Moisture barrier coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0066] A UV-curable polymer solution was made containing 100 grams of epoxy acrylate, commercially available from UCB Chemicals, Smyrna, Ga. under the trade designation “Ebecryl 629”; 2 grams of 1-hydroxy-cyclohexyl-phenyl ketone, commercially available from Ciba Specialty Chemicals, Tarrytown, N.Y. under the trade designation “Irgacurel 84” dissolved in 1000 grams of methyl ethyl ketone. The resulting solution was coated at a web speed of 20 ft / min on a 6.5 inch wide, 100 micron polyethylene terephthalate (“PET”) liner commercially available from Teijin Corp., Japan under the trade designation “HSPE 100” using a microgravure coater commercially available from Yasui Seiki, Japan under the trade designation “Model CAG150” fitted with a 90R knurl. The coating was dried in-line at 70° C. and cured under a nitrogen atmosphere with UV lamp commercially available from Fusion UV systems, Gaithersburg, Md. under the trade designation “F-600 Fusion D UV lamp” operating at 100% power, resulti...

example 2

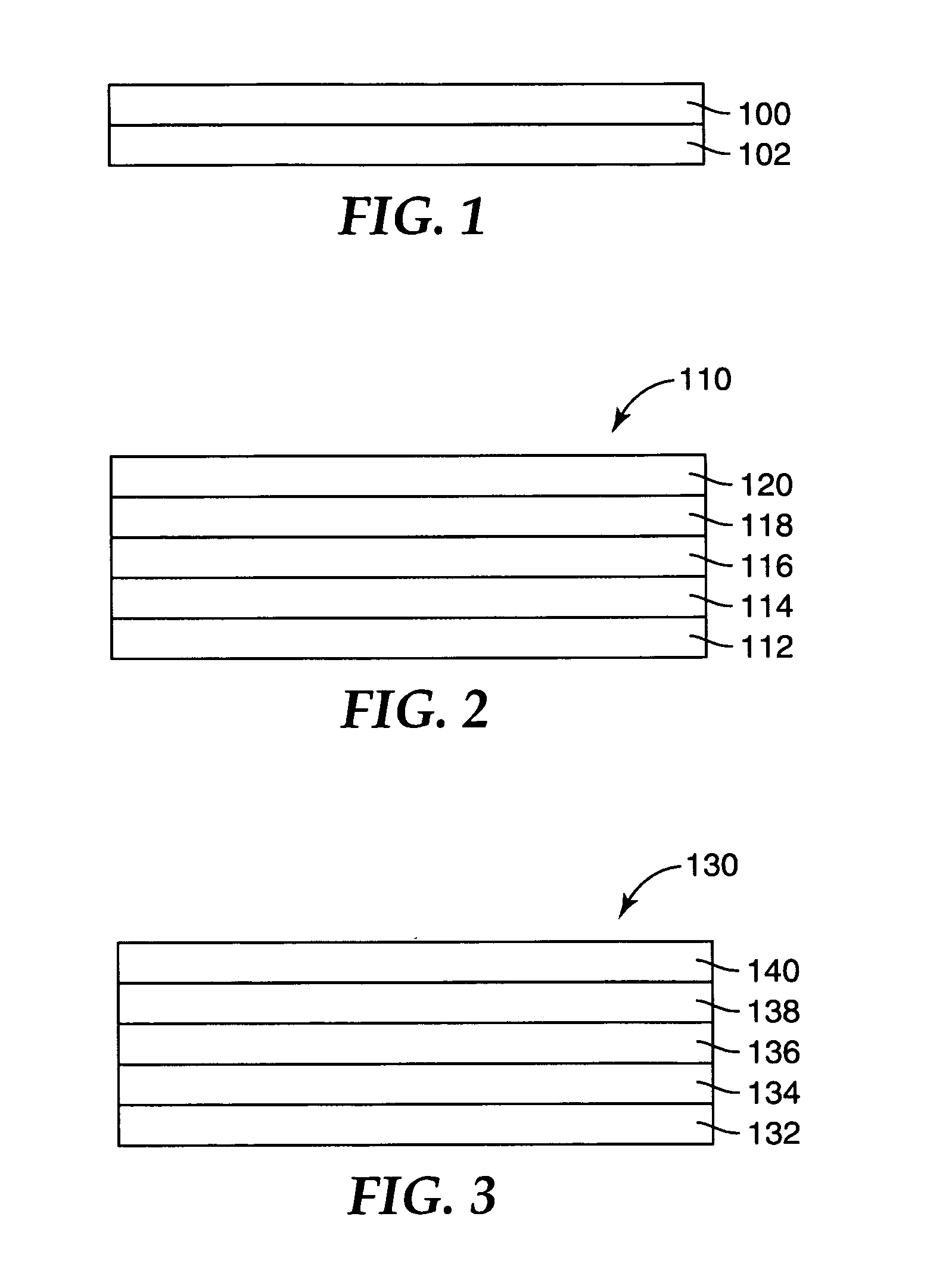

[0070] The effect of the diamond-like film deposition conditions was established by depositing a two-dyad stack of solution coated acrylate and a diamond-like film. In particular, referring to FIG. 2, the sample analyzed included a PET substrate 112, acrylate layers 114 and 118, and DLG film layers 116 and 120. The process for coating the acrylate layers is described in Example 1.

[0071] The primary variables explored in the study of the sample were as follows: (1) tetramethylsilane (TMS) / oxygen ratio and plasma power; (2) plasma power; and (3) deposition time (thickness) of the DLG film.

[0072] Sixteen different conditions were studied as shown in Table 4 below, and the moisture barrier properties of these films was measured for each of these conditions at 50° C. The MVTR values are shown in the last column in Table 4 below. From these results, it may be seen that there were several conditions that yield MVTR values that are at or below the detection limit of the Mocon tester at 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com