduction apparatus, the barcode data can be played back using the same optical pickup.

Owner:PANASONIC CORP

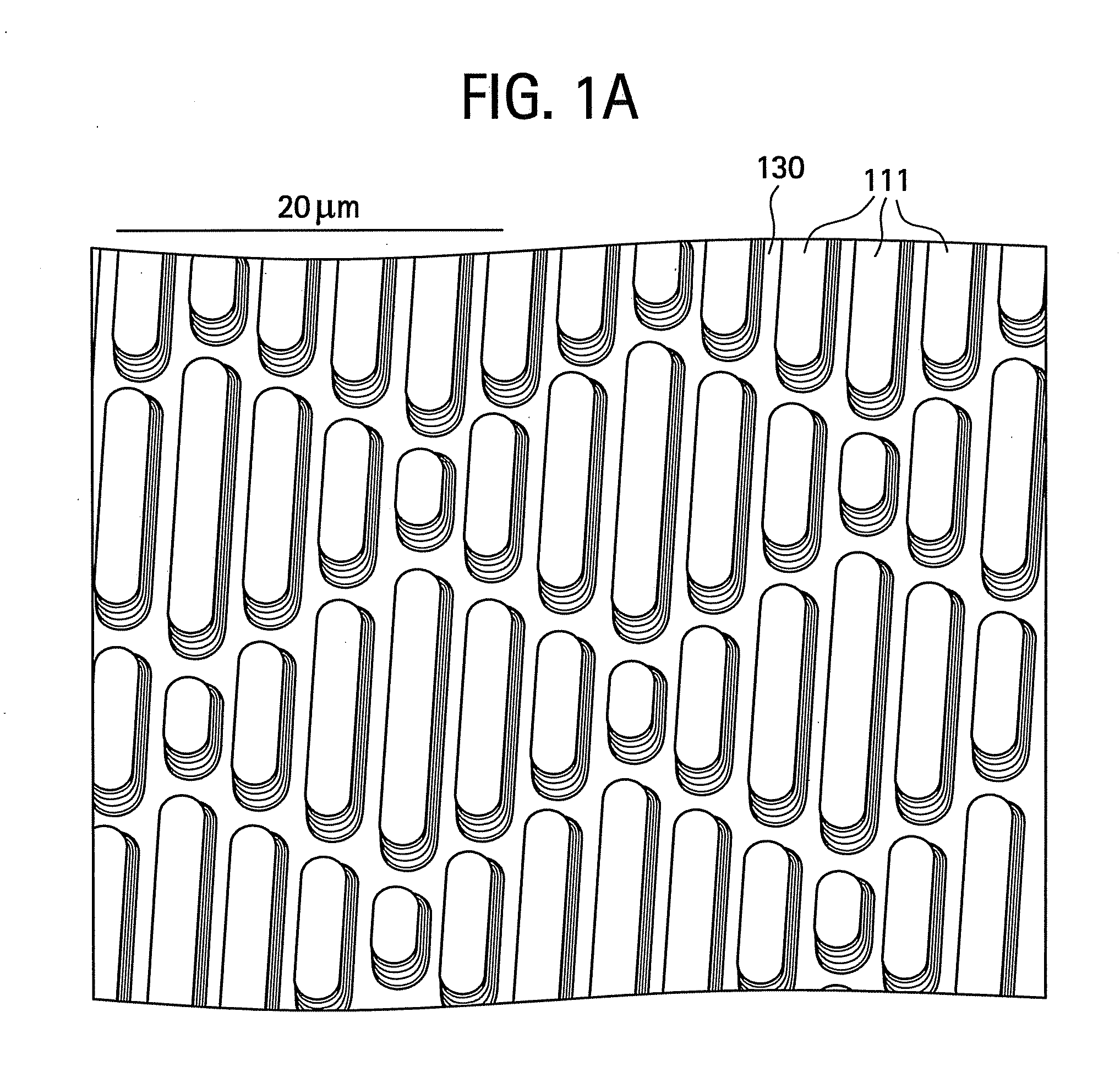

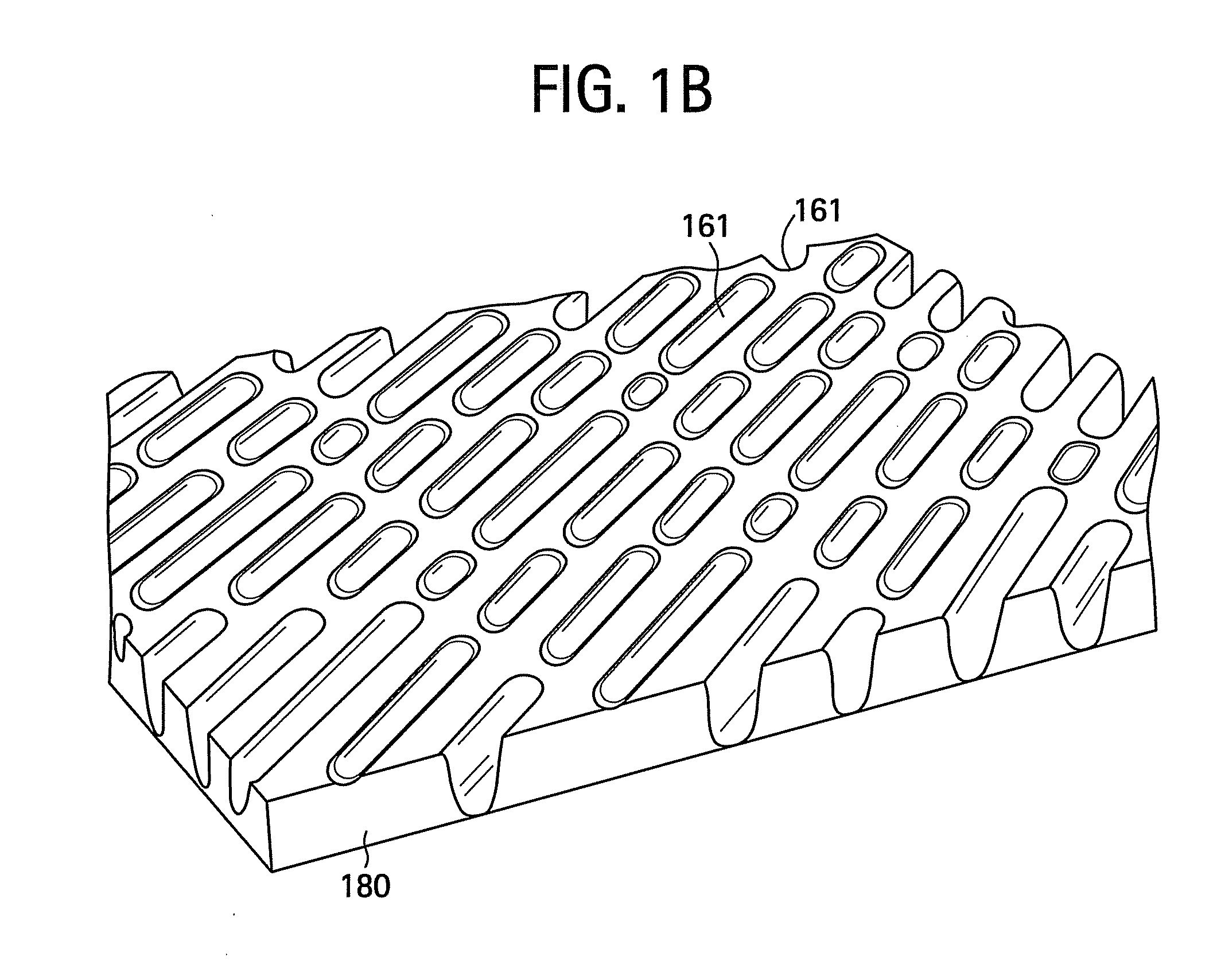

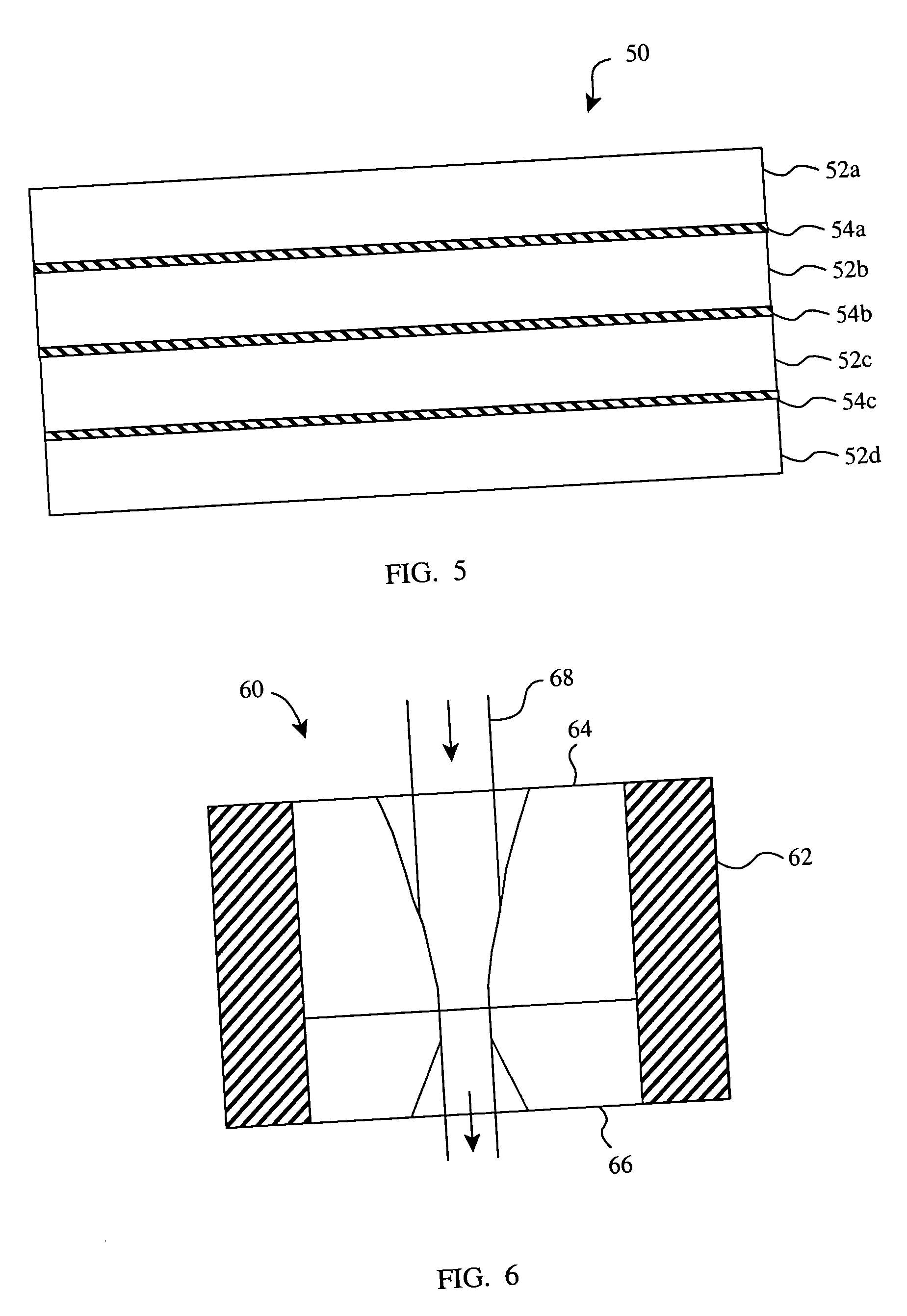

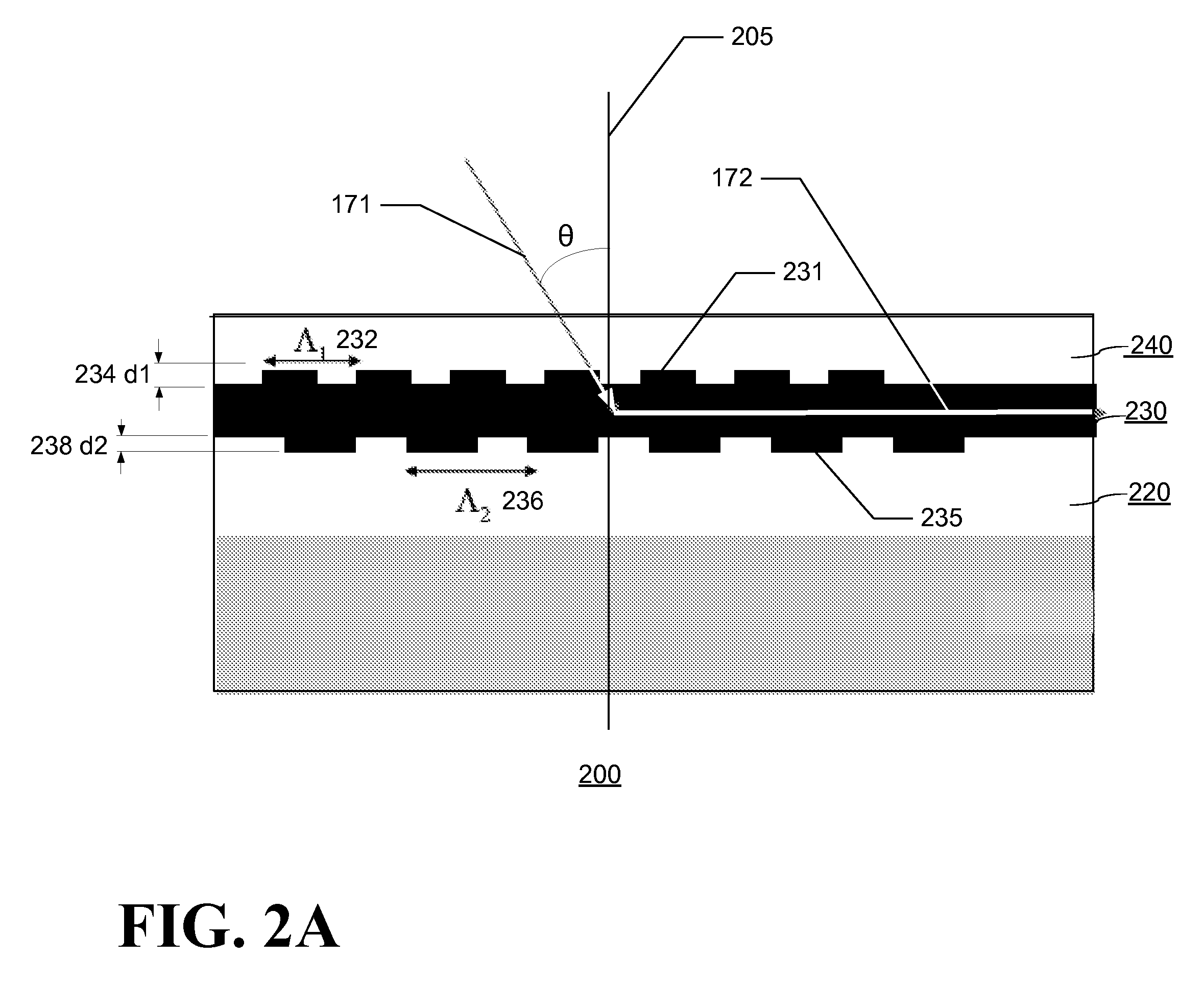

High efficiency grating coupling for light delivery in EAMR

ActiveUS8200054B1Maximise couplingCoupling efficiency is improvedRecord information storageMagnetic recordingGratingLight delivery

A magnetic head comprising a waveguide coupler for coupling incident electromagnetic (EM) radiation into a waveguide is disclosed. The waveguide coupler includes a bottom clad layer and a waveguide core layer formed above the bottom clad layer. An interface between the bottom clad layer and the waveguide core layer includes a first grating having a first period and a first etch depth, which are configured to couple a first portion of the incident EM radiation into the waveguide core layer. The waveguide coupler can further comprise a top clad layer formed above the waveguide core layer. An interface between the waveguide core layer and the top clad layer includes a second grating having a second period and a second etch depth. The second period and the second etch depth are configured to couple a second portion of the incident EM radiation into the waveguide core layer.

Owner:WESTERN DIGITAL TECH INC

Trailing edge optimized near field transducer having non-rectangular pin cross section

A near field transducer (NFT) for use in an energy assisted magnetic recording (EAMR) head and configured to direct energy to a recording media is disclosed. The NFT comprises a disk section; and a pin section extending towards an air bearing surface (ABS) from the disk section. The pin section has a proximal end adjoining the disk section and a distal end opposite to the proximal end and facing the ABS, wherein at least the distal end of the pin section has a non- rectangular cross section in a plane parallel to the ABS.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com